Patents

Literature

2371 results about "Vacuum state" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In quantum field theory, the quantum vacuum state (also called the quantum vacuum or vacuum state) is the quantum state with the lowest possible energy. Generally, it contains no physical particles. Zero-point field is sometimes used as a synonym for the vacuum state of an individual quantized field.

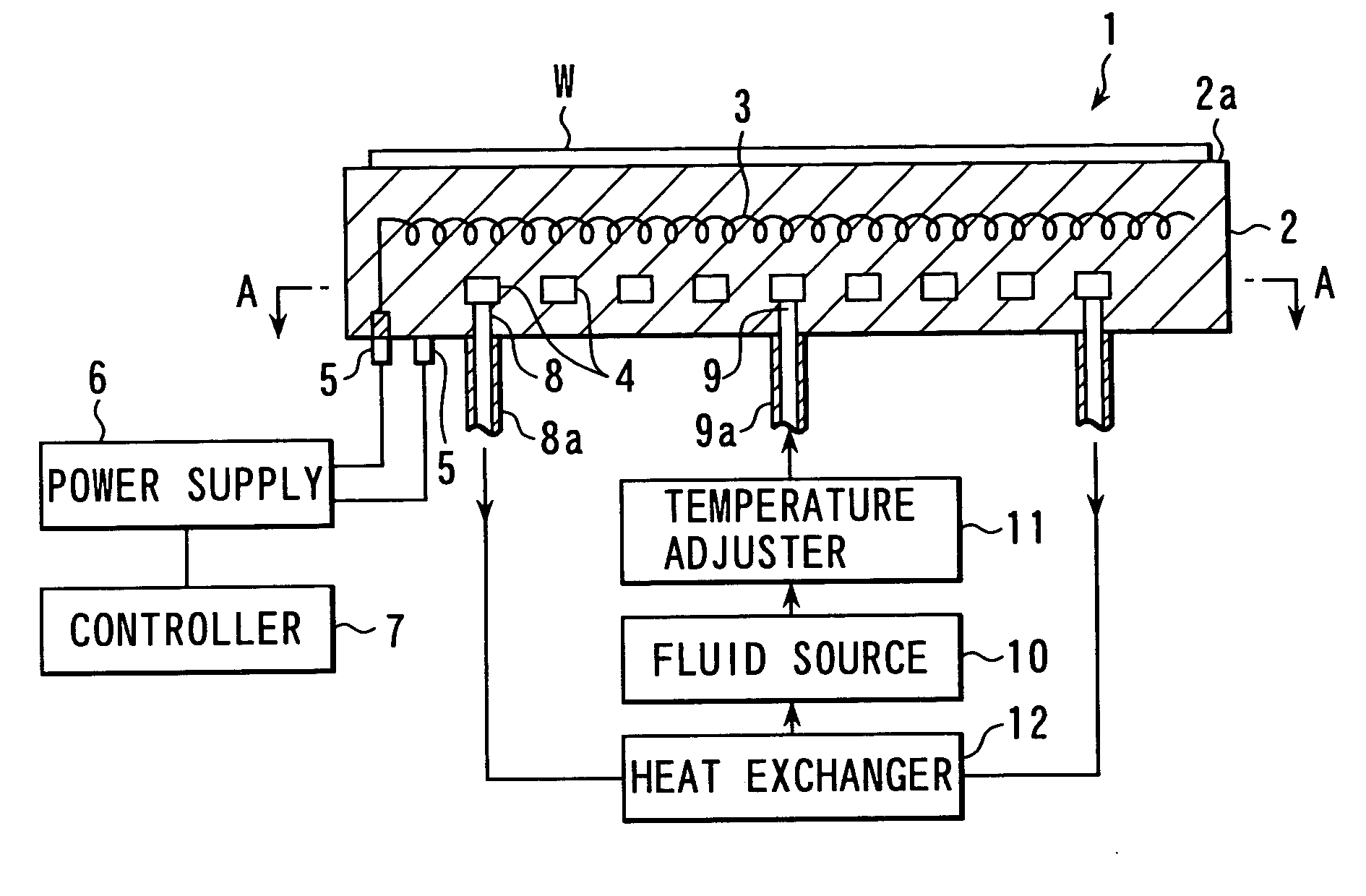

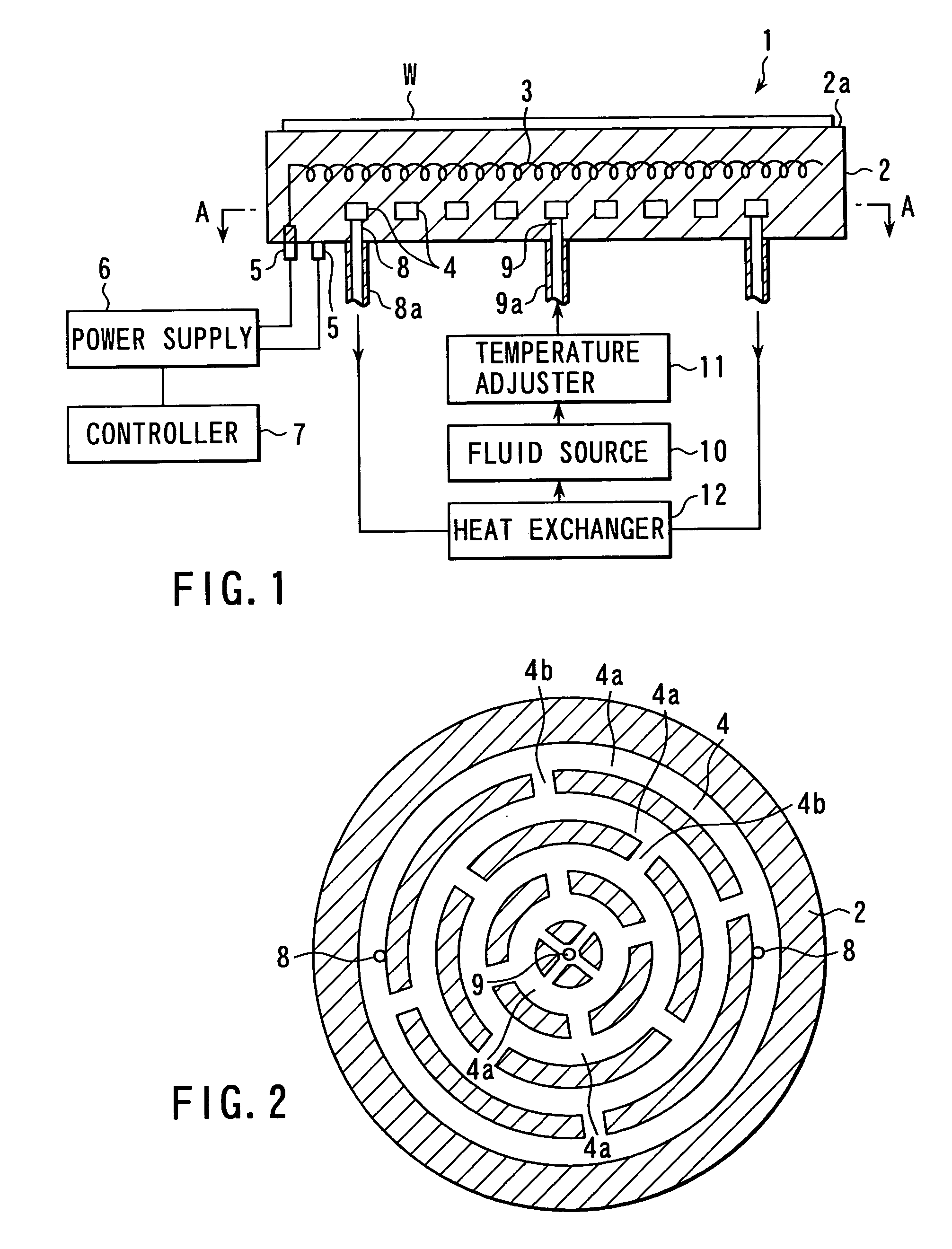

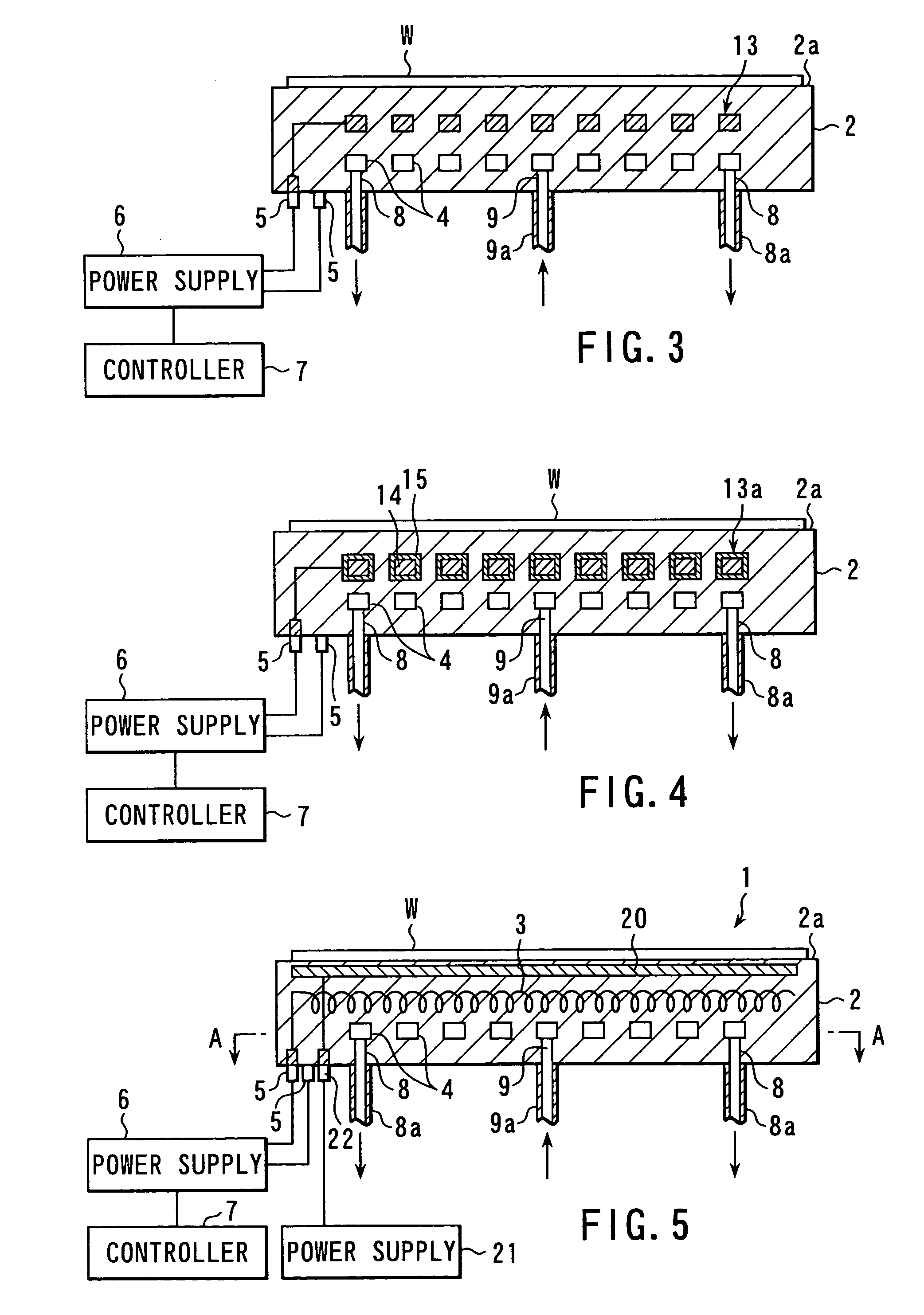

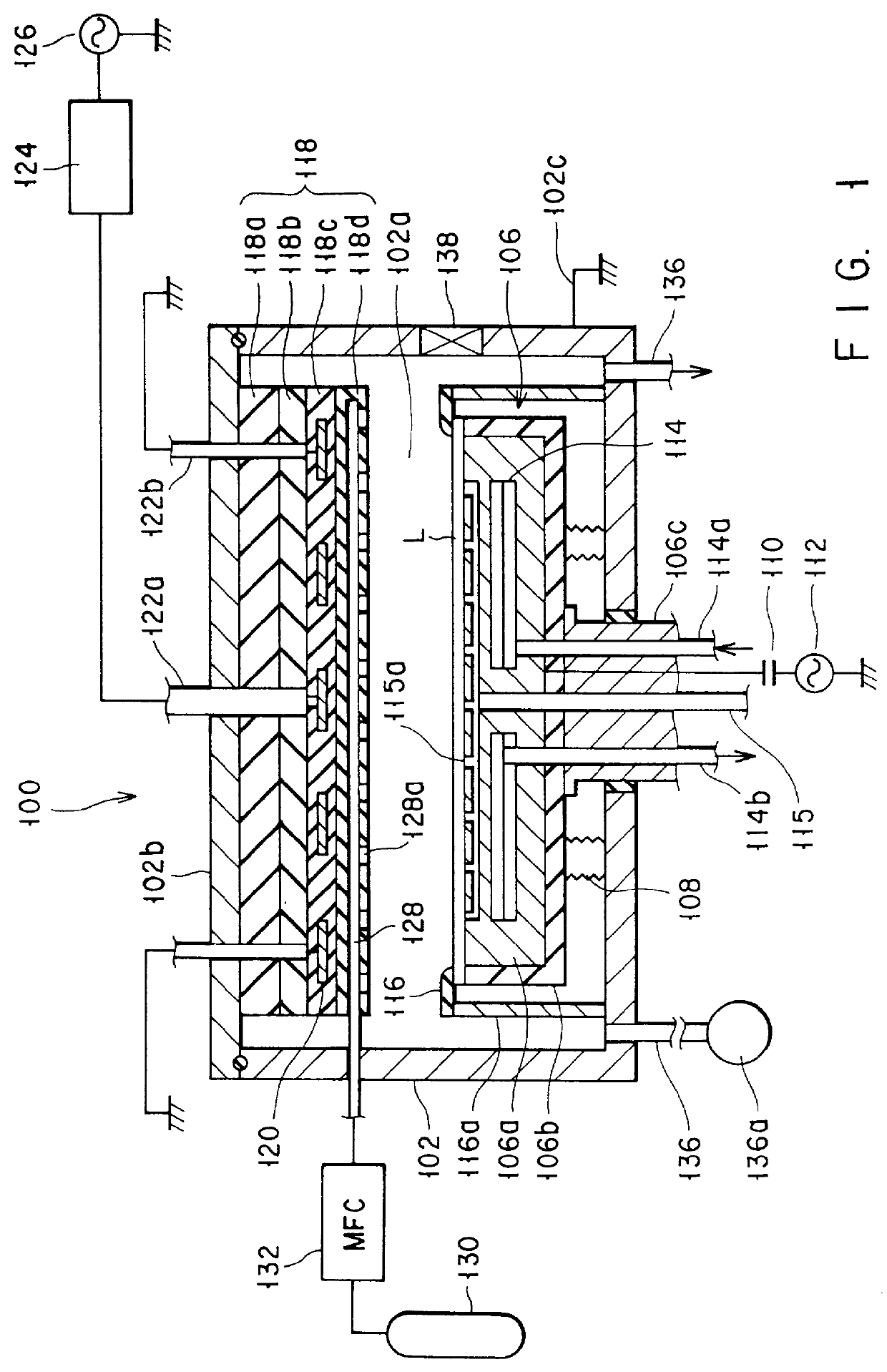

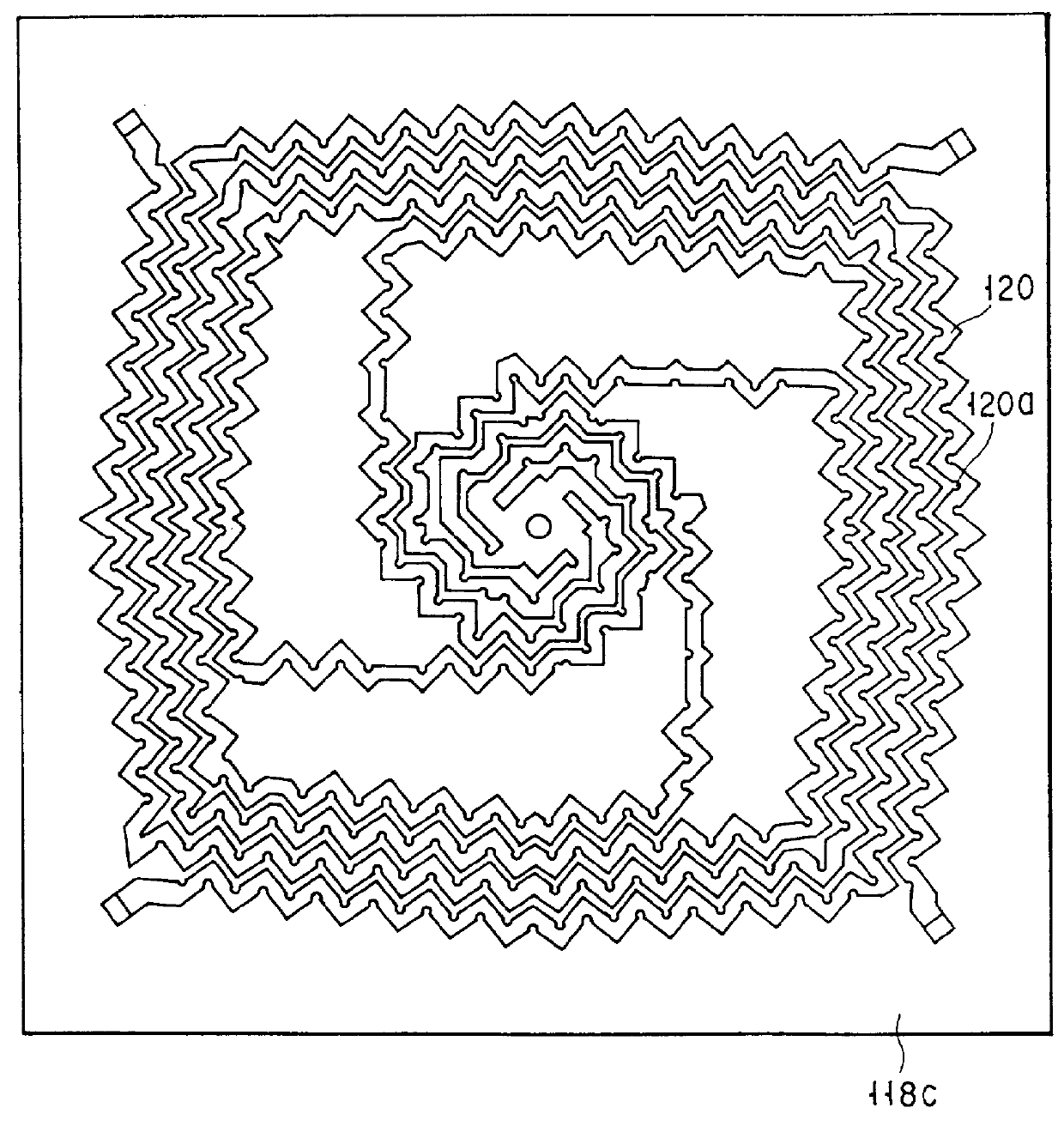

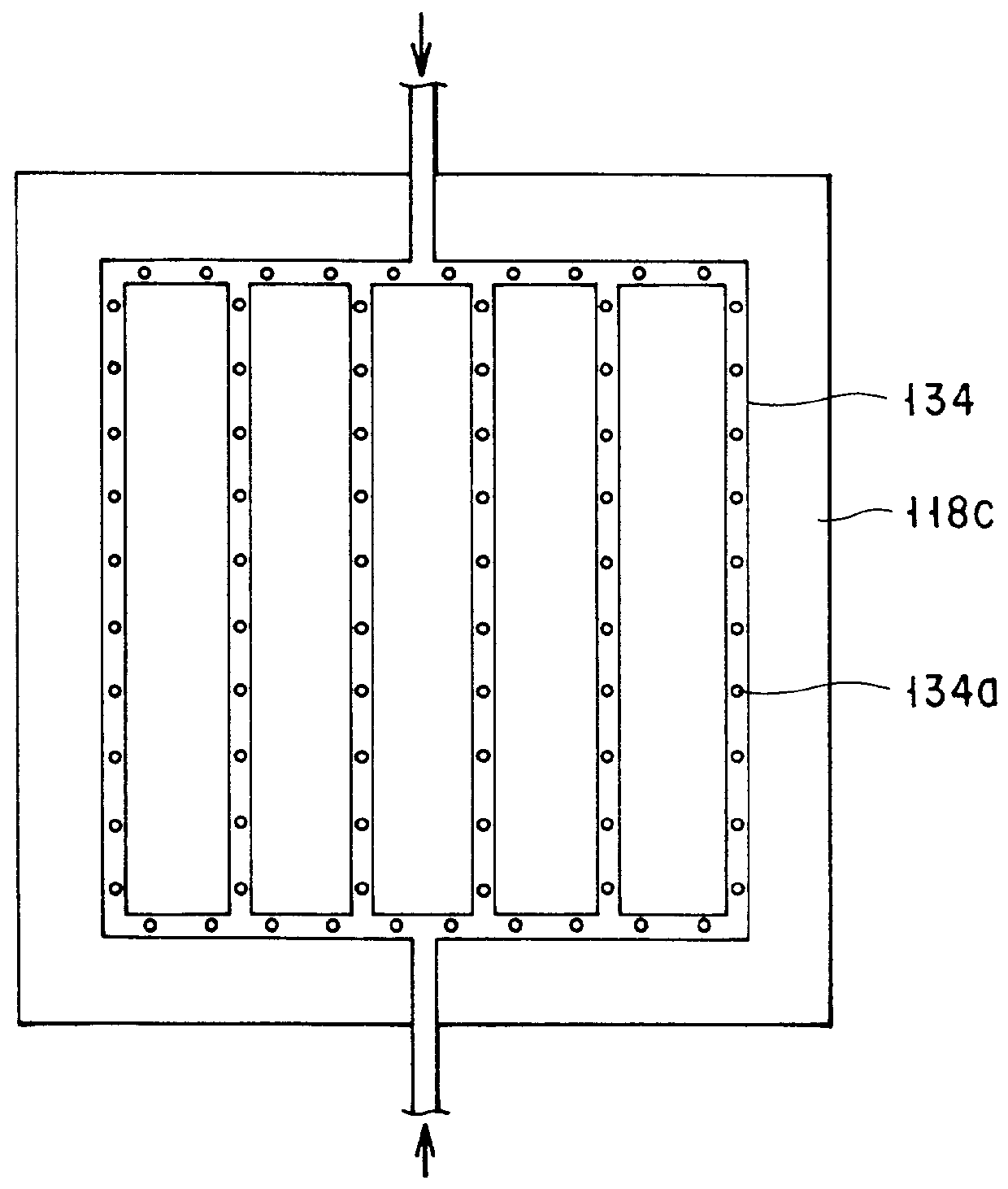

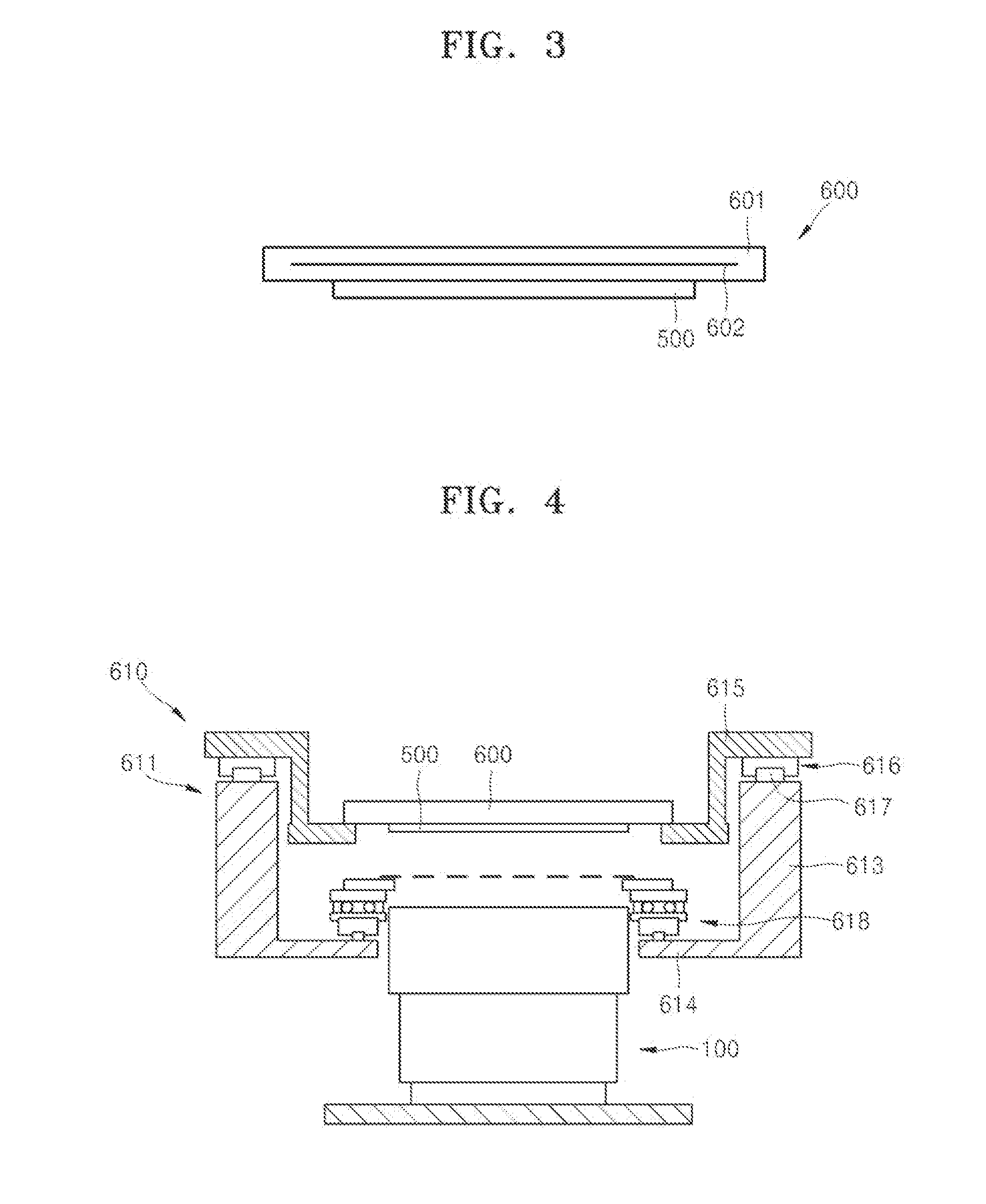

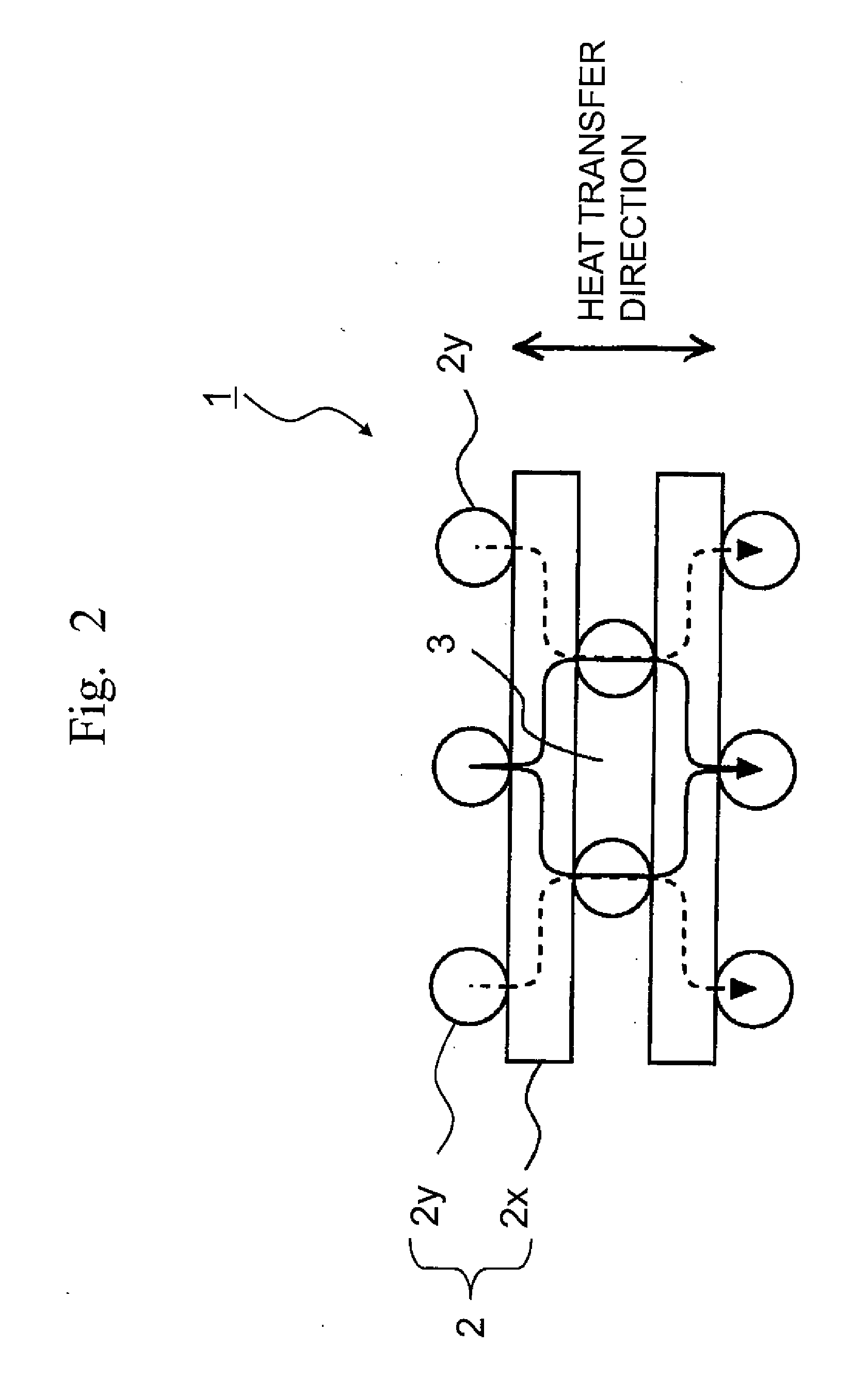

Ceramic heater system and substrate processing apparatus having the same installed therein

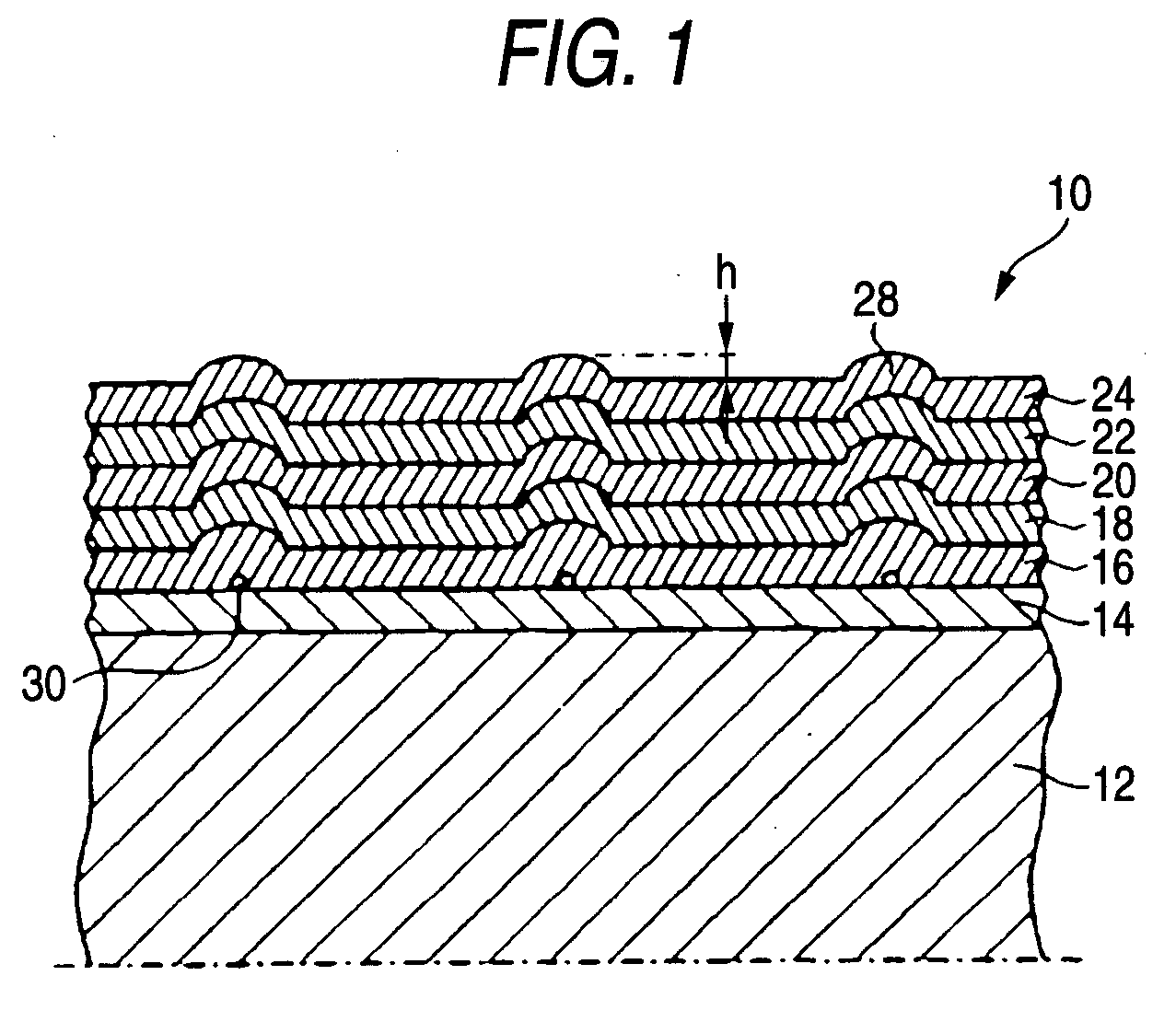

InactiveUS6951587B1Improve cooling efficiencyUniform heating effectSemiconductor/solid-state device manufacturingOhmic-resistance heatingMetallurgyGas supply

A ceramic heater system has a ceramic heater base having a substrate-mounting surface formed on the top surface thereof and a heater, buried in the heater base, for heating a substrate. A fluid passage is formed buried in the heater base below where the heater is buried. The heater base is cooled as a fluid whose temperature is lower than the temperature of the heater base is let flow in the fluid passage. A substrate processing apparatus has the ceramic heater system installed in a process chamber whose vacuum state can be maintained, a gas supply mechanism for feeding a gas into the process chamber, and a power supply. The substrate processing apparatus performs a heat treatment, etching and film deposition on a substrate placed in the process chamber.

