A continuous process for synthesizing oxamide

An oxamide and process technology, applied in the field of continuous oxamide synthesis process, can solve the problems of not seeing, not seeing, not seeing the continuous process of synthesizing oxamide, etc., and achieving the effect of reducing raw material cost and sufficient raw material sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

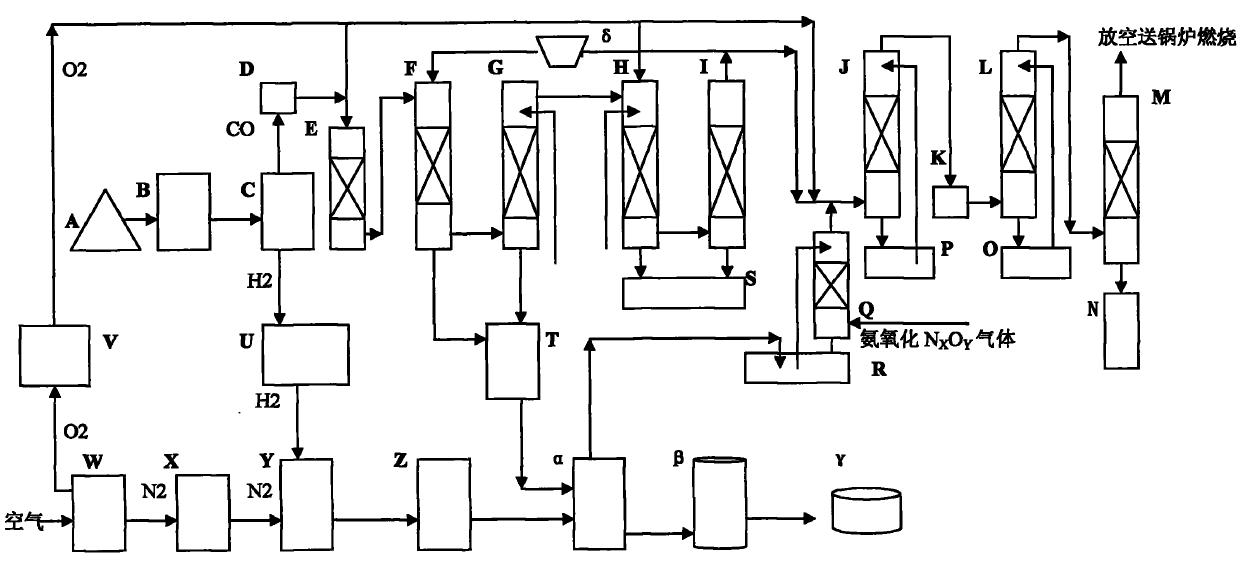

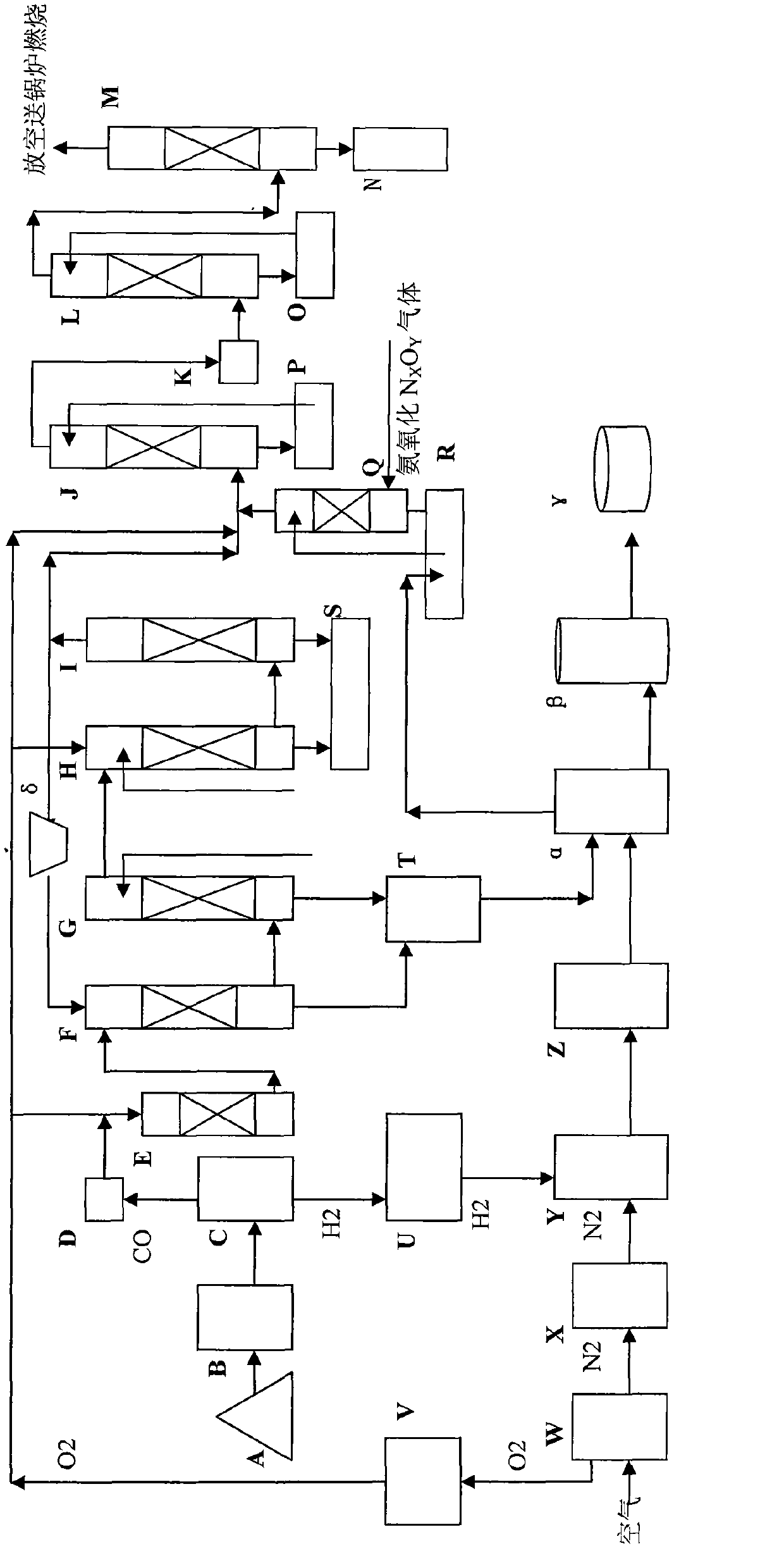

[0044] In the first step, the production of syngas and its separation:

[0045] Coal or natural gas or oilfield gas A is used to produce synthesis gas (CO+H2) through synthesis gas generator B, and CO and H2 in the synthesis gas are separated through pressure swing adsorption separation device or cryogenic separation device or membrane separation device C. The separated H2 ≥ 99.0V% hydrogen is stored in the hydrogen gas storage tank U to provide the hydrogen source required for ammonia synthesis; the separated CO gas is stored in the carbon monoxide gas storage tank D to provide CO gas for the synthesis of oxalate source. The composition of CO gas is: CO≈30~99V%, H2≈0.01~10V%, and a small amount of N2, CH4, Ar, CO2, etc. The CO raw material gas required for the synthesis of oxalate ester reaction can also use various recovered CO resources, such as: CO gas recovered from ammonia copper washing, steelmaking converter tail gas, yellow phosphorus furnace tail gas, ferroalloy fur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com