Patents

Literature

77results about How to "Play a covering role" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Innovative flame-retardant, water-proof, mildew-proof and radiation-proof insulating mortar and product

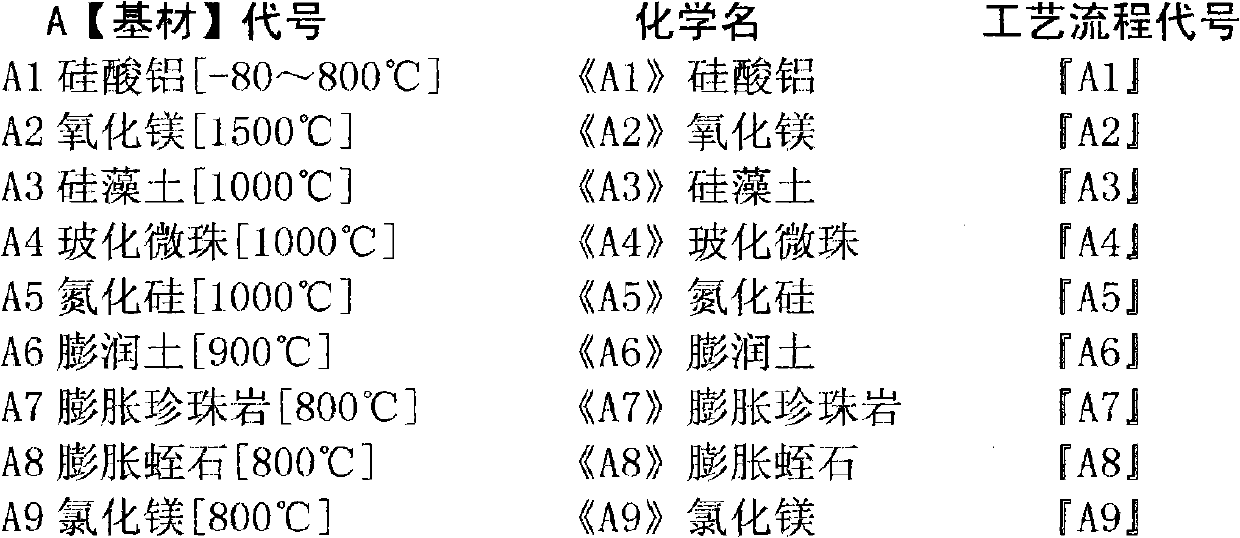

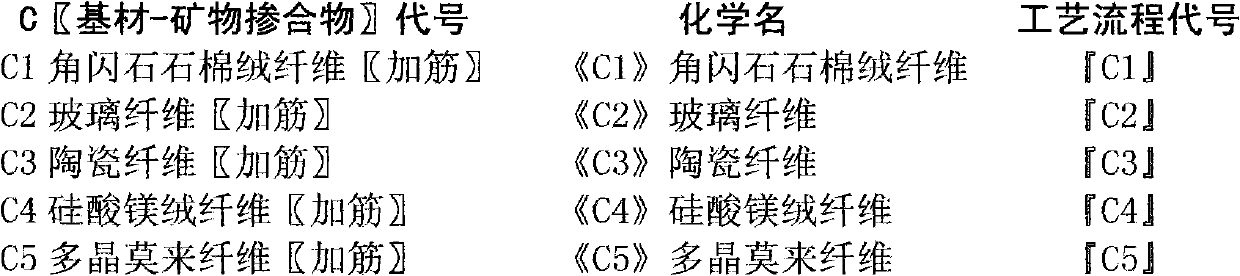

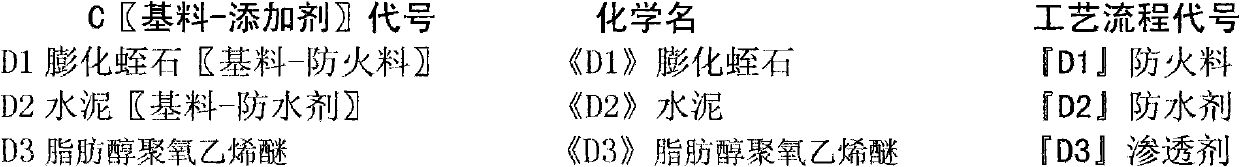

The invention discloses innovative flame-retardant, water-proof, mildew-proof and radiation-proof insulating mortar and products, which comprise nine base materials resisting the temperature of 80 DEG C below zero to 1,000 DEG C, i.e., aluminum silicate, magnesium oxide [1,500 DEG C], diatomite [1,000 DEG C], vitrified micro bubbles [1,000 DEG C], silicon nitride [1,000 DEG C], bentonite [900 DEG C], expanded perlite [800 DEG C], expanded vermiculite [800 DEG C] and magnesium chloride [800 DEG C], two mineral admixtures, five reinforcements, i.e., amphibole asbestos wool fiber, glass fiber, ceramic fiber, magnesium silicate wool fiber and polycrystalline mullite fiber and 14 base material-additives of different functions, i.e., a fire-proof material, a water-proof agent, an anti-radiation agent, an anti-mildew agent, an adhesive, an anti-freezing agent, a thixotropic agent, a curing agent, a brightening agent, an early strength agent, a foaming agent, an expanding agent and a masking agent, wherein nine kinds of low-carbon fire-proof insulating mortar which are used in different environments are developed through an innovative technical formula and are used for coating interior and exterior walls and manufacturing an insulating material for various plates, pipes and irregularly-shaped products; and the innovative flame-retardant, water-proof, mildew-proof and radiation-proof insulating mortar and product are national initiative environment-friendly low-carbon and fire-proof insulating mortar and product.

Owner:于斌 +2

Preparation method of low-cost ultra-white porcelain tile

The invention relates to a preparation method of a low-cost ultra-white porcelain tile. The preparation method comprises the following steps of (1) weighing materials, mixing the materials, adding water, a bonding agent and a dispersing agent, carrying out ball milling to prepare slurry, wherein sieving the slurry by 250 meshes with the weight percent of residues being less than 0.5%; carrying out ageing for 24-72 hours for spare use, wherein the materials comprise the following components by weight percent: 25-40% of kaolin, 40-50% of low-cost whitening mineral, 9-15% of feldspar and 6-11% of quartz sand, and the low-cost whitening mineral is mixture of black talc and diopside; (2) feeding the slurry into a spraying and drying tower to carry out spraying granulation so as to obtain body powder; (3) pressing the body powder to obtain a green body, feeding the green body into a drying kiln for drying so as to obtain the dried green body; and (4) applying transparent glaze on the dried green body, entering a roller kiln for firing so as to obtain the low-cost ultra-white porcelain tile. The preparation method has the advantages that the cost is lower, the prepared porcelain tile is high in whiteness and good in mechanical property and thermal stability property.

Owner:WUHAN UNIV OF TECH +1

Acid corrosion inhibitor

The present invention belongs to the field of chemical technology, and discloses one kind of acid corrosion retardant. The acid corrosion retardant contains urotropine, thiourea, benzotriazole, mercaptobezothiazole, sodium silicate and water. The acid corrosion retardant of the present invention is developed based on that some acids and some metals have high corrosion retarding rate.

Owner:SHANGHAI WANSEN WATER TREATMENT CO LTD

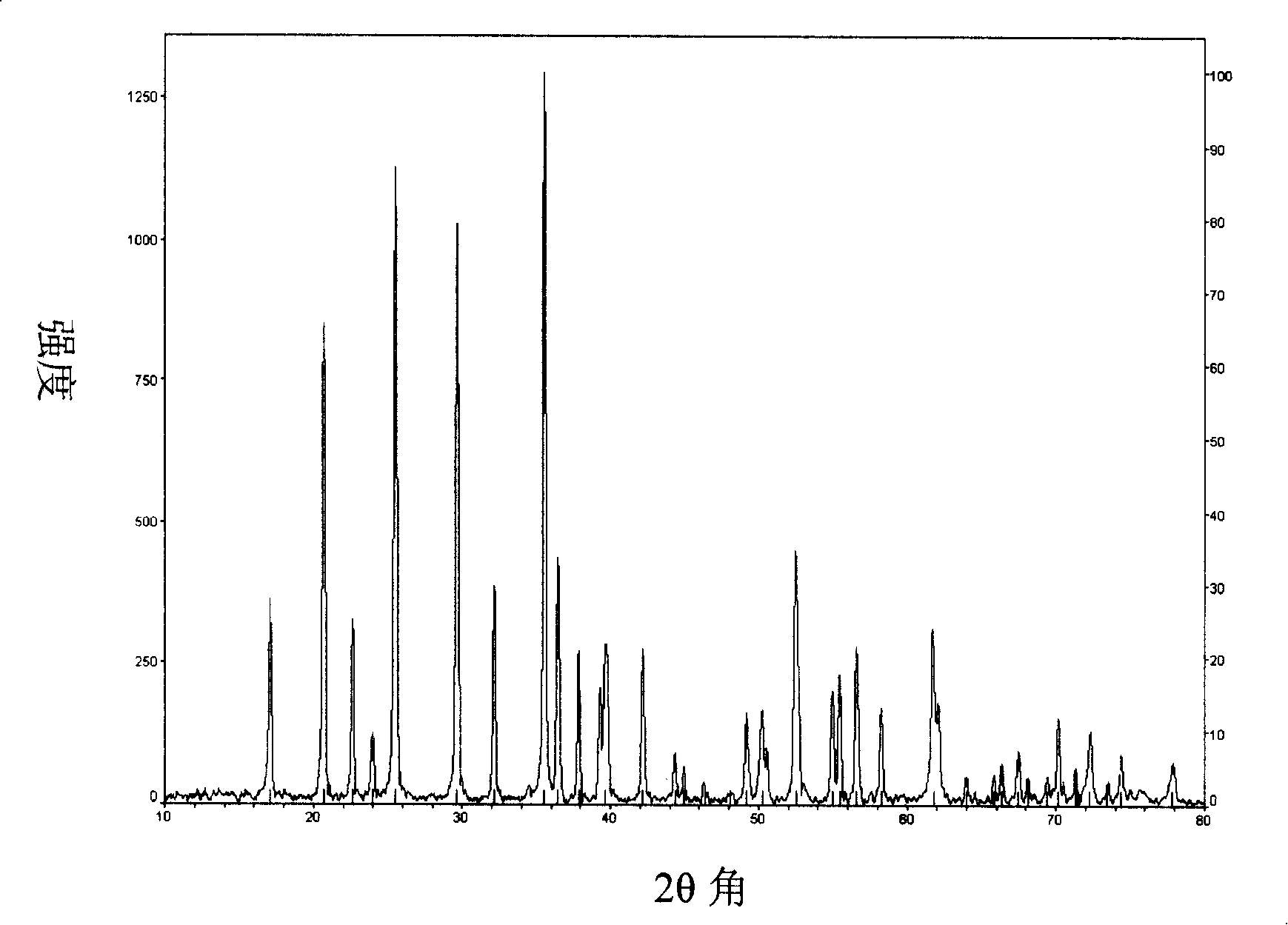

Preparation method for lithium ion secondary battery positive pole active substance lithium iron phosphate

ActiveCN101209827AImprove conductivityImprove electrical conductivityCell electrodesPhosphorus compoundsLithium compoundAnode

The invention relates to a preparation method of lithium iron phosphate, an active substance applied in the anode of lithium-ion secondary batteries. The method comprises a mixture that contains lithium compound, iron compound, phosphorus compound and carbon source additive is sintered and cooled to get a sintering product; wherein, the sintering method comprises the step: the mixture that contains lithium compound, iron compound, phosphorus compound and partial carbon source additive is sintered at a first constant sintering temperature, then a mixture of the product acquired at the first sintering temperature and the residual carbon source additive is sintered at a second constant sintering temperature, and the second sintering temperature is at least 100 DEG C higher than the first sintering temperature. The batteries made of the lithium iron phosphate prepared by the method of the invention have markedly improved discharge performance at high current.

