Patents

Literature

120 results about "Performance grade" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

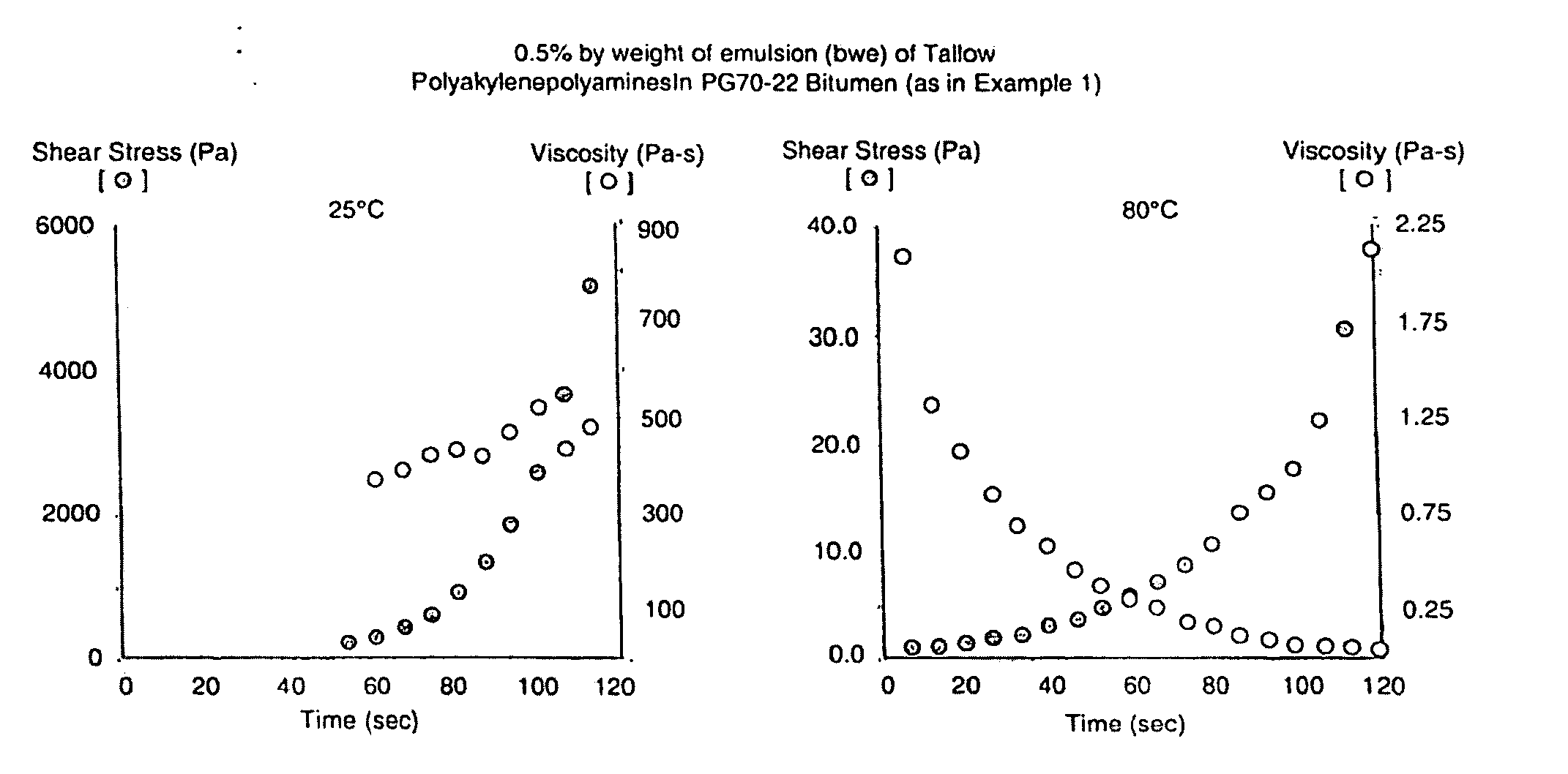

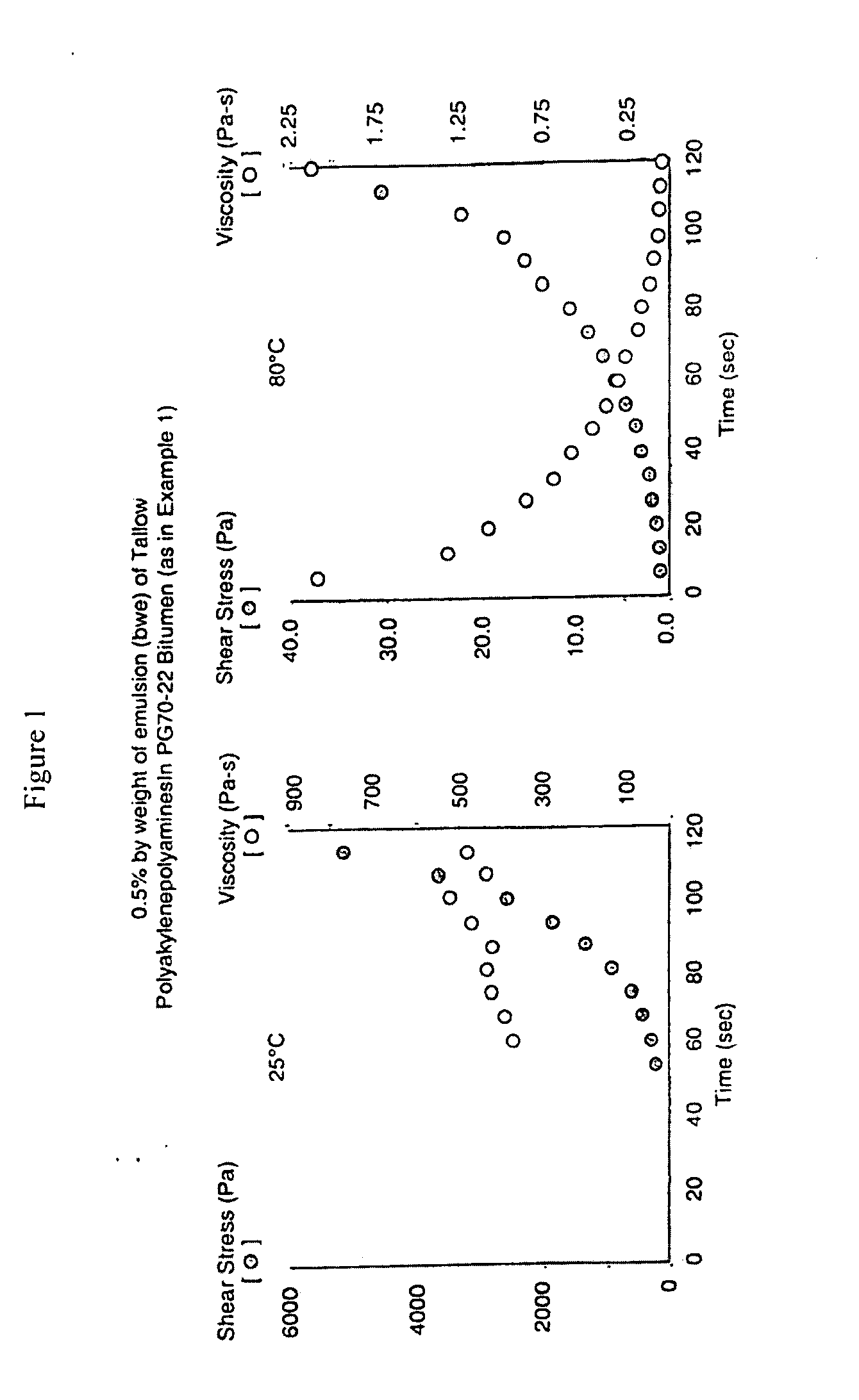

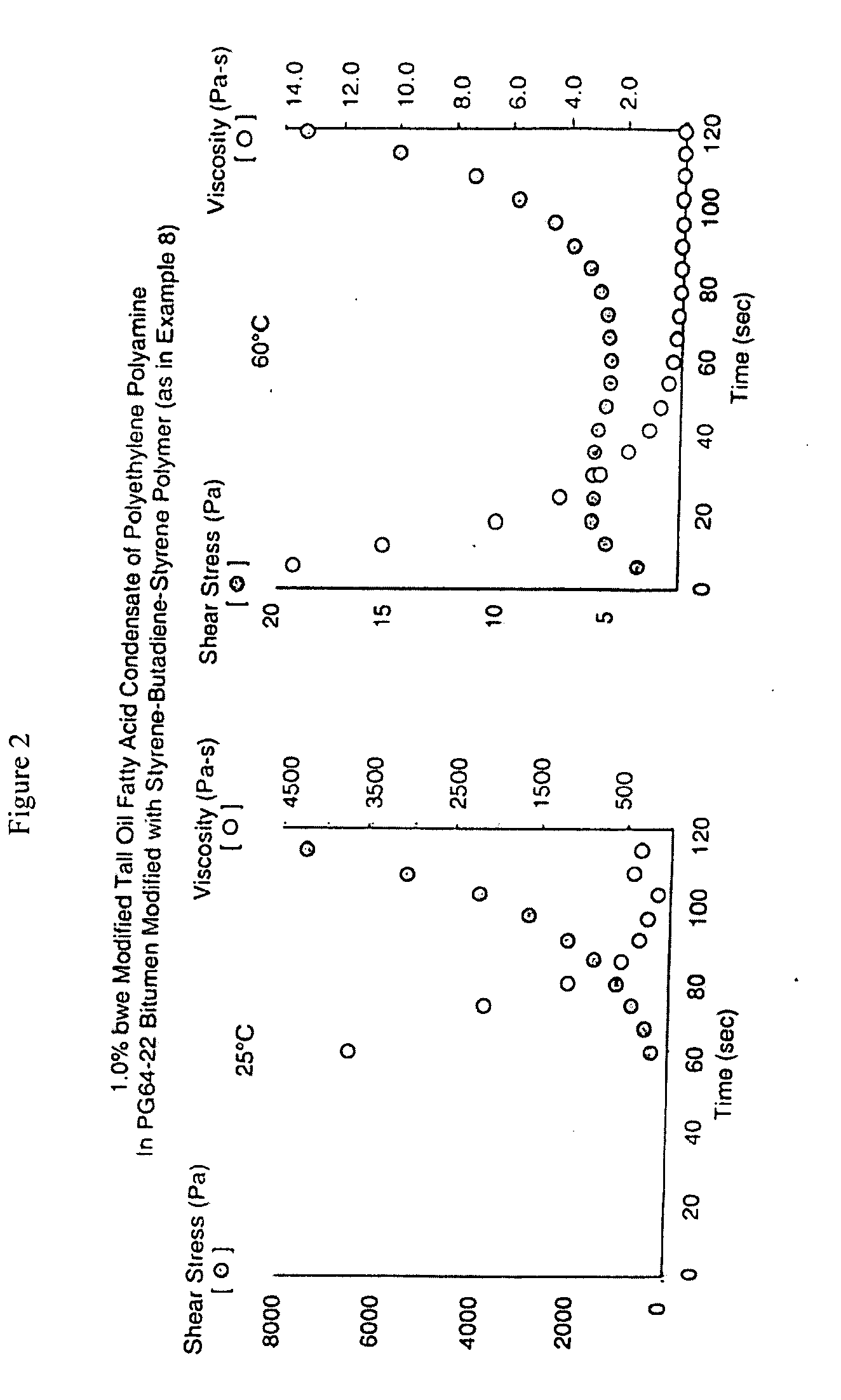

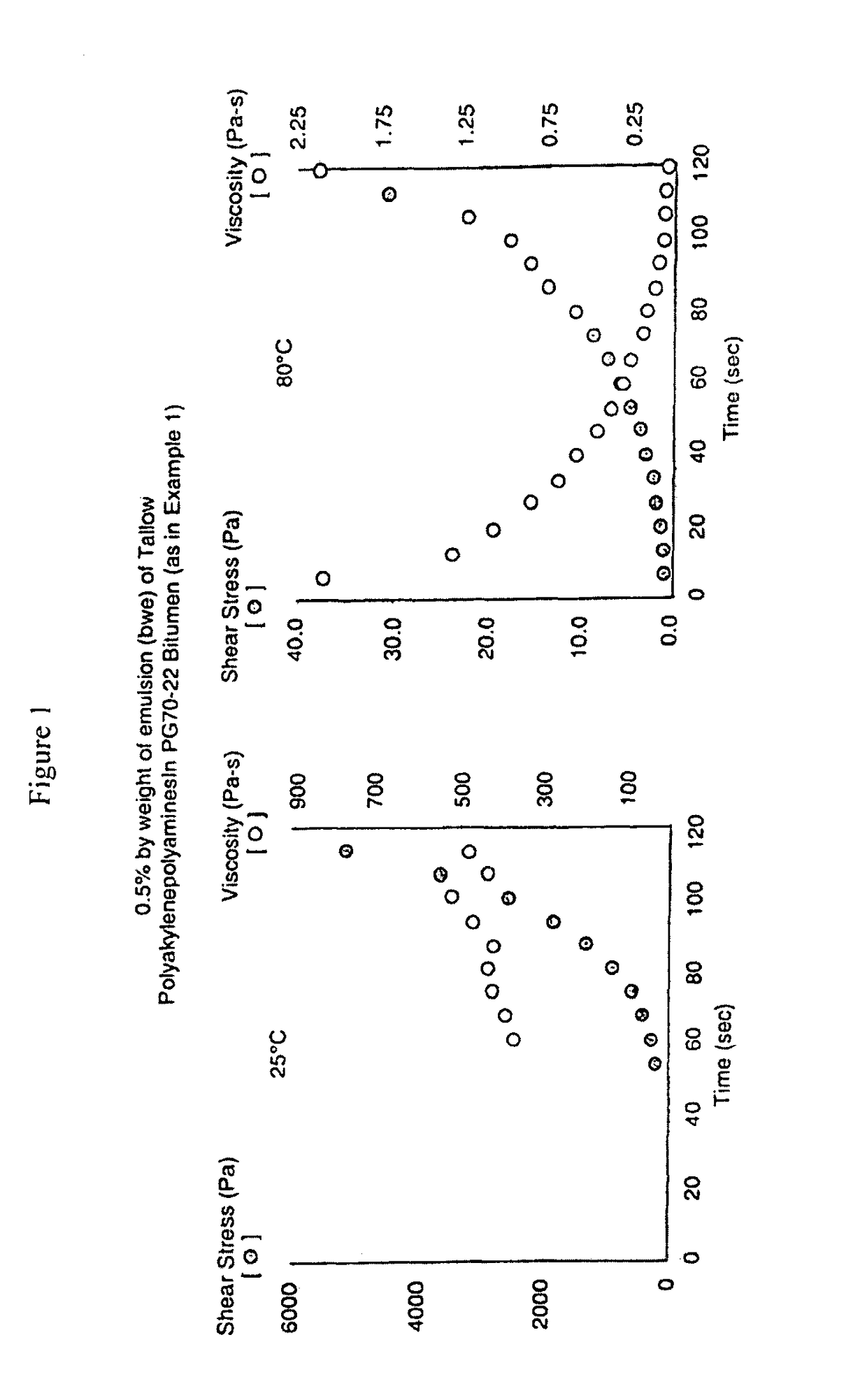

Method for producing bitumen compositions

ActiveUS20080060551A1Low viscosityHighly preventive effectBuilding insulationsBitumen emulsionRoad surface

