Patents

Literature

583 results about "Wet-bulb temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The wet-bulb temperature (WBT) is the temperature read by a thermometer covered in water-soaked cloth (wet-bulb thermometer) over which air is passed. At 100% relative humidity, the wet-bulb temperature is equal to the air temperature (dry-bulb temperature) and it is lower at lower humidity. It is defined as the temperature of a parcel of air cooled to saturation (100% relative humidity) by the evaporation of water into it, with the latent heat supplied by the parcel. A wet-bulb thermometer indicates a temperature close to the true (thermodynamic) wet-bulb temperature. The wet-bulb temperature is the lowest temperature that can be reached under current ambient conditions by the evaporation of water only.

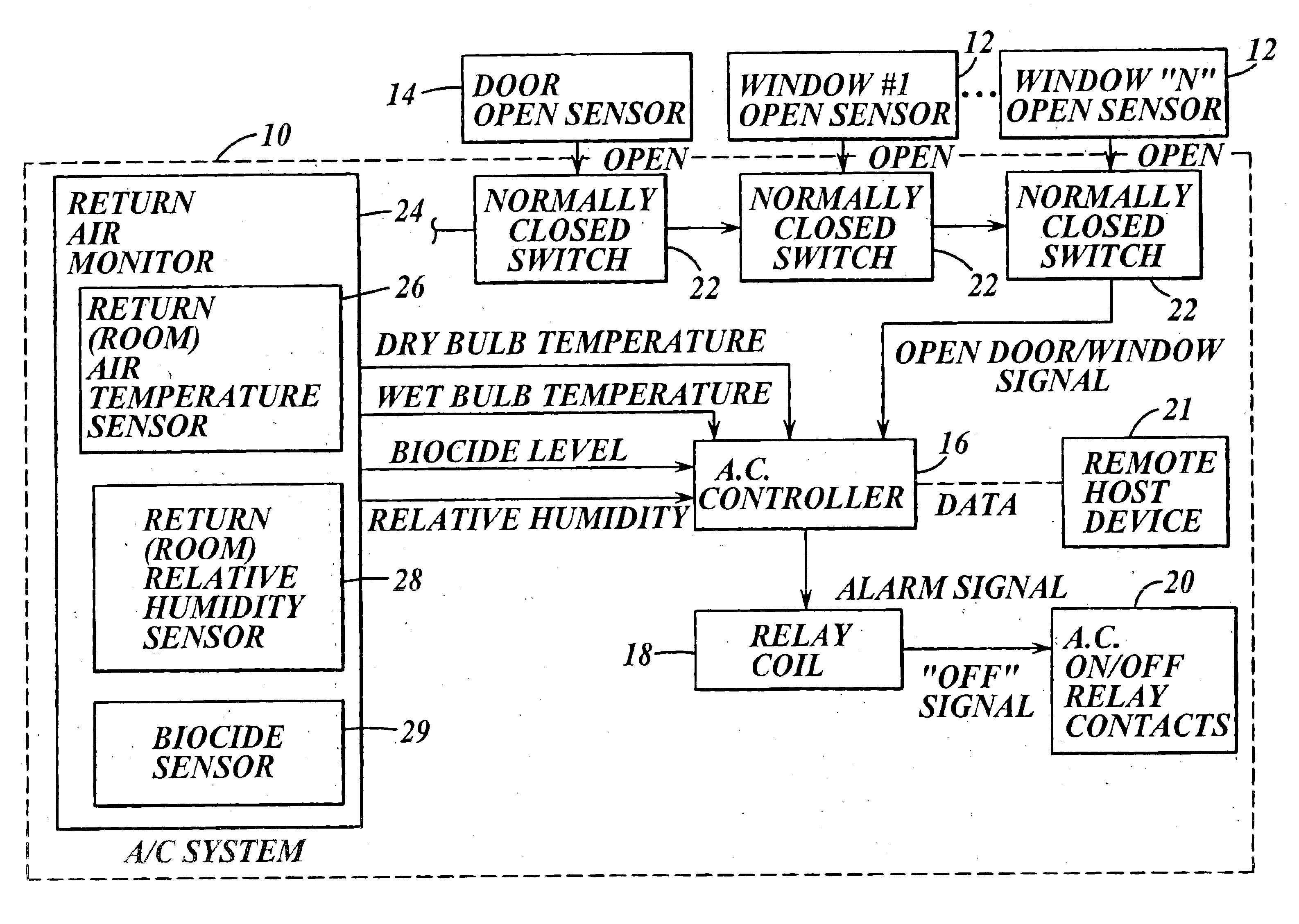

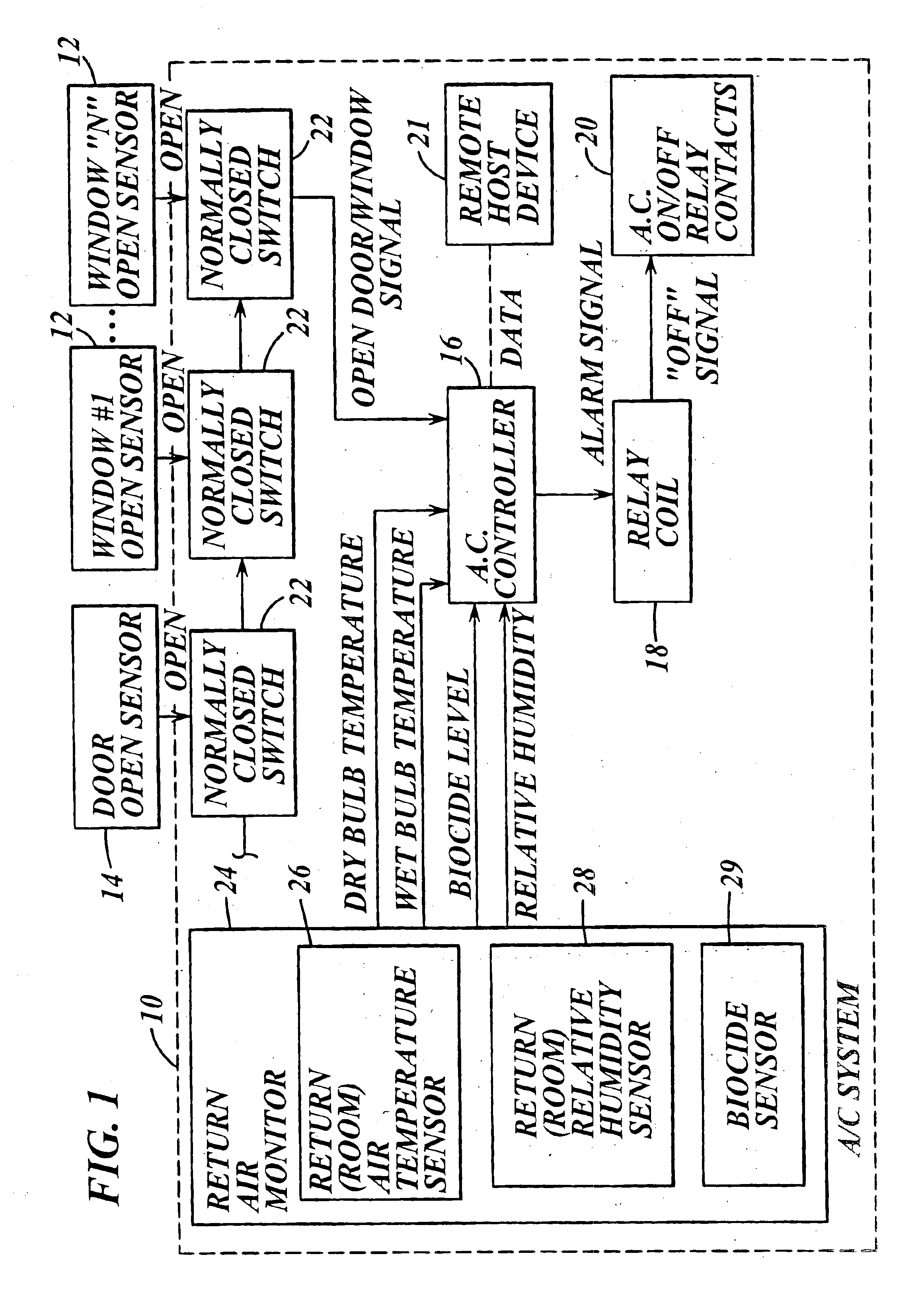

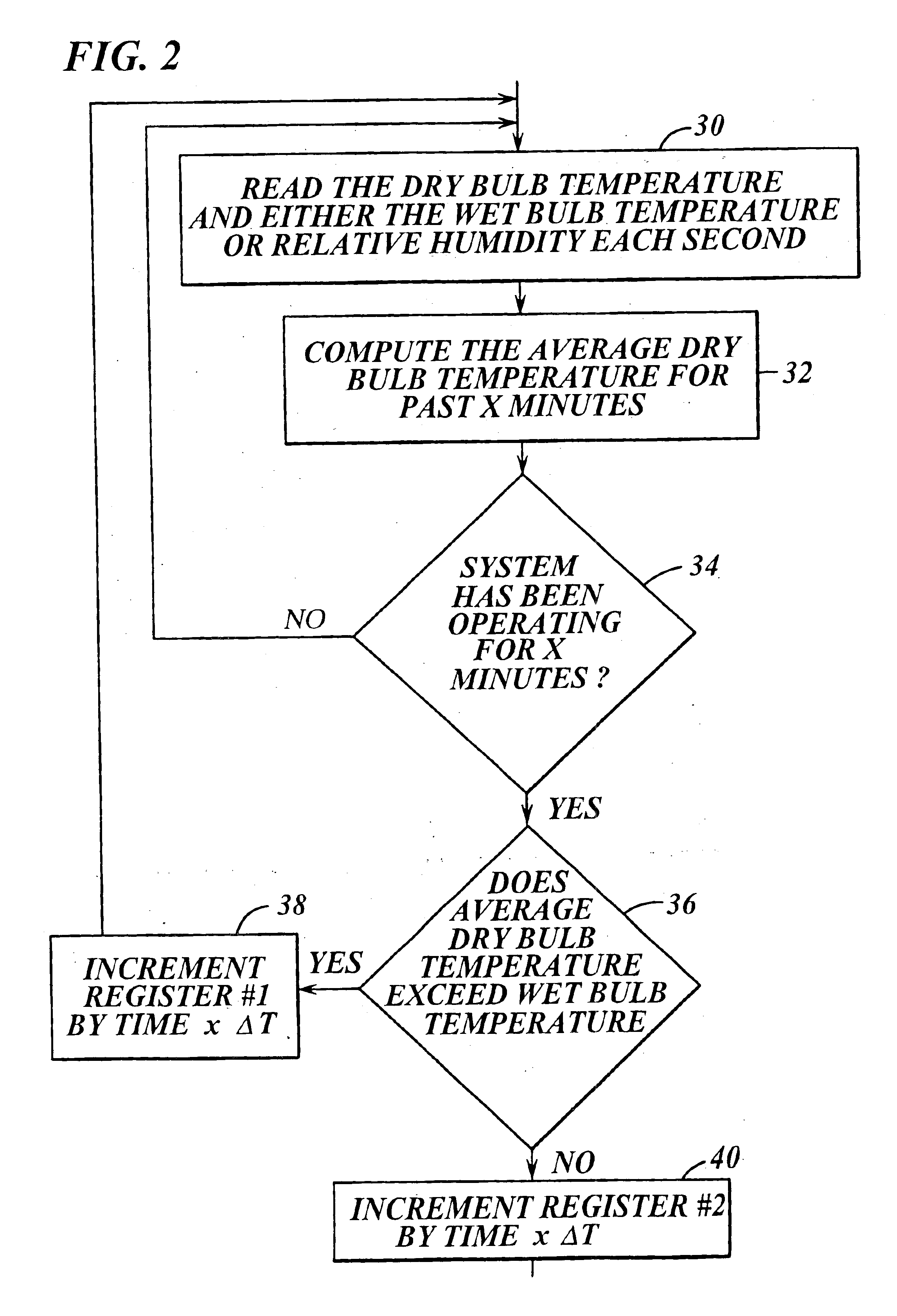

Air conditioning system

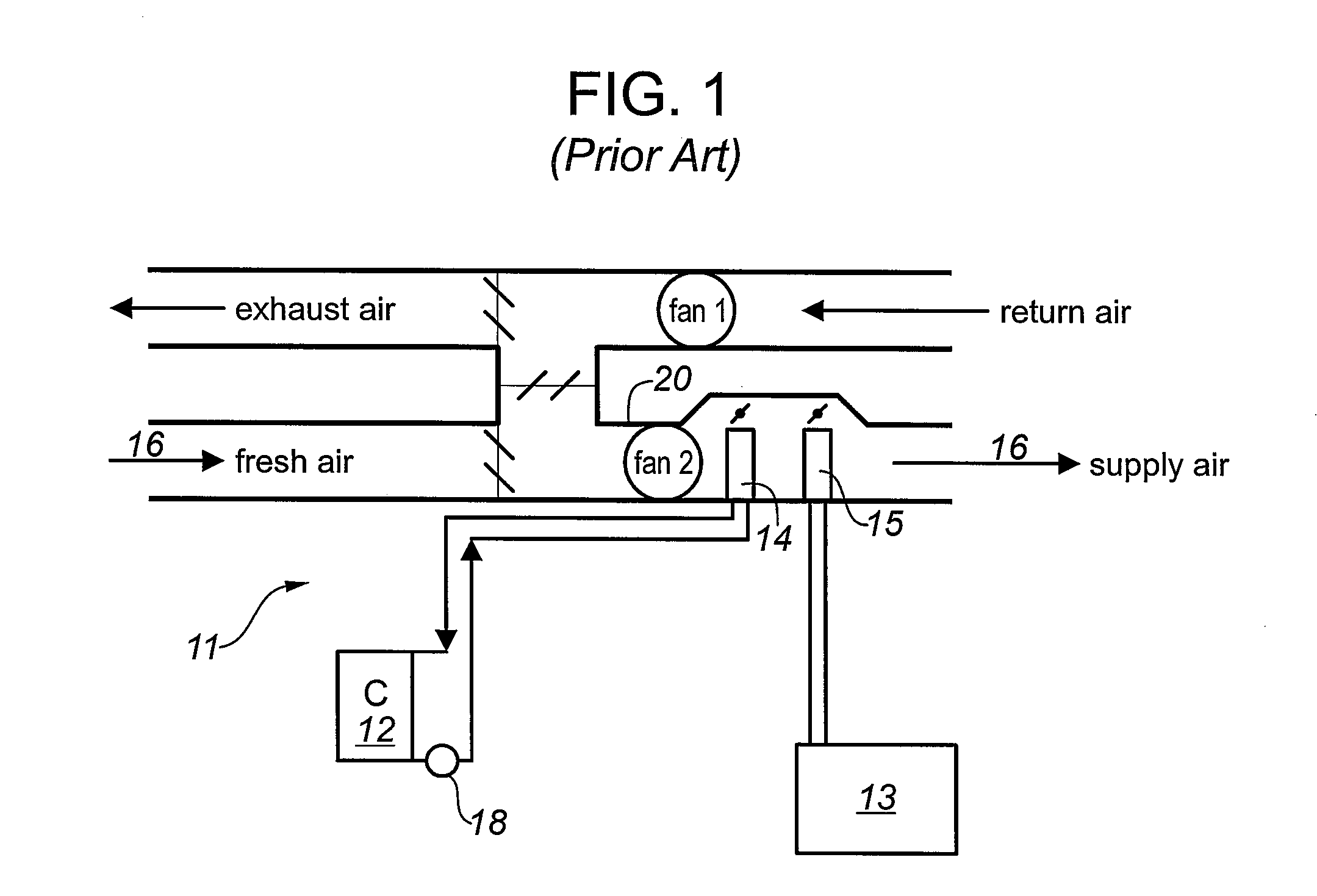

InactiveUS6840052B2Minimizing conditionEncouraging growthMechanical apparatusSpace heating and ventilation safety systemsEngineeringAir conditioning

An air conditioning system cools air within an area. An air conditioner controller defines information based on input data from door and window open status sensors and a return air monitor sensing the dry bulb temperature and the wet bulb temperature or relative humidity of the air within the area being cooled by the air conditioning system and shuts down the system when specific conditions exist. The defined information is transmitted to a remote host device which retains and presents the transmitted information or information derived therefrom.

Owner:WELLSPRING WIRELESS A DE CORP

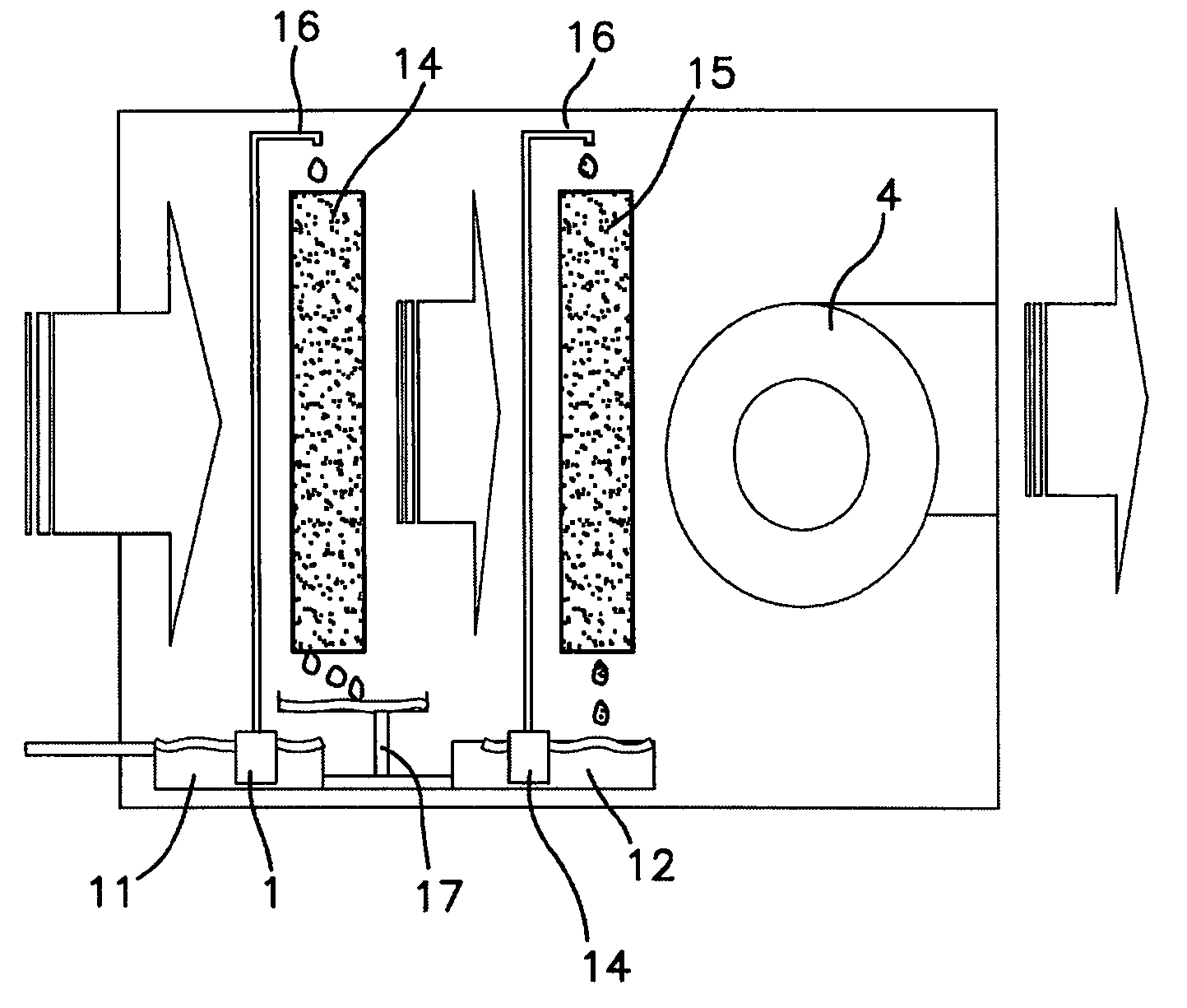

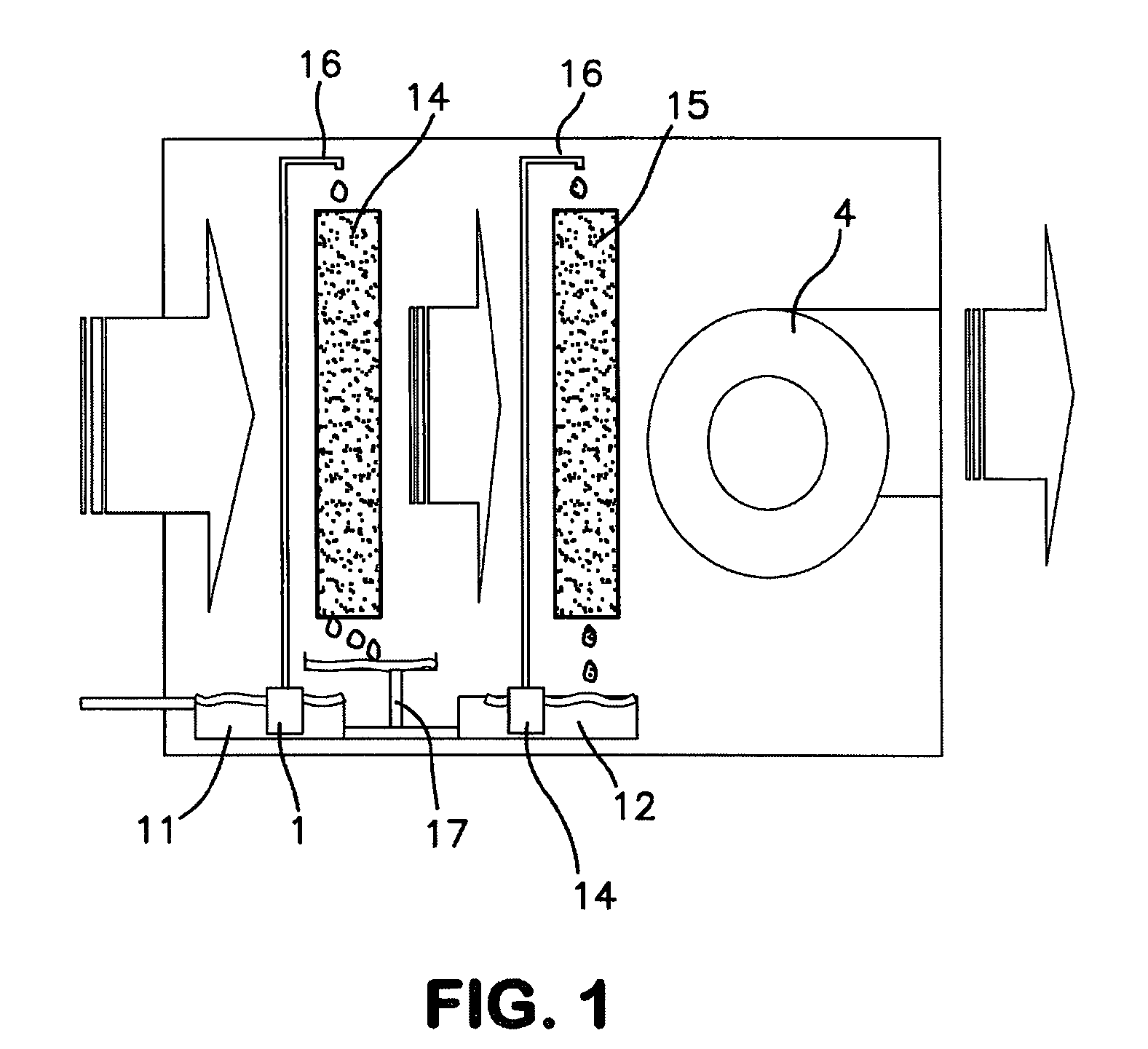

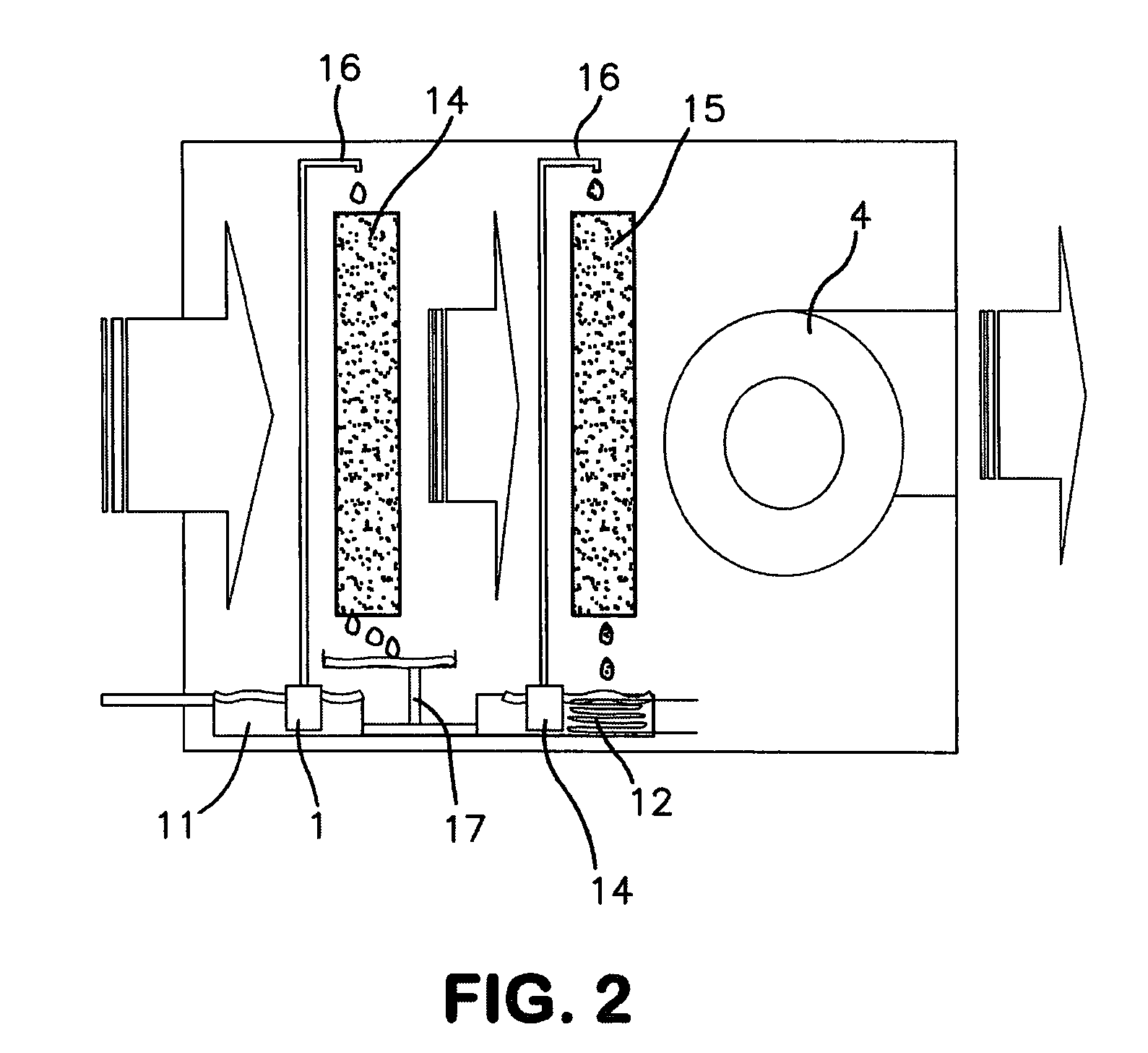

Evaporative Air Cooler With Multi Stages Cooling And Or Heating With Or Without Cooling Coil

InactiveUS20100281896A1Free-cooling systemsStationary conduit assembliesEvaporative coolerCooling coil

An outdoor air cooler with two stages includes a first stage for cooling and humidification with constant wet bulb temperature. The air cooler has a first stage pump circulating water over the first stage evaporative cooling media operating at conditions having a constant adiabatic wet bulb temperature line. The first stage tank is supplied with water from external source. The second stage includes a second set of evaporative cooling media using water from the first stage media, which is equal to or lower than outdoor air wet bulb temperature. The temperature of air leaving the second stage evaporative media follows the adiabatic wet bulb temperature line toward the second stage tank water temperature thereby cooling humidifying the treated air to stable wet and dry bulb temperatures.

Owner:AL WATBAN ALAA ABDULKAREEM

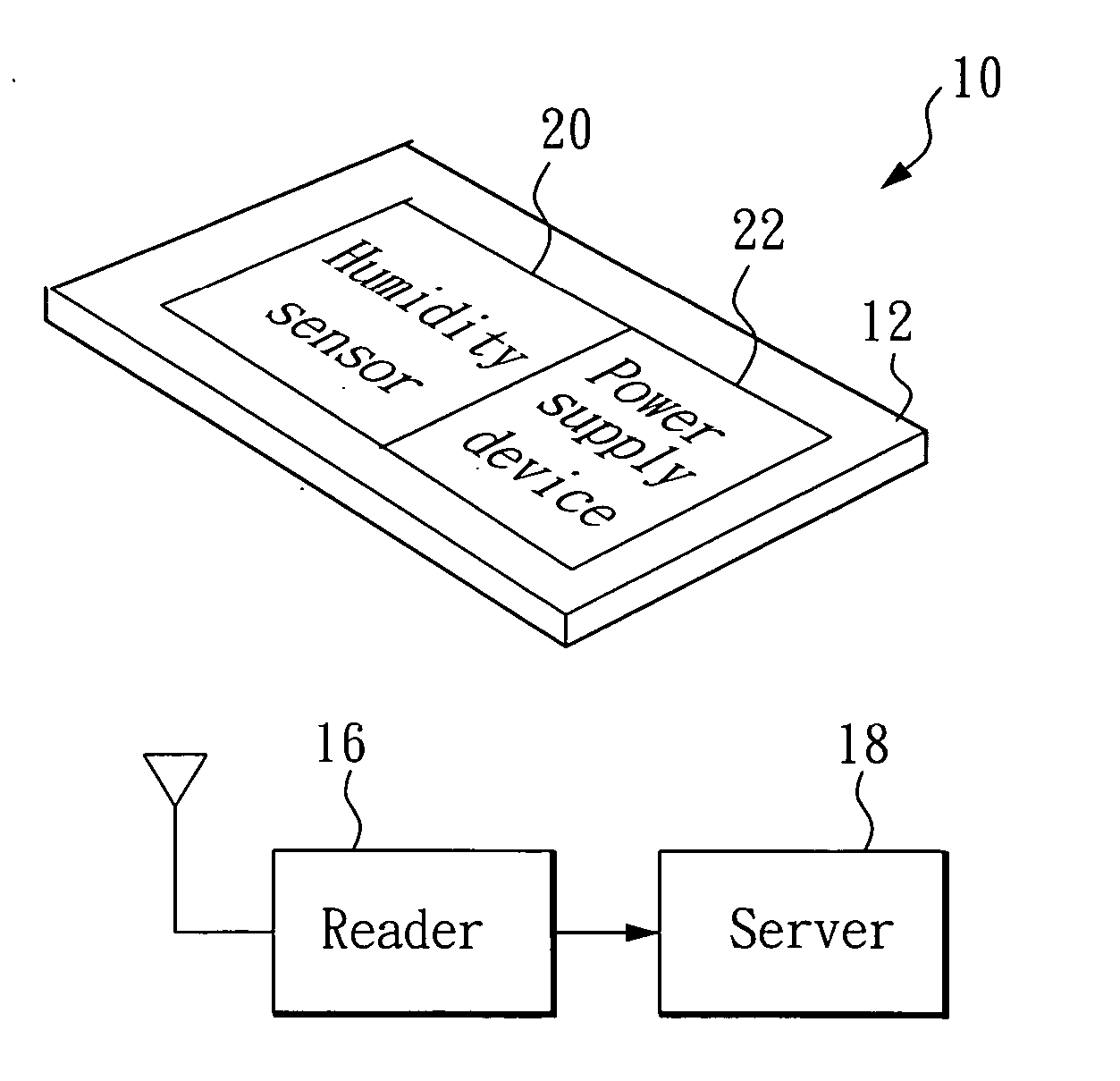

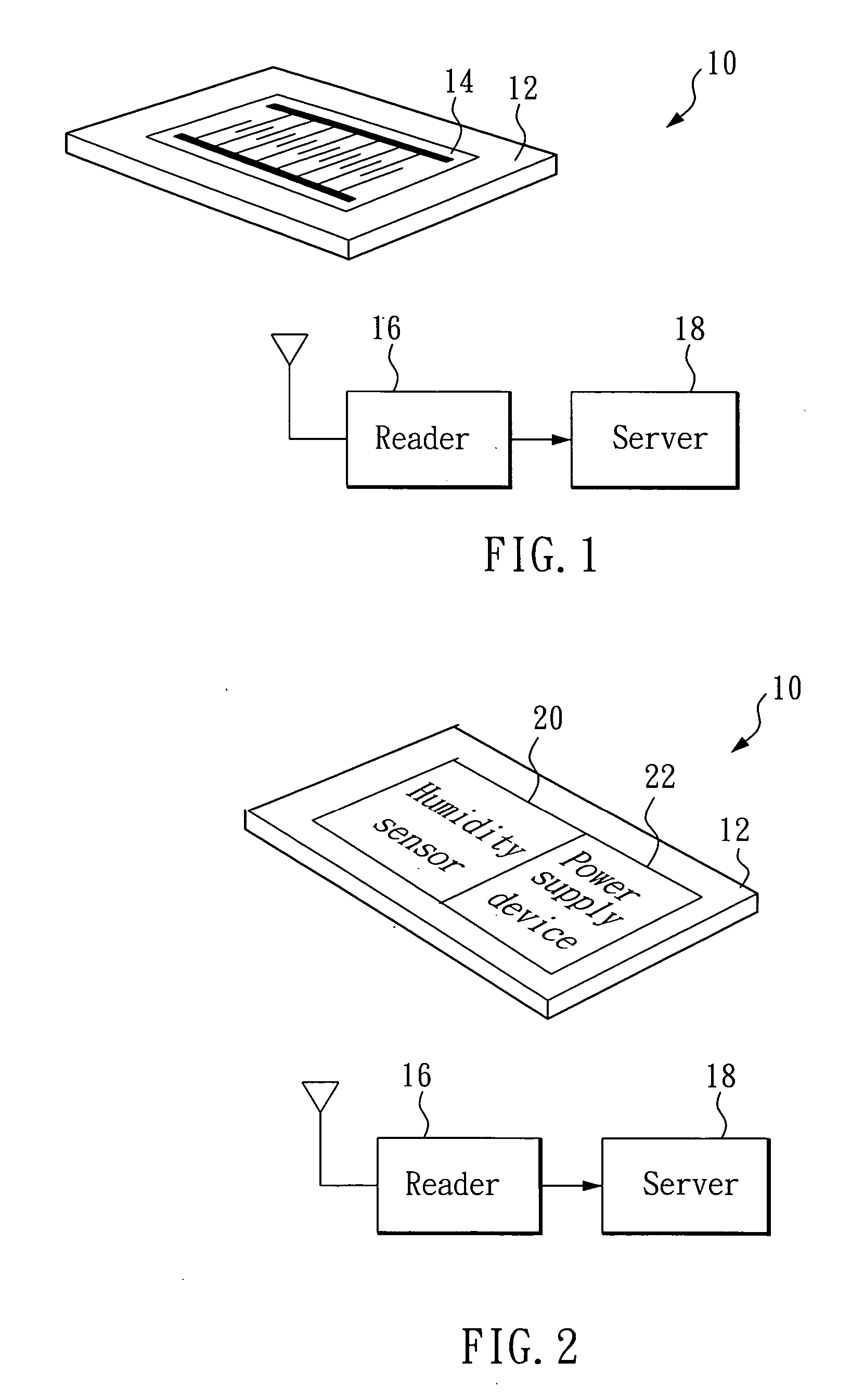

Remote humidity monitoring system

A remote humidity monitor system for detecting a targeted object utilizes a humidity sensor to detect humidity and sends a result to a reader via the wireless communication device; a server can execute monitor management. The humidity sensor can be a mass hygrometer, an optical condensation dew-point hygrometer, a psychrometer (wet-and-dry bulb thermometer), a hair hygrometer, an electrolysis humidity sensor, a lithium chloride humidity sensor, an aluminum oxide humidity sensor, a high polymer humidity sensor, or an infrared hygrometer.

