Patents

Literature

145results about How to "Solve yellowing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method of high-transmittance self-healing ionic liquid gel with good mechanical properties

A preparation method of high-transmittance self-healing ionic liquid gel with good mechanical properties comprises: adding a monomer and a photoinitiator into ionic liquid, mixing well, removing oxygen, adding to a light-transmitting container, and exposing to an ultraviolet lamp to obtain the ionic liquid gel; or comprises: adding a monomer and a thermal initiator into ionic liquid, mixing well, removing oxygen, adding to a mold, mixing well under stirring, and curing to obtain ionic liquid gel. By modifying ionic liquid gel synthetic process parameters, such as the monomer for reaction, molar ratio of the monomer, reaction time, and initiating mode, self-healing property can be introduced to the field of ionic liquid gels successfully, and certain stress tolerance is imparted; the mechanical properties of the gel are significantly improved, the yellowing problem common in ionic gels is solved, and the gel has good light transmittance; the gel has a promising application prospect in the crossing field of gels.

Owner:XI AN JIAOTONG UNIV

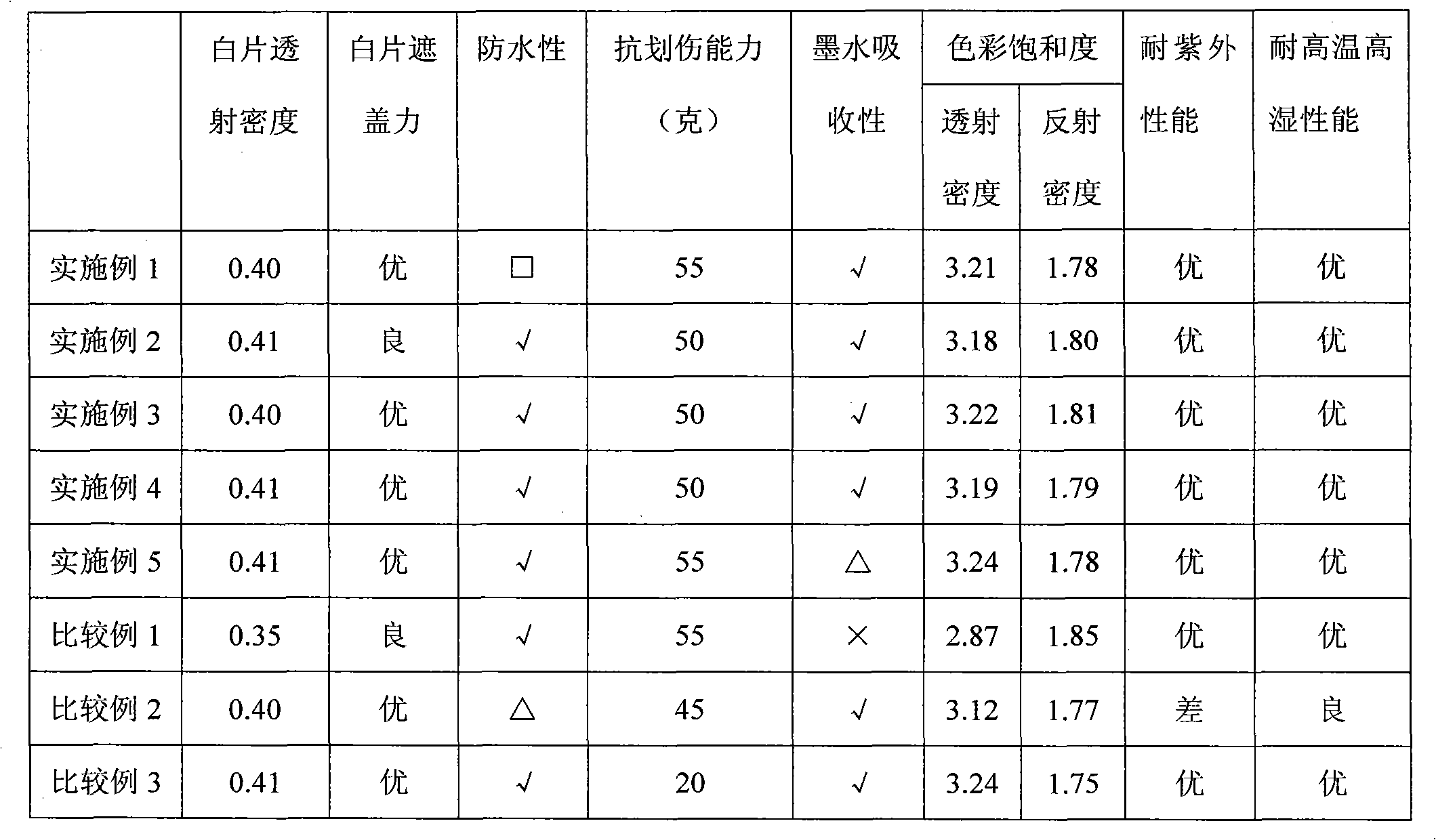

Ink-jet recording material used for full-face spray light box film

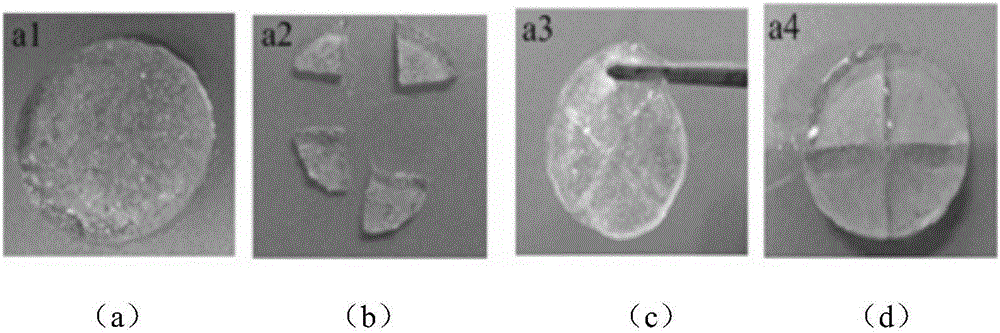

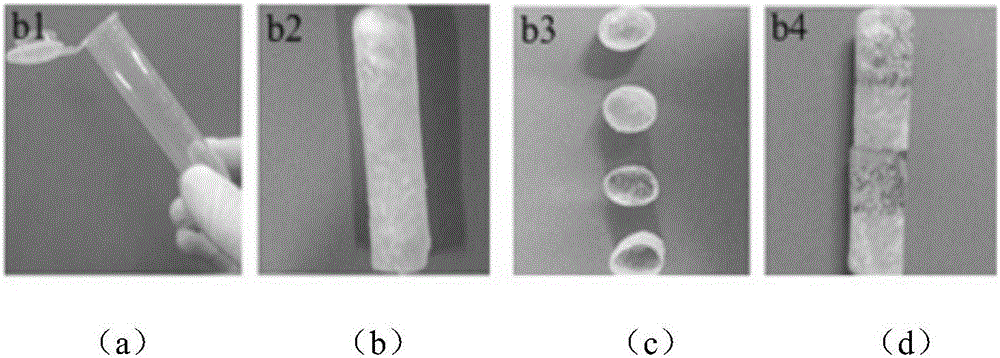

ActiveCN101879820ASolve yellowingGuaranteed inkjet printing performancePolyurea/polyurethane coatingsColor saturationEmulsion

The invention discloses an ink-jet recording material used for a full-face spray light box film, which comprises a support body, an ink fixing layer and an ink-absorbing covering layer. The ink fixing layer and the ink-absorbing covering layer respectively contain inorganic dyes, aqueous polymer emulsions, water-soluble high polymer resin and cationic fixing agents; the inorganic dyes in the ink-absorbing covering layer are silica with 0.5 to 10 micrometers by a precipitation method and titanium dioxide with 10 to 500 nanometers; the inorganic dye in the ink fixing layer is silica with 0.5 to 10 micrometers by a precipitation method; and the aqueous polymer emulsions in the ink fixing layer and the ink-absorbing covering layer are an aqueous biopolymer emulsion with an ethylene segment with self-plasticizing action and an aqueous polyurethane emulsion. The recording material has the advantages of good light fastness, weather resistance and scratch resistance, high image color saturation, good covering power and high light transmission.

Owner:乐凯胶片股份有限公司

High-temperature resistant yellowing nylon material and preparation method thereof

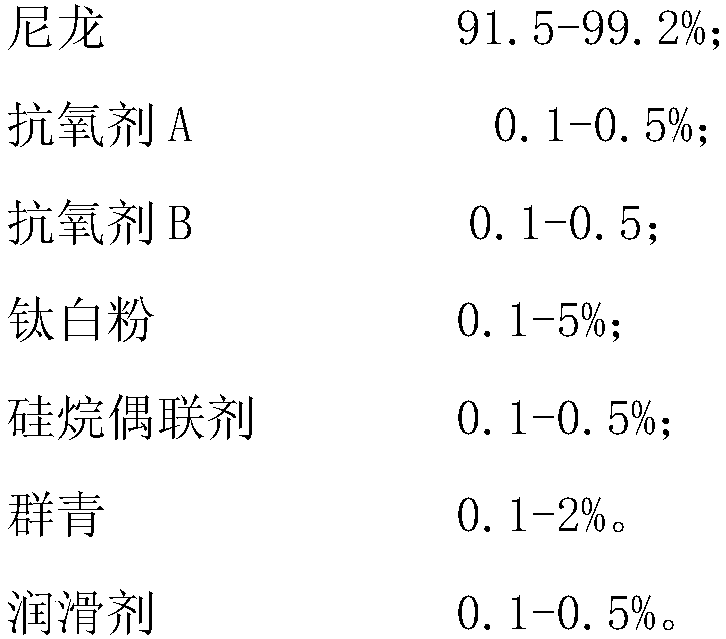

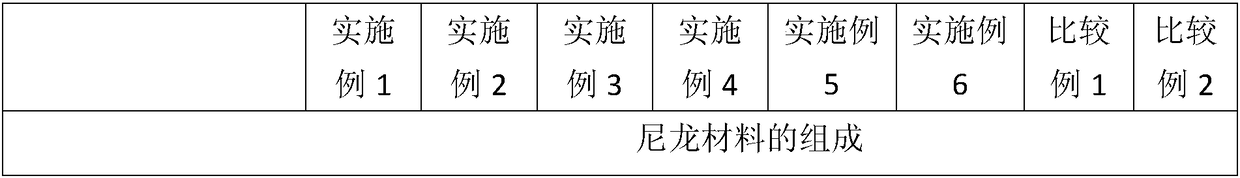

The invention discloses a high-temperature resistant yellowing nylon material and a preparation method of the high-temperature resistant yellowing nylon material. The high-temperature resistant yellowing nylon material comprises the following raw materials calculated in percentage by weight: 91.5 to 99.2% of nylon, 0.1 to 0.5% of an antioxidant A, 0.1 to 0.5% of an antioxidant B, 0.1 to 5% of TiO2, 0.1 to 0.5% of a silane coupling agent, 0.1 to 2% of Na6A14Si6S4020 and 0.1 to 0.5% of a lubricant. Compared with the prior art, the high-temperature resistant yellowing nylon material disclosed bythe invention has the advantages of inhibiting the thermal oxidative aging behavior and yellowing phenomenon of the nylon material through selecting organic copper salt and an anti-yellowing additiveto be in a compound use on the one hand, being capable of slowing down or inhibiting yellowing to some extent by reasonably selecting an aging system, and further having an eliminating effect and a covering effect on yellow color light through a toner system for solving inevitable yellowing under some particularly harsh conditions to ensure that the nylon material still remains whiteness under relatively harsh conditions, thereby ensuring that the nylon material meets strict requirements for whiteness at high temperature.

Owner:ZHEJIANG PRET NEW MATERIALS +4

Production method for preparing ammonium sulfate by alkylating waste acid

InactiveCN104628012ASolve yellowingReduce manufacturing costAmmonia compoundsAlkyl transferActivated carbon filtration

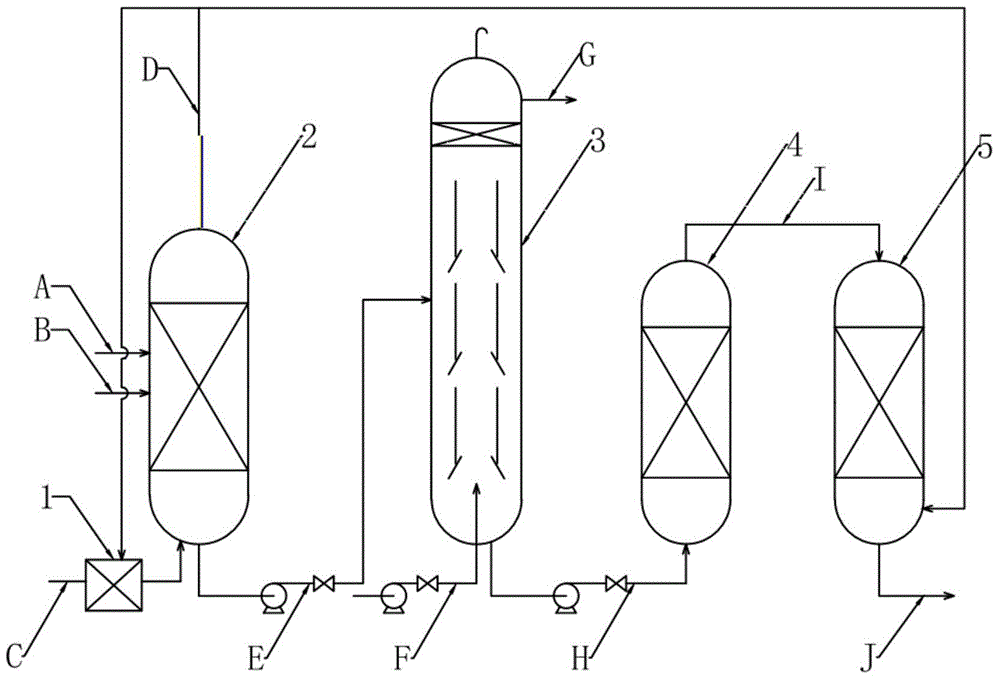

The invention relates to a production method for preparing ammonium sulfate by alkylating waste acid. The production method consists of four parts namely neutralization reaction, flotation oil removal, activated carbon filtration and crystallization, and specifically comprises the following steps: enabling waste acid and ammonia water to perform neutralization reaction in a reactor; conveying hot steam which is produced by reaction to a raw material liquid ammonia vaporizer and a crystallizer by virtue of a steam pipeline to be applied to liquid ammonia vaporization and ammonium sulfate solution crystallization processes; performing flotation oil removal on the ammonium sulfate solution obtained by reaction and air by virtue of steam stripping flotation, and then performing activated carbon decoloration and deodorization on the ammonium sulfate solution after being subjected to flotation oil removal; and crystallizing the ammonium sulfate solution after being subjected to activated carbon adsorption to prepare an ammonium sulfate crystal. By adopting the production method disclosed by the invention, the problems that waste sulfuric acid is difficult to treat and polymerized oil is difficult to recycle can be solved, an alkylation process can be improved, and 13-15% of the total cost of the alkylation process can be reduced; and compared with a conventional ammonium sulfate preparation process, the time and cost can be saved, and the production efficiency can be increased by more than 20%.

Owner:TIANJIN UNIV

Method for removing impurity 2,3,4,5-tetrahydropyridine in nylon salt and purified nylon salt

ActiveCN105753718ASolve yellowingContains less impuritiesAmino compound purification/separationOrganic compound preparationNylon materialDicarboxylic acid

The present invention provides a purified nylon salt formed from diamines and dicarboxylic acids, the diamines at least comprise 1,5-Diaminopentane, the content of impurity 2,3,4,5-tetrahydropyridine in the nylon salt is less than 0.1wt%, and the content is calculated on the basis of the weight of the 1,5-Diaminopentane. The present invention further provides a method for removing the impurity 2,3,4,5-tetrahydropyridine in the nylon salt. Compared with conventional nylon salts, the purified nylon salt has the characteristics of less impurities in particular low content of the impurity 2,3,4,5-tetrahydropyridine, and the yellowing problem of nylon obtained by subsequent polymerization can be effectively solved.

