Patents

Literature

78 results about "Kapton" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Kapton is a polyimide film developed by DuPont in the late 1960s that remains stable across a wide range of temperatures, from −269 to +400 °C (−452 to 752 °F; 4 to 673 K). Kapton is used in, among other things, flexible printed circuits (flexible electronics) and thermal blankets used on spacecraft, satellites, and various space instruments.

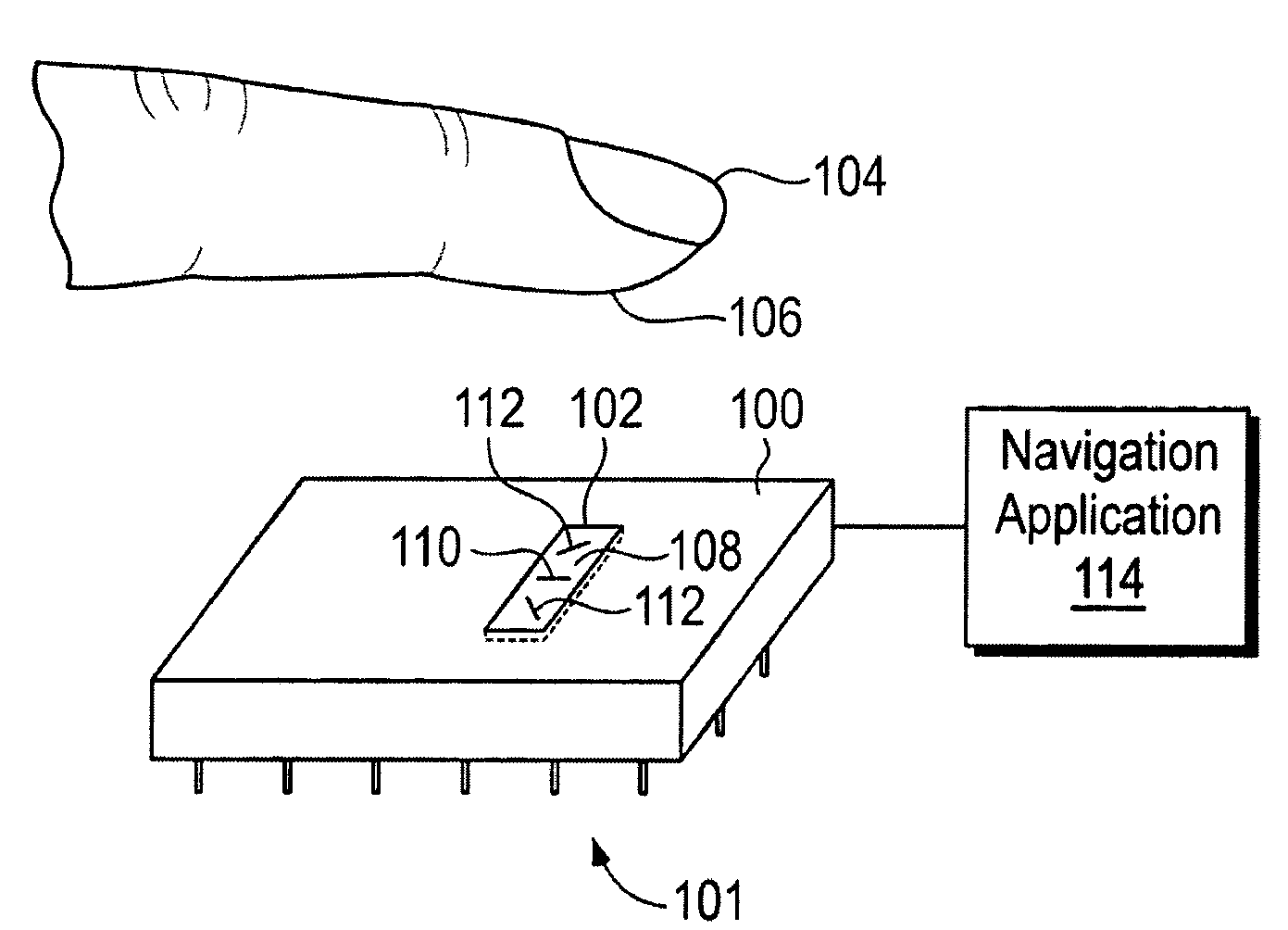

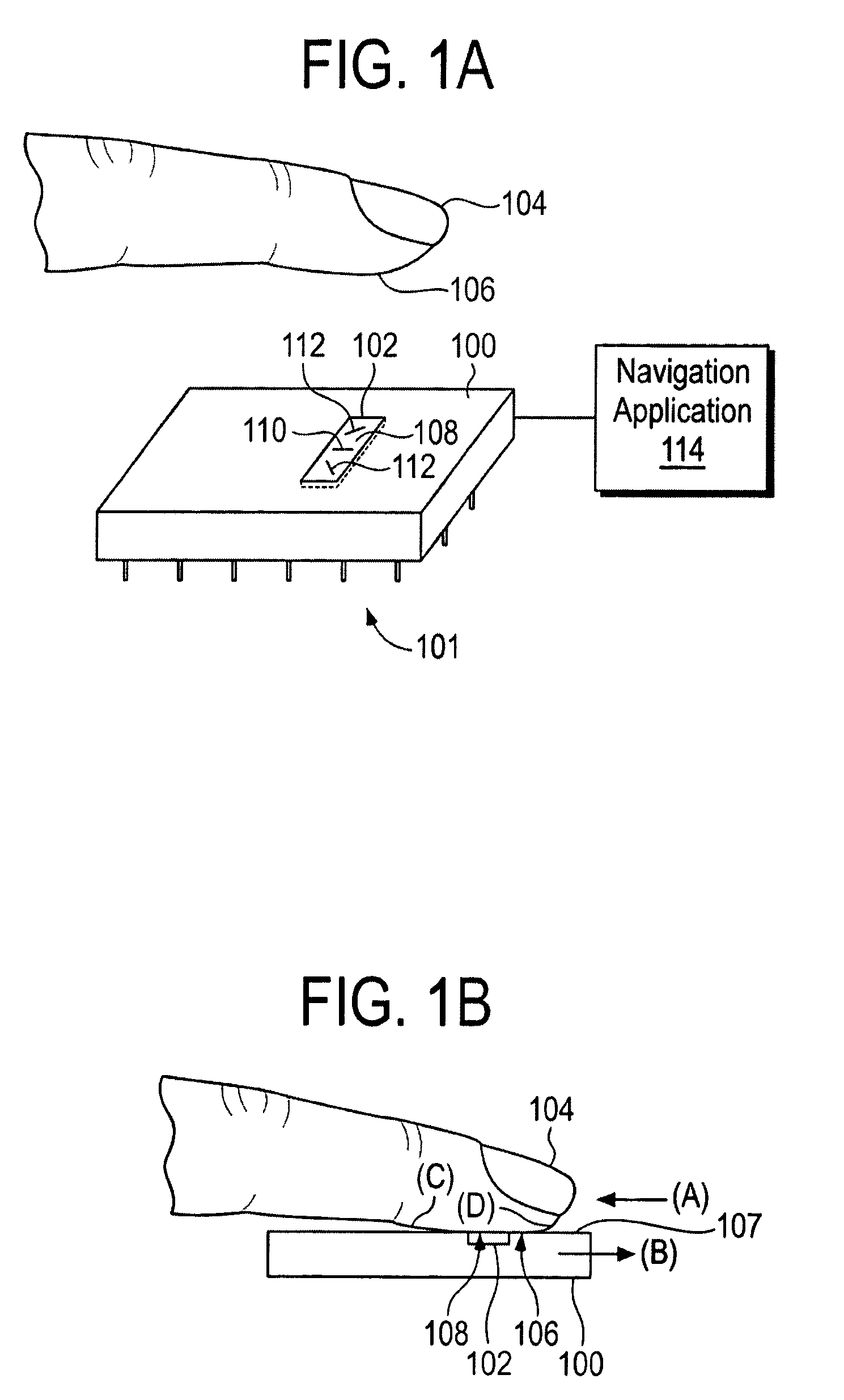

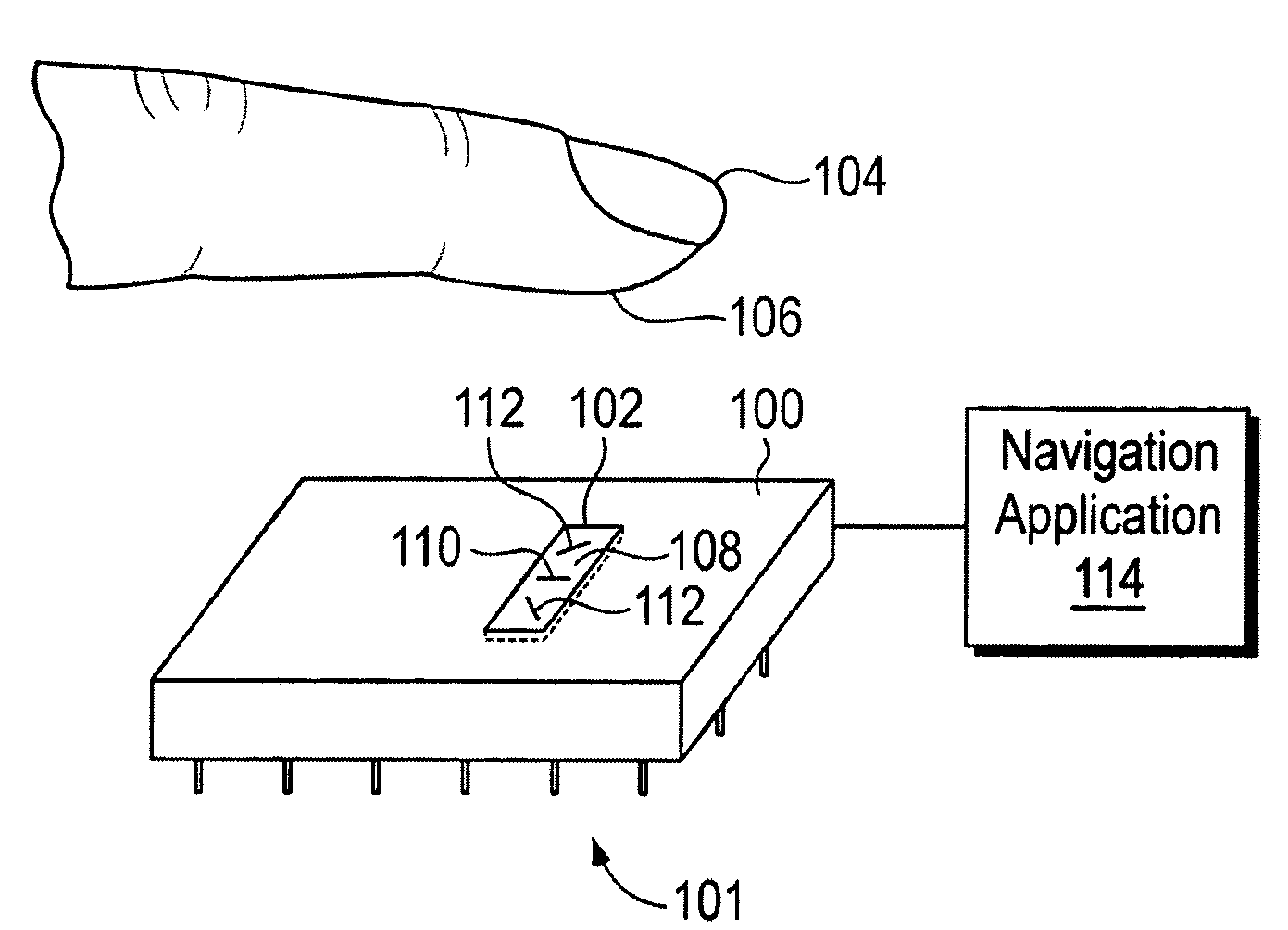

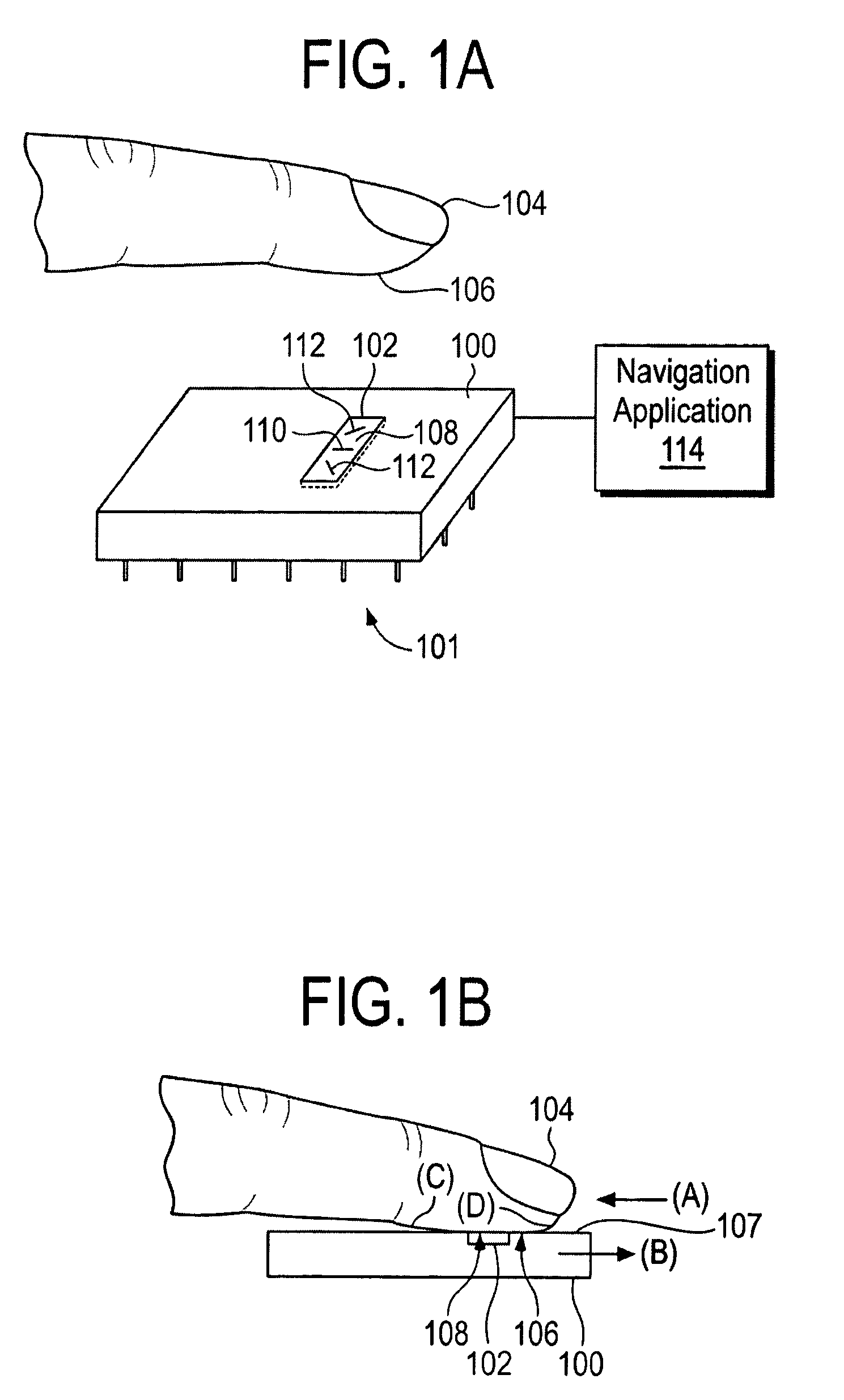

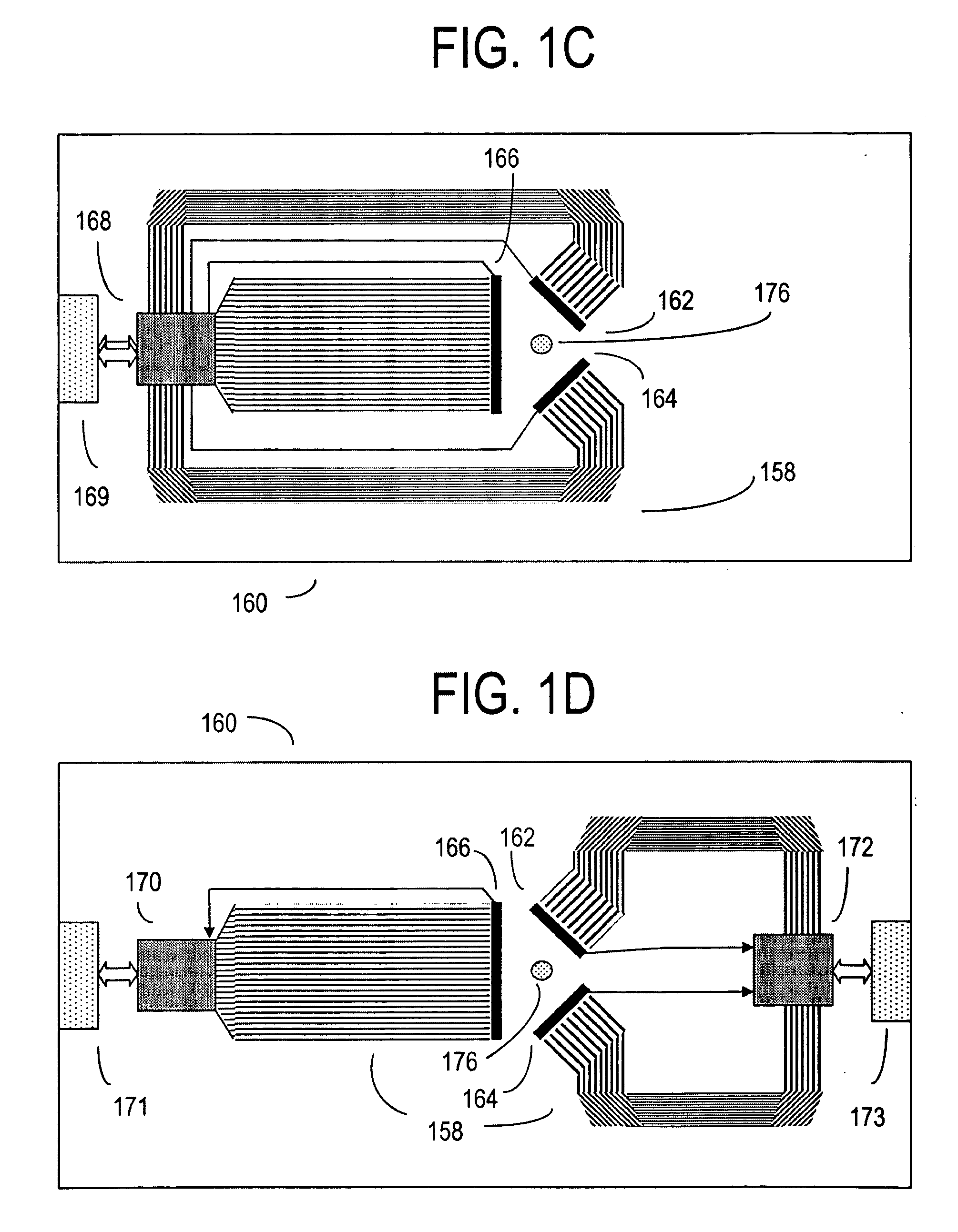

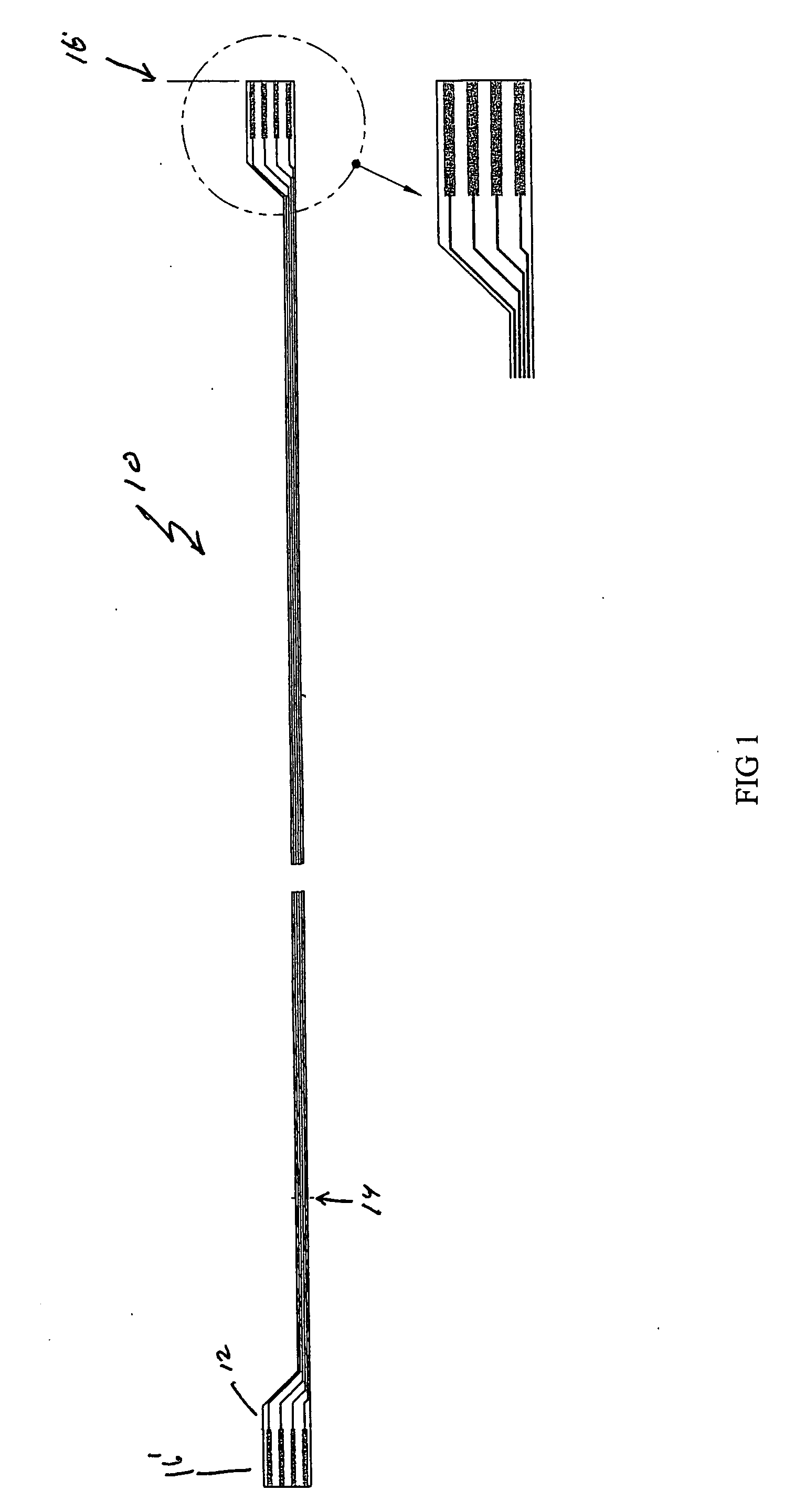

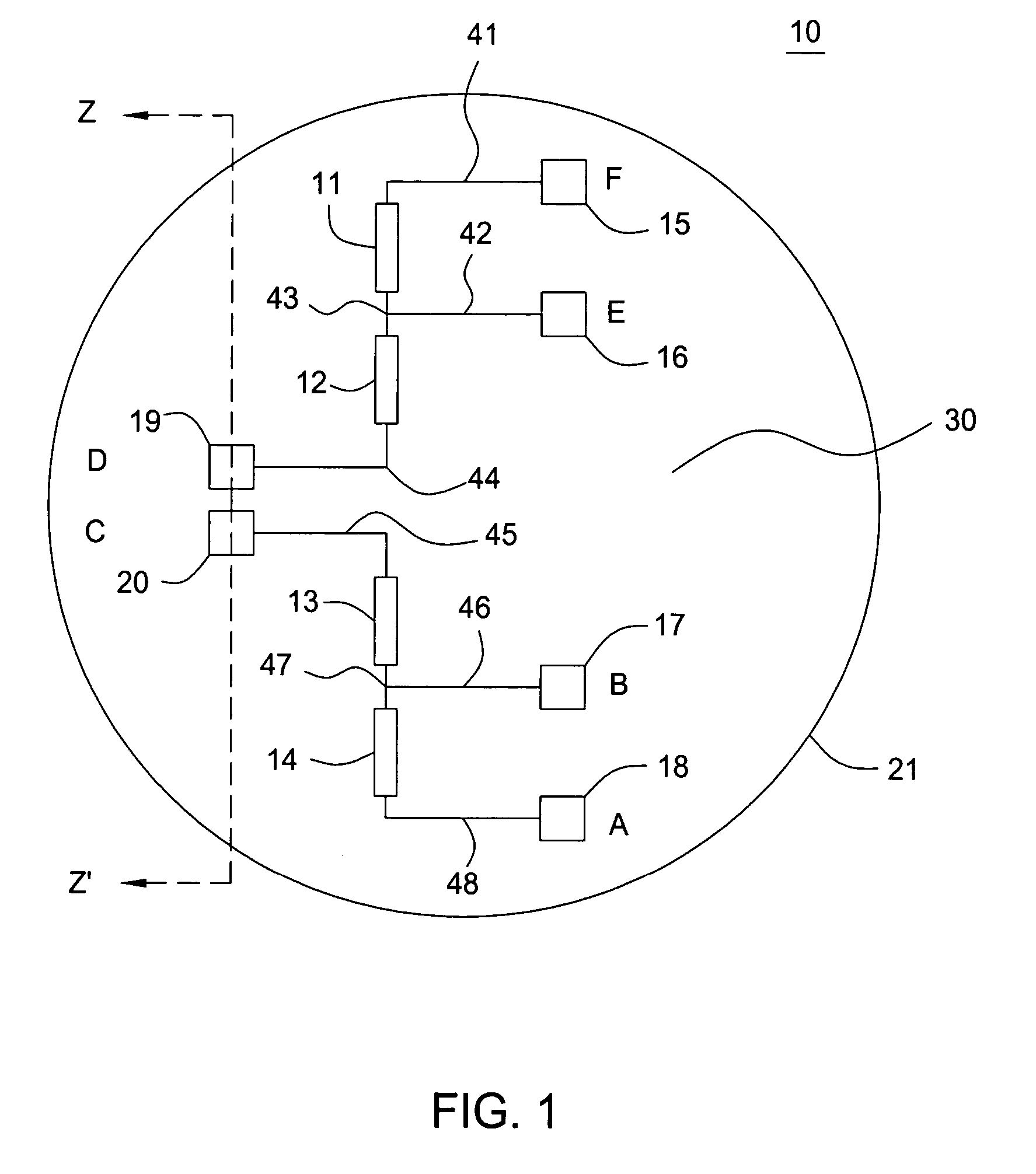

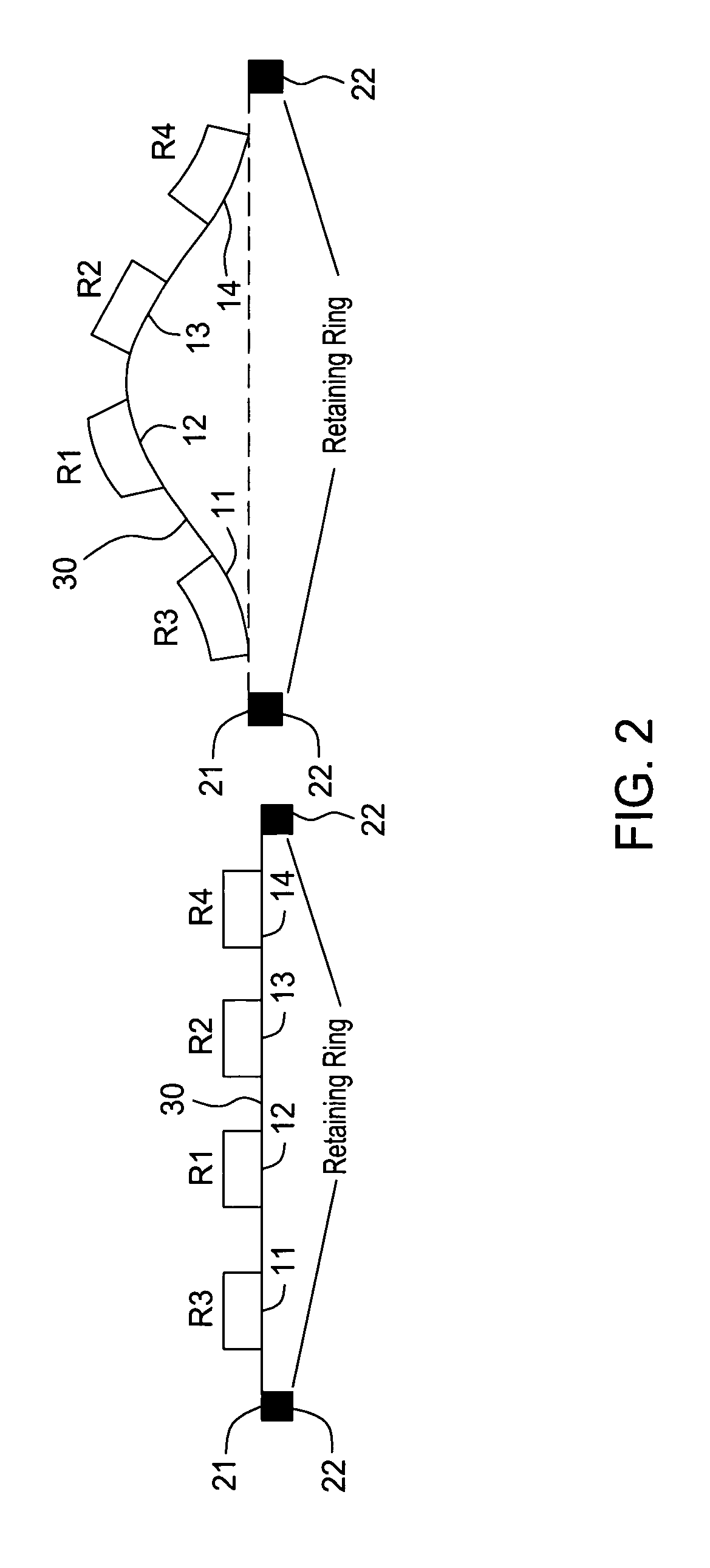

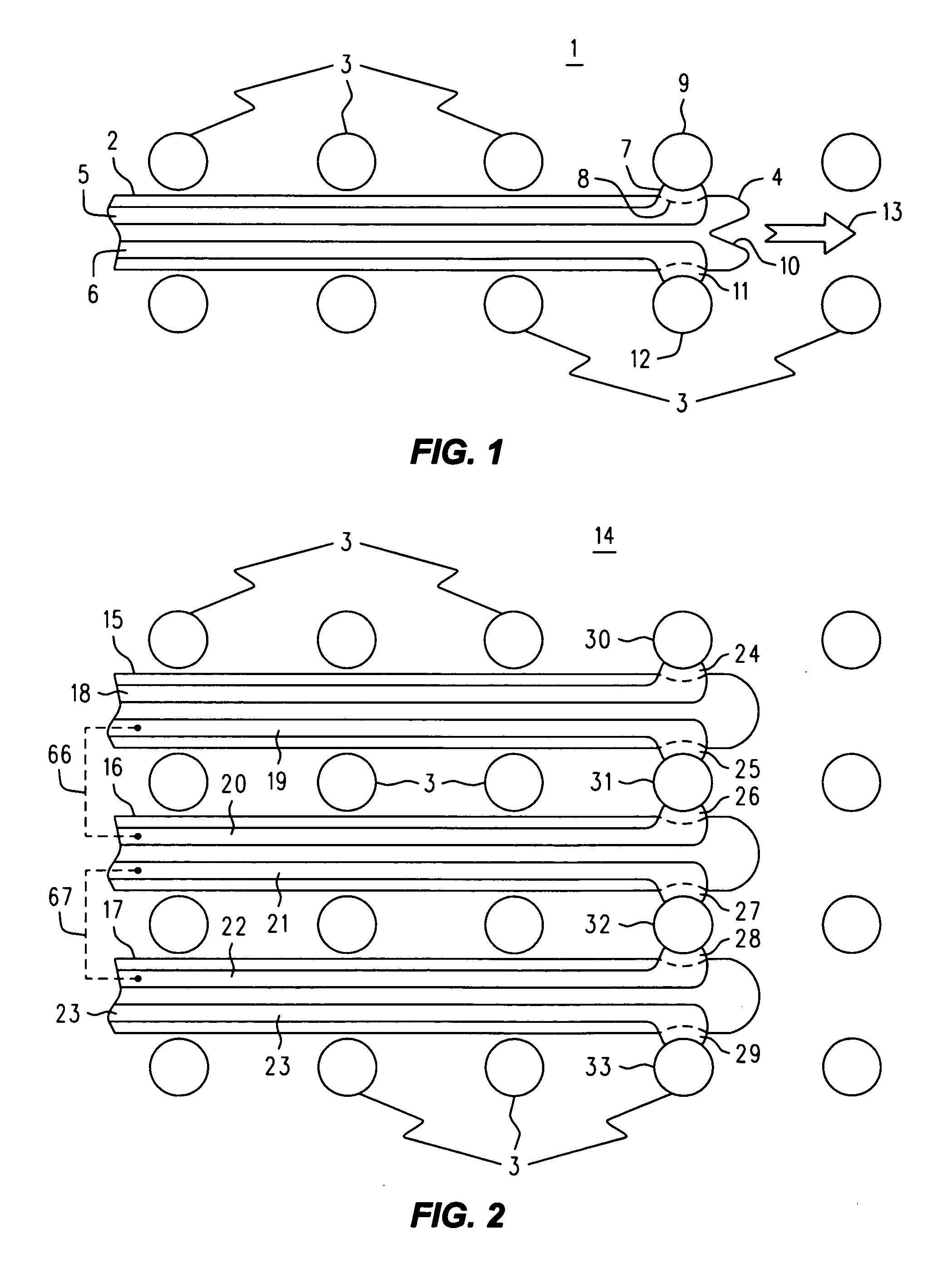

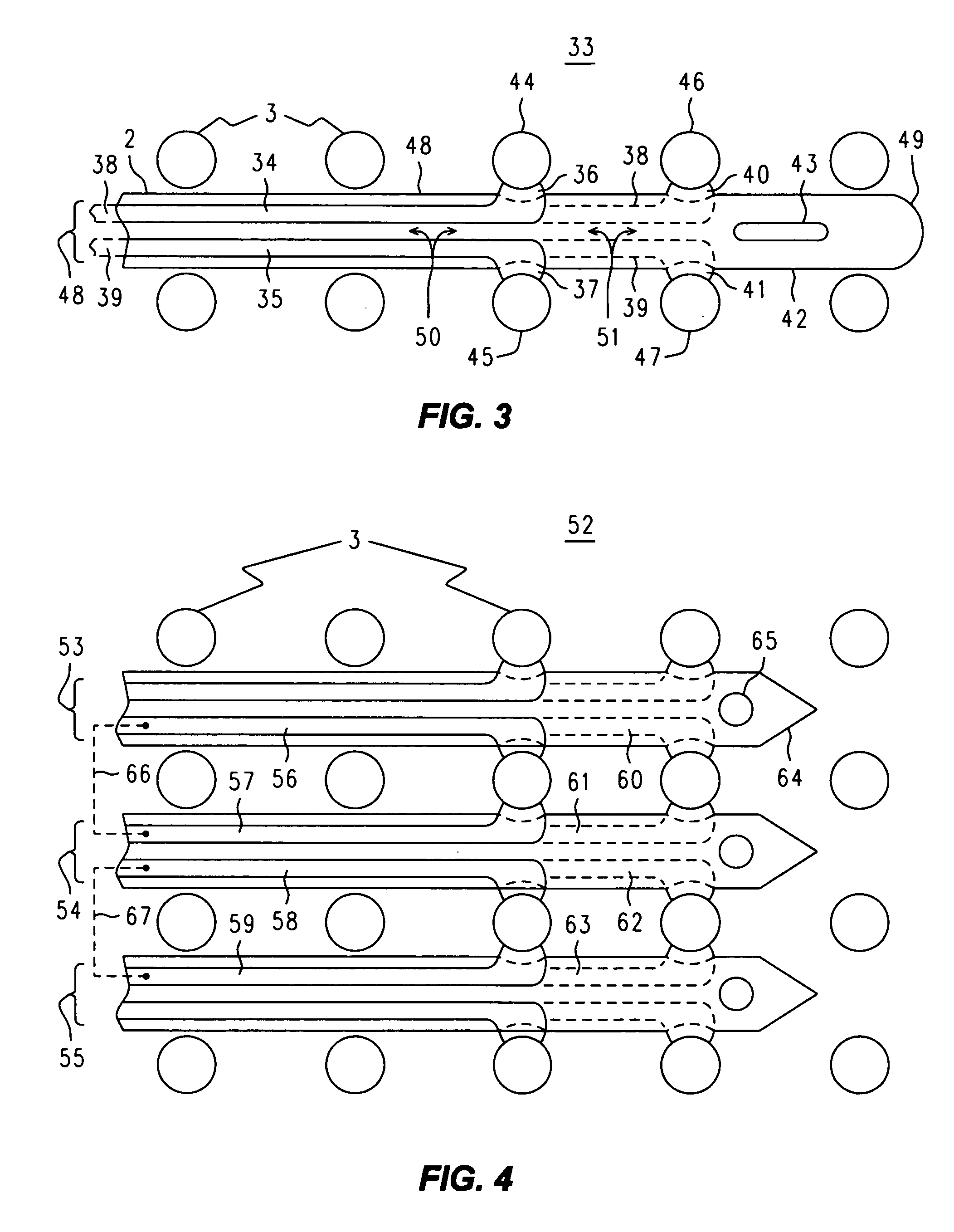

Unitized Ergonomic Two-Dimensional Fingerprint Motion Tracking Device and Method

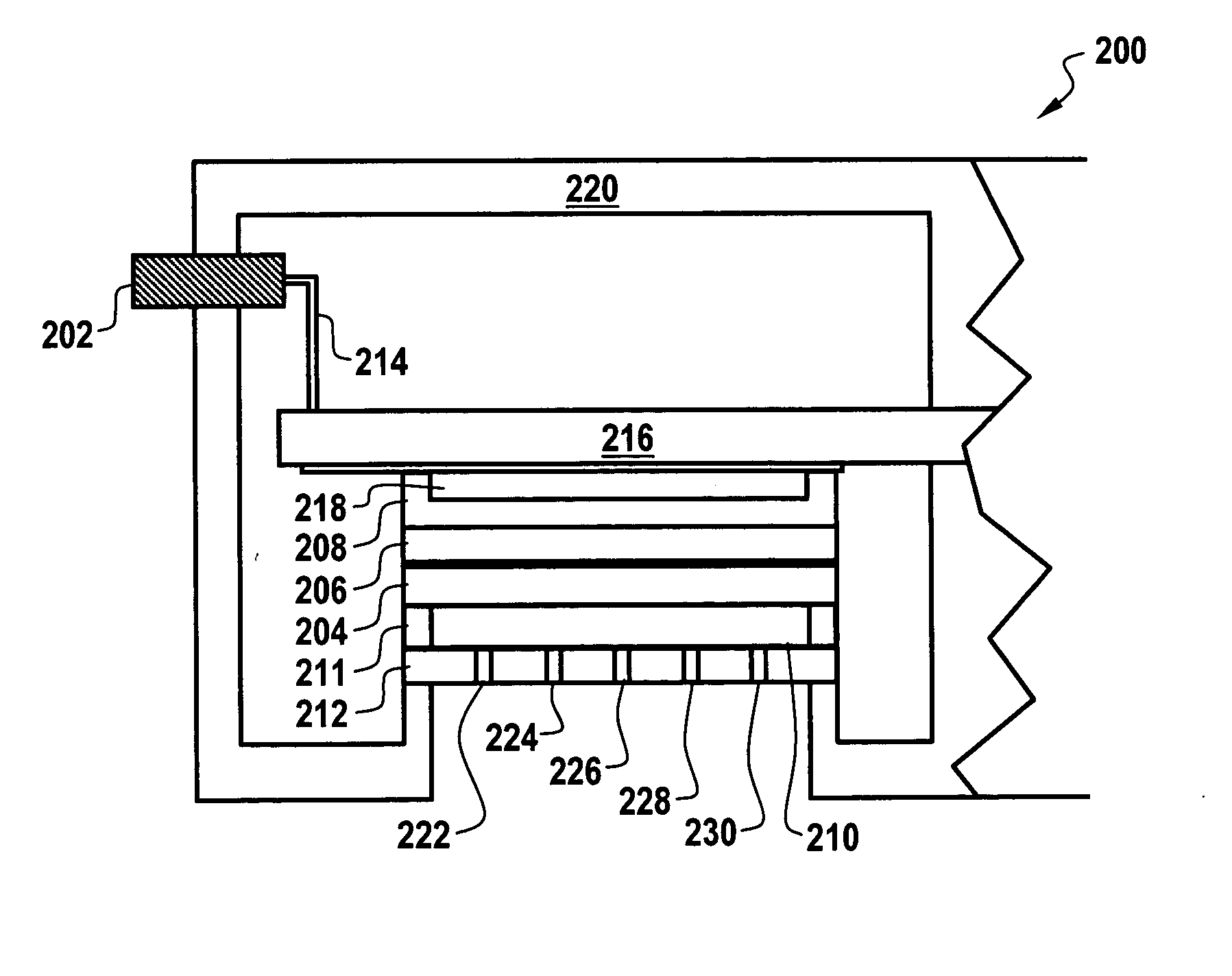

InactiveUS20080226132A1Improve accuracyPrecise positioningCharacter and pattern recognitionRadio frequencyFinger movement

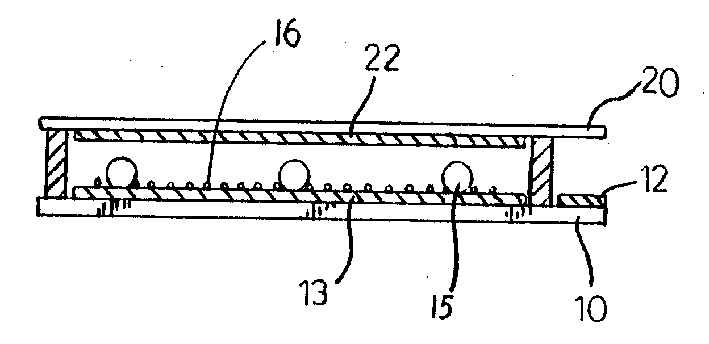

A sensor which uses a plurality of partial fingerprint readers (imagers), and various computational algorithms, to detect changes in fingerprint images as a function of finger movement. The sensor can provide both finger motion information and fingerprint images. The sensor uses multiple partial fingerprint readers, arranged in different directions on a surface, to detect finger motion in two dimensions. The sensor can also detect the relative speed and direction of finger movement. Some sensor embodiments use deep finger penetrating radio frequency (RF) based circuits, which can be inexpensively printed or formed on the surface of robust and flexible dielectric materials such as Kapton tape. The sensor also has textured surfaces to help guide the user. The sensor both small and robust, and is well suited for control applications for low-cost mass market microprocessor controlled devices such as cell phones, MP3 players, laptop computers, and other devices.