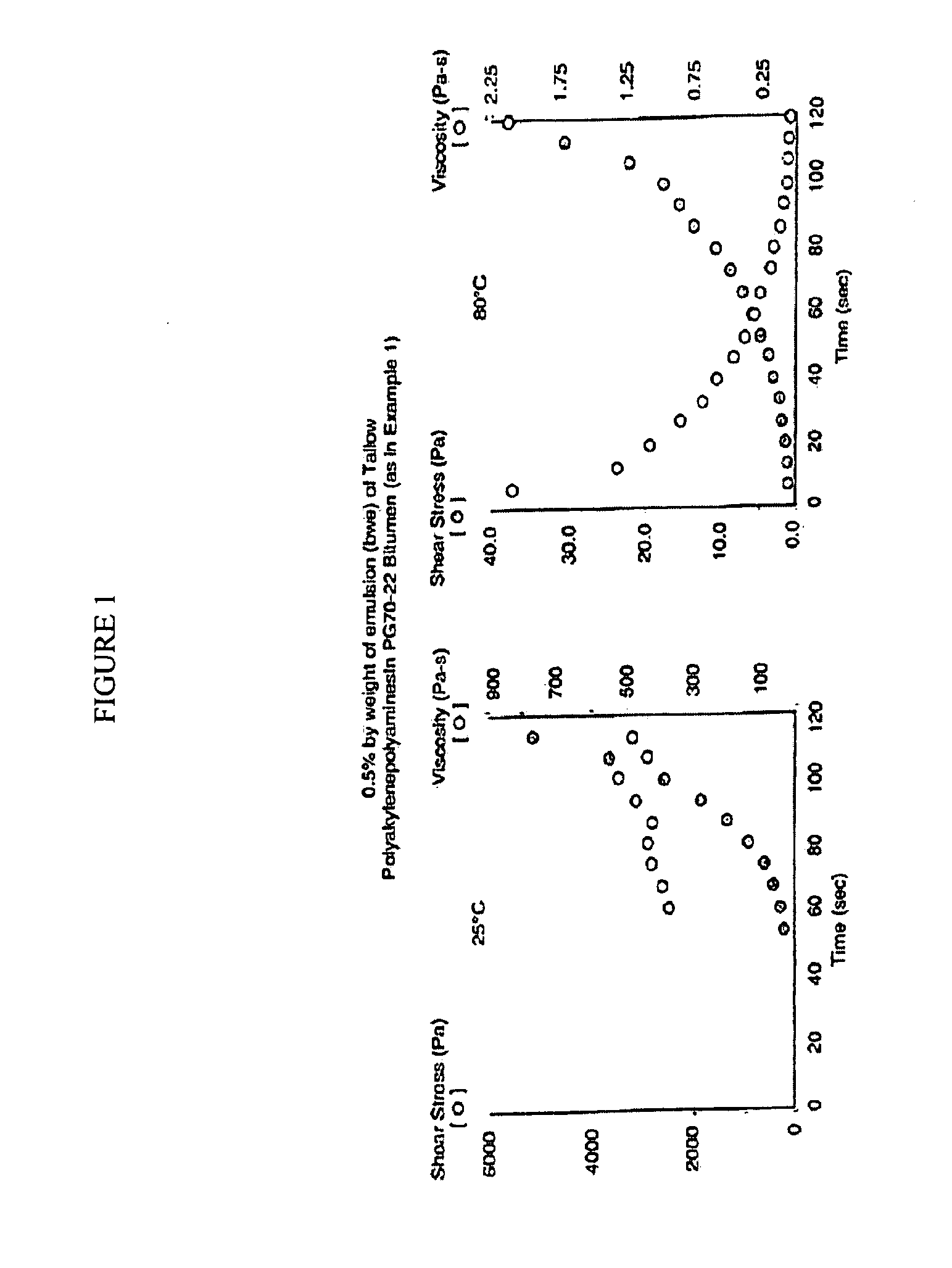

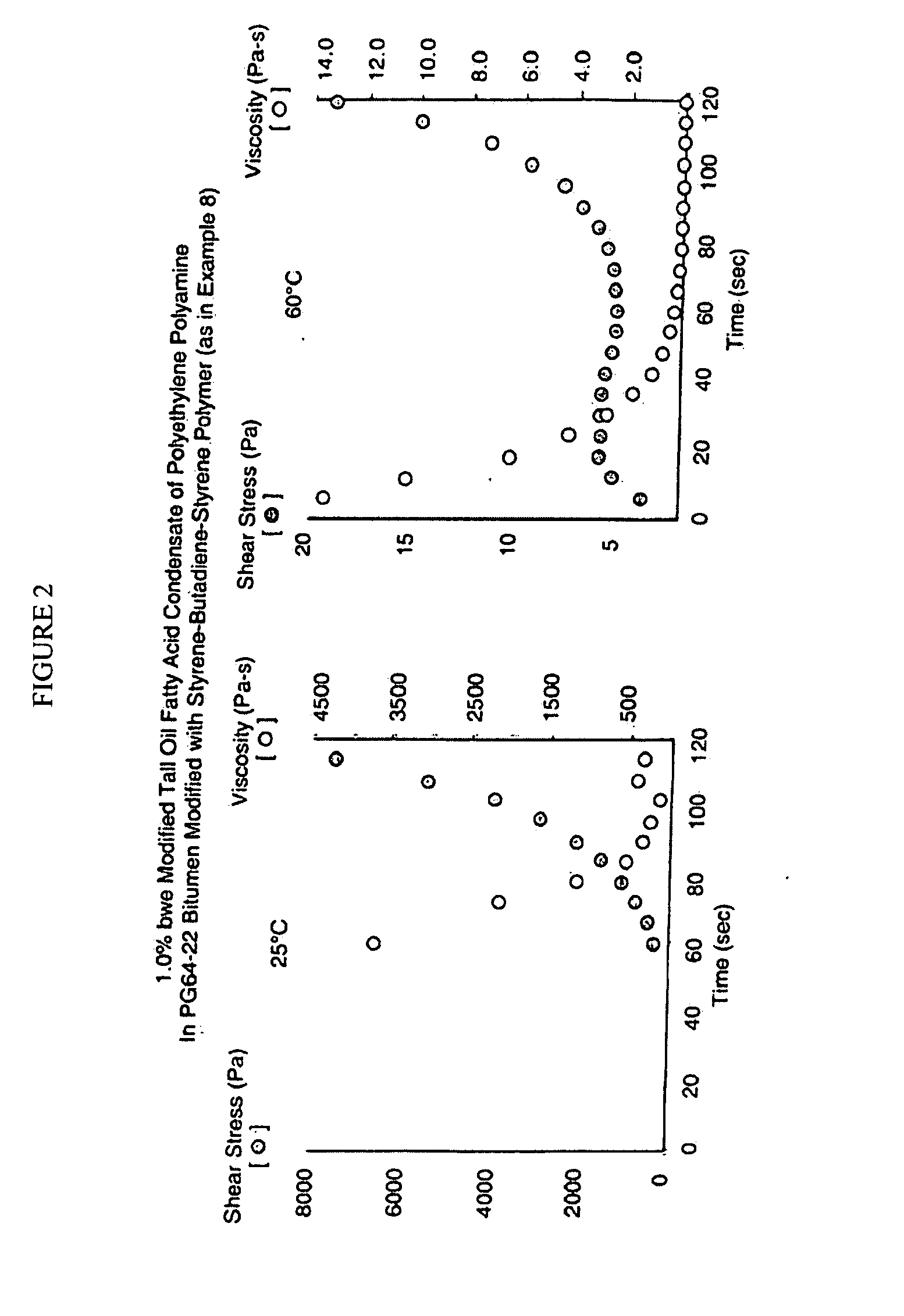

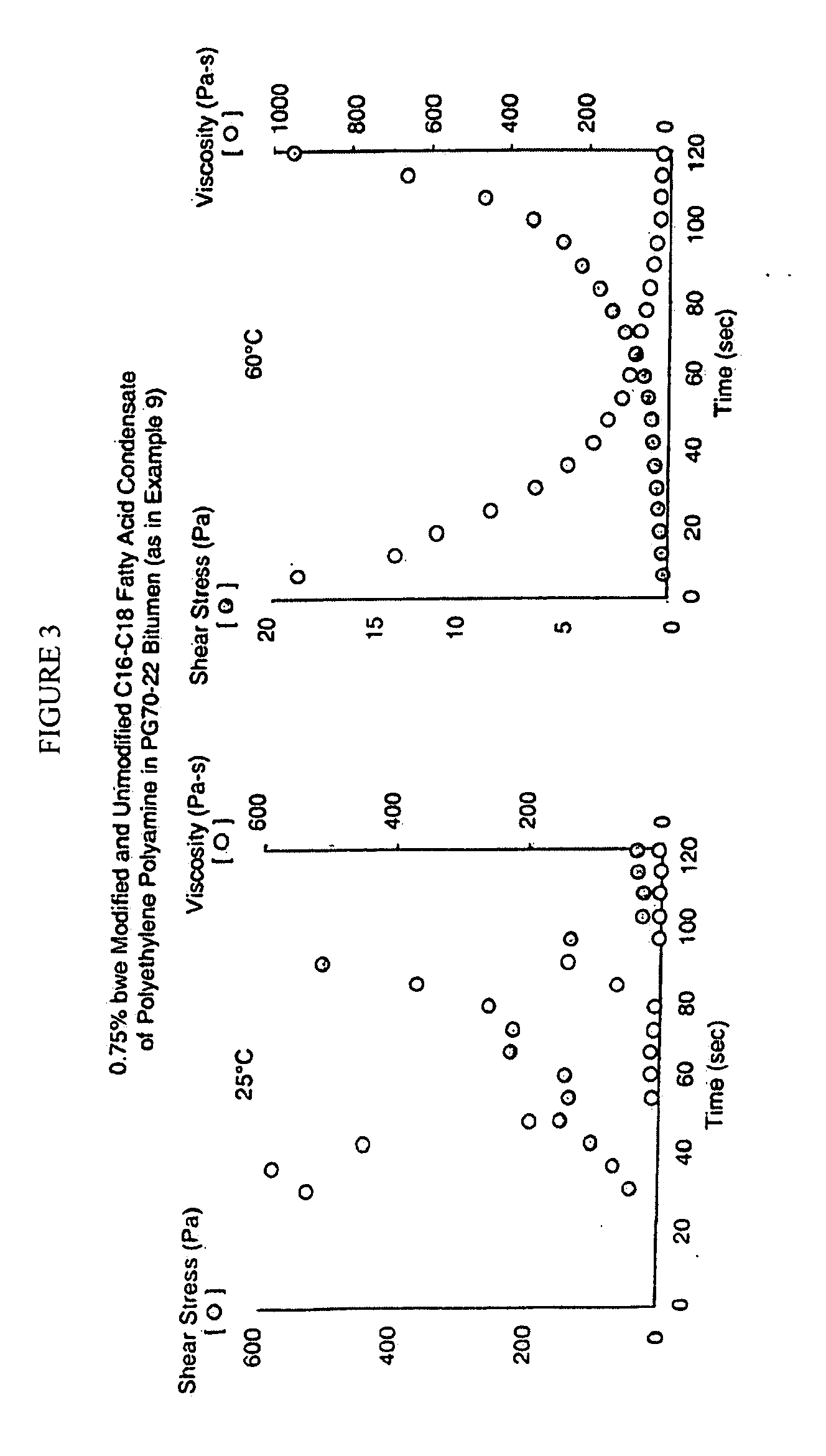

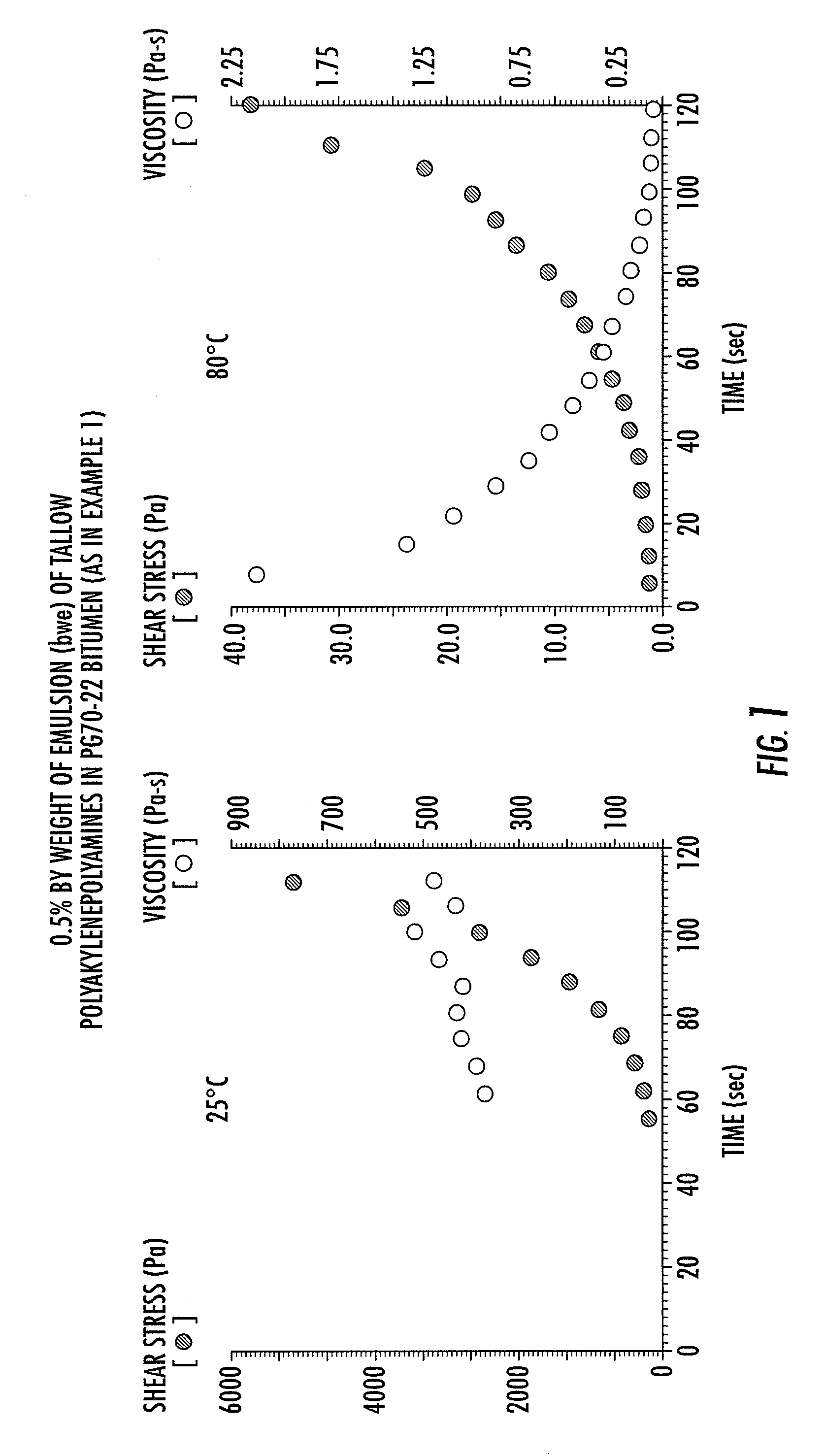

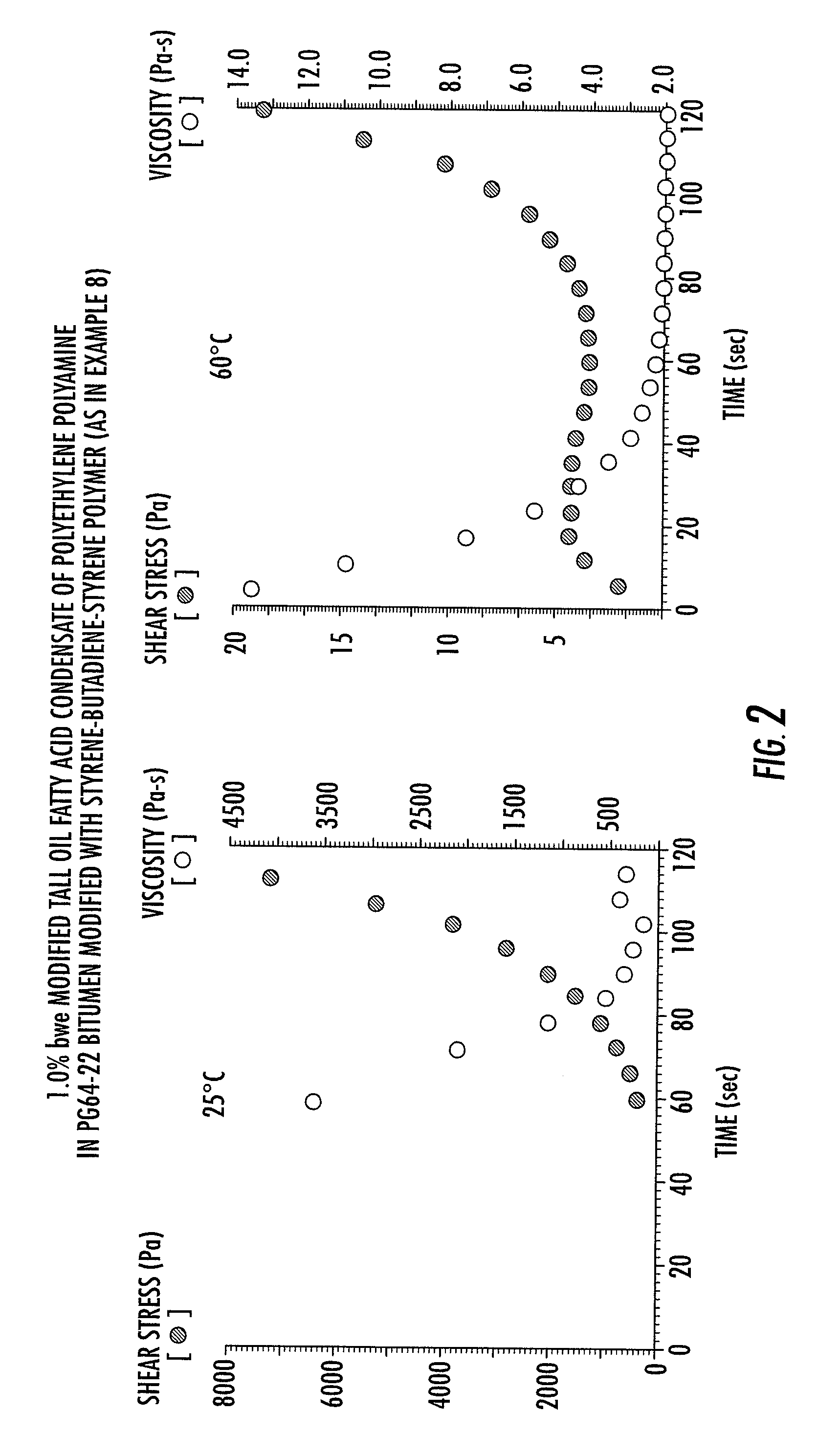

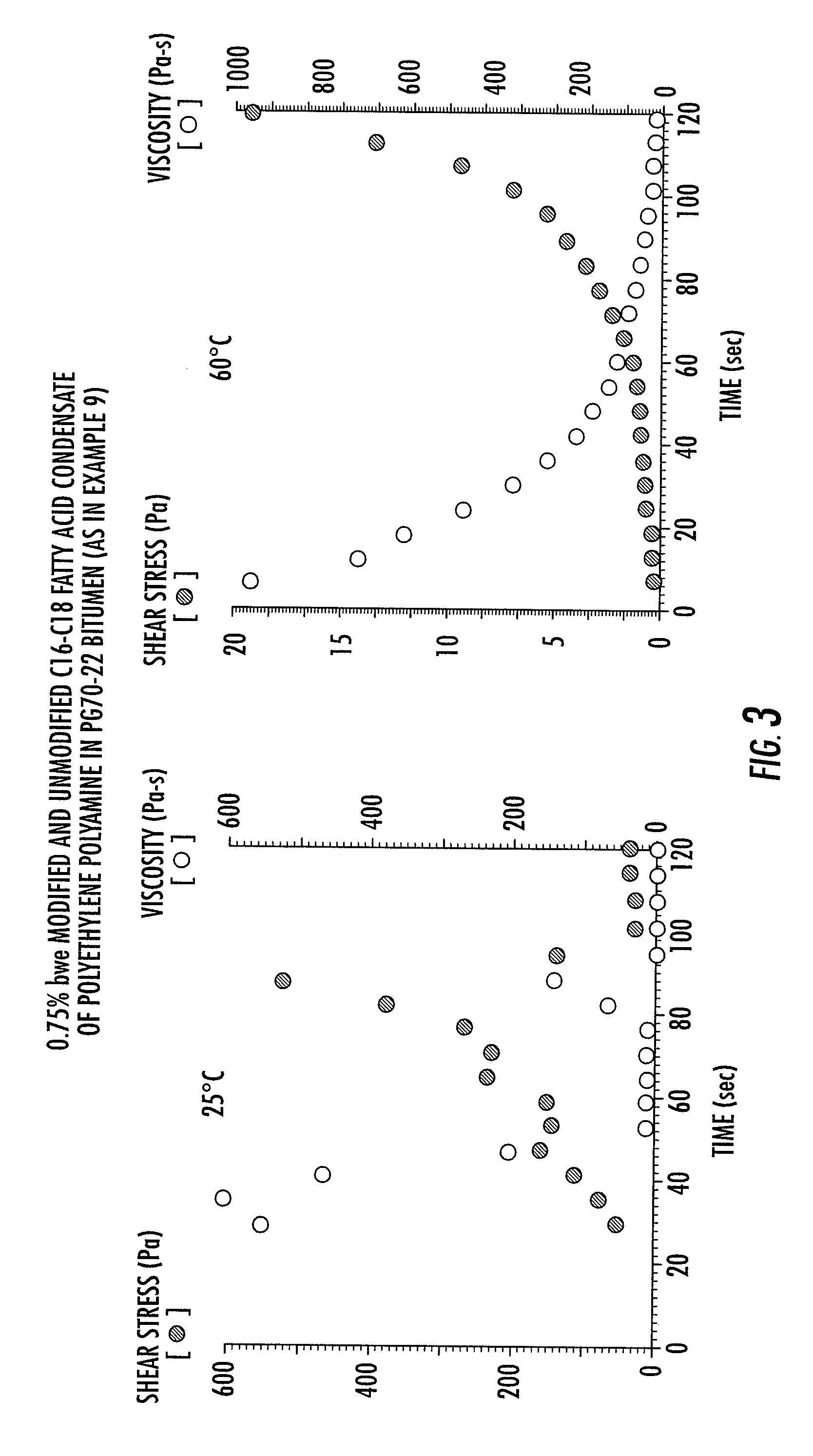

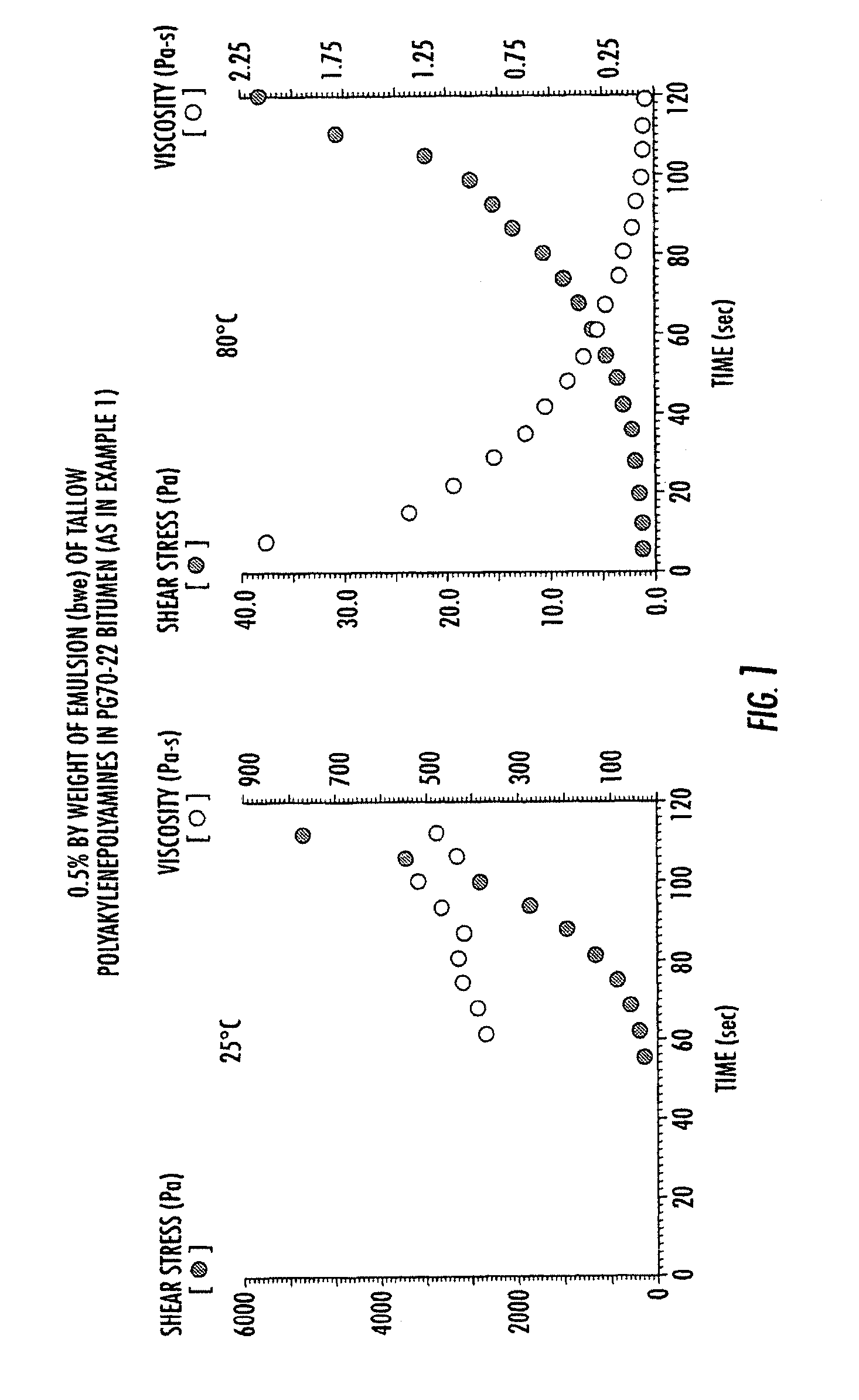

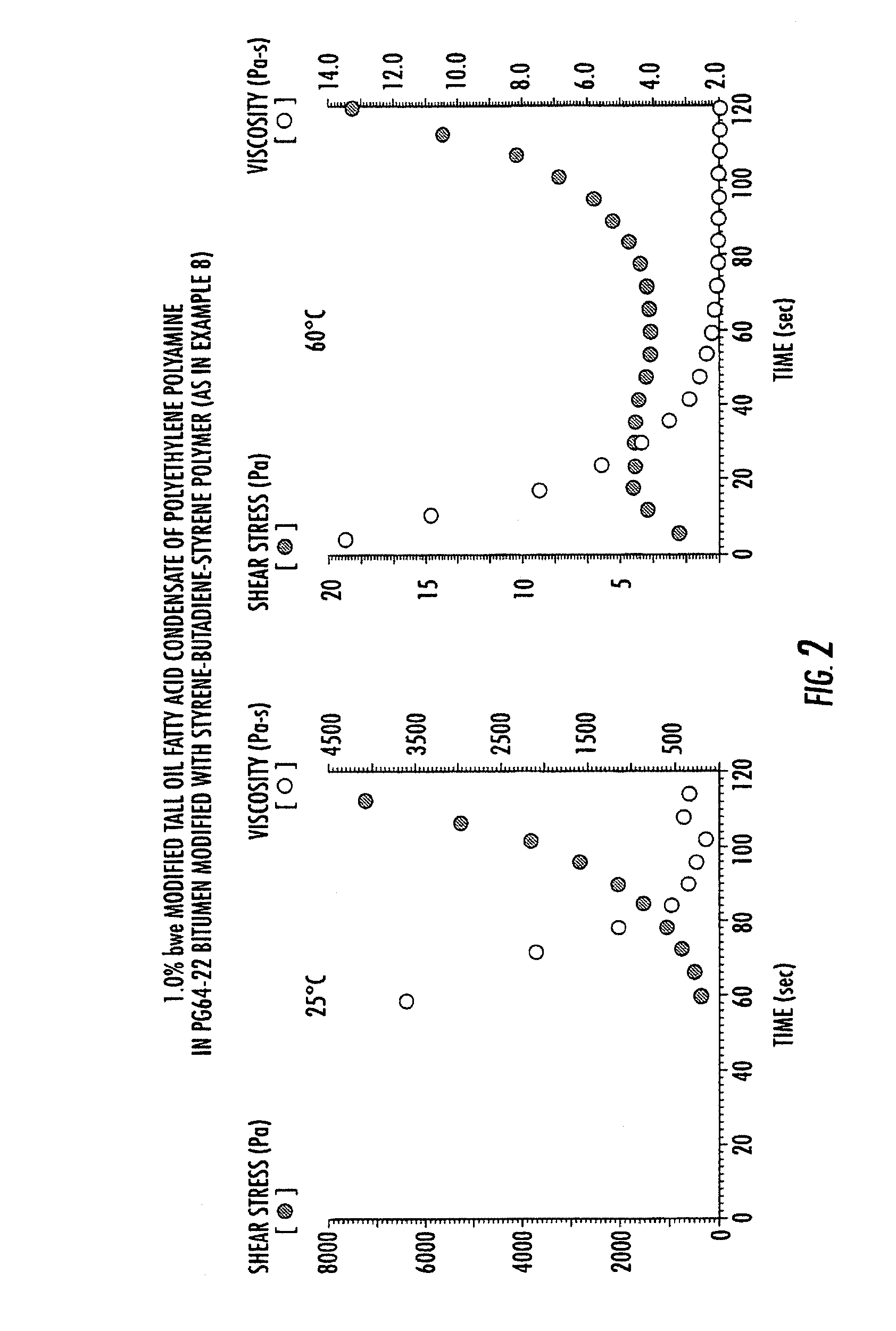

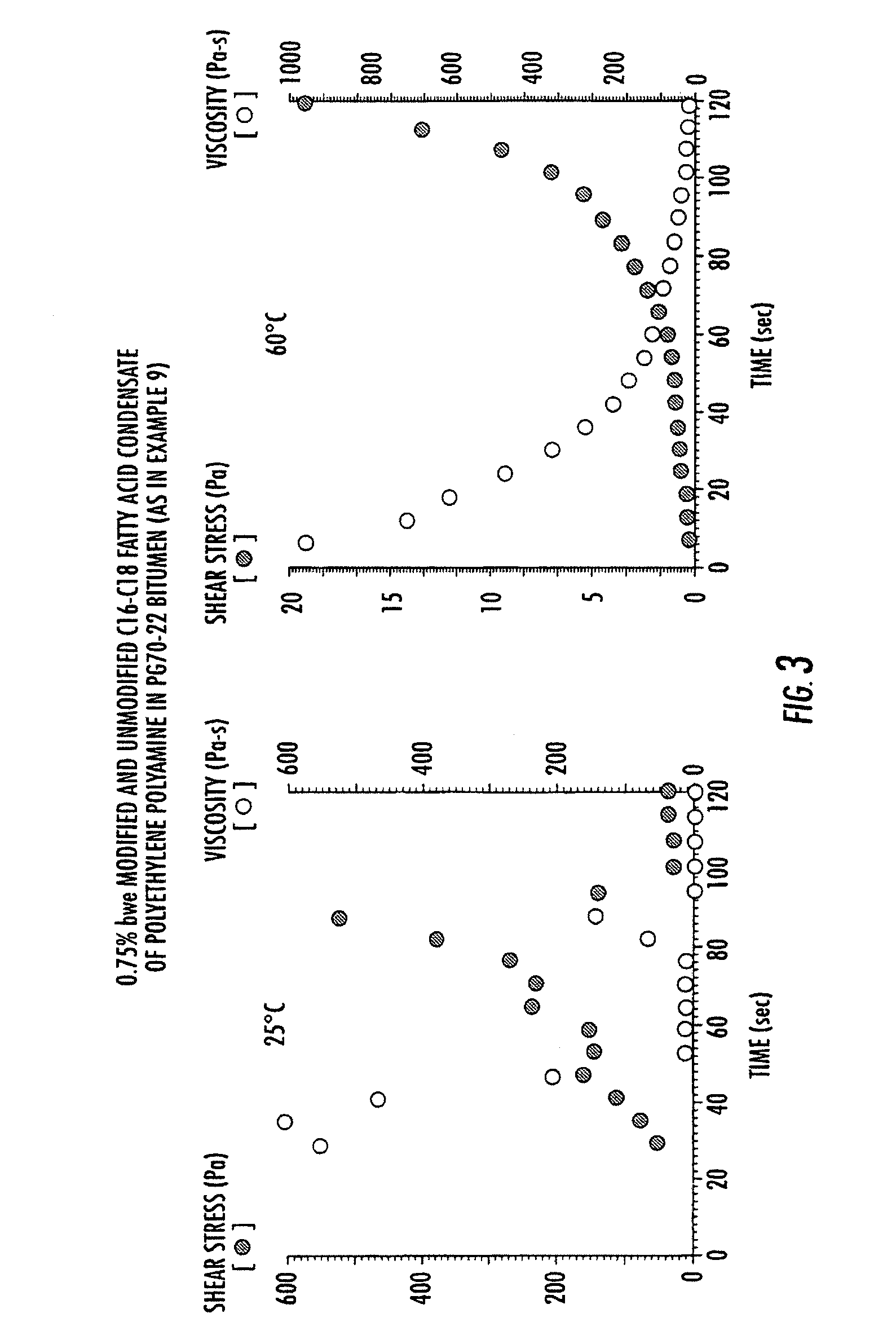

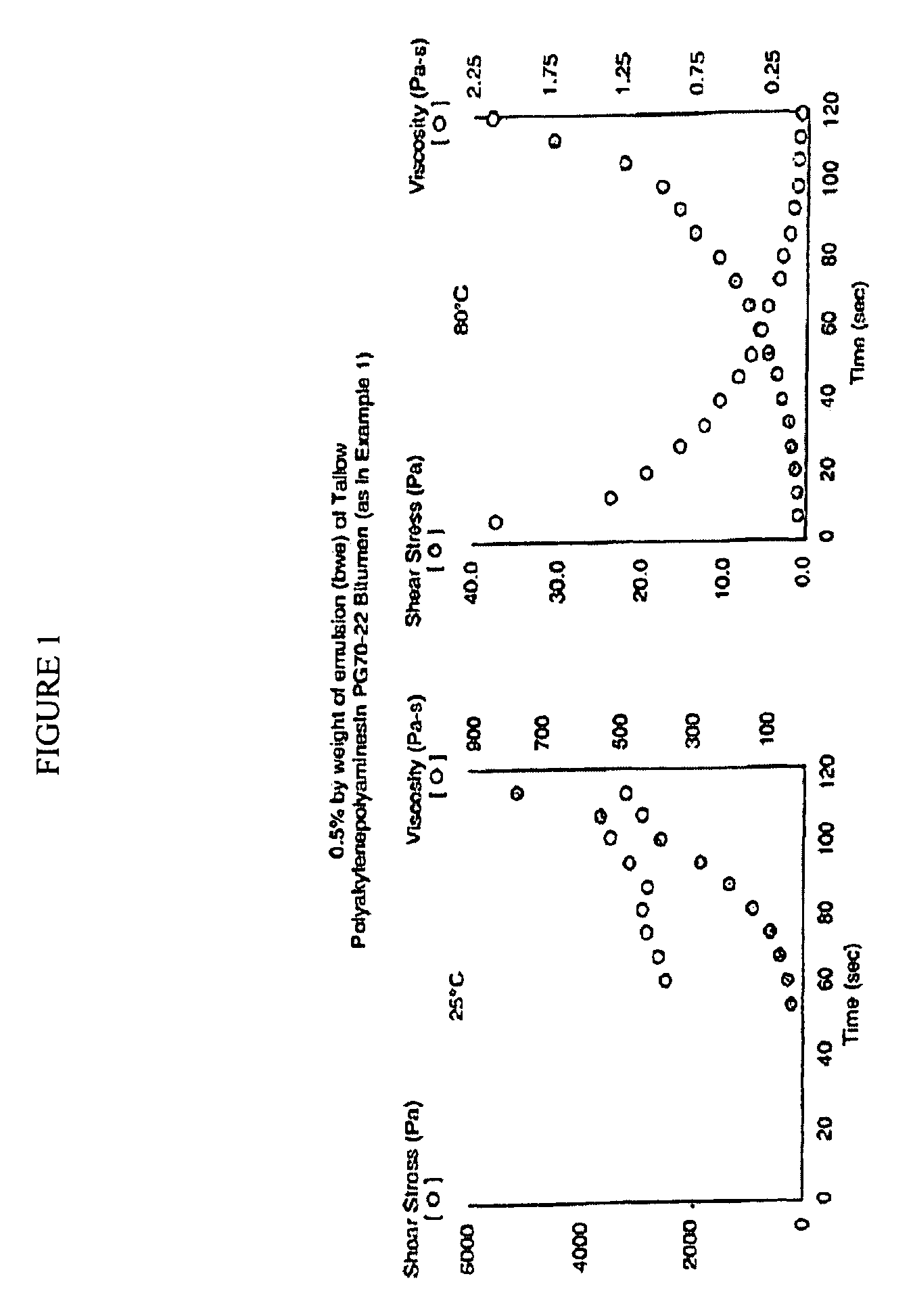

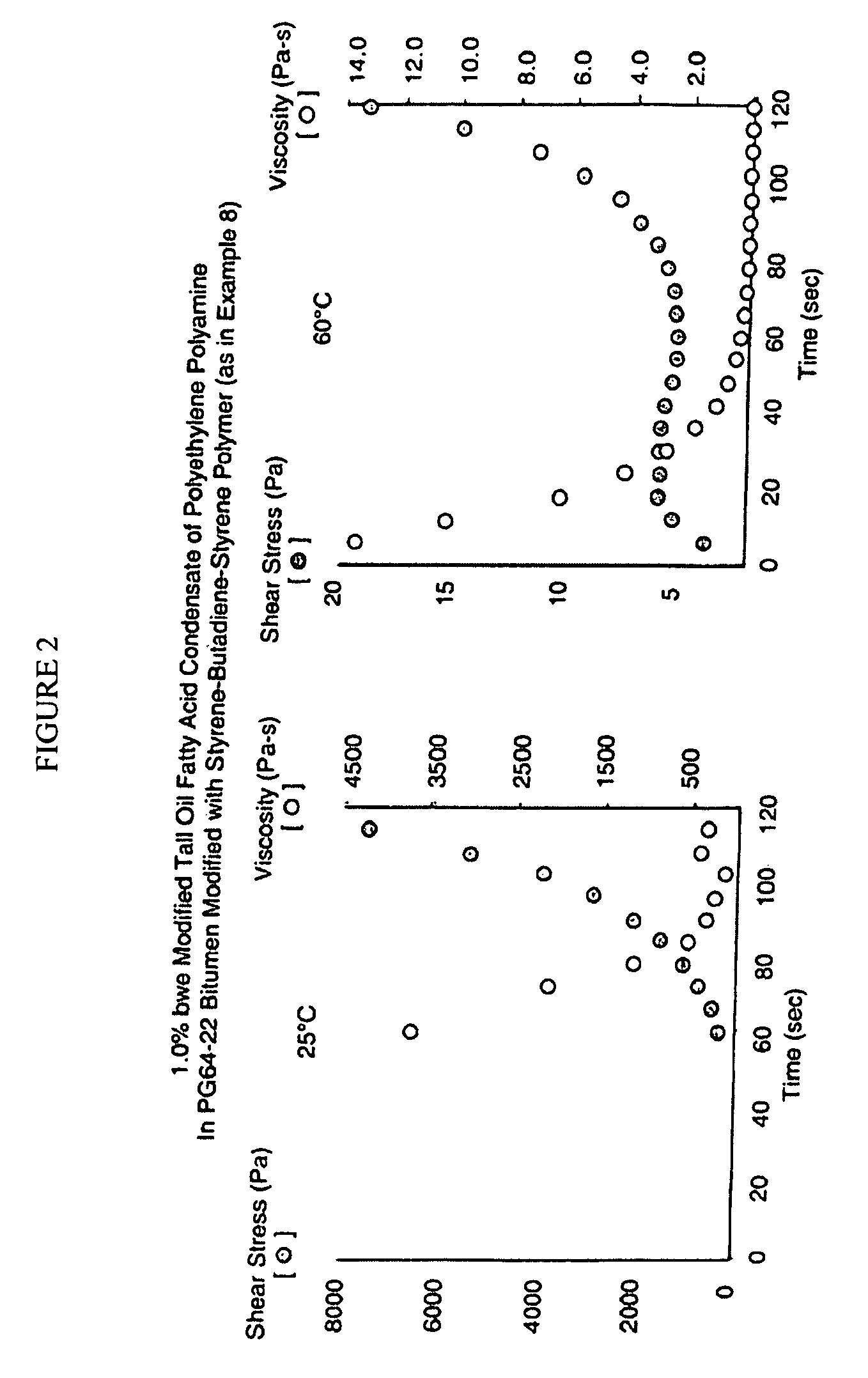

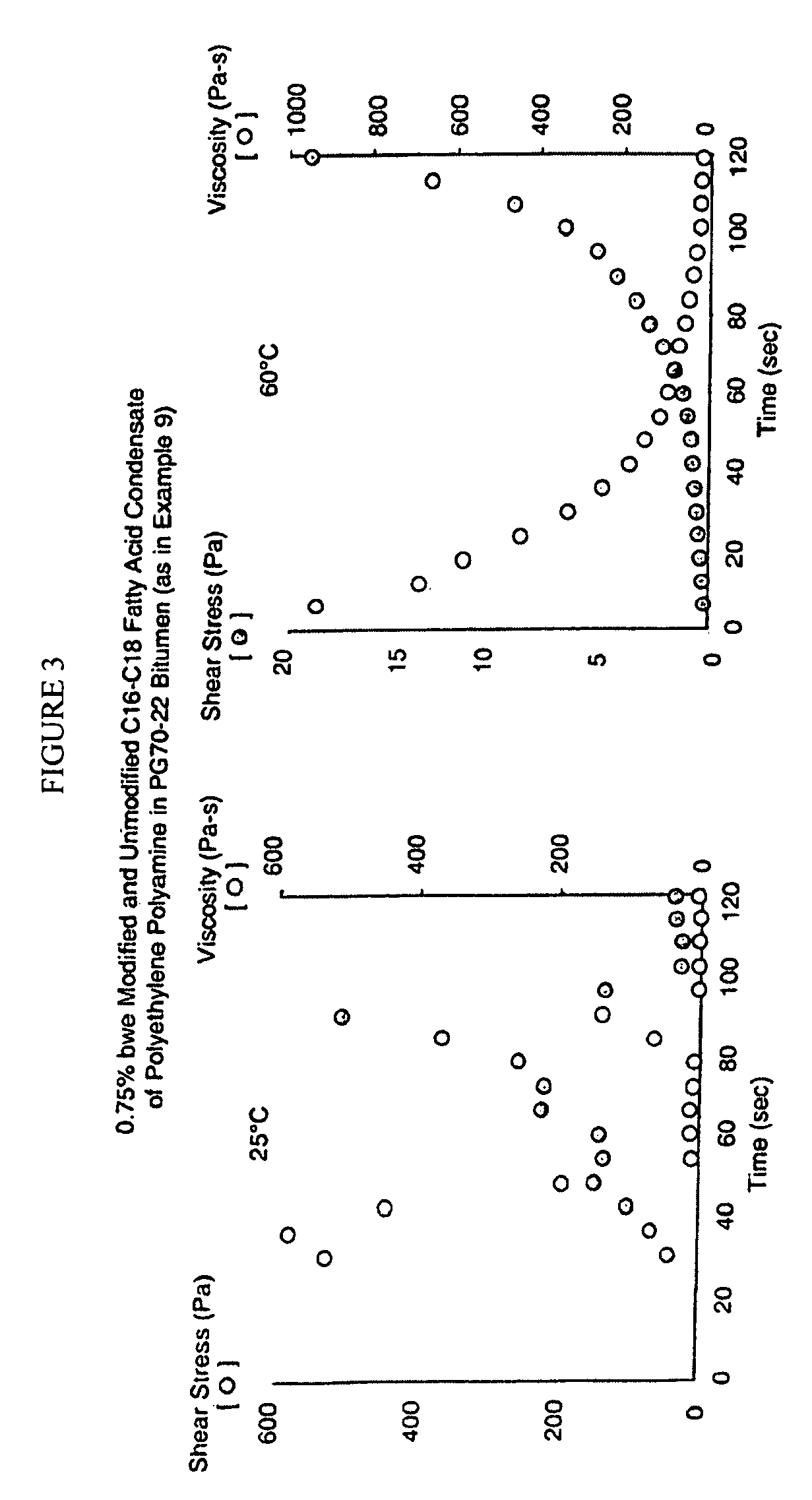

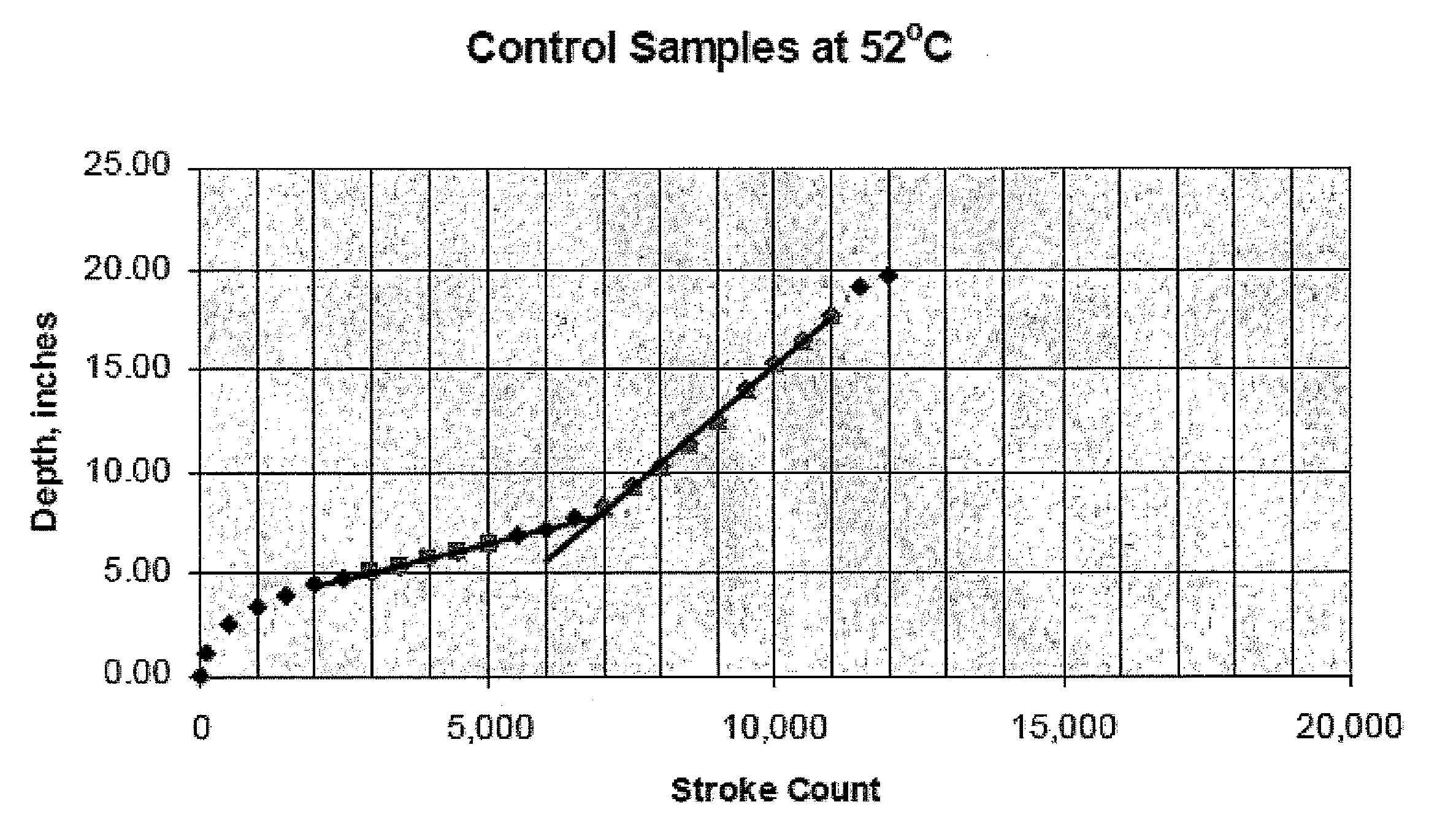

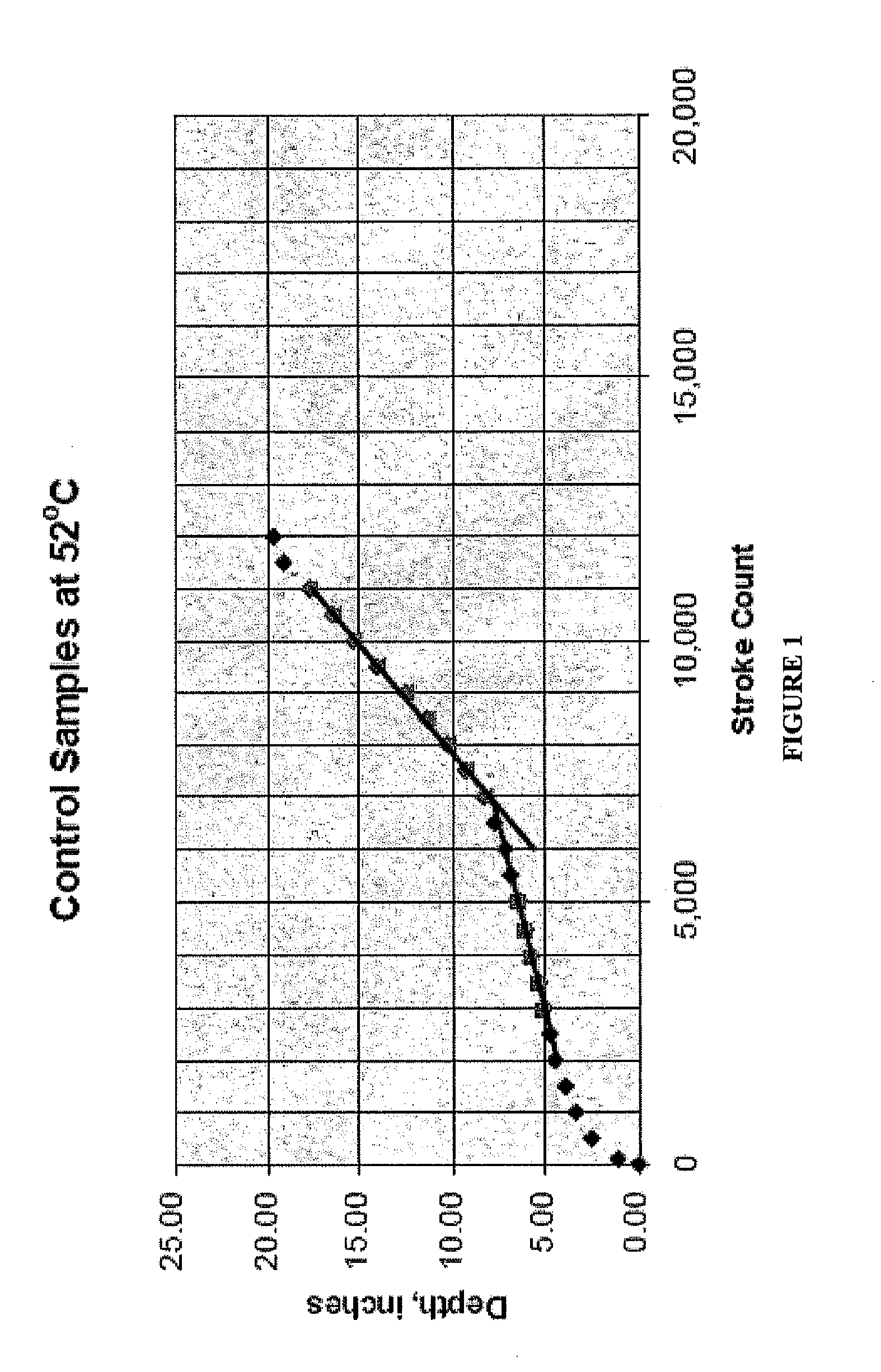

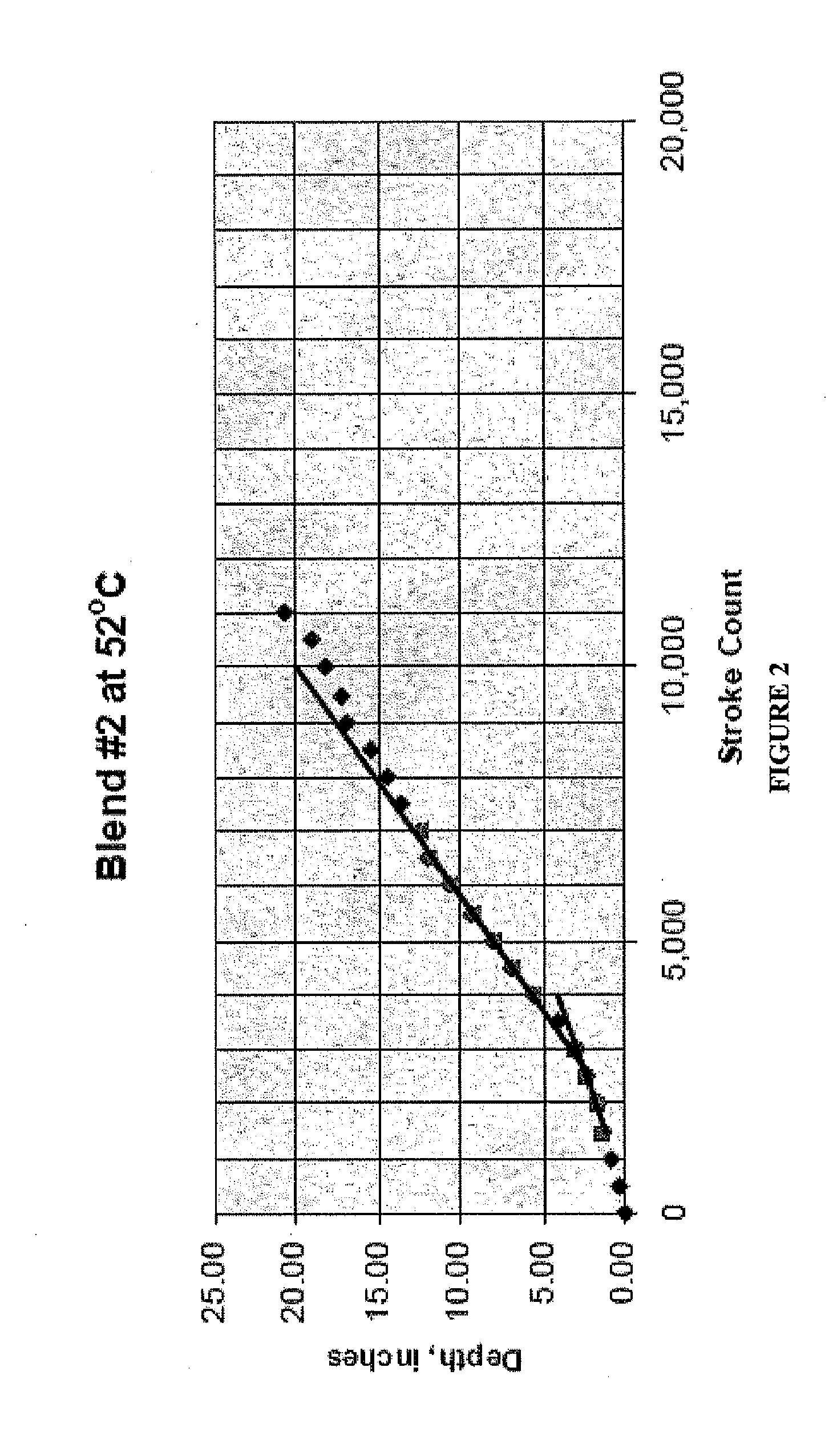

The present invention relates to bituminous compositions suitable for use in paving applications containing bitumen emulsion of performance-grade bitumen that is substantially free of volatile solvents and made by controlling temperature-dependent interfacial rheology through the use of selected emulsifiers. The invention bituminous paving compositions are suitable for the construction of load-bearing pavements with improved compaction to densities similar or superior to those achieved in the conventional hot mix bituminous paving compositions. Cure rate of the invention bituminous compositions is higher than those of cold mix bitumen emulsion-based paving compositions, and at least equal to those of hot mix bituminous paving compositions. Additionally, the invention bituminous compositions develop adhesive strength and load-bearing strength properties at rates comparable to those of hot mix bituminous paving compositions, and at rates faster than those of cold mix bituminous paving compositions.

Owner:INGEVITY SOUTH CAROLINA

Method for producing bituminous compositions

InactiveUS20070039520A1Low viscosityHighly preventive effectOrganic chemistrySingle unit pavingsEmulsionSolvent free