Owner:TOKYO ELECTRON LTD

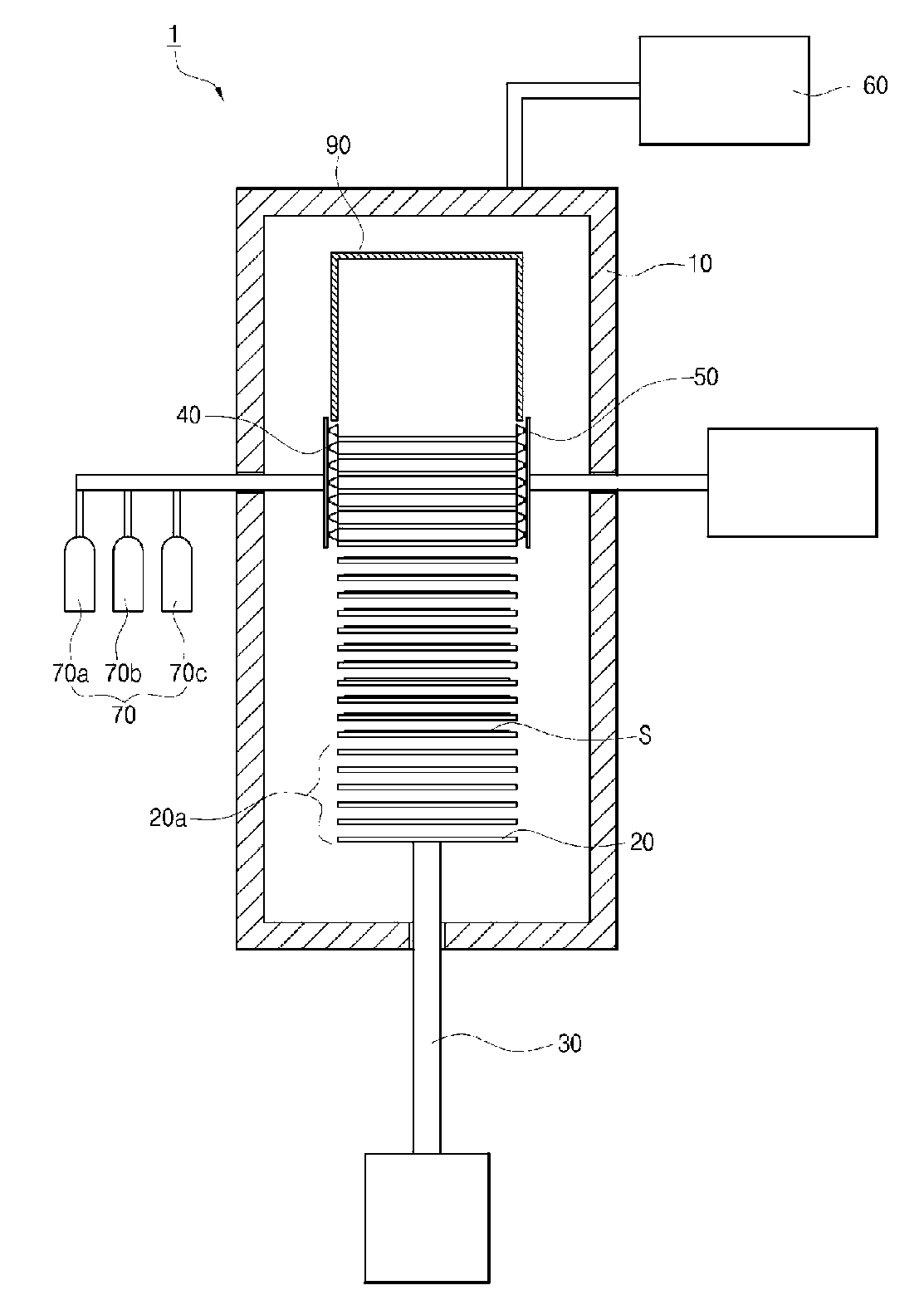

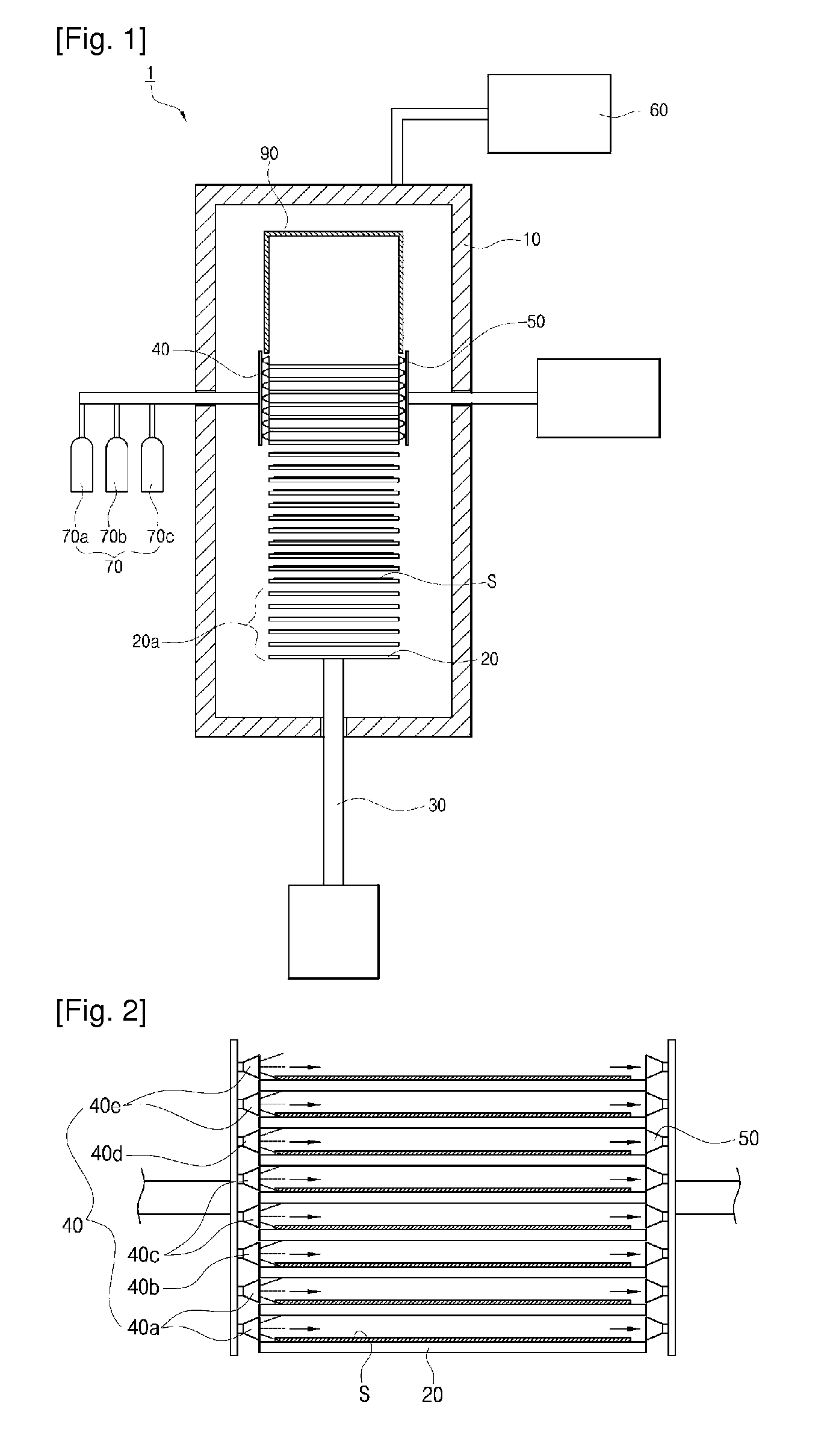

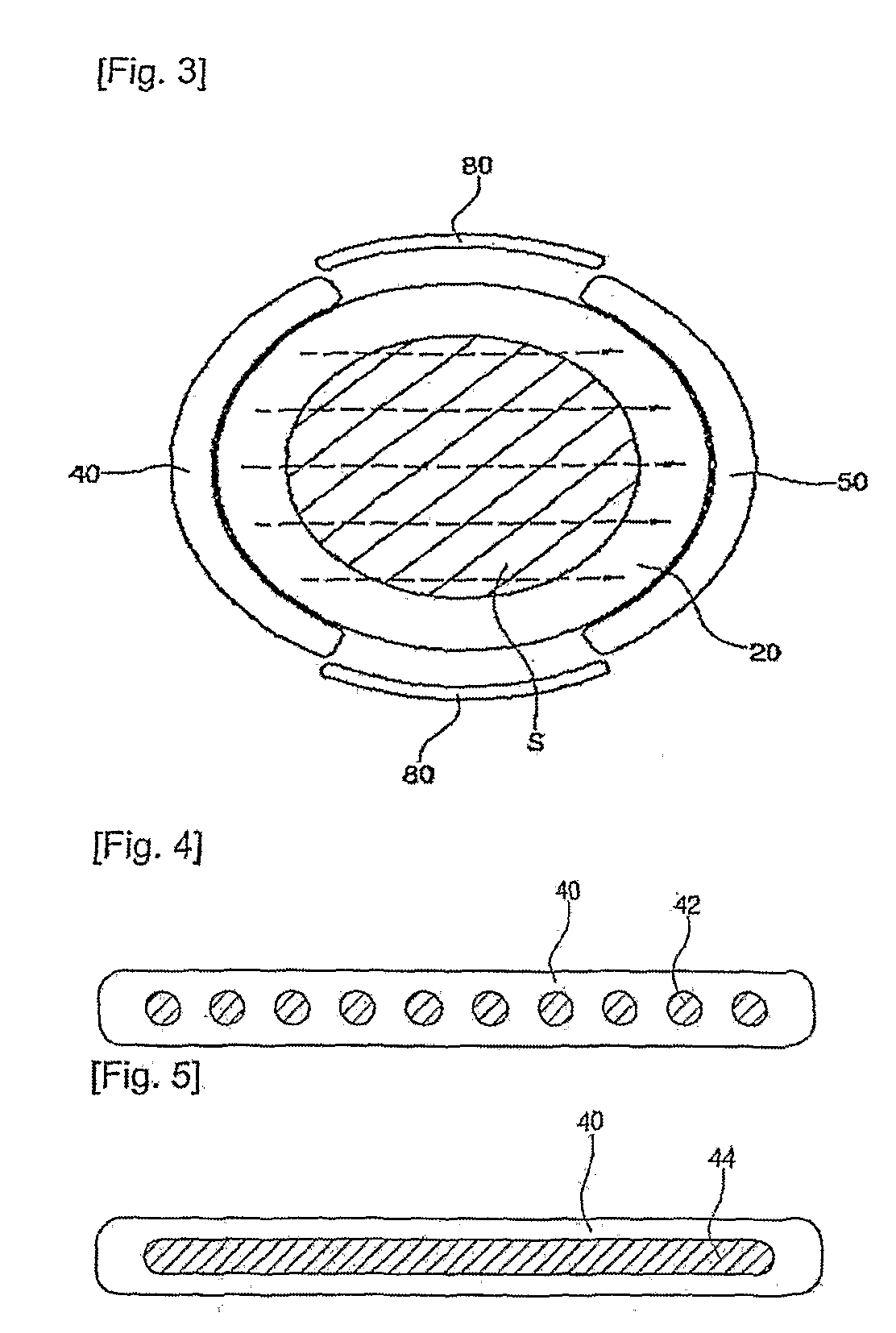

Batch type atomic layer deposition apparatus

InactiveUS20100326358A1Improve throughputImprove deposition efficiencyChemical vapor deposition coatingEngineeringAtomic layer deposition

Provided is a batch-type Atomic Layer Deposition (ALD) apparatus for performing ALD processing collectively for a plurality of substrates, leading to an improved throughput, and achieving perfect uniformity of ALD on the substrates. The batch-type ALD apparatus includes: a chamber that can be kept in a vacuum state; a substrate support member, disposed in the chamber, supporting a plurality of substrates to be stacked one onto another with a predetermined pitch; a substrate movement device moving the substrate support member upward or downward; a gas spray device continuously spraying a gas in a direction parallel to the extending direction of each of the substrates stacked in the substrate support member; and a gas discharge device, disposed in an opposite side of the chamber to the gas spray device, sucking and evacuating the gas sprayed from the gas spray device.

Owner:CHOI KYU JEONG

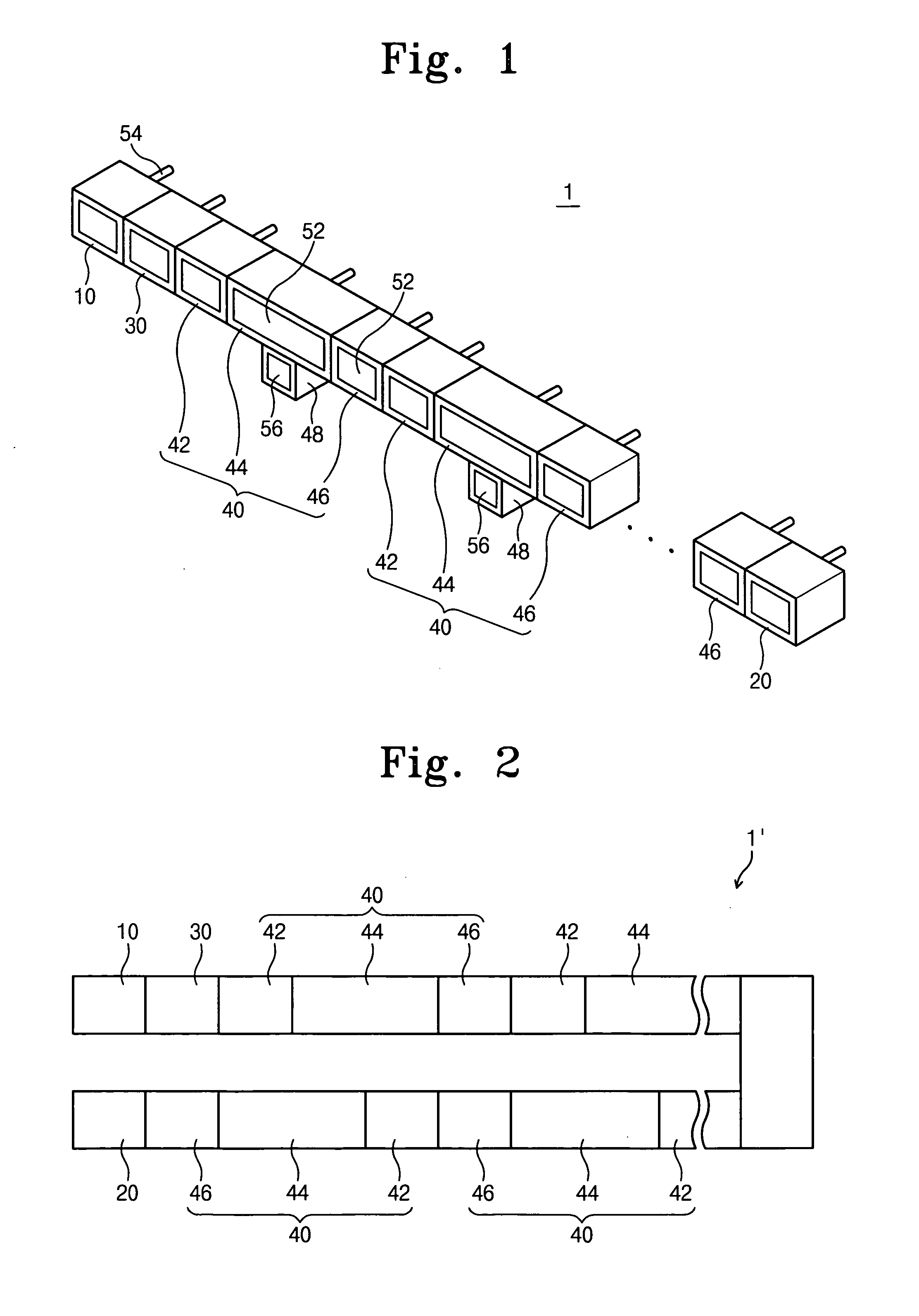

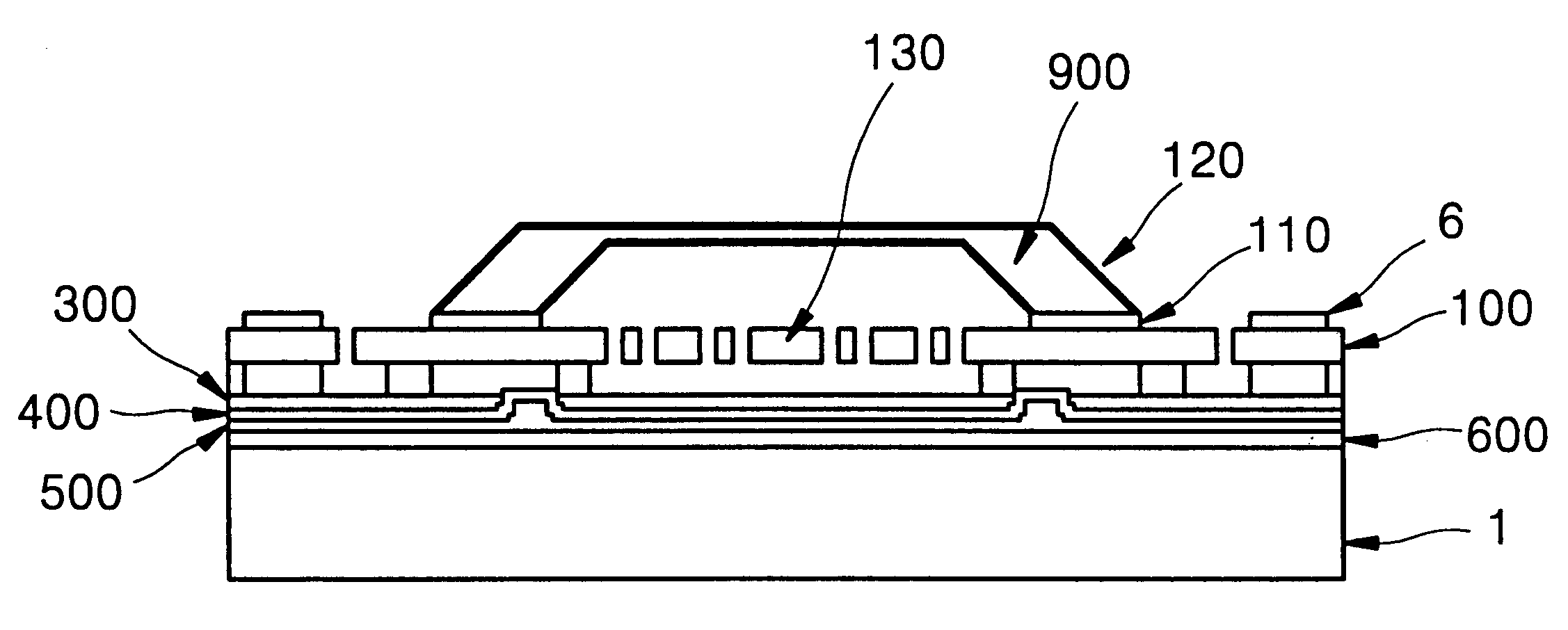

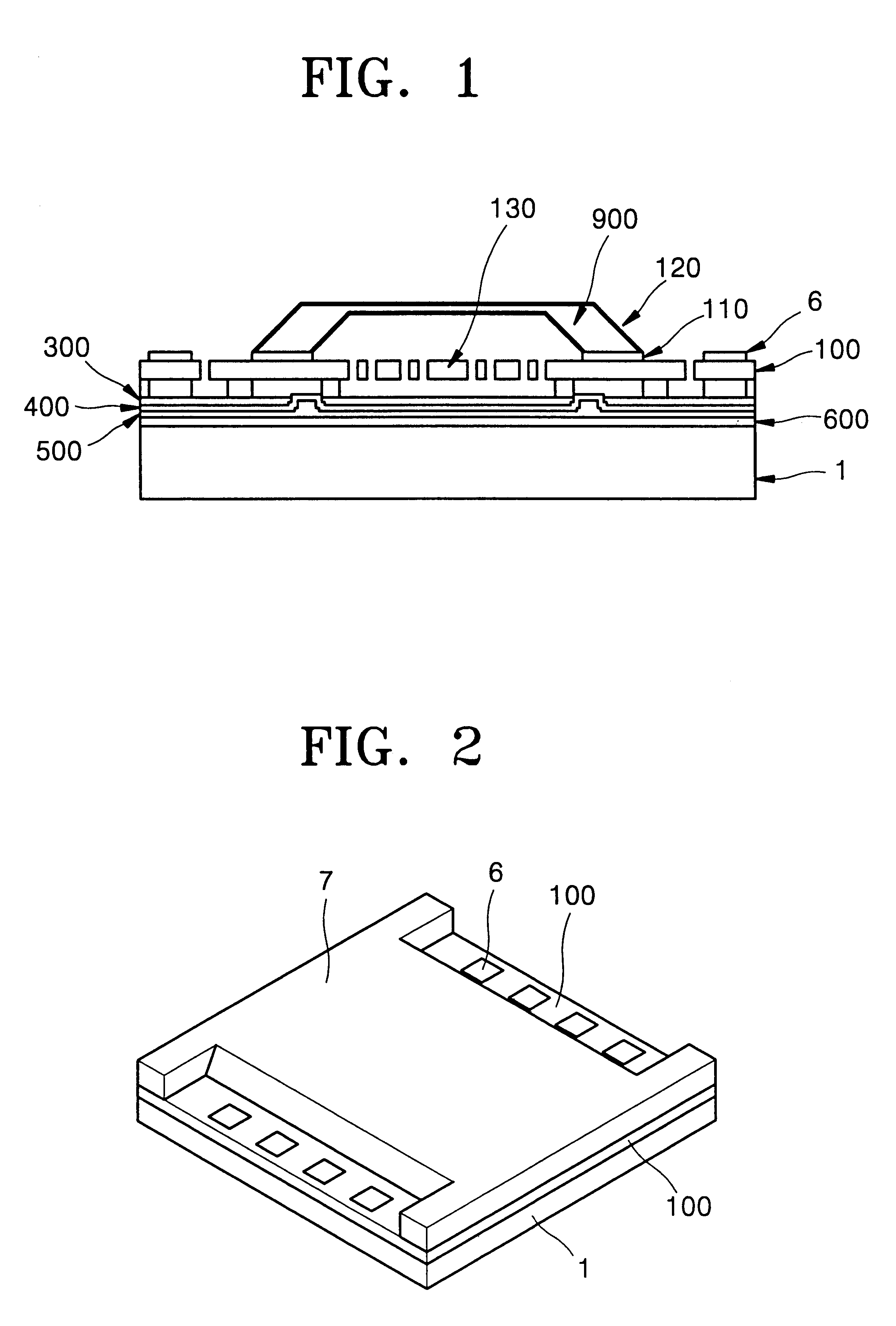

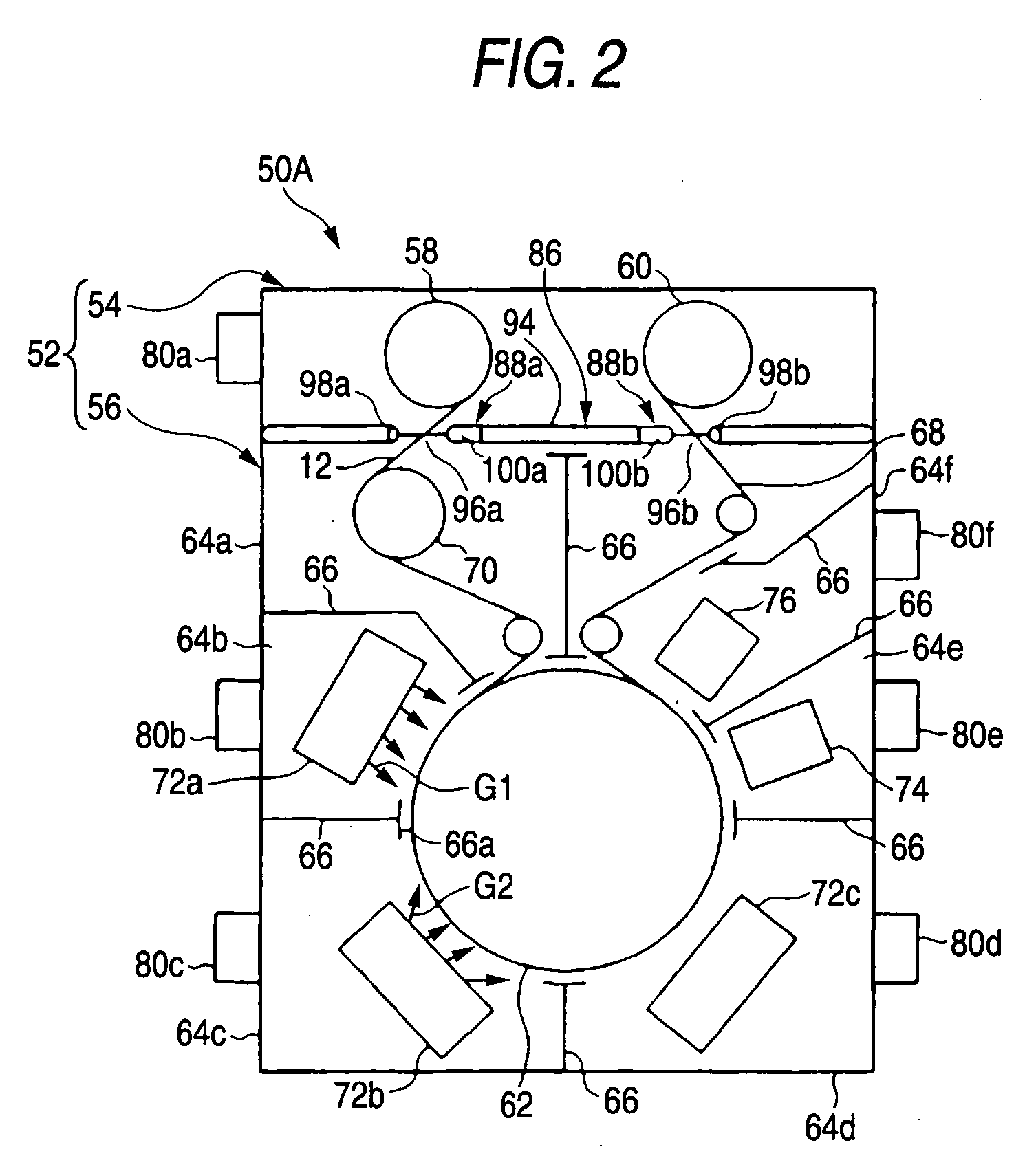

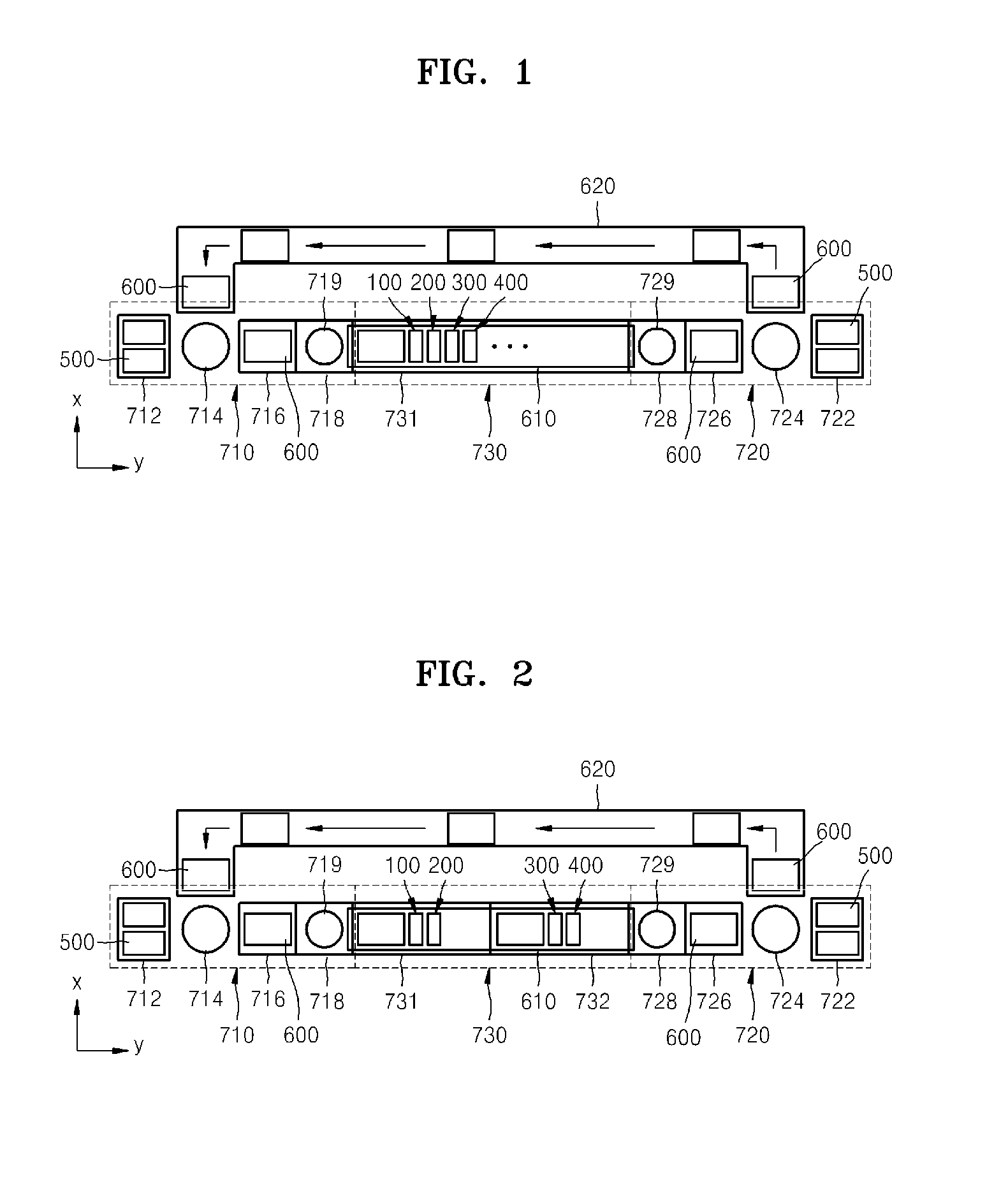

Apparatus for processing substrate

ActiveUS20060174829A1Reduce areaShorten the timeLiquid surface applicatorsSemiconductor/solid-state device manufacturingThin layerLight-emitting diode

In a substrate processing apparatus for forming thin layers on a substrate used for an organic light emitting diode, the apparatus includes a mask attaching chamber, a deposition chamber and a mask detaching chamber. The mask attaching chamber, the deposition chamber and the mask detaching chamber are provided with a transferring guide installed thereinside, and a substrate supporter for supporting the substrate moves along the transferring guide in or between the chambers. Thus, a time for processing the substrate and an area for the apparatus may be reduced. Also, the chambers are grouped in one or more, and a gate valve is installed between the grouped chambers for opening and closing a path between the grouped chambers. Accordingly, the chambers may be continuously maintained in a vacuum state when any one of the chambers is repaired.

Owner:SEMES CO LTD

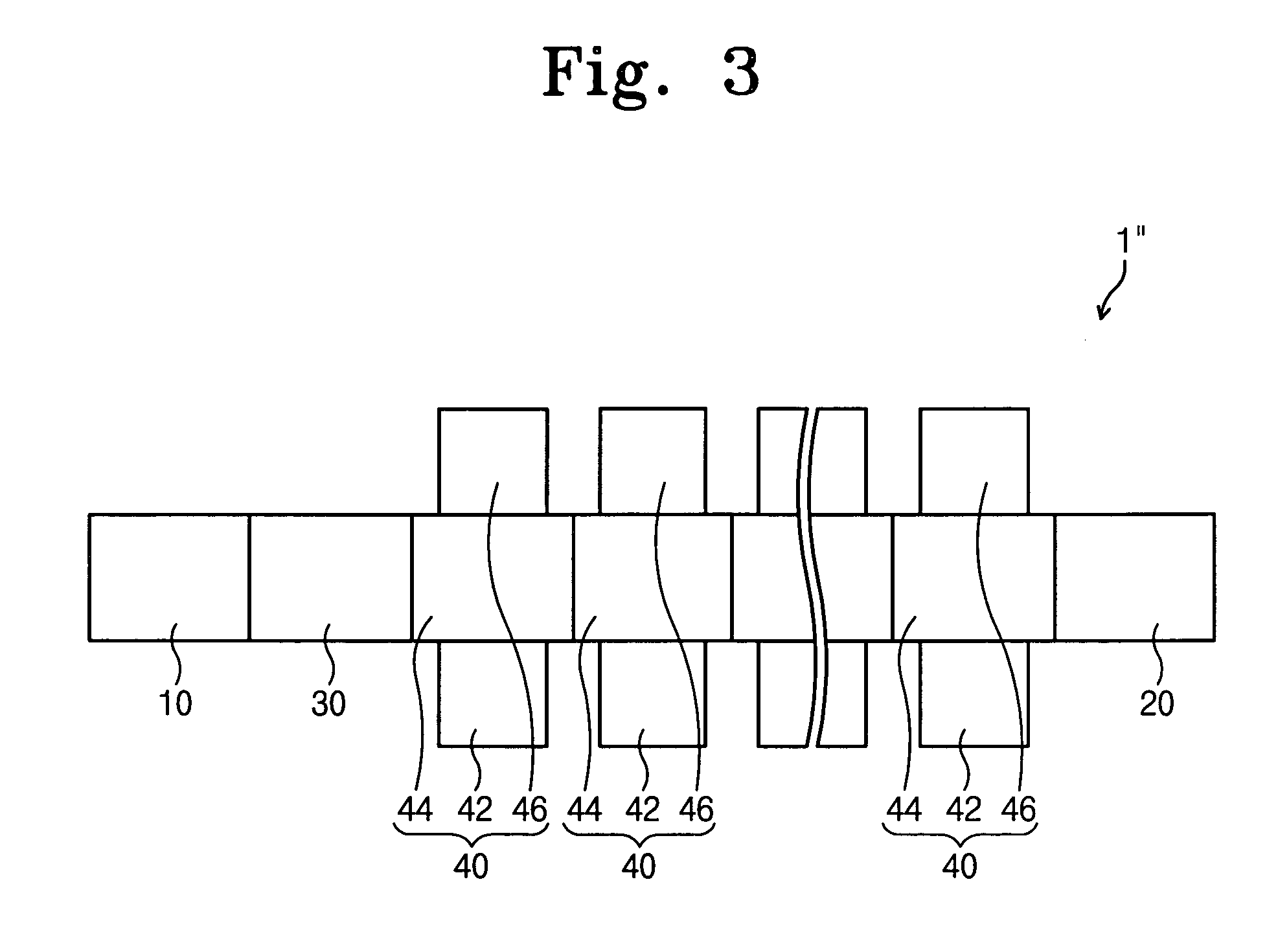

Method of fabricating micro electro mechanical system structure which can be vacuum-packed at wafer level

InactiveUS6391673B1Acceleration measurement using interia forcesSemiconductor/solid-state device detailsVacuum packVacuum level

A method of fabricating a micro electromechanical system (MEMS) structure which can be vacuum-packaged at the wafer level is provided. The method includes the steps of forming a multilayered stack including a signal line on a first wafer; bonding a second wafer to the multilayered stack; polishing the first wafer to a predetermined thickness; forming a MEMS structure in a vacuum area of the first wafer and a pad outside the vacuum area, the MEMS structure and the pad being connected to the signal line; forming a structure in a third wafer to have space corresponding to the vacuum area of the MEMS structure; and bonding the third wafer to the polished surface of the first wafer in a vacuum state. For protection of the structure and maintaining a vacuum level required for operation, the fabricated structure is vacuum-packaged at the wafer level, thereby improving the yield of fabrication. In addition, since a special vacuum packaging process is not necessary, the fabrication can be simplified.