Owner:THINKFAR NANOTECH CORP

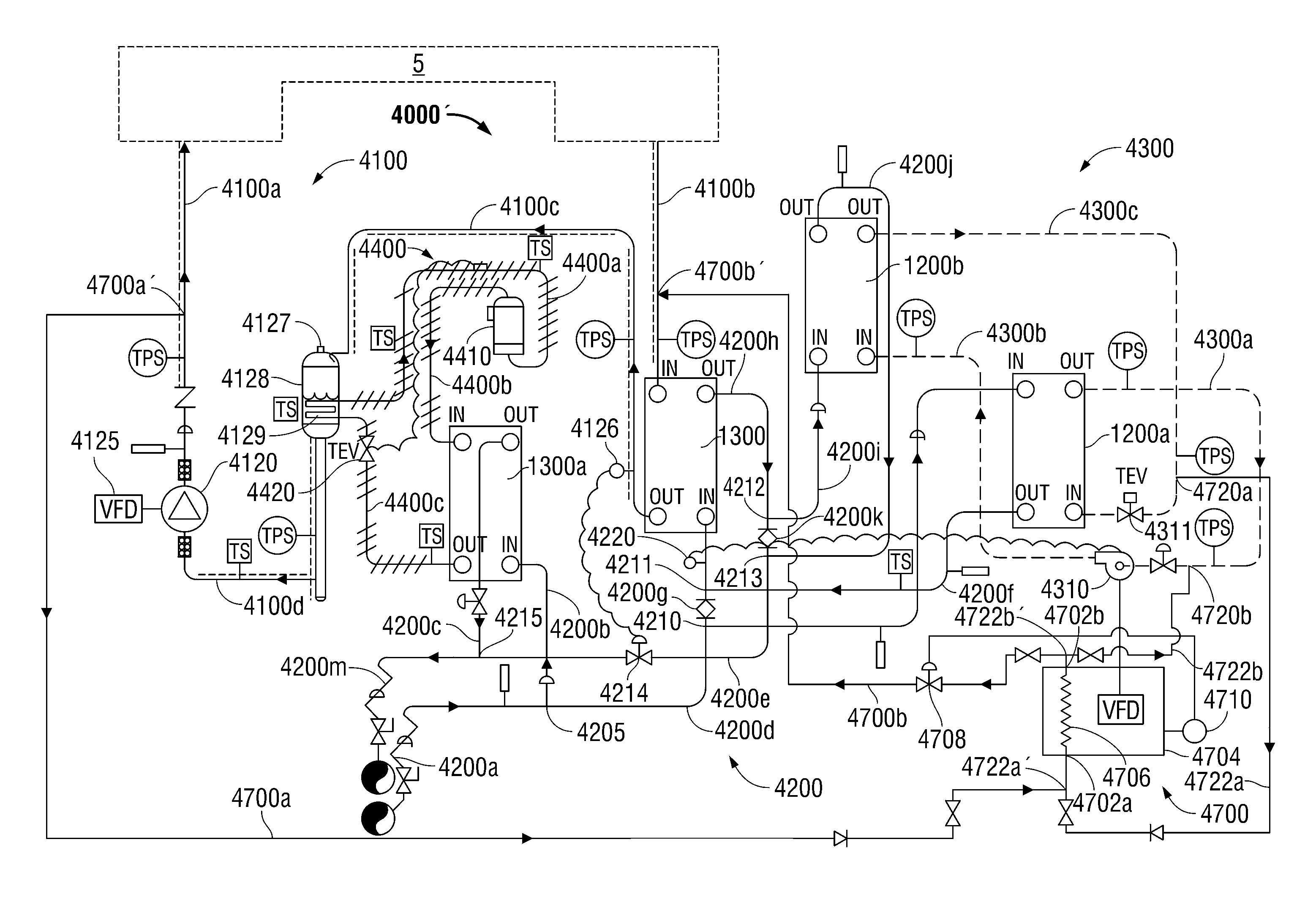

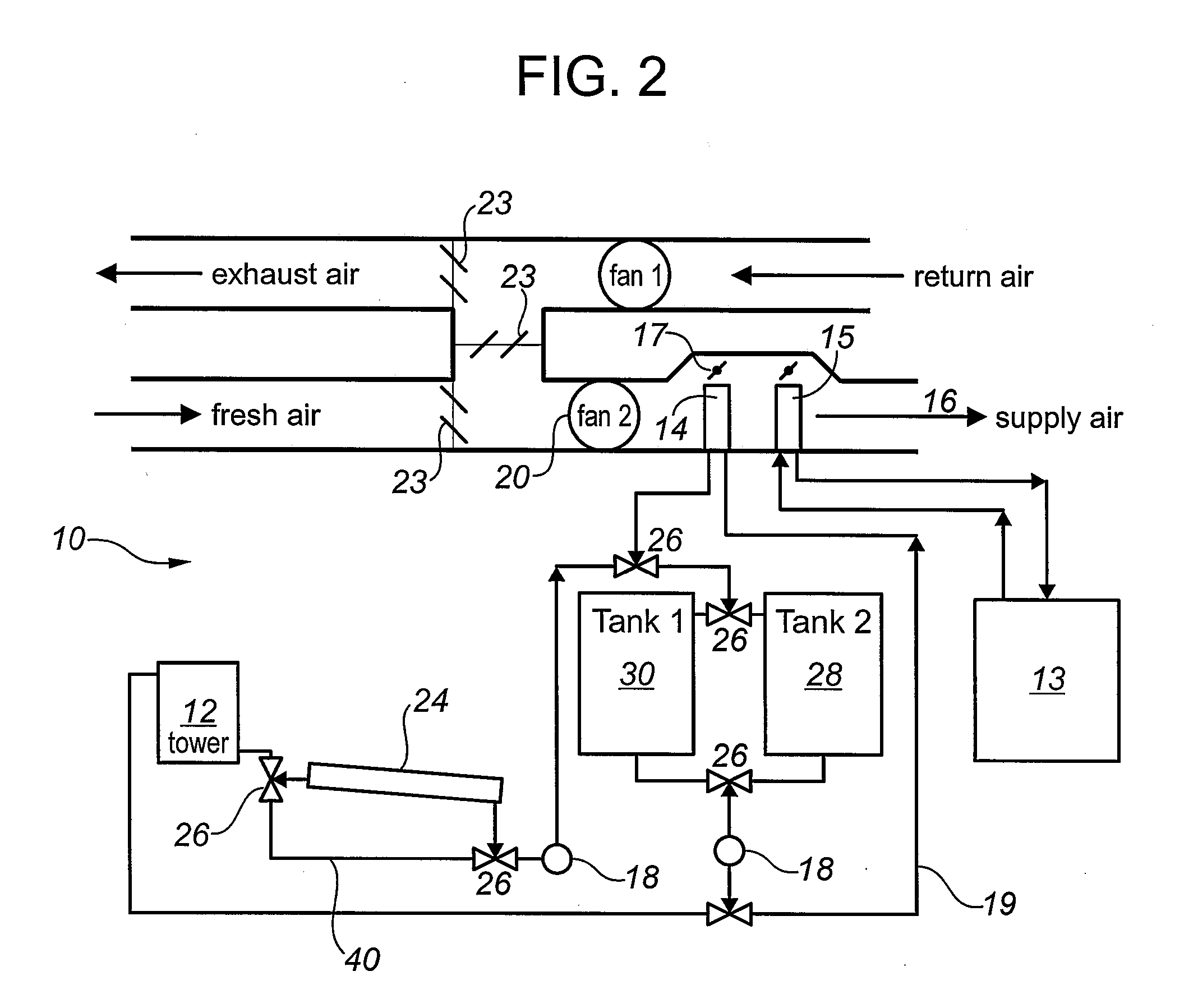

System and methods for cooling electronic equipment

ActiveUS9119326B2Stable toleranceImprove securityCompressorEfficient regulation technologiesAtmospheric airWet-bulb temperature

Systems and methods for cooling an inverter of a variable frequency drive that drives a compressor in a cooling system for electronic equipment are disclosed. The system includes a first fluid circuit that cools electronic equipment using a first fluid flowing therethrough and a second fluid circuit that free cools a second fluid flowing therethrough. The second fluid circuit cools the first fluid using the free-cooled second fluid. The system further includes a third fluid circuit that mechanically cools the second fluid using a third fluid flowing therethrough as a function of the wet bulb temperature of atmospheric air. The third fluid circuit includes at least one compressor compresses the third fluid and is driven by a motor coupled to the variable frequency drive. At least a portion of the first fluid flowing through the third fluid circuit is diverted to cool the inverter of the variable frequency drive.

Owner:INERTECH IP

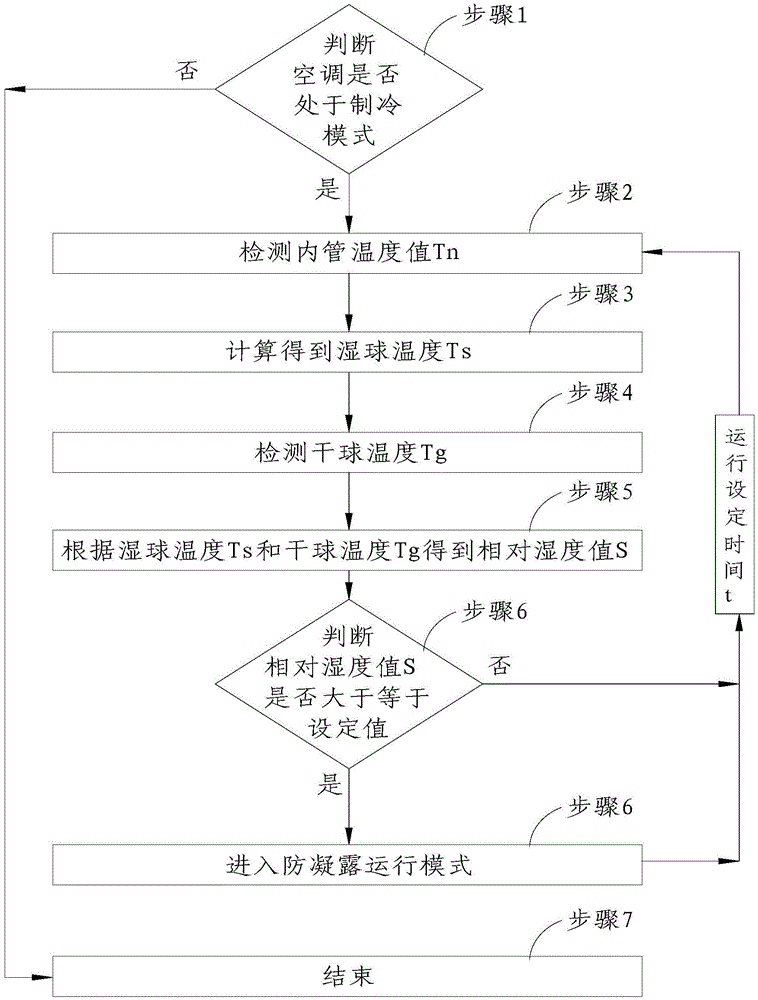

Air conditioner control method

InactiveCN104534618AReliable valuePracticalMechanical apparatusCondensate preventionWorking environmentOperation mode

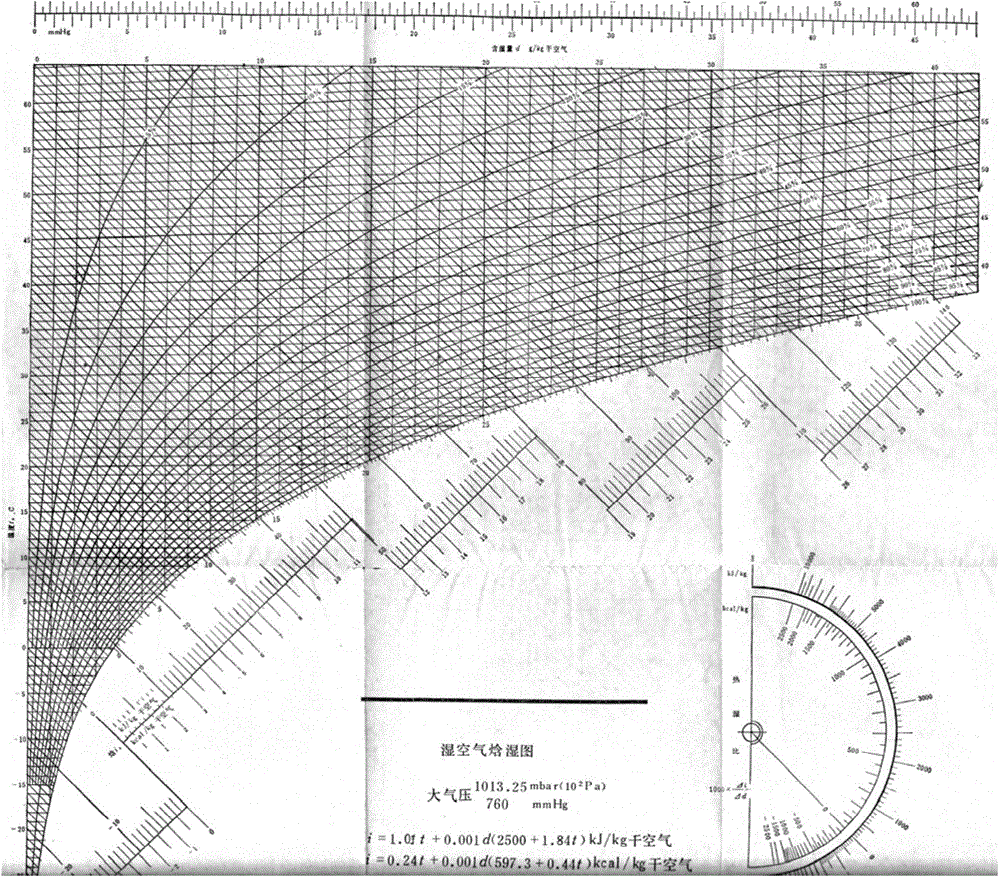

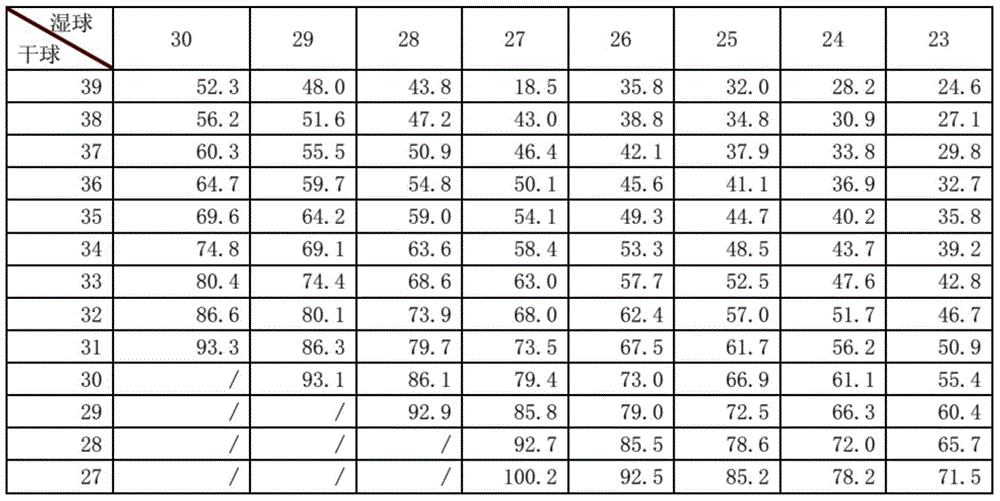

The invention discloses an air conditioner control method, belongs to the field of an anti-condensation control method of an air conditioning device and is designed for solving the problems of high cost, poor practicability and the like of the existing method. The air conditioner control method comprises the following steps: when judging that an air conditioner is in a refrigeration mode, substituting an inner pipe temperature value Tn detected by a first thermometer bulb of an indoor unit into a formula, namely a wet bulb temperature Ts=A* inner pipe temperature value Tn+B, so as to obtain the wet bulb temperature Ts, wherein A and B are constant numbers, the A belongs to [-10,10] and the B belongs to [-20,20]; obtaining a relative humidity value S by checking a psychrometric chart or checking a table composed of dry bulb temperatures Tg and wet bulb temperatures Ts in the psychrometric chart; and when the relative humidity value S is more than or equal to 60%, enabling the air conditioner to enter an anti-condensation operation mode. The air conditioner control method can be used for accurately judging according to an actual working environment of the air conditioner and has strong practicability and good anti-condensation effect.

Owner:GREE ELECTRIC APPLIANCES INC

Apparatus and Methods to Measure Economizer Outdoor Air Fractions and Fault Detection Diagnostics of Airflow, Cooling Capacity, and Heating Capacity

ActiveUS20170343227A1Accurate temperatureLow accuracyMechanical apparatusSpace heating and ventilation safety systemsActuatorControl theory

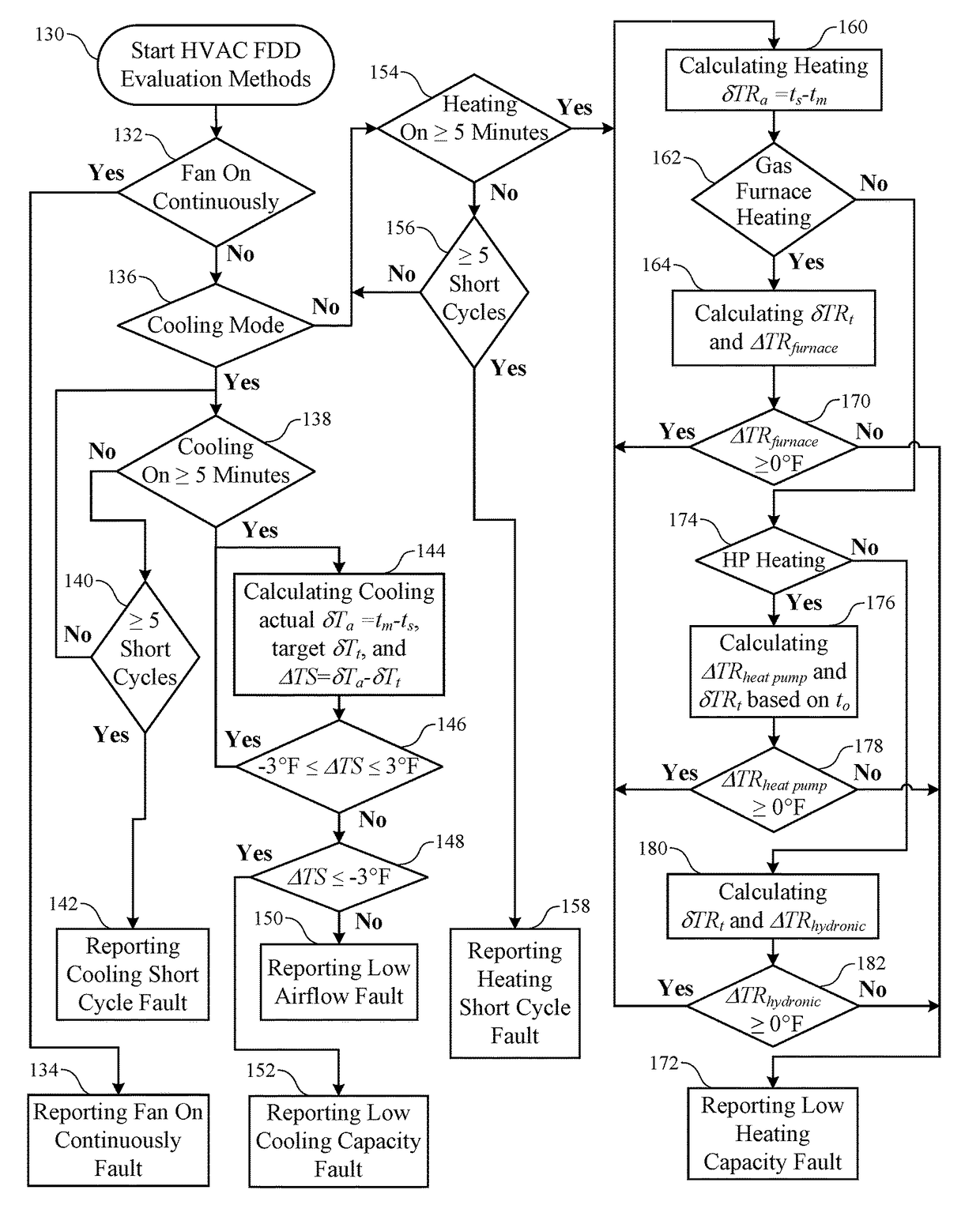

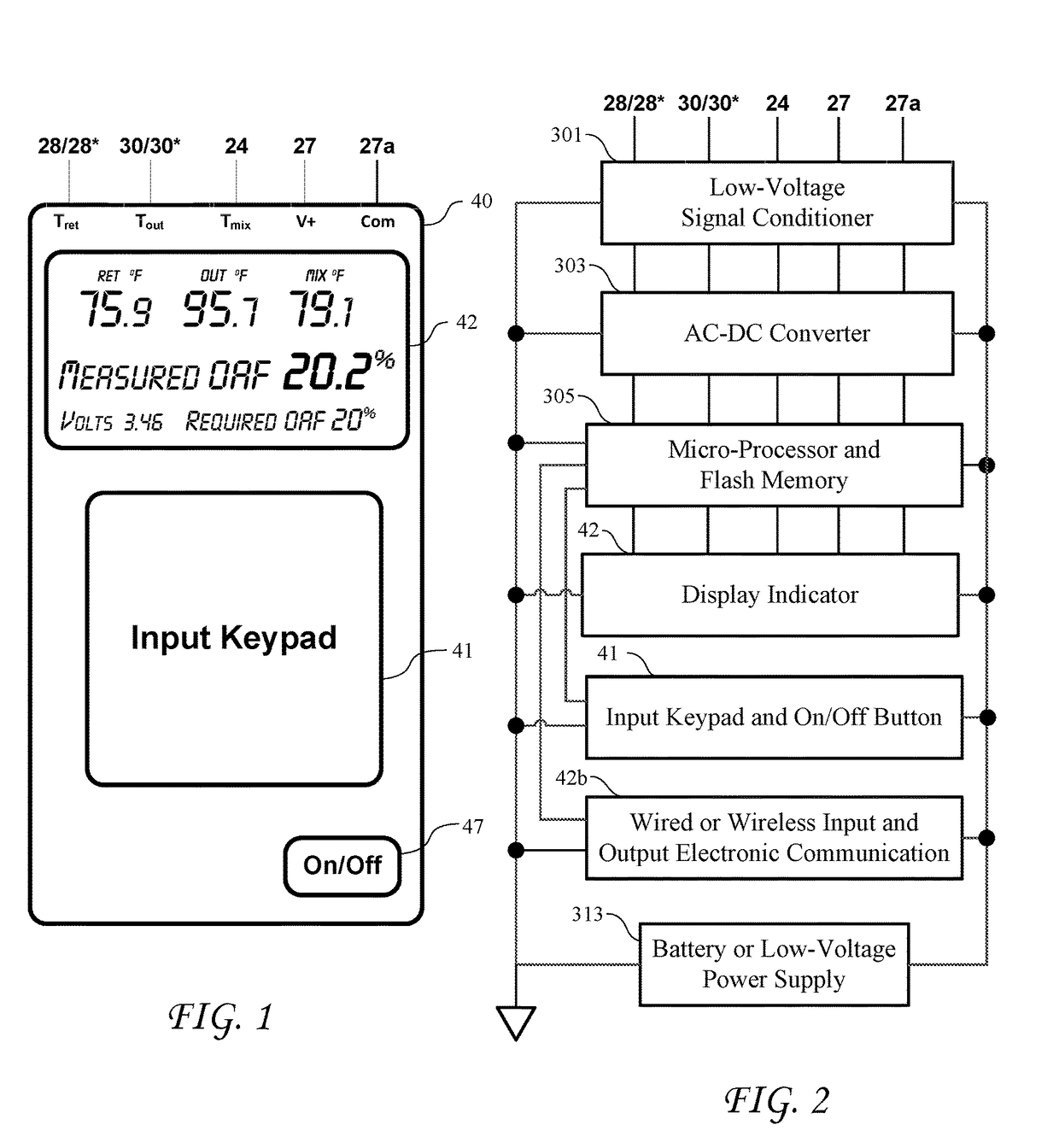

An apparatus and method for measuring or controlling the Outdoor Air Fraction (OAF) ratio through economizer or outdoor air dampers and cabinet to total system airflow and mixed-air humidity ratio and wetbulb temperature for HVAC equipment. An OAF exceeding the minimum regulatory requirements wastes energy and contributes to global warming. OAF is used to optimize economizer damper position either manually or automatically using an economizer Fault Detection Diagnostic controller and actuator to meet minimum outdoor airflow requirements. After the outdoor air damper position is optimized, the mixed-air humidity ratio and mixed-air wetbulb temperature are determined and used with the measured mixed-air drybulb and supply-air drybulb temperatures to evaluate evaporator airflow, cooling capacity, and heating capacity, and, if necessary, provide a visual or electronically-transmitted error code signal indicating maintenance requirements to check or correct economizer damper position, cabinet leakage, airflow, cooling or heating capacity, and / or other faults for the HVAC system.

Owner:MOWRIS ROBERT J

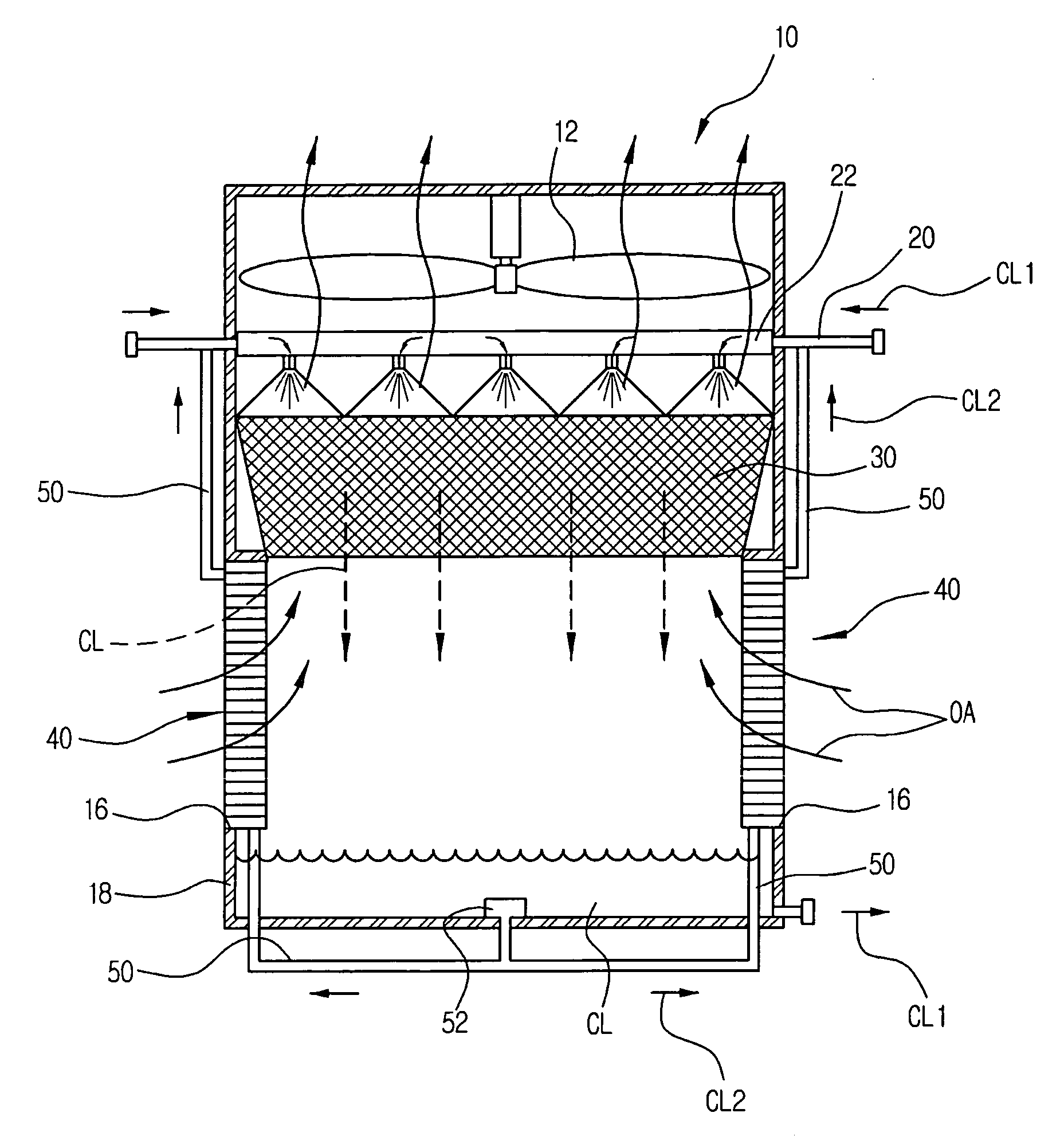

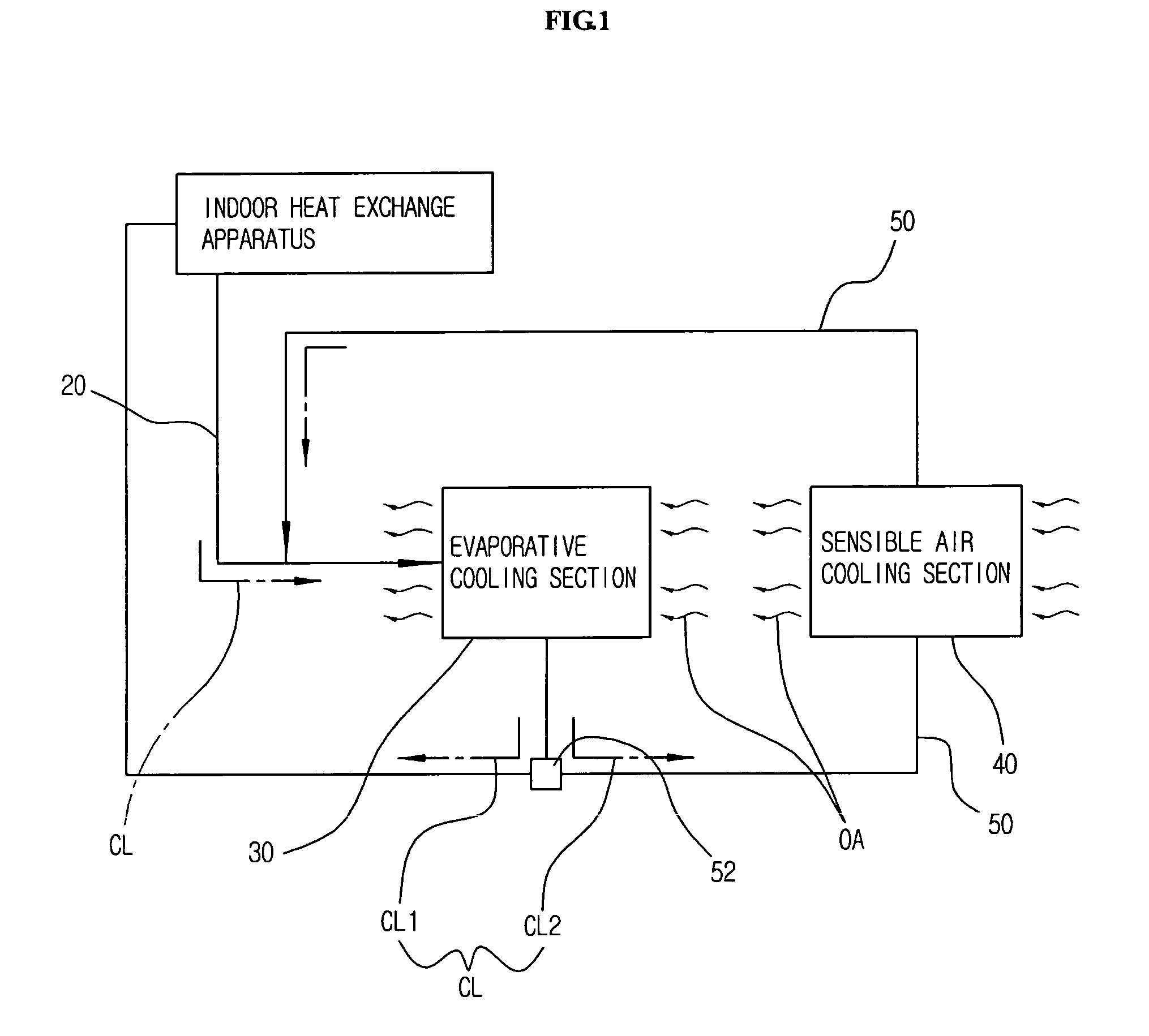

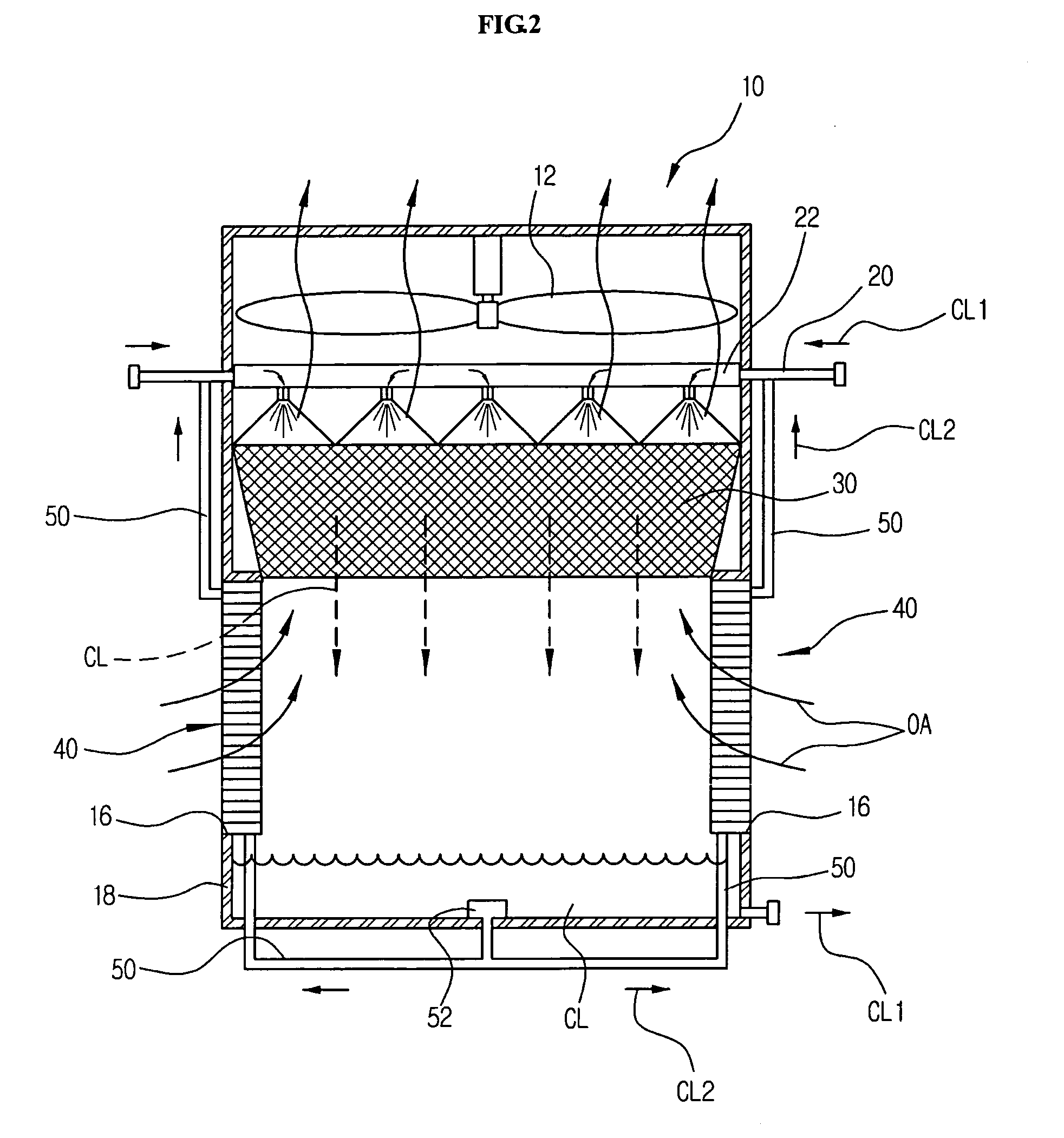

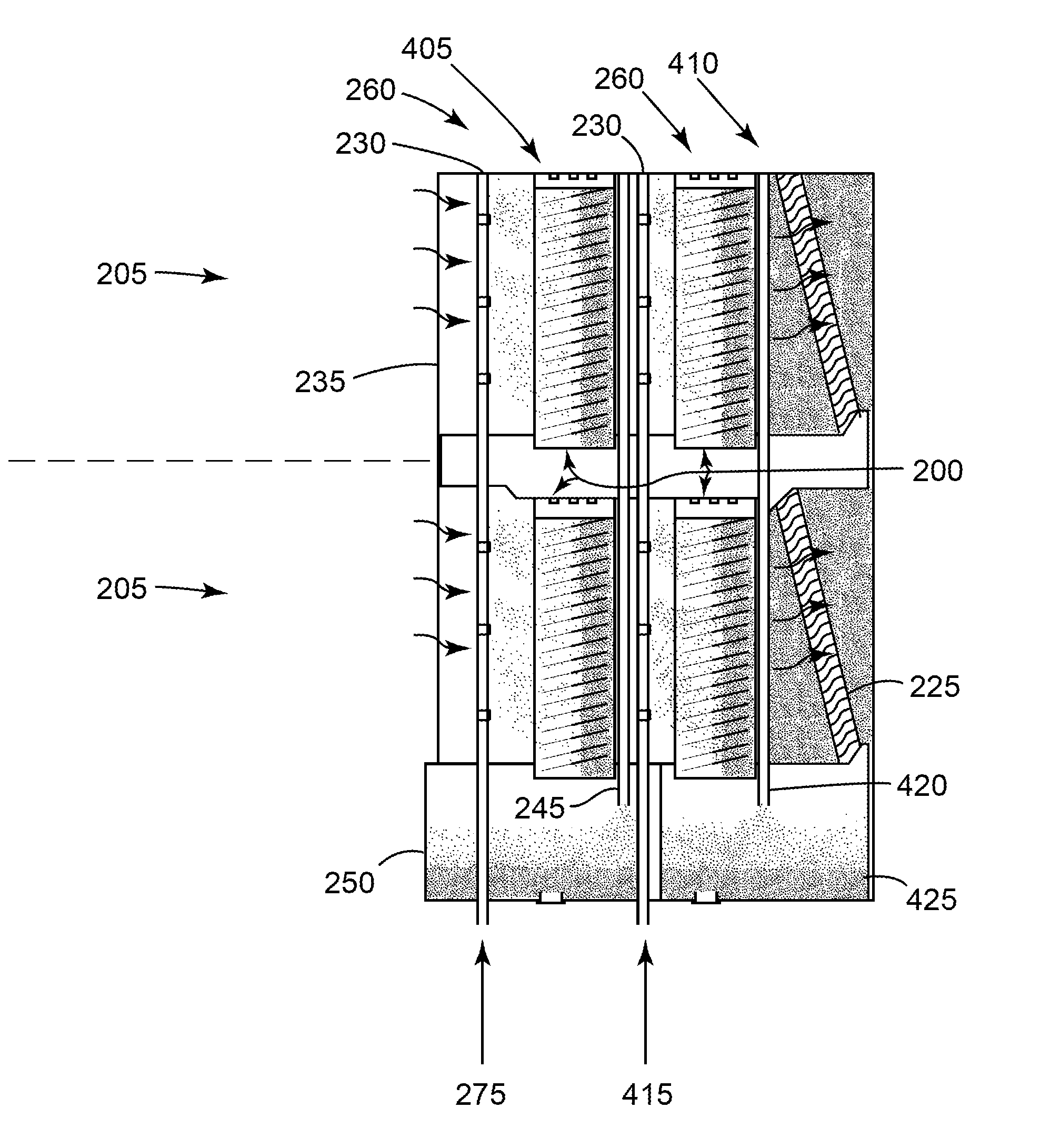

Method and apparatus for evaporative cooling of a cooling fluid

InactiveUS20050279115A1Maximize Cooling EfficiencyReduce the temperatureFree-cooling systemsEfficient regulation technologiesEvaporative coolerCooling tower

