Patents

Literature

405 results about "Poly tetra fluoro ethylene" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Fluorinated ethylene propylene or FEP is a copolymer of hexa fluoro propylene and tetra fluoro ethylene. It differs from the PTFE (poly tetra fluoro ethylene) resins in that it is melt-processible using conventional injection molding and screw extrusion techniques.

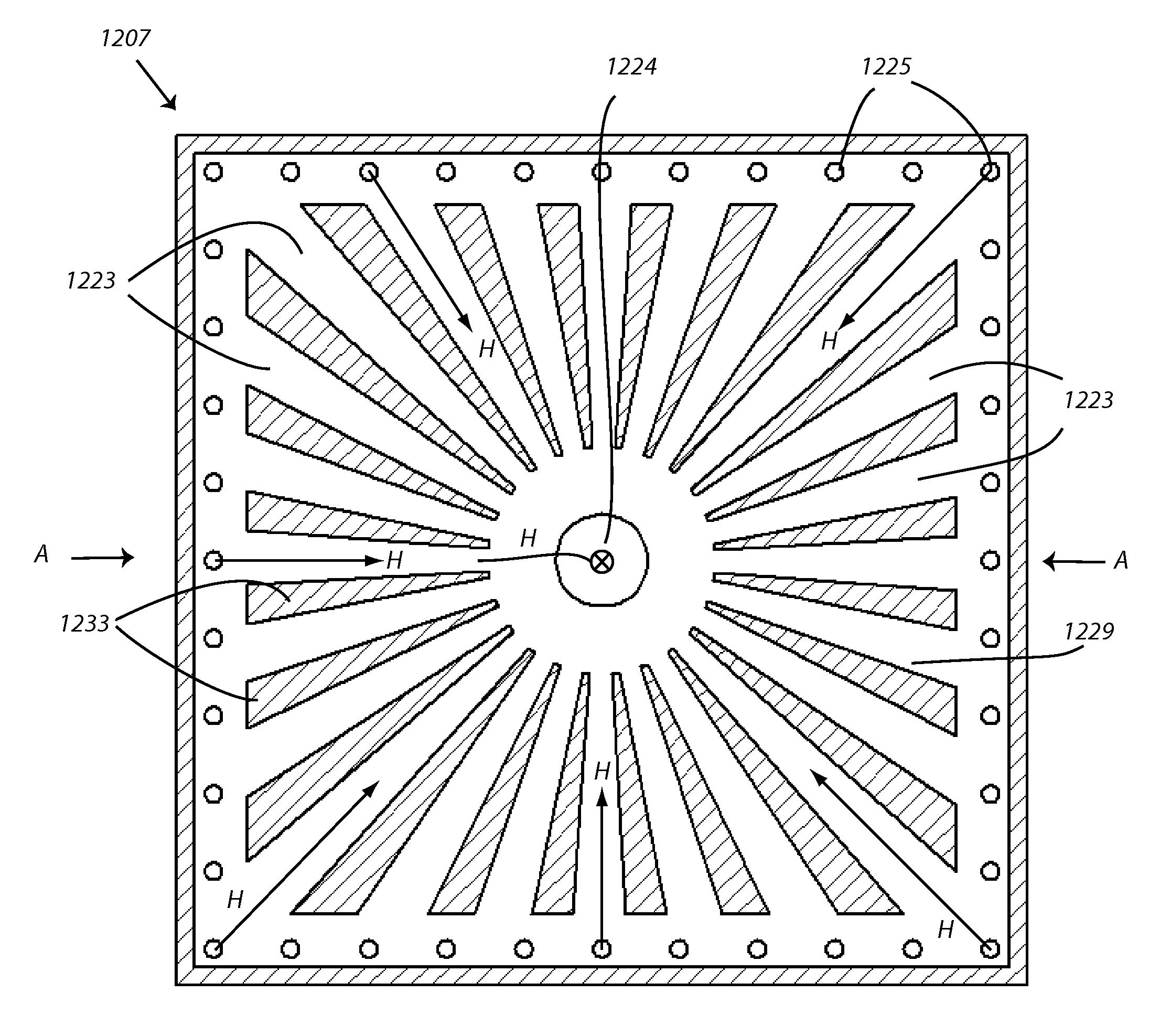

Lattice

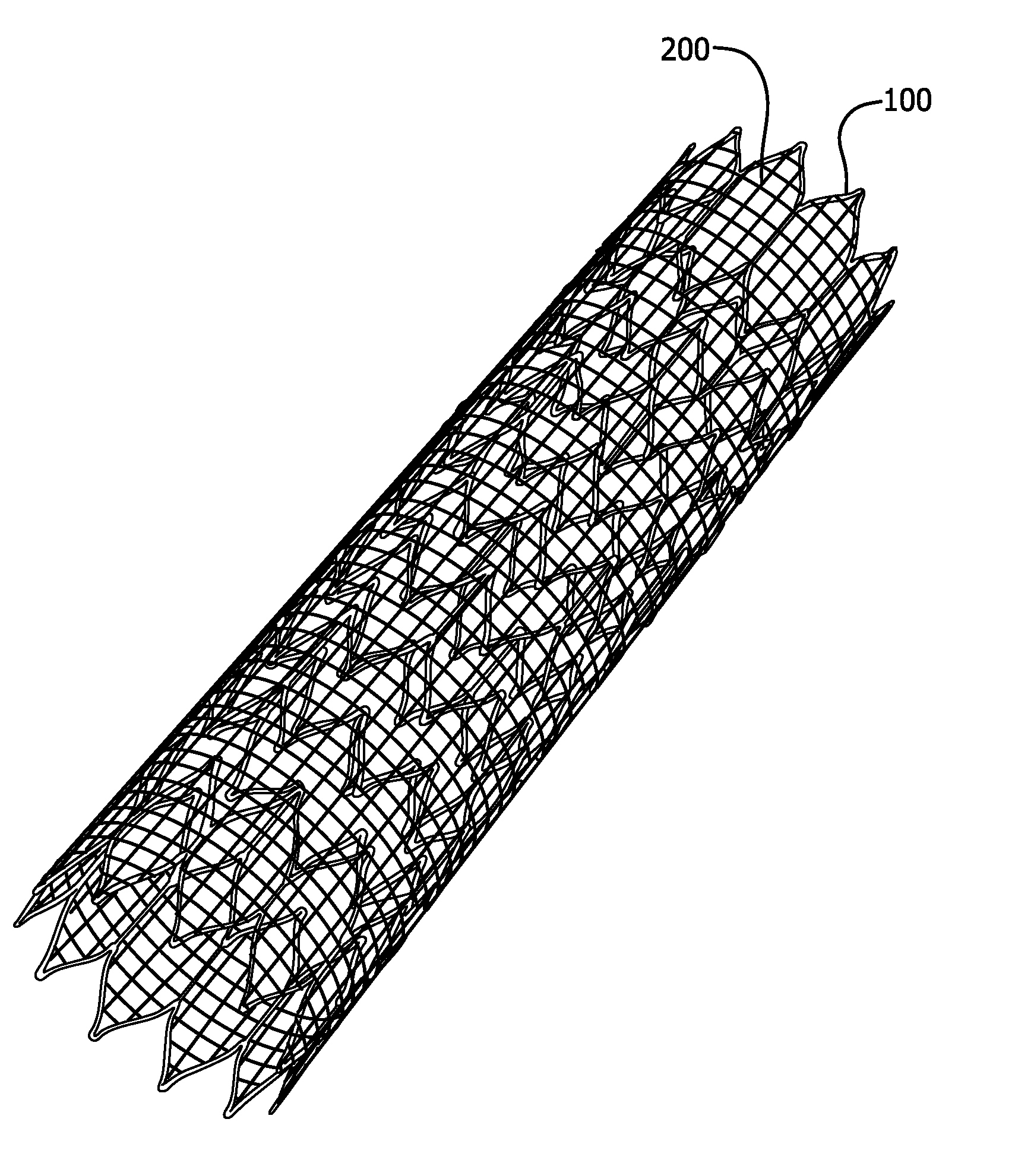

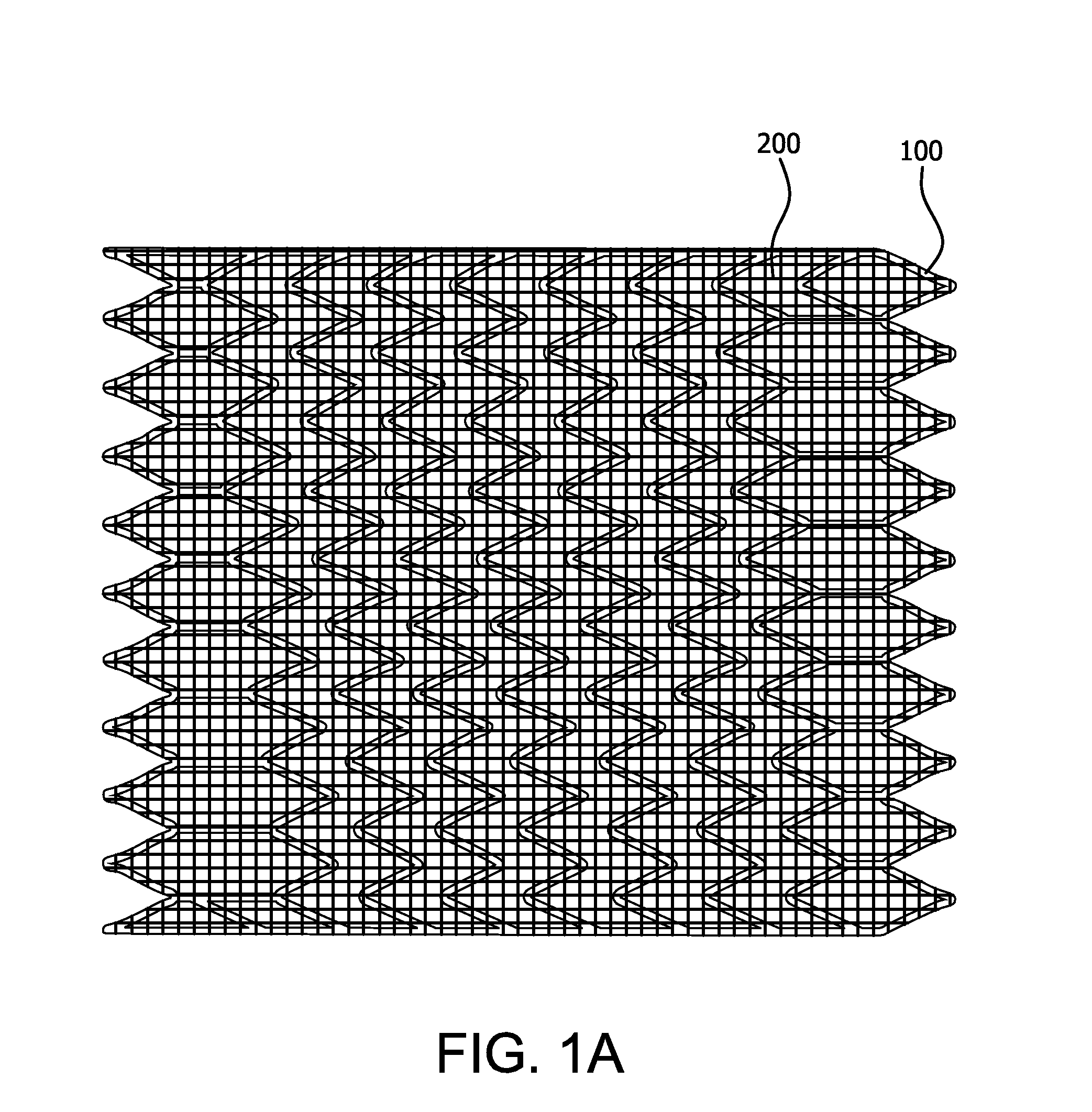

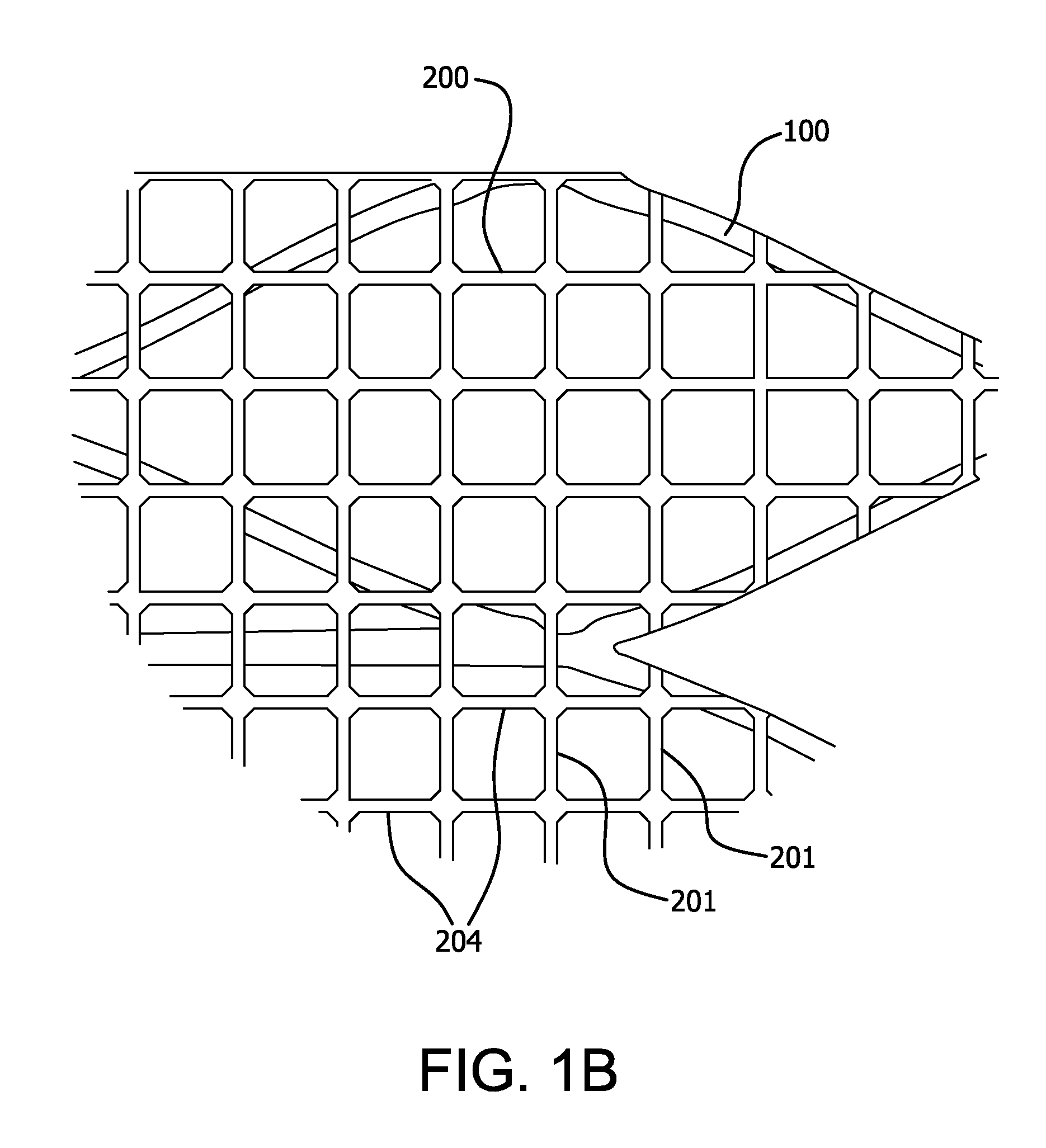

The invention relates to medical devices and methods of using them. The devices are prostheses which can be percutaneously deliverable with (or on) an endovascular catheter or via other surgical or other techniques and then expanded. The prostheses are configured to have a lattice resistant to dilation and creep, which is defined by a plurality of openings. The prosthesis may also optionally have a stent disposed proximal to the lattice. In exemplary embodiments, the fluoropolymer is expanded polytetrafluoroethylene. The composite materials exhibit high elongation while substantially retaining the strength properties of the fluoropolymer membrane. In at least one embodiment, the lattice is made of a composite material that includes a least one fluoropolymer membrane including serpentine fibrils and an elastomer. A lattice including a generally tubular member formed of a composite material including a least one fluoropolymer membrane containing serpentine fibrils and an elastomer is also provided.

Owner:WL GORE & ASSOC INC

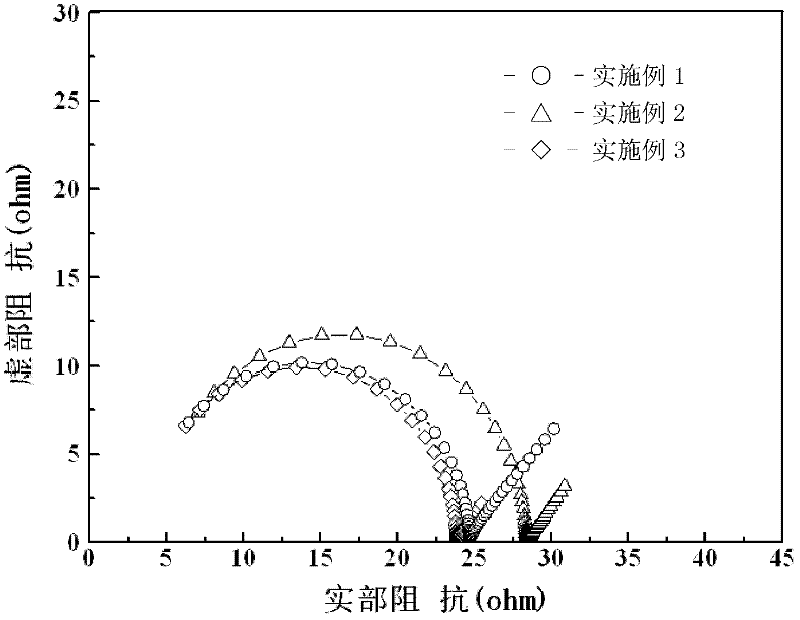

Preparation method of full-solid-state nano composite polymer electrolyte

InactiveCN102891335APrevent crystallizationIncrease the fast transfer areaMaterial nanotechnologySecondary cellsAll solid stateOrganic solvent

The invention relates to a preparation method of a full-solid-state nano composite polymer electrolyte. The preparation method comprises the following steps of: mixing surface functional graphene, dissociated lithium salt and a polymer substrate and dissolving into an organic solvent, thereby obtaining a sol-like compound through ultrasonic treatment and mechanical blending; pouring on a Teflon template; and drying in a vacuum drying tank, thereby obtaining an electrolyte membrane. According to the invention, the full-solid-state nano composite polymer electrolyte is prepared through adding chemically modified graphene, not only room temperature conductivity is high, but also the surface is smooth and even, the internal components are uniform, and the full-solid-state nano composite polymer electrolyte is high in lithium ion transference number and electrochemical stability.