Owner:BYD CO LTD

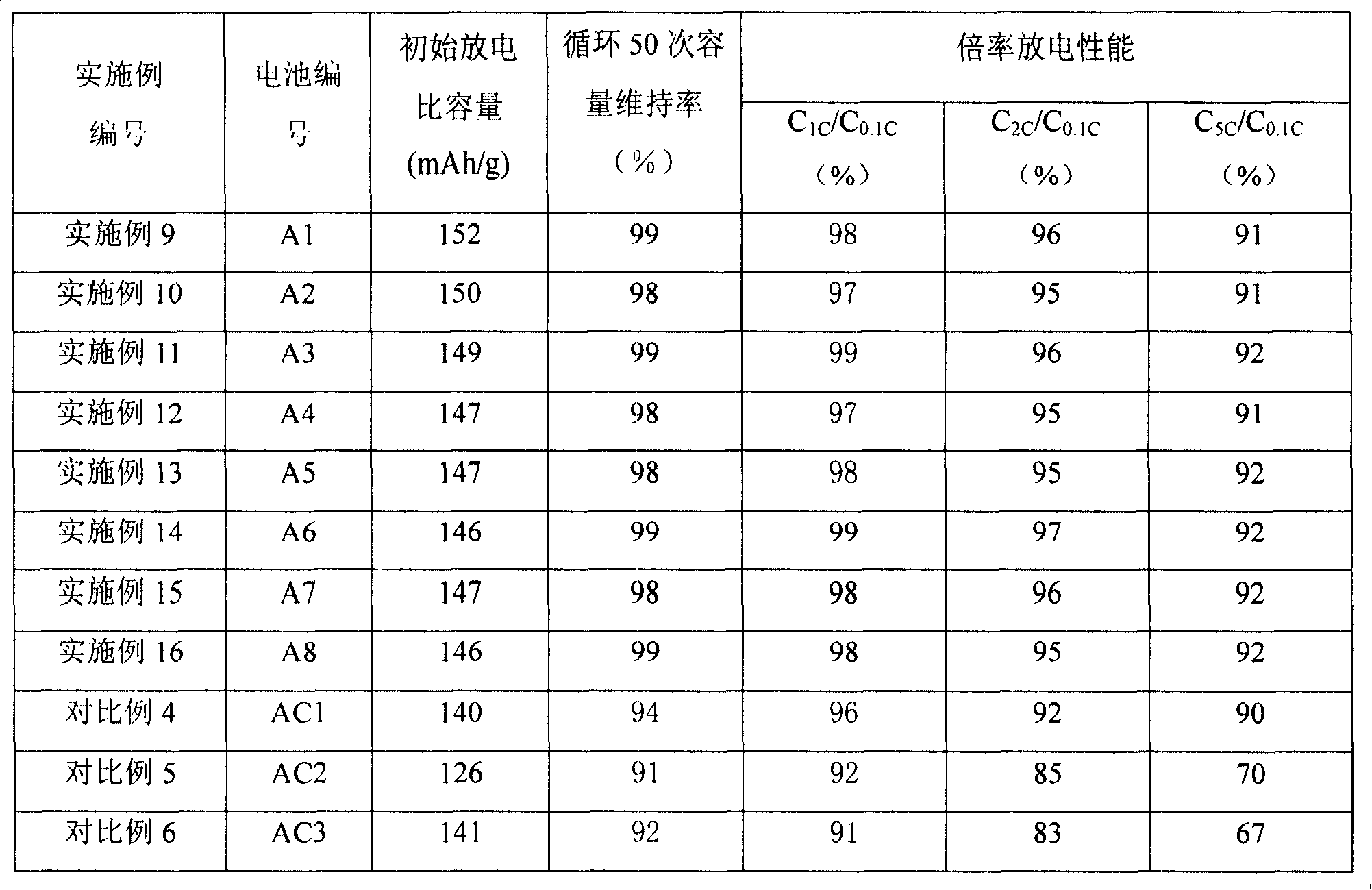

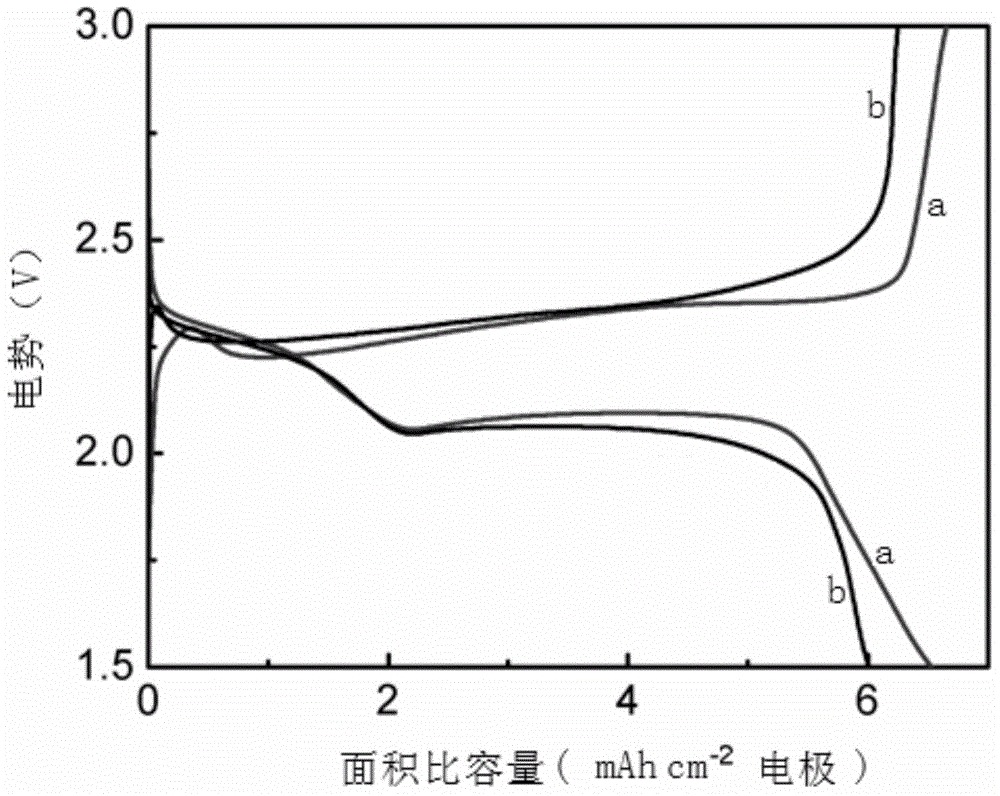

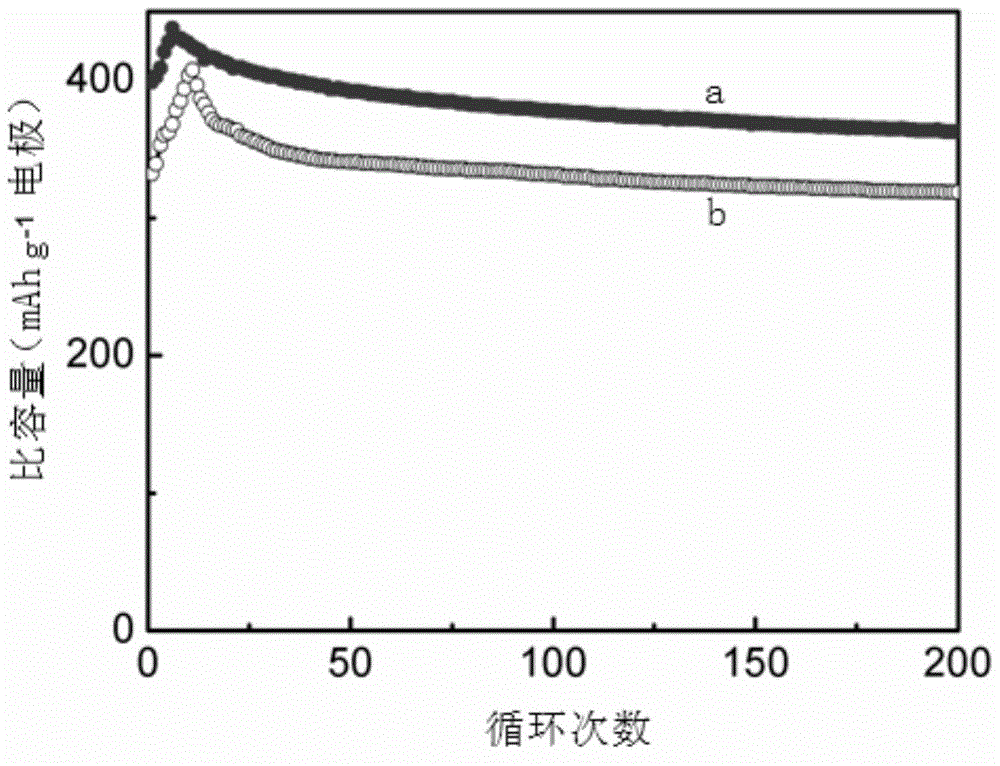

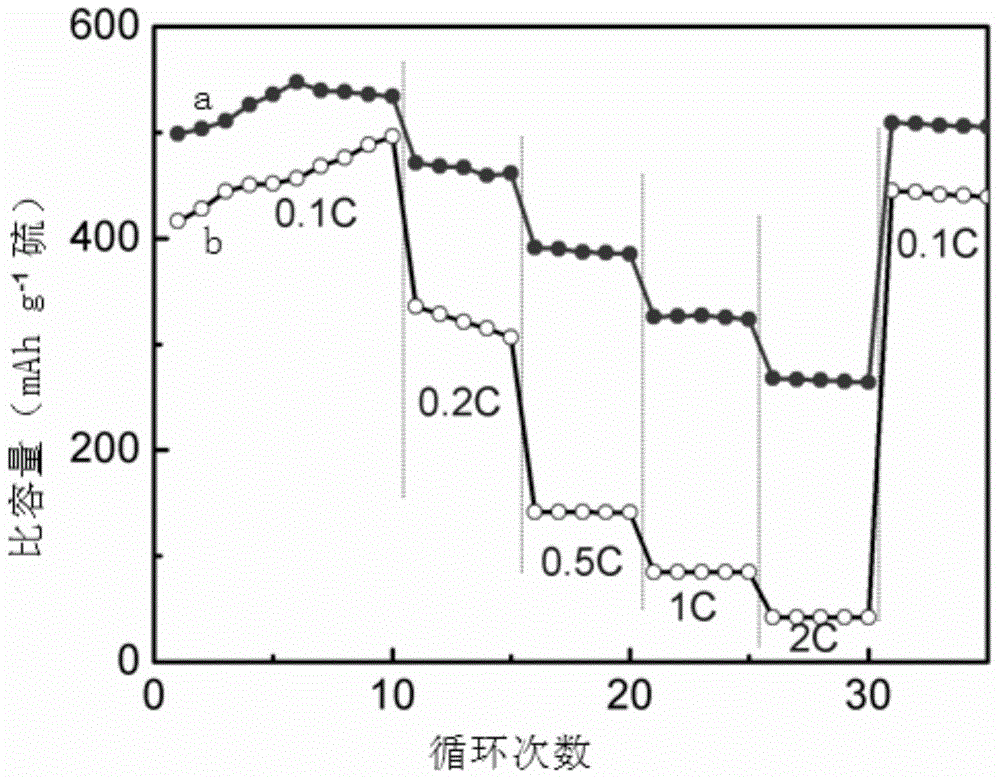

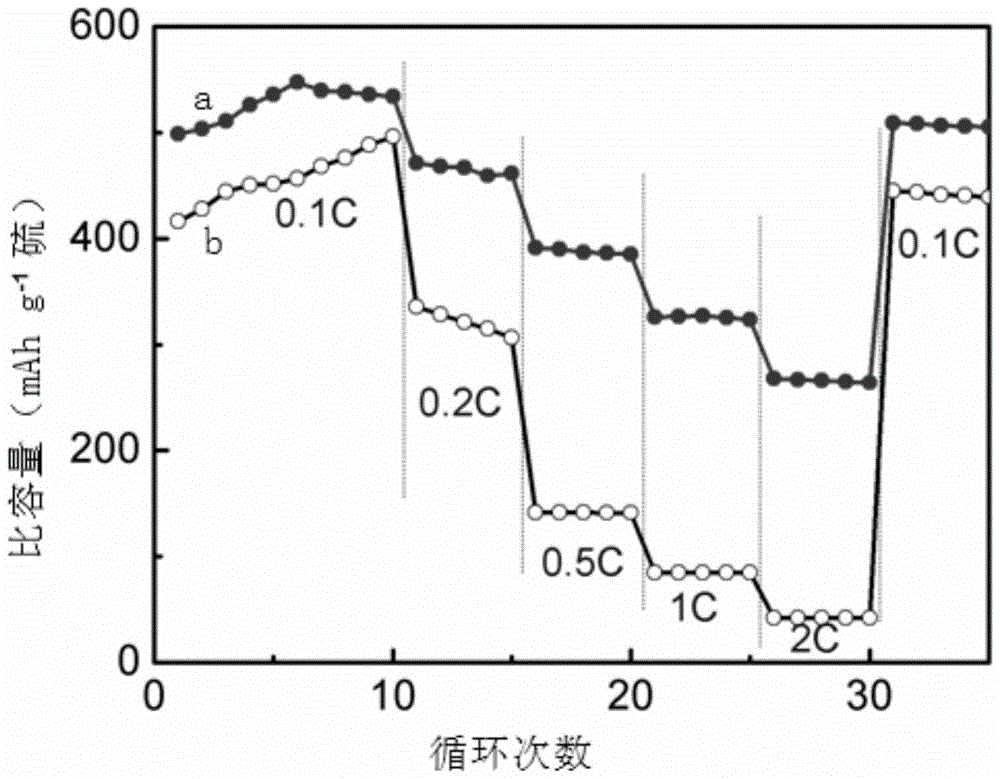

Lithium-sulfur battery carbon fiber reinforced three-dimensional graphene-sulfur positive electrode material, preparation method of material and preparation method of positive electrode

ActiveCN104617283AInhibition of agglomerationImprove conductivityElectrode manufacturing processesFiberCarbon fibers

