Patents

Literature

136results about How to "Fine cells" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Three dimensional micro-environments and methods of making and using same

InactiveUS20070003595A1Promote cell growthPromote differentiationBioreactor/fermenter combinationsBiological substance pretreatmentsControlled releasePorosity

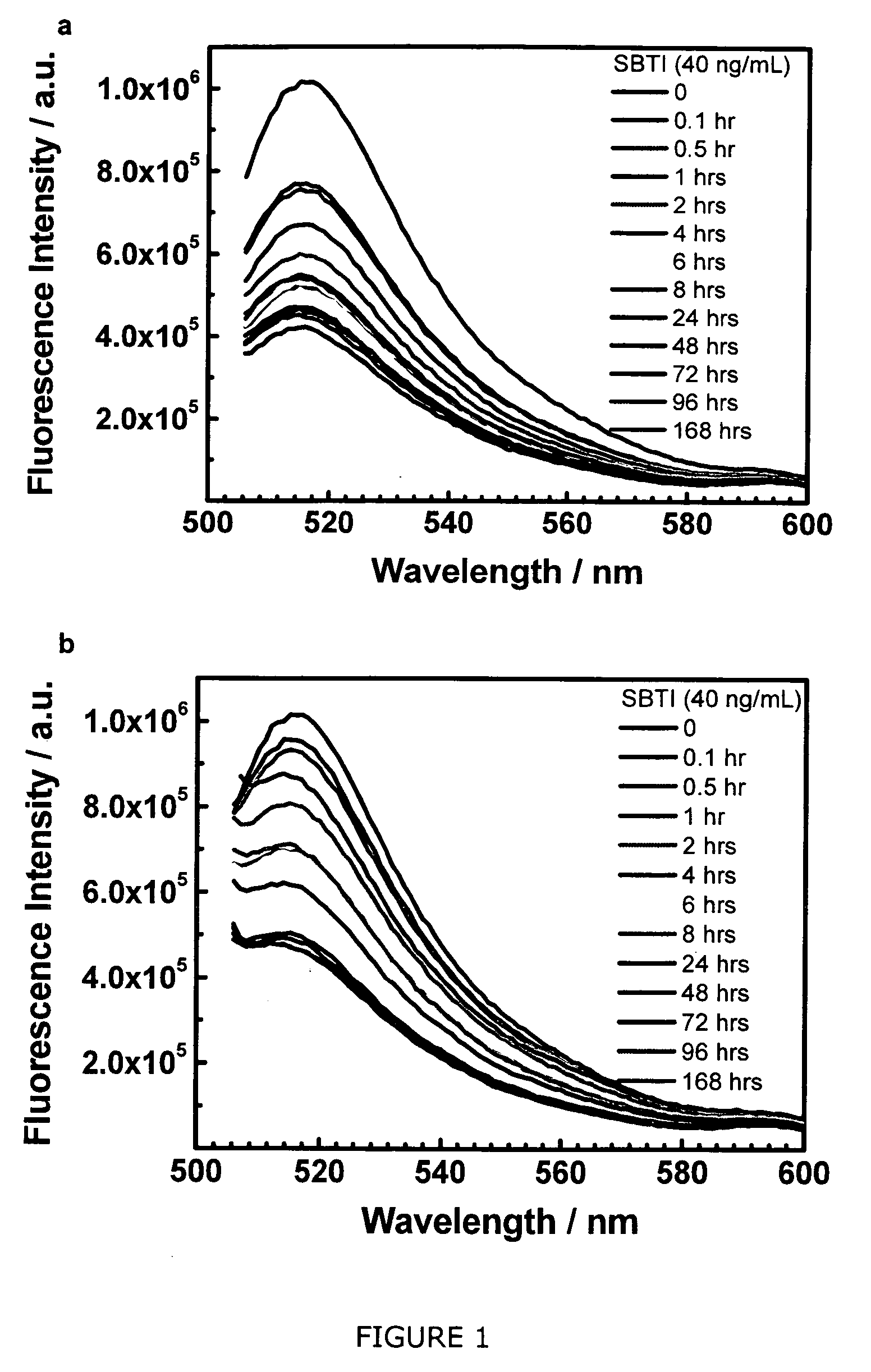

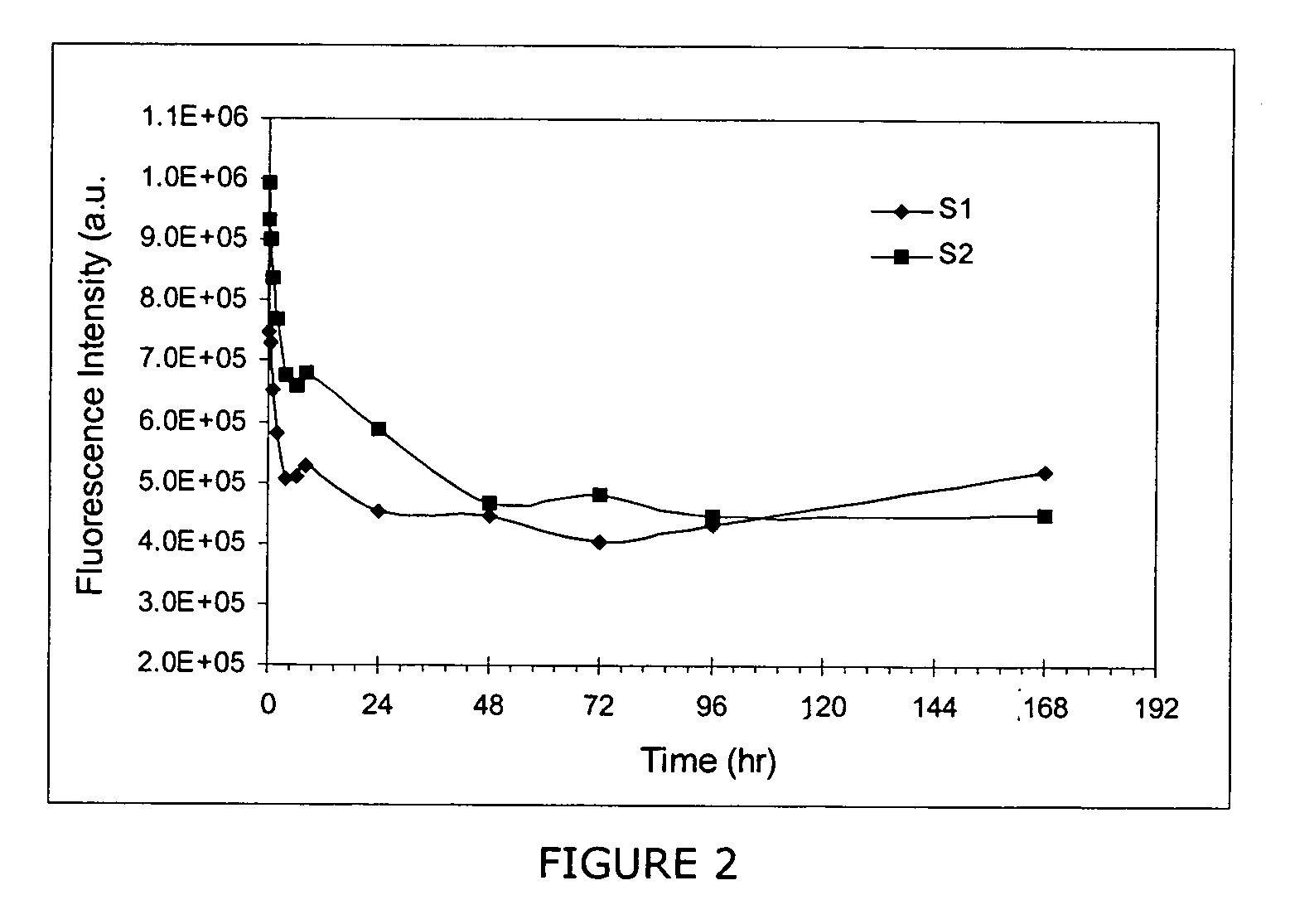

The presently claimed and disclosed invention relates, in general, to three dimensional micro-environments and, in particular, to three dimensional (“3D”) micro-environments found in inverted-opal scaffolds made from hydrogel therein for controlled release of nutrients. Specifically, the scaffolds have exceptionally ordered, three-dimensional organization that provides excellent porosity, permeability, and transportation properties can that are especially well suited for use as a nutrient carrier in the emerging technologies of drug delivery and cell culture. Methods for incorporation of or to control the release of nutrients and other substances from such scaffold materials are also herein disclosed and claimed.

Owner:FLIR DETECTION

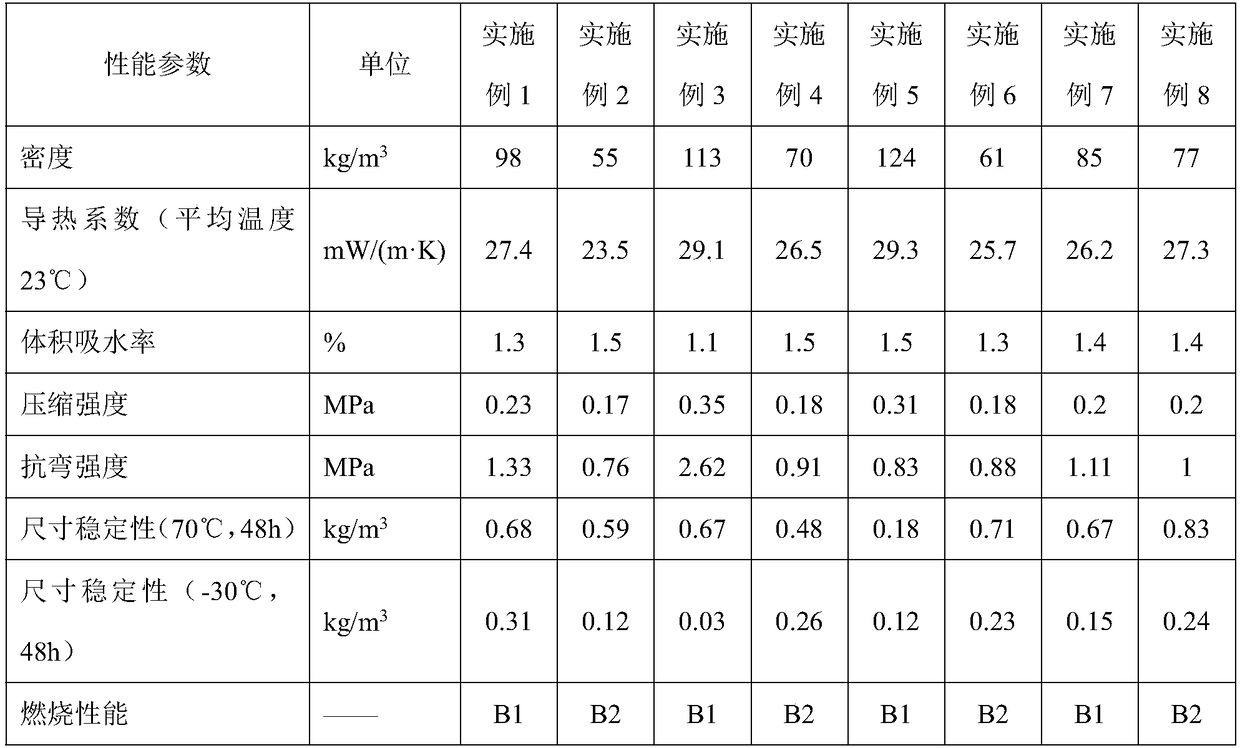

Homogenous low-heat-conductivity inorganic heat insulation board and preparation method thereof

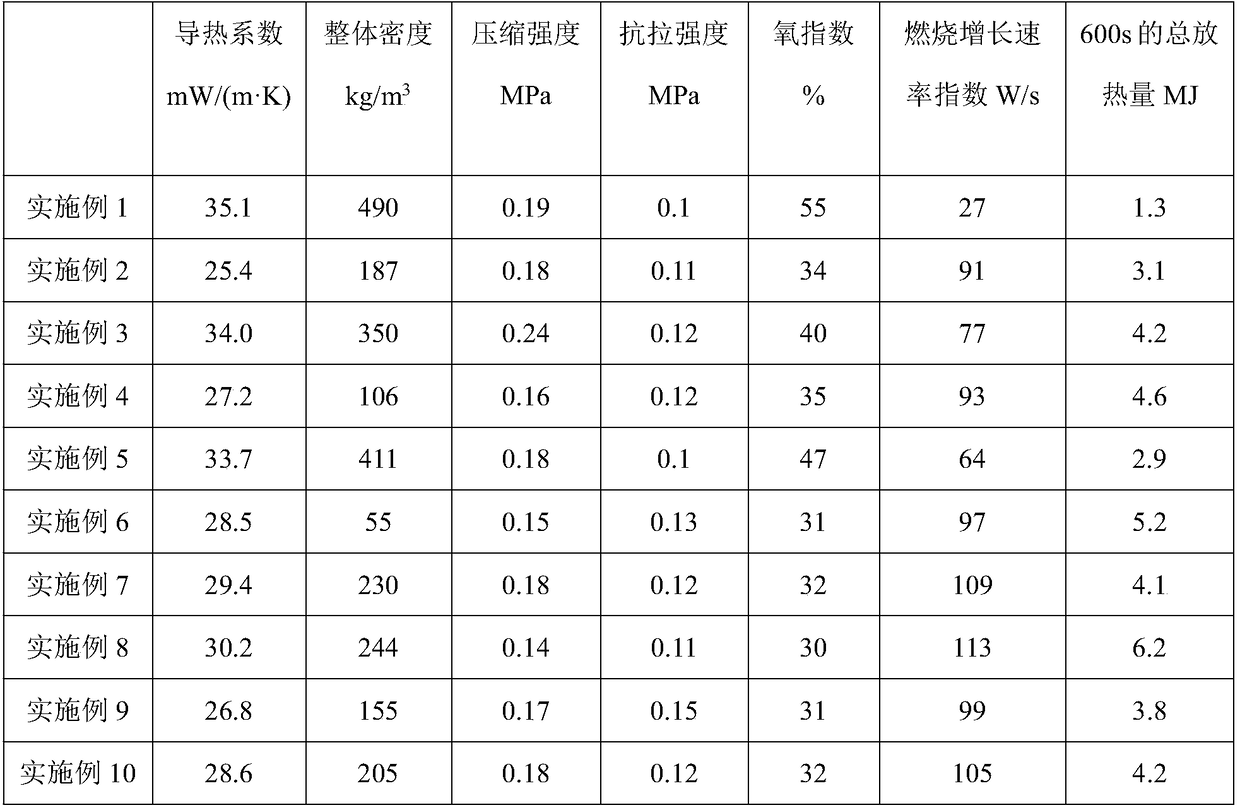

The invention discloses a homogenous low-heat-conductivity inorganic heat insulation board and a preparation method thereof. The homogenous low-heat-conductivity inorganic heat insulation board is prepared from the reaction of an inorganic material, filler and polyurethane hard foam and prepared from the following raw materials in parts by weight: 31 to 85 parts of the inorganic material, 0 to 20parts of the filler, and 15 to 49 parts of the polyurethane hard foam. The heat conduction coefficient of the prepared insulation board is less than 40mW / (m.K), the integral density is 35 to 500 kg / m<3>, and the thermal insulation and heat preservation performance is good. The compressive strength is greater than or equal to 0.1MPa, the tensile strength is greater than or equal to 0.1MPa, the mechanical strength is high, and the durability is good. The oxygen index is greater than or equal to 30 percent, the combustion growth rate index is less than or equal to 120W / s, the total heat release amount in 600s is less than or equal to 7.5MJ, and the homogeneous low-heat-conductivity inorganic insulation board is difficult to combust and high in fireproof grade. The preparation process is simple and suitable for the industrialized production.

