Patents

Literature

594 results about "Oligoester" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

An oligoester is an ester oligomer chain containing a small number of repeating ester units (monomers). Oligoesters are short analogs of polymeric polyesters. An example is oligo-(R)-3-hydroxybutyrate.

Compositions with Improved Adhesion to Low Surface Energy Substrates

InactiveUS20080113094A1Excellent low surface energyImprove adhesionSynthetic resin layered productsOrganic dyesOligomerEnd-group

Acrylic-based pressure sensitive adhesives are modified with a telechelic hydrocarbon oligomer. The oligomer comprises a hydrocarbon polymer chain or backbone and a functional end group, e.g., an oligomer prepared from a mono hydroxyl polybutadiene polymer and toluene diisocyanate. The oligomer attaches to the acrylic backbone of the polymer as a pendant group and in a preferred embodiment, the oligomer is mixed with the PSA shortly before the PSA is coated.

Owner:BRADY WORLDWIDE INC

Oxygen scavenging condensation copolymers for bottles and packaging articles

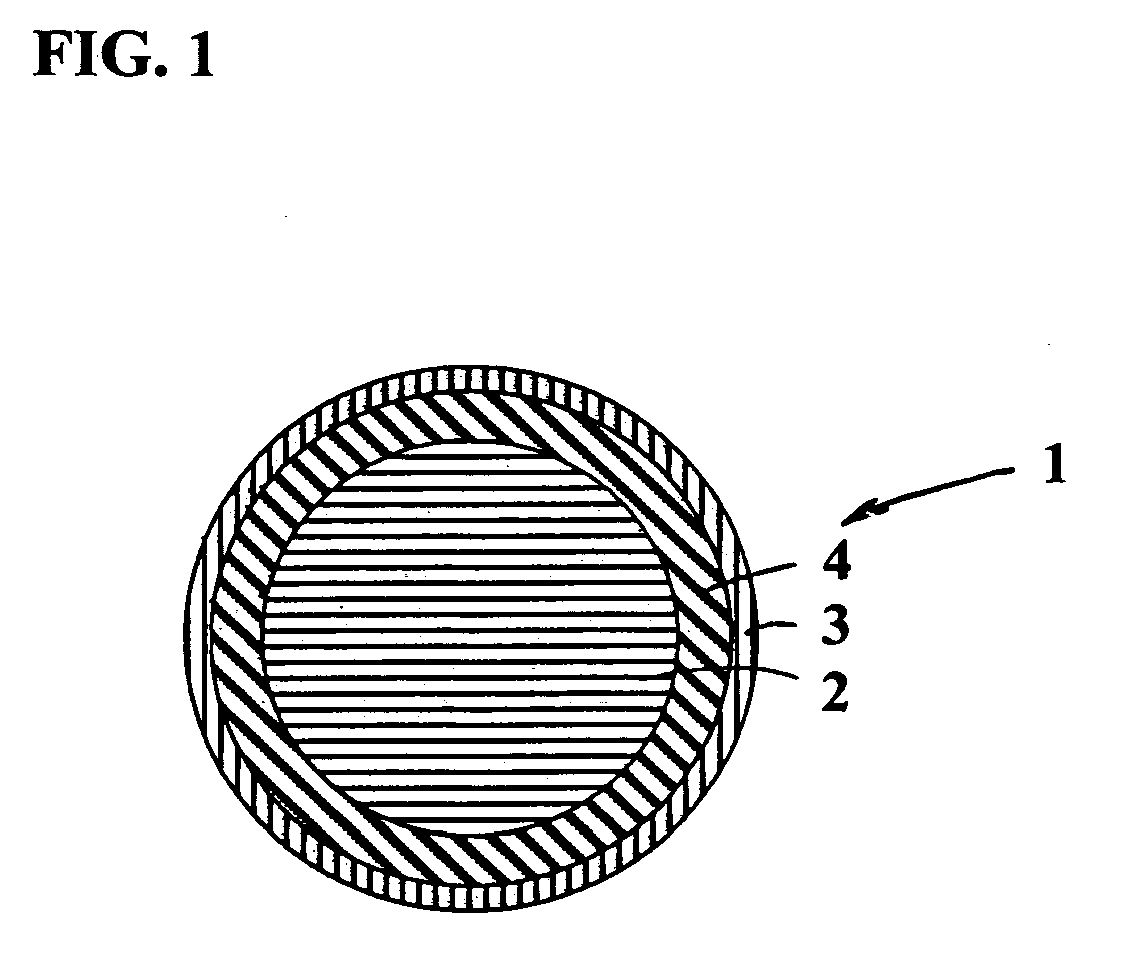

Compositions for scavenging oxygen are disclosed. These compositions comprise condensation copolymers comprising predominantly polyester segments and an oxygen scavenging amount of polyolefin oligomer segments. The polyester segments comprise segments derived from typical bottling and packaging polyesters such as PET and PEN. The copolymers are preferably formed by transesterification during reactive extrusion and typically comprise about 0.5 to about 12 wt % of polyolefin oligomer segments. The copolycondensates are capable of absorbing at least 0.4 cc of oxygen per gram of copolymer in the solid state at ambient temperatures and are typically used as layers in films, liners, cups, wraps, bottles, etc. Use of these oxygen scavenging compositions in bottles provides a clear and rigid bottle similar in appearance to unmodified polyester bottles. In a series of preferred embodiments, bottles fabricated with the oxygen scavenging copolycondensates of this invention are over 99.4 wt % polyester and suitable for recycle with other polyester bottles.

Owner:COLORMATRIX HLDG

Composition for use in golf balls and sports equipment

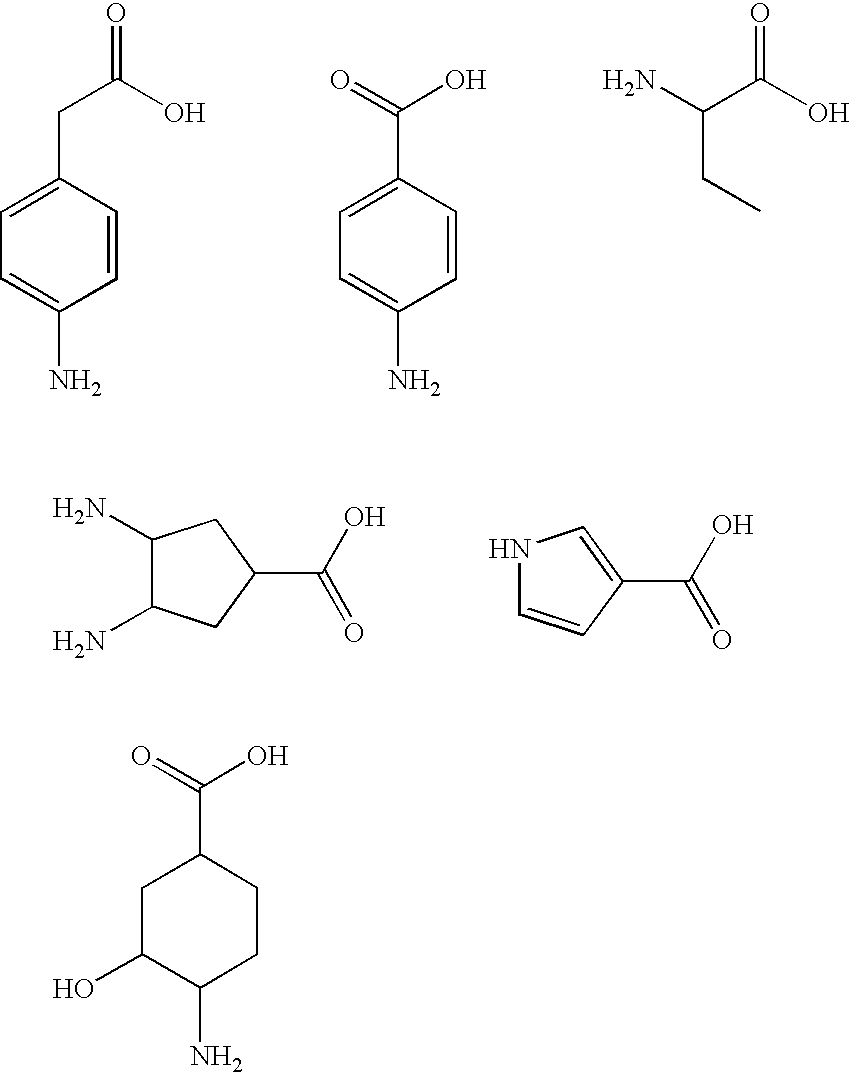

The present invention relates to a novel blend composition suitable for use in sports equipment in general and in particular for use in golf ball manufacture. The composition is the reaction product of; A) a polymer of ethylene and / or one or more alpha olefins, and an acid, ester, or anhydride (“Component (A)”); and B) a compound comprising both an amine and a carboxylic acid in the same molecule which may be present in either a neutral or ionic or zwitterionic form (“Component (B)”); and C) a basic metal ion salt, capable of neutralizing the acid groups of Component (A) and / or Component (B). The metal ions including Li+, Na+, K+, Zn+, Co2+, Ca2+, Ni2+, Cu2+, Pb2+, and Mg2+, with Li+, Na+, Zn2+, Ca2+, and Mg2+ being preferred, and their salts include those of, for example, formic acid, acetic acid, nitric acid, sulfuric acid, carbonic acid, bicarbonic acid, as well as the metal oxides, hydroxides, and alkoxides (“Component (C)”). The present invention is also embodied in a blend composition including the reaction product of one or more ionomers and Component (B) which is a compound having a general formula (R2N)m—R′—(X(O)nORy)m, where R is either hydrogen, one or more C1-C20 aliphatic systems, one or more cycloaliphatic systems, one or more aromatic systems, or a combination of these. Also R′ is a bridging group comprising one or more unsubstituted C1-C20 straight chain or branched aliphatic or alicyclic groups, or one or more substituted straight chain or branched aliphatic or alicyclic groups, or one or more aromatic groups, one or more oligomers each containing up to 12 repeating units, and when X is C or S or P, m is 1-3. Also when X=C, n=1 and y=1, and when X=S, n=2 and y=1, and when X=P, n=2 and y=2. The present invention also resides in a golf ball including a core, an outer cover layer; and from 0 to 5 intermediate layers, wherein one or more of said core, outer cover, and / or intermediate layers, if present, includes the aforementioned blend compositions. Finally, the present invention is also embodied in sports equipment items comprising the aforementioned blend compositions.

