Patents

Literature

52results about How to "Reduce stuck problems" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

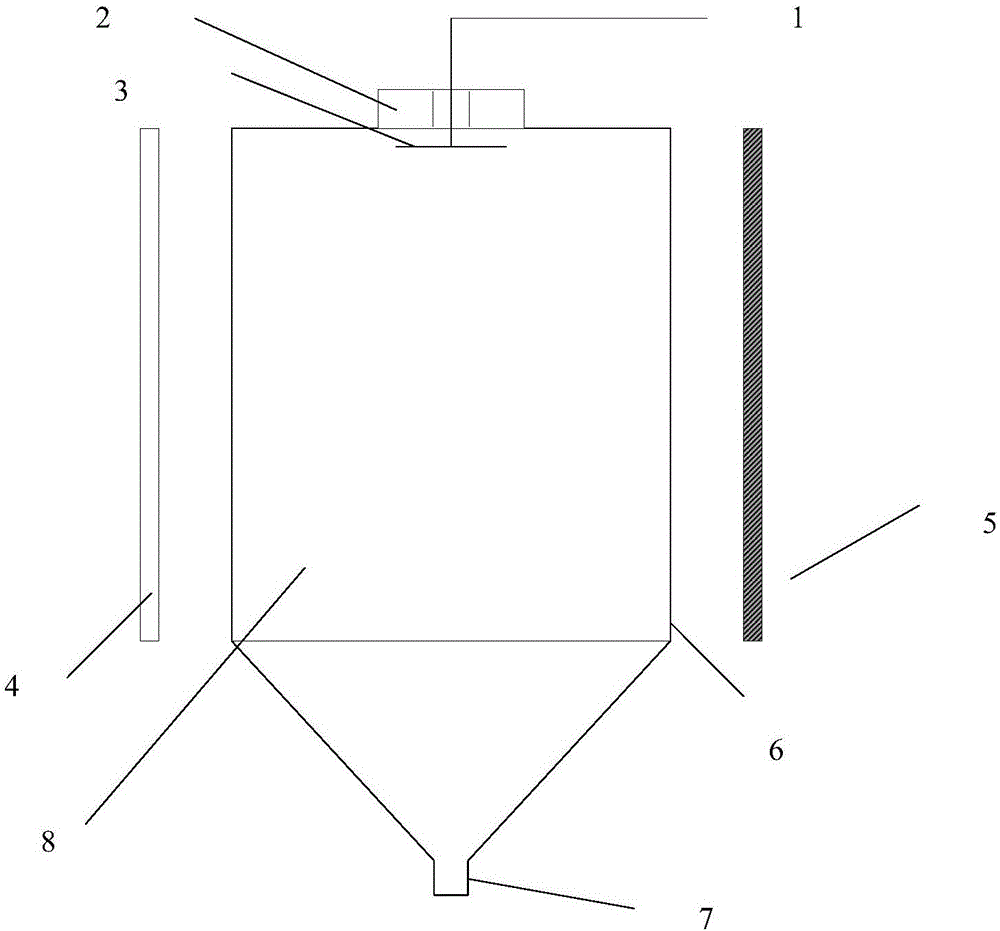

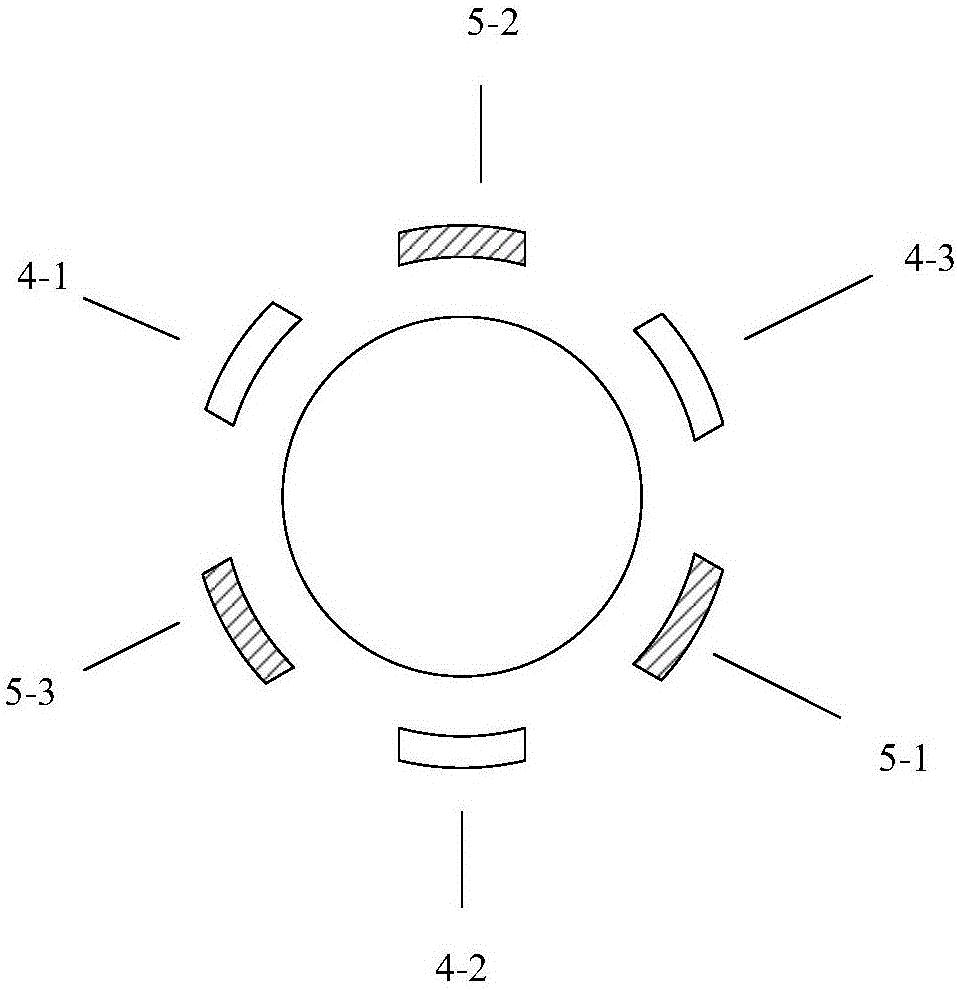

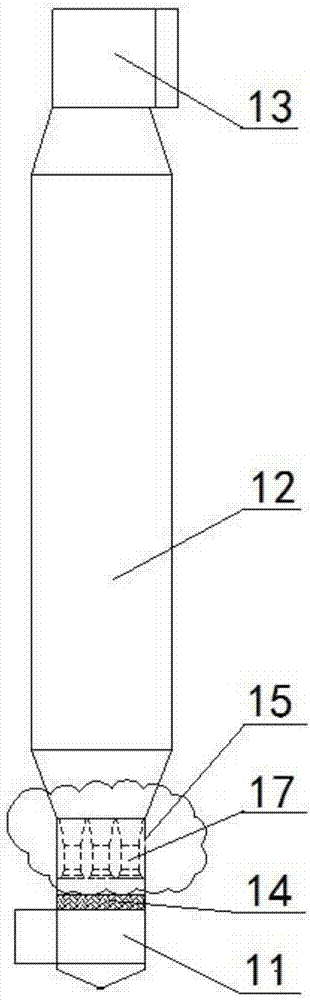

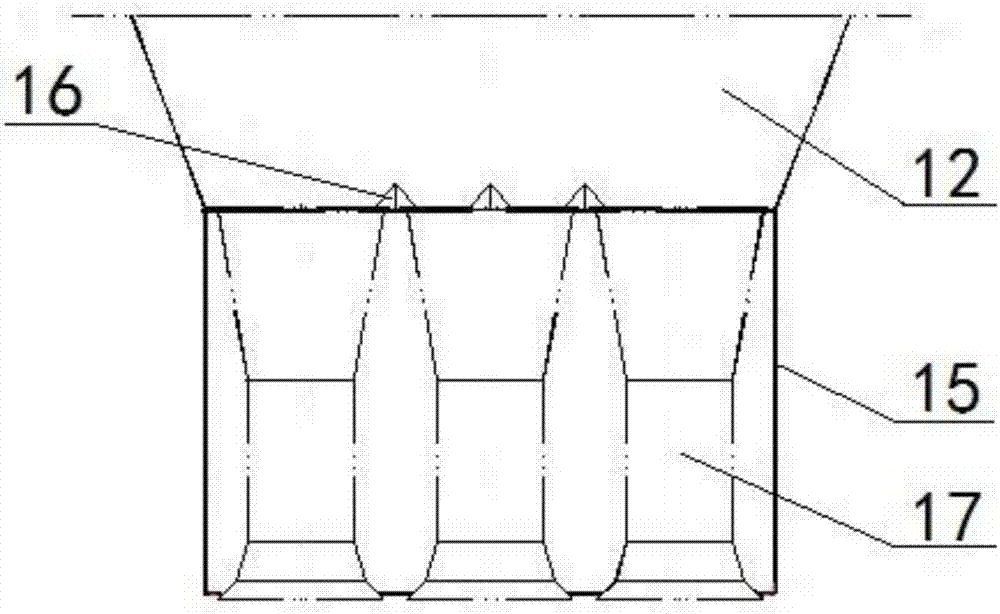

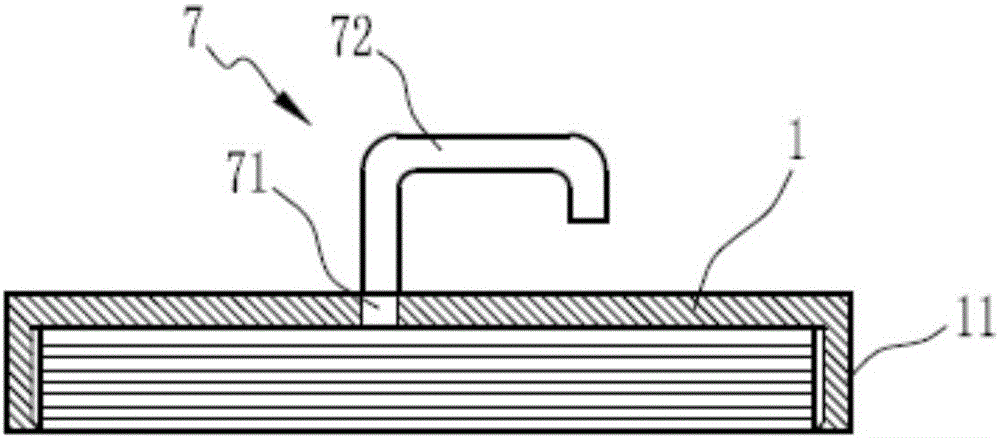

Seasoner sponging drying machine group

InactiveCN101178283AReduce stuck problemsReduce sticky topDrying solid materials with heatHearth type furnacesCycloneFeed technique