Owner:南京红宝丽新材料有限公司

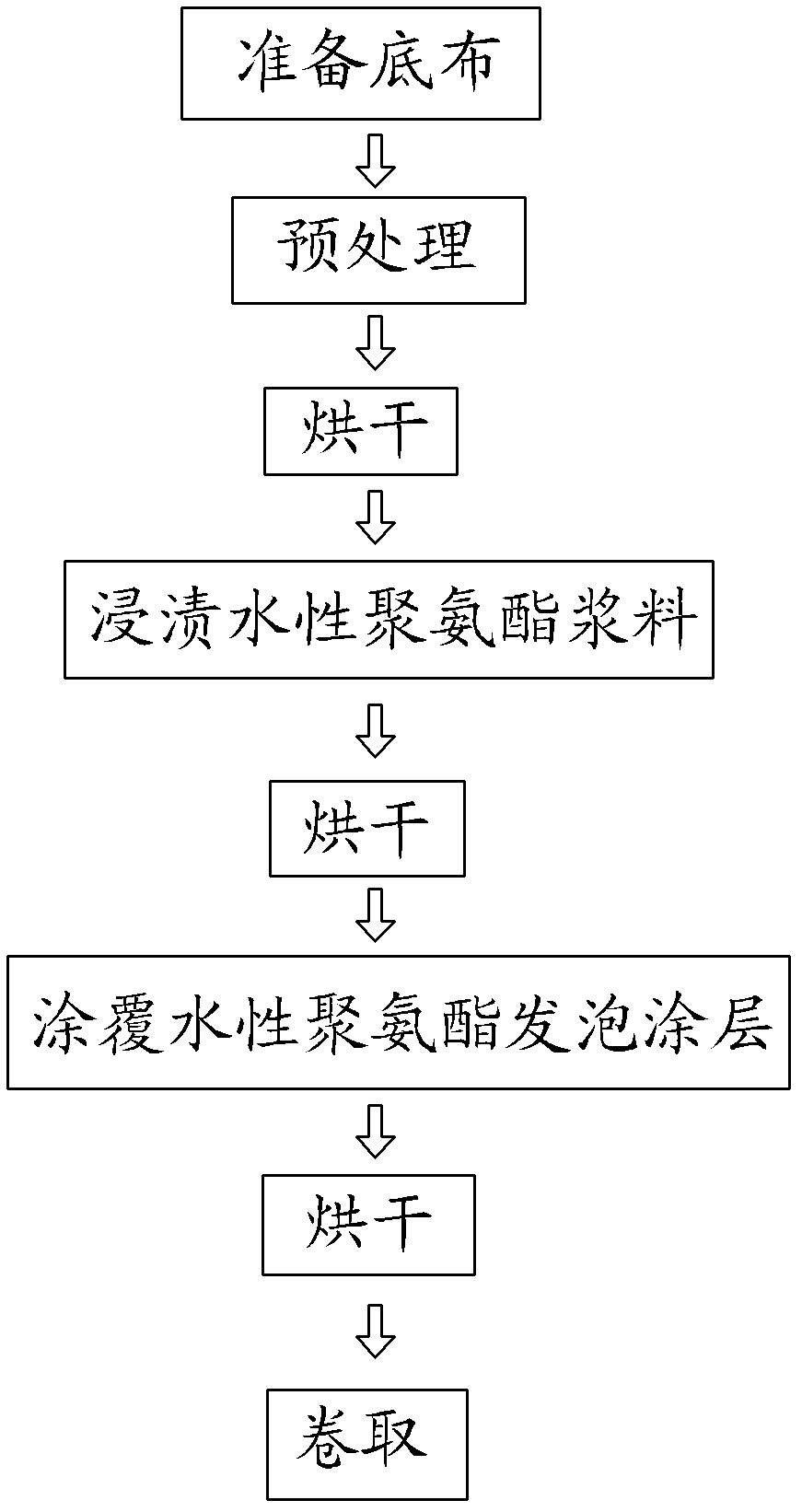

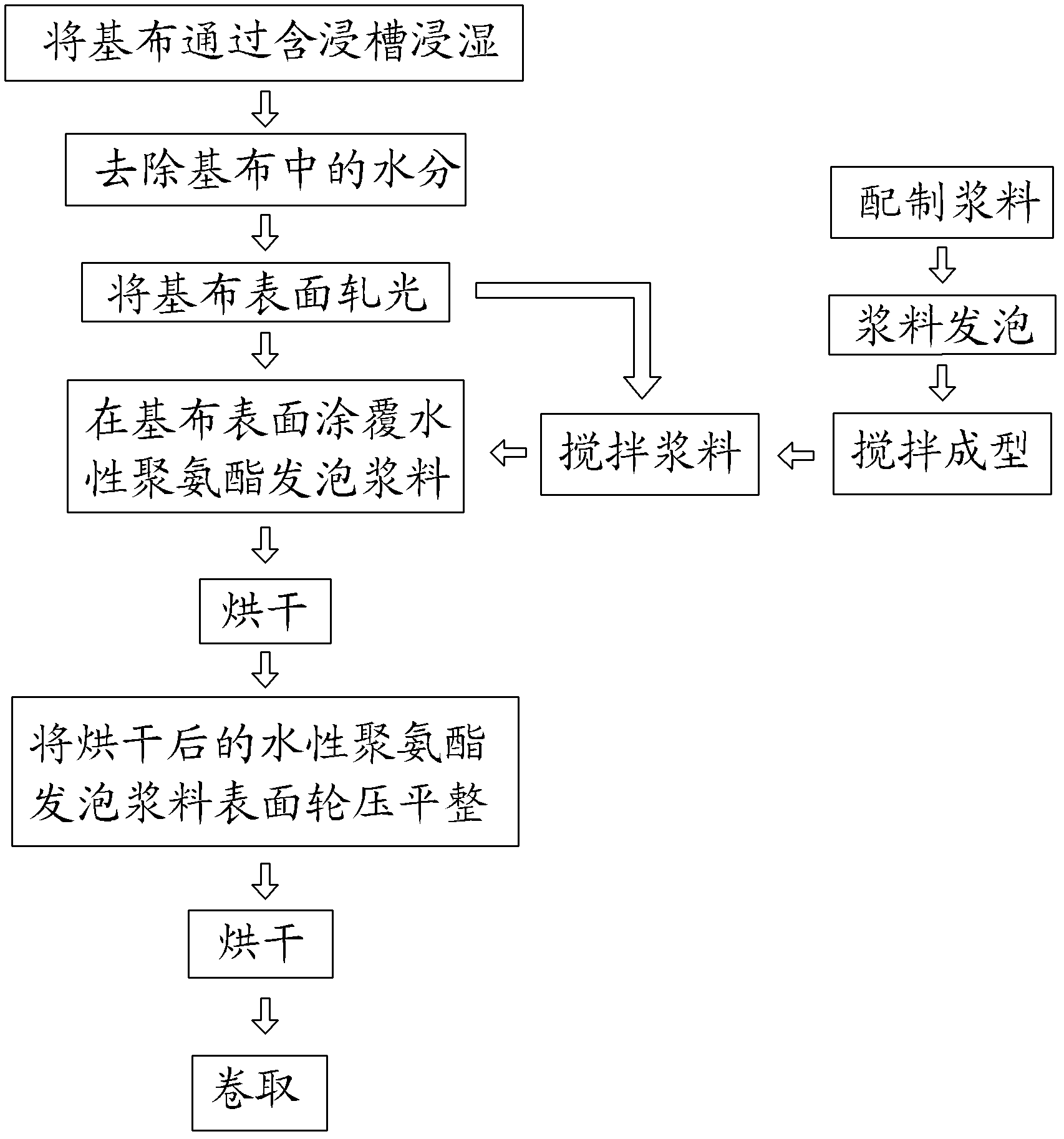

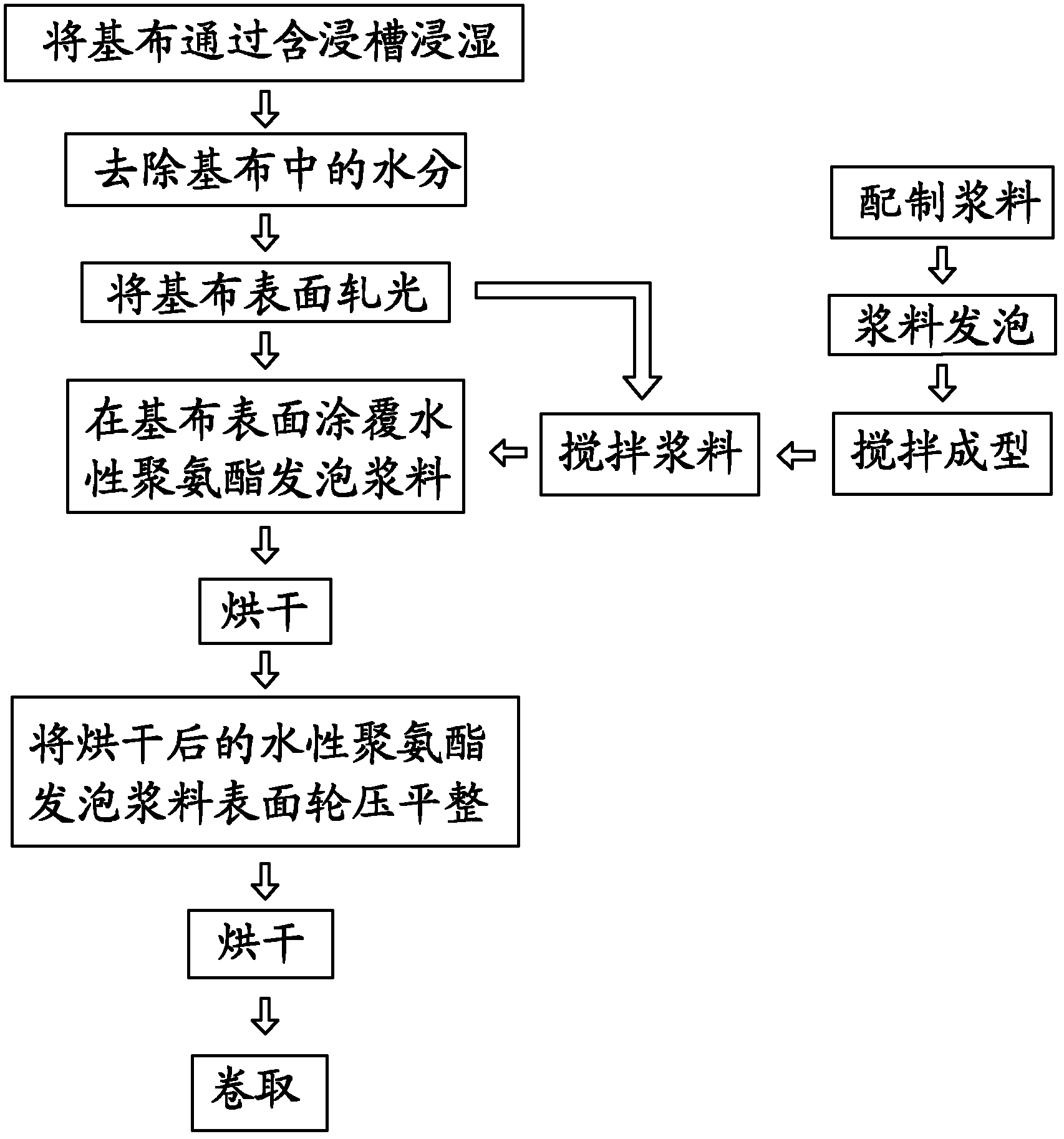

Preparation method of water-soluble polyurethane leather beth

ActiveCN102418284AReduce dosageHigh surface flatnessLiquid/gas/vapor textile treatmentPolymer scienceSolvent based

The invention relates to a preparation method of water-soluble polyurethane leather beth. The preparation method sequentially comprises the following steps of: a step A, soaking a base fabric; a step B, removing moisture in the base fabric; a step C, calendaring the surface of the base fabric; a step D, coating a water-soluble polyurethane foaming paste on the surface of the base fabric and then drying; and a step E, carrying out wheel loading and flattening on the surface of the dried water-soluble polyurethane foaming paste. By adopting the preparation method of the water-soluble polyurethane leather beth provided by the invention, the surface evenness of the product can be improved, the production cost can be reduced, the handfeel of the product is softer, and simultaneously the product is closer to a solvent-based synthetic leather beth product in appearance performance and physical properties.

Owner:FUJIAN POLYTECH TECH CO LTD

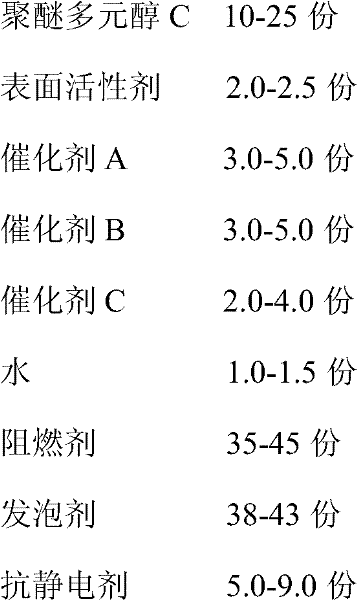

Spraying and wind leaking stoppage polyurethane combined polyether for coal mine as well as preparation and use methods thereof

InactiveCN102585139AReduce dosageFine cellsUnderground chambersTunnel liningHigh resistanceChemical synthesis

The invention belongs to the field of chemical synthesis and in particular relates to a spraying and wind leaking stoppage polyurethane combined polyether for a coal mine as well as preparation and use methods thereof. According to the invention, the polyether is prepared through formulation regulation by using HCFC (hydrochlorofluorocarbon)-365mfa and / or HCFC-245fa as foaming agents, is free of fluorine and is environment-friendly; because the boiling point of HCFC-245fa is low, prepared foam is good in size stability; a reaction type amine catalyst with low VOC (volatile organic compound) and low smell is applied, thus the problem of irritative smell is solved; and the foam prepared by using a fire retardant is good in fire retardant property, and an antistatic agent is added so as to improve the problem of high resistance on the surface of polyurethane foam.

Owner:SHANGHAI DONGDA POLYURETHANE

Plant-fiber-base polyether ester polylol, and preparation method and applications thereof

The invention discloses a preparation method of a plant-fiber-base polyether ester polylol, which belongs to the field of high polymer chemistry. The preparation method comprises the following steps:liquefying plant fiber materials and a liquefacient under the catalysis of an acid catalyst to obtain a liquefying product; and carrying out the reaction of the liquefying product and cyclic carboxylic ethers, open-chain hydroxyl carboxylic ethers or estolides, and the like under the catalysis of acids, organic tin compounds or titanic acid esters so as to obtain the polyether ester polylol. The method realizes the high functionality and the high reactive activity of the plant-fiber-base polyether ester polylol. The hydroxyl value and the relative molecular mass of the product can be regulatedby changing the material proportions and the technique conditions to obtain the required product so as to prepare the polylol material required by different polyurethane materials and enhance the performance of the polyurethane materials.

