Patents

Literature

678 results about "Masking agent" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A masking agent is a reagent used in chemical analysis which reacts with chemical species that may interfere in the analysis. In sports a masking agent is used to hide or prevent detection of a banned substance or illegal drug like anabolic steroids or stimulants. Diuretics are the simplest form of masking agent and work by enhancing water loss via urine excretion and thus diluting the urine, which results in lower concentrations of the banned substance as more of it is being excreted from the body making it more difficult for laboratories to detect.

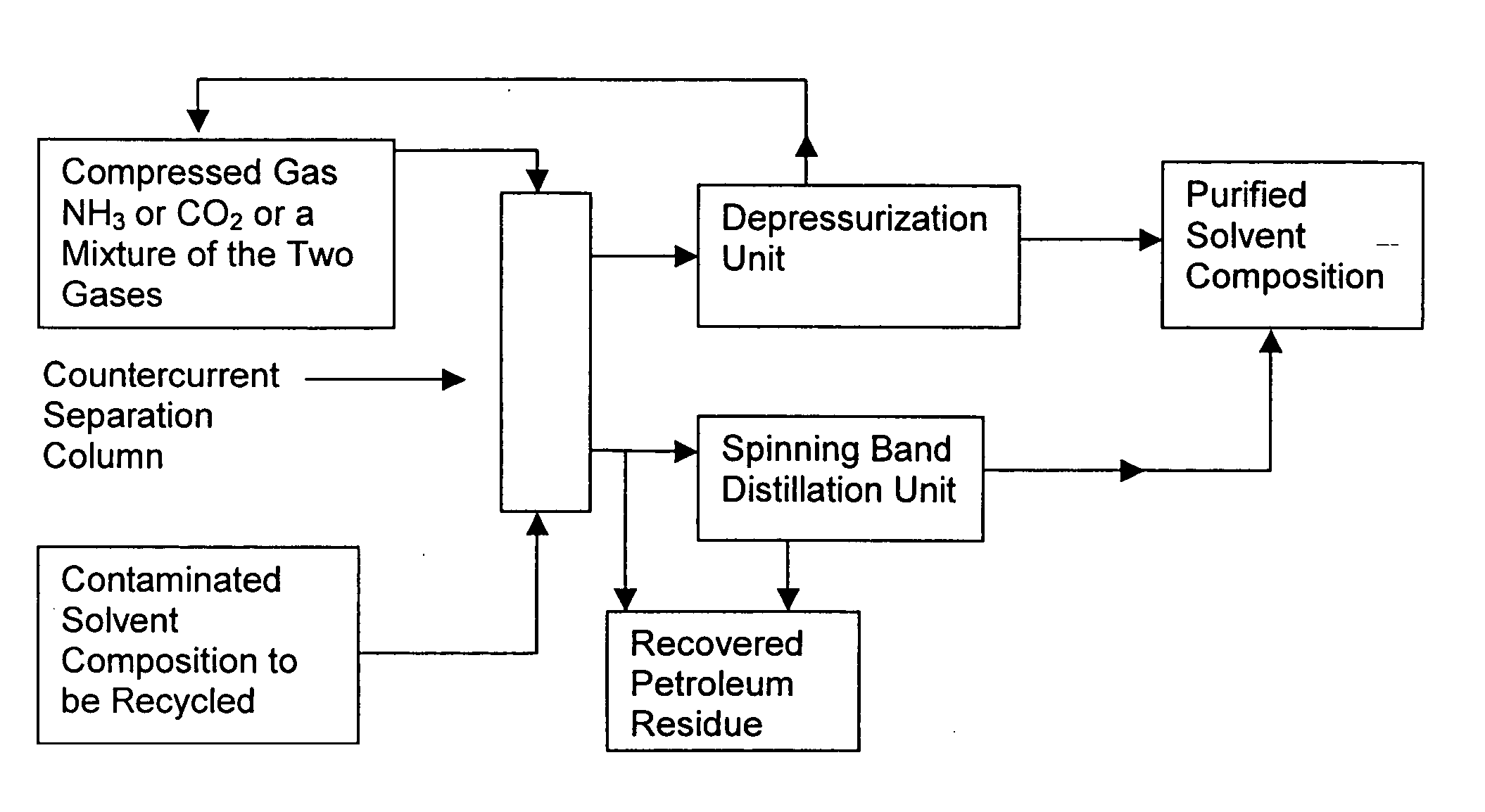

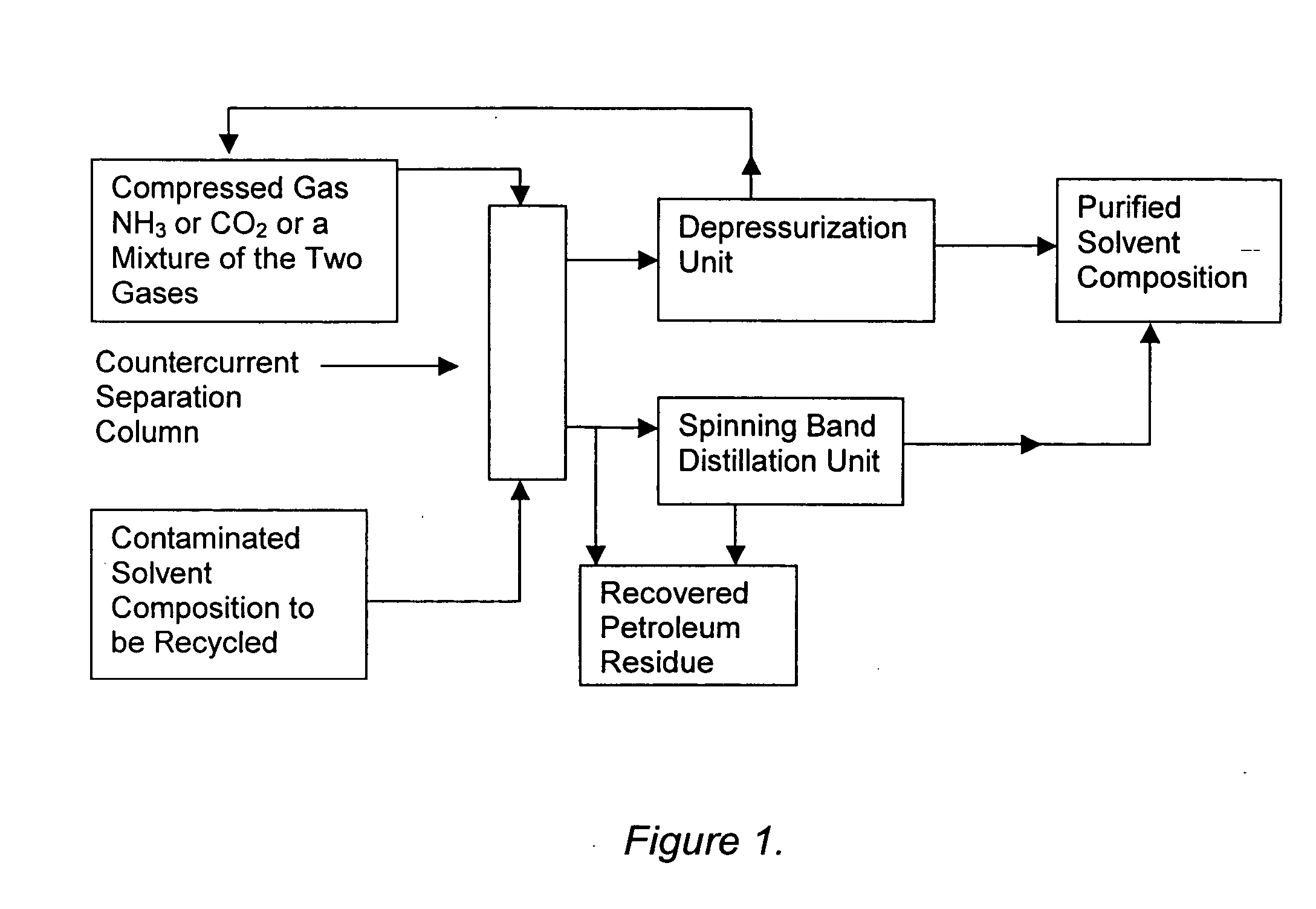

Solvent compositions for removing petroleum residue from a substrate and methods of use thereof

ActiveUS20050197267A1Cationic surface-active compoundsNon-ionic surface-active compoundsSpinning band distillationPetroleum

Water-soluble solvent compositions, including from about 10% to about 60% by weight of an aromatic ester; from about 30% to about 60% by weight of an aliphatic ester; from 0% to about 15% by weight of a co-solvent; from 0% to about 20% of one of a cyclic terpene and a terpenoid; from 0% to about 1% by weight of an odor-masking agent; and from 0% to about 20% by weight of a nonionic surfactant, for removing petroleum residue from a substrate, and methods of use thereof. The composition can further comprise water. The composition also can comprise an aqueous solution. The method for removing petroleum residue from a substrate can further comprise recycling the solvent composition by using a countercurrent separation column charged with compressed ammonia and / or carbon dioxide and a spinning band distillation column to separate the solvent composition from the petroleum residue.

Owner:CRUDE SPILL CLEANING CO INC

Aripiprazole oral solution

The present invention provides for a pharmaceutical solution suitable for oral administration comprising aripiprazole, a pharmaceutically suitable solvent system, one or more taste-enhancing / masking agents and one or more agents selected from the group consisting of lactic acid, acetic acid, tartaric acid and citric acid, wherein said solution has a pH from 2.5 to 4.5.

Owner:OTSUKA PHARM CO LTD

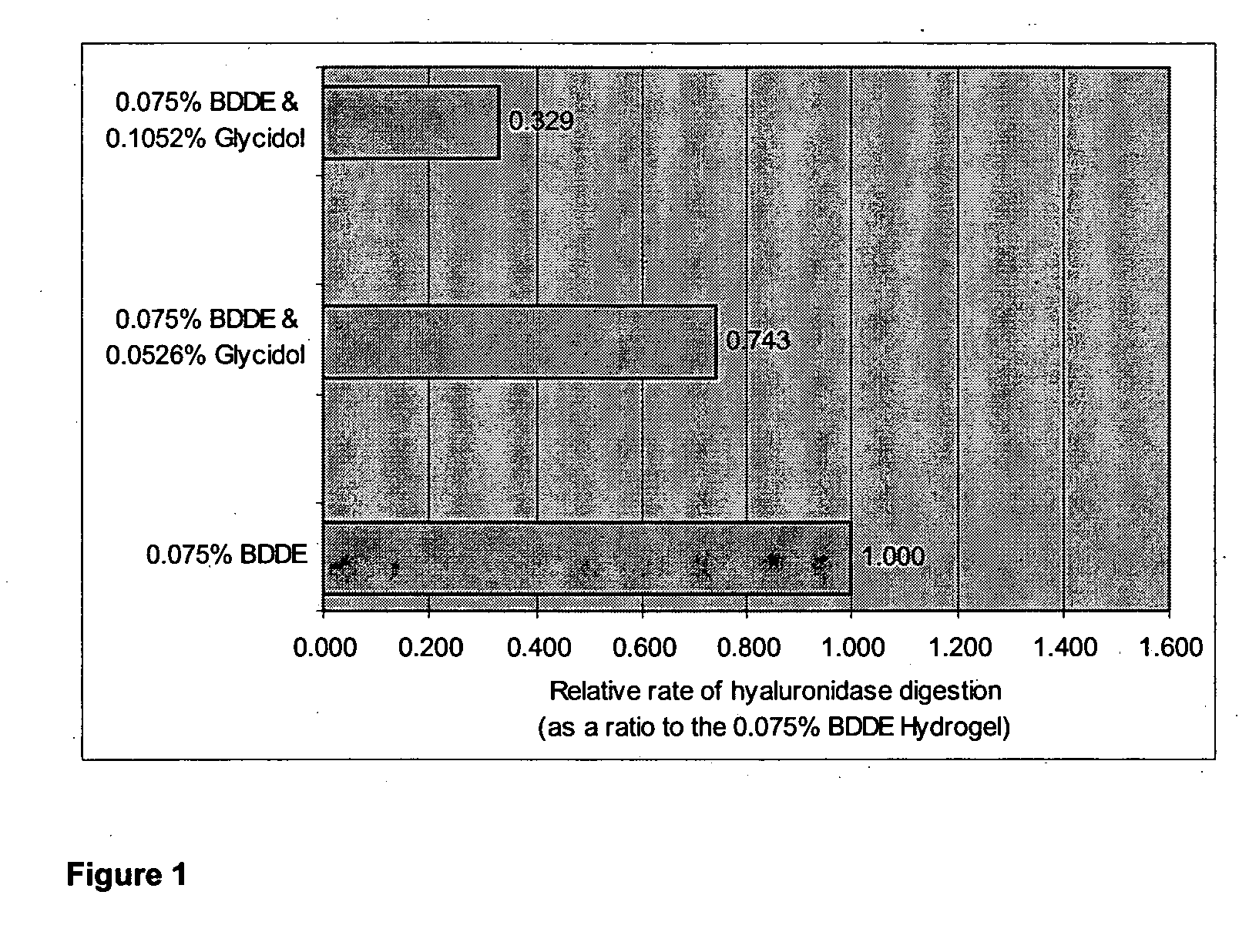

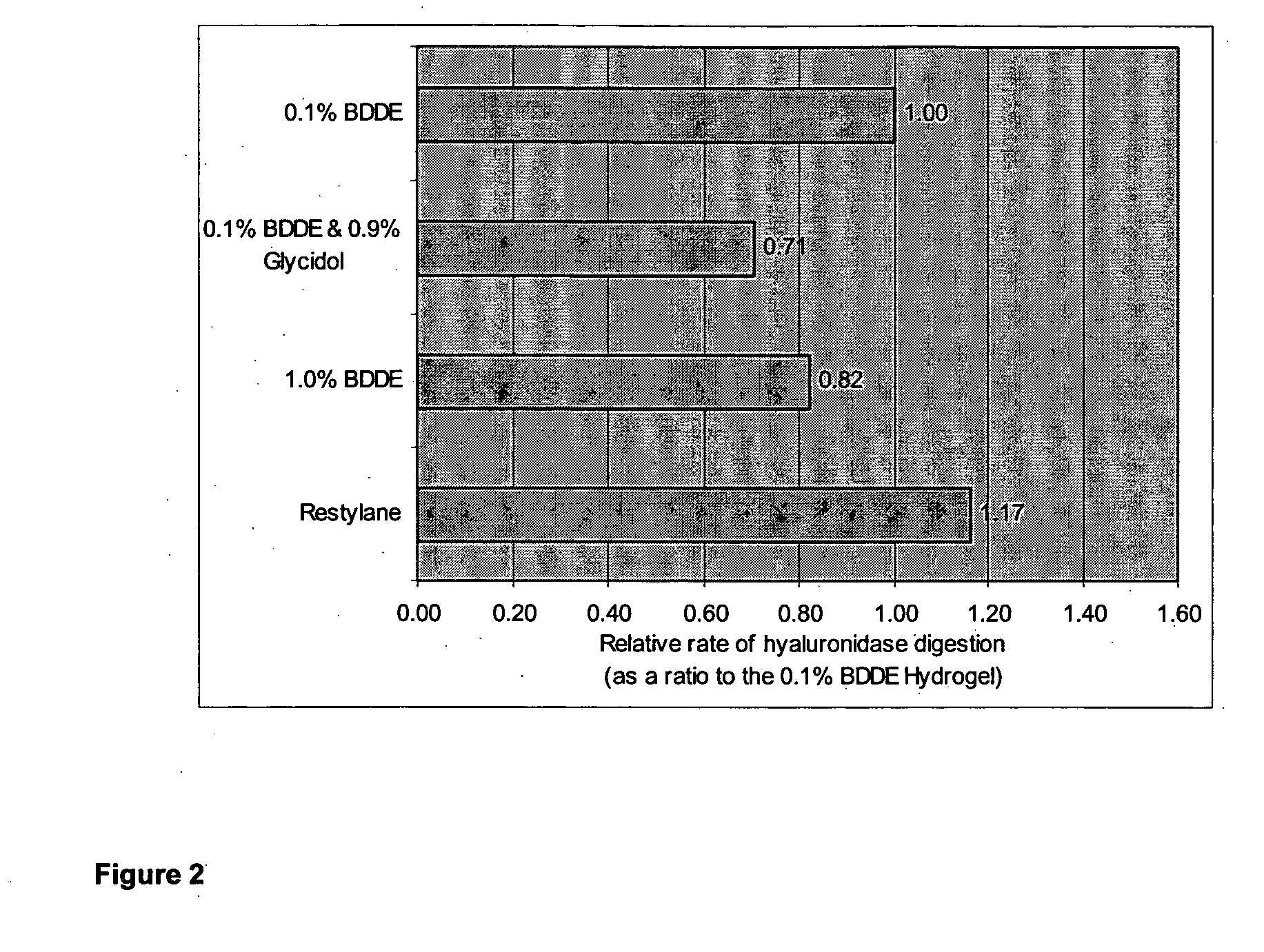

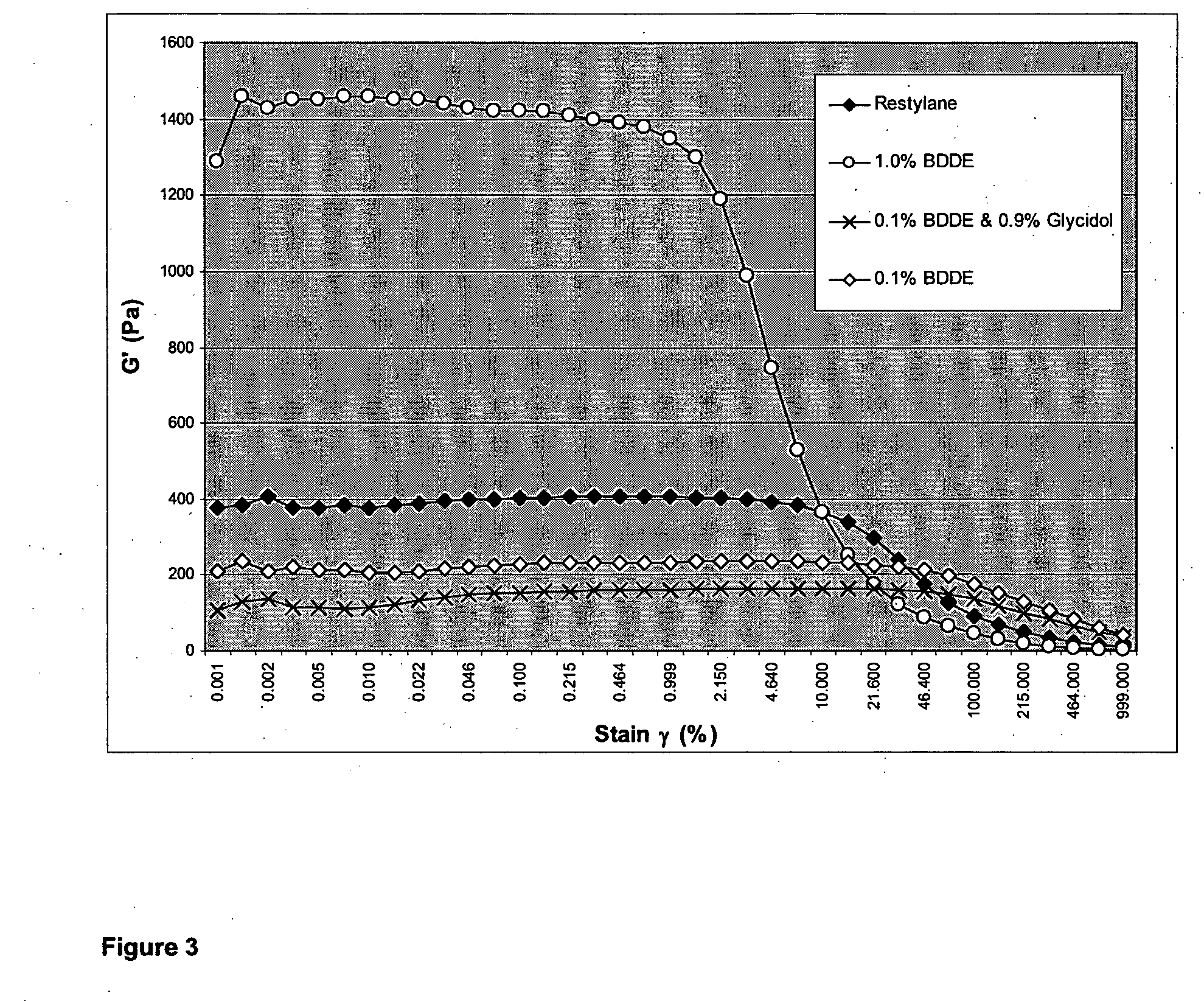

Cross-linked polysaccharide gels

InactiveUS20100035838A1Improve the immunityGood degradation propertiesOrganic active ingredientsBiocideCross-linkPolysaccharide

The present invention relates to a process for preparing a cross-linked polysaccharide gel comprising contacting a polysaccharide with a cross-linking agent and a masking agent to form a cross-linked polysaccharide gel having resistance to degradation under physiological conditions.

