Patents

Literature

33results about How to "Fast light curing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ultraviolet-curing liquid-state optical cement

ActiveCN102965067AGood adhesionLaminating thickness is thinNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesPolyesterPolymer science

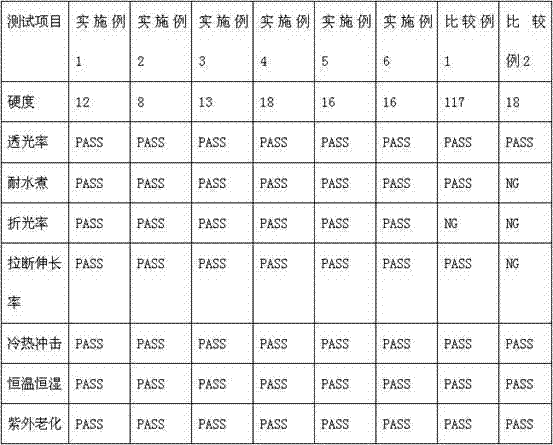

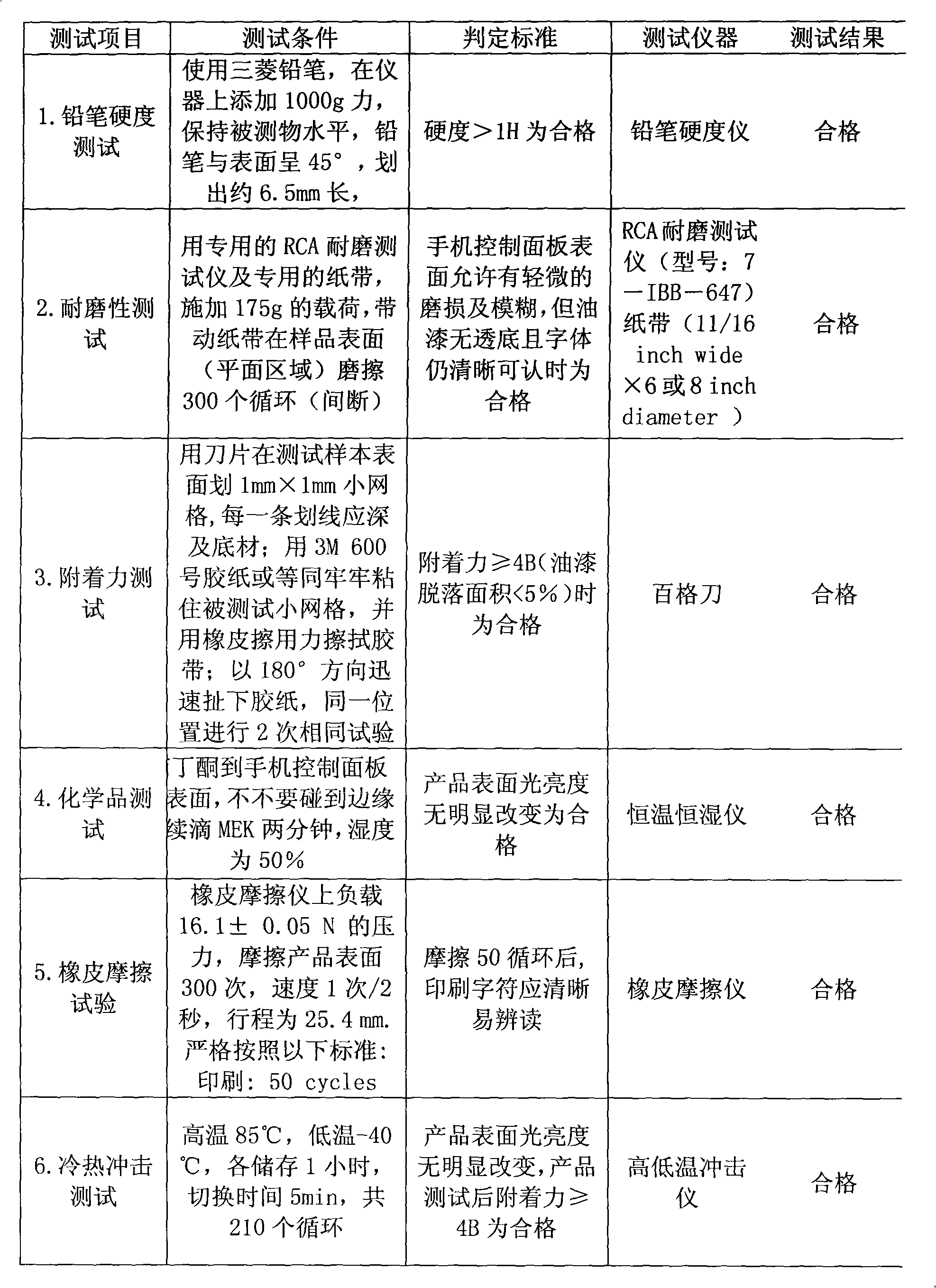

The invention discloses a ultraviolet-curing liquid-state optical cement. The ultraviolet-curing liquid-state optical cement includes the following components by weight percent: 50-75% of low polymer, 20-40% of activated monomer, 3-6% of free radical type photoinitiator and 2-4% of accessory ingredient, wherein the low polymer comprises one or more of organosilicone modification polybutadiene acrylate, urethane acrylate and polyester acrylate, and the activated monomer is one of mono-functional group, bi-functional group and poly-functional group. The ultraviolet-curing liquid-state optical cement can be applied to fixed bonding between touch screen protective glass and protective glass as well as between the touch screen protective glass and an LCD (Liquid Crystal Display) screen, can be adequately cured within an energy of 3000 mj / cm<2> under a room temperature, the whole-line light transmittance can reach 93% or more, the refractive index exceeds 1.50, the light transmittance of a touch screen can be greatly improved, and the rate of finished products is improved; the ultraviolet-curing liquid-state optical cement is more suitable for continuous production; the production efficiency is improved; and the ultraviolet-curing liquid-state optical cement is stable in performance and good in environmental protection property in a high-temperature and high-humidity environment.

Owner:SUZHOU BETELY POLYMER MATERIALS CO LTD

Ultraviolet (UV) curing ink and preparation method thereof

The invention relates to ultraviolet (UV) curing ink and a preparation method thereof. The UV curing ink comprises the components by mass percent: 32-42% of non-isocyanate polyurethane acrylate oligomer, 16-24% of epoxy acrylate oligomer, 18-32% of reactive diluent, 3-6% of photoinitiator, 2-4% of nano silicon dioxide, 1-2% of auxiliary agents and 6-12% of pigments. The invention also discloses the preparation method of the UV curing ink. The UV curing ink does not contain a polyisocyanic acid functional group, has environmental protection property, is rapid in photocuring, and has good gloss as well as excellent adhesive force, mechanical property and oil resistance.

Owner:广东理想彩色印务有限公司

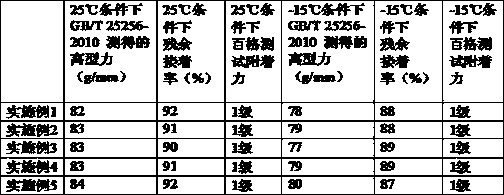

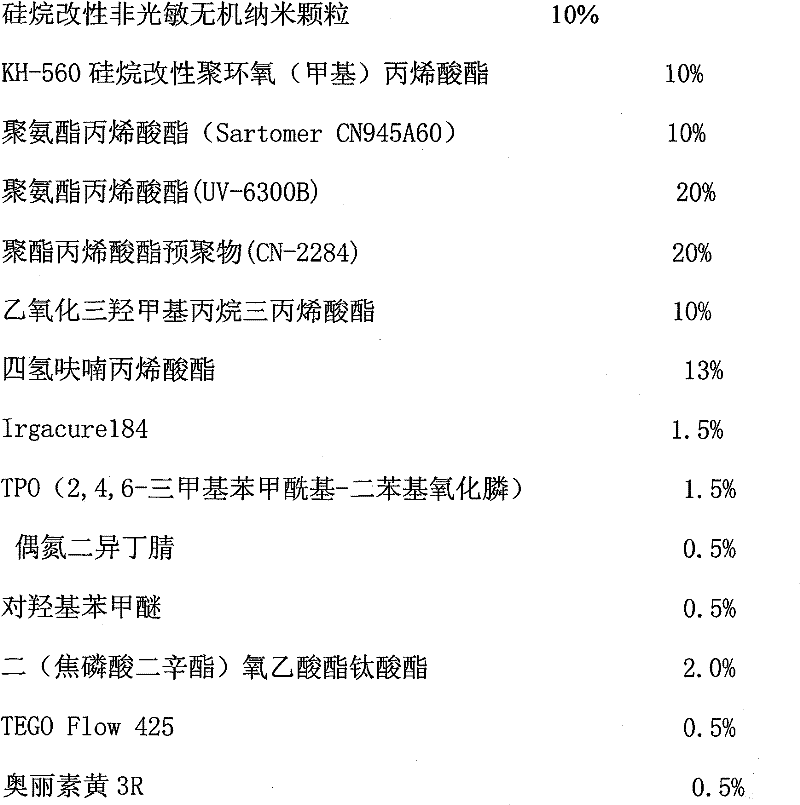

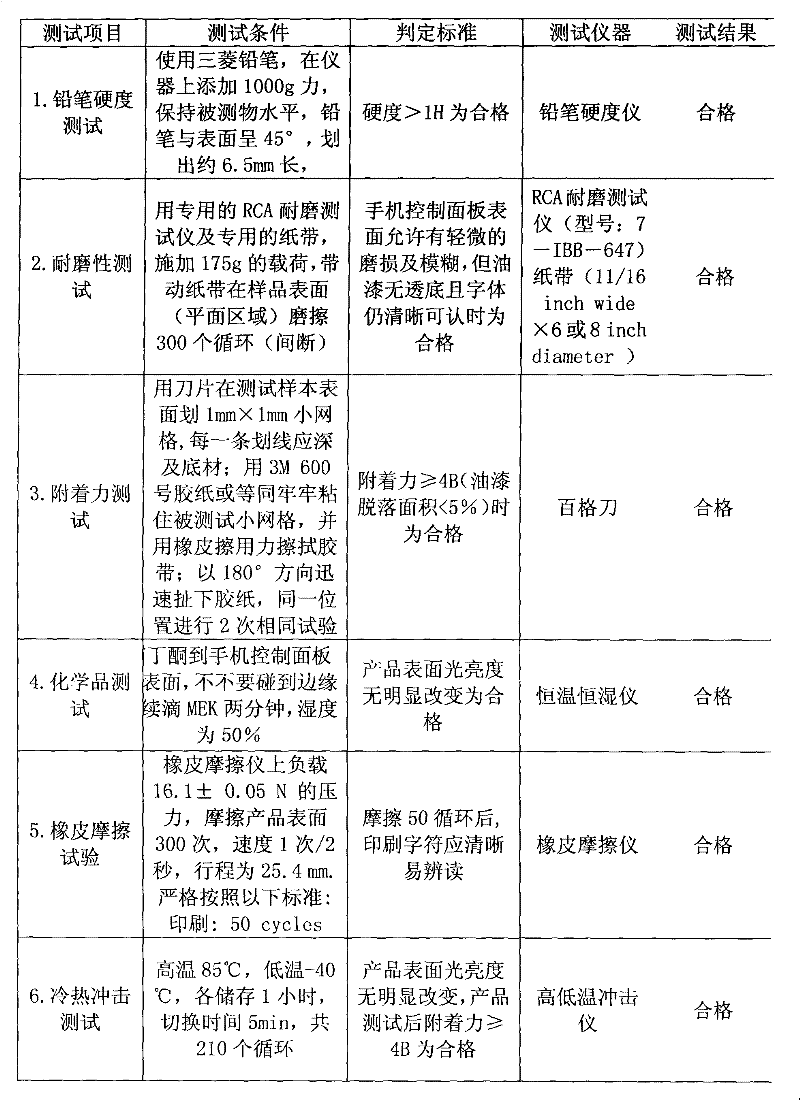

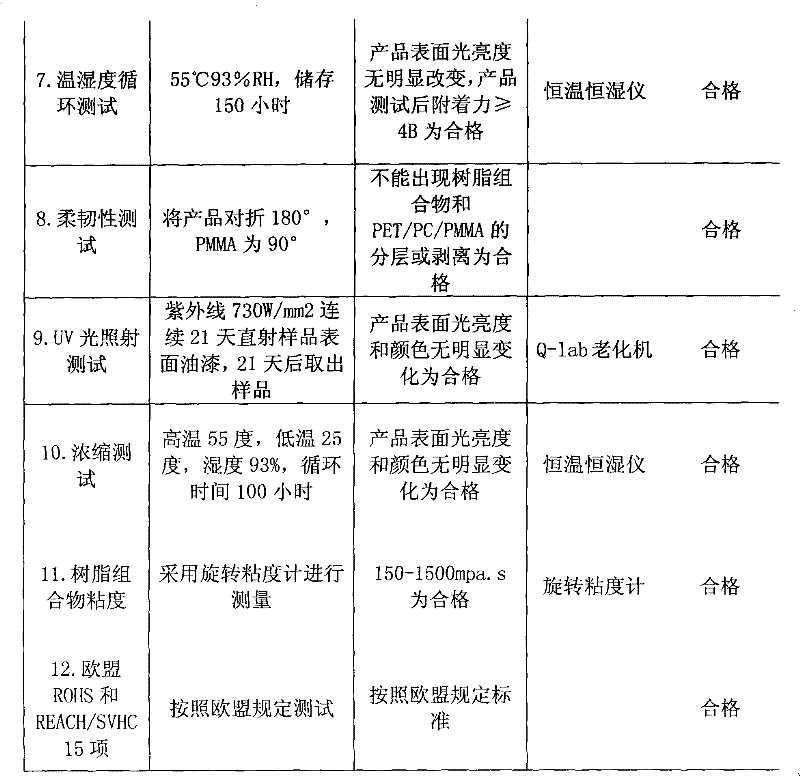

Modified photo-hardening resin composition for high-wear-resistance/high-toughness/high-hardness nanometer materials

InactiveCN101665559ALow costFast light curingPigment treatment with non-polymer organic compoundsPolymer scienceSilanes

The invention discloses a modified photo-hardening resin composition for high-wear-resistance / high-toughness / high-hardness nanometer materials, which consists of silane-modified non-photosensitive inorganic nanometer particles, silane-modified polypropylene (methyl) oxide acrylate prepolymers, resin prepolymer mixture, mixed active monomers, a photo initiator, a thermal initiator and assistants. The resin composition has the advantages of high hardness, high wear resistance, high toughness, high yellowing resistance, high temperature and humidity resistance, wide applicability and the like.

