Patents

Literature

31results about "Lactams stabilisation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

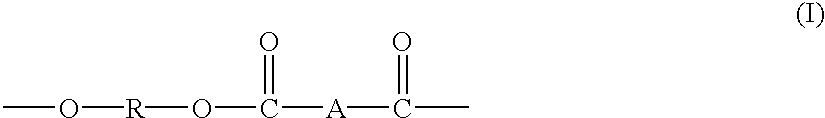

Blend material including macrocyclic polyester oligomers and processes for polymerizing the same

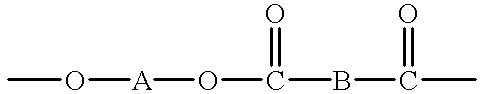

A blend of a macrocyclic polyester oligomer and a polymerization catalyst as a one component ready-to-use material with a long shelf life enables production of parts from macrocyclic polyester oligomers without the modification of existing equipment, thereby reducing time and cost of manufacture while expanding the application of macrocyclic polyester oligomers. In this blend material, the macrocyclic polyester oligomer remains intact in solid state at ambient conditions. Upon melting, the blend material initially forms low viscosity fluid, and then rapidly polymerizes to form high molecular weight polyesters which subsequently solidify to form crystalline polymers. In the case of certain macrocyclic polyester oligomers, for example, poly(1,4-butylene terephthalate), demolding can take place at the polymerization temperature, e.g., at about 180° C. to 200° C., because the resulting polyester polymer solidifies fairly rapidly at that temperature without cooling. In one aspect, the invention generally features a blend material that includes a macrocyclic polyester oligomer, a polymerization catalyst, and optionally, a filler. In another aspect, the invention generally features a process for preparing a blend material. In yet another aspect, the invention features processes such as rotational molding, resin film infusion, pultrusion, resin transfer molding, filament winding, making and using powder-coated or hot melt prepreg, compression molding, and roll wrapping, which use the blend material.

Owner:CYCLICS CORP

Catalyst for polyester production, process for producing polyester using the catalyst, polyester obtained by the process, and uses of the polyester

InactiveUS6346070B1High catalytic activityLow in acetaldehydeLactams stabilisationDevelopersFiberPolyester

The present invention provides a catalyst for polyester production capable of producing a polyester with high catalytic activity and a process for producing a polyester using the catalyst. The catalyst for polyester production comprises a solid titanium compound which is obtained by dehydro-drying a hydrolyzate obtained by hydrolysis of a titanium halide and which has a molar ratio (OH / Ti) of a hydroxyl group (OH) to titanium (Ti) exceeding 0.09 and less than 4. The present invention also provides a method to obtain a polyester having a small increase of the acetaldehyde content during the molding. This method comprises bringing a polyester, which is obtained by the use of a titanium compound catalyst and in which the reaction has been completed, into contact with a phosphoric ester aqueous solution or the like having a concentration of not less than 10 ppm in terms of phosphorus atom. The present invention further provides a polyester having excellent transparency and tint and molded products of the polyester such as a blow molded article, a film, a sheet and a fiber. The polyester is obtained by polycondensing an aromatic dicarboxylic acid or an ester-forming derivative thereof and an aliphatic diol or an ester-forming derivative thereof in the presence of a catalyst for polyester production which comprises a polycondensation catalyst component comprising a solid titanium compound and a co-catalyst component comprising a magnesium compound. This polyester has a titanium content of 1 to 100 ppm, a magnesium content of 1 to 200 ppm and a weight ratio (Mg / Ti) of magnesium to titanium of not less than 0.01.

Owner:MITSUI CHEM INC

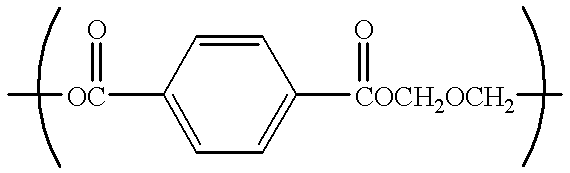

Block copolymers from macrocyclic oligoesters and dihydroxyl-functionalized polymers

InactiveUS6436549B1Lactams stabilisationSynthetic resin layered productsPolyesterPolymerization catalysts

Block copolymers are prepared from polymerization of a macrocyclic oligoester and a dihydroxyl-functionalized polymer at an elevated temperature in the presence of a polymerization catalyst.

Owner:LIQUID THERMO PLASTICS

Process for making polymers having nanostructures incorporated into the matrix of the polymer

ActiveUS20060047058A1Material nanotechnologyPlastic/resin/waxes insulatorsPolymer scienceNanostructure

The present invention is directed toward a method for making a polymer that has nanostructures incorporated into the matrix of the polymer. The method of the invention involves the following steps: mixing a precursor solution for the polymer with a precursor for the nanostructures to form a mixture; forming nanostructures in the mixture from the precursor of the nanostructures; and forming a polymer from the precursor solution of the polymer so that the nanostructures are incorporated into the polymer matrix.

Owner:PPG IND OHIO INC

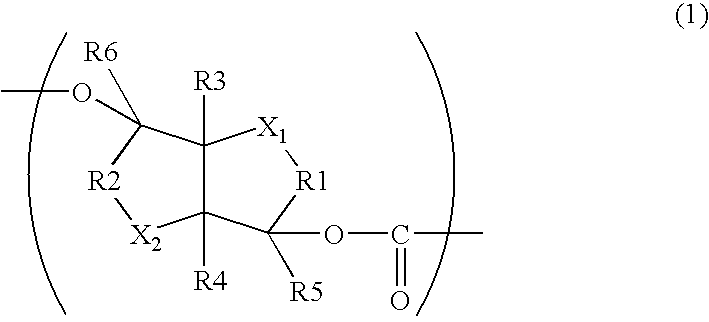

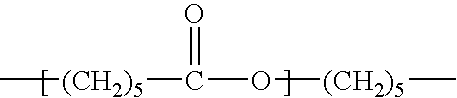

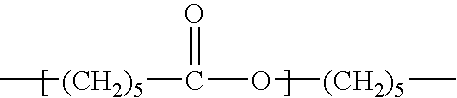

Aliphatic Polyester Copolymer

InactiveUS20080015331A1Improve heat resistanceSolve the lack of mechanical propertiesBiocideLactams stabilisationPolyesterMolten state

An aliphatic polyester copolymer comprising an aliphatic carbonate unit (a) and an aliphatic polyester unit (b), and a molded body composed of said aliphatic polyester copolymer. The aliphatic polyester copolymer is excellent in heat resistance while having adequate mechanical properties and properties in the molten state.

Owner:MITSUI CHEM INC

Biodegradable polyester polymer and method for preparing the same using compressed gas

InactiveUS6913826B2High molecular weightReduce molecular weightLactams stabilisationSynthetic resin layered productsEthylene HomopolymersSolvent

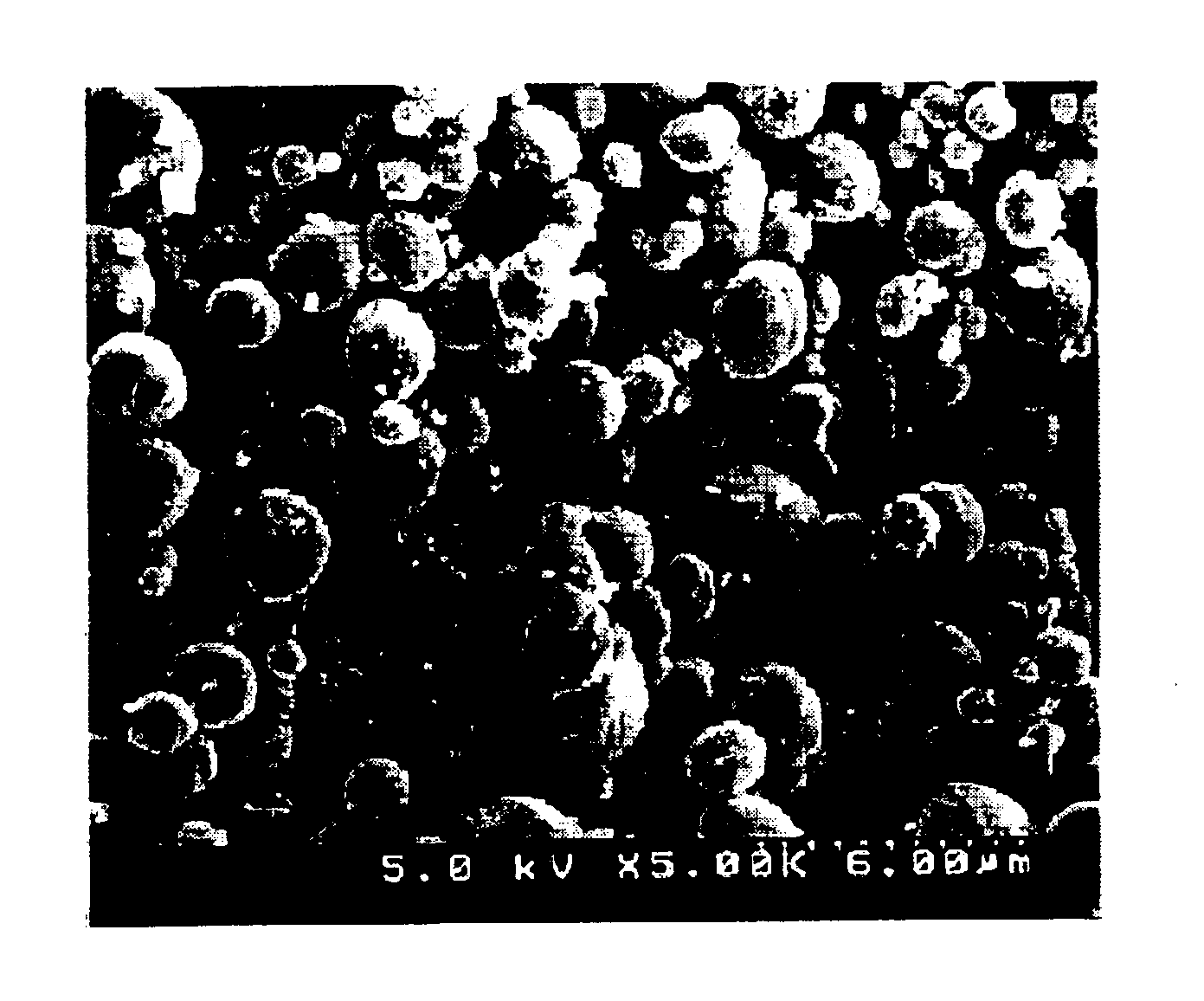

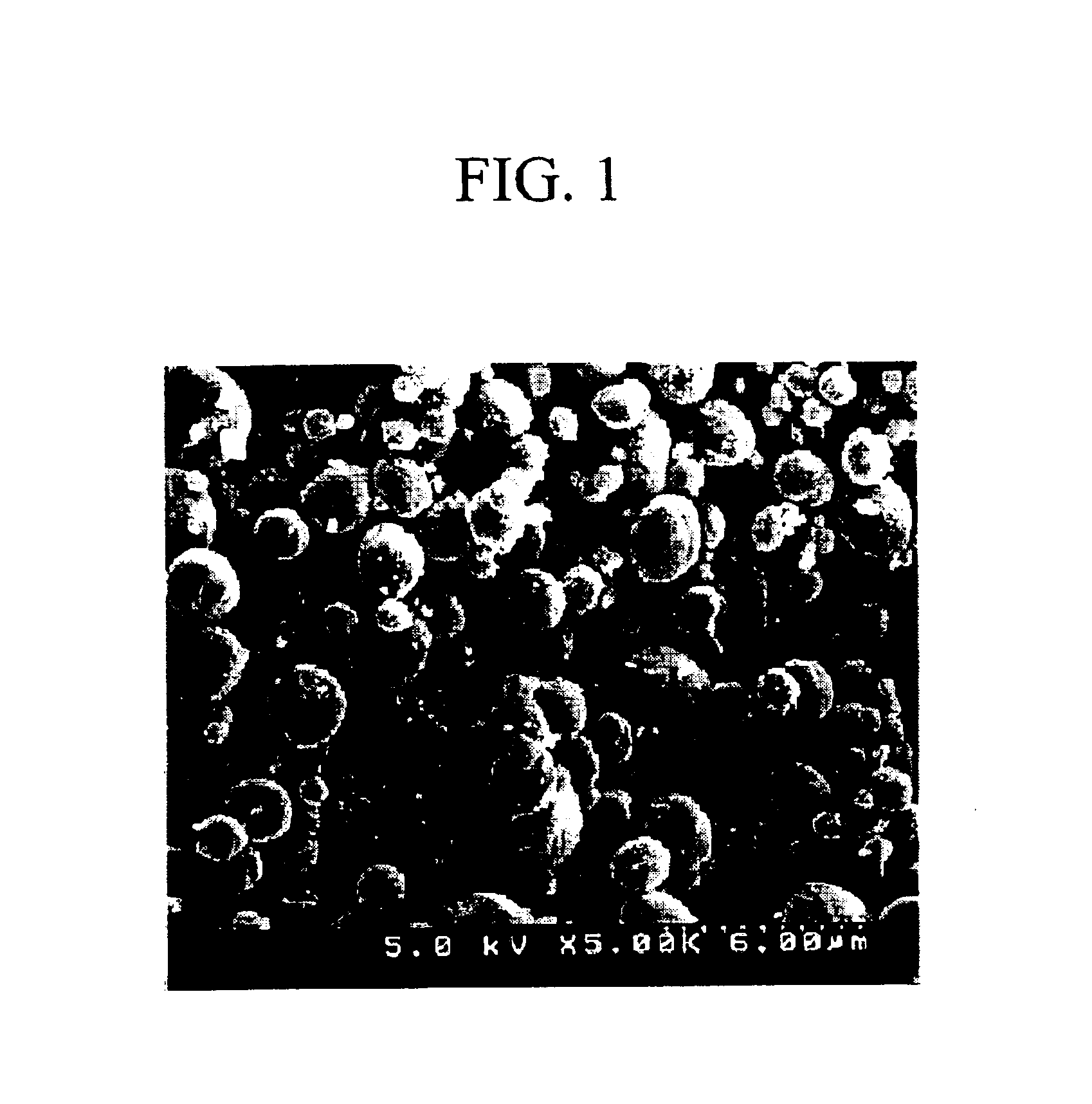

In polymerizing biodegradable polymer material, a compressed gas is used as a reaction solvent for a solution-polymerization, in order to prepare biodegradable polyester homopolymer and copolymer with a high molecular weight in a fine powder form with a particle size of 0.01˜1000 μm.

Owner:KOREA INST OF SCI & TECH

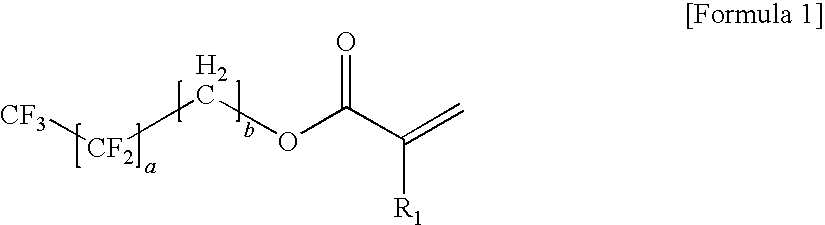

Coating composition for antireflection and antireflection film prepared by using the same

InactiveUS20100271699A1Excellent optical propertiesReduce manufacturing costLactams stabilisationLayered productsManufacturing cost reductionPolymer science

The present invention provides a coating composition for antireflection that includes a) a low refractive material having a refractive index of 1.2 to 1.45, b) a high refractive material having a refractive index of 1.55 to 2.2 and comprising high refractive fine particles and an organic substituent, in which the difference in the surface energy between two materials is 5 mN / m or more; an antireflection film manufactured using the coating composition for antireflection; and a method of manufacturing the antireflection film. According to the present invention, the antireflection film having excellent antireflection characteristic can be manufactured by one coating process, thereby reducing manufacturing cost.

Owner:LG CHEM LTD

Resist composition excellent in flame resistance

InactiveUS6528552B1Improve flame retardant performanceGood self-extinguishingLactams stabilisationSemiconductor/solid-state device detailsResistStannate

A resist composition for permanent protective coating of a printed wiring board, which resist composition is excellent in flame resistance and is obtained by incorporating as essential components a flame retardant containing 100 to 140 parts by weight of (a) aluminum hydroxide, 0.1 to 15 parts by weight of (b) a molybdenum compound and 0.1 to 10 parts by weight of (c) a zinc stannate type compound into 100 parts by weight of a resin.

