Fresh air heat recovery method and equipment

A technology of fresh air heat recovery and fresh air, applied in heating methods, ventilation systems, piping arrangements, etc., can solve the problems of inability to achieve full heat recovery rate, expensive model materials, limited recovery efficiency, etc., to improve the quality of life and cost. Low and energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

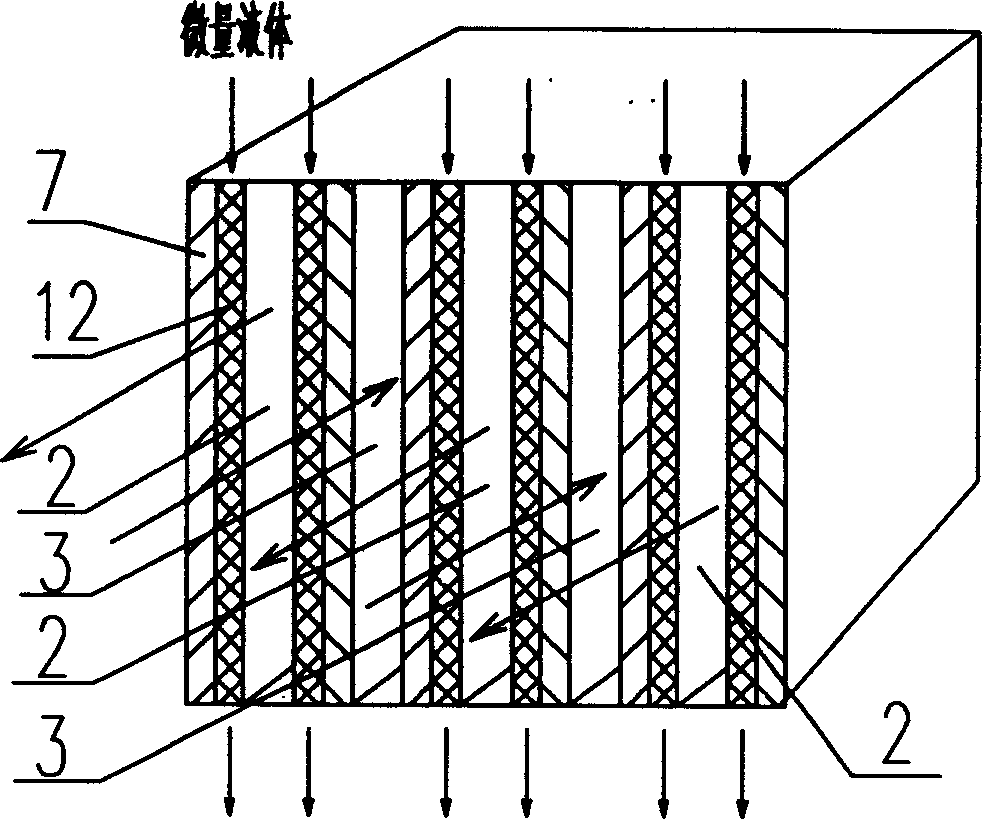

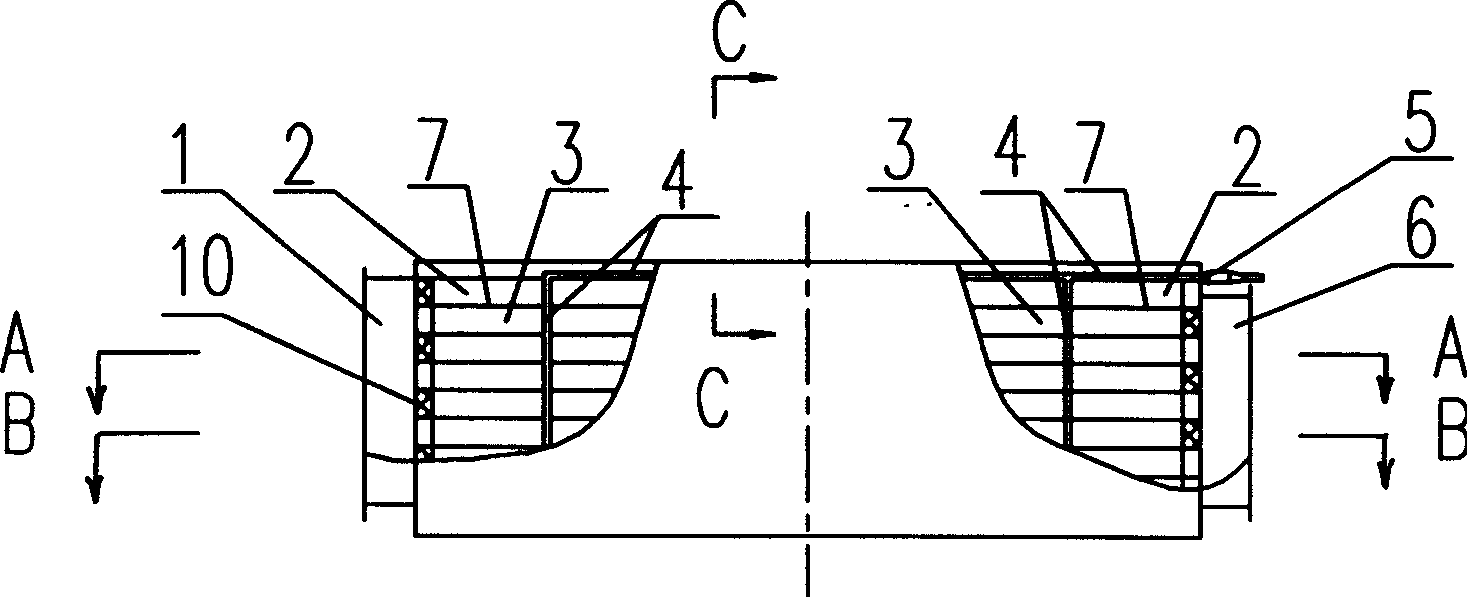

[0035] see figure 1A number of air duct plates 7 are used to isolate several exhaust ducts 2 and new air ducts 3, the exhaust ducts 2 and the new air ducts 3 are arranged at intervals, and a liquid-wetting layer is arranged on the surface of the air duct plates 7 located on the side of the exhaust duct 12. During cooling, a small amount of liquid flows into the liquid-wetting layer 12 from the upper part of the liquid-wetting layer 12 in the direction shown in the figure, and then spreads to various parts of the liquid-wetting layer 12, wherein part of the liquid evaporates into the exhaust duct 2, and the remaining liquid flows from The lower part of the liquid wetting layer 12 flows out. Since the surface temperature of the air duct plate 7 on the side of the exhaust duct is close to the wet bulb temperature of the exhaust air, through heat conduction, the surface temperature of the air duct plate 7 on the side of the new air duct is close to the surface temperature of the ...