Owner:TONGJI UNIV

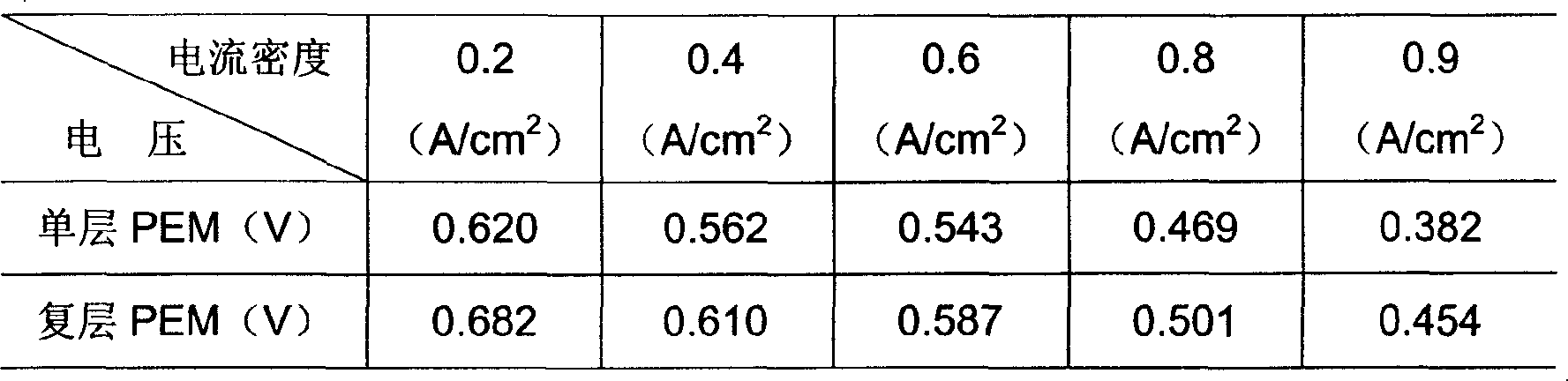

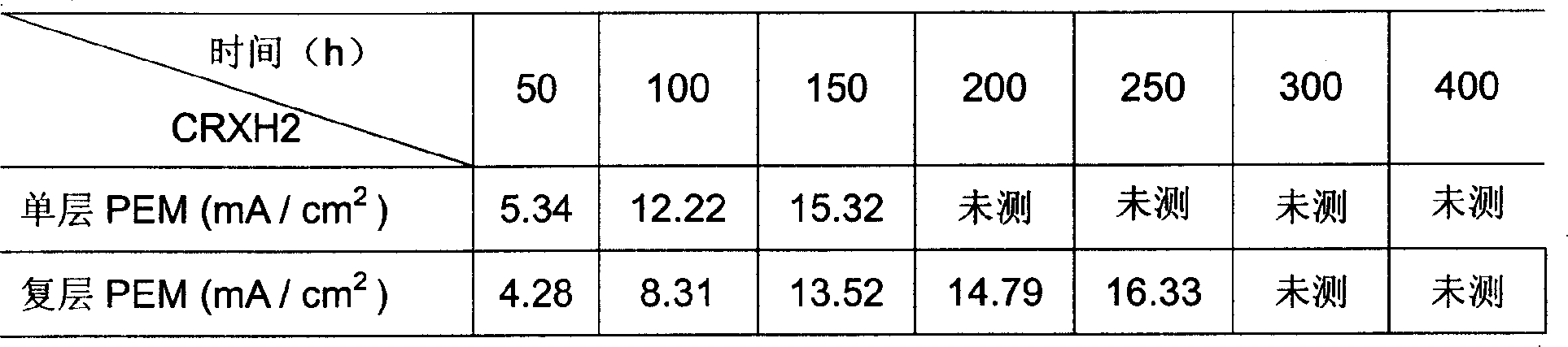

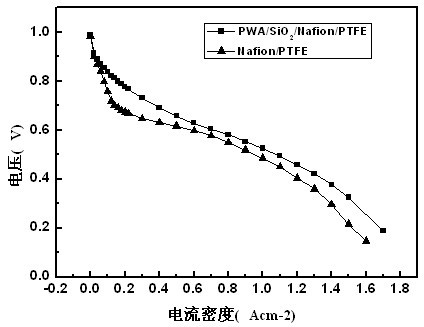

Composite proton exchange membrane for high-temp proton exchange membrane fuel cell and preparation method

InactiveCN1694290AImprove mechanical propertiesGood water retention at high temperatureCell component detailsSolid electrolyte fuel cellsProtonPre treatment

This invention relates to a compound proton exchange film of a high temperature proton exchange film fuel battery, characterizing that said film is a multiplayer proton exchange film composite by multiplayer multi-hole polymer intensified compound proton exchange films. The multi-hole polymer is a buck Teflon micro-hole film, which makes up of the multi-hole polymer enhanced compound proton exchange film together with the inorganic nm particles and solid poly-electrolyte fillers. The preparation method of the exchange film is: a micro- pore film is pre-processed and fastened filled by inorganic nm particles and solid poly electrolytes to be rolled to single layer multi-hole polymer intensified proton exchange film to be laminated and hot-pressed to form a multiplayer proton exchange film.

Owner:WUHAN UNIV OF TECH

Composite conductive paper of carbon fiber

InactiveCN101003956AHigh porosityImprove conductivityPaper/cardboardSynthetic cellulose/non-cellulose material pulp/paperFiberCarbon fibers

The present invention discloses a composite conductive carbon fiber paper. Its preparation process includes the following steps: using acrylonitrile carbon fiber and other carbon material as raw material, adopting polyphenylamine, conventional polyvinyl alcohol and water-soluble phenolic resin and mixing them, and using their mixture as adhesive, the polyphenylamine is conductive high-molecular polymer; mixing sodium alginate and conventional dispersing agent; adopting wet-process paper-making technique to make paper; vacuum drying the obtained carbon paper, then using Teflon emulsion whose concentration is 5%-20% to make treatment; finally, introducing nitrogen gas and making carbonization, carbonization temperature is higher than 1000 deg.C, so as to obtain the invented composite conductive carbon fiber paper. Said composite conductive carbon fiber paper mainly is used in fuel cell field.

Owner:DONGHUA UNIV

Modified liquid for filter paper of filter and its preparation method and use

InactiveCN1831243AParty economyLong-lasting functionSpecial paperNon-macromolecular organic additionSolventChemistry

The invention relates to a filter paper modified liquid for a filter and the preparing method and use thereof, comprising phenylpropyl latex or organic silicone acrylic acid 4-20 weight shares, melamine 1-4 weight shares, and solvent 24-78.9 weight shares, where the solvent is any one of the water, deionized water, alcohol and isopropanol; also comprising Teflon latex 15-35 weight shares; further able to comprise micrometer or nanometer titanium dioxide particles 1-10 weight shares, and NP-13 0.1-2 weight shares; and able to the filtering performance and service life of the filter paper of the filter. And the making method is the traditional mixing method. and the use: adopting traditional methods spraying and dipping to form a film layer on each side of the filter paper, then keeping temperature at 110-130DEG C for 1.5-2min, thus able to obtain two layers of modified films on the filter paper, which can help improve filtering efficiency and service life of the filter.