Owner:MITSUBISHI GAS CHEM CO INC

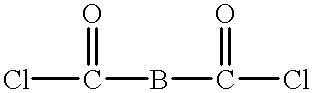

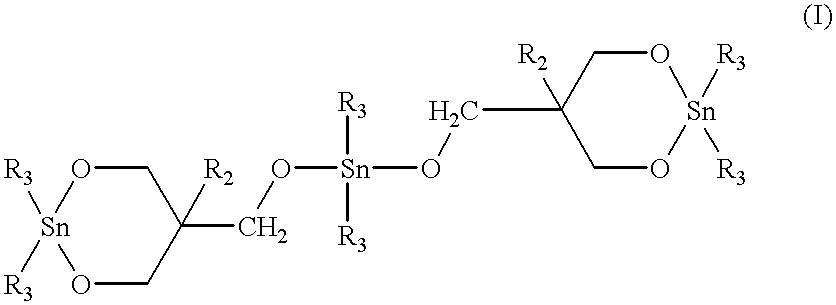

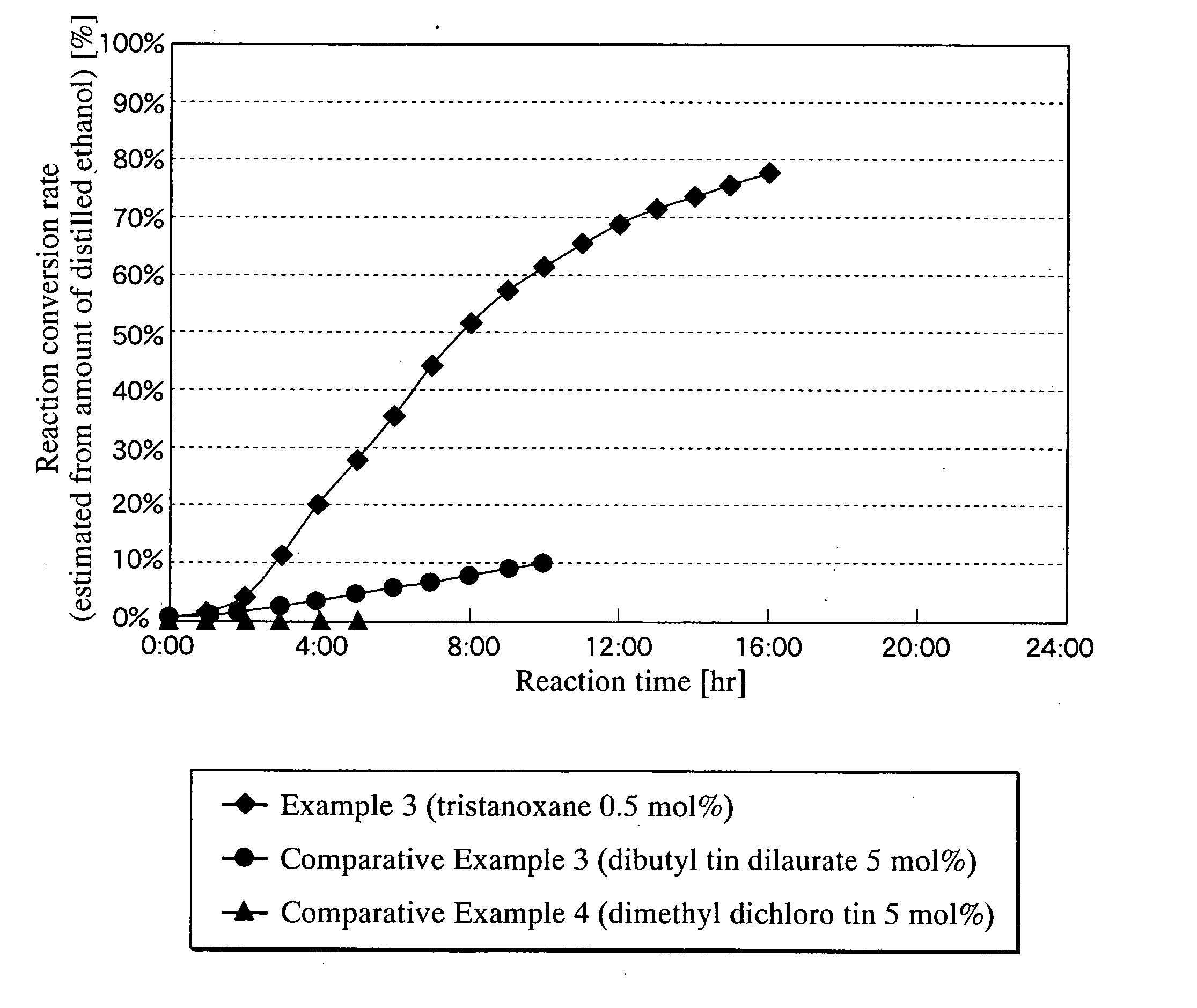

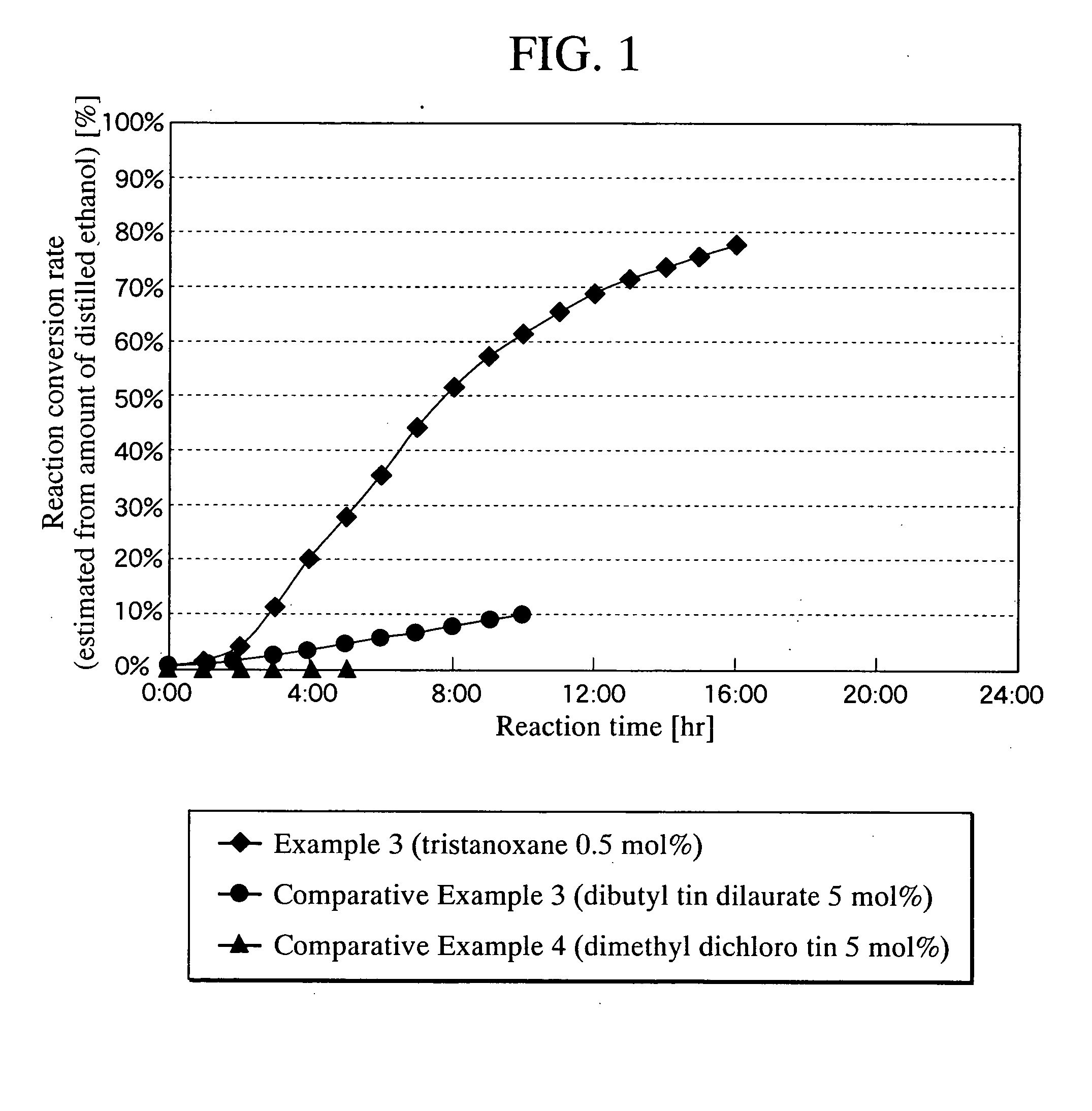

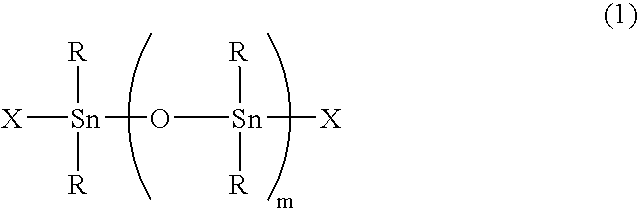

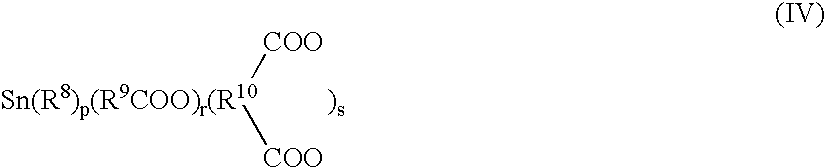

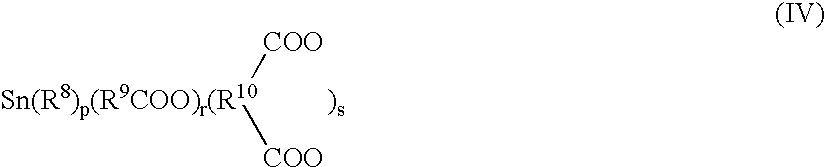

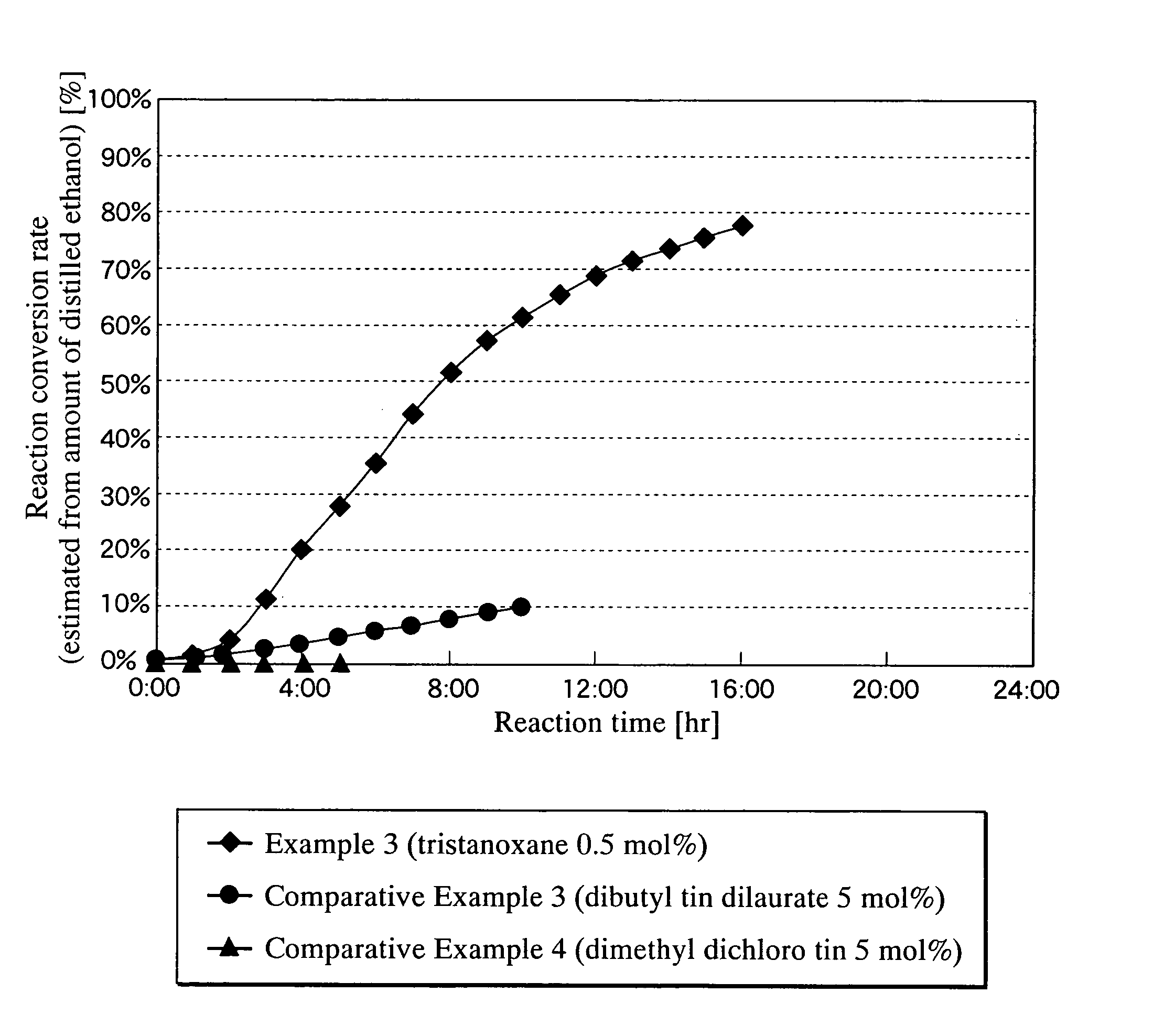

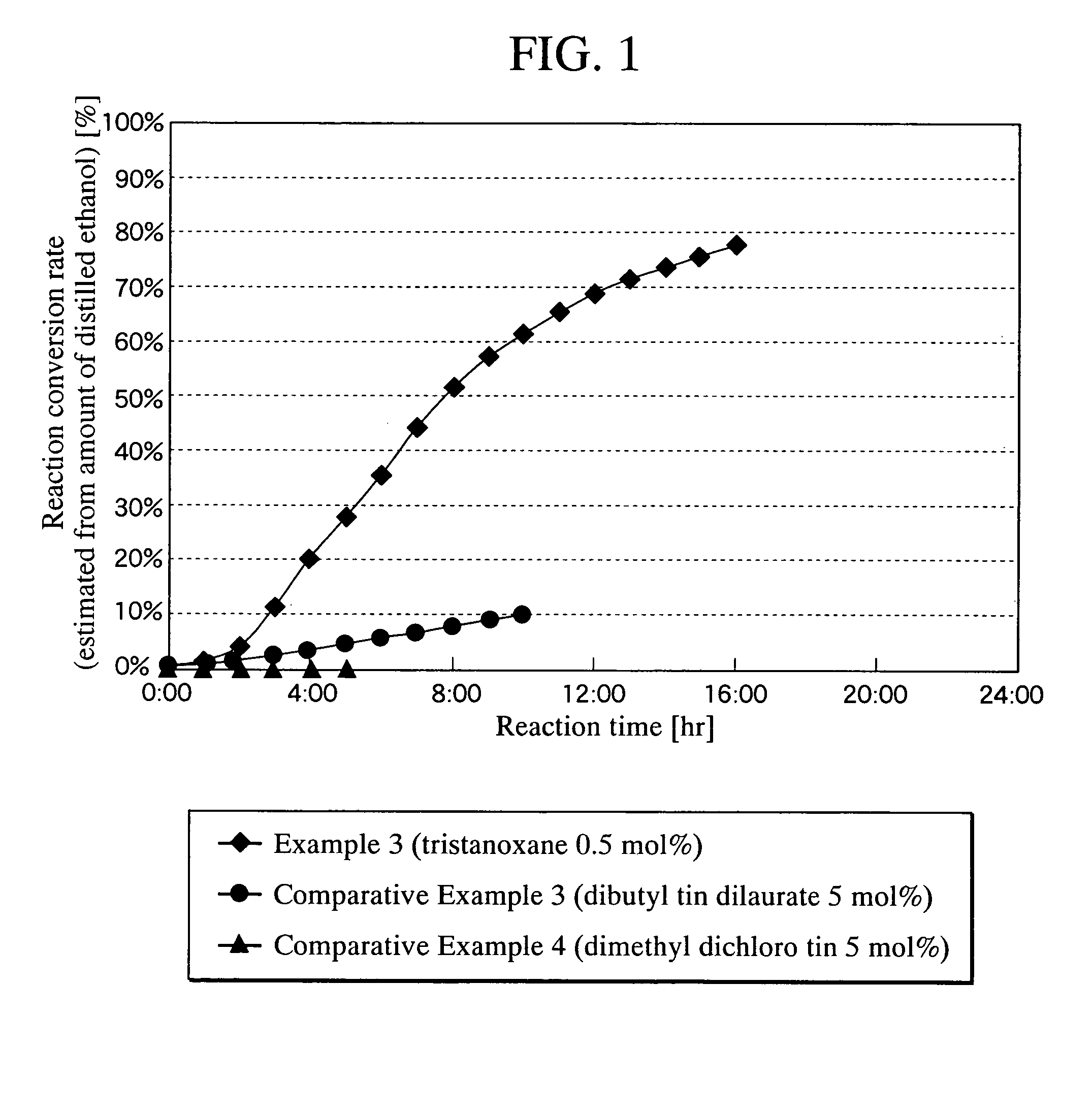

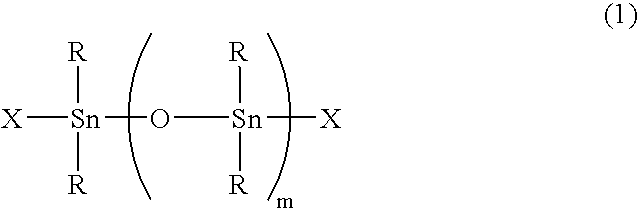

Catalysts and methods for polymerizing macrocyclic oligomers

Cyclic oligomers containing ester linkages are polymerized in the presence of a catalyst having at least one oxygen atom bonded to two metal atoms. At least one of the metal atoms is a tin atom, which is preferably tetravalent, i.e., bonded to three other groups in addition to the oxygen atom. The other metal atom may also be another tin atom, which is again preferably tetravalent, or a zinc, aluminum or titanium atom. The catalyst may contain multiple oxygen atoms that are bonded to two such metal atoms as described. These catalysts are active, efficient polymerization catalysts. They are often liquids at polymerization temperatures. The catalysts can be formed in situ in the polymerization process, which provides additional flexibility in the process and increased storage stability of starting materials.

Owner:DOW GLOBAL TECH LLC

Process for making polymers having nanostructures incorporated into the matrix of the polymer

The present invention is directed toward a method for making a polymer that has nanostructures incorporated into the matrix of the polymer. The method of the invention involves the following steps: mixing a precursor solution for the polymer with a precursor for the nanostructures to form a mixture; forming nanostructures in the mixture from the precursor of the nanostructures; and forming a polymer from the precursor solution of the polymer so that the nanostructures are incorporated into the polymer matrix.

Owner:PPG IND OHIO INC

Catalysts and methods for polymerizing macrocyclic oligomers

Cyclic oligomers containing ester linkages are polymerized in the presence of a catalyst having at least one oxygen atom bonded to two metal atoms. At least one of the metal atoms is a tin atom, which is preferably tetravalent, i.e., bonded to three other groups in addition to the oxygen atom. The other metal atom may also be another tin atom, which is again preferably tetravalent, or a zinc, aluminum or titanium atom. The catalyst may contain multiple oxygen atoms that are bonded to two such metal atoms as described. These catalysts are active, efficient polymerization catalysts. They are often liquids at polymerization temperatures. The catalysts can be formed in situ in the polymerization process, which provides additional flexibility in the process and increased storage stability of starting materials.

Owner:DOW GLOBAL TECH LLC

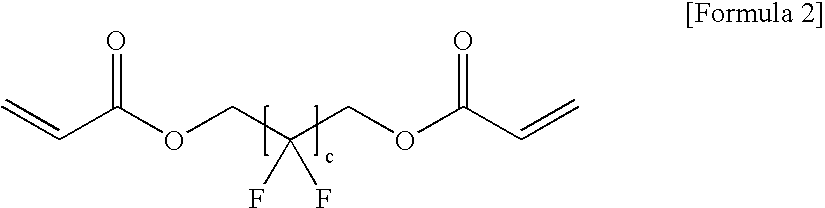

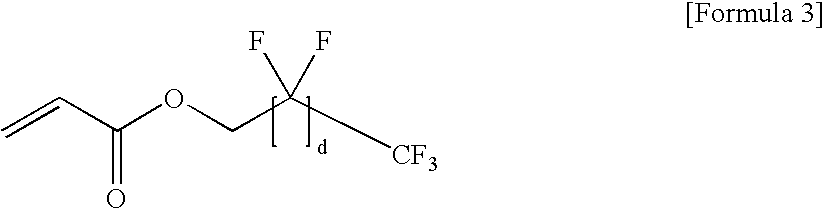

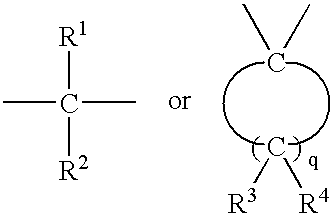

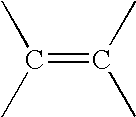

Process for producing polymerizable polybranched polyester

InactiveUS20060047140A1Improve efficiencyOrganic compound preparationLactams stabilisationDouble bondCarboxylic acid

The present invention allows the production of a polymerizable hyperbranched polyester by introducing polymerizable unsaturated double bonds into the molecular terminals of a hyperbranched polyester polyol (A), which is obtained by condensation polymerization a polyhydroxy monocarboxylic acid in which there are at least two hydroxyl groups, the carbon atom adjacent to the carboxy group is saturated carbon atom, and the hydrogen atoms on said carbon atom are all substituted, by reacting the hyperbranched polyester polyol (A) and an alkyl ester of a carboxylic acid having a polymerizable unsaturated double bond (B) by a transesterification in the presence of at least one type of transesterification catalyst (C) selected from the group consisting of a dialkyl tin oxide and a stanoxane, without causing side reactions such as nucleophilic addition reactions of terminal hydroxyl groups to polymerizable unsaturated double bonds of the hyperbranched polyester polyol (A), or thermal polymerization of the polymerizable unsaturated double bonds. The polymerizable hyperbranched polyester can be produced at high efficiency using a transesterification that uses as an alkyl ester of a carboxylic acid having a polymerizable unsaturated double bond (B), which is easily obtained as an industrial raw material, and without altering the original backbone structure of the molecular chains of the hyperbranched polyester polyol (A) by hydrolysis and so forth.

Owner:DAINIPPON INK & CHEM INC

Aliphatic polyester copolymer

InactiveUS7645852B2Improve heat resistanceSufficient mechanical propertyBiocideLactams stabilisationMolten statePolyester

An aliphatic polyester copolymer comprising an aliphatic carbonate unit (a) and an aliphatic polyester unit (b), and a molded body composed of said aliphatic polyester copolymer. The aliphatic polyester copolymer is excellent in heat resistance while having adequate mechanical properties and properties in the molten state.