Owner:NANTONG MEMTECH TECH

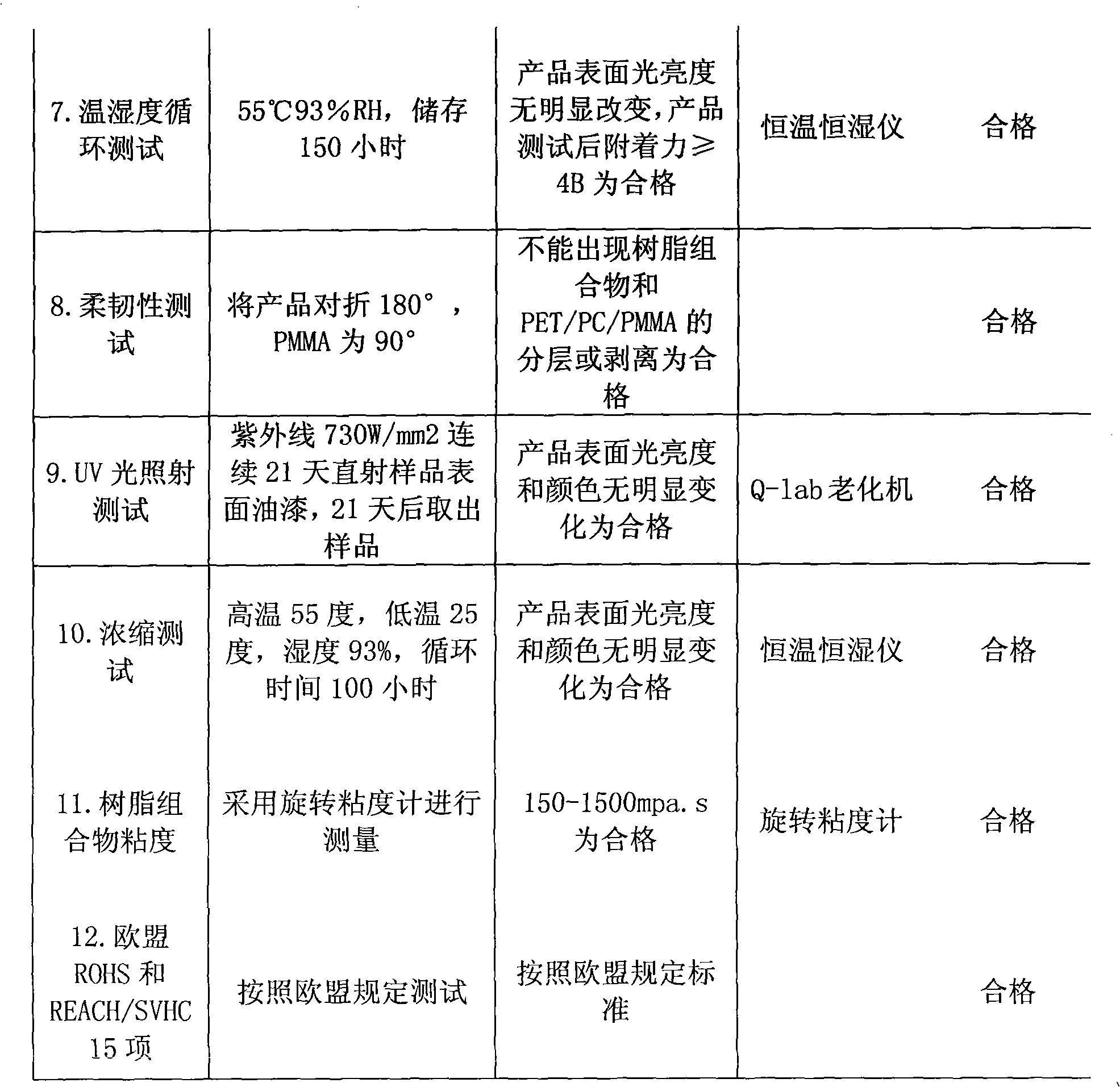

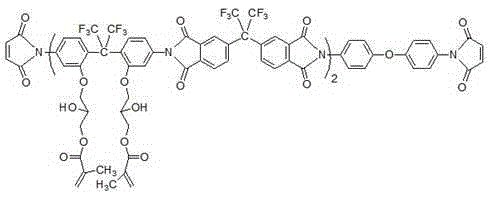

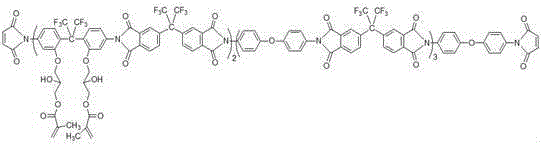

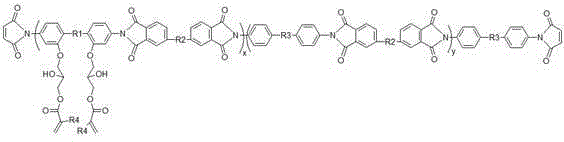

Polyimide oligomer capable of quick photocuring and preparation method and application thereof

ActiveCN105153127AControllable functionalityMolecular weight controllableOrganic chemistryCoatingsHydrogenOligomer

The invention discloses a polyimide oligomer capable of quick photocuring. The structural general formula of the oligomer is disclosed in the specification, wherein 1<=x<=25, and 0<=y<=25; R1 is selected from one of isopropylidene group and sulfinyl group; R2 and R3 are selected from one of ether oxy group, sulfinyl group, carbonyl group, hexafluoroisopropylidene group, bis(4-phenoxy)isopropylidene group, 1,4-p-diphenoxy group and 1,3-m-diphenoxy group; and R4 is selected from one of hydrogen and methyl group. The invention also discloses a preparation method and application of the oligomer. The method is simple, and has the advantages of accessible raw materials and lower cost. The preparation technique is compatible with universal technological equipment, and is beneficial to industrialization.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Photocurable polyetheretherketone oligomer and preparation method thereof

The invention discloses a photocurable polyetheretherketone oligomer. The photocurable polyetheretherketone oligomer has molecular weight of 1000 to 10000 and has a general structural formula shown inthe description. In the formula, n is greater than or equal to 1 and less than or equal to 10, R1 represents one or more of groups shown in the description, R2 represents one or more of groups shownin the description, R3 represents one or more of O and groups shown in the description and R4 represents one of H and CH3. The invention also discloses a preparation method of the photocurable polyetheretherketone oligomer. The preparation method improves the solubility of polyetheretherketone in an active diluent, realizes the unsaturation and molecular weight controllable preparation of the polyetheretherketone oligomer and solves the problems of dissolution difficulty and melting difficulty. Through use of the active double bond, the polyetheretherketone resin can be directly and fast curedand molded without the conventional high-temperature molding method.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

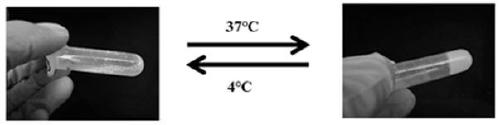

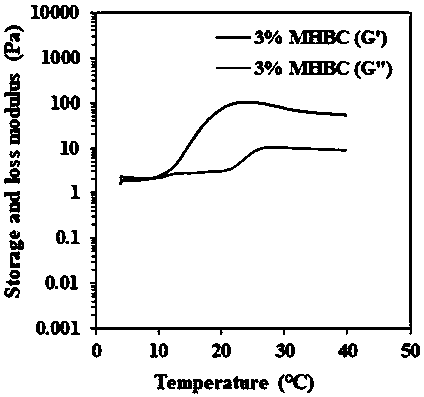

Light/temperature double sensitive hydrogel and preparation method thereof

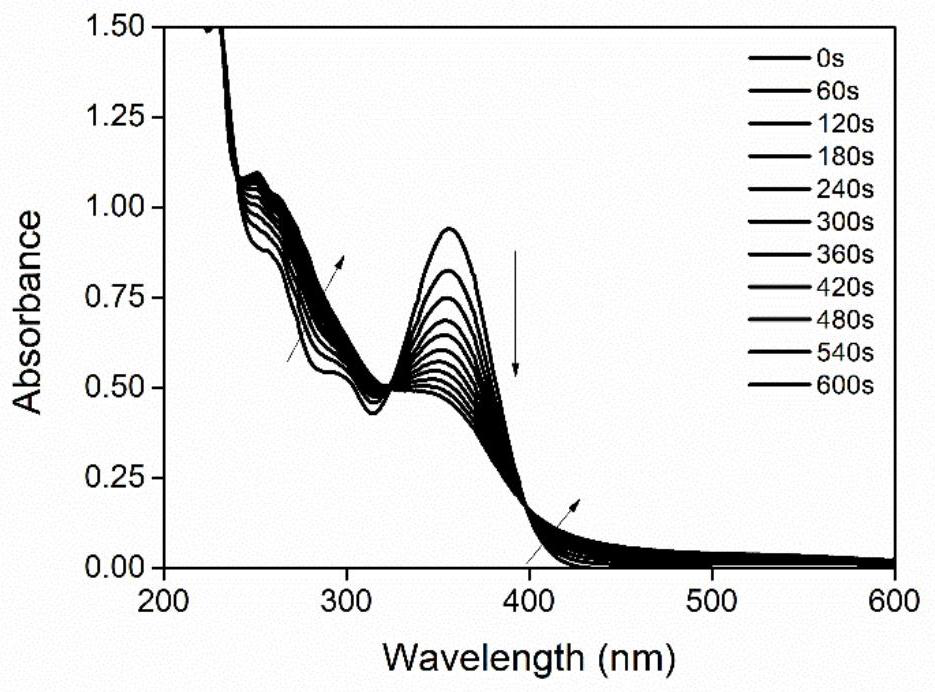

The invention discloses a light / temperature double sensitive hydrogel and a preparation method thereof, wherein the temperature sensitive part of the hydrogel is obtained by introducing hydroxybutyl into a chitosan molecular chain (Patent No. 201110214776.X), and the free amino group of hydroxybutyl chitosan and the epoxy group of glycidyl methacrylate are subjected to a ring-opening reaction to introduce a photosensitive group so as to obtain the photosensitive part. According to the present invention, the methacrylylated hydroxybutyl chitosan hydrogel is in a solution state at a low temperature, can be subjected to flowing injection, and can form a hydrogel within 1 min when a temperature is raised to around 37 DEG C; a photoinitiator is added into a prepolymer solution, the obtained solution is exposed to ultraviolet light, and the photoinitiator generates free radicals to initiate methacryloyl-substituted chain polymerization, such that the strength of the gel is significantly enhanced; and the light / temperature double sensitive hydrogel has good application prospects in the fields of tissue engineering scaffolds or drug sustained-release delivery and the like.

Owner:OCEAN UNIV OF CHINA

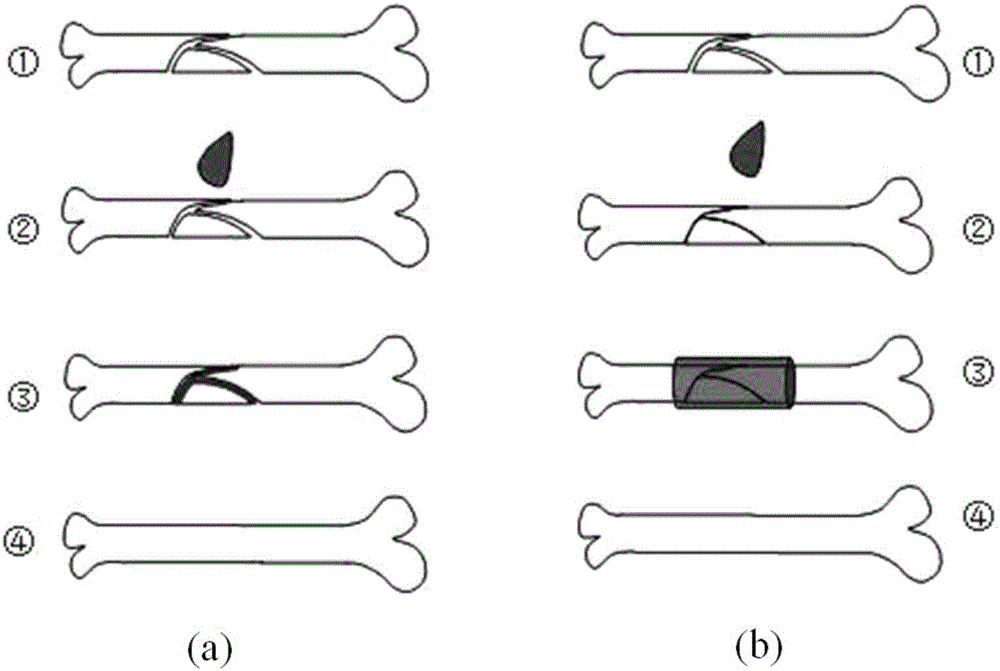

Application of PPF/PPF-DA (Poly(propylene fumarate)/Poly(propylene fumarate)-Diacrylate) light-curing material to preparation of bone adhesive tape

The invention discloses application of a PPF / PPF-DA (Poly(propylene fumarate) / Poly(propylene fumarate)-Diacrylate) light-curing material to preparation of a bone adhesive tape. The double-bond ratio of PPF to PPF-DA in the PPF / PPF-DA light-curing material ranges from (1 to 4) to (3 to 1); a preparation method comprises the following steps: uniformly mixing the PPF and the PPF-DA in dichloromethane; decompressing and distilling to remove a solvent for later use; adding BAPO into a mixture; carrying out ultrasonic vibration and uniformly mixing. The PPF / PPF-DA light-curing material has the characteristics of short curing time, high strength of the cured material, less heat releasing in a curing process, degradability and the like and can be applied to the field of biological medical materials; the mechanical problems of treatment of comminuted fracture in orthopaedics clinical and the like are solved.

