Yellowing-resistant permanent antistatic breathable film as well as preparation method and application thereof

An antistatic and anti-yellowing technology, applied in the field of modified plastics, can solve the problems of easy yellowing and poor antistatic effect

Active Publication Date: 2021-05-04

KINGFA SCI & TECH CO LTD

View PDF1 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0005] In order to overcome the defects of poor antistatic effect and easy yellowing described in the above-mentioned prior art, the present invention provides a permanent anti-yellowing antistatic breathable film

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

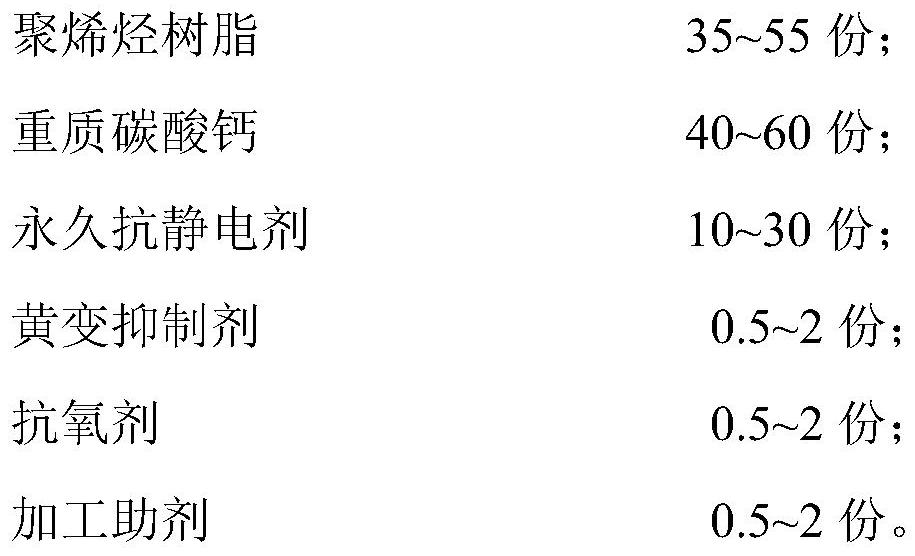

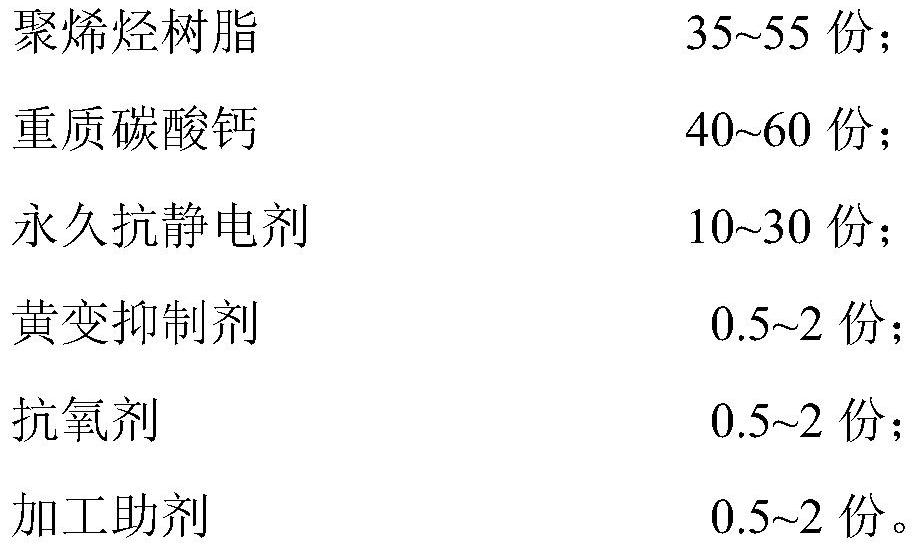

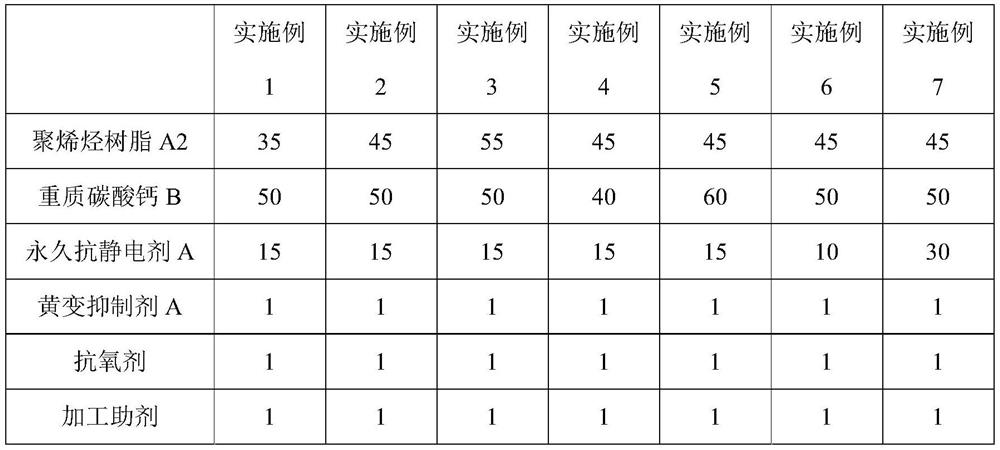

Embodiment 1~7

[0072] The formula (part) of table 1 embodiment 1~7

[0073]

Embodiment 8~13

[0075] The formula (part) of table 2 embodiment 8~13

[0076]

[0077]

Embodiment 14~20 and comparative example 1~3

[0079] The formula (part) of table 3 embodiment 14~20 and comparative example 1~3

[0080]

[0081]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses a yellowing-resistant permanent antistatic breathable film as well as a preparation method and application thereof. The breathable film comprises the following components in parts by weight: 35-55 parts of polyolefin resin; 40-60 parts of heavy calcium carbonate; 10-30 parts of a permanent antistatic agent; 0.5-2 parts of a yellowing inhibitor; 0.5 to 2 parts of an antioxidant; and 0.5-2 parts of a processing aid. The surface resistivity of the breathable film is within 1 * 10 < 9 > omega. M, the yellowing degree delta b is less than or equal to 0.4, and the moisture permeability is greater than or equal to 2159 g / m < 2 >. 