Patents

Literature

399 results about "Electronic ceramics" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Microwave dielectric ceramic material and preparation method therefor

ActiveCN106083033AHas the advantage of energy savingHigh quality factor QfTemperature coefficientElectronic ceramics

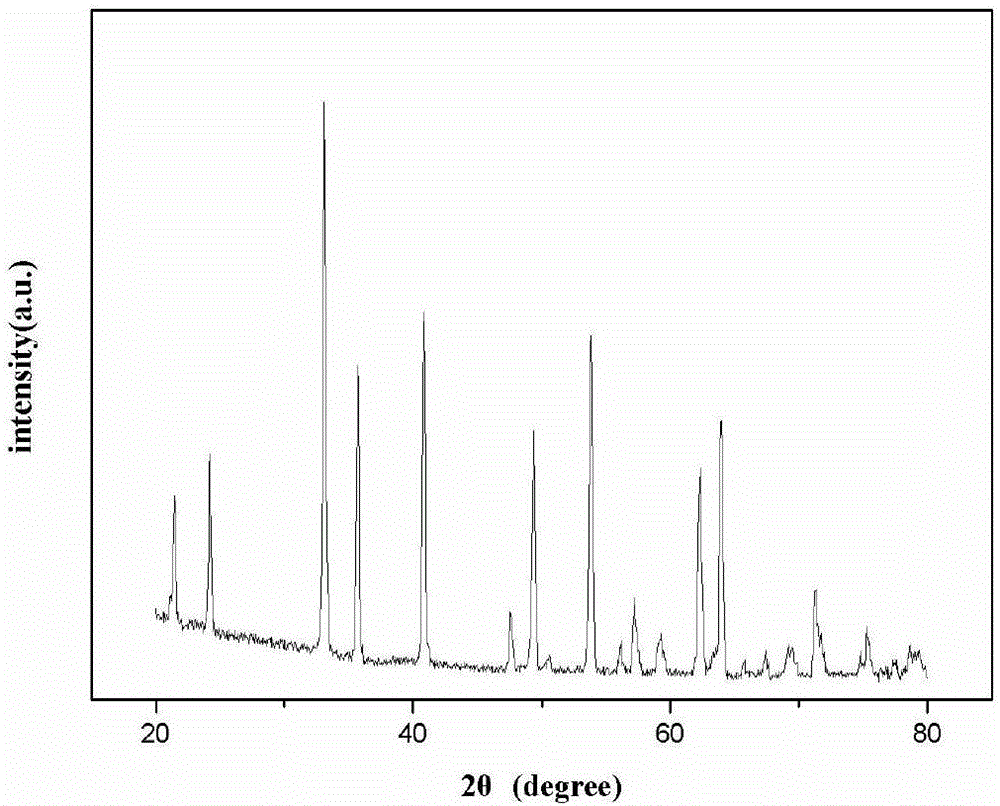

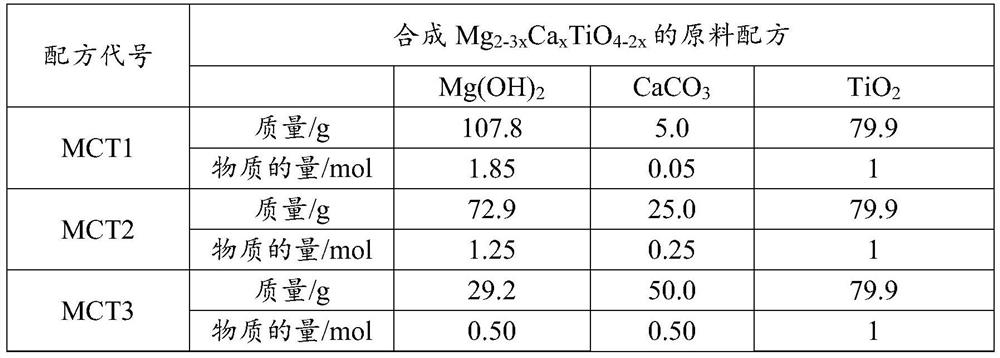

The invention discloses a microwave dielectric ceramic material and a preparation method therefor and belongs to the technical field of electronic ceramics. The ceramic material disclosed by the invention is prepared from (MgCa)TiO3 system ceramics and a composite burning improver through carrying out ball-milling mixing, granulating, shaping, binder burnout and sintering; a chemical formula of the (MgCa)TiO3 system ceramics is aMgTiO3.bCaTiO3, wherein a is greater than 0.92 and is smaller than 0.98, and b is greater than 0.02 and is smaller than 0.08; and the composite burning improver contains Al2O3, ZnO and Nd2O3. According to the ceramic material prepared by the preparation method, a Q*_f value is 71,000GHz to 82,000GHz, a relative dielectric constant [epsilon]r is 19 to 21, and a temperature coefficient of resonance frequency is + / -10ppm per DEG C; and the microwave dielectric ceramic material disclosed by the invention is simple in preparation process, is easy to produce industrially and can be extensively applied to microwave devices such as wave filters and oscillators.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

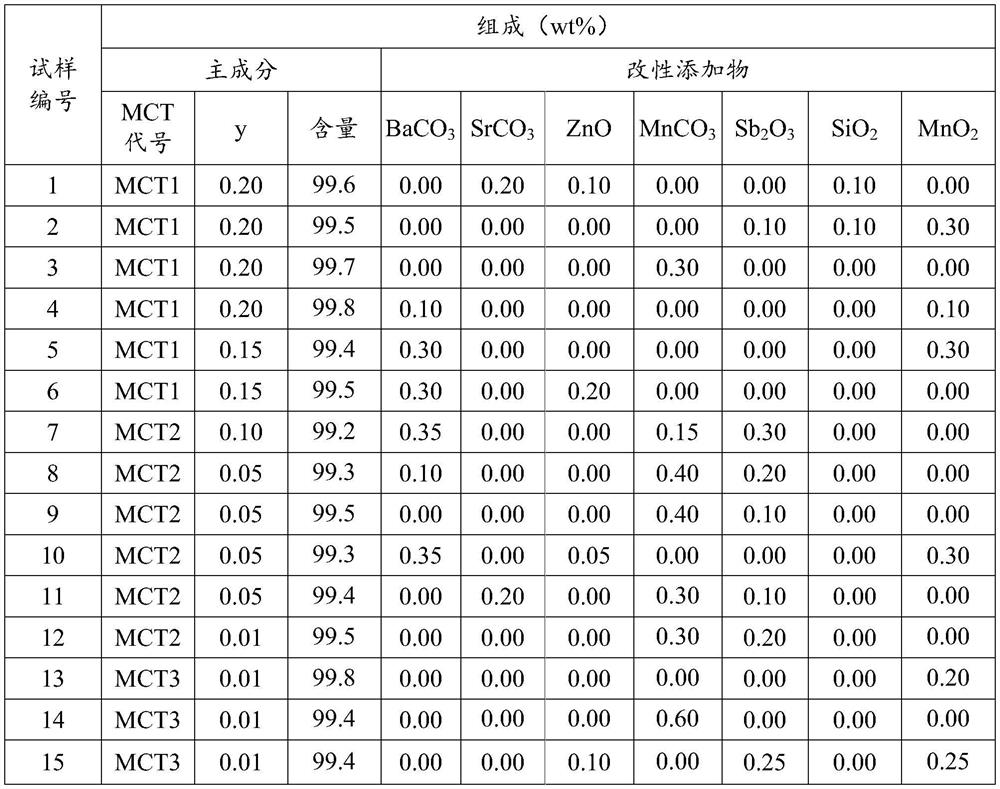

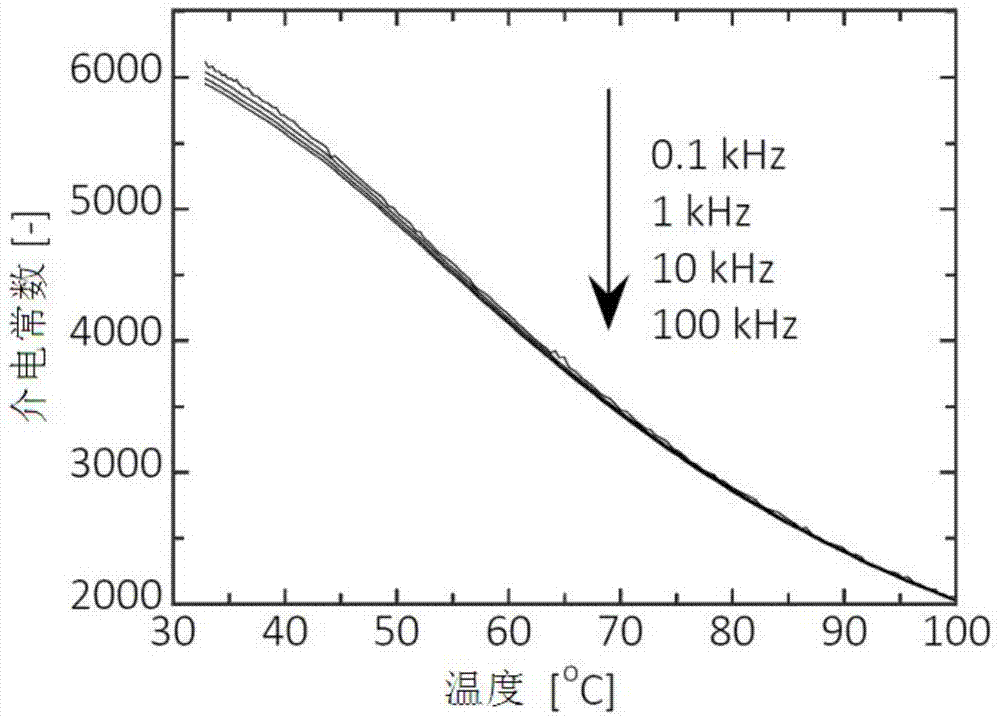

Heat sensitive resistor for high Curie temperature BaTiO3 base positive temperature coefficient and its making method

InactiveCN101188156AAchieve lead-freeReduce synthesisPositive temperature coefficient thermistorsElectrical resistance and conductanceMixed materials

The invention relates to a BaTiO3 group positive temperature coefficient thermistance and a preparation method thereof, wherein, the BaTiO3 group positive temperature coefficient thermistance has high Curie temperature. The invention belongs to the electronic ceramics technique. The recombination positive temperature coefficient thermistance is composed of main materials and assistant materials. The mol ratio of TiO2 and (BaCO3+SrCO3+Bi2O3+Na2CO3) of the main materials is 1:1. The mol components of the assistant materials are that Nb2O5 is 0.0011; TiO2 is 0.01; Sb2O3 is 0.0006; MnO2 is 0.0004; SiO2is 0.005; Al2O3 is 0.0017. The preparation process comprises that materials are weighed and mixed according to the mol prescription; the mixed materials are processed with ball milling after being added with water, and preparative complex materials are made through drying and heat preservation. The preparative complex materials are again added with raw materials, and then the preparative complex materials are processed with ball milling after being added with the water, thus the positive temperature coefficient thermistance is made through drying, granulation, foliation and baking. The invention has the advantages that the process of the composite (Na0.5Bi0.5)TiO3 is simple; the made positive temperature coefficient thermistance is unleaded and environment-friendly.