Owner:TAYLOR MADE GOLF

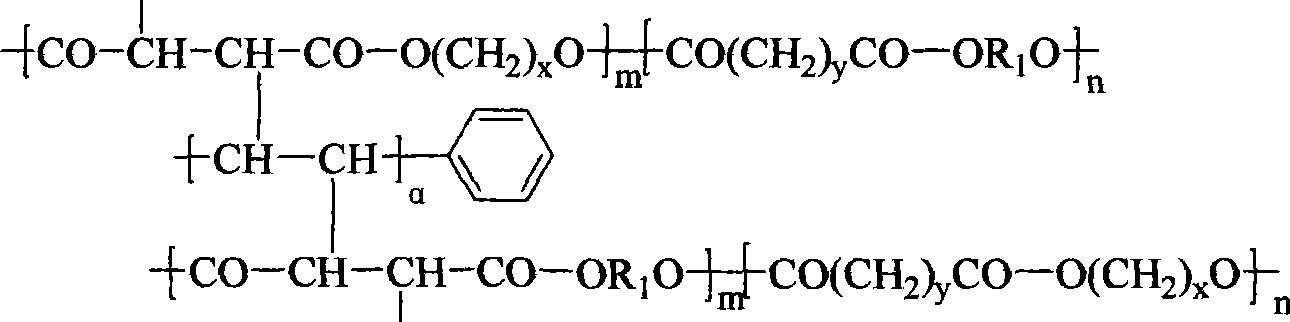

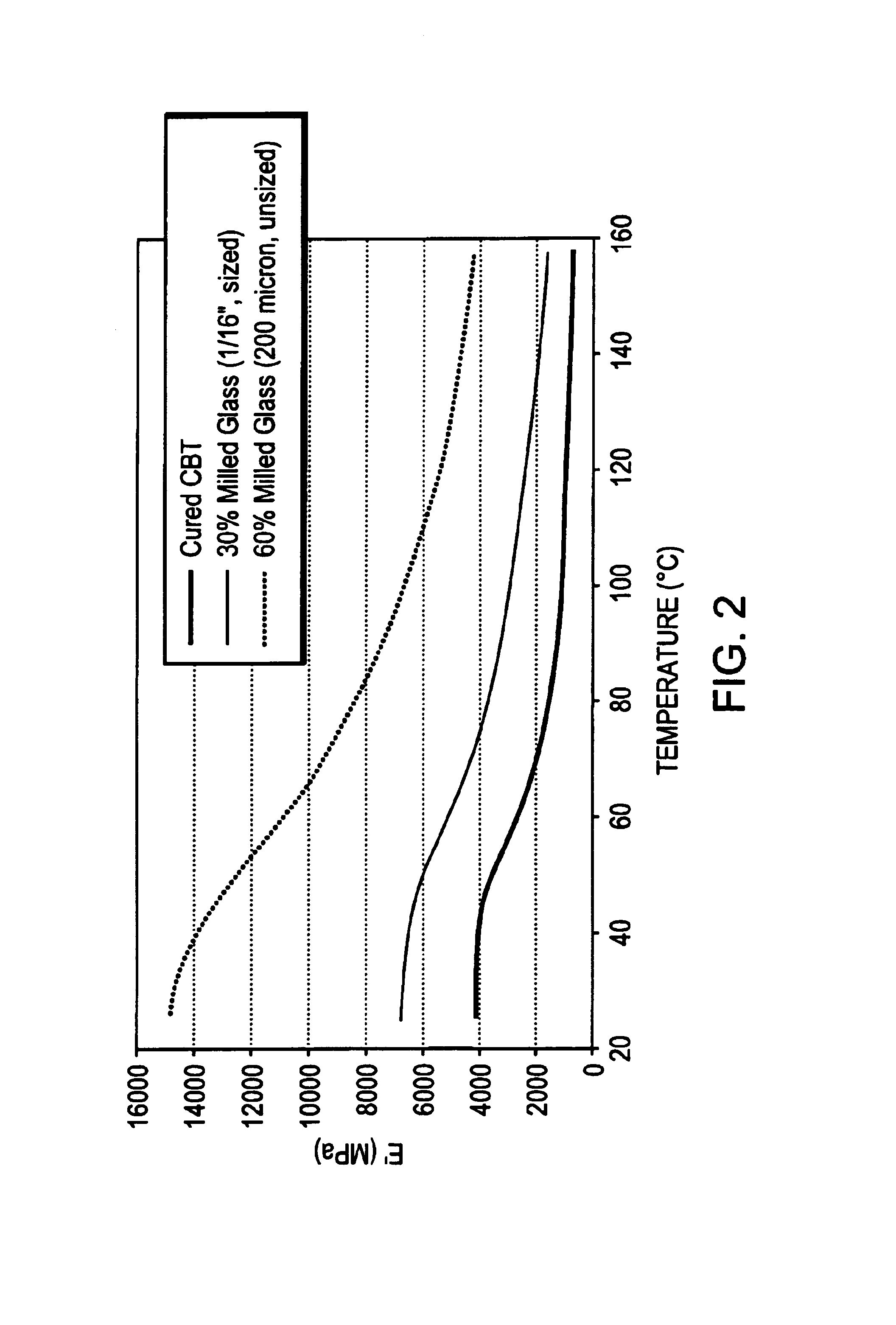

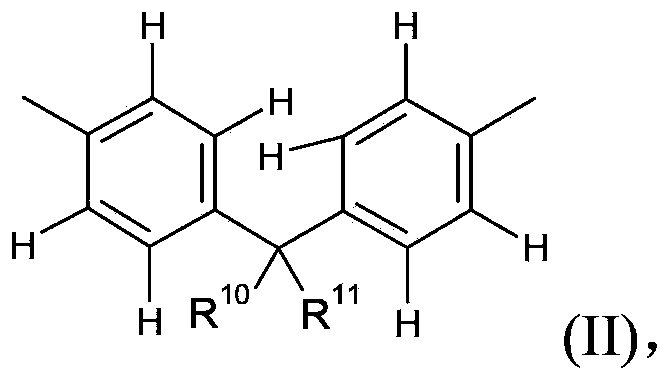

High molecular weight copolyesters from macrocyclic oligoesters and cyclic esters

InactiveUS6420048B1Synthetic resin layered productsThin material handlingTransesterificationCopolyester

High molecular weight copolyesters have been prepared from macrocyclic oligoesters and cyclic esters in the presence of a transesterification catalyst. The invention generally features a method of making a copolyester, a method of making a block copolymer of copolyester, and a copolyester prepared from macrocyclic oligoesters and cyclic esters.

Owner:CYCLICS CORP

Methods for converting linear polyesters to macrocyclic oligoester compositions and macrocyclic oligoesters

InactiveUS6525164B2Low viscosityCost-effectivePreparation by ester-hydroxy reactionOrganic compound preparationPolyesterDicarboxylic acid

Owner:LIQUID THERMO PLASTICS

Organic silicon modified aqueous polyurethane

InactiveCN1854165AImprove water resistanceFeel goodFibre treatmentPolyureas/polyurethane adhesivesWater basedCross-link

An organic silicon modified water-based polyurethane and its production are disclosed.The polyurethane consists of low-polymer polybasic alcohol, vulcabond and chain extender. The production is carried out by dispersing pre-polymer in water, adding ammonia silane coupling agent into system, synthesizing pre-polymer, reacting amine base with residual vulcabond base, chain extending for pre-polymer while hydrolytic condensation polymerizing, cross-linked reacting and obtaining final product. It has better water resistance and handle, less surface performance and wider temperature range. It can be used for pigment, leather finishing agent and adhesive.

Owner:广州宏昌胶粘带厂

Block copolymers from macrocyclic oligoesters and dihydroxyl-functionalized polymers

InactiveUS6436549B1Lactams stabilisationSynthetic resin layered productsPolyesterPolymerization catalysts

Block copolymers are prepared from polymerization of a macrocyclic oligoester and a dihydroxyl-functionalized polymer at an elevated temperature in the presence of a polymerization catalyst.

Owner:LIQUID THERMO PLASTICS

Macrocyclic polyester oligomers as carriers and/or flow modifier additives for thermoplastics

InactiveUS20070216067A1High trafficReduce molding pressureMaterial nanotechnologyThermoplasticPolyester

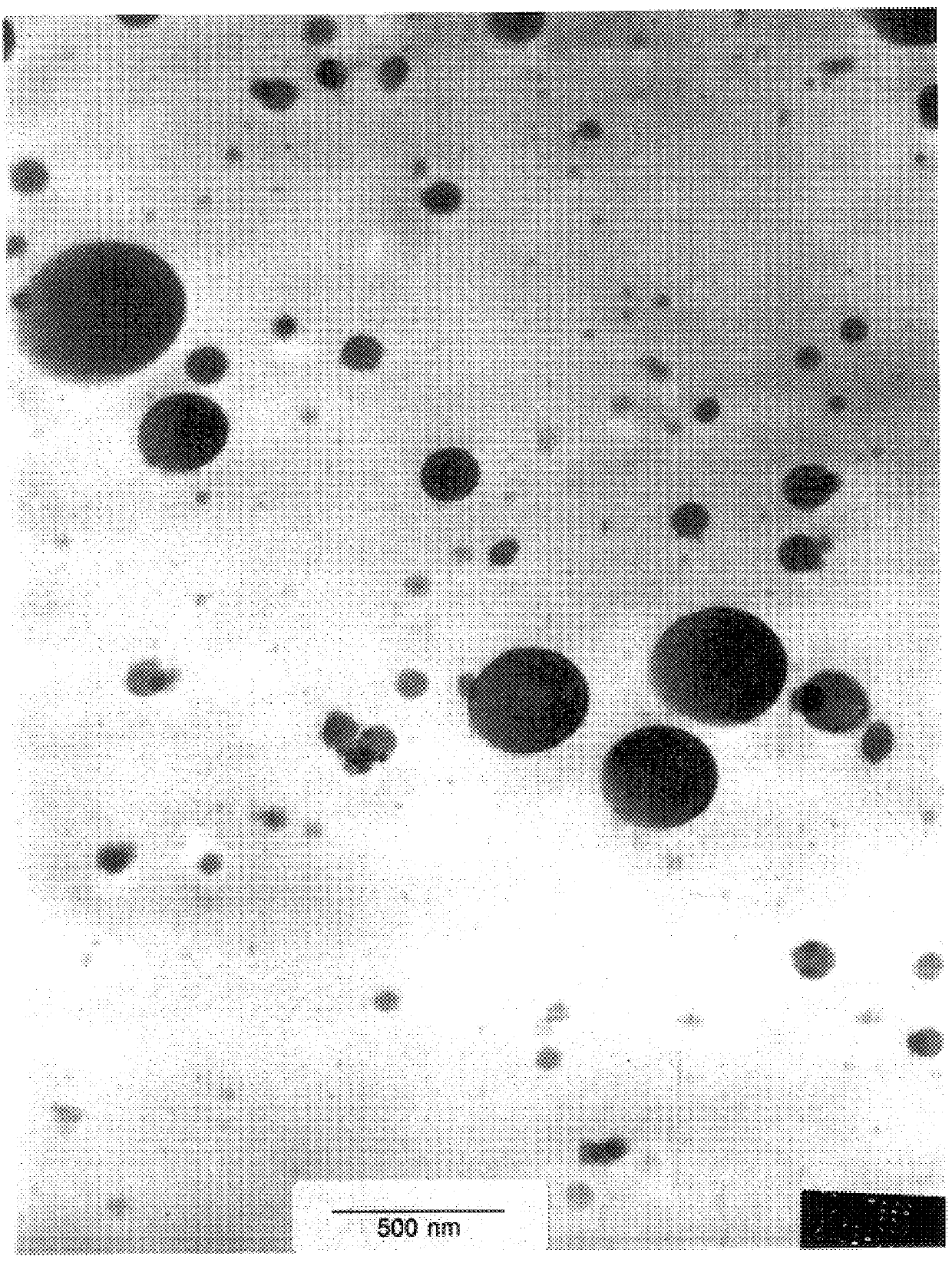

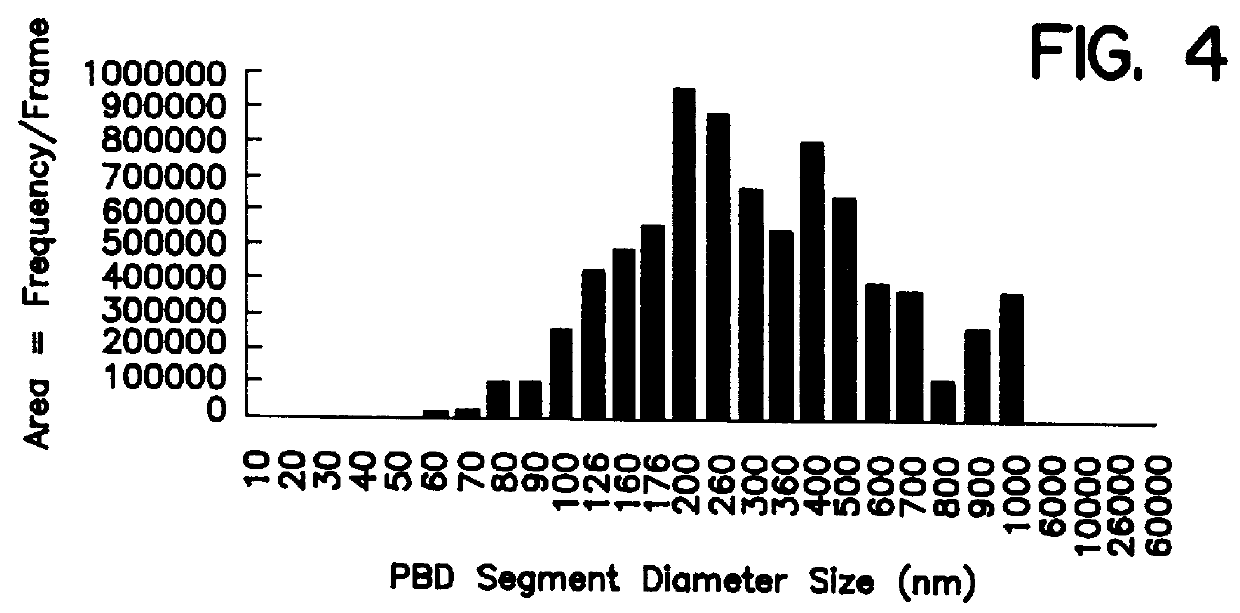

Concentrates of a carbon-based filler—such as carbon nanotubes, exfoliated graphite, and the like—and a macrocyclic polyester oligomer (also referred to herein as macrocyclic oligoester or MPO) are presented. When mixed with polymer, the MPO can act as a flow modifier, as well as a carrier for the carbon-based filler, allowing enhanced processability of the polymer-filler composite without adversely affecting the properties of the composite.