Embodiment 2

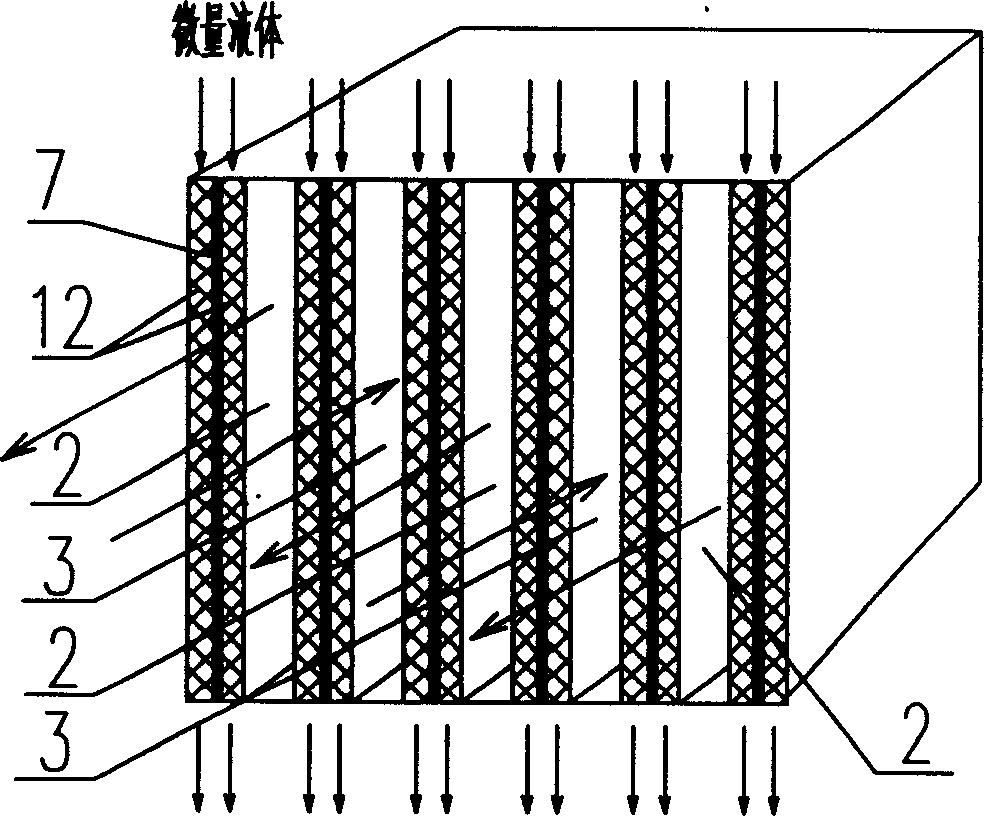

[0037] see figure 2 , use some air duct plates 7 to isolate into several exhaust ducts 2 and new air ducts 3, the exhaust ducts 2 and the new air ducts 3 are arranged at intervals, and the surfaces of the air duct plates 7 on the side of the new air duct and on the side of the exhaust duct Liquid-wetting layers 12 are provided on both sides of the air channel plate 7 , that is, liquid-wetting layers 12 are provided on both sides of the air duct plate 7 . During cooling, a small amount of liquid flows into the liquid-wetting layer 12 from the upper part of the liquid-wetting layer 12 in the direction shown in the figure, diffuses to various parts of the liquid-wetting layer 12, and part of the liquid evaporates into the exhaust air in the exhaust air channel 2, and the remaining liquid Flowing out from the lower part of the liquid-wetting layer 12, the surface temperature of the air channel plate 7 on the side of the exhaust air channel 2 is close to the wet bulb temperature o...

Embodiment 3

[0050] see Figure 10 ~ Figure 11 , compared with Embodiment 1, the arrangement direction of the air duct plates 7 in this embodiment is different, and the air duct plates 7 are arranged vertically; Hole, its structure is simpler than embodiment 1, and all the other structures are the same.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com