Patents

Literature

72results about How to "Good anti-fouling function" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

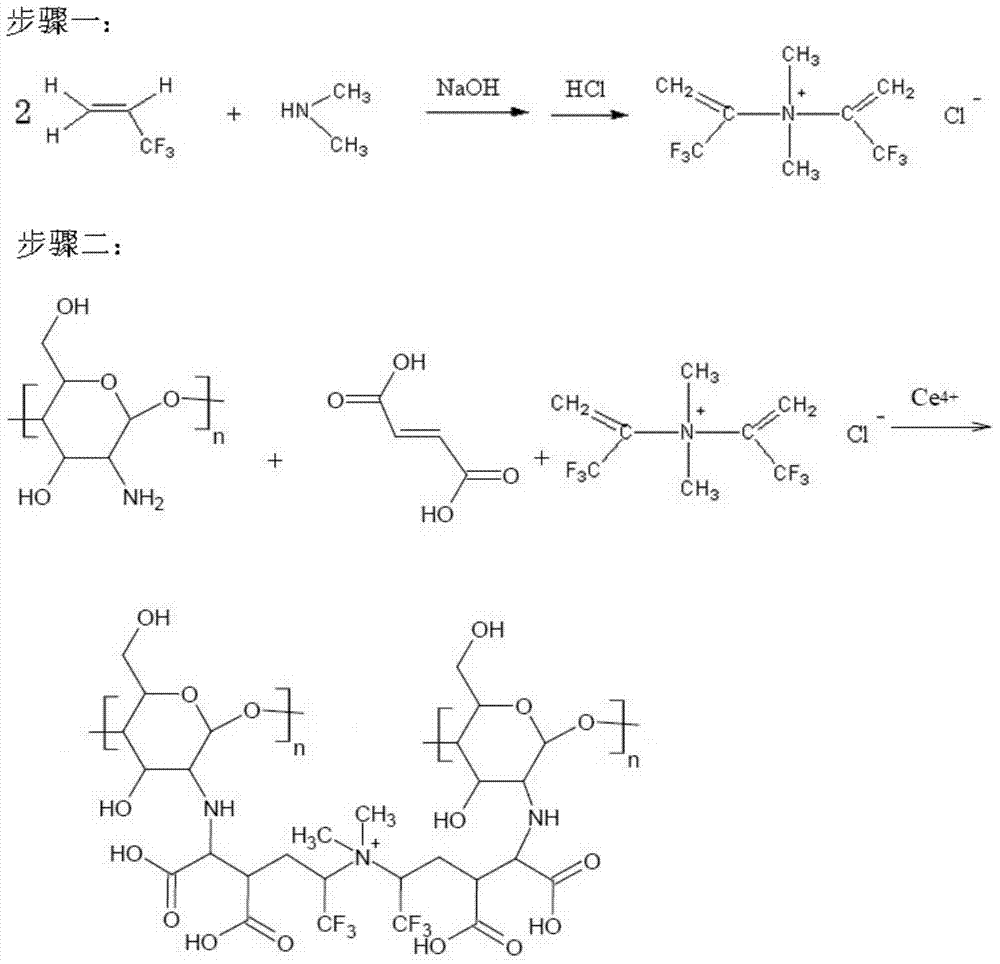

Composite high molecular surfactant, preparation method thereof and application of composite high molecular surfactant in foam coating process

ActiveCN104844729ABiocompatibleHas antibacterial propertiesVegetal fibresPolymer sciencePtru catalyst

The invention relates to a composite high molecular surfactant, a preparation method thereof and application of the composite high molecular surfactant in a foam coating process. Enabling chitosan, maleic acid and dimethyl 2, 3-trifluoropropenyl ammonium chloride to react at 90 DEG C to 110 DEG C under the action of a catalyst, the composite high molecular surfactant is formed. By compounding the composite high molecular surfactant and a micromolecule surfactant, and then adding a thickener and a three-proofing agent, a foam coating agent with good foaming performance, high solution viscosity, high foam film strength and good compactness is formed, and is applied to the foam coating process in the textile dyeing and finishing industry, the control on foam film thickness can be realized, and the liquid carrying quantity of foam is increased in a certain range, so that the thickness of a single-face coating is increased, the firmness of the coating is strengthened, and the problem that the single-face coating is not washable is solved.