Owner:CYCLICS CORP

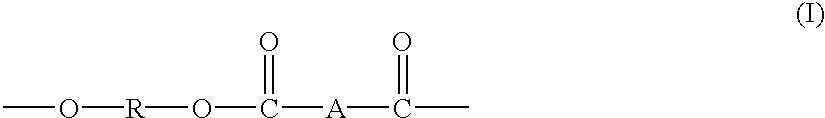

Composition that can be cured by polymerisation for the production of biodegradable, biocompatible, cross-linkable polymers on the basis of polyvinyl alcohol

ActiveUS20100303804A1Improve adhesionPromote cell adhesionImpression capsCarbamic acid derivatives preparationSolventVinyl ester

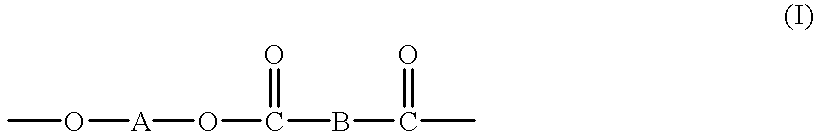

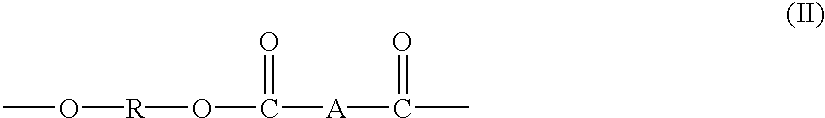

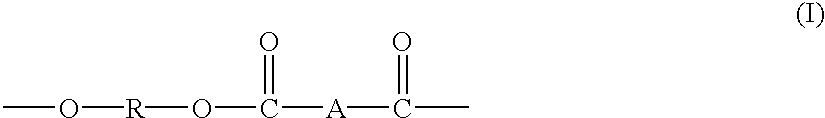

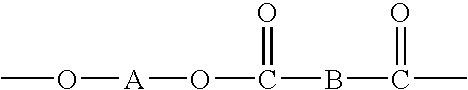

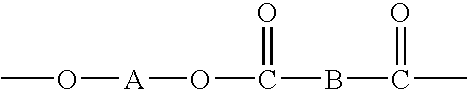

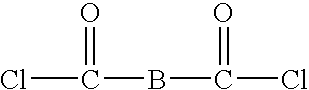

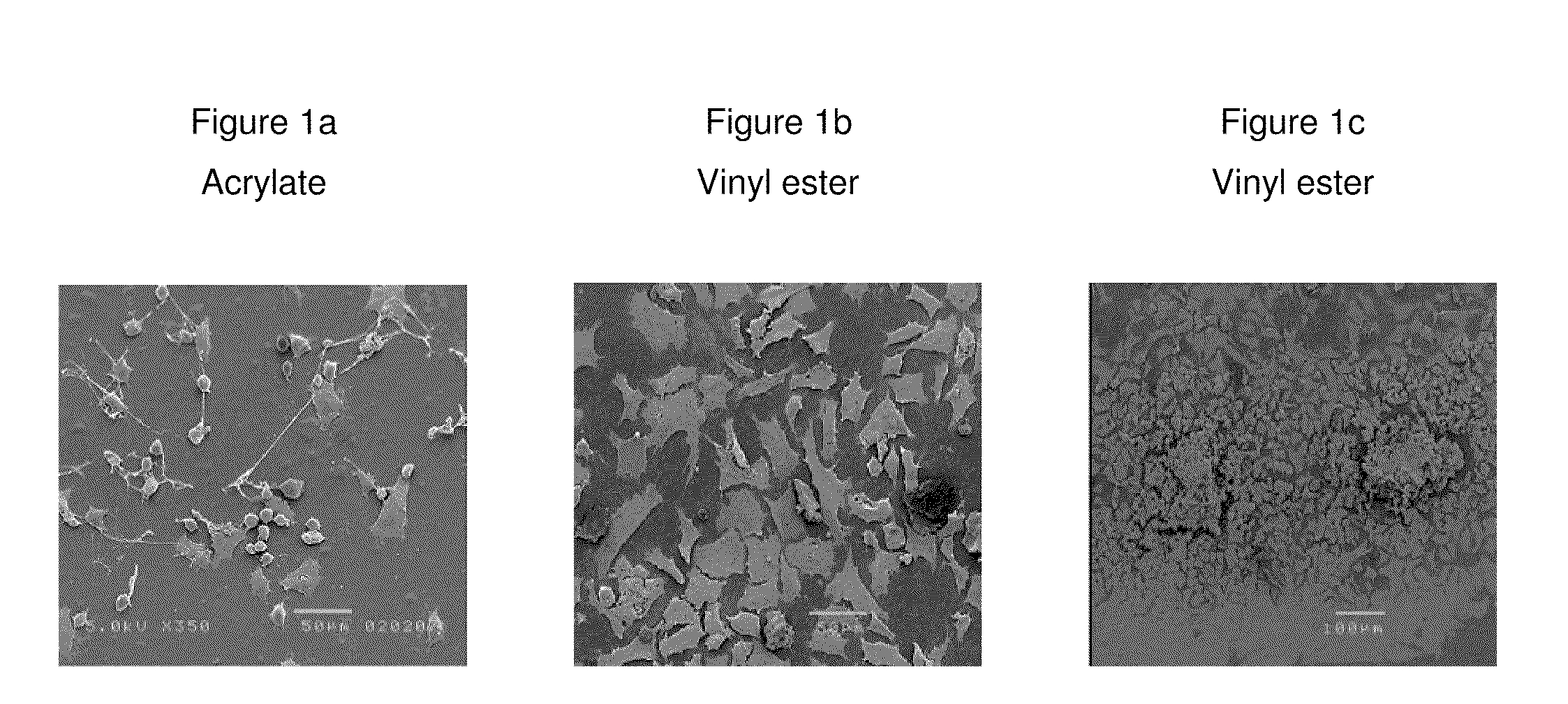

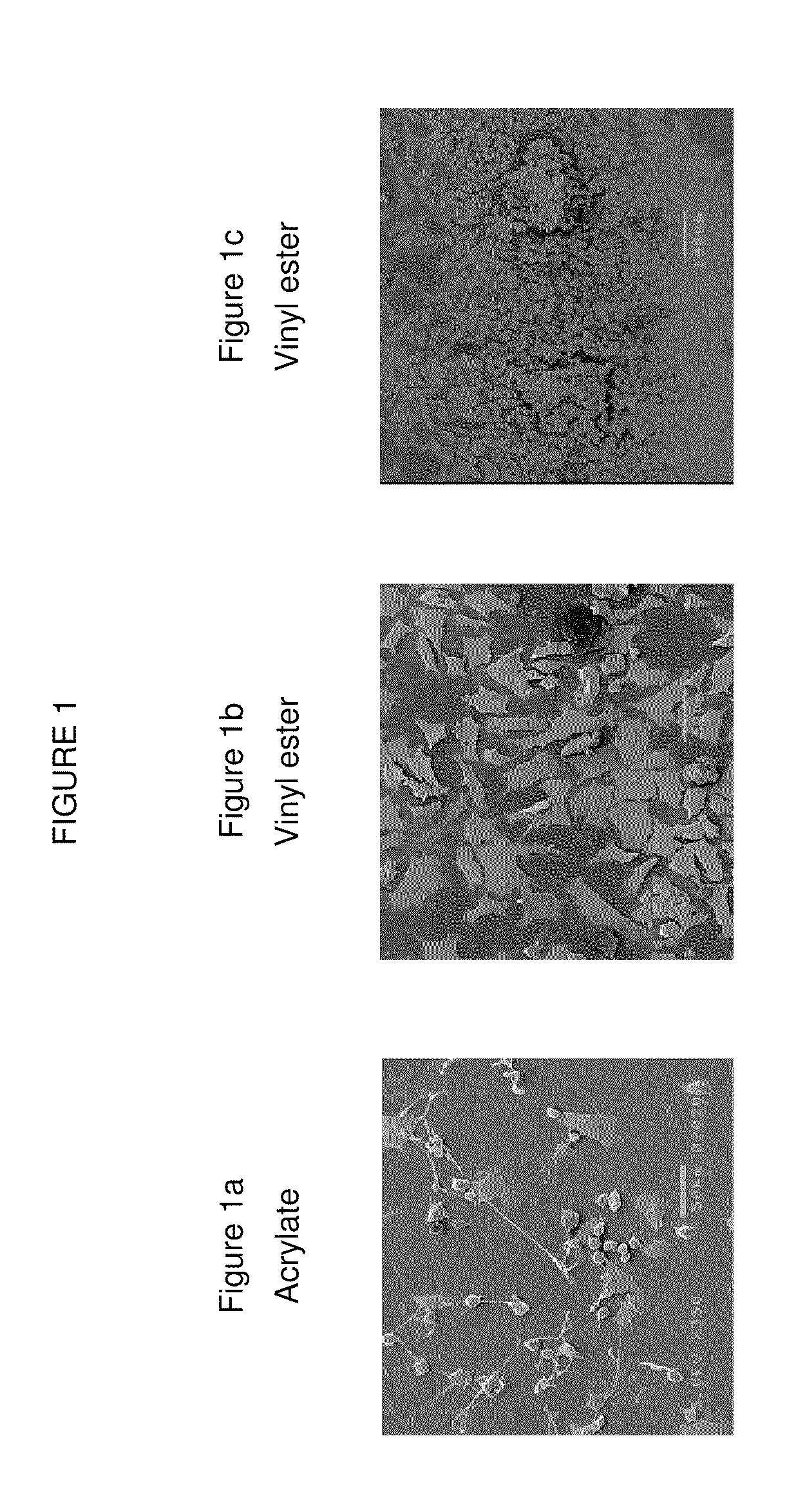

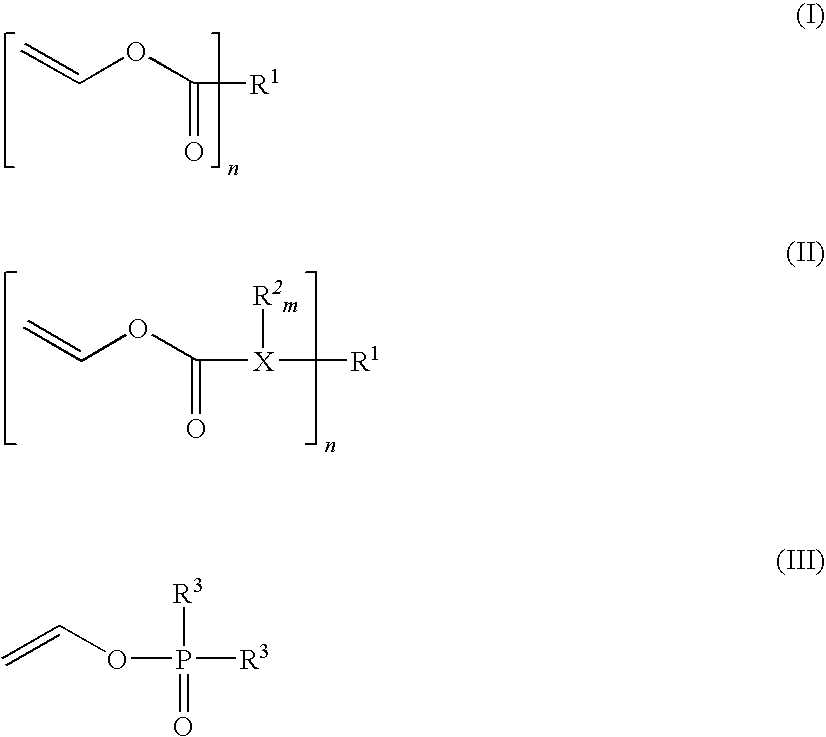

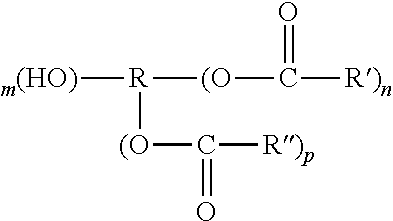

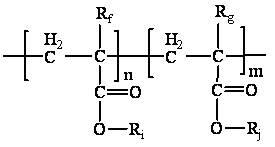

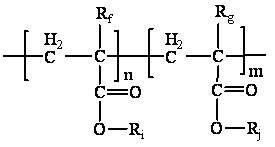

The present invention relates to a polymerization-curable composition for the preparation of biodegradable, biocompatible, cross-linked polymers on the basis of polyvinyl alcohol comprising: 5 to 100% by weight of (a) vinyl ester monomer(s) of one of the general formulas (I) to (III):wherein X is oxygen, sulfur, nitrogen, or phosphorus; n is 1 to 1000, at least 20% of the n being ≧2; the R1 are selected from hydrogen; straight, branched or cyclic, saturated or unsaturated, n-valent hydrocarbon groups having 1 to 30 carbon atoms, which optionally have heteroatoms and are optionally substituted with one or more substituents selected from —OH, —COON, —CN, —CHO, and ═O, and n-valent radicals of biodegradable, biocompatible oligomers and polymers; m is an integer from 1 to 5; the R2 are selected from hydrogen, —OH, ═O, and the options listed for R1; and the R3 are selected from hydrogen, —OH, and the options listed for R1; 0 to 50% by weight of ethylenically unsaturated co-monomers; 0 to 10% by weight of (a) polymerization initiator(s); and 0 to 95% by weight of solvent(s).

