Patents

Literature

403 results about "Micro pattern" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

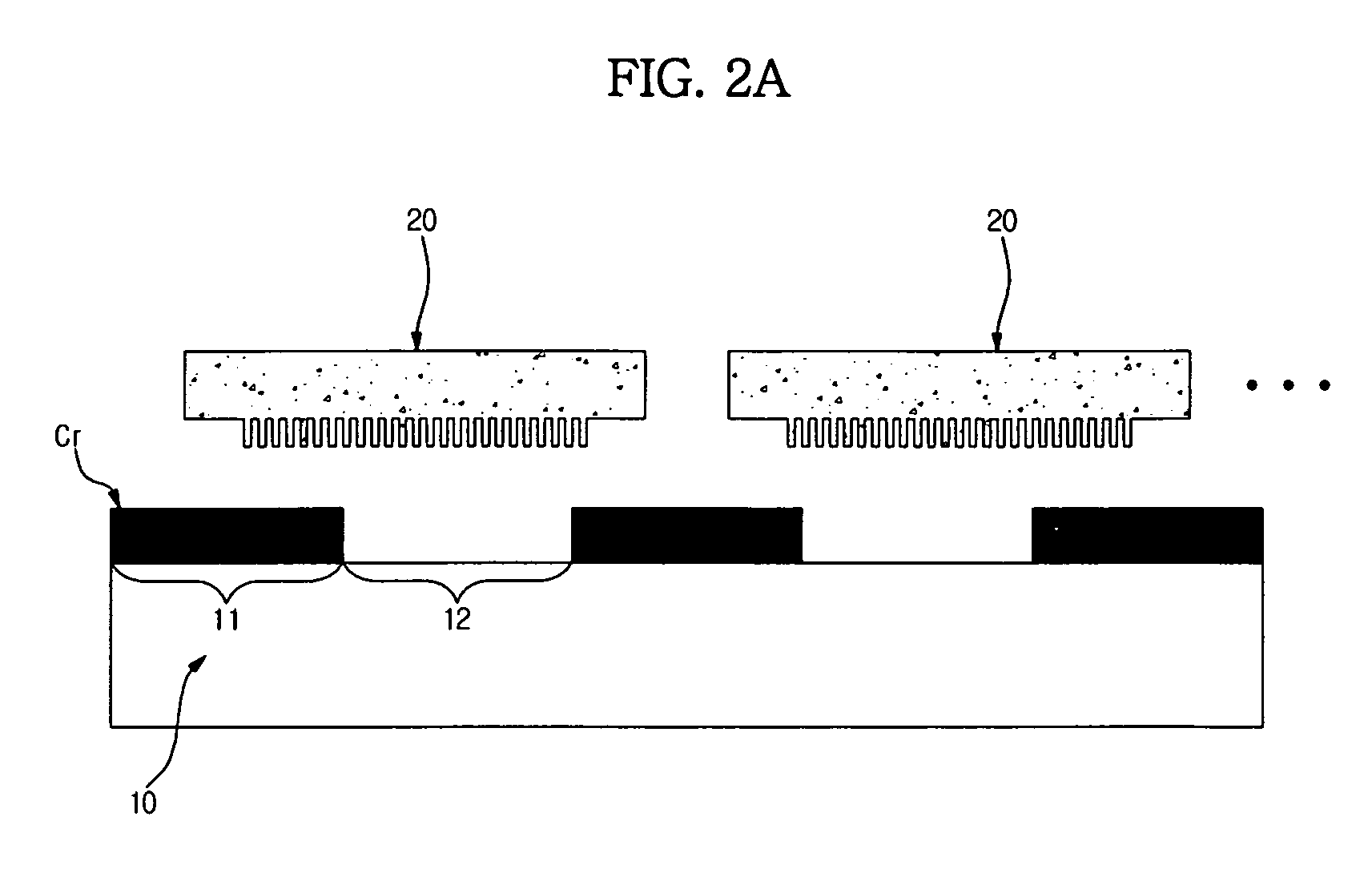

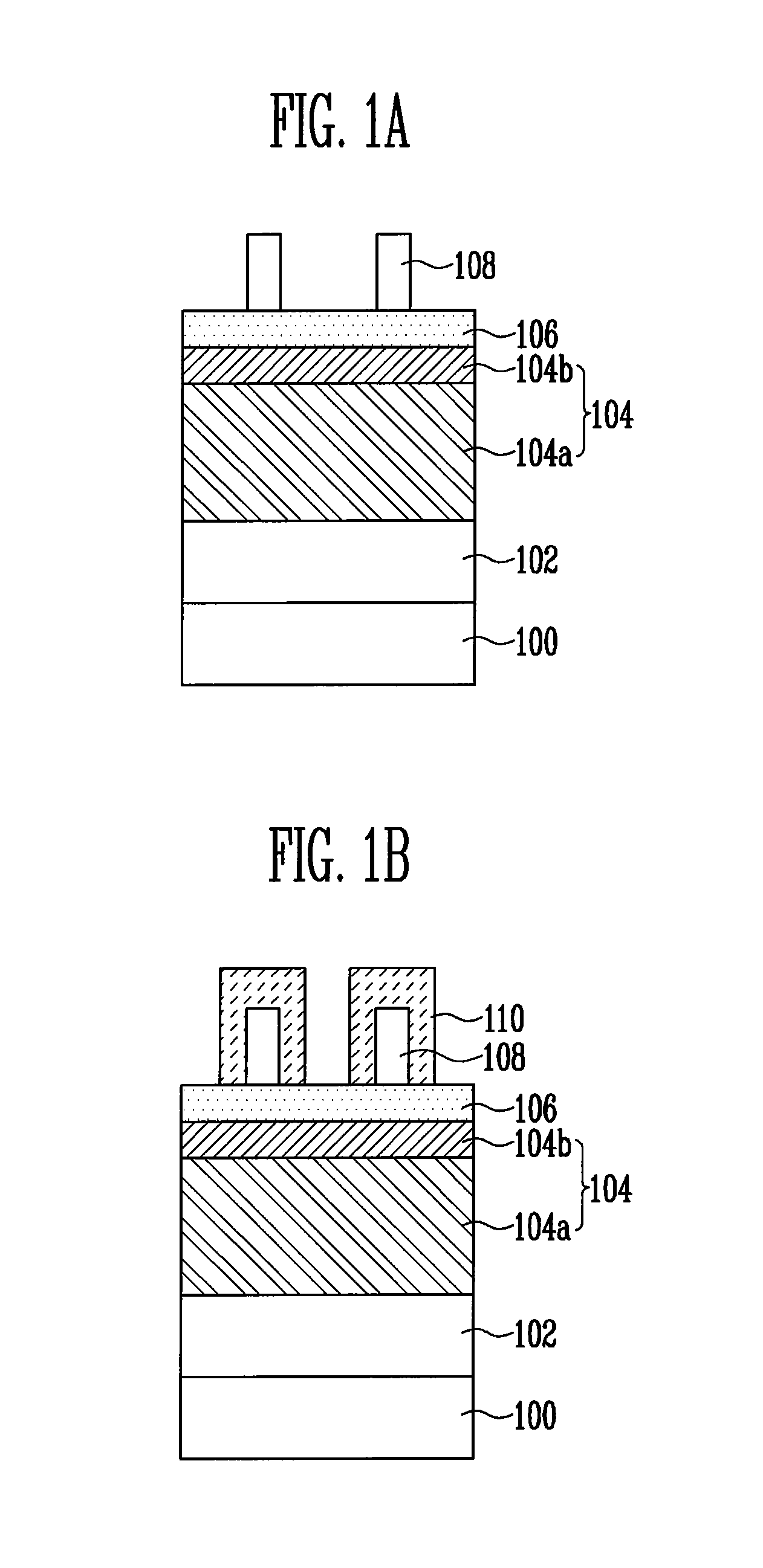

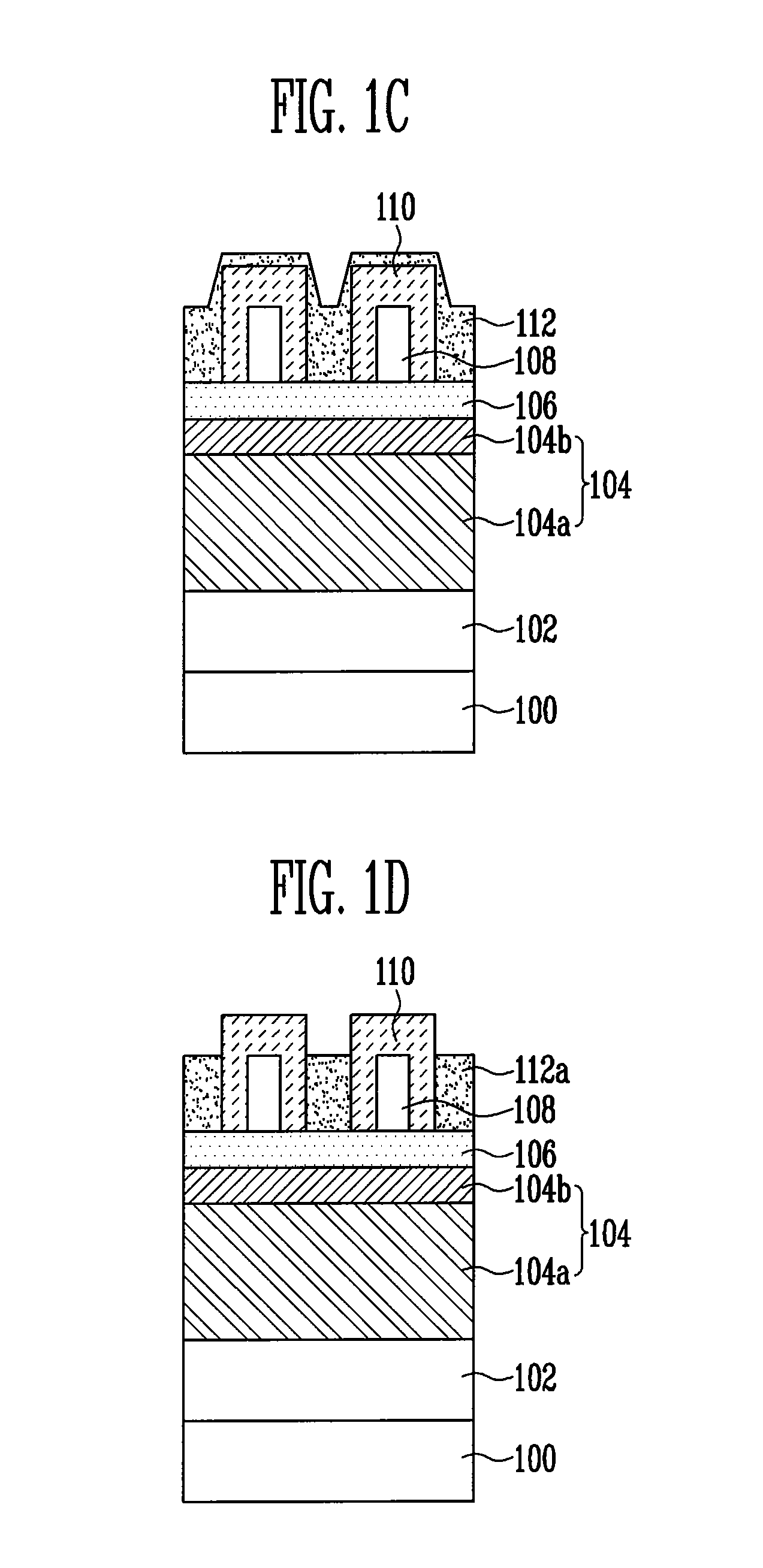

Method of forming micro pattern in semiconductor device

InactiveUS7202174B1Decrease CD variationReduce variationSolid-state devicesSemiconductor/solid-state device manufacturingEngineeringNitride

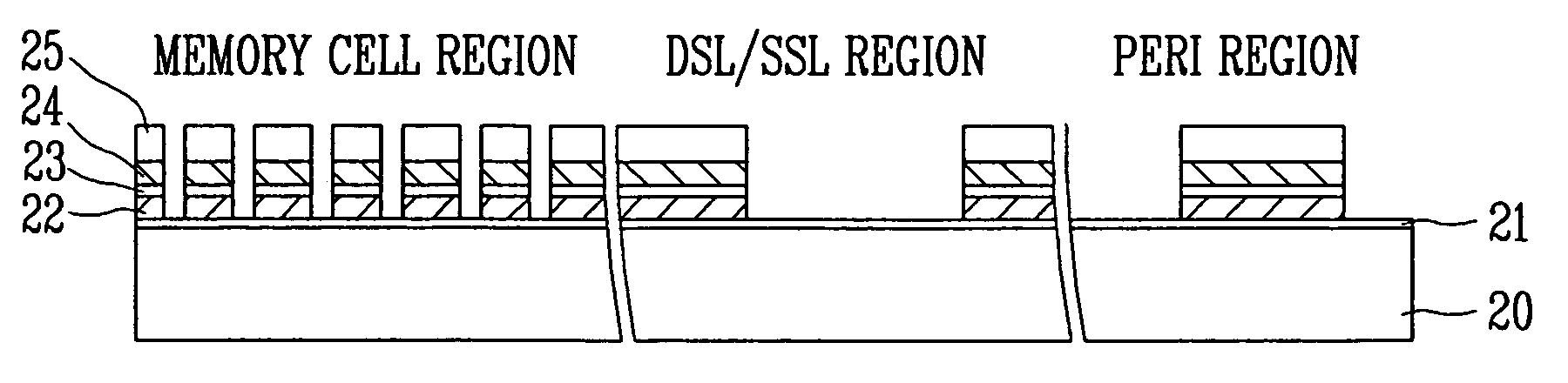

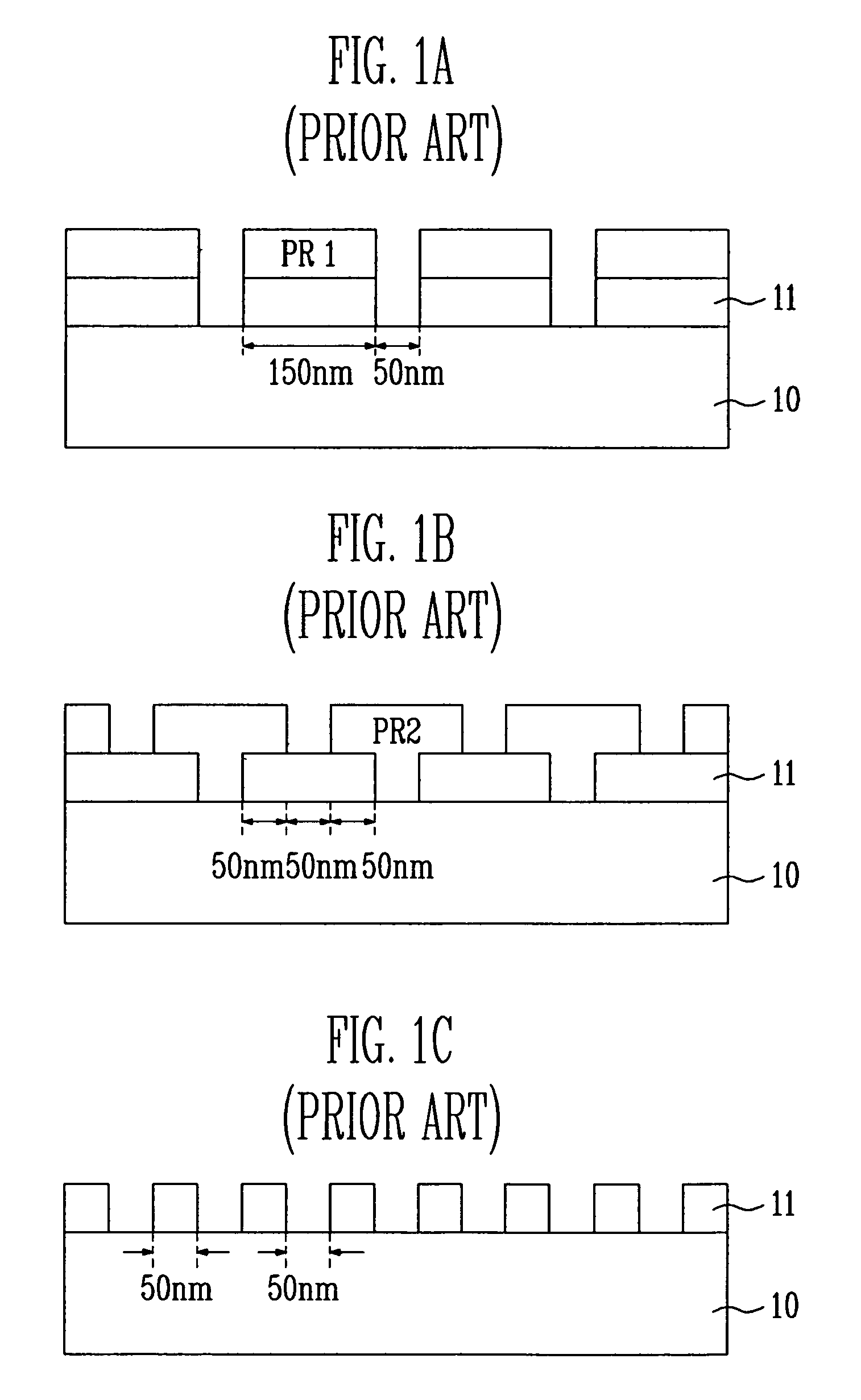

A method of forming a micro pattern in a semiconductor device, wherein a first polysilicon film, a buffer oxide film, a second polysilicon film, an anti-polishing film, and a first oxide film are sequentially laminated on a semiconductor substrate having a to-be-etched layer. The first oxide film, the anti-polishing film and the second polysilicon film are patterned. After nitride film spacers are formed on the patterned lateral portions, a second oxide film is formed on the entire structure. A Chemical Mechanical Polishing (CMP) process is performed using the anti-polishing film as a stopper. Thereafter, after the nitride film spacers are removed, the second oxide film and the second polysilicon film are removed using a difference in etch selective ratio between the oxide film and the polysilicon film. A hard mask for forming a micro pattern having a structure in which the first polysilicon film and the buffer oxide film are laminated is formed. The to-be-etched layer is etched using the hard mask as an etch barrier.

Owner:SK HYNIX INC

Semiconductor device and a manufacturing method of the same

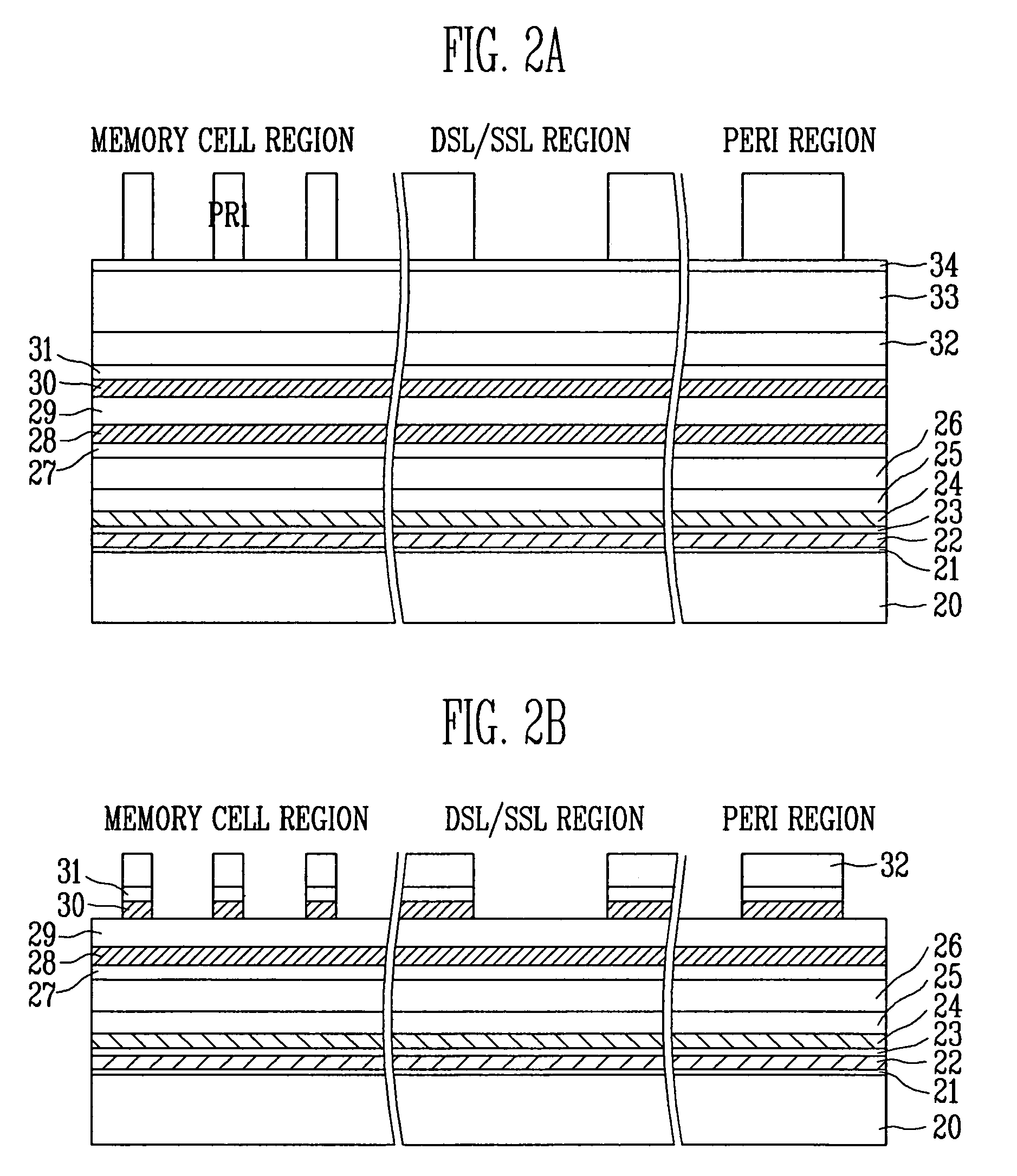

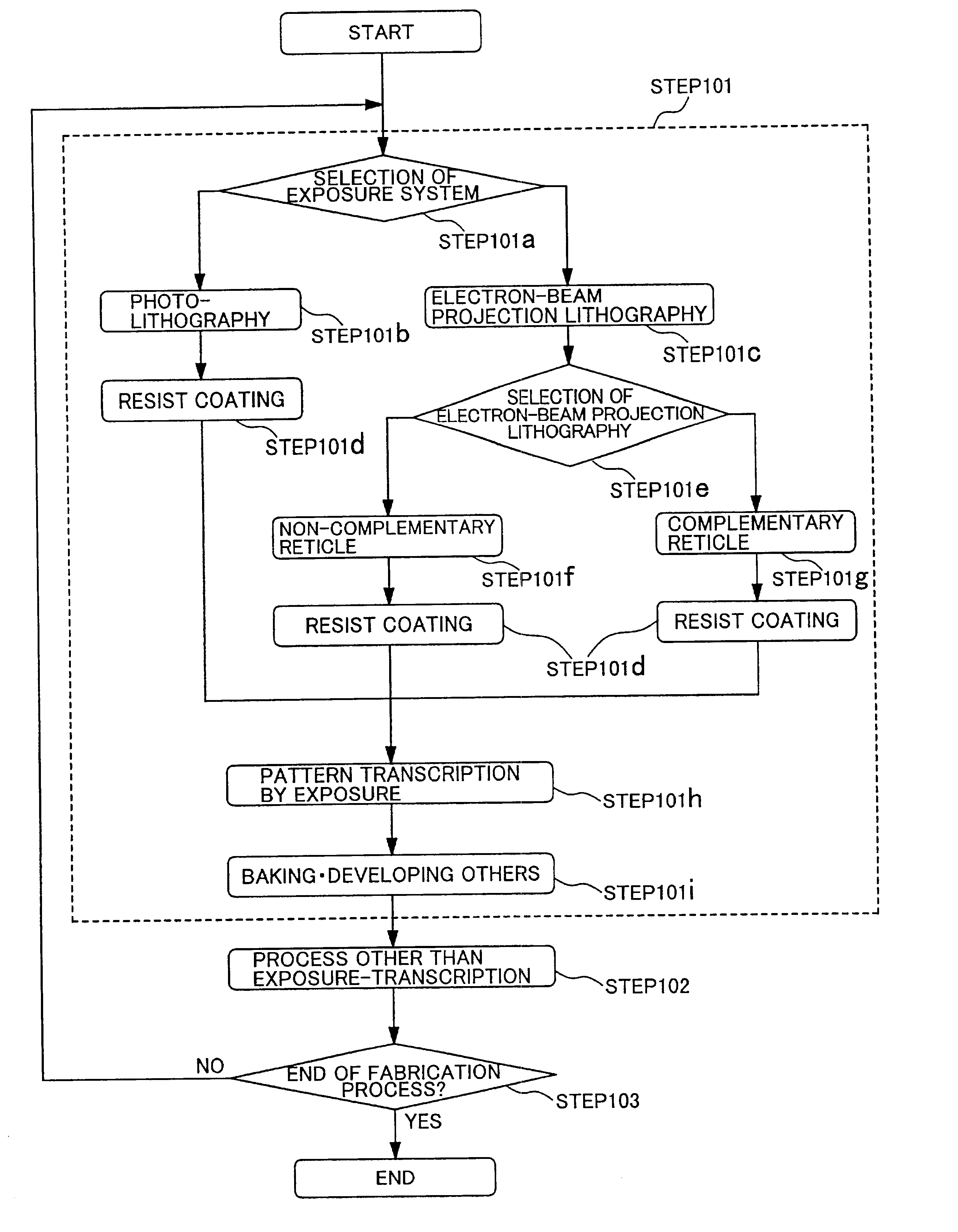

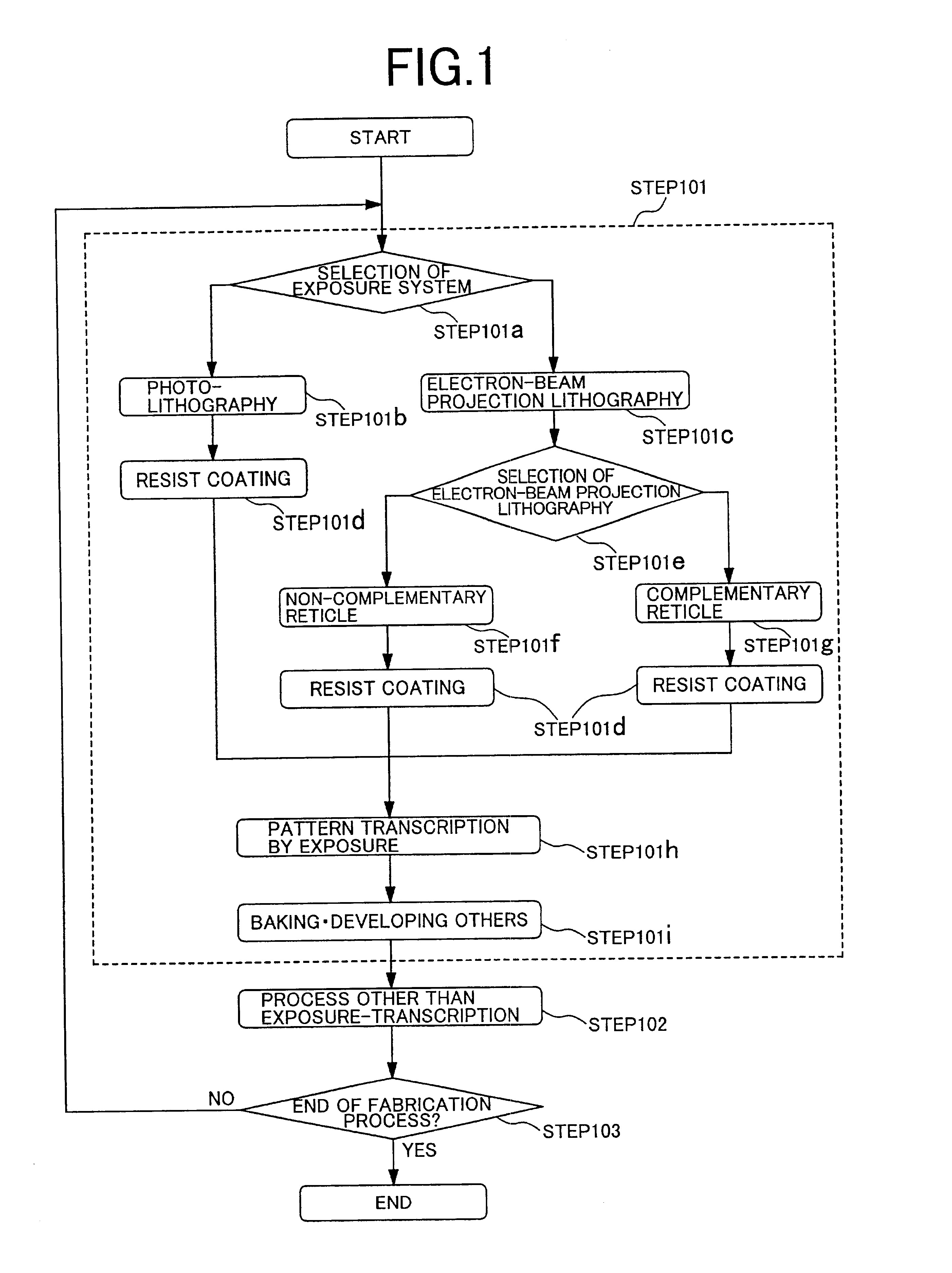

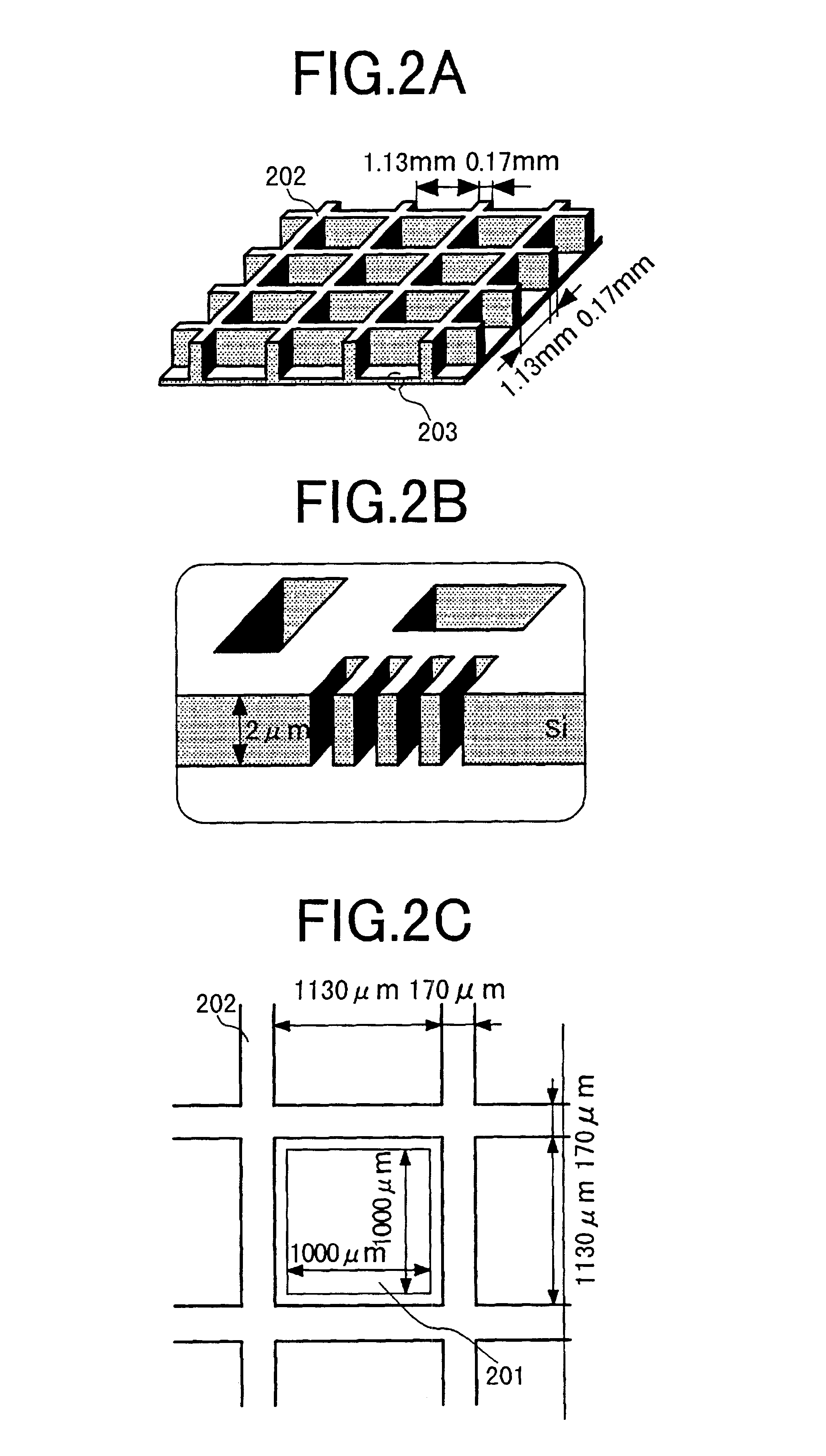

There is disclosed a method for forming micro patterns in a semiconductor integrated circuit device with high productivity and high accuracy. A photolithography having high throughput and electron beam lithography using a reticle and having relatively high throughput and high resolution are selectively used so as to obtain highest throughput while satisfying accuracy and resolution required for each product / layer. In the case of using the electron beam lithography, a non-complementary reticle and a complementary reticle are selectively used so as to obtain highest throughput while satisfying required accuracy and resolution. Thus, productivity and integration can be improved for the semiconductor integrated circuit device.