Owner:BENGBU HAOYE FILTER

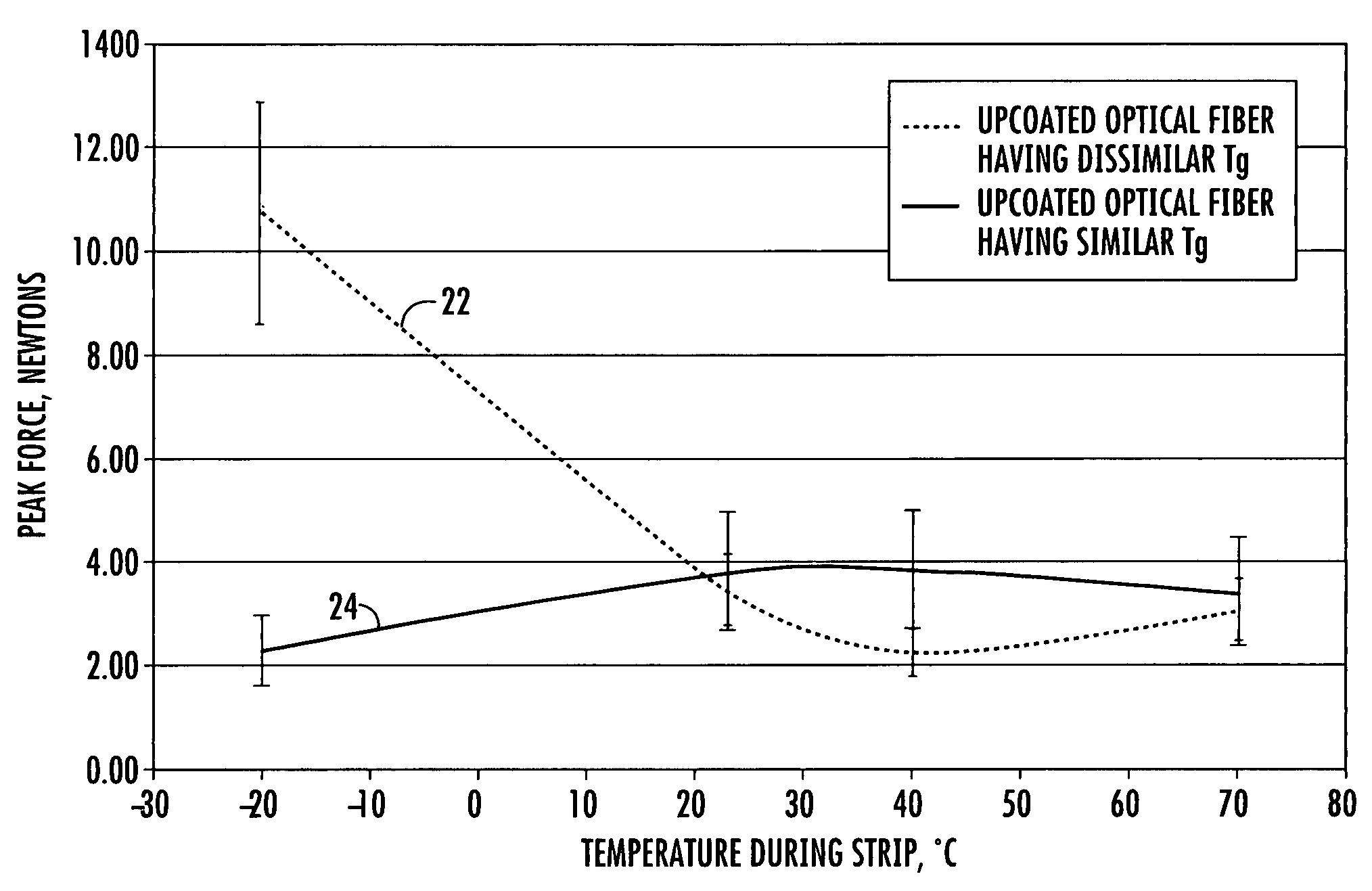

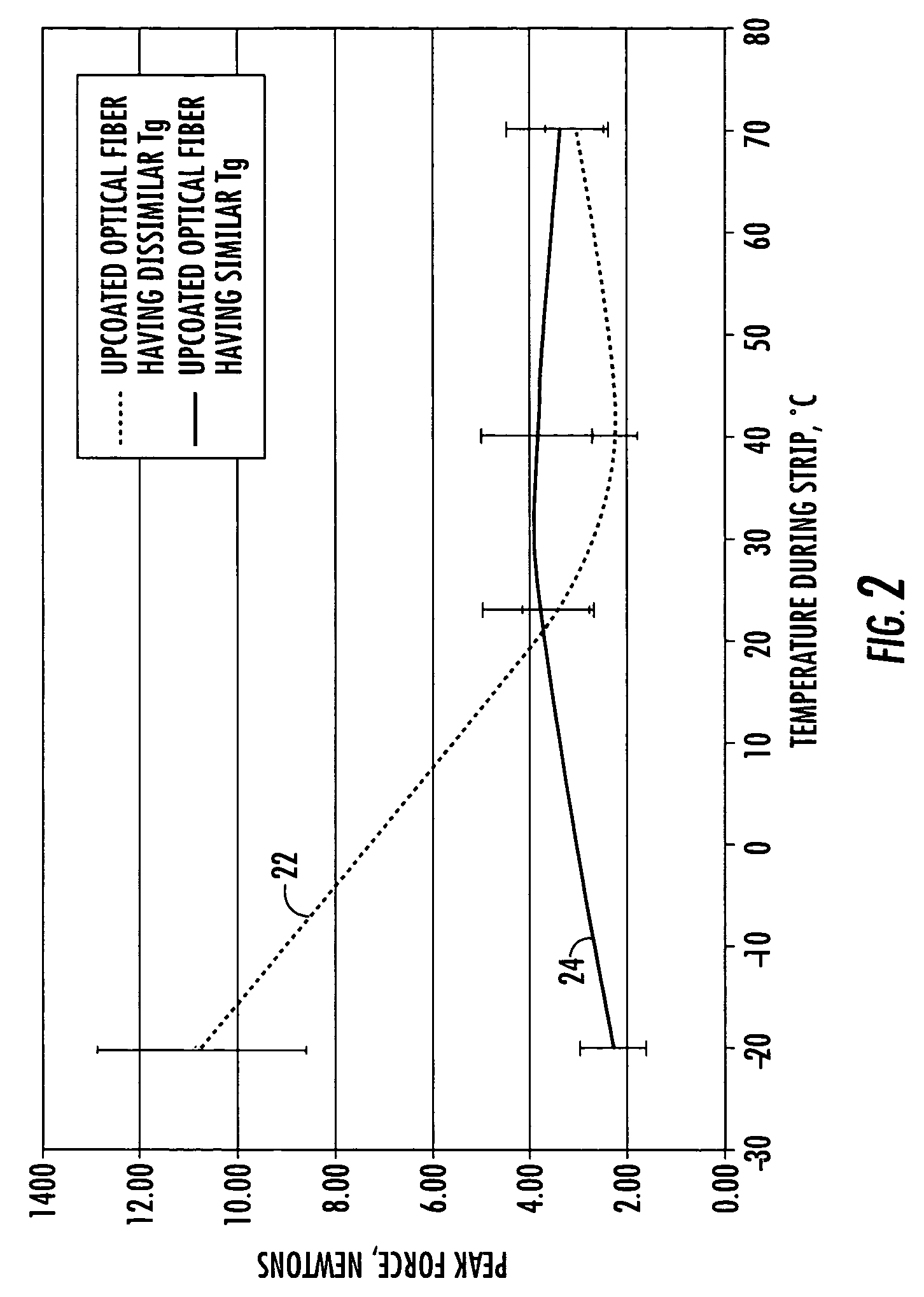

Mechanically strippable upcoated optical fiber

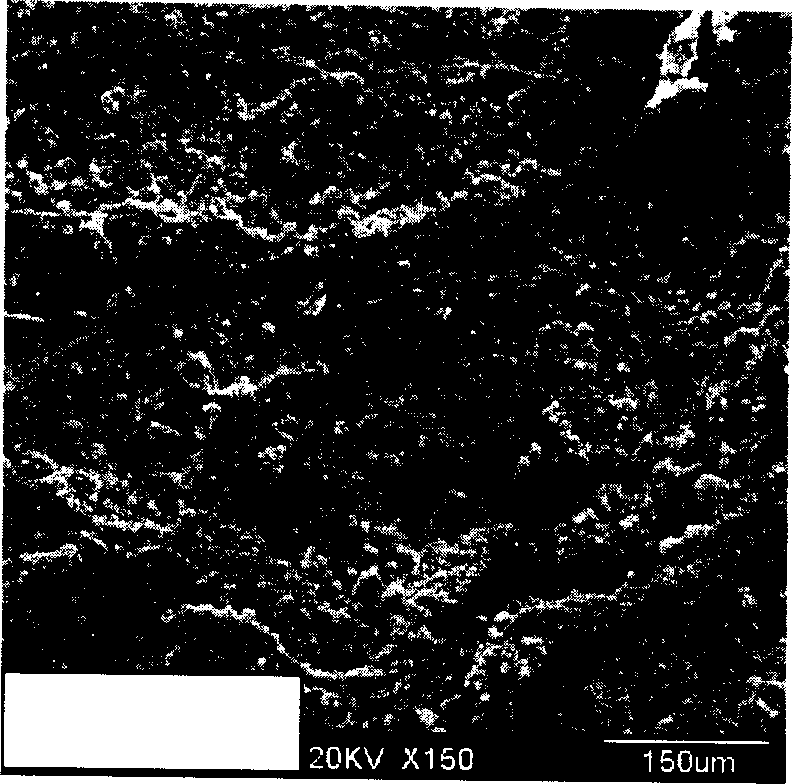

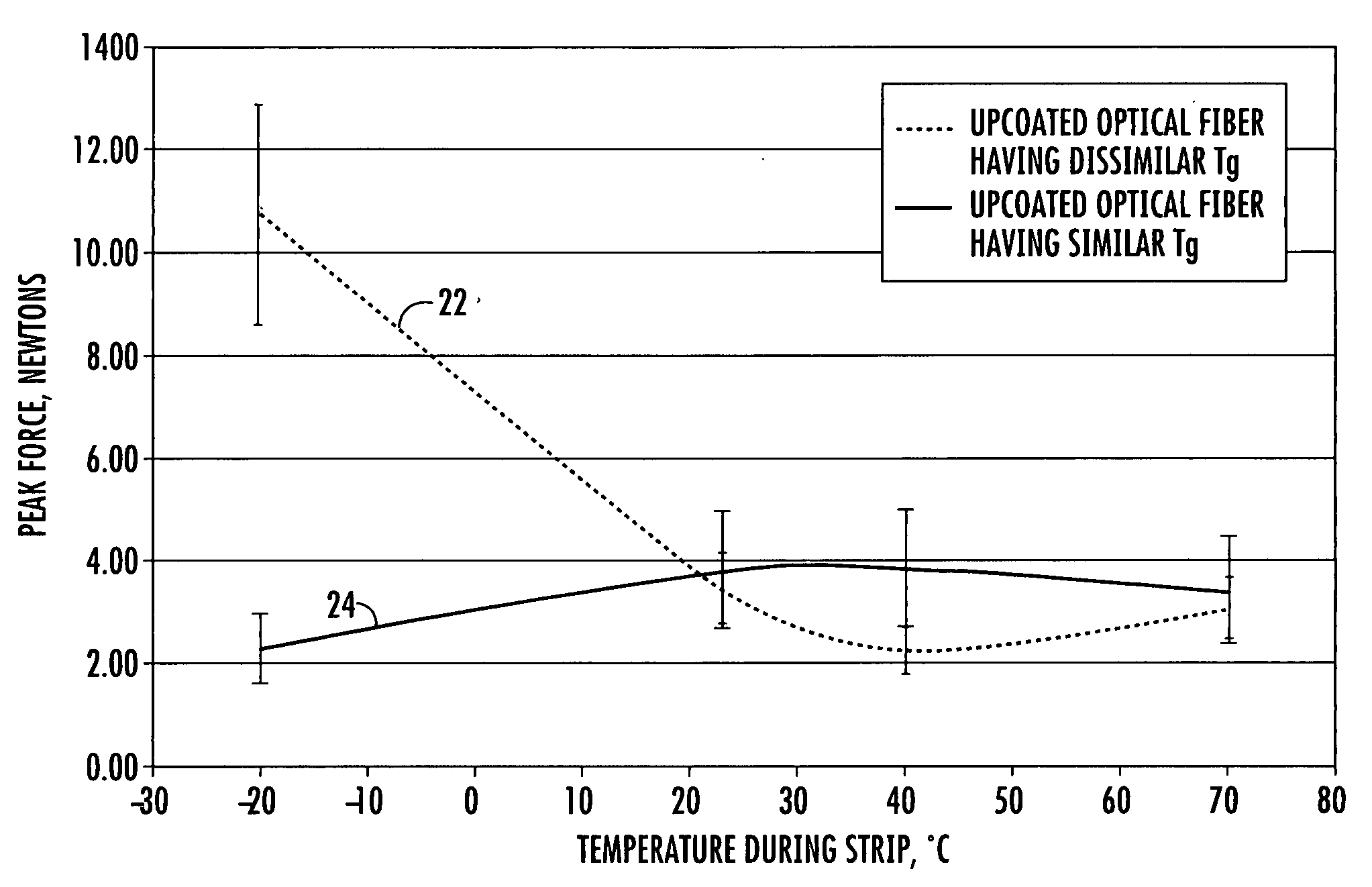

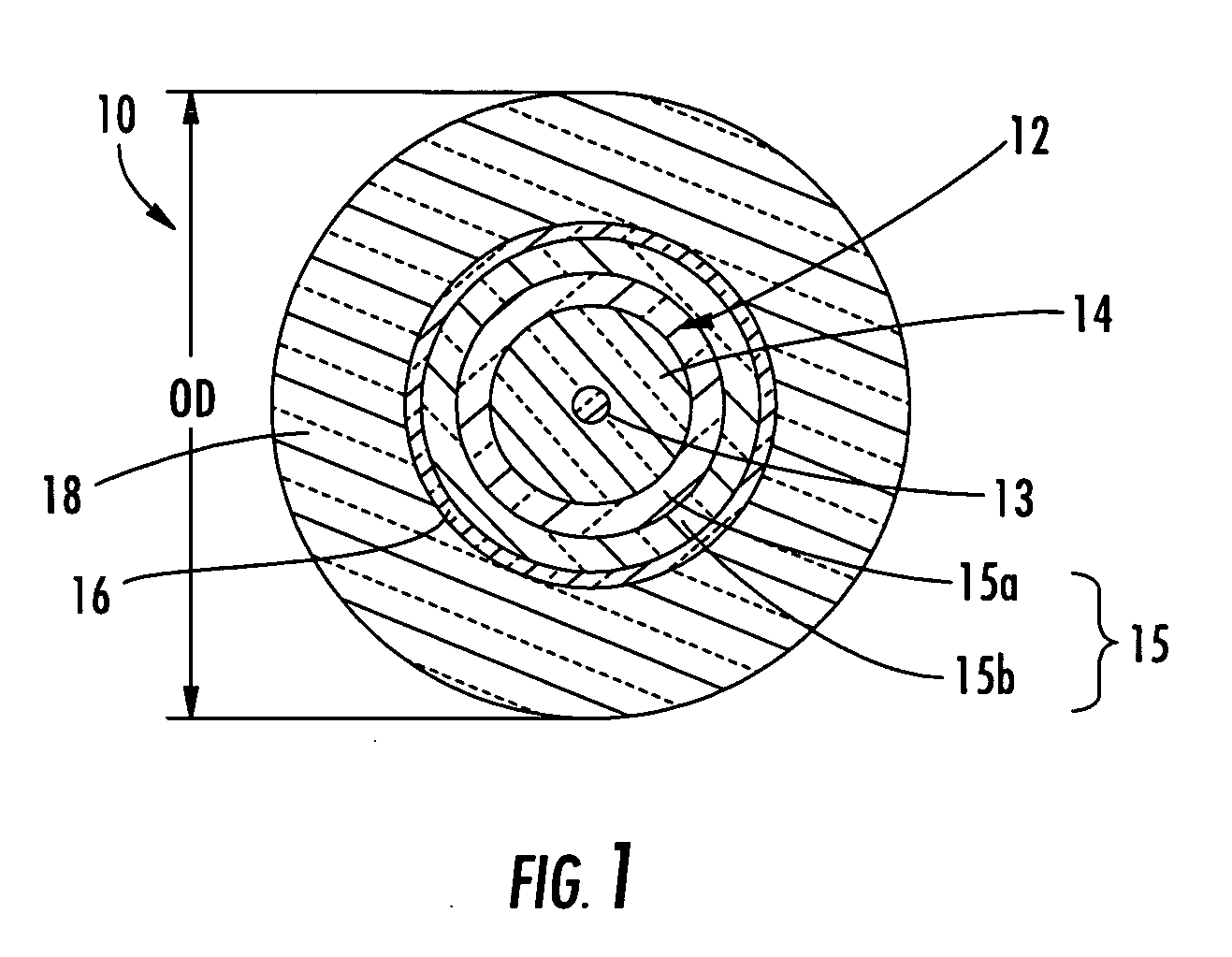

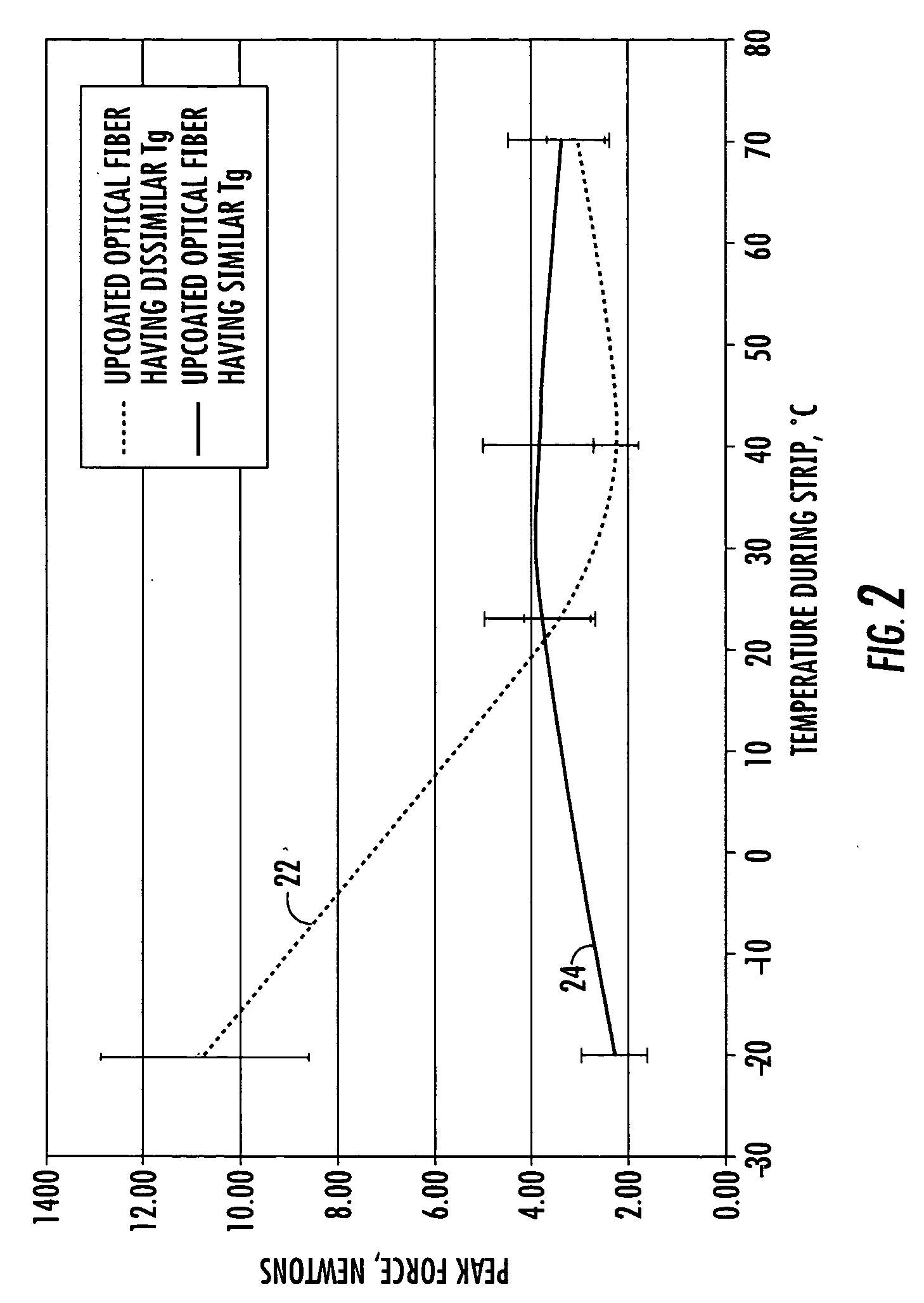

ActiveUS20070031096A1Reduce surface tensionOptical fibre with multilayer core/claddingOptical waveguide light guideVitrificationUltraviolet

An upcoated optical fiber includes an optical fiber having a ultra-violet (UV) curable upcoating and a slip layer disposed between the optical fiber and the upcoating. The upcoating is mechanically strippable from the optical fiber and may be colored for identification of the optical fiber. In one embodiment, the slip layer and upcoating both have predetermined glass transition temperatures that are within about 15° C. of each other for improving mechanical characteristics. The slip layer may be essentially the same color as the upcoating for identification of the optical fiber after the upcoating is removed or it may be uncolored. In suitable embodiments, the slip layer may include a micronized poly-tetra-fluoro-ethylene (PTFE), a silicone, and / or a dispersing agent for enhancing the strip performance of the upcoating over a range of temperatures.

