Carbon coated layer thickness adjustable nanometer ferroferric oxide composite material, preparation method and application thereof

A technology of triiron tetroxide and composite materials, applied in the field of electrochemical materials, can solve problems such as volume expansion, and achieve the effects of inhibiting agglomeration, easy industrial production, and short reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

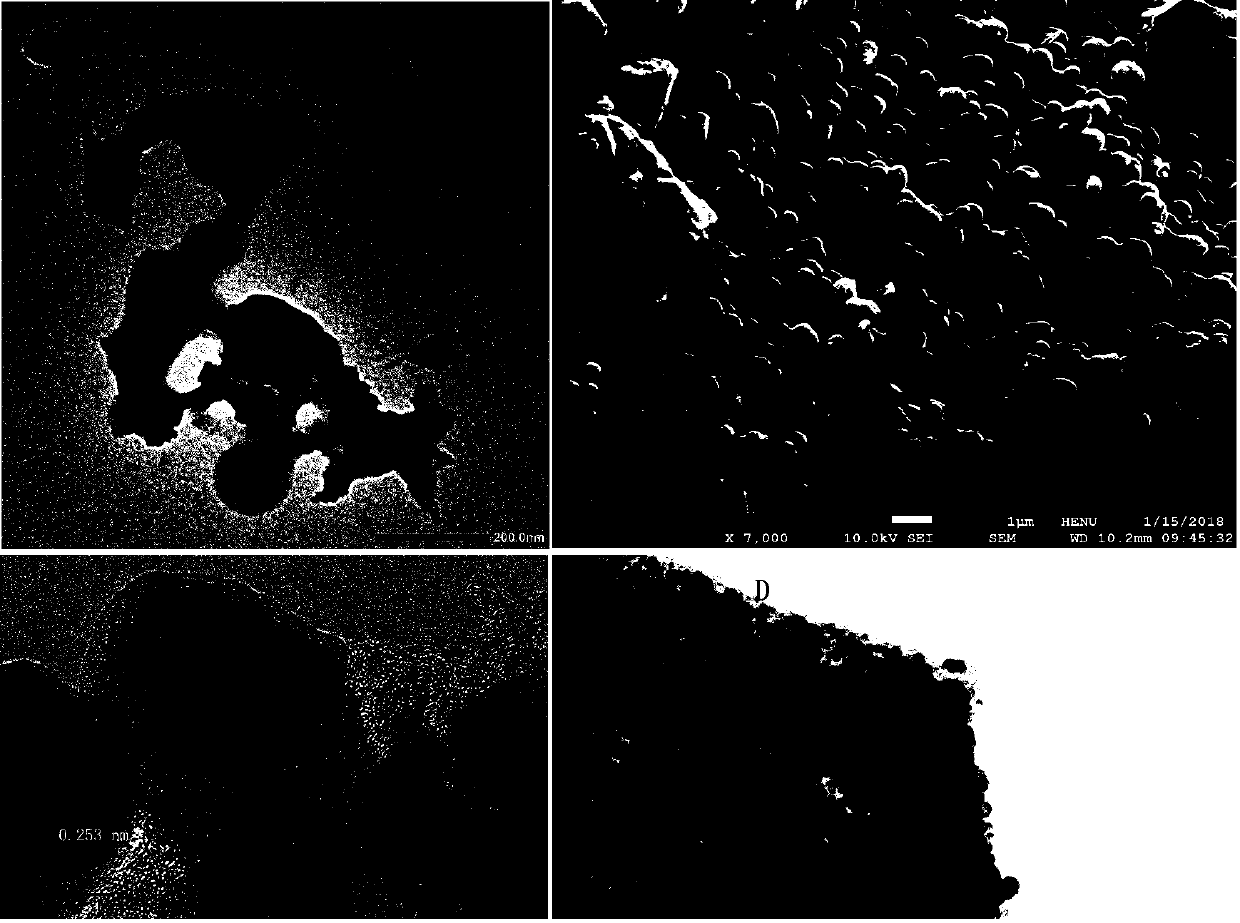

Image

Examples

Embodiment 1

[0033] The preparation method of the nano-iron tetroxide composite material with adjustable coating carbon layer thickness of the present embodiment, the steps are as follows:

[0034] 1. Preparation of the precursor glucose-iron complex

[0035] Glucose and trisodium citrate were dissolved in 40 mL of water, and a certain amount of FeCl was added after stirring to dissolve. 3 solution (dissolved in 0.1 mol / L HCl), adjust the pH to 9.5 with 3 mol / L sodium hydroxide, and react at 70 °C for 6 h; in the reaction solution, glucose, trisodium citrate, Fe 3+ The ratio of the substances is 1:1:2; after the reaction, add 4 times the amount of anhydrous ethanol, wash the precipitate with 80% ethanol three times, and dry at 50 °C, which is the glucose-citric acid-iron complex, named as GCFe.