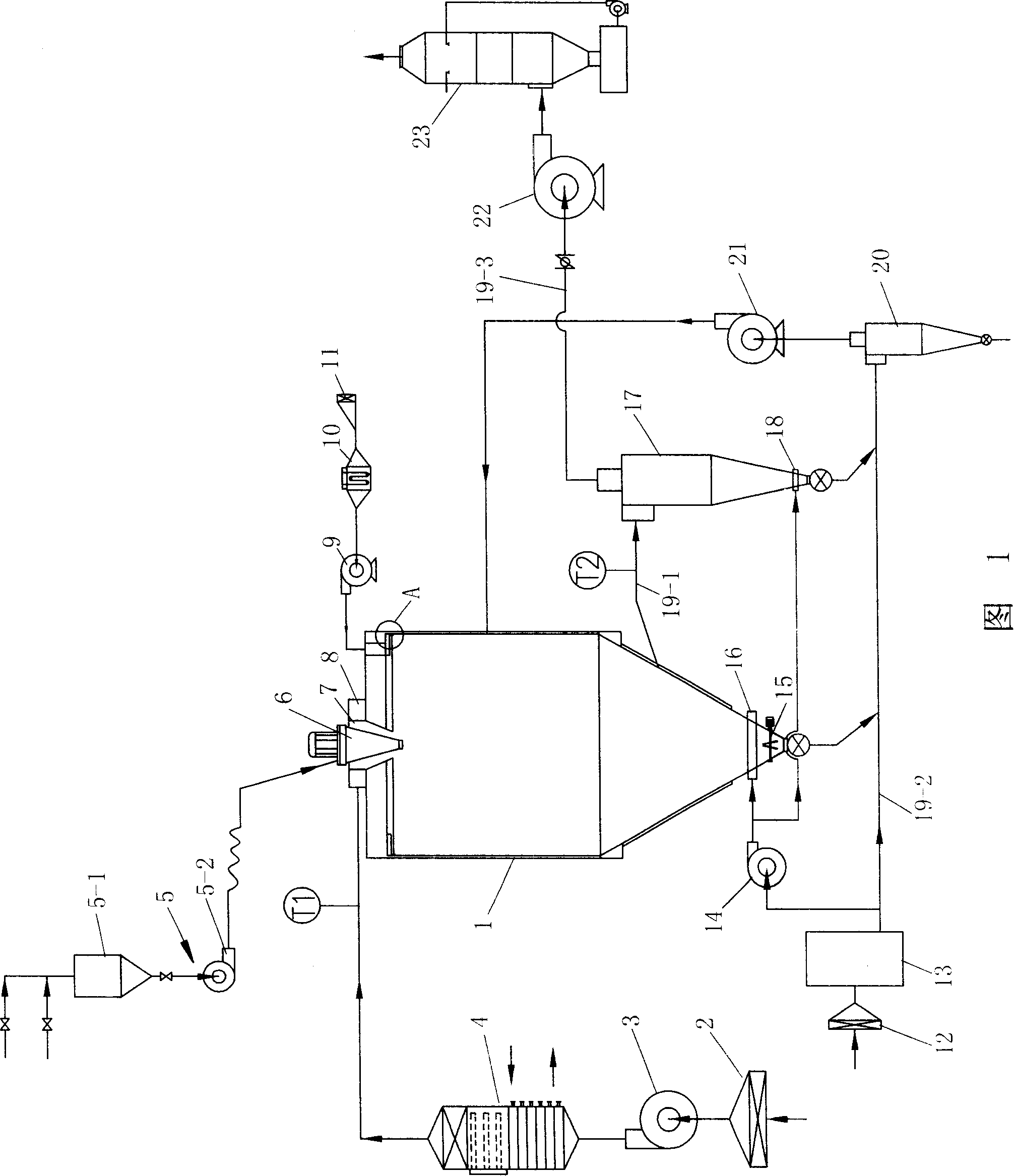

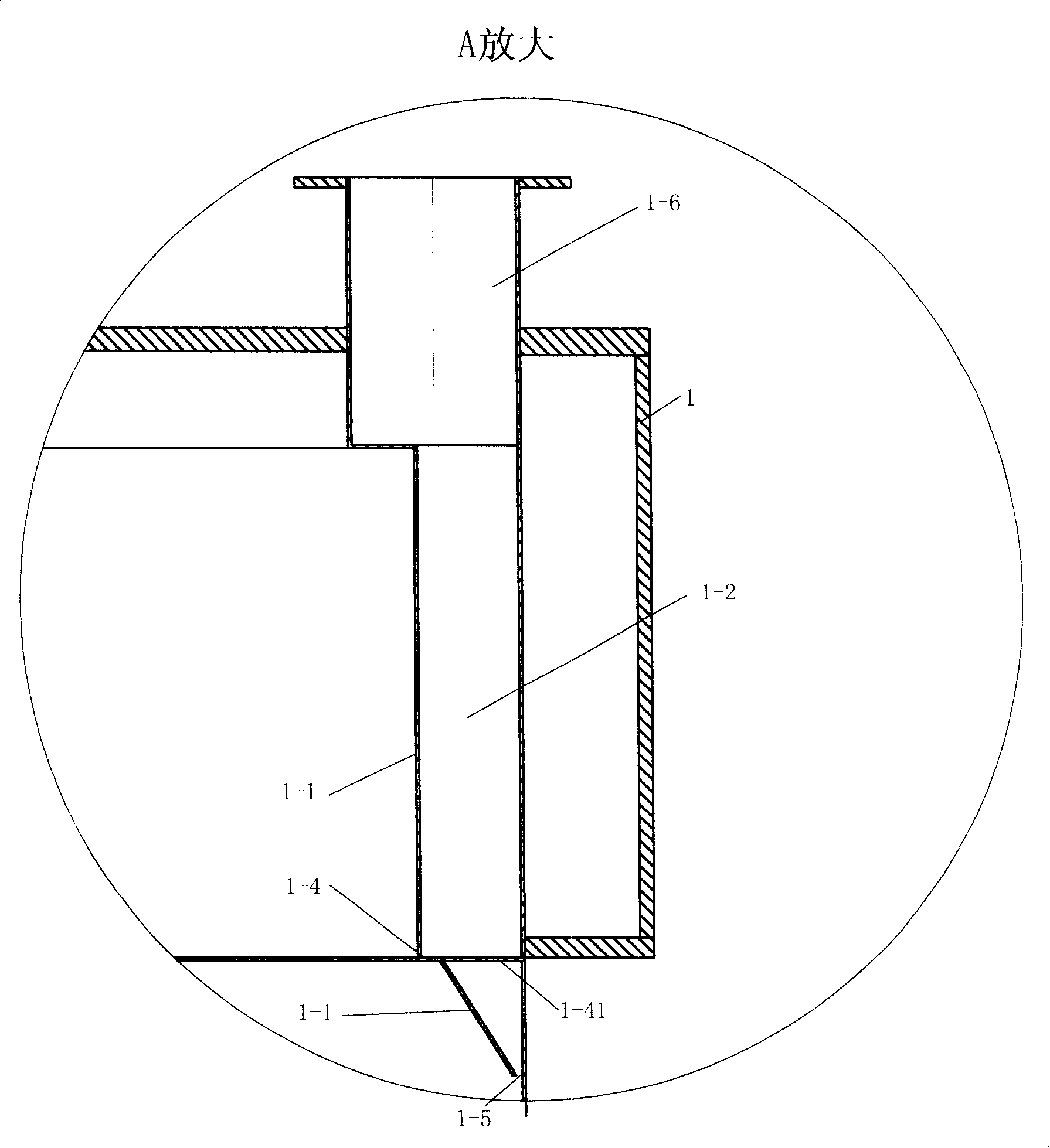

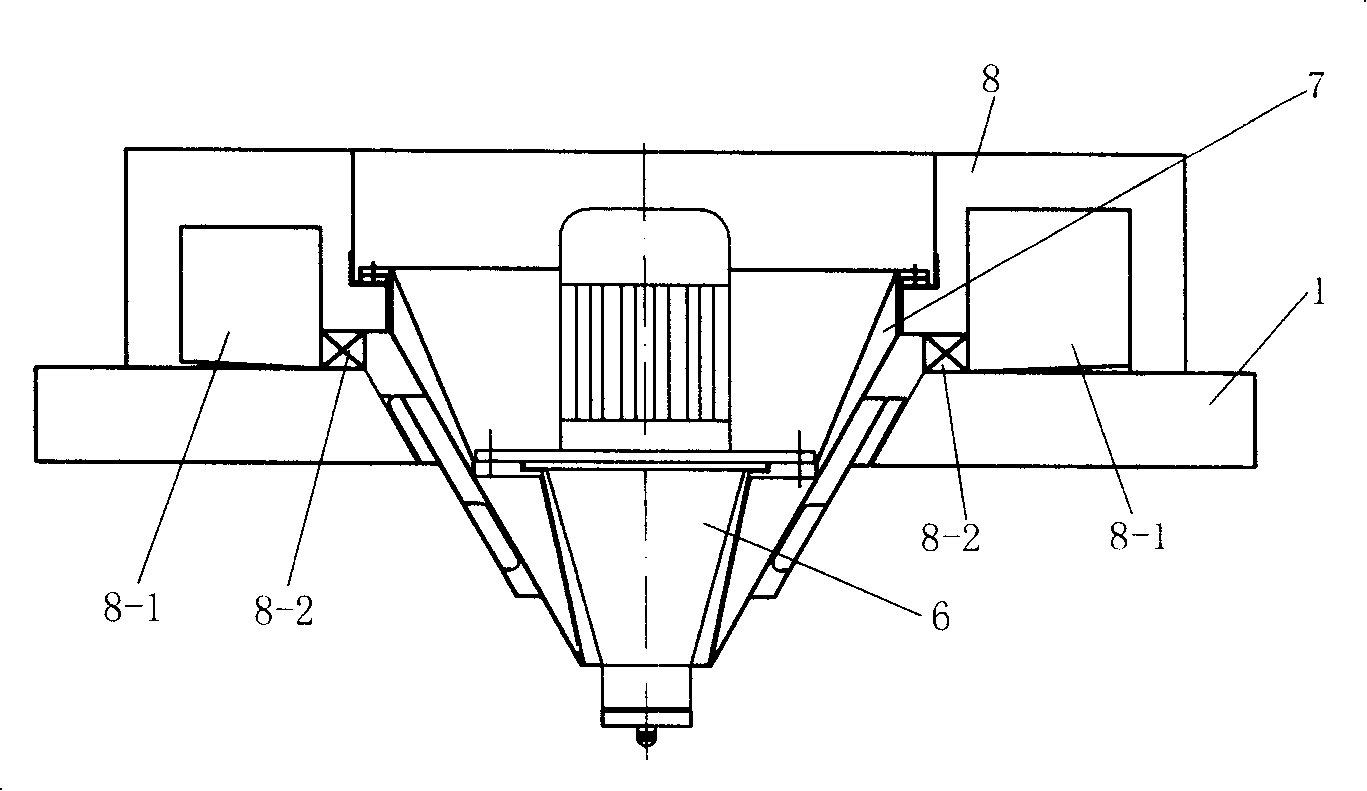

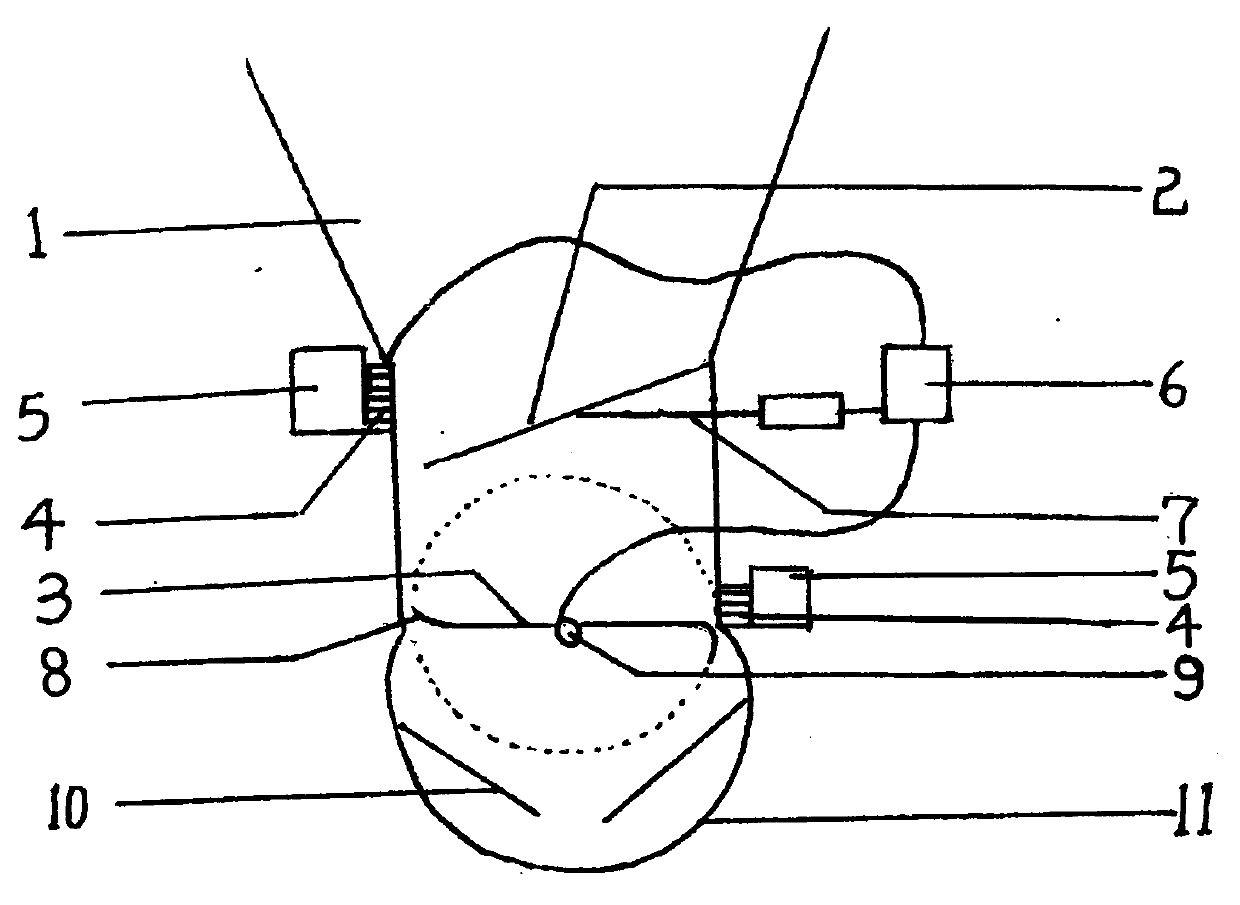

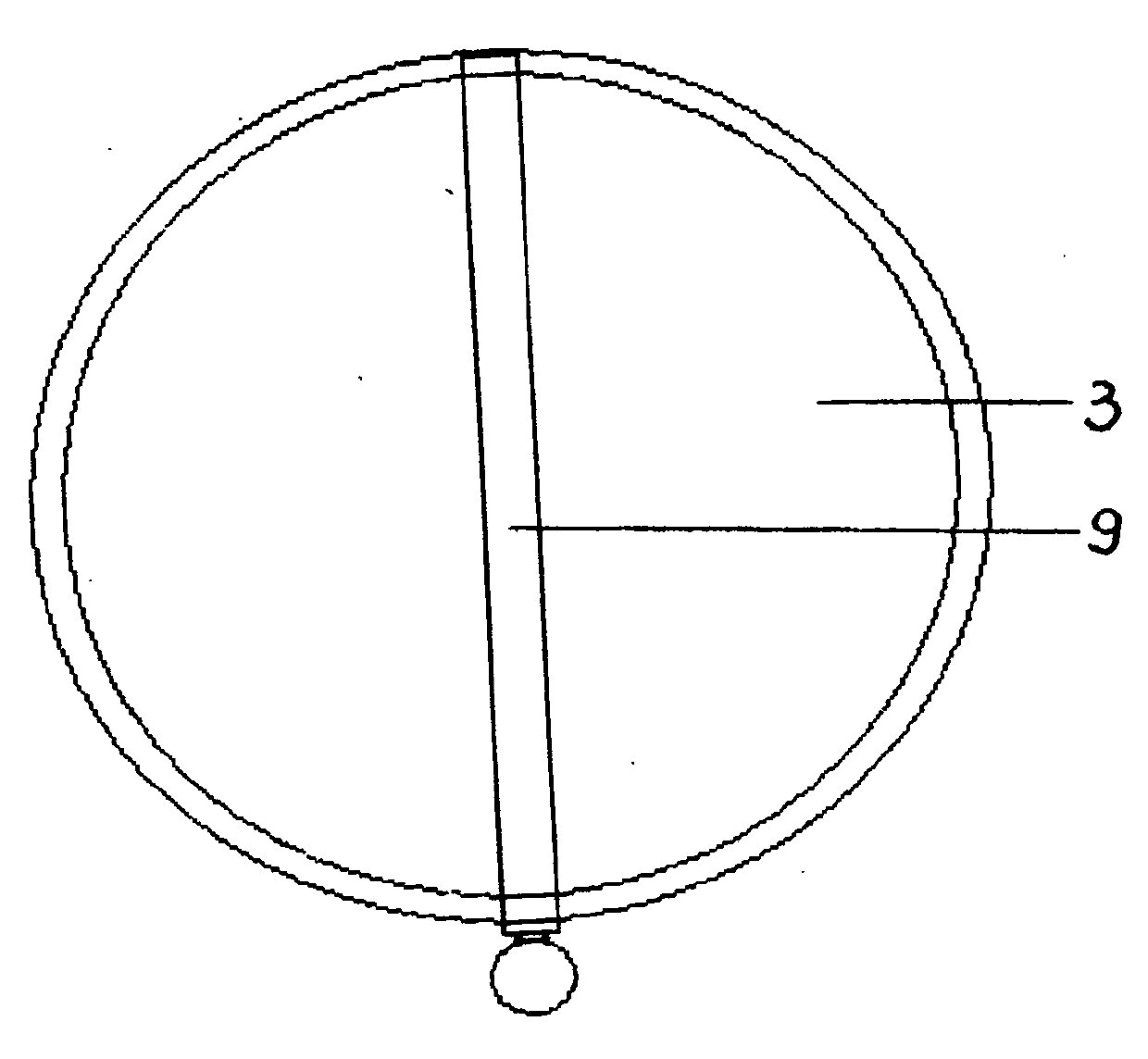

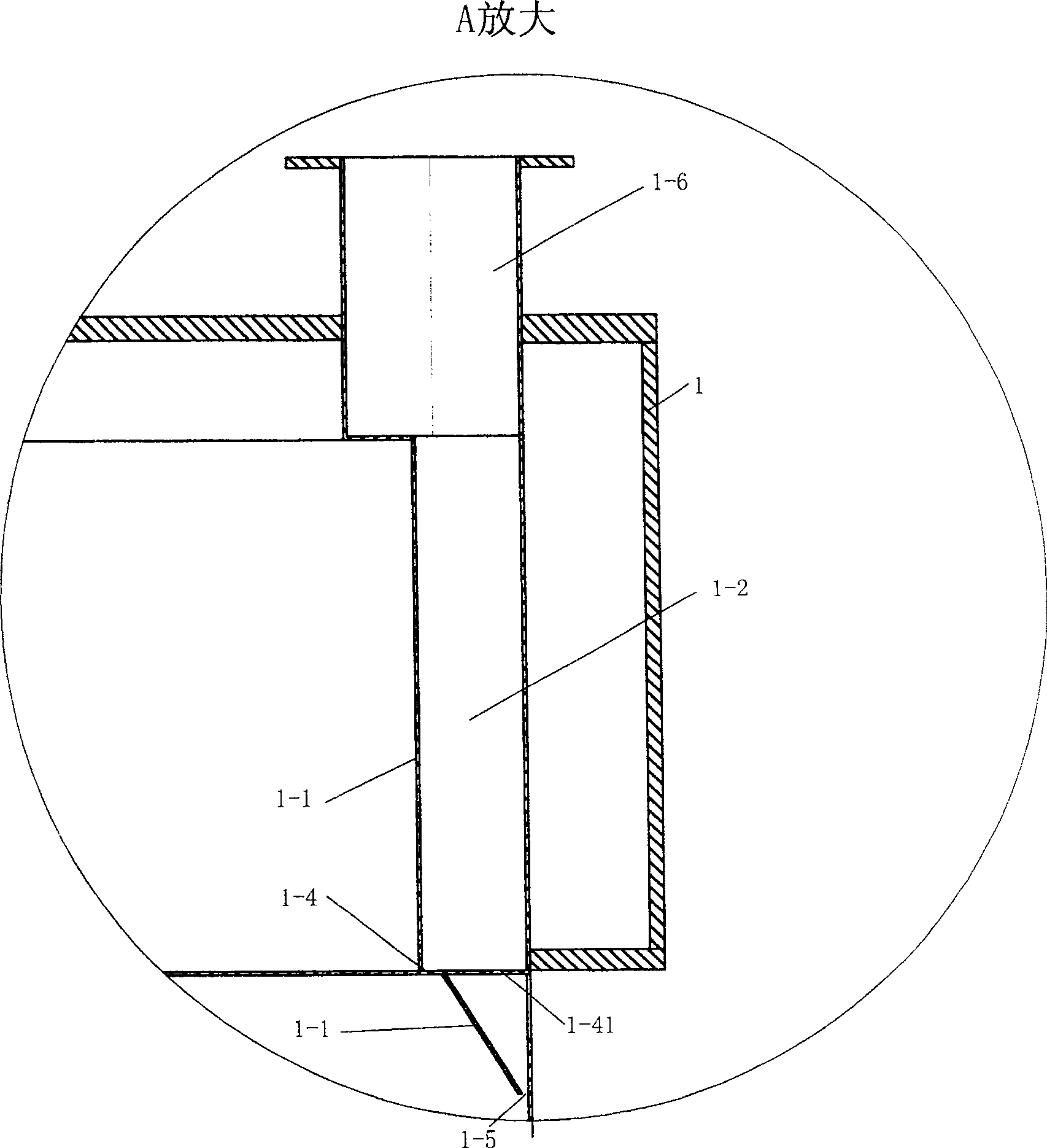

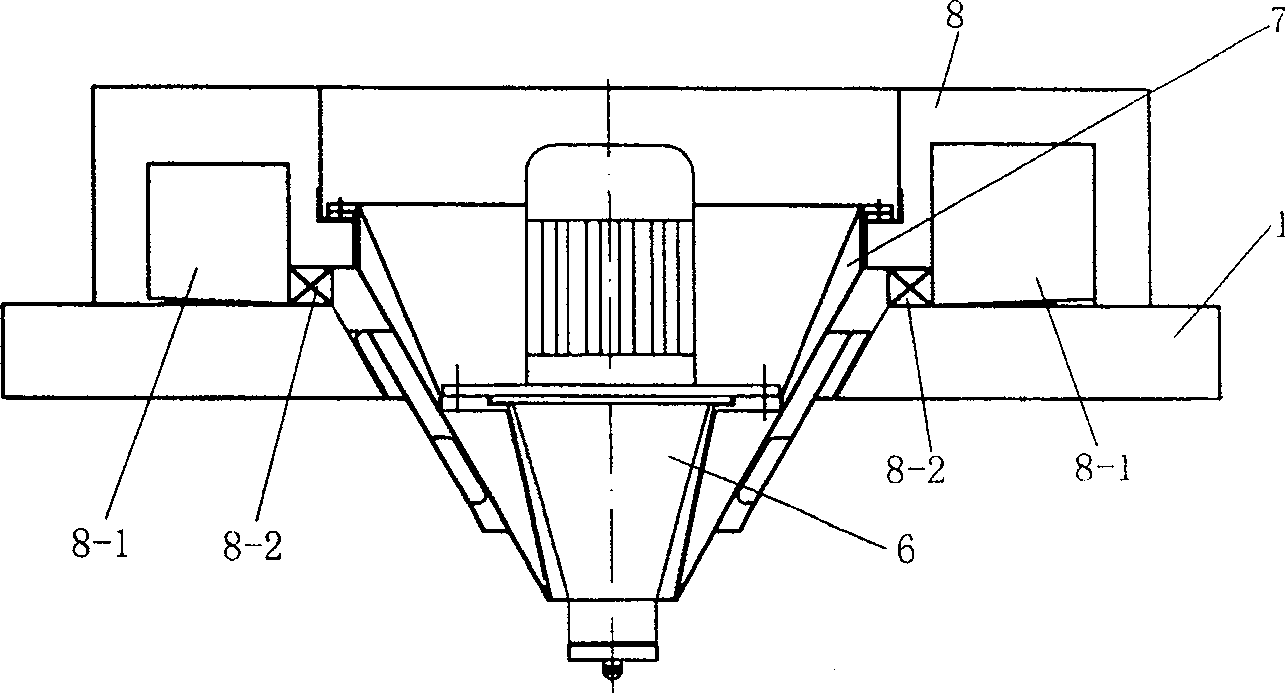

The invention comprises a material feeding device, a drying tower, a No 1 fan, a No 1 heater, a first-level cyclone separator and water-membrane dust remover. A hot air distributor and an atomizer which is arranged at the center of the hot air distributor and is connected with the material feeding device are arranged on the top of the drying tower. An air channel disk with a spiral-case shaped air channel is arranged on the top of the drying tower. The inlet of the air channel disk is connected with the output pipeline of the No1 heater, and the outlet of the spiral-case shaped air channel is connected with the inlet of the hot air distributor. A clamp sleeve is arranged in the internal tower body and near the top of the drying tower. A wall-blowing air channel is a space between the clamp sleeve and the inner side wall of the tower body. An annular clearance between the clamp bottom and the inner wall of the tower body is an air vent, and the air forms the wall-blowing air through the annular clearance. The invention adopts the air channel disk spiral air-feeding and wall-blowing feeding technique of the spiral-case shaped air channel, which not only can enhance drying efficiency but also can provide the wall-blowing air to form an air membrane in the drying tower. The air membrane can isolate powder materials from the tower wall so as to avoid a wall-sticking phenomenon.

Owner:JIANGSU XIANFENG DRYING ENG

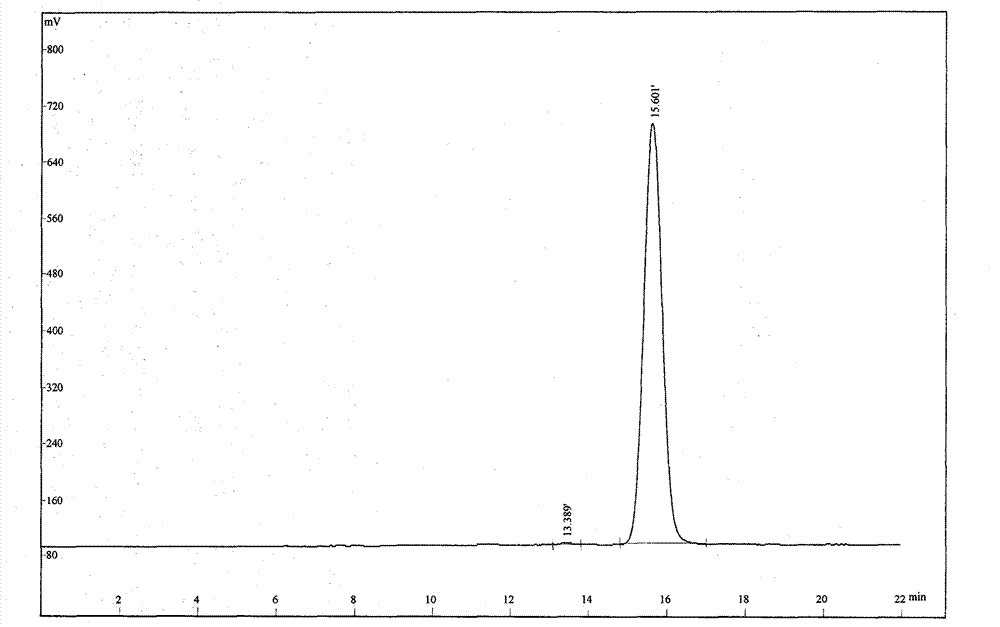

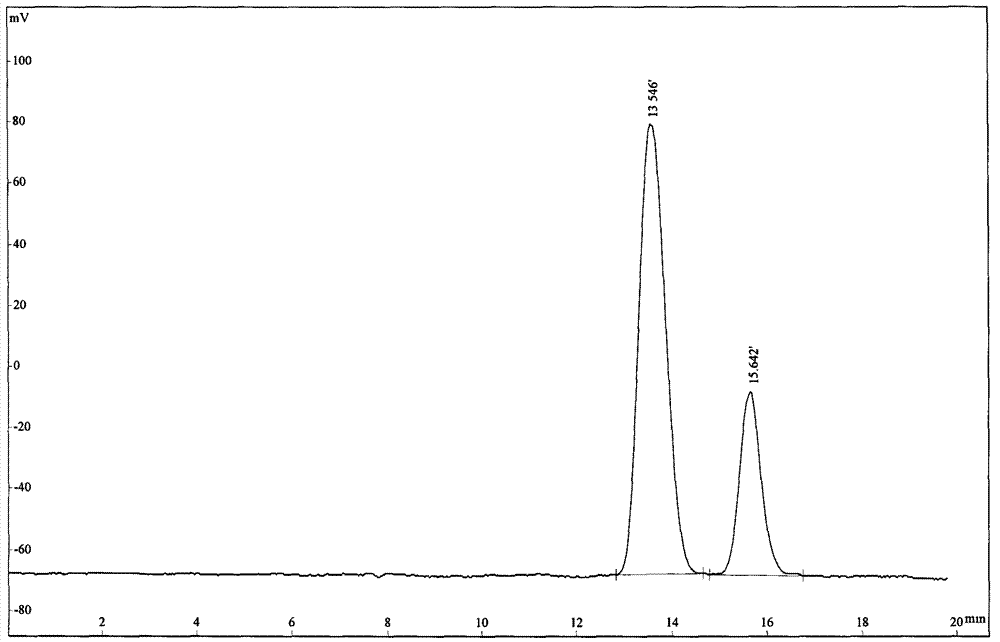

Preparation method of mannose

InactiveCN102807593AReduce viscosityOvercome the disadvantage of easy moisture absorptionSugar derivativesSugar derivatives preparationSimulated moving bedD-Glucose

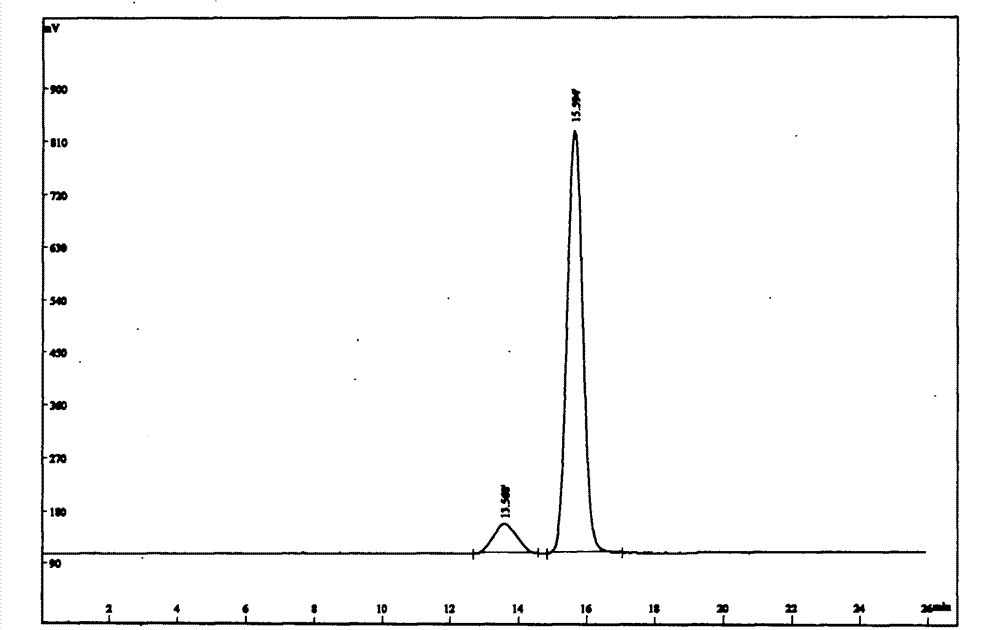

The invention discloses a preparation method of D-mannose, which comprises the following steps that glucose is epimerized under a normal pressure or pressurized condition by using ammonium molybdate as catalyst to obtain mixed solution of glucose and mannose; the mixed solution is discolored, desalted and refined and then enters a simulated moving bed 1 for separation and purification to obtain a component A rich in mannose and a component B rich in glucose; the component A enters a simulated moving bed 2 for separation to obtain a component C rich in mannose and a component D rich in glucose; the component B is filtered through a membrane and then enters the step of epimerization; the component D is filtered through a membrane and then enters the simulated moving bed 1 for cyclic separation; and the component C is centrifugally spray-dried to obtain D-mannose finished products. The preparation method of the D-mannose has the advantages of simple steps and easiness in operation. The purity of the D-mannose finished products prepared by adopting the method reaches more than 99 percent and the total yield reaches 53-60.4 percent.