Owner:HITACHI LTD +1

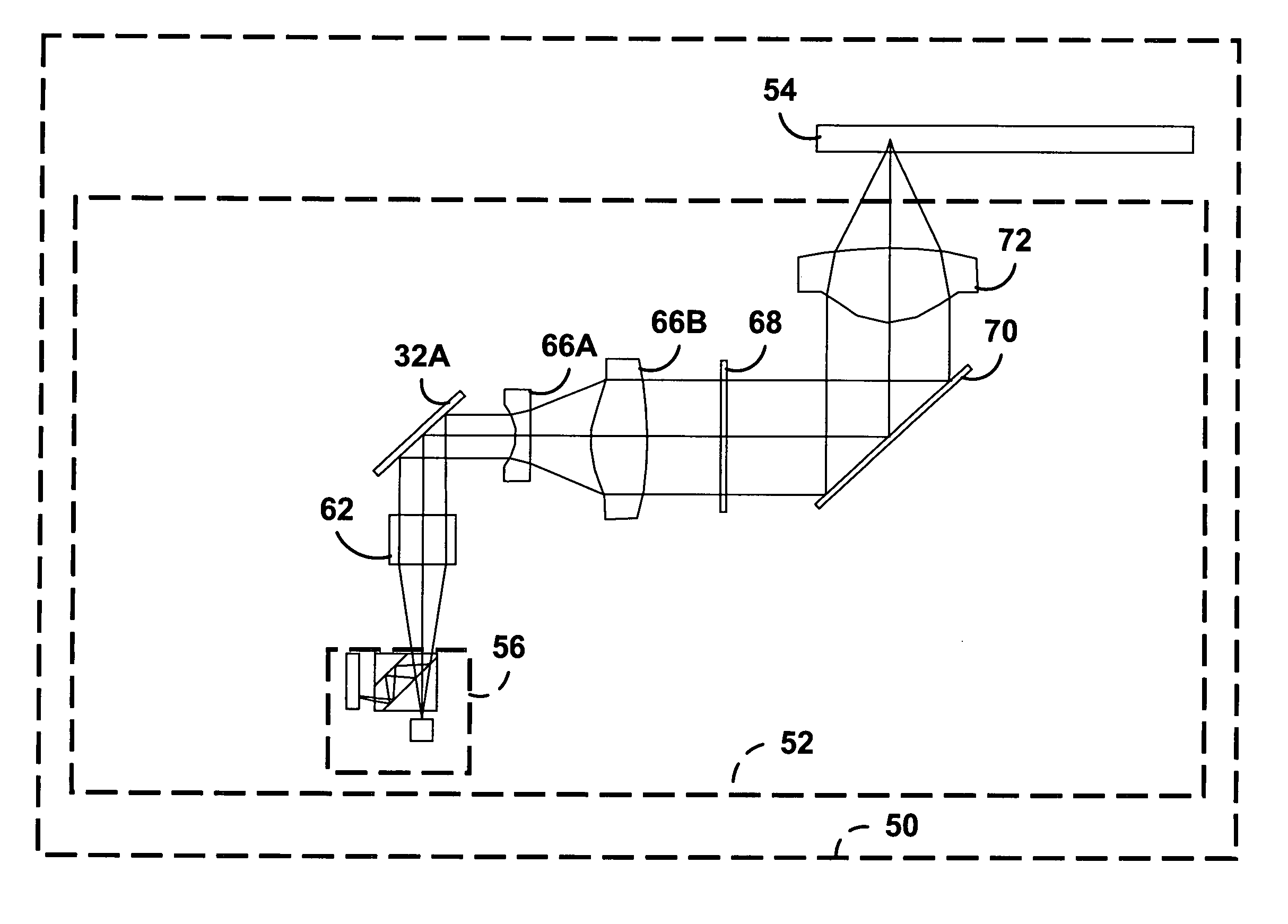

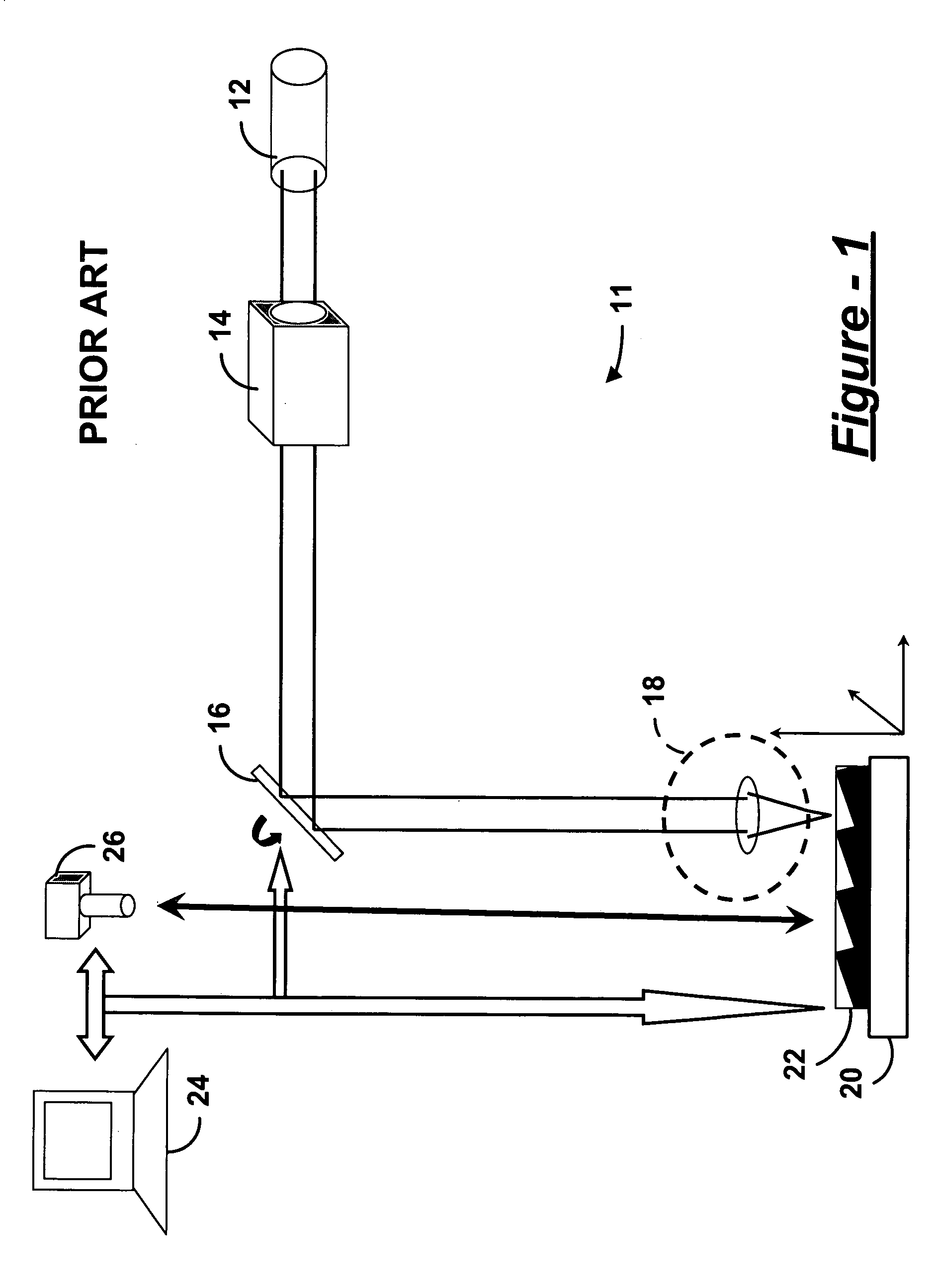

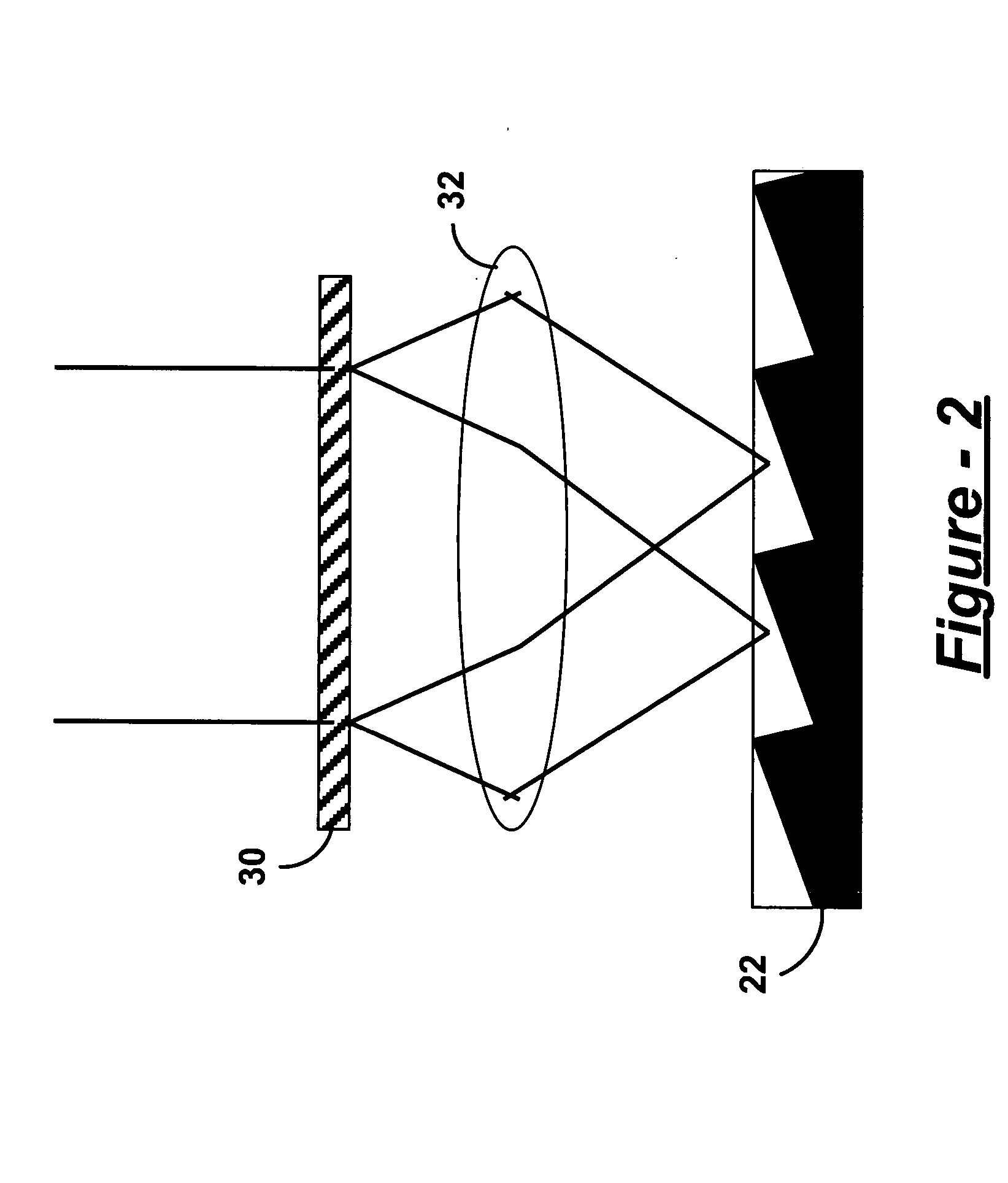

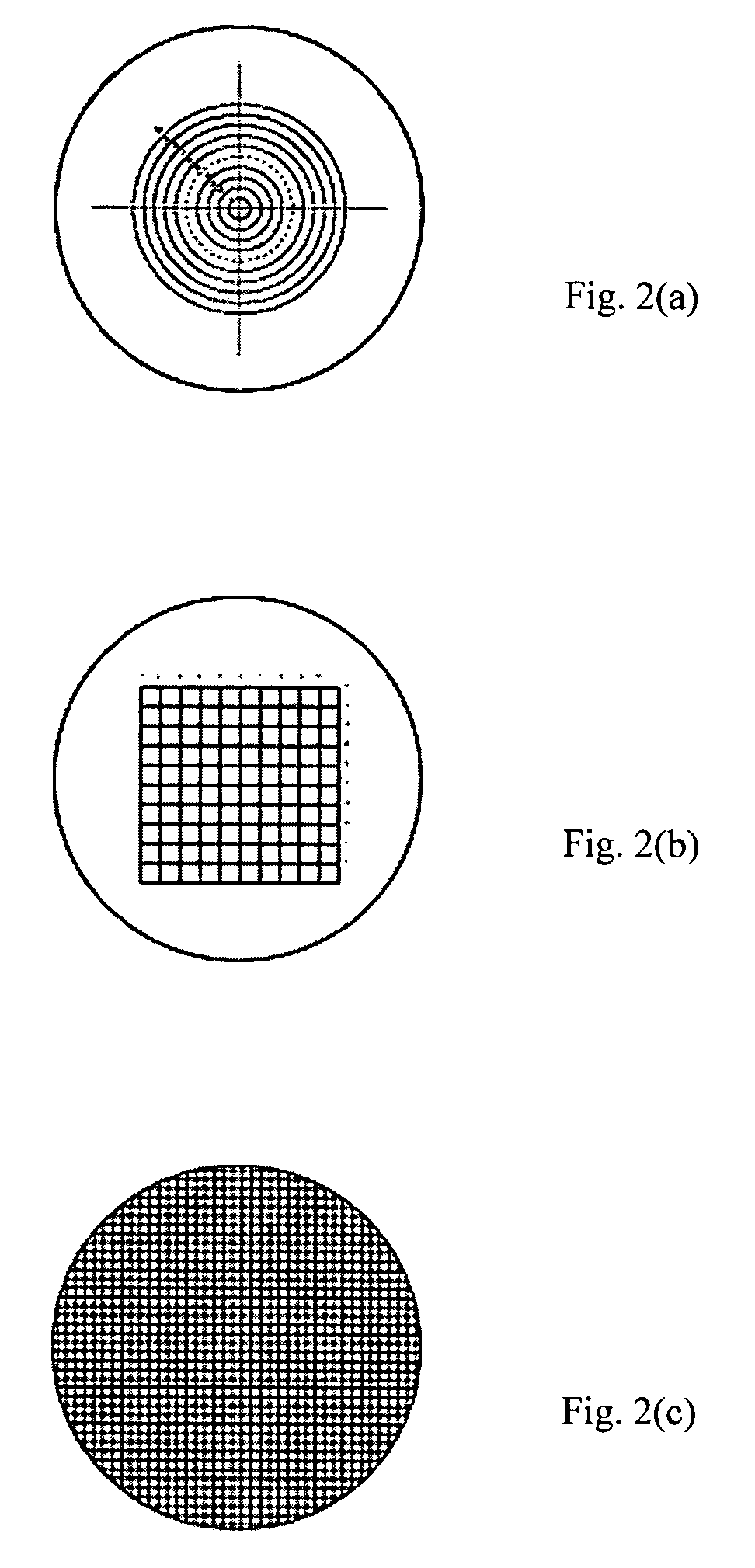

Method and apparatus of making highly repetitive micro-pattern using laser writer

InactiveUS20060086898A1Beam/ray focussing/reflecting arrangementsPhotomechanical apparatusLight beamRepeatability

An apparatus for making a highly repetitive micro-pattern using a laser writer includes one or more diffractive optical elements. At least one diffractive optical element is adapted to split a beam of a laser writer into sub-beams based on a separation distance matching a period of a repetitive structure to be formed in a laser-writable substrate. One or more f-theta lenses are also included. At least one f-theta lens is disposed to intercept the sub-beams, forming a periodic distribution of laser writer output beams.

Owner:PANASONIC CORP

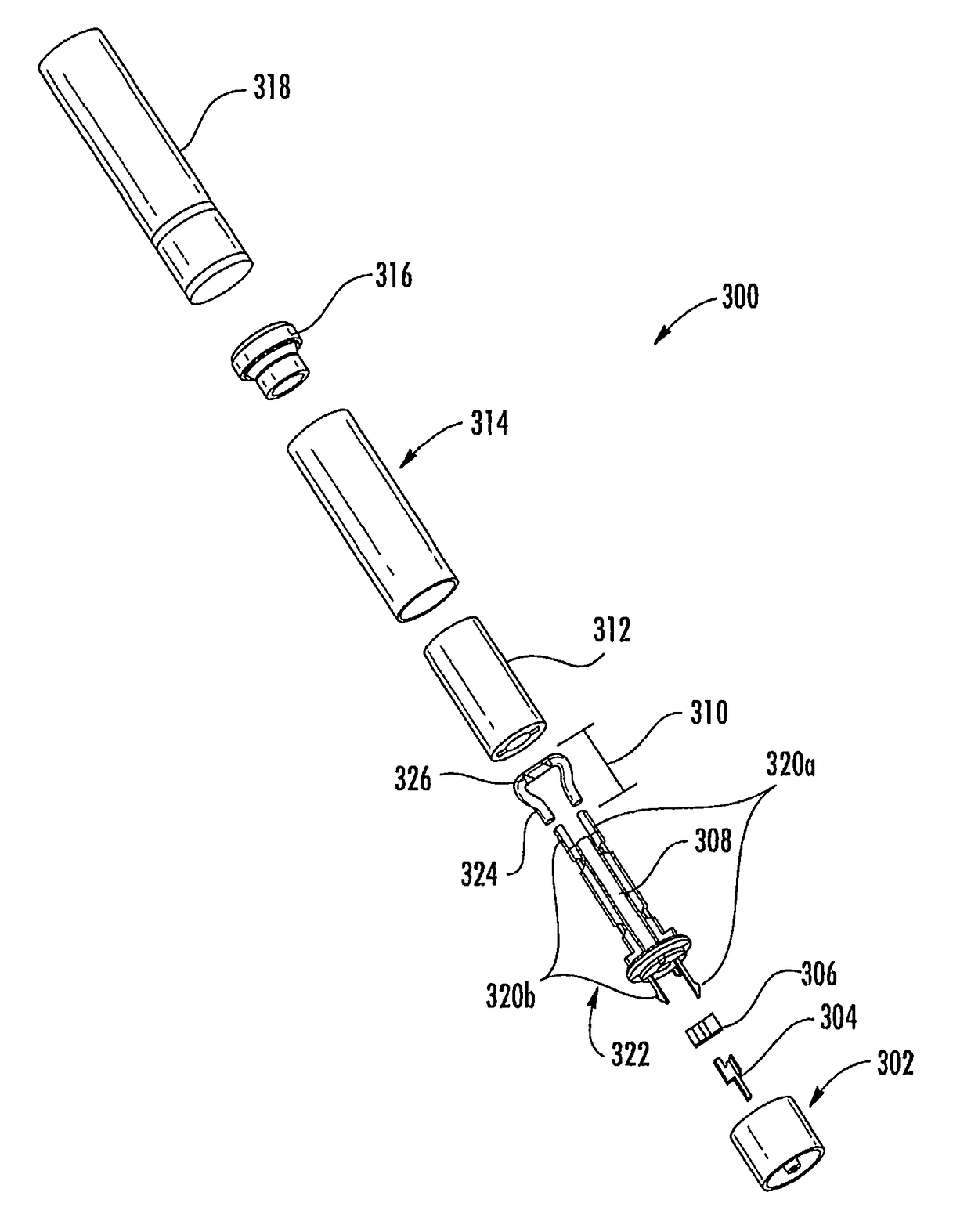

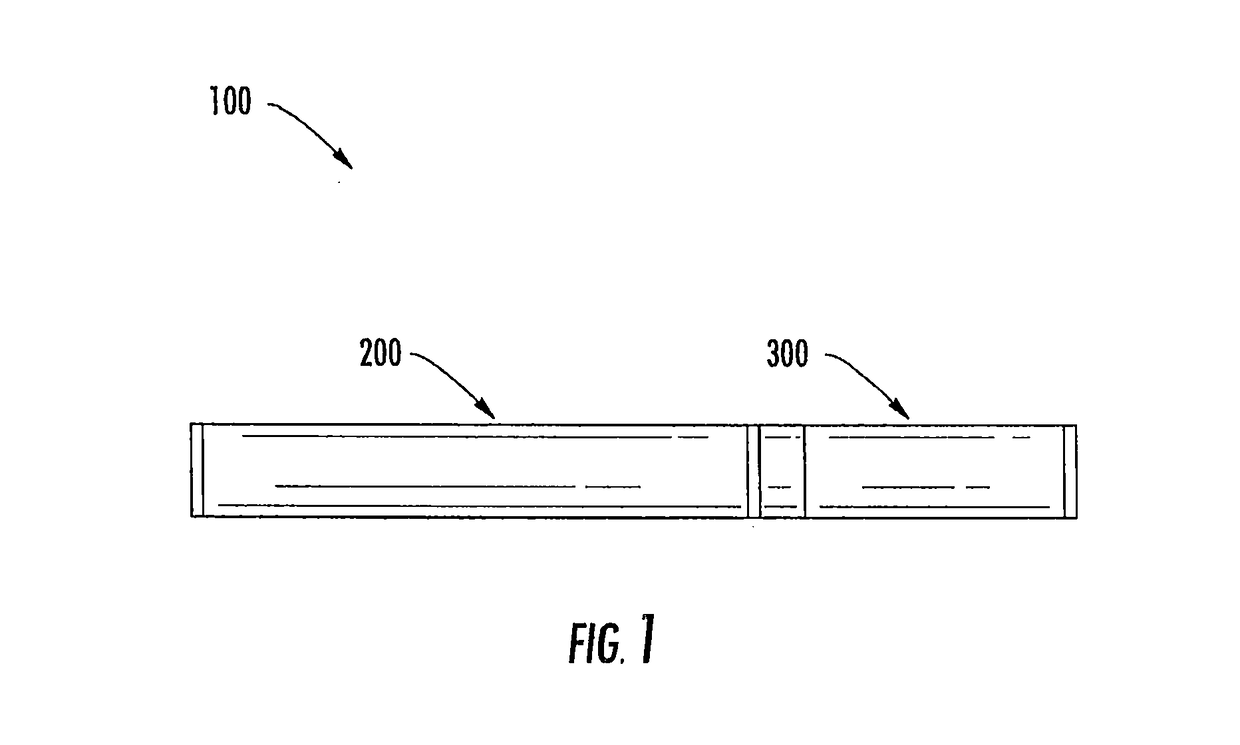

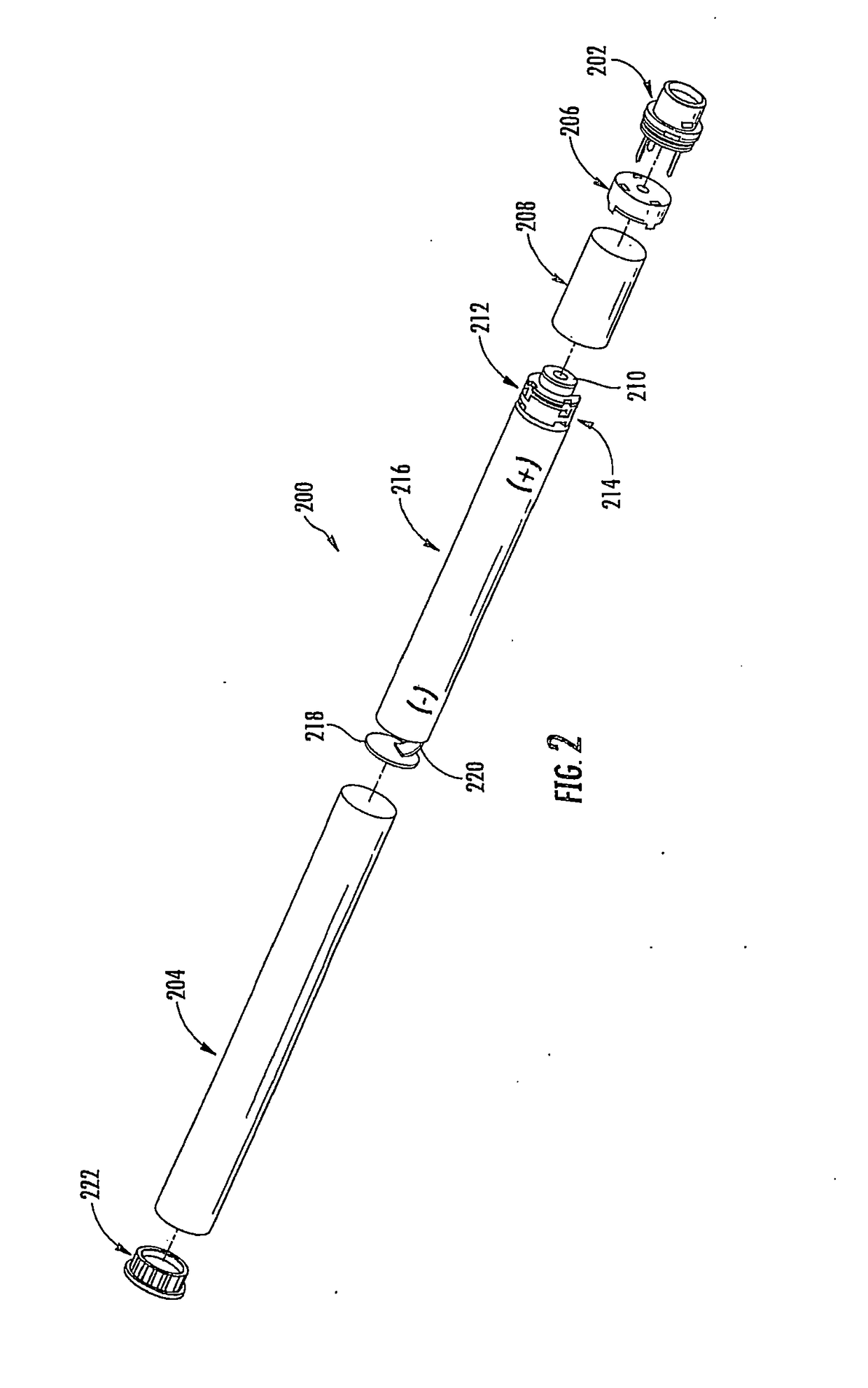

Aerosol delivery device

ActiveUS20170273360A1Reduce wasteMinimize abilityTobacco pipesTobacco devicesEngineeringAerosol delivery

An aerosol delivery device is disclosed. The aerosol delivery device includes an atomizer and a body. The body has an outlet and houses the atomizer. The aerosol delivery device also includes a structure configured to inhibit liquid droplets of an aerosol precursor from exiting the outlet. Embodiments of the structure include micro-patterned surfaces, absorbers, and macro structures to create droplet capturing chambers.

Owner:RAI STRATEGIC HLDG INC

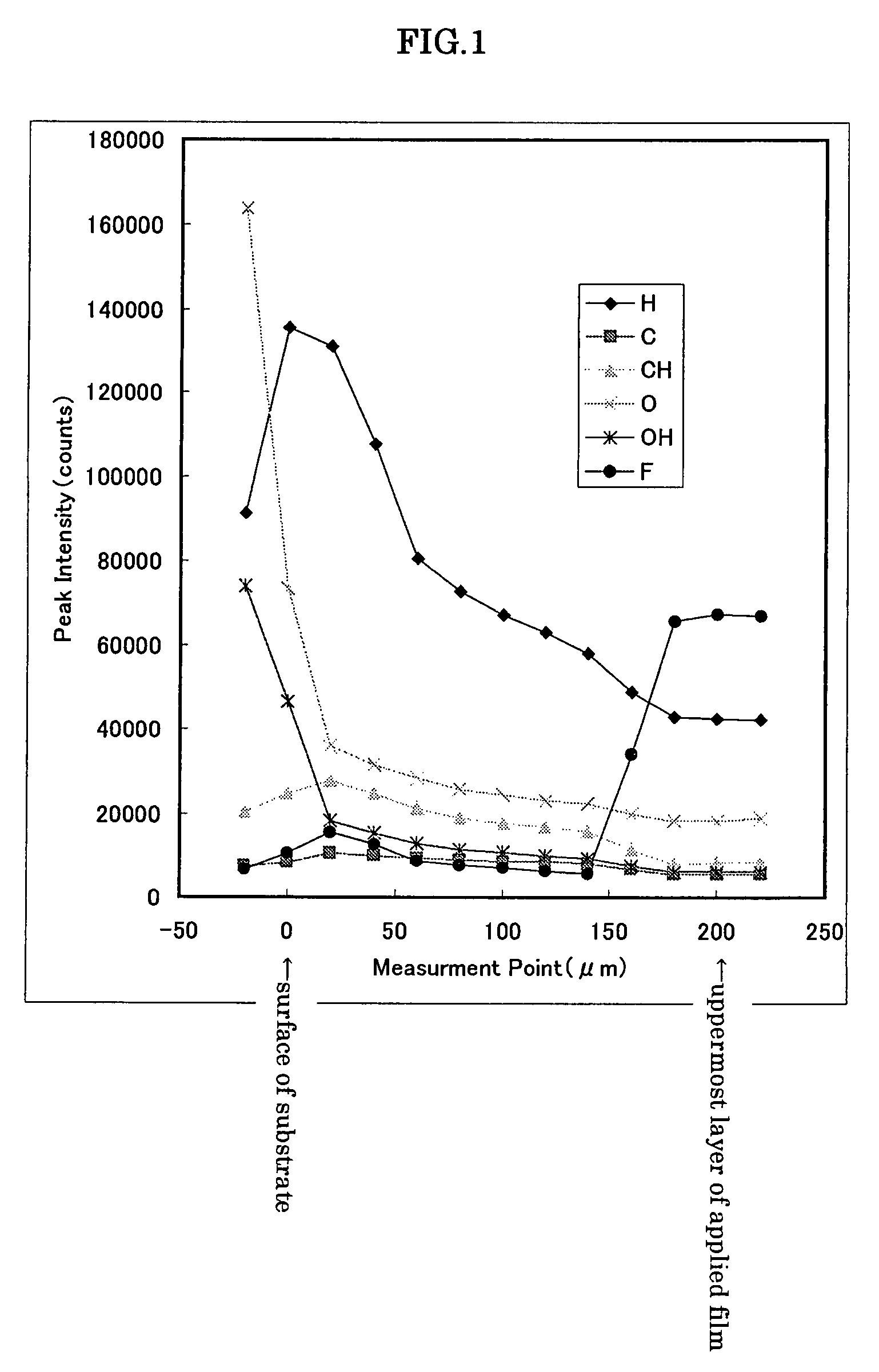

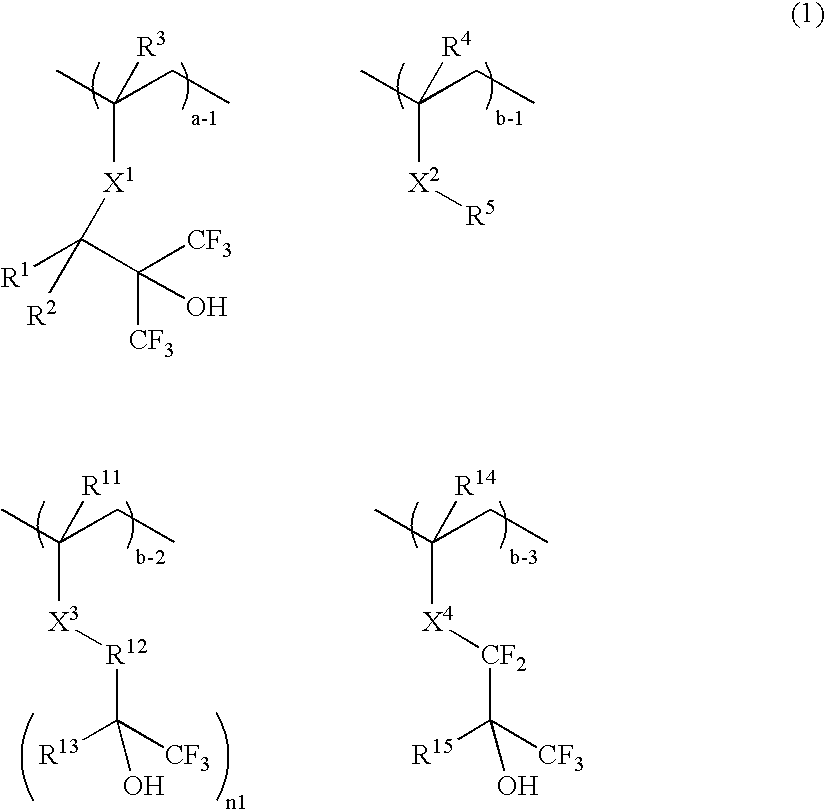

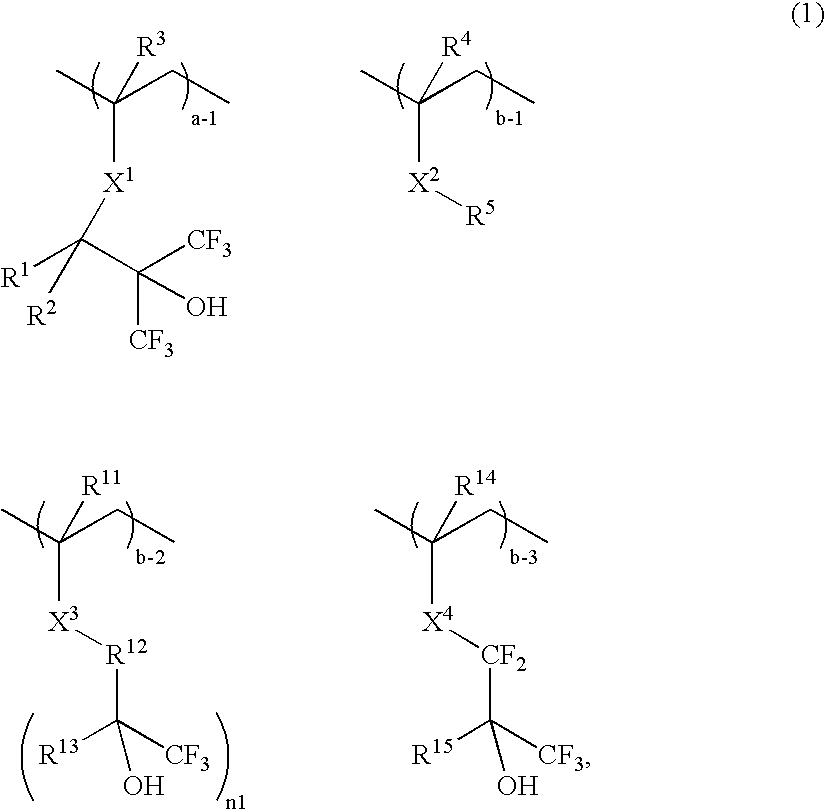

Resist composition and patterning process using the same

ActiveUS7771913B2Improve barrier propertiesPrevents resist componentPhotosensitive materialsRadiation applicationsRepeat unitChemistry

There is disclosed a resist composition comprising, at least, a polymer including repeating units represented by the following general formula (1). There can be provided a resist composition that has a good barrier property against water, prevents resist components from leaching to water, has high receding contact angle against water, does not require a protective film, has an excellent process applicability, suitable for the liquid immersion lithography and makes it possible to form micropatterns with high precision.