Owner:SUZHOU TANGHUA NANO TECH

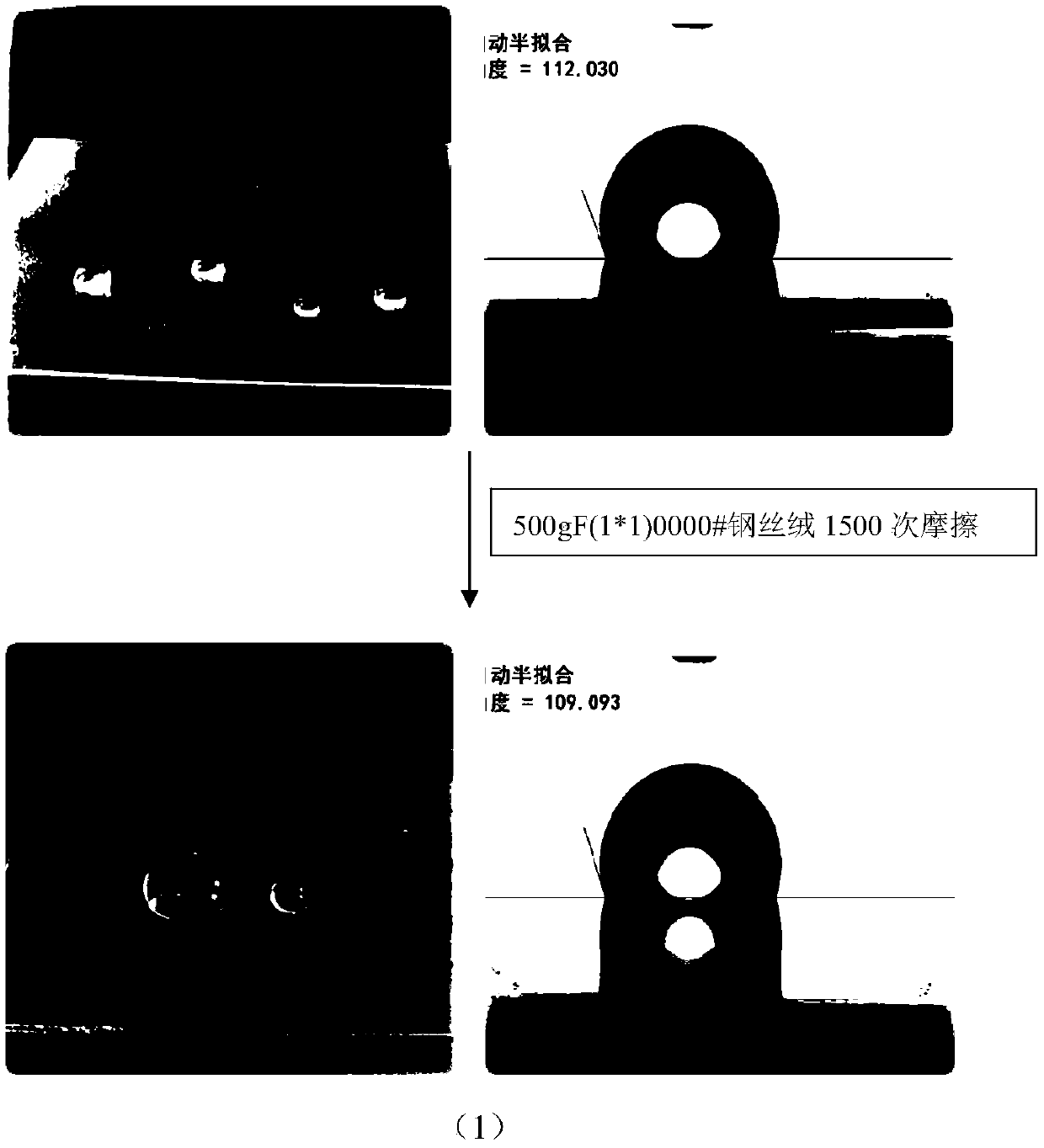

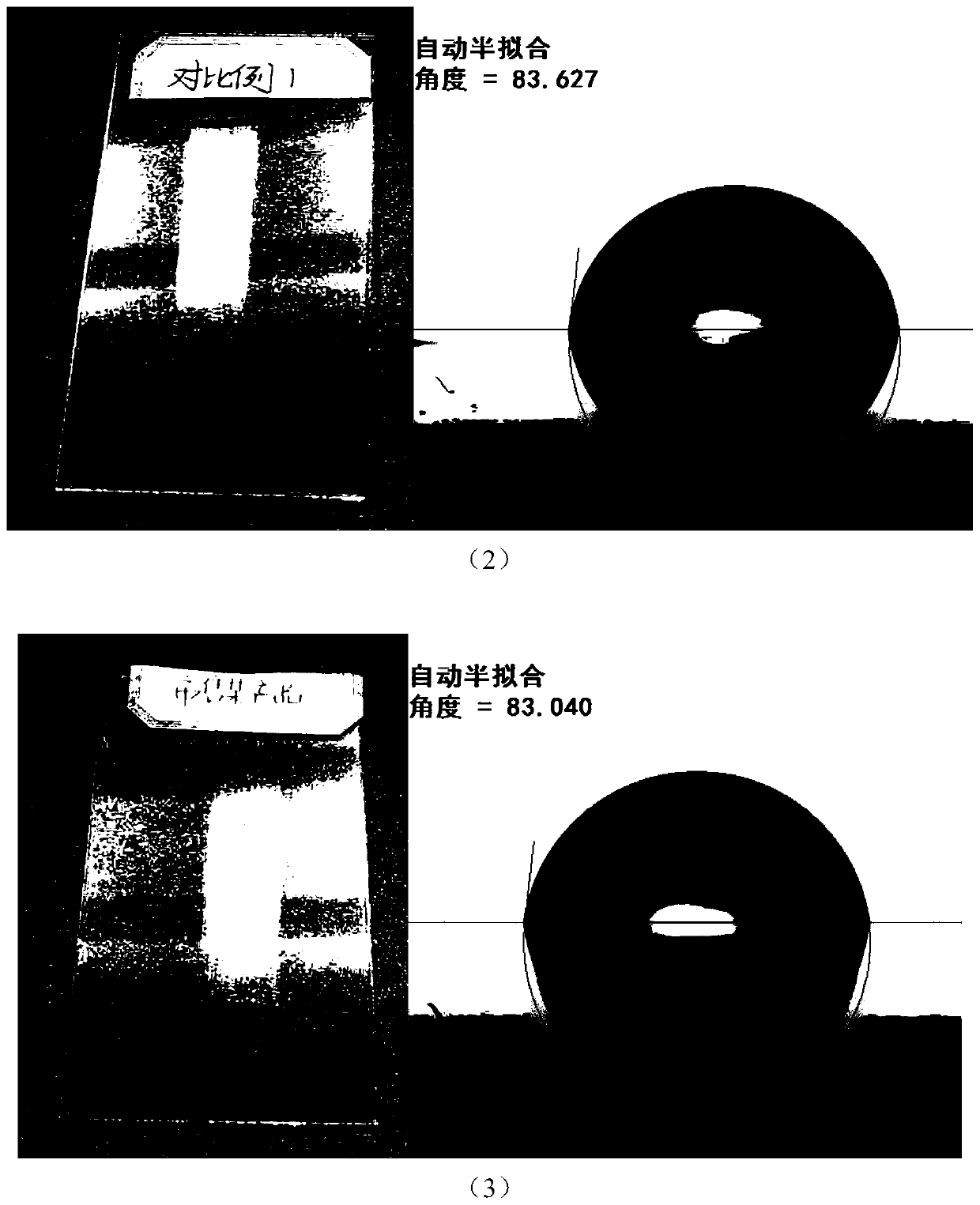

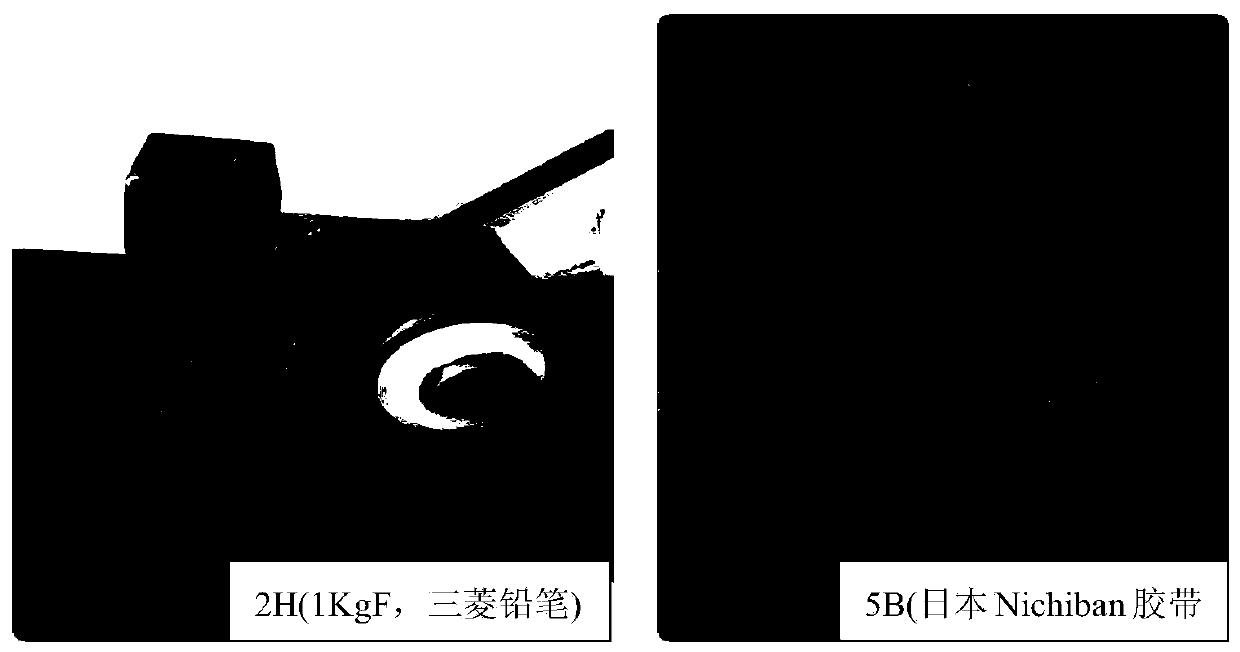

High hardness wear-resistant fingerprint-proof nano coating for PC material and preparation method of high hardness wear-resistant fingerprint-proof nano coating

InactiveCN110760256AImprove wear resistanceImprove hydrophobicity and oleophobicityAntifouling/underwater paintsPaints with biocidesFunctional monomerWeather resistance

The invention provides a high hardness wear-resistant fingerprint-proof nano coating for a PC material and a preparation method of the high hardness wear-resistant fingerprint-proof nano coating. Theraw materials formula of the high hardness wear-resistant fingerprint-proof nano coating is prepared from the following components in parts by weight: 20-30 parts of matrix resin, 8-10 parts of a high-functional monomer, 3-5 parts of a low-functional monomer, 2-3 parts of a fluorine-containing functional monomer, 0.5-1.5 parts of an inorganic filler, 2-3 parts of an auxiliary agent, 1-3 parts of aphotoinitiator and 1-3 parts of a composite solvent. The matrix resin is a mixture of at least three polyurethane acrylates with different degrees of functionality, and respectively selected from 6-9functional, 9-10 and 10-15 functional aliphatic polyurethane acrylates; the high-functional monomer is 6 functional dipentaerythritol hexaacrylate, the low-functional monomer is one or two of 2 functional and 3 functional acrylate monomers; and the inorganic filler is nano-diamond particles. According to the high hardness wear-resistant fingerprint-proof nano coating, the preparation process is simple and efficient, mass production is convenient, the prepared coating is high in hardness, wear-resistant, fingerprint-proof, good in weather resistance and long in service life, and has good application prospects in the fields of automobiles and mobile phones.

Owner:NINGBO FUNA NEW MATERIALS TECH CO LTD

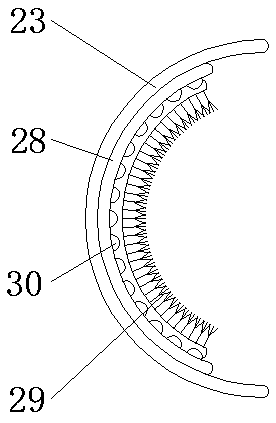

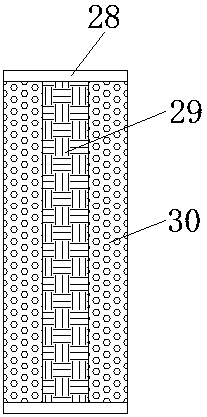

Marine ranching dike netting gear component assembly method

The invention discloses a marine ranching dike netting gear component assembly method, wherein a double-layer fiber net, a medium-soft connection net and a woven net are used. The marine ranching dike netting gear component assembly method is characterized in that an upper margin line of the woven net and a lower line of the double-layer fiber net are bound and tightened with a single fast knot through a sixteen-strand polyester woven rope with the diameter of 4.6mm and are spaced by 5cm; next, a lower line of the medium-soft connection net and a connecting steel cable on the woven net are bound and tightened with a single fast knot through a sixteen-strand polyester woven rope with the diameter of 4.6mm and are spaced by 5cm; then, an upper line of the medium-soft connection net and a connecting net line on the double-layer fiber net are bound and tightened with a single fast knot through a sixteen-strand polyester woven rope with the diameter of 4.6mm and are spaced by 5cm; after an upper line of the double-layer fiber net, the upper line of the medium-soft connection net, the lower line of the medium-soft connection net, a lower margin line of the woven net and the double-layer fiber net are subjected to anti-dirt treatment, a large-mesh ultra-high molecular weight polyethylene warp knitting net is directly bound, connected and fixed to a marine ranching dike netting gear pile.

Owner:EAST CHINA SEA FISHERIES RES INST CHINESE ACAD OF FISHERY SCI

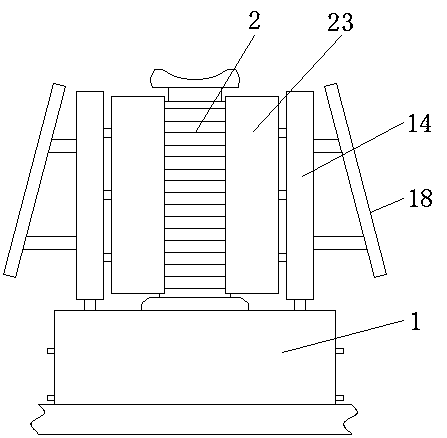

An antifouling self-cleaning pillar composite insulator

The invention discloses an antifouling self-cleaning type pillar composite insulator, Including mounting box, An insulator is fixedly installed on the top of the mounting box, and fixing blocks are fixedly connected on both sides of the inner wall of the mounting box, and a sleeve is fixedly connected between opposite sides of the two fixing blocks, the inner surface of the sleeve is fixedly connected with teeth, the bottom of the inner wall of the mounting box is fixedly connected with a motor box, the bottom of the inner wall of the motor box is rotatably connected with a rotating shaft through a bearing, and the top end of the rotating shaft penetrates the motor box and extends to the top of the motor box. The invention relates to the technical field of composite insulators. The anti-fouling self-cleaning pillar composite insulator can clean the outer surface of the insulator very well by cleaning the brush and the circumferential rotation of the cleaning pad, and the cleaning effect is very good, the anti-fouling function is very good, and the manual cleaning of the staff is not required, the time and labor are saved, and the service life of the insulator is greatly prolonged.