Owner:HEBER GEOFFREY KENNETH +1

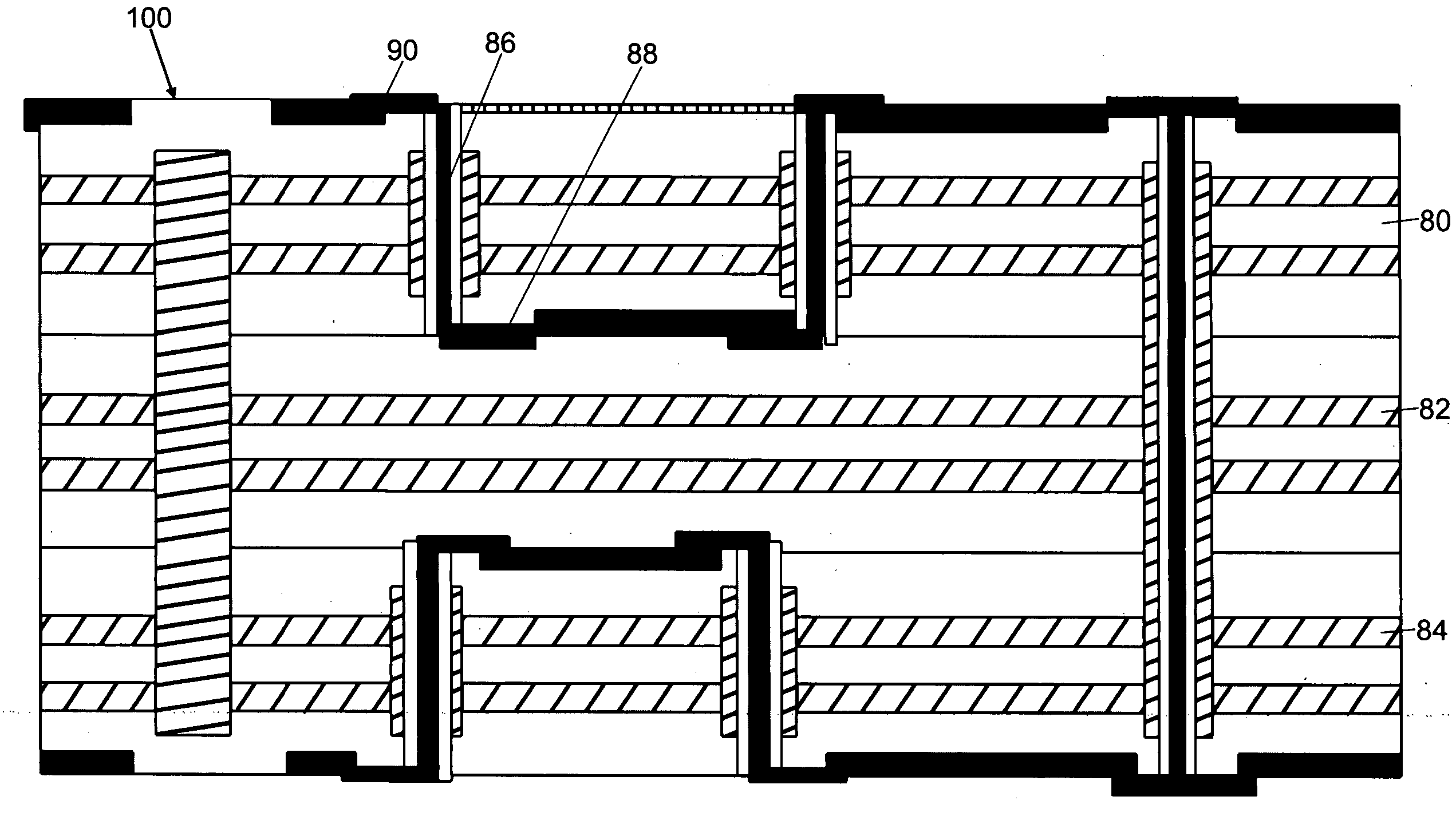

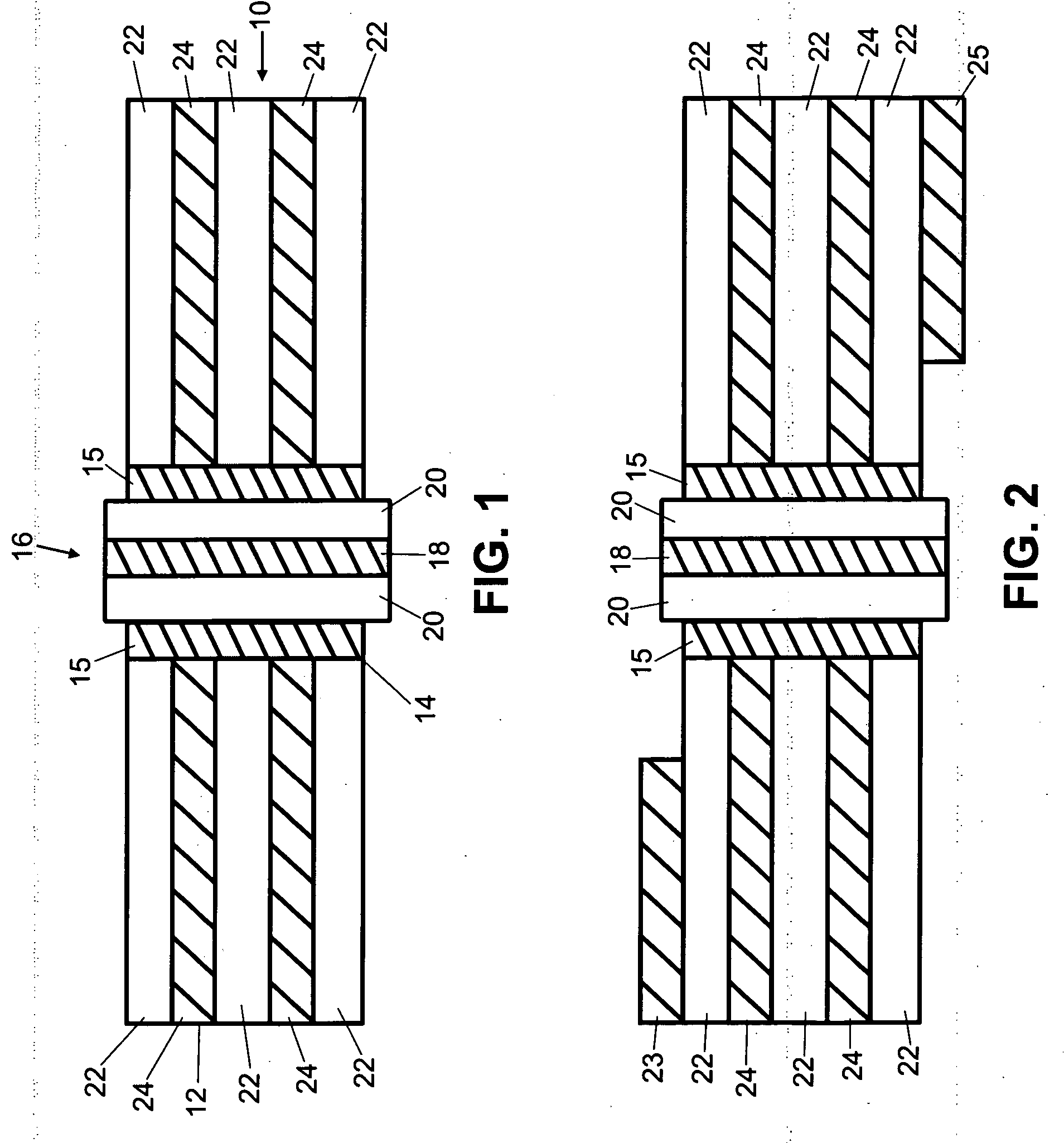

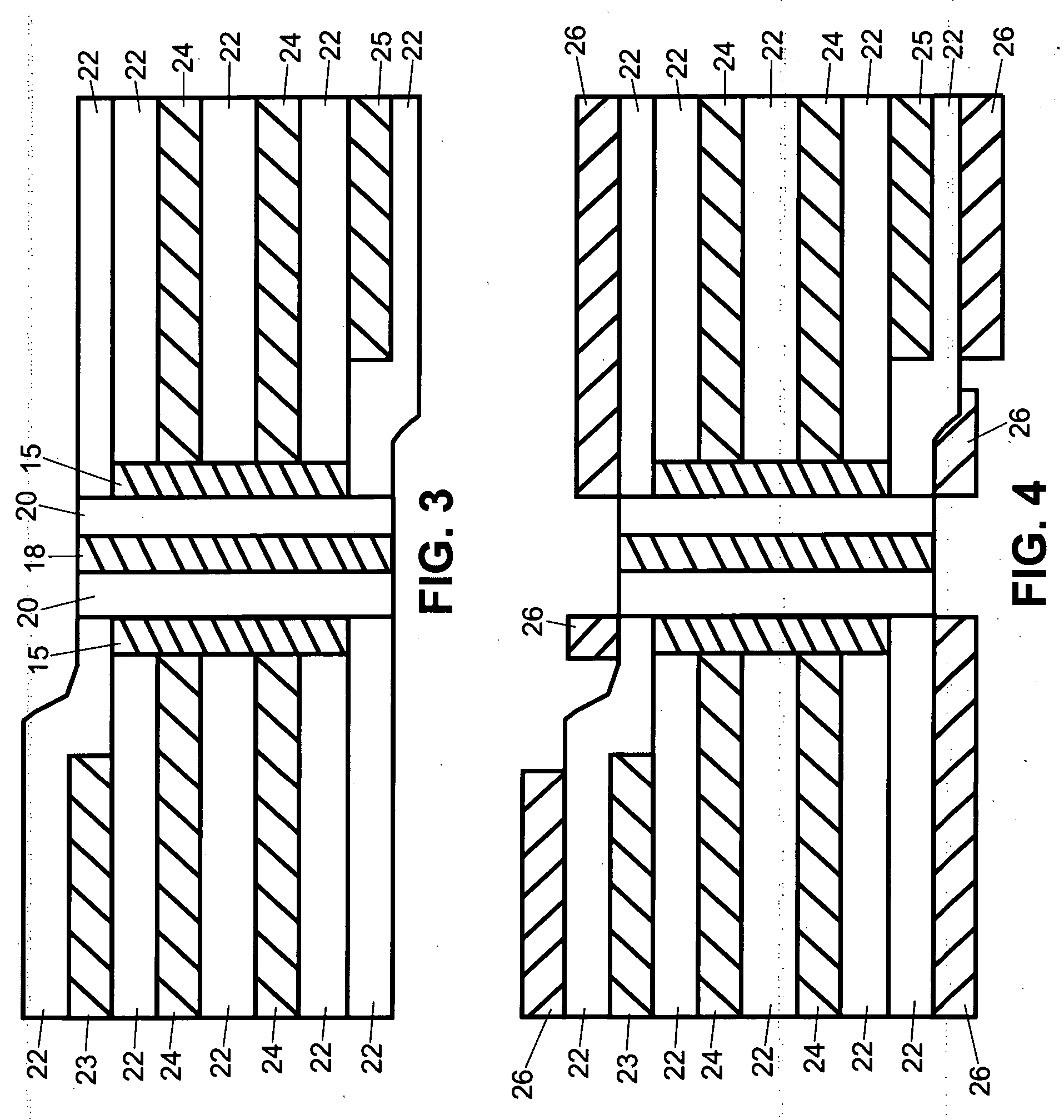

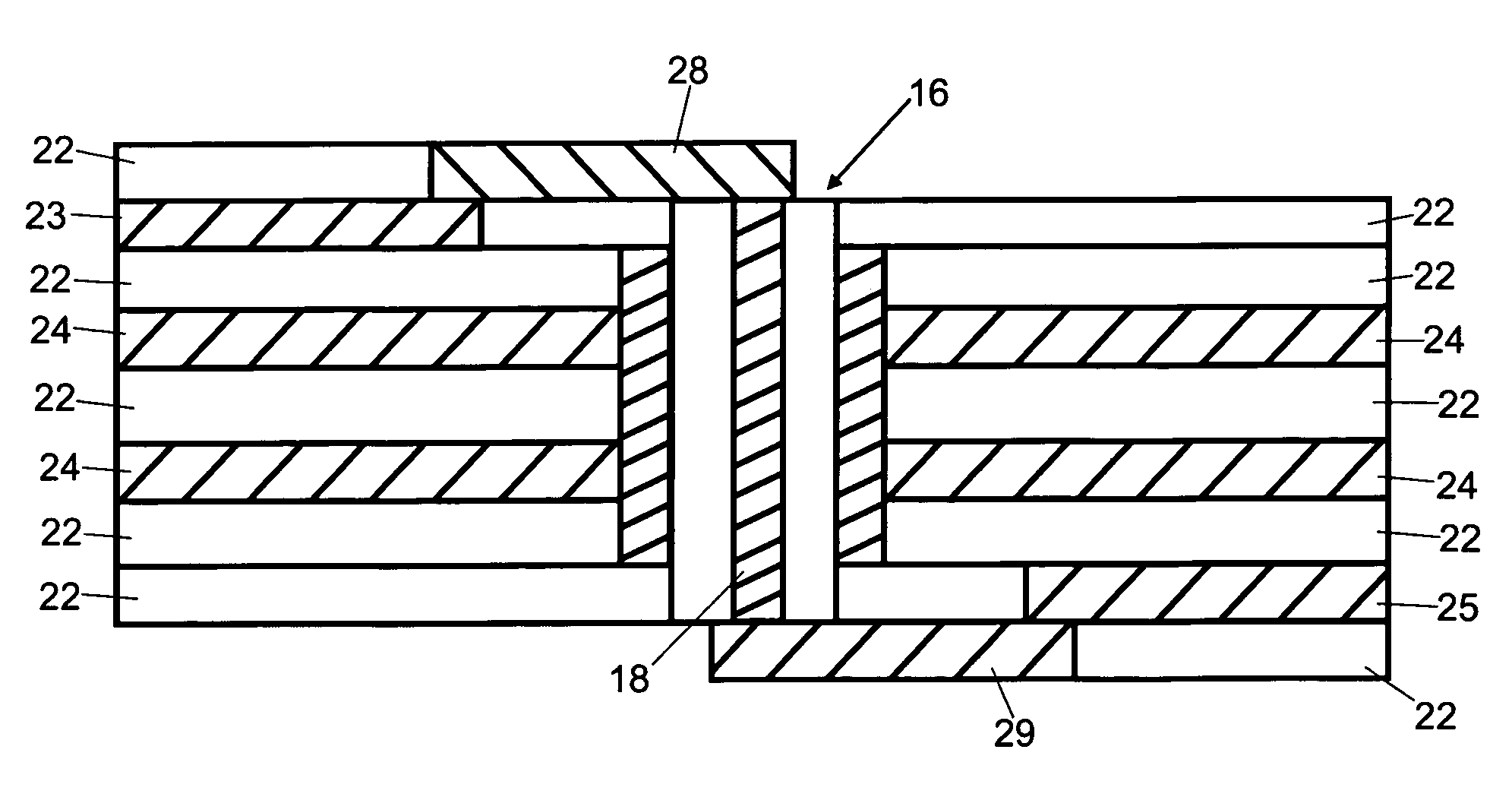

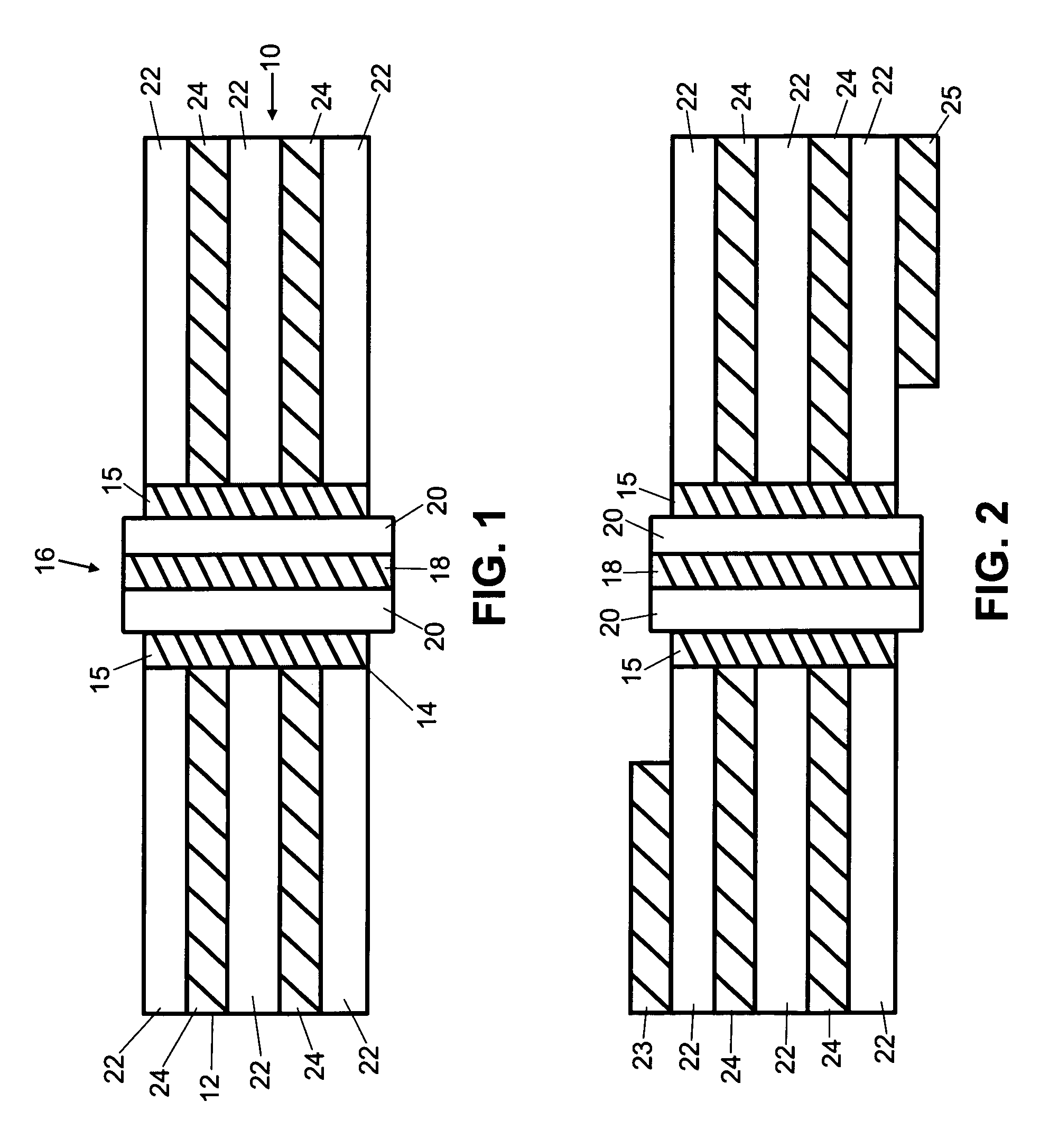

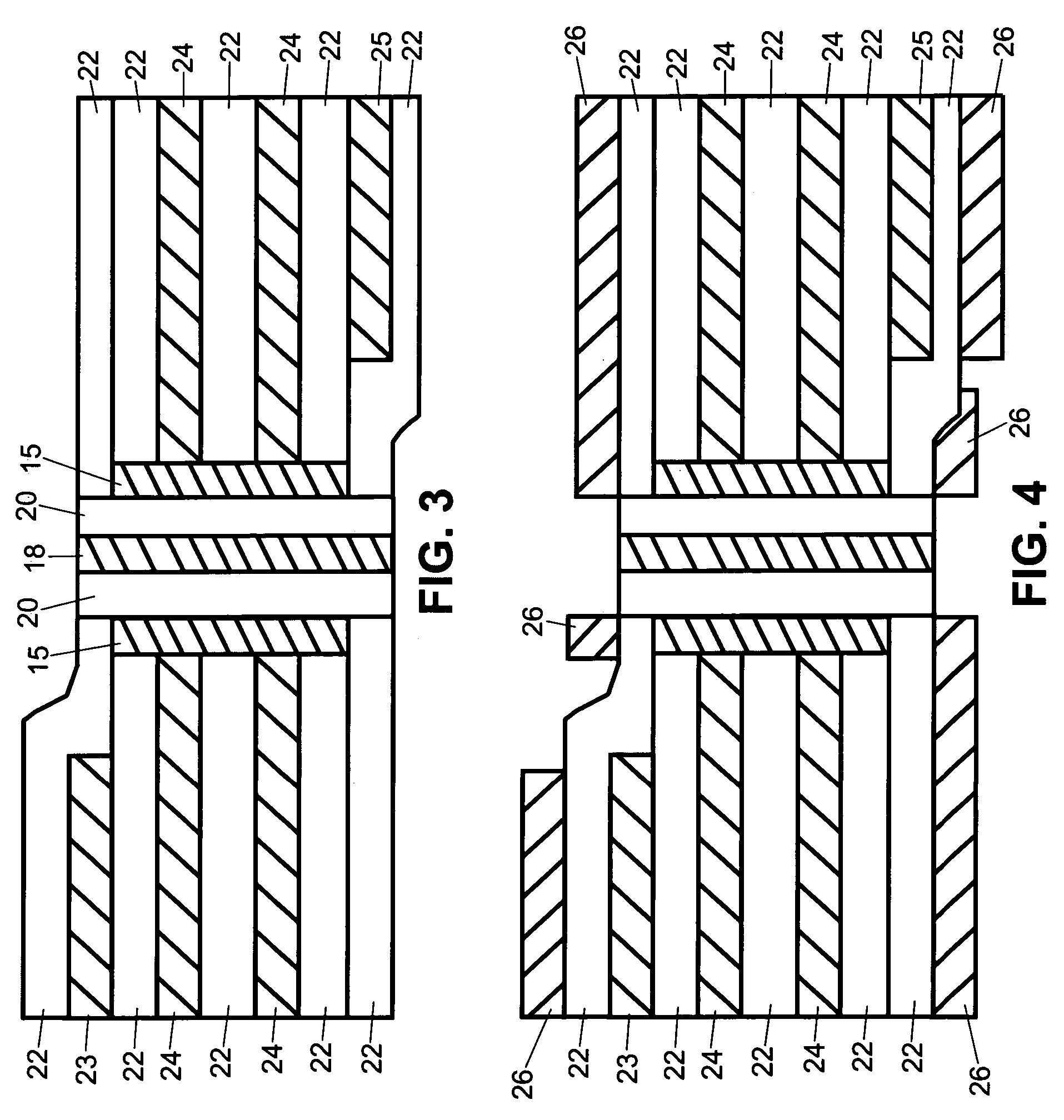

Coaxial via in PCB for high-speed signaling designs

ActiveUS20070124930A1Printed circuit assemblingPrinted circuit aspectsEngineeringConductive materials

A method of fabricating a printed circuit board having a coaxial via is disclosed. The method includes assembling a plurality of layers configured in a stack so that the plurality of layers has a top signal layer and a bottom signal layer; forming a hollow via through the plurality of layers to connect GND layers in the printed circuit board, forming or inserting into the hollow via a conductor coated with non-conductive material, covering the top layer and bottom layer with dielectric and patterned signal layers, covering the top layer and bottom layer with a masking agent, plating the top layer and bottom layer with a conductive material that connects signal traces within via, and removing the masking agent from the top layer and bottom layer.

Owner:CISCO TECH INC

Liquid compositions of calcium acetate

ActiveUS20080021104A1Patient compliance is goodLess side effectsBiocideOrganic chemistryAcetic acidAqueous solution

The invention relates to an aqueous liquid composition of calcium acetate, sweetener, and taste masking agent. Also provided is a method for binding phosphorus within the gastrointestinal tract of an individual by administering to the individual an aqueous solution of at least calcium acetate.

Owner:LYNE LAB

Animal litter containing activated carbon

Disclosed herein is the use of activated carbon in amounts as low as 0.03% by wt. to control odor combined with a color-masking agent in traditional litter compositions. Powdered activated carbon (PAC) having a mean particle diameter less than 500 μm is preferred. The color-masking agent and activated carbon can be incorporated into the litter composition by dry blending, agglomeration or spray coating.