Owner:SOUTH CHINA UNIV OF TECH

Polyurethanes compound modified phenolic foam plastic and method for preparing same

The present invention is polyurethane compound modified phenolic foam plastic and its preparation process. The modified phenolic foam plastic is prepared with aniline phenolic resin 100 weight portions, polyurethane compound 15-30 weight portions and curing agent 15-30 weight portions, and through mixing, reaction and foaming. The polyurethane compound modified phenolic foam plastic has fine hand feeling, low density, low heat conducting coefficient, high heat insulating performance and environment friendship. It is used as the heat insulating material for outer wall and roof, and can raise the heat insulating and fire-proofing effect.

Owner:北京振利高新技术有限公司

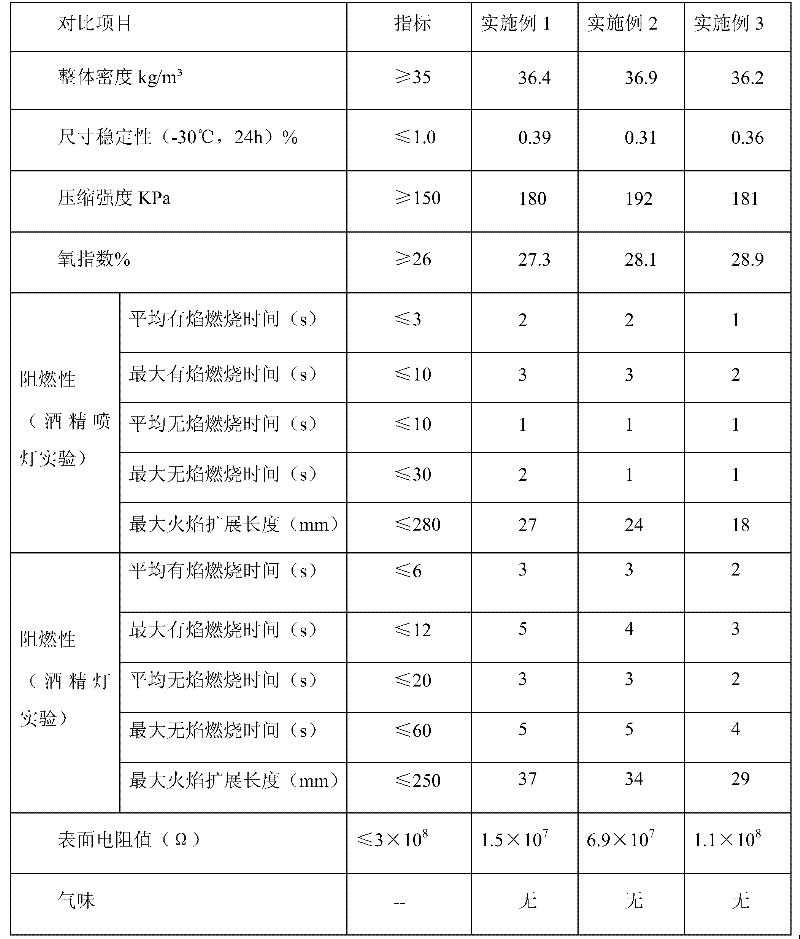

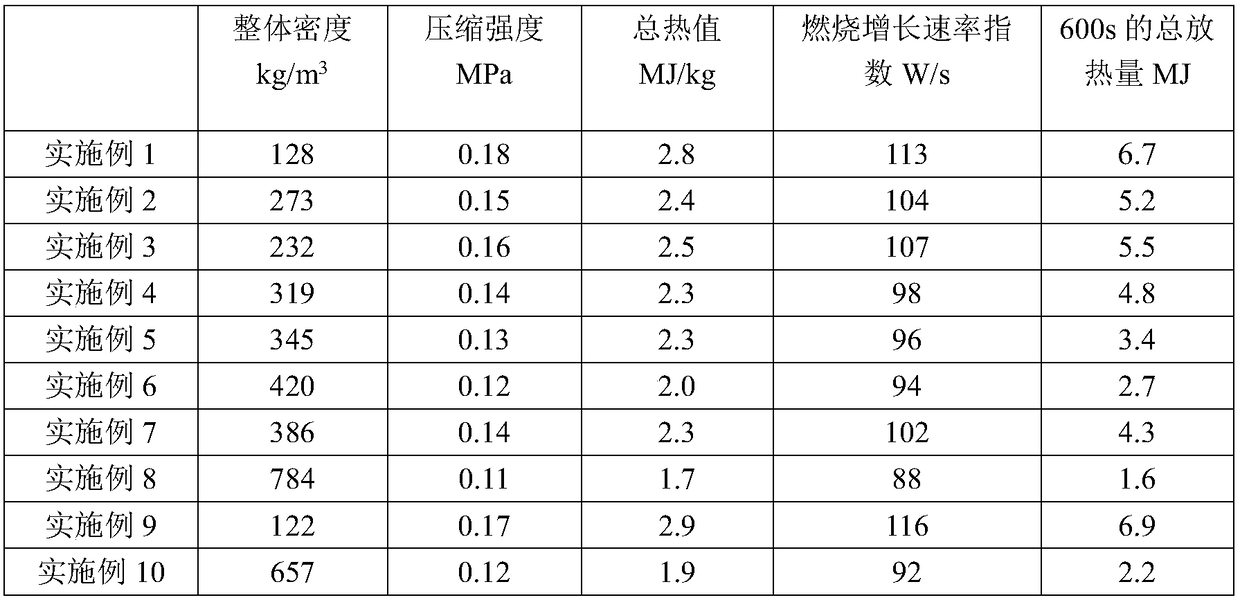

Homogeneous non-combustible polyurethane foam heat insulating material and preparation method thereof

ActiveCN108774306AHigh fire ratingImprove flame retardant performanceCombustionVolumetric Mass Density

The invention discloses a homogeneous non-combustible polyurethane foam heat insulating material and a preparation method thereof. The heat insulating material is prepared by reacting the following raw materials in parts by weight: 6~20 parts of polyurethane rigid foaming material, 4~20 parts of flame retardant and 60~90 parts of inorganic filler, wherein the loose packing density of the inorganicfiller is 1.0~2.0 g / cm<3>. The heat insulating material prepared by the invention has overall density between 120 and 800 kg / m<3>, compressive strength being greater than and equal to 0.10 MPa, highmechanical strength, good durability, total heat value being smaller than and equal to 3.0 MJ / kg, combustion growth rate index being smaller than and equal to 120 W / s and 600 s total heat release ratebeing smaller than and equal to 7.5 MJ, and belongs to A2 grade non-combustible material, and has high fire-proofing safety and simple preparation process, and can realize industrial production.