Owner:WUHU KAIXIN ARRESTER

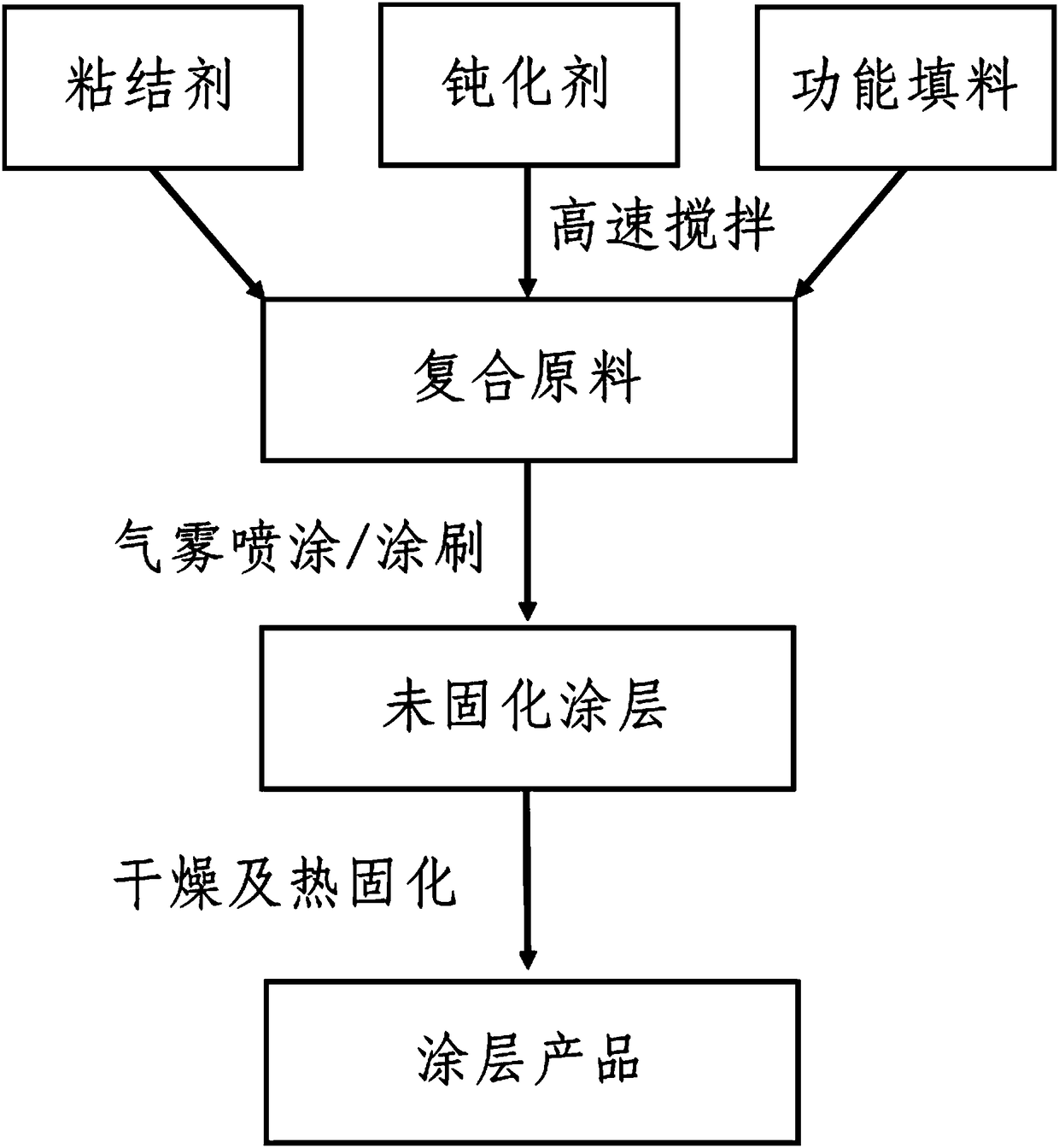

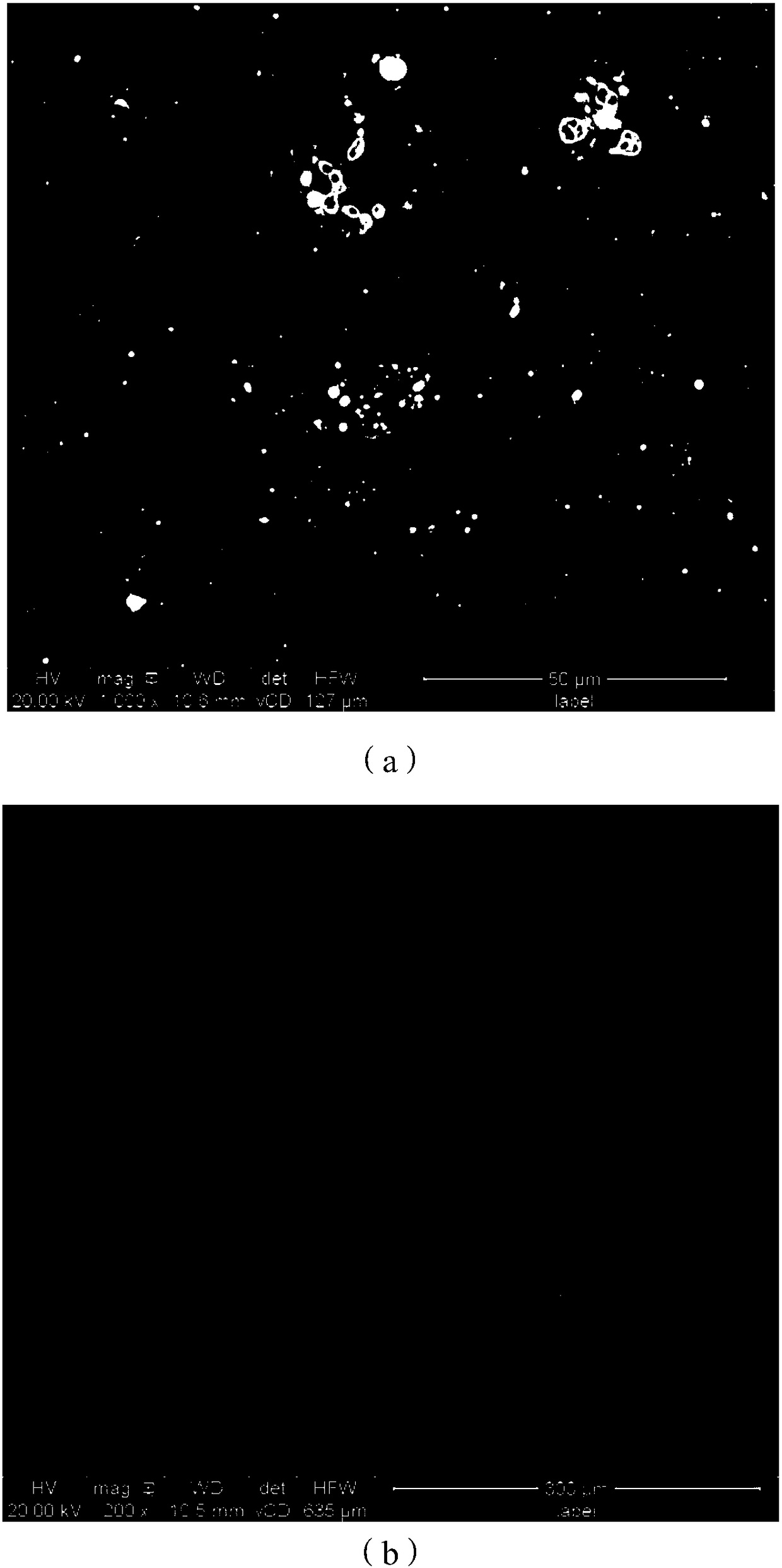

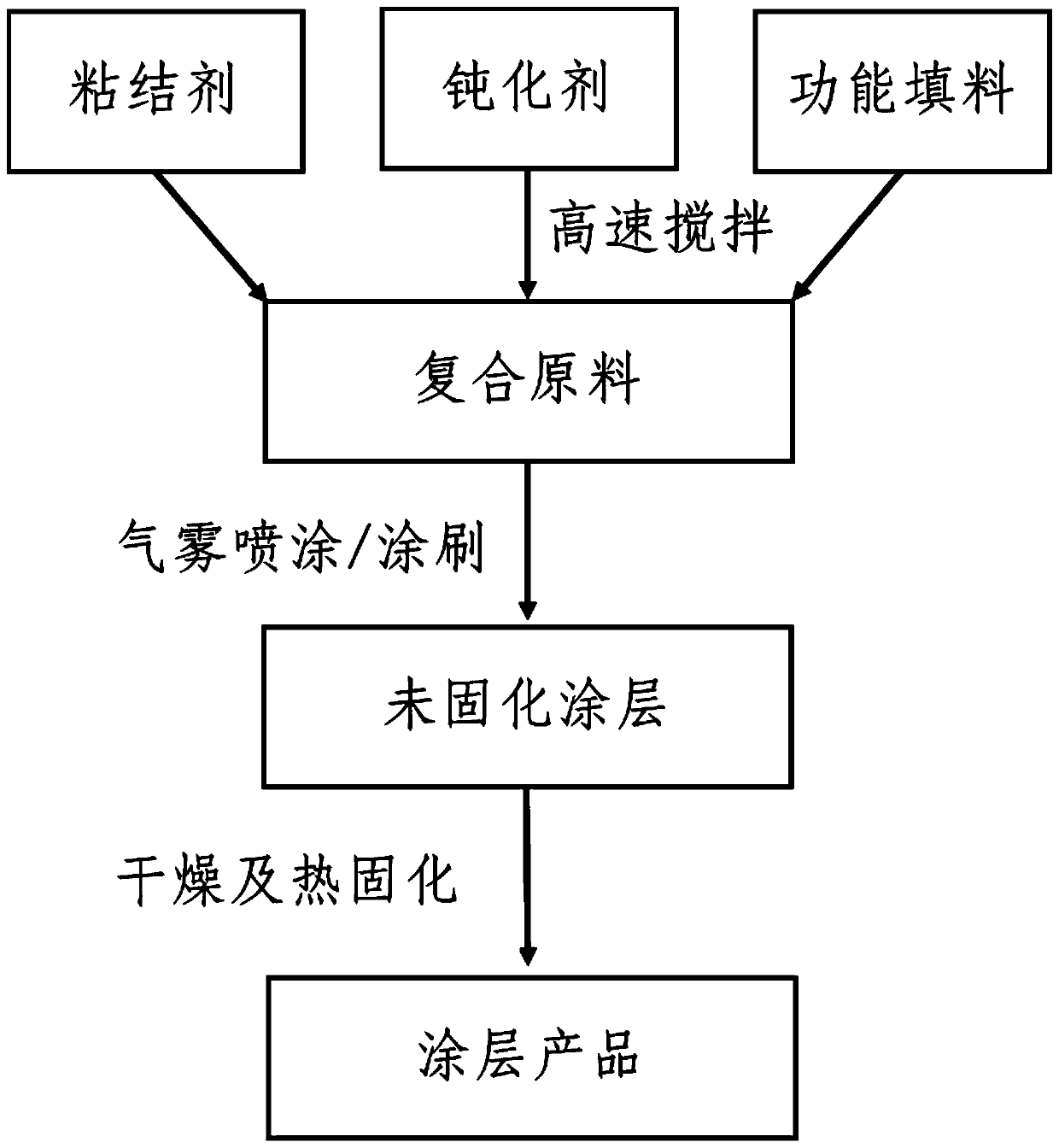

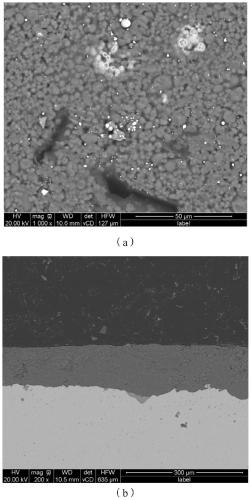

Anti-corrosion antifouling coating and preparing method thereof

ActiveCN108587262ABroaden the field of applicationEasy to operateAntifouling/underwater paintsPaints with biocidesSodium silicatePhotocatalysis

