Patents

Literature

122results about How to "Solve the smell problem" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Spraying and wind leaking stoppage polyurethane combined polyether for coal mine as well as preparation and use methods thereof

InactiveCN102585139AReduce dosageFine cellsUnderground chambersTunnel liningHigh resistanceChemical synthesis

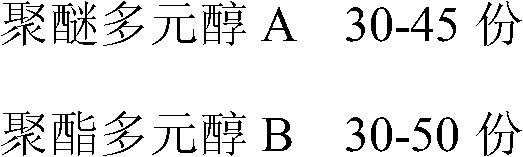

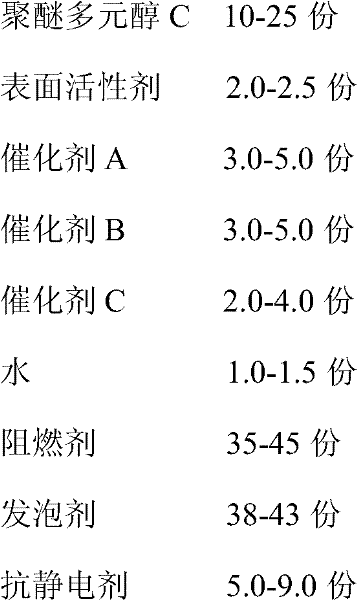

The invention belongs to the field of chemical synthesis and in particular relates to a spraying and wind leaking stoppage polyurethane combined polyether for a coal mine as well as preparation and use methods thereof. According to the invention, the polyether is prepared through formulation regulation by using HCFC (hydrochlorofluorocarbon)-365mfa and / or HCFC-245fa as foaming agents, is free of fluorine and is environment-friendly; because the boiling point of HCFC-245fa is low, prepared foam is good in size stability; a reaction type amine catalyst with low VOC (volatile organic compound) and low smell is applied, thus the problem of irritative smell is solved; and the foam prepared by using a fire retardant is good in fire retardant property, and an antistatic agent is added so as to improve the problem of high resistance on the surface of polyurethane foam.

Owner:SHANGHAI DONGDA POLYURETHANE

Siloxane-group light-initiated polyacrylic ester/silicon dioxide nanometer material and preparation method thereof

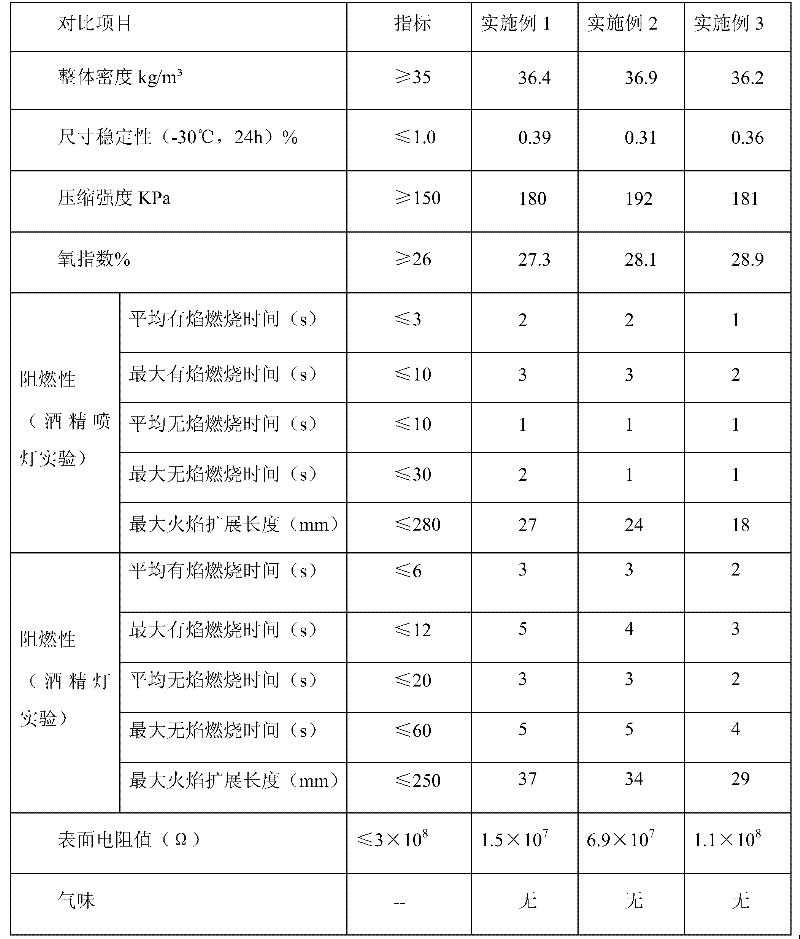

ActiveCN101875710ASimple preparation conditionsEase of industrial applicationCoatingsUltraviolet lightsCarboxylic acid

The invention discloses a siloxane group contained bifunctional light initiator initiated polymerized ultraviolet light cured acrylic ester / silicon dioxide nanometer hybrid material and a preparation method thereof. The preparation method is characterized by comprising the following steps of: firstly, preparing a light initiator with a sulfhydryl group by adopting sulfhydryl carboxylic acid and a hydroxyl functional light initiator; then reacting the light initiator with a silane coupling agent to obtain a siloxane group contained bifunctional light initiator; and mixing the bifunctional light initiator with an acrylic ester monomer, an acrylic ester low polymer and a tetraethyl orthosilicate prepolymer to prepare an ultraviolet light curable acrylic ester / silicon dioxide nanometer hybrid coating of the invention. The ultraviolet light cured acrylic ester / silicon dioxide nanometer hybrid material obtained through the irradiation of a medium-pressure mercury lamp for the hybrid coating has good physical and mechanical performance and heat resisting property and wide industrial application prospect. The preparation method of the invention has simple and easy operation and can obtain an organic-inorganic nanometer hybrid coating with excellent dispersibility and better two-phase compatibility.

Owner:ETERNAL SPECIALTY MATERIALS ZHUHAI CO LTD

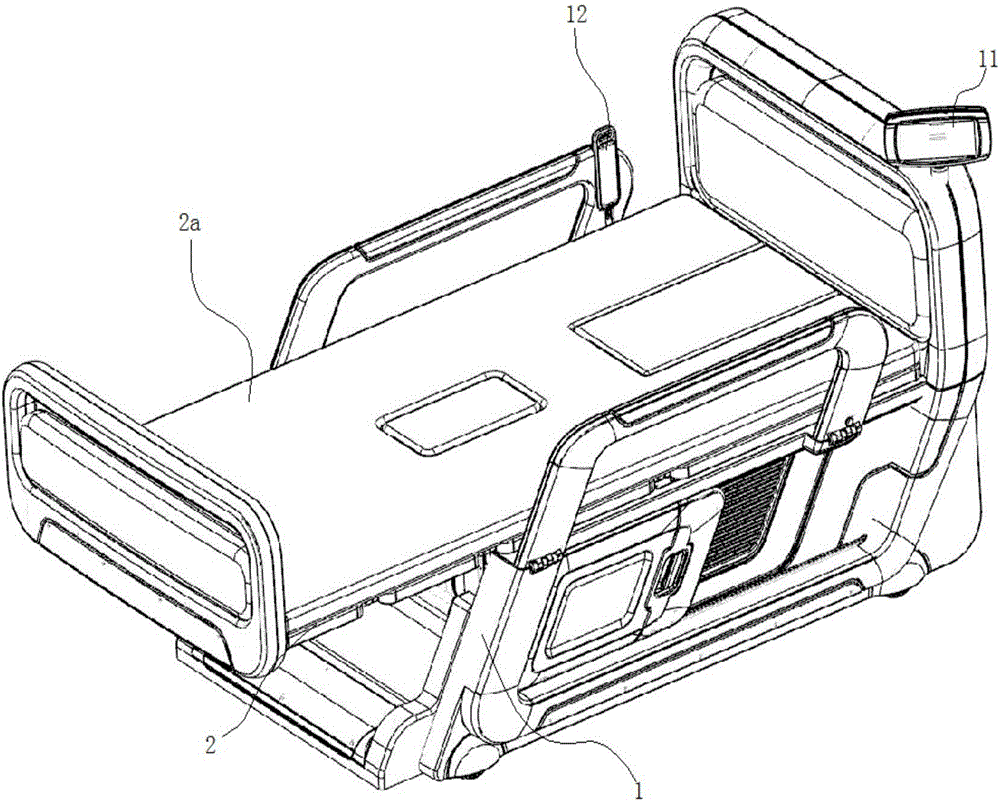

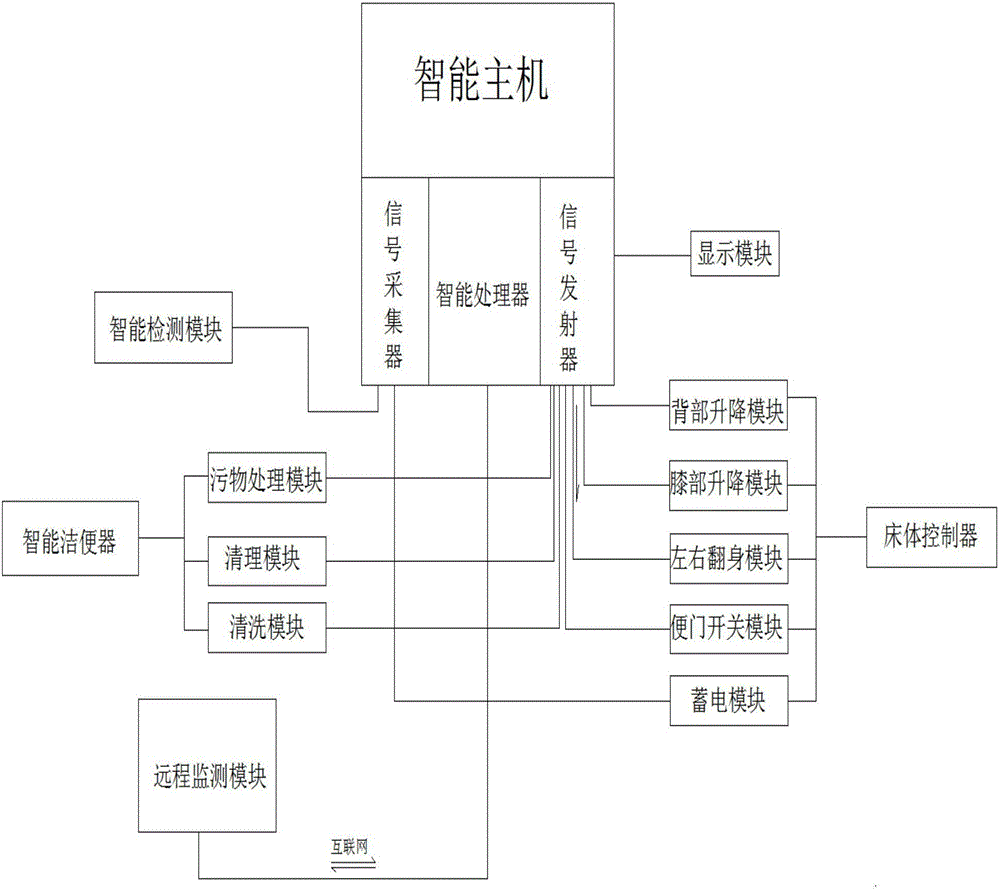

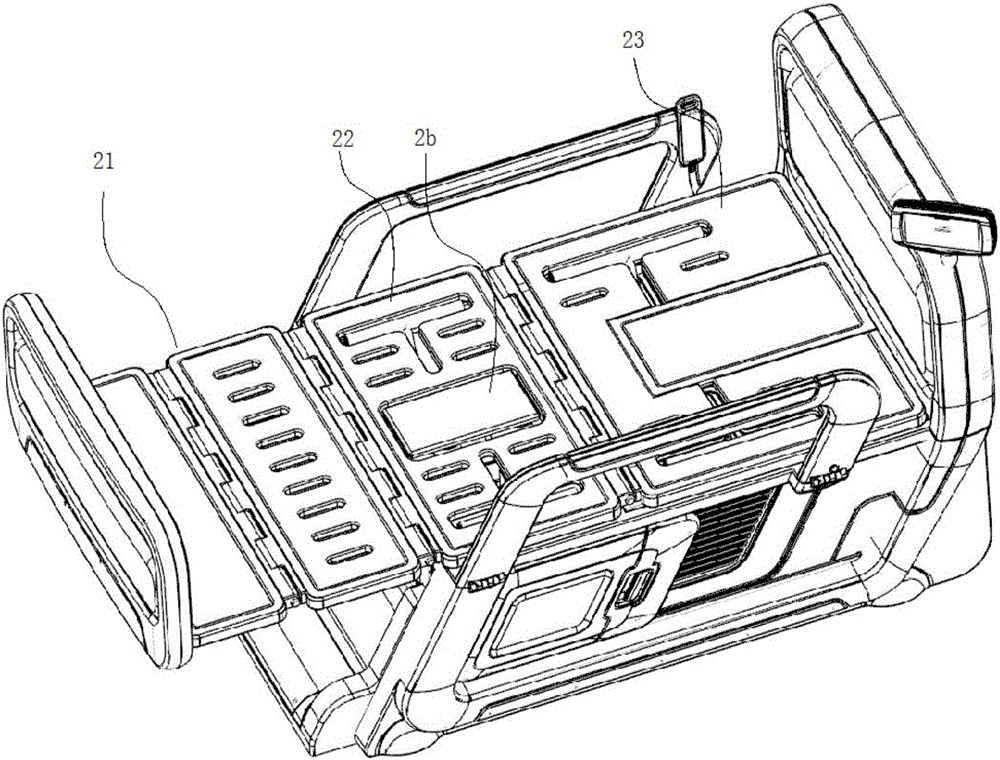

Intelligent control system for nursing bed

The invention relates to the technical field of medical apparatuses, in particular to an intelligent control system for a nursing bed. The intelligent control system comprises a bed body controller for controlling motion of a bed body, an intelligent anus cleaner for controlling an intelligent closestool to work, and an intelligent detection module for detecting the motion state of the bed body of the nursing bed and the intelligent closestool; and the bed body controller, the intelligent anus cleaner and the intelligent detection module are fed-back and driven by virtue of an intelligent host. The intelligent control system disclosed by the invention is convenient to operate, and the intelligent control system has the capacities of achieving intelligent management and constant monitoring.

Owner:浙江强鹰科技股份有限公司

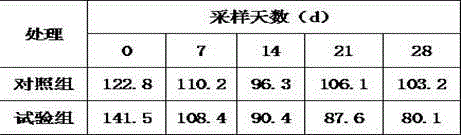

Biological deodorant for animal feeding

ActiveCN104814276AIncrease profitPromote Microecological BalanceFood processingAnimal feeding stuffSynbioticsHuman waste

The invention discloses a biological deodorant for animal feeding and belongs to the field of feed additives. The biological deodorant for animal feeding is composed of an active ingredient and an auxiliary protection carrier, wherein the active ingredient comprises synbiotics, the weight proportion of the synbiotics to the auxiliary protection carrier is (25-35): (50-65), the synbiotics are compounds of probiotics and prebiotics, and the mass fractions of the probiotics and the prebiotics are 65-80% and 20-35% respectively. After the biological deodorant for the animal feeding is used for feeding animals, all the active ingredients are synergistic in animal intestinal tracts, and finally the aim of reducing or eliminating odour of animal excrements is foundationally achieved, so that the biological deodorant for the animal feeding has good popularization and application values.

Owner:山东君德生物科技有限公司

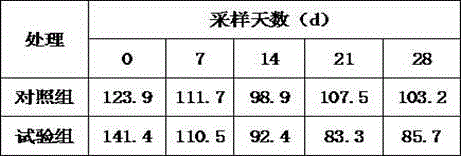

High-fluidity and reinforced-flame-retardant PBT material and preparation method thereof

The invention relates to a high-fluidity and reinforced-flame-retardant PBT material. The PBT material is composed of the following raw materials, in percent by weight: 49-68% of PBT resin, 11.5-13.5% of a flame retardant, 0-3% of a toughening agent, 20-33% of glass fibers, 0.2-0.5% of hyperbranched resin and 0.3-1% of other auxiliary agents. A preparation method of the high-fluidity and reinforced-flame-retardant PBT material is simple, firstly, the PBT resin is dried, and the dried PBT resin and the flame retardant are mixed and stirred, secondly, the toughening agent, the hyperbranched resin and the other auxiliary agents are added, and uniform stirring is performed, and finally, the uniformly mixed raw materials and the glass fibers are added to a melt extruder for extrusion, so that the high-fluidity and reinforced-flame-retardant PBT material is obtained. Compared with the prior art, the high-fluidity and reinforced-flame-retardant PBT material has the beneficial effects that the high-fluidity and reinforced-flame-retardant PBT material has good thermal stability, no white stripes precipitate during injection molding at 300 DEG C, besides, pungent smells cannot be emitted under high-temperature heating, the surface of a product is smooth, and the high-fluidity and reinforced-flame-retardant PBT material can be used for electronic appliance appearance parts such as blade handles, air discharging grilles and hot-runner one-module-multiple-output products which need high fluidity.

Owner:武汉顺威赛特工程塑料有限公司

Polypropylene-talc composite with reduced malodour

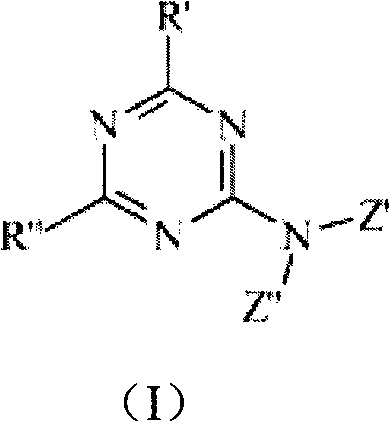

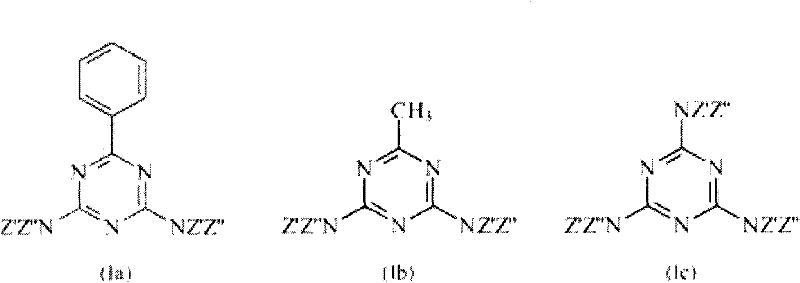

Polymer composition comprising a heterophasic propylene copolymer, talc, an organic antioxidant, and a triazine derivative.