Owner:CATHAY R&D CENT CO LTD +1

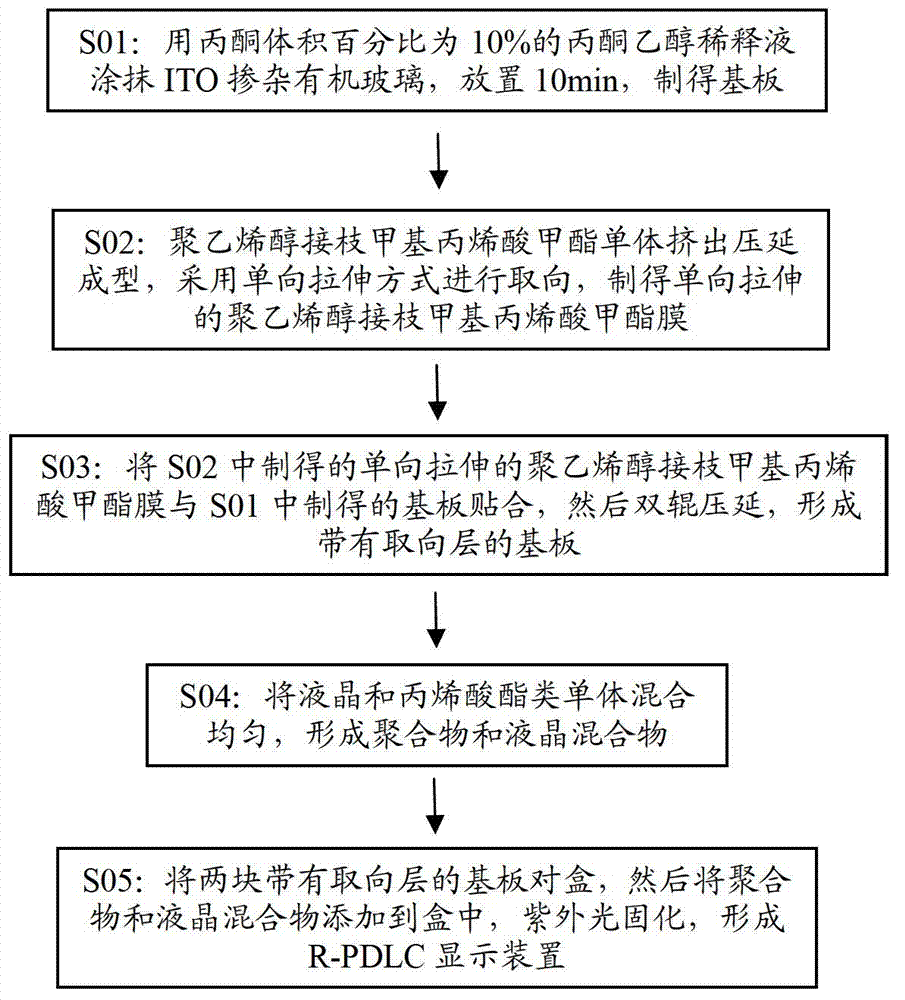

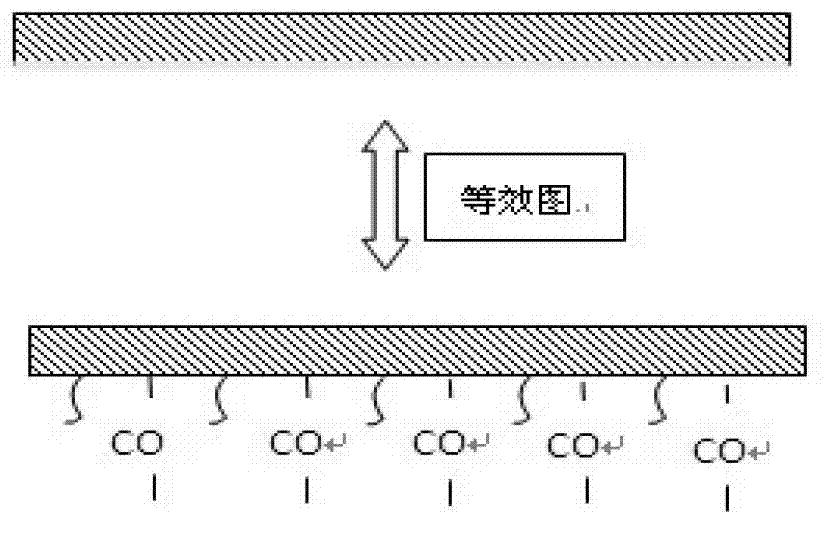

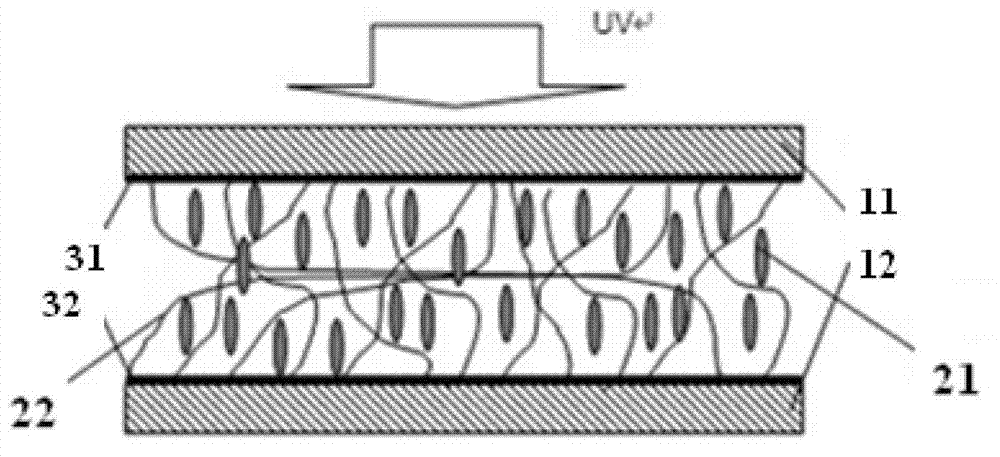

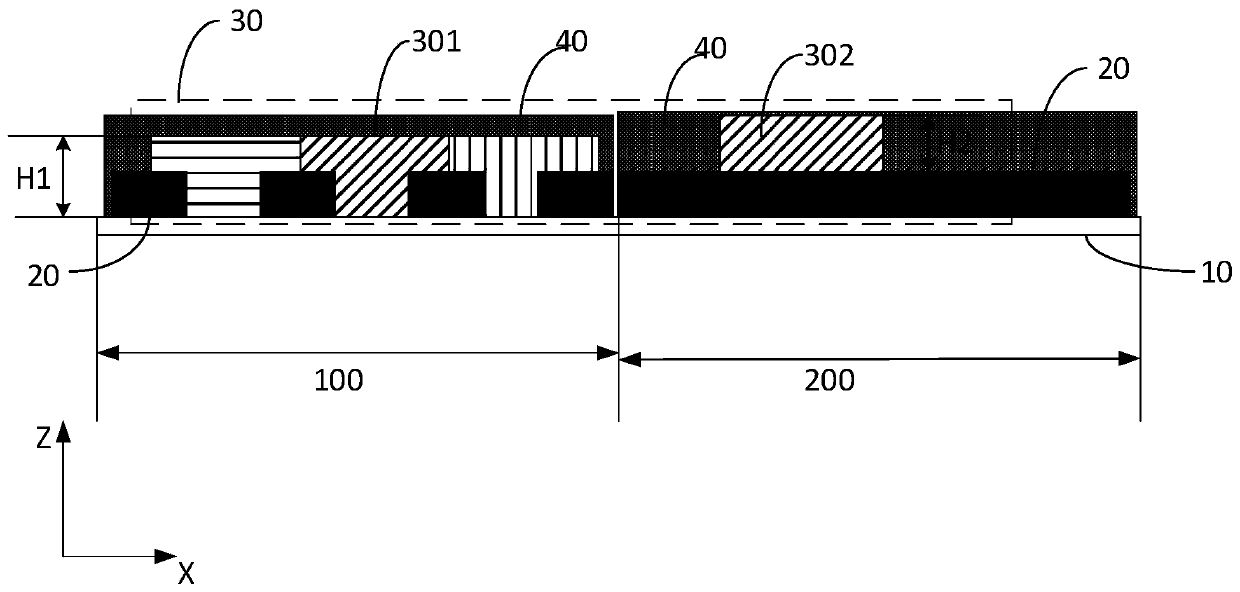

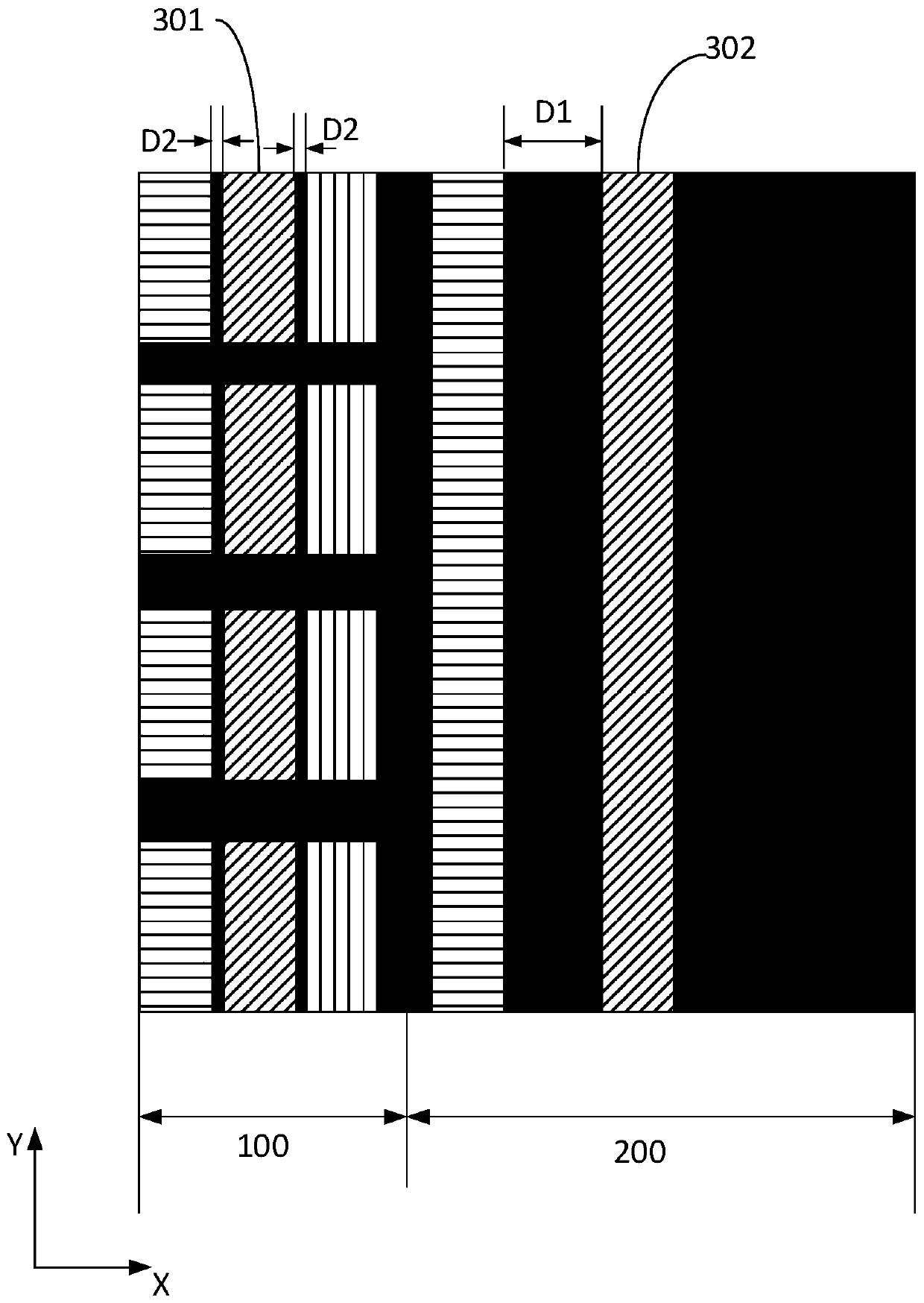

Transparent polymer dispersed liquid crystal display device and manufacturing method and application thereof

InactiveCN102967962AGood expressionSolve yellowingNon-linear opticsMethyl methacrylateLiquid-crystal display

The invention relates to a transparent polymer dispersed liquid crystal display device and a manufacturing method and application thereof. The transparent polymer dispersed liquid crystal display device comprises first and second substrates, first and second alignment layers and a polymer dispersed liquid crystal clamped between the first and second substrates, wherein the first alignment layer is formed on the first substrate, and the second alignment layer is formed on the second substrate. The transparent polymer dispersed liquid crystal display device is characterized in that the first and second substrates are ITO ((Indium Tin Oxide))-doped organic glass with the degraded surface, and the first and second alignment layers are uniaxially stretched polyvinyl alcohol grafted methyl methacrylate films. According to the transparent polymer dispersed liquid crystal display device, the alignment layers and the substrates, and the alignment layers and the polymer dispersed liquid crystal can be prevented from generating gaps caused by stripping.

Owner:BOE TECH GRP CO LTD

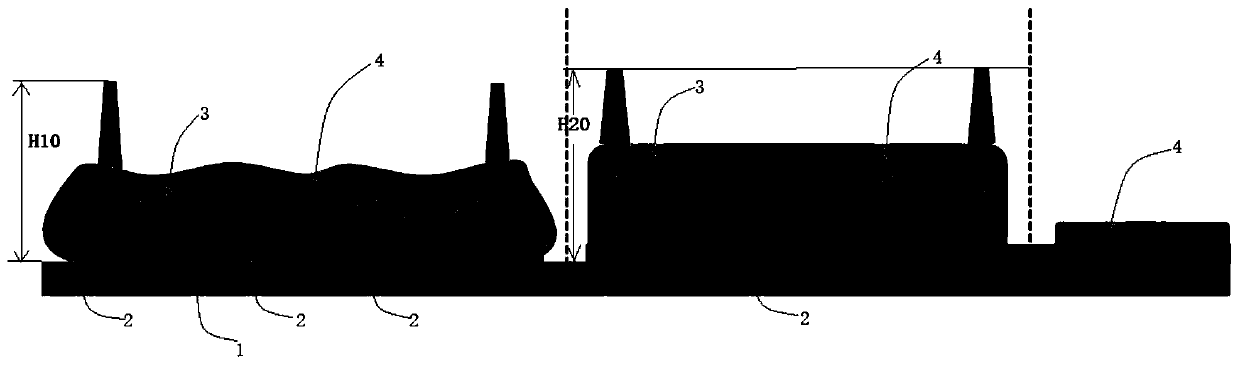

Color film substrate, display panel and display device

PendingCN110850629AImprove box thickness varianceSolve yellowingNon-linear opticsColor filmDisplay device

The invention discloses a color film substrate, a display panel and a display device. The color film substrate comprises a substrate; the substrate comprises a display area and a non-display area; a shading layer and a color resistance layer are located on one side of the substrate; a planarization layer is further arranged on one side, deviating from the substrate, of the color resistance layer;the display area comprises a plurality of display color resistance units, the display color resistance units comprise a plurality of display color resistance patterns with different colors, and the display color resistance patterns comprise a first display color resistance pattern; the non-display area comprises a plurality of dummy color resistance units, each dummy color resistance unit comprises at least one dummy color resistance pattern, and each dummy color resistance pattern comprises a first dummy color resistance pattern; the colors of the first display color resistance patterns are the same as these of the first dummy color resistance patterns; the thicknesses of the first dummy color resistance patterns is smaller than these of the first display color resistance patterns in thedirection perpendicular to a plane where the substrate is located. By improving the box thickness difference between the display area and the non-display area, the phenomenon of peripheral yellowing is improved, and the yield is increased.

Owner:XIAMEN TIANMA MICRO ELECTRONICS

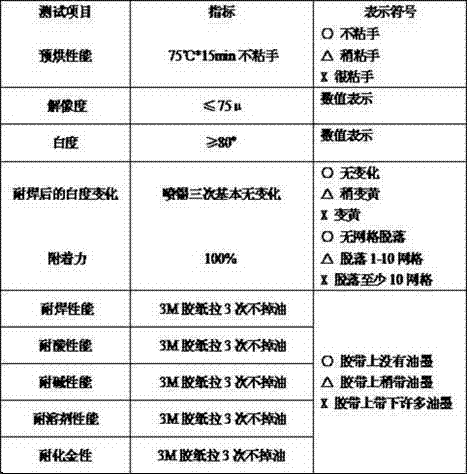

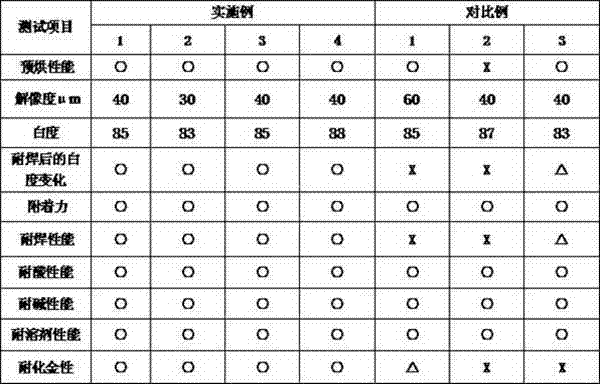

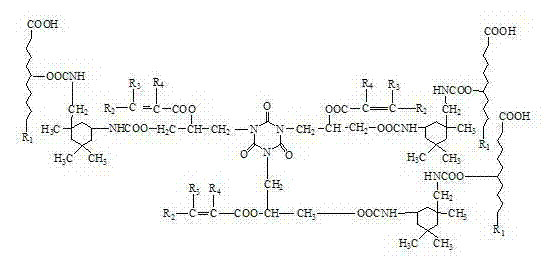

Polyurethane acrylic ester photosensitive resin oligomer and preparation method thereof

ActiveCN102775363ASolve the problem that it cannot be developed with sodium carbonate without acidic groupsSolve yellowingOrganic chemistryInksOligomerPolymer science

The invention belongs to the technical field of materials and particularly relates to a polyurethane acrylic ester photosensitive resin oligomer for light-emitting diode (LED) light-sensation solder-proof printing ink. The oligomer is of a polyurethane acrylic ester structure, an oligomer molecule comprises at least one carboxyl and one triazine heterocycle. A preparation method of the polyurethane acrylic ester photosensitive resin oligomer comprises enabling a polyurethane compound containing at least one carboxyl and at least one NCO group and an acrylic ester compound containing at least two carboxyls and at least one triazine ring structure to be dissolved through a solvent, heating and stirring, removing the solvent after the reaction is finished, and obtaining the final product. Besides fundamental performances of ordinary solder-proof printing ink, the LED light-sensation solder-proof printing ink prepared through the oligomer further has unique high whiteness and high reflection and strengthened performances of resisting chemical gold and heat, and development can be achieved through alkaline solution.

Owner:恒昌涂料(惠阳)有限公司

Polyurethane paint applied to woodworking and application thereof

InactiveCN102504682ANot easy to yellowSolve yellowingPolyurea/polyurethane coatingsOrganic solventKetone solvents

The invention discloses polyurethane paint applied to woodworking and application thereof. The polyurethane paint is used for preventing a paint film of conventional polyurethane paint sprayed on a bleached wooden ware from being yellowed. The polyurethane paint consists of components A, B and C. When the polyurethane paint is in use, the components A, B and C are mixed according to a certain ratio. The component A consists of 30 to 70 percent of hydroxy-containing alkyd resin or acrylic resin, 29 to 45 percent of organic solvent, 1 to 7 percent of zinc stearate and 0 to 18 percent of talcum powder; the component B consists of 20 to 80 percent of isocyanate curing agent and 20 to 80 percent of esters solvent; and the component C is diluent and mainly consists of one or more of an esters solvent, an arene solvent or a ketones solvent. The polyurethane primer is used on a high-end bleached furniture, is used as a primer of the bleached wooden ware and can be used for ensuring the paint film of the conventional polyurethane paint sprayed on a bleached wooden ware not to be yellowed.