Owner:VIENNA UNIVERSITY OF TECHNOLOGY

Ultraviolet-curing liquid-state optical cement

ActiveCN102965067AGood adhesionLaminating thickness is thinNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesPolyesterPolymer science

The invention discloses a ultraviolet-curing liquid-state optical cement. The ultraviolet-curing liquid-state optical cement includes the following components by weight percent: 50-75% of low polymer, 20-40% of activated monomer, 3-6% of free radical type photoinitiator and 2-4% of accessory ingredient, wherein the low polymer comprises one or more of organosilicone modification polybutadiene acrylate, urethane acrylate and polyester acrylate, and the activated monomer is one of mono-functional group, bi-functional group and poly-functional group. The ultraviolet-curing liquid-state optical cement can be applied to fixed bonding between touch screen protective glass and protective glass as well as between the touch screen protective glass and an LCD (Liquid Crystal Display) screen, can be adequately cured within an energy of 3000 mj / cm<2> under a room temperature, the whole-line light transmittance can reach 93% or more, the refractive index exceeds 1.50, the light transmittance of a touch screen can be greatly improved, and the rate of finished products is improved; the ultraviolet-curing liquid-state optical cement is more suitable for continuous production; the production efficiency is improved; and the ultraviolet-curing liquid-state optical cement is stable in performance and good in environmental protection property in a high-temperature and high-humidity environment.

Owner:SUZHOU BETELY POLYMER MATERIALS CO LTD

Process for producing polyester resins

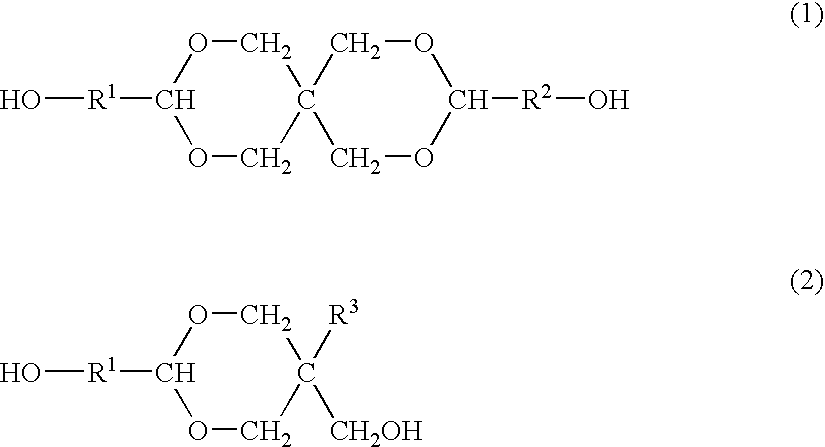

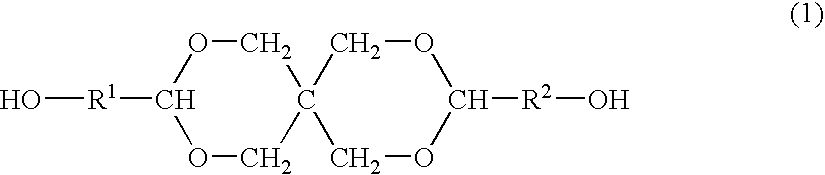

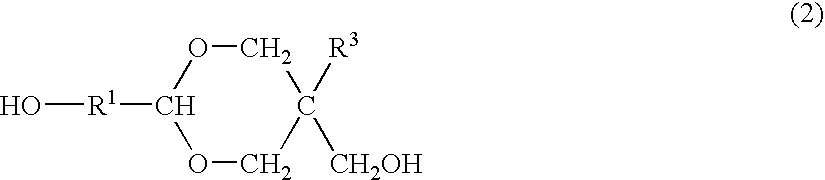

The process of the present invention for producing a polyester resin comprising a dicarboxylic acid constitutional unit and a diol constitutional unit having a cyclic acetal skeleton comprises a step (1) of subjecting a diol (A) having a cyclic acetal skeleton and an ester (D) to transesterification reaction and a step (2) of mainly converting the resultant oligomer into a high polymer. The step (1) simultaneously satisfies the requirements (i) to (iv) as described in the specification. In the process of the present invention, the polyester resins having excellent moldability and mechanical properties are stably produced by a transesterification method which is less detrimental to environments.

Owner:MITSUBISHI GAS CHEM CO INC

Hydrolysis-stable polycarbonate molding composition

InactiveUS6107375AImprove the immunityAluminium compoundsGroup 5/15 element organic compoundsPolycarbonateThermoplastic

A thermoplastic composition featuring an improved resistance to hydrolysis is disclosed. The composition comprises (i) thermoplastic polycarbonate resin (ii) about 0.01 to 3 percent of a compound selected from the group consisting of phosphite and phosphonite and (iii) an additive amount of an oligomer or polymer the structure of which features at least one pendant cyclic iminoether group per molecular chain. The additive amount is that which is sufficient to improve the resistance of the polycarbonate resin to hydrolysis.

Owner:BAYER CORPORATION

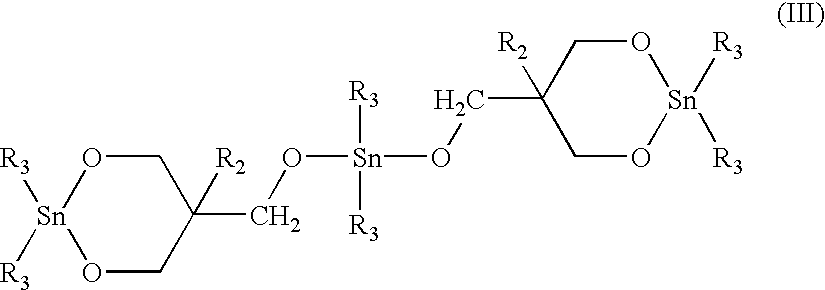

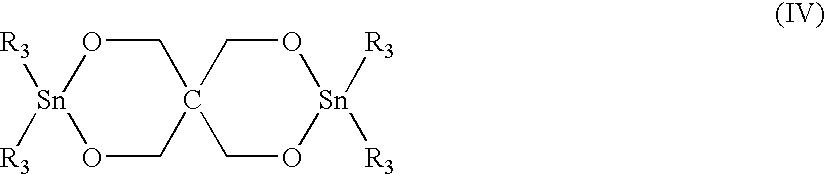

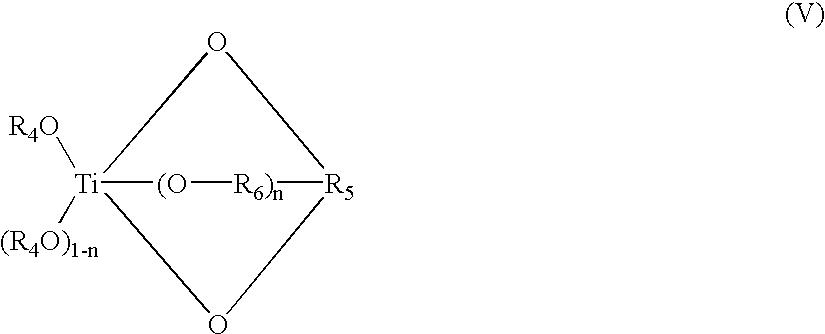

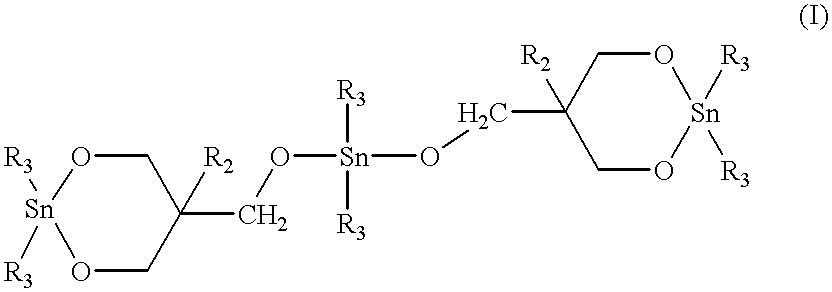

Organo-titanate catalysts for preparing pure macrocyclic oligoesters

InactiveUS6787632B2Organic-compounds/hydrides/coordination-complexes catalystsCatalytic reactionsPolyesterDepolymerization

Organo-titanate catalysts are prepared that are useful to catalyze depolymerization of a polyester to produce macrocyclic oligoesters substantially free from macrocyclic co-oligoesters.

Owner:CYCLICS CORP

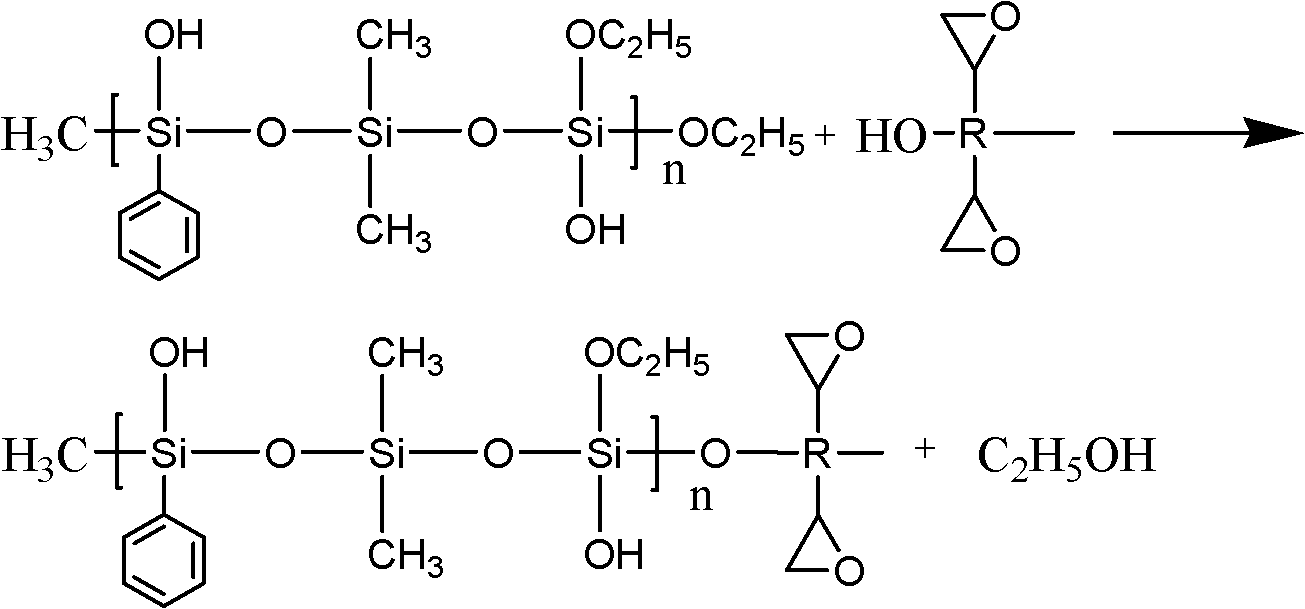

Organic silicon modified epoxy heat-resistant and anti-corrosive coating and preparation method thereof

ActiveCN102101964AImprove heat resistanceImprove anti-corrosion performanceAnti-corrosive paintsEpoxy resin coatingsEpoxyResin coating

The invention relates to an organic silicon modified epoxy resin coating and a preparation method thereof. The coating consists of a coating main agent A component and a curing agent B component, wherein a coating main agent consists of substrate resin, a pigment-filler, a solvent and an aid; the substrate resin is obtained by modifying epoxy resin E-20 by using a methyl phenyl organic silicon low polymer; the using amount of the substrate resin accounts for 50-55 percent of the weight of the coating main agent; the weight ratio of the methyl phenyl organic silicon low polymer to the epoxy resin E-20 is (11-20):(15-16); the curing agent is polyamide; and the weight ratio of the coating main agent to the curing agent is 100:(7-12). The method comprises the following steps of: undergoing a condensation copolymerization reaction on hydroxyl, amino and alkoxyl in organic silicon resin with hydroxyl in epoxy resin; and grafting organic silicon -Si-O-group into the epoxy resin to obtain the modified epoxy heat-resistant coating with high heat resistance, high corrosion resistance and high paint film property.