Owner:BOREALIS AG

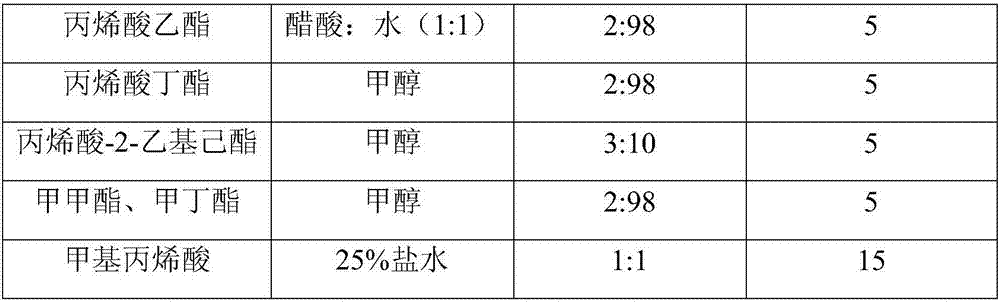

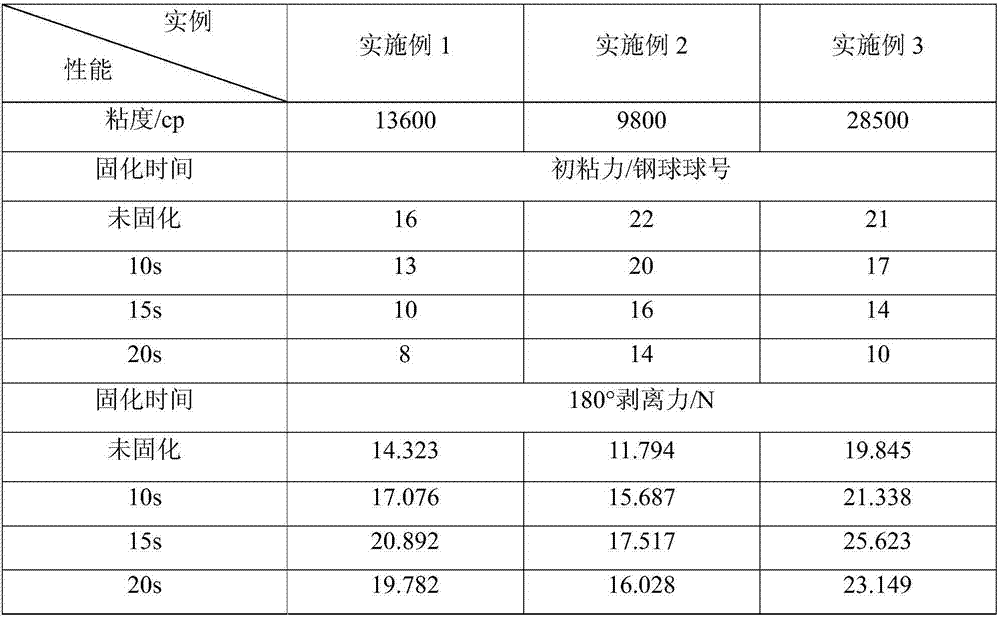

Ultraviolet-cured acrylic ester hot-melt pressure-sensitive adhesive and preparation method thereof

InactiveCN107201180ASolve the dangerSolve the smell problemNon-macromolecular adhesive additivesMacromolecular adhesive additivesPolymer scienceUltraviolet

The invention discloses a preparation method of an ultraviolet-cured acrylic ester hot-melt pressure-sensitive adhesive. The ultraviolet-cured acrylic ester hot-melt pressure-sensitive adhesive for an adhesive tape is in the form of a non-solvent 100-percent hot melt adhesive, is mainly prepared from an acrylic ester series polymer, a photo-initiator component binding to a main chain of the polymer, and a tackifying resin which is adopted as required, can be cured rapidly under the radiation of ultraviolet C (the wavelength is 190 to 280 nanometers), has high heat resistance characteristic at the temperature of 120 to 140 DEG C, can be applied to industrial adhesive tapes, can be taken as a bonding agent for automobile heating components, has the characteristics of nontoxicity, safety, skin affinity and adjustable glass transition temperature, and can be applied in the field of sanitary and medical products. The ultraviolet-cured acrylic ester hot-melt pressure-sensitive adhesive can be coated under a high gram weight and at a high speed on the aspect of coating implementation; the problems of solvent explosion danger, solvent discharge and odor in the solvent type acrylic acid series pressure-sensitive adhesive are solved.

Owner:WUXI WANLI ADHESION MATERIALS

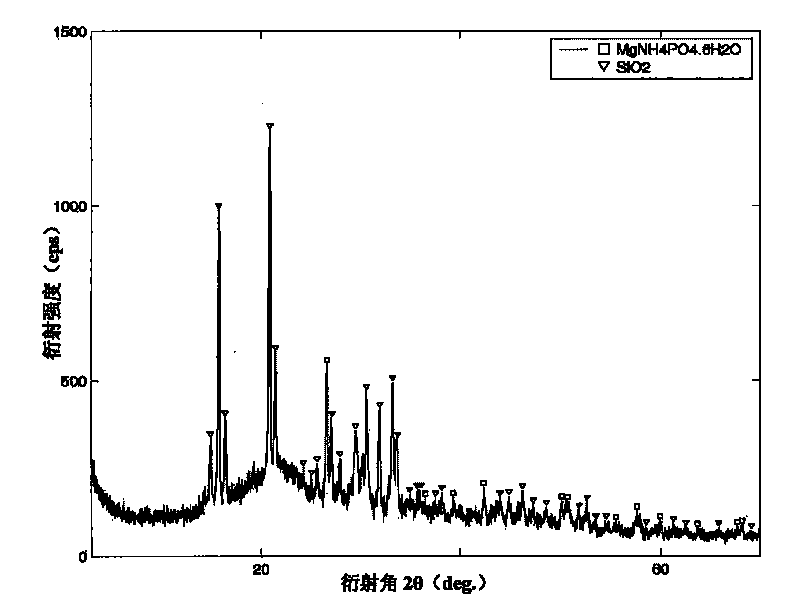

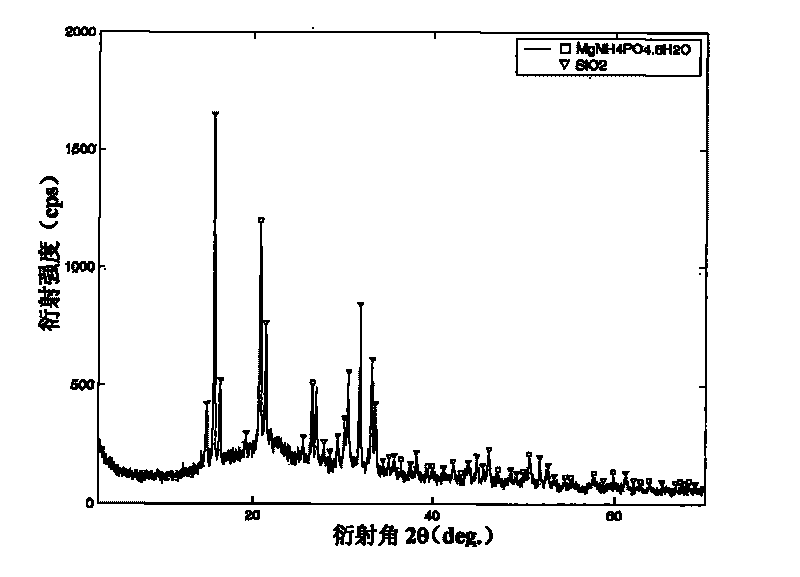

Fertilizer rich in nitrogen and phosphorus and preparation method thereof

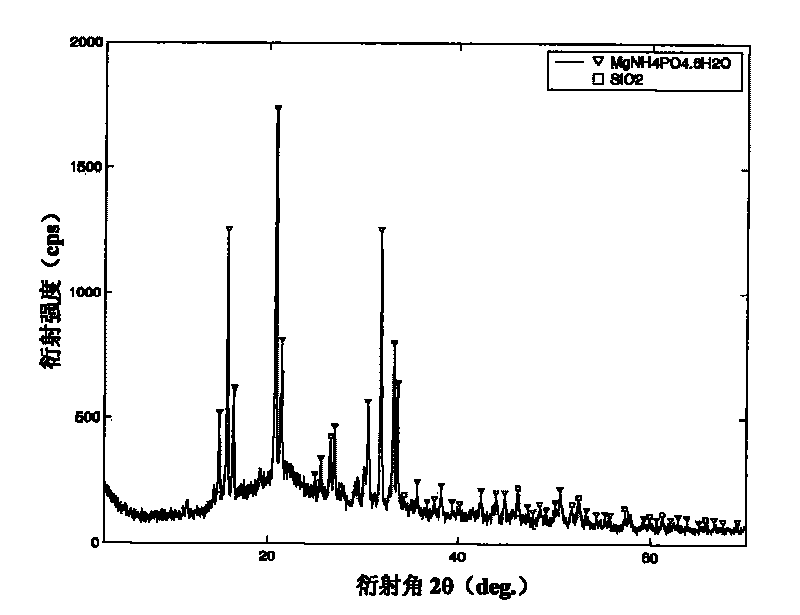

InactiveCN101723730AImprove fertilizer efficiencyTotal nitrogen highClimate change adaptationExcrement fertilisersDry weightPhosphate

The invention discloses a fertilizer rich in nitrogen and phosphorus and a preparation method thereof. The fertilizer is prepared by using 1.4 to 1.7 parts by mass of magnesium hydroxide, 2.4 to 7.4 parts by mass of phosphate, water, 2.1 to 2.2 parts by mass of urea, 39 to 41 parts by mass of straw and 50 to 53 parts by mass of manure as raw materials and comprising the following steps of: (1) mixing the magnesium hydroxide and the phosphate with the water for preparing emulsion; (2) mixing the emulsion of step (1) and the urea with compost materials and then statically closing and fermenting for obtaining the fertilizer, wherein the compost materials are the straw and the manure; and the parts by mass of the straw and the manure are both dry weight. The fertilizer has simple operation and easy execution and is suitable for composting rubbish, manure and the like. By using the method for composting, nitrogen loss and odor are reduced, the fertilizer effect of composting products is increased, the fertilizer containing guano is finally obtained, and the composting quality is enhanced.

Owner:CHINA AGRI UNIV

Organosilicon surfactant and application thereof in preparation of polyurethane flexible foam

The invention provides an organosilicon surfactant. The organosilicon surfactant has the following general formula: MDxD'yD ''zM, wherein M is selected from any one of (CH3) 3SiO1 / 2 and (CH3) 2RSiO1 / 2, D is (CH3) 2SiO2 / 2, D'is (CH3) 2 (R) SiO2 / 2, D ''is (CH3) 2 (R') SiO2 / 2, x + y + z is 70-100, x is 68-98, y is 1-16, and z is 1-16. The invention also provides an application of the organic siliconsurfactant in polyurethane flexible foam. Alkynediol polyether, high-molecular-weight hydrogen-containing silicone oil and at least one alkynediol polyether are introduced, and a high-molecular organosilicon copolymer surfactant is formed through hydrosilylation. The preparation method is used for preparing the polyurethane flexible foam, and the rebound resilience of the polyurethane flexible foam can be improved.