Owner:SAMSUNG ELECTRONICS CO LTD

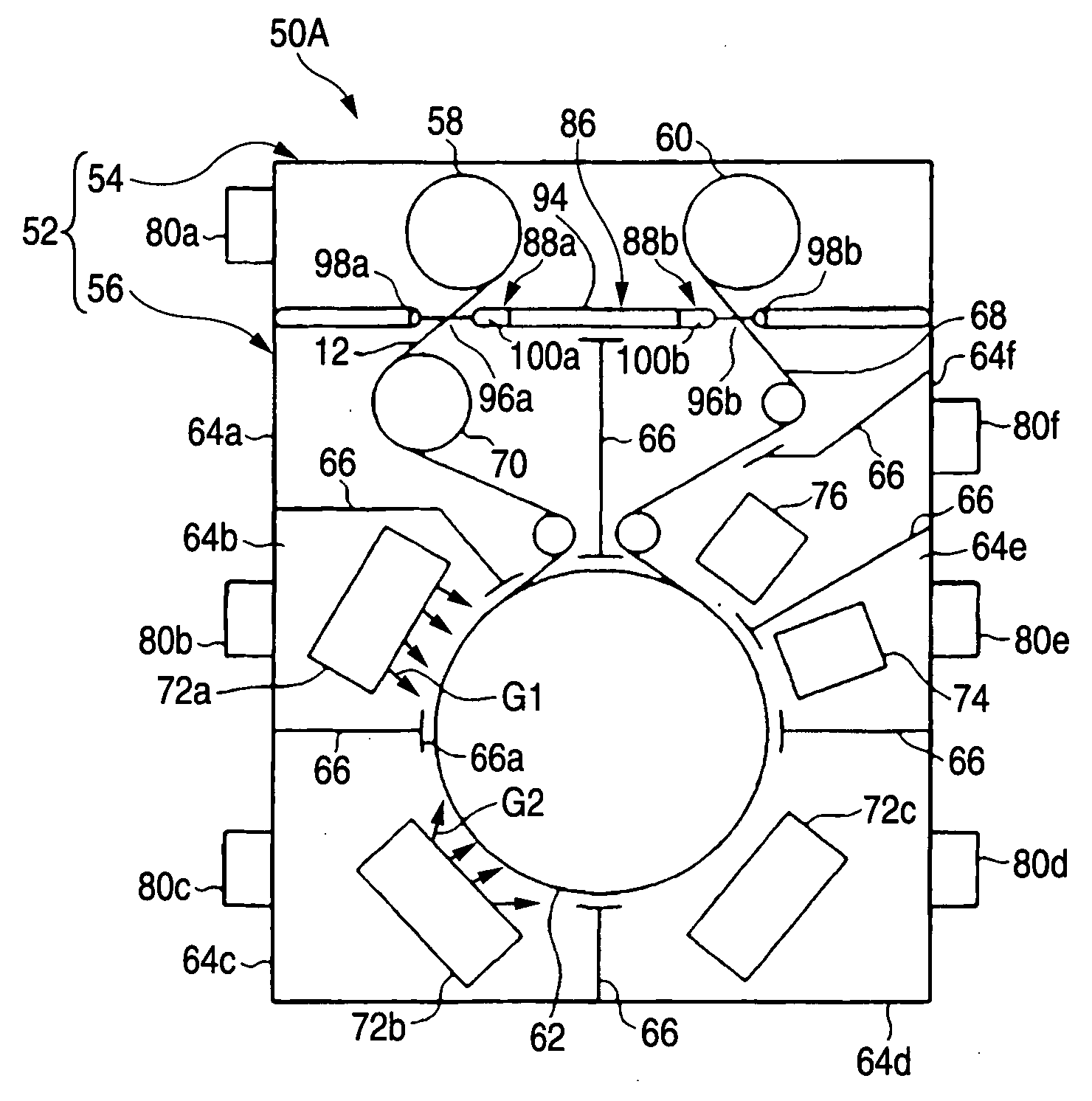

Plasma processing apparatus

InactiveUS6089182AIncrease the use factorHigh densityElectric discharge tubesChemical vapor deposition coatingProject areaCoupling

A plasma etching apparatus of the induction coupling type for processing an LCD substrate has a process container forming an airtight process room. A work table is arranged in the process room for supporting the LCD substrate. A vacuum pump is arranged for exhausting and setting the process room into a vacuum state. An antenna block having a plurality of dielectric layers is arranged to face the work table. An RF antenna is embedded in one of the dielectric layers of the antenna block for forming an electric field. A power supply is connected to the RF antenna for applying an RF power. The lowermost layer of the antenna block is formed as a shower head for supplying a process gas into the process room from a position between the RF antenna and the work table. At least part of the process gas is turned into plasma by the electric field. In the layer formed as the shower head, the gas passage has such a projected area ratio, on a planar outer-contour of the mount surface of the work table, that is from 15% to 25%.

Owner:TOKYO ELECTRON LTD +1

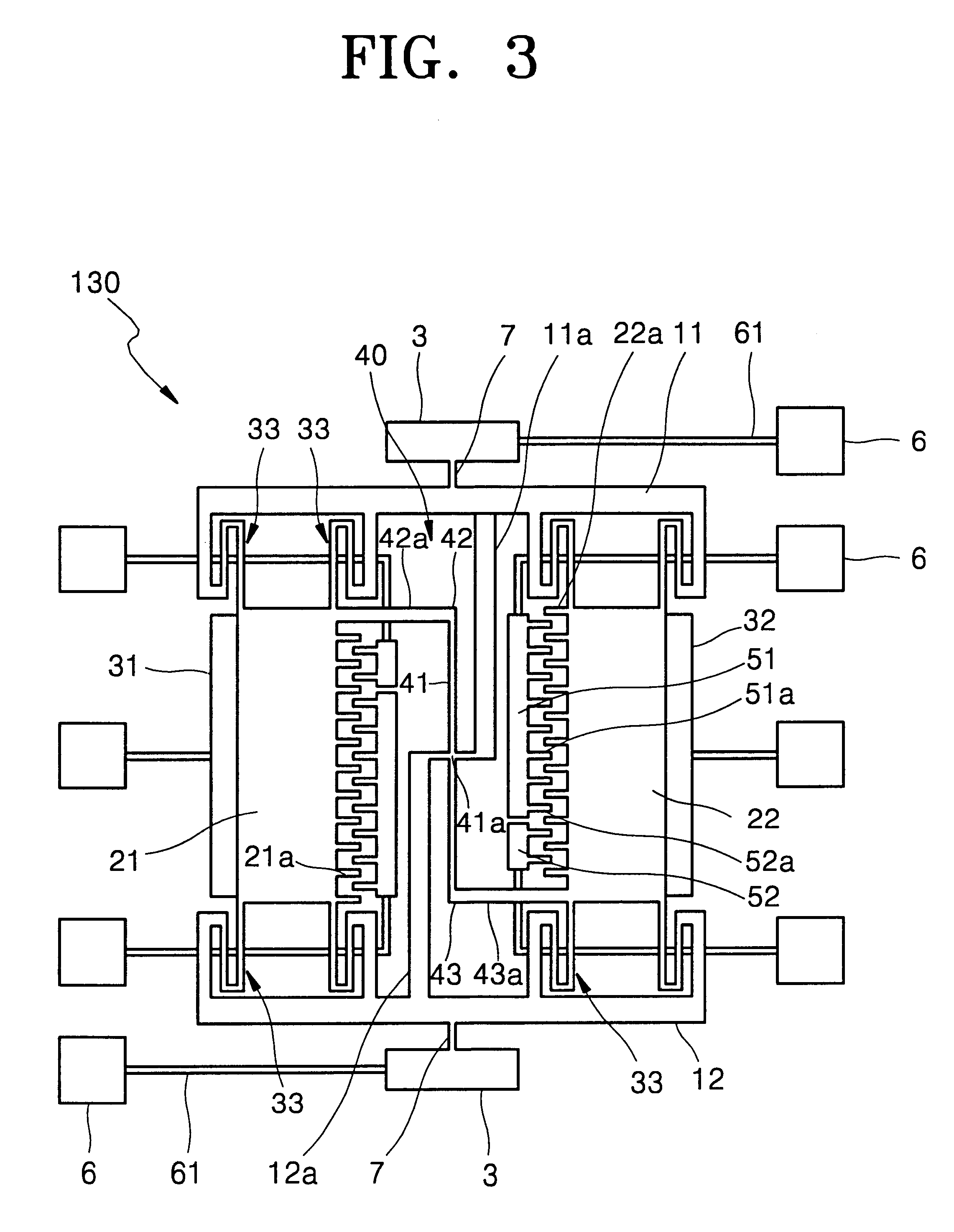

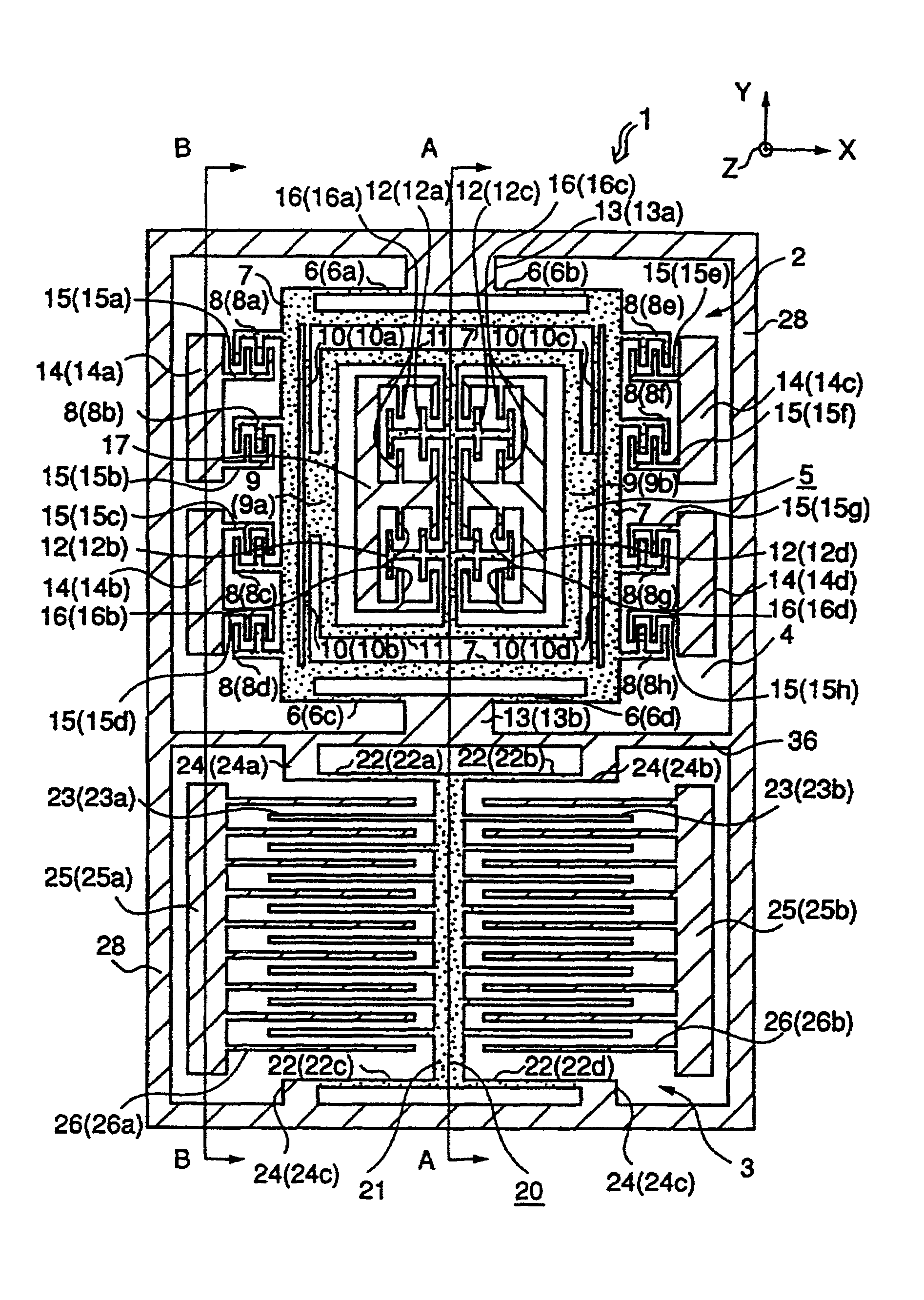

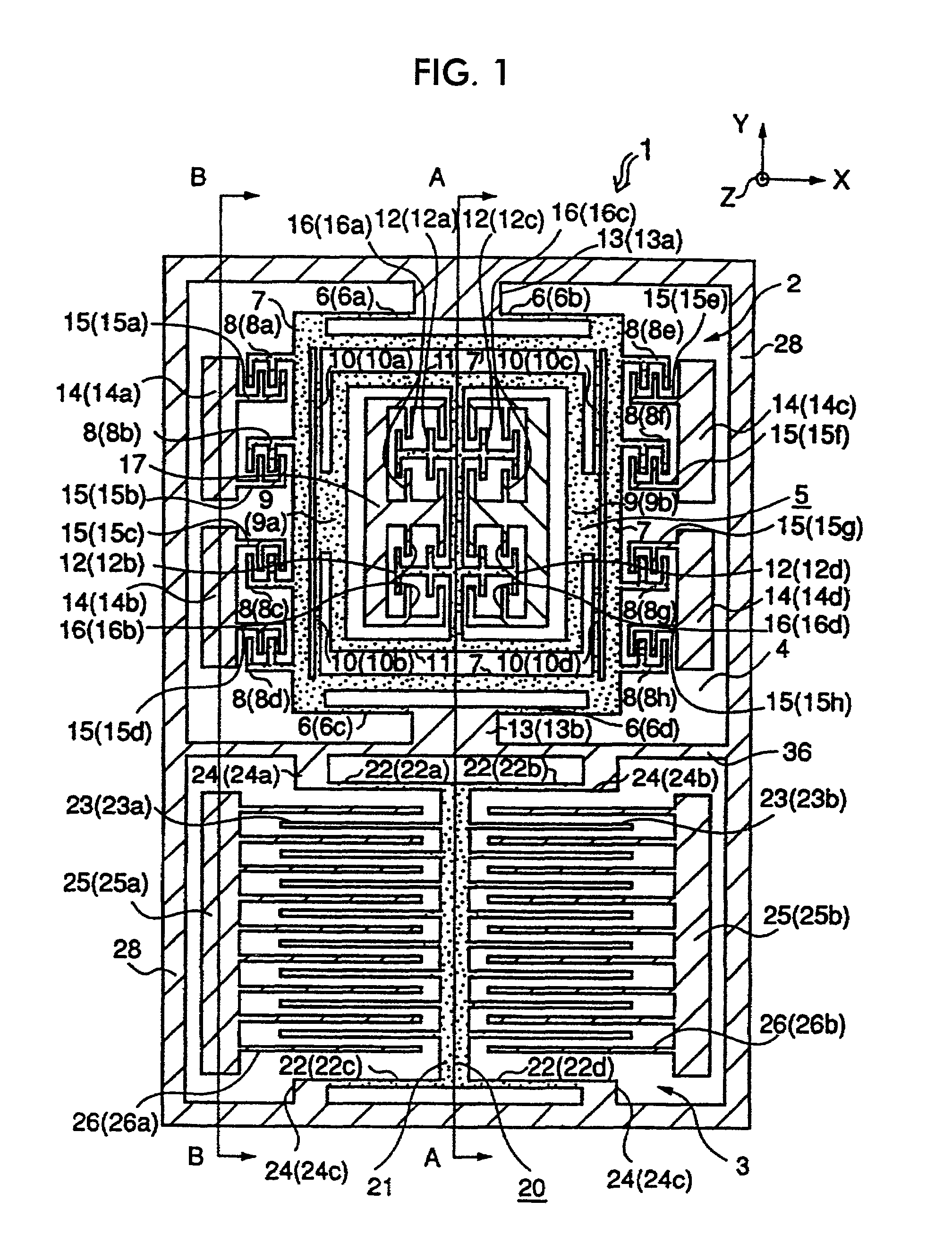

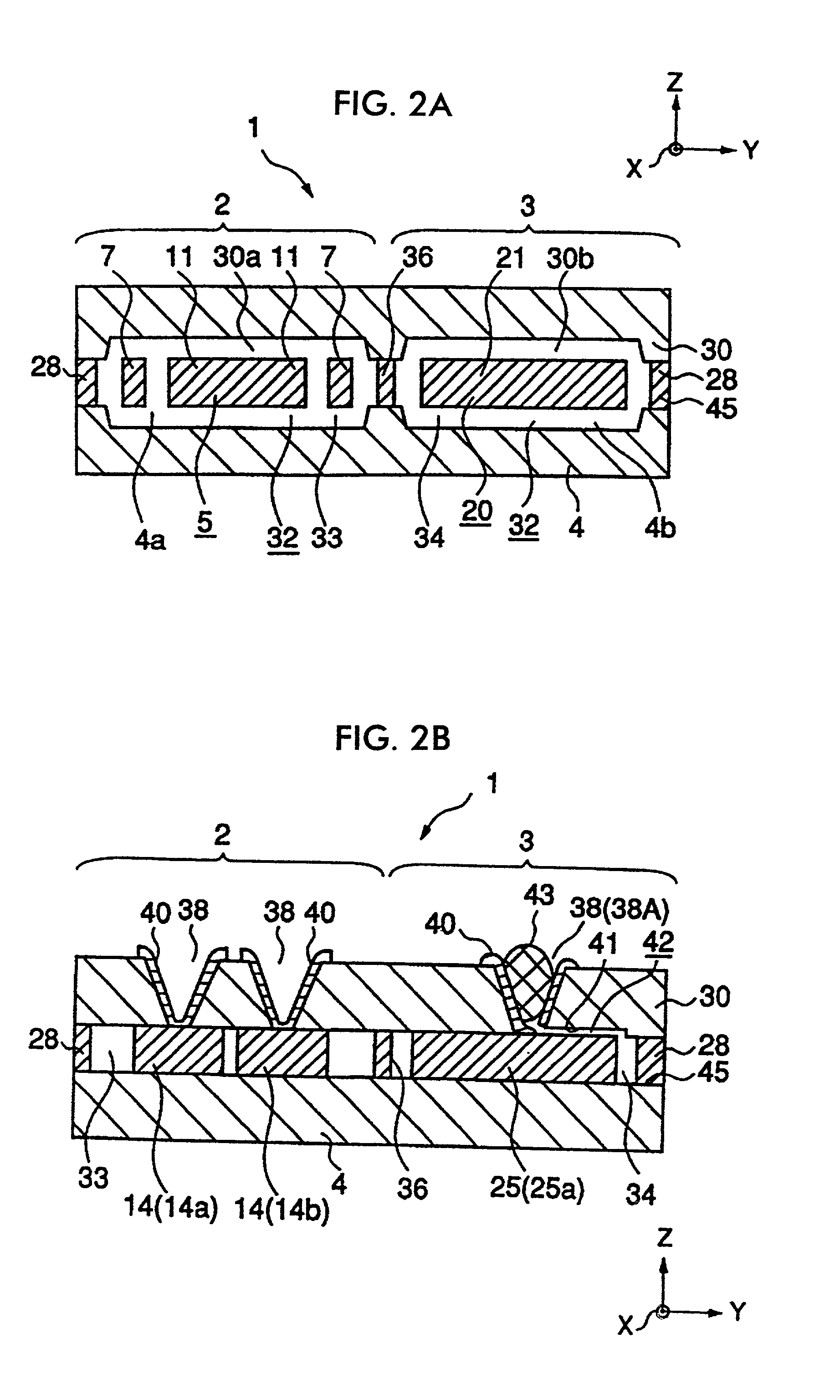

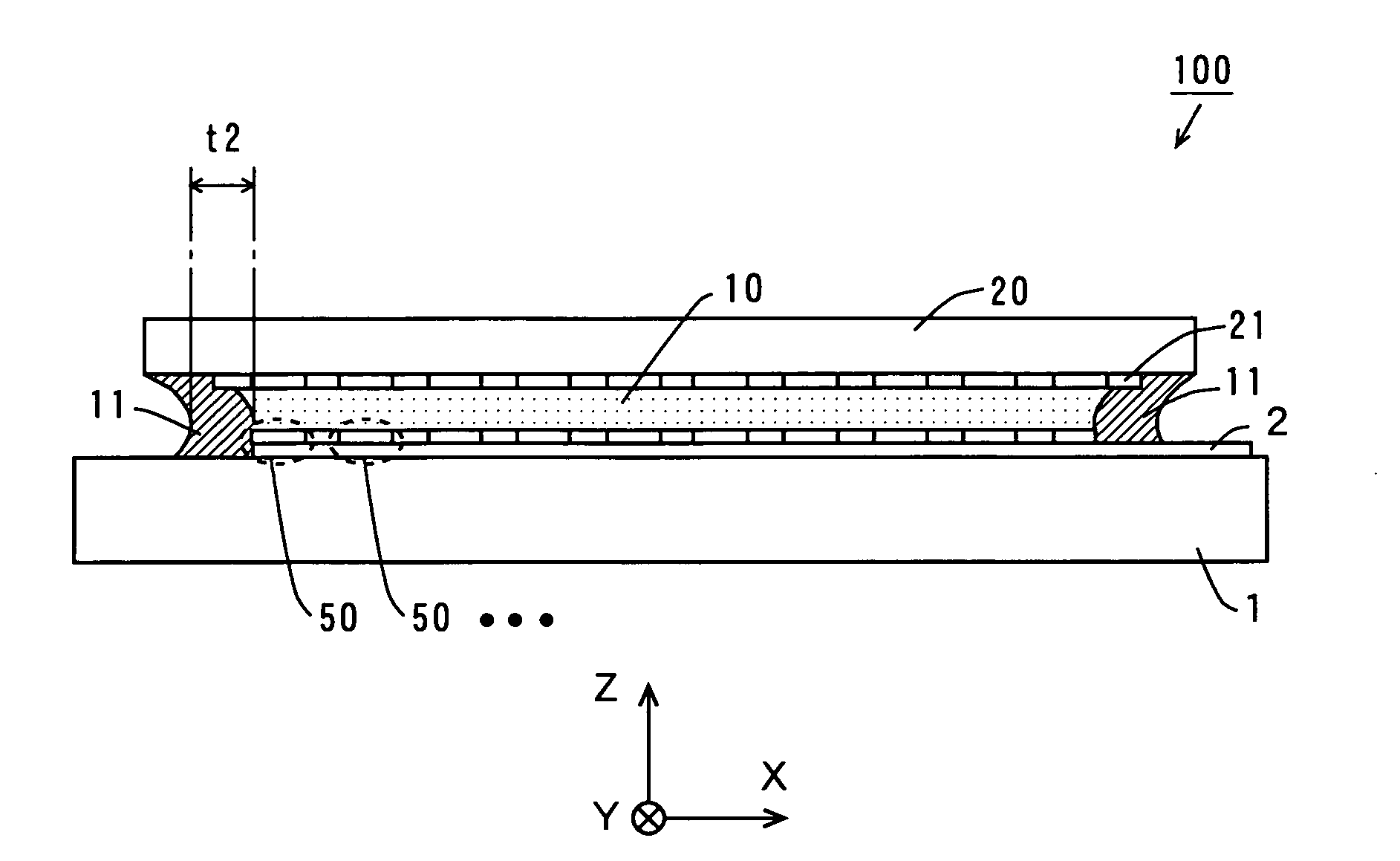

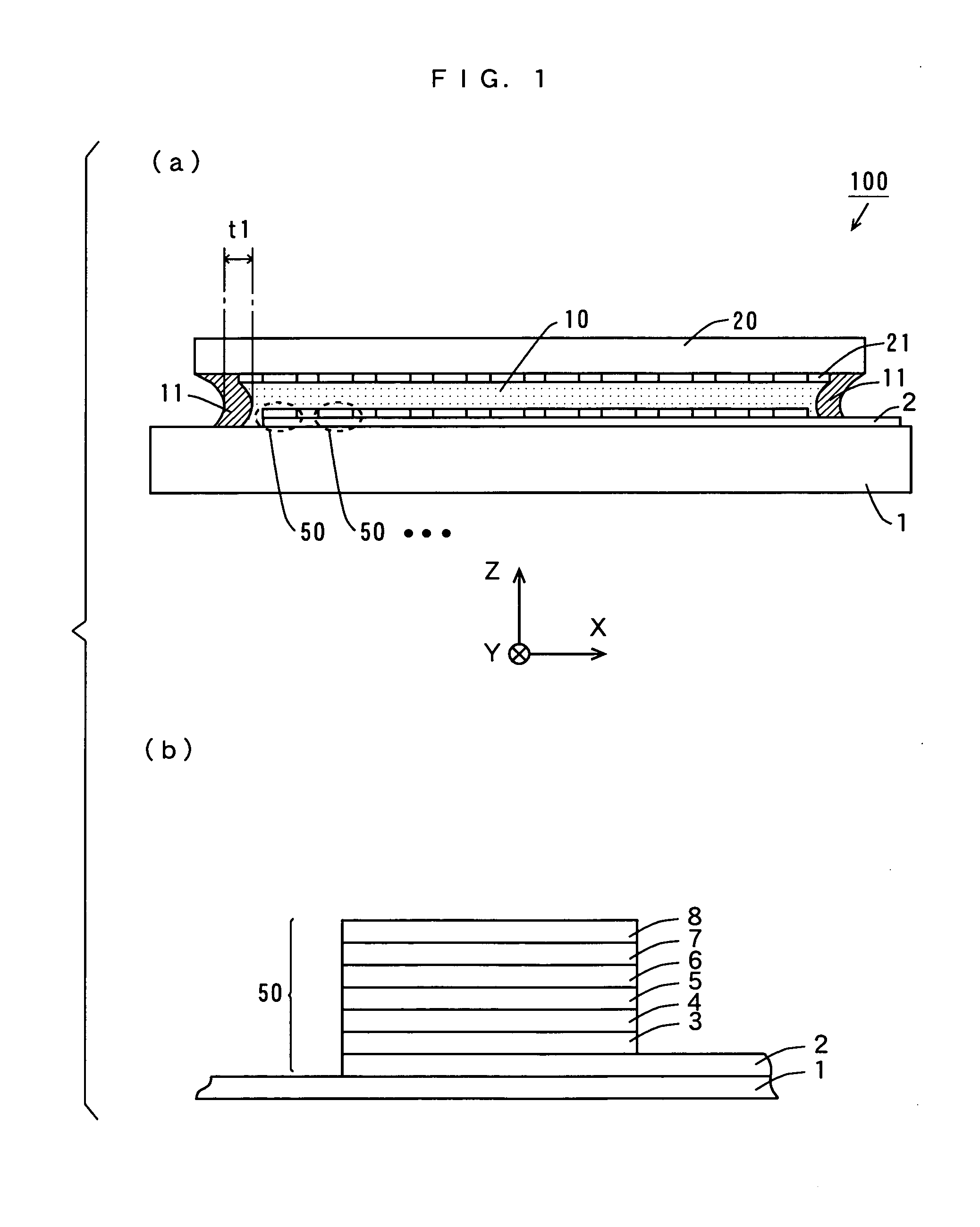

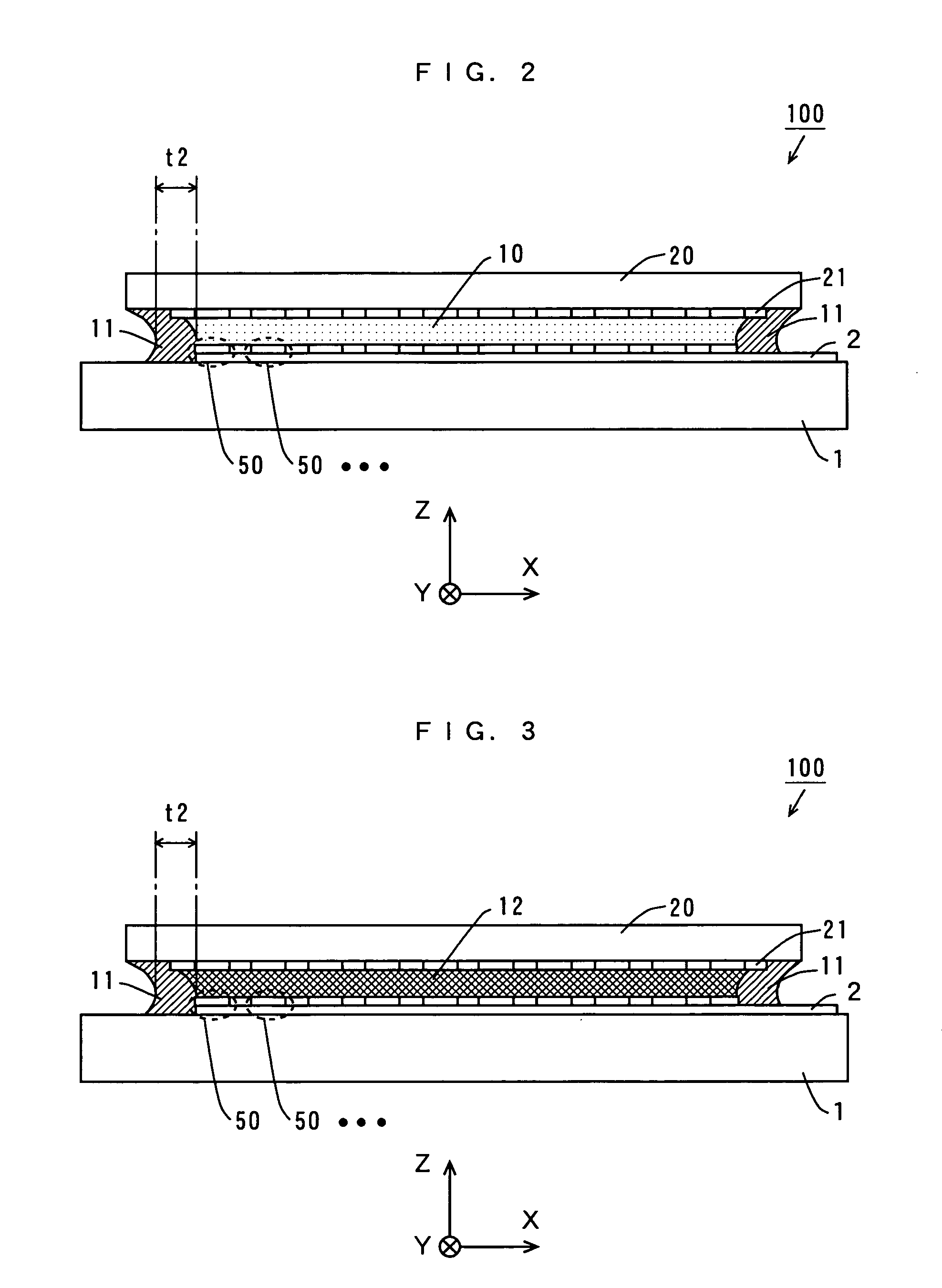

Composite sensor device and method of producing the same

InactiveUS7004025B2High detection sensitivityAvoid vibrationAcceleration measurement using interia forcesSpeed measurement using gyroscopic effectsAngular velocityAtmospheric pressure

A plane vibrator of an angular velocity sensor and a movable member of an acceleration sensor are provided in a spaced floating state on the same substrate. A lid is formed so as to cover and be spaced from the upper side of the plane vibrator and the movable member. A space defined by the substrate and the lid is sectioned into a angular velocity sensor space and an acceleration sensor space by use of a sectioning wall. The angular velocity sensor space is hermetically sealed to be in the vacuum state. The acceleration sensor space is hermetically sealed to be under atmospheric pressure. The plane vibrator is vibrated at a high frequency and a large amplitude so that the angular velocity detection sensitivity is enhanced. The movable member, even if vibration of the plane vibrator is transmitted thereto, is prevented from vibrating at a high frequency and a large amplitude, due to the damping effect of air. Thus, the acceleration detection sensitivity is enhanced.