Owner:GUANGDONG LANYANG SCI & TECH

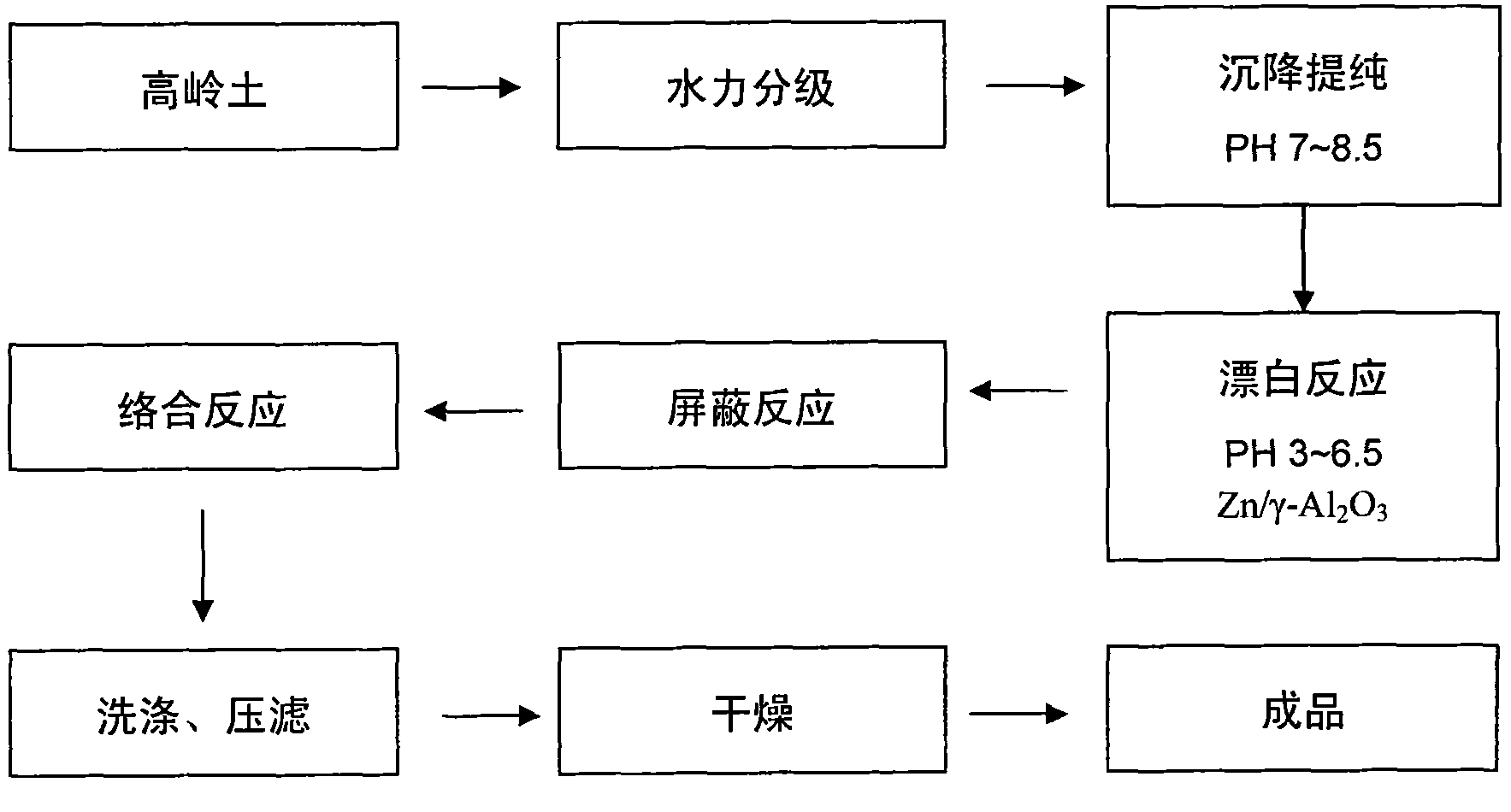

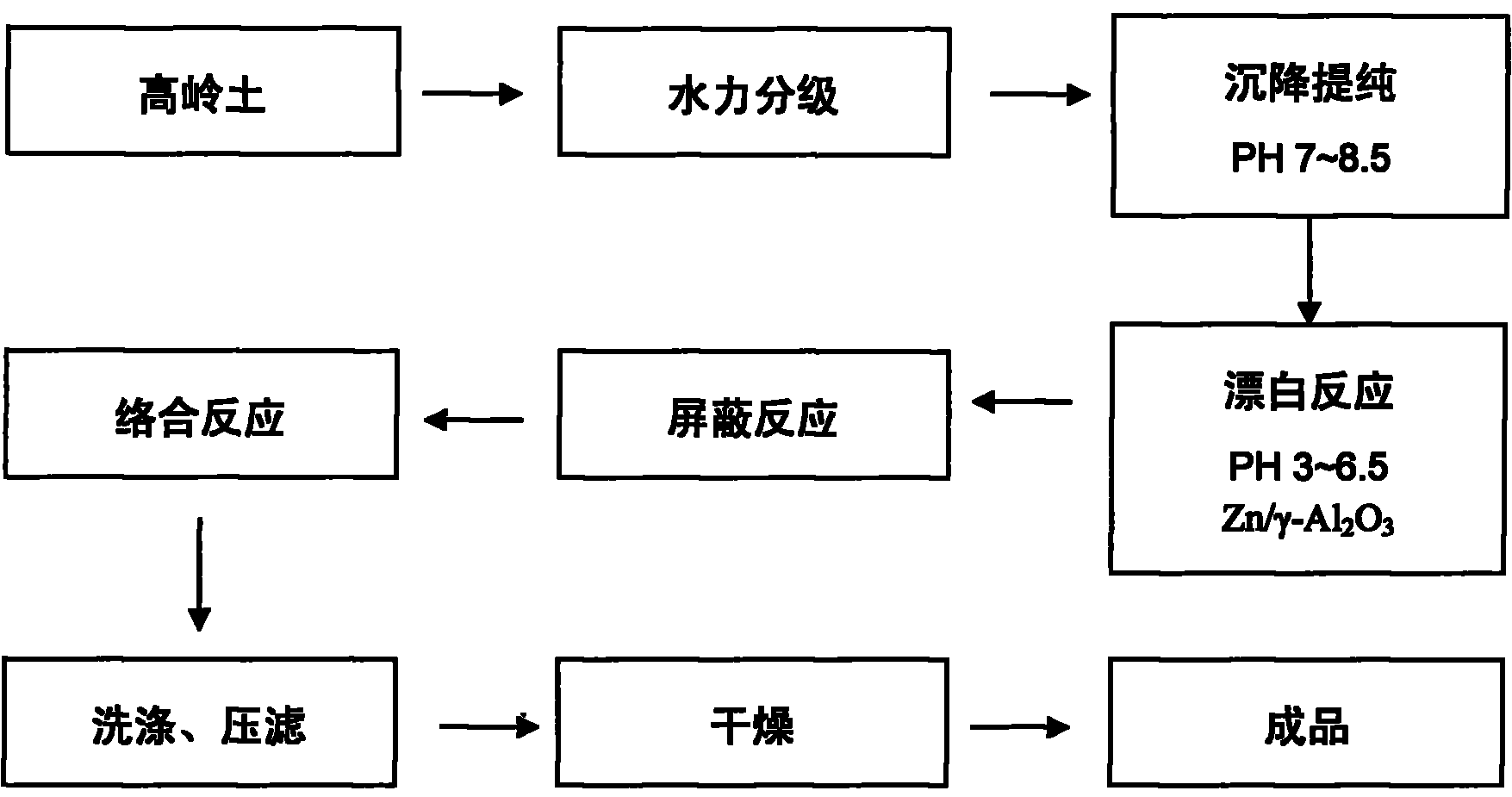

Process for enhanced reduction bleaching of kaolin by using thiocarbamide

The invention relates to a process for enhanced reduction bleaching of kaolin by using thiocarbamide, which uses sodium dithionite as a main reducing agent and the thiocarbamide as an auxiliary reducing agent to perform combined enhanced bleaching on the kaolin under a Zn / gamma-Al2O3 catalyzed condition with the pH value of 3.0 to 6.5 at the normal temperature, and simultaneously perform a shielding reaction and a complex reaction. The process solves the problem that the kaolin is yellowed after bleaching, and has the characteristics of low cost, good bleaching effect and small environmental pollution; besides, a kaolin powder product has the natural whiteness of over 85 percent and the calcination whiteness of over 90 percent, has high brightness, stability and dispersity, and can be widely used in the industries of high-grade fine ceramics, coatings, papermaking and the like.

Owner:广西兖河矿业有限公司 +1

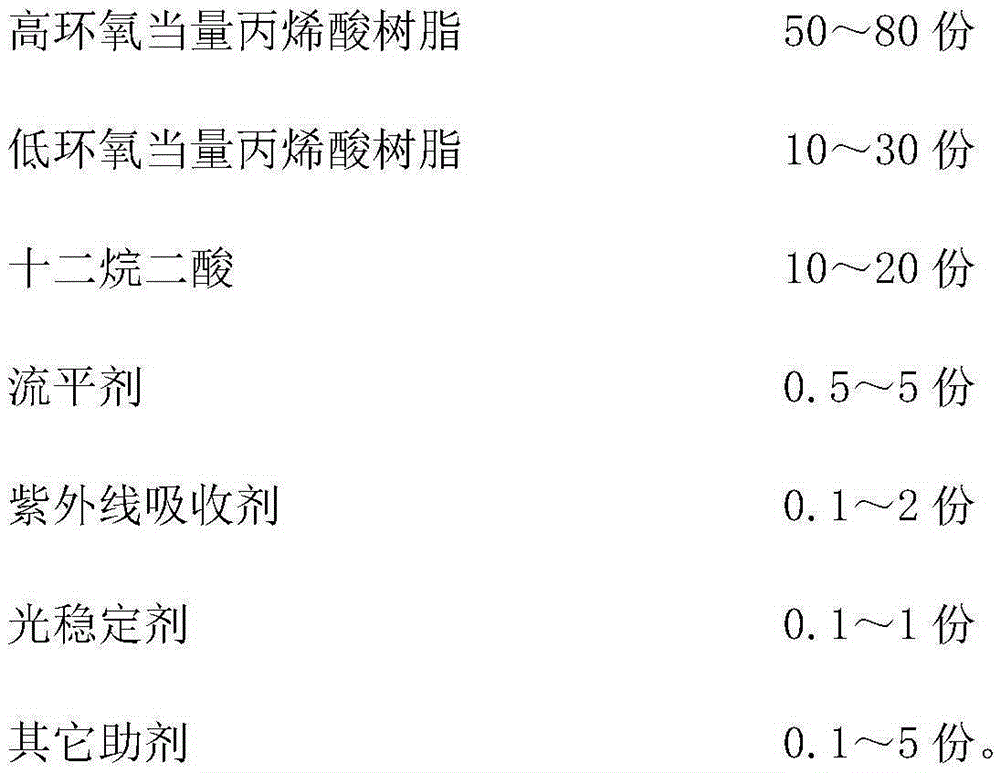

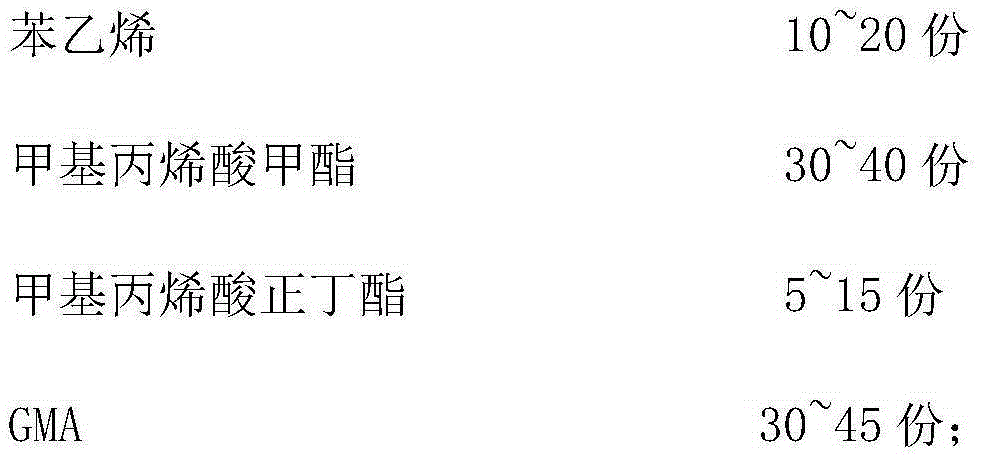

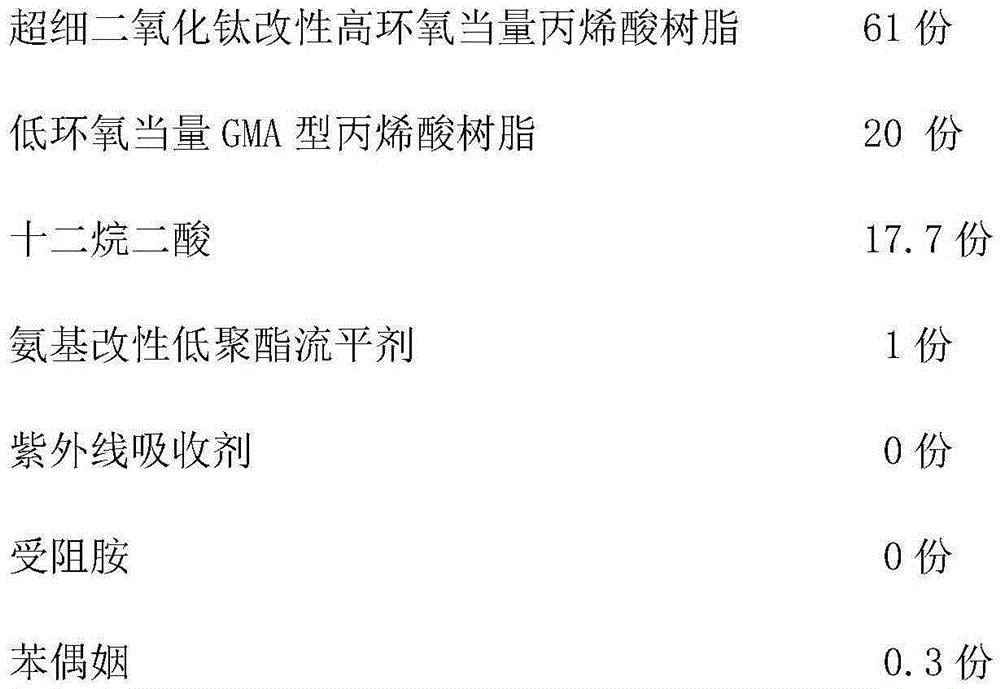

Low-temperature curing type epoxy group acrylic acid transparent powder coating and preparation method thereof

ActiveCN105273558ALower the initial reaction temperatureAchieving Low Temperature CuringPowdery paintsAcrylic resinUltraviolet lights

The invention discloses a low-temperature curing type epoxy group acrylic acid transparent powder coating. The low-temperature curing type epoxy group acrylic acid transparent powder coating is mainly prepared from high-epoxide-equivalent acrylic resin, low-epoxide-equivalent acrylic resin, dodecanedioic acid, an ultraviolet light absorber, a light stabilizer, a flatting agent and other auxiliaries. The high-epoxide-equivalent acrylic resin is modified by ultrafine titanium dioxide, and the low-epoxide-equivalent acrylic resin is in a GMA type. By the adoption of the high-epoxide-equivalent acrylic resin, the low-epoxide-equivalent acrylic resin and the dodecanedioic acid, the initial reaction temperature of the powder coating is decreased, and low-temperature curing is achieved; due to the auxiliary curing of the low-epoxide-equivalent acrylic resin, the enough compactness of the powder coating is improved, and then the corrosion resistance of the coating is improved; by the adoption of the high-epoxide-equivalent acrylic resin modified by the ultrafine titanium dioxide, the best ultraviolet absorption effect is obtained, and the weather resistance of the coating is improved.

