Polyurethane resin prepolymer solution and artificial leather fog washing bright finishing agent prepared by using same

A technology of polyurethane resin and prepolymer, which is used in the field of polyurethane resin finishing agent and fog washing and brightening polyurethane resin finishing agent

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

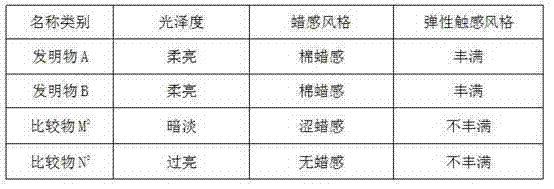

Examples

Embodiment 1

[0025] Preparation of hydroxyl terminated fluoropolysiloxane intermediates.

[0026] In parts by mass, add 20 parts of small molecule hydroxyl silicone oil with 8% hydroxyl content and viscosity of 30mpa.s, 30 parts of octamethylcyclotetrasiloxane (D4), methyldodecylcyclotetrasiloxane 25 parts, 25 parts of methyl trifluoropropyl cyclotrisiloxane (D3F), 3 parts of dry sulfated clay (activated clay), and then start electric stirring (100 ~ 500 rev / min), heating to 80 ~ 120°C, maintain this temperature range, after stirring for 12 hours, the reactant is at 0.01 ~ Under the vacuum of 0.03Mpa, use a sand core funnel or filter cloth to filter while hot to remove sulfated clay, and then filter the reactant at 150 ~ 160°C, 0.01 ~ Pull it down for 2 hours under a vacuum of 0.03Mpa to obtain a colorless and transparent hydroxyl-terminated fluoropolysiloxane intermediate with a viscosity of 1050mpa.s and a hydroxyl mass content of 1.5%. The yield is 91%, and the low boiling point can ...

Embodiment 2

[0029] In parts by mass, add 20 parts of small molecule hydroxyl silicone oil with a hydroxyl content of 5% and a viscosity of 40mpa.s, 30 parts of octamethylcyclotetrasiloxane (D4), methyl a-methyl styryl ring 25 parts of tetrasiloxane, 25 parts of methyl trifluoropropyl cyclotrisiloxane (D3F), 8 parts of dry strongly acidic spherical granular polystyrene resin, and then start electric stirring (100 ~ 500 rev / min), heating to 60 ~ 80°C, maintain this temperature range, after stirring the reaction for 20h, the reactant is heated with 100 ~ 200 mesh screens were filtered while hot to remove the spherical granular polystyrene resin, and then the filtered reactant was heated at 150 ~ 160°C, 0.01 ~ Pull it down for 2 hours under a vacuum of 0.03Mpa to obtain a colorless and transparent hydroxyl-terminated fluoropolysiloxane intermediate with a viscosity of 2100mpa.s and a hydroxyl mass content of 1%. The yield is 90%, and the low boiling point can be reused. The structural formul...

Embodiment 3

[0032] Preparation of Polyurethane Resin Prepolymer Solution Modified by Fluoropolysiloxane

[0033] In parts by mass, add 5 parts of hydroxyl-terminated fluoropolysiloxane intermediates prepared in Example 1, 20 parts of polycaprolactone polyol PCL-3000, 20 parts of DMF, 20 parts of toluene, 4 parts of acetone in the container , 3 parts of ethylene glycol (EG), 1.5 parts of dibutyltin dilaurate, after electric stirring (150 rpm) at 40°C for 60 minutes, heat to 75-85°C, add 20 parts of TDI at a uniform speed within 150 minutes under reflux condensation After the addition, continue to keep stirring at 75-85°C for 2 hours, and cool down to room temperature to obtain a fluoropolysiloxane-modified polyurethane resin prepolymer solution with a solid content of 45.4% and a system viscosity of 1450mpa.s.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com