Owner:CORNING OPTICAL COMM LLC

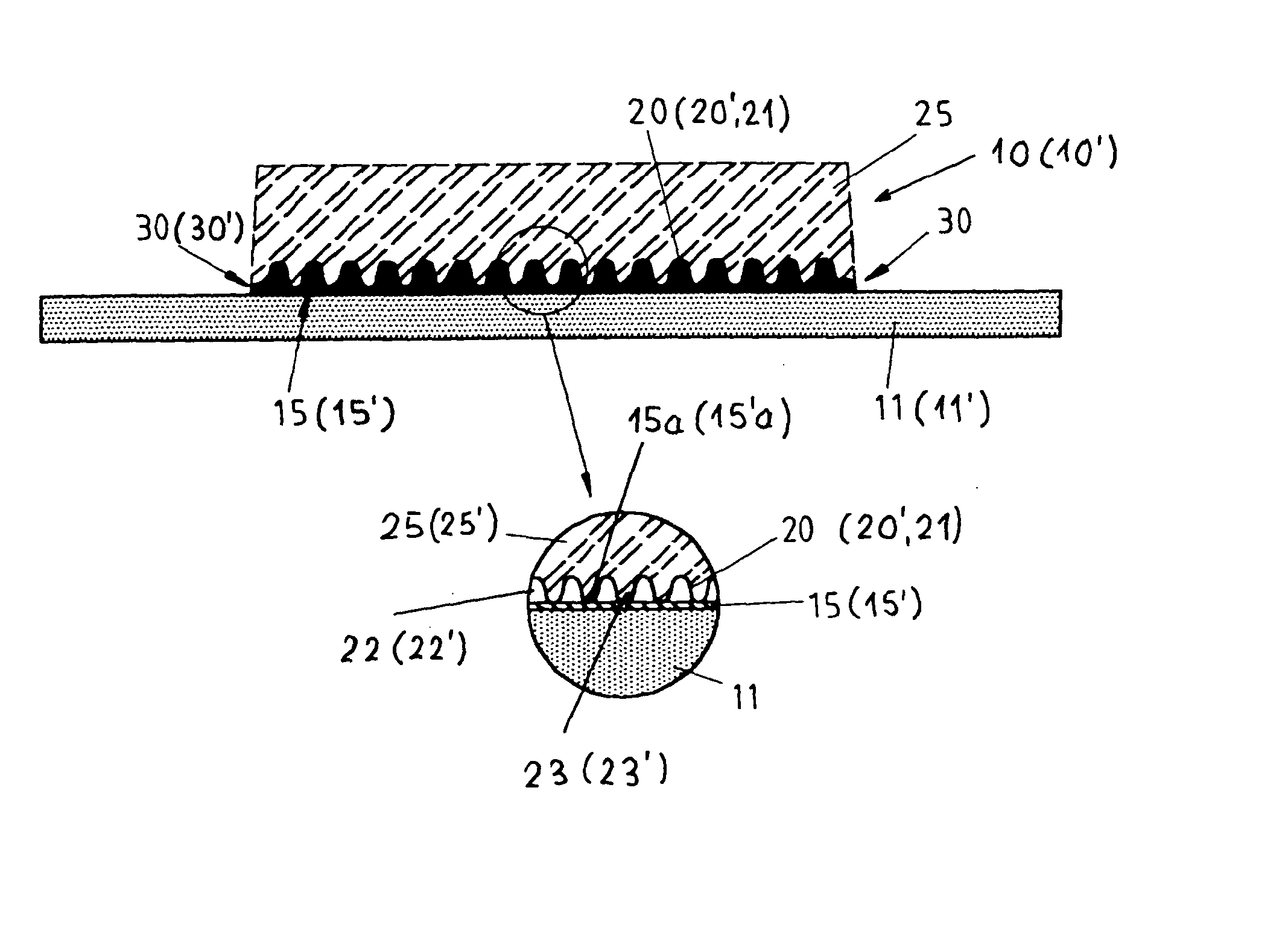

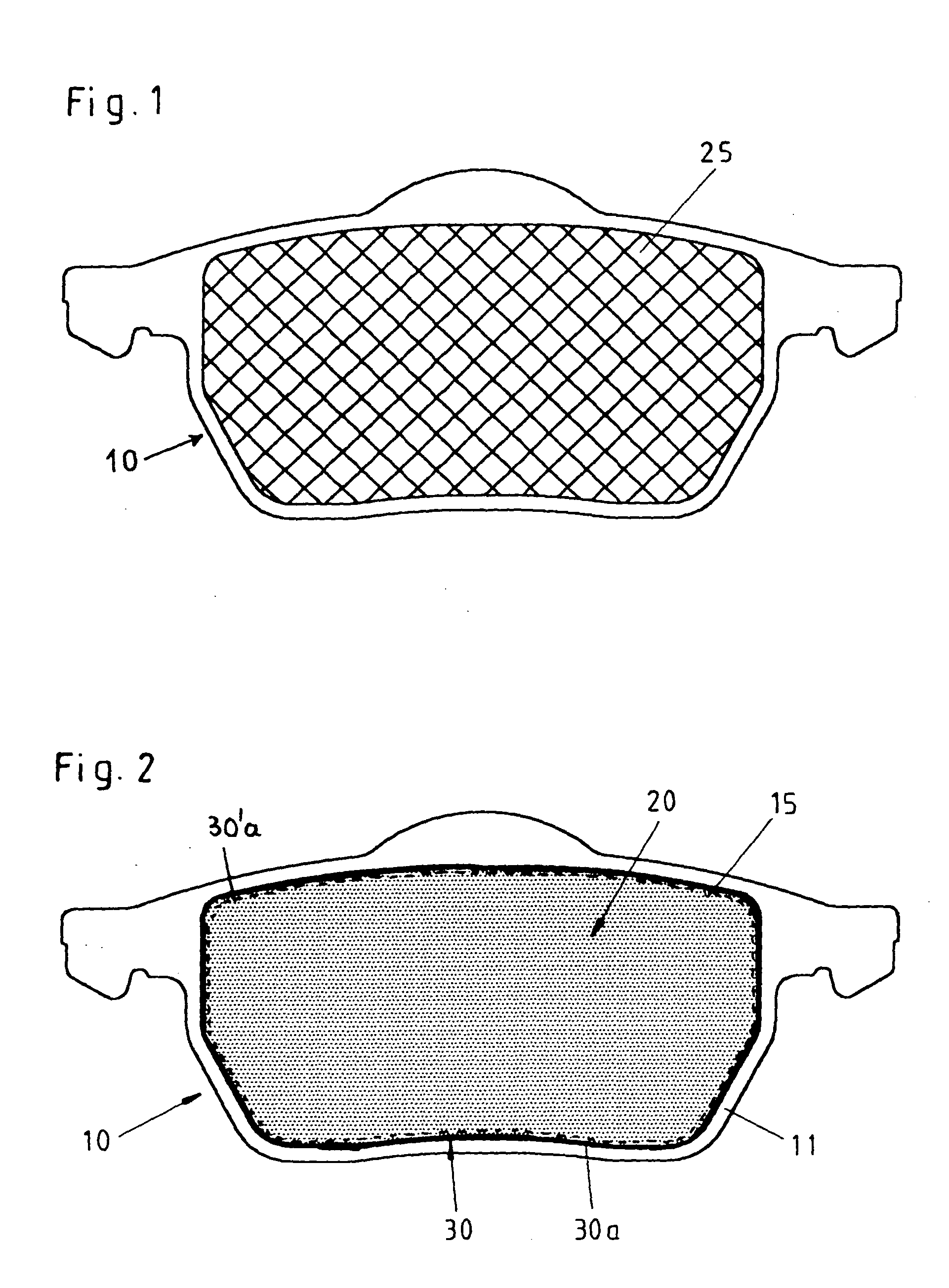

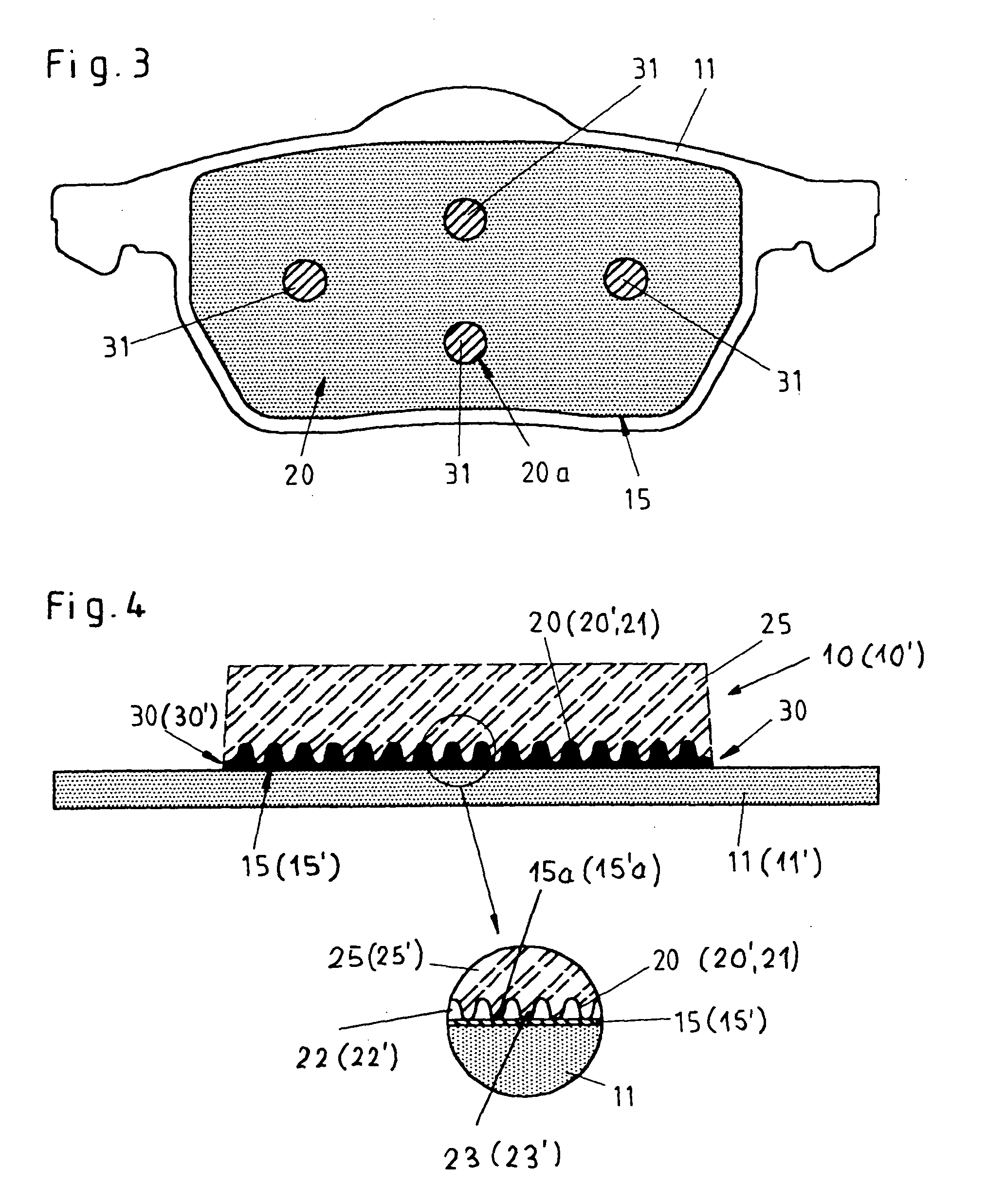

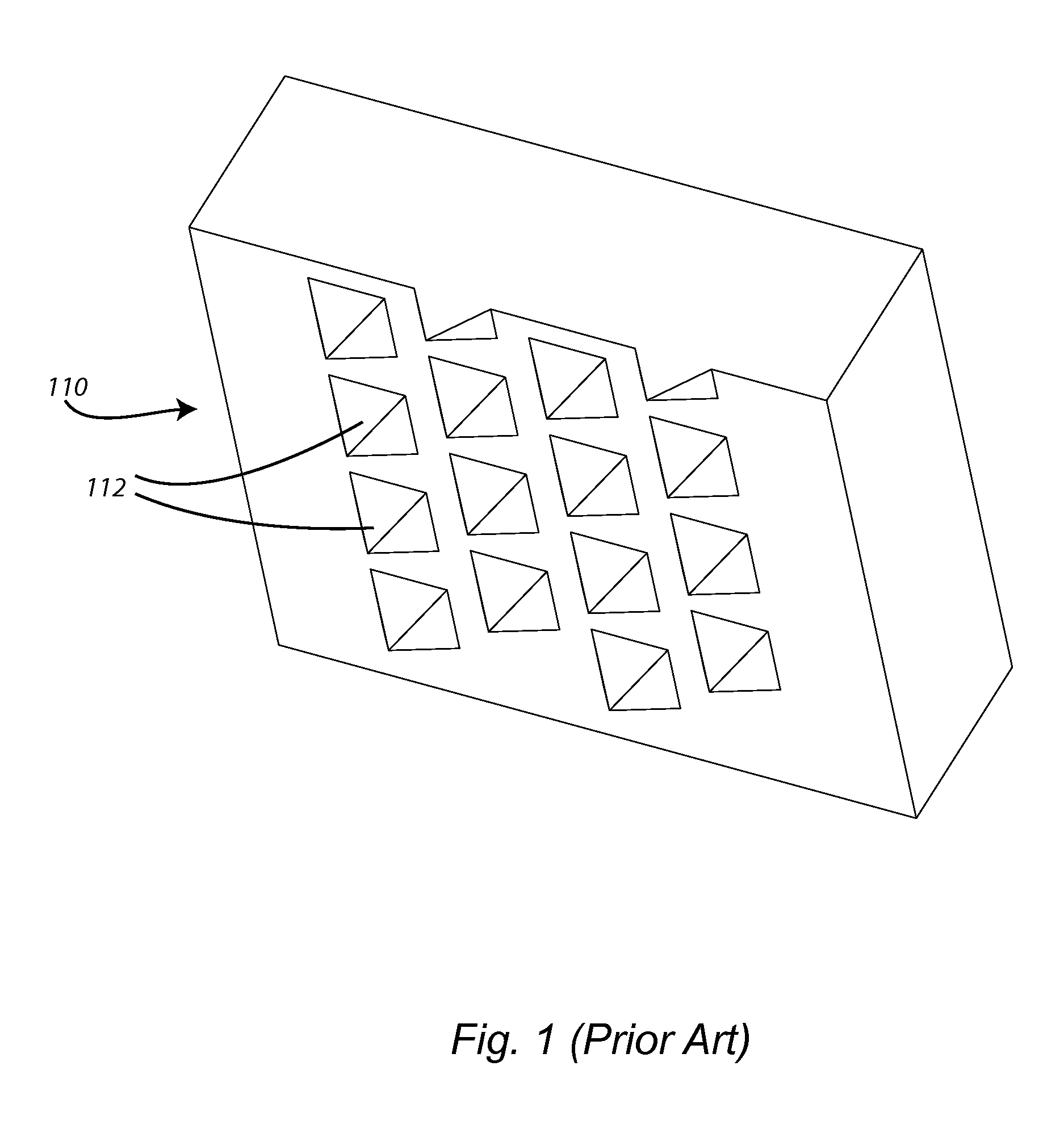

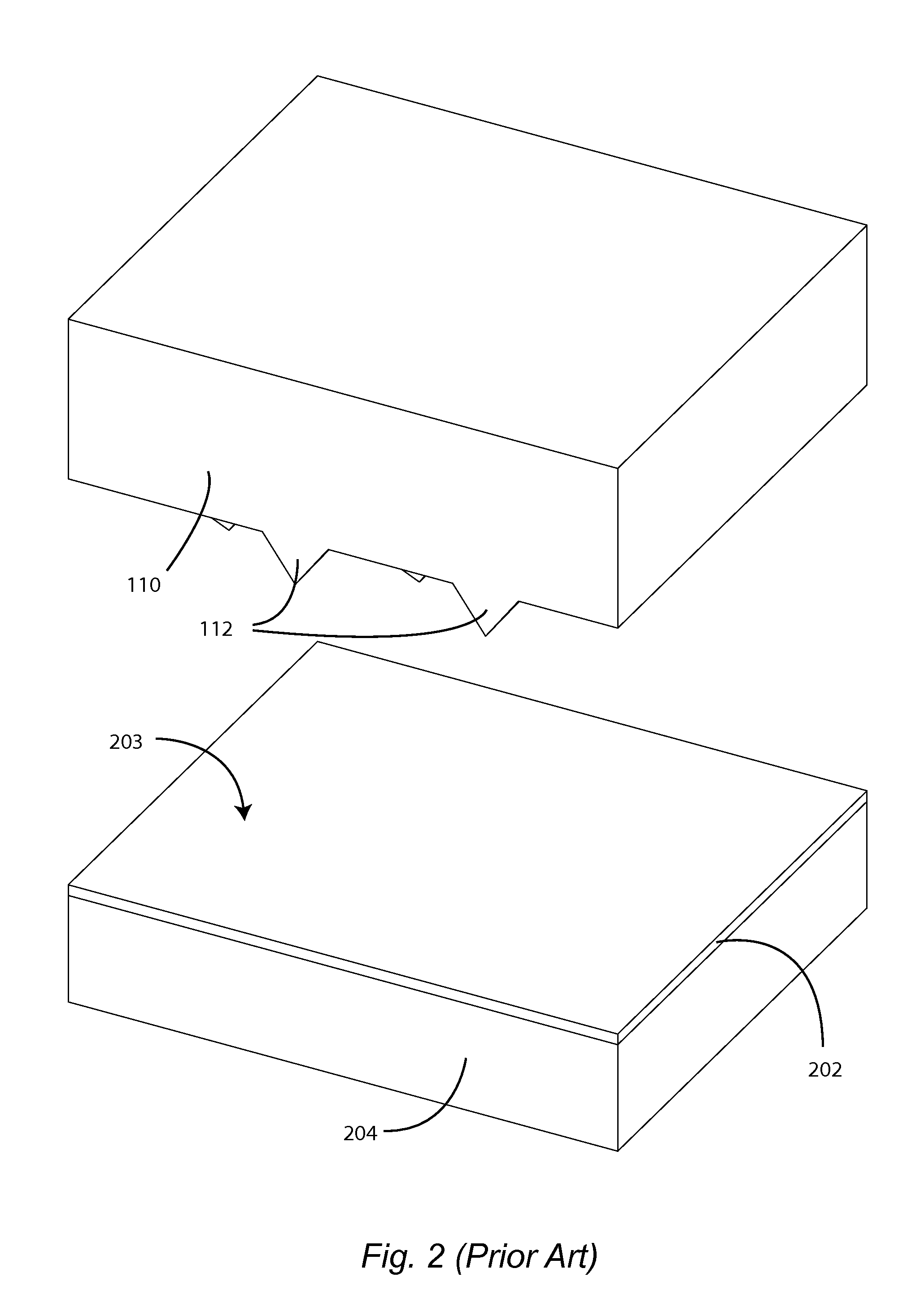

Lining, in particular friction lining for disc brakes

InactiveUS20040099493A1Improve strength propertiesMaintain propertiesNoise/vibration controlFriction liningSynthetic materialsMetal sheet

The lining or functional body (10) consists a carrier (11) in form of a ground plate, for example a carrier plate or a carrier sheet, of a thin-walled rough ground carrier (15; 15') made of a metal sheet or of another appropriate material placed on the carrier (11; 11'), of a rough ground (20') made of a support base (20; 20'; 21) sintered on the surface (15a; 15'a) of the rough ground carrier (15; 15') which is turned away from the lining carrier (11; 11'), this support base being made of single moulded bodies (22') with undercuts, recesses or the like which are positively and frictionally connected with the rough ground carrier (15; 15'), and of a functional block (25; 25') fixed on the rough ground carrier (15; 15') with the rough ground (20'), this functional block being made of a friction material, a synthetic material, in particular of such a synthetic material which is not appropriate to be glued together or to be applied in another manner, for example of a polymer or teflon, whereby the rough ground carrier (15; 15') is fixed on the lining carrier (11; 11') by means of a welded, riveted or glued joint (30; 30') or other connecting procedures, such as engraving.

Owner:HONEYWELL BREMSBELAG GMBH

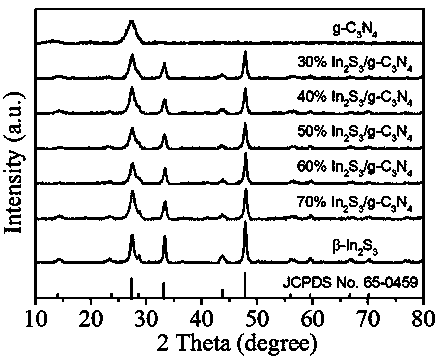

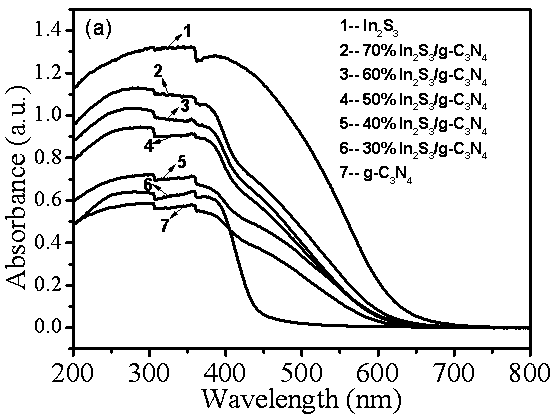

Preparation method of indium sulfide/carbon nitride composite nano material

The invention relates to a photocatalytic material, and particularly relates to a preparation method of an indium sulfide / carbon nitride composite nano material. The preparation method of the indium sulfide / carbon nitride composite nano material comprises the following steps: weighing g-C3N3 powder, dissolving into purified water, carrying out ultrasonic dispersion uniformly, then adding In(NO3)3.4.5H2O, carrying out magnetic stirring until dissolving completely, dropwise adding the prepared C2H5NS solution, carrying out magnetic stirring, transferring into a reaction kettle with an inner liner made of Teflon, putting into a baking oven, and carrying out hydrothermal reaction; and cleaning and drying to obtain the indium sulfide / carbon nitride composite nano material. The method protects the environment, is efficient, simple, convenient and feasible, and the prepared In2S3 / g-C3N4 composite material has a favorable application prospect in the fields of photocatalysis and the like.

Owner:江苏良基集团有限公司

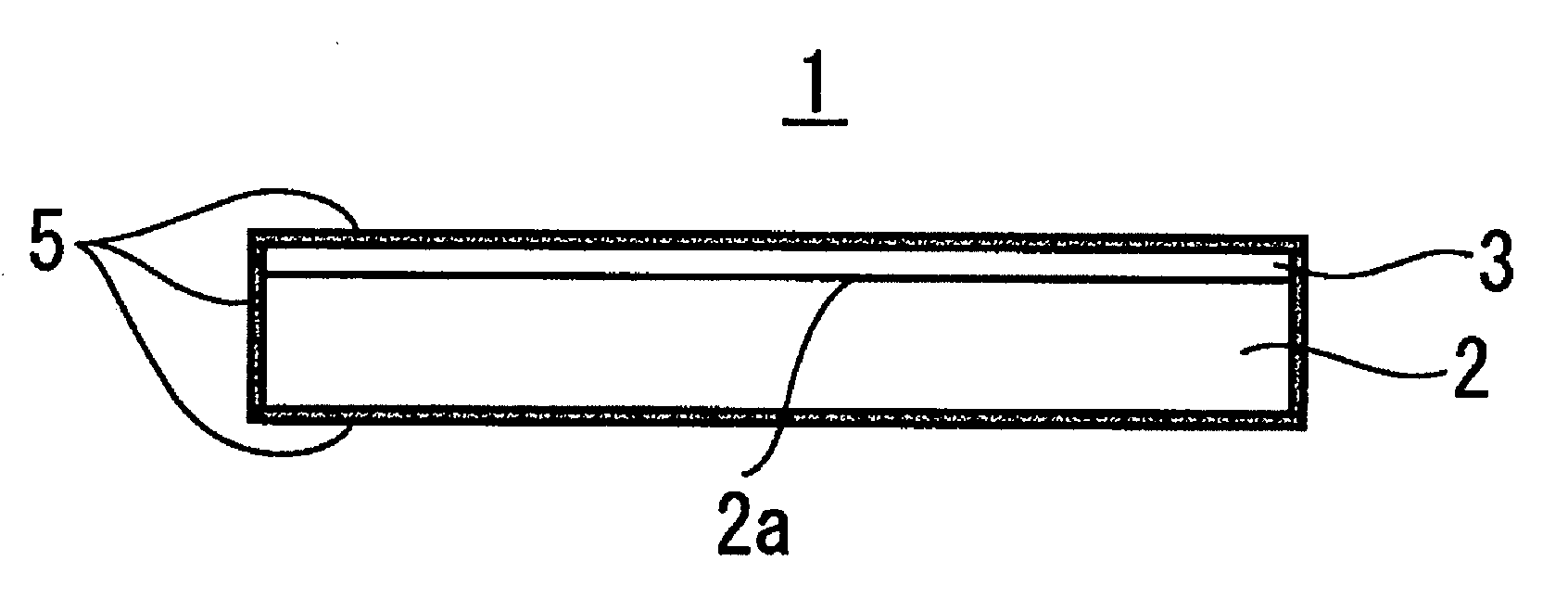

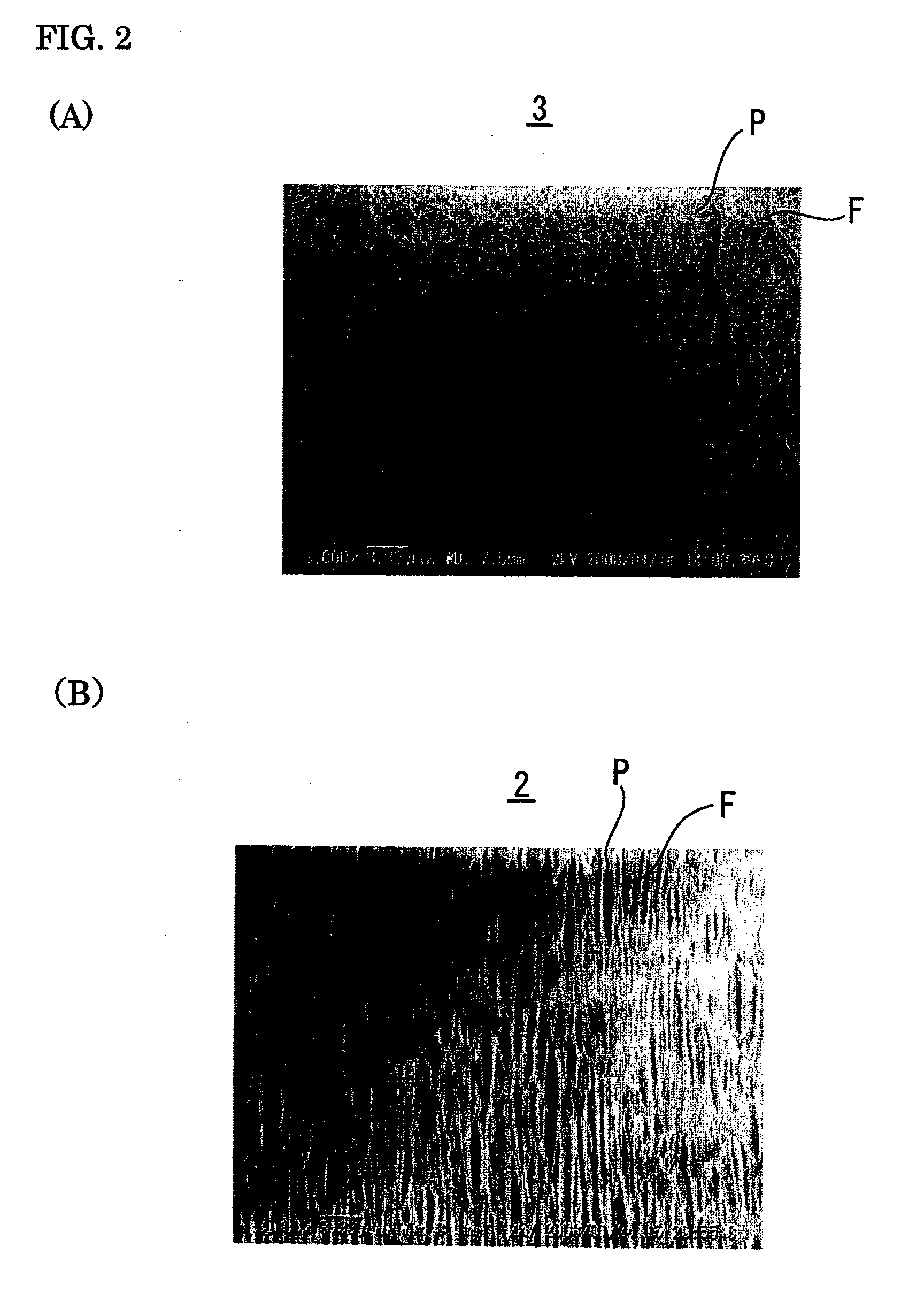

Porous multilayer filter and method for producing same

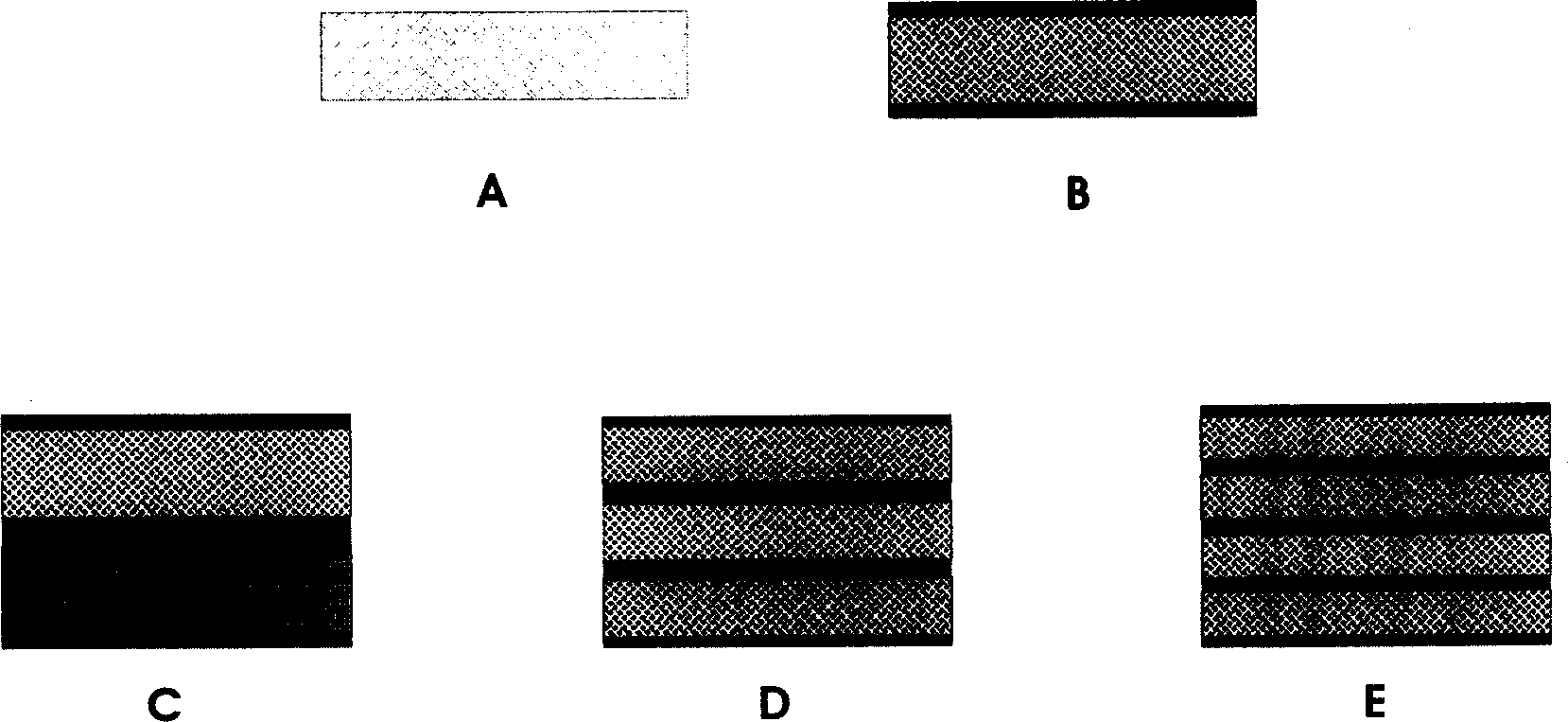

InactiveUS20110052900A1Large poresReduce thicknessMembranesSemi-permeable membranesFiberHydrophilization

Provided is a porous multilayer filter which can trap ultrafme particles and in which permeability is high and treatment can be performed at a high flow rate. A porous multilayer filter is characterized by including a support layer 2 composed of a porous expanded PTFE sheet, and a filtration layer 3 composed of a porous expanded PTFE sheet which is different from that of the support layer 2, wherein at least a liquid-to-be-treated inflow surface of the filtration layer 3 is subjected to hydrophilization treatment, the filtration layer 3 and the support layer 2 are fusion-bonded to each other at a boundary therebetween to form a multilayer structure, pores of the support layer 2 three-dimensionally communicate with pores of the filtration layer 3, and pores surrounded by a fibril skeleton of the filtration layer 3 are smaller than pores of the support layer 2.