Owner:GUANGZHOU KINTE IND

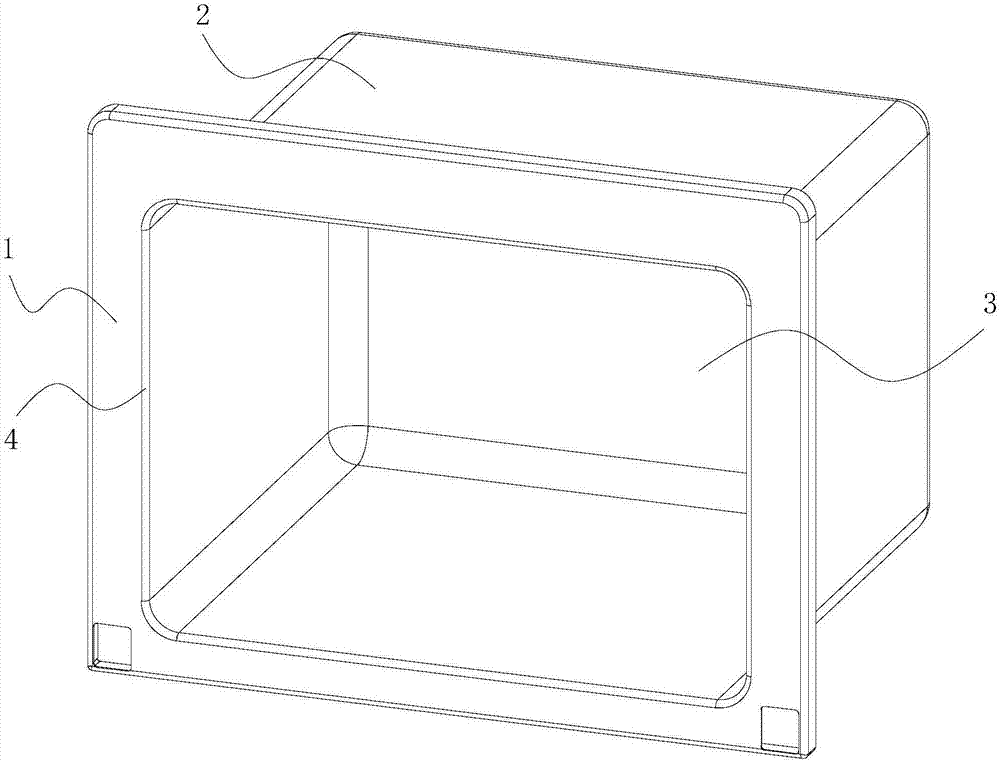

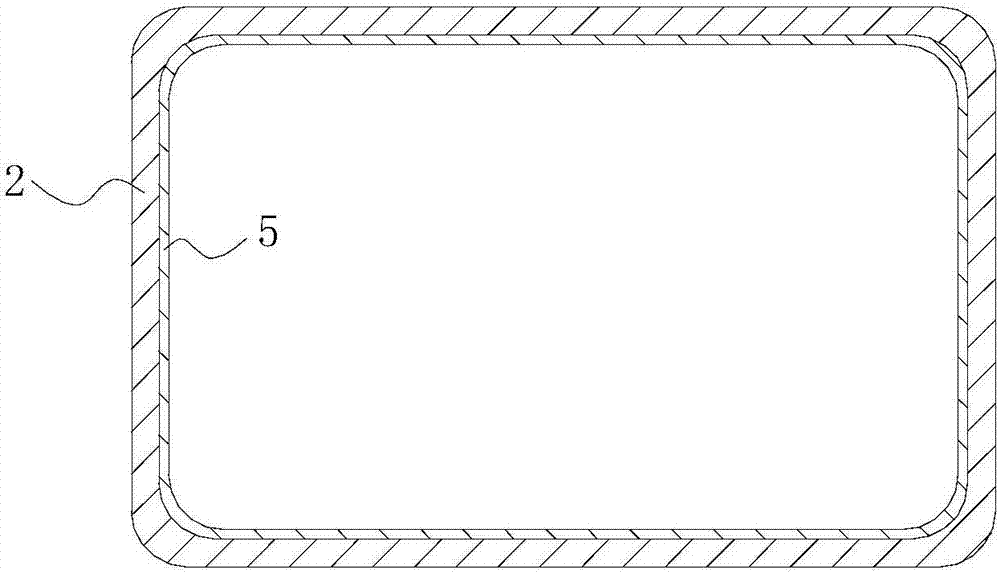

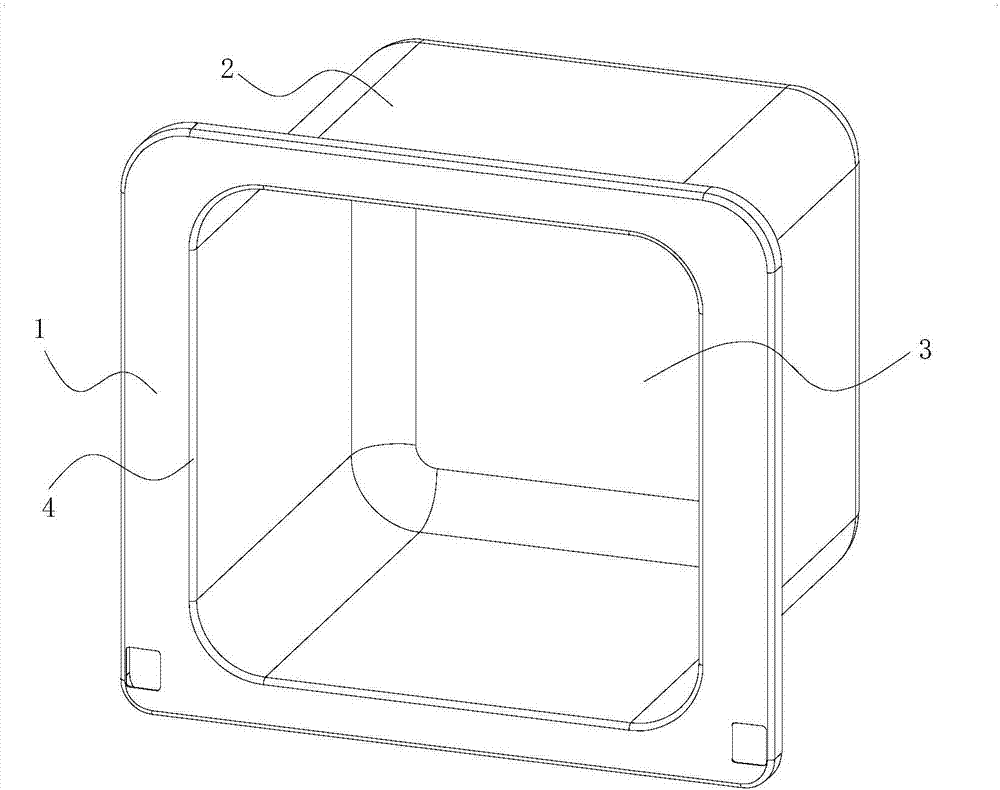

Cavity applying steam oven and steam oven

InactiveCN107485304AImprove air tightnessImprove rust resistanceCooking-vessel materialsSteam cooking vesselsSS - Stainless steelSilica gel

The invention discloses a cavity applying a steam oven. The cavity is formed by stretching and forming whole metal. The cavity comprises a front installation plate, a U-shaped frame and a rear plate, the cavity is formed by stretching and forming the front installation plate, the U-shaped frame and the rear plate at a time, the inner surface of the cavity formed by integrated stretching and forming is coated with an inorganic glassy material, and a metallic matrix of the cavity and the inorganic glassy material are used for coating and sticking through an enameling technology. The invention further provides the steam oven with the cavity. The cavity obtained by integrated stretching and forming is low in mold cost, no splicing gap exists, the consumption of sealing silica gel can be lowered, the sealing performance is good, the surface of the cavity can be completely covered with the inorganic glassy material, the rusting problem is eliminated, an enameled pressed steel plate is adopted for replacing expensive 304 stainless steel, the whole oven cost can be lowered, meanwhile the problems of yellowing and not resisting high temperature can be solved, the 400 DEG C or more high-temperature self-cleaning function can be achieved, and the problem that an existing steam oven is hard to clean is solved.

Owner:广东天倬智能家居有限公司

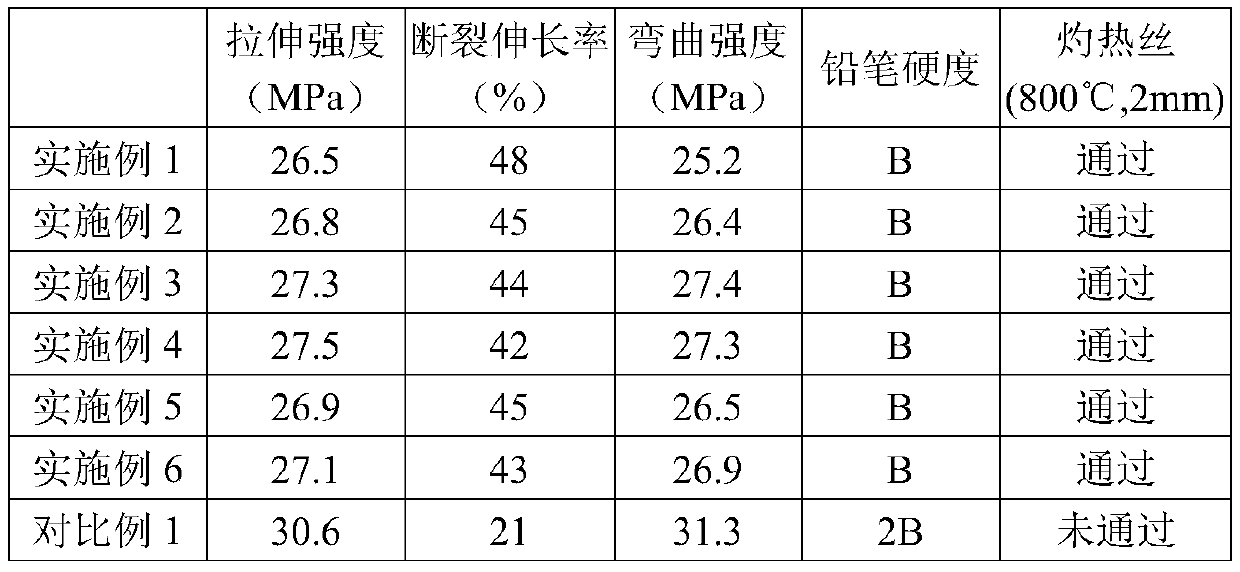

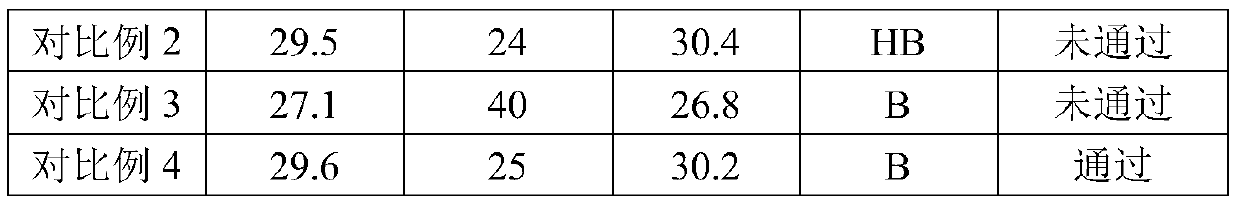

Scratch-resistant flame-retardant PP modified material and preparation method thereof

The invention belongs to the technical field of high polymer materials, and especially, relates to a scratch-resistant flame-retardant PP modified material. The scratch-resistant flame-retardant PP modified material is composed of the following components in parts by mass: 35 to 60 parts of block co-polypropylene, 10 to 20 parts of random co-polypropylene, 3 to 8 parts of a scratch-resistant additive, 1 to 5 parts of a toughening modifier, 2 to 7 parts of a halogen-free flame retardant, 1 to 2 parts of a flame-retardant synergist, 1 to 3 parts of a lubricant and 1 to 2 parts of an antioxidant,wherein the scratch-resistant additive is nano aluminum oxide and polypropylene grafted high-molecular-weight polyorganosiloxane, and the toughening modifier is an acrylic acid-polysiloxane rubber-methyl methacrylate multipolymer and / or an acrylic acid-ethylene propylene rubber-methyl methacrylate multipolymer. Compared with the prior art, the PP modified material disclosed by the invention has scratch resistance, and the toughness and flame retardancy of the PP modified material are correspondingly improved.

Owner:东莞毅工工程塑料有限公司

Production method of spinning primary liquid of plant protein and acrylonitrile graft copoly fiber

InactiveCN1410464ASolve yellowingSolving Elasticity ProblemsConjugated cellulose/protein artificial filamentsFiberAcrylonitrile

A process for preparing the spinning dope includes such steps as immersing vegetable protein curd in the aqueous solution of NaCl, regulating pH value to obtain the vegetable protein, further dissolving it in the aqueous solution of zinc chloride, regualting pH value with hydrochloric acid to raise temp. for modifying, further adding hydrogen peroxide, and after trimming the protein, graft copolymerizing with acrylonitrile under the protection of N2 gas. Its advantages are low cost and gay color and high elasticity of its product.

Owner:宋惠远 +1

Rice seed cold storage method

ActiveCN104126661ASolve dehydrationSolve agingSeed preservation by freezing/coolingSeed preservation by dryingGas compositionProduction chain

The present invention discloses a rice seed cold storage method, and relates to a field of agricultural product fresh keeping storage. The method includes the following steps: cleaning and selecting, pre-cooling, sterilization, spraying of a fresh-keeping agent, loading of a moisture bag, warehouse disinfection, controlling of the temperature, controlling of the content of oxygen and carbon dioxide, controlling of the moisture of warehouse and ex-warehousing. The method of the present invention has the following advantages that the cold storage method determines appropriate conditions for the rice seed storage, ensures reasonable temperature, moisture and gas composition inside the warehouse, solves the problems of water losing, aging, yellowing, germination, fast decaying during the process of rice seed storage, improves the rice storage time without destroying the texture of the rice seed, promotes the development of the rice industry, increases the added value and promotes the construction of an agricultural production chain demonstration mode.

Owner:巢湖春友种业科技有限公司

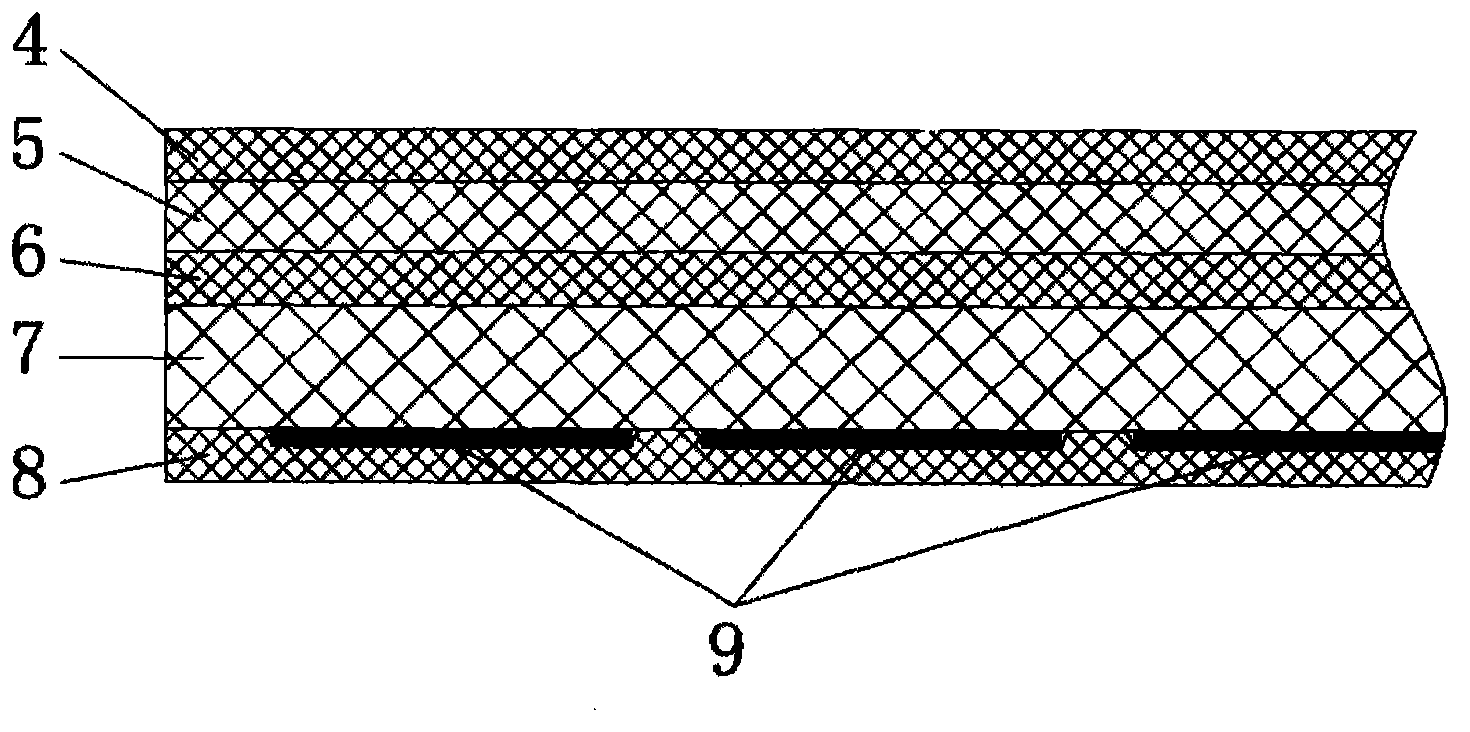

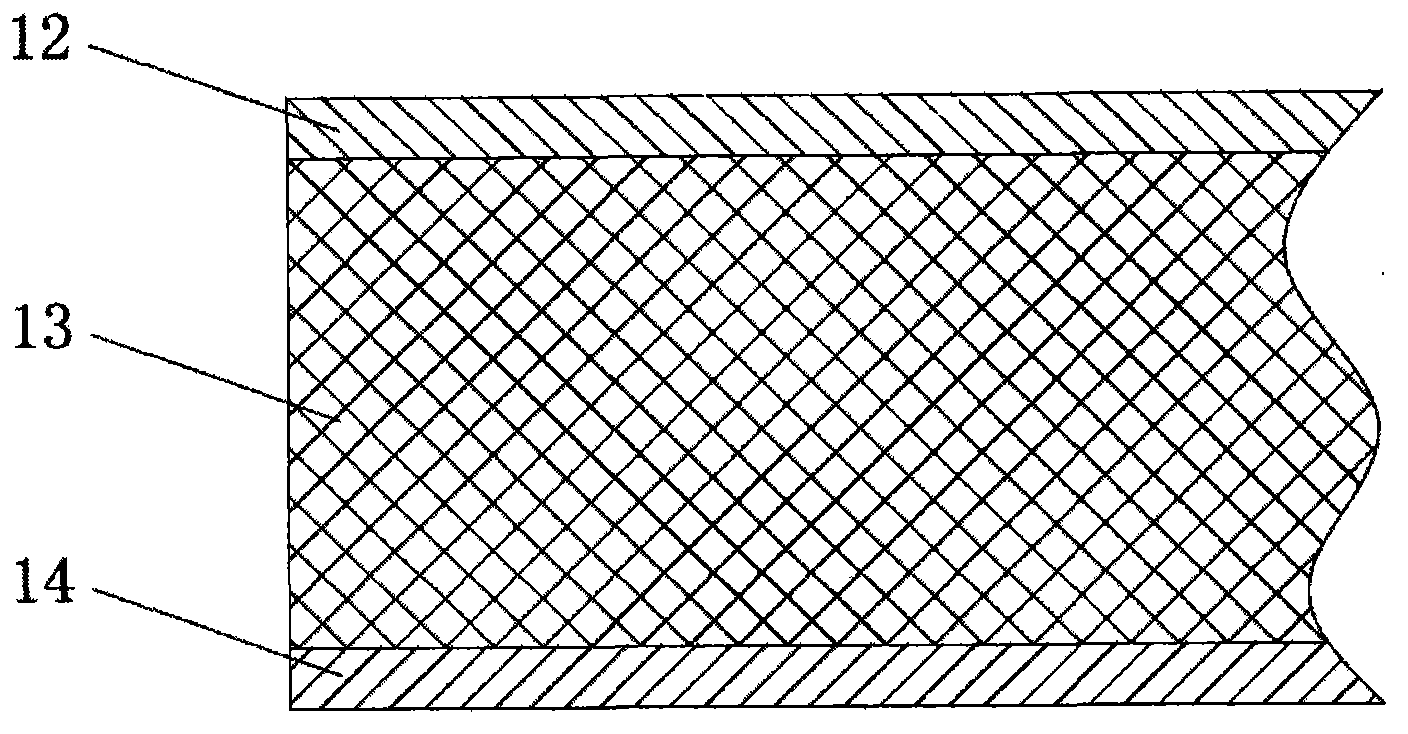

Carbon crystal heating wall heating product and production process thereof

ActiveCN103322611AQuality assuranceFirmly connectedLighting and heating apparatusElectric heating systemScreen printingFixed frame

