Patents

Literature

58 results about "Dense packing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

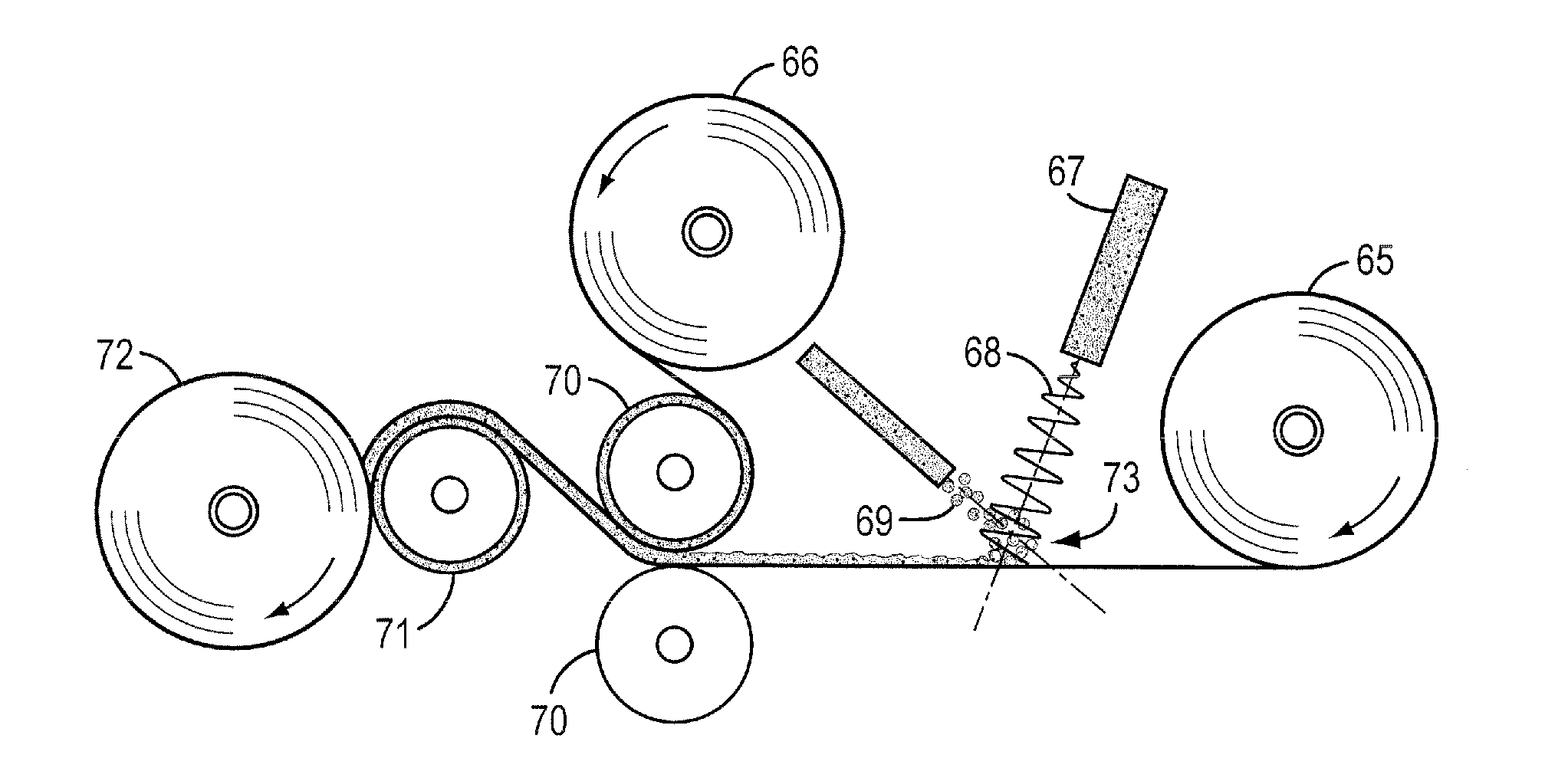

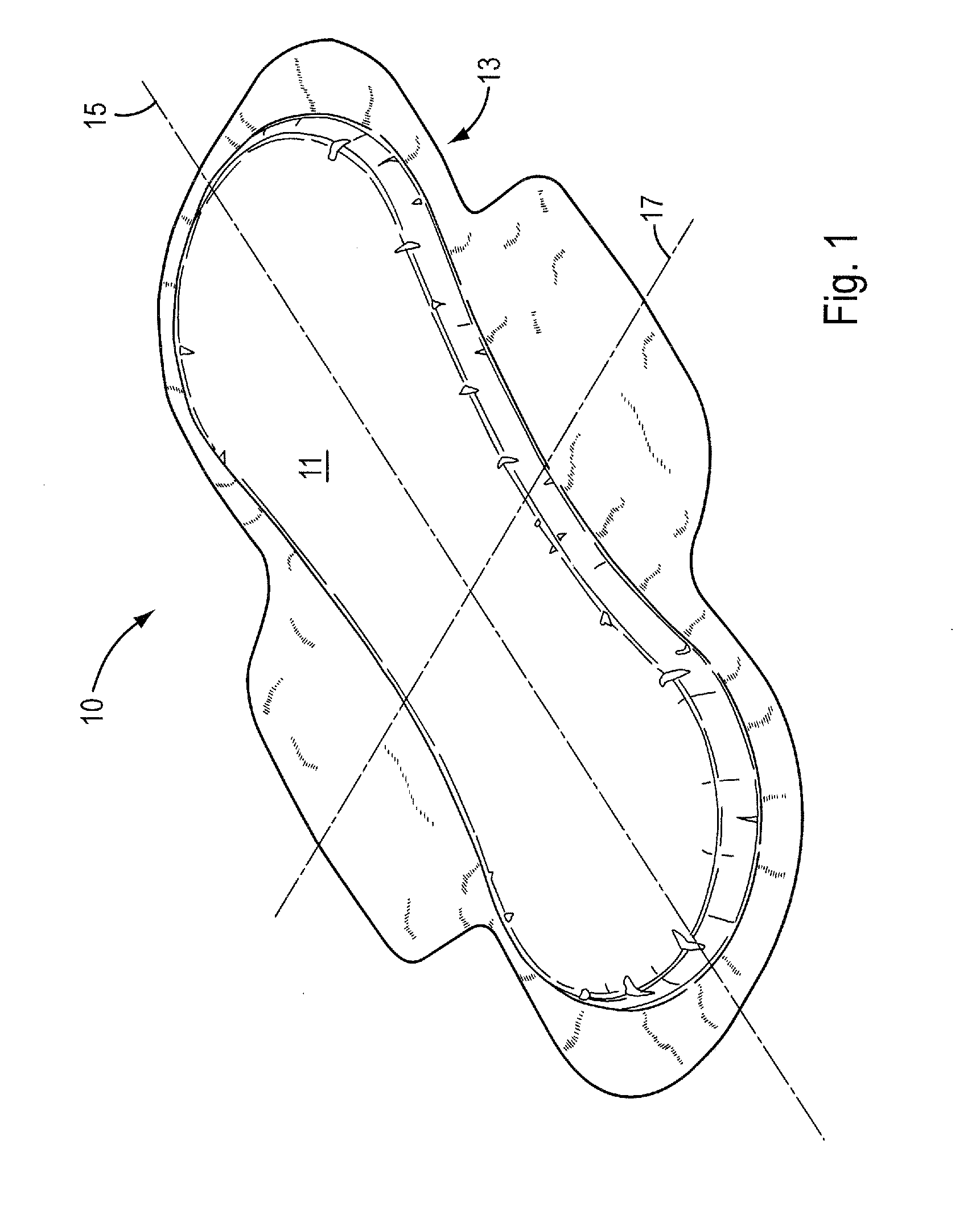

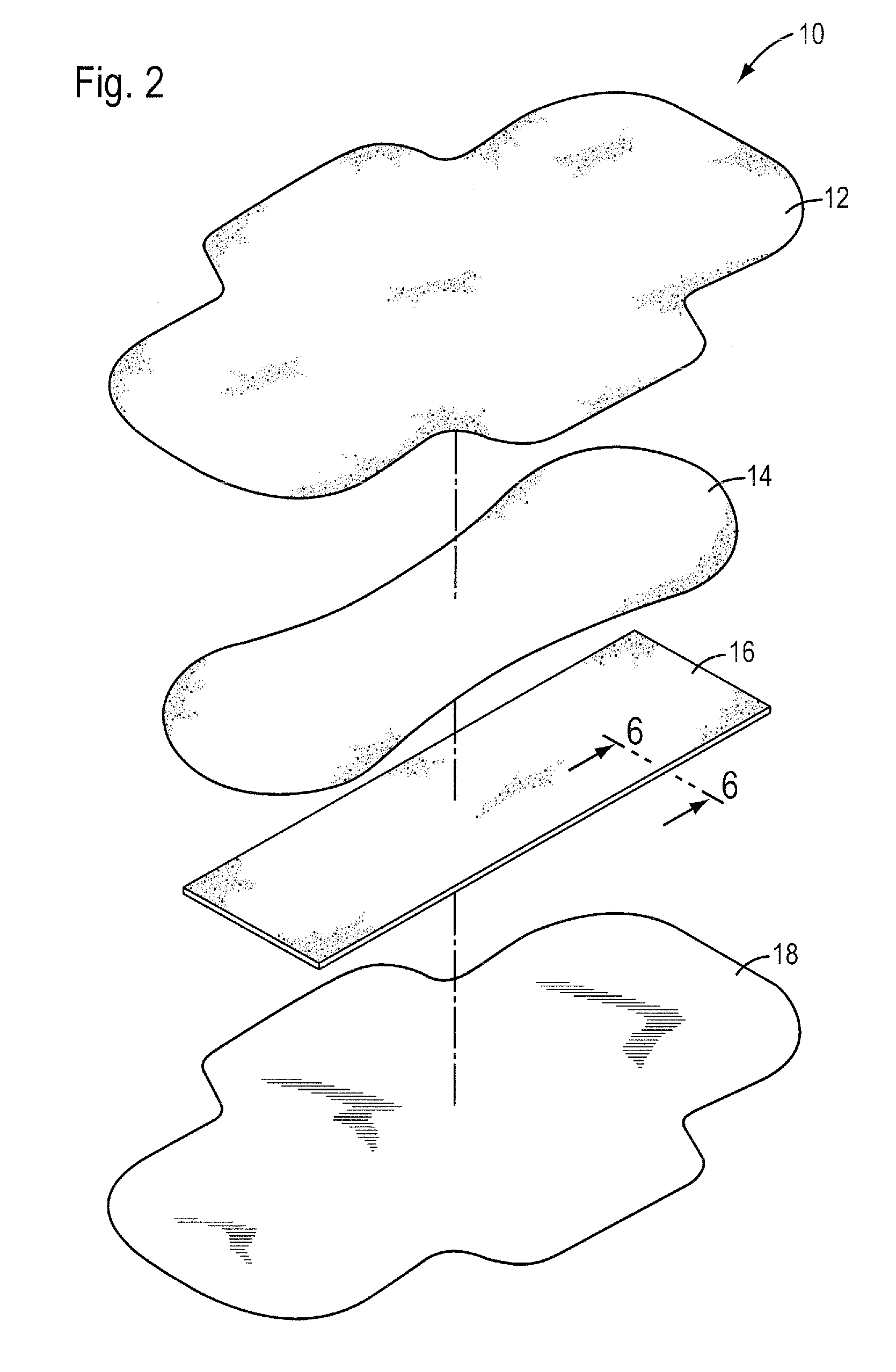

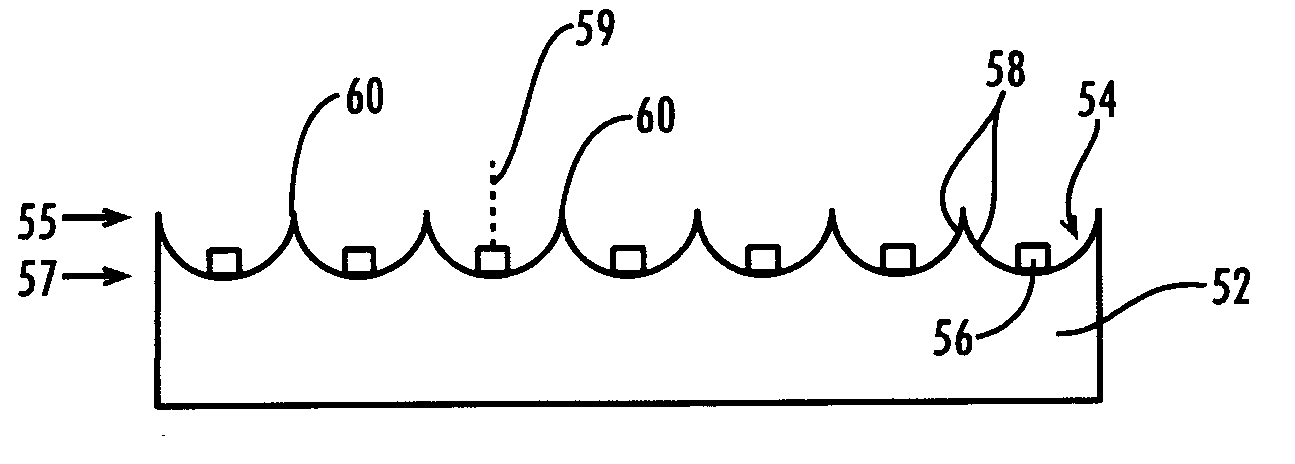

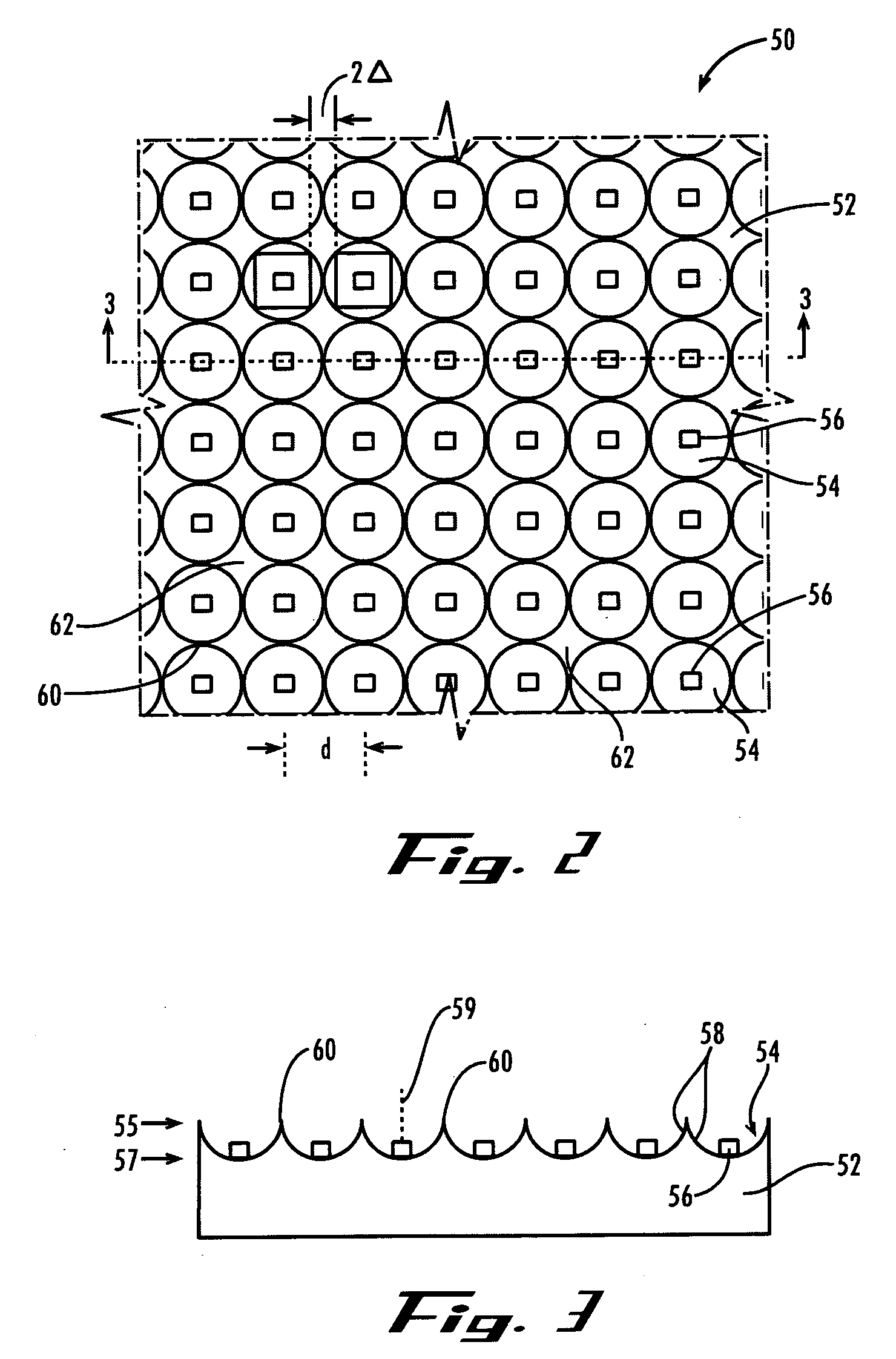

Ultra thin laminate with particulates in dense packages

The present invention is directed to a method of forming a laminate absorbent structure, and a resulting package containing a single continuous running web of the laminate material. Notably, formation of the material is effected by blending a curtain of adhesive fibers with a curtain of particulate material, and depositing the mixture on a moving substrate, preferably provided in the form of a tissue layer. A second substrate, also preferably comprising a tissue layer, is applied on top of the deposited mixture, and pressure applied to form the laminated structure. Notably, attendant to packaging of the laminated material, adjacent layers of the material tend to nest into one another, to form a sandwich in which the density of the material in the package is more than 1.5 times the density of the material after its removal from the package.

Owner:EVEREADY BATTERY CO INC +1

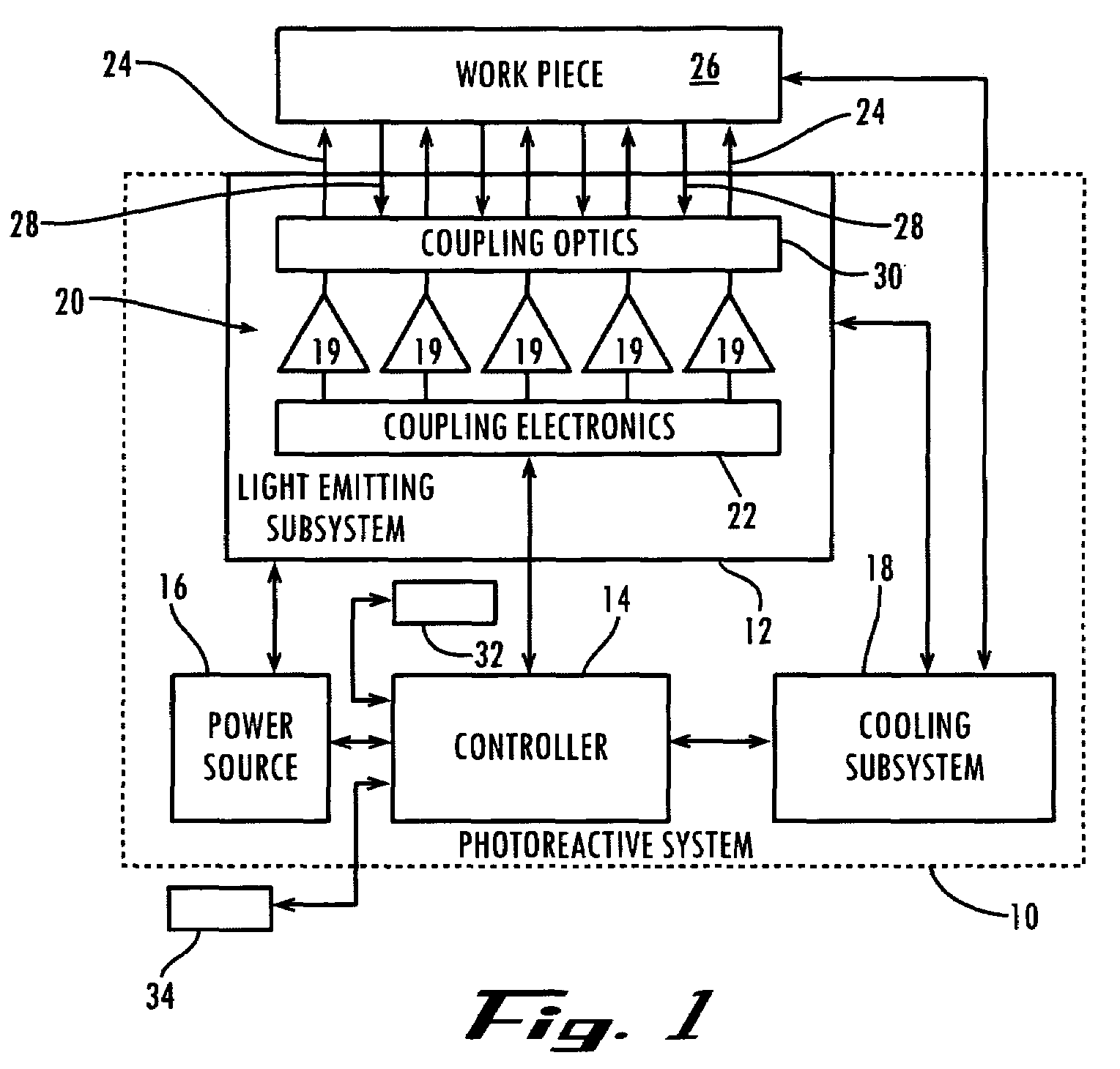

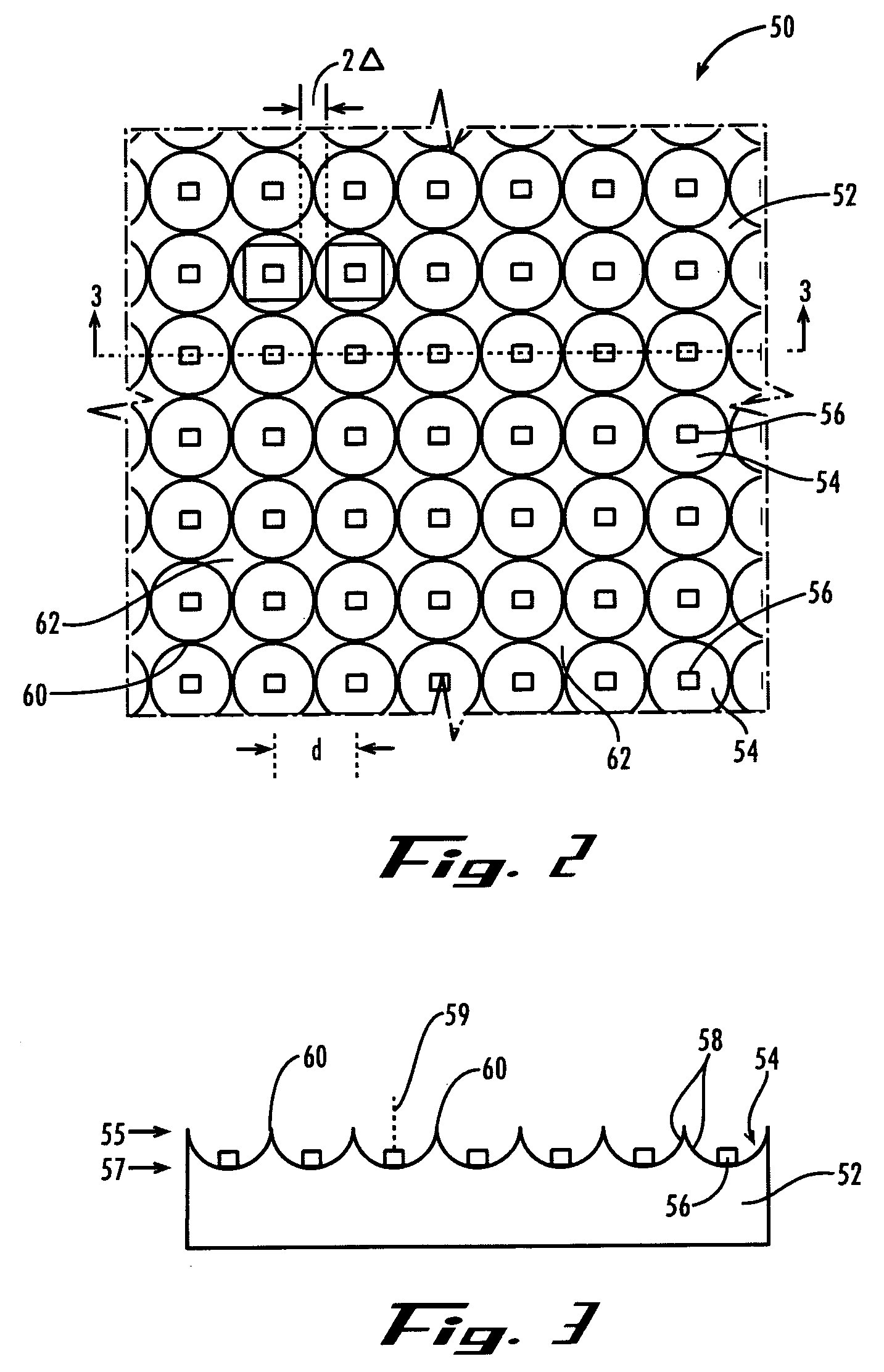

High density LED array

ActiveUS7071493B2Improved matingHigh bulk densitySolid-state devicesSemiconductor devices for light sourcesHigh densityLed array

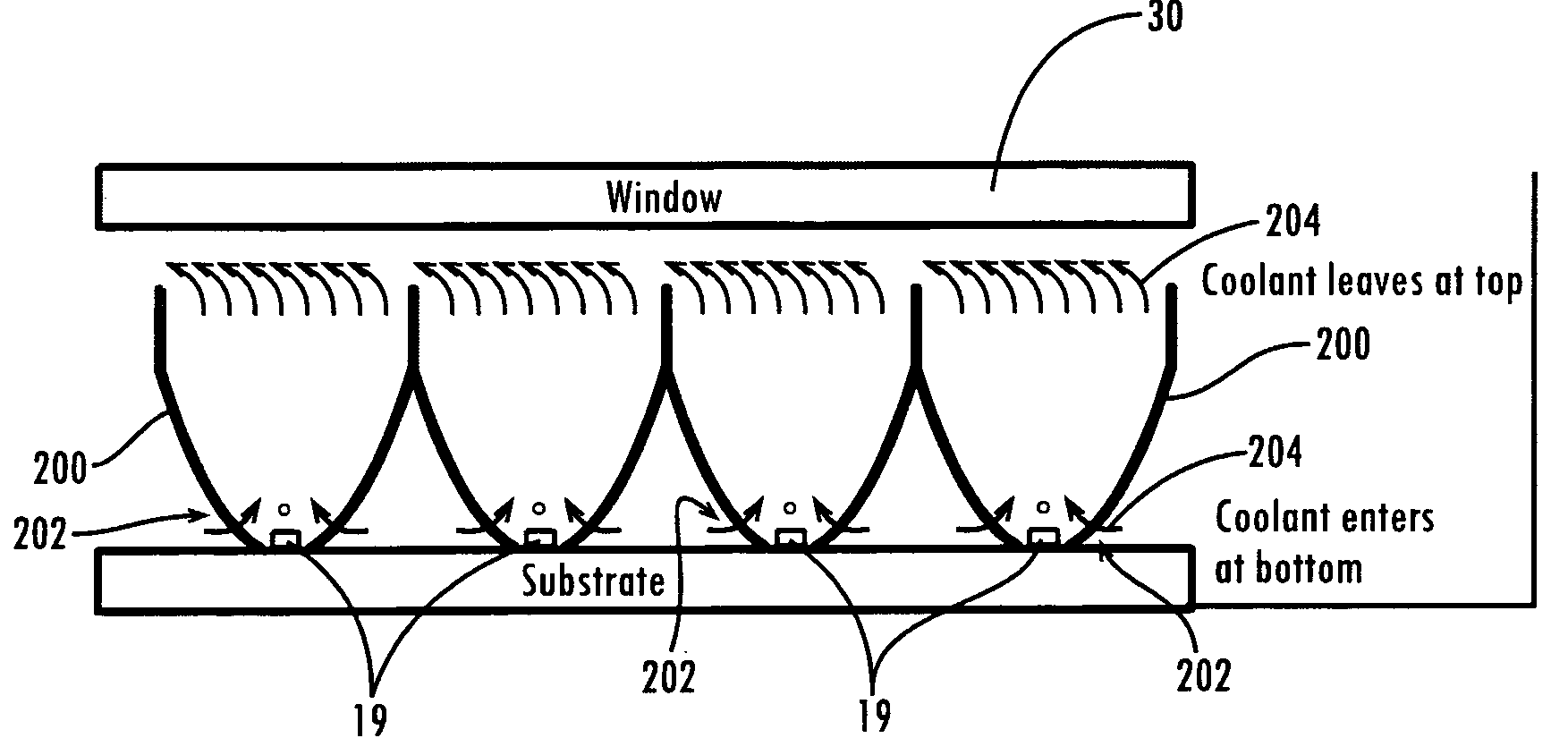

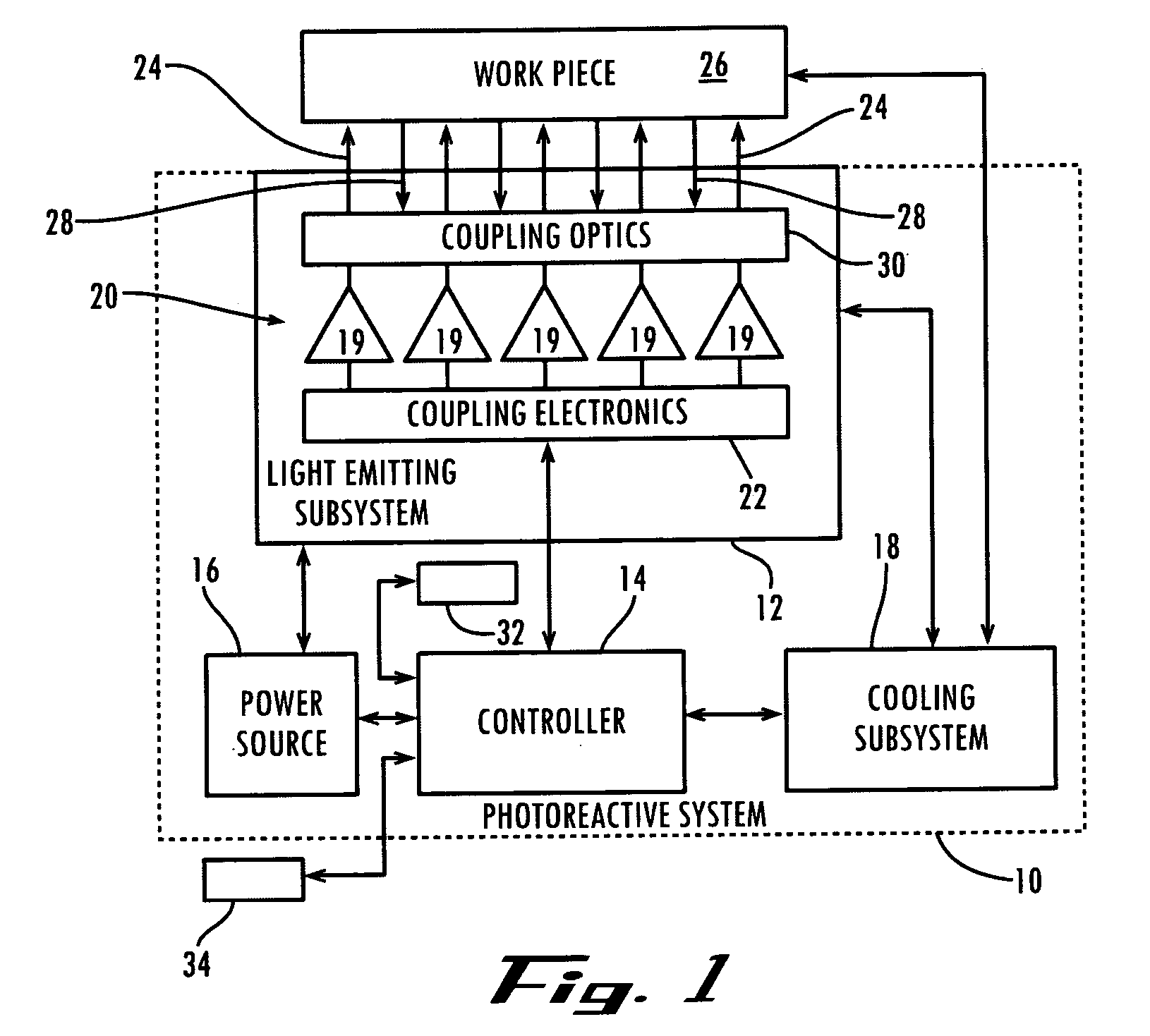

A dense array of semiconductor devices having an array of micro-reflectors, the micro-reflectors having characteristics that enhance dense packing of the array in balance with collection and collimation of the array's radiant output.