Owner:MITSUI CHEM INC

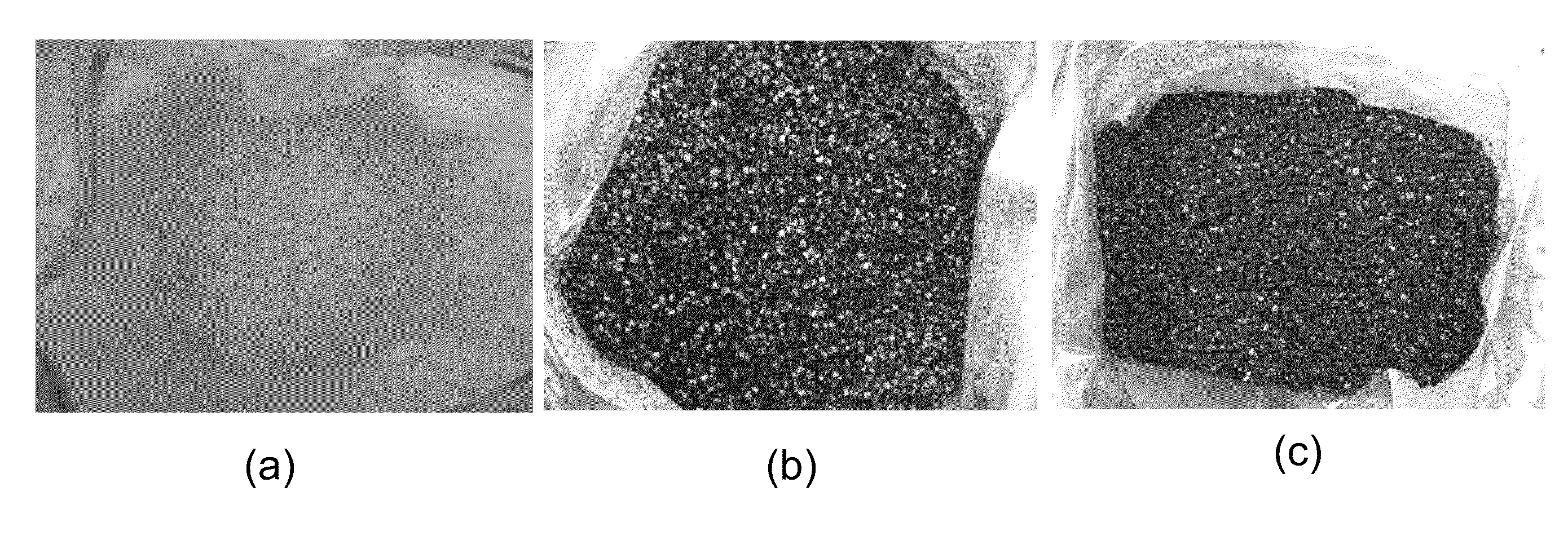

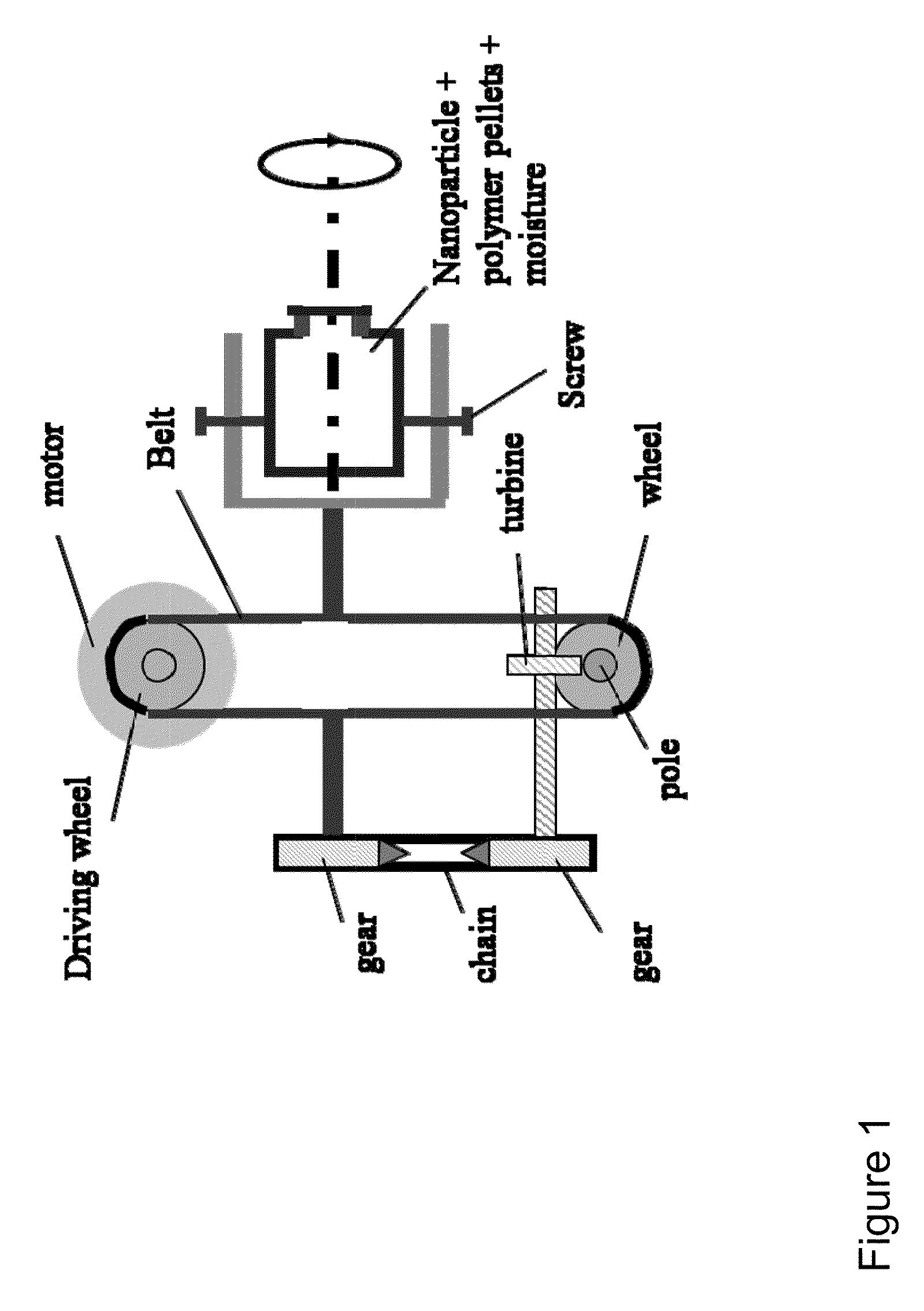

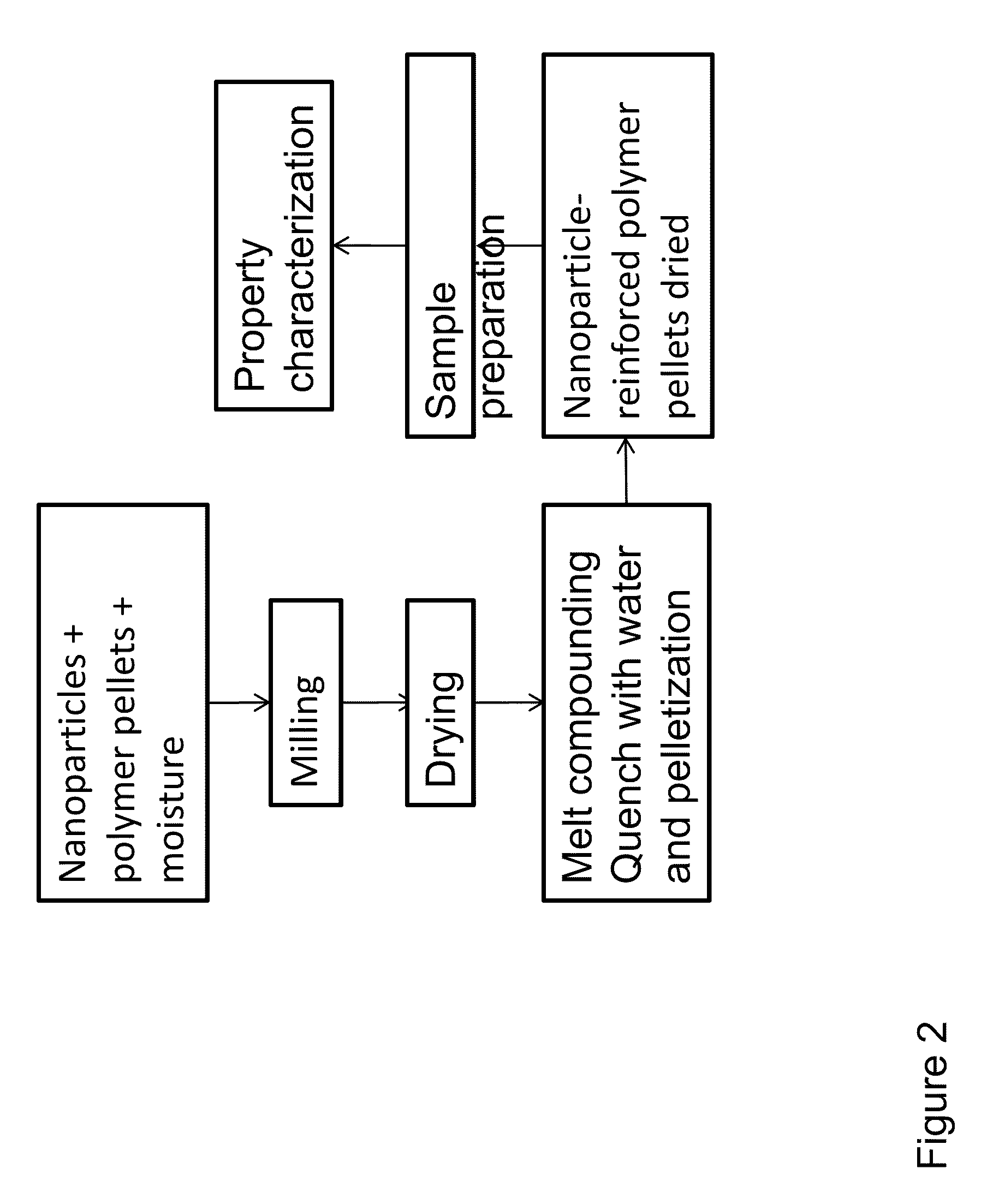

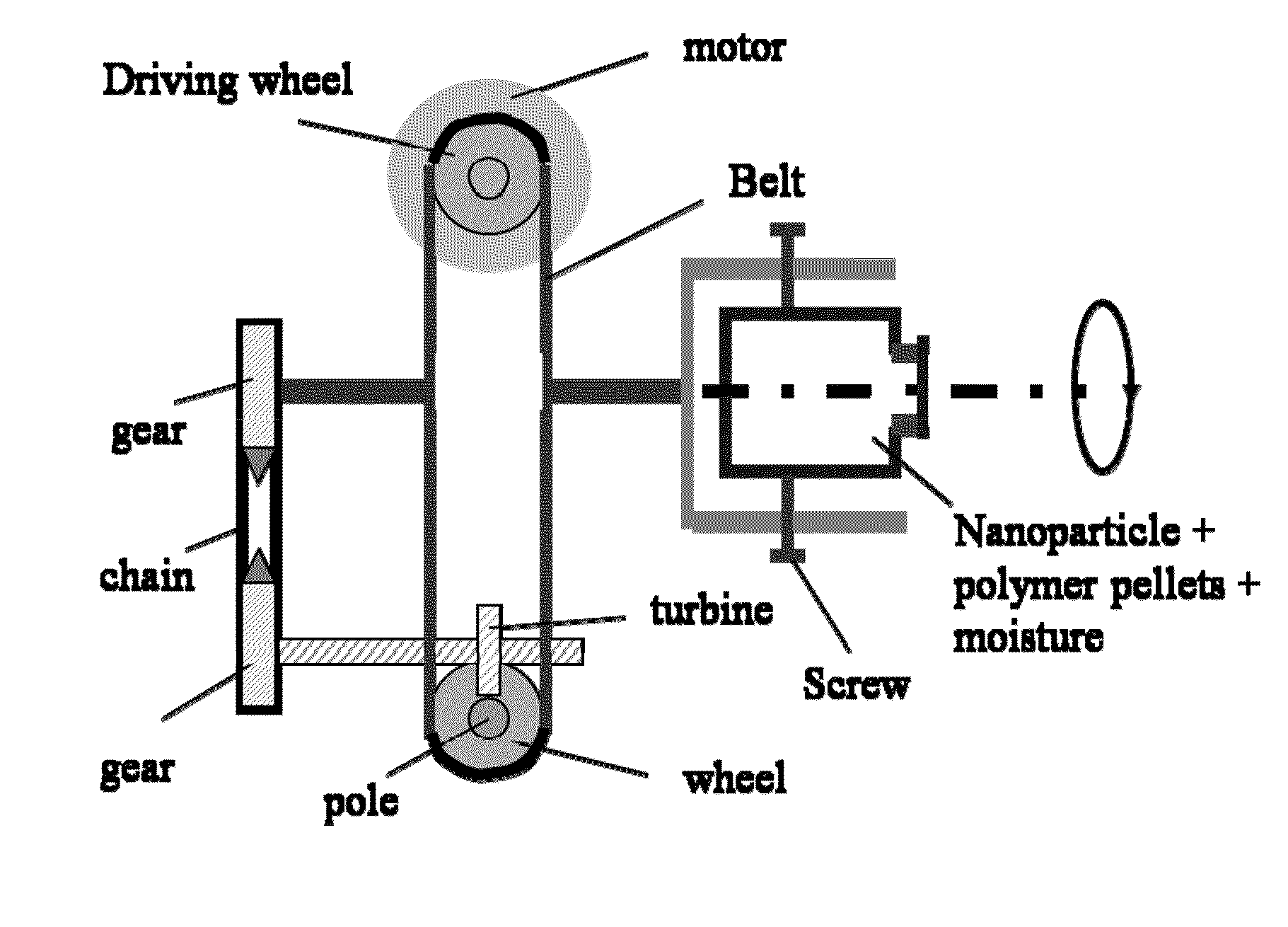

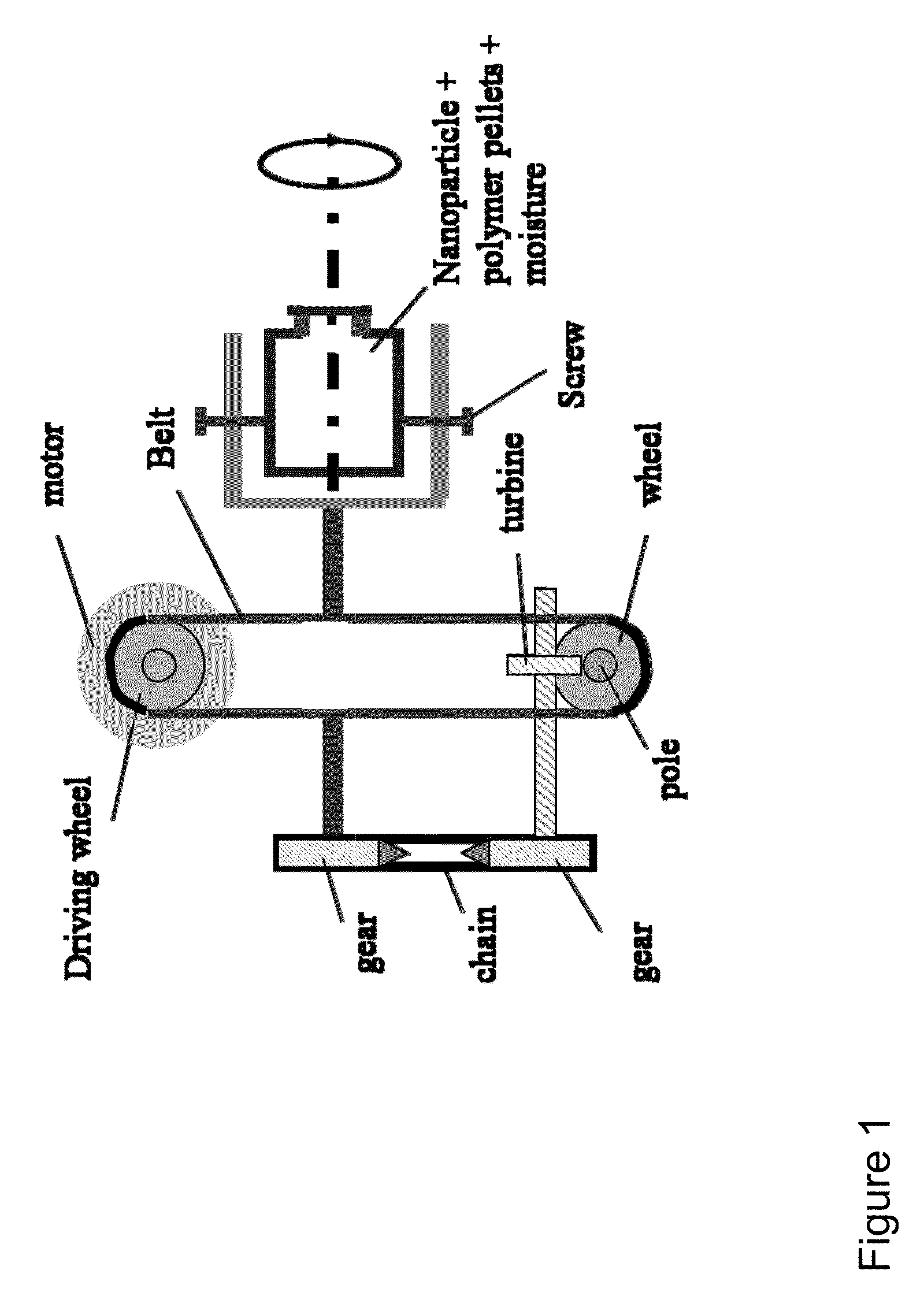

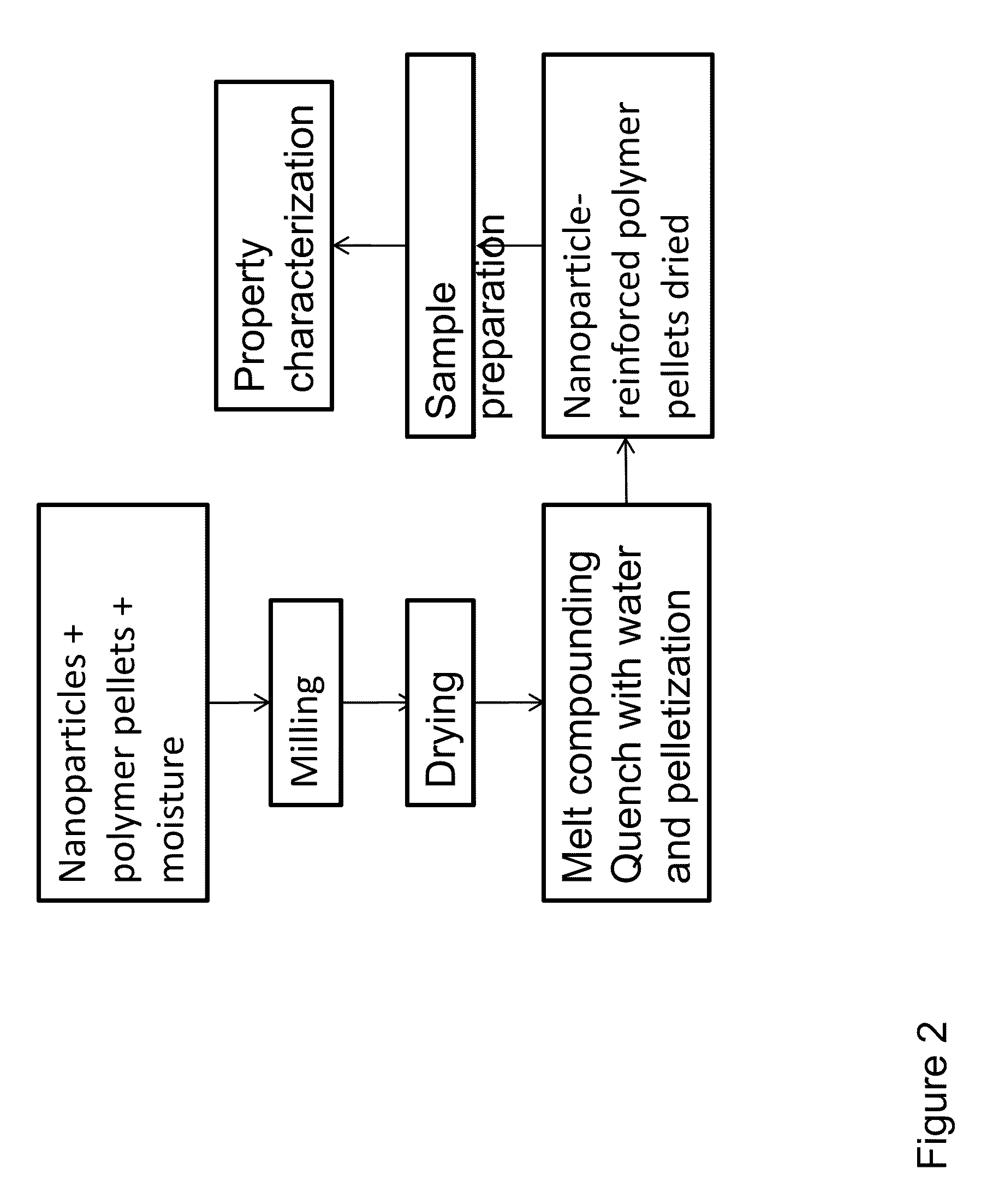

Composites

Improved mechanical properties of either clay or carbon nanotube (CNT)-reinforced polymer matrix nanocomposites are obtained by pre-treating nanoparticles and polymer pellets prior to a melt compounding process. The clay or CNTs are coated onto the surfaces of the polymer pellets by a milling process. The introduction of moisture into the mixture of the nanoparticles and the polymer pellets results in the nanoparticles more easily, firmly, and thoroughly coating onto the surfaces of the polymer pellets.

Owner:APPLIED NANOTECH HLDG

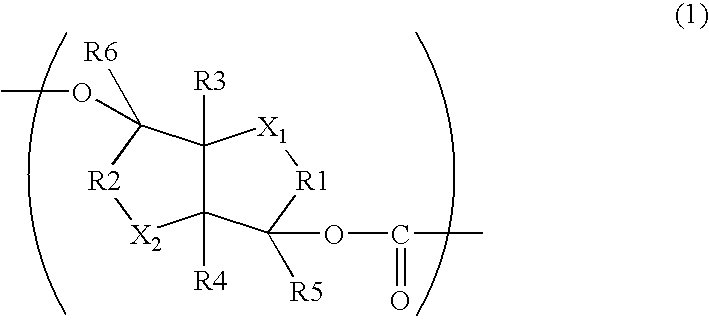

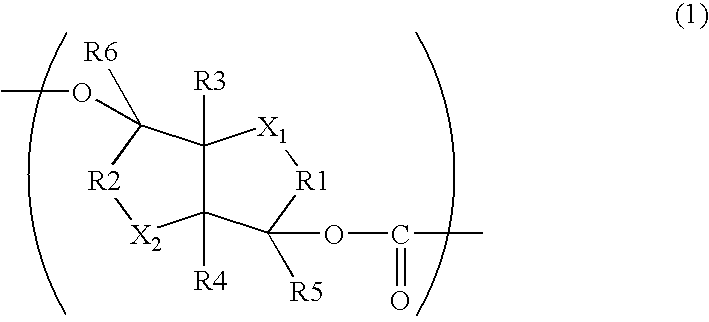

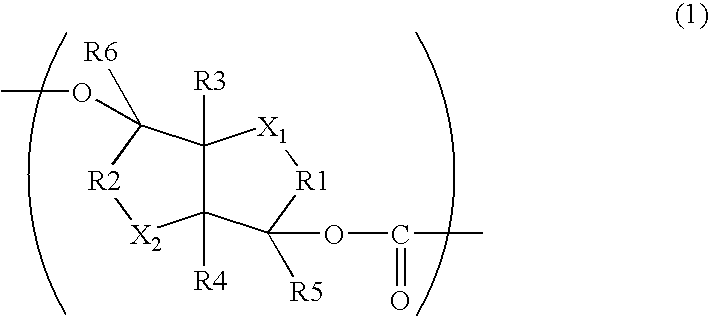

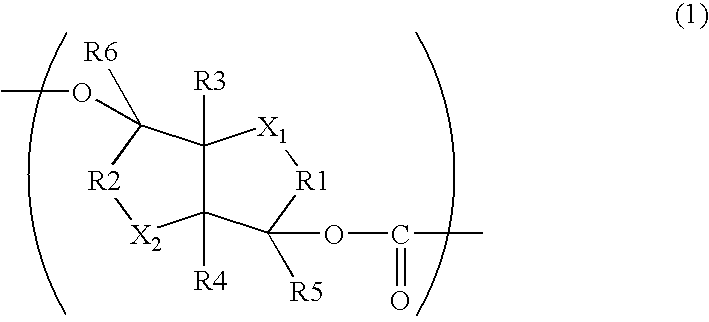

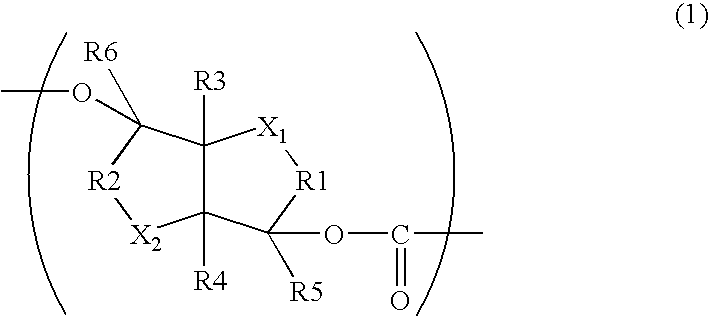

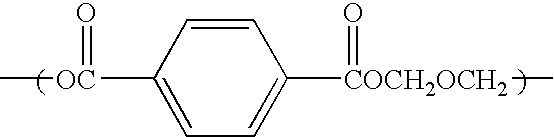

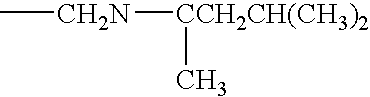

Flame retardant polybutyleneterephthalate resin

InactiveUS6610796B2Improve flame retardant performanceImprove propertiesLactams stabilisationMixingPolytetramethylene terephthalateFire retardant