Owner:浙江大桥油漆有限公司

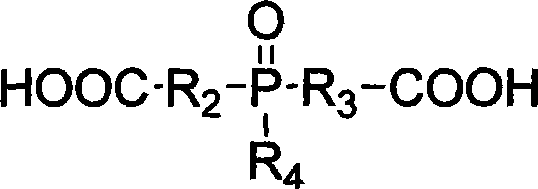

Reaction-type transparent halogen-free flameproof unsaturated polyester and preparation method thereof

The invention discloses a method for preparing a reaction type transparent halogen-free flame retardation unsaturated polyester. A program temperature control melting polycondensation reaction method is adopted; C2-6 dihydric alcohol, C3-8 saturated binary acid or anhydride, C4 unsaturated binary acid or anhydride, and a difunctional reactivity phosphatic flame retardant are used to synthesize an unsaturated polyester oligomer; styrene is taken as a crosslinking agent to prepare the unsaturated polyester which can be solidified at room temperature with transparent appearance, moderate viscosity and lower cost. After solidification, no added dissociated flame retardant component is contained in the cross linked network of the unsaturated polyester. The mechanical property, the flame retardation property and the electricity property of the product can be stable in a long period, the oxygen index of the product can be increased from 19 to 29 percent, and the product can pass the vertical firing UL94-V0 level. The reaction type transparent halogen-free flame retardation unsaturated polyester can be applied to the field of electronic and electric appliance insulating materials with higher performance requirements, construction flame retardation coating, ship-building material, flame retardation fiber glass reinforced plastics, and the like.

Owner:SOUTH CHINA UNIV OF TECH

Hair Care Composition Comprising Metathesized Unsaturated Polyol Esters

A hair care composition having from about 0.05% to about 15% of one or more oligomers derived from unsaturated polyol esters. The hair care composition further includes a gel matrix phase. The gel matrix has from about 0.1% to about 20% of one or more high melting point fatty compounds, from about 0.1% to about 10% of a cationic surfactant system, and at least about 20% of an aqueous carrier, by weight of said hair care composition. The present invention may further comprise a deposition polymer.

Owner:THE PROCTER & GAMBLE COMPANY

Preparation method of acrylic ester oligomer modified aqueous polyurethane pressure-sensitive adhesive

ActiveCN102020967ATo achieve mutual toleranceReduce usagePolyureas/polyurethane adhesivesPolymer scienceEmulsion

The invention relates to the technical field of preparation of aqueous adhesive and discloses a preparation method of acrylic ester oligomer chemical modified aqueous polyurethane pressure-sensitive adhesive. The preparation method comprises the following steps of: making hydroxyl monomers, a hydrophilic chain extender and polyisocyanate which are mainly used as man raw materials react to generate a prepolymer; adding an acrylic ester oligomer and making the acrylic ester oligomer and polyurethane prepolymer properly grafted; carrying out multiple modification through a cross-linking agent; and finally, carrying out water emulsification to obtain the acrylic ester oligomer modified aqueous polyurethane pressure-sensitive adhesive. In the invention, the acrylic ester oligomer is introducedinto the polyurethane system, and good characteristics of aqueous polyurethane and polyacrylic ester are integrated. Compared with solvent-based pressure-sensitive adhesive, water is used as a solvent in the invention, the usage amount of organic solvents is small so that the requirement of clean production processes are met, and the low temperature resistance is greatly improved. The synthesizedacrylic ester oligomer chemical modified aqueous polyurethane pressure-sensitive adhesive has more excellent mechanical property, strong bonding capacity, good film forming property and stable emulsion.

Owner:溧阳常大技术转移中心有限公司

Preparation method and application of photosensitive resin for ultrasonic curing 3D printing

InactiveCN104570603AEliminate cure shrinkageImprove curing forming accuracyPhotosensitive materials for photomechanical apparatusPolymer scienceAcrylate ester

The invention discloses a preparation method and application of photosensitive resin for ultrasonic curing 3D printing. The photosensitive resin mainly comprises the following raw material components in percentage by mass: active components: 70-90 percent (in percentage by total mass of the active components, and the same below) of a mixture of a low polymer A, a low polymer B and an acrylic ester monomer according to the ratio of 50: 15: 35 and 10-30 percent of an active diluent, and auxiliaries: 1-10 percent of a cationic initiator, 1-6 percent of a free radical photoinitiator, 1-8 percent of a promoter, 0.1-1.5 percent of a flatting agent and 0.1-1.5 percent of a defoaming agent. The raw material components are mixed according to the mass percentage, and then heated and stirred into transparent light-yellow liquid to prepare the photosensitive resin. After ultrasonic curing 3D printing molding, the volume shrinkage of a product is smaller than or equal to 1.0 percent, the warpage factor CF (6) is equal to + / - 0.2 percent, and the warpage factor CF (11) is equal to + / - 0.8 percent. The molded product is high in precision and can be applied to manufacturing of key parts for aviation.

Owner:QINGDAO ADVANCED MATERIAL TECH

Flame retardant thermoplastic resin composition

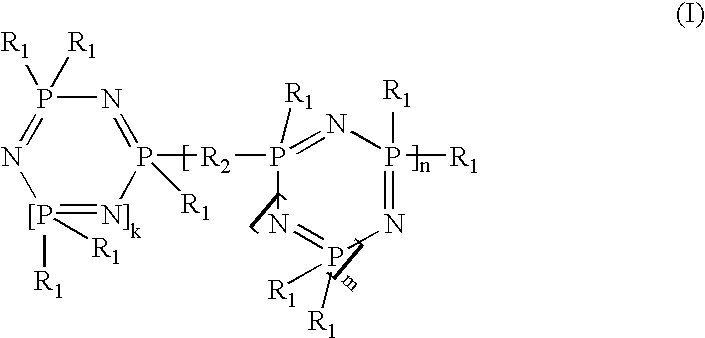

InactiveUS20040249027A1Improve flame retardant performanceImprove heat resistanceGroup 5/15 element organic compoundsLiquid carbonaceous fuelsPhosphoric Acid EstersPolymer science

The present invention relates to a flame retardant polycarbonate thermoplastic resin composition that comprises a polycarbonate resin, a rubber modified vinyl-grafted copolymer, a phosphorous mixture of a cyclic phosphazene oligomer compound and a phosphate ester morpholide compound as a flame retardant, and a fluorinated polyolefin resin, which has good flame retardancy, heat resistance, mechanical strength, impact strength, heat stability, processability, and appearance.