Owner:THE CLOROX CO

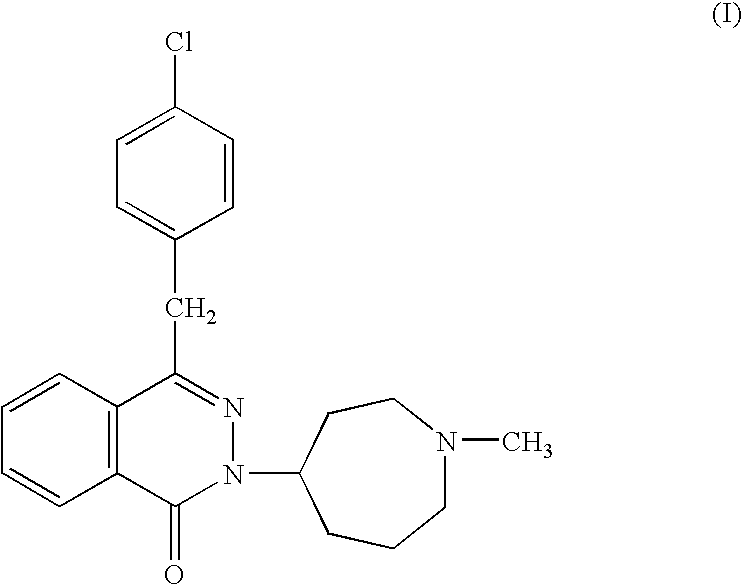

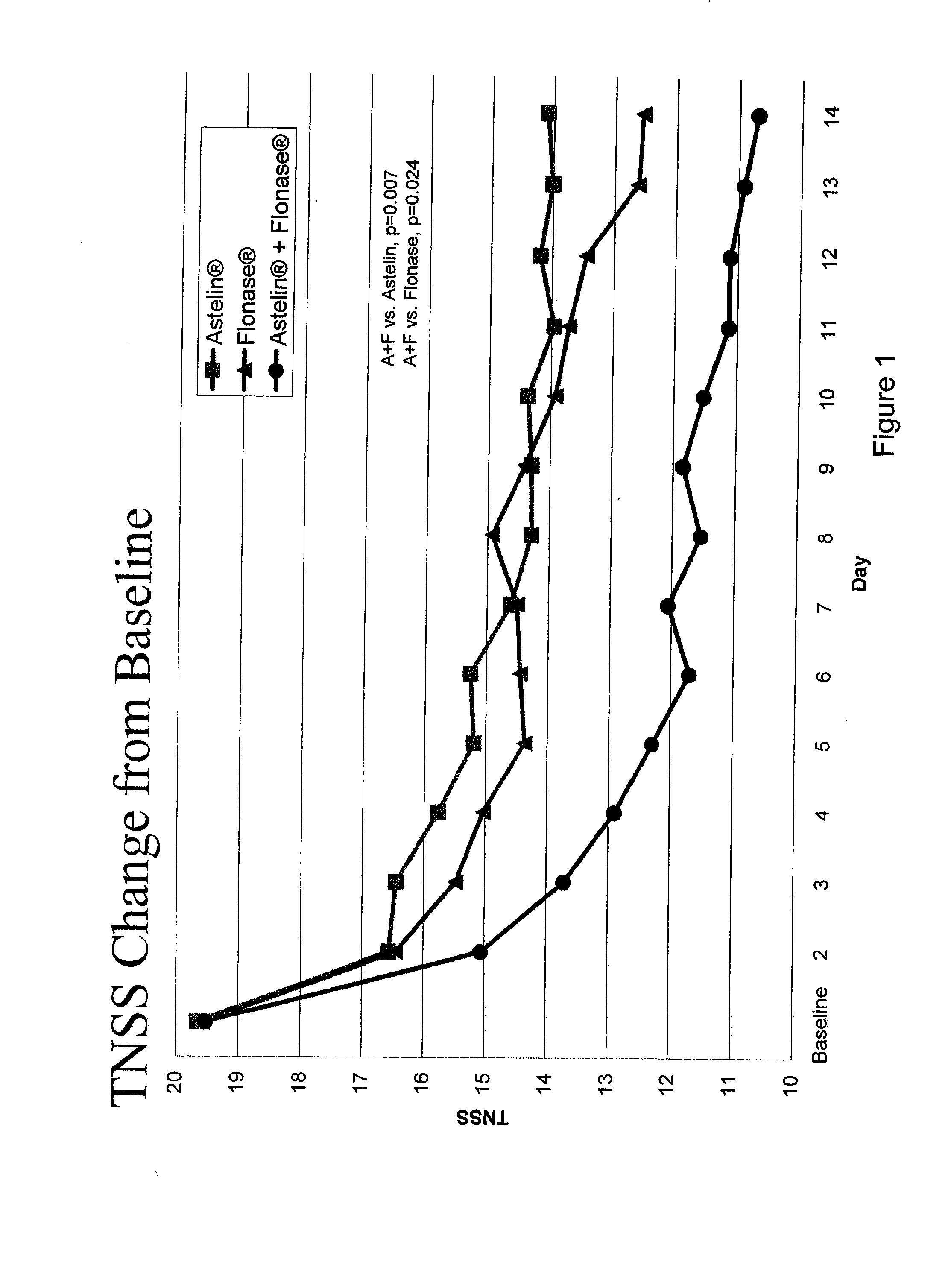

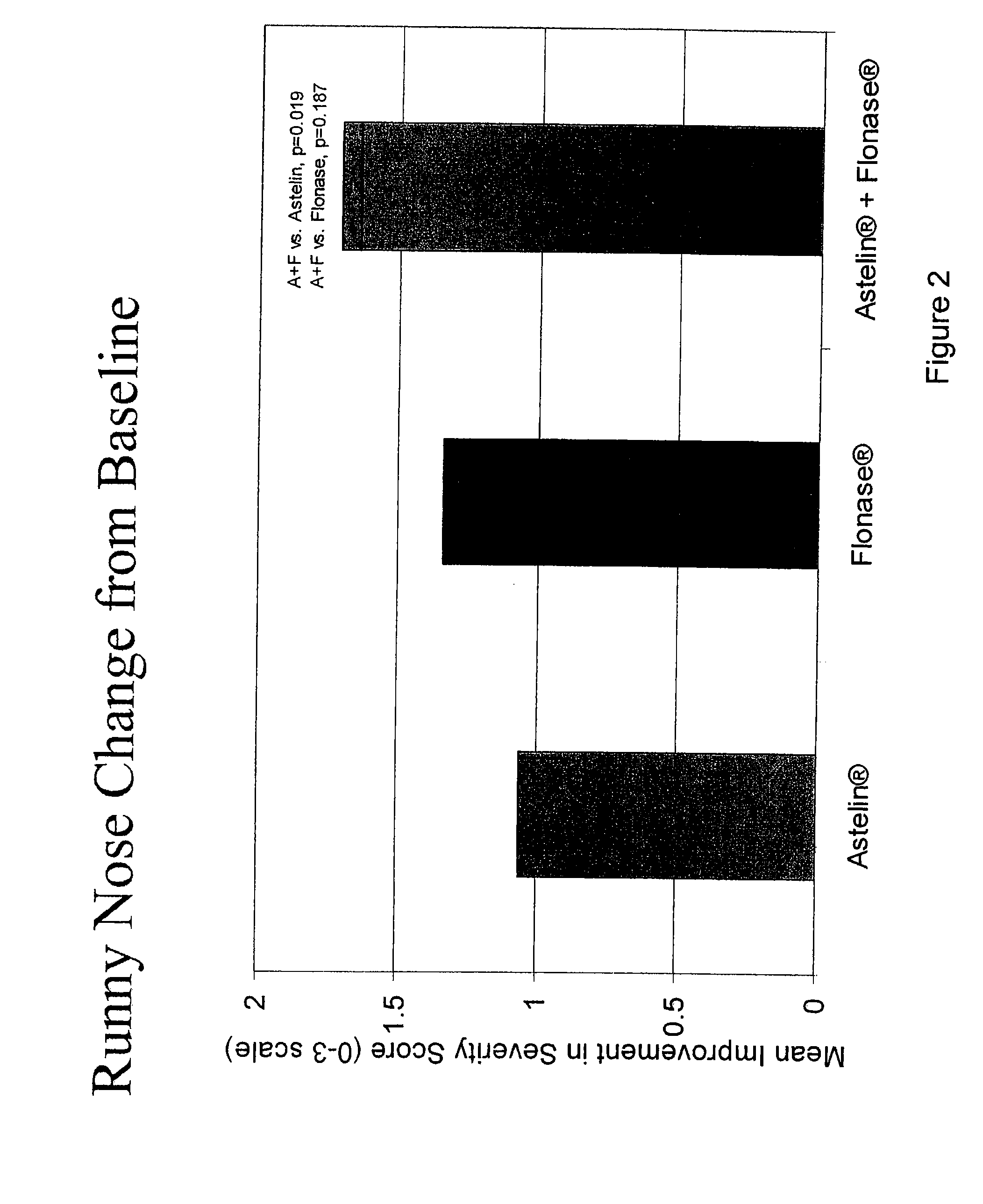

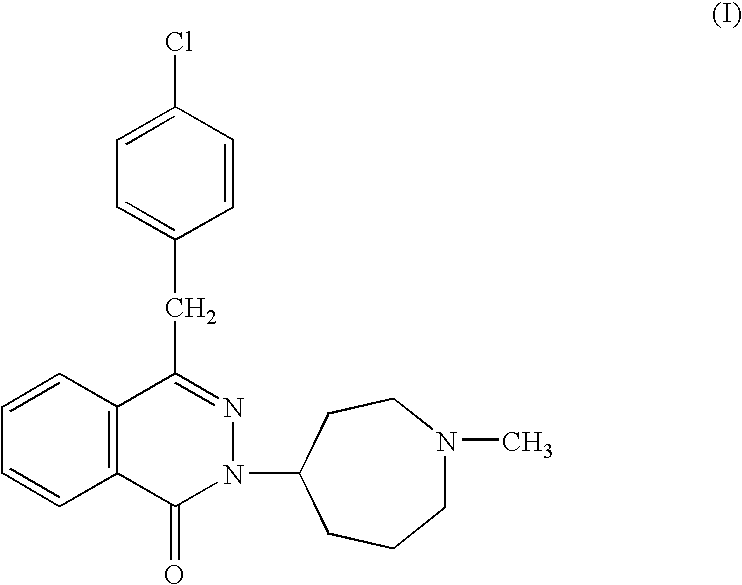

Compositions comprising azelastine and methods of use thereof

The present invention provides pharmaceutical compositions comprising azelastine, or a pharmaceutically acceptable salt or ester thereof including azelastine hydrochloride, and optionally one or more additional active agents. Preferred such compositions further comprise one or more pharmaceutically acceptable carriers or excipients that reduce the amount of post-nasal drip, and / or that minimize or mask the unpleasant bitter taste associated with post-nasal drip, of the compositions into the oral cavity, upon intranasal or ocular administration of the compositions. Especially effective excipients used in the compositions of the present invention are hypromellose as a viscosity modifier and sucralose as a taste-masking agent. The invention also provides methods of treating or preventing certain disorders, or symptomatic relief therefrom, by administering the compositions of the invention to a patient, e.g., for the symptomatic relief of allergic rhinitis, non-allergic vasomotor rhinitis, allergic conjunctivitis, as well as other disorders. The compositions and methods of the present invention provide significant value in terms of patient acceptability, convenience, and compliance.