The invention discloses an anti-corrosion antifouling coating and a preparing method thereof. The anti-corrosion antifouling coating is prepared from, by weight, 10%-30% of binding agent, 1%-10% of passivating agent, 20%-50% of anti-corrosion functional filler and 20-50% of photocatalysis functional filler; the binding agent is selected from an aluminum dihydrogen phosphate water solution; the passivating agent is selected from at least one of chromic oxide, sodium tungstate and sodium silicate; the anti-corrosion functional filler is selected from aluminum powder and / or zinc powder; the photocatalysis functional filler is selected from metal-doped nanometer titania or pure nanometer titania. All the raw materials and water are mixed, coating, heating and solidifying are carried out, and the anti-corrosion antifouling coating is prepared. According to the anti-corrosion antifouling coating, under the condition that the anti-corrosion performance of the coating is not damaged, the goodantifouling function of the coating is given, and the application field of the anti-corrosion antifouling coating is further expanded.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

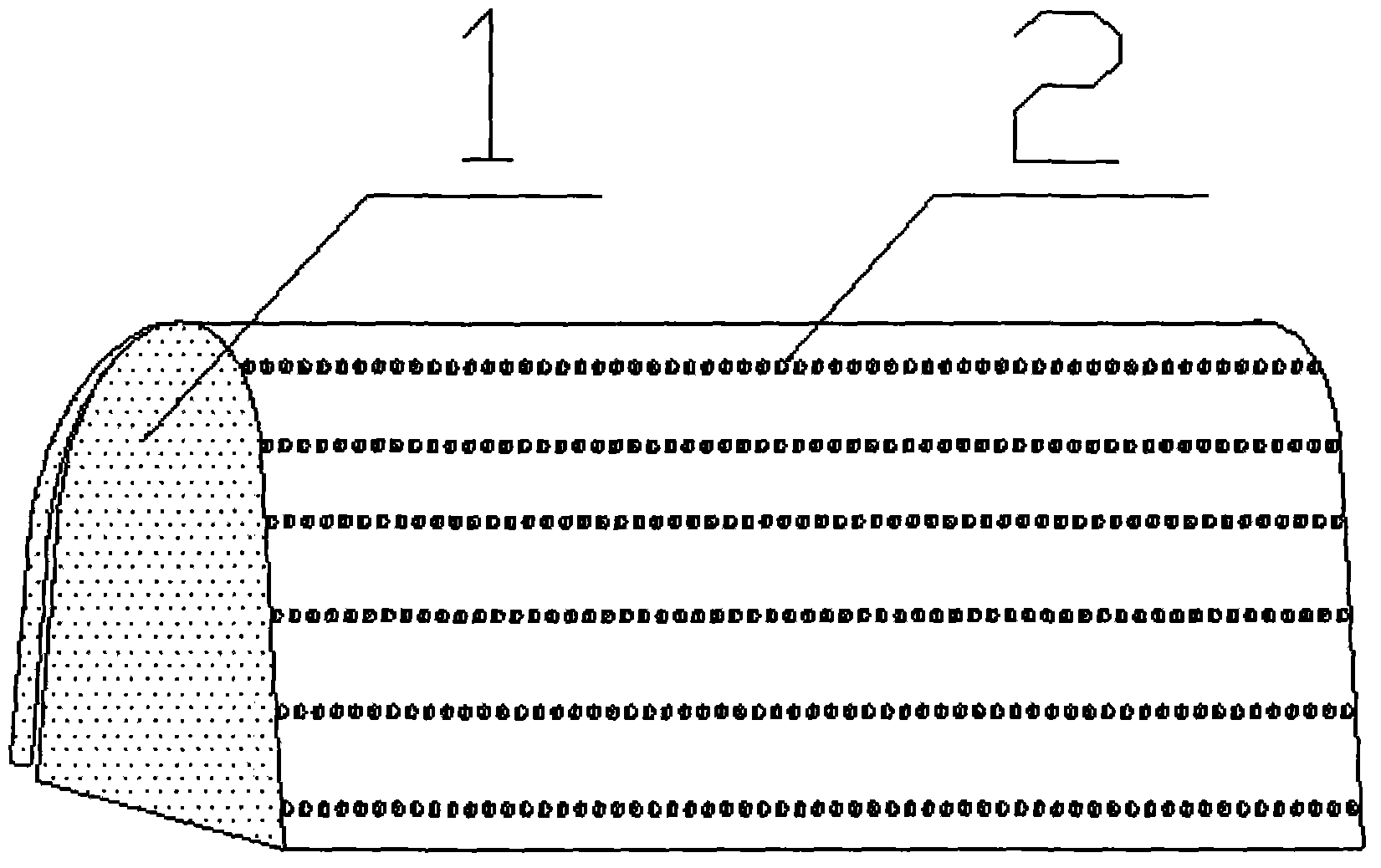

Processing method for antifouling melt spinning for far-reaching-sea net cage or floating-rope surrounding net

ActiveCN106192030AImprove liquidityImprove spinnabilityMelt spinning methodsMonocomponent polyolefin artificial filamentTurpentineHydroxystearic Acid

The invention discloses a processing method for antifouling melt spinning for a far-reaching-sea net cage or a floating-rope surrounding net. The processing method is characterized by including the steps that UHMWPE powder, nanometer Cu powder, HDPE powder, silicone powder, antioxidant B225, assistant antioxidant DLTP, hydroxy stearic acid, nanoscale white carbon black, nanoscale kieselguhr, nanoscale aedelforsite, ethylene-vinyl acetate copolymer and turpentine assistant are weighed in the formula, then premixed to be poured into a high-speed kneading pot and subjected to high-speed kneading, and a blending-modification UHMWPE material is obtained; the blending-modification UHMWPE material is belted and extruded through a double-screw extruder, the extruded substance is metered through a metering pump additionally arranged through a double-screw outlet and belted and extruded through a spinneret hole, the extruded primary raw silk is cooled and pre-drafted, the pre-drafted silk is subjected to heat setting, then tows are winded through a silk winding machine of a torque motor, and are subjected to silk dividing through a silk dividing machine, and the antifouling melt spinning for the far-reaching-sea net cage or the floating-rope surrounding net is obtained.

Owner:威海市宏威塑料有限公司

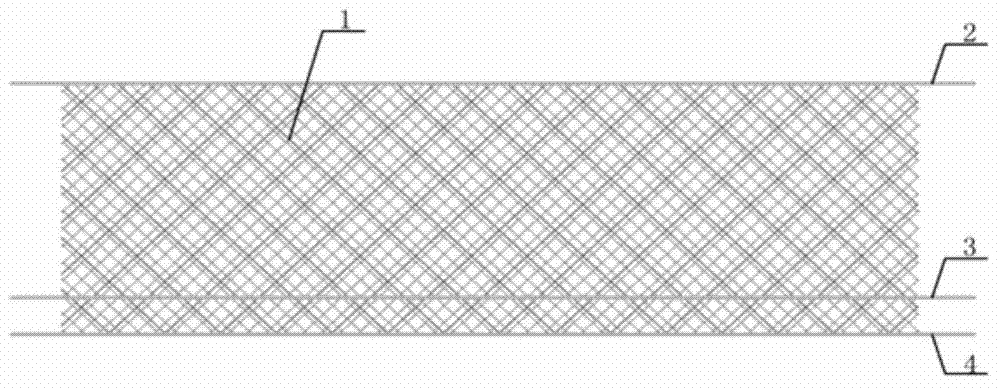

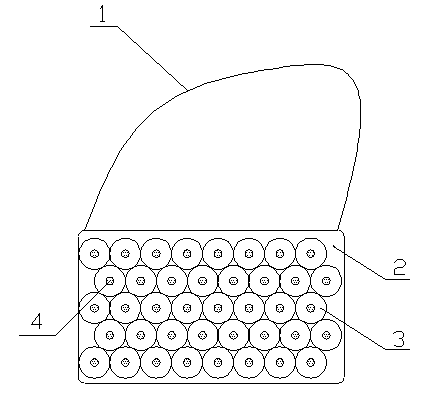

Wear-resistant fabric with water, oil and stain proofing functions

InactiveCN107718766ASimple processLow costSynthetic resin layered productsClothingsPolyesterMicrofiber

The invention relates to a wear-resistant fabric with waterproof, oil-proof, and anti-fouling functions, which comprises an inner layer (1), and a base cloth layer (2), a breathable layer (3), a wear-resistant layer (4) and a coating Layer (5), the air-permeable layer is woven from a three-dimensional mesh superfine fiber base cloth; the coating layer is a polytetrafluoroethylene coating. The back of the inner layer is provided with a lining fabric layer, the lining fabric layer includes three layers, the outer layer is a Teflon coating, the interlayer is a textile, the inner layer is a Teflon coating, and the textile is a nylon waterproof fabric Or polyester fabric, the thickness of Teflon coating is 10μm~13μm. The invention improves the tensile strength and wear resistance of the fabric. The invention has waterproof, oil-proof and anti-fouling functions.

Owner:JIANGYIN HUADONG DECORATIVE MATERIAL

Antifouling glaze

The invention provides an antifouling glaze material. The glaze material is prepared from the following raw materials: polymethylsilane, nano zinc oxide, sodium hexametaphosphate, wollastonite, pyrophyllite, barium oxide and a stabilizer. Nano-zinc oxide in the raw materials of the antifouling glaze can improve the glossiness, whiteness and glaze microhardness of the glaze surface of a ceramic finished product, and can reduce the initial melting temperature of the glaze; sodium hexametaphosphate is a polyphosphoric acid weak acid sodium salt with a cyclic molecular structure. A nano zinc oxidedispersion system is stabilized by an electrostatic stabilization mechanism; sodium hexametaphosphate forms a molecular layer protective film on the surface of zinc oxide; the surface energy of zincoxide particles is reduced; the coating effect is achieved to a certain degree; therefore, agglomeration among particles can be effectively prevented; the nano zinc oxide is stably and uniformly dispersed in the glaze; the polymethylsilane has very good oxidation resistance; pyrophyllite forms a compact mineral protection layer on the surface of the glaze; by adding wollastonite, the wear resistance of the product can be improved, the surface roughness is reduced, the accumulation space of pollutants is lost, the pollution resistance of the ceramic product is effectively improved, and the wollastonite can enable the hardness of a fired glaze layer to be higher and the glaze layer to be more wear-resistant, so that the glaze disclosed by the invention not only has a very good antifouling function, but also has good wear resistance.