Owner:SILICON VALLEY BANK

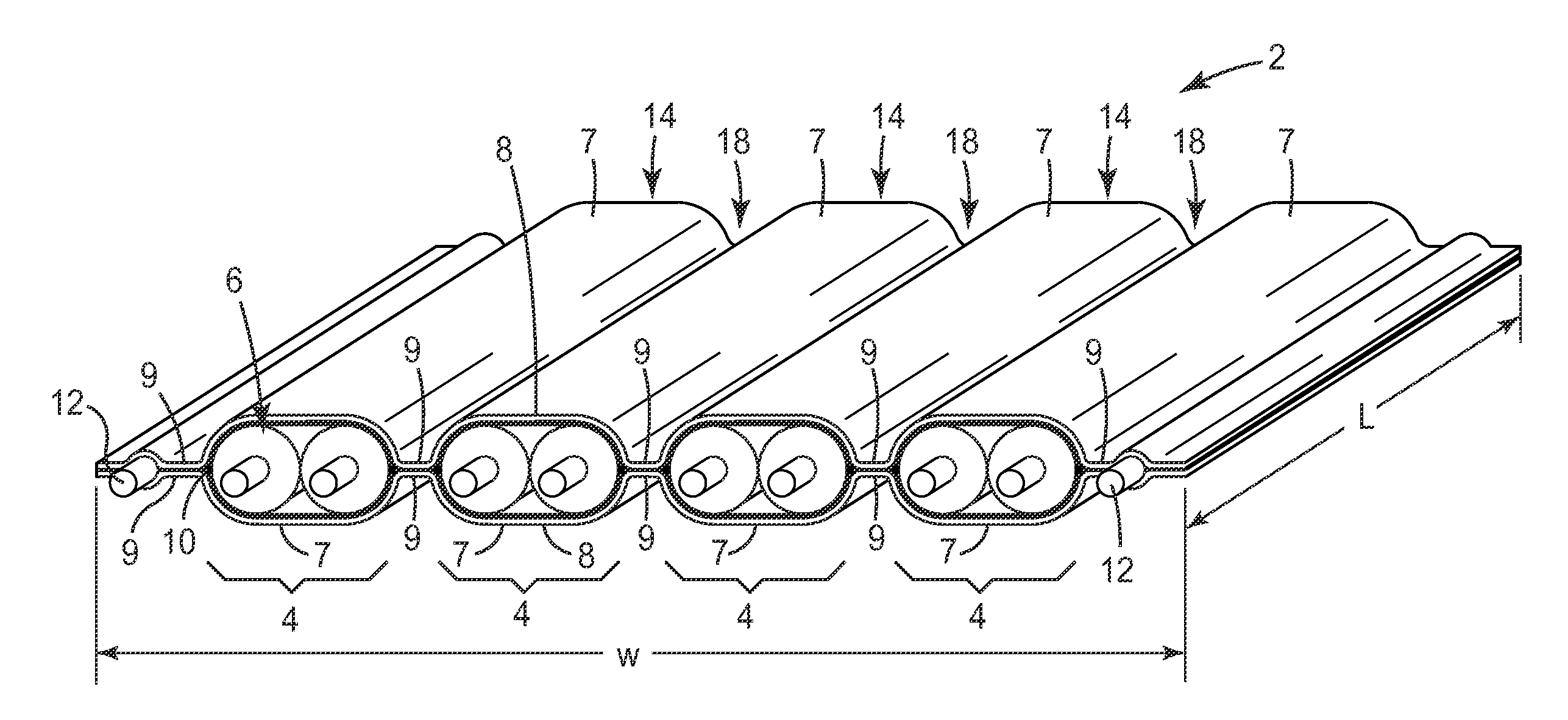

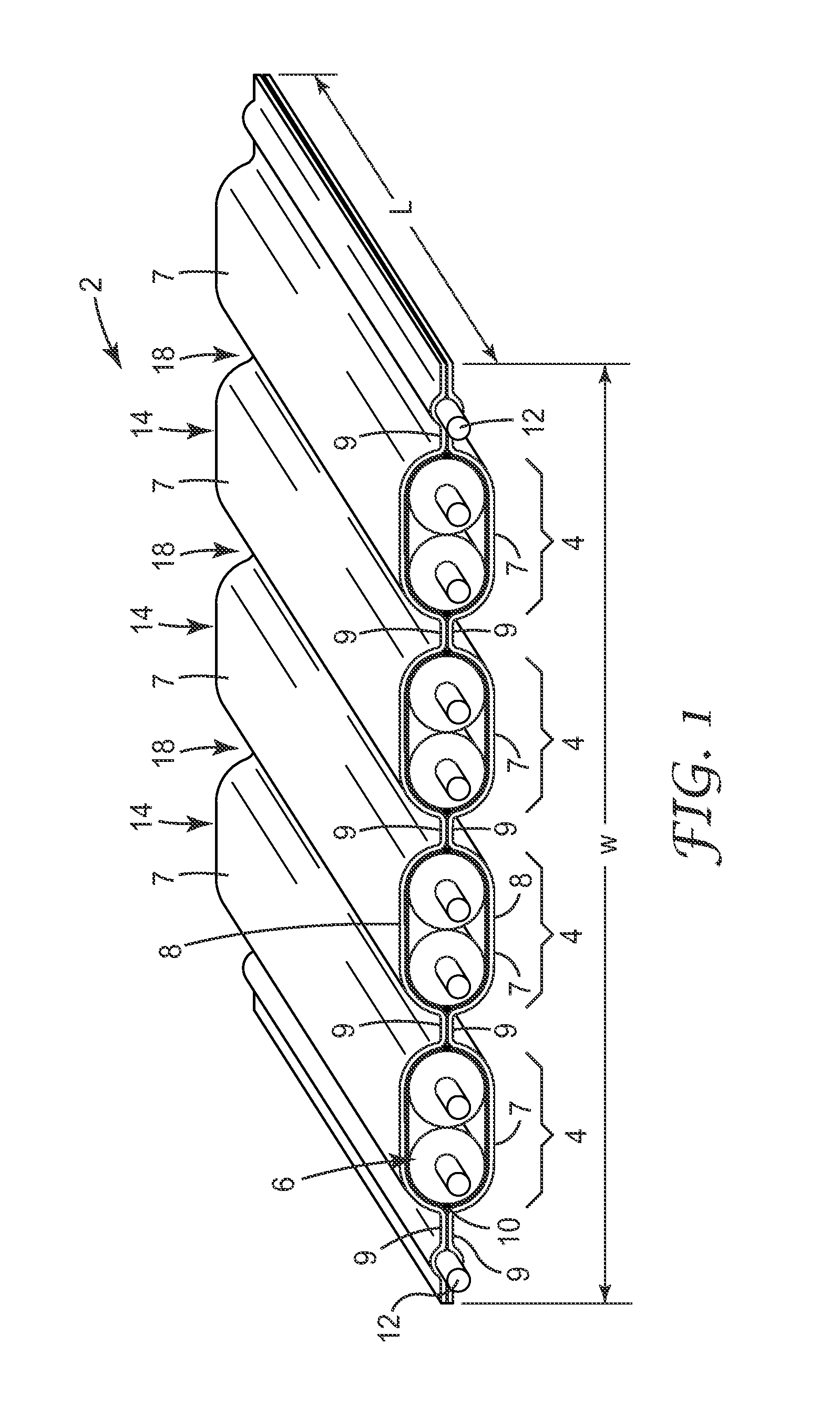

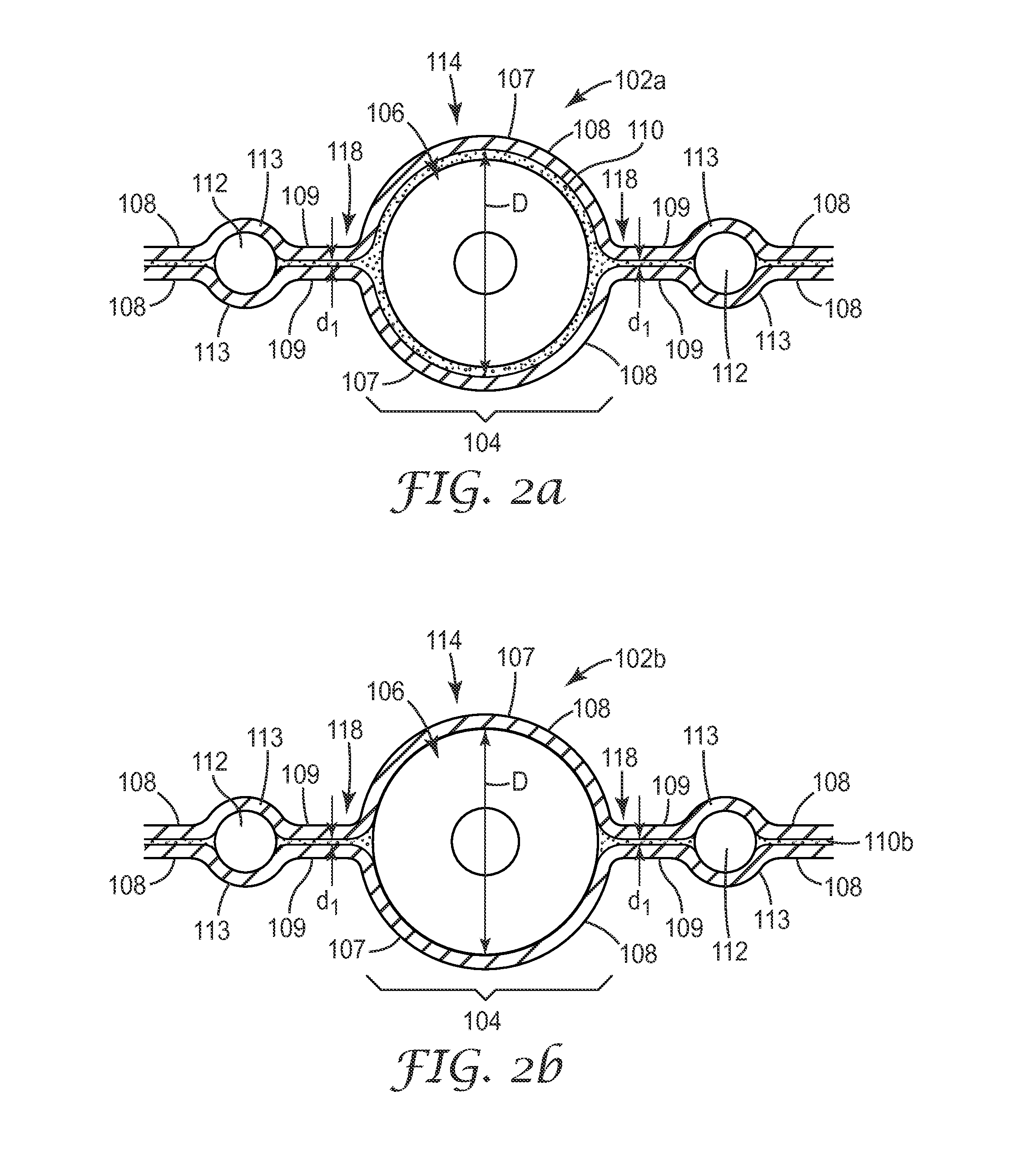

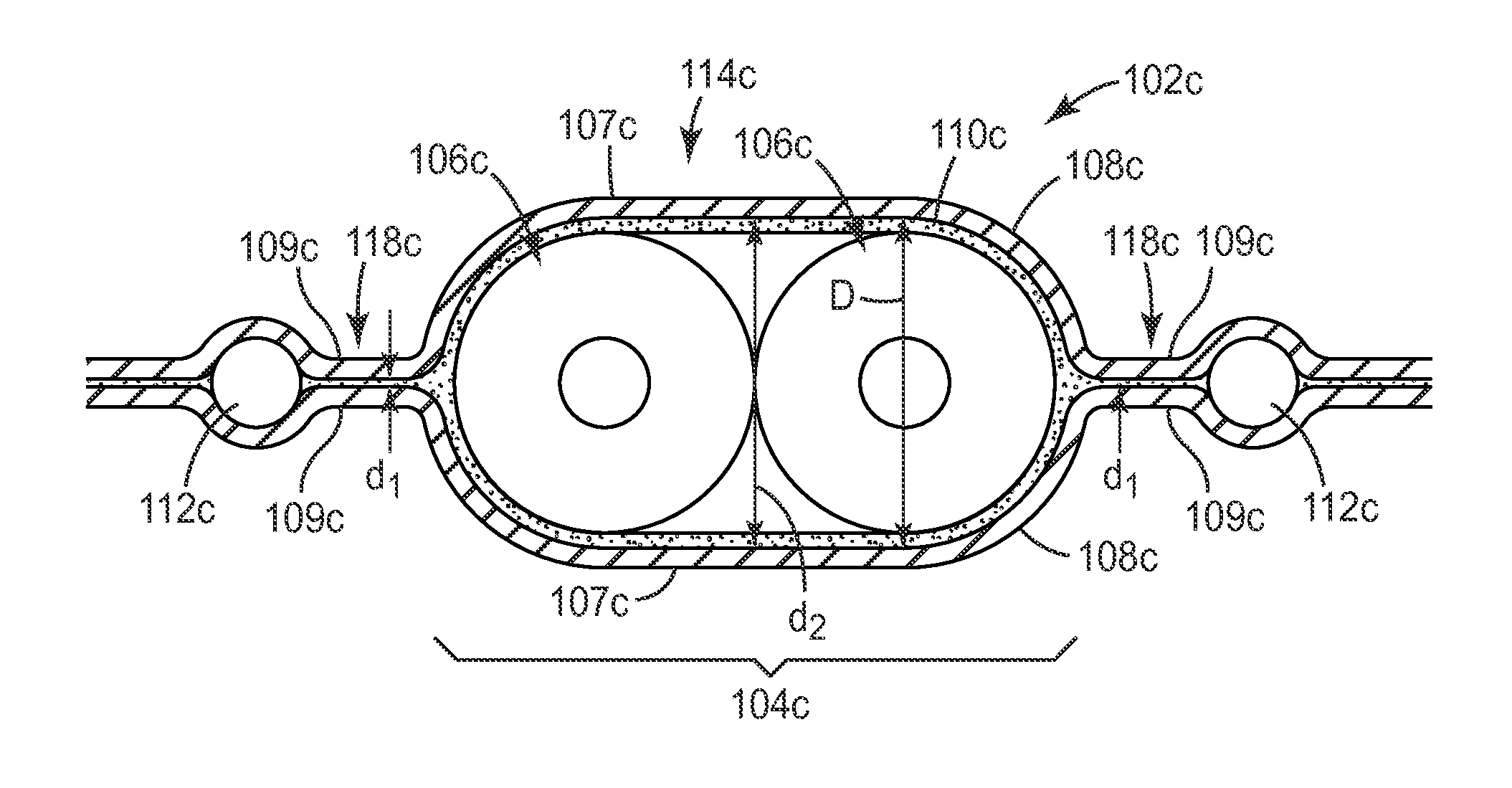

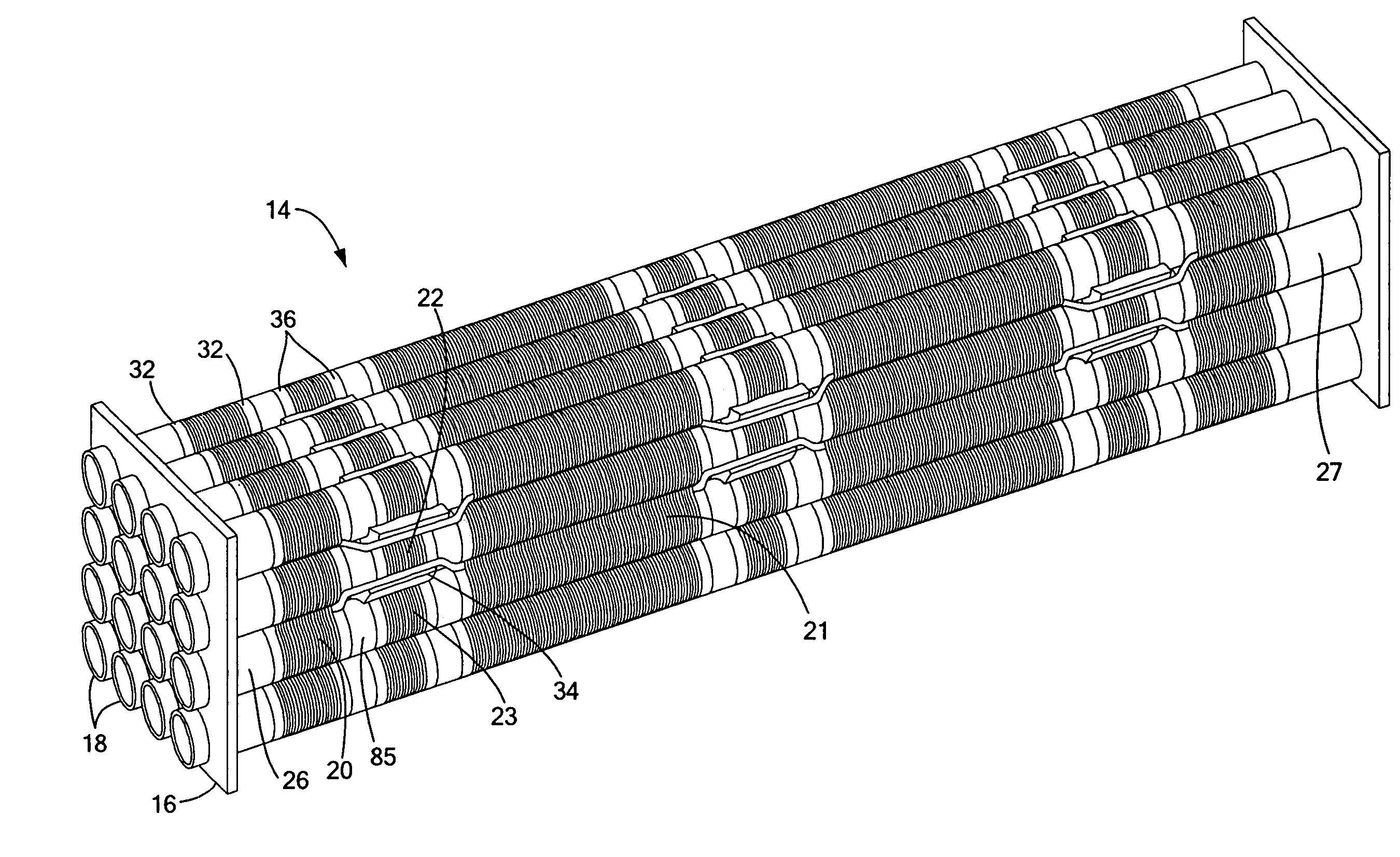

High density shielded electrical cable and other shielded cables, systems, and methods

ActiveUS20130146326A1Improve manufacturing speedReduce complexityQuad constructionsPower cables with screens/conductive layersShielded cableHigh density

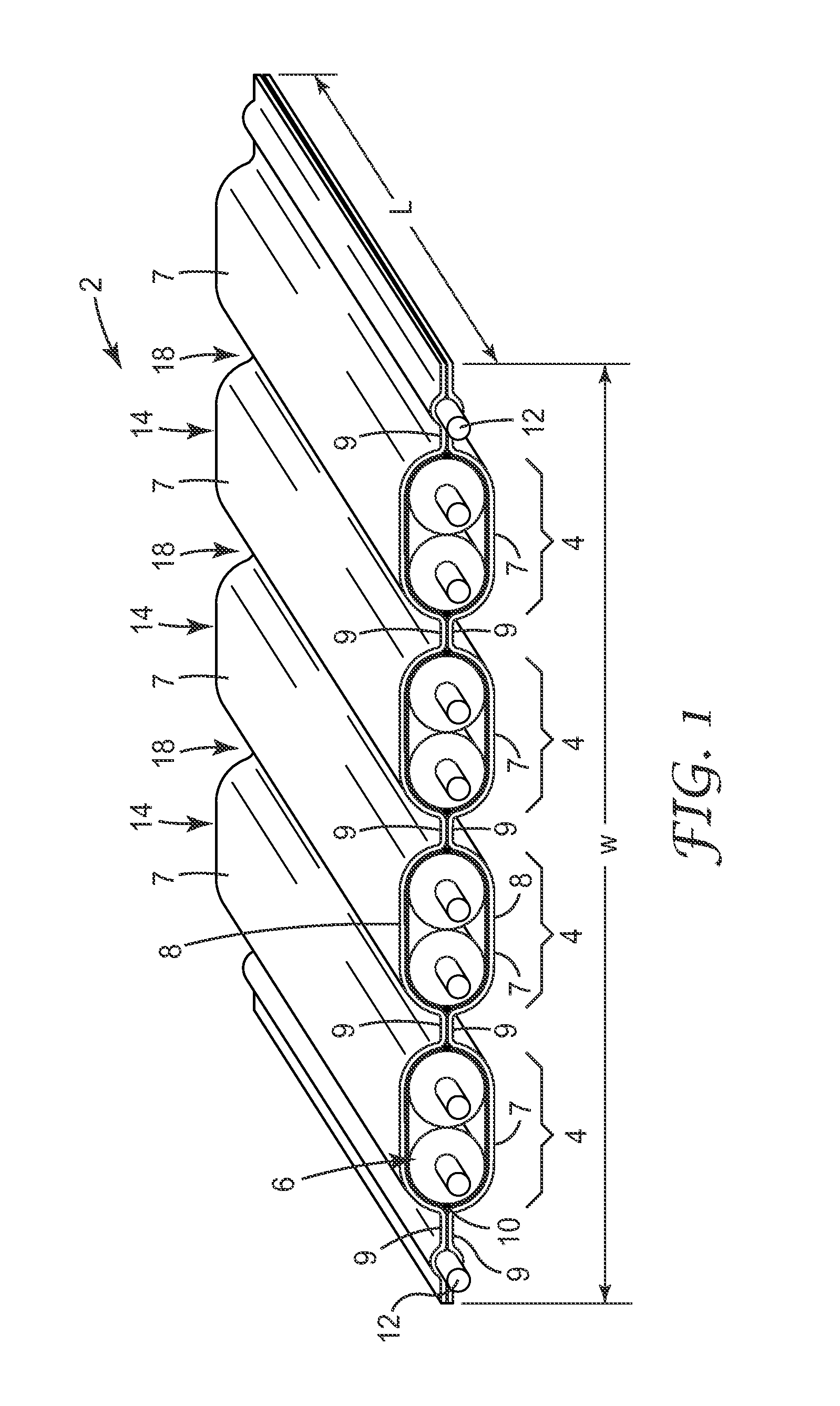

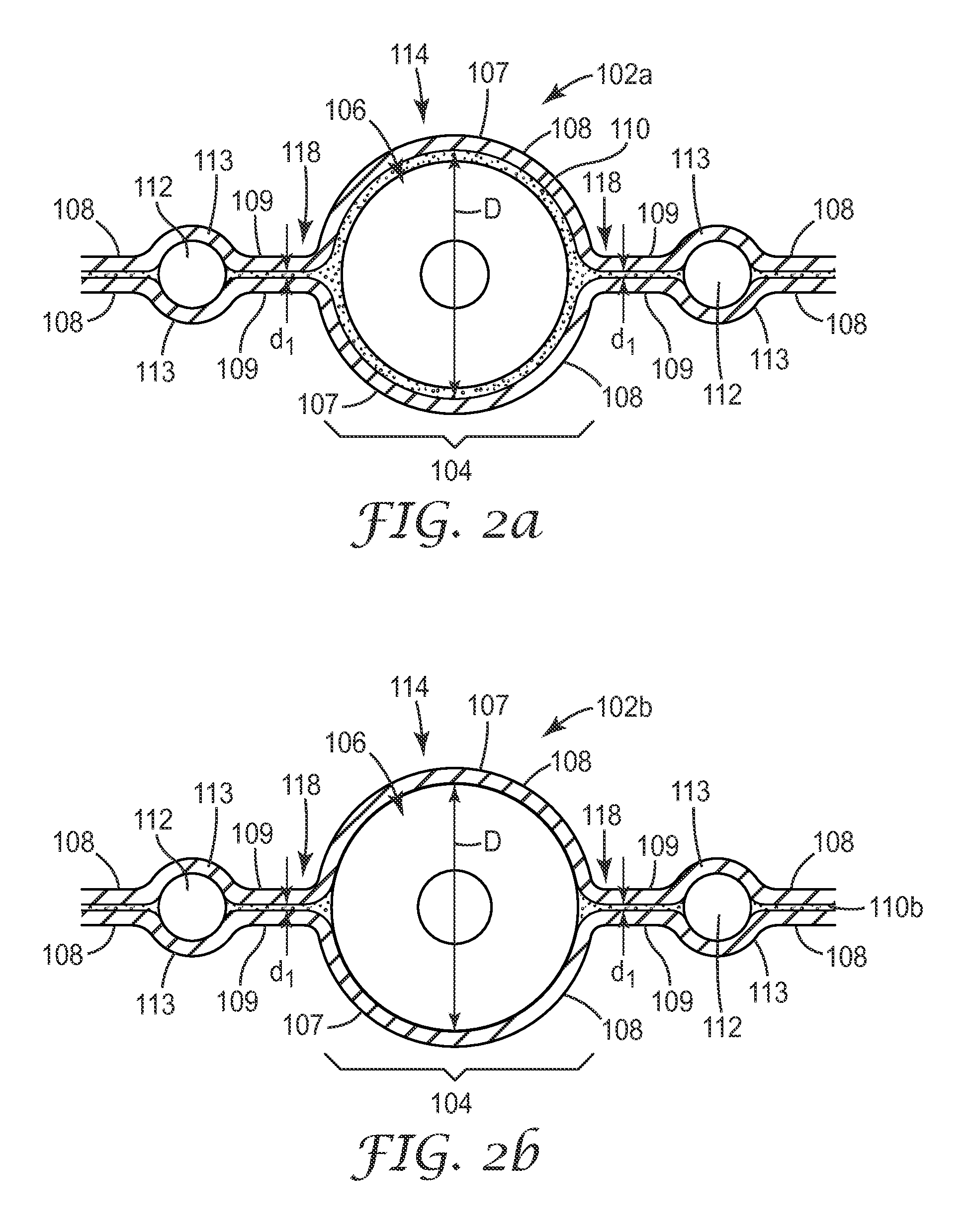

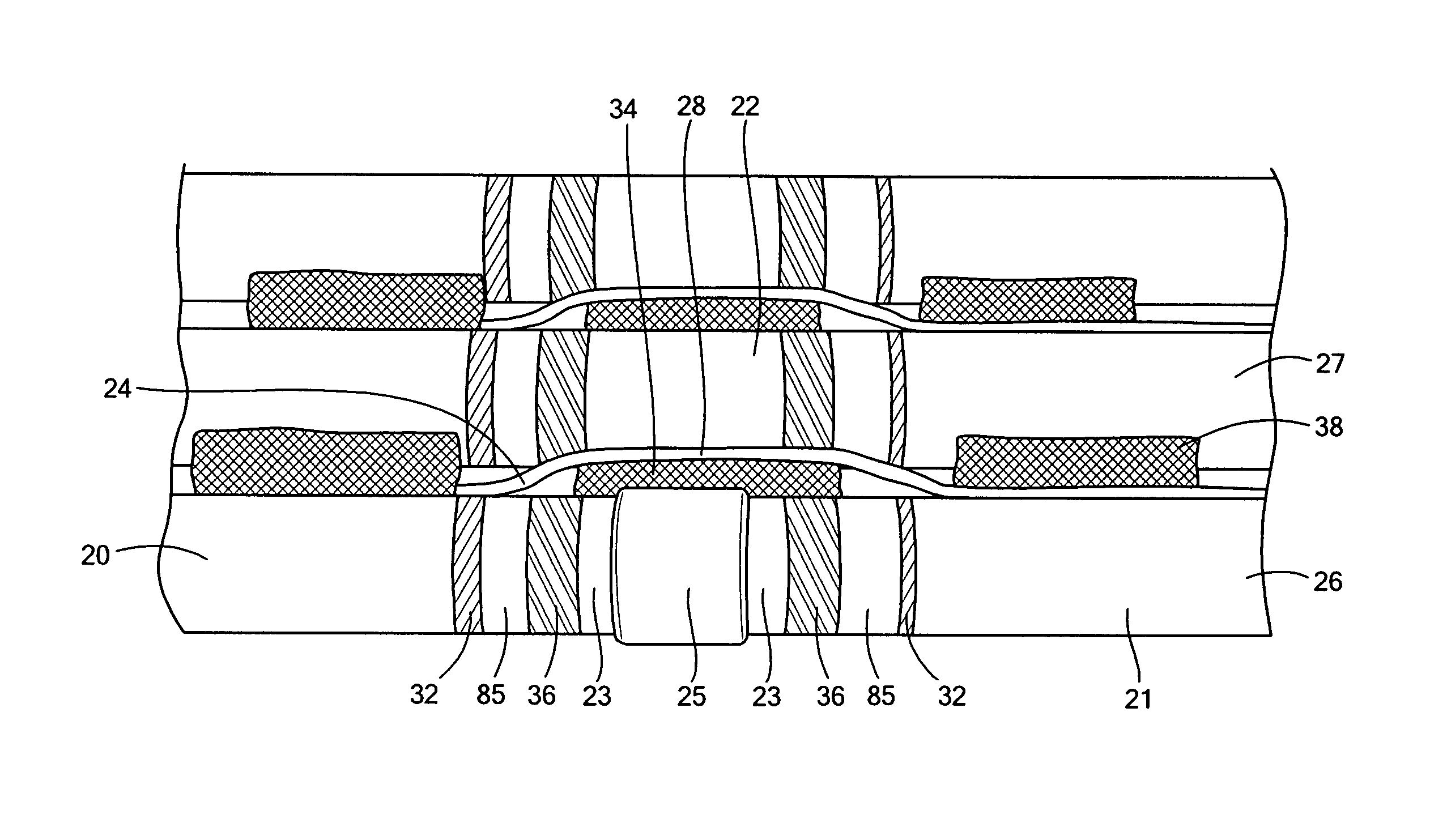

A shielded electrical ribbon cable (2) includes conductor sets (4) each including one or more insulated conductors (6), and a first and second shielding film (8) on opposite sides of the cable. In transverse cross section, cover portions (7) of the shielding films (8) substantially surround each conductor set (4), and pinched portions (9) of the films (8) form pinched portions of the cable on each side of each conductor set (4). Dense packing is achieved while maintaining high frequency electrical isolation between conductor sets (4). When the cable (2) is laid flat, a quantity s / Dmin is in a range from 1.7 to 2, where S is a center-to-center spacing between nearest insulated conductors (6) of two adjacent conductor sets (4), and Dmin is the lesser of the outer dimensions of such nearest insulated conductors (6). Alternatively, a first and second conductor set each having only one pair of insulated conductors can satisfy a condition that Σ / σ1 is in a range from 2.5 to 3. Other shielded cables, systems, and methods, which may or may not utilize the dense packing, are also disclosed.

Owner:3M INNOVATIVE PROPERTIES CO

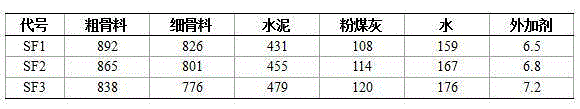

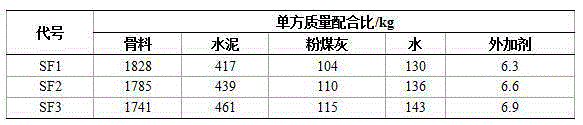

Design method for mixing proportion of self-compacting concrete mixture

ActiveCN105224727AQuick lockPrevent disengagementSpecial data processing applicationsParticulatesVoid ratio

The present invention belongs to the technical field of concrete construction and particularly relates to a design method for a mixing proportion of a self-compacting concrete mixture. The method comprises the steps of: determining a performance design target; determining mixing strength and a water-binder ratio; determining densest gradation (or a sand rate) of aggregates and void ratios of different packing states; determining the usage amount of binding materials and mixing water; determining the usage amount of the aggregates; determining the usage amount of additives; determining the actual adding amount of the mixing water; and the like. According to the method provided by the present invention, aimed at blindness of material selection during self-compacting concrete mixing proportion design in the prior art, based on a fundamental theory of particulate dense packing and a composition rule of reaching a densest packing state of solid particulate materials with different particulate diameters, a mixing proportion of different materials is determined by an actually measured densest packing state, and relationships are established between the material mixing proportions corresponding to different densest packing states and expected self-compacting performance grades of the mixture, so that the design method used for the mixing proportion of the self-compacting high-performance concrete mixture and based on a use performance as a target is constructed.