Owner:XI AN JIAOTONG UNIV

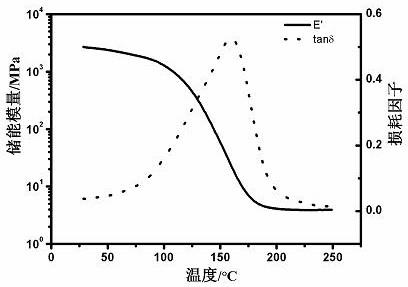

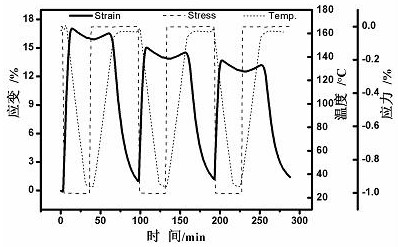

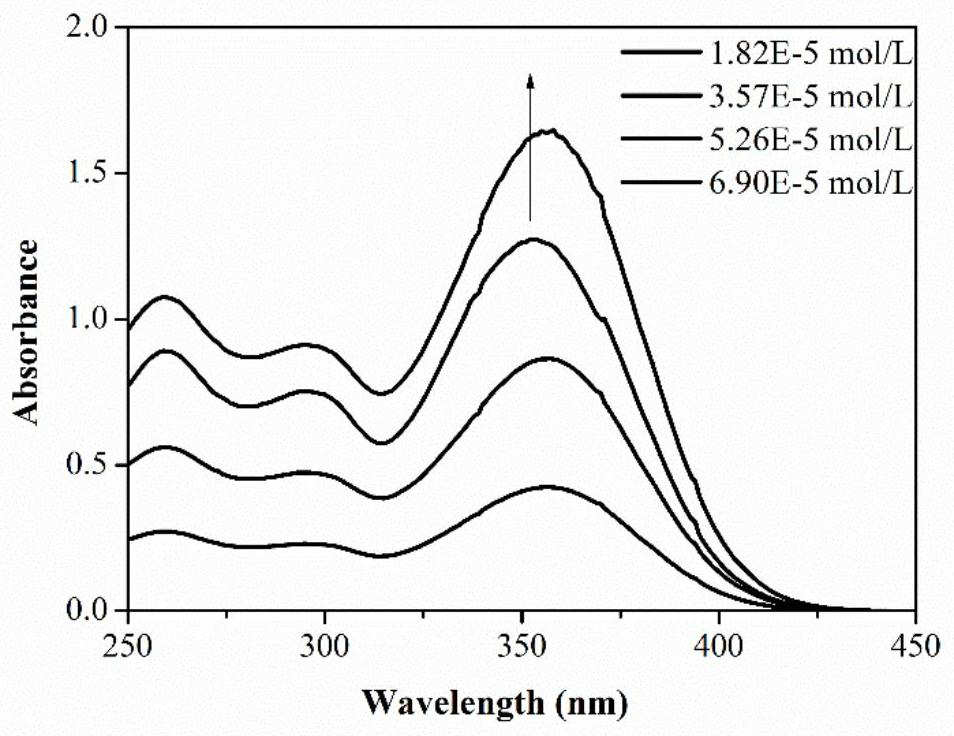

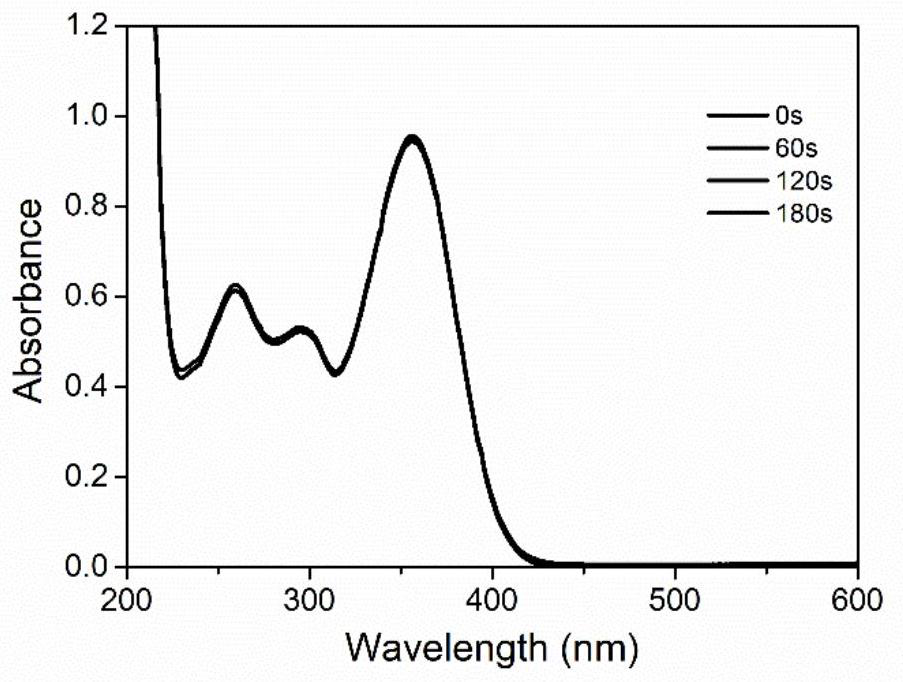

Application and preparation method of photocurable polyimide ink for 3D printing

ActiveCN109485851AImprove the accuracy of light curingHigh mechanical strengthAdditive manufacturing apparatusBenzoic acidPolymer science

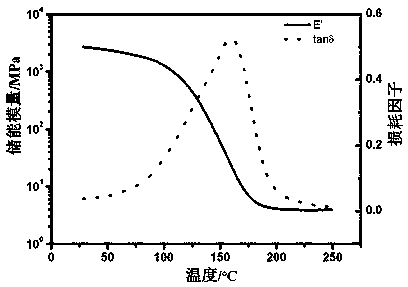

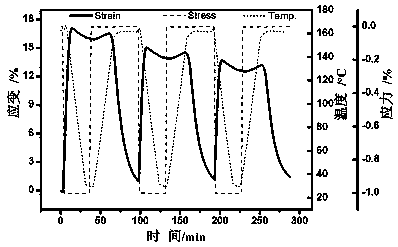

The invention relates to a preparation method of photocurable polyimide ink for 3D printing. The method includes steps: (1) sequentially adding N-methyl-2-pyrrolidone, 4, 4'-(4,4'-isopropyl diphenoxyl)diphthalic anhydride and 4,4' diaminodiphenyl ether into 3,5-diaminobenzoic acid to obtain copolyimide through imidization; (2) preparing methacrylate grafted polyimide, to be more specific, adding N-methyl-2-pyrrolidone into a copolyimide product to obtain solution A, adding methylacrylic acid-beta-hydroxyethyl ester, N,N'-dicyclohexyl carbimide and 4-dimethylamino pyridine into N-methyl-2-pyrrolidone to obtain solution B, and subjecting the solution A and the solution B to Steglich esterification reaction to obtain methacrylate grafted polyimide; (3) dissolving methacrylate grafted polyimide into N-vinyl-2-pyrrolidone, and sequentially adding isobornyl methacrylate, hydroquinone and Irgacure2100 to obtain photocurable polyimide ink. The invention further discloses application of the ink. The method is simple, and the obtained ink has a shape memory effect and is available for quick photocuring.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