Owner:JIANGXI MENHOVER CHEM TECH CO LTD

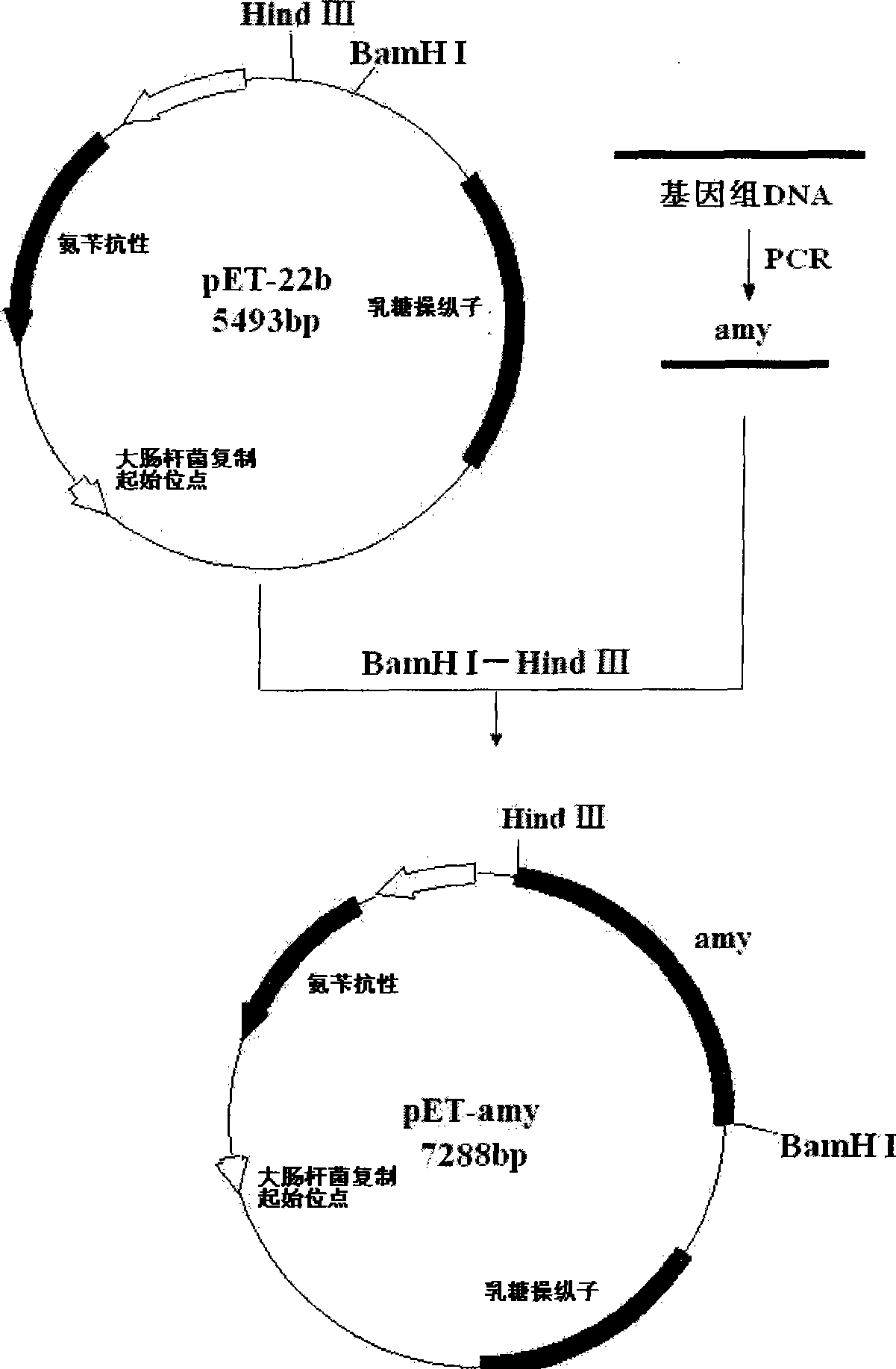

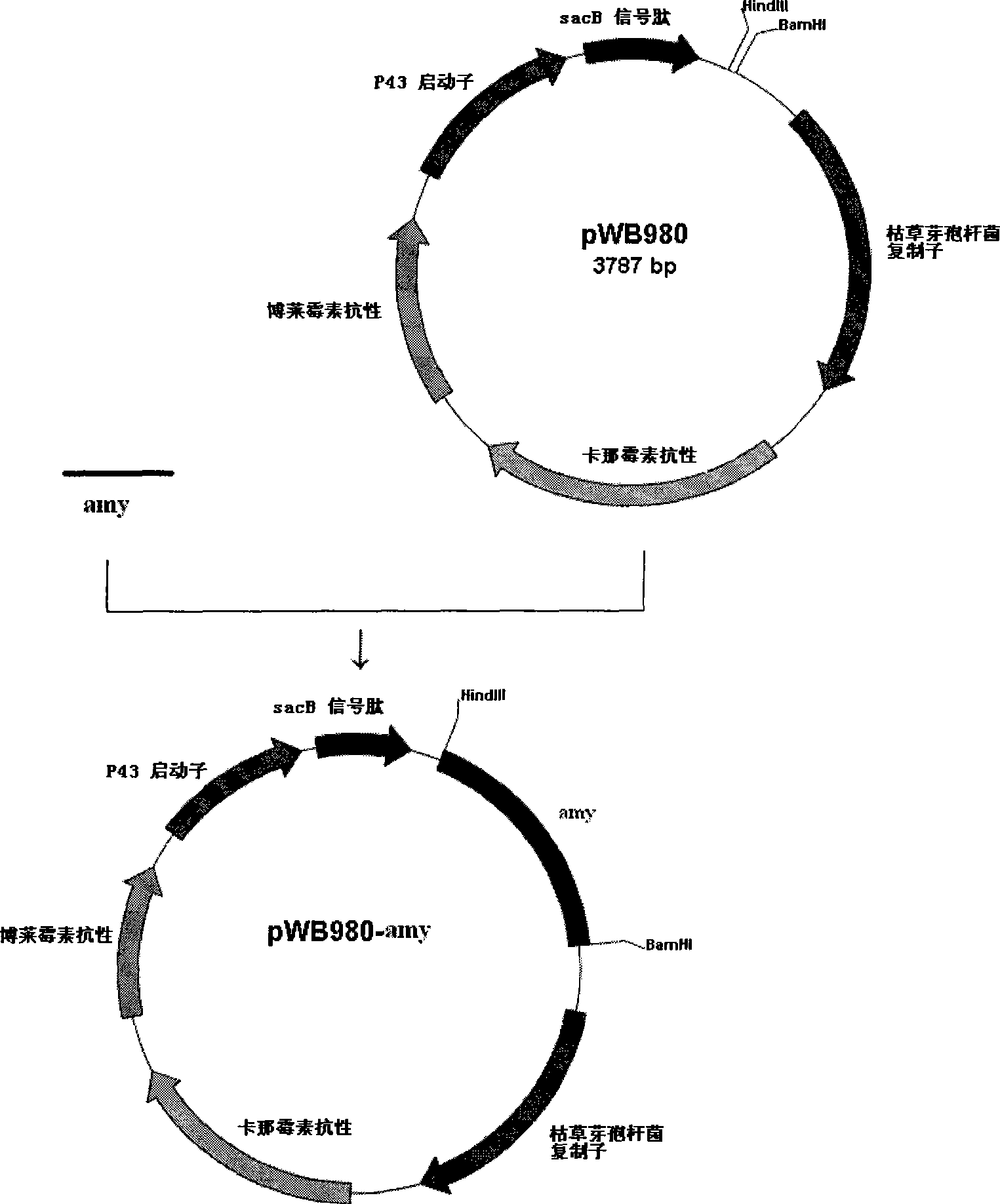

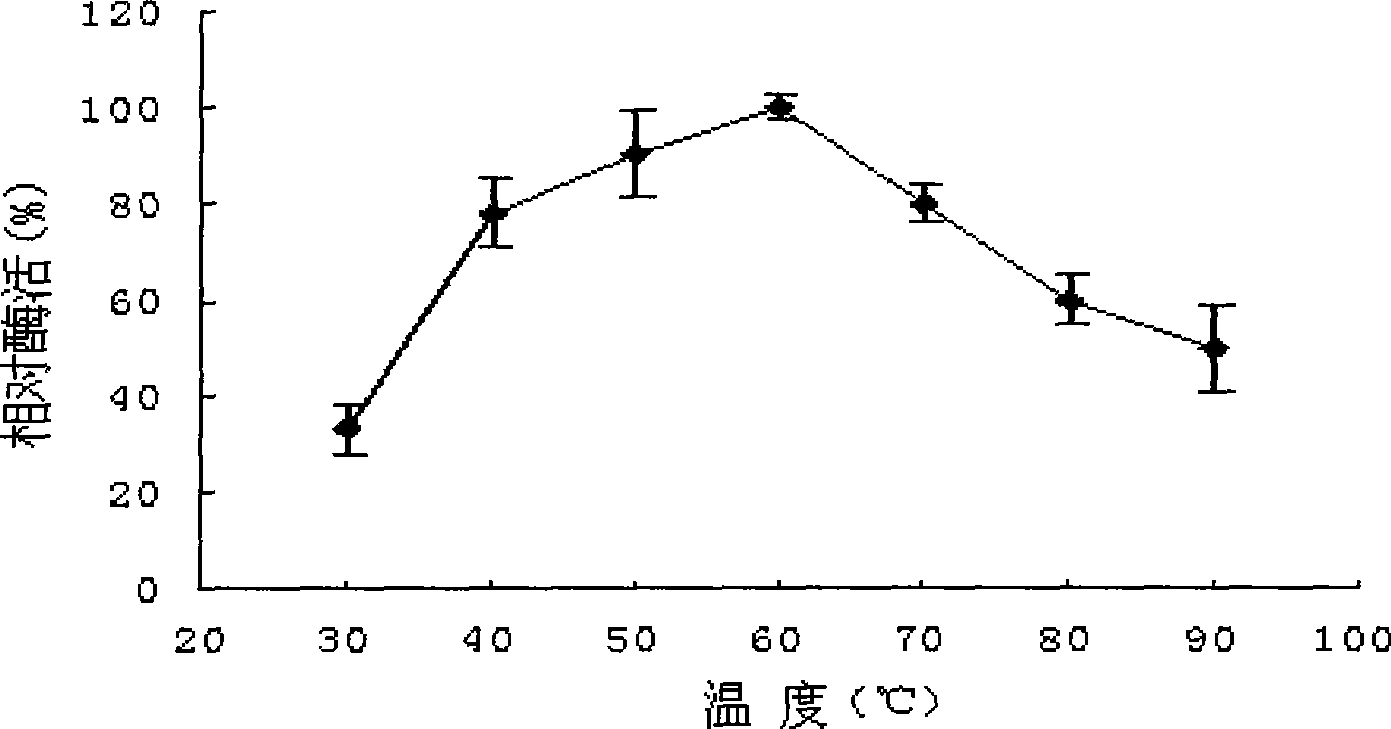

Medium temperature Alpha-amylase high yielding strain and building method thereof

InactiveCN101531987ASave industrial foodLow costBacteriaMicroorganism based processesChemistryAlpha-amylase

The invention relates to a medium temperature Alpha-amylase strain and a building method thereof. Bacillus subtilis AS 1.108 medium temperature Alpha-amylase gene obtained by PRC is cloned to bacillus subtilis expression plasmid pWB980 and is switched to WB600 to facilitate medium temperature Alpha-amylase to obtain high expression. The medium temperature Alpha-amylase gene has 1431 basic groups and codes 447 amino acids. The molecular mass of recombinase is 49.1KDa by SDS-PAGE detection, the optimal operation temperature and pH value are 60 DEG C and 6.0 respectively. The activity of the enzyme is about 2 times of the activity of the original strain, thus the problems of stink generated by the original strain and long fermentation period are solved. The method not only saves grains for industrial uses, reduces cost and provides better condition for deep processing of starch material, but also greatly reduces energy consumption and better suits industrialized production and application, thus having important economic benefits and obvious social benefits.

Owner:TIANJIN UNIVERSITY OF SCIENCE AND TECHNOLOGY

Environmentally-friendly damping rubber sheet

PendingCN110540730ATo achieve the effect of noise reduction and vibrationIncrease dampingCoatingsPetroleum resinDeodorant

The invention discloses an environmentally-friendly damping rubber sheet, which comprises a damping rubber layer comprising 10-20% by mass of a petroleum resin, 3-20% by mass of a butyl rubber, 3-20%by mass of polyisobutene, 2-10% by mass of a deodorant and the balance of a filler, wherein an isolation layer is arranged on an isolation layer. The preparation method comprises: (1) weighing the materials; (2) synthesizing; (3) calendering; (4) blanking; and (5) coating with an isolation layer, and loading into a packaging box. According to the present invention, the butyl rubber with high damping performance is used as the matrix, and the adhesive property and the strength of the rubber sheet are improved by adopting the viscous resin and the filler, such that the high damping performance of the whole damping rubber sheet in a relatively wide range is ensured while the high viscosity of the damping rubber sheet is ensured; and the selected materials are odorless at a normal temperature,and have weak odor at a temperature of 60-80 DEG C, such that the odor problem of the product can be solved by adding 2-5% of the chelating deodorant.

Owner:长春和成汽车零部件有限公司

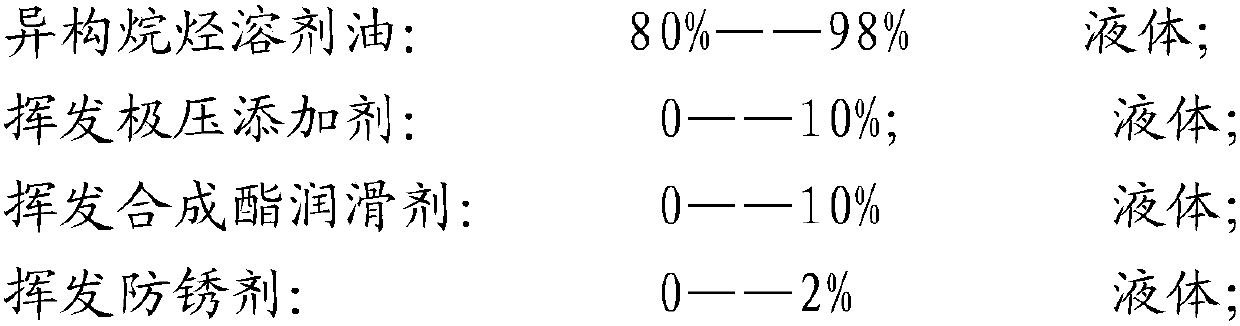

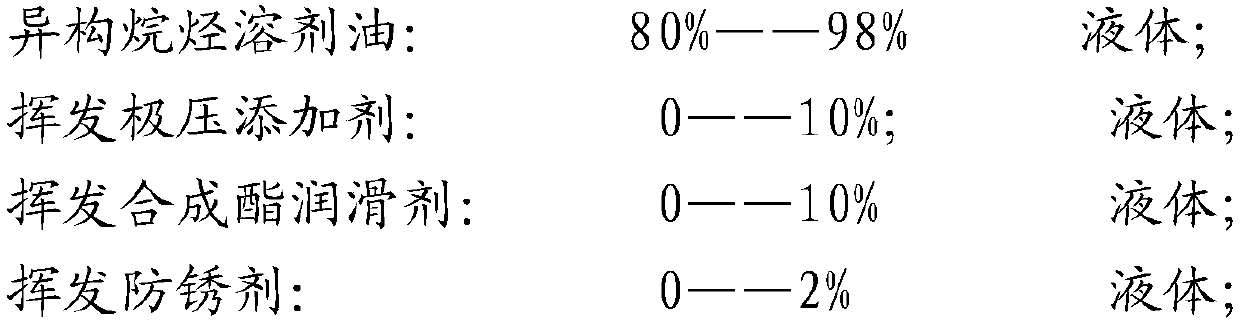

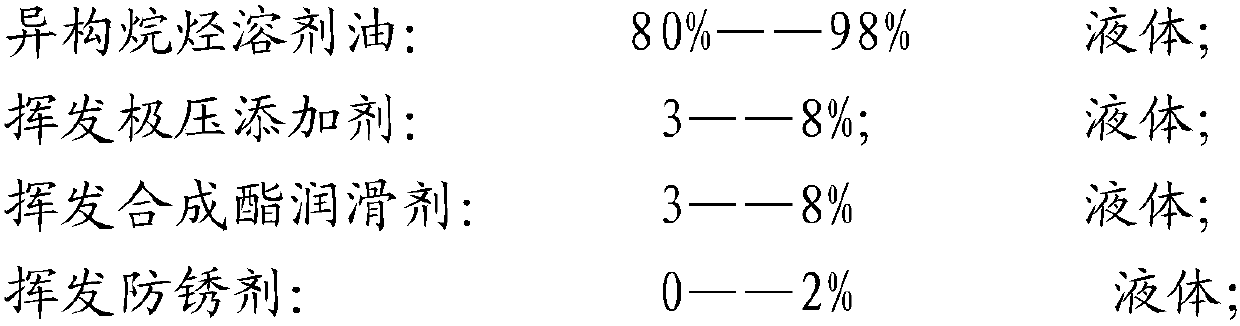

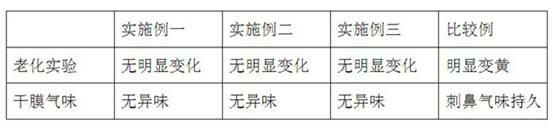

Odorless and safe volatile punching oil

The invention discloses odorless and safe volatile punching oil. The odorless and safe volatile punching oil in the formula is prepared from 80%-98% by weight of isoparaffin solvent oil, 0-10% by weight of a volatile extreme pressure additive, 0-10% by weight of a volatile synthetic ester lubricant and 0-2% by weight of a volatile antirust agent. The odorless and safe volatile punching oil prepared from the isoparaffin solvent oil, the volatile extreme pressure additive, the volatile synthetic ester lubricant and the volatile antirust agent by compounding has no odor and volatilizes thoroughly, so that environmental protection odor and volatility are perfectly integrated in the punching oil, and odorlessness and thorough volatilization can be realized; the problems of residues and odor ofthe volatile punching oil in the prior art are solved fundamentally, the process is simple, the preparation cost is appropriate, the performance is stable, the extreme-pressure lubrication effect is good, the punching oil volatilizes thoroughly and is free of odor and residues, subsequent cleaning cost is reduced, and the volatile punching oil is environmentally friendly and safe.

Owner:诺而曼环保科技(江苏)有限公司

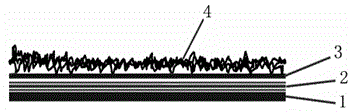

Recoverable carpet and production method thereof

ActiveCN104814648ASolve the smell problemEasy to recycleNon-macromolecular adhesive additivesSynthetic resin layered productsYarnAdhesive

The invention provides a recoverable carpet and a production method thereof. The recoverable carpet is of a laminated structure and sequentially comprises a nonwoven fabric layer, a hot melting composite adhesive layer, carpet bottom cloth and a carpet fluff yarn layer from bottom to top. The hot melting composite adhesive layer comprises, by mass, 30% of polypropylene and polyethylene thermoplasticity high polymers, 23% of recovered chemical fiber carpet yarn waste, 18% of recovered thermoplasticity waste, 12% of calcium carbonate, 10% of pulverized fuel ash, 0.8% of dispersing agents, 3% of fire retardant, 3.0% of functional auxiliaries and 0.2% of coloring agents, and the mixture of the components is mixed and refined into hot melting composite adhesive master batches through a threaded rod extruding machine. The carpet is free of foreign smell and can be completely recovered or repeated recovered; by menas of the process method, the problems that due to the fact that a PVC bottom layer, vinyl acetate monomer, polyurethane, butadiene-styrene rubber or pitch are used as various materials of adhesives of an existing carpet, the carpet can not be completely recovered at a time and needs to be screened are solved, the problem of smell of plasticizer which is used is solved, the recovery cost is reduced, and the recovery of resources and environment protection are facilitated.

Owner:威海德瑞合成纤维有限公司

Surface light-curing odor-free paint for wood and construction technology thereof

InactiveCN102618151AReduce pollutionLess irritatingPretreated surfacesPolyurea/polyurethane coatingsUrethane acrylateBenzophenone

The invention discloses a surface light-curing odor-free paint for wood and a construction technology of the paint. The surface light-curing odor-free paint for wood is low in environment pollution, rapid in curing speed, energy-saving, capable of a and less in irritation to human body; and through adoption of the paint, the cured product has good performance and a substrate hardly gets yellow after film formation. In addition, the invention also provides the construction technology of the surface light-curing odor-free paint for wood. The surface light-curing odor-free paint for wood comprises the following components by weight percent: 25-45% of bisphenol-A epoxy acrylate, 8-10% of urethane acrylate, 35-45% of trimethylopropane triacrylate, 1-5% of 4-phenyl-benzophenone, 1-5% of dimethylaminobenzoate, 8-12% of filler and 0.1-1% of additives, wherein the additives include defoaming agent, dispersing agent and flatting agent. The invention can be widely applied to the production manufacturing field of flat plate coating.