Owner:LOTTE ADVANCED MATERIALS CO LTD

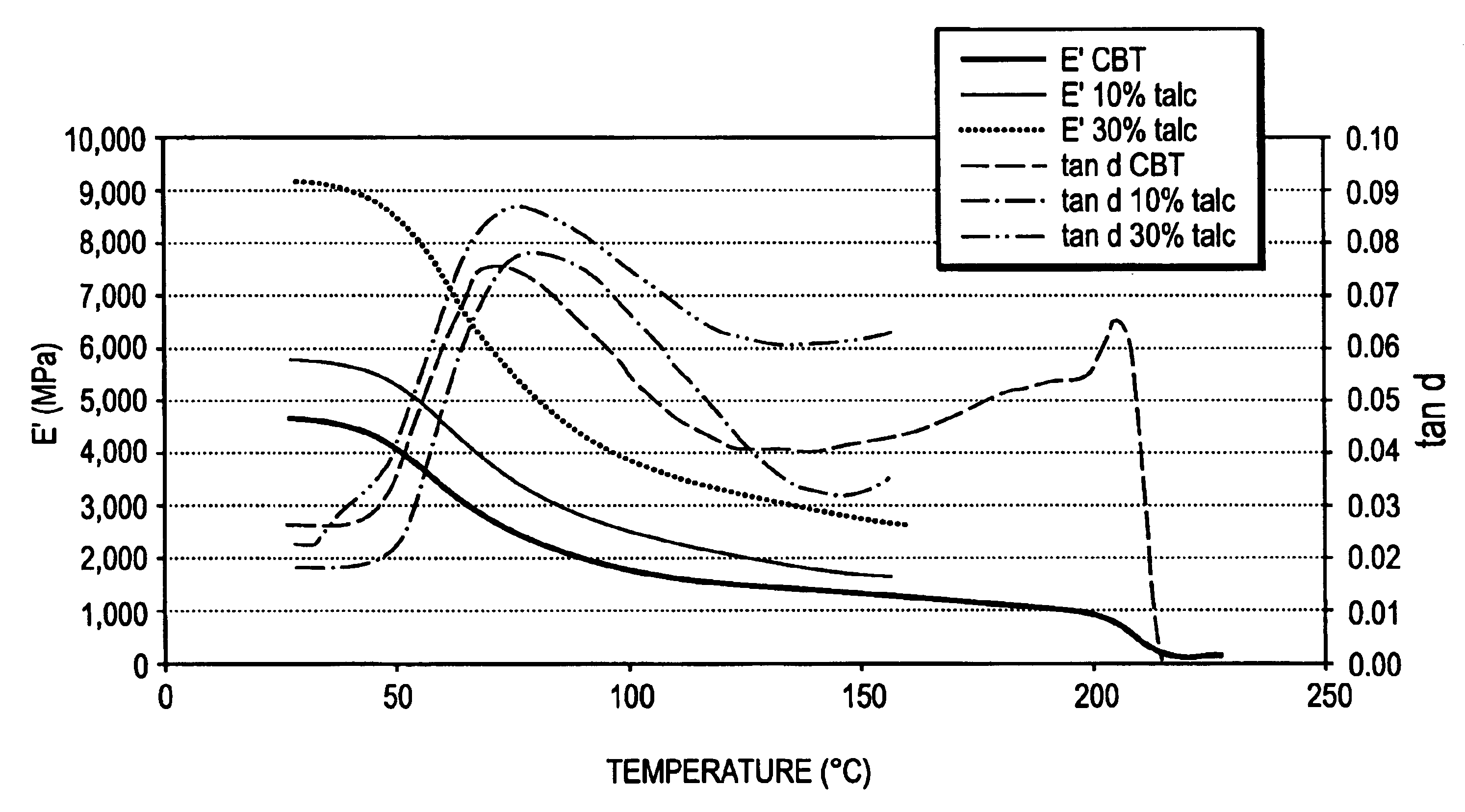

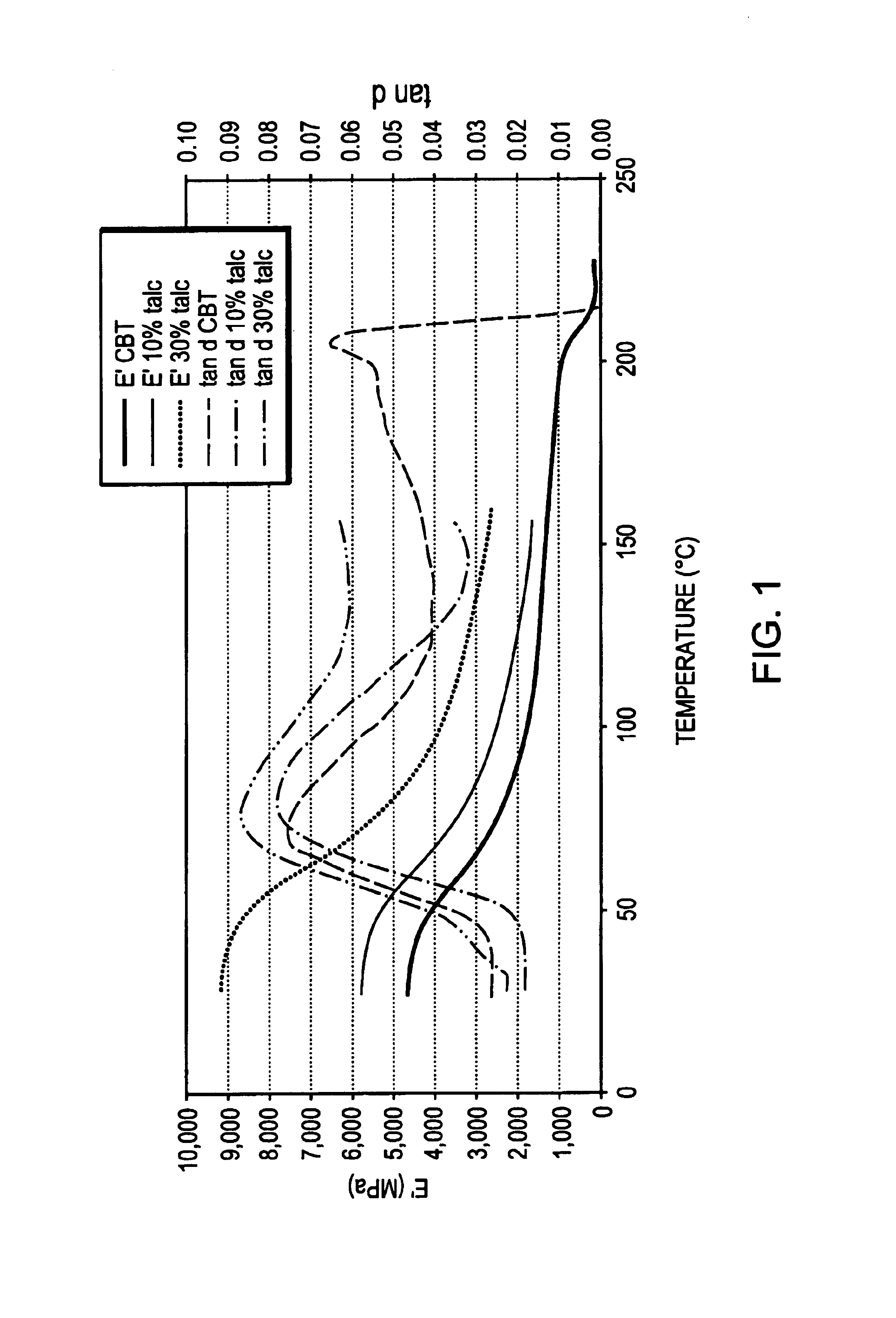

Intimate physical mixtures containing macrocyclic polyester oligomer and filler

InactiveUS6960626B2Improve filler dispersionImprove compatibilityTin organic compoundsSynthetic resin layered productsPolyesterOligomer

The invention provides intimate physical mixtures of macrocyclic polyester oligomer (MPO) and filler, as well as methods for their preparation and use. Improved dispersion of filler in a polymer matrix is achieved upon polymerization, and larger amounts of filler with high aspect ratio can be used. In one aspect, the invention provides mixtures of MPO with magnesium silicate. In another aspect, the invention provides a mixture of MPO, filler, and polymerization catalyst as a one-part, ready-to-polymerize material with a long shelf life. The one-part material can be used, for example, in the manufacture of parts without modification of existing processing equipment.

Owner:CYCLICS CORP

Macrocyclic polyester oligomers and processes for polymerizing the same

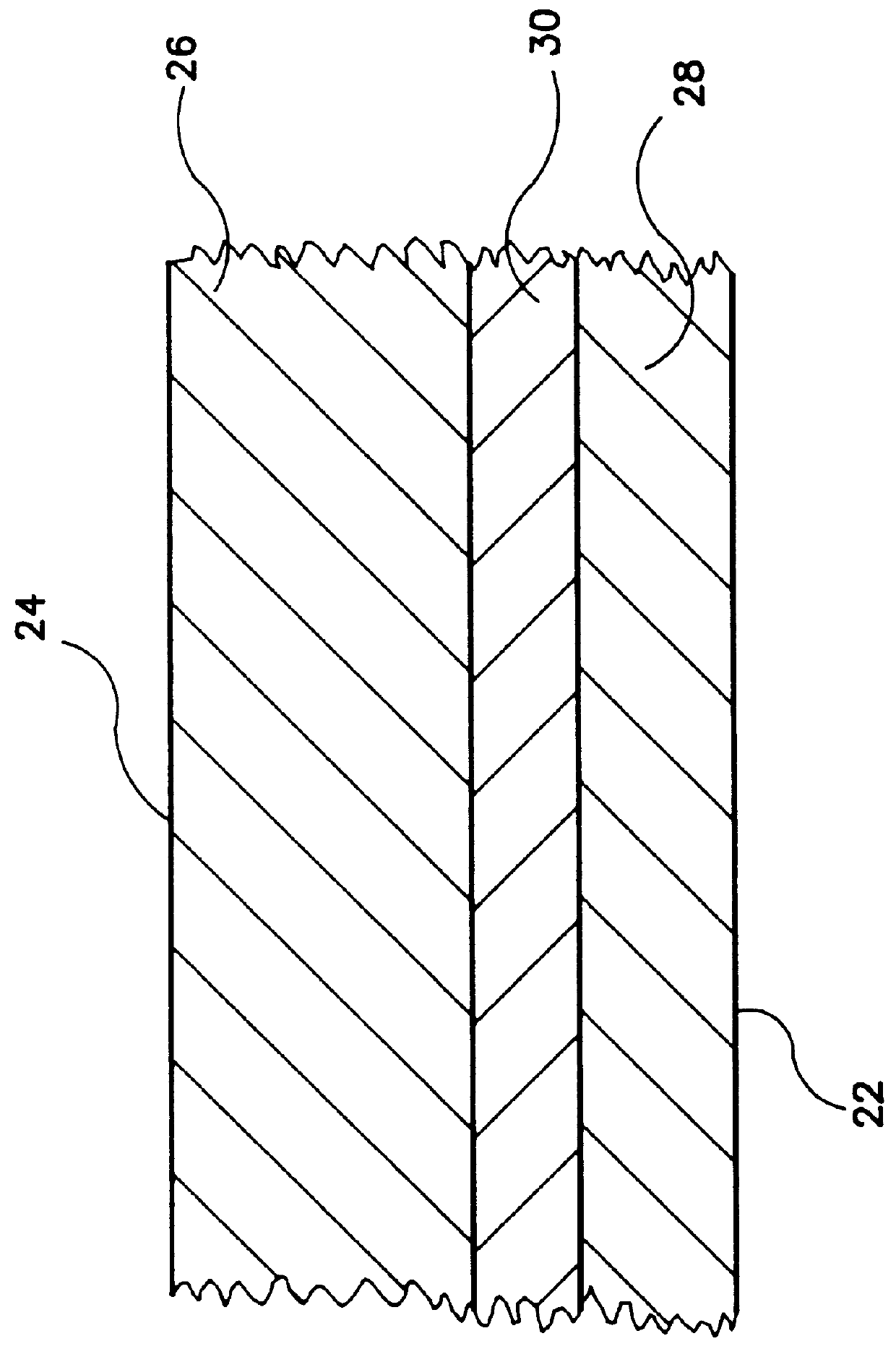

A water slurry process is used to prepare a prepreg and to manufacture articles from macrocyclic polyester oligomers. In one embodiment, a process for preparing a water suspension of macrocyclic polyester oligomers includes the steps of contacting a macrocyclic polyester oligomer and a polymerization catalyst with water and a surfactant, and mixing the macrocyclic polyester oligomer and polymerization catalyst with water and the surfactant thereby forming a suspension. In another embodiment, a process for impregnating macrocyclic polyester oligomers for polymerization includes the steps of providing a suspension of a macrocyclic polyester oligomer and a polymerization catalyst in water, applying the suspension to a base material, drying to remove water from the suspension, and pressing the dried suspension to a desired form. In yet another embodiment, a composition of macrocyclic polyester oligomer includes a macrocyclic polyester oligomer, a polymerization catalyst, and water. In yet another embodiment, a process for polymerizing macrocyclic polyester oligomers includes the steps of mixing a blend material having a macrocyclic polyester oligomer and a polymerization catalyst with water to form a mixture, applying the mixture to a base material, drying to remove water, heating to polymerize the macrocyclic polyester oligomer, and pressing the polymerized macrocyclic polyester oligomer to a desired form.

Owner:CYCLICS CORP

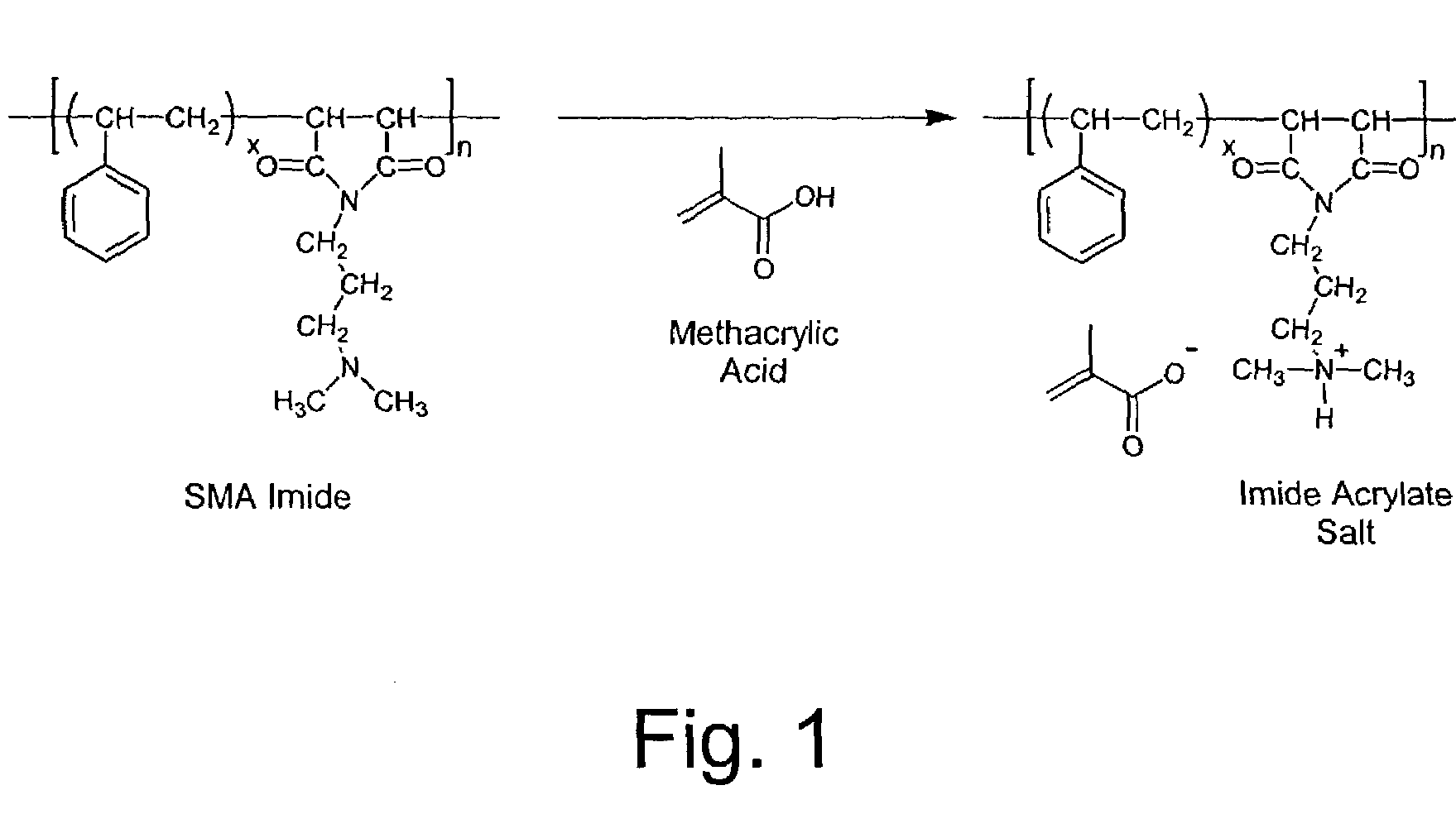

Acid salts of amine-functionalized SMA imide resins

Compositions comprising acid salts of amine-functionalized styrene-maleic anhydride resins are disclosed. The salts can be dissolved in organic solvents, UV / EB polymerizable monomers and / or oligomers, and / or water and act as a polymeric surfactants to disperse pigments or fillers, emulsifying agents, or hard resin additives in a variety of formulations. The compositions react under UV / EB cure conditions, and provide enhanced properties such as cure speed, hardness and adhesion to polymer compositions.