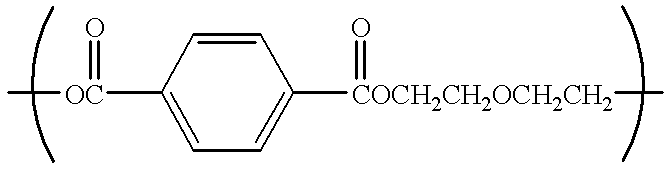

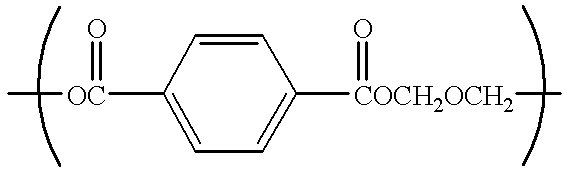

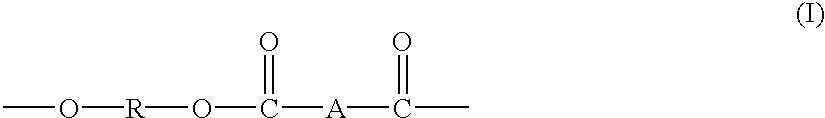

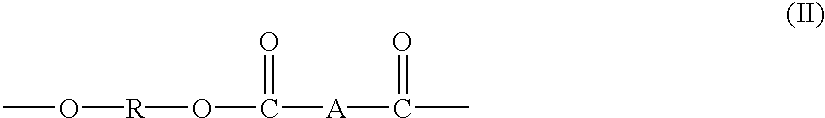

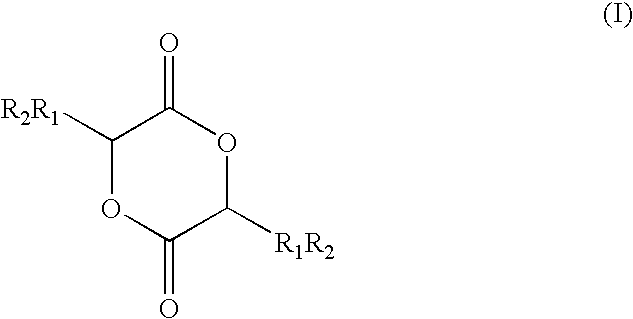

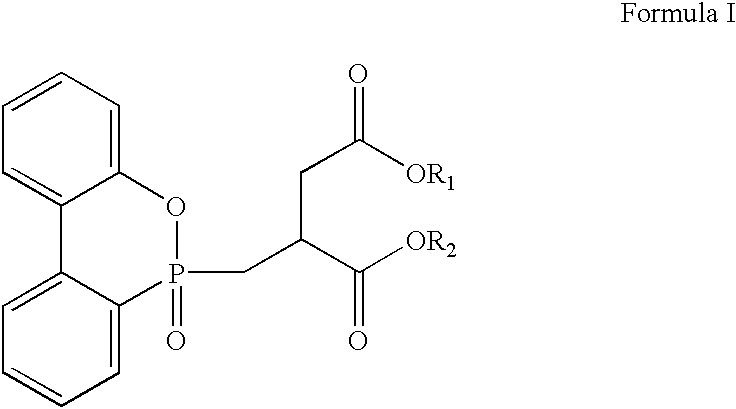

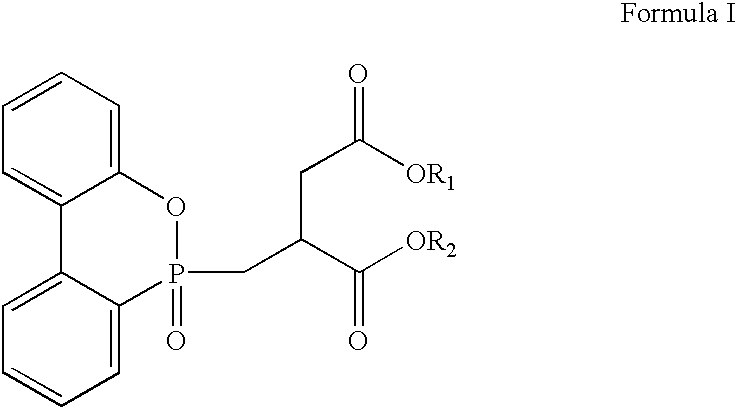

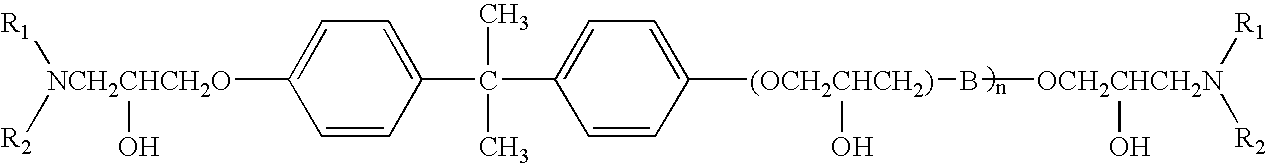

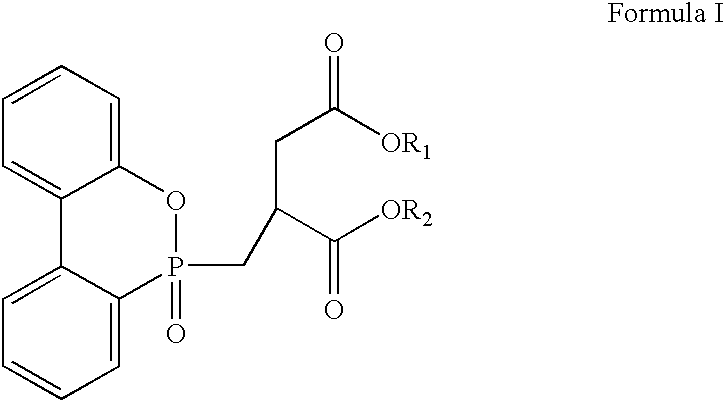

Disclosed is a flame retardant polybutyleneterephthalate resin prepared be copolymerizing a phosphorus-based flame retardant represented by the following formula I and a butyleneterephthalate unit:wherein R1 and R2 are different or the same and are methyl or butyl including a hydroxyl group.