A method and an apparatus of evaporative cooling for reducing the volume of an evaporative cooler by considerably lowering the temperature of a cooling fluid are disclosed. A first cooling fluid, which comprises most part of the cooling fluid evaporatively cooled by an outside air while passing through an evaporative cooling section after circulating in an apparatus to be cooled, re-circulates in the apparatus to be cooled. A second cooling fluid, which is separated from the cooling fluid after being cooled in the evaporative cooling section, passes through a sensible air-cooling section placed at an outside air inlet. Thereby, the inflow outside air is sensibly cooled. The second cooling fluid, which passes through the sensible cooling section, re-circulates in the evaporative cooling section. Also, the outside air that is sensibly cooled by the second cooling fluid evaporatively cools the cooling fluid, which passes through the evaporative cooling section, again. This process is repeated. Accordingly, the cooling efficiency in the apparatus to be cooled becomes maximized. The second cooling fluid indirectly contacts with the outside air, so the outside air is sensibly cooled without increasing its humidity. Thus, the wet-bulb temperature of the air inhaled into the evaporative cooling section is reduced and the cooling fluid can be cooled to even a lower temperature. Also, the above structure can provide a cooling fluid of even a lower temperature, so the volume of a cooling tower or outdoor unit, etc. can be reduced considerably.

Owner:WHIZEN GLOBAL

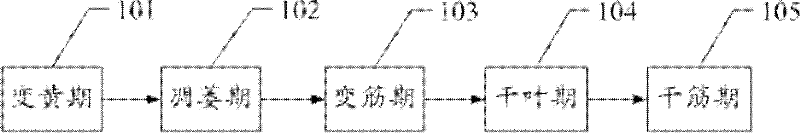

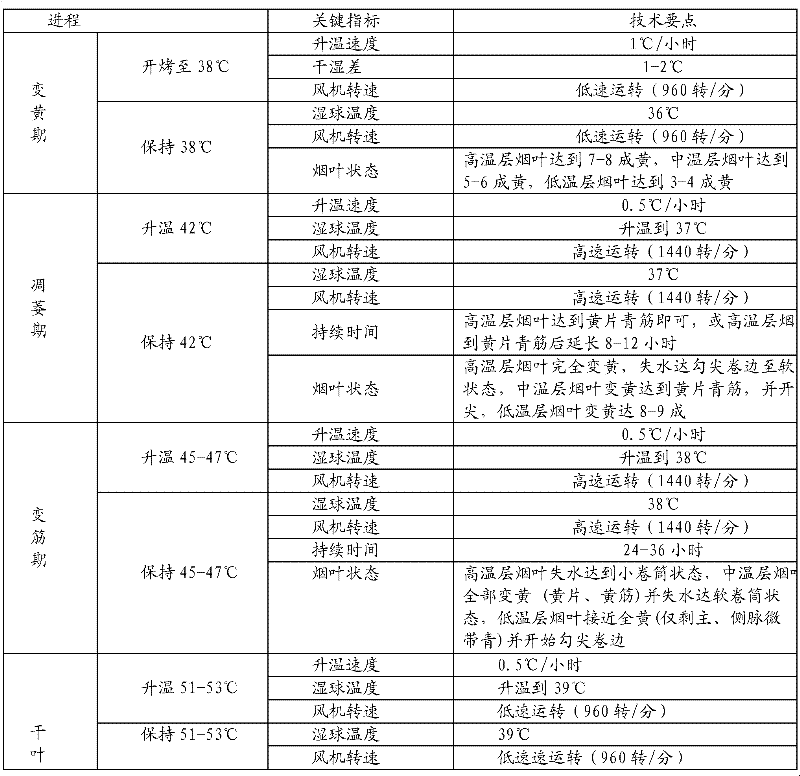

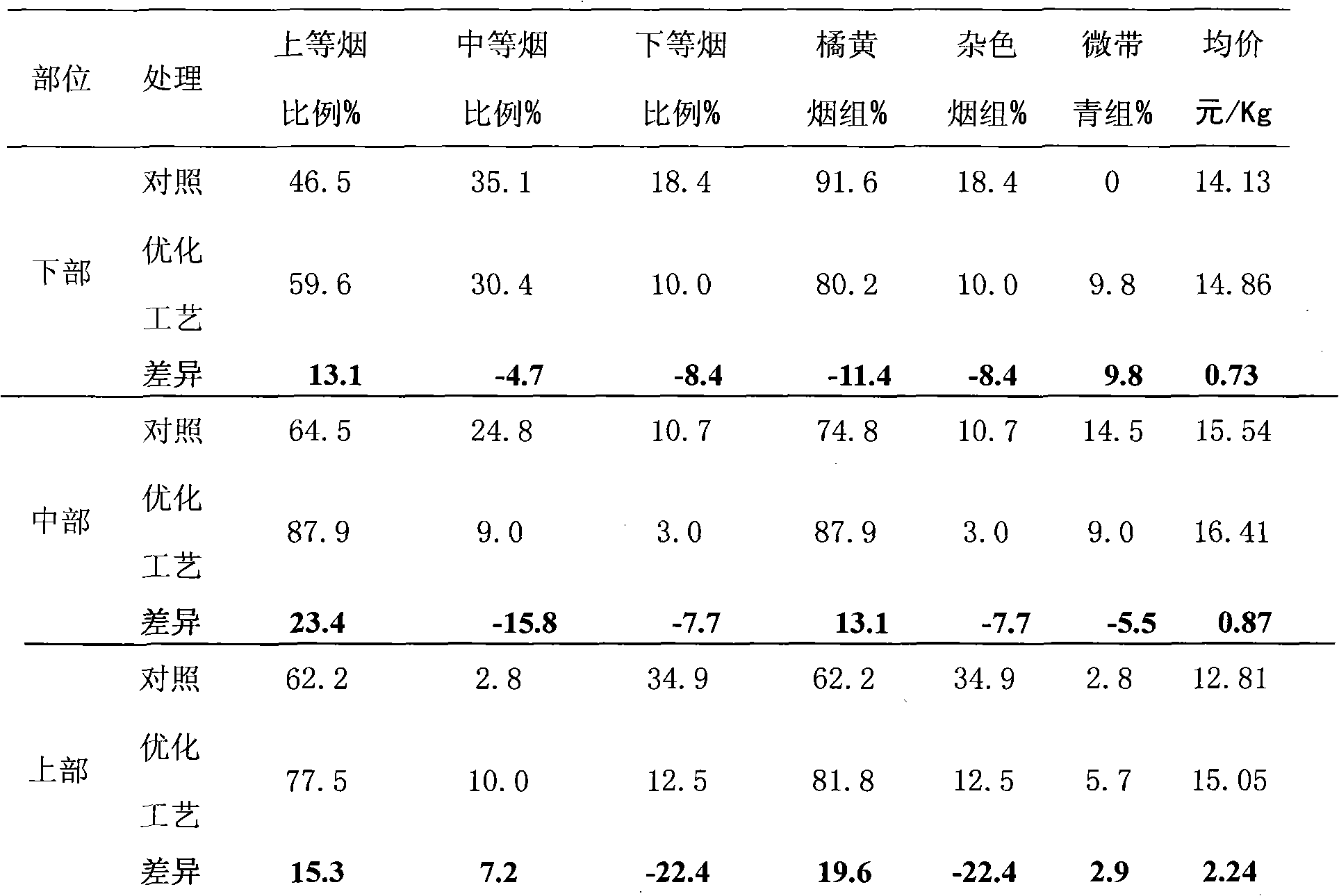

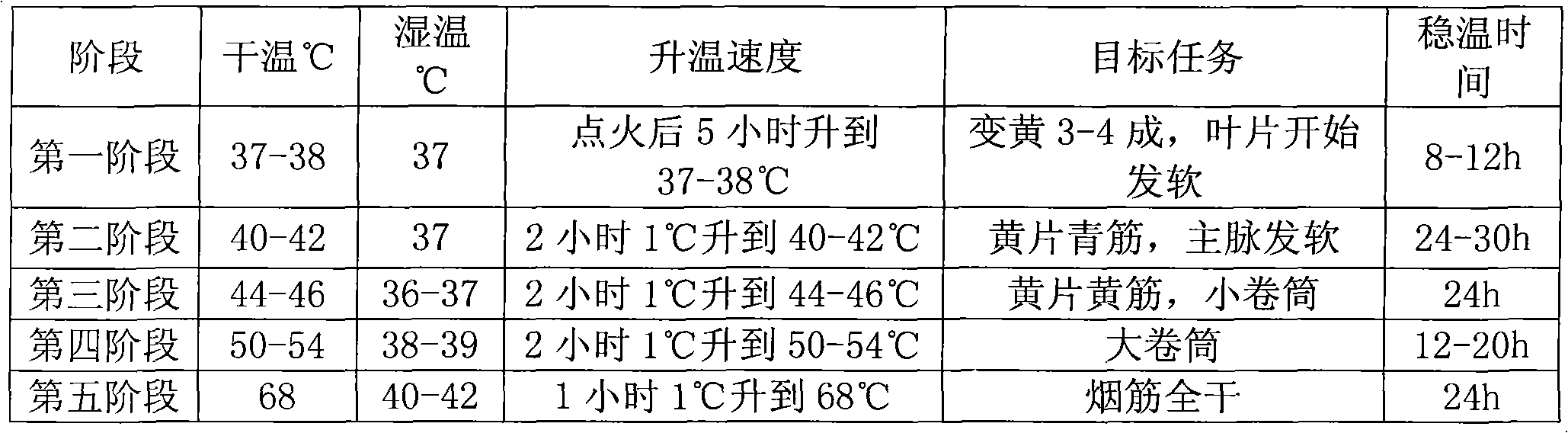

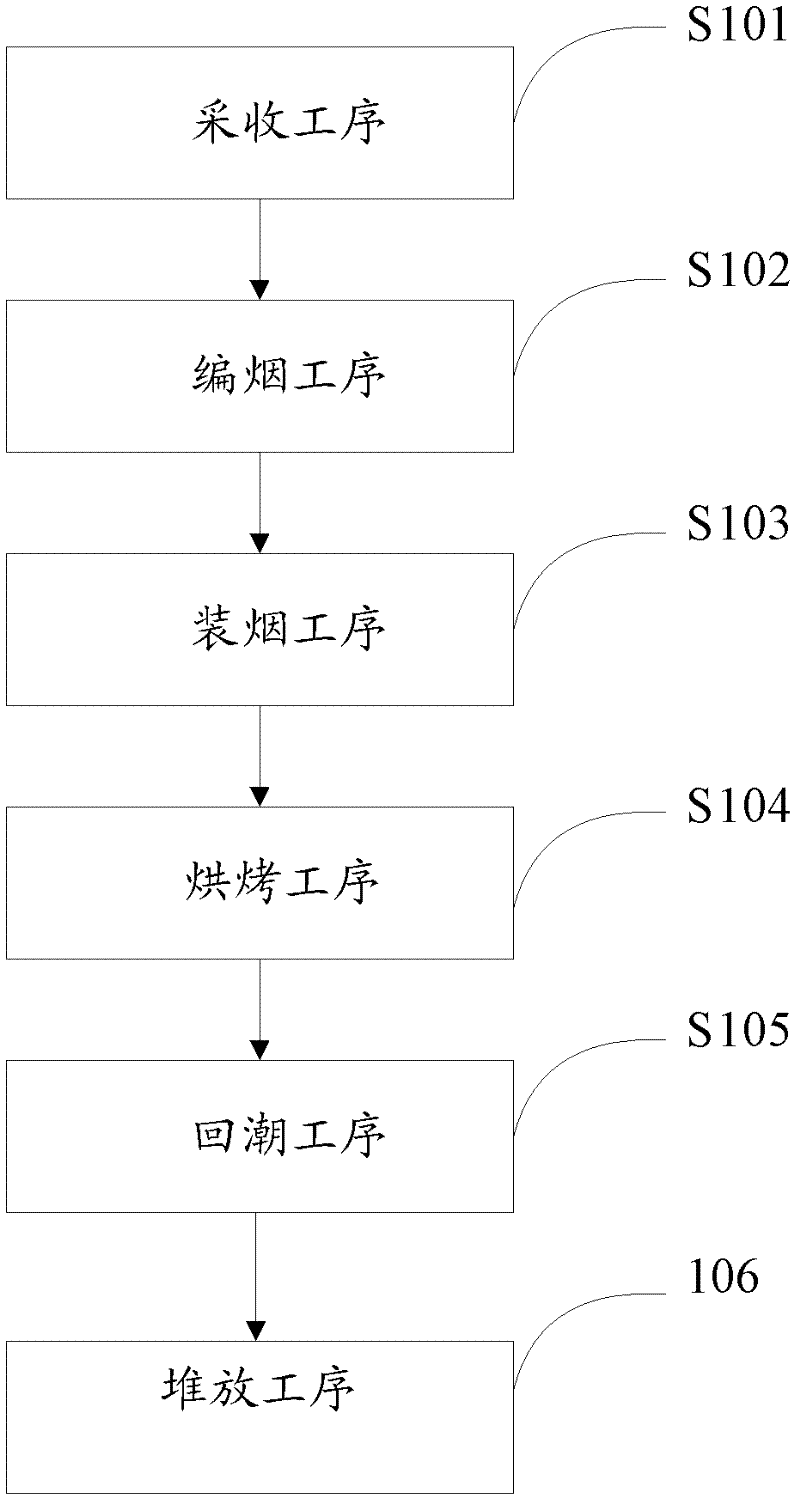

Tobacco flue-curing method for bulk curing barn

The invention relates to the technical field of flue-cured tobacco modulation, in particular to a tobacco flue-curing method for a bulk curing barn. The flue-curing process of the tobacco flue-curing method includes a yellowing period, a withering period, a stem yellowing period, a tobacco leaf drying period and a stem drying period according to factors such as dry-bulb temperature, wet-bulb temperature, drying time, heating rate, variable speed ventilation and tobacco leaf change targets, a color fixing period in the traditional tobacco flue-curing method is prolonged at a fixed point and steady temperature under the condition of hot air circulation, and sufficient decomposition and transformation of amylum, protein and other macromolecular substances in tobacco leaves and forming of aromatic matters are promoted. The tobacco flue-curing method for the bulk curing barn is easy to operate, safe and secure, can keep tobacco leaf yellow to be stable, leaf shrinking degree to be good, oil content to be increased and tobacco leaf aromatic amount to be increased greatly, further can reduce or avoid tobacco leaf roasting damage of green smoke roasting, ash smoke hanging, black bad smoke, lousy smoke roasting and the like, and can obtain high-quality tobacco leaves through roasting.

Owner:四川省烟草公司宜宾市公司

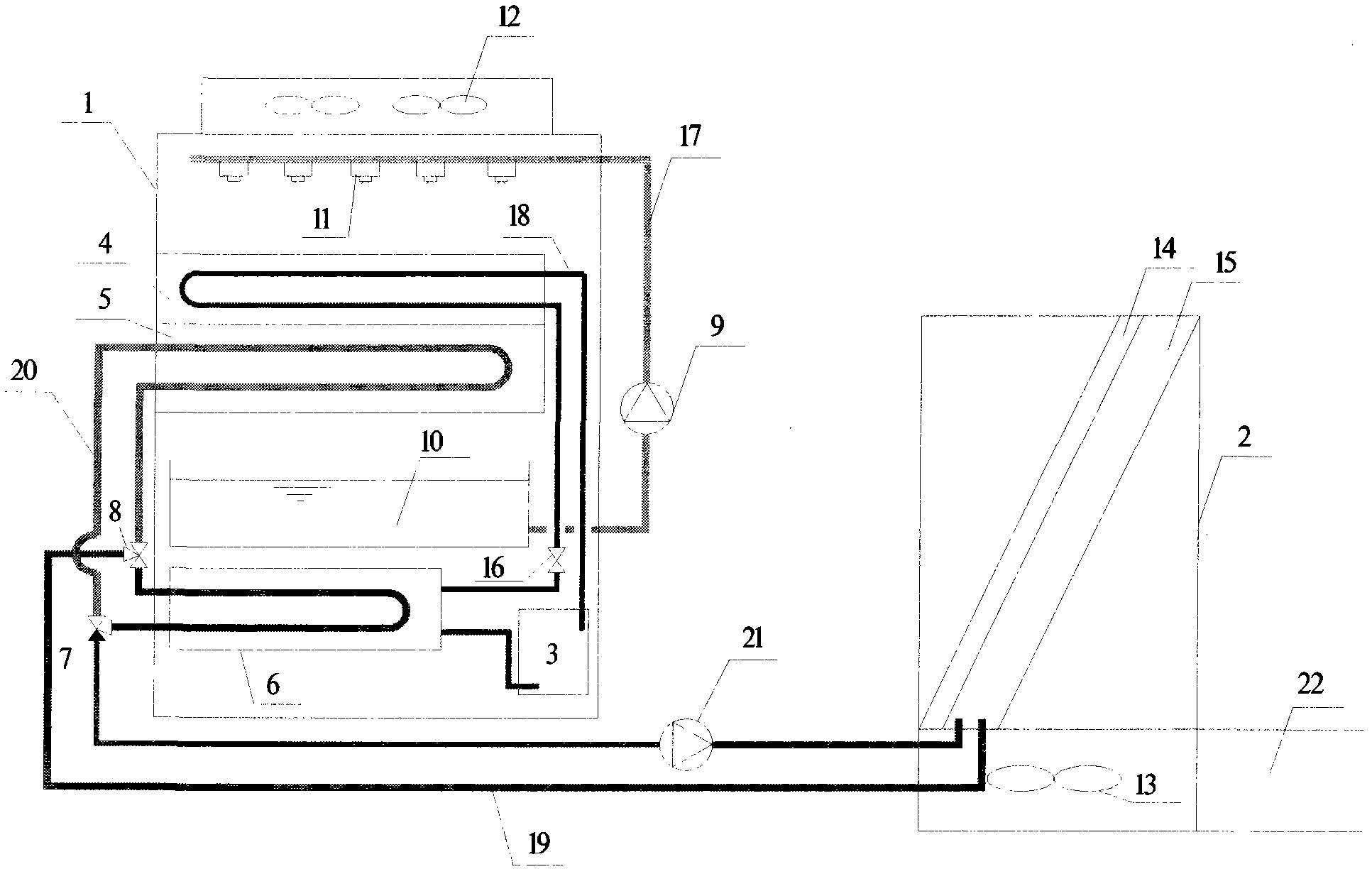

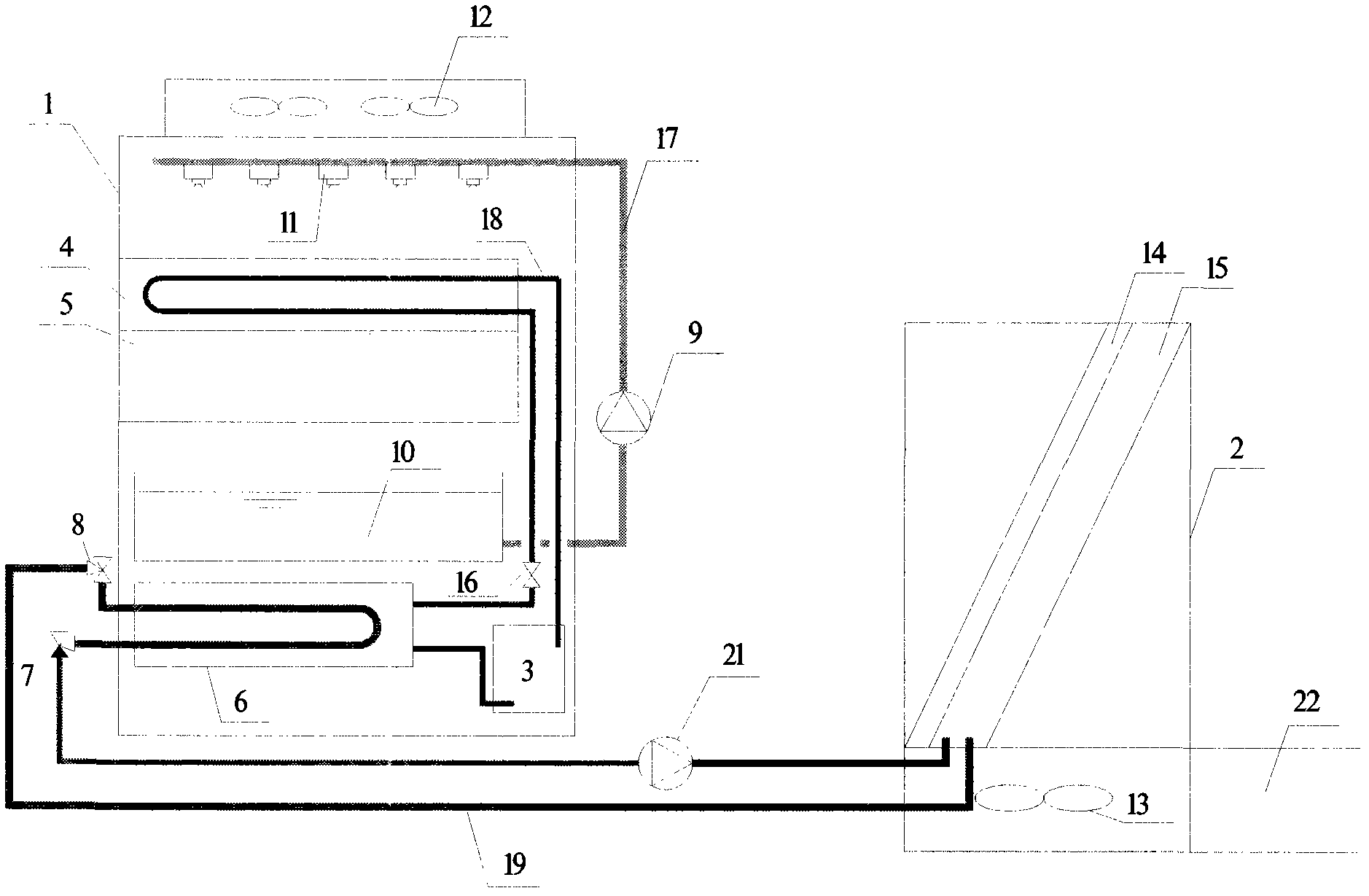

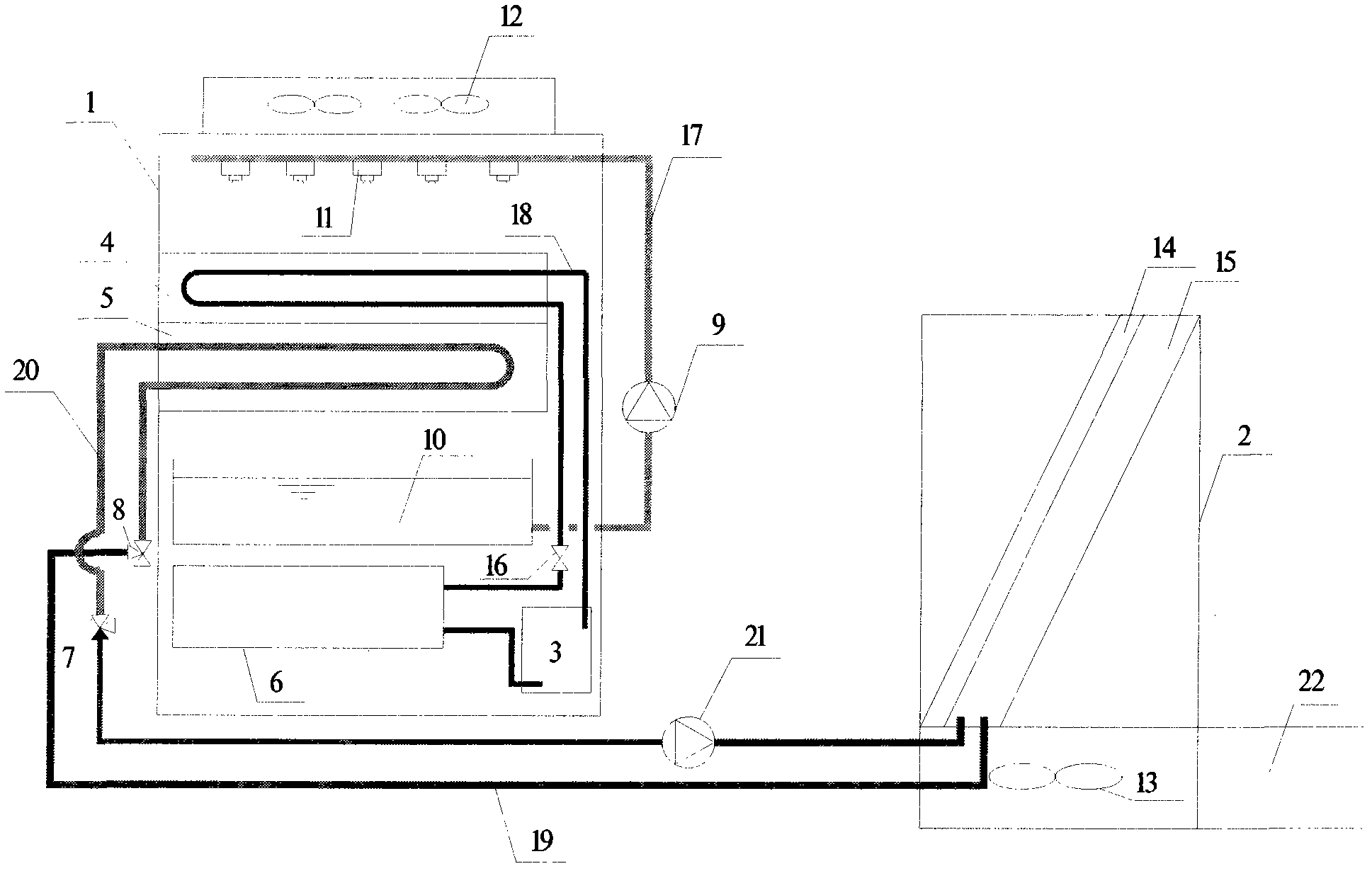

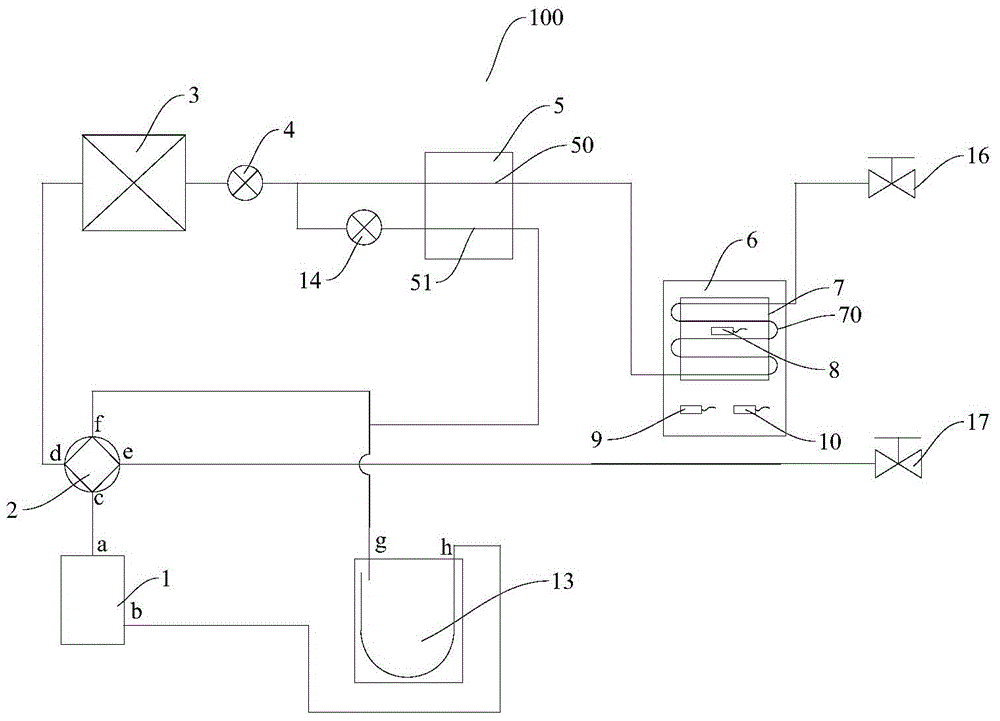

Natural cold source cooling water chiller

InactiveCN101988722AReduce noiseSolution to short lifeLighting and heating apparatusSpace heating and ventilation detailsEvaporative coolerCooling tower

The invention relates to a natural cold source cooling water chiller which comprises an outdoor unit and an indoor unit, wherein the outdoor unit mainly consists of a refrigeration system composed of a totally-enclosed scroll compressor, an evaporator, an evaporative condenser and a natural cold source collection device, and a water channel circulating system with a three-way valve so as to realize the mechanical refrigeration of the evaporative condenser and the evaporative cooling and the air cooling of the natural cold source collection device. The water chiller is characterized in that the evaporative condenser and the high-efficiency natural cold source collection device are arranged simultaneously above a cooling circulating water pool, and an axial-flow fan is installed on upper space. When the outdoor wet-bulb temperature is higher than 6 DEG C to 8 DEG C, the evaporative condenser is mainly used to realize refrigeration, when the outdoor wet-bulb temperature is lower than 6 DEG C to 8 DEG C and higher than 0 DEG C and 2 DEG C, the natural cold source collection device which is in the form of cooling tower spraying is mainly used to realize the evaporative cooling, and when the outdoor wet-bulb temperature is lower than 0 DEG Cto 2 DEG C, the natural cold source collection device which is in the form of air cooling is mainly used to realize cooling.