Owner:MEDA PHARMA INC

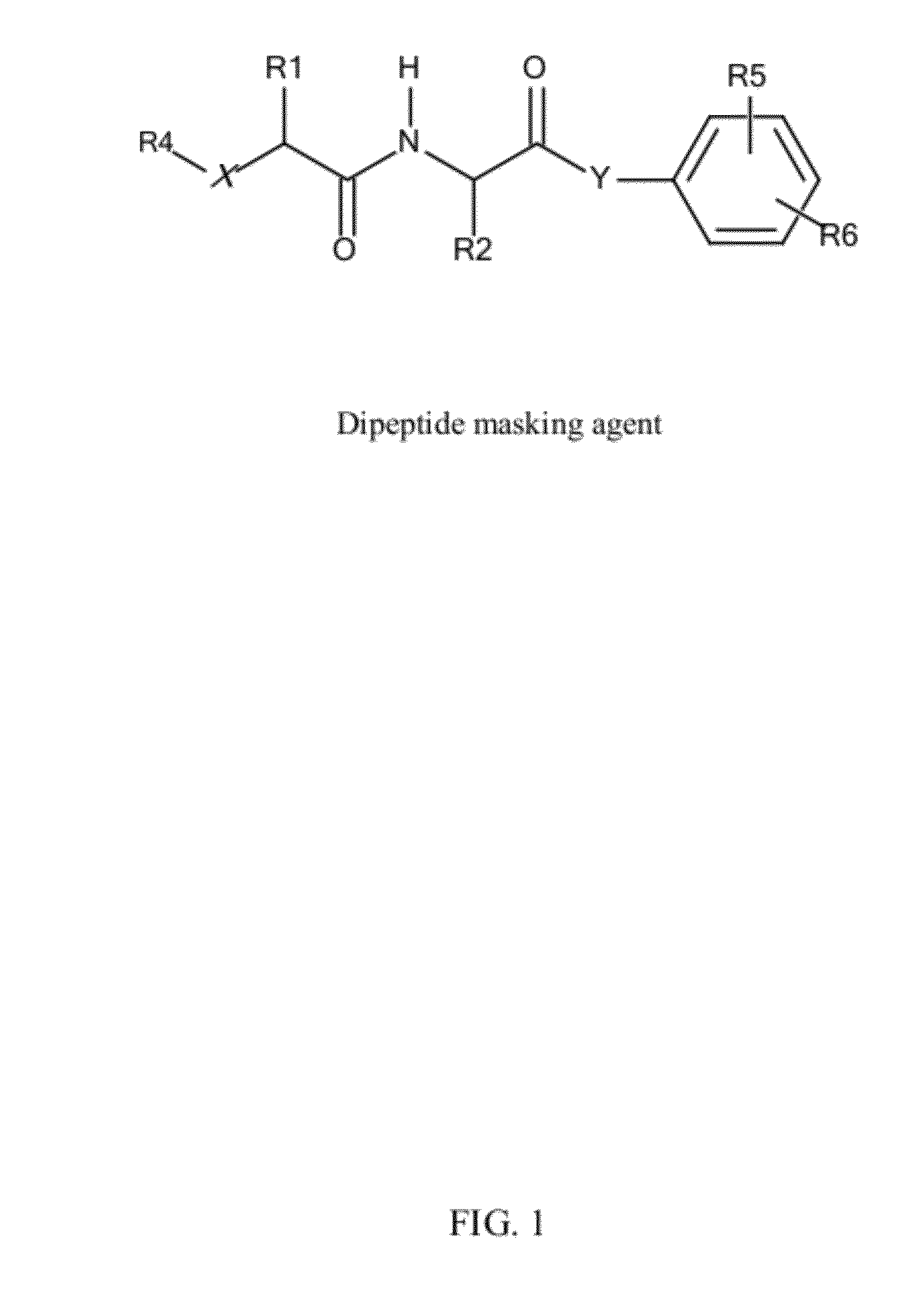

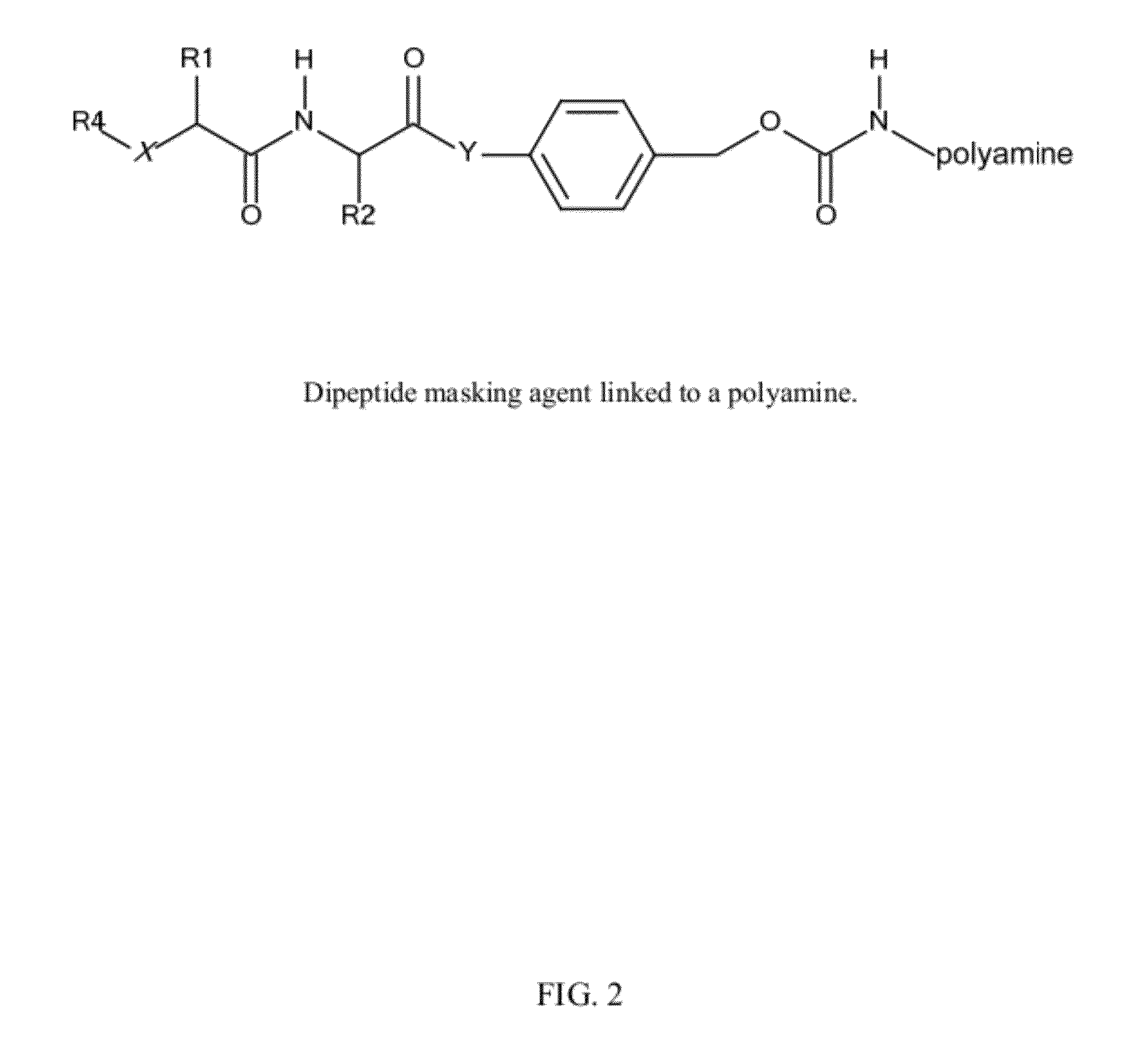

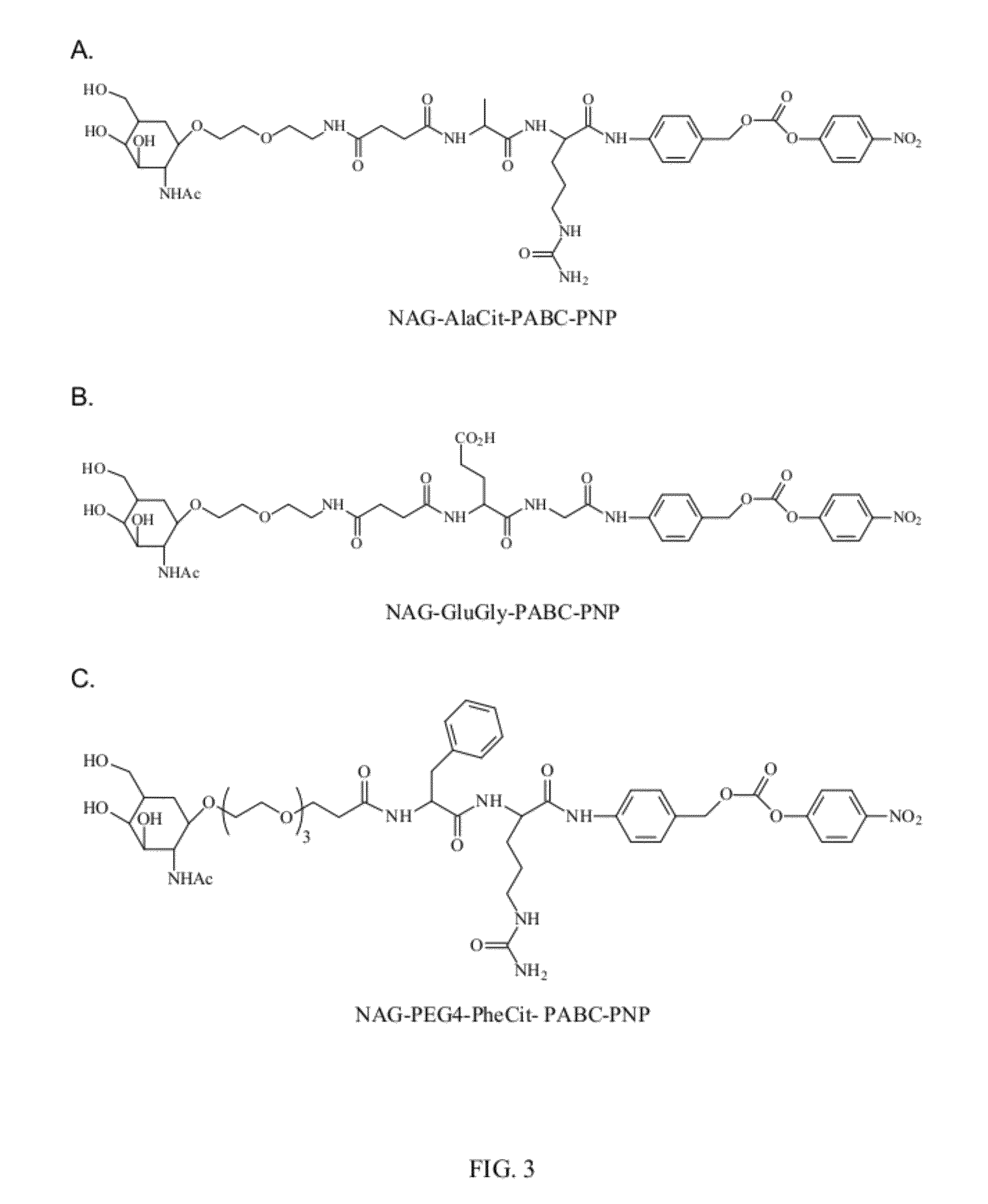

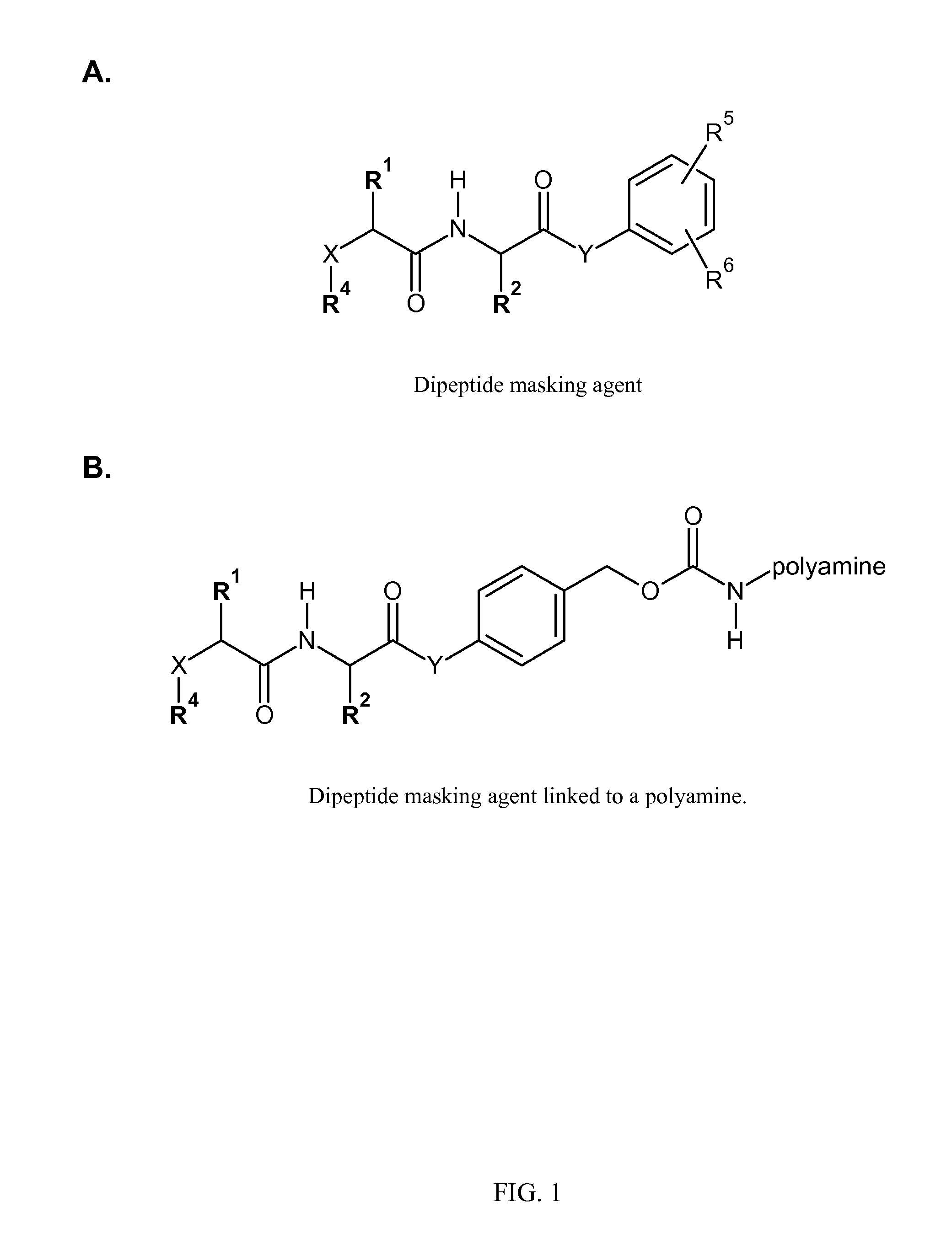

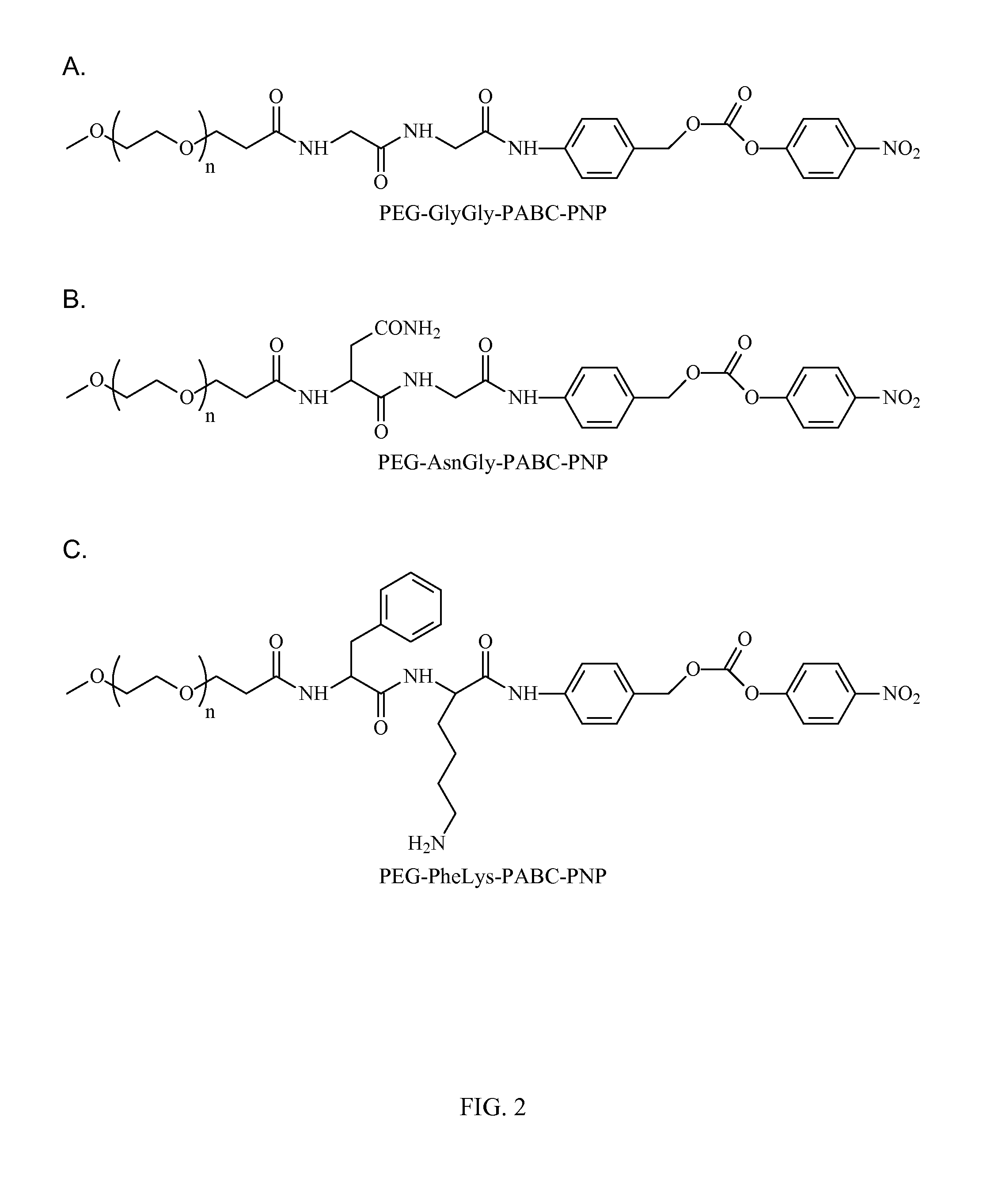

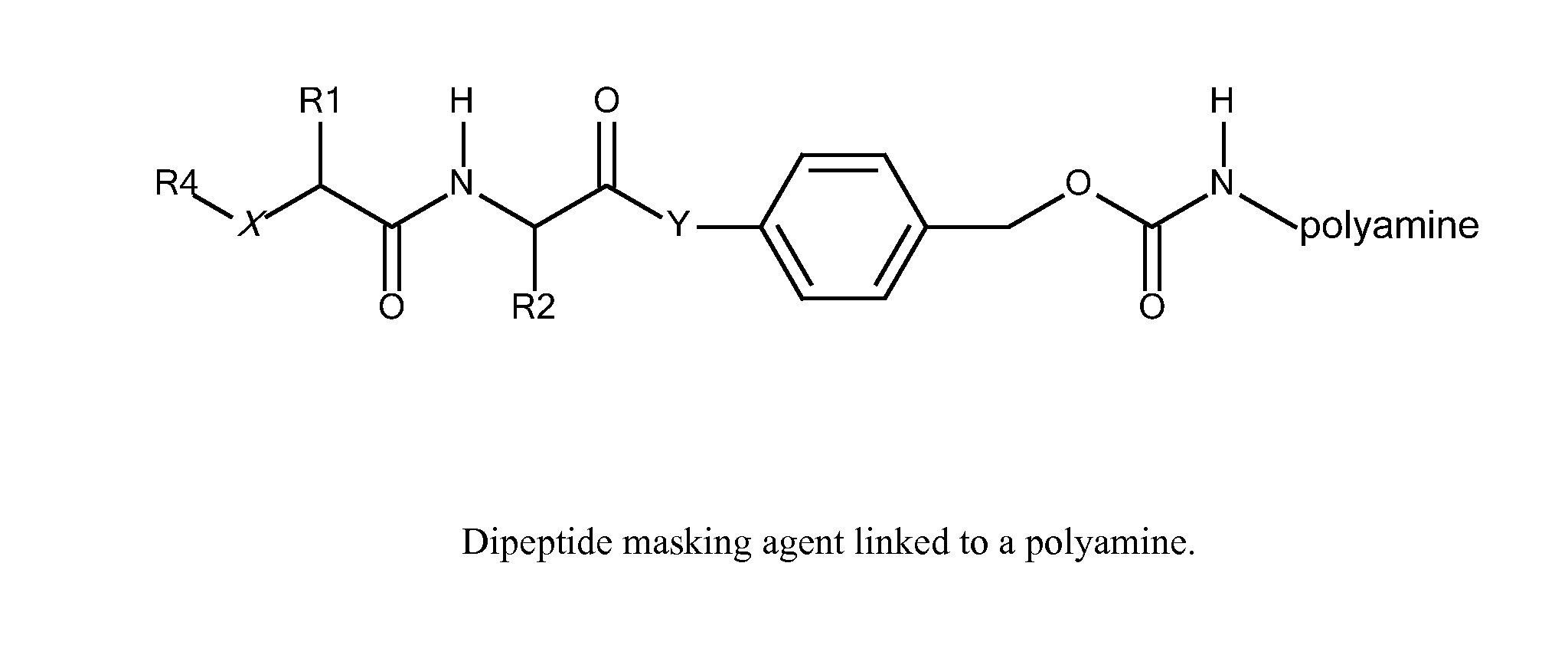

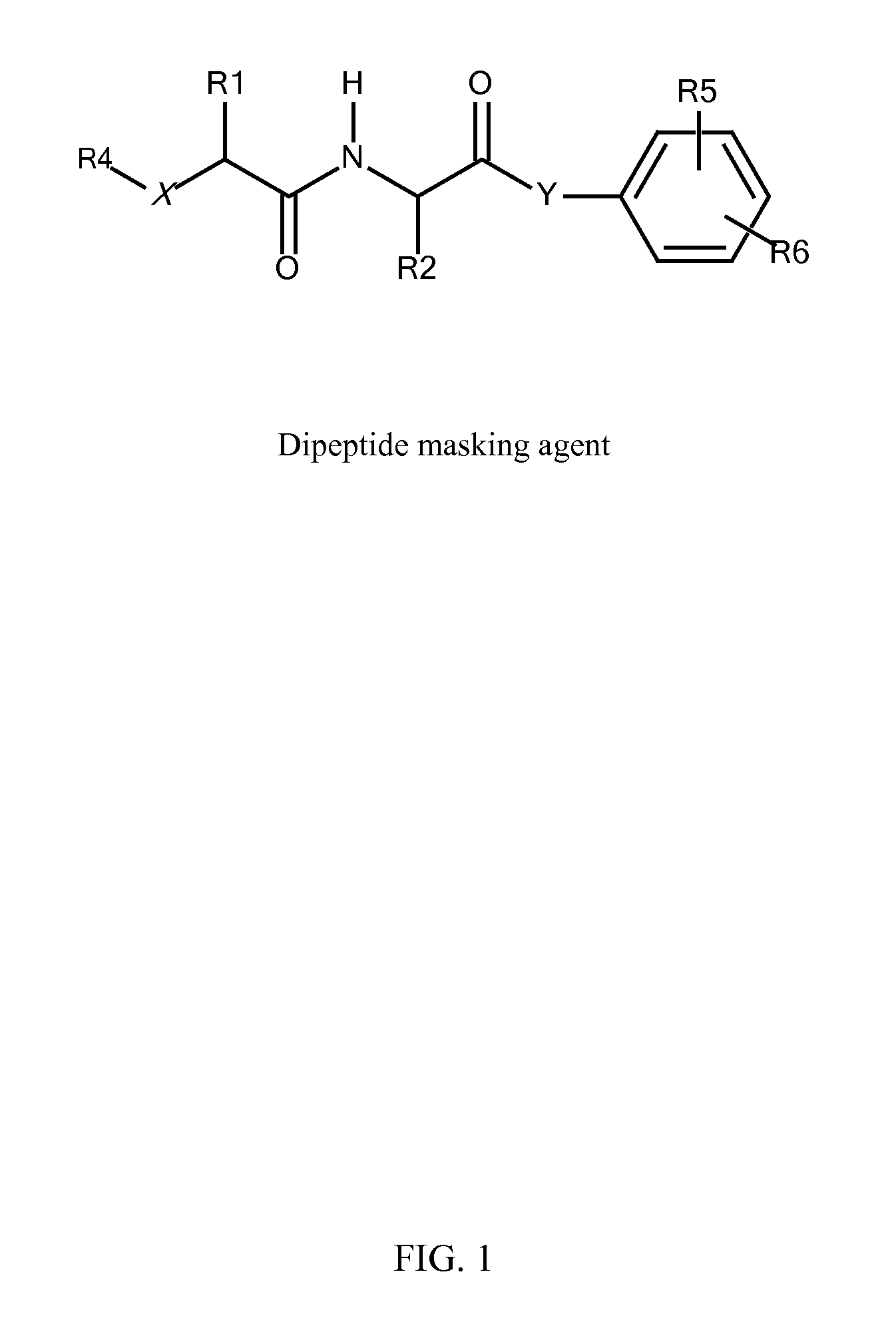

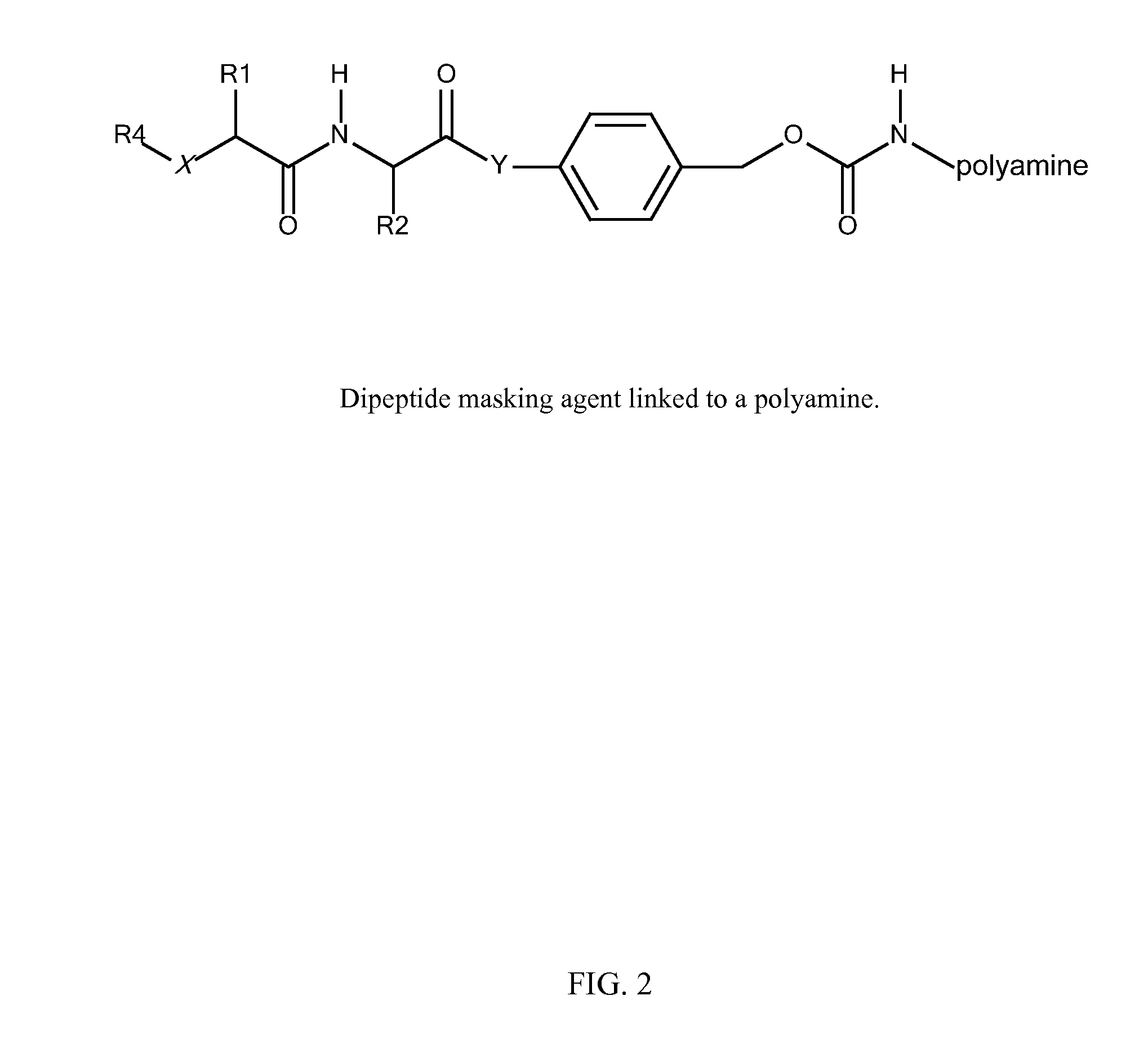

In vivo polynucleotide delivery conjugates having enzyme sensitive linkages

The present invention is directed compositions for delivery of RNA interference (RNAi) polynucleotides to cells in vivo. The compositions comprise amphipathic membrane active polyamines reversibly modified with enzyme cleavable dipeptide-amidobenzyl-carbonate masking agents. Modification masks membrane activity of the polymer while reversibility provides physiological responsiveness. The reversibly modified polyamines (dynamic polyconjugate or DPC) are further covalently linked to an RNAi polynucleotide or co-administered with a targeted RNAi polynucleotide-targeting molecule conjugate.

Owner:ARROWHEAD MADISON

Bags having odor management capabilities

ActiveUS20090067760A1Reduce odorReduce perceptionCosmetic preparationsToilet preparationsEngineeringMasking agent

Bags or liners having incorporated therein an effective amount of odor management agents including a counteractant agent, a neutralizing agent and optionally, a masking agent, whereby the odor management agent imparts no perceptible scent to the bags or liners, such that the bags or liners are substantially free of fragrance while the odor management agent reduces malodor emanating from products disposed within the bag. Further, the invention is drawn to web materials for use in forming the bags or liners having odor management agents. The odor management agent is disposed within the bag or dispersed substantially uniformly throughout the web.

Owner:REYNOLDS CONSUMER PROD INC

Tobacco smoke filter elements

InactiveUS20040074507A1Stay rigidAvoid absorptionCigar manufactureTobacco smoke filtersEngineeringTobacco smoke

This invention relates to the provision in a cigarette filter element of a capsule containing a deodoriser. The capsule is resistant to the handling endured before and during smoking, yet ruptures to release or expose the deodoriser upon extinguishing of the smoked cigarette. The deodoriser may comprise neutralising or masking agents, or mixtures of both.

Owner:BRITISH AMERICAN TOBACCO (INVESTMENTS) LTD

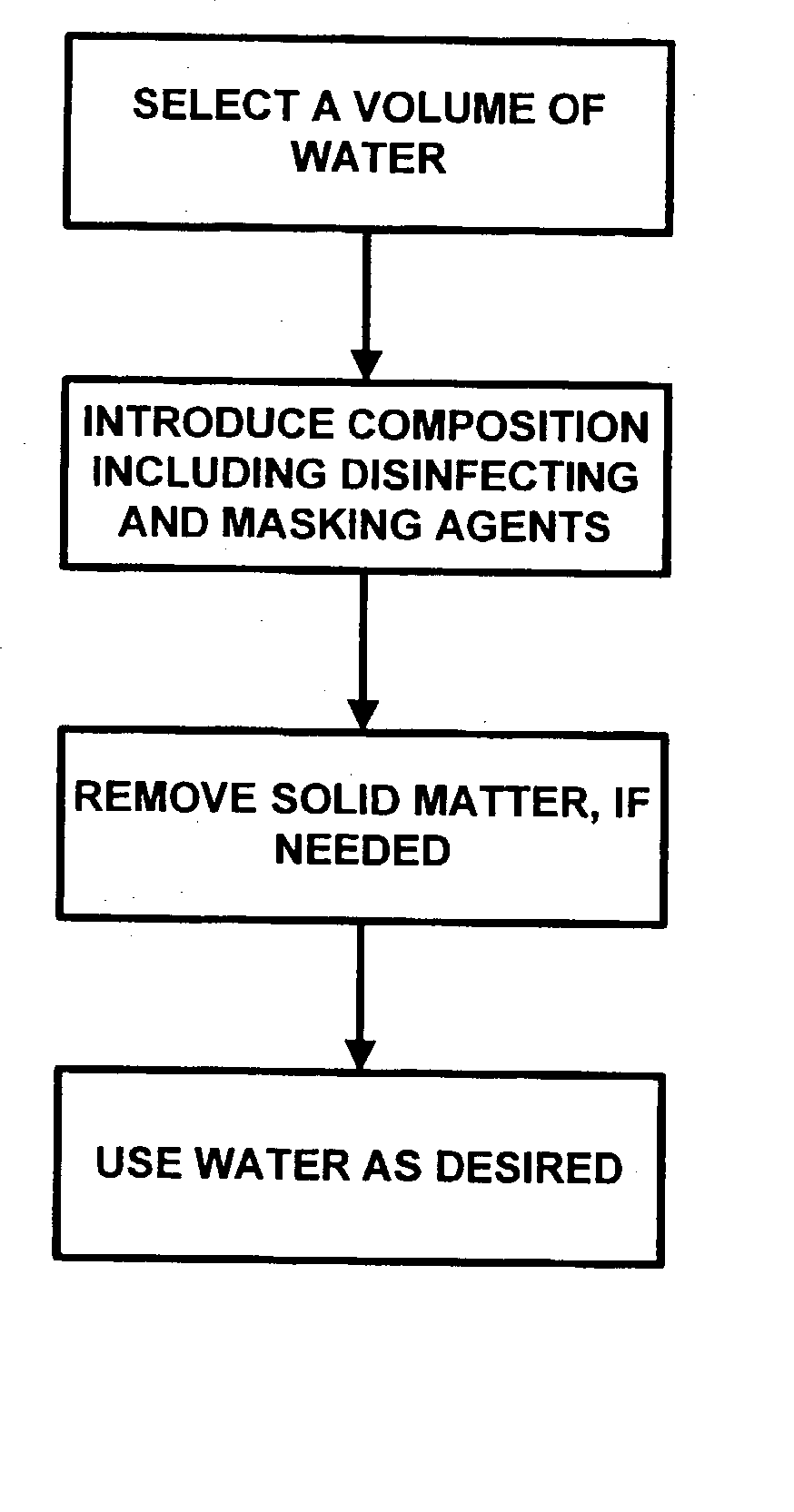

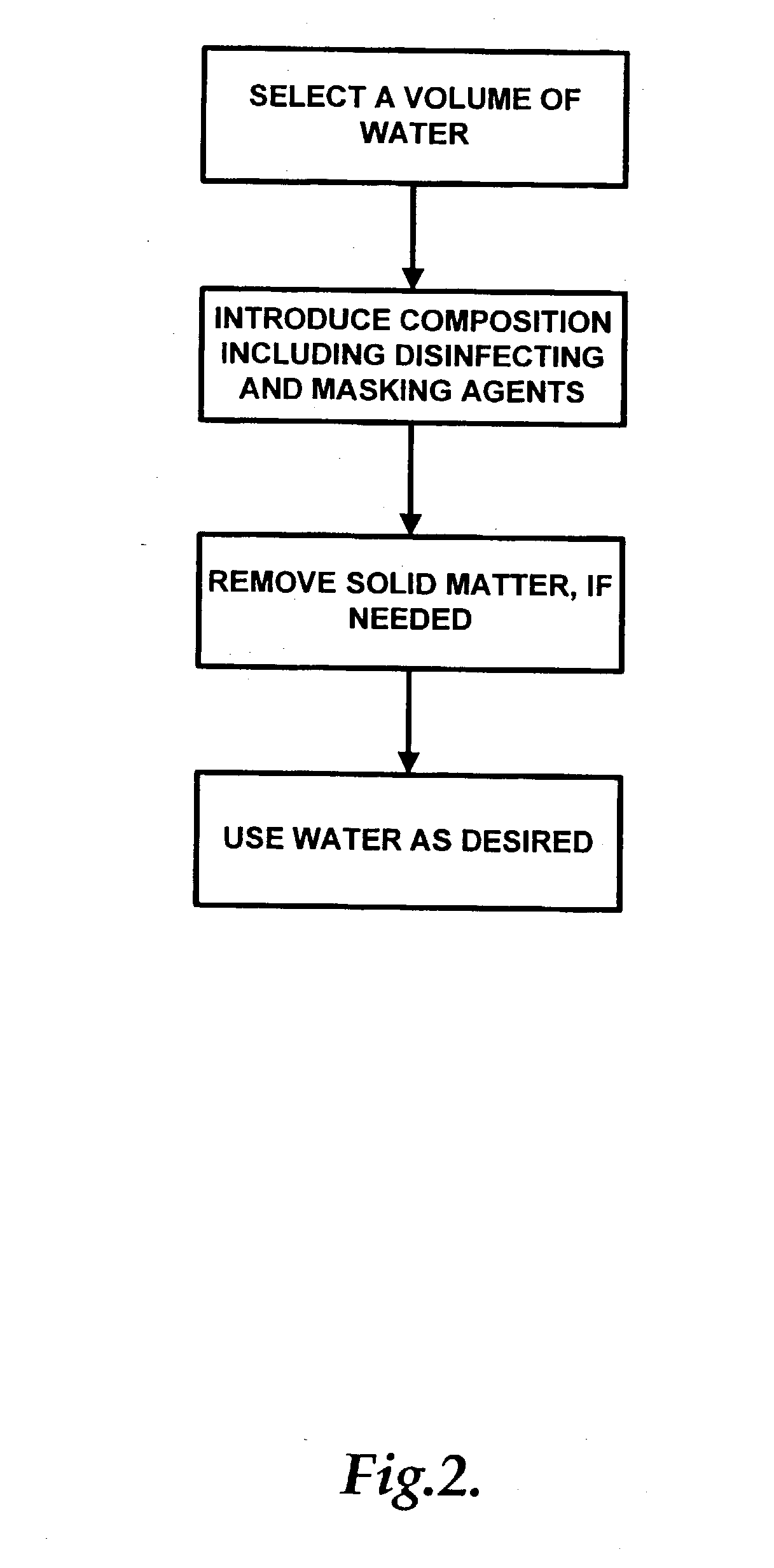

Water treatment compositions with masking agent

A composition for disinfecting contaminated drinking water. The composition can include a disinfecting agent for disinfecting or sanitizing the water and a masking agent for masking or minimizing undesired characteristics of the disinfecting agent, such as taste and odor. The disinfecting agent can be a halogen-based disinfecting agent, such as a chlorine-based disinfecting agent. The masking agent can be a chlorine-compatible masking agent or flavorant, such as a citrus fruit derived flavor. The composition can also include a substrate. The substrate can be a clay, zeolite, water-soluble carrier, water-insoluble carrier, or mixtures thereof. The flavorant can be loaded onto the substrate. The composition can include other components, such as a primary coagulant, a coagulant aid, a bridging flocculant, a polymeric material, an alkali agent, an autocatalytic oxidant, and mixtures thereof.