Owner:KOLON IND INC

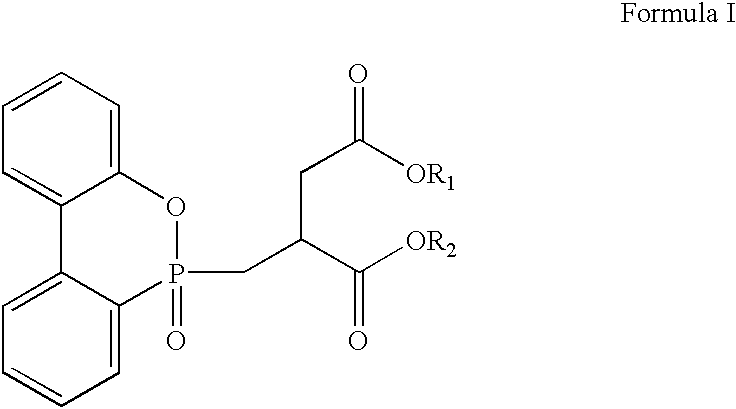

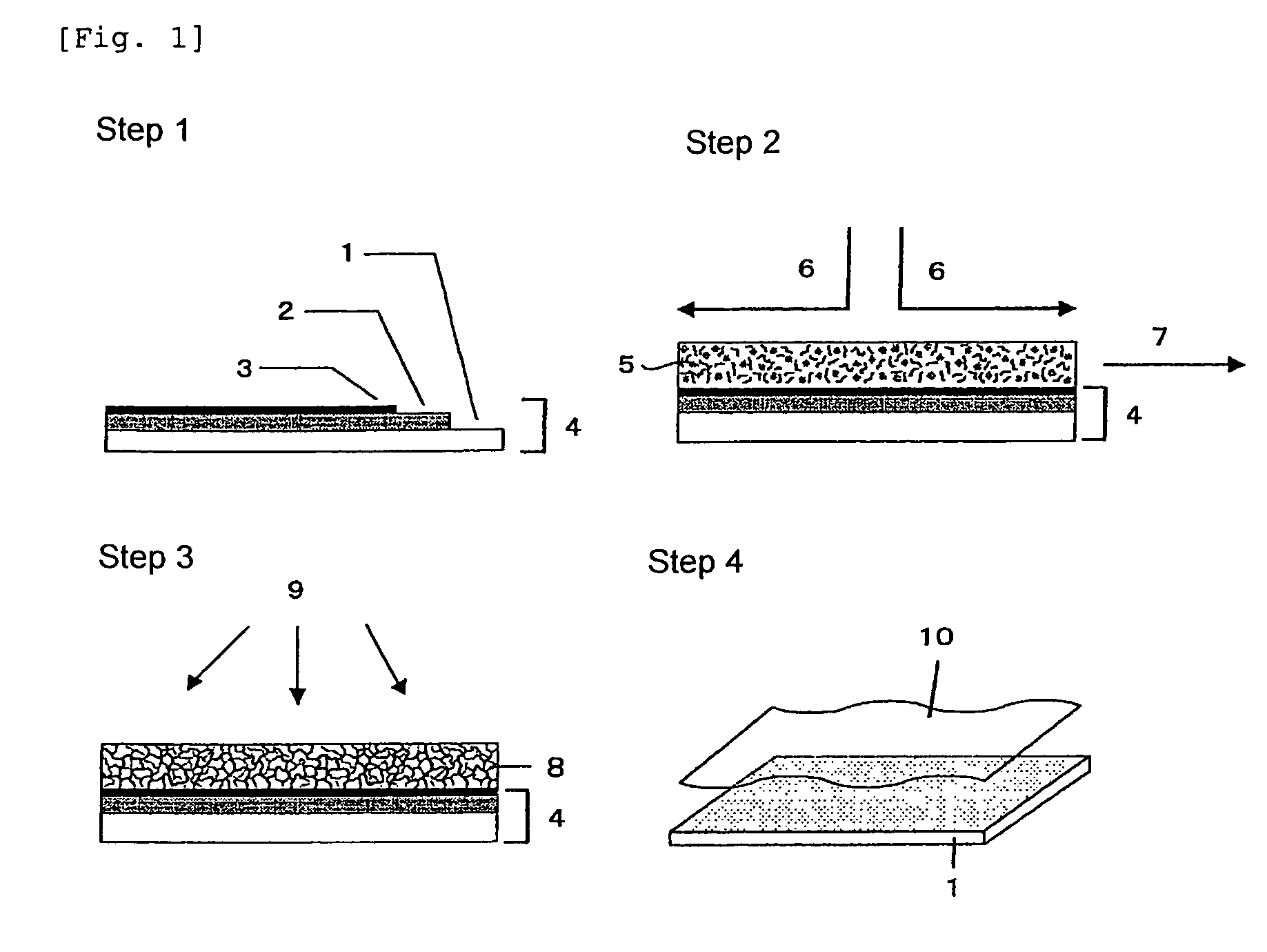

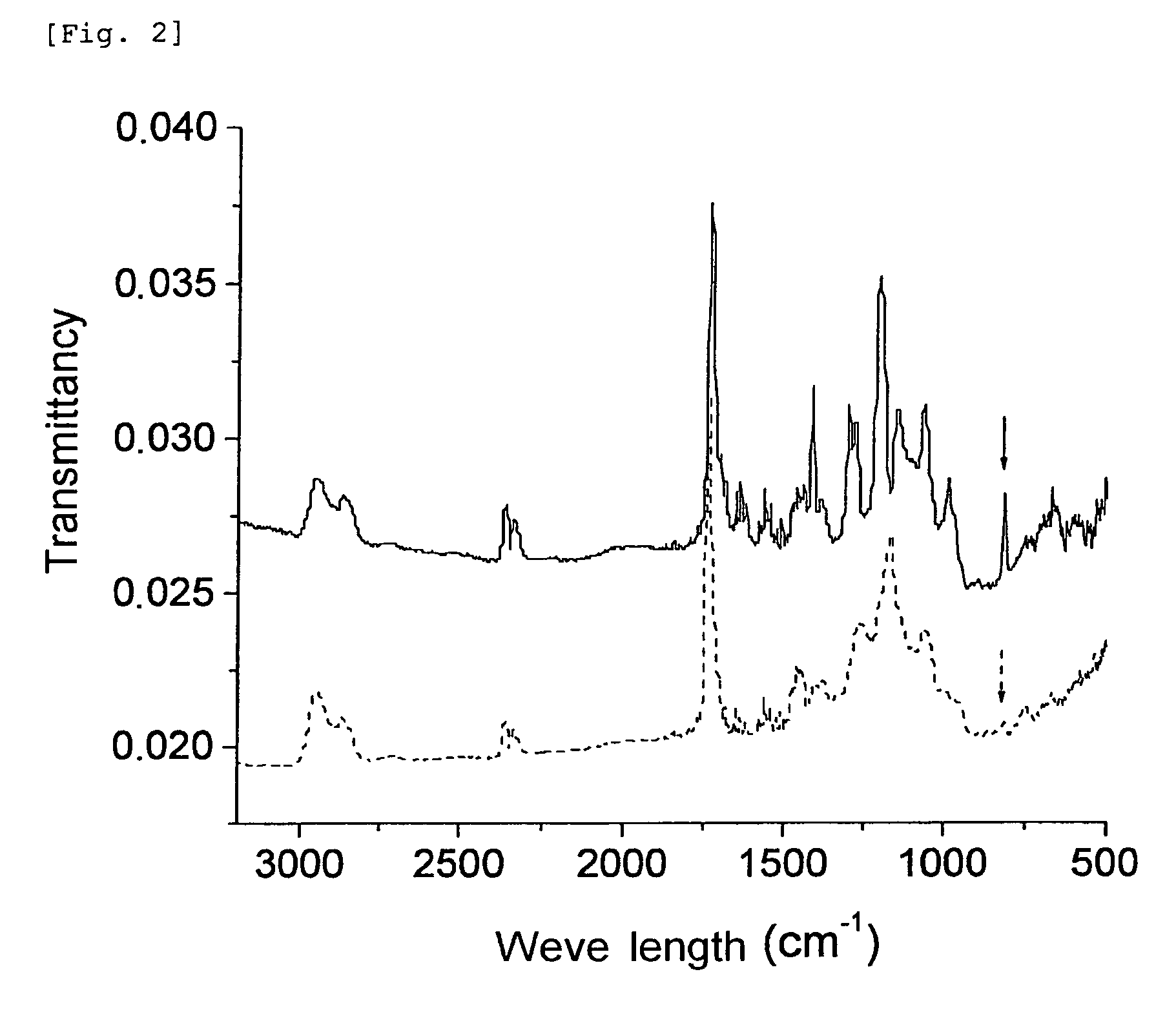

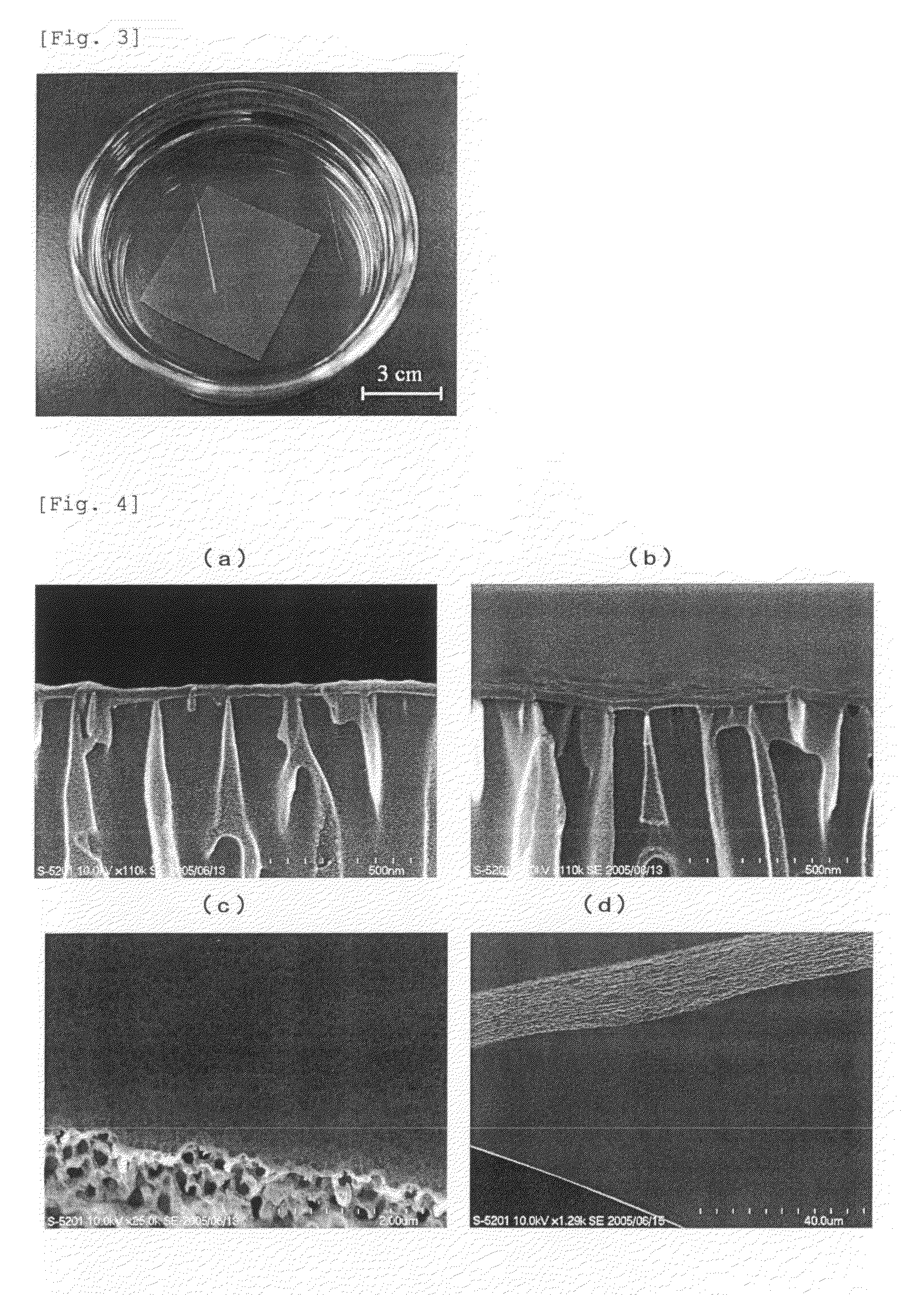

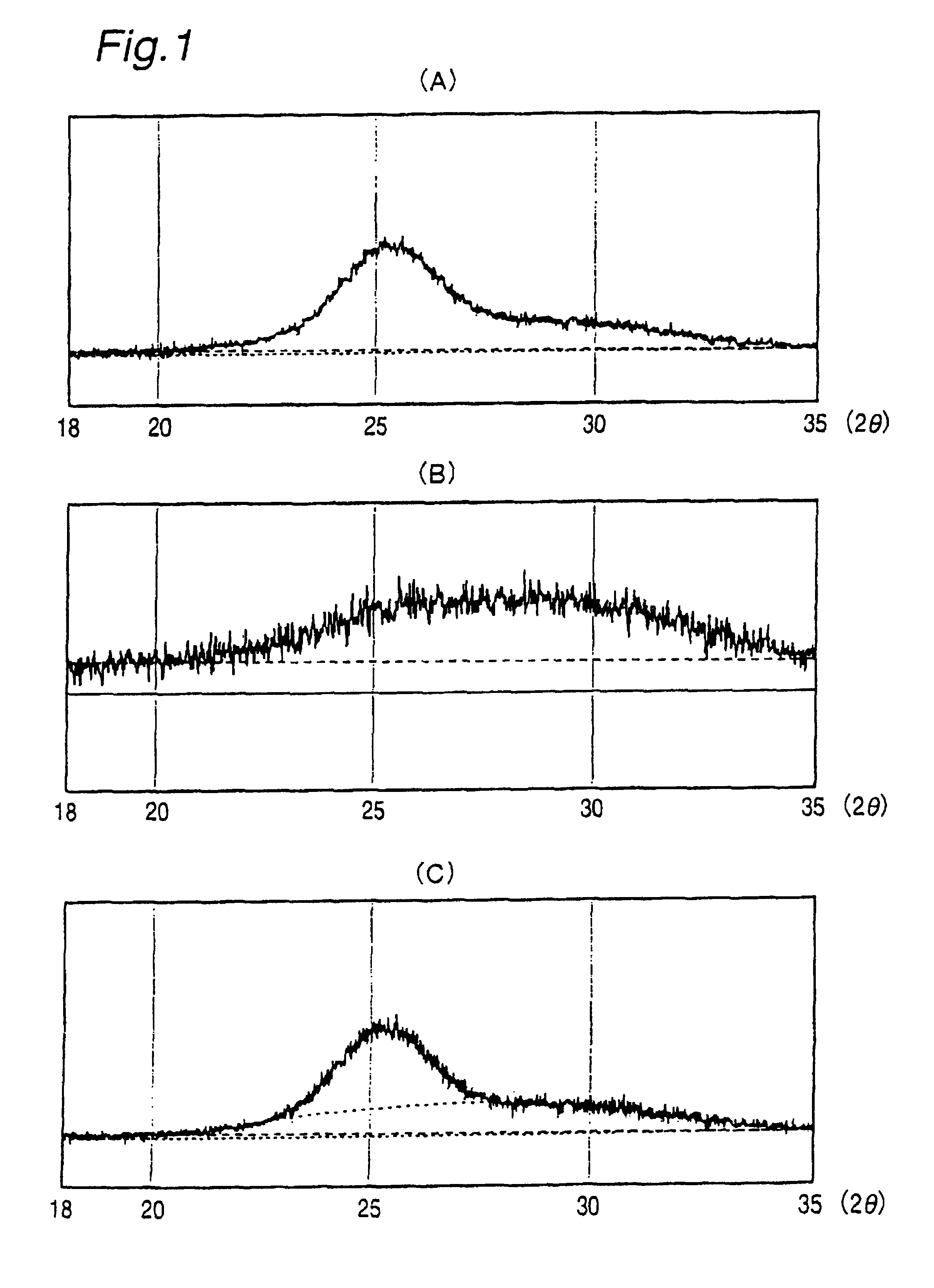

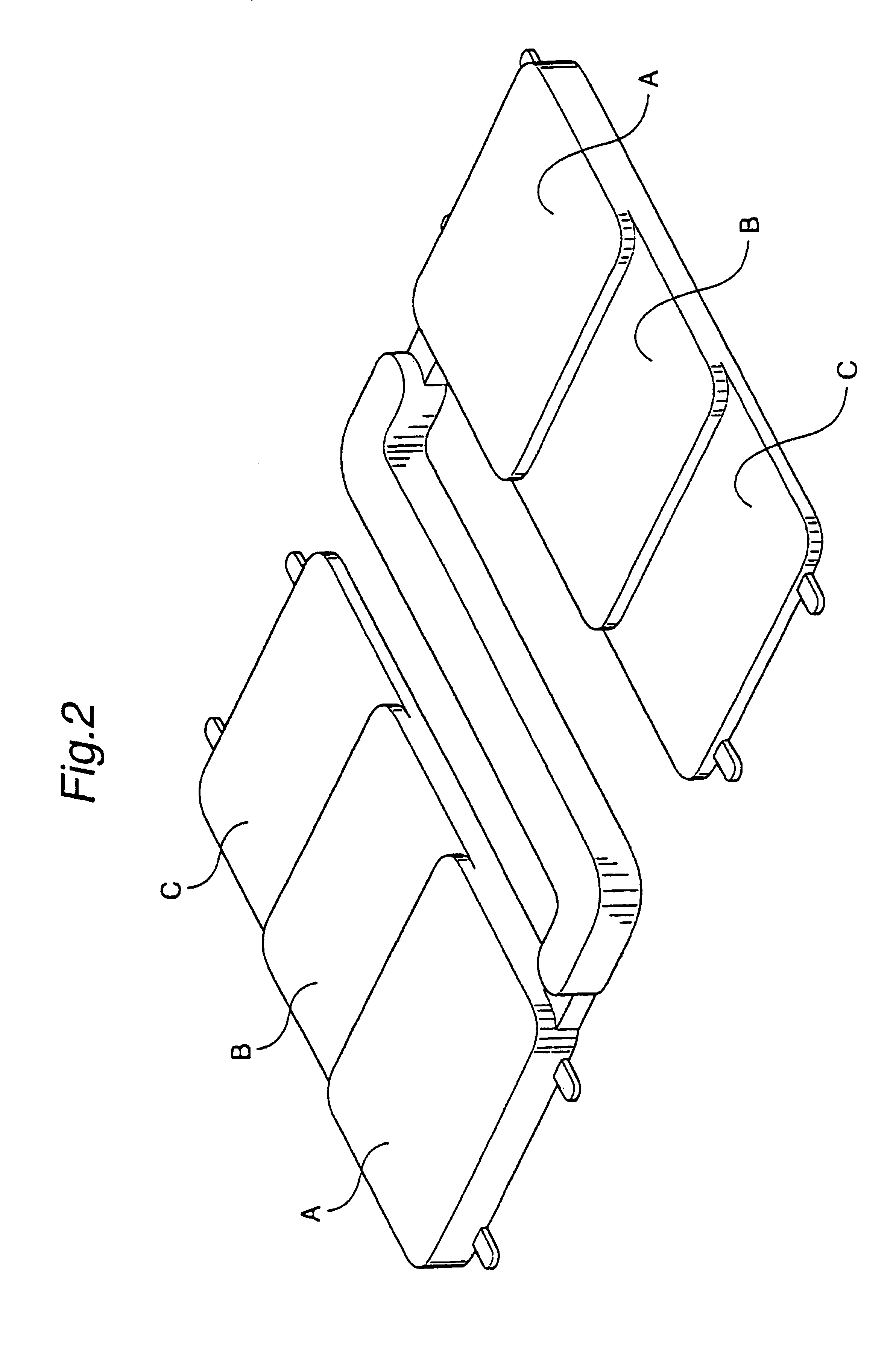

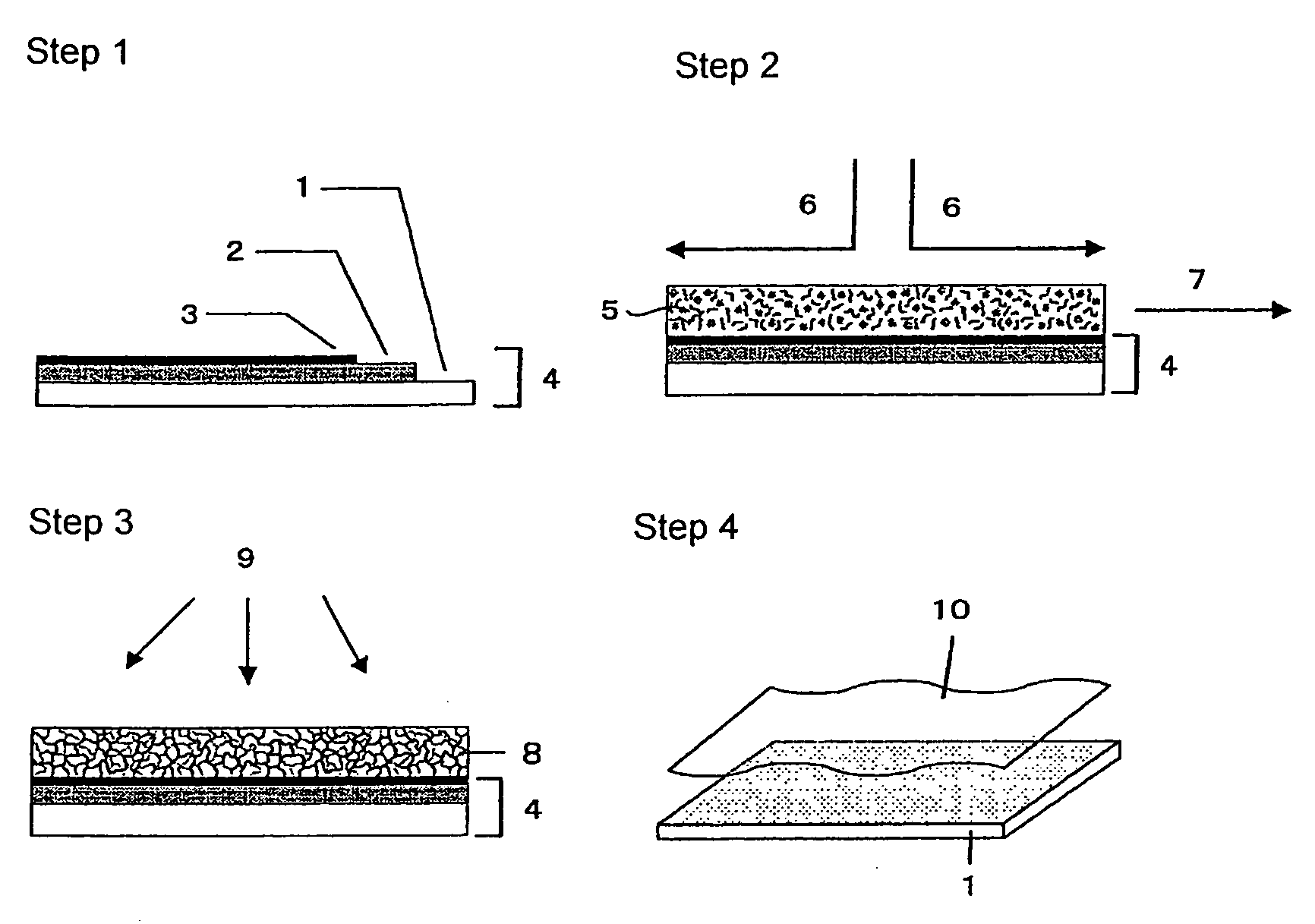

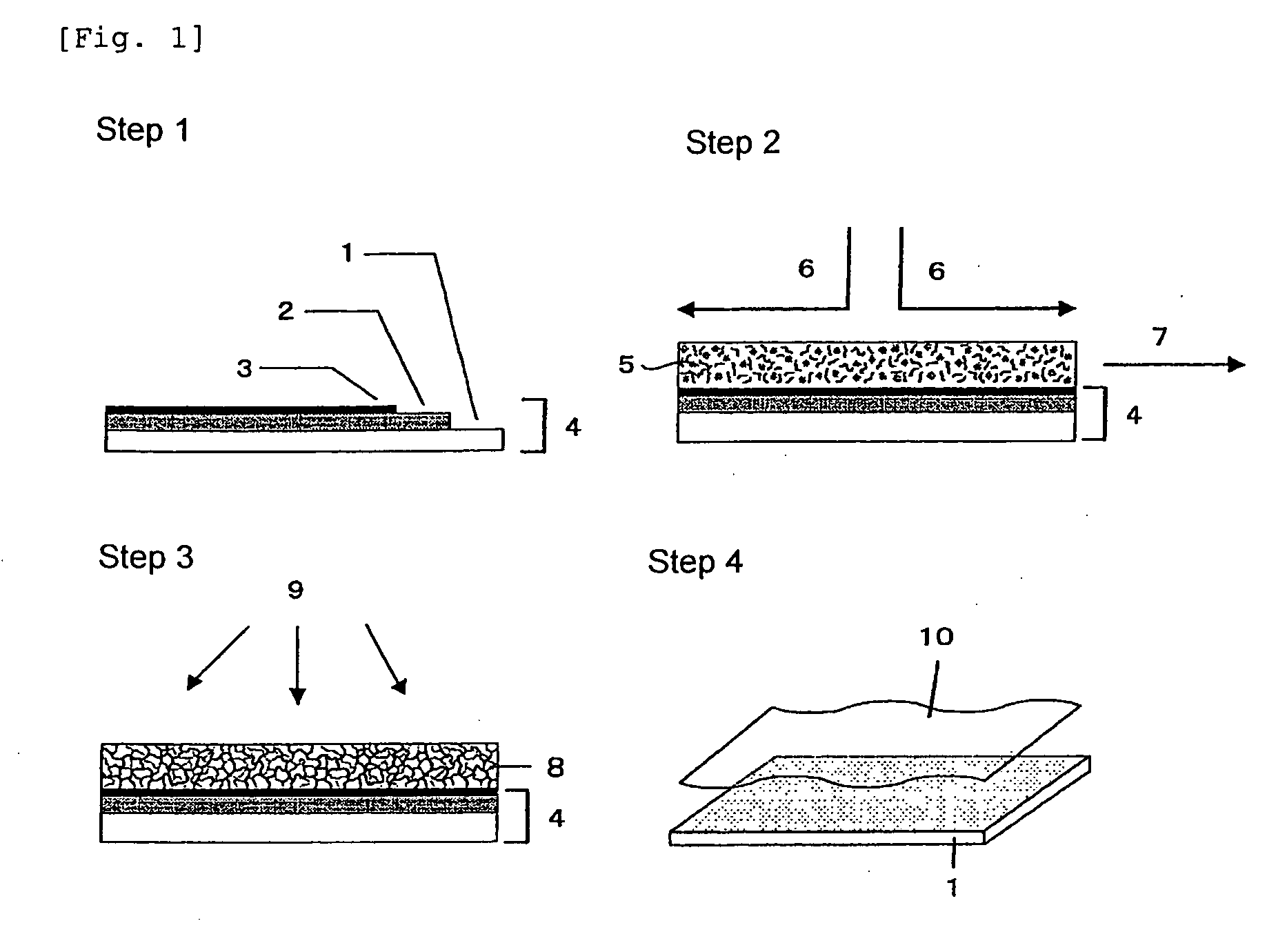

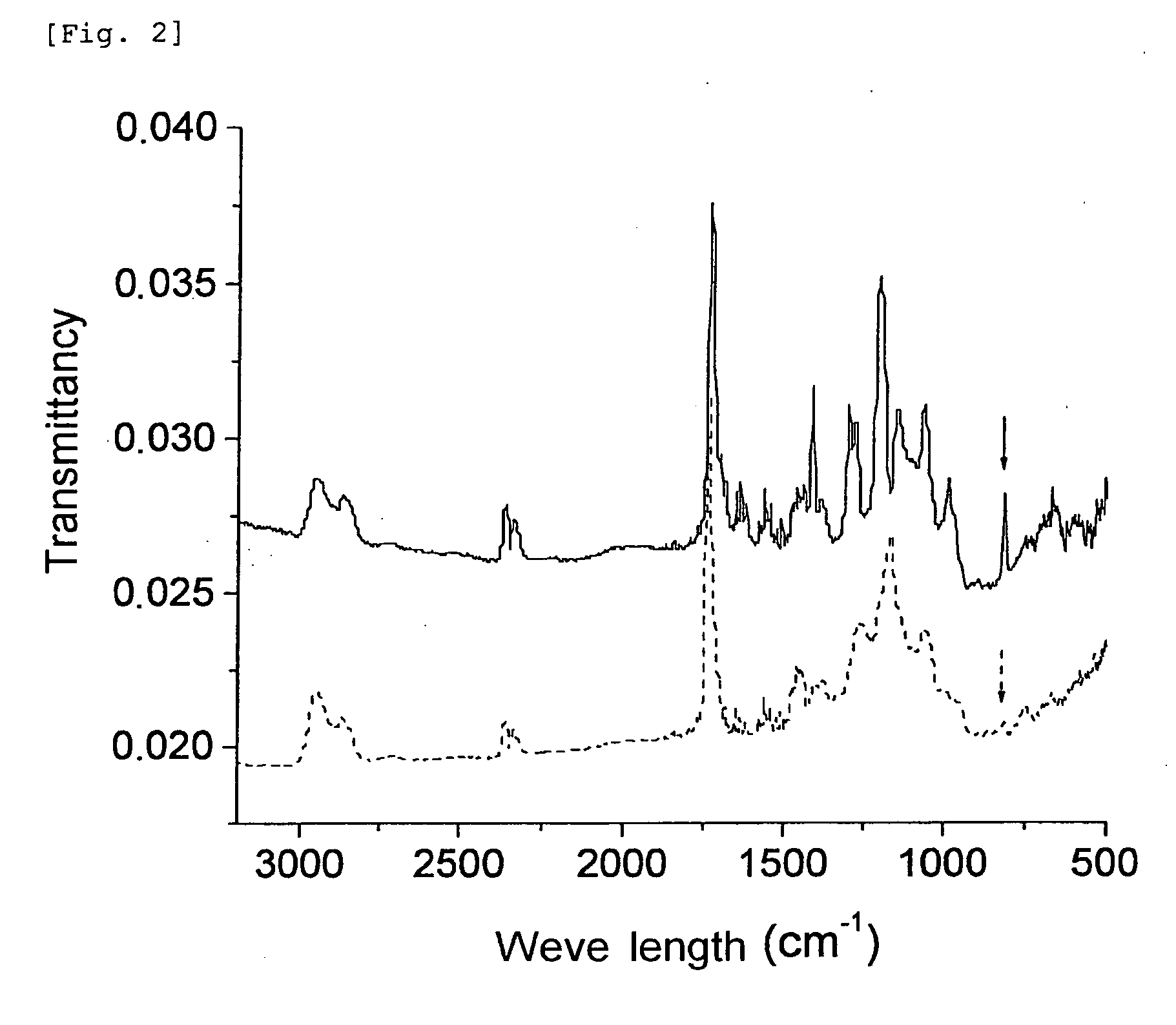

Thin film having interpenetrating network layer and method for manufacturing the thin film

InactiveUS7723430B2Increased durabilityHigh strengthLactams stabilisationSynthetic resin layered productsPliabilityOptoelectronics

Owner:RIKEN

Catalyst for polyester production, process for producing polyester using the catalyst, polyester obtained by the process, and uses of the polyester

InactiveUSRE40571E1High catalytic activityHigh transparencyLactams stabilisationOrganic-compounds/hydrides/coordination-complexes catalystsPolyesterDiol

The present invention provides a catalyst for polyester production capable of producing a polyester with high catalytic activity, a process for producing a polyester using the catalyst and a polyester produced thereby. The catalyst comprises a solid titanium compound obtained by dehydro-drying a hydrolyzate obtained by hydrolysis of a titanium halide and which has a molar ratio (OH / Ti) of a hydroxyl group (OH) to titanium (Ti) exceeding 0.09 and less than 4. In the process, the polyester is obtained by polycondensing