This invention relates to bituminous compositions and methods of producing the same. More particularly, the invention relates to the production of bituminous compositions formulated with performance-graded bitumen-containing solvent-free bitumen emulsions which exhibit controllable, temperature-dependent interfacial rheology. When employed in paving applications, these bituminous compositions develop adhesive strength and load-bearing strength properties at rates comparable to traditional hot mix paving compositions and at rates faster than traditional cold mix paving compositions.

Owner:MEADWESTVACO CORP

Asphalt modifier, modified asphalt and asphalt mixture

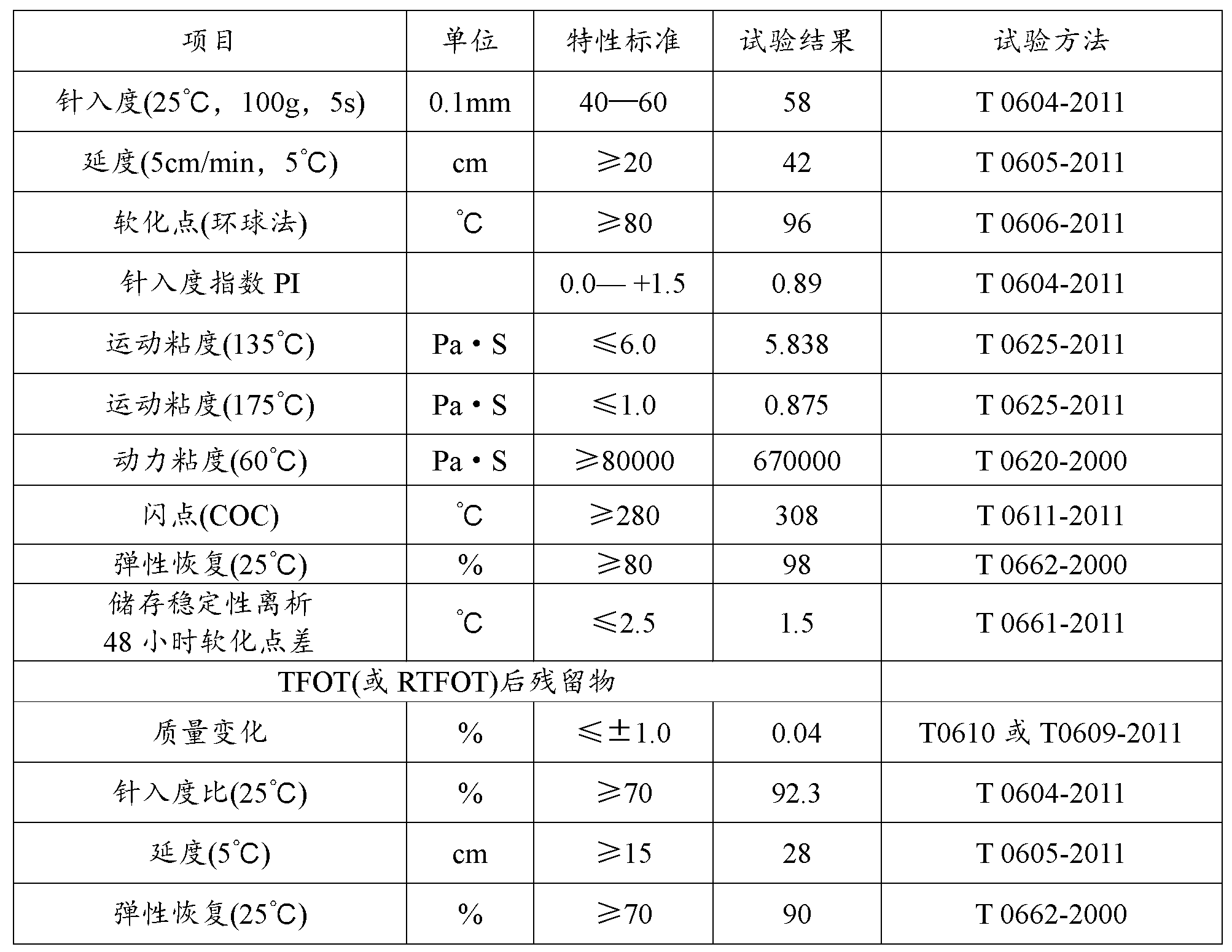

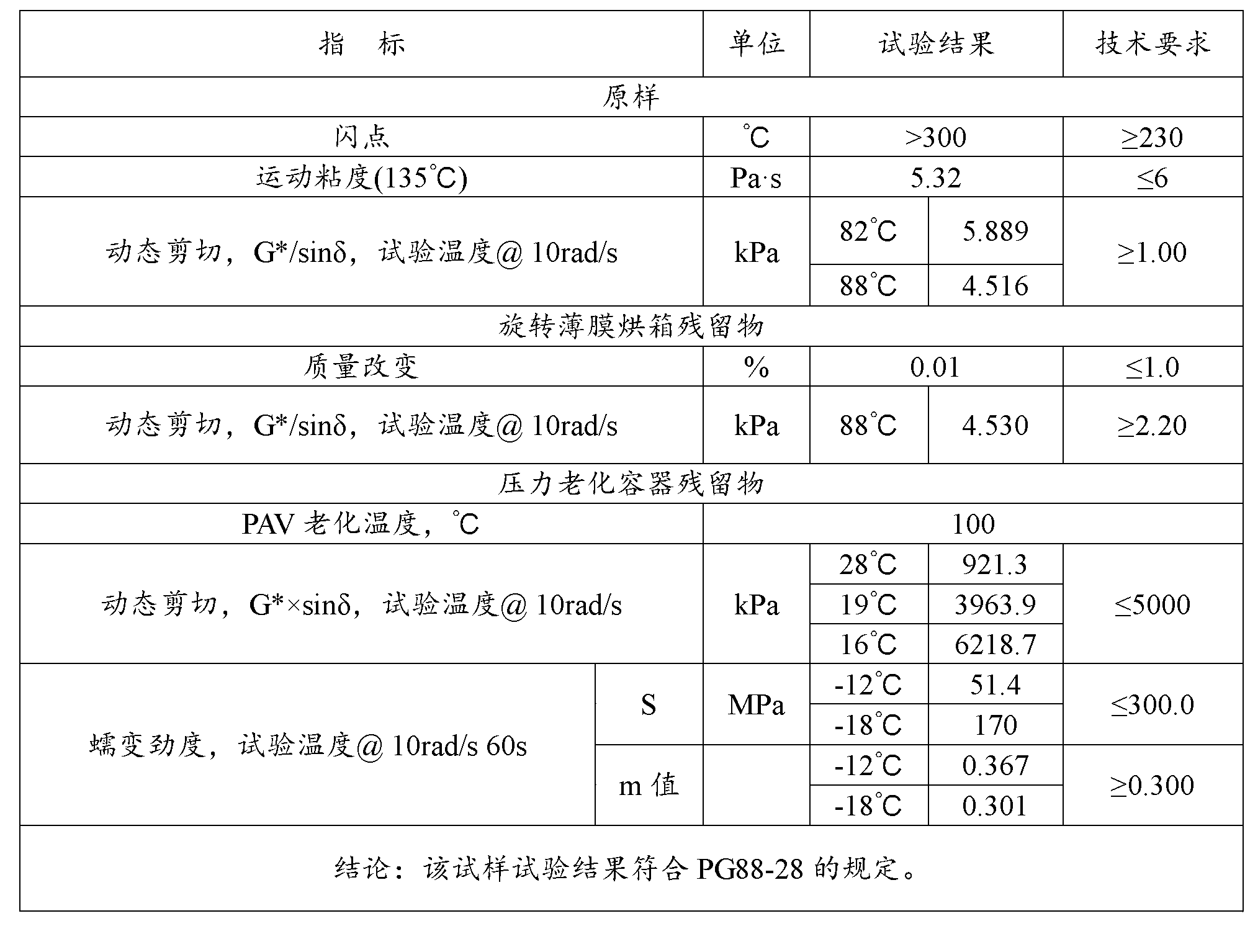

ActiveCN102838874AExcellent Adhesive PropertiesImprove low temperature 60°C viscosityIn situ pavingsBuilding insulationsRoad engineeringBridge deck

The invention belongs to the field of road engineering, and particularly relates to a hyperviscous and high-elastic asphalt modifier applicable to steel bridge deck pavement. The asphalt modifier comprises the following raw materials in parts by weight: 3-10 parts of junked tire rubber powder, 3-10 parts of polyethylene wastes, 3-8 parts of styrene-butadiene-styrene block copolymer, 1-5 parts of styrene-isoprene-styrene block copolymer, 1-5 parts of terpene resin, 5-10 parts of solvent naphtha, and 0.3-0.7 part of alcohol ether carboxylate adhesion agent. In addition, a modified asphalt and amodified asphalt mixture are prepared on the basis of the modifier, the 60 DEG C dynamic viscosity of the modified asphalt prepared by applying the modifier can reach more than 300000Pa.s, and the performance grading reaches PG 88-28; and the asphalt mixture has favorable water stability, higher dynamic modulus, higher track dynamic stability and low temperature failure strain, and can resist complicated mechanics and temperature environment of a steel bridge deck.