Owner:珠海市佳家光合材料科技有限公司

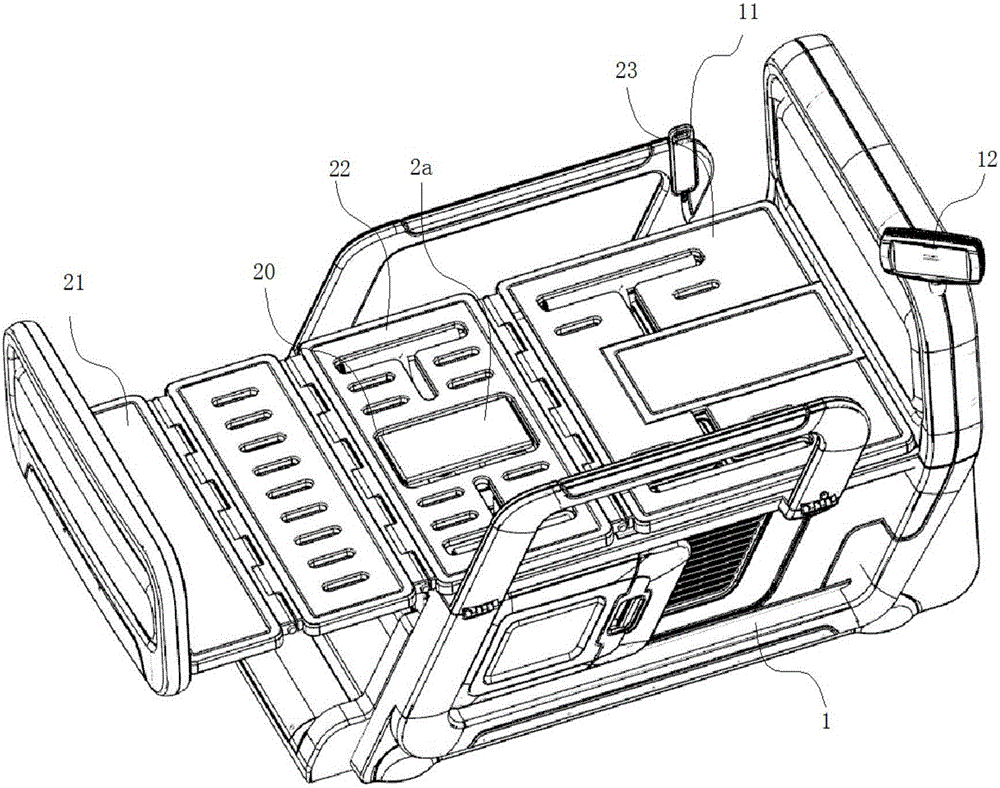

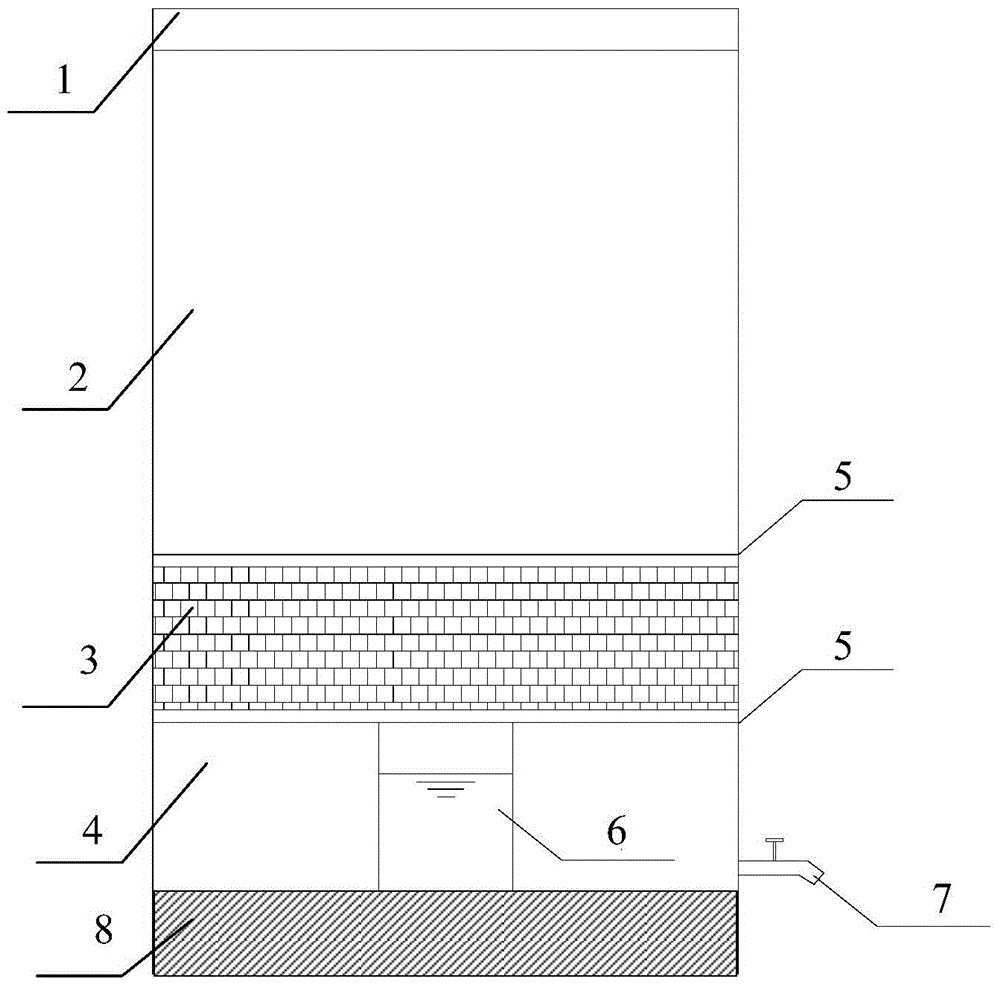

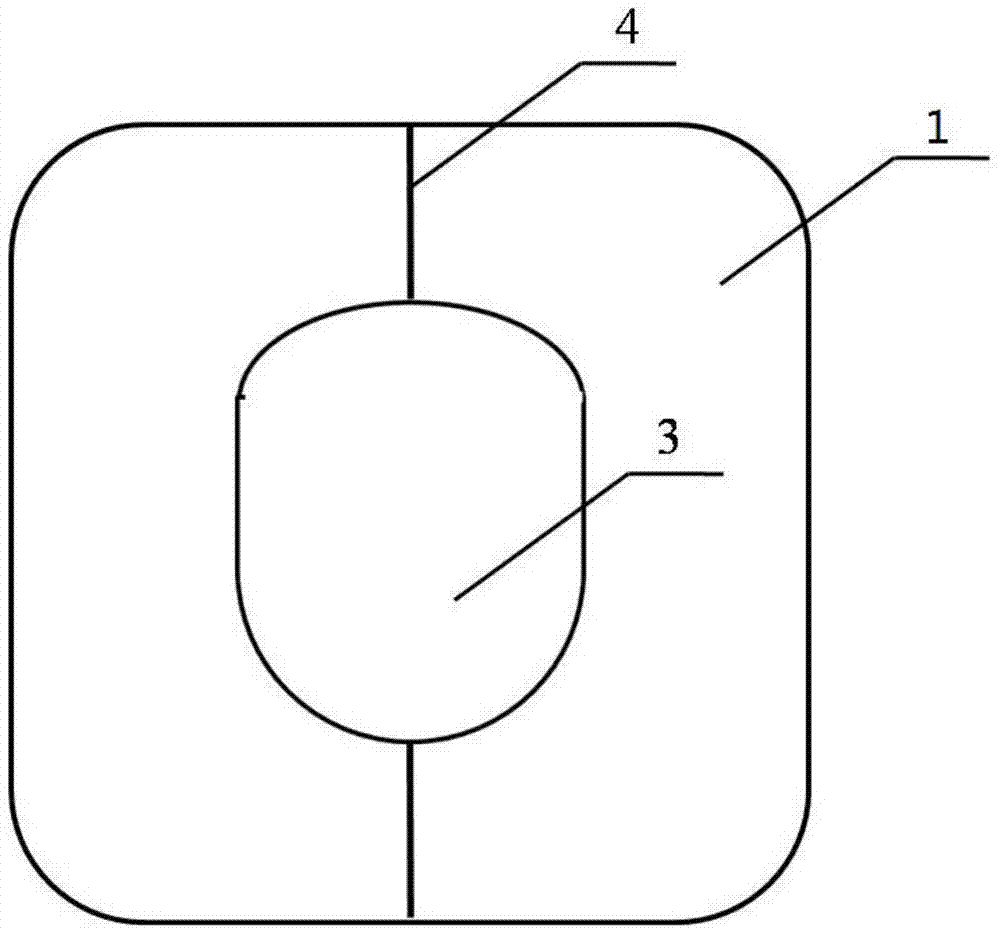

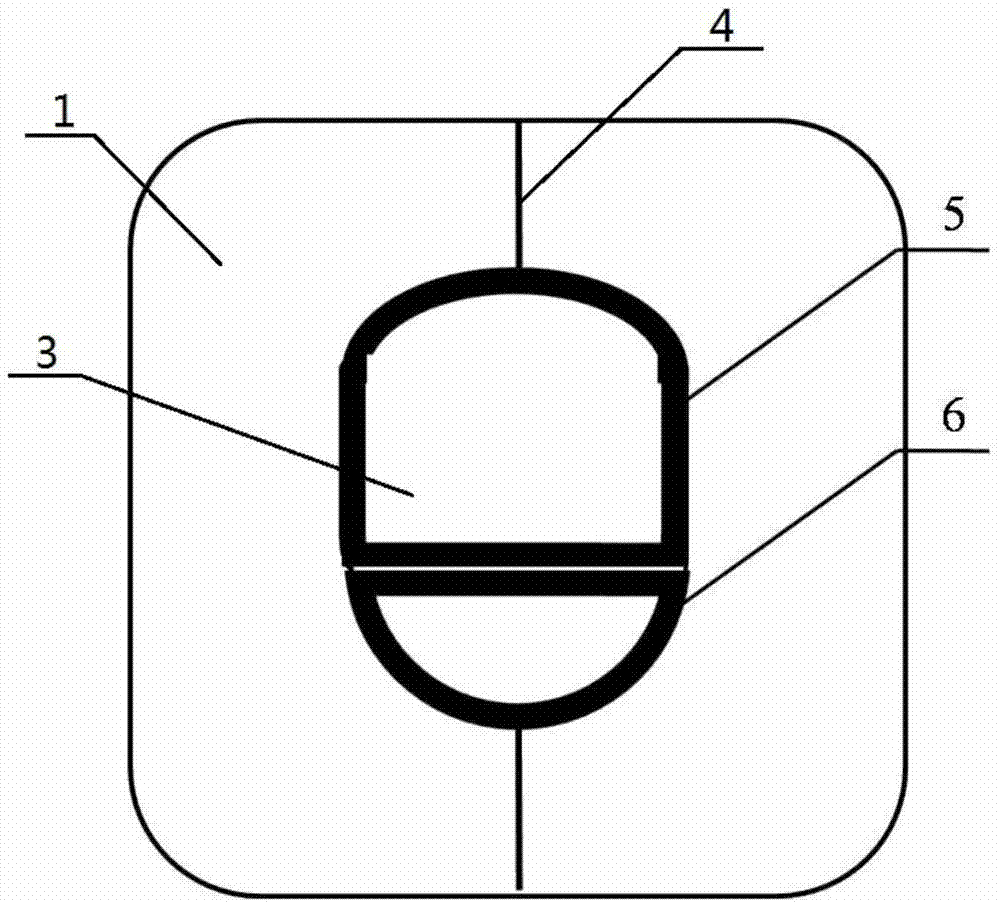

Excrete cleaning device for nursing bed

InactiveCN106264927ASolve the trouble of getting in and out of bedProtect personal privacyNursing bedsMedical transportEngineeringWaste treatment

The invention relates to the technical field of medicine equipment, in particular to an excrete cleaning device for a nursing bed. The nursing bed comprises a bed, wherein the bed comprises a bed frame and a bed body; the bed body is arranged on the bed frame, and comprises a foot bed plate, a hip bed plate and a back bed plate which are sequentially and rotationally connected; the hip bed plate is provided with a nursing opening, an excrete door is arranged on the nursing opening, and the excrete cleaning device is arranged under the excrete door; an electric push rod is arranged on the bed frame and is used for controlling the lifting of the excrete cleaning device. The nursing bed is characterized in that a water conveying mechanism and a waste treatment mechanism are arranged on the bed frame, the water conveying mechanism is used for flushing the excrete cleaning device, and the waste treatment mechanism is used for discharging the wastes after the excrete cleaning device is flushed; the excrete cleaning device comprises a closestool and an urinal cover; a cleaning mechanism and a drying mechanism are arranged in the closestool, the cleaning mechanism is used for cleaning the lower part of a human body, and the drying mechanism is used for drying the lower part of the human body after cleaning. The nursing bed has the advantages that the structure is reasonable and simple, the function is strong, and the convenience in use is realized.

Owner:浙江强鹰科技股份有限公司

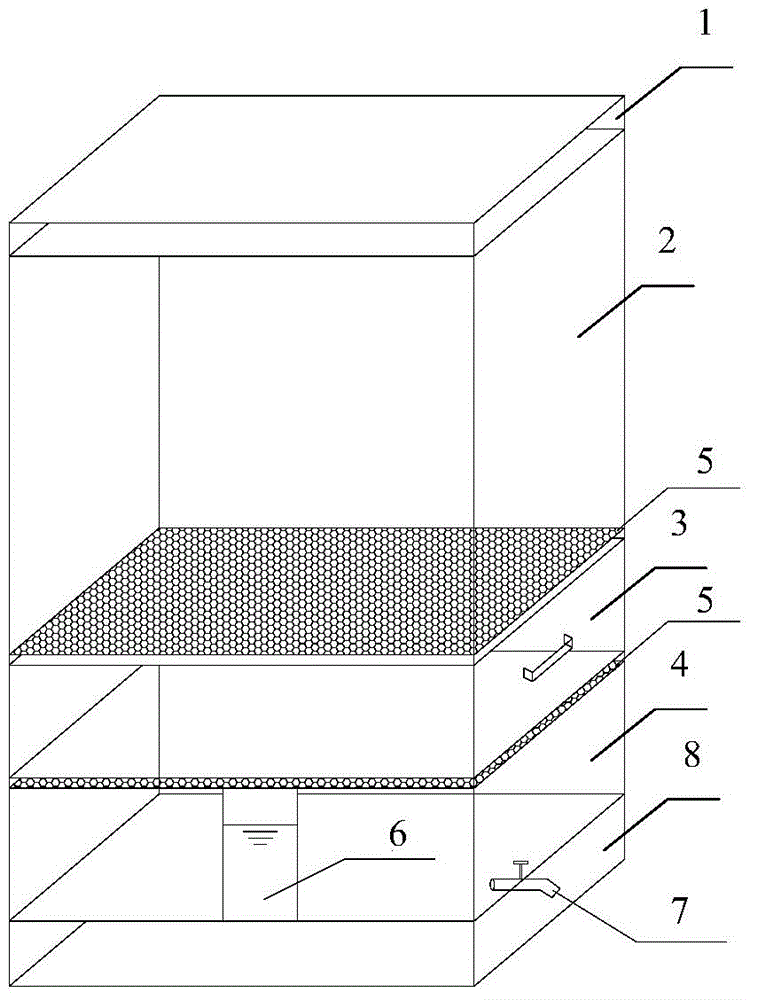

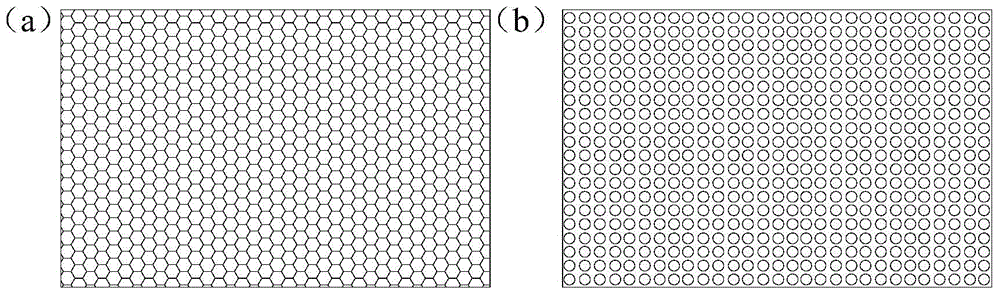

Deodorization garbage can and using method thereof

ActiveCN104986477ASolve the smell problemSolve the leakWaste collection and transferRefuse receptaclesWater dischargeLitter

The invention discloses a deodorization garbage can and a using method thereof. The deodorization garbage can is characterized by comprising an upper can cover, a can body and a base, wherein the can body is divided into three layers; the upper layer is a garbage storage layer; the middle layer is a drawer type filler layer; the lower layer is a garbage percolate collecting layer; the three layers are separated by laminate boards; the laminate boards are net-shaped structure or are provided with a plurality of through holes; a composite filter used for deodorizing and adsorbing garbage percolate is filled in the drawer type filler layer; and a transparent observation window used for observing height of the garbage percolate in the garbage percolate collecting layer and a water discharge faucet used for discharging the garbage percolate in the garbage percolate collecting layer are arranged on the barrel wall of the garbage percolate collecting layer. According to the deodorization garbage can, the problems that a current garbage can is simple in function and odor and the garbage percolate are generated in high-temperature weather are solved; and in a using process, the garbage percolate collected and the composite filter material which adsorbs the garbage percolate further can be directly used as raw materials of a community forestry fertilizer or an organic fertilizer for being further utilized.

Owner:HEFEI UNIV OF TECH

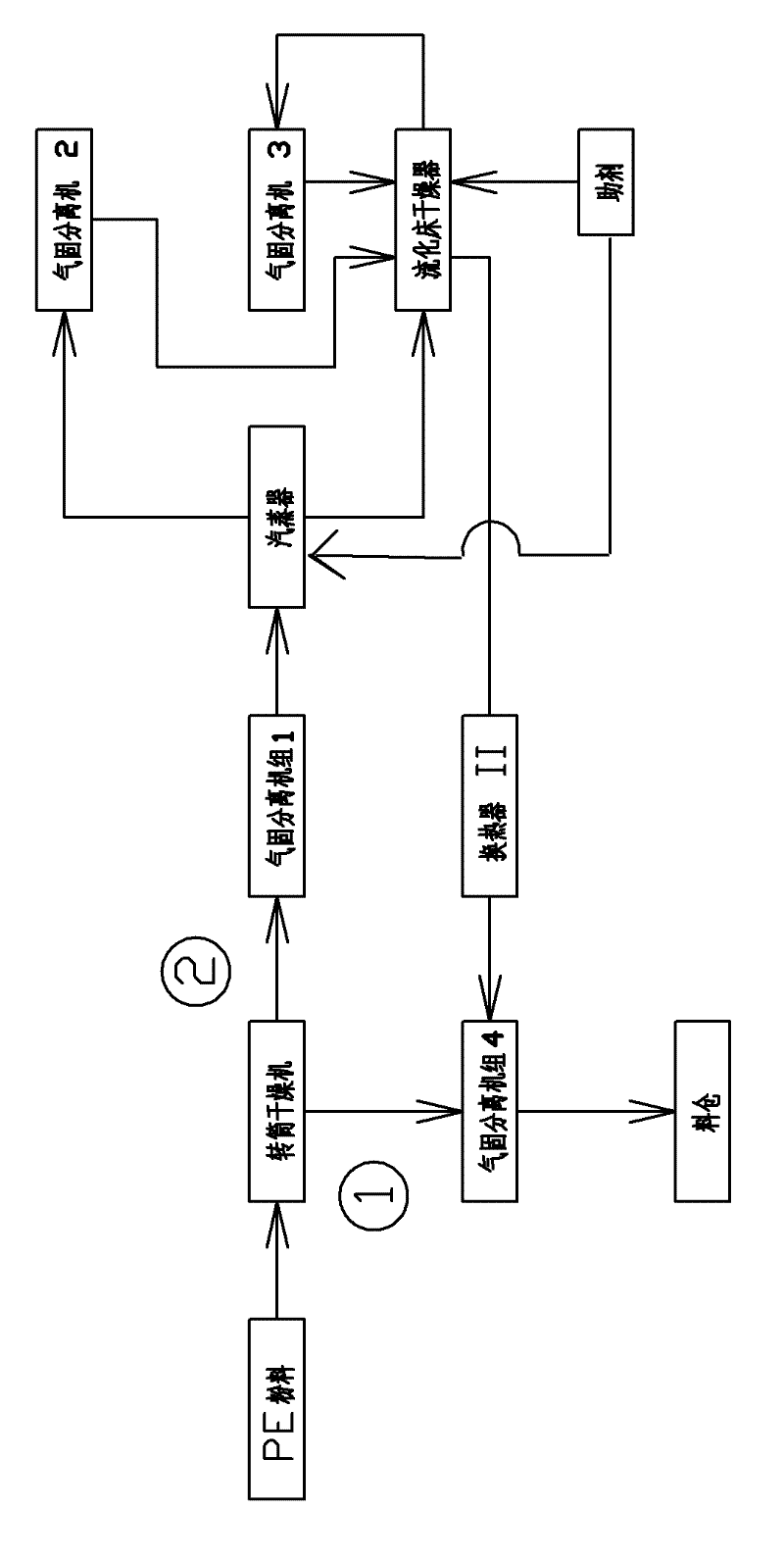

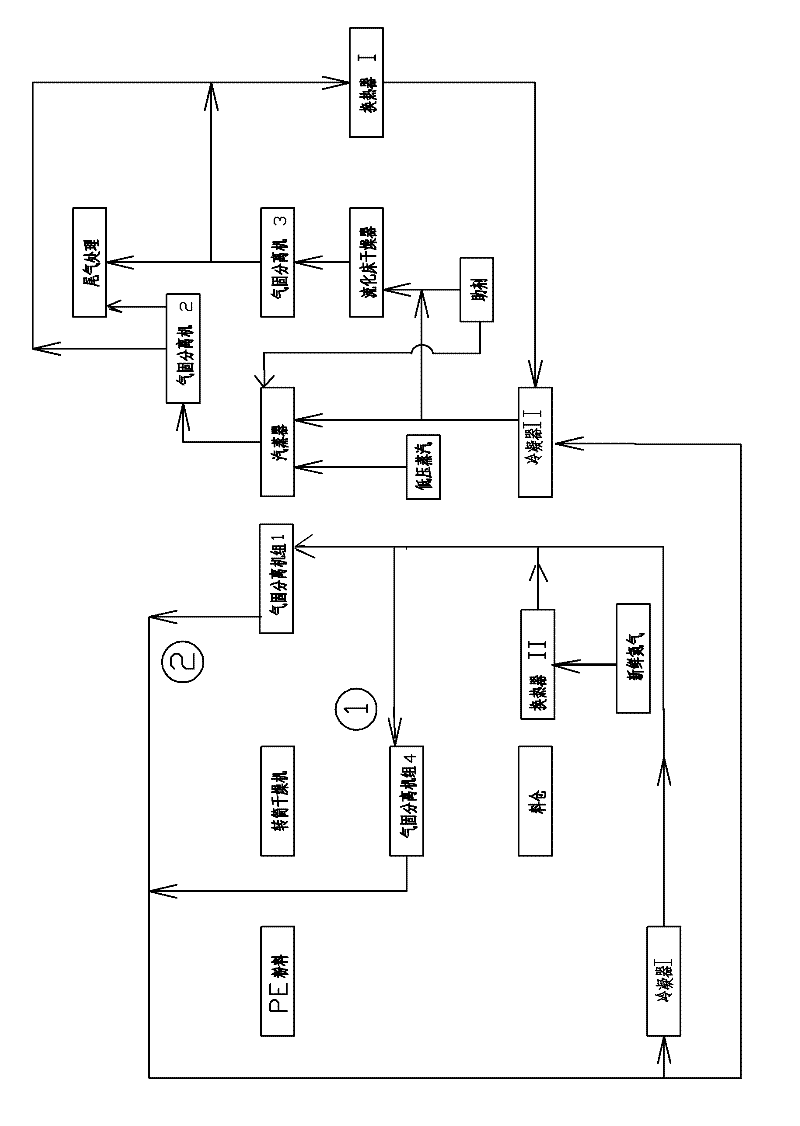

Degassing process of high density polyethylene

InactiveCN102603934ALow volatile contentSolve the smell problemLow-density polyethylenePolymer science