Owner:SUMITOMO ELECTRIC FINE POLYMER INC

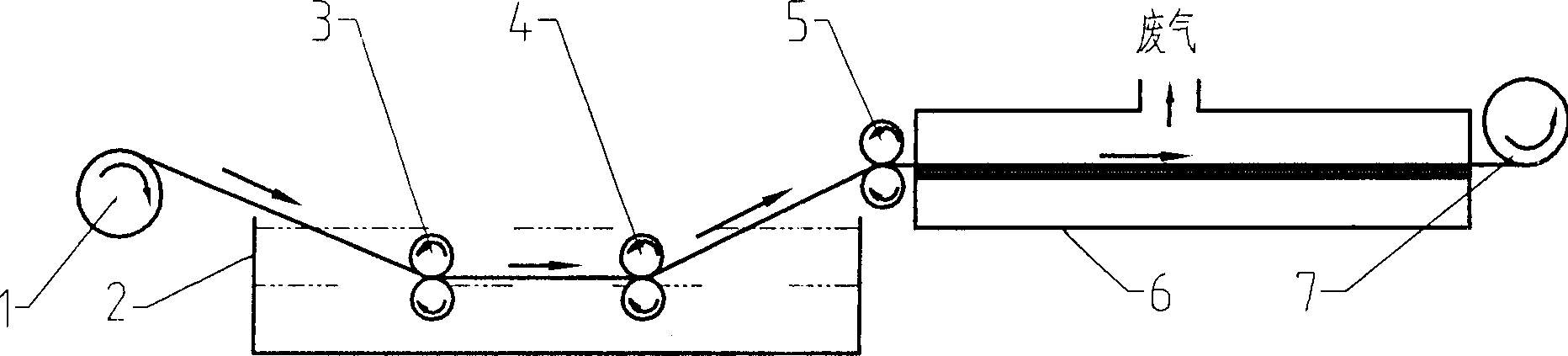

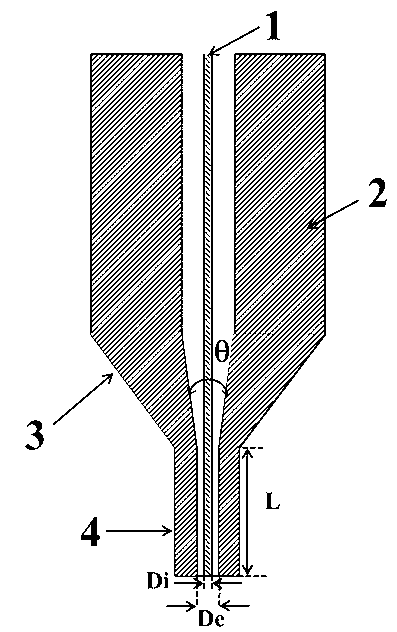

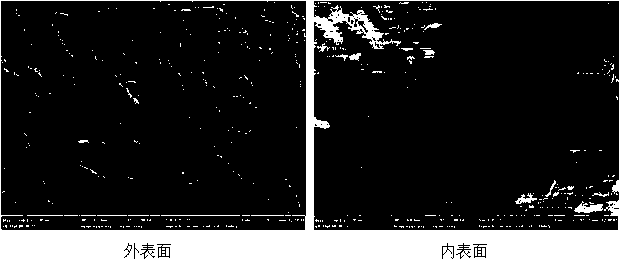

Preparation method of teflon hollow fiber membrane for membrane distillation

InactiveCN102941025ALow costAvoid loss of product water qualitySemi-permeable membranesIndustrial effluentPhysical chemistry

The invention discloses a preparation method of a teflon hollow fiber membrane for membrane distillation, which comprises the following steps of: mixing teflon dispersion powder and a extruding-aid agent, pressing a blank, extruding the blank into a teflon hollow tube through a pushing and pressing machine with a cone mould and a mouth mould, and performing longitudinal stretch, sintering and heat setting on the teflon hollow tube in a drying oven to obtain the teflon hollow fiber membrane. The processed teflon hollow fiber membrane is in an asymmetric structure, the mean pore size of an outer layer is 0.10-1.0 micrometer, the mean pore size of an inner layer is 5.0-20 micrometers, the wall thickness is 0.1-0.5 millimeter, the bubble point pressure is 0.5-2.0 kgf / square centimeter, and the water resistance pressure is 1.5-6kgf / square micrometer. The invention is mainly used for the membrane distillation separation process, and can be applied to the fields of sea water desalination, industrial wastewater treatment, cryoconcentration of food and biological products, and the like.

Owner:ZHEJIANG SCI-TECH UNIV

Method for preparing hollow fiber membranes and tubular membranes with microporous PTFE hybrid flat membrane wrapping method

ActiveCN103386256AHigh hardnessEasy to cutSemi-permeable membranesPolymer sciencePolyvinylidene difluoride

The invention discloses a method for preparing hollow fiber membranes and tubular membranes with a microporous PTFE hybrid flat membrane wrapping method. Dispersed PTFE resin and polyvinylidene fluoride resin are mixed with a liquid lubricant, and microporous PTFE hybrid flat membranes are prepared from the mixture through extrusion, calendaring, stretching and sintering. Then the microporous PTFE hybrid flat membranes are cut into membrane strips which wrap around supporting tubes, and finally the wrapped supporting tubes are sintered to obtain the hollow fiber membranes and the tubular membranes. The polyvinylidene fluoride resin added into the products of the invention has a melting point around 160 DEG C, fuses while sintered at a temperature between 250 and 340 DEG C, and can largely increase the hardness of the flat membranes after solidification, which facilitates slitting of the flat membranes. During the process of sintering after wrapping, the polyvinylidene fluoride resin contained in the flat membranes fuses again when sintered at a temperature between 260 and 340 DEG C, and thus can be used as overlapping parts between the wrapped flat membranes and as binders between the flat membranes and the microporous supporting tubes, so that the bonding strength is substantially improved.

Owner:ZHEJIANG SCI-TECH UNIV

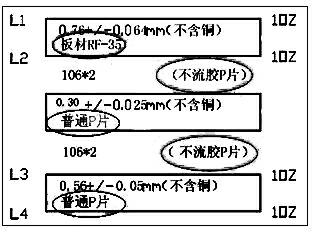

Process for manufacturing printed circuit boards having high-frequency and low-frequency mixed board structures

InactiveCN102523693AIncrease cooling areaImprove securityHigh frequency circuit adaptationsLaminationEpoxySolder mask

The invention discloses a process for manufacturing printed circuit boards having high-frequency and low-frequency mixed board structures, which includes steps of A) cutting high-frequency boards and low-frequency boards, manufacturing inner patterns, performing brownification, pressing, removing liquid adhesives and drilling holes; B) removing adhesives by plasmas, plating copper outside the high-frequency and low-frequency pressed board with drilled holes and electroplating the integral pressed board; C) forming outer patterns; D) printing solder mask and texts after solder mask of plug holes in a screen manner; E) printing characters after plating the integral board with nickel and gold and forming a circuit board in a screen manner; and F) testing and detecting electric performance and appearance of a finished board and manufacturing the finished product. By the design of the high-frequency and low-frequency mixed press structure, a necessary layer can be made of high-frequency boards with PTFE (poly tetra fluoro ethylene) structures so as to guarantee high speed and undistorted transmission of signals and the requirement of impedance matching, and other signal layers can be made of common boards with epoxy resin substrates on the condition of meeting the requirements of the integral performance, and cost is saved for clients by optimized combination.

Owner:SHENZHEN SUNTAK MULTILAYER PCB

Microbial fuel cell air cathode and preparation method thereof

The invention discloses a microbial fuel cell air cathode which is composed of a diffusion layer thin film, a stainless steel net and an active layer thin film in an overlapped mode from an air side to an electrolyte side. The preparation method comprises the following steps of: mixing a carbon powder material which has good electrical conductivity and is hydrophilic and PTFE (Poly tetra fluoro ethylene) emulsion which is hydrophobic and is air conductive in ethanol; clustering through ultrasound and water bath; and finally rolling into a thin-film-shaped diffusion layer and an active layer; with the stainless steel net as an electrical conductive framework, overlapping and rolling so as to form the air cathode. The microbial fuel cell air cathode and the preparation method thereof have the following advantages: according to the preparation method, since electrical conductive carbon black is added into the air diffusion layer, the resistance of an air diffusion electrode is reduced; since the ultrasound stirring is carried out after the PTFE emulsion is dropped in, uniform and fine air holes can be formed in the electrode and the three-phase interface reduction site in the active layer is increased; and heating and curing are carried out twice in a muffle furnace, thus PTFE forms an air conveying pore canal of a three-dimensional network structure, the three-phase interface in the active layer is increased, and the microbial fuel cell air cathode is applicable to normalized mass production.

Owner:NANKAI UNIV

Titanium base whisker reinforced polyether ether ketone wearable composite material and its preparation method

The invention relates to polyether ether-ketone wear-resisting compound material which is strengthened by titanium base crystal as well as preparative method. The mentioned titanium base crystal has a diameter of 0.5-3.0 mum, length-diameter ratio of 5-50 and its surface reshaped. The ingredient of the compound material includes titanium base crystal, polytef and PEEK, it's shaped by hot mould pressing or pouring so it has very good strength, and abradability. Compared to the carbon fiber strengthened polyether ether-ketone of the same content, the abradability of the invention has been increased by 10 times, the frictional coefficient has been decreased by 30% and the temperature of the friction surface has been lowered by half. The invention has very good alkali resistance, so it is adaptable to be the ware and wear-resisting material in lye; it's also applicable to special conditions such as high temperature, vacuum, radiation and causticity; it can be widely used as piston link, filling, sliding piece and valve piece, the service life of the material in the invention has been greatly prolonged.