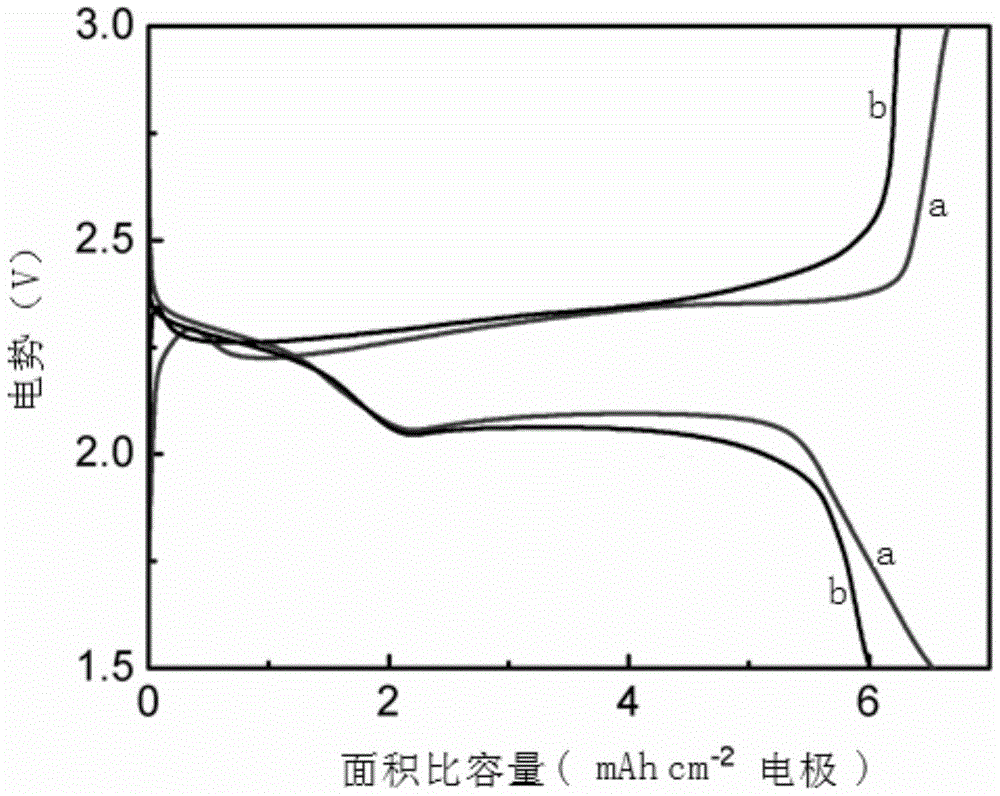

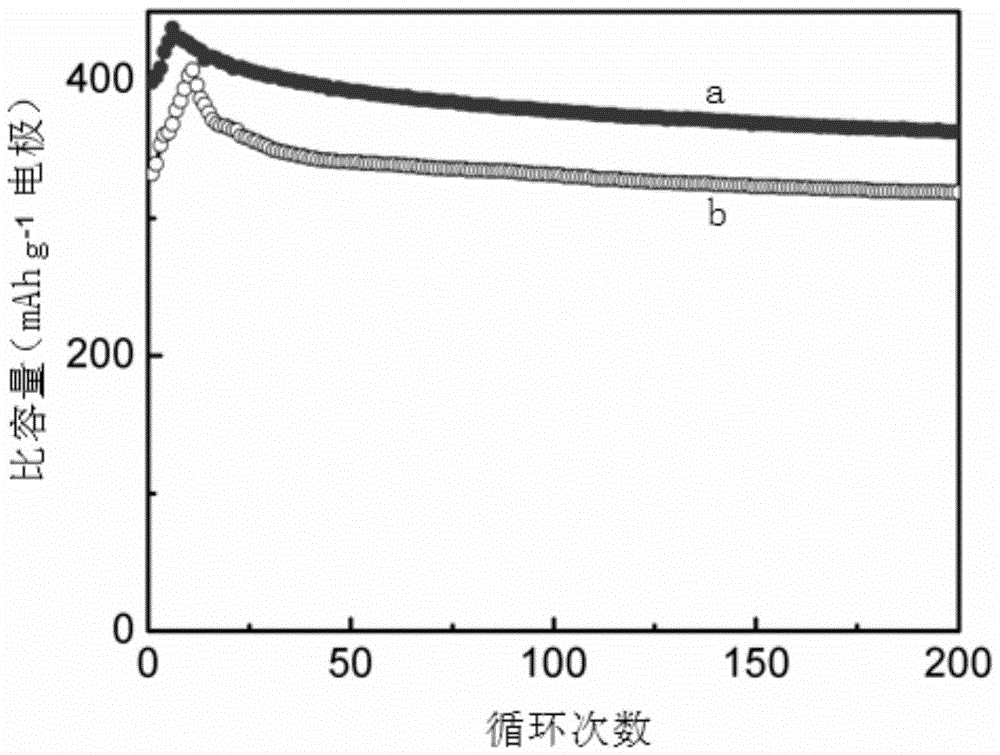

The invention discloses a lithium-sulfur battery carbon fiber reinforced three-dimensional graphene-sulfur positive electrode material, a preparation method of the positive electrode material and a preparation method of the positive electrode, relates to a lithium-sulfur battery positive electrode material, a preparation method of the positive electrode material and a preparation method of the positive electrode, and can be used for solving the technical problem that the conventional graphene-sulfur electrode is low in area specific capacity and bad in rate capability. The positive electrode material is formed by dispersing elemental sulfur in holes of carbon fiber modified spongy graphene. The preparation method of the positive electrode material comprises the following steps: adding carbon fibers into mixed liquid of graphene oxide dispersion liquid, carrying out hydro-thermal synthesis to obtain hydrogel and carrying out freeze-drying to obtain carbon fiber modified three-dimensional spongy graphene; cutting the carbon fiber modified three-dimensional spongy graphene into slices, sprinkling the elemental sulfur on the surfaces of the slices, placing the slices in a vacuum tank and heating to obtain the lithium-sulfur battery carbon fiber reinforced three-dimensional graphene-sulfur positive electrode material. The positive electrode is prepared by slicing the positive electrode material and then pressing. The area specific capacity of the electrode material is up to 10 mAh / cm<2>, so that the electrode material can be applied to lithium ion batteries.

Owner:HARBIN INST OF TECH

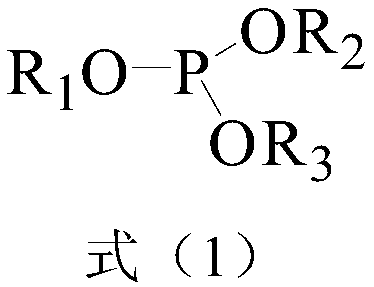

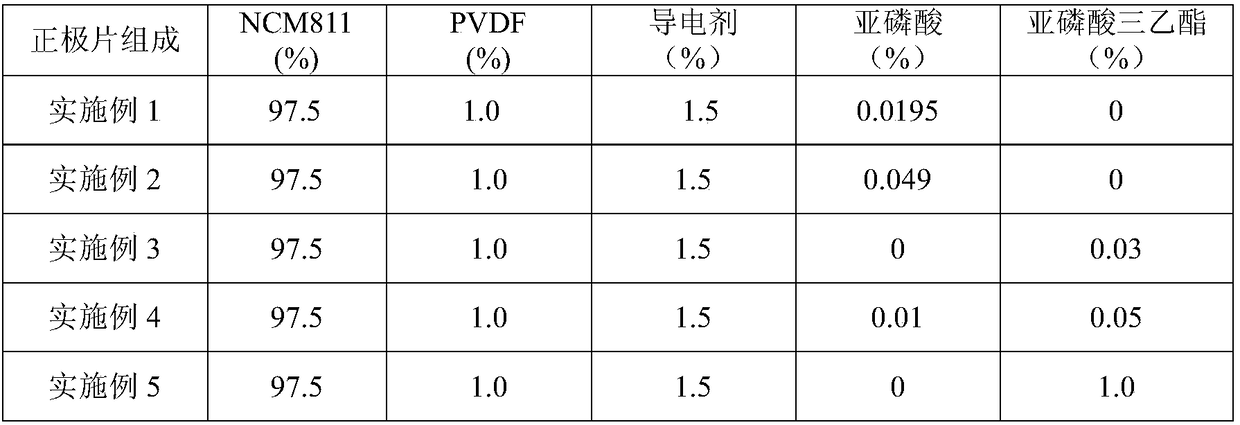

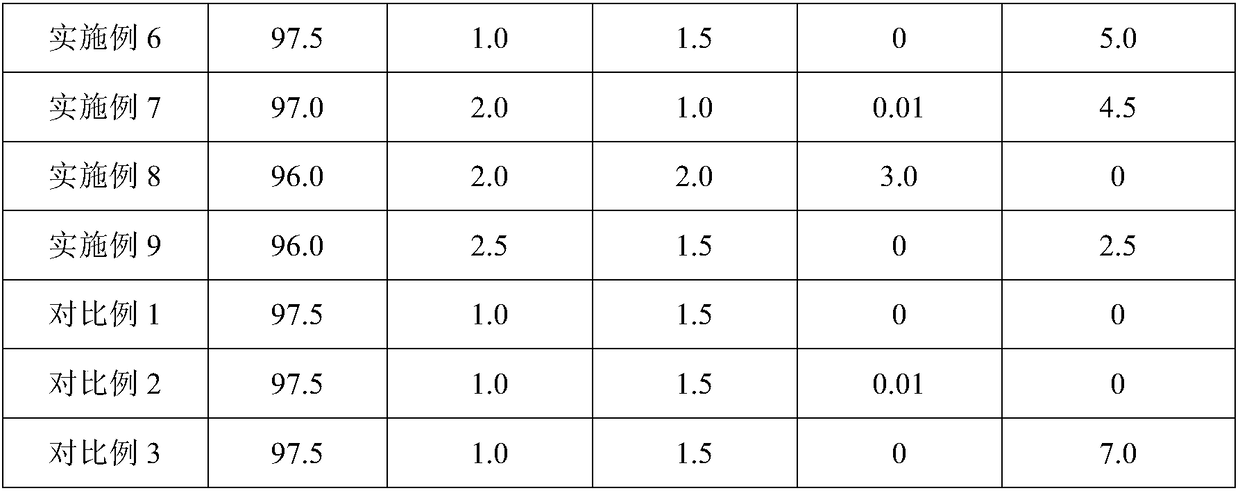

Positive electrode sheet and lithium ion secondary battery with same

ActiveCN108539122APlay a covering roleReduce concentrationCell electrodesSecondary cellsLithiumPhosphorous acid

The invention belongs to the technical field of lithium secondary batteries and discloses a positive electrode sheet preparation method and a lithium ion secondary battery with a positive electrode sheet. Prepared positive electrode sheet paste contains an additive in a molecular formula (1), and the additive can be phosphorous acid or phosphite ester. By adding of the appropriate quantity of phosphorous acid and / or phosphite ester into the positive electrode sheet paste, the problem of powder shedding of the positive electrode sheet can be improved, adhesiveness between a positive electrode sheet coating and an aluminum foil is improved, a positive electrode material particle coating effect is achieved, and accordingly battery gas-producing expansion is remarkably inhibited while batterycycle stability is improved.

Owner:HENGDIAN GRP DMEGC MAGNETICS CO LTD

Low-gram weight white impregnated bond paper and producing method thereof

The present invention relates to a production method of titanium white paper. Said production method includes the following steps: mixing the titanium white powder and adhesive B to obtain titanium white powder mixed adhesive B; mixing the titanium white powder and adhesive A to obtain titanium white powder mixed adhesive A; impregnating base paper with adhesive; spray-coating titanium white powder mixed adhesive B on one side or two sides of base paper impregnated with adhesive; drying said base paper; then spray-coating the titanium white powder mixed adhesive A on two sides of the base paper coated with titanium white powder mixed adhesive B; drying said base paper; cooling and cutting so as to obtain the invented low-gum white impregnated adhesive film paper finished product.

Owner:张志利

Method for planting paeonia lactiflora in saline-alkali area

InactiveCN108307968AChange structureInhibit salt returnFlowers cultivationObserved SurvivalPaeonia lactiflora

The invention discloses a method for planting paeonia lactiflora in a saline-alkali area, and relates to the technical field of planting of the paeonia lactiflora. The method comprises the following steps: (1) amelioration of saline-alkali land; (2) planting of auxiliary plants; (3) digging of planting holes; (4) seedling raising of seeds of the paeonia lactiflora; (5), transplanting; and (6), daily management. The method provided by the invention improves a survival rate and growth speed of planting of the paeonia lactiflora in the saline-alkali land, improves ornamental value and beautifiesthe environment.

Owner:HEFEI BAILYVSHENG AGRI TECH CO LTD

Coagulation controllable type cement based pore sealing material and application method thereof

InactiveCN106186976AExtended hydration timeCompensates for hydration shrinkageDrilling compositionAl powderAluminite

The invention relates to a coagulation controllable type cement based pore sealing material and application method thereof. A sulfoaluminate-silicate composite cement system with a certain ratio is adopted, a proper amount of industrial aluminum powder, a high efficient water reducer, and a resin type polymer material is added; an individual grinding technology is adopted, sulfoaluminate cement clinker and resin are grinded together at first so that fine resin particles can be adsorbed on the surface of the mineral particles in sulfoaluminate cement clinker; during the construction process, after the material is contacted with water, the resin wrapped on the surface of the clinker particles reacts with water to form a crosslinking coating film, the hydration of sulfoaluminate minerals is sustained-controlled therefore; the forming speed and forming amount of hydration products such as ettringite (Aft), hydrated aluminate, and the like can be adjusted; the setting time of sealing materials is effectively delayed; the construction becomes convenient, moreover, the sealing material can continuously and slightly expands in the sealed holes, a high early strength is provided for the material, the hydration shrinkage of silicate phase is compensated at the same time, and thus the pore sealing material can be used for a long time.