Owner:MURATA MFG CO LTD

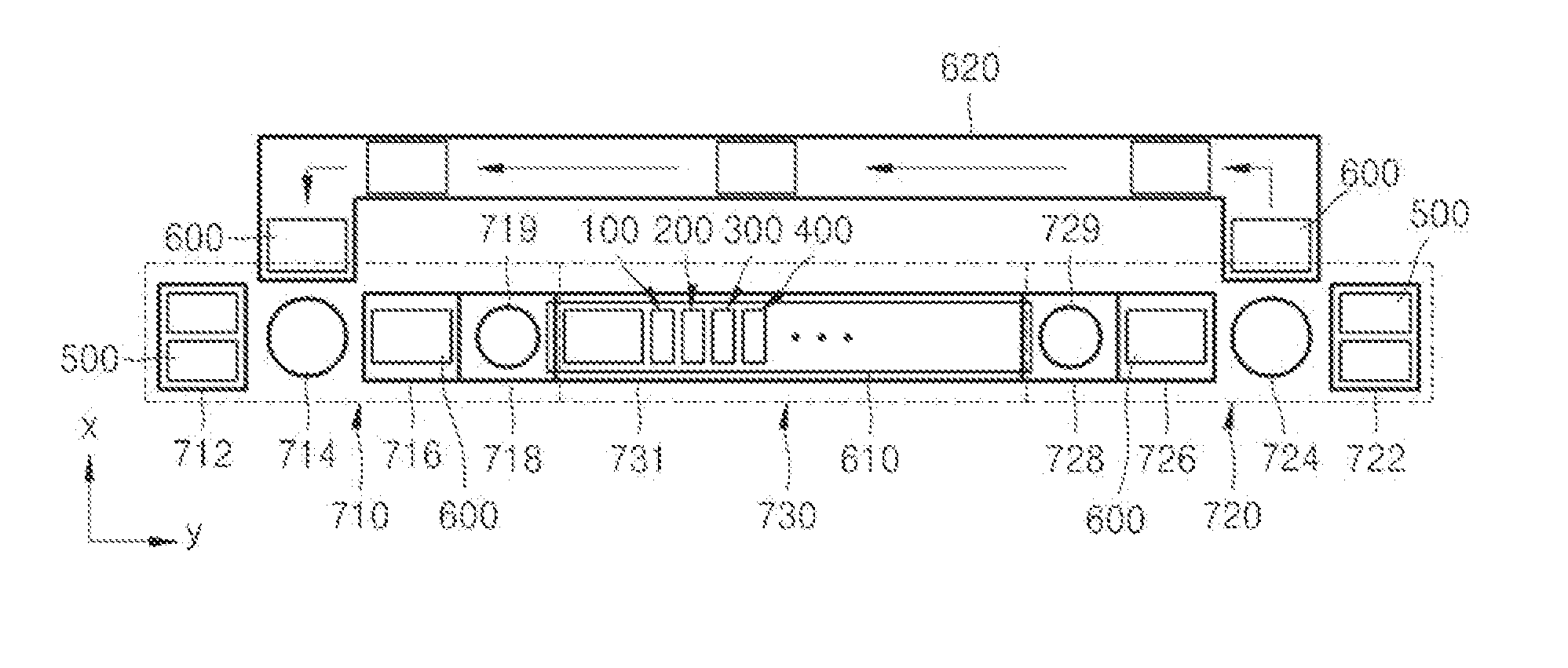

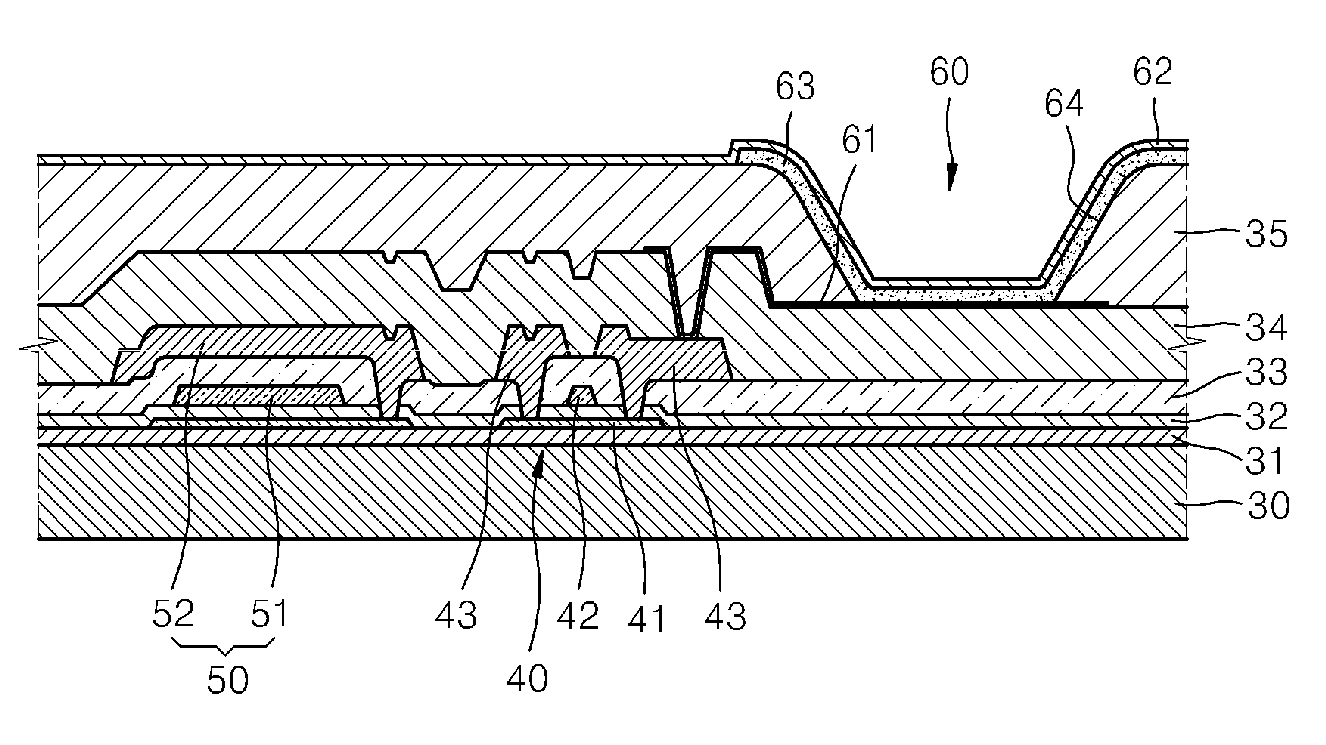

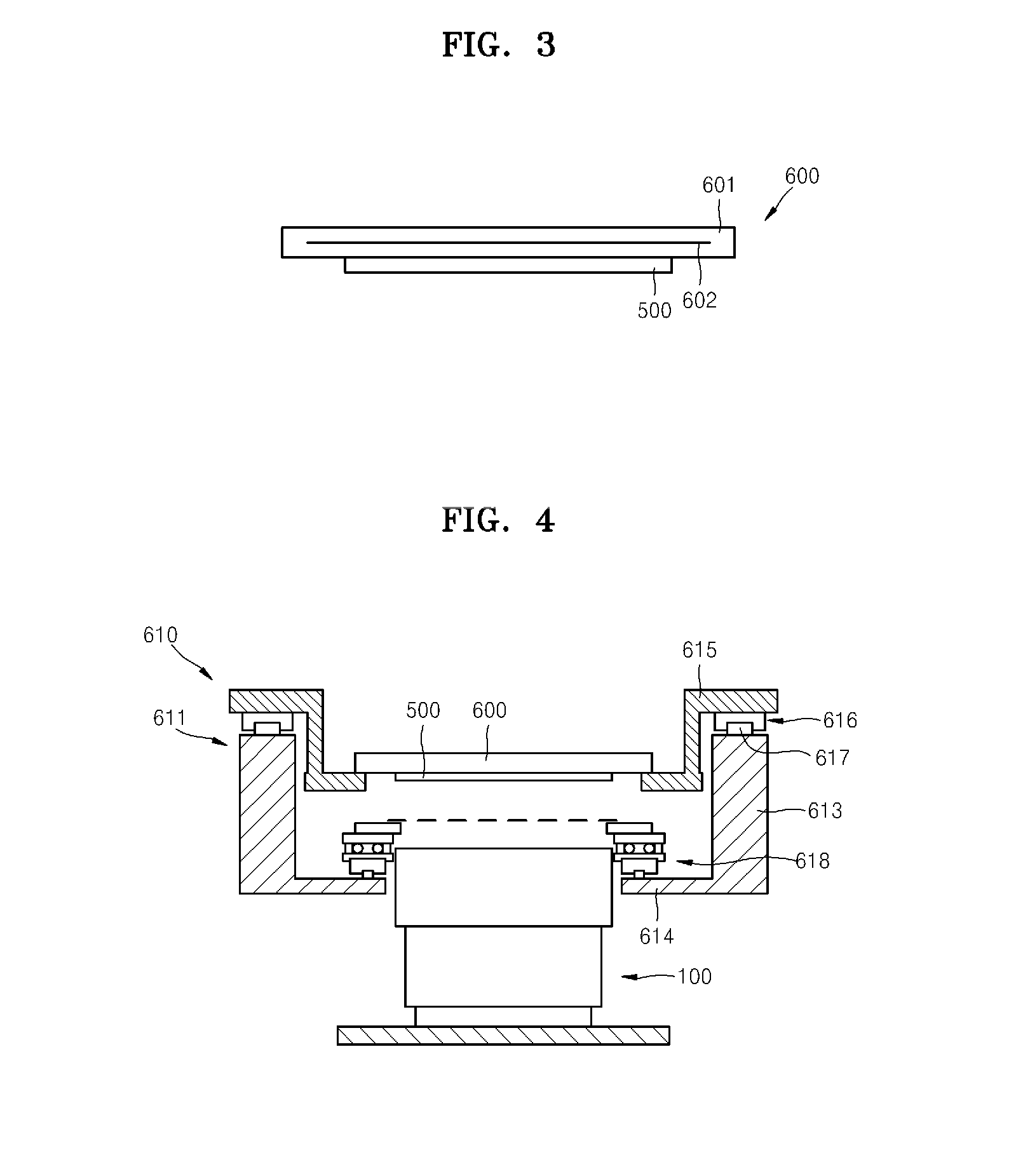

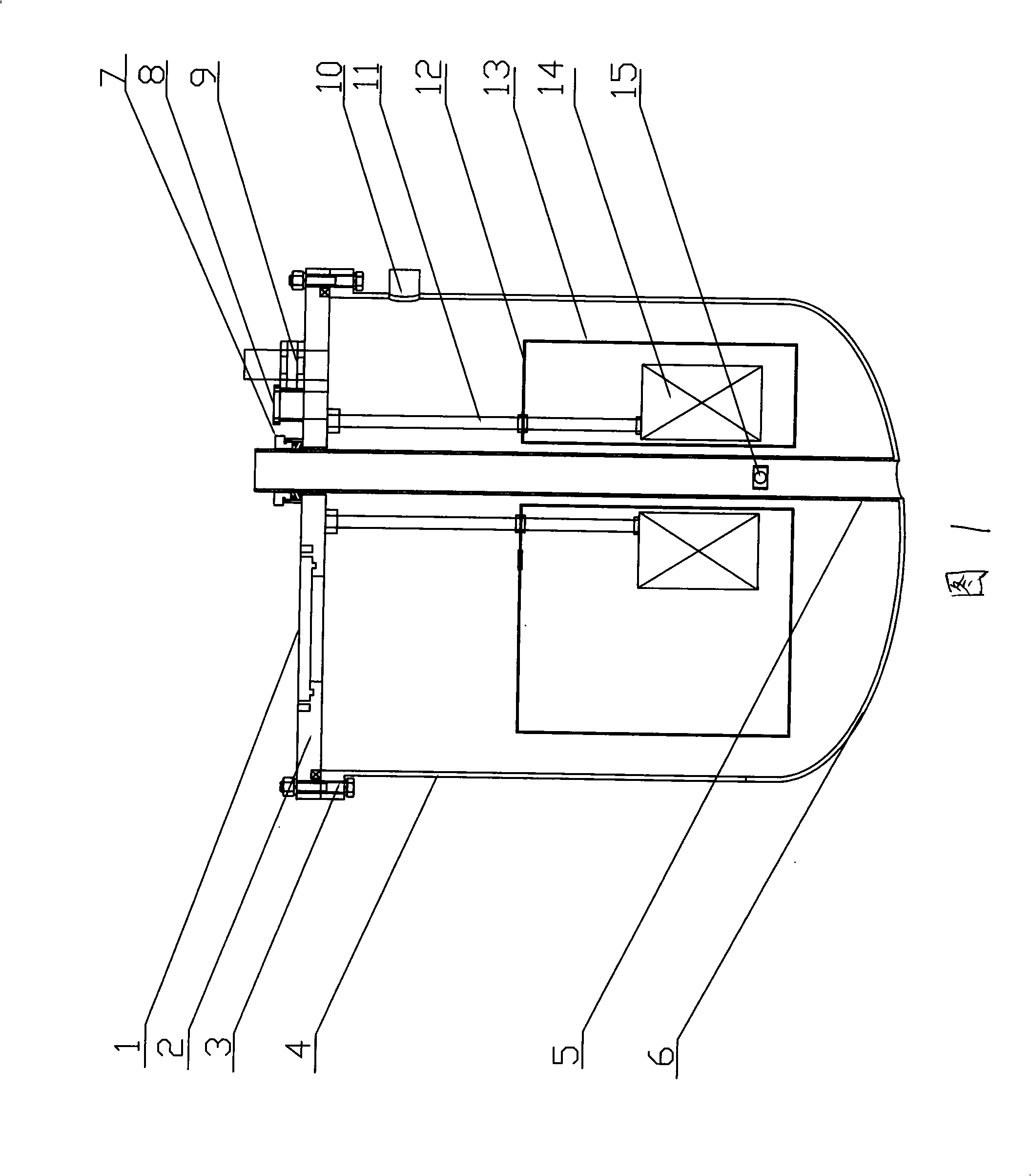

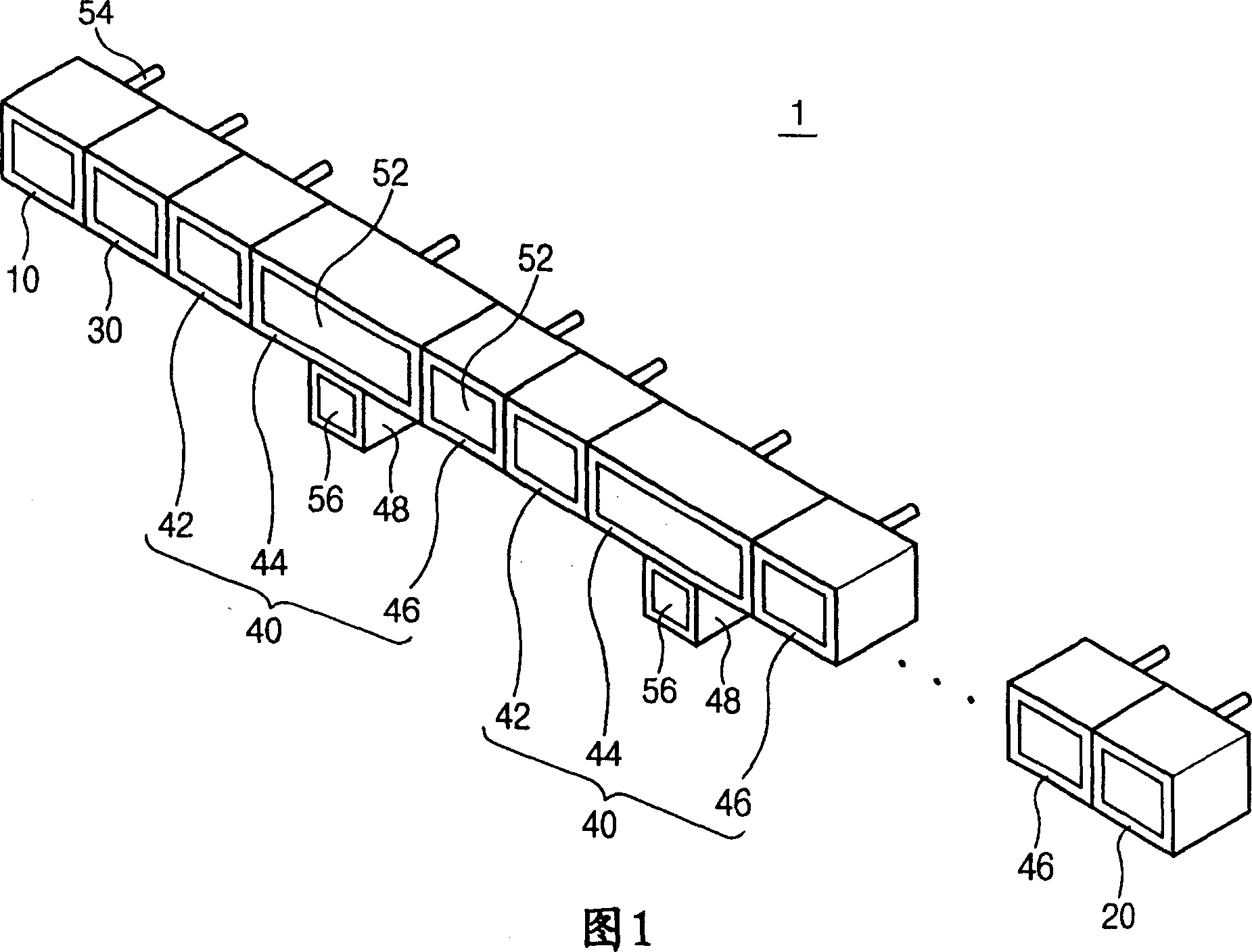

Thin film deposition apparatus and method of manufacturing organic light-emitting display apparatus using the same

ActiveUS20110052791A1Easy to manufactureEasy to useSolid-state devicesVacuum evaporation coatingMass scaleEngineering

A thin film deposition apparatus used to manufacture large substrates on a mass scale and that allows high-definition patterning, and a method of manufacturing an organic light-emitting display apparatus using the same, the apparatus includes a loading unit fixing a substrate onto an electrostatic chuck; a deposition unit including a chamber maintained in a vacuum state and a thin film deposition assembly disposed in the chamber, separated from the substrate by a predetermined distance, to deposit a thin film on the substrate fixed on the electrostatic chuck; an unloading unit separating the substrate on which a deposition process is completed, from the electrostatic chuck; a first circulation unit sequentially moving the electrostatic chuck on which the substrate is fixed, to the loading unit, the deposition unit, and the unloading unit; and a second circulation unit returning the electrostatic chuck separated from the substrate to the loading unit from the unloading unit, wherein the first circulation unit passes through the chamber when passing through the deposition unit.

Owner:SAMSUNG DISPLAY CO LTD

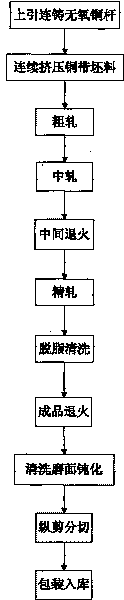

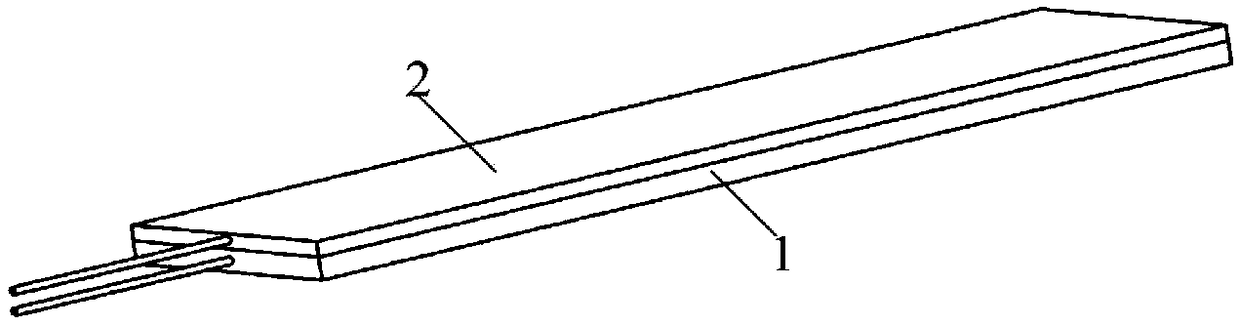

Production technique of copper strips for solar modules

InactiveCN101719527AHigh purityImprove conductivityFinal product manufactureSemiconductor devicesElectrolysisLiquid surfaces

The invention discloses a production technique of copper strips for solar modules, which belongs to the technical field of nonferrous metal processing and comprises the following steps: drawing-up of continuous-casting oxygen-free copper bar: using high-quality electrolytic copper as the raw material, melting at 1150+ / -10 DEG C, keeping the temperature, covering the copper liquid surface with charcoal and graphite scales to ensure the vacuum state during melting, degassing on line, deoxidizing, stirring, and drawing up the copper bar with a tractor set in an on-off vacuum way; continuous extrusion of copper strip blanks: using oxygen-free copper rods as the raw material, producing copper strip blanks by using a continuous extruder set, cooling the extruded copper strip blanks through a vacuum oxidation-resisting pipe and a water tank, drying and coiling; and rough-rolling the copper strip blanks, medium-rolling, interstage annealing, finish rolling, degreasing, washing, annealing the finished product, washing, grinding the surface to passivate, and longitudinally cutting to obtain the finished product. The product of the invention has the advantages of high purity, low oxygen content and high electrical conductivity.

Owner:浙江力博实业股份有限公司

Organic electroluminescent device and method for manufacturing same

InactiveUS20070013292A1Prevent intrusionDensely formedDischarge tube luminescnet screensElectroluminescent light sourcesOrganic electroluminescenceSealant

A plurality of organic EL devices are formed first on a substrate. Next, a film of a sealing agent is formed over the outer periphery of a lower surface (color filter side) of a sealing plate. Then, a sealing agent is dropped onto a central portion of the sealing plate. After that, the sealing plate and the substrate are laminated at a predetermined pressure in a vacuum chamber in a vacuum, and then the vacuum chamber is released from its vacuum state. The substrate and the sealing plate are removed from the vacuum chamber, and the sealing agents between the substrate and the sealing plate are cured by the curing methods suitable for the respective materials.

Owner:SANYO ELECTRIC CO LTD

Process and apparatus for producing magnetic recording medium

InactiveUS20060159844A1Reduce defectsImprove applicabilityVacuum evaporation coatingSputtering coatingPolymer substrateEngineering

A process for producing a magnetic recording medium comprising: unrolling a flexible polymer substrate from a feed roll; forming a magnetic layer on at least one side of the flexible polymer substrate by a vacuum film forming method in a film forming chamber; and taking up the flexible polymer substrate on a take-up roll, wherein at least one of the feed roll and the take-up roll is replaced while maintaining a vacuum state for forming the magnetic layer in the film forming chamber.

Owner:FUJIFILM CORP +1

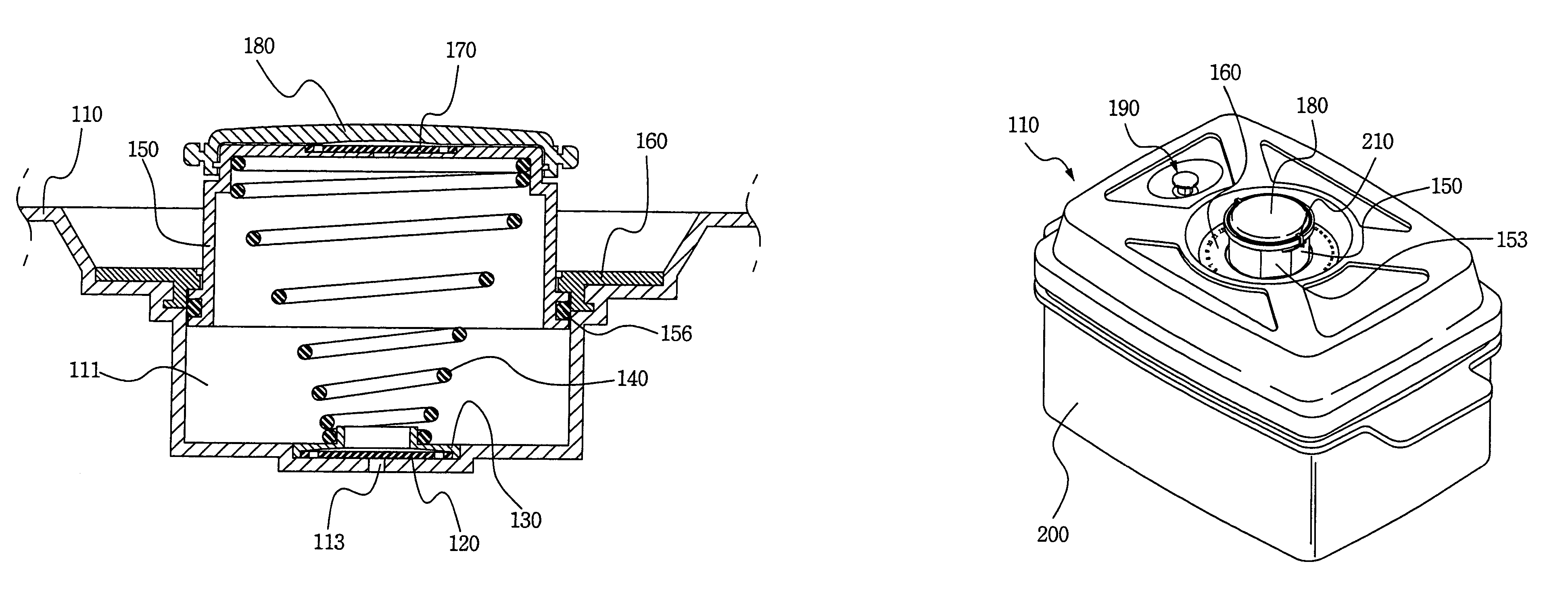

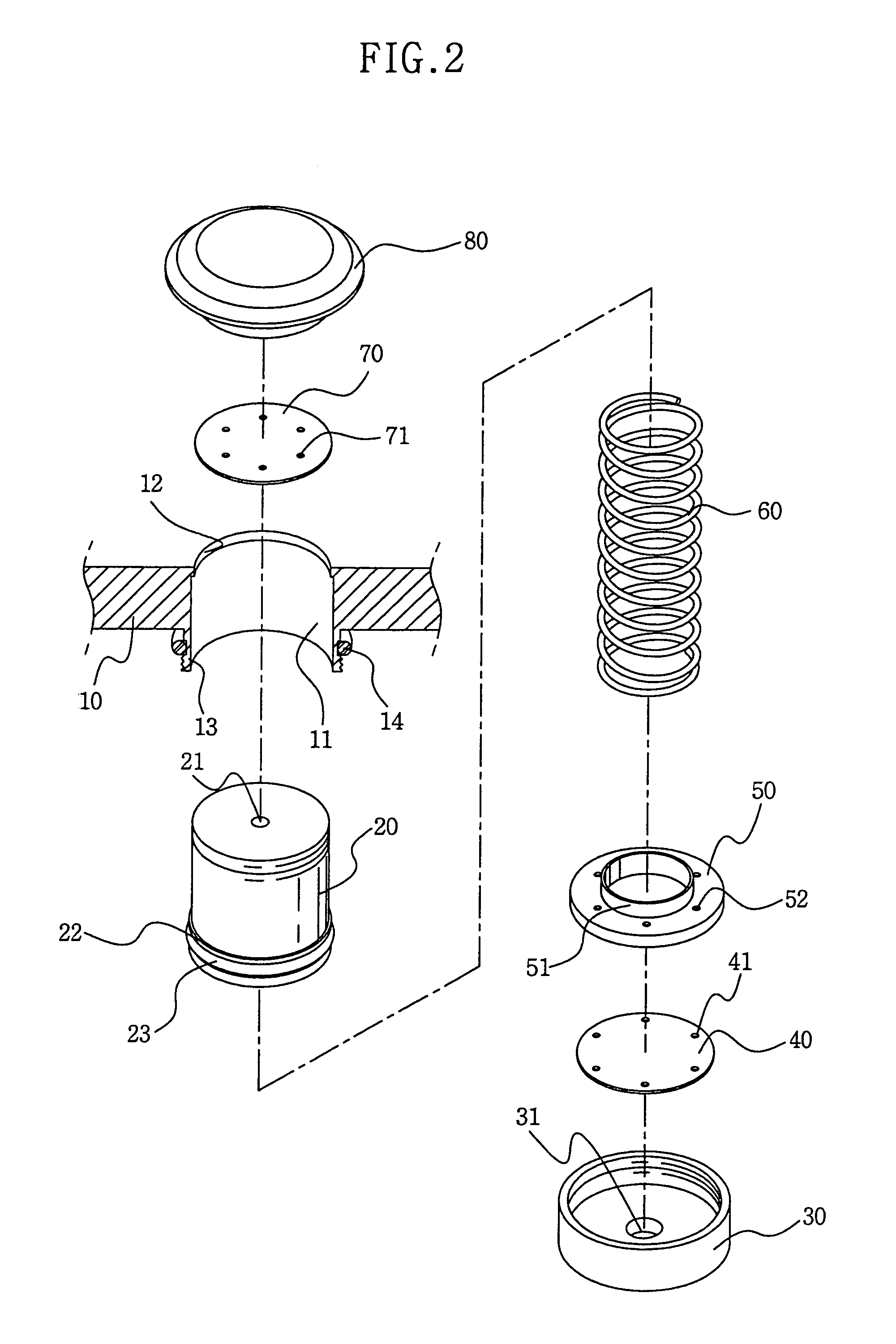

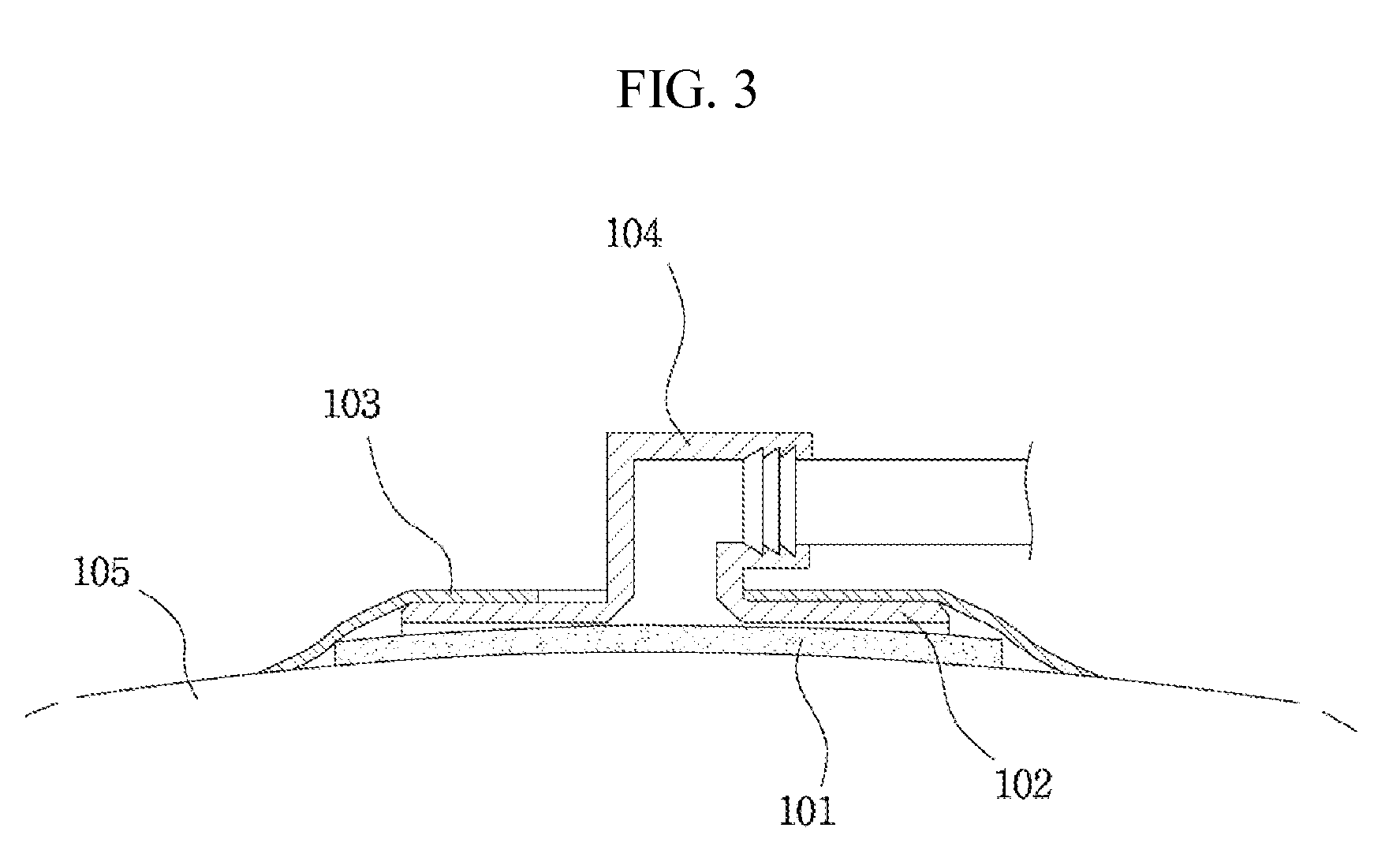

Low vacuum and vacuum release device for electric rice cooker

The present invention relates to a low vacuum and vacuum release device for an electric rice cooker, the device being capable of releasing a vacuum and maintaining a vacuum state by the rotation of an operation lever. The electric rice cooker has: the operation lever provided at the upper part of a lid; and the low vacuum and vacuum release device provided inside the lid, elastically connected to the operation lever such that when the operation lever is rotated, the device rises so as to open an air inlet, thereby releasing the vacuum while external air flows therein, and when the operation lever is released, the device lowers by the elastic force of a spring so as to maintain the vacuum state by blocking the air inlet, wherein the low vacuum and vacuum release device comprises: a housing provided in the inside of the lid; a first pressure opening / closing operation part provided inside the housing and rising or lowering according to the vapor pressure during cooking, thereby opening or closing the first vapor outlet of a first lower sealing member; a second vacuum release operation part provided inside the housing and rising or lowering according to the rotation of the operation lever, thereby opening or closing the air inlet of a second lower sealing member; and a raising / lowering operation connection part provided at the upper part of the housing and raising or lowering the second vacuum release operation part while being mounted with the operation lever.