Owner:ARKEMA FRANCE SA

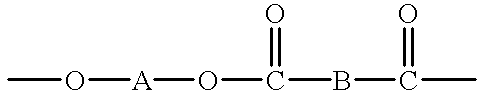

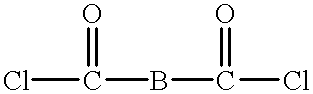

Process For Preparing A High Molecular Weight Heteroaromatic Polyester Or Coplyester

A process for preparing a high molecular weight heteraromatic polyester or copolyester is disclosed. A process for preparing a high molecular weight heteroaromatic polyester or copolyester includes the steps of: (a) processing comonomers by mixing together to form a homogeneous solution (1) at least one heteroaromatic dicarboxylic acid having 2-12 carbon atoms or a diester or an acid anhydride derived therefrom, or a mixture thereof; (2) at least one alcohol having 2 to 12 carbon atoms and at least two hydroxyl functionalities; and (3) optionally aromatic or aliphatic dicarboxylic acids or diesters or acid anhydrides derived therefrom; (b) converting the paste / solution obtained in step a) into an esterification product containing at least one diester or at least one oligoester formed from the at least one heteroaromatic dicarboxylic acid and the at least one alcohol; and (c) polycondensing / copolycondensing the reaction product obtained from step b) under reduced pressure.

Owner:UHDE INVENTA FISCHER

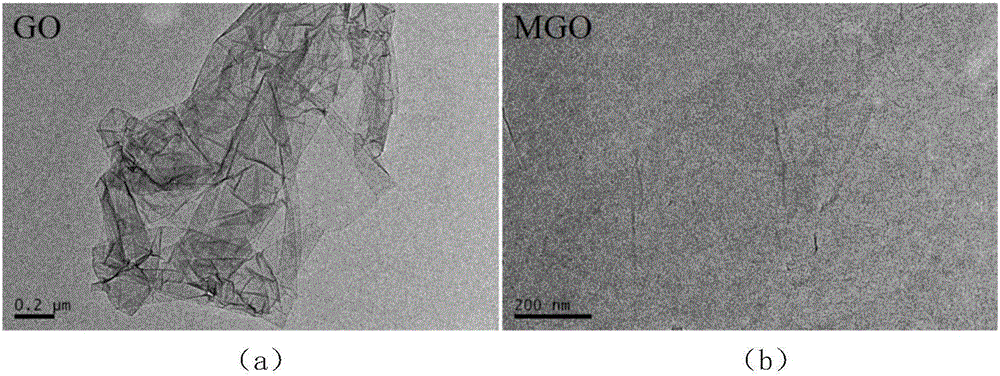

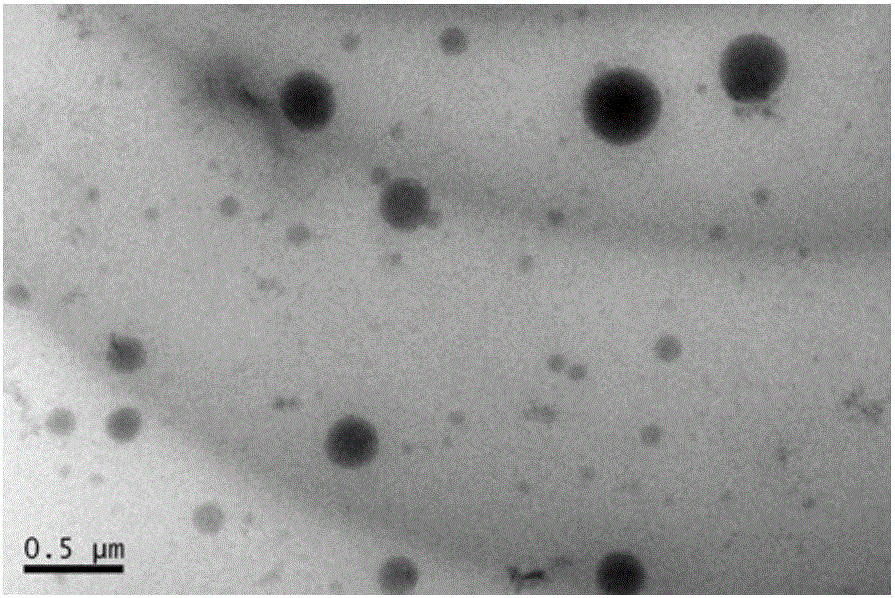

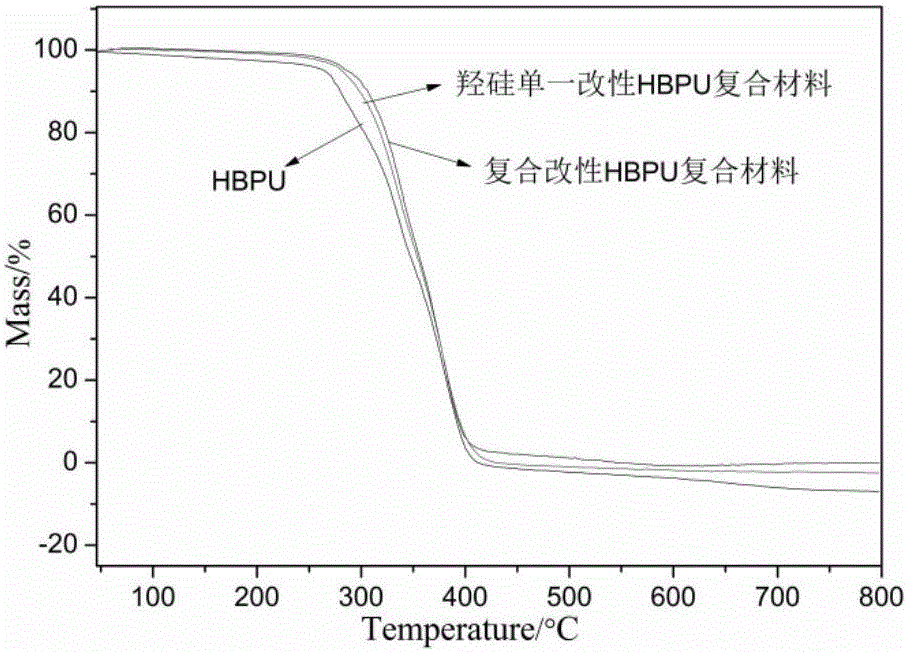

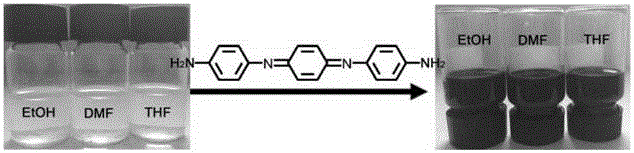

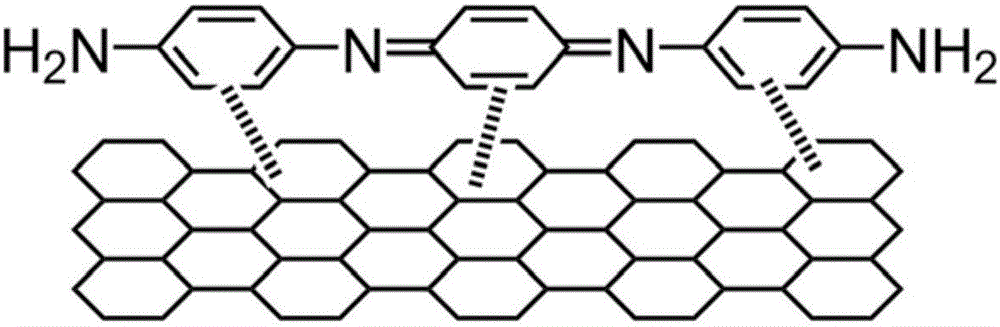

Preparation method of graphene/polyacrylic ester-silicon-containing hyperbranched waterborne polyurethane multi-element composite emulsion

The invention discloses a preparation method of a graphene / polyacrylic ester-silicon-containing hyperbranched waterborne polyurethane multi-element composite emulsion. The method comprises the following steps: preparing graphene oxide (GO) by an improved Hummers method, modifying the GO by ethanediamine, enabling reaction with butyl acrylate to introduce double bonds to obtain MGO (ethylenediamined graphene oxide), and performing solution polymerization on the MGO and an acrylic ester monomer in DMF to prepare an MGO / PA solution; and grafting a partial double-bond end-sealed hydroxyl silicone oil modified linear polyurethane prepolymer, which is prepared by in-situ polymerization, on the periphery of a polyhydroxyl hydrophilic hyperbranched polyurethane core by diisocyanate, an oligomer dihydric alcohol and a chain extender and by a hyperbranched polymer chain extending method, mixing with the MGO / PA, and performing polycondensation and crosslinkage to obtain aminated graphene oxide / polyacrylic ester-silicon-containing hyperbranched polyurethane quaternary composite emulsion.

Owner:ANHUI UNIVERSITY

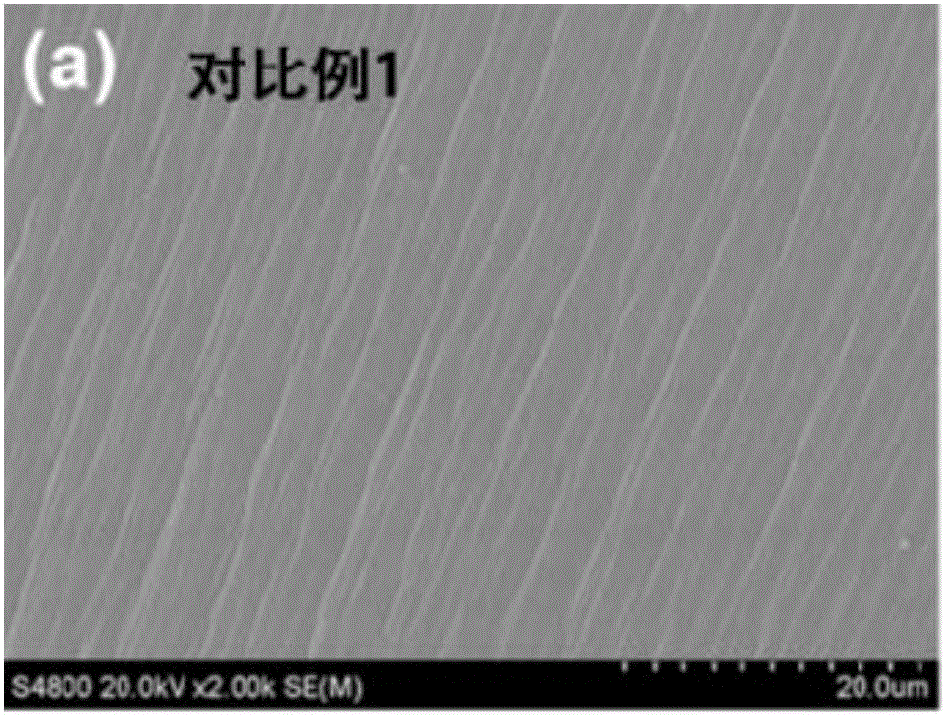

Hexagonal boron nitride epoxy anticorrosive wear-resistant paint as well as preparation method and application thereof

ActiveCN106752676AImprove dispersion stabilityHigh barrierFireproof paintsAnti-corrosive paintsEpoxyHexagonal boron nitride

The invention discloses hexagonal boron nitride anticorrosive wear-resistant paint as well as a preparation method and application thereof. The preparation method comprises the following steps of the provision of a first component, which comprises the following steps of mixing hexagonal boron nitride with an aniline low polymer in a solvent, so as to obtain hexagonal boron nitride dispersion liquid, and then uniformly mixing the hexagonal boron nitride dispersion liquid with epoxy resin and a paint aid; the provision of a second component, wherein the second component comprises a curing agent or a mixture of the curing agent and the solvent. When the paint is used, the first component and the second component can be mixed firstly, then an obtained mixture is coated on the surface of a matrix, and afterwards, the mixture is cured to form a coating. The hexagonal boron nitride anticorrosive wear-resistant paint provided by the invention has the advantages of being good in storage stability and difficultly sinking to a bottom, and the like; further, the coating formed by the hexagonal boron nitride anticorrosive wear-resistant paint has quite good barrier property, antiseptic property and wear-resisting property; the hexagonal boron nitride anticorrosive wear-resistant paint has wide application prospects in industries of construction, chemical engineering, petroleum, electric power, metallurgy, shipping, light textiles, storage, traffic, spaceflight and the like.