Owner:NANJING UNIV OF TECH

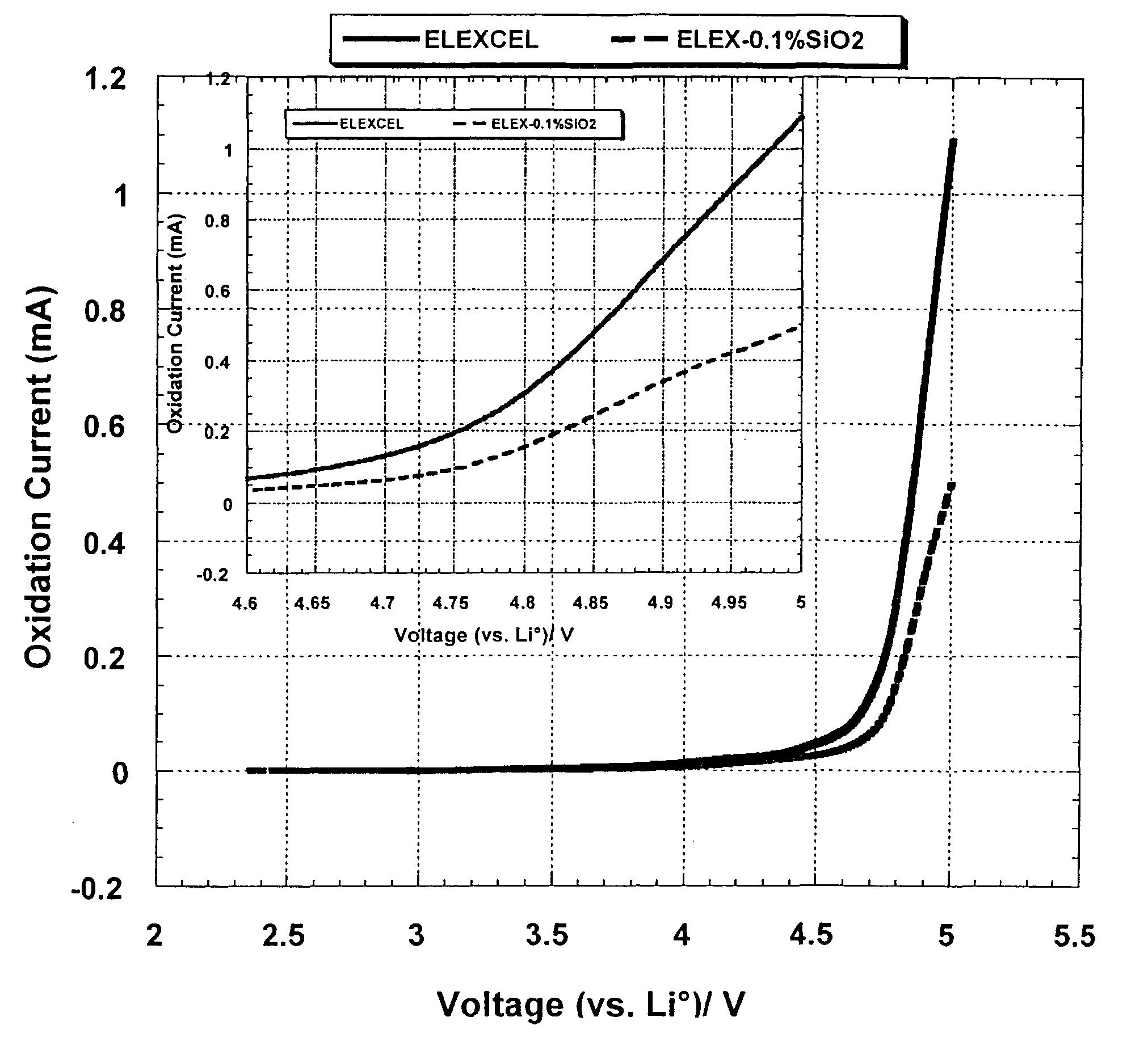

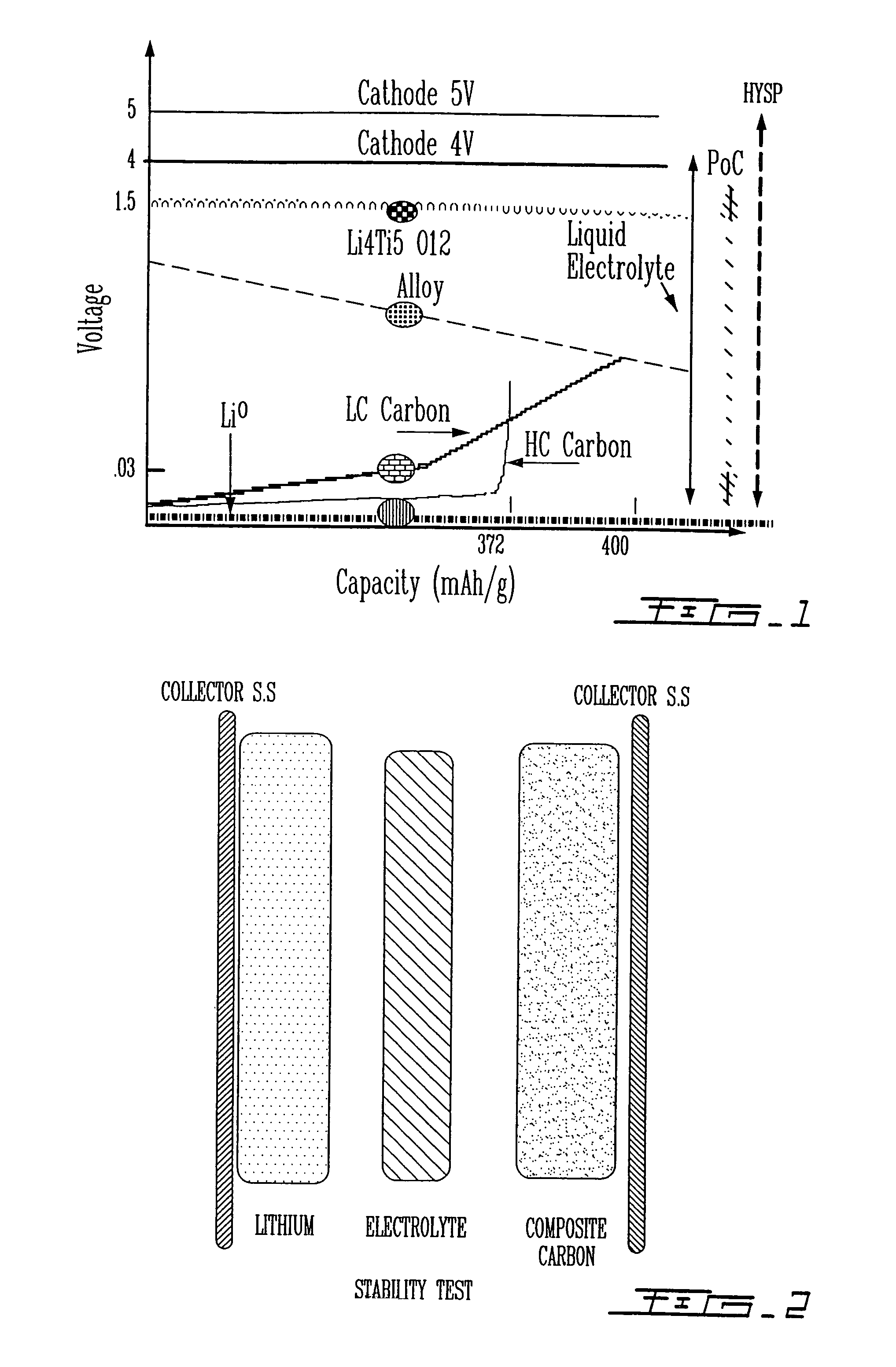

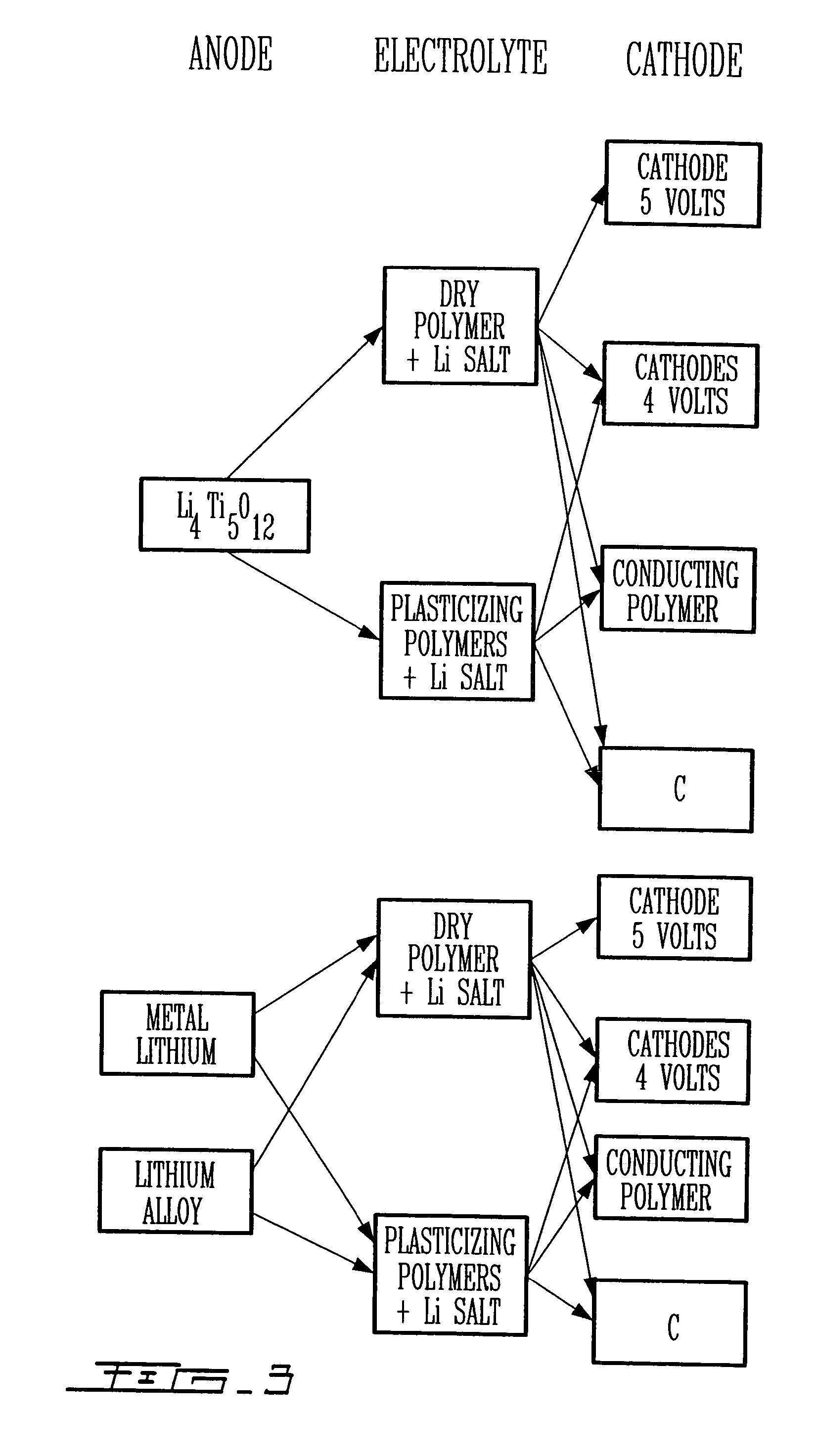

Polymer electrolyte with high stability, its use in electrochemical systems

ActiveUS7897674B2Hybrid capacitor electrolytesHybrid capacitor electrodesPolymer electrolytesTetrafluoroethylene

Polymer electrolyte for an electrochemical generator based on at least a four branched polymer, at least a poly(vinylyldienefluoride), a poly(vinyldiene fluoro-co-hexafluoropropene copolymer), a poly(tetrafluoroethylene), a poly(ethylene-co-propylene-co-5-methylene-2-norbornene) or an ethylene propylene-diene copolymer, a polyol, a poly(methylmethacrylate, a poly(acrylonitrile), SiO2Al2O3, or nano TiO2 non coated or coated with an organic material. This electrolyte allows to prepare electrolytic compositions that can be used in high performance electrochemical devices.

Owner:HYDRO QUEBEC CORP

Composite aramid fiber/polyimide material and its prepn

InactiveCN1487020AImprove mechanical propertiesImprove tribological propertiesFibre treatmentNitrogen atmosphereGraphite

During the preparation of composite aramid fiber / polyimide material, aramid fiber is first surface modified via gamma-ray irradiation of dosage 300-500 kGy in nitrogen atmosphere to raise surface activity; the surface modified aramid fiber, additive polyimide powder, PTEF and graphite are then airflow crushed and mixed in an air flow crusher of air pressure 4-6 MPa; the mixture powder is hot pressing molded at 200-240 deg.c and 16-23 MPa for 0.5-1 hr. Thus prepared composite aramid fiber / polymide material has excellent mechanical performance and friction performance and may be used in the structural part and friction part in aeronautic and astronautic fields.

Owner:SHANGHAI JIAO TONG UNIV

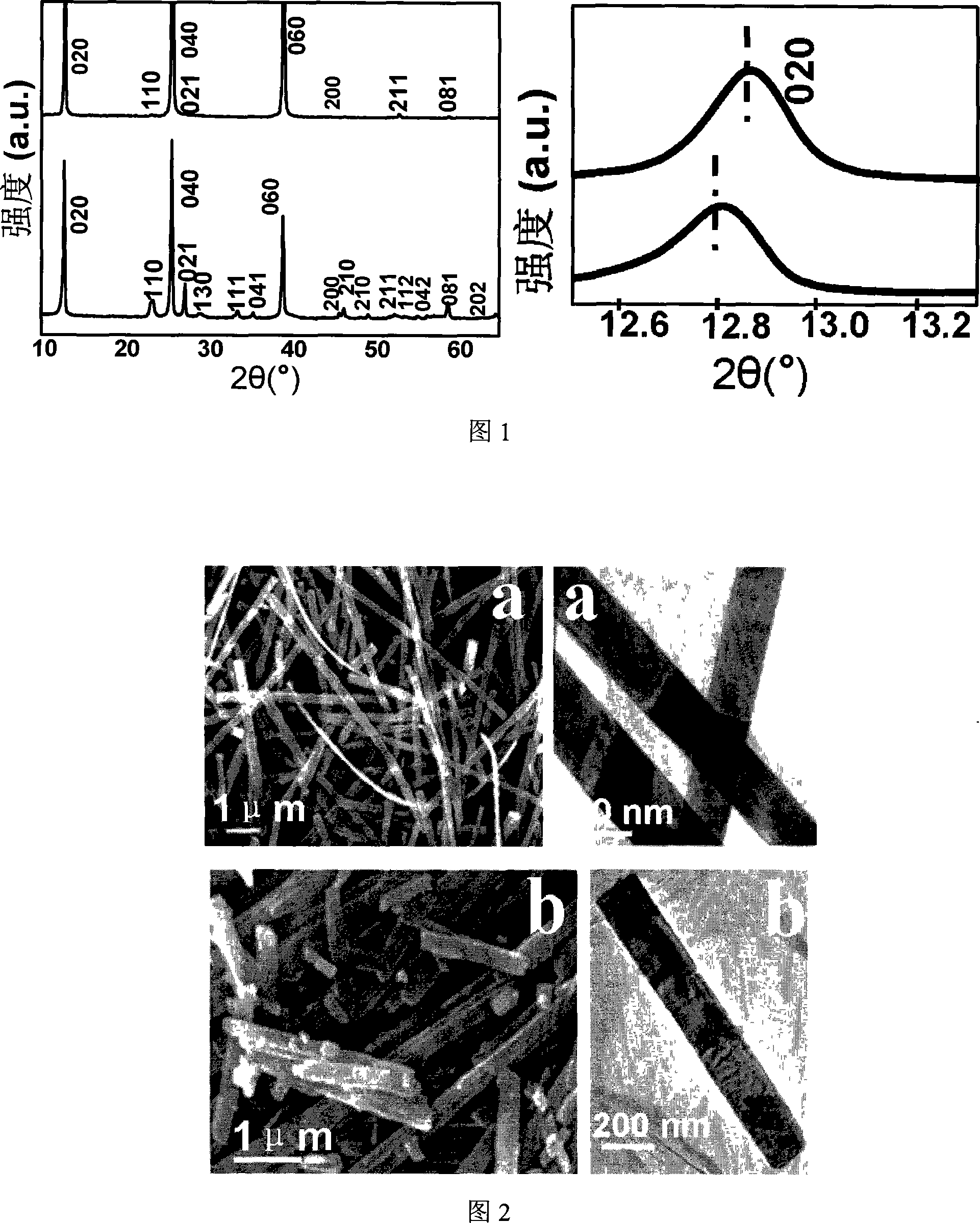

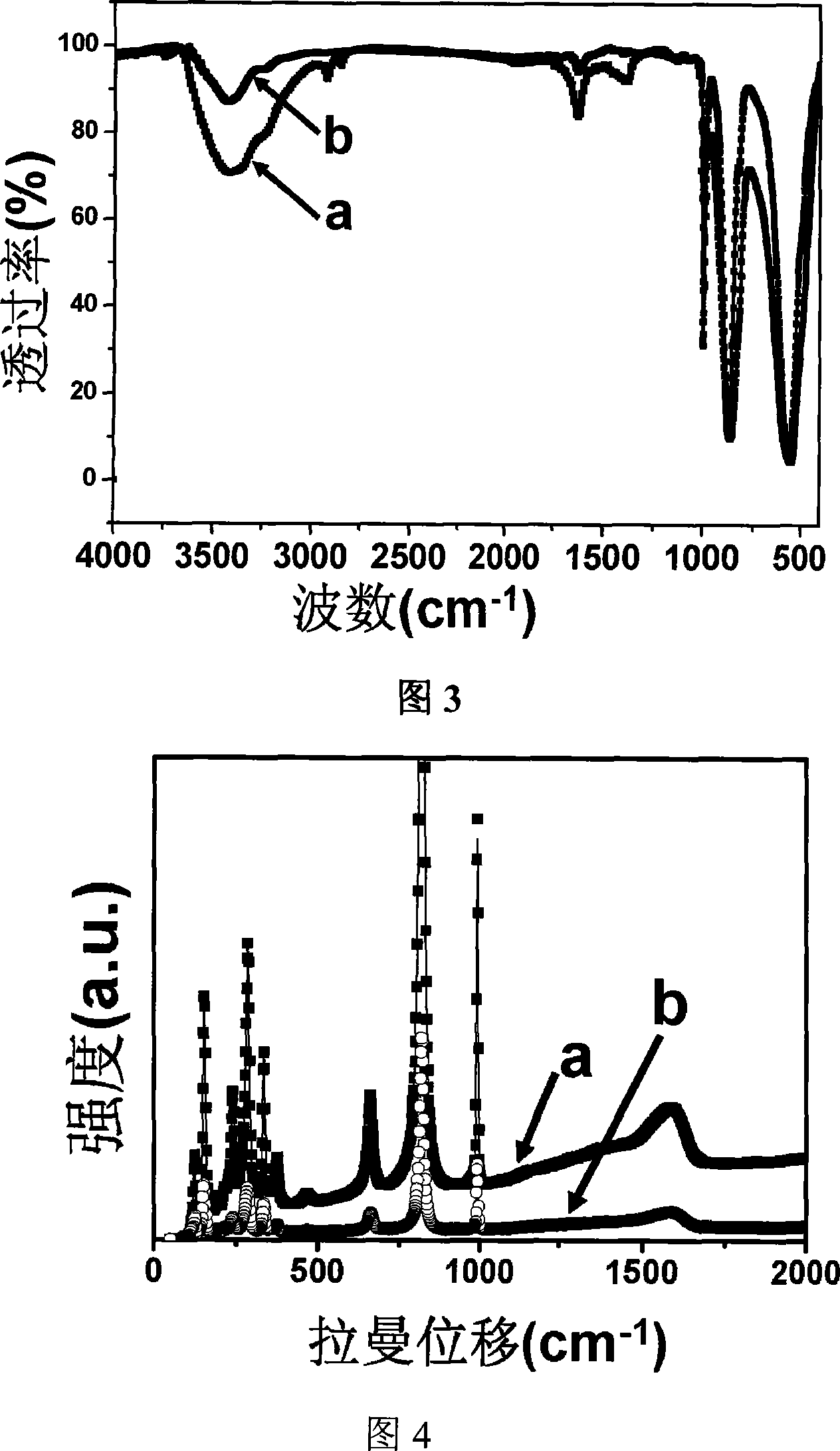

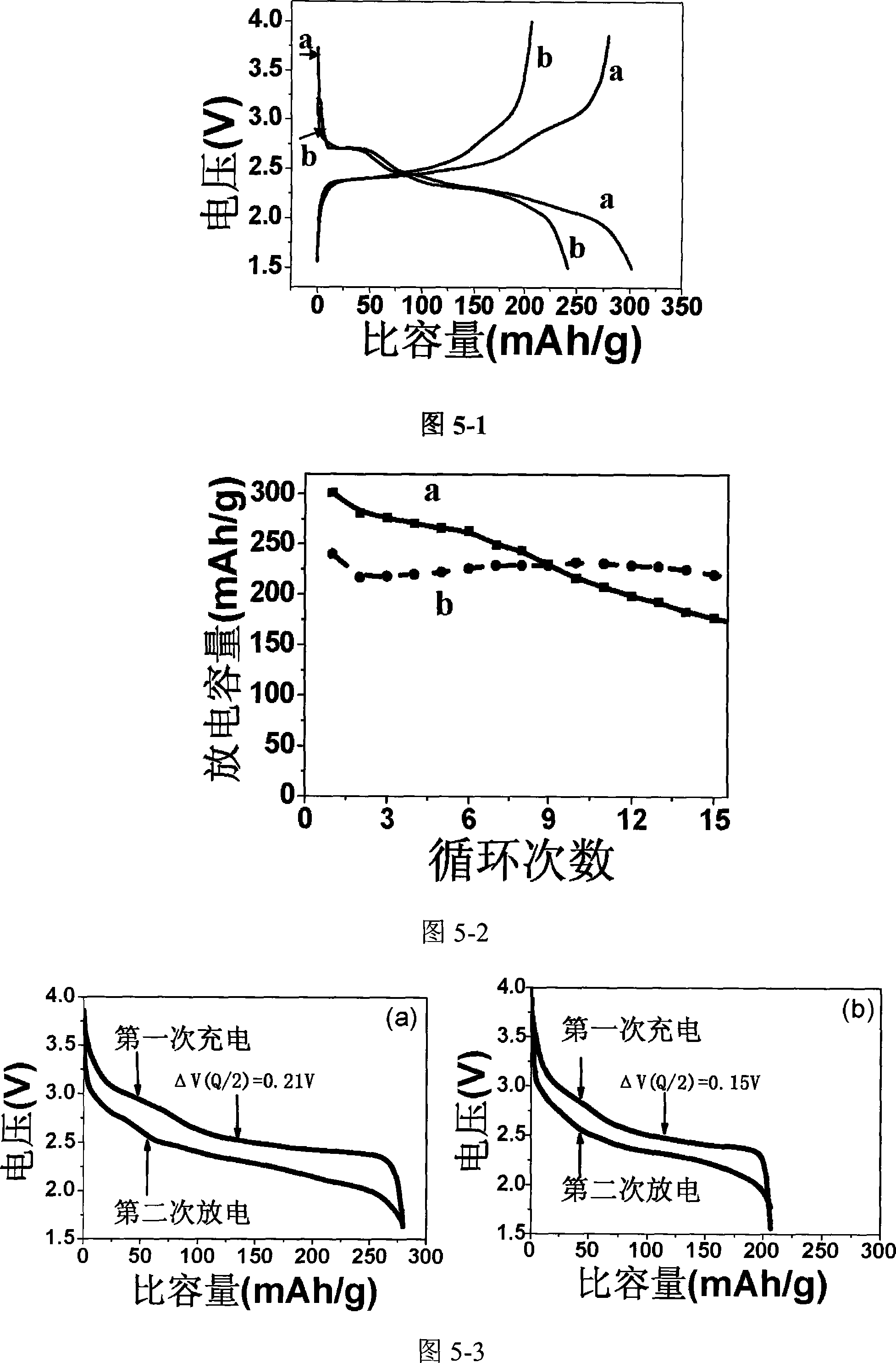

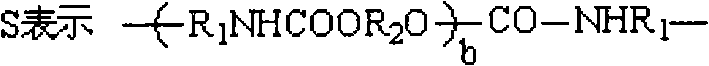

Lithiation molybdenum trioxide nano band electrode material and its lithiation modifying method

ActiveCN101071849AEasy to prepareGood reproducibilityElectrode manufacturing processesActive material electrodesLithiumStructural stability

A lithiated molybdenum trioxide nanometer belt electrode material and its the lithiation modification method, its characteristic is that: put molybdenum trioxide nanometer belt in deionized water to conduct supersonic dispersing, then add lithium salt powder to make the mole ratio of molybdenum element and lithium element be 1: 3 to 1: 10; stir; move the obtained suspension liquid into the stainless reaction pot with poly-tetre-fluro-ethylene substrate to conduct hydrothermo reaction; cool and filter the hydrothermo product and wash the product by deionized water to obtain the molybdenum trioxide nanometer belt.

Owner:武汉经开科创运营有限公司

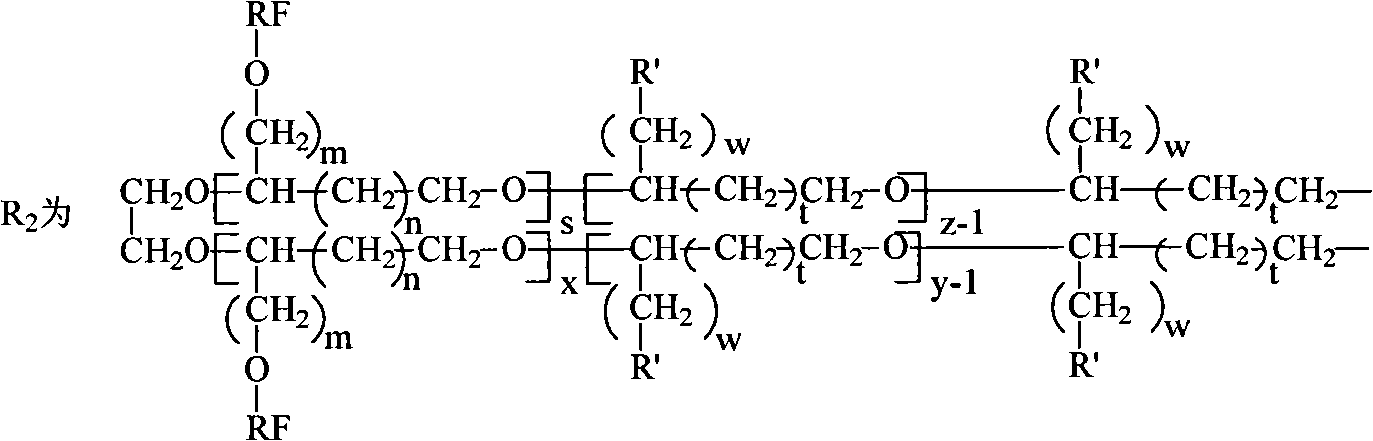

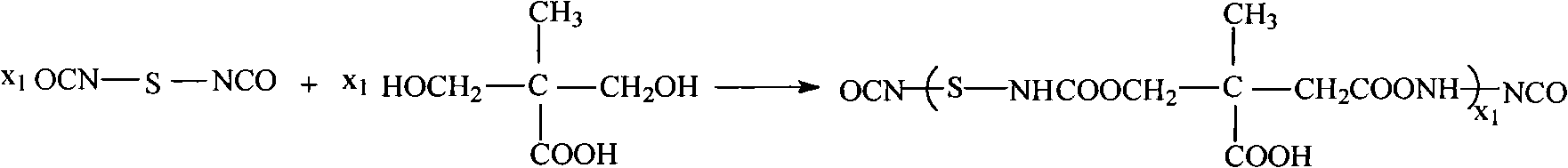

Room-temperature self-crosslinked aqueous polyurethane-polyacrylate containing fluoroalkyl groups in lateral chains and preparation method thereof

InactiveCN101792592AGood water resistanceAnti-pollution mechanical propertiesPolyurea/polyurethane coatingsPrepolymerChemistry

The invention discloses a room-temperature self-crosslinked aqueous polyurethane-polyacrylate containing fluoroalkyl groups in lateral chains and a preparation method thereof. The preparation method comprises following steps: vacuum-dehydrating polyether glycol containing fluorine, and reacting with polyisocyanate to obtain FPU prepolymer containing -NCO end groups; chain-extending with dimethylolpropionic acid to obtain FPU prepolymer containing carboxyl groups; neutralizing with triethylamine to obtain hydrophilic FPU prepolymer, adding water, stirring, and dispersing at high speed to obtain an emulsion; adding a water solution containing a chain extender ADH to obtain chain-extended FPU; orderly adding diacetone acrylamide and vinyl monomer, and initiating by stirring to obtain the PUA copolymerized emulsion; and finally, uniformly mixing the chain-extended FPU with the PUA copolymerized emulsion, coating the mixture on a teflon plate, and drying and crosslinking at room temperature to form the film. The invention can be widely used for surface protection for plastics, rubber, leather, fabrics, ceramics, glass, high-rise building external walls, solar batteries and other materials and devices.