Owner:SAMMY CORPORATION

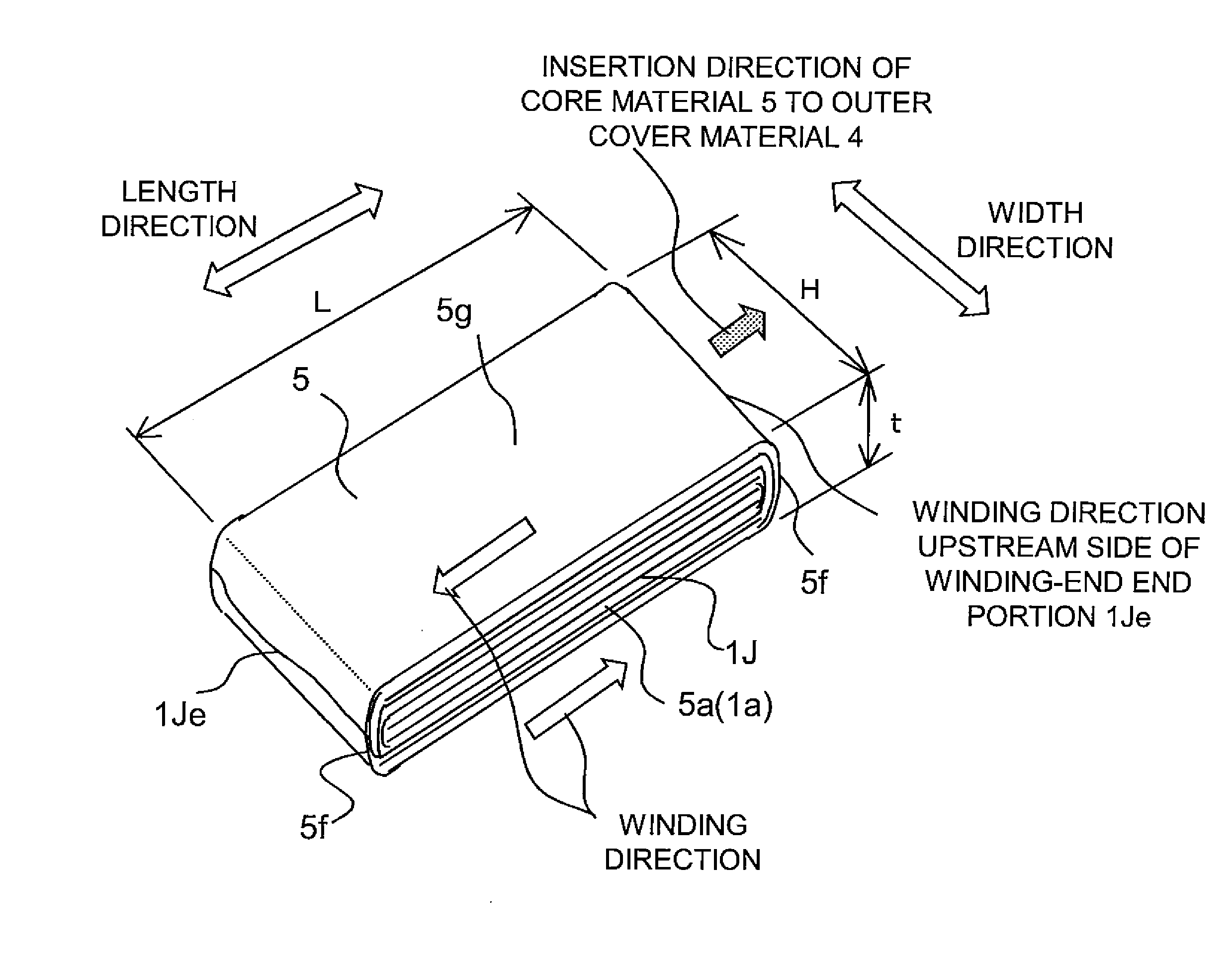

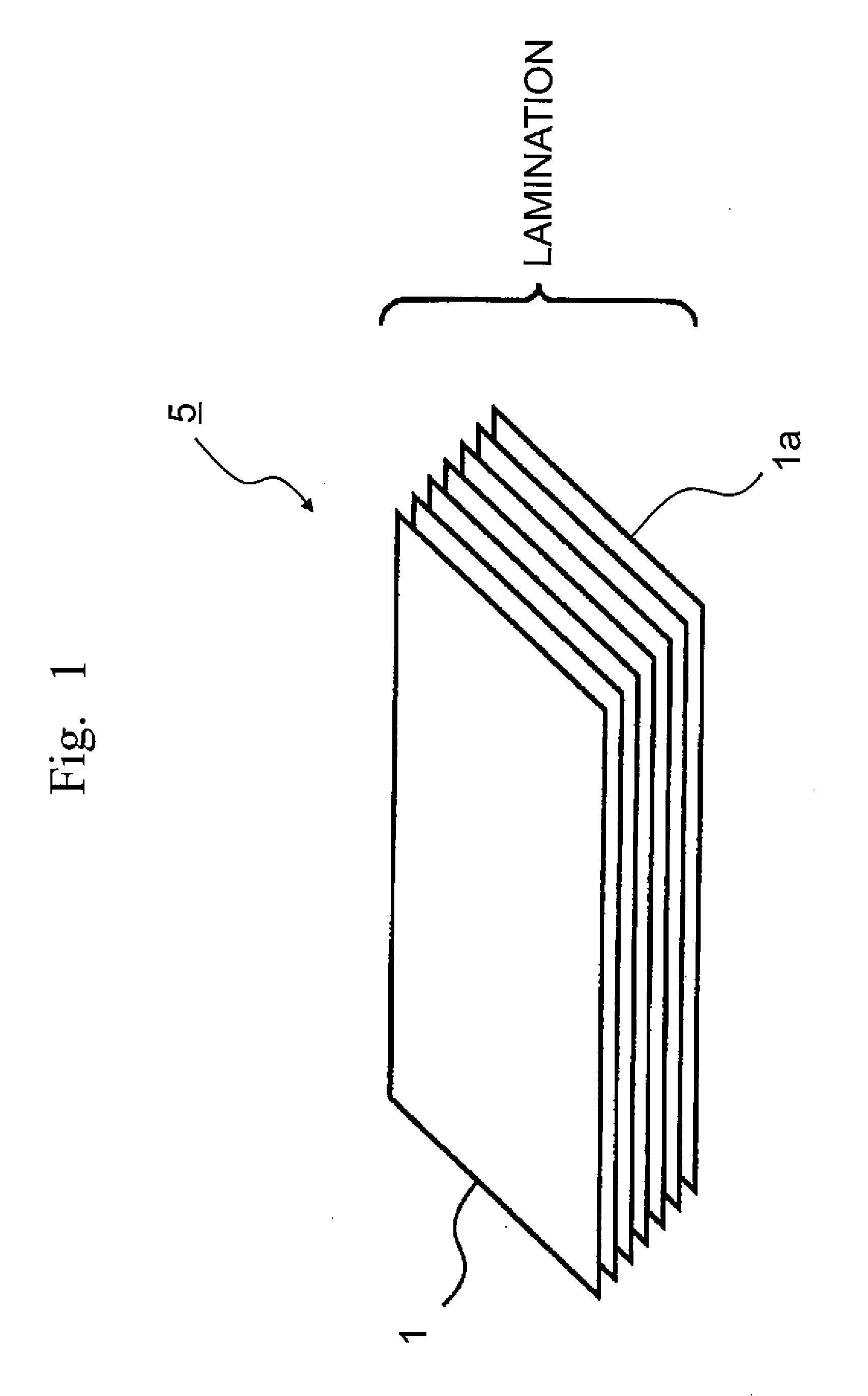

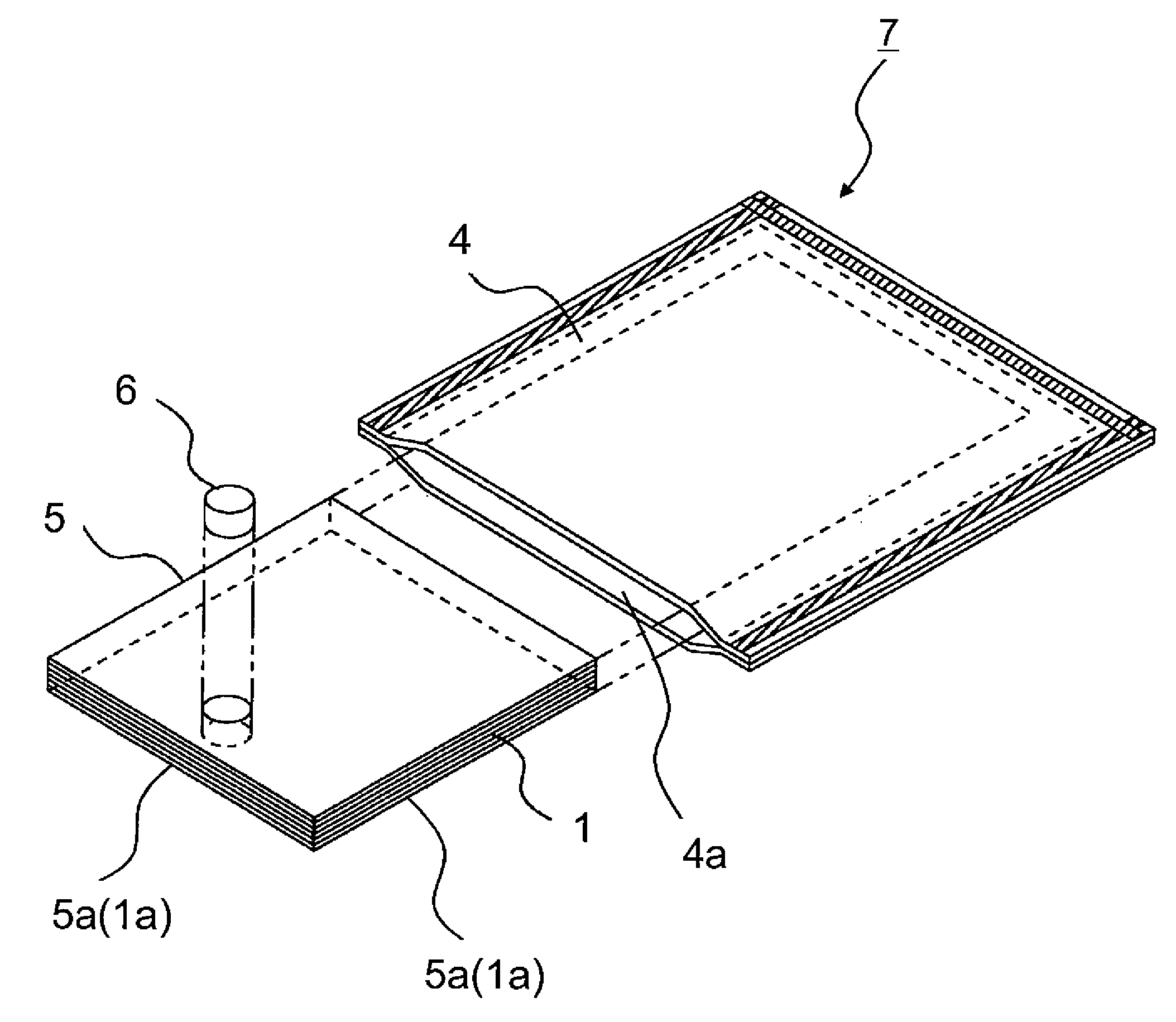

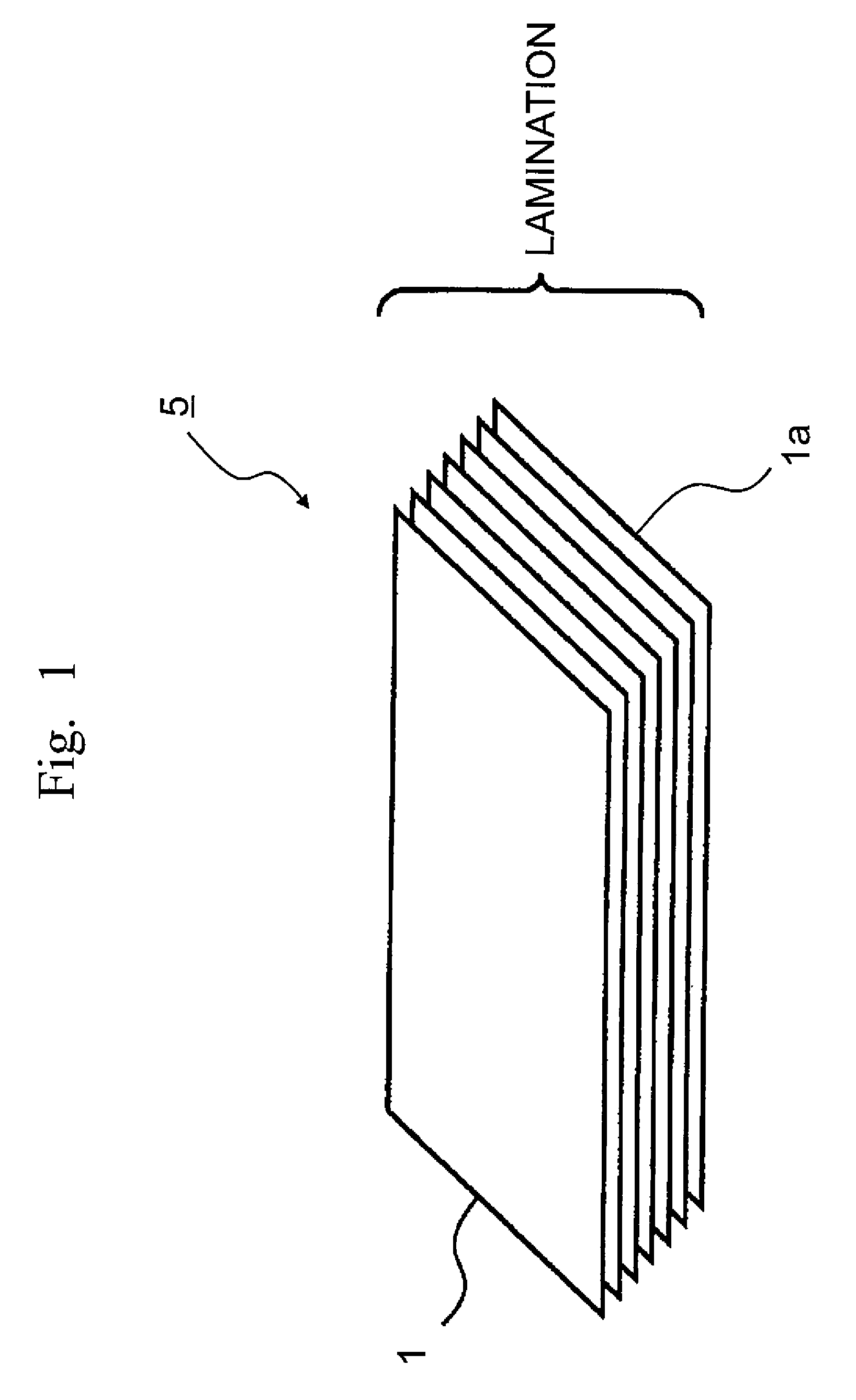

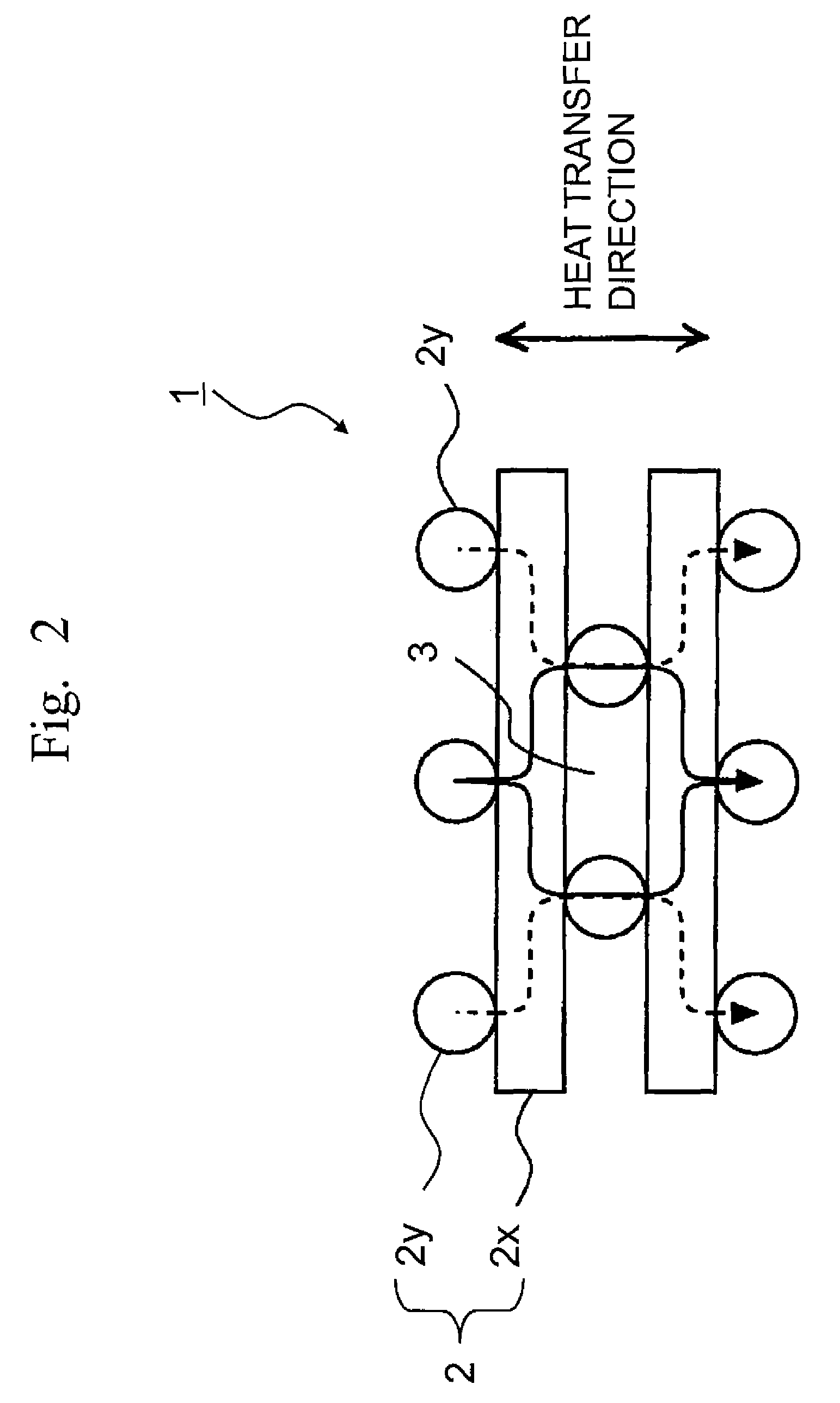

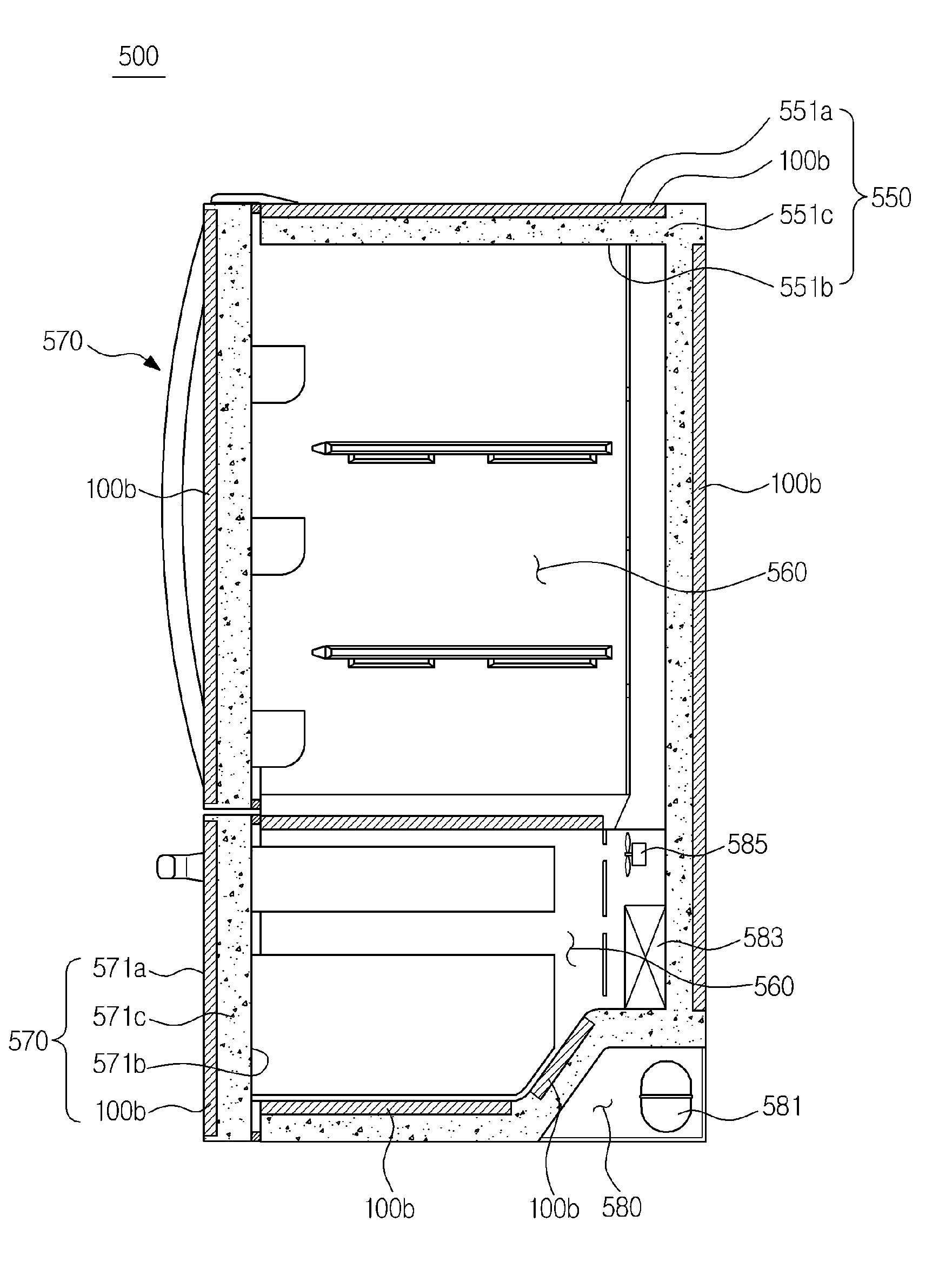

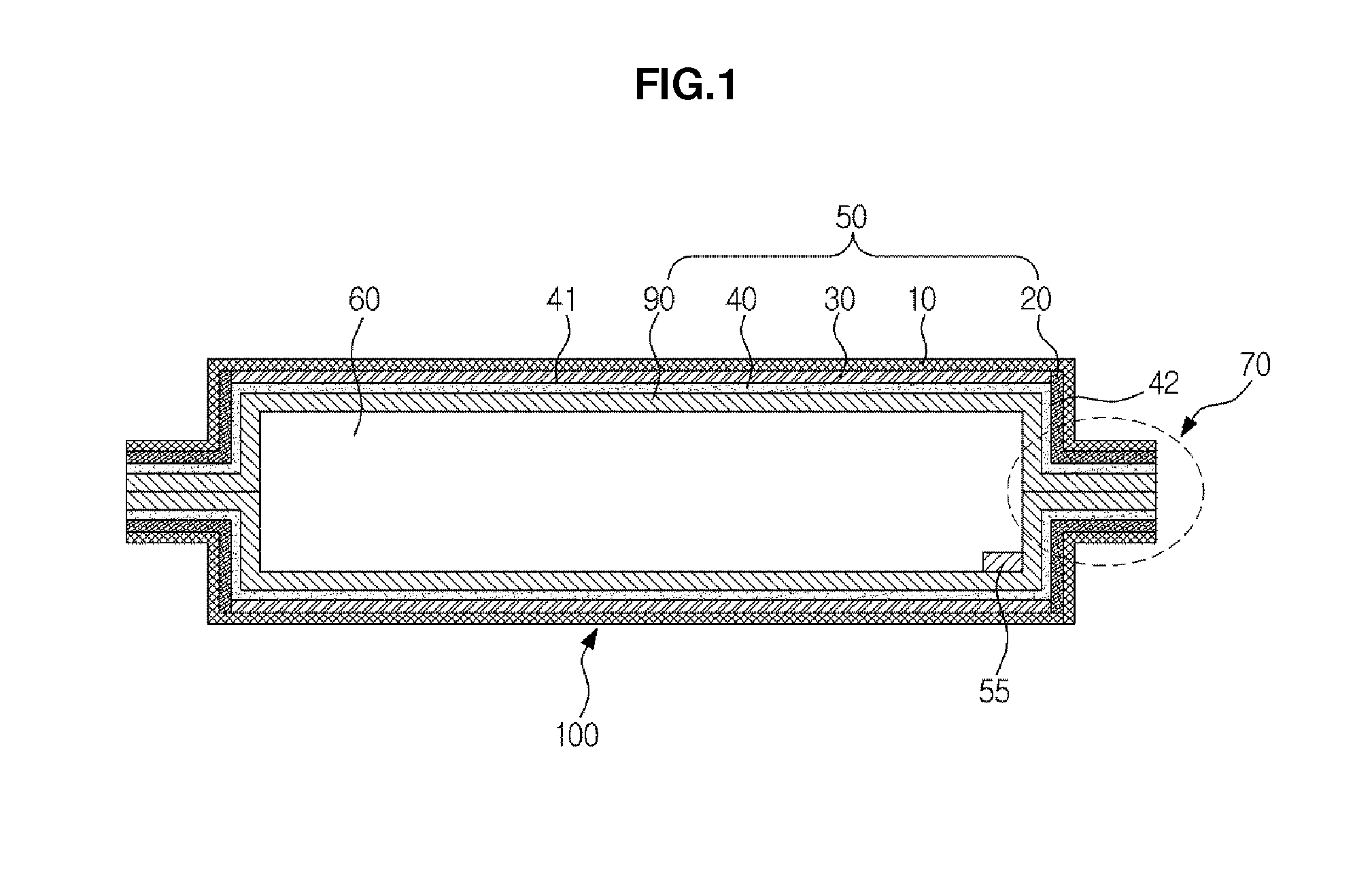

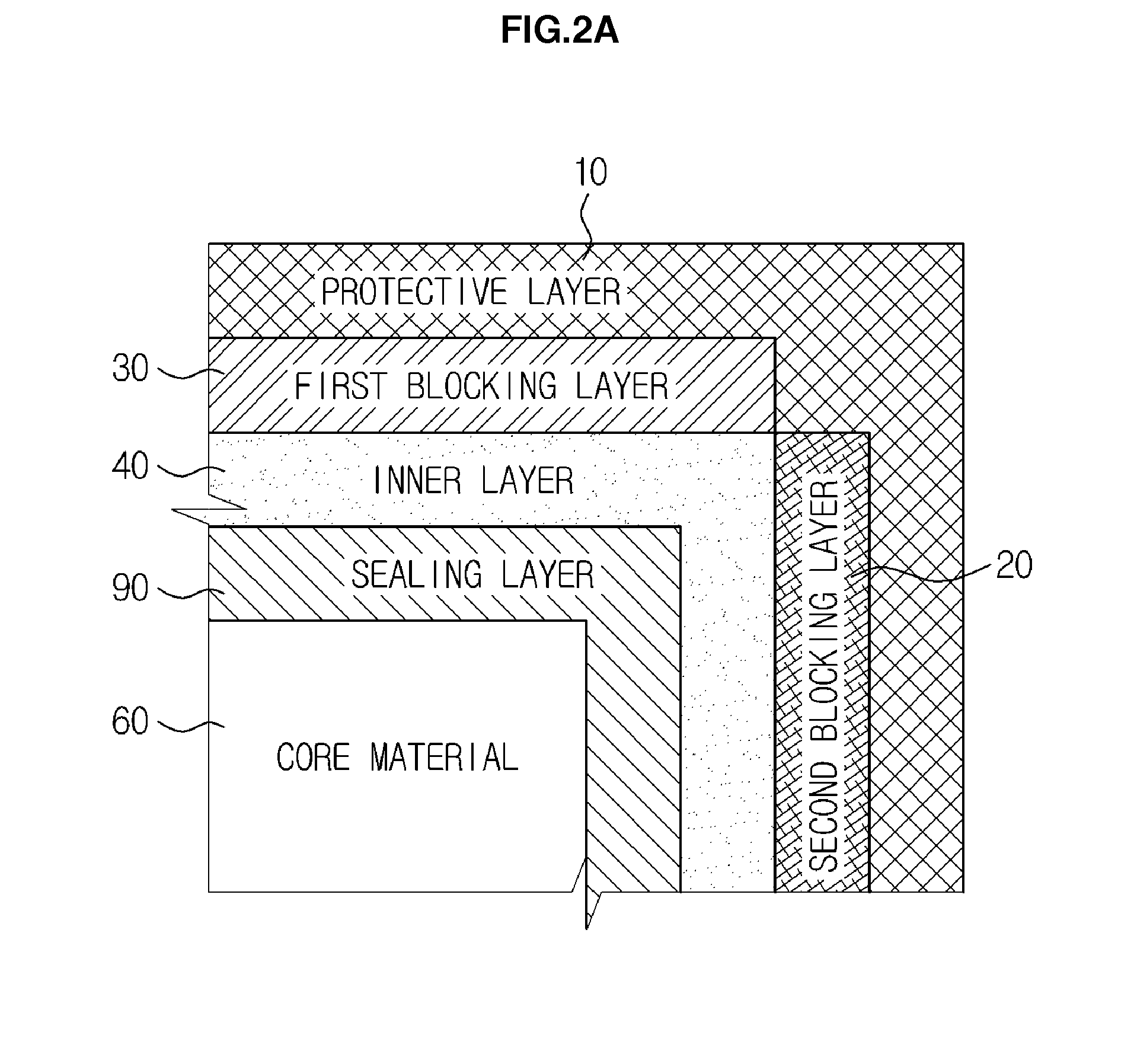

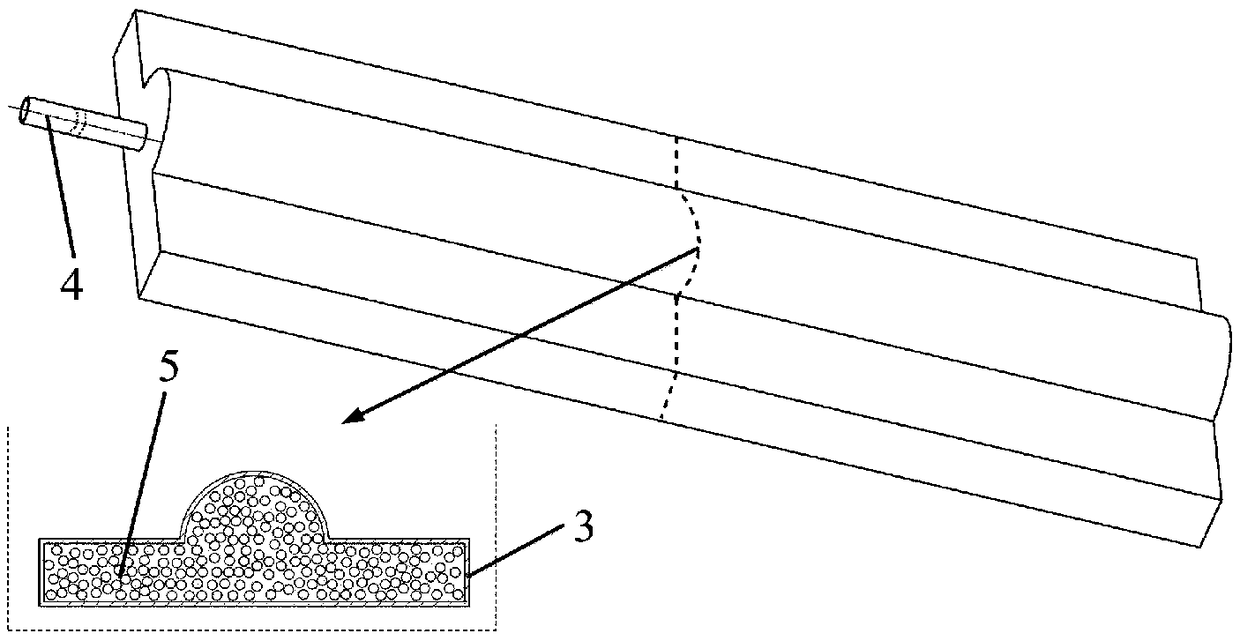

Vacuum heat insulating material, heat insulating box, refrigerator, refrigerating/air-conditioning apparatus, water heater, appliance, and manufacturing method of vacuum heat insulating material

InactiveUS20120196059A1Protrusion suppressionEasy to processEnvelopes/bags making machineryThermal insulationFiberAir conditioning

A highly reliable vacuum heat insulating material having excellent processability, handleability and heat insulating performance, and a heat insulating box using the vacuum heat insulating material are provided. In the vacuum heat insulating material with the inside in an approximately vacuum state by sealing a core material 5 having a structure wherein plural pieces of fiber assembly 1 are laminated by a gas-barrier outer cover material 4, by using long fiber for the core material, fiber dust or remaining fiber by cutting is prevented from protruding into a sealing portion of the outer cover material from a cut surface of a sheet or an opening portion, and sealing failure is reduced. Further, since the core material is structured so as to be wound continuously from an inner side toward an outer side, the vacuum heat insulating material is easily manufactured, and excellent in handleability.

Owner:MITSUBISHI ELECTRIC CORP

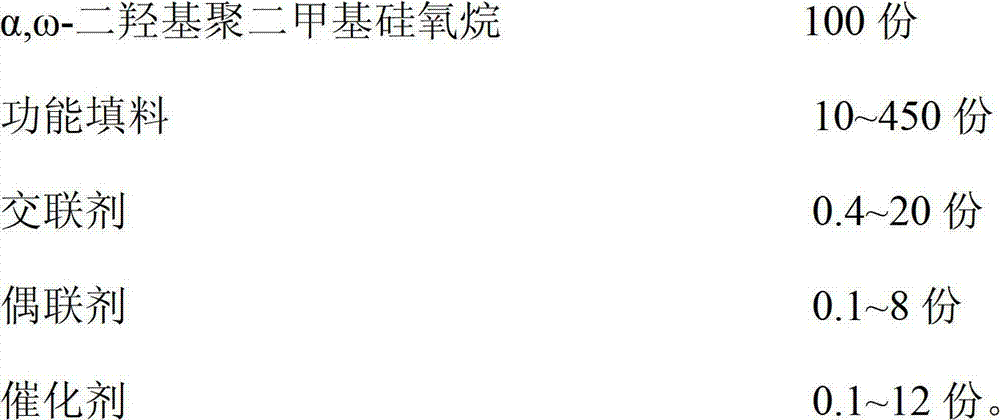

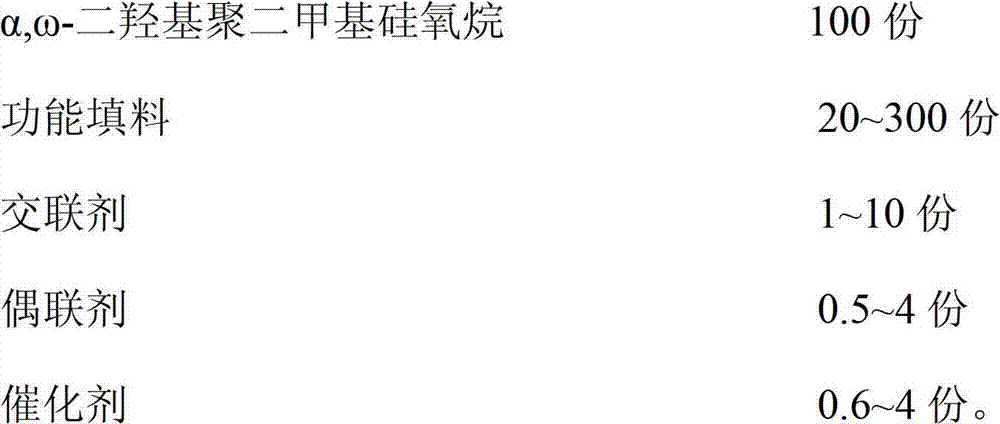

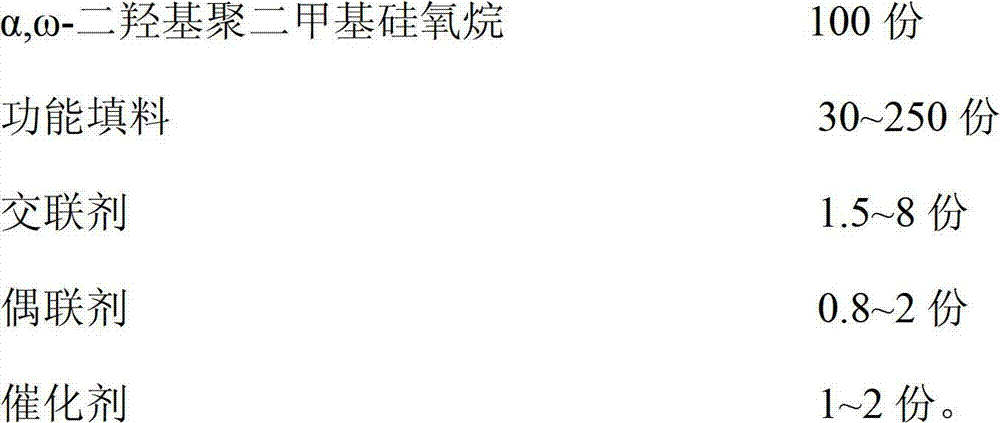

Single-component catalytic dealcoholized room temperature vulcanized (RTV) silicone rubber and preparation method thereof

InactiveCN102757647ANo viscosity peaksSimple processNon-macromolecular adhesive additivesOther chemical processesPolymer scienceRoom temperature

The invention relates to a single-component catalytic dealcoholized room temperature vulcanized (RTV) silicone rubber which comprises the following components in parts by weight: 100 parts of alpha, omega-dihydroxyl polydimethylsiloxane, 10-450 parts of function filler, 0.4-20 parts of crosslinking agent, 0.1-8 parts of coupling agent and 0.1-12 parts of catalyst. The invention also relates to a preparation method of the single-component catalytic dealcoholized RTV silicone rubber, and the method comprises the following steps of: preparing a ground mass, namely dewatering and blending the alpha, omega-dihydroxyl polydimethylsiloxane and the function filler to obtain the ground mass; stirring the taken ground mass in a vacuum state, adding the crosslinking agent, and stirring the materials in a vacuum state; adding the coupling agent, and stirring the materials; and adding the catalyst, vacuumizing, introducing inert gas, stirring, vacuumizing, and stirring to obtain the single-component catalytic dealcoholized RTV silicone rubber. The method provided by the invention has the advantages of no generation of viscosity peak, simple process and cost saving; and the single-component catalytic dealcoholized RTV silicone rubber has excellent comprehensive properties.