Owner:TIANJIN UNIV

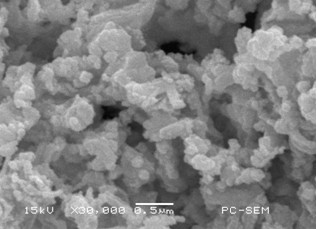

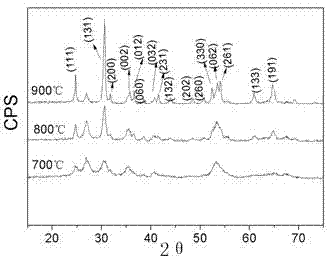

Preparation process for superfine powder of zirconium oxide

InactiveCN1559982AUniform particle size distributionNarrow particle size rangeZirconium oxidesGranularityMetallic materials

The invention relates to a ultrafine zirconium oxide (ZrO2) powder preparing method. ZrO2 is a high temperature-resistant, wearable, corrosion-resistant inorganic nonmetallic material, the proper-sized ultrafine ZrO2 powder is an important chemical raw material to prepare high-performance refined ceramics, like electronic ceramics, functional ceramics, structural ceramics, etc. and has increasingly wide applications in the technical fields of aviation, spaceflight, machinery, chemical engineering, electronics, automobiles, energy sources, etc. It adopts zirconium oxychloride and salvolatile as precursor raw material, uses uniform codeposition method to prepare wet ZrO2 gel, then drying at 100-150 deg.C at 0.3-1.0 MPa, and burning at 700-1000 deg.C to make ultrafine ZrO2 powder. It can obtain the ultrafine ZrO2 powder, particle size 0.1-0.5 mum, specific surface area 15-30 sq m / g and distribution range of particle size narrow. The ultrafine ZrO2 powder properly acts as the chemical raw material for refined ceramics.