The invention provides a degassing technology capable of effectively removing the odor of high density polyethylene (HDPE). The polyethylene (PE) material particles with a certain particle size are steamed and inactivated by low-pressure steam in a steamer, are fluidized and dried by hot nitrogen in a fluidized drier, and are added with an auxiliary and the like to achieve the purposes of inactivating a catalyst, removing a catalyst oxide and effectively reducing volatile matters, so that the technology provided by the invention thoroughly solves the problem of the odor of a product, and remarkably improves the product quality.

Owner:INNOVATIVE COAL CHEMICAL DESIGN INSTITUTE (SHANGHAI) CO LTD

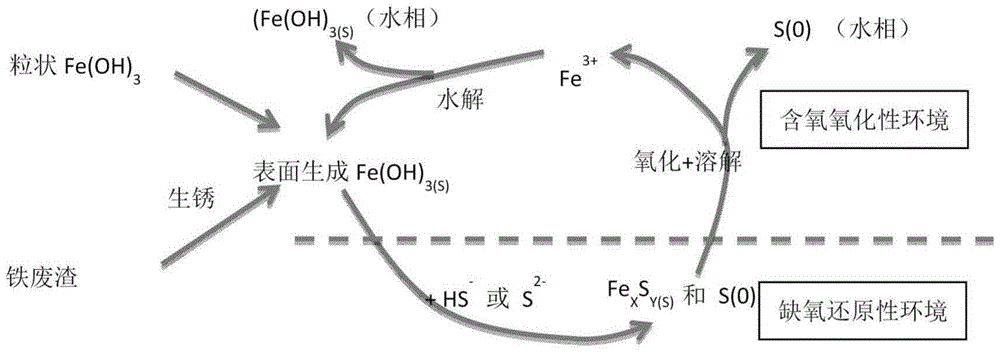

Method for in-situ control of hydrogen sulfide odor in sediments

ActiveCN106495425AAchieve recyclingSolve the problem of hydrogen sulfide odorSludge treatment by oxidationSewer pipelinesSewageSanitary sewer

The invention provides a method for in-situ control of hydrogen sulfide odor in sediments. The sediments are allowed to contact with indissolvable or insoluble particle oxidizing agents to remove hydrogen sulfide in the sediments through an in-situ oxidation and reduction process, and the oxidizing agent is recycled by in-situ regeneration. The method is further used for control of hydrogen sulfide odor of the sediments in rainwater pipelines, rivers or sewage pipelines.

Owner:THE HONG KONG UNIV OF SCI & TECH

Reinforced and scratch-resistant polypropylene material and preparation method thereof

The invention relates to a reinforced and scratch-resistant polypropylene material and a preparation method thereof, wherein the material is prepared from 70-95 parts of polypropylene, 30-5 parts of SiAlON, 0.1-0.5 part of a coupling agent, 0.1-1 part of a thermal stabilizer, 0-1 part of a lubricant, and 0-0.5 part of white oil, and the weight sum of the polypropylene and the SiAlON is 100 parts. According to the present invention, the one-dimensional beta-SiAlON adopted as the scratch-resistant agent is added to the polypropylene material so as to concurrently provide advantages of material scratch resistance enhancing and material strength increasing and overcome the disadvantage of the material scratch resistance reducing of the traditional reinforcing filling material; and the obtained reinforced and scratch-resistant polypropylene material is used in vehicle interior decoration materials, and does not have disadvantages of scratch-resistant agent precipitation, odor, appearance and the like compared to the traditional scratch-resistant agent adding material.

Owner:HEFEI GENIUS NEW MATERIALS

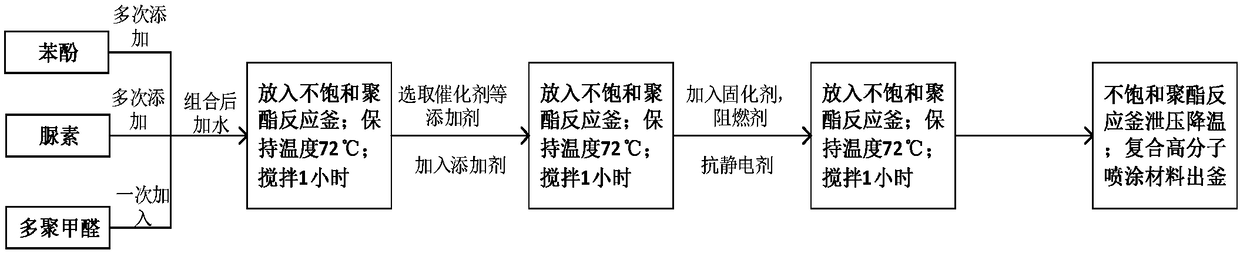

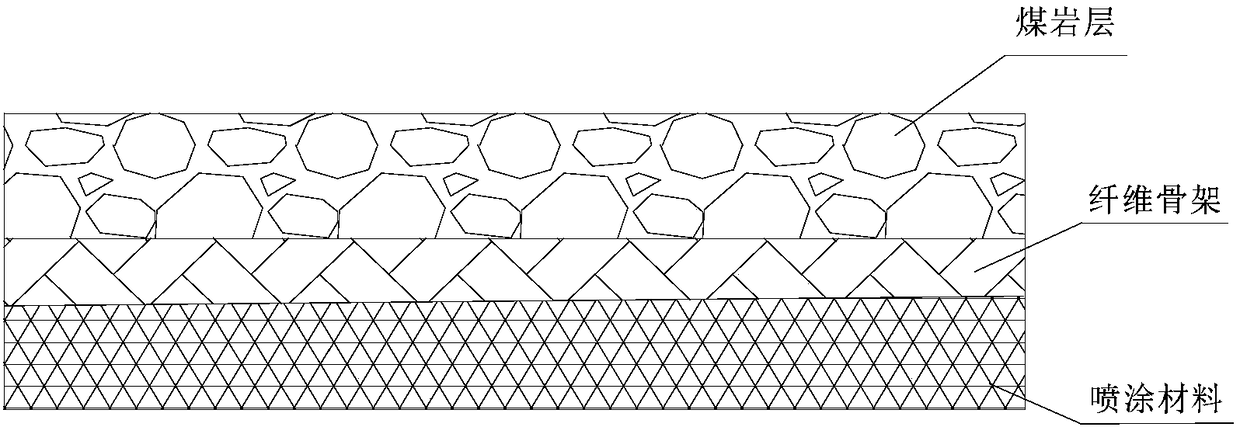

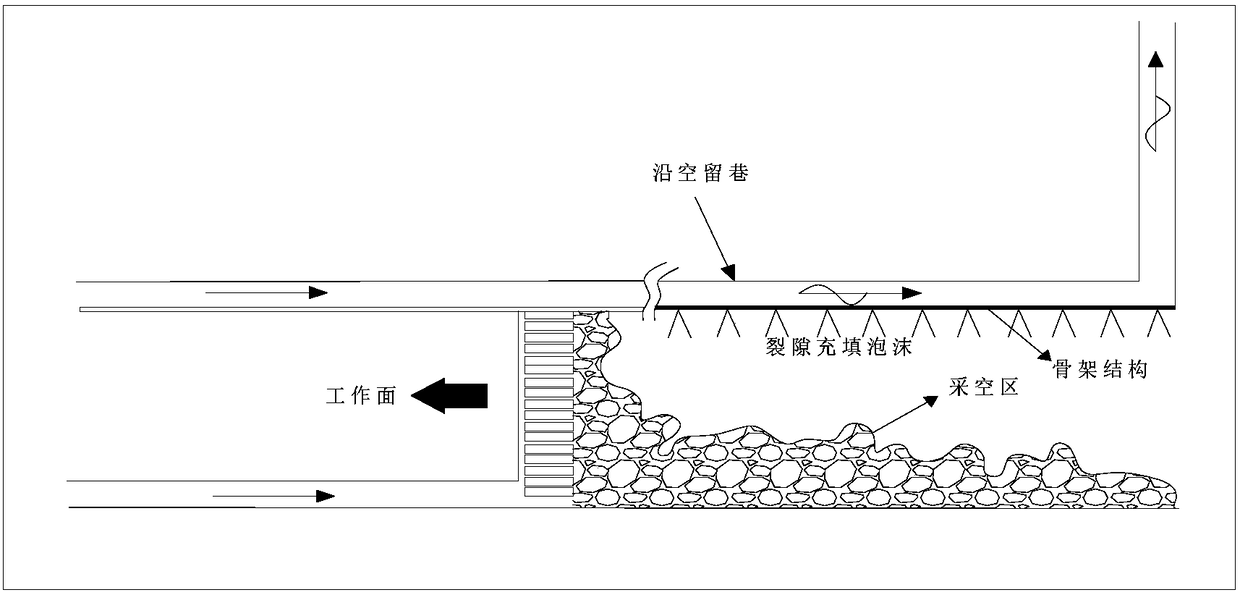

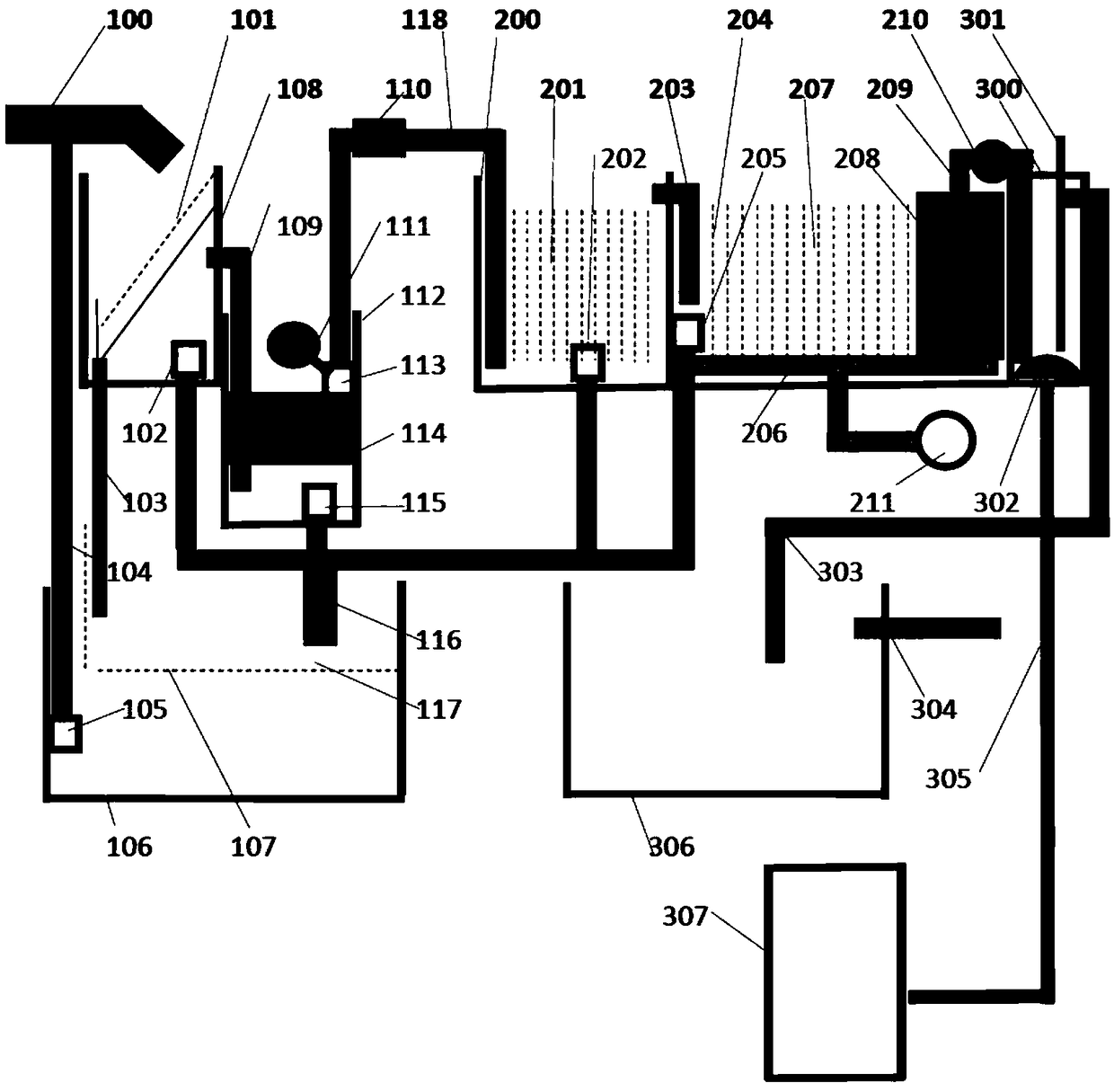

Composite spraying material and frame for downhole quick leaking stoppage and filling and implementing method thereof

InactiveCN108129943AImprove applicabilityImprove extraction efficiencyFireproof paintsProductsFoaming agentKevlar

The invention discloses a composite spraying material and frame for downhole quick leaking stoppage and filling and an implementing method thereof, and belongs to the composite spraying material and the sealing frame, and the implementing method thereof. A set reasonable proportion of phenolic foam, polyurethane foam and urea formaldehyde foam is selected, a base material of the spraying materialis synthesized, a proper flame retardant is added, and the properties of the base material are increased; an antistatic material, a catalyst, a curing agent, a surfactant, a foaming agent and other materials are added, and the flame-retardant and anti-static composite macromolecular spraying material is formed through specific technological process. Fiber-Kevlar is selected as a raw material to form the sealing frame and is used as a carrier of the spraying material, the structure deformation is flexible, and a whole for quick sealing and leaking stoppage is formed jointly. Through different embodiments, the composite spraying material is verified to have the characteristics of light mass, fast forming, strong sealing and good fire prevention and leaking stoppage effects, can effectively prevent downhole air leakage and harmful gas gushing and ensures the safety of workers.

Owner:CHINA UNIV OF MINING & TECH

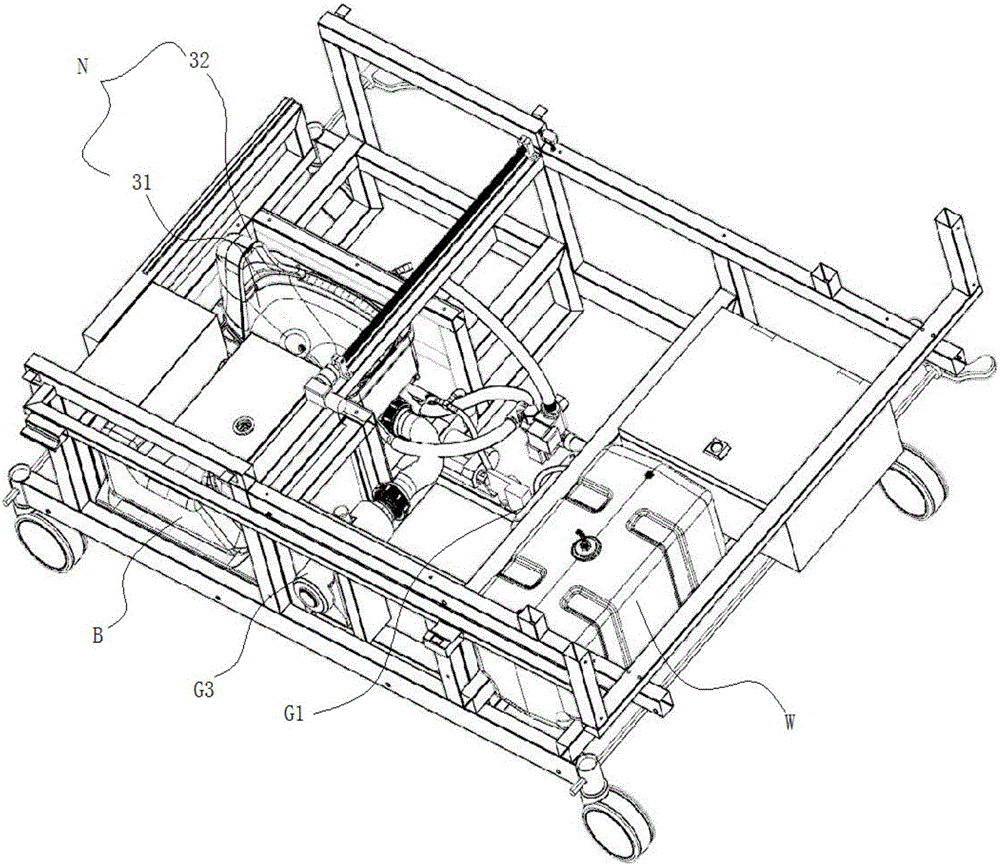

Resourceful treatment equipment for excrement and urine of toilet

PendingCN108609814AGuaranteed cleanlinessReduce odorTreatment using aerobic processesWater/sewage treatment by irradiationUrineSewage

Resourceful treatment equipment for excrement and urine of a toilet comprises an excrement decomposing system, a microbial treatment system and an advanced oxidation system. The problems that excrement and urine sewage is directly drained into a sewer line, thus, water resources are wasted and the environment is polluted are solved effectively, and furthermore, the problems of wastewater recyclingand odor in an existing toilet are solved effectively.

