Bituminization rubber particle modifying agent and preparation method thereof

A technology of rubber particles and modifiers, which is applied in building components, building insulation materials, buildings, etc., can solve the problems of insignificant improvement of asphalt high-temperature performance, damage of asphalt low-temperature performance, unstable product quality, etc., and achieve simple modification equipment , low production cost, excellent high and low temperature performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0027] 1. The preparation process of bituminized rubber particle modifier is to add 50 parts of waste tire rubber powder to the twin-screw machine, and then add 2 parts of plasticizer, 20 parts of petroleum asphalt, and 13 parts of rock asphalt to melt at 250 ° C , and finally add 3 parts of polyethylene for extrusion granulation, and pelletize through a pelletizer to obtain the bituminized rubber particle modifier.

[0028] 2. Prepare bituminized rubber-modified asphalt with the above-mentioned modifier, and its parts by weight are composed of 25 parts of modifier, 0.5 part of stabilizer, and 75 parts of 70# petroleum asphalt. See Table 1 for conventional technical indicators of asphalt, and Table 2 for PG classification.

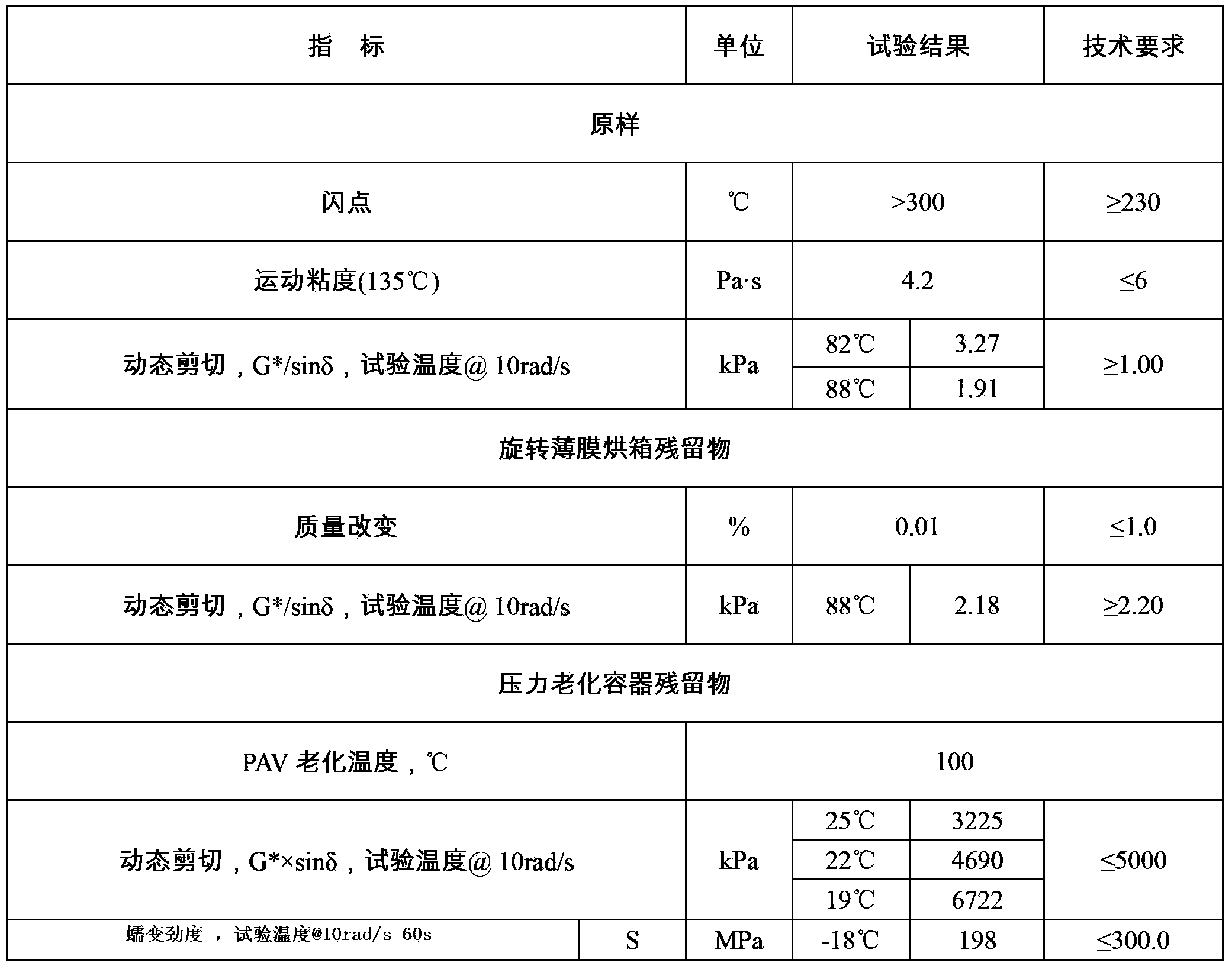

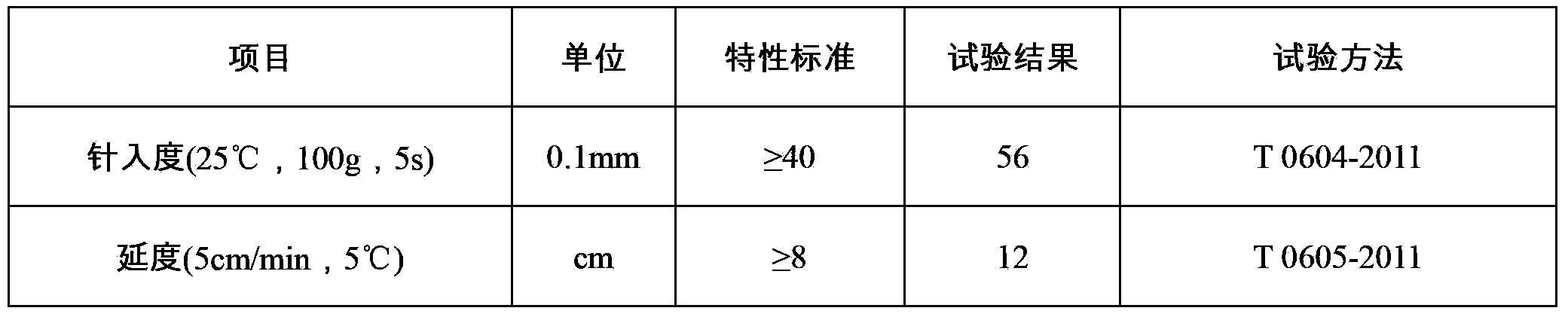

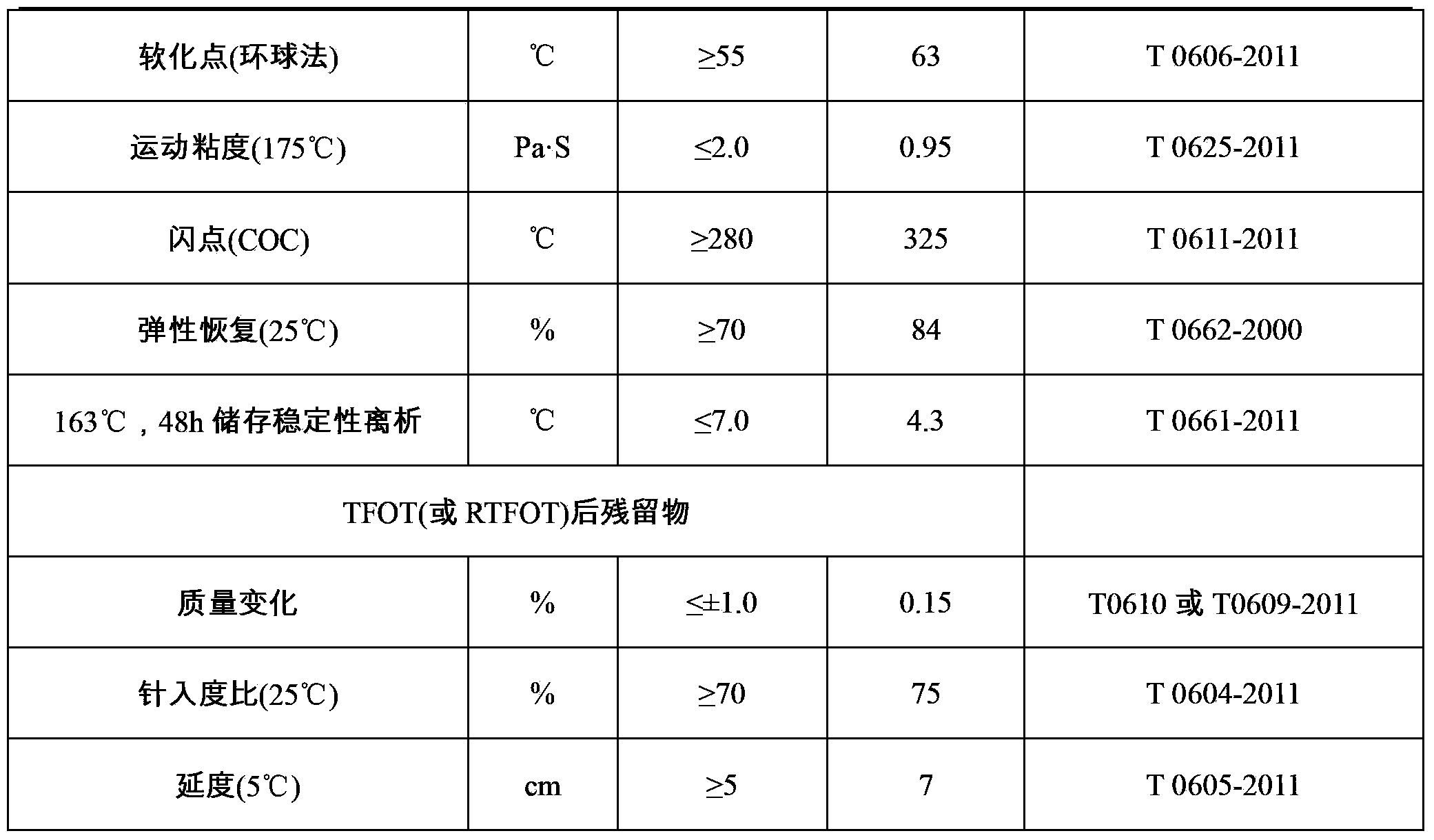

[0029] Table 1 Conventional technical indicators of asphaltized rubber modified asphalt

[0030]

[0031]

[0032] Table 2 PG classification of asphaltized rubber modified asphalt

[0033]

[0034]

[0035] It can be seen from Table 1 that th...

Embodiment approach 2

[0041] 1. Modifier preparation: The preparation process of bituminized rubber particle modifier is to first add 40 parts of waste tire rubber powder to the twin-screw machine, and then add 2.5 parts of plasticizer, 25 parts of petroleum asphalt, 10 Parts of rock asphalt were melted, and finally 4.5 parts of polyethylene was added to extrude and granulate, and pelletized by a pelletizer to obtain the asphaltic rubber particle modifier.

[0042] 2. Prepare bituminized rubber-modified asphalt with the above-mentioned modifier. The parts by weight are composed of 20 parts of modifier, 0.5 part of stabilizer, and 80 parts of 70# petroleum asphalt. The PG classification of the modified asphalt can reach PG82-28.

[0043] 3. Use the modified asphalt prepared above as the cementing material, follow my country's "Technical Specifications for Highway Asphalt Pavement Construction" F40-2004, and use the continuous dense graded asphalt mixture AC-13 as the asphalt mixture type, wherein the...

Embodiment approach 3

[0045] 1. Modifier preparation: The preparation process of bituminized rubber particle modifier is to first add 60 parts of waste tire rubber powder to the twin-screw machine, and then add 5 parts of plasticizer, 30 parts of petroleum asphalt, 15 parts of Parts of rock asphalt are melted, and finally 6 parts of polyethylene are added to extrude and granulate, and pelletized by a pelletizer to obtain the asphaltic rubber particle modifier.

[0046] 2. Prepare bituminized rubber-modified asphalt with the above-mentioned modifier. The parts by weight are composed of 25 parts of modifier, 0.5 part of stabilizer, and 75 parts of 70# petroleum asphalt. The PG classification of the modified asphalt can reach PG82-28.

[0047] 3. Use the modified asphalt prepared above as the cementing material, follow my country's "Technical Specifications for Highway Asphalt Pavement Construction" F40-2004, and use the continuous dense graded asphalt mixture AC-13 as the asphalt mixture type, wherein...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com