Dealcoholized room temperature vulcanized silicone rubber and preparation method thereof

A room temperature vulcanization and silicone rubber technology, which is applied in the field of dealcoholization room temperature vulcanization silicone rubber and its preparation, can solve the problems of high energy consumption and high resistance, and achieve the effect of solving yellowing and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

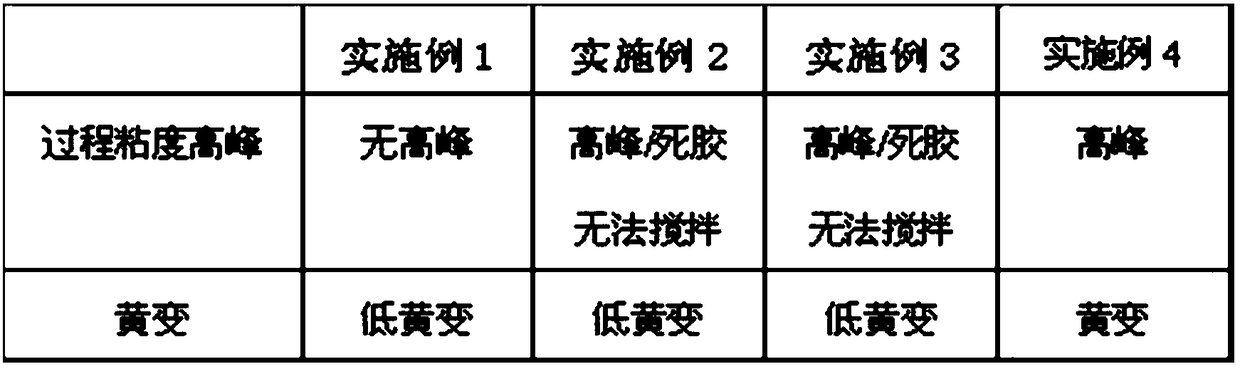

Examples

Embodiment 1

[0023] A dealcoholized room temperature vulcanized silicone rubber, comprising the following components in parts by weight: 100 parts of α, ω-dihydroxy polydimethylsiloxane with a viscosity of 20 Pa·s, 15 parts of dimethyl silicone oil, 130 parts of calcium carbonate, 1.5 parts of a cocatalyst, 2.5 parts of a first crosslinking agent, 0.8 parts of a silane coupling agent, 3.0 parts of a second crosslinking agent, and 0.2 parts of a catalyst.

[0024] The preparation method of the above-mentioned dealcoholized room temperature vulcanized silicone rubber comprises the following steps:

[0025] Step 1: Add α, ω-dihydroxypolydimethylsiloxane, dimethyl silicone oil and reinforcing filler into a vacuum stirred tank, stir and dehydrate at 150°C at -0.095MPa for 3 hours, then cool down to below 40°C to obtain Base glue;

[0026] Step 2: Add the cocatalyst and the first crosslinking agent to the rubber base in sequence, vacuumize to above -0.095MPa, stir for 60min, then add the silane...

Embodiment 2

[0028] A dealcoholized room temperature vulcanized silicone rubber, comprising the following components in parts by weight: 100 parts of α, ω-dihydroxy polydimethylsiloxane with a viscosity of 20 Pa·s, 15 parts of dimethyl silicone oil, 130 parts of calcium carbonate, 2.5 parts of a first crosslinking agent, 0.8 parts of a silane coupling agent, 3.0 parts of a second crosslinking agent, and 0.2 parts of an organotin catalyst.

[0029] The preparation method of the above-mentioned dealcoholized room temperature vulcanized silicone rubber comprises the following steps:

[0030] Step 1: Add α,ω-dihydroxy polydimethylsiloxane, dimethyl silicone oil and reinforcing filler into a vacuum stirred tank, stir and dehydrate at 150°C at -0.095MPa for h, then cool down to below 40°C to obtain Base glue;

[0031] Step 2, add the first cross-linking agent to the rubber base in sequence, vacuumize to above -0.095MPa, stir for 60min, then add the silane coupling agent, the second cross-linkin...

Embodiment 3

[0033] A dealcoholized room temperature vulcanized silicone rubber, comprising the following components in parts by weight: 100 parts of α, ω-dihydroxy polydimethylsiloxane with a viscosity of 20 Pa·s, 15 parts of dimethyl silicone oil, 130 parts of calcium carbonate, 0.8 parts of a silane coupling agent, 3.0 parts of a second crosslinking agent, and 0.2 parts of an organotin catalyst.

[0034] The preparation method of the above-mentioned dealcoholized room temperature vulcanized silicone rubber comprises the following steps:

[0035] Step 1: Add α, ω-dihydroxypolydimethylsiloxane, dimethyl silicone oil and reinforcing filler into a vacuum stirred tank, stir and dehydrate at 150°C at -0.095MPa for 3 hours, then cool down to below 40°C to obtain Base glue;

[0036] Step 2, vacuumize to above -0.095MPa, add silane coupling agent, second crosslinking agent and catalyst in sequence, vacuumize to -0.095MPa, stir for 60min to get dealcoholized room temperature vulcanized silicone ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com