Owner:SYNAPTICS INC

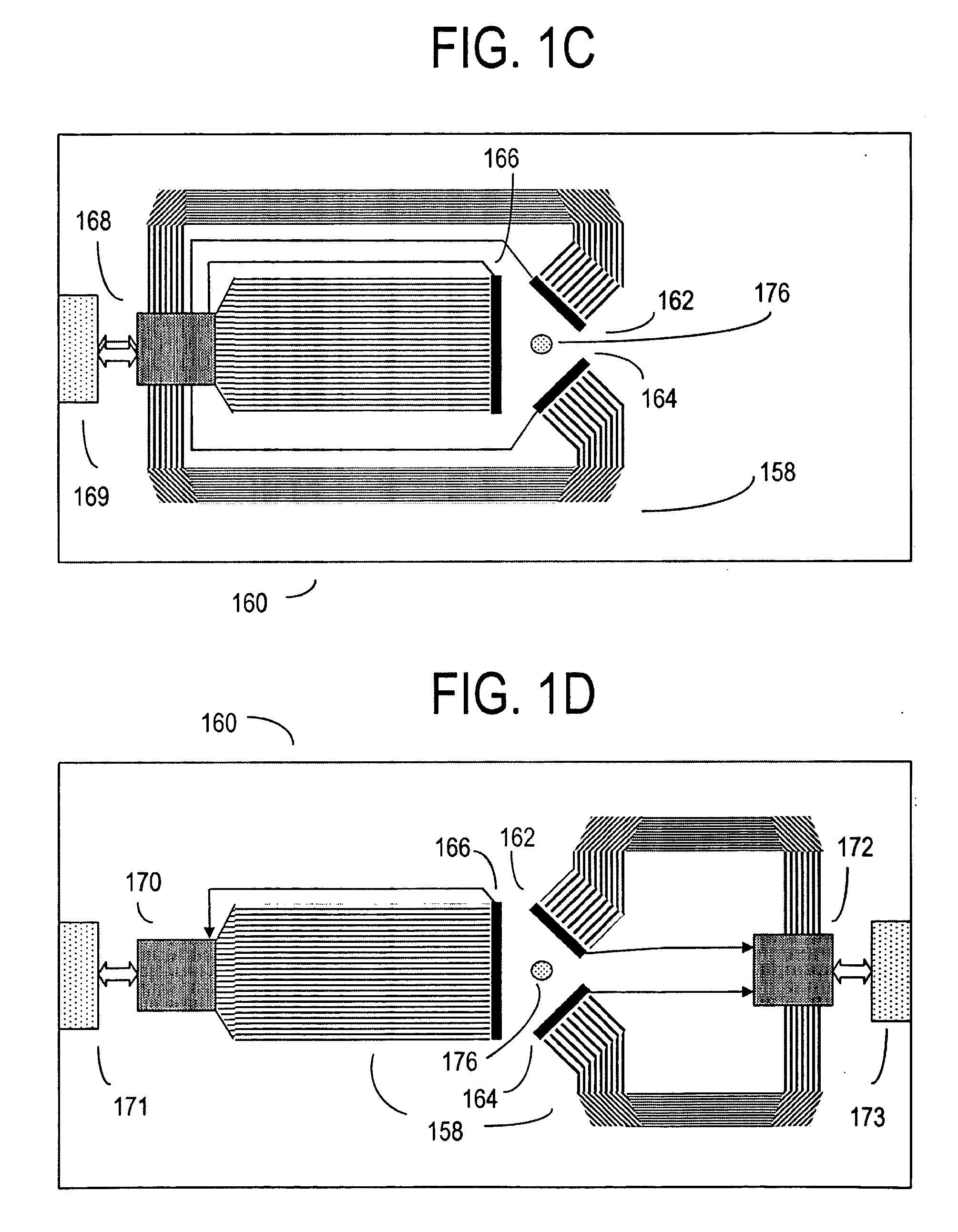

Hybrid tactile sensor

ActiveUS20060260417A1Ease and repeatabilityOvercomes drawbackForce measurementWork measurementSensor arrayEpoxy

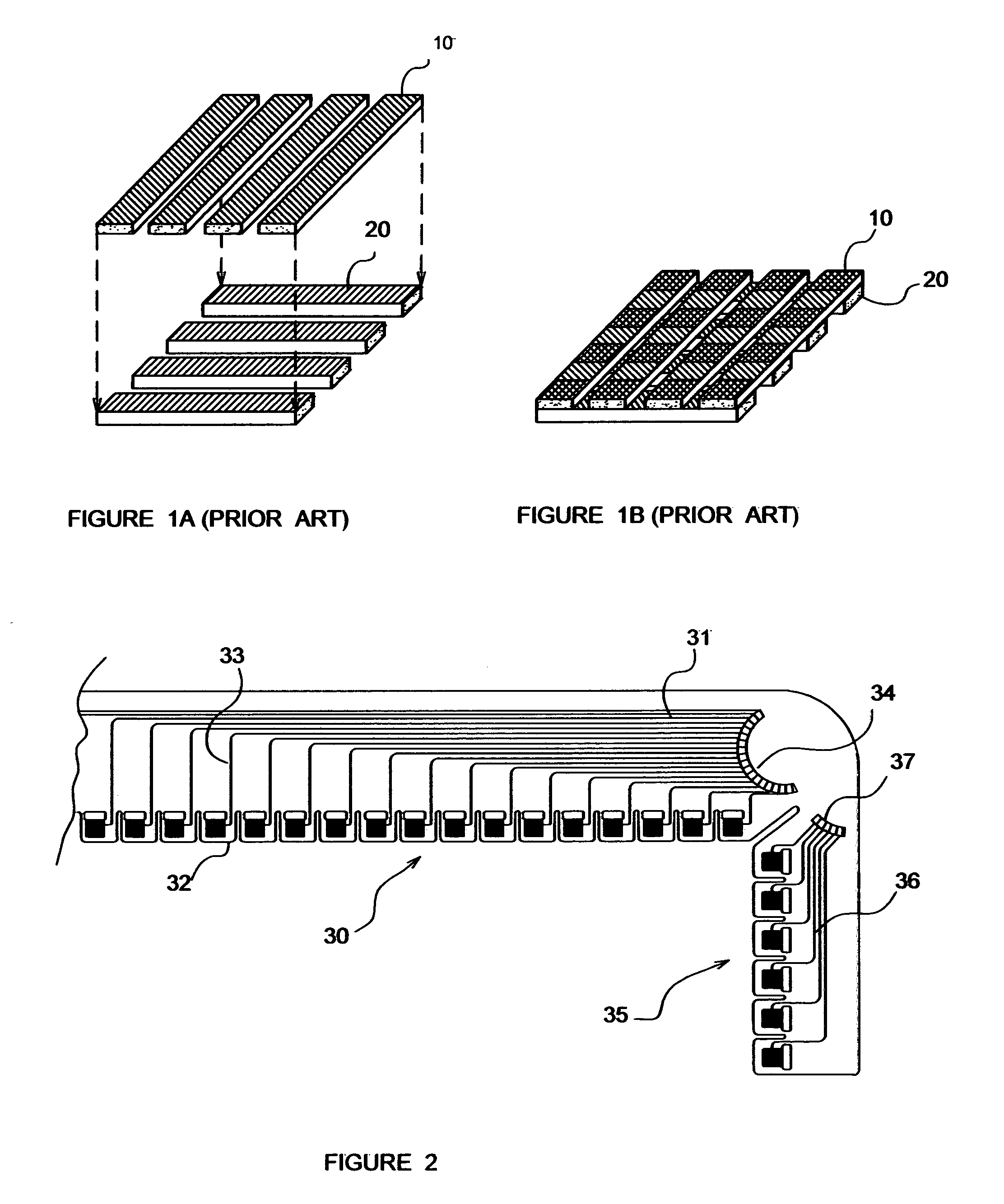

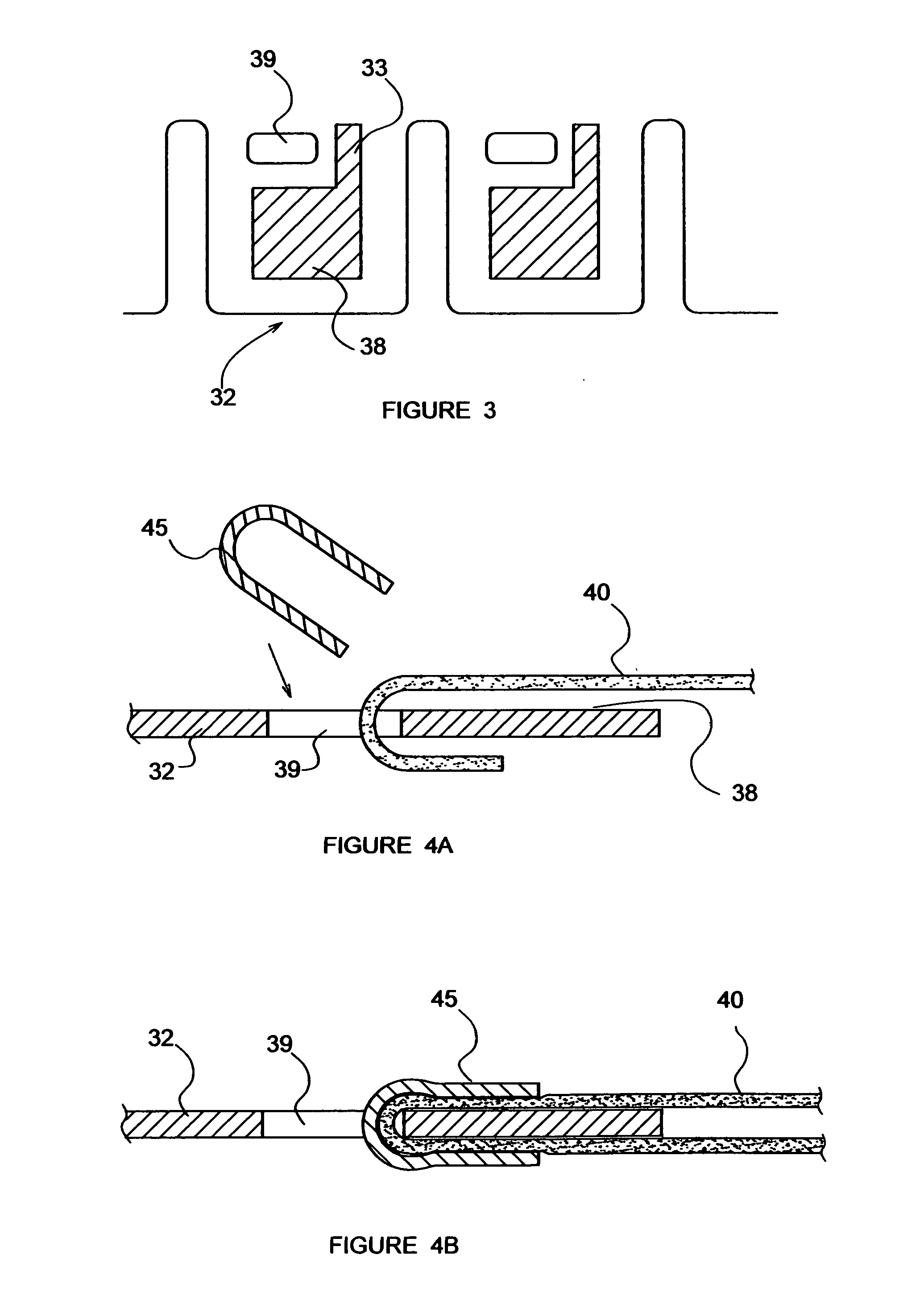

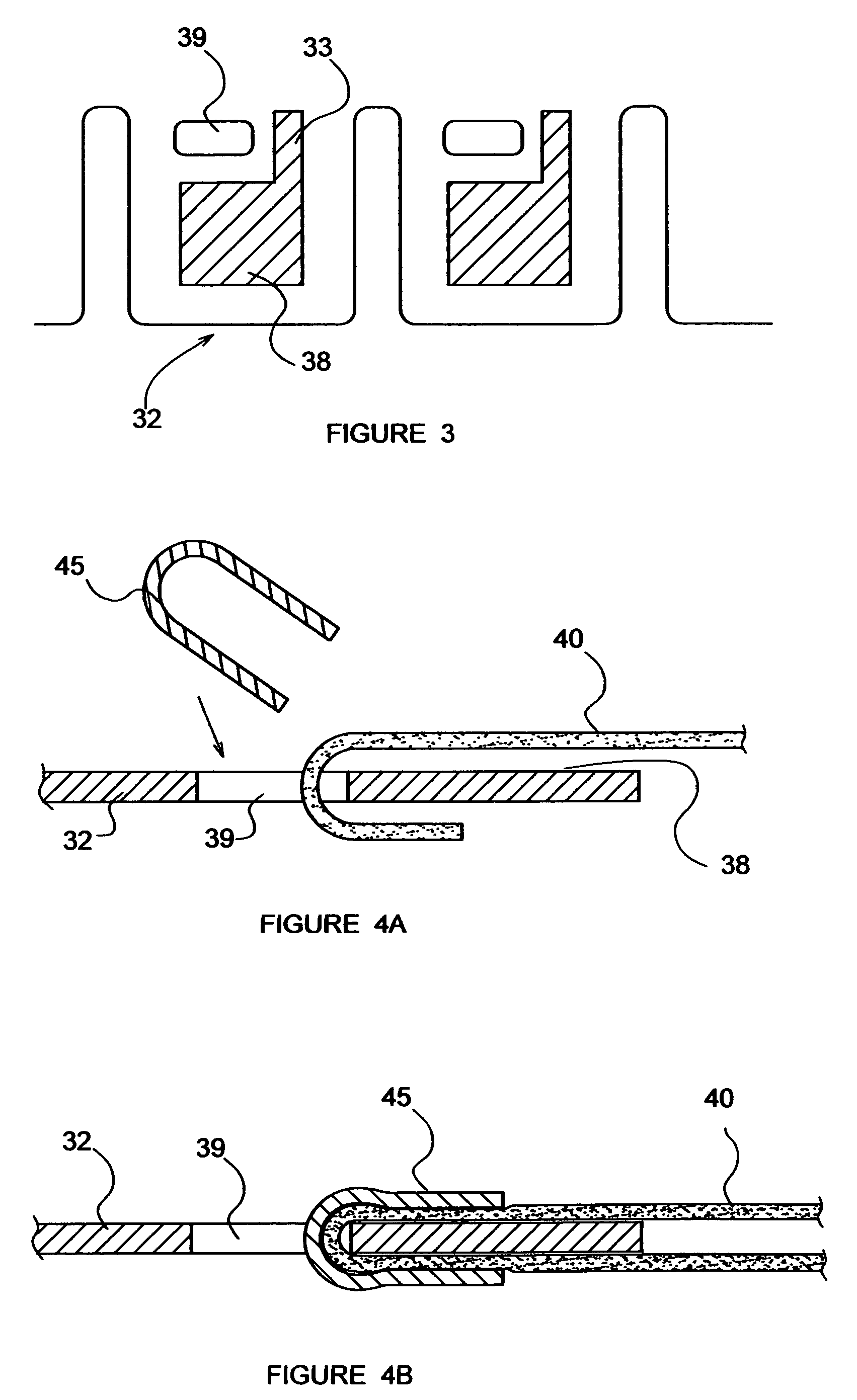

A hybrid tactile sensor includes a flexible cloth-based tactile sensor array including a plurality of electrodes, each of the electrodes connected to a corresponding connecting zone of an intermediate connecting harness made from a flexible film such as Kapton®. The harness includes a common bundle of parallel conductors etched or printed onto the harness and connecting each of the connecting zones to a common terminal for further attaching to a control unit of the sensor. The use of the harness allows repeatable manufacturing of sensor arrays with large number of electrodes or when they are located close to each other. Each connecting zone may include an interconnecting pad for crimping, soldering, or adhering the electrode thereto using a conductive epoxy. Alternative embodiments describe the use of U-shaped malleable connectors, jumper wires including those equipped with U-shaped clips, and other means of attaching electrodes to corresponding connecting zones. The use of alternating connections with electrodes of the array allows to double the distance between individual electrodes available for making a connection.

Owner:PRESSURE PROFILE SYST

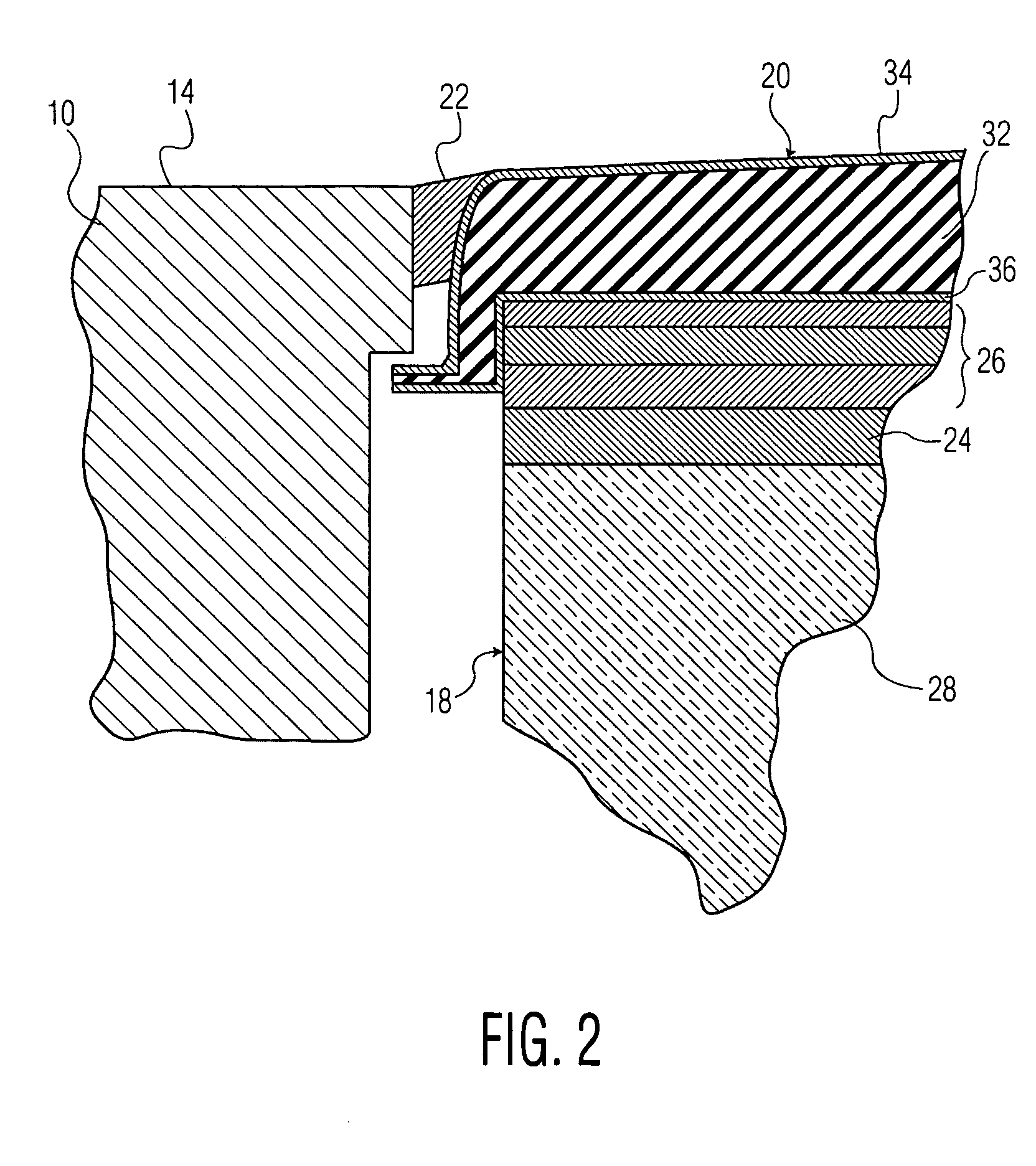

Acoustic window for ultrasound probes

InactiveUS20050165312A1Ultrasonic/sonic/infrasonic diagnosticsInfrasonic diagnosticsCompound (substance)Transducer

Acoustic window for an ultrasound probe including a layer of PEBAX™ having a surface adapted to face a transducer array and an opposed surface adapted to face the object being examined and optionally impervious polymer layers arranged on one or both surfaces of the PEBAX™ layer. An outer polymer layer on the object-facing surface, when present, protects the PEBAX™ layer from chemicals while the inner polymer layer on the transducer array-facing surface, when present, is bonded to the transducer array of the probe. The polymer layers may each be made from an impervious polymer which has a negligible acoustic impact including, for example, polyethylene, Mylar™ and Kapton™. A method for manufacturing the acoustic window and an ultrasound probe including the same are also disclosed.

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

Unitized ergonomic two-dimensional fingerprint motion tracking device and method

InactiveUS8175345B2Precise positioningCharacter and pattern recognitionRadio frequencyFinger movement

A sensor which uses a plurality of partial fingerprint readers (imagers), and various computational algorithms, to detect changes in fingerprint images as a function of finger movement. The sensor can provide both finger motion information and fingerprint images. The sensor uses multiple partial fingerprint readers, arranged in different directions on a surface, to detect finger motion in two dimensions. The sensor can also detect the relative speed and direction of finger movement. Some sensor embodiments use deep finger penetrating radio frequency (RF) based circuits, which can be inexpensively printed or formed on the surface of robust and flexible dielectric materials such as Kapton tape. The sensor also has textured surfaces to help guide the user. The sensor both small and robust, and is well suited for control applications for low-cost mass market microprocessor controlled devices such as cell phones, MP3 players, laptop computers, and other devices.