Owner:ZHENGZHOU UNIV

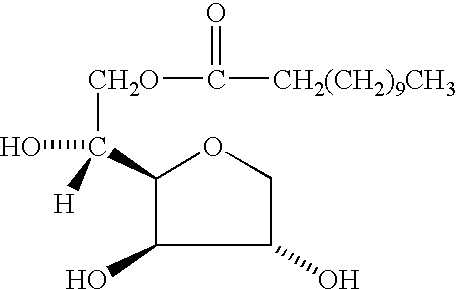

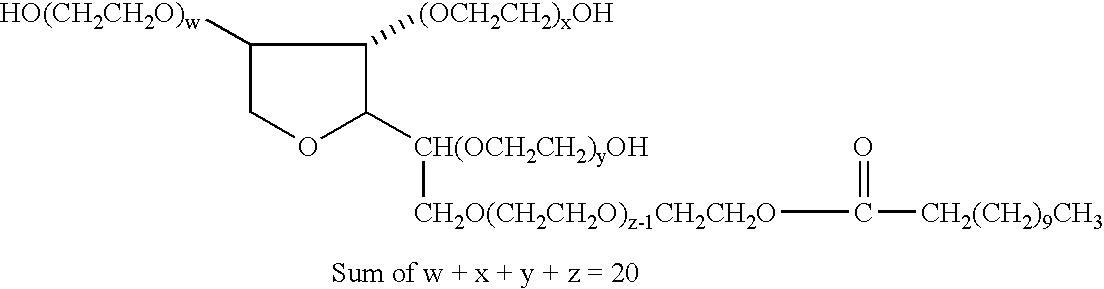

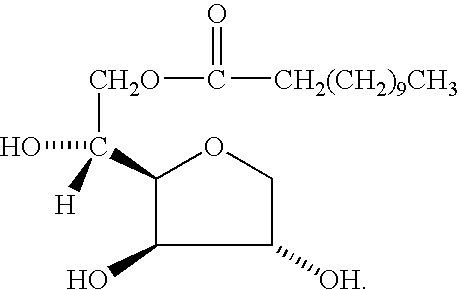

Electrically conductive oil-based mud

InactiveUS6691805B2Electric/magnetic detection for well-loggingSurveyElectrical resistance and conductanceEmulsion

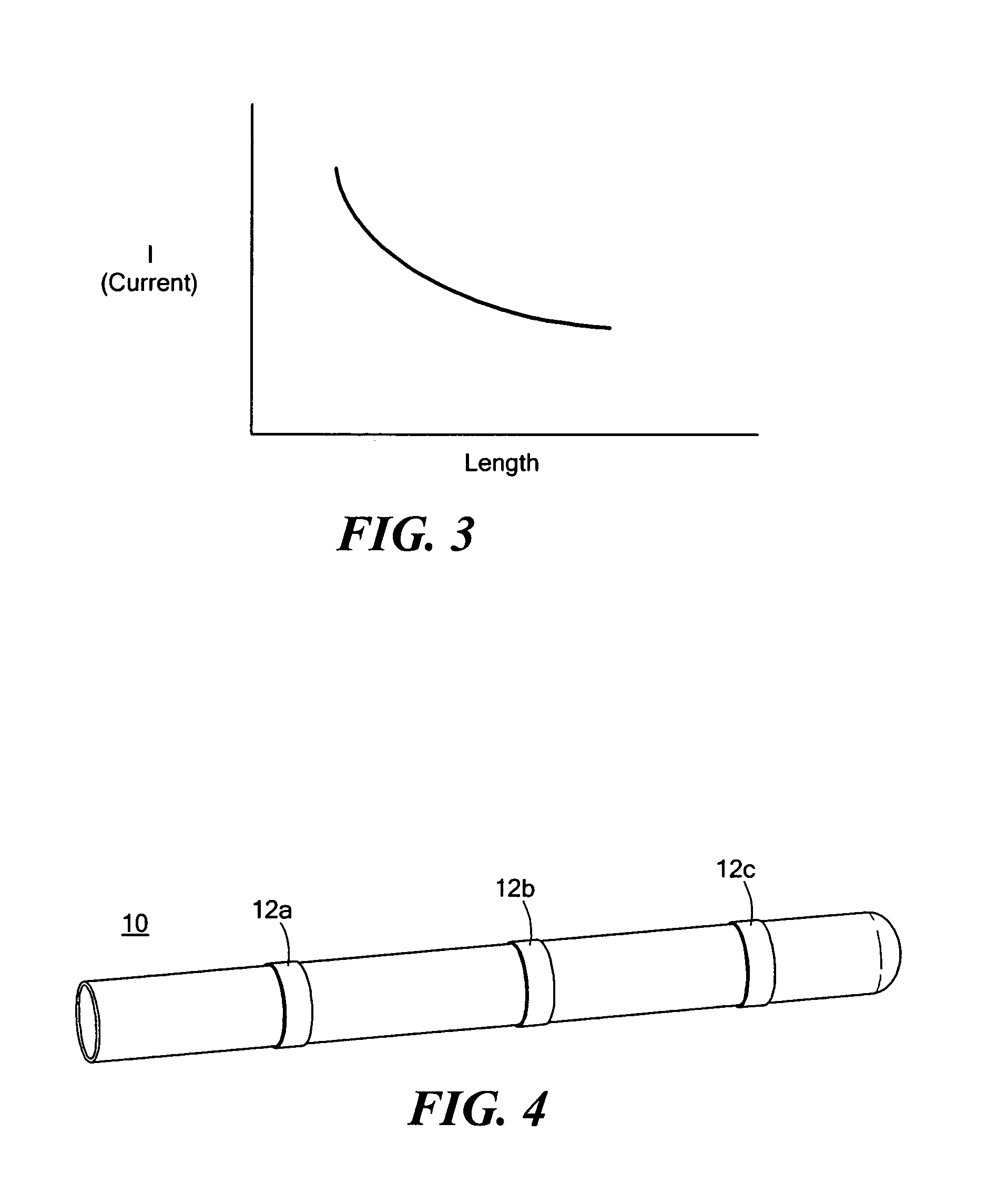

An electrically conductive oil mud meeting the fluid requirements for resistive logging tools and a method for preparing such mud is disclosed. The fluid has been optimized to deliver performance in a manner as similar to that of a traditional invert emulsion drilling fluid as is practical while still maintaining the required electrical conductivity for resistivity-based logging tools. This electrically conductive oil-based mud comprises a polar synthetic ester base and complimentary ester surfactants, one being more oil soluble, the other being more water soluble. The surfactants interact synergistically to provide dense packing of micelles at the palisade layer. This fluid is oil-wetting to solids, and in general behaves like a traditional oil mud.

Owner:HALLIBURTON ENERGY SERVICES INC

High density shielded electrical cable and other shielded cables, systems, and methods

ActiveUS8841554B2Improve manufacturing speedReduce complexityCoaxial cables/analogue cablesQuad constructionsShielded cableElectricity

Owner:3M INNOVATIVE PROPERTIES CO

High density LED array

ActiveUS20050247947A1Improved matingHigh bulk densitySemiconductor/solid-state device detailsSolid-state devicesHigh densityLed array

A dense array of semiconductor devices having an array of micro-reflectors, the micro-reflectors having characteristics that enhance dense packing of the array in balance with collection and collimation of the array's radiant output.

Owner:SILICON VALLEY BANK

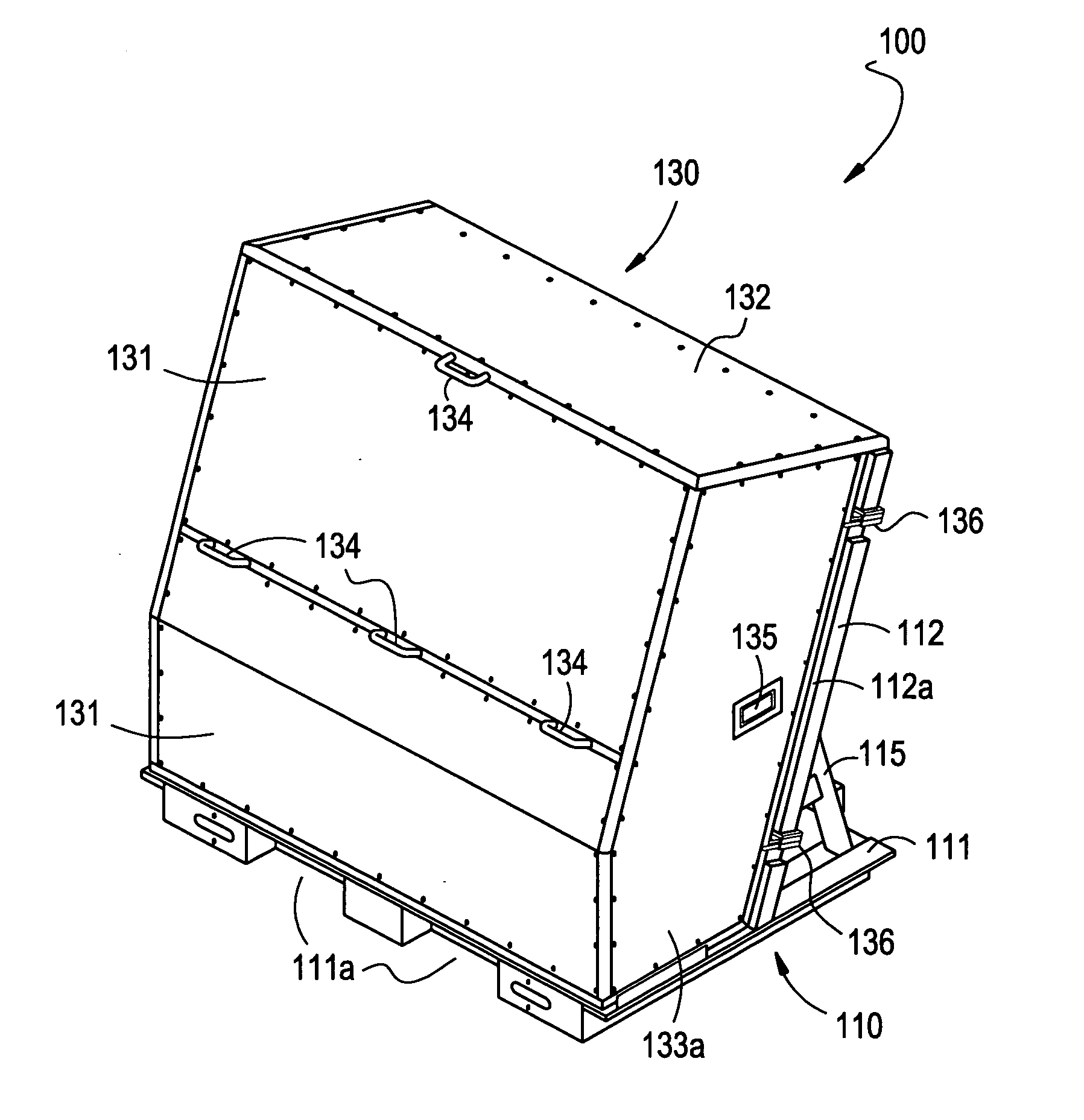

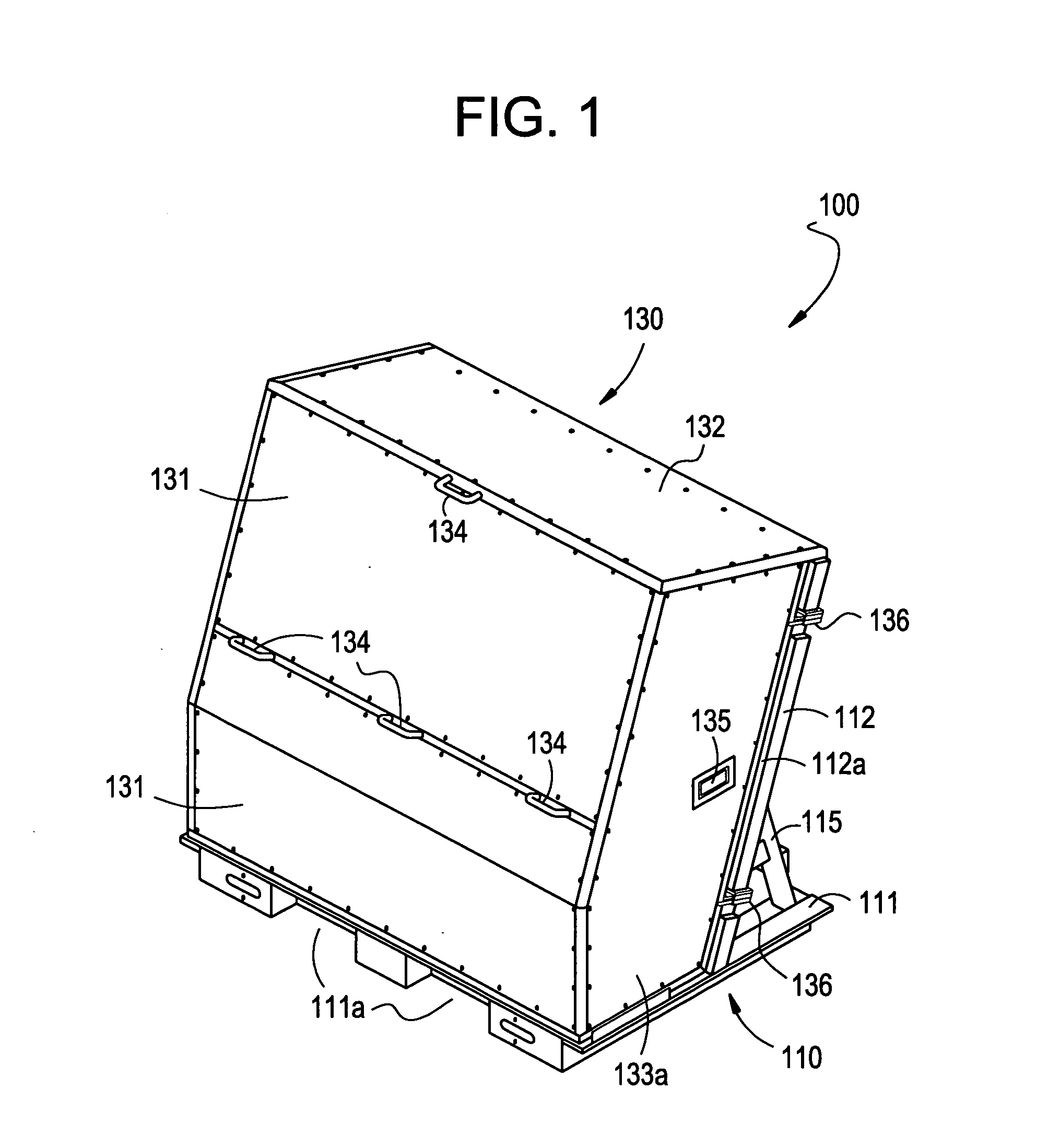

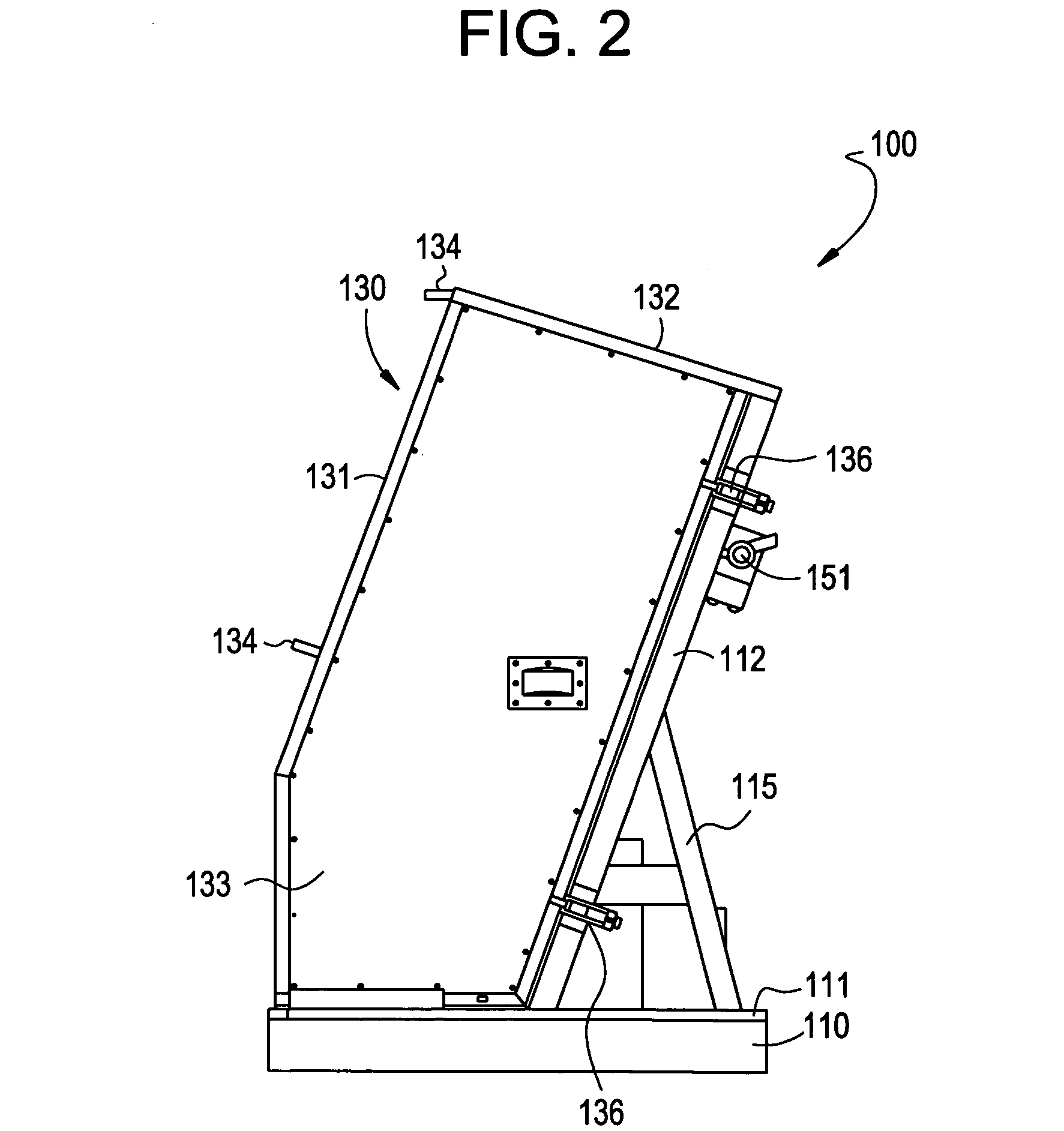

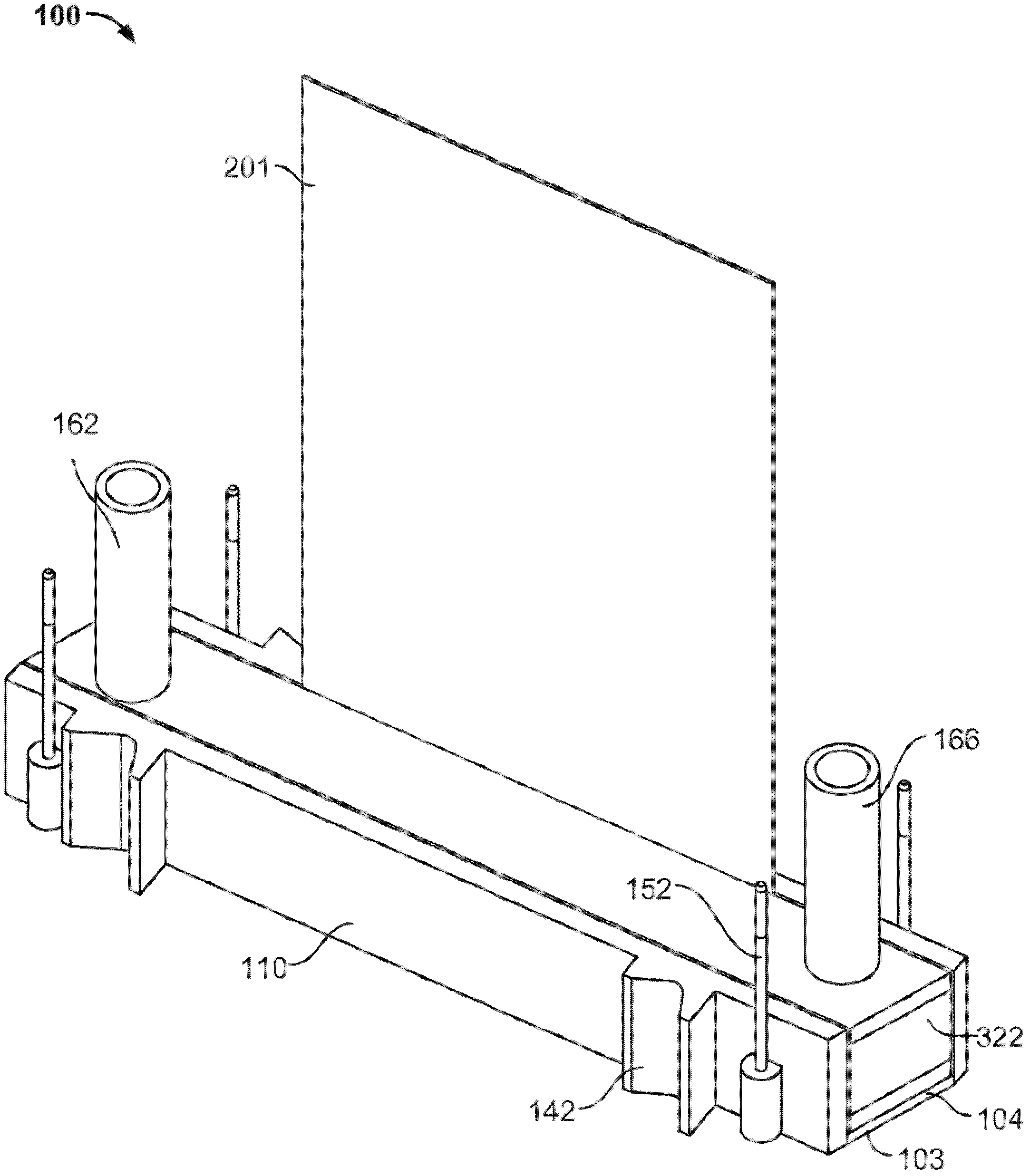

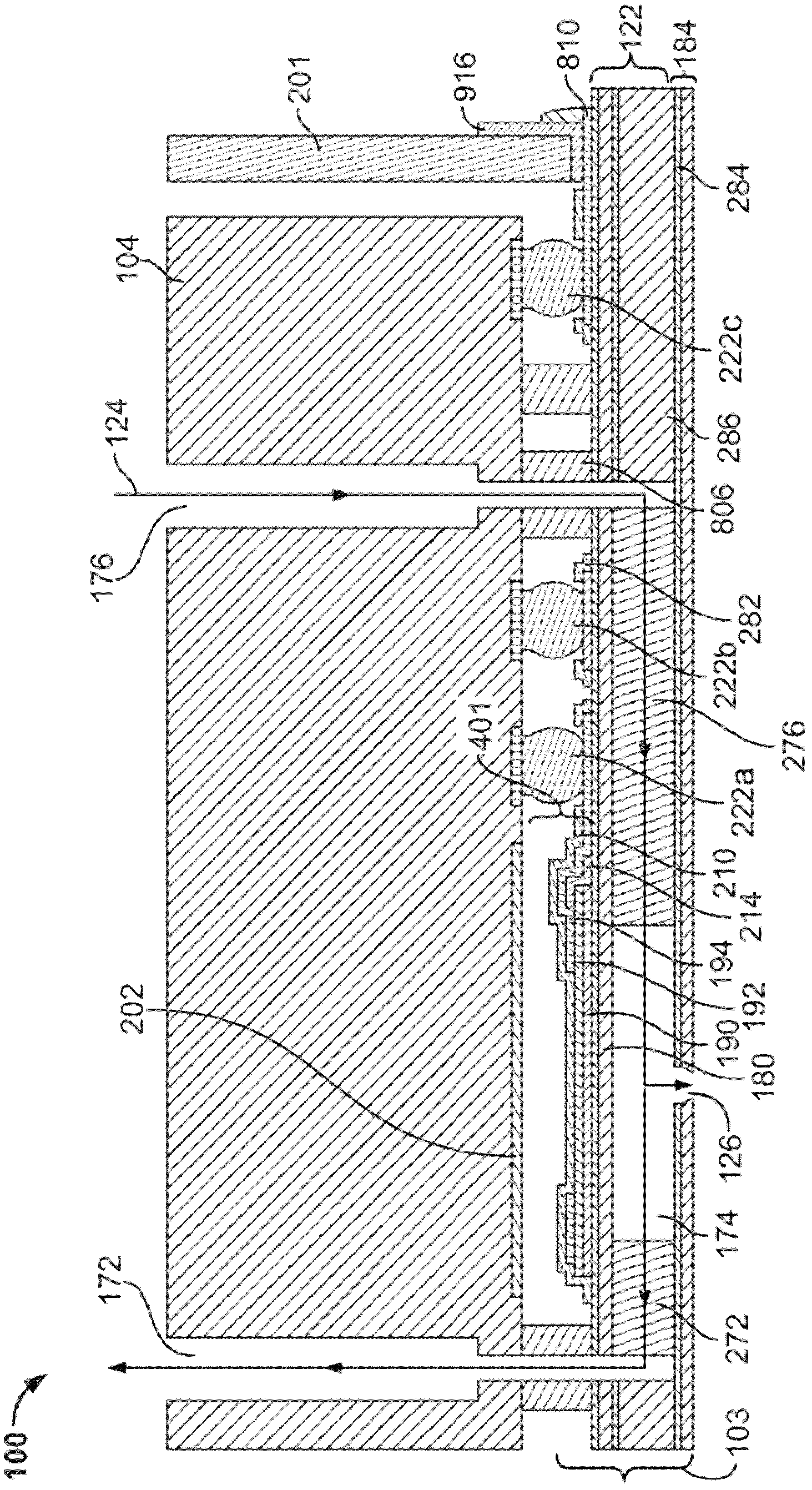

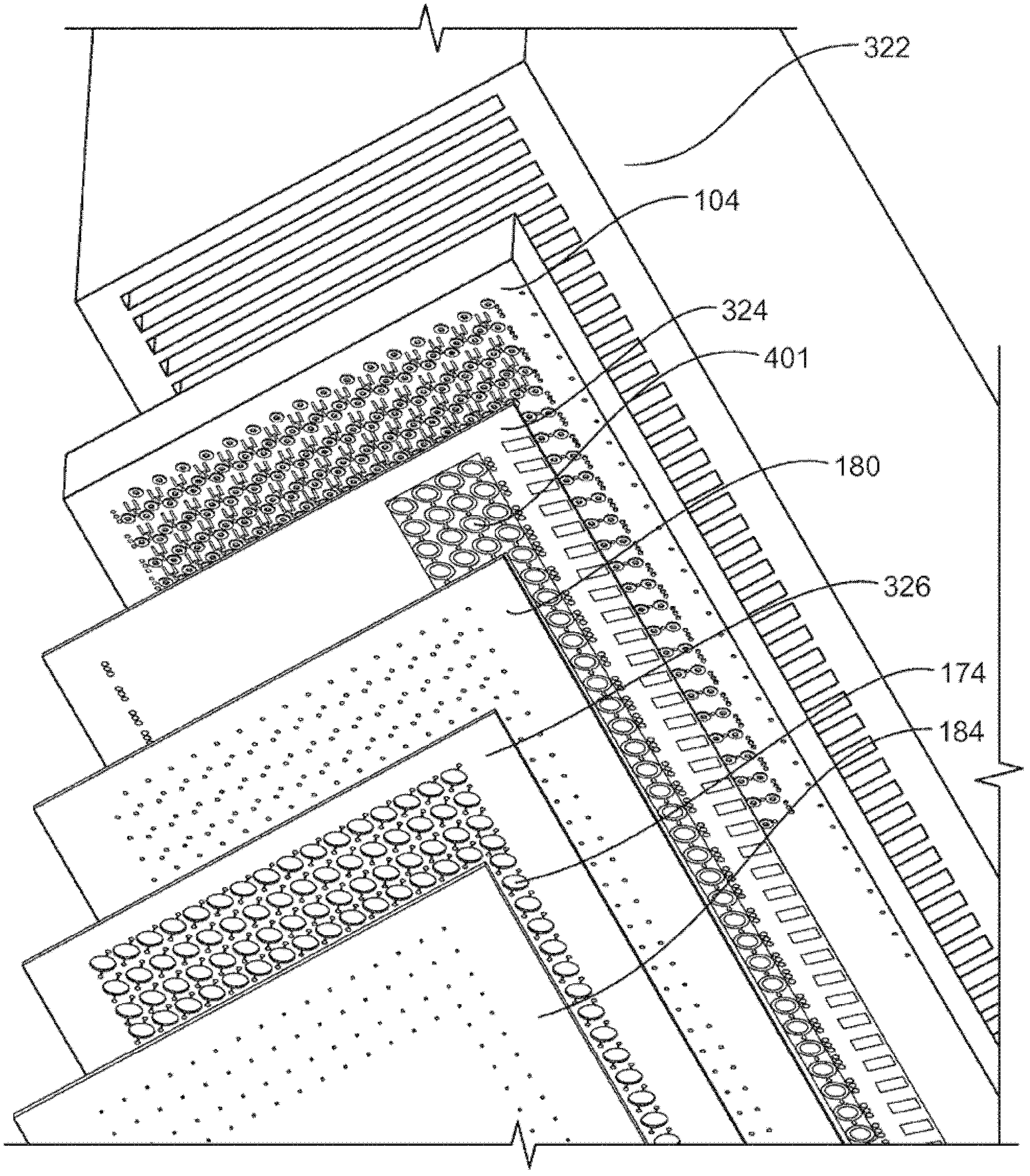

Restraining dense packaging system for LCD glass sheets

A reusable dense packaging system used to transport large size display substrates, is provided made up of three main components; a pallet frame, a cover, and restraining means. The restraining means securely hold the glass sheets within the cover and on the pallet frame. Restraining means includes one or more retaining bars moving towards and away from the front of the glass sheets and a mechanical system. The mechanical system may include the use of a pressing panel, a belt apparatus, a scissor-like mechanism, positioning devices, or a retaining bar pulling system, each capable of moving towards and away from the front of the glass sheets. Each embodiment allows for packaging from 1 to N glass sheets with flexibility and stability and with manual or automatic operation.