Owner:郭海新 +1

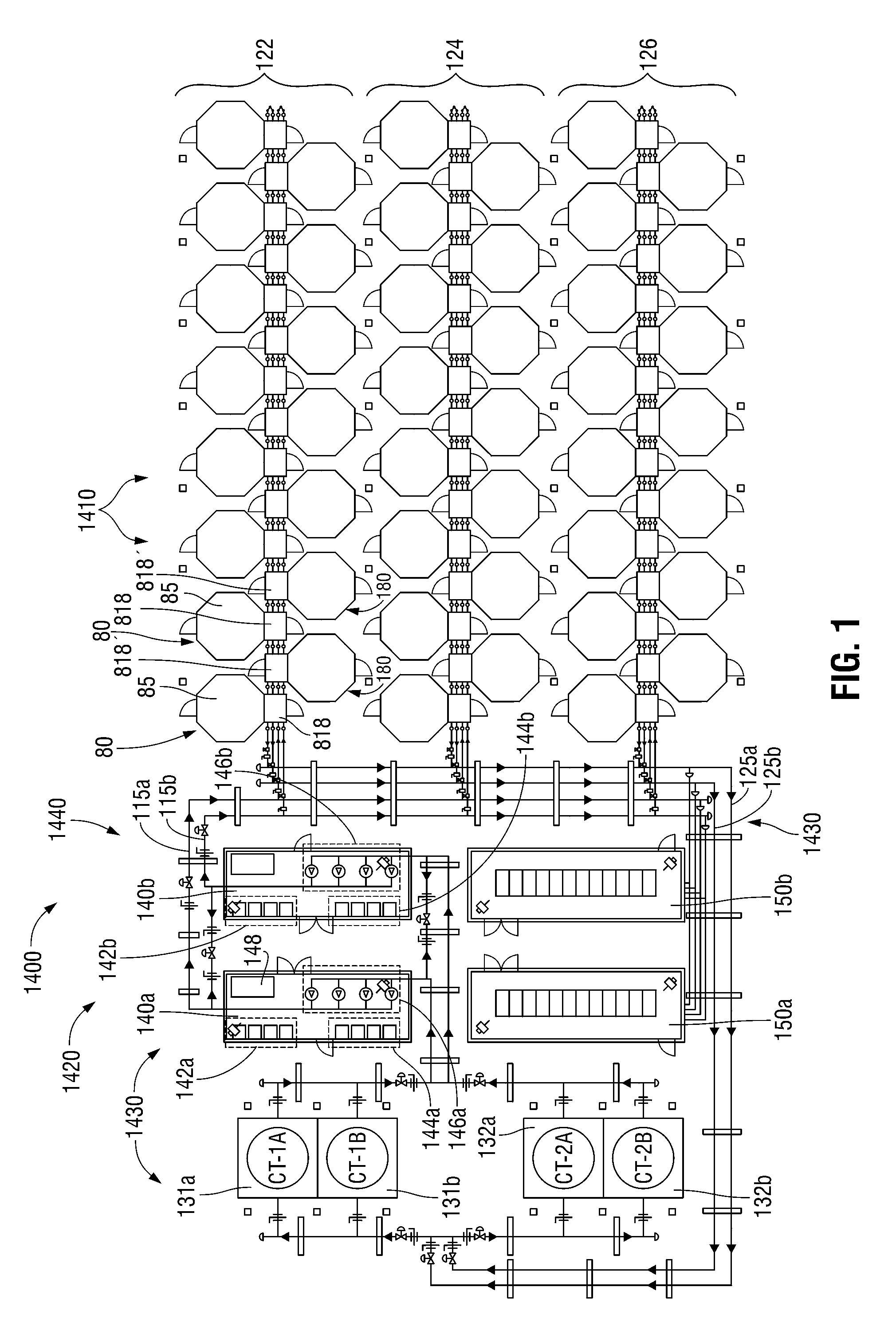

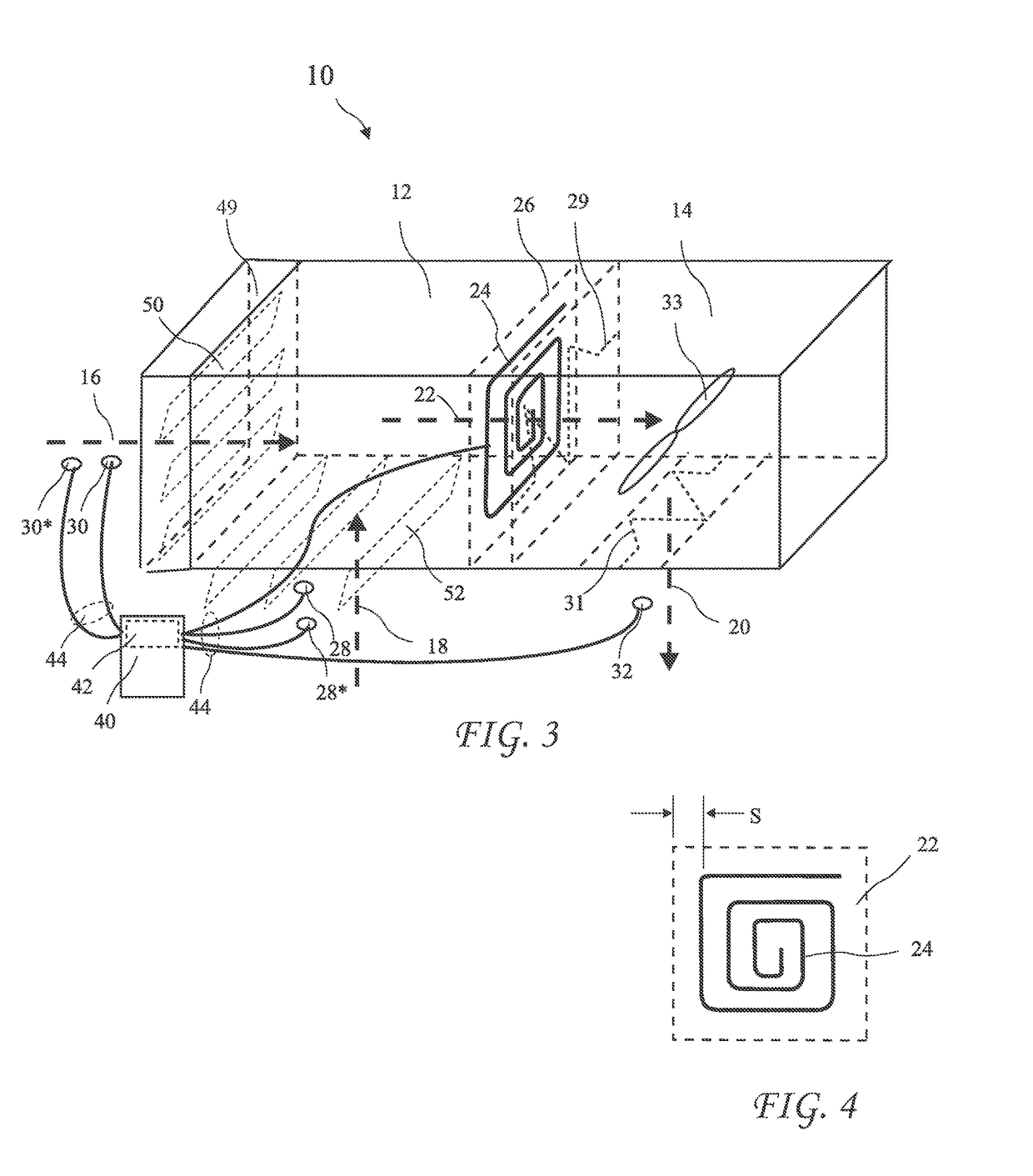

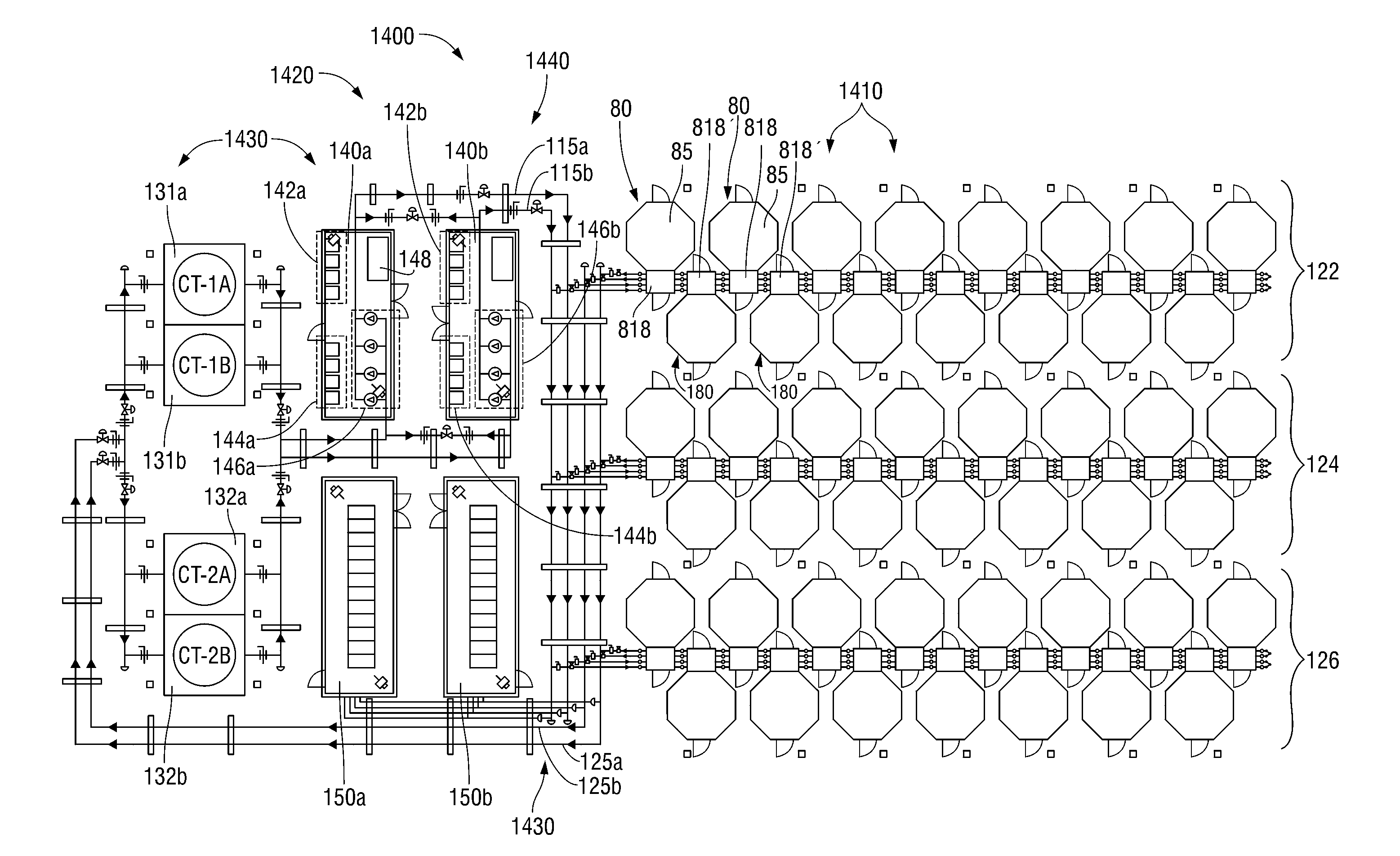

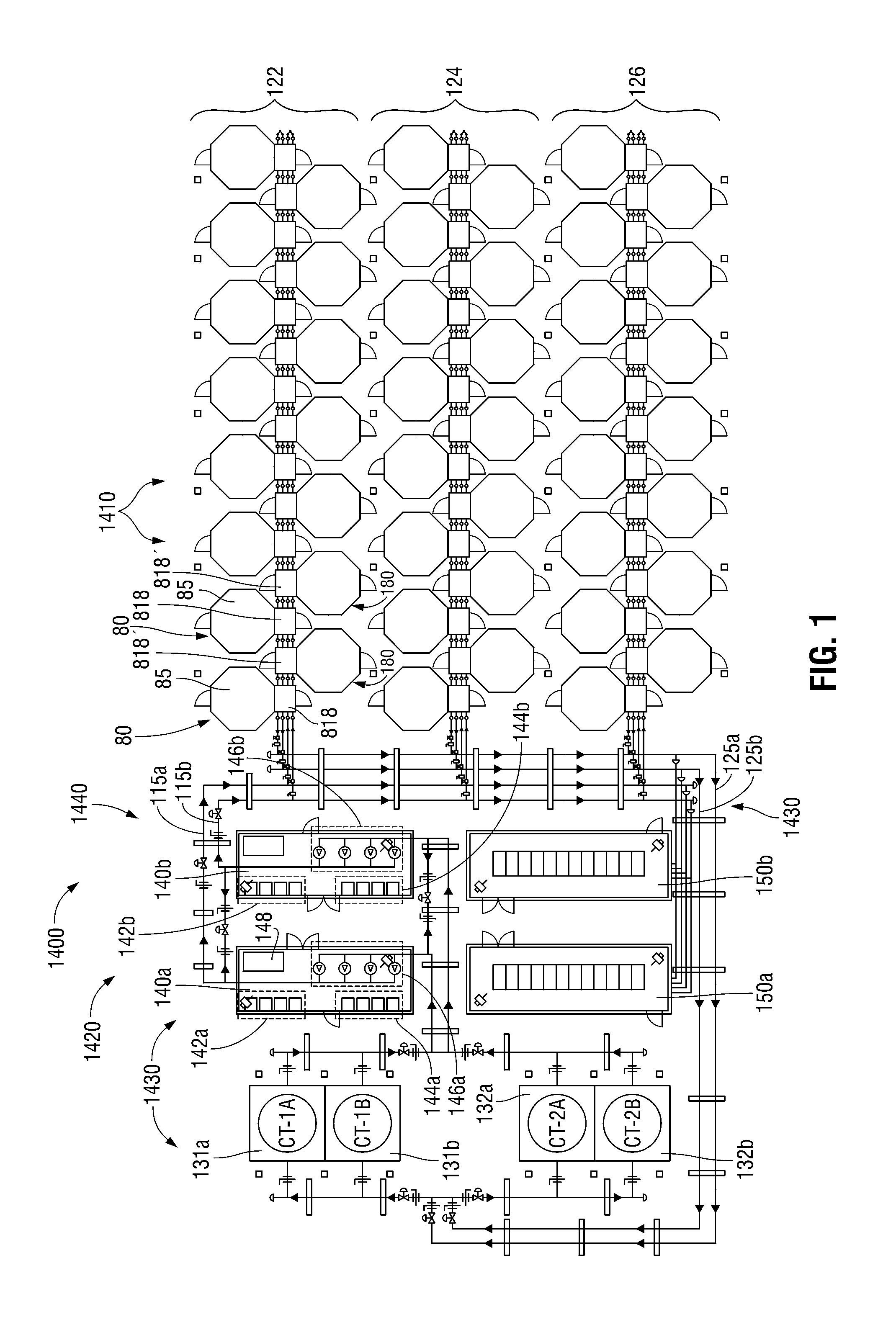

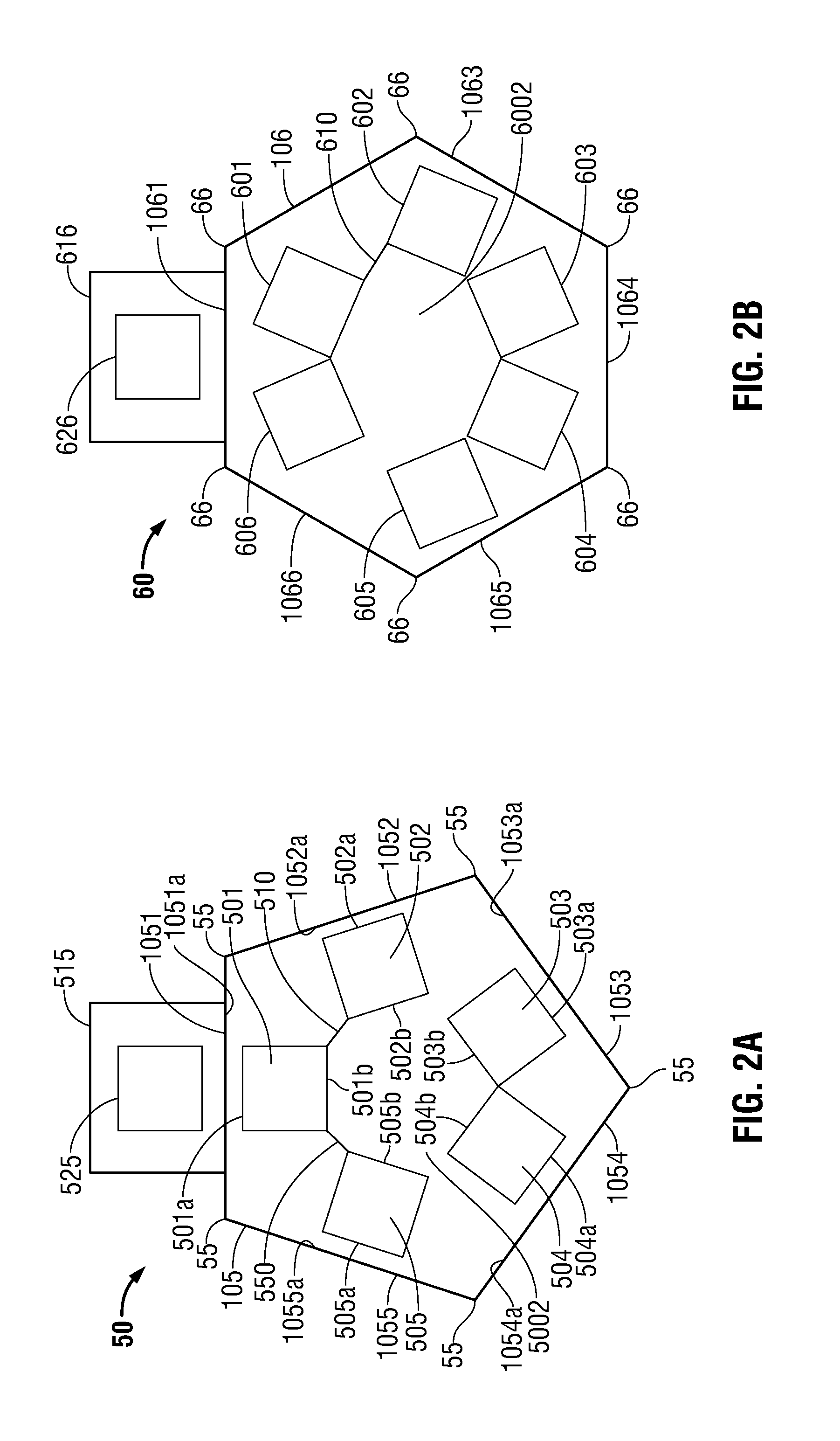

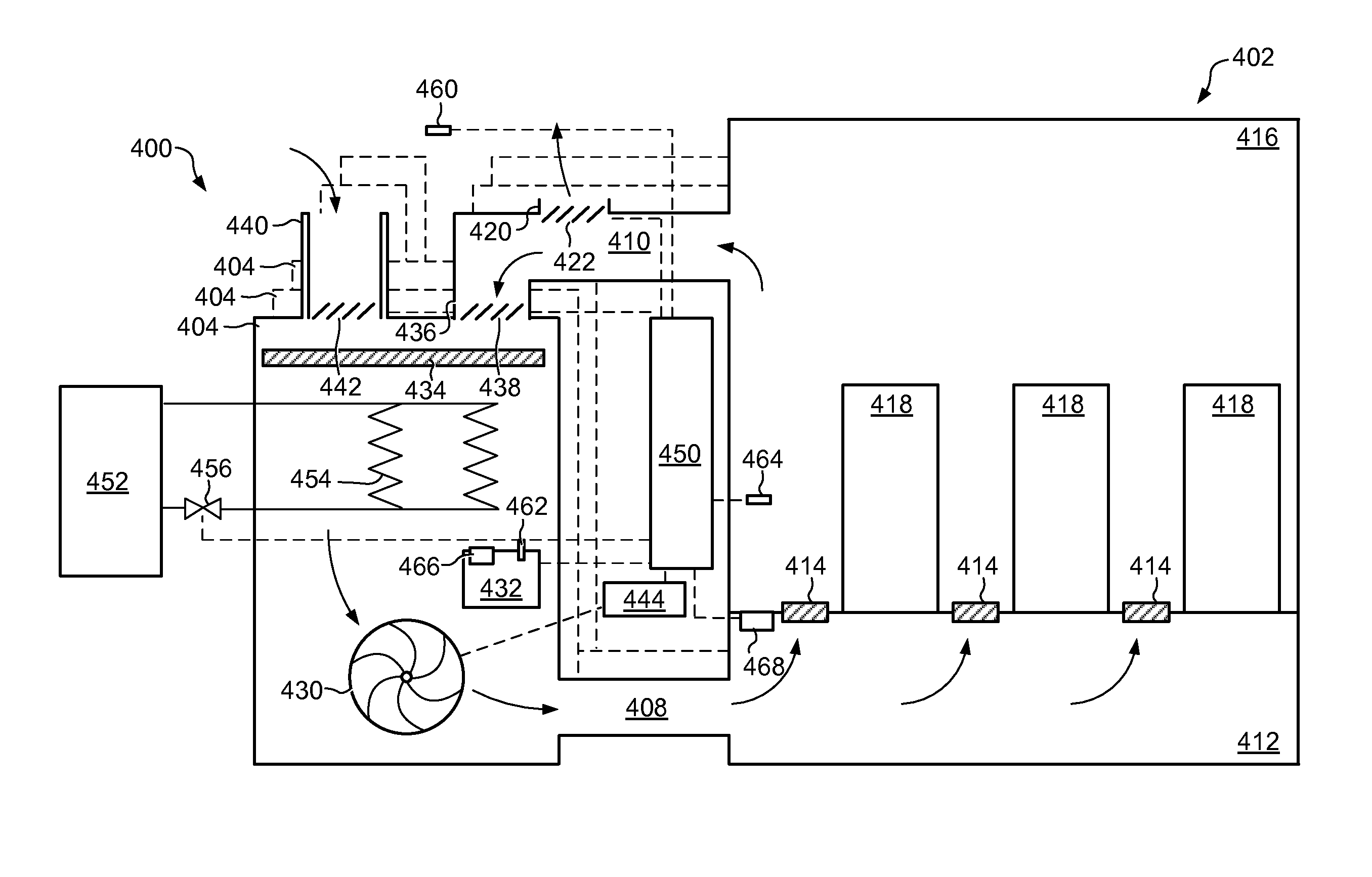

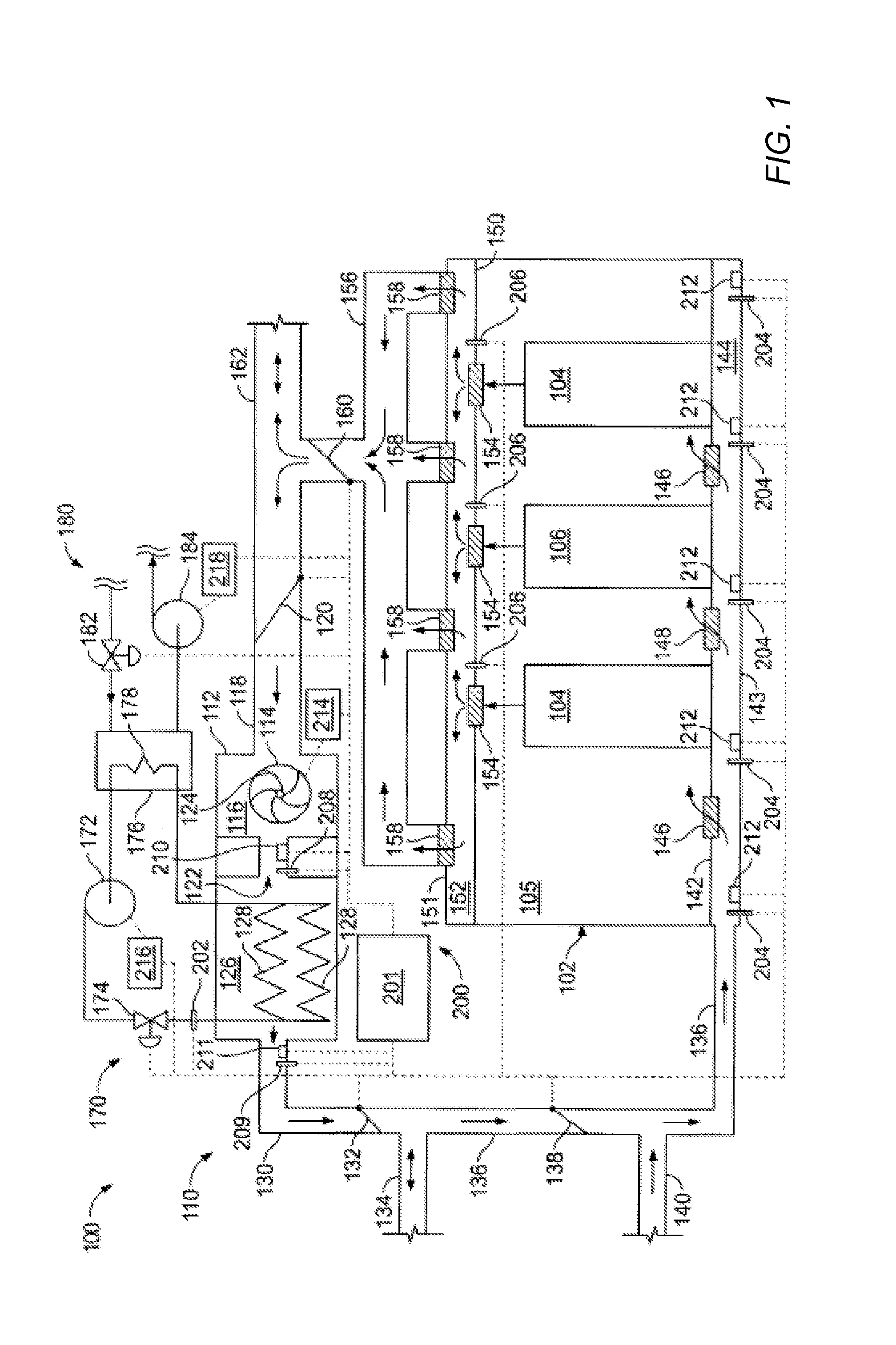

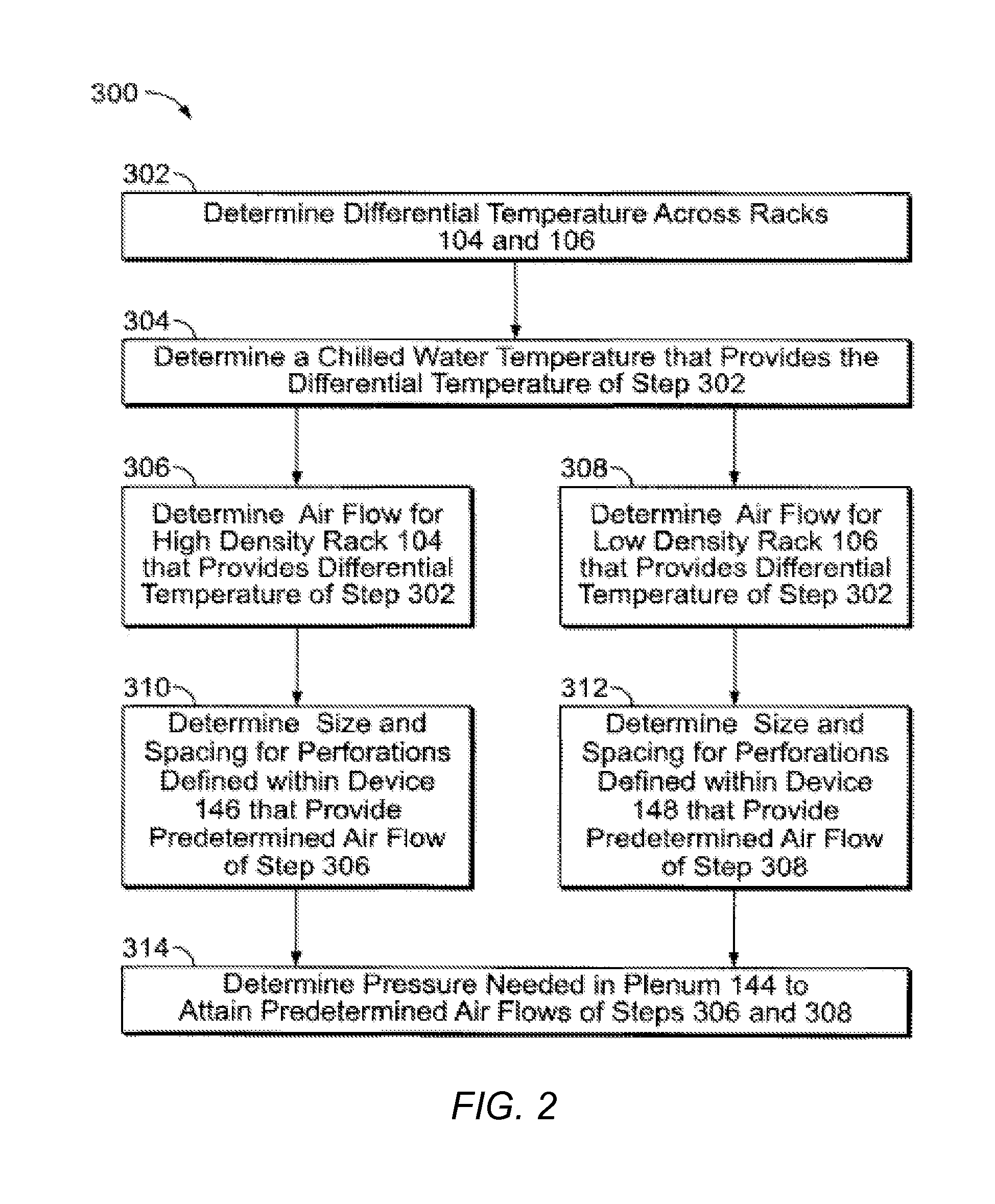

Space-saving high-density modular data pod systems and energy-efficient cooling systems

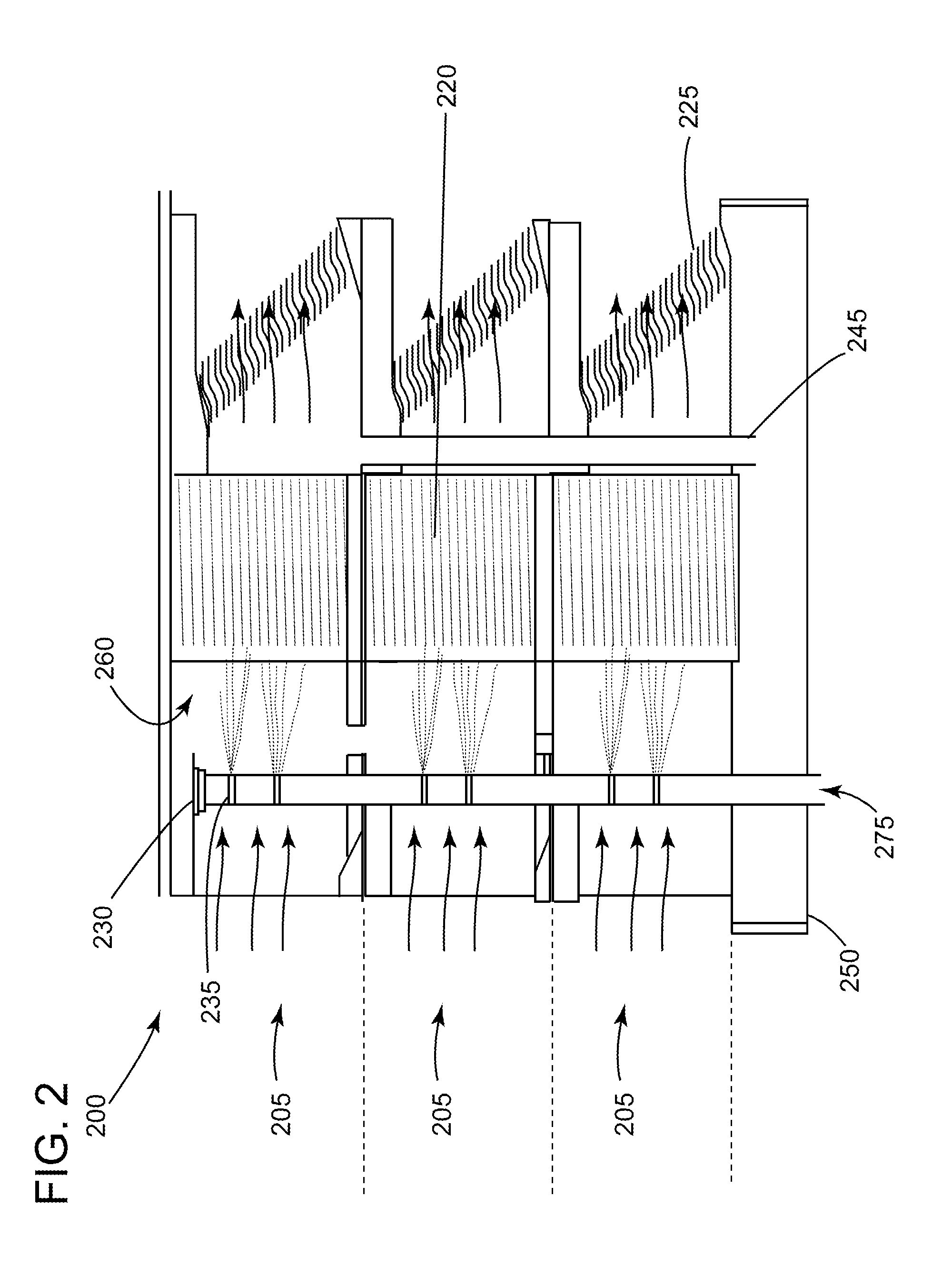

ActiveUS20120125028A1Easily restackedLow costLevel controlDigital data processing detailsHigh densityAtmospheric air

A space-saving, high-density modular data pod system and an energy-efficient cooling system for cooling electronic equipment and method of cooling are disclosed. The cooling system includes a free-cooling system cooling a first fluid in thermal communication with the electronic equipment using atmospheric air and a mechanical sub-cooling system coupled to the free-cooling system. The mechanical system cools a second fluid flowing in the free-cooling system as a function of an amount by which the free-cooling system has exceeded its maximum cooling capacity. The method of cooling includes using a first fluid, enabling heat transfer from the first fluid to a second fluid that has been cooled using atmospheric air, and mechanically cooling the second fluid to the extent that free cooling the first fluid is insufficient to cool the first fluid. The cooling system operates by the wet bulb temperature exceeding a first predetermined wet bulb temperature.