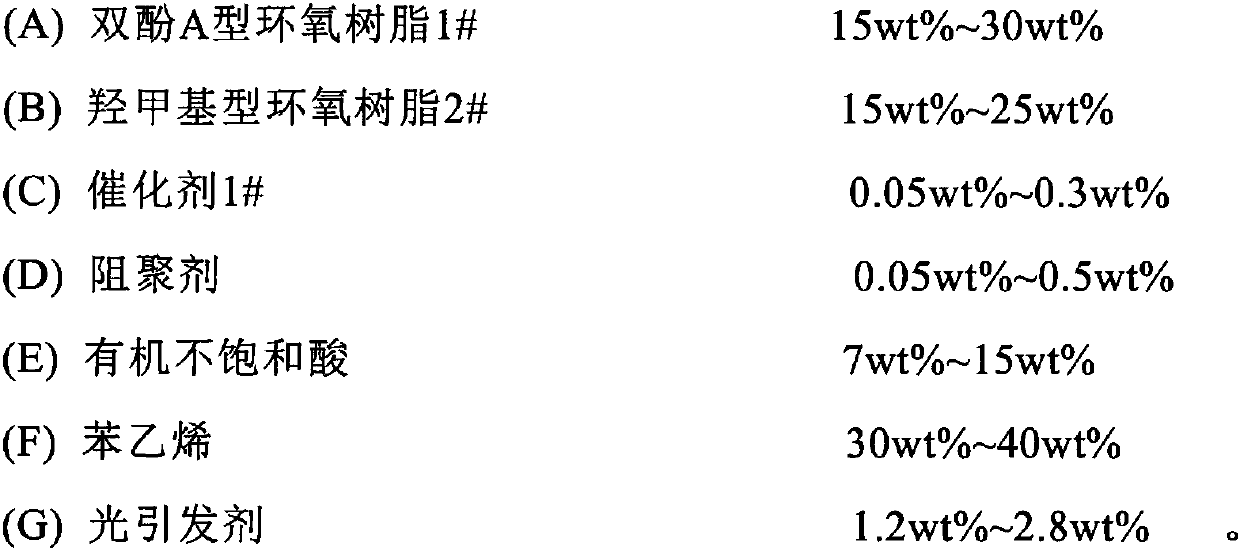

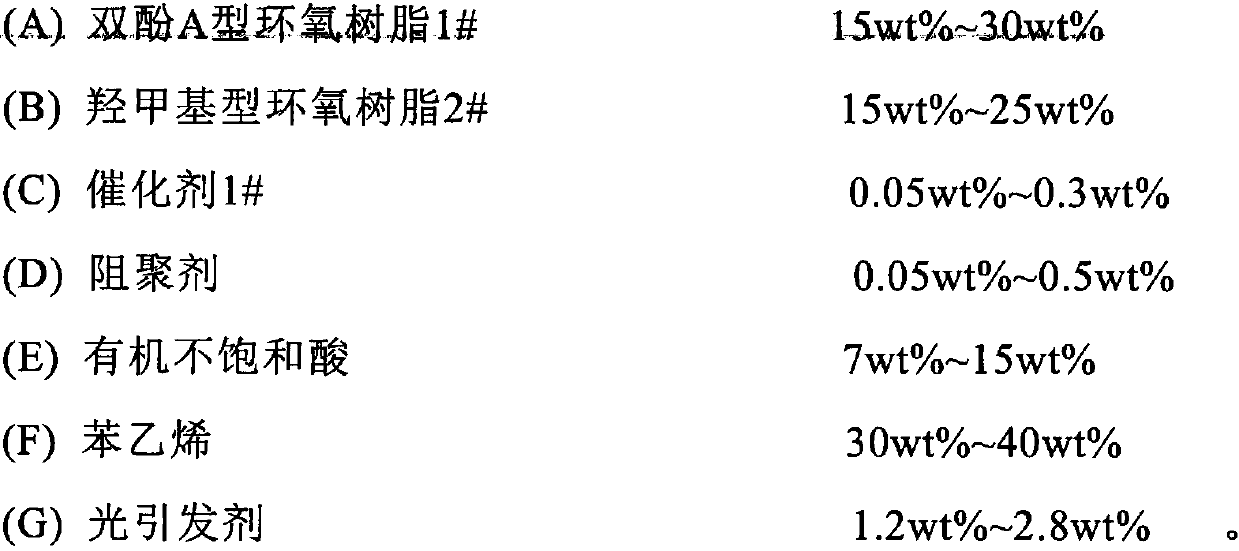

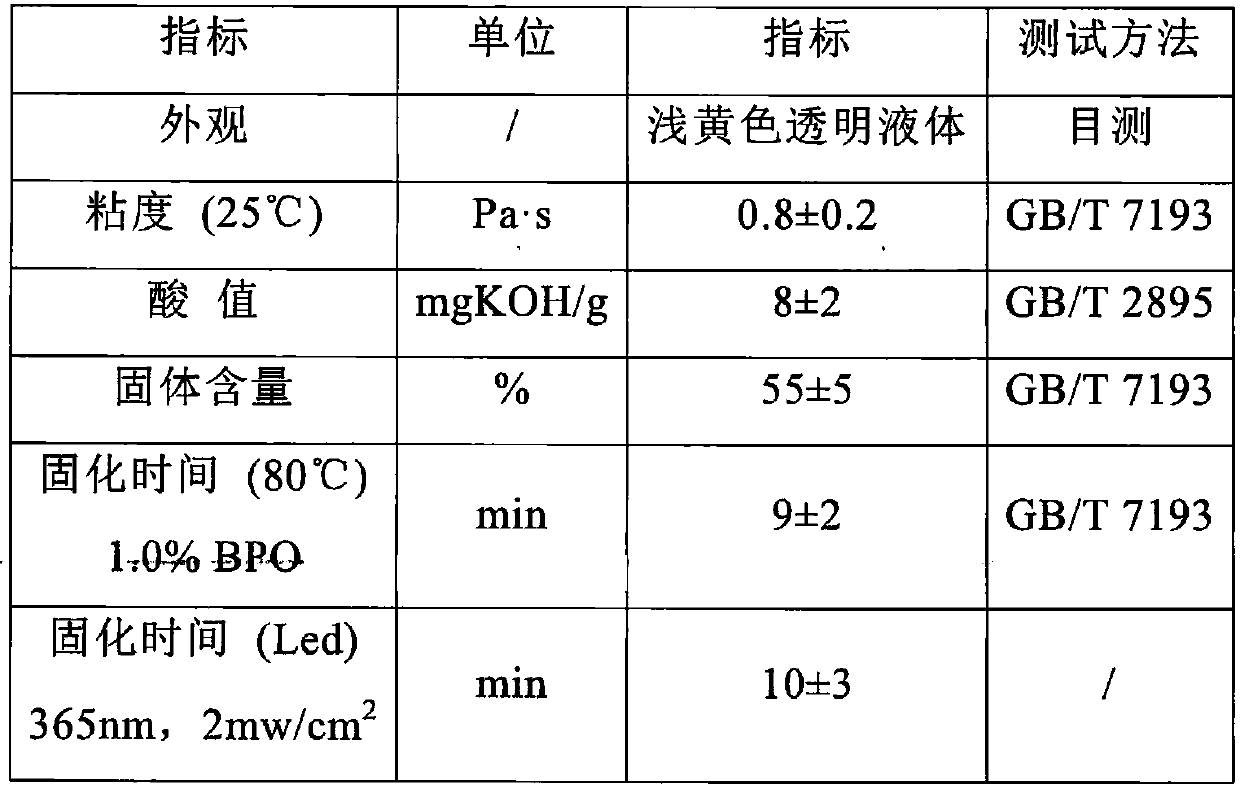

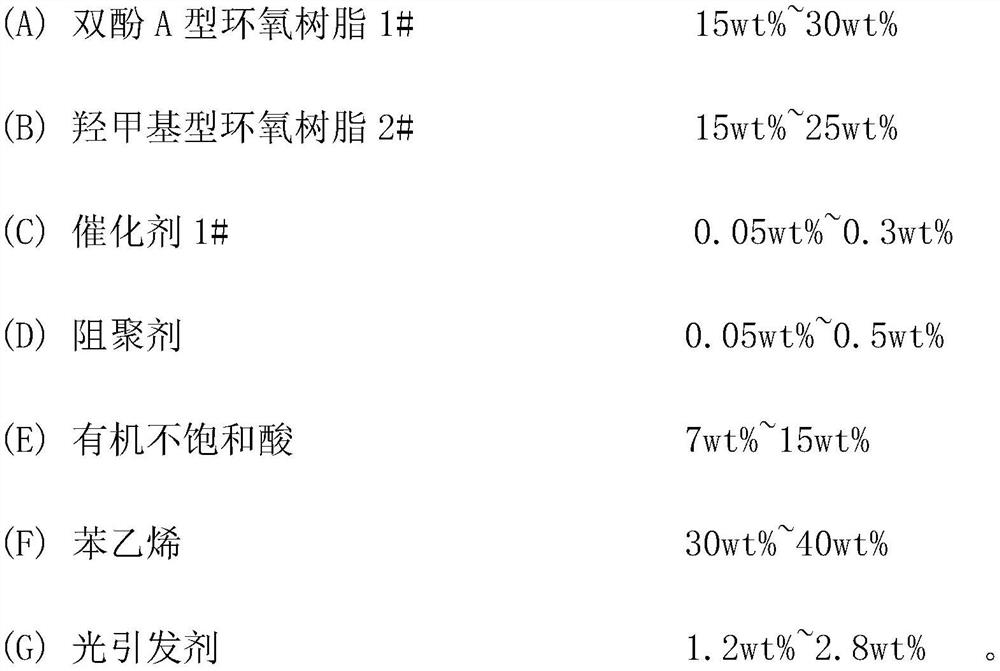

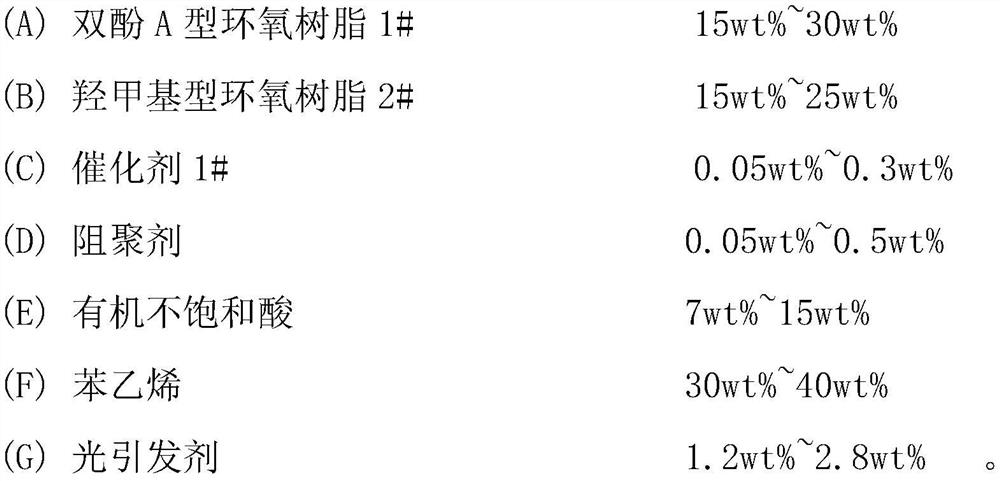

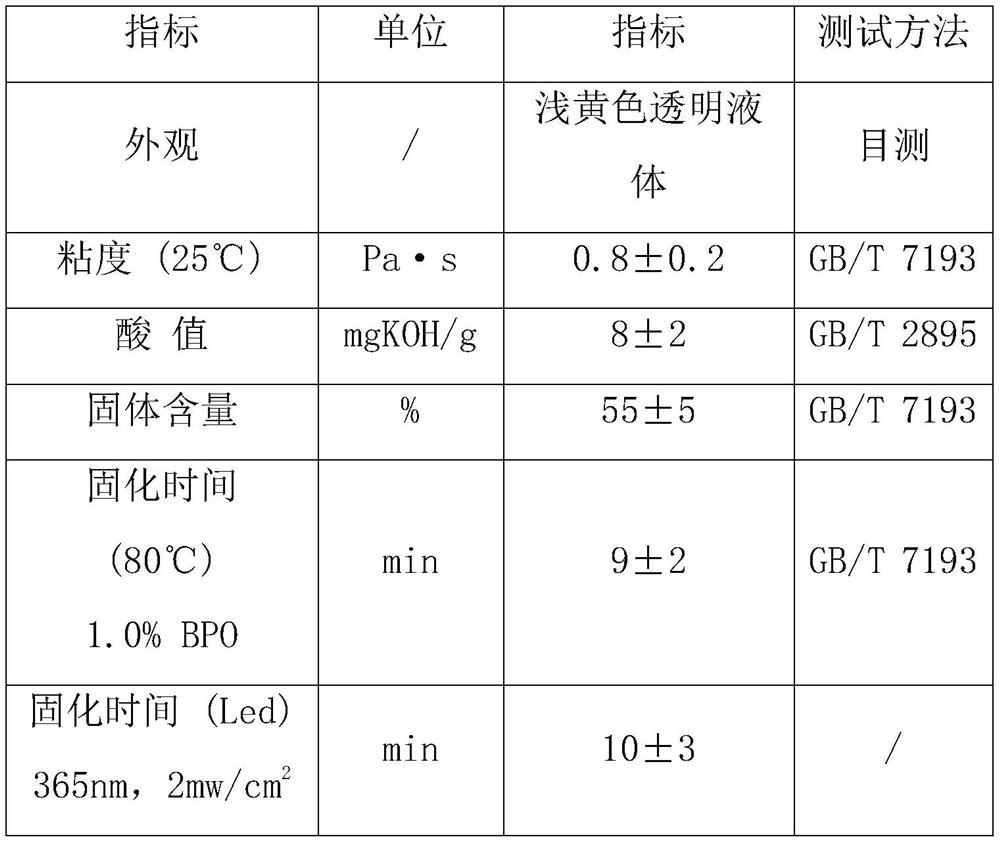

Temperature-resistant thickening light-cured epoxy vinyl ester resin and preparation method thereof

The invention relates to a temperature-resistant thickening light-cured epoxy vinyl ester resin and a preparation method thereof, and specifically discloses an epoxy vinyl ester resin composition. Thecomposition comprises components (A) to (G). The invention also discloses a method for preparing the resin composition, and a resin product comprising the resin composition.

Owner:HUACHANG POLYMER EAST CHINA UNIV OFSCI & TECH

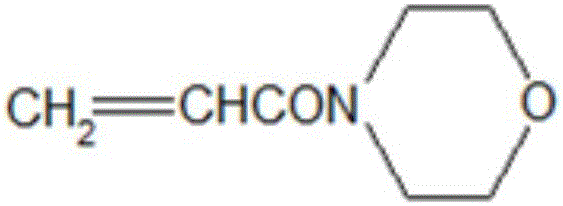

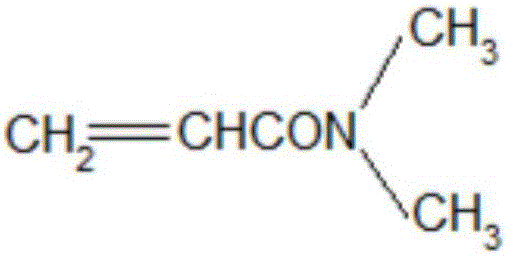

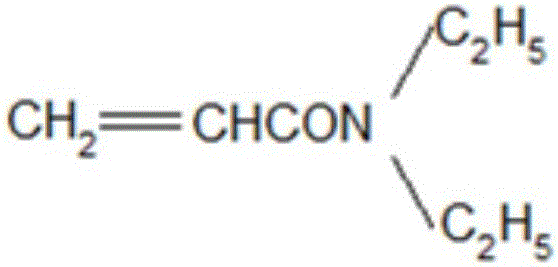

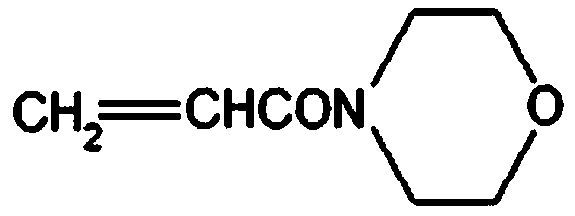

Photo-curable resin composition

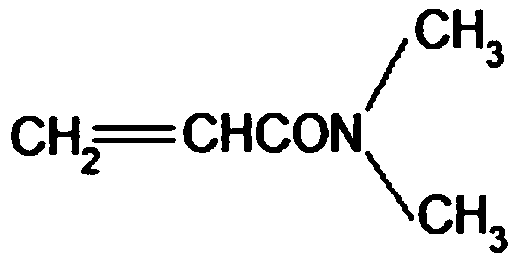

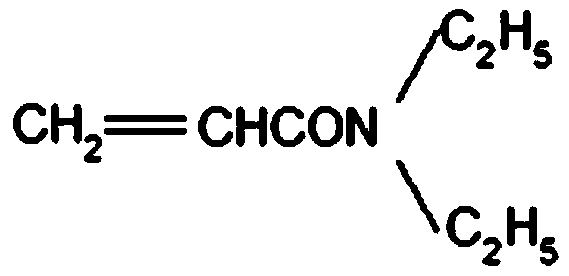

The present invention relates to a photo-curable resin composition and, more particularly, to a photo-curable resin composition for forming micro patterns, the photo-curable resin composition being applicable to a flexible display substrate since the composition can be cured at high speed and has excellent coating properties, adhesive properties and acid resistance by virtue of comprising acrylamide monomer.

Owner:DONGJIN SEMICHEM CO LTD

Photocurable resin composition

Owner:DONGJIN SEMICHEM CO LTD

A kind of photocurable polyether ether ketone oligomer and preparation method thereof

The invention discloses a photocurable polyetheretherketone oligomer. The photocurable polyetheretherketone oligomer has molecular weight of 1000 to 10000 and has a general structural formula shown inthe description. In the formula, n is greater than or equal to 1 and less than or equal to 10, R1 represents one or more of groups shown in the description, R2 represents one or more of groups shownin the description, R3 represents one or more of O and groups shown in the description and R4 represents one of H and CH3. The invention also discloses a preparation method of the photocurable polyetheretherketone oligomer. The preparation method improves the solubility of polyetheretherketone in an active diluent, realizes the unsaturation and molecular weight controllable preparation of the polyetheretherketone oligomer and solves the problems of dissolution difficulty and melting difficulty. Through use of the active double bond, the polyetheretherketone resin can be directly and fast curedand molded without the conventional high-temperature molding method.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

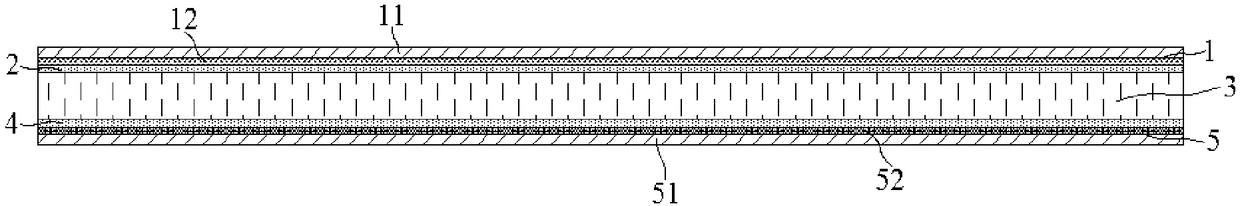

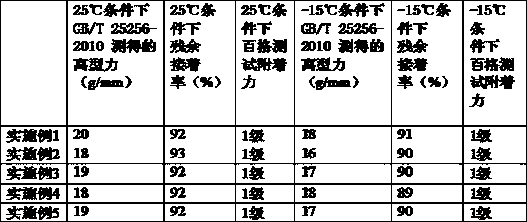

Optical transparent double-sided tape

InactiveCN108690521AImprove residual adhesionReduce transfer rateCoatingsFilm/foil adhesive release linersAdhesiveHigh heat

The invention discloses an optical transparent double-sided tape. The optical transparent double-sided tape comprises a light-peeling release film, a first optical adhesive layer, a transparent substrate layer, a second optical adhesive layer, and a heavy-peeling release film, the light-peeling release film comprises a first basic film layer and a light-peeling release agent layer used for coatingthe surface of the first basic film layer, the light-peeling release agent layer is obtained by solidifying with a light-peeling release agent, the heavy-peeling release film comprises a second basicfilm layer and a heavy-peeling release agent layer used for coating the surface of the second basic film layer, and the heavy-peeling release agent layer is obtained by solidifying with a heavy-peeling release agent. The optical transparent double-sided tape overcomes the defects that the current release agents can keep stable low peel strength under normal temperature and high temperature, realizes low peel strength under low temperature, and increases the product weatherability.