Owner:SHIN ETSU CHEM IND CO LTD

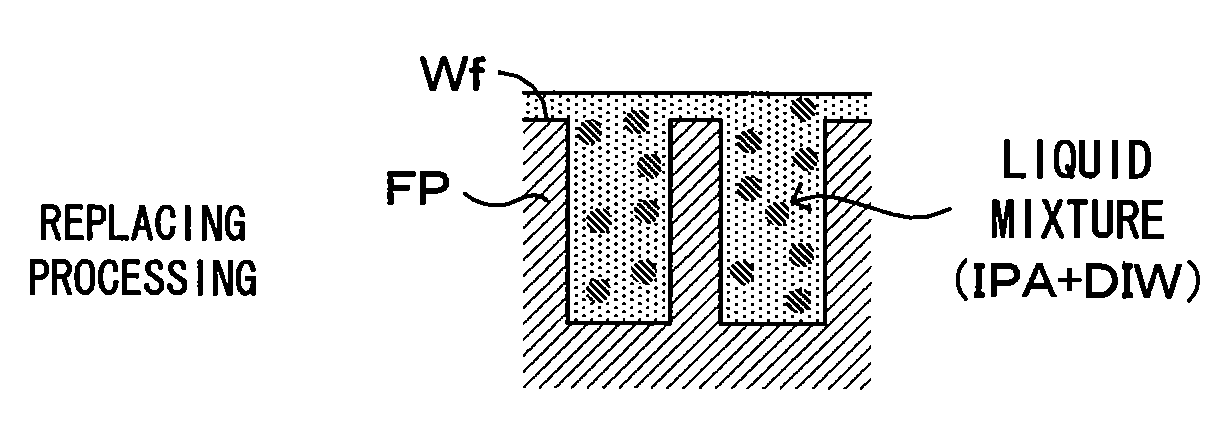

Substrate processing method and substrate processing apparatus

InactiveUS20070295365A1Avoid destructionFavorable drying of surfaceSemiconductor/solid-state device manufacturingCleaning using liquidsSubstrate surfaceLiquid composition

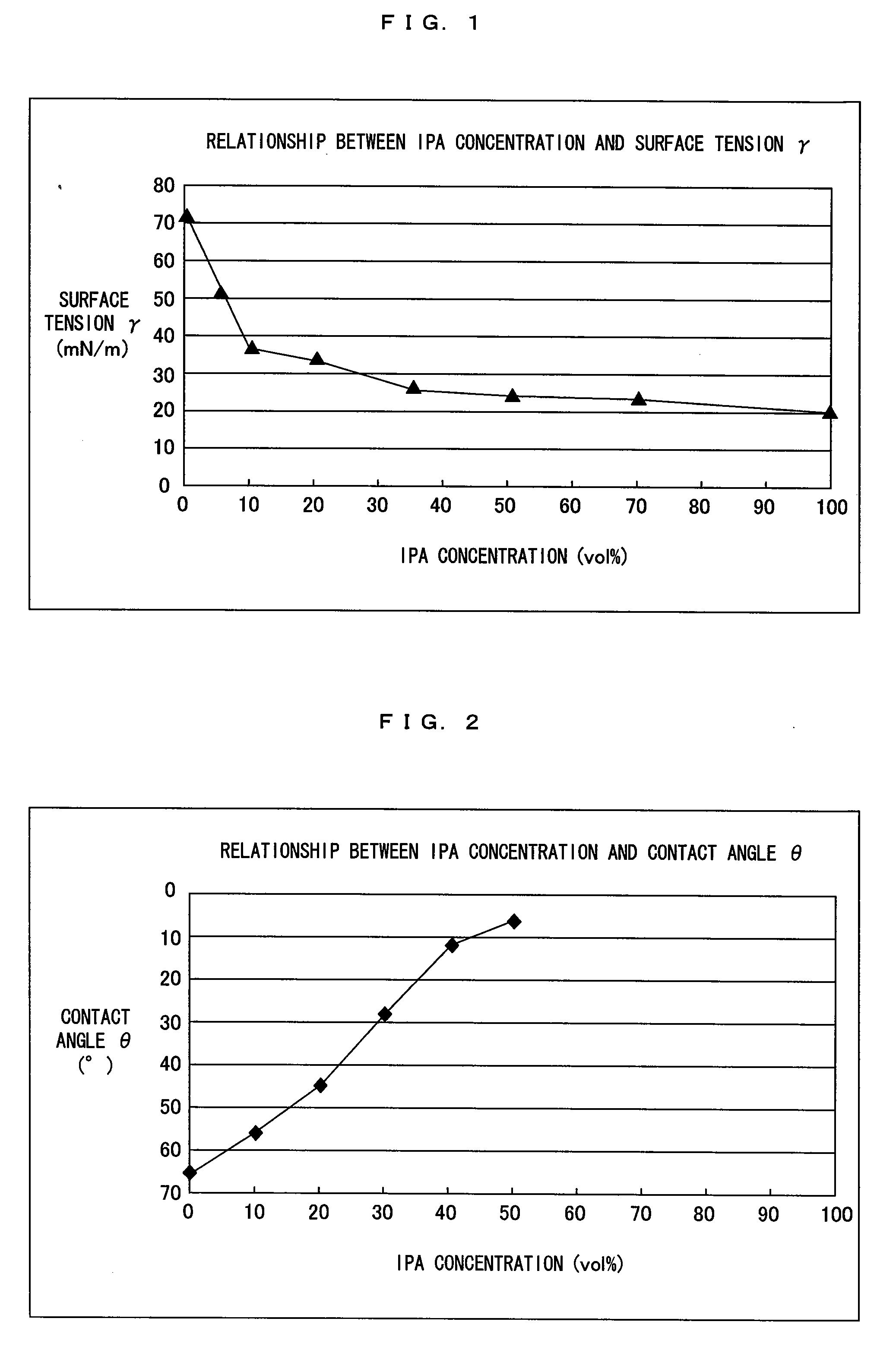

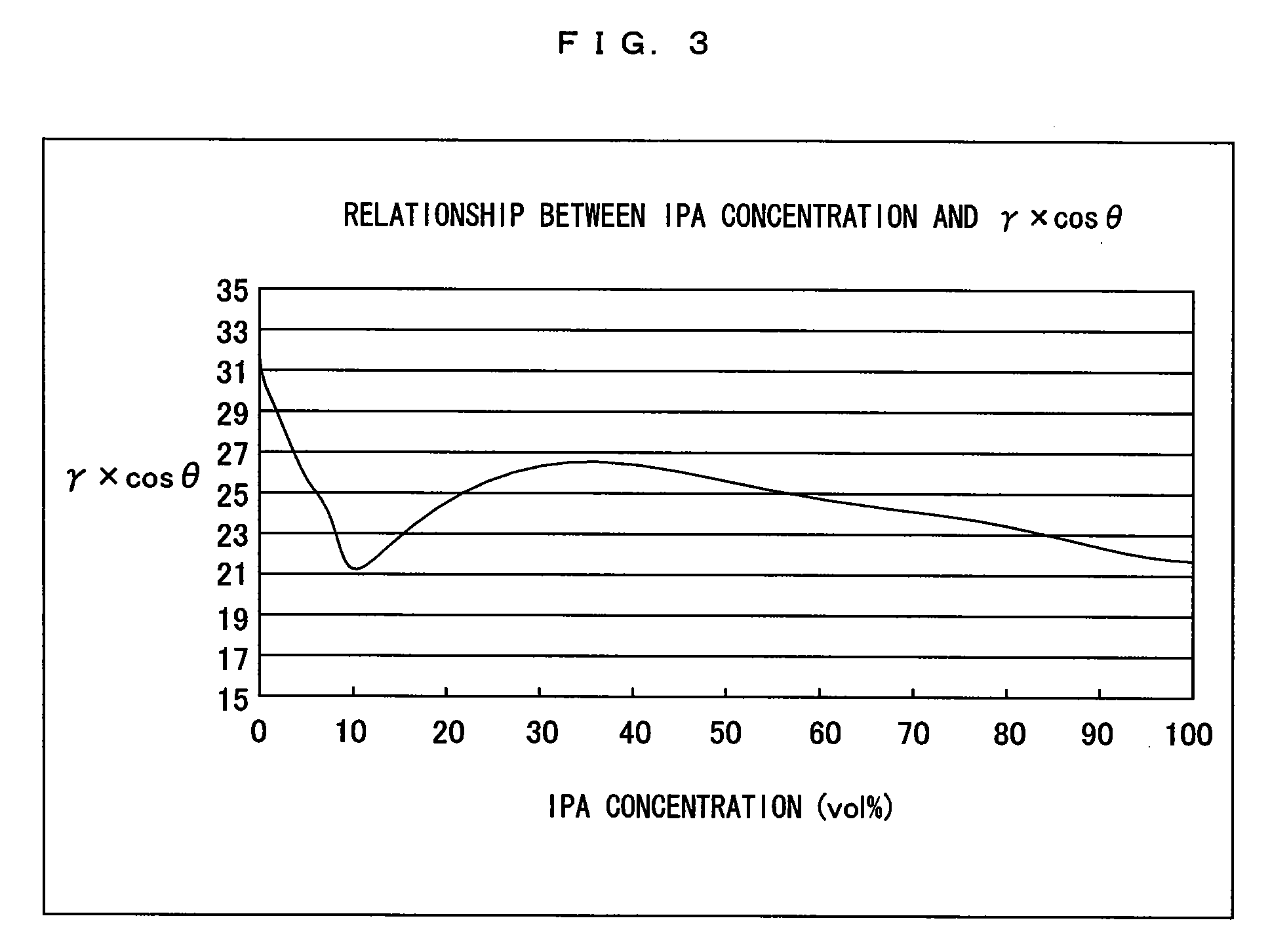

After rinsing, while rotating a substrate, a front layer part of a rinsing liquid (DIW) adhering to a substrate surface is drained and removed from the substrate surface. This is followed by supply to the substrate surface of a liquid mixture which is obtained by mixing IPA and DIW together. Since a majority of the rinsing liquid on the substrate surface is removed off from the substrate surface, even when micro patterns are formed on the substrate surface, the liquid mixture replaces the liquid component adhering to the gaps between the patterns. Further, the IPA concentration in the liquid mixture supplied to the substrate surface is set to 50% or below. Hence, it is possible to effectively prevent destruction of the patterns while suppressing the consumption amount of

Owner:DAINIPPON SCREEN MTG CO LTD

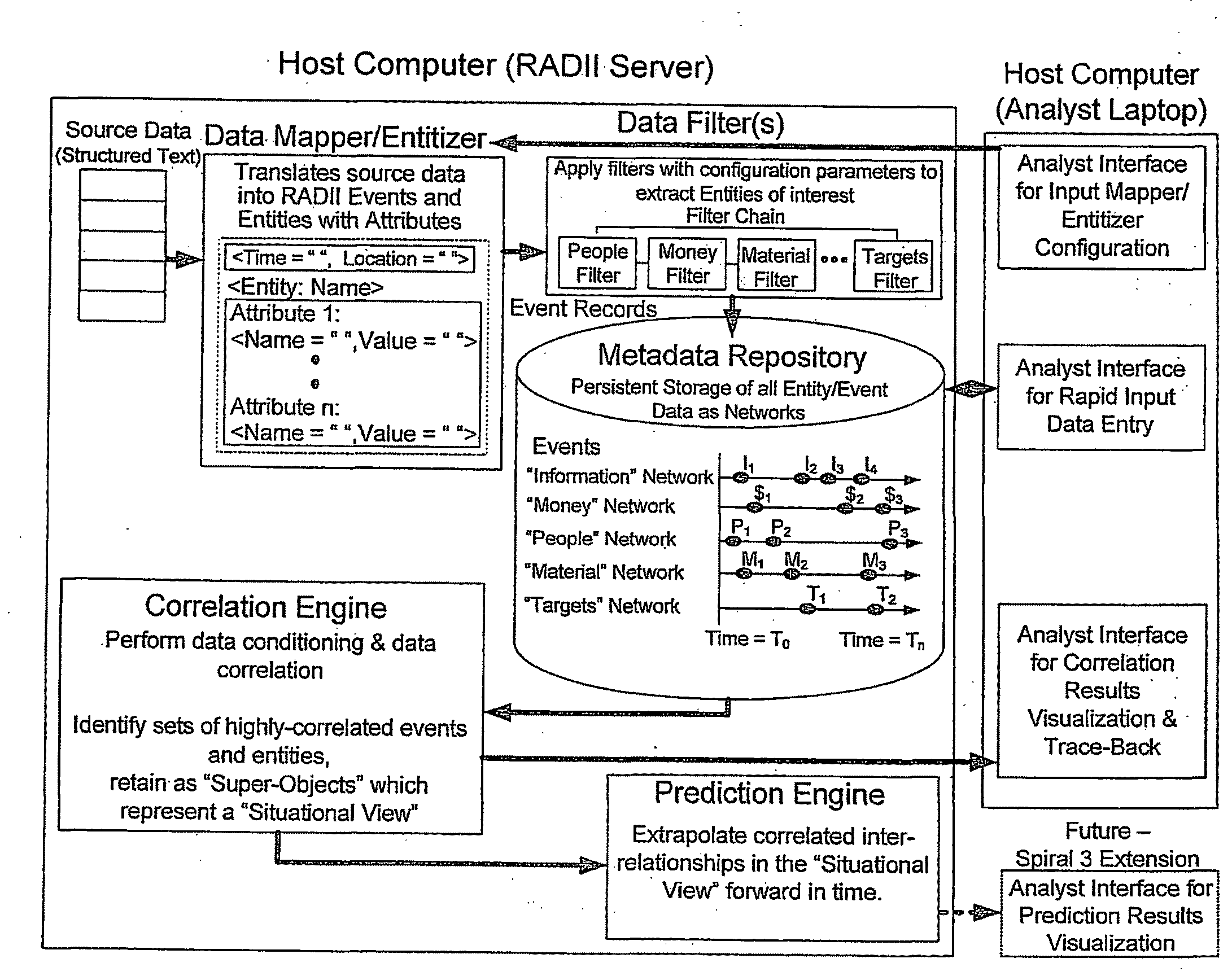

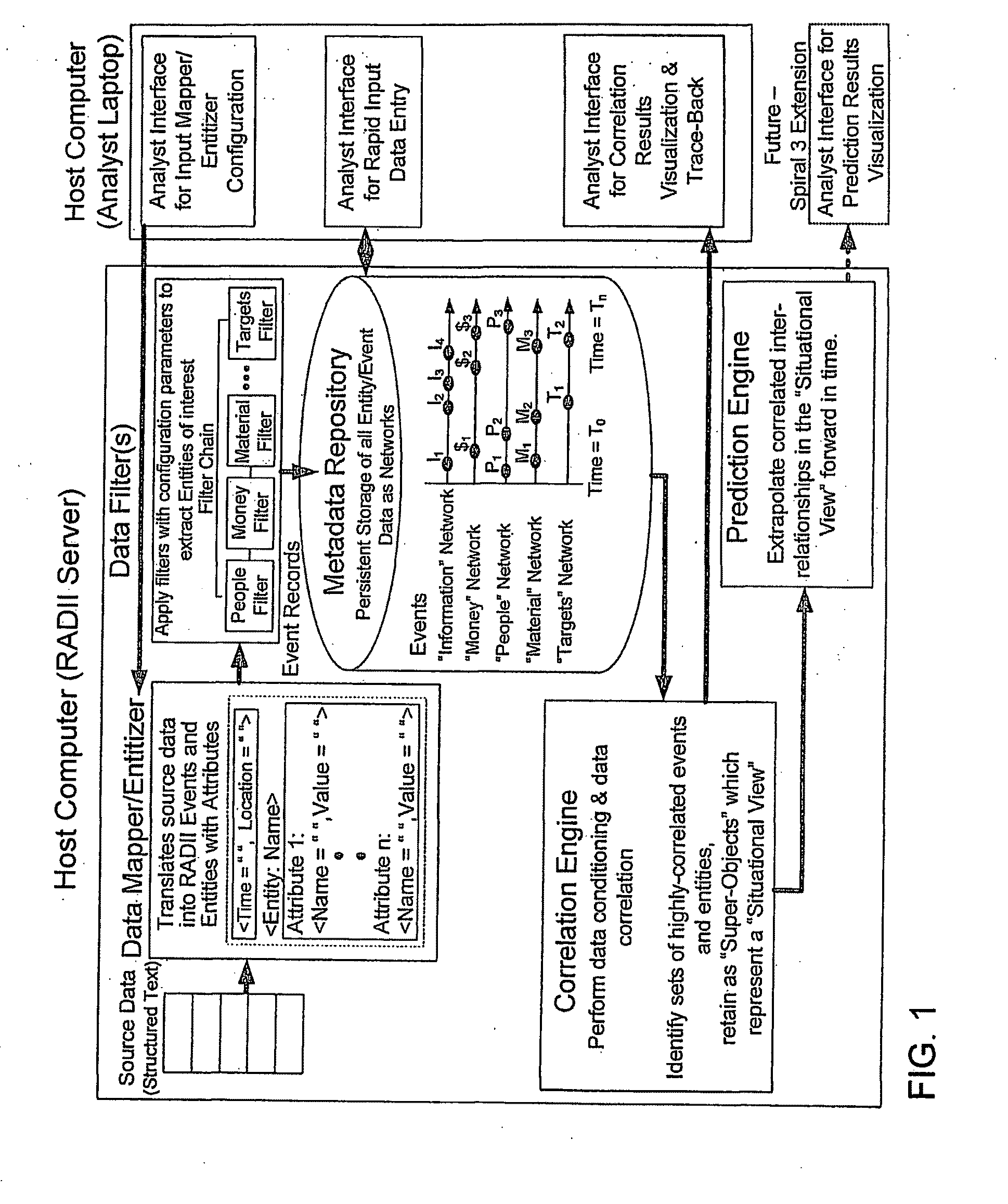

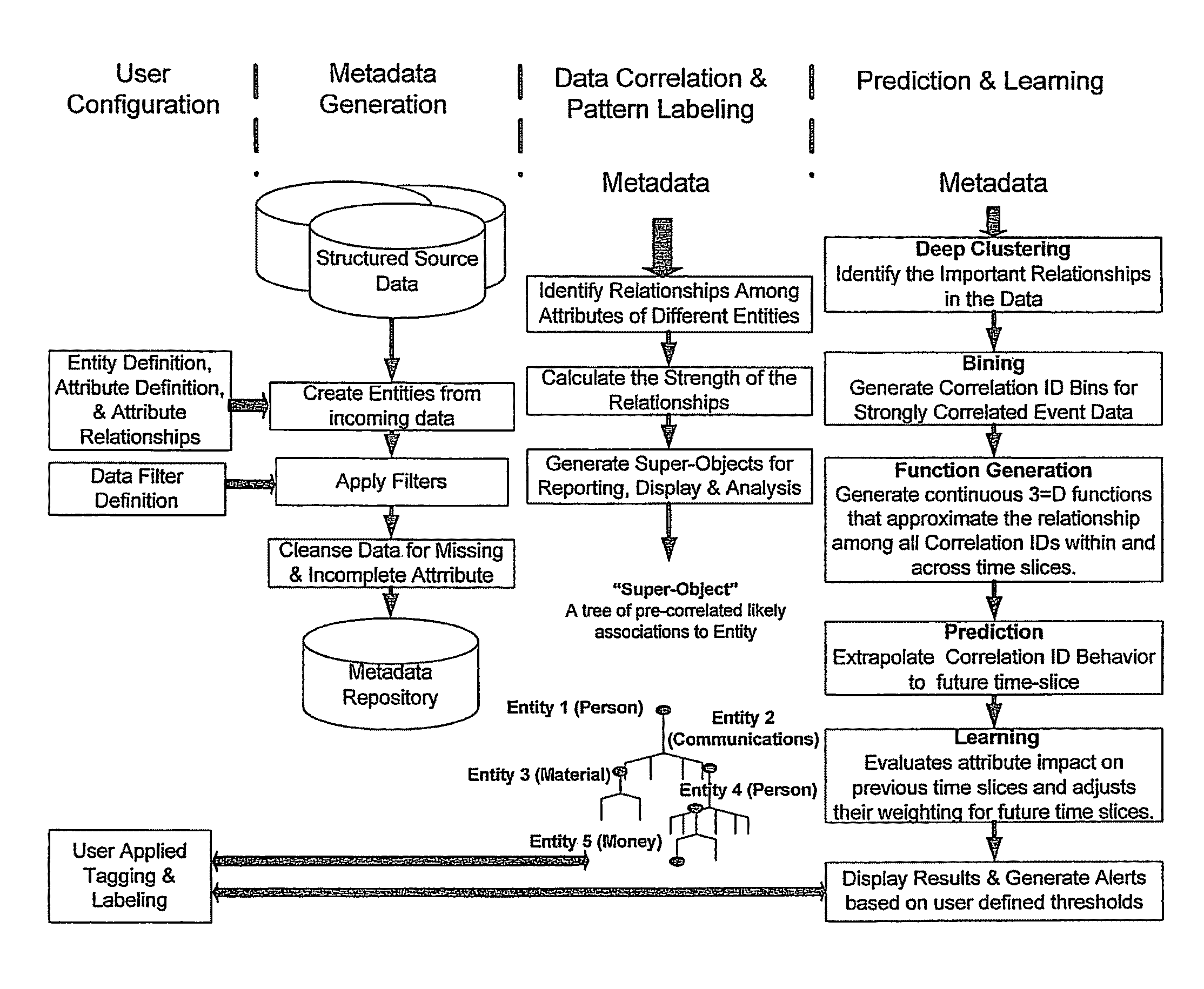

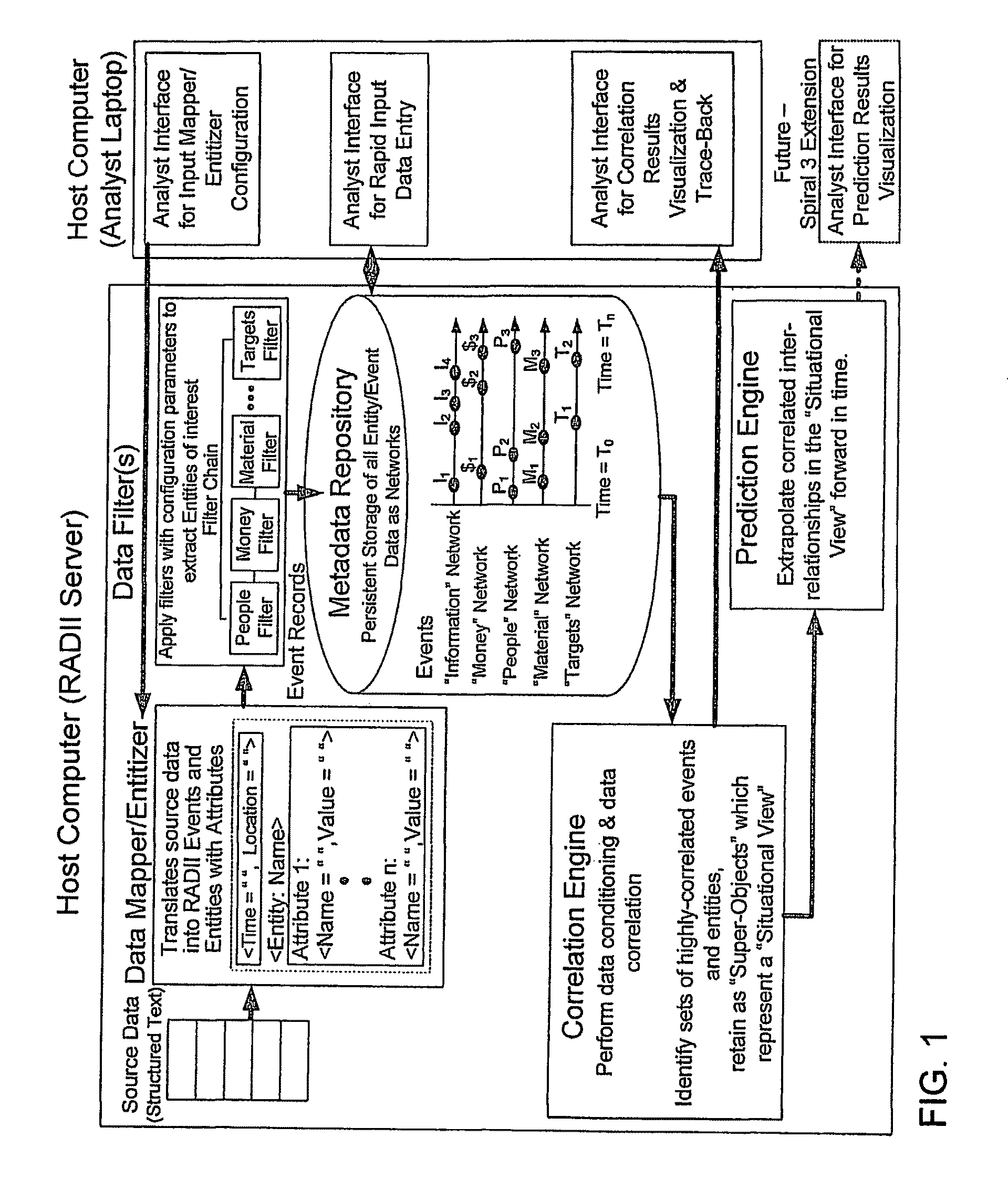

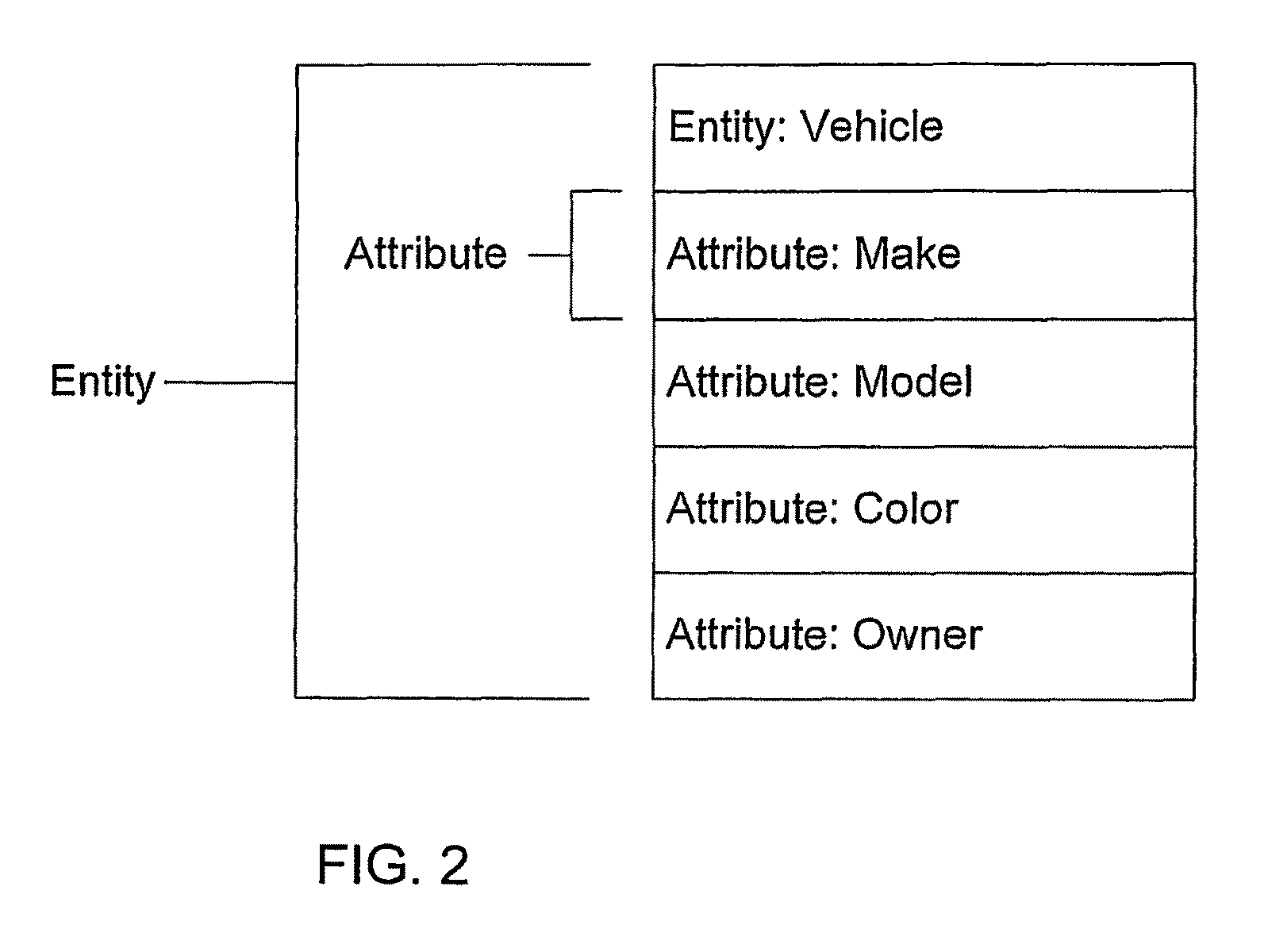

System and method for correlating past activities, determining hidden relationships and predicting future activities

A system and method of data correlation and analysis of past activities and prediction of future activity that includes establishing a database comprising structured metadata on at least one computer and a distributed system of networked computers having a plurality of access levels, configuring a database front-end to parse incoming data, the database front-end defining a plurality of entities and events, each having one or more attributes, and correlation IDs, which are user defined attribute relationships that correlate events and entities, collecting data, parsing the incoming data in the database front-end into structured metadata, the distributed analysis engine correlating the incoming structured metadata with structured metadata in the database and determining micro-patterns in the structured metadata, generating a graphical representation of a composite network of the determined micro-patterns as super-objects, and predicting future activity from the one or more super-objects representing the determined micro-patterns.

Owner:SENSIS CORPORATION

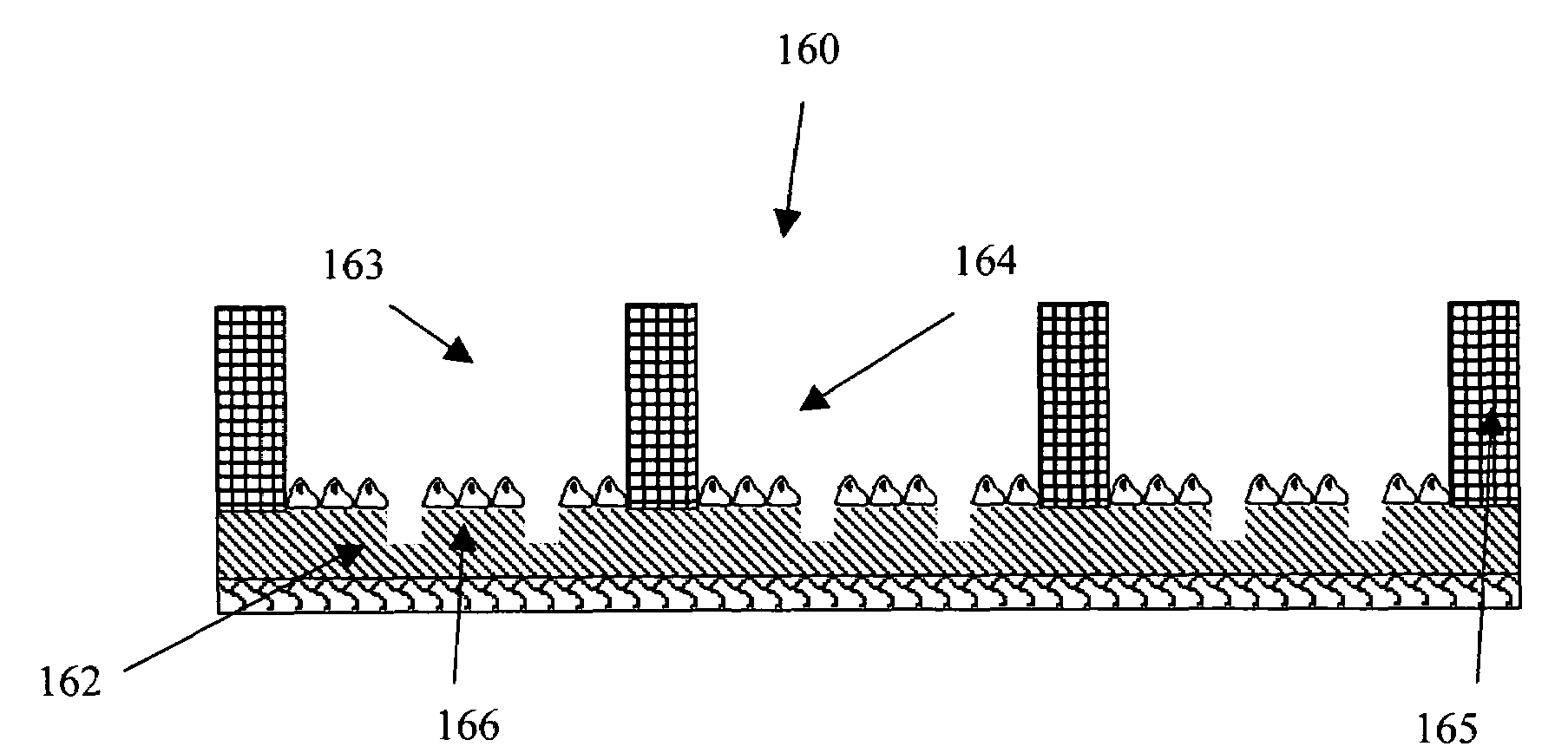

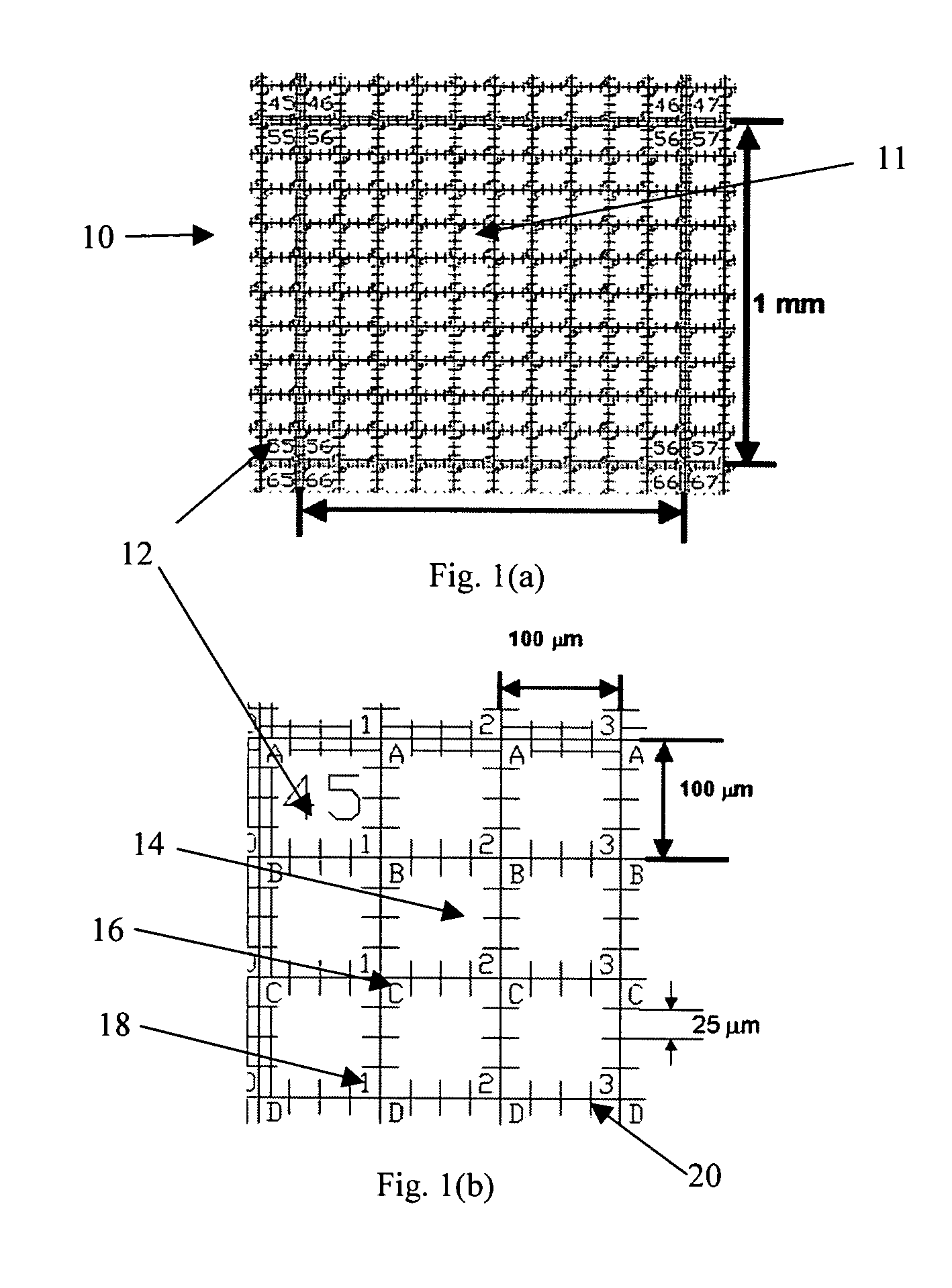

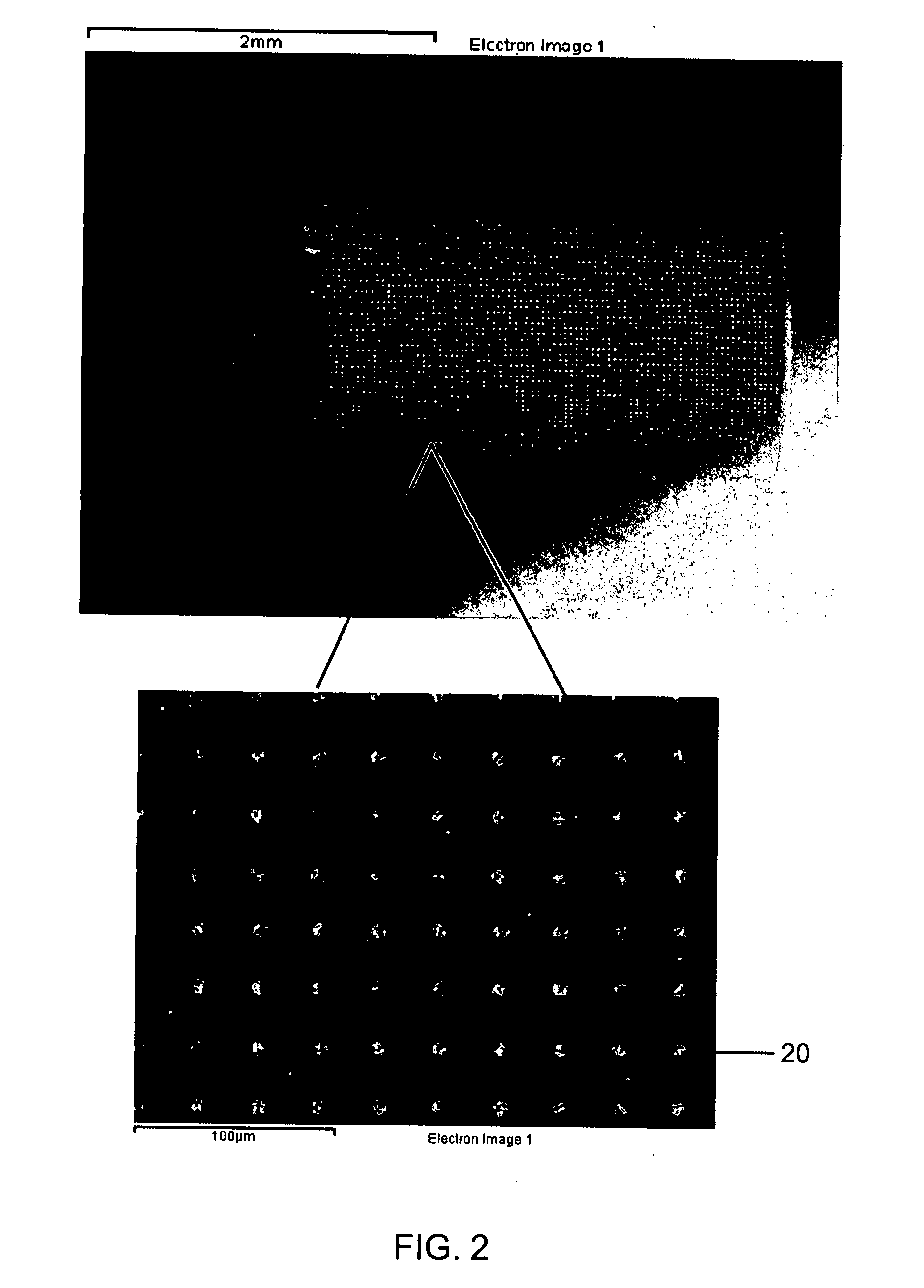

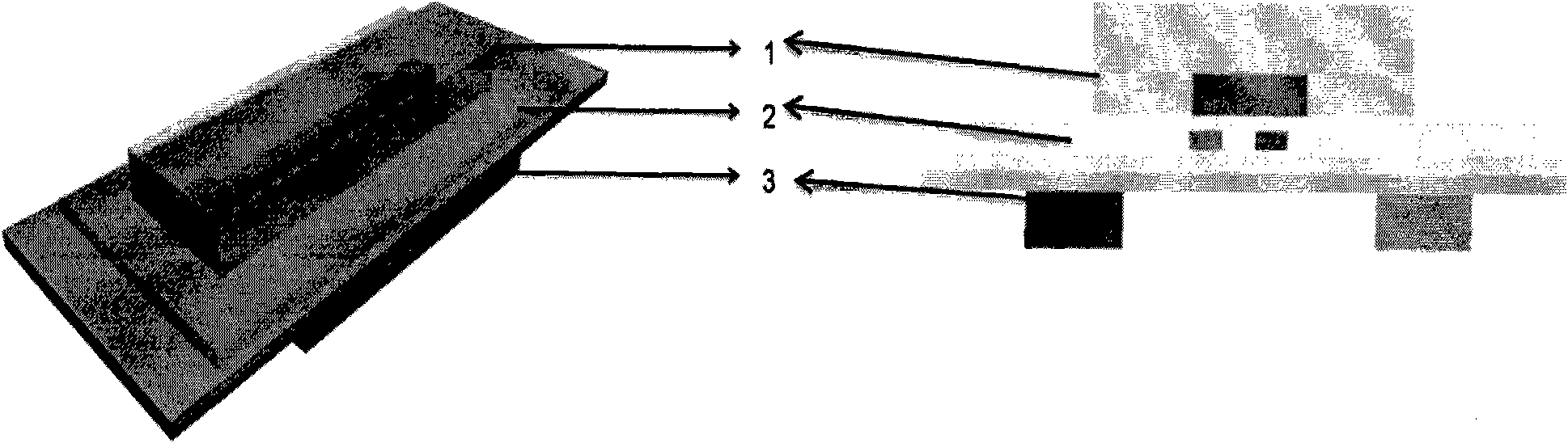

Micro-pattern embedded plastic optical film device for cell-based assays

ActiveUS7329537B2Provide mechanical strengthBioreactor/fermenter combinationsBiological substance pretreatmentsCell based assaysCell growth

In the present invention, a micro-pattern embedded optical film for cell-based assays is described. The optical film contains micro-patterns in the form of geometric shapes, such as lines and curves, and numbers and letters. Furthermore, the optical film contains a coordinate system that allows identification of each location on the optical film for cell-based assays, including cell growth, identification, and measurements under an optical microscope. Furthermore, an apparatus with the micro-pattern embedded optical film and a supporting part is described. Methods for making the optical film and apparatus are disclosed. A method for performing cell-based assays using the optical film or apparatus is shown.