Owner:THE PROCTER & GAMBLE COMPANY

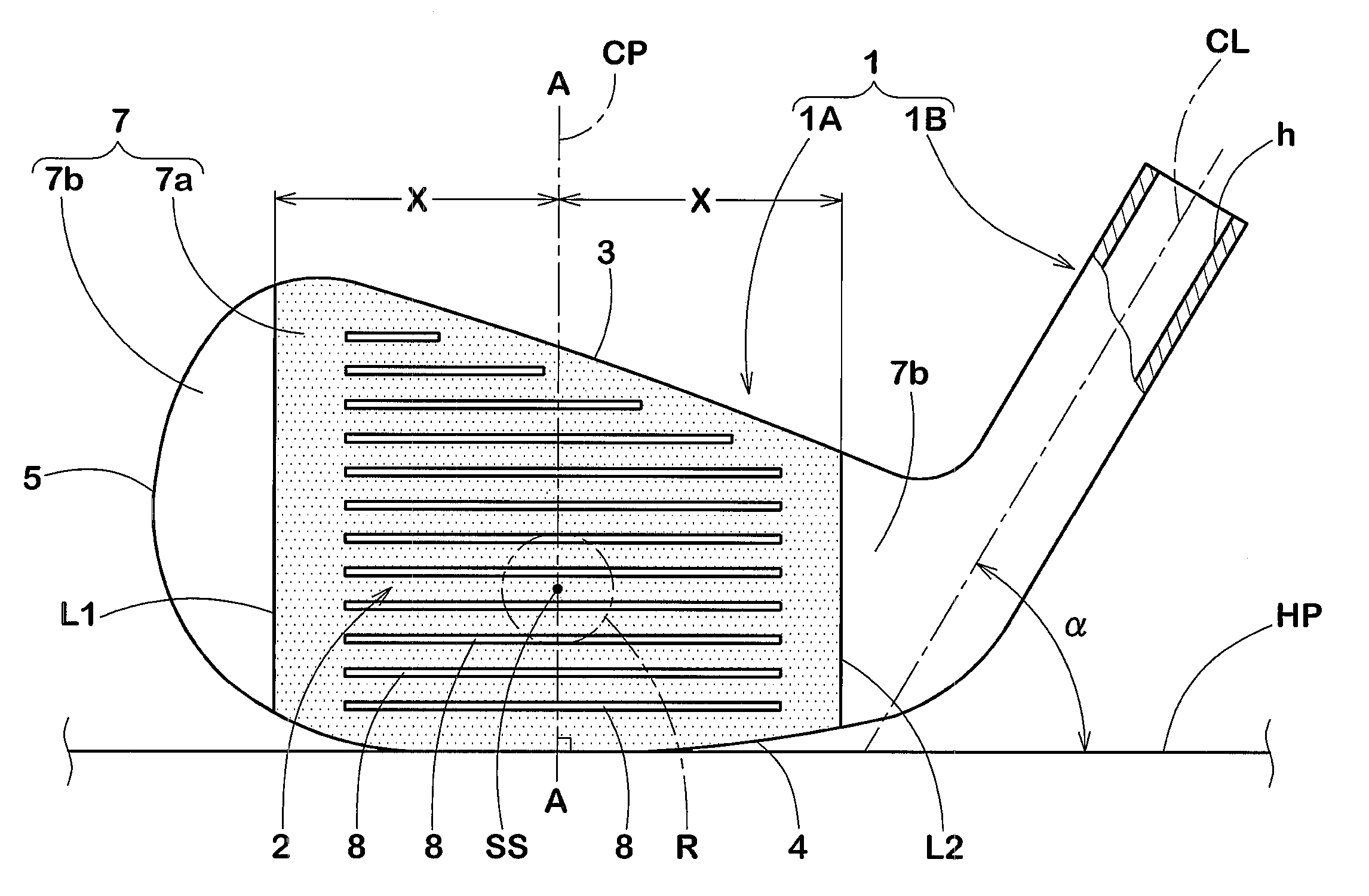

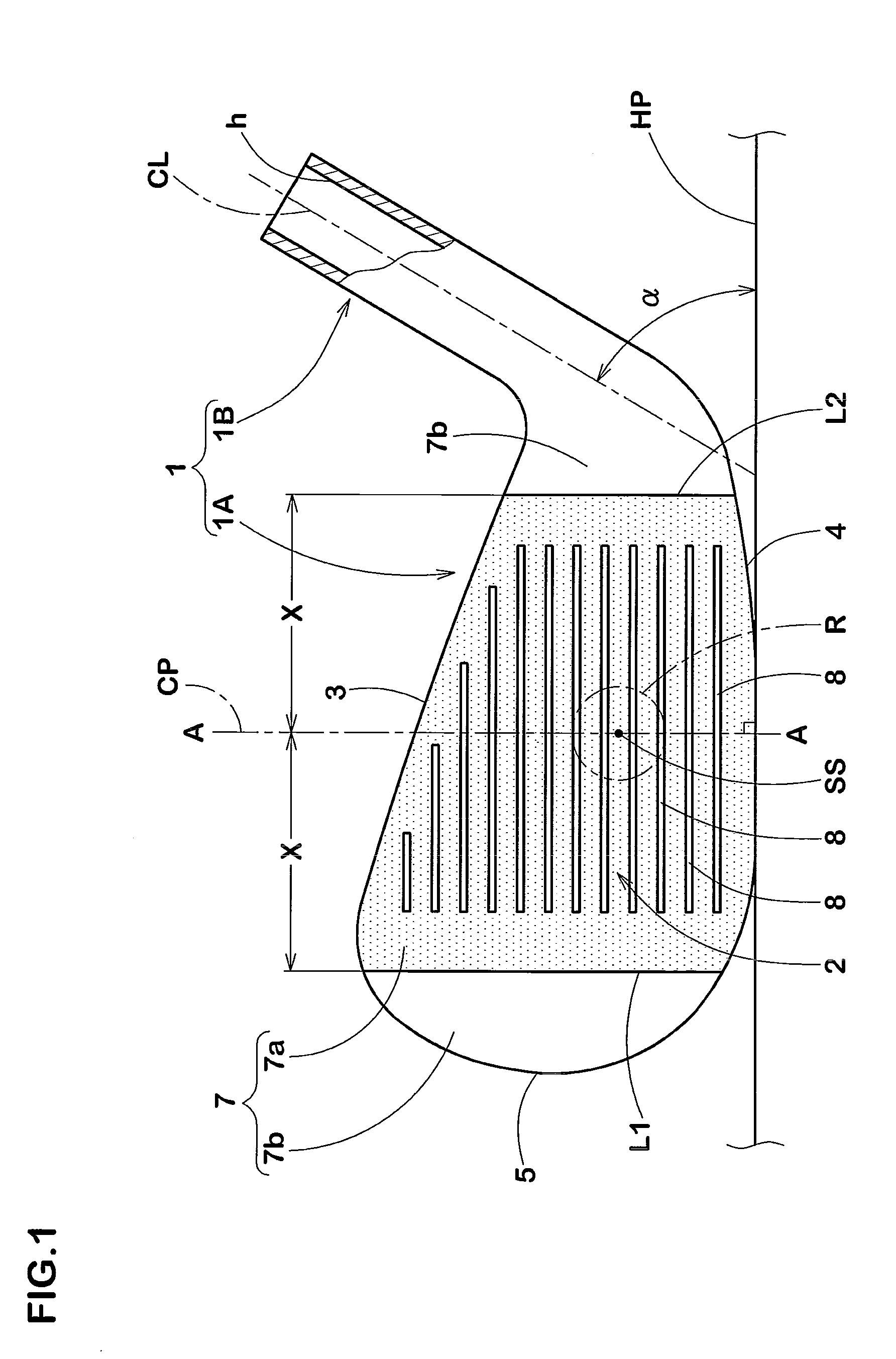

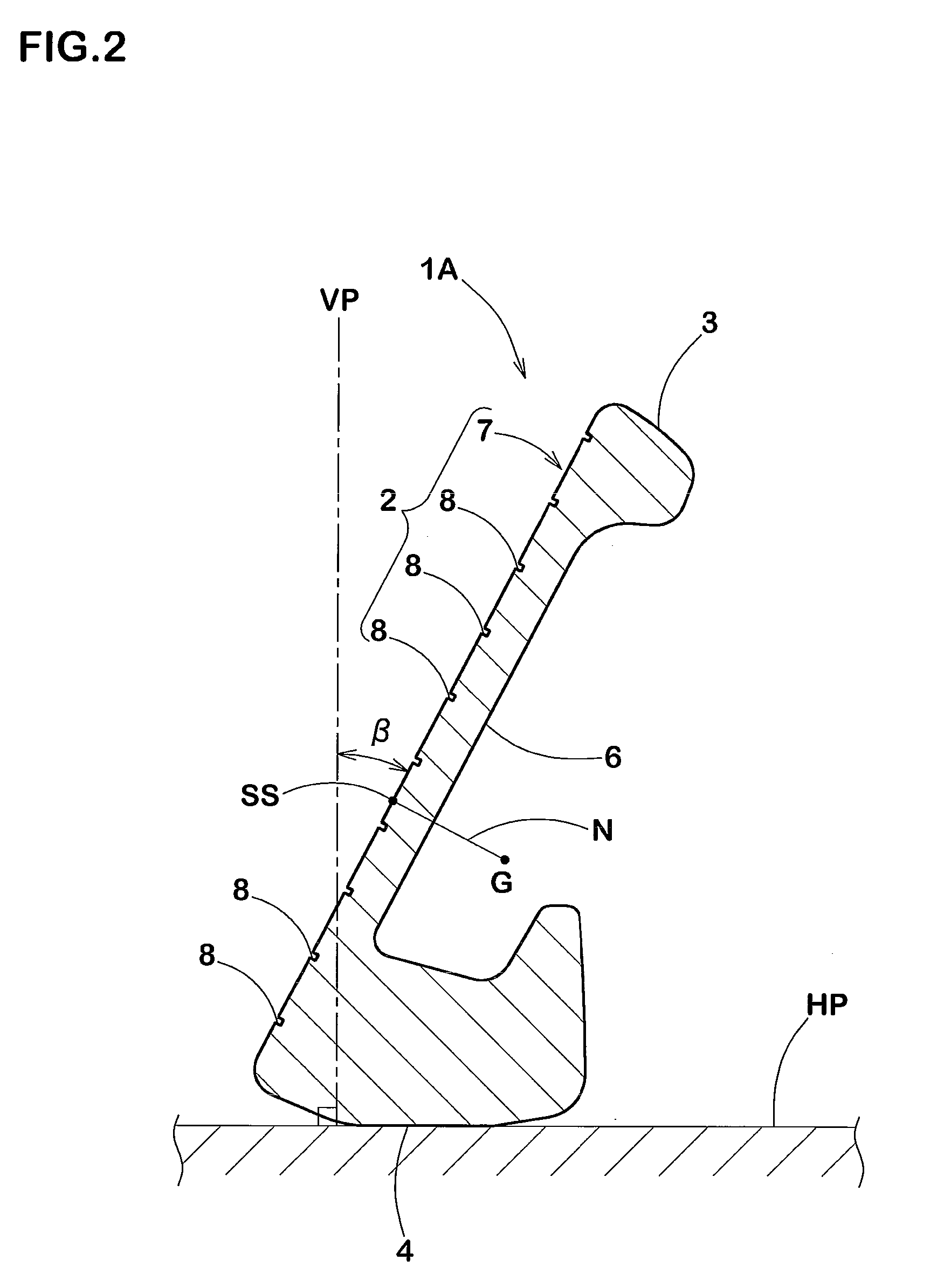

Golf club head and method for manufacturing the same

ActiveUS20100113180A1Stable backspinAvoid insufficient frictionMetal rolling stand detailsMetal working apparatusMicrometerSurface roughness

Owner:SUMITOMO RUBBER IND LTD

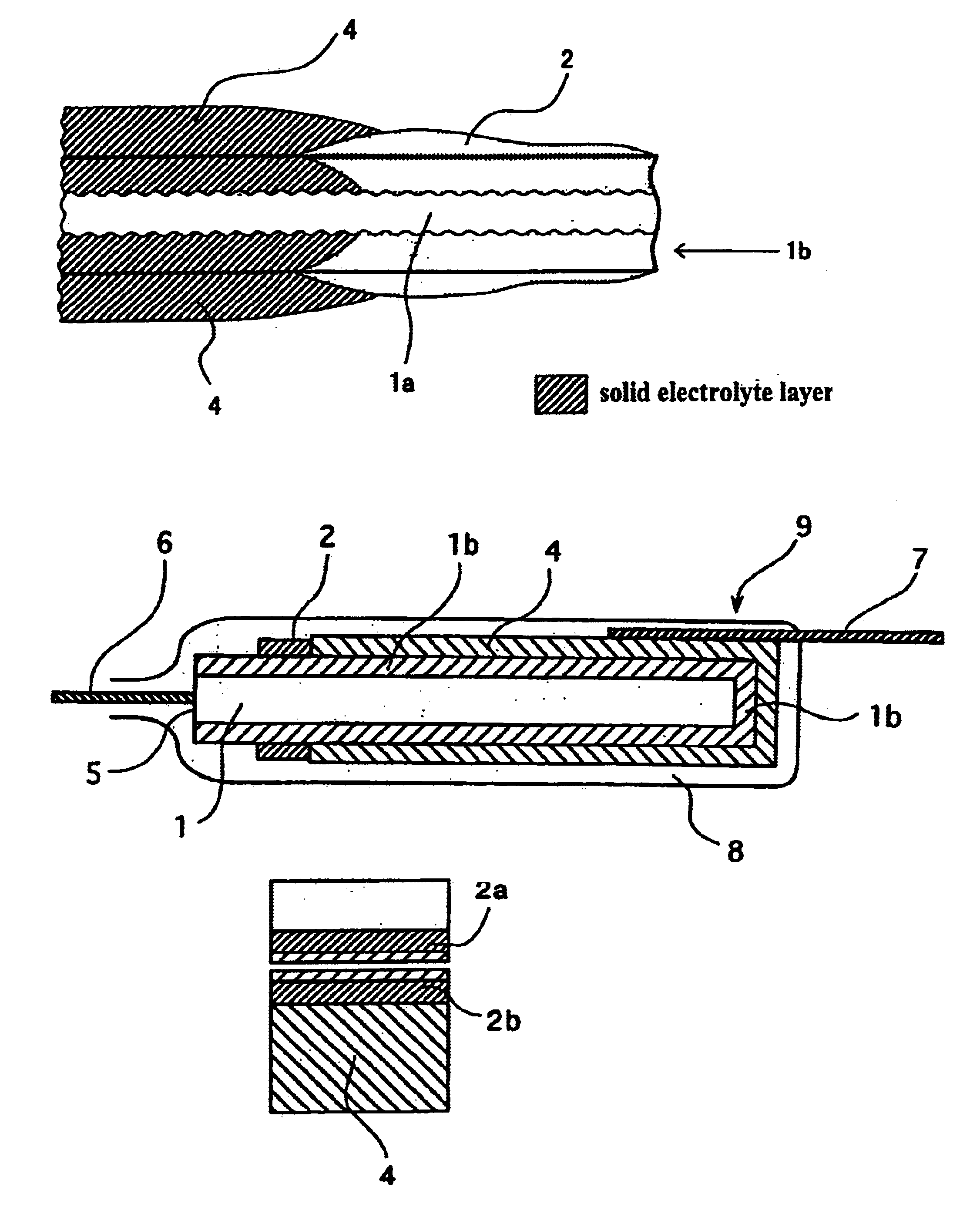

Solid electrolytic capacitor and method for producing the same

InactiveUS6890363B1Efficient executionImprove leakage currentHybrid capacitor electrolytesSolid electrolytic capacitorsElectrolysisMetallic materials

The present invention relates to a solid electrolytic capacitor having a masking structure in which the insulation between the anode part and the cathode part can be ensured without fail, to its production method, to a method for coating a masking agent on a solid electrolytic capacitor substrate, and to an apparatus therefor. According to the present invention, the masking material covers the dielectric film on the metal material having valve action and sufficiently infiltrates into the core metal made of a metal having valve action while the solid electrolyte is masked by the masking material without fail, so that a solid electrolytic capacitor can be produced that has a reduced leakage current and a reduced stress generated at the reflow treatment or the like.

Owner:MURATA MFG CO LTD

Particle formation methods and their products

Preparation of particles of an active substance having a layer of an additive at the particle surfaces, by dissolving both the active substance and the additive in a vehicle to form a target solution, and contacting the target solution with an anti-solvent fluid using a SEDS(TM) particle formation process, to cause the active substance and additive to coprecipitate. The additive is typically a protective additive, in particular a taste and / or odour masking agent. Also provided is a particulate coformulation made by the method, which has a finite gradient in the relative additive concentration, which concentration increases radially outwards from the active-rich core to the additive-rich surface of the particles.

Owner:NEKTAR THERAPEUTICS INC

Polyconjugates for Delivery of RNAi triggers to Tumor Cells In Vivo

ActiveUS20150045573A1Beneficial level of expressionEffective amountOrganic active ingredientsSpecial deliveryDipeptideIn vivo

The present invention is directed compositions for delivery of RNA interference (RNAi) triggers to integrin positive tumor cells in vivo. The compositions comprise RGD ligand-targeted amphipathic membrane active polyamines reversibly modified with enzyme cleavable dipeptide-amidobenzyl-carbonate masking agents. Modification masks membrane activity of the polymer while reversibility provides physiological responsiveness. The reversibly modified polyamines (dynamic polyconjugate or conjugate) are further covalently linked to an RNAi trigger.

Owner:ARROWHEAD MADISON

Compositions Comprising Azelastine and Methods of Use Thereof

The present invention provides pharmaceutical compositions comprising azelastine, or a pharmaceutically acceptable salt or ester thereof including azelastine hydrochloride, and optionally one or more additional active agents. Preferred such compositions further comprise one or more pharmaceutically acceptable carriers or excipients that reduce the amount of post-nasal drip, and / or that minimize or mask the unpleasant bitter taste associated with post-nasal drip, of the compositions into the oral cavity, upon intranasal or ocular administration of the compositions. Especially effective excipients used in the compositions of the present invention are hypromellose as a viscosity modifier and sucralose as a taste-masking agent. The invention also generally relates to pharmaceutical compositions comprising one or more active pharmaceutical ingredients, such as azelastine or pharmaceutically acceptable salts or esters thereof including azelastine hydrochloride, particularly wherein the compositions are provided in unit dosage form. In certain embodiments, the invention provides such unit dosage pharmaceutical compositions comprising azelastine hydrochloride formulated for use as nasal sprays and / or ocular solutions or drops. The invention also provides methods of treating or preventing certain disorders, or symptomatic relief therefrom, by administering the compositions of the invention to a patient, e.g., for the symptomatic relief of a variety of allergic and non-allergic conditions, particularly conjunctivitis, sinusitis, rhinitis and rhinosinusitis. The compositions and methods of the present invention provide significant value in terms of patient acceptability, convenience, and compliance.

Owner:MEDA PHARMA INC

Method for fabricating a printed circuit board having a coaxial via

Owner:CISCO TECH INC

Method of enhancing beverages by means of a unique microencapsulated delivery system