Owner:SYNAPTICS INC

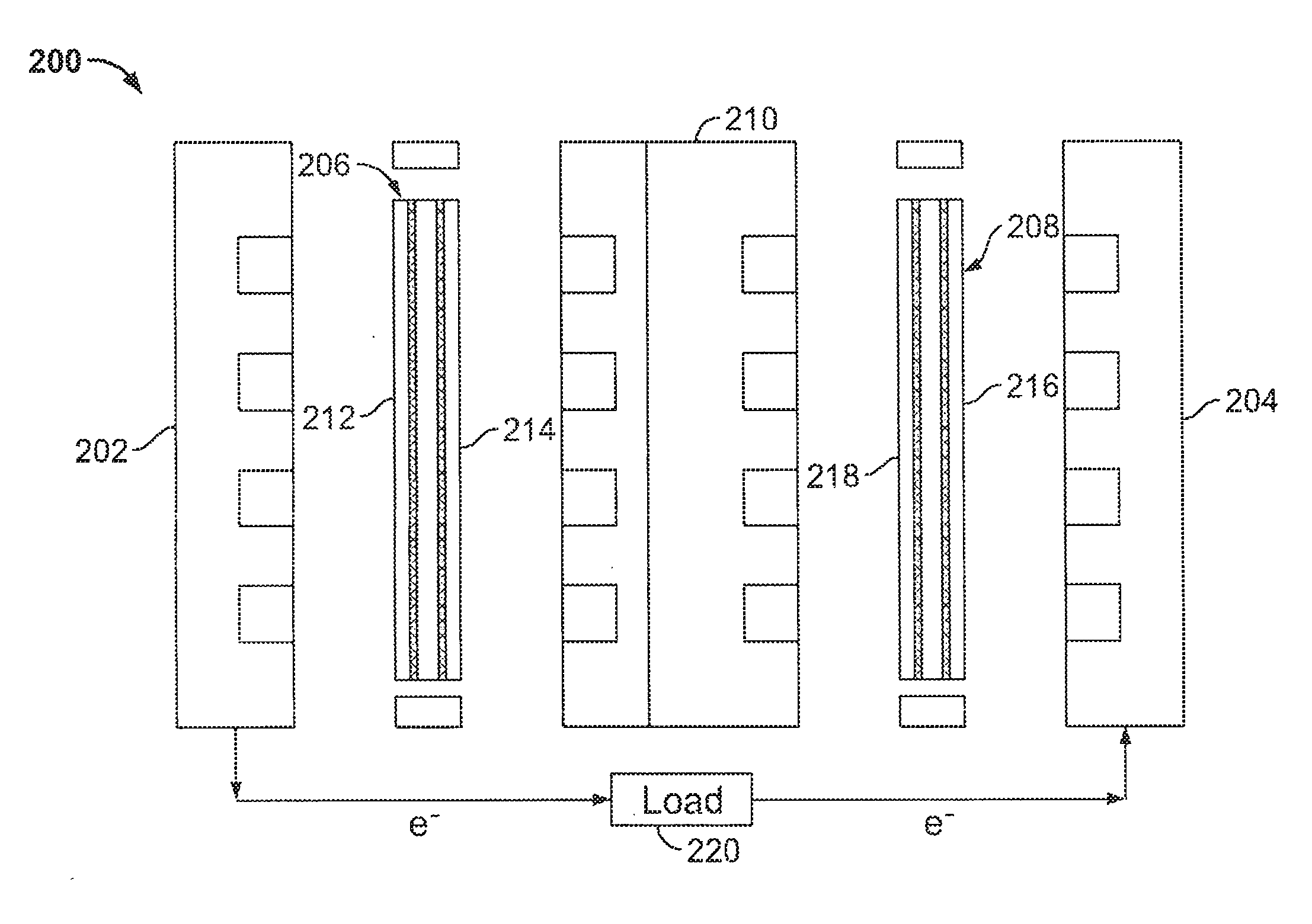

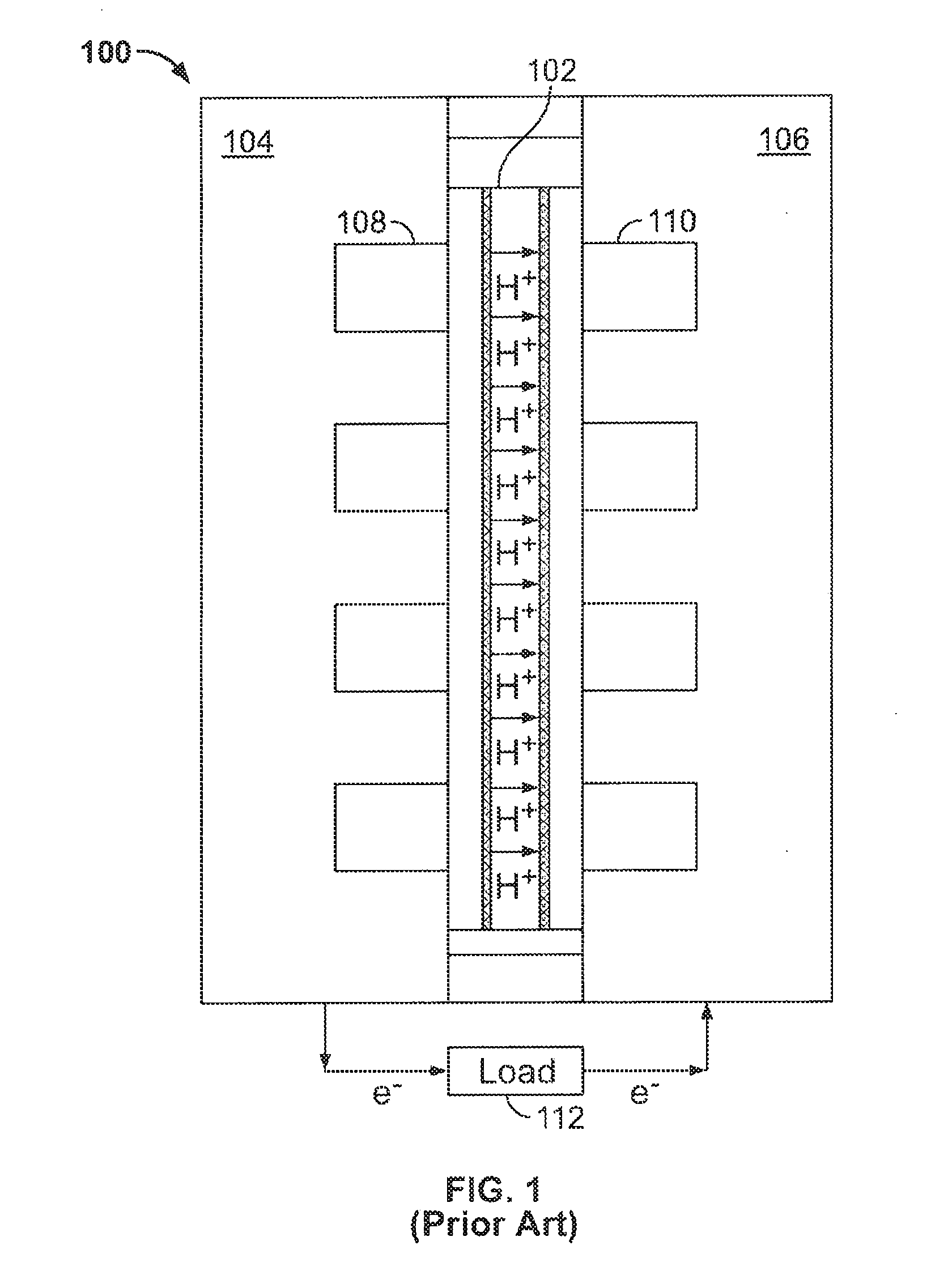

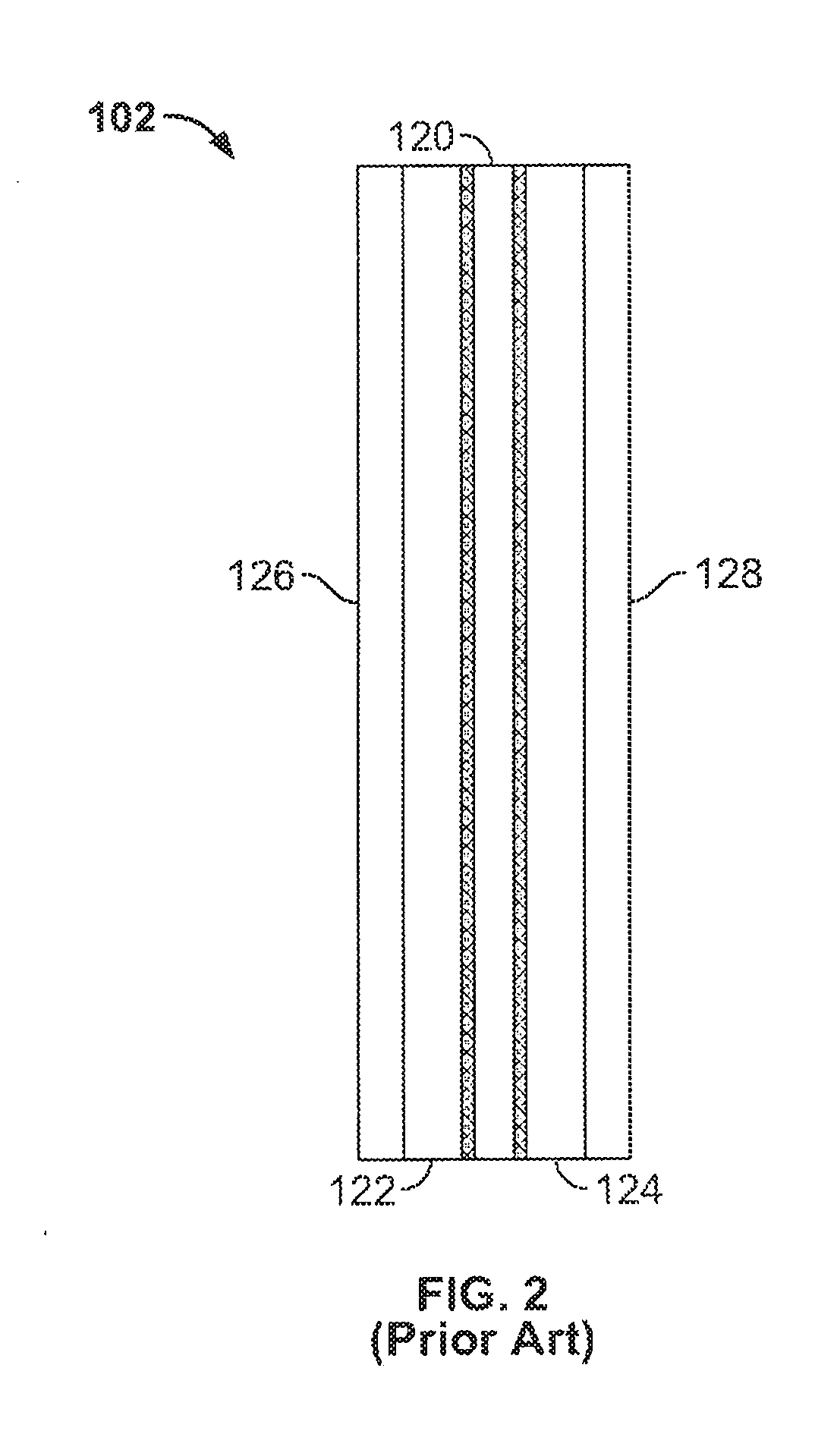

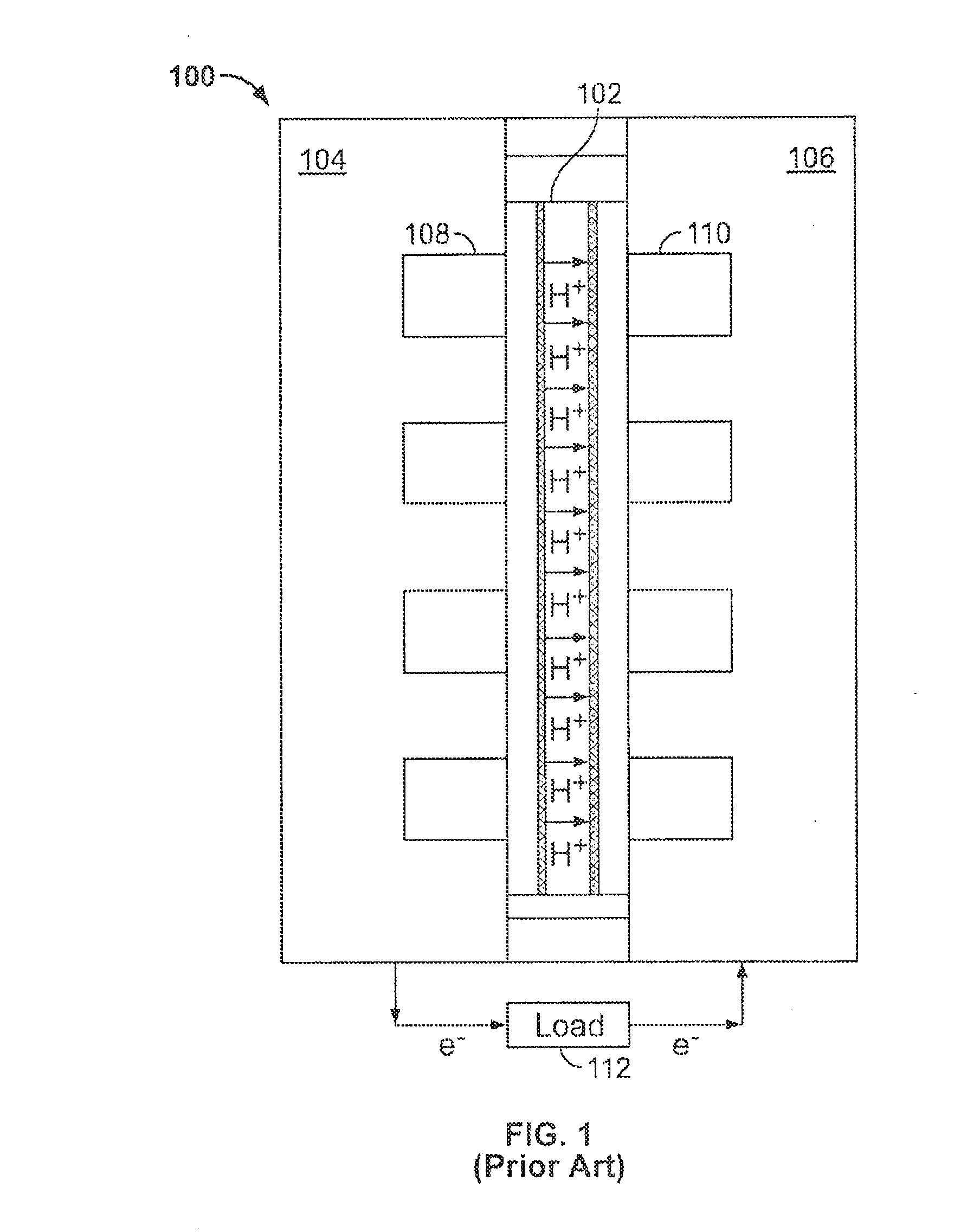

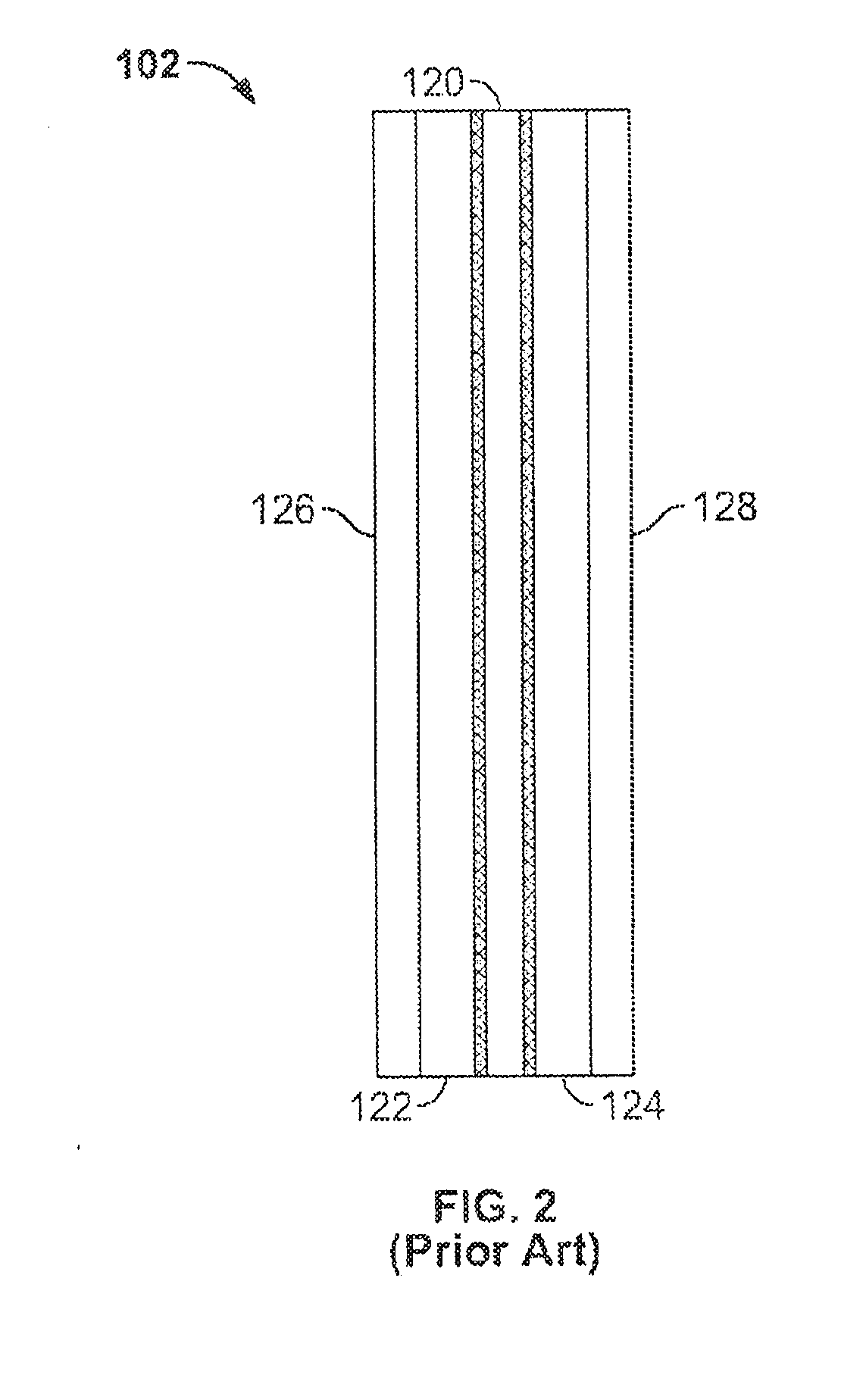

Fuel cell apparatus and method of fabrication

InactiveUS20050202305A1Easy to manufactureCost-effective to produceNon-metal conductorsFuel cells groupingSputteringMulti material

A fuel cell is described. The fuel cell includes current collectors, each of which includes a substrate of lightweight material, such as Kapton material. Micro channels are formed via laser machining or chemical etching into the substrate. The current collectors further include conductive layers sputtered on the substrate, and protective coating on the conductive layers. A variety of materials are available for the conductive layers. The fuel cell so developed is particularly well suited to mobile applications, such as electronic devices.

Owner:INI POWER SYST

ECG cable for use in MRI

InactiveUS20060247509A1Motion resistanceElectrocardiographySensorsElectrical resistance and conductanceElectric cables

A cable for use in monitoring patients in an MRI environment. In one embodiment the cable is constructed of a flexible substrate on which are drawn conductive traces with a conductive ink. In one embodiment the flexible substrate is Kapton. In one embodiment the conductive ink is a carbon ink. In one embodiment the carbon ink has a resistance of 10 ohms / sq. In one embodiment the cable has a distributed impedance of 10,000 ohms / ft.

Owner:IVY BIOMEDICAL SYST

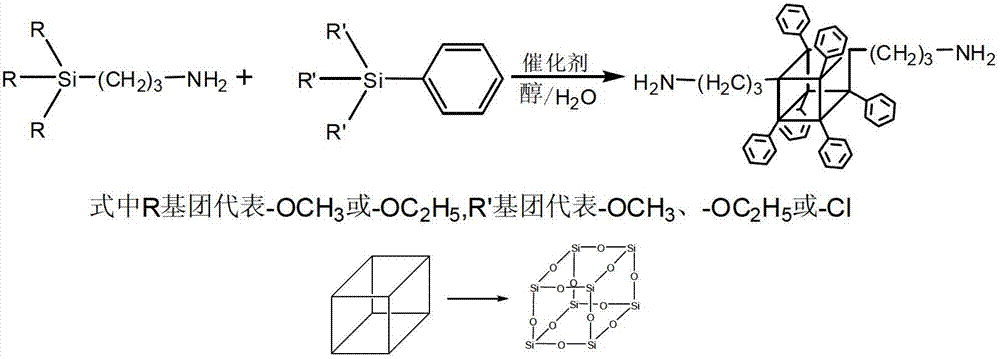

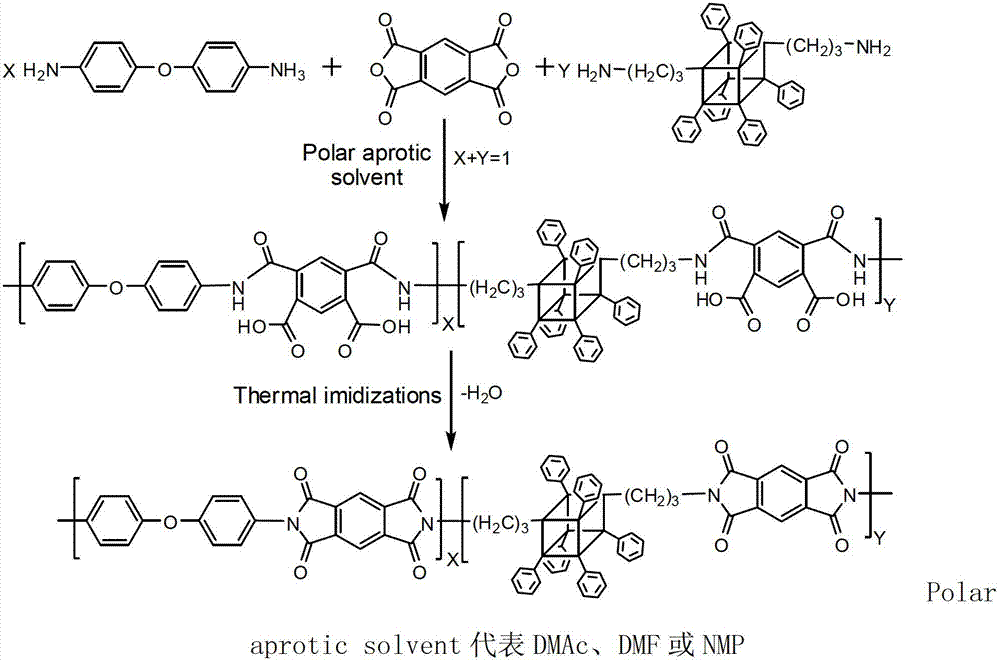

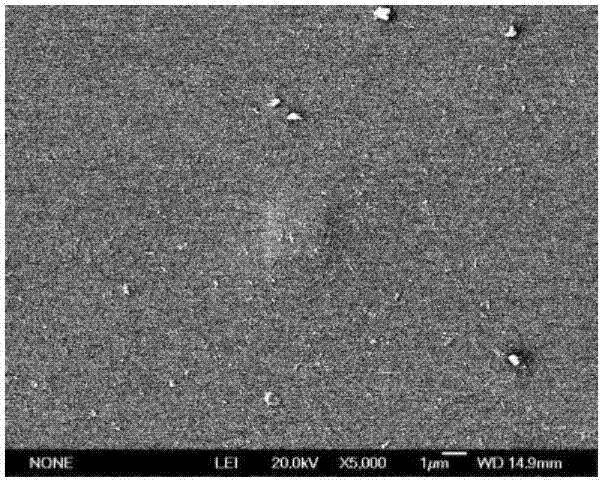

Preparation method of atomic oxygen-resistant polyimide hybrid films containing POSS (polyhedral oligomeric silsesquioxanes) structures

InactiveCN102731809AImprove anti-atomic oxygen performanceMild reaction conditionsSilicon organic compoundsAviationAlcohol

The invention relates to a preparation method of atomic oxygen-resistant polyimide hybrid films containing POSS structures. The preparation method comprises the following steps: reacting phenyl-containing monomers with aminopropyl-containing silane monomers in an alcohol / water cosolvent system under the action of a catalyst, volatilizing the solvent, washing, lyophilizing to obtain diamine POSS, modifying a polyimide material with the diamine POSS to prepare polyamide acid containing the POSS structure, and carrying out thermal imidization to obtain a series of polyimide hybrid films with different contents of the diamine POSS. Reaction conditions for synthesizing the diamine POSS are mild, the cost is low, and the POSS structure is introduced to the main chain of a polyimide molecule in a chemical bond manner, so the polyimide material has an excellent intrinsic atomic oxygen resistance, the hybrid films have excellent comprehensive performances, and the atomic oxygen resistances of the hybrid films are 6 times higher than that of unmodified Kapton polyimide films, thereby the hybrid films of the invention have important meanings to the development of the aviation and space industry.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