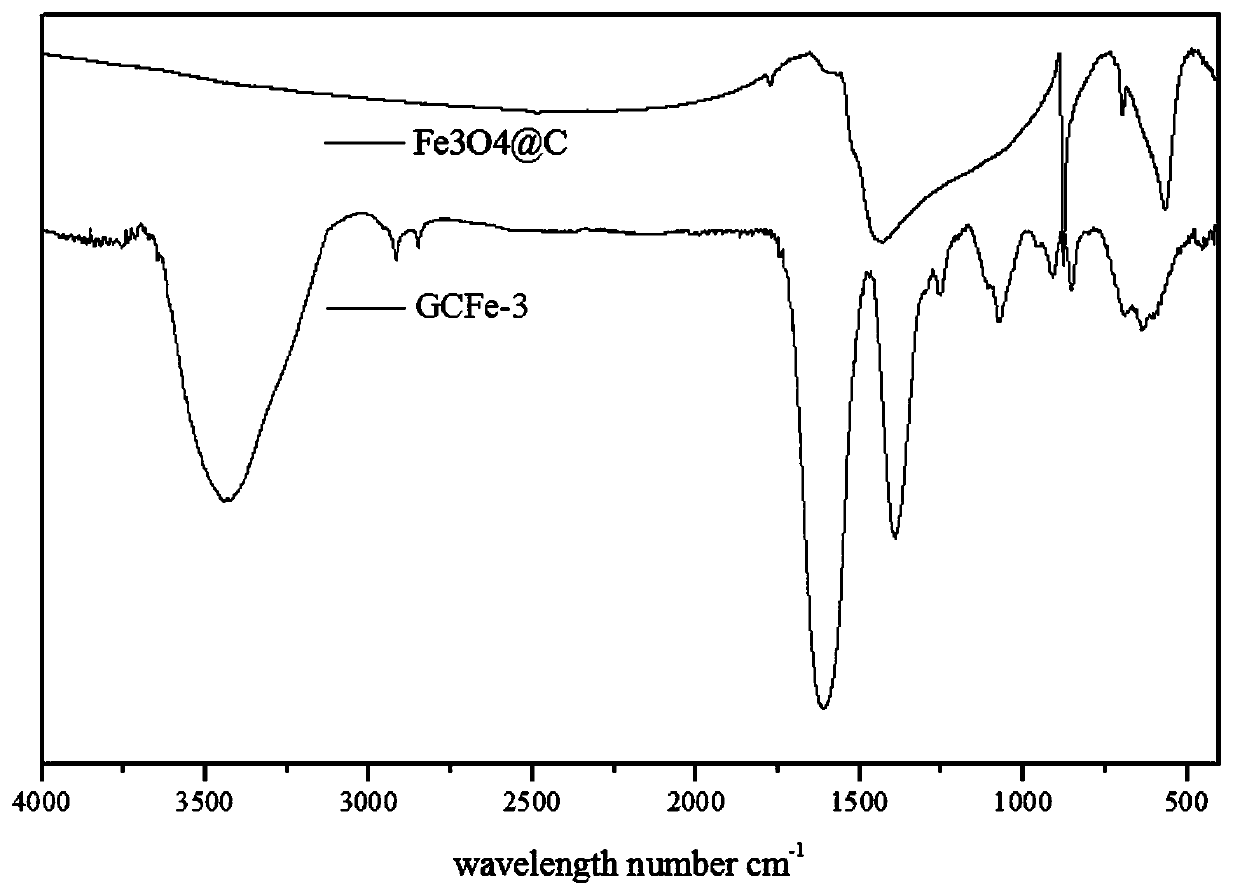

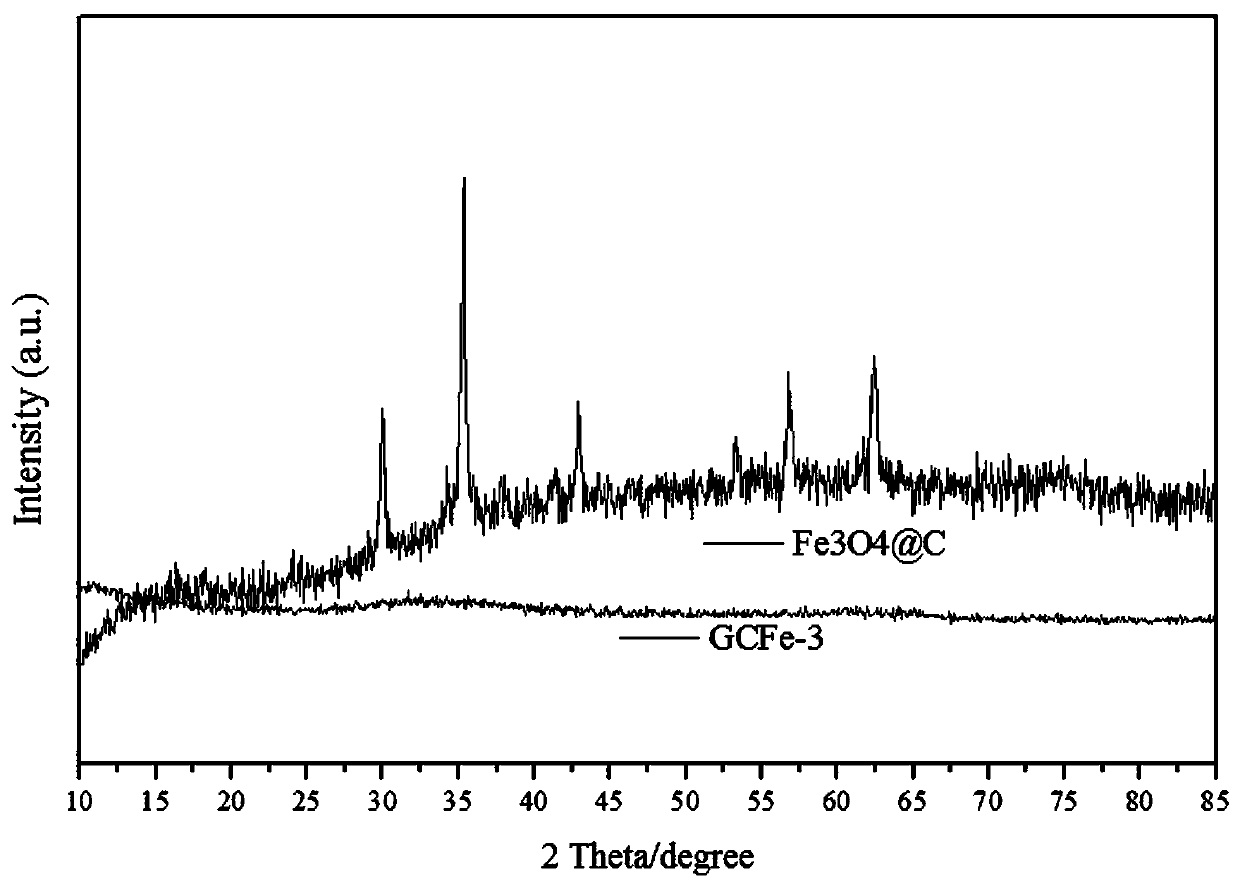

[0036] 2. Fe with carbon-coated structure 3 O 4 Preparation of composite materials

[0037] The obtained precursor GCFe was placed in air, pre-calcined at 200 °C for 3 h, then placed in a tub...

Embodiment 2

[0039] The preparation method of the nano-iron tetroxide composite material with adjustable coating carbon layer thickness of the present embodiment, the steps are as follows:

[0040] 1. Preparation of the precursor Huaiyam polysaccharide-iron complex

[0041] Huai yam polysaccharide and trisodium citrate were dissolved in 40 mL of water, and a certain amount of FeCl was added after stirring to dissolve. 3 solution (dissolved in 0.1 mol / L HCl), adjusted to pH 9.0 with 3 mol / L sodium hydroxide, and reacted at 65 °C for 6 h; trisodium citrate, Fe in the reaction solution 3+ The mass ratio of the substances is 1:3; the mass ratio of Huaiyam polysaccharide and trisodium citrate is 1:1.5. After the reaction, 4 times the amount of anhydrous ethanol was added, the precipitate was washed three times with 80% ethanol, and dried at 50°C to obtain the Huaiyam polysaccharide-citric acid-iron complex, named as HSYFe.

[0042] 2. Fe with carbon-coated structure 3 O 4 Preparation of com...

Embodiment 3

[0045] The preparation method of the nano-iron tetroxide composite material with adjustable coating carbon layer thickness of the present embodiment, the steps are as follows:

[0046] 1. Preparation of the precursor glucose-iron complex

[0047] Glucose and trisodium citrate were dissolved in 40 mL of water, and a certain amount of FeCl was added after stirring to dissolve. 3 solution (dissolved in 0.1mol / L HCl) and a small amount of potassium phosphate, adjust the pH to 9.3 with 3 mol / L ammonia water, and react at 70°C for 10h; in the reaction solution, glucose, trisodium citrate, Fe 3+ , the substance ratio of potassium phosphate is 1:0.1:3:2. After the reaction, 4 times the amount of anhydrous ethanol was added, the precipitate was washed three times with 80% ethanol, and dried at 50 °C, which was a nitrogen-phosphorus doped glucose-citric acid-iron complex, named GC-NP-Fe.

[0048] 2. Fe with carbon-coated structure 3 O 4 Preparation of composite materials

[0049] T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com