Surface light-curing odor-free paint for wood and construction technology thereof

A wood surface and photocuring technology, which is applied to the surface coating liquid device, pretreatment surface, epoxy resin coating, etc., can solve the problems of difficult stability of product quality, high production cost, high labor intensity, etc., and achieve curing Good product performance, less environmental pollution and high degree of mechanization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

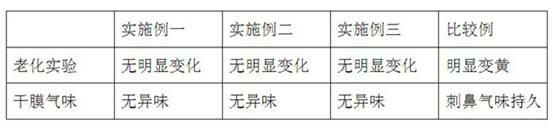

Examples

Embodiment 1

[0043] In this embodiment, 31.5% of bisphenol A epoxy acrylate, 8% of polyurethane acrylate, 50% of trimethylolpropane triacrylate, 1% of 4-phenylbenzophenone, and ethyl p-dimethylaminobenzoate are selected. 1%, filler 8%, additive 0.5%, and described additive comprises the defoamer of 0.2%, the dispersant of 0.2%, the leveling agent of 0.1%.

Embodiment 2

[0045] In this embodiment, 35% of bisphenol A epoxy acrylate, 9.3% of polyurethane acrylate, 40% of trimethylolpropane triacrylate, 3% of 4-phenylbenzophenone, and ethyl p-dimethylaminobenzoate are selected. 2%, filler 10%, additive 0.7%, and described additive comprises the defoamer of 0.4%, the dispersant of 0.2%, the leveling agent of 0.1%.

Embodiment 3

[0047] In this embodiment, 37% of bisphenol A epoxy acrylate, 10% of polyurethane acrylate, 30% of trimethylolpropane triacrylate, 5% of 4-phenylbenzophenone, and ethyl p-dimethylaminobenzoate are selected. 5%, filler 12%, additive 1%, and described additive comprises the defoamer of 0.5%, the dispersant of 0.3%, the leveling agent of 0.2%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com