Owner:ZHEJIANG OUREN NEW MATERIALS CO LTD

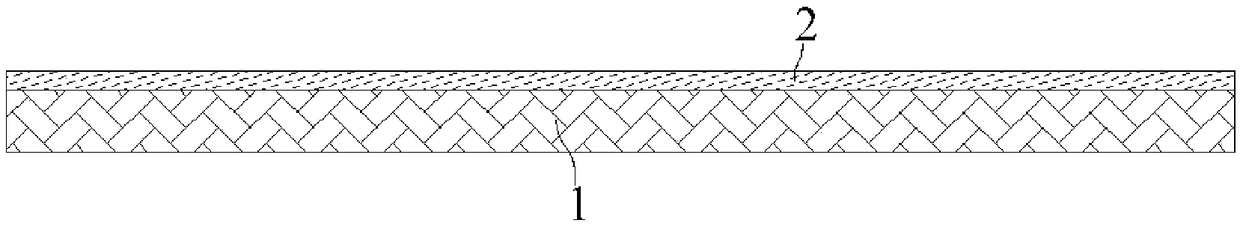

Optical release film

InactiveCN108690525AImprove weather resistanceImprove residual adhesionCoatingsFilm/foil adhesive release linersDistillationDibenzoyl Peroxide

The invention discloses an optical release film. The optical release film comprises a base film layer, a release agent layer coated at the surface of the base film layer, and the release agent layer is obtained by solidifying a release agent. The release agent comprises the following components: prepolymerized resin, methylhydroquinone, 3-epoxypropane, dodecyl glycidyl ether, and 1-hydroxy cyclohexyl phenylketone. The prepolymerized resin is obtained by the following steps: mixing cyclohexyl methacrylate, beta-carboxyethyl acrylate, and acrylic acid in a stirring barrel, and uniformly stirringthe materials at a low speed to form a primary mixture; mixing primary mixture, xylene, and benzoyl peroxide and adding a mixture in a reaction vessel to obtain a polymer solution; stirring the polymer solution and 2-hydroxyethyl vinyl ether at a high speed, and heating the materials and performing heating distillation to remove xylene to obtain the prepolymerized resin. The release film increases the product weatherability, cannot generate unfavorable influence on electric property of a circuit board, and increases the reliability of the circuit board.

Owner:ZHEJIANG OUREN NEW MATERIALS CO LTD

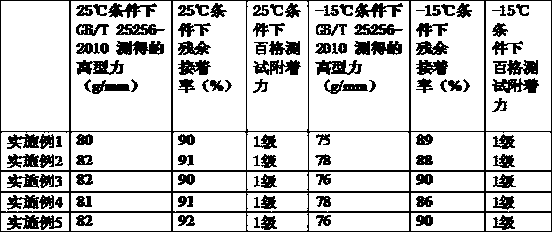

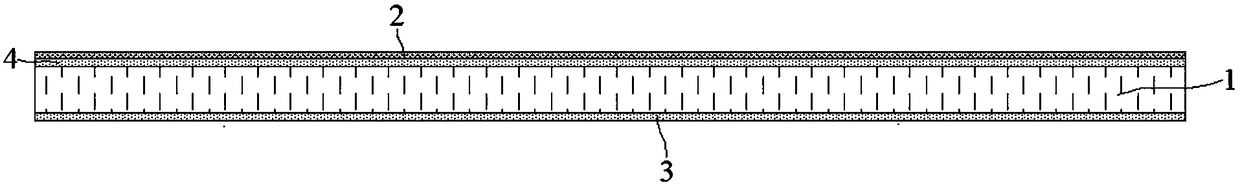

Double-resisting one-side release material

InactiveCN108690522AImprove residual adhesionReduce transfer rateCoatingsFilm/foil adhesive release linersVinyl etherBenzoyl peroxide

The invention discloses a double-resisting one-side release material. The release material comprises a base film layer, a release agent layer coated at the upper surface of the base film layer, an antistatic coating layer coated at the lower surface of the base film layer, and the release agent layer is obtained by solidifying a release agent. The release agent comprises the following components:prepolymerized resin, methylhydroquinone, 3-epoxypropane, dodecyl glycidyl ether, and 1-hydroxy cyclohexyl phenylketone. The prepolymerized resin is obtained by the following steps: mixing a primary mixture, xylene, and benzoyl peroxide, adding a mixture in a reaction vessel to obtain a polymer solution; stirring the polymer solution and 2-hydroxyethyl vinyl ether at a high speed, and heating thematerials and performing heating distillation to remove xylene to obtain the prepolymerized resin. The release material keeps stable low peel strength under low temperature, and realizes low-energy rapid light-curing under UV light irradiation.

Owner:ZHEJIANG OUREN NEW MATERIALS CO LTD

Modified photo-hardening resin composition for high-wear-resistance/high-toughness/high-hardness nanometer materials

InactiveCN101665559BLow costFast light curingPigment treatment with non-polymer organic compoundsPolymer scienceSilanes

The invention discloses a modified photo-hardening resin composition for high-wear-resistance / high-toughness / high-hardness nanometer materials, which consists of silane-modified non-photosensitive inorganic nanometer particles, silane-modified polypropylene (methyl) oxide acrylate prepolymers, resin prepolymer mixture, mixed active monomers, a photo initiator, a thermal initiator and assistants. The resin composition has the advantages of high hardness, high wear resistance, high toughness, high yellowing resistance, high temperature and humidity resistance, wide applicability and the like.

Owner:NANTONG MEMTECH TECH

A kind of temperature-resistant thickening light-curable epoxy vinyl ester resin and preparation method thereof

The invention relates to a temperature-resistant thickening light-curable epoxy vinyl ester resin and a preparation method thereof. Specifically, the present invention discloses an epoxy vinyl ester resin composition comprising components (A) to (G). Also disclosed are a preparation method of the resin composition and a resin product comprising the resin composition.

Owner:HUACHANG POLYMER EAST CHINA UNIV OFSCI & TECH

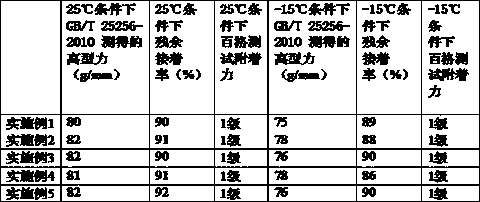

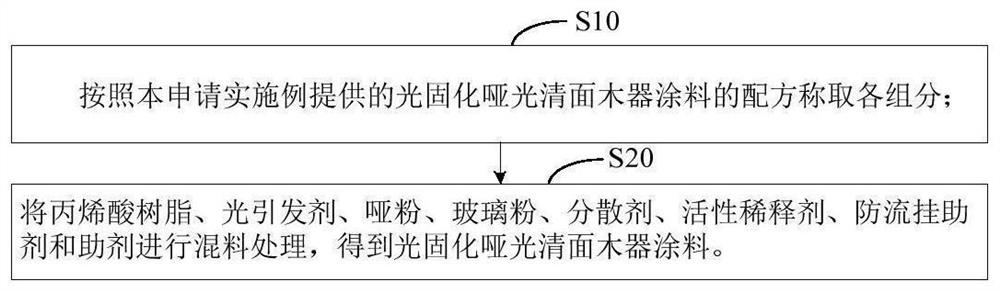

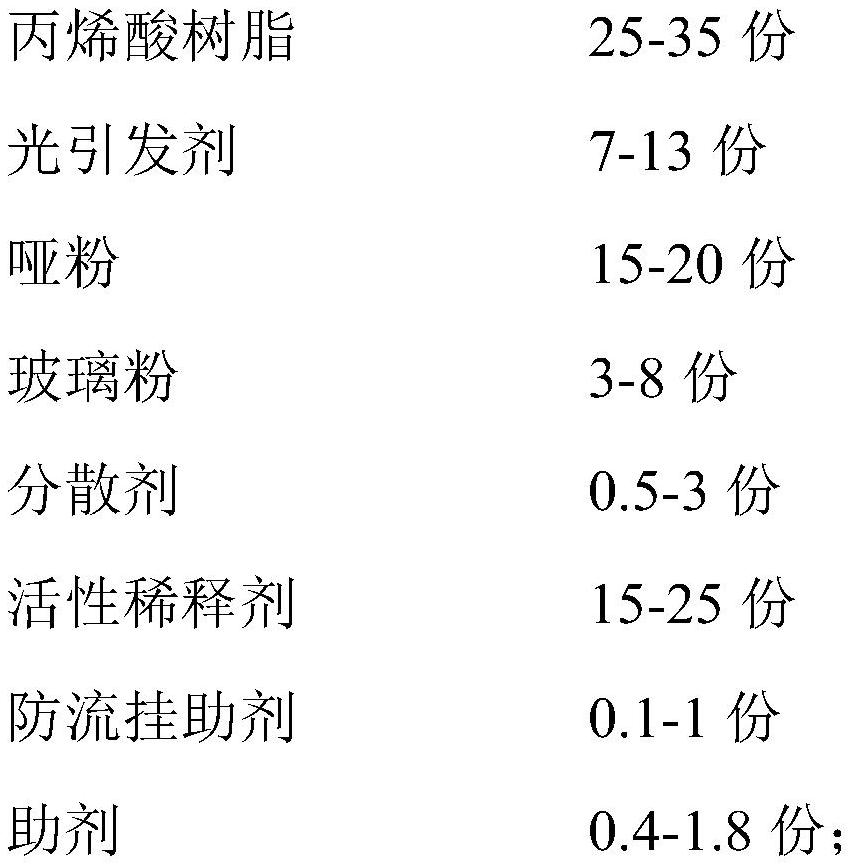

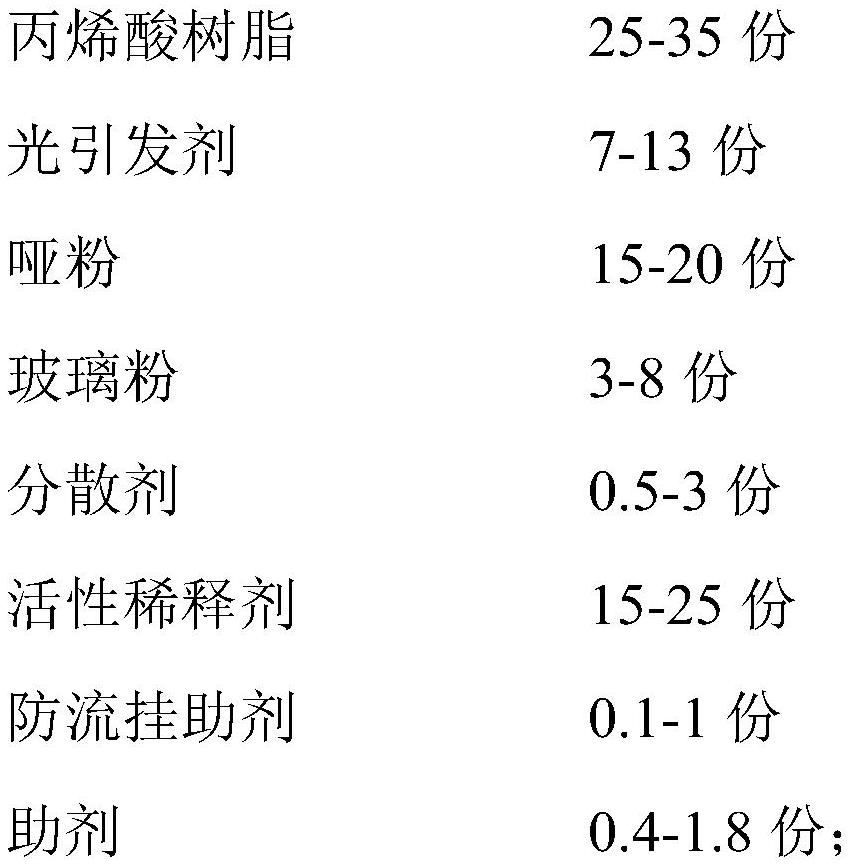

Photo-curing matte surface-cleaning wood coating and preparation method thereof

ActiveCN114456687AImprove light reaction speedReduce viscosityPolyurea/polyurethane coatingsPolyester coatingsPhoto irradiationAcrylic resin

The invention relates to the technical field of coatings, and provides a photocuring matte clean-surface wood coating. The invention provides a light-cured matte surface-cleaning wood coating. The light-cured matte surface-cleaning wood coating is prepared from 25-35 parts of acrylic resin, 7-13 parts of a photoinitiator, 15-20 parts of matte powder, 3-8 parts of glass powder, 0.5-3 parts of a dispersing agent, 15-25 parts of a reactive diluent, 0.1-1 part of an anti-sagging auxiliary agent and 0.4-1.8 parts of an auxiliary agent. Acrylic resin is used as a main component, contains carboxyl groups with higher reaction activity, can be compounded with a photoinitiator for use, can be quickly polymerized, cross-linked and cured within a very short time under the irradiation of LED (Light Emitting Diode) light, and is mixed with glass powder, matt powder, a dispersing agent, a reactive diluent, an anti-sagging auxiliary agent and an auxiliary agent at the same time; after a paint film is formed, the interlayer adhesive force is good, the covering power is high, the hardness is high, the scratch resistance is good, and the requirement that the Martindeer is smaller than or equal to the first grade can be met.