Owner:夏海宗

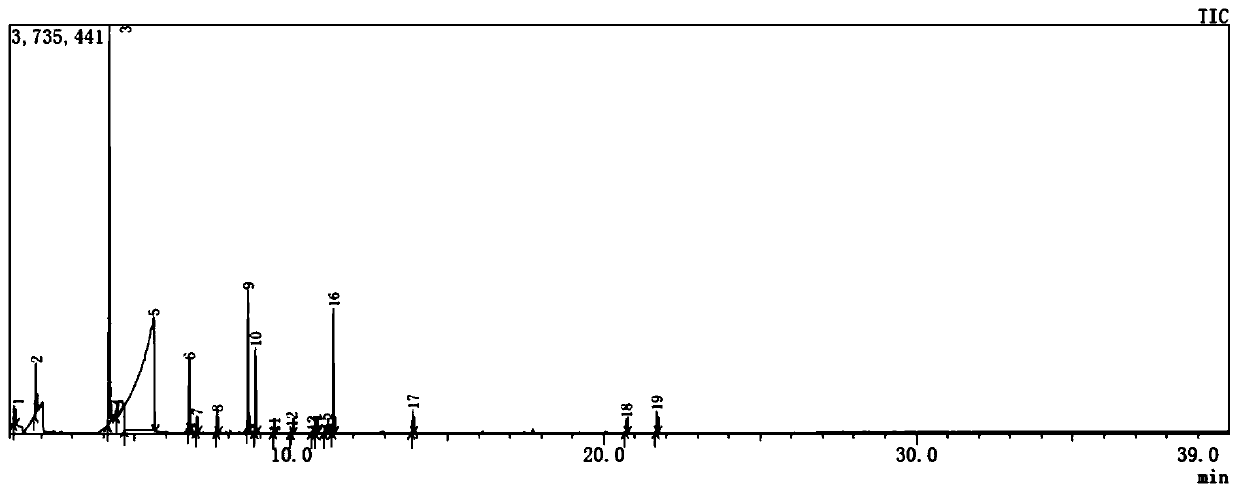

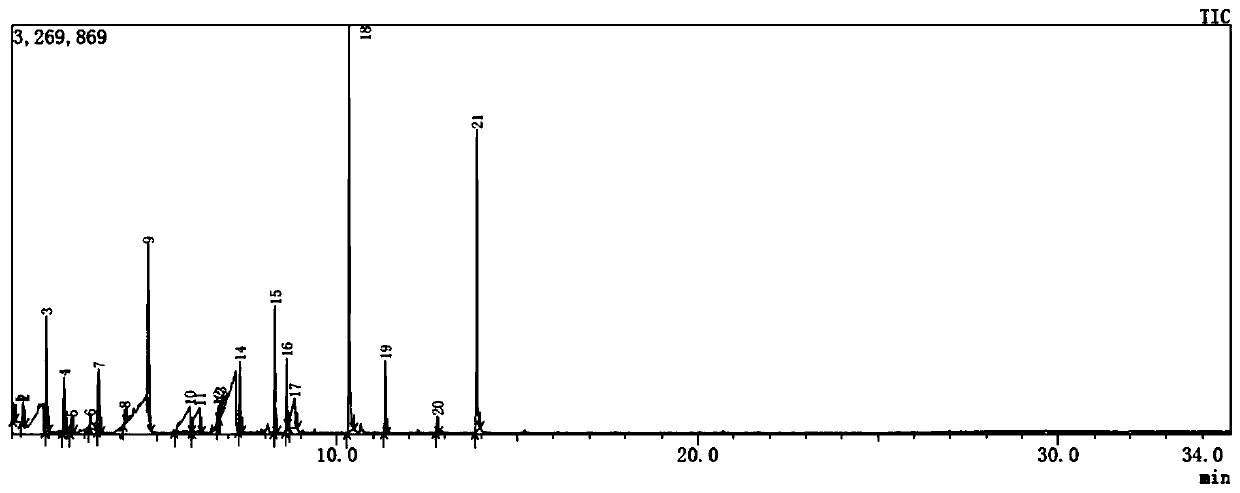

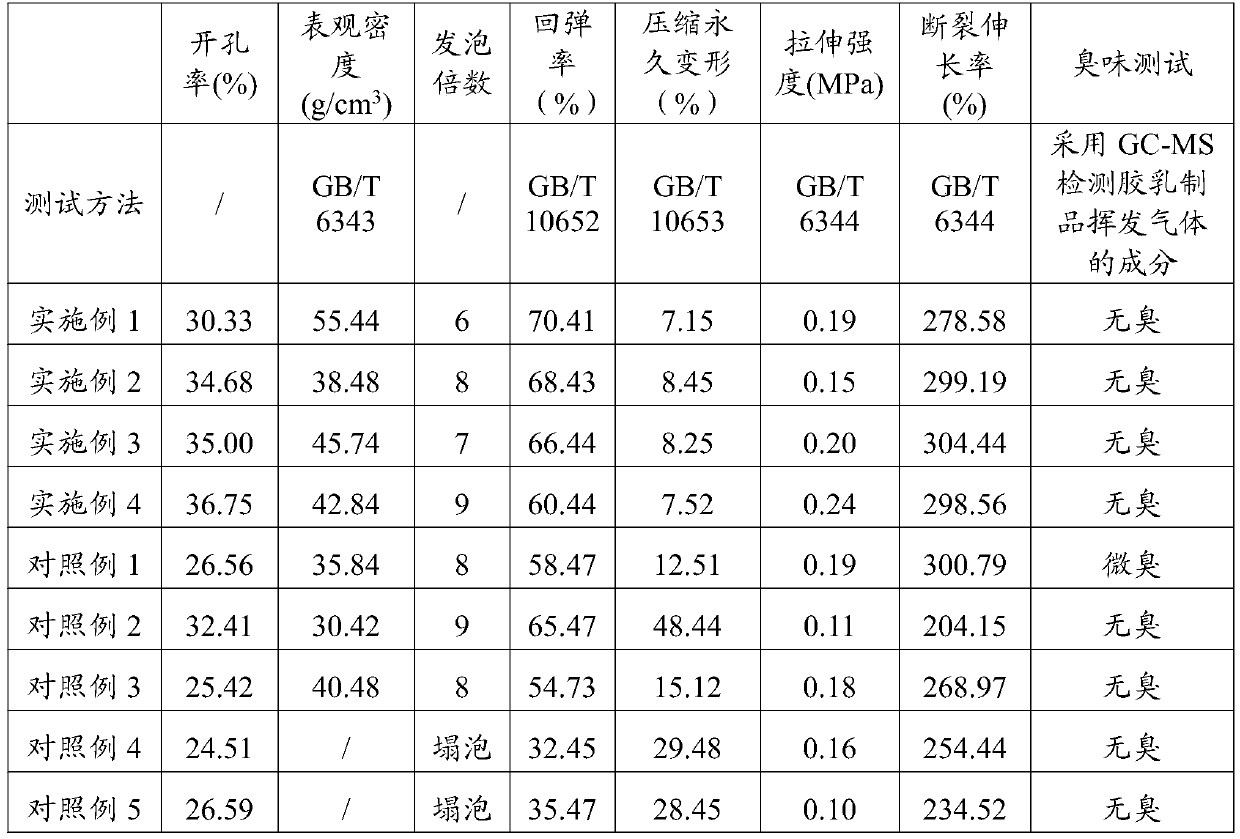

Natural latex sponge product as well as preparation method and application thereof

The invention provides a natural latex sponge product as well as a preparation method and application thereof, and belongs to the technical field of natural latex. The natural latex sponge product provided by the invention is prepared from the following components in parts by weight: 100 parts of low-protein natural latex; 0.5 to 2 parts of coconut shell activated carbon; 0.5 to 2 parts of a composite vulcanization accelerator; 0.5 to 2 parts of an antioxidant; 1 to 2 parts of a foaming agent; 2 to 3 parts of zinc oxide; 0.5 to 1 part of a gelling agent; and 0.1 to 0.3 part of a bactericide. The natural rubber latex sponge product provided by the invention uses the low-protein natural rubber latex as a raw material and uses the foaming agent, the gelling agent, the antioxidant and the zincoxide in a cooperation mode to obtain the natural latex sponge product under the combined action of the coconut shell activated carbon, the composite vulcanization accelerator and the bactericide, and the natural latex sponge product has high porosity, excellent mechanical properties, aging resistance, and no odor, and is suitable for promotion and application in latex sheets, latex sponge mattresses, latex sponge pillows or latex sponge cushions.