Owner:CORNING INC

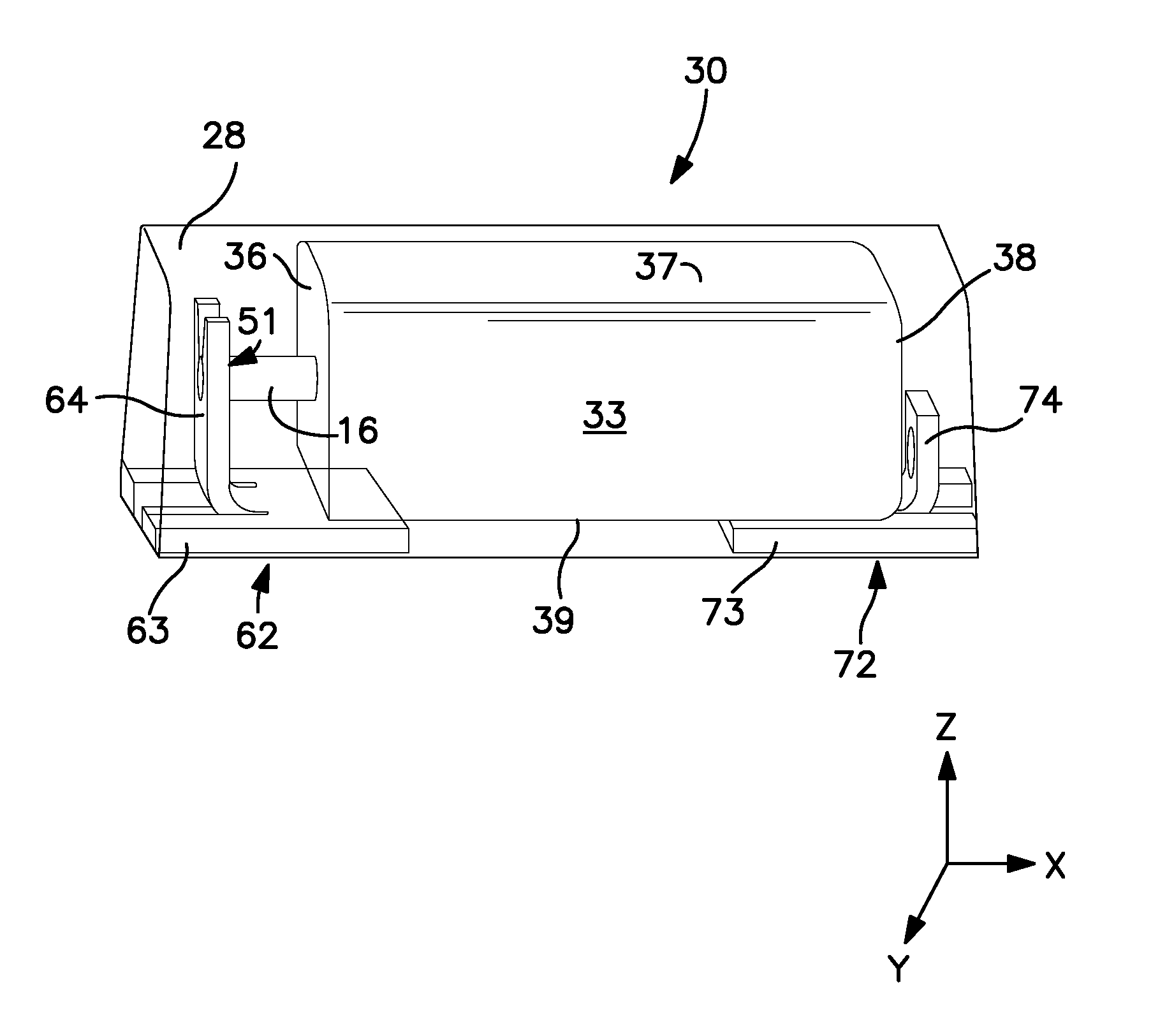

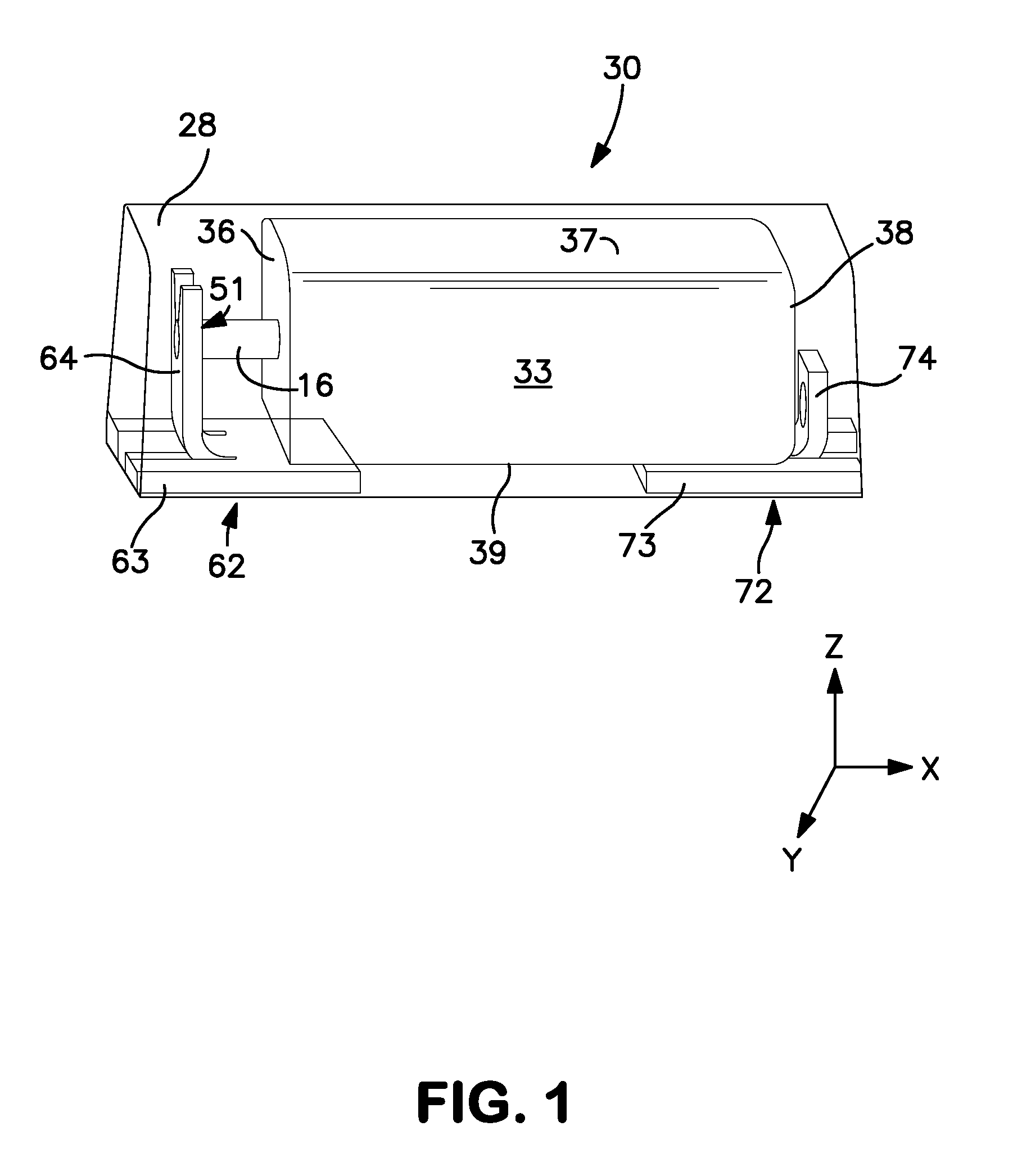

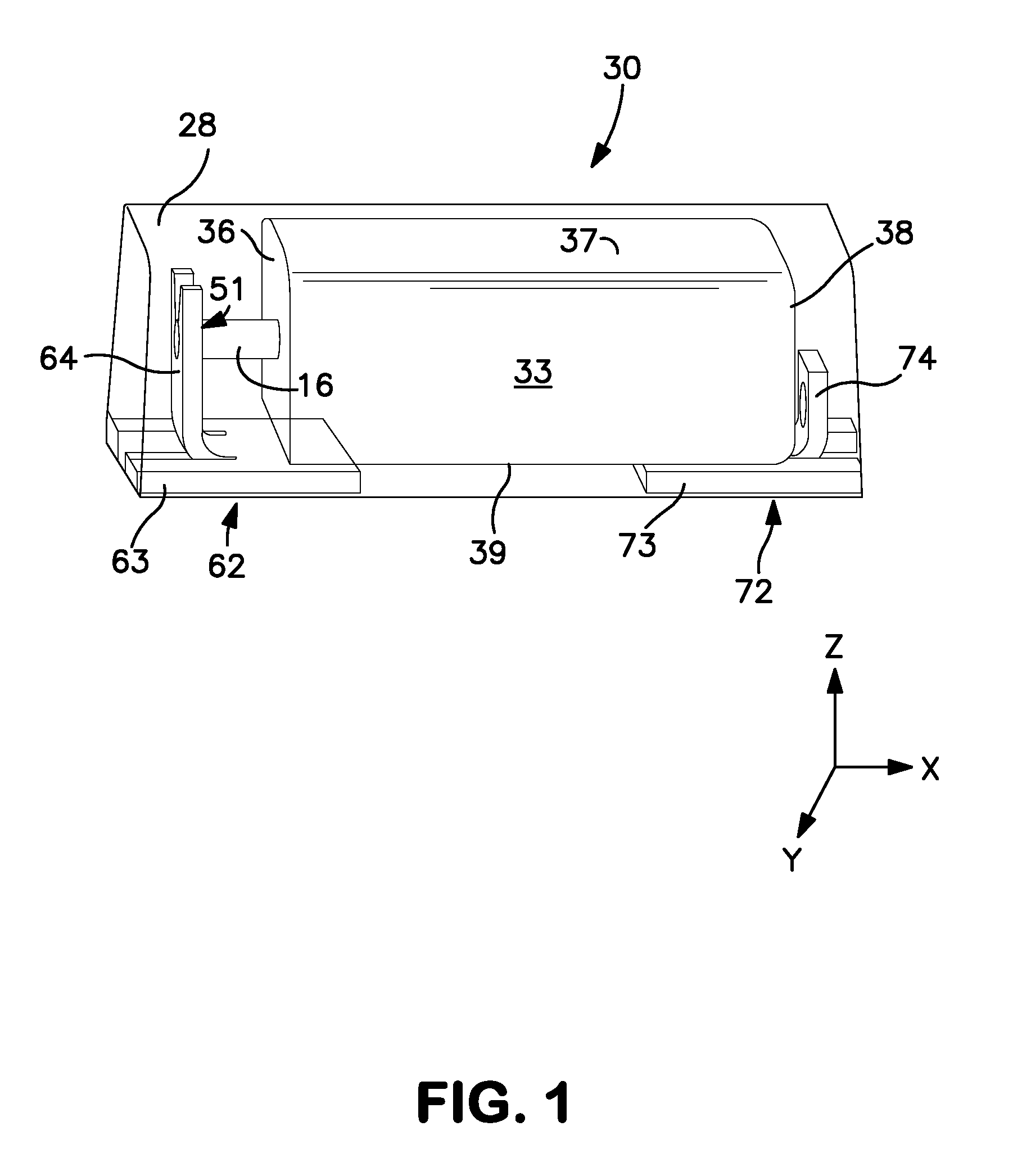

Mems Jetting Structure For Dense Packing

ActiveCN102481789AReduce maintenance downtimeHigh densityInking apparatusSpraying apparatusElectrical connectionEngineering

A fluid ejector includes a fluid ejection module having a substrate and a layer separate from the substrate. The substrate includes a plurality of fluid ejection elements arranged in a matrix, each fluid ejection element configured to cause a fluid to be ejected from a nozzle. The layer separate from the substrate includes a plurality of electrical connections, each electrical connection adjacent to a corresponding fluid ejection element.

Owner:FUJIFILM DIMATIX

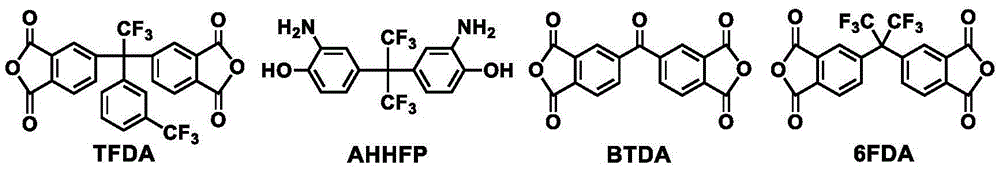

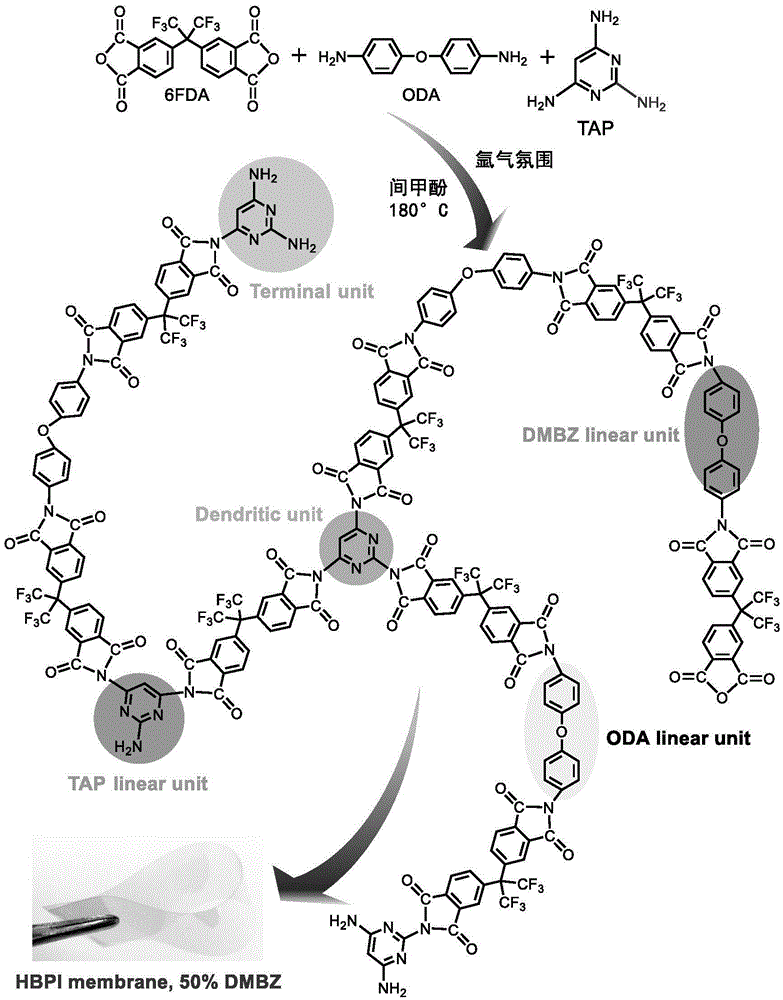

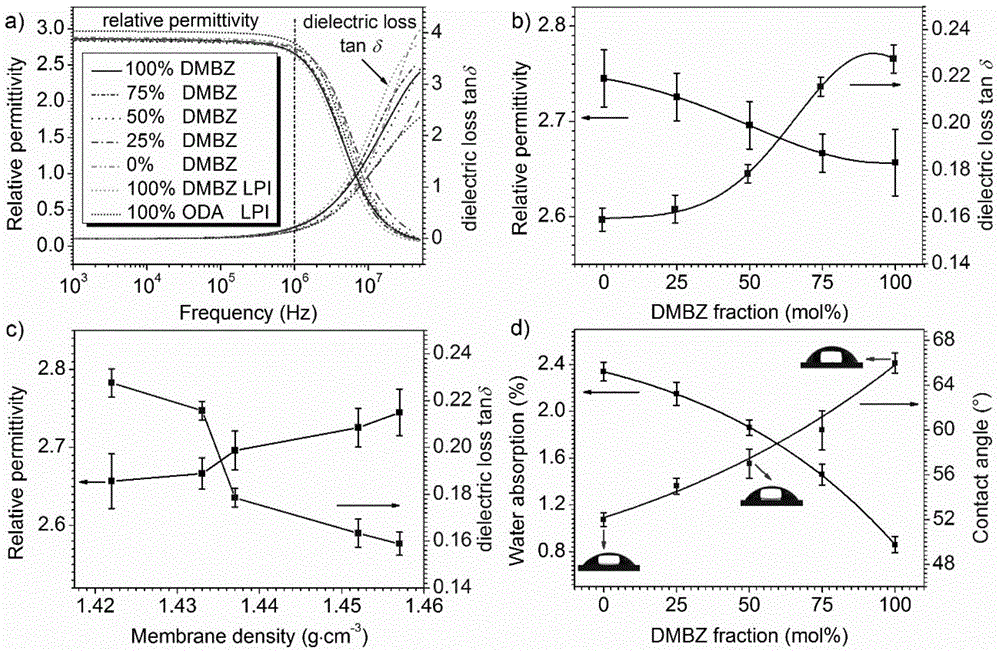

Preparation method for hyperbranched polymide film with low dielectric constant

The invention relates to a preparation method for a hyperbranched polymide film with the low dielectric constant. A series of the low-dielectric constant PI films with a hyperbranched structure are synthesized by taking 2,4,6-triaminopyrimidine (TAP) as a branching center through a one-step method. Through introduction of the hyperbranched structure, the dielectric constant of the PI film is significantly lowered, the inherent advantages of PI are better kept, and the good mechanical strength and thermo-oxidative stability are supplied to the film. The hyperbranched structure contains a large quantity of molecular chain end groups, dense packing of molecular chains is effectively inhibited, and therefore the hyperbranched PI film has the excellent dissolution characteristic to be more prone to be processed into a complex device. Compared with a Kapton standard film which is generally used at present, under the same testing conditions, the dielectric constant of the hyperbranched PI film prepared through the method is lowered by 20%-40%, the lowest dielectric constant even gets close to 2.0 and reaches the ultralow dielectric constant level, and the urgent demand for micro-electronic industry development in future can be met.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

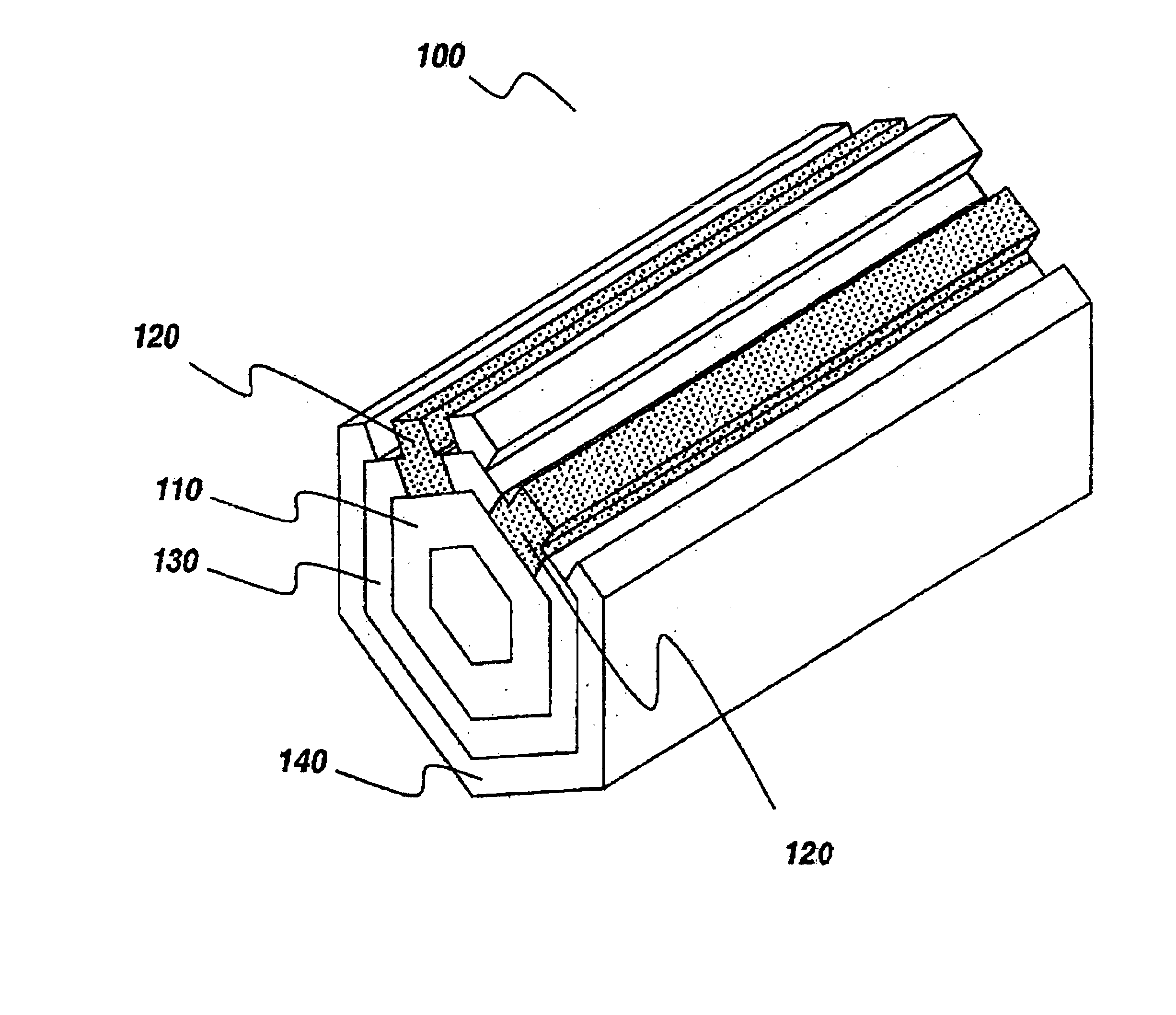

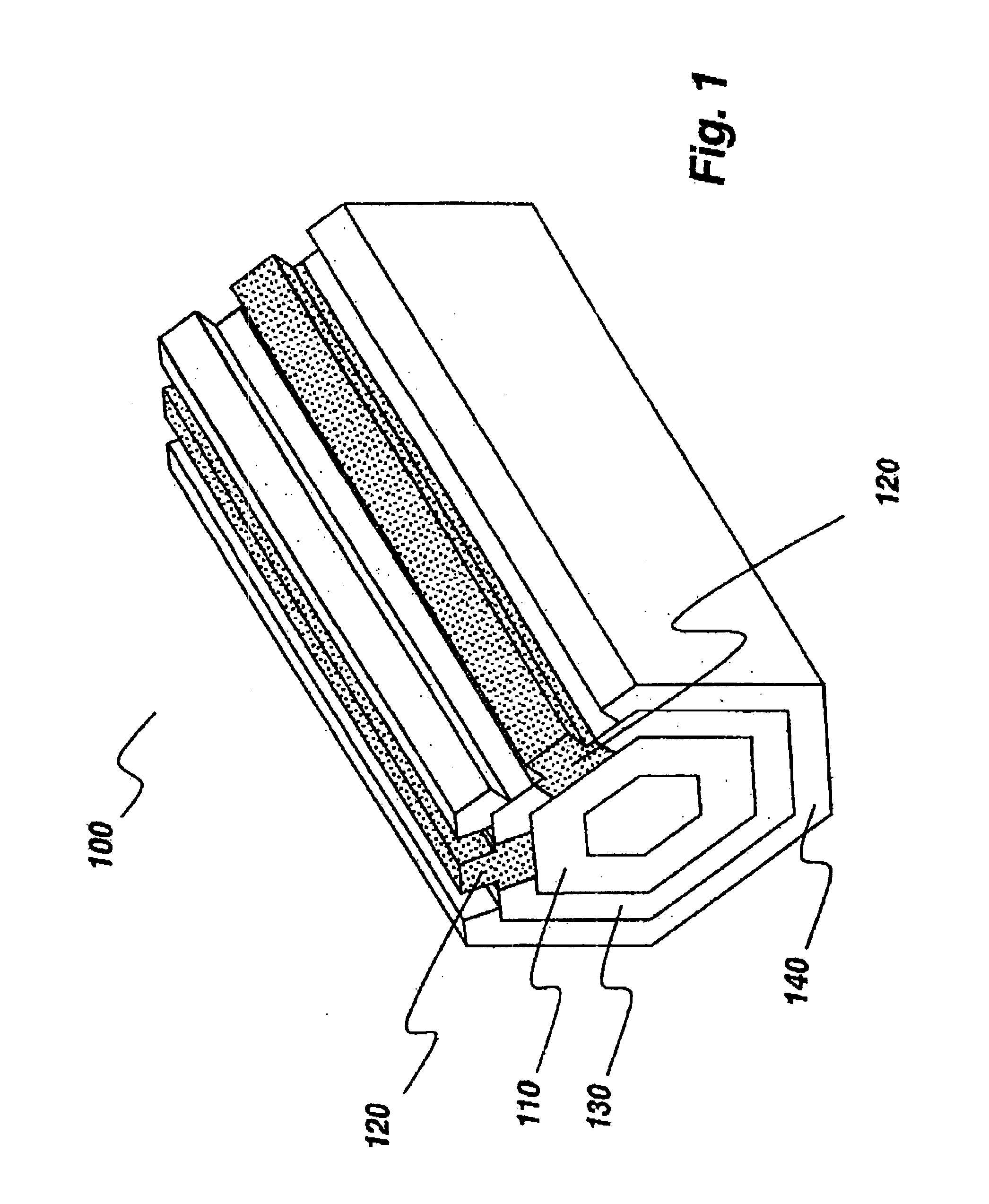

Polygonal fuel cell apparatus and method of making

In one embodiment of the present invention, a polygonal fuel cell comprises: a cathode layer having a tubular shape; a contact layer electrically coupled to and disposed on the cathode layer to leave an uncovered cathode surface portion; an electrolyte layer disposed on the uncovered cathode surface portion; and an anode layer electrically isolated from the contact layer, disposed on the electrolyte layer such that the polygonal fuel cell has a polygonal cross section to facilitate dense packing.

Owner:GENERAL ELECTRIC CO

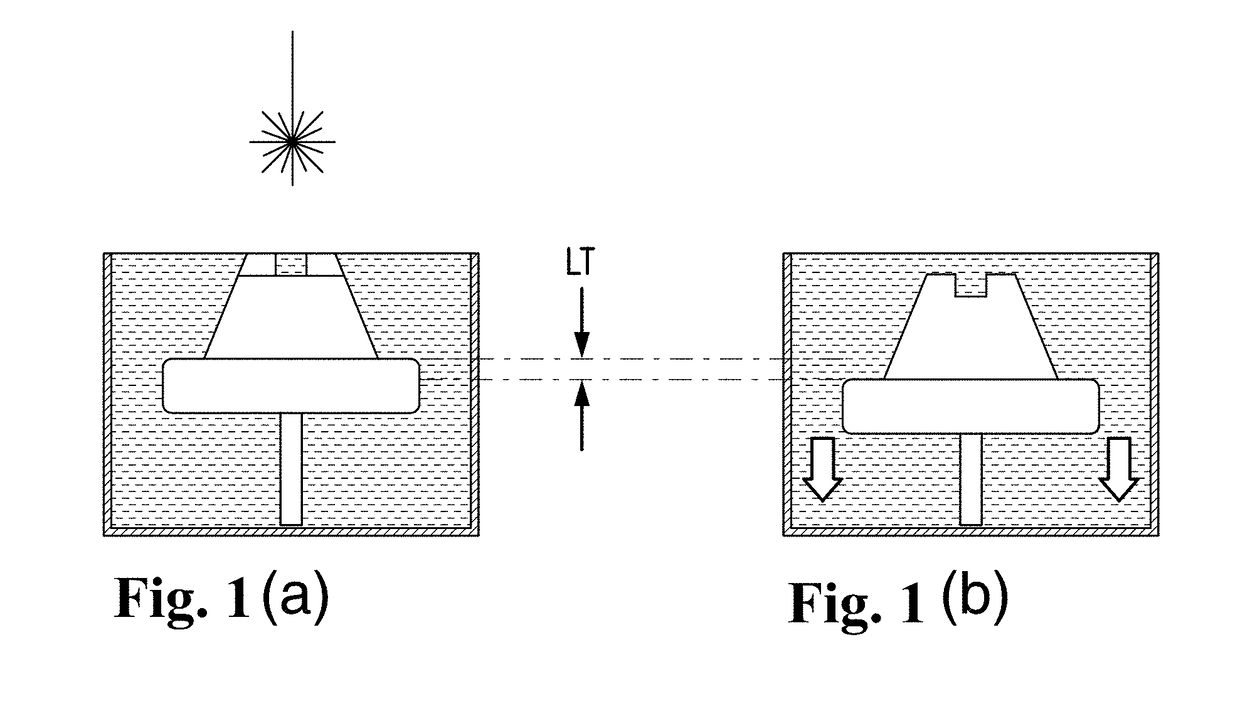

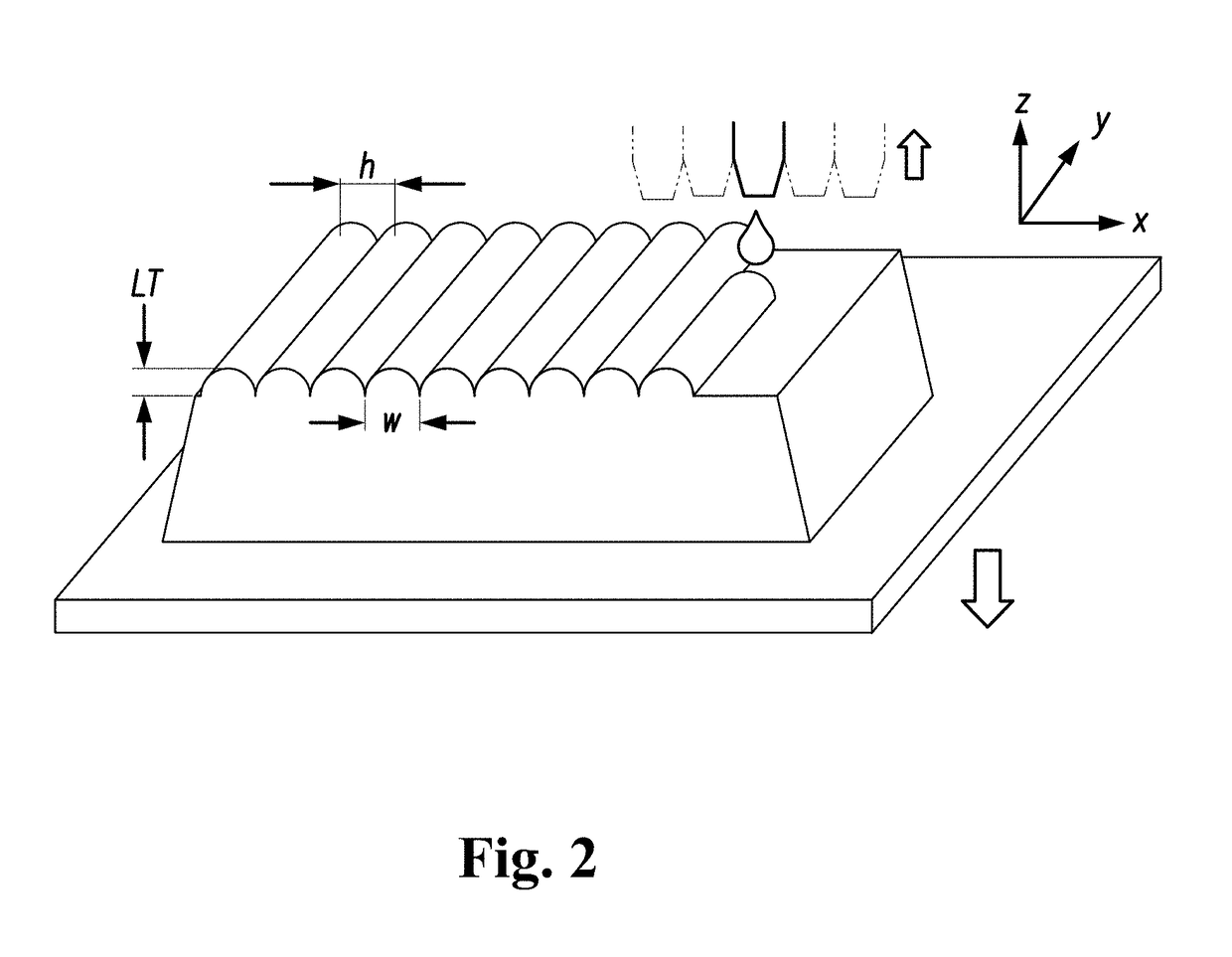

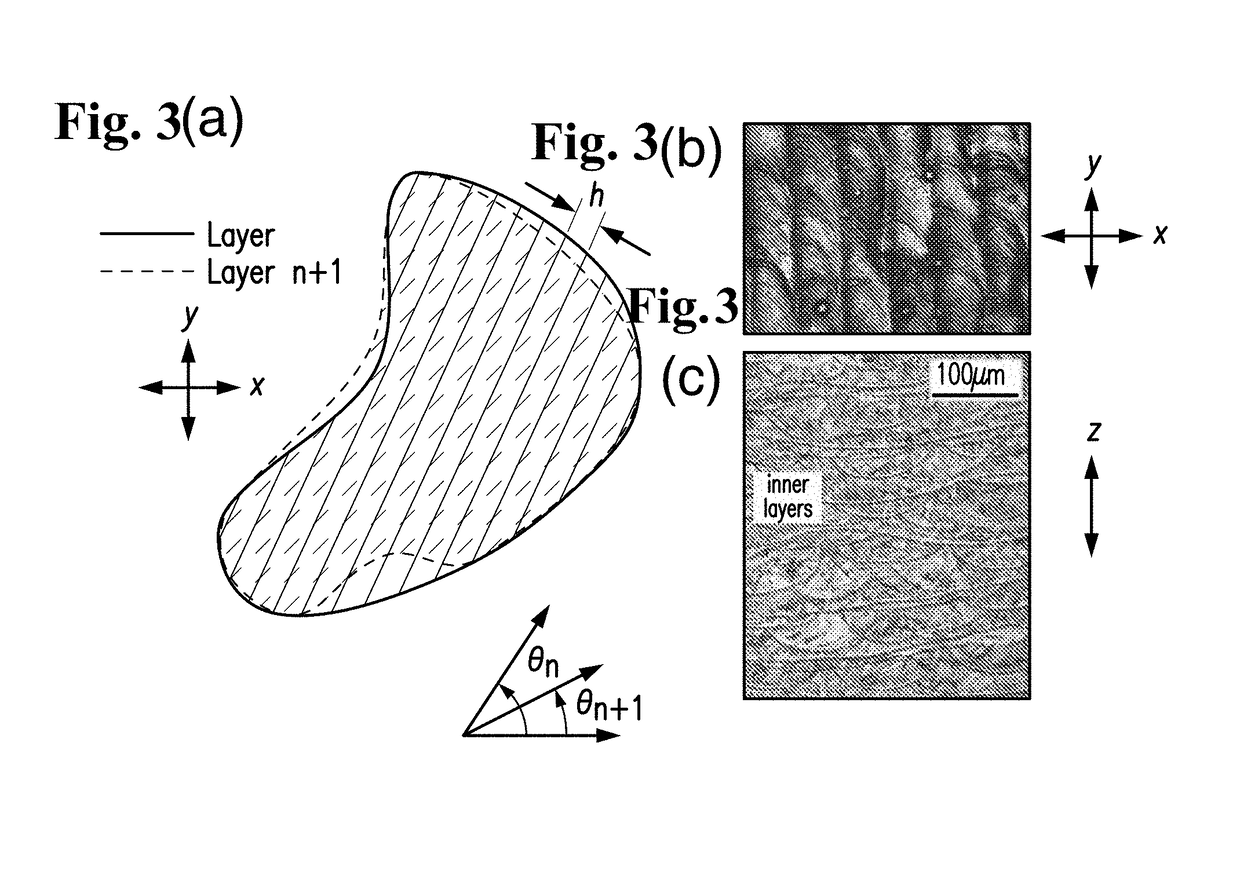

Multilayer parameter-varying fusion and deposition strategies for additive manufacturing

ActiveUS20180370114A1Altered thicknessAdditive manufacturing processesApplying layer meansSlice thicknessEngineering

The invention encompasses compositions and methods for designing or producing three-dimensional articles layer-by-layer, whereby the specific approach to build-up a region of a single layer by fusion, deposition of material, or other path-based process or non-path process that creates track-like geometries requires either differing track or track-like geometry, or track or track-like geometry printing parameters, within a region of a single layer or within adjoining regions of multiple layers, is disclosed. Employing this method, single layer or multilayer parameter-varying fusing and deposition strategies can be generated that reduce article fabrication time and improve article physical properties, in part by targeting a distribution of scan paths that satisfy covering problem overlap and / or dense packing criteria. Additionally, methods and compositions for designing or producing three-dimensional articles by altering the thickness of a material layer deposited during a print relative to the slice thickness or net displacement of a stage or of a material and / or energy-depositing print head, are disclosed. Employing this method can result in the reduction of article fabrication time and / or the improvement of printed article physical properties, where these results advantageous to printing are dependent on the print process, material properties, and feedstock properties employed during the print.