an aromatic dicarboxylic acid, or an ester-forming derivative thereof, and an aliphatic diol, or ester-forming derivative thereof, in the presence of the catalyst. The resulting polyester has excellent transparency and tint, a titanium content of 1 to 100 ppm, a magnesium content of 1 to 200 ppm and a magnesium to titanium weight ratio of not less than 0.01.

Owner:MITSUI CHEM INC

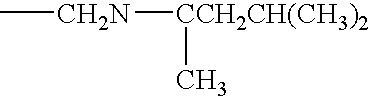

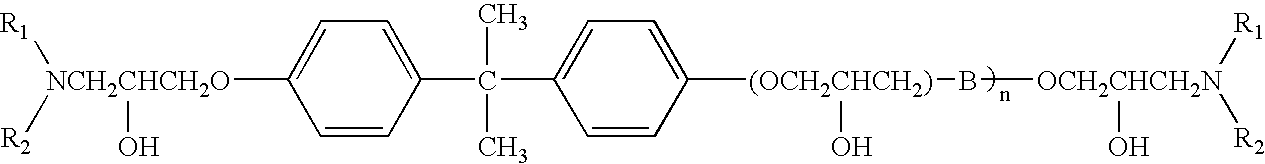

Resin dispersion for cationic electrodeposition and cationic electrodeposition coating composition including the same

InactiveUS20050107496A1Quantity minimizationImprove weather-resistanceLactams stabilisationPaints for electrolytic applicationsAqueous dispersionLayered structure

Disclosed are a resin dispersion and a cationic electrodeposition coating composition including the same, in which the dried coating film of the electrodeposition paint is lead-free and has an epoxy-acrylic double-layered structure for displaying excellent properties, and in which an organic solvent content can be minimized. A resin dispersion of a cationic electrodeposition includes an aqueous dispersion prepared by the following processes. The resin dispersion includes a cationic electrodeposition resin, deionized water, an acid for neutralization, a reaction product of manganese phosphate and an acid diluted in an deionized water to 10%, and a cationic surfactant. The cationic electrodeposition