Owner:南京红宝丽新材料有限公司

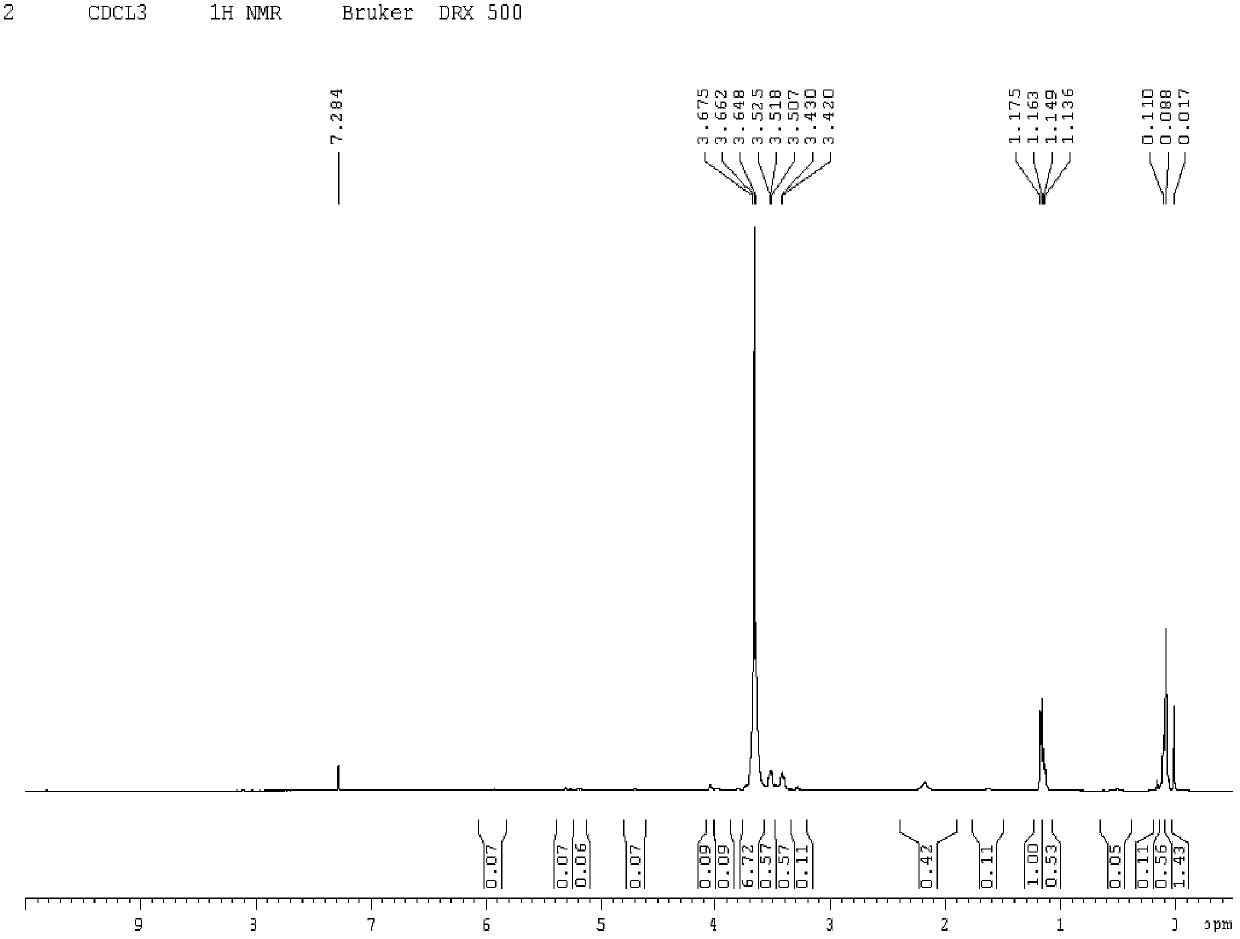

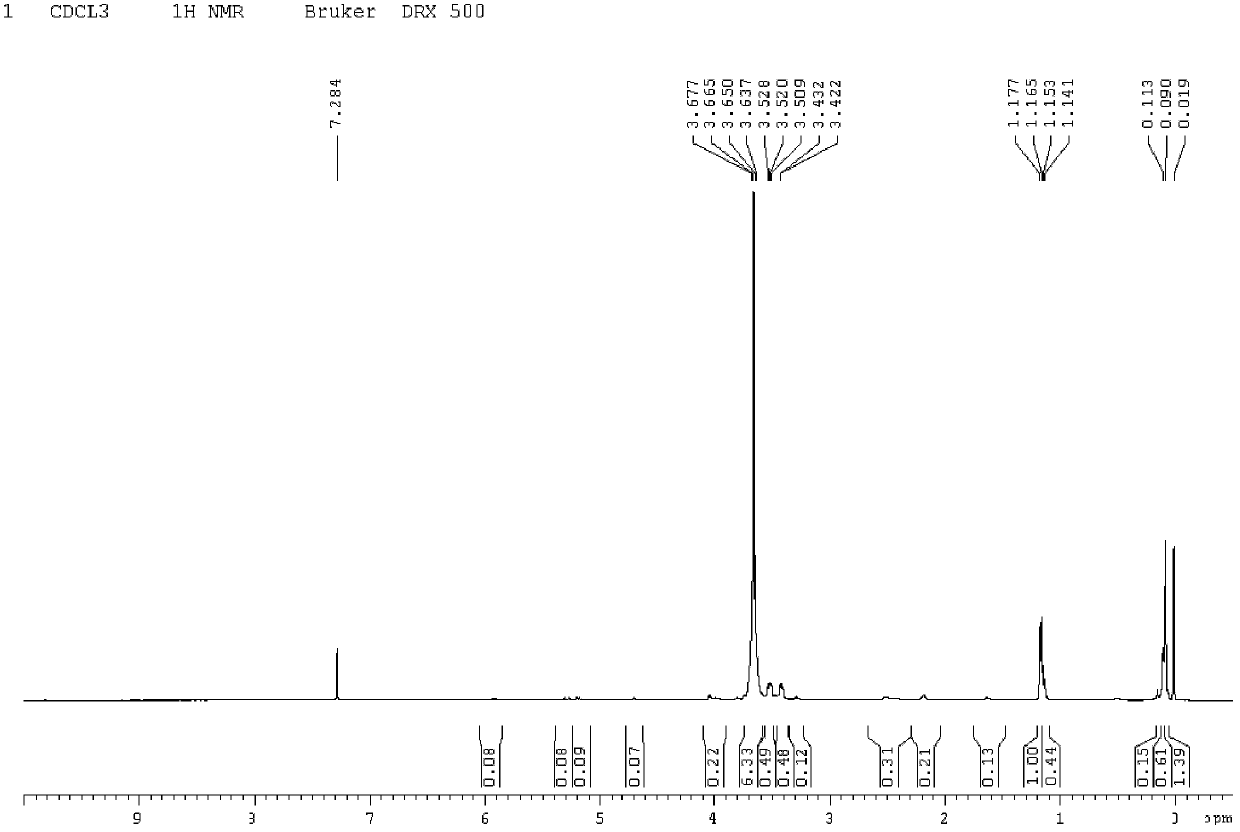

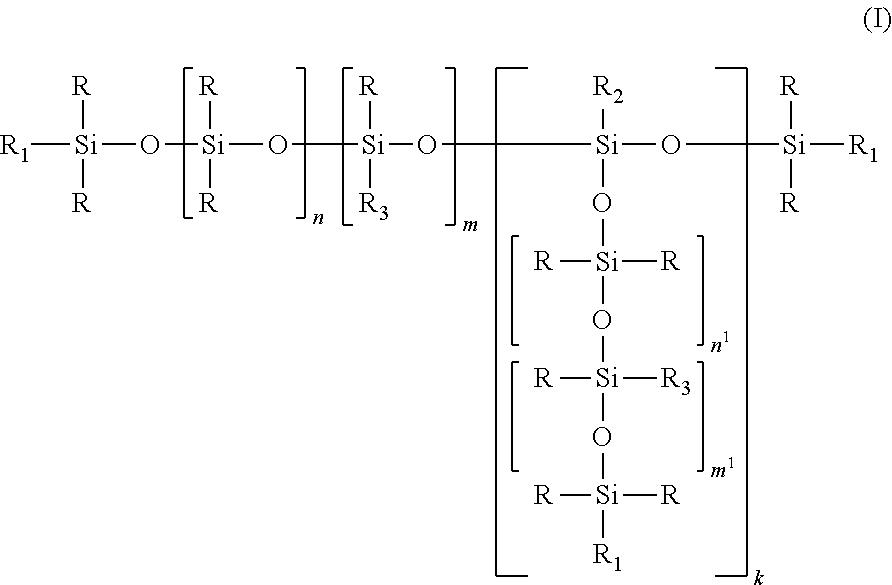

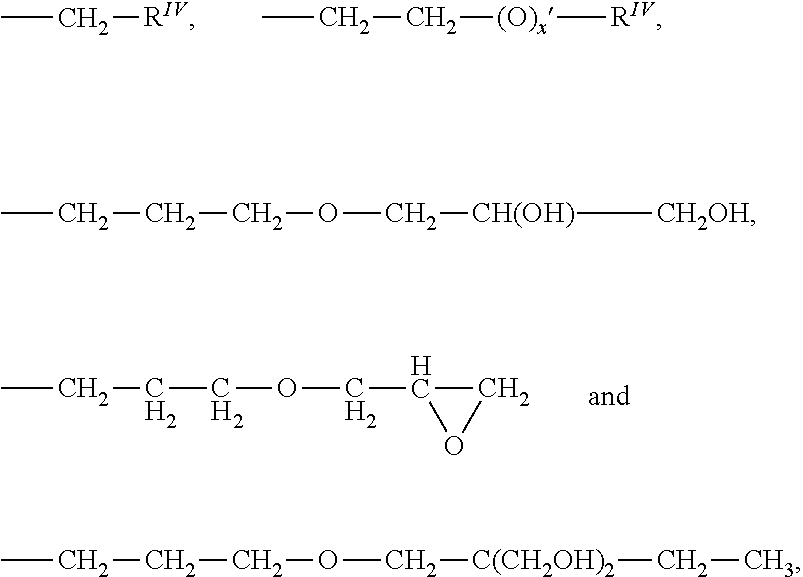

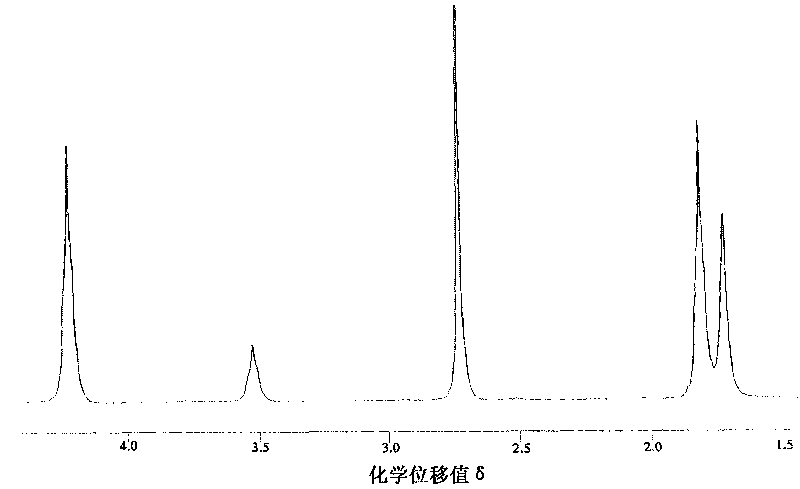

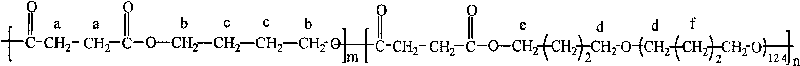

Polyurethane foam stabilizer with good nucleating property and preparation method thereof

The invention discloses a polyurethane foam stabilizer with good nucleating property, which can effectively reduce the surface expansion of a foaming system. The organic foam stabilizer has the following structure: the value of a is 1-10, the value of b is 5-85, the value of c is 1-4, the value of x is 8-70, the value of y is 0-30, a+b+c is 7-99, and x+y is 8-100; R1 is alkane, aromatic groups, acyloxy or hydrogen atoms with the carbon atom number being 1-4; and R2 has a structure.

Owner:南京美思德新材料有限公司

Method for recycling waste polyurethane product

A method for recycling waste polyurethane products. The method is as below: cutting or crushing waste polyurethane product with surface non-polyurethane attachments removed into small pieces, carrying out alcoholysis to produce a mixture of polyol and aromatic amine, and reproducing polyether polyols or polyester polyols (a mixture of aromatic amines); preparing the obtained mixture of polyol and aromatic amine, polyether polyol and polyester polyol into a combined polyether for rigid foam; and foaming to prepare a new polyurethane rigid foam. The method conducts treatment and reutilization of waste polyurethane products through alcoholysis, not only reduces the cost and increases the benefit, but also eliminates the environment pollution caused by waste polyurethane foam. The method is applicable to for the regeneration and recycling of waste polyurethane rigid foam, semi hard foam, soft foam and elastic body in the production of polyurethane products.

Owner:NANJING MEIDING TECH

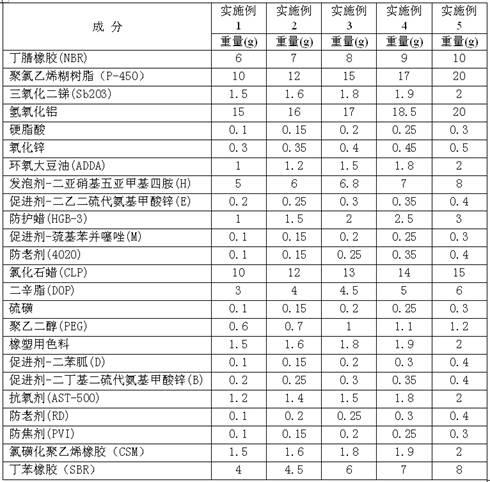

Color rubber and plastic heat-insulating material and preparation method thereof

The invention relates to a color rubber and plastic heat-insulating material and a preparation method thereof. The rubber and plastic heat-insulating material is prepared from polrvinyl chloride paste resin, dinitrosopentamethylene tetraamine, an antiager, styrene rubber, protective wax, an antioxidant, chlorosulfonated polyethylene rubber, diphenyl guanidine, mercaptobenzothiazole, zinc dibutyl dithiocarbamate, zinc diethydithiocarbamate and the like. The performance and the color difference of the product are stabilized by adding a coloring material to perform banburying on the finished rubber again and combining a new vulcanizing foaming technology and a super-long water-cooling system; the prepared color rubber and plastic heat-insulating material does not have fibers and dust, prevents dew formation, has a smooth surface and high cleanliness, has the same bright color as equipment, is environmentally-friendly and non-toxic, reduces secondary construction, saves cost, greatly improves the using performance of the product, prolongs the service life and takes full advantage of the product performance.

Owner:WINCELL INSULATION CO LTD

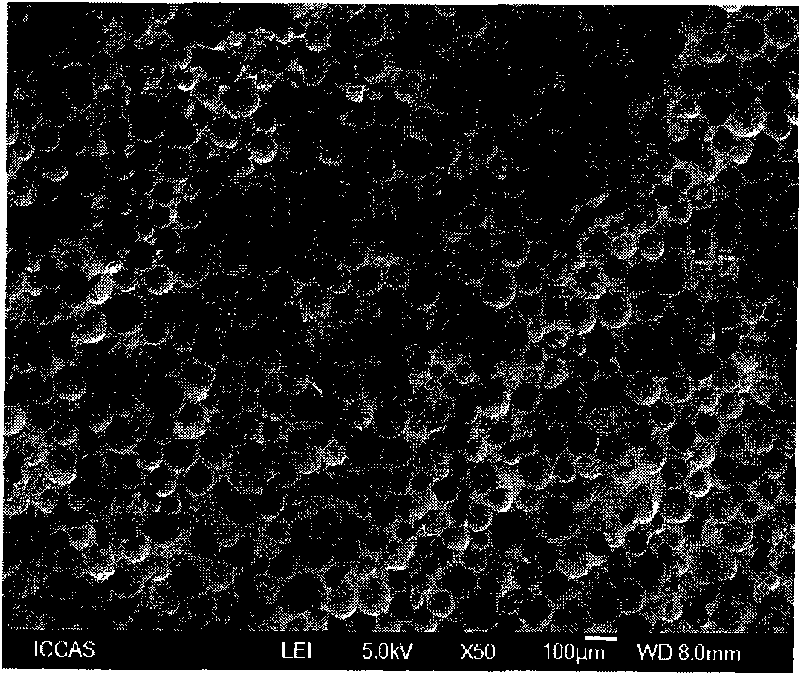

Polyimide foam plastic and preparation method thereof

ActiveCN103275319AImprove mechanical propertiesGood flexibilityAdhesivesPolymer scienceHeat resistance

The invention provides a preparation method of polyimide foam plastic. The method comprises the steps as follows: firstly, after dianhydride is mixed with low-level aliphatic alcohol, an esterification reaction is performed, and a diacid diester solution is obtained; then the obtained diacid diester solution is mixed with polymerized monomer amine and polyamic acid powder to obtain a mixed solution; and finally, the obtained mixed solution is sequentially subjected to foaming and thermal imidization after concentration to obtain the polyimide foam plastic. The invention further provides the polyimide foam plastic and the preparation method thereof, and the method comprises the step that polyamic acid powder is added when dianhydride and isocyanate are used for preparing the polyimide foam plastic. According to the invention, the polyamide acid powder serves as a nucleating agent, so that a cell of an objected formed by foaming of polyimide is fine and smooth, that is, the size distribution of the cell is improved, the cell uniformity is better, then the flexibility performance and the like of the polyimide foam plastic are improved; meanwhile, the heat resistance is not influenced; and besides, the preparation method of the polyimide foam plastic is concise in processing, and low in energy consumption and production cost.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

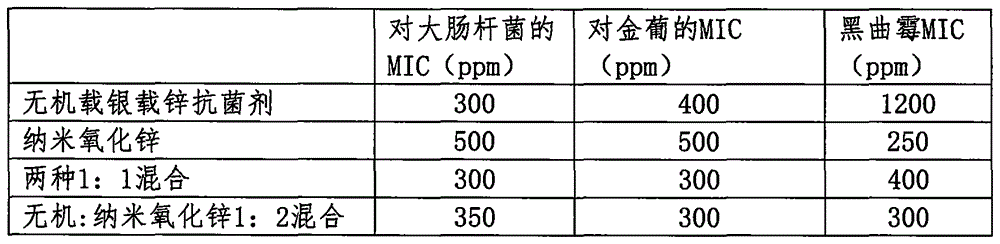

Antibacterial and mildewproof latex foam material and preparation method thereof

The invention provides an antibacterial and mildewproof latex foam material and a preparation method thereof. The foaming material comprises, by weight, 100 parts of latex (based on dry weight), 0.58 parts of potassium hydroxide, 2-5 parts of potassium vegetable oleate, 1-2 parts of potassium ricinate, 4-6 parts of sulfur, 1-2 parts of an antiager, 1-2 parts of sodium silicofluoride, 1-1.5 parts of bentonite, 4-6 parts of a vulcanization accelerator nanometer zinc oxide, and 0.5-1 part of an inorganic silver-carrying zinc-carrying antibacterial agent. The preparation method comprises removing ammonia, stirring ingredients, aging the mixture, and carrying out foaming, material filling, setting, vulcanization, cleaning and drying setting. The antimicrobial efficiency of the antibacterial and mildewproof latex foam material is 99% or more. The anti-mildew performance of the antibacterial and mildewproof latex foam material reaches the level 0-1. The elasticity, rebound resilience, strength and hardness of the foam material are excellent.

Owner:福家汇(北京)电子商务有限公司

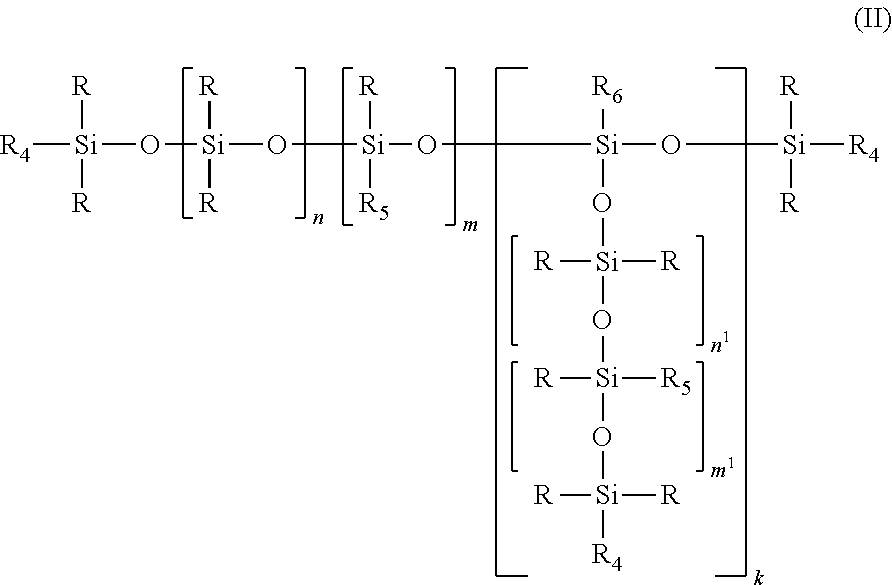

Polysiloxane polyether copolymers having (polyether)moieties comprising carbonate groups and their use as stabilizers for the production of polyurethane foams

InactiveUS20130035409A1Improve distributionBalanced property profileSilicon organic compoundsCopolymerCarbonate

The present invention relates to polysiloxane polyether copolymers which comprise at least one (polyether) moiety which comprises at least one unit —O—C(O)—O—, to a process for the production of the polysiloxane polyether copolymers, and also to the use of the polysiloxane polyether copolymers as stabilizers in the production of polyurethane foams, and also to polyurethane foams and items therefrom which are obtainable through the process.

Owner:EVONIK OPERATIONS GMBH

Method of preparing pnenolic aldehyde foam from modified foamable phenolic resin

The invention relates to a method for preparing phenolic foam with the modified phenolic resin. In the invention, it mixes 100 weight share of cashew oil modified phenolic resin, 1~4 weight share of surfactant, 2~8 weight share of foaming agent, and then it adds 8~15 weight share of curing agent into the mixture and stirs it for 2~15 minutes, and then it cures the mixture at 65 ~ 80deg.C environment for 30 ~ 125 minutes to achieve the phenolic foam.

Owner:安徽复材科技有限公司

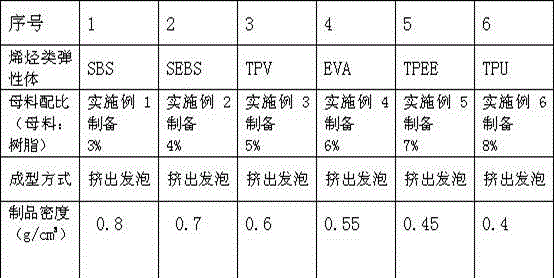

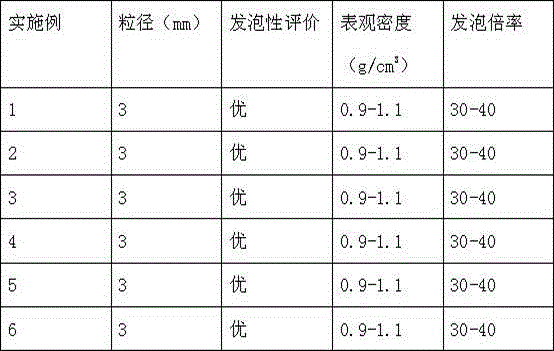

TPE (thermoplastic elastomer) foamed master batch and preparation method thereof

The invention relates to TPE (thermoplastic elastomer) foamed master batch and a preparation method thereof and belongs to the field of new chemical materials. The TPE foamed master batch is prepared from raw materials in parts by weight as follows: 10-30 parts of a styrene-butadiene block copolymer, 10-30 parts of an ethylene-octylene block copolymer, 30-80 parts of white oil, 20-80 parts of a microsphere foaming agent, 10-50 parts of a chemical foaming agent, 1-3 parts of a lubricating agent and 1-3 parts of a dispersing agent. The prepared TPE foamed master batch has high modulus, fine and uniform foam holes and adjustable density.