Owner:HEAVY METAL LLC

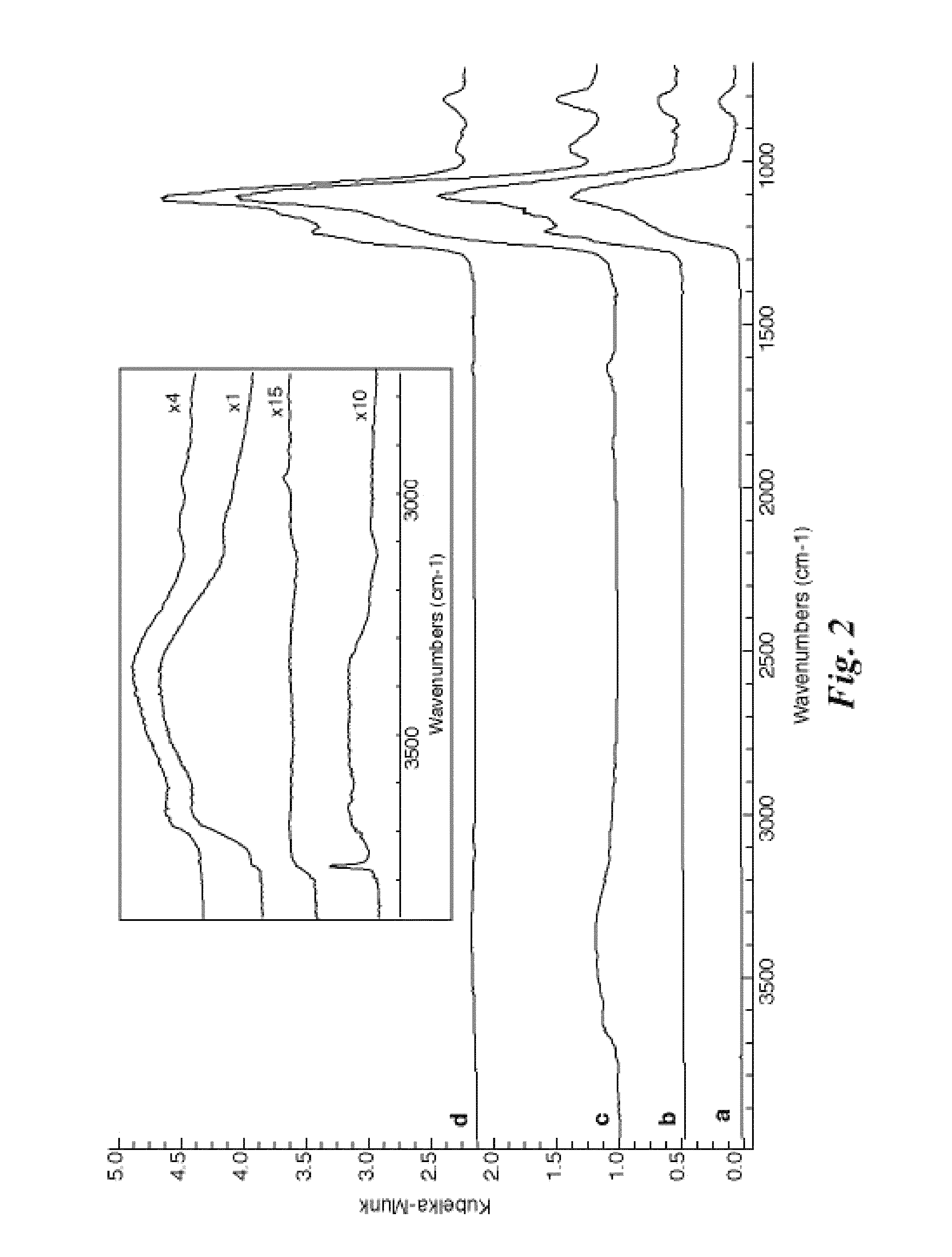

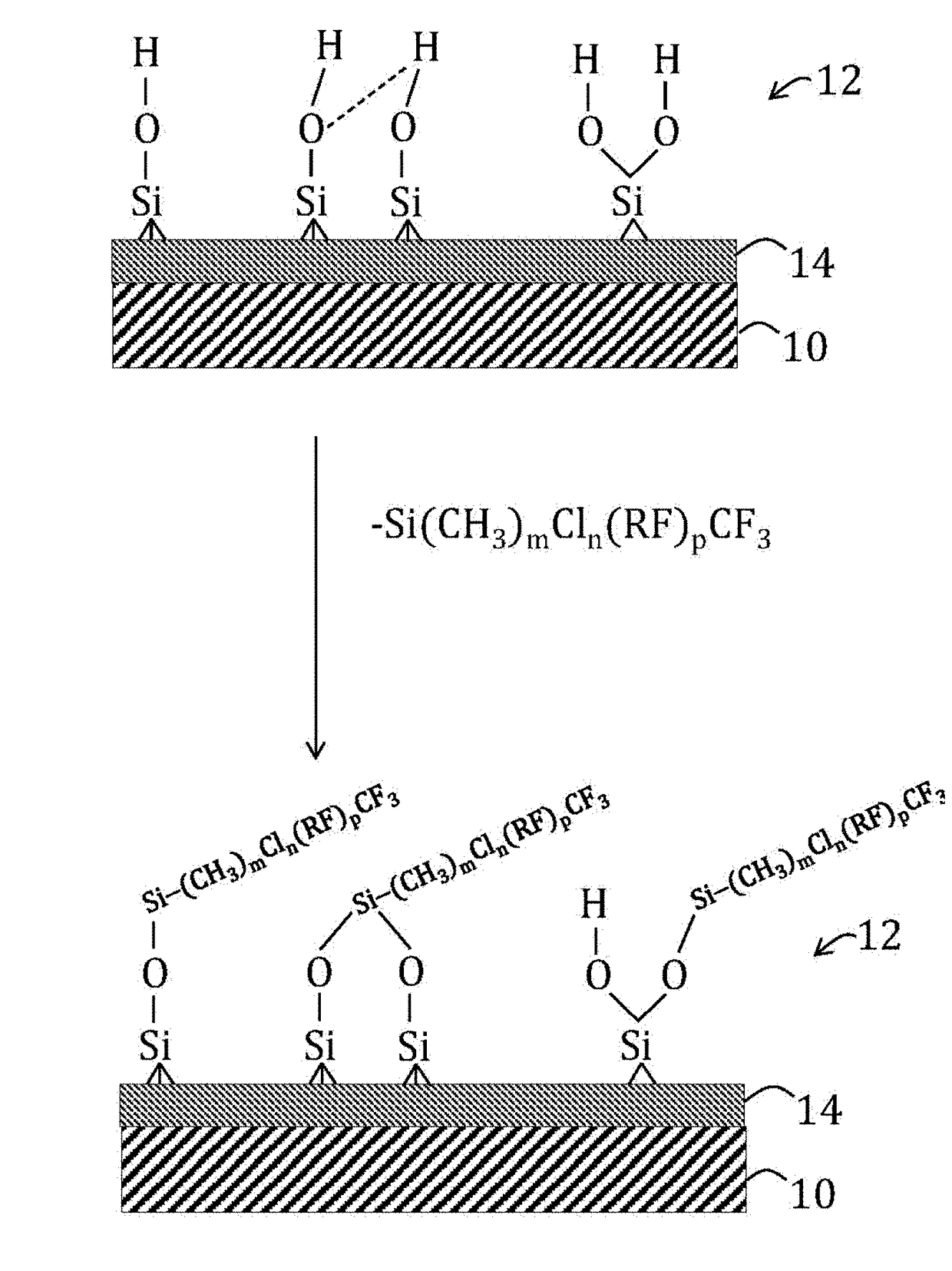

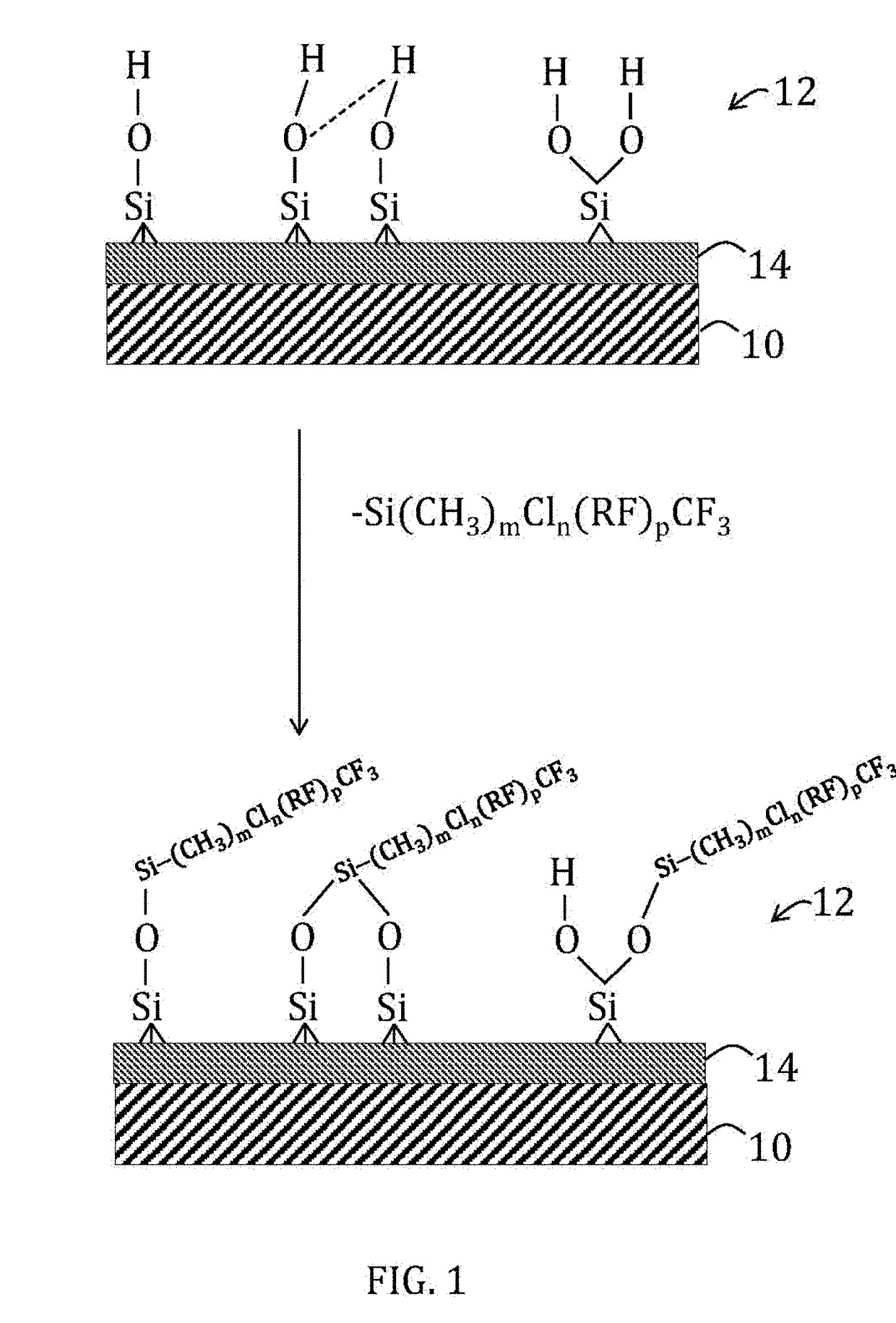

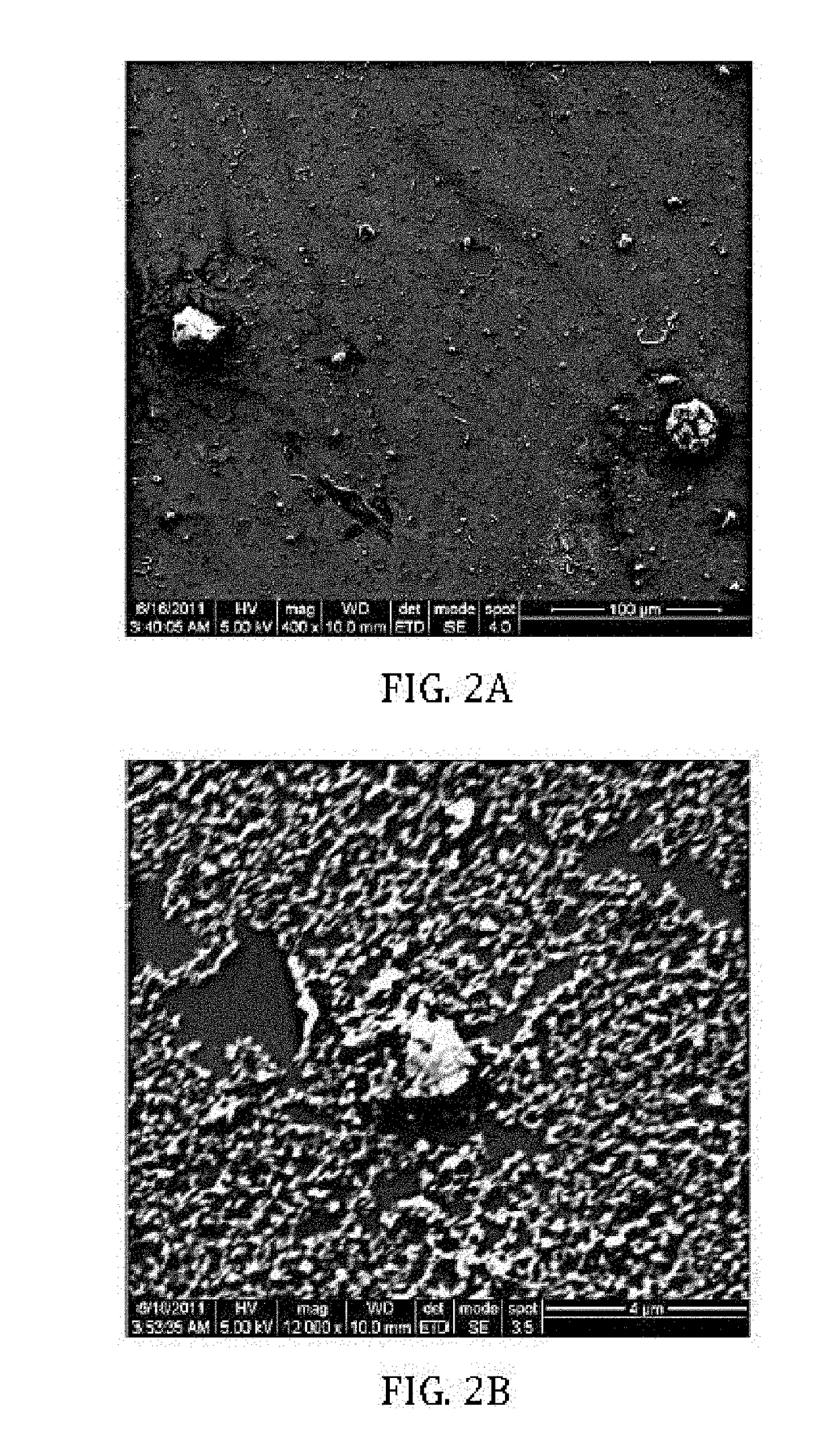

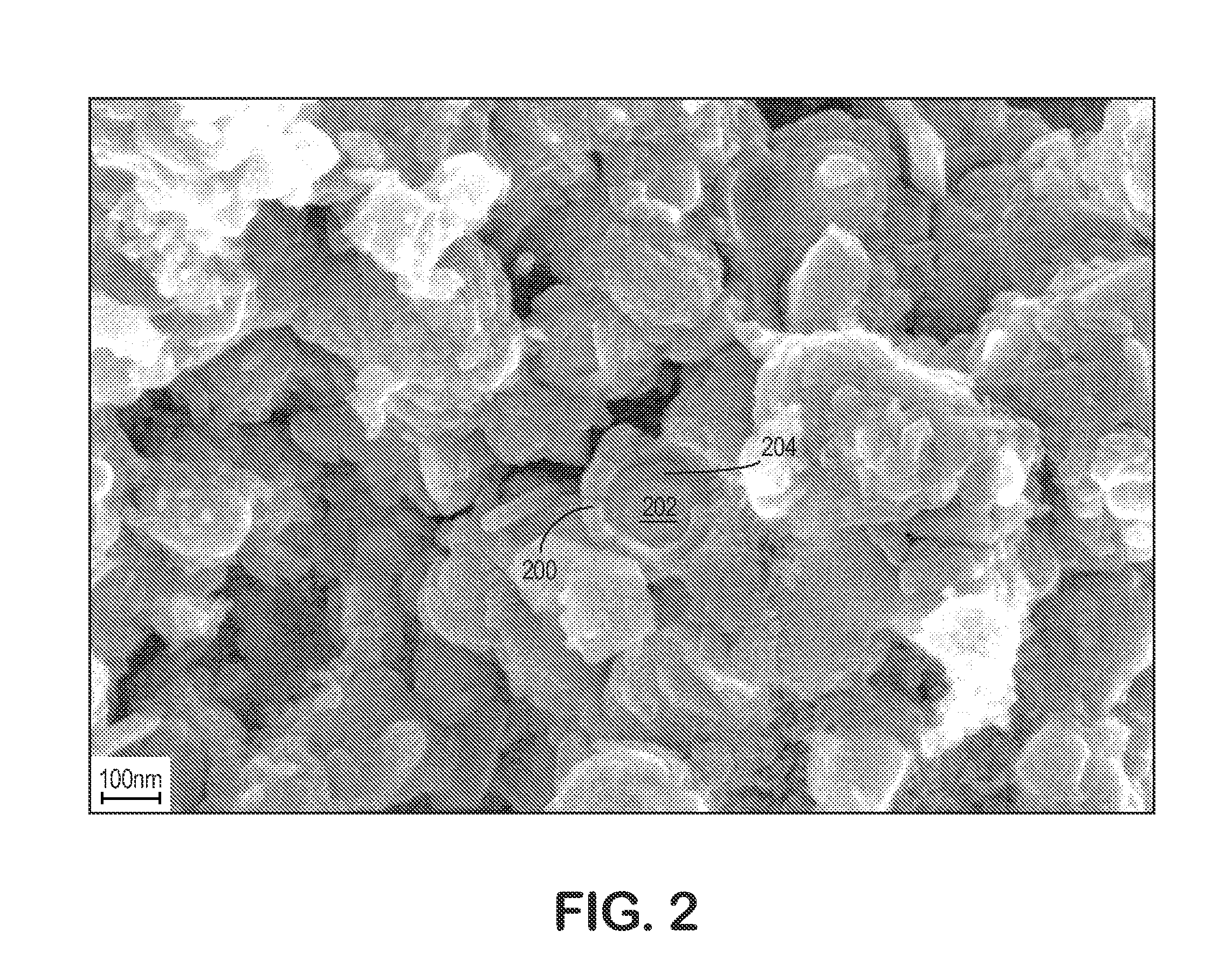

Fluoroalkylsilanated mesoporous metal oxide particles and methods of preparation thereof

InactiveUS8741432B1Lower surface energySynthetic resin layered productsCellulosic plastic layered productsGas phaseVolumetric Mass Density

Coated particles comprise a core of fumed or precipitated inorganic metal oxide having a surface area of about 50 to about 500 square meters per gram and a shell consisting of an array of fluoroalkyl molecular chains at a density of at least 1 chain per square nanometer, joined to the core by covalent chemical bonds and with a total organic content of at least 9.9 percent by weight. These particles are formed by the chemical attachment of fluoroalkyl-alkylsilanes after exposure to an alkylamine and followed by an extraction to remove any organic material not covalently bound. The dense packing of molecular chains in the fluoroalkyl shell combined with a mesoporous structure imparts a very low surface energy, a very high specific surface area, and surface texture over a wide range of length scales. Such features are highly desirable for the creation of, for example, superhydrophobic and superoleophobic surfaces, separation media, and release films.

Owner:UNITED STATES OF AMERICA AS REPRESENTED BY THE SEC OF THE UNITED STATES

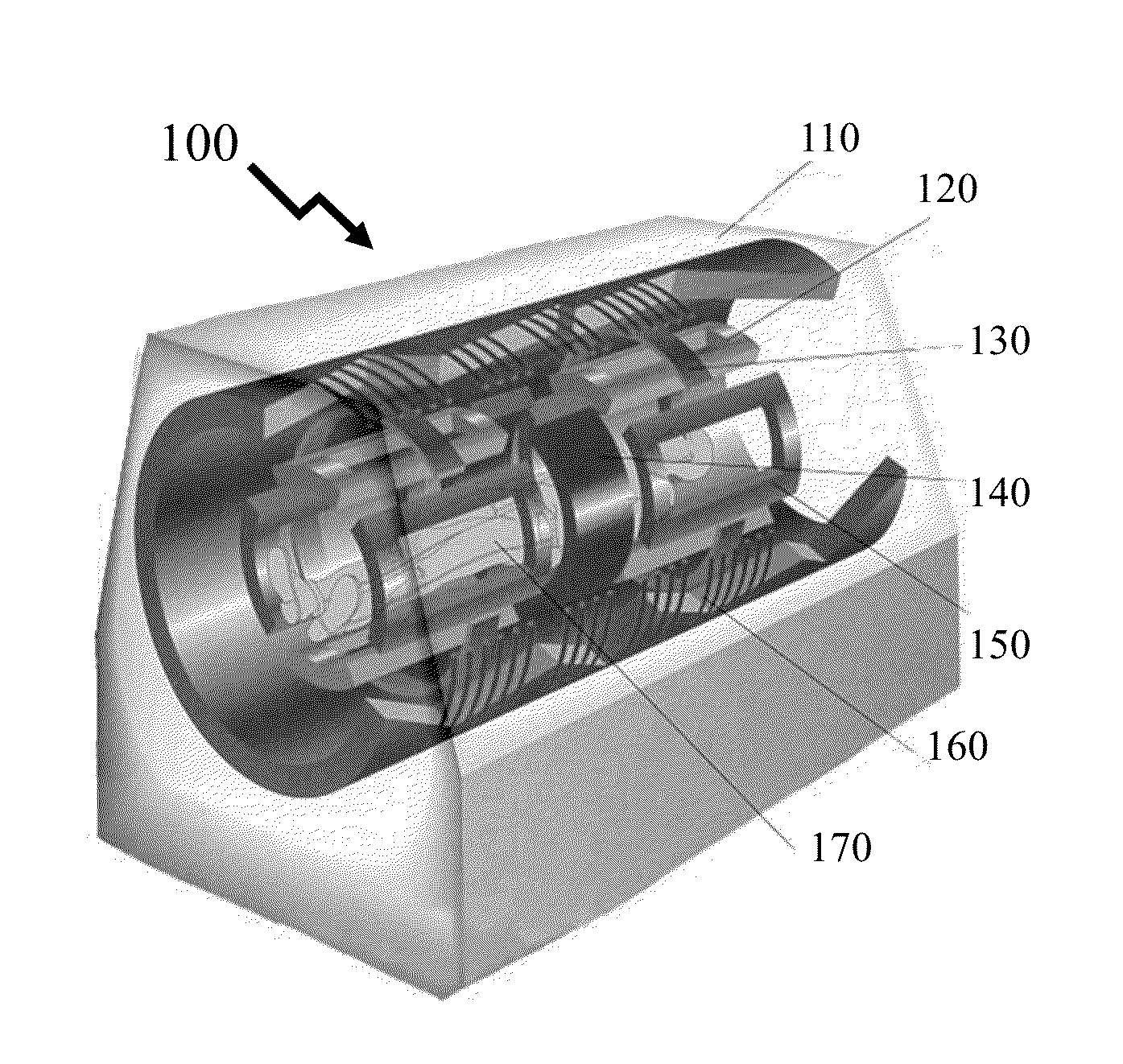

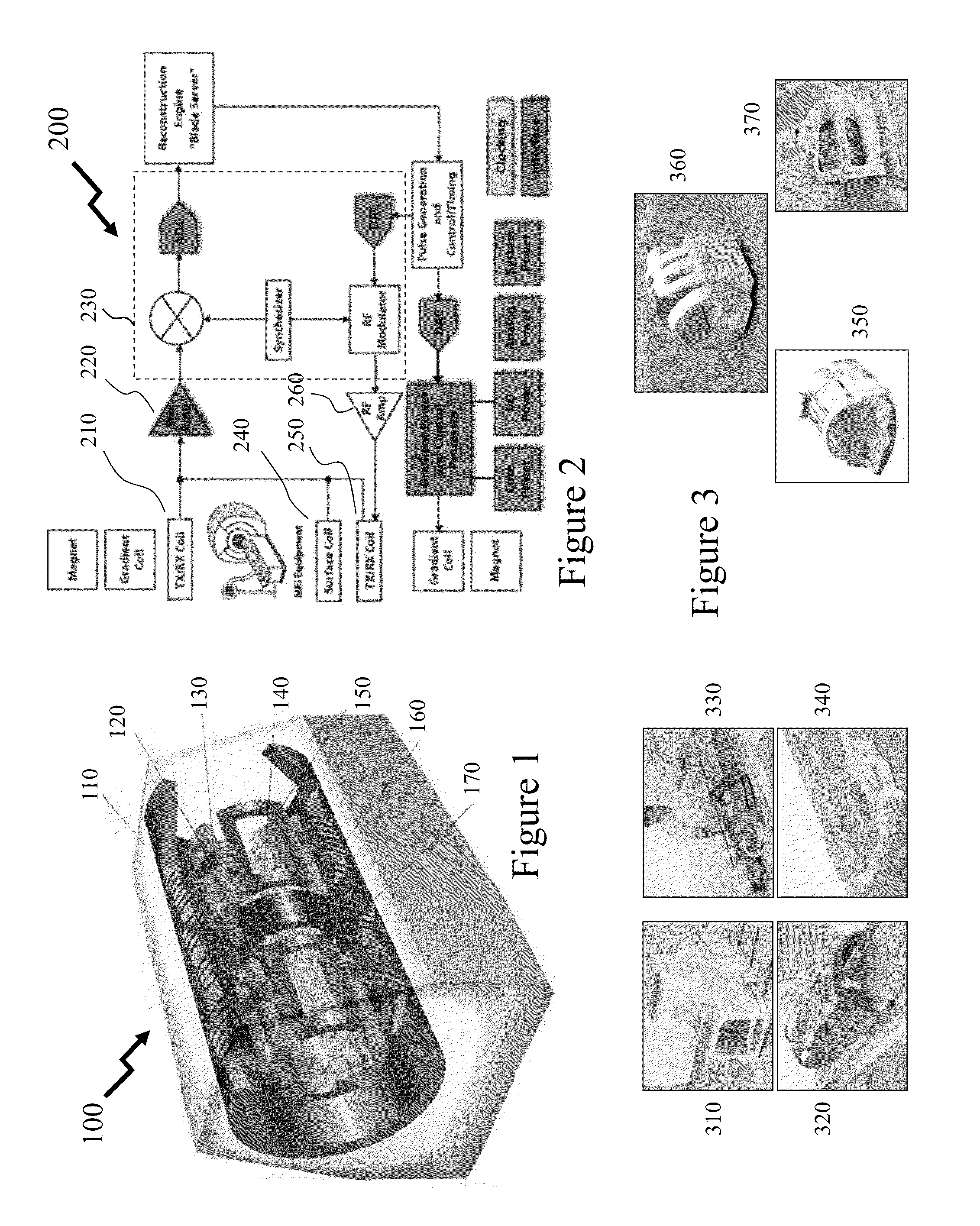

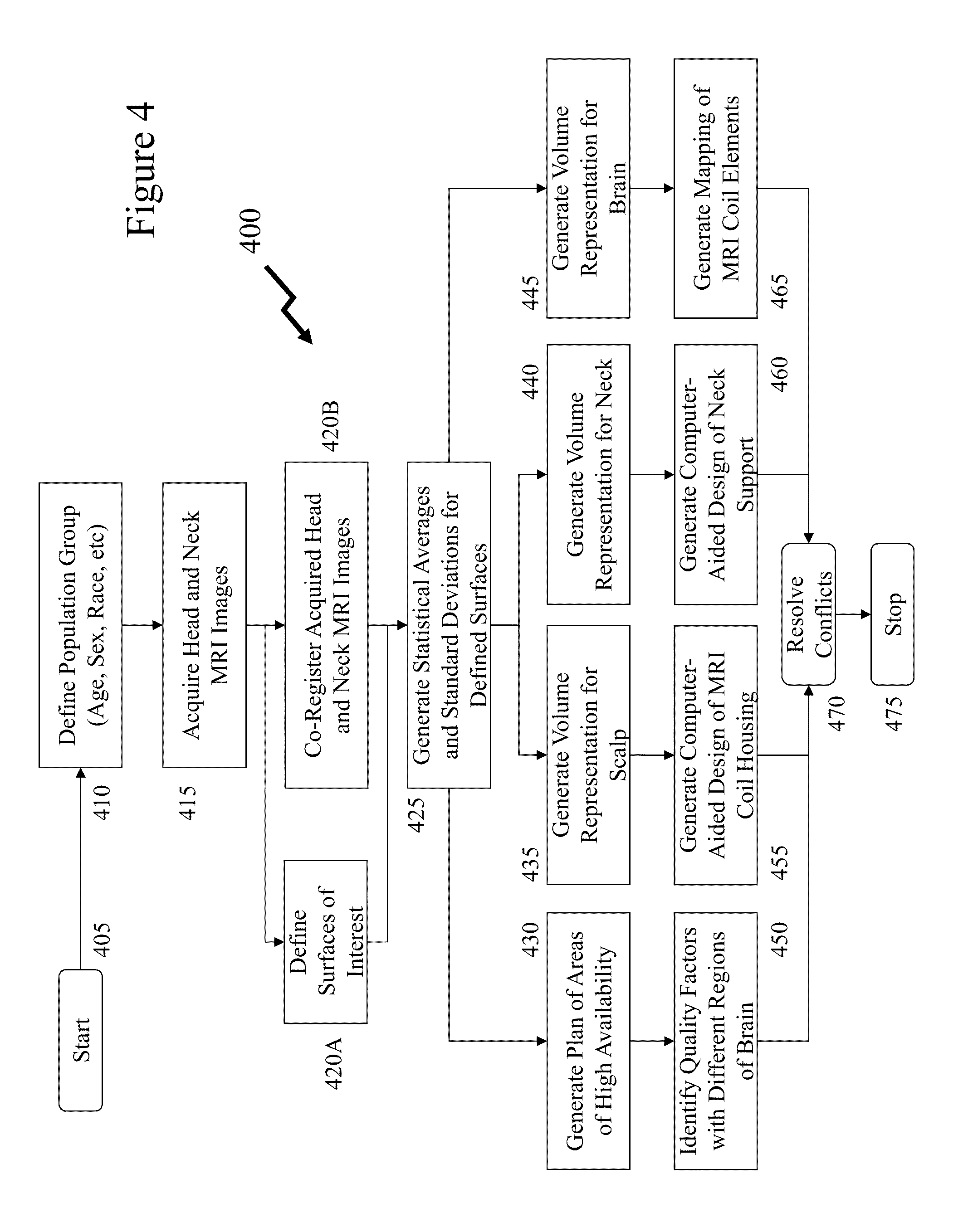

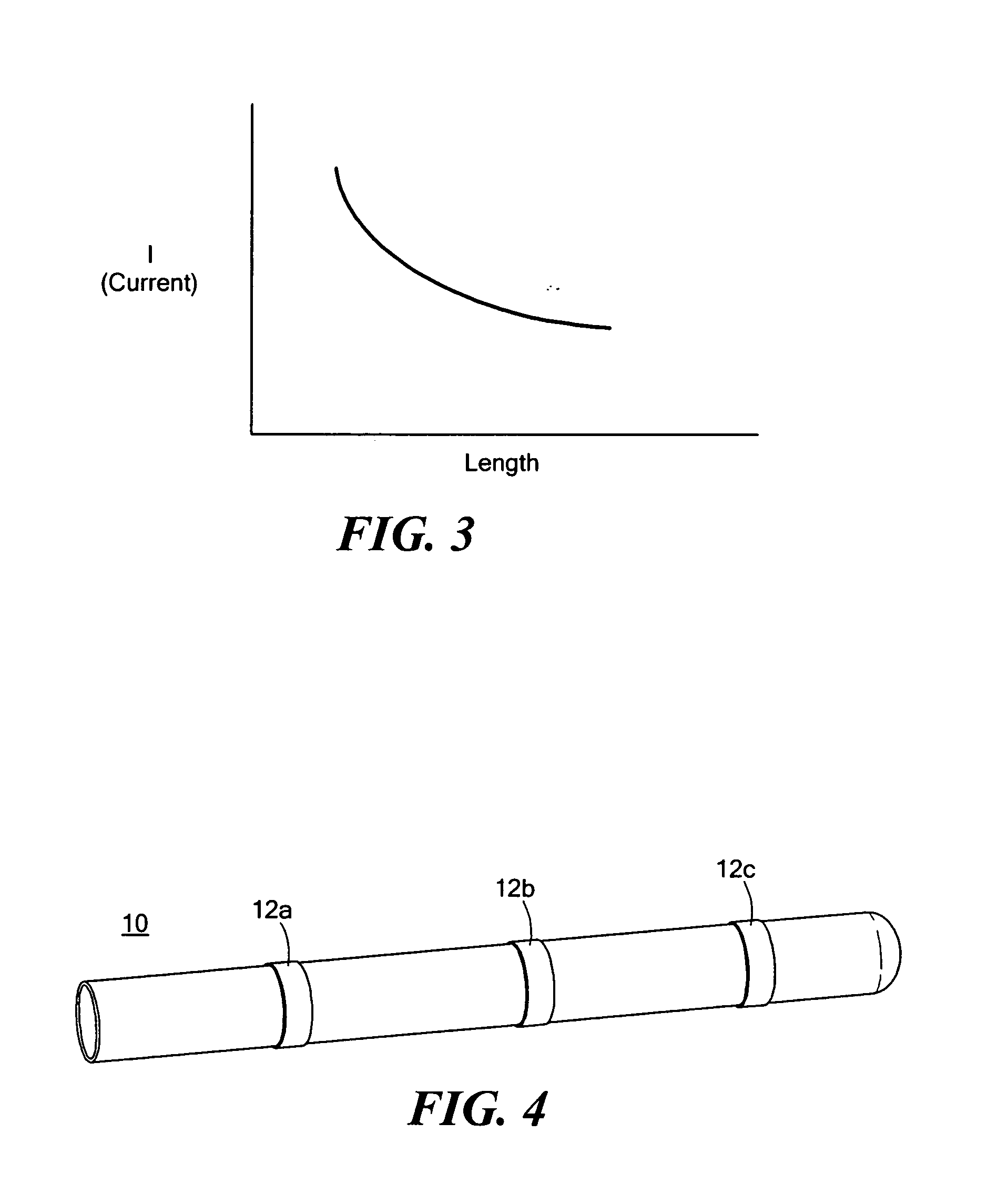

Methods and systems relating to high resolution magnetic resonance imaging

InactiveUS20160018489A1Easy to assembleImprove usabilityDiagnostic recording/measuringMeasurements using NMR imaging systemsShape optimizationSingle shot

The inventors have established design principles for phased-array MRI coils from the considerations of the target region of the anatomy being evaluated and physical anatomy of the patients. Accordingly, the inventors have demonstrated shape-optimized phased array coils with dense packing of 32 channels for posterior-head imaging exhibiting the SNR gains required to realize not only sub-millimeter fMRI BOLD imaging but also allowing single-shot Gradient Echo-EPI imaging to be performed upon general 3 T MRI instruments. At the same time the design techniques address ergonomic considerations of the patient and designing shape-optimized phased-array MRI coils and patient supports that account for variations within the human population arising from factors such as race, gender, etc.