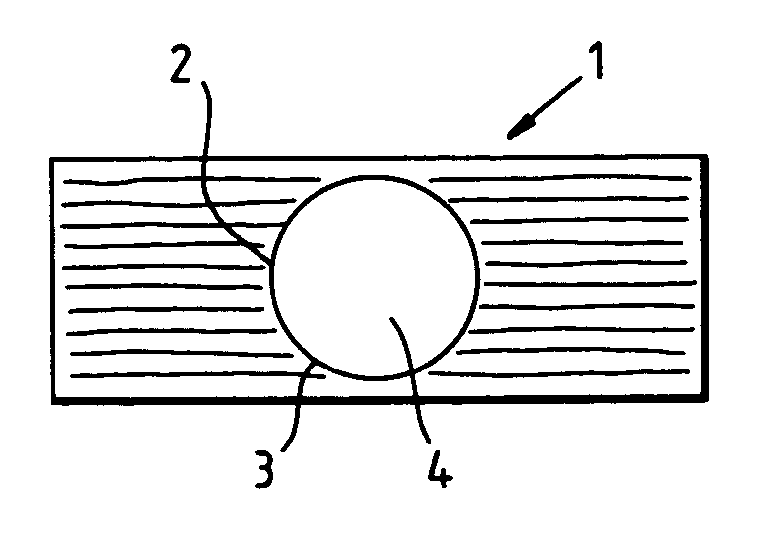

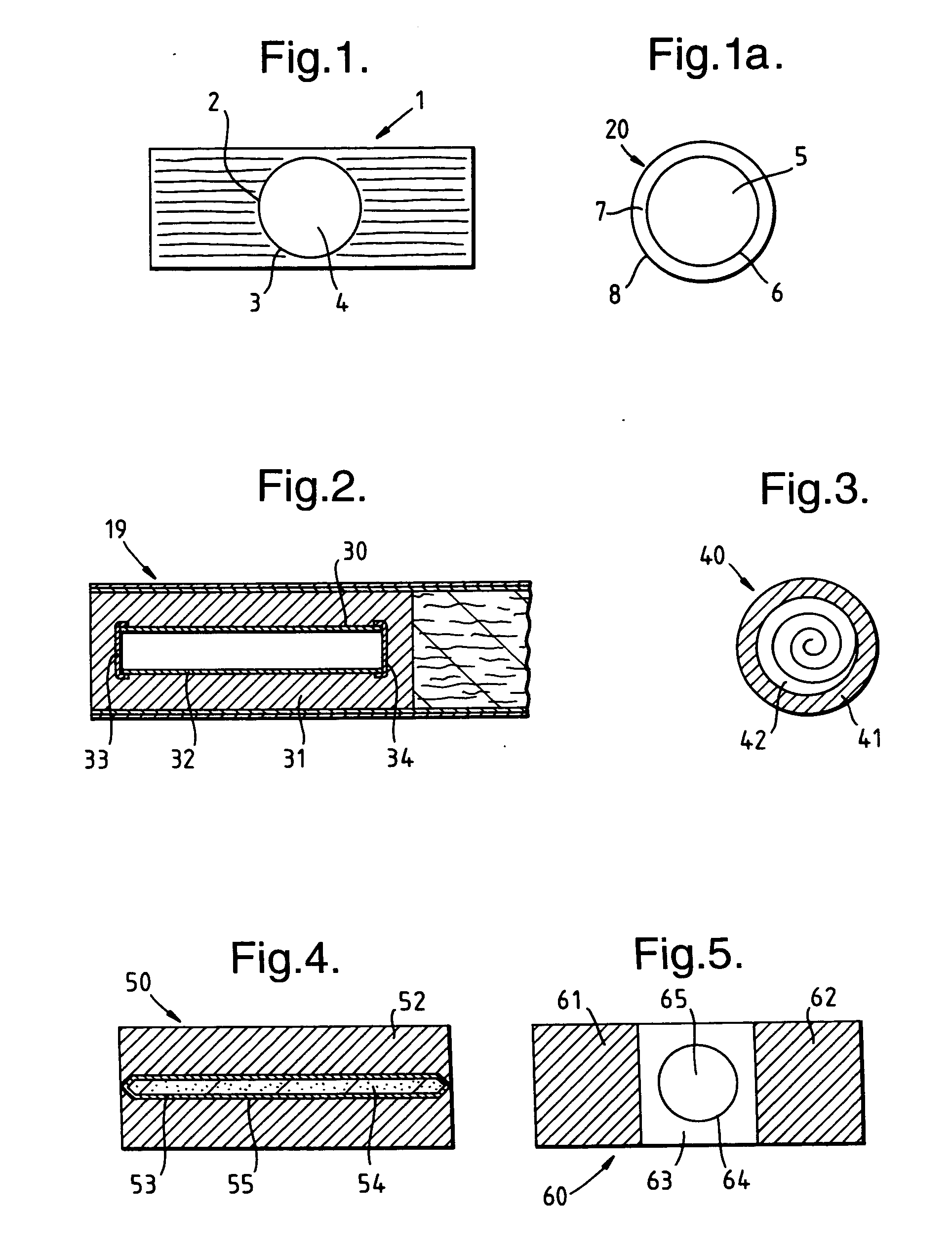

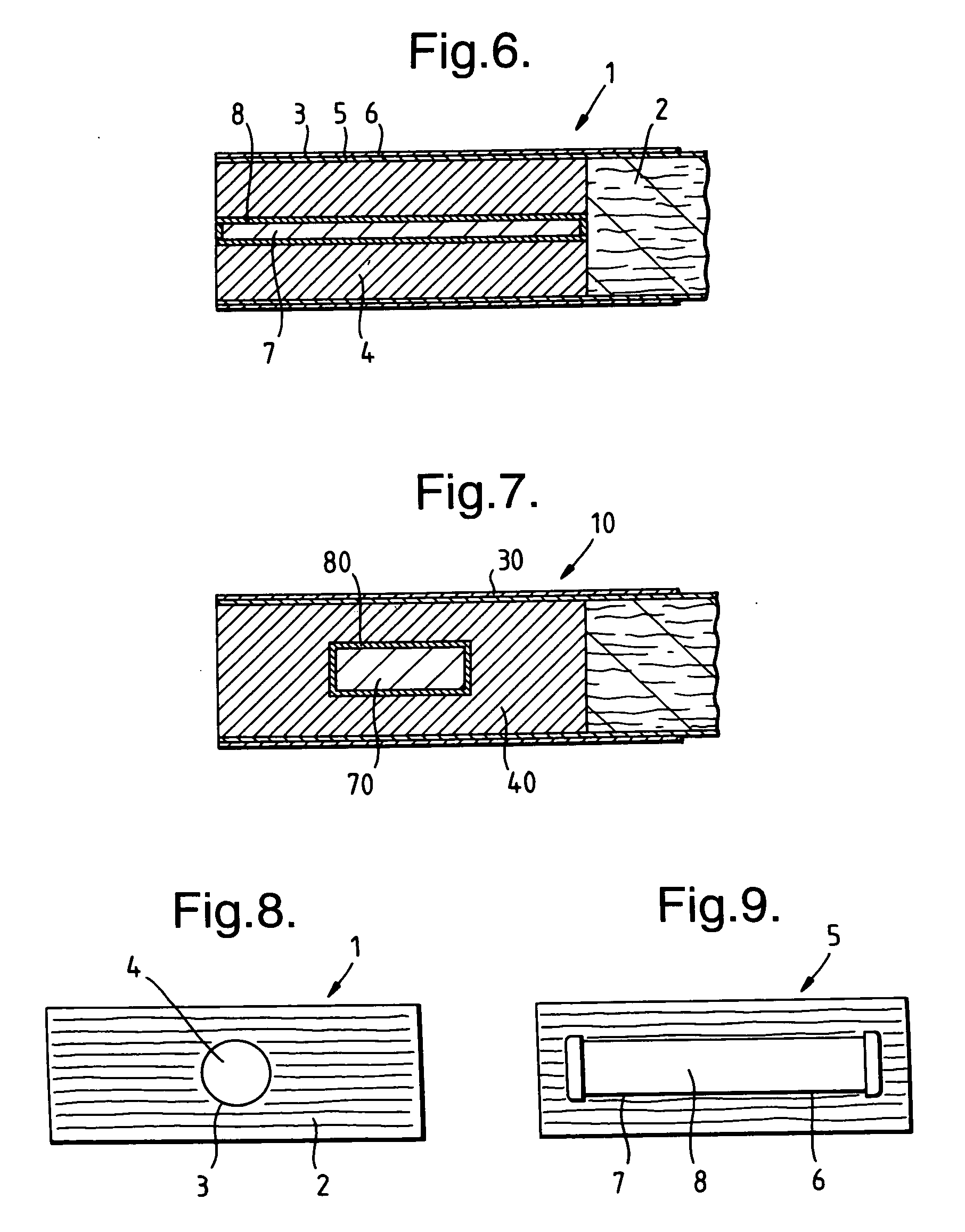

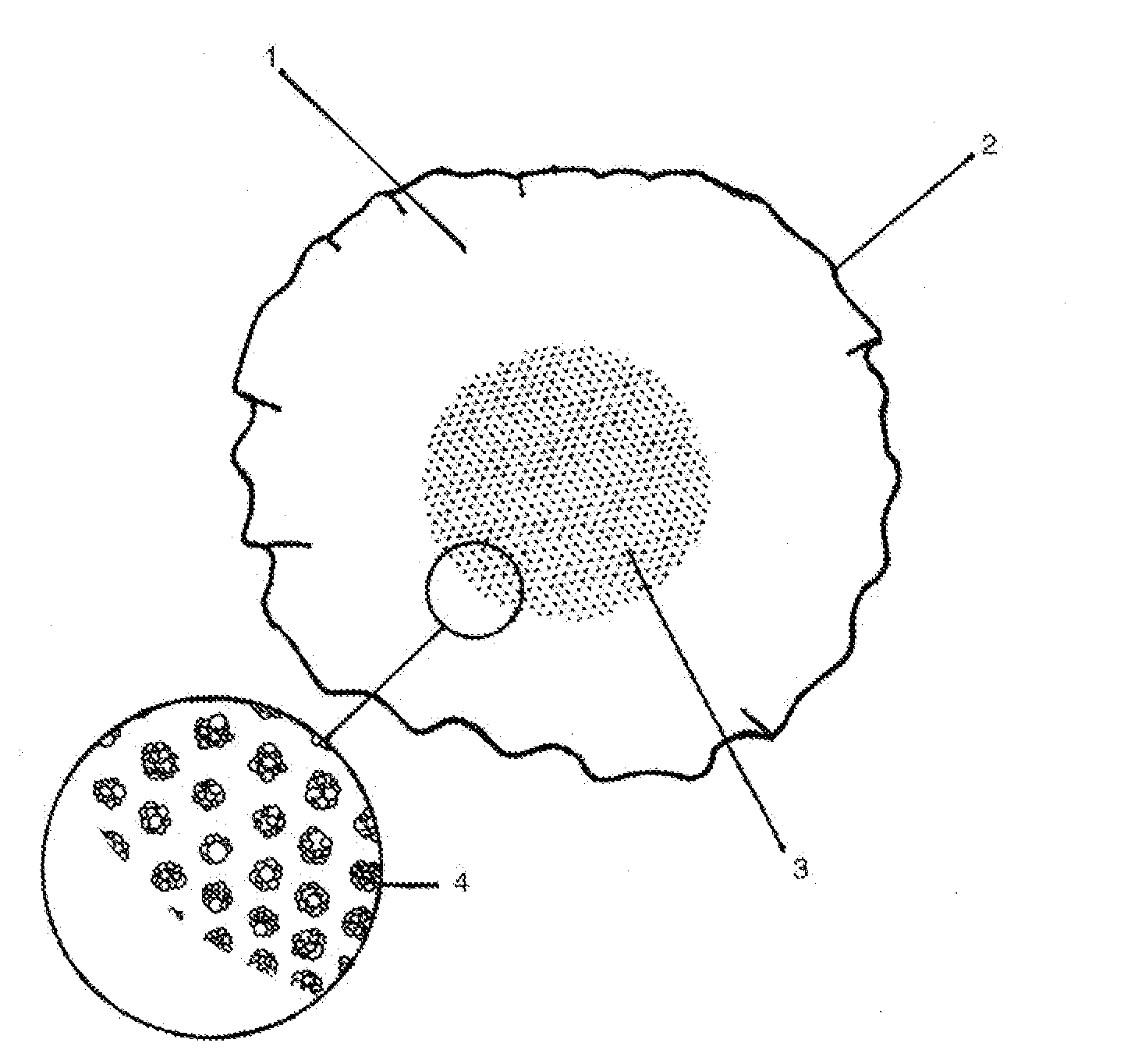

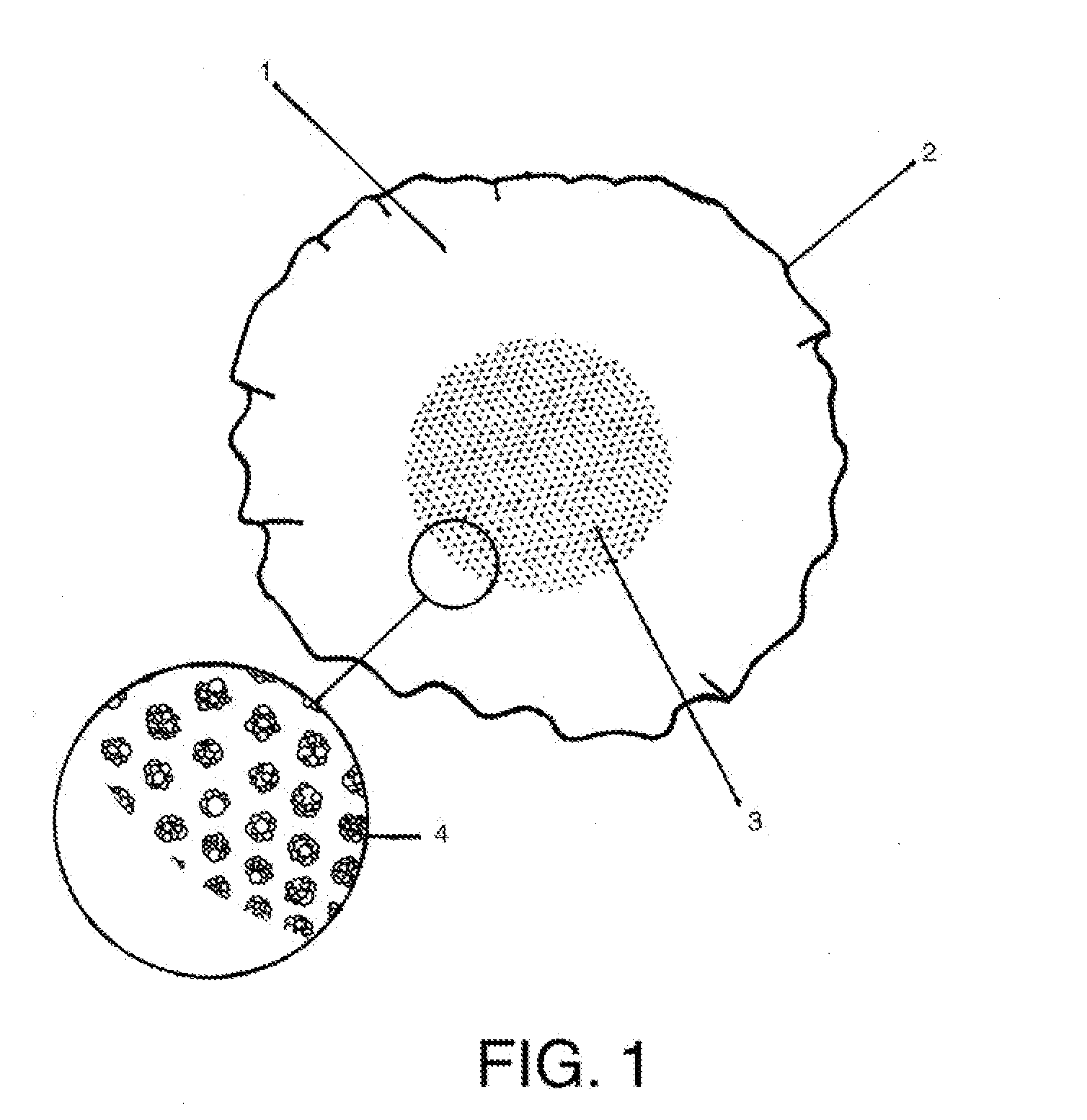

The present invention provides a method of imparting flavor enhancers, (flavorings) flavor or aroma masking agents, medicinal additives, fragrances, vitamins, colorants, homeopathic and herbal remedies, appearance and characteristic modifiers and other ingredients to a brewed or steeped beverage such as coffee or tea by means of a microencapsulated delivery system incorporated onto a substrate or filter material such as those used in drip coffee makers or tea bags. The microcapsules are “printed” or laminated to the substrate filter paper in a pattern that allows water to pass through while the microcapsules filled with a flavoring liquid or solid is dissolved thus releasing the contents into the water stream resulting in a flavor-enhanced beverage. Alternative delivery may also be achieved by means of:a) A microcapsule coated paper disc that may simply be immersed in the hot beverage or;b) A microcapsule coated interior wall of a disposable container or cup (A paper coffee cup for example) until such time the hot fluid within the container dissolves the microcapsules thus releasing the latent additive ingredient or a primary formulation of ingredients constituting the entire beverage solution or mixture.Several variations of this technology may be adapted for use with hot, cold or ambient temperature beverage preparation methods. Further aspects of the invention will become apparent from consideration of the drawings and the ensuing description of preferred embodiments of the invention. A person skilled in the art will realize that other embodiments of the invention are possible and that the details of the invention can be modified in a number of respects, all without departing from the inventive concept. Thus, the following drawings, photos and description are to be regarded as illustrative in nature and not restrictive.

Owner:THE ADDITIVE ADVANTAGE

Pharmaceutical composition with anaesthetic effect

InactiveUS6031007ARapid onsetSuitable thermoreversible gelling propertyBiocideNervous disorderLocal anaestheticSURFACTANT BLEND

PCT No. PCT / SE97 / 00566 Sec. 371 Date Aug. 6, 1997 Sec. 102(e) Date Aug. 6, 1997 PCT Filed Apr. 1, 1997 PCT Pub. No. WO97 / 38675 PCT Pub. Date Oct. 23, 1997The invention is directed to a novel pharmaceutical composition comprising one or more local anaesthetics in oil form, one or more surfactants, water and optionally a taste masking agent. The novel composition is advantageously used as a local anaesthetic for pain relief within the oral cavity.

Owner:MAILLEFER INSTR TRADING R L

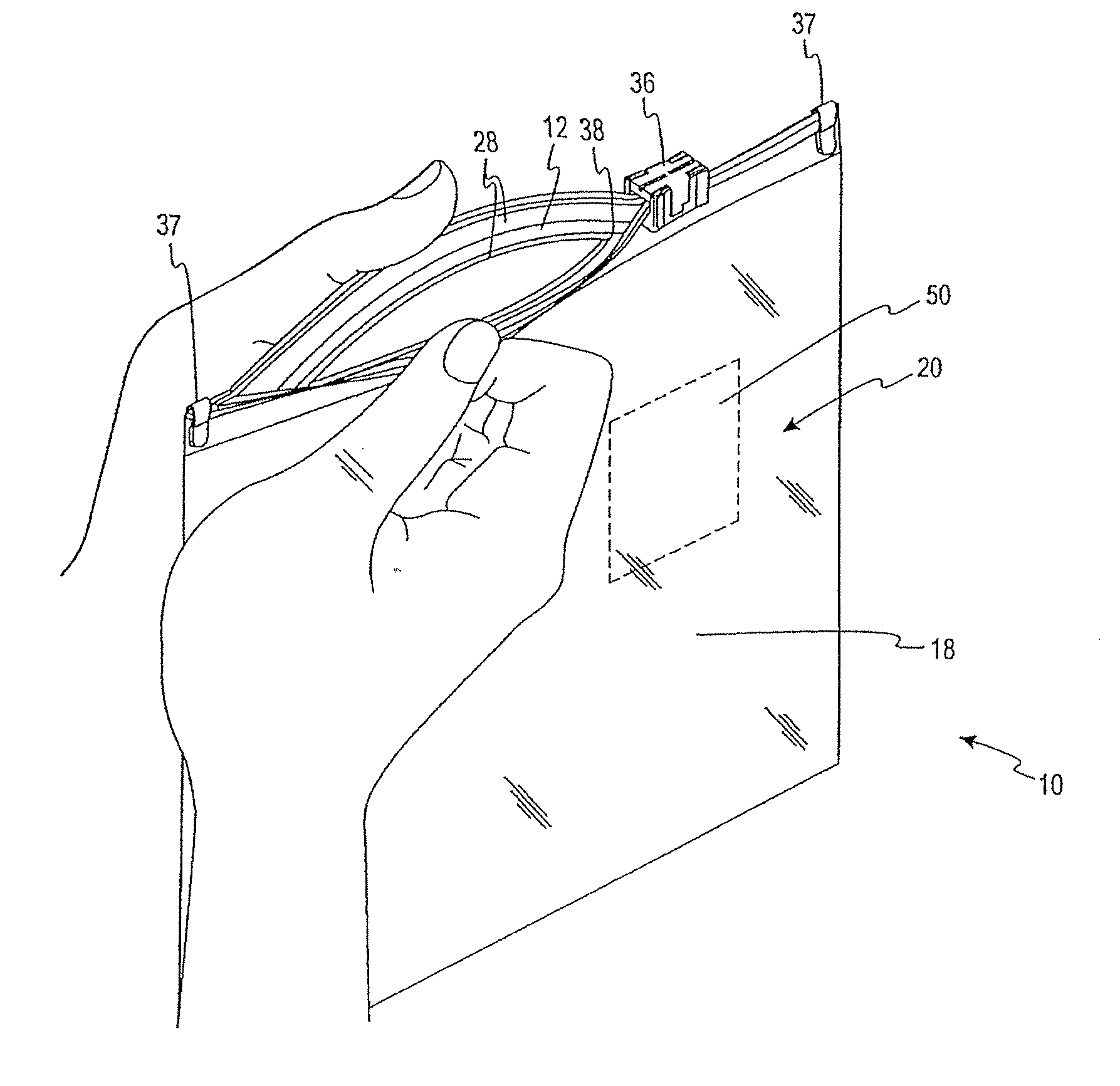

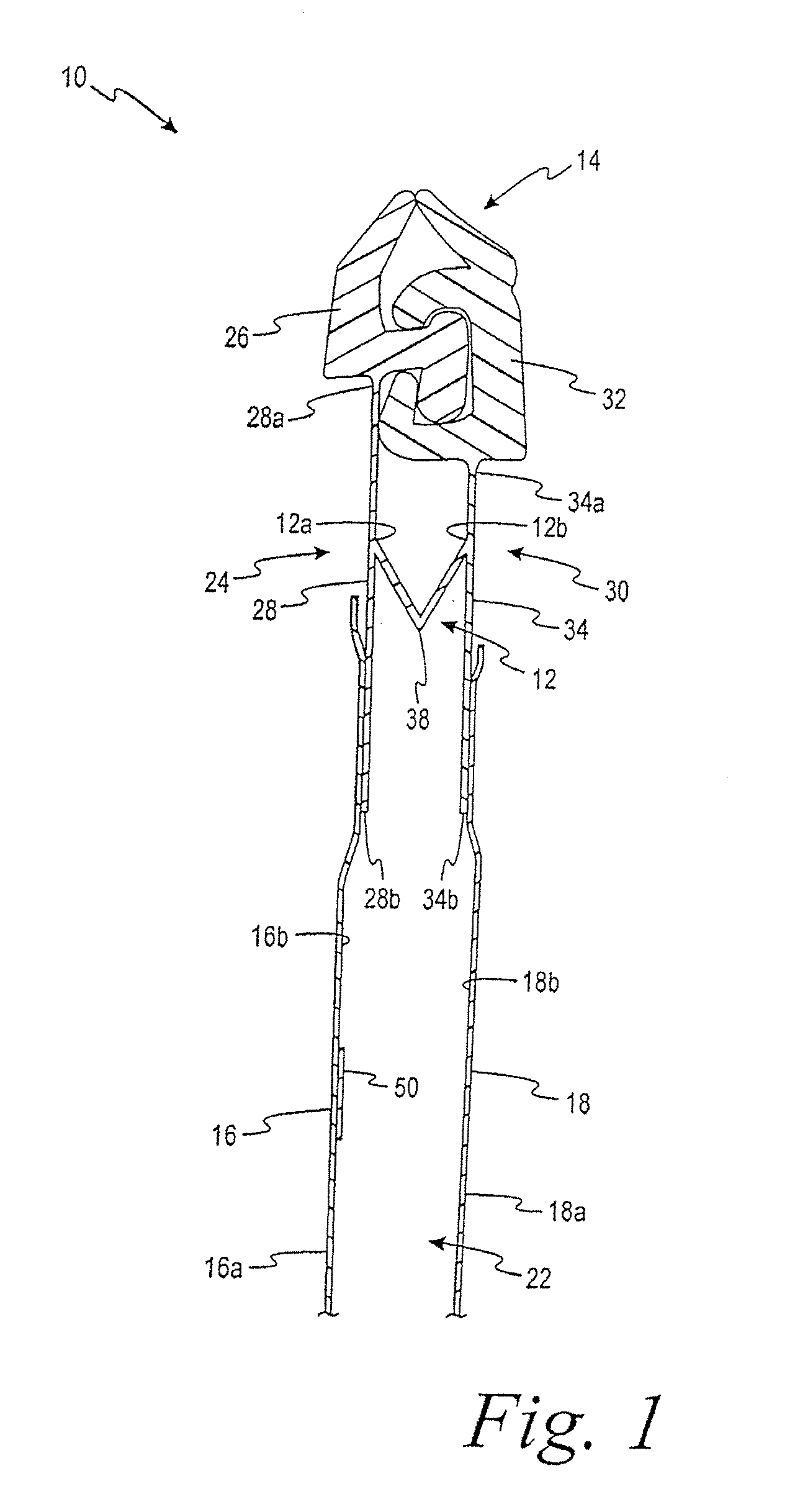

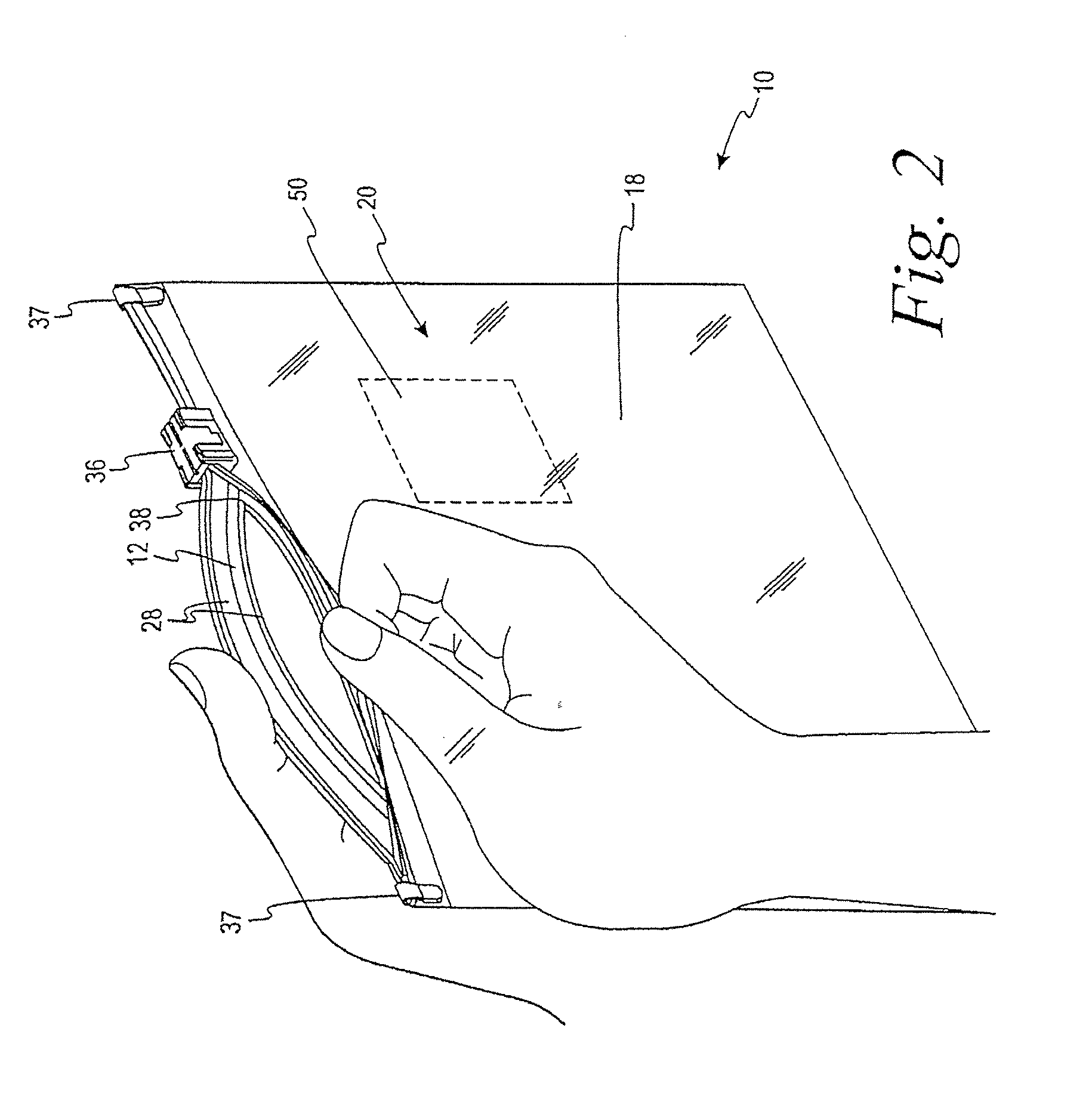

Transfer Sheets

InactiveUS20080302470A1Good masking effectImprove mechanical propertiesStampsDecorative surface effectsTitanium oxideMasking agent

In a transfer sheet which comprises a support and a transfer layer releasable from the support, the transfer layer comprises (i) an adhesive layer formed on one surface of the support and (ii) a masking layer formed on the adhesive layer and containing a masking agent and a binder resin which may have a crosslinking group, and the transfer layer is adjusted to have an elongation at break of not less than 30% (e.g., 30 to 200%). The masking layer may comprise a white pigment such as a titanium oxide and a urethane-series resin which may have an isocyanate group. The transfer sheet may comprise an image-receiving layer at least containing a urethane-series resin particle formed on the masking layer. Moreover, the transfer sheet may comprise an anchor layer between the masking layer and the image-receiving layer. The transfer layer is capable of recording an image thereon the image being transferred from a recording sheet. These transfer sheets may be used for forming the image on a colored object by transferring to the object.

Owner:DAICEL CHEM IND LTD

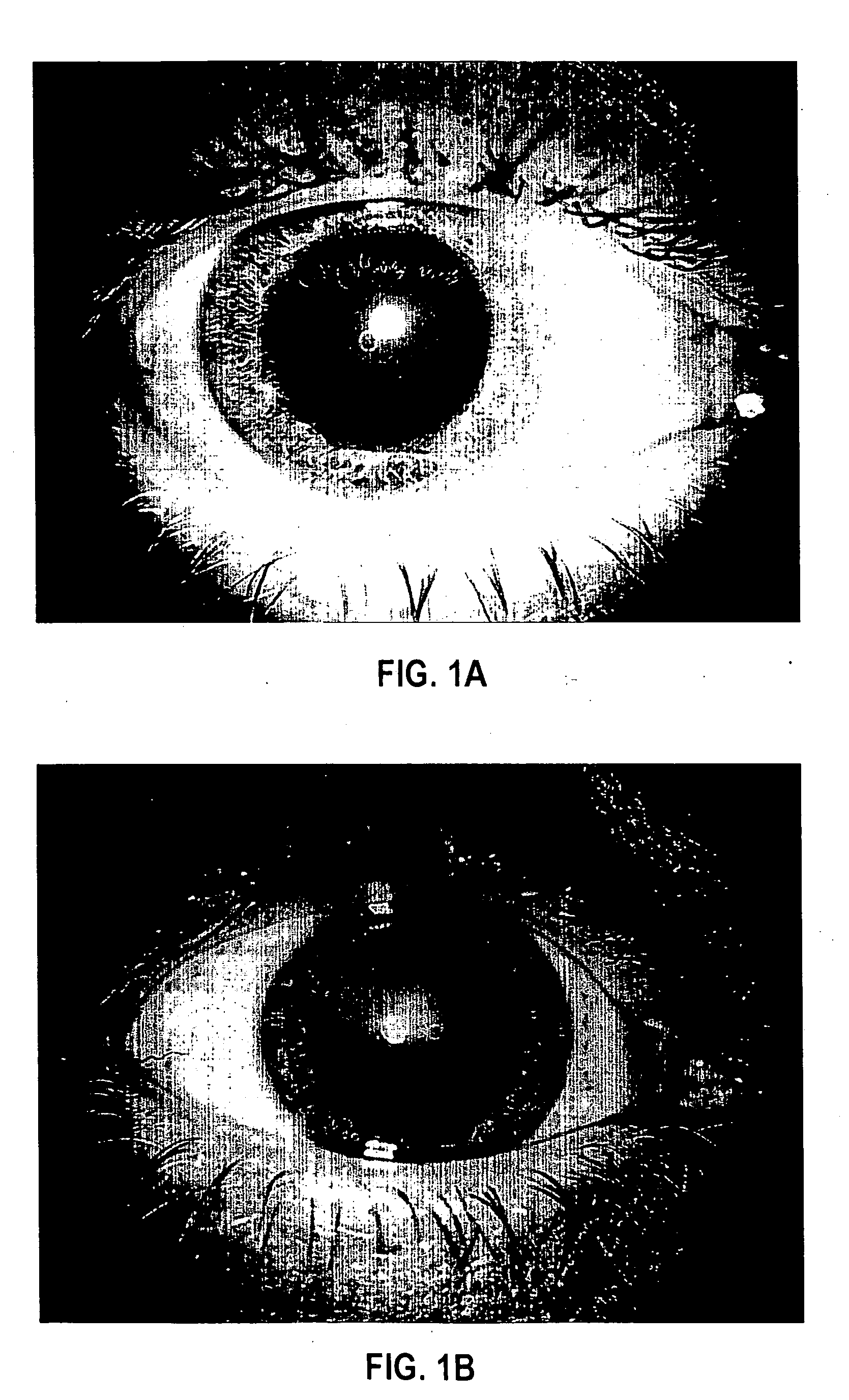

Treatment of conditions associated with the presence of macromolecular aggregates, particularly ophthalmic disorders

A method and formulation are provided for the treatment of medical conditions associated with the formation and / or deposition of macromolecular aggregates, particularly those associated with adverse ocular conditions. The formulation contains a non-cytotoxic chelating agent containing at least three negatively charged chelating atoms and a charge-masking agent containing at least one polar group and having a molecular weight of less than about 250, wherein the polar group contains at least one and preferably at least two heteroatoms having a Pauling electronegativity greater than about 3.00, and further wherein the molar ratio of the charge-masking agent to the chelating agent is sufficient to ensure that substantially all negatively charged chelating atoms are associated with a heteroatom on the charge-masking agent.

Owner:LIVIONEX

In Vivo Polynucleotide Delivery Conjugates Having Enzyme Sensitive Linkages

ActiveUS20120172412A1Suppression problemBeneficial level of expressionOrganic active ingredientsPeptide/protein ingredientsDipeptideIn vivo

The present invention is directed compositions for delivery of RNA interference (RNAi) polynucleotides to cells in vivo. The compositions comprise amphipathic membrane active polyamines reversibly modified with enzyme cleavable dipeptide-amidobenzyl-carbonate masking agents. Modification masks membrane activity of the polymer while reversibility provides physiological responsiveness. The reversibly modified polyamines (dynamic polyconjugate or DPC) are further covalently linked to an RNAi polynucleotide or co-administered with a targeted RNAi polynucleotide-targeting molecule conjugate.