Owner:FUZHOU HAOWANG MATERIALS TECH CO LTD

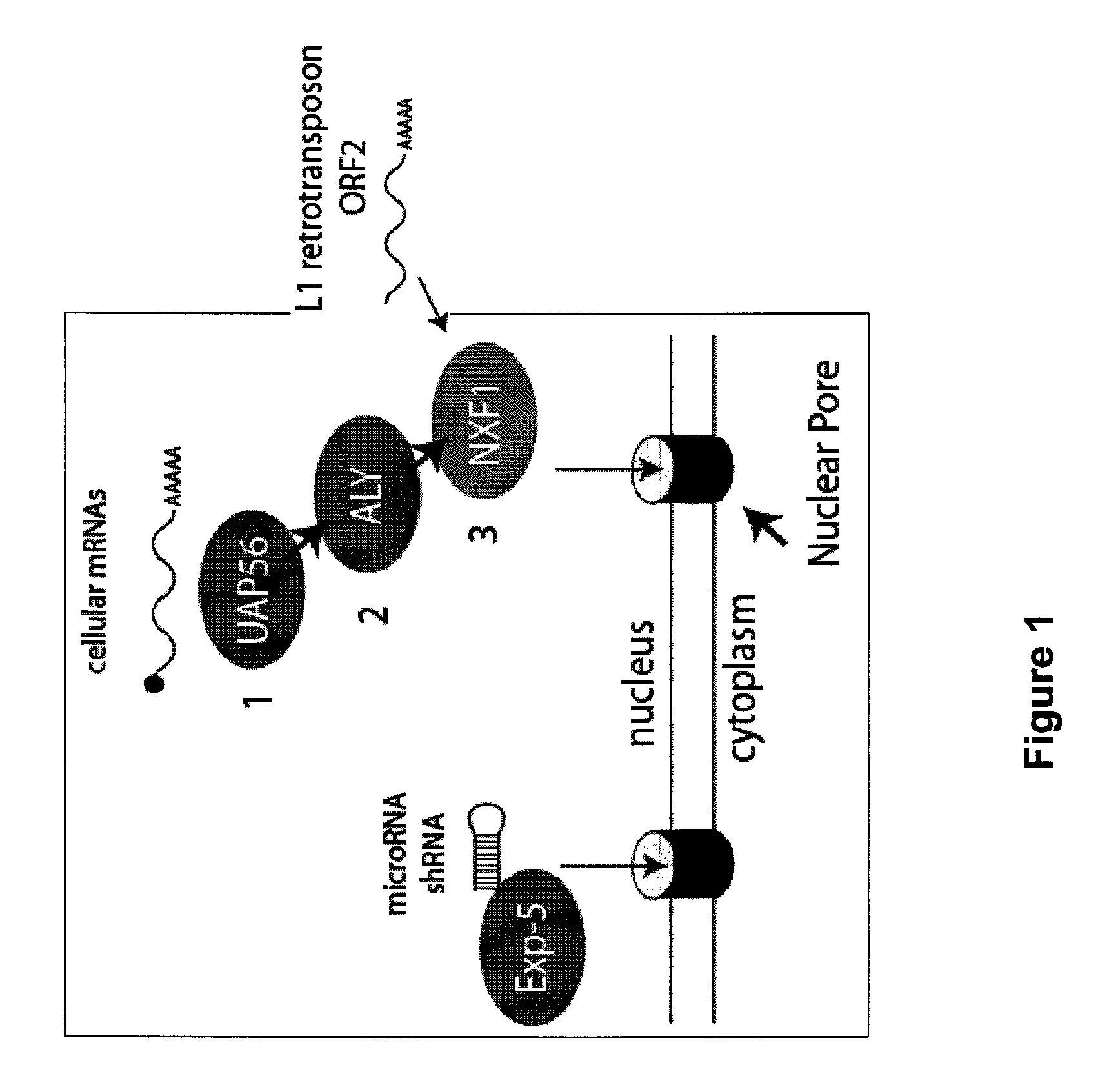

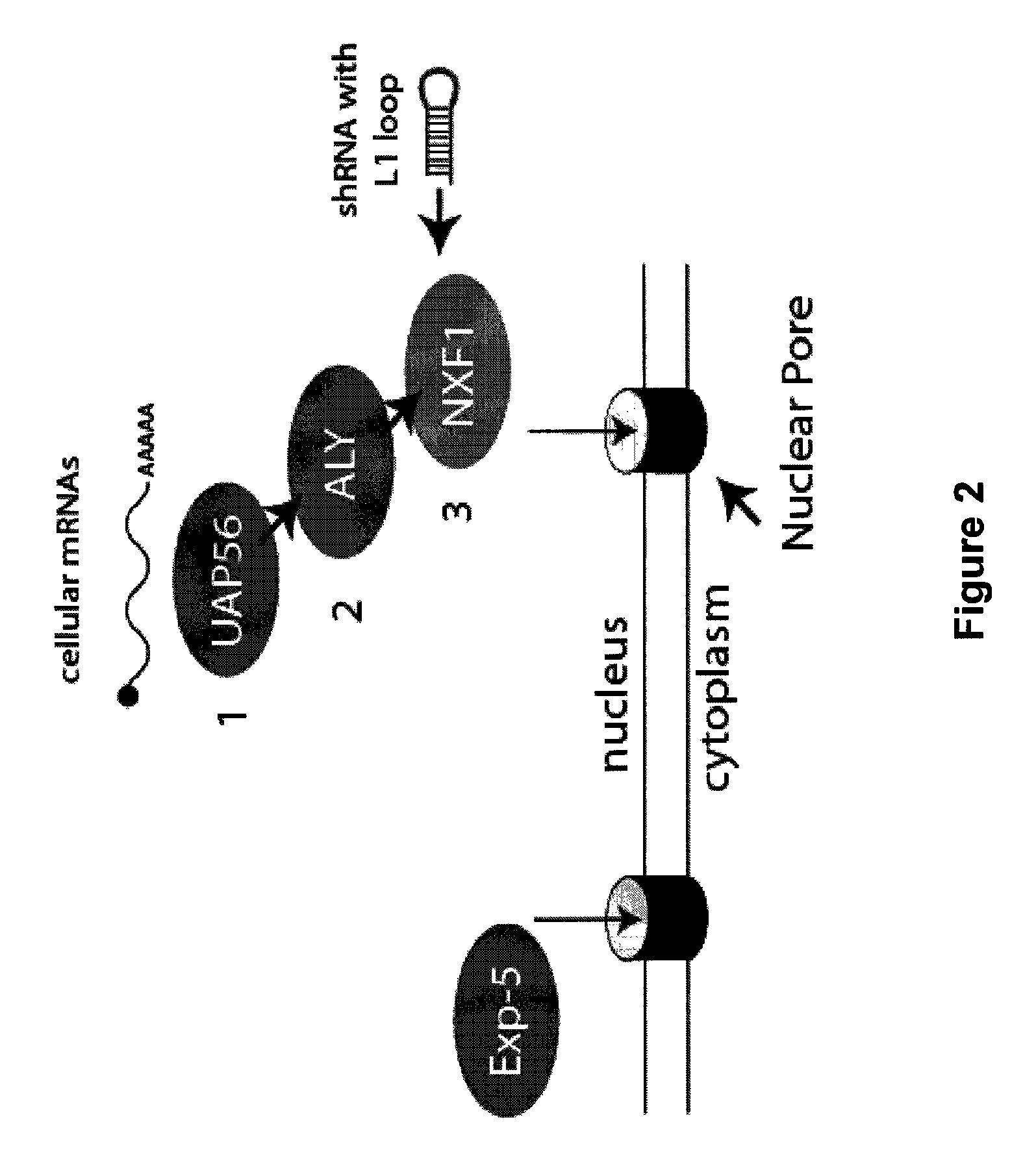

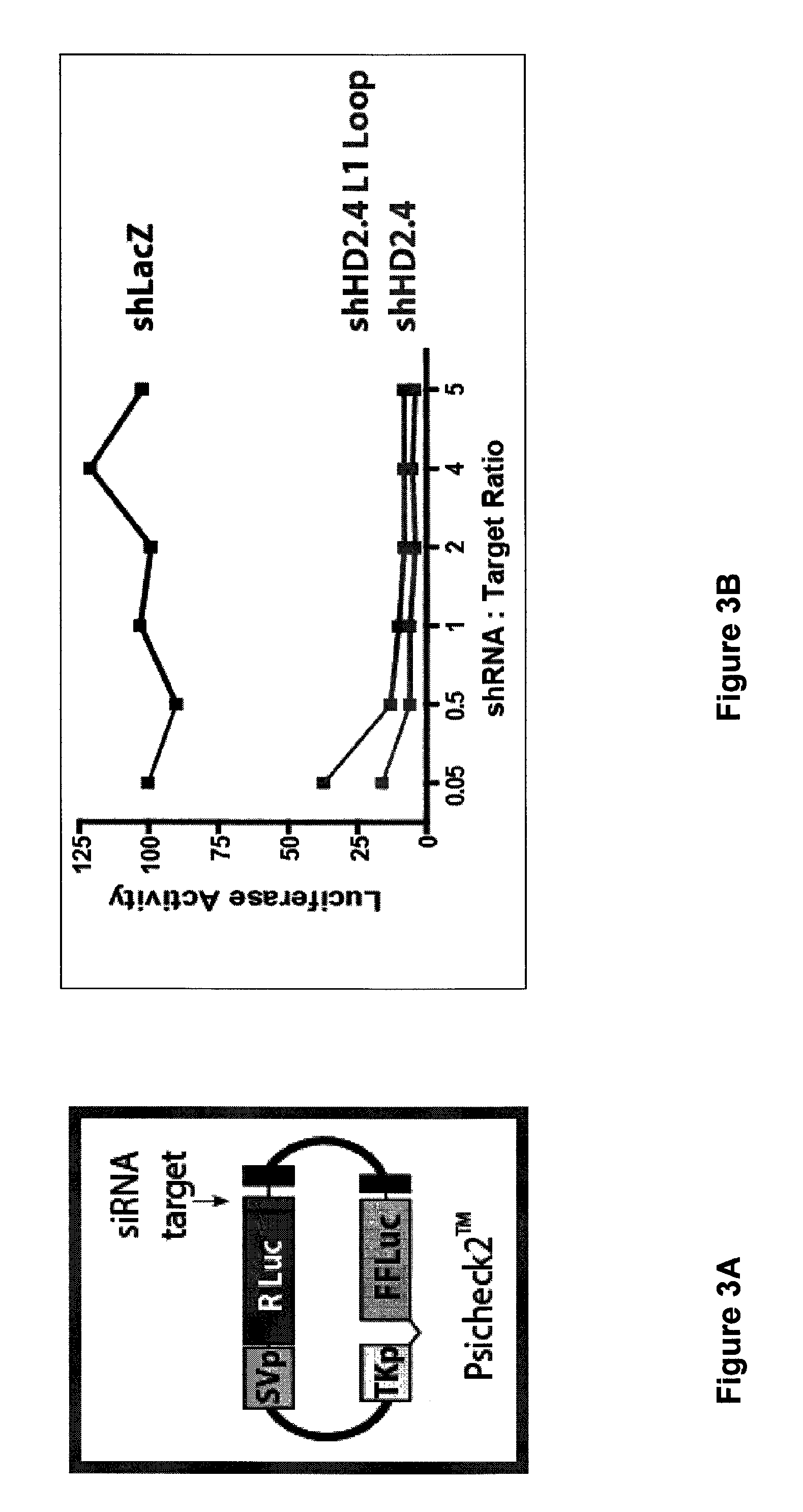

Alternative export pathways for vector expressed RNA interference

ActiveUS8227592B2More amenable to RNAiLess saturableBiocideSugar derivativesSequence designProtein C

The present invention is directed to nucleic acid molecules containing a loop sequence designed to circumvent exportin-5 mediated export, and methods using these novel molecules.

Owner:UNIV OF IOWA RES FOUND

Pre-foaming high-expansion polyurethane caulking compound and preparation method thereof

InactiveCN102977313AFix stability issuesSolve liquidity problemsOther chemical processesPolyureas/polyurethane adhesivesPolyesterPolymer science

The invention discloses a pre-foaming high-expansion polyurethane caulking compound which is mainly composed of the following raw materials by weight: 18 to 35 parts of polyether polyol, 2 to 15 parts of polyester polyol, 30 to 45 parts of polymethylisocyanate, 8 to 10 parts of dimethyl dimethanamide and 10 to 15 parts of a solvent. Polyether polyol, polyester polyol, polymethylisocyanate, dimethyl dimethanamide and the solvent are mixed together and stirred at room temperature, then an obtained mixture is filled into a pressure vessel, and finally an additive is filled into the pressure vessel. The caulking compound provided by the invention is a pre-foaming product, foaming of the caulking compound reaches 80 to 90% in seconds after the caulking compound is extruded, the extent of later foaming is small, so a worker can well control hand power when using a foaming gun, easiness and convenience are realized, glue is not wasted, cost is substantially saved, and deformation of a product is avoided. The caulking compound has high expansion performance and has a foaming volume reaching 70 to 80 times, one time greater that of a traditional caulking compound, and production cost is reduced.

Owner:SHANGHAI SHUODE BUILDING MATERIALS

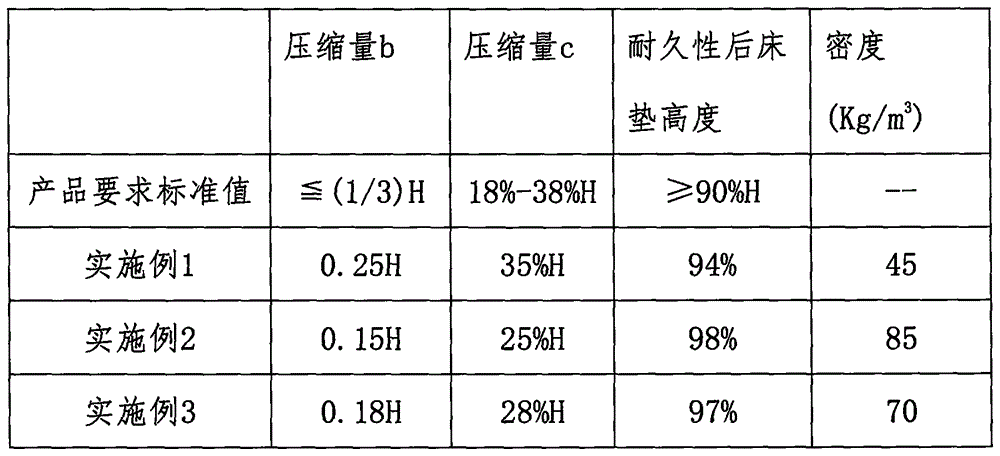

Slowly-recoverable foam

The invention relates to slowly-recoverable foam which is characterized by being foamed by the following raw materials in parts by weight: 100 parts of polyether, 0.1-10 parts of a pore-forming agent, 0.2-2 parts of a catalyst, 0.01-3.5 parts of a foam stabilizer, 0.01-4 parts of a crosslinking agent, 30-70 parts of toluene diisocynate and 0.5-7 parts of water. The slowly-recoverable foam can be obtained when content of toluene 2, 4-diisocyanate changes from 50-79%. The cellular diameters of the slowly-recoverable foam are distributed in a mixed manner with a great aperture ratio. The slowly-recoverable foam has a relatively good handfeel and good ventilation, and is low in production cost, low in release of VOC and environment-friendly.