Owner:SHANGHAI APPLIED TECHNOLOGIES COLLEGE

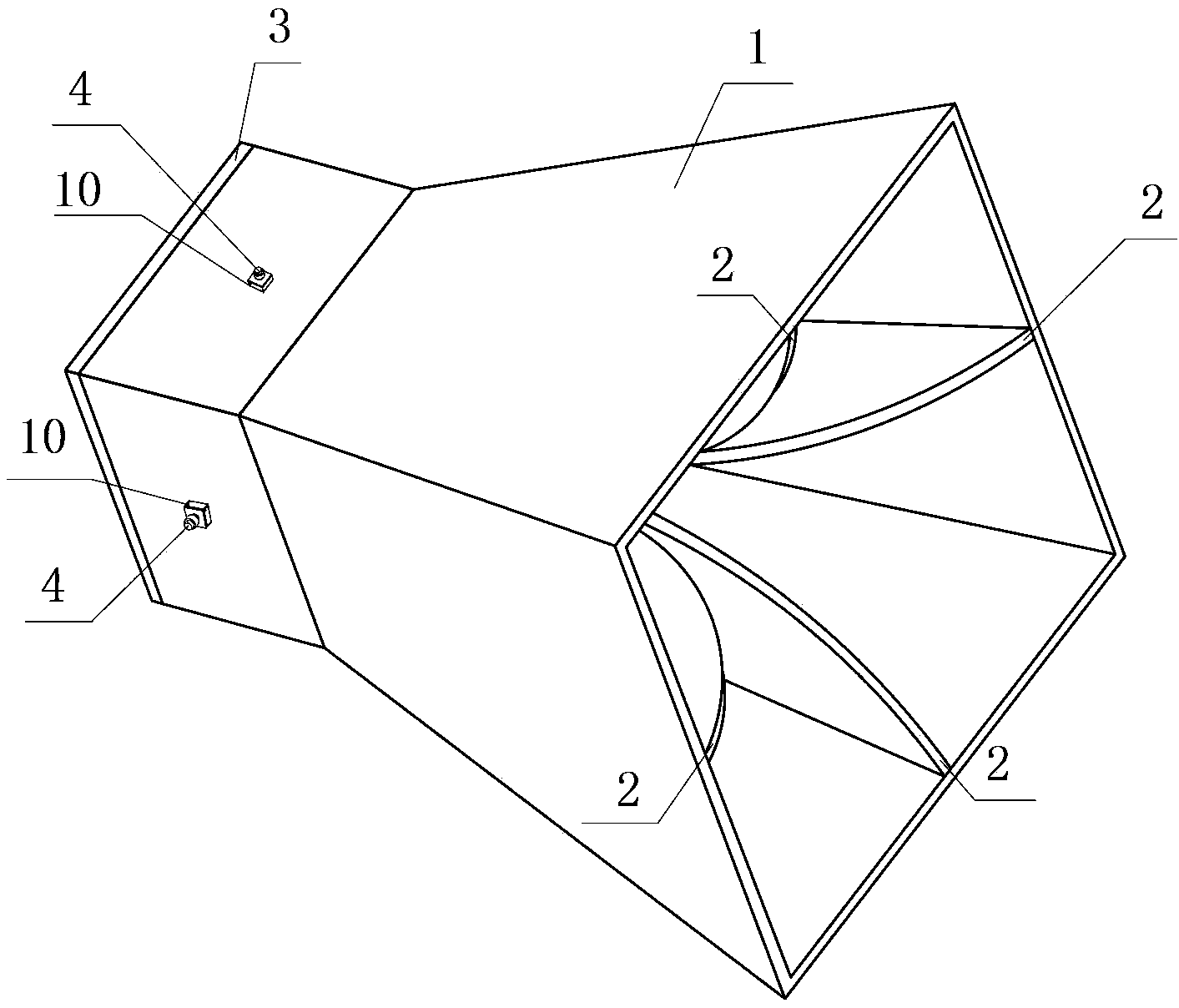

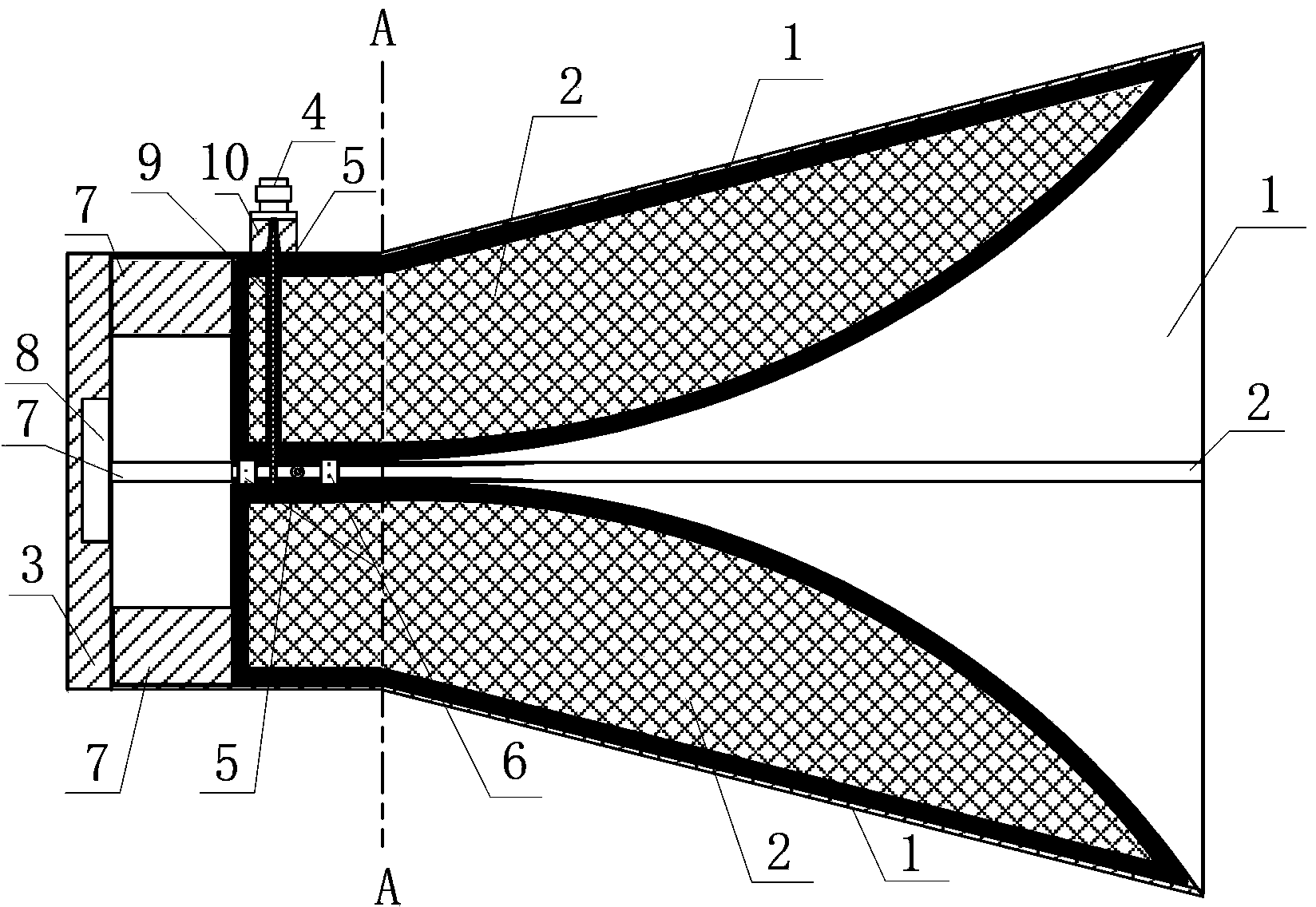

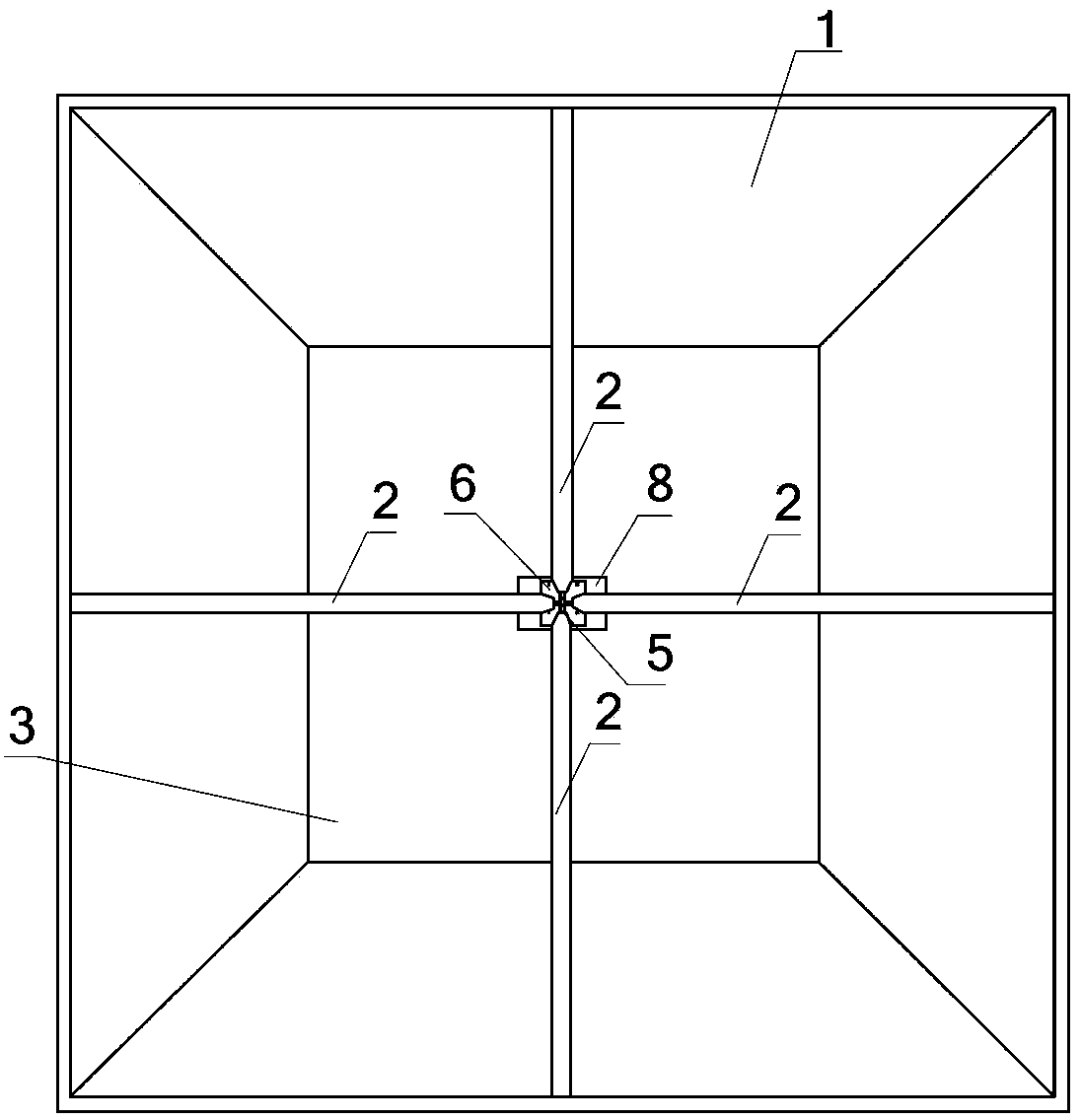

LFBB (Low Frequency Broadband) dual-polarization four-ridge horn antenna

The invention discloses an LFBB (Low Frequency Broadband) dual-polarization four-ridge horn antenna, which mainly solves the problems that the test requirement of a low-frequency antenna cannot be met by the prior art, the low-frequency antenna is very heavy and not easy to move and rotate, and the processing is difficult. The LFBB dual-polarization four-ridge horn antenna comprises an antenna wall (1), ridges (2), a short-circuit board (3), coaxial connectors (4), feed probes (5), a PTFE (Poly Tetra Fluoro Ethylene) board (6), short-circuit pins (7), a rectangular groove (8), a cylindrical groove (9) and transition cones (10), wherein the inner walls of four ridges (2) adopt hollow structures, the top part of each ridge is provided with a cutting angle, the PTFE board (6) is fixedly arranged at the middle part of the four ridges (2), one side of the short-circuit board (3) is provided with the rectangular groove (8), the top part of each feed probe (5) is of a conical structure, and the surface of the tail end of each feed probe (5) is plated with a flexible conducting material such as silver or tin. The LFBB dual-polarization four-ridge horn antenna disclosed by the invention has the advantages that the weight is light, the structure is stable, and the lowest frequency can be stabilized at 75 MHz; and the LFBB dual-polarization four-ridge horn antenna is suitable for a source antenna in low-frequency antenna test.