Owner:白心亮

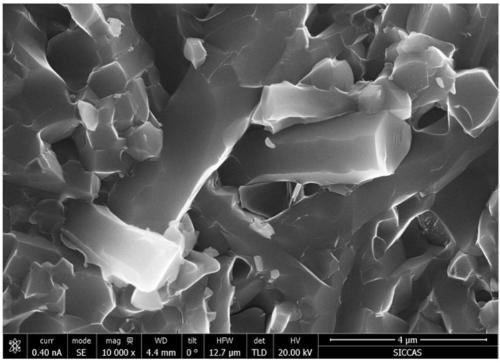

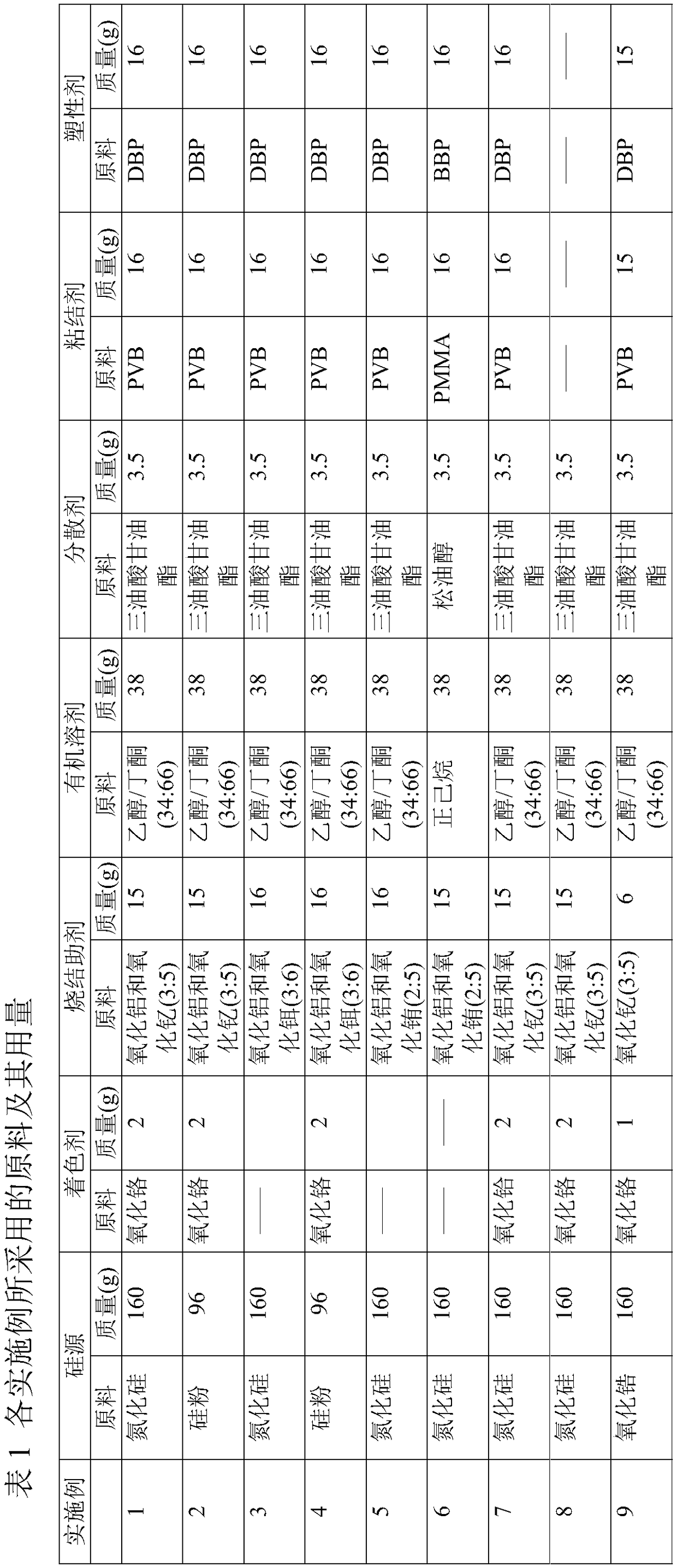

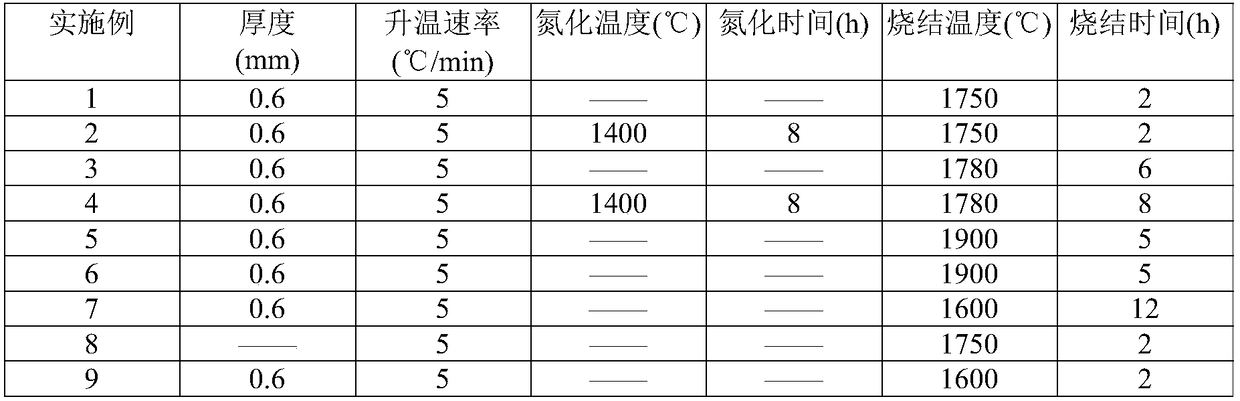

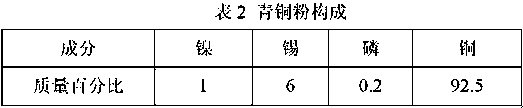

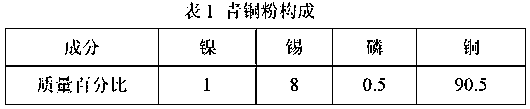

Silicon nitride ceramic material for backboard of mobile phone and preparation method thereof

ActiveCN108947539AMeet the mechanical performance requirementsImprove toughnessTelephone set constructionsDielectric lossHardness

The invention relates to a silicon nitride ceramic material for a backboard of a mobile phone and a preparation method thereof. The preparation method comprises the step of mixing, molding and sintering a raw material component which is a mixture of a silicon source, a coloring agent and a sintering additive to prepare the silicon nitride ceramic material. The invention further provides the silicon nitride ceramic material prepared by the method and application of the silicon nitride ceramic material in a backboard of a mobile phone. The silicon nitride ceramic material is a material with excellent performance and has great application potential, and has the advantages of good toughness reaching 12MPa.m<1 / 2> or more, high strength, good impact toughness, high conductivity reaching 40-70W / m.K, low dielectric loss which is general at 10<-4> order, high hardness to prevent scraping or easy extending even microcrack occurs, small density, transparency, good texture, easy coloring and goodcoloring effect; and the method is simple and reliable in process and easy to operate, and has low raw material cost.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

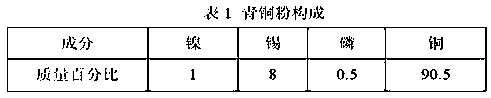

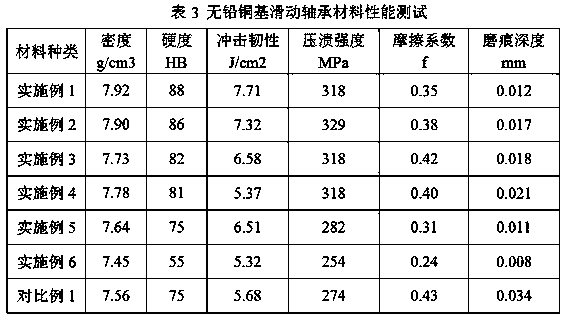

High-strength antifriction lead-free copper-based sliding bearing material

InactiveCN108277379AImprove the phenomenon of easy reunionResolve inhalationCopper atomChemical reaction

The invention discloses a high-strength antifriction lead-free copper-based sliding bearing material. A ball milling process is adopted to enable copper powder, iron powder and copper sulphide powderto be mechanically alloyed, and CuS and Fe mixed powder can generate superfine particle nanocrystalline FeS in a high-energy guide-in manner through a mechanically induced chemical reaction. The reaction in situ composite process is used for solving the problems that enhanced particles are added externally, air suction and wettability are poor, and the interface combination is poor; meanwhile, through the ball milling process, the phenomenon that when ferrous sulfide is directly added, agglomeration is easily caused is avoided; in the ball milling process, the other part of Fe atoms is added into copper atoms in a solid solution manner so as to achieve the solid solution reinforcing effect, and the copper base composite is reinforced. The antifriction and anti-sticking capacity of FeS is mainly used for replacing lead in the original copper base bearing material, lead pollution is avoided, meanwhile, through Fe solid solution, the copper-based sliding bearing material is reinforced, and effective unifying of high strength and good lubricating characteristics of the lead-free copper-based sliding bearing material is achieved.

Owner:HEFEI UNIV OF TECH

Automatic dust discharge device of dust collector

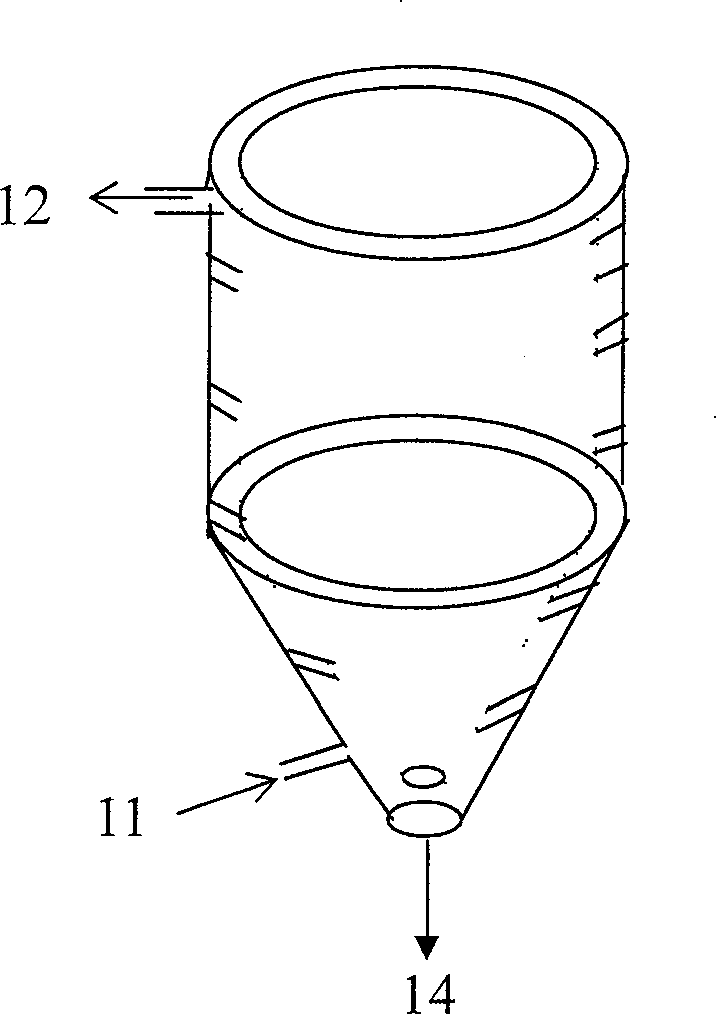

The invention discloses an automatic dust discharge device of a dust collector. The automatic dust discharge device comprises a lower conical cylinder, an upper turning plate, a rotating plate, a weight sensor, a signal processing unit, a motor, an electric-hydraulic push rod, a sealed side, a rotating shaft, a dust guide plate and a dust funnel, wherein the weight sensor, the signal processing unit and the motor are arranged outside the lower conical cylinder of the dust discharge device; the upper turning plate and the rotating plate are arranged inside the lower part of the lower conical cylinder; the upper turning plate is controlled to be opened and closed by pushing the electric-hydraulic push rod to stretch out and withdraw through the motor; the rotating plate is provided with the sealed side and the rotating shaft is arranged in the middle of the rotating plate; the rotating shaft is connected with the motor; the weight sensor and the signal processing unit are used for controlling the motor to be powered on or powered off; the bottom of the dust funnel is a round bottom and is internally provided with a dust guide plate. The upper turning plate and the rotating plate are controlled by the corresponding weight sensor and the corresponding signal processing unit. The automatic dust discharge device is applied to automatic secondary dust discharge, and meanwhile is capable of keeping the sealing capability of the dust collector and preventing secondary pollution.

Owner:山西玉竹活性石灰制造有限公司

Preparation method of composite micro-encapsulated soybean lecithin powder for livestock breeding

The invention relates to a preparation method of composite micro-encapsulated soybean lecithin powder for livestock breeding. The preparation method particularly comprises the following steps:(1) sufficiently stirring and extracting soybean phospholipid oil with ethanol, performing centrifugation on the extracted liquid and insoluble matters, collecting upper-layer extracted liquid, and repeating the extraction step twice; (2) merging the extracted liquid obtained by performing extraction twice, performing distillation under reduced pressure, recovering an ethanol solvent, and leaving soybean lecithin oily liquid; (3) heating water, adding sodium tripolyphosphate, whey powder and modified starch, and uniformly stirring the heated water, the sodium tripolyphosphate, the whey powder and the modified starch so that the sodium tripolyphosphate, the whey powder and the modified starch are dissolved; and (4) adding the soybean lecithin oil, uniformly emulsifying the soybean phospholipid oil, filtering out solids, and drying remaining liquid with a spray drying machine so as to obtain the micro-encapsulated soybean lecithin powder. According to the preparation method disclosed by the invention, the preparation technology is simple, the properties are stable, the lecithin powder is easy to store, the quality guarantee period is long, the prepared lecithin powder has notable effects in the respects of nutritional requirements of poultry and livestock and the health of livers, the bioactivity of the poultry and the livestock can be obviously improved, and the breeding benefits are improved.

