Polyurethane thermal insulation board for refrigeration storage and refrigeration box and preparation method thereof

A technology of polyurethane insulation board and refrigerator, which is applied in the field of cold chain technology industry, can solve problems such as non-compliance with environmental protection requirements, harmful gases, economic losses, etc., and achieve the effects of easy installation and maintenance, convenient installation and maintenance, and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

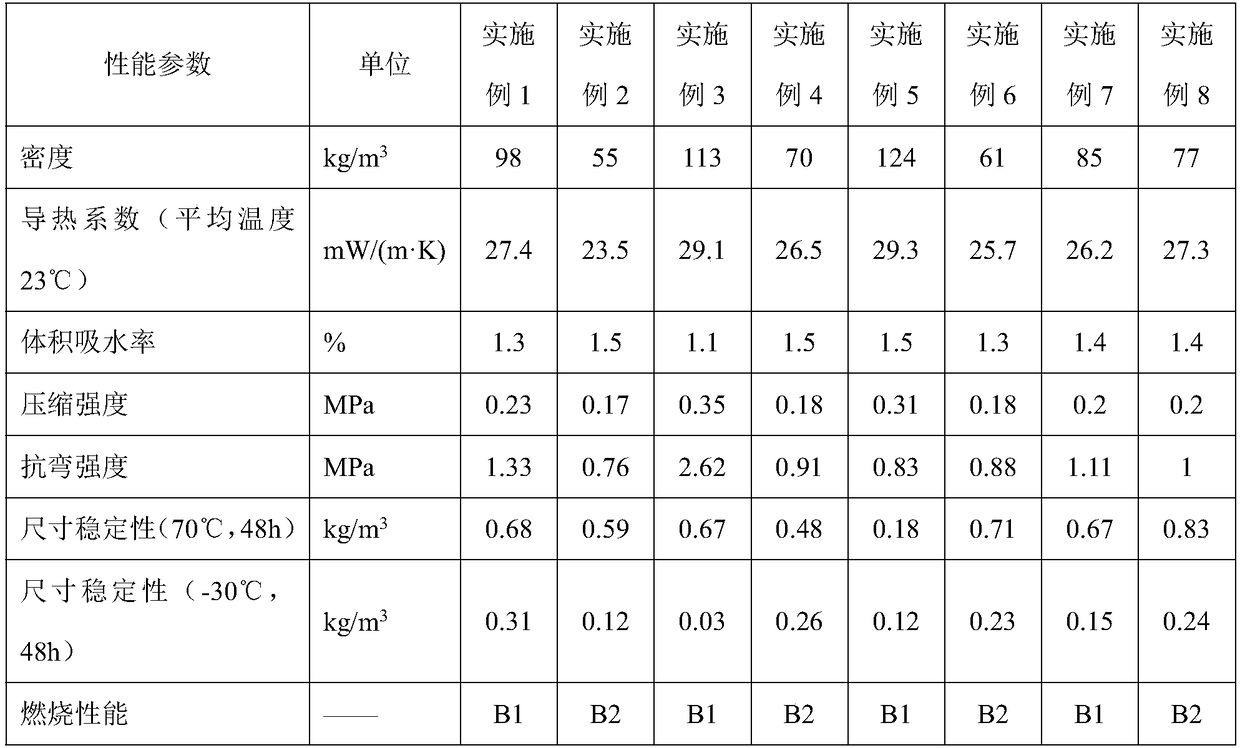

Examples

Embodiment 1

[0034] Preparation of reinforcing fiber: take 30 parts by weight of aramid fiber with a fiber length of 0.5 to 6 mm;

[0035] Filler preparation: take 20 parts by weight of 140-200 mesh quartz sand, 5 parts by weight of 100-200 mesh red phosphorus, and 5 parts by weight of 200 mesh montmorillonite;

[0036] The preparation of rigid polyurethane foam foaming material: get 75 parts by weight of polyester polyol HF-8730 (Huafeng), 25 parts by weight of polyester polyol HF-86304 (Huafeng), 4.5 parts by weight of dimethylcyclohexylamine, 0.5 parts by weight of stannous octoate, 9 parts by weight of HFC-365mfc, 8 parts by weight of pentane, 1.3 parts by weight of water, 15 parts by weight of triethyl phosphate, 5 parts by weight of trimethylolphosphine oxide, foam stabilizer B8481 (Degussa ) 2 parts by weight, polyphenyl polymethylene polyisocyanate M50 (Basf) 232 parts by weight;

[0037] The weight ratio of reinforcing fiber, filler and rigid polyurethane foaming material is 30:30:...

Embodiment 2

[0039] Preparation of reinforcing fibers: get 5 parts by weight of carbon fibers with an average fiber length of 10 mm, and 5 parts by weight of glass fibers with an average fiber length of 5 mm;

[0040] Preparation of filler: take 10 parts by weight of 180 mesh gypsum powder;

[0041] Preparation of polyurethane rigid foam foaming material: get 27 parts by weight of polyether polyol HP2502 (Hongbaoli), 73 parts by weight of polyester polyol HF-8730 (Huafeng), 2 parts by weight of dimethylcyclohexylamine, three parts by weight 1.6 parts by weight of ethylenediamine, 0.4 parts by weight of potassium isooctanoate-dipropylene glycol solution, 8 parts by weight of pentane, 7 parts by weight of HFC-245fa, CO 2 5 parts by weight, 1.1 parts by weight of water, 25 parts by weight of tris(2-chloropropyl) phosphate, 1.7 parts by weight of foam stabilizer B8460 (Degussa), polyphenyl polymethylene polyisocyanate PM-400 (ten thousand China Chemical) 258 parts by weight;

[0042] The wei...

Embodiment 3

[0044] Preparation of reinforcing fibers: get 60 parts by weight of glass fibers with an average fiber length of 5 mm;

[0045] Preparation of polyurethane rigid foam foaming material: take 100 parts by weight of polyether polyol H4110 (Red Polaroid), 2 parts by weight of triethanolamine, 1,3,5-tris(dimethylaminopropyl) symmetrical hexahydrotriazine 1 Parts by weight, 2 parts by weight of blowing agent water, 1.15 parts by weight of water, 30 parts by weight of diphenylisooctyl phosphate, 1.8 parts by weight of foam stabilizer AK8830 (Meister), polyphenyl polymethylene polyisocyanate M20S (Basf) 221 parts by weight;

[0046] The reinforcing fiber and the rigid polyurethane foaming material are formulated into a mixture in proportion, and the weight ratio of the reinforcing fiber and the rigid polyurethane foaming material is 60:40. The mixture is poured on the surface material polycarbonate film (thickness 0.5mm) of the lower surface of the substrate, and the surface layer ma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fiber length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com