Owner:山东高速交通建设集团股份有限公司

Design method for mixing proportion of self-compacting concrete mixture

ActiveCN105224727AQuick lockPrevent disengagementSpecial data processing applicationsParticulatesVoid ratio

The present invention belongs to the technical field of concrete construction and particularly relates to a design method for a mixing proportion of a self-compacting concrete mixture. The method comprises the steps of: determining a performance design target; determining mixing strength and a water-binder ratio; determining densest gradation (or a sand rate) of aggregates and void ratios of different packing states; determining the usage amount of binding materials and mixing water; determining the usage amount of the aggregates; determining the usage amount of additives; determining the actual adding amount of the mixing water; and the like. According to the method provided by the present invention, aimed at blindness of material selection during self-compacting concrete mixing proportion design in the prior art, based on a fundamental theory of particulate dense packing and a composition rule of reaching a densest packing state of solid particulate materials with different particulate diameters, a mixing proportion of different materials is determined by an actually measured densest packing state, and relationships are established between the material mixing proportions corresponding to different densest packing states and expected self-compacting performance grades of the mixture, so that the design method used for the mixing proportion of the self-compacting high-performance concrete mixture and based on a use performance as a target is constructed.

Owner:ZHENGZHOU UNIV

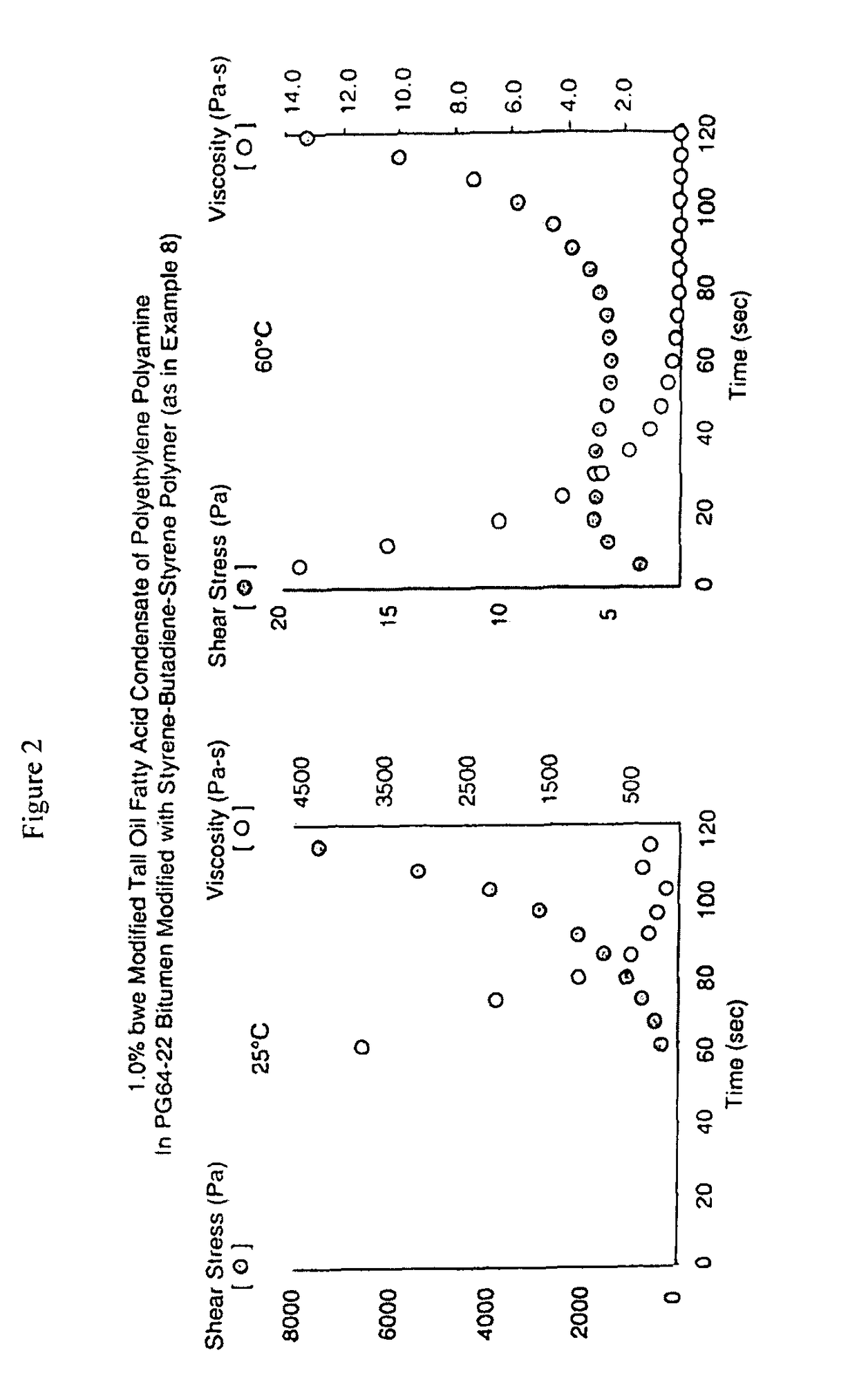

Bituminous Composition

ActiveUS20110021672A1Low viscosityHighly preventive effectOrganic chemistryIn situ pavingsEmulsionSolvent free

This invention relates to bituminous compositions and methods of producing the same. More particularly, the invention relates to the production of bituminous compositions formulated with performance-graded bitumen-containing solvent-free bitumen emulsions which exhibit controllable, temperature-dependent interfacial rheology. When employed in paving applications, these bituminous compositions develop adhesive strength and load-bearing strength properties at rates comparable to traditional hot mix paving compositions and at rates faster than traditional cold mix paving compositions.

Owner:INGEVITY SOUTH CAROLINA

Performance Grade Asphalt Composition and Method of Production Thereof

InactiveUS20090012214A1Low viscosityBuilding insulationsBituminous coatingsPolymer modifiedWater insoluble

An asphalt material having improved paving characteristics and processes for its preparation. An asphalt base material is heated in a mixing chamber to a temperature sufficient to melt the asphalt so that it can be stirred. A water-insoluble heavy metal soap is incorporated into the chamber in an amount effective to reduce the PAV-DSR temperature of the asphalt base material by an incremental amount of at least 1° C. Thereafter, the asphalt material is recovered from the mixing chamber to provide an asphalt product containing the heavy metal soap which exhibits a PAV-DSR temperature which is less than the PAV-DSR temperature for the corresponding base material without the addition of the heavy metal soap. The water-insoluble soap is a C14-C18 heavy metal soap such as a C16-C18 zinc- or calcium-based soap including zinc stearate, zinc oleate and zinc palmitate. The heavy metal soap is added to the mixing chamber in an amount within the range of 0.05-3.0 wt. % of the amount of asphalt based material in the mixing chamber. A thermoplastic polymer may be added to the asphalt based material to provide a polymer-modified asphalt blend. An asphalt paving composition comprising an asphalt base material and a water-insoluble heavy metal soap in an amount to provide a PAV-DSR temperature lower than the PAV-DSR temperature of the corresponding asphalt material without the addition of the heavy metal soaps.

Owner:FINA TECH

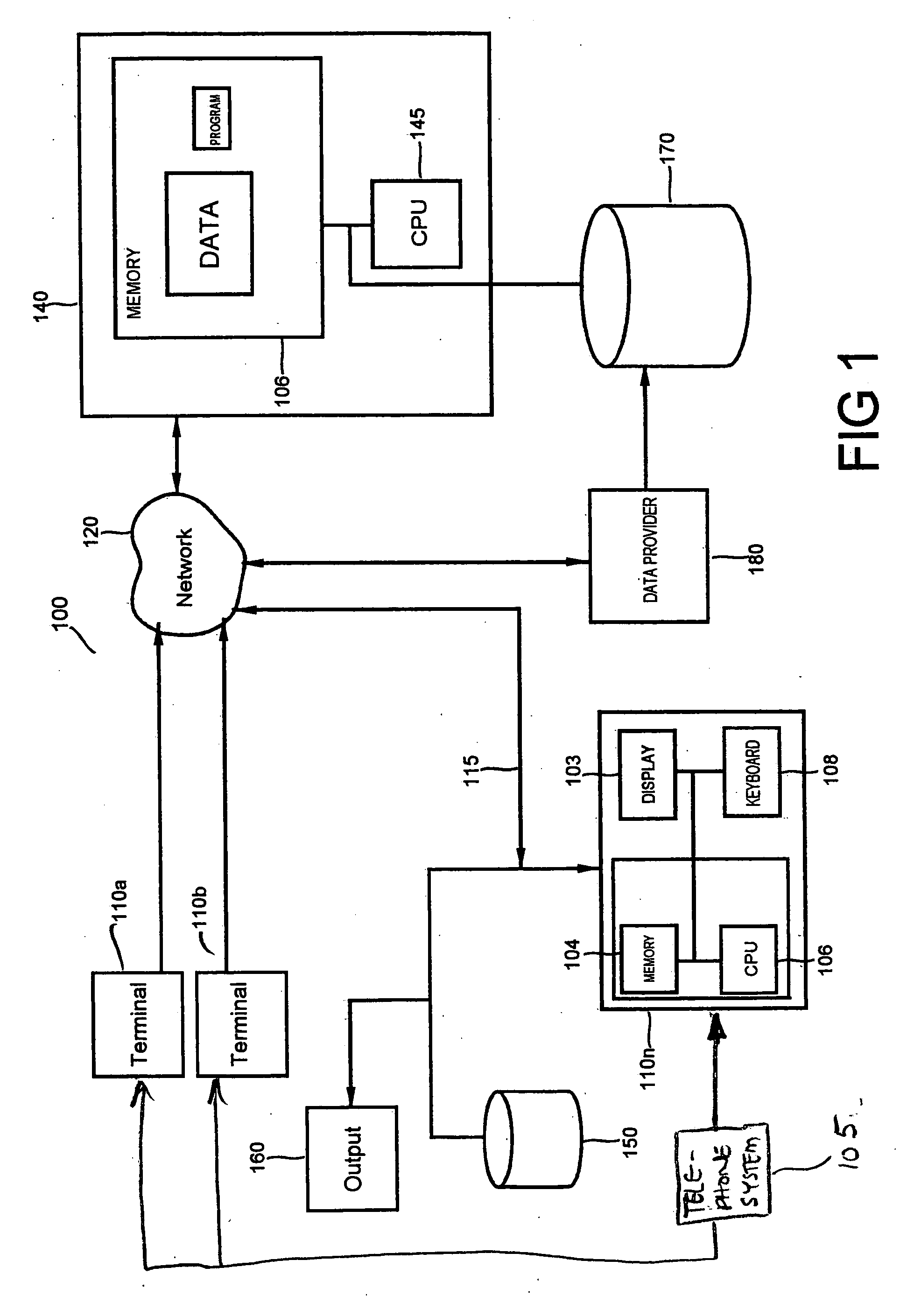

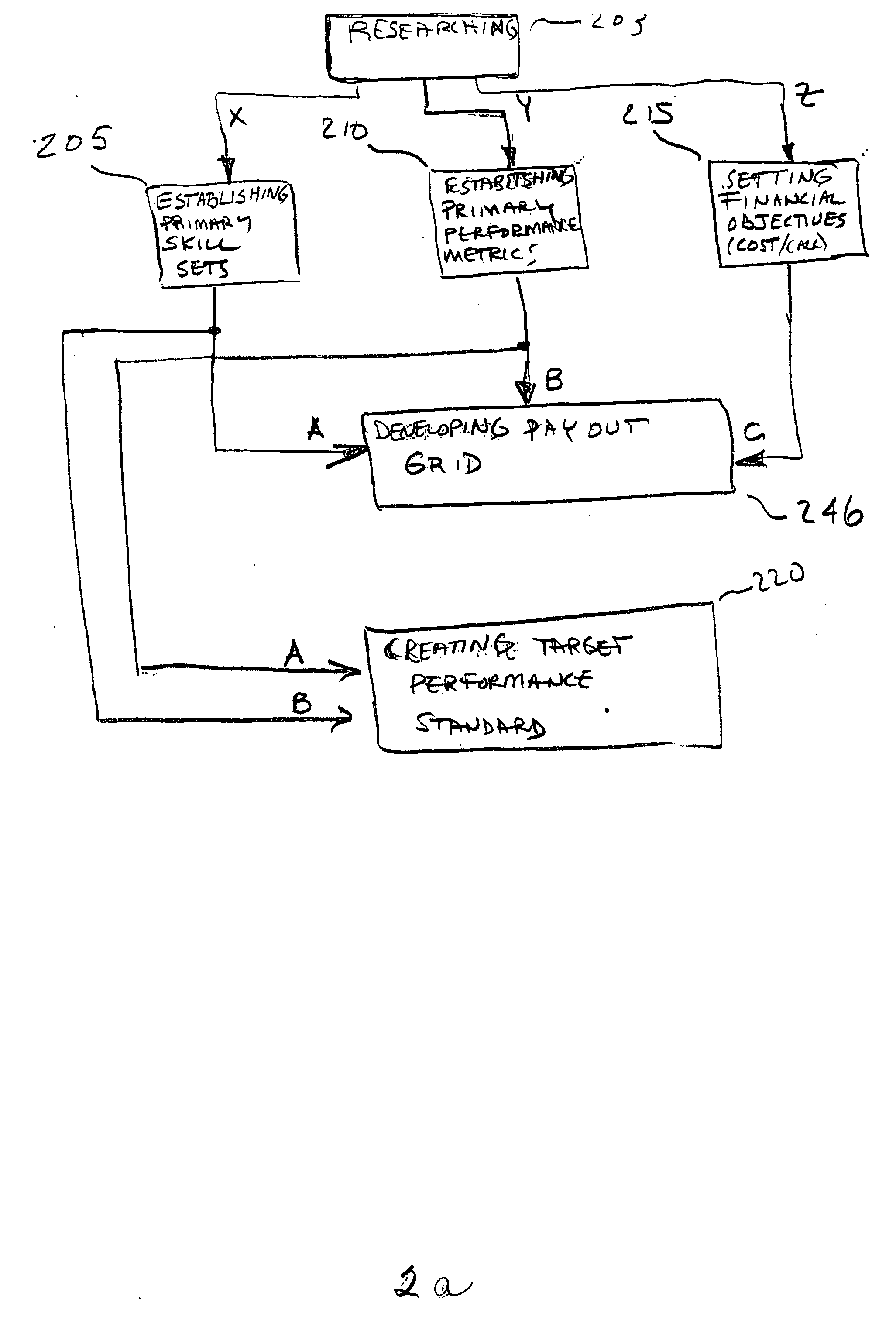

Method and system for improving performance of customer service representatives

ActiveUS20060047566A1Affect performanceSpecial service for subscribersHardware monitoringComputer methodsPerformance grade

The computer method for managing performance of a customer service representative comprising: establishing a target performance grade, collecting a set of quantitative data generated as a result of customer contact; collecting a set of qualitative data input characterizing service representative performance; generating a performance grade based on the sets of quantitative and qualitative data; and determining if the target performance grade has been met; and if the performance grade has been met, paying the service representative based upon said successful performance grade and if the performance grade has not been met, then paying displaying a the performance grade.

Owner:HARTFORD FIRE INSURANCE

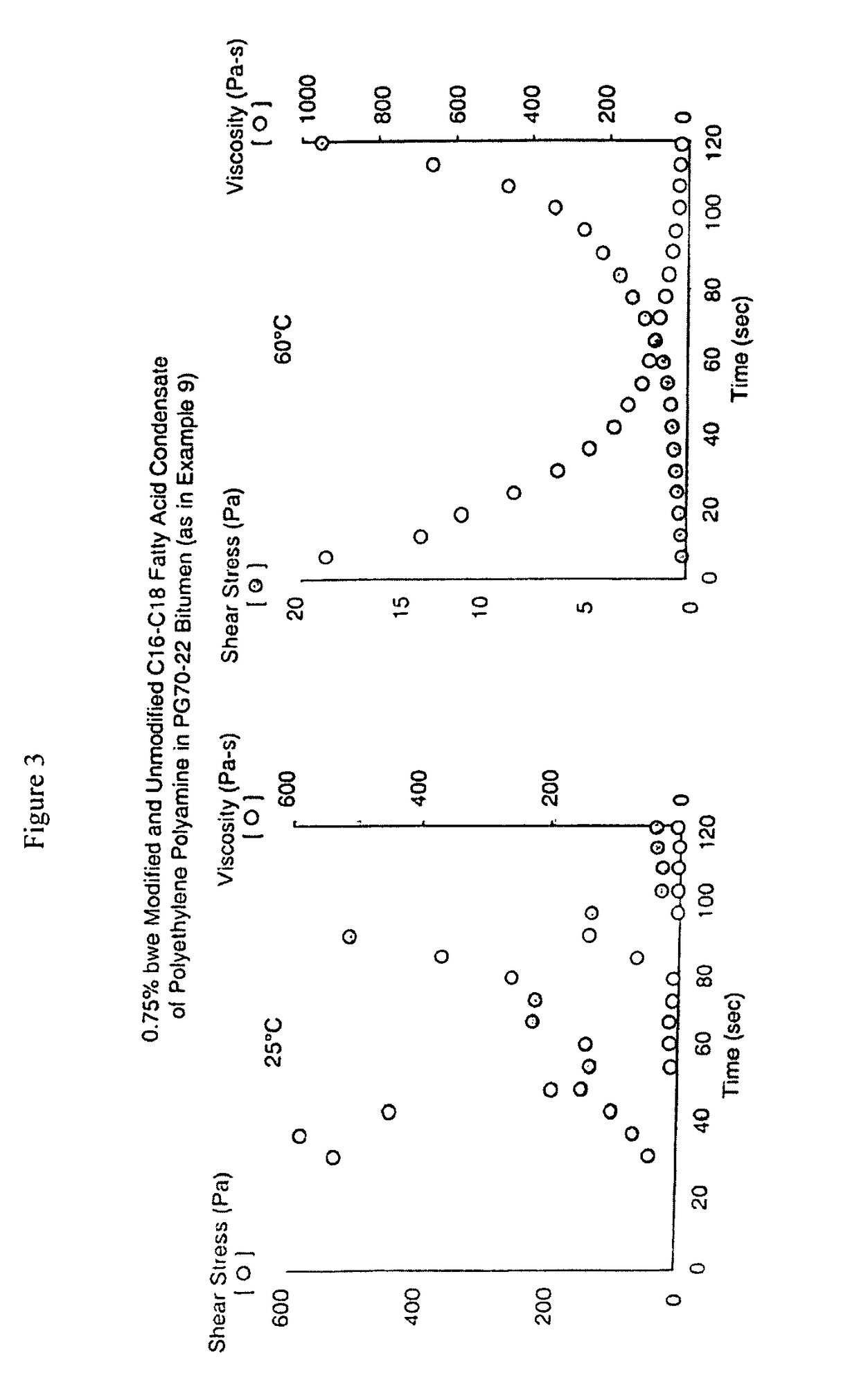

Method for producing bituminous compositions

ActiveUS20080069638A1Low viscosityHighly preventive effectIn situ pavingsPaving detailsEmulsionSolvent free

Owner:INGEVITY SOUTH CAROLINA

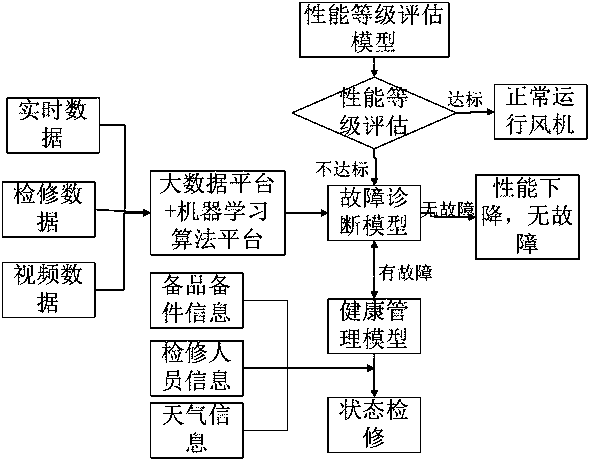

Wind turbine generator health management method based on machine learning algorithm platform

PendingCN109492777AAccurate Health Assessment ReportAccurate device health analysisCharacter and pattern recognitionResourcesEngineeringPerformance grade

The invention provides a wind turbine generator health management method based on machine learning algorithm platform. The health management method includes: theoretical power generation balance analysis, performance grade evaluation, fault diagnosis model and health management model design, health evaluation and health analysis, health management is the realization of condition-based maintenance.According to the deep application of the theoretical electric quantity balance analysis method, Combining Big Data Technology, through the combination of machine learning and artificial intelligence,to realize the prediction and evaluation of the health status of the fan and its accessories and main equipment, finally, the maintenance mode of wind turbine generator system is transited from planned maintenance and fixed maintenance to condition-based maintenance, so as to reduce the power loss of planned maintenance, unplanned maintenance and performance loss of wind turbine generator system,so as to achieve the goal of increasing the power generation of wind farm station and improving the economic benefit of wind farm station.