Owner:无锡华诺威动物保健品有限公司

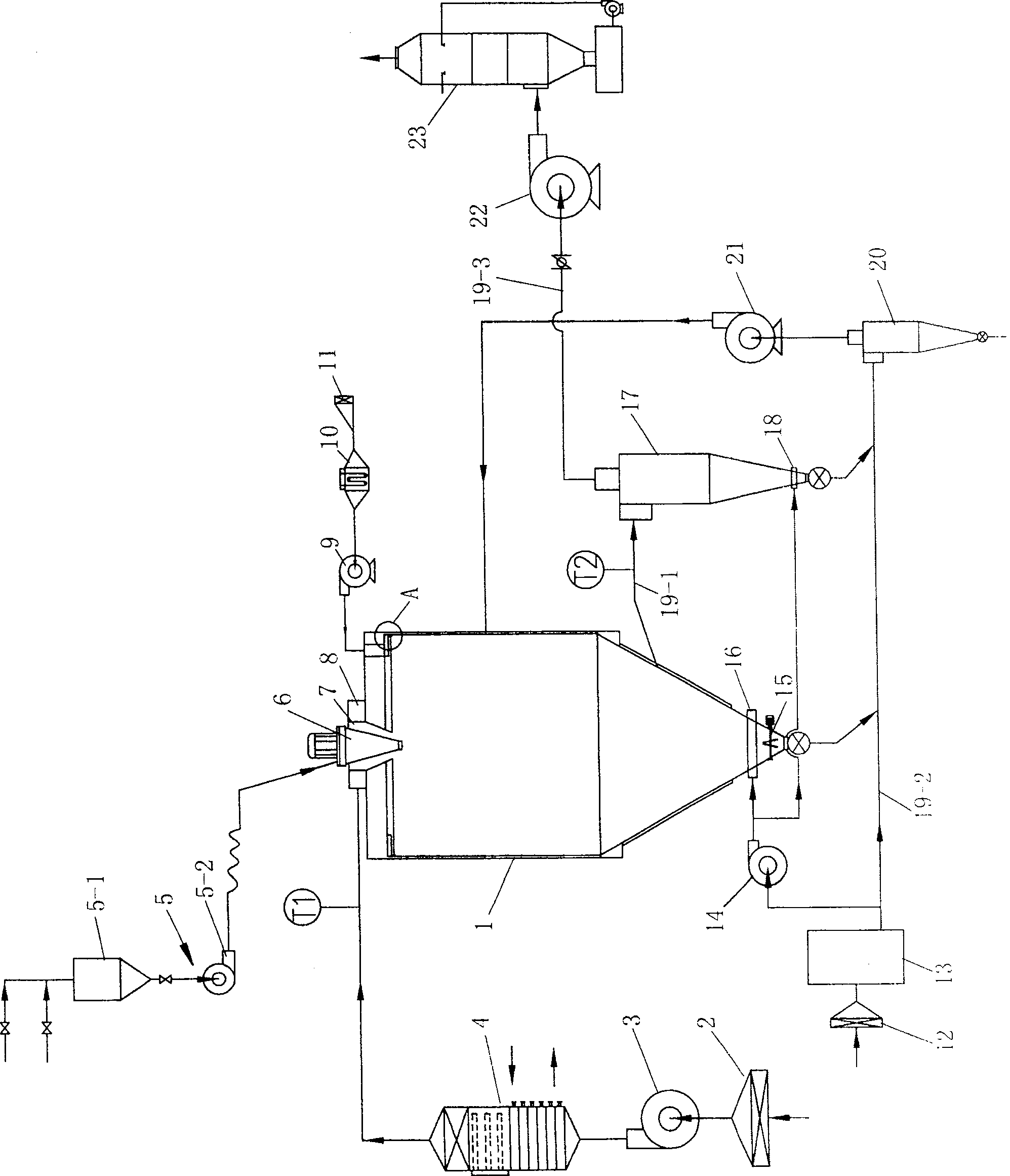

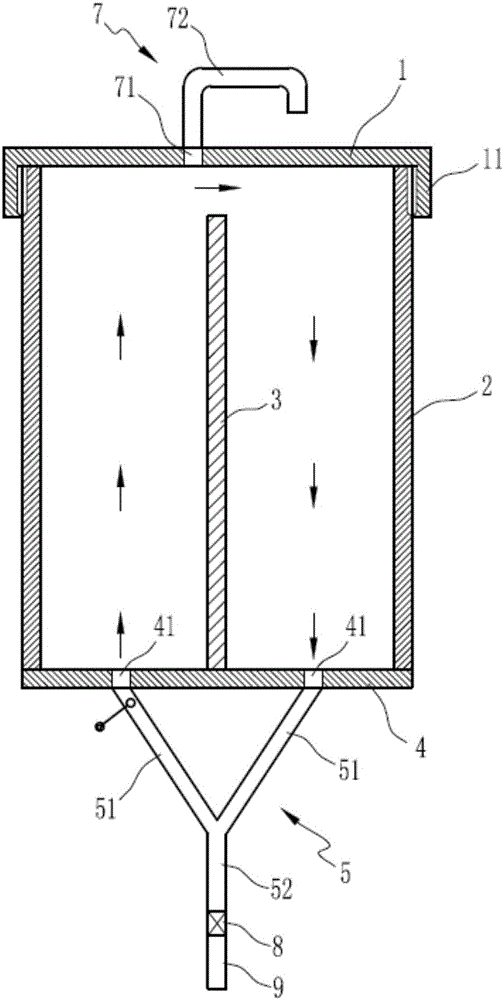

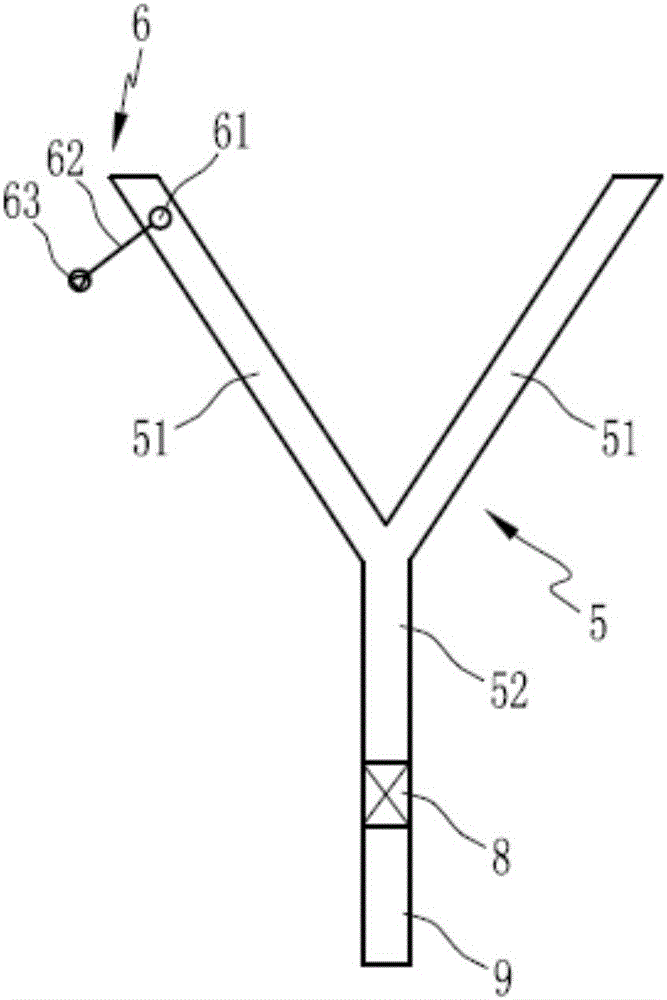

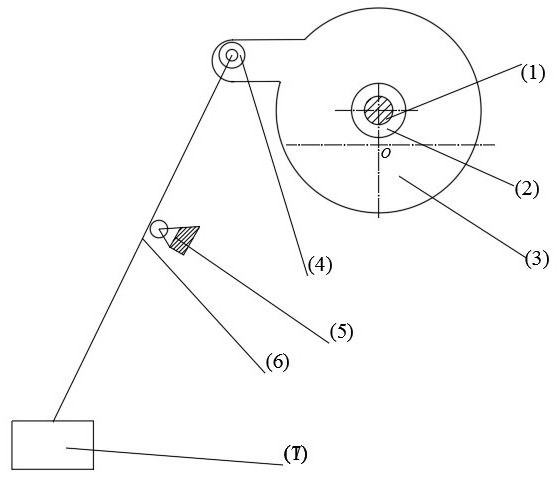

Drying process and equipment for powdered urea formaldehyde condensate

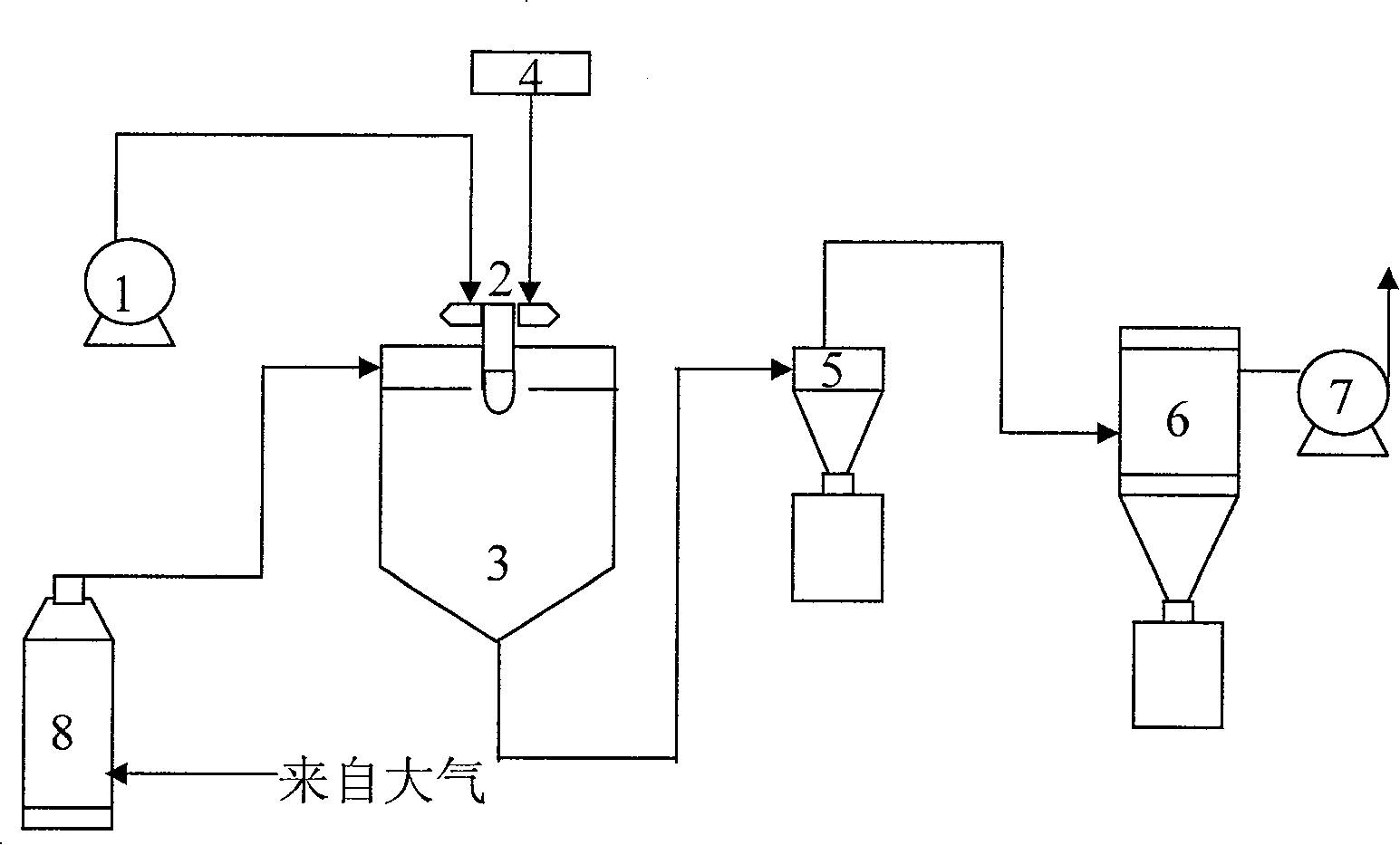

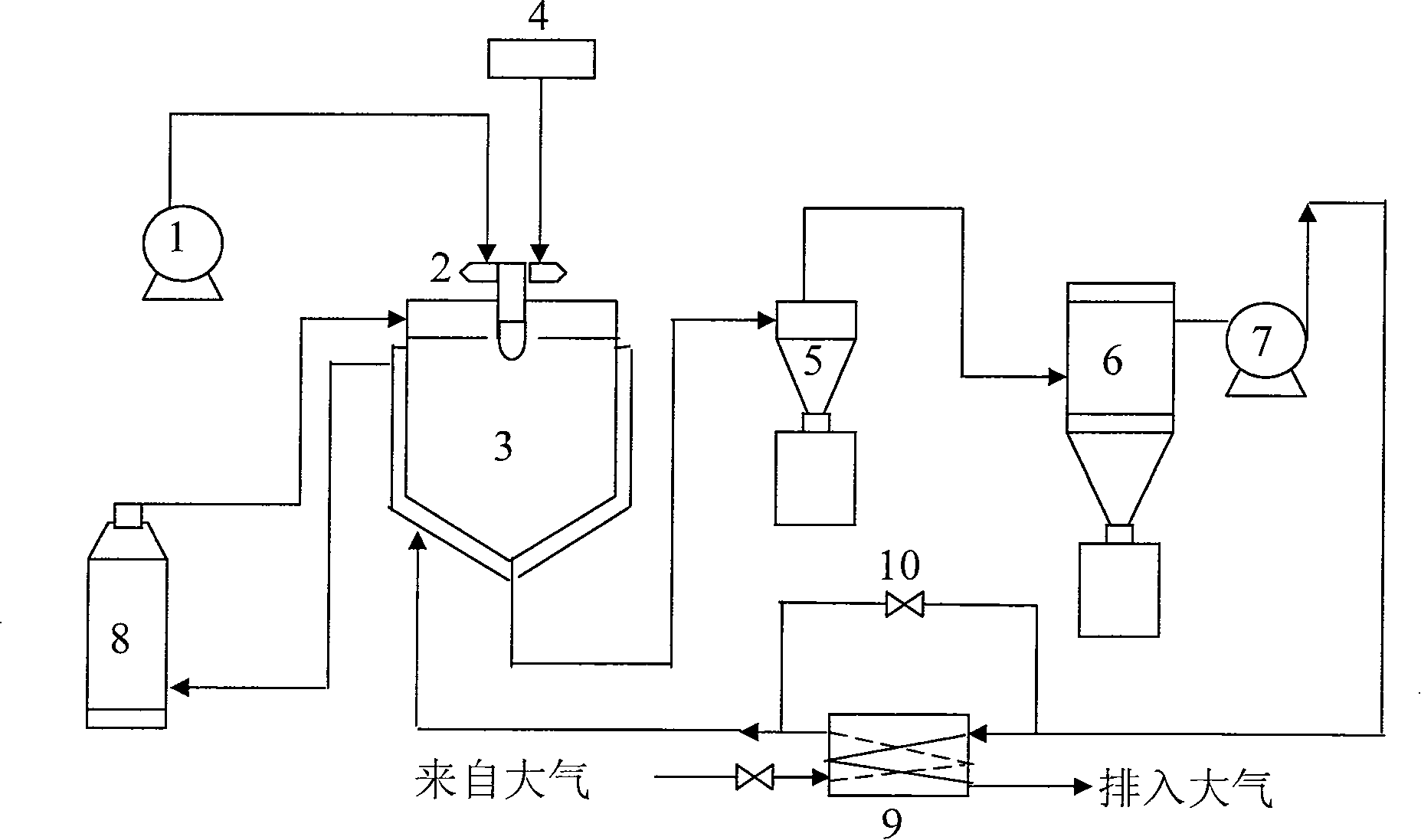

InactiveCN101196365AReduce the temperatureReduce stickinessDrying solid materials with heatHearth type furnacesAir preheaterCold air

The invention relates to drying process and equipment of powder urea resin, which mainly pumps urea-formaldehyde resin emulsion into an atomizer (2) by a pump (1). The urea-formaldehyde resin emulsion is sprayed into droplet by compressed air in a nozzle of a sprayer and enters a dryer (3) together with the compressed air. After being dried, the powder urea resin enters a cyclone separator (5) and waste gas is exhausted by an induced draft fan after filtered by a bag filter (6). The invention is characterized in that: the dryer (3) is provided with interlayer on the external wall; the waste gas hot air exhausted from the exit of the induced draft fan (7) is led into a primary air preheater (9) provided with an input port for cold air; the cold air enters the interlayer of the dryer after preheated and ascends along the dryer interlayer duct in a spiral; the air exhausted from the dryer interlayer is led into an air heater (8). The adoption of the drying process and equipment of powder urea resin can effectively recover energy by grades and has the characteristics of saving energy and reducing sticking on the wall.

Owner:PETROCHINA CO LTD

Filter used for producing nano-coating

InactiveCN107433070AAvoid cloggingPrevent splashFiltration circuitsStationary filtering element filtersHelical bladeFilter effect

The invention provides a filter used for producing a nano-coating. The filter comprises a filter body and a filter cover, the filter body includes a main shaft, a filtering module and a filter screen, the filtering module is concentrically and detachably arranged in the filter body, the cooperating filter screen is arranged in the filtering module, the filter screen is uniformly provided with a plurality of through holes, and a feeding opening communicating with the inner chamber of the filter body is arranged at the upper end of the filter cover; and a discharging opening and an electric heating tube communicating with the interlayer of the filter body are arranged at the lower end of the filter body. The nano-material rapidly moves under the driving of helical blades, and is filtered by the filter screen, and a wall scraping device drives a scraper to rotate in order to momentarily clean the material on the inner wall of the filter body, so adherence to the wall is reduced, and the filtering efficiency and the filtering quality are improved; and the heating tube is used to heat in order to make the coating keep a high temperature and not form large blocks, and then the heated material is filtered by the filter screen, so the filtering effect is effectively enhanced, and the obstruction phenomenon is less likely to occur.

Owner:NINGBO DUNCOTEK NEW MATERIAL CO LTD

Filtering device for coating

The invention provides a filtering device for a coating. The filtering device comprises a filter body and a filter cover, wherein the filter body comprises a main shaft, filtering modules and filter screens; the filtering modules are concentrically arranged in the filter body; the interior of each filtering module is provided with a matching filter screen; each filtering screen is uniformly provided with a plurality of through holes; the upper end of the filter body is provided with a feeding inlet which is communicated with the inner chamber of the filter body; the feeding inlet is connected with a stirrer connecting pipe through a valve; and the lower end of the filter body is provided with a discharge outlet and an electric heating pipe which is communicated with the interlayer of the filter body. The filtering device provided by the invention rapidly moves under the driving of spiral blades and clean materials on the inner wall of the filter body at any time through filtering via the filter screens and rotation of scraper blades under the driving of a wall scraping unit, so the materials are substantially prevented from adhering to the wall and the efficiency and quality of filtering are improved; the filtering device is heated through the heating pipe, so the coating can be kept at a high temperature, and is not easy to form large caked blocks; and filtering is carried out in virtue of the filter screens, so filtering effect can be effectively improved, and blockage hardly occurs.

Owner:NINGBO DUNCOTEK NEW MATERIAL CO LTD

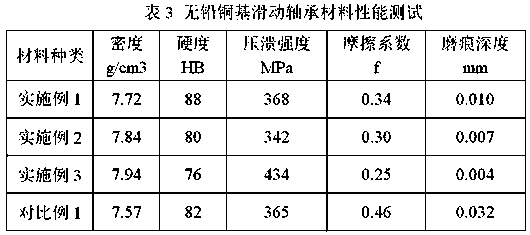

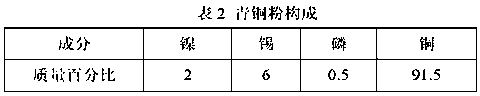

Antifriction lead-free copper-based sliding bearing material and preparation method thereof

InactiveCN108486404AImprove friction and wear propertiesAchieve lead-freeShaftsBearing componentsWear resistantBronze

The invention discloses an antifriction lead-free copper-based sliding bearing material and a preparation method thereof. The ferrous sulfide powder, the bismuth powder and the bronze powder are subjected to mechanical alloying by adopting a ball milling technology to improve the interface adhesive strength of the ferrous sulfide, the bismuth and the bronze, and the phenomenon that the ferrous sulfide is easy to agglomerate when the content of copper matrix is relatively high is improved, the structure of FeS is good in oil storage capacity, the stability of the liquid-solid lubricating film is enabled to be good, so that the process of Bi spalling, the fusion of the low-melting-point component Bi and separating out of the low-melting-point component Bi are relieved, and the liquid-solid lubricating film can also be repaired and completed, so that the antifriction performance of the material is improved; in conclusion, the antifriction and wear-resistant properties of the copper-basedsliding bearing material are improved, the lead which is used as a lubricant in the copper-based bearing material is replaced by the good synergistic effect of the ferrous sulfide and the bismuth, sothat the pollution of lead is avoided; and the antifriction lead-free copper-based sliding bearing material and the preparation method thereof have the advantages of being low in cost and suitable forindustrial production.

Owner:HEFEI UNIV OF TECH

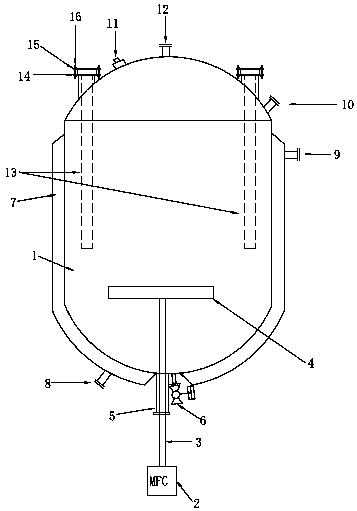

Tracer method based particle concentration measurement system for closed cyclic spray drying system

InactiveCN106596364AOptimize structureReduce material sticking to the wallParticle suspension analysisEngineeringLight source

The invention discloses a tracer method based particle concentration measurement system for a closed cyclic spray drying system. The tracer method based particle concentration measurement system comprises a laser source, aluminum powder colloid, an image acquisition device and a spray drying system. The laser source is positioned on one side of a drying chamber to illuminate fluid in the drying chamber. The image acquisition device is positioned on the other side of the drying chamber and opposite to the laser source and is used for recording the position of fluid tracer particle aluminum powder illuminated by the laser source. The tracer method based particle concentration measurement system is used for displaying particle concentration of raw material fluid in the drying chamber under atomization and rotating hot air action and can be used for research stimulation and structural optimization in a drying process.

Owner:HOHAI UNIV CHANGZHOU

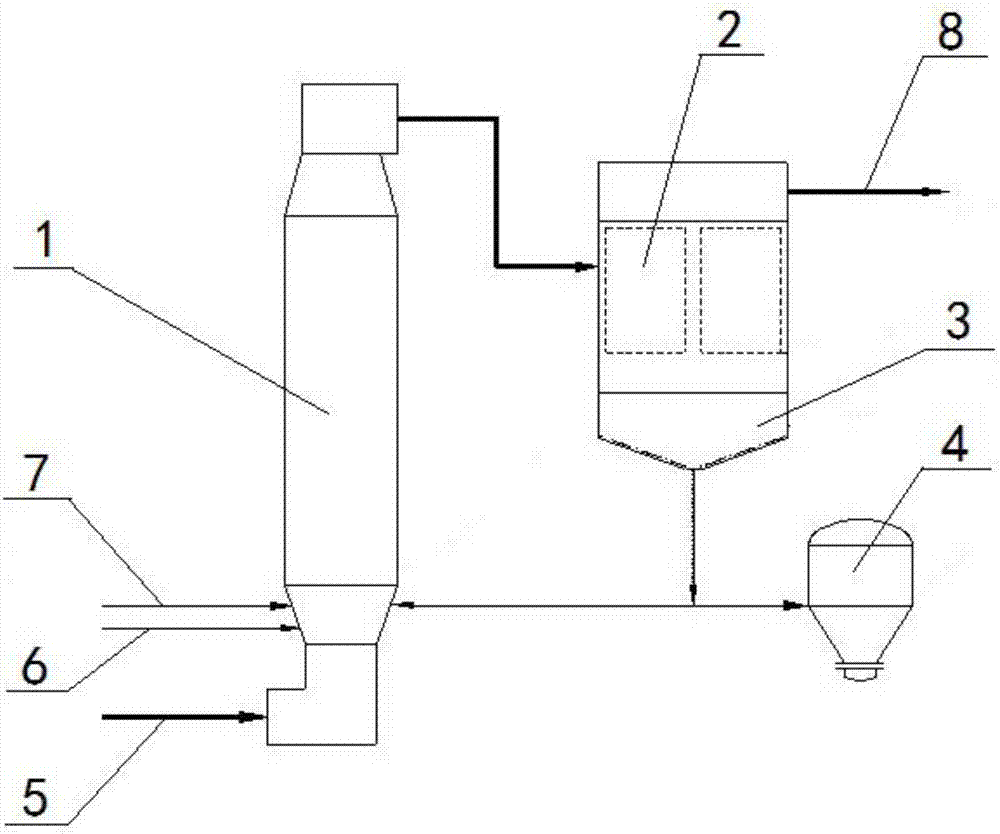

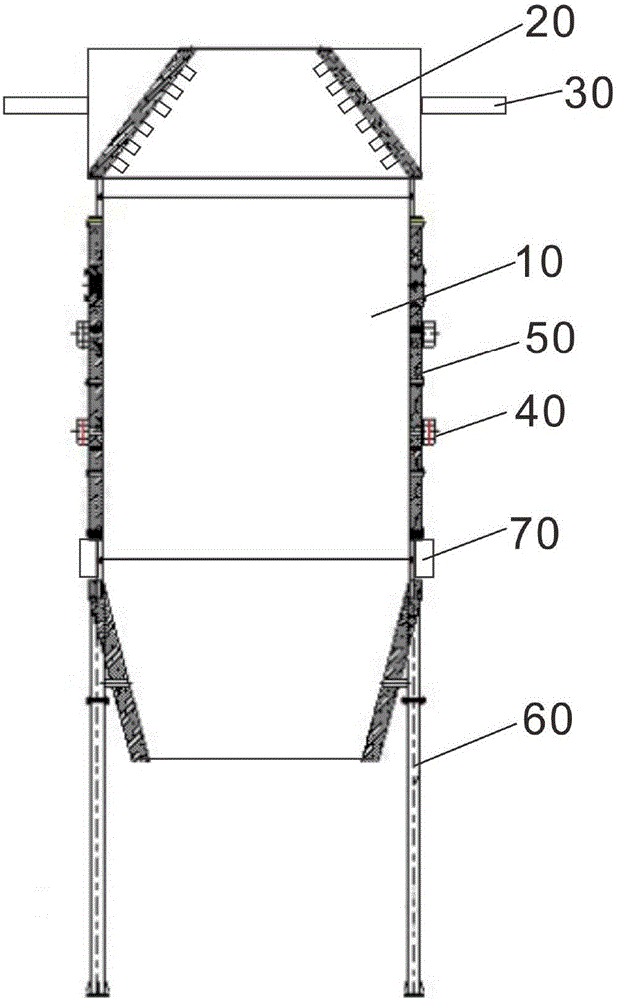

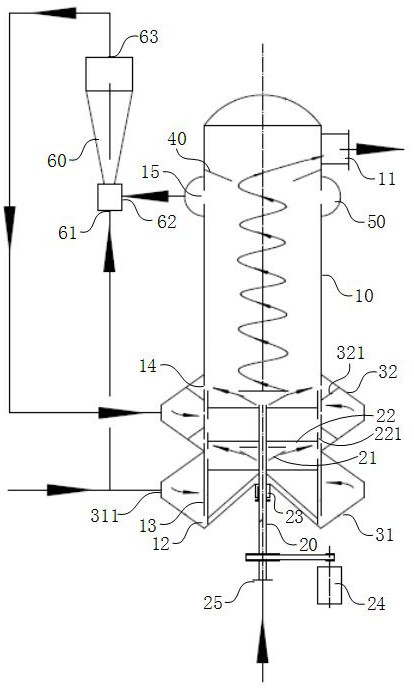

Novel circulating fluidized bed flue gas desulfurization system

PendingCN107029540AReduce stuck problemsReduce cloggingGas treatmentDispersed particle separationSlagPetrochemical

The invention relates to a novel circulating fluidized bed flue gas desulfurization system and belongs to the technical field of semidry-method flue gas desulfurization. According to the technical scheme, the novel circulating fluidized bed flue gas desulfurization system comprises a desulfurization absorption tower, a dust collector, a dust hopper and a dust storage, wherein the a slag-preventing cone is arranged between every two adjacent Venturi nozzles in the nozzle section of the desulfurization absorption tower, a slag-preventing cone is arranged at the upper end of a gap between each Venturi nozzle and the inner wall of the nozzle section, and a fluidizing air system is mounted on the dust hopper and comprises a pressure measuring device for measuring fluidizing air pressure. The novel circulating fluidized bed flue gas desulfurization system which is mainly applicable to flue gas deep purification of industry such as electric power industry, petrochemical industry and smelting industry has the advantages that wall sticking and blocking cannot occur easily in the desulfurization absorption tower, and the system is good in material level measuring reliability and high in accuracy.