Owner:AGRI PRODS PROCESSING RES INST CHINESE ACAD OF TROPICAL AGRI SCI +1

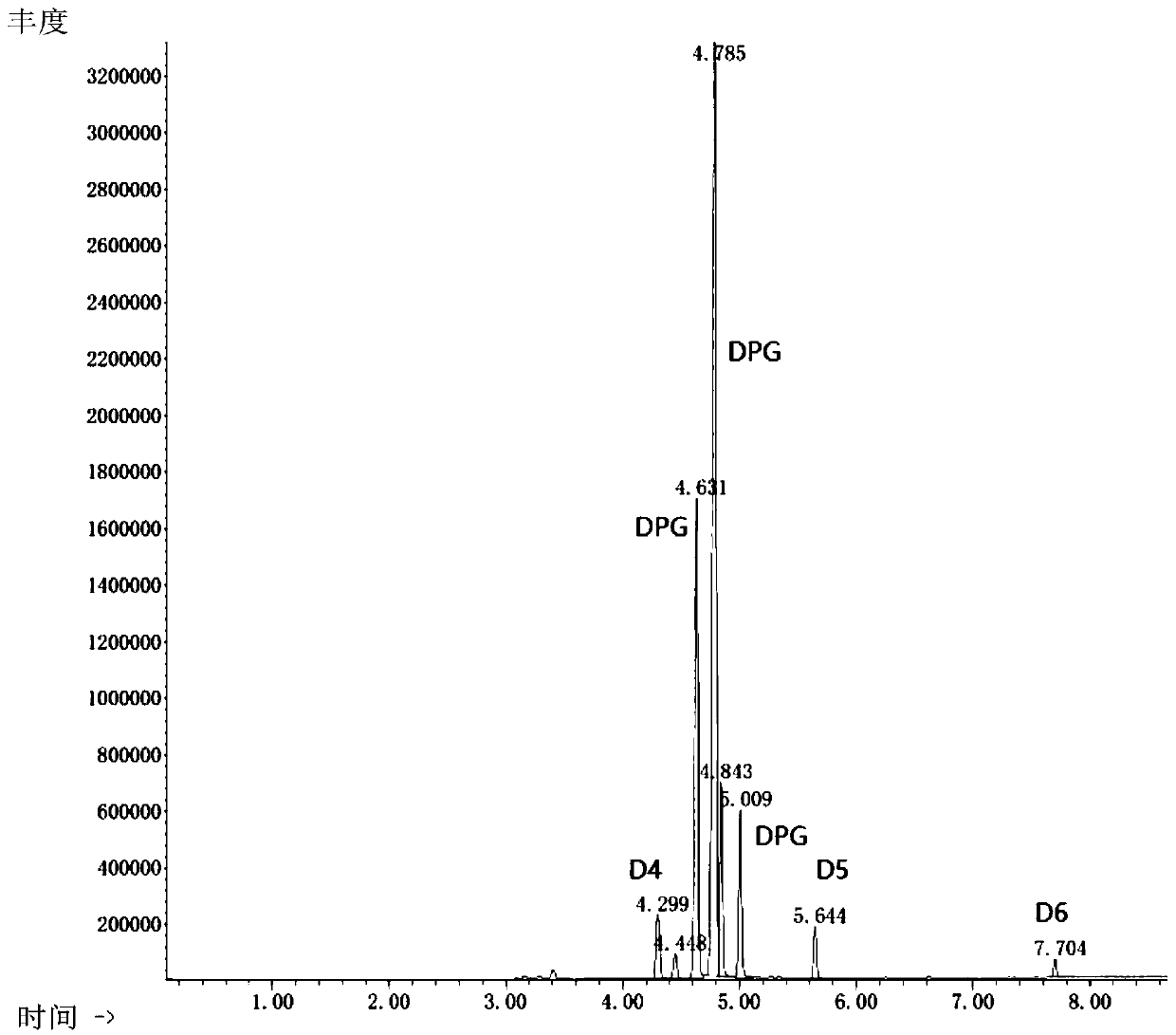

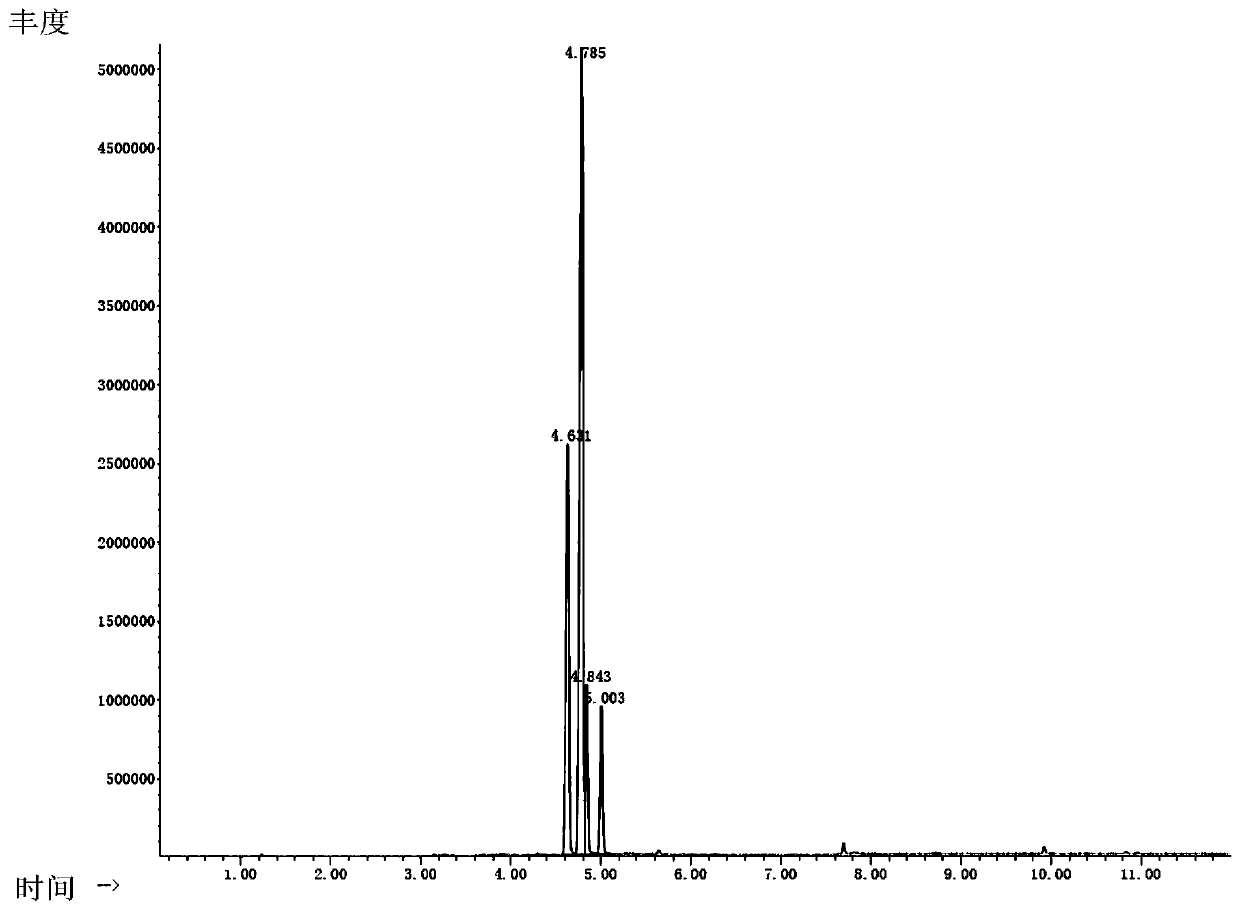

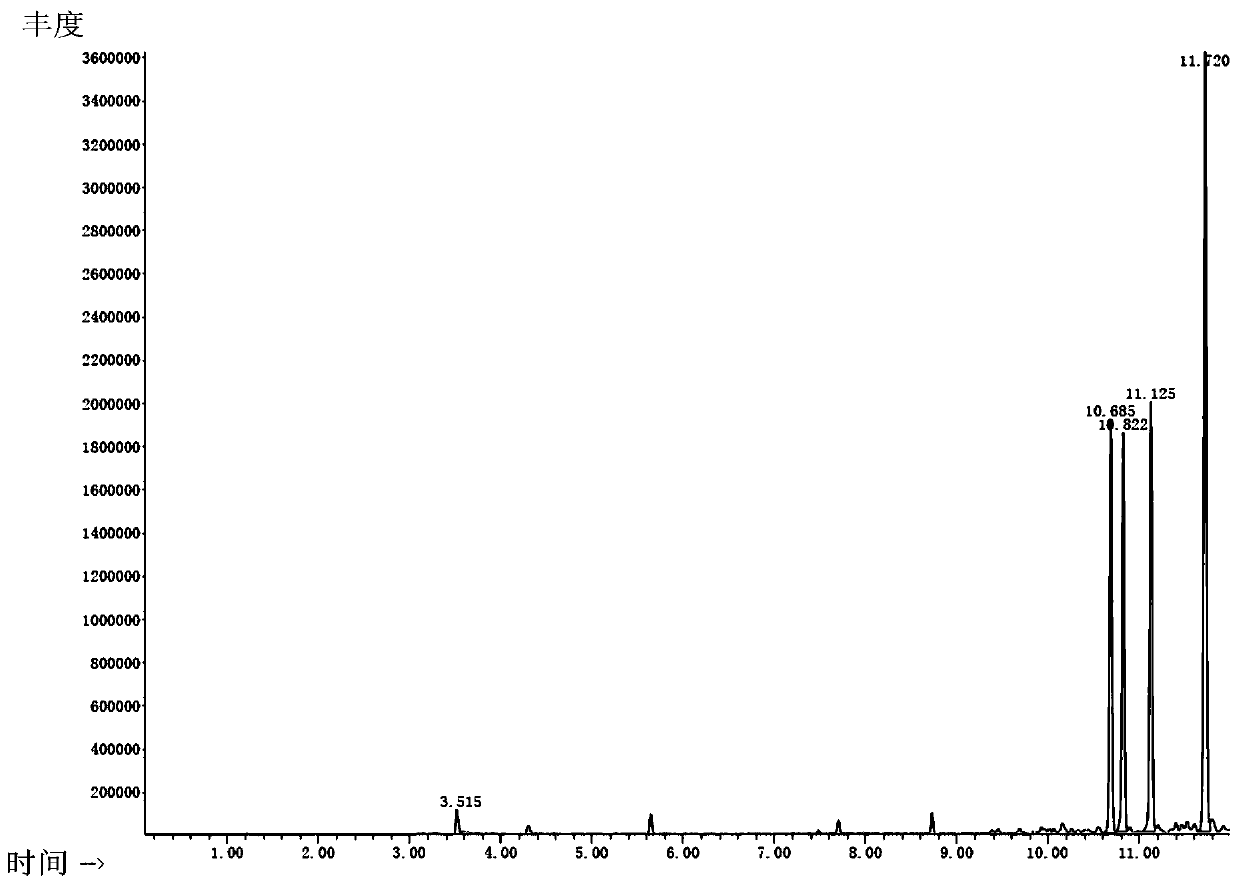

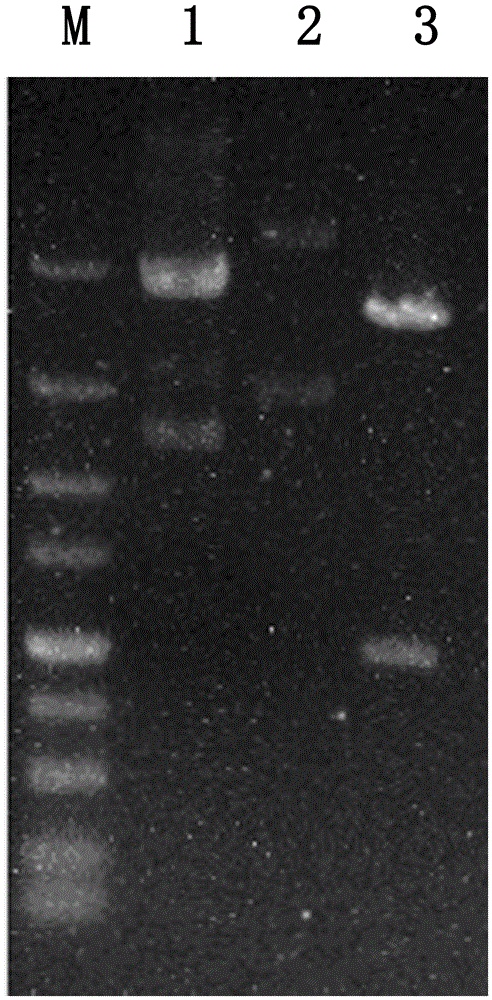

Low-peculiar smell bacitracin production bacillus licheniformis and construction method and application thereof

InactiveCN106755047ASolve the smell problemImprove qualityBacteriaMicroorganism based processesBacillus licheniformisGenomic DNA

The invention provides a low-peculiar smell bacitracin production bacillus licheniformis and a construction method and an application of the low-peculiar smell bacitracin production bacillus licheniformis. A ptb gene in a genomic DNA sequence of the bacillus licheniformis DW2 is knocked out through a genetic engineering method to obtain the bacillus licheniformis DW2deltaptb, and compared with the bacillus licheniformis DW2, the synthetic amounts of isobutyric acid and isovaleric acid of the bacterial strain are respectively reduced to 33% and 37% in the fermentation process of the bacitracin, and the peculiar smell is remarkably reduced.

Owner:LIFECOME BIOCHEM

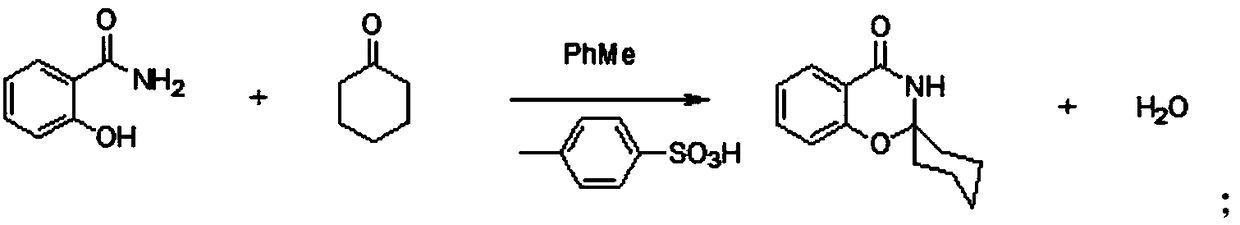

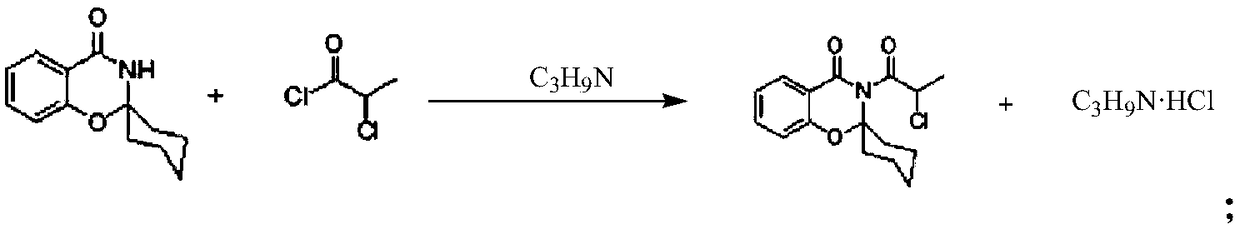

A preparation method of a meropenem intermediate

InactiveCN108774188AThe process is simple and reliableShorten the production cycleOrganic chemistryCyclohexanoneReaction temperature

A preparation method of a meropenem intermediate is disclosed. The method includes adding salicylamide and cyclohexanone into an organic solvent that is toluene; reacting the mixture under the function of a catalyst that is p-toluenesulfonic acid; then performing material centrifugation, rinsing and centrifugation until a product is dry to obtain white crystals; raising the temperature until the obtained material is dissolved; then adding an organic solvent that is toluene and a catalyst that is n-propylamine; then adding 2-chloropropionyl chloride dropwise and reacting the mixture until the reaction is finished; performing vacuum distillation to remove the toluene; performing centrifugation after crystallization; and after a centrifugation product is dry, discharging and drying. The moleratio of the salicylamide, the cyclohexanone, the p-toluenesulfonic acid, the n-propylamine and the 2-chloropropionyl chloride is 1:1.3-1.7:0.01-0.04:0.2-0.5:0.2-0.5. The salicylamide, the cyclohexanone and the 2-chloropropionyl chloride are adopted as raw materials, the p-toluenesulfonic acid and the n-propylamine are adopted as catalysts, the one-time product yield is 92.4% by reaction temperature control and material ratio control, and the mother liquor recovery rate is 5%.

Owner:湖北宇阳药业有限公司

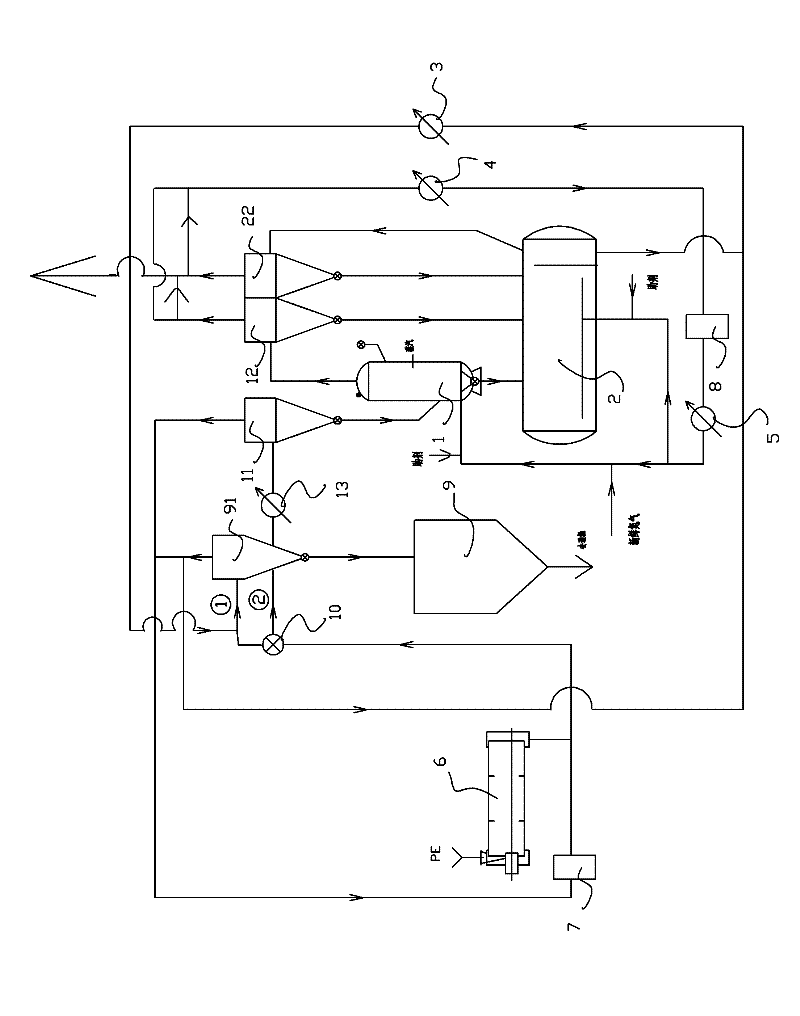

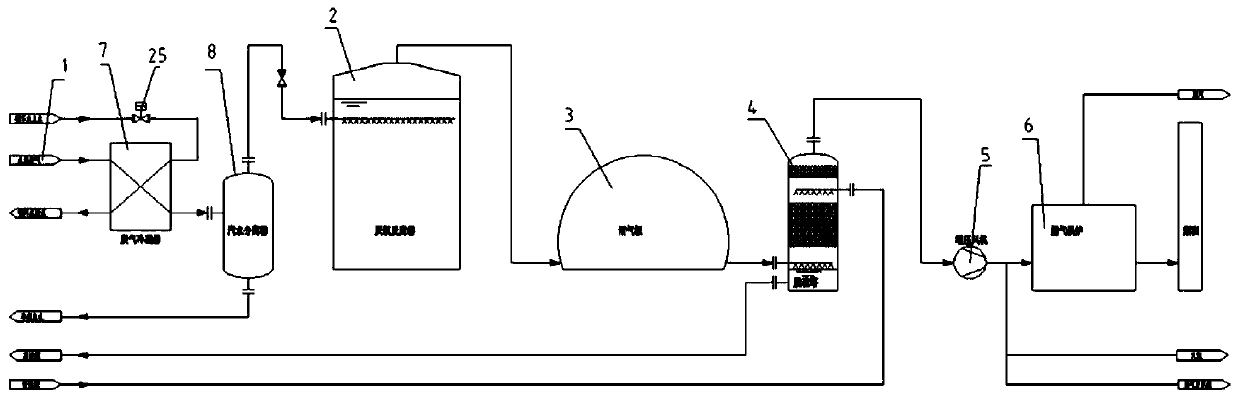

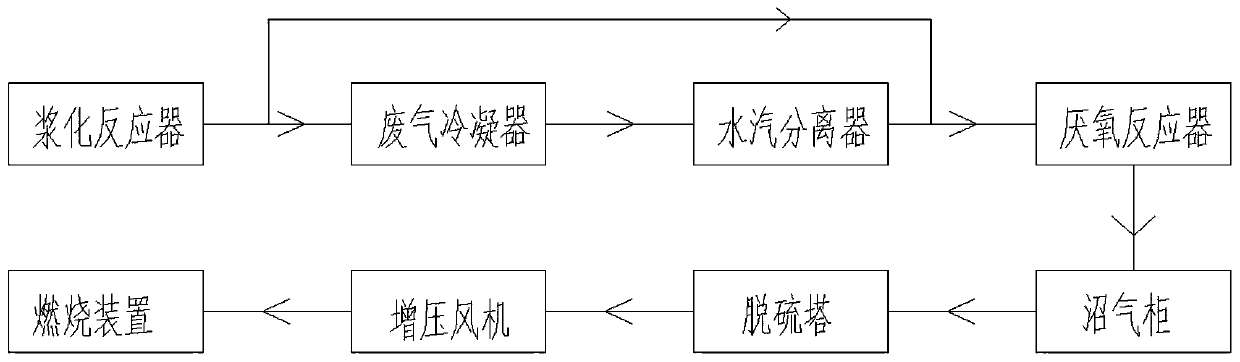

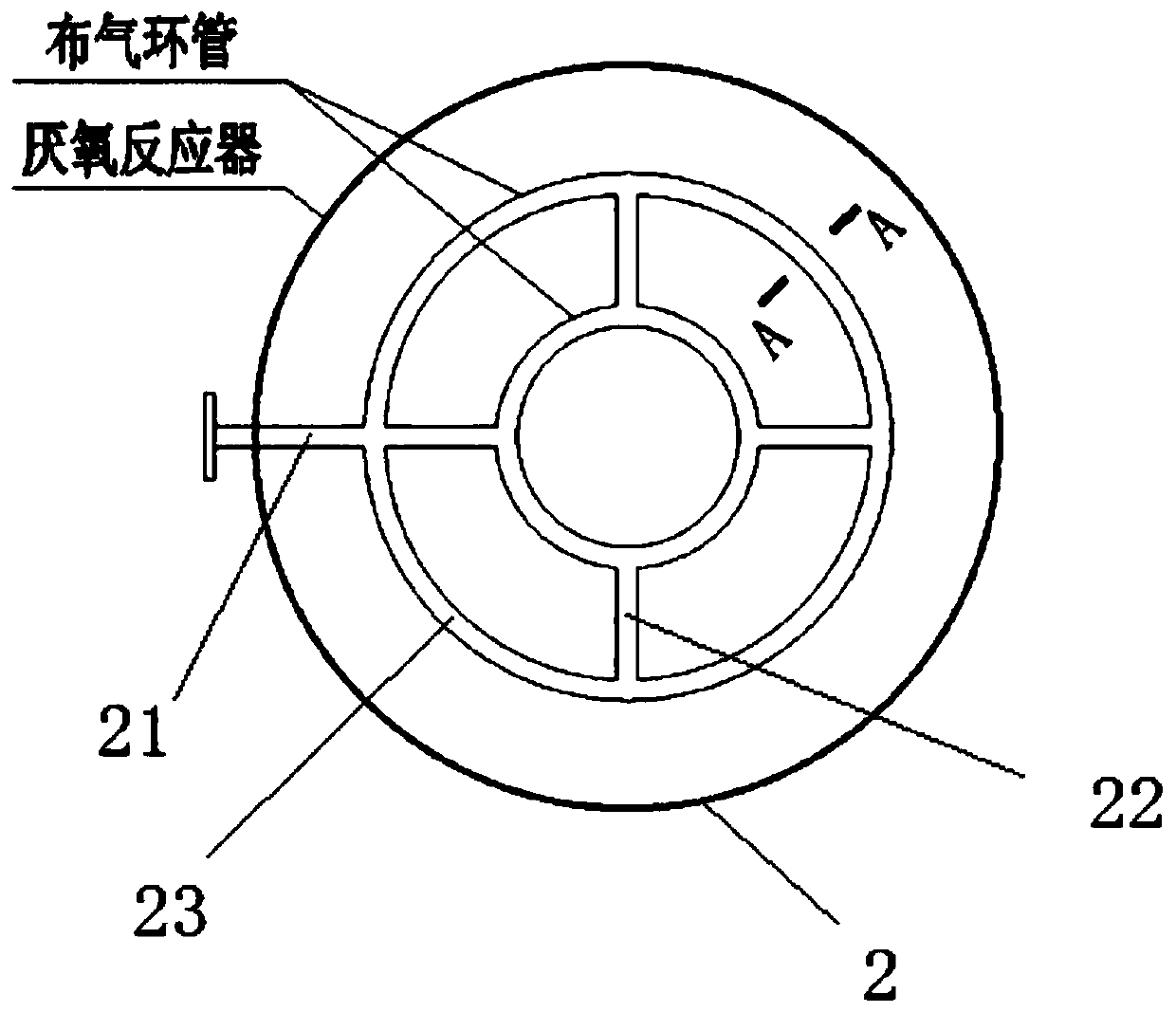

Hydrothermal or pyrohydrolysis tail gas resource utilization system and hydrothermal or pyrohydrolysis tail gas resource utilization method

InactiveCN111001277AFull recoveryLess investmentGas treatmentDispersed particle separationExhaust fumesProcess engineering

The invention discloses a hydrothermal or pyrohydrolysis tail gas resource utilization system, which comprises a slurrying reactor, an anaerobic reactor, a biogas cabinet and a desulfurizing tower, wherein the slurrying reactor is communicated with the anaerobic reactor, the anaerobic reactor is communicated with the biogas cabinet, the biogas cabinet is communicated with the desulfurizing tower,a waste gas condenser and a steam-water separator are arranged between the slurrying reactor and the anaerobic reactor, the waste gas outlet of the slurrying reactor is connected with the gas inlet ofthe waste gas condenser, the gas outlet of the waste gas condenser is connected with the gas inlet of the anaerobic reactor, a check valve is arranged between the gas outlet of the waste gas condenser and the gas inlet of the anaerobic reactor, and the gas inlet of the anaerobic reactor is lower than the working liquid level of the anaerobic reactor. According to the invention, the hydrothermal waste gas of an anaerobic reaction needing heat is directly connected with an anaerobic reactor, and the hydrothermal waste gas of an anaerobic reaction doing not need heat passes through a waste gas condenser and a steam-water separator and then is connected with the anaerobic reactor.