Owner:FOSHAN UNIVERSITY

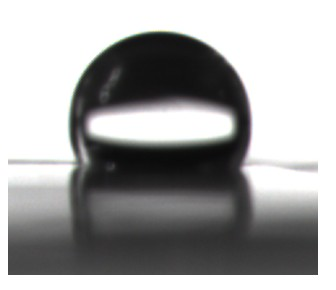

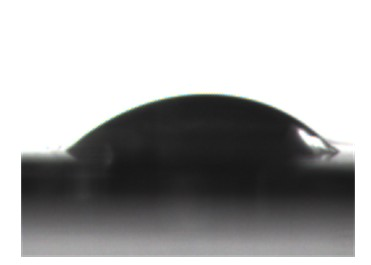

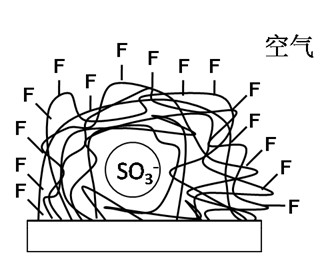

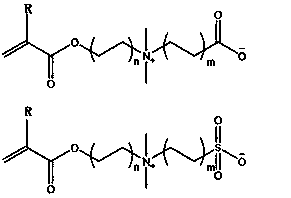

Humidity-sensitive intelligent betaine fluorinated antifouling paint and preparation method thereof

ActiveCN102676015AWith anti-fouling functionGood antifouling functionAntifouling/underwater paintsPaints with biocidesAntifoam agentPolymer chemistry

The invention relates to humidity-sensitive intelligent betaine fluorinated antifouling paint and a preparation method thereof. The paint is mainly made of, by weight, 10%-60% of betaine fluorinated copolymer, 60%-10% of inorganic salt filler, 0.1%-0.5% of water-based paint antifoaming agent, 0.1%-5.0% of dispersing agent and 20%-50% of water. The preparation method includes: firstly, uniformly mixing the betaine fluorinated copolymer solution, the antifoaming agent, the dispersing agent and the water, and secondly, adding the inorganic salt filler while stirring to obtain the humidity-sensitive intelligent betaine fluorinated antifouling paint. The characteristic of foul resistance of fluorinated groups in air and the characteristic of foul resistance of betaine groups in water are integrated to prepare the humidity-sensitive intelligent antifouling paint, and distribution of the fluorinated groups and the betaine groups in coatings can be adjusted according to variation of external media, so that better antifouling function can be kept constantly.

Owner:SOUTH CHINA UNIV OF TECH

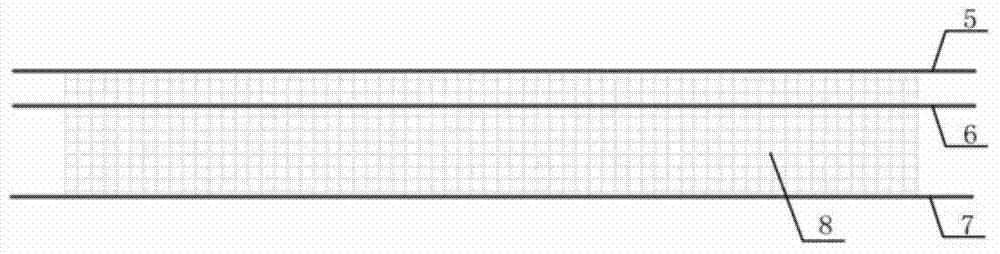

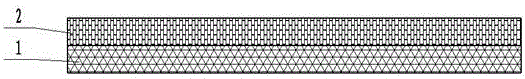

Easy-dry and non-ironing fabric having water-proof, oil-proof and anti-fouling functions

InactiveCN106273845AGood waterproofDehydration fastSynthetic resin layered productsWoven fabricsPolyesterEngineering

The invention relates to an easy-dry and non-ironing fabric having water-proof, oil-proof and anti-fouling functions. The fabric comprises a base layer (1), and a quick-dry layer (2) is arranged at the outer side of the base layer. A lining fabric layer is arranged on the back of the base layer, the lining fabric layer comprises three layers, wherein the outer layer is a Teflon coating, the interlayer is a textile fabric, the inner layer is a Teflon coating, the textile fabric is a nylon water-proof fabric or a polyester fabric, and the thickness of the Teflon coating is 10-13 microns. The fabric can be quickly dried, is naturally straight after washing, does not need ironing and is stiff and smooth, and the inner layer is comfortable.

Owner:JIANGYIN CHUNZHILAN SPECIAL YARN

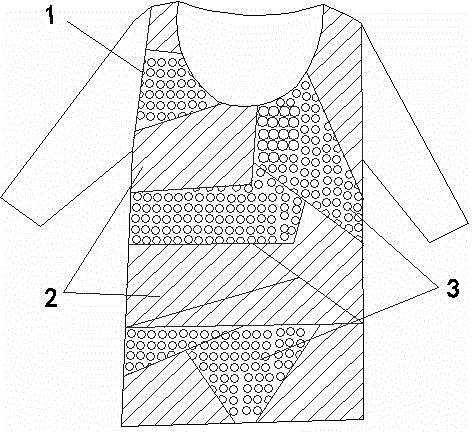

Leather and gauze spliced oil stain resistant fabric clothing

InactiveCN104413956AShow contradictory beautyIncrease fashionFibre typesCoatingsEngineeringPoly tetra fluoro ethylene

The invention relates to leather and gauze spliced oil stain resistant fabric clothing. The leather and gauze spliced oil stain resistant fabric clothing comprises a clothing body (1); a front body and a rear body of the clothing body (1) are spliced by leather (2) and gauze (3); the leather (2) and the gauze (3) are in irregular shapes. The adopted fabric of the clothing body (1) comprises three layers, the external layer is a PTFE (Poly Tetra Fluoro Ethylene) coating, the interlayer is woolen fabric, and the internal layer is PTFE coating. The woolen fabric is nylon waterproof fabric or Dacron fabric. The thickness of the PTFE coating is 15mu.m. The leather and gauze spliced oil stain resistant fabric clothing increases the layering, enriches the clothing modes and has good waterproof, oil-proof and stain-proof functions.

Owner:JIANGYIN QIANGLI CHEM FIBER

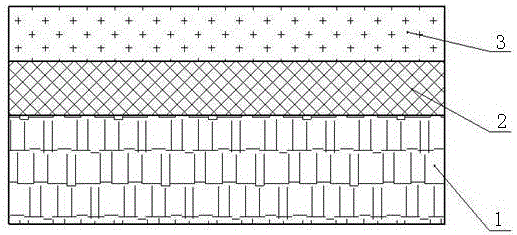

Waterproof fabric having waterproof, oilproof and antifouling functions

InactiveCN106273755AImprove waterproof performanceGood oil resistanceSynthetic resin layered productsClothingsPolyesterFiber

The invention relates to a waterproof fabric having waterproof, oilproof and antifouling functions which comprises a basic layer (1). An antibacterial layer (2) and a waterproof layer (3) are sequentially arranged on the surface of the basic layer (1). The antibacterial layer (2) is made of bamboo fibers. The waterproof layer (3) is a TPU coating. A lining fabric layer is arranged on the back side of thebasic layer and comprises three layers including the outer layer Teflon coating, an interlayer textile fabric and the inner layer Teflon coating, the textile fabric is a waterproof nylon fabric or a polyester fabric, and the thickness of the Teflon coating is 10-13 microns. The waterproof fabric is breathable, comfortable, waterproof and antibacterial and further has waterproof, oilproof and antifouling functions.

Owner:JIANGYIN DONGFA GARMENT MAKING

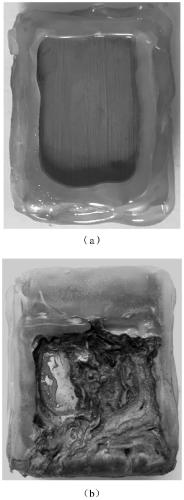

Antifouling tablecloth

The invention discloses an antifouling tablecloth which is characterized in that the outside surface of the tablecloth is provided with an antifouling protective layer. The antifouling tablecloth disclosed by the invention has a good antifouling function; and when oil, juice, beverages and the like are splashed on the tablecloth, the oil, juice, beverages and the like do not permeate into the tablecloth and can be cleaned by way of wiping by using a rag, so that the workload is reduced, therefore, the antifouling tablecloth is convenient to use.

Owner:WUJIANG LANRUITE TEXTILE

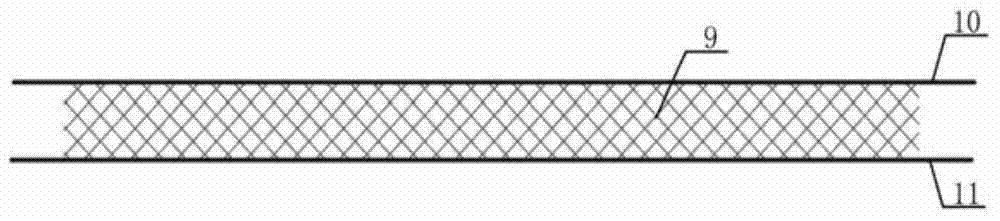

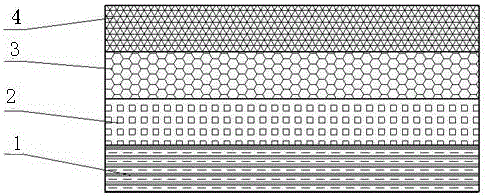

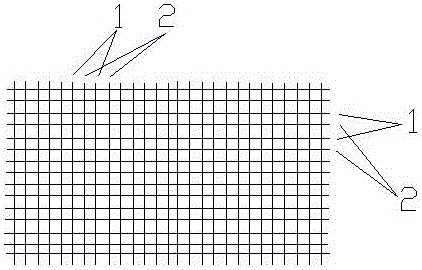

Waterproof, oil-proof and antifouling functional high-resilience mercerized cotton fabric

InactiveCN106142714APrevent moistureAvoid stuffySynthetic resin layered productsClothingsEngineeringCOTTON WOOL

The invention relates to a high-elastic mercerized cotton fabric with waterproof, oil-proof and anti-fouling functions, which comprises a bottom layer (1), a breathable layer (2), an elastic layer (3) and a mercerized layer (4). The back of the bottom layer is provided with a lining fabric layer, and the lining fabric layer includes three layers, the outer layer is a Teflon coating, the interlayer is a textile, the inner layer is a Teflon coating, and the textile is a nylon waterproof fabric or Polyester fabric, Teflon coating thickness is 10μm ~ 13μm. The invention is breathable and comfortable to wear, has good thermal insulation performance, avoids dampness and stuffiness of the bottom layer, has high elasticity, and has a beautiful mercerized surface and a comfortable handle. The invention has waterproof, oil-proof and anti-fouling functions.

