White-light LED device and manufacturing method thereof

A technology of LED devices and LED chips, applied in semiconductor devices, electrical components, circuits, etc., can solve problems such as damage, and achieve the effects of thin thickness, change in thickness, and increase in resistance to external mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

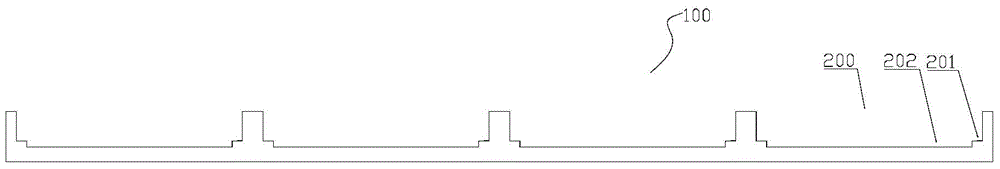

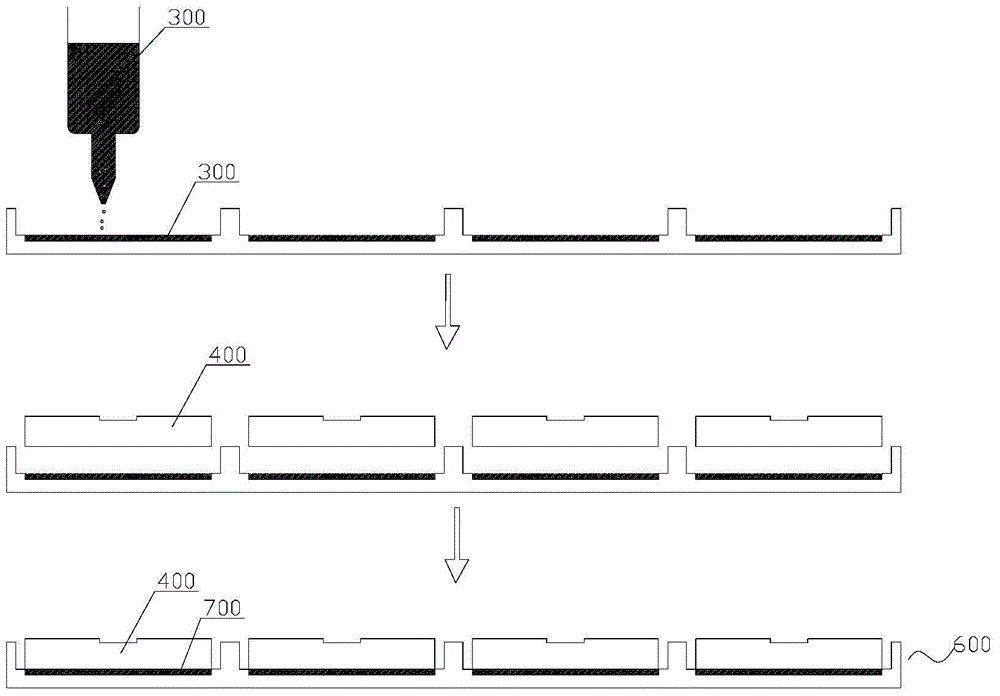

[0029] This embodiment provides a white light LED device, and its structural schematic diagram can be found in Figure 5 . The white LED device 800 includes a transparent container 200 , an LED chip 400 , and a fluorescent glue layer 700 . Wherein, the transparent container 200 is provided with a first containing groove 201 and a second containing groove 202, the second containing groove 202 is formed by a bottom surface depression of the first containing groove 201, and the bottom surface area of the second containing groove 202 is smaller than that of the first containing groove The area of the bottom surface of 201 and the connection between the first receiving groove 201 and the second receiving groove 202 form a step. The fluorescent adhesive layer 700 is disposed in the second receiving groove 202 , the LED chip 400 is disposed in the first receiving groove 201 , and the opposing surfaces of the LED chip 400 and the fluorescent adhesive layer 700 are bonded to each ...

Embodiment 2

[0035] This embodiment provides a method for preparing the white LED device 800 of Embodiment 1, including the following steps:

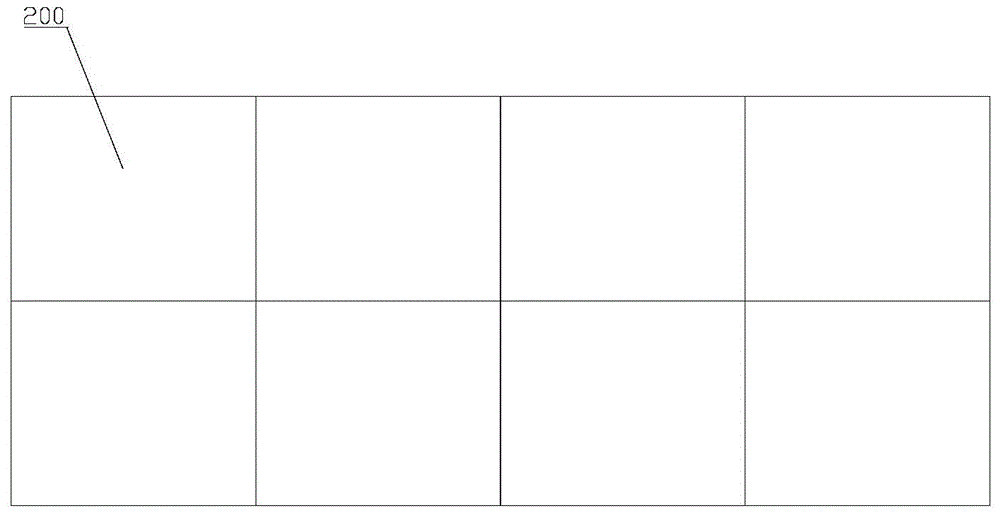

[0036]1) Use transparent materials to make the transparent container array 100, the transparent container array 100 includes a plurality of transparent container 200 distributed in an array, each transparent container 200 includes a first container 201 and the first The bottom of the receiving groove 201 is recessed to form the second receiving groove 202 , and the bottom surface area of the second receiving groove 202 is smaller than that of the first receiving groove 201 , and the depth of the second receiving groove 202 is controlled between 20-200 μm. The preparation process of the transparent container array 100 can adopt the existing mold prefabrication process, etching method, 3D printing molding or stamping process, etc., which are existing technologies and will not be repeated here. Specifically, the transparent material can be selected f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com