Owner:国电电力宁夏新能源开发有限公司

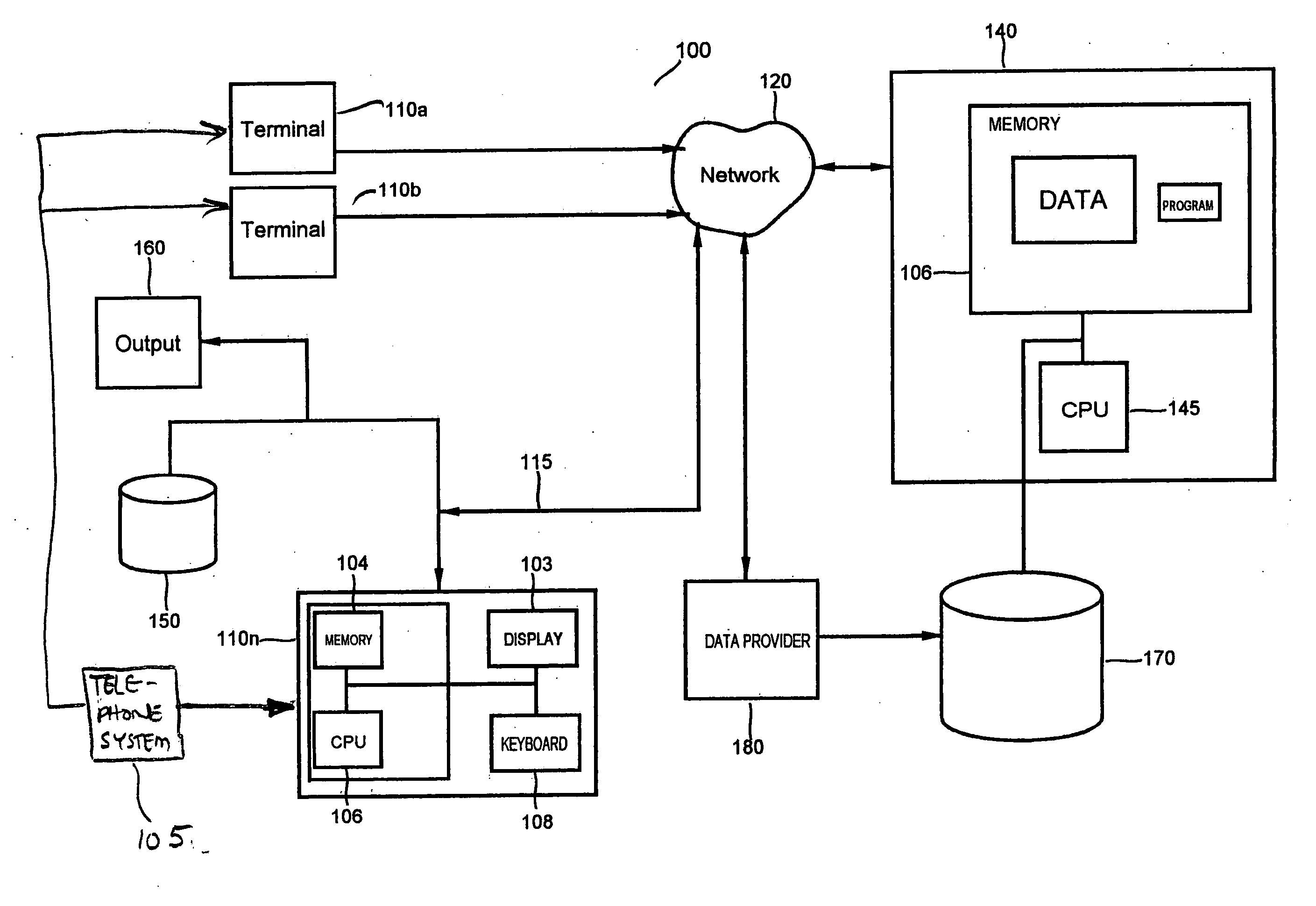

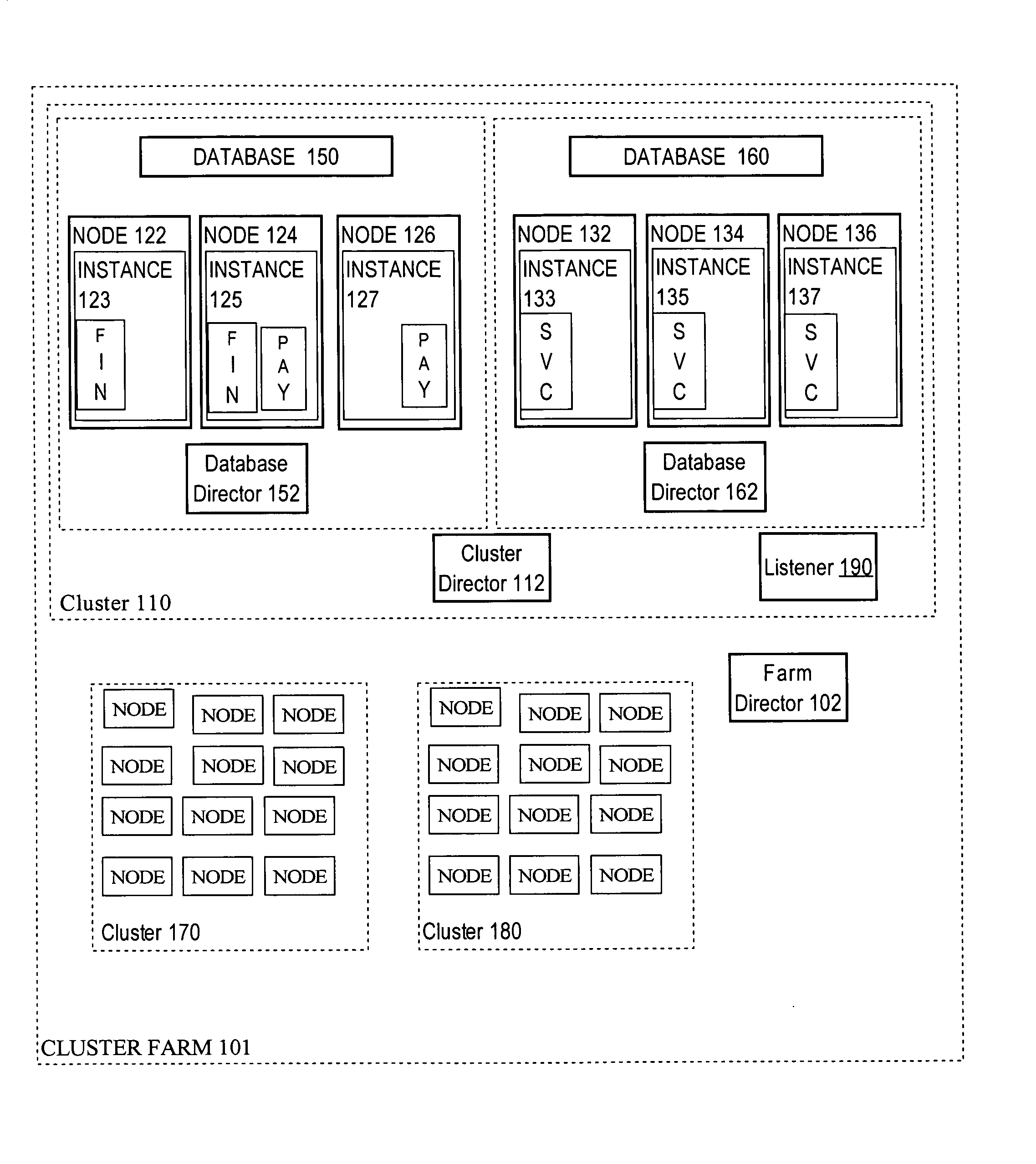

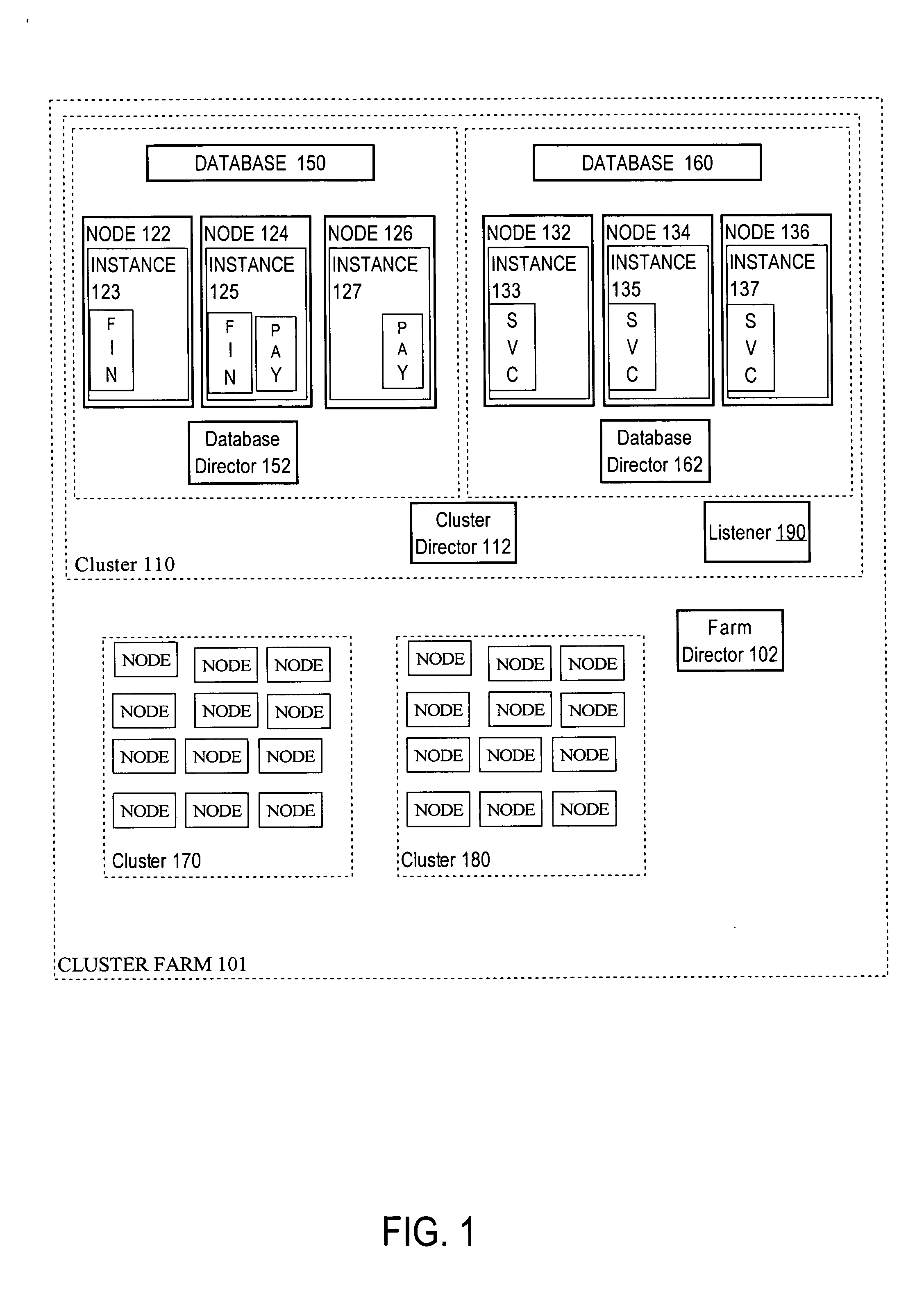

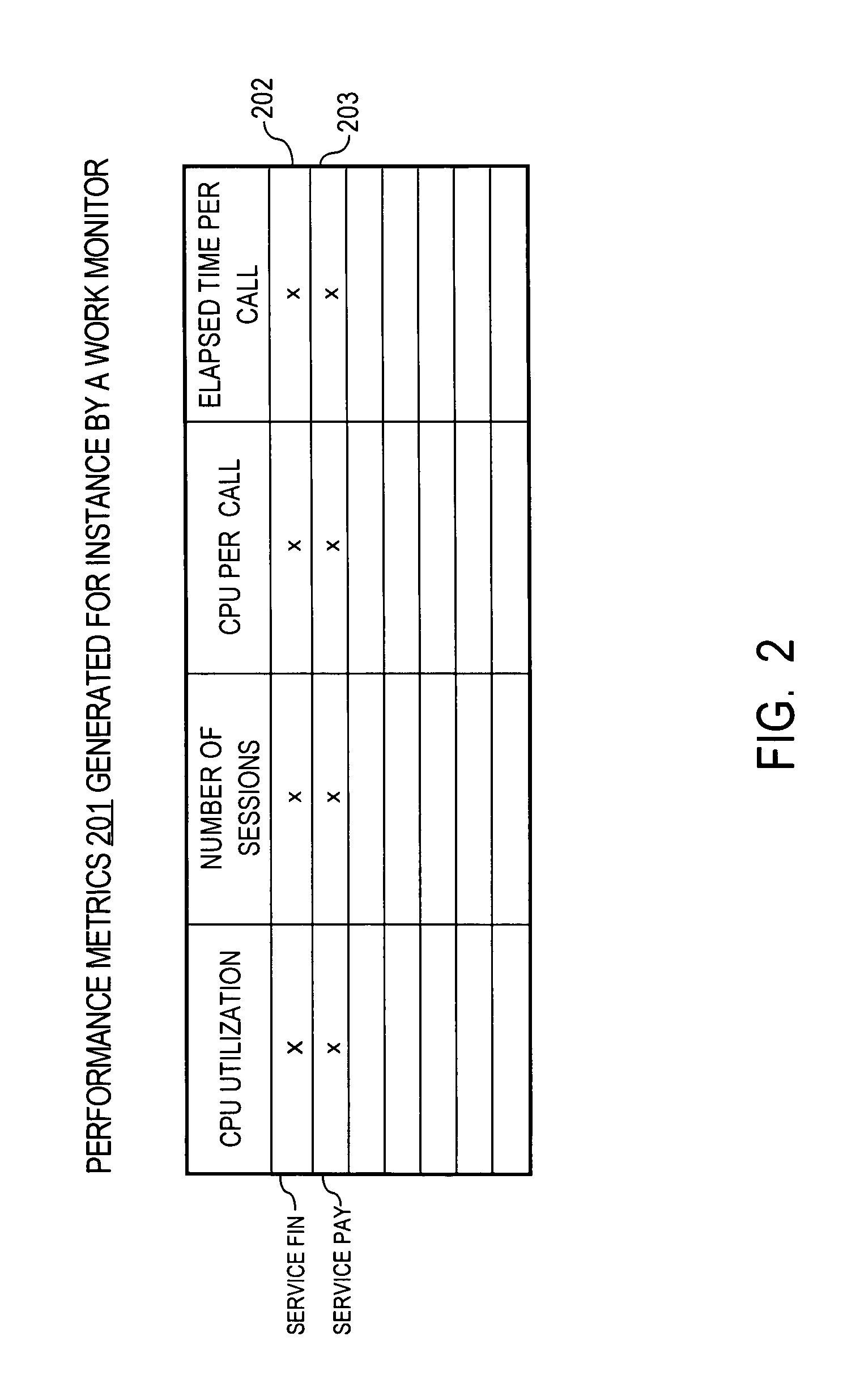

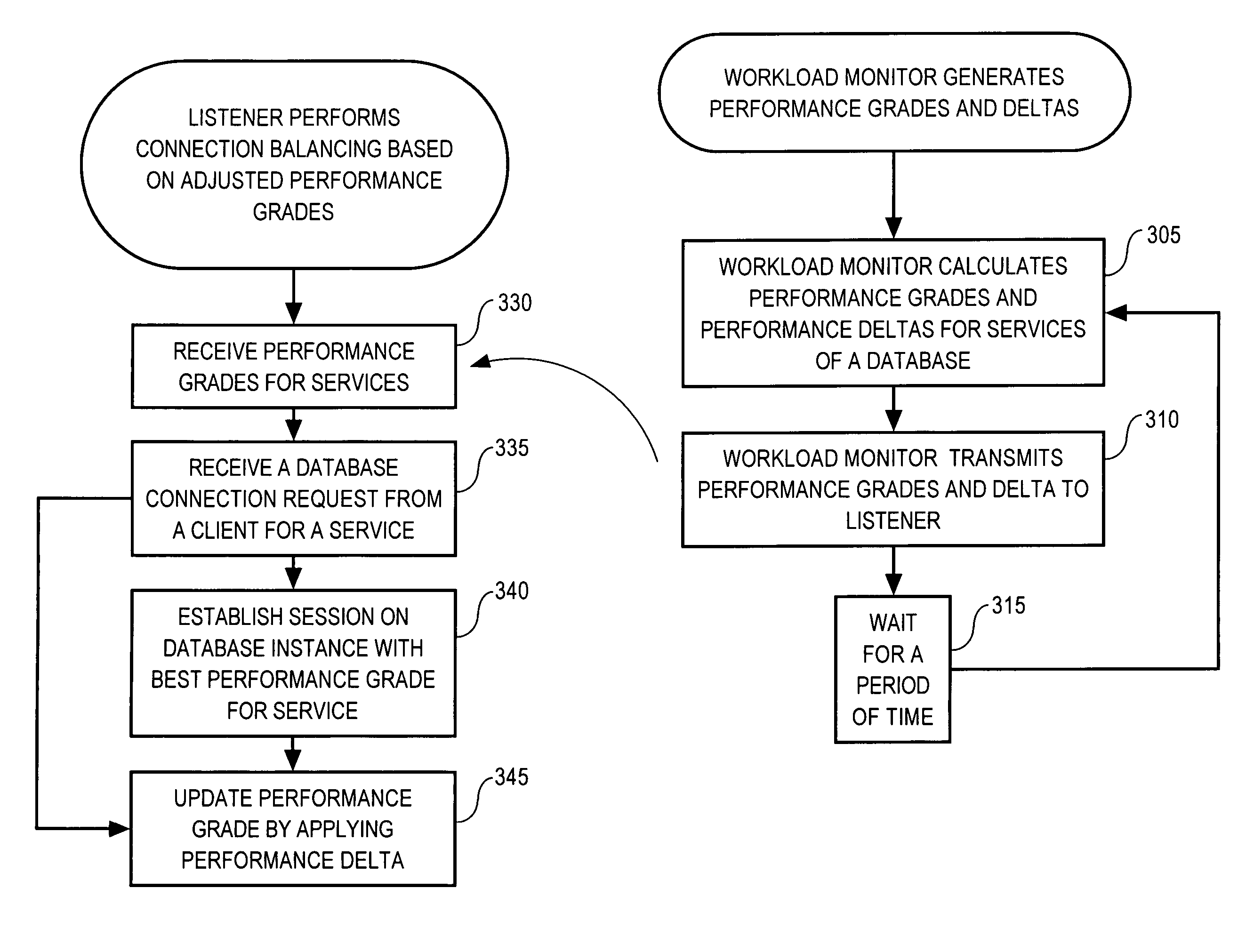

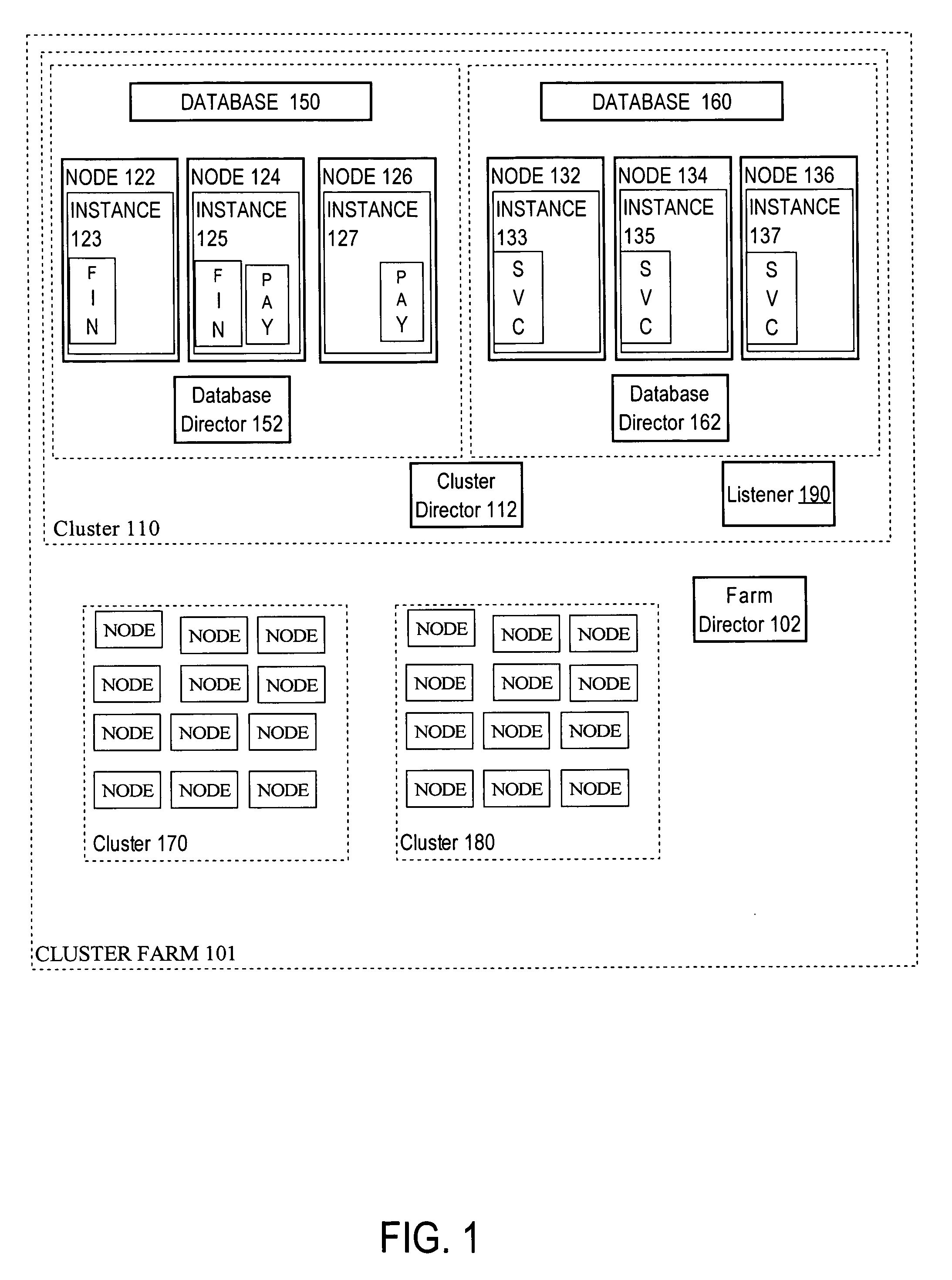

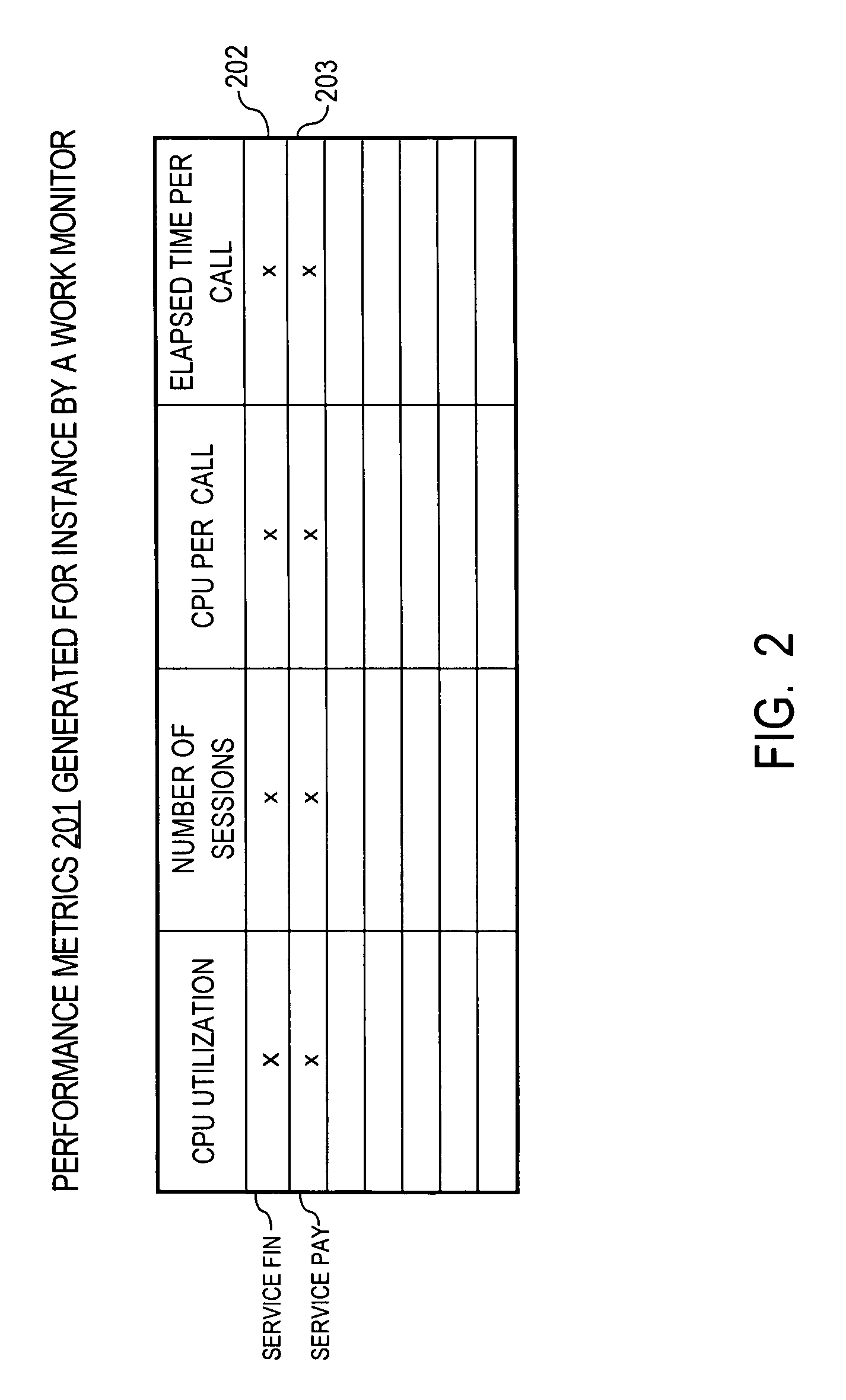

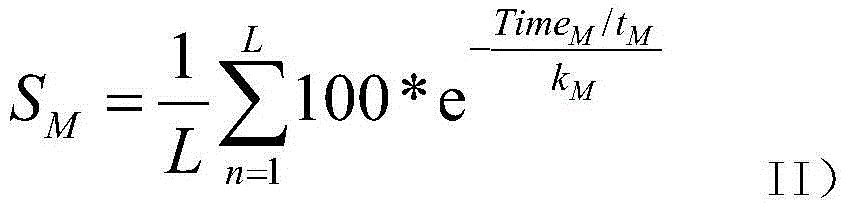

Calculation of sevice performance grades in a multi-node environment that hosts the services

An approach generates performance grades. A performance grade is a value or set of values that indicates the relative work performance offered by a resource, such as a server in a multi-node system, relative to other resources. Performance grades are used to dynamically allocate work within a multi-node computer system. For example, performance grades are used for connection-time balancing, and to direct a database connection request to a multi-node database instance that a performance grade indicates provides better performance. Performance grade deltas are generated that reflect the incremental change in performance grade for additional sessions or work. Performance deltas are used to direct incoming sessions, to more optimally balance workload, and to deal with logon storms where a large number of connect requests arrive in a very short time period.