Owner:MCGILL UNIV

Interconnection of bundled solid oxide fuel cells

ActiveUS20070148523A1Improve fuel cell densityDensely packedFuel cells groupingFuel cell shape/formFuel cellsElectrical connection

Owner:ACUMENTRICS

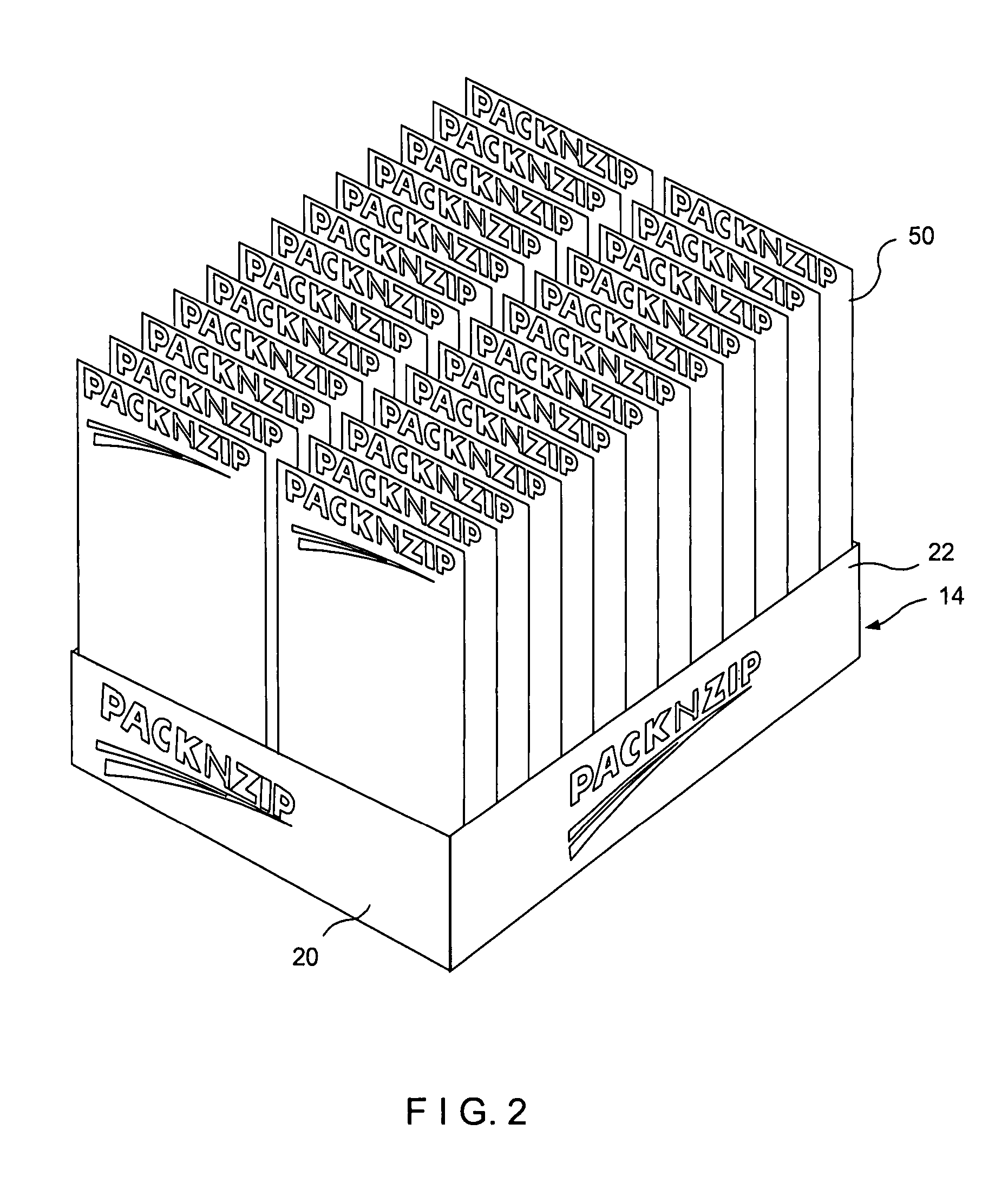

Packing method for soft packages

The present disclosure relates to using a wholesale package to ship a large number of densely packed retail packages. The wholesale package includes an a top portion which receives a tray portion. At the retail site, the top portion is removed and discarded whereby the tray portion forms a retail display which holds the retail packages in the densely packed configuration. The retail packages are preferably soft packages, such as those using polymeric film to form the walls and being manufactured by form fill seal methods.

Owner:ILLINOIS TOOL WORKS INC

Fluoroalkylsilanated mesoporous metal oxide particles and methods of preparation thereof

Treated, mesoporous aggregates comprising a plurality of coated particles that comprise an inorganic oxide core having a surface area of about 50 to about 500 square meters per gram and a shell or coating consisting of an array of fluoroalkyl molecular chains covalently bonded to the core at a density of at least one chain per square nanometer. The aggregates are formed by the chemical attachment of fluoroalkyl-alkylsilanes after exposure to an alkylamine and followed by an extraction to remove any unbound organic material. The dense packing of molecular chains in the fluoroalkyl shell combined with a mesoporous structure imparts a very low surface energy, a very high specific surface area, and surface texture over a wide range of length scales. Such features are highly desirable for the creation of, for example, superhydrophobic and superoleophobic surfaces, separation media, and release films.

Owner:THE UNITED STATES OF AMERICA AS REPRESETNED BY THE SEC OF THE AIR FORCE

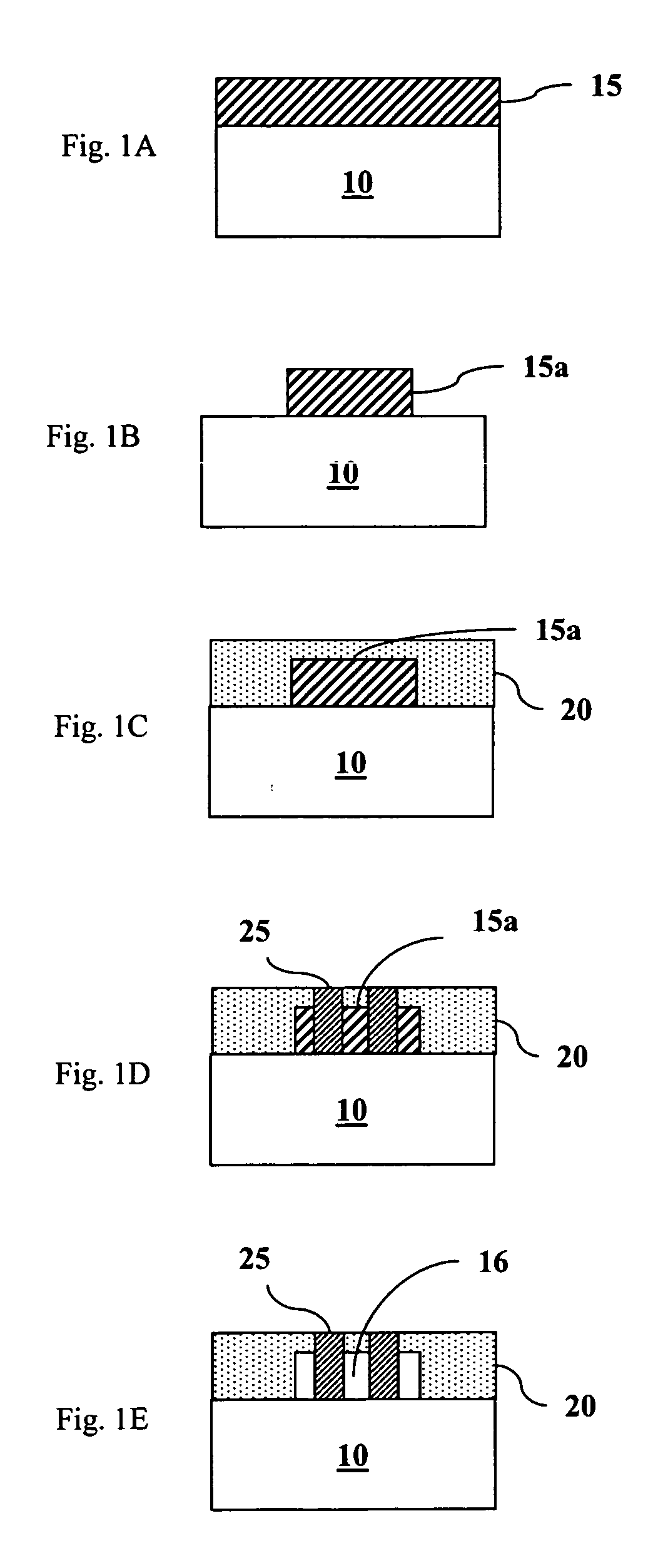

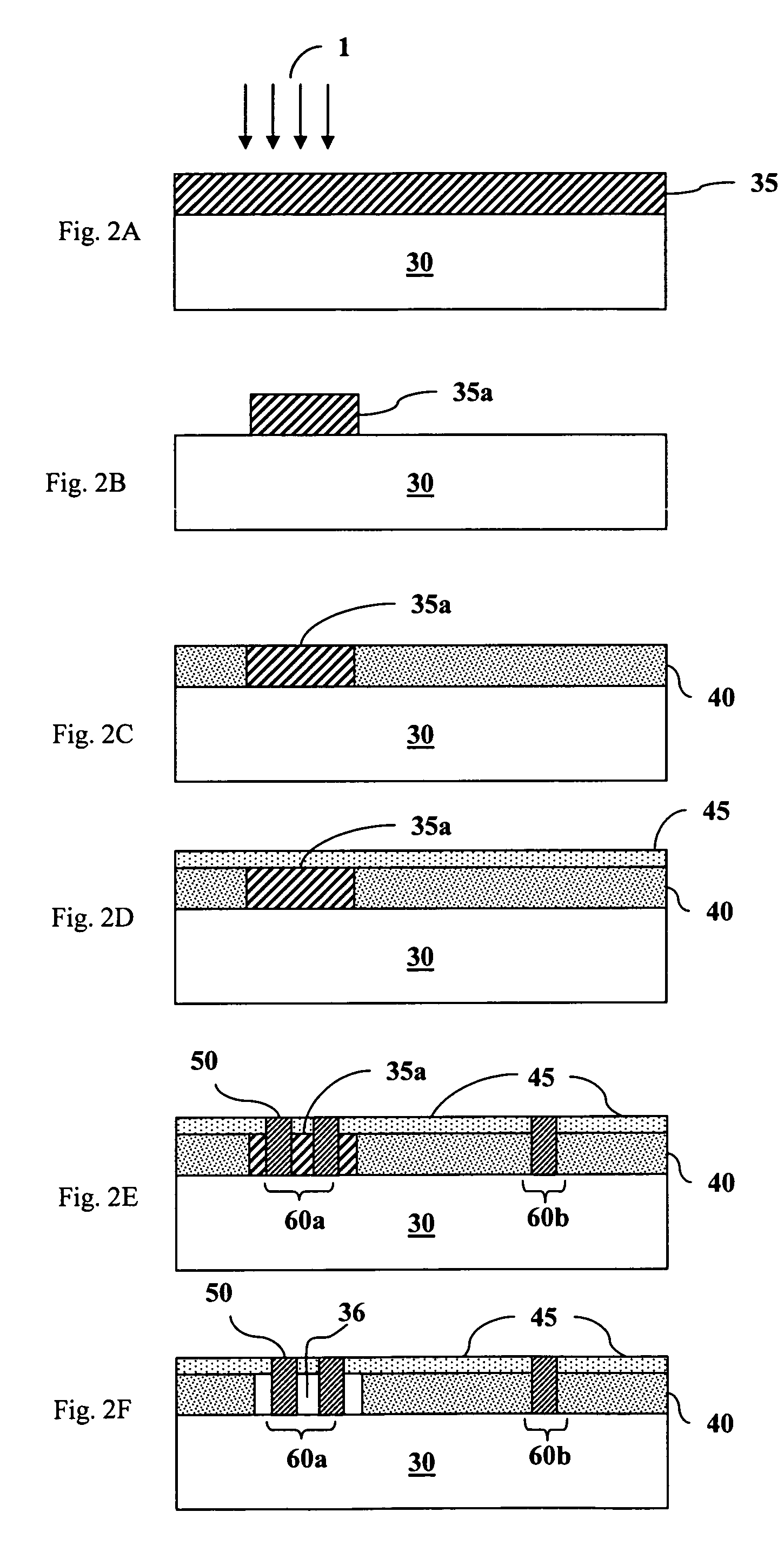

Electronic device manufacture

InactiveUS20060073423A1Photomechanical apparatusSemiconductor/solid-state device manufacturingMaterials scienceMetal

Electronic devices having a metal line-containing layer including an air gap region and a low-k dielectric material region where the air gap region includes a dense packing of metal lines is provided. Methods of forming such electronic devices are also provided.

Owner:ROHM & HAAS ELECTRONICS MATERIALS LLC

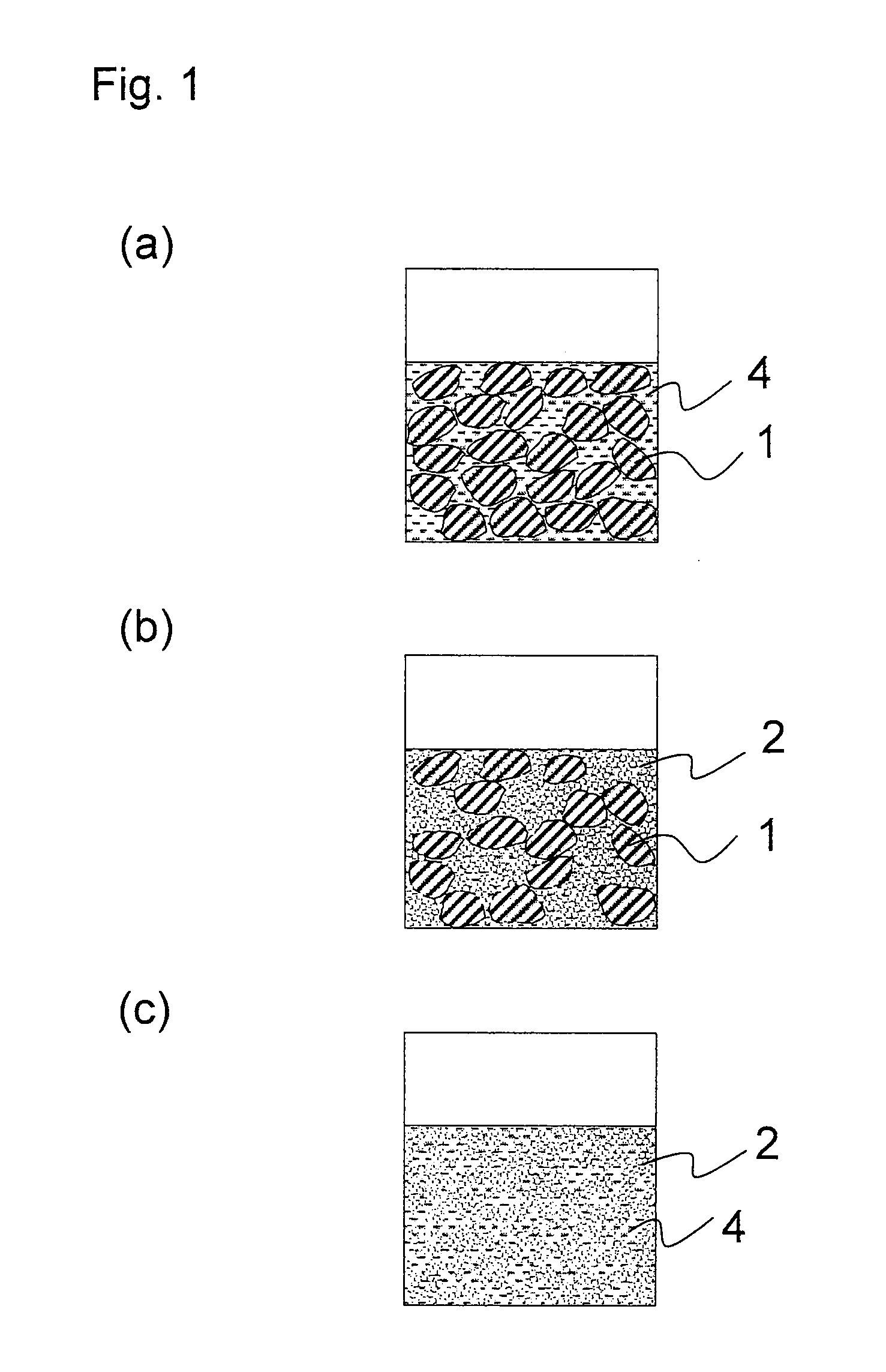

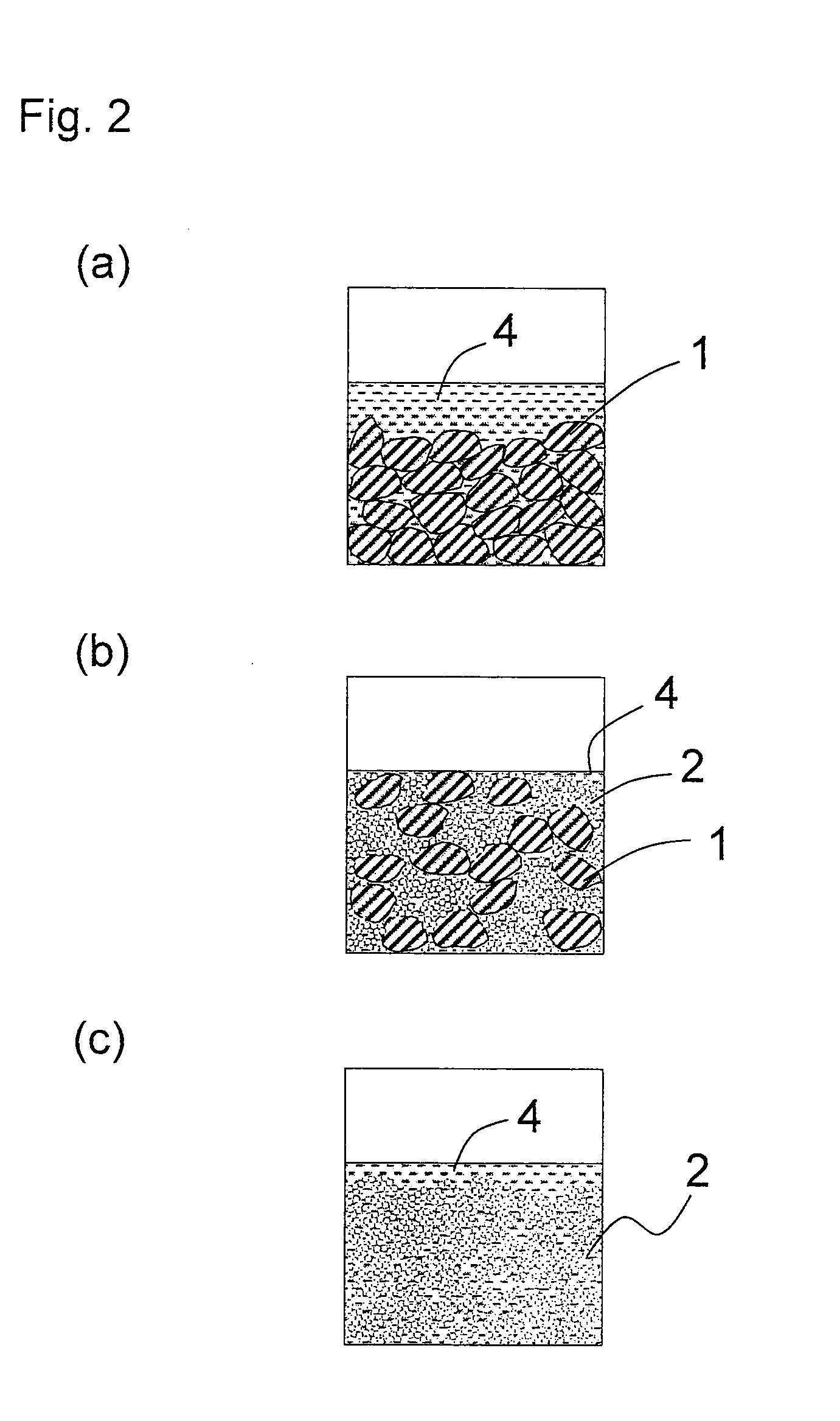

Coating liquid for use in formation of positive electrode for lithium secondary battery, positive electrode for lithium secondary battery, and lithium secondary battery

InactiveUS20100040949A1Good storage stabilityGood coating performancePositive electrodesNanotechnologyHigh energyDiameter ratio

A coating liquid for use in formation of a positive electrode for a lithium secondary battery of the present invention includes a large-particle-size active material having an average particle diameter of 1 to 20 μm and a small-particle-size active material having an average particle diameter of 5 to 100 nm, such that the blending ratio by volume between two materials is 90:10 to 50:50, and the average particle diameter ratio (the average particle diameter of large-particle-size active material / the average particle diameter of small-particle-size active material) is from 50 to 500. The coating liquid is excellent in storage stability over a long period of time and makes dense packing of active material possible, and therefore a positive electrode produced with the use of the coating liquid of the present invention can provide a lithium secondary battery having a high energy density and a high capacity.

Owner:PANASONIC CORP

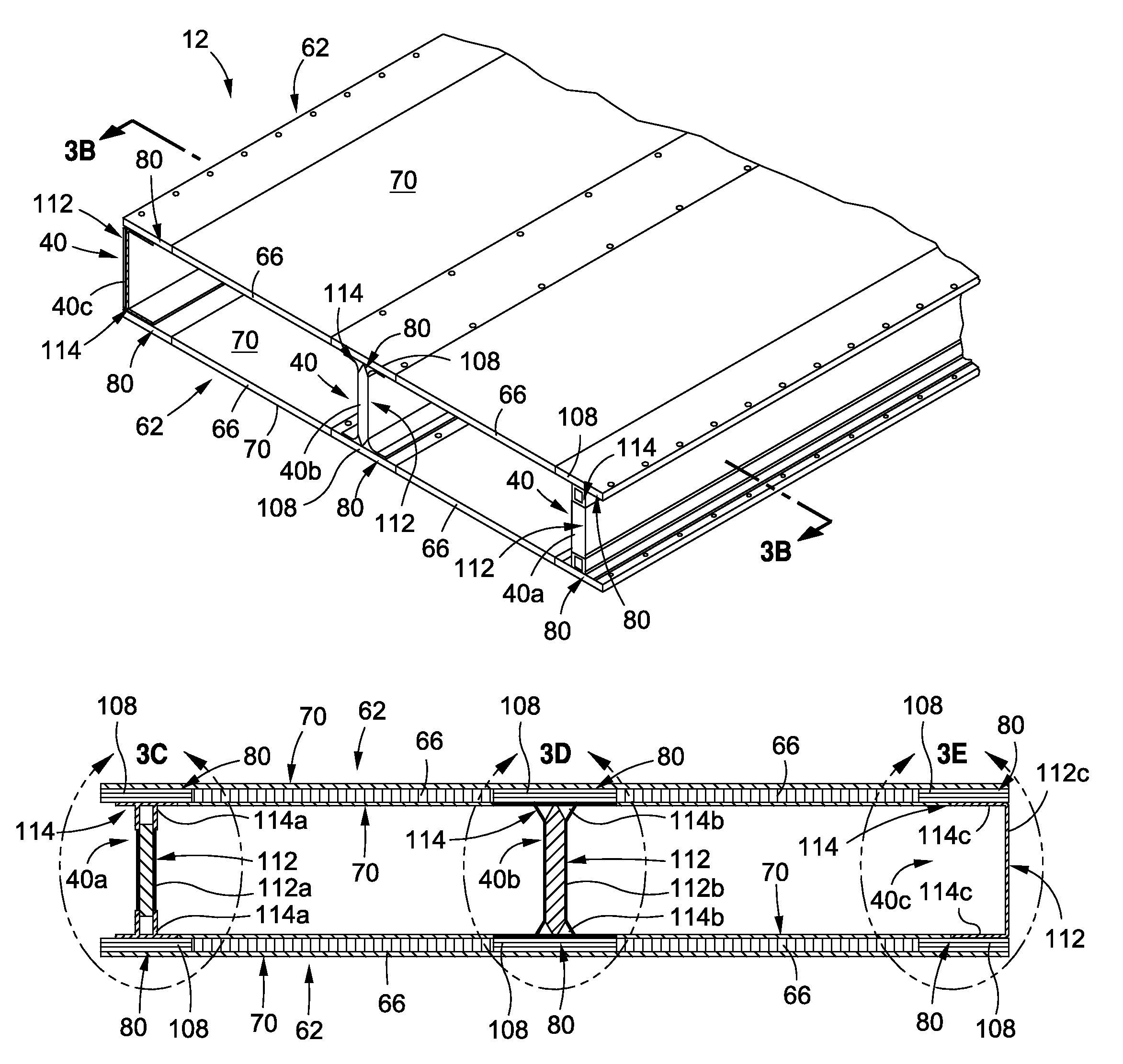

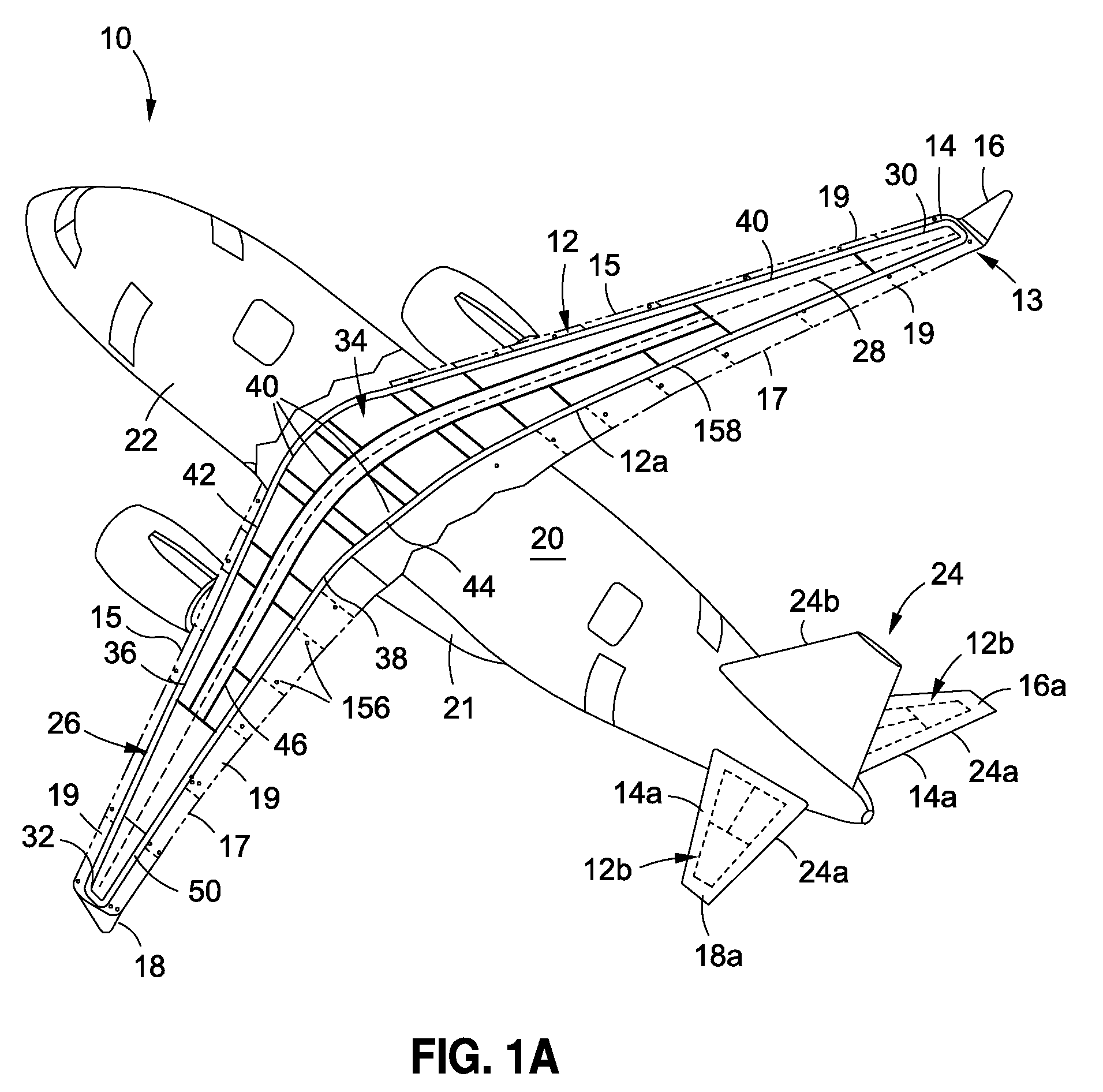

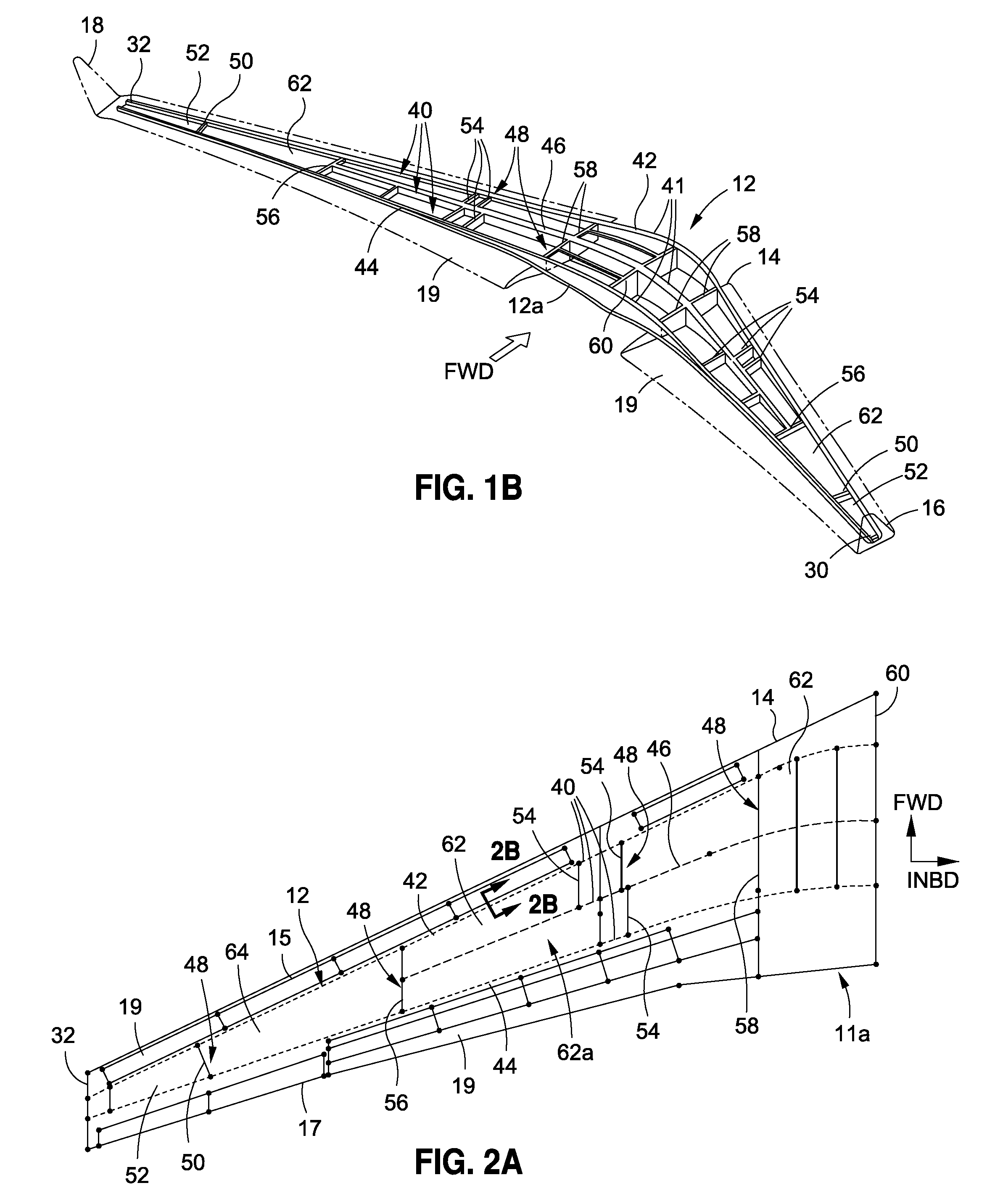

Box structures for carrying loads and methods of making the same

Owner:THE BOEING CO

Coal gangue processing method and coal gangue foamed concrete and roadway backfilling method

InactiveCN102285772AReduce pile up emissionsSelf-fillingSolid waste managementUnderground chambersFoam concreteSlurry

The invention discloses a method for processing coal gangue, a coal gangue foamed concrete produced by the method and a method for backfilling a mine roadway with the foamed concrete. First, crush the gangue into powder or granules; then mix the gangue powder or granules, cement, and water to form a gangue concrete slurry; then mix the gangue concrete slurry with foam to form a coal gangue foamed concrete slurry; Finally, the coal gangue foamed concrete slurry is transported into the roadway to be backfilled, and the coal gangue foamed concrete filling body is formed in the roadway after the slurry is solidified. Backfill the roadway with coal gangue foamed concrete, reduce the accumulation and discharge of coal gangue, realize the nearby materials for backfilling the roadway, and realize the dense filling of the roadway without blind areas without mechanical compaction, and improve the safety of the mining area. The gangue foamed concrete of the present invention can also be used for filling roadbeds, pipe foundations, bridge foundations and high fill.