Owner:JIANGYIN HULIAN DYEING & FINISHING

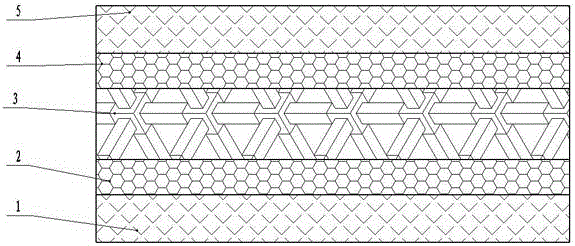

Compound leather fabric with waterproofing, oil-proofing and fouling-resisting functions

InactiveCN106183256AEnsuring resistance to torsional bendingGuaranteed cleanlinessSynthetic resin layered productsCoatingsPolyesterSurface cleaning

The invention relates to a composite leather fabric with waterproof, oil-proof and anti-fouling functions. It comprises an inner skin layer (1), a first air-permeable layer (2), a support layer (3), a second air-permeable layer (4) and an outer skin layer (5) in sequence. The back of the inner skin layer is provided with a lining fabric layer, and the lining fabric layer includes three layers, the outer layer is a Teflon coating, the interlayer is a textile, the inner layer is a Teflon coating, and the textile is a nylon waterproof fabric Or polyester fabric, the thickness of Teflon coating is 10μm~13μm. The invention ensures that the inner and outer surfaces of the cortex are clean. The invention has the function of waterproofing, oilproofing and antifouling.

Owner:JIANGYIN FANRONG YARN DYE FABRIC

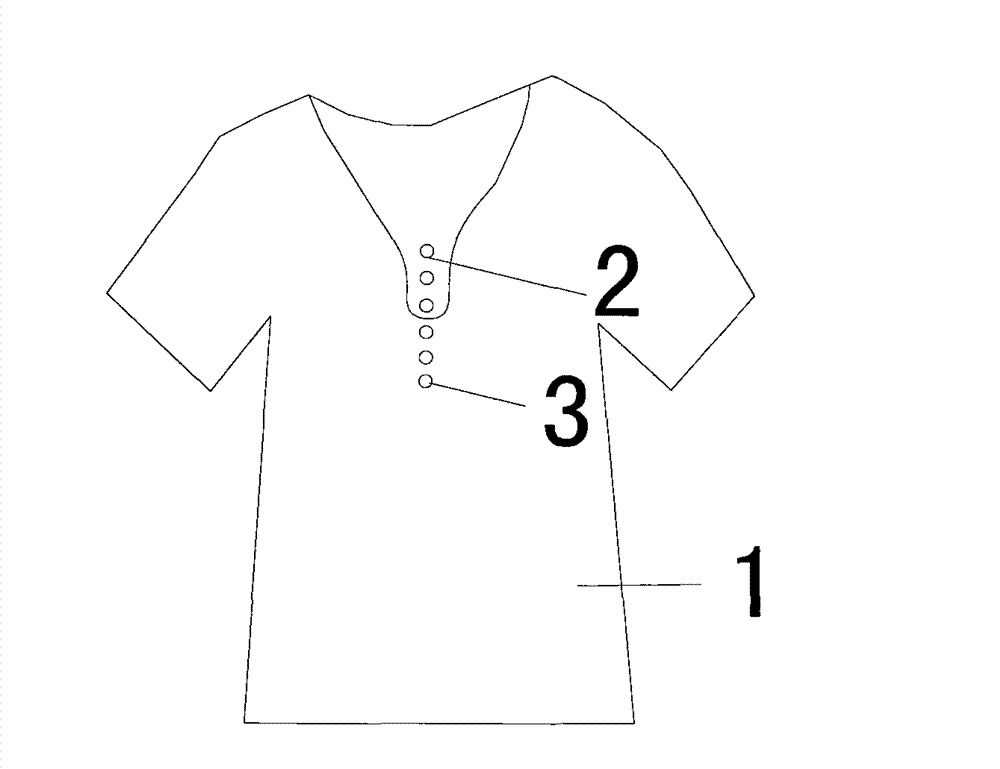

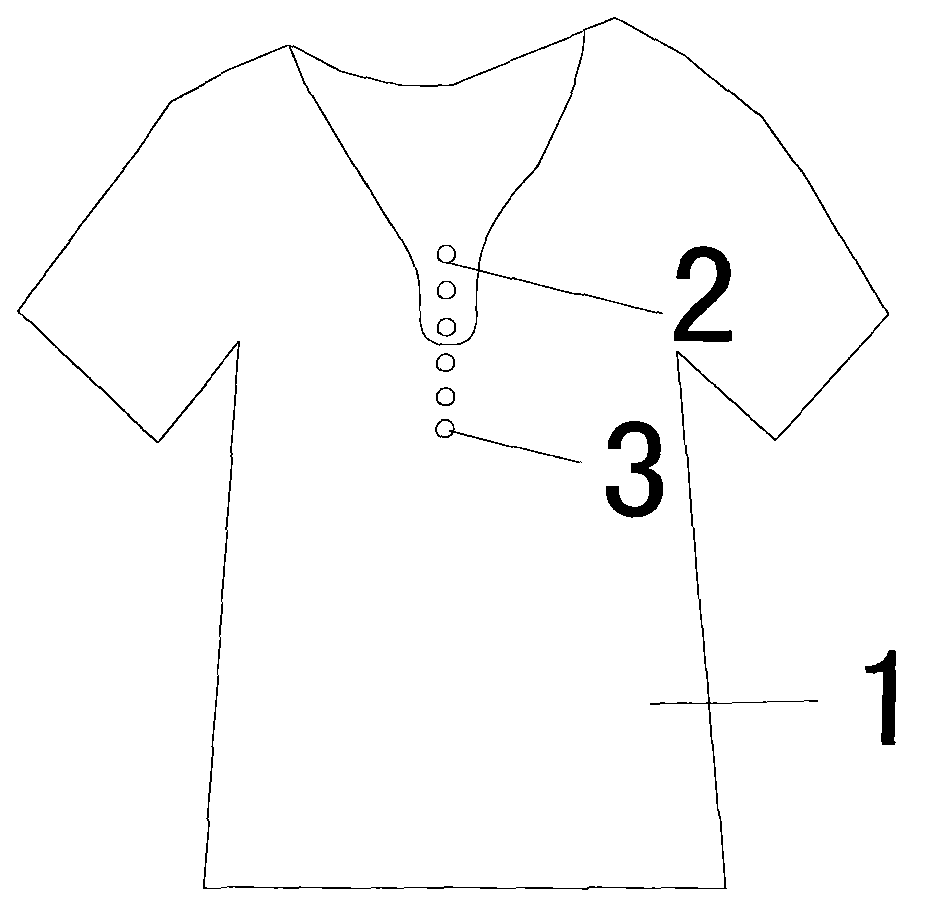

Woven fabric short sleeve with buttons

InactiveCN103584335AImprove the decorative effectStay cool and comfortableWoven fabricsProtective garmentWoven fabricCivil engineering

The invention relates to a woven fabric short sleeve with buttons. The woven fabric short sleeve with the buttons comprises a short sleeve body (1). A column of buttonsI(2) are vertically arranged under the neckline of the short sleeve body and a column of buttonsII(3) are vertically arranged under the buttonsI(2). The buttonsI(2) are open-close practical buttons and the buttonsII(3) are decorative buttons which can not be opened and closed. The short sleeve body is made by fabric and the fabric is consisted by three layers of structural fabric. Upper and lower structures are interwoven by warp and weft and a reinforced layer is arranged between the fabric in upper and lower layers. The reinforced layer is wrapped by the fabric in upper and lower layers and makes the fabric form weft stripe-typed bosses. Since the buttonsIare arranged under the neckline of the short sleeve, the anti-oil fabric short sleeve with the buttons can be opened and closed as required and ventilatory performance and cool and comfort feeling of users can be guaranteed; the buttonsIIcan increase aesthetics and decorativeness of the short-sleeve. The anti-oil fabric short sleeve with the buttons improves fabric gas permeability.