Owner:NANJING LONGYUAN ENVIRONMENTAL CO LTD

Seasoner sponging drying machine group

InactiveCN100523685CReduce stuck problemsReduce sticky topDrying solid materials with heatHearth type furnacesCyclonePulp and paper industry

The invention includes a feeding device, a drying tower, a No. 1 fan, a No. 1 heater, a first-stage cyclone separator and a water film dust collector; a hot blast distributor is installed at the central hot blast inlet of the drying tower top and installed in the center of the hot blast distributor. And the atomizer connected with the feeding device, the top of the drying tower is provided with an air channel plate with a volute-shaped air channel, the inlet of the air channel plate is connected to the output pipeline of No. 1 heater, and the outlet of the air channel plate is connected to the The inlet connection of the hot air distributor; there is a jacket near the top of the drying tower body, the space between the jacket and the inner wall of the tower body is the air inlet channel for sweeping the wall, and the ring between the bottom of the jacket and the inner wall of the tower body The gap is the air outlet, and the wind passes through the annular gap to form a wall-sweeping wind. The invention adopts the air duct spiral cutting and wall-sweeping air inlet technology, which not only improves the drying efficiency, but also forms a wind film on the drying tower wall by providing the wall-sweeping wind. , The air film isolates the powder from contacting the tower wall to prevent the phenomenon of sticking to the wall.

Owner:JIANGSU XIANFENG DRYING ENG

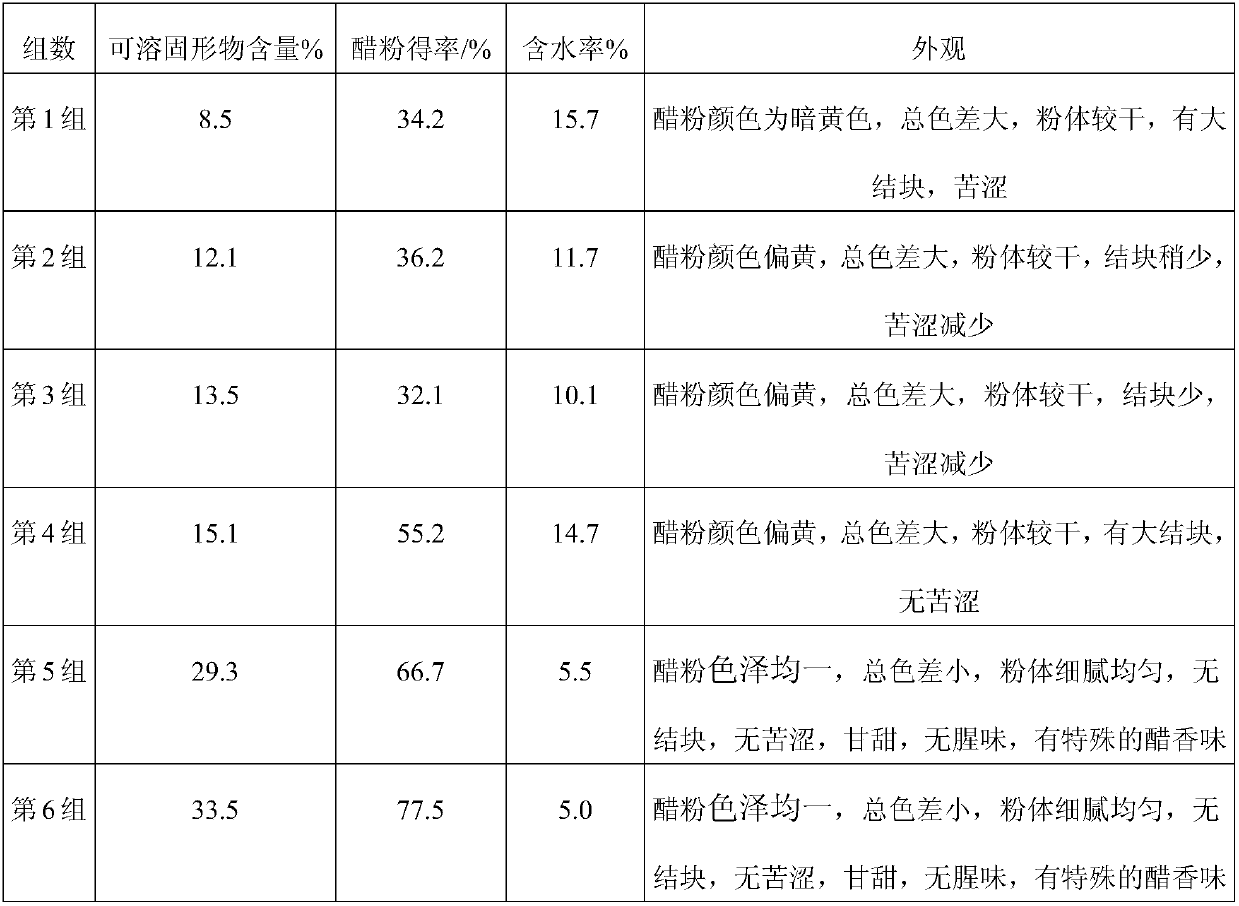

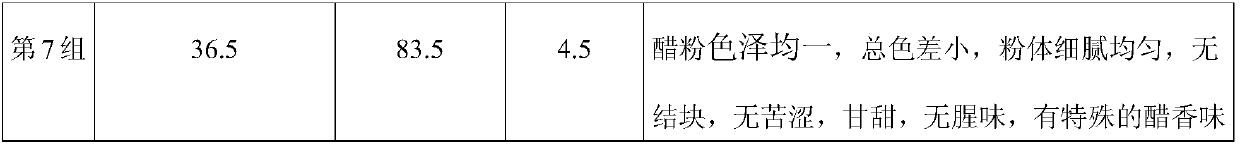

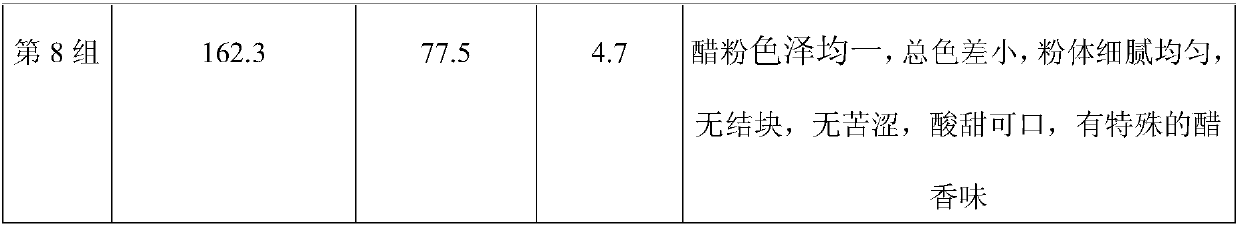

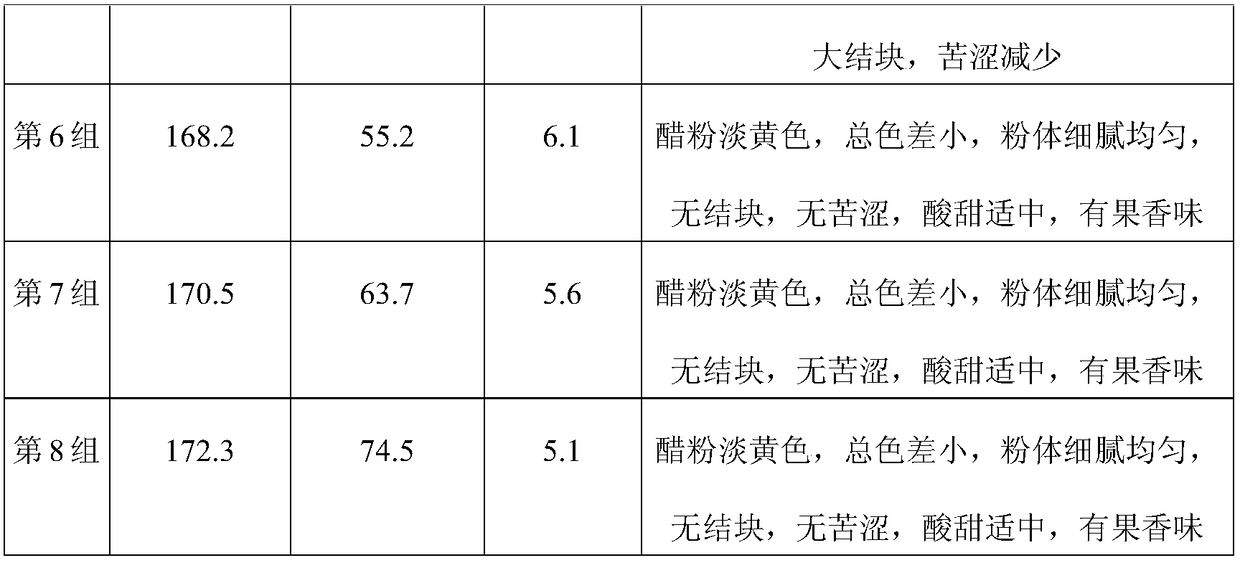

Preparation method of sugarcane vinegar powder with blood fat reduction effect

ActiveCN107619772ARich in nutrientsWith hypolipidemicMetabolism disorderVinegar preparationFreeze-dryingAdditive ingredient

The invention relates to the technical field of food processing, in particular to a preparation method of sugarcane vinegar powder with blood fat reduction effect. The preparation method comprises thefollowing steps of using 65 to 80 parts of raw vinegar of sugarcane, 5 to 10 parts of acetic bacteria film, 12 to 15 parts of plant, 3 to 5 parts of hydroxypropyl-beta-cyclodextrin, 3 to 6 parts of maltodextrin, and 2 to 4 parts of sweetening agent by weight as raw materials; treating the raw materials by alcohol soaking, microwave and ultrasonic wave joint treatment, rotary evaporation and the like; soaking by ultrasonic waves in an assisting way, blending and mixing, freeze-drying under the vacuum condition, crushing in an ultrafine way, screening, and the like. The sugarcane vinegar powderhas the advantages that the rich nutritional matters are contained; multiple health-care effects of blood fat reduction and the like are realized; the preparation method is simple, the yield rate ofvinegar powder is effectively increased, the effective ingredients of the vinegar powder are protected, the water content is low, the powder is fine and uniform, the caking is avoided, the mouth feelis sweet, and a kind of health-care and nutritional green food is obtained.

Owner:GUANGXI ZHUANG AUTONOMOUS REGION ACAD OF AGRI SCI

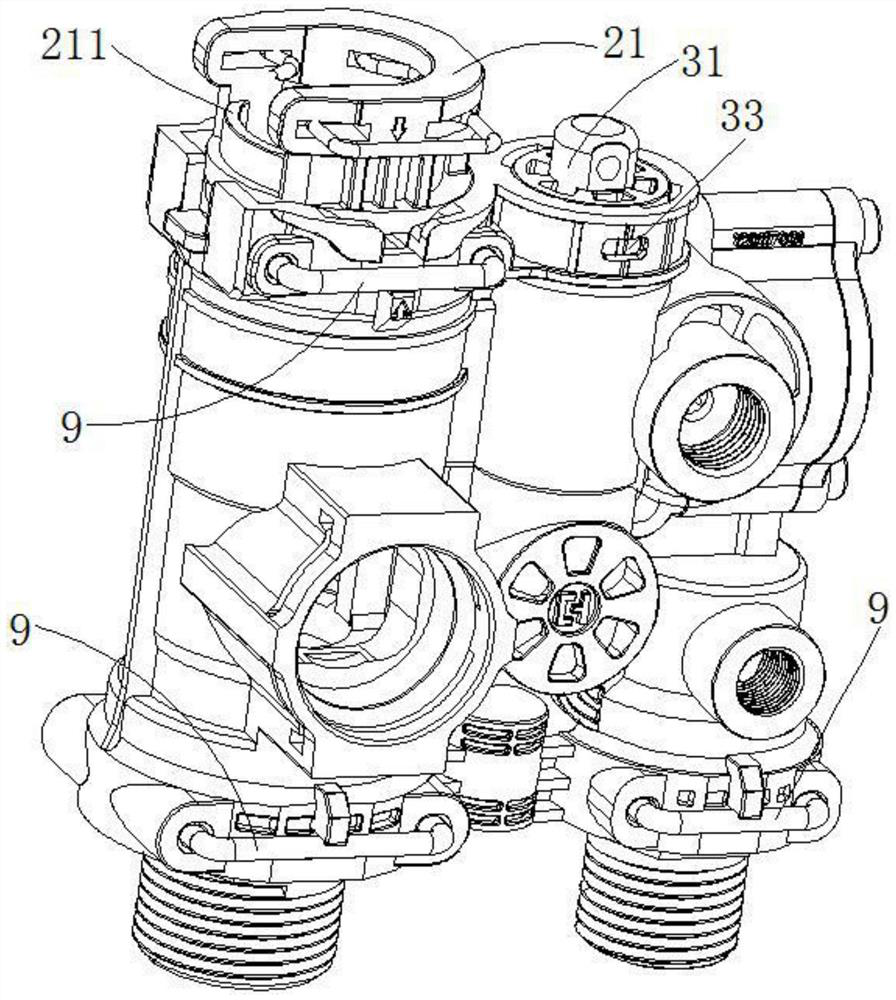

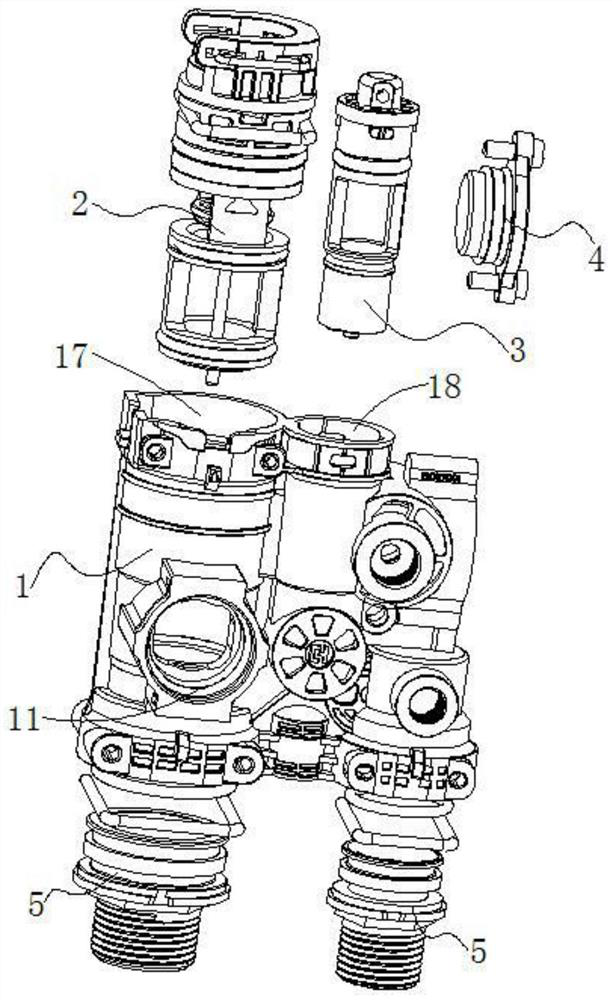

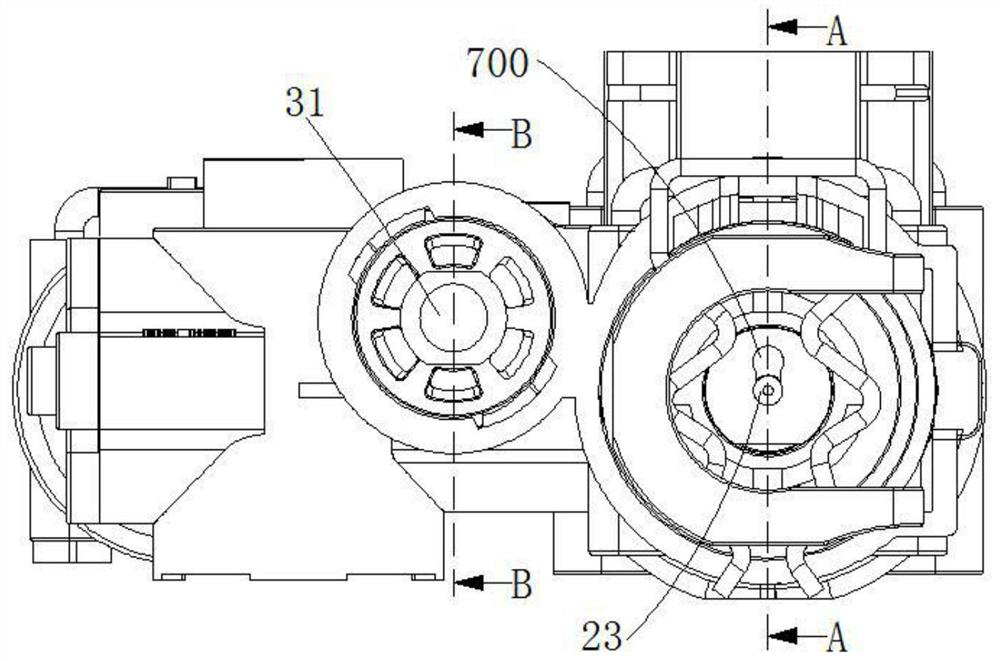

Self-locating high-sealing large-flow three-way valve

ActiveCN112483695ALower the altitudeFew partsSpindle sealingsOperating means/releasing devices for valvesPlastic materialsElectric machinery

The invention discloses a self-locating high-sealing large-flow three-way valve. The three-way valve comprises a shell, wherein the shell comprises a water inlet channel, a first water outlet channel,a second water outlet channel and a valve cavity, the first water outlet channel and the second water outlet channel communicates with the water inlet channel in a switching mode, a valve element ismounted in the valve cavity and comprises a motor base and a three-way framework, the shell, the motor base and the three-way framework are made of plastic materials, the lower end of the motor base extends downwards to form a motor base clamping head, a three-way framework clamping groove allowing the motor base clamping head to be mounted from the side face is formed in the upper end of the three-way framework, the motor base and the three-way framework are connected by inserting the motor base clamping head into the three-way framework clamping groove in a matched mode, and the motor base is connected with the shell through clamping screws. According to the three-way valve, self-locating during mounting can be conveniently realized through the motor base and the three-way framework.