Owner:甘肃银光聚银化工有限公司

Organosilicon surfactant and application thereof in preparation of polyurethane flexible foam

The invention provides an organosilicon surfactant. The organosilicon surfactant has the following general formula: MDxD'yD ''zM, wherein M is selected from any one of (CH3) 3SiO1 / 2 and (CH3) 2RSiO1 / 2, D is (CH3) 2SiO2 / 2, D'is (CH3) 2 (R) SiO2 / 2, D ''is (CH3) 2 (R') SiO2 / 2, x + y + z is 70-100, x is 68-98, y is 1-16, and z is 1-16. The invention also provides an application of the organic siliconsurfactant in polyurethane flexible foam. Alkynediol polyether, high-molecular-weight hydrogen-containing silicone oil and at least one alkynediol polyether are introduced, and a high-molecular organosilicon copolymer surfactant is formed through hydrosilylation. The preparation method is used for preparing the polyurethane flexible foam, and the rebound resilience of the polyurethane flexible foam can be improved.

Owner:JIANGXI MENHOVER CHEM TECH CO LTD

Polyurethane thermal insulation board for refrigeration storage and refrigeration box and preparation method thereof

The invention discloses a polyurethane thermal insulation board for a refrigeration storage and a refrigeration box and a preparation method thereof. The polyurethane thermal insulation board comprises surface layer materials and a base material. The surface layer materials are arranged on the upper surface and the lower surface of the base material, and are fiber cloth or polycarbonate films. Thebase material formed by reaction of reinforcing fibers, a filler and a rigid polyurethane foam foaming material includes 0-60 parts by weight of the reinforcing fibers, 0-60 parts by weight of the filler and 40-80 parts by weight of the rigid polyurethane foam foaming material. The burning performance grade of the obtained polyurethane thermal insulation board is not lower than grade B2 in GB8624-2012 'classification for burning behavior of building materials and products'. The polyurethane thermal insulation board for the refrigeration storage / box has the advantages of waterproof and thermalinsulation decoration, lightweight, high strength, integral molding and continuous production and easy installation and maintenance.

Owner:南京红宝丽新材料有限公司

Preparing method of super-soft polyurethane flexible foam

The invention relates to the field of application of polyurethane, in particular to a preparing method of super-soft polyurethane flexible foam. The environment temperature is controlled to be 20-25 DEG C, polyether polyol, a foam stabilizer, an amine catalyst, a tin catalyst and a cross-linking agent are weighed according to the formula amount and then added into a material bucket, a stirring machine is used for carrying out stirring and mixing for 20 s-30 s, and standing is carried out for 3 min-5 min; then weighed toluene diisocynate is poured into a material mixing bucket, the temperature of the materials is controlled to be 20-30 DEG C, timing is started, quick stirring is carried out for 5 s-8 s, then the mixed materials are poured into a foaming box for foaming, the reaction time ranges from 90 s to 150 s, and the product is cut into needed dimension after curing. The prepared super-soft polyurethane flexible foam is low in production cost, pores of the obtained super-soft polyurethane flexible foam are fine, and the super-soft polyurethane flexible foam is good in tearing strength, high in rebounding rate, soft in touch and more suitable for the fields with the high requirement for the soft degree of foam.

Owner:甘肃银光聚银化工有限公司

Biodegradable foam plastic and preparation method thereof

The invention discloses a biodegradable foam plastic and a preparation method thereof. The raw materials for preparing the foam plastic comprise 100 parts by weight of a or b and 0.01-10 parts by weight of UV photoinitiator, cross-linking agent and foaming agent, wherein a is poly(butylene succinate), and b is a copolymer formed by the poly(butylene succinate) and polyether; the number-average molecular weight of the poly(butylene succinate) is 10,000-100,000; and the number-average molecular weight of the copolymer formed by the poly(butylene succinate) and the polyether is 10,000-100,000. The method for preparing the biodegradable foam plastic comprises the steps of melting and mixing the raw materials of the foam plastic, then pressing into a sheet, carrying out UV irradiation on the obtained sheet, carrying out foaming and obtaining the biodegradable foam plastic.

Owner:INST OF CHEM CHINESE ACAD OF SCI

Waste polyurethane foam aminolysis recycling method

InactiveCN103012838ASolve pollutionTo achieve the goal of cost reduction and efficiency increasePlastic recyclingMechanical crushingPolyol

The invention relates to a waste polyurethane foam aminolysis recycling method, which comprises: a, removing surface attachments of waste polyurethane products; b, carrying out cutting or mechanical crushing on the surface attachment-removed waste polyurethane products into small blocks; c, preparing a mixture of regeneration polyol and aromatic amine; and d, preparing the mixture of the regeneration polyol and the aromatic amine into combination polyether for hard foam, and carrying out foaming. According to the present invention, a chemical recovery method is adopted to decompose waste polyurethane products, and processing utilization is performed, such that an environment pollution problem caused by the polyurethane foam is solved.

Owner:绍兴广佳庄鑫建材制造有限公司

Polyurethane composite heat-insulating material for solar heat-insulating water tank

The invention discloses a polyurethane composite heat-insulating material for a solar heat-insulating water tank. The polyurethane composite heat-insulating material for the solar heat-insulating water tank is characterized by being prepared from the following components in parts by weight: 90 to 100 parts of compound polyether polyol, 110 to 130 parts of isocyanate, 1 to 3 parts of nano-kaolin, 2to 5 parts of a foaming agent, 0.1 to 0.5 parts of a foam stabilizing agent, 0.5 to 3 parts of a catalyst, 0.5 to 1 part of a cross-linking agent, and 0.1 to 0.5 part of a composite flame retardant,wherein the compound polyether polyol comprises sorbitol polyether polyol, glycerol polyether polyol and diphenylmethane diamine polyether polyol. The tensile strength and the compressive strength ofthe polyurethane composite heat-insulating material are enhanced, the defect of high contractility after the polyurethane composite heat-insulating material is foamed and formed is overcome, and meanwhile, the heat conductivity coefficient of the polyurethane composite heat-insulating material is reduced, and the heat insulating property is improved by optimizing a basic formula, adopting the compound polyether polyol and adding the nano-kaolin.

Owner:NANNING KEYU ENERGY TECH CO LTD

Electron radiation cross-linked polypropylene foam sheet and preparation method thereof

The invention provides an electron radiation cross-linked polypropylene foam sheet and a preparation method thereof. The electron radiation cross-linked polypropylene foam sheet comprises 55-68wt% of a polypropylene resin, 10-20wt% of a polyethylene resin, 10-15wt% of a polyoxyethylene resin, 4-9wt% of a cross-linking agent, 3-8wt% of an antioxidant and 5-10wt% of a foaming agent. The performances of materials and the characteristics of a production technology are fully combined, a radiation process is utilized to overcome the rapid decrease trend of the intensity of polypropylene when the temperature is higher than the melting point, the content of polyethylene in the sheet plays a substantial role in the cross-linking degree of polypropylene, and the cross-linking degree of polypropylene is the key for polypropylene foaming. Compared with polypropylene foam sheets obtained through common radiation cross-linking methods, the polypropylene foam sheet prepared in the invention has the advantages of substantially improved performances, obviously improved tensile strength and elongation at break, fine foam holes, and uniform foaming.

Owner:北京斯维浩特新材料科技有限公司

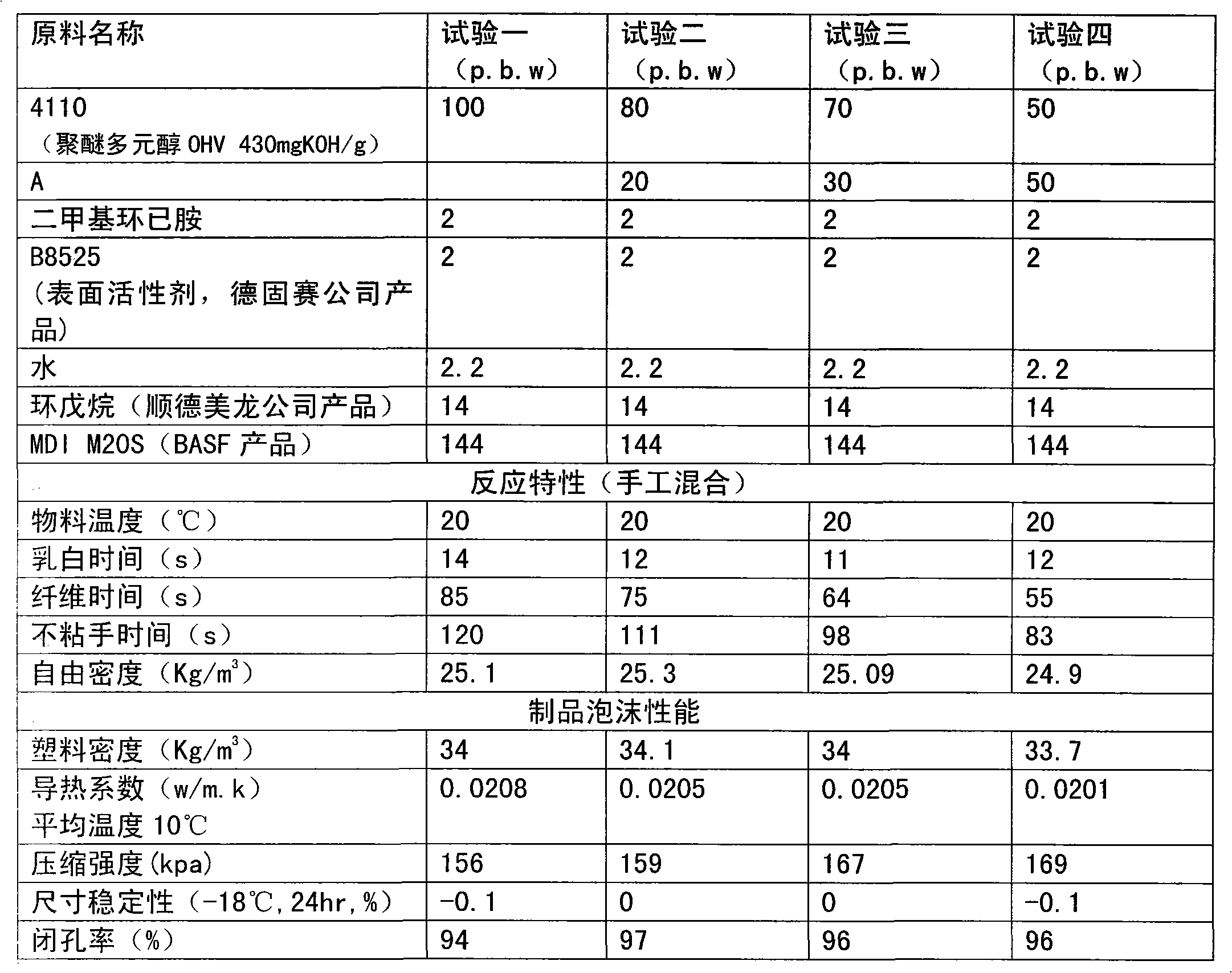

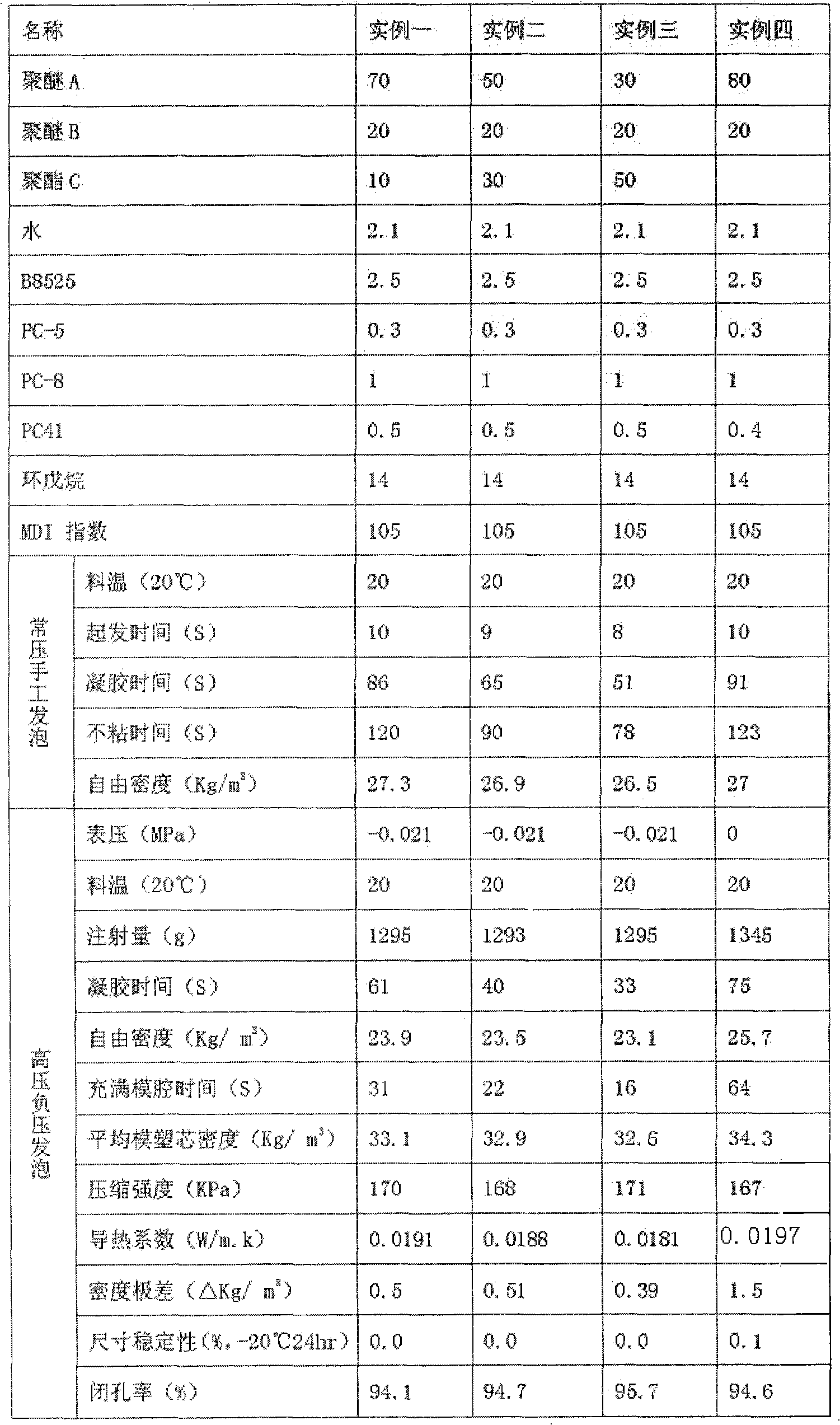

Hard polyurethane molding foam negative pressure foaming raw material formula and hard polyurethane molding foam negative pressure foaming production method

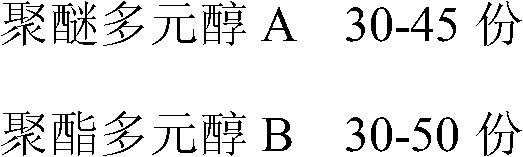

The invention relates to a formula of a hard polyurethane molding foam negative pressure foaming raw material, wherein the raw material is prepared by mixing polyether polyol, a polyester polyol, a foam stabilizer, a catalyst and water, and a weight ratio of the polyether polyol to the polyester polyol to the foam stabilizer to the catalyst to the water is 50-90:10-50:2-3:2-3:1-2.5. The hard polyurethane molding foam negative pressure foaming production method comprises carrying out hard polyurethane foaming under a state with a negative pressure of 0 to -0.025 MPa, wherein polyurethane foaming is performed under the negative pressure state so as to reduce polyurethane raw material requirements. In addition, a high functionality polyester polyol can be adopted as a main polyol to prepare a combination polyether so as to carry out foaming, such that a mold cavity can be filled in a short time, and the prepared foam has characteristics of thin cell, high strength and good size stability.

