Omnibearing vibration ultrasonic ball mill with high efficiency

A ball mill, all-round technology, applied in grain processing, etc., can solve the problems of poor powder dispersibility, affecting the powder ball milling efficiency, particle size consistency, etc., achieve the effect of large speed change, improve protection efficiency, and reduce the difficulty of circuit design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

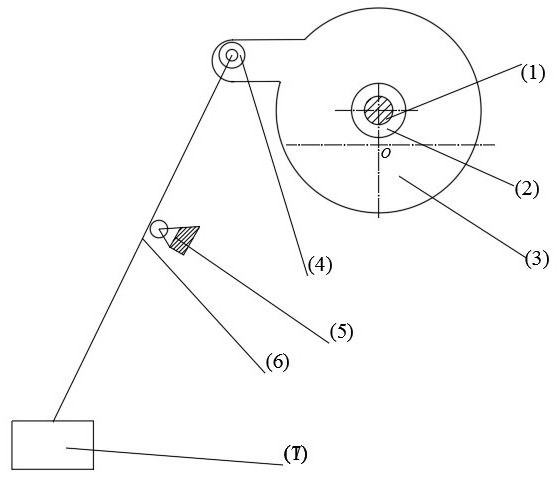

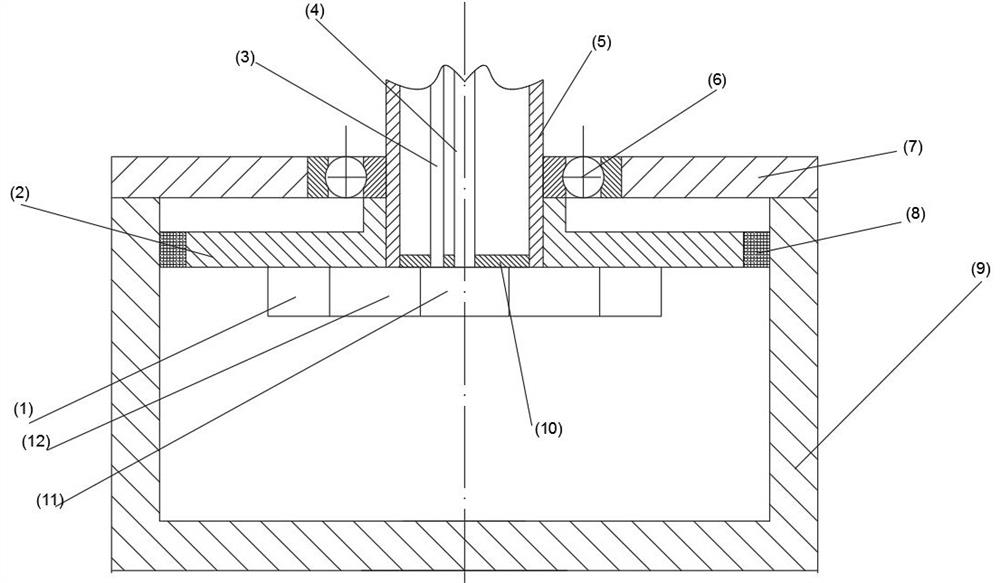

[0027] Example 1: An omnidirectional vibration ultrasonic ball mill,

[0028] The ball mill device consists of a frame, a motor, a synchronous pulley, a synchronous belt, an eccentric spindle, a bearing, a rotating support, an eccentric wheel frame, a ball mill tank, a ball mill tank connection shaft, a gas delivery pipe, an ultrasonic generator, a gas pressure sensor, a temperature sensor, Valve, operation and controller system composition.

[0029] The motor adopts a DC brushless servo motor with a power of 300W. The motor, fixed fulcrum, rotating support of the eccentric spindle, operation and control system are all fixed on the frame, and the motor and the eccentric spindle are driven by a synchronous pulley with a transmission ratio of 2. :1.

[0030] The eccentric wheel frame is made of aluminum alloy, and the eccentric wheel frame is arranged in the horizontal plane; the eccentric wheel frame and the eccentric wheel frame are connected by bearings. Hinge connection, s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com