The invention discloses a carbon crystal heating wall heating product and a production process thereof. The carbon crystal heating wall heating product comprises a carbon crystal heating plate, a reflecting heat insulation plate and a fixing frame. The carbon crystal heating plate comprises a surface protecting layer, a decorating layer, a connecting layer, a heating layer, an insulation layer, a carbon crystal heating film, a first conductive copper bar and a second conductive copper bar. The reflecting heat insulation plate comprises an upper reflecting layer, a heat insulation layer and a lower reflecting layer. The first conductive copper bar and the second conductive copper bar are fixed at two ends on the same side of the heating layer. The carbon crystal heating film is printed on one side of the heating layer where the conductive copper bars are fixed through a silk-screen printing method, and two ends of the heating film are in contact with the first conductive copper bar and the second conductive copper bar. The surface protecting layer, the decorating layer, the connecting layer and the insulation layer are sequentially connected and fixed. The carbon crystal heating plate and the reflecting heat insulation plate are connected and fixed through the fixing frame. The carbon crystal heating wall heating product has the advantages of being long in service life, not easy to age, not prone to be yellow, high in heating efficiency and the like. A protruding process is environmentally friendly, high in efficiency and strict in quality control.

Owner:浙江王品科技有限公司

UV lacquer

InactiveCN101173150AImprove performanceSolve yellowingPolyurea/polyurethane coatingsLacquerReactive diluent

The invention discloses a low yellowing UV varnish for the coating of black plastic substrates, comprising a plurality of components in weight percentage: bi-functional acrylate monomer 20 to 30 percent, hexa-functional acrylate monomer 10 to 20 percent, low yellowing aliphatic polyurethane acrylate 45 to 65 percent, glyoxylate mixture photoinitiators 2.5 to 5, promoter 0.1 to 0.4 percent, and solvent 20 to 50 percent; wherein, the promoter is BYK333 and the solvent is also formed by toluene, butyl and isopropanol. By matching low yellowing resins with reactive diluents, and adopting glyoxylate mixture photoinitiators, the invention has the advantages of low yellowing and excellent comprehensive performance.

Owner:MITAC PRECISION TECH CO LTD SHUNDE DISTRICT FOSHAN CITY

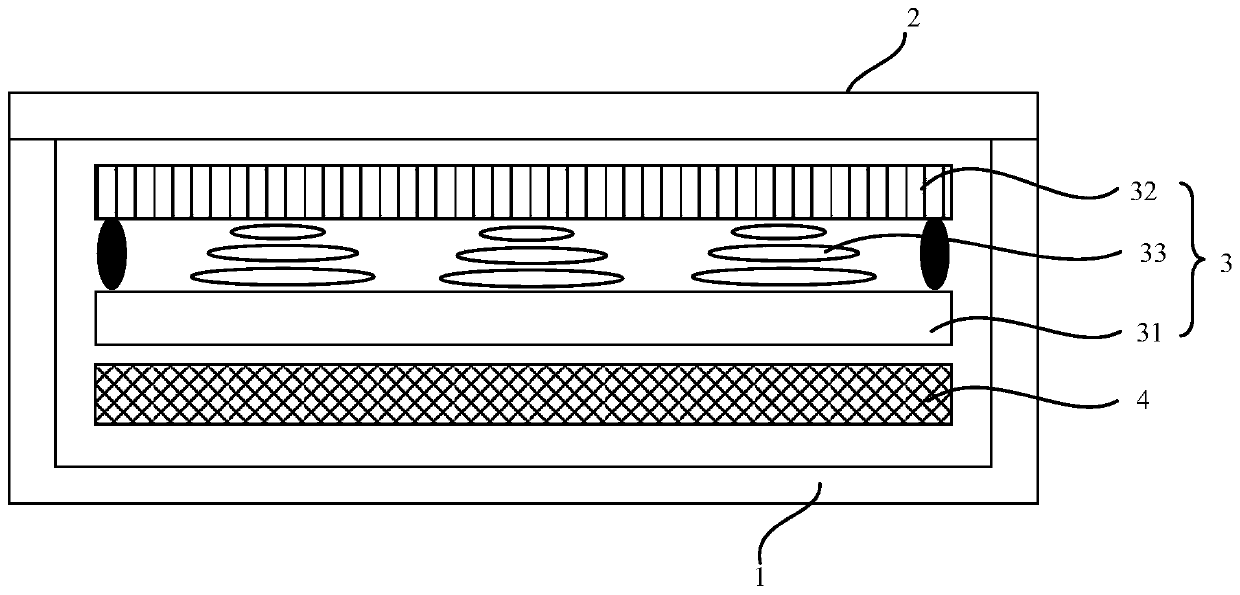

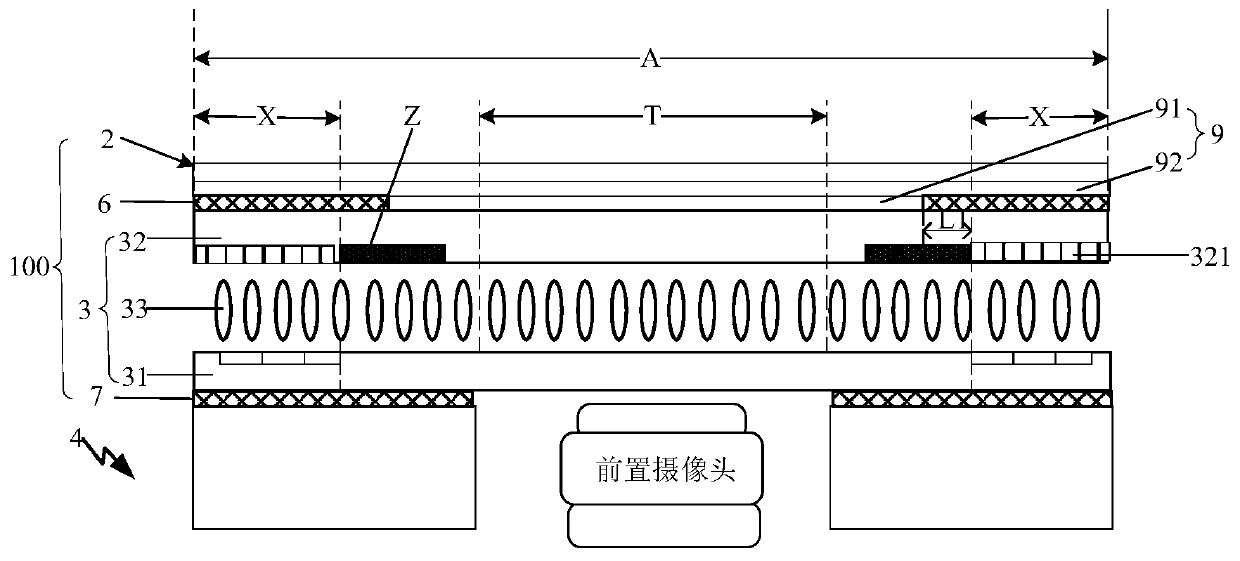

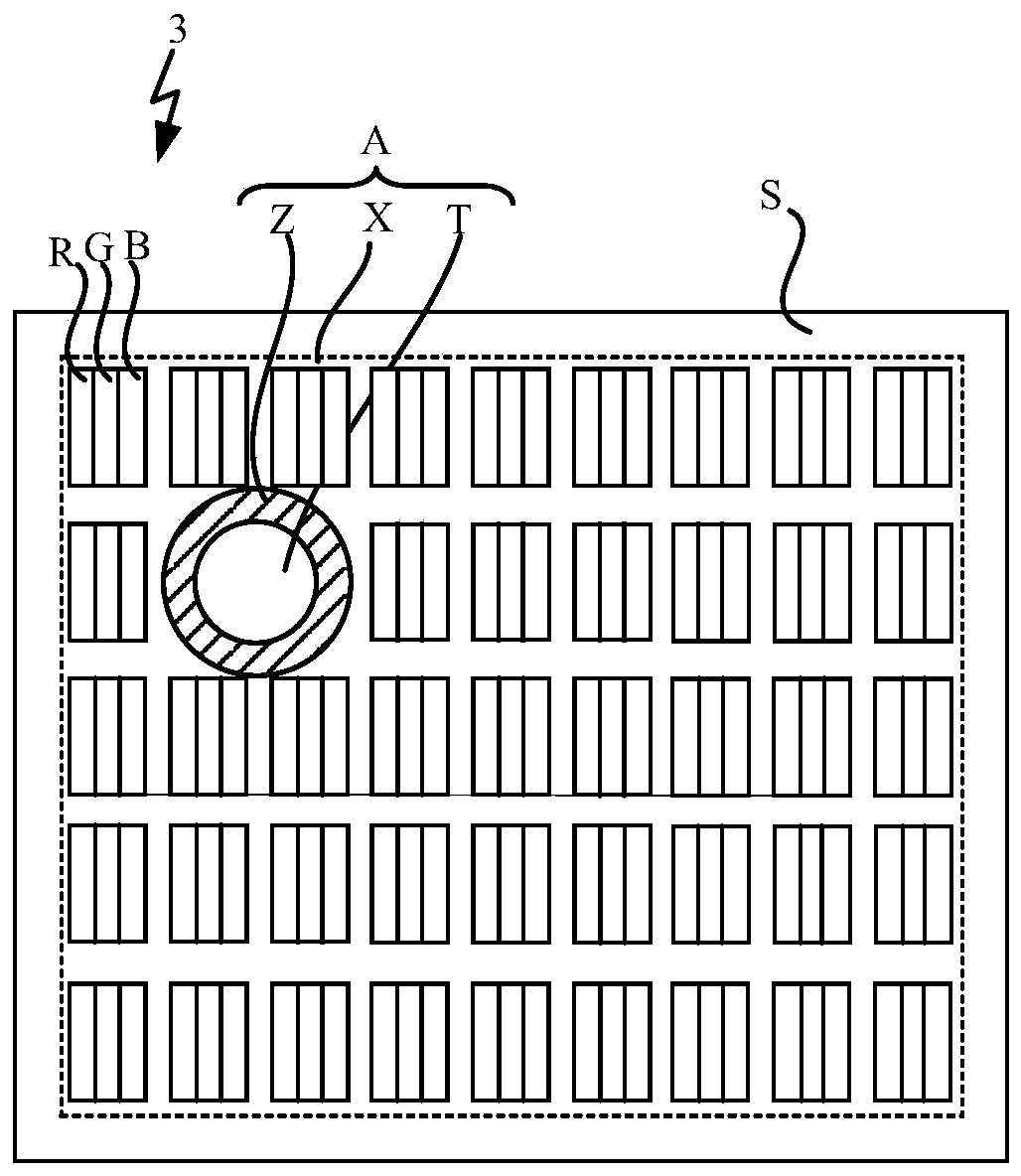

Display module, display device and display control method thereof

The invention relates to the technical field of the display, and especially relates to a display module, a display device and a display control method thereof. The problem hat the photic zone edge is yellowing is solved. The embodiment of the invention provides the display module, the display module comprises a display panel, the display panel is provided with a display area, the display area comprises a pixel zone, a photic zone and a shading zone located between the pixel zone and the photic zone and surrounding a circle of the photic zone; the pixel zone comprises multiple pixel units, each pixel unit comprises red subpixels, green subpixels and blue subpixels; and blue subpixels are closer to the shading zone in comparison with the red subpixels and the green subpixels in each pixel unit surrounding a circle of the shading zone. The display module disclosed by the embodiment of the invention is used for solving the problem hat the photic zone edge is yellowing.

Owner:BOE TECH GRP CO LTD +1

Tomato precooling technological process

InactiveCN103478226ASolve dehydrationSolve agingFruit and vegetables preservationPreservativeAdditional values

The invention discloses a tomato precooling technological process, relating to the field of freshness retaining and storing agricultural products. The tomato refrigerating and freshness retaining technological process comprises the steps of picking, cleaning, precooling, sterilizing and disinfecting tomatoes, washing, spraying a preservative, filling the tomatoes in a breathable bag, disinfecting a storehouse, controlling the temperature, controlling contents of oxygen and carbon dioxide, controlling the humidity of the storehouse, and delivering the tomatoes from the storehouse. According to the tomato refrigerating and freshness retaining technological process, suitable conditions beneficial to storing the tomato are determined, reasonable temperature, humidity and gas components in the storehouse are ensured, the problems of water loss, ageing, yellowing and rotting in the tomato storage process are solved, the storage time of the tomato is prolonged, the color and the texture can not be damaged, the development in the vegetable industry is promoted, the additional value is increased, and the building of a demonstrative mode in a high-efficiency agriculture industry chain is promoted.

Owner:怀远县兴达蔬菜有限公司

Method for preparing nylon 6 for fibers from hindered amine prepolymerization unit

ActiveCN103204989AImprove distribution uniformityImprove unevennessMonocomponent copolyamides artificial filamentHindered amine light stabilizersWeight distribution

The invention relates to a method for preparing nylon 6 for fibers from a hindered amine prepolymerization unit. The nylon 6 for fibers is formed by polymerizing caprolactam and the hindered amine prepolymerization unit in the mass ratio of 1000:(0.5-10). The hindered amine prepolymerization unit is generated by pre-condensing a piperidine derivative with a steric-hinerance effect and 6-aminocaproic acid in the presence of a catalyst, wherein the molar ratio of the piperidine derivative with the steric-hinerance effect to 6-aminocaproic acid to the catalyst is equal to 2:1:(0.1-0.3); the reaction temperature is 125-270 DEG C; and the reaction time lasts for 0.5-20 hours. By the method, the problems of nylon fiber yellowing and unstable quality can be effectively solved, and the obtained anti-yellowing nylon 6 for fibers is uniform in molecular weight distribution, good in viscosity stability, free of oxidization and ageing, and suitable for processing high-quality nylon fibers.