Owner:兆舜科技(广东)有限公司

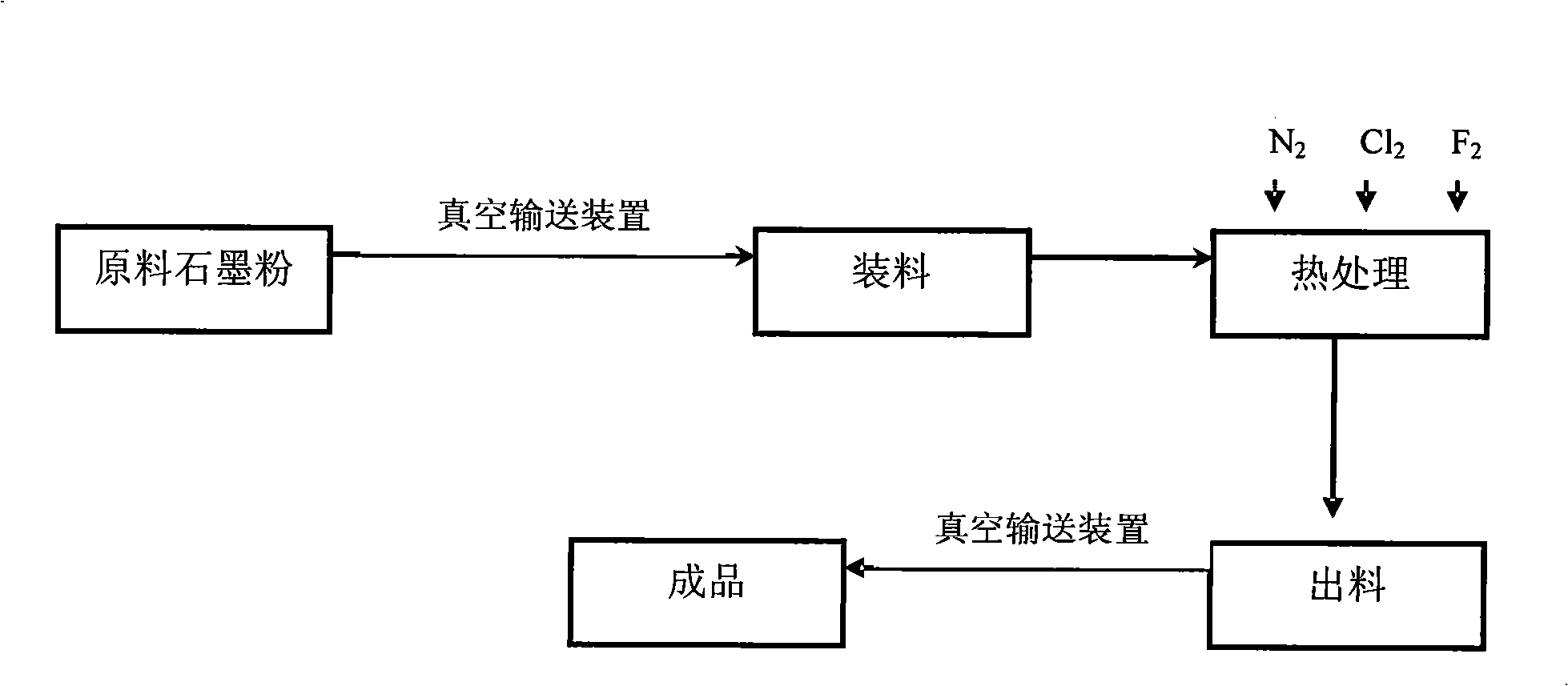

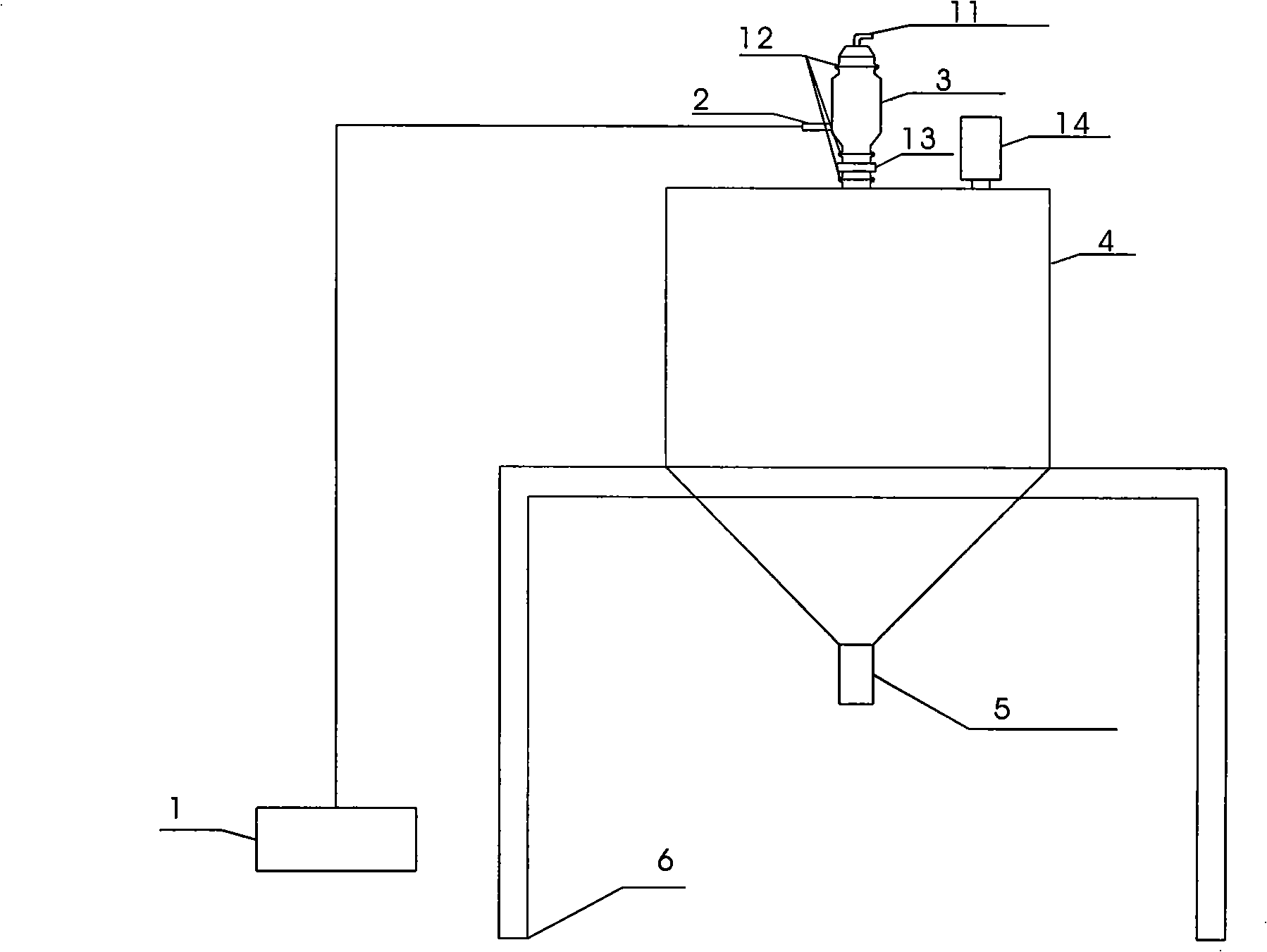

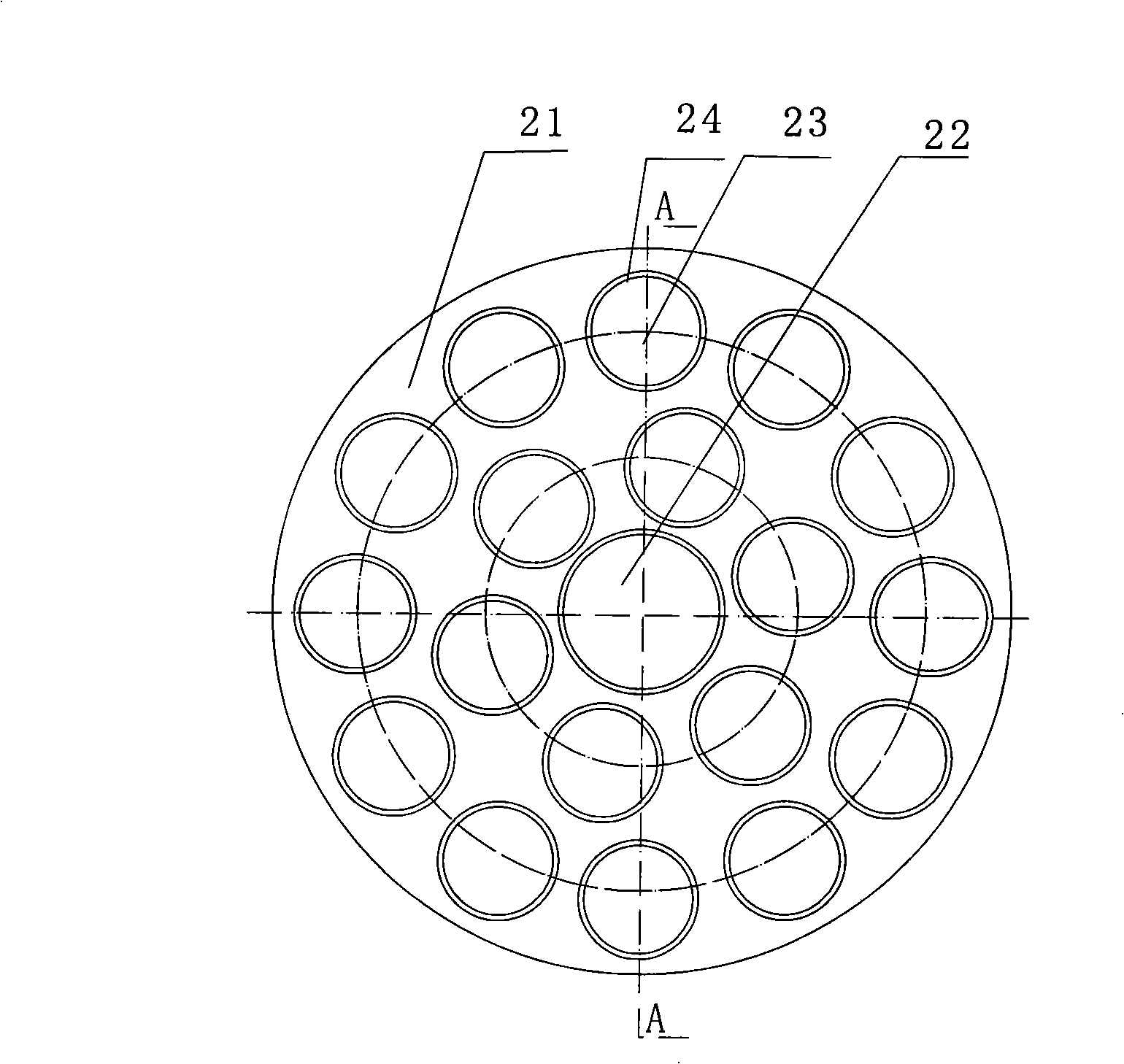

Process and equipment for producing graphite dust

ActiveCN101318648AReduce entryImprove graphitization heat treatment efficiencyCell electrodesChemical industryState of artVacuum delivery

The invention discloses a method for preparing graphite powder and the equipment thereof and aims at solving the technical problems of improving the purity of graphite powder and reducing cost. The method of the invention comprises the following steps: the raw micro powder is delivered to a graphite crucible under vacuum state and put into a graphitizing furnace; and a graphite powder product is obtained after heat treatment and cooling. The preparation equipment of graphite powder is composed of a vacuum delivery device, a graphitizing furnace and a vacuum discharging device sequentially connected; the graphitizing furnace is equipped with a graphite crucible and connected with a gas filling system. Compared with the prior art, the method and the equipment of the invention are characterized in that the raw micro power is put into the graphite crucible after vacuum delivery, thus the entry of impurities is reduced in the treatment process, the product purity is greatly improved after heat treatment, graphitization is even, the consistency of the product is good, the graphitization and heat treatment efficiency of the powder material is improved, the technique is simple and the cost is low.

Owner:BTR NEW MATERIAL GRP CO LTD

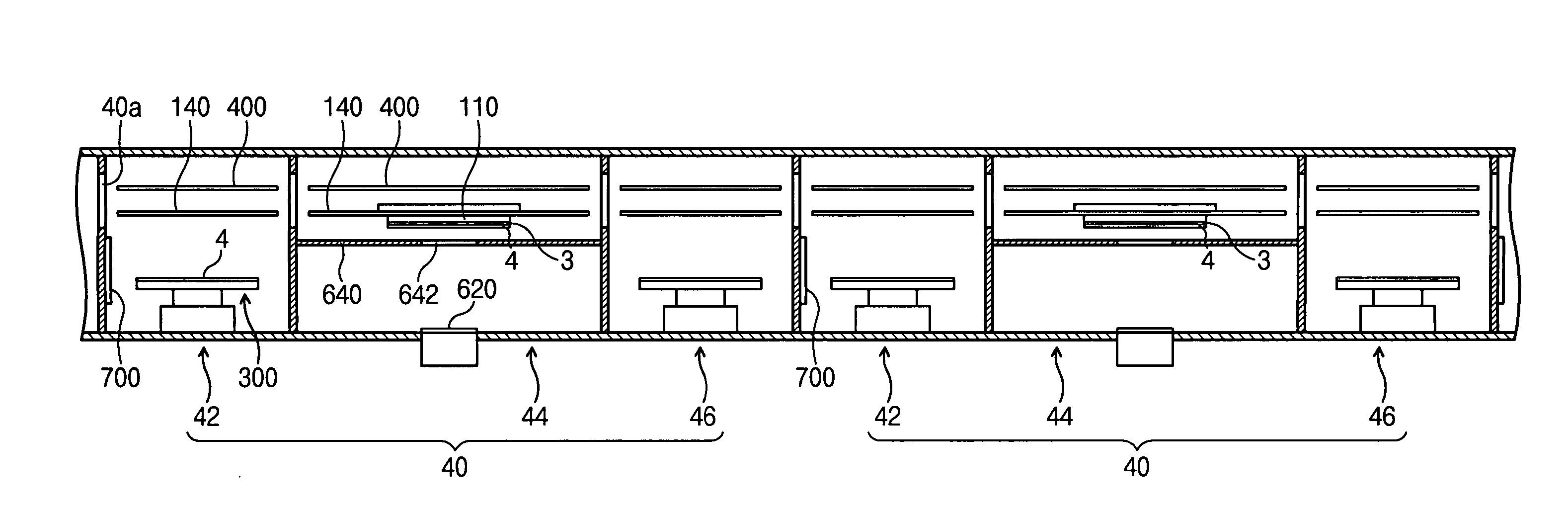

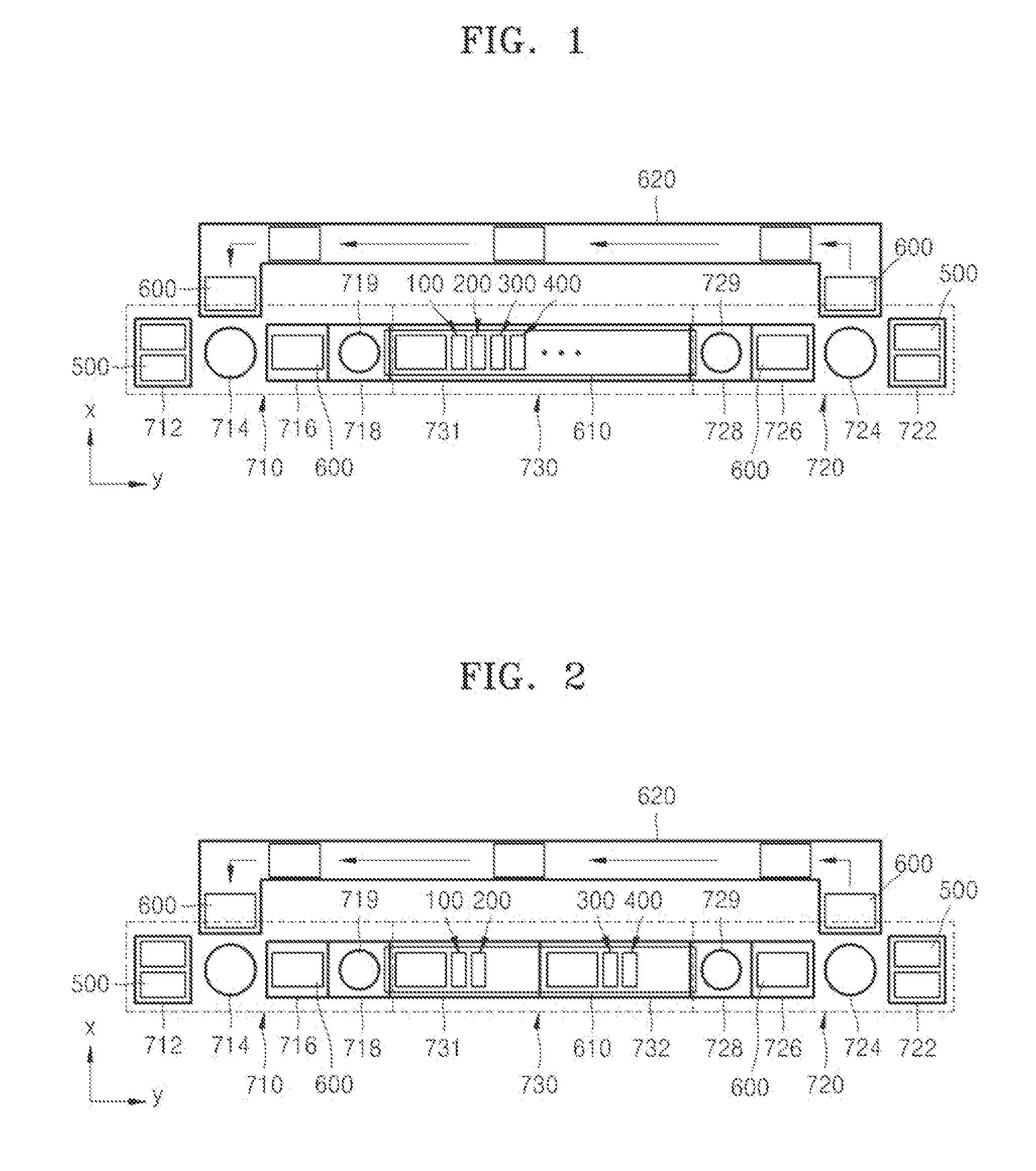

Thin film deposition apparatus and method of manufacturing organic light-emitting display device by using the same

A thin film deposition apparatus and an organic light-emitting display device by using the same. The thin film deposition apparatus includes an electrostatic chuck, an a plurality of chambers; at least one thin film deposition assembly; a carrier; a first power source plug; and a second power source plug. The electrostatic chuck includes a body having a supporting surface that contacts a substrate to support the substrate, wherein the substrate is a deposition target; an electrode embedded into the body and applying an electrostatic force to the supporting surface; and a plurality of power source holes formed to expose the electrode and formed at different locations on the body. The plurality of chambers are maintained in a vacuum state. The at least one thin film deposition assembly is located in at least one of the plurality of chambers, is separated from the substrate by a predetermined distance, and is used to form a thin film on the substrate supported by the electrostatic chuck. The carrier is used to move the electrostatic chuck to pass through the plurality of chambers. The first power source plug is installed to be attachable to and detachable from one of the power source holes in order to supply power to the electrode. The first power source plug is installed at an upstream of a path in which the electrostatic chuck is moved by the carrier. The second power source plug is installed to be attachable to and detachable from another of the power source holes in order to supply power to the electrode. The second power source plug is installed in the path to be downstream to the first power source plug with respect to the path.

Owner:SAMSUNG DISPLAY CO LTD

Vacuum container to preserve food

ActiveUS6994227B2Reduce forcePreserving food sanitarily and stablyCapsCheck valvesPreserved FoodsEngineering

A vacuum container for preserving food is disclosed herein that includes a cover member for covering an upper part of a container member in which food is filled, a piston member equipped with the cover member and ascending and descending movable, and first and second valve members that alternately operate by a pumping operation using ascending and descending operation of the piston member to make a suction aperture and an exhaust aperture alternately open and close, thus discharging air from within the container member. Such operation allows the interior of the container member to become a vacuum state, thereby allowing food within the container member to be preserved for a longer time period, in a more sanitary manner, and a simple manufacture and a low manufacturing cost to provide users with convenience.

Owner:DAEIL ADVANCED MATERIALS CO LTD

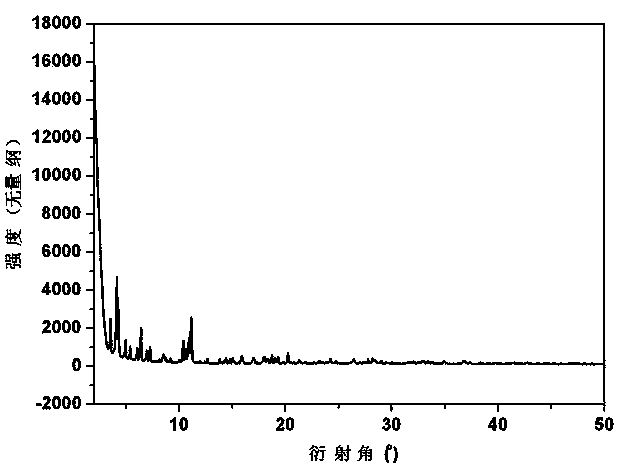

Preparation method of magnetic porous carbon/ ferric oxide nano composite material for oil-water separation

InactiveCN103908947ALarge specific surface areaMacroporous natureOther chemical processesAlkali metal oxides/hydroxidesPorous carbonMetal-organic framework

The invention discloses a preparation method of a magnetic porous carbon / ferric oxide nano composite material for oil-water separation, wherein the magnetic porous carbon / ferric oxide nano composite adsorption material for oil-water separation is porous carbon / Fe3O4 magnetic powder or porous carbon / gamma-Fe2O3 magnetic powder. The preparation method comprises the following steps: firstly, preparing a Fe-MIL-101 or Fe-MIL-100 metal-organic framework material of a porous structure by utilizing a hydrothermal method; then controlling the temperature to be 500-700 DEG C at the N2 / H2 atmosphere or the vacuum state, and forging for 2-8 hours, thereby obtaining the magnetic porous carbon / ferric oxide nano composite adsorption material for oil-water separation. The adsorption material can adsorb oil substances in water well; moreover, adsorption materials dispersed into a solution as well as the adsorbed oil materials can be recycled only by magnets; the preparation method is simple to operate, is low in production cost, is good safety performance, and is high in practicability.

Owner:SHANGHAI INST OF TECH

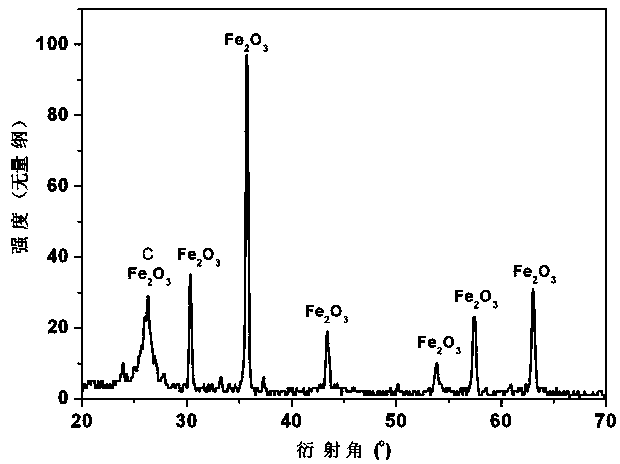

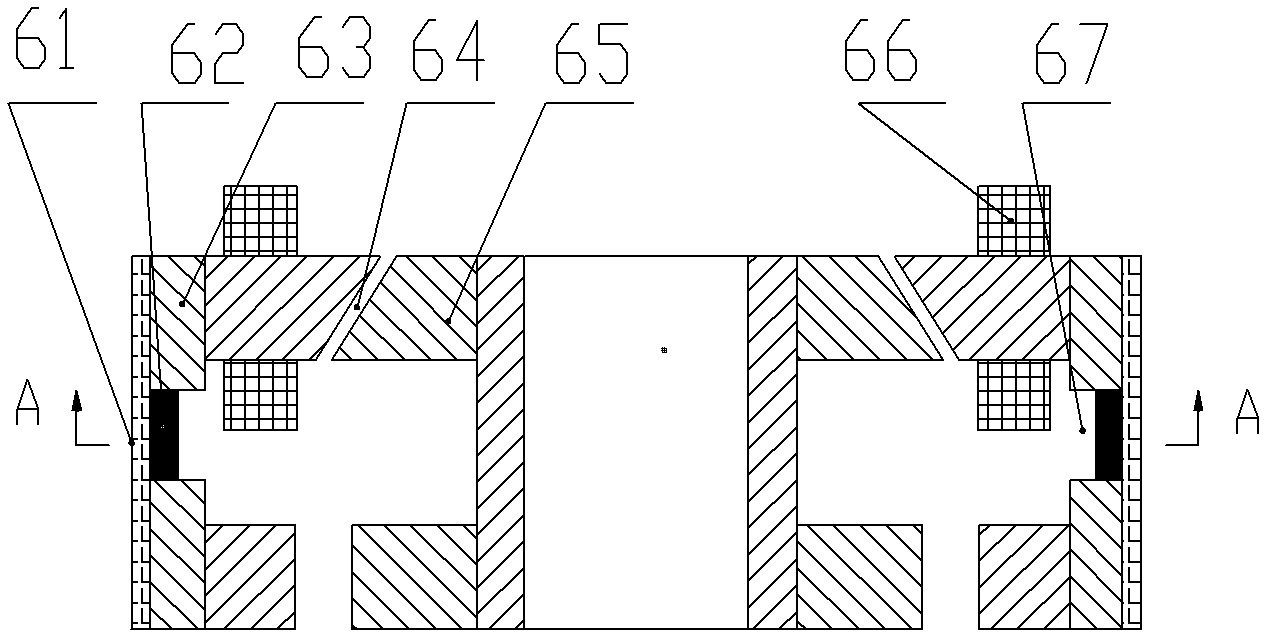

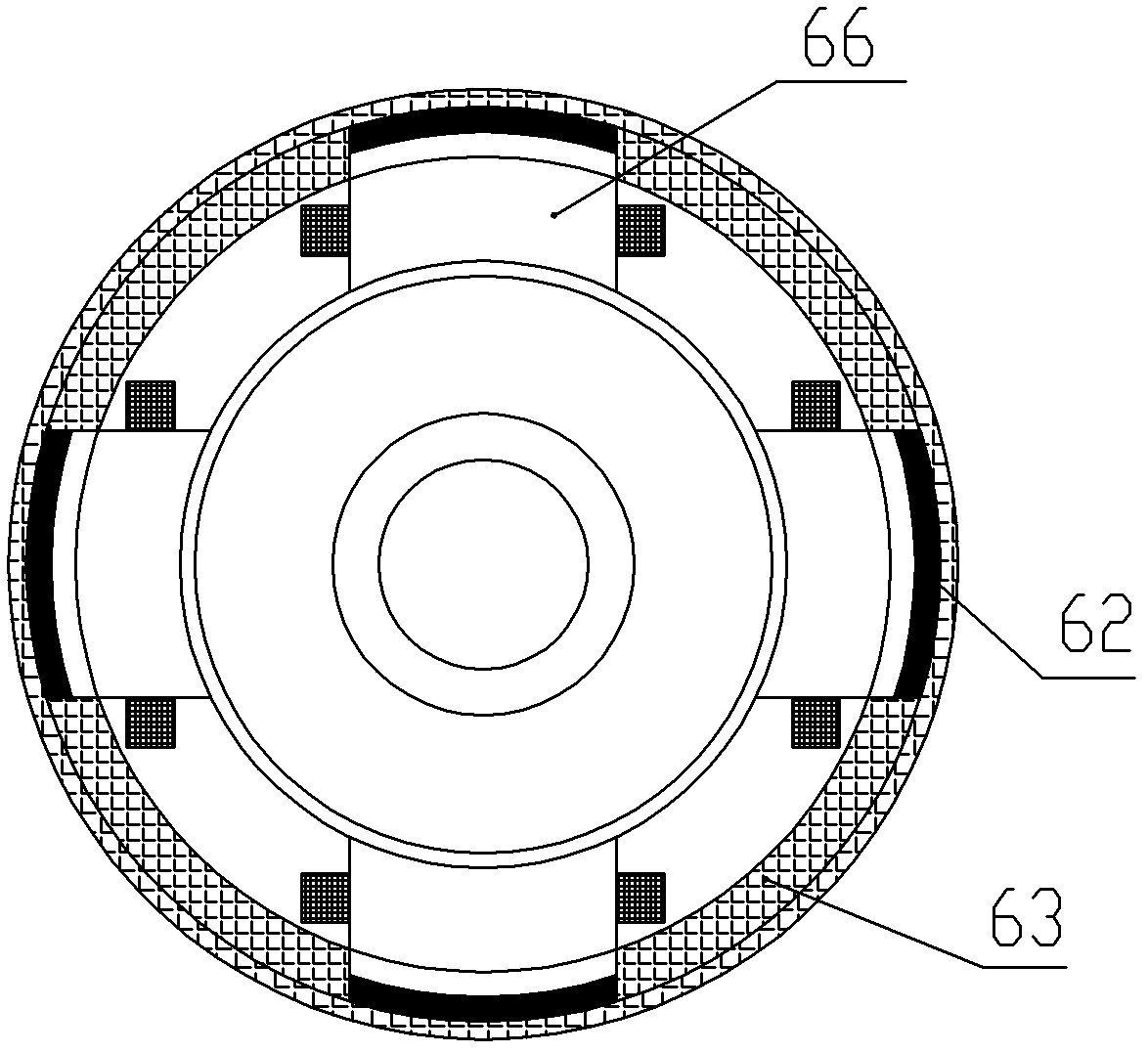

Energy storage device of magnetic suspension flywheel

InactiveCN102437675AReduce the burden onImprove reliabilityMechanical energy handlingMagnetic holding devicesMagnetic bearingEngineering

The invention discloses an energy storage device of magnetic suspension flywheel, comprising an energy storing and converting part, a magnetic suspension supporting part and an auxiliary part, wherein the energy storing and converting part includes a flywheel, a rotor of the motor / generator and a stator part; the magnetic suspension supporting part comprises a radial magnetic bearing, an axial magnetic bearing, an axial sensor, a radial sensor and a protection bearing; the auxiliary part includes a shell and a mounting shaft; the radial magnetic bearing is a radial mixed conical magnetic bearing; the suction disk of each axial magnetic bearing is respectively installed on two side wheel surfaces of the flywheel; the radial mixed conical magnetic bearing and the axial magnetic bearing are non-mechanically contacted magnetic suspension bearings; the mounting shafts of the energy storing and converting part, the magnetic suspension supporting part and the auxiliary part are sealed in the shell of the auxiliary part; the inside of the shell is in vacuum state. The invention has the characteristics of compact structure, high specific energy density and discharge depth, long service life, low power consumption and stable performance without pollution.

Owner:SHANDONG UNIV OF SCI & TECH

Conduction cooling superconducting magnet dewar convenient for loading and unloading

The invention relates to a conduction-cooled superconducting magnet Dewar with easy loading-unloading, comprising a Dewar cylinder. The conduction-cooled superconducting magnet Dewar is characterized in that the Dewar cylinder is a hollow annular cylinder, the middle of the annular cylinder is provided with a room temperature hole, an annular copper cold shield is arranged in the Dewar cylinder, a refrigerator and a superconducting magnet are arranged in the copper cold shield, a vacuum pumping port is arranged on the Dewar cylinder, a measuring device is arranged on an upper cover of the Dewar cylinder and the Dewar cylinder is in a vacuum state. Compared with the prior Dewar container, the conduction-cooled superconducting magnet Dewar is simpler, has small conduction heat leakage, and has the advantages of easy installation and disassembly; the refrigerator is used for conducting and cooling without a low temperature liquid (such as liquid helium and so on) cooling system; because of simple and safe system, a first-level cold junction of the refrigerator is operated under a temperature of 77K, thereby realizing heat sink of the copper cold shield, an electric lead and a support device; the first-level cold junction of the refrigerator adopts soft connection, thereby reducing temperature increment of the magnet due to vibration of the refrigerator; and the conduction-cooled superconducting magnet Dewar has the advantages of easy operation of manufacture, processing and installation, and is applicable to scale production.

Owner:INST OF PLASMA PHYSICS CHINESE ACAD OF SCI

Apparatus for processing substrate

In a substrate processing apparatus for forming thin layers on a substrate used for an organic light emitting diode, the apparatus includes a mask attaching chamber, a deposition chamber and a mask detaching chamber. The mask attaching chamber, the deposition chamber and the mask detaching chamber are provided with a transferring guide installed thereinside, and a substrate supporter for supporting the substrate moves along the transferring guide in or between the chambers. Thus, a time for processing the substrate and an area for the apparatus may be reduced. Also, the chambers are grouped in one or more, and a gate valve is installed between the grouped chambers for opening and closing a path between the grouped chambers. Accordingly, the chambers may be continuously maintained in a vacuum state when any one of the chambers is repaired.