24h; and the hydrostatic pressure is greater than or equal to 819 mmH2O. The breathable film can be applied to protective clothing, paper diapers and sanitary napkins.

Description

technical field [0001] The invention relates to the technical field of modified plastics, in particular to a yellowing-resistant permanent antistatic breathable film and a preparation method and application thereof. Background technique [0002] Static electricity in textiles and clothing is mainly generated by the friction and induction of fabrics. After static electricity is generated, it will absorb dust, particles, and pathogenic bacteria with opposite charges to the surface of clothing. In extreme cases, the discharge phenomenon will cause safety accidents. The following protective clothing application scenarios have strict antistatic requirements: (1) Hospitals, operating rooms and other places with high risk of infection; (2) Microelectronic components processing and operating occasions to prevent breakdown caused by discharge phenomena; (3) Mine, volatile solvents, dust processing and other occasions where there is a risk of explosion. [0003] Traditional antistati...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C08L23/08C08L23/06C08L23/12C08L23/14C08L53/00C08L101/02C08L71/00C08L79/08C08K13/06C08K9/10C08K9/04C08K3/26C08K5/00C08J5/18

CPCC08J5/18C08J2323/08C08J2323/06C08J2423/06C08J2323/12C08J2323/14C08J2353/00C08J2471/00C08J2479/08C08J2400/106C08K13/06C08K9/10C08K9/04C08K3/26C08K5/005

Inventor 张文昊黄险波叶南飚王斌安方振刘乐文何浏炜赵振平李力

Owner KINGFA SCI & TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com