Owner:NEXCELOM BIOSCIENCE LLC

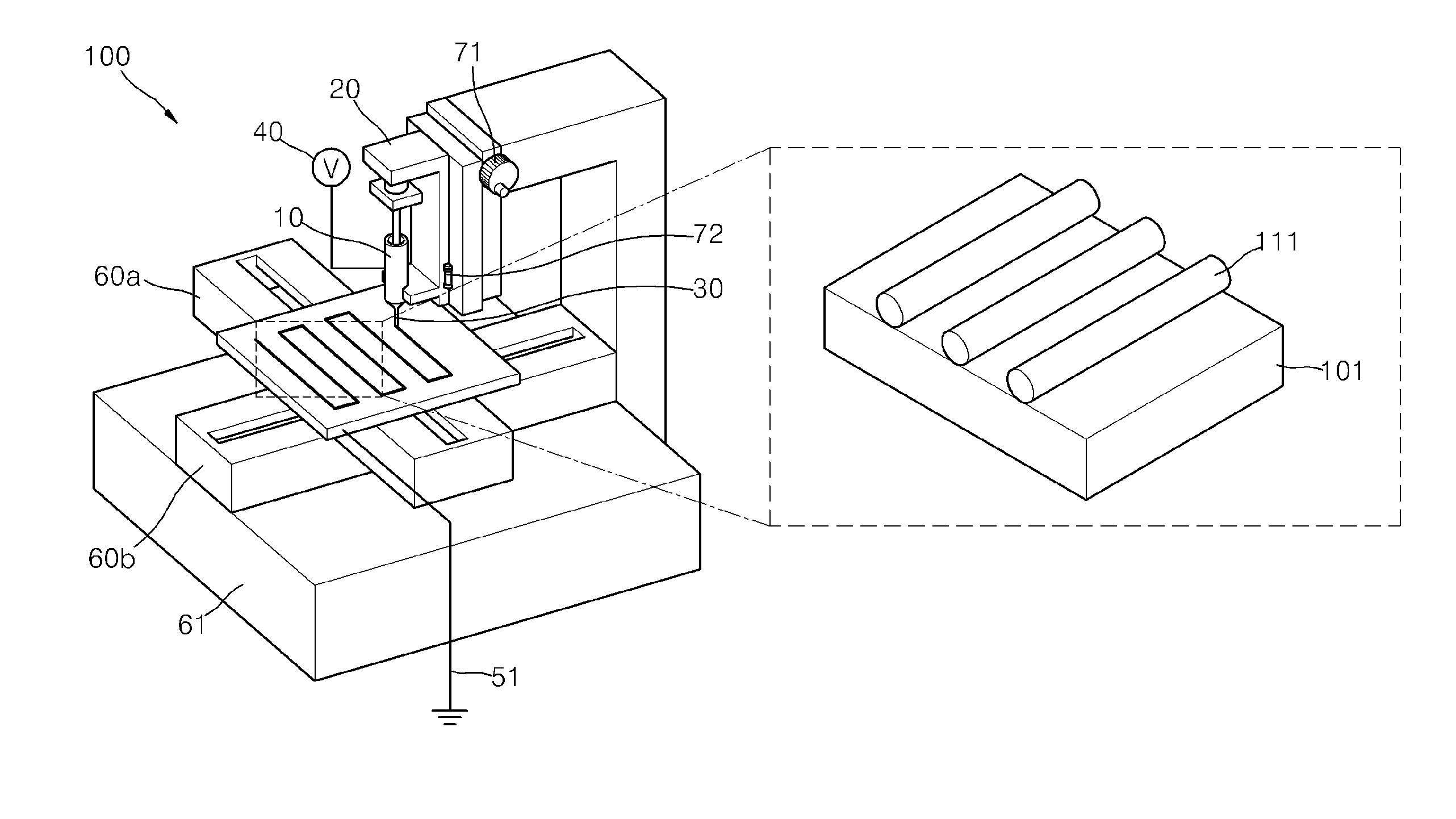

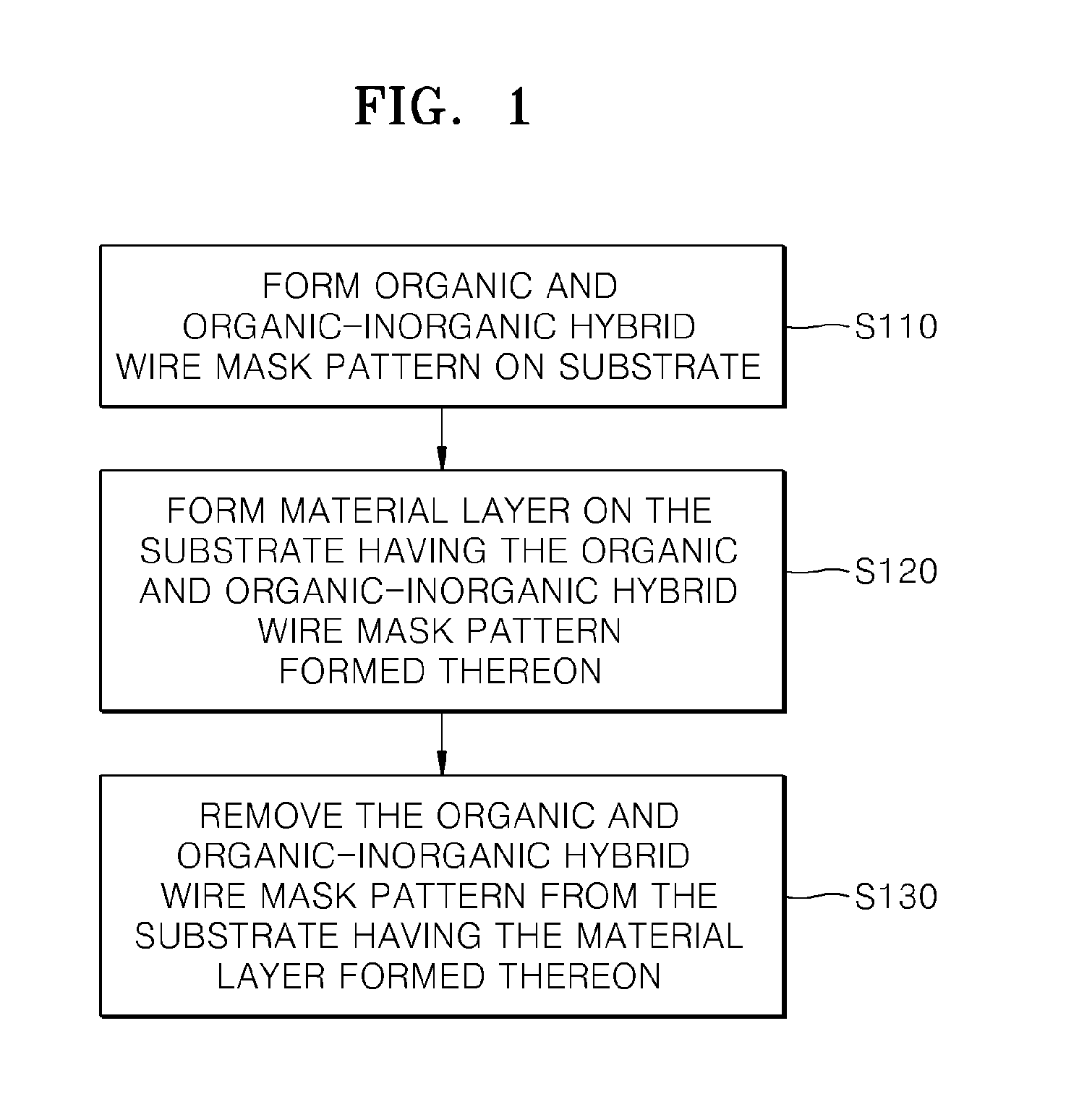

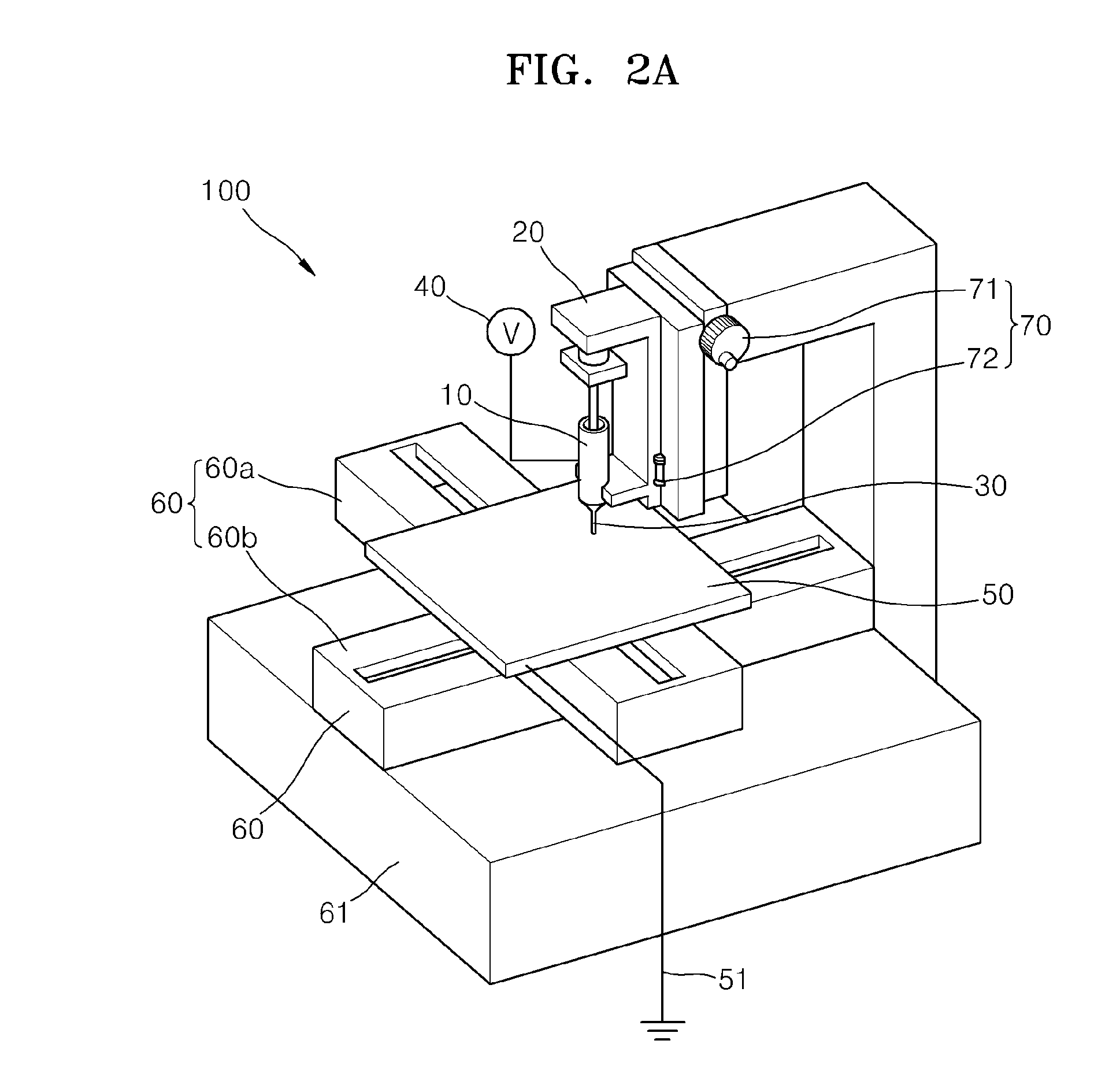

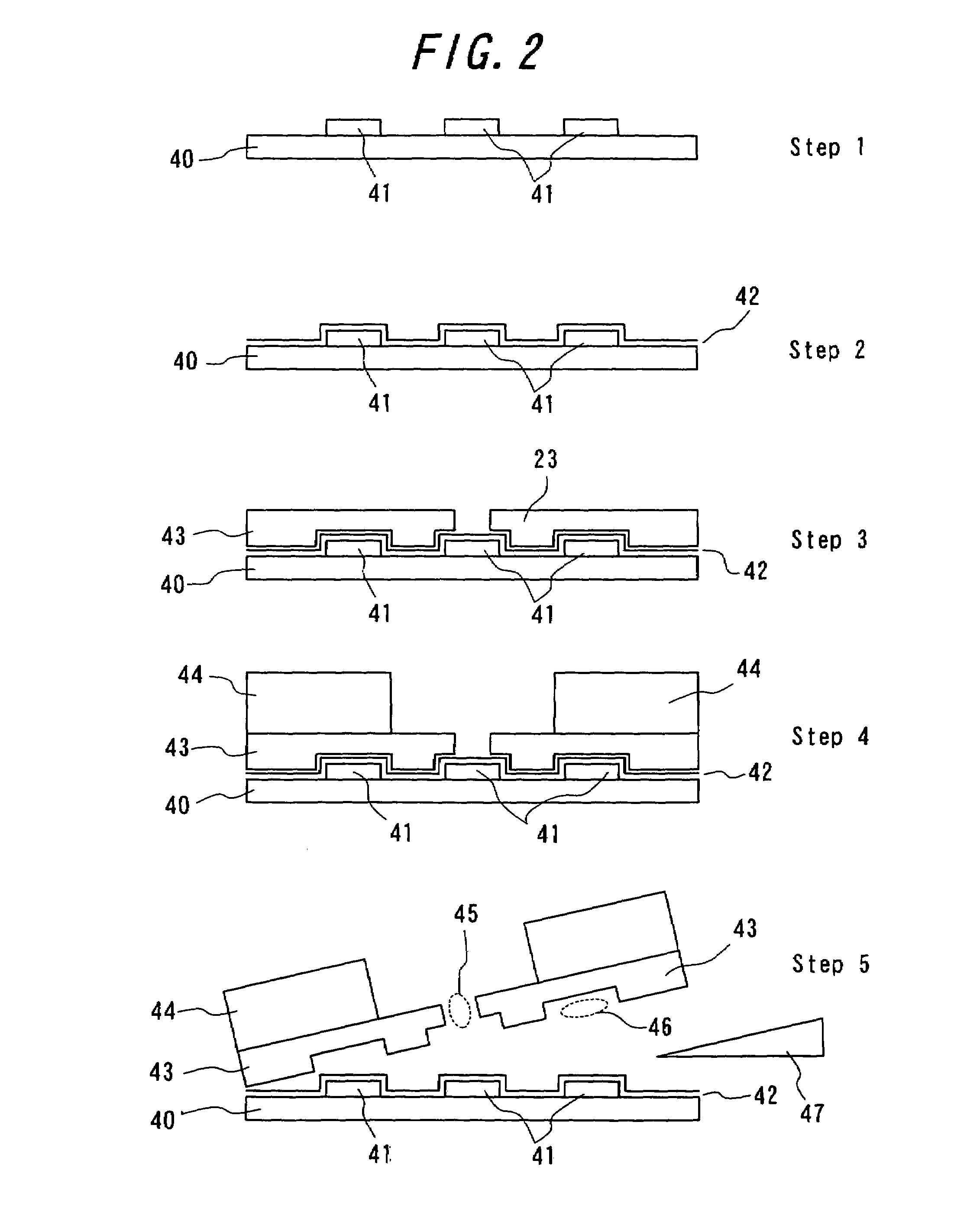

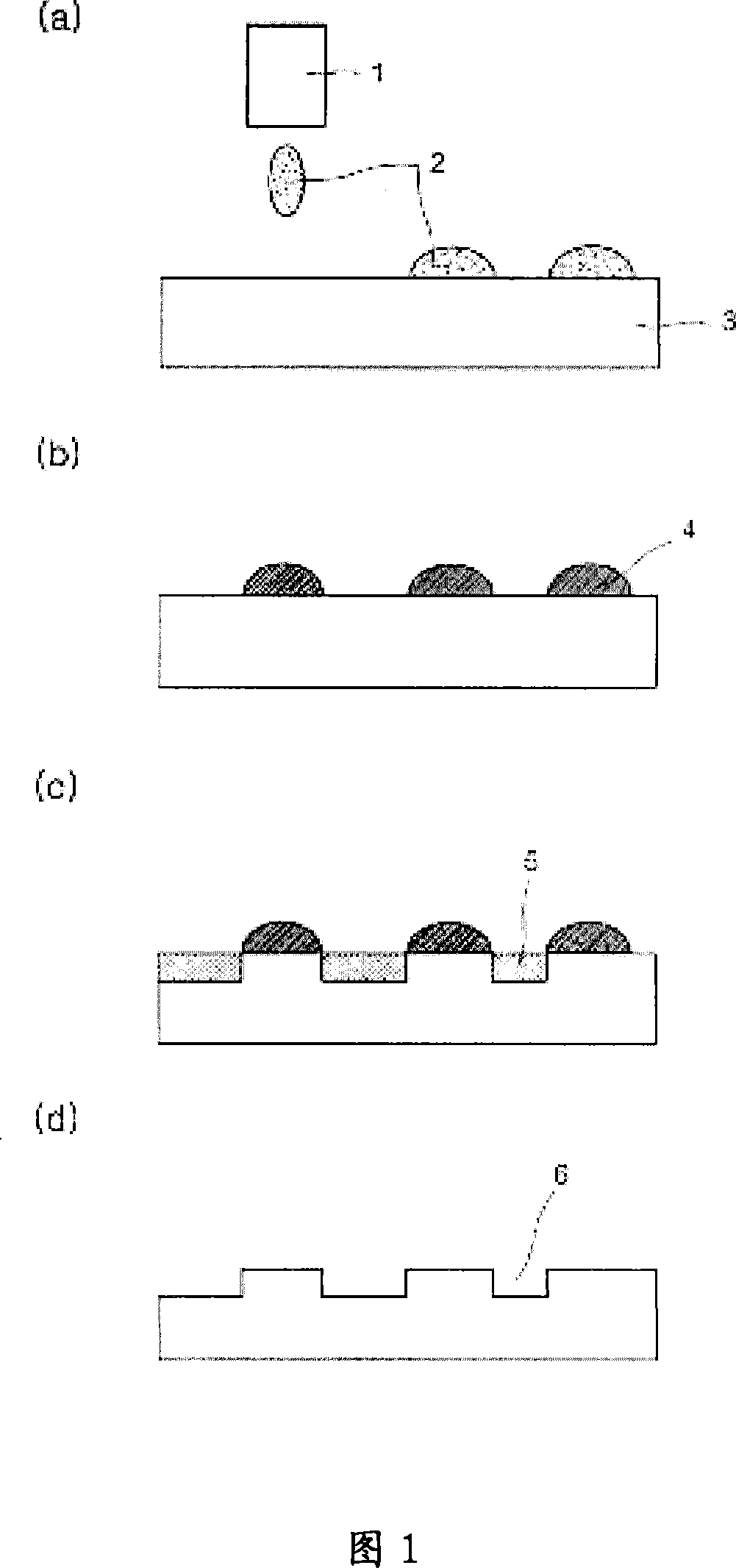

Micro-Pattern Forming Method, and Micro-Channel Transistor and Micro-Channel Light-Emitting Transistor Forming Method Using Same

ActiveUS20130203198A1Low costForming accuratelySpecific nanostructure formationSolid-state devicesEngineeringOrganic inorganic

Provided is a method of forming a micropattern according to an aspect of the present invention. The method of forming a micropattern may include forming an organic wire or organic-inorganic hybrid wire mask pattern having a circular or elliptical cross section on a substrate, forming a material layer on an entire surface of the substrate having the organic wire or organic-inorganic hybrid wire mask pattern formed thereon, and removing the organic wire or organic-inorganic hybrid wire mask pattern from the substrate to allow only the material layer on a portion of the substrate having no organic wire or organic-inorganic hybrid wire mask pattern formed thereon to be remained.

Owner:POSTECH ACAD IND FOUND

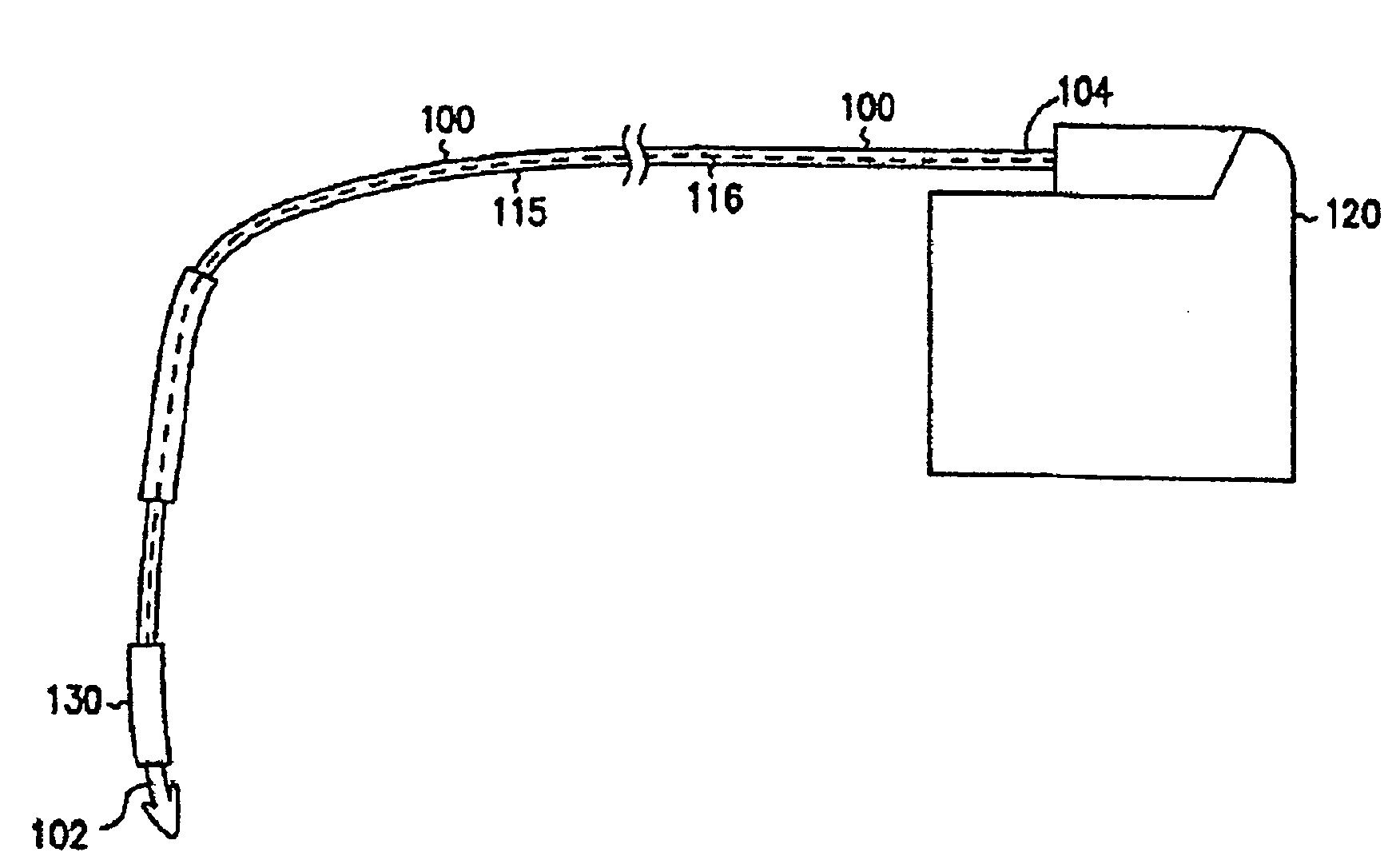

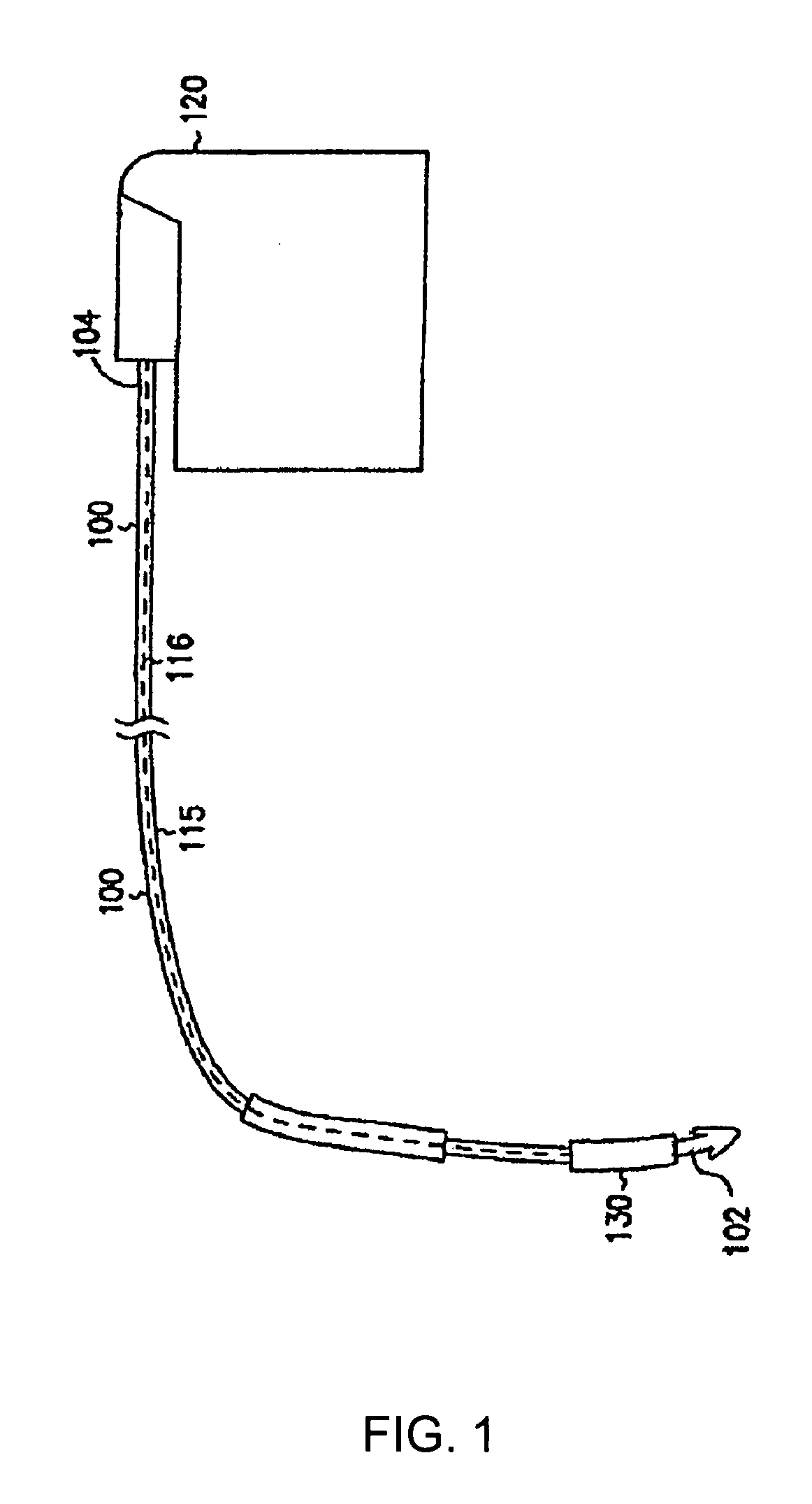

Conductive polymer patterned electrode for pacing

ActiveUS20080071338A1Transvascular endocardial electrodesDiagnostic recording/measuringConductive polymerBiocompatibility Testing

The present invention is an apparatus and method for making a polymer patterned electrode for cardiac pacing and sensing. The electrode surface includes a polymer overlayed on an electrode. The polymer layer is patterned to form an electrode surface consisting of a polymer and a conductive metal surface. The electrode can be made of a high or low impedance electrode by changing the conductivity of the polymer. Furthermore, the electrode surface texture can be optimized with a micro pattern that may enhance the biocompatibility. The polymer may be conductive or insulative.