Owner:ARROWHEAD MADISON

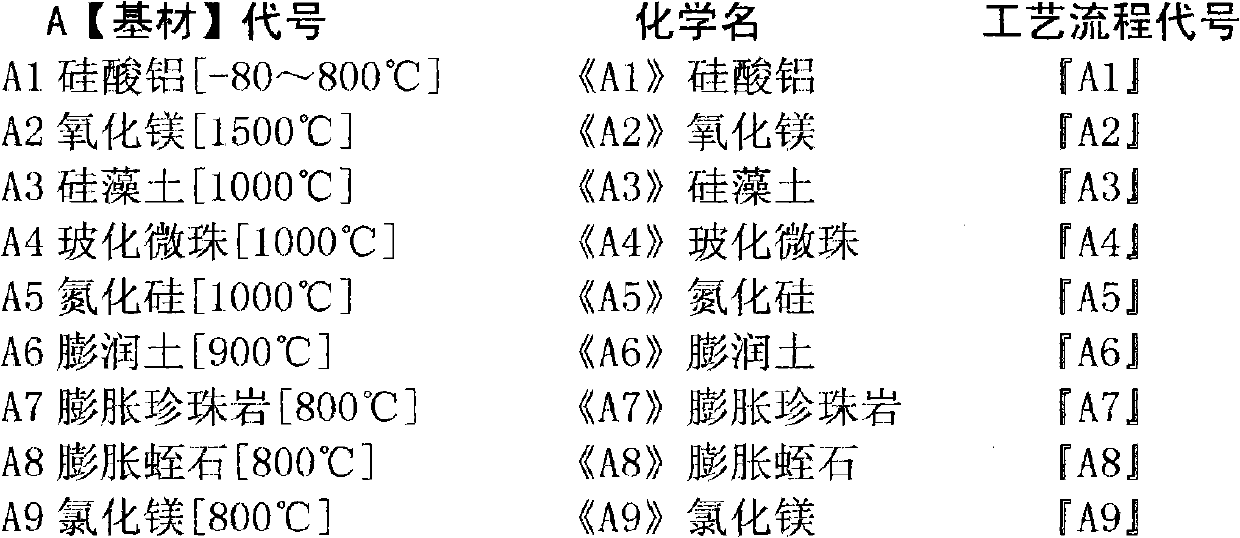

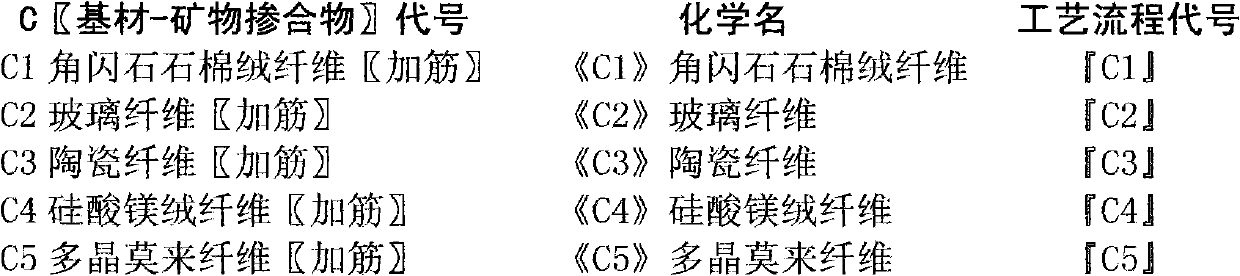

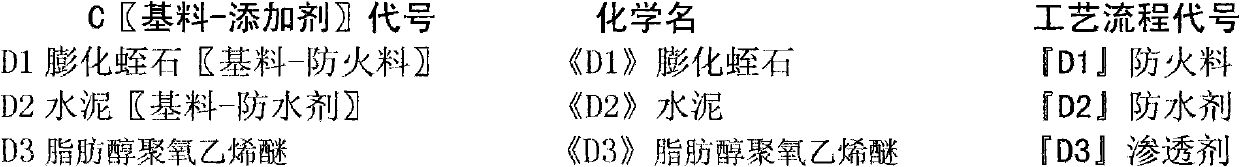

Innovative flame-retardant, water-proof, mildew-proof and radiation-proof insulating mortar and product

The invention discloses innovative flame-retardant, water-proof, mildew-proof and radiation-proof insulating mortar and products, which comprise nine base materials resisting the temperature of 80 DEG C below zero to 1,000 DEG C, i.e., aluminum silicate, magnesium oxide [1,500 DEG C], diatomite [1,000 DEG C], vitrified micro bubbles [1,000 DEG C], silicon nitride [1,000 DEG C], bentonite [900 DEG C], expanded perlite [800 DEG C], expanded vermiculite [800 DEG C] and magnesium chloride [800 DEG C], two mineral admixtures, five reinforcements, i.e., amphibole asbestos wool fiber, glass fiber, ceramic fiber, magnesium silicate wool fiber and polycrystalline mullite fiber and 14 base material-additives of different functions, i.e., a fire-proof material, a water-proof agent, an anti-radiation agent, an anti-mildew agent, an adhesive, an anti-freezing agent, a thixotropic agent, a curing agent, a brightening agent, an early strength agent, a foaming agent, an expanding agent and a masking agent, wherein nine kinds of low-carbon fire-proof insulating mortar which are used in different environments are developed through an innovative technical formula and are used for coating interior and exterior walls and manufacturing an insulating material for various plates, pipes and irregularly-shaped products; and the innovative flame-retardant, water-proof, mildew-proof and radiation-proof insulating mortar and product are national initiative environment-friendly low-carbon and fire-proof insulating mortar and product.

Owner:于斌 +2

Method for using purified water sludge as severely-polluted river sediment masking agent

InactiveCN102775030AWide variety of sourcesAchieve reuseWater resource protectionSludge treatment by de-watering/drying/thickeningParticulatesEcological environment

The invention discloses a method for using purified water sludge as a severely-polluted river sediment masking agent. The method comprises: a purified water sludge regeneration step that purified water sludge is burned to remove organic matters, microbes and the like in the purified water sludge to make the purified water sludge treat inorganic minerals comprising aluminum oxide and the like as main components; and a severely-polluted river restoration step comprising that the regenerated purified water sludge is covered on polluted sediments of water to be restored to physically separate the polluted sediments from covered water in order to inhibit the release of polluted sediment endogenous pollutants to the water, make polluters of nitrogen, phosphorus and the like in the water be absorbed by inorganic particulate substances treating metal oxides as main components and contained in the purified water sludge, and accelerate the migration of the polluters in the water to the sediments. According to the method, the resource utilization of an aluminum resource in the purified water sludge can be realized, the harmless treatment of the purified water sludge is realized, and the water restoration is completed without destroying the ecological environment of the water.

Owner:SUZHOU UNIV OF SCI & TECH

Method for manufacturing EO-grade flame-proof, abrasion-proof, mildew resistant and moisture-proof veneer overlay wood veneer

InactiveCN101367219AThe preparation process is matureIncrease productivityAldehyde/ketone condensation polymer adhesivesWood veneer joiningMoistureMasking agent

The invention relates to a method for manufacturing E0 grade veneer overlaid plywood with inflaming retardance, abrasion resistance, rot resistance and moisture protection. The method comprises the following steps: selecting a dried veneer; rubberizing the veneer in two sides; assembling after rubberizing, with veneer structure layers being odd number; carrying out prepressing treatment after assembly; carrying out hot pressing treatment after the prepressing treatment; entering naturally cooling, depositing and sanding after the hot pressing treatment; coating masking agent, which is to apply aldehydeless gummy masking agent on a baseplate of the plywood to cover color difference of the baseplate surface to lead the baseplate surface to be in light yellow; applying E0 grade urea-formaldehyde resin adhesive on the baseplate by a pasting machine after the masking agent is dried; and pasting veneer on the baseplate, and carrying out abrasion-resistant treatment to the surface after hot pressing. The method has the advantages that the veneer overlaid plywood is an environment-friendly decoration material reaching E0 grade, has the functions of inflaming retardance, rot resistance, moisture protection and abrasion resistance, achieves the bonding strength of national standard, has mature manufacturing process, can implement industrial production so as to greatly improve the production efficiency and ensure product quality, and is convenient for popularization and application.

Owner:DEHUA TB NEW DECORATION MATERIAL CO LTD +1

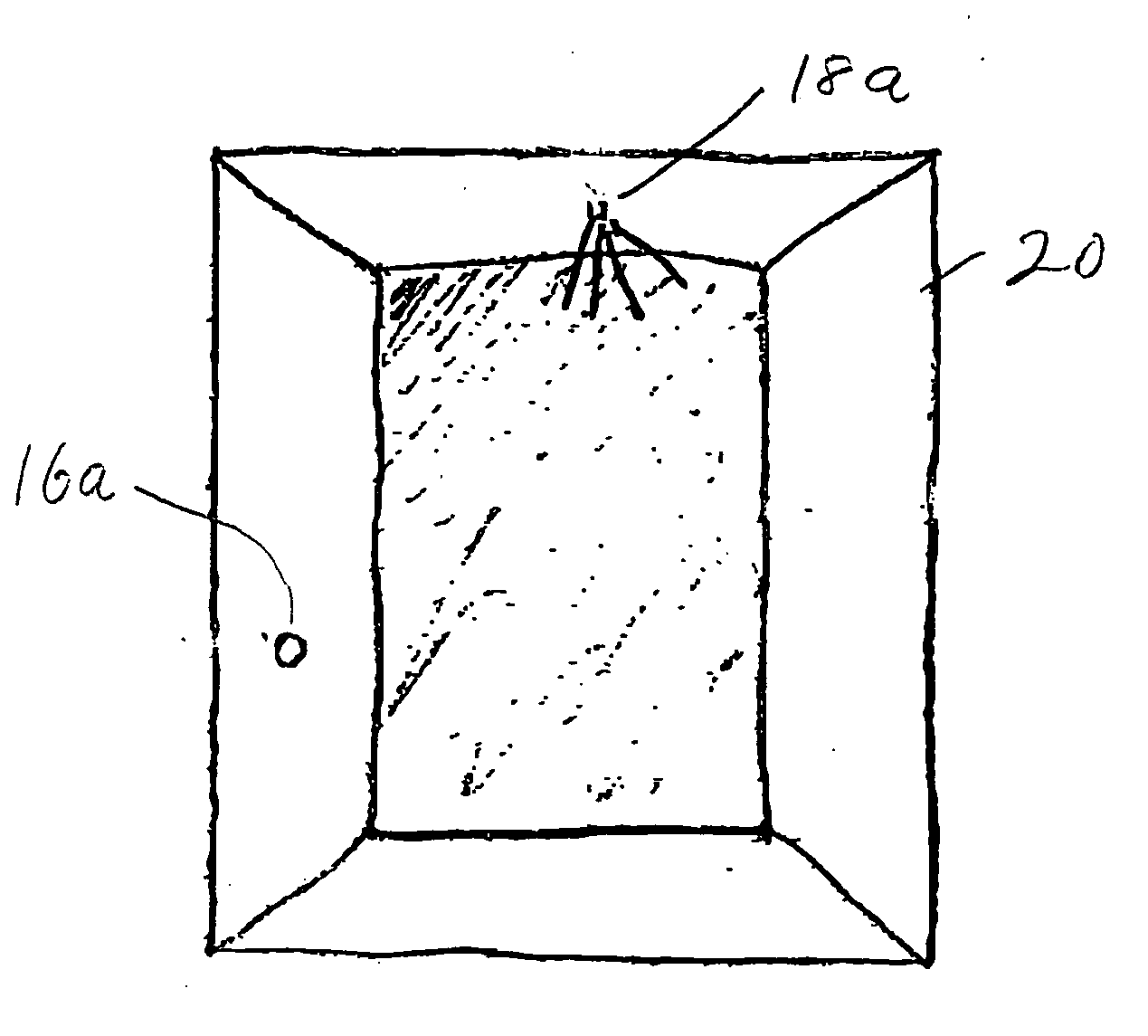

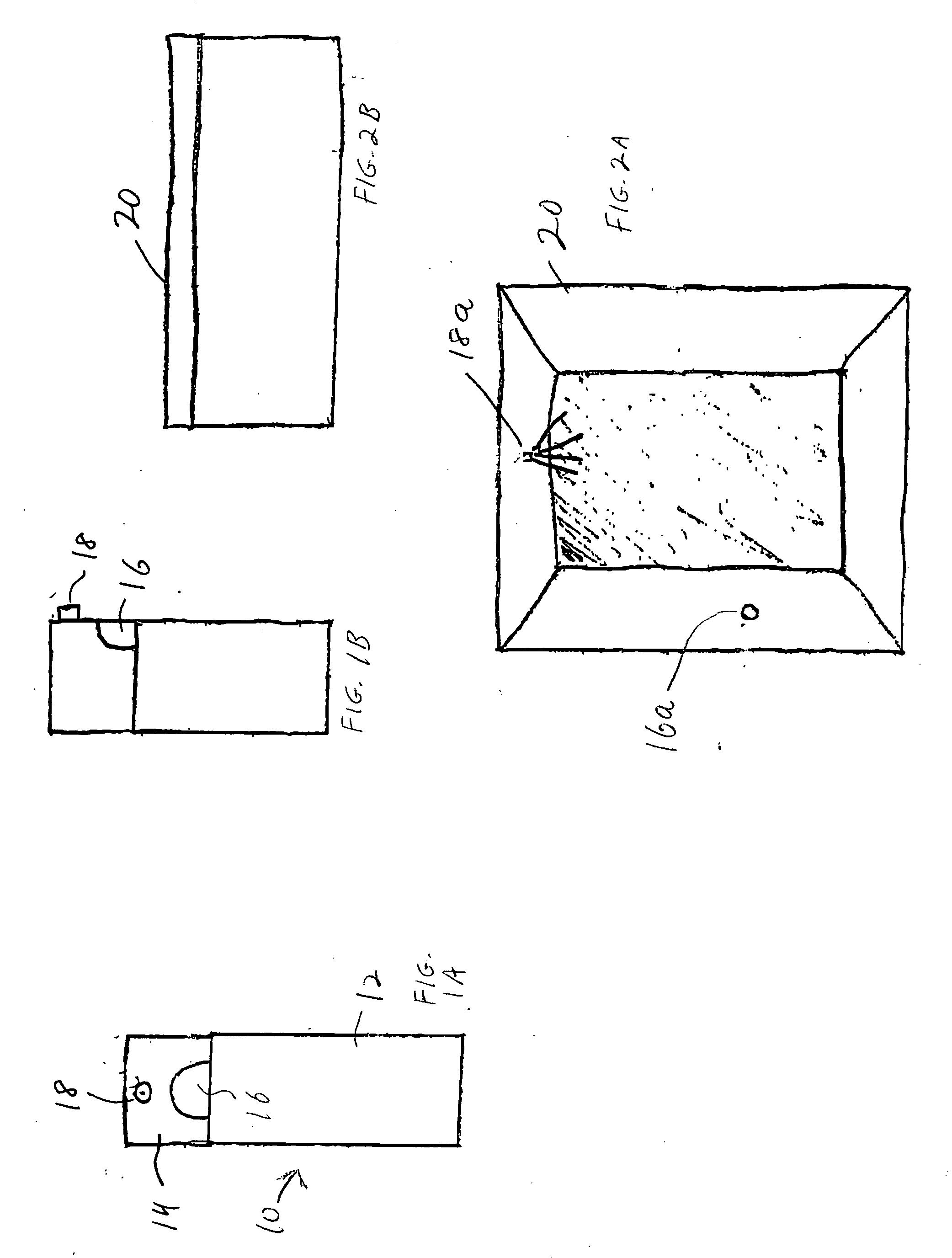

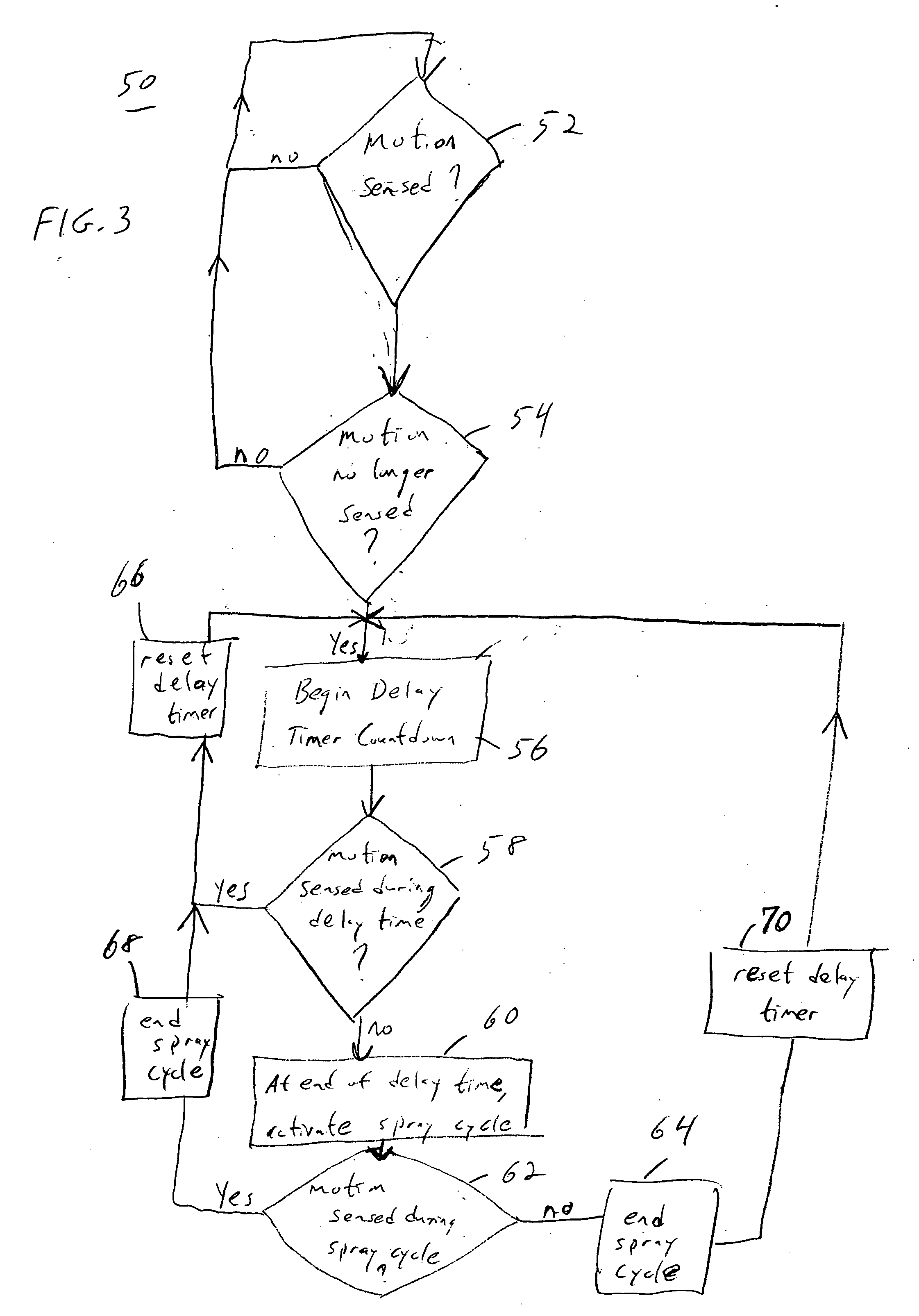

Automatic freshener system and method

InactiveUS20060137619A1Increase attractivenessLavatory sanitoryAnimal housingEngineeringMasking agent

A system and method for automatically applying an odor neutralizing or masking agent or a pheromonal agent to a cat litter box, or an odor neutralizing or masking agent to an area around a human toilet. There is a source of spray delivery of the agent, and a motion sensor. The spray delivery source applies the agent in response to the motion sensor, so that the agent is applied only after the cat or human has finished using the facility.

Owner:DODMAN DANIEL N +1

Compositions comprising azelastine and methods of use thereof

The present invention provides pharmaceutical compositions comprising azelastine, or a pharmaceutically acceptable salt or ester thereof including azelastine hydrochloride, and optionally one or more additional active agents. Preferred such compositions further comprise one or more pharmaceutically acceptable carriers or excipients that reduce the amount of post-nasal drip, and / or that minimize or mask the unpleasant bitter taste associated with post-nasal drip, of the compositions into the oral cavity, upon intranasal or ocular administration of the compositions. Especially effective excipients used in the compositions of the present invention are hypromellose as a viscosity modifier and sucralose as a taste-masking agent. The invention also provides methods of treating or preventing certain disorders, or symptomatic relief therefrom, by administering the compositions of the invention to a patient, e.g., for the symptomatic relief of allergic rhinitis, non-allergic vasomotor rhinitis, allergic conjunctivitis, as well as other disorders. The compositions and methods of the present invention provide significant value in terms of patient acceptability, convenience, and compliance.

