Preparation method for hyperbranched polymide film with low dielectric constant

A polyimide film, low dielectric constant technology, applied in the field of hyperbranched polyimide film preparation, can solve the problems of microporous structure collapse, low Dk, etc., achieve outstanding heat resistance, reduced dielectric constant, The effect of reducing the dielectric constant

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

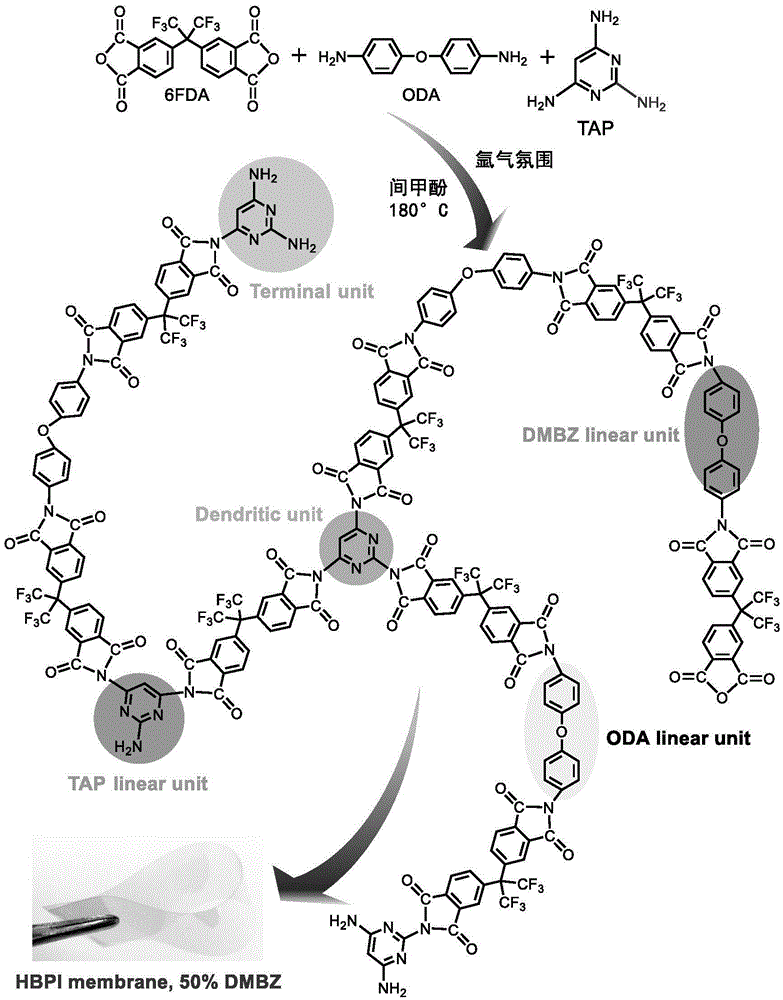

Method used

Image

Examples

Embodiment 1

[0041] Add 0.8342g of 2,4,6-triaminopyrimidine (TAP), 2.9422g of BPDA and 15g of o-cresol to the reaction vessel equipped with mechanical stirring successively, protect with argon, turn on the stirring and cool down the system until the temperature of the system drops to 5 ℃, add 0.25g quinoline, continue to stir for 4h, then react at 70℃ for 3h, and then raise the system temperature to 140℃ for 24h; after the reaction, when the system is cooled to 25℃, pour the reaction solution into 140mL methanol A solid product was precipitated in , and the crude product F was obtained after filtration. The crude product F was washed 3 times with 60 mL of methanol to afford the product G. The product G was extracted with 70 mL methanol for 24 h in a Soxhlet extractor to obtain product H. Dry the product H in a vacuum oven for 12 hours with the temperature controlled at 120°C to obtain product J; dissolve 1 g of product J in 19 g of chloroform, filter through a tetrafluoro filter element w...

Embodiment 2

[0043] Add 0.4171g of 2,4,6-triaminopyrimidine (TAP), 2.0526g of BAPP, 2.9422ga-BPDA and 16g of p-cresol to the reaction vessel equipped with mechanical agitation in sequence. When the temperature of the system drops to 1°C, add 0.4g of isoquinoline, continue to stir for 5h, then react at 80°C for 4h, then raise the temperature of the system to 160°C, and react for 30h; after the reaction, when the system is cooled to 25°C The reaction solution was poured into 130 mL of ethanol to precipitate a solid product, and the crude product F was obtained after filtration. The crude product F was washed 4 times with 50 mL of ethanol to obtain product G. Product G was extracted with 65 mL ethanol for 30 h in a Soxhlet extractor to obtain product H. Dry the product H in a vacuum oven for 15 hours with the temperature controlled at 130°C to obtain product J; dissolve 2 g of product J in 32 g of dichloromethane, filter through a tetrafluoro filter element with a pore size of 220 nm, and po...

Embodiment 3

[0045] Add 0.5005g of 2,4,6-triaminopyrimidine (TAP), 1.3371g of 6FBA, 3.1022g of ODPA and 12g of m-cresol in sequence to the reaction vessel equipped with mechanical stirring, protect with argon, turn on the stirring and cool down the system. When the temperature drops to 4°C, add 0.5g of benzoic acid, continue to stir for 7h, then react at 85°C for 5h, then raise the temperature of the system to 180°C, and react for 35h; Pour into 100mL of n-propanol to precipitate a solid product, and obtain the crude product F after filtration. The crude product F was washed 5 times with 40 mL of n-propanol to obtain product G. Product G was extracted with 50 mL n-propanol for 35 h in a Soxhlet extractor to obtain product H. Dry the product H in a vacuum oven for 18 hours with the temperature controlled at 140°C to obtain product J; dissolve 2 g of product J in 45 g of tetrahydrofuran, filter through a tetrafluoro filter element with a pore size of 220 nm, and pour it on a glass plate adj...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com