Owner:四川深蓝环保科技有限公司

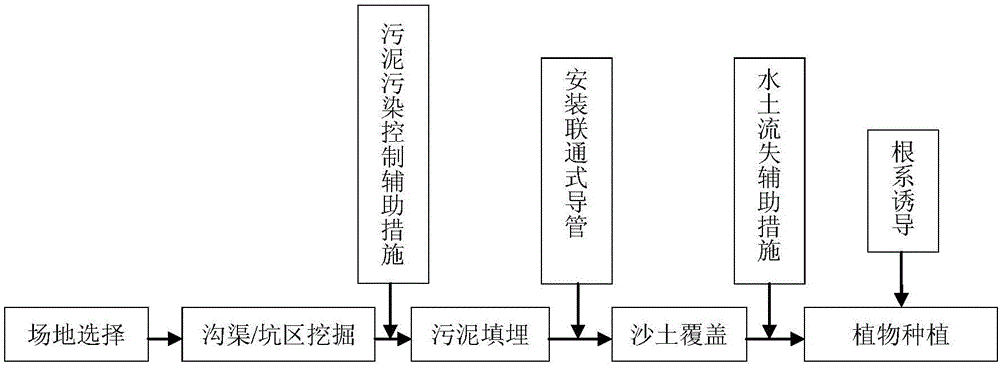

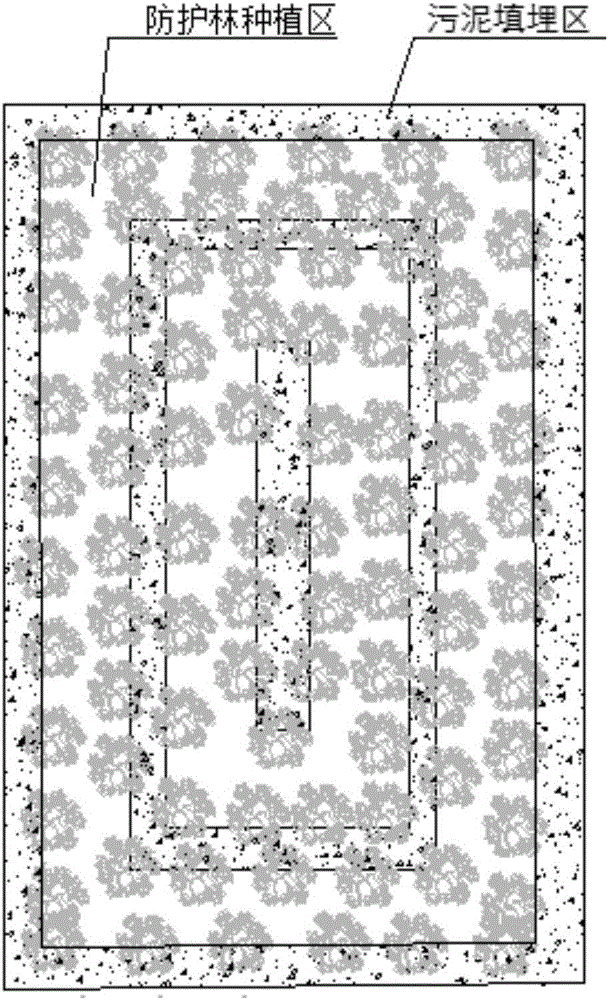

Method for reclaiming desert or desertified soil through utilizing sludge

InactiveCN106489343AReduce soil erosionIncrease flexibilityAgriculture gas emission reductionSoil-working methodsFertilizerRoot system

The invention provides a method for reclaiming desert or desertified soil through utilizing sludge. The method comprises the following steps: digging a ditch or a pit region: digging the ditch or the pit region by guaranteeing that the depth is smaller than or equal to 3m, the width is 3m-5m and the coverage area is 10%-40% of a needed reclaiming area; backfilling the sludge: backfilling the sludge into the ditch or the pit region to form a sludge backfilling region, wherein the backfilling depth of the sludge is smaller than or equal to 3m; covering sandy soil: covering the sandy soil on the surface of the sludge, wherein the thickness of a covering layer is 10cm-30cm; and planting plants: planting the plants above and at the periphery of the sludge backfilling region to form a protection forest planting region, and enabling roots of the plants to extend toward the sludge backfilling region, so as to realize soil reclamation. The method provided by the invention adopts sludge backfilling and the desertified soil is treated by wastes; the sludge has a good water holding capacity and a good fertilizer effect; and measures that the sandy oil covers a sludge layer, suitable grass is planted on the sludge backfilling region, soil improvement is carried on the sandy soil covering layer and a surface layer of a region which is not backfilled, and the slope of the region which is not backfilled is adjusted are adopted, so that the effect of alleviating water loss and soil erosion is realized.

Owner:SHENYANG JIANZHU UNIVERSITY

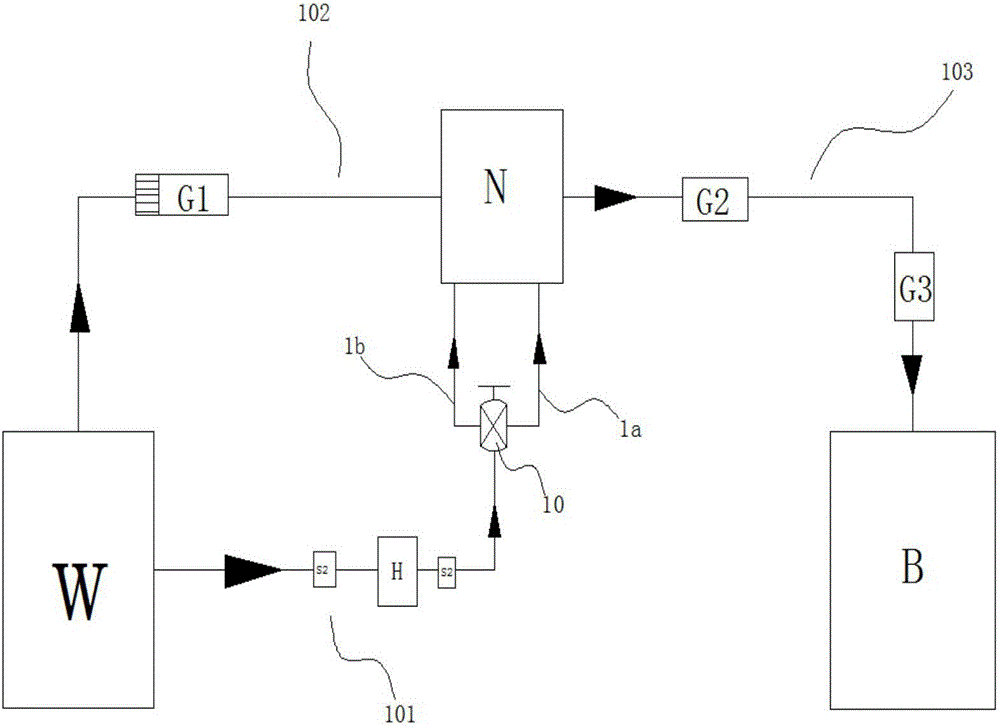

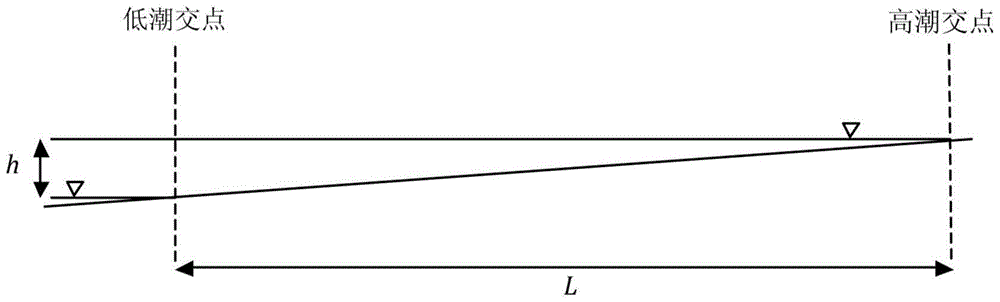

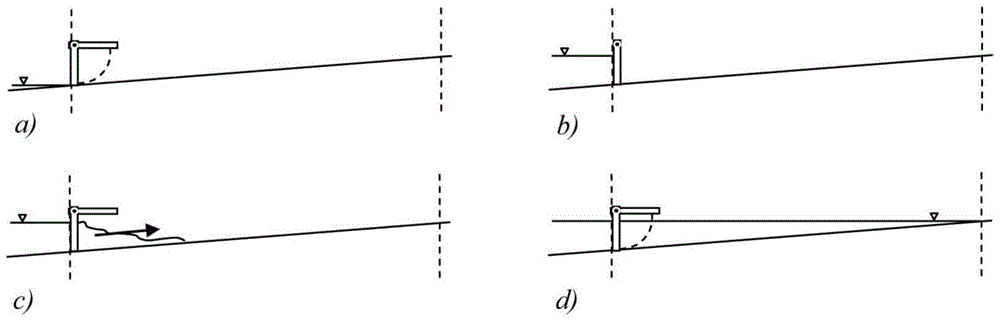

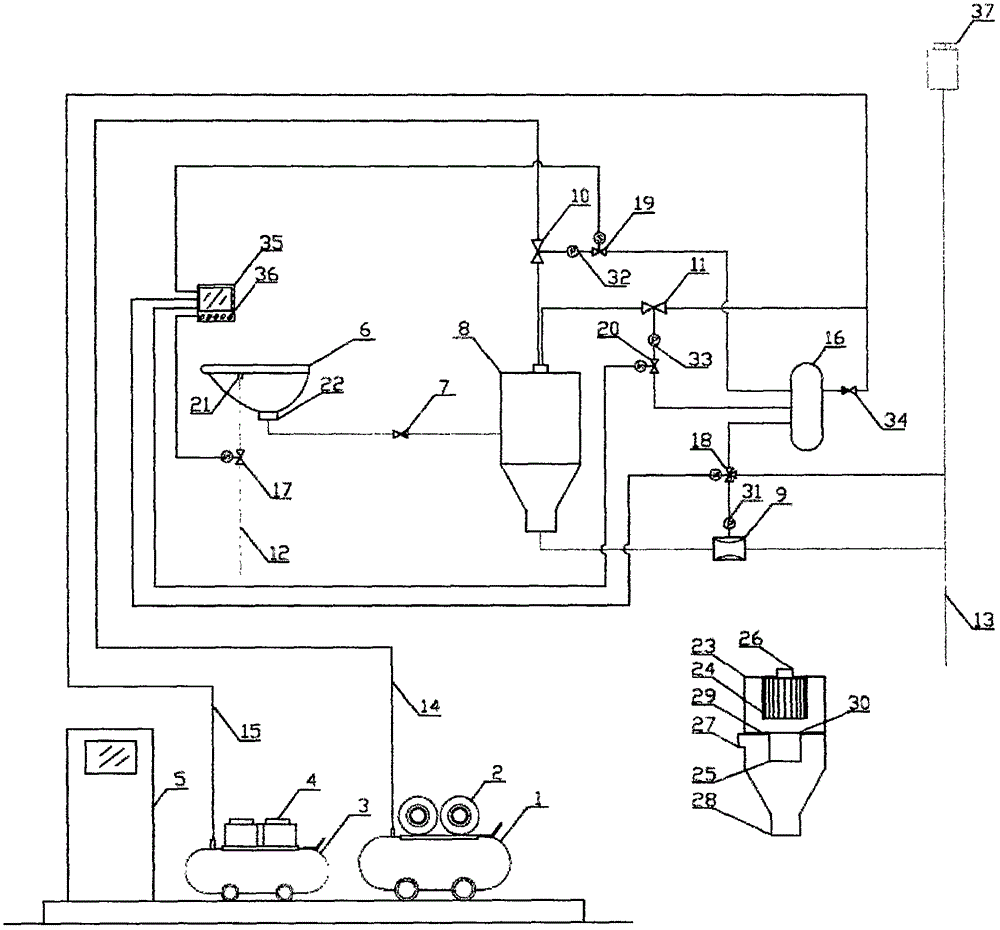

Positive and negative pressure composite-type pneumatic toilet flushing system

ActiveCN105714895ASave flushing waterPrevent escapeFlushing devicesLavatory sanitoryControl systemProgrammable logic controller

The invention relates to the field of sanitary equipment, in particular to a positive and negative pressure composite-type pneumatic toilet flushing system, which comprises a PLC (programmable logic controller) control cabinet, a vacuum and compressor machine room system, a gas and dirt separating system and a toilet flushing control system, wherein a control vacuum pump and an air compressor of the vacuum and compressor machine room system work in accordance with a logic program in a mode of being connected to the PLC control cabinet. The toilet flushing system disclosed by the invention has the beneficial effects that the toilet flushing system can save water consumed in toilet flushing, solve the problem of odor dissipation and simplify application conditions.

Owner:SHANGHAI FLORY ENVIRONMENT TECH CO LTD

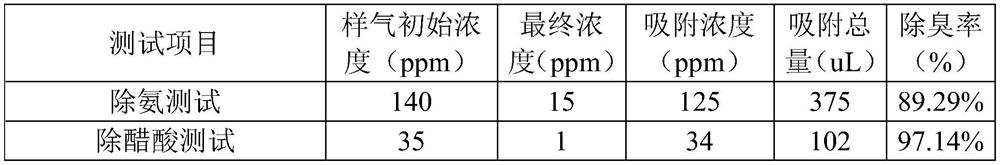

Efficient zirconium phosphate deodorant and deodorization polyurethane

ActiveCN113279077AGood dispersionGuaranteed adsorption effectTextile/flexible product manufactureMonocomponent synthetic polymer artificial filamentSpinningDeodoriser

The invention relates to an efficient zirconium phosphate deodorant and deodorization polyurethane. The efficient zirconium phosphate deodorant is prepared by the following steps of mixing nano zirconium phosphate, glycerol monolaurate and ethanol, and uniformly stirring to obtain modified zirconium phosphate; and then mixing the modified zirconium phosphate with nano titanium dioxide, tungsten sol, a compatilizer and a dispersing agent, and performing heating and stirring to obtain the efficient zirconium phosphate deodorant. The efficient zirconium phosphate deodorant is added into a polyurethane spinning solution, and the deodorant polyurethane is obtained through stirring, curing and dry spinning. The deodorant polyurethane is high in strength, is improved in air permeability, can be widely applied to various products such as outerwear, underwear, socks, sportswear, bandages and paper diapers, and has relatively good market application prospects.

Owner:晋大纳米科技(厦门)有限公司

Assembled folding feces and urine separation toilet bowl and use method thereof

ActiveCN104257316ASolve the degradation problemAvoid cross infectionBathroom accessoriesAgainst vector-borne diseasesAnimal fecesEngineering

Disclosed are an assembled folding feces and urine separation toilet bowl and a use method thereof. The assembled folding feces and urine separation toilet bowl comprises a toilet bowl surface, a feces pool supporting bag, a toilet bowl opening, a rotating shaft, a feces supporting frame, a urine supporting frame, a cushion, four supporting legs, four mounting holes and a urinal supporting bag, the toilet bowl surface is of an axially symmetric structure, and the four mounting holes are used for fixing the supporting legs. A urine bag sleeves a urinal supporting frame, urination can be finished, and the urine bag and a feces bag sleeve a urinal and a feces pool supporting frame respectively, so that defecation can be finished. The urine bag is packed after urination, the packed feces bag, toilet paper and disinfectant tissues are placed into an outer feces bag containing adsorbing agents after defecation, the outer feces bag is sealed, and bagged feces and urine can be stored for a long time and can be used for producing fertilizers, biological products, feed, methane and the like. Water and a special space are omitted, and the toilet bowl is small in size, light in weight, convenient to convey and distribute and simple to use and can be directly used for a family without a toilet, an earthquake stricken area, a flood stricken area and emergency water failure.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

Chicken manure treatment method

InactiveCN102898186ASolve the dry and wet problemSolve the smell problemClimate change adaptationExcrement fertilisersDecompositionWater filter

The invention discloses a chicken manure treatment method, which is used for treating chicken manure in chicken coops, and the chicken manure falls into a manure passage under the chicken coops through hollow bottoms of the chicken coops. The chicken manure treatment method comprises the following steps that a water filter groove is additionally arranged at the bottom of the manure passage; rice husks are scattered on the manure passage into the thickness being 5 centimeters, and a uniform rice husk layer is formed; EMs (effective microorganisms) are sprayed on the rice husk layer to be used as decomposition floras of the chicken manure; and according to the number of 20 chickens in per square meter of the manure passage, the EMs need to be sprayed once every 20 days and are directly sprayed on the chicken manure, and when the spraying times of the EMs reaches more than four, materials in the chicken passage together form agricultural fertilizers. The chicken manure treatment method has the advantages that 1, a small amount of manure liquid can be effectively filtered away by the water filter groove; 2, the rice husk layer and the EMs are mutually matched and designed, and the problems of fermentation and odor of the chicken manure are solved; 3, the formed agricultural fertilizers belong to green and natural fertilizers, and environment protection and health are realized; and 4, the waste materials are changed into valuable materials, the pollution is reduced, and meanwhile, the extra income is brought for chicken farms.

Owner:FEIXI LAOMUJI AGRI ANIMAL HUSBANDRY TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com