Owner:MEDA PHARMA INC

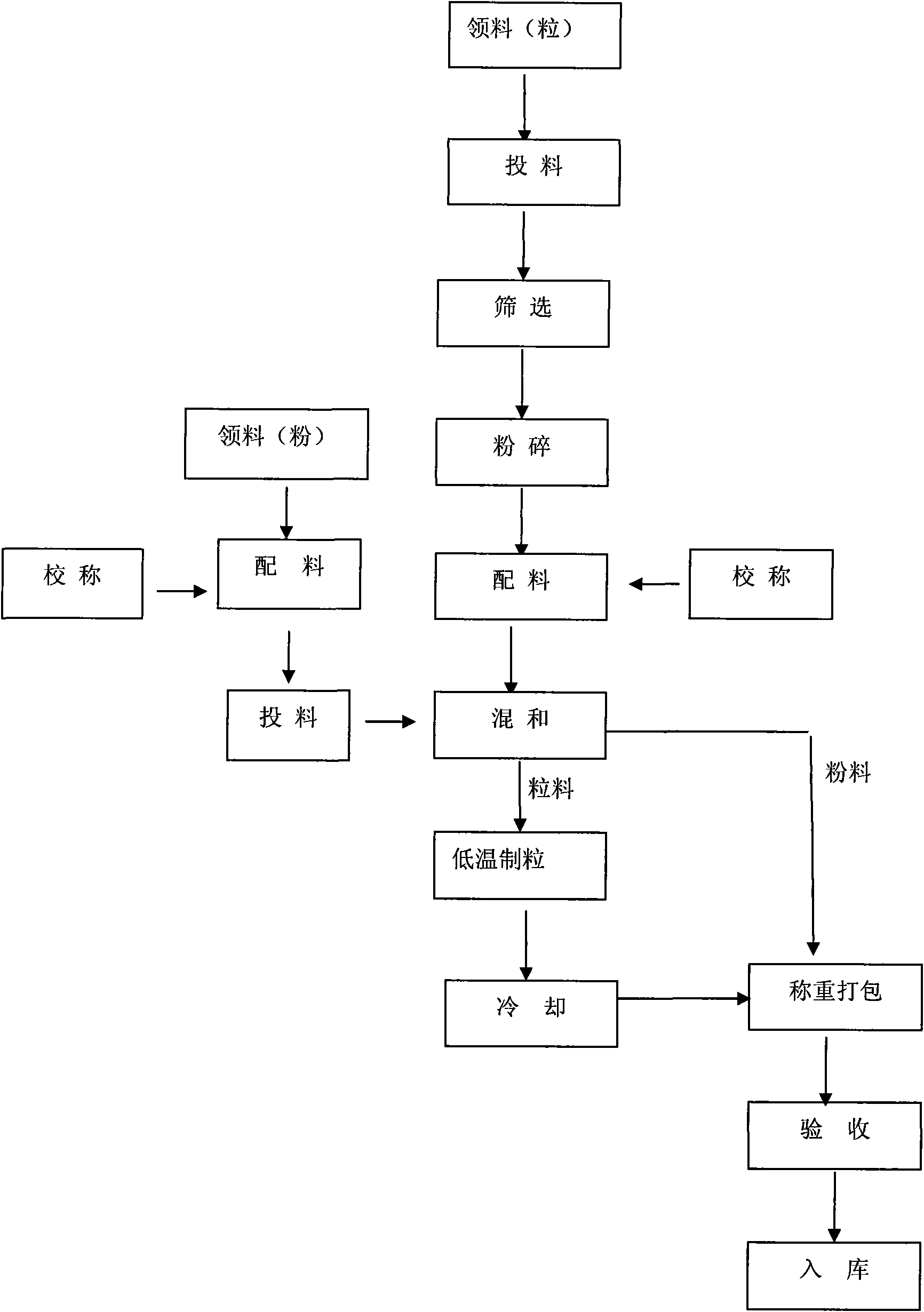

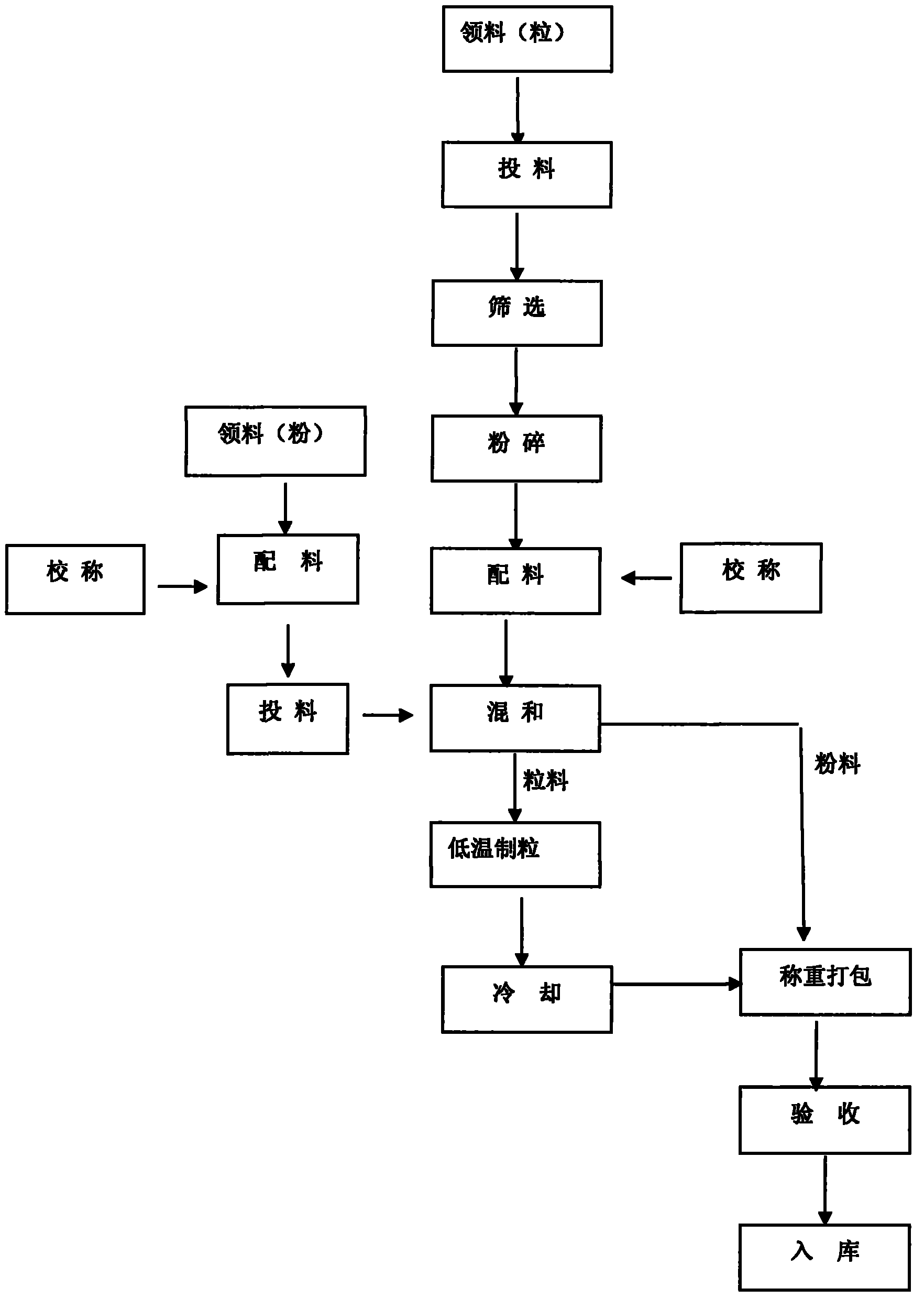

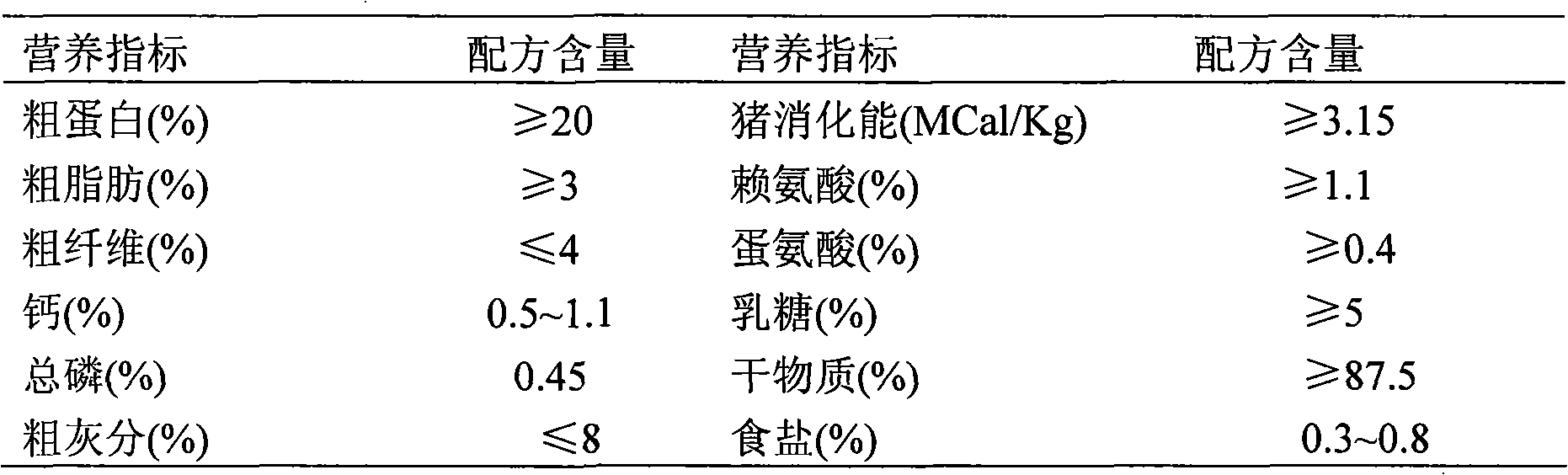

Creep, early weaned porket feeding and preparation method thereof

ActiveCN101773210AImprove digestibilityImprove digestion efficiencyAnimal feeding stuffAntigenAnimal science

The invention discloses a creep and an early weaned porket feeding. The early weaned porket feeding comprises the following components by weight part: 350 to 550 parts of Alpha-grain; 0.5 to 1 parts of choline chloride; 50 to 100 parts of peeled soybean meal; 1 to 5 parts of acidulant; 50 to 100 parts of antigen-extracted soybean meal; 0.5 to 0.75 parts of flavouring agent and masking agent; 25 to 75 parts of fish mel; 0.5 to 1 parts of lysine; 0.1 to 0.5 parts of methionine; 0.1 to 0.25 parts of probiotic (lactic acid bacteria and saccharomycetes); 1 to 4 parts of calcium hydrophosphate; 25 to 50 parts of oil meal; and 5 to 10 parts of mountain meal. A preparation method for the feeding includes the following steps: (a) the peeled soybean meal and the grain are first ground, and preferably, all the ground grain sizes can pass through a 40-mesh sieve; (b) the ground grain is cured by adopting a wet extrusion technique; (c) the materials are accurately weighed according to a formula, and the large materials and then the small materials are sequentially added in the mixer and sufficiently mixed; (d) the mixed material is dedusted; (e) the mixed material is palletized under the low temperature of less than 65 DEG C, and the powdery material directly enters the packaging process; (f) a conventional counterflow type feeding cooler is adopted for cooling.

Owner:ANYOU BIOTECH GRP

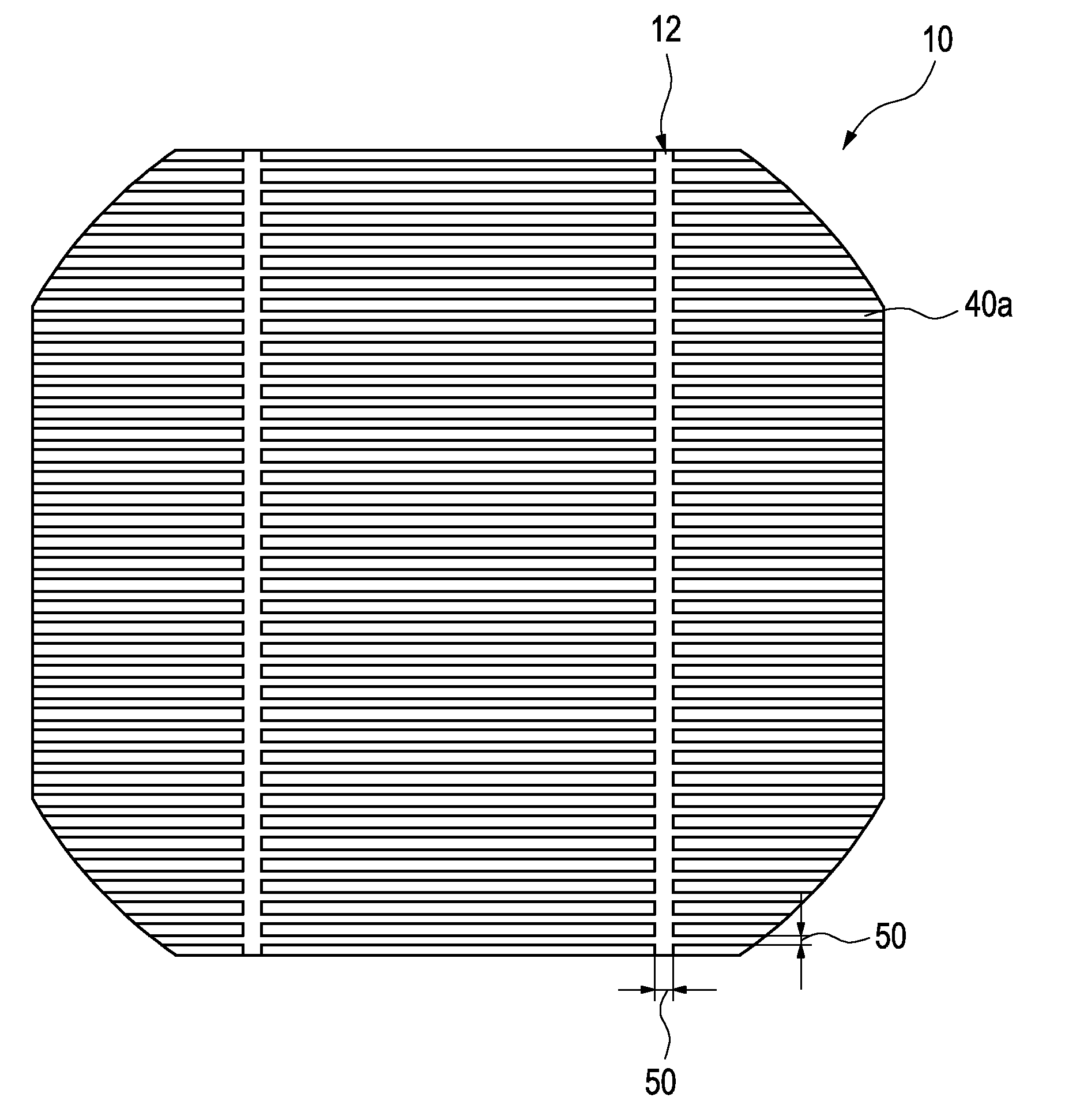

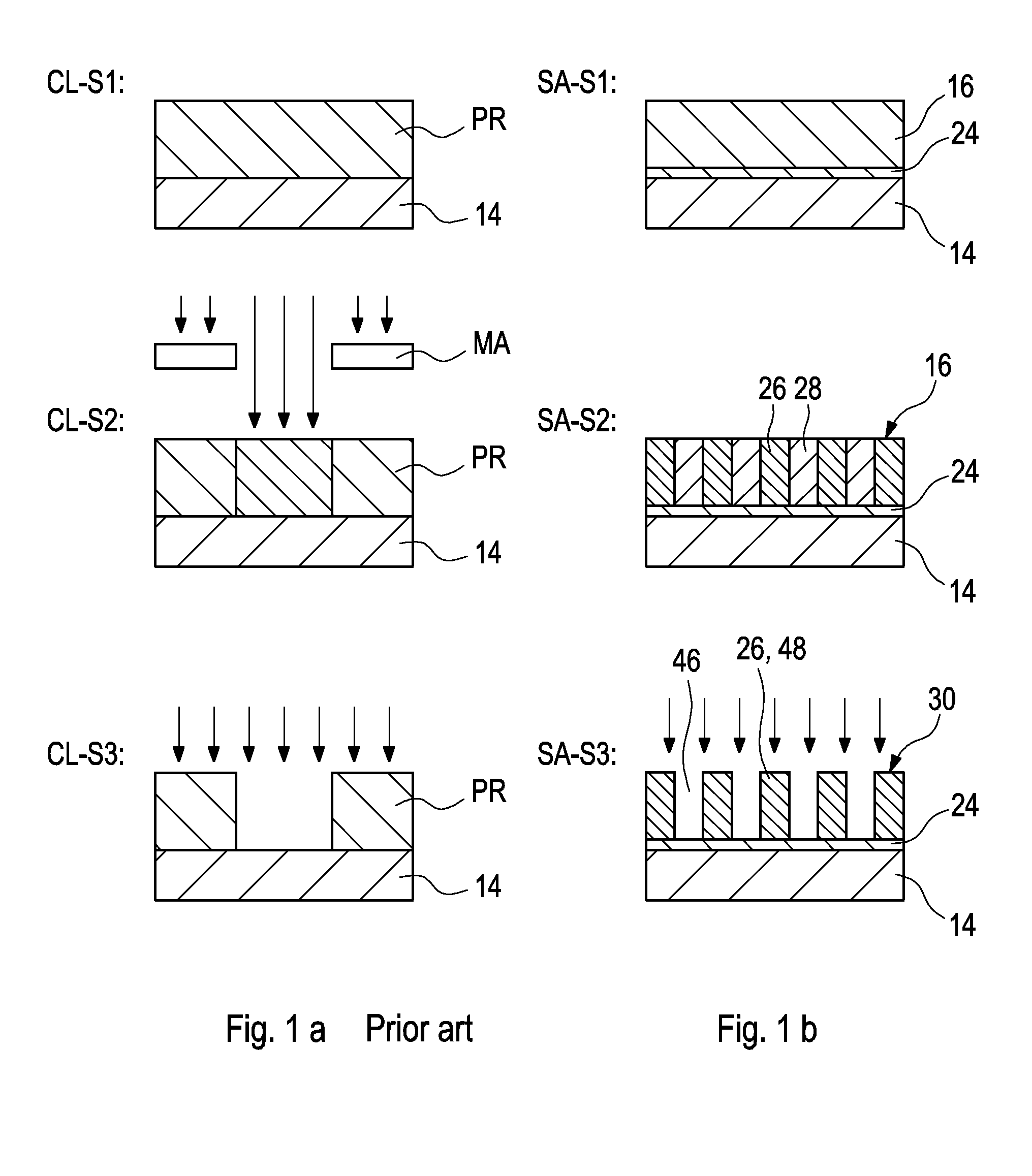

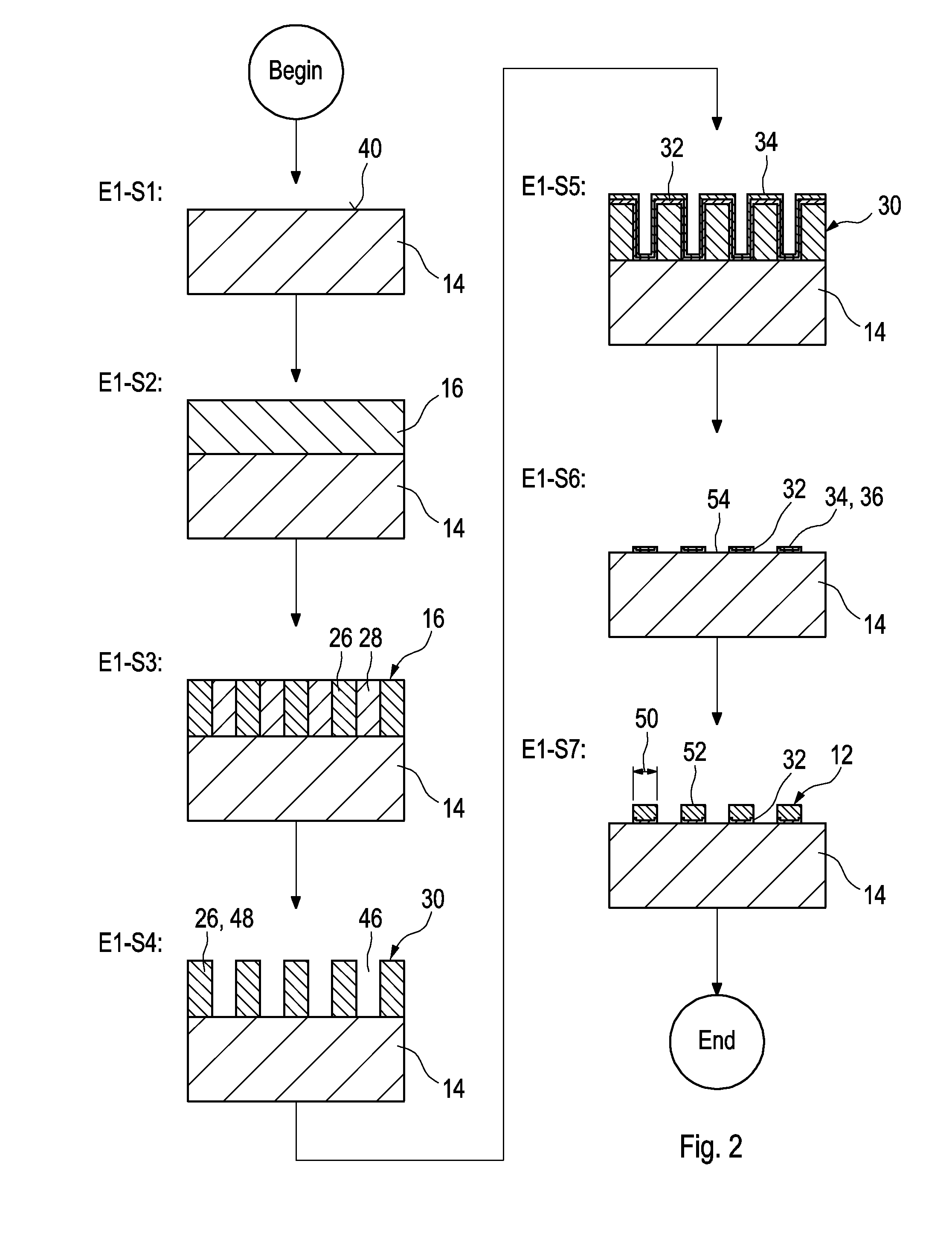

Electrically contactable grids manufacture

InactiveUS20110100453A1Semiconductor/solid-state device manufacturingPhotovoltaic energy generationHeat sensitiveSolar cell

A method for manufacturing one or more electrically contactable grids on at least one surface of a semiconductor substrate for use in a solar cell product includes the following. A heat-sensitive masking agent layer is deposited on the surface of the substrate of the solar cell product. The masking agent layer is locally heated to form a grid mask. Selected parts of the masking agent layer defined by locally heating are removed to form openings in the grid mask. A contact metallization is applied on the grid mask.

Owner:IBM CORP

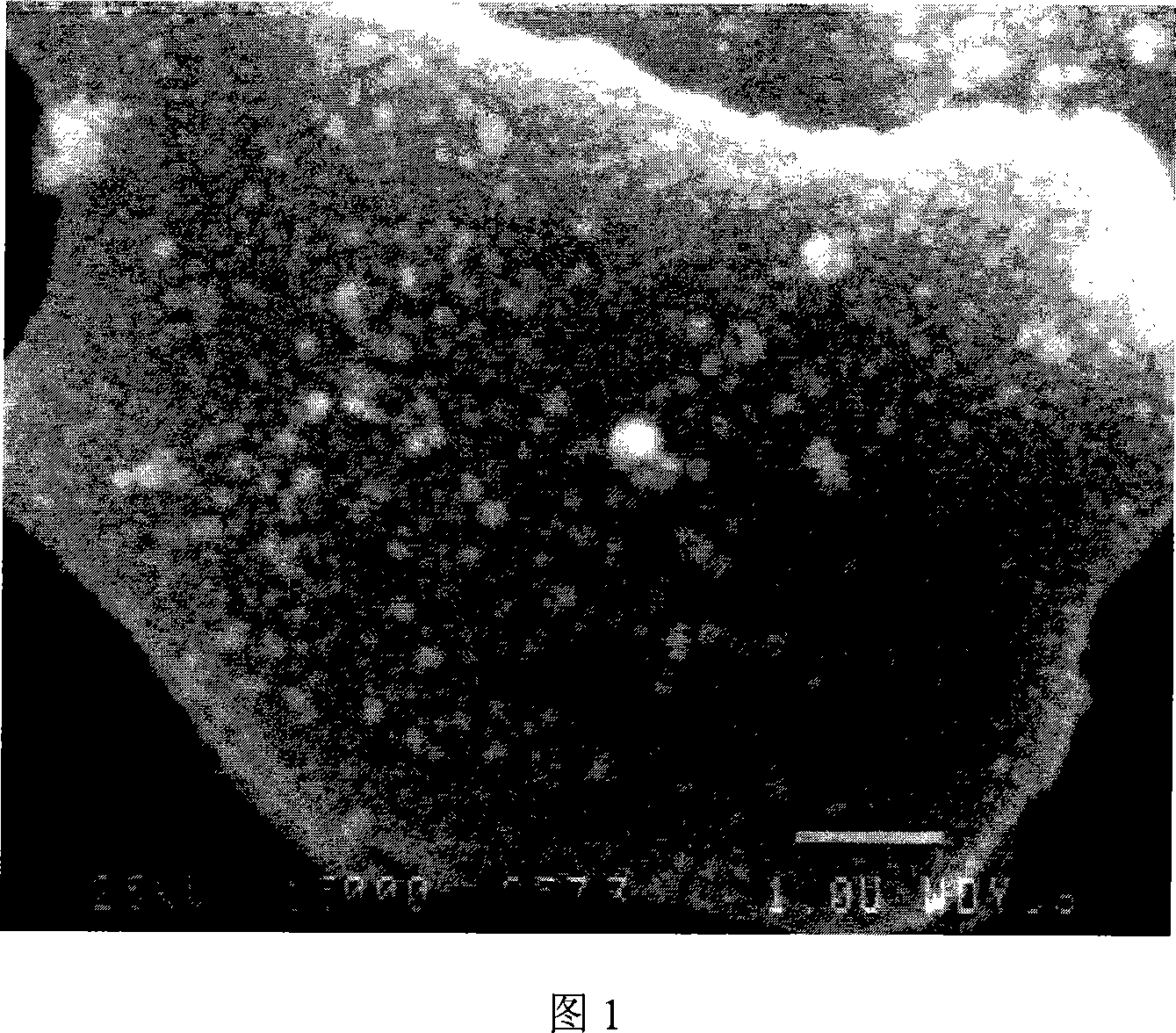

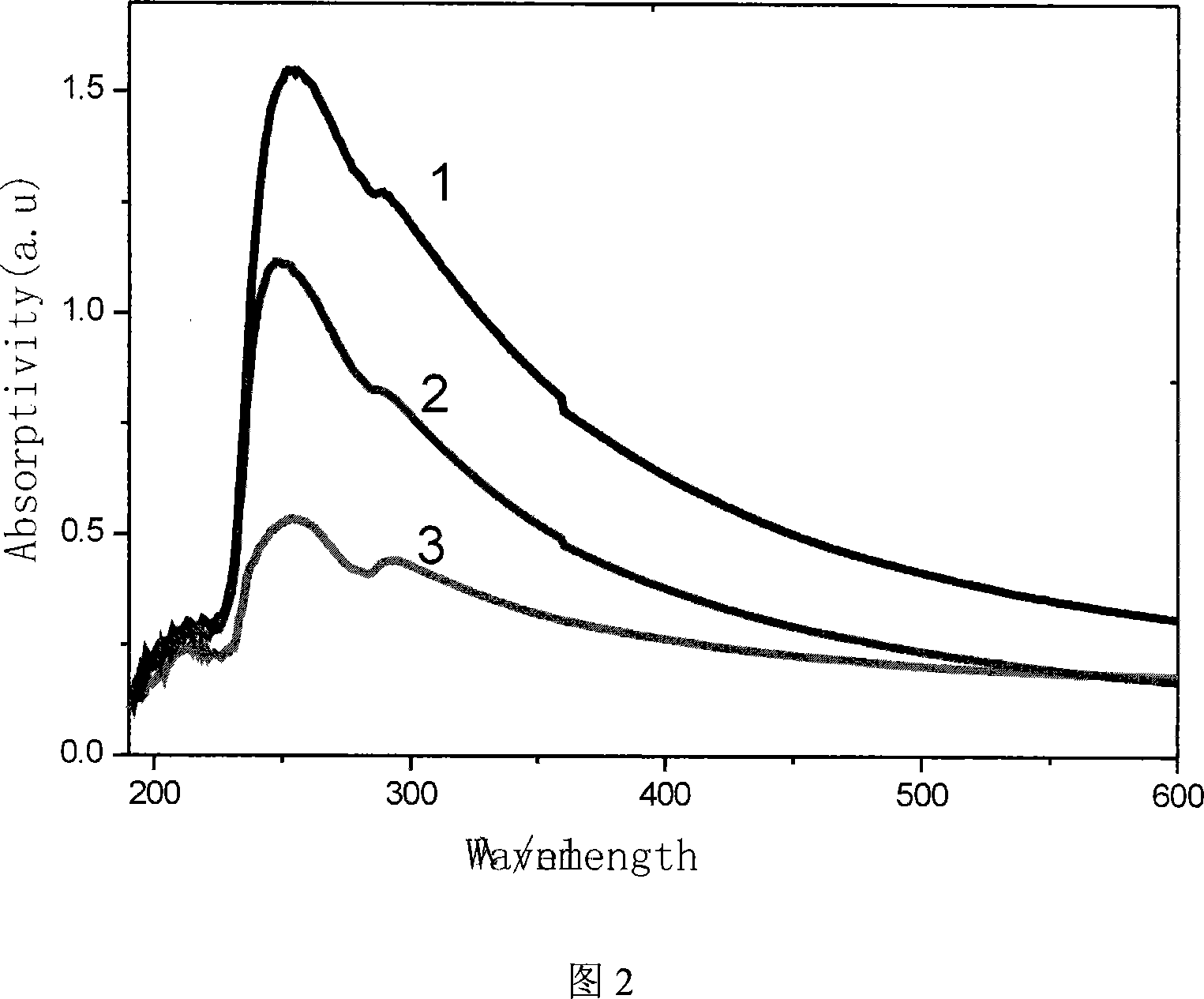

Method of preparing sericite ultraviolet radiation screening agent

InactiveCN101058679AGood coating effectGood dispersionOther chemical processesInorganic pigment treatmentChlorideVolumetric Mass Density

The invention discloses a making method of ultraviolet masking agent of sericite mica, which comprises the following steps: 1) preparing fined sericite mica; 2) activating the sericite mica powder; 3) adding water in the sericite mica to form the suspension with density at 2. 5-5%; adjusting the pH value to 2. 0-2. 5 through alcaine as system C; 4) allocating titanic chloride solution with density at 10-15%; adding zinc chloride in the titanic chloride solution; making the molar rate of Zn and Ti at 1: 2; obtaining the solution D; 5) dripping the solution D into the system D; controlling the pH value to 7. 0; 6) filtering the sediment; washing; drying at 95 deg. c; 7) grinding the drier; placing the drier in the electric furnace at 600 deg. c for 2-3h; 8) grinding the sintered material; beating to 10-15um; obtaining the product.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com