Owner:CARDIAC PACEMAKERS INC

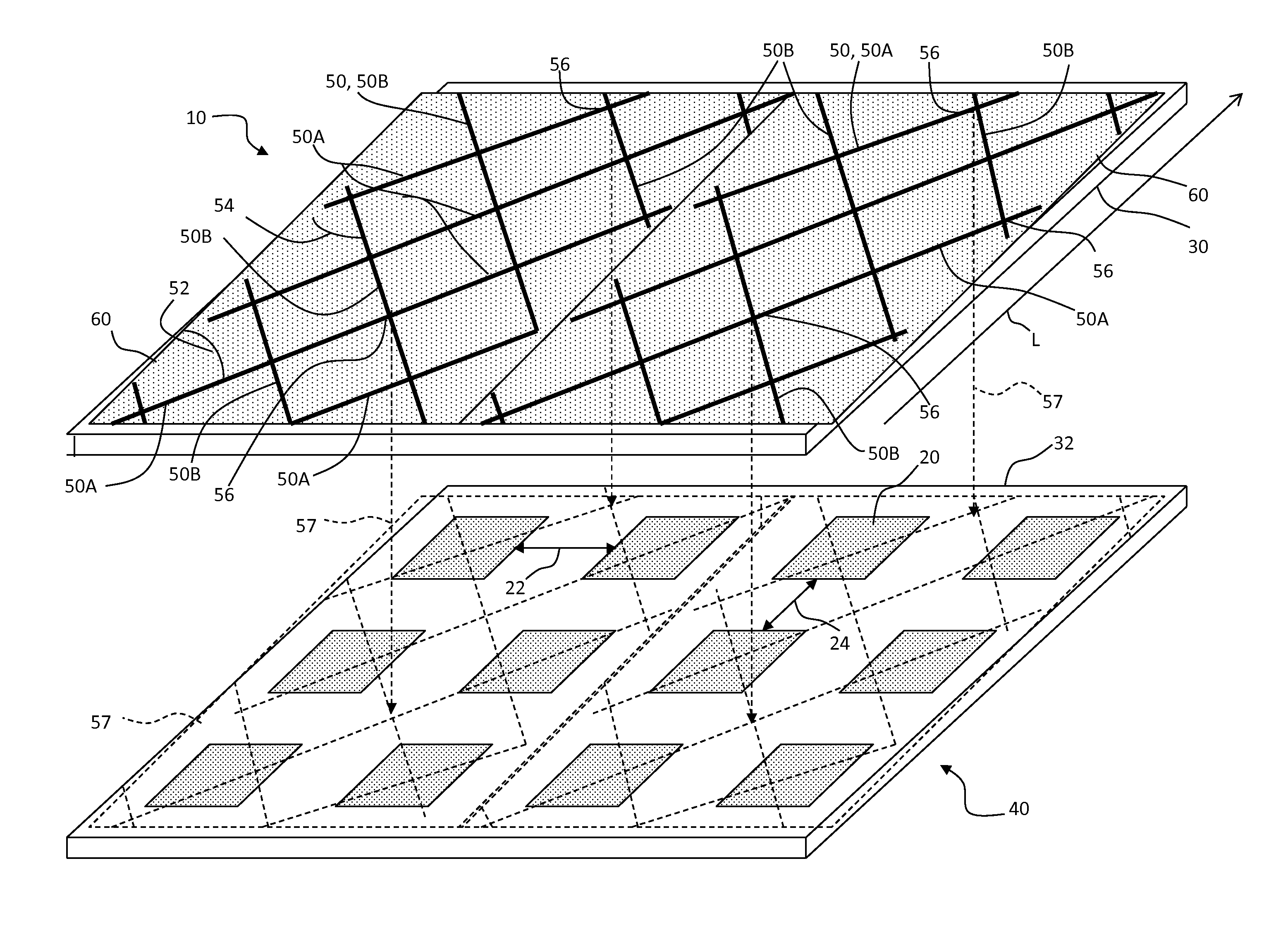

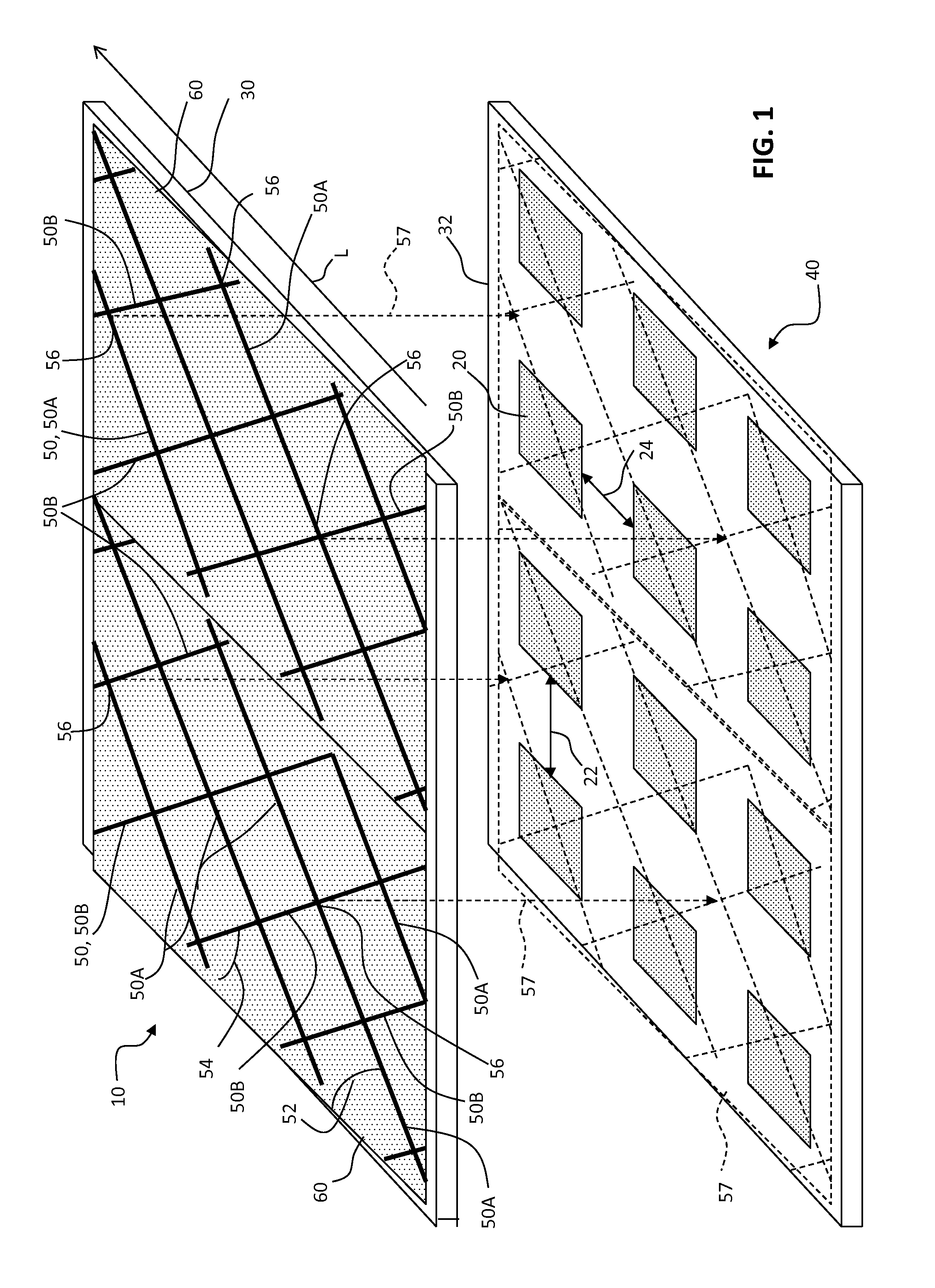

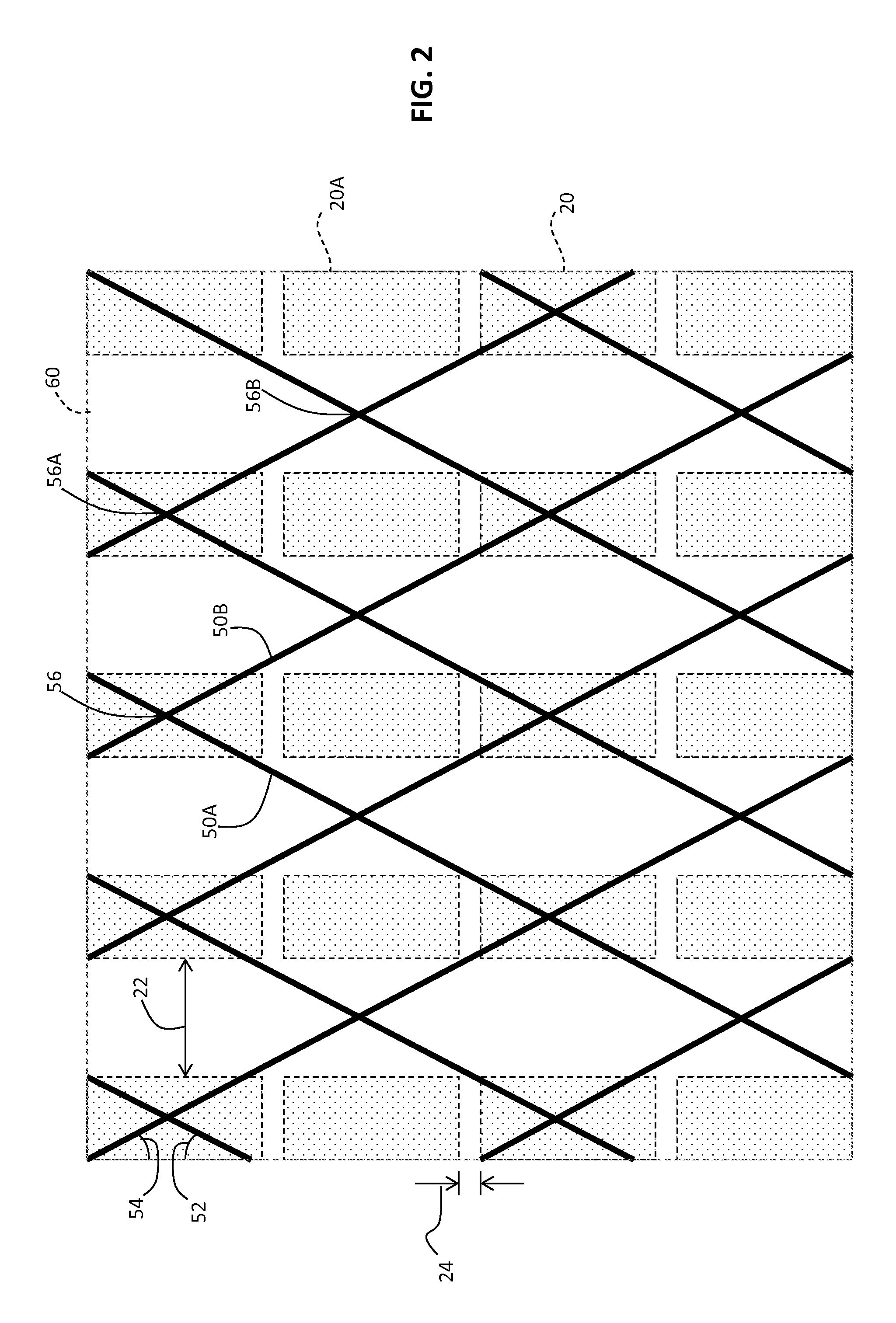

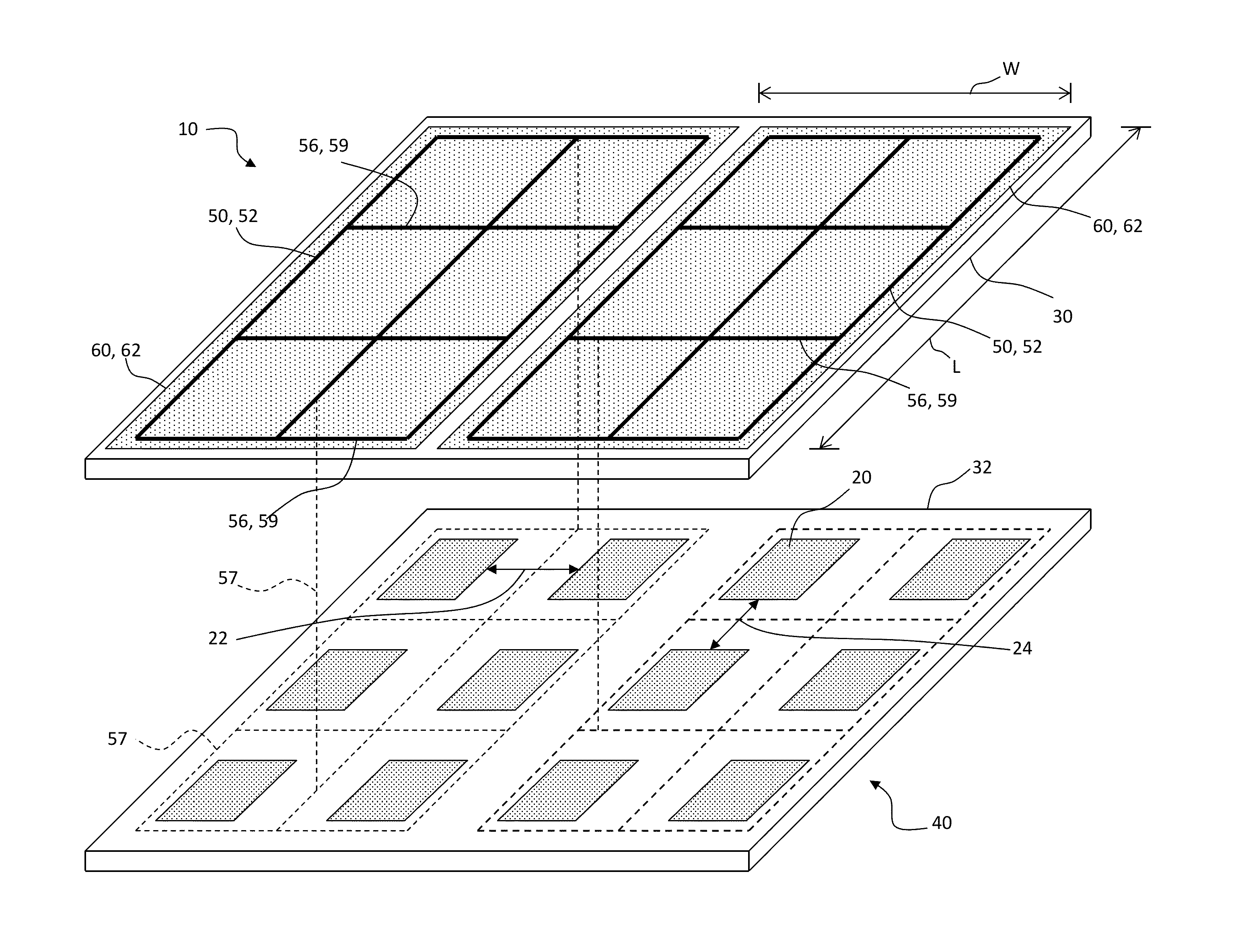

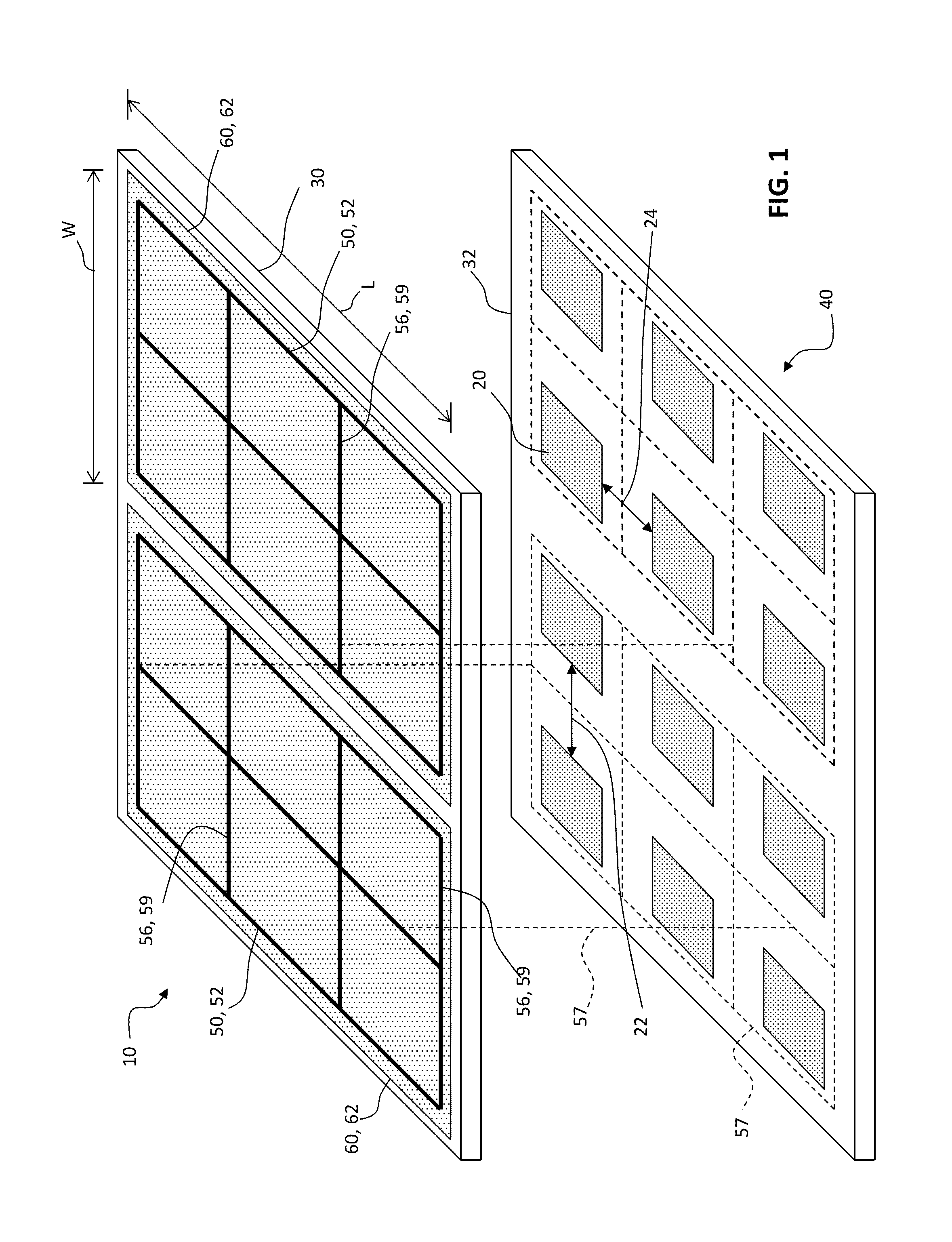

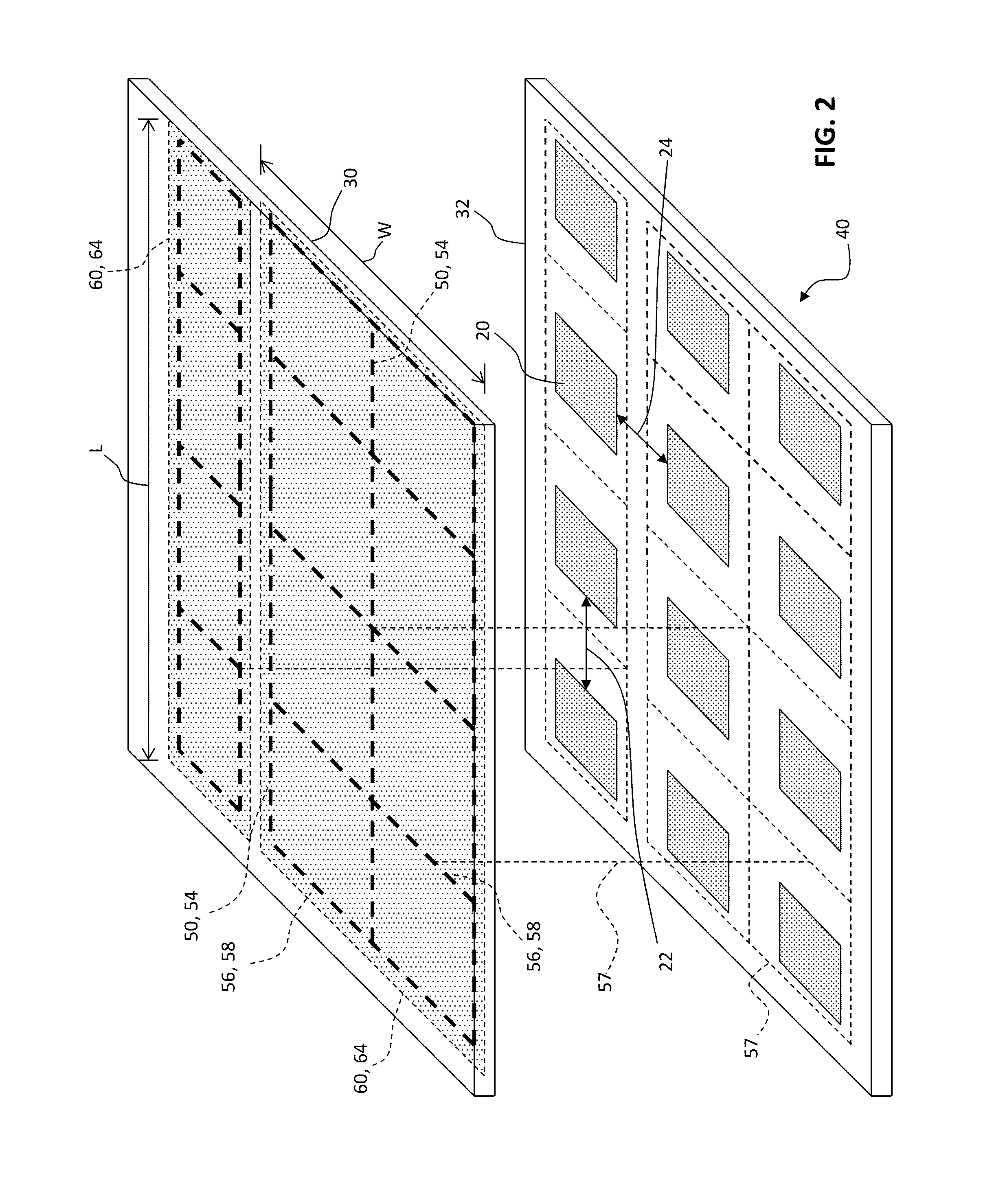

Display apparatus with diamond-patterned micro-wire electrode

ActiveUS20140055403A1High transparencyFew optical interactionInput/output processes for data processingDisplay deviceNon orthogonal

A display apparatus includes a display having an array of pixels separated by inter-pixel gaps and a touch screen. The touch screen includes a dielectric layer located over the display having first and second electrodes each having a length direction and extending across at least a portion of the array of pixels. Each electrode includes a plurality of electrically connected micro-wires formed in a micro-pattern. The micro-patterns each have a first set of parallel micro-wires oriented at a first angle non-orthogonal to the length direction and a second set of parallel micro-wires oriented at a second angle non-orthogonal to the length direction different from the first angle. The micro-wires of the first and second sets intersect to form an array of electrically connected micro-wire intersections. At least every other micro-wire intersection on the micro-wires of the first set is located between the pixels in the inter-pixel gaps.

Owner:EASTMAN KODAK CO

System and method for correlating past activities, determining hidden relationships and predicting future activities

A system and method of data correlation and analysis of past activities and prediction of future activity that includes establishing a database comprising structured metadata on at least one computer and a distributed system of networked computers having a plurality of access levels, configuring a database front-end to parse incoming data, the database front-end defining a plurality of entities and events, each having one or more attributes, and correlation IDs, which are user defined attribute relationships that correlate events and entities, collecting data, parsing the incoming data in the database front-end into structured metadata, the distributed analysis engine correlating the incoming structured metadata with structured metadata in the database and determining micro-patterns in the structured metadata, generating a graphical representation of a composite network of the determined micro-patterns as super-objects, and predicting future activity from the one or more super-objects representing the determined micro-patterns.

Owner:SENSIS CORPORATION

Camouflage U.S. Marine Corps combat utility uniform: pattern, fabric, and design

InactiveUS20090313740A1Accelerated destructionImprove concealmentDecorative surface effectsDuplicating/marking methodsFiberInfrared

A camouflage system to be used for both military uniforms and equipment. The system includes specialized means of printing the camouflage system unto fabric. The system can also be used for civilian applications, particularly with sportsman hunters. The system provides camouflage in both the human visible light range and the infrared. The system depends on the use of a macro-pattern resulting from a repeat of a micro-pattern. When applied to fabric, a polyamide-cotton fiber blend has a macro pattern resulting from a repeat of a micro pattern printed on at least one surface. The coloring system used comprises at least four colorings from dyes that in combination produce a percent reflectance value comparable to the negative space of the surroundings near the camouflaged subject. The system functions by a macro pattern being disruptive of the shape of the subject and a micro pattern comprising sharp edge units of a size capable of blending the subject into the background. The relative lightness values and percentages of total pattern are sufficient to produce a percent reflectance of acceptable colors, wet or dry in terms of lightness values compared to current military four-color camouflage. On fabric, the results are achieved by printing A macro pattern that disrupts the sensed shape and a micro pattern with a repeat size that produces the macro pattern. The reflectance of the material is comparable to the negative space surrounding a subject so the subject does not appear too dark or too light (out of place). The variation in the lightness between wet and dry is not greater than 17-28%, achieved during the printing process.

Owner:THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SECRETARY OF THE NAVY

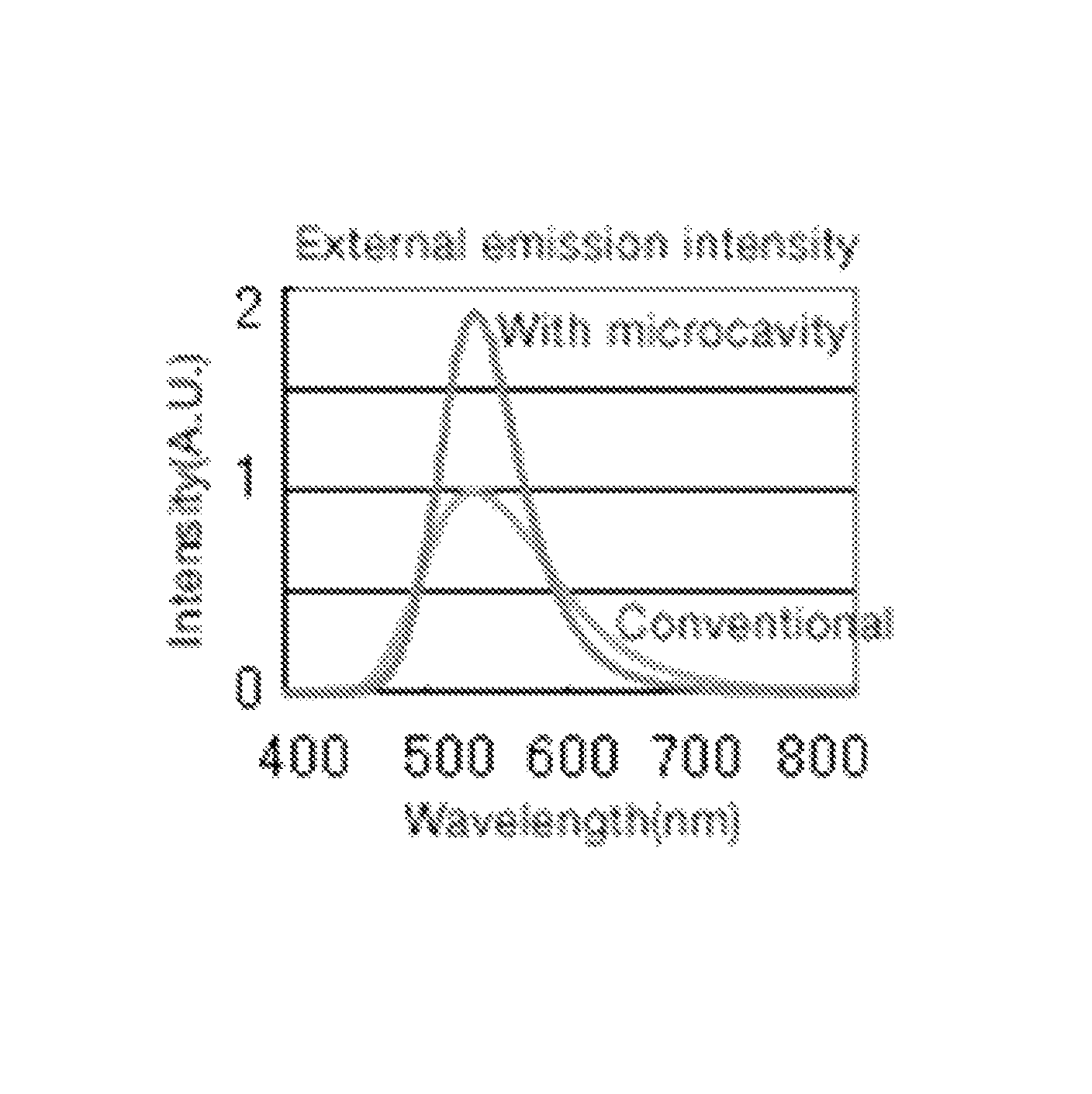

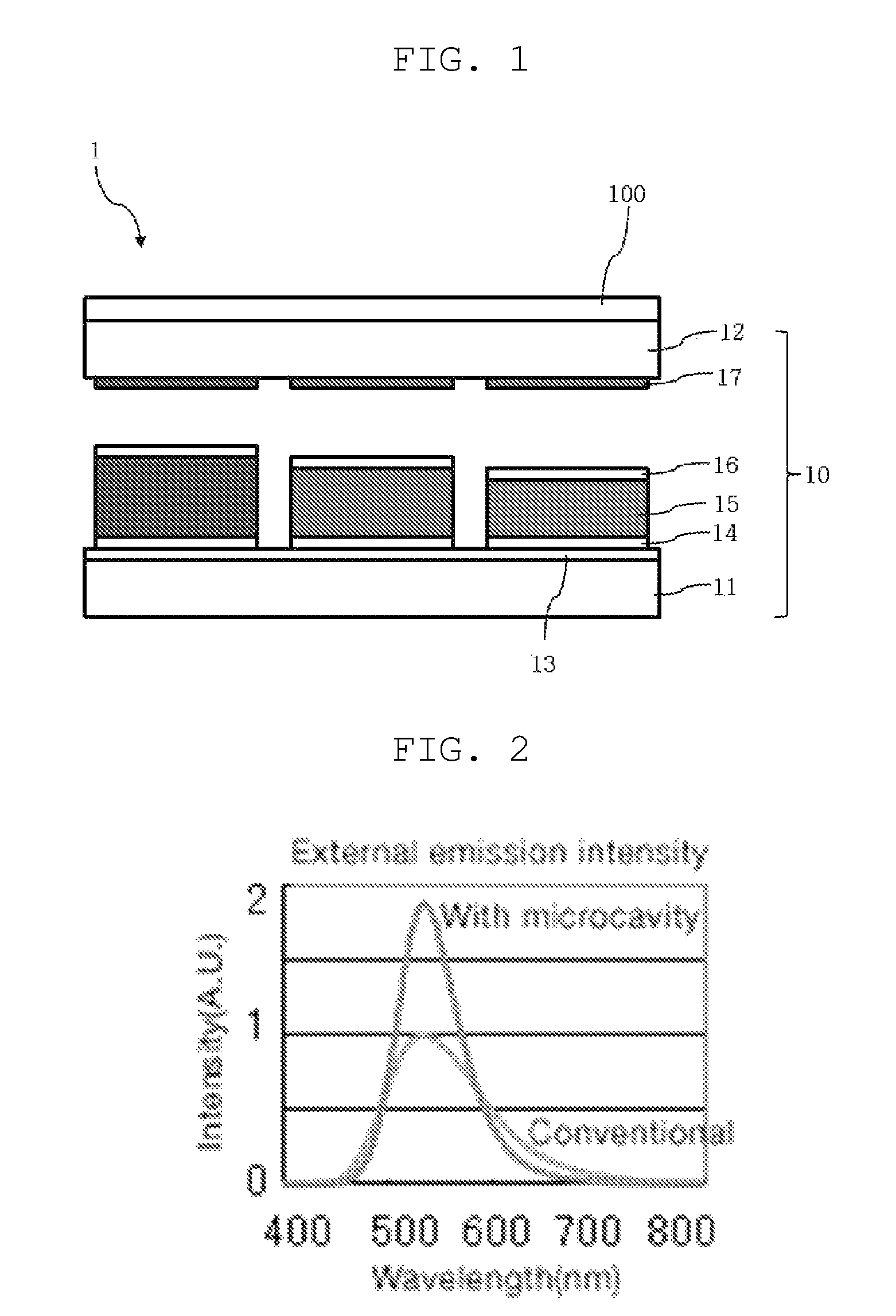

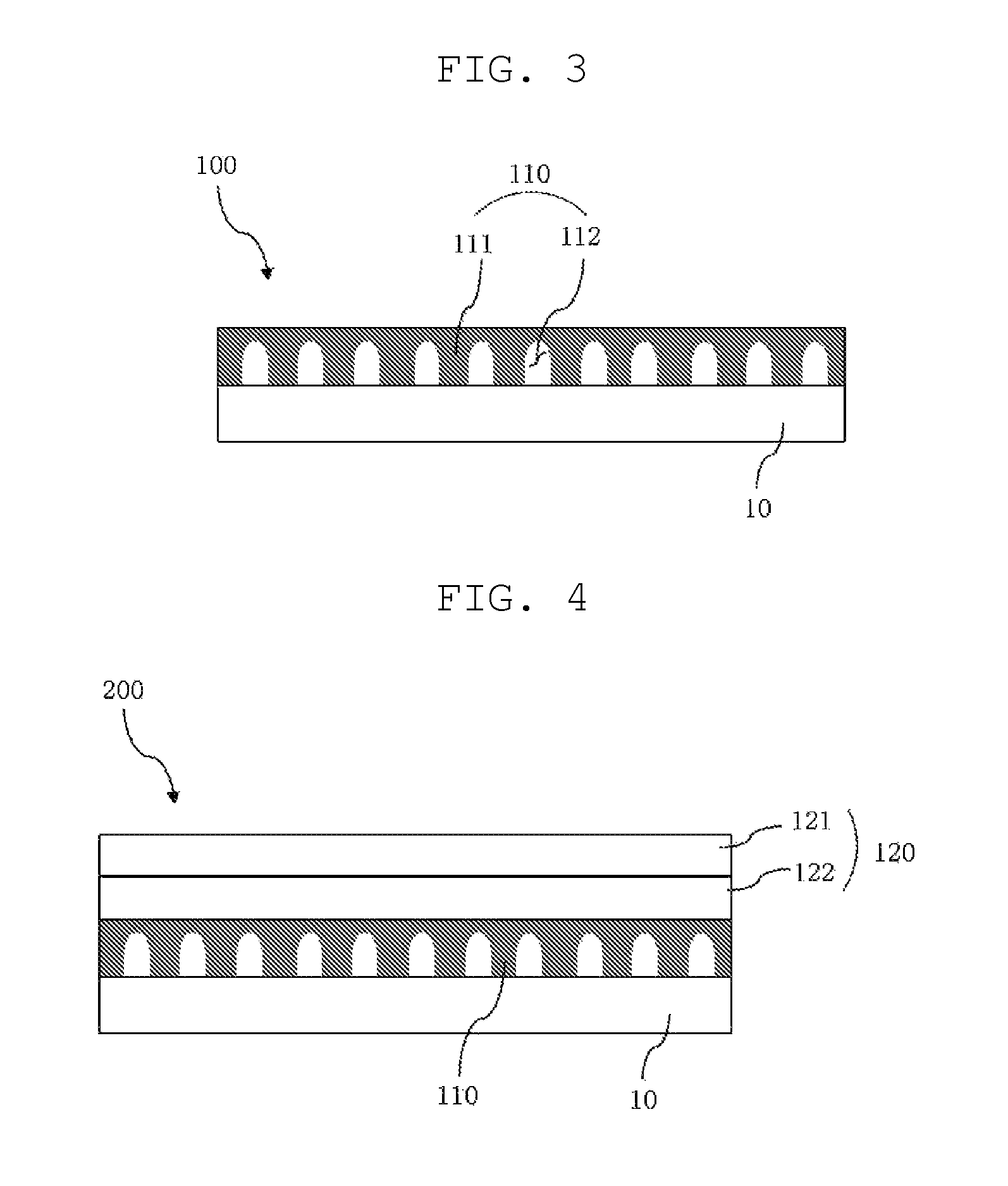

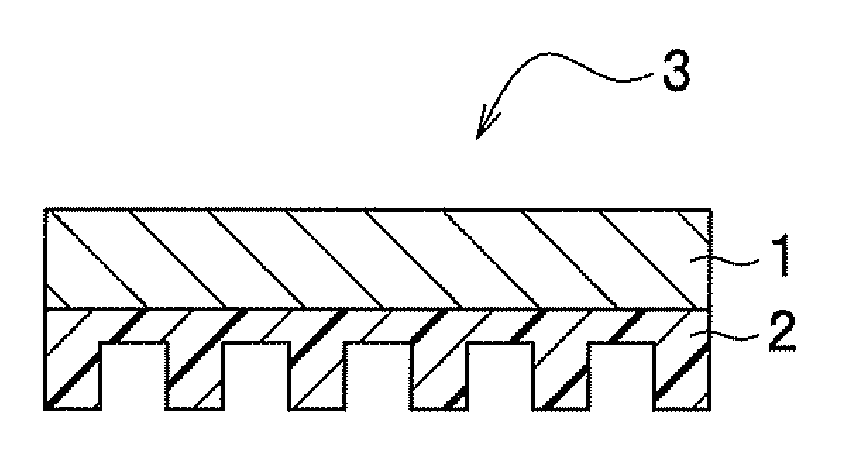

Organic light emitting display having improved color shift and visibility

ActiveUS8894243B2Minimizes colorIncrease brightnessSpectral modifiersNon-linear opticsVisibilityColor shift

An optical filter which minimizes color shift, increases brightness and improves visibility and an organic light-emitting display having the same. The optical filter includes a micro pattern film disposed on an organic light-emitting panel. The micro pattern film includes a base material and a micro pattern engraved from the surface of the base material that adjoins the organic light-emitting panel. The micro pattern has a plurality of engraved shapes with a non-circular cross-section which has a depth greater than a width.