Owner:SEMES CO LTD

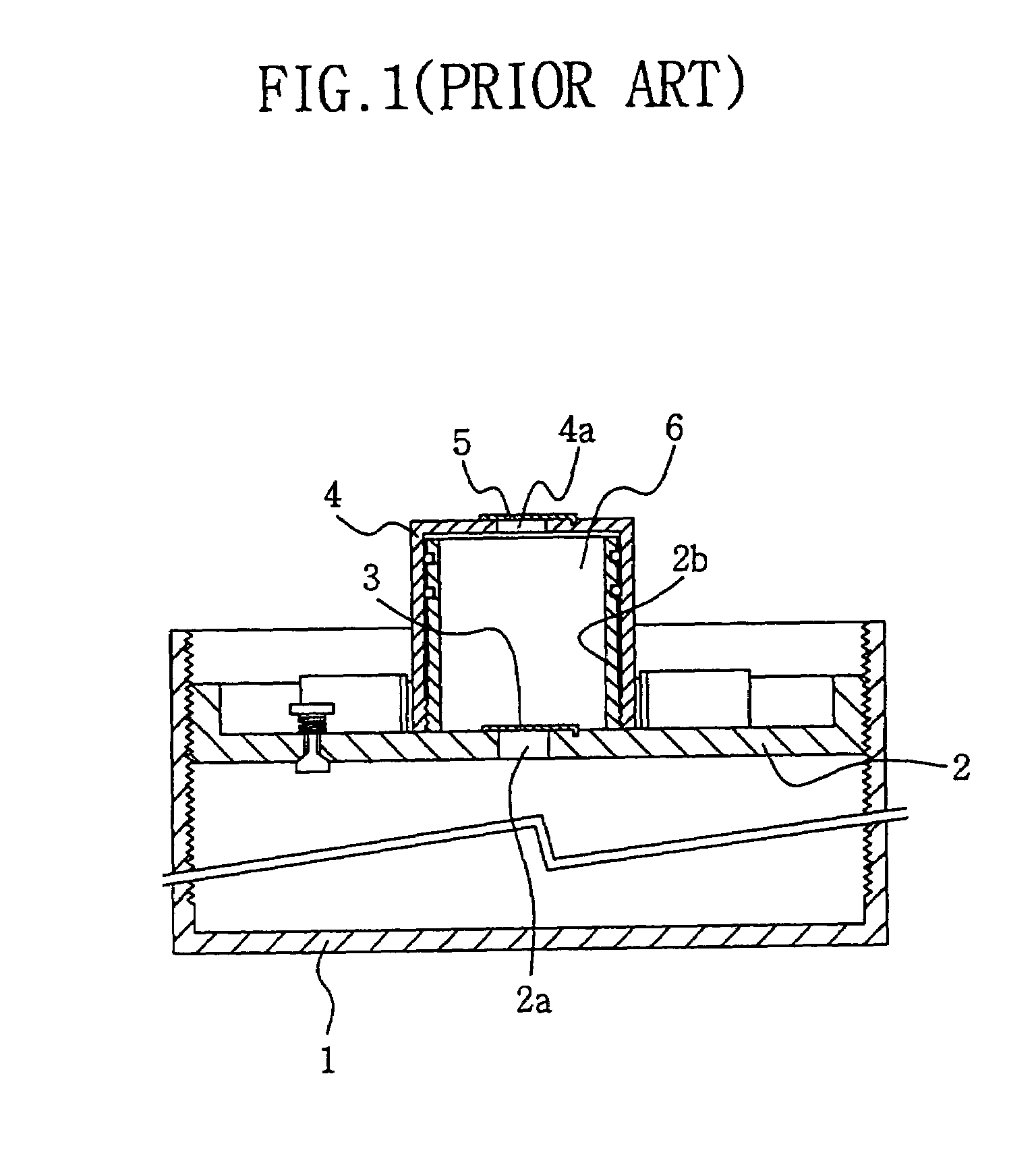

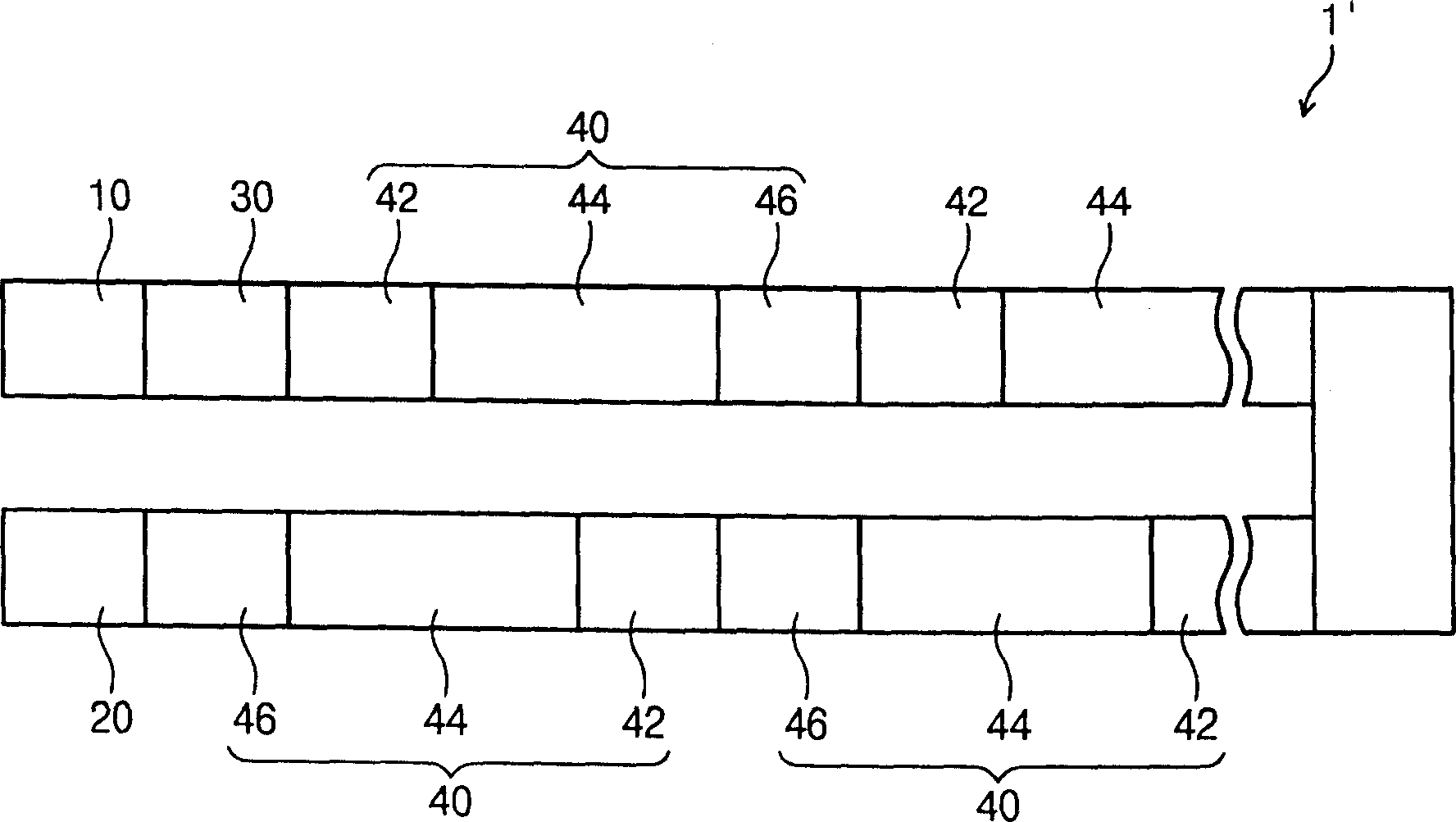

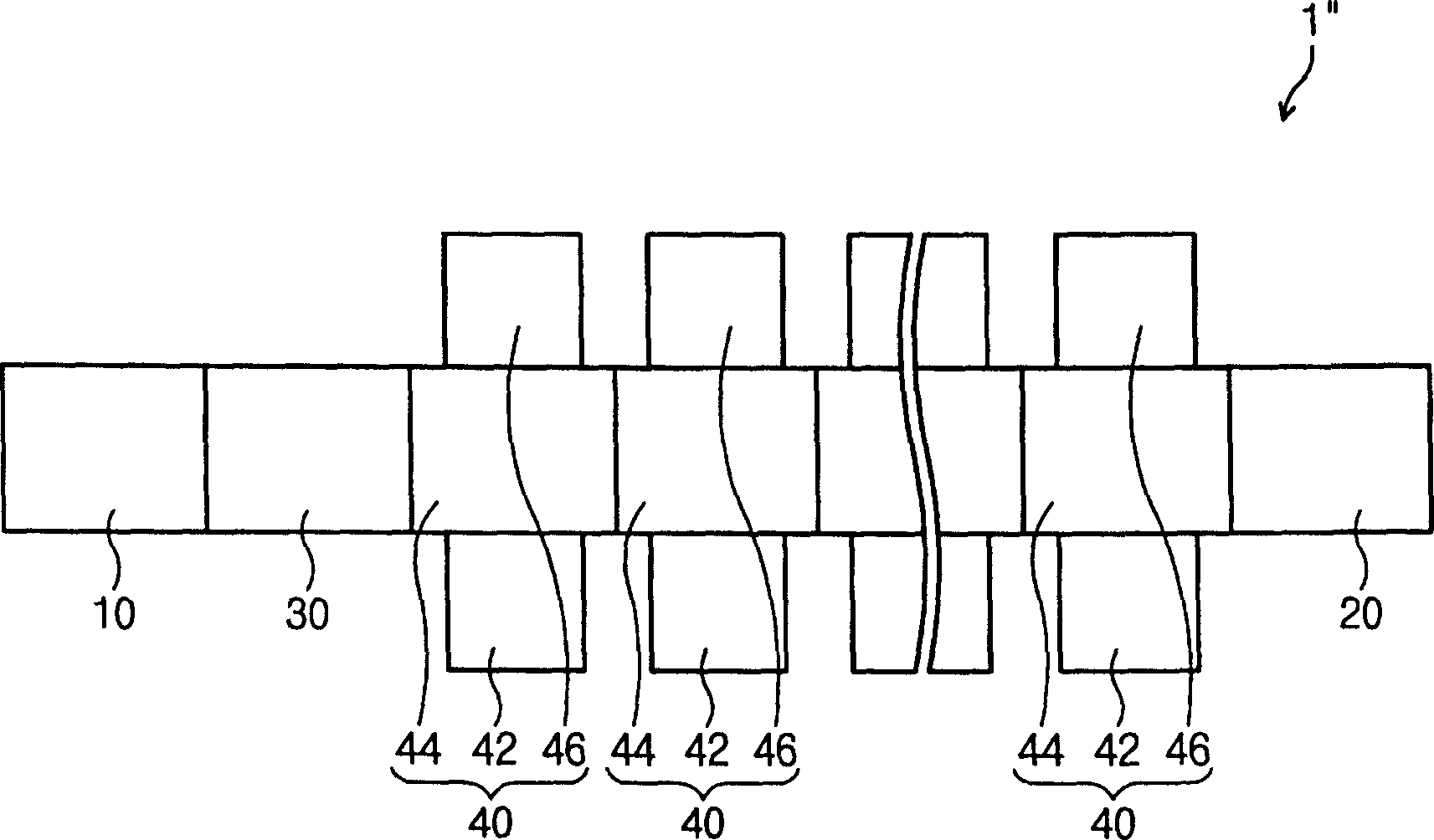

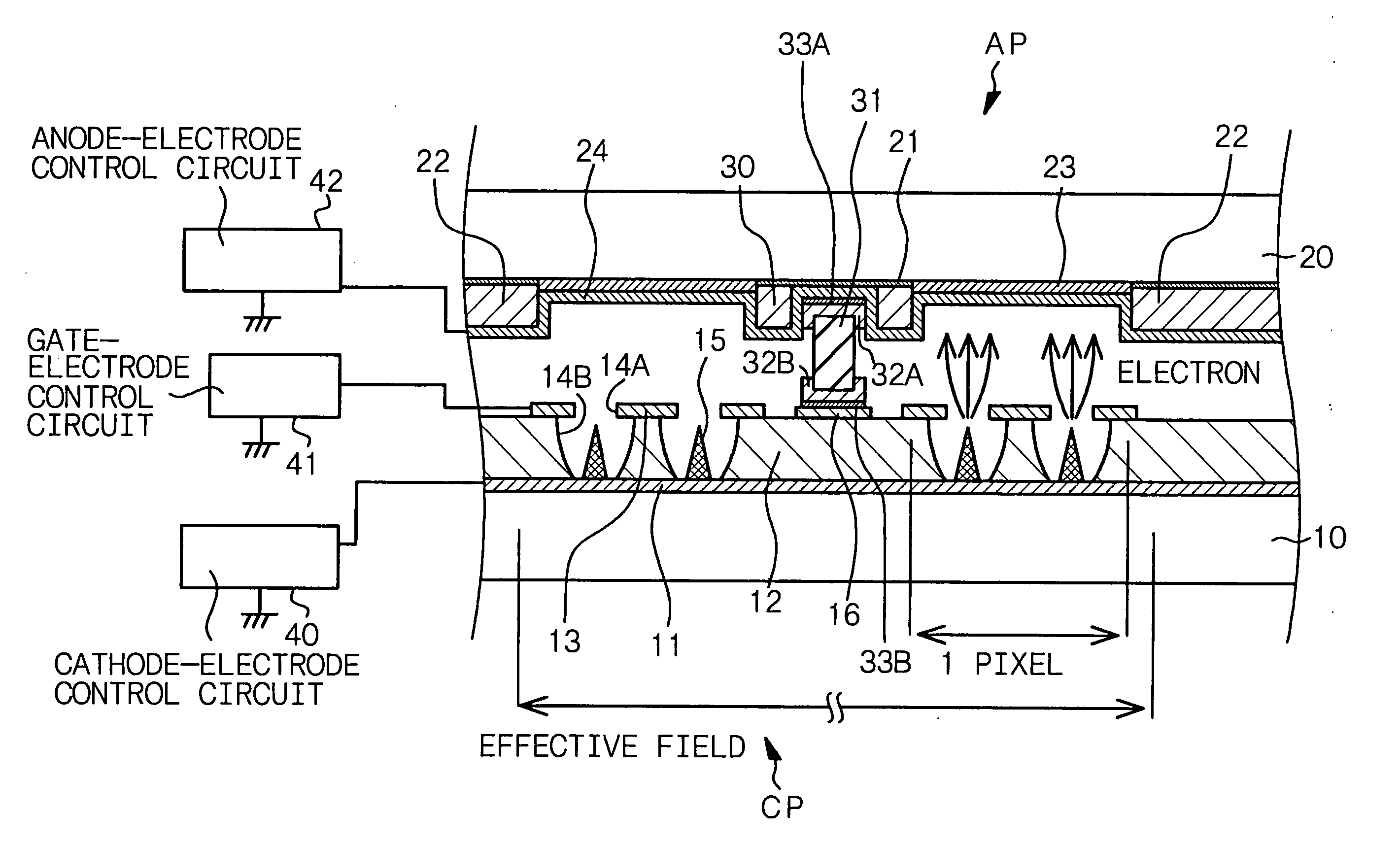

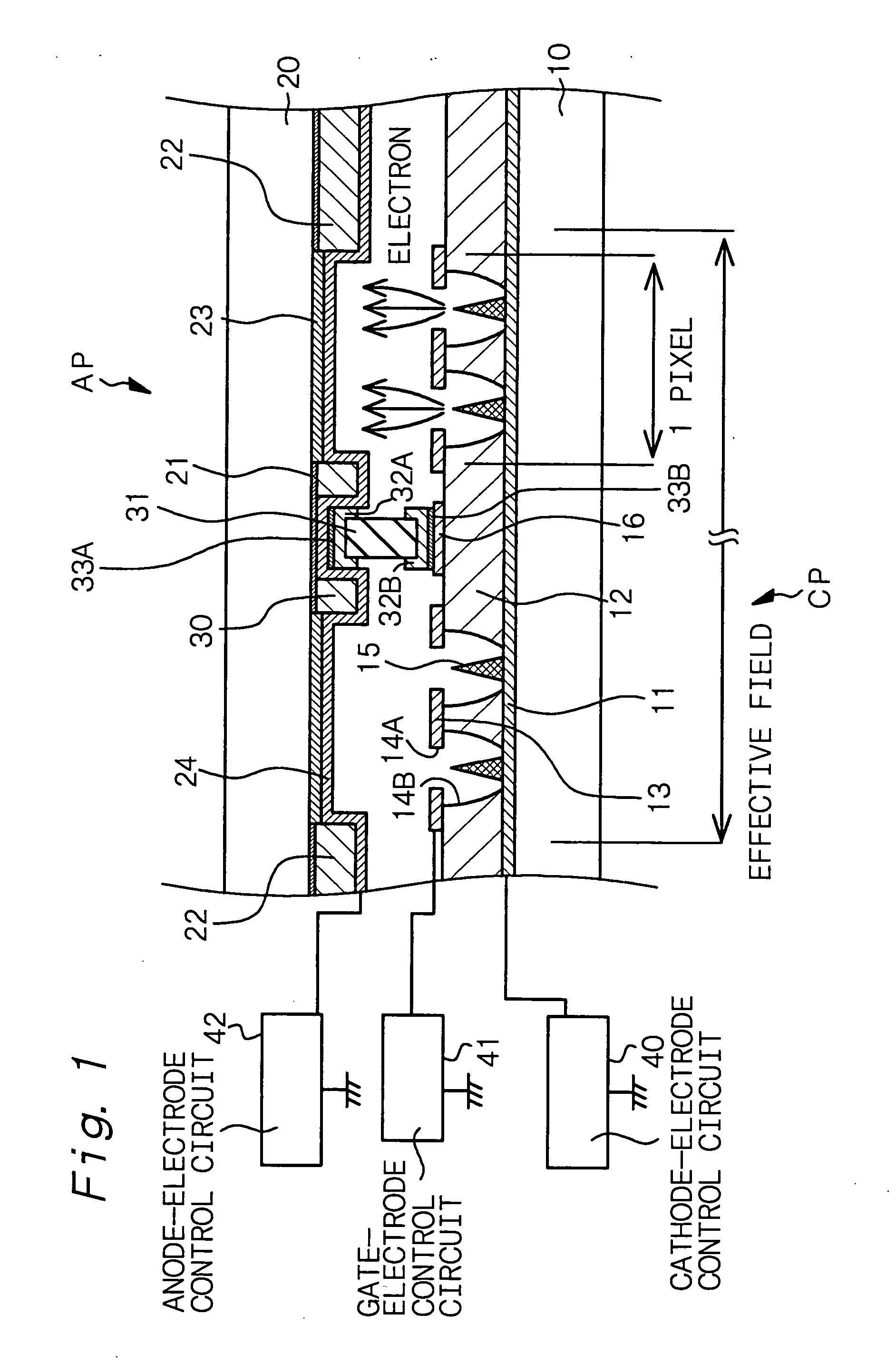

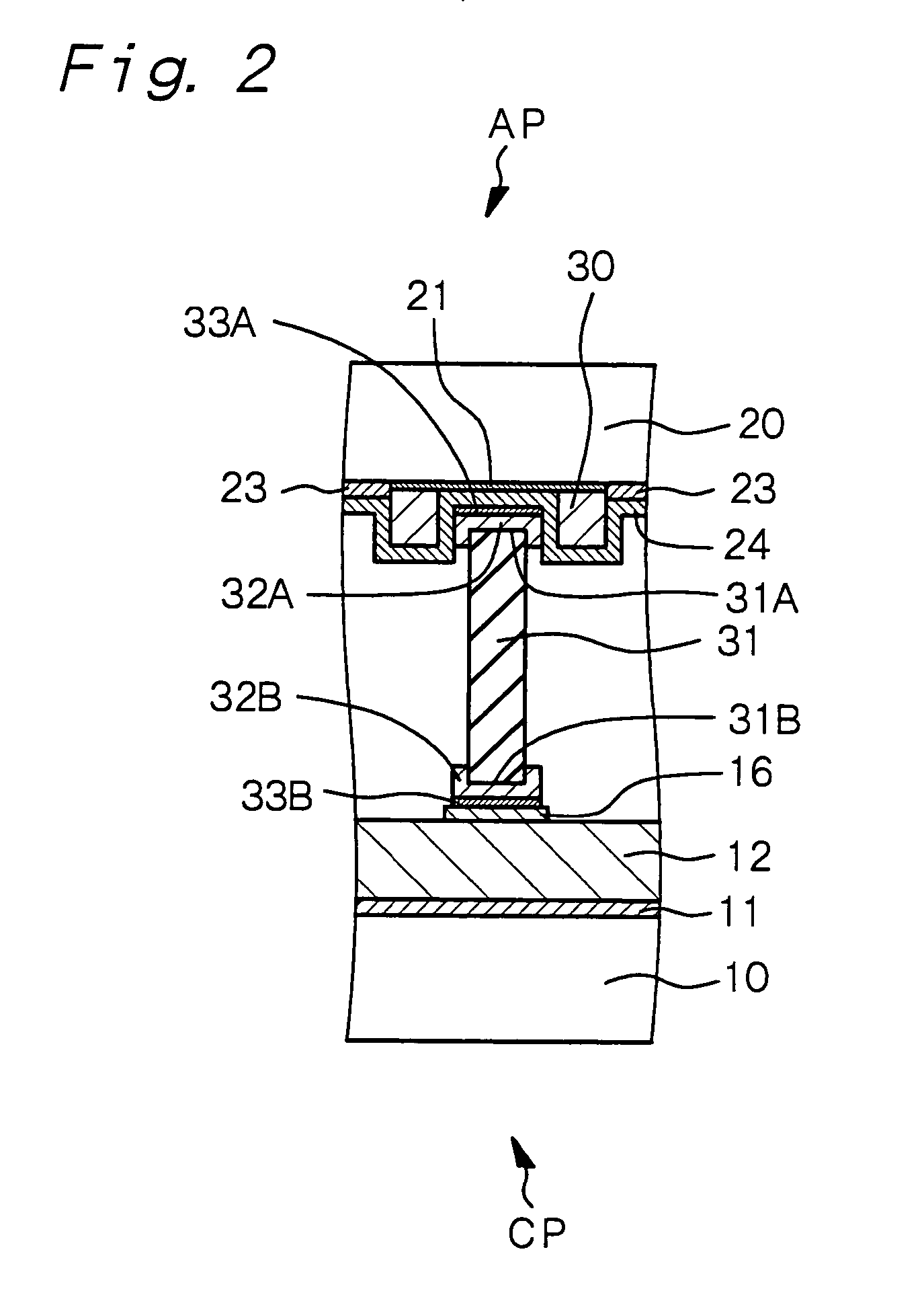

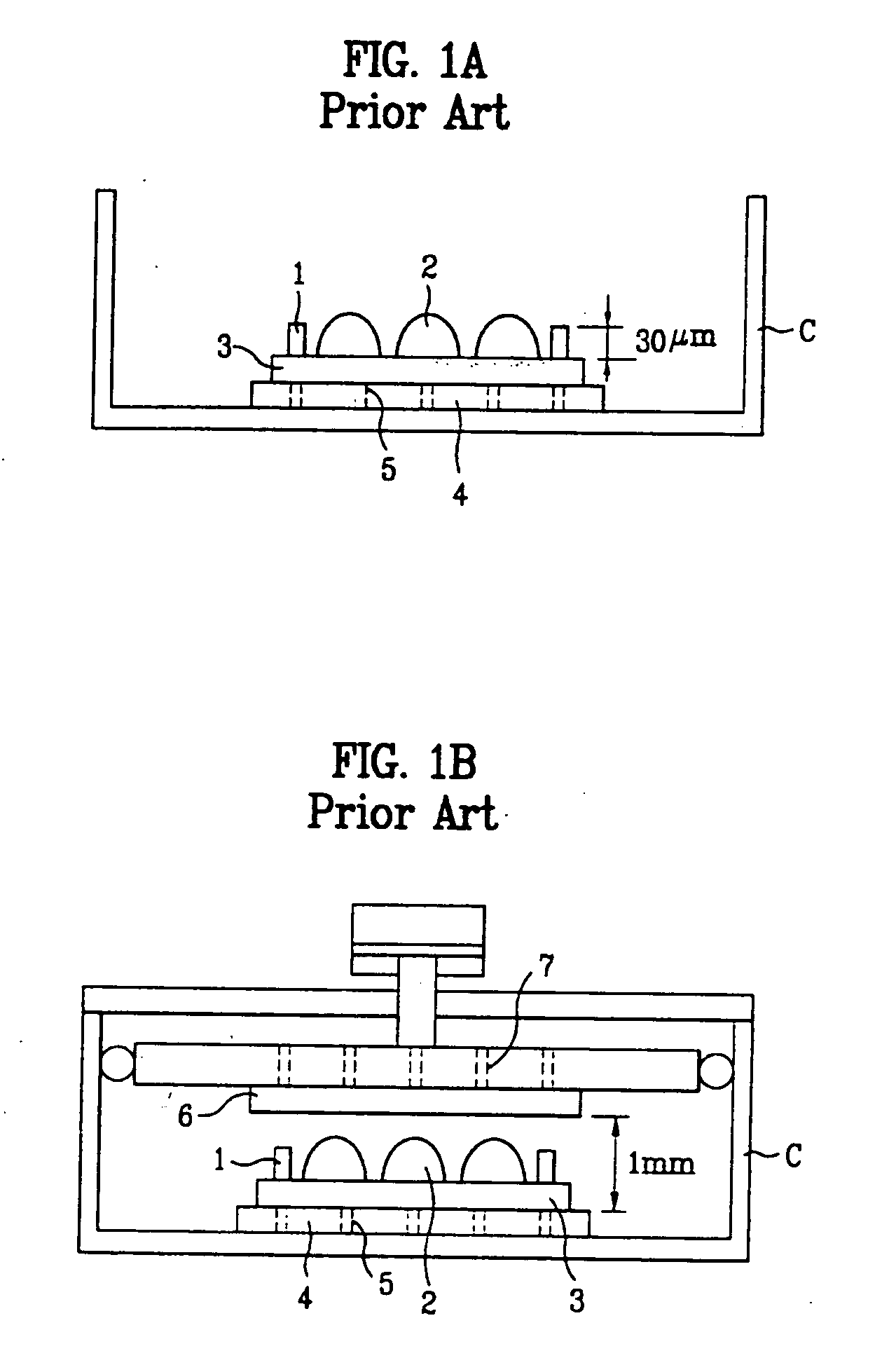

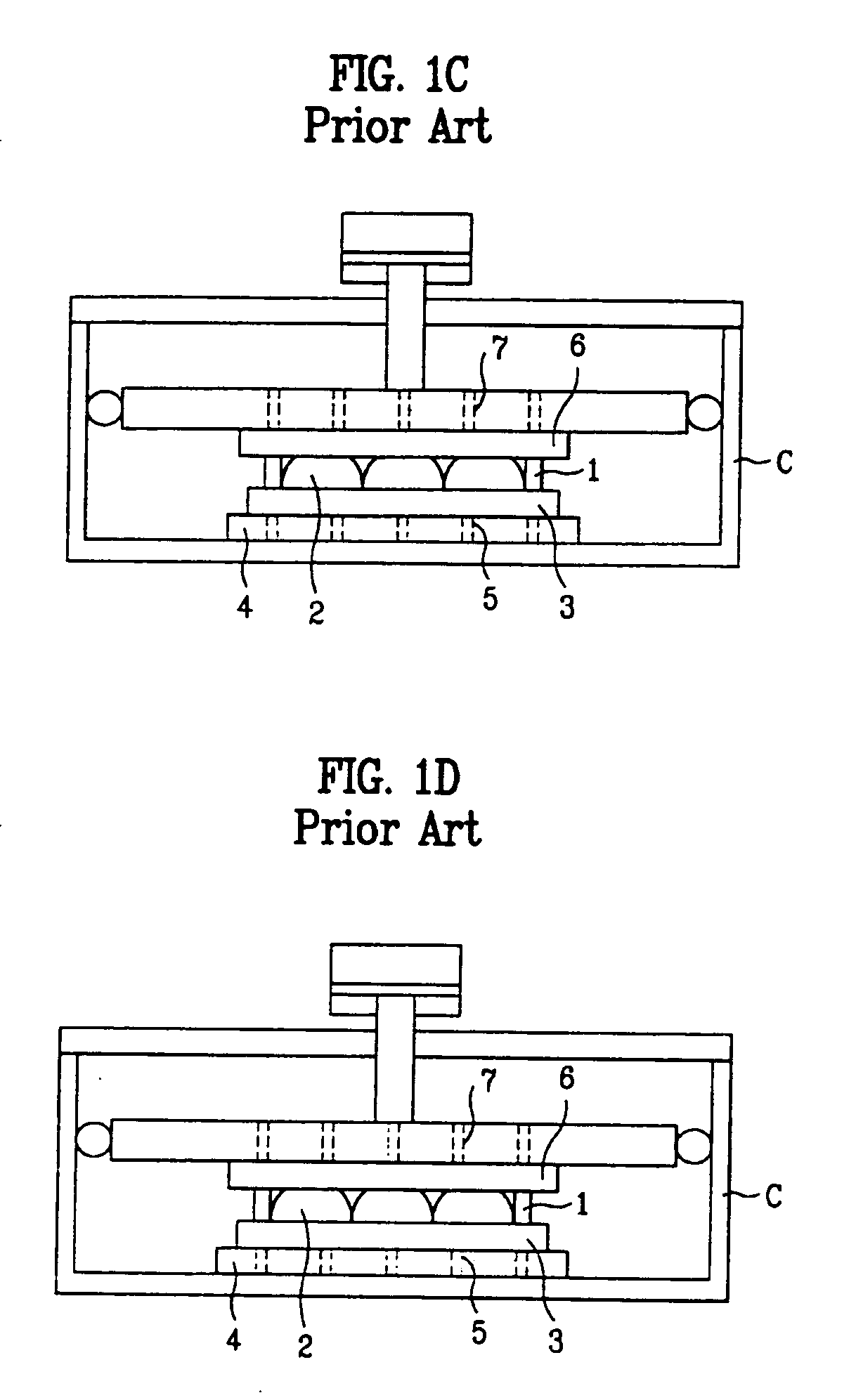

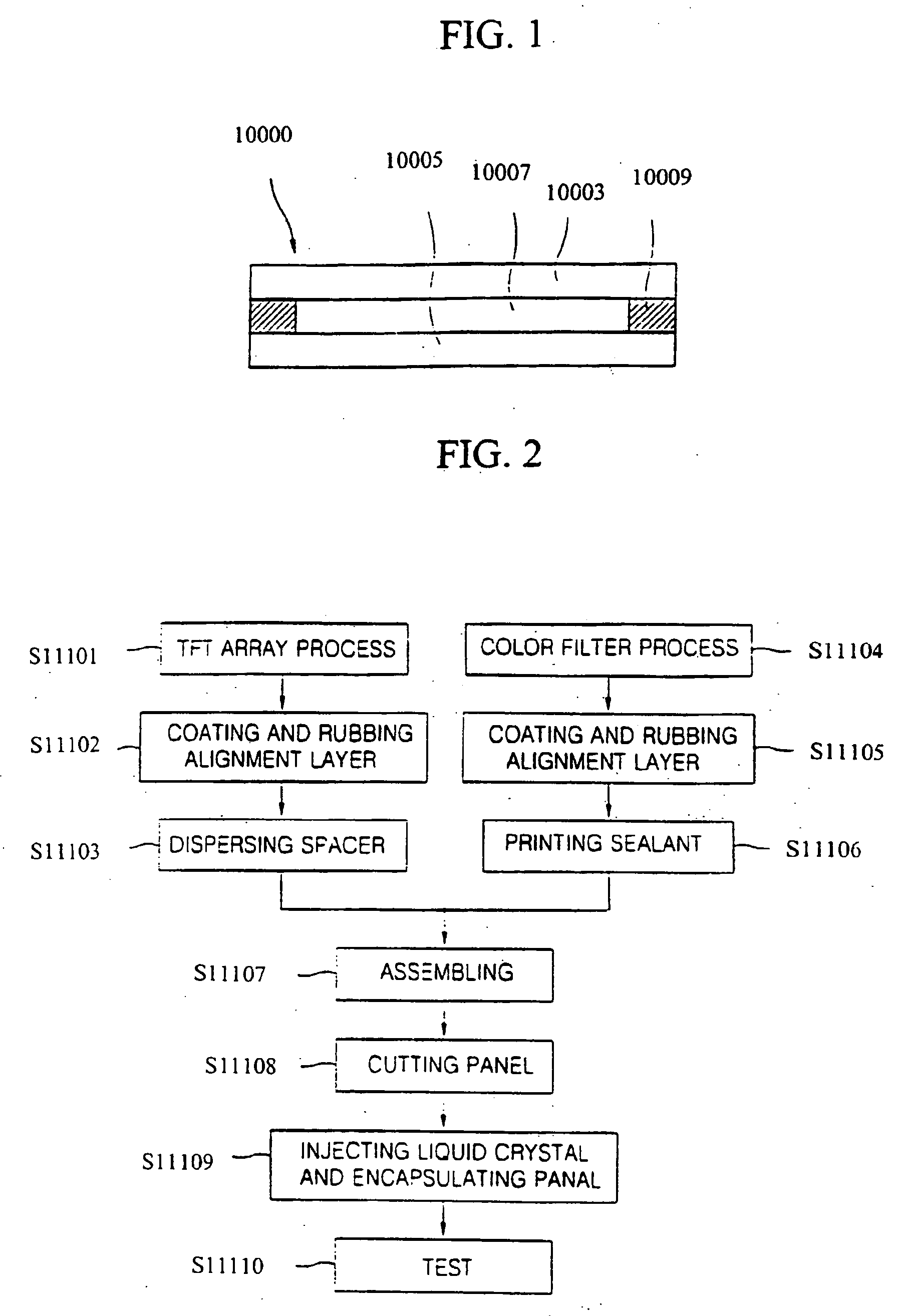

Flat display device and method for making the same

InactiveUS20060091780A1Falling or tilting of the spacer can be reliably preventedElectrode assembly support/mounting/spacing/insulationIncadescent body mountings/supportDisplay deviceEngineering

A flat-type display comprising a first panel AP and a second panel CP which are bonded to each other in their circumferential portions and having a space between the first panel AP and the second panel CP, the space being in a vacuum state, a spacer being disposed between a first panel effective field and a second panel effective field that work as a display portion, said spacer being fixed to the first panel effective field and / or the second panel effective field with a low-melting-point metal material layers 33A and 33B.

Owner:SONY CORP

Vacuum heat insulating material, heat insulating box, refrigerator, refrigerating/air-conditioning apparatus, water heater, appliance, and manufacturing method of vacuum heat insulating material

InactiveUS9103482B2Protrusion suppressionEasy to processThermal insulationLayered productsFiberAir conditioning

Owner:MITSUBISHI ELECTRIC CORP

Vacuum heat insulating material and refrigerator including the same

InactiveUS20150030800A1Preventing heat bridgeReduce heat lossDomestic cooling apparatusThermal insulationEngineeringProtection layer

A vacuum heat insulating material having an improved structure to prevent the heat bridge phenomenon while improving the durability thereof, and a refrigerator having the same, the vacuum heat insulating material including a core material in a vacuum state, a sealing layer surrounding the core material, an inner layer covering the sealing layer, and having a first side and a second side connected to the first side, a protective layer located at an outside of the inner layer, a first blocking layer having at least one portion located between the first side of the inner layer and the protective layer, and a second blocking layer having at least one portion located between the second side of the inner layer and the protective layer.

Owner:SAMSUNG ELECTRONICS CO LTD

Preparation method for lubricating oil of graphene loaded nanometer oxides

ActiveCN105176628AImprove the lubrication effectImprove carrying capacityAdditivesCarrying capacityFreeze-drying

The invention relates to a preparation method for lubricating oil of graphene loaded nanometer oxides, and belongs to the technical field of lubricating oil. The preparation method adopts the technical scheme that a graphene oxide solution is subjected to low-speed separation, and supernatant liquid is taken for use; the supernatant liquid and nanometer oxides are mixed and are subjected to freeze drying to obtain fluffy few-layer graphene oxide and nanometer oxide composite powder; the composite powder is heated in a vacuum state until the constant drying condition is reached, the composite powder in the constant drying condition and base oil are blended to be put in a sealed reaction kettle for heating treatment, and after the filtering or centrifugal separation, the repeated washing is carried out for 3 to 5 times to obtain an oleophylic graphene nanometer oxide compound; the oleophylic graphene nanometer oxide compound is uniformly mixed with composite additives and the base oil to obtain the lubricating oil of the graphene loaded nanometer oxides. The preparation method has the advantages that the process is simple; the performance price ratio is high; all ingredients have excellent dispersibility and stability. The prepared lubricating oil has good lubricating performance and high carrying capacity, and the beneficial influence can be generated on the lubricating oil in the aspects of viscosity-temperature characteristics, heat conduction effect and the like.

Owner:TANGSHAN XIRUN SCI TECH DEV CO LTD

Novel drying method of fresh traditional Chinese medicine materials and application of dried traditional Chinese medicine materials

InactiveCN104288227ADrying solid materials without heatUnknown materialsMedicinal herbsFreeze-drying

The invention discloses a novel drying method of fresh traditional Chinese medicine materials and application of dried traditional Chinese medicine materials. The novel drying method disclosed by the invention comprises the following steps: performing pretreatment on the fresh traditional Chinese medicine materials, then pre-freezing, further performing microwave vacuum freeze-drying to obtain the freeze-dried medicine materials, crushing and packaging at low moisture and low temperature and further preparing a traditional Chinese medicine preparation. The materials are dried at low temperature in a microwave vacuum state, and are less prone to oxidative deterioration; and the quality is good, the drying time is shortened in comparison with freeze-drying, and the drying efficiency is improved.