resin can be prepared in the presence of an organic solvent from (a) a cationic electrodeposition synthetic resin produced by an epoxy-amino addition reaction (b) an acrylic cationic electrodeposition resin having an amino group (c) a fatty acid ester resin synthesized by an esterification reaction of styrene-allylalcohol copolymer and fatty acid and (d) blocked polyisocyanatecuring agent. The cured film has an epoxy-acrylic double-layered structure to give a high functionality, for improving properties such as weather-resistance, yellowing resistance, etc.

Owner:NOROO PAINT & COATINGS

Method for making reinforced polymer matrix composites

Improved mechanical properties of either clay or carbon nanotube (CNT)-reinforced polymer matrix nanocomposites are obtained by pre-treating nanoparticles and polymer pellets prior to a melt compounding process. The clay or CNTs are coated onto the surfaces of the polymer pellets by a milling process. The introduction of moisture into the mixture of the nanoparticles and the polymer pellets results in the nanoparticles more easily, firmly, and thoroughly coating onto the surfaces of the polymer pellets.

Owner:APPLIED NANOTECH HLDG

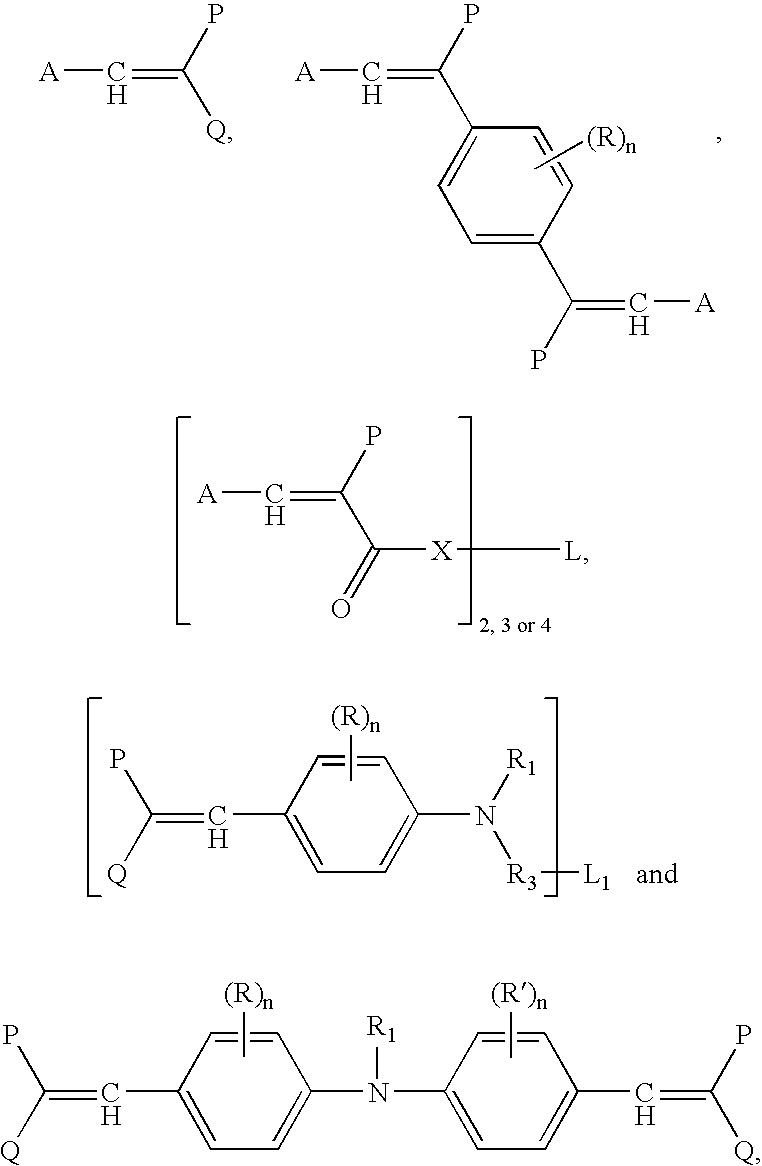

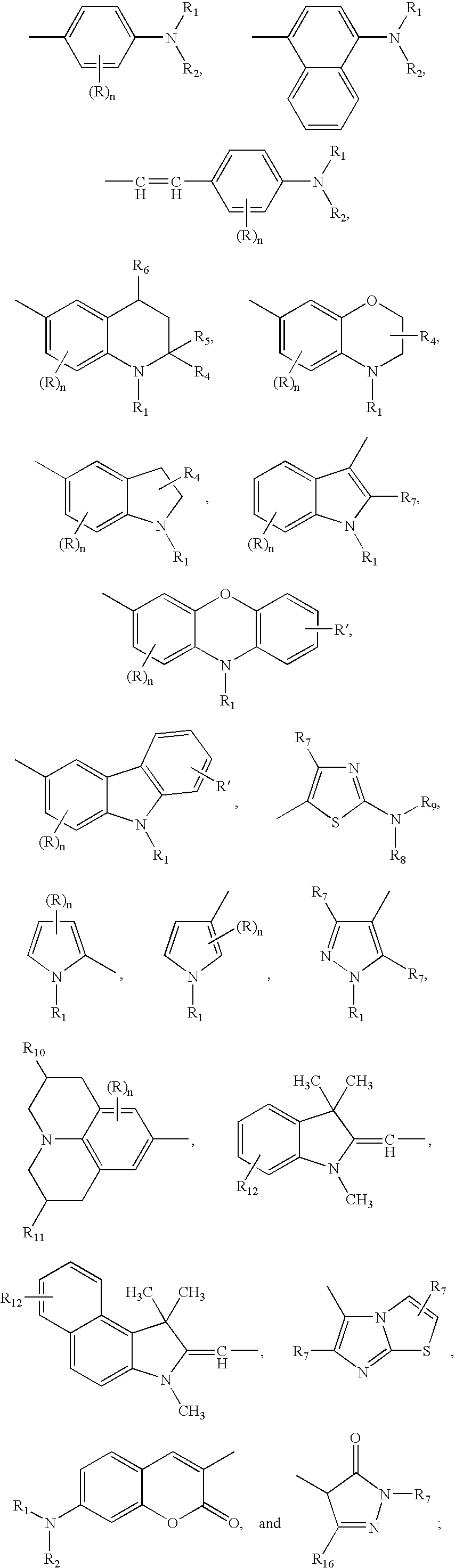

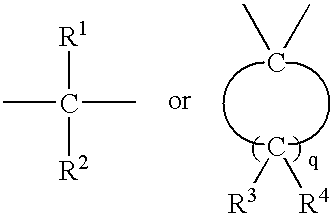

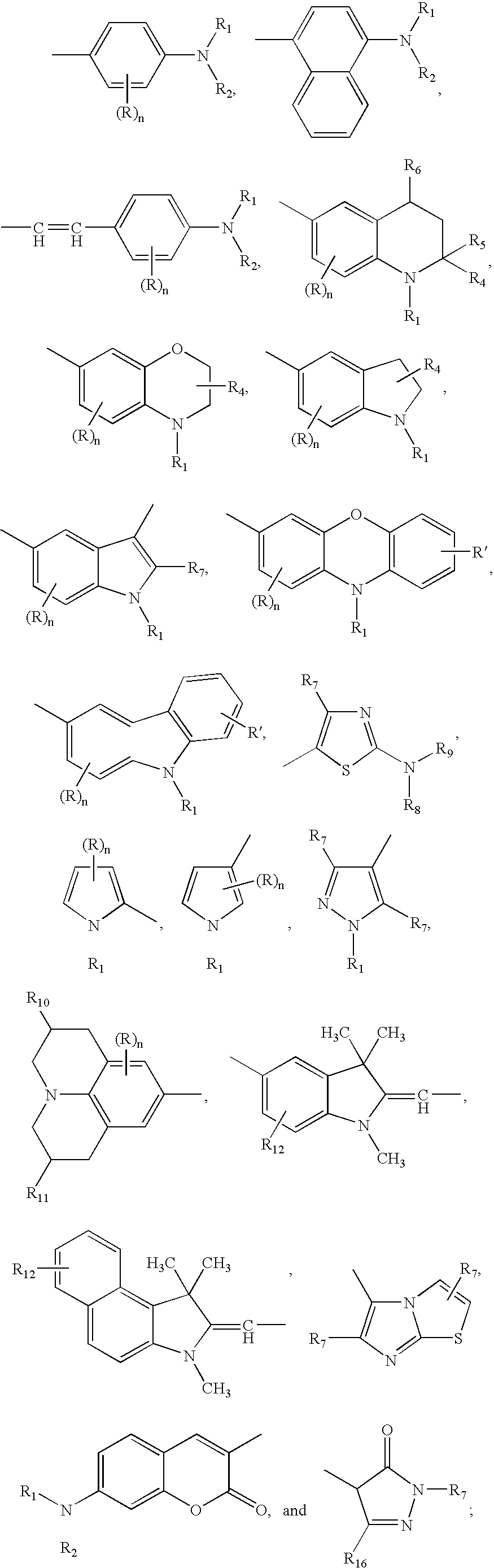

Method for incorporating nitrogen containing methine light absorbers in pet and compositions thereof

