Preparation method of plant-polysaccharide-enriched sugarcane vinegar powder

A technology of plant polysaccharides and sugarcane vinegar, which is applied in the field of food processing, to achieve the effects of increased yield, simple preparation method, and sweet and sour taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

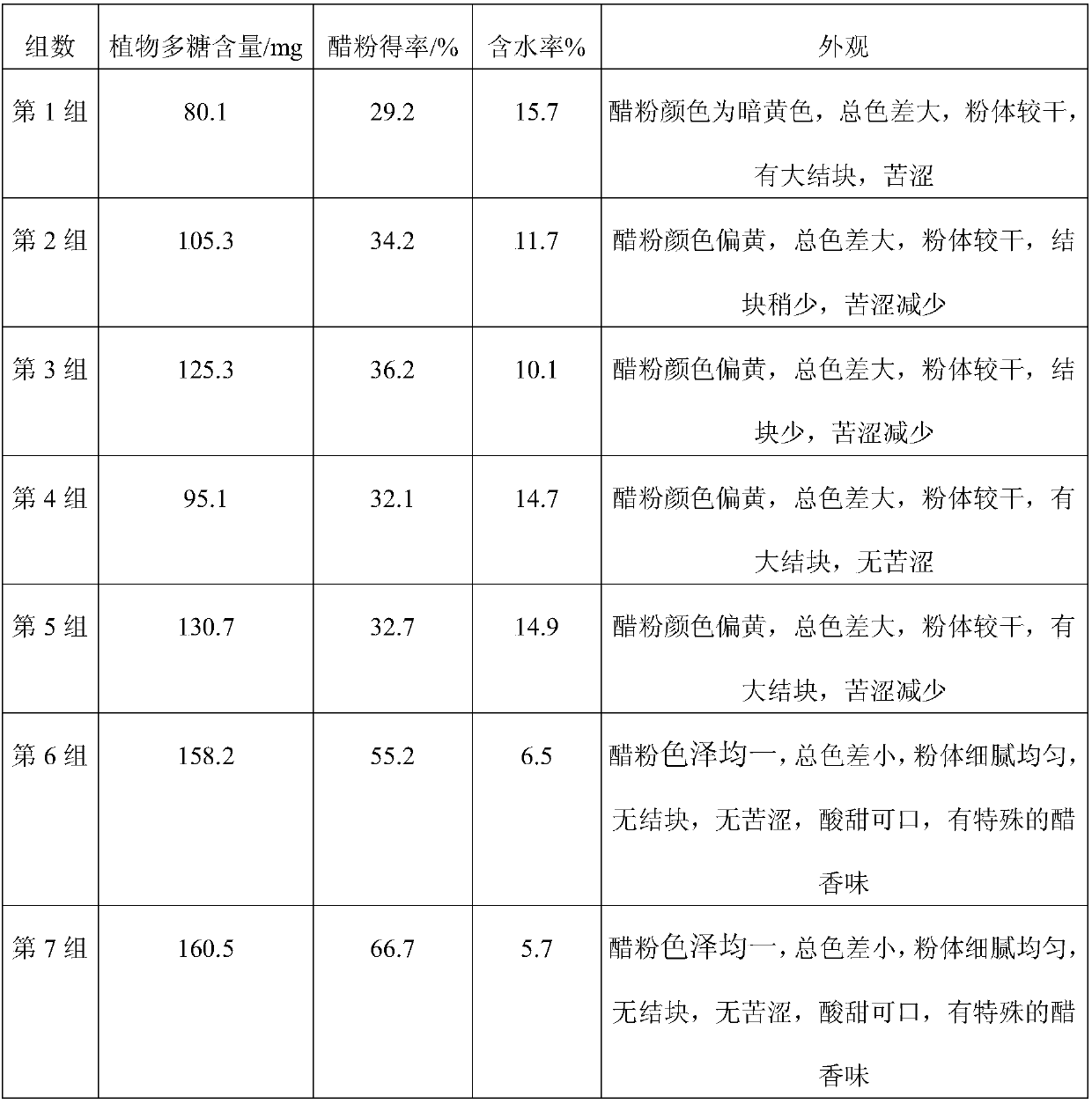

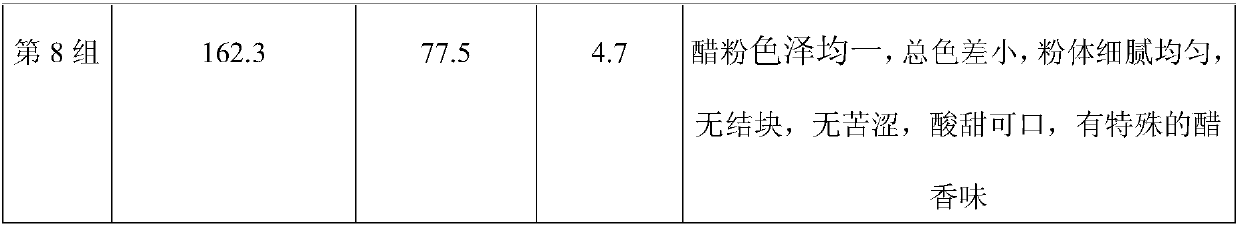

Examples

Embodiment 1

[0022] A preparation method of sugarcane vinegar powder rich in plant polysaccharides, with 40 parts by weight of sugarcane raw vinegar, 8 parts by weight of acetic acid bacteria film, 10 parts by weight of wolfberry, 6 parts by weight of Bawang flower, 8 parts by weight of dragon fruit flower, 6 parts by weight of Dendrobium candidum, 2 parts by weight of Ganoderma lucidum, 3 parts by weight of sodium alginate, 6 parts by weight of maltodextrin, 0.3 parts by weight of a taste masking agent, and 0.8 parts by weight of a sweetener are raw materials;

[0023] Among them, the sweetener is formed by mixing hesperetin, fructose syrup and stachyose in equal mass ratio; the taste masking agent is formed by mixing tannic acid, aminobutyric acid and sodium citrate in equal mass ratio;

[0024] Specifically include the following steps:

[0025] (1) Aging the raw sugarcane vinegar for 90 days at 27°C after being canned, there will be an acetic acid film with a thickness of 2 cm on the su...

Embodiment 2

[0032]A preparation method of sugarcane vinegar powder rich in plant polysaccharides, with 47 parts by weight of sugarcane raw vinegar, 9 parts by weight of acetic acid bacteria film, 13 parts by weight of wolfberry, 7 parts by weight of Bawang flower, 9 parts by weight of dragon fruit flower, 7.5 parts by weight of Dendrobium officinale, 2.5 parts by weight of Ganoderma lucidum, 4 parts by weight of sodium alginate, 8 parts by weight of maltodextrin, 0.4 parts by weight of a taste masking agent, and 1.2 parts by weight of a sweetener are raw materials;