Owner:王新华

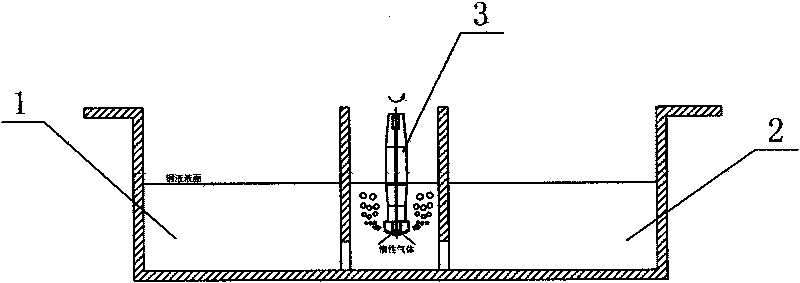

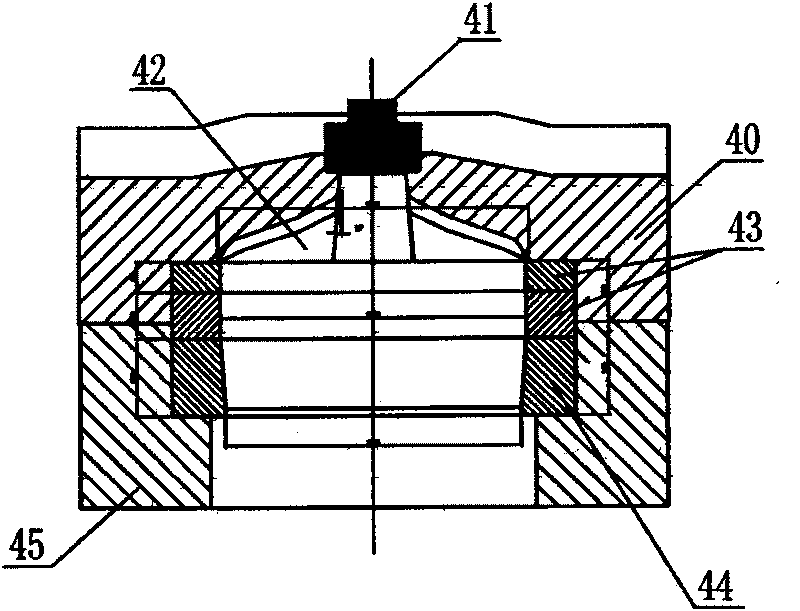

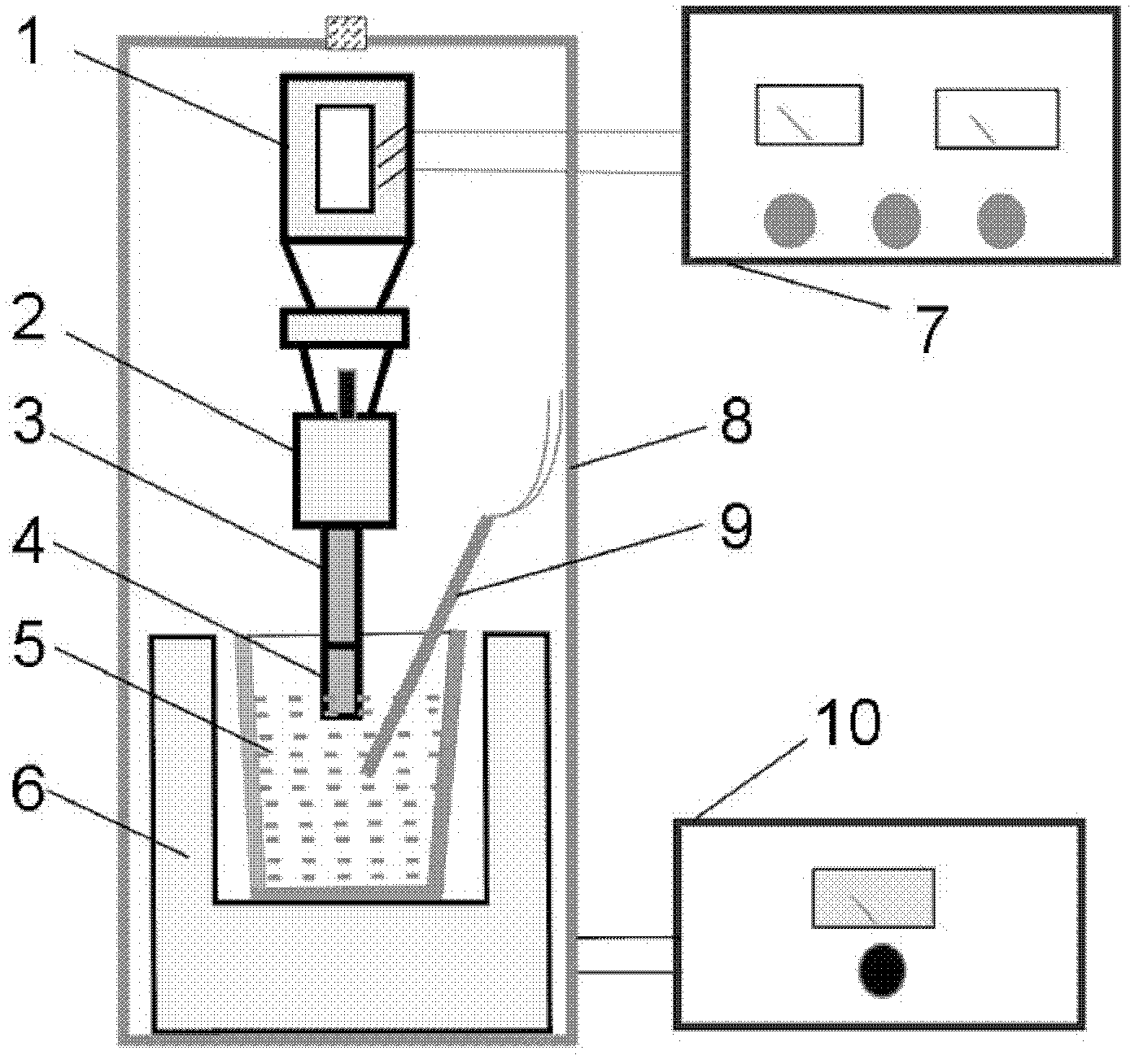

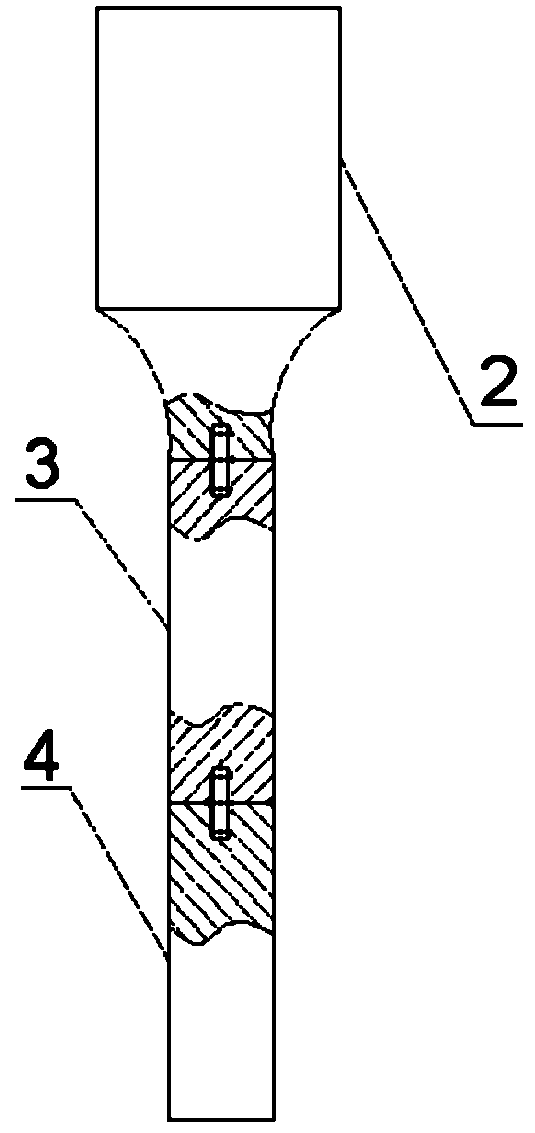

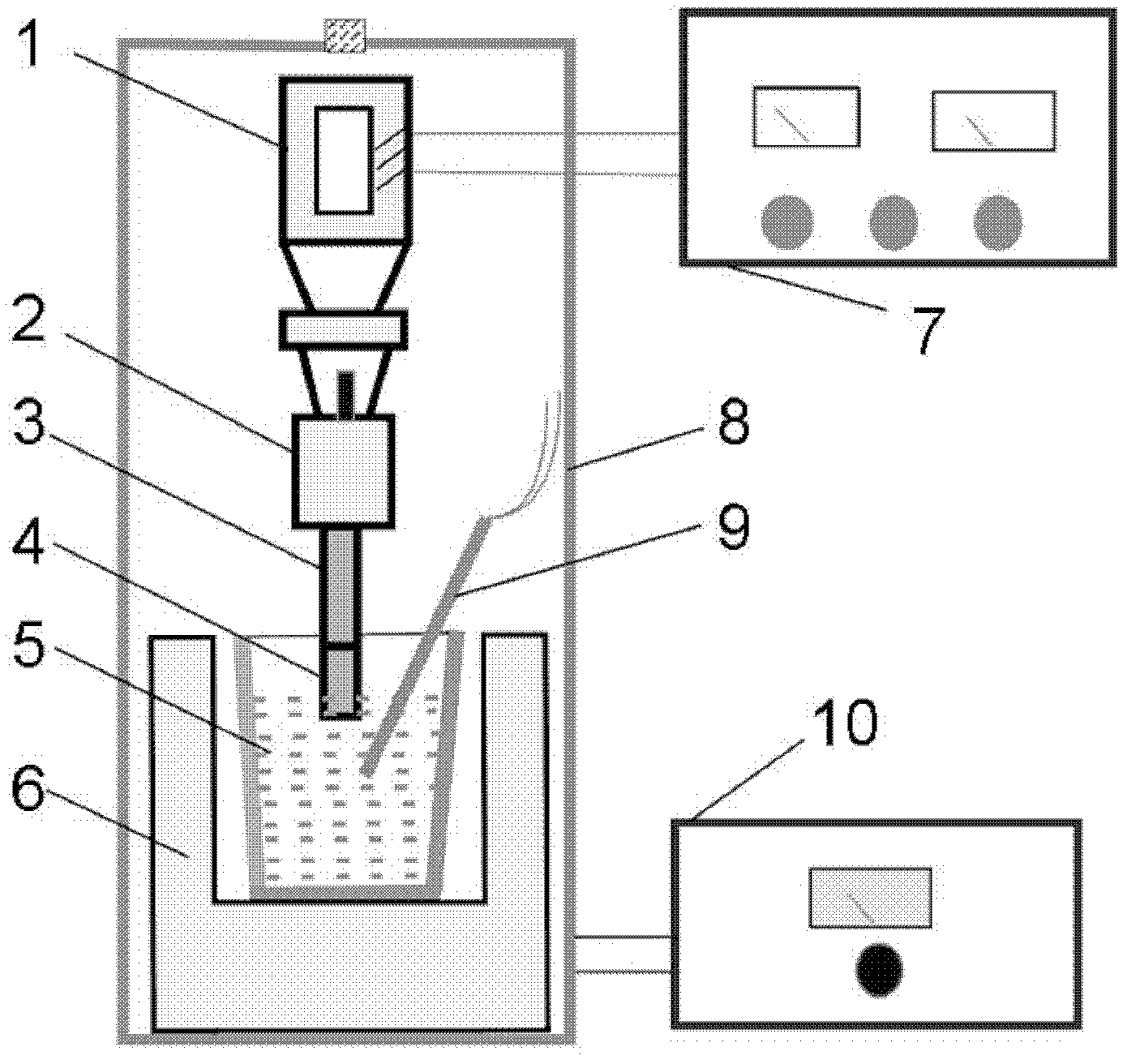

Power ultrasonic device for treating high-temperature metal melt under vacuum state and method thereof

The invention relates to a power ultrasonic device for treating high-temperature metal melt under vacuum state and a method thereof, and belongs to the field of preparation of metal materials. The method has the technical characteristics that the power ultrasonic device is used for treating the high-temperature metal melt under the vacuum state. The power ultrasonic device is characterized in that tantalum with purity being 99.98% is taken as the material of a tool head, and stable and continuous ultrasonic waves can be conducted, and the power ultrasonic device can be prevented from being corroded by high-temperature metal liquid. During the casting process, a vacuum device is adopted for protecting an ultrasonic transducer, alloy to be treated and a temperature preservation device, on one hand, the tantalum tool head can be prevented from being oxidized to deteriorate, one the other hand, the degassing effect of the ultrasonic treatment on the metal melt can be improved by virtue of the vacuum condition. For the produced alloy material, the solidification tissue is fine and compact, the distribution is uniform, and the clarifying effect is good, so that the mechanical property is greatly improved. The invention provides a new technical means for application of ultrasonic treatment of high-temperature melt in industrial production.

Owner:DALIAN UNIV OF TECH

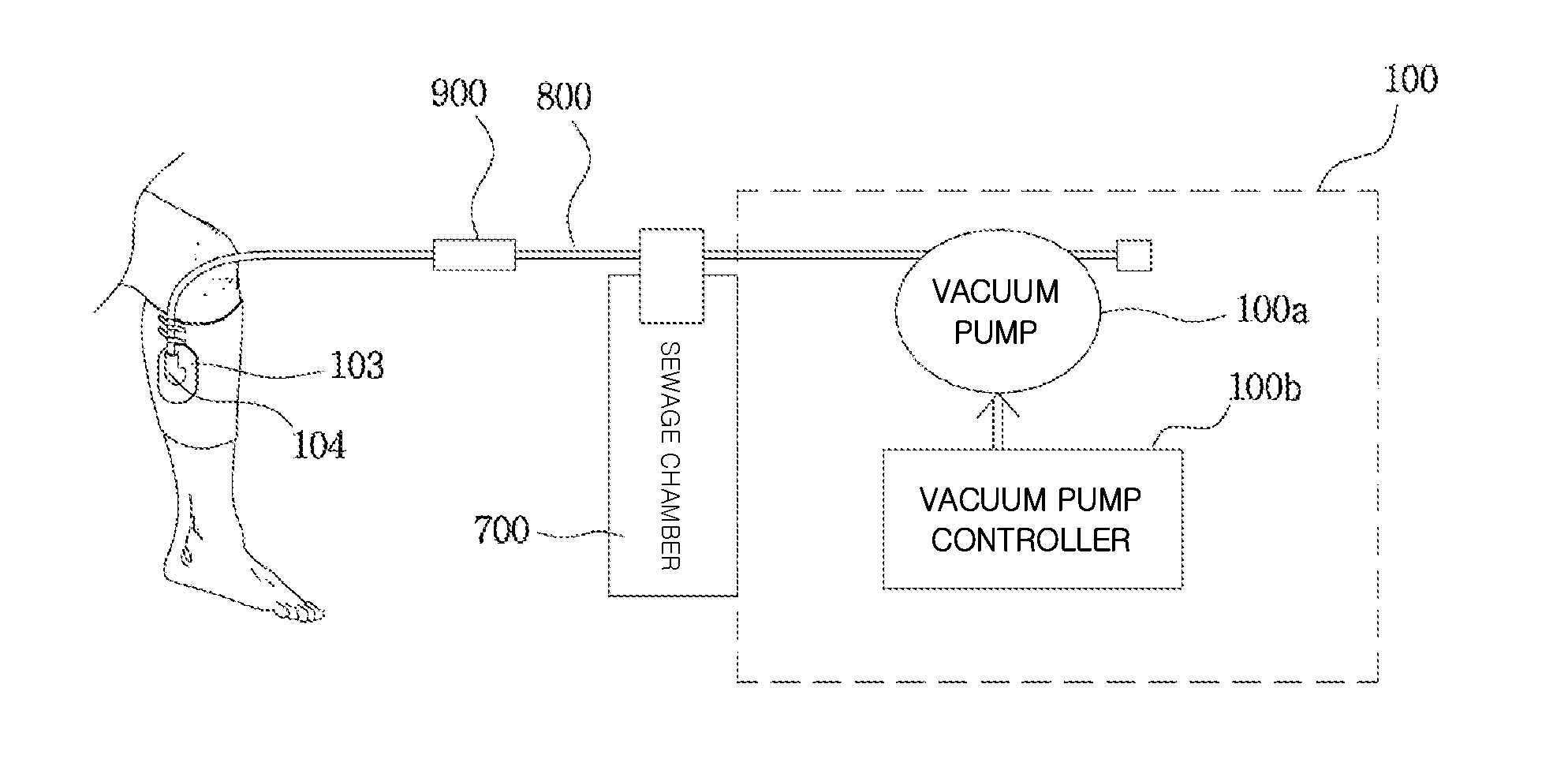

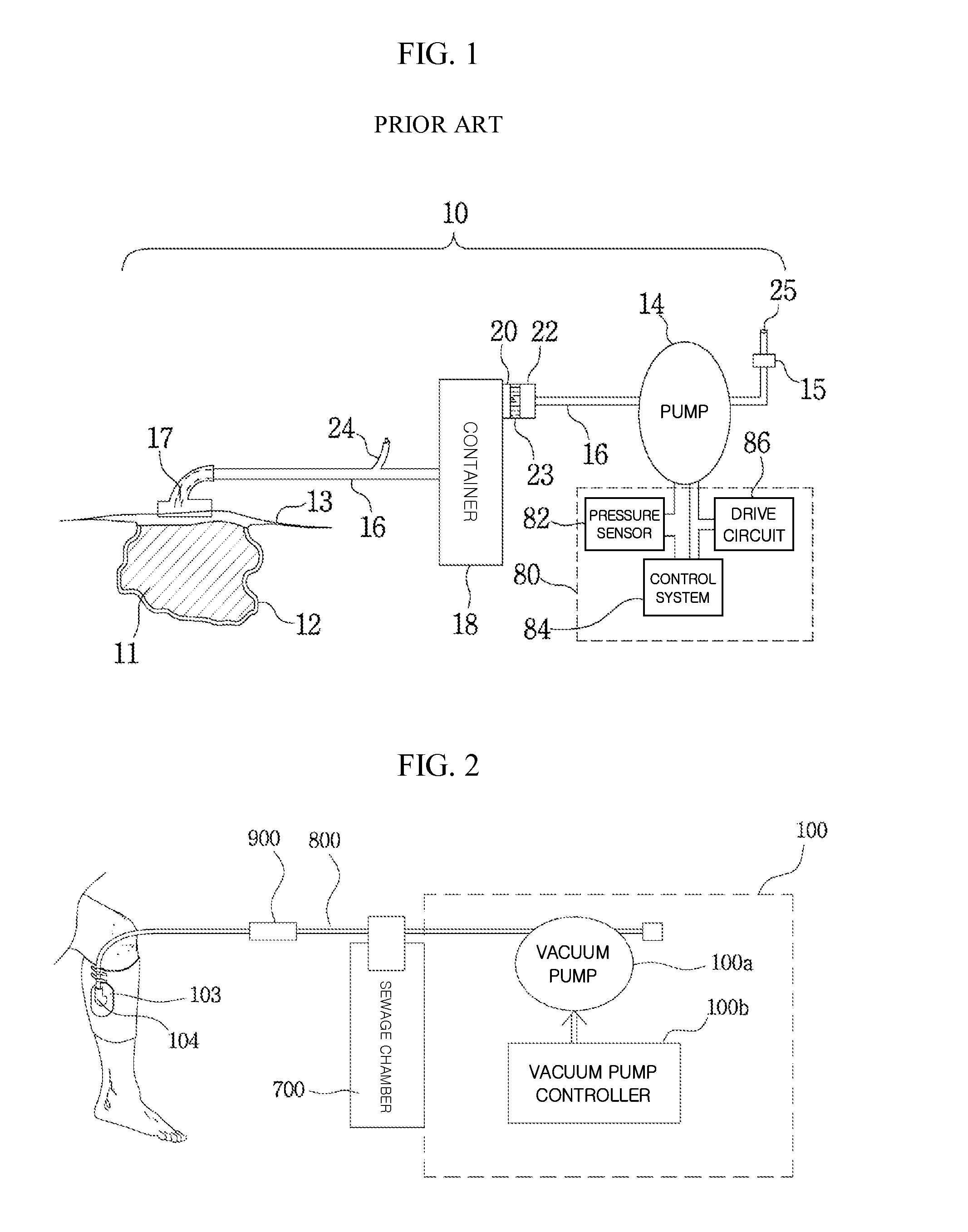

Portable vacuum generation device, and medical suction device using same

ActiveUS20120259299A1Extend battery lifeMinimize operation of pumpWound drainsMedical devicesEngineeringMaximum pressure

Provided is a portable vacuum generator that can effectively save battery power of a vacuum pump for absorbing exudates from a suction head that is connected to a tube, and a medical suction device using the same. The medical suction device includes: a connection tube whose one end is connected to a connector of the suction head; and a vacuum generator including a vacuum pump that is connected to the other end of the connection tube and having a motor for generating negative pressure, and a vacuum pump controller that controls a power supply for the vacuum pump so as to maintain a vacuum state, in which the vacuum pump controller blocks the power supply for the vacuum pump until pressure of the vacuum pump falls down to preset minimum pressure in the case that the current pressure that is applied to the vacuum pump reaches preset maximum pressure, and drives the vacuum pump until pressure of the vacuum pump reaches the preset maximum pressure in the case that the current pressure falls down to the preset minimum pressure.

Owner:CG BIO CO LTD

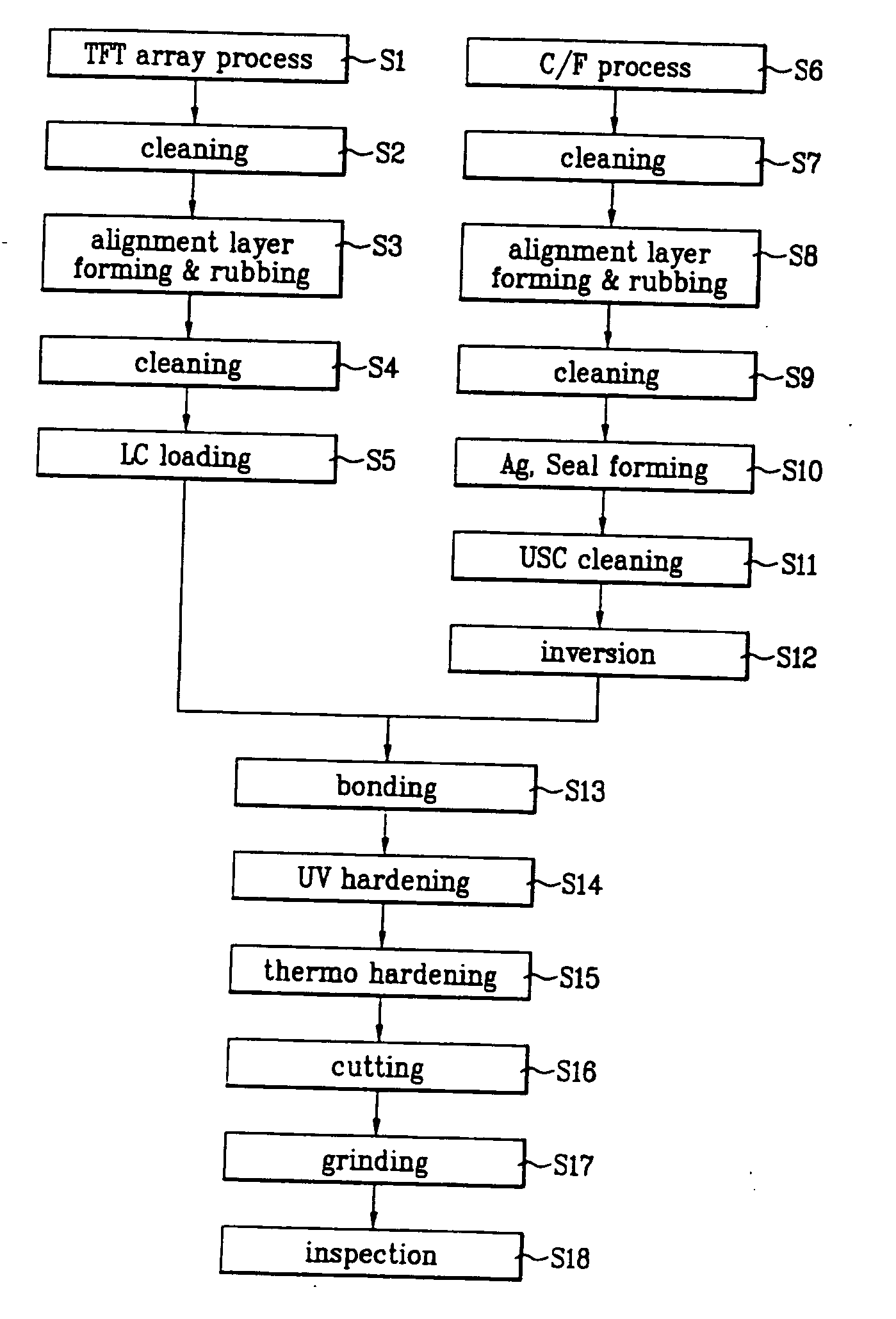

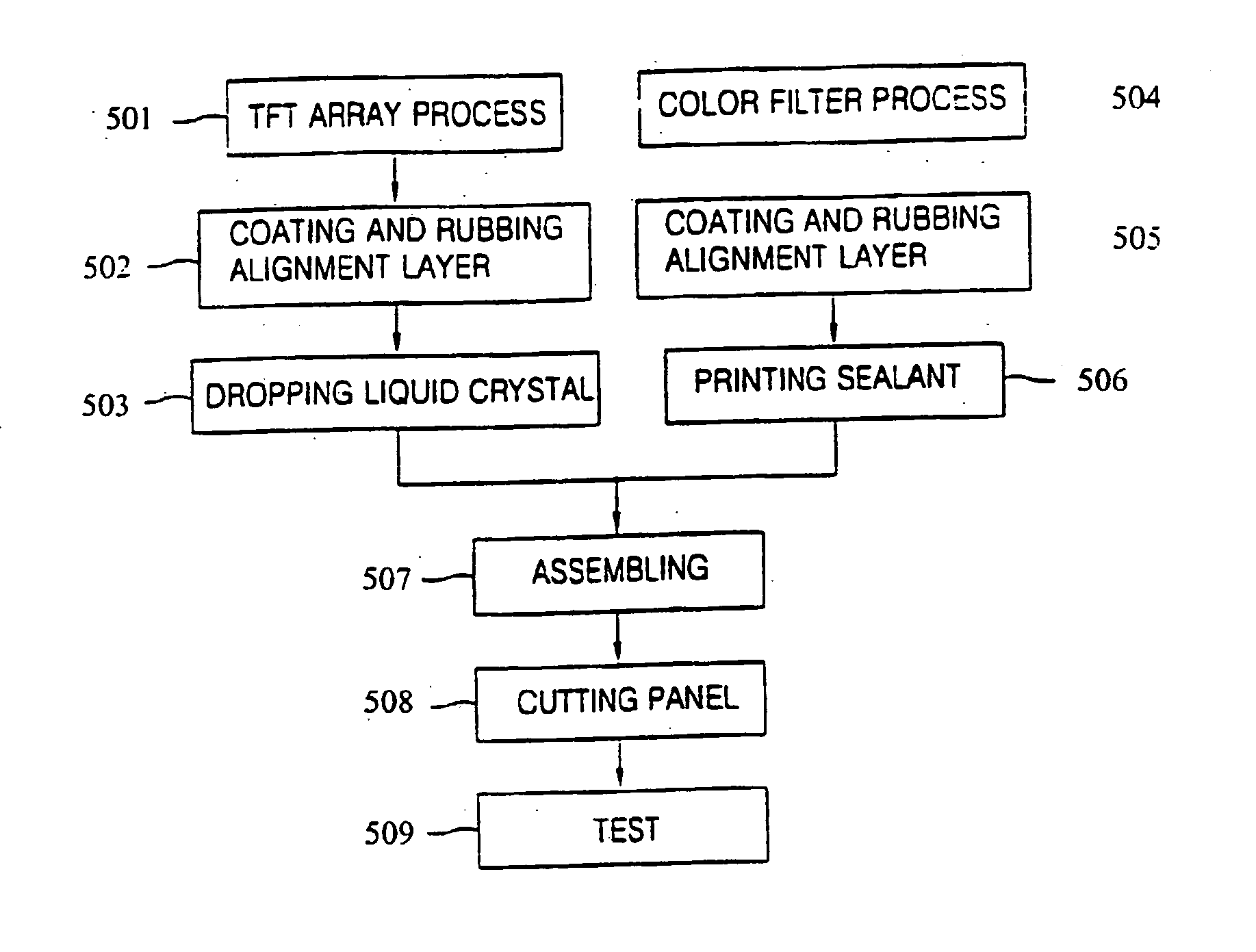

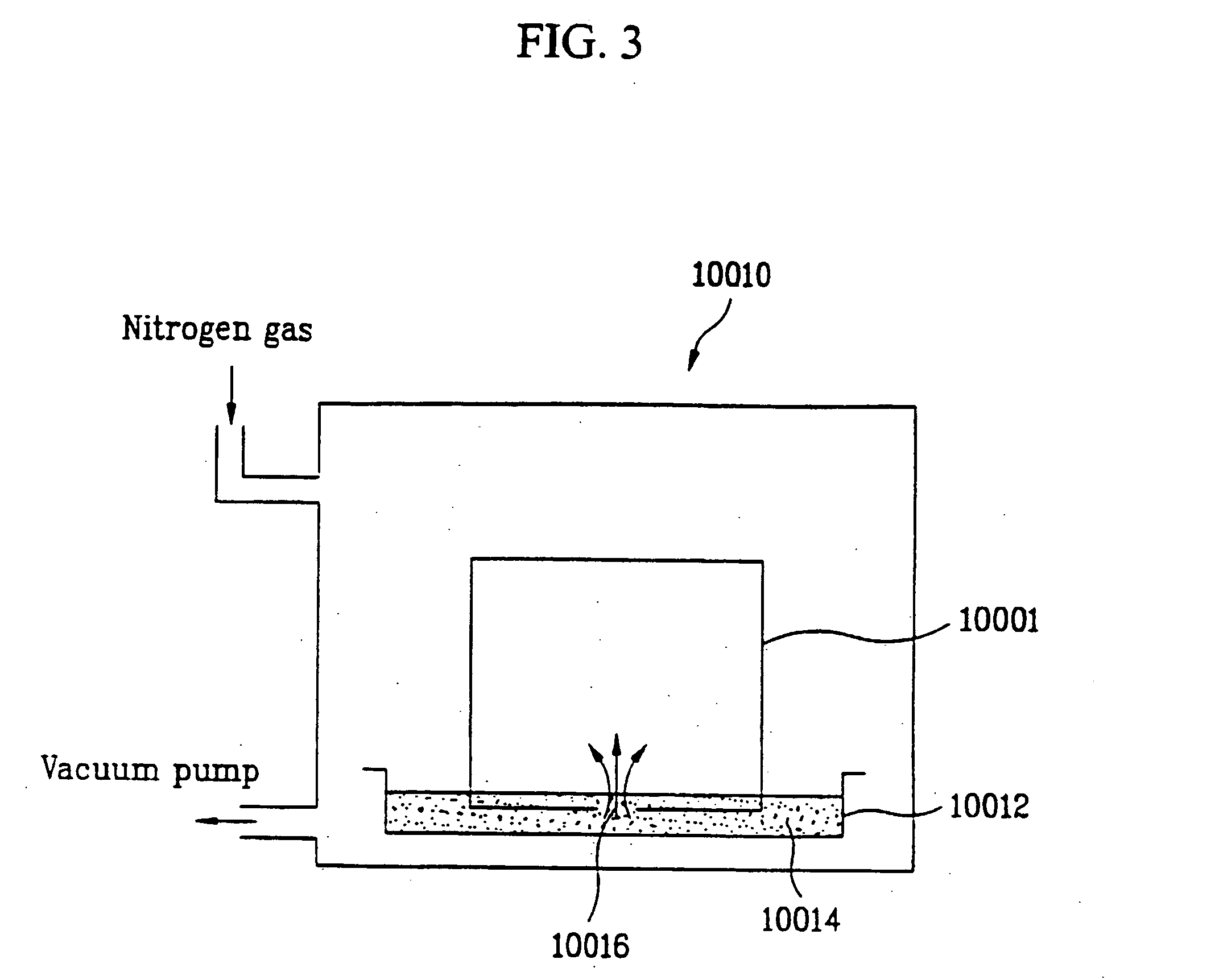

System for fabricating liquid crystal display and method of fabricating liquid crystal display using the same

InactiveUS20050248715A1Reduce processing timeImprove productivityNon-linear opticsLiquid-crystal displaySealant

Disclosed is a system for fabricating a liquid crystal display using liquid crystal dropping and a method of fabricating a liquid crystal display using the same. The present invention includes a liquid crystal forming line dropping liquid crystals on the first substrate, a sealant forming line forming the sealant on the second substrate, and a bonding and hardening line bonding the two substrates to each other and hardening the sealant, printing a sealant, bonding the substrates each other, and hardening the sealant and an inspection process line of cutting the bonded substrates into panel units and grinding and inspecting the unit panels. And, the GAP process line includes And, the present invention includes the processes of dropping LC on a first substrate using a dispenser, forming a main UV hardening sealant on a second substrate, bonding the first and second substrates to each other in a vacuum state, UV-hardening the main UV hardening sealant, cutting the bonded substrates into cell units, grinding the cut substrates, and inspecting the grinded substrates finally.

Owner:LG DISPLAY CO LTD

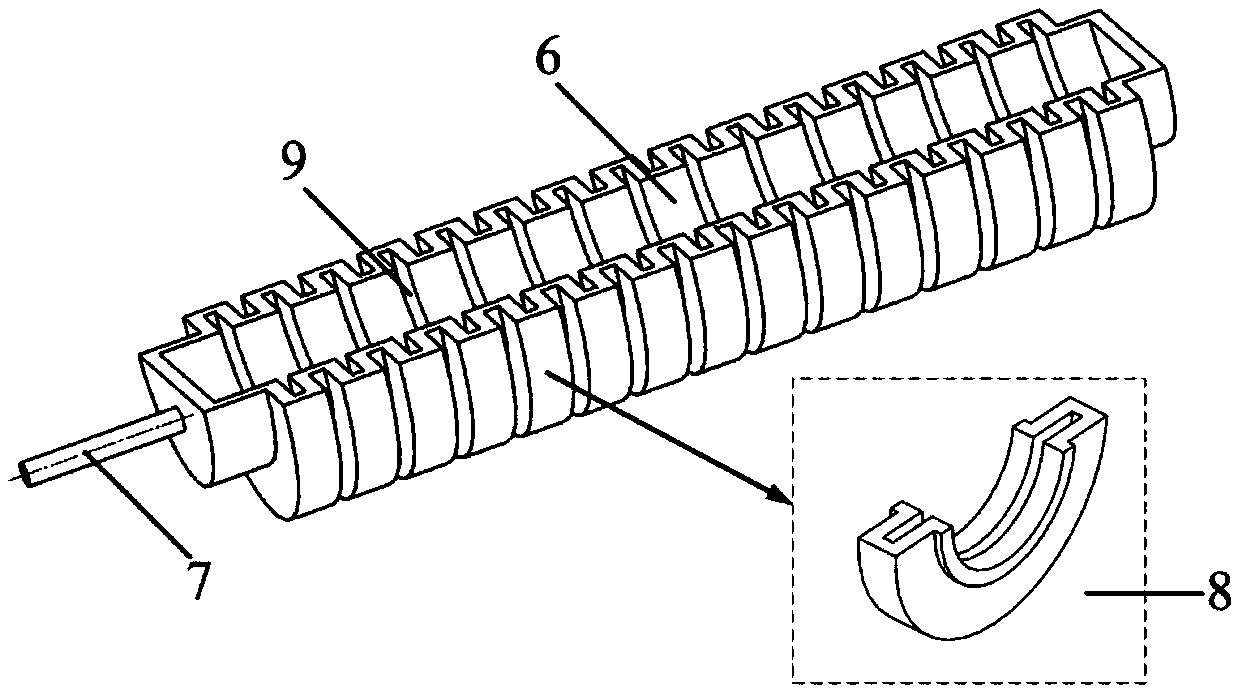

Variable-stiffness pneumatic software driver based on particle blocking

ActiveCN109249385AEasy to bend and deformActs as a strain limiting layerProgramme-controlled manipulatorVariable stiffnessEngineering

The invention discloses a variable-stiffness pneumatic software driver based on particle blocking. The variable-stiffness pneumatic software driver comprises a blocking layer and a driving layer whichare connected with each other in an upper-lower layer relationship manner, the driving layer is positioned on an upper layer and realizes bending deformation of the driver, and the blocking layer ispositioned on a lower layer and realizes variable stiffness of the driver by the aid of particle blocking. A flexible bag of the blocking layer is of a strip-shaped flexible film structure and comprises an upper portion and a lower portion, the section of an upper flexible film is semicircular, and the section of a lower flexible film is rectangular to form a cavity capable of being filled with blocking particles. The blocking particles show a flow state and a solid state in a non-vacuum state and a vacuum state, so that stiffness change of the blocking layer is realized. An expansion deformation layer of the driving layer comprises a plurality of equidistantly and linearly arranged expansion airbags with arched external structures and arched groove internal structures. Stiffness change ofthe driver is adjusted by stiffness change of the blocking layer in the non-vacuum state and the vacuum state.

Owner:JIANGXI UNIV OF SCI & TECH

System and method for manufacturing liquid crystal display devices

InactiveUS20050122463A1Reduce processing timeImprove productivityNon-linear opticsLiquid-crystal displayElectrical battery

Disclosed is a system for fabricating a liquid crystal display using liquid crystal dropping and a method of fabricating a liquid crystal display using the same. The present invention includes a liquid crystal forming line dropping liquid crystals on the first substrate, a sealant forming line forming the sealant on the second substrate, and a bonding and hardening line bonding the two substrates to each other and hardening the sealant, printing a sealant, bonding the substrates each other, and hardening the sealant and an inspection process line of cutting the bonded substrates into panel units and grinding and inspecting the unit panels. And, the GAP process line includes And, the present invention includes the processes of dropping LC on a first substrate using a dispenser, forming a main UV hardening sealant on a second substrate, bonding the first and second substrates to each other in a vacuum state, UV hardening the main UV hardening sealant, cutting the bonded substrates into cell units, grinding the cut substrates, and inspecting the grinded substrates finally.

Owner:LG DISPLAY CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com