Owner:FUJIAN JINGFENG TECH

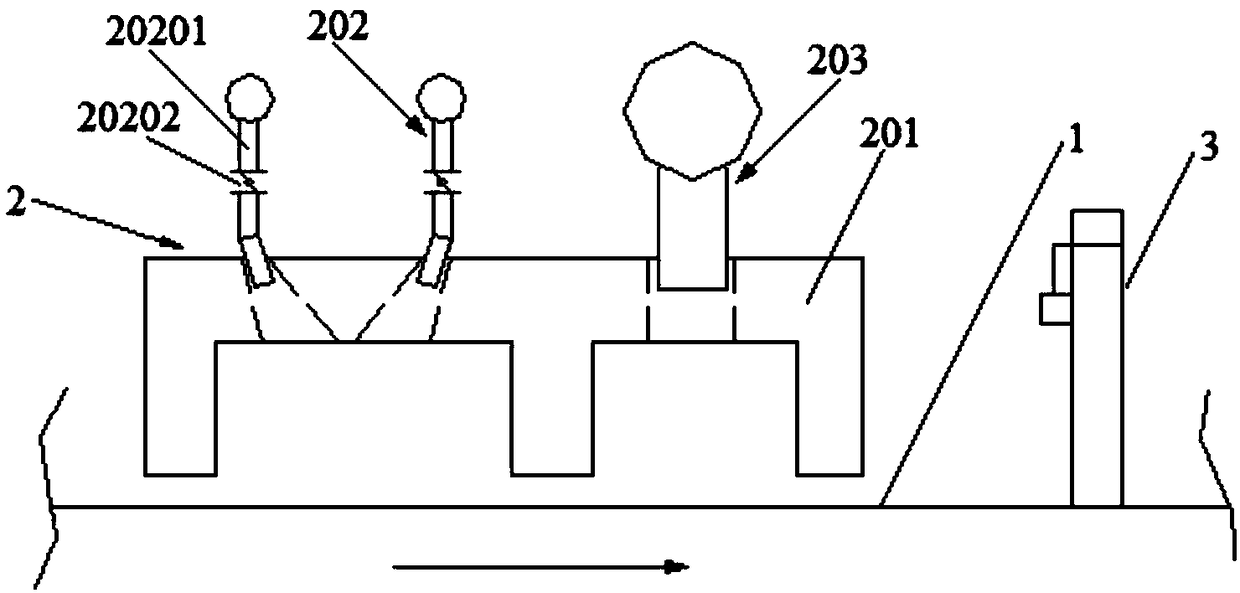

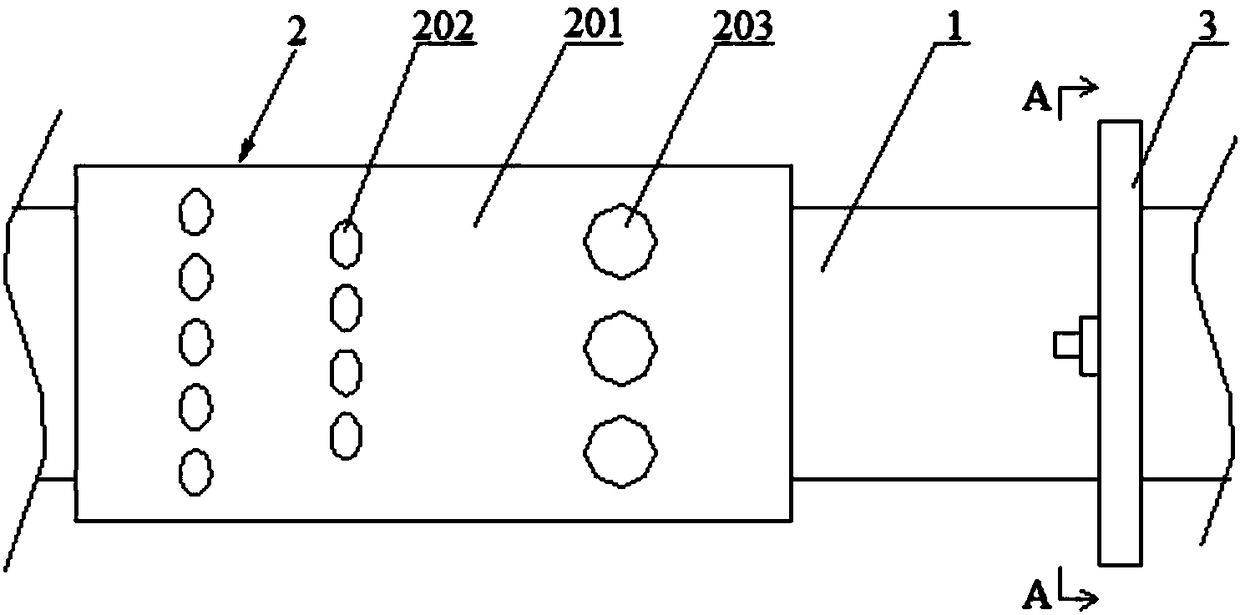

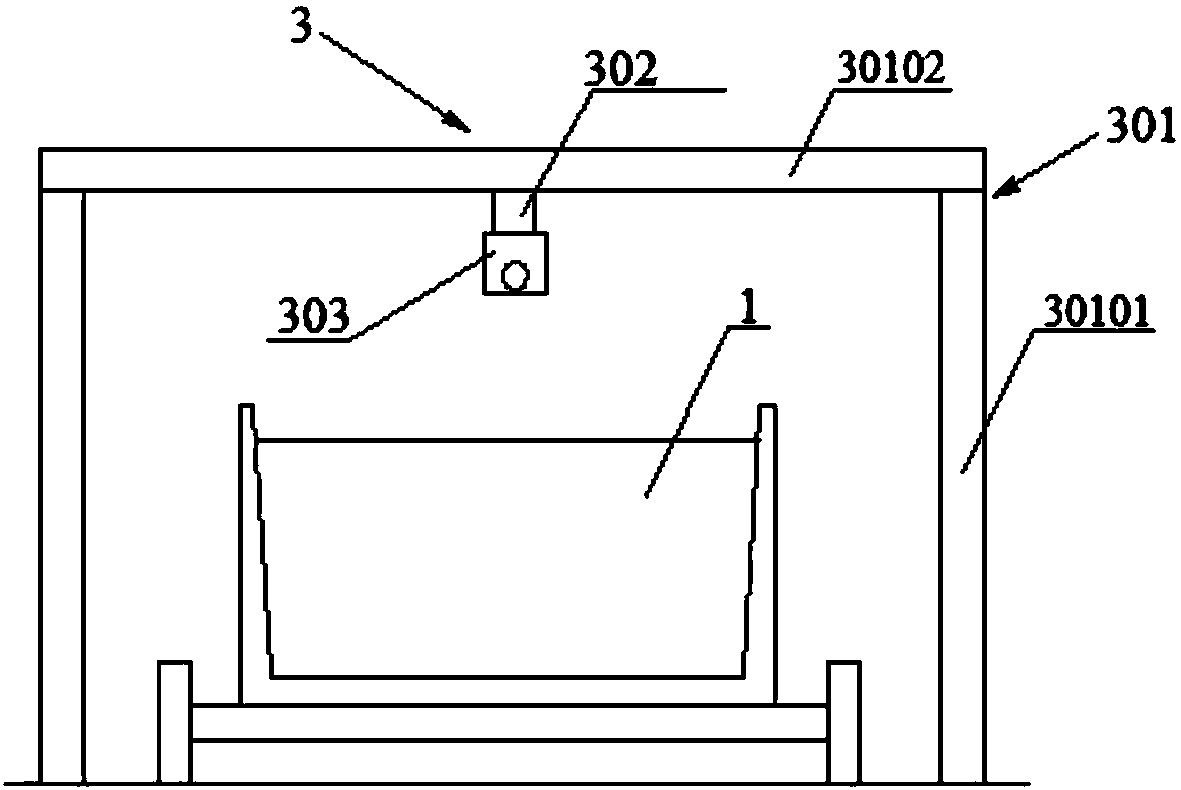

Video identification-based charge level diagnosis and self-adaptive control device and method for sintering machine

PendingCN108120311ASolve yellowingSolve the problem of whiteningControl devices for furnacesEngineeringIdentification device

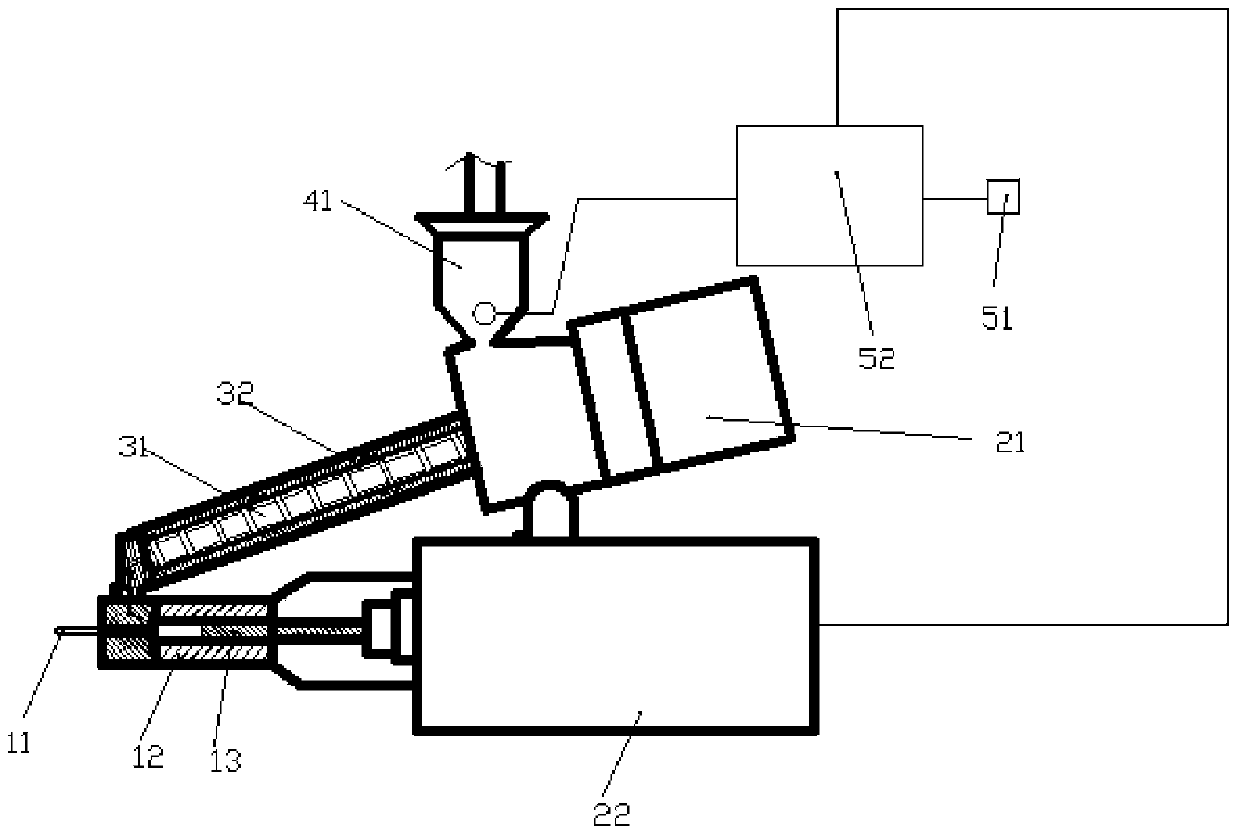

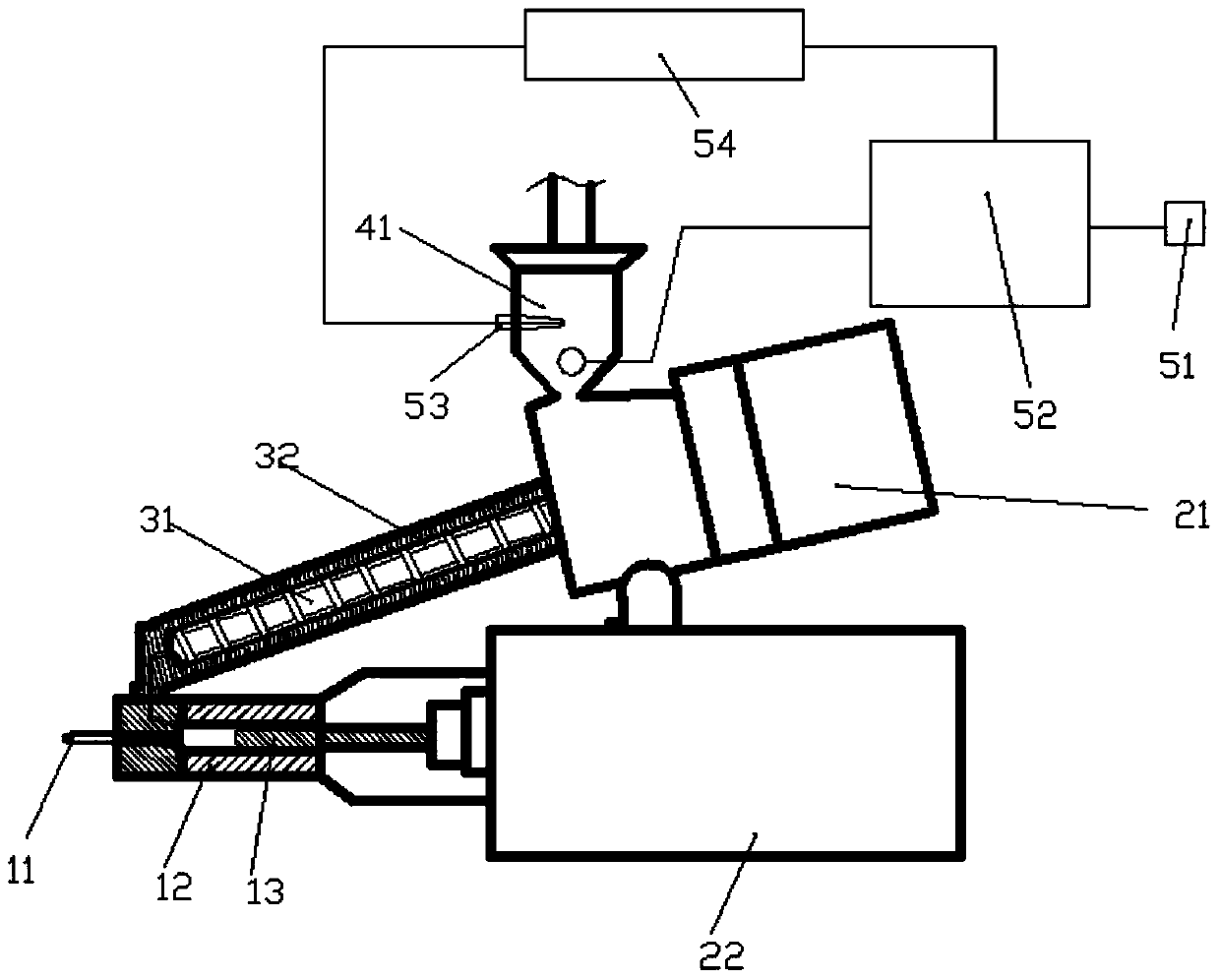

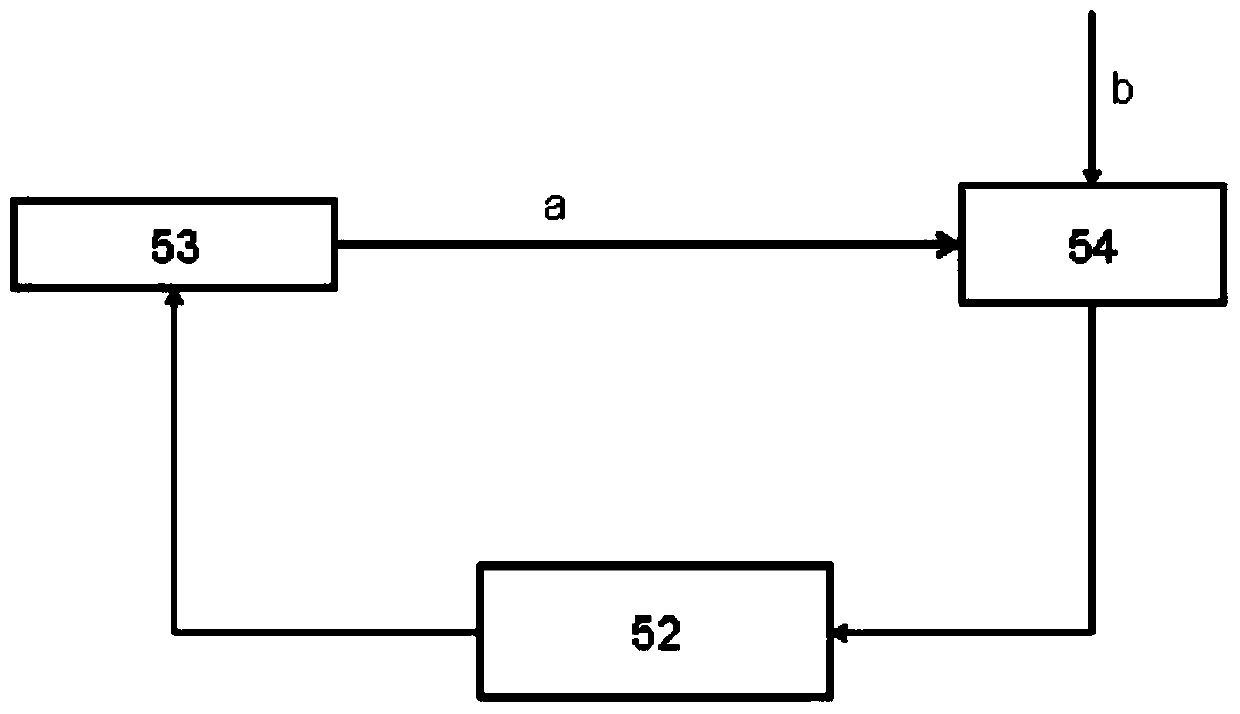

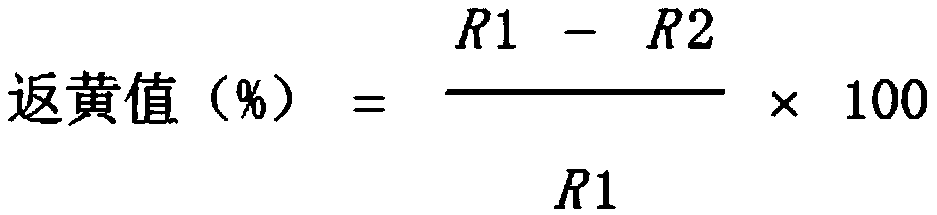

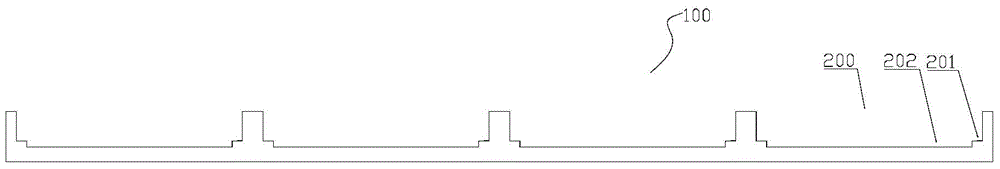

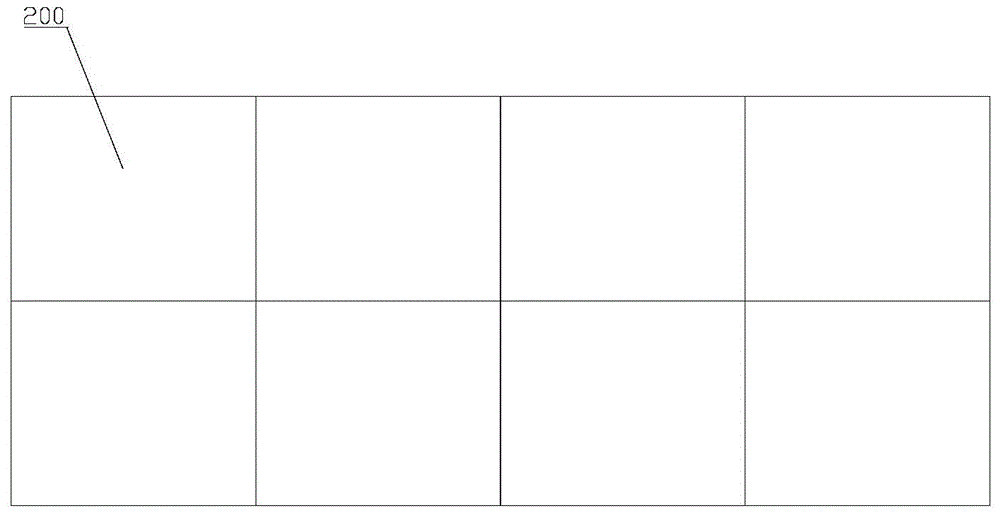

The invention discloses a video identification-based charge level diagnosis and self-adaptive control device for a sintering machine. The device comprises a sintering machine trolley (1) and an ignition furnace (2), wherein the ignition furnace (2) comprises a furnace body (201), an ignition burner (202) and a heat-insulation burner (203); the furnace body (201) of the ignition furnace (2) is arranged on the upper part of the sintering machine trolley (1); the ignition burner (202) and the heat-insulation burner (203) are both arranged at the top of the furnace body (201), and the ignition burner (202) is located at the upstream part of the heat-insulation burner (203). The device is characterized by further comprising a charge level video identification device (3) arranged at the downstream part of the ignition furnace (2) and located above the sintering machine trolley (1) in the running direction of the sintering machine trolley (1). The device disclosed by the invention is capableof judging the ignition burner and a fuel gas blowing pipe which correspond to an unhealthy charge level according to the identified charge level color, and the opening degrees needing to be adjusted,of the corresponding electric valve of the ignition burner and the corresponding electric valve of the fuel gas blowing pipe, and then accurately and rapidly detecting and solving the unhealthy condition of charge level ignition, so that unmanned stable production of the ignition furnace is realized.

