Hydrodynamic fan cooling tower capable of generating sub wet bulb temperature water

A wet-bulb temperature and water-driven fan technology, which is applied in the direction of water shower coolers, engine components, machines/engines, etc., can solve the problem of high energy consumption, achieve the effect of compact unit structure, save space, and improve heat exchange efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in detail below with reference to the drawings and specific embodiments.

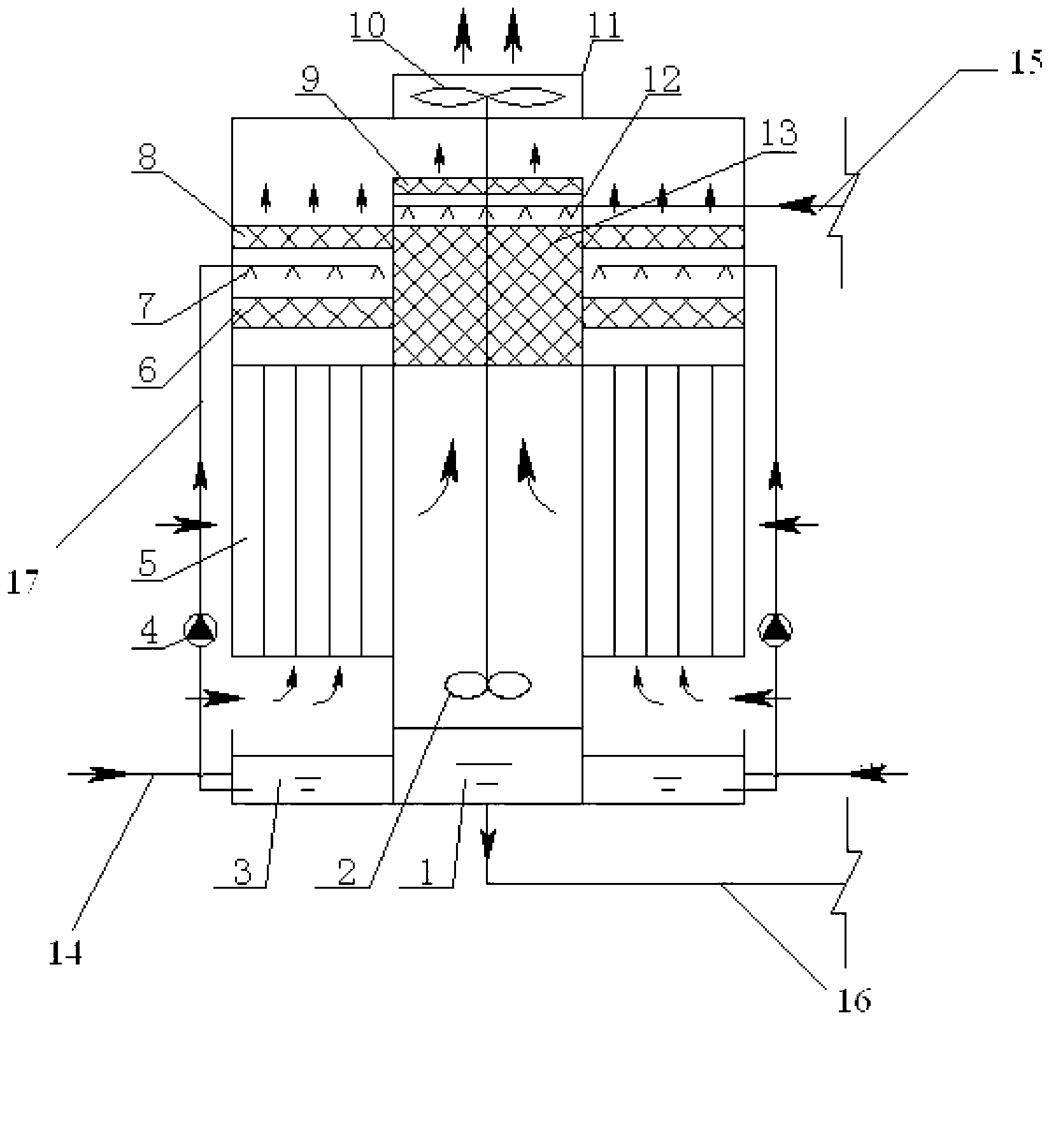

[0018] The water driven fan cooling tower capable of producing sub-humid bulb temperature water of the present invention has a structure such as figure 1 As shown, a cooling tower shell is included. The left and right sides of the cooling tower shell are symmetrically provided with riser-type indirect evaporative coolers with the same structure. A direct evaporative cooler is installed between the two riser-type indirect evaporative coolers. An exhaust fan 10 is provided on the upper part of the evaporative cooler, and an exhaust port 11 is provided on the top wall of the cooling tower shell corresponding to the exhaust fan 10.

[0019] The vertical tube type indirect evaporative cooler includes a vertical heat exchange tube group 5, the upper part of the vertical heat exchange tube group 5 is sequentially provided with filler a6, nozzle a7 and water baffle a8, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com