General electronic paste based on graphene filler

A general-purpose electronics and graphene technology, applied in the direction of conductive materials dispersed in non-conductive inorganic materials, etc., can solve the problems of poor conductivity of aluminum powder and achieve the effects of improving conductivity, reducing usage, and excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

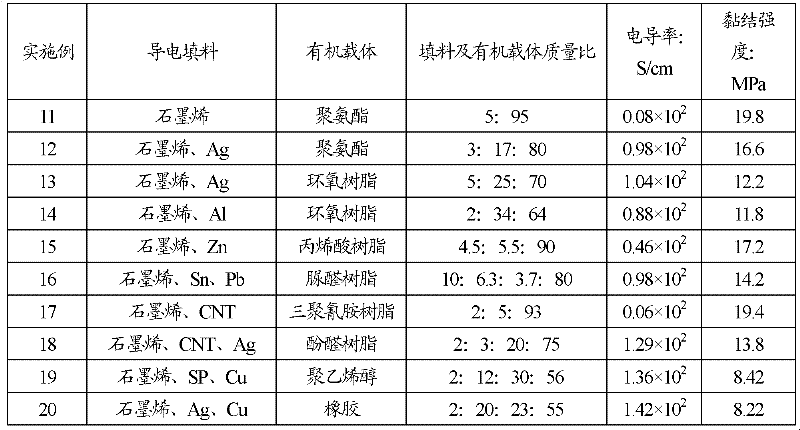

Examples

Embodiment 1

[0051] Graphene / Acrylic Conductive Coatings

[0052] Step 1: Weigh 1ml of silane coupling agent (KH-570, γ-(methacryloyloxy)propyltrimethoxysilane) into 30ml of deionized water, and at the same time add 1ml of methanol for hydrolysis for 30min. The role of methanol is to inhibit the cross-linking of silanols and shorten the time required to reach hydrolysis equilibrium. Then, 0.61 g of graphene was added into the solution of the silane coupling agent, stirred and reacted for 3 hours, and dried by filtration.

[0053] Second step, choose methyl methacrylate as organic carrier, the solubility parameter δ of this resin r 9.2~9.4cal 1 / 2 cm -3 / 2 ; According to the principle that the solubility parameters are close, acetone is selected as the solvent (δ r =9.8cal 1 / 2 m -3 / 2 ), 60g of methyl methacrylate was added to 20ml of acetone, and mechanically stirred for 4 hours to prepare a methyl methacrylate solution.

[0054] Step 3: Weigh 1g of organic bentonite 801-D, and dispers...

Embodiment 2

[0059] Graphene / Ni / Acrylic Resin Conductive Coatings

[0060] The preparation method is basically the same as in Example 1, except that the mixture of graphene and nickel powder is used as the conductive filler. Wherein when the mass ratio of graphene to nickel powder is 2:48, the prepared conductive coating has good dispersibility, thereby overcoming the problem of coating failure caused by the sedimentation of nickel powder. The properties of the conductive coating prepared in this example are shown in Table 1.

Embodiment 3-10

[0062] Using the same preparation method as in Example 2, a conductive paint was prepared, and the raw materials and properties of the conductive paint are shown in Table 1.

[0063] The conductive coatings prepared in Examples 1-10 were tested for conductivity, adhesion and hardness on the ABS board, and the results are shown in Table 1.

[0064] Among them, the adhesion is measured according to GB / T 9286-88 (cross-cut test of lacquer box and varnish film), and the classification is defined as: 0) the cutting edge is completely smooth, and no grid falls off; 1) there is a little coating at the intersection of the cut. The layer is peeled off, but the cross-cut area is not affected significantly more than 5%; 2) There is coating peeling off at the intersection of the cut and / or along the edge of the cut, and the affected cross-cut area is obviously greater than 5%, but not significantly greater than 15%; 3) The coating is partly or completely peeled off in large fragments alon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| electron mobility | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com