Owner:ZHONGYE-CHANGTIAN INT ENG CO LTD

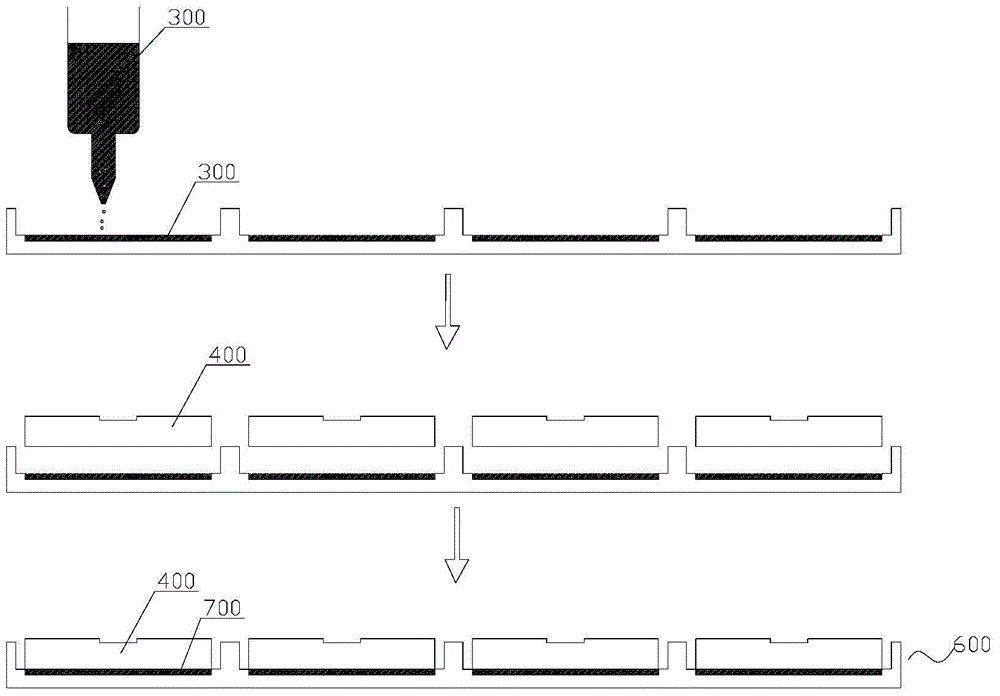

Injection molding machine and injection molding method adopting injection molding machine

The invention relates to the technical field of liquid crystal display, and discloses an injection molding machine. The injection molding machine comprises a hopper used for placing a material, and an inert gas generating device connected with the hopper, wherein the inert gas generating device is used for feeding an inert gas in the hopper. According to the injection molding machine provided by the invention, plasticizing of the material is completed under the protection of nitrogen, the problem of yellowing of a light guide plate due to oxygenolysis of the material is effectively solved; the injection molding machine has the characteristics of being low in cost, easy to implement and high in reliability.

Owner:BOE OPTICAL SCI & TECH +1

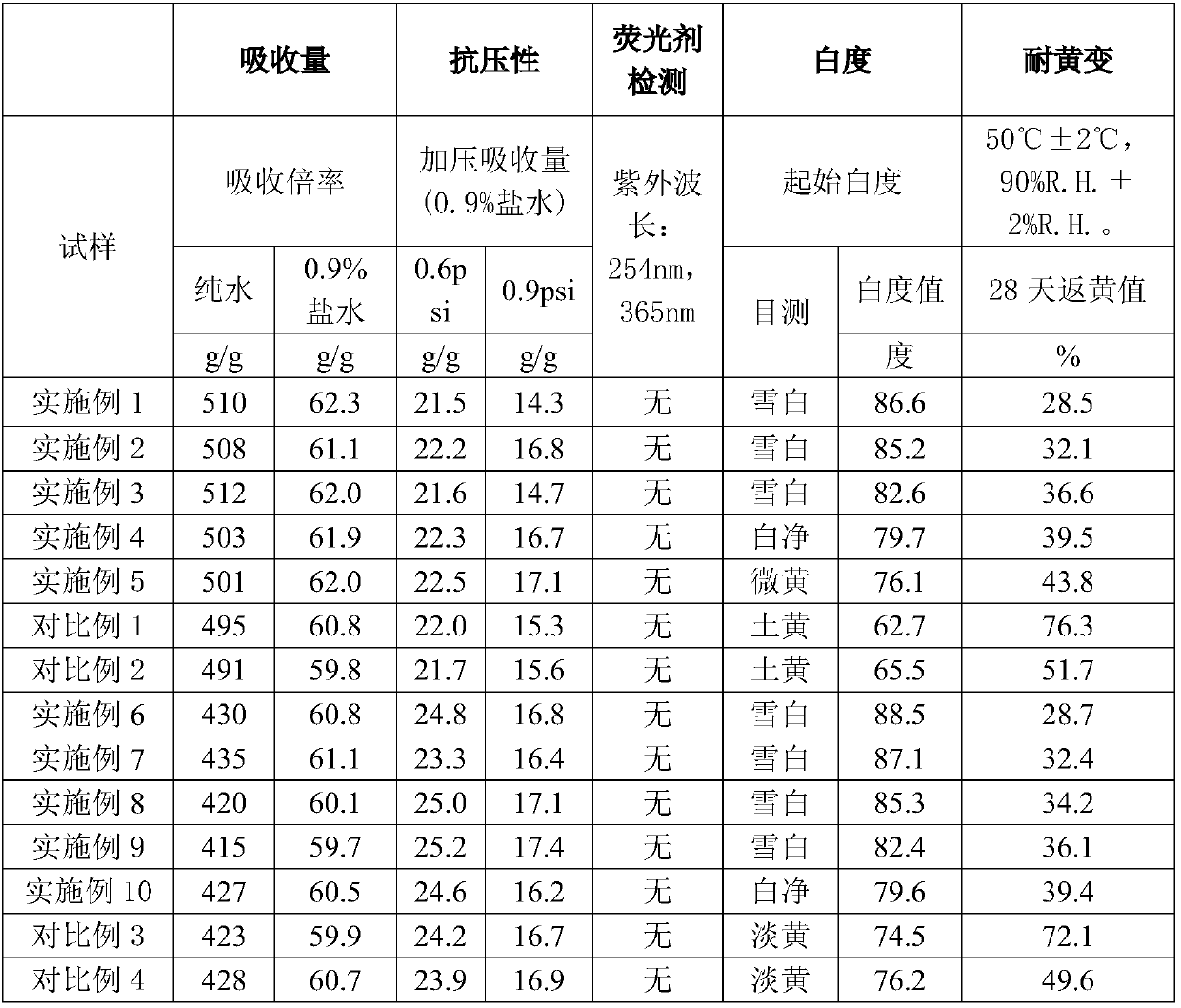

Preparation method of white and yellowing resistant water-absorbent resin

The invention discloses a preparation method of a white and yellowing resistant water-absorbent resin. The preparation method is a pre-neutralization method or a post-neutralization method, wherein the pre-neutralization method comprises the following steps: adding acrylic acid into a neutralization solution to be neutralized, carrying out a radical polymerization reaction to obtain sodium polyacrylate and polyacrylic acid hydrogel of a certain neutralization degree, performing squeezing granulation on the hydrogel in the presence of a soluble reducing agent, and performing after-treatment toobtain a super absorbent resin; and the post-neutralization method comprises the following steps: carrying out a radical polymerization reaction on an aqueous solution of acrylic acid so as to obtainpolyacrylic acid gel, and adding a neutralization solution into the polyacrylic acid gel to carry out a neutralization reaction; and adding the soluble reducing agent to perform squeezing granulation,and performing after-treatment, thereby obtaining the super absorbent resin. According to the preparation method disclosed by the invention, the initial whiteness of the product can be effectively improved, and the yellowing resistance of the product can also be effectively enhanced.

Owner:刘常红

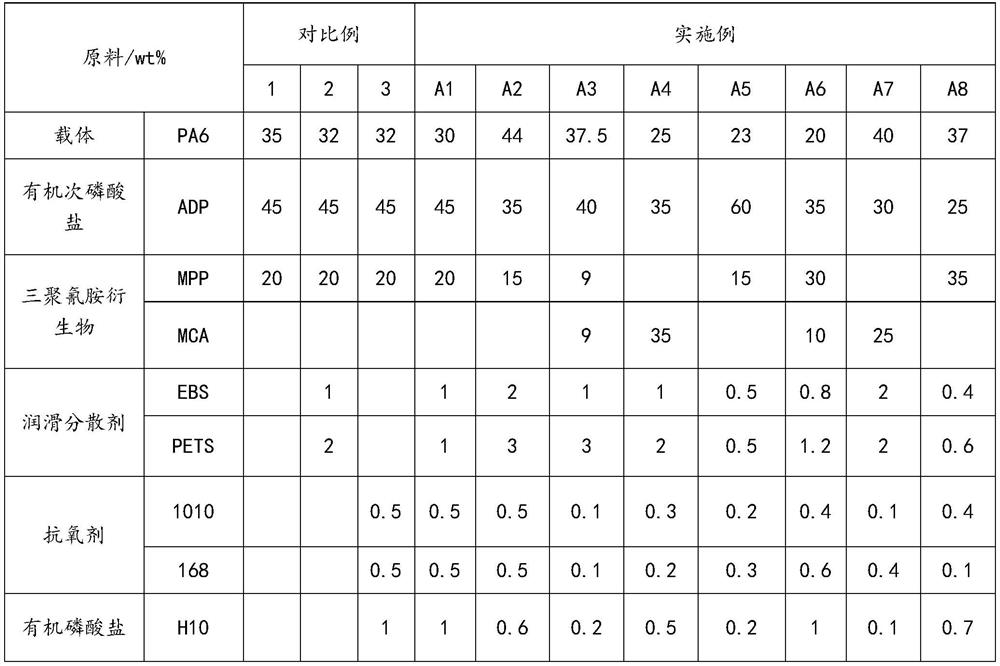

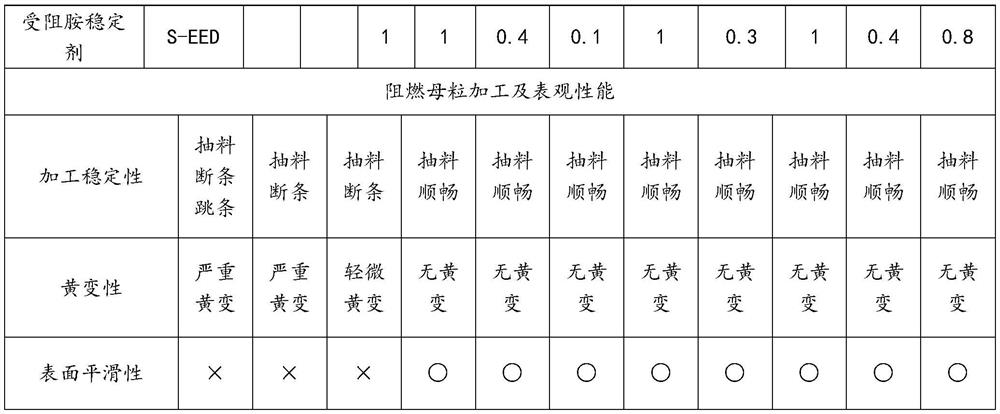

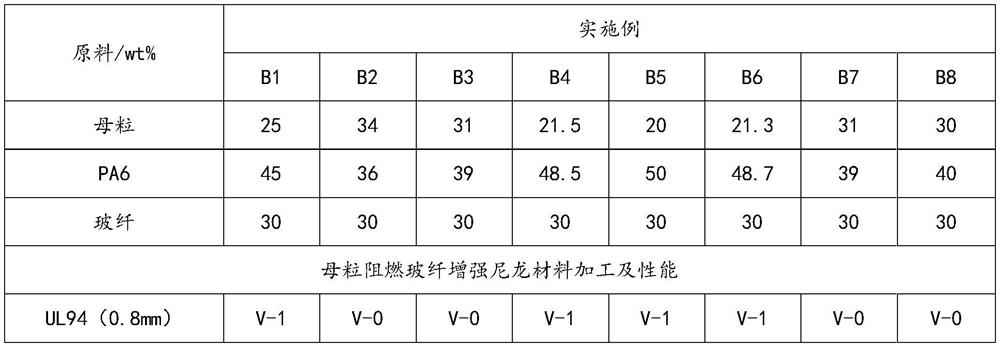

High-dispersity high-concentration nylon-based halogen-free flame-retardant master batch and preparation method thereof

The invention discloses a high-dispersity high-concentration nylon-based halogen-free flame-retardant master batch and a preparation method thereof. The high-dispersity high-concentration nylon-based halogen-free flame-retardant master batch comprises the following components in parts by mass: 20%-45% of a nylon resin carrier and 25%-60% of organic hypophosphite, wherein the mass percentage content of the melamine derivative is 15%-40%, the relative viscosity of the nylon resin carrier is 1.8-3.0, and the effective concentration of the flame-retardant masterbatch is 50%-75%. By screening nylon resin, a lubricating dispersant and an anti-yellowing agent, high filling performance of the nylon carrier is achieved, the organic hypophosphite and melamine derivative compound flame retardant masterbatch is prepared, the effective concentration is 50%-75%, and the flame retardant efficiency is high. The invention also provides a preparation method of the halogen-free flame-retardant master batch.

Owner:ZHEJIANG XUSEN NON HALOGEN SMOKE FLAME RETARDANT CO LTD

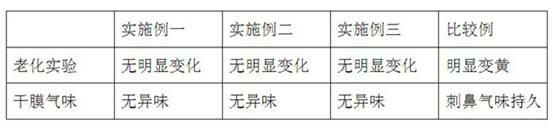

Surface light-curing odor-free paint for wood and construction technology thereof

InactiveCN102618151AReduce pollutionLess irritatingPretreated surfacesPolyurea/polyurethane coatingsUrethane acrylateBenzophenone

The invention discloses a surface light-curing odor-free paint for wood and a construction technology of the paint. The surface light-curing odor-free paint for wood is low in environment pollution, rapid in curing speed, energy-saving, capable of a and less in irritation to human body; and through adoption of the paint, the cured product has good performance and a substrate hardly gets yellow after film formation. In addition, the invention also provides the construction technology of the surface light-curing odor-free paint for wood. The surface light-curing odor-free paint for wood comprises the following components by weight percent: 25-45% of bisphenol-A epoxy acrylate, 8-10% of urethane acrylate, 35-45% of trimethylopropane triacrylate, 1-5% of 4-phenyl-benzophenone, 1-5% of dimethylaminobenzoate, 8-12% of filler and 0.1-1% of additives, wherein the additives include defoaming agent, dispersing agent and flatting agent. The invention can be widely applied to the production manufacturing field of flat plate coating.

