Ultraviolet-curing liquid-state optical cement

A technology of optical glue and ultraviolet light, which is applied in the direction of adhesives, adhesive types, polyurea/polyurethane adhesives, etc., can solve the problems of difficult thickness reduction, high cost, low refractive index, etc., and achieve thin lamination thickness, Yield improvement, effect of high refractive index

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

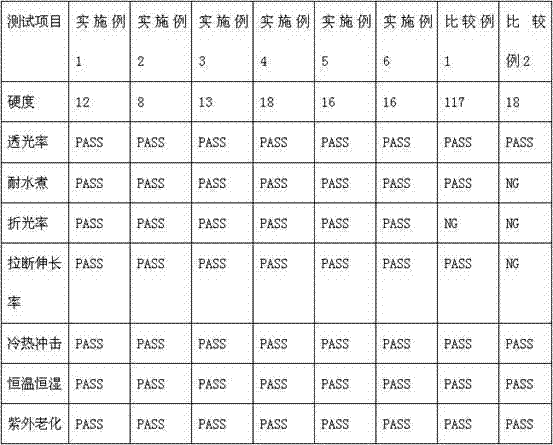

Examples

Embodiment 1

[0024] A UV-curable transfer adhesive, which is composed of the following raw materials: 30g silicone modified polybutadiene acrylate, 25g polyurethane acrylate, 24g isobornyl methacrylate, 16g triethylene glycol dimethacrylate, 2g of 1-hydroxycyclohexyl phenyl ketone, 1g of phenyl bis(2,4,6-trimethylbenzoyl) phosphine oxide, 1g of γ-(methacryloxy)propyltrimethoxysilane, 2 -(2',4'-dihydroxyphenyl)-5,6-dihydroxybenzotriazole 0.5g, 2-(2'-hydroxy-3',5'-di-tert-phenyl)-5- Chlorinated benzotriazole 0.5g.

[0025] Prepare according to the following method: add the above initiator and 24g of isobornyl methacrylate to a star vacuum mixer in a thousand-level dust-free workshop, heat to 55°C, stir and dissolve; then add the above oligomer and triethylene glycol 16g of bismethacrylate, heated to 55°C under vacuum, and stirred uniformly; finally, add the above-mentioned additives, disperse at high speed with a disperser, press and filter, and then pack to obtain UV-curable liquid optical ad...

Embodiment 2

[0028] A UV-curable transfer adhesive composed of the following raw materials: 61g of silicone modified polybutadiene acrylate, 18g of isobornyl methacrylate, 12g of phenoxymethylethyl acrylate, and 2-hydroxy- 2Methyl-1-phenyl-1-acetone 2g, phenylbis(2,4,6-trimethylbenzoyl)phosphine oxide 3g, N-(β-aminoethyl)-γ-aminopropyl 2g of methyldimethoxysilane, 1g of 2,6-di-tert-butylphenol, 0.5g of 2-(2',4'-dihydroxyphenyl)-5,6-dihydroxybenzotriazole, 2 -(2'-hydroxy-3',5'-di-tert-phenyl)-5-chlorobenzotriazole 0.5g.

[0029] Prepare according to the following method: add the above initiator and 18g of isobornyl methacrylate to a star vacuum mixer in a thousand-level dust-free workshop, heat to 50°C, stir and dissolve; then add the above oligomer and phenoxy 12g of methethyl acrylate, heated to 50°C in a vacuum state and stirred uniformly; finally, add the above additives, disperse at a high speed with a disperser, press and filter, and then divide and pack to obtain a UV curable liquid op...

Embodiment 3

[0032] A UV-curable transfer adhesive, composed of the following raw materials: 30g of silicone modified polybutadiene acrylate, 14g of polyester acrylate, 20g of polyurethane acrylate, 16.5g of propylene oxide glycerol triacrylate, and phenoxymethyl Hydroxyethyl acrylate (PHEMA) 13.5g, 1-hydroxycyclohexyl phenyl ketone 2g, 2,4,6-trimethylbenzoyl-diphenyl phosphine oxide 2g, vinyl trimethoxysilane 1g, 2-(2',4'-dihydroxyphenyl)-5,6-dihydroxybenzotriazole 0.5g, 2-(2'-hydroxy-3',5'-di-tert-phenyl)-5 -Chlorinated benzotriazole 0.5g.

[0033] Prepare according to the following method: add the above initiator and 16.5g of propylene oxide glycerol triacrylate to a star vacuum mixer in a thousand-level dust-free workshop, heat to 60℃, stir and dissolve; then add the above oligomer and phenoxy 13.5g of methethyl acrylate (PHEMA), heated to 60°C under vacuum, and stirred evenly; finally, add the above additives, disperse at high speed with a disperser, press and filter, and pack to obtain...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com