Owner:SAMSUNG CORNING PRECISION MATERIALS CO LTD

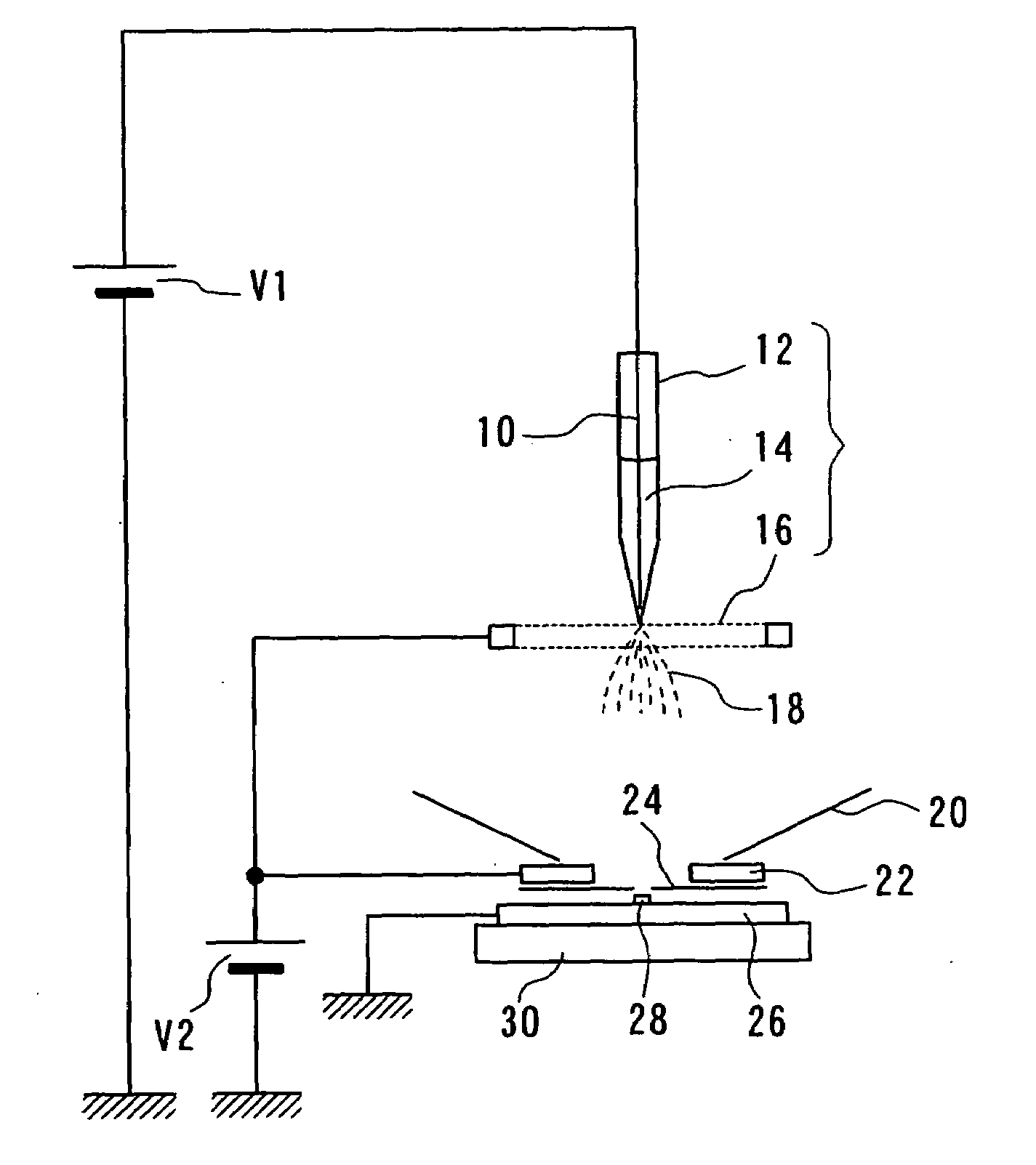

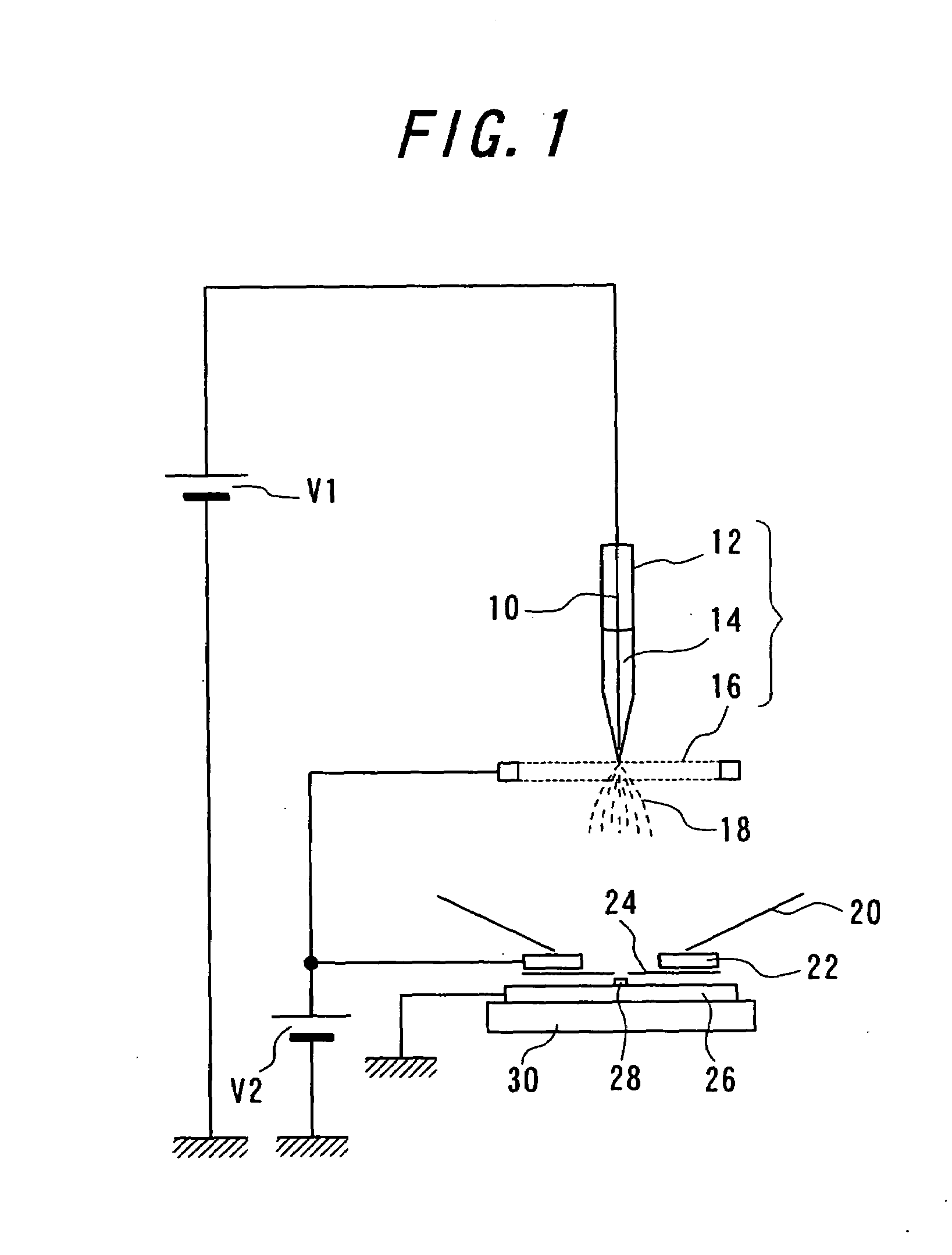

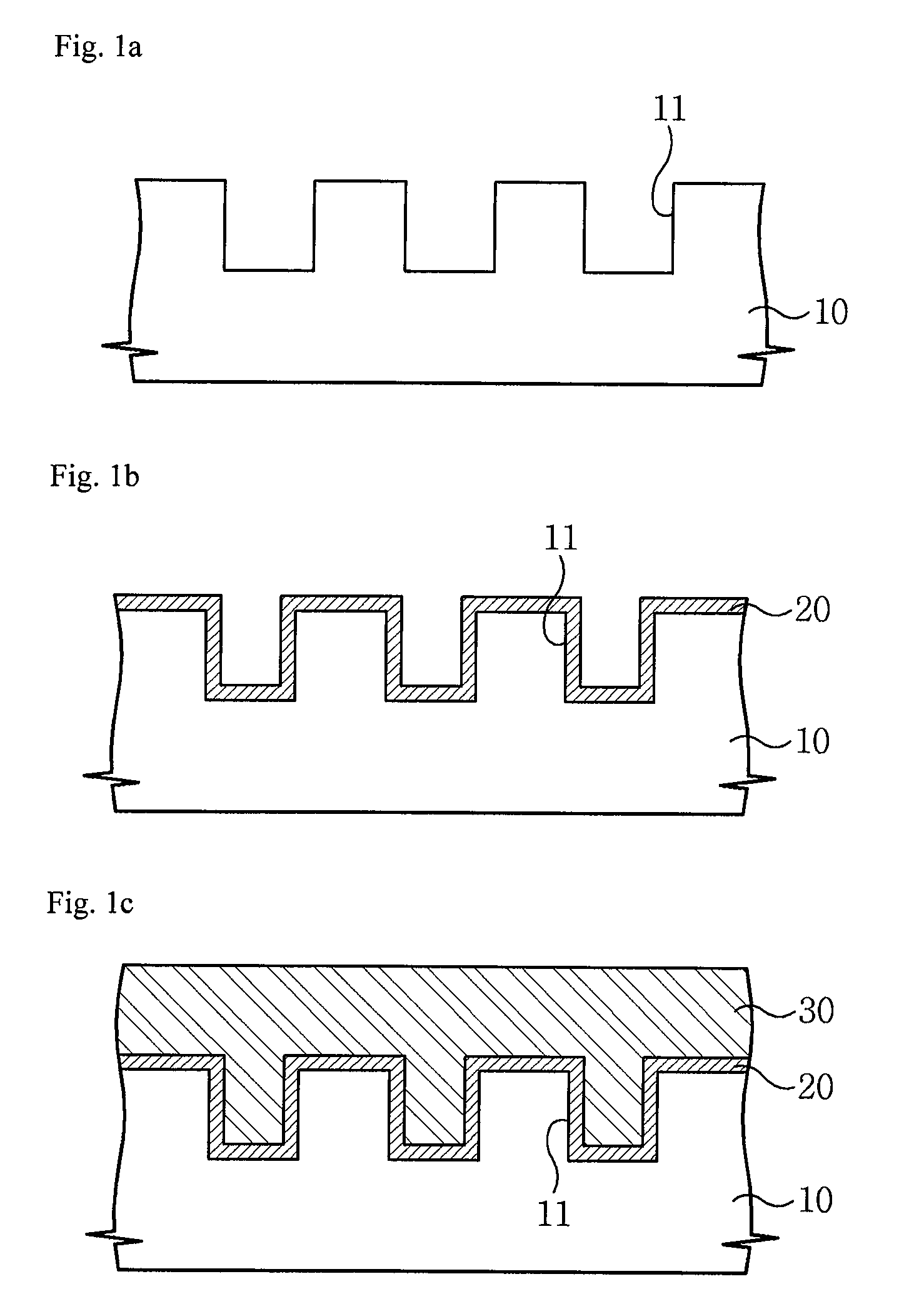

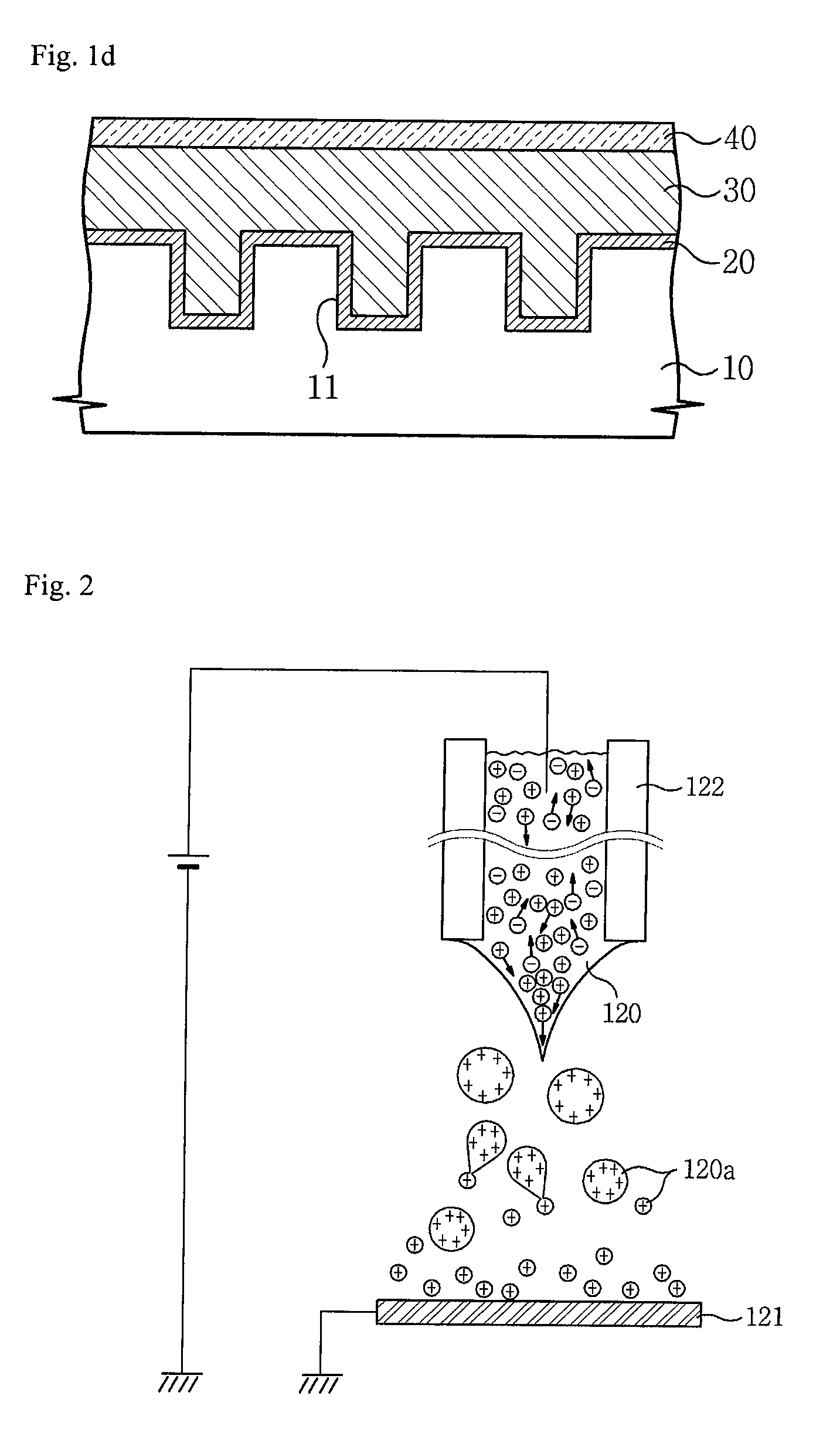

Micro-pattern forming apparatus, micro-pattern structure, and method of manufacturing the same

InactiveUS20070202258A1High strengthEasy to handlePhotomechanical apparatusLaboratory glasswaresBiomedical engineeringMicro pattern

There is provided a micro-pattern forming apparatus including an electrospraying part for applying a voltage to a solution containing a sample to electrostatically atomizing the solution; a supporting part (30) for supporting a chip (26), on which the sample in the solution electrostatically atomized by the electrospraying part, is to be deposited; and a fine mask part (24) disposed between the electrospraying part and the supporting part, having a mask pattern for being passed through by the electrostatically atomized solution in order to form a micro-pattern of the sample upon the chip, wherein the mask pattern is made from a photoresist material with concavity and convexity on the side of the supporting part.

Owner:RIKEN +1

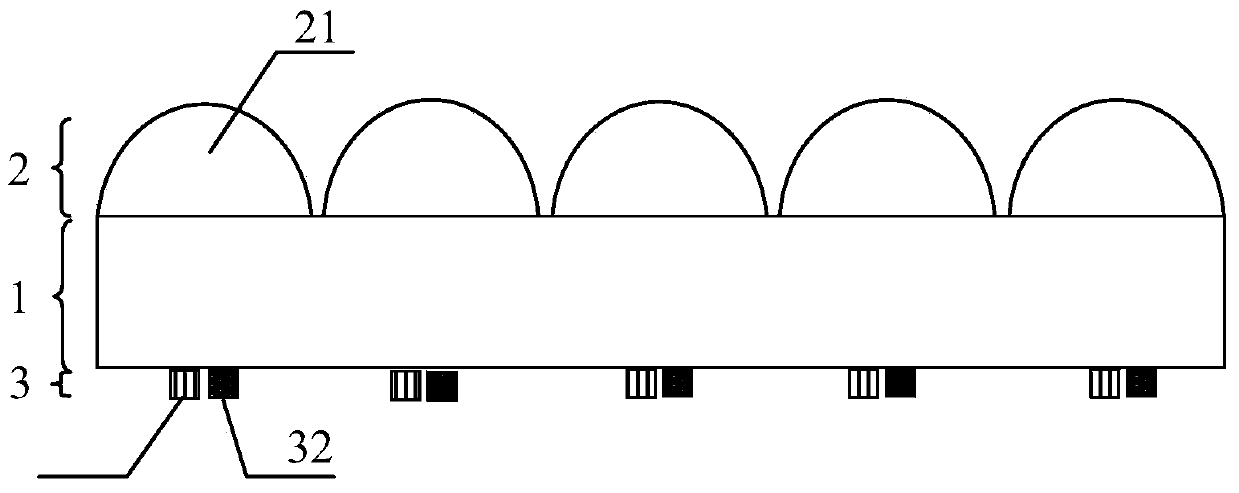

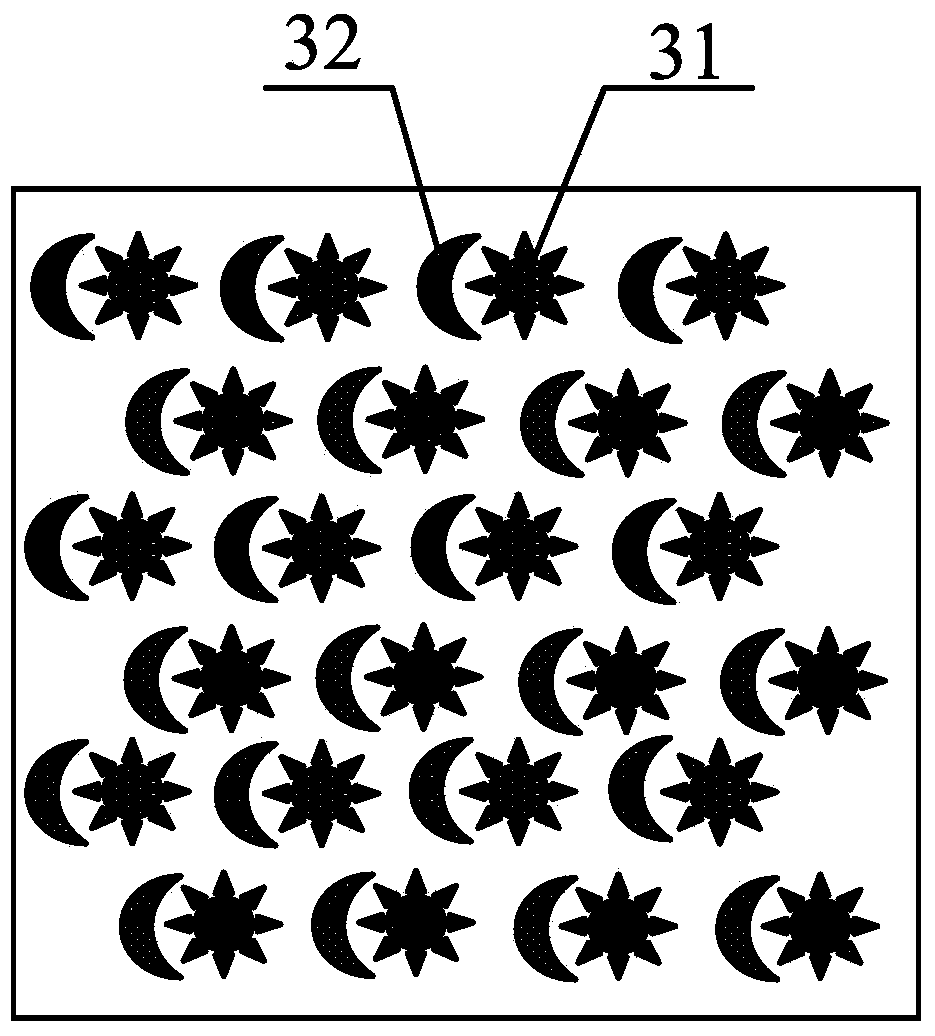

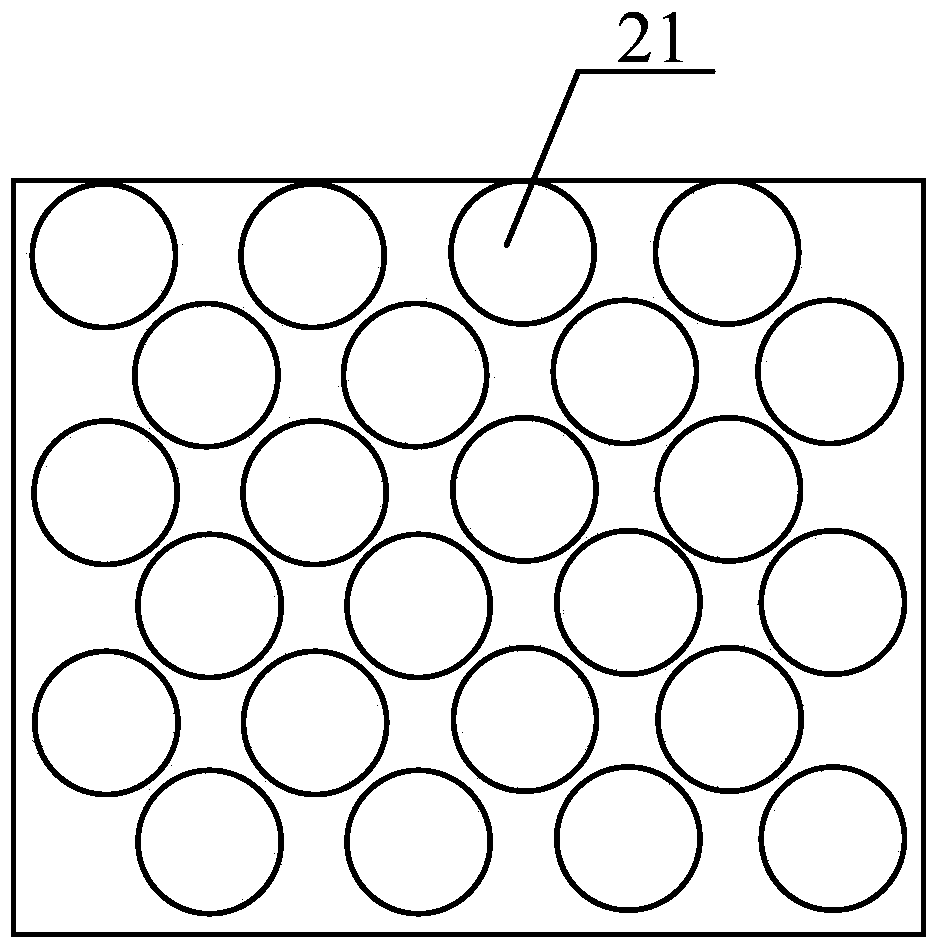

Colored dynamic three-dimensional moire image thin film based on micro printing and preparation method thereof

ActiveCN104191860AIncrease manufacturing difficultyPreserve Horizontal ParallaxInformation cardsDynamic patternMicro lens array

The invention discloses a colored dynamic three-dimensional moire image thin film based on micro printing and a preparation method of the colored dynamic three-dimensional moire image thin film. The moire image thin film comprises a transparent base material layer, a micro-lens array layer located on one side of the transparent base material layer, and a micro-pattern array layer located on the other side of the transparent base material layer. The micro-lens array layer comprises a plurality of micro-lenses arranged in an array. The micro-pattern array layer comprises a plurality of micro-patterns which are arranged in an array and are different in color. The array arrangement of the micro-lenses is matched with the array arrangement of the micro-patterns. The moire image formed by the moire image thin film is characterized by being colored, dynamic and three-dimensional, and an observer can directly observe a colored three-dimensional dynamic pattern without any special observation skills under any luminous environment.

Owner:SUZHOU UNIV +1

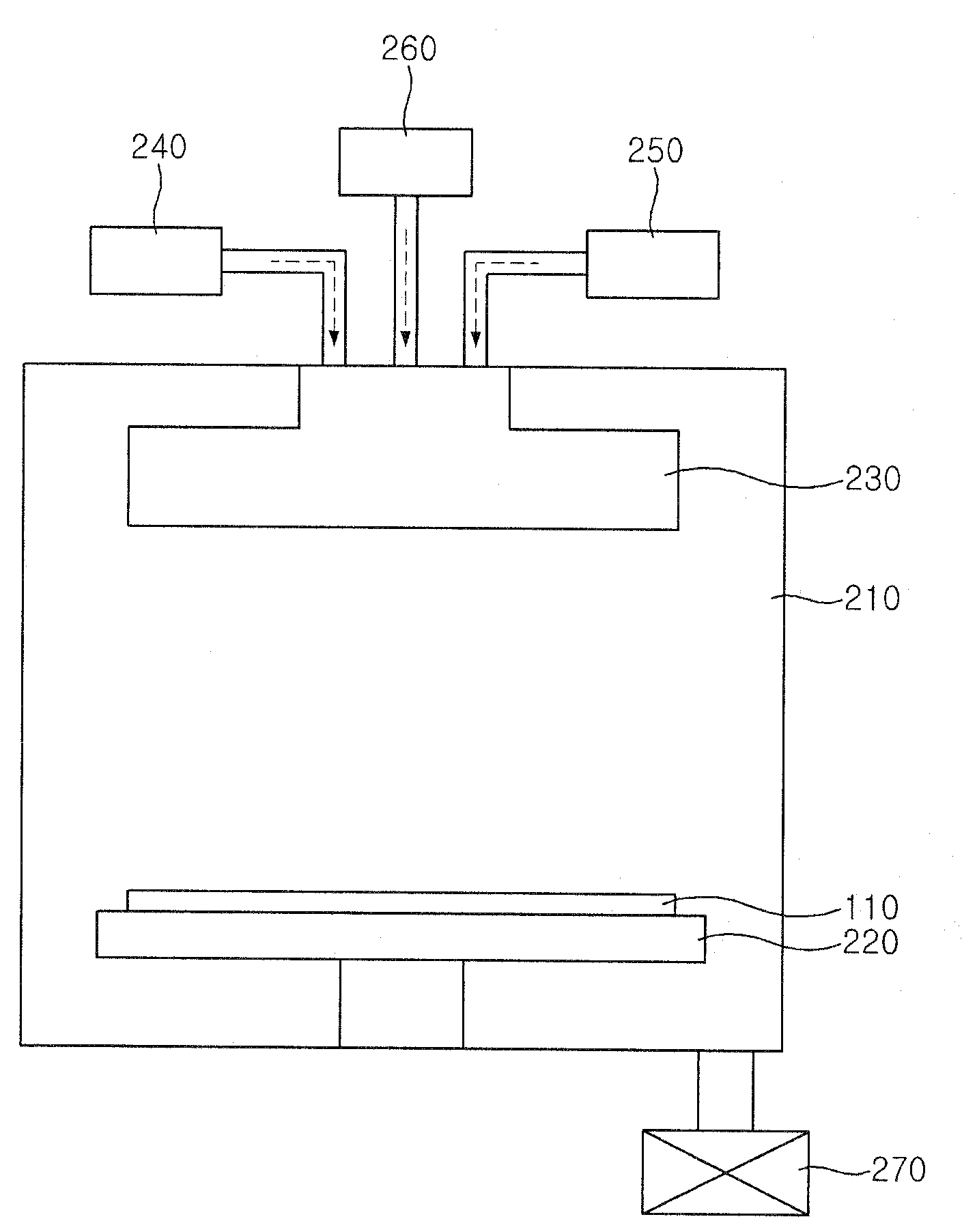

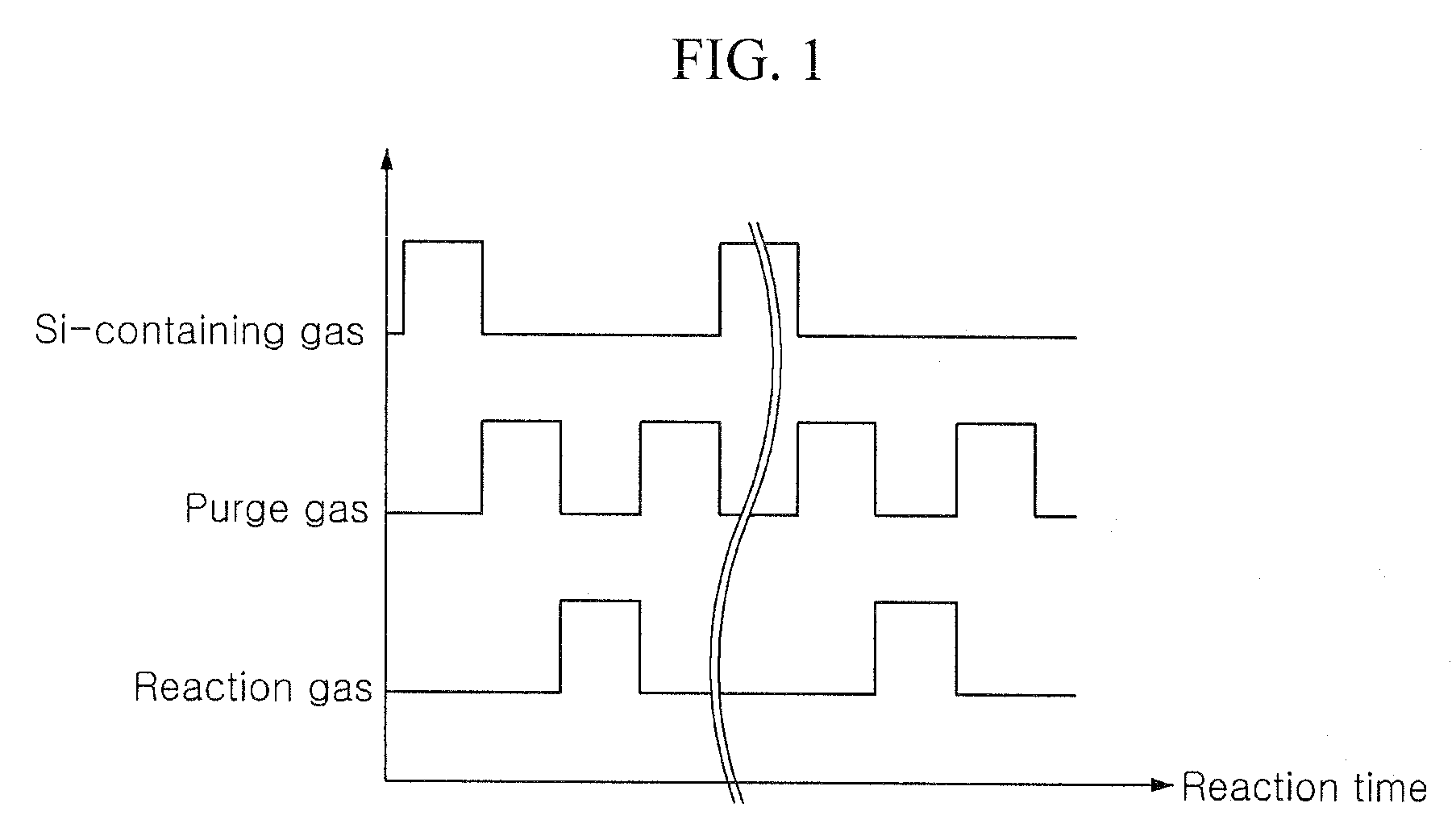

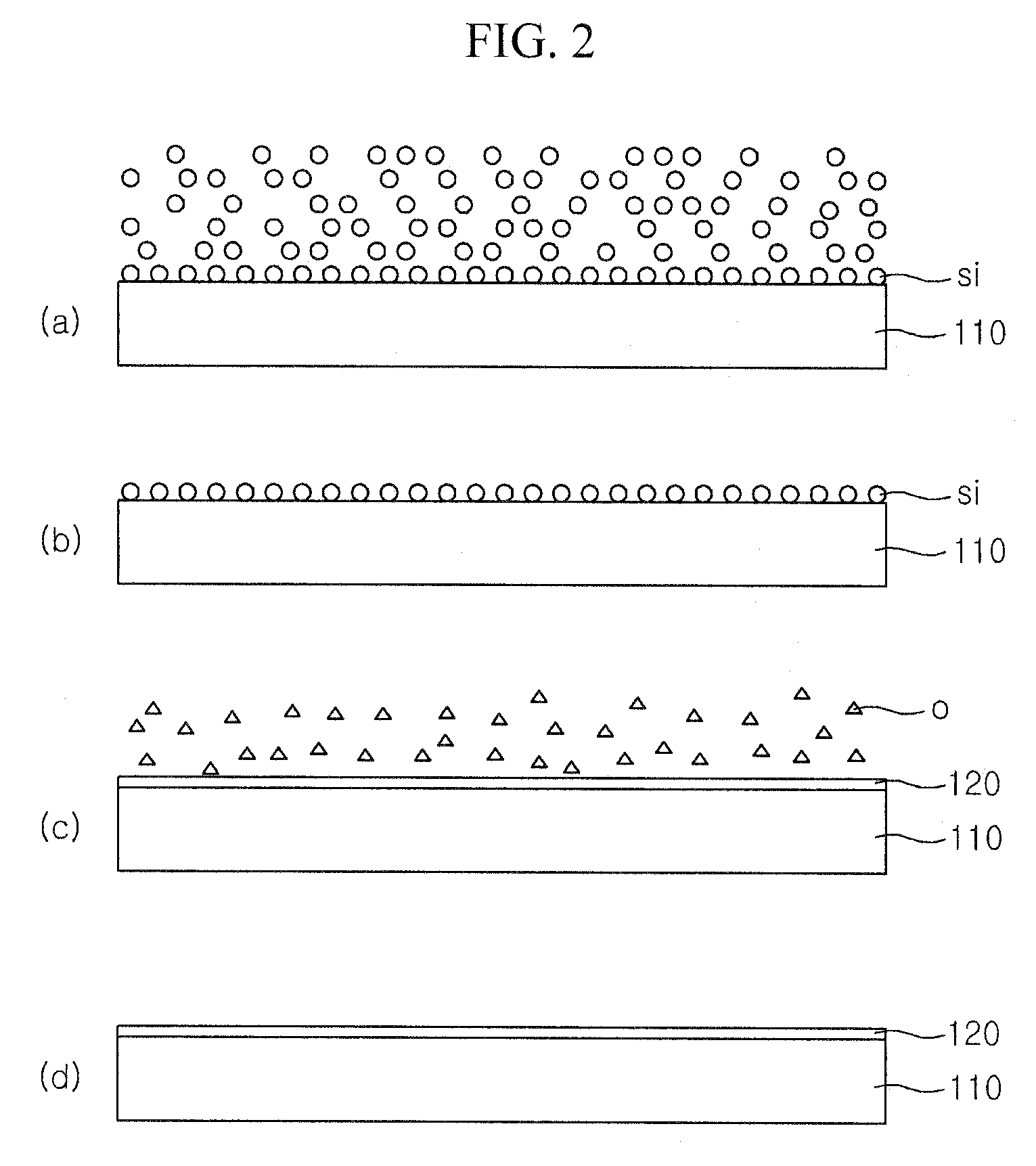

Method of forming oxide film and oxide deposition apparatus

ActiveUS20070234957A1Uniform thicknessGood step coverageSemiconductor/solid-state device manufacturingChemical vapor deposition coatingPhysical chemistryAtomic layer deposition

The present invention relates to an oxide film forming method and an oxide deposition apparatus, which make it possible to form an oxide film at a low temperature of 350° C. or less by respectively supplying a silicon-containing gas including at least one of SiH4, Si2H6, Si3H8, TEOS, DCS, HCD and TSA, a purge gas, and a reaction gas including at least one of O2, N2O, O3, H20 and H2O2 into a reaction space continuously and simultaneously while rotating gas injector, and to form an oxide film with a uniform thickness along a step of a lower structure with a micro-pattern since step coverage is improved due to an atomic layer deposition process.