Owner:UNIV OF JINAN

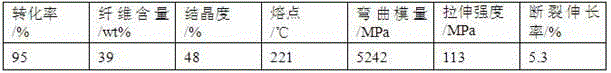

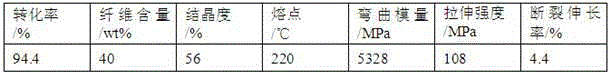

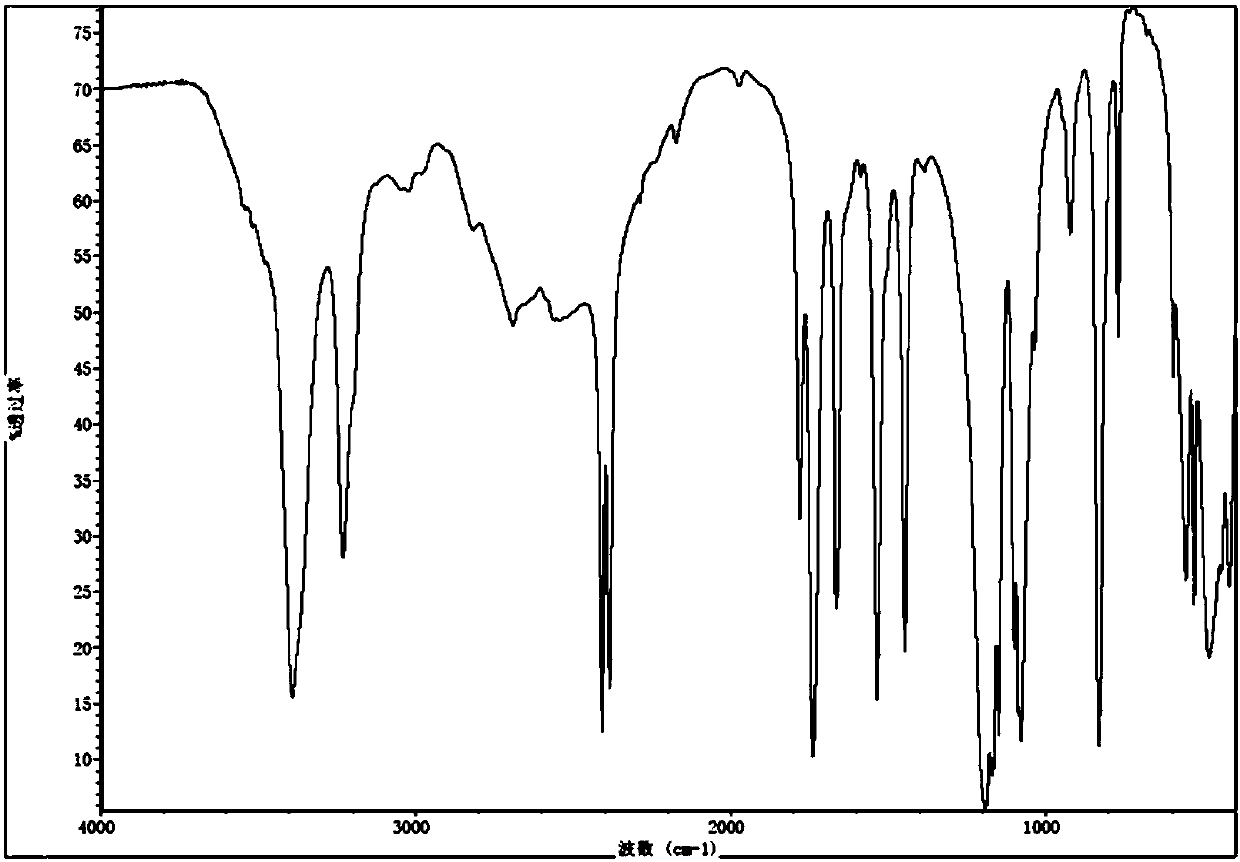

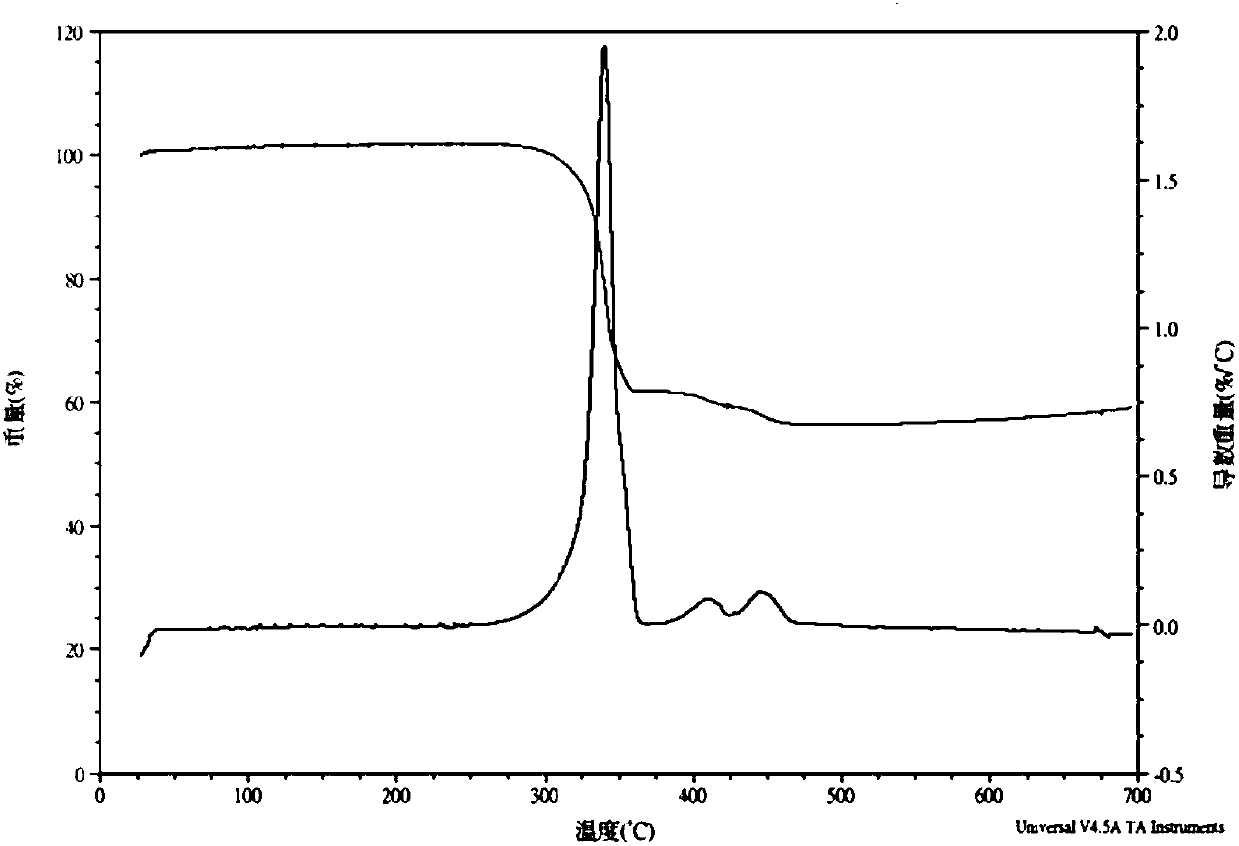

Method for modifying natural fibers for anion polymer nylon 6 reaction

InactiveCN104313876AAggregate perfectStrong interfaceLiquid/gas/vapor removalDry-cleaning apparatus for textilesPolymer scienceNatural fiber

The invention discloses a method for modifying natural fibers for anion polymer nylon 6 reaction, in particular relates to a method for primarily modifying the natural fibers in a specific solution and removing impurities which are attached on the surface of the natural fiber and can produce adverse effect on the anion polymerization process. In order to further improve the reaction processing process, the primarily modified natural fibers are modified in a specific coupling agent solution, so that the surface of the natural fiber is coated by a given coupling agent molecular layer, and the coupling agent molecular layer can play a role in shielding active groups, and also can play a role in facilitating interface interaction between the fiber and a polymer substrate. The modified natural fibers successfully react with anion polymer nylon 6, so that a novel natural fiber composite material is produced, and the natural fibers can be widely used in the field of a macromolecular material; meanwhile, the utilization rate of the natural fibers also can be increased, and the development of the natural fiber industry in China can be promoted.

Owner:SICHUAN UNIV

Modified aluminum hypophosphate flame retardant and preparation method thereof

The invention relates to the field of flame retardants, in particular to a modified aluminum hypophosphate flame retardant. A preparation method of the modified aluminum hypophosphate flame retardantcomprises the following steps: 1) adding aluminum hypophosphate and a dispersing agent in a reaction kettle and fully stirring, so that a solution is uniformly dispersed; 2) adding an adhesive and a modifying agent, raising the temperature, stirring and fully reacting to obtain a crude product; and 3) washing, filtering and drying the crude product to obtain the modified aluminum hypophosphate flame retardant. The modified aluminum hypophosphate flame retardant prepared by the preparation method provided by the invention can effectively solve the problems of low aluminum hypophosphate heat resistance, low compatibility, low dispersing performance and the like.

Owner:广东顺德同程新材料科技有限公司

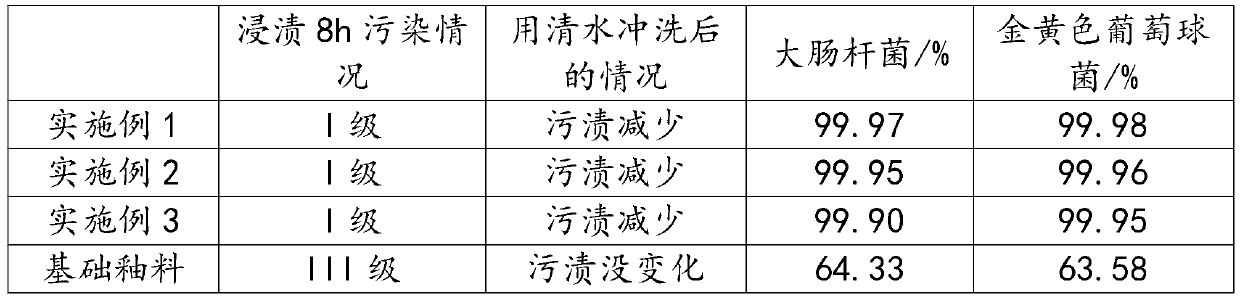

Antifouling antibacterial ceramic glaze and preparation method thereof

The invention discloses an antifouling antibacterial ceramic glaze, which is prepared from, by weight, 50-60 parts of basic glaze slurry, 7-9 parts of calcium oxide, 3-5 parts of calcium carbonate, 4-6 parts of aluminum hydroxide, 4-5 parts of an antibacterial agent, 5-7 parts of nano zinc oxide, 2-3 parts of sodium hexametaphosphate, 8-10 parts of a phosphoric acid aqueous solution and 2-3 partsof an yttrium nitrate aqueous solution. The invention further discloses a preparation method of the antifouling antibacterial ceramic glaze. By the adoption of the antifouling antibacterial ceramic glaze and the preparation method thereof, the antibacterial agent is added into basic glaze, the antibacterial agent can be uniformly distributed in the glaze, and sintered ceramic can continuously andslowly release silver ions in water, so that a continuous antibacterial effect is achieved; the phosphoric acid aqueous solution and the yttrium nitrate aqueous solution are adopted in the glaze, so that the ceramic sintered by the glaze has good hydrophobicity, dirt cannot be firmly attached to the surface of the coating, the dirt can be washed away when water drops flow past a surface layer, andan antifouling effect is achieved; and a preparation process is simple, the conditions are easy to control, and production cost is low.

