Ultraviolet-curing liquid-state optical cement

A technology of ultraviolet light and optical adhesive, applied in the direction of adhesives, adhesive types, polyurea/polyurethane adhesives, etc., can solve the problems of high cost, difficult to reduce thickness, poor adhesion of liquid optical adhesives, etc., to achieve the yield Improve the effect of thin lamination thickness and strong adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

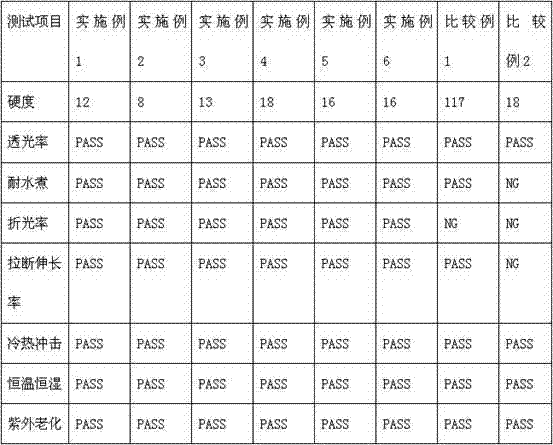

Examples

Embodiment 1

[0024] An ultraviolet light curing transfer adhesive, which is composed of the following raw materials: 30g of silicone modified polybutadiene acrylate, 25g of polyurethane acrylate, 24g of isobornyl methacrylate, 16g of triethylene glycol dimethacrylate, 1-hydroxycyclohexyl phenyl ketone 2g, phenylbis(2,4,6-trimethylbenzoyl)phosphine oxide 1g, γ-(methacryloyloxy)propyltrimethoxysilane 1g, 2 -(2',4'-dihydroxyphenyl)-5,6-dihydroxybenzotriazole 0.5g, 2-(2'-hydroxy-3',5'-di-tert-phenyl)-5- Benzotriazole chloride 0.5g.

[0025]Prepare according to the following method: add the above-mentioned initiator and 24 g of isobornyl methacrylate to the star-shaped vacuum mixer in the thousand-level dust-free workshop, heat to 55 ° C, stir and dissolve; then add the above-mentioned oligomer and triethylene glycol 16g of dimethacrylate, heated to 55°C under vacuum, and stirred evenly; finally, add the above-mentioned additives, disperse at high speed with a disperser, press filter and pack,...

Embodiment 2

[0028] A UV-curable transfer adhesive, consisting of the following raw materials: 61g of silicone-modified polybutadiene acrylate, 18g of isobornyl methacrylate, 12g of phenoxymethylethyl acrylate, 2-hydroxy- 2-methyl-1-phenyl-1-propanone 2g, phenylbis(2,4,6-trimethylbenzoyl)phosphine oxide 3g, N-(β-aminoethyl)-γ-aminopropyl Methyldimethoxysilane 2g, 2,6-di-tert-butylphenol 1g, 2-(2',4'-dihydroxyphenyl)-5,6-dihydroxybenzotriazole 0.5g, 2 -(2'-Hydroxy-3',5'-di-tert-phenyl)-5-chlorinated benzotriazole 0.5 g.

[0029] Prepare according to the following method: add the above-mentioned initiator and 18 g of isobornyl methacrylate to the star-shaped vacuum mixer in the thousand-level dust-free workshop, heat to 50 ° C, stir and dissolve; then add the above-mentioned oligomer, phenoxy 12g of methyl ethyl acrylate, heated to 50°C under vacuum, and stirred evenly; finally, add the above-mentioned additives, disperse at high speed with a disperser, press filter and pack, and then the U...

Embodiment 3

[0032] An ultraviolet light curing transfer adhesive, which is composed of the following raw materials: 30g of silicone modified polybutadiene acrylate, 14g of polyester acrylate, 20g of polyurethane acrylate, 16.5g of propoxylated glycerin triacrylate, phenoxymethyl 13.5 g of ethyl ethyl acrylate (PHEMA), 2 g of 1-hydroxycyclohexyl phenyl ketone, 2 g of 2,4,6-trimethylbenzoyl-diphenylphosphine oxide, 1 g of vinyltrimethoxysilane, 2-(2',4'-dihydroxyphenyl)-5,6-dihydroxybenzotriazole 0.5g, 2-(2'-hydroxy-3',5'-di-tert-phenyl)-5 - Benzotriazole chloride 0.5 g.

[0033] Prepare according to the following method: add the above-mentioned initiator and 16.5 g of propoxylated glycerol triacrylate to the star-shaped vacuum mixer in the thousand-level dust-free workshop, heat to 60 ° C, stir and dissolve; then add the above-mentioned oligomer, phenoxy 13.5g of methyl ethyl acrylate (PHEMA), heated to 60°C in a vacuum state, stirred evenly; finally added the above-mentioned additives, d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com