Owner:JUSUNG ENG

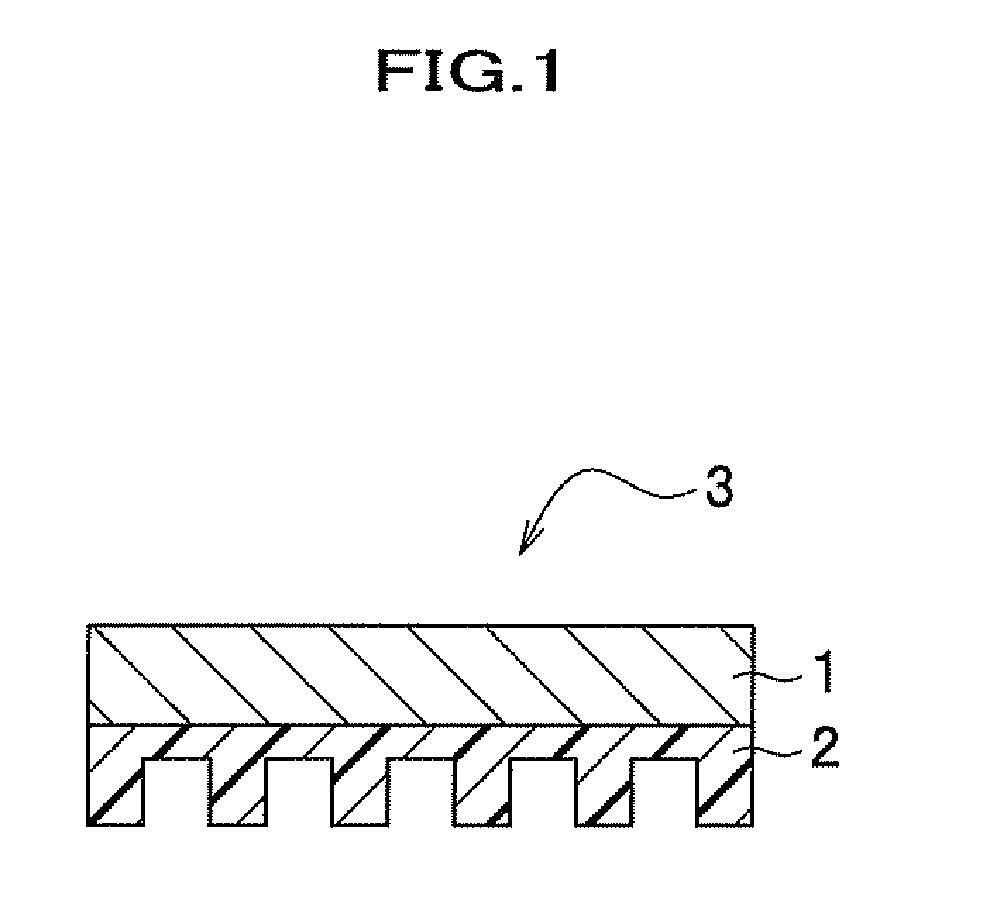

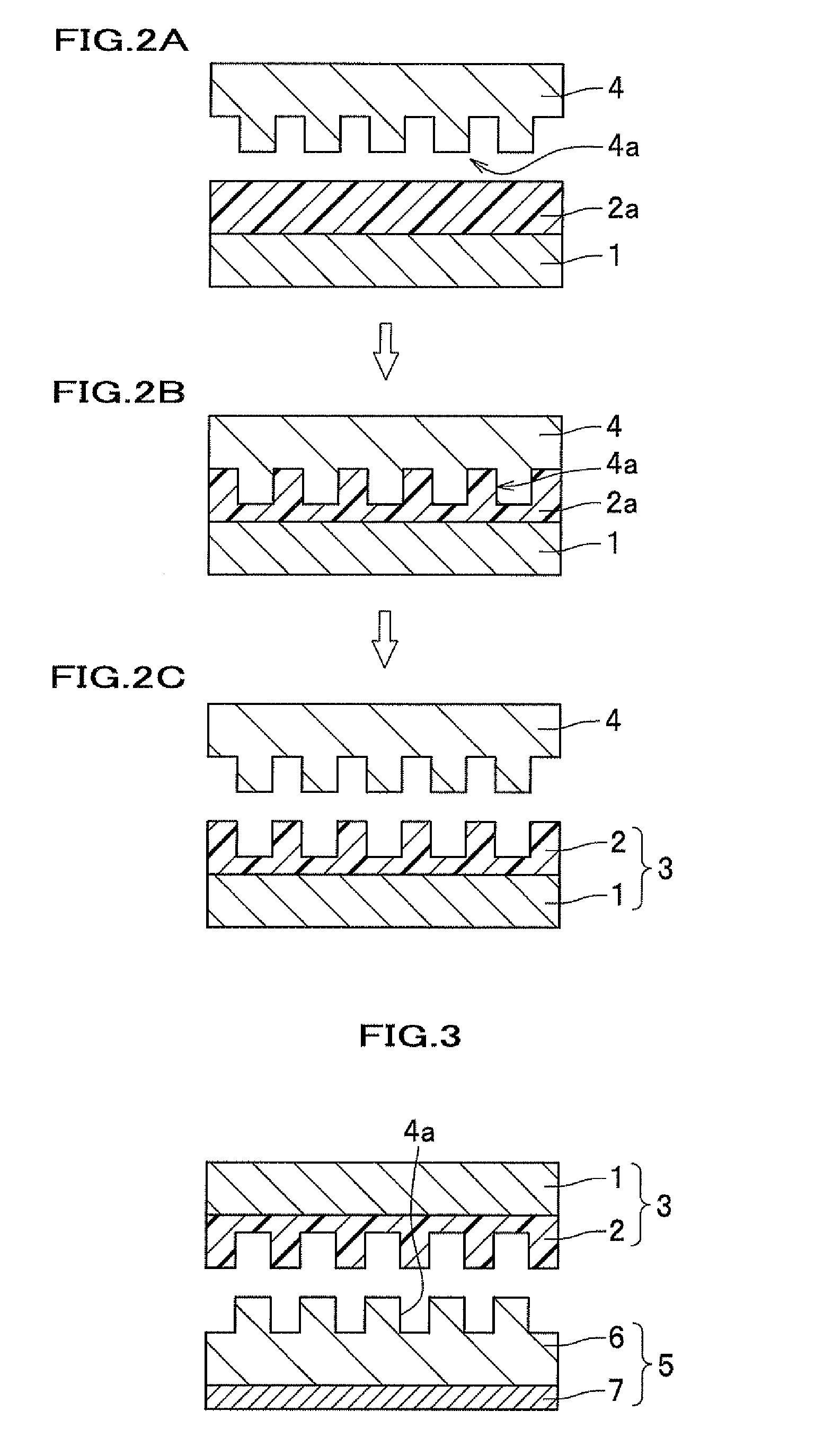

Micro-pattern transferring stamper

InactiveUS20120321738A1Not decrease transfer precisionImprove precisionConfectioneryNanoinformaticsSilsesquioxanePolymer chemistry

A micro-pattern transferring stamper includes a supporting base material and a microstructure layer formed on the supporting base material, the microstructure layer is a polymer of a resin composition that mainly contains a silsesquioxane derivative containing a plurality of polymerizable functional groups, and one or plural kinds of monomer elements containing a plurality of polymerizable functional groups.

Owner:HITACHI HIGH-TECH CORP

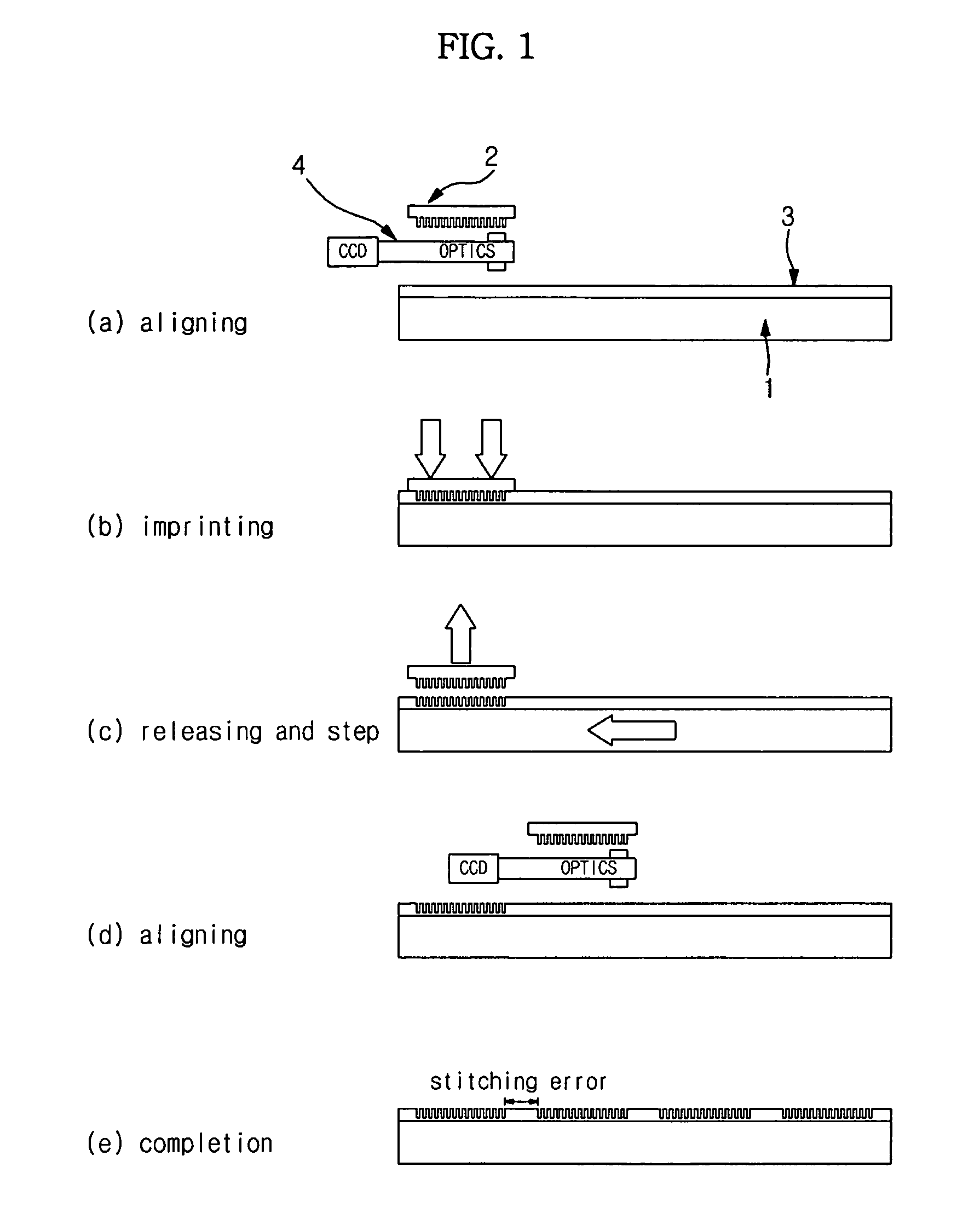

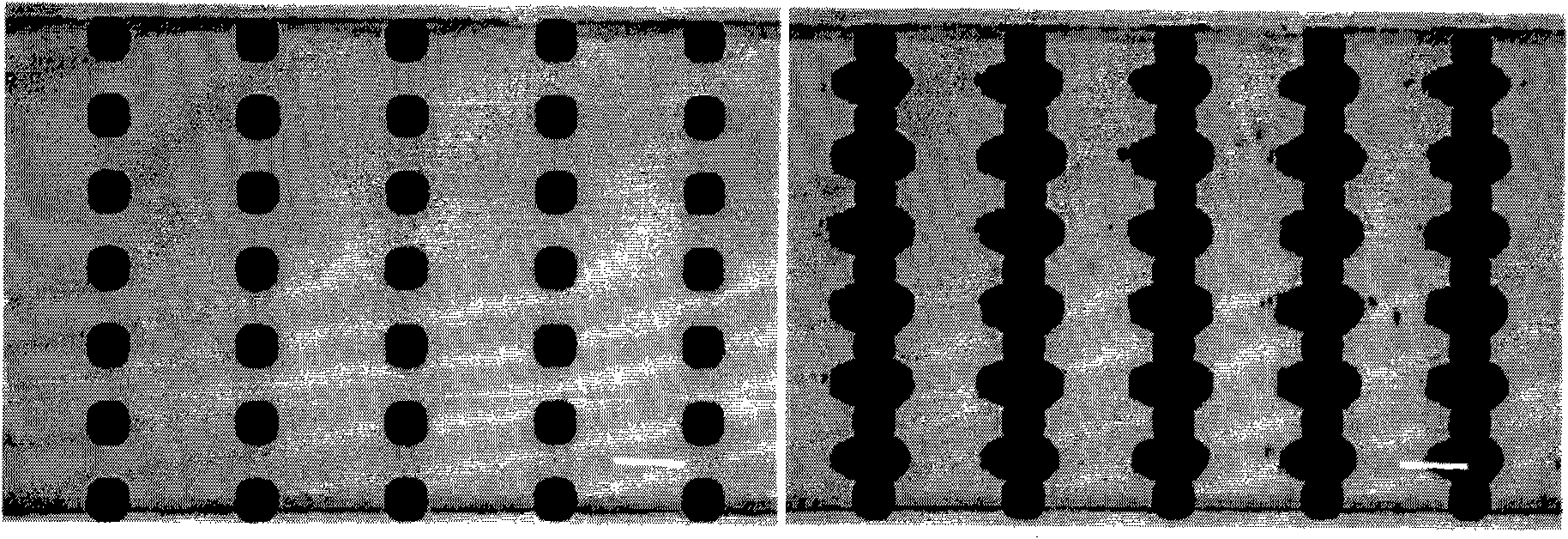

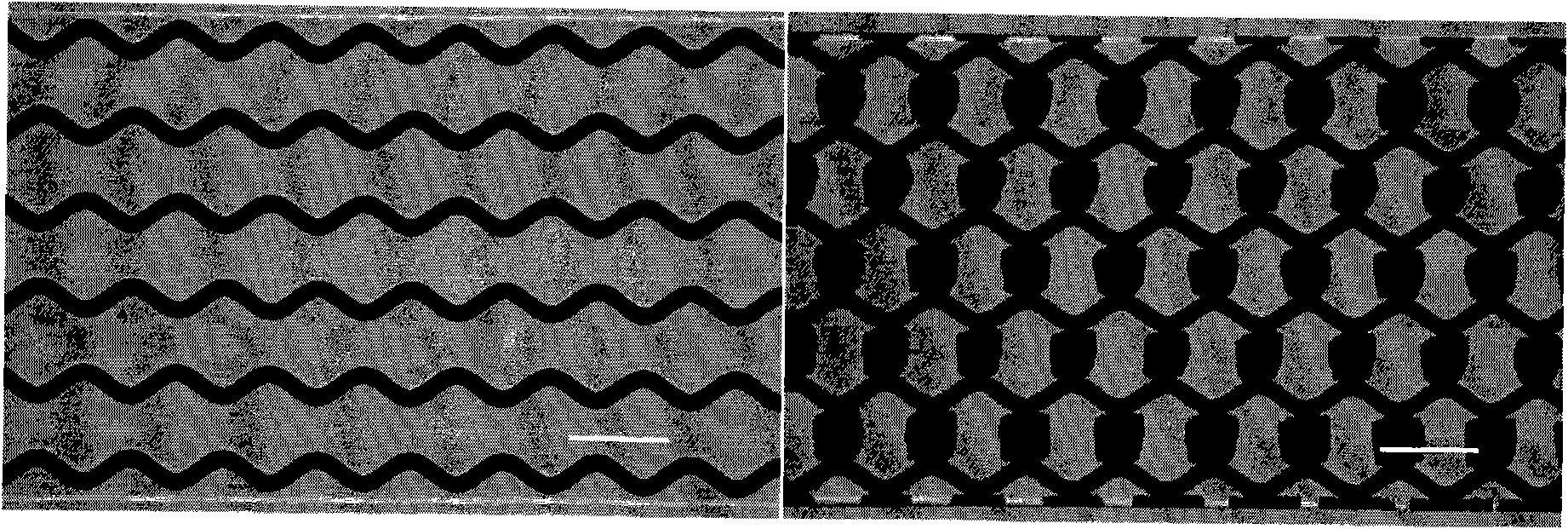

Mask mold, manufacturing method thereof, and method for forming large-sized micro pattern using mask mold

InactiveUS20080299467A1Low costStitching errorNanoinformaticsSemiconductor/solid-state device manufacturingResistMaterials science

Disclosed are a mask mold, a manufacturing method thereof, and a method for forming a large-sized micro pattern using the manufactured mask mold, in which the size of a nano-level micro pattern can be enlarged using a simple method with low cost and interference and stitching errors between cells forming a large area can be minimized. The method for manufacturing the mask mold includes the operations of coating resist on a mask or a plurality of small molds having an engraved micro pattern, pressing the small molds to imprint the micro pattern on the resist, curing the resist, and releasing the small molds from the resist.

Owner:SAMSUNG ELECTRONICS CO LTD

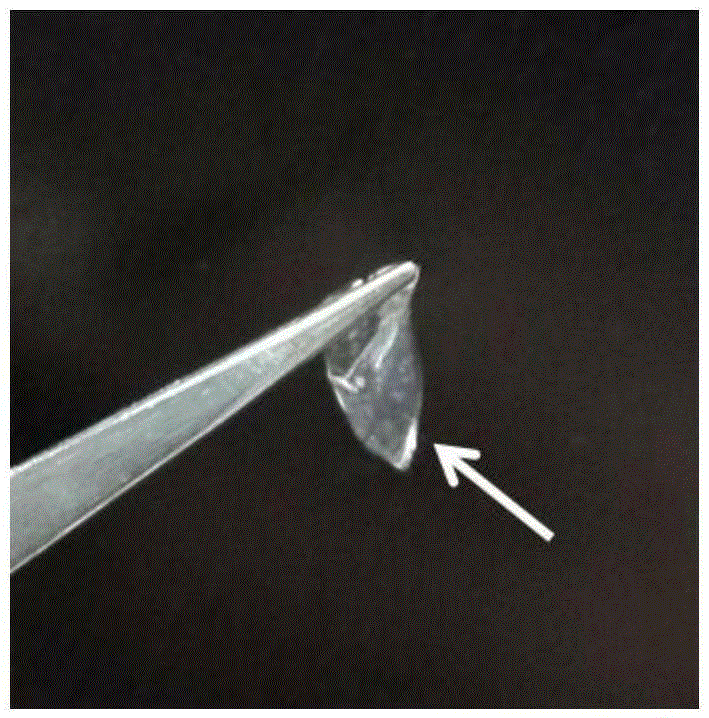

Surface patterning high-strength and high-toughness hybrid hydrogel membrane and preparation method thereof

With the continuous development of tissue engineering, a surface patterning technology is concerned by people more and more and widely applied; and a micro-patterning technology is already used for accurately controlling the position and form of a cell and the co-culture of multiple cells, but a micro-pattern is more difficult to be directly constructed on the surface of hydrogel with good biocompatibility. The high-elasticity and high-toughness patterning hydrogel membrane is prepared on a patterning silicon slice base body by taking sodium alginate as a high-molecular framework, acrylamide and a derivative thereof as polymerization monomers, divinylbenzene, N,N'-methylene bisacrylamide or ethylene glycol dimethacrylate as chemical cross-linking agents and a metal salt water solution as an ionic cross-linking agent and adding inorganic nanoparticles as strengthening agents. The preparation method disclosed by the invention has the advantages of good controllability, simple process, low cost, good material biocompatibility, and the like; and the patterning hydrogel membrane disclosed by the invention is hopeful to be applied to the fields of stem cell culture, tissue regeneration, and the like.

Owner:嘉兴智德睿控新能源有限公司

Making display device with pixel-aligned micro-wire electrode

ActiveUS20140051318A1High transparencyImprove conductivityVessels or leading-in conductors manufactureInput/output processes for data processingDisplay deviceOptoelectronics

A method of making a display device includes providing a first substrate having an array of pixels located in correspondence thereto, the pixels separated by inter-pixel gaps in at least one dimension. A first electrode having a length and width is formed and located over the first substrate and extends across at least a portion of the array of pixels, the first electrode including a plurality of electrically connected micro-wires formed in a first micro-pattern. The method further includes locating the gap micro-wires of the first micro-pattern between the pixels in the inter-pixel gaps so that the gap micro-wires substantially extend continuously along the first electrode length.

Owner:EASTMAN KODAK CO

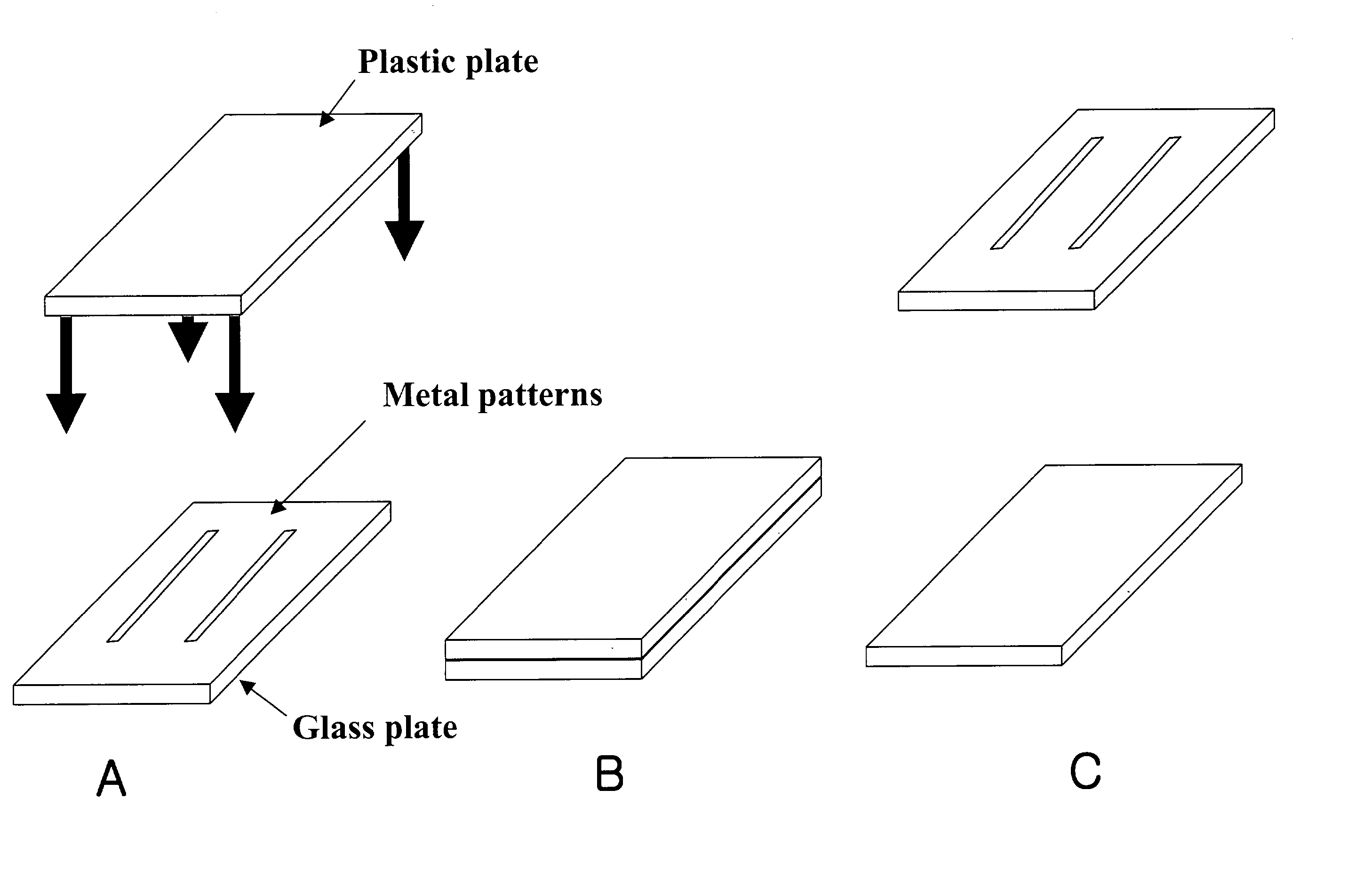

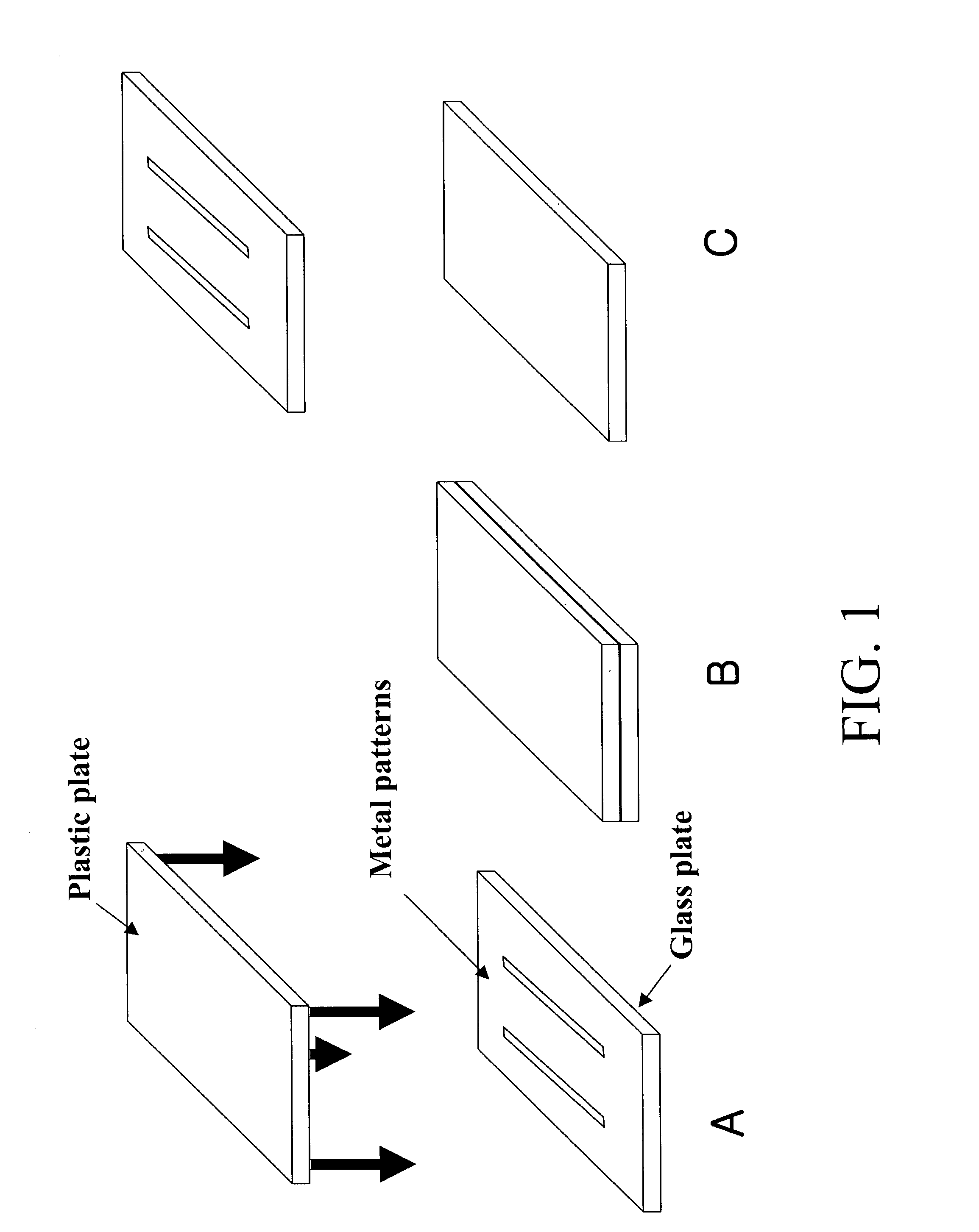

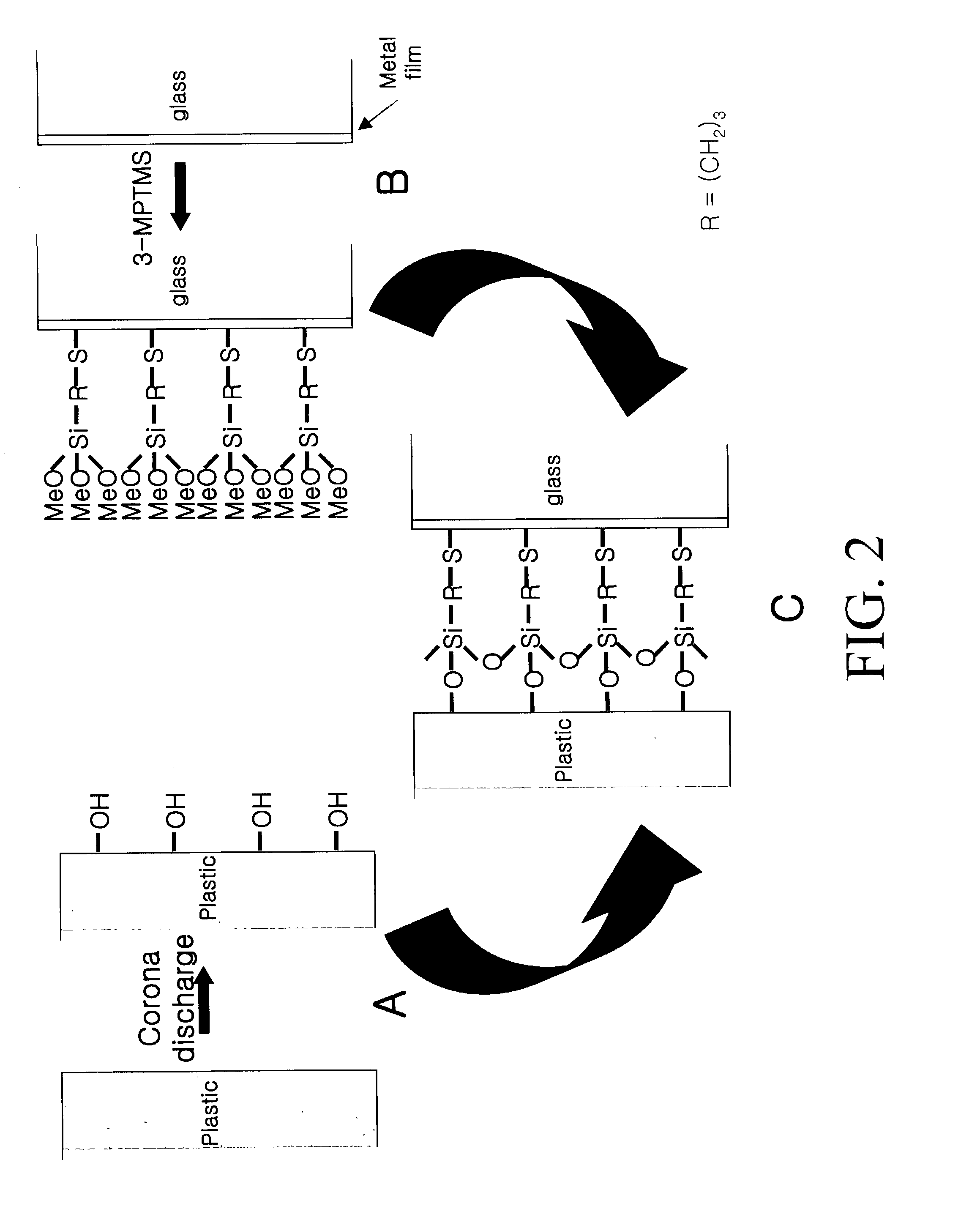

Process for forming metal micro-patterns on plastic substrate

A process, which comprises forming a metal micro-pattern on the surface of an inorganic substrate, surface-treating the surface of the metal micro-pattern and the surface of the plastic substrate to make it chemically reactive, and bringing the metal micro-pattern into contact with the surface of the plastic substrate to transfer the metal micro-pattern from the surface of the inorganic substrate to the surface of the plastic substrate, can be easily and simply carried out using conventional equipments to produce one or more metal pattern fixed on a plastic material.

Owner:POSTECH ACAD IND FOUND

Micro-fluidic chip for micro-magnetic field control and manufacturing method thereof

InactiveCN101879467APermanent irreversible bondingPermanent bondingLaboratory glasswaresChemical/physical/physico-chemical processesMagnetic field gradientMagnetic bead

The invention discloses a micro-fluidic device for micro-magnetic field control and a manufacturing method thereof. The device consists of a micro-fluidic fluid layer chip, a substrate provided with soft magnetic material micro-patterns, and a magnetic source body. The substrate provided with the soft magnetic material micro-patterns is a transparent conducting substrate, wherein the micro-patterns are arranged and designed corresponding to needed magnetic beads, and a layer of a polymeric material is covered on the micro-patterns to realize a connection in a permanent irreversible bonding mode with the micro-fluidic fluid layer chip. Under the action of an external magnetic field, nickel micro-patterns are magnetized and generate a strong local magnetic field gradient to realize the magnetic field control in a micron range. The device can capture magnetic substances at a high flow speed, and can release the magnetic substances at a low flow speed after the magnetic source body is removed. The device can be used in the fields of organism-targeted material detection, gene analysis, quick immunoassay, cell screening and the like.

Owner:WUHAN UNIV

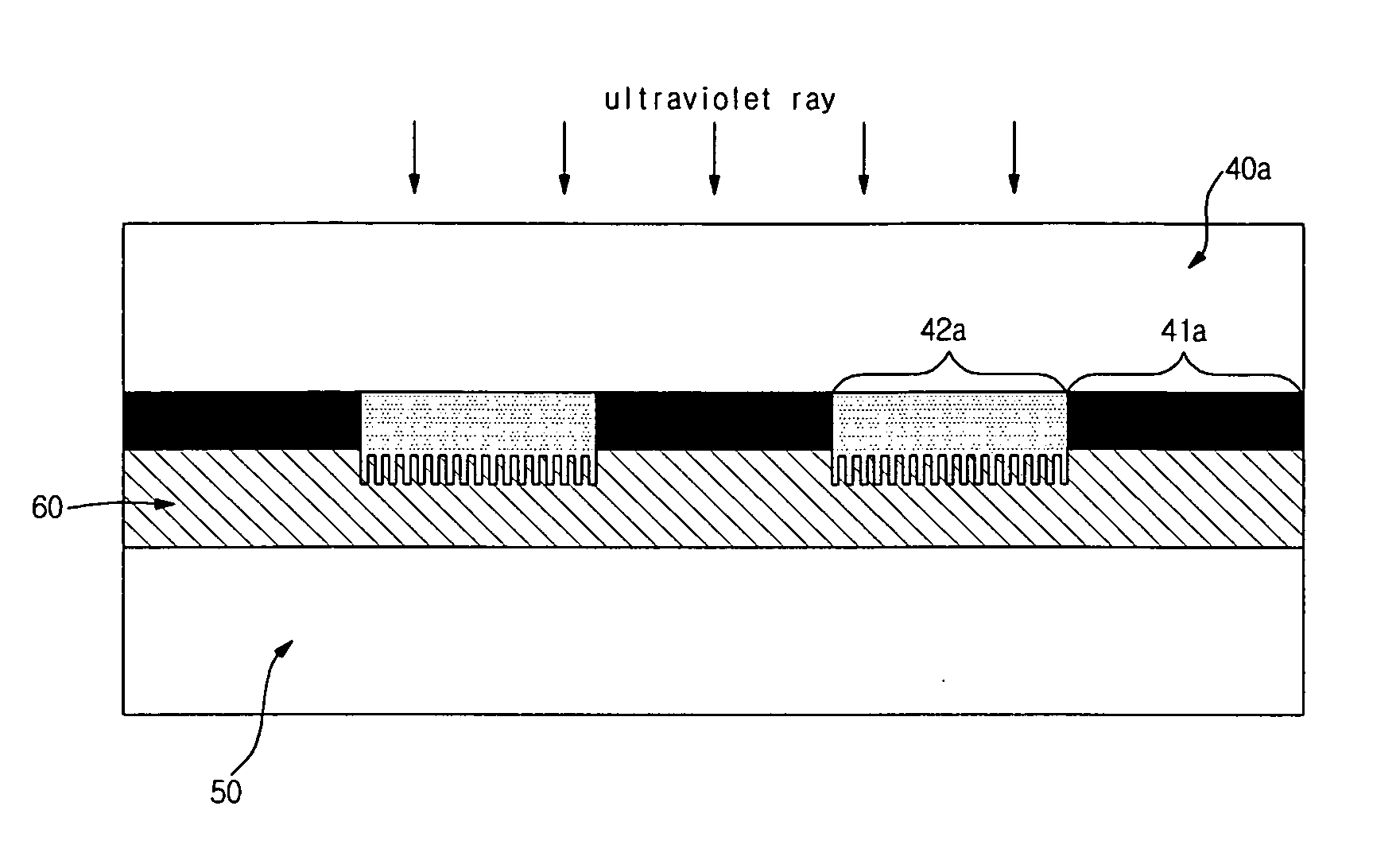

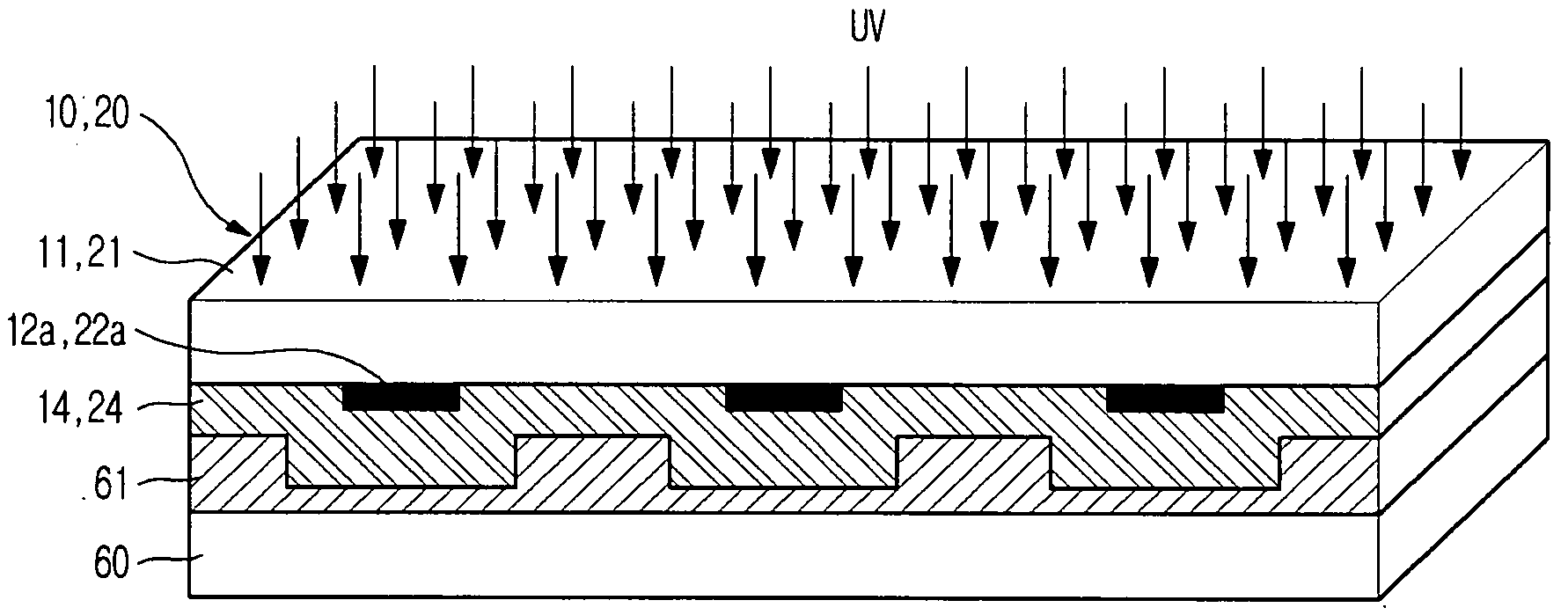

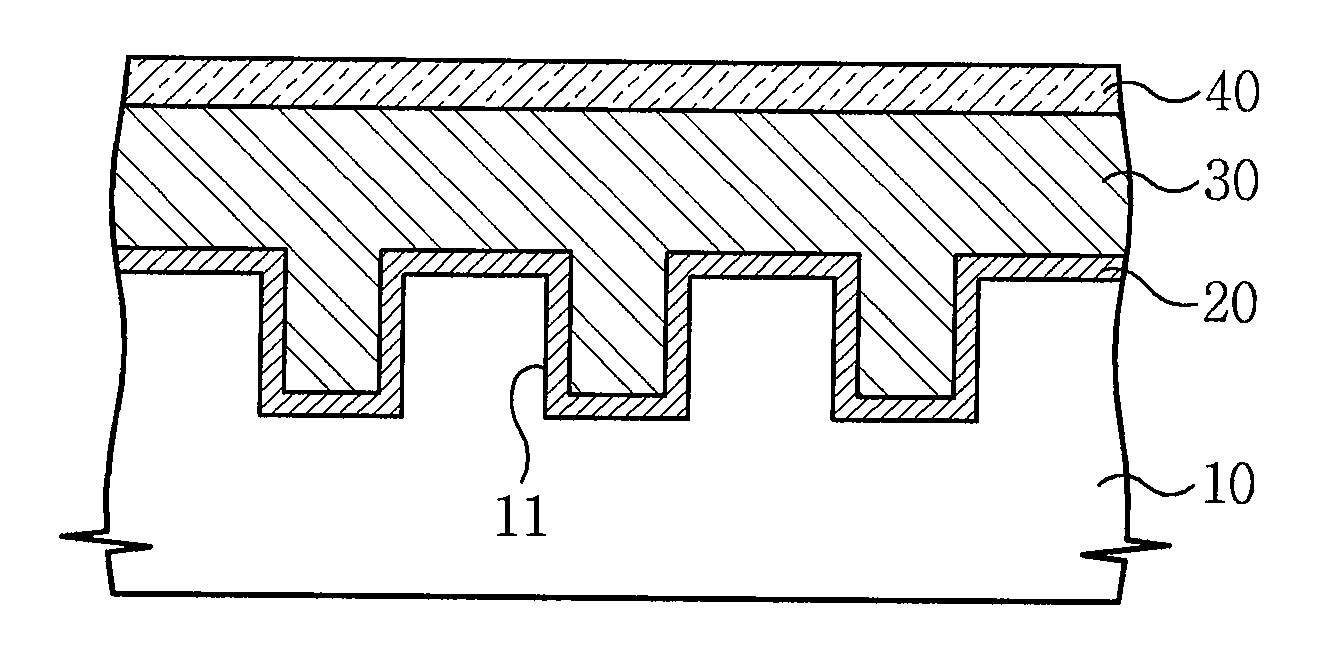

Method of forming a pattern using nano imprinting and method of manufacturing a mold to form such a pattern