Owner:潮州市华利达陶瓷制作有限公司

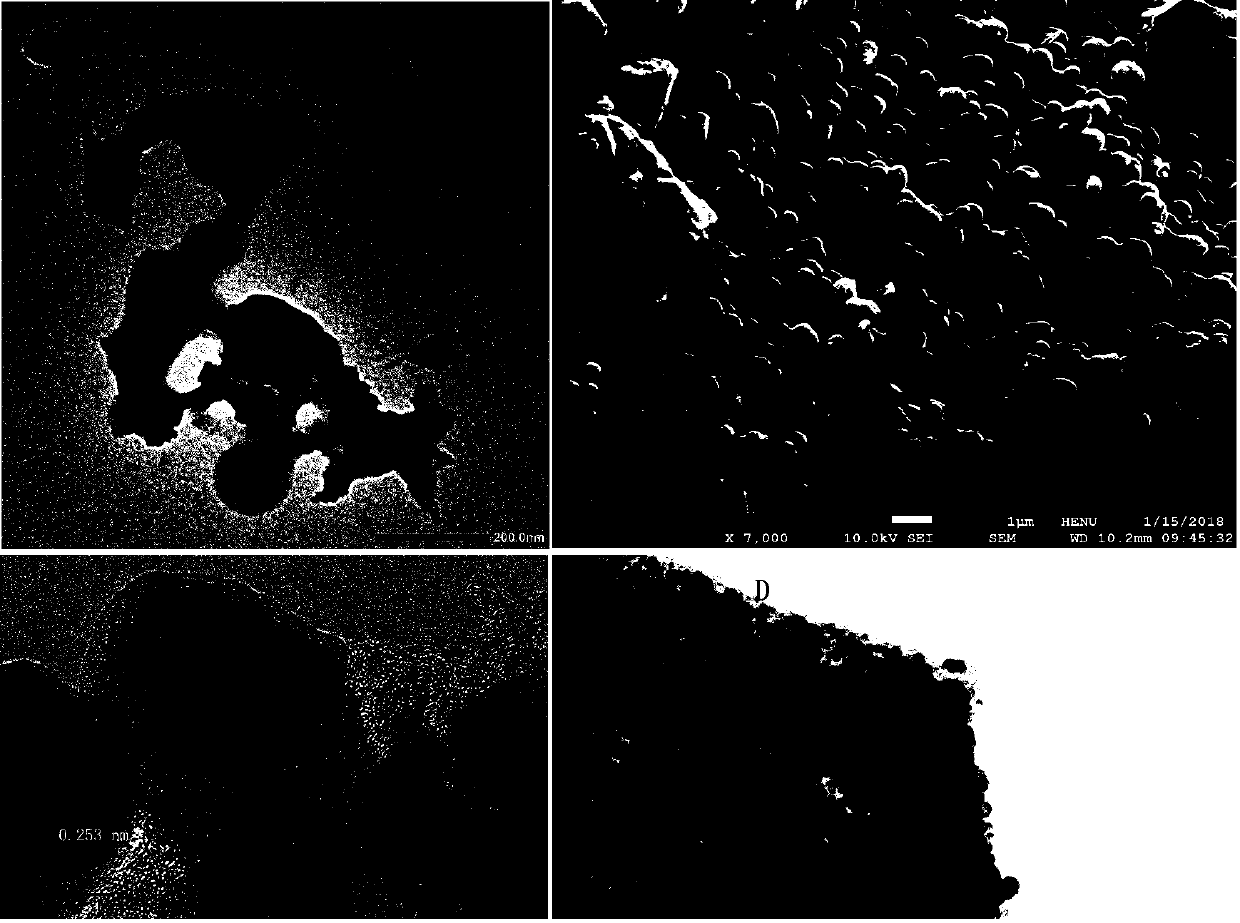

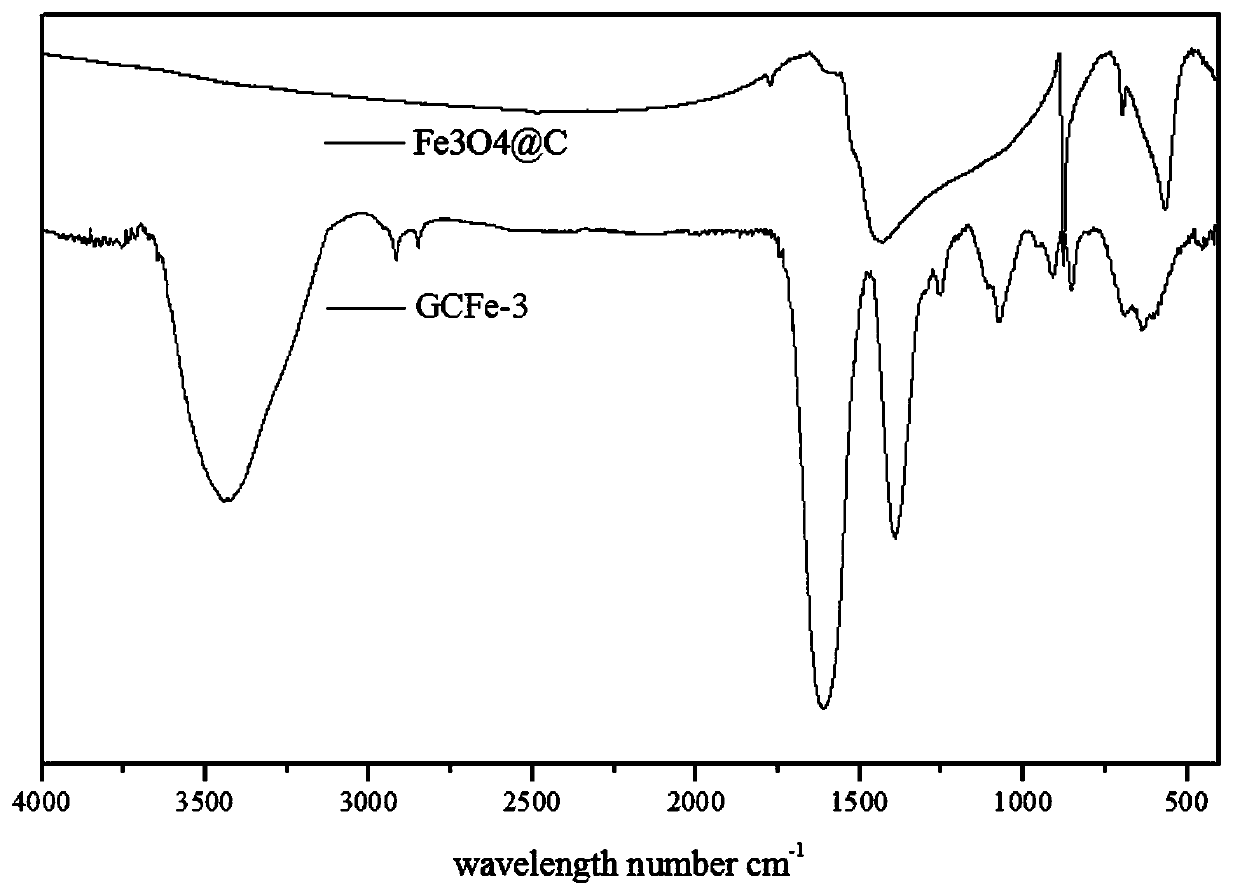

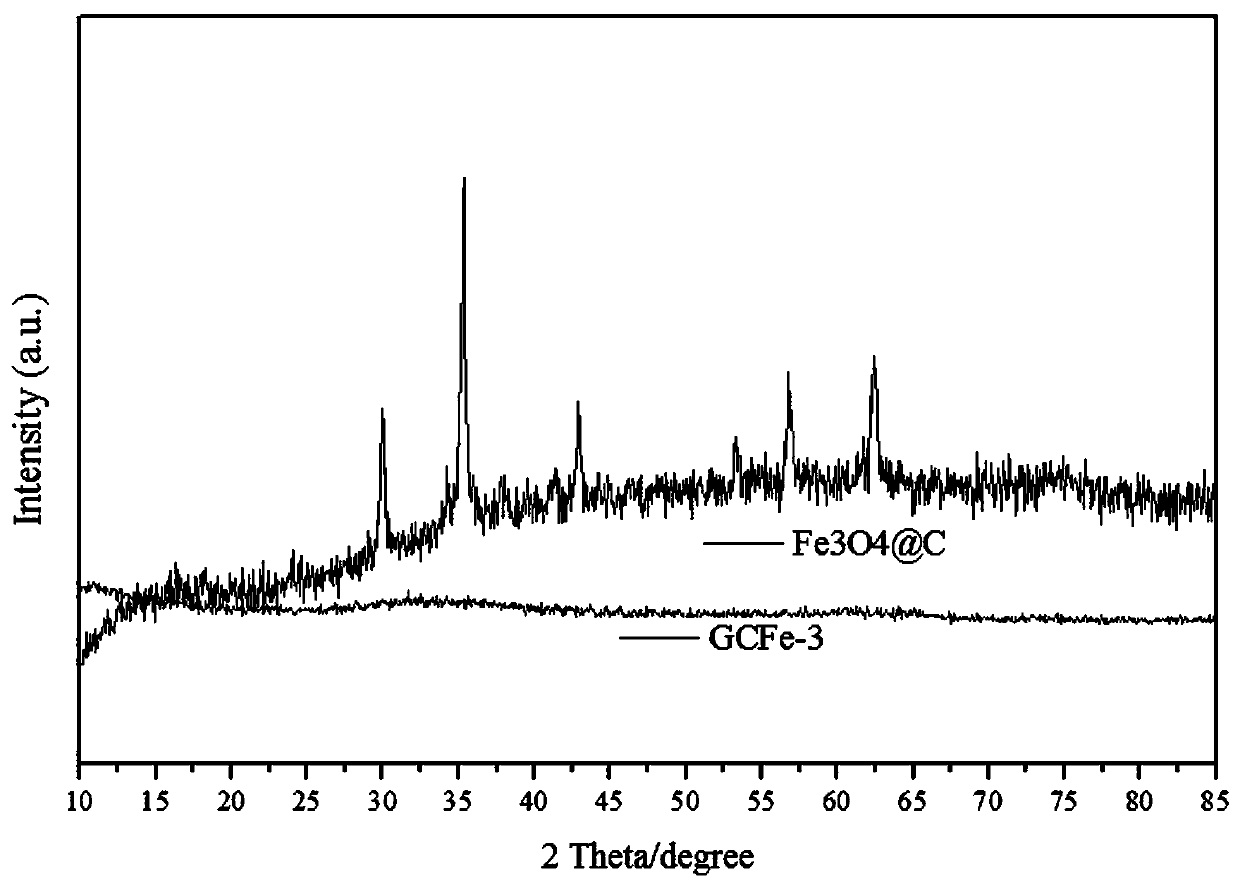

Carbon coated layer thickness adjustable nanometer ferroferric oxide composite material, preparation method and application thereof

InactiveCN110212192APlay a covering roleInhibition of agglomerationMaterial nanotechnologyCell electrodesCarbon layerOxide composite

The invention relates to the field of electrochemical materials, in particular to a carbon coated layer thickness adjustable nanometer ferroferric oxide composite material, a preparation method and application thereof. The preparation method comprises the following steps: firstly, taking sugar, a catalyst and a ferric salt solution as raw materials, reacting for 0.1 to 24 h under the conditions that the pH is 5 to 10 and the temperature is 5 to 90 DEG C, preparing an iron-sugar complex, and thus preparing the carbon coated layer thickness adjustable nanometer ferroferric oxide composite material from the iron-sugar complex through in situ calcinations or a hydrothermal method. The nanometer ferroferric oxide composite material with a carbon coated layer is prepared through different in situ calcinations conditions or the hydrothermal method by using the iron-sugar complex as a precursor, and due to the fact that a multi-stage carbon structure array can play the role of a fixed frame for ferroferric oxide, the volume effect in the charge and discharge cycle process is reduced, and when the composite material serves as the negative electrode of a battery, the performance of the battery can be improved obviously. The thickness of the carbon coated layer inside the carbon coated ferroferric oxide composite material can be changed by changing the additive amounts of sugar and the catalyst.

Owner:HENAN UNIVERSITY

Nano-titanium dioxide automobile topcoat coating

The invention discloses a nano-titanium dioxide automobile topcoat coating. The nano-titanium dioxide automobile topcoat coating is characterized by being prepared from the following raw materials in parts by weight: 55-70 parts of titanium dioxide slurry, 8.5-21.4 parts of nano-titanium dioxide slurry, 6-8 parts of polar resin, 0.2-0.4 part of a flatting agent and 15-20 parts of a dispersing agent, wherein the nano-titanium dioxide slurry comprises the following components in percentage by mass: 88 percent of hydroxy acrylic resin, 7 percent of nano-titanium dioxide, 2 percent of dimethylbenzene, 2.6 percent of butyl alcohol and 0.4 percent of butyl acetate; the particle diameter of the nano-titanium dioxide is 65-130 nanometers; the dispersing agent is the combination of butyl alcohol, butyl acetate and dimethylbenzene. By adopting the coating, the agglomeration, flocculation and dispersion of titanium dioxide are avoided, and stable ultraviolet resistance, high hardness and high compactness are realized.

Owner:CHONGQING UNIVERSITY OF SCIENCE AND TECHNOLOGY

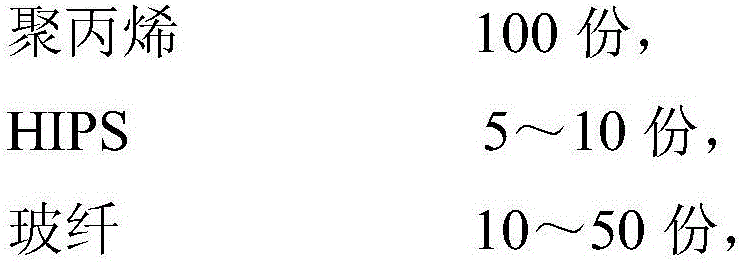

Attractive-appearance and anti-corrosive polypropylene composite material and preparation method thereof

The invention relates to an attractive-appearance and anti-corrosive polypropylene composite material and a preparation method thereof. The attractive-appearance and anti-corrosive polypropylene composite material is prepared from the following raw materials in parts by weight: 100 parts of polypropylene, 5 to 10 parts of high impact polystyrene, 10 to 50 parts of glass fibers, 3 to 5 parts of compatilizer 1, 1 to 3 parts of compatilizer 2, 0.3 to 1 parts of antioxidant, 0.5 to 5 parts of lubricant, and 0.2 to 0.5 part of coupler. The invention also provides the preparation method of the attractive-appearance and anti-corrosive polypropylene composite material. The attractive-appearance and anti-corrosive polypropylene composite material has the advantages that the appearance is attractive, the anti-chemical corrosive property is realized, the tensile strength and notch impact strength are higher, the comprehensive property is excellent, and the attractive-appearance and anti-corrosive polypropylene composite material can be applied to the fields of washing machine drums, dish-washing machine brackets, pumps and the like.

Owner:上海日之升科技有限公司

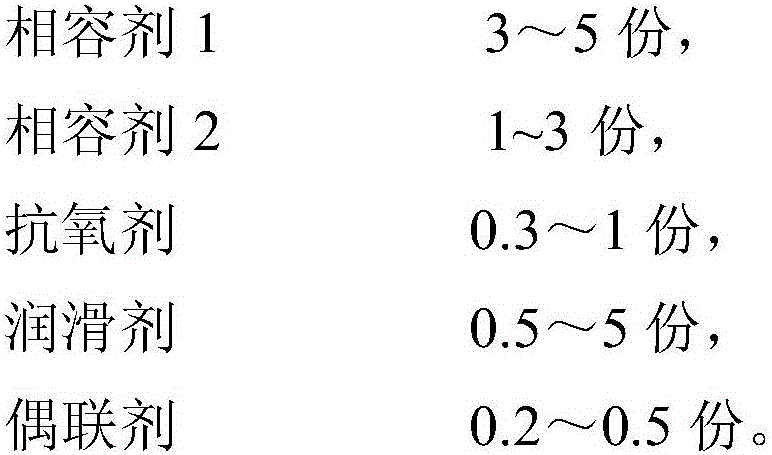

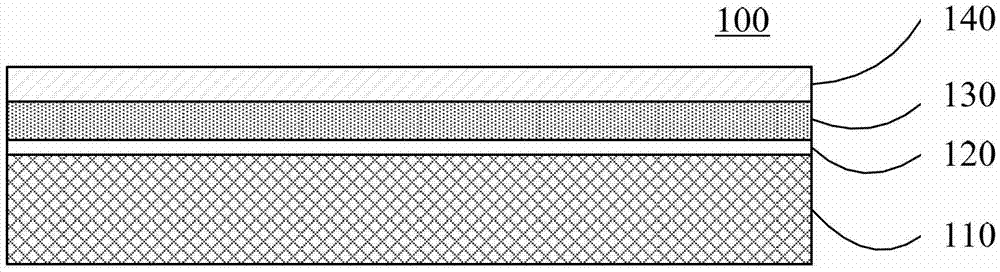

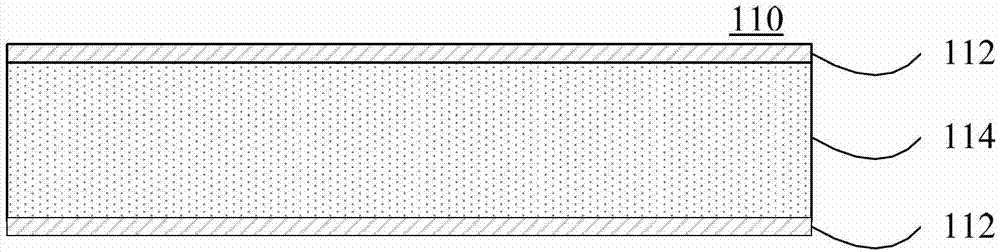

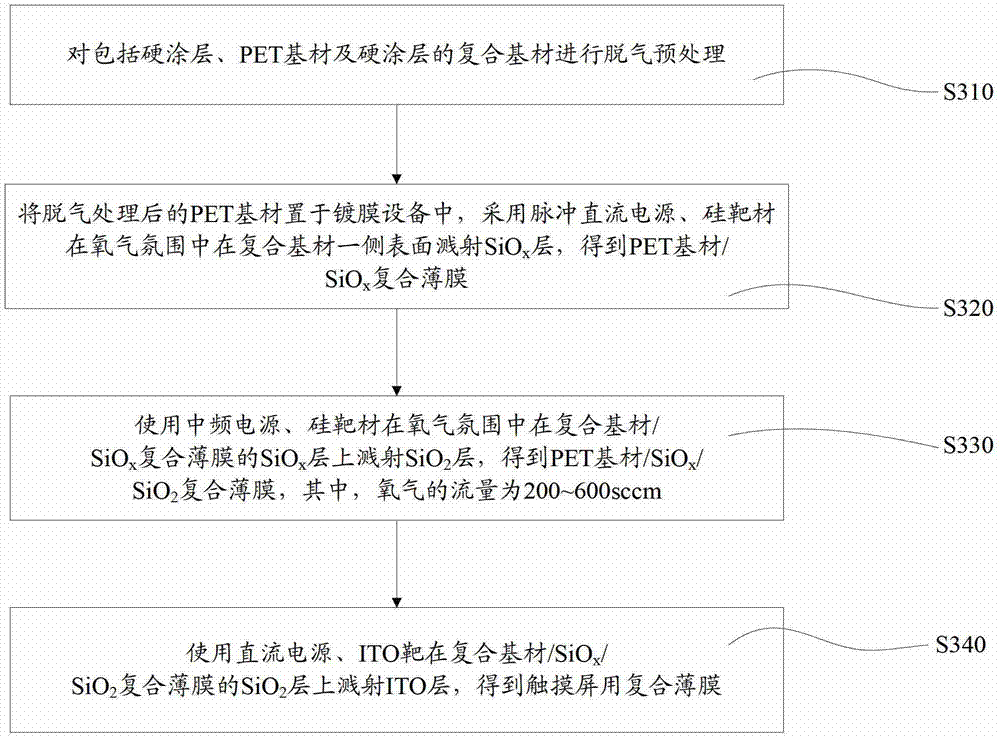

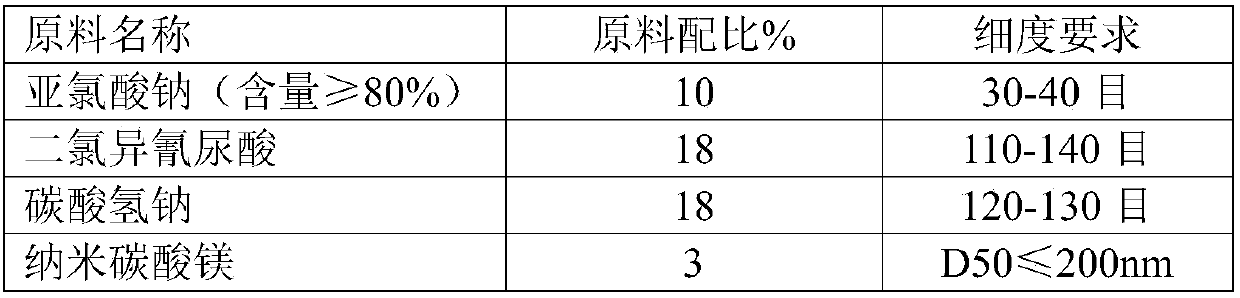

Composite film for touch screen and production method of composite film

ActiveCN102776476AIncrease productivityReduced degassing requirementsVacuum evaporation coatingSputtering coatingPolyethylene terephthalateComposite film

The invention relates to a composite film for a touch screen and a production method of the composite film. The composite film comprises a hard coating, a composite base material, an SiOx layer, an SiO2 layer and an ITO layer, wherein the x ranges between 1.0 and 1.9, a transition layer of the SiOx layer is added between a polyethylene terephthalate (PET) base material and the SiO2 layer, a certain Si-dangling bond exists in the SiOx layer, the Si-dangling bond and a C-H bond or C-OH bond, which exists on the surface of the composiste material are combined to form a C-Si or a C-O-Si covalent bond, adhesive force of the SiO2 layer and the ITO layer on the composite material is enhanced, the degassing requirement for the composite base material is reduced greatly, the degassing processing time is shortened, the production efficiency is improved, and the SiOx layer and the SiO2 layer have covering functions for the base material, so that water in the composite material is prevented from affecting ITO coating films, and the stability of ITO resistance is guaranteed.