Owner:梁林华 +1

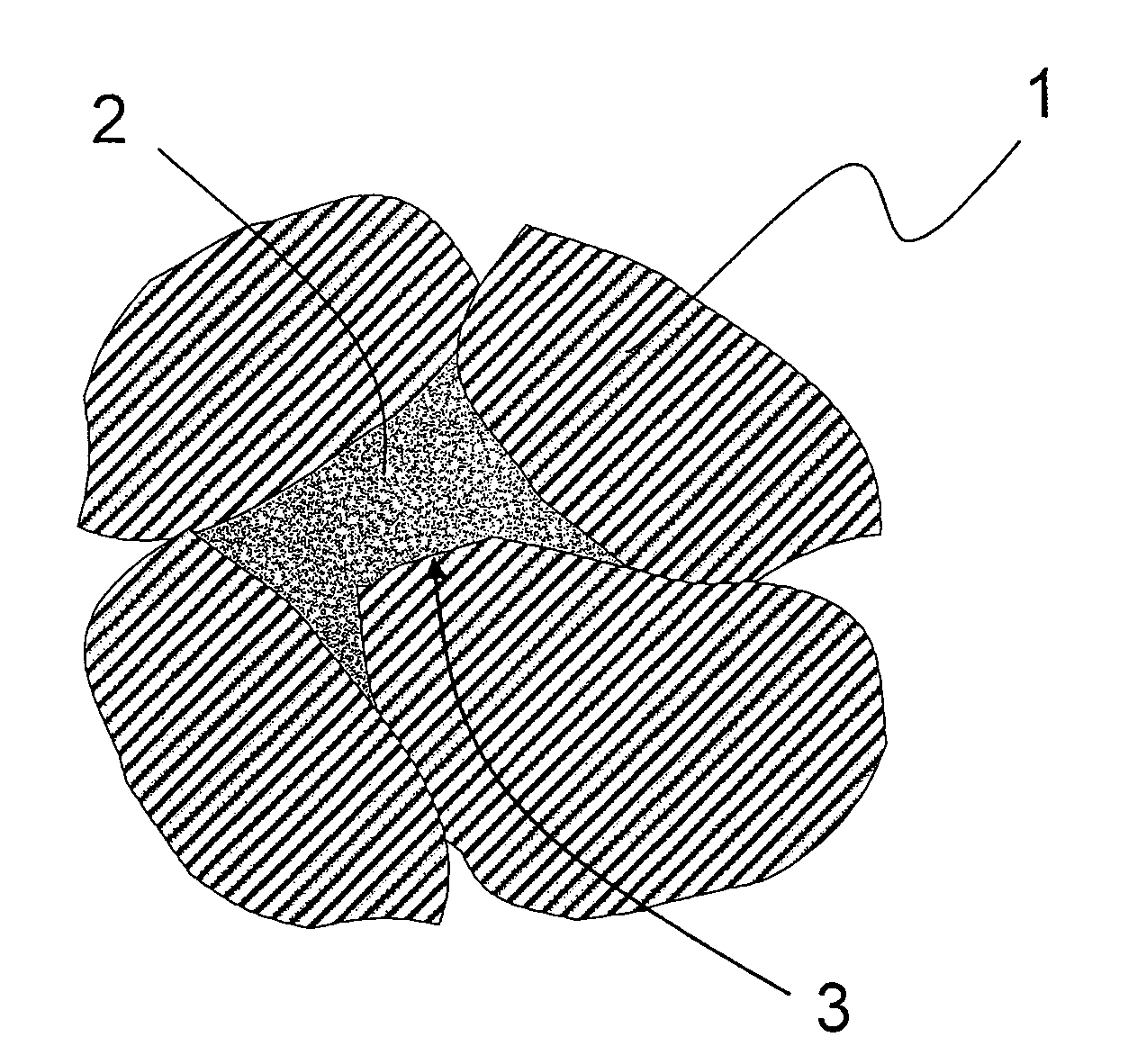

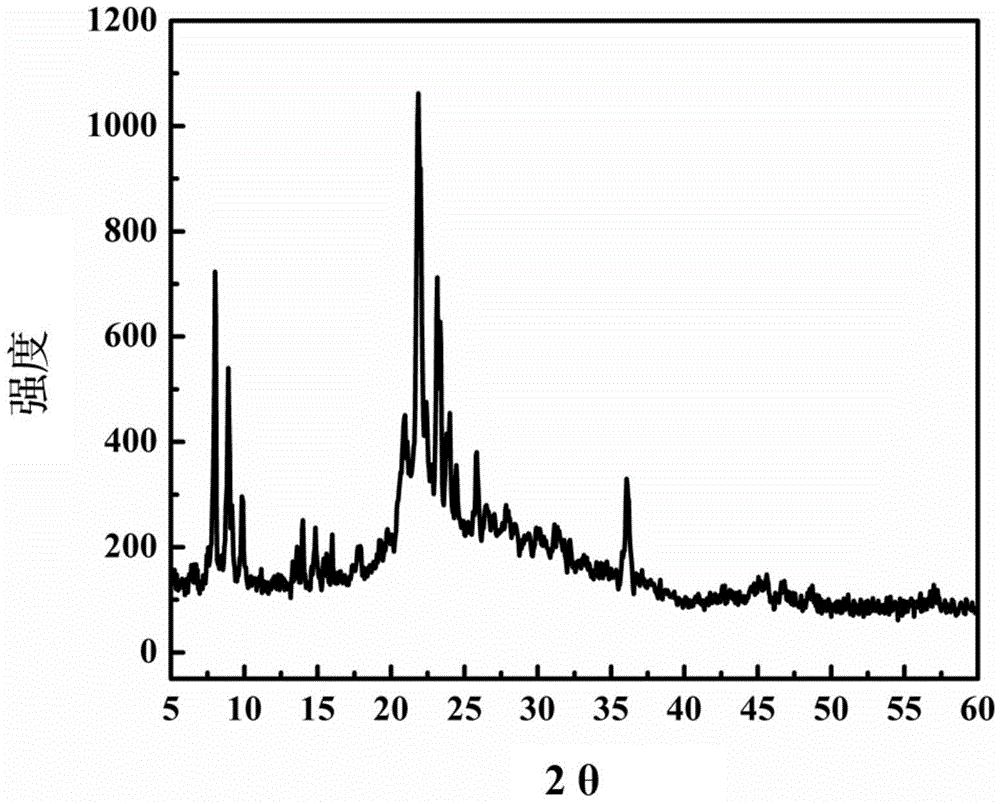

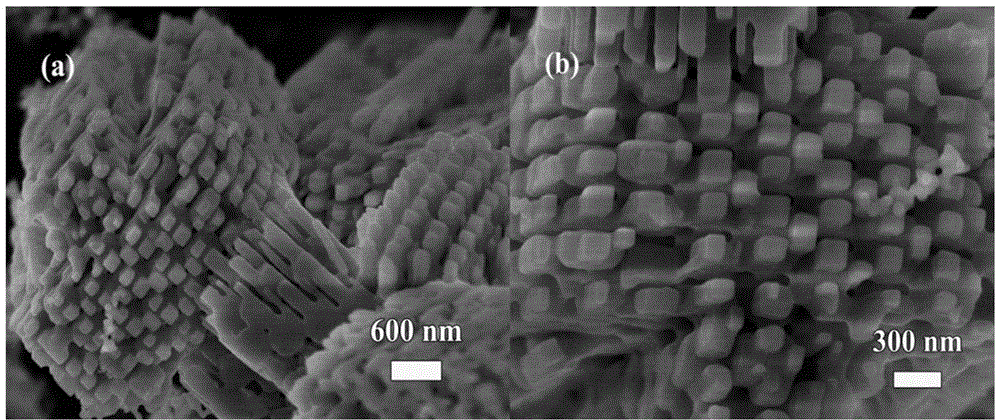

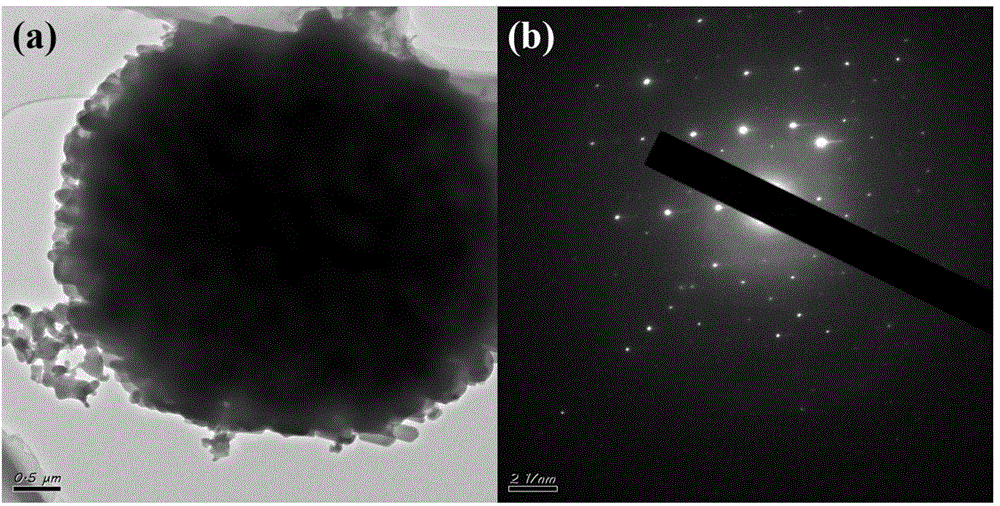

Ordered macropore-mesopore hierarchical pore titanium silicalite molecular sieve TS-1 single crystal with opal structure and synthesis method thereof

ActiveCN106276958AImprove circulation and diffusivityImproved selective catalytic performanceCrystalline aluminosilicate zeolitesMolecular sieveSynthesis methods

The invention discloses an ordered macropore-mesopore hierarchical pore titanium silicalite molecular sieve TS-1 single crystal with an opal structure and a synthesis method thereof. The ordered macropore-mesopore hierarchical pore titanium silicalite molecular sieve TS-1 single crystal is formed by connected molecular sieve nanostructure units in a highly-ordered face-centered dense packing mode. By combining a hard template method and a dry glue method, macropore channels and mesopore channels are successfully introduced into a molecular sieve TS-1 single crystal at the same time for the first time. The synthesized ordered macropore-mesopore hierarchical pore titanium silicalite molecular sieve TS-1 single crystal has both the advantage of a hierarchical pore channel structure and the advantage of a single-crystal structure, has a super-large pore volume, a high specific area, high catalytic activity, high catalytic oxidation performance and high structural stability, and has broad application prospects.

Owner:WUHAN UNIV OF TECH

Solid electrolytic capacitor containing an improved manganese oxide electrolyte

A solid electrolytic capacitor that contains an anode body formed from an electrically conductive powder and a dielectric coating located over and / or within the anode body is provided. The powder has a high specific charge and in turn a relative dense packing configuration. Despite being formed from such a powder, the present inventors have discovered that a manganese precursor solution (e.g., manganese nitrate) can be readily impregnated into the pores of the anode. This is accomplished, in part, through the use of a dispersant in the precursor solution that helps minimize the likelihood that the manganese oxide precursor will form droplets upon contacting the surface of the dielectric. Instead, the precursor solution can be better dispersed so that the resulting manganese oxide has a “film-like” configuration and coats at least a portion of the anode in a substantially uniform manner. This improves the quality of the resulting oxide as well as its surface coverage, and thereby enhances the electrical performance of the capacitor.

Owner:KYOCERA AVX COMPONENTS CORP

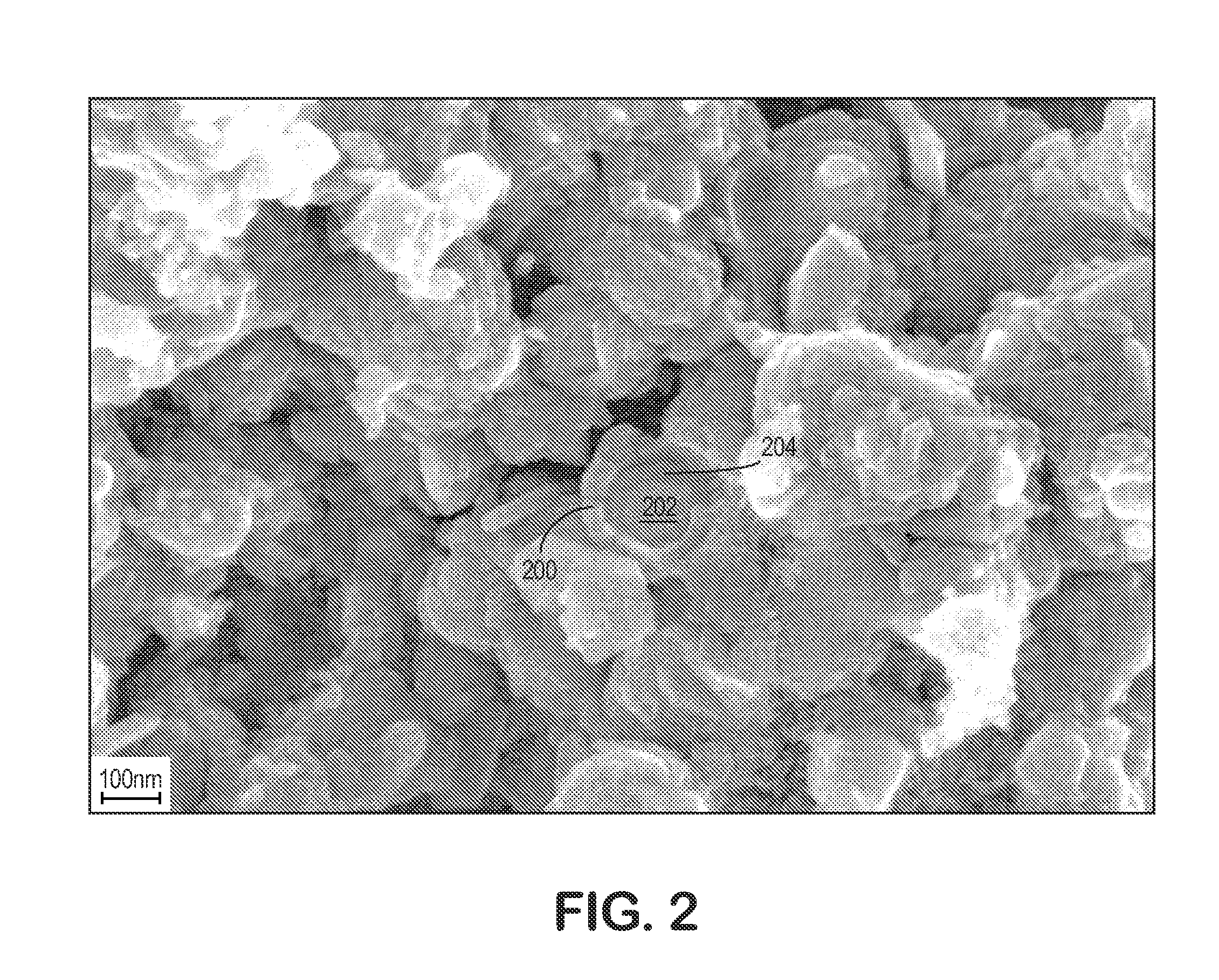

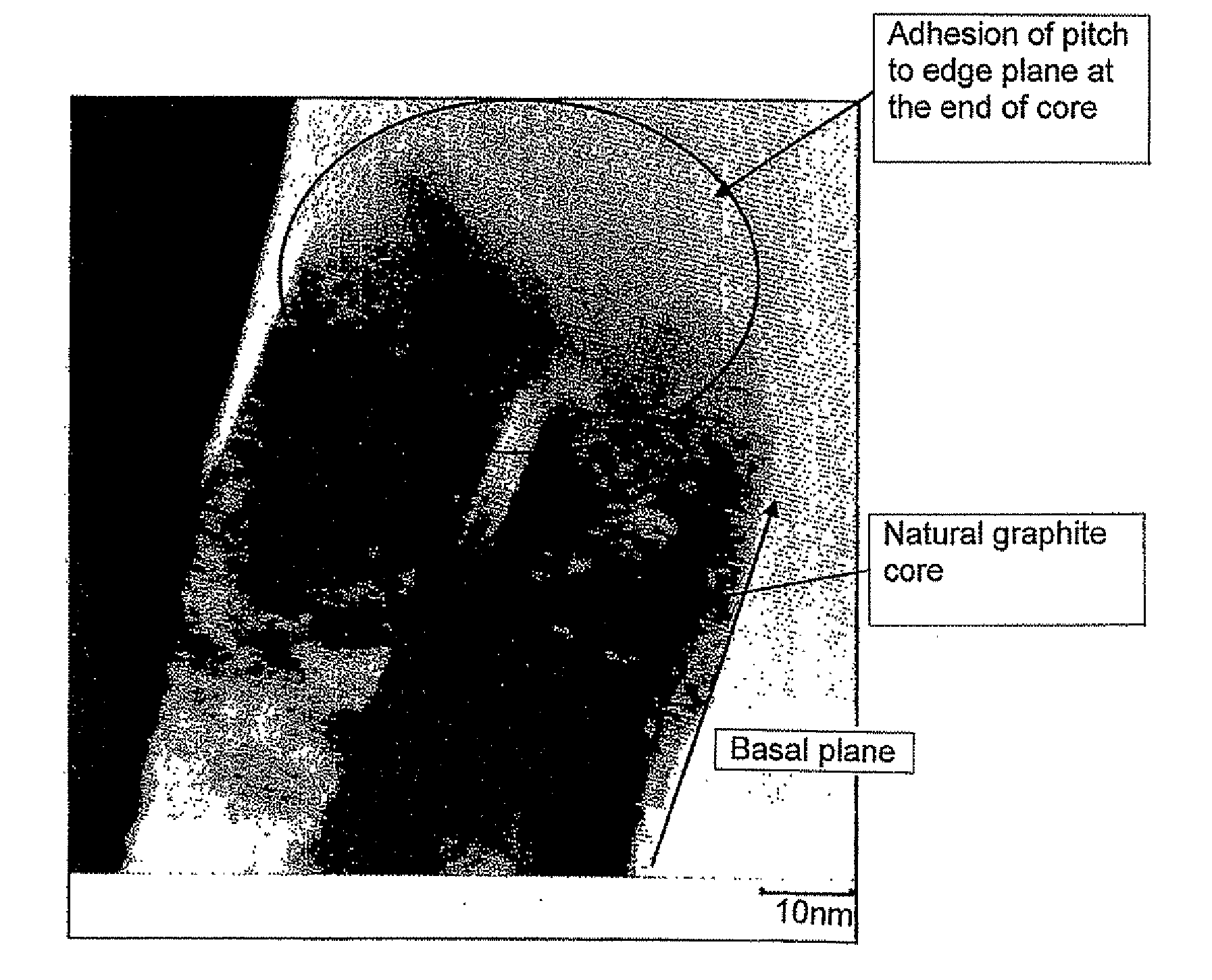

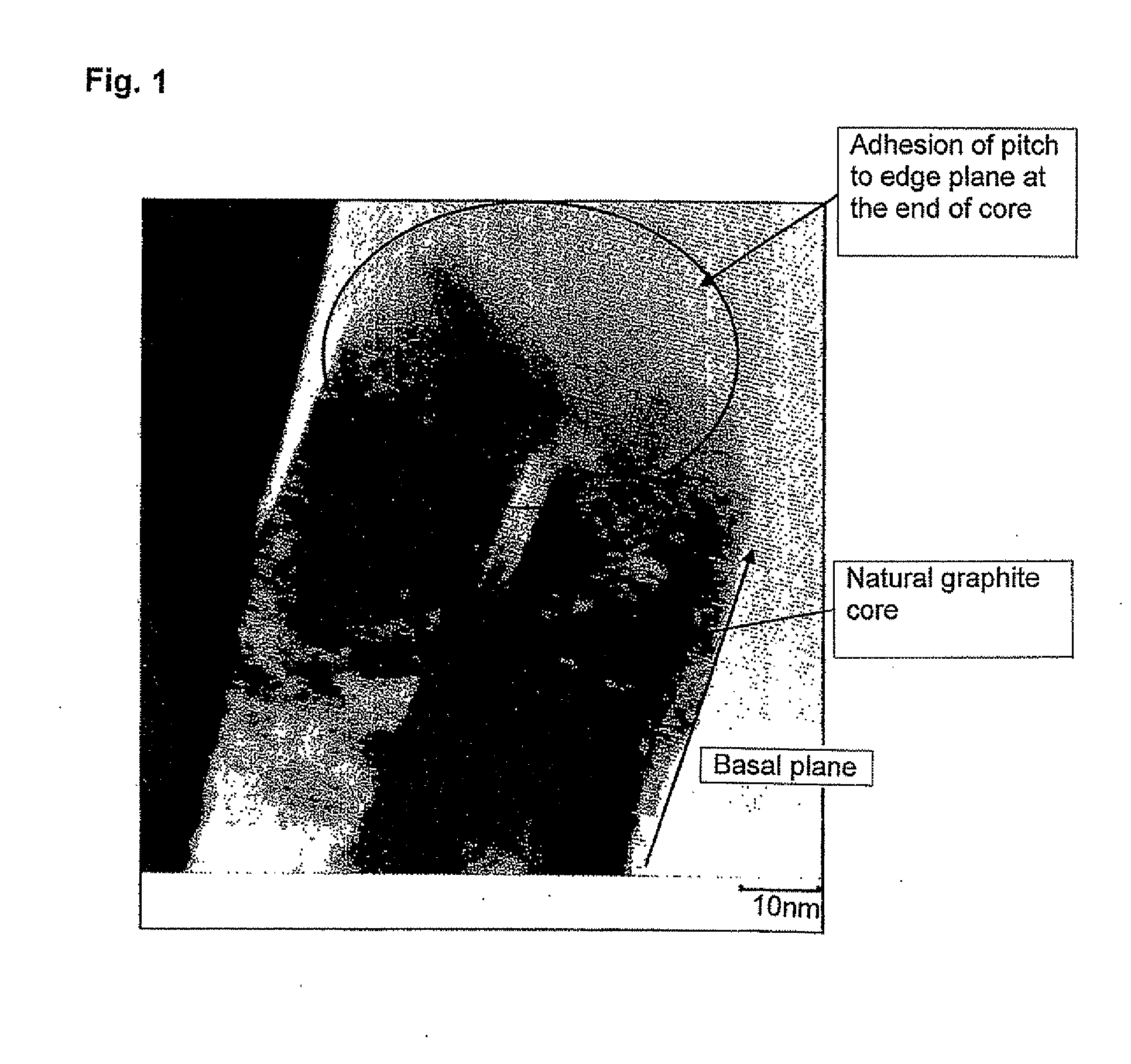

Carbon material and a process for its manufacture

InactiveUS20100035149A1High densityDecomposition is suppressedSecondary cellsActive material electrodesStationary conditionsDecomposition

A carbon material suitable as a negative electrode material for a lithium ion battery which can suppress decomposition of a nonaqueous electrolytic solution, which has excellent compressibility capable of highly dense packing, and which can form an electrode of high capacity without worsening charge and discharge efficiency or cycling performance. Graphite powder A having an average particle diameter of 10-30 μm and a specific surface area S1 of at most 12.5 m2 / g and pitch powder B having a softening point of 80-180° C. and an average particle diameter of 15-150 μm are mixed in proportions such that the mass ratio A / B is 98 / 2-95.5 / 4.5, and the resulting mixed powder is subjected to heat treatment in a stationary condition in an inert atmosphere at 900-1100° C. to carbonize the pitch and thereby manufacture a carbon material having carbon adhered to the surface of the above-described graphite powder. Carbon preferentially adheres to the edge planes of the graphite particles. The carbon material has a specific surface area S2 of 1.0-5.0 m2 / g, and it satisfies 0.4≦S2 / S1≦0.8.

Owner:NIPPON DENKO CO LTD

Interconnection of bundled solid oxide fuel cells

ActiveUS8628891B2Increase cell densityDensely packedFuel cells groupingFuel cell shape/formElectricityFuel cells

Owner:ACUMENTRICS

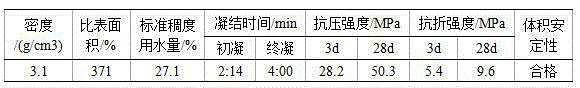

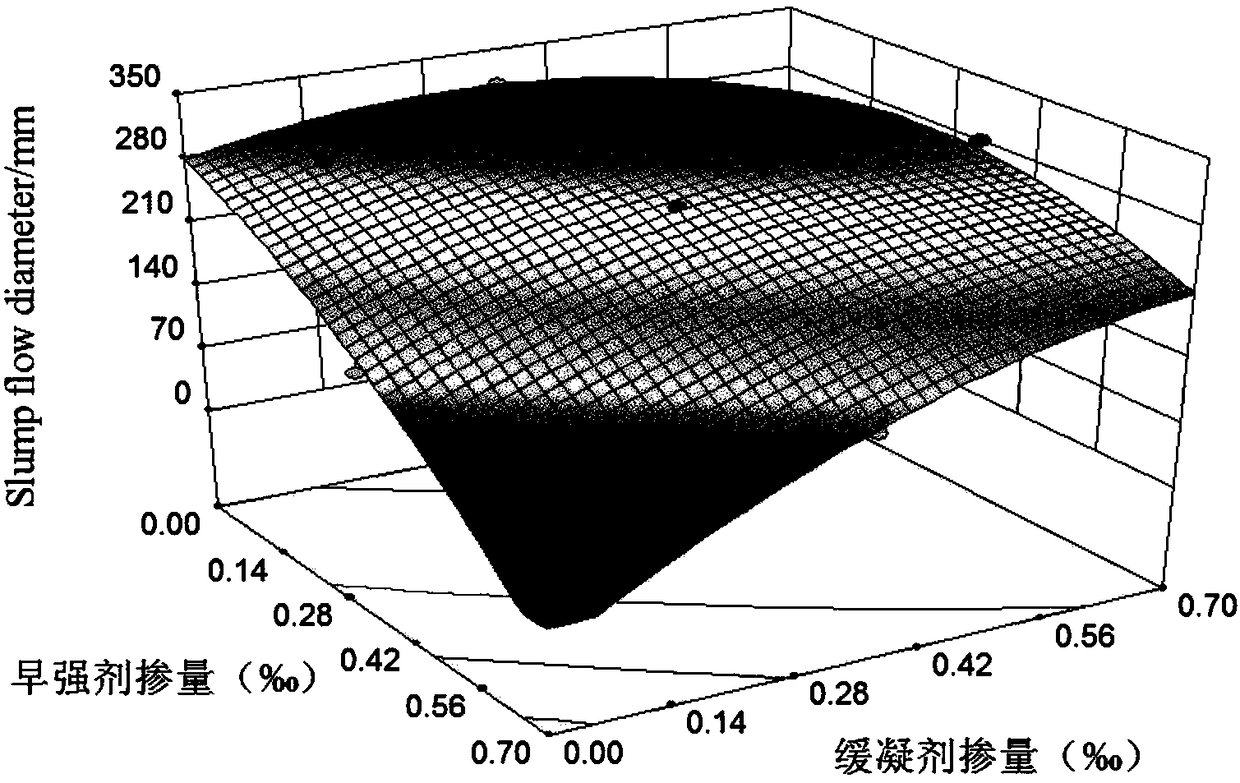

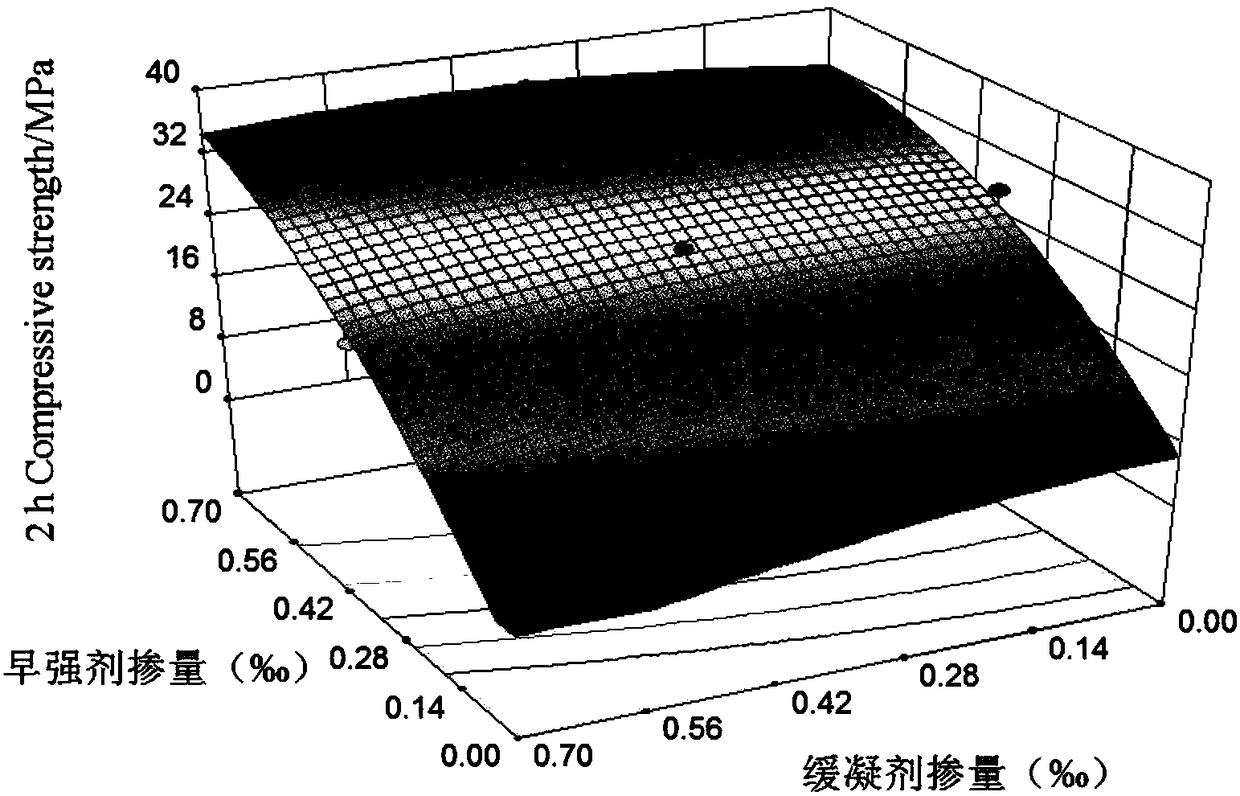

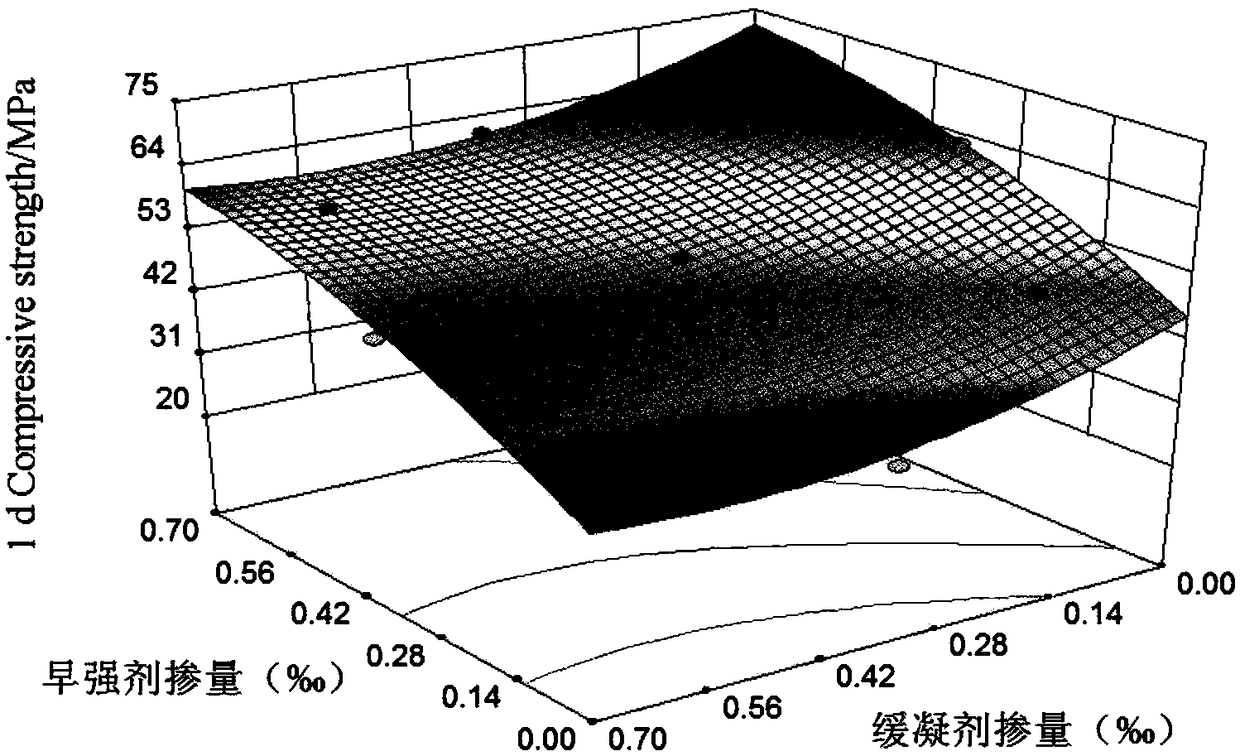

Design method for determining formula of super early strength cement-based material

The invention discloses a design method for determining the formula of a super early strength cement-based material. The method comprises the following steps: determining the solid component proportion of a matrix according to a dense packing theory; determining a water-to-binder ratio; determining the mixing mass of a water reducer; determining an investigation factor and a response target basedon a response surface technology, designing test, and calculating the best theoretical value of the investigation factor by using a model fitted according to the obtained test result; and adding fibers with different volumes and determining the best volume of the fibers based on the mass content of each component of the super early strength cement-based material, obtained in the above steps, in order to obtain the formula of the super early strength cement-based material. The ratio of the super early strength cement-based material with the ability to maintain excellent workability and mechanical properties is obtained by optimizing the proportion of the matrix and the mass content of the investigation factor. The method is simple to operate, can accurately determine the reasonable ratio ofcomponents needed by the super early strength cement-based material, and provides a basis for the precise design of the performances of the super early strong cement-based material.