Owner:ZHEJIANG CHUNHUI INTELLIGENT CONTROL

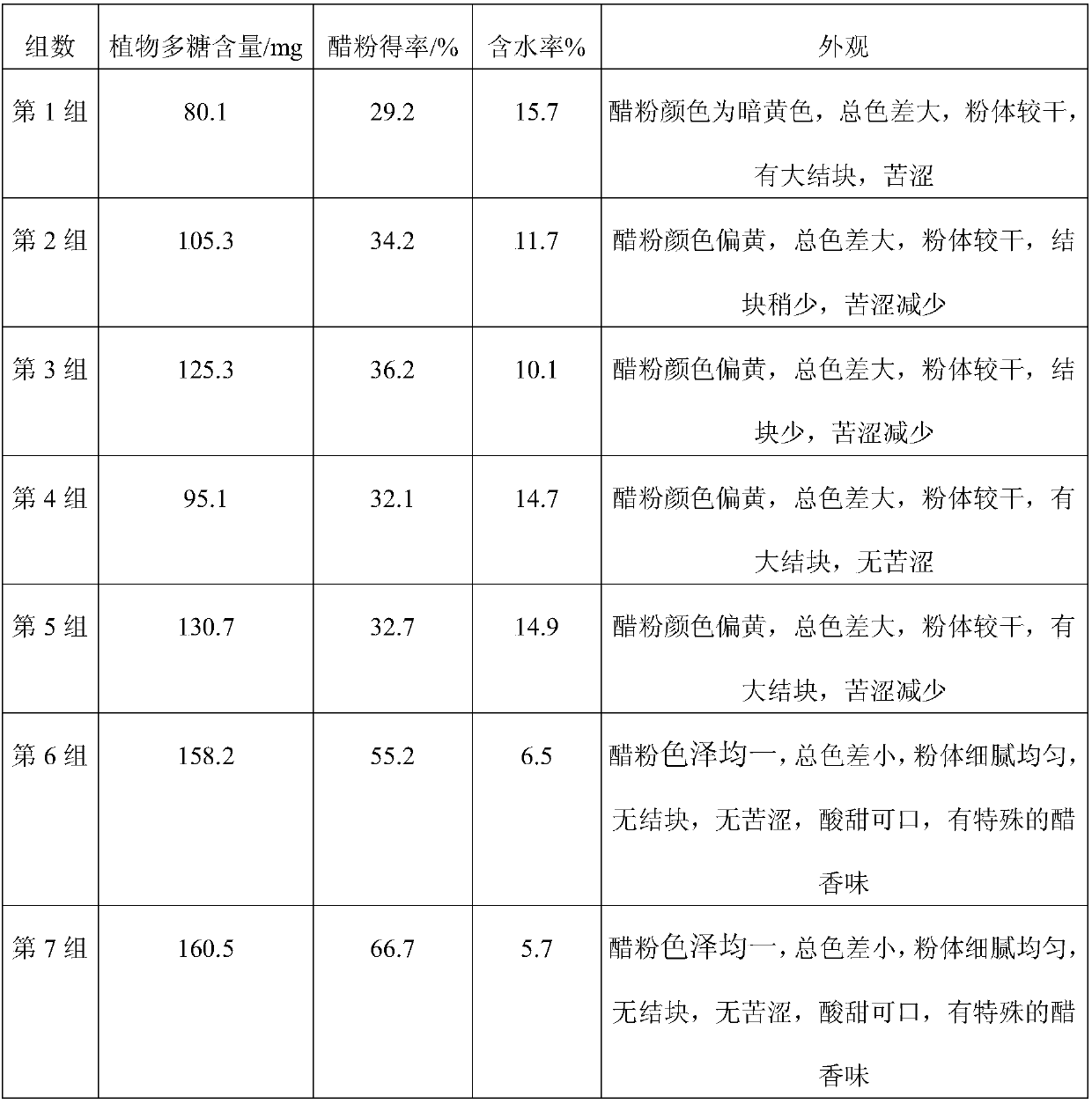

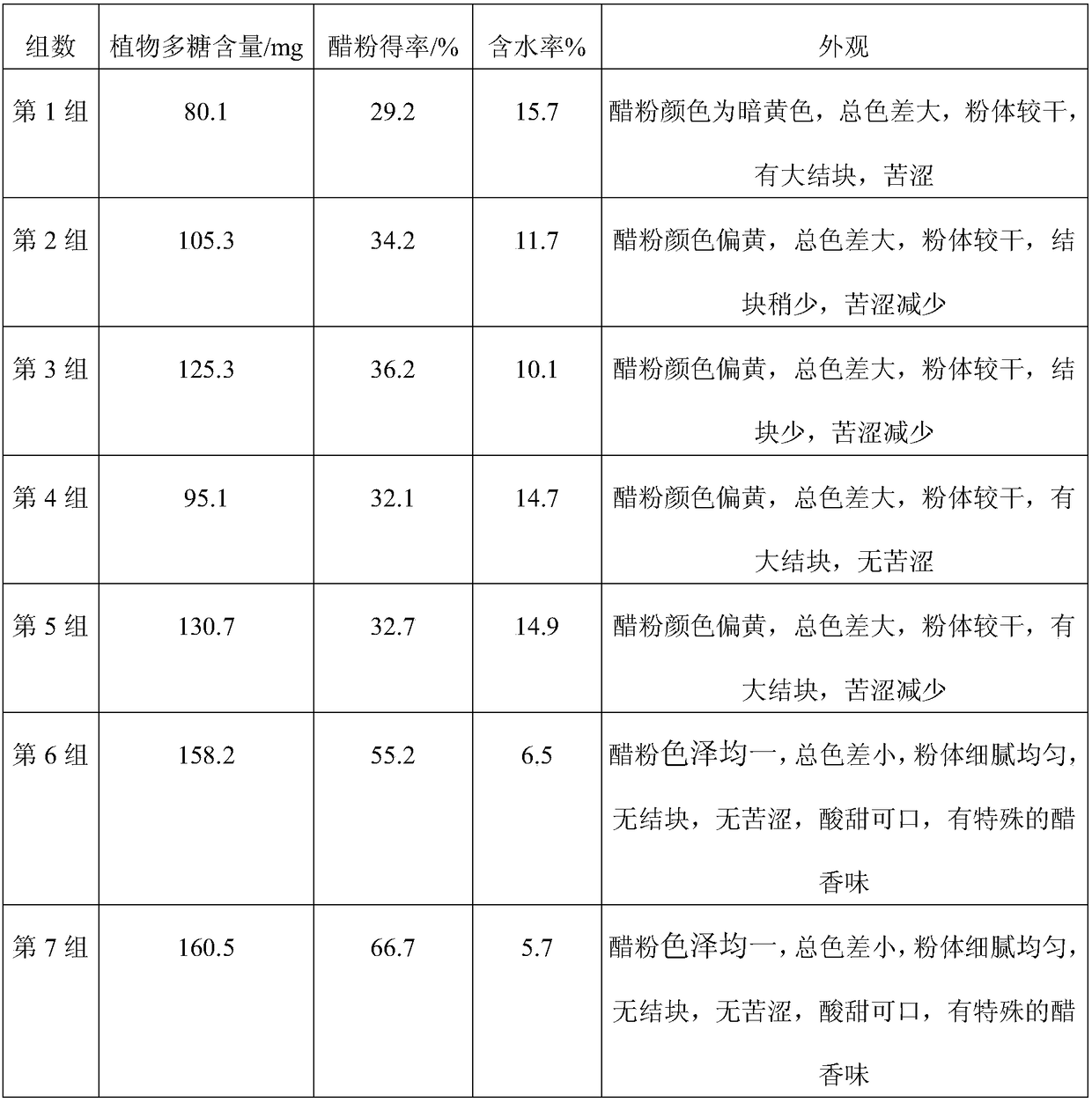

Preparation method of plant-polysaccharide-enriched sugarcane vinegar powder

ActiveCN107841440AHigh nutritional valueEasy to prepareVinegar preparationHylocereus undatusMoisture

The invention relates to the technical field of food processing and in particular relates to a preparation method of plant-polysaccharide-enriched sugarcane vinegar powder. The plant-polysaccharide-enriched sugarcane vinegar powder is prepared from the following raw materials in parts by weight: 40 to 55 parts of raw sugarcane vinegar, 8 to 10 parts of an acetic acid bacterium film, 10 to 15 partsof fructus lycii, 6 to 8 parts of pitaya flowers, 8 to 10 parts of hylocereus undatus flowers, 6 to 9 parts of dendrobium officinale kimura ex migo, 2 to 3 parts of ganodorma lucidum, 3 to 5 parts ofsodium alginate, 6 to 10 parts of maltodextrin, 0.3 to 0.5 part of a taste masking agent and 0.8 to 2 parts of a sweetener; the plant-polysaccharide-enriched sugarcane vinegar powder is prepared by the steps of preparing the acetic acid bacterium film, pulping by liquid nitrogen, carrying out microwave combined ultrasonic extraction, blending, freezing and drying and the like. The sugarcane vinegar powder provided by the invention contains abundant plant polysaccharide and the nutrient value is improved; the preparation method is simple and the yield of the vinegar powder is effectively improved; the vinegar powder has the advantages of low moisture content, fine, smooth and uniform performances, no cakes and slight sweet mouthfeel and is a health-care and nutritional green food.

Owner:GUANGXI ZHUANG AUTONOMOUS REGION ACAD OF AGRI SCI

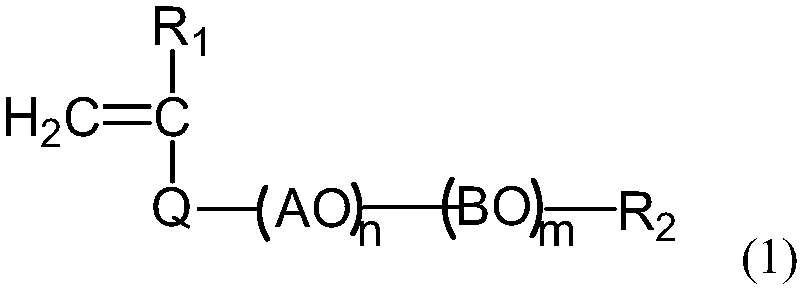

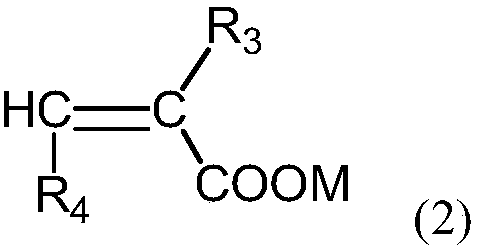

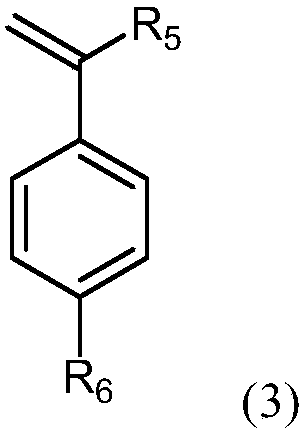

Powdery shrinkage-reducing polycarboxylic acid water reducing agent and preparation method thereof

The invention discloses a powdery shrinkage-reducing type polycarboxylic acid water reducing agent and a preparation method thereof. The powdery shrinkage-reducing type polycarboxylic acid water reducing agent is prepared by introducing a hydrophobically modified polyether chain, a rigid group and ester bond bridged small molecular alcohol into a grafted copolymer to prepare a shrinkage-reducing type polycarboxylic acid water reducing agent mother solution, and then introducing a calcium-magnesium expanding agent as a separant to spray-dry the mother solution. The prepared powder is low in mixing amount, good in dispersing performance and excellent in shrinkage reducing effect, unification of water reducing and shrinkage reducing is achieved, and the powder is good in flowability, free ofcaking, good in storage stability and suitable for various dry-mixed mortars.