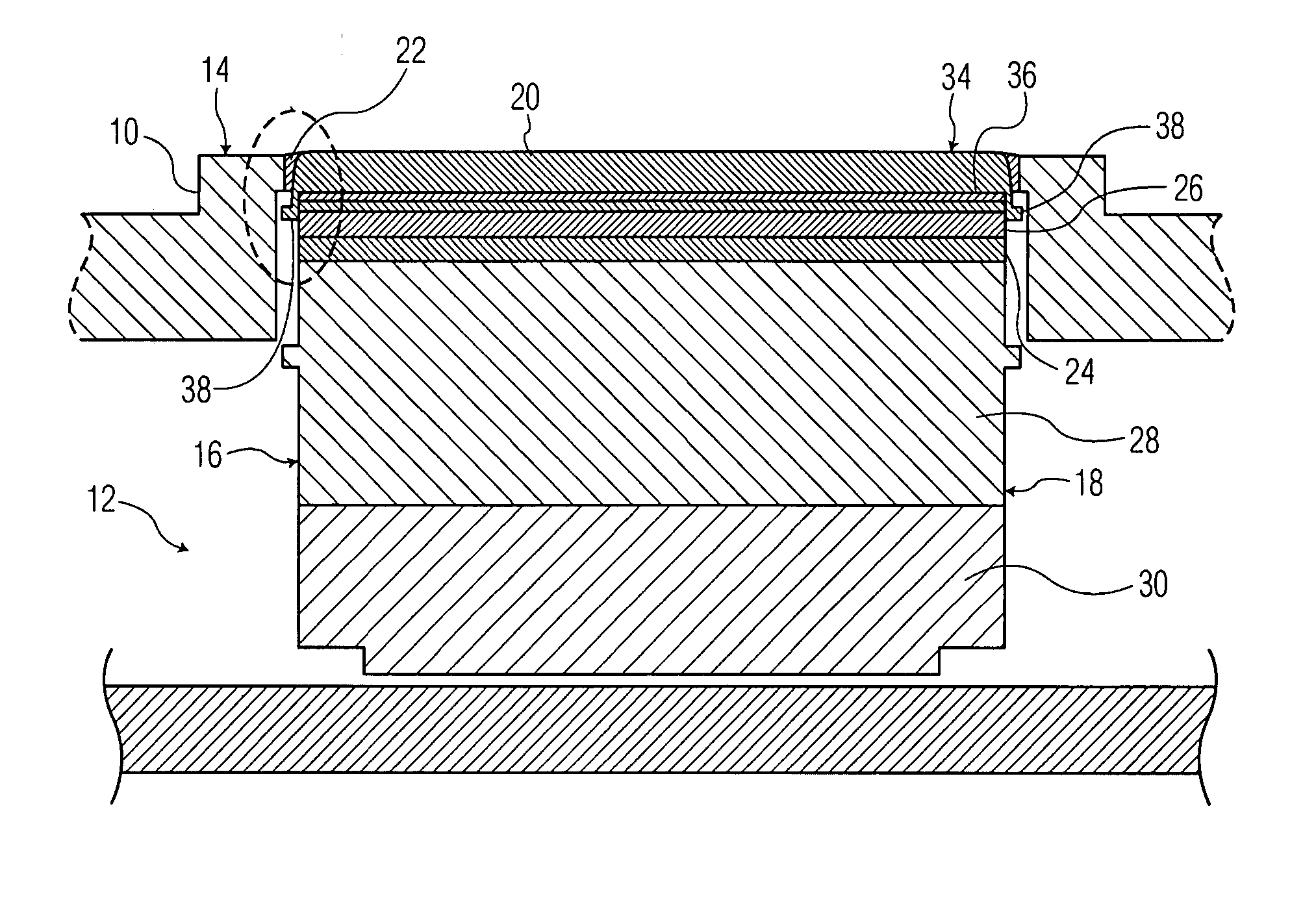

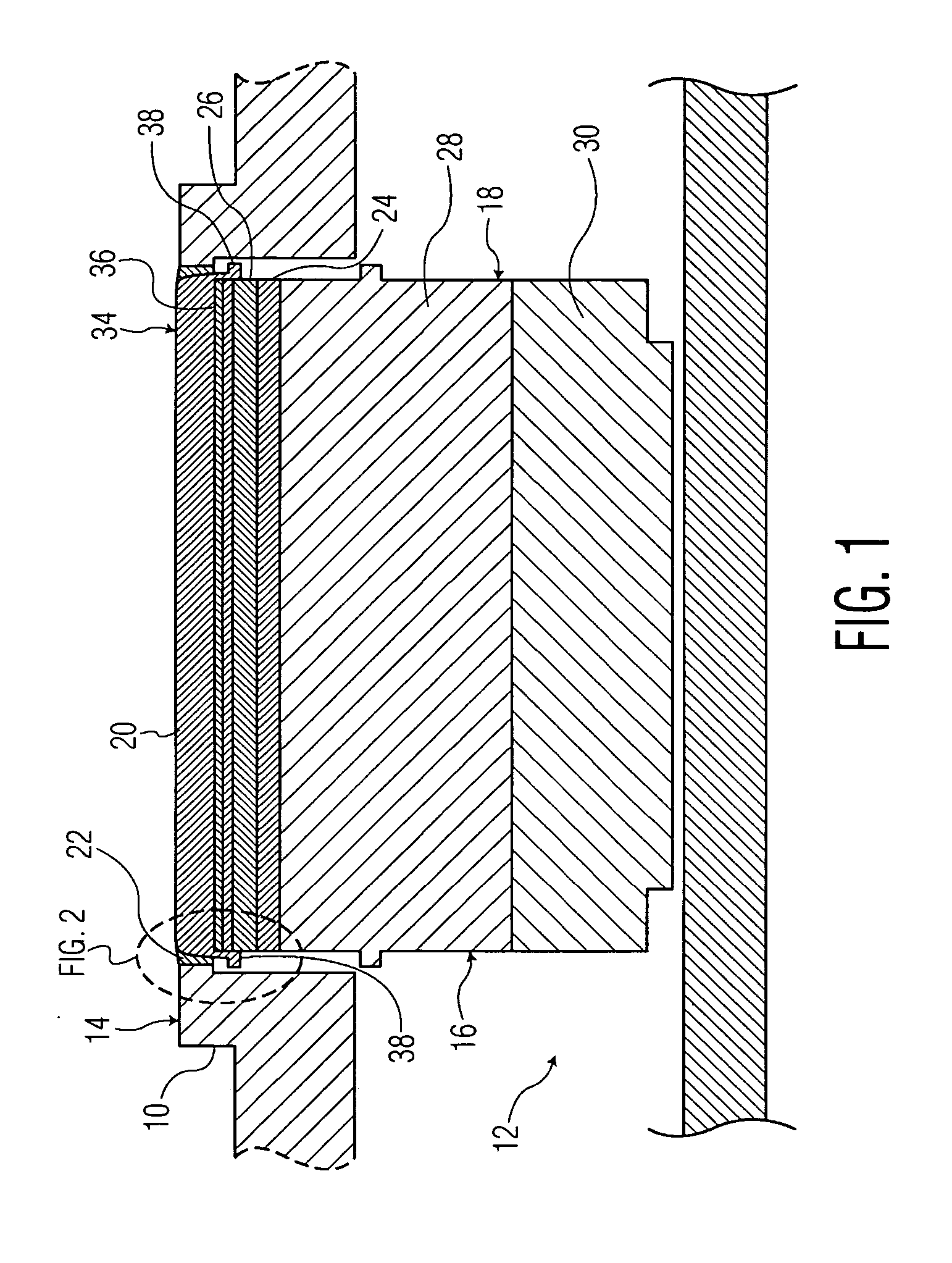

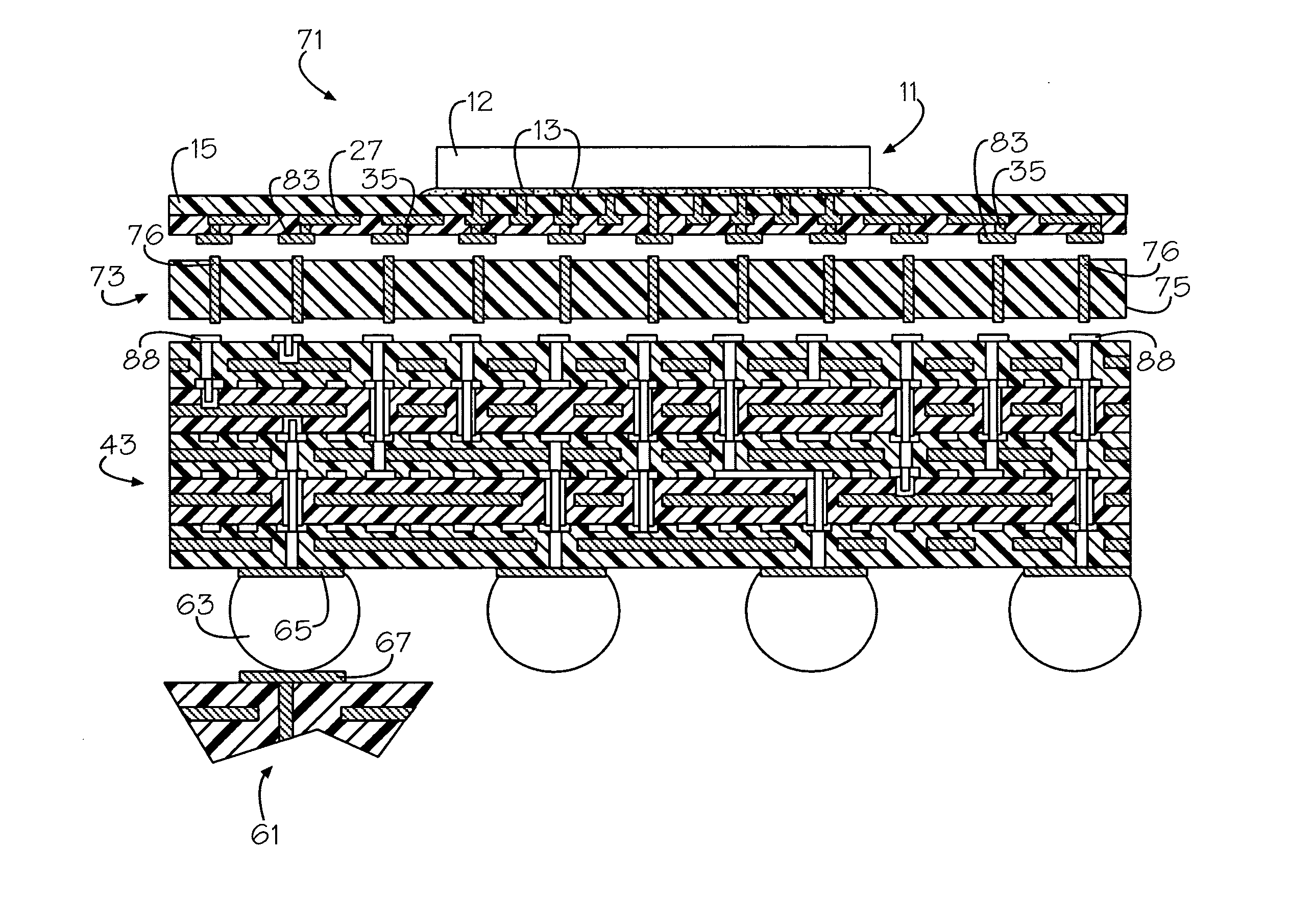

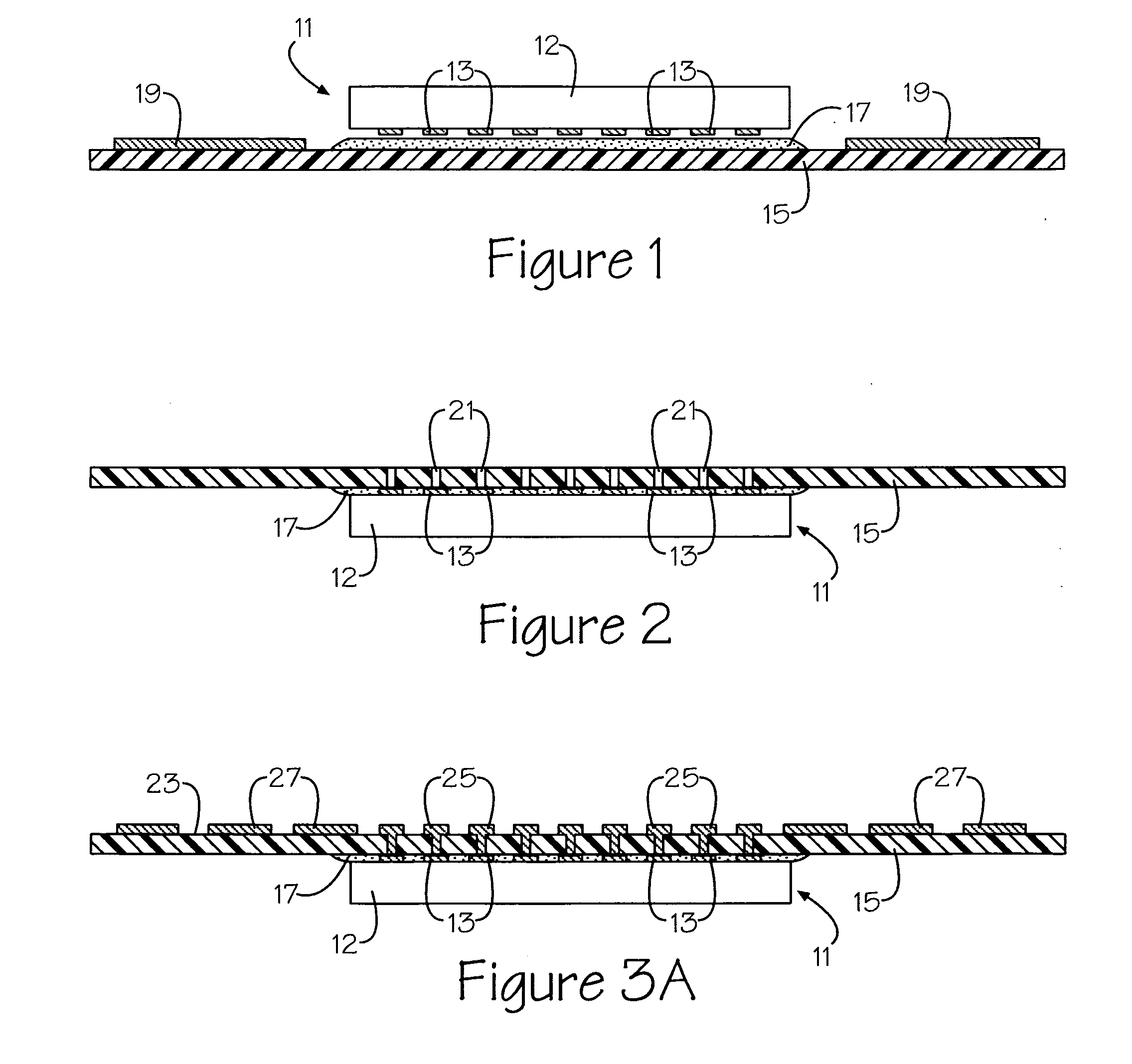

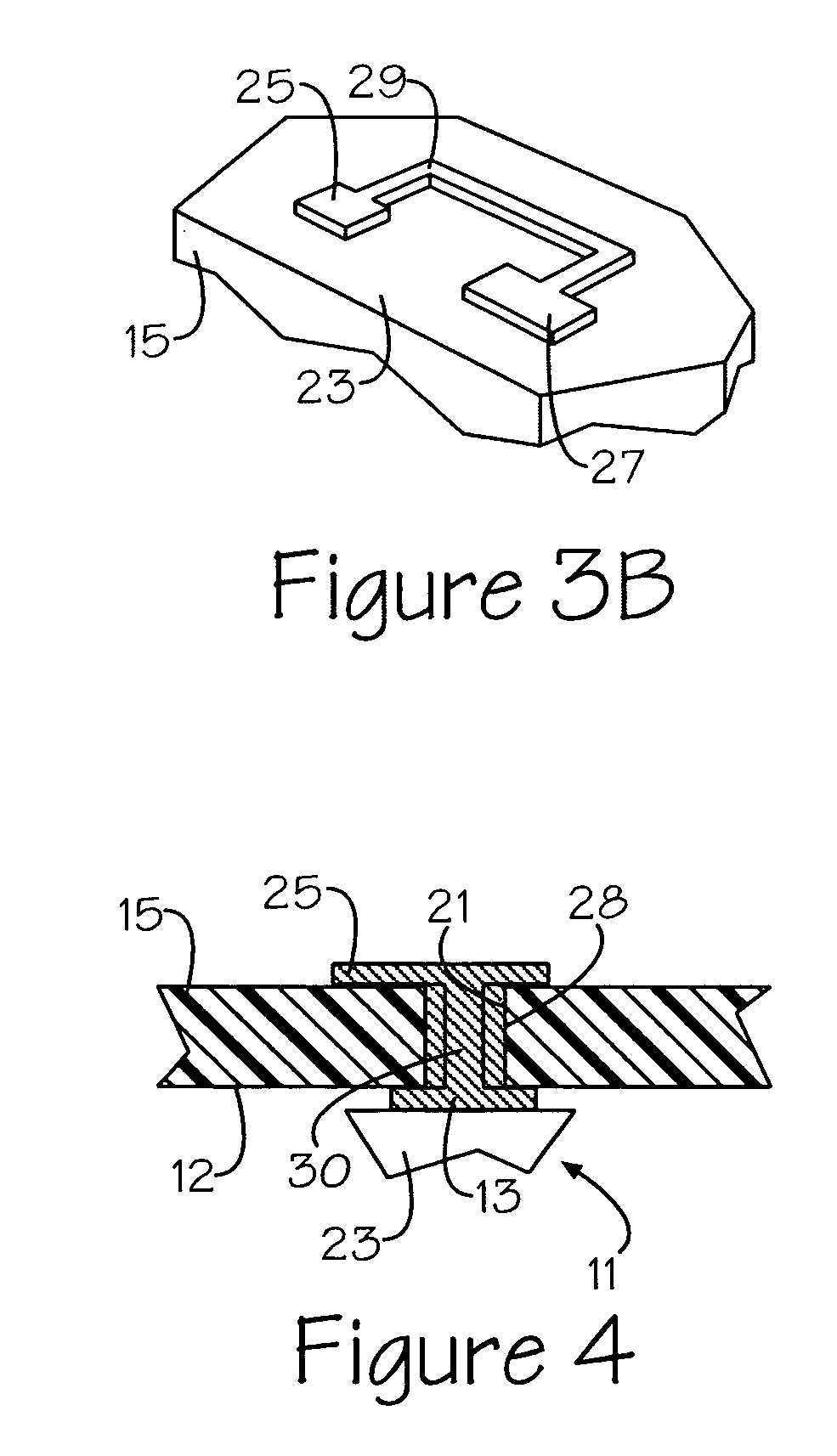

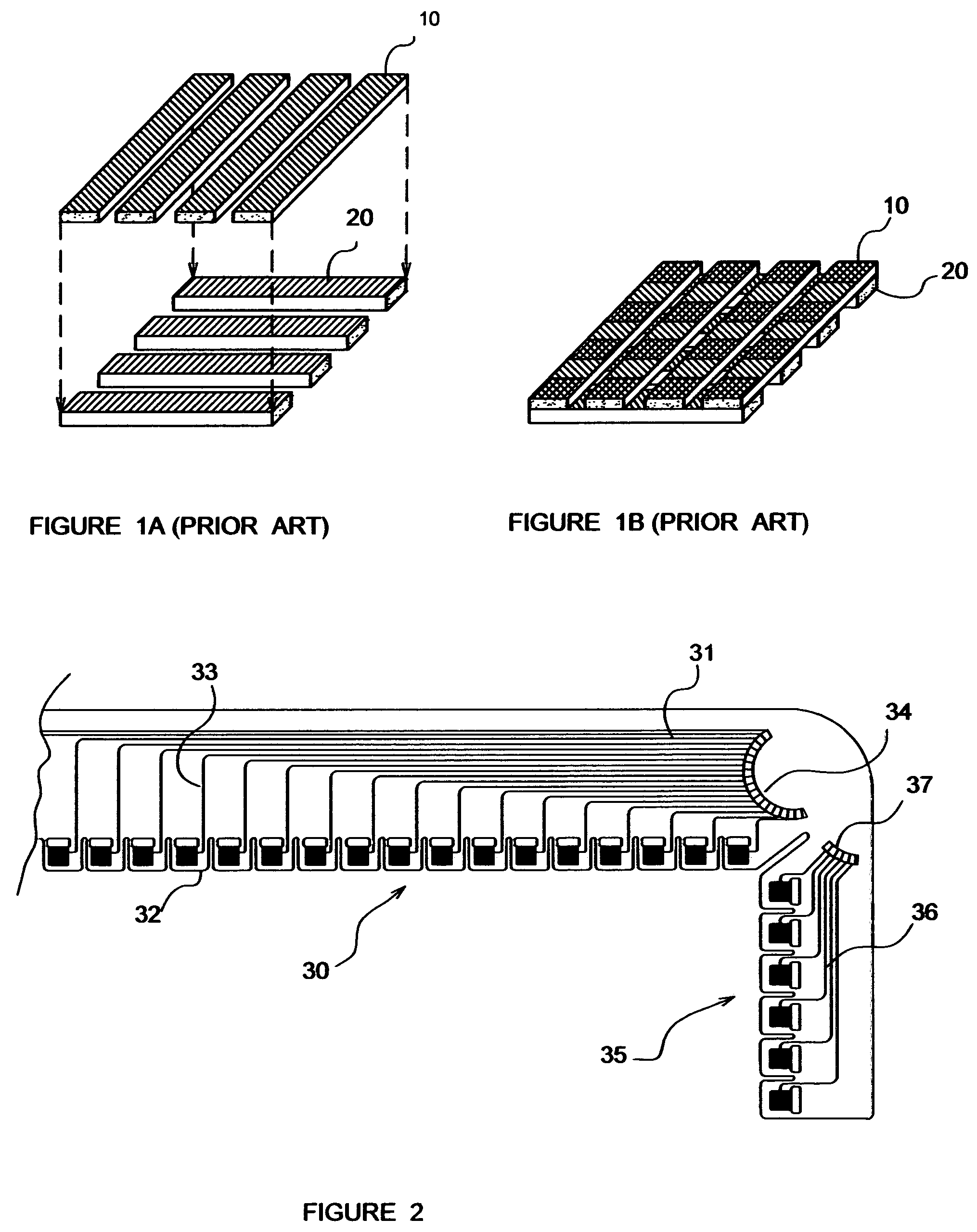

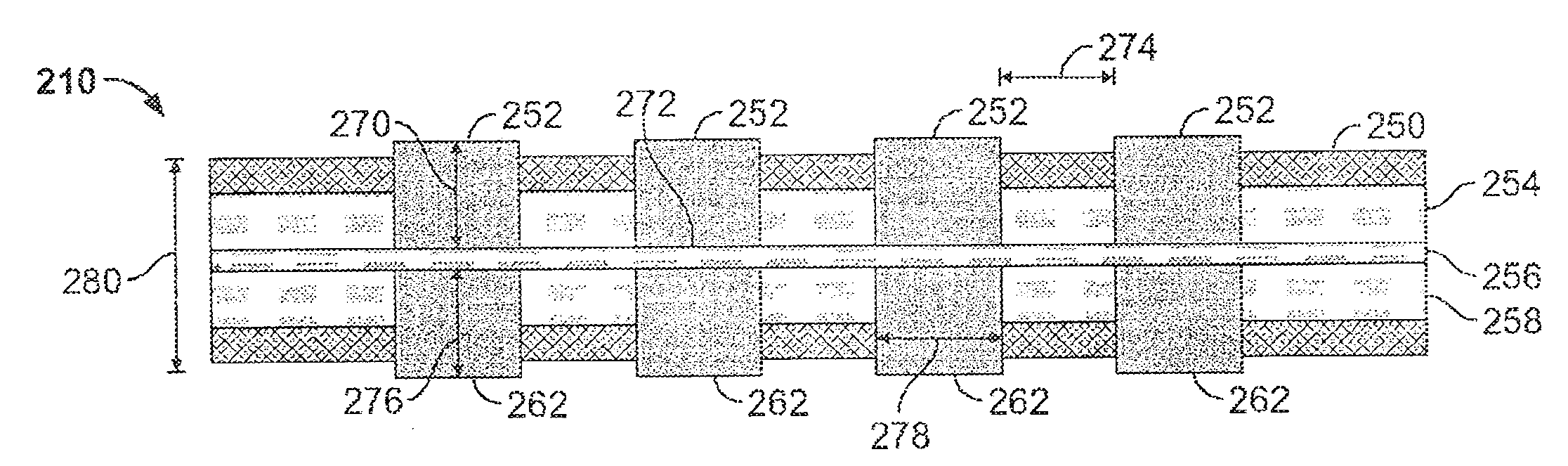

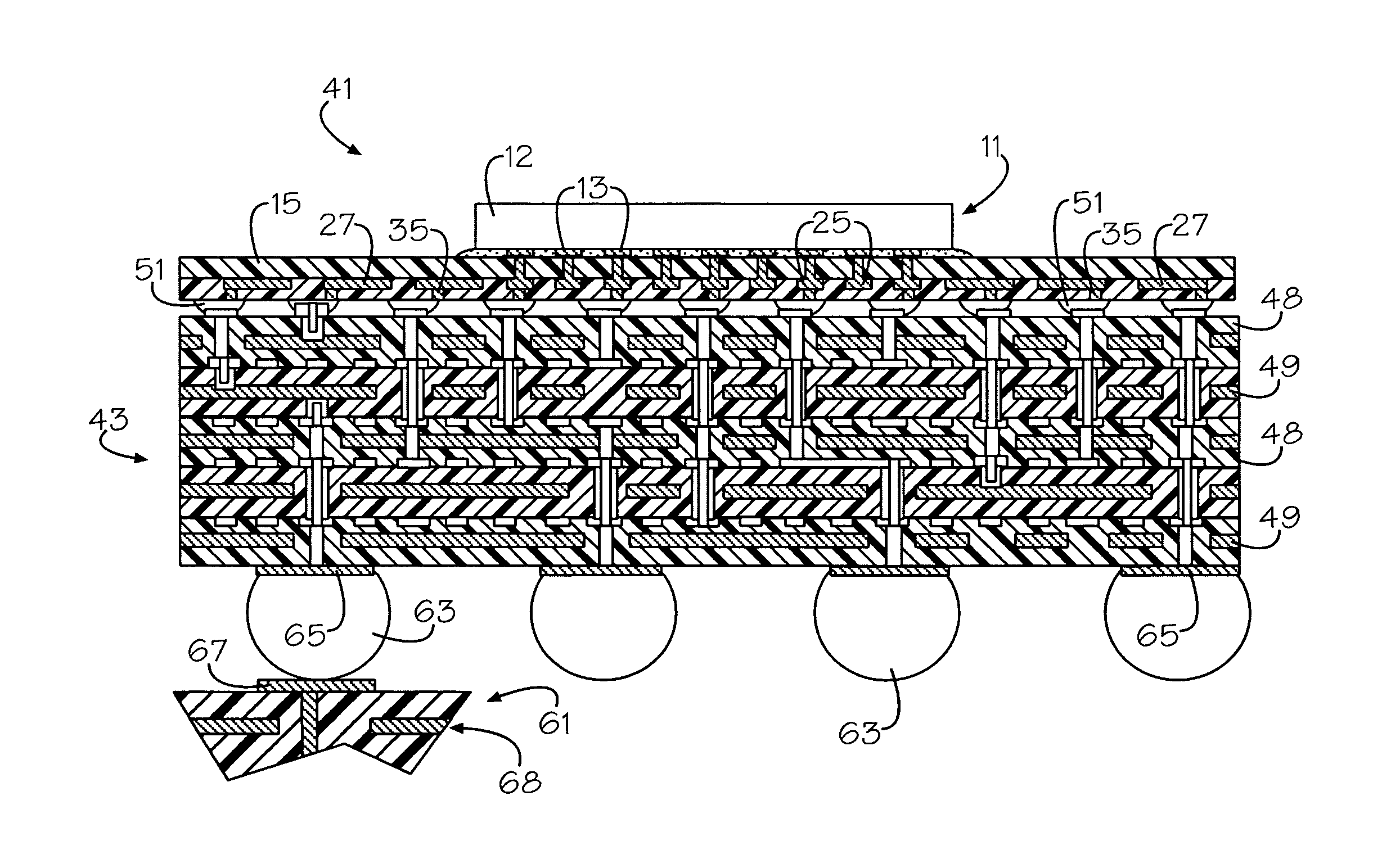

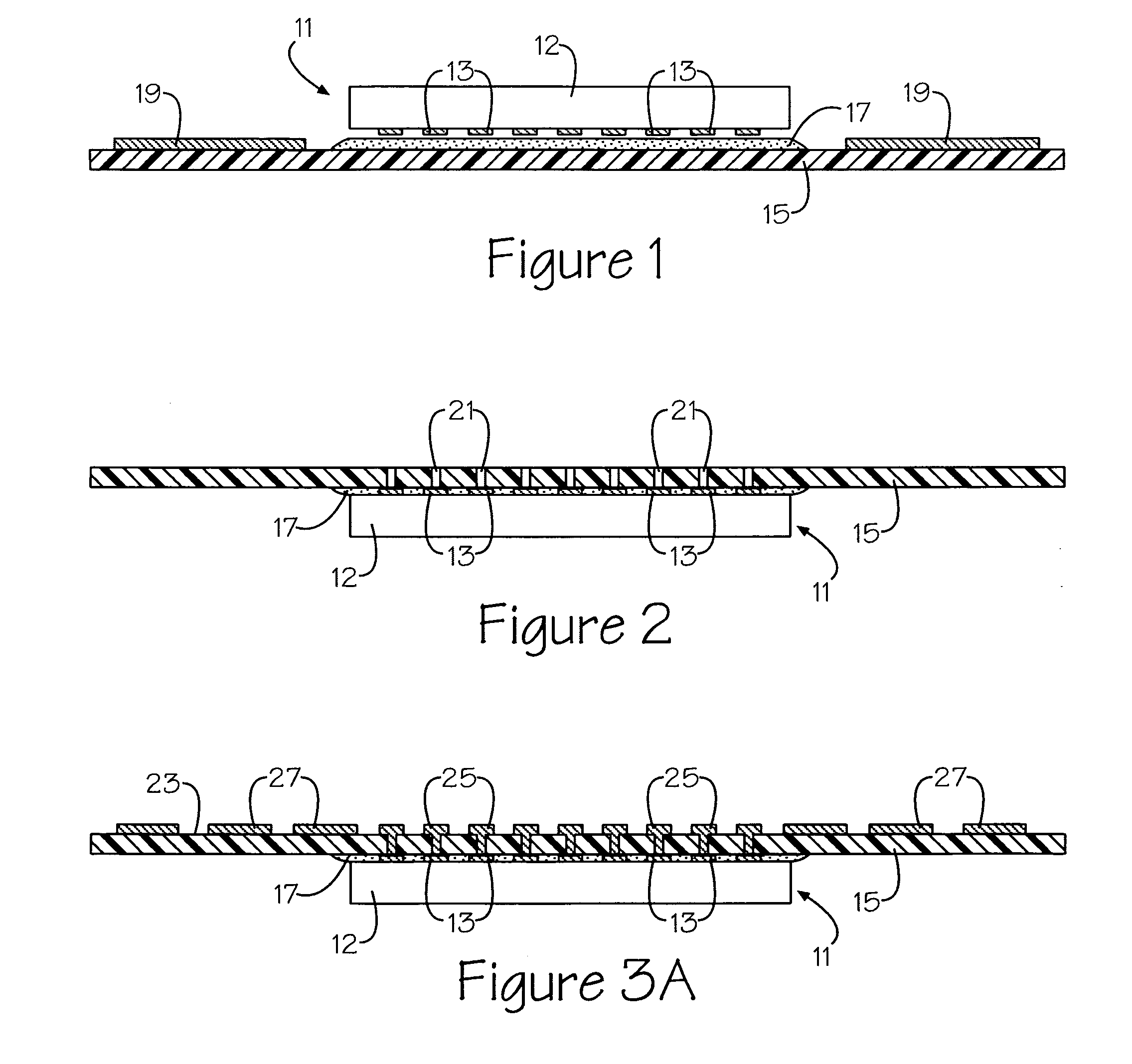

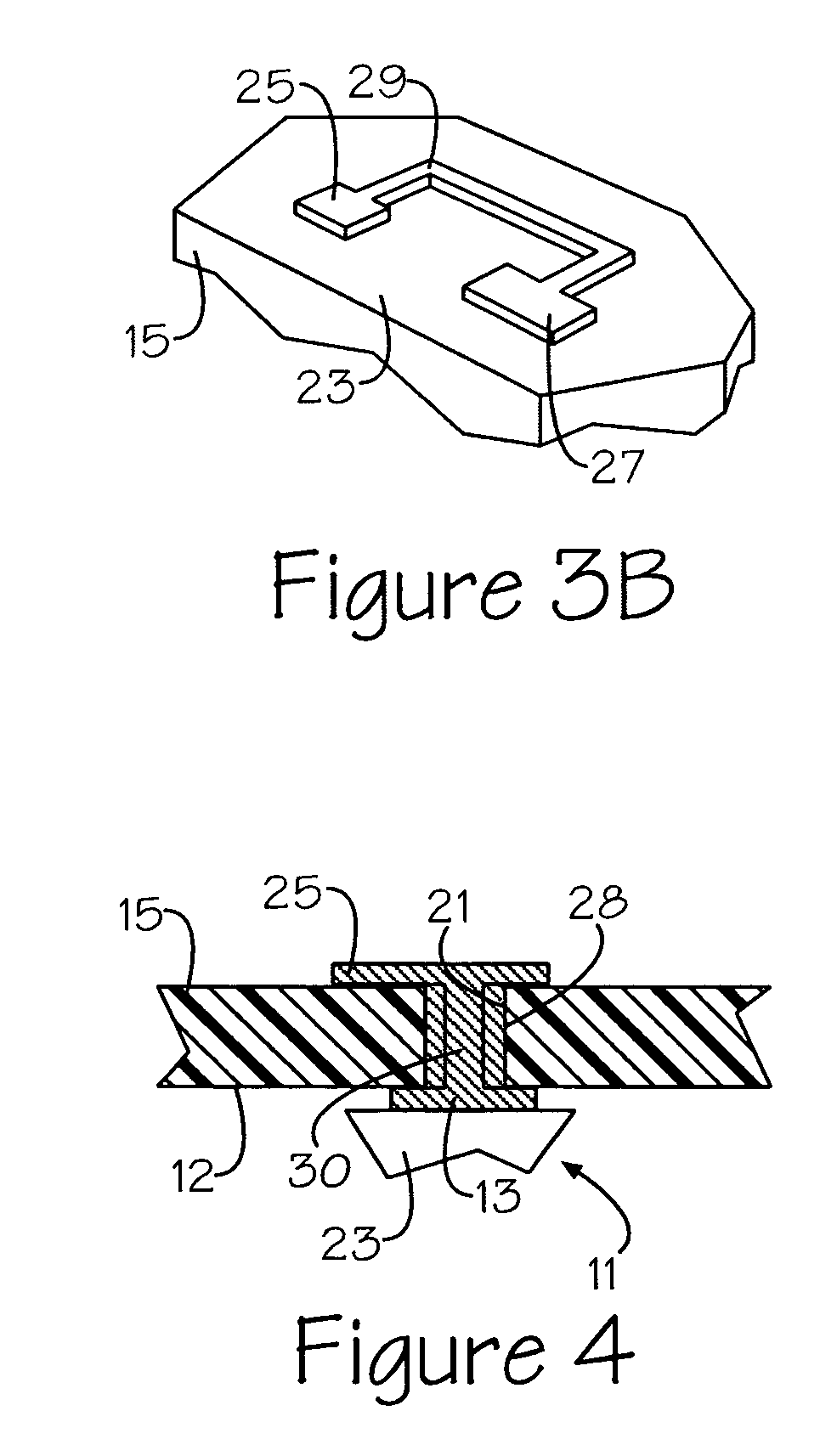

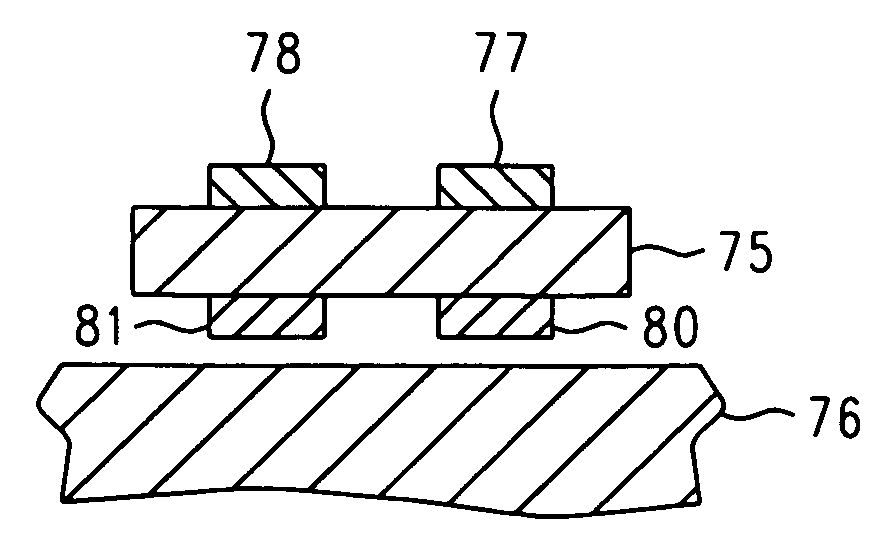

Electronic package including high density interposer and circuitized substrate assembly utilizing same

InactiveUS20110127664A1Reliable electrical connectionSemiconductor/solid-state device detailsSolid-state devicesElectrical conductorHigh density

An electronic package for interconnecting a high density pattern of conductors of an electronic device (e.g., semiconductor chip) of the package and a less dense pattern of conductors on a circuitized substrate (e.g., PCB), the package including in one embodiment but a single thin dielectric layer (e.g., Kapton) with a high density pattern of openings therein and a circuit pattern on an opposing surface which includes both a high density pattern of conductors and a less dense pattern of conductors. Conductive members are positioned in the openings to electrically interconnect conductors of the electronic device to conductors of the circuitized substrate when the package is positioned thereon. In another embodiment, the interposer includes a second dielectric layer bonded to the first, with conductive members extending through the second layer to connect to the less dense pattern of circuitized substrate conductors. Circuitized substrate assemblies using the electronic packages of the invention are also provided.

Owner:TTM TECH NORTH AMERICA LLC

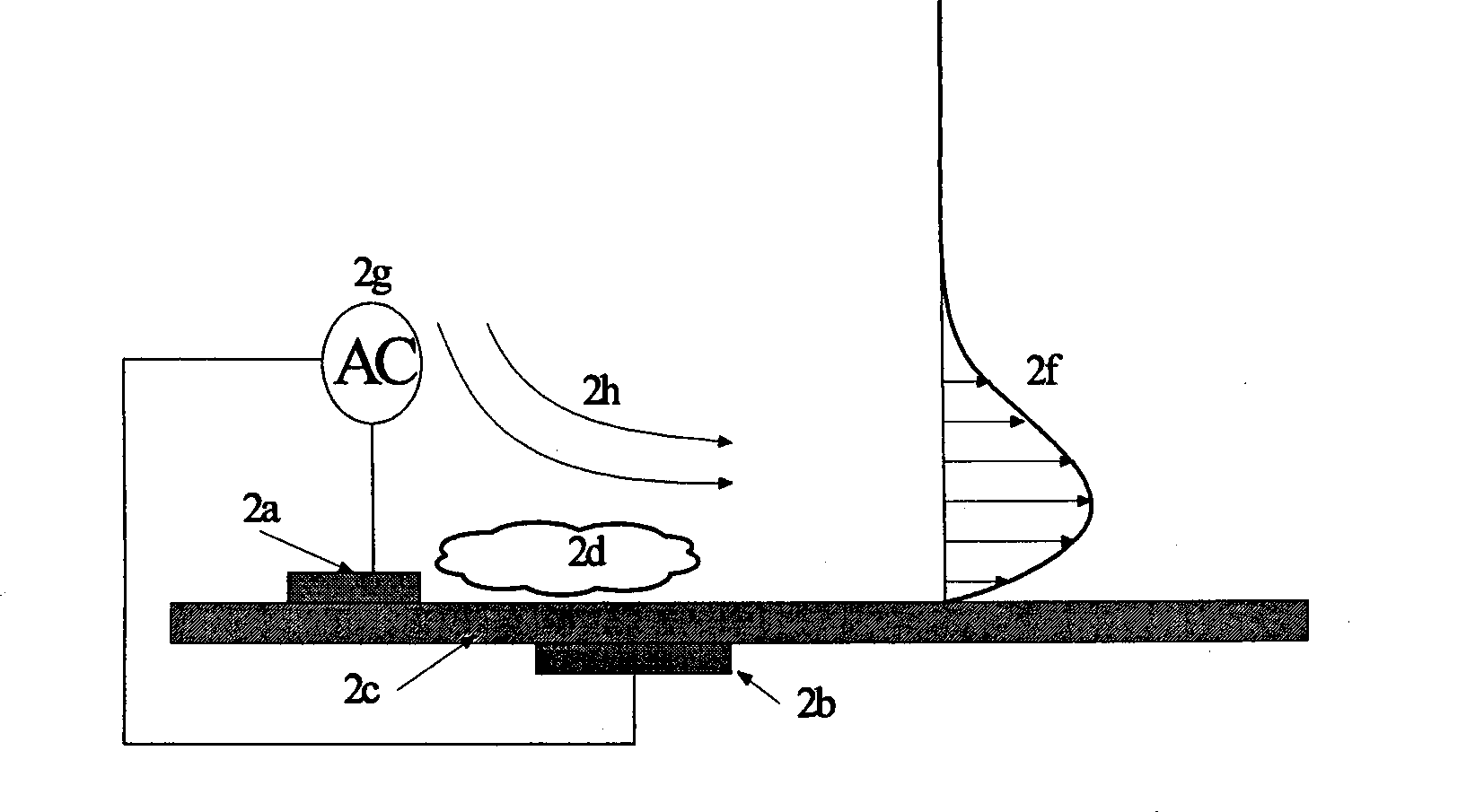

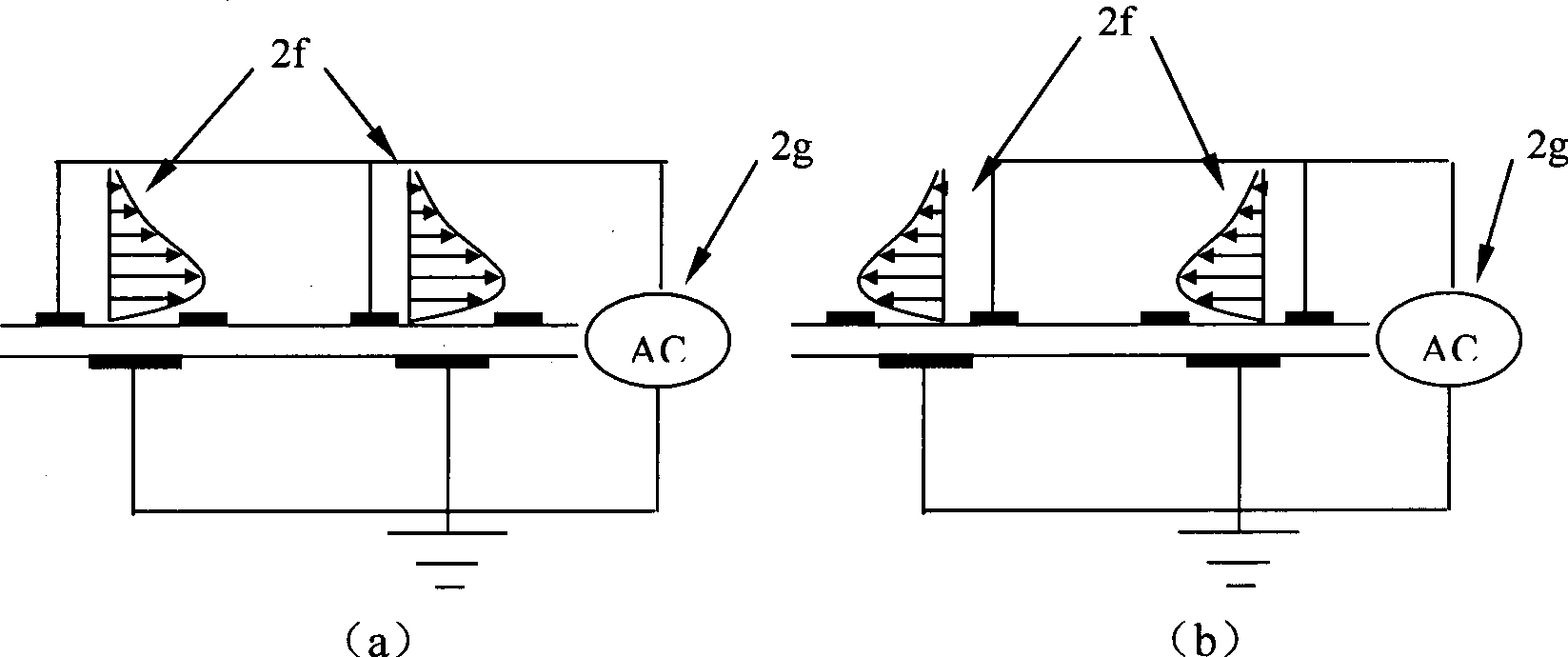

Plasma gurney flap

The invention relates to a plasma Gurney flap. The adopted plasma exciter is based on the principle of surface dielectric barrier discharge (DBD). The plasma Gurney flap comprises a single plasma exciter or a plasma exciter bar which is arranged on the airfoil shape trailing edge or the pressure surface at the trailing edge. The plasma exciter comprises two dissymmetrically placed electrodes, one of which (cathode) is exposed in the air directly while the other one (anode) is embedded in an insulating medium, wherein the electrodes are made of sheet metal, and the sizes thereof can be determined according to concrete conditions of application; if the insulating medium adopts polytetrafluoroethylene, epoxy resin, and the like, the plasma exciter can be made by adopting a printed circuit board; if the insulating medium adopts flexible insulating materials such as Kapton, Teflon, and the like, the plasma exciter can be made in a pasting mode; and the flexible insulating materials can adapt to different shapes of the airfoil trailing edge, thus the plasma Gurney flap is quite simple and convenient and is convenient to maintain.

Owner:BEIHANG UNIV

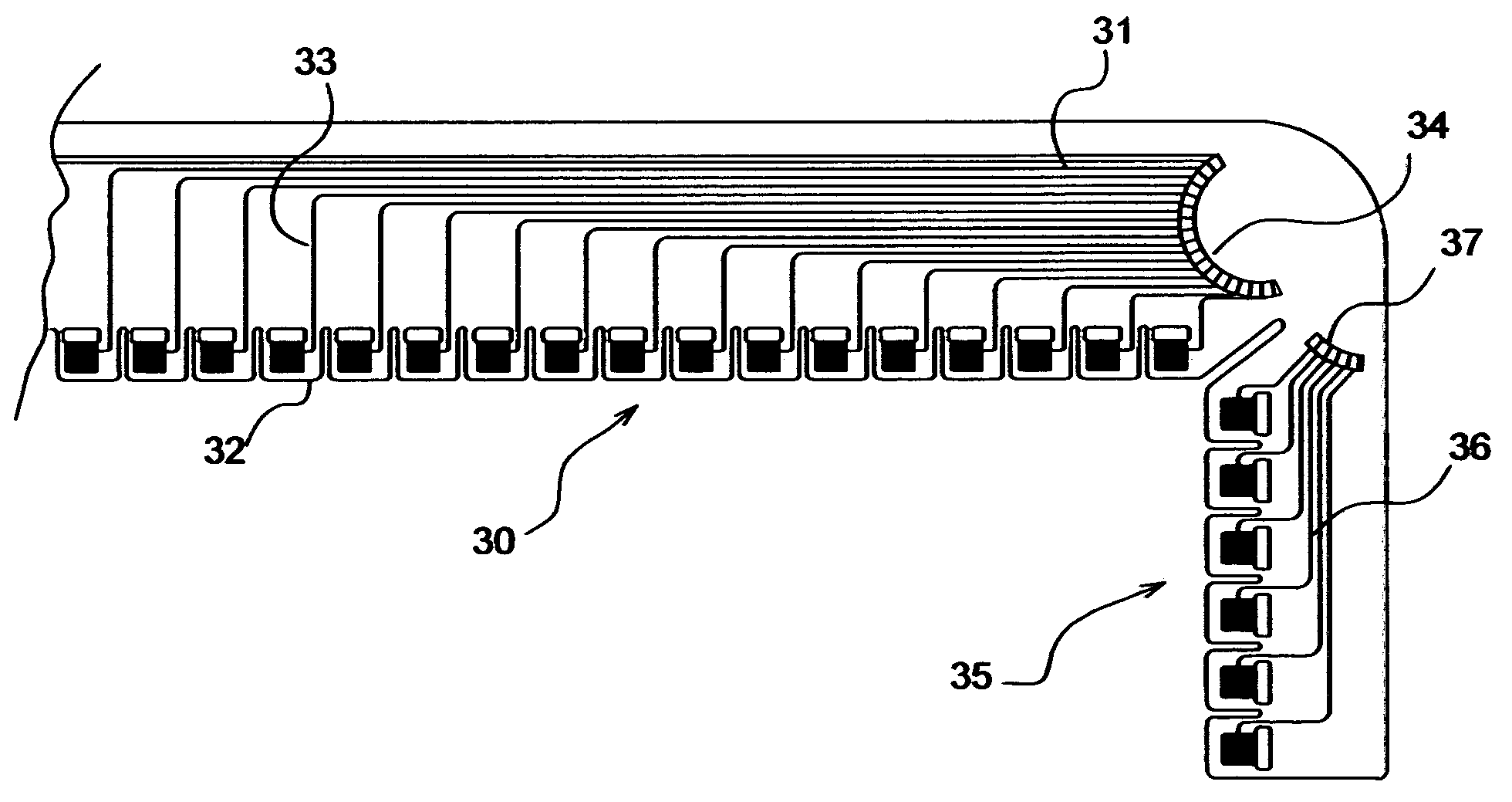

Hybrid tactile sensor

ActiveUS7430925B2Ease and repeatabilityOvercomes drawbackWork measurementTension measurementEpoxySensor array

A hybrid tactile sensor includes a flexible cloth-based tactile sensor array including a plurality of electrodes, each of the electrodes connected to a corresponding connecting zone of an intermediate connecting harness made from a flexible film such as Kapton®. The harness includes a common bundle of parallel conductors etched or printed onto the harness and connecting each of the connecting zones to a common terminal for further attaching to a control unit of the sensor. The use of the harness allows repeatable manufacturing of sensor arrays with large number of electrodes or when they are located close to each other. Each connecting zone may include an interconnecting pad for crimping, soldering, or adhering the electrode thereto using a conductive epoxy. Alternative embodiments describe the use of U-shaped malleable connectors, jumper wires including those equipped with U-shaped clips, and other means of attaching electrodes to corresponding connecting zones. The use of alternating connections with electrodes of the array allows to double the distance between individual electrodes available for making a connection.

Owner:PRESSURE PROFILE SYST

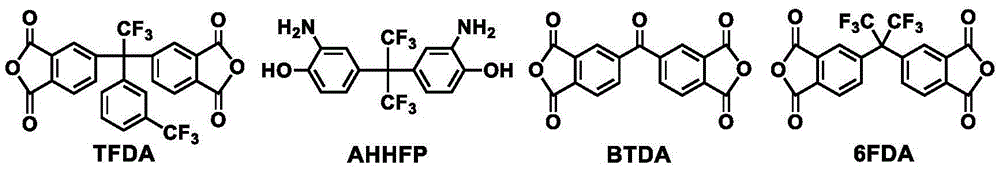

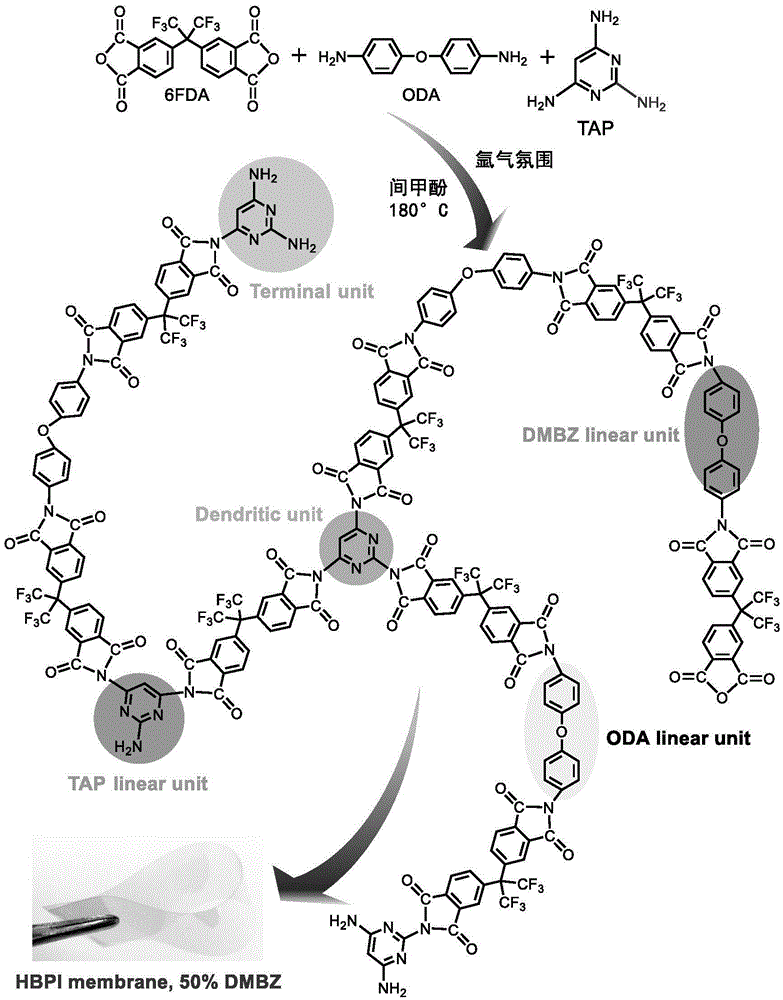

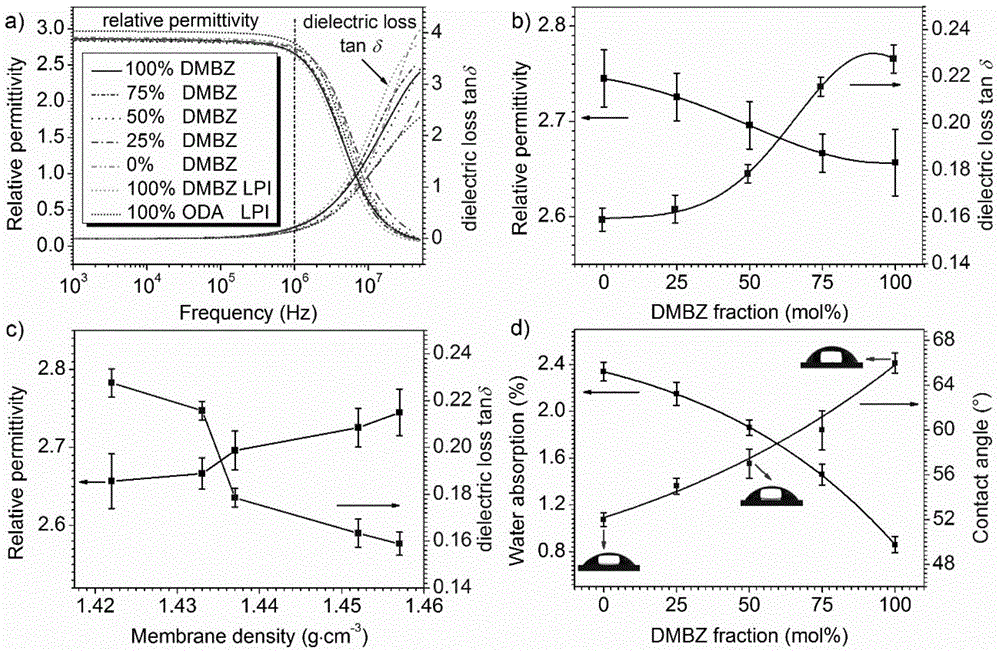

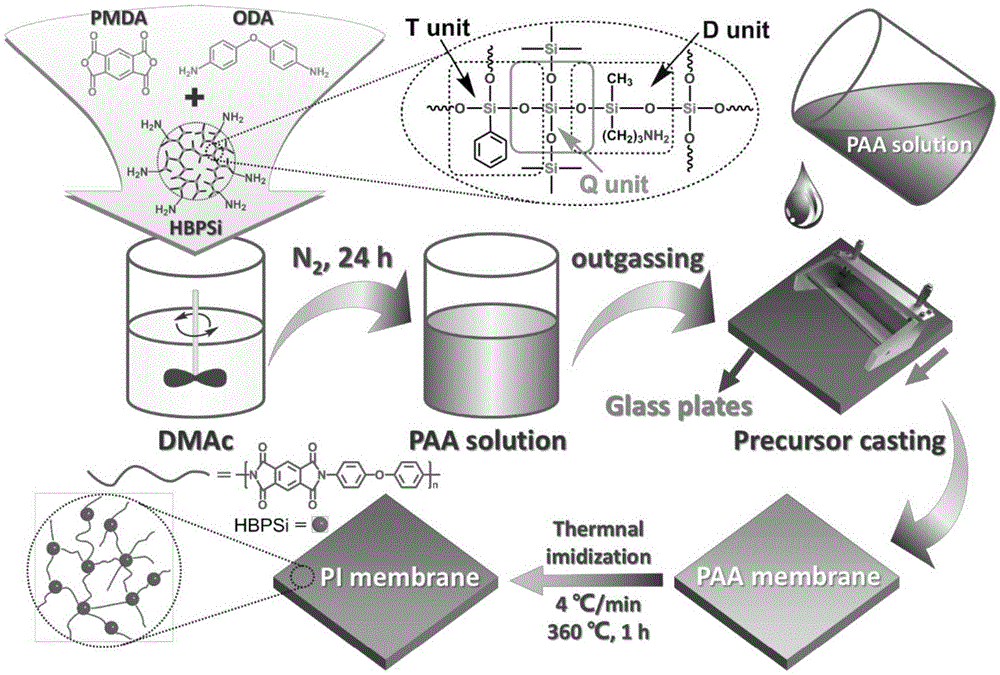

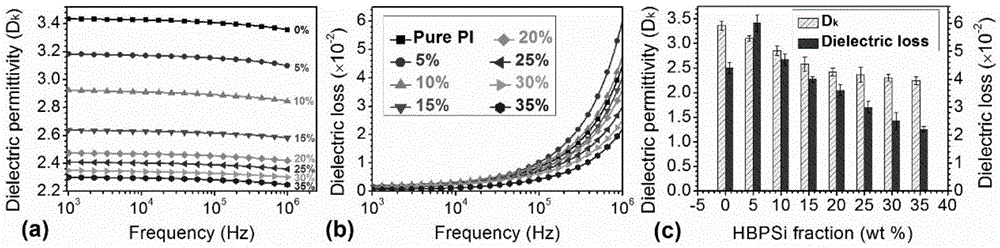

Preparation method for hyperbranched polymide film with low dielectric constant

The invention relates to a preparation method for a hyperbranched polymide film with the low dielectric constant. A series of the low-dielectric constant PI films with a hyperbranched structure are synthesized by taking 2,4,6-triaminopyrimidine (TAP) as a branching center through a one-step method. Through introduction of the hyperbranched structure, the dielectric constant of the PI film is significantly lowered, the inherent advantages of PI are better kept, and the good mechanical strength and thermo-oxidative stability are supplied to the film. The hyperbranched structure contains a large quantity of molecular chain end groups, dense packing of molecular chains is effectively inhibited, and therefore the hyperbranched PI film has the excellent dissolution characteristic to be more prone to be processed into a complex device. Compared with a Kapton standard film which is generally used at present, under the same testing conditions, the dielectric constant of the hyperbranched PI film prepared through the method is lowered by 20%-40%, the lowest dielectric constant even gets close to 2.0 and reaches the ultralow dielectric constant level, and the urgent demand for micro-electronic industry development in future can be met.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