Owner:INERTECH IP

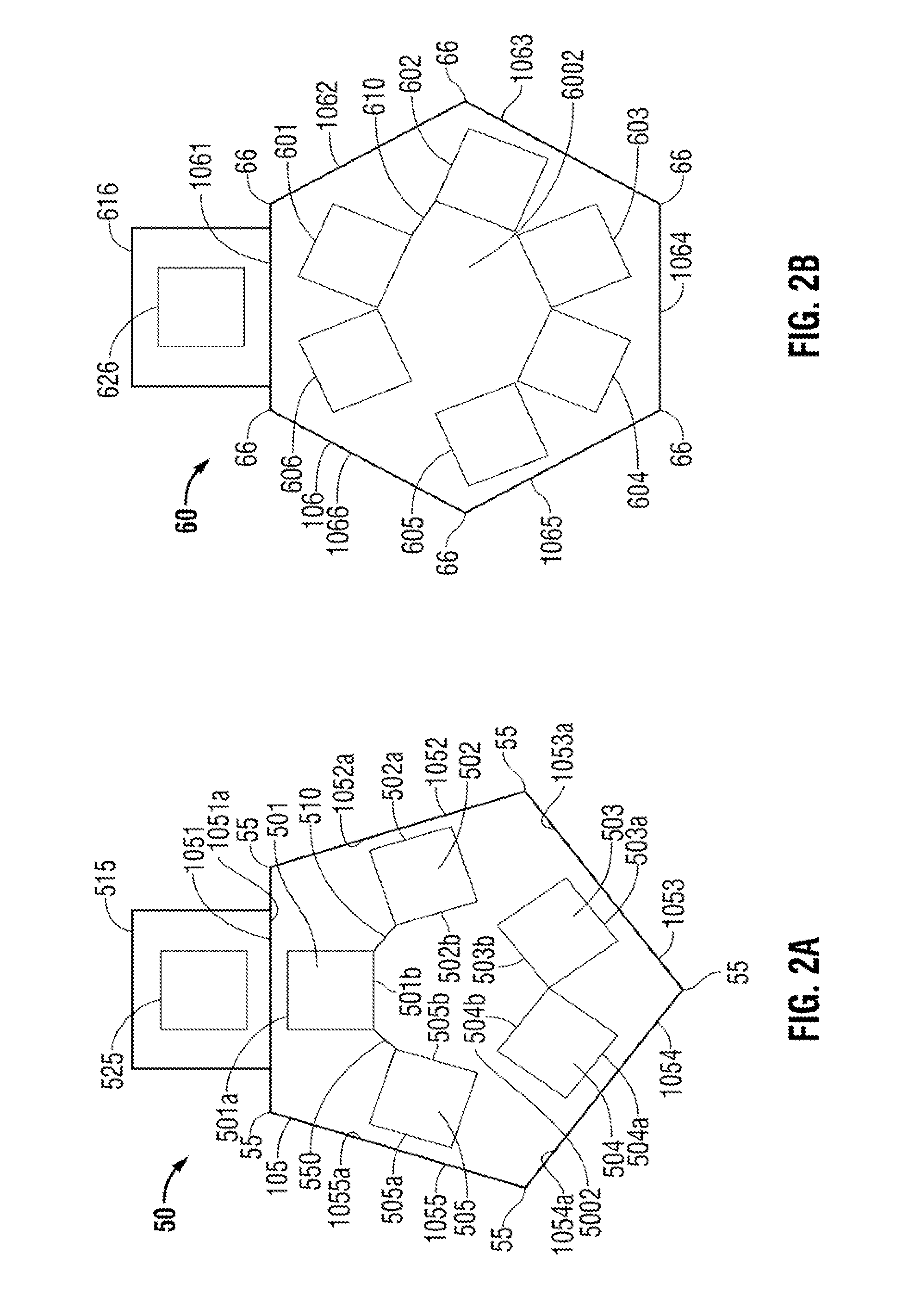

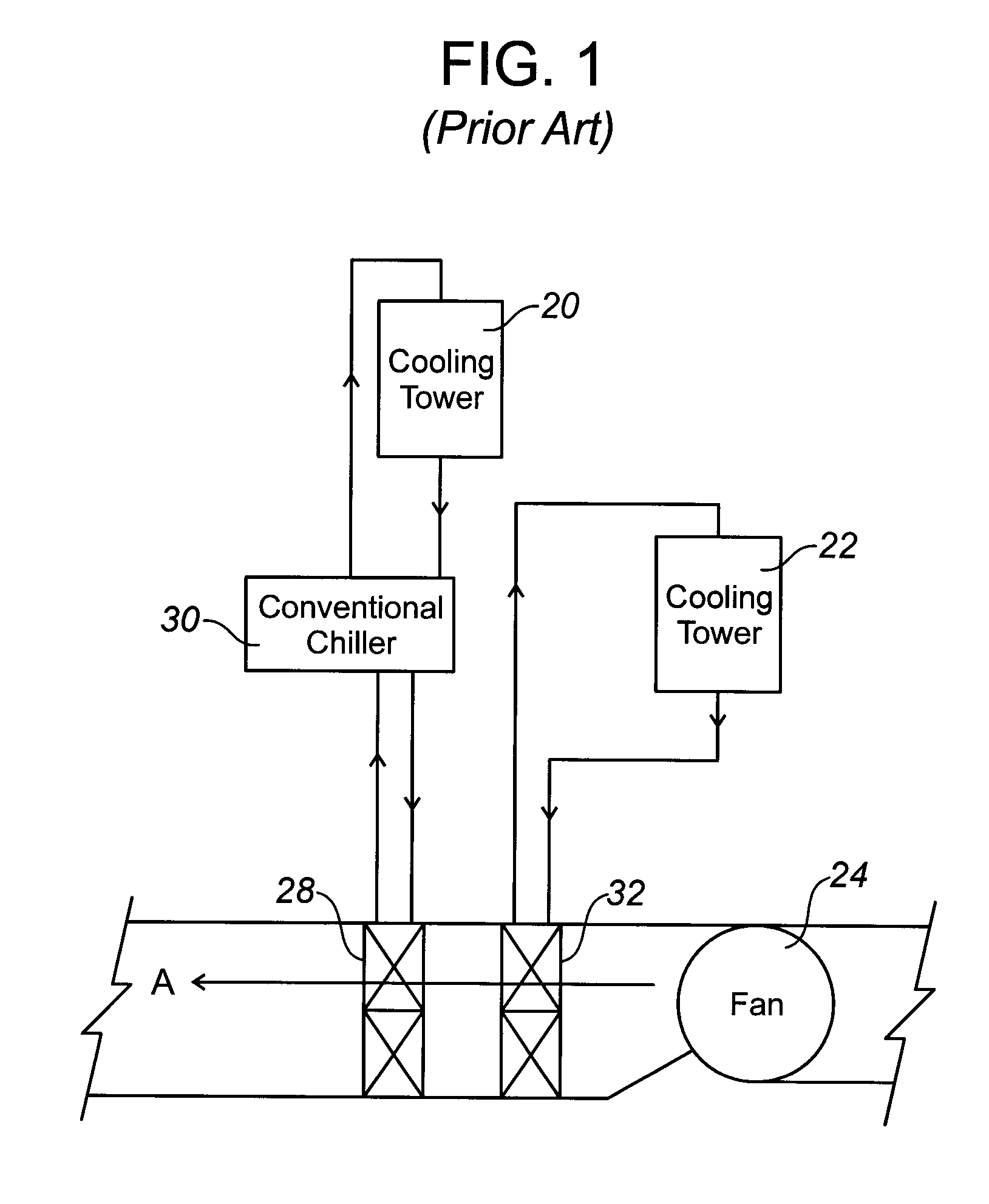

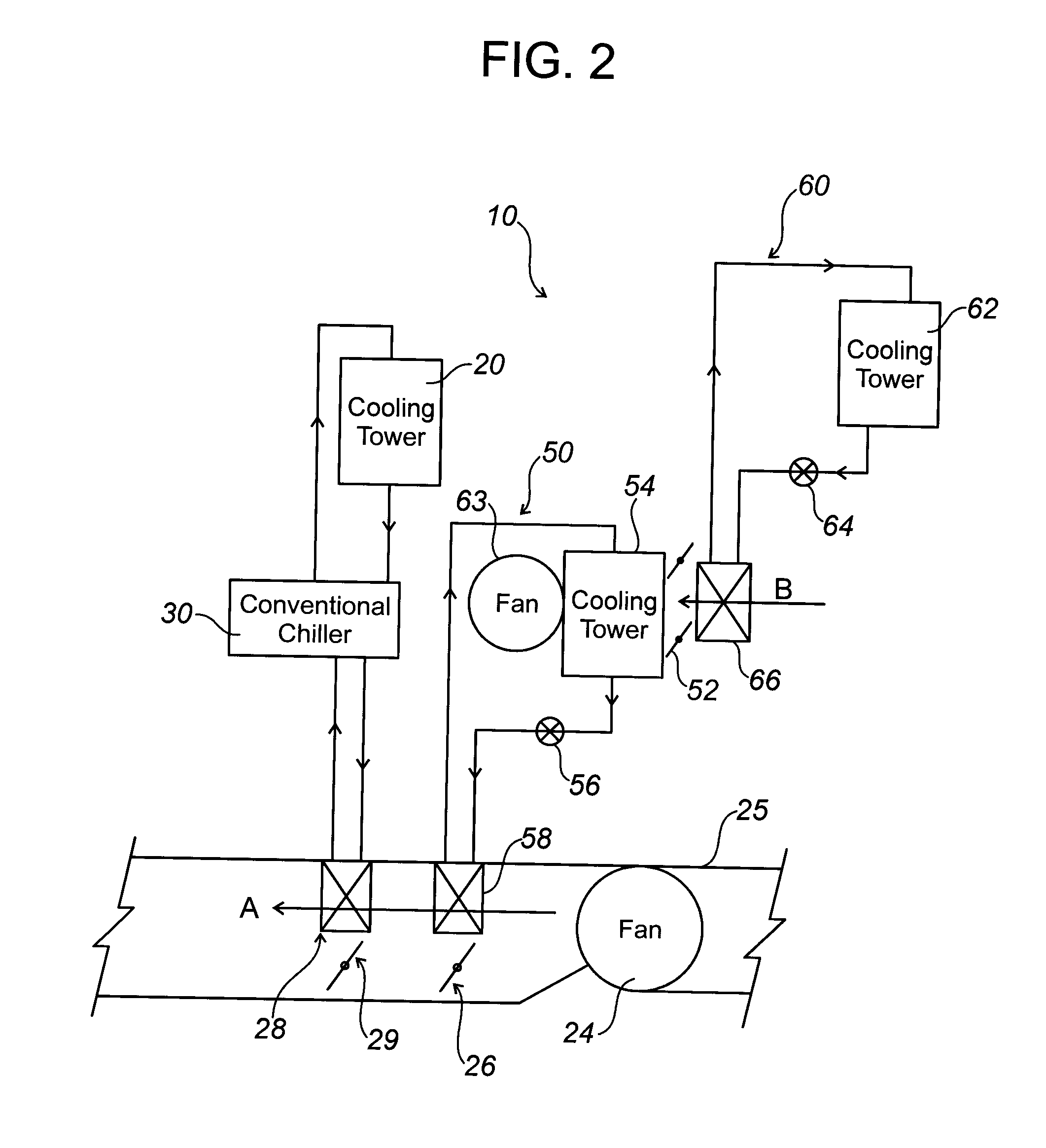

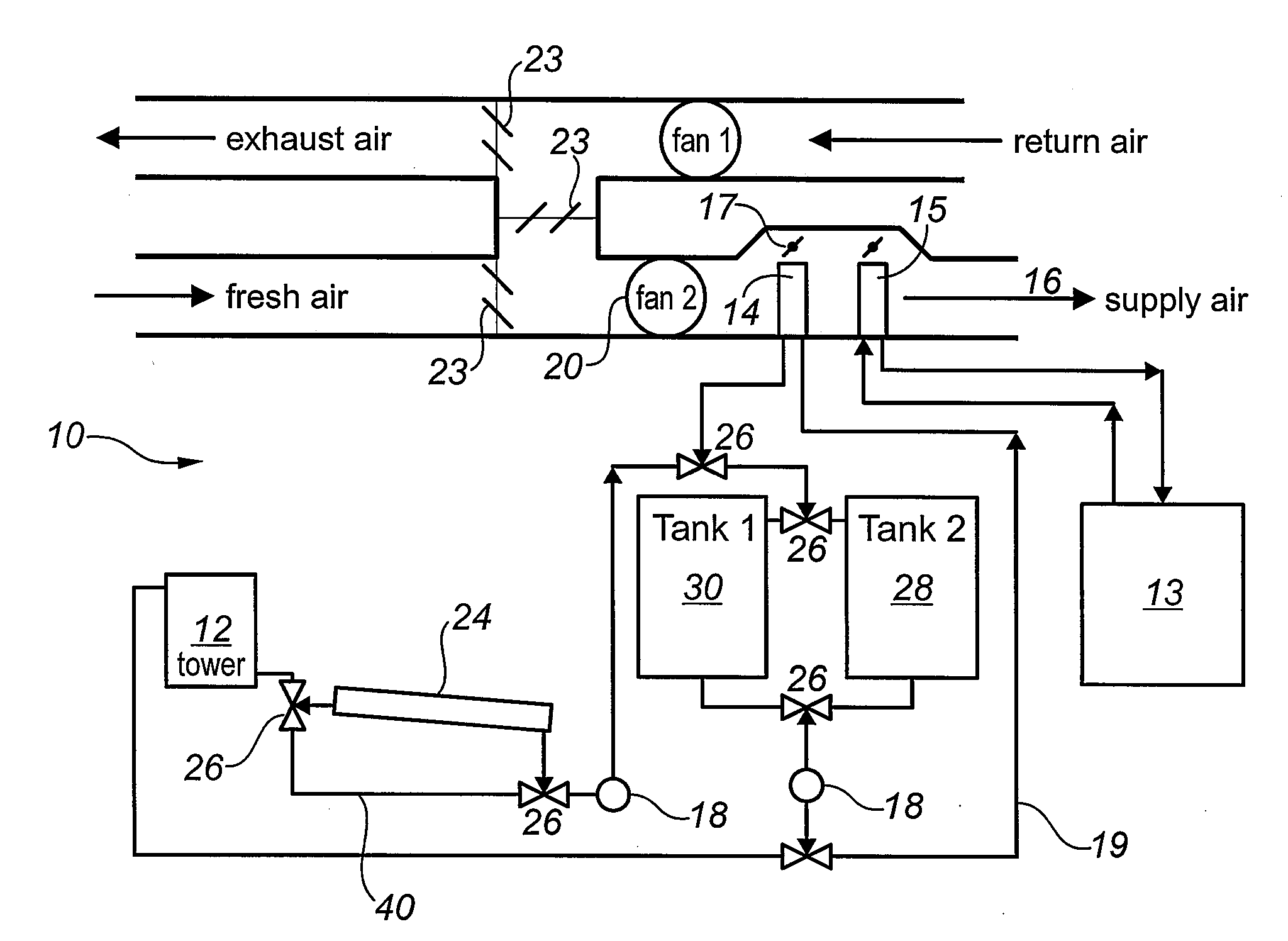

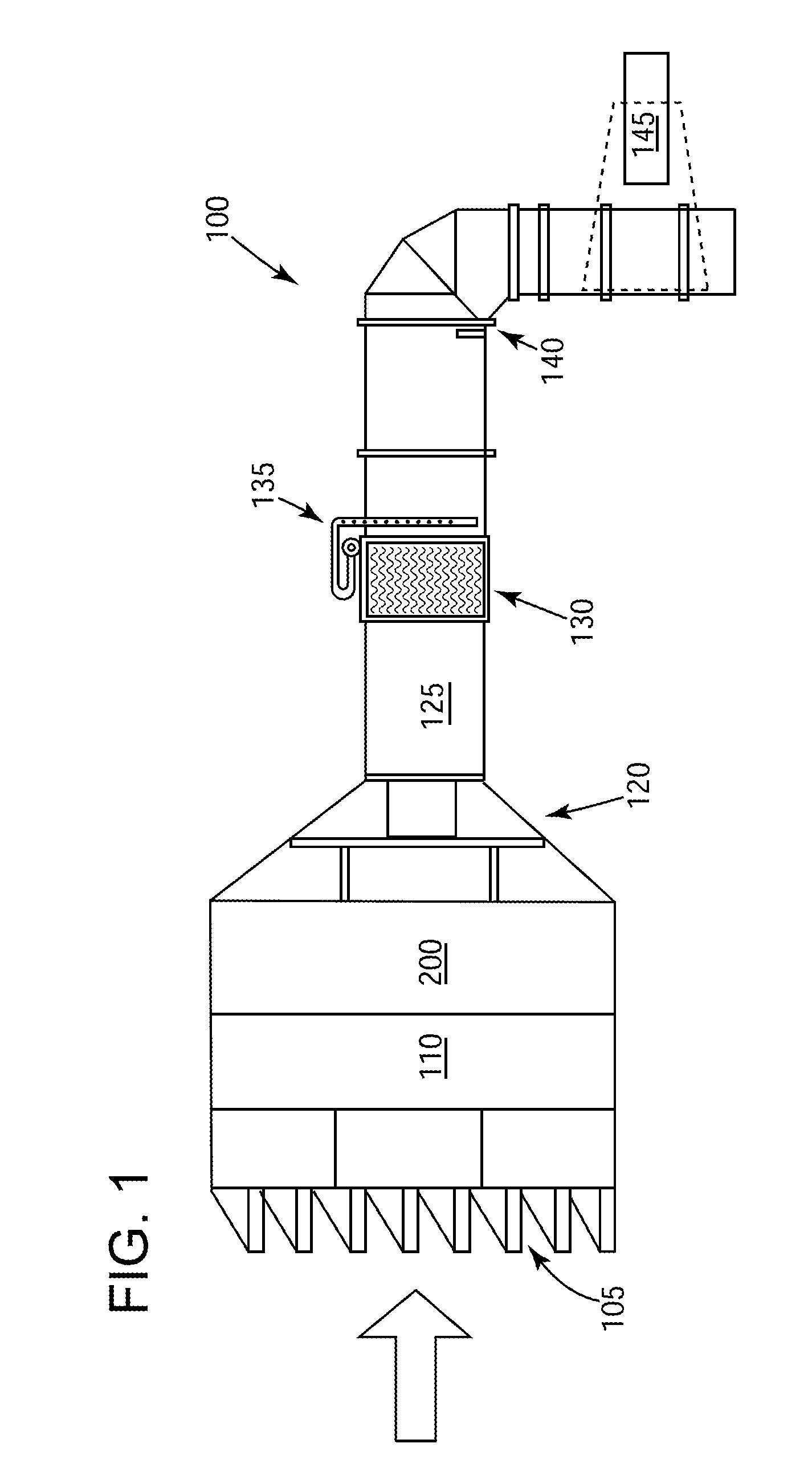

Cooling system

ActiveUS8783053B2Improve cooling effectDomestic cooling apparatusFree-cooling systemsCooling towerNuclear engineering

An evaporative cooling system that can be used to cool fluid and to cool an air supply to a building. The air supply to a cooling tower in a first evaporative system also having a fluid pump and a heat exchange element is cooled by the heat exchange element of a second evaporative cooling system. As a result, the inlet air wet bulb temperature of the primary cooling tower will be reduced, enhancing the cooling capacity of the primary cooling tower.

Owner:MCNNNAC ENERGY SERVICES

Tobacco leaf curing process capable of improving curing quality of flue-cured tobacco variety KRK26

ActiveCN101991180AMaintain moisture contentImprove roast qualityTobacco preparationDecompositionCell membrane

The invention relates to a tobacco leaf curing process capable of improving the curing quality of a flue-cured tobacco variety KRK26, belonging to the technical field of flue-cured tobacco modulation processes. The curing process comprises the following steps of: regulating the humidity at low temperature to yellow tobacco leaves; stabilizing the temperature and removing moisture for withering; ventilating and dewatering for drying the leaves; and controlling the temperature and the humidity to dry leaf ribs. In the invention, the method of keeping the tobacco leaves at lower temperature to reduce water evaporation in the tobacco leaves and guarantee the water content of the tobacco leaves is adopted to solve the problems of less water and difficult yellowing of the tobacco leaves of the KRK26 variety in the yellowing period; the dry-bulb temperature is between 41 DEG C and 44 DEG C, and the tobacco leaves can be sufficiently dewatered and shrunk to reduce the cell membrane turgor; the tobacco leaf cell membranes cannot be broken between 45 DEG C and 48 DEG C so as to smoothly fix the color; and in the whole process of tobacco leaf curing, the wet bulb temperature is controlled tobe between 34 DEG C and 38 DEG C so as to actively promote the decomposition and the conversion of macromolecular substances and the synthesis of flavoring substances. The invention has the advantages of simple and convenient operation, safety and insurance, can ensure that the tobacco leaves of the variety KRK26 can be smoothly yellowed, timely subjected to color fixing and subjected to rib drying in good time and improves the tobacco leaf curing quality.

Owner:YUNNAN ACAD OF TOBACCO AGRI SCI

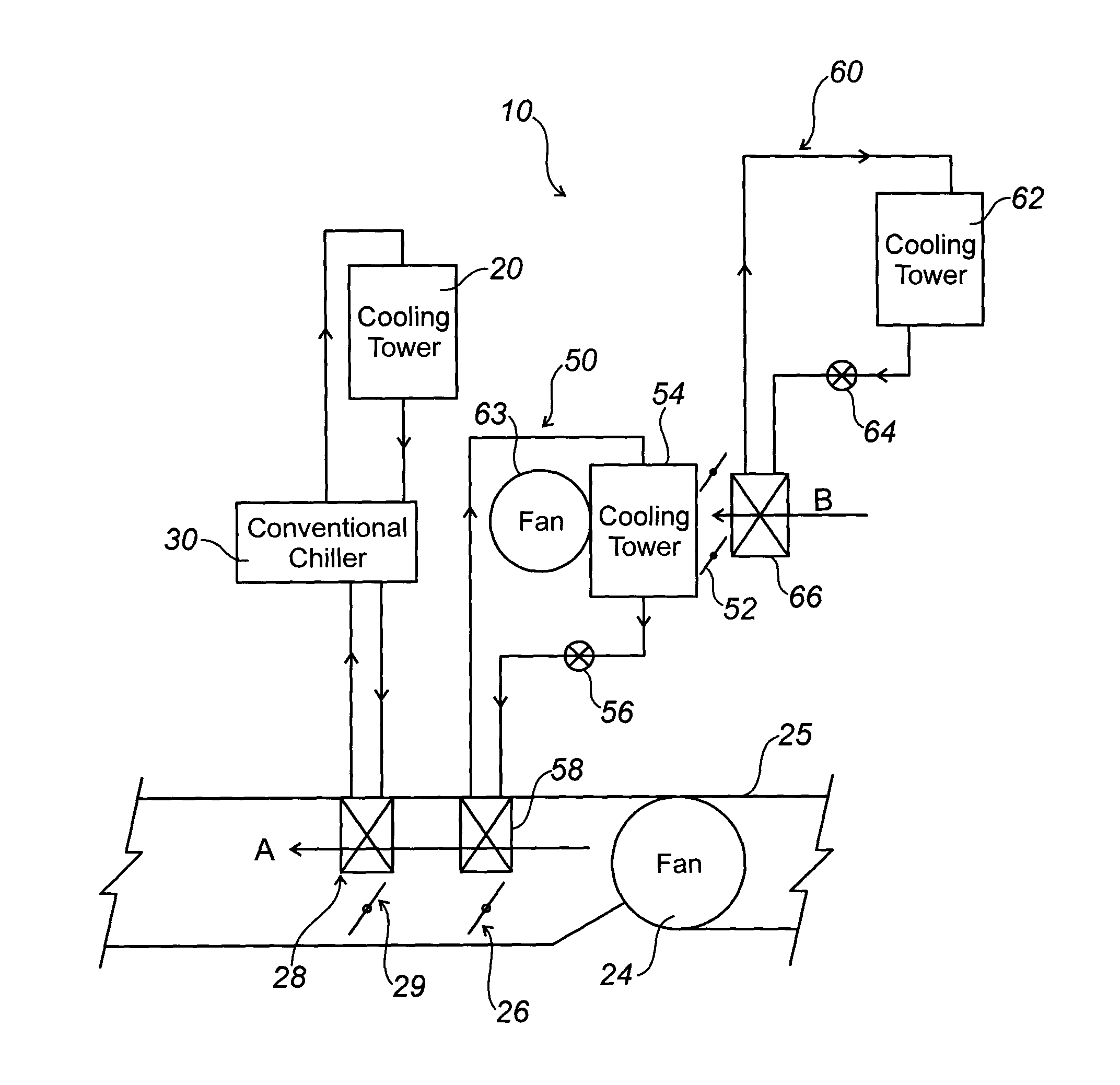

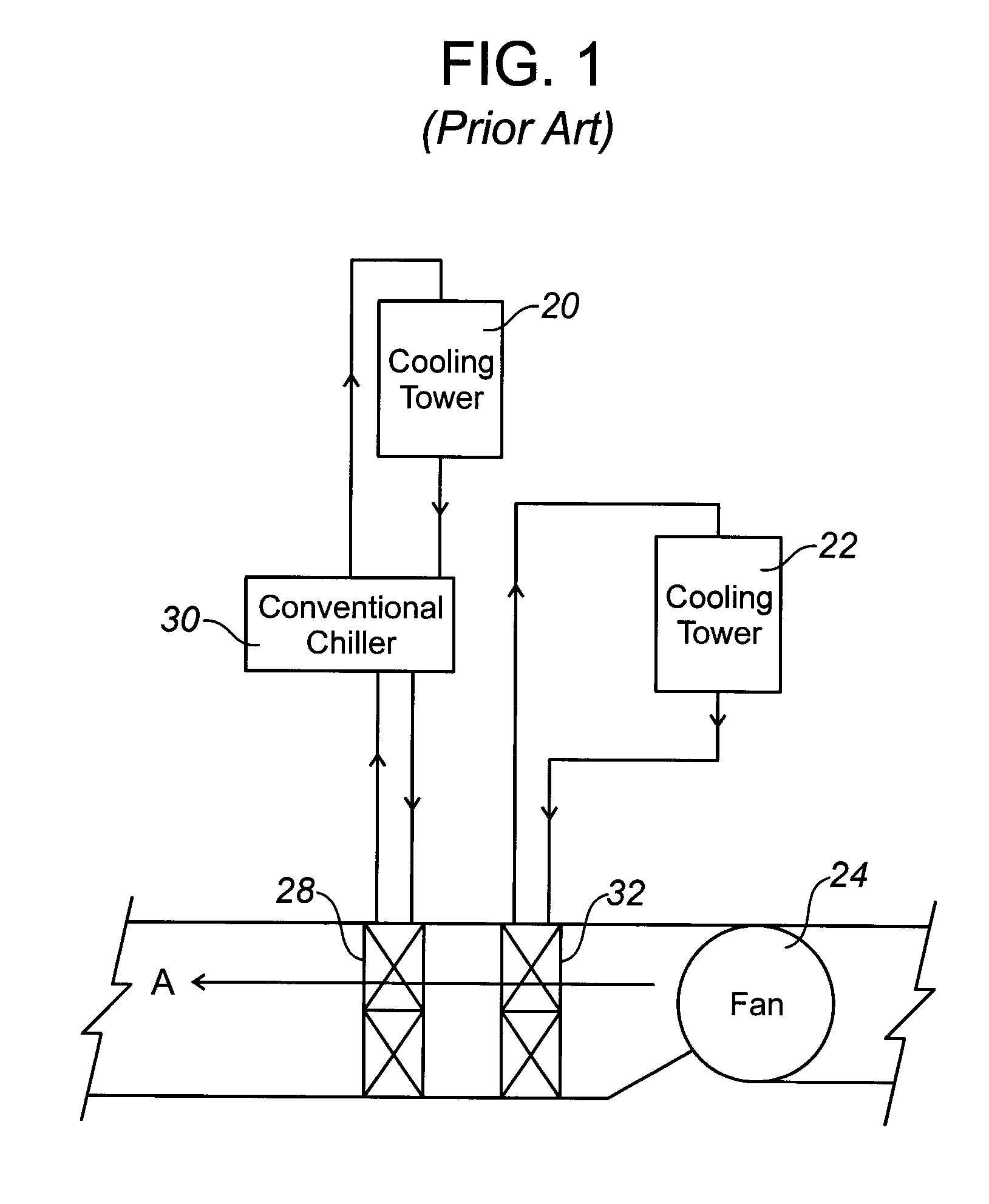

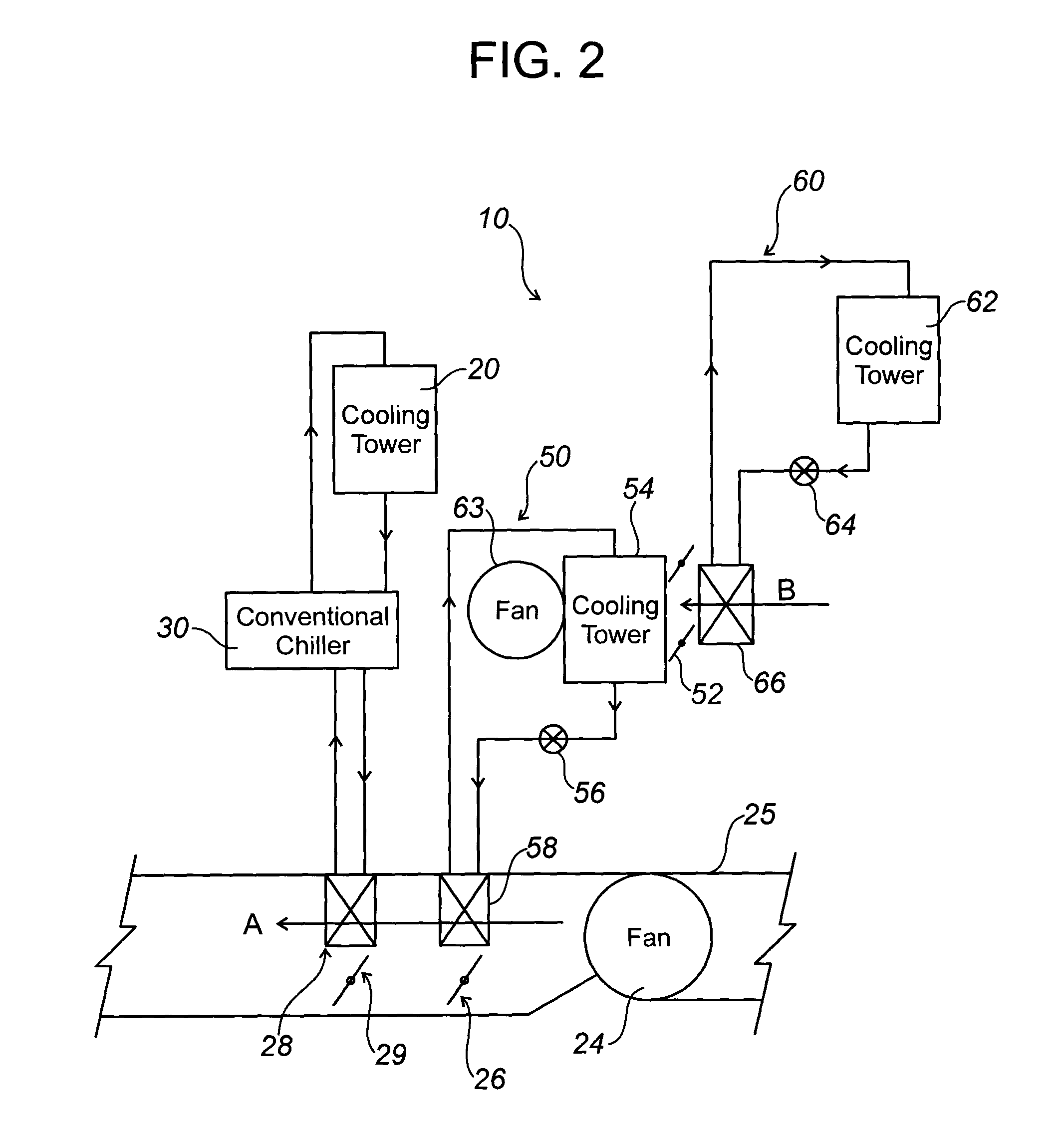

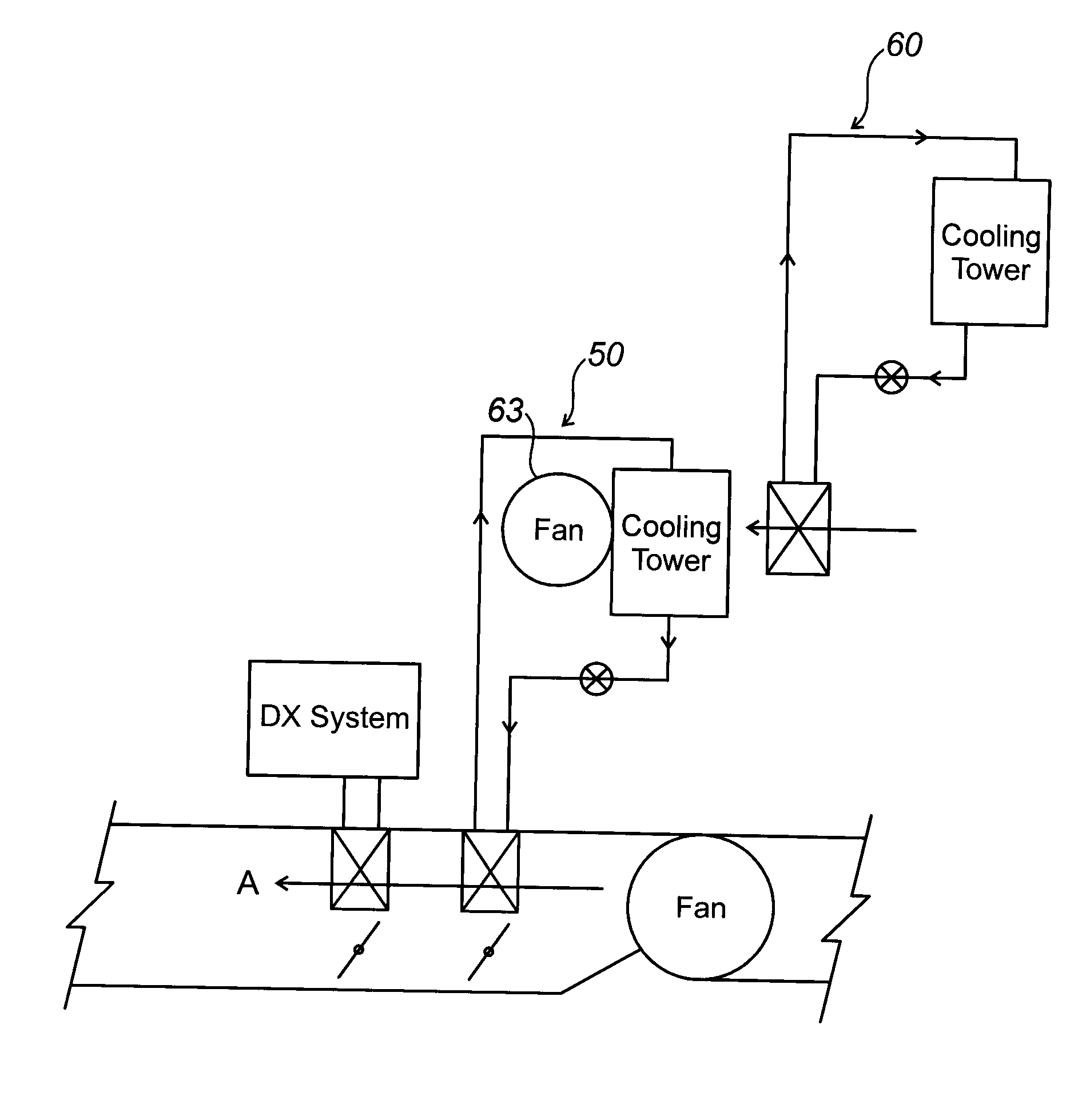

Cooling system

ActiveUS20100181062A1Improve cooling effectDigital data processing detailsTemperatue controlCooling towerNuclear engineering

An evaporative cooling system that can be used to cool fluid and to cool an air supply to a building. The air supply to a cooling tower in a first evaporative system also having a fluid pump and a heat exchange element is cooled by the heat exchange element of a second evaporative cooling system. As a result, the inlet air wet bulb temperature of the primary cooling tower will be reduced, enhancing the cooling capacity of the primary cooling tower.

Owner:MCNNNAC ENERGY SERVICES

Airflow control system with external air control

ActiveUS8721409B1Space heating and ventilation safety systemsLighting and heating apparatusControl systemEngineering

A cooling system includes one or more air channeling sub-systems that provide cooling air to electronic equipment, at least one heat removal sub-system that removes heat from the cooling air in at least one of the air channeling sub-systems, at least one temperature sensor measures a wet bulb temperature of outside air, and at least one controller. At least one of the air channeling sub-systems includes an outside air damper operable allow outside air into the air channeling sub-system. The at least one controller at least partially opens the outside air damper if a wet bulb temperature measured at the at least one temperature sensor drops to or below a predetermined temperature.

Owner:AMAZON TECH INC

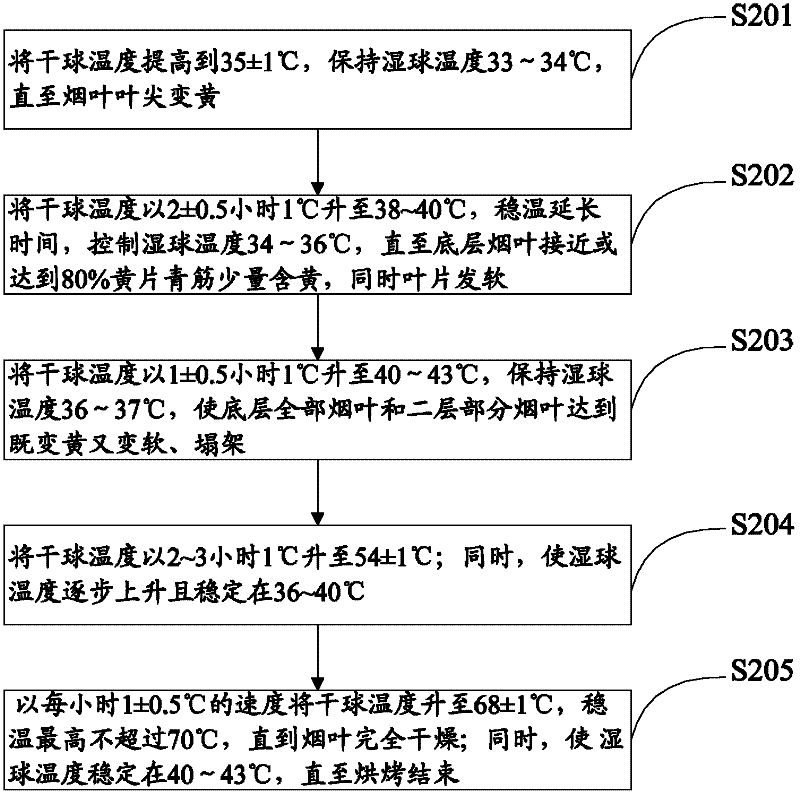

Bulk curing process for cured tobacco K326

The invention discloses a bulk curing process for cured tobacco K326. In the process, on the basis of the traditional three-stage curing, the curing stage is detailed into five stages, wherein the main yellowing temperature in curing is increased by 1 to 2 DEG C, while the wet bulb temperature in a later yellowing stage and an early color fixing stage is reduced by 1 to 2 DEG C. The process combines qualitative description and quantitative index, is scientific and practical, easy and safe to operate and has strong operability, can remarkably reduce rotten tobacco and soot attached tobacco and increase the color and oil content of the tobacco. By the process, the curing quality of the tobacco is remarkably improved.