Owner:珠海市佳家光合材料科技有限公司

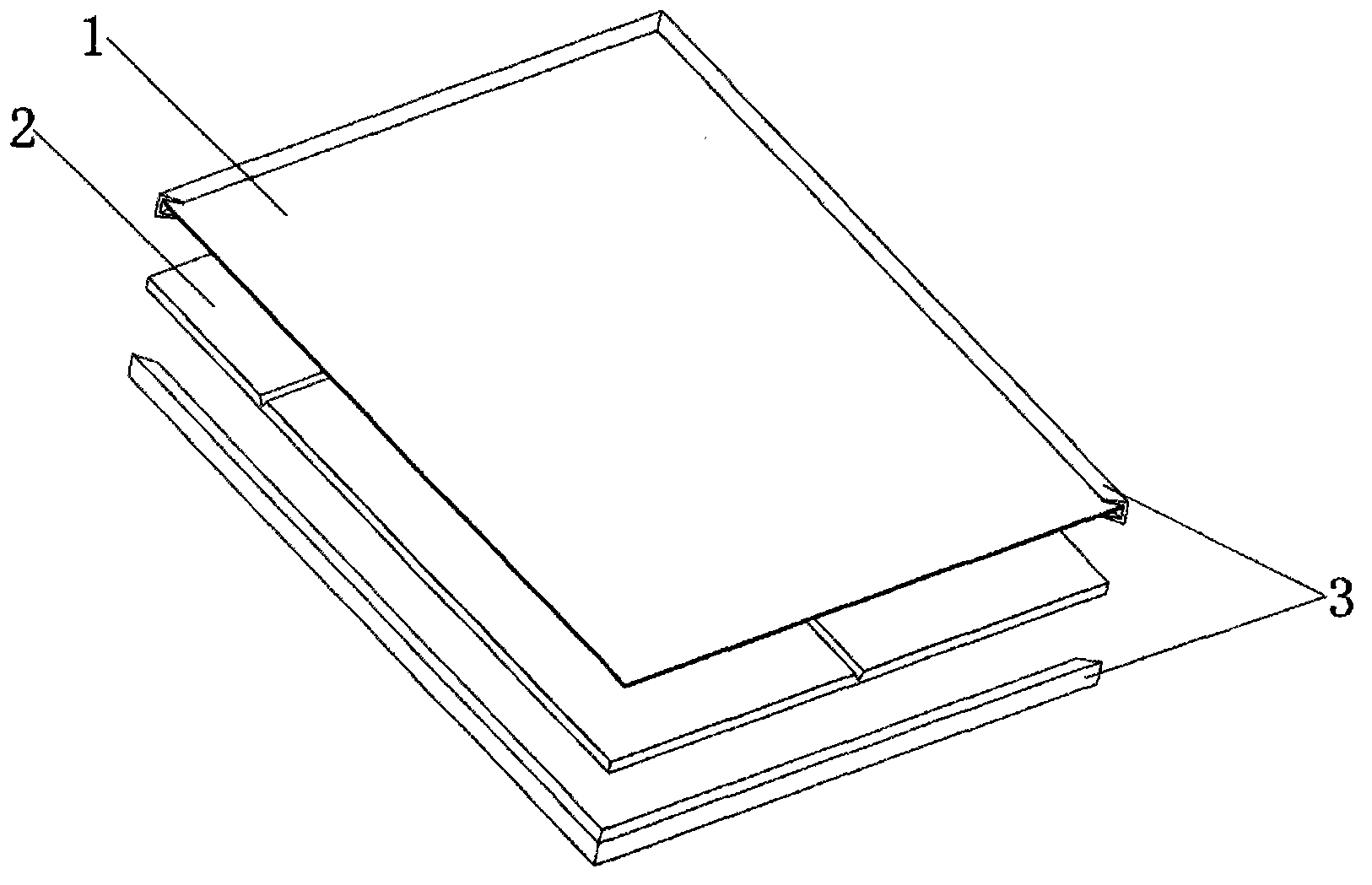

White-light LED device and manufacturing method thereof

ActiveCN104993032AHigh mechanical strengthMechanical strength is thinSemiconductor devicesEngineeringUltimate tensile strength

The invention provides a white-light LED device and a manufacturing method thereof. The white-light LED device comprises a transparent accommodating device, an LED chip and a fluorescent glue layer used for adhering the LED chip and the transparent accommodating device, wherein the transparent accommodating device comprises a first accommodating groove and a second accommodating groove which is formed by depressing the bottom surface of the first accommodating groove, the bottom surface area of the second accommodating groove is smaller than that of the first accommodating groove, the fluorescent glue layer is arranged in the second accommodating groove, the LED chip is arranged in the first accommodating groove, and opposite surfaces of the LED chip and the fluorescent glue layer are adhered together. The white-light LED device provided by the invention helps to achieve the thinner fluorescent glue layer , thereby the problem of reliability failure because the fluorescent glue layer is too thick is avoided, and the white-light LED device has high mechanical strength.

Owner:APT ELECTRONICS

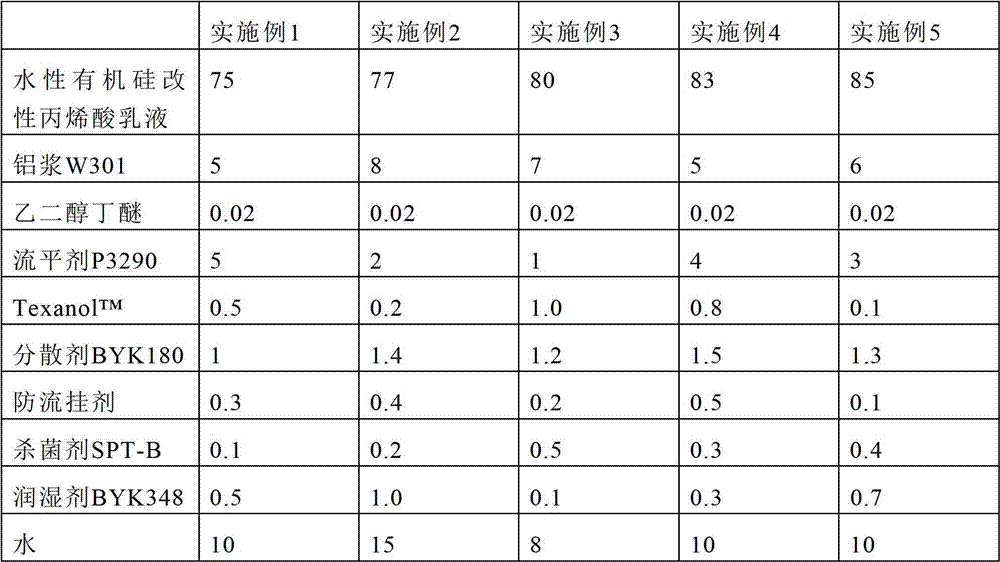

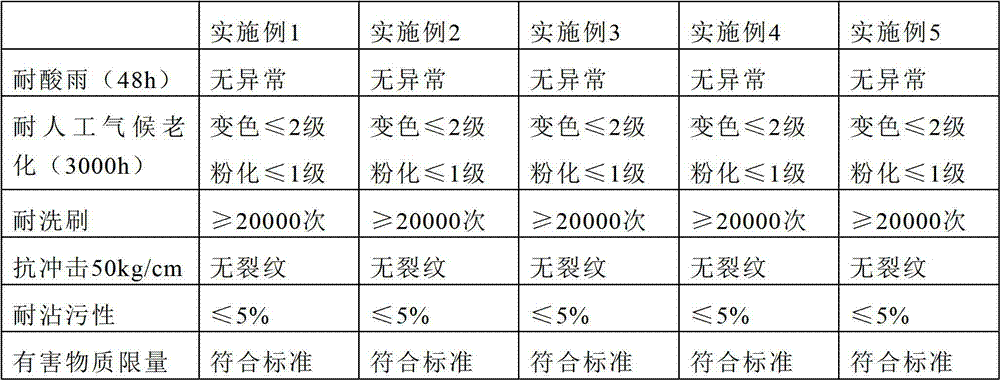

Water-based super weather-resistant modified silicone-acrylic acid metal paint coating

InactiveCN103589256ASolve easy fadingSolve dullAntifouling/underwater paintsPaints with biocidesWater basedEmulsion

The invention discloses a water-based super weather-resistant modified silicone-acrylic acid metal paint coating. The water-based super weather-resistant modified silicone-acrylic acid metal paint coating mainly comprises, by mass, 75 to 85 parts of water-based organosilicon modified acrylic emulsion, 5 to 8 parts of aluminium paste, 0.01 to 0.03 part of butyl cellosolve), 1 to 5 parts of a levelling agent, 1 to 5 parts of a film forming auxiliary agent and 8 to 15 parts of water. The water-based super weather-resistant modified silicone-acrylic acid metal paint coating can be used for one-step spraying; the surface of obtained paint film is compact, bright and smooth; and the obtained paint film possesses high tenacity, and excellent impact resistance and stain resistance. Coating of the water-based super weather-resistant modified silicone-acrylic acid metal paint coating is capable of obtaining endurance, acid and alkali resistance, effective inhibition on growth of algae and fungus, and environmental protection performance. The properties can be maintained unchanged under long-term complex weather conditions for more than 3000 hours; simulation of decorative effect of aluminium-plastic panel can be realized; dazzling metallic luster can be observed; it is difficult for dust to accumulate on the paint film; and the paint film is clean and beautiful.

Owner:SHANGHAI HANCAI INDAL

Method for processing soya milk film

InactiveCN101433293AHigh in proteinHigh nutritional valueCheese manufactureFood preparationFiltrationNutrient

The invention relates to a method for processing bean curd skins which are bean products. The method for processing the bean curd skins comprises the following steps: (1) high-quality black beans with a cleanliness of more than 95 percent are roughly ground to remove hulls; (2) after hulls are removed, the black bean are washed in clear water in two groups; (3) the first group of the black beans and the second group of the black beans are subjected to filtration, pulping, siruping and filtration sequentially; and (4) after filtration, the first group of black bean milk is poured into a film making pot completely; after the black bean milk is heated for 3 to 7 minutes, a film begins to form on the surface of the black bean milk, and then is taken out to be dried; and when the black bean milk in the film making pot begins to turn yellow, the second group of black bean milk is poured into the film making pot, and a film is taken out and dried. The method for processing the bean curd skin has the advantages that the processing amount is large and the bean curd skins have excellent taste and high nutrient value.

Owner:盛晓星

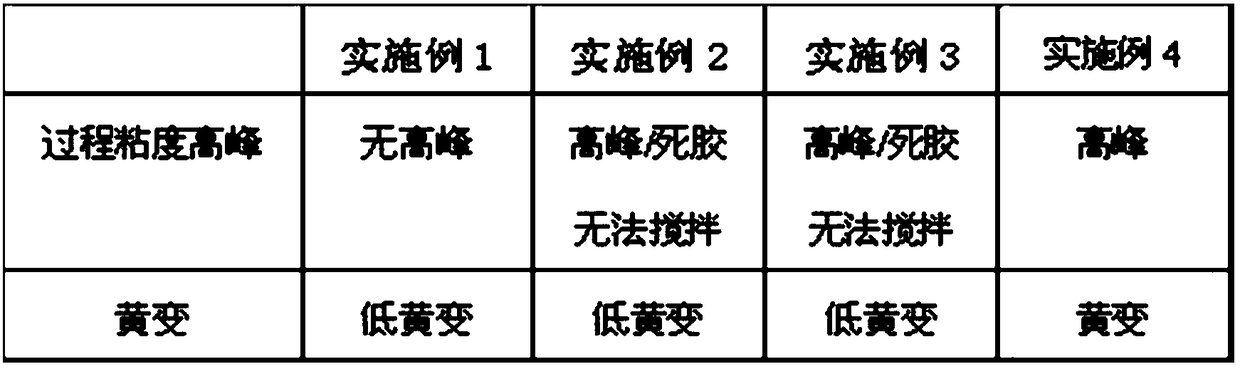

Dealcoholized room temperature vulcanized silicone rubber and preparation method thereof

The invention discloses dealcoholized room temperature vulcanized silicone rubber and a preparation method thereof. The vulcanized silicone rubber comprises the following components of: alpha,omega-dihydroxypolydimethylsiloxane, dimethicone, reinforcing filler, a cocatalyst, a first cross-linking agent, a silane coupling agent, a second cross-linking agent and a catalyst. The preparation method thereof comprises the steps of: adding the alpha,omega-dihydroxypolydimethylsiloxane, dimethicone and reinforcing filler into a vacuum stirring kettle, performing stirring for dehydration at 130-170 DEGC and (-0.09)-(-0.1) MPa for 2-4 hours, and performing cooling to obtain base rubber; and adding the cocatalyst and first cross-linking agent sequentially into the base rubber, performing vacuum pumping and even stirring, then adding the silane coupling agent, second cross-linking agent and catalyst sequentially, performing vacuum pumping to (-0.09)-(-0.1) MPa, and performing stirring to obtain the dealcoholized room temperature vulcanized silicone rubber. During preparation of the vulcanized silicone rubber by using the preparation method, no viscosity peaks are generated, and the problem ofhigh energy consumption caused by rapid thickening of rubber viscosity is solved.

Owner:GOLOHO TECH CHANGZHOU CO LTD

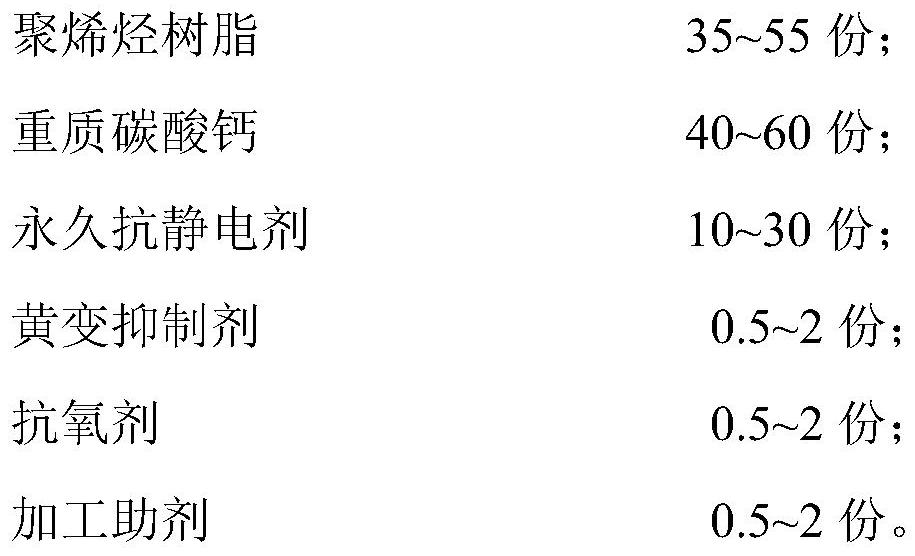

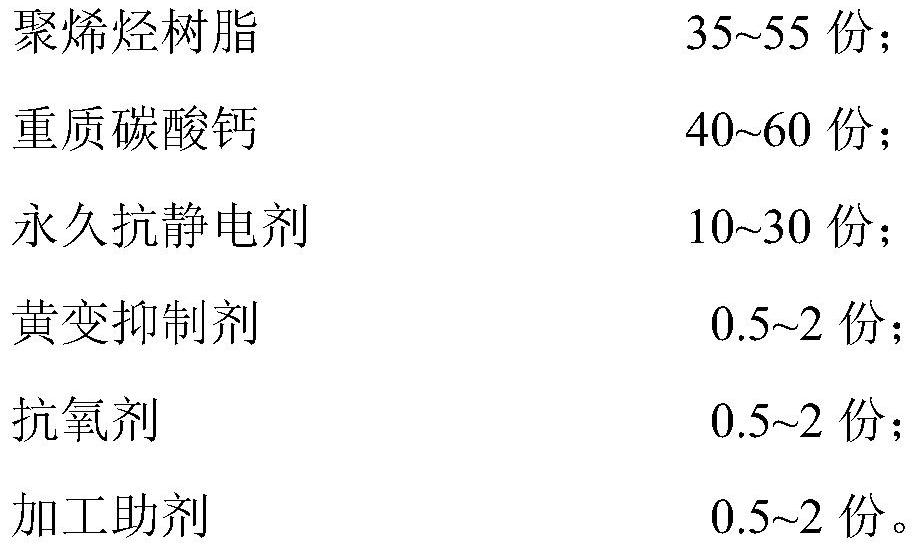

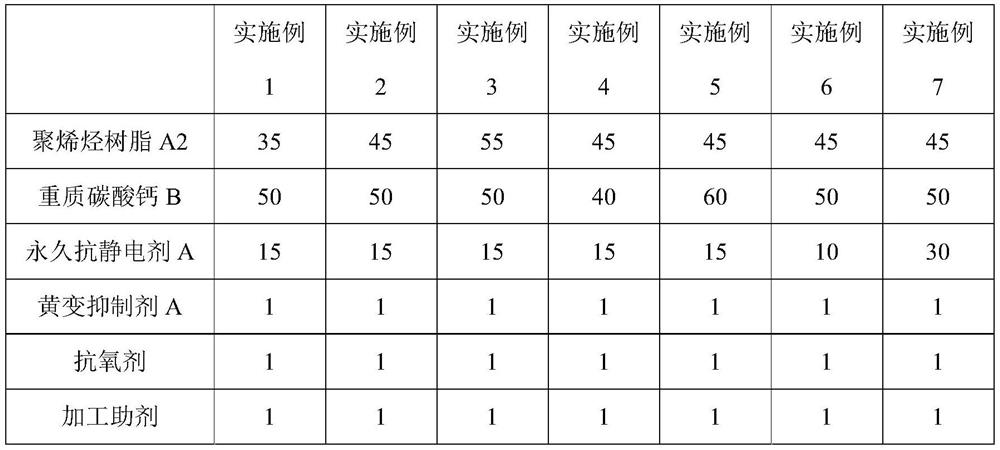

Yellowing-resistant permanent antistatic breathable film as well as preparation method and application thereof

The invention discloses a yellowing-resistant permanent antistatic breathable film as well as a preparation method and application thereof. The breathable film comprises the following components in parts by weight: 35-55 parts of polyolefin resin; 40-60 parts of heavy calcium carbonate; 10-30 parts of a permanent antistatic agent; 0.5-2 parts of a yellowing inhibitor; 0.5 to 2 parts of an antioxidant; and 0.5-2 parts of a processing aid. The surface resistivity of the breathable film is within 1 * 10 < 9 > omega. M, the yellowing degree delta b is less than or equal to 0.4, and the moisture permeability is greater than or equal to 2159 g / m < 2 >. 24h; and the hydrostatic pressure is greater than or equal to 819 mmH2O. The breathable film can be applied to protective clothing, paper diapers and sanitary napkins.

Owner:KINGFA SCI & TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com