Owner:翟文卓

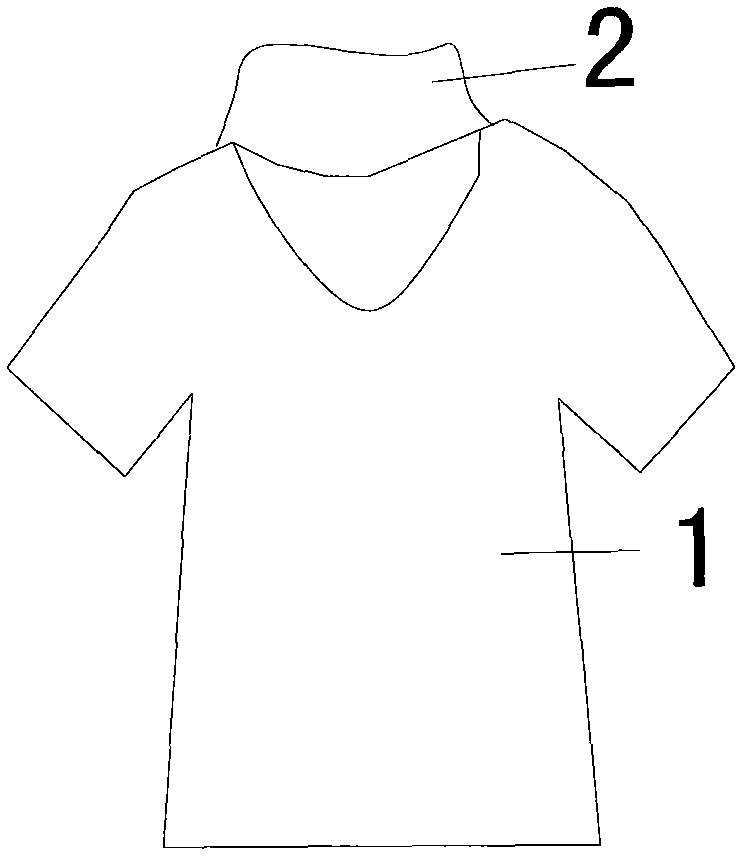

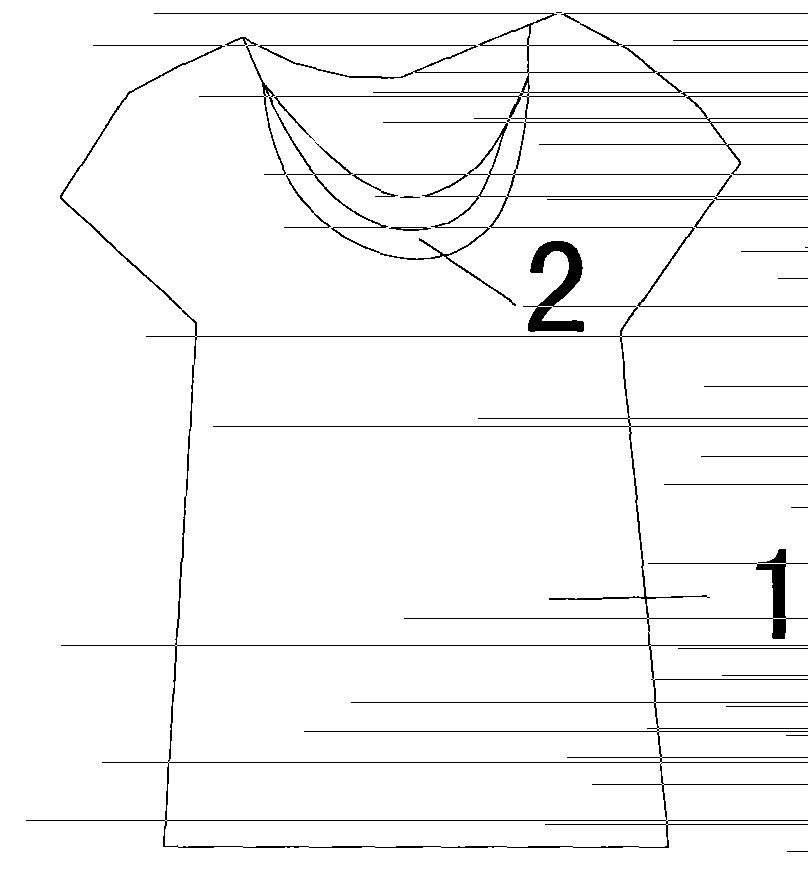

Anti-oil fabric short sleeve with buttons

InactiveCN103584295AImprove the decorative effectStay cool and comfortableFibre treatmentProtective garmentPolyesterEngineering

The invention relates to an anti-oil fabric short sleeve with buttons. The anti-oil fabric short sleeve with the buttons comprises a short sleeve body (1). A column of buttonsI(2) are vertically arranged under the neckline of the short sleeve body and a column of buttonsII(3) are vertically arranged under the buttonsI(2). The buttonsI(2) are open-close practical buttons and the buttonsII(3) are decorative buttons which can not be opened and closed. The short sleeve body is made by fabric and the fabric comprises three layers. The first and third layers are teflon coating layers and the second layer is fabric. The fabric is waterproof nylon fabric or polyester fabric. Since the buttonsIare arranged under the neckline of the short sleeve, the anti-oil fabric short sleeve with the buttons can be opened and closed as required and ventilatory performance and cool and comfort feeling of users can be guaranteed; the buttonsIIcan increase aesthetics and decorativeness of the short-sleeve. The anti-oil fabric short sleeve with the buttons has the advantages of good waterproof, anti-oil and antifouling functions.

Owner:夏宏希

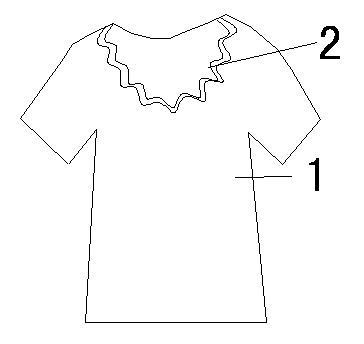

Water-proof short-sleeved clothes with wrinkled collar

The invention relates to a piece of water-proof short-sleeved clothes with a wrinkled collar. The short-sleeved clothes comprise a short-sleeved clothes body (1), wherein the collar of the short-sleeved clothes body (1) is provided with a wrinkled edge (2); the wrinkled edge (2) comprises two layers and is made of a silk fabric; the short-sleeved clothes body (1) is made of a fabric; the fabric comprises three layers, of which the first and third layers are Teflon coatings and the second layer is a textile fabric layer; the textile fabric is a nylon water-proof fabric or a terylene fabric. The wrinkled edge is arranged at the collar of the short-sleeved clothes, so that the collar is widened, the breathability effect is greatly improved, and the short-sleeved clothes are comfortable to wear and have attractive appearance. The clothes have excellent water-proof, oil-proof and anti-fouling functions.

Owner:JIANGSU ZHENXIN IND

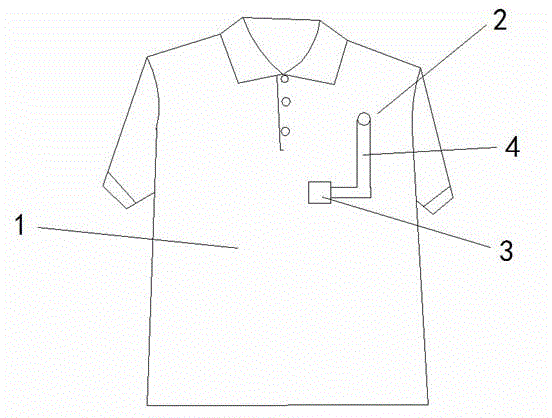

Waterproof and oil-proof garment with mobile phone holder

InactiveCN104413593AAvoid sorenessImprove waterproof performanceWoven fabricsProtective garmentPolyesterMechanical engineering

The invention relates to a waterproof and oil-proof garment with a mobile phone holder. The waterproof and oil-proof garment comprises a garment body (1), a plastic gear (2) is arranged on the front body of the garment body (1), and the mobile phone holder (3) is connected onto a support (4) which is connected onto the plastic gear (2). The garment is made of a fabric which consists of three layers including an outer layer, an interlayer and an inner layer, the inner layer and the outer layer are teflon coatings 15 micrometers in thickness, and the interlayer is made of a woolen fabric which is a waterproof nylon fabric or polyester fabric. A person feeling sore of arms due to holding of a mobile phone for a long time can put the mobile phone on the holder and adjust the support to a proper position, so that hands can get free, and soreness is avoided. The waterproof and oil-proof garment with the mobile phone holder has excellent waterproof, oil-proof and anti-fouling functions.

Owner:JIANGYIN CHUANGJIA ELECTRICAL APPLIANCE

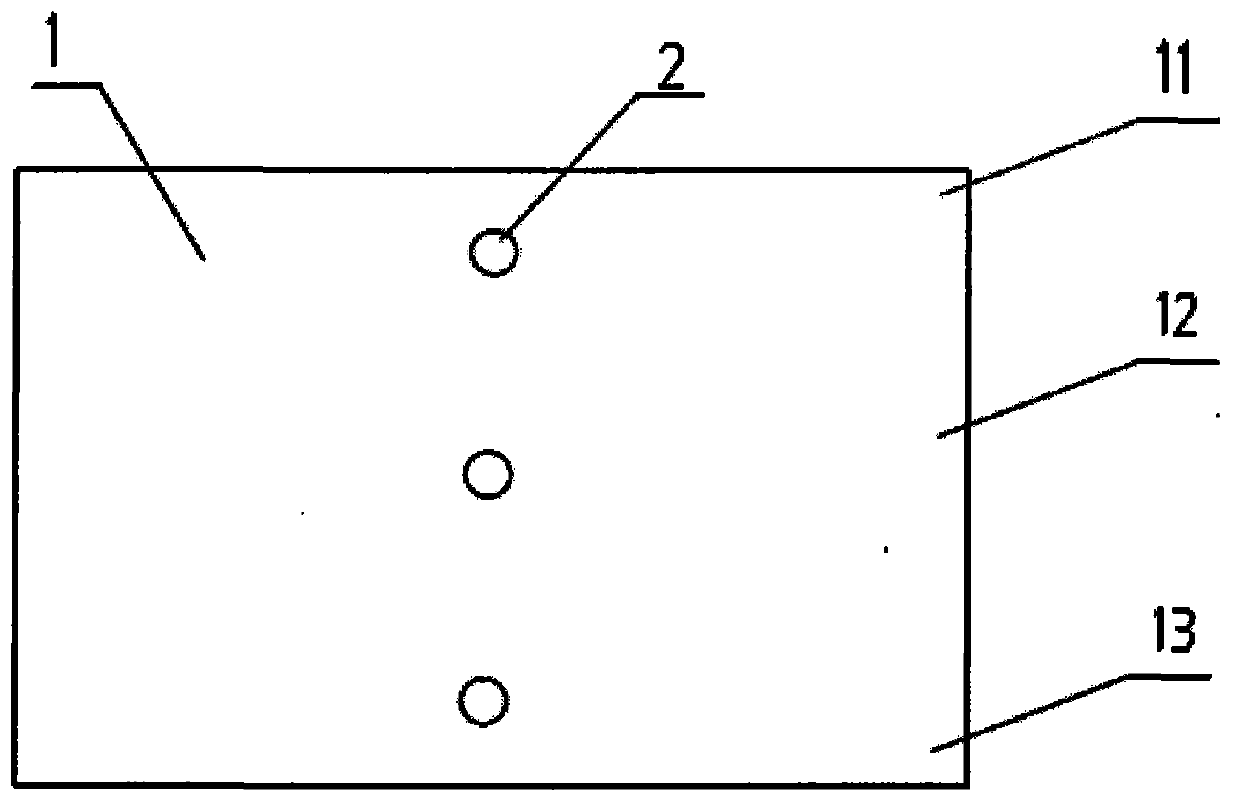

Novel oil-contamination-resistant curtain cloth with observation holes

The invention relates to novel oil-contamination-resistant curtain cloth with observation holes. The novel oil-contamination-resistant curtain cloth comprises base cloth. The base cloth comprises a top portion, a middle portion and a bottom portion, wherein the middle portion and the bottom portion are arranged below the top. A plurality of the hollowed observation holes are formed in the base cloth, the number of the observation holes is at least 3, and the observation holes are respectively formed in the top portion, the middle portion and the bottom portion of the base cloth. The base cloth is made of fabric, the fabric comprises three layers, the first layer and the third layer are Teflon coatings, the second layer is textile fabric, and the textile fabric is nylon waterproof shell fabric or dacron shell fabric. The novel oil-contamination-resistant curtain cloth is simple in structure, users can know the external weather conditions conveniently, and the requirements of people of different heights can be met at the same time. In addition, the novel oil-contamination-resistant curtain cloth has good waterproof, oil-proof and fouling-proof functions.

Owner:杨洁

Waterproof oil-resistant antifouling glittery knitted wool fabric

InactiveCN106218072AGood waterproofBreak the limitation of single colorSynthetic resin layered productsClothingsWoolYarn

The invention relates to a waterproof oil-resistant antifouling glittery knitted wool fabric. The front surface of a knitted wool fabric body (1) of the glittery knitted wool fabric is fixedly provided with colorful glittery silk yarns (2); and the back surface of the knitted wool fabric body is provided with a lining fabric layer which is composed of three layers, with a Teflon coating as an outer layer, a textile fabric as a middle layer and another Teflon coating as an inner layer, wherein the textile fabric is a nylon waterproof fabric or terylene fabric, and the thickness of the Teflon coatings is 10 to 13 [mu]m. Clothes prepared from the glittery knitted wool fabric in the invention are warm, comfortable, glittery and fashionable. The glittery knitted wool fabric has waterproof, oil-resistant and antifouling functions.