Owner:TOBACCO RES INST CHIN AGRI SCI ACAD

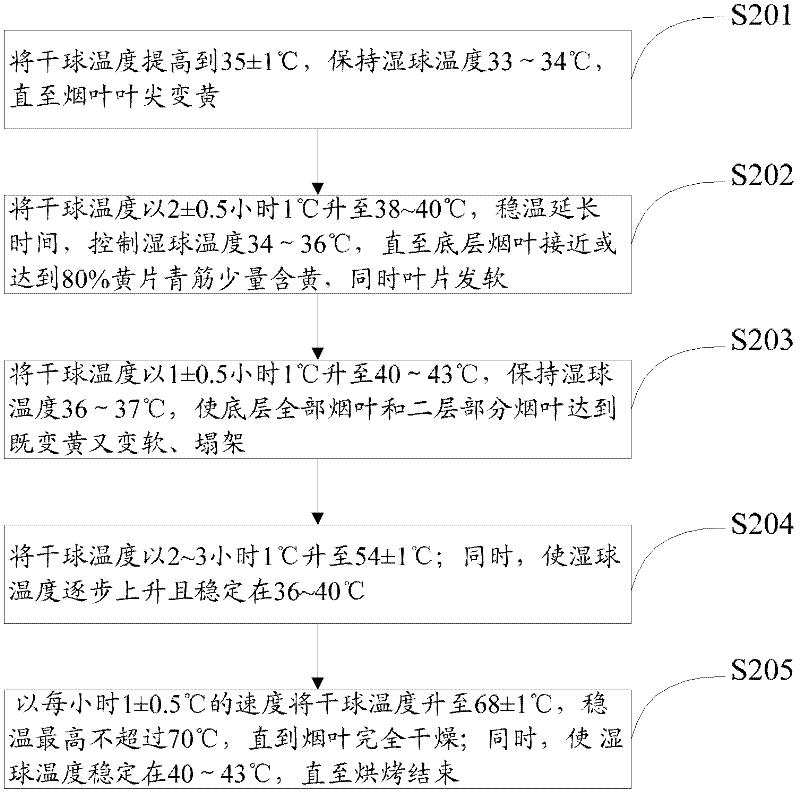

Tobacco leaf baking method

ActiveCN102499424AGood lookingIncrease the fragranceTobacco preparationTemperature controlEngineering

The invention discloses a tobacco leaf baking method, which comprises the following steps of: raising the dry ball temperature to 35+ / -1 DEG C, and maintaining the wet ball temperature at 33 to 34 DEG C until the tobacco leaf tops become yellow; raising the dry ball temperature to 38 to 40 DEG C at a speed being 1 DEG C in 2+ / -0.5 hours, prolonging the time after the temperature is stable, and controlling the wet ball temperature at 34 to 36 DEG C until the bottom layer tobacco leaves approach to or reach the state that yellow leaves account for 80 percent, green ribs become slightly yellow, and simultaneously, the leaves become soft; raising the dry ball temperature to 40 to 43 DEG C at a speed being 1 DEG C in 1+ / -0.5 hour, and maintaining the wet ball temperature being 36 to 37 DEG C so that all tobacco leaves at the bottom and partial tobacco leaves at the second layer become yellow and soft and are collapsed; raising the dry ball temperature to 54+ / -1 DEG C at a speed being 1 DEG C per hour, and simultaneously, gradually raising the wet ball temperature and stabilizing the wet ball temperature at 36 to 40 DEG C; raising the dry ball temperature to 68+ / -1 DEG C at a speed being 1+ / -0.5 DEG C per hour, stabilizing the temperature at the highest temperature not exceeding 70 DEG C until the tobacco leaves are completely dried; and simultaneously, stabilizing the wet bal temperature at 40 to 43 DEG C until the baking is completed. Through optimizing the tobacco leaf baking temperature control scheme, the tobacco baking quality can be improved, and the tobacco leaf baking cost can be reduced.

Owner:CHINA TOBACCO GUANGDONG IND

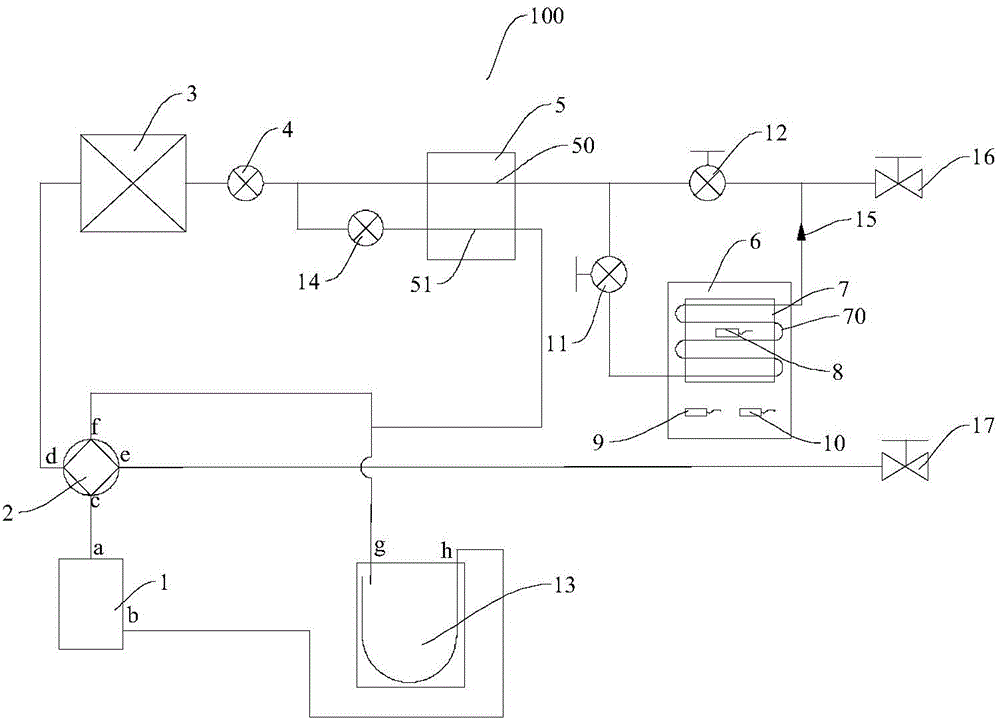

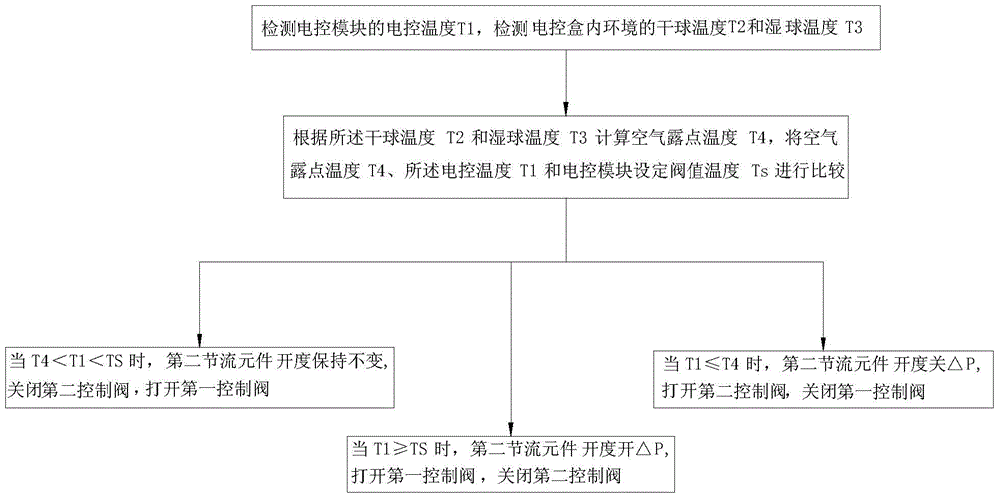

Air conditioner and cooling control method thereof

ActiveCN105091258AExtended service lifeAvoid short circuitSpace heating and ventilation safety systemsLighting and heating apparatusEngineeringControl valves

Owner:GD MIDEA HEATING & VENTILATING EQUIP CO LTD +1

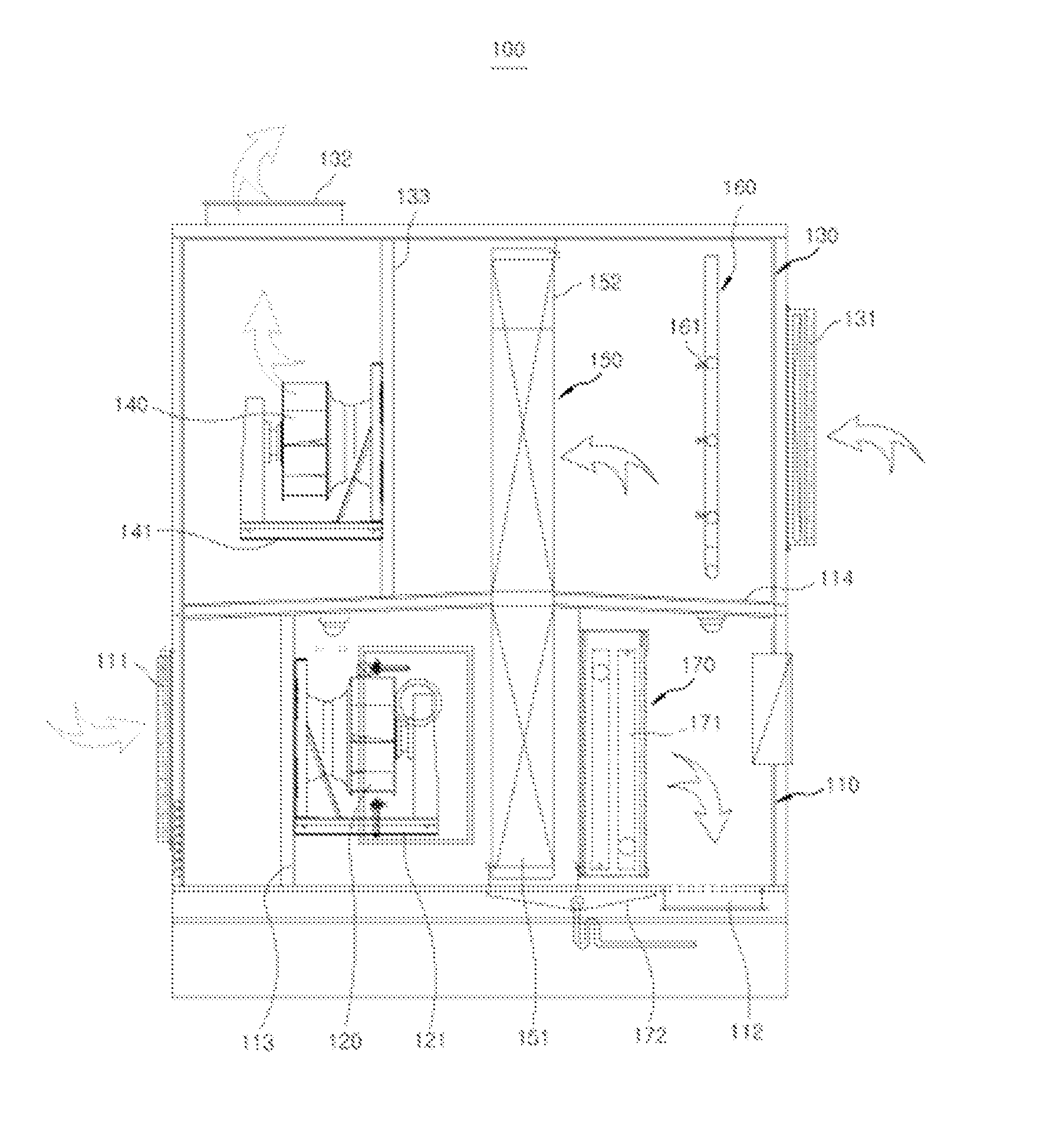

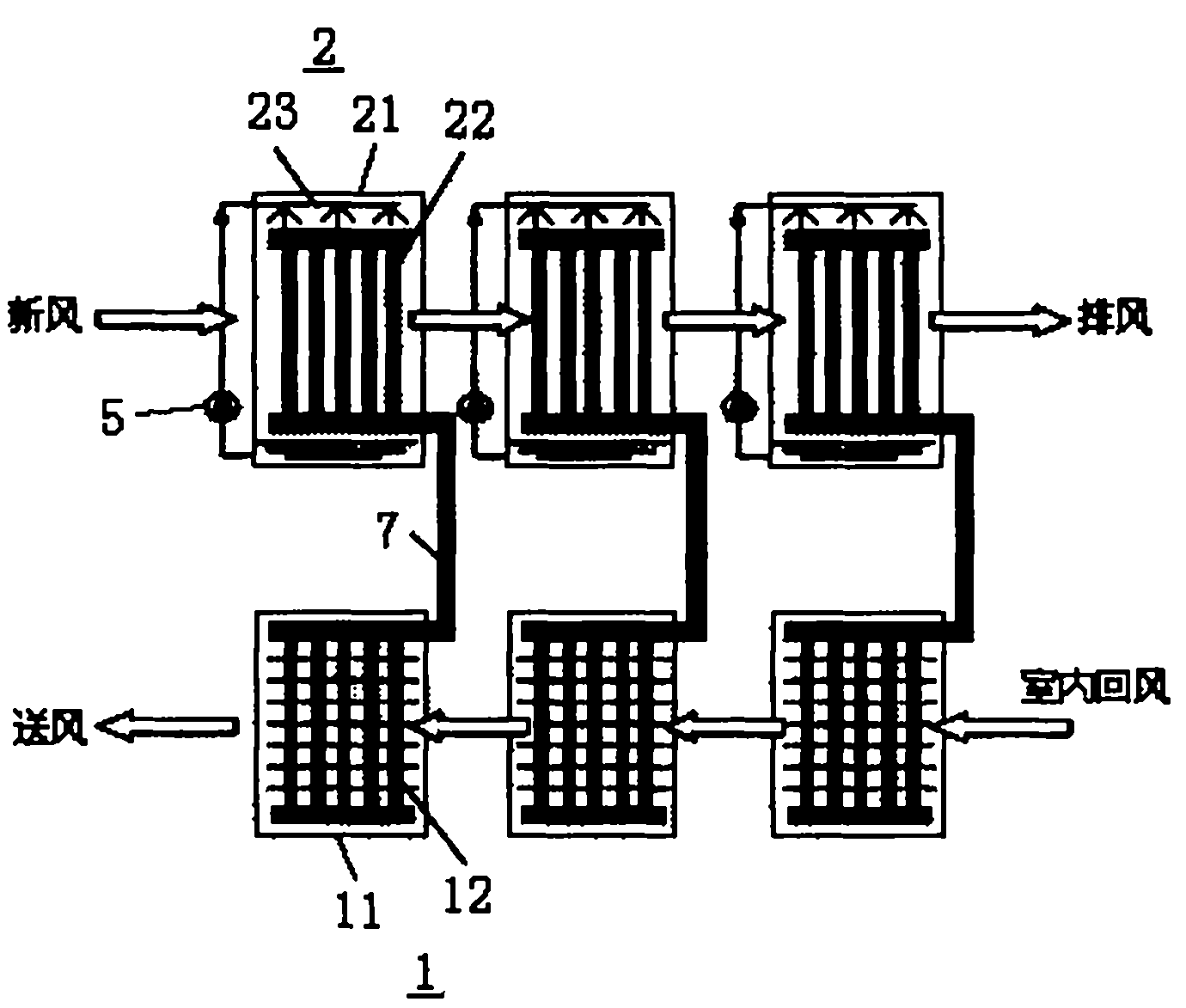

Air conditioning system of data center using heat pipe and method for controlling thereof

InactiveUS20150034270A1Avoid lostOptimizationAir-treating devicesMechanical apparatusData centerEngineering

An air conditioning system of data center using heat pipe includes a cooling room that allows air within the data center to be drawn in by a first fan and circulated and fed back to the data center; a heat radiation room located separately from the cooling room; a heat pipe installed such that evaporator and condenser are located in the cooling room and heat radiation room, respectively; a sprayer installed in the heat radiation room and provided with a plurality of spray nozzles for spraying cooling fluid to the condenser; a cooling unit installed in the cooling room and cooling the air that passed the evaporator through heat exchange; dry bulb temperature measurement unit and wet bulb temperature measurement unit; and a control unit that receives the detection signal from the dry and wet bulb temperature measurement units and controls the sprayer and the cooling unit.

Owner:THERMOTEK

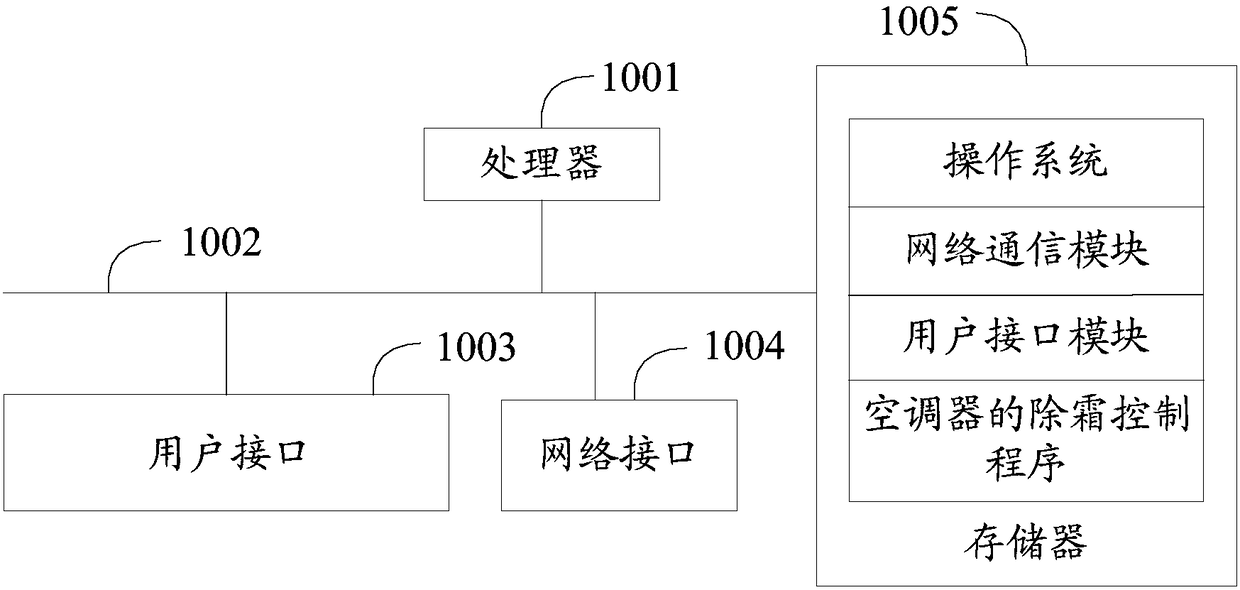

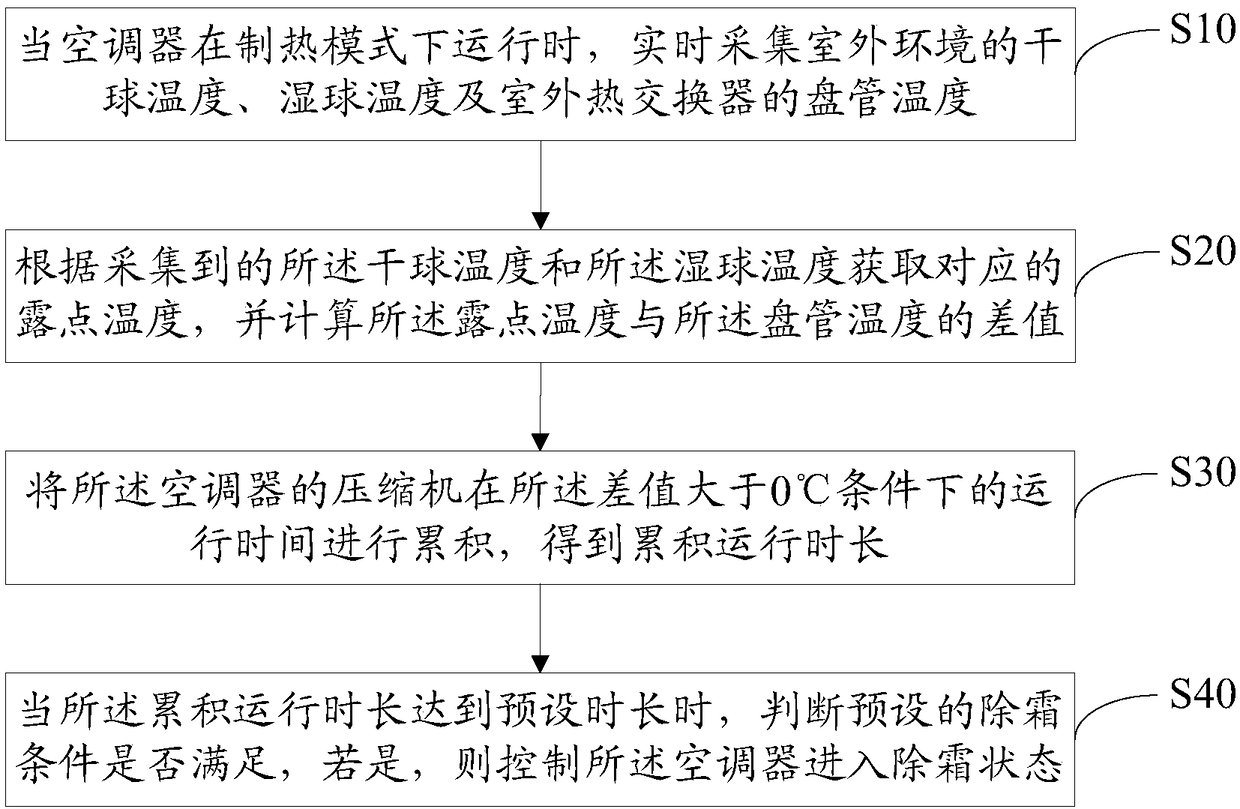

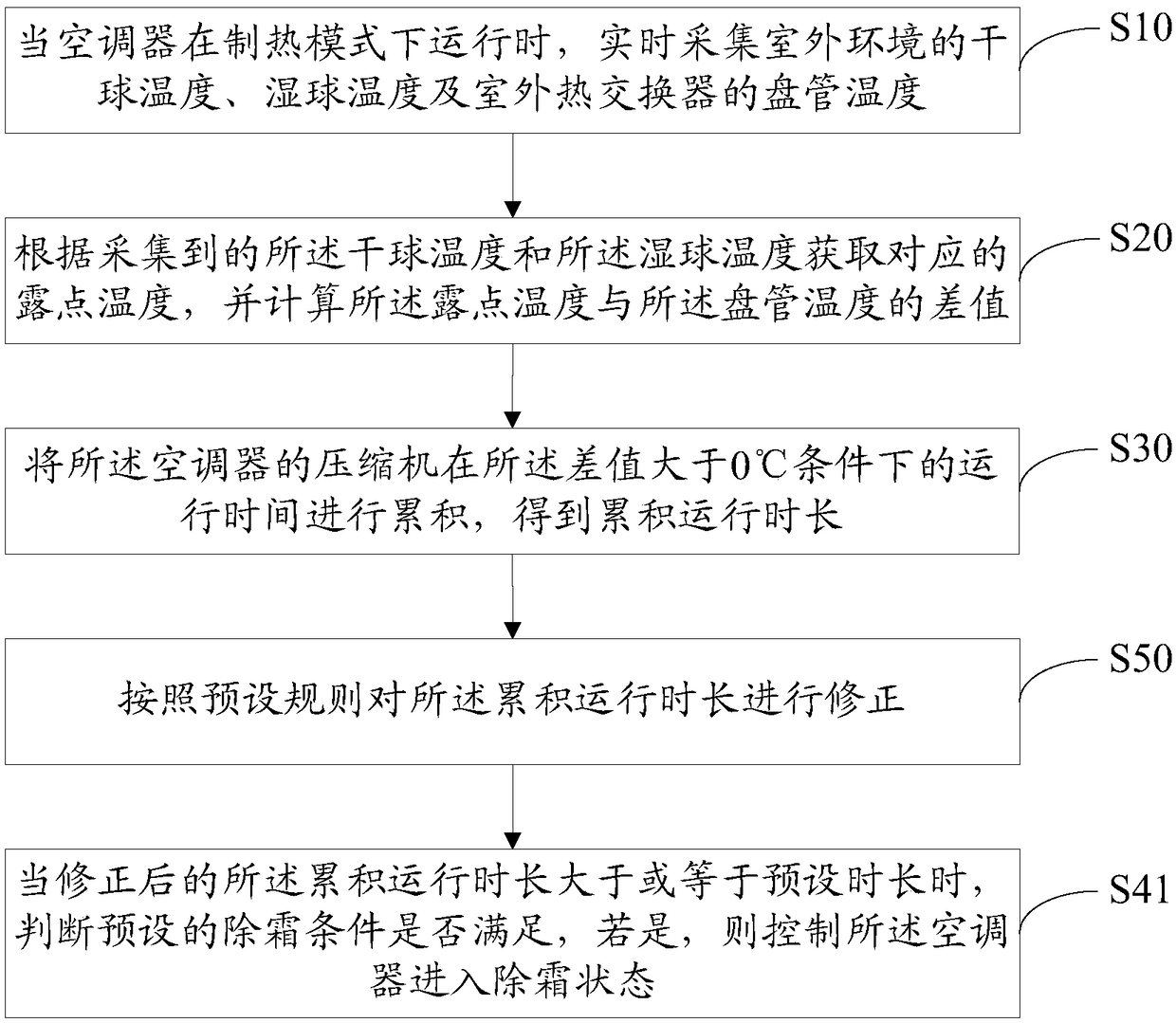

Defrosting control method for air conditioner, air conditioner and computer readable storage medium

ActiveCN108195027ASolve too frequent defrostingSolve the problem of defrostingMechanical apparatusSpace heating and ventilation safety systemsRunning timeWet-bulb temperature

The invention discloses a defrosting control method for an air conditioner. The method comprises the following steps that when the air conditioner runs in a heating mode, the dry bulb temperature andthe wet bulb temperature of an outdoor environment and the coil temperature of an outdoor heat exchanger are acquired in real time; the corresponding dew point temperature is obtained according to theacquired dry bulb temperature and the acquired wet bulb temperature, and the difference value between the dew point temperature and the coil temperature is calculated; the running time of a compressor of the air conditioner under the condition that the difference value is greater than 0 DEG C is accumulated, and the accumulated running time is obtained; and when the accumulated running time reaches the preset time, whether the preset defrosting condition is met or not is judged, if yes, the air conditioner is controlled to enter a defrosting state. The invention further discloses the air conditioner and a computer readable storage medium. The defrosting control method, the air conditioner and the computer readable storage medium can solve the technical problem of too frequent defrosting or untimely defrosting of the air conditioner due to a large judgment error of an existing air conditioner on the frosting degree of the outdoor heat exchanger.

Owner:TCL AIR CONDITIONER ZHONGSHAN CO LTD

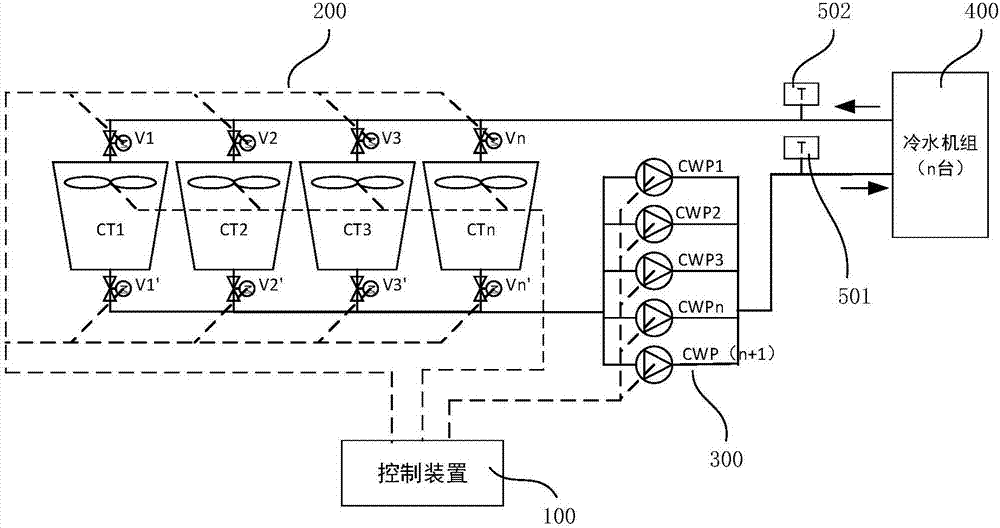

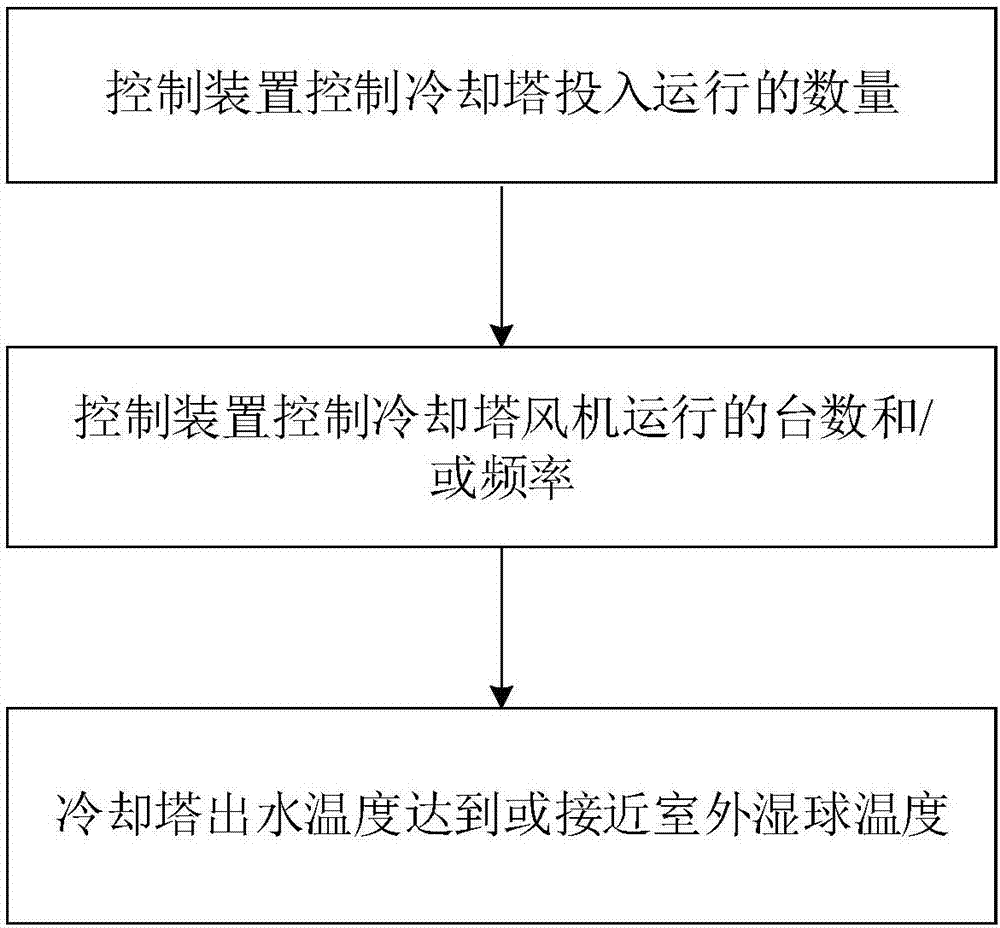

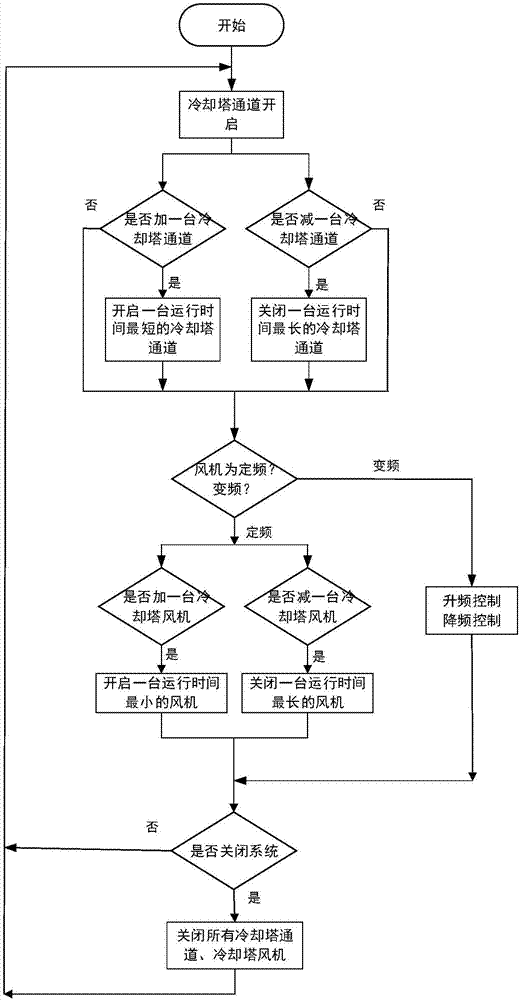

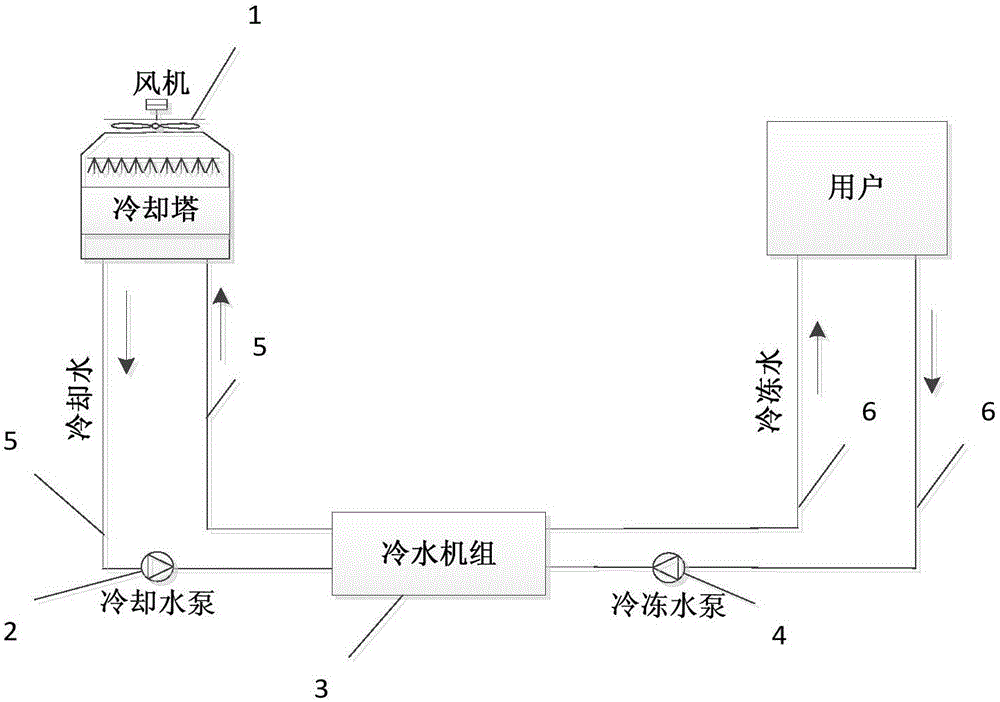

Control method of cooling tower water outlet temperature of central air-conditioning system

ActiveCN106871364AGood Feng Shui ratioMechanical apparatusSpace heating and ventilation safety systemsCooling towerEngineering

The invention discloses a control method of cooling tower water outlet temperature of a central air-conditioning system. The central air-conditioning system comprises a control device, a cooling tower set, a cooling pump set and a cold water unit; the inlet side of the cooling pump set is connected with the water tank side of the cooling tower set, the outlet side of the cooling pump set is connected with a water inlet in the cooling side inlet of the cold water unit, a water outlet of the cooling side of the cold water unit is connected with the spraying side of the cooling pump set, and the control device is connected with the cooling tower set and the cooling pump set. The control method includes the steps that the control device achieves the aim that the cooling tower water outlet temperature reaches or is close to the outdoor wet ball temperature by controlling the number of cooling towers putting into operation and / or controlling the number and / or frequency of draught fans of the cooling towers putting into operation. By means of the control method, the cooling tower water outlet temperature can reach or be close to the outdoor wet ball temperature, and the central air-conditioning system has the character of finding the wet ball temperature by itself.