Owner:ORACLE INT CORP

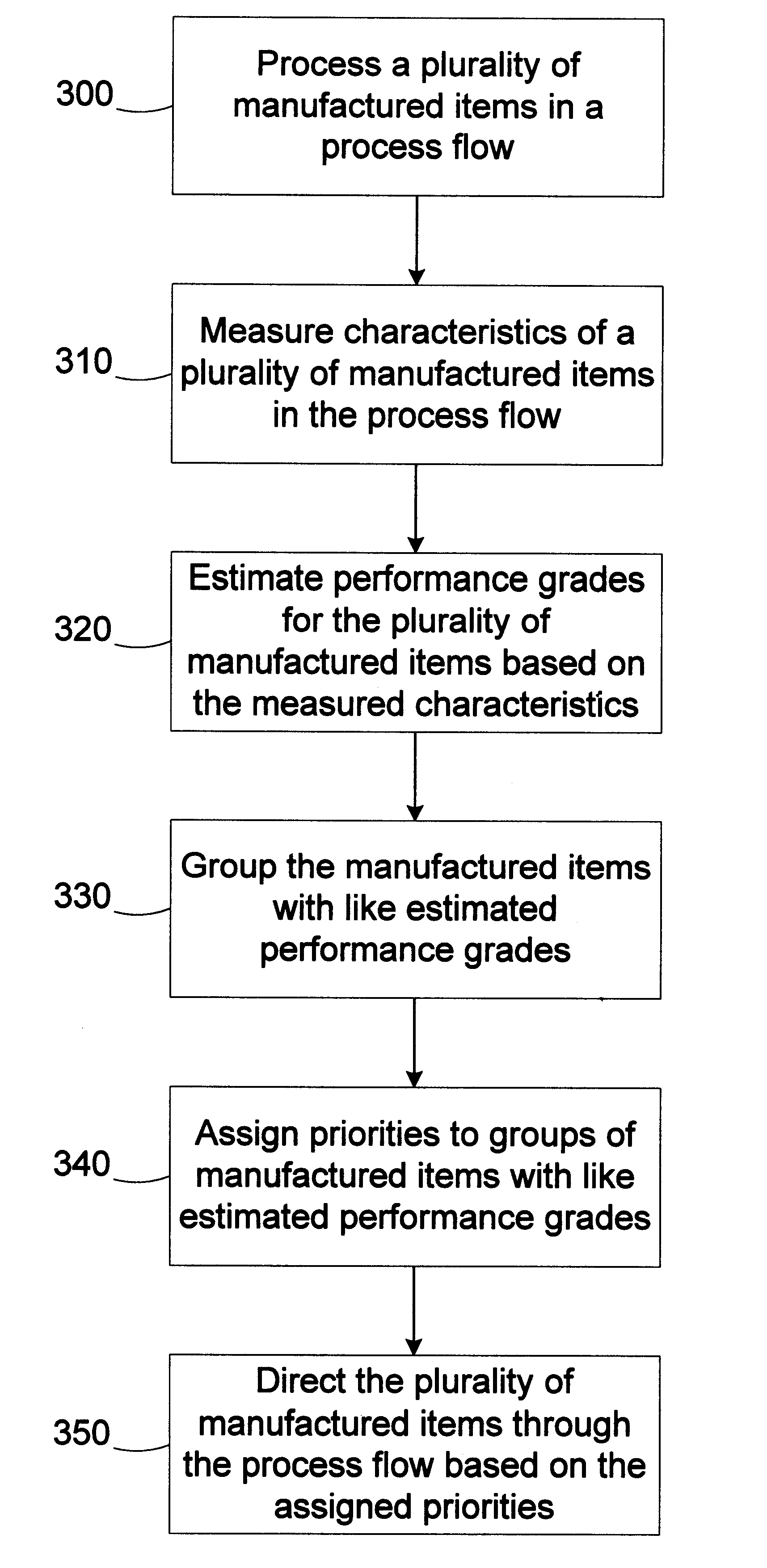

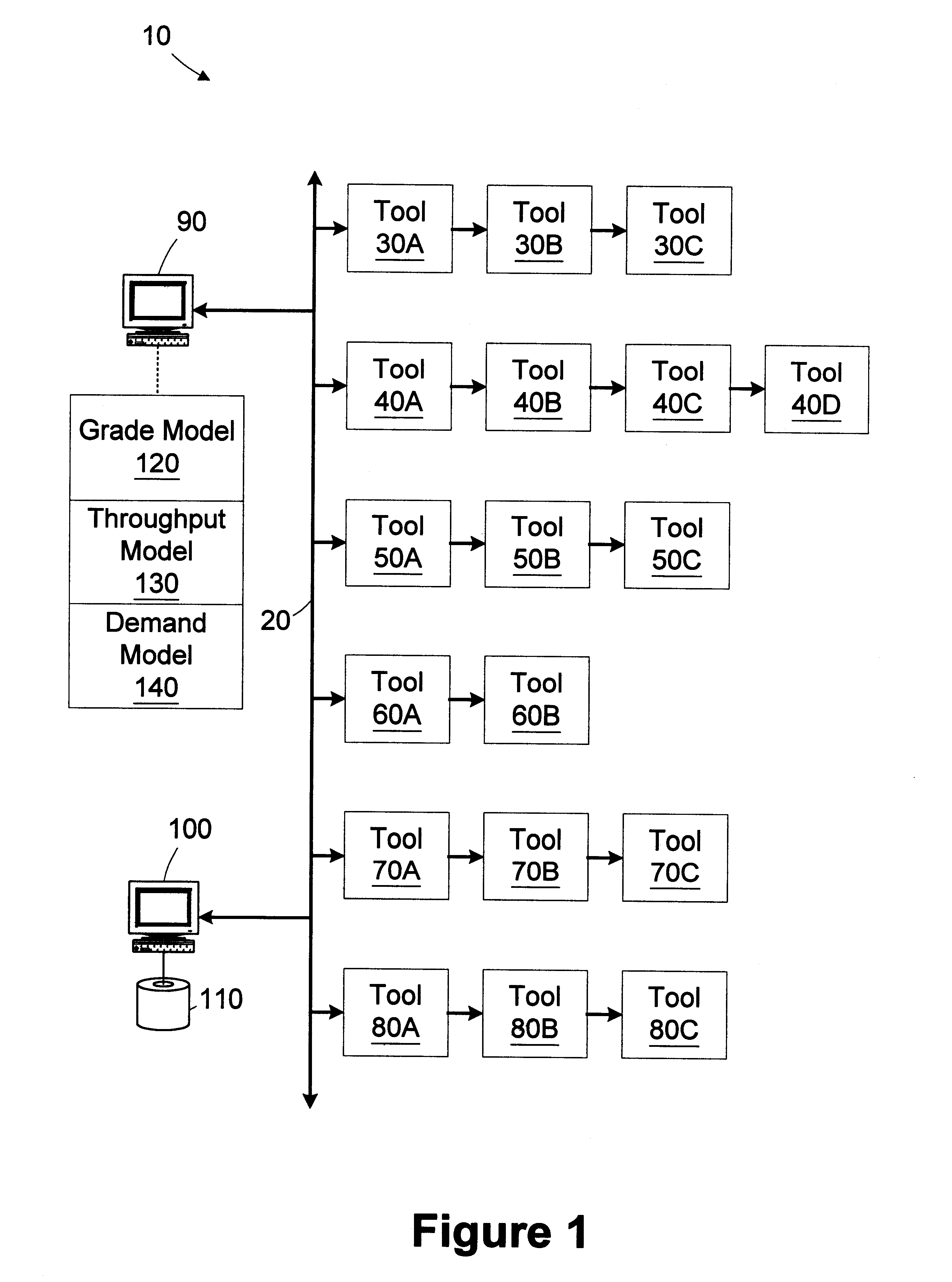

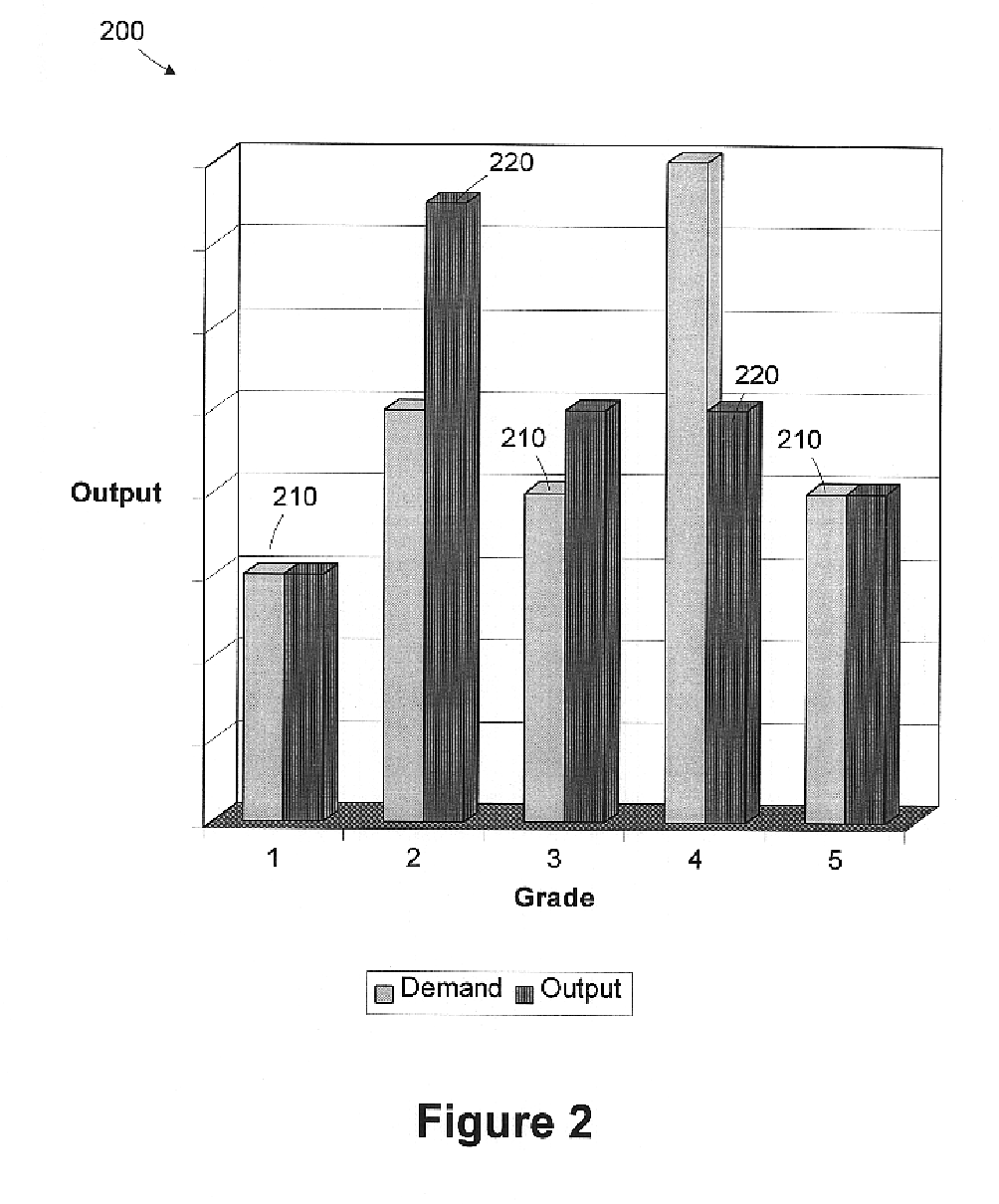

Method for prioritizing production lots based on grade estimates and output requirements

InactiveUS6699727B1Semiconductor/solid-state device testing/measurementSemiconductor/solid-state device manufacturingMetrologyPerformance grade

A method for prioritizing production flow includes processing a plurality of manufactured items in a process flow; measuring characteristics of a plurality of manufactured items in the process flow; estimating performance grades for the plurality of manufactured items based on the measured characteristics; grouping the manufactured items with like estimated performance grades; assigning priorities to groups of manufactured items with like estimated performance grades; and directing the plurality of manufactured items through the process flow based on the assigned priorities. A manufacturing system includes a plurality of processing tools adapted to process a plurality of manufactured items in a process flow, a metrology tool, and a process control server. The metrology tool is adapted to measure characteristics of a plurality of manufactured items in the process flow. The process control server is adapted to estimate performance grades for the plurality of manufactured items based on the measured characteristics, group the manufactured items with like estimated performance grades, assign priorities to groups of manufactured items with like estimated performance grades, and direct the plurality of manufactured items through the process flow based on the assigned priorities.

Owner:GLOBALFOUNDRIES US INC

Method for producing bitumen compositions

ActiveUS7833338B2Low viscosityHighly preventive effectBuilding insulationsBituminous coatingsBitumen emulsionRoad surface

Owner:INGEVITY SOUTH CAROLINA

Sulfur-modified asphalt emulsion and binder compositions

ActiveUS20130104776A1Reduce probabilityImproves asphalt binder asphalt binder emulsion user safetyRoads maintainenceEmulsionPolymer science

A Performance Grade sulfur-extended asphalt binder emulsion is made by combining a viscosifier, an emulsifier, a Performance Grade sulfur-extended asphalt binder, optionally a saponification agent, and a base aqueous solution. During creation of the asphalt emulsion, none of the components or combinations of them exceeds 275° F. A Performance Grade sulfur-extended asphalt binder emulsion residue is made by treating the Performance Grade sulfur-extended asphalt binder emulsion using the Texas Department of Transportation Evaporation Recovery Procedure. A Performance Grade sulfur-extended asphalt binder composition is made by combining free or element sulfur, a linear alkane material, optionally a saturated-backbone polymer modifier, optionally a non-aqueous acid, and a base asphalt. During creation of the asphalt binder, none of the components or combinations of them exceeds 275° F.

Owner:SAUDI ARABIAN OIL CO

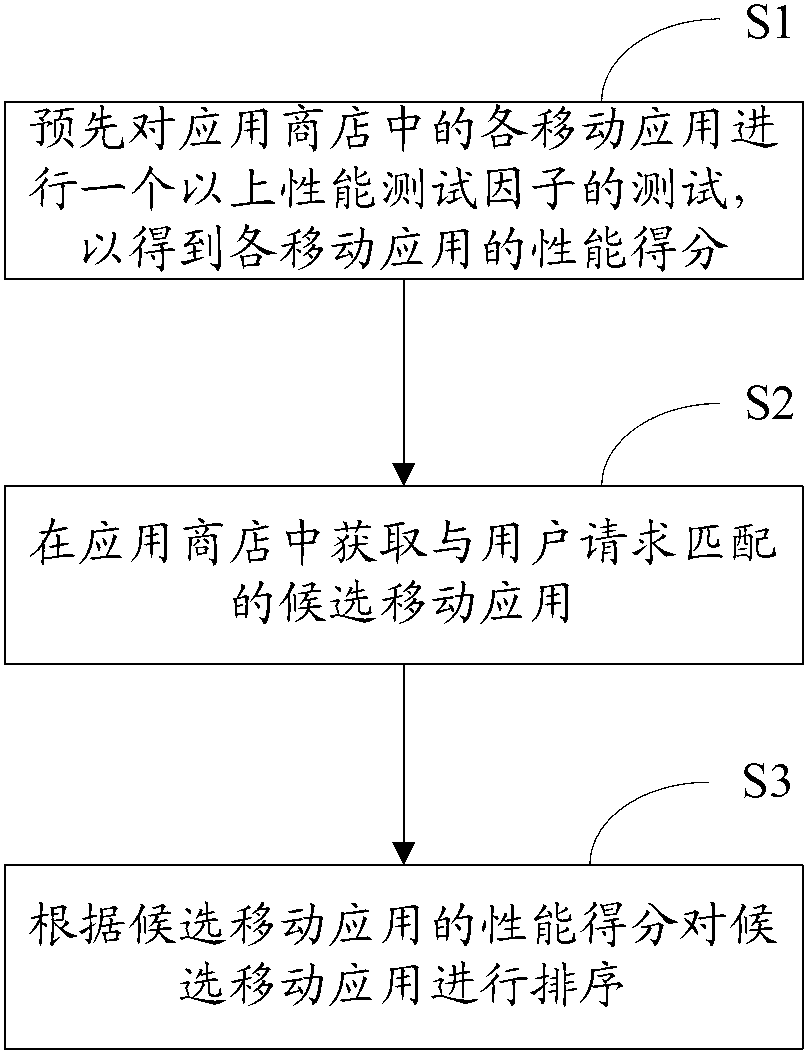

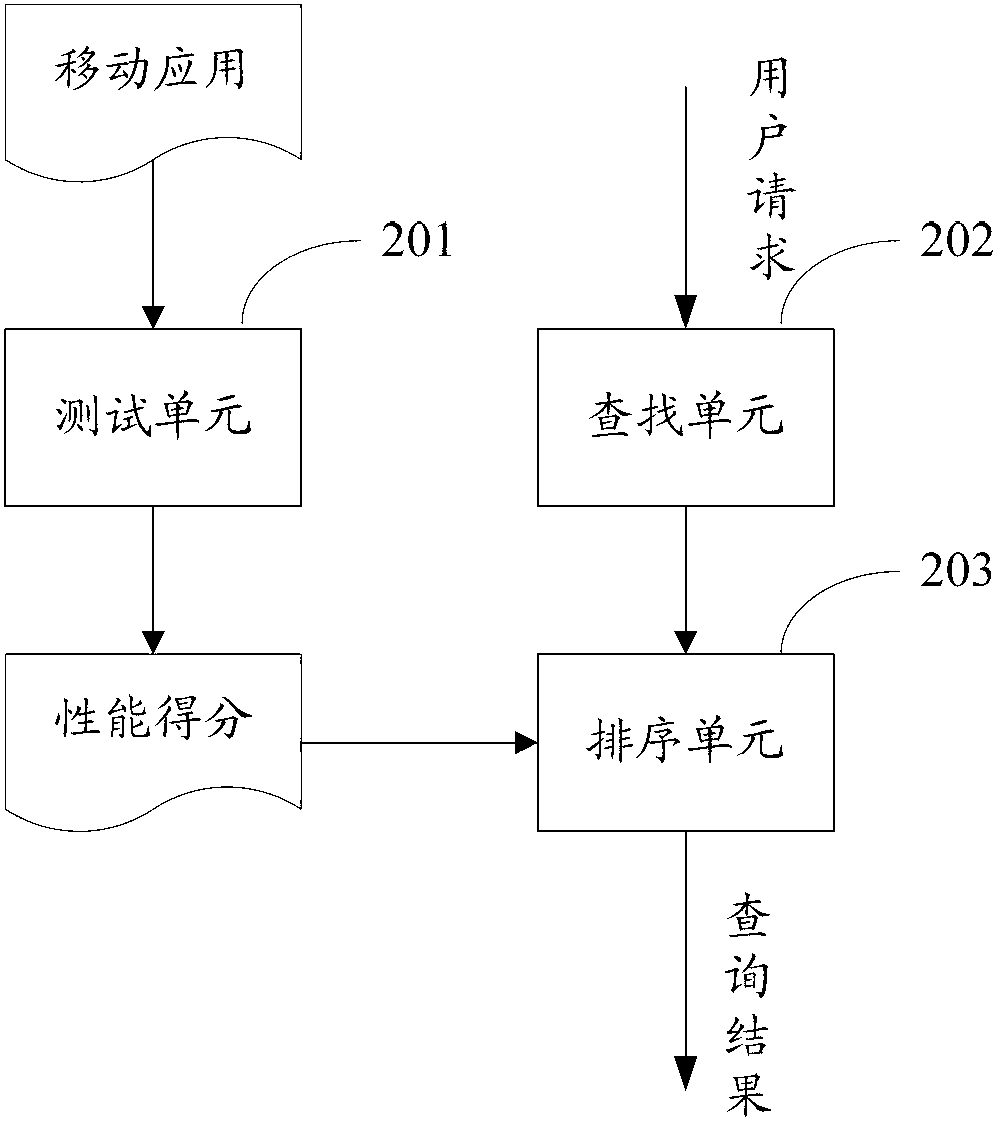

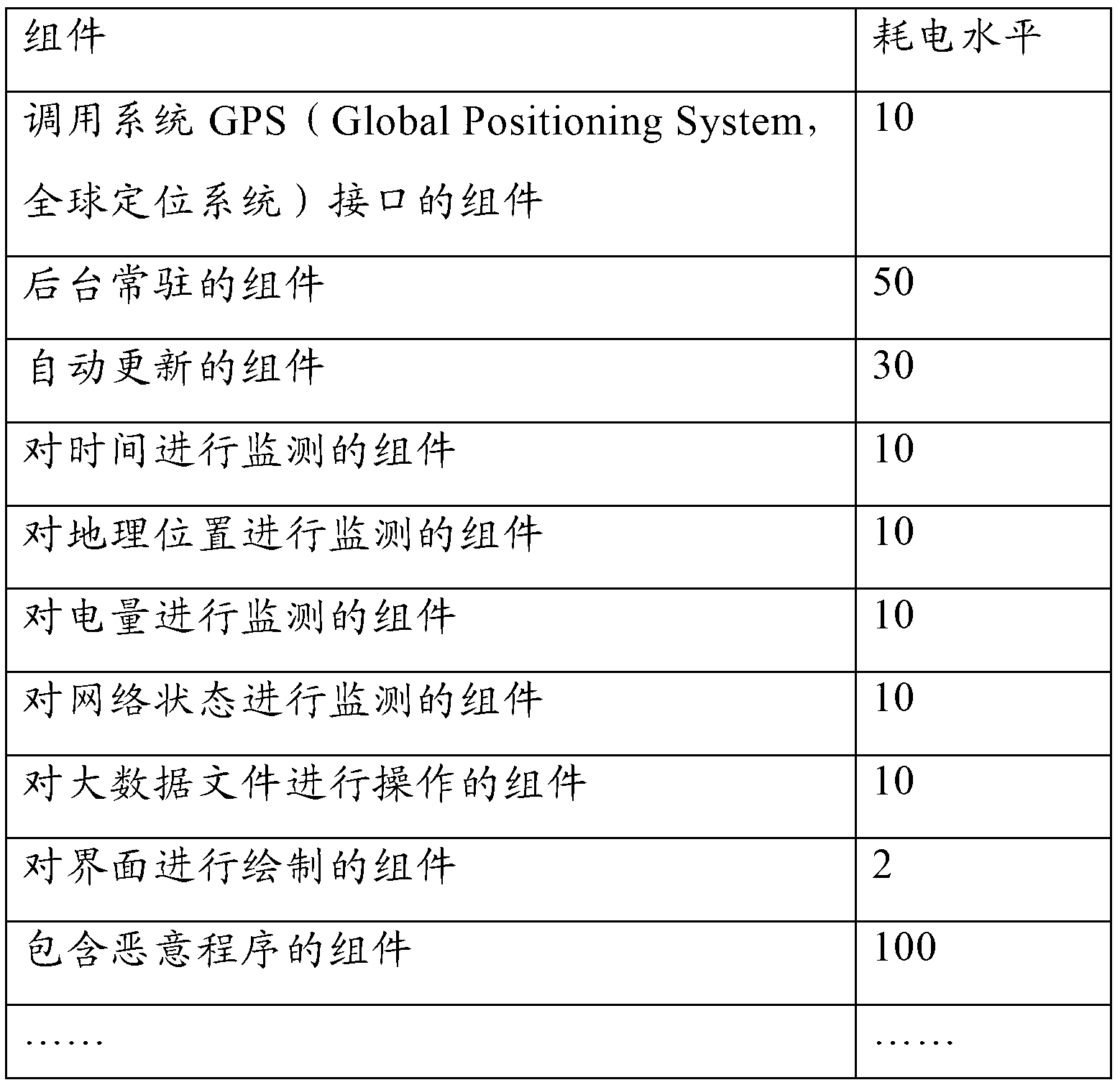

Method and device for ranking order through using searching result correspondingly

ActiveCN103177086AAvoid cheating situationsImprove objectivitySpecial data processing applicationsRankingPerformance grade

The invention provides a method and a device for ranking an order through using a searching result correspondingly. The method for ranking the order through using the searching result correspondingly comprises the steps: a test of more than one performance test factor is conducted to each mobile application program in an application shop in advance so that a performance grade of each mobile application program is obtained; candidate mobile application programs matched with a user request are obtained from the application shop; and the order of the candidate mobile application programs are arranged according to the performance grade of each candidate mobile application program. According to the method, the method and the device for ranking the order through using the searching result correspondingly can improve objectivity of a mobile application searching result ranking.

Owner:BAIDU ONLINE NETWORK TECH (BEIJIBG) CO LTD

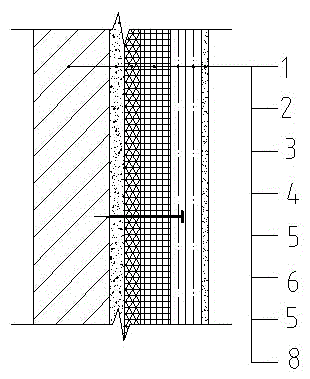

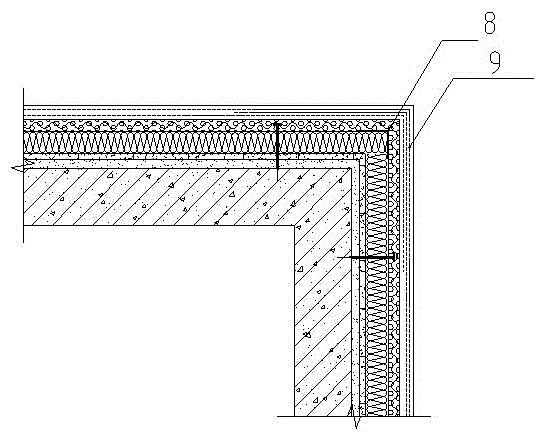

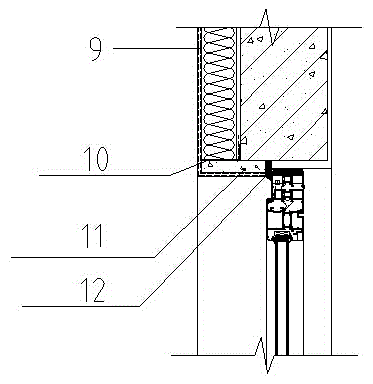

Construction method for outer wall outer thermal insulation rock wool boards

InactiveCN106284706AReasonable designEasy constructionHeat proofingBuilding material handlingCombustionThermal insulation

A construction method for outer wall outer thermal insulation rock wool boards is characterized by comprising the following steps that a, a controlling line is snapped, and a datum line is hung; b, the rock wool boards are pasted; c, a plastering layer is constructed; d, a system deformation joint is constructed; and e, an outer layer is constructed. The construction method for the outer wall outer thermal insulation rock wool boards has the advantages that the construction procedures are reasonably designed, construction is convenient, and the constructed rock wool boards are low in thermal conductivity, good in air permeability and high in combustion performance grade and can be popularized and applied to outer wall energy-saving thermal insulation projects of newly-built, extended and rebuilt residential buildings and public buildings.

