Single-component catalytic dealcoholized room temperature vulcanized (RTV) silicone rubber and preparation method thereof

A silicon rubber and dealcoholized technology, which is applied in chemical instruments and methods, adhesives, and other chemical processes, can solve the problems of high cost platinum catalysts, affecting the overall performance of rubber, and viscosity peaks, etc., to achieve easy operation, cost saving, The effect of improving productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

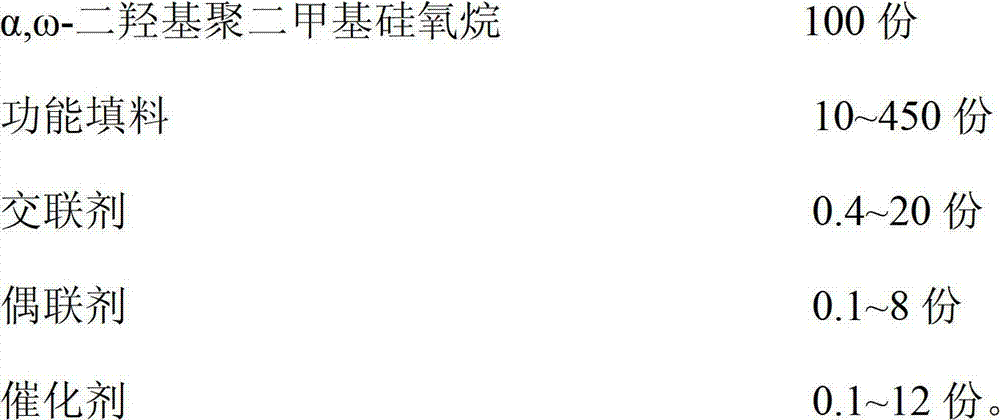

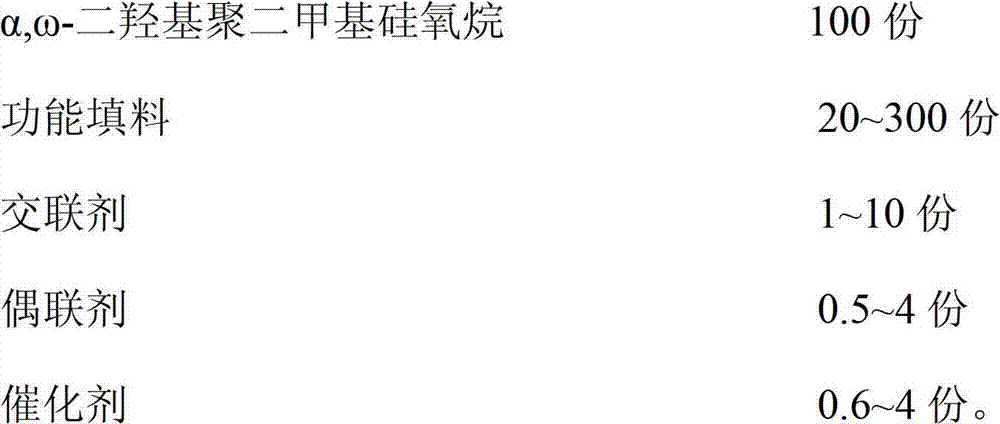

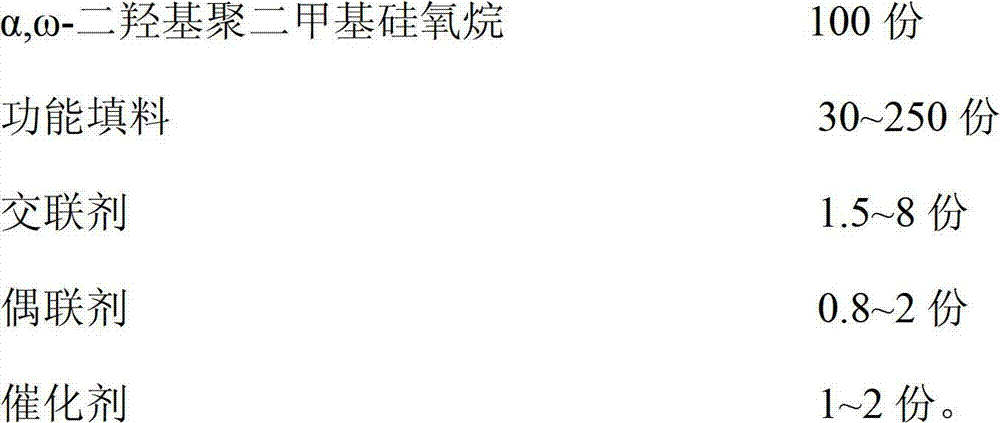

Method used

Image

Examples

Embodiment 1

[0066] (1) Preparation of the base material, 100 parts of α, ω-dihydroxypolydimethylsiloxane with a viscosity of 20000cps, 80 parts of aluminum hydroxide, and 140 parts of aluminum oxide were placed in a power mixer at temperature 130°C, vacuum degree -0.09MPa dehydration and blending for 200min, isolated from the air and cooled to room temperature to obtain the base material;

[0067] (2) Take 100 parts of the base material and add it to the power mixer, vacuumize to -0.1MPa, stir for 10 minutes, add 5 parts of crosslinking agent, vacuumize to -0.1MPa, and stir for 30 minutes;

[0068] (3) Add 0.32 parts of γ-aminopropyltriethoxysilane, 0.53 parts of vinyltriethoxysilane, 0.21 parts of N-aminoethyl-γ-aminopropyltrimethoxy, and vacuum to -0.1MPa , stirring for 35min;

[0069] (4) Add 1.35 parts of isopropyl titanate, dilute it with 10cps polydimethylsiloxane 1.5 times, add it together, and vacuumize to -0.1MPa, pass in nitrogen, stir for 35min, and then vacuumize To -0.1MPa,...

Embodiment 2