Owner:深圳南玻显示器件科技有限公司

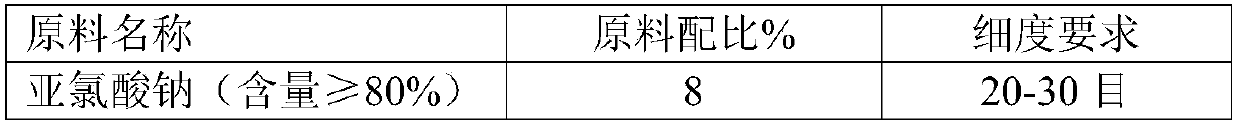

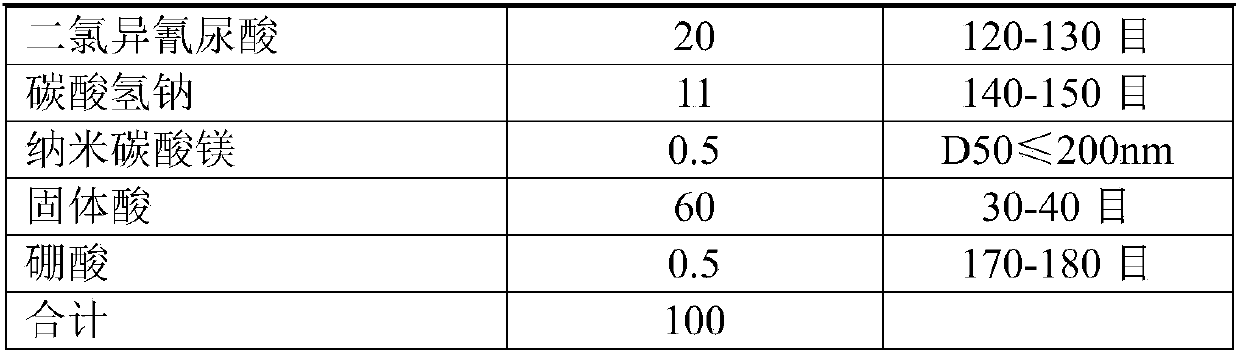

Compound disinfection tablet and preparation method thereof

InactiveCN107593720ARapid bactericidal effectReduce environmental pollutionBiocideDisinfectantsChemical disinfectionChemistry

A compound disinfection tablet belongs to the technical field of chemical disinfection and comprises the following components by weight percent: 8-31% of sodium chlorite, 5-20% of dichlord isocyanurice acid, 10-20% of sodium bicarbonate, 0.5-3% of nanometer magnesium carbonate, 25-60% of solid acid and 0.5-1.0% of boric acid. The invention also discloses a preparation method of the compound disinfection tablet. The preparation method is simple, the prepared disinfection tablet is uniform in ingredient, can produce various disinfection ingredients including chlorine dioxide, hypochlorous acid and active oxygen after being dissolved in water, and is improved in sterilization and disinfection performance, the solution is good in stability and small in corrosivity, and the product using cost is lowered. The compound disinfection tablet is mainly used for sterilization and disinfection of swimming pool water, industrial circulating water, aquaculture water, daily life and the like.

Owner:河北冀衡化学股份有限公司

Processing method of waterproof and moisture permeable polytetrafluoroethylene millipore membrane laminated fabric

InactiveCN101532257BLow solid contentPlay a bond strengthSynthetic resin layered productsTextiles and paperFiberTetrafluoroethylene

Owner:宁波登天氟材有限公司

External wall penal with excellent silencing and fireproof performances

InactiveCN105838231AImprove lipophilicityPromote softeningFireproof paintsCovering/liningsAntioxidantPotassium hydroxide

The invention discloses an exterior wall panel with excellent sound-absorbing and fire-proof performance, which comprises a base layer, a sound-absorbing fireproof layer, a plastering mortar layer, a waterproof layer, a decorative coating and a wear-resistant layer; the preparation method of the sound-absorbing fireproof layer is as follows: hydroquinone, Potassium hydroxide and toluene are mixed evenly, and then a toluene solution containing hexachlorocyclotriphosphazene is added dropwise, heated up, kept warm, washed with an alkali solution to obtain an organic phase, then the organic phase is distilled under reduced pressure, dried in vacuum, and recrystallized to obtain material a ; Mix material a and polytetrahydrofuran ether glycol evenly, then add trimethyl-1,6-hexamethylene diisocyanate, fill with dry nitrogen for protection, heat up, keep warm, and cool down to obtain material b; Add trimethylpentanediol, glycerin, bismuth neodecanoate, foaming agent, foaming aid, expanded perlite, palygorskite, diatomaceous earth, glass fiber, flax fiber, zinc borate hydrate, anti-aging agent and Acetone is mixed evenly, coated on the surface of the base layer, then heated up, and kept warm to obtain a sound-absorbing and fire-proof layer.

Owner:ANHUI DEQUAN NEW BUILDING MATERIALS TECH CO LTD

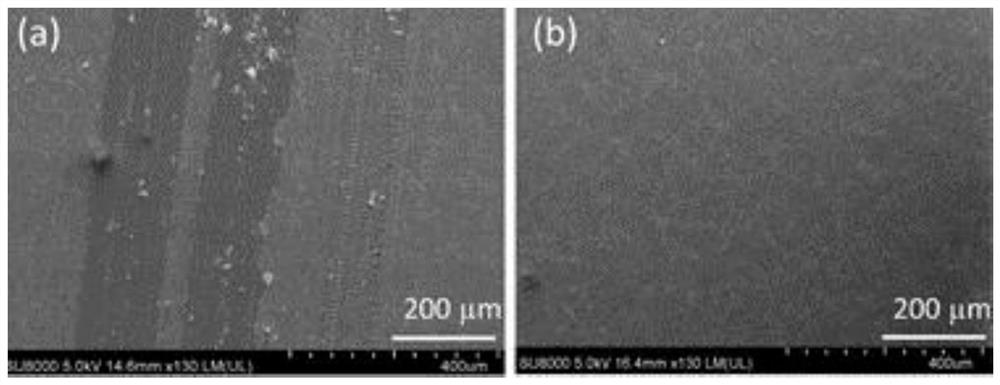

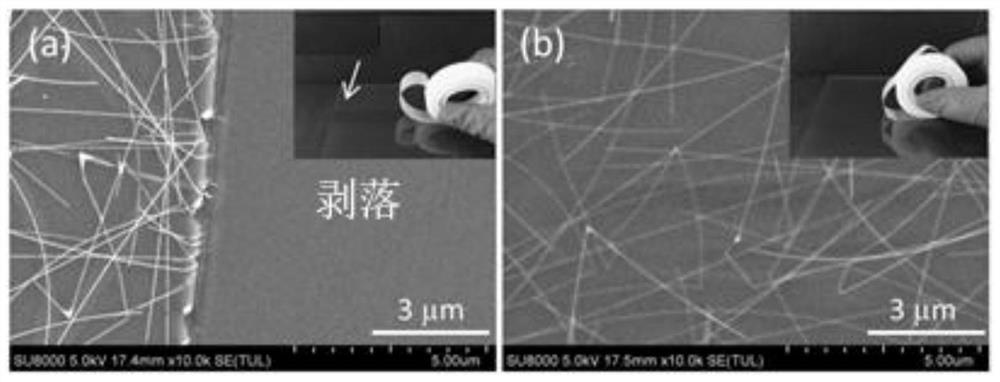

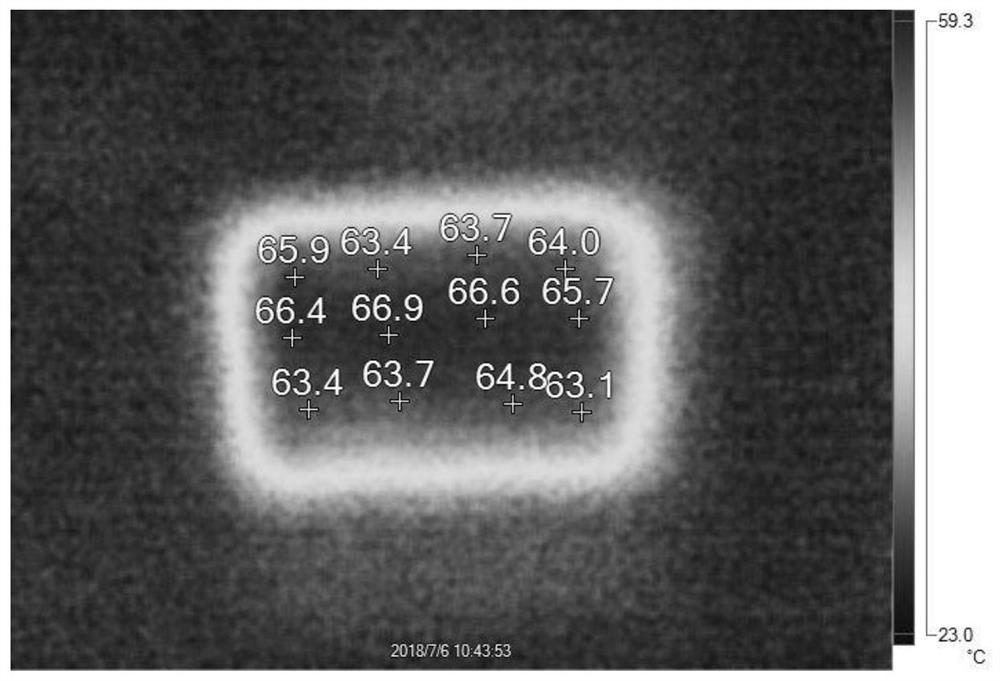

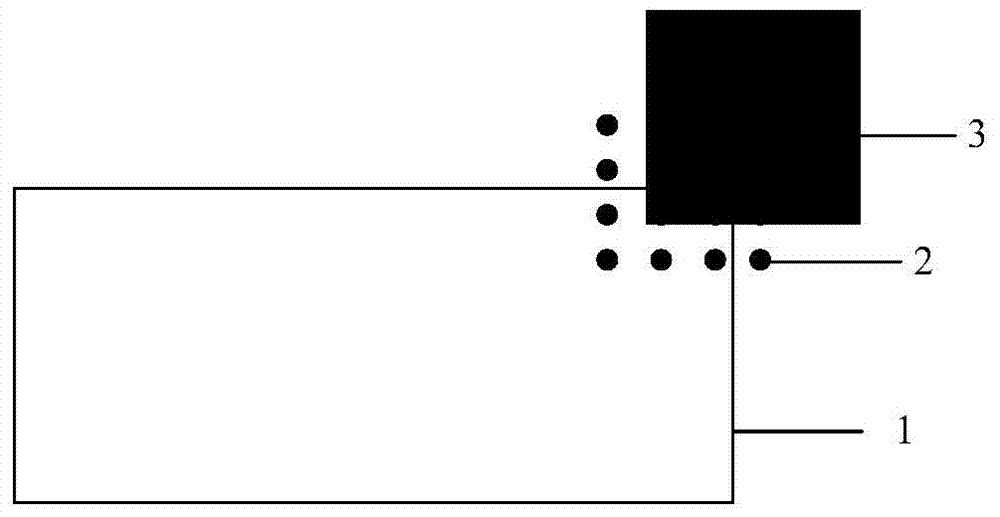

Preparation method of silver nanowire film heater resistant to repeated scraping

InactiveCN111698796AEasily brokenImprove scratch resistanceLiquid surface applicatorsCoatingsThin membraneDip-coating

The invention discloses a preparation method of a silver nanowire film heater resistant to repeated scraping. The method comprises the steps: coating a high-temperature-resistant substrate with silvernanowire glue; preparing line electrodes at the two ends of a conductive thin film; performing the dip coating of the surface layer of a metal thin film device with a layer of silica sol and then performing curing; finally, coating a device with a layer of glass glaze in a silk-screen or blade coating mode, and after high-temperature annealing, obtaining the heater resistant to repeated scrapingof the metal nano conductive thin film. The problems that an existing heater is complex in process, uneven in heating and not resistant to scratching are solved. According to the invention, the silvernanowire synthesized by a low-temperature liquid phase method is used as a raw material, the conductive film is coated by a non-vacuum and non-high-temperature film preparation process, and the thin-layer protective film is obtained by coating silica sol and glass glaze, so the raw material is low in cost, the preparation process condition requirement is low, and large-scale production can be realized.

Owner:NANJING SILVERNANO NEW MATERIALS TECH CO LTD

Anti-counterfeiting identification with interference element layer and method and device for identifying anti-counterfeiting identification with interference element layer