Owner:GREE ELECTRIC APPLIANCES INC

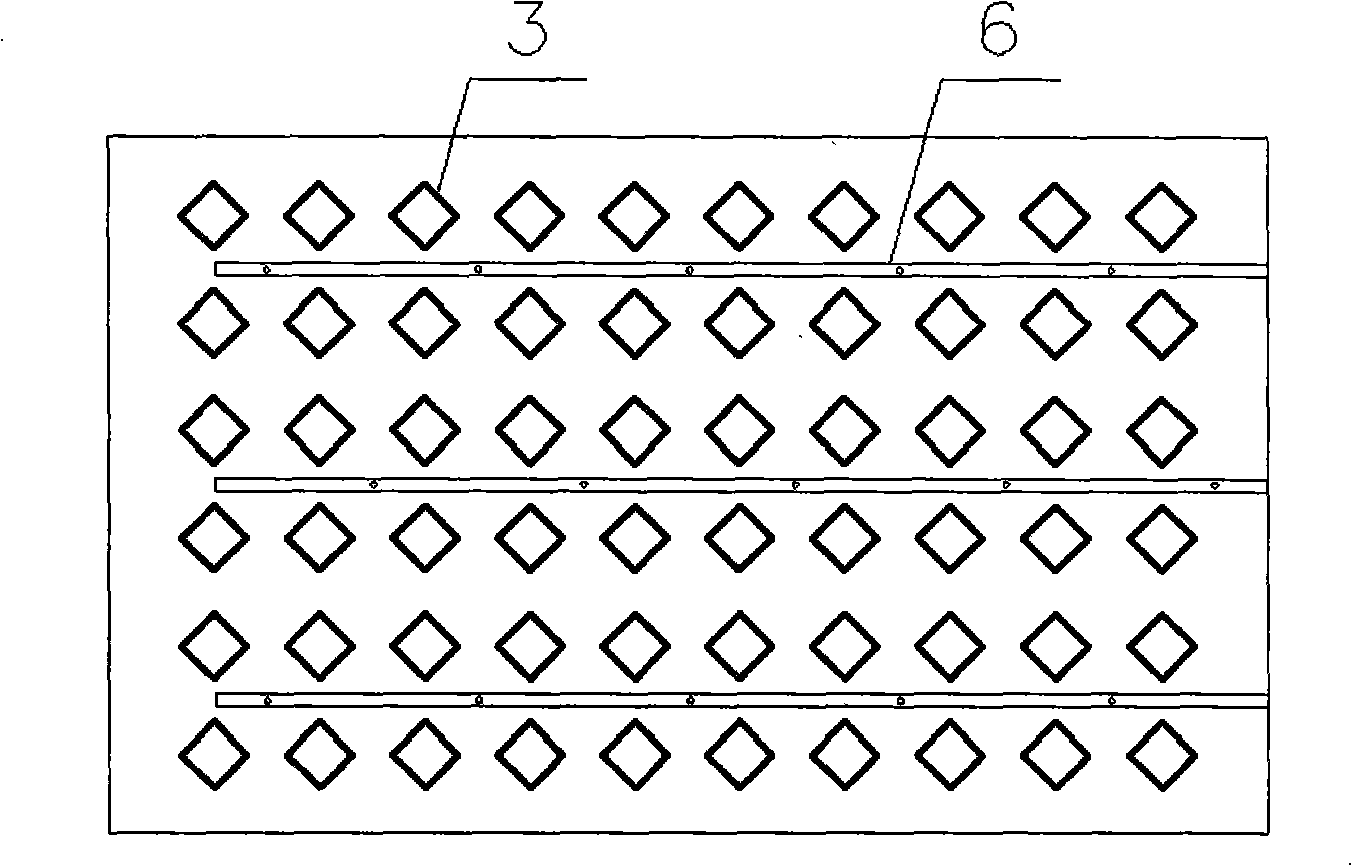

Square porous ceramic vertical tube type dew point indirect evaporative cooler

InactiveCN101329104AObvious advantage of energy savingMoisture content unchangedLighting and heating apparatusSpace heating and ventilation detailsEvaporative coolerVertical tube

The invention discloses a square porous ceramics vertical-tube dew point indirect evaporation cooler device comprising a cooler core, a water-distributing device, a fan, a water-storage and a pump which are arranged inside a cooler casing. The cooler core is formed by a plurality of heat exchanging tubes which are vertically arranged to form a multi-line multi-row matrix form which is divided into three sections; the length of the three sections of heat exchanging tube decreases progressively along a first-time air feeding direction, and clapboards are arranged between each two sections of heat exchanging tube; the water-distributing device comprises a diversion grid and a spraying tube which are arranged on the top of each heat exchanging tube. The structure of the invention leads the first-time air to horizontally pass the square ceramics bundle and leads a second-time air to flow through the bundle from bottom to top; then the first-time air sequentially passes through the three sections of the core and the temperature of the air entering the second-air channels from different section is decreased gradually, and the temperature of the final wet-bulb is also decreased gradually after a heat and moisture exchanging with water. The structure of the invention can greatly enhance the heat and moisture exchanging efficiency and the water distribution becomes more equal so as to lead the temperature of vented air to approach that of the dew point.

Owner:XI'AN POLYTECHNIC UNIVERSITY

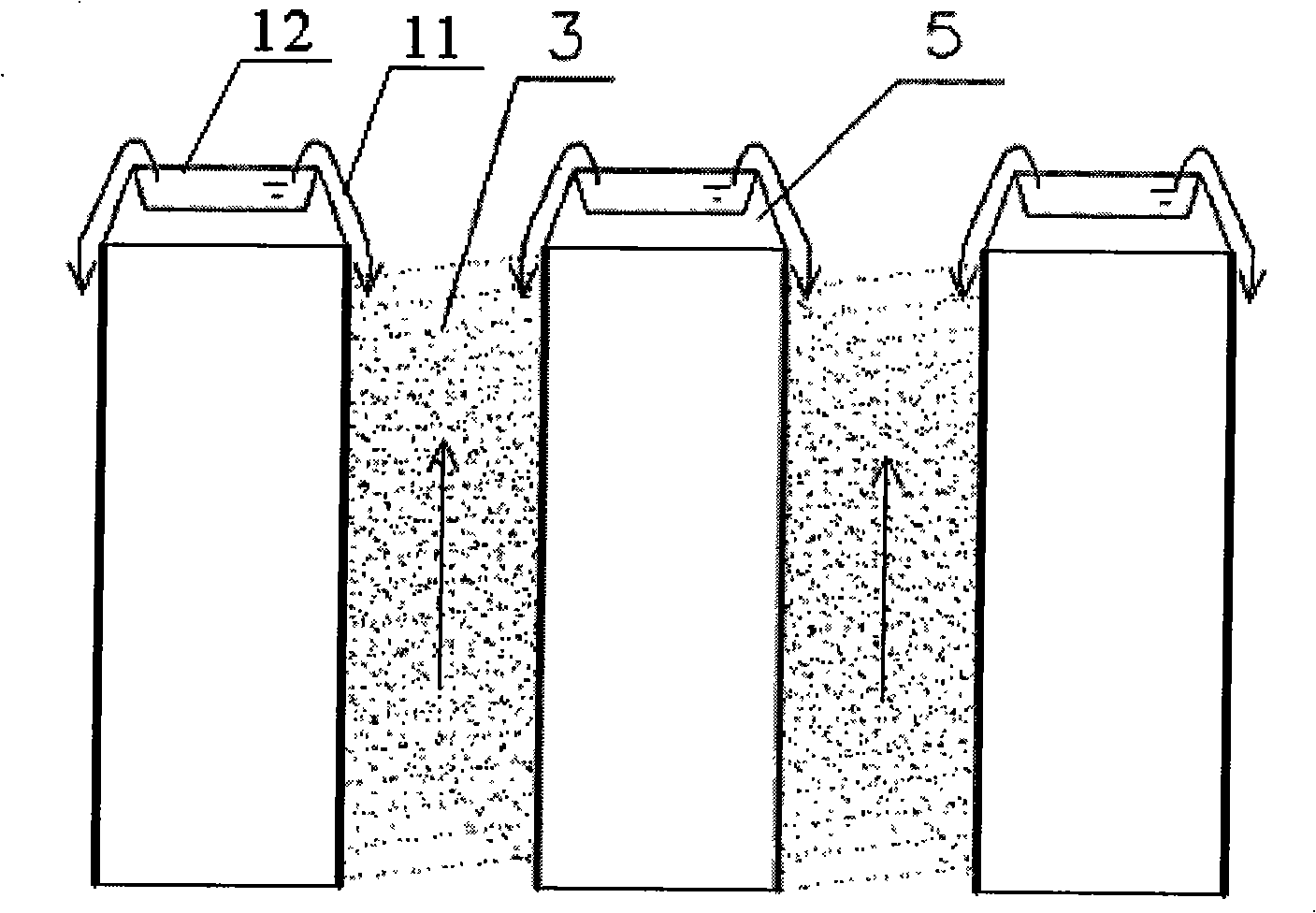

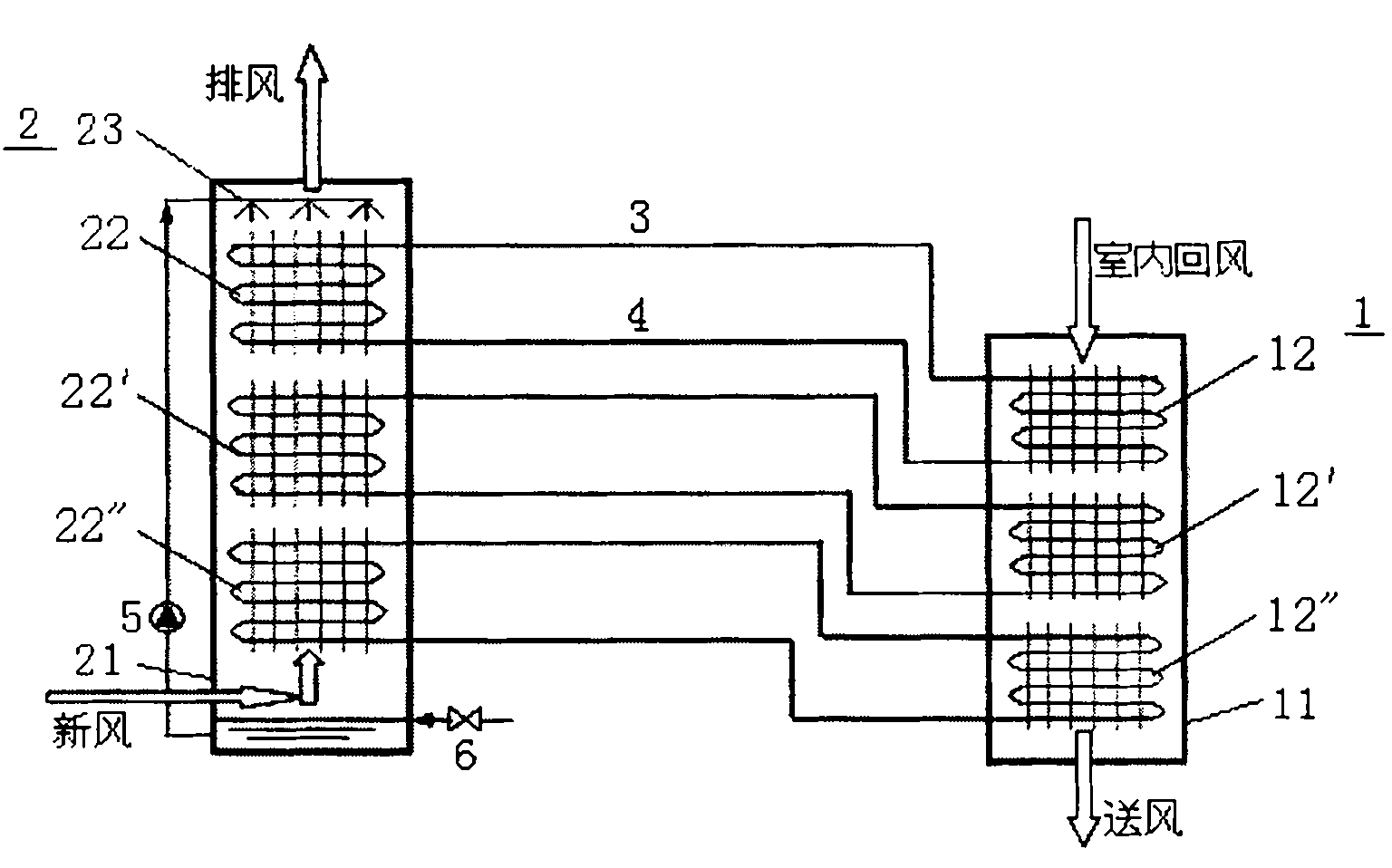

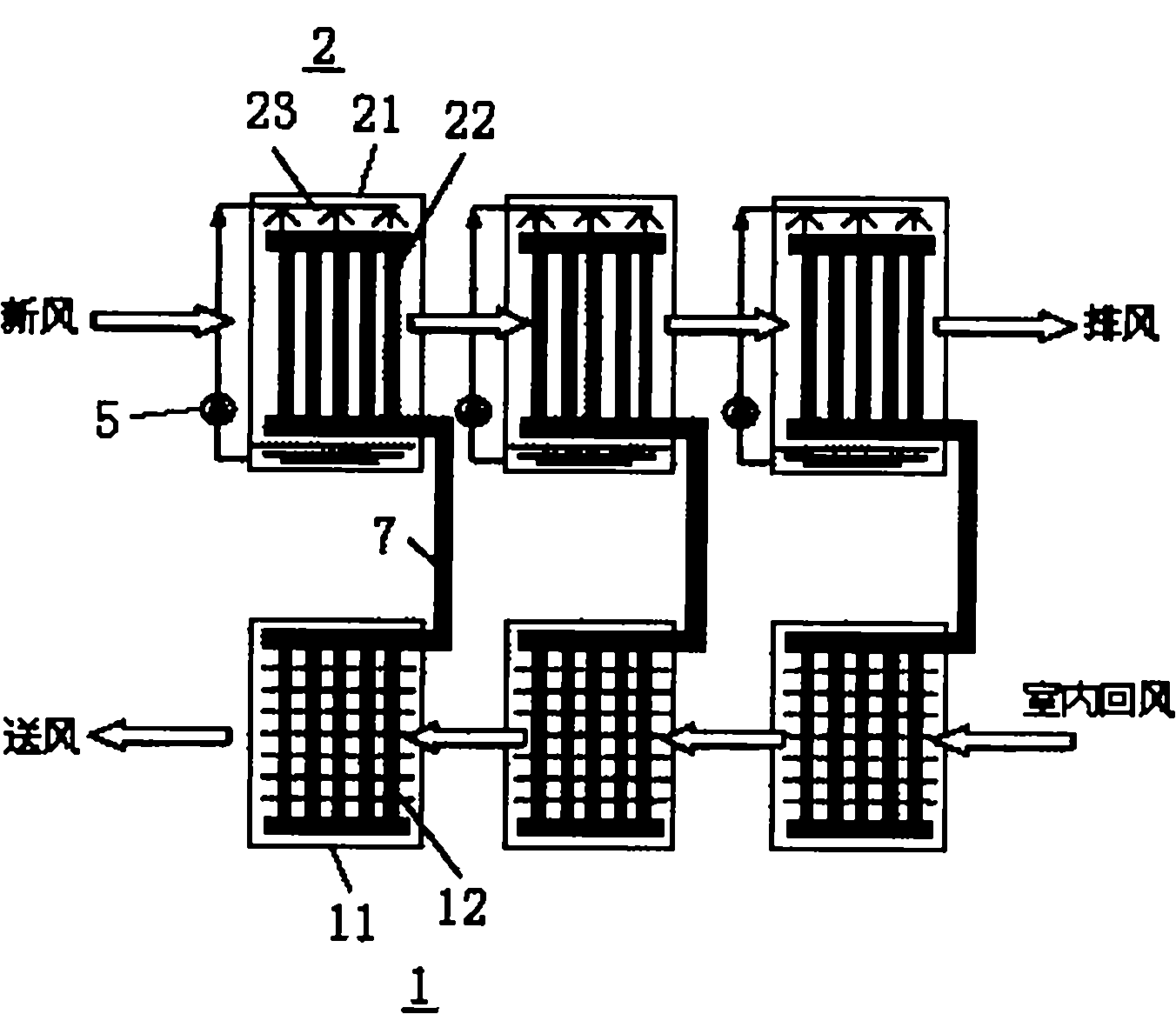

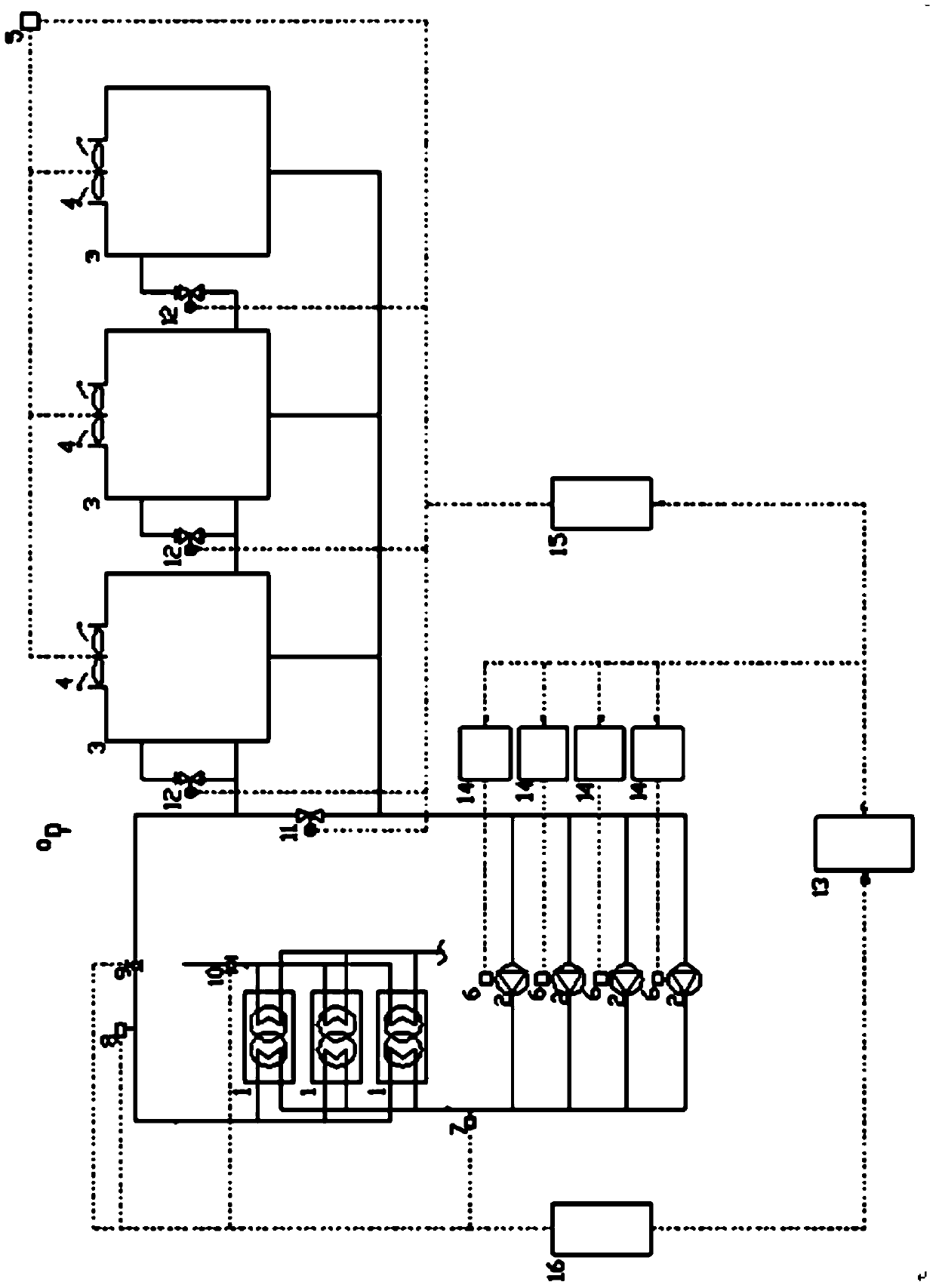

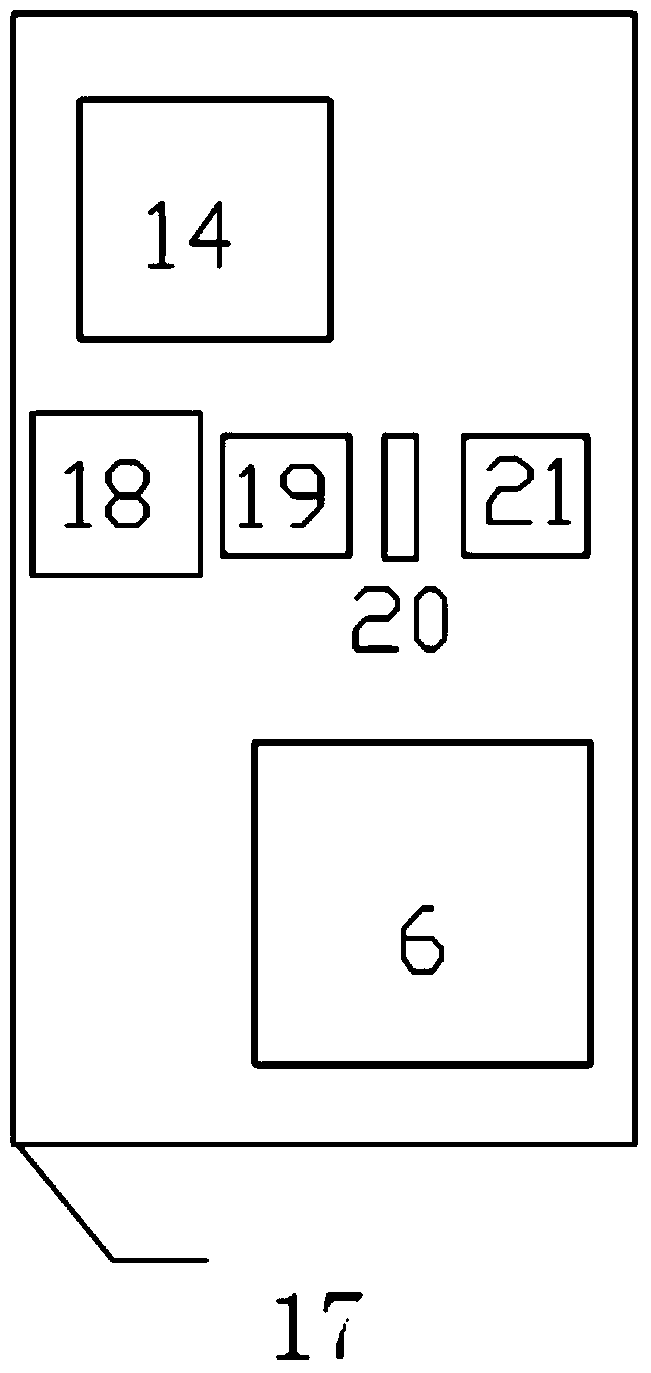

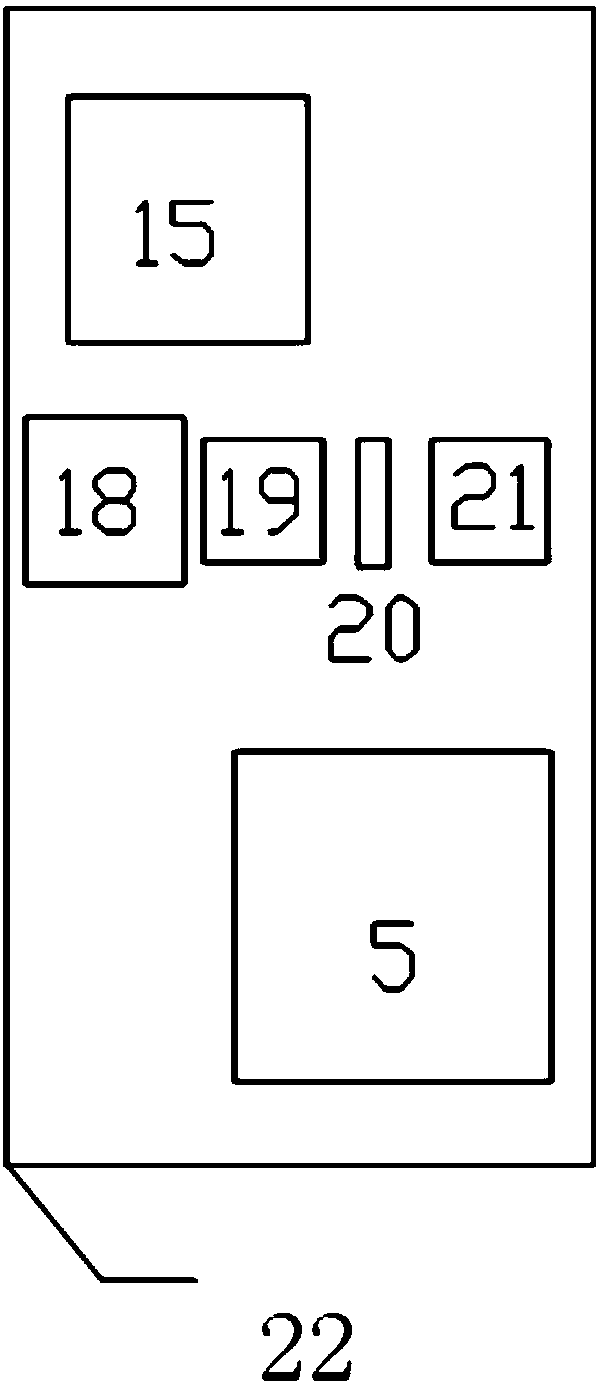

Machine room heat removal device for evaporation cooling type heat-pipe heat exchange

ActiveCN101886836AUniform temperature differenceExtended use timeLighting and heating apparatusSpace heating and ventilation detailsWater cyclingEvaporation

The invention relates to a machine room heat removal device for evaporation cooling type heat-pipe heat exchange. The device is characterized by comprising more than one group of evaporators arranged in a machine room, more than one group of water-cooled condensers arranged outside the machine room and more than one gas-liquid main pipe, wherein each group of evaporators comprises an evaporation tank body and an evaporation side heat pipe arranged in the evaporation tank body; each group of water-cooled condensers comprises a condensation tank body, a condensation side heat pipe arranged in the condensation tank body and a spray device arranged on the top of the condensation tank body; a cooling water circulating loop is formed by communicating the spray device and the bottom of the condensation tank body through a water pump; the top of each group of evaporation side heat pipe is communicated with the bottom of the corresponding condensation side heat pipe through one gas-liquid main pipe; and the evaporation side heat pipe and the condensation side heat pipe are filled with a refrigerating medium. The device ensures more uniform temperature difference between the groups of heat pipes during the heat transfer, has an overall heat exchange efficiency close to one and air supply temperature close to the wet bulb temperature of outdoor air, can reduce the starting temperature difference between indoor temperature and outdoor temperature and further increase the service time of the heat pipe to achieve better energy saving effect.

Owner:TSINGHUA UNIV

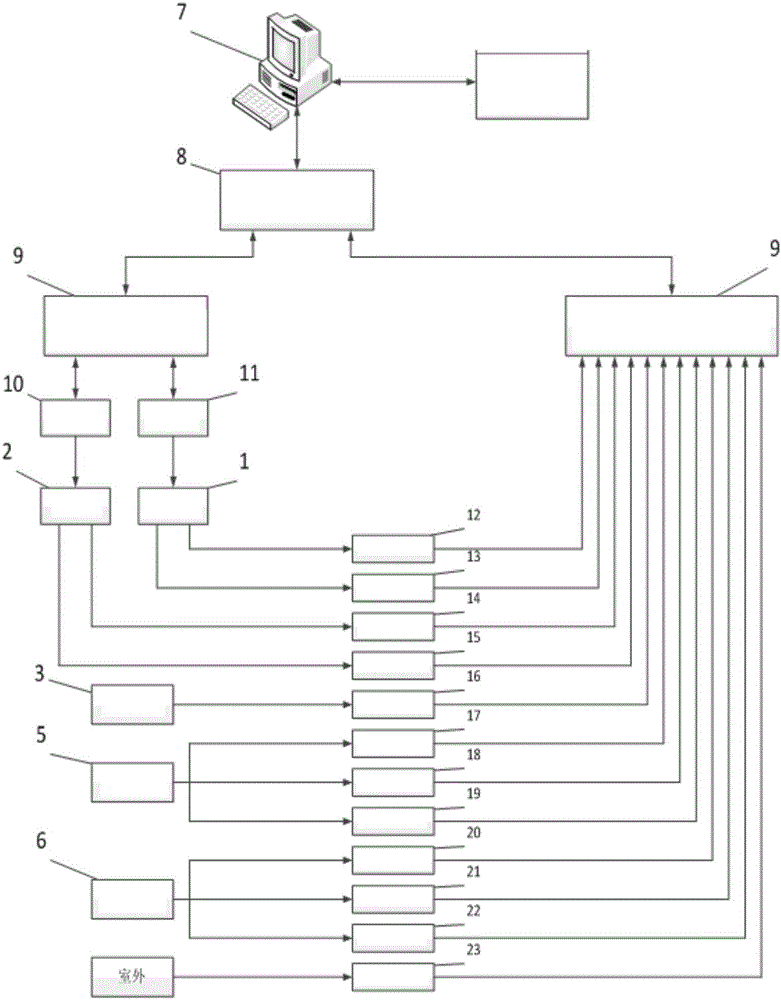

Cooling efficiency maximization method for cooling water system in central air-conditioner and control device

ActiveCN104089362ALow powerImprove dynamic performanceSpace heating and ventilation safety systemsLighting and heating apparatusNerve networkCooling tower

The invention relates to the field of energy conservation of central air-conditioner systems and aims at providing a cooling efficiency maximization method for a cooling water system in a central air-conditioner and a control device. The control device comprises a cooling water pump control cabinet, a cooling tower control cabinet, a main controller and an information acquisition module, wherein the information acquisition module, the cooling water pump control cabinet and the cooling tower control cabinet are bidirectionally connected with the main controller through signal wires respectively to achieve data transmission and signal control; the cooling water pump control cabinet comprises an intelligent cooling water pump controller with a communication port; the cooling tower control cabinet comprises an intelligent cooling tower controller with a communication port. The control device has the benefits that the cooling water system is dynamically adjusted according to the best condensation temperature under different loads and different outdoor wet-bulb temperatures; compared with fuzzy control, a self-organized fuzzy control mode based on a nerve network has the characteristics that the dynamic performance is improved and the target value can be closely followed.