Owner:GUANGDONG SHENGLU TELECOMM TECH +1

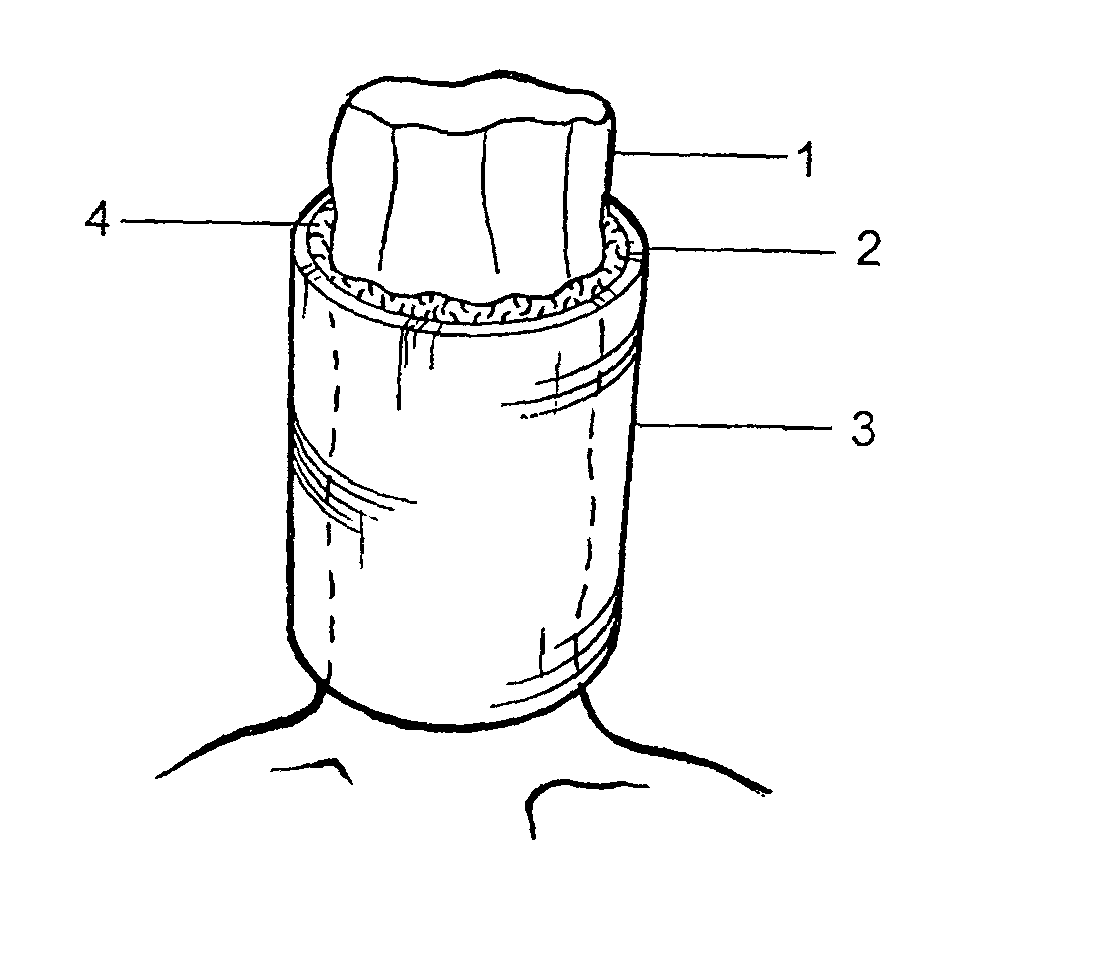

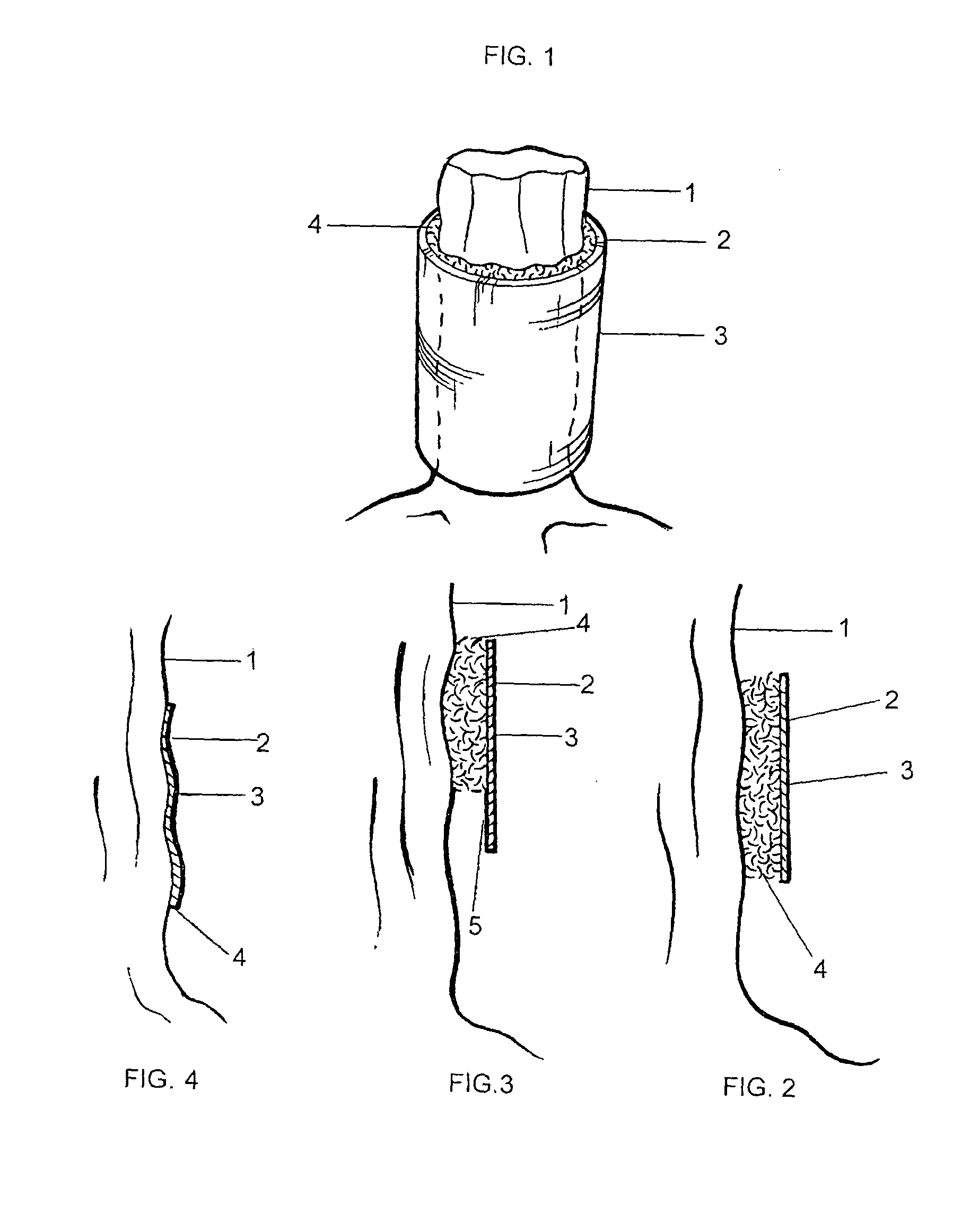

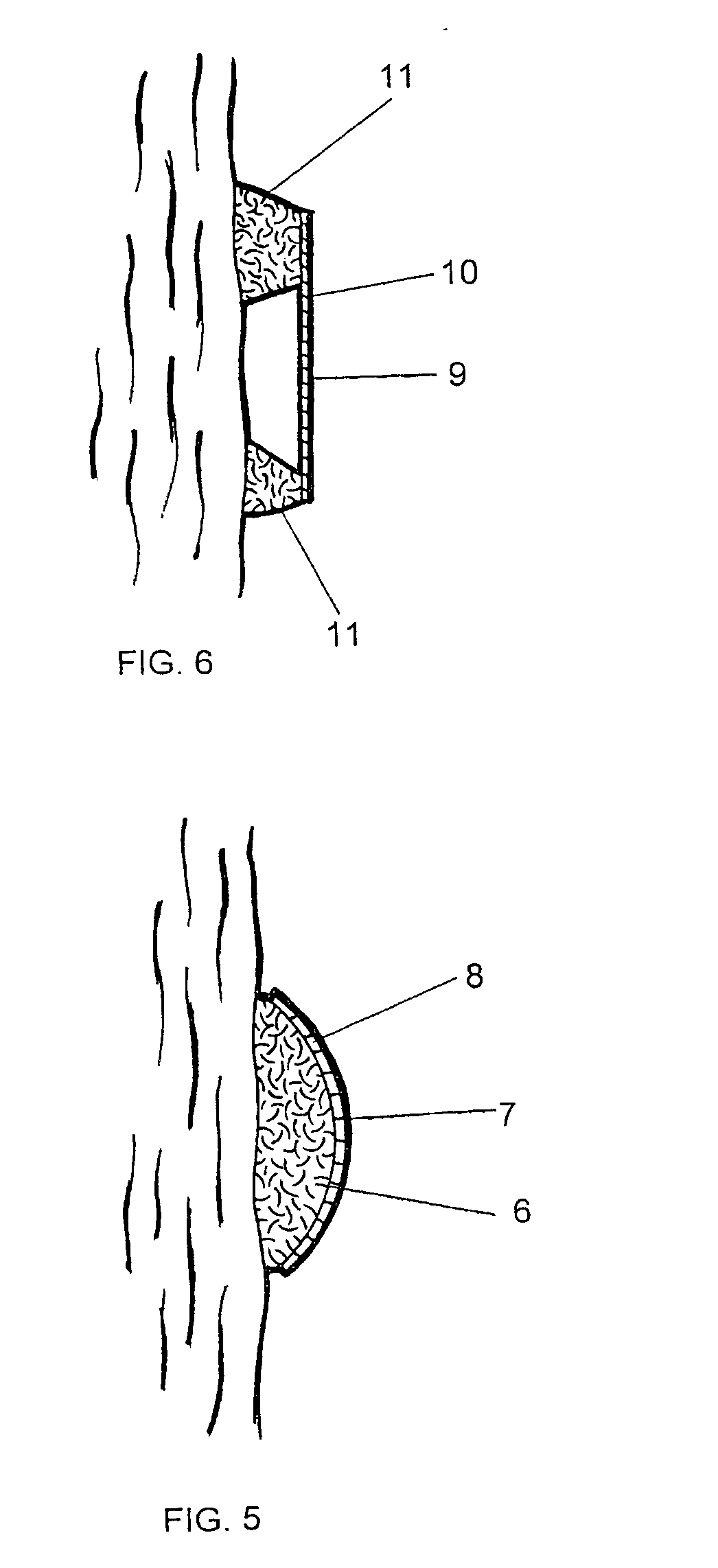

System for protecting trees and structures against infestation

InactiveUS20040040199A1Promote lowerAnimal repellantsPlant protective coveringsEngineeringPlastic film

A system for protecting trees and structures from infestation by crawling or climbing insects by attaching an insect barrier to the wall surface of the object to be protected. The barrier consists of a belt means, which may be made from a plastic sheet material and may be wrapped around the object to be protected, including a contact means that engages the surface of the object. The contact means may have a deformable thickness, such as provided by a layer of a non-woven fabric, to prent the passage of insects between the barrier and the surface of the objet. The free ends of the belt means are secured to each other to retain the belt means against the surface of the tree and engage the contact means against the tree surface. The belt means has slippery surface means, having a low coefficient of friction with respect to insects, that prevents the travel of insects on the belt means, preventing them from proceeding over the belt means and infesting the tree or structure to be protected. The slippery surface means may be provided by application of a coating of a fluoro-polymer, such as poly-tetra-fluoro ethylene (PTFE), to the belt means or may be otherwise suitably attached to or integrally formed with the belt means.

Owner:ENVIROMETRICS SYST

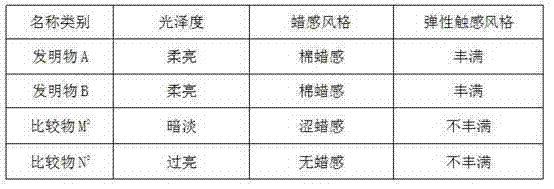

Polyurethane resin prepolymer solution and artificial leather fog washing bright finishing agent prepared by using same

ActiveCN102199270AReflective natural soft brightGood water repellency and temperature resistanceFibre treatmentPolyesterFumed silica

The invention discloses a polyurethane resin prepolymer solution which is prepared from the following raw materials in parts by weight: 5-10 parts of hydroxyl-terminated fluoropolysiloxane, 20-30 parts of toluene diisocynate (TDI), 20-30 parts of polyester polyol, 1-5 parts of ethylene glycol (EG), 20-30 parts of dimethylformamide (DMF), 20-25 parts of toluene, 3-5 parts of acetone and 1-2 parts of organic tin catalyst. The invention also discloses an artificial leather fog washing bright finishing agent prepared by using the polyurethane resin prepolymer solution. The finishing agent is prepared from the following raw materials in parts by weight: 20-60 parts of the fluoropolysiloxane modified polyurethane resin prepolymer solution, 2-10 parts of Teflon wax powder, 2-10 parts of precipitated silica or fumed silica, 10-30 parts of dimethylformamide and 20-30 parts of toluene.

Owner:HUAIAN KAIYUE TECH DEV

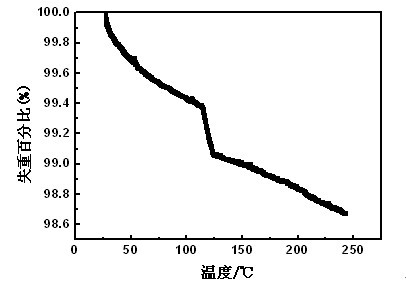

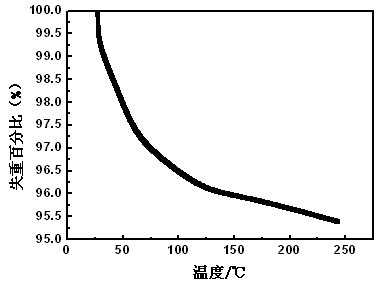

Preparation method of compact and composite proton exchange membrane

InactiveCN102304234AImprove permeabilityEasy to fillFinal product manufactureCell component detailsAlcoholHeteropoly acid

The invention provides a preparation method of a compact and composite proton exchange membrane, comprising the following steps of: dissolving perfluorinated sulfonic acid resin in alcohol aqueous solution of low boiling point; preparing to form perfluorinated sulfonic acid resin solution; then, adding solvent of high boiling point to replace solvent of low boiling point; adding water-retaining substance, such as SiO2, heteropolyacid and the like; impregnating mixed solution of alcohol of low boiling point and solvent of high boiling point in advance by a processed PTFE (Poly Tetra Fluoro Ethylene) porous basement membrane firstly; then, evenly dipping resin solution added with water retention substance onto the surface of the PTFE porous basement membrane; heating evaporating solvent andcarrying out heat treatment to obtain the composite proton exchange membrane; and rolling in to obtain the compact and composite proton exchange membrane. The preparation method is simple to operate,the composite membrane has the advantages of controllable thickness, good mechanical strength and water-retaining property, good size stability and compactness, is easy to realize large-scale production and can be used for improving the stability, the service life and the specific power of the battery if being applied to a fuel battery proton exchange membrane.

Owner:SOUTH CHINA UNIV OF TECH

Reformable soft gasket

The reformable soft gasket consists of chloroprene rubber 2-10 wt%, teflon emulsion 50-84 wt%, silk floss or polymer fiber 3-20 wt%, reinforcing stuffing 0.5-5 wt%, lubricating oil 10-20 wt%, plasticizer 0.5-3 wt% and graphite 0-24 w. The gasket of the present invention has the features of excellent sealing performance, high durability, low friction coefficient, no need of water cooling, good self-lubricating performance, no wear of shaft and muff, power saving, corrosion resistance, capacity of being reused, etc.

Owner:关晓辉

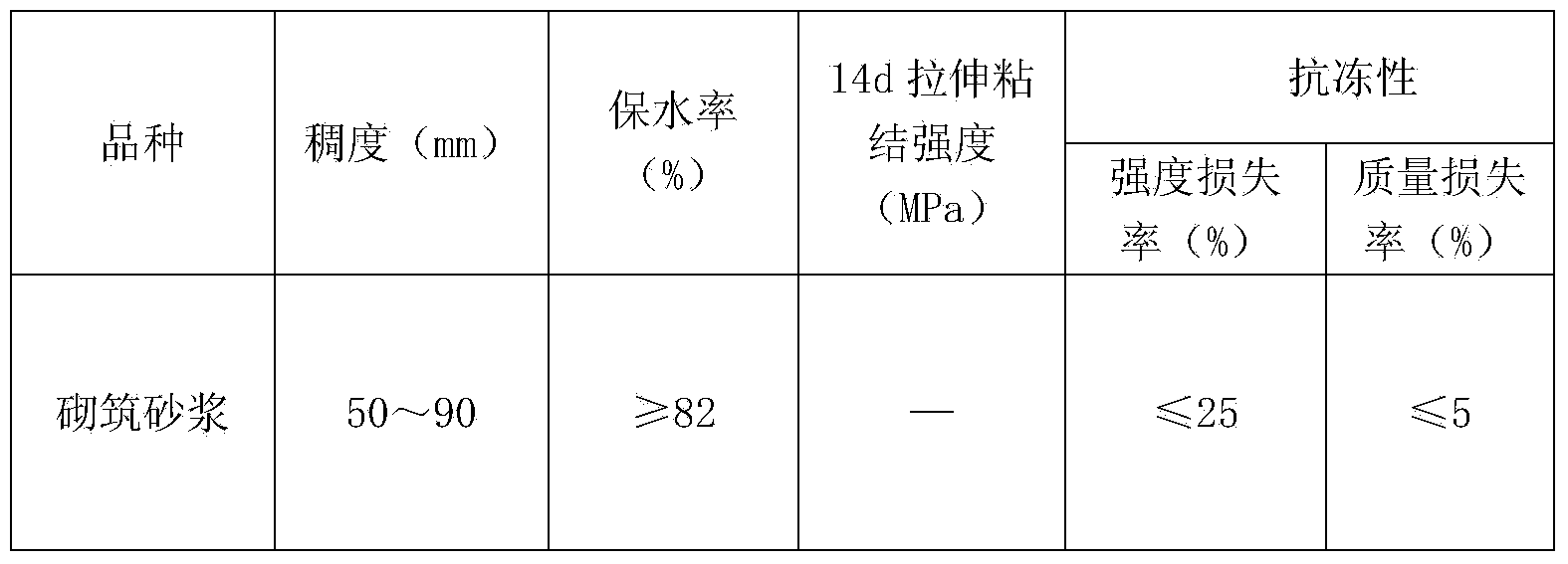

Masonry mortar produced by construction solid waste

The invention discloses a masonry mortar produced by construction solid waste. The masonry mortar comprises the following raw materials in parts by weight: 150-200 parts of cement, 900-1,200 parts of construction solid waste, 20-30 parts of glazed hollow beads, 30-40 parts of limestone, 10-20 parts of shell powder, 2-3 parts of magnesium sulfate heptahydrate, 5-10 parts of redispersible emulsion powder, 2-3 parts of polytetrafluoroethylene fibers, 0.8-1 part of Butyl tin tris-2-ethylexanoate, 2-3 parts of calcium phosphate, 4-6 parts of graphite powder, 1-2 parts of nano carbon powder, 1-2 parts of aluminium dihydric phosphate, 0.8-1 part of triethavolamine oleate soap and 2-4 parts of aluminum nitride powder. The masonry mortar provided by the invention is low in cost, can be used only by adding water and uniformly stirring according to the required amount during construction operation, is low in material consumption and waste, and has the advantages of high adhesion strength, low dry shrinkage rate, excellent anti-freezing durability, low thermal conductivity, good heat preservation performance, favorable workability, environmental friendliness and innocuity.

Owner:CHINA CONSTR 4TH ENG BUREAU 6TH

Fluoropolymer modified polyacrylate dispersion and its preparation and use

InactiveCN1594381AExpensive to fixReduce number average molecular weightTetrafluoroethylenePolymer science

The invention relates to structural elements represented by constitutional formula (I) and (II), which is linear macromolecular luminescent material in linear random arrangement by the mol ration of 1 : 0.5 - 1:200 and molecular weight 20000-100000 containing 8-hydroxyquinoline metallic complex, the preparation comprises copolymerizing polyalkene monomer of 8hydroxyquinoline metallic complex containing a polymerisable functional group with polyalkenes monomers through initiating agent at 20-200 deg. C.

Owner:JILIN UNIV

Making method for charcoal electrode of liquid flow type electroadsorption desalinization device

InactiveCN1544116AImprove conductivityHigh strengthIon-exchange process apparatusIon-exchanger regenerationFiberPorosity

The invention relates to a method of making carbon electrode of fluid electric-absorption desalter. It mainly mixes high specific surface area electrode carbon, nano carbon tube absorption material, carbon fiber, and nano carbon tube conductive material as well as adhesive polytetrafluoroethylene in a certain proportion and in a certain mode to make cold press molding and makes them into a double-faced electrode with a collector interlaid; the carbon electrode has good electric conductivity, small resistance, large electric capacity and low energy consumption; in addition, the modified carbon electrode has larger specific surface area and mesoporous porosity, therefore able to increase the absorption quantity of electrode to salt ions. The carbon electrode is especially applied to the fluid electric-absorption desalter and has higher desalting efficiency.

Owner:上海维安新材料研究中心有限公司 +1

Mechanically strippable upcoated optical fiber

ActiveUS7295737B2Optical fibre with multilayer core/claddingOptical waveguide light guideVitrificationUltraviolet

An upcoated optical fiber includes an optical fiber having a ultra-violet (UV) curable upcoating and a slip layer disposed between the optical fiber and the upcoating. The upcoating is mechanically strippable from the optical fiber and may be colored for identification of the optical fiber. In one embodiment, the slip layer and upcoating both have predetermined glass transition temperatures that are within about 15° C. of each other for improving mechanical characteristics. The slip layer may be essentially the same color as the upcoating for identification of the optical fiber after the upcoating is removed or it may be uncolored. In suitable embodiments, the slip layer may include a micronized poly-tetra-fluoro-ethylene (PTFE), a silicone, and / or a dispersing agent for enhancing the strip performance of the upcoating over a range of temperatures.

Owner:CORNING OPTICAL COMM LLC

Methods and apparati for handling, heating and cooling a substrate upon which a pattern is made by a tool in heat flowable material coating, including substrate transport, tool laydown, tool tensioning and tool retraction

ActiveUS20140367887A1Rapid productionHeating fastPhotomechanical apparatusCeramic shaping apparatusMaterials scienceCoating

Owner:CUBICPV INC

Method for preparing copper oxide based on acidic etching liquid as raw material

ActiveCN102303892AHigh purityUniform particle sizeCopper oxides/halidesPhysical chemistryPotassium hydroxide

The invention relates to a method for preparing copper oxide based on an acidic etching liquid as a raw material. The method comprises the following steps: (1) regulating the pH of the acidic etching liquid to 10-13 with sodium hydroxide or potassium hydroxide; (2) transferring the etching liquid obtained in the step (1) into a stainless steel reaction kettle with a teflon lining, adding pure water to 70%-80% of total kettle volume, and carrying out hydrothermal synthesis for 2-10 hours at the temperature of 120-200 DEG C; and (3) after the reaction is finished, naturally cooling to room temperature, collecting materials at the kettle bottom, and successively washing with deionized water and alcohol, and then drying so as to obtain copper oxide. According to the invention, copper oxide isprepared from the acidic etching liquid by using the hydrothermal synthesis method, and obtained copper oxide has the advantages of high purity, high activity and uniform particle diameter. In addition, the method has no secondary pollution and low production cost.

Owner:昆山德阳新材料科技有限公司

Surface hydrophilicity modification process for separating fluoric polymer film

InactiveCN1986038AEasy to controlGood repeatabilitySemi-permeable membranesChemical LinkagePolymer science

The process of modifying surface hydrophilicity of separating fluoric polymer film includes the first pre-irradiating separating fluoric polymer film with high energy ray to make the surface macromolecular main chain generate active free radical, and the subsequent grafting the surface fluoric polymer film with high ionized hydrophilic sulfonic group in the grafting polymerization reaction system with double monomer of acrylic cid and sodium styrene sulfonate and water as dispersing medium in controlled reactant concentration, molar ratio, temperature and pH value. The process can improve the hydrophilicity of separating fluoric polymer film obviously, and the modified separating membrane has obviously decreased contact angle and lasting hydrophilicity.

Owner:ZHEJIANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com