High-temperature resistant yellowing nylon material and preparation method thereof

A technology of high temperature resistance and nylon, applied in the field of high temperature resistant yellowing nylon material and its preparation, to achieve the effect of expanding the application range, inhibiting yellowing and increasing stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

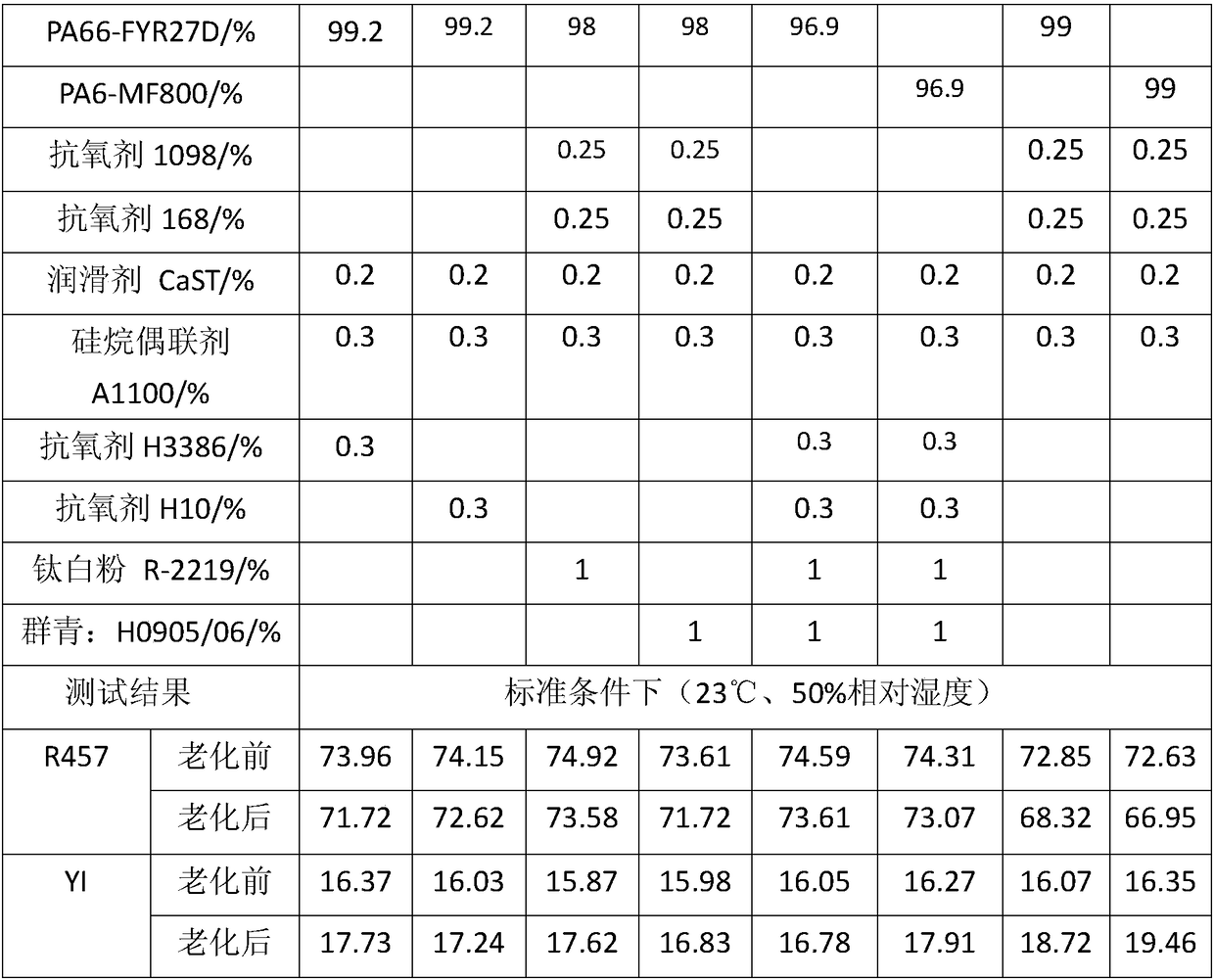

Embodiment 1

[0037] Weigh 3.968kg of PA66-FYR27D and dry it at 100°C for 4 hours for use.

[0038] Weigh 12g of antioxidant H3386; 8g of lubricant CaST; 12g of silane coupling agent A1100 and mix well in a high-speed mixer to obtain a mixture of additives;

[0039] The dried nylon resin and additives are mixed uniformly through a high-speed mixer, and then added to the twin-screw extruder (screw diameter 35mm, L / D=44) through the main feed port, twin-screw extruder The control temperature of each section of the machine (from the feeding port to the machine head exit) is 230℃, 240℃, 265℃, 265℃, 265℃, 265℃, 265℃, 265℃, 265℃, 265℃, 265℃, The speed of the twin-screw extruder is 380r / min, and the extruded material is cooled in a water tank, dried by a blast desiccant, and then pelletized to obtain the product.

[0040] The above-mentioned materials were dried in a blast drying oven at 110°C for 4 hours and then injection molded into standard color swatch samples at a temperature of 275°C. Place the ...

Embodiment 2

[0042] Weigh 3.968kg of PA66-FYR27D and dry it at 100°C for 4 hours for use.

[0043] Weigh 12g of antioxidant H10; 8g of lubricant CaST; 12g of silane coupling agent A1100 and mix well in a high-speed mixer to obtain a mixture of additives;

[0044] The dried nylon resin and additives are mixed uniformly through a high-speed mixer, and then added to the twin-screw extruder (screw diameter 35mm, L / D=44) through the main feed port, twin-screw extruder The control temperature of each section of the machine (from the feeding port to the machine head exit) is 230℃, 240℃, 265℃, 265℃, 265℃, 265℃, 265℃, 265℃, 265℃, 265℃, 265℃, The speed of the twin-screw extruder is 380r / min, and the extruded material is cooled in a water tank, dried by a blast desiccant, and then pelletized to obtain the product.

[0045] The above-mentioned materials were dried in a blast drying oven at 110°C for 4 hours and then injection molded into standard color swatch samples at a temperature of 275°C. Place the in...

Embodiment 3

[0047] Weigh 3.92kg of PA66-FYR27D and dry it at 100°C for 4 hours for use.

[0048] Weigh 10g of antioxidant H1098; weigh 10g of antioxidant 168, 40g of titanium dioxide R-2219, and 8g of lubricant CaST; and 12g of silane coupling agent A1100 in a high-speed mixer and mix evenly to obtain a mixture of additives;

[0049] The dried nylon resin and additives are mixed uniformly through a high-speed mixer, and then added to the twin-screw extruder (screw diameter 35mm, L / D=44) through the main feed port, twin-screw extruder The control temperature of each section of the machine (from the feeding port to the machine head exit) is 230℃, 240℃, 265℃, 265℃, 265℃, 265℃, 265℃, 265℃, 265℃, 265℃, 265℃, The speed of the twin-screw extruder is 380r / min, and the extruded material is cooled in a water tank, dried by a blast desiccant, and then pelletized to obtain the product.

[0050] The above-mentioned materials were dried in a blast drying oven at 110°C for 4 hours and then injection molded in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com