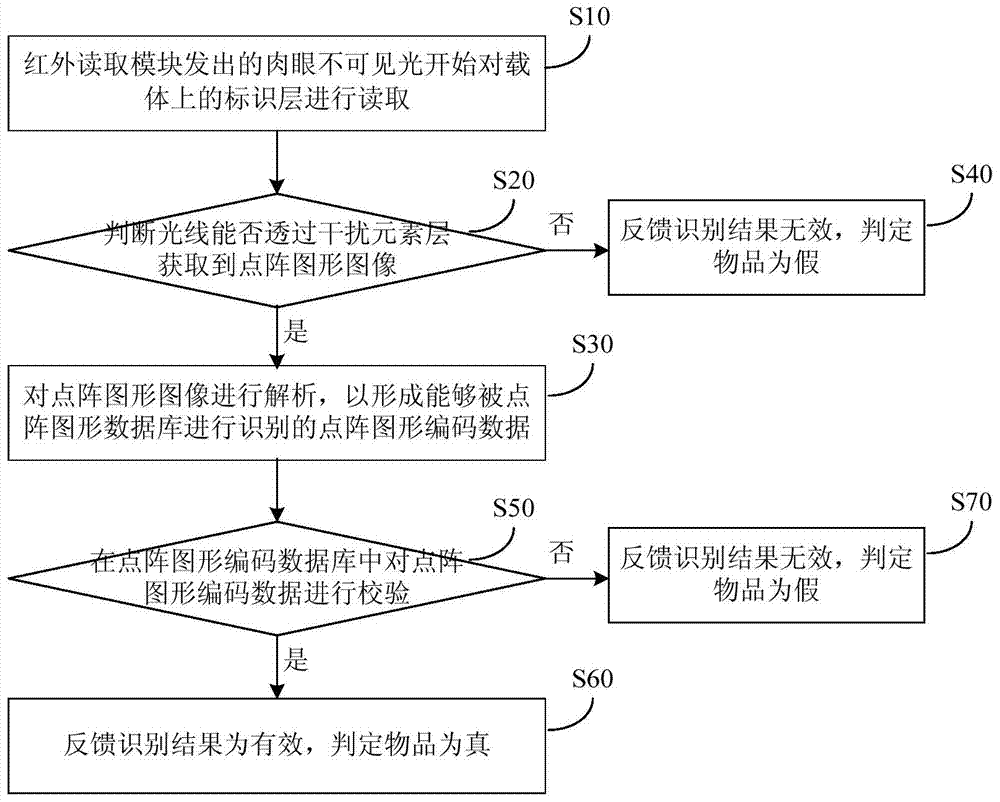

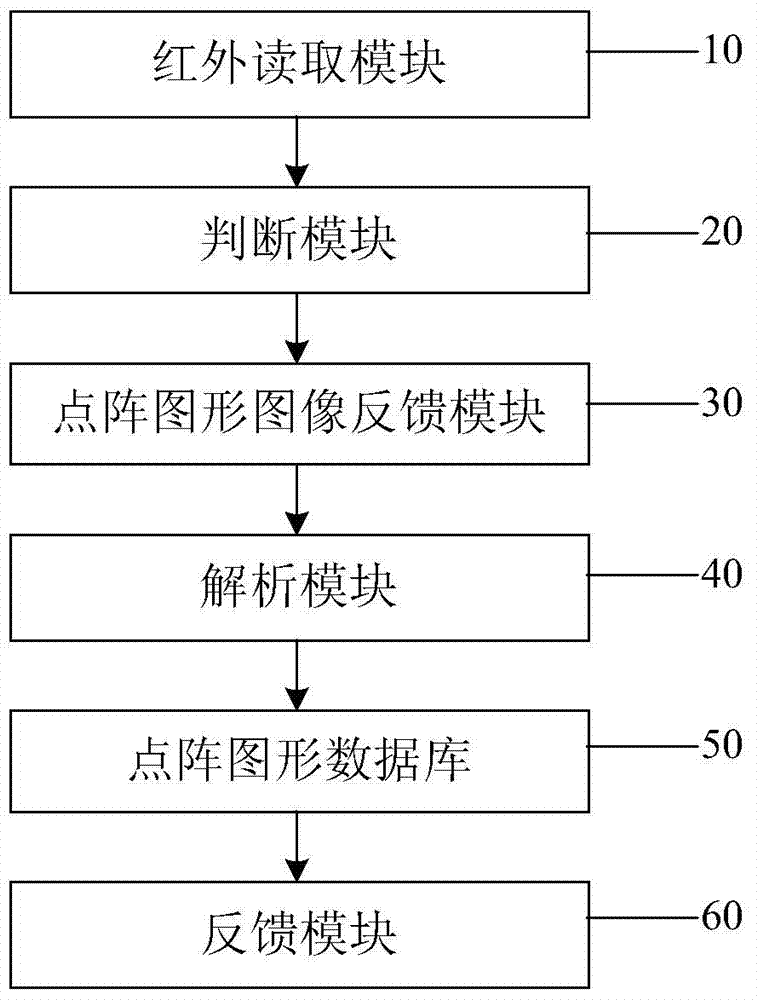

ActiveCN103794137AImprove anti-counterfeiting performancePlay a covering roleStampsCharacter and pattern recognitionRaster graphicsGraphics

The invention provides anti-counterfeiting identification with an interference element layer. The color of an identification layer and the color of the interference element layer belong to the same color system, the identification layer is covered with the interference element layer and characterized in that coatings capable of absorbing light invisible to the eyes are attached to a carrier, and light used for reading raster graphics can reach the raster graphics through the interference element layer. A method for identifying the anti-counterfeiting identification includes the steps that the light passes through the interference element layer to read the raster graphics; images of the raster graphics are analyzed to form raster graphic data capable of being identified; the raster graphic data are verified to distinguish the authenticity of the raster graphics and feed back relevant information. A device for achieving the method comprises an infrared reading module, a judgment module, a raster graphic image feedback module, an analysis module, a raster graphic database and a feedback module. According to the anti-counterfeiting identification and the method and the device for identifying the anti-counterfeiting identification, the identification layer can be shielded and covered with the interference element layer, and influences on identifying of the identification layer are avoided.

Owner:GUANGZHOU PULISI TECH CO LTD

Container protective finish coating and preparation method thereof

InactiveCN107384174APlay a covering roleHas a bonding effectPolyurea/polyurethane coatingsEmulsion paintsWater basedCoating system

The invention discloses a container protective finish coating and a preparation method thereof. The container protective finish coating is prepared from 20.1-25 parts of water, 0.7-1 part of a wetting agent, 1.1-1.5 parts of a dispersant, 18-20 parts of titanium dioxide, 1.8-2.0 parts of barium sulfate, 7-10 parts of kaolin, 18-20 parts of talcum powder, 0.8-1 part of a defoamer, 32-35 parts of waterborne polyurethane and 0.5-1 part of a flatting agent. According to the technical scheme, the container protective finish coating is a water-based coating system, is extremely low in VOC amount, environment-friendly and good in adhesion, aging resistance, waterproofness and hardness.

Owner:SHENZHEN JIADA HIGH TECH IND DEV

Early strength durable hole sealing material based on hydration controlled-release aluminate cement and application method

InactiveCN106186977AImprove early strengthControllable clotting timeClay processing apparatusCement mixing apparatusAluminiumSetting time

The invention relates to an early strength durable hole sealing material based on hydration controlled-release aluminate cement and an application method. The sealing material is controllable in condensation, easy to construct and sufficient in gas expansion. An aluminate-silicate composite cement system with a certain matching ratio is adopted, and an appropriate amount of aluminum powder and resin high polymer materials are added. A grinding technology is adopted for preferentially grinding aluminate cement clinker and resin, and micro resin particles are adsorbed to the surfaces of mineral particles of the aluminate cement clinker. In the construction process, after the materials make contact with water, resin wrapping the surface of the clinker particle surfaces reacts with water to form an interwoven coating film, slow release control over hydration of aluminate mineral can be achieved, the forming speed and amount of ettringite, hydrated aluminate and other products are adjusted, the setting time of the sealing material can be effectively delayed, construction is convenient, the sealing material is allowed to be continuously expanded in a sealed hole, high early strength is provided for the material, hydration shrinkage of a silicate phase is compensated for, and the hole sealing material can be continuously and durably used.

Owner:UNIV OF JINAN

Automotive polyvinyl chloride interior trimming panel and preparation method thereof

InactiveCN109161132AHigh hardnessHigh bending strengthChemical industryFlexural strengthPolyvinyl chloride

The invention discloses an automotive polyvinyl chloride interior trimming panel and a preparation method thereof, belongs to the technical field of polyvinyl chloride panels, and solves the problemsthat the thickness, the hardness, the bending strength and the like of existing wood-plastic panels cannot meet the requirements of automotive interior trimming panels. The polyvinyl chloride interiortrimming panel is prepared from 80-100 parts of polyvinyl chloride SG8-type resin, 40-50 parts of heavy calcium carbonate, 10-20 parts of a wood-plastic reclaimed material, a foaming regulator as well as ingredients including a calcium-zinc stabilizer, an interior lubricant, an exterior lubricant, a foaming agent, wood flour and the like. The preparation method of the panel comprises steps as follows: the polyvinyl chloride SG8-type resin and the ingredients are put into a hot-mixing pot for hot-mixing, then the foaming regulator and calcium powder are put sequentially for hot-mixing, the wood-plastic reclaimed material is put finally, the mixture is put into a cold-mixing pot for cooling after hot-mixing, is sent to a mold for extrusion finally after being plasticized by seven sections of double screws of a barrel, is subjected to cooling press-fitting shaping by a shaping platform and is pulled out by a pulling machine for cutting forming, and a finished product is obtained. The invention is applicable to the automotive interior trimming panel.

Owner:SHANDONG HUIFENG NEW MATERIAL TECH CO LTD

A preparation method of carbon fiber reinforced three-dimensional graphene-sulfur cathode material for lithium-sulfur battery and preparation method of cathode

ActiveCN104617283BInhibition of agglomerationImprove conductivityElectrode manufacturing processesFiberCarbon fibers

Owner:HARBIN INST OF TECH

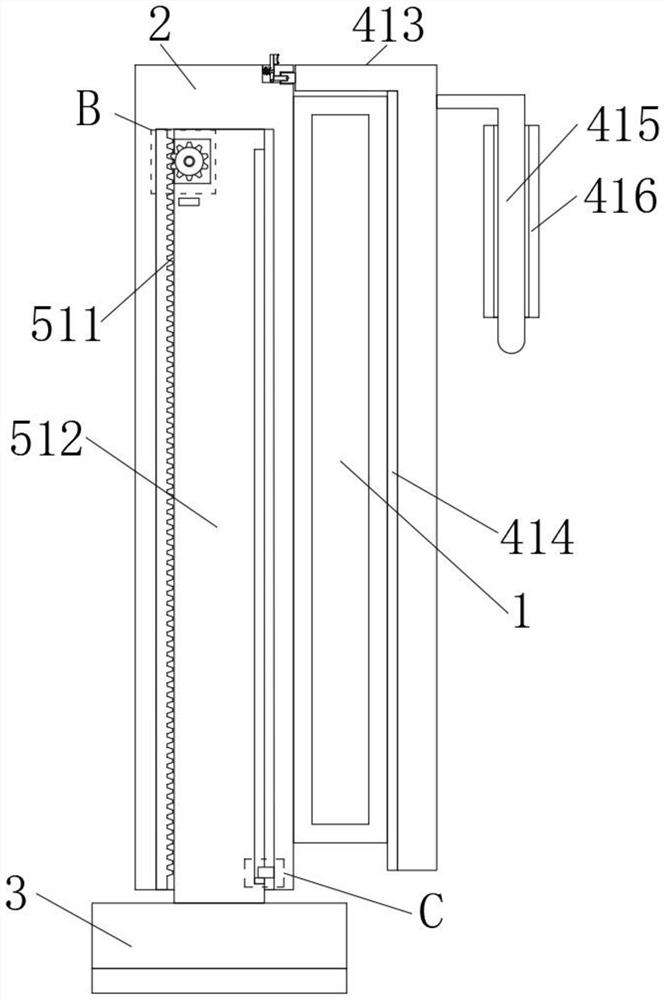

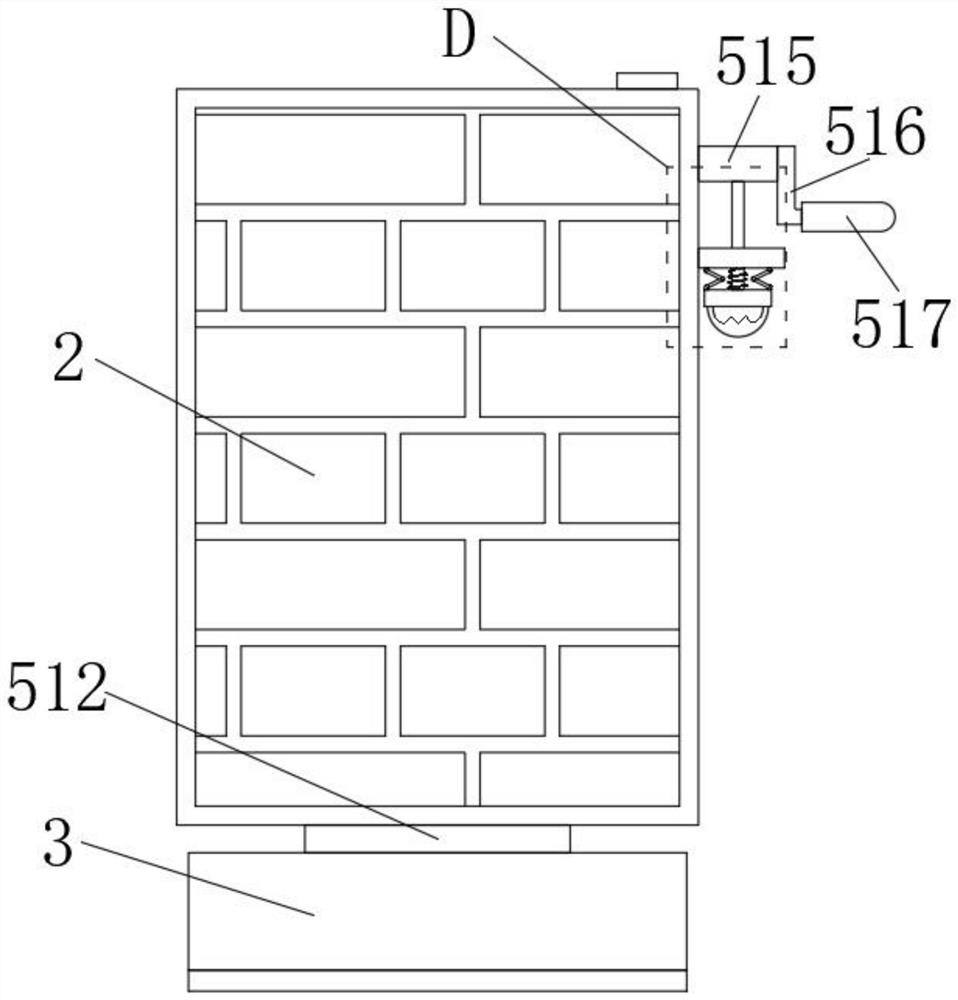

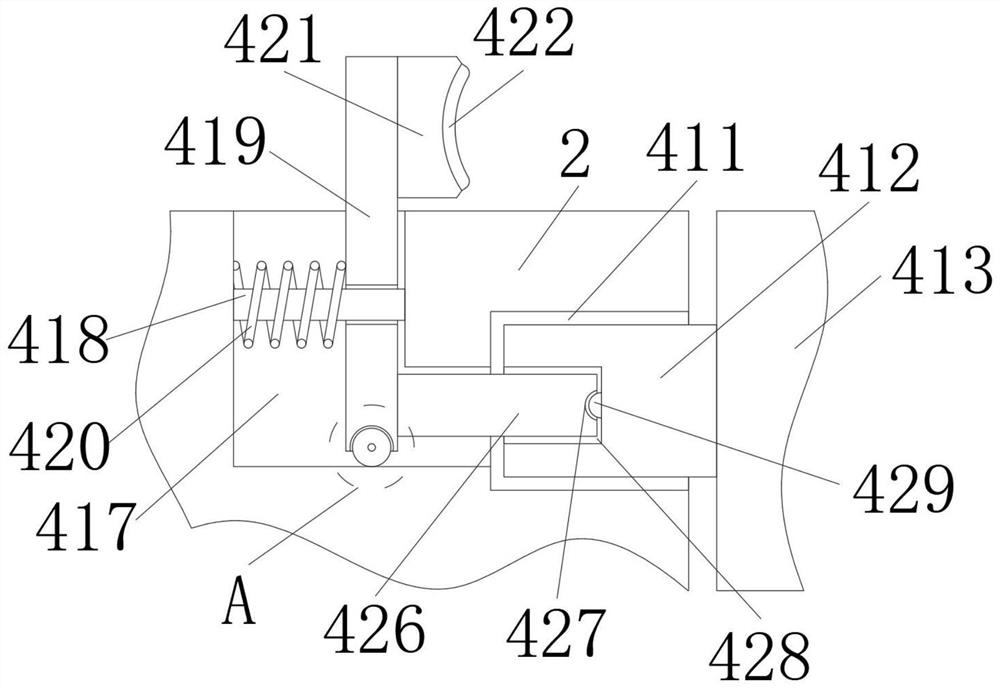

Solar panel with anti-covering structure

InactiveCN112436788AReduce wearExtended service lifePhotovoltaic supportsSolar heating energyEngineeringStructural engineering

The invention discloses a solar panel with an anti-covering structure. The solar panel comprises a solar panel main body, a support column main body and a pedestal main body, the left side of the solar panel main body is fixedly connected with the support column main body, the bottom end of the support column main body is equipped with the pedestal main body, and the outer wall of the solar panelmain body is equipped with an anti-covering mechanism. The anti-covering mechanism comprises a first sliding groove, and the interior of the supporting column body is provided with the first sliding groove. By arranging the mechanism, when the solar panel is not used, the solar panel can be correspondingly covered, the abrasion to the solar panel is further reduced, the service life of the solar panel is greatly prolonged, the practicability of the solar panel is further improved, and by arranging the mechanism, the height of the supporting column fixedly connected with the solar panel can becorrespondingly adjusted, the practical operability of the solar panel is improved, and the data acquisition accuracy of workers on the solar panel is further improved.