Owner:CHENGDU ZHANCHEN PAINT

A kind of preparation method and application of photocurable polyimide ink for 3D printing

ActiveCN109485851BImprove the accuracy of light curingHigh mechanical strengthAdditive manufacturing apparatusBenzoic acidPolymer science

The invention relates to a preparation method of photocurable polyimide ink for 3D printing. The method includes steps: (1) sequentially adding N-methyl-2-pyrrolidone, 4, 4'-(4,4'-isopropyl diphenoxyl)diphthalic anhydride and 4,4' diaminodiphenyl ether into 3,5-diaminobenzoic acid to obtain copolyimide through imidization; (2) preparing methacrylate grafted polyimide, to be more specific, adding N-methyl-2-pyrrolidone into a copolyimide product to obtain solution A, adding methylacrylic acid-beta-hydroxyethyl ester, N,N'-dicyclohexyl carbimide and 4-dimethylamino pyridine into N-methyl-2-pyrrolidone to obtain solution B, and subjecting the solution A and the solution B to Steglich esterification reaction to obtain methacrylate grafted polyimide; (3) dissolving methacrylate grafted polyimide into N-vinyl-2-pyrrolidone, and sequentially adding isobornyl methacrylate, hydroquinone and Irgacure2100 to obtain photocurable polyimide ink. The invention further discloses application of the ink. The method is simple, and the obtained ink has a shape memory effect and is available for quick photocuring.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

ppf/ppf-da light curing material bone tape

ActiveCN106729952BShort curing timeModerate degradation rateSurgical adhesivesPolymer scienceAdhesive belt

The invention discloses application of a PPF / PPF-DA (Poly(propylene fumarate) / Poly(propylene fumarate)-Diacrylate) light-curing material to preparation of a bone adhesive tape. The double-bond ratio of PPF to PPF-DA in the PPF / PPF-DA light-curing material ranges from (1 to 4) to (3 to 1); a preparation method comprises the following steps: uniformly mixing the PPF and the PPF-DA in dichloromethane; decompressing and distilling to remove a solvent for later use; adding BAPO into a mixture; carrying out ultrasonic vibration and uniformly mixing. The PPF / PPF-DA light-curing material has the characteristics of short curing time, high strength of the cured material, less heat releasing in a curing process, degradability and the like and can be applied to the field of biological medical materials; the mechanical problems of treatment of comminuted fracture in orthopaedics clinical and the like are solved.

Owner:XI AN JIAOTONG UNIV

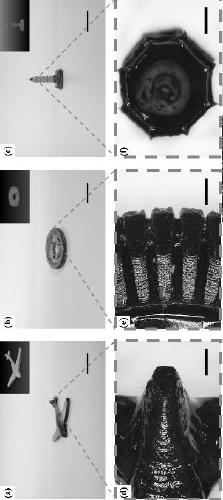

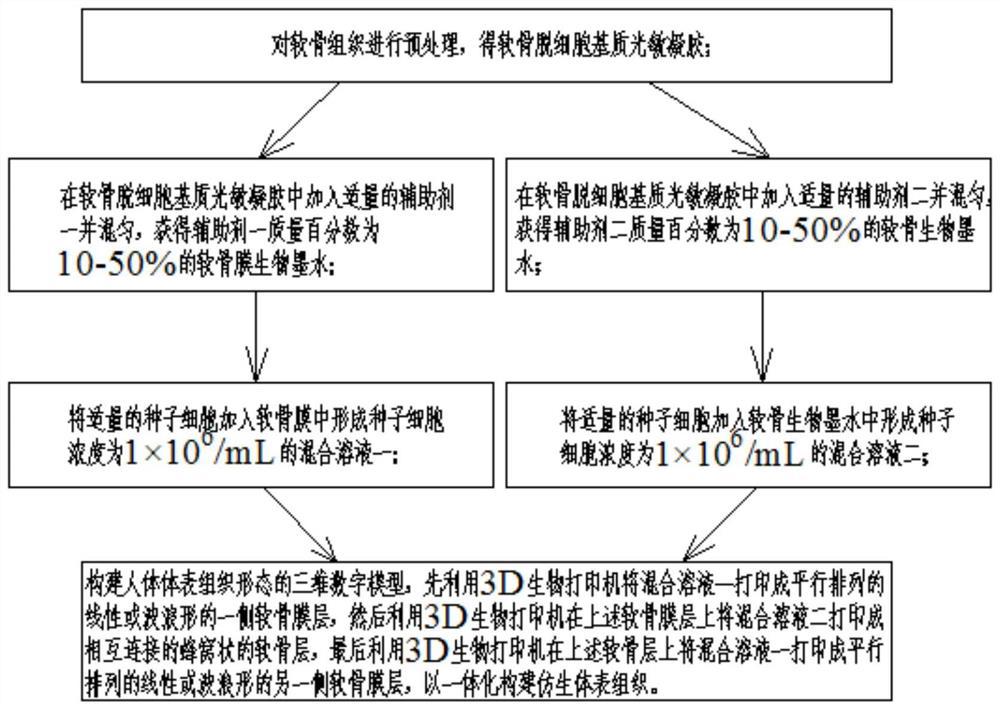

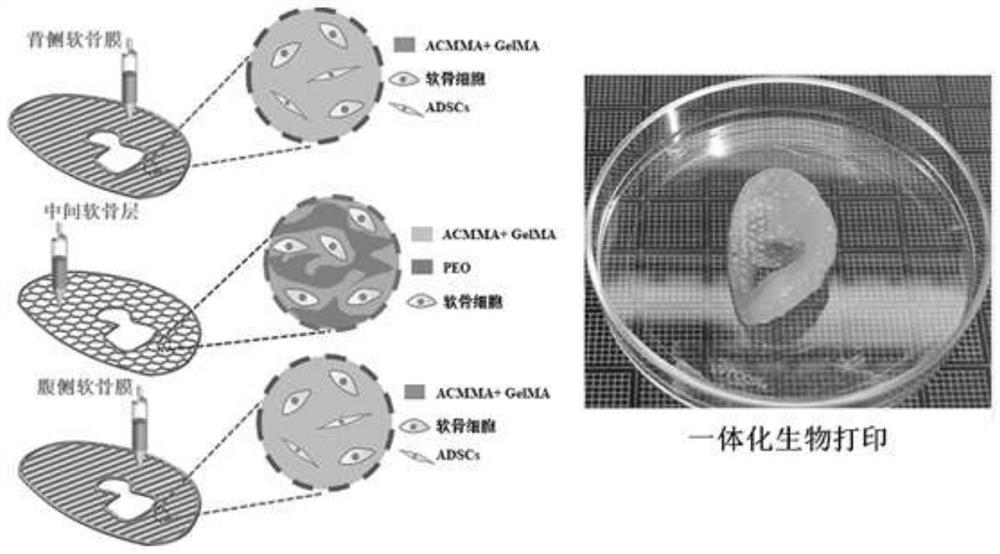

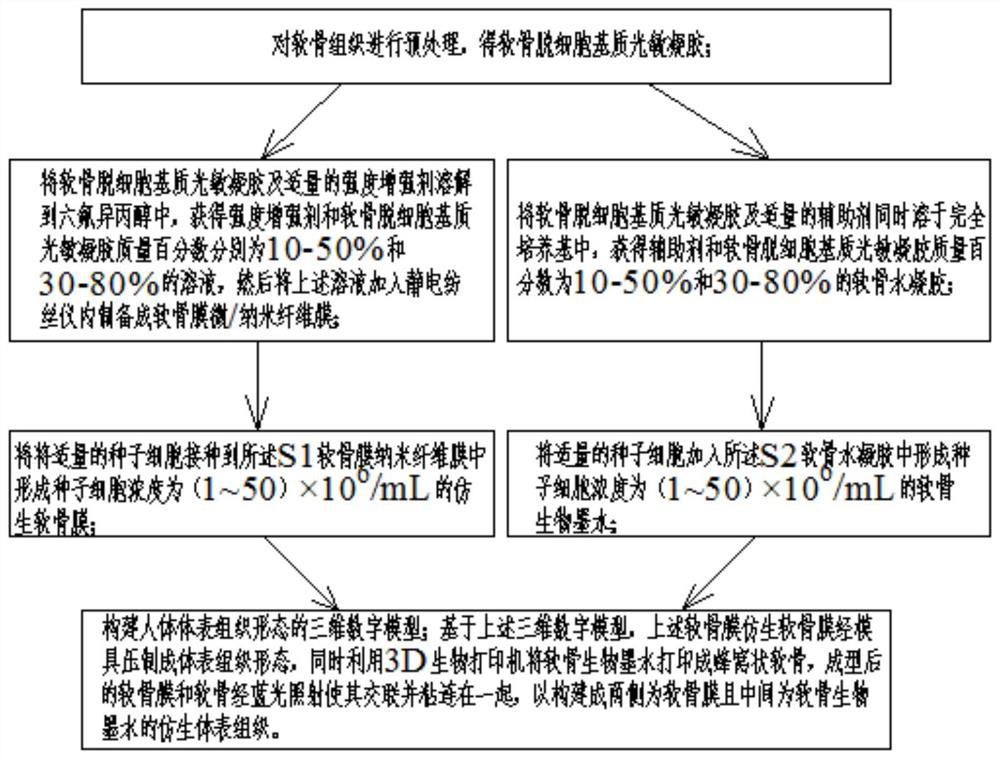

Composite bionic body surface tissue and integrated construction method thereof

ActiveCN114366855AImprove mechanical strengthMeet the needs of clinical applicationsAdditive manufacturing apparatusTissue regenerationAcellular matrixBiology

The invention relates to a composite bionic body surface tissue and an integrated construction method thereof, and the method comprises the following specific steps: adding a proper amount of an auxiliary agent into cartilage acellular matrix photosensitive gel, and uniformly mixing to obtain cartilage membrane bio-ink; adding a proper amount of auxiliary agent II into the cartilage acellular matrix photosensitive gel, and uniformly mixing to obtain cartilage biological ink; adding seed cells into cartilage membrane bio-ink to form a mixed solution I, and adding a proper amount of seed cells into cartilage bio-ink to form a mixed solution II; and integrally constructing the composite bionic body surface tissue by using the mixed solution I and the mixed solution II. The method has the beneficial effects that the body surface tissue with the bilateral cartilage membranes and the middle cartilage tissue is constructed, the structure and composition characteristics of the body surface tissue containing the cartilage membranes are simulated, and different bionic scaffold materials and functional cells are utilized to realize mechanical bionics through structure and composition bionics, so that the mechanical strength of the construction material is improved, and the construction cost is reduced. The clinical application requirements of body surface tissue reconstruction are met.

Owner:PLASTIC SURGERY HOSPITAL CHINESE ACAD OF MEDICAL SCI

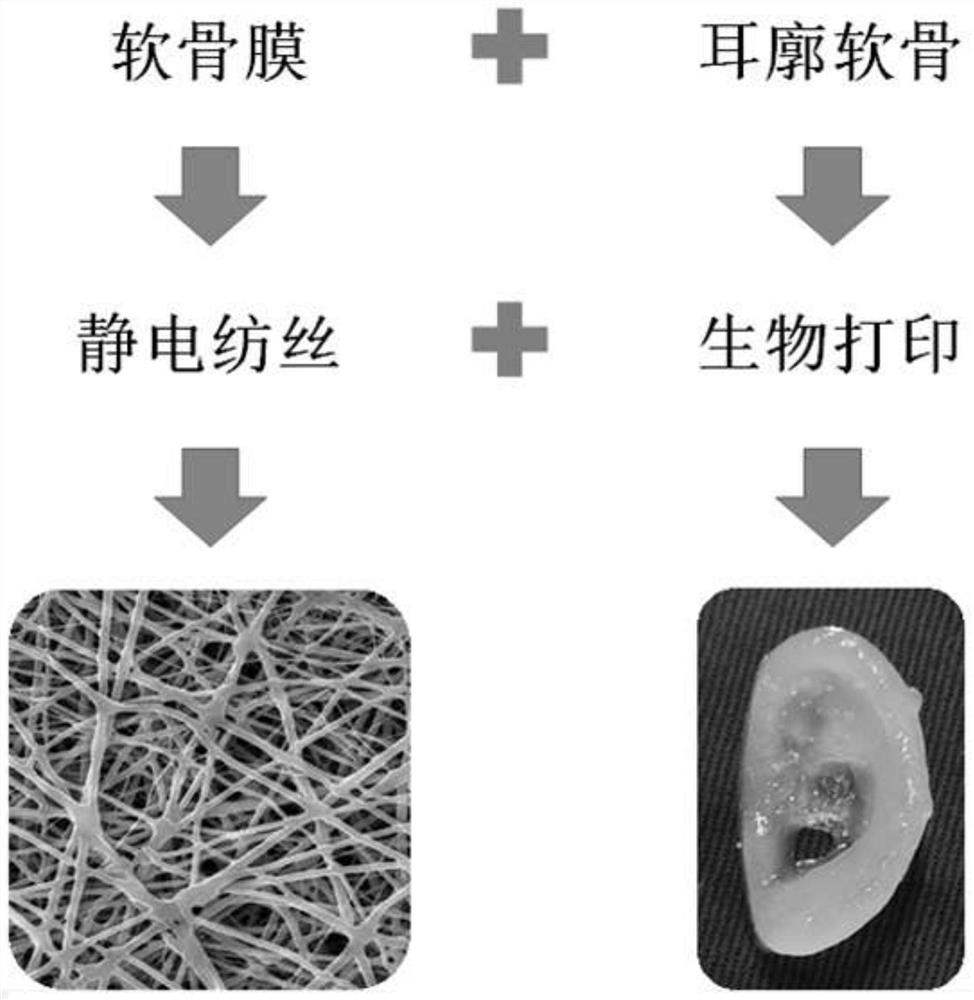

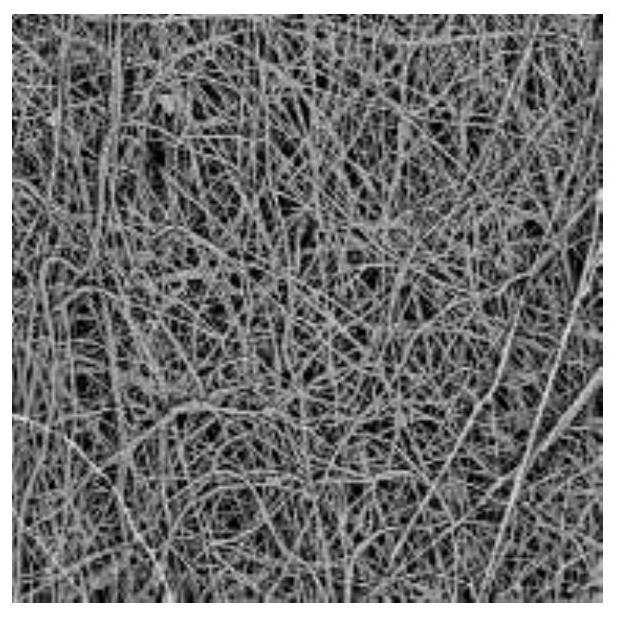

Bionic body surface tissue and step-by-step construction method thereof

ActiveCN114404661AMeet the needs of clinical applicationsImprove the mechanical strength of the structureBone implantTissue regenerationMicro nanoFiber