Owner:JIANGYIN DONGFA GARMENT MAKING

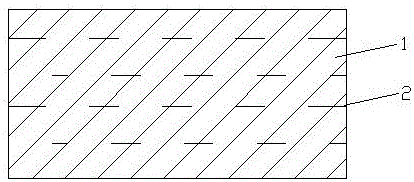

Waterproof oil-resistant antifouling bamboo-fiber fabric for gauze kerchief

InactiveCN106218026AGood waterproofHigh transparencySynthetic resin layered productsClothingsCotton fibreYarn

The invention relates to a waterproof oil-resistant antifouling bamboo-fiber fabric for a gauze kerchief. The fabric is formed by interlacing of cotton-fiber yarns (1) used as warp and bamboo-fiber yarns (2) as weft. The back surface of the fabric is compounded with a lining fabric layer which is composed of three layers, with a Teflon coating as an outer layer, a textile fabric as a middle layer and another Teflon coating as an inner layer, wherein the textile fabric is a nylon waterproof fabric or terylene fabric, and the thickness of the Teflon coatings is 10 to 13 [mu]m. The fabric for the gauze kerchief in the invention has an anti-ultraviolet function and natural health-care functions like antibiosis, bacteriostasis, mite elimination and odor prevention and has good hand feel; and the fabric has waterproof, oil-resistant and antifouling functions.

Owner:JIANGYIN HONGWEI QINGSHAN SPINNING

Humidity-sensitive intelligent betaine fluorinated antifouling paint and preparation method thereof

ActiveCN102676015BWith anti-fouling functionGood antifouling functionAntifouling/underwater paintsPaints with biocidesInorganic saltsBetaine

The invention relates to a humidity-sensing betaine-based fluorine-containing intelligent antifouling paint and a preparation method thereof. The main weight components of the coating include: betaine fluorine-containing copolymer 10%-60%; inorganic salt filler 60%-10%; water-based paint defoamer 0.1%-0.5%; dispersant 0.1%-5.0% ; Water 20%-50%. The preparation method is to firstly mix betaine fluorine-containing copolymer solution, defoamer, dispersant and water evenly, and then add inorganic salt filler under stirring to obtain humidity-sensitive betaine fluorine-containing intelligent antifouling coating. The present invention combines the antifouling characteristics of fluorine-containing groups in the air and the antifouling characteristics of betaine groups in water, and prepares a type of intelligent antifouling coating sensitive to humidity. Changes to adjust the distribution of fluorine-containing groups and betaine groups in the coating film, so as to maintain a good antifouling function.

Owner:SOUTH CHINA UNIV OF TECH

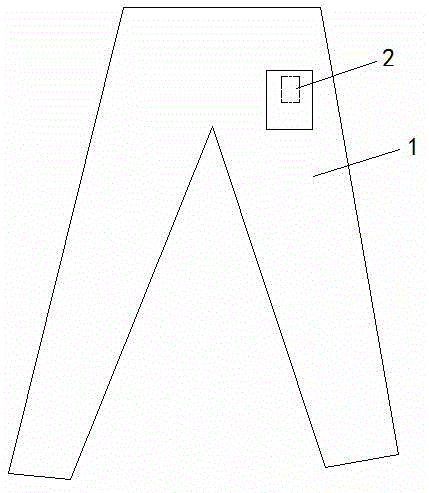

Oil stain resistance fabric garment with key pocket

The invention relates to an oil stain resistance fabric garment with a key pocket. The oil stain resistance fabric garment comprises a garment body (1); the key pocket (2) is arranged in a trouser pocket of the garment body (1); the key pocket (2) is made of cow leather and an elastic fabric; the cow leather is sewn on the trouser pocket. A fabric adopted by the garment body (1) comprises three layers, i.e. a Teflon coating used as an outer layer, a woolen fabric used as an interlayer and a Teflon coating used as an inner layer; the woolen fabric is a nylon waterproof fabric or a polyester fabric; the Teflon coatings have thicknesses of 15mum. Therefore, keys are isolated from other articles, so that other articles are prevented from being scratched and keys also can be prevented from being lost. The oil stain resistance fabric garment has good waterproof, oil-proof and stain-proof functions.

Owner:JIANGYIN NEW QUANSHENG TEXTILE PRINTING & DYEING

Waterproof oil-resistant anti-fouling short sleeve shirt with detachable collar

InactiveCN103504535AGood waterproofAnti-fouling functionFibre treatmentProtective garmentPolyesterFastener

The invention relates to a waterproof oil-resistant anti-fouling short sleeve shirt with a detachable collar. The waterproof oil-resistant anti-fouling short sleeve shirt comprises a short sleeve shirt body (1), the neckline of the short sleeve shirt body (1) is provided with the detachable collar (2), the collar (2) and the short sleeve shirt body (1) are connected through snap fasteners or a zipper, the collar and the short sleeve shirt body are made of fabrics, each fabric comprises three layers, the first layers and the third layers are Teflon coatings, the second layers are textile fabrics, and the textile fabrics are nylon waterproof fabrics or polyester fabrics. Due to the fact that the collar is detachable, the short sleeve shirt can be of different styles before the collar is detached and after the collar is detached, diversity of the structure of the same short sleeve shirt is achieved, and the short sleeve shirt is more fashionable and has good waterproof, oil-resistant and anti-fouling functions.

Owner:孙建良

A kind of anti-corrosion and anti-fouling coating and preparation method thereof

ActiveCN108587262BGood dispersionGood anti-fouling functionAntifouling/underwater paintsPaints with biocidesPhosphatePhosphoric acid

The invention discloses an anti-corrosion antifouling coating and a preparing method thereof. The anti-corrosion antifouling coating is prepared from, by weight, 10%-30% of binding agent, 1%-10% of passivating agent, 20%-50% of anti-corrosion functional filler and 20-50% of photocatalysis functional filler; the binding agent is selected from an aluminum dihydrogen phosphate water solution; the passivating agent is selected from at least one of chromic oxide, sodium tungstate and sodium silicate; the anti-corrosion functional filler is selected from aluminum powder and / or zinc powder; the photocatalysis functional filler is selected from metal-doped nanometer titania or pure nanometer titania. All the raw materials and water are mixed, coating, heating and solidifying are carried out, and the anti-corrosion antifouling coating is prepared. According to the anti-corrosion antifouling coating, under the condition that the anti-corrosion performance of the coating is not damaged, the goodantifouling function of the coating is given, and the application field of the anti-corrosion antifouling coating is further expanded.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Anti-oil fabric short-sleeved shirt with hood

InactiveCN103564674AConvenient sunshade and rain protectionGood decorationGarmentsPolyesterMechanical engineering

The invention relates to an anti-oil fabric short-sleeved shirt with a hood. The anti-oil fabric short-sleeved shirt comprising a short-sleeved shirt body (1) is characterized in that a hood (2) is arranged at the rear of a neck opening of the short-sleeved shirt body (1), and is in a double-layer structure; a lining of the hood (2) is made of meshed single knitted fabric, an outer layer of the hood (2) is made of artificial leather, the short-sleeved shirt body (1) is made of fabric including three layers, the first and third layers are Teflon coatings, and the second layer is made of woven fabric which is nylon waterproof fabric or polyester fabric. The anti-oil fabric short-sleeved shirt has the advantages that the hood arranged at the rear of the neck opening of the short-sleeved shirt provides convenience of shading from sun and rain and allows the anti-oil fabric short-sleeved shirt to be well attractive; the anti-oil fabric short-sleeved shirt is well water proof, oil proof and stain proof.

Owner:那忠良

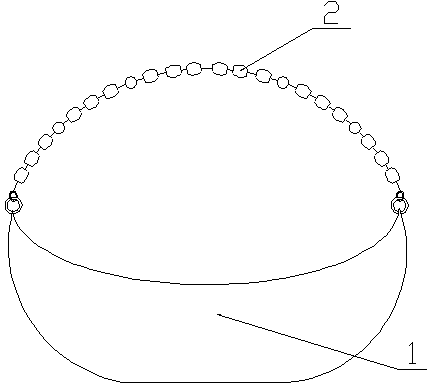

Anti-oil pollutant fabric good handfeel bag

The invention relates to a bag, in particular to an anti-oil pollutant fabric good handfeel bag, which comprises a crescent bag body (1), and a bag tape (2) that is a bead chain composed of spherical beads and elliptical beads. The bag body (1) is made of a fabric consisting of three layers, the first layer and the third layer are Teflon coatings, and the second layer is a textile that is a nylon waterproof fabric or polyester fabric. The anti-oil pollutant fabric good handfeel bag provided by the invention has the bead chain composed of spherical beads and elliptical beads as the bag tape, and people can have good handfeel while holding the bag, thus meeting people's needs. The bag provided by the invention has very good waterproof, oil-proof and anti-pollution functions.

Owner:JIANGYIN ZHENGZHONG SCI & EDUCATION EQUIP

Anti-oil fabric bag not easy to slip and capable of shining by illumination

The invention relates to an anti-oil fabric bag not easy to slip and capable of shining by illumination. The bag comprises a bag body (2), wherein a bag belt (1) is arranged on the upper part of the bag body (2), a plurality of bead sheets (3) are closely arranged on the external surface of the bag body (2), each bead sheet (3) is provided with a bead (4), the bag body (2) is made of a fabric, the fabric comprises three layers, a first layer and a third layer are Teflon coatings, a second layer is a textile fabric, and the textile fabric is a nylon waterproof fabric or polyester fabric. The surface of the bag body of the bag may shine when in illumination, and the bag has good waterproof, anti oil, and anti pollution functions.

Owner:WUXI HENGTONG LIGHT IND PROD

Difficult-slippage and oil-stain-resistant fabric bag

The invention relates to bags and particularly relates to a difficult-slippage and oil-stain-resistant fabric bag. The bag comprises a bag body (1), wherein multiple bead strings (2) are transversely arranged on the back face of the bag body (1) in parallel, the bag body (1) is made from fabrics, the fabrics comprise three layers, a first layer and a third layer are made from Teflon coatings, a second layer is made from textiles, and the textiles are nylon waterproof shell fabrics or polyester shell fabrics. According to the difficult-slippage and oil-stain-resistant fabric bag disclosed by the invention, the multiple bead strings are transversely arranged on the back face of the bag in parallel, so that the coefficient of friction of the back face of the bag is increased, the slippage is difficult when the bag is held by people, and then the needs of people are met. The bag has good waterproofing, oil-proofing and anti-fouling functions.

Owner:梅建熙

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com