ActiveUS20100072675A1Simple methodAvoid makingNanoinformaticsPhotomechanical apparatusFlat panel displayMicro pattern

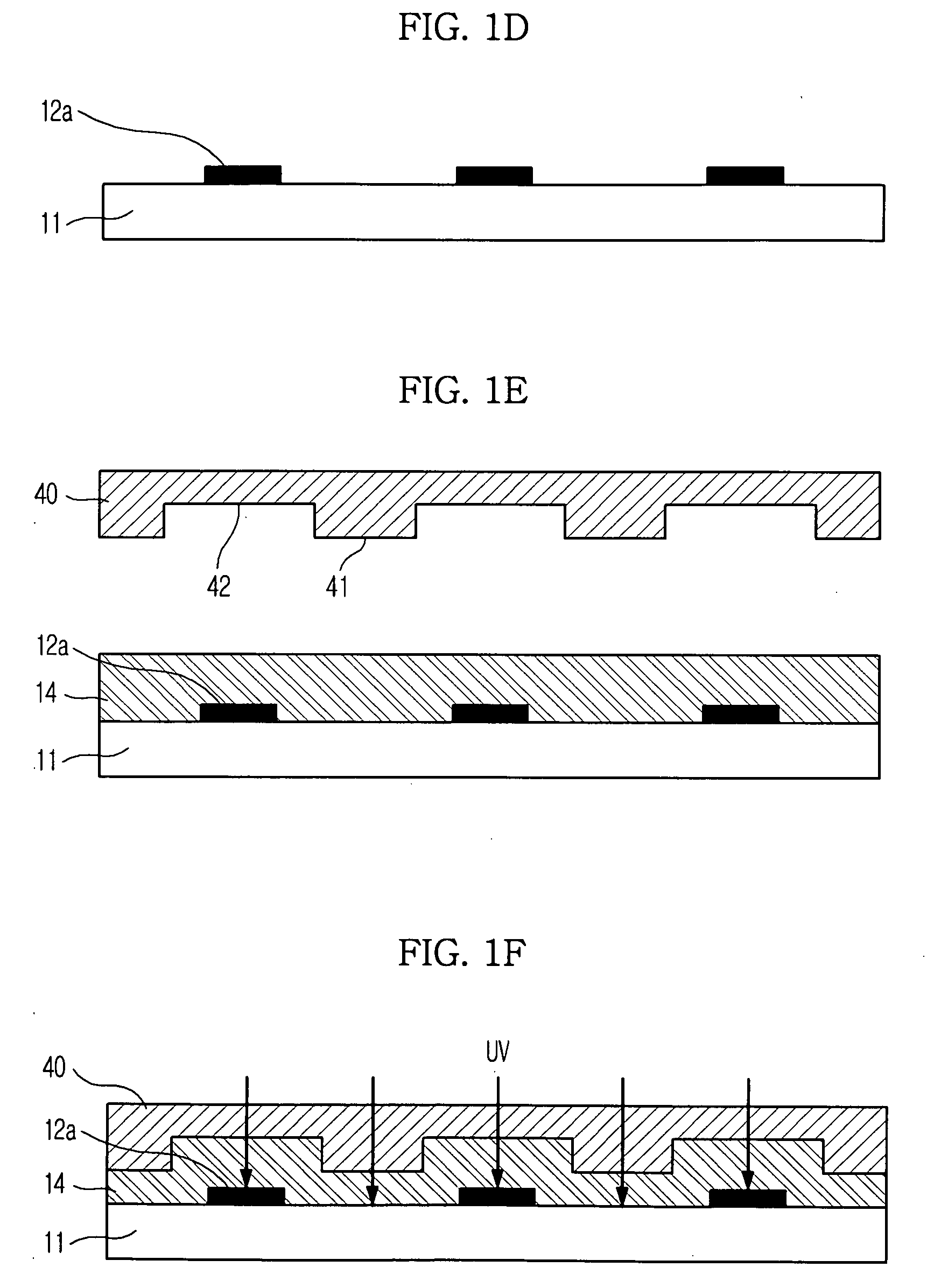

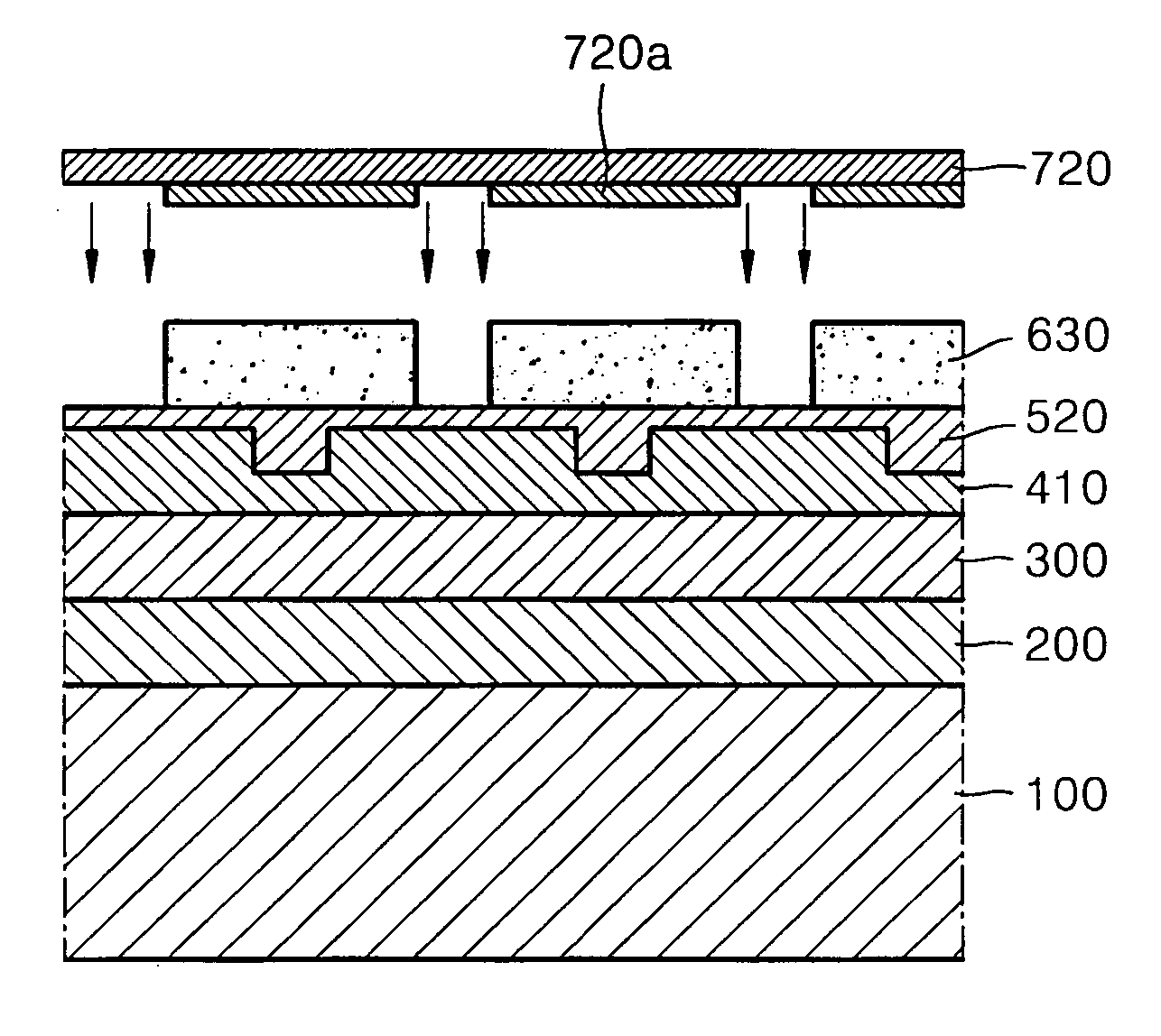

Example embodiments relate to a method of forming a three-dimensional micro pattern or a multi-step pattern using a nano imprinting process and a method of manufacturing a mold to form such a pattern. A molding polymer may be patterned in a one-step shape on a substrate having UV barrier patterns, thereby easing the manufacture of a mold for multi-step imprinting and simplifying the formation of a multi-step pattern using the one-step shaped mold by avoiding the repetition of more complicated processes. Consequently, it may be possible to form a relatively large-area micro pattern, a relatively large-area pattern usable in flat panel displays, and a nano pattern having a size of several tens of nanometers in a semiconductor process, thereby contributing to the reduction of process costs, the reduction of process time, and the improvement of production yield.

Owner:SAMSUNG ELECTRONICS CO LTD

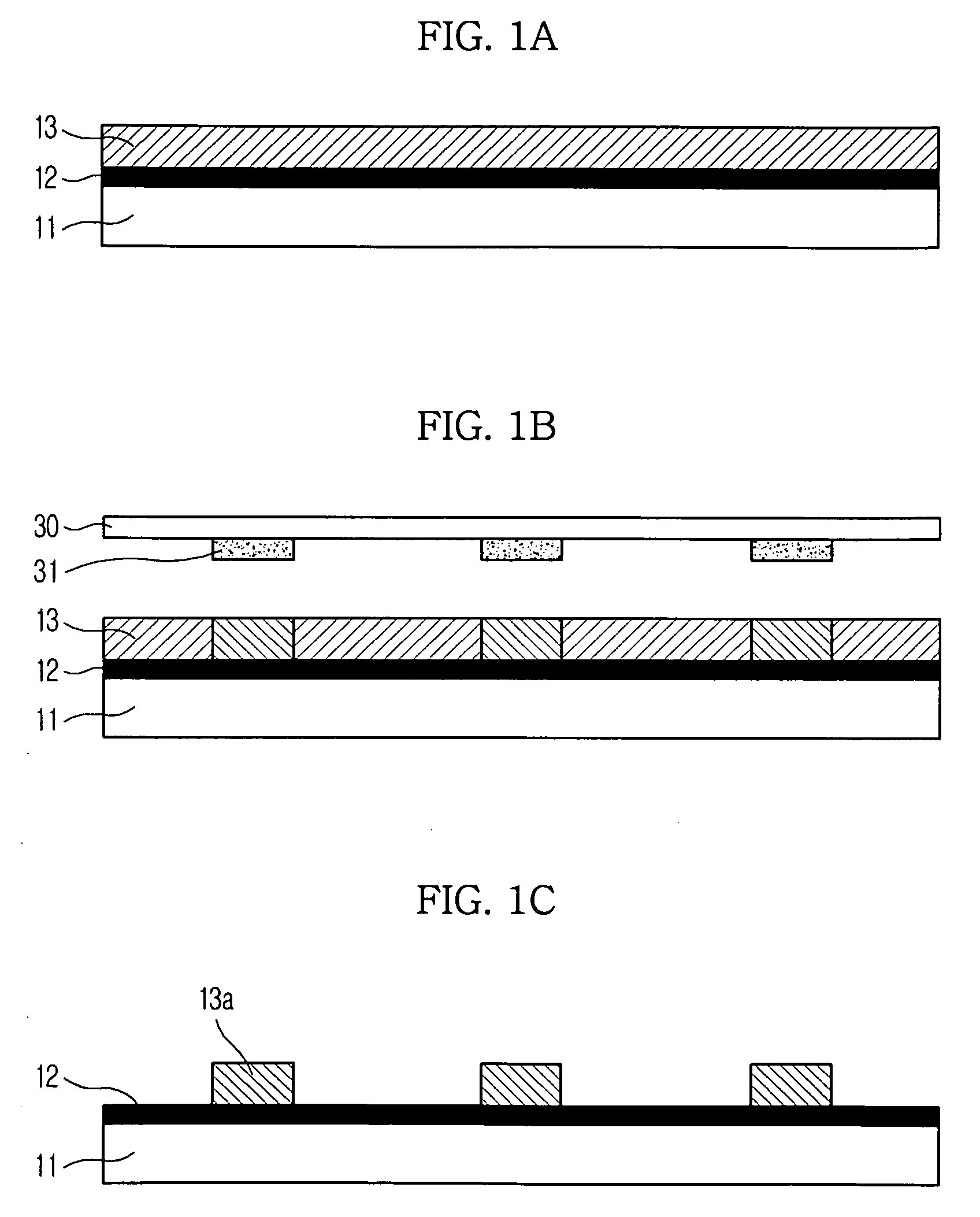

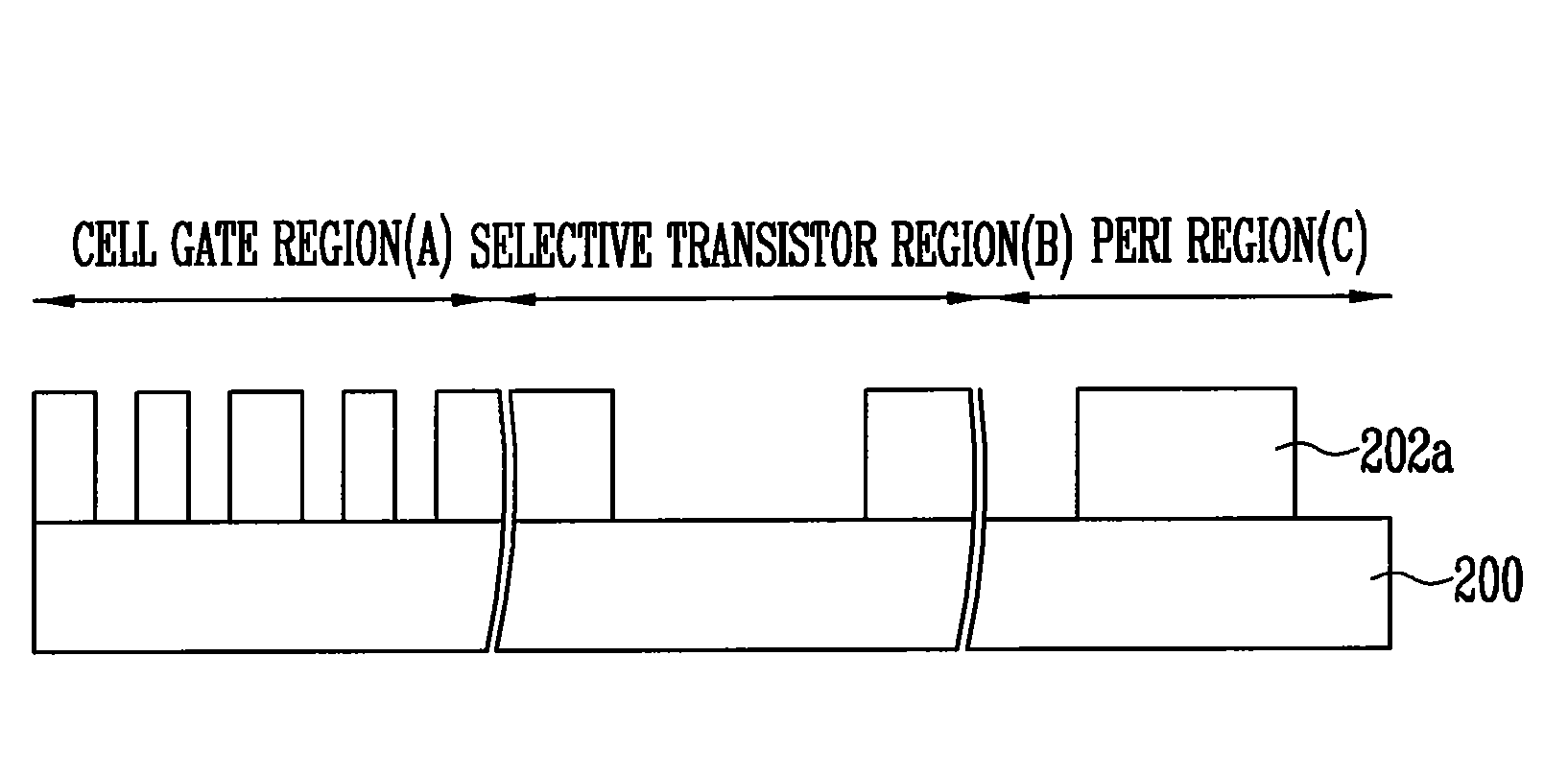

Method of forming micro-patterns using multiple photolithography process

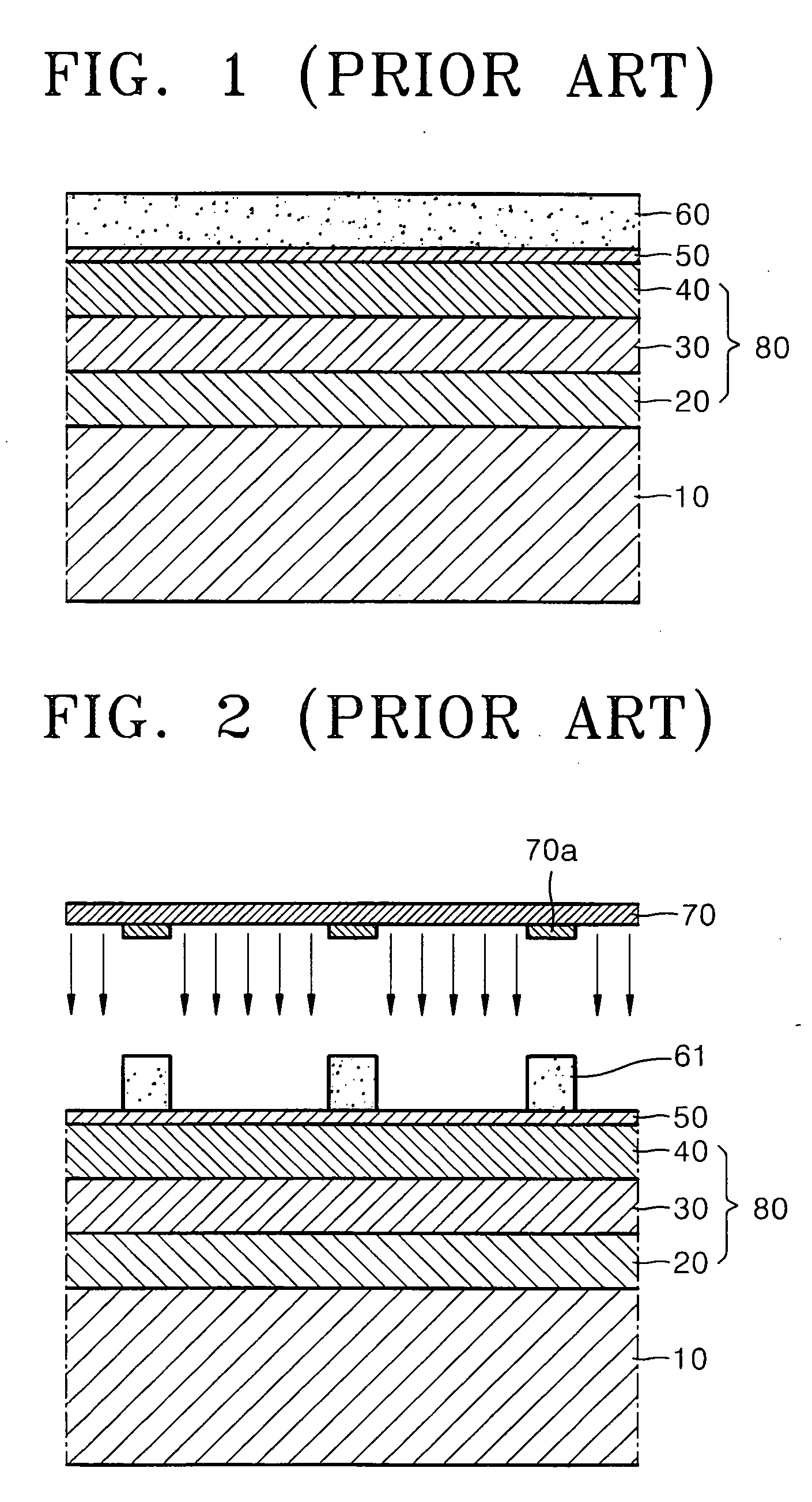

InactiveUS20070082296A1Easy to usePhotomechanical apparatusSemiconductor/solid-state device manufacturingLithography processPhotolithography

Provided is a method of forming micro-patterns using a multi-photolithography process, including: providing an etch target layer where micro-patterns are to be formed; forming a mask layer on the etch target layer; forming a first mask pattern including engraved portions and embossed portions by etching a predetermined region of the mask layer; forming a final mask pattern in the first mask pattern by etching a predetermined region of the residual embossed portions of the mask layer; and forming micro-patterns by etching the etch target layer using the final mask pattern as an etch mask.

Owner:SAMSUNG ELECTRONICS CO LTD

Ink composition for etching resist, method of forming etching resist pattern using the same, and method of formng microchannel using the ink composition

Provided are an ink composition for an etching resist, a method of forming an etching resist pattern using the ink composition, and a method of forming a microchannel using the ink composition. The ink composition is suitable for forming a micro pattern due to its poor spreading on the substrate and is suitable for etching-resist for copper of a printed circuit board and deep etching a stainless steel substrate due to its excellent chemical properties that allow it to resist an etching solution.

Owner:LG CHEM LTD

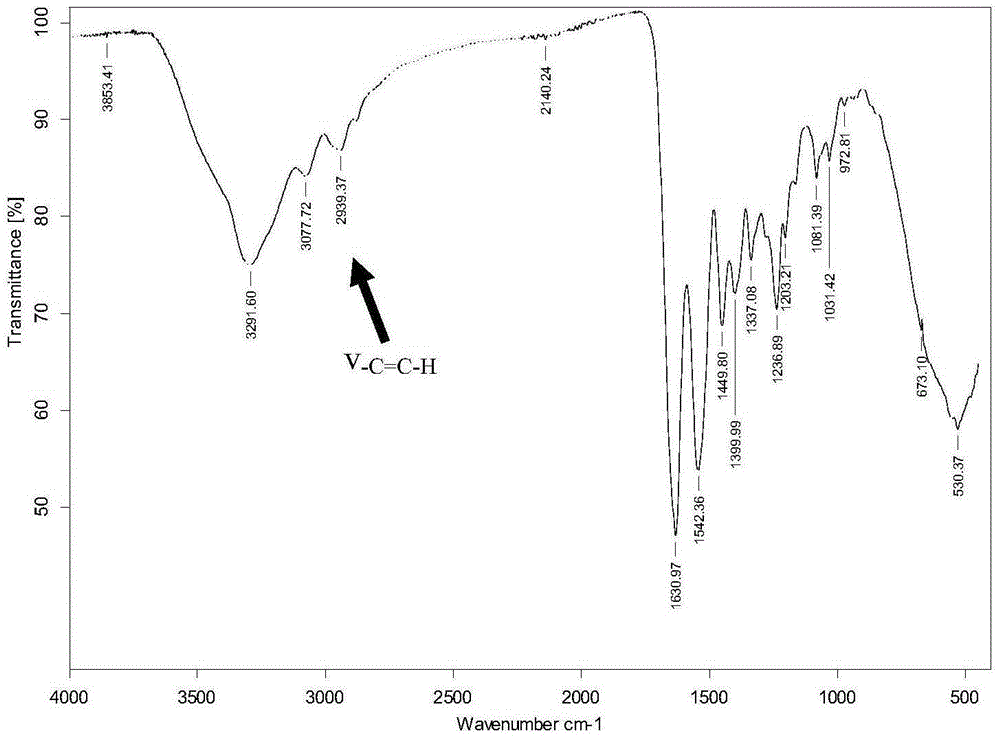

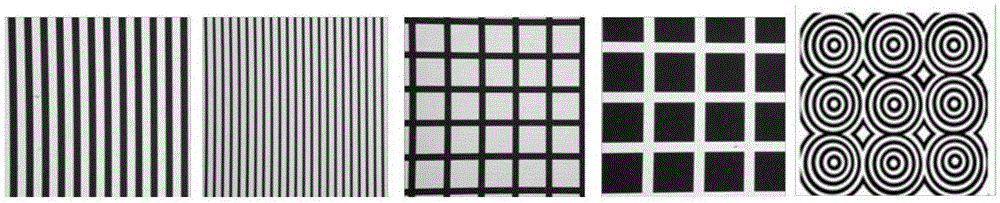

Photo-curing hydrogel for multi-cell sorting and stem cell area-selecting differentiation and preparation method thereof

ActiveCN105294955AHigh affinityGood formabilityArtificial cell constructsSkeletal/connective tissue cellsHardnessPhoto curing

The invention belongs to the field of biomedical materials, and particularly relates to photo-curing hydrogel for multi-cell sorting and stem cell area-selecting differentiation and a preparation method thereof. The photo-curing hydrogel is prepared by taking modified high-polymer materials with the photo-curing performance as raw materials and are divided into multiple different areas by straight-stripe-shaped or net-stripe-shaped or annular-stripe-shaped micro-pattern structures, the hardness of the photo-curing hydrogel in the same area is same, the hardness of the photo-curing hydrogel in the different areas is same or different, and the overall photo-curing hydrogel at least has two kinds of the hardness. According to the photo-curing hydrogel for multi-cell sorting and stem cell area-selecting differentiation and the preparation method thereof, on one hand, the elasticity moduli of all the areas of the photo-curing hydrogel are different by controlling the ultraviolet radiation curing degree; on the other hand, all the areas with the different elasticity moduli present the micro-pattern structures on the photo-curing hydrogel, selective adhesion, proliferation and differentiation of cells on the photo-curing hydrogel can be achieved by combining the elasticity moduli with the micro-pattern structures, and therefore controllable cell sorting or stem cell area-selecting differentiation can be achieved.

Owner:HUAZHONG UNIV OF SCI & TECH

Method of forming a micro pattern of a semiconductor device

ActiveUS20080248654A1Reducing device mass-production costReduce processing stepsSolid-state devicesSemiconductor/solid-state device manufacturingAnti-reflective coatingDevice material

A method of forming a micro pattern of a semiconductor device includes forming an etch target layer, a hard mask layer, a Bottom Anti-Reflective Coating (BARC) layer and a first photoresist pattern over a semiconductor substrate. An organic layer is formed on a surface of the first photoresist pattern. A second photoresist layer is formed over the BARC layer and the organic layer. An etch process is performed so that the second photoresist layer remains on the BARC layer between the first photoresist patterns and becomes a second photoresist pattern. The organic layer on the first photoresist pattern and between the first and second photoresist patterns is removed. The BARC layer formed below the organic layer is removed. The hard mask layer is etched using the first and second photoresist patterns as an etch mask. The etch target layer is etched using a hard mask pattern as an etch mask.

Owner:SK HYNIX INC

Organic solar cell using conductive polymer transparent electrode and fabricating method thereof

InactiveUS20090032107A1Well formedExcellent electrical propertiesLiquid surface applicatorsFinal product manufactureScreen printingConductive polymer

The present invention relates to an organic solar cell made of a transparent conductive polymer electrode and a fabricating method thereof. An anode electrode is formed on a substrate, a photoactive layer is formed on the anode electrode, and a cathode electrode is then formed on the photoactive layer. The anode electrode is formed by stacking conductive polymer particles by an electrostatic spray printing method, and a micro pattern is formed on the substrate before forming the anode electrode. The micro pattern is formed by hot embossing, the photoactive layer is formed by gravure printing or spin coating, and the cathode electrode is formed by screen print or evaporation deposition. A series of processes for fabricating an organic solar cell is performed using a roll-to-roll process.

Owner:KOREA INST OF MASCH & MATERIALS

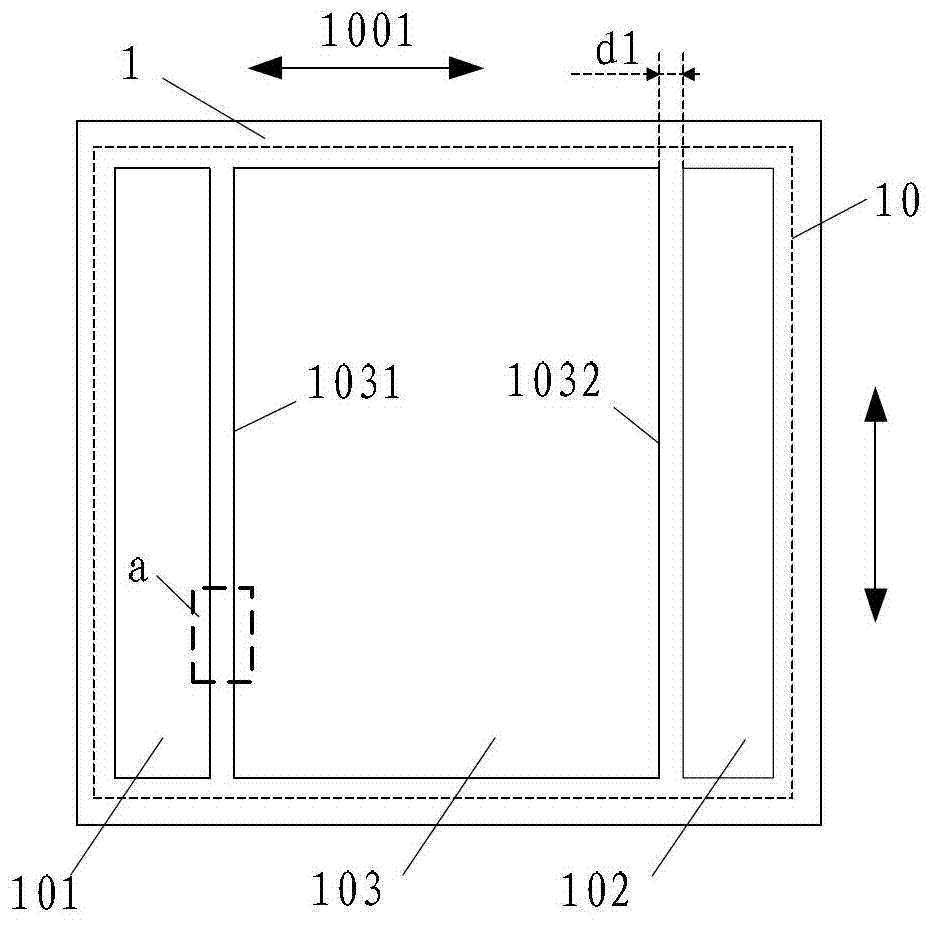

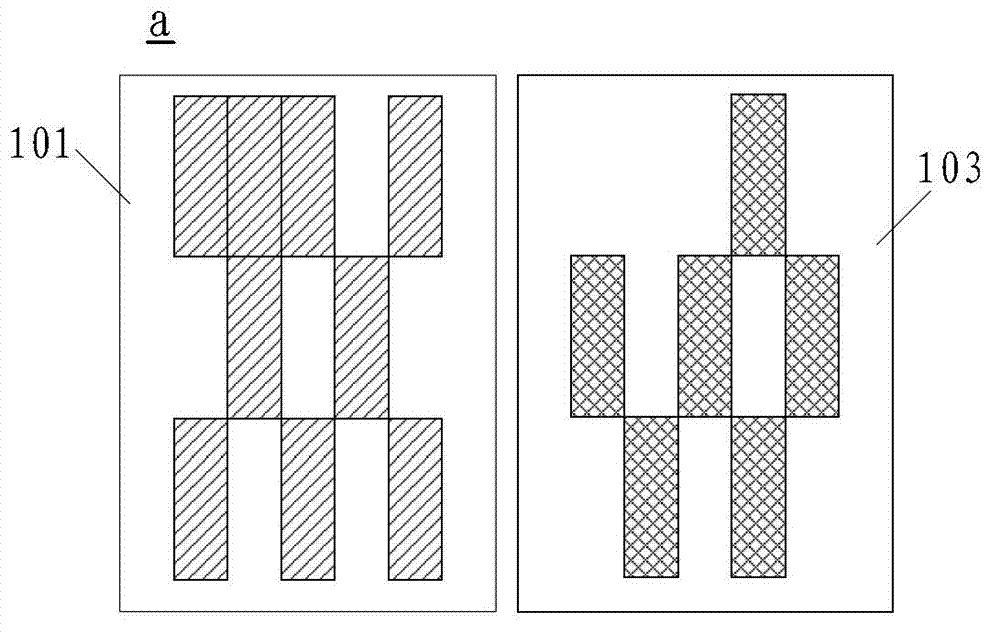

Mask plate and method for composing a picture with same

ActiveCN103033975APhotomechanical exposure apparatusMicrolithography exposure apparatusLiquid-crystal displayColor film

The invention provides a mask plate and a method for composing a picture with the same, and the mask plate and the method relate to the technical field of displaying and solve the problem of the prior art that no color film substrate with a large size can be manufactured. The mask plate comprises at least one mask unit group; each mask unit group form a row, and comprises a first mask unit which is arranged on one end, a second mask unit which is arranged on the other end, and at least one third mask unit which is arranged between the two ends; each mask unit is provided with a mask pattern; the mask pattern of each mask unit comprises a plurality of micro patterns and gaps on one side which is close to the adjacent mask unit and below the outline of the mask pattern; and the micro patterns and the gaps of the mask patterns of the two adjacent mask units on two sides which are close to each other are mutually matched. The mask plate and the method for composing the picture with the same are applicable to the field of the manufacturing of liquid crystal display devices.

Owner:BOE TECH GRP CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com