The invention relates to a bionic body surface tissue and a step-by-step construction method thereof, and the method comprises the following specific steps: preparing cartilage acellular matrix photosensitive gel and an auxiliary agent into a micro / nano fiber membrane by using an electrostatic spinning instrument, and preparing a bionic cartilage membrane; dissolving the cartilage acellular matrix photosensitive gel and an auxiliary agent in a complete culture medium to form cartilage hydrogel; adding the seed cells into the cartilage hydrogel to form biological ink; and constructing a bionic body surface tissue by using the bionic cartilage membrane and the biological printed cartilage. The structure and composition characteristics of the cartilage membrane-containing body surface tissue are simulated, an acellular matrix material is used, the electrostatic spinning and biological printing technologies are combined to realize dual biomimetic of the composition and the structure, different functional cells are used to realize matrix biomimetic, and the body surface cartilage tissue with the cartilage membranes on the two sides and the cartilage tissue in the middle is constructed step by step. And mechanical bionics are achieved through structure and component bionics, the mechanical strength of constructors is improved, and the clinical application requirements of body surface tissue reconstruction are met.

Owner:PLASTIC SURGERY HOSPITAL CHINESE ACAD OF MEDICAL SCI

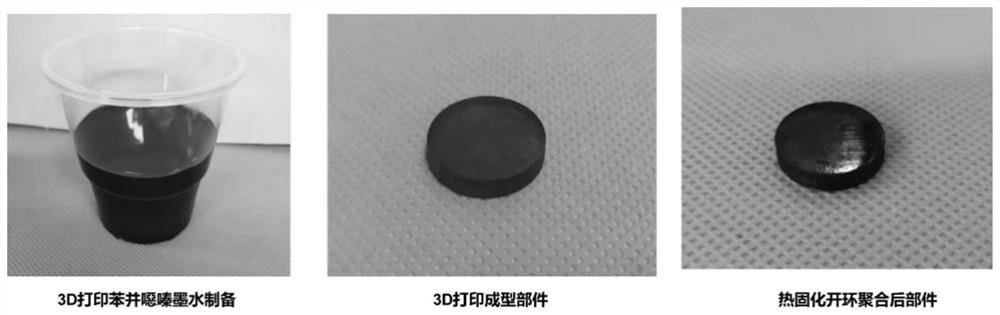

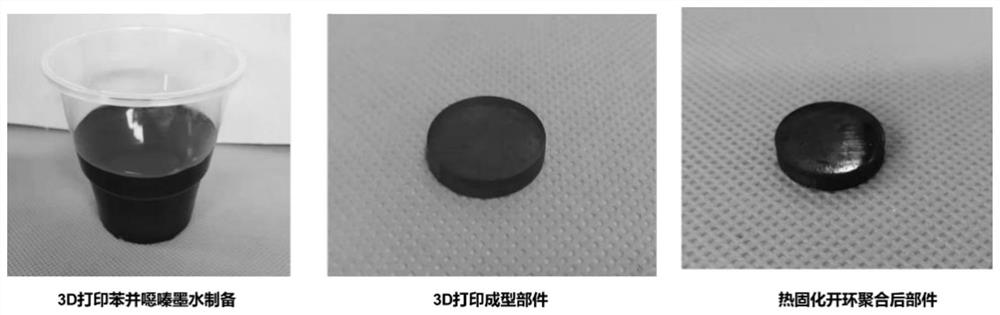

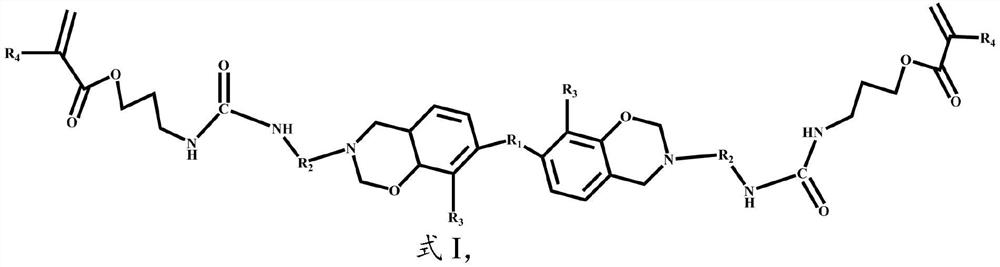

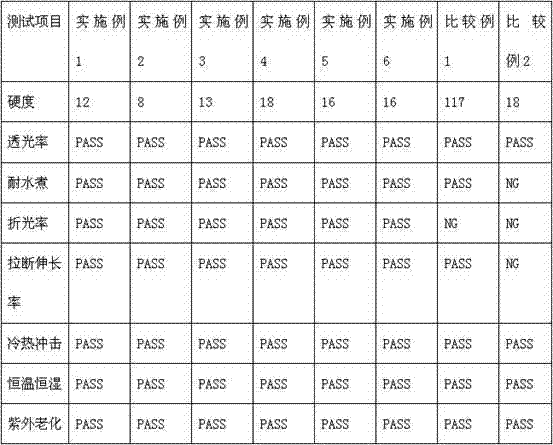

Preparation method and application of benzoxazine capable of being rapidly photo-cured, and photo-cured benzoxazine resin

ActiveCN114409644AAchieving photosensitivityMaintain ring-opening cure capabilityAdditive manufacturing apparatusOrganic chemistryPolymer scienceDouble bond

The invention provides a preparation method and application of benzoxazine capable of being rapidly photo-cured and photo-cured benzoxazine resin, and belongs to the technical field of preparation, manufacturing and application of benzoxazine. Through design and preparation of a molecular structure, an active double bond is introduced into two ends of the benzoxazine molecular structure or into the benzoxazine molecular structure through grafting modification of diamine and methacrylic acid isocyanate or acrylic acid isocyanate, so that the photosensitivity and the rapid presetting function of the benzoxazine are realized; the inherent ring-opening curing capacity and excellent comprehensive performance of the benzoxazine are kept, the rapid preforming and intelligent manufacturing capacity of the benzoxazine is also endowed, and the technical problem that secondary processing of existing benzoxazine is difficult to directly realize in complex parts, miniature parts, precision manufacturing and the like is solved; and the application of the material in the technical fields of 5G communication, additive manufacturing, photocuring coatings and the like is expanded.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Ultraviolet-curing liquid-state optical cement

ActiveCN102965067BGood adhesionLaminating thickness is thinNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesPolyesterPolymer science

The invention discloses an ultraviolet light-curable liquid optical adhesive, which comprises 50-75% of oligomers, 20-40% of active monomers, 3-6% of free radical photoinitiators, and 2-4% of auxiliary agents in terms of weight percentages. %; the oligomer is one or more of silicone modified polybutadiene acrylate, polyurethane acrylate, polyester acrylate; the active monomer is monofunctional, difunctional or polyfunctional One of the functional group acrylates. The UV-curable liquid optical adhesive can be used for fixed bonding between touch screen protective glass and glass, touch screen protective glass and LCD screen, and can be fully cured within 3000mj / cm2 energy at room temperature, and the overall light transmittance can reach 93 % or more, the refractive index exceeds 1.50, which can greatly improve the light transmittance of the touch screen, increase the yield, and is more suitable for continuous production, improve production efficiency, and have stable and reliable performance in high temperature and high humidity environments and good environmental protection.

Owner:SUZHOU BETELY POLYMER MATERIALS CO LTD

Thixotropic photocurable hydrogel and its preparation method and application

ActiveCN109851727BFast light curingHigh transparencyAdditive manufacturing apparatusPolymer sciencePhoto irradiation

The invention discloses a thixotropic photocurable hydrogel and its preparation method and application. The preparation method comprises the following steps: fully mixing a rheology modifier and deionized water to obtain a mixture A; The mixture B is fully stirred with polyethylene glycol diacrylate; add a free radical photoinitiator to the mixture B, mix well and vacuum defoam to obtain a gel without bubbles; use ultraviolet light or ultraviolet light to irradiate defoaming After the gel, a cured hydrogel is obtained. The thixotropic photocurable hydrogel of the present invention is a new type of printing medium that can be photocured, has thixotropic properties, is transparent, and is soft, and can print transparent, soft, and photocurable complex models; The functions of glue light curing and thixotropy can preserve the complex entities after embedded 3D printing, and the properties of transparent software have great potential in the prediction of medical operations.

Owner:SOUTHEAST UNIV

Ultraviolet (UV) curing ink and preparation method thereof

A UV curable ink and a preparation method thereof, the UV curable ink comprises the following components in mass percentage: 32%-42% of non-isocyanate urethane acrylate oligomer, 16%-24% of epoxy acrylate oligomer, active Thinner 18%-32%, photoinitiator 3%-6%, nano-silica 2%-4%, additive 1%-2%, pigment 6%-12%. The invention also includes a preparation method of the UV curable ink. The UV curable ink of the present invention does not contain polyisocyanate functional groups, has environmental protection, can be quickly cured by light, and has good gloss, excellent adhesion, mechanical properties and oil resistance.

Owner:广东理想彩色印务有限公司

Application of a Class of Dianilino-Biphenyl Carbonyl Compounds in Photocuring Formula System

ActiveCN108299213BImprove conversion rateFast light curingOrganic compound preparationInksPolymer scienceAniline

The invention relates to the technical field of novel material organic chemicals, in particular to a diphenylamino biphenyl carbonyl compound shown as a formula (I), a purpose of the compound as a radiation curing photoinitiator, and application purposes of the compound in various occasions such as radiation curing recipe products, particularly photocuring paint or ink and the like. The formula (I) is shown in the description.

Owner:TONGJI UNIV

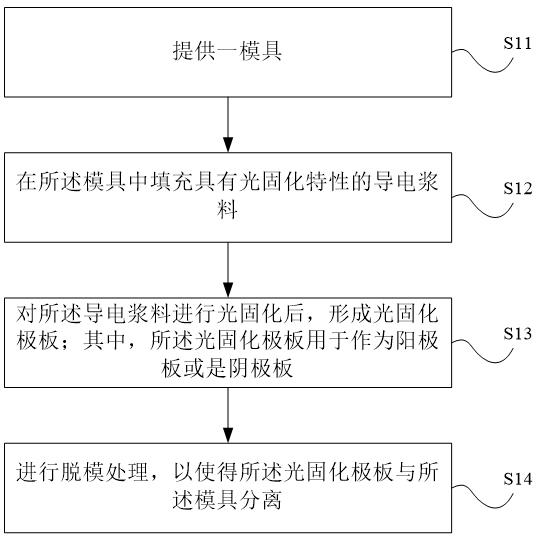

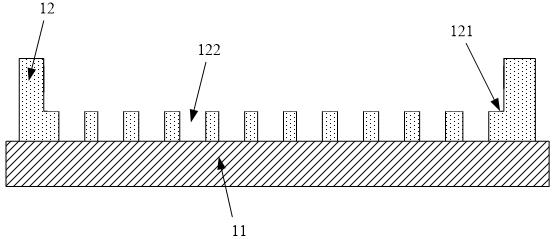

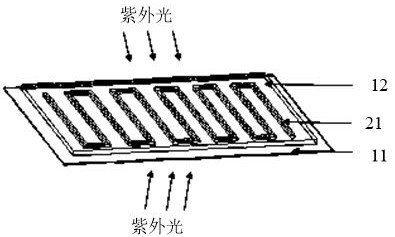

Manufacturing method of bipolar plate

InactiveCN113977871AFast light curingSimple processingFinal product manufactureDomestic articlesHigh volume manufacturingSlurry

The technical scheme of the invention discloses a manufacturing method of a bipolar plate. The manufacturing method comprises the following steps: providing a mold; filling a conductive slurry with a photocuring characteristic in the mold; carrying out light curing on the conductive slurry to form a light-cured polar plate used as an anode plate or a cathode plate; and carrying out demolding treatment, so that the light-cured polar plate is separated from the mold. According to the technical scheme, a simple and rapid photocuring bipolar plate processing mode is provided. The preparation method is carried out at normal temperature, and is low in production cost, simple in process and suitable for mass production.