Owner:JIANGSU SOBUTE NEW MATERIALS +2

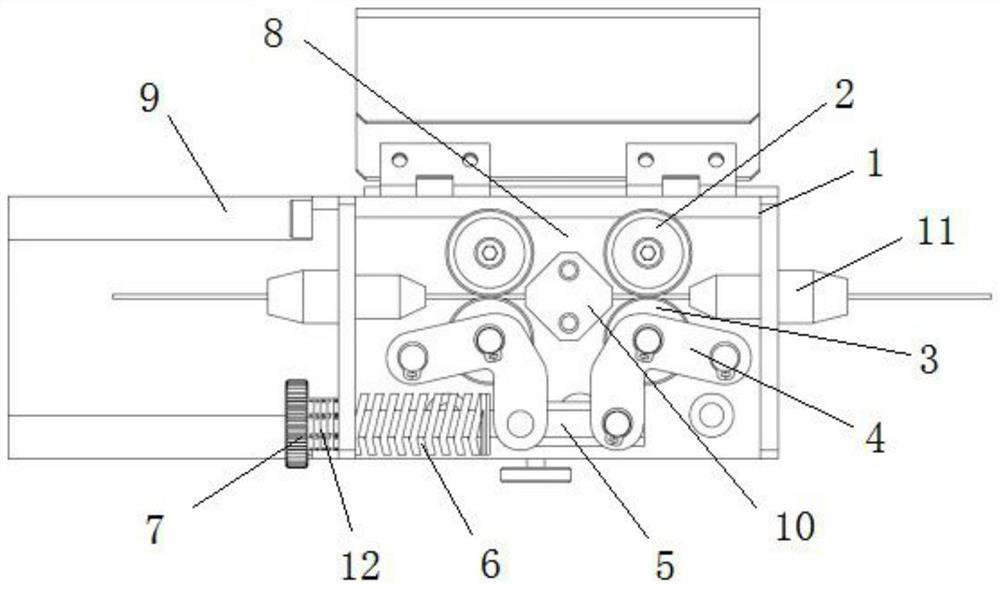

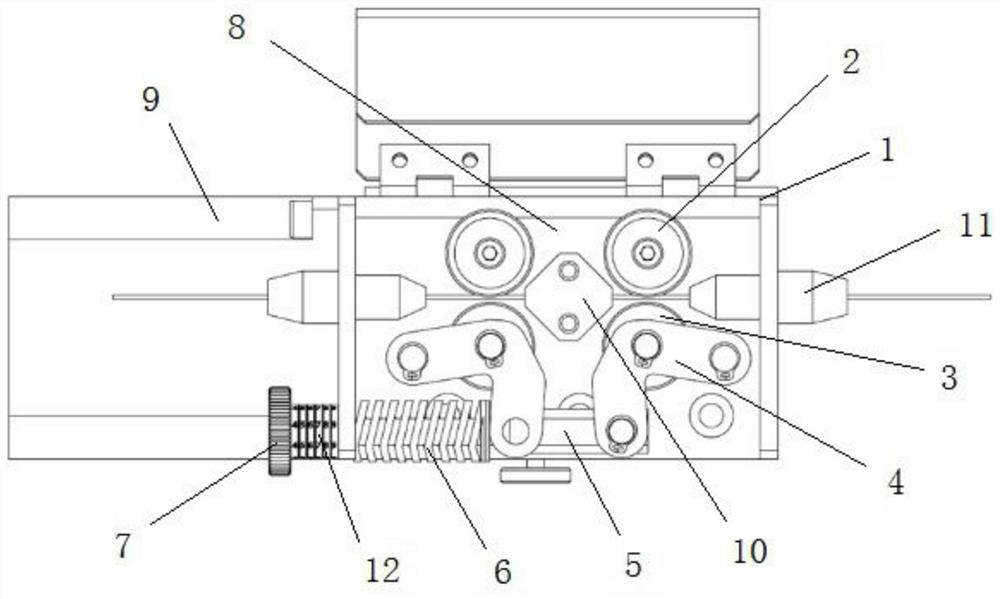

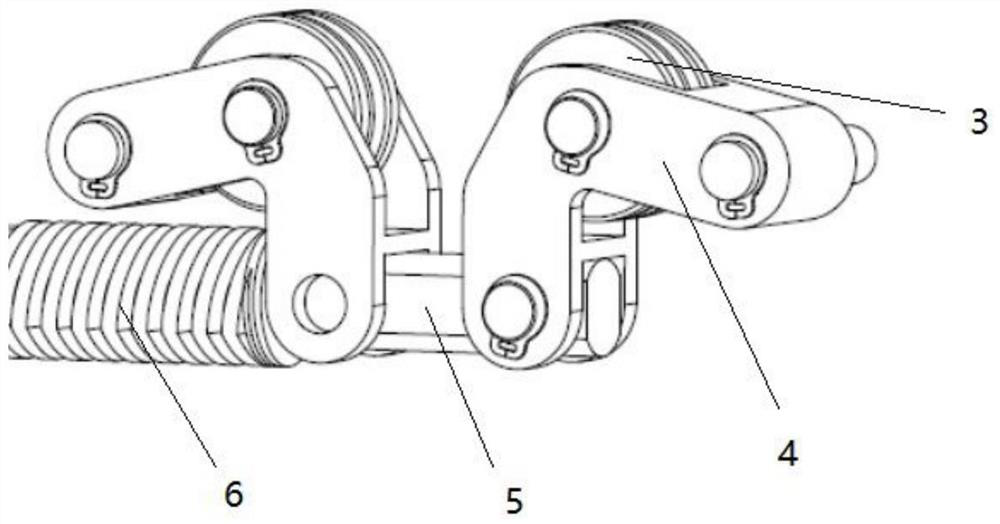

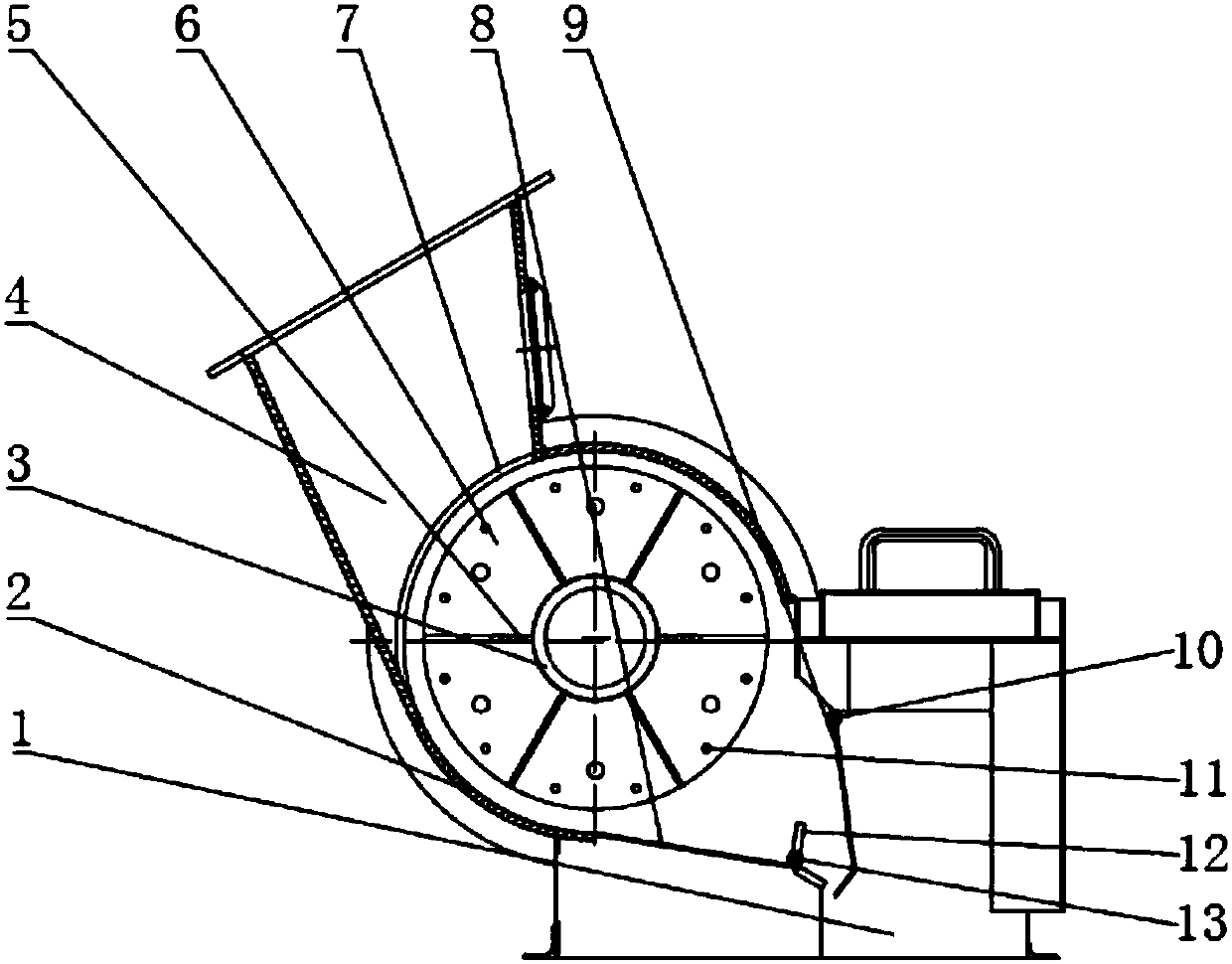

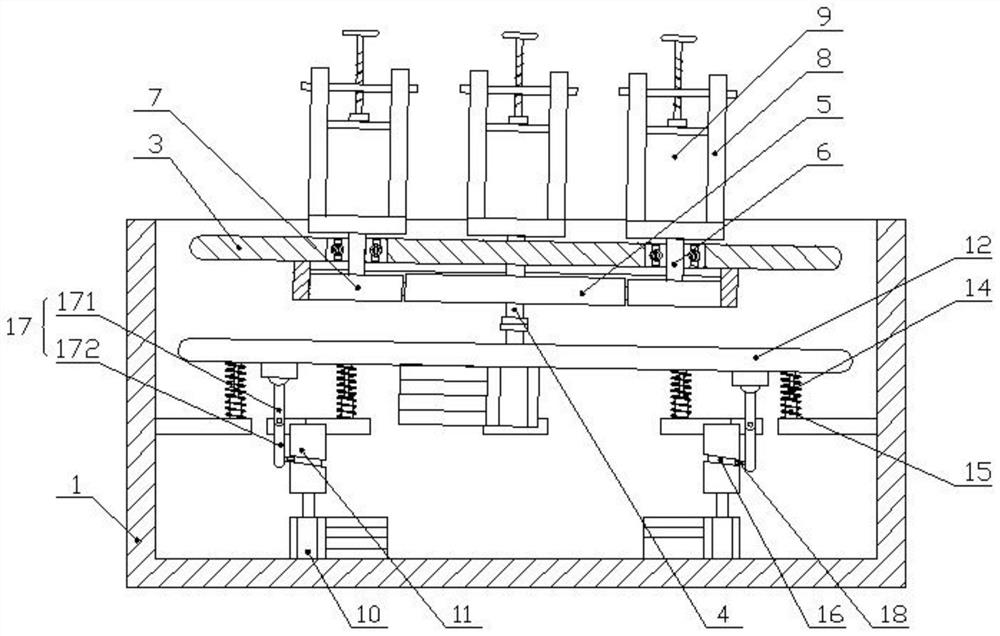

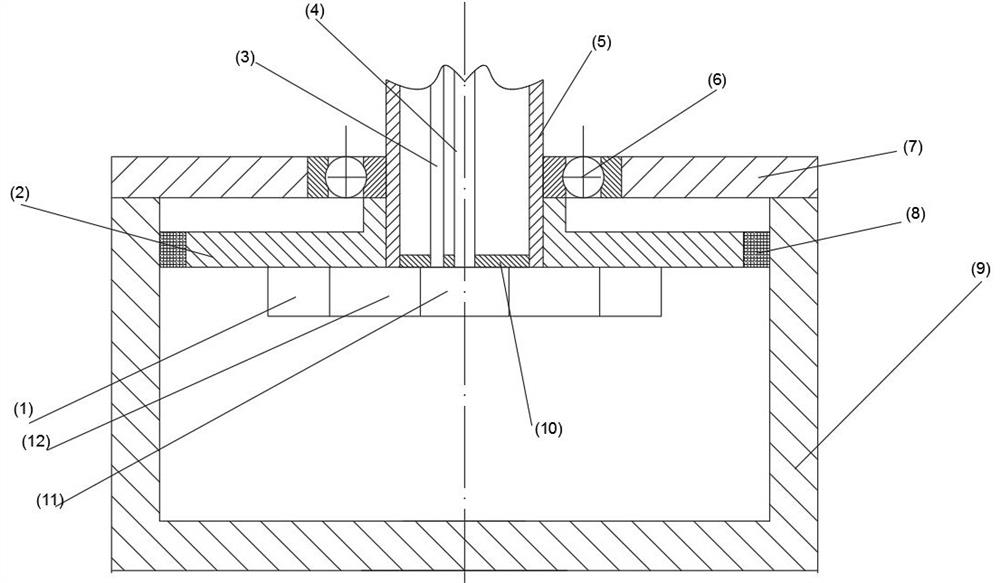

Synchronous pressure adjusting device for double wire feeding wheels of laser filler wire welding

PendingCN114260605AGuaranteed stabilityReduce stuck problemsLaser beam welding apparatusDrive wheelStructural engineering

The invention discloses a laser filler wire welding double-wire-feeding-wheel pressure synchronous adjusting device, and relates to the technical field of laser welding equipment, the laser filler wire welding double-wire-feeding-wheel pressure synchronous adjusting device comprises a mounting frame, driving wheels, wire feeding wheels, a pressure connecting rod, an adjusting rod, a spring and a threaded knob, the two driving wheels are arranged in the mounting frame, and the lower side of each driving wheel is provided with one wire feeding wheel; a pressure connecting rod is arranged on each wire feeding wheel, the two pressure connecting rods are connected through an adjusting rod, one end of the adjusting rod extends out of the mounting frame, a threaded knob is arranged at one end of the adjusting rod, a spring is arranged on the outer edge of one end of the adjusting rod and located in the mounting frame, one end of the spring abuts against one pressure connecting rod, and the other end of the spring abuts against the other pressure connecting rod. The other end of the spring abuts against the inner wall of the mounting frame. According to the welding device, the wire outlet stability of the wire feeding mechanism in the welding process is guaranteed, appropriate pressure can be adjusted according to different welding wires, the situations of wire clamping and wire breaking are effectively reduced, and the welding quality and the welding efficiency are improved.

Owner:SHANGHAI FANUC ROBOTICS

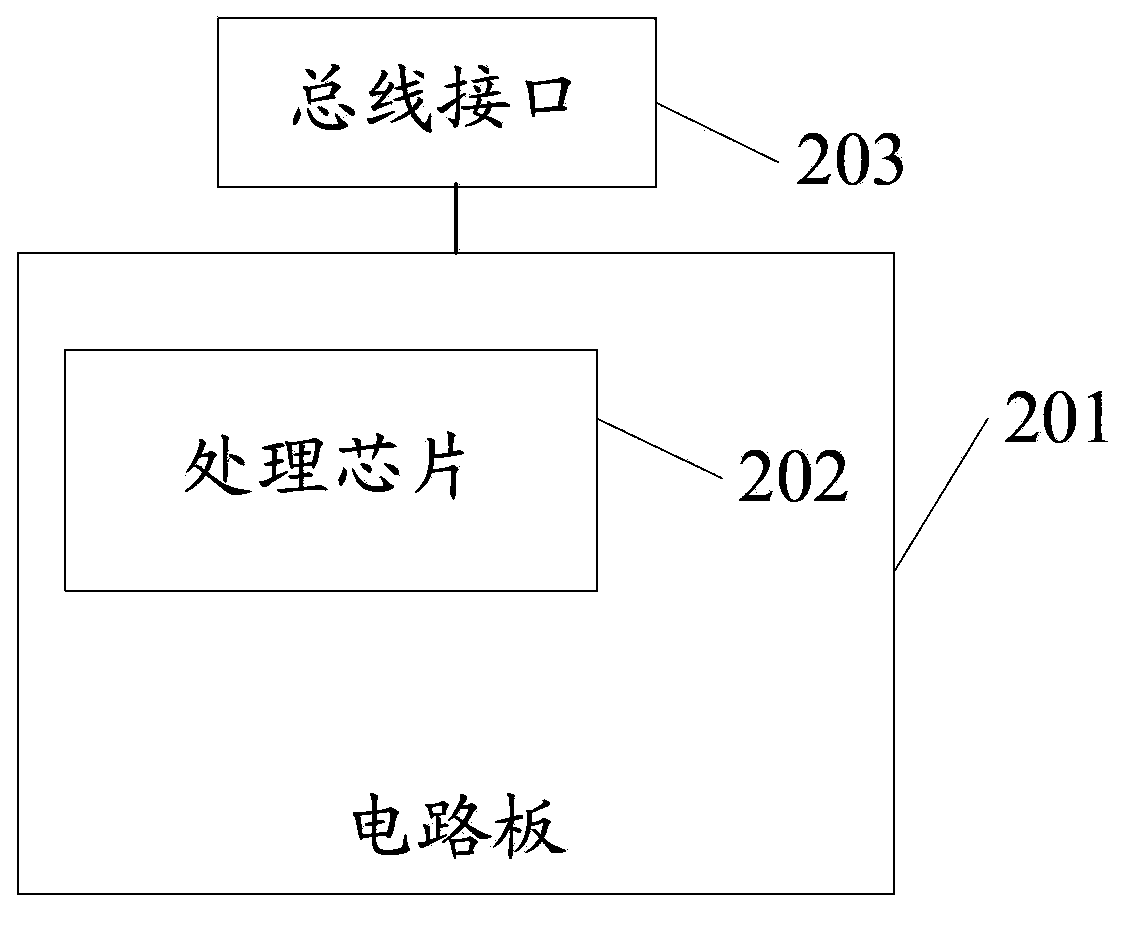

Method and mobile terminal for information processing

ActiveCN103870320AImprove computing performanceReduce data processing timeMultiprogramming arrangementsBus interfaceInstalled base

The invention discloses a method and a mobile terminal for information processing. The mobile terminal comprises a first hardware system and a first operating system installed based on the first hardware system, wherein the mobile terminal is internally provided with bus interfaces; when the first operating system in the mobile terminal needs to process a first calculating task, it is detected whether the mobile terminal is connected with N hardware resources through the bus interfaces, wherein each hardware resource in the N hardware resources at least corresponds to one function, and N is an integer being not less than 1; when the mobile terminal is connected with the N hardware resources through the bus interfaces, the first calculating task is processed through the first operating system at least based on one hardware resource in the N hardware resources.

Owner:LENOVO (BEIJING) CO LTD

Drying device

InactiveCN106075942AAvoid gatheringPrevent adhesionEvaporator accessoriesEvaporation by sprayingAirflowDry gas

The invention relates to a drying device which comprises a drying cavity, a gas jet plate, an intake tube and vibrators. The drying cavity is of a cylindrical structure, the upper end of the drying cavity is inclined by the preset angle and is provided with the gas jet plate connected with the intake tube, the gas jet plate is provided with a plurality of air guiding pipes capable of jetting dry gas into the drying cavity so as to blow off attachment on the inner wall of the drying cavity. The outer side wall of the drying cavity is provided with a plurality of vibrators connected with a motor to peel off the attachment on the inner side wall of the drying cavity. Due to the arrangement of the vibrators, materials can be prevented from being gathered on the inner wall of the drying cavity. Meanwhile, the air guiding pipes of the gas jet plate guide wind in the direction of the inner wall of the drying cavity, materials attached to the wall are reduced, a small number of materials attached to the wall can be brought away, and the phenomenon that materials are attached to the wall of the tower for a long time is avoided.

Owner:扬州日发干燥工程有限公司

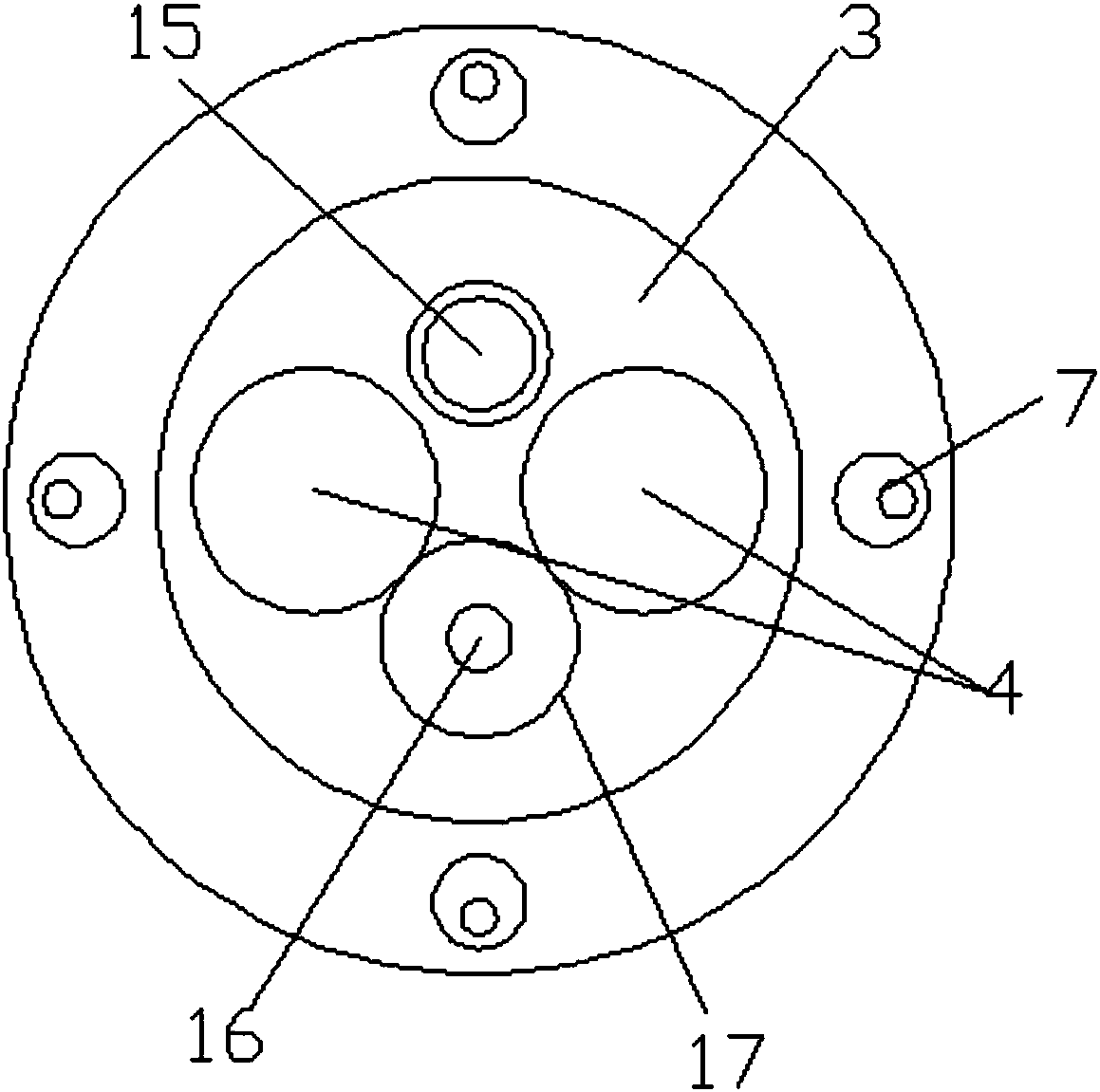

Internal circulation column photoreactor

InactiveCN105838584AEasy to achieve internal circulationImprove absorption efficiencyBioreactor/fermenter combinationsBiological substance pretreatmentsProduct gasEngineering

The invention relates to an internal circulation column photoreactor which comprises a transparent cylinder body. A partition plate is arranged in the transparent cylinder body and divides the lower portion of the transparent cylinder body into two chambers with the same size. The bottom end of the transparent cylinder body is connected with a bottom plate in a sealed mode. The positions, located on the two sides of the partition plate, of the bottom plate are each provided with a liquid circulating hole. A three-way pipe is arranged at the lower portion of the bottom plate. The two chambers are communicated through the three-way pipe. The three-way pipe is connected with a liquid inlet and outlet channel. The branch, close to the bottom plate, of the three-way pipe is provided with a ventilating assembly. A top cover is connected with the top end of the transparent cylinder body and provided with a gas outlet assembly. Supply of carbon dioxide can be improved, and molecular oxygen in a culture solution can be removed in time; meanwhile, energy consumption in the culture process is lowered, gas distribution uniformity in the photoreactor is improved, sufficient stirring of alga cells is ensured, and the running cost of the photoreactor is reduced.

Owner:彭小伟

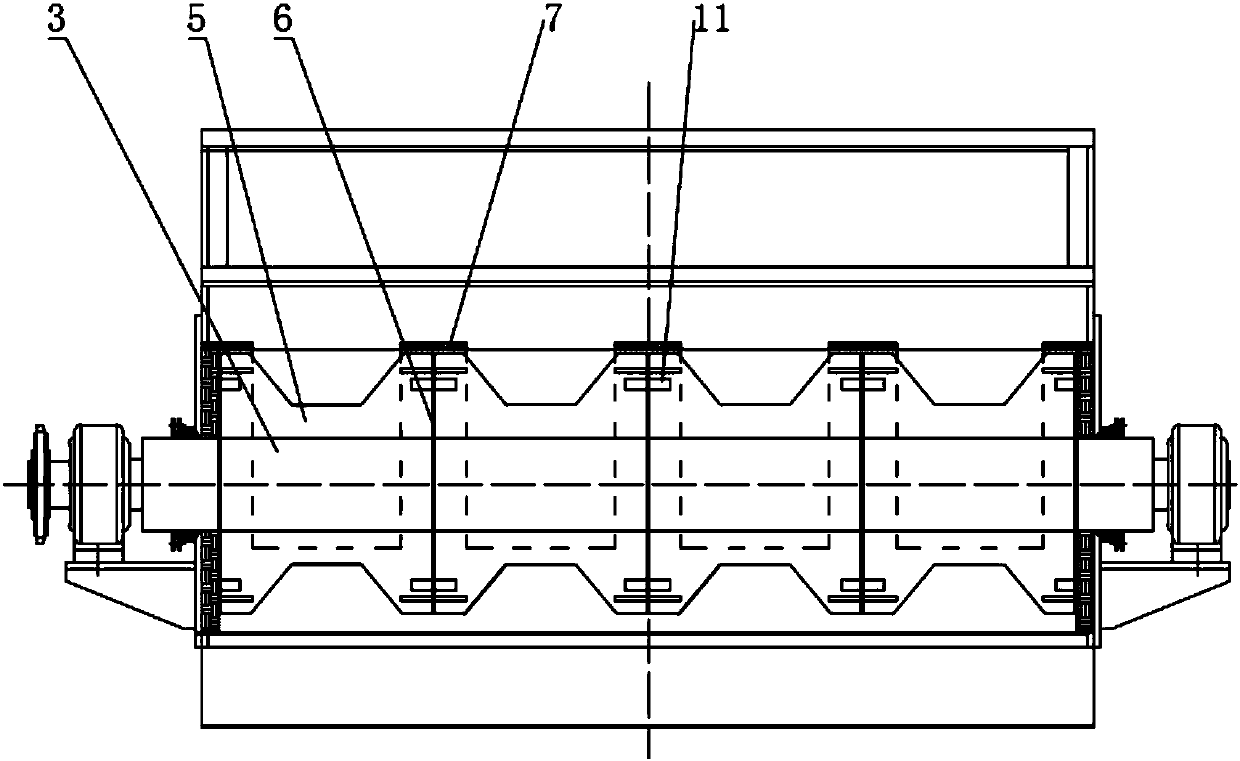

Wide-body controllable feed device and feed method thereof

PendingCN109867119AIncrease mandatoryImprove controllabilityConveyor partsControllabilityMechanical engineering

The invention discloses a wide-body controllable feed device and a feed method thereof, and belongs to the field of material feed equipment, which aims to solve the problems of poor feed capability and the like of an existing feed device. The wide-body controllable feed device comprises a feed channel, a discharge channel, an outer barrel and a rotor assembly, wherein the rotor assembly comprisesa rotating shaft, pushing blades and a plurality of spacing boards, a plurality of pushing blades which are uniformly arranged at intervals in the circumferential direction of the rotating shaft are arranged between two adjacent spacing boards, one side, which is close to the rotating shaft, of the pushing blades is fixedly connected with the rotating shaft, and both sides, which are close to thespacing boards, of the pushing blades are fixedly connected with the adjacent spacing boards. According to the wide-body controllable feed device and the feed method, the integral controllability andstability of the conveying flow are increased, and the phenomenon of material blockage of a rotary blade type forced feed device is solved.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Spin flash dryer

ActiveCN112742049AEvenly distributedKeep dryFlow mixersRotary stirring mixersRotational axisEngineering

The invention discloses a spin flash dryer, which comprises a cylinder body which is of a cylindrical structure, wherein the cylinder body sequentially comprises a rotary drying section, an impact drying section and a grading section from bottom to top, a product outlet is formed in the upper portion of the cylinder body, and an air inlet is formed in the lower portion of the cylinder body; a classifier arranged in the cylinder body and is lower than the product outlet; a rotating shaft coaxially penetrating through the bottom of the cylinder body, wherein the rotating shaft is a hollow shaft, and materials enter the cylinder body through the rotating shaft; at least a disperser, wherein the dispersers are coaxially communicated with the outside of the rotating shaft and are used for dispersing materials; at least one layer of stirring paddle coaxially connected outside the rotating shaft; and a gas distributor arranged at the lower part of the barrel in a surrounding manner, wherein the outer side of the gas distributor is communicated with hot air, and the inner side of the gas distributor is communicated with the gas inlet of the barrel. The spin flash dryer can treat materials with large viscosity and high moisture content, and is good in drying effect and stable in operation.