Owner:HARBIN ENG UNIV

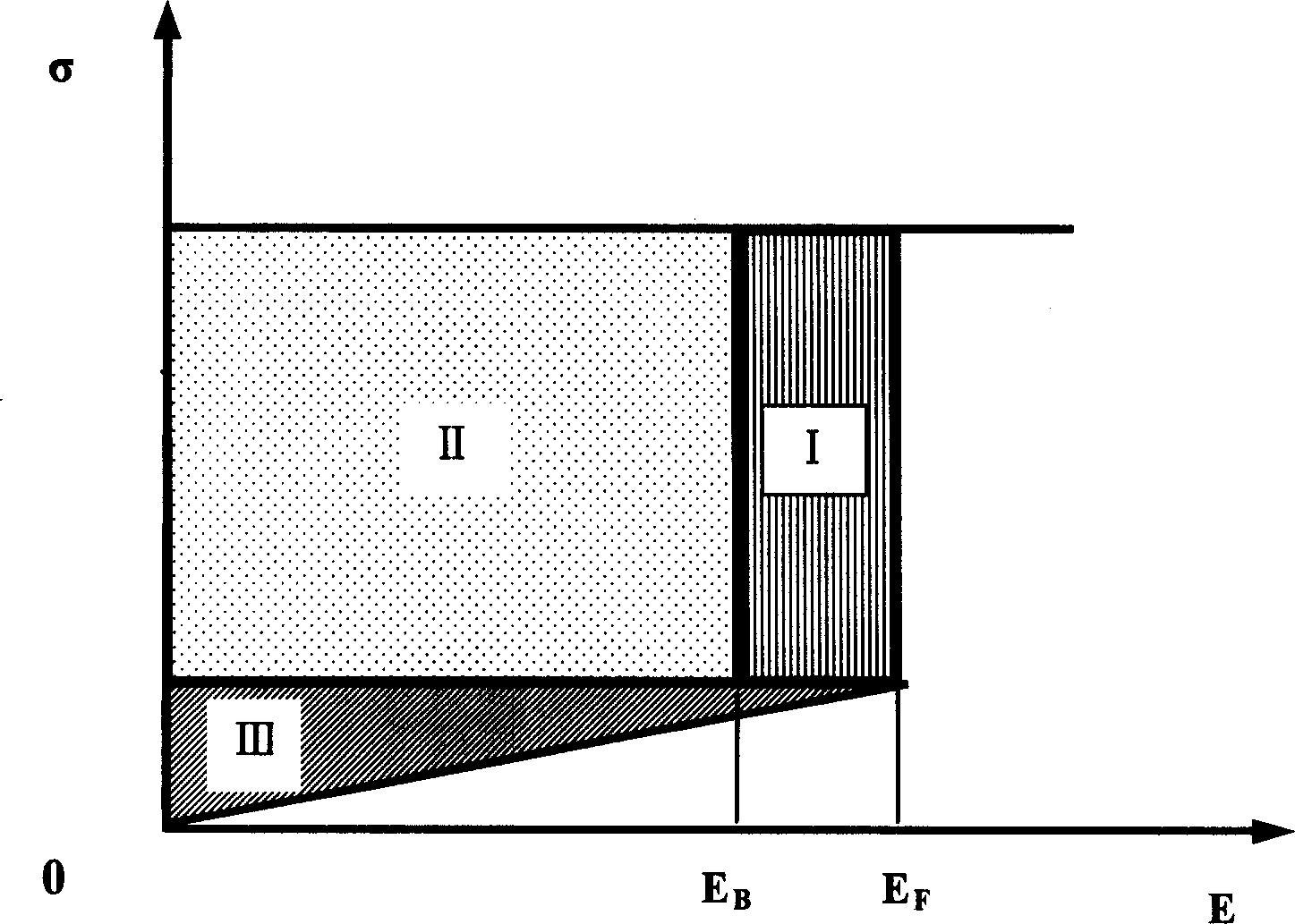

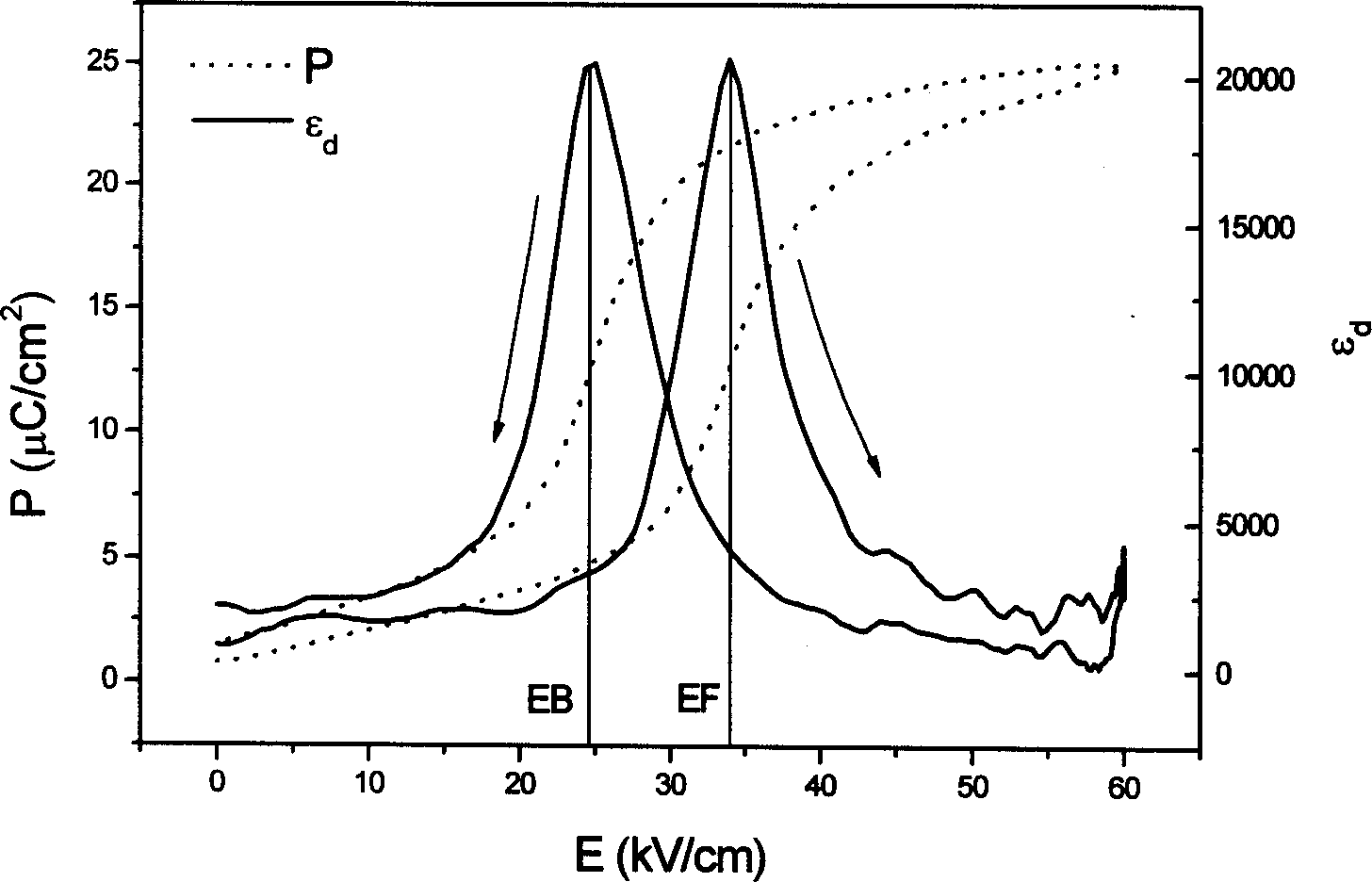

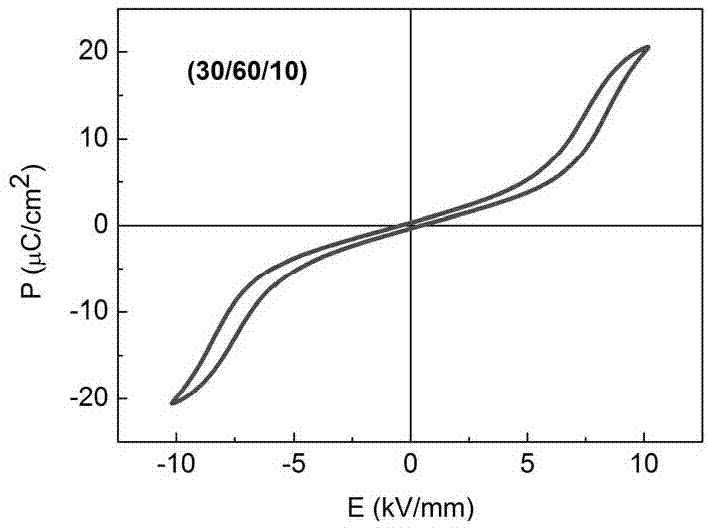

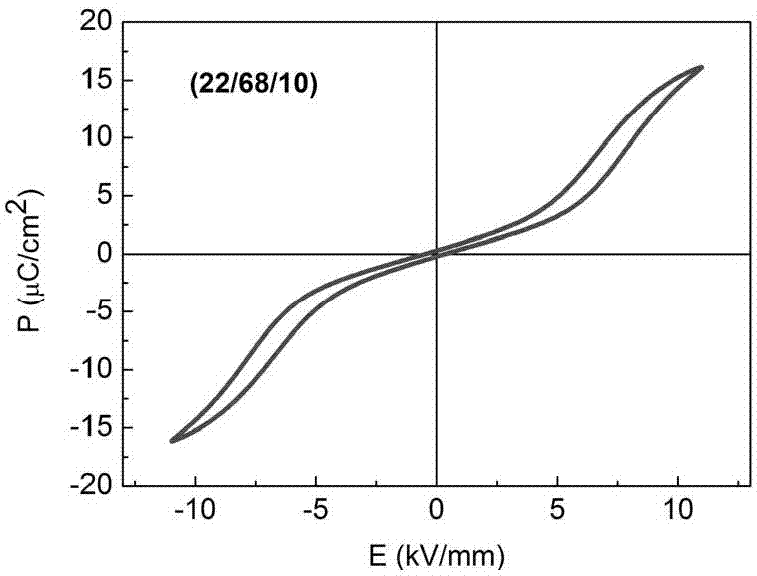

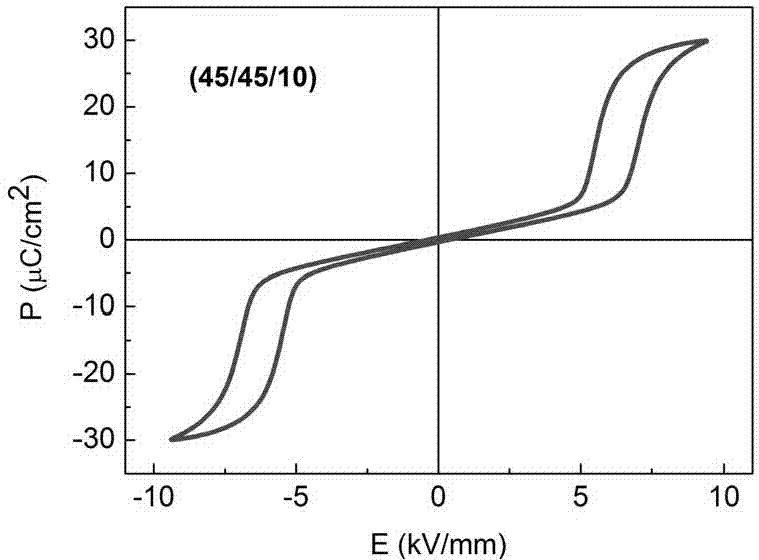

Dielectric nonlinear capacitor ceramic material and its making technique

InactiveCN1688004AHigh energy storage densityIncrease the number of cyclesFixed capacitor dielectricCeramicsLead zirconate titanateStrontium

This invention discloses an anti-ferroelectric ceramic capacitor material and its preparation technology, which applies Sn of positive four valency to replace Zr of positive 4 valency, applies the positive 3 valency La to replace 2 valency Pb in the compound of Pb(Zr, Ti) O3 to form a multi-component solid solution with Pb vacancy. The balanced formula of the charge and the valency is: (Pb1-3 2 / 2Laz)[(Zri-ysny)1-Tix]O3, in which, x varies between 0.06`0.20, y: 0.2010.40, z varies between 0.02-0.08, or positive 2 valency Sr or Ba is added to replace 2 valency Pb in Pb(zr, Ti) O3, the formula is [(Pb1-wBw)1-3z / 2Laz][Zr1-ySny]1-xTix ]O3, B expresses Sr or Ba of 2 valency, w varies between 0.02-0.12. A conventional electronic ceramic preparation method is applied in the method.

Owner:XI AN JIAOTONG UNIV

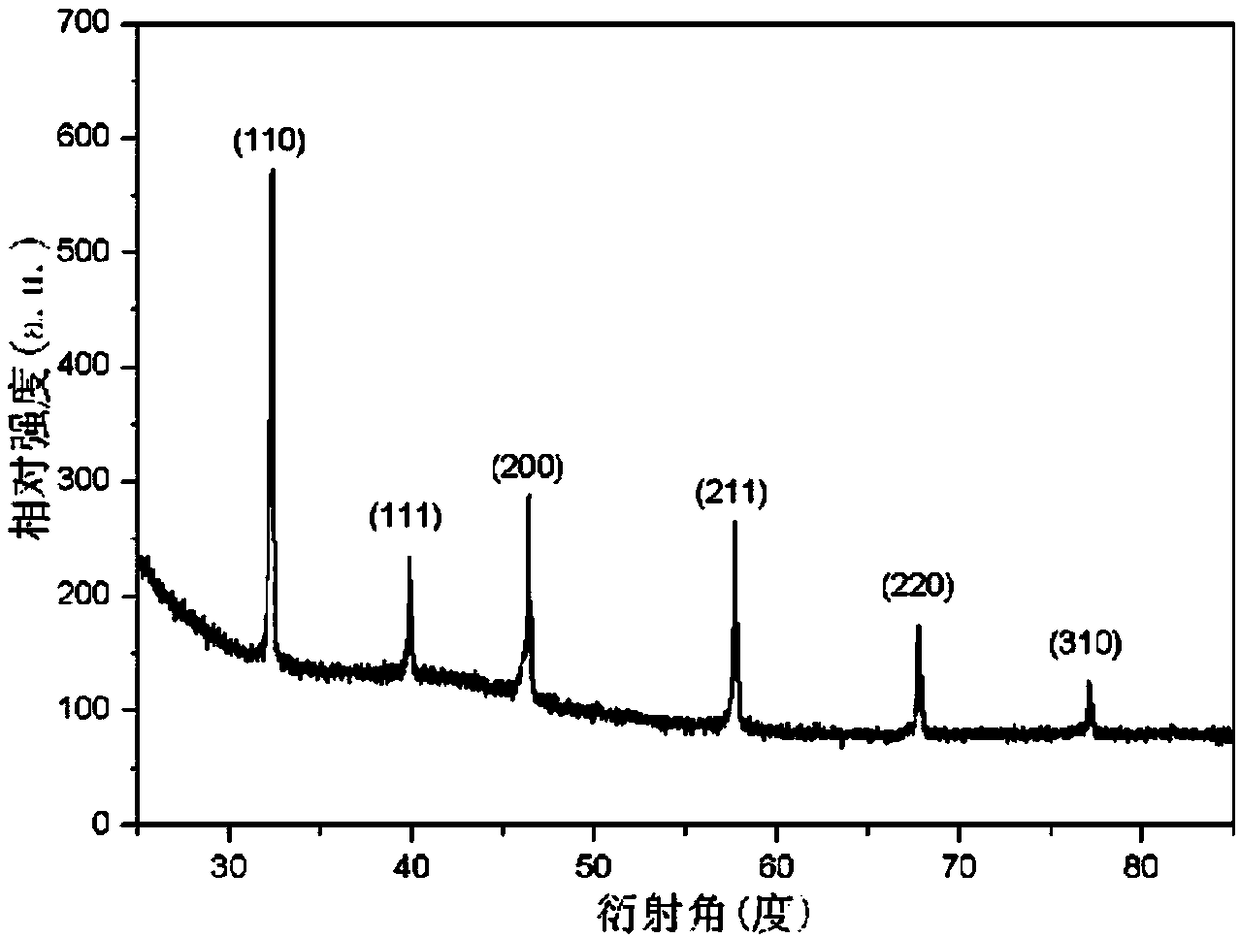

Preparation method of perovskite-like varistor ceramic material CaCu3Ti4O12 with high dielectric constant

ActiveCN102432062AOvercome energy consumptionOvercome granularityTitanium compoundsNitrateVaristor ceramics

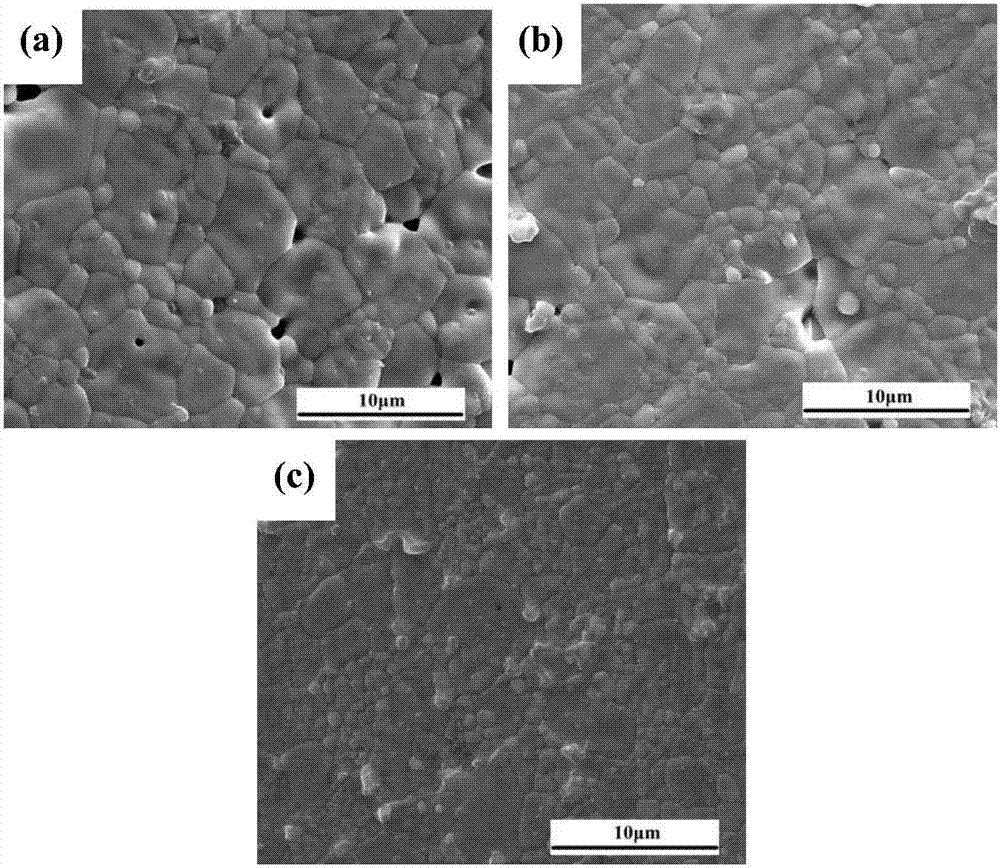

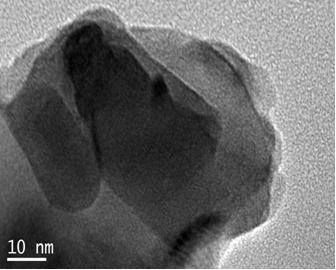

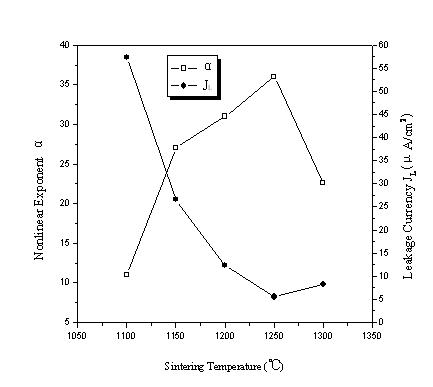

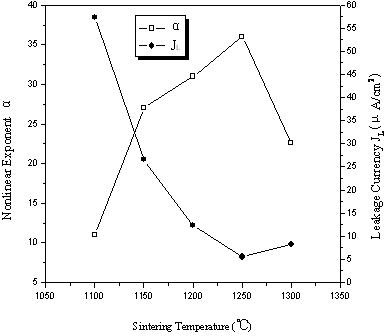

Belonging to the technical field of preparation and application of electronic ceramics, the invention relates to a preparation method of a perovskite-like varistor ceramic material CaCu3Ti4O12 (CCTO) with a high dielectric constant. With nitrates of Cu and Ca as well as Ti (OC4H9)4 as starting materials, the method of the invention combines a hydrothermal method for preparing nanometer CCTO powder so as to prepare high performance CCTO varistor ceramics, thus realizing the purposes of lowering temperature, and improving varistor as well as dielectric properties.

Owner:江苏津沂菊源生物健康产业研究院有限公司

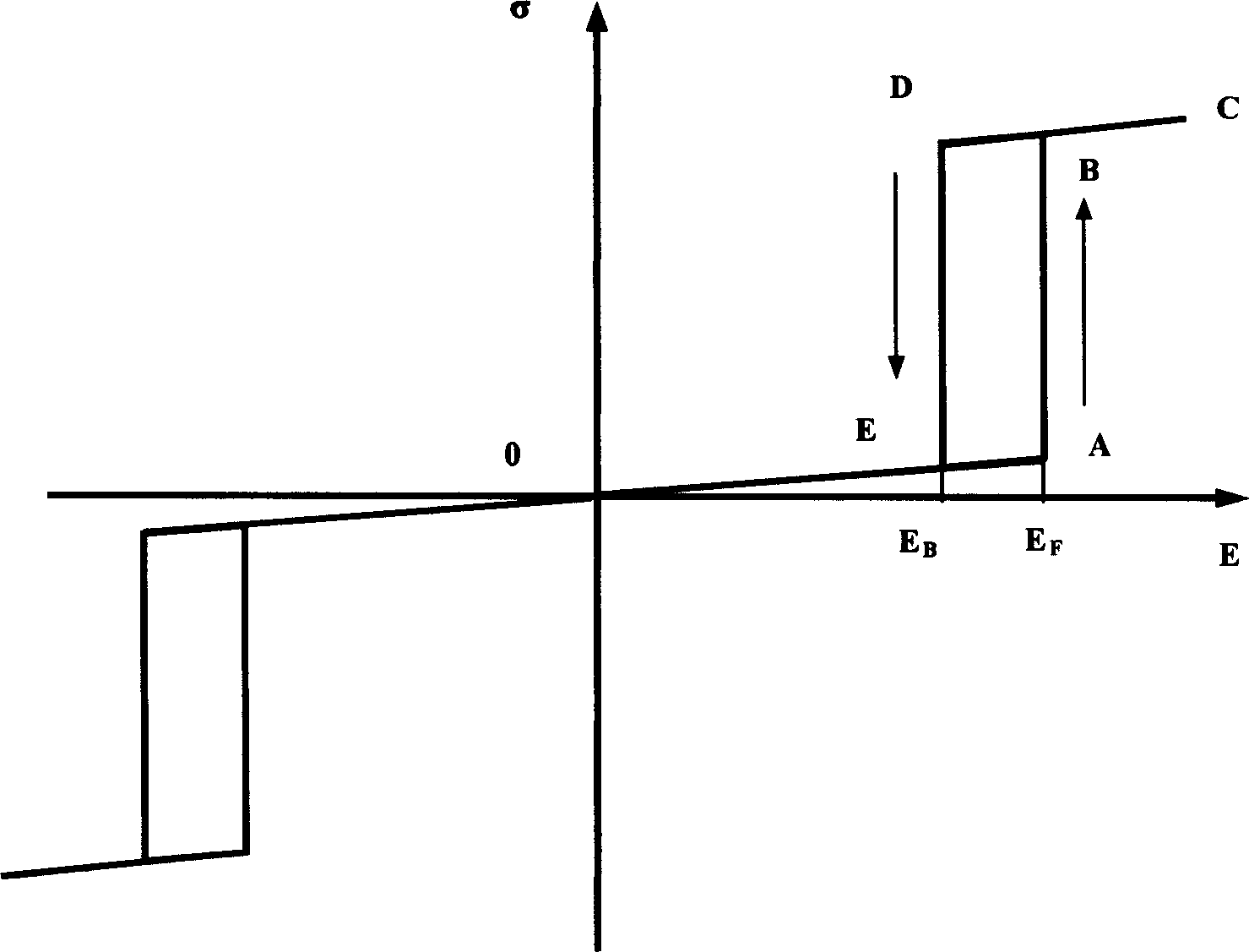

La-doped lead zirconate stannate titanate anti-ferroelectric ceramics with high energy storage efficiency and preparation method thereof

The invention relates to La-doped lead zirconate stannate titanate anti-ferroelectric ceramics with high energy storage efficiency and a preparation method thereof. The constitutional chemical formula of the anti-ferroelectric ceramics is (Pb1-1.5xLax)(ZrySn0.9-yTi0.1)O3, wherein x is greater than or equal to 0.02 and smaller than or equal to 0.04, and y is greater than or equal to 0.1 and smaller than or equal to 0.5. According to the preparation method, the anti-ferroelectric ceramics are prepared with a tradional preparation method of electronic ceramics, have the energy storage characteristics of small electric hysteresis and high energy storage efficiency, and have very important significance in developing a high-pressure impulse power capacitor with high energy storage density and high energy storage efficiency.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

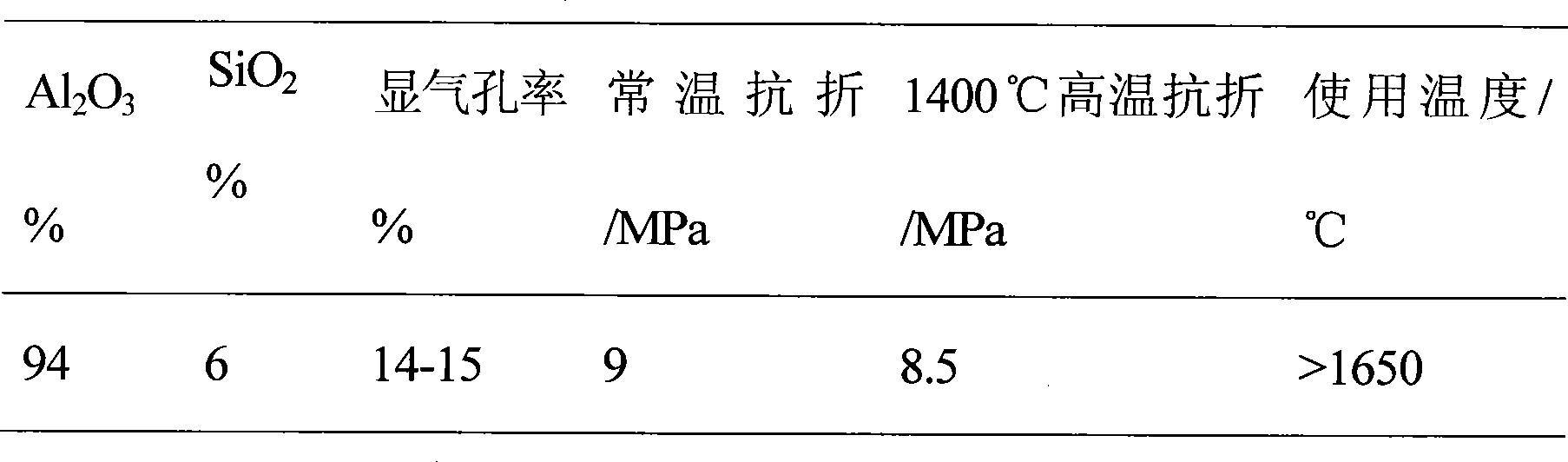

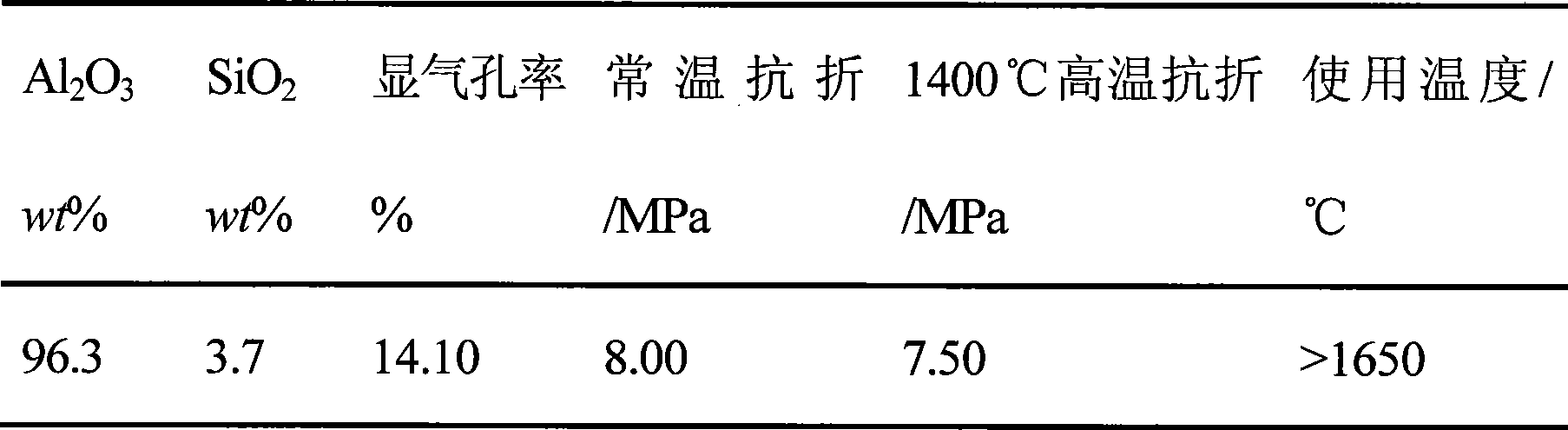

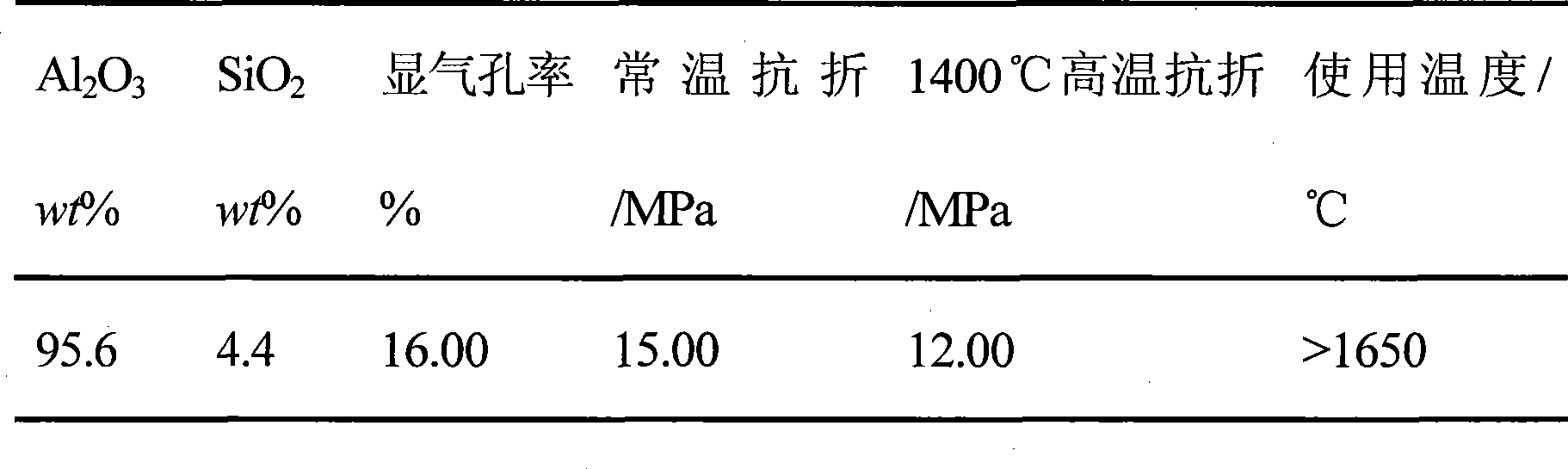

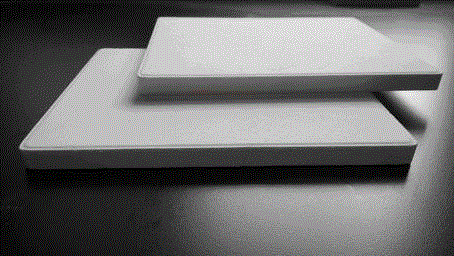

High temperature and creep resistance corundum-mullite load bearing board and preparation method thereof

ActiveCN101423414AIncrease temperatureImprove thermal shock resistanceMulliteHigh-temperature corrosion

The invention belongs to the technical field of ceramic kiln furniture and provides a corundum-mullite load bearing board and a preparation method. The corundum-mullite load bearing board comprises raw material compositions in the following mass percentage: 70 to 85 percent of alpha-Al2O3 particle material with the grain diameter of between 5 and 0.088 mm, 5 to 15 percent of alumina-silica sol fine powder with the grain diameter less than 0.08 mm, 5 to 15 percent of fused mullite fine powder with the grain diameter less than 0.088 mm, and 3 to 5 percent of bonding agent which is externally added. The characteristics of high purity and small particle size of alumina-silica sol are utilized to prepare the high-temperature creep-resistant load bearing board which has high purity and is formed by large-grained mullite bonded with corundum through high-temperature calcination, and the load bearing board does not deform and has good thermal shock resistance when the load bearing board is used at high temperature, and can be taken as the load bearing board used at a temperature higher than 1,650 DEG C in the fields of electronic ceramics and high temperature ceramics.

Owner:SINOSTEEL LUOYANG INST OF REFRACTORIES RES

Bismuth-based lead-free high energy storage density ceramic material and preparation method thereof

The invention discloses a bismuth-based lead-free high energy storage density ceramic material and a preparation method thereof, the material and the preparation method relate to the technical field of electronic ceramics and components, and are used in related fields of energy storage capacitor application. The chemical composition of the material conforms to the general formula: (1-x)Bi0.5Na0.5TiO3+x SrTiO3+ywt%Nb2O5, which is synthesized by traditional ceramic preparation process. Through the addition of Nb, the grain size of ceramics is refined, and the breakdown field strength is increased. The ceramic components can obtain Wrec-1.8J / cm3 energy storage density under a direct current field of E = 13kV / mm, and the energy efficiency eta can reach 80 %; and meanwhile, the material has good temperature stability of energy storage performance.

Owner:INST OF OPTICS & ELECTRONICS - CHINESE ACAD OF SCI

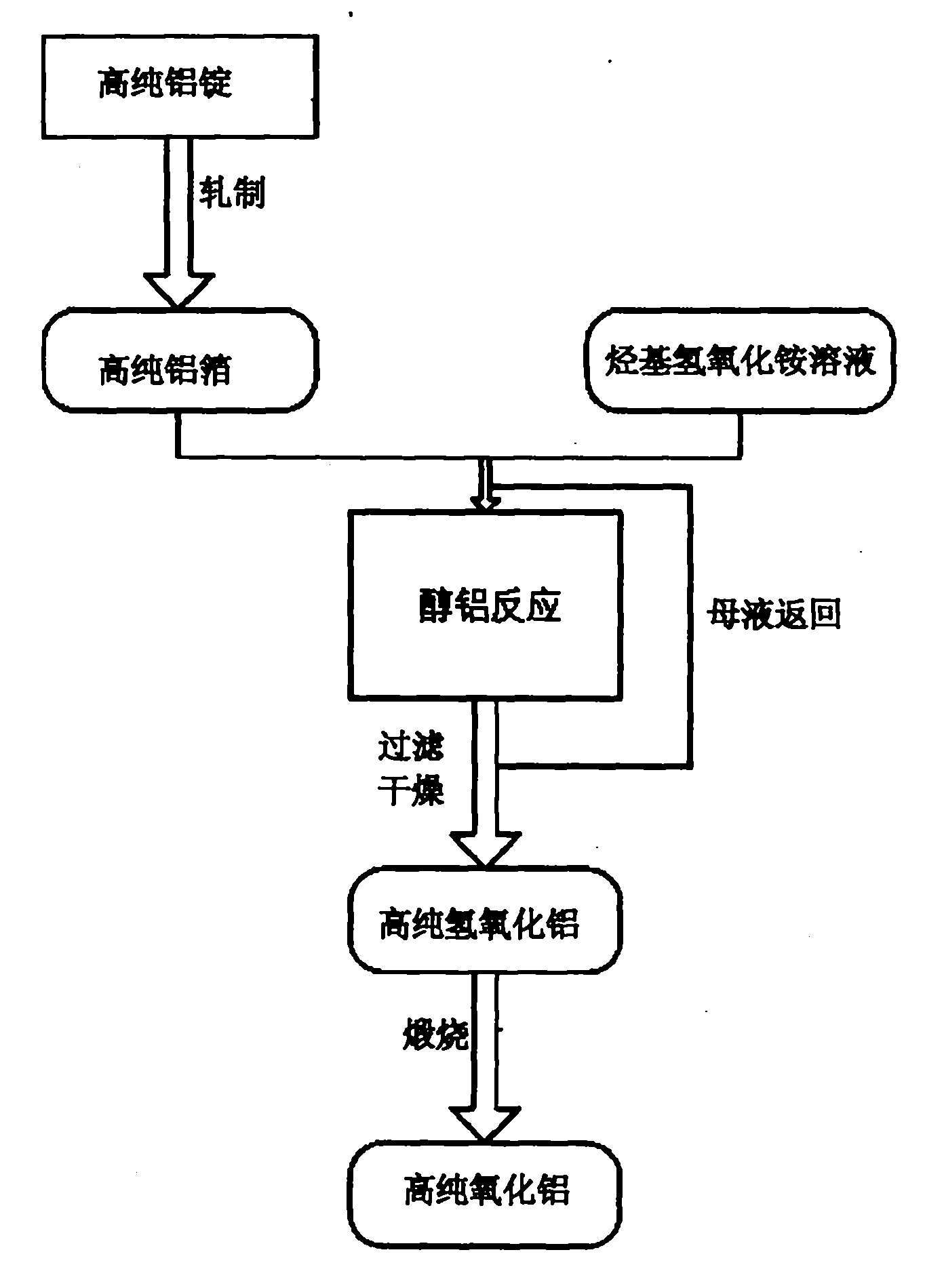

Preparation method of high-purity aluminum oxide

ActiveCN103523810ANo emissionsAvoid enteringAluminium oxide/hydroxide preparationAluminium hydroxideControllability

The invention provides a preparation method of high-purity aluminum oxide, which is mainly characterized by comprising the following steps: reacting high-purity aluminum and an electronic grade alkyl ammonium hydroxide solution to generate organic aluminum complex salt; further hydrolyzing the organic aluminum complex salt to obtain aluminum hydroxide and the alkyl ammonium hydroxide; and filtering the generated aluminum hydroxide, washing, performing vacuum drying, and performing high-temperature calcination to obtain high-purity aluminum oxide powder. The preparation method has the advantages of short production flow, high process controllability, no environmental pollution, high product purity, low cost and the like. The high-purity aluminum oxide powder prepared by the method is applicable to the fields of LED (light-emitting diode) sapphires, laser crystals, electronic ceramics, special ceramics, luminescent materials and the like.

Owner:何礼君 +2

Base metal combination electrode of electronic ceramic component and manufacturing method thereof

ActiveUS20140339955A1Low costSimple processPiezoelectric/electrostrictive device manufacture/assemblyMolten spray coatingSilver pasteMetallic electrode

The present invention provides a base metal combination electrode of electronic ceramic component and manufacturing method thereof, wherein said base metal combination electrode comprises a first base metal electrode layer covering on two sides of said electronic ceramic chip and a second base metal electrode layer covering on said first base metal electrode layer, the manufacturing method for base metal combination electrode of electronic ceramic component comprises using thermal spray equipment to spray the electrode material to the surface of electronic ceramic chip. Comparing with using silver paste or copper paste only, it reduces the cost of electrode material without destroying the function of the electrode. The manufacturing method for base metal combination electrode of the present invention has simple technological process, high preparation efficiency and low cost, and it reduces the production cost of electrode of the electronic ceramic component on the whole.

Owner:LONGKE ELECTRONICS HUIYANG

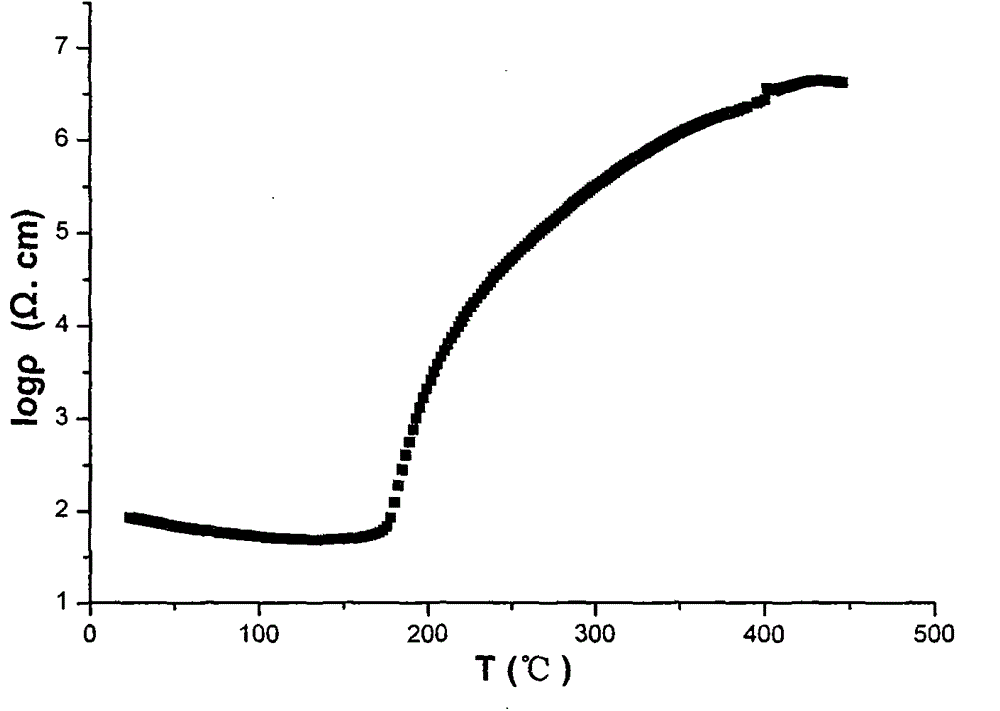

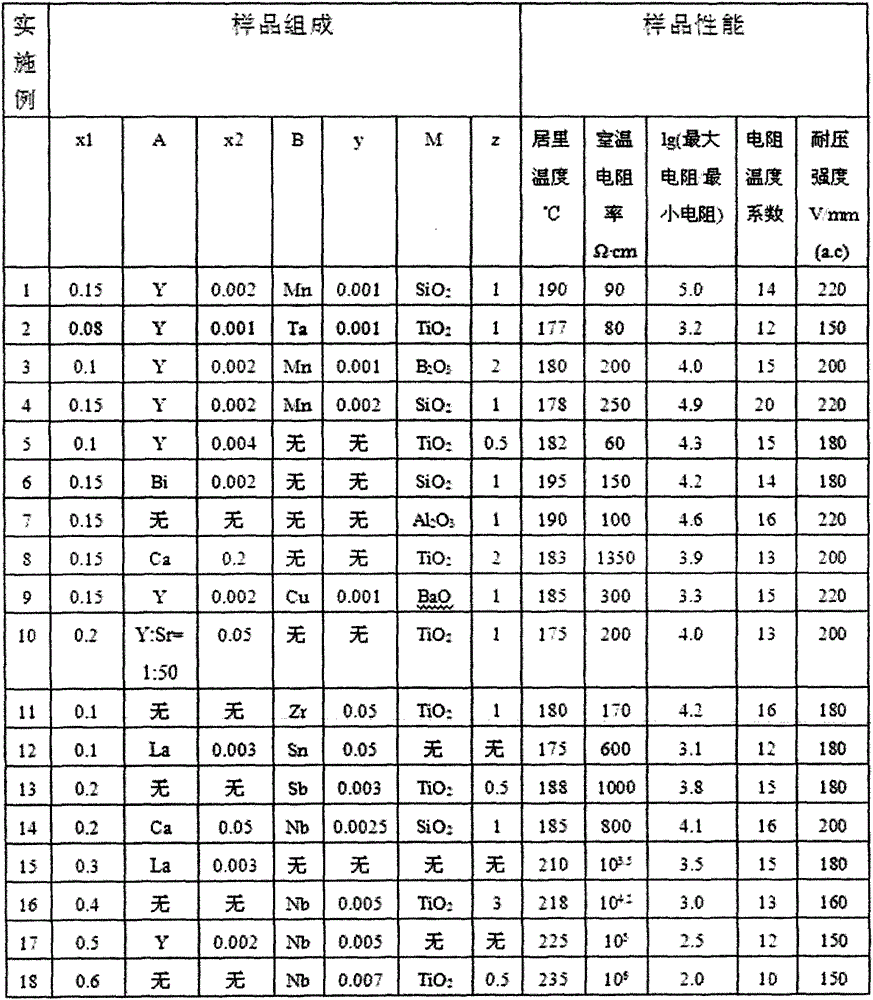

High use temperature lead-free PTCR (positive temperature coefficient resistance) ceramic and preparation method thereof

The invention discloses a high use temperature lead-free PTCR (positive temperature coefficient resistance) ceramic and a preparation method thereof, and belongs to the field of lead-free electronic ceramic materials. A general formula of the material composition is as follows: (Na0.5Bi0.5)x1 (Ba1-x1-x2Ax2) Ti1-yByO3+zmol%M), wherein x1 is greater than or equal to 0.08 and less than or equal to 0.6, x2 is greater than or equal to 0 and less than or equal to 0.2, y is greater than or equal to 0 and less than or equal to 0.05, z is greater than or equal to 0 and less than or equal to 3, A is one or more of Sr, Ca, Bi, Y and La, B is one or more of Zr, Sn, Mn, Cu, Nb, Ta and Sb, and M is one or more of Al2O3, SiO2, TiO2, BaO and B2O3. The high use temperature lead-free PTCR ceramic prepared by method has the following performance indicators: Curie temperature is at 175 to 235 DEG C; resistance jump ratio is 2 to 5 orders of magnitude; room temperature resistivity is 60-106 Omega .cm; temperature coefficient of resistance is 10-20% / DEG C; and withstand voltage strength is 150-220V / mm (a.c.). A ceramic sample is prepared in nitrogen by one-step sintering method, and has the advantages of simple controllable process, stable material performance and good repeatability.

Owner:TONGREN UNIV

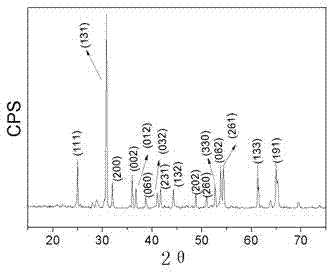

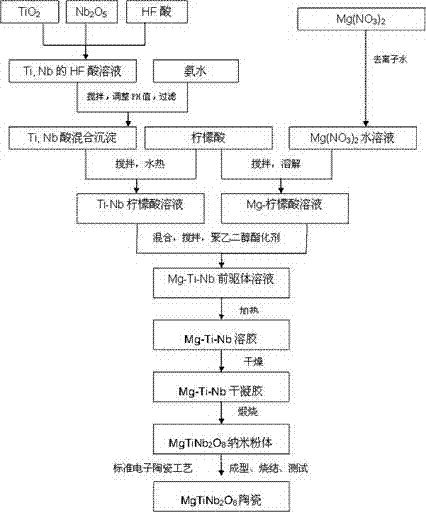

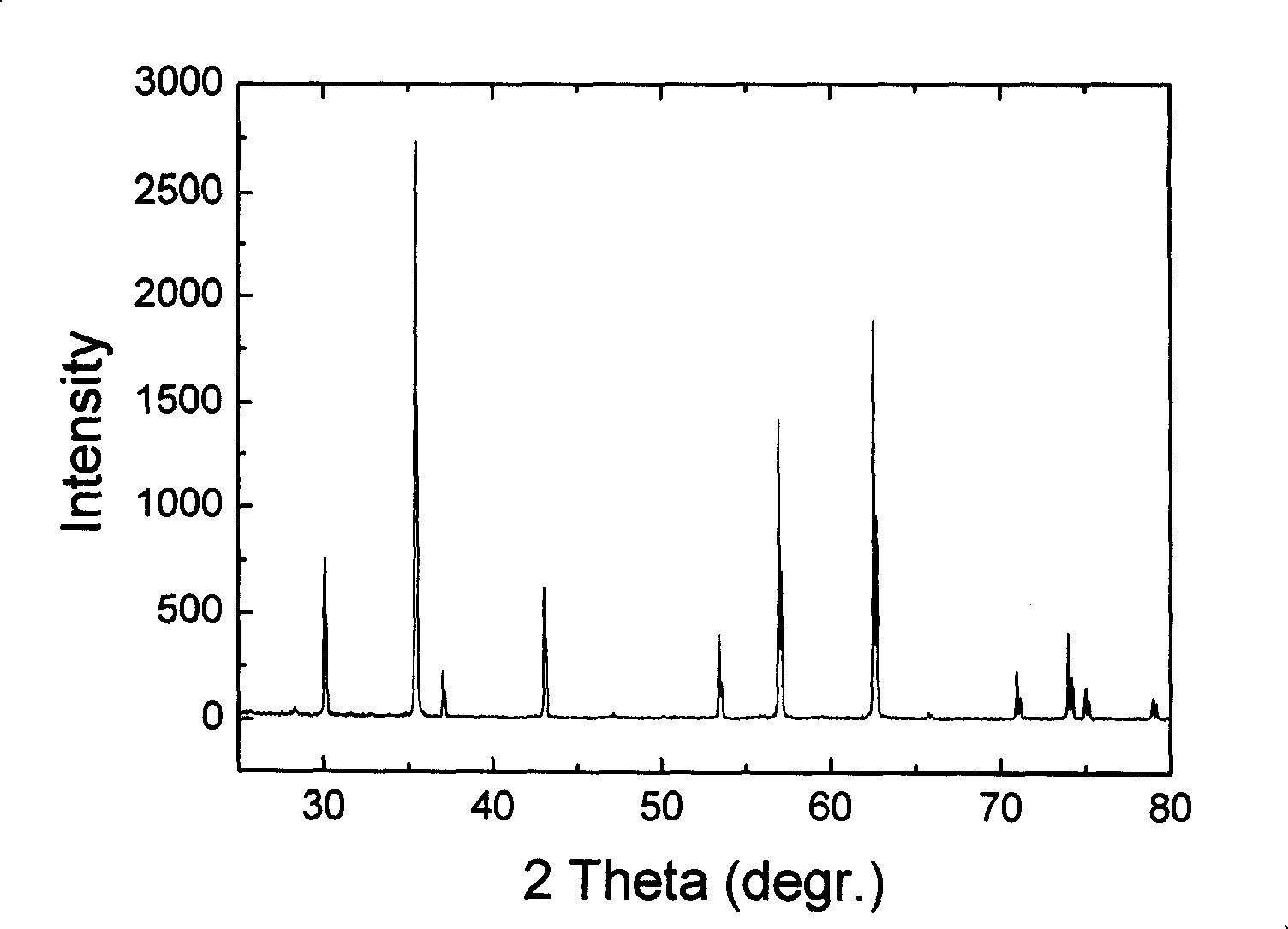

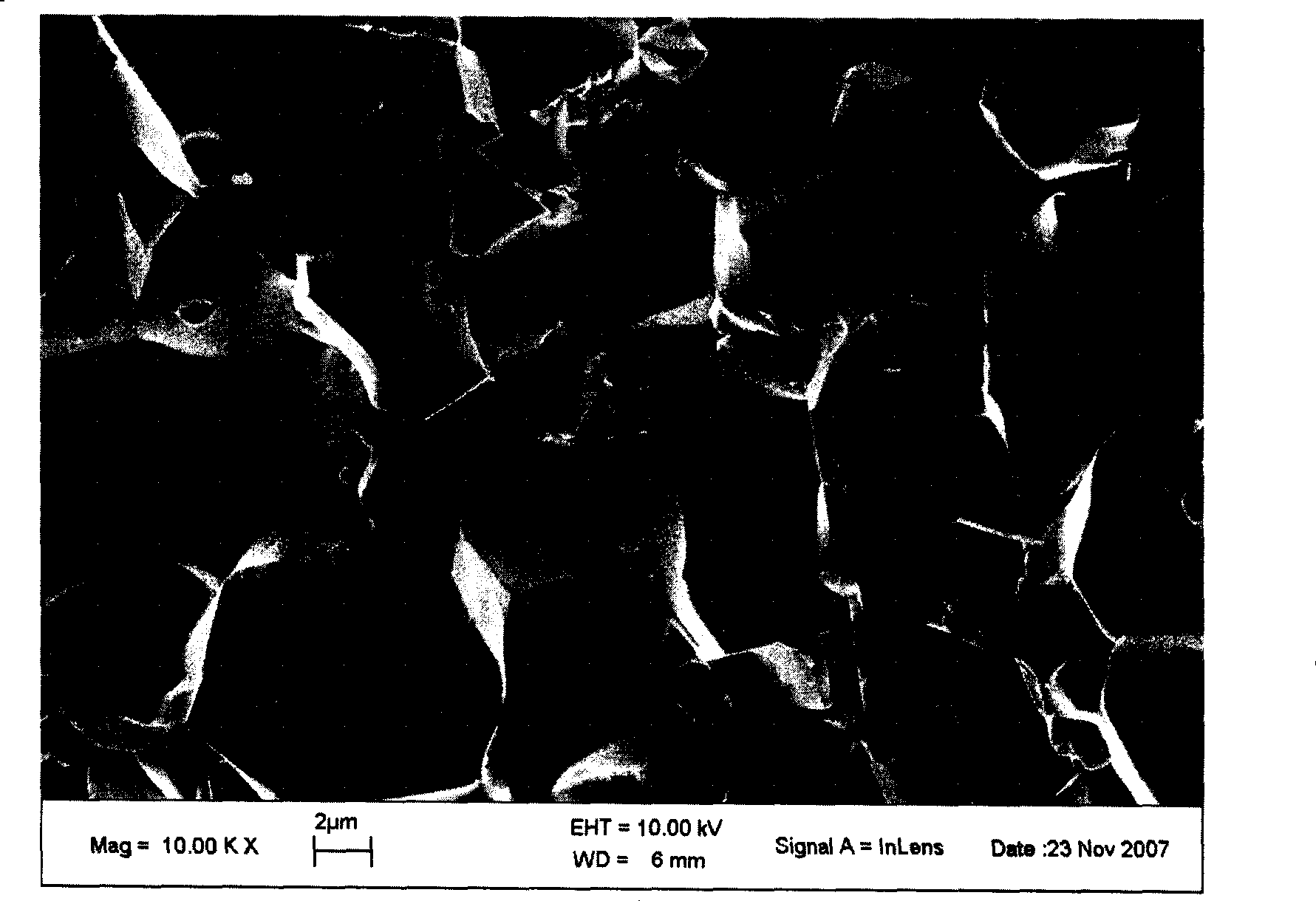

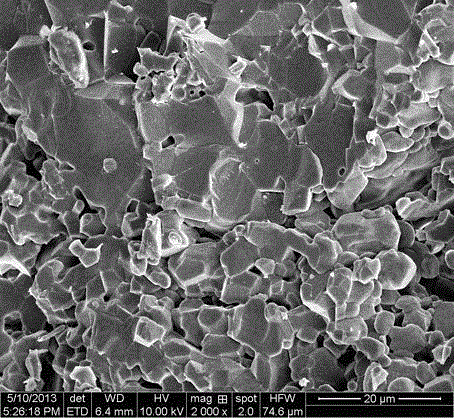

New method for finely preparing ixiolite structure MgTiNb2O8 microwave dielectric ceramic by using chemical process

Owner:UNIV OF JINAN

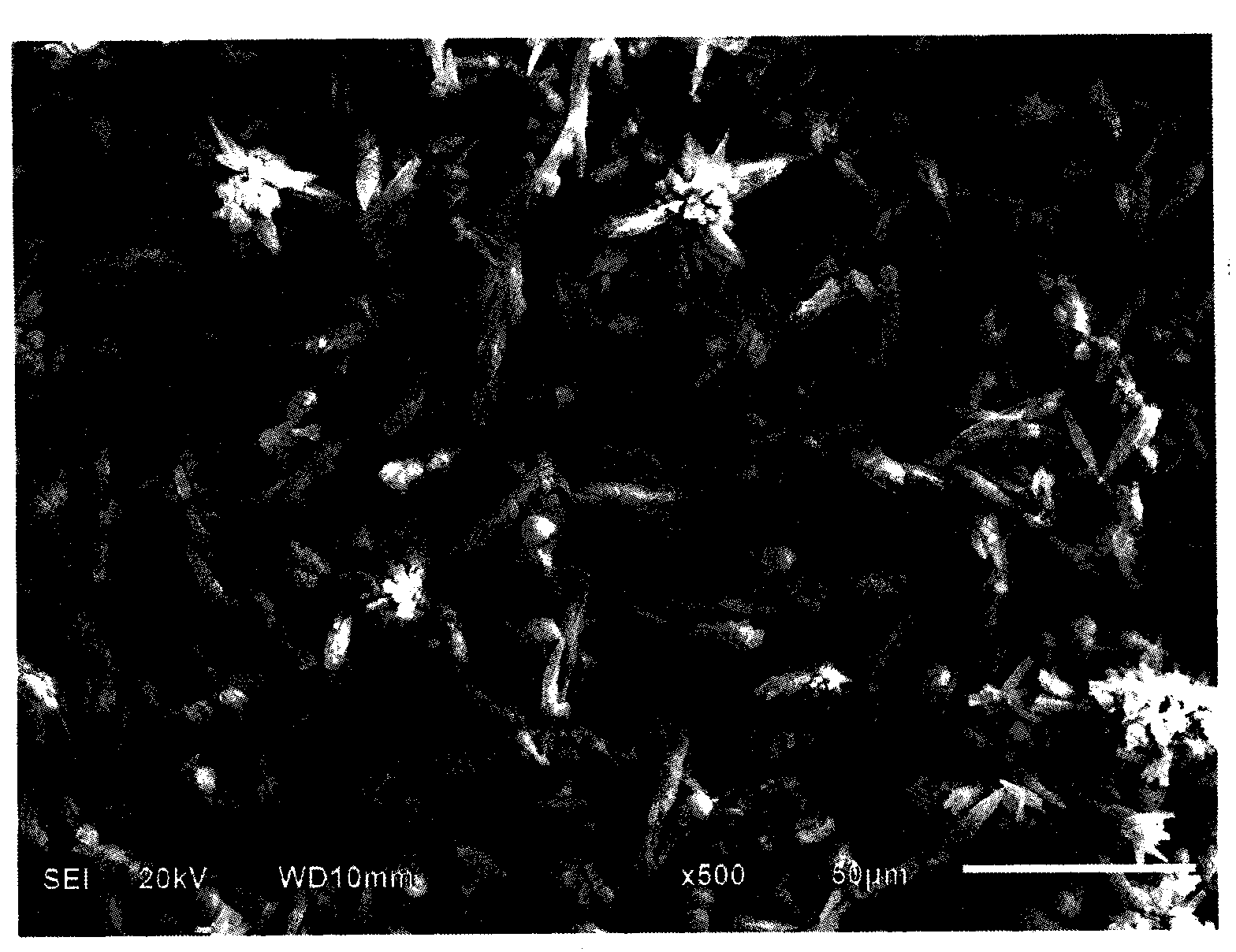

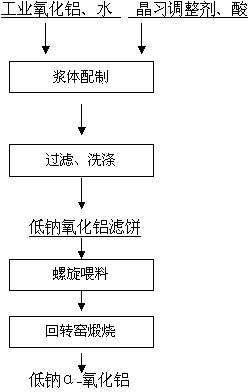

Method for preparing alpha-aluminum oxide

ActiveCN104386719ALarge specific surface areaLow impurity contentAluminates/aluminium-oxide/aluminium-hydroxide purificationAluminium oxides/hydroxidesPotassiumSlurry

The invention discloses a method for preparing an alpha-aluminum oxide, and relates to a method for preparing a low-sodium alpha-aluminum oxide which is used for producing electronic ceramics, glass substrates and finely polished and refractory materials. The method is characterized by comprising the following preparation processes: by adopting an industrial aluminum oxide as a raw material, carrying out hydrothermal reaction on industrial aluminum oxide slurry, carrying out liquid-solid separation and washing the slurry; and finally calcining to obtain a low-sodium alpha-aluminum oxide product. According to the method disclosed by the invention, soluble impurities such as sodium oxide and potassium oxide in the aluminum oxide raw material can be effectively removed; a crystal shape modifier is added in the wet treatment process; a trace crystal shape modifier can be fully mixed with the aluminum oxide by virtue of the adsorptive property of the aluminum oxide; the aluminum oxide of which the sodium oxide content is smaller than 0.15% is obtained after filtering and washing; and the low-sodium alpha-aluminum oxide product is obtained in a calcining manner in a high-temperature kiln. The method disclosed by the invention has the advantages of being simple in process, environment-friendly, high in production efficiency and the like, and the alpha-aluminum oxide is uniform in crystal particle.

Owner:ZHENGZHOU HICER HIGH TECH CERAMICS +1

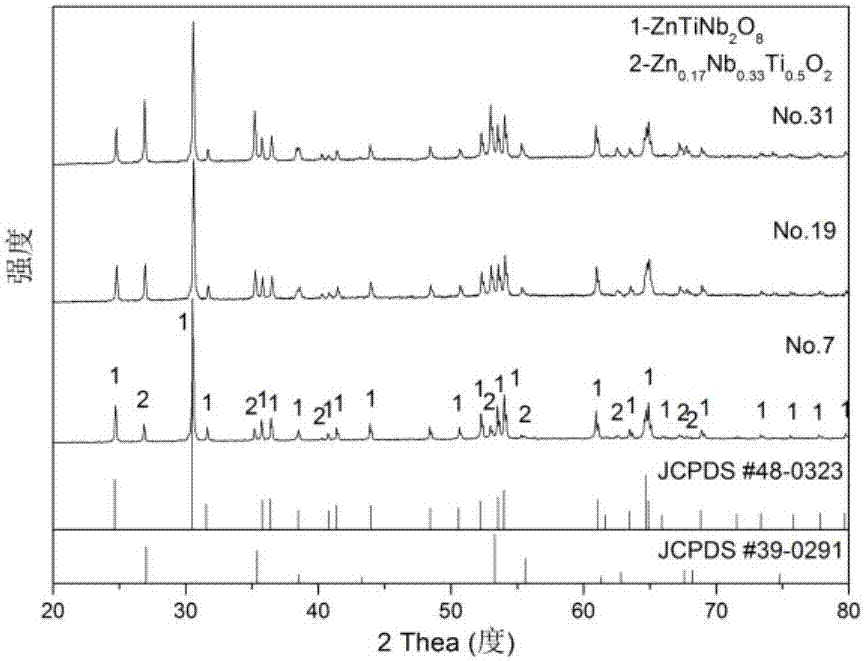

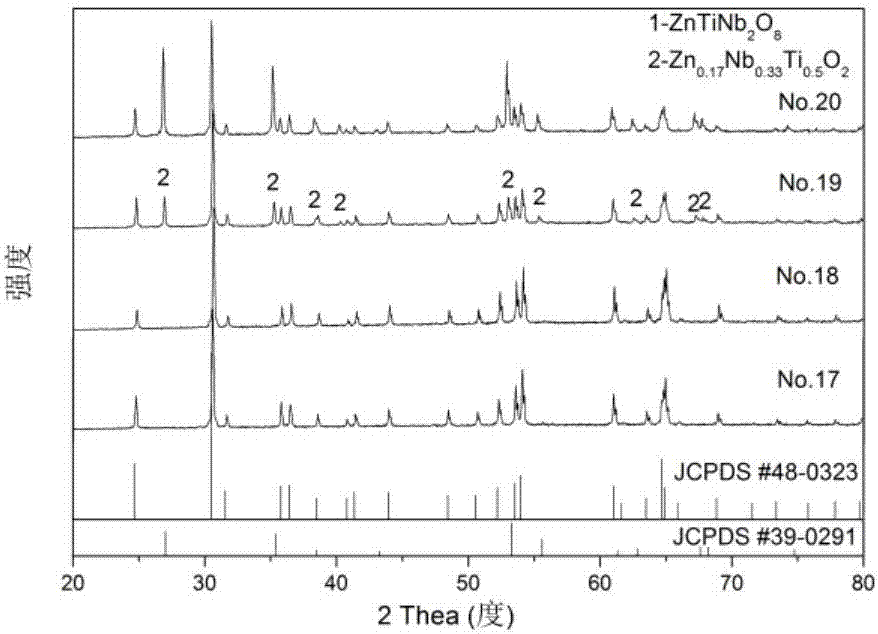