Owner:绍兴广佳庄鑫建材制造有限公司

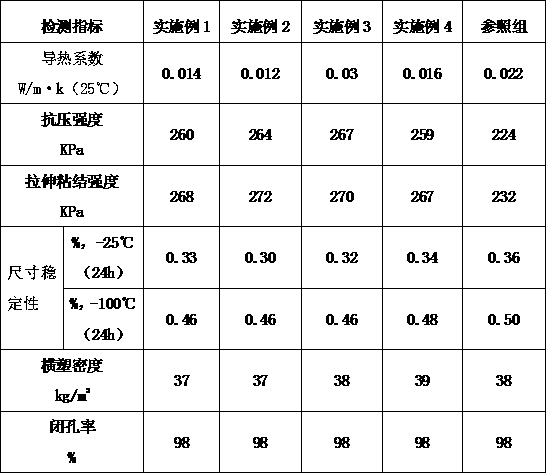

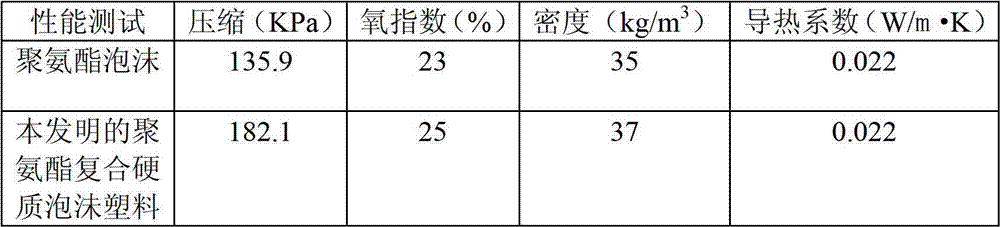

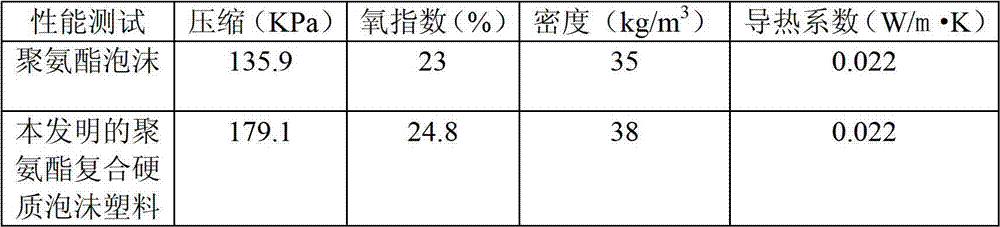

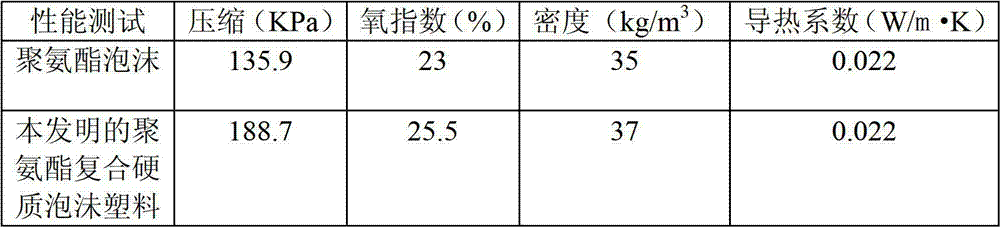

Polyurethane composite hard polyfoam as well as preparation method and application of polyurethane composite hard polyfoam

The invention relates to polyurethane composite hard polyfoam as well as a preparation method and application of the polyurethane composite hard polyfoam, wherein the polyurethane composite hard polyfoam consists of ingredients A and ingredients B, wherein the ingredients A are formed by mixing isocyanate and inorganic materials, the ingredients B are formed by mixing combined polyether, catalysts and foaming agents, and the weight ratio of the ingredients A to the ingredients B is (1.1-.14):1. The isocyanate in the ingredients A used by the polyurethane composite hard polyfoam contains -N-C=0 which can easily take reaction with active-hydrogen-atom-containing compounds such as amine, water, alcohol, acid and alkali. The isocyanate is a vacuum dehydration raw material, the dispersion of superfine powder cannot be influenced, and the uniform dispersion can be realized in organic solvents. Meanwhile, some inorganic materials can also be added into the ingredients B, for example, hydroxyl ions are contained in the oxyhydrate and can be possibly and perfectly compatible with the combined polyether containing hydroxy functional groups. The added inorganic materials can be one single ingredient and can also be composite materials obtained through compounding polyurethane inorganic materials and adding other fire retardants. Various kinds of inorganic materials are adopted for compounding, and the problem of poor foam performance generated by the single use can be solved.

Owner:HENAN TIANFON ENERGY SAVING PANEL SCI & TECH

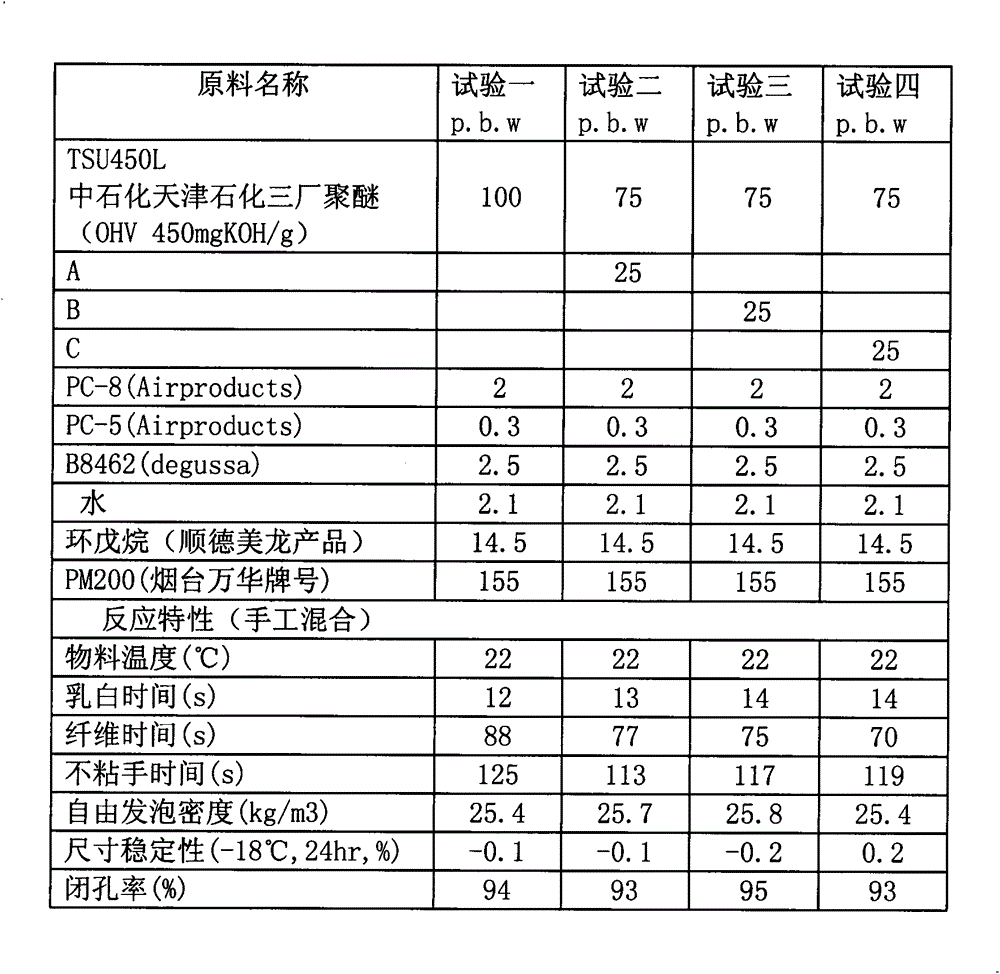

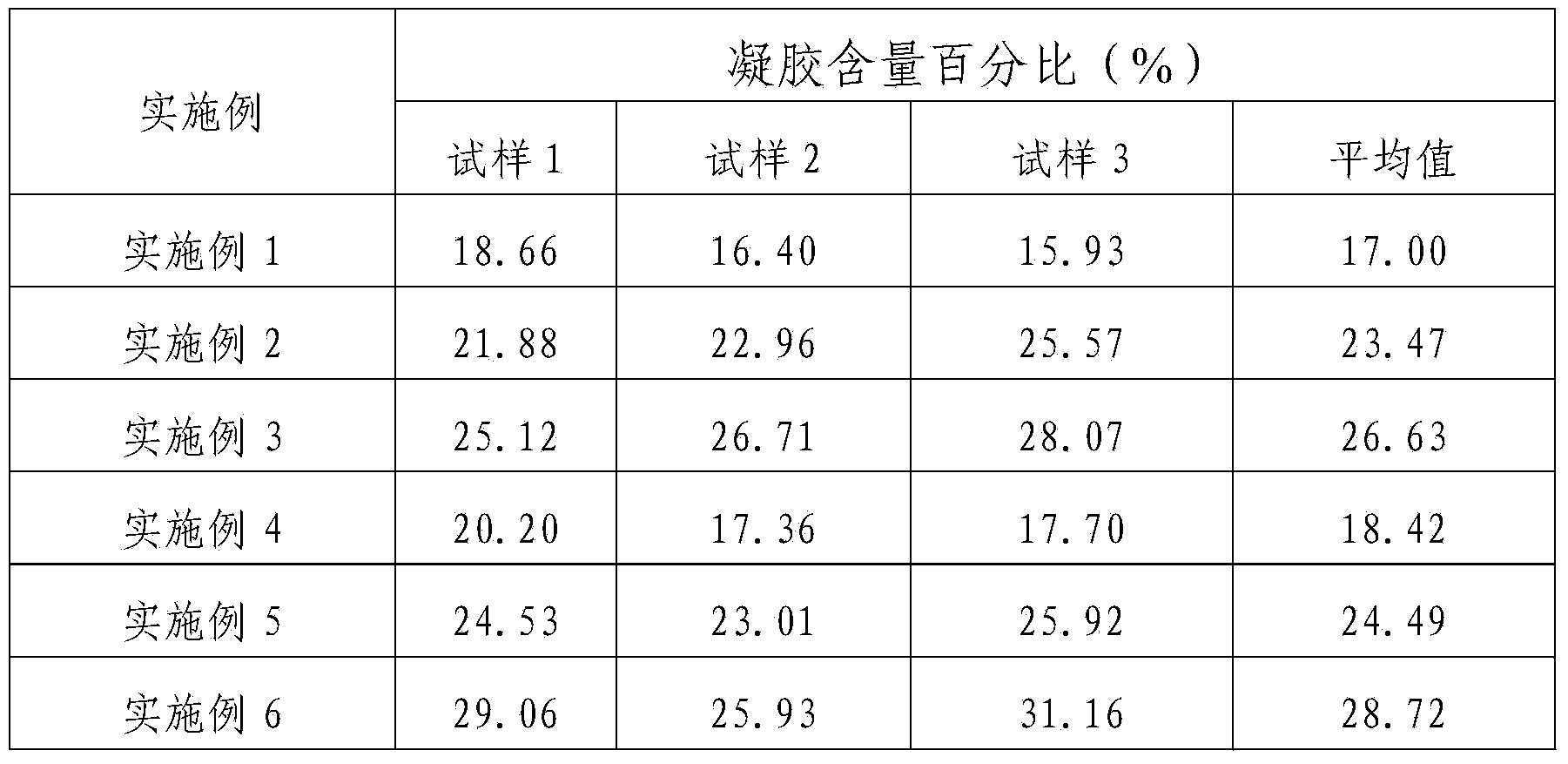

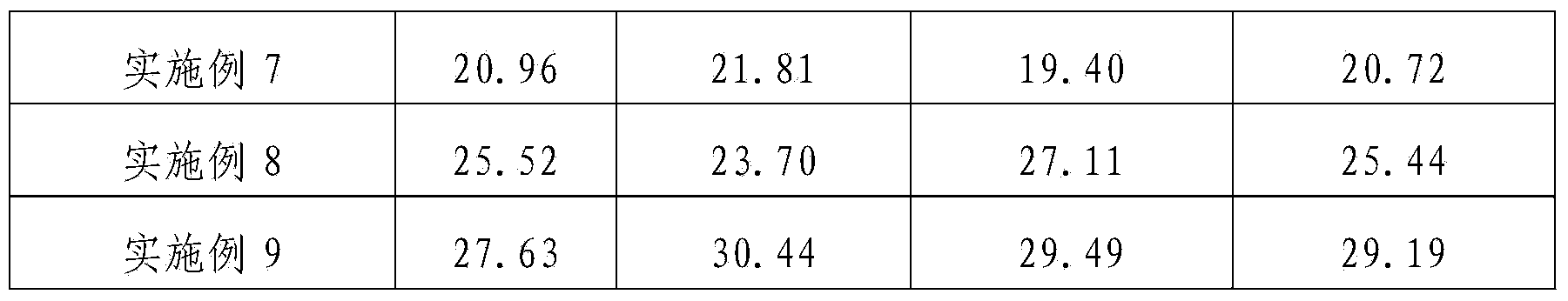

High flame retardant combined polyether for continuous production of polyurethane sheet and preparation method thereof