Owner:HANGZHOU ZETA TECH

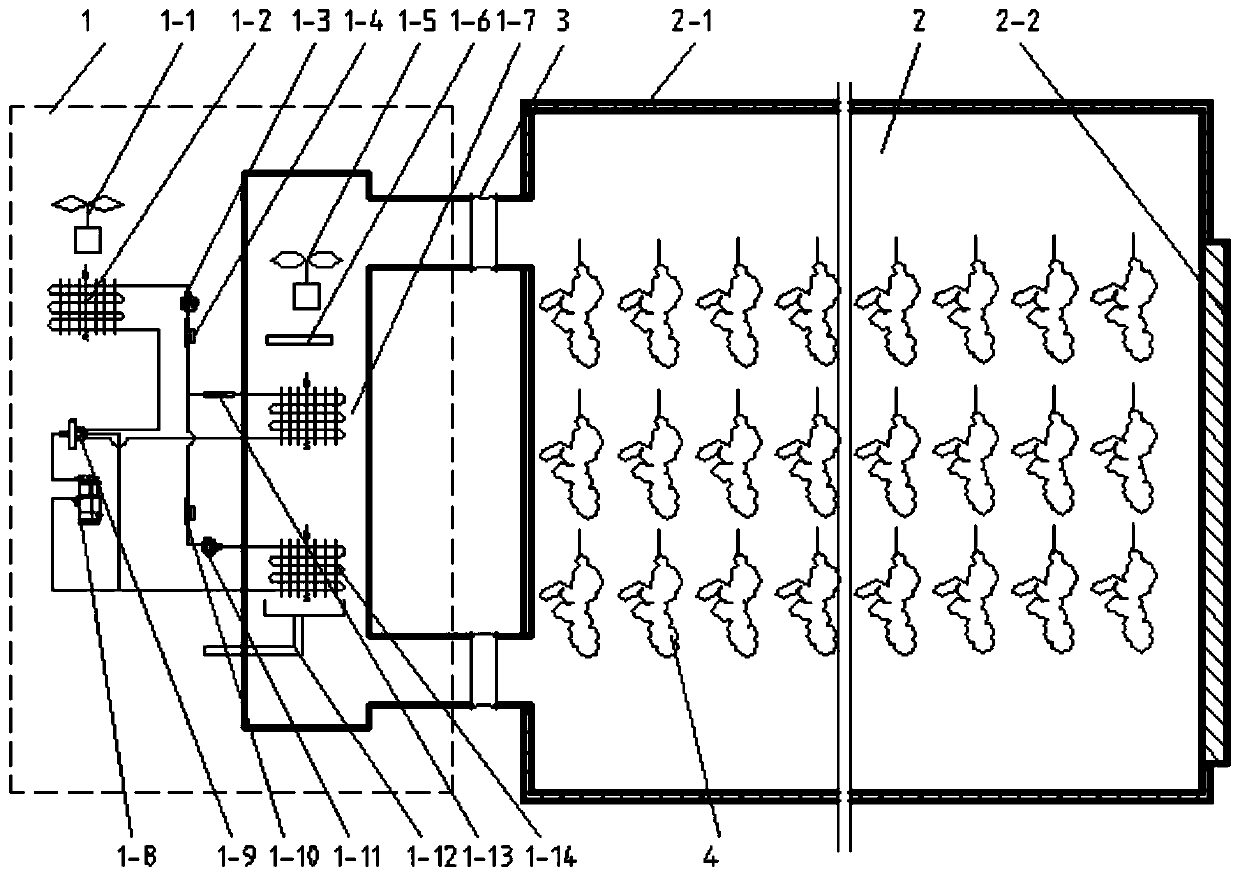

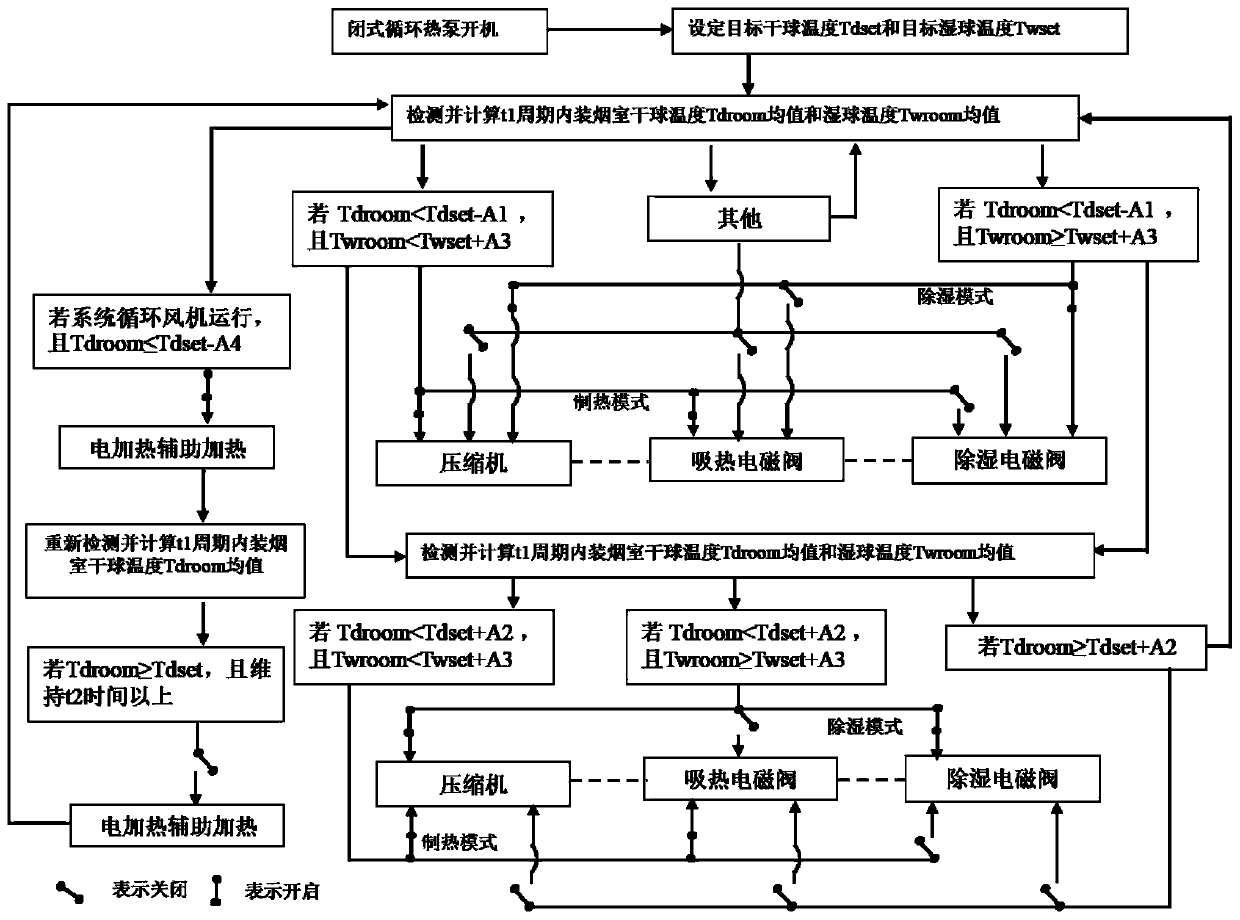

Intelligent temperature and humidity control method for closed circulation heat pump tobacco curing barn

ActiveCN110906698AImprove control effectDrying gas arrangementsDrying solid materialsThermodynamicsMedicine

The invention discloses an intelligent temperature and humidity control method for a closed circulation heat pump tobacco curing barn, which comprises the following steps of: (1) starting a closed circulation heat pump system, and setting a target dry bulb temperature Tdset and a target wet bulb temperature Twset, (2) detecting a dry bulb temperature and a wet bulb temperature in a tobacco loadingchamber, and comparing the dry bulb temperature and the wet bulb temperature with the target dry bulb temperature Tdset and the target wet bulb temperature Twset to realize starting and stopping of acompressor and switching control of heating and dehumidifying modes. In combination of control on auxiliary electric heating equipment, the compressor starting dry bulb temperature control amplitudedifference A1, the compressor stopping dry bulb temperature control amplitude difference A2, the compressor wet bulb temperature control amplitude difference A3 and the electric heating starting dry bulb temperature control amplitude difference A4 are creatively combined, and thus the compressor can be reasonably started and stopped and can be switched between the heating mode and the dehumidifying mode, the temperature and the humidity of the curing barn are ensured to be matched with the target temperature and the target humidity, the temperature and the humidity are both considered, the control effect is good, and high market application and popularization prospects are achieved.

Owner:TOBACCO RES INST CHIN AGRI SCI ACAD +3

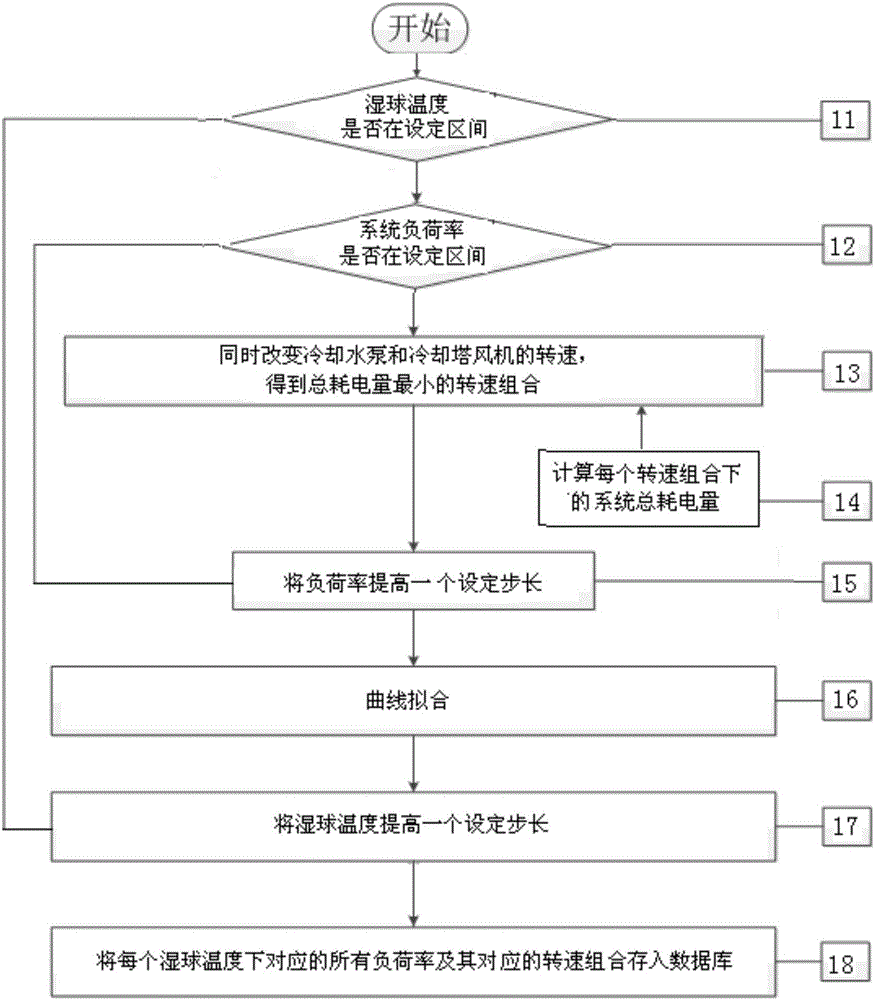

Energy saving control system and energy saving control method used for central air conditioner cooling water system

ActiveCN105004002AOvercome the disadvantages of not saving energyOvercoming optimal point deviationMechanical apparatusSpace heating and ventilation safety systemsCooling towerControl system

The invention discloses an energy saving control system and an energy saving control method used for a central air conditioner cooling water system. The method comprises the following steps that set rotating speeds of a cooling water pump and a cooling tower fan are combined to form a plurality of rotating speed combinations; the cooling water pump and the cooling tower fan are controlled to operate at each rotating speed combination; corresponding general power consumption is calculated; the rotating speed combination at which the general power consumption of the cooling water system is minimum is obtained; a load rate of a central air conditioner system and a current wet-bulb temperature are subjected to step length increasing and repetitive computation; a load rate and the rotating speed combination corresponding to the load rate are obtained; and the rotating speed combination is introduced to the control system, thereby controlling the operation of the cooling water pump and the cooling tower fan. When the wet-bulb temperature changes, the above control process is repeated by selecting the control law corresponding to the wet-bulb temperature, so that the energy consumption of the cooling water system is always kept at the optimum point, the maximum energy saving is realized, and the disadvantage that single equipment is higher in energy efficiency but an integrated system does not save the energy is overcome.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

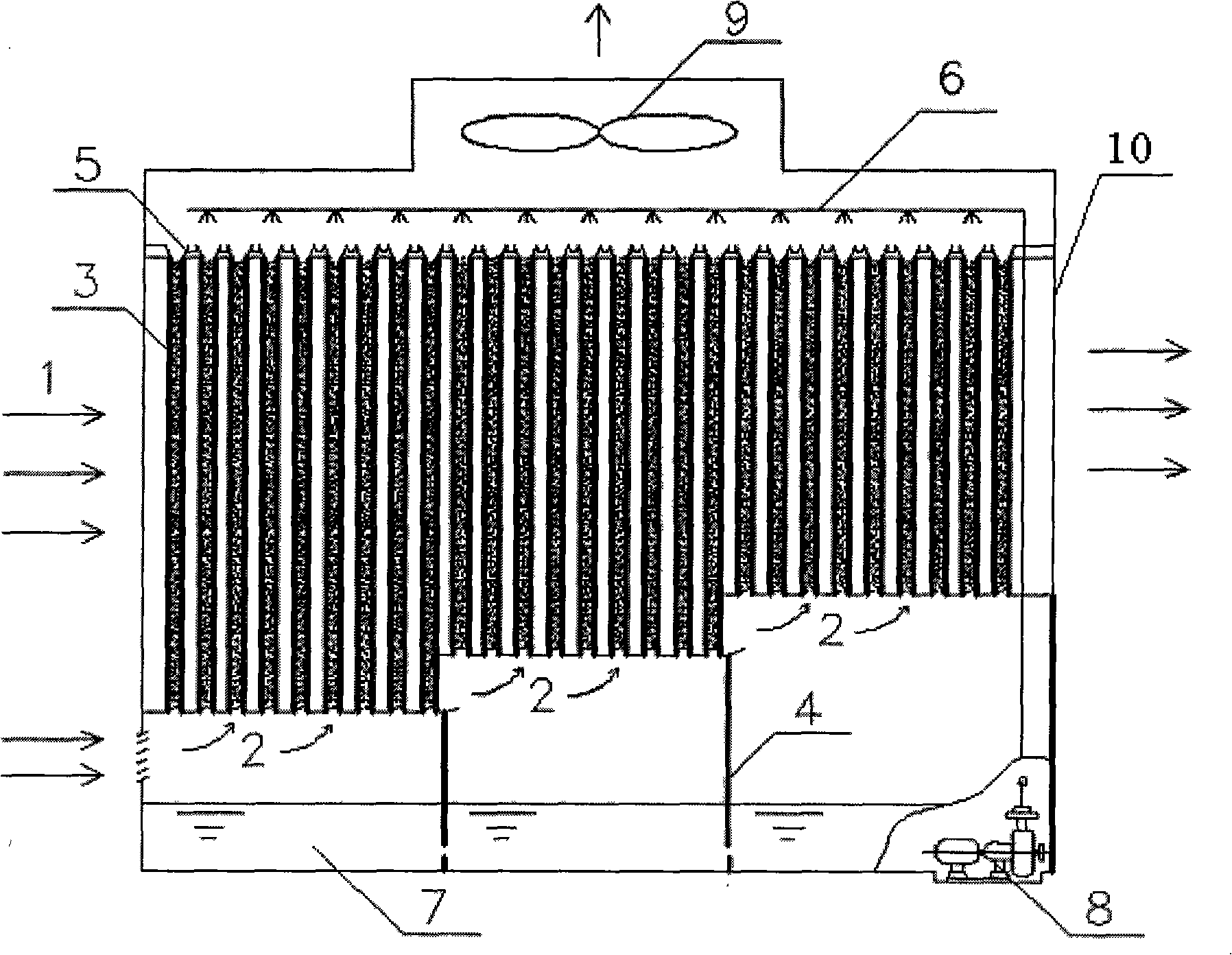

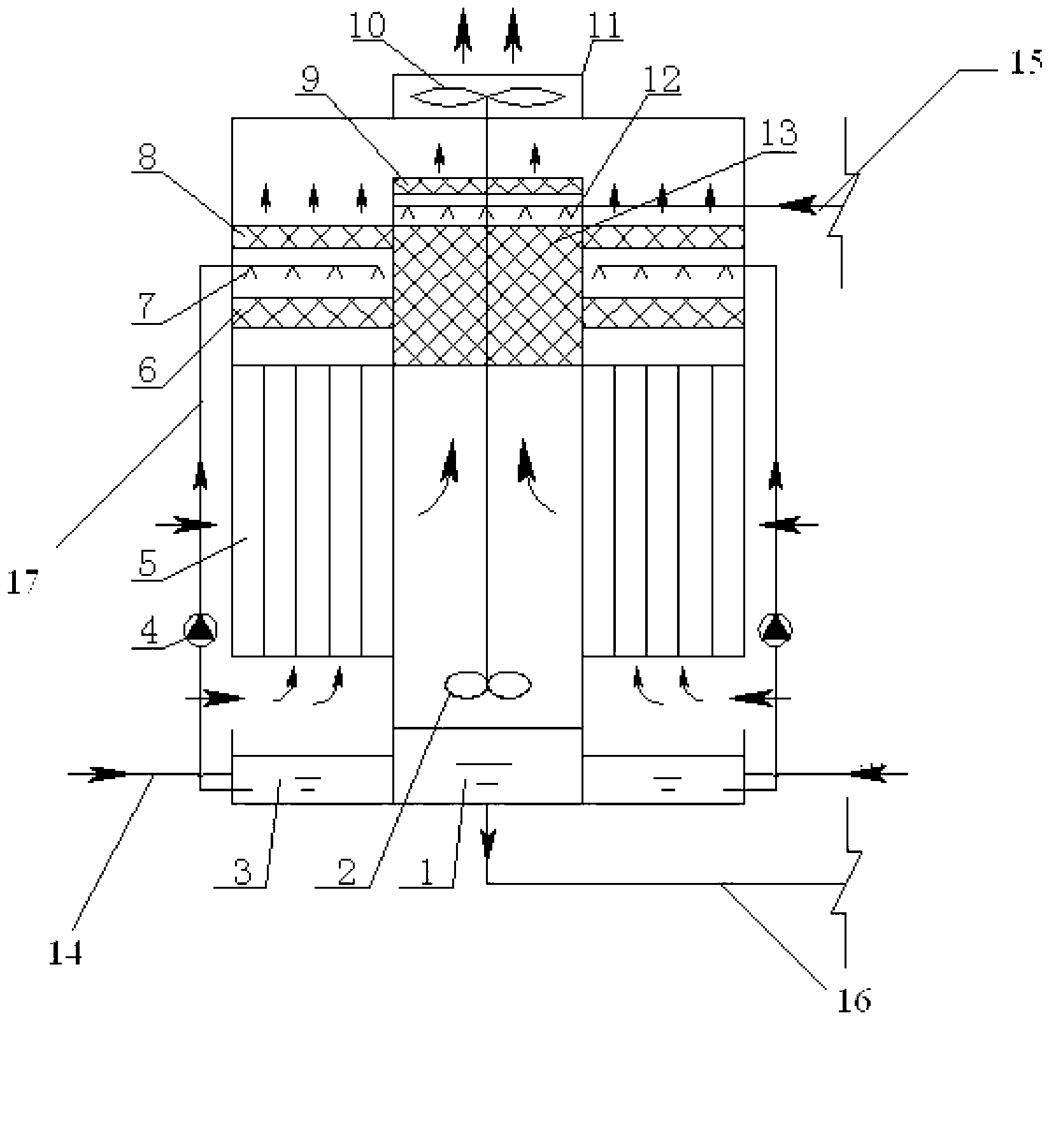

Hydrodynamic fan cooling tower capable of generating sub wet bulb temperature water

InactiveCN103075896ATo achieve the purpose of energy savingCompact structureMachines/enginesEngine componentsEvaporative coolerCooling tower

The invention discloses a hydrodynamic fan cooling tower capable of generating sub wet bulb temperature water. The hydrodynamic fan cooling tower comprises a cooling tower shell; vertical pipe type indirect evaporative coolers with the same structure are symmetrically arranged on the left side and the right side of the cooling tower shell; a direct evaporative cooler is arranged between the two vertical pipe type indirect evaporative coolers; an exhaust fan is arranged at the upper part of the direct evaporative cooler; and an exhaust port is formed on the top wall of the cooling tower shell corresponding to the exhaust fan. The hydrodynamic fan cooling tower capable of generating the sub wet bulb temperature water has the benefits that a water turbine is used for replacing a motor to be taken as a power source of the exhaust fan, so that the energy consumption is reduced; and the vertical pipe type indirect evaporative coolers and the direct evaporative cooler are combined, and the leading effects of the evaporative coolers are fully exerted, therefore, the cooling tower has the advantages of environmental friendliness, high efficiency and energy conservation.

Owner:XI'AN POLYTECHNIC UNIVERSITY

Night sky cooling system

A cooling system that can be used to cool water and to cool an air supply to a building. The system employs a stand alone cooling tower and a night sky cooler. As a result, the water can be cooled below the ambient wet bulb temperature.

Owner:MCNNNAC ENERGY SERVICES

System for conditioning the airflow entering a turbomachine

ActiveUS20110042836A1Increase productionCombination devicesFlow mixersEngineeringVolumetric Mass Density

An embodiment of the present invention provides an air conditioning system (ACS) for conditioning the airstream entering an air-consuming machine, such as, but not limiting of, a gas turbine. Conditioning may be considered a process that adjusts at least one physical property of the airstream. The physical property may comprise: a wet-bulb temperature, a dry-bulb temperature, relative humidity, density, or the like. In an embodiment of the present invention, the major components of the ACS may be located in a single structure, which may be considered a module. Depending on the application of the ACS, multiple modules may be physically and / or operationally integrated on the air-consuming machine. An alternate embodiment of the ACS may comprise a module having multiples stages. Here, each stage may operate independently other stages. Furthermore, each stage may use a separate fluid from other stages.

Owner:GENERAL ELECTRIC CO

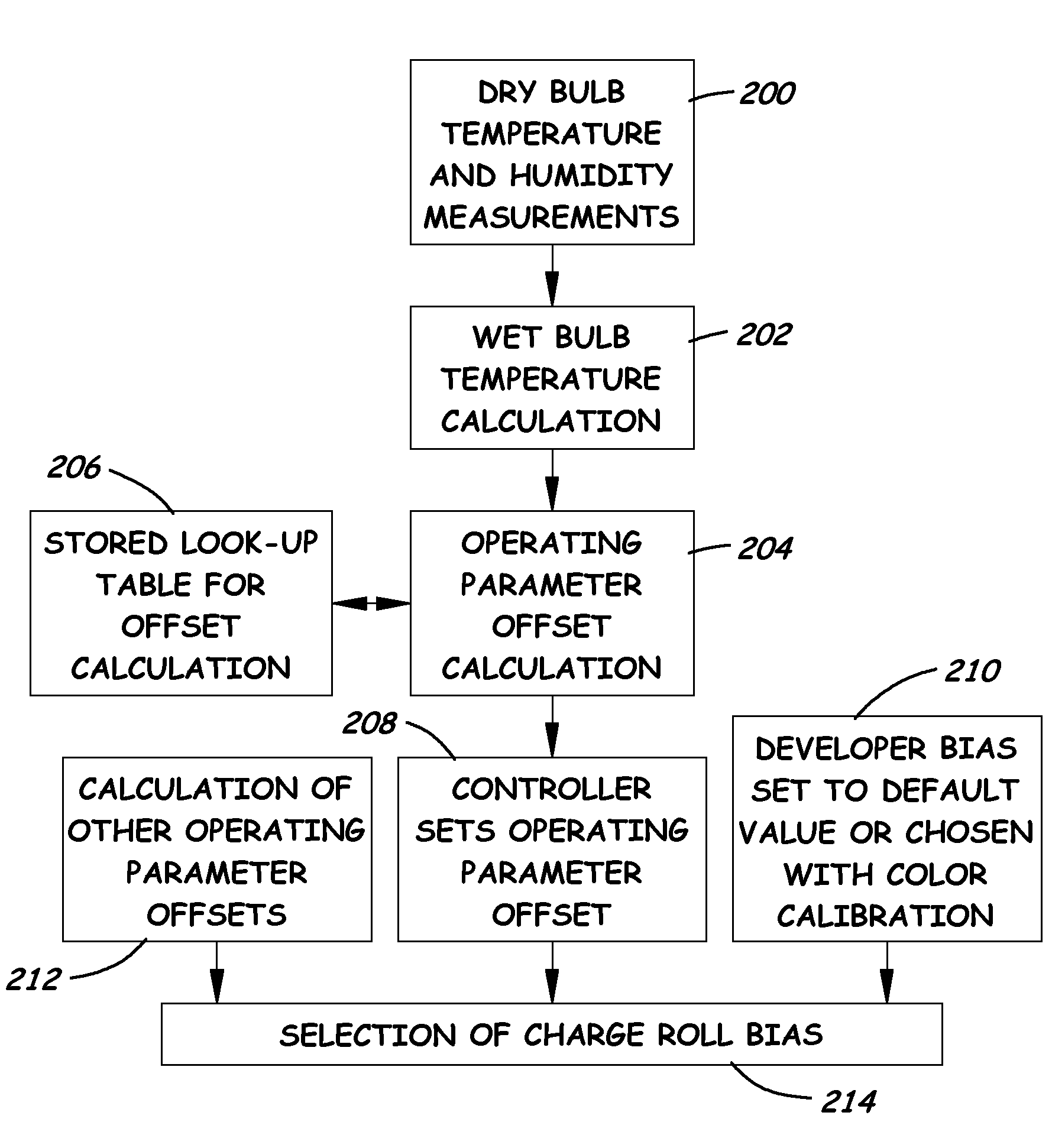

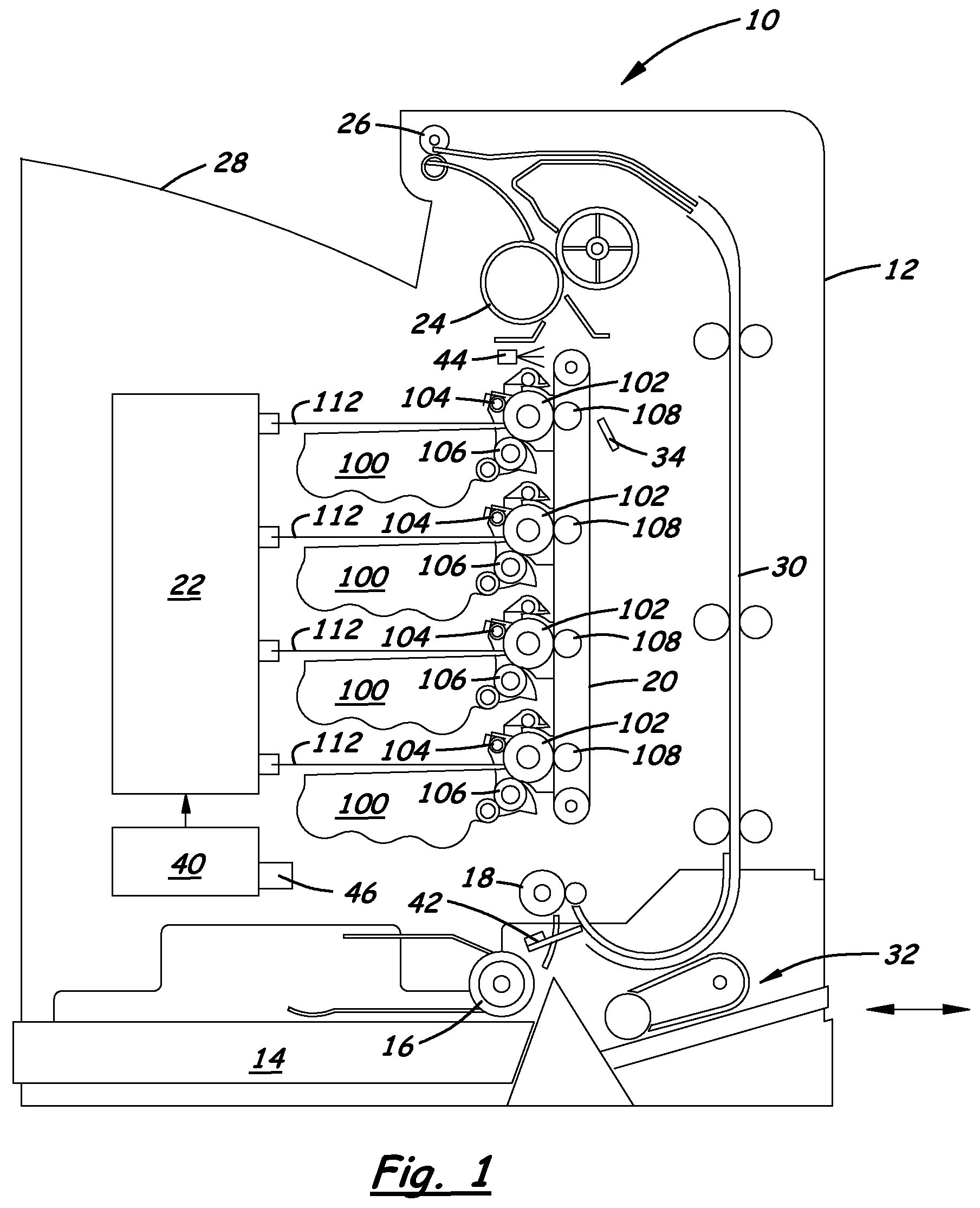

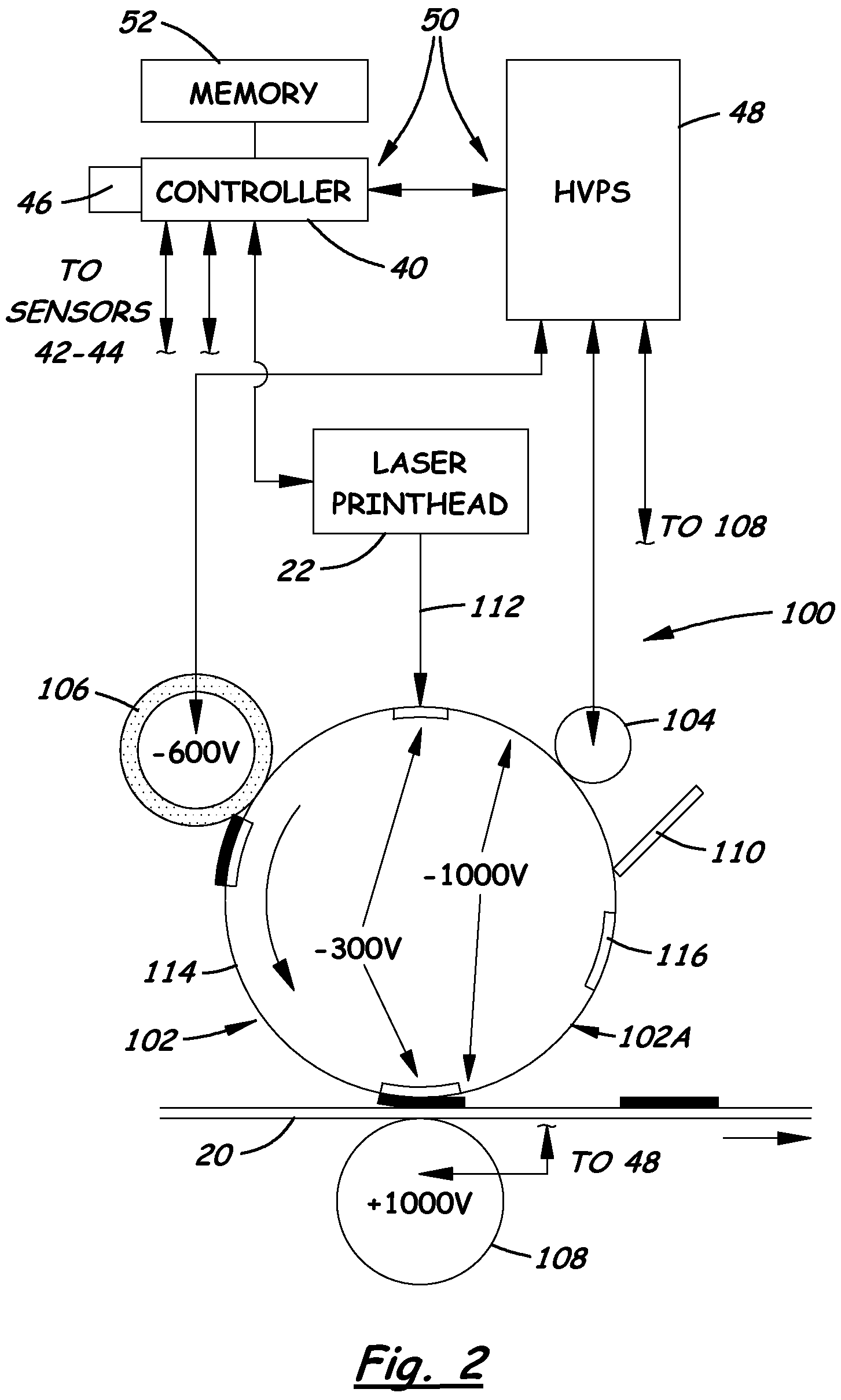

System and Method for Adjusting Selected Operating Parameter of Image Forming Device Based on Selected Environmental Conditions to Control White Vector

InactiveUS20100080585A1High voltageEasy to controlElectrographic process apparatusCorona dischargeLatent imageImage formation

A system for adjusting a selected operating parameter of an image forming device to control white vector based on selected environmental conditions includes an image forming station having a photoconductive surface with a latent image formed by discharged areas leaving non-discharged areas different from the discharged areas, a sensor mechanism for measuring selected environmental conditions of dry-bulb temperature and relative humidity, a control mechanism for reading the sensor mechanism to adjust the voltage bias of a charging unit by an offset applied to the charging unit based on a wet-bulb temperature value so as to minimize white vector without enabling onset of development of toner background on non-discharged areas, and a memory connected to and accessible by the control mechanism and storing a lookup table of a list of wet-bulb temperature values related to measured dry-bulb temperature and relative humidity values and correlated to a list of voltage bias offsets.

Owner:LEXMARK INT INC

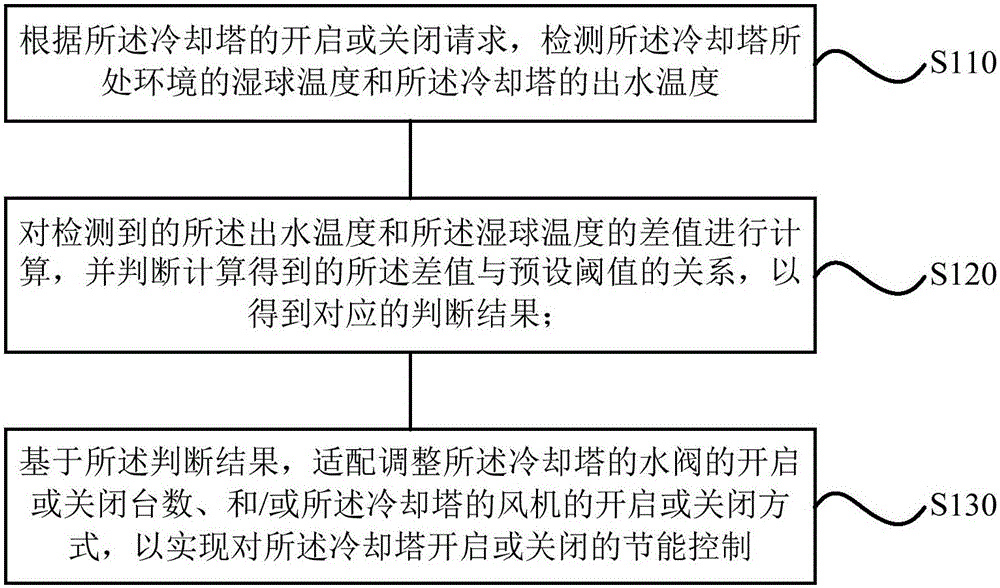

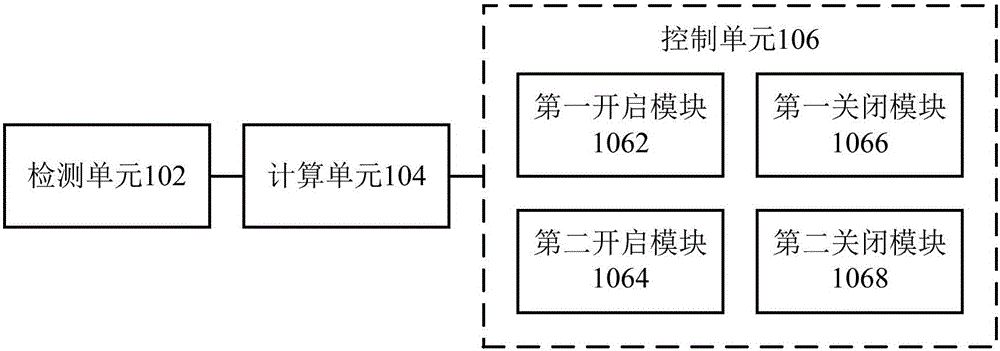

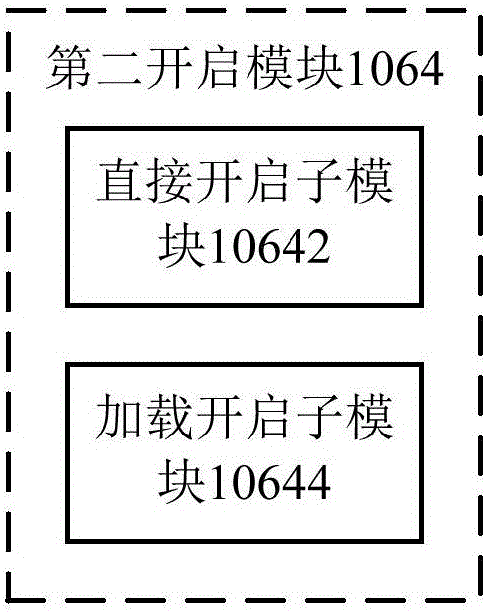

Energy-saving control method and device used for cooling tower and air-conditioning system

ActiveCN105953602AGuaranteed cooling effectRealize energy-saving operationHeat exchange apparatusTrickle coolersCooling towerEngineering

The invention discloses an energy-saving control method and device used for a cooling tower and an air-conditioning system. The method comprises: detecting the wet bulb temperature of the cooling tower in the environment and the outlet water temperature of the cooling tower based on the starting or closing request of the cooling tower, calculating the difference value between the detected outlet water temperature and the wet bulb temperature, determining the relationship between the calculated difference value and the preset threshold value to obtain the corresponding determine result, adapting and adjusting the number of starting or closing water valve of the cooling tower, and / or the starting or closing form of the fan of the cooling tower, and realizing the energy-saving control of starting or closing the cooling tower. The energy-saving control method and device used for a cooling tower and the air-conditioning system can overcome the defects such as inflexible temperature regulation, low reliability, and poor energy-saving effect, and can realize the beneficial effects of flexible temperature regulation, high reliability, and good energy-saving effect.

Owner:GREE ELECTRIC APPLIANCES INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com