Owner:CHINA PETROLEUM & CHEM CORP +1

Paint sewage coagulation treatment agent and application thereof

InactiveCN108191028AImprove processing efficiencyReduce dosageNature of treatment waterWater/sewage treatment by flocculation/precipitationSimple Organic CompoundsSilanes

The invention provides a paint sewage coagulation treatment agent and application thereof. The paint sewage coagulation treatment agent is prepared from an adhesion eliminating agent A and a coagulation agent B, wherein the adhesion eliminating agent A is a polymer obtained by taking an organic compound containing an amino group and aldehydes to react; the coagulation agent B is a mixture of an amide polymer with the relative molecular weight of 10 to 14 million, and a compound, wherein the compound is one or a mixture of more than two of isobutyltriethoxysilane, 3-methacryloxymethyltris(trimethylsiloxy)silane and polydimethylsiloxane. The paint sewage coagulation treatment agent provided by the invention has efficient adhesion eliminating and coagulation effects on paint and has high paint mist treatment efficiency; the paint sewage coagulation treatment agent has the advantages of wide raw material source, low price, small dosage and remarkable cost performance advantage.

Owner:WUHAN UNIV OF TECH

A kind of preparation method of sugarcane vinegar powder rich in plant polysaccharide

ActiveCN107841440BHigh nutritional valueEasy to prepareVinegar preparationHylocereus undatusMoisture

The invention relates to the technical field of food processing and in particular relates to a preparation method of plant-polysaccharide-enriched sugarcane vinegar powder. The plant-polysaccharide-enriched sugarcane vinegar powder is prepared from the following raw materials in parts by weight: 40 to 55 parts of raw sugarcane vinegar, 8 to 10 parts of an acetic acid bacterium film, 10 to 15 partsof fructus lycii, 6 to 8 parts of pitaya flowers, 8 to 10 parts of hylocereus undatus flowers, 6 to 9 parts of dendrobium officinale kimura ex migo, 2 to 3 parts of ganodorma lucidum, 3 to 5 parts ofsodium alginate, 6 to 10 parts of maltodextrin, 0.3 to 0.5 part of a taste masking agent and 0.8 to 2 parts of a sweetener; the plant-polysaccharide-enriched sugarcane vinegar powder is prepared by the steps of preparing the acetic acid bacterium film, pulping by liquid nitrogen, carrying out microwave combined ultrasonic extraction, blending, freezing and drying and the like. The sugarcane vinegar powder provided by the invention contains abundant plant polysaccharide and the nutrient value is improved; the preparation method is simple and the yield of the vinegar powder is effectively improved; the vinegar powder has the advantages of low moisture content, fine, smooth and uniform performances, no cakes and slight sweet mouthfeel and is a health-care and nutritional green food.

Owner:GUANGXI ZHUANG AUTONOMOUS REGION ACAD OF AGRI SCI

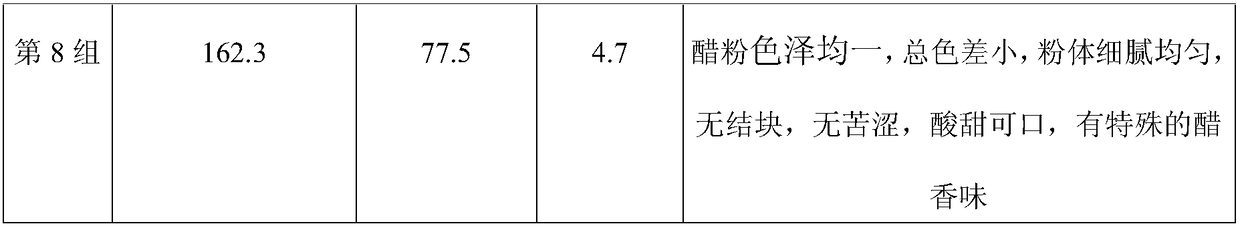

A kind of preparation method of sugarcane vinegar powder rich in vitamin C

ActiveCN107841441BHigh yieldReduce moisture contentMicroorganism based processesVinegar preparationAcetic acidVitamin C

The invention relates to the technical field of food processing and in particular relates to a preparation method of VC-enriched sugarcane vinegar powder. The VC-enriched sugarcane vinegar powder is prepared from the following raw materials in parts by weight: 35 to 40 parts of raw sugarcane vinegar, 8 to 10 parts of an acetic acid bacterium film, 35 to 45 parts of fruits, 3 to 5 parts of starch,14 to 16 parts of maltodextrin, 0.3 to 0.5 part of neodiosmin and 0.8 to 2 parts of a sweetener; the VC-enriched sugarcane vinegar powder is prepared by the steps of preparing the raw sugarcane vinegar, preparing the acetic acid bacterium film, treating the raw materials, blending, spraying and drying and the like. The sugarcane vinegar powder provided by the invention contains abundant vitamin Cand the yield of the vinegar powder is effectively improved; the vinegar powder has the advantages of low moisture content, light yellow color, small total color difference, fine, smooth and uniform performance, no cakes and slight sweet mouthfeel; the preparation method has the advantages of simplicity and easiness for production; the VC-enriched sugarcane vinegar powder is a health-care and nutritional green food.

Owner:AGRI PROD PROCESSING INST GUANGXI ACADEMY OF AGRI SCI

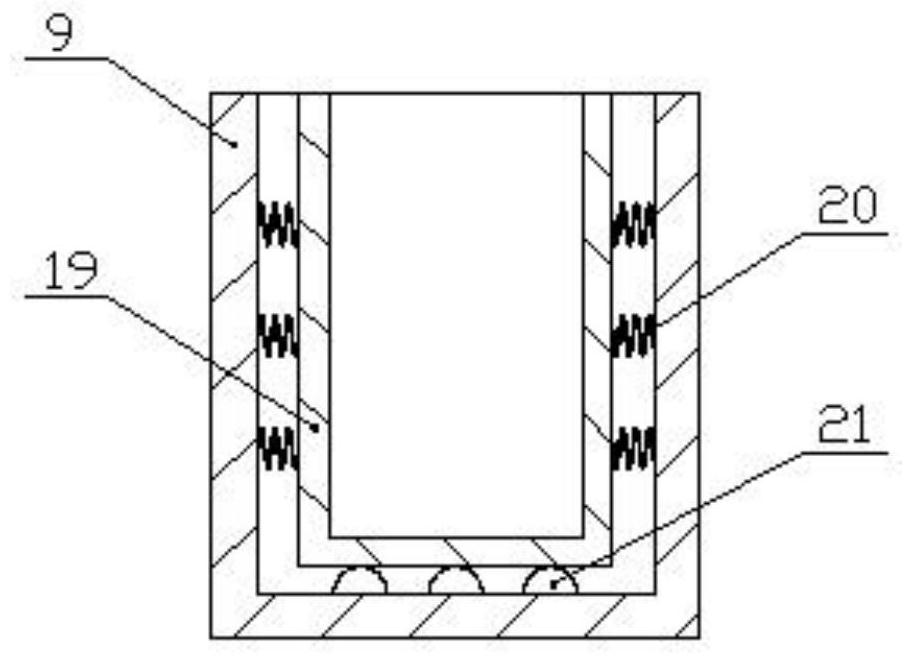

Planetary vibration ball mill

ActiveCN112371266AReduce stuck problemsReduce reunion and other phenomenaGrain treatmentsRotational axisGear wheel

The invention discloses a planetary vibration ball mill, and belongs to the field of ball mills. The planetary vibration ball mill comprises a base with the upper end open. A main motor is arranged inthe base. An output shaft of the main motor is connected with a rotating shaft at the lower end of a rotating disc. A driving gear on the rotating shaft is engaged with a planetary gear on a planetary shaft. The upper end of the planetary shaft penetrates through the rotating disc to be connected with a milling tank base. A ball milling tank is placed in the milling tank base. A support is arranged at the lower end of the main motor. An auxiliary motor is arranged in the base and located below the support. An output shaft of the auxiliary motor is connected with a driving shaft. The driving shaft is arranged in a non-horizontal mode and used for driving one side of the support to ascend and descend vertically. According to the planetary vibration ball mill, the phenomena of wall sticking,agglomeration and the like of samples during the working of the planetary ball mill can be reduced.

Owner:CHANGSHA MITR INSTR EQUIP CO LTD

Omnibearing vibration ultrasonic ball mill with high efficiency

An omnibearing vibration ultrasonic ball mill with high efficiency is composed of a rack, a motor, a synchronous belt wheel, a synchronous belt, an eccentric main shaft, a bearing, an eccentric wheelframe, a ball-milling tank, a ball-milling tank connecting shaft, a gas conveying pipe, an ultrasonic generator, a gas pressure sensor, a temperature sensor and an operation and control device system.One end of the eccentric wheel frame is connected with the eccentric main shaft through the bearing, and the other end of the eccentric wheel frame is connected with the ball-milling tank connectingshaft through a hinge, so that the eccentric wheel frame drives the ball-milling tank connecting shaft to swing back and forth around a fulcrum under the driving of the eccentric main shaft. The ball-milling tank connecting shaft is of a two-section structure, the section, connected with the eccentric wheel frame, of the ball-milling tank connecting shaft is a solid rod piece, the section, connected with the ball-milling tank, of the ball-milling tank connecting shaft is a hollow rod piece with high elasticity, and all connecting wires between the sensors and the operation and control device system and between the ultrasonic generator and the operation and control device system and the gas conveying pipe are led out of the ball-milling tank through the hollow rod piece, wherein the sensorsand the ultrasonic generator are arranged in the ball-milling tank.

Owner:CHANGSHA MITR INSTR EQUIP CO LTD

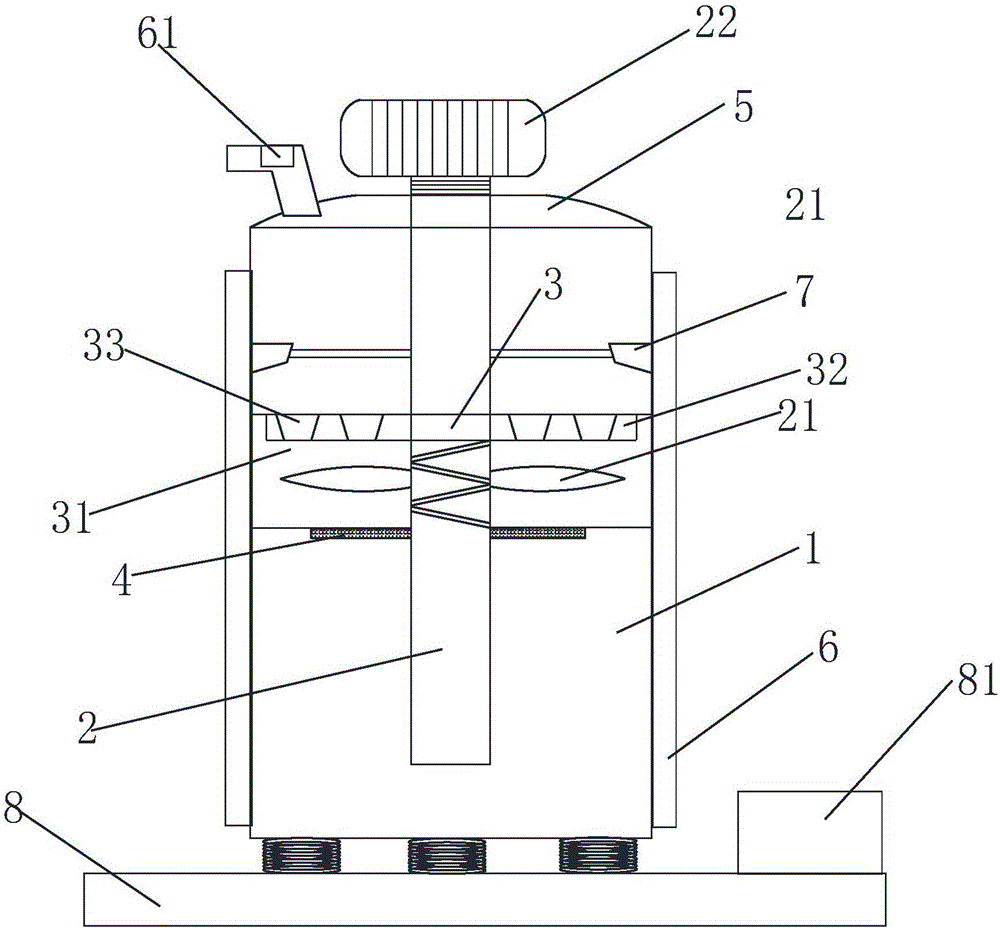

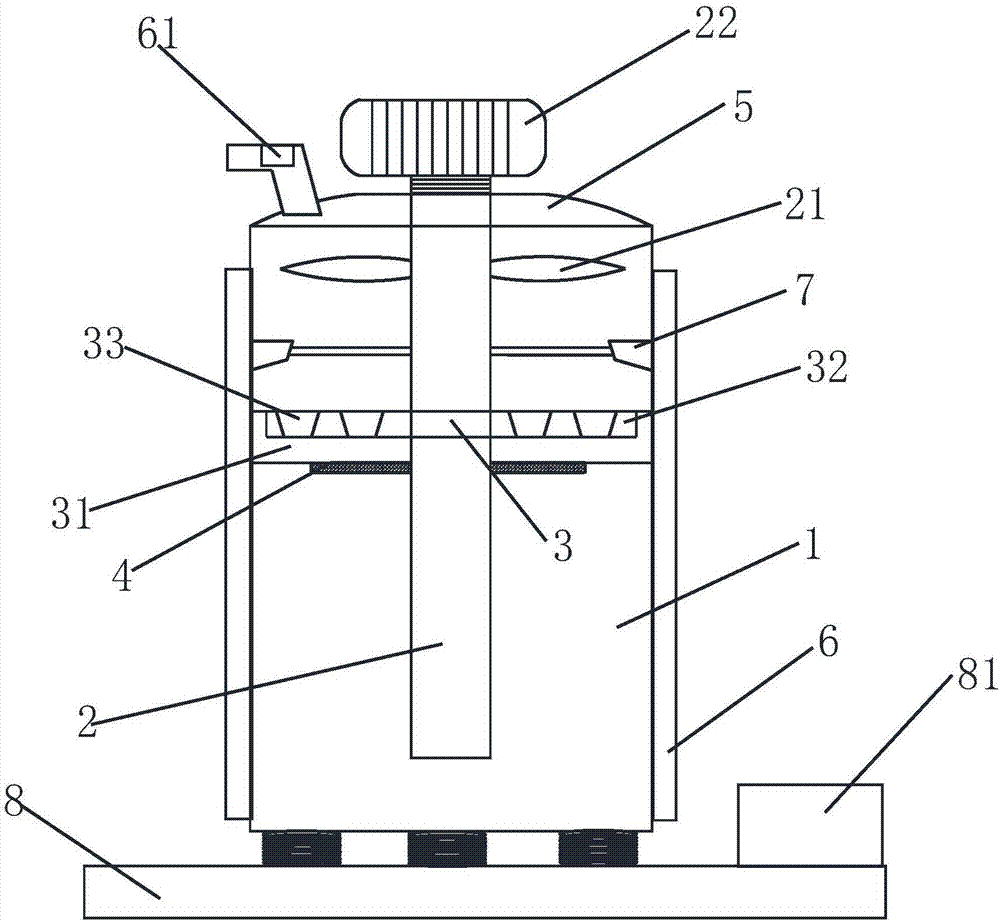

Pig feed beneficial to pig growth and processing device thereof

ActiveCN107927403AIncrease productionReduce stuck problemsFeeding-stuffFood processingFiberAnimal science

The invention relates to the technical field of feed processing, and in particular designs a pig feed beneficial to pig growth. A preparation method of the pig feed comprises adding 55-60 parts of corn, 45-55 parts of peeled soybean meal, 5-20 parts of fish meal, 20-40 parts of wood fiber, 20-35 parts of alfalfa powder, 1-2 parts of soybean oil, 2-5 parts of coconut oil and 1-2 parts of common salt into a processing device for mixing and stirring so as to obtain the pig feed. The invention further provides a processing device of the pig feed beneficial to pig growths. By reasonably matching feed raw materials, the pig feed provided by the invention can supplement the nutrition needed by pig growth and help improve the pig yield. In addition, the processing device of the pig feed adopts roller rotation, and a scraper is used to scrape the inner wall, thus reducing wall adhesion of the feed and improving the mixing uniformity.

Owner:南宁艾格菲饲料有限公司

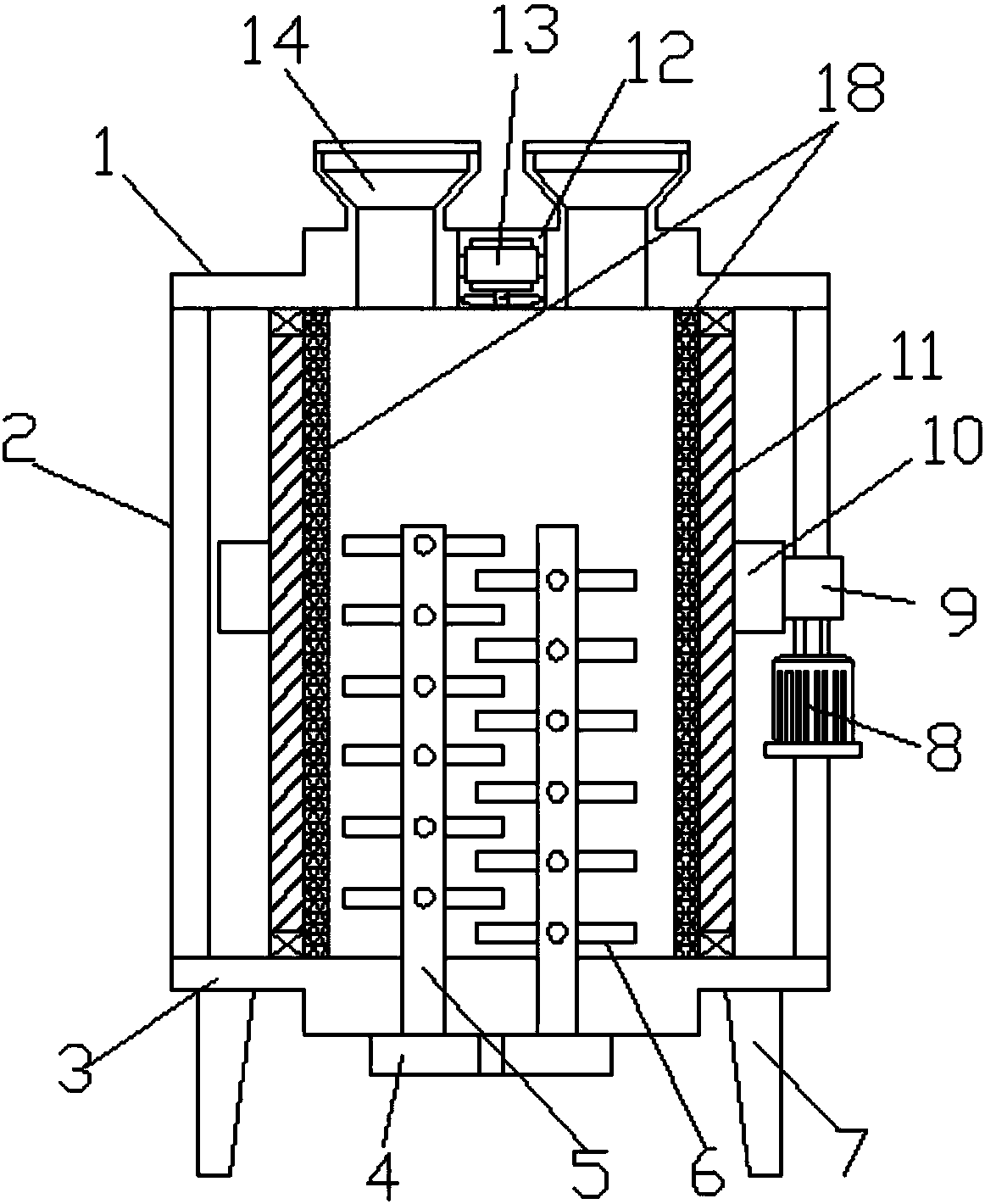

Polymerization kettle for producing suspension polytetrafluoroethylene

InactiveCN110449105AEasy to cleanReduce stuck problemsChemical/physical/physico-chemical reactor detailsChemical/physical/physico-chemical stationary reactorsReaction rateRates reactions

The invention discloses a polymerization kettle for producing suspension polytetrafluoroethylene, and relates to the field of polymerization kettles. The polymerization kettle comprises a kettle body,a stirrer shaft is installed at the inner lower part of the kettle body, a stirring blade is installed at the top of the stirrer shaft, and a machine seal system is arranged between the stirrer shaftand the kettle body; a motor system is installed at the bottom for driving, a material discharging ball valve is installed at the lower part of the kettle body, the exterior of a kettle wall is provided with a reaction kettle jacket, an upper refrigerant inlet and a lower refrigerant outlet, and energy released during a reaction can be taken away in time; a material inlet, a hand hole and a manhole are arranged in an upper seal head of the kettle body; two baffles are inserted into the kettle from the upper seal head of the kettle body in a suspended mode, and each baffle flange is arranged between one corresponding flange and one corresponding flange gland and is fixed through a bolt; and a reinforcing plate is welded to the upper portion of each baffle, and each baffle adopts an oval polished pipe. The polymerization kettle provided by the invention can reduce material sticking to the wall by adjusting the reaction rate through the baffles, and is easy to clean.

Owner:JIANGXI LEE & MAN CHEM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com