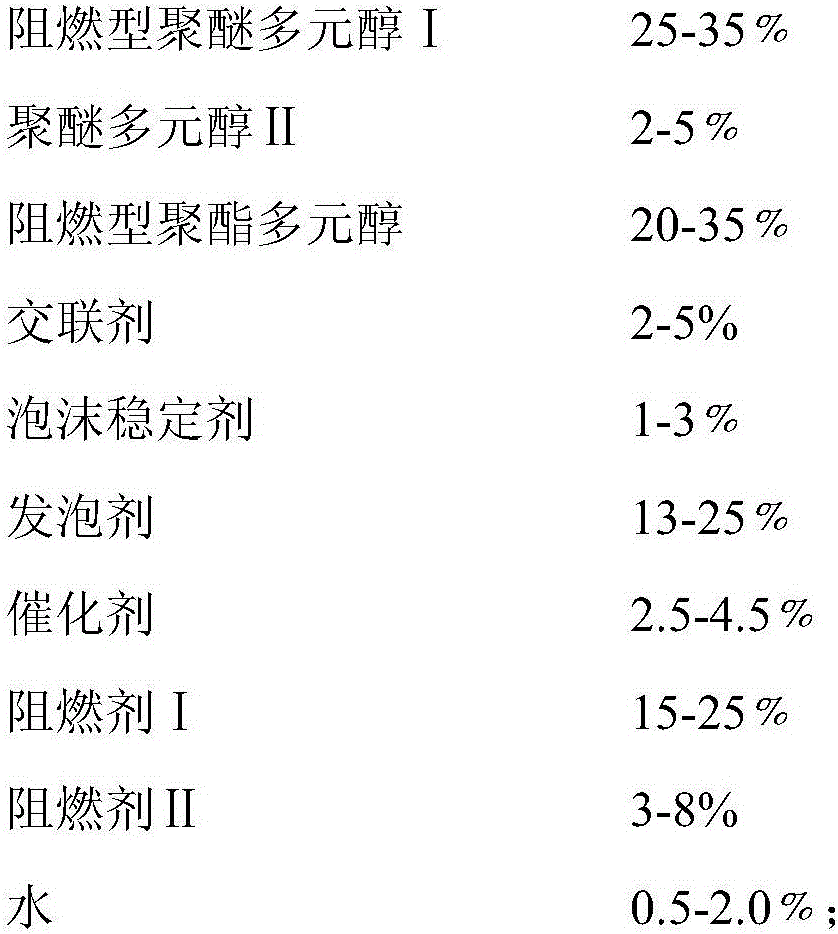

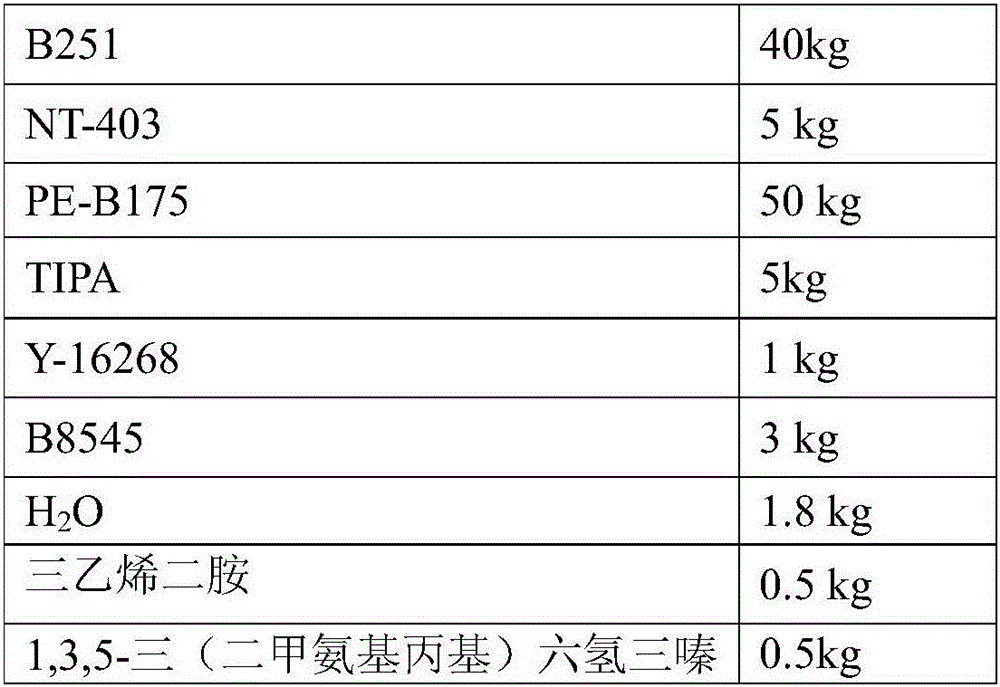

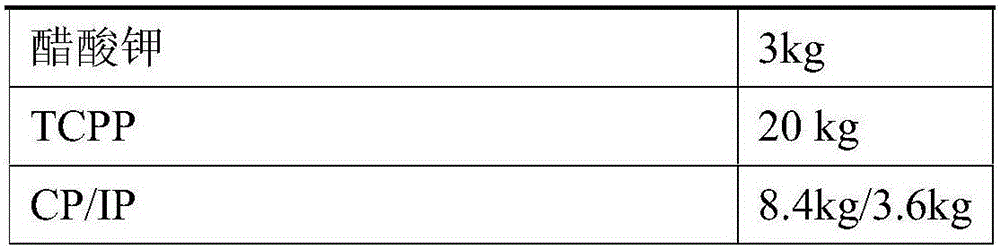

Belonging to the technical field of polyurethane, the invention in particular relates to a high flame retardant combined polyether for continuous production of polyurethane sheet and a preparation method thereof. The high flame retardant combined polyether is composed of a component A and a component B that are in a weight ratio of 1:1.5-1.8, wherein the component A is prepared from the following raw materials by weight percentage: 25-35% of flame retardant polyether polyol I; 2-5% of polyether polyol II; 20-35% of flame retardant polyester polyol; 2-5% of a crosslinking agent; 1-1.5% of a foam stabilizer; 13-25% of a foaming agent; 2.5-4.5% of a catalyst; 15-25% of a flame retardant I; 3-8% of a flame retardant II; and 0.5-2.0% of water; and the component B is polyaryl polymethylene isocyanate. The high flame retardant combined polyether provided by the invention has good adiabaticity and high percentage of close area, and the overall flame retardant level can reach the national B2 level flame retardant standard.

Owner:SHANDONG INOV NEW MATERIALS CO LTD

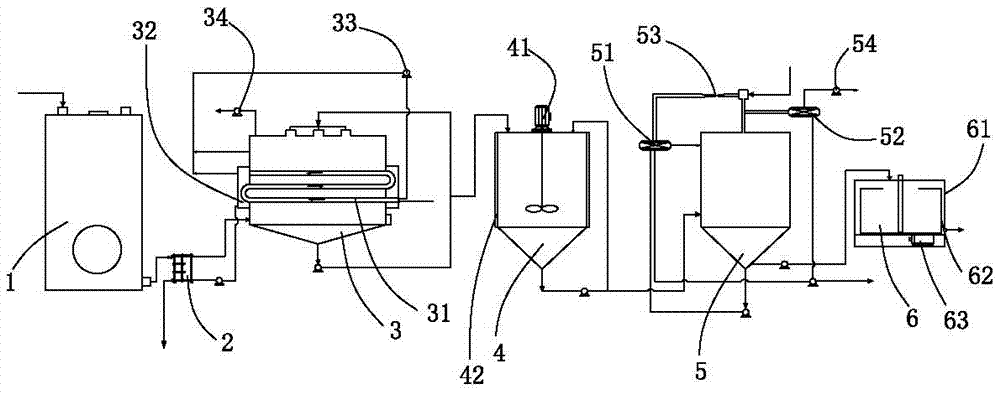

Evaporative crystallization zero-emission system and method for industrial high-salinity wastewater

PendingCN107265737AUniform cellsFine cellsWater/sewage treatment by centrifugal separationWater/sewage treatment bu osmosis/dialysisWastewaterProcess engineering

The invention relates to the technical field of wastewater purification, in particular to an evaporative crystallization zero-emission system and method for industrial high-salinity wastewater; the system comprises: a heat exchanger for heating high-salinity wastewater; an evaporative tank for receiving the high-salinity wastewater from the heat exchanger and heating for evaporating; an insulation tank for receiving the high-salinity wastewater from the evaporative tank and performing heat-insulated stirring; a crystallizing tank for receiving the high-salinity wastewater from the insulation tank and performing flashing condensation; a centrifugal separation device for receiving the high-salinity wastewater from the crystallizing tank and performing centrifugal separation. The industrial high-salinity wastewater processed via the system can be condensed to 30-60 times, derivatives are solid and condensate, the solid is a composite salt and may be separated and dried to obtain industrial finished salt, the condensate may be recycled to a production line, and accordingly zero emission of the high-salinity wastewater is achieved.

Owner:DONGGUAN DONGYUAN ENVIRONMENTAL TECH CO LTD

Low-density hard polyurethane foam and preparation method thereof

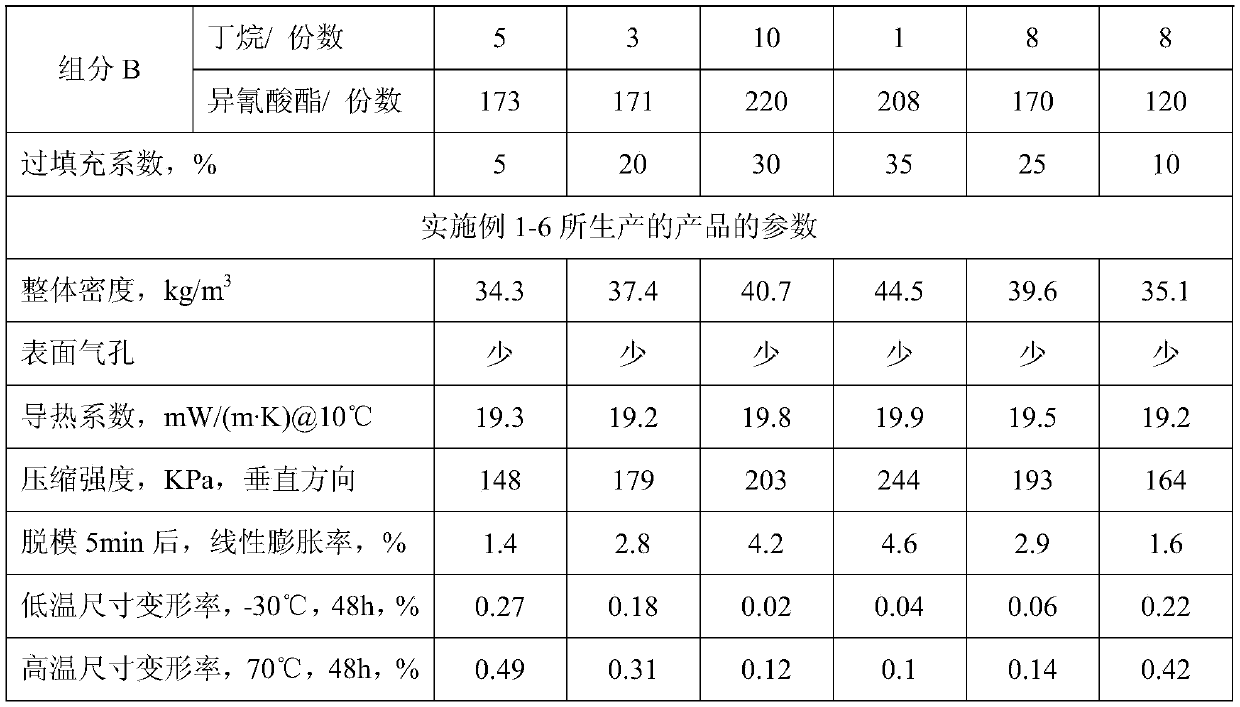

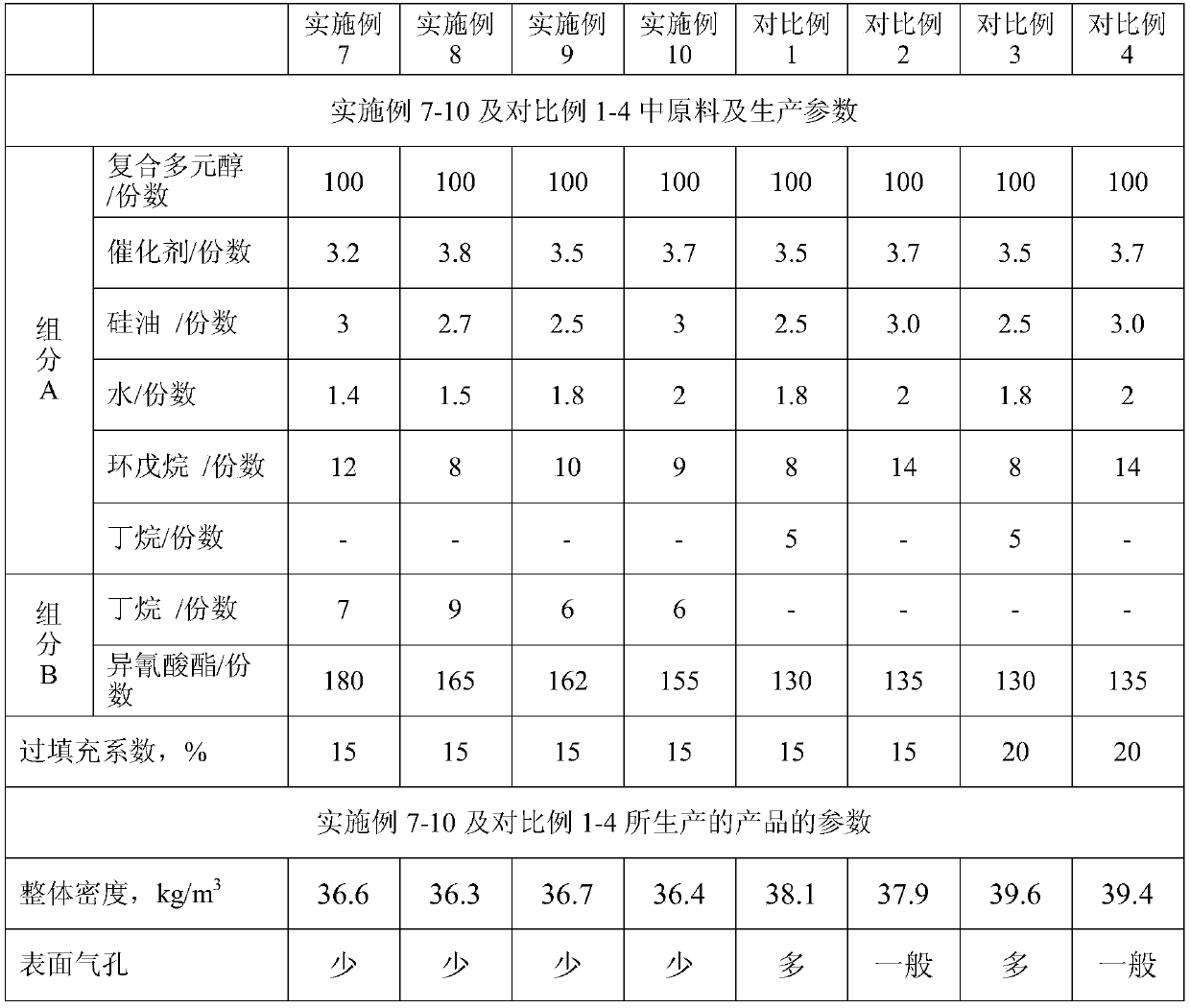

The invention discloses low-density hard polyurethane foam which is prepared by respectively premixing components A and components B, jointly mixing and foaming. The components A include, by weight, 100 parts of composite polyol, 5-15 parts of cyclopentane, 1.5-6 parts of amine catalyst, 1-5 parts of silicon surfactant and 0.8-2.5 parts of water, and the components B include, by weight, 1-10 partsof butane and 120-220 parts of isocyanate, wherein each raw material above is based on 100 parts of composite polyol. The preparation method includes following steps: (1), preparing the components A;(2), preparing the components B; (3), injecting the components A and the components B into a closed mold, allowing sufficient reaction, and demolding to obtain the hard polyurethane foam. The low-density hard polyurethane foam is environment-friendly and excellent in performance.

Owner:HONGBAOLI GRP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com