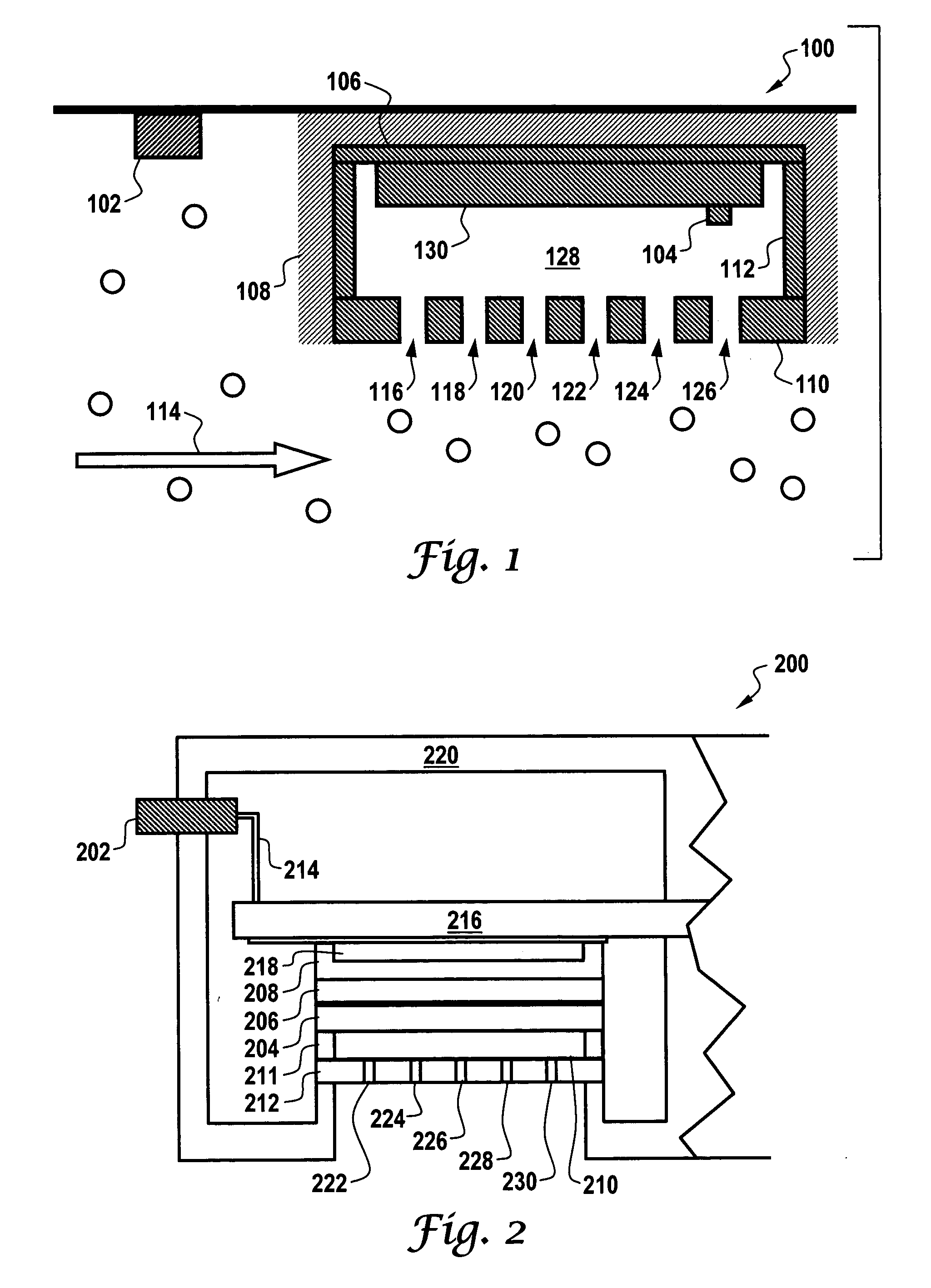

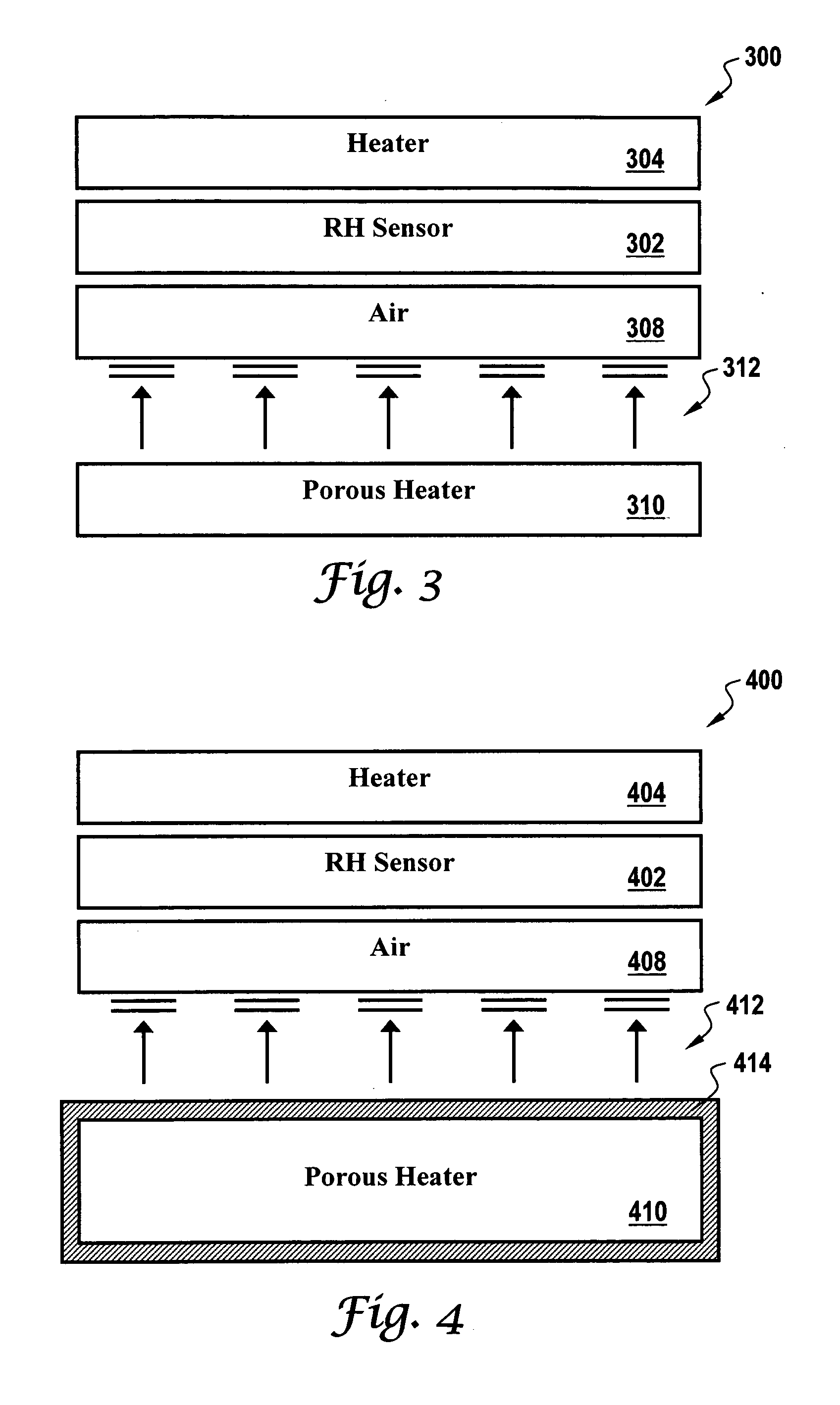

Relative humidity sensor enclosed with kapton type heater

Sensor systems and methods are disclosed herein. A relative humidity sensor can be associated with one or more heating elements, wherein a perimeter of the relative humidity sensor is surrounded with a relatively conductive material. A thin substrate material can surround and laminate the heating element, such that the heating element is porous to permit humid air to pass through the heating element and wherein the at the heating element is assembled slightly offset from a surface of the relative humidity sensor. Air that is saturated with water vapor can then pass through and be heated by the heating element in order to evaporate water droplets associated with the water vapor to thereby reduce relative humidity to a measurable level.

Owner:HONEYWELL INT INC

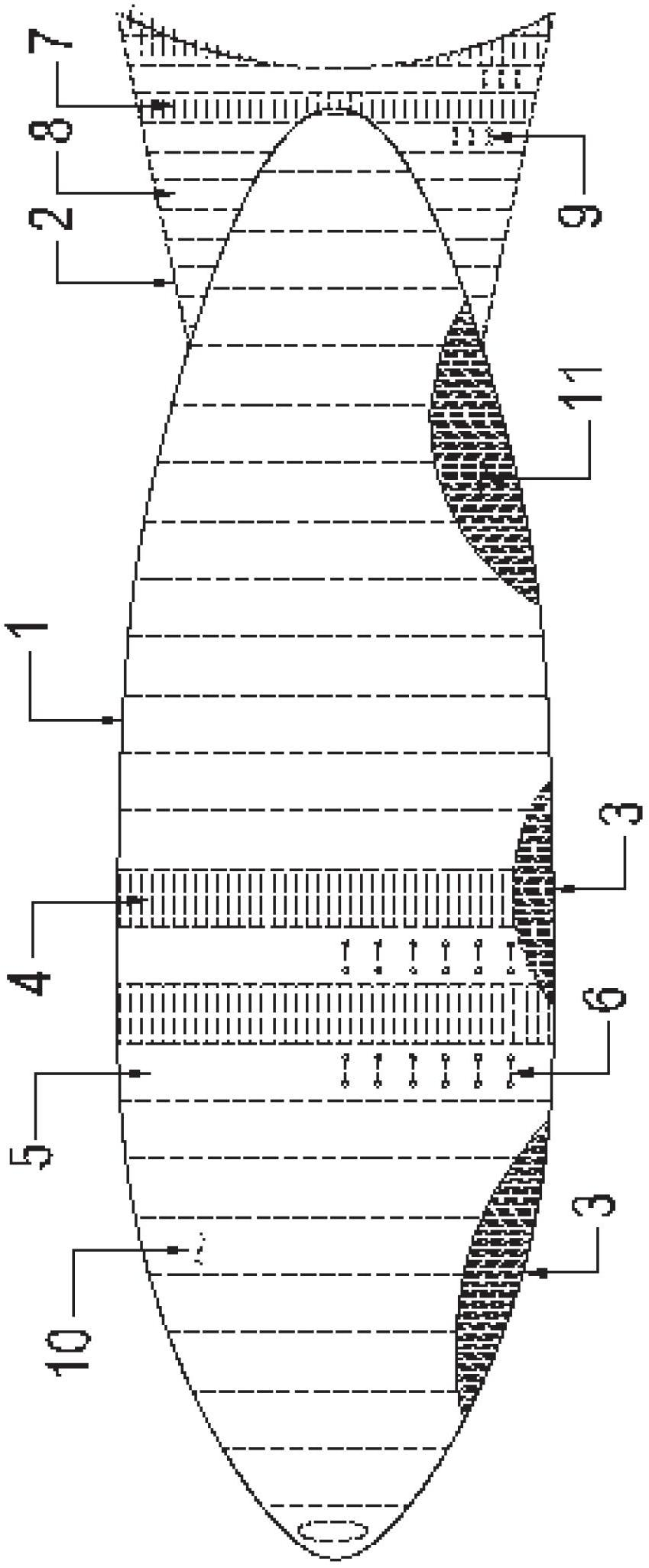

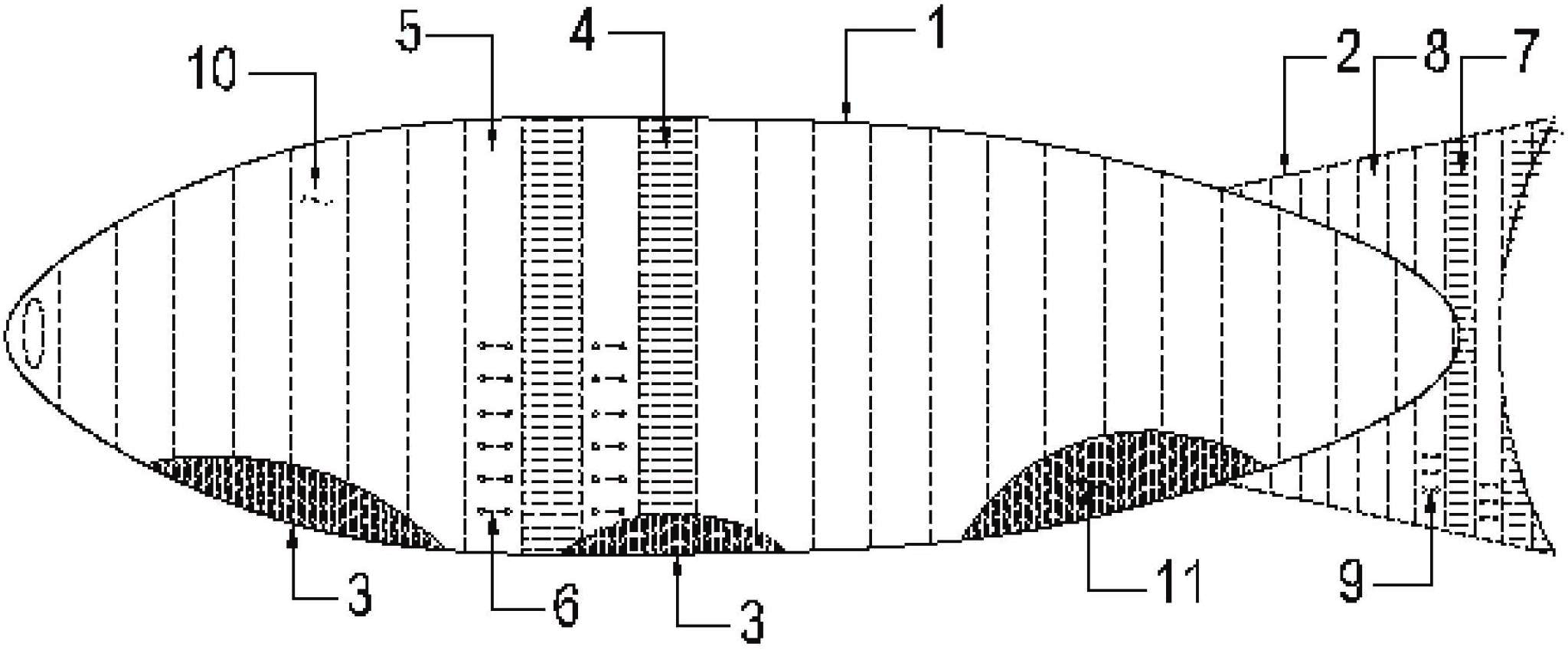

Bionic fish type suspended aerostat for near space

The invention provides a bionic fish type suspended aerostat for a near space. The bionic fish type suspended aerostat comprises an outer skin, a tail fin, and one secondary airbag or more than one secondary airbags for inflating air, wherein the outer skin is formed by a plurality of alternatively-connected first rigid ribs and a first flexible rib; the tail fin is formed by a plurality of alternatively-connected second rigid ribs and a plurality of second flexible ribs; a buoyancy working medium is filled in the outer skin; the first rigid ribs and the second rigid ribs are manufactured by using a plurality of layers of Kapton thin films to laminate curing colloid; when the suspended aerostat blasts off until the air in the secondary airbags is discharged out and is in a stable form, the first rigid ribs and the second rigid ribs are cured in a rigid thin-wall shell structure in a space heat radiation condition; and the first flexible rib, the second flexible ribs, and the secondary airbags are made of a high polymer composite thin film material.