Owner:CHINA RAILWAY BRIDGE SCI RES INST LTD +1

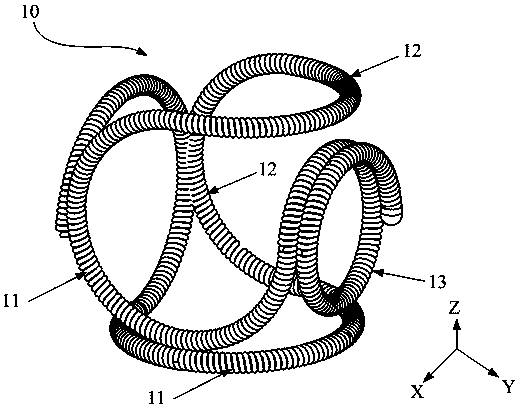

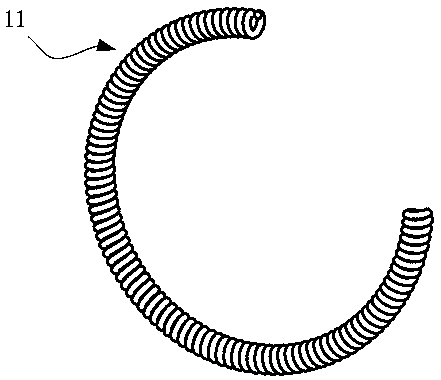

Embolism device and spring rings thereof

ActiveCN108814669AImprove stabilityEmbolization effect is goodTissue regenerationOcculdersEngineeringOmega

A spring ring is formed by connecting at least four basic units on different planes. The at least four basic units comprises at least two c-shaped units and at least one o-shaped unit or omega-shapedunit, and the at least two C-shaped units are arranged on two adjacent planes and are sequentially connected to form an S-shaped structure. The embolism device preferably comprises a plurality of spring rings arranged side by side, the plurality of spring rings are connected end to end and one of any adjacent two spring rings is capable of twisting relative to the other about the axis of the embolism device. Because the stability of the omega-shaped structure is good, the stability of the spring ring can be maintained. Meanwhile, because a three-dimensional S-shaped structure has good turningcapability, the spring ring has better compliance. According to the construction mode, the spring ring can simultaneously meet the requirements of stable basket forming and compliant filling, therebybeing beneficial for the spring ring to conform to aneurysms with different shapes and sizes, and obtaining a better dense packing effect.

Owner:MICROPORT NEUROTECH SHANGHAI

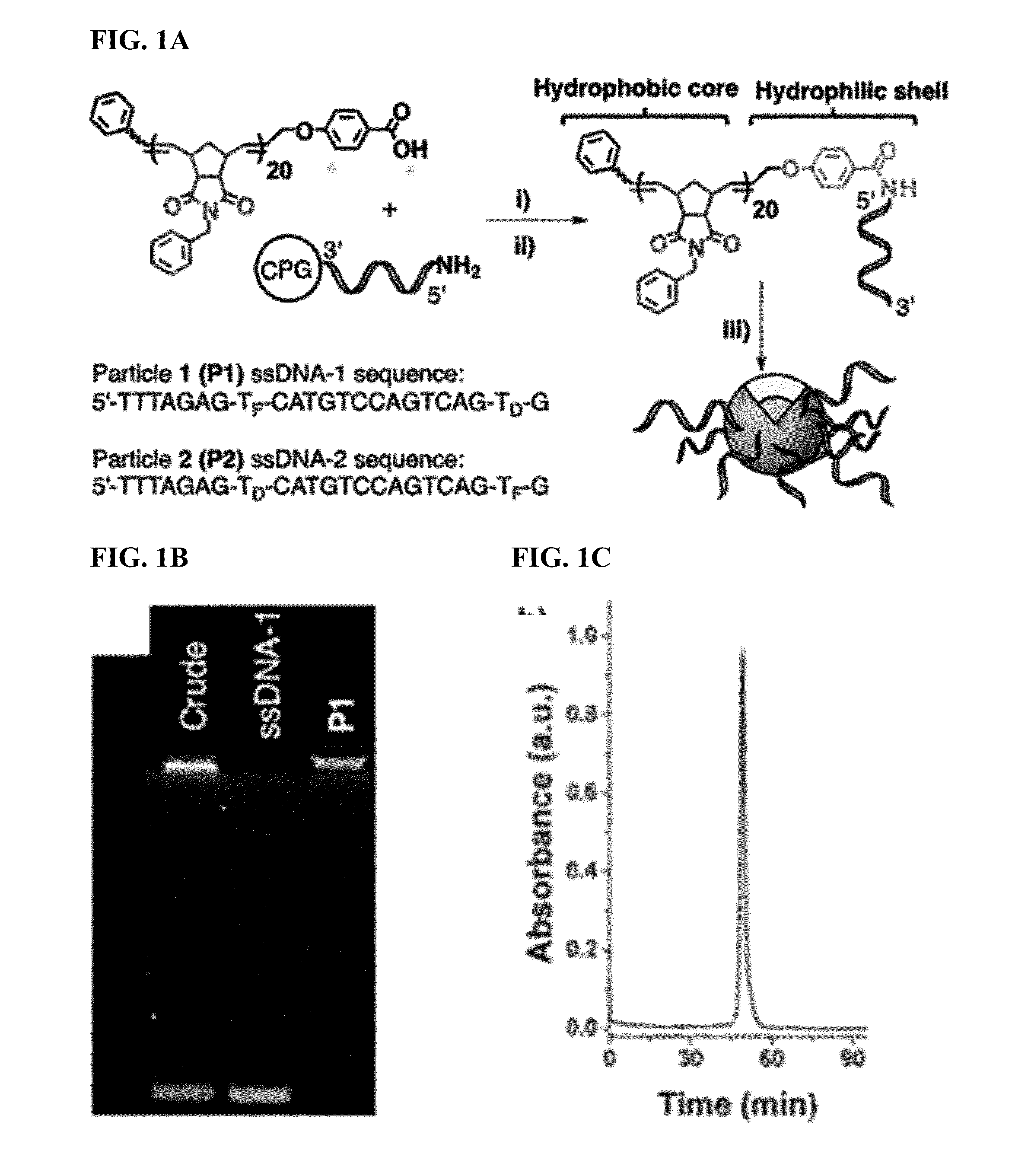

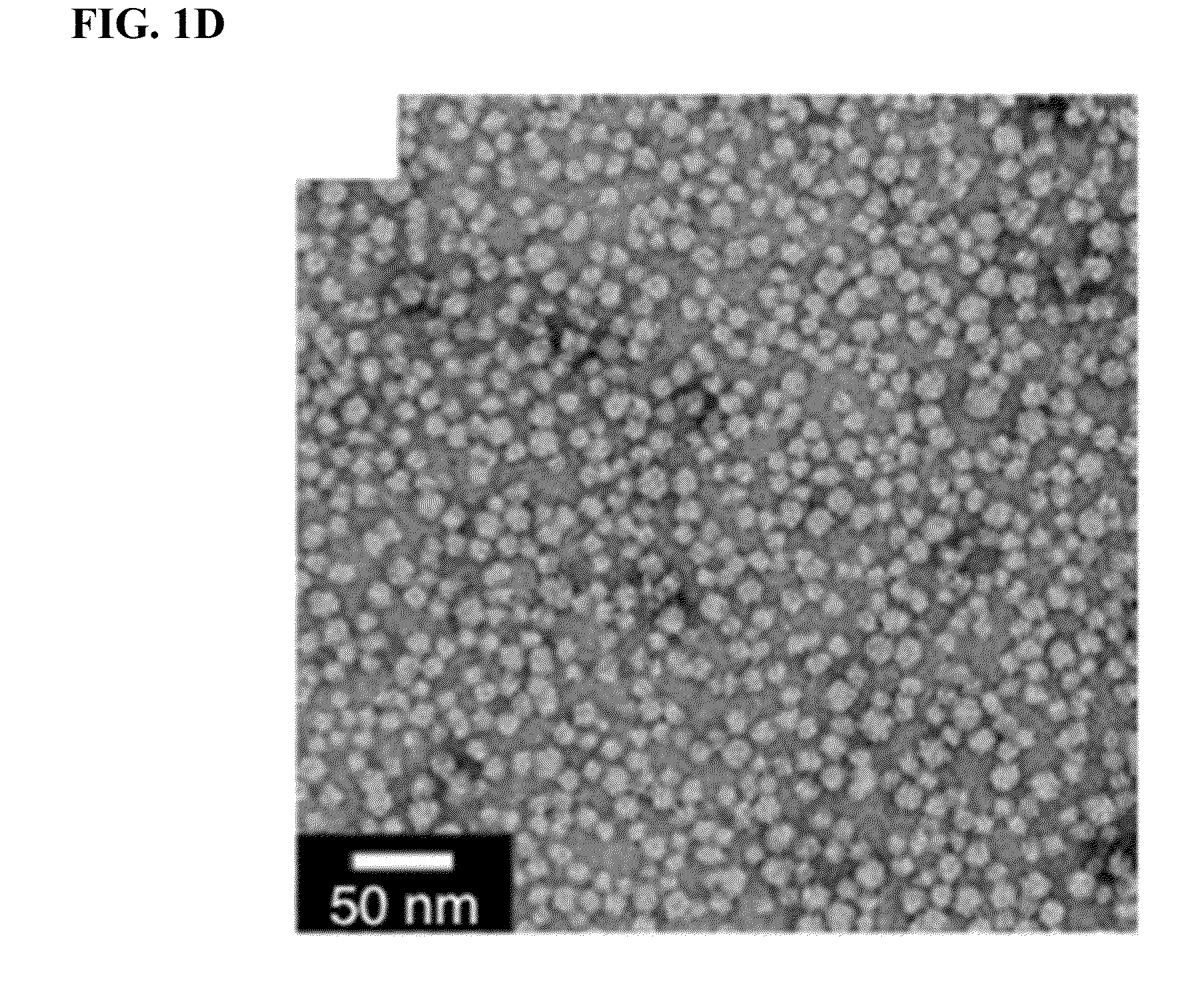

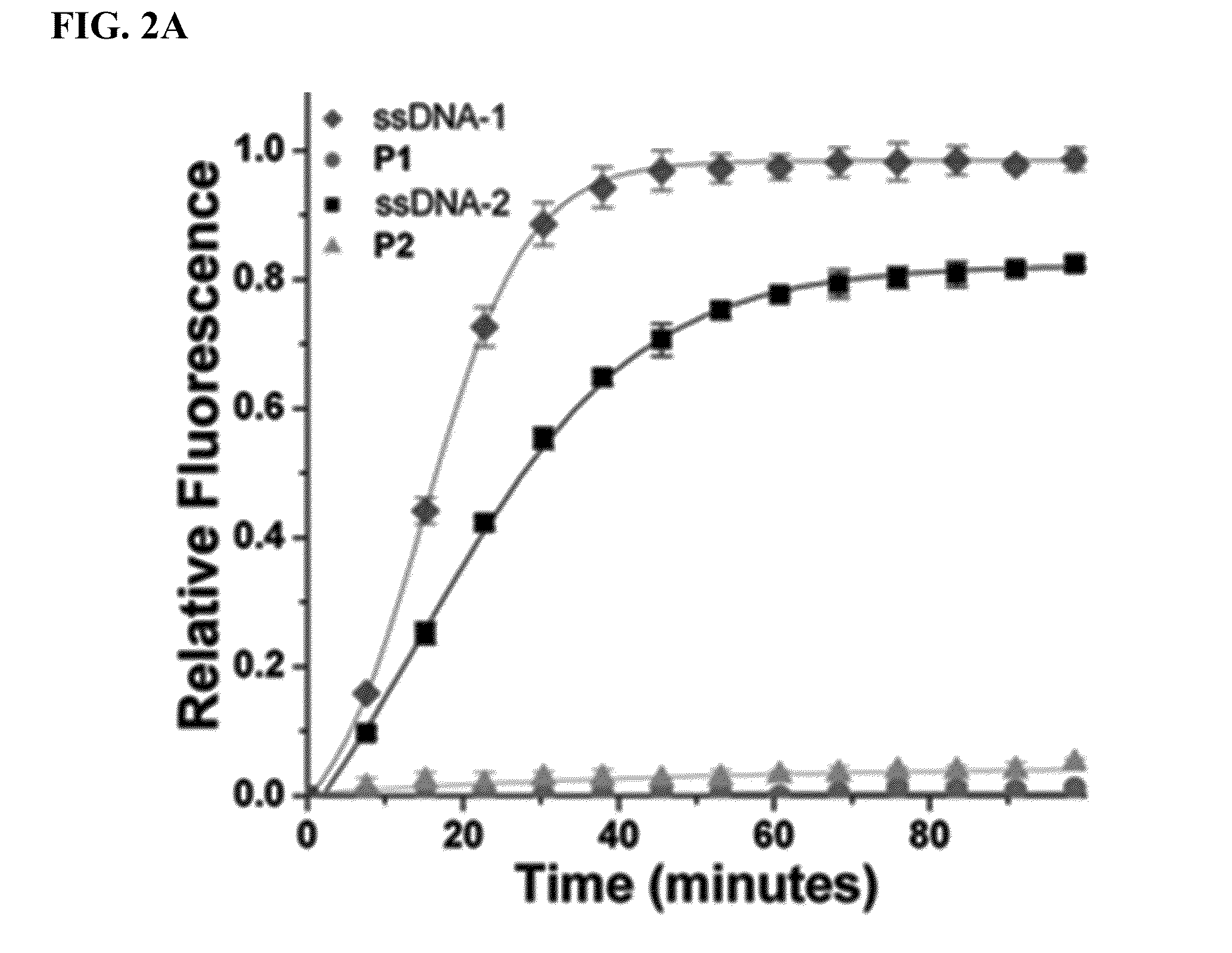

Methods for arranging and packing nucleic acids for unusual resistance to nucleases and targeted delivery for gene therapy

ActiveUS20150190525A1High densityOrganic active ingredientsSpecial deliveryEnzymatic degradationSequence selectivity

There are disclosed compositions and methods to render nucleic acids resistant to nuclease digestion while maintaining sequence selective hybridization competency. The approach relies on utilizing nucleic acids as the polar head group of a nucleic acid-polymer amphiphile in order to assemble well-defined, discrete micellar nanoparticles. Dense packing of nucleic acid in the micelle corona allows for hybridization of complementary oligonucleotides while prohibiting enzymatic degradation.

Owner:RGT UNIV OF CALIFORNIA

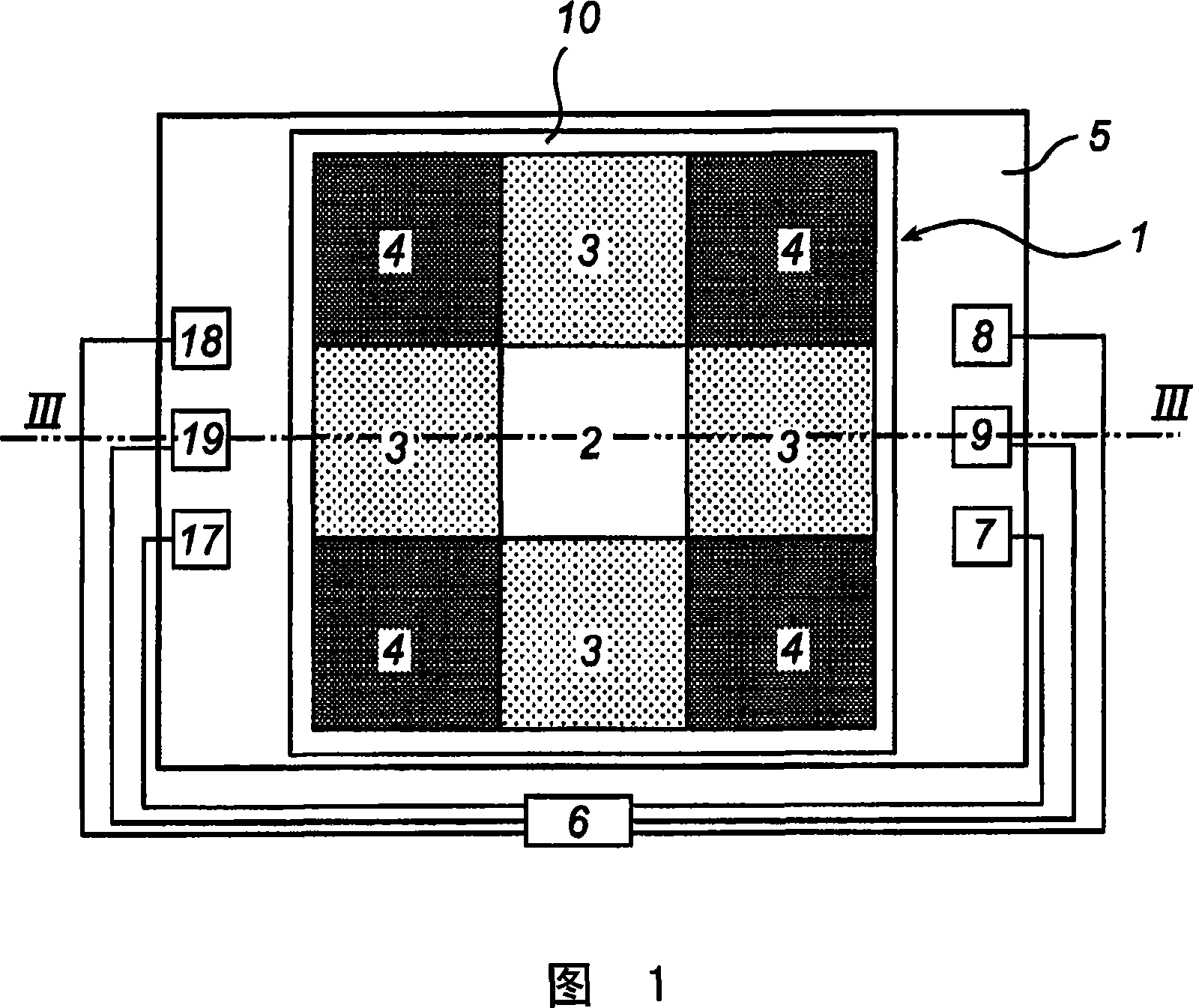

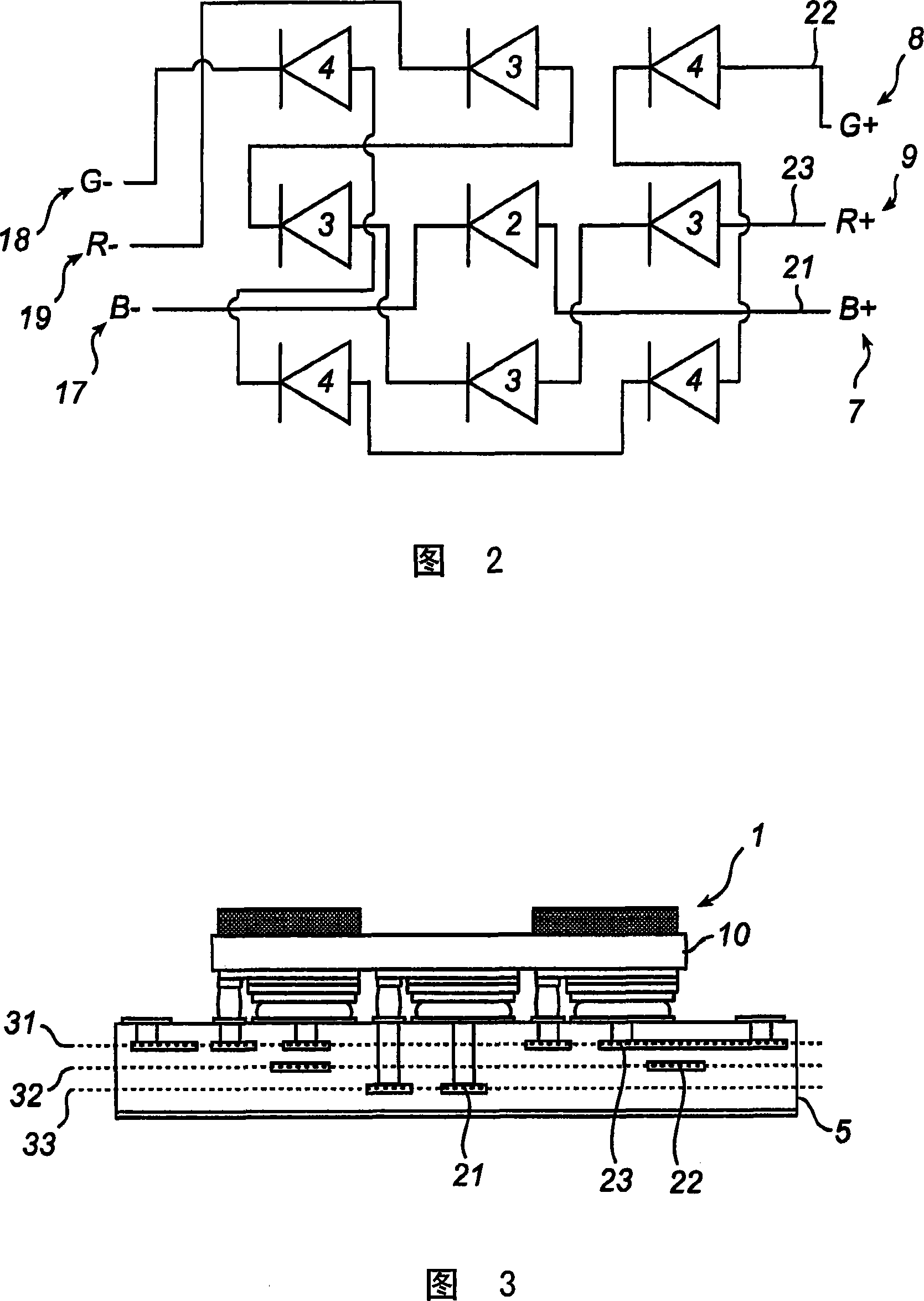

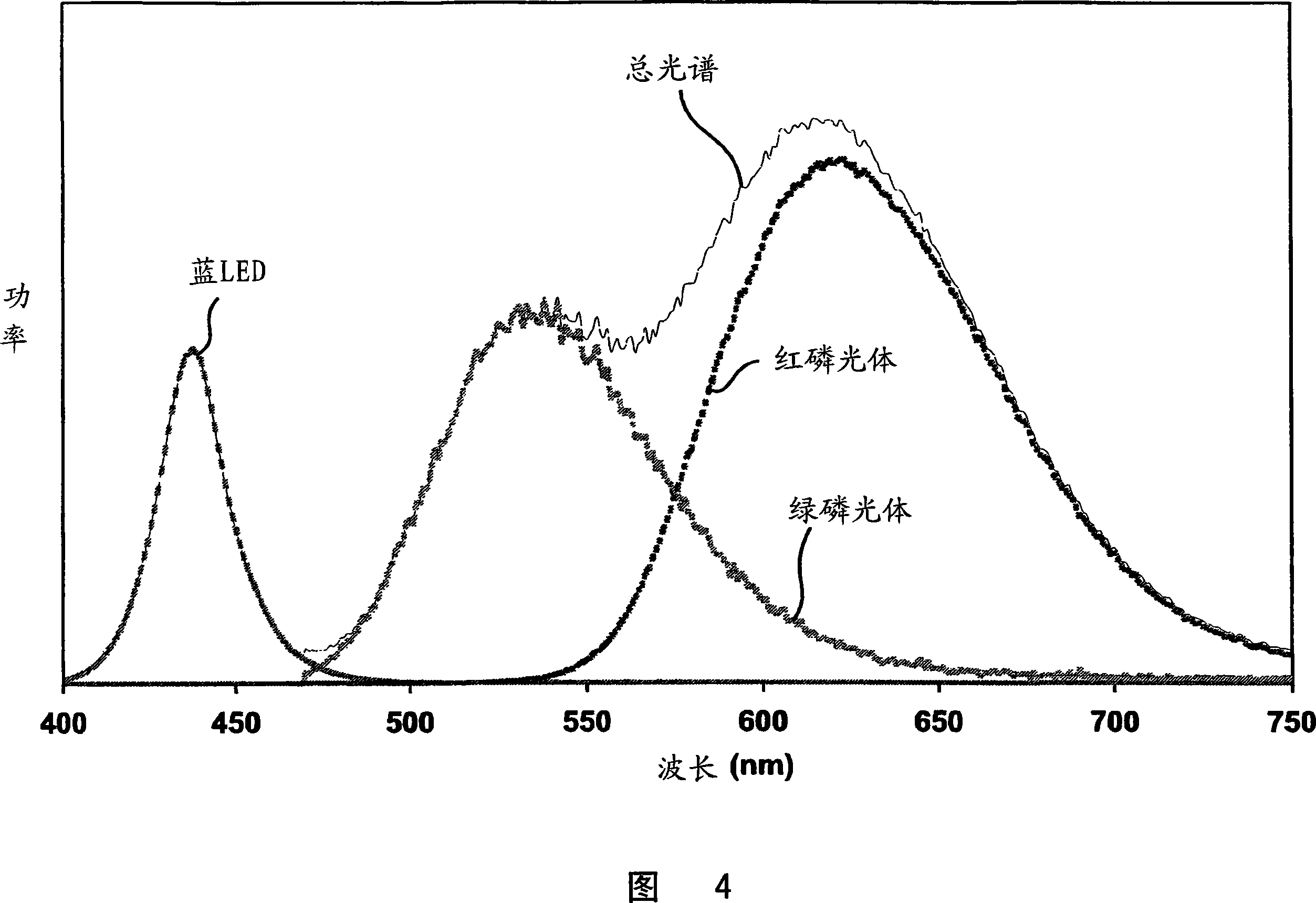

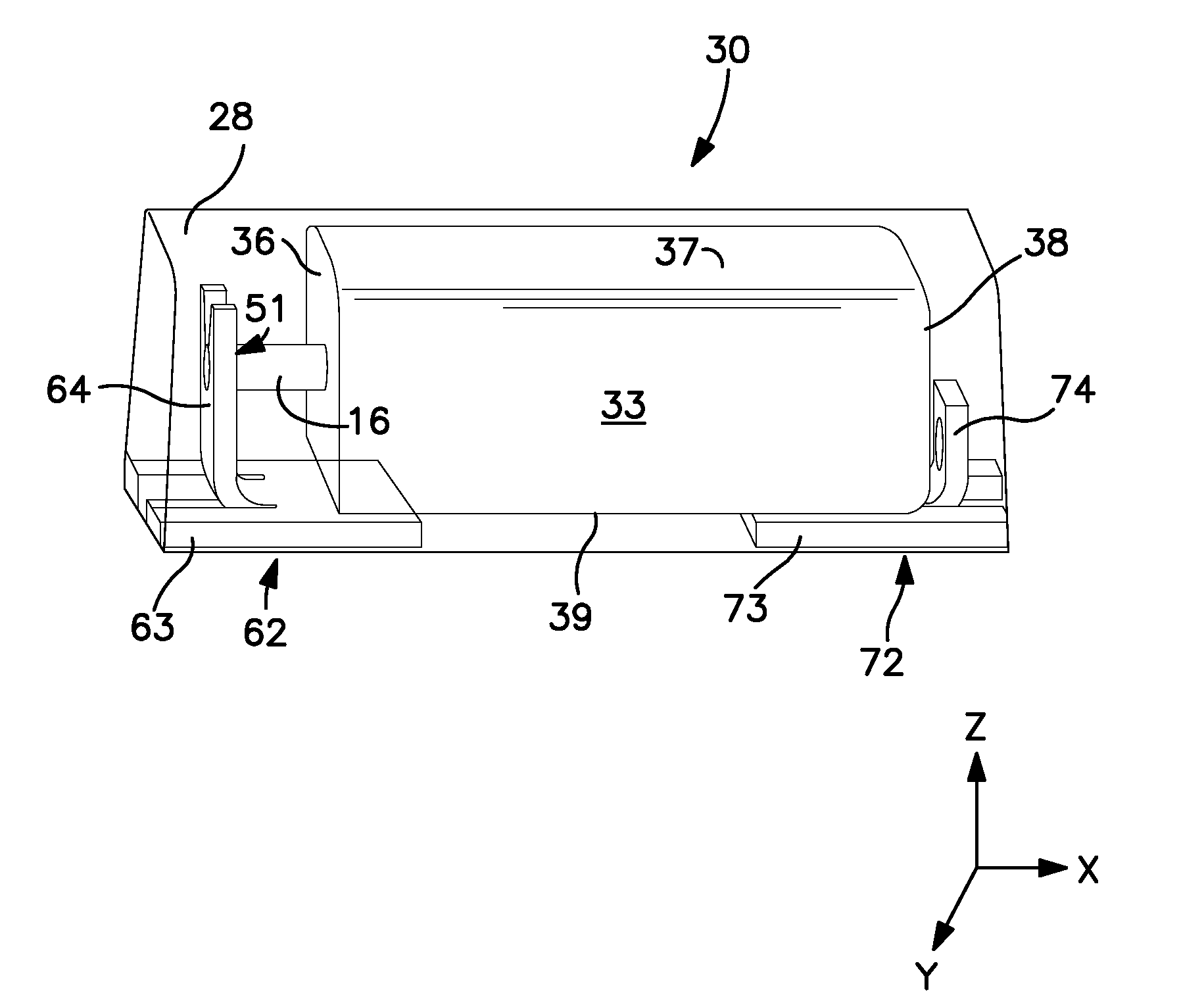

Single chip LED as compact color variable light source

ActiveCN101073155AIncrease luminous fluxSolid-state devicesSemiconductor devicesSingle chipLight emitting device

The present invention relates to a color variable light-emitting device comprising an array of a plurality of LEDs formed on one highly resistive substrate, which array comprises a first, a second and a third set of at least one LED arranged to provide light of a first, a second and a third color, respectively. At least one of the sets is independently addressable. Further, each light-emitting diode in the array has a separate connection to a circuitry, and at least one of the sets comprises at least two LEDs, interconnected in series via the circuitry. Thus, all connections between separate LEDs, for example in the same set, can be done via the circuitry. This also allows for a very dense packing of the LEDs in the array, as no interconnects between different LEDs of the array need to be arranged in the array.

Owner:SIGNIFY HLDG BV

Solid Electrolytic Capacitor Containing an Improved Manganese Oxide Electrolyte

A solid electrolytic capacitor that contains an anode body formed from an electrically conductive powder and a dielectric coating located over and / or within the anode body is provided. The powder has a high specific charge and in turn a relative dense packing configuration. Despite being formed from such a powder, the present inventors have discovered that a manganese precursor solution (e.g., manganese nitrate) can be readily impregnated into the pores of the anode. This is accomplished, in part, through the use of a dispersant in the precursor solution that helps minimize the likelihood that the manganese oxide precursor will form droplets upon contacting the surface of the dielectric. Instead, the precursor solution can be better dispersed so that the resulting manganese oxide has a “film-like” configuration and coats at least a portion of the anode in a substantially uniform manner. This improves the quality of the resulting oxide as well as its surface coverage, and thereby enhances the electrical performance of the capacitor.

Owner:KYOCERA AVX COMPONENTS CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com