The present invention is a method for efficiently incorporating a nitrogen containing methine light absorber into a polyester resin. The method includes forming a reaction mixture comprising combining a diol component, a diacid component selected from the group consisting of dicarboxylic acids, dicarboxylic acid derivatives, and mixtures thereof, an antimony containing compound, a phosphorus containing compound, a metal containing compound, and a nitrogen containing methine light absorber. The reaction mixture is polymerized in a polycondensation reaction system. In another embodiment the light absorber is added while the reaction products of one reactor are being transferred to the next reactor in the polycondensation reaction system. The present invention is also directed articles made from the polyester resin.

Owner:ALPEK POLYESTER SA DE CV

Flame retardant polybutyleneterephthalate resin

InactiveUS20030139565A1Improve flame retardant performanceImprove propertiesLactams stabilisationMixingPolytetramethylene terephthalatePolymer science

Disclosed is a flame retardant polybutyleneterephthalate resin prepared by copolymerizing a phosphorus-based flame retardant represented by the following formula I and a butyleneterephthalate unit: wherein R1 and R2 are different or the same and are methyl or butyl including a hydroxyl group.

Owner:KOLON IND INC

Thin Film Having Interpenetrating Network Layer and Method for Manufacturing the Thin Film

InactiveUS20090098353A1Increased durabilityHigh strengthLactams stabilisationSynthetic resin layered productsPliabilityOptoelectronics

Provided is a thin film having self-supporting properties and having excellent strength, durability and flexibility and a method for manufacturing the thin film. A thin film having an interpenetrating net-work layer and having a film thickness of 500 nm or less, the interpenetrating net-work layer being constituted of at least a metal oxide and an organic polymer.

Owner:RIKEN

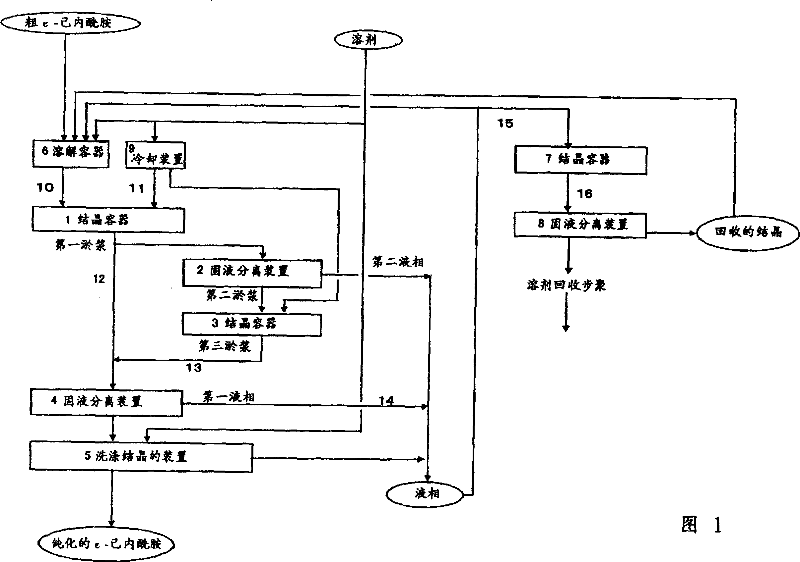

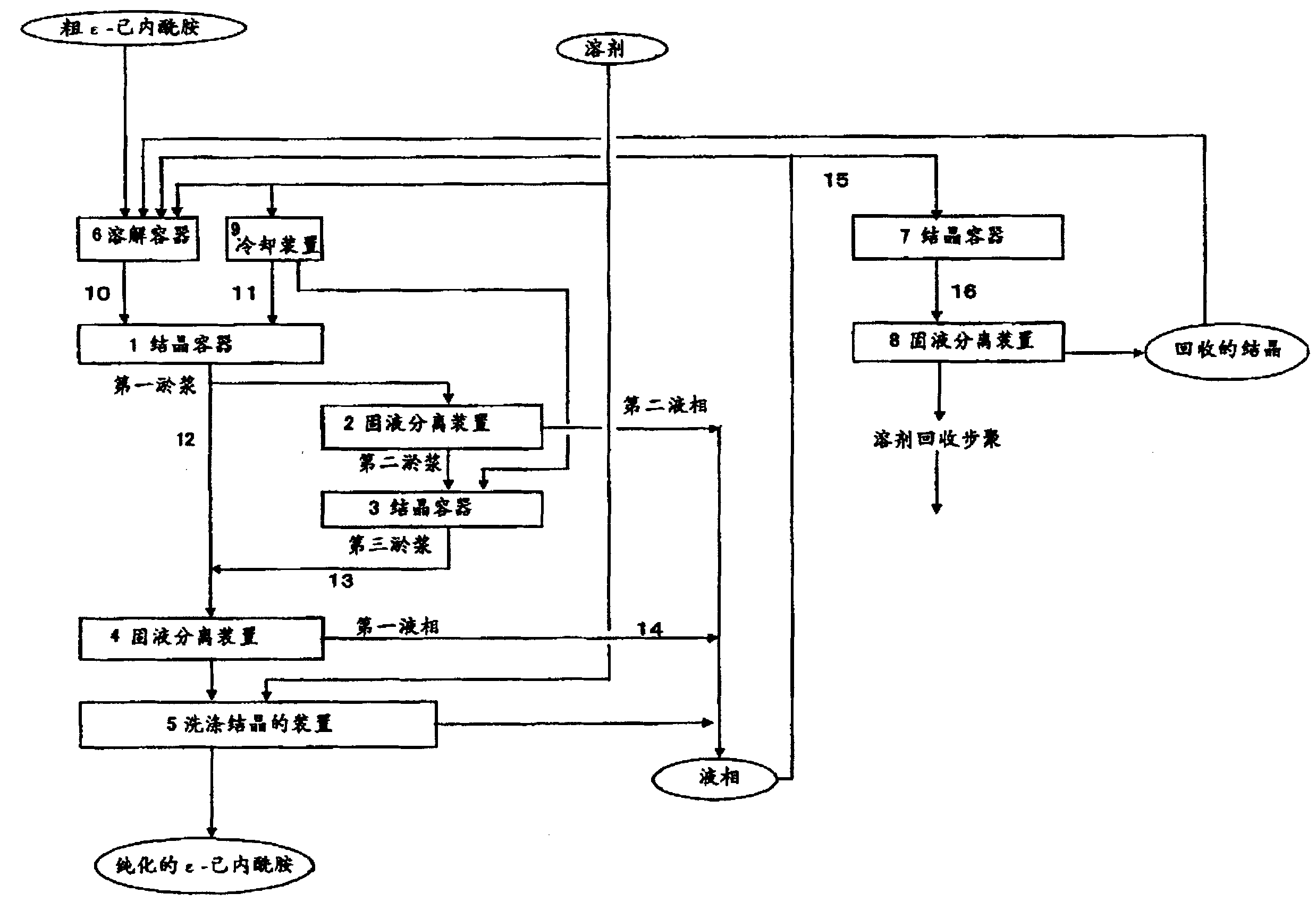

Prep. of epsilon-hexanolactam

InactiveCN100354266CLactams stabilisationOrganic chemistry methodsBeckmann rearrangementAliphatic hydrocarbon

A high purity epsi-caprolactam is prepared by pouring a molten crude epsi-caprolactam and a solvent comprising an aliphatic hydrocarbon and having a lower temperature than that of the crude epsi-caprolactam, into a vessel and mixing them to obtain a first slurry containing a crystallized epsi-caprolactam. The slurry is then subjected to a solid-liquid separation to obtain epsi-caprolactam and a first liquid phase. This process can effectively remove impurities from a crude epsi-caprolactam, which is obtained by for example, subjecting cyclohexanone oxime to the Beckmann rearrangement.

Owner:SUMITOMO CHEM CO LTD

Wholly aromatic polyester and process for producing the same

InactiveUS20030027972A1Good colorMaintain good propertiesLactams stabilisationCarboxylic acidIndustrial scale

A process for producing a wholly aromatic polyester which is excellent in heat resistance, mechanical properties and yet color and has a high degree of polymerization by melt polymerizing a dicarboxylic acid and a diol directly on an industrial scale at a low cost in a short period of time without esterifying the dicarboxylic acid or diol in advance. To produce the wholly aromatic polyester by reacting and molding an aromatic dicarboxylic acid such as terephthalic acid, an aromatic diol such as 2,2-bis(4-hydroxyphenyl)propane and a diaryl carbonate by heating, a combination of a specific pyridine compound and an alkali metal (bi)carbonate, a combination of a specific pyridine compound and an organic tin compound or a specific titanium compound is existent as a catalyst. Thereby, the wholly aromatic polyester having the above properties is obtained.

Owner:TEIJIN LTD

Method for incorporating nitrogen containing methine light absorbers in pet and compositions thereof

ActiveUS20050267284A1Promote condensation polymerizationMethine/polymethine dyesLactams stabilisationNitrogenCarboxylic acid

The present invention is a method for efficiently incorporating a nitrogen containing methine light absorber into a polyester resin. The method includes forming a reaction mixture comprising combining a diol component, a diacid component selected from the group consisting of dicarboxylic acids, dicarboxylic acid derivatives, and mixtures thereof, an antimony containing compound, a phosphorus containing compound, a metal containing compound, and a nitrogen containing methine light absorber. The reaction mixture is polymerized in a polycondensation reaction system. In another embodiment the light absorber is added while the reaction products of one reactor are being transferred to the next reactor in the polycondensation reaction system. The present invention is also directed articles made from the polyester resin.

Owner:ALPEK POLYESTER SA DE CV

Wholly aromatic polyester and production process therefor

InactiveUS6596839B2Good colorMaintain good propertiesLactams stabilisationCarboxylic acidOrganic compound

A process for producing a wholly aromatic polyester which is excellent in heat resistance, mechanical properties and yet color and has a high degree of polymerization by melt polymerizing a dicarboxylic acid and a diol directly on an industrial scale at a low cost in a short period of time without esterifying the dicarboxylic acid or diol in advance. To produce the wholly aromatic polyester by reacting and molding an aromatic dicarboxylic acid such as terephthalic acid, an aromatic diol such as 2,2-bis(4-hydroxyphenyl)propane and a diaryl carbonate by heating, a combination of a specific pyridine compound and an alkali metal (bi)carbonate, a combination of a specific pyridine compound and an organic tin compound or a specific titanium compound is existent as a catalyst. Thereby, the wholly aromatic polyester having the above properties is obtained.

Owner:TEIJIN LTD

Resin dispersion for cationic electrodeposition and cationic electrodeposition coating composition including the same

InactiveUS7179853B2Quantity minimizationImprove the immunityLactams stabilisationPaints for electrolytic applicationsLayered structureAqueous dispersion

Disclosed are a resin dispersion and a cationic electrodeposition coating composition including the same, in which the dried coating film of the electrodeposition paint is lead-free and has an epoxy-acrylic double-layered structure for displaying excellent properties, and in which an organic solvent content can be minimized. A resin dispersion of a cationic electrodeposition includes an aqueous dispersion prepared by the following processes. The resin dispersion includes a cationic electrodeposition resin, deionized water, an acid for neutralization, a reaction product of manganese phosphate and an acid diluted in an deionized water to 10%, and a cationic surfactant. The cationic electrodeposition resin can be prepared in the presence of an organic solvent from (a) a cationic electrodeposition synthetic resin produced by an epoxy-amino addition reaction (b) an acrylic cationic electrodeposition resin having an amino group (c) a fatty acid ester resin synthesized by an esterification reaction of styrene-allylalcohol copolymer and fatty acid and (d) blocked polyisocyanatecuring agent. The cured film has an epoxy-acrylic double-layered structure to give a high functionality, for improving properties such as weather-resistance, yellowing resistance, etc.

Owner:NOROO PAINT & COATINGS

Process for producing polymerizable polybranched polyester

The present invention allows the production of a polymerizable hyperbranched polyester by introducing polymerizable unsaturated double bonds into the molecular terminals of a hyperbranched polyester polyol (A), which is obtained by condensation polymerization a polyhydroxy monocarboxylic acid in which there are at least two hydroxyl groups, the carbon atom adjacent to the carboxy group is saturated carbon atom, and the hydrogen atoms on said carbon atom are all substituted, by reacting the hyperbranched polyester polyol (A) and an alkyl ester of a carboxylic acid having a polymerizable unsaturated double bond (B) by a transesterification in the presence of at least one type of transesterification catalyst (C) selected from the group consisting of a dialkyl tin oxide and a stanoxane, without causing side reactions such as nucleophilic addition reactions of terminal hydroxyl groups to polymerizable unsaturated double bonds of the hyperbranched polyester polyol (A), or thermal polymerization of the polymerizable unsaturated double bonds. The polymerizable hyperbranched polyester can be produced at high efficiency using a transesterification that uses as an alkyl ester of a carboxylic acid having a polymerizable unsaturated double bond (B), which is easily obtained as an industrial raw material, and without altering the original backbone structure of the molecular chains of the hyperbranched polyester polyol (A) by hydrolysis and so forth.

Owner:DAINIPPON INK & CHEM INC

Method for incorporating nitrogen containing methine light absorbers in pet and compositions thereof

The present invention is a method for efficiently incorporating a nitrogen containing methine light absorber into a polyester resin. The method includes forming a reaction mixture comprising combining a diol component, a diacid component selected from the group consisting of dicarboxylic acids, dicarboxylic acid derivatives, and mixtures thereof, an antimony containing compound, a phosphorus containing compound, a metal containing compound, and a nitrogen containing methine light absorber. The reaction mixture is polymerized in a polycondensation reaction system. In another embodiment the light absorber is added while the reaction products of one reactor are being transferred to the next reactor in the polycondensation reaction system. The present invention is also directed articles made from the polyester resin.

Owner:ALPEK POLYESTER SA DE CV

Composition and process for manufacturing polyester

InactiveUS7335410B2Lactams stabilisationOrganic-compounds/hydrides/coordination-complexes catalystsPolyesterCOMPONENT II

The invention relates to a composition suitable for catalysis in a process for the manufacture of polyester containing as Component I a carrier substance on which catalytically effective metal compounds are adsorbed and as Component II a phosphonic acid compound.

Owner:LURGI ZIMMER GMBH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com