[0071] (1) Preparation of the base material, 100 parts of α, ω-dihydroxy polydimethylsiloxane with a viscosity of 80000cps, 180 parts of silicon carbide, 140 parts of ferric oxide, and 130 parts of zinc carbonate were mixed in a power mixer Inside, dehydrate and blend at a temperature of 180°C and a vacuum of -0.01MPa for 30 minutes, and cool to room temperature in isolation from the air to obtain the base material;

[0072] (2) Take the base material and add it to the power mixer, evacuate to -0.3MPa, stir for 80 minutes, add 10 parts of tetrapropoxysilane, 5 parts of methyltrihexyloxysilane, dimethoxydiethoxysilane 5 parts, vacuumize to -0.3MPa, stir for 100min;

[0073] (3) Add 2 parts of N-aminoethyl-γ-aminopropyltrimethoxysilane, 3 parts of γ-methacryloxypropyltrimethoxysilane, divinyltriaminopropyltrimethoxysilane 3 parts, vacuumed to -0.3MPa, stirred for 50min;

[0074] (4) Mix tetraisopropyl titanate and 50cps polydimethylsiloxane in a volume ratio of 1:20, a total o...

Embodiment 3

[0076] (1) Preparation of the base material, 100 parts of α, ω-dihydroxy polydimethylsiloxane with a viscosity of 2000cps, 2 parts of white carbon black, 5 parts of quartz powder, and 3 parts of talc powder were mixed in a power mixer , dehydrated and blended at a temperature of 80°C and a vacuum of -0.3MPa for 280min, and cooled to room temperature in isolation from the air to obtain the base material;

[0077] (2) Take the base material and add it to a power mixer, vacuumize to -0.01MPa, add 0.1 part of tetrapropoxysilane, 0.3 part of methyltrihexyloxysilane, vacuumize to -0.01MPa, and stir for 5 minutes;

[0078] (3) Add 0.05 parts of vinyltriethoxysilane and 0.05 parts of N-aminoethyl-γ-aminopropyltrimethoxysilane, vacuumize to -0.01MPa, and stir for 5 minutes;

[0079] (4) Mix 0.1 parts of tetraisopropyl titanate and 1 cps of polydimethylsiloxane at a volume ratio of 1:0.5, add in, and vacuumize to -0.3MPa, and then pass in helium, and stir for 5 minutes. Then evacuate to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| time | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com