Method for operating flexible powering frequency changing regulating speed control apparatus of direct control oil pumping unit

A technology of control device and frequency conversion speed regulation, which is applied in the direction of AC motor control, control system, earthwork drilling and mining, etc., can solve the problems of energy waste and low load utilization rate, achieve stable motor driving power, reduce installed power, reduce The effect of peak load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

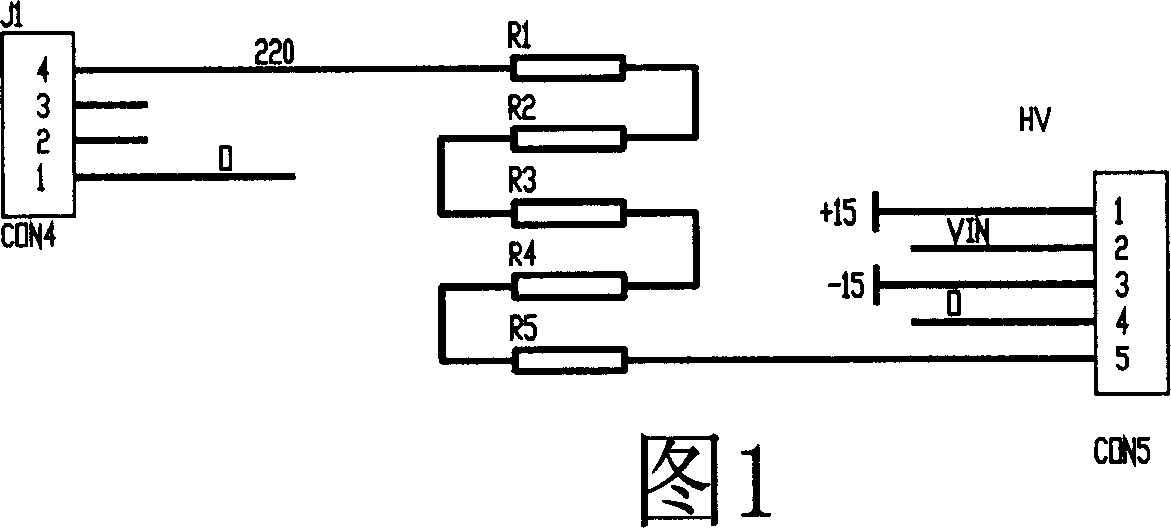

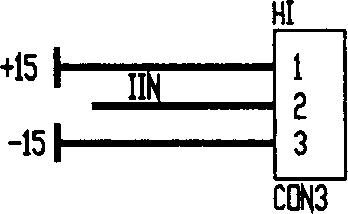

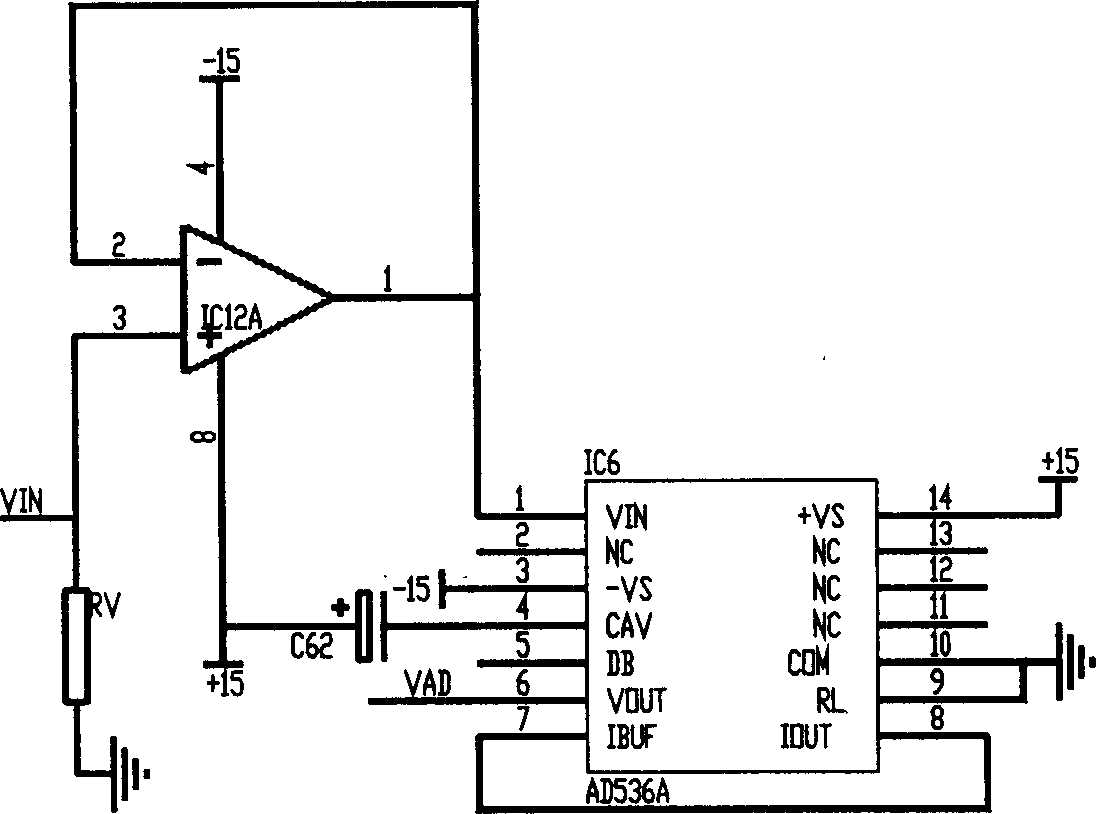

[0029] Figure 1~ Figure 14 As shown, an operating method of a direct-controlled oil pumping unit flexible dragging frequency conversion speed regulation control device, including a frequency converter and a control device, wherein the control includes a detection module circuit, a button module circuit, a central processing module circuit, a display Module circuit, output module circuit and control quantity input module circuit, wherein the detection module circuit is a KV50 / AP magnetic balance voltage sensor, which is connected to the measurement terminal by using the 1 and 4 corners of CON4. When measuring voltage, the measured voltage Connect with the sensor through resistors R1; R2; R3; R4; R5. The output current VIN is proportional to the measured voltage. The module also includes a KT150A magnetic balance current sensor, and the output current IIN is proportional to the measured current. The voltage VIN output by the voltage sensor enters the effective value conversio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com