Innovative flame-retardant, water-proof, mildew-proof and radiation-proof insulating mortar and product

A waterproof, mildew-proof, and heat-insulating slurry technology, which is applied to ceramic products, other household appliances, household appliances, etc., and can solve problems that are not included in national design specifications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

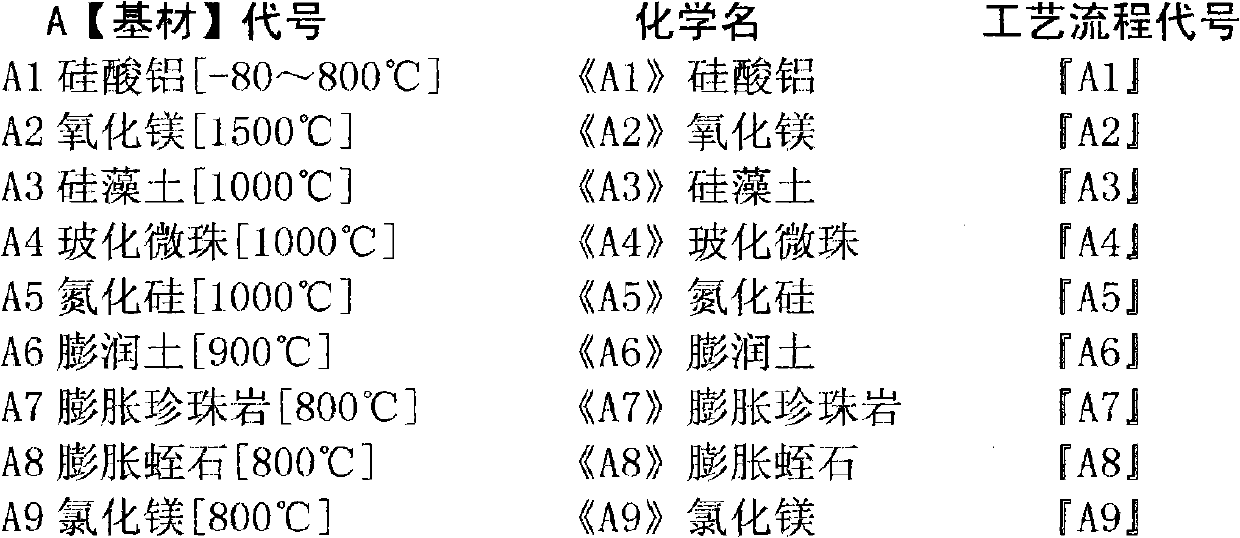

[0221] Formula 1 of this patented product: Applicable temperature -80~800°C (Note: ▲Adjust according to the measurement instructions of the product)

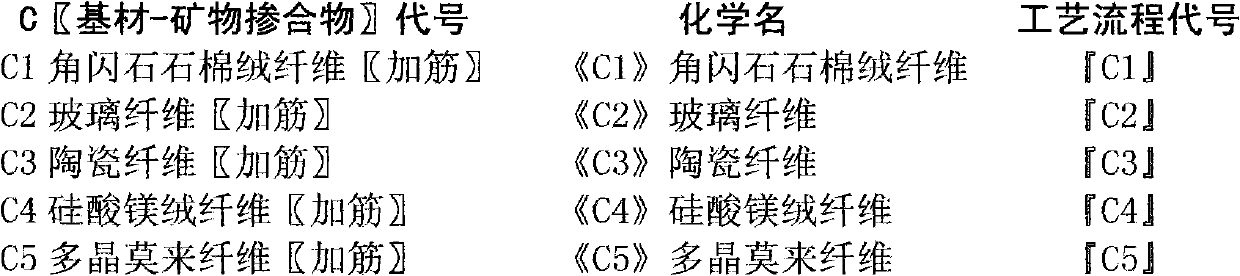

[0222] The first mixing [substrate] low-speed mixing process [mixer 50-150 rpm] → [water] 100kg → "A1" aluminum silicate 100kg (5-10 minutes) → "C1" amphibole asbestos fiber 30 ~60Kg (5-10 minutes)→[soaking pool material] (24 hours);

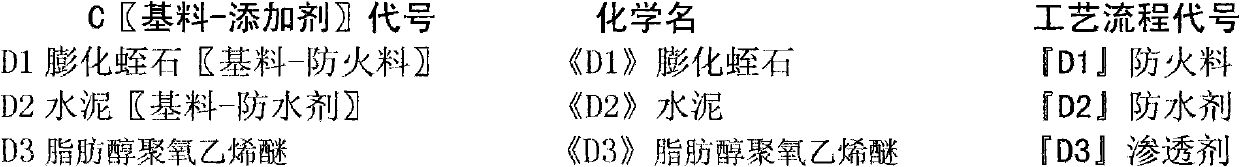

[0223] The second composite 〖mud〗 medium-speed mixing process [mixer 350-500 rpm] → [soaking pool material] → "D1" fireproof material ▲ (5-10 minutes) → "D2" waterproofing agent ▲ (5-10 minutes) points)→『D3』penetrant ▲ (5-10 points)→『D4』anti-ray▲ (5-10 points)→『D5』anti-fungal agent▲ (5-10 points)→〖slurry〗

[0224] The third mold processing [product] process → [slurry] → {plate mold} or {pipe mold} → [product]

[0225] Formula 2 of this patented product: Applicable temperature 1000°C (Note: ▲Adjusted according to the measurement instructions of the product)

[0226] The first mixing [substrate] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| thermal decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com