[0033] Among them, the sweetener is formed by mixing hesperetin, fructose syrup and stachyose in equal mass ratio; the taste masking agent is formed by mixing tannic acid, aminobutyric acid and sodium citrate in equal mass ratio;

[0034] Specifically include the following steps:

[0035] (1) Aging the raw sugarcane vinegar for 95 days at 29°C after putting it into a can, there will be a 3 cm thick acetic acid film on the sur...

Embodiment 3

[0042] A preparation method of sugarcane vinegar powder rich in plant polysaccharides, with 55 parts by weight of sugarcane raw vinegar, 10 parts by weight of acetic acid bacteria film, 15 parts by weight of wolfberry, 8 parts by weight of Bawang flower, 10 parts by weight of dragon fruit flower, 9 parts by weight of Dendrobium officinale, 3 parts by weight of Ganoderma lucidum, 5 parts by weight of sodium alginate, 10 parts by weight of maltodextrin, 0.5 parts by weight of a taste masking agent, and 2 parts by weight of a sweetener are raw materials;

[0043] Among them, the sweetener is formed by mixing hesperetin, fructose syrup and stachyose in equal mass ratio; the taste masking agent is formed by mixing tannic acid, aminobutyric acid and sodium citrate in equal mass ratio;

[0044] Specifically include the following steps:

[0045] (1) Aging the raw sugarcane vinegar for 100 days at 32°C after being canned, there will be a layer of acetic acid film with a thickness of 4 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com