Owner:MCC5 GROUP CORP SHANGHAI

Calculation of service performance grades in a multi-node environment that hosts the services

An approach generates performance grades. A performance grade is a value or set of values that indicates the relative work performance offered by a resource, such as a server in a multi-node system, relative to other resources. Performance grades are used to dynamically allocate work within a multi-node computer system. For example, performance grades are used for connection-time balancing, and to direct a database connection request to a multi-node database instance that a performance grade indicates provides better performance. Performance grade deltas are generated that reflect the incremental change in performance grade for additional sessions or work. Performance deltas are used to direct incoming sessions, to more optimally balance workload, and to deal with logon storms where a large number of connect requests arrive in a very short time period.

Owner:ORACLE INT CORP

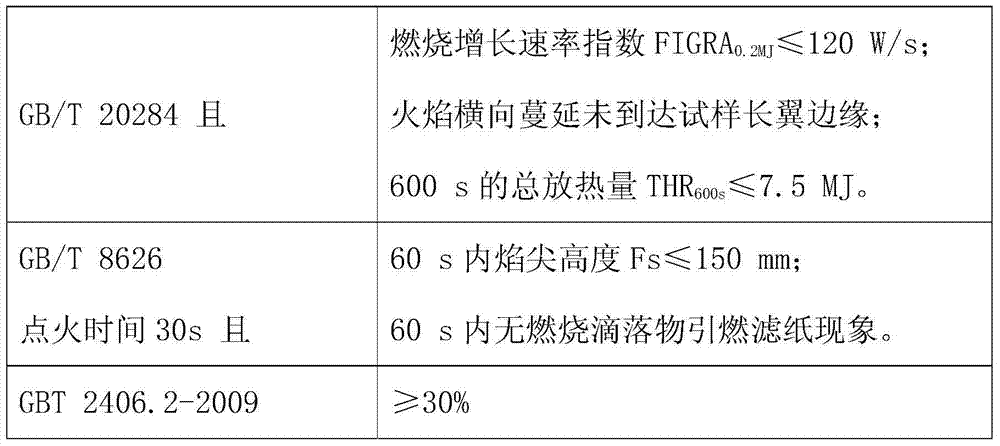

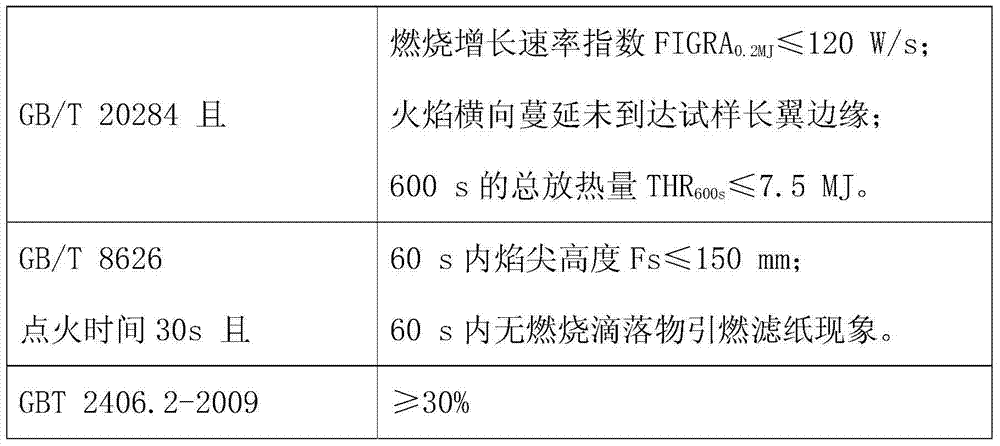

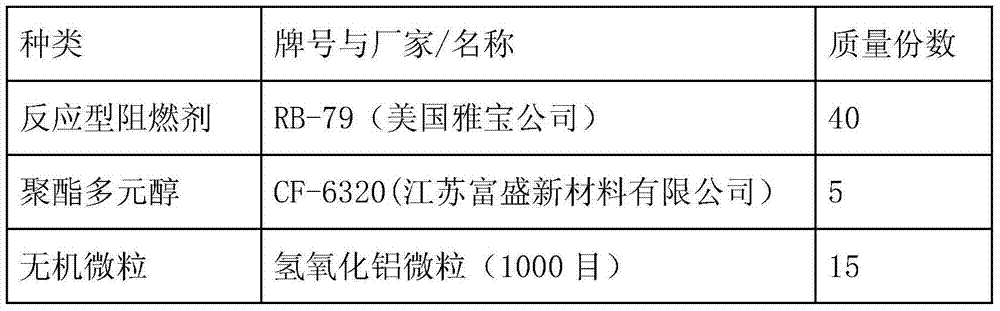

Flame-retardant polyurethane spraying rigid foam plastic

ActiveCN104119498AImprove flame retardant performanceMeet Class B requirements for flame retardant materialsCoatingsPolyesterInorganic particle

The invention relates to a flame-retardant polyurethane spraying rigid foam plastic, belonging to the field of rigid foam plastics. The rigid foam plastic is polymerized from an isocyanate component and a polyalcohol component in a volume ratio of 1:1, wherein the polyalcohol component comprises the following components in percentage by weight: 10-40% of polyester polyol, 5-40% of reactive flame retardant, 10-20% of inorganic particle and 24-50% of assistant. The rigid foam plastic can be sprayed and formed by a polyurethane high-pressure spraying machine, and has excellent flame retardancy. The polyurethane spraying rigid foam plastic can satisfy the requirements for combustion performance level for flat building materials and products and nonflammable material Grade B in graded criteria in Chinese Standard GB8624-2012 Combustion Performance Grade for Building Material and Product, and is suitable for the application fields with high flame-retardant requirements, such as architectural walling, roofing, ground insulation and the like.

Owner:WANHUA ENERGY-SAVING TECH GRP CO LTD

Bituminization rubber particle modifying agent and preparation method thereof

ActiveCN103408953ALess investmentLow investment, small production costBuilding insulationsPolymer sciencePolymer modified

The invention discloses a bituminization rubber particle modifying agent and a preparation method thereof. The bituminization rubber particle modifying agent comprises the following compositions in parts by weight: 20-30 parts of petroleum asphalt, 10-15 parts of rock asphalt, 40-60 parts of discarded tire rubber powder, 2-5 parts of plasticizer and 3-6 parts of polythene. According to the invention, the hard petroleum asphalt is taken as a liquid transitional medium, and the rock asphalt is used for filling and degrading the softened discarded rubber tire powder, so that waste rubber powder can be subjected to high-temperature degradation in a double screw machine; in addition, the plasticizer is used for softening waste rubber powder to enable the molecular structure of rubber powder to be comparatively incompact, and then the rock asphalt is filled; the prepared modifying agent has the advantage of improving the high-and-low temperature performance of asphalt, so that the performance grade of the asphalt modified by the modifying agent can reach PG 88-28, the performance of the modified asphalt is far superior to other polymer modified asphalt, and the modified asphalt product cannot be isolated, cannot deposit, and can be stored at low temperature or high temperature for a long time; the bituminization rubber particle modifying agent has excellent compatibility with asphalt, the normal technical index of the asphalt is superior to the traditional rubber asphalt, the rubber modified asphalt manufacturing technology and modifying equipment can be greatly simplified, the modified asphalt production efficiency can be improved, and the production cost can be reduced.

Owner:JIANGSU ZHONGHONG ENVIRONMENT TECH CO LTD

Testing method for cloud desktop virtual environment performance

The invention discloses a testing method for cloud desktop virtual environment performance. The testing method comprises the following steps that the number of started virtual machines in a server is obtained, pressurizing testing is carried out on virtual machines not to be tested, and the physical resource occupying situation of the server meets the testing condition; the testing circulation frequency is set according to the obtained operating system type, a CPU and an internal storage parameter of the virtual machine to be tested; multi-route thread circulation testing is carried out on the CPU, internal storage and IO performance of the virtual machine to be tested according to the obtained operating system type of the virtual machine to be tested, and the average grade of the CPU, internal storage and IO performance of the virtual machine to be tested and the comprehensive performance grade are calculated. According to the method, the virtual machines are directly tested, and therefore the performance of the actual virtual environment is visually reflected.

Owner:安徽中科云信创信息技术有限公司

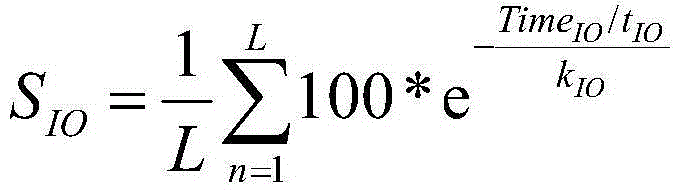

Utilization of heavy oil fly ash to improve asphalt binder and asphalt concrete performance

ActiveUS8062413B1Improve propertiesSolid waste managementWorking-up pitch/asphalt/bitumenFuel oilPerformance grade

Disclosed herein are an asphalt concrete mixture, an asphalt binder composition, and methods of preparing the related compositions. The asphalt binder compositions include heavy oil fly ash that contains more than about 90 wt. % carbon. The compositions are capable of being performance graded. The binder can be used to modify the asphalt and also as a filler in asphaltic concrete compositions.

Owner:SAUDI ARABIAN OIL CO +1

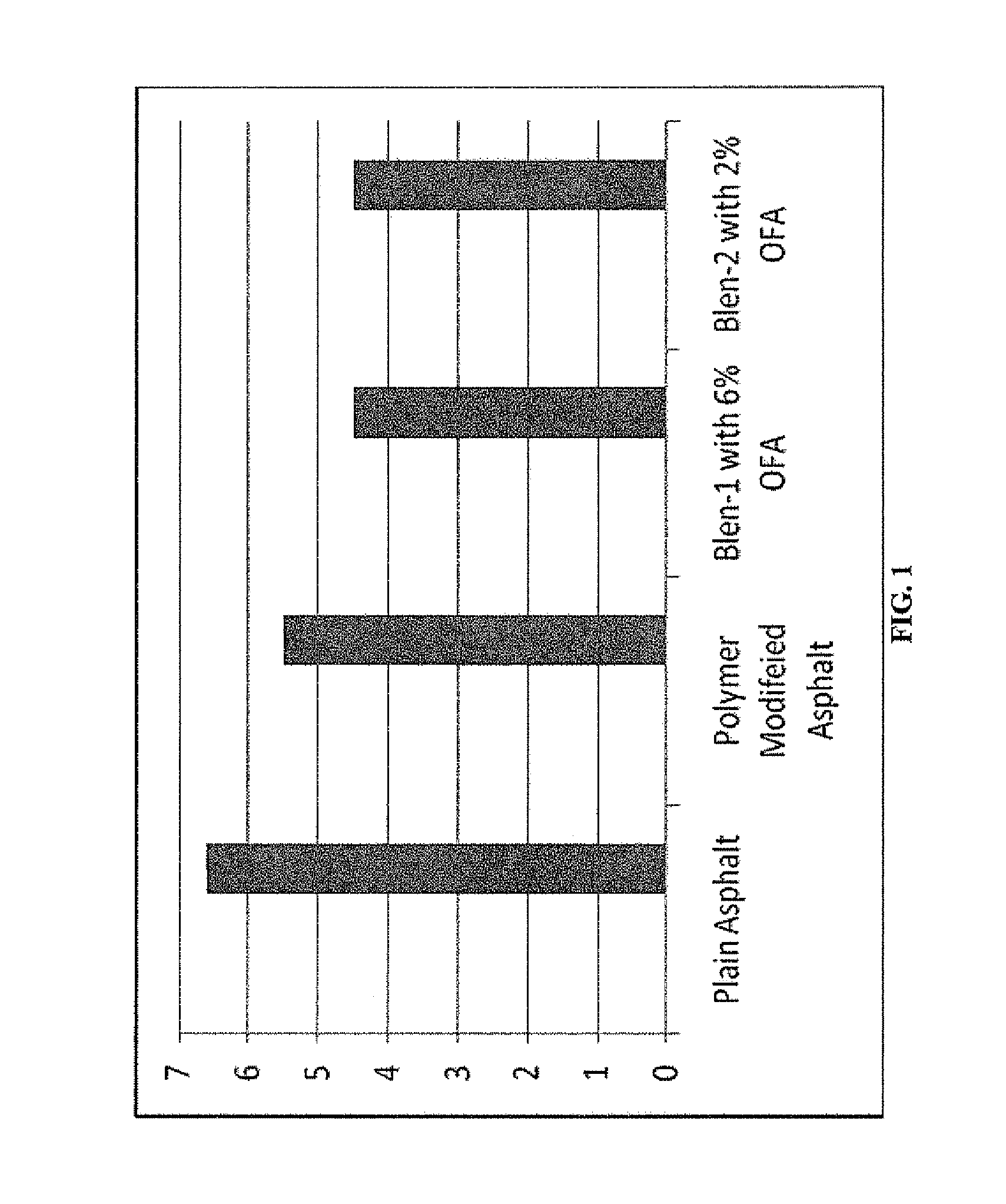

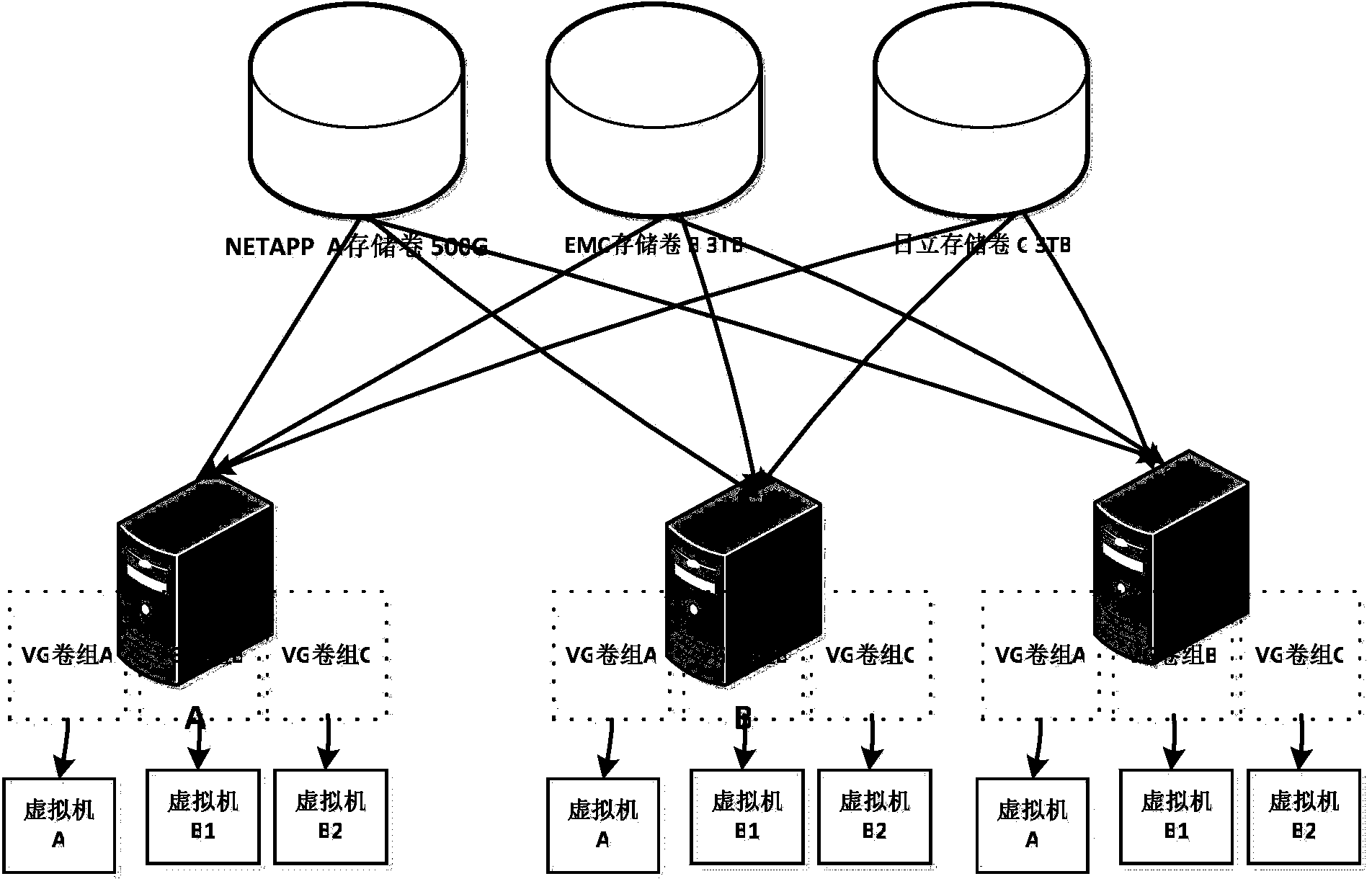

Performance-grading-based storage mechanism suitable for cloud platform

ActiveCN104283959AImprove I/O efficiencyIncrease profitProgram controlTransmissionStorage managementPerformance grade

The invention relates to the field of cloud computing, in particular to a performance-grading-based storage mechanism suitable for a cloud platform. The storage mechanism includes the steps that LUN dividing is firstly carried out inside special storage devices, and storage resources are outwards provided in an SAN mode; then, LUN devices are found and logged in to, and the storage devices are localized; logical volume groups are created on physical servers through the localized devices and shared; after sharing on all the LUN devices is completed, when virtual machines are created, the storage devices are selected according to the requirements of the virtual machines for IO speeds, and then logical volumes corresponding to the sizes of hard disks of the virtual machines are created on the volume groups corresponding to the storage devices; images of the virtual machines are injected into the logical volumes created on the corresponding volume groups, and the virtual machines are created through the logical volumes. By means of the storage mechanism, the capacity of balancing IO load storage of the whole cloud platform is provided, and the cloud platform can be scheduled on the physical servers; the storage mechanism can be used for storage management of the cloud platform.

Owner:G CLOUD TECH

Method for producing bituminous compositions

ActiveUS7905949B2Low viscosityHighly preventive effectIn situ pavingsPaving detailsEmulsionSolvent free

This invention relates to bituminous compositions and methods of producing the same. More particularly, the invention relates to the production of bituminous compositions formulated with performance-graded bitumen-containing solvent-free bitumen emulsions which exhibit controllable, temperature-dependent interfacial rheology. When employed in paving applications, these bituminous compositions develop adhesive strength and load-bearing strength properties at rates comparable to traditional hot mix paving compositions and at rates faster than traditional cold mix paving compositions.

Owner:INGEVITY SOUTH CAROLINA

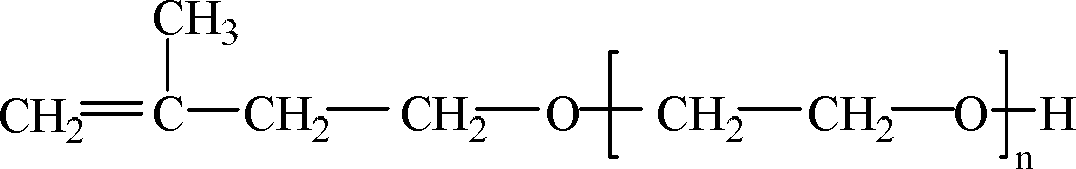

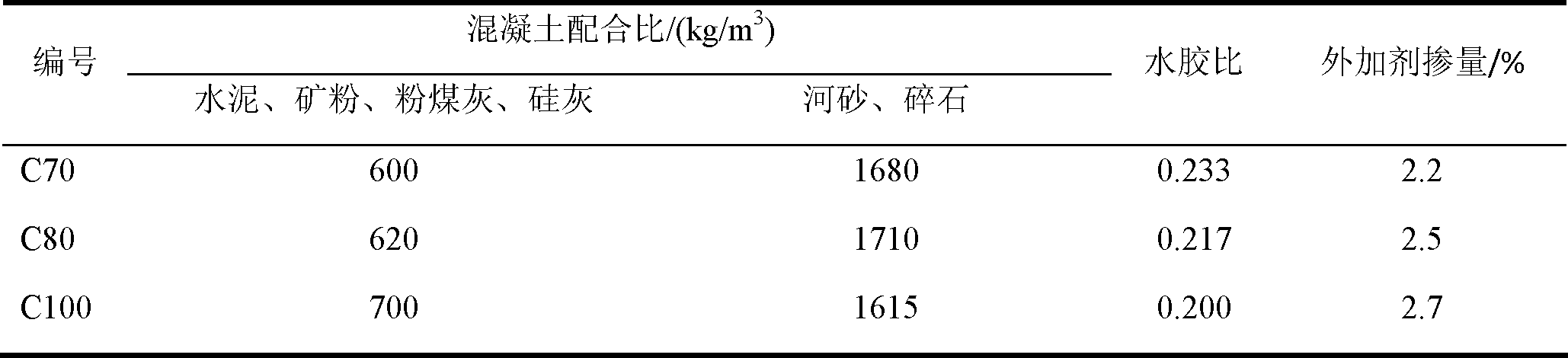

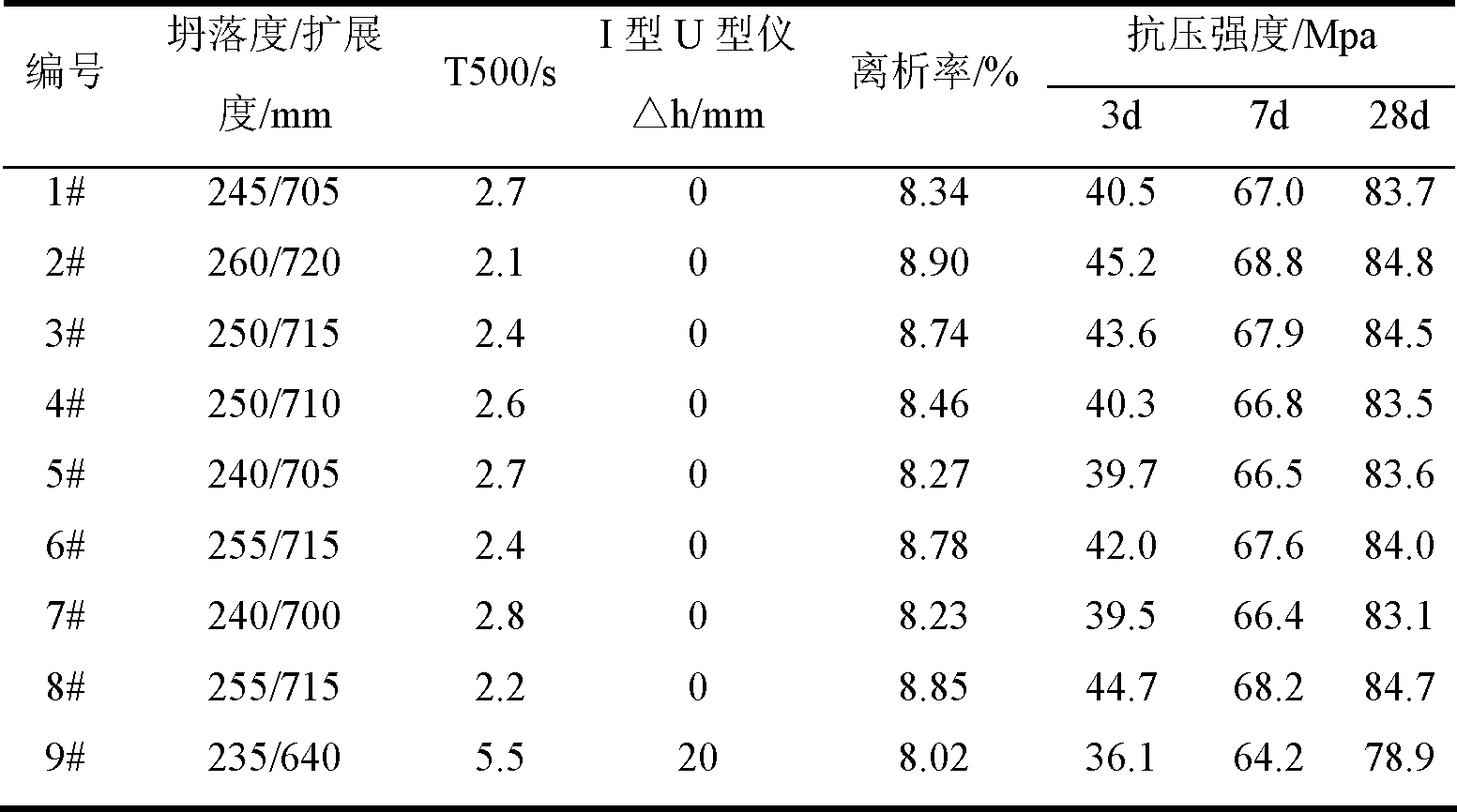

Polycarboxylic acid water reducing agent suitable for high-strength self-compacting concrete and preparation method of polycarboxylic acid water reducing agent

The invention relates to a polycarboxylic acid water reducing agent suitable for high-strength self-compacting concrete and a preparation method of the polycarboxylic acid water reducing agent. The agent is characterized by comprising 70-90wt% of a isopentene group polyoxyethylene ether monomer a, 5-25wt% of binary unsaturated carboxylic acid and a derivative monomer b of the binary unsaturated carboxylic acid and 1-10wt% of unitary unsaturated carboxylic acid and a derivative monomer c, wherein a+b+c=10wt%, under the action of an initiator and a chain transfer agent, an inductive copolymerization assistant agent monomer d is subjected to copolymerization for 1-3.5h in a water solution at the temperature of 60-80 DEG C, then alkali is added, and neutralization is conducted to obtain the polycarboxylic acid water reducing agent. The water reducing agent is not only can be compounded into an addition agent and used in ordinary concrete and also can be used in the C70-C100 high-strength self-compacting concrete, high mobility and low viscosity are provided, and the requirement (the performance grade can reach SR2) for segregation resistance in engineering construction is met, the performance is excellent, and the construction application requirement is met; and the cost is low, and the agent is convenient to popularize.