Owner:SHANGHAI JIAO TONG UNIV

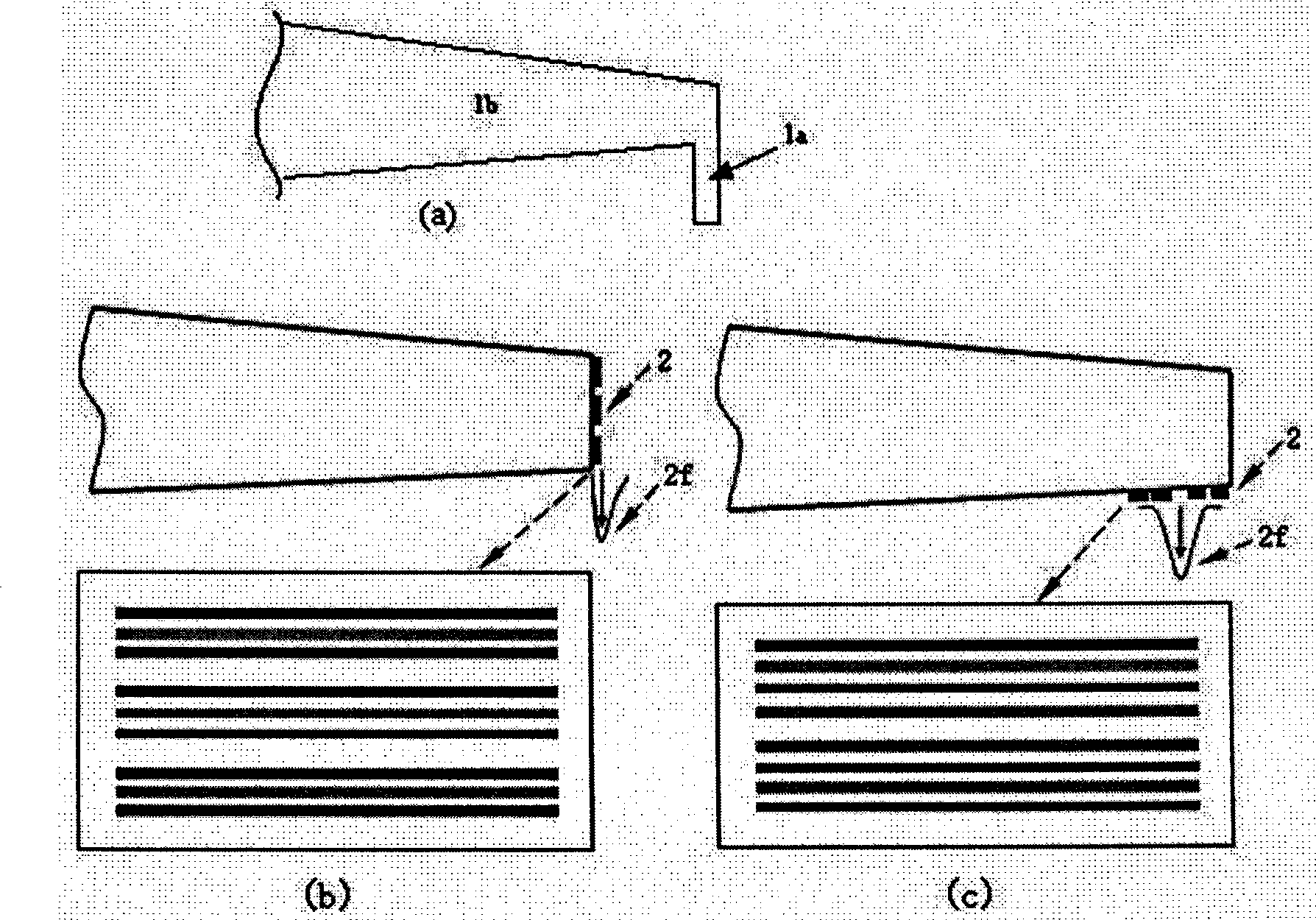

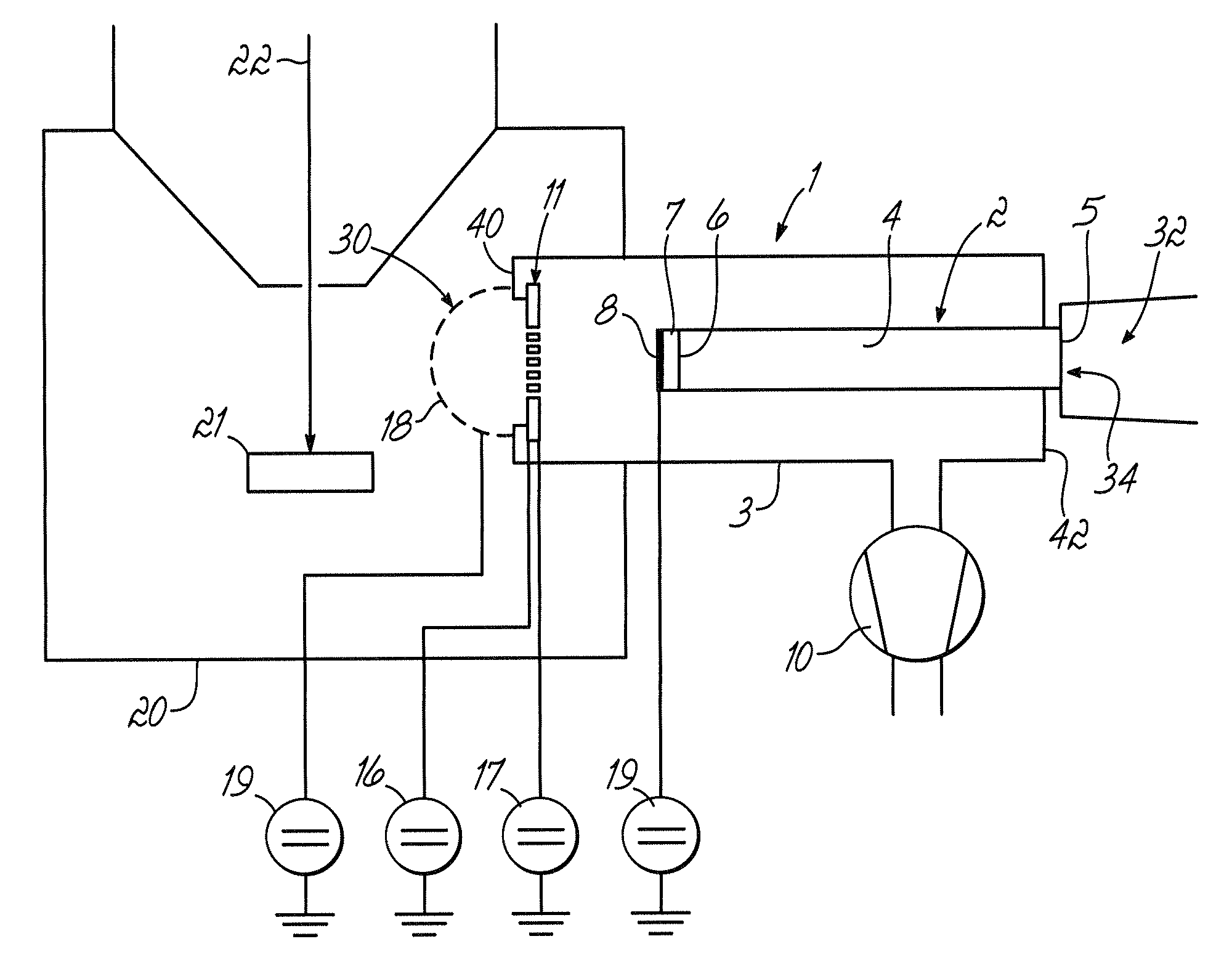

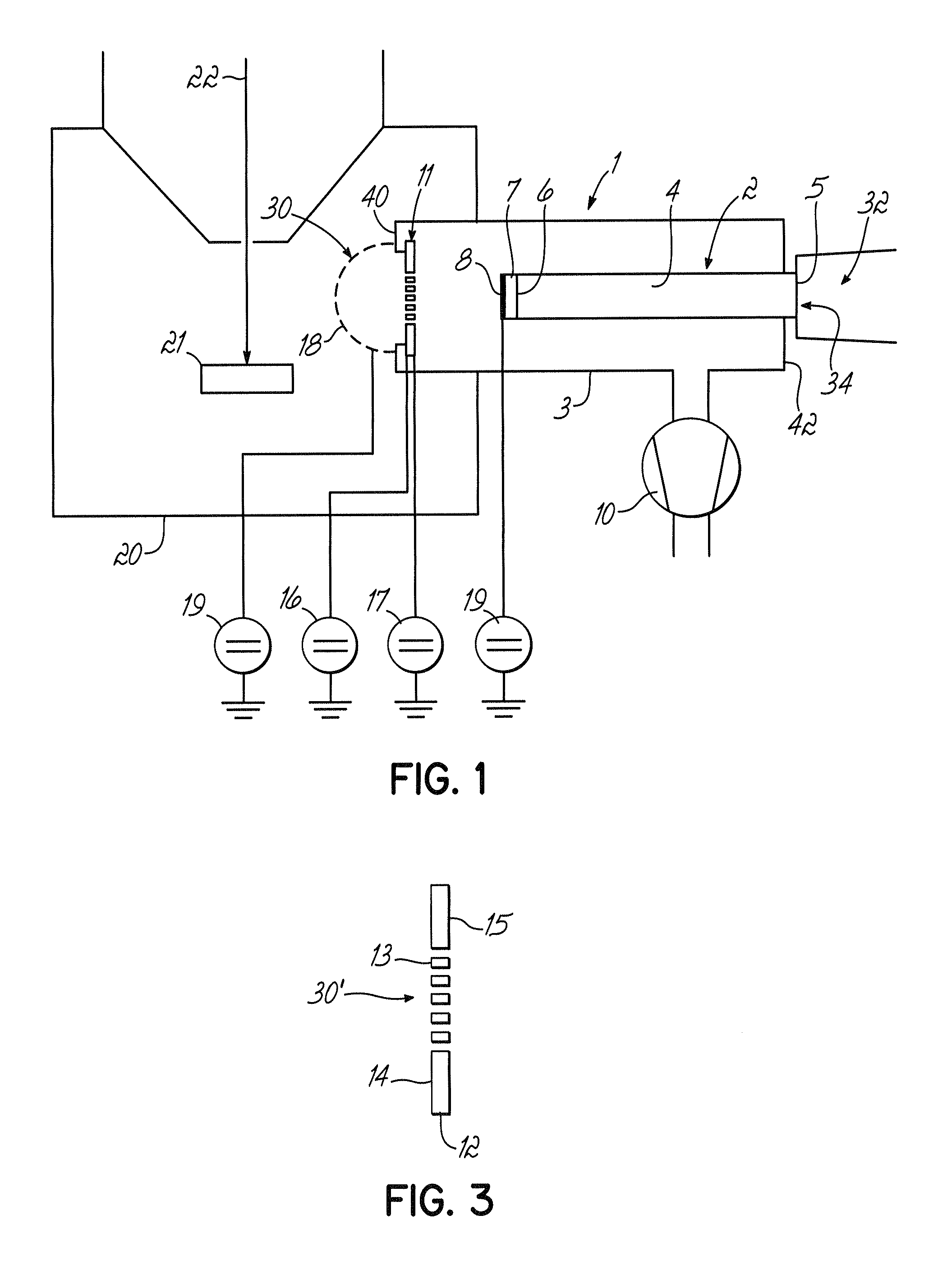

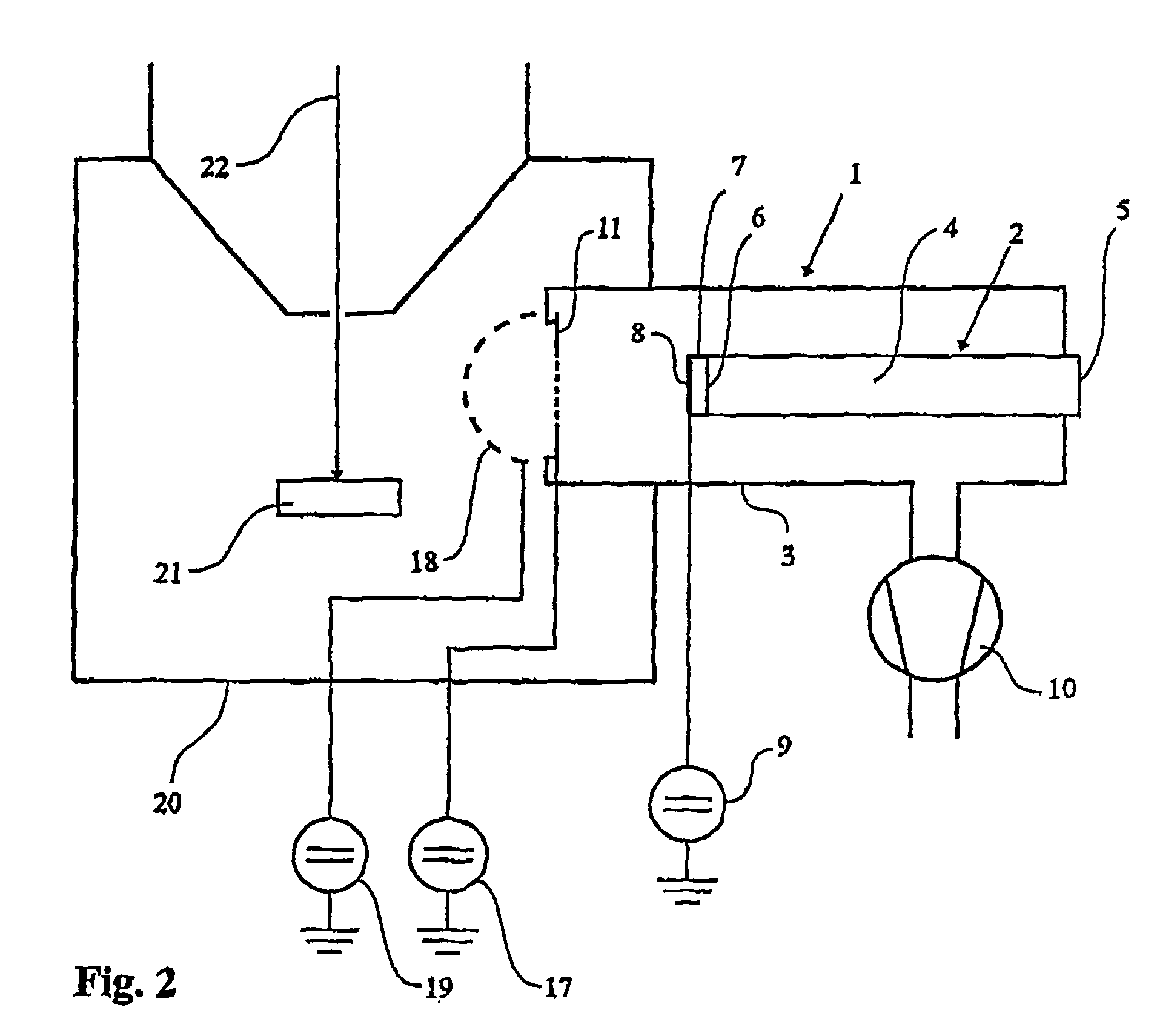

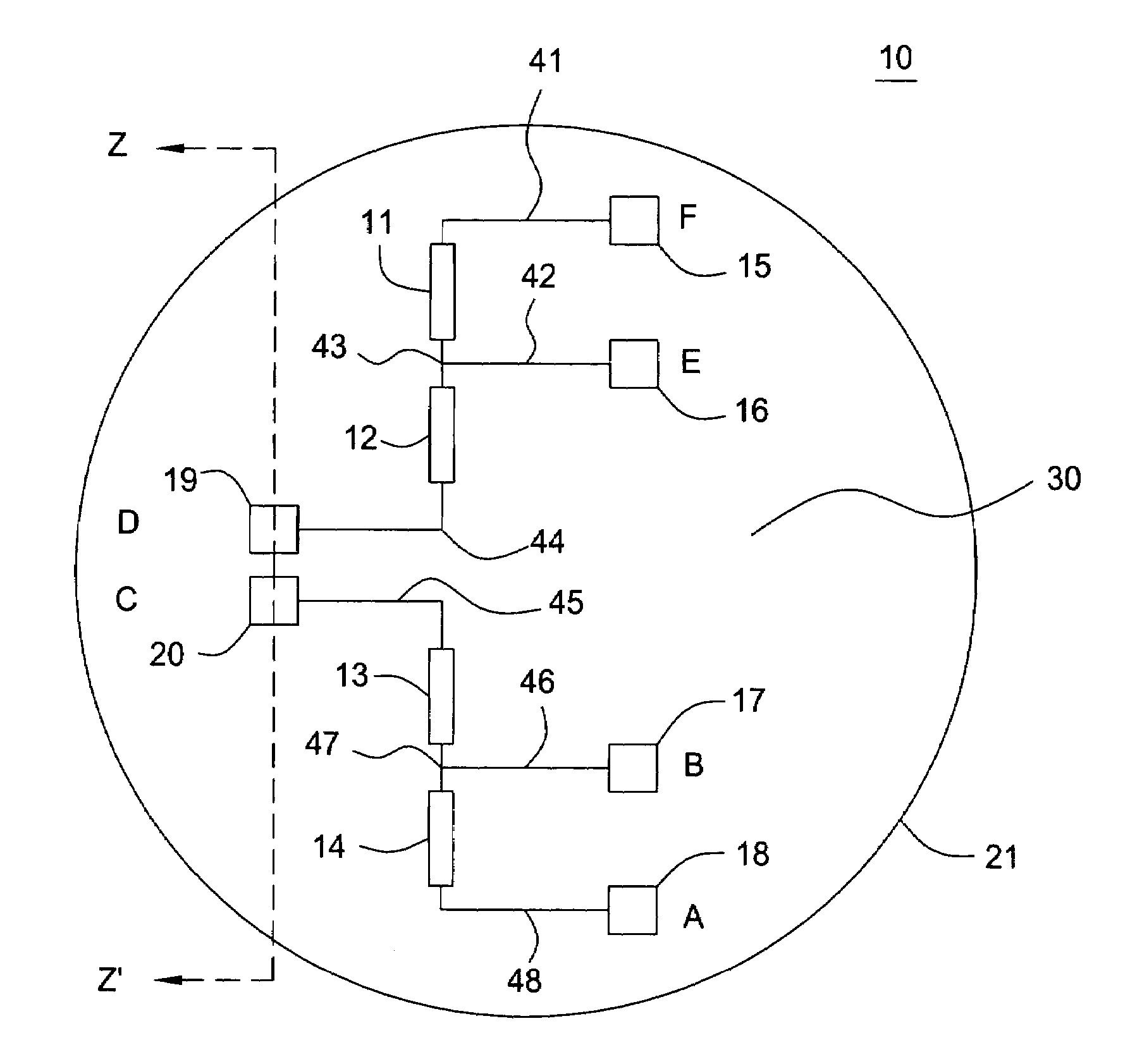

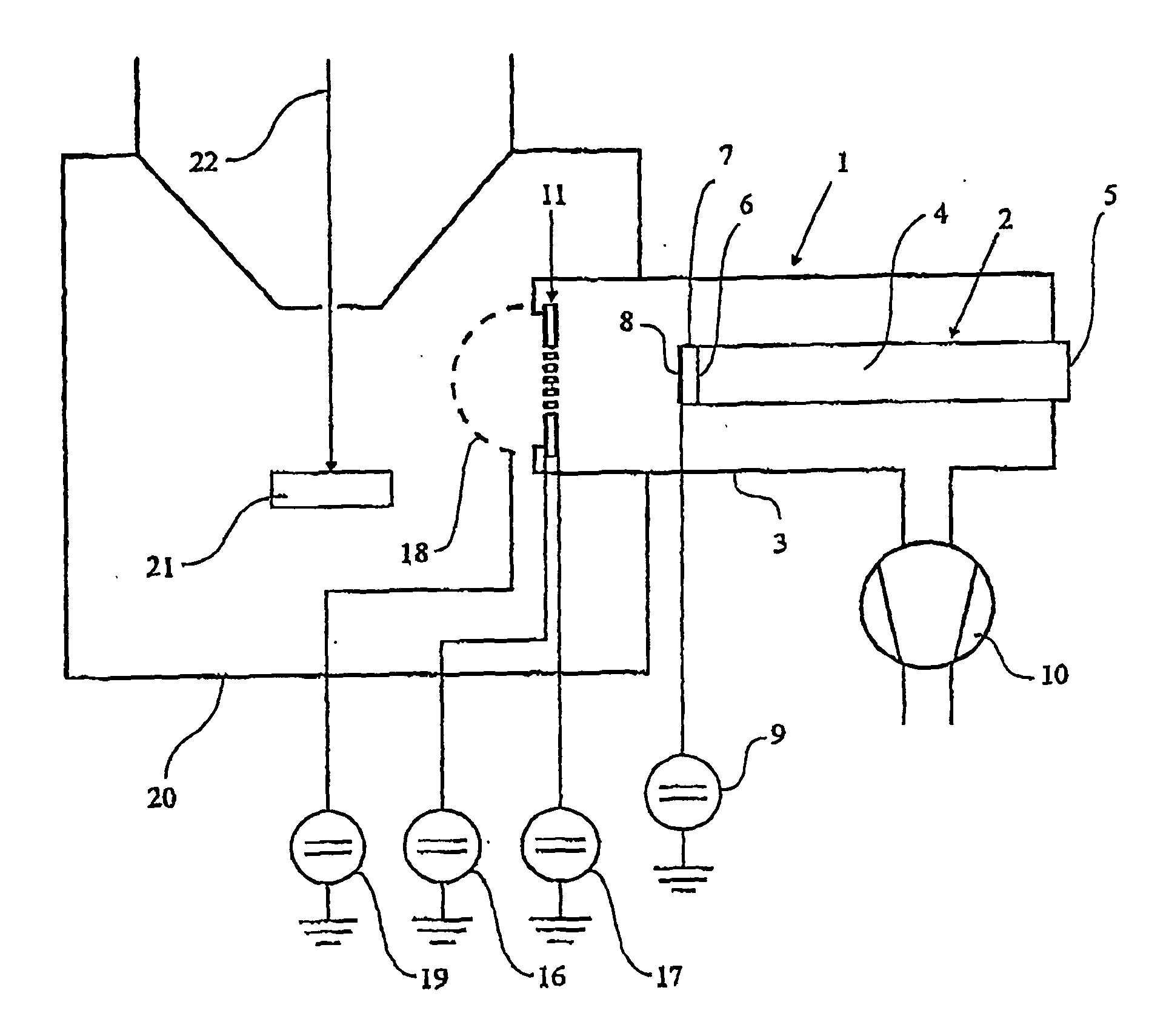

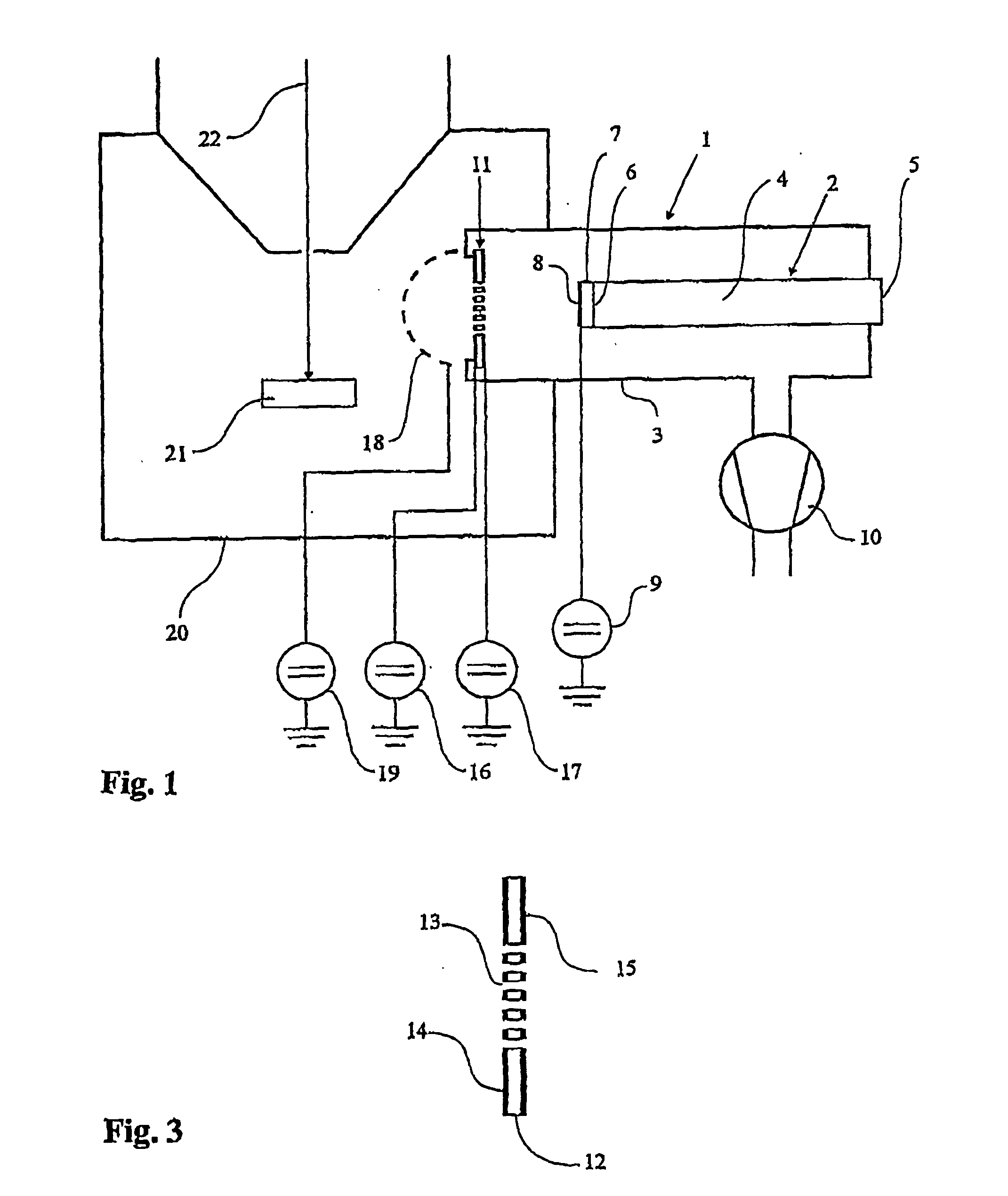

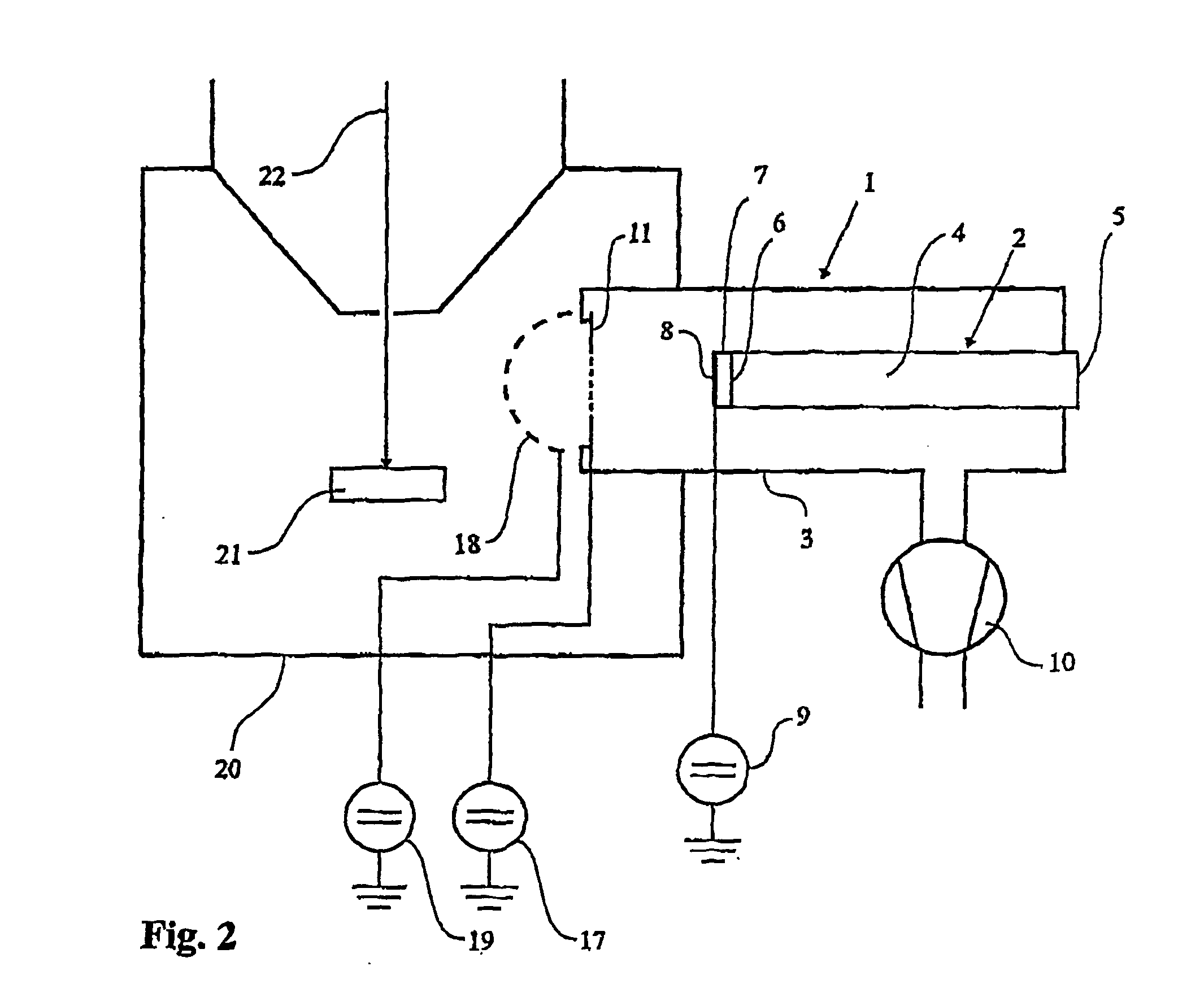

Secondary electron detector, especially in a scanning electron microscope

InactiveUS7193222B2Thermometer detailsMaterial analysis using wave/particle radiationHigh resistanceScanning tunneling microscope

The present invention deals with a secondary electron detector (1), especially in a scanning electron microscope. The subject matter of the invention provides a secondary electrons detector (1) constituted by a sensor (2) located in a detector chamber (3), to which a vacuum air pump (10) is connected to produce vacuum inside the detector chamber (3), the detector chamber (3) being in its wall near to the active surface of the sensor (2) enclosed with a diaphragm featuring high resistance to the transmission of gas and low resistance to the transmission of the electrons. The electrically conductive grid (11) is produced either in the form of a copper screen or as a kapton membrane (12) with orifices (13) and it is equipped on both sides with conductive coating (14, 15). Outside the detector chamber (3), the electrically conductive grid (11) is covered with an input screen (18), which is usually of hemispherical shape and is connected to the low voltage source (19) of 80 to 150 V.

Owner:TESCAN

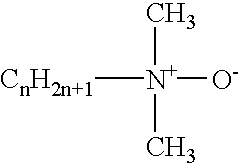

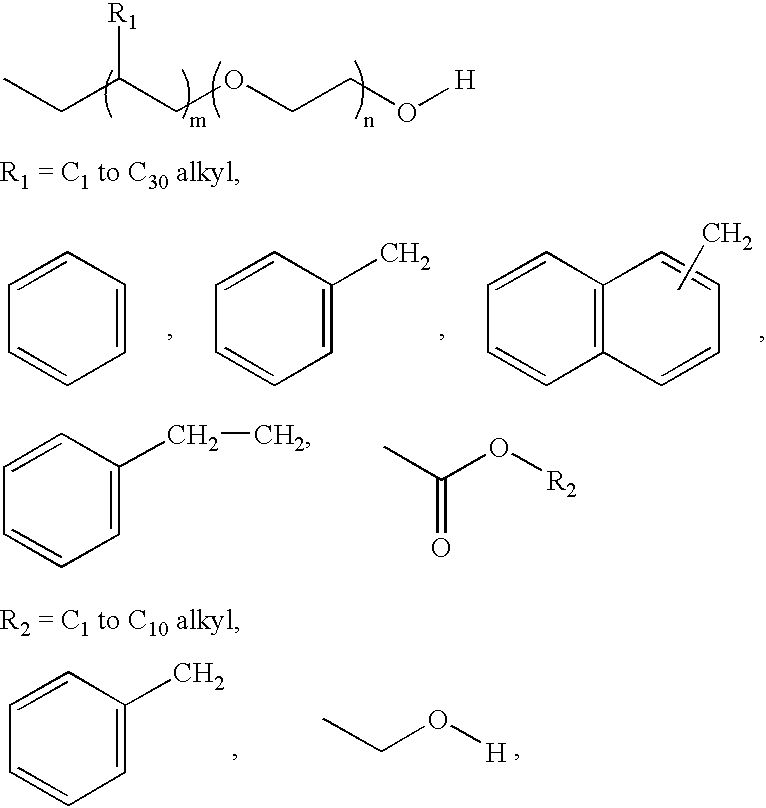

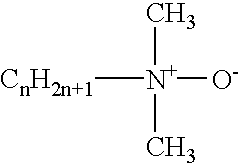

Inkjet ink having improved directionality by controlling surface tension and wetting properties

InactiveUS6478418B2Minimal tail breakupImproved drop trajectoryMeasurement apparatus componentsDuplicating/marking methodsDyneEngineering

An inkjet ink for printing onto a print medium is provided. The inkjet ink evidences minimal tail breakup and improved drop trajectory, thereby evidencing improved print quality. The minimal tail breakup and improved drop trajectory are achieved by adding at least one surface active additive to the ink to provide the ink with a surface tension of at least 35 dyne / cm and a contact angle (with an orifice plate comprising KAPTON, an aromatic polyimide) of about 35 to 65 degrees.

Owner:HEWLETT PACKARD DEV CO LP

Flexible thin film pressure sensor

InactiveUS7082834B2Reduce stressHarsh effectFluid pressure measurement using elastically-deformable gaugesFluid pressure measurement by electric/magnetic elementsContact padPlastic materials

Low pressure sensing and imperviousness to corrosion and to the effects of harsh environments are achieved in a pressure sensor that employs a flexible membrane supporting piezoresistive elements. A plurality of piezoresistive elements are aligned substantially collinearly across one surface of the flexible membrane. Innermost piezoresistive elements are disposed in such a way that they experience tension in response to an applied pressure, whereas outermost piezoresistive elements are disposed in such a way that they experience compression in response to the same applied pressure. Contact pads for each end of each piezoresistive element allow the elements to be configured in any number of desirable arrangements. In one exemplary embodiment, four piezoresistive elements are disposed along a main central axis of the membrane. The contacts of the elements are connected to form a Wheatstone bridge. Conventional Wheatstone bridge techniques are utilized to convert an applied pressure into an output electrical signal. The membrane includes amorphous or nanocrystalline semiconductor layers grown on a flexible substrate such as Kapton or suitable plastic materials.

Owner:NEW JERSEY INSTITUTE OF TECHNOLOGY

Secondary electron detector, especially in a scanning electron microscope

InactiveUS20050230620A1Thermometer detailsMaterial analysis using wave/particle radiationHigh resistanceLow voltage

The present invention deals with a secondary electron detector (1), especially in a scanning electron microscope. The subject matter of the invention provides a secondary electrons detector (1) constituted by a sensor (2) located in a detector chamber (3), to which a vacuum air pump (10) is connected to produce vacuum inside the detector chamber (3), the detector chamber (3) being in its wall near to the active surface of the sensor (2) enclosed with a diaphragm featuring high resistance to the transmission of gas and low resistance to the transmission of the electrons. The electrically conductive grid (11) is produced either in the form of a copper screen or as a kapton membrane (12) with orifices (13) and it is equipped on both sides with conductive coating (14, 15). Outside the detector chamber (3), the electrically conductive grid (11) is covered with an input screen (18), which is usually of hemispherical shape and is connected to the low voltage source (19) of 80 to 150 V.

Owner:TESCAN

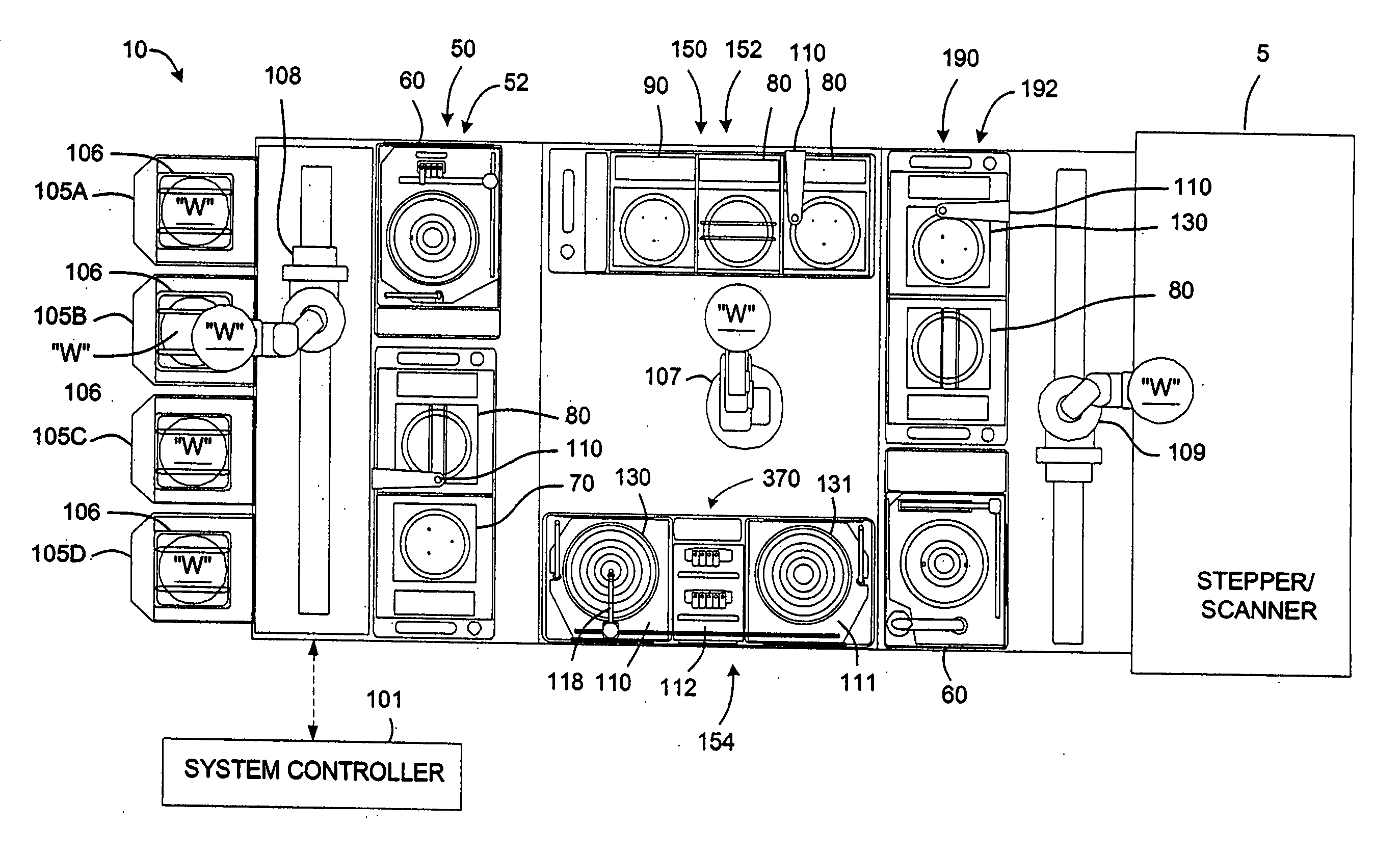

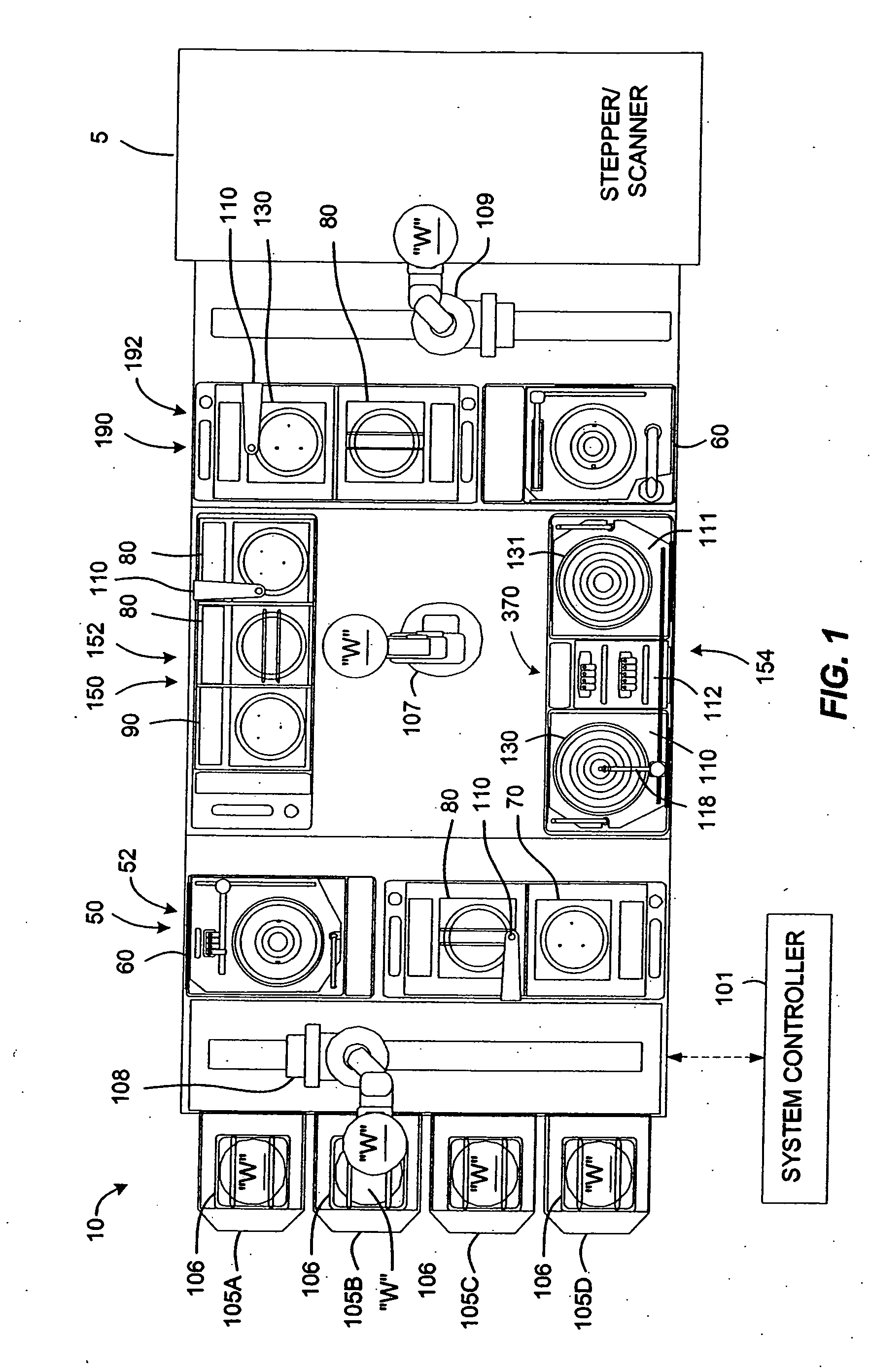

Electrostatic chuck for track thermal plates

InactiveUS20060238954A1Semiconductor/solid-state device manufacturingPositioning apparatusElectrical resistance and conductanceElectrical conductor

A chuck for a semiconductor workpiece features integrated resistive heating and electrostatic bipolar chucking elements on a thermal pedestal. These integrated heating and chucking elements maintain wafer flatness, as well as uniformity of an underlying gap accommodating a thermal gas between the workpiece and the chuck. In accordance with one embodiment of the present invention, a laminated Kapton wafer heater is attached to the top of the thermal surface, under the wafer: At least two electrical voltage zones are isolated within the heater, in order to create a chucking force between the chuck and the wafer without having to contact the wafer with an electrical conductor. These voltage zones can be created by using separate conducting elements as well as by imposing a DC bias on zones including the resistive heating elements.

Owner:SOKUDO CO LTD

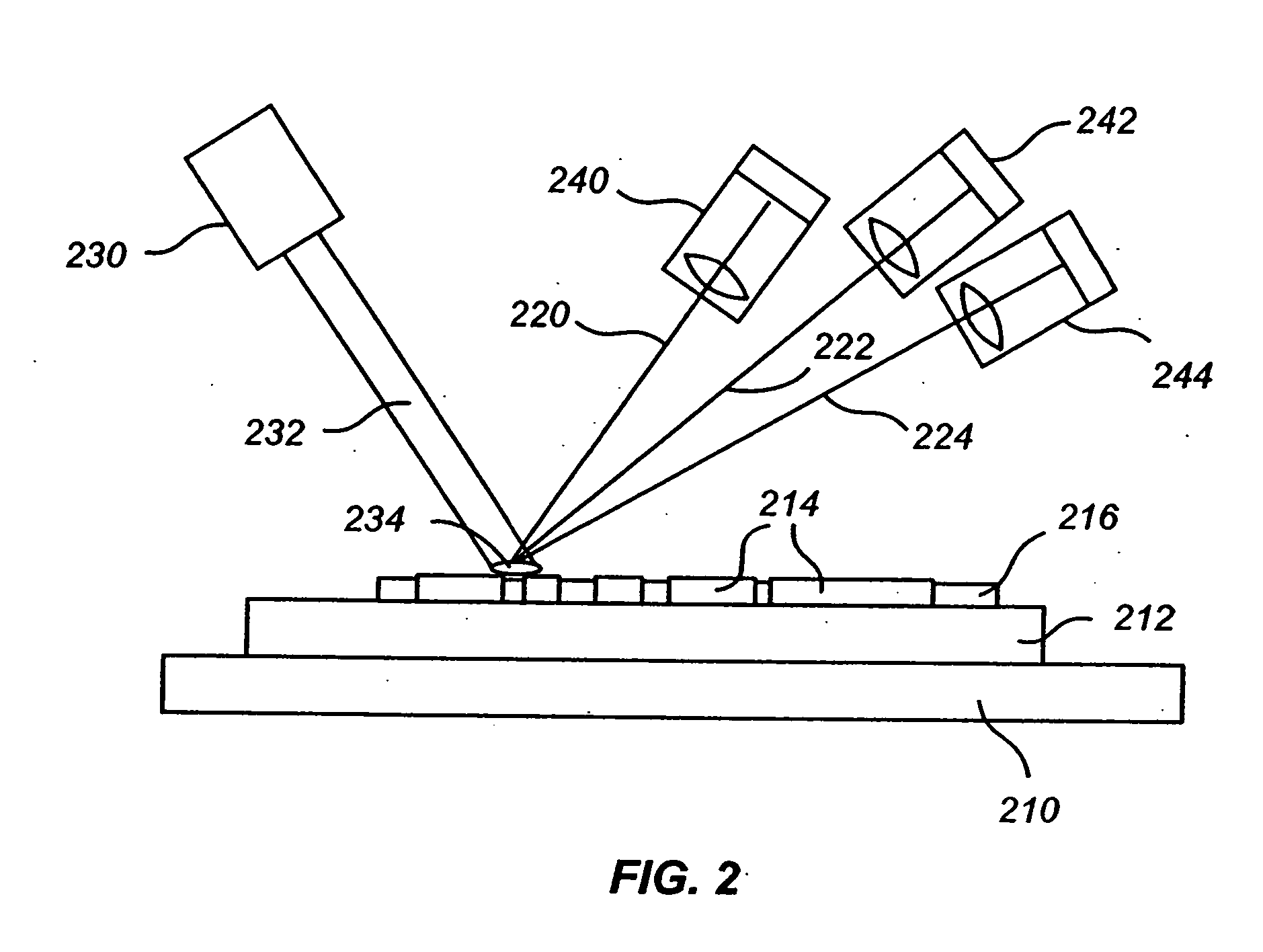

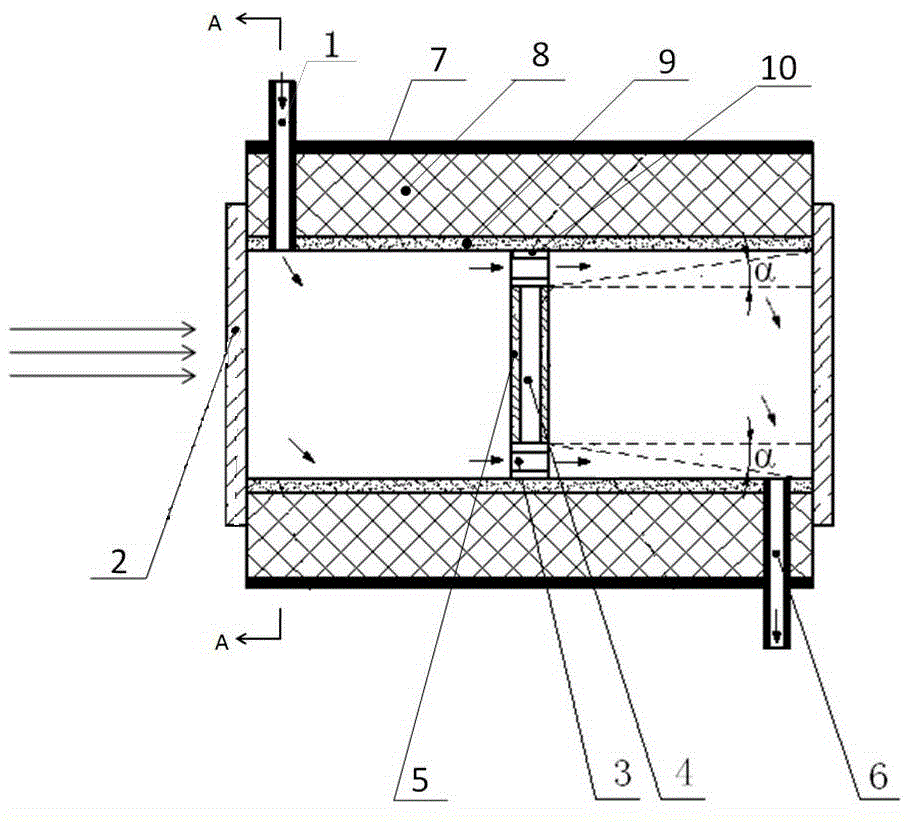

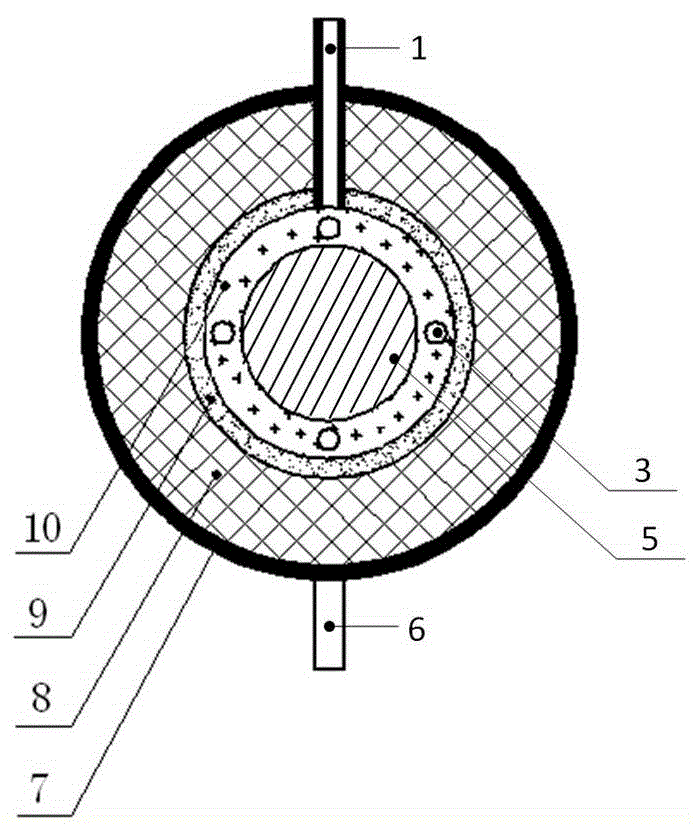

Hot stage for small-angle scattering experiment

InactiveCN104833687AEvenly heatedAvoid influenceMaterial analysis using wave/particle radiationX-rayEngineering

The present invention provides a hot stage for small-angle scattering experiment. The hot stage includes an intake passage, a sealed window, a translucent window, an exhaust passage, a heating layer package wall, a heating layer, a sample chamber and a sample clamp layer. The hot stage for small angle scattering experiment has thermal station temperature in the range of -40 to 1200 DEG C; and the connecting lines between two end ports of the sample chamber and the edges of the transparent window have included angle of 4- 90 DEG with the axial parallel of the sample chamber. Surrounding heating on the sample chamber by the heating layer ensures uniform heating of the sample, and avoids the effects of the heating layer on neutron and X-ray path. The sealed window and translucent window uses quartz glass, sapphire or Kapton film with high transmittance of neutrons and X-rays, so as to achieve high transmittance of neutrons and X-ray, and ensure normal operation of the neutron and X-ray small-angle scattering experiments.

Owner:INST OF NUCLEAR PHYSICS & CHEM CHINA ACADEMY OF

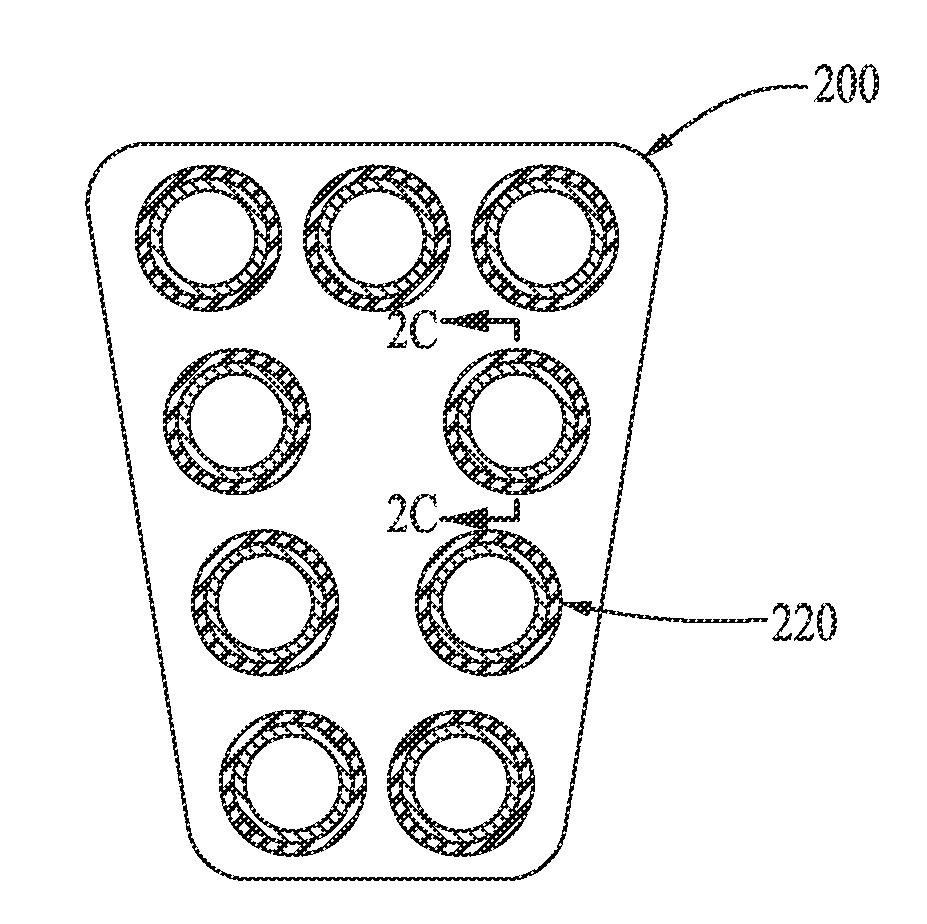

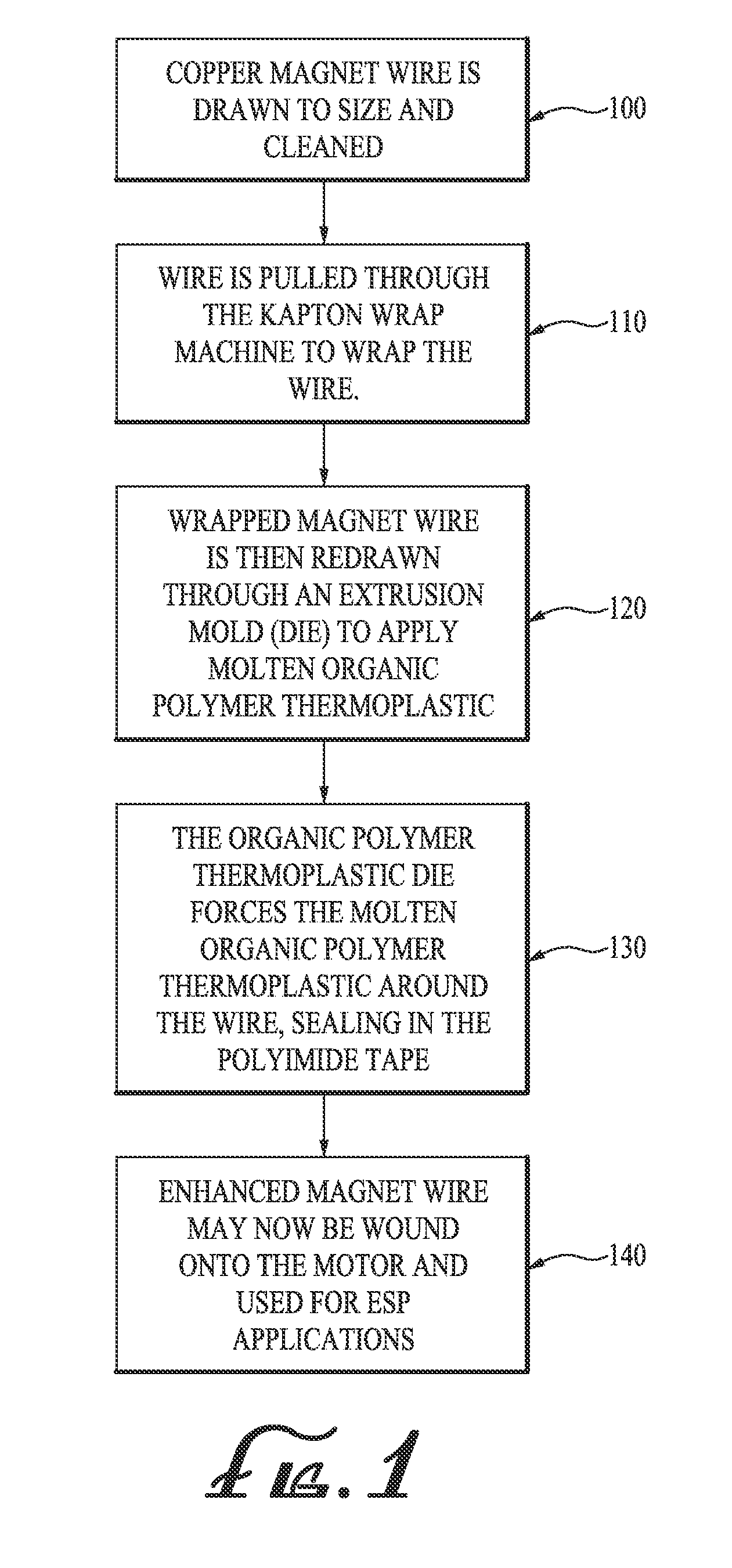

System and method for enhanced magnet wire insulation

ActiveUS20130278117A1Enhanced magnet wire insulationWindings insulation materialInsulated cablesThermoplasticEngineering

A system and method for enhanced magnet wire insulation is described. The system of the invention provides an enhanced insulation for magnet wire that is capable of withstanding high temperatures and provides a seal against water that is needed in electric submersible pump (ESP) applications. The enhanced insulation of the system of the invention provides the dielectric advantages of polyimide tape, such as Kapton tape, while also including the advantages of organic polymer thermoplastic insulation that prevents the delaminating at high temperatures that may occur in pumping applications using a variety of electrical submersible motors.