Owner:XINHE NEW MATERIALS CO LTD

Isolation, formulation and shaping of macrocyclic oligoesters

InactiveUS7071291B2Effective and efficient and low cost processGood benefitOrganic chemistryFibre treatmentPolyesterSolvent

Processes for isolating, formulating, and shaping macrocyclic oligesters were developed which allow efficient production of macrocyclic oligoesters substantially free from solvent, which may include additives, fillers, and catalysts.

Owner:LIQUID THERMO PLASTICS

Polyorganosiloxane emulsion composition and a cosmetic material made therefrom

InactiveUS20040138373A1Avoid bacterial contaminationLess irritatingCosmetic preparationsHair removalOligomerEmulsion

A polyorganosiloxane emulsion composition characterized by comprising (A) a polyorganosiloxane, (B) an N-acylalkyl taurine and / or a salt thereof, and (C) water, the content of cyclic organosiloxane oligomers in said component (A) being within 3.5 wt. %, and a cosmetic raw material characterized by consisting of said polyorganosiloxane emulsion composition. The emulsion composition is characterized by superior cosmetic functionality in terms of moisture and smoothness.

Owner:DOW TORAY CO LTD +1

Hot-melt adhesive for bonding layer of artificial leather and preparation method as well as application thereof

InactiveCN102618204AImprove high temperature resistanceGood chemical resistanceNatural rubber adhesivesNon-macromolecular adhesive additivesPolymer scienceAdhesive

The invention relates to a hot-melt adhesive for the bonding layer of artificial leather and a preparation method as well as application thereof. The preparation method comprises the following steps of: firstly reacting low polymer polyalcohol, an expoxy resin and aromatic polyhydroxy special polyether with diisocyanate, then adding a hydrophilic chain extender and a micromolecule polyalcohol chain extender for carrying out chain extension reaction to obtain an intermediate product, neutralizing by using organic amine, emulsifying by using water to generate a polyurethane emulsion, finally removing an organic solvent at a reduced pressure to obtain a waterborne polyurethane emulsion, adding a special organic silicon surface active agent, a FeCl3 aqueous solution, a waterborne curing agent, natural rubber, chloroprene rubber, nitrile butadiene rubber and a thickening agent, and preparing the hot-melt adhesive for the bonding layer of artificial leather. The bonding layer of artificial leather is used for compositing spinning fabrics and PVC (Polyvinyl Chloride) / cloth in the fields of bags, suitcases and clothing. The prepared adhesive has the excellent performances of firm bonding strength, water resistance, acid resistance, alkali resistance and the like and is applied to the artificial leather fields of clothing, bags, suitcases and the like.

Owner:江阴市诺科生物新材料科技有限公司

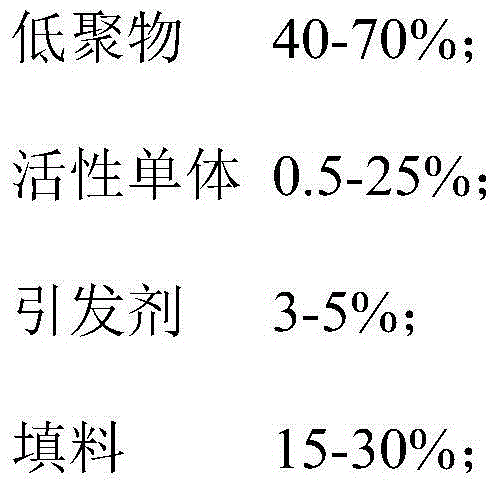

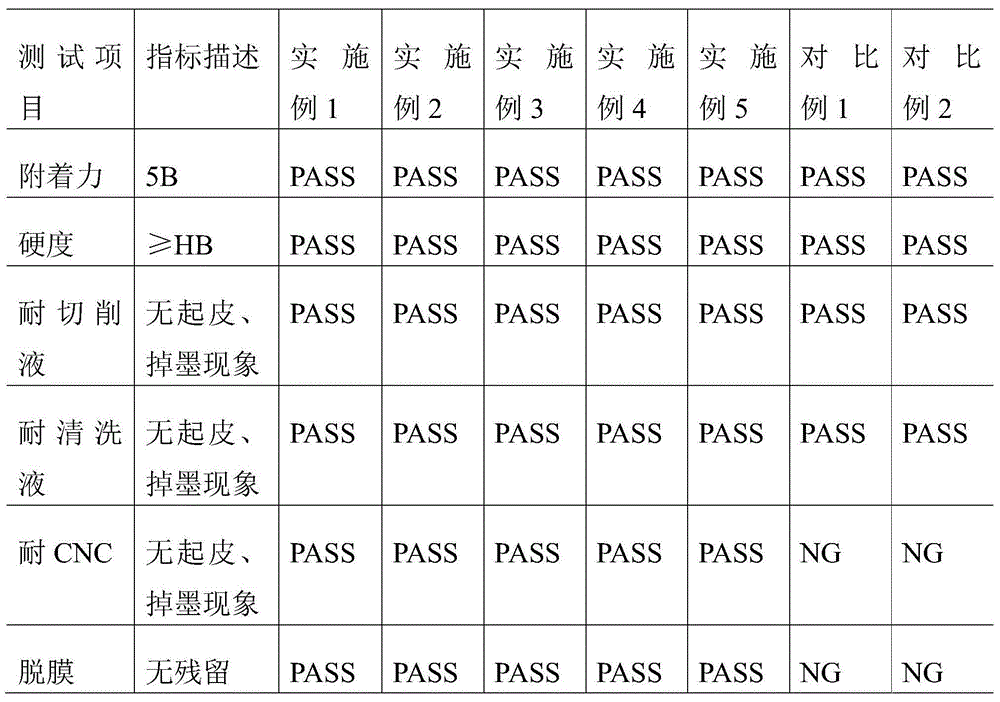

Ultraviolet curing full-shielding protection printing ink

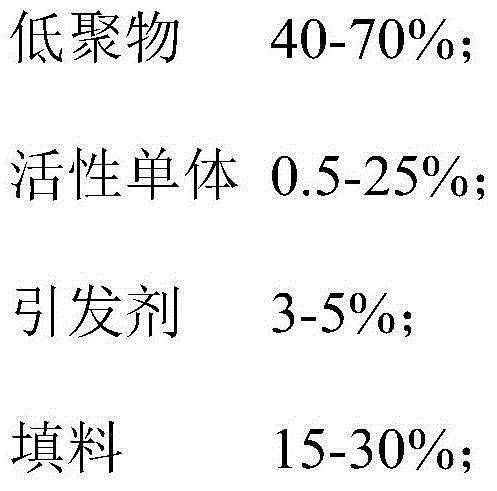

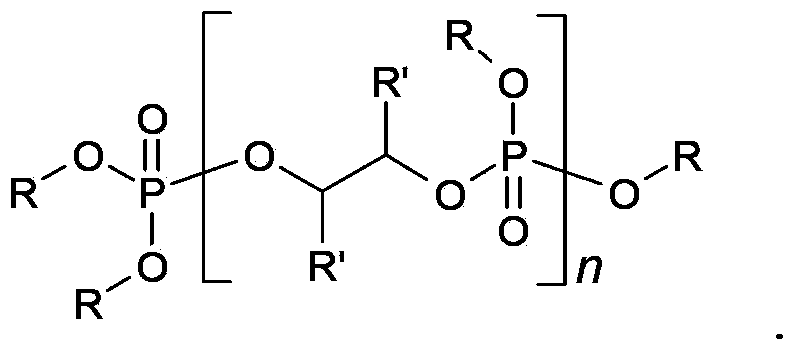

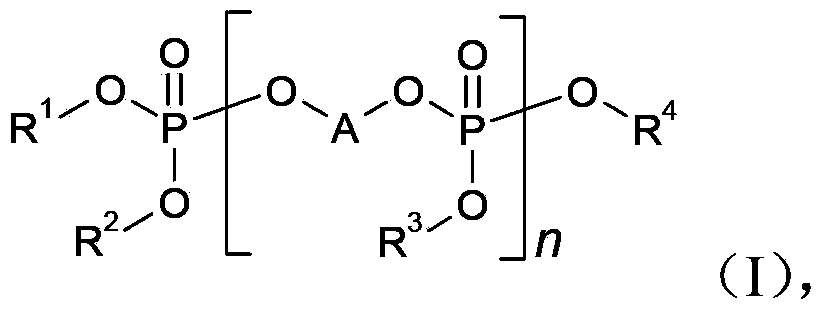

The invention provides an ultraviolet curing full-shielding protection printing ink, by taking total weight of a printing ink composition as a reference, the ultraviolet curing anti-sandblasting shielding protection printing ink comprises the following components by weight percentage: 40-70% of low polymer, 0.5-25% of active monomer, 3-5 parts of initiator and 15-30% of filling material; wherein the low polymer is acrylate resin derived from ester long-chain polyhydric alcohols. The printing ink has the advantages of simple operation, high efficiency, CNC resistance, scratch resistance, easy stripping, no residues after film-stripping, and no base material corrosion; is suitable for metal base material and plastic cement base material, and is especially suitable for a metal and plastic cement-embedded composite base material.

Owner:VITAYON FINE CHEM SCI & TECH CO LTD SHENZHEN

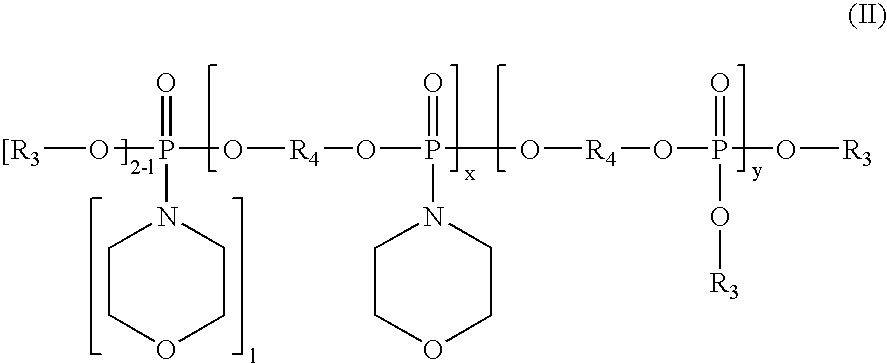

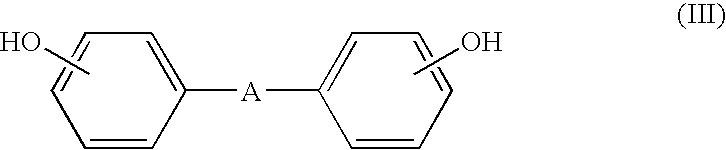

Oligomer mixtures, producing process and use of oligomer mixtures, and flame-retardant polyurethanes comprising oligomer mixtures

ActiveCN103570972AEasy to measureMeet the requirements of flame retardancyGroup 5/15 element organic compoundsPhosphateHalogen free

Owner:LANXESS DEUTDCHLAND GMBH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com