Owner:CHINA STATE CONSTR READY MIXED CONCRETE CO LTD

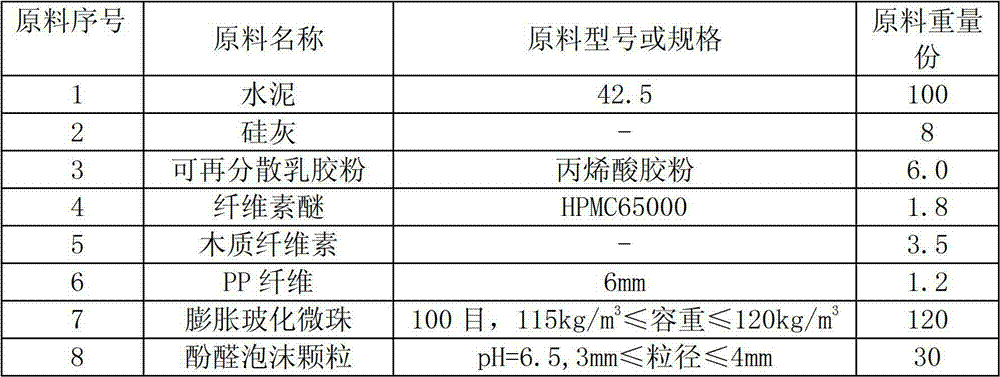

Inorganic phenolic aldehyde composite thermal mortar

The invention discloses an inorganic phenolic aldehyde composite thermal mortar which comprises 90-100 parts of cement, 8-18 parts of silica fume, 30-50 parts of phenolic foam particles, 100-120 parts of expanded and vitrified small balls, 4-6 parts of redispersible powder, 1.2-1.8 parts of cellulose ether, 2.5-3.5 parts of lignocellulose, and 0.8-1.2 parts of PP fibers. The phenolic foam particles are subjected to alkali neutralization and water-proof treatment, so that the corrosion on a wall body and the water absorption rate are improved. The composite thermal mortar not only keeps the advantages of excellent construction performance, high compression strength and high combustion performance grade up to A2 level of the inorganic thermal mortar, but also is lower in dry density and thermal conductivity, thereby being a good thermal insulation material having the advantages of good energy saving effect and high level of combustion performace grade and capable of being widely applied to the thermal insulation construction of a building outer wall.

Owner:上海英硕聚合材料股份有限公司

Sulfur Modified Asphalt for Warm Mix Applications

Disclosed herein are an asphalt concrete mixture, an asphalt binder composition, and methods of preparing the related compositions. The asphalt binder compositions include a polyphosphoric acid, a macromolecular polymer having a saturated backbone with macromolecular modifications, sulfur, and non-surfactant additives based on wax chemistry. The compositions are capable of being performance graded and being used in warm mix asphalt applications.

Owner:SAUDI ARABIAN OIL CO

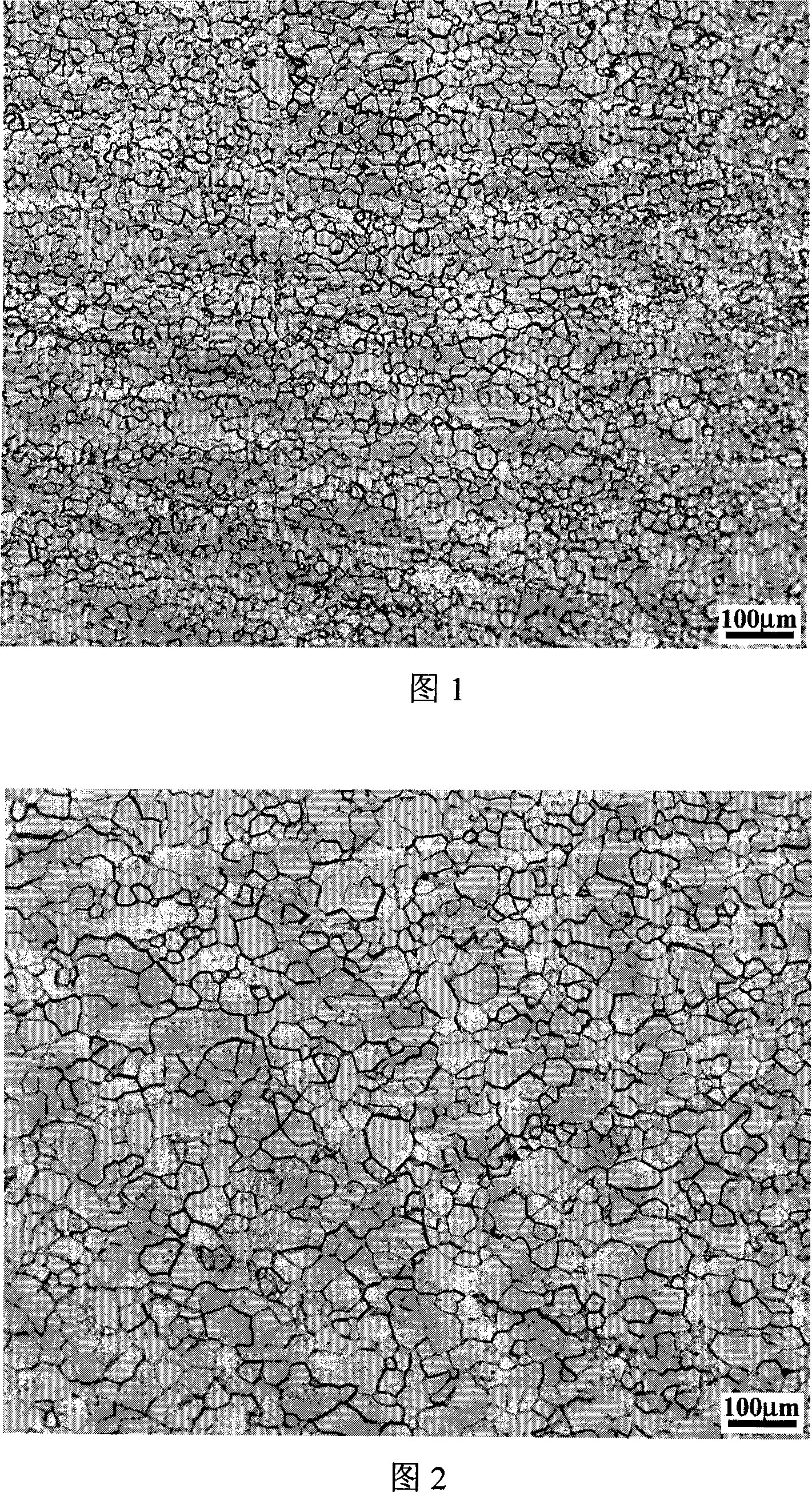

Method for preparing niobium sheet metal strip

ActiveCN101177768AHigh elongationIncrease grain size gradeRoll mill control devicesMetal rolling arrangementsNiobiumIngot

A method for preparing metal niobium strips relates to a method for preparing metal niobium strips with high elongation and high grain size grade performance by using a forging and rolling process. Its preparation process includes the following processes in turn: (1) Electron beam melting niobium ingots with a diameter of 150-160mm are forged with an air hammer at a temperature of 800-1100°C; the processing rate of forging is controlled to upset 30%-40% once , pull 40% to 50% once, and the processing rate of flattening is 50% to 70%; (2) The processing rate of the first rolling pass is ≥ 40%, and the processing rate of the second pass is ≥ 35%. The processing rate of each pass is ≥15%; the direction of the extension of the billet during the rolling process is always the axial direction of the original ingot; (3) the annealing process is adopted at 850-900°C for 3-4 hours. The method of the present invention can obtain the refractory metal niobium strip with an elongation rate of 30% to 41% and a grain size grade of 8.5 to 10 to obtain excellent deep drawing performance, which can be punched into a CCFL electrode with a diameter of 1.6mm and a height of 8mm head.

Owner:WESTERN METAL MATERIAL

Composite building heat-insulation board

The invention discloses a composite building heat-insulation board which is prepared from, by weight, 30-50 parts of cement, 10-15 parts of bamboo charcoal, 5-10 parts of perlite, 8-15 parts of sepiolite powder, 12-15 parts of organosilicon modified epoxy resin, 12-18 parts of gypsum, 15-25 parts of polyurethane waterproof paint, 4-9 parts of polyester fiber, 10-20 parts of sodium silicate solution, 2-10 parts of polyacrylamide, 1-8 parts of tributyl phosphate, 11-17 parts of acrylate, 2-8 parts of hydroxypropyl methyl cellulose, 1-8 parts of chromium boride and 2-8 parts of synthetic rubber. The composite building heat-insulation board can effectively integrate advantages of conventional organic boards and inorganic boards, can reach heat-insulation performance grade of organic materials, has performances like noninflammability of inorganic materials, are high in durability and weatherability and can be in service as long as a building is in service.

Owner:芜湖浩权建筑工程有限公司

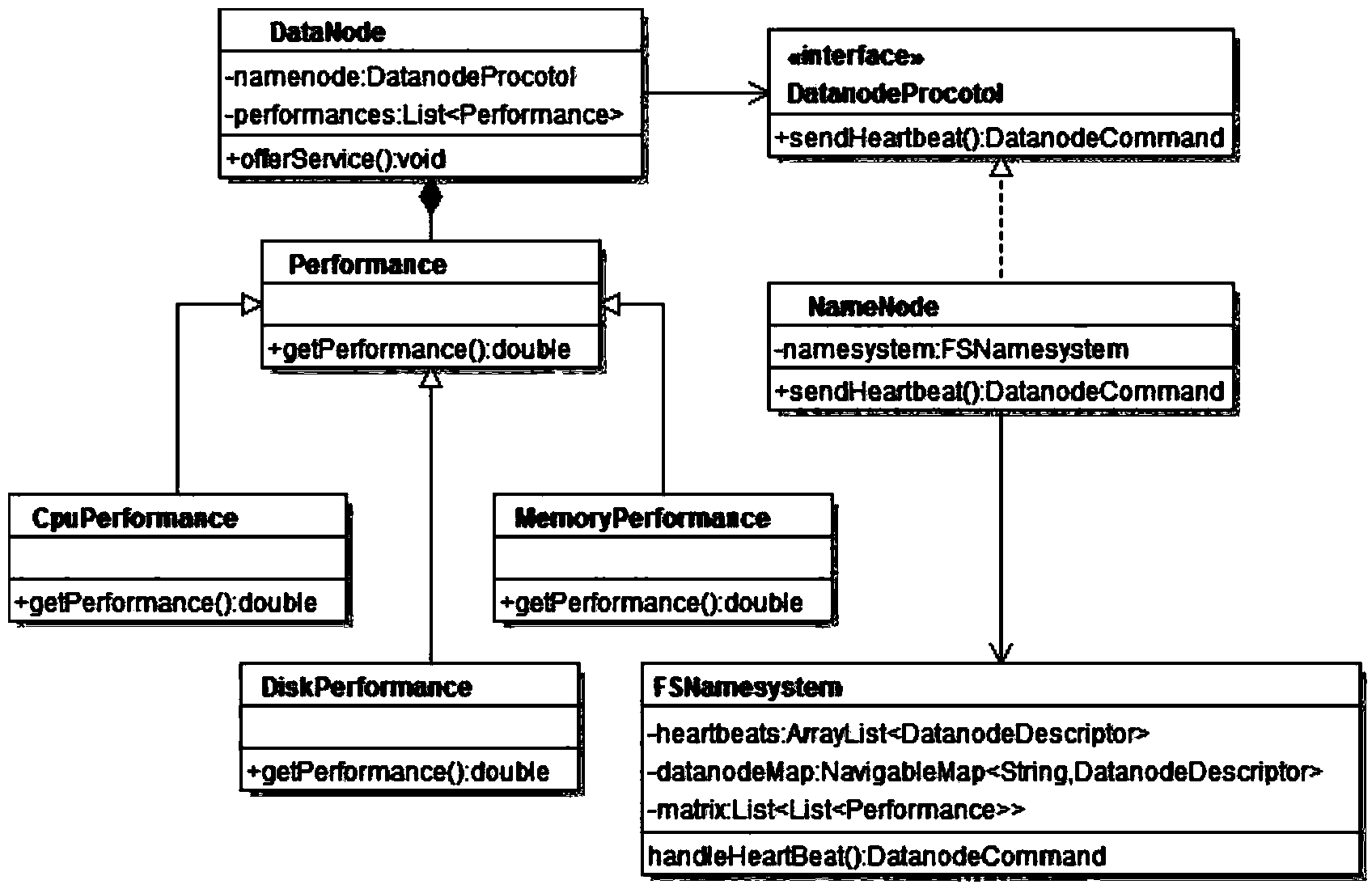

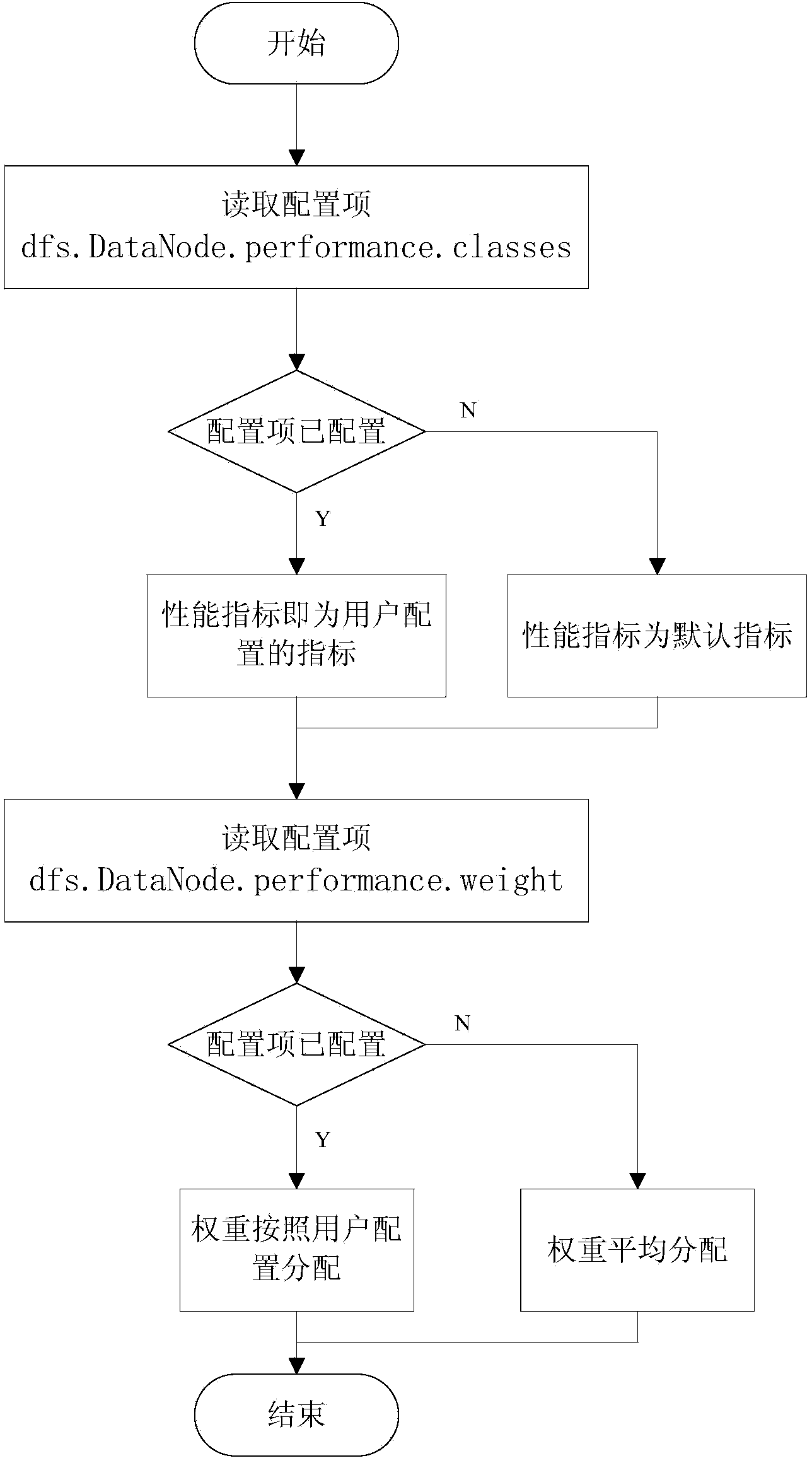

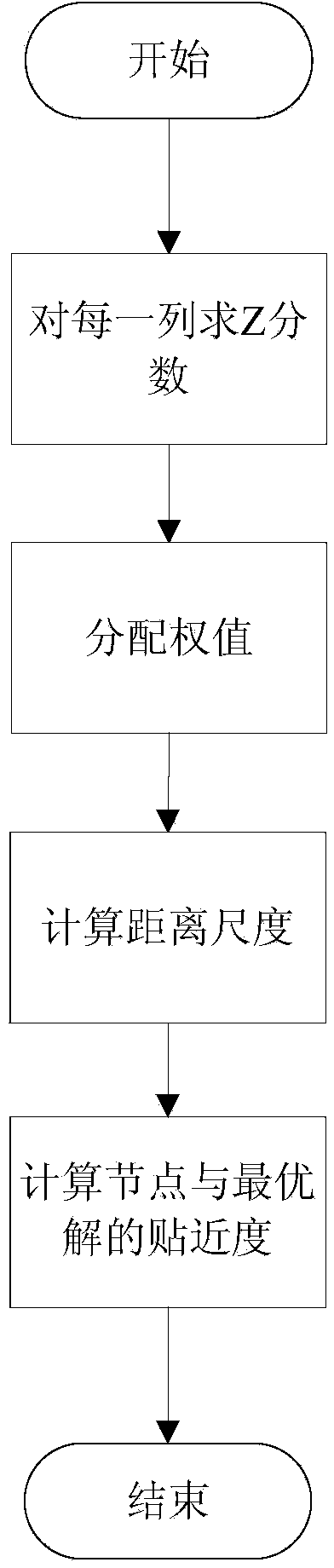

Copy balancing method based HDFS

ActiveCN104063501AImprove load balancingImprove cluster performanceSpecial data processing applicationsConfiguration itemFile system

The invention discloses a copy balancing method based on an HDFS. An abstract Performance class is designed in configuration items of a cluster, and performance data of all DataNodes are collected through heartbeat information; in the data migration process, matching of the DataNodes needs to meet node matching rules of an existing Balancer program, and the performance index data of the DataNodes also need to be referred; evaluation is conducted according to the specific value of performance grades and memory spaces of the DataNodes, and matching is conducted between the DataNode with the optimal evaluation and the DataNode with the worst evaluation; the amount of data stored by the DataNodes is made to be in direct proportion to the performance of the DataNodes, the load balancing capability of the HDFS is improved, and the performance of the cluster is improved. When the cluster is established, the performance difference of the configuration of all the nodes in the cluster does not need to be considered.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

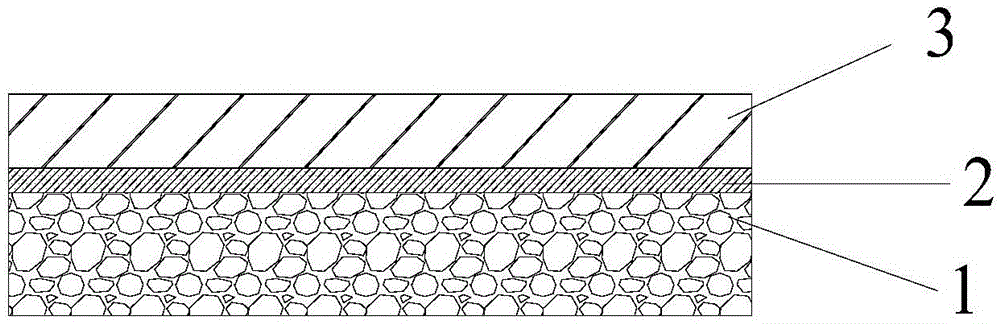

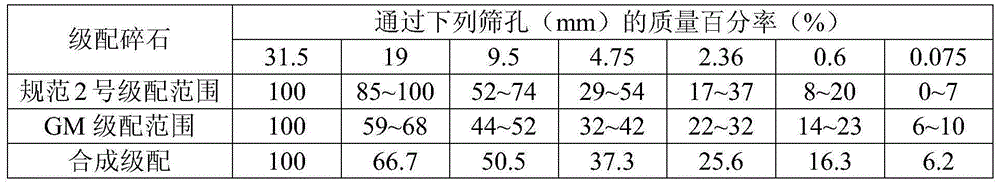

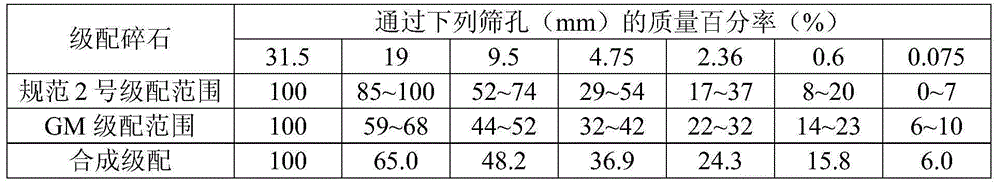

Reflection crack resistant asphalt pavement structure and construction method thereof

ActiveCN105019328AImprove structural strengthImprove road performanceIn situ pavingsChipsealSurface layer

The invention belongs to the technical field of road design and construction and discloses a reflection crack resistant asphalt pavement structure and a construction method thereof. The pavement structure sequentially comprises a high-performance graded broken stone base layer, a modified emulsified asphalt adhesive layer and a rock asphalt layer from bottom to top. The construction method comprises the following steps: clearing the surface of a lower supporting layer; mixing, spreading and rolling the raw material of high-performance graded broken stone; spraying the modified emulsified asphalt adhesive layer onto the surface of the high-performance graded broken stone base layer; spreading a rock asphalt modified asphalt mixture on the surface of the modified emulsified asphalt adhesive layer by using an asphalt mixture spreading machine; and then rolling by using a double-drum vibratory roller and a tyre roller. The reflection crack resistant asphalt pavement structure has the advantages that the performance advantages of all structural layers are fully exerted, the generation and development of reflective cracks of pavements are reduced and delayed, the blocking property and waterproof property between the asphalt surface layer and the base layer are increased, the asphalt pavement structure strength is increased, and the asphalt pavement performance is improved.

Owner:SOUTH CHINA UNIV OF TECH

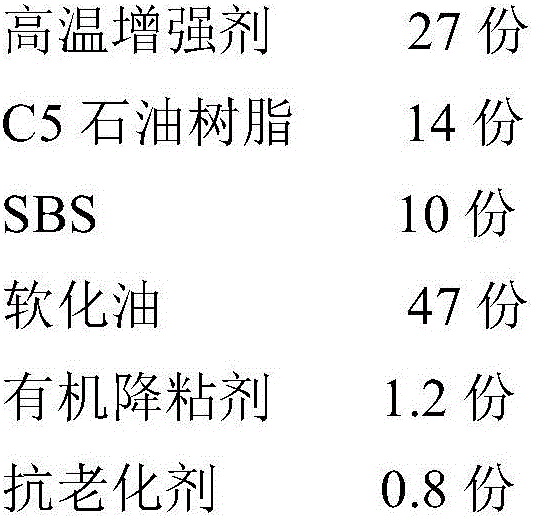

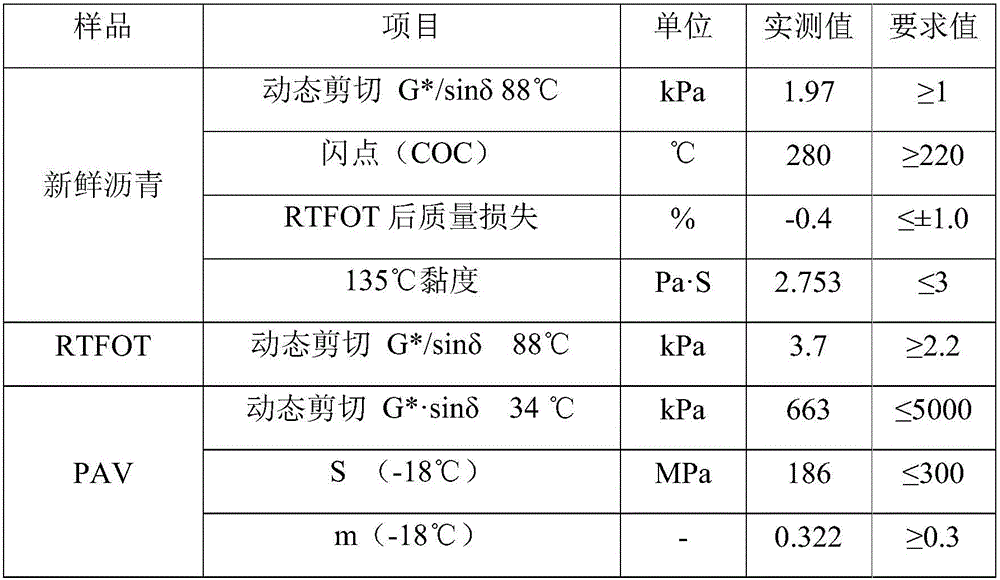

PG (performance graded) compound asphalt modifier and modified asphalt prepared from same

The invention discloses a PG (performance graded) compound asphalt modifier and modified asphalt prepared from the same. The PG compound asphalt modifier comprises raw materials in parts by weight as follows: 25-35 parts of a high-temperature reinforcing agent, 13-20 parts of petroleum resin, 8-10 parts of SBS, 30-50 parts of softening oil, 1-8 parts of an organic viscosity reducer and 0.5-1 part of an anti-aging agent. The PG88-28 modified asphalt is prepared from the PG compound asphalt modifier and matrix asphalt in the mass ratio being 1: (1.8-2.2). The modifier comprising SBS and the like can combine high-temperature performance and low-temperature performance, the combination property is improved remarkably, and the PG performance of the asphalt can reach PG88-28 or higher under assistance of the high-temperature reinforcing agent. The asphalt performance can reach the level I-D or I-C of the penetration degree when meeting the PG88-28.

Owner:CHINA OFFSHORE BITUMEN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com