Owner:HALLIBURTON ENERGY SERVICES INC

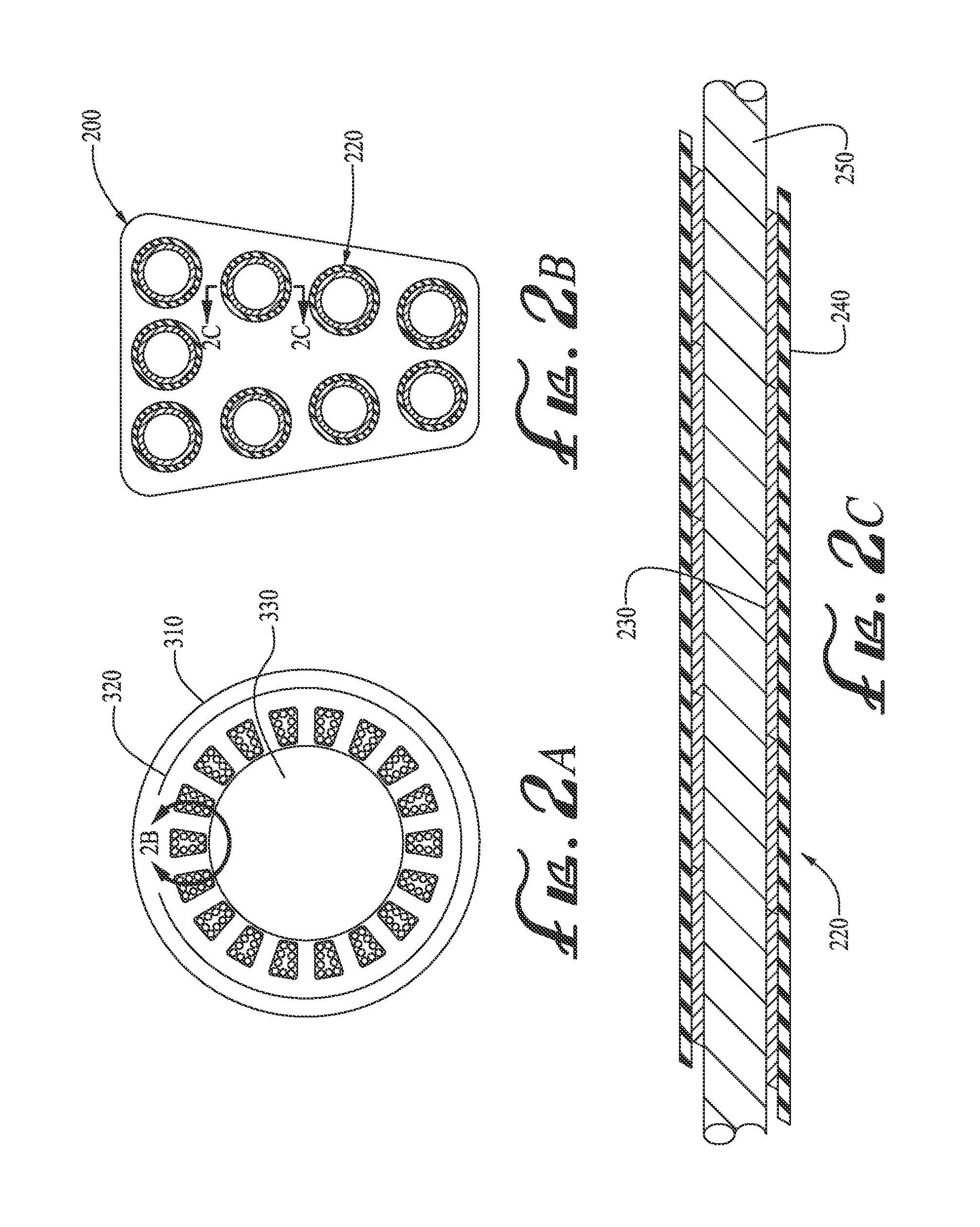

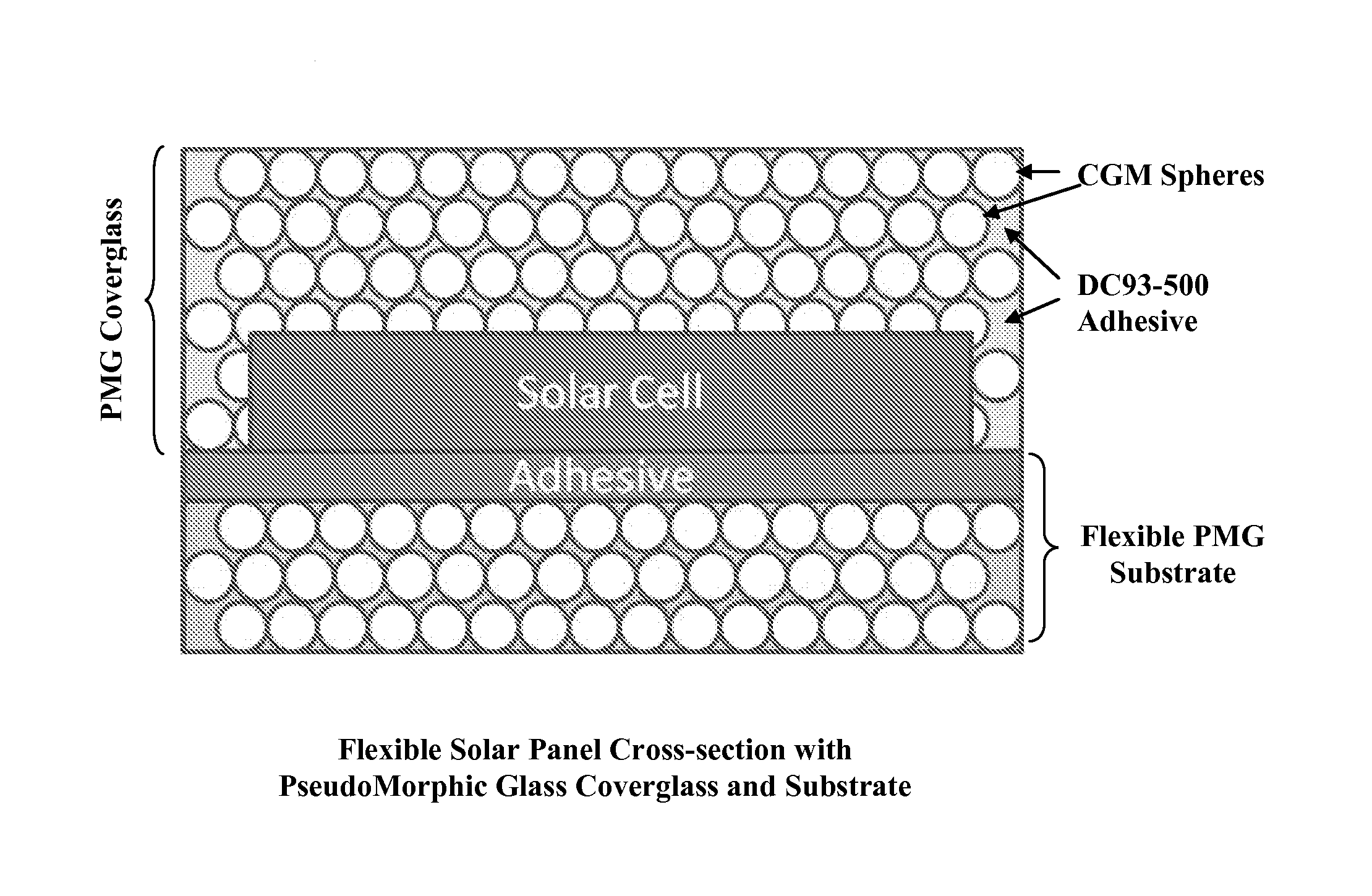

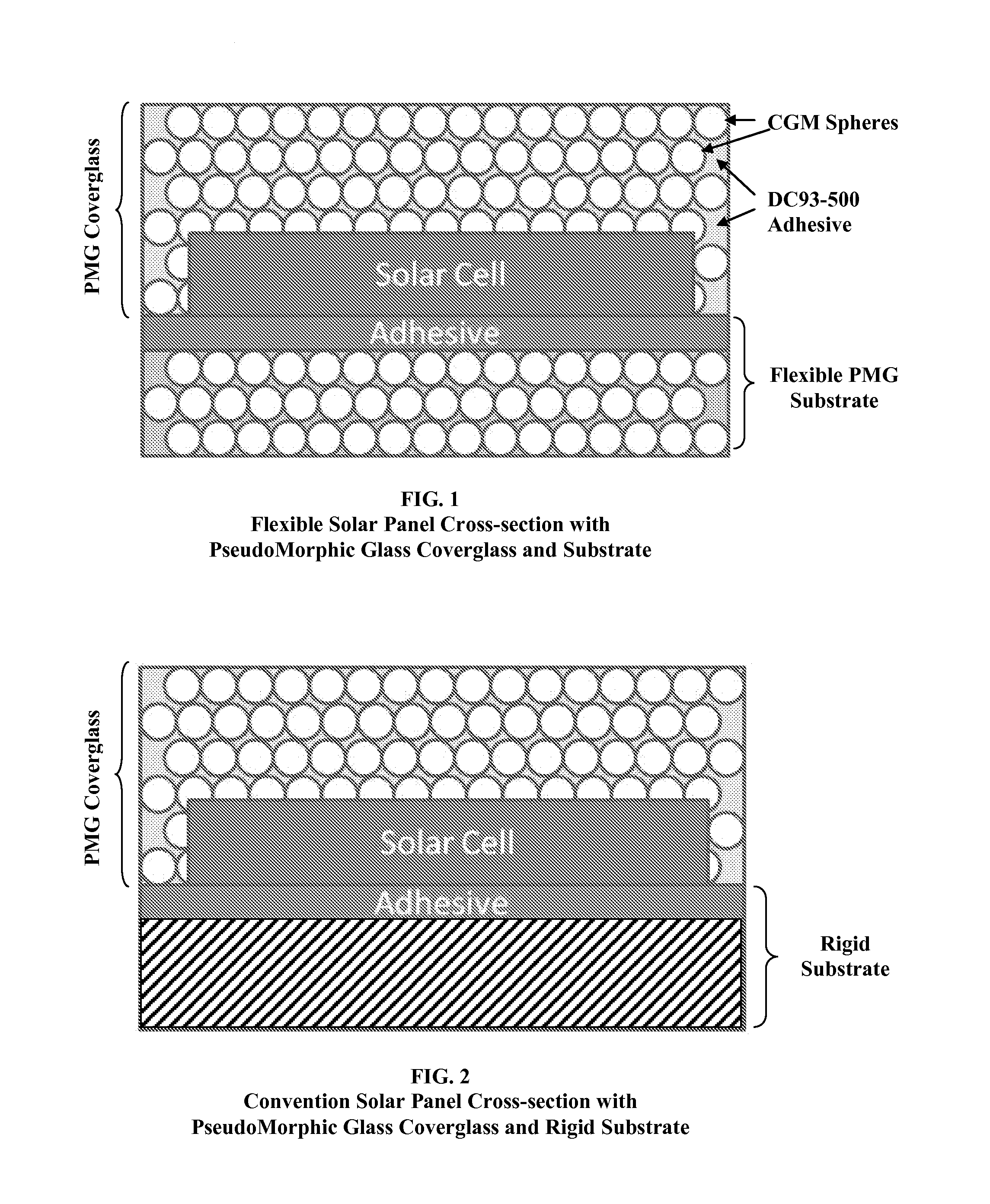

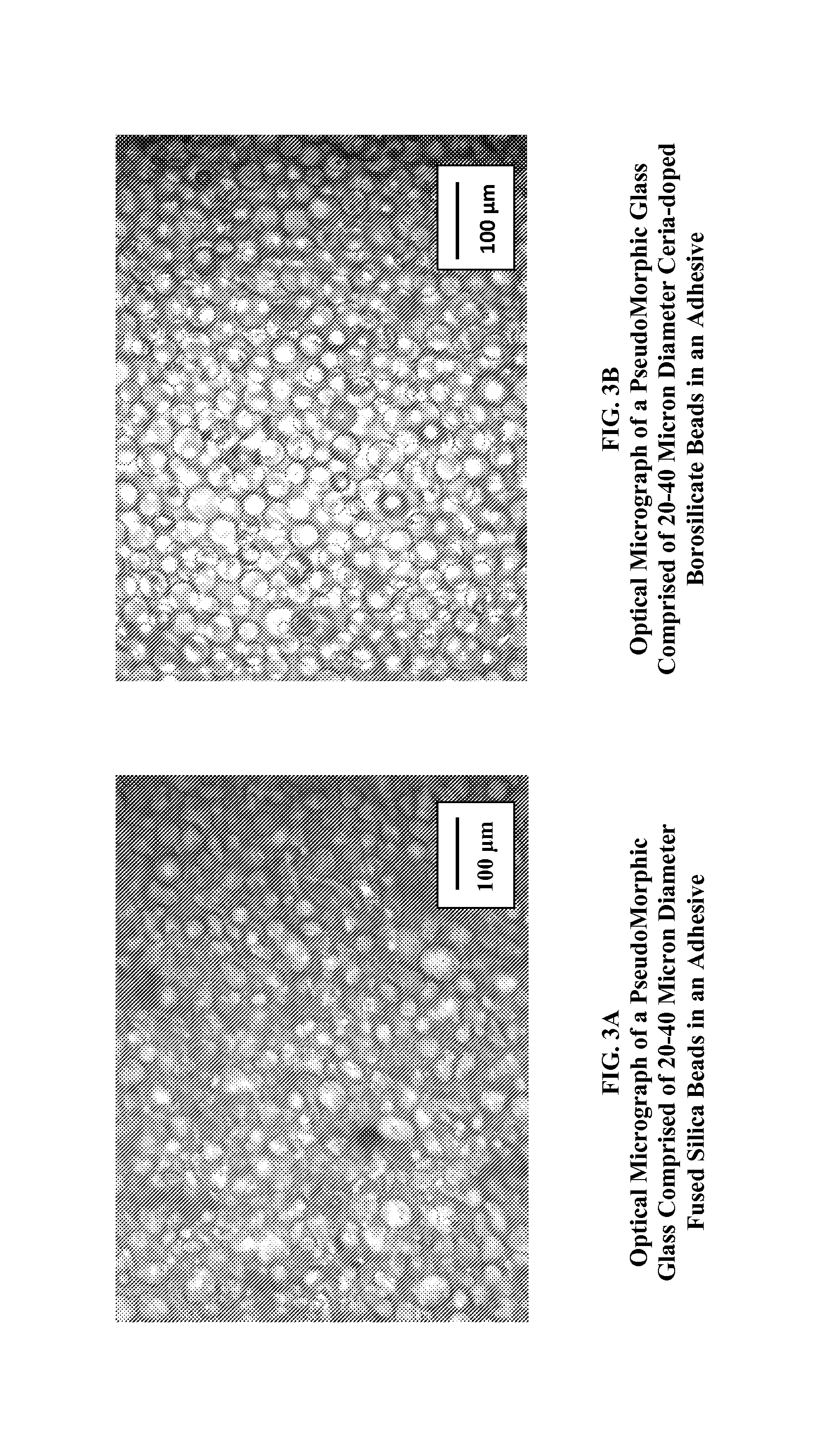

Pseudomorphic glass for space solar cells

InactiveUS8974899B1Optimum transmission bandwidthImproves UV protectionMaterial nanotechnologyPV power plantsSpace-based solar powerAdhesive

A flexible hybrid coverglass for spacecraft solar panels comprised of small beads of either fused silica or ceria-doped borosilicate glass embedded in a matrix of conventional coverglass adhesives. These beads may also be used in a matrix of Kapton as the solar panel's substrate which may be combined with flexible solar cells to form flexible solar panels.

Owner:GONDOLA SKATE MOVING SYST INC +1

Fuel cell apparatus and method of fabrication

InactiveUS20110003226A1Easy to manufactureCost-effective to produceFuel cells groupingCell electrodesSputteringFuel cells

A fuel cell is described. The fuel cell includes current collectors, each of which includes a substrate of lightweight material, such as Kapton material. Micro channels are formed via laser machining or chemical etching into the substrate. The current collectors further include conductive layers sputtered on the substrate, and protective coating on the conductive layers. A variety of materials are available for the conductive layers. The fuel cell so developed is particularly well suited to mobile applications, such as electronic devices.

Owner:MARKOSKI LARRY J +2

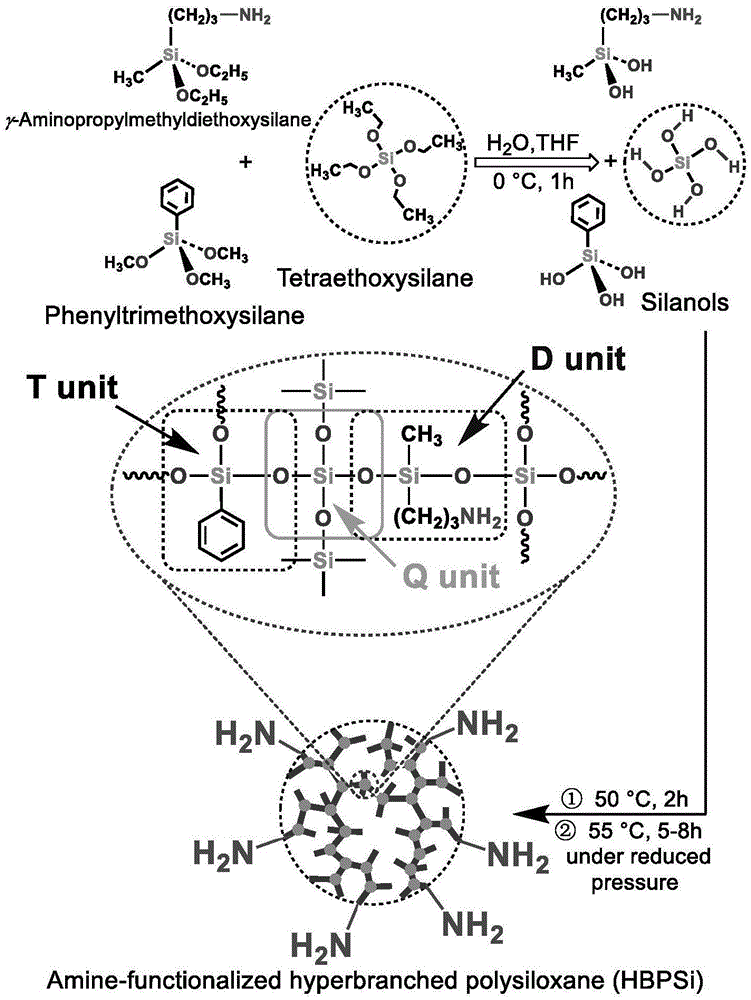

Preparation method of polyimide film with ultralow dielectric constant and low dielectric loss

The invention relates to a preparation method of a polyimide film with an ultralow dielectric constant and low dielectric loss. HBPSi (Hyperbranched Polysiloxane) is first obtained by adopting a hydrolytic cocondensation method and multistep purification; finally, an HBPSi structure is introduced into a PI (Polyimide) molecular main chain in the form of a chemical bond; the modification on a PI material on a molecular level is realized; the dielectric constant of the PI material is obviously decreased; the inherent advantage of the PI material is maintained better. A PI film is excellent in dielectric property, favorable in heat resistance, outstanding in mechanical strength, low in water absorption, high in surface evenness, mild in reaction condition in a preparation process and lower in research and development costs, and is beneficial to large-scale commercial production. In comparison with a Kapton standard film which is currently used generally, the dielectric constant of an HBPSi-PI film is decreased by 30 percent to 40 percent in an equal test condition; a lowest dielectric constant is even approximate to 2.0; the level of the ultralow dielectric constant is reached; the active demand of the development of a microelectronic industry in the future can be met.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

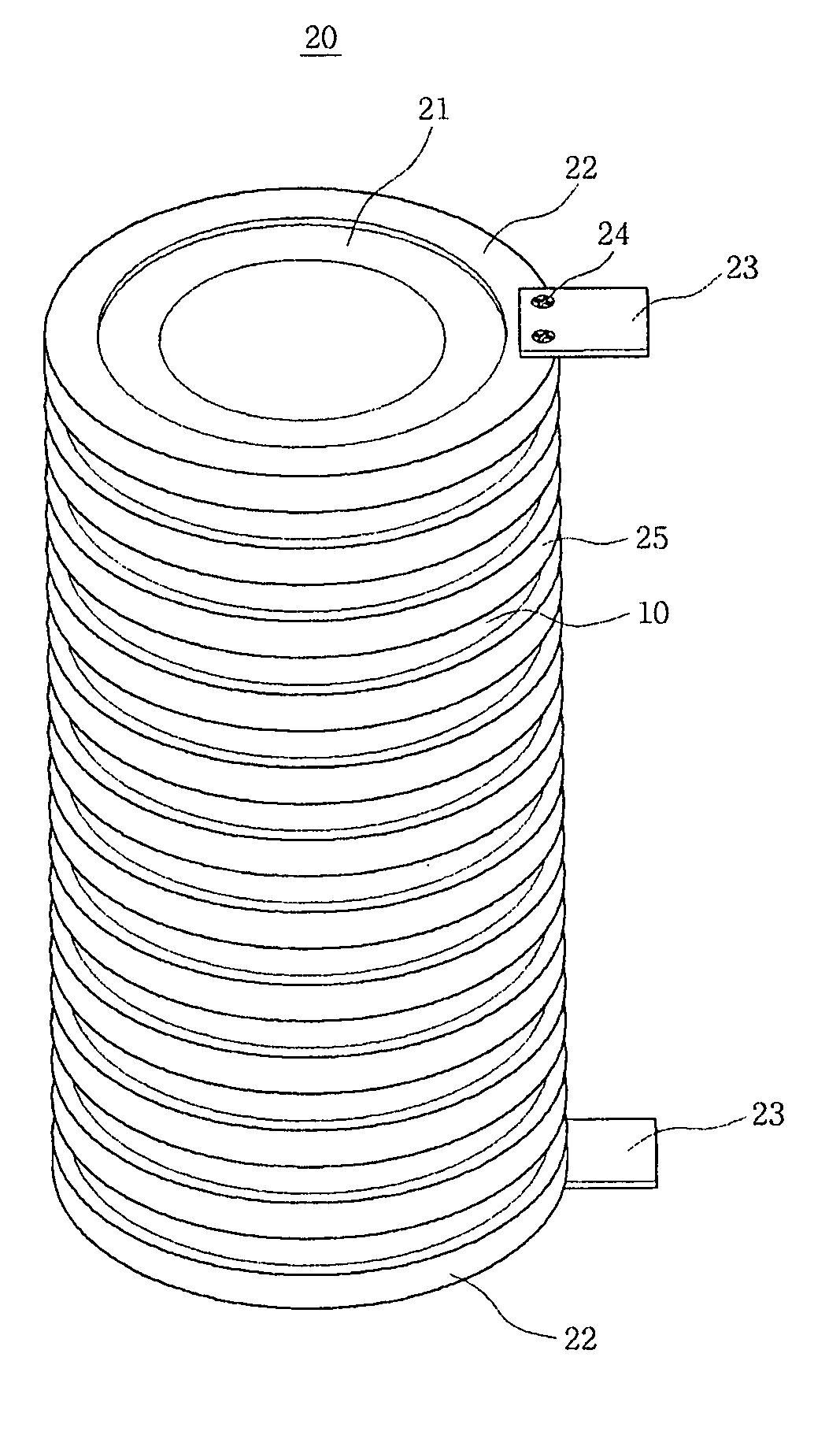

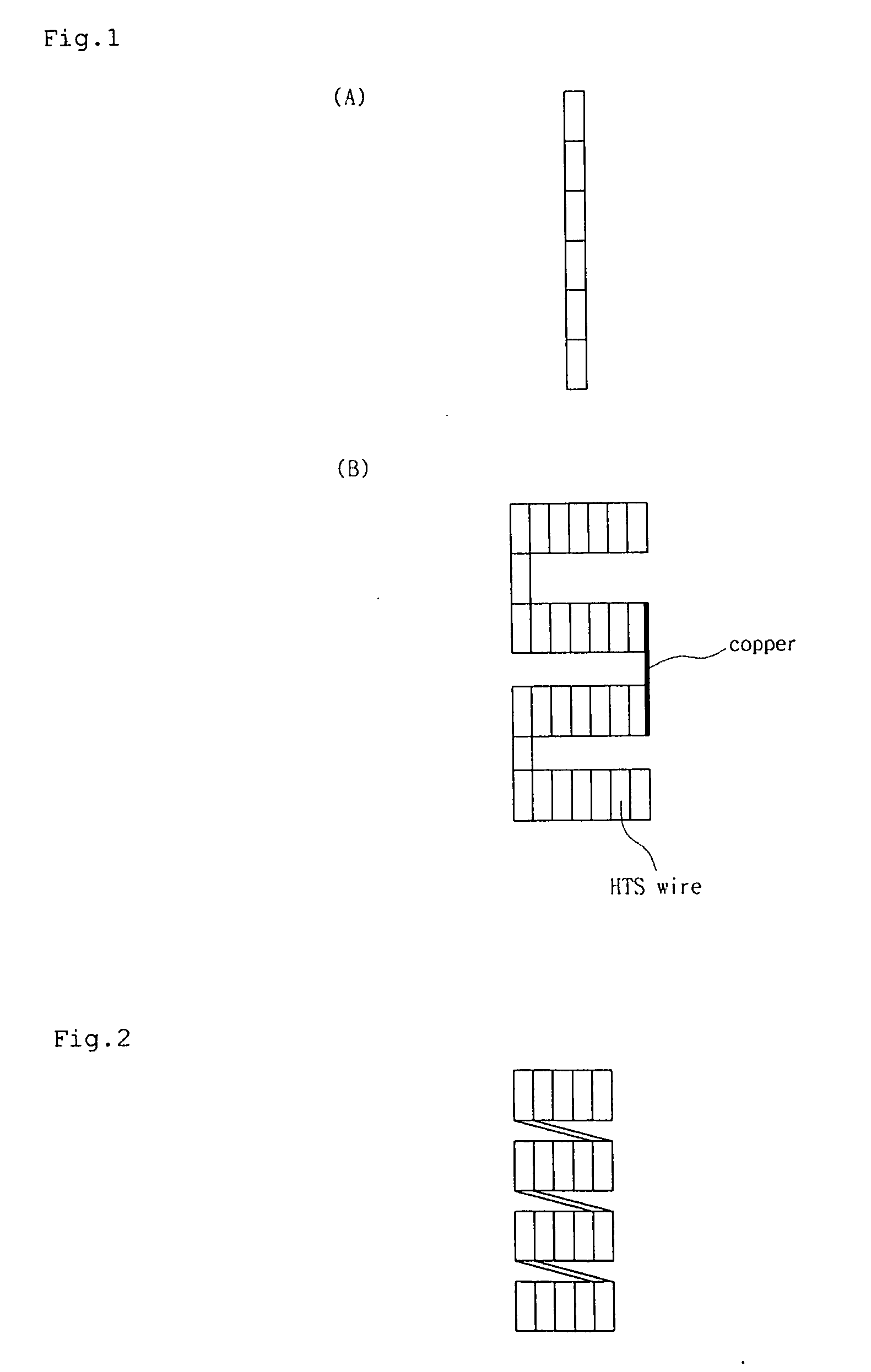

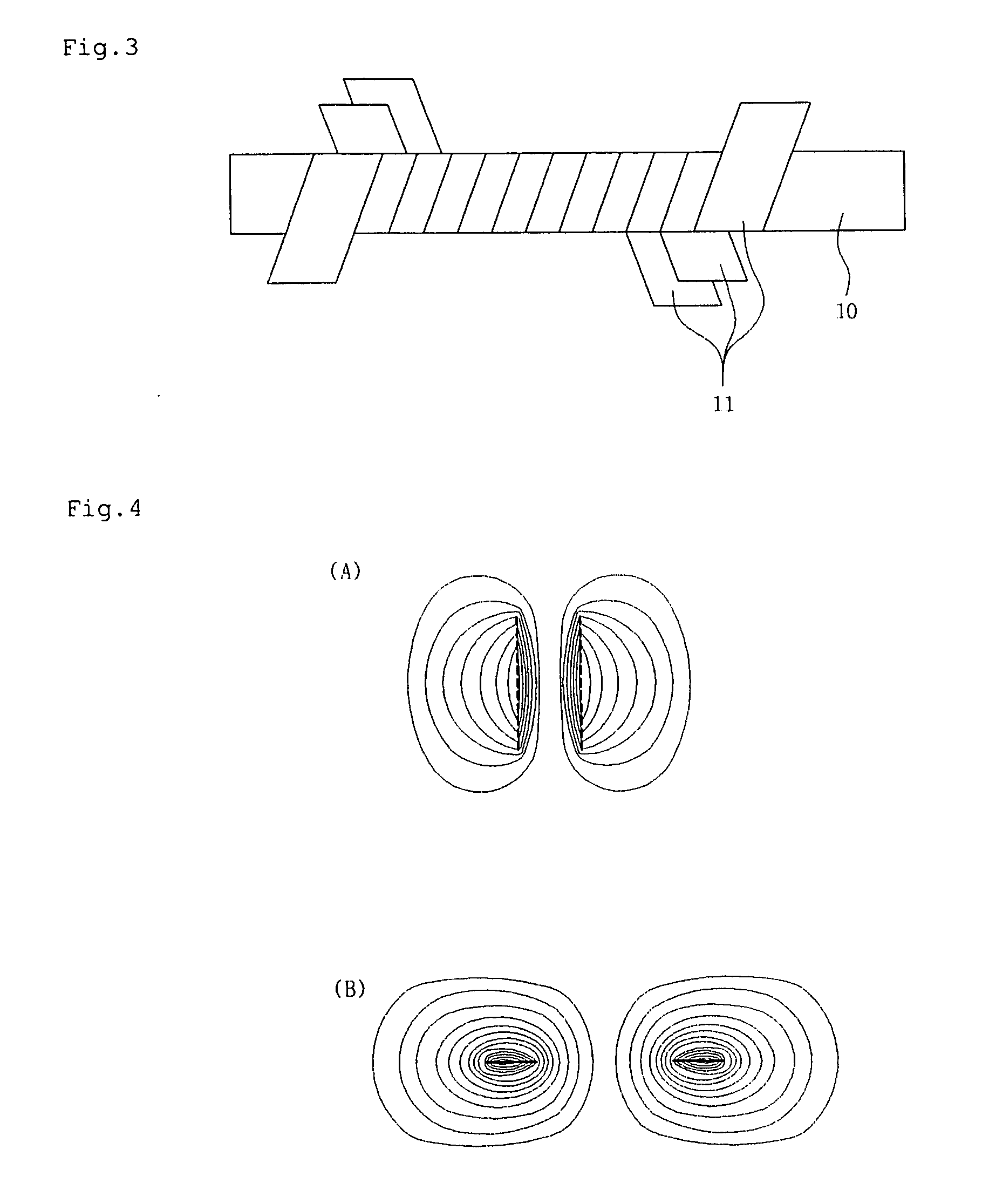

Method of manufacturing continuous disk winding for high-voltage superconducting transformers

ActiveUS20070152786A1Reduce lossNo jointSuperconductors/hyperconductorsTransformers/inductances coils/windings/connectionsBobbinTransformer

Disclosed herein is a method of manufacturing a continuous disk winding for high-voltage superconducting transformers that has special features of no joint and low loss, which are advantages of a layer winding, while being formed in the shape of a disk winding, which is advantageous in voltage distribution and insulation. The method includes lapping a high-temperature superconducting wire using Kapton films to apply multiple layers of insulation around the high-temperature superconducting wire, fixing one end of the high-temperature superconducting wire to a current inlet terminal of a bobbin, to the lower end of which is attached a fixing plate, which has the current inlet terminal, and winding the high-temperature superconducting wire on the bobbin by the predetermined number of turns, fitting a disk having a slit formed therein onto the bobbin to form high-temperature superconducting wire layers, inserting the high-temperature superconducting wire into a front end of the slit of the fitted disk and moving high-temperature superconducting wire to a rear end of the slit such that the high-temperature superconducting wire can be wound on the next layer by the predetermined number of turns, fitting a plurality of disks, each of which has a slit formed therein, onto the bobbin at predetermined intervals to form a plurality of high-temperature superconducting wire layers, and repeatedly winding the high-temperature superconducting wire for each disk such that the high-temperature superconducting wire is wound from one end of the bobbin to the other end of the bobbin, and, after the winding operation is completed, fixing the other end of the high-temperature superconducting wire to a current inlet terminal of another fixing plate attached to the upper end of the bobbin.