Owner:WEICHAI POWER CO LTD

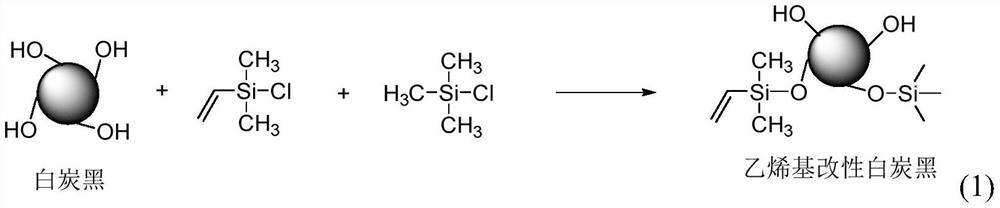

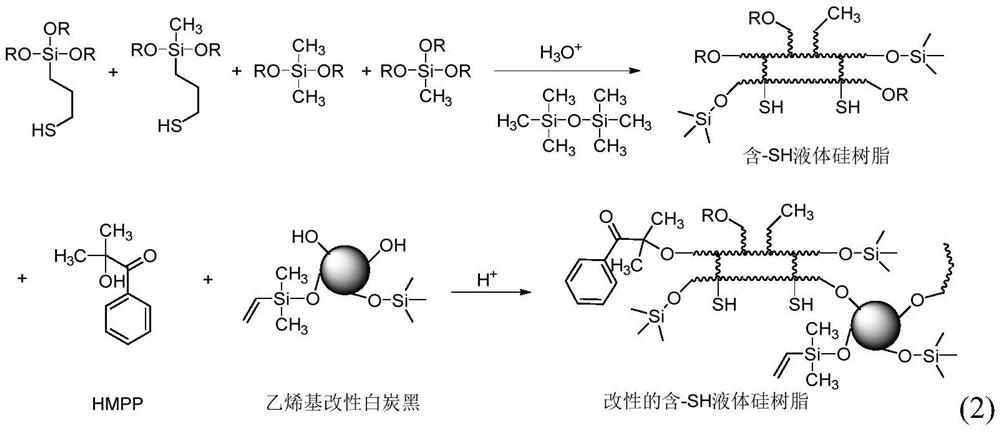

Modified sulfydryl-containing liquid silicone resin, non-toxic, colorless and odorless light-cured liquid silicone rubber and preparation method and application thereof

The invention discloses a preparation method and application of modified sulfydryl-containing liquid silicone resin and non-toxic, colorless and odorless light-cured liquid silicone rubber. The modified sulfydryl-containing liquid silicon resin is prepared by the following steps: S1-1) preparing vinyl modified white carbon black; S1-2) preparing modified sulfydryl-containing liquid silicon resin: stirring and reacting a mercaptopropyl silane coupling agent, dimethyl dialkoxy silane, trialkoxy silane, an end-capping reagent, a solvent and an acid catalyst under a heating condition to obtain the sulfydryl-containing liquid silicon resin; and reacting a photoinitiator, the vinyl modified white carbon black prepared in the step S1) and an acid catalyst to obtain the modified sulfydryl-containing liquid silicon resin. The initiator, the filler, the cross-linking agent and other components are in bond connection with the self-made-SH liquid silicon resin through chemical reaction, the problems that traditional light-cured silicon rubber has unpleasant smell before curing, small molecule components are prone to escaping and the like are fundamentally solved, and the light-cured silicon rubber can be applied to medical light-cured materials.

Owner:SHENZHEN INST OF ADVANCED TECH

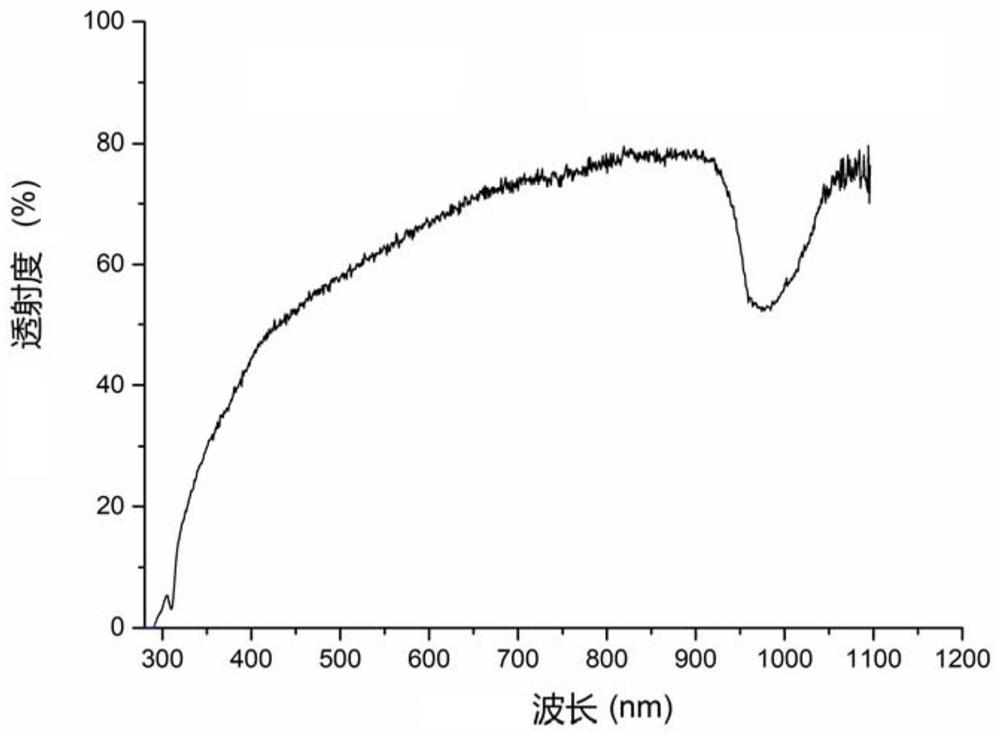

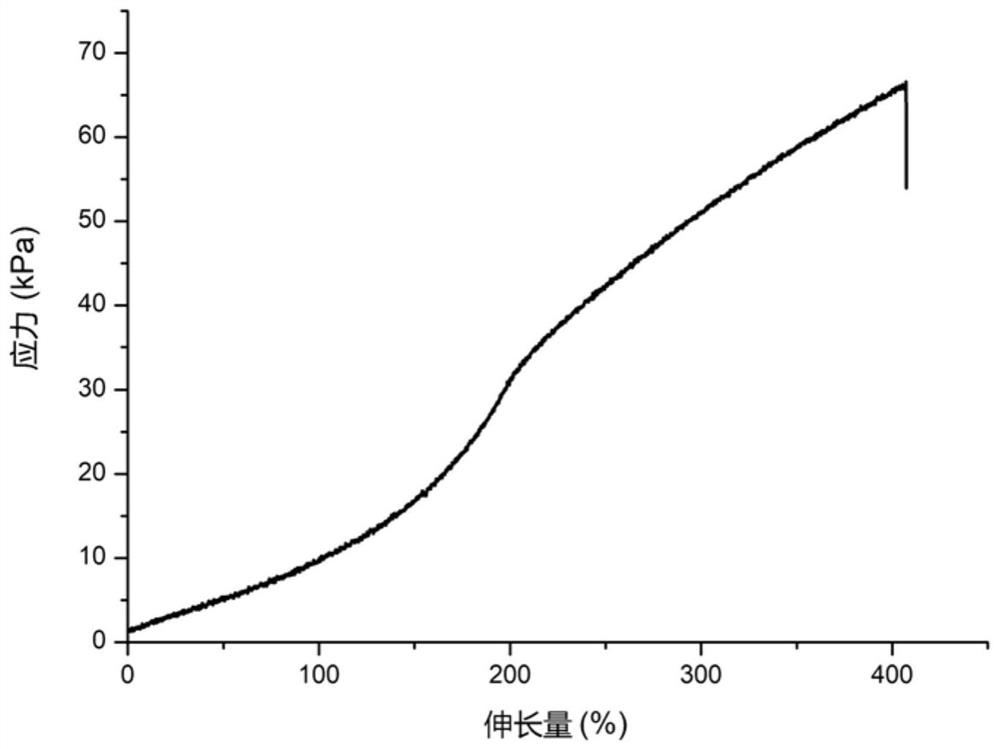

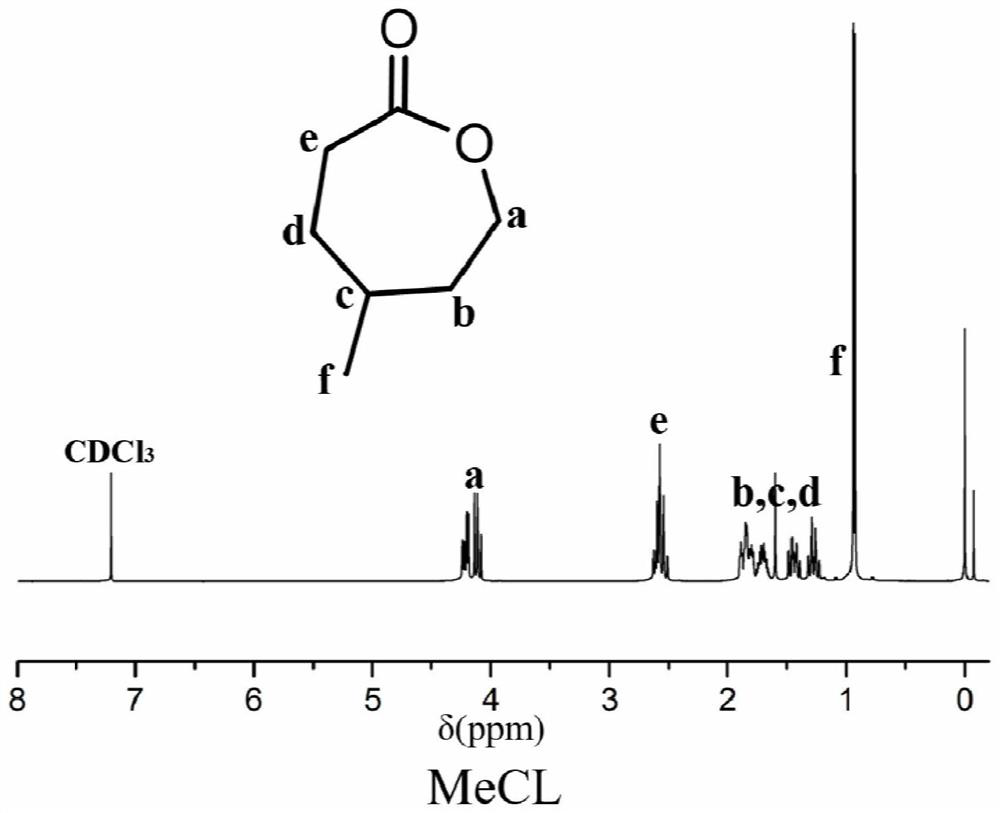

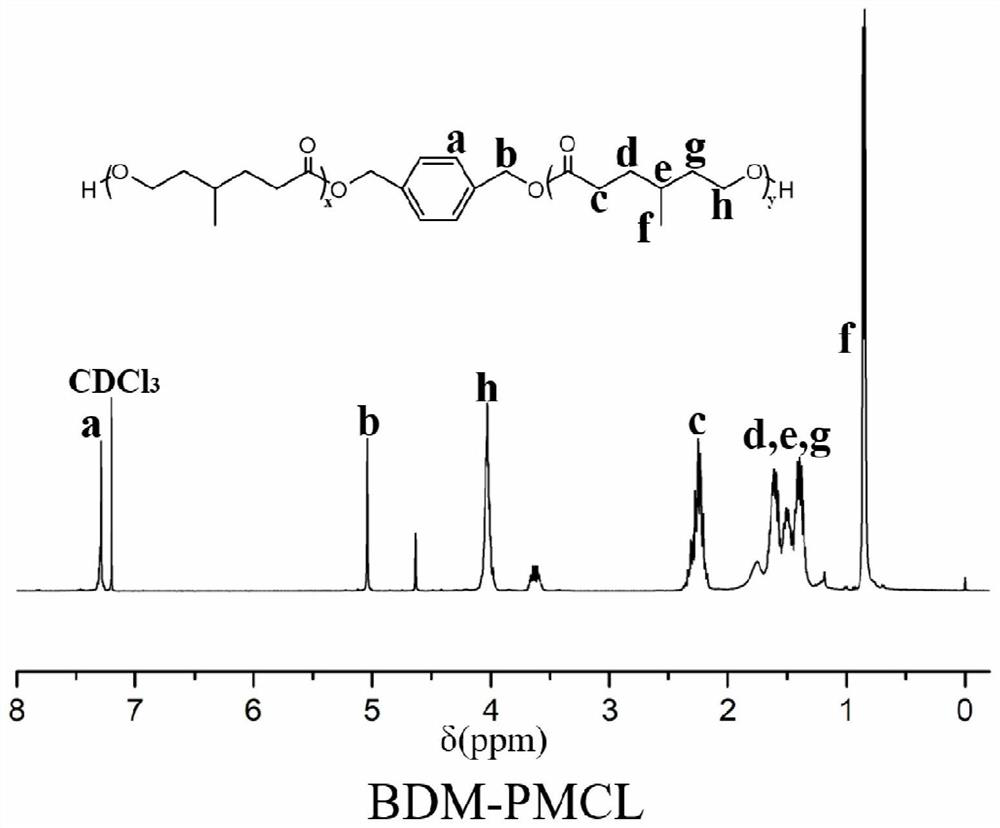

A kind of biodegradable transparent liquid polyester that can be quickly photocured with mercapto crosslinking agent and preparation method and application

ActiveCN112457479BFast light curingIncrease cured thicknessAdditive manufacturing apparatusProsthesisPolyesterPolymer science

The invention discloses a biodegradable transparent liquid polyester that can be quickly photocured with a mercapto crosslinking agent. The structure is as follows: x+y is 10-100, and theoretically x=y. The invention also discloses a fast photocurable transparent polyester photocurable mixed solution prepared from the biodegradable transparent liquid polyester. The transparent polyester light-curing mixed solution of the invention adopts liquid alkynyl-terminated modified poly(4-methylcaprolactone) as the main material, which has both good biocompatibility and biodegradability of polycaprolactone , and because of the liquid properties at room temperature, the light curing does not require any solvent, achieves zero VOC standards, and the material is transparent, which can smoothly penetrate the curing light.

Owner:EAST CHINA UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com