Owner:江门市南燕新能源开发有限公司

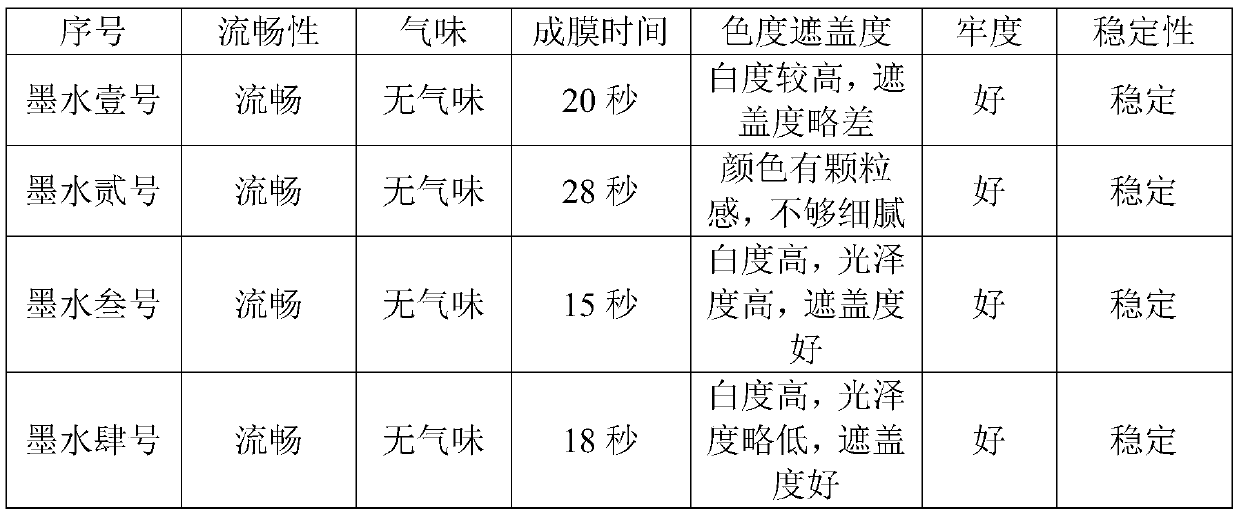

Water-based propylene marker pen ink and preparation method thereof

The invention discloses water-based propylene marker pen ink and a preparation method thereof. The water-based propylene marker pen ink comprises 10-20% of titanium dioxide, 0-4% of pigment, 5-8% of an interphase modifier, 40-50% of an acrylic resin emulsion film-forming agent and 25-40% of water, wherein the interphase regulator comprises an amphiphilic polymer and a polymer with a moisturizing effect. According to the ink, titanium dioxide and pigment are used, an environment-friendly non-toxic polymer is used as a functional interphase regulator, and a film-forming emulsion is matched, so that the ink which is stable in performance, smooth in water discharging, uniform in distribution and high in color fastness is obtained. The raw materials of the ink are cheap and easily available, the preparation process is simple and feasible, the process and the product are environment-friendly and non-toxic, and the ink does not contain any volatile organic small molecular substances.

Owner:苏州雄鹰笔墨新材料有限公司 +1

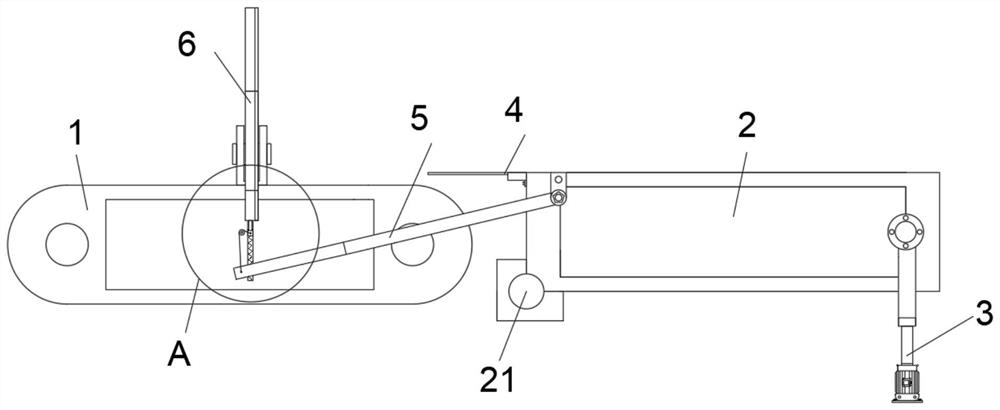

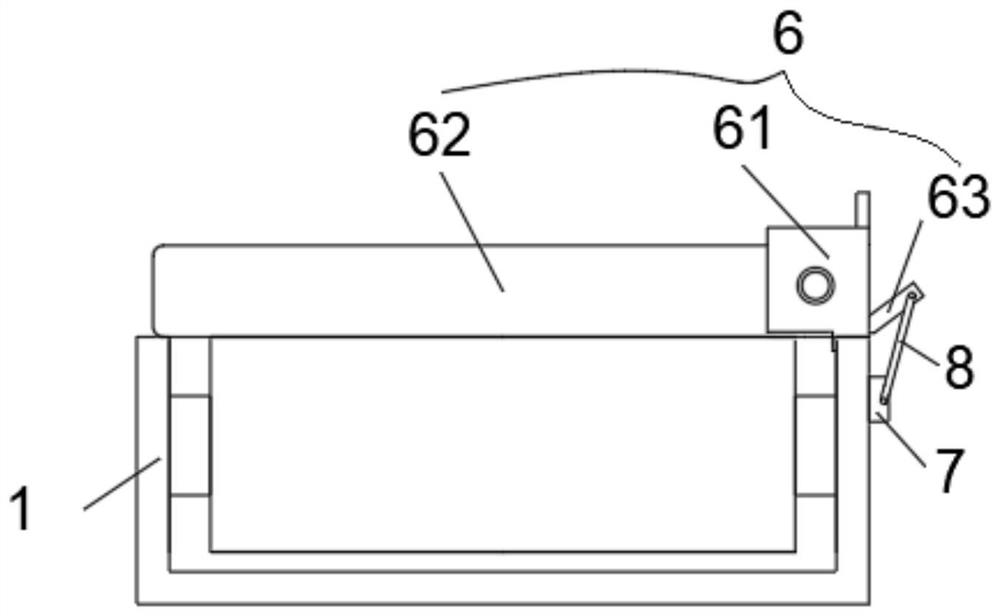

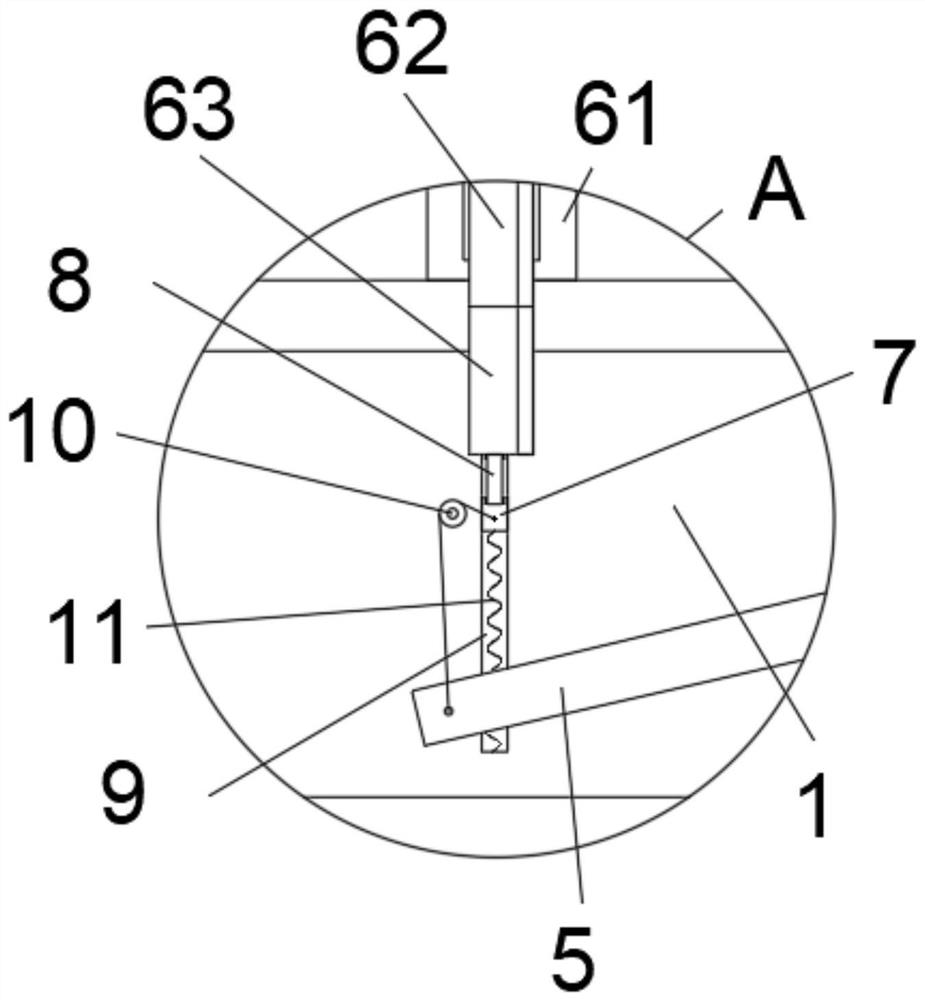

Automatic device for preventing falling

PendingCN112374118ASimple structureReduce use costConveyor partsStructural engineeringMechanical engineering

An automatic device for preventing falling comprises a first conveying channel, a second conveying channel; a blocking piece used for blocking movement of materials is arranged on the outer wall of one side of the first conveying channel; and a shaft rod is arranged at one end of the bottom side of the second conveying channel, an electric air cylinder is installed on the other side of the bottomside of the second conveying channel, a piston rod matched with the electric air cylinder can drive the second conveying channel to do circular motion with a shaft rod as the circle center, and a fixing plate is fixedly arranged on the outer wall of the second conveying channel. According to the technical scheme, only a single electric air cylinder is used in the device, transmission operation between structures is utilized, transferring, blocking and conveying treatment of materials can be completed, and meanwhile the whole device is simple in structure and low in use cost; and the connectingassembly is adopted, the blocking piece and the fixing plate are combined, when the second conveying channel operates in an inclined mode, a baffle in the blocking piece can automatically block materials, and the phenomenon that the materials fall off in the material conveying process is avoided.

Owner:GUANGXI YUCHAI MASCH CO LTD

Antifouling glaze

The invention provides an antifouling glaze material. The glaze material is prepared from the following raw materials: polymethylsilane, nano zinc oxide, sodium hexametaphosphate, wollastonite, pyrophyllite, barium oxide and a stabilizer. Nano-zinc oxide in the raw materials of the antifouling glaze can improve the glossiness, whiteness and glaze microhardness of the glaze surface of a ceramic finished product, and can reduce the initial melting temperature of the glaze; sodium hexametaphosphate is a polyphosphoric acid weak acid sodium salt with a cyclic molecular structure. A nano zinc oxidedispersion system is stabilized by an electrostatic stabilization mechanism; sodium hexametaphosphate forms a molecular layer protective film on the surface of zinc oxide; the surface energy of zincoxide particles is reduced; the coating effect is achieved to a certain degree; therefore, agglomeration among particles can be effectively prevented; the nano zinc oxide is stably and uniformly dispersed in the glaze; the polymethylsilane has very good oxidation resistance; pyrophyllite forms a compact mineral protection layer on the surface of the glaze; by adding wollastonite, the wear resistance of the product can be improved, the surface roughness is reduced, the accumulation space of pollutants is lost, the pollution resistance of the ceramic product is effectively improved, and the wollastonite can enable the hardness of a fired glaze layer to be higher and the glaze layer to be more wear-resistant, so that the glaze disclosed by the invention not only has a very good antifouling function, but also has good wear resistance.

Owner:FOSHAN UNIVERSITY

Flame-retardant polyurethane resin and preparation method thereof

The invention discloses a flame-retardant polyurethane resin which is prepared from the following raw materials in parts by weight: 37-40 parts of organic phosphorus polyester polyol, 52-55 parts of modified toluene diisocyanate, 2.5-4 parts of diglycol, 1.3-1.6 parts of tartaric acid, 7-10 parts of epoxy resin, 0.4-0.7 part of cobalt octoate, 3-4 parts of dimethylethanolamine and 3.5-5 parts of bis(2-hydroxyethyl)aniline. The invention also discloses a preparation method of the flame-retardant polyurethane resin, which comprises the following steps: uniformly mixing the organic phosphorus polyester polyol and modified toluene diisocyanate, heating, keeping the temperature, cooling, adding the diglycol, tartaric acid, epoxy resin and acetone, uniformly mixing, adding the cobalt octoate, heating, and keeping the temperature to obtain a material a; cooling the material a, dropwisely adding a solution containing the dimethylethanolamine and bis(2-hydroxyethyl)aniline, heating, and keeping the temperature to obtain a material b; and regulating the pH value of the material b to neutrality, and removing the acetone in vacuum to obtain the flame-retardant polyurethane resin.

Owner:ANHUI ANDA HUATAI NEW MATERIALS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com