Owner:SUNAM

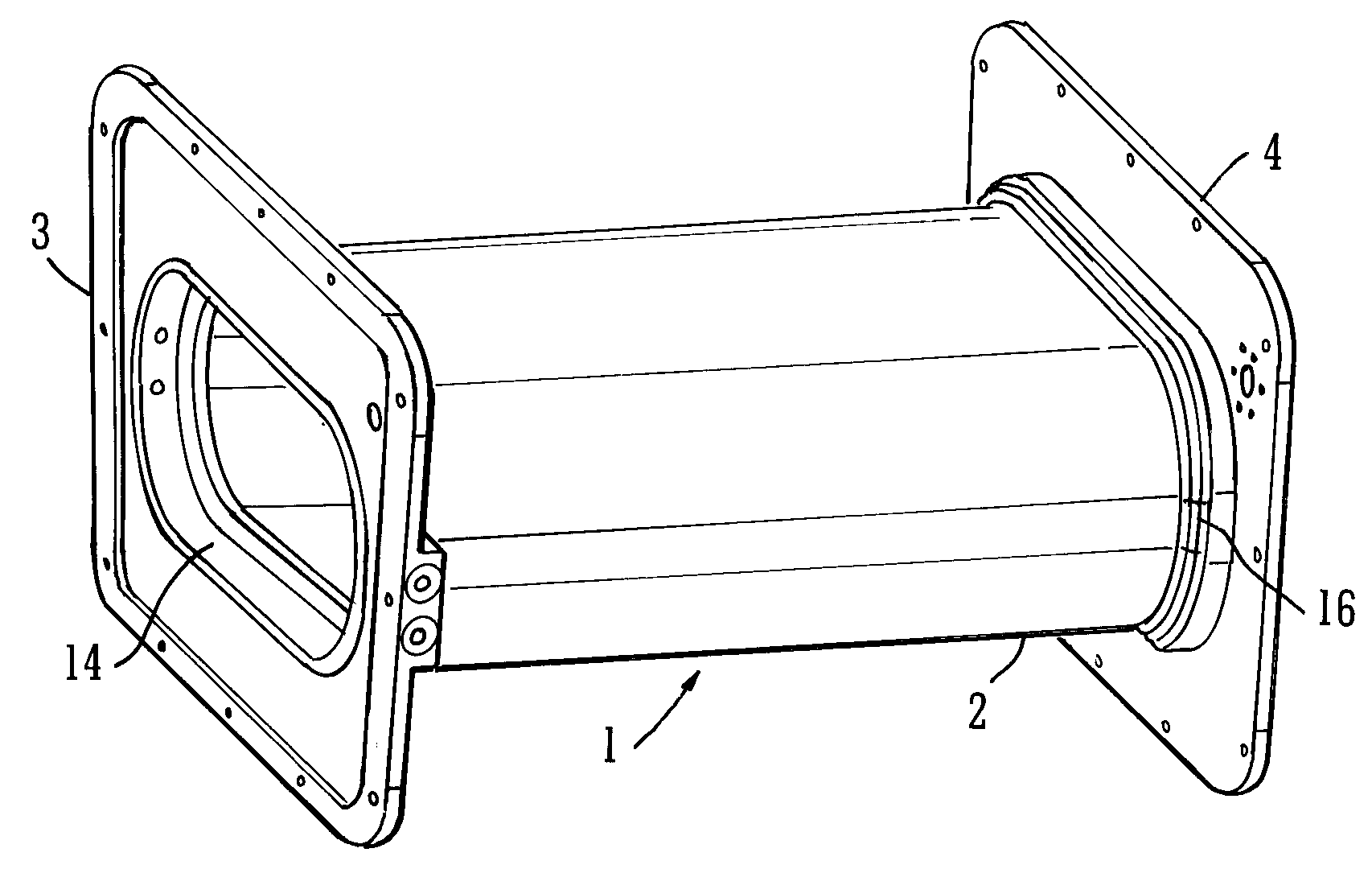

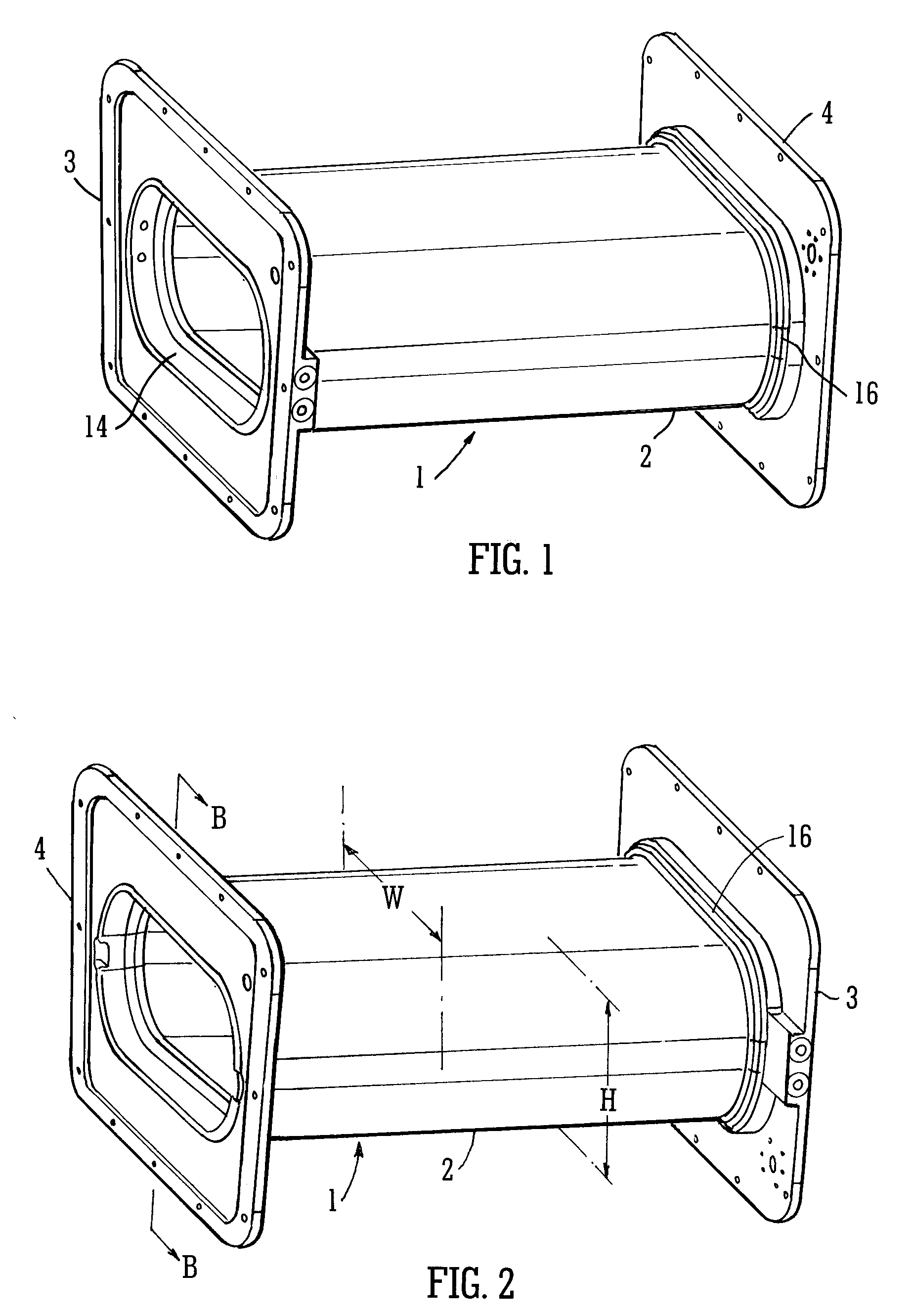

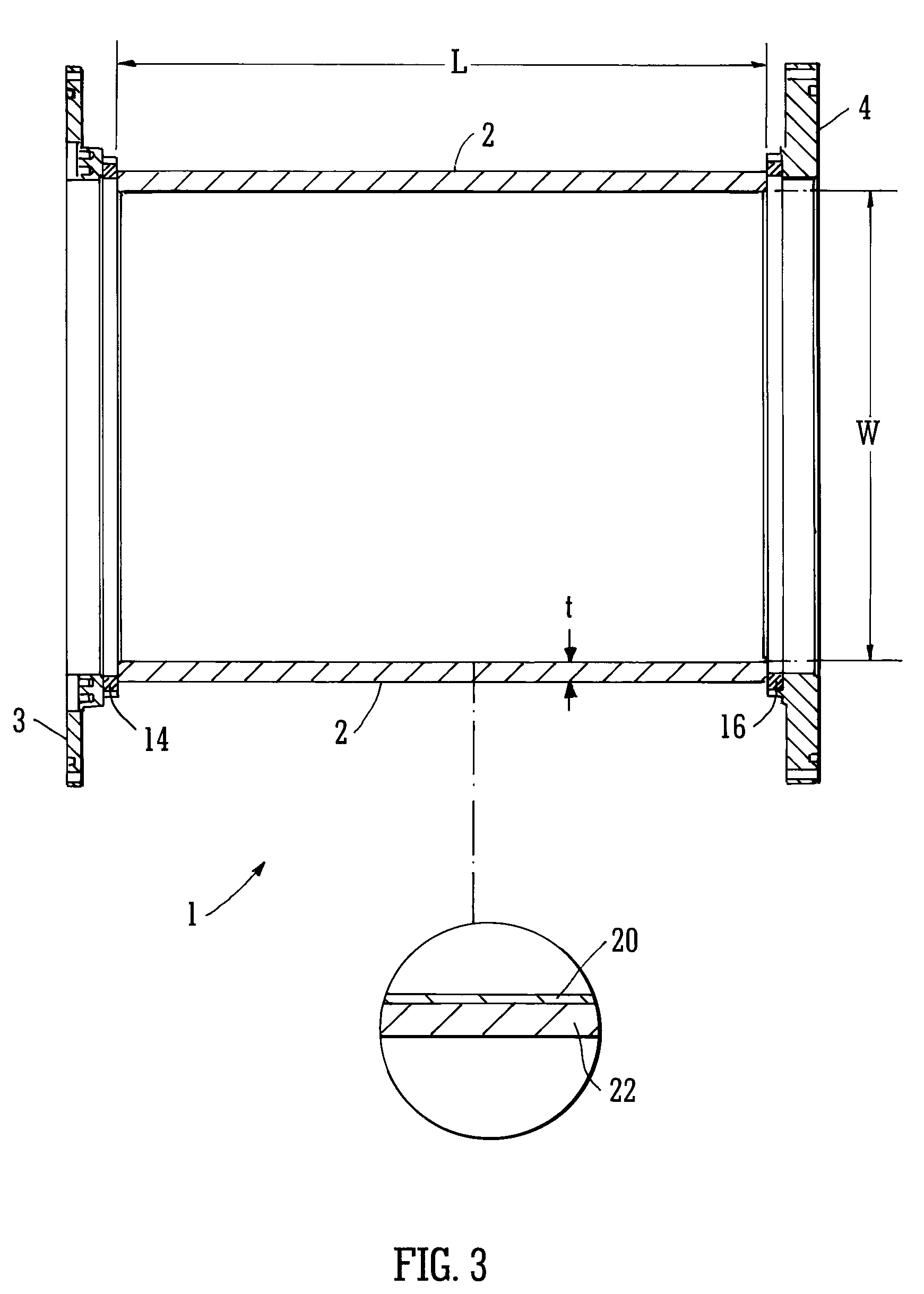

Vacuum chamber

InactiveUS20090291035A1Total current dropReduce the risk of contaminationSemiconductor/solid-state device manufacturingEnergy based chemical/physical/physico-chemical processesEpoxyGlass fiber

A vacuum chamber 2 has walls having an inner layer 20 of a gas impermeable electrically non-conductive material and an outer layer 22 of a different electrically non-conducting material. The inner layer 20 is a polymeric film layer of Kapton® polyimide. The outer layer 22 is a composite material which includes reinforcing carbon or glass fibers bound in a matrix of epoxy resin. The vacuum chamber has end flanges for attaching it to adjacent parts of a vacuum system. The vacuum chamber is made by placing a sheet of Kapton® material around a mould and sealing its ends together. The composite material is then wound onto the inner layer in its wet form to provide the outer layer. The outer layer material is then cured to dry the epoxy resin, binding the layer to the inner layer, and the multi-layer structure removed from the mould. The vacuum chamber is particularly suitable for use in an ion implantation system in the presence of a time varying magnetic field.

Owner:TESLA ENG

Electronic package including high density interposer and circuitized substrate assembly utilizing same

InactiveUS8405229B2Semiconductor/solid-state device detailsSolid-state devicesElectrical conductorHigh density

An electronic package for interconnecting a high density pattern of conductors of an electronic device (e.g., semiconductor chip) of the package and a less dense pattern of conductors on a circuitized substrate (e.g., PCB), the package including in one embodiment but a single thin dielectric layer (e.g., Kapton) with a high density pattern of openings therein and a circuit pattern on an opposing surface which includes both a high density pattern of conductors and a less dense pattern of conductors. Conductive members are positioned in the openings to electrically interconnect conductors of the electronic device to conductors of the circuitized substrate when the package is positioned thereon. In another embodiment, the interposer includes a second dielectric layer bonded to the first, with conductive members extending through the second layer to connect to the less dense pattern of circuitized substrate conductors. Circuitized substrate assemblies using the electronic packages of the invention are also provided.

Owner:TTM TECH NORTH AMERICA LLC

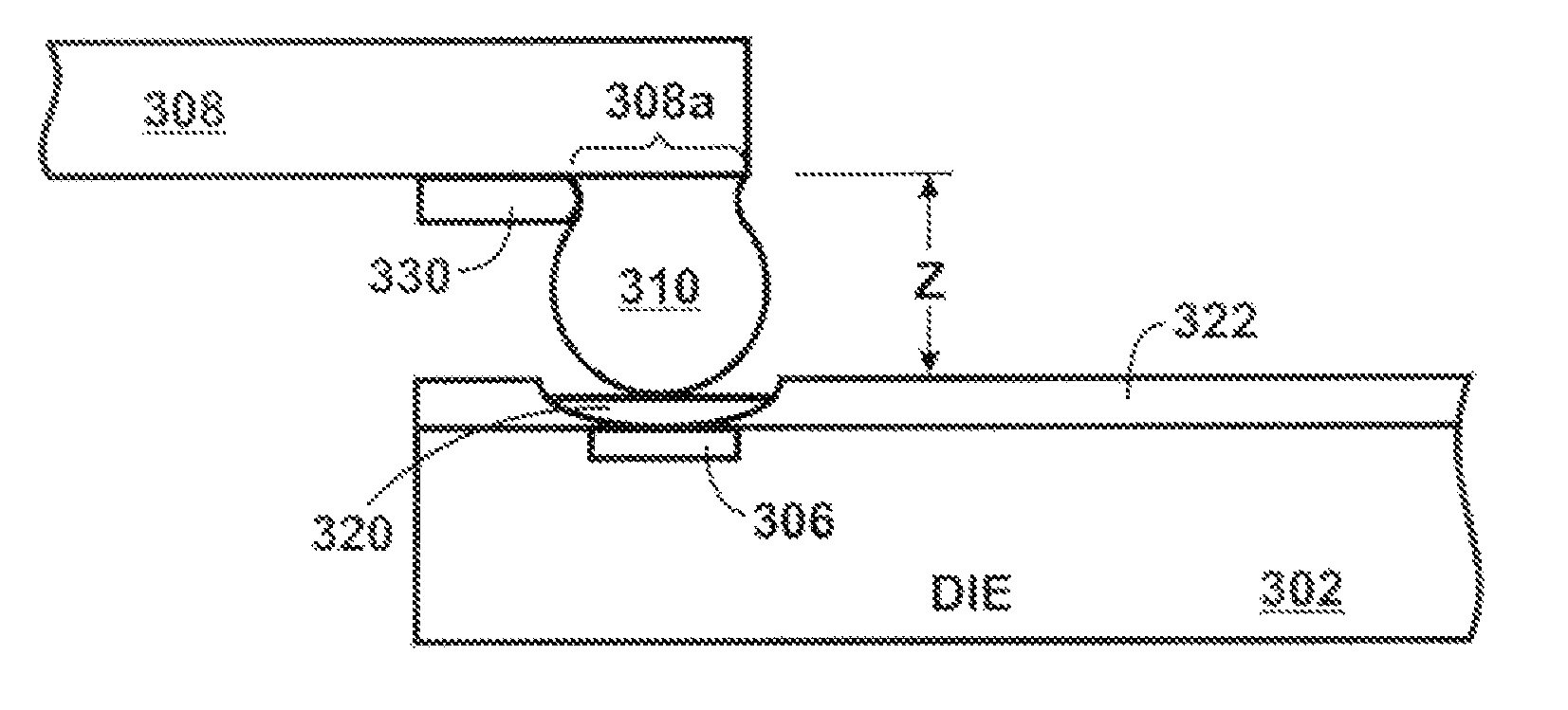

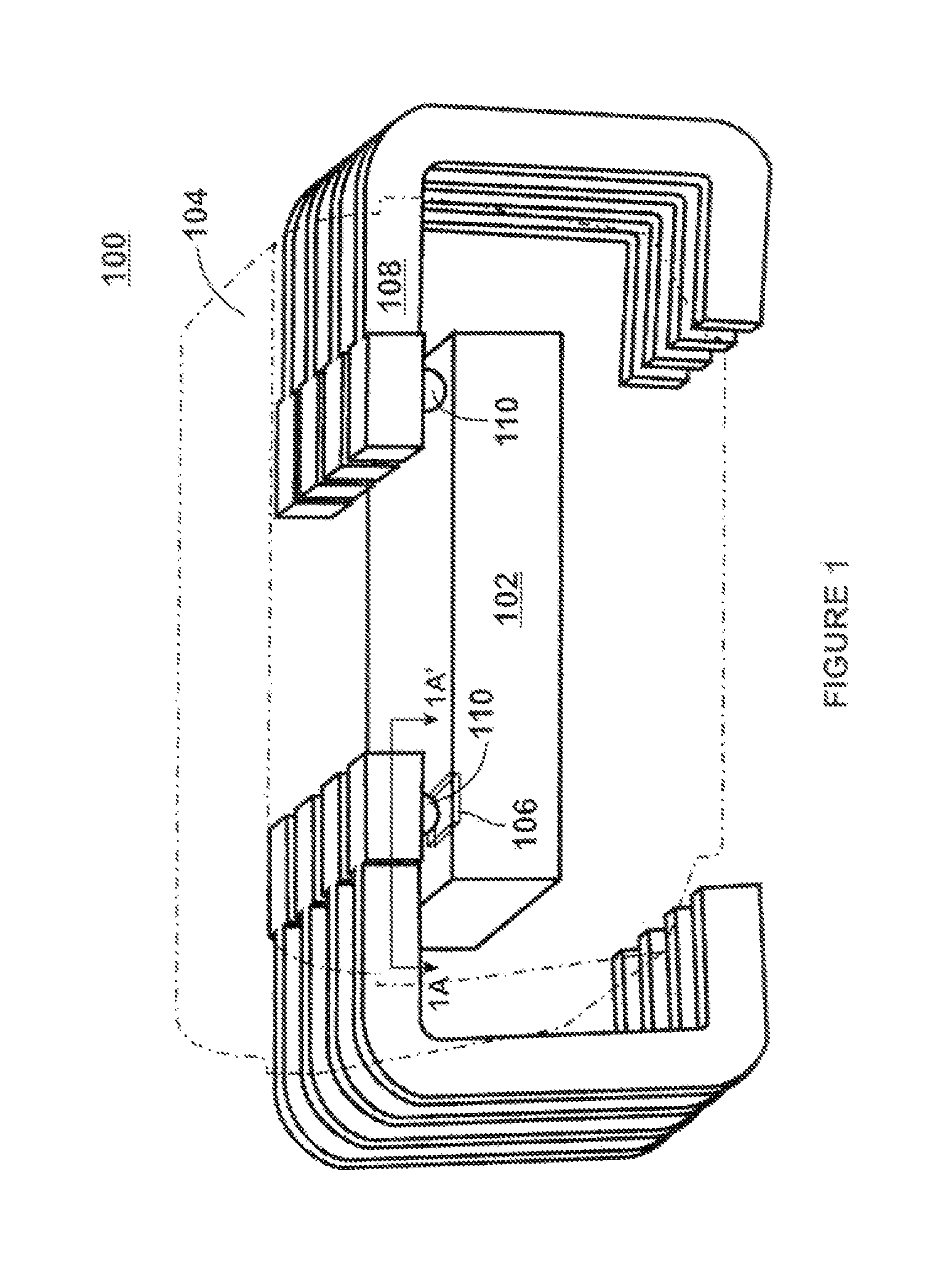

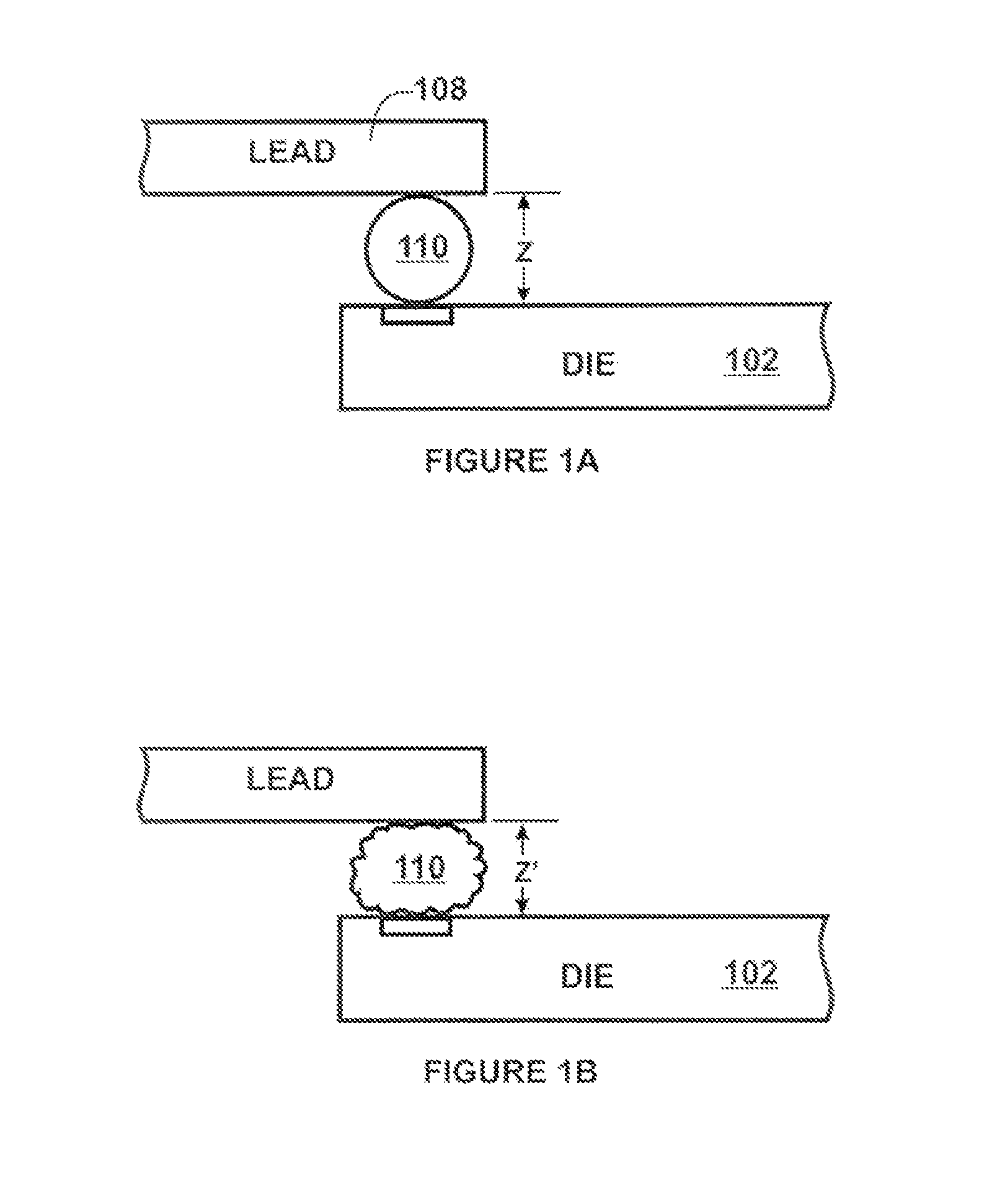

Interconnection of lead frame to die utilizing flip chip process

ActiveUS7691670B2Semiconductor/solid-state device testing/measurementSemiconductor/solid-state device detailsPlastic materialsSolder ball

Embodiments in accordance with the present invention relate to techniques which avoid the problems of deformation in the shape of a solder connection in a flip chip package, resulting from solder reflow. In one embodiment, a solder-repellent surface is created adjacent to the solder to constrain the reflow and thereby maintain the vertical profile of the solder. Examples of such a solder-repellent surface include an oxide (such as Brown Oxide) of the lead frame, or a tape (such as Kapton) which is used as a dam bar to control / constrain the solder flow on the leads prior to the encapsulation step. In another embodiment, the solder connection may be formed from at least two components. The first component may reflow at high temperatures to provide the necessary adhesion between solder ball and the die, with the second component reflowing at a lower temperature to provide the necessary adhesion between the solder ball and the leads. An example of such multi-component connections include a first high temperature reflow solder ball paired with a second low temperature reflow solder. Another example includes a solder ball with a hard core (such as Cu, stainless steel, or a plastic material stable at high temperatures) coated with a lower temperature reflow material.

Owner:GEM SERVICES

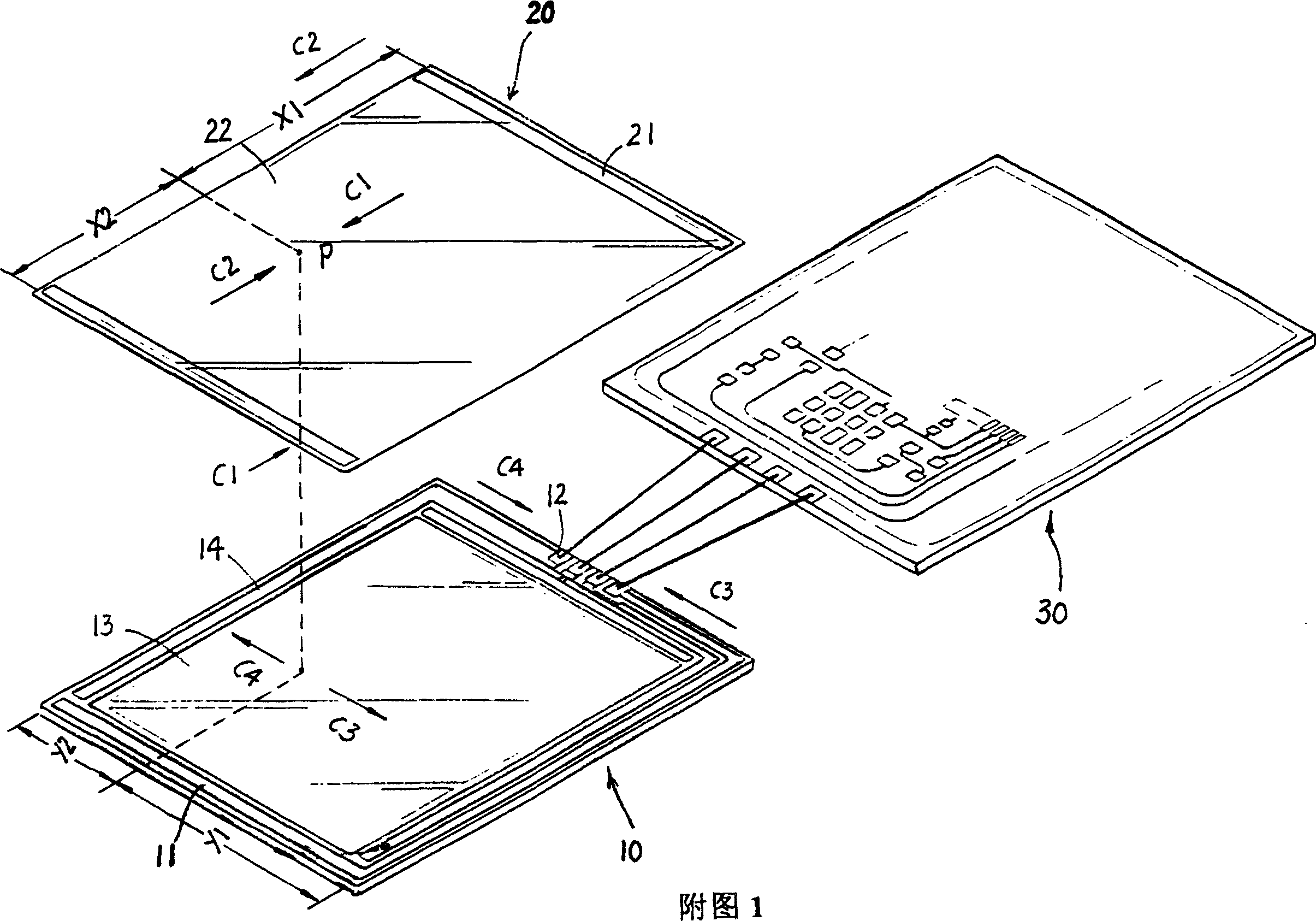

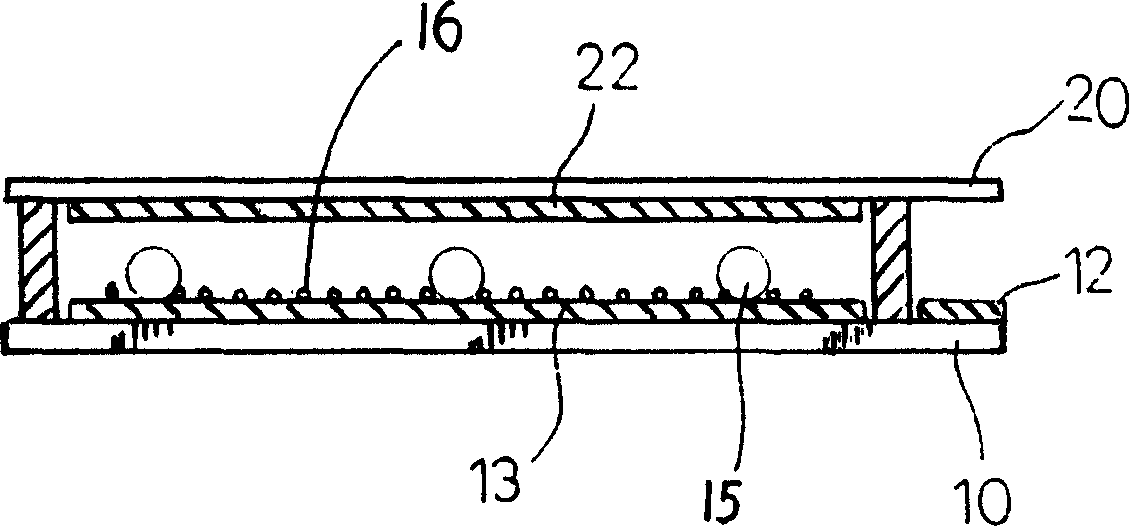

Thin type touch control panel

InactiveCN1567164AMerit manufacturingAdvantages usabilityInput/output for user-computer interactionTouch panelKapton

This invention relates to a input apparatus touch panel of electronic products, which comprises base plate and panel matched with the base plate, wherein, the opposite plate to them is located with high resistance conductive film with support points between. The said base plate is plastic plate or glass or electronic ceramics plate. The said panel is of PET or Nyloon or Kapton materials. The said high resistance conductive film is thin metal film or mixture film of synthetic resin and carbon glue with ultrathin metal power attached on surface. This invention can decreases the space occupied by the touch control panel in the electron products; decreases the touch resistance and improves the measuring accuracy of the system and makes great difference between flow measured values of the adjacent coordinates to improves the sensitivity of the system.

Owner:陈弘岳

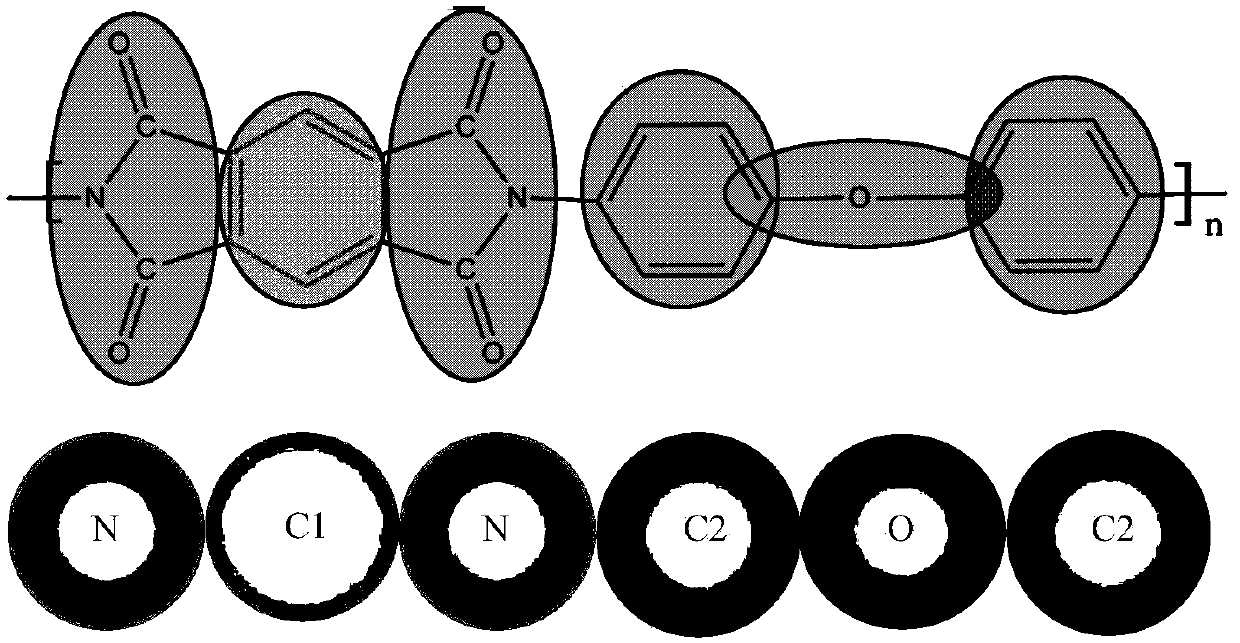

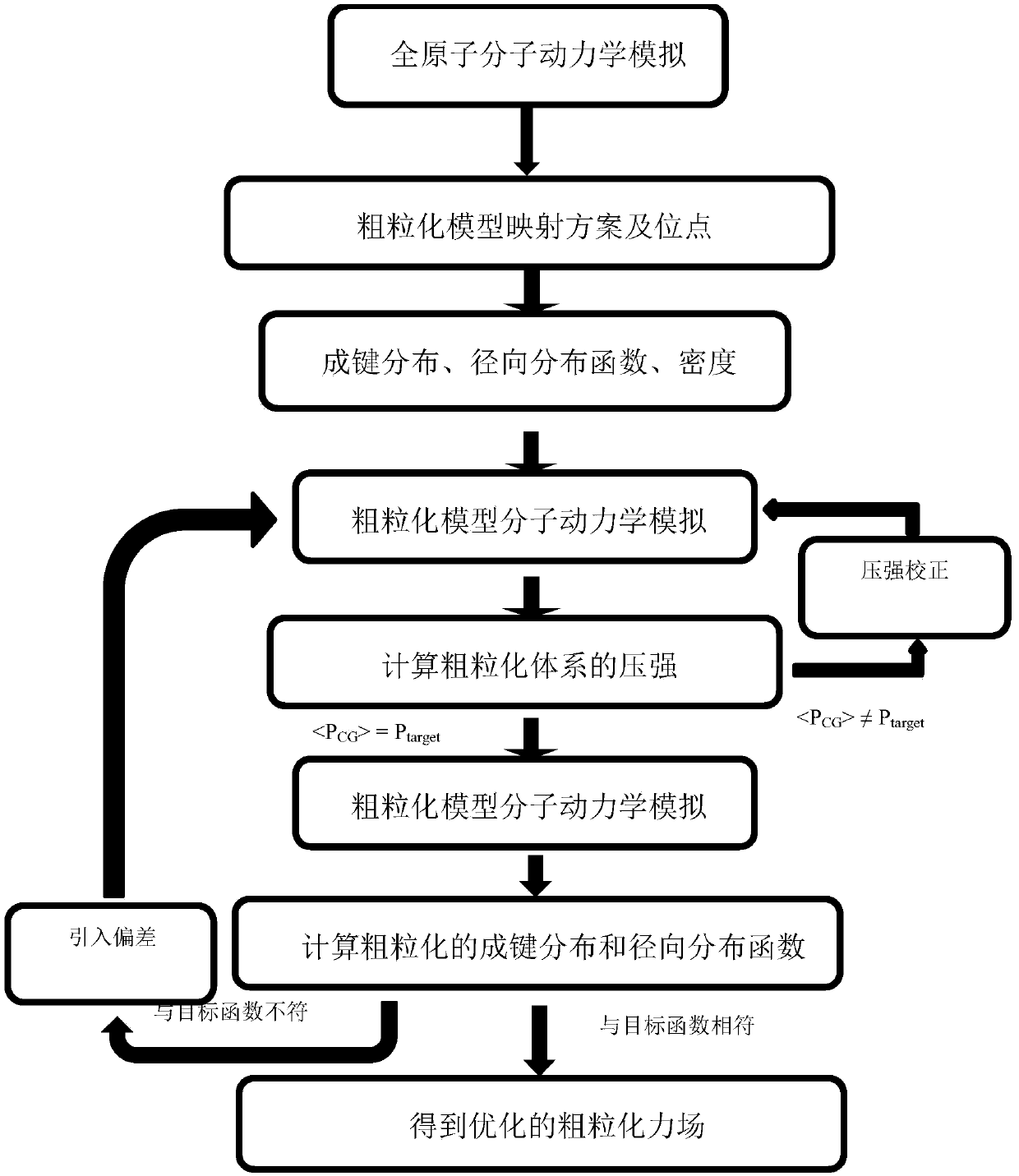

Model construction method for researching thermodynamic properties of repeated polyimide system by adopting system coarse graining molecular dynamics

Owner:INST OF CHEM CHINESE ACAD OF SCI +1

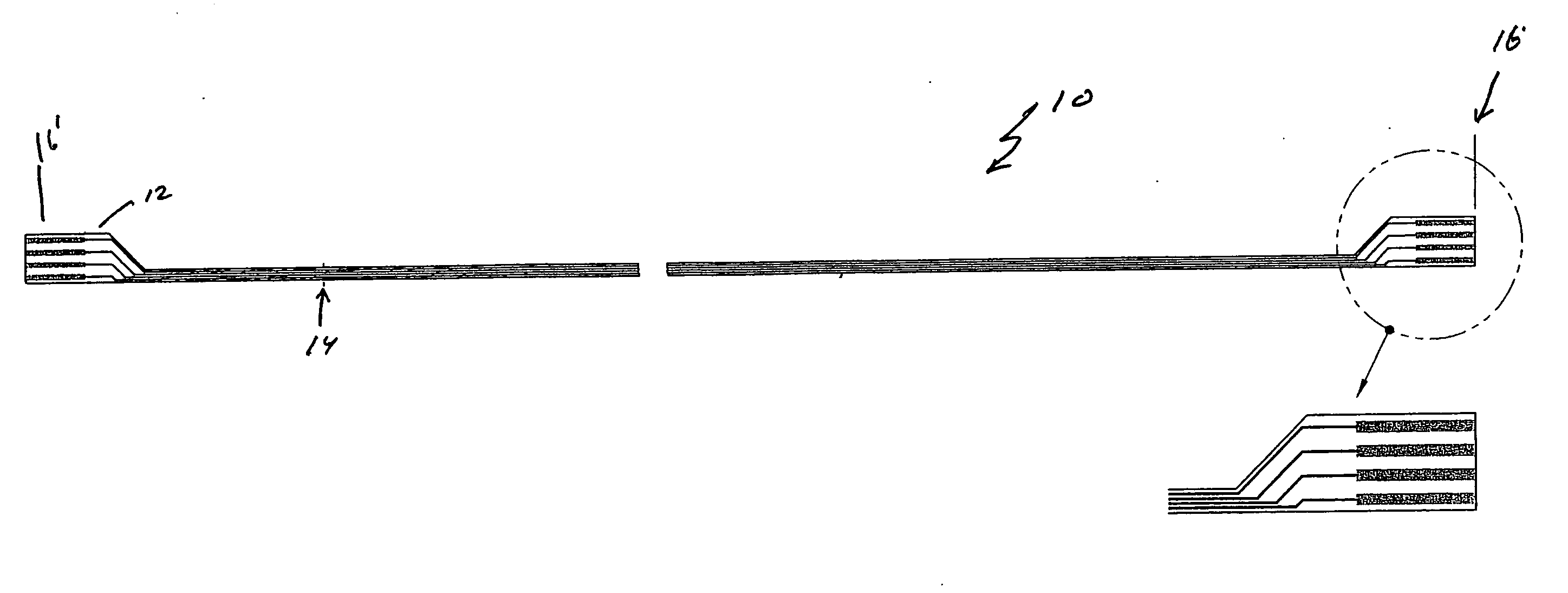

Method and apparatus for probing at arbitrary locations within an inaccessible array of leads the solder balls or pins actually connecting a VLSI IC package to a substrate or socket

InactiveUS20070176611A1Wider widthElectrical testingMeasurement instrument housingElectricitySolder ball

A probe for an array of interconnecting leads between a PCA and an IC has one or more contacts extending laterally from or plated upon one or more arms formed of a flexible printed circuit, and connected by traces along the arm(s) to a header that itself affords connection to measurement equipment. The flexible printed circuit is thin enough to loosely slide between the top of the PCA or PCB and the bottom of the IC. The arm or arms is / are narrow enough to slide between the adjacent leads forming the array, while the normally flat contacts will successively interfere with, to engage and electrically contact, consecutive layers of leads as the probe is progressively inserted. An arm is not so stiff that it cannot yield by a slight compressive warping as the contacts encounter leads. Indexing may be ‘by feel’ or by visible indicia along a top surface of the probe or by a reticle device that moves over the top of the IC, which then has a pattern of indicia corresponding to lead location. Forming the shape of a Kapton substrate may also include use of a CVL operating in the range of 250 nm to 290 nm for the creation of extended copper contacts by the removal of underlying Kapton. Plating processes may also be used in the fabrication of (non-extended) wrap-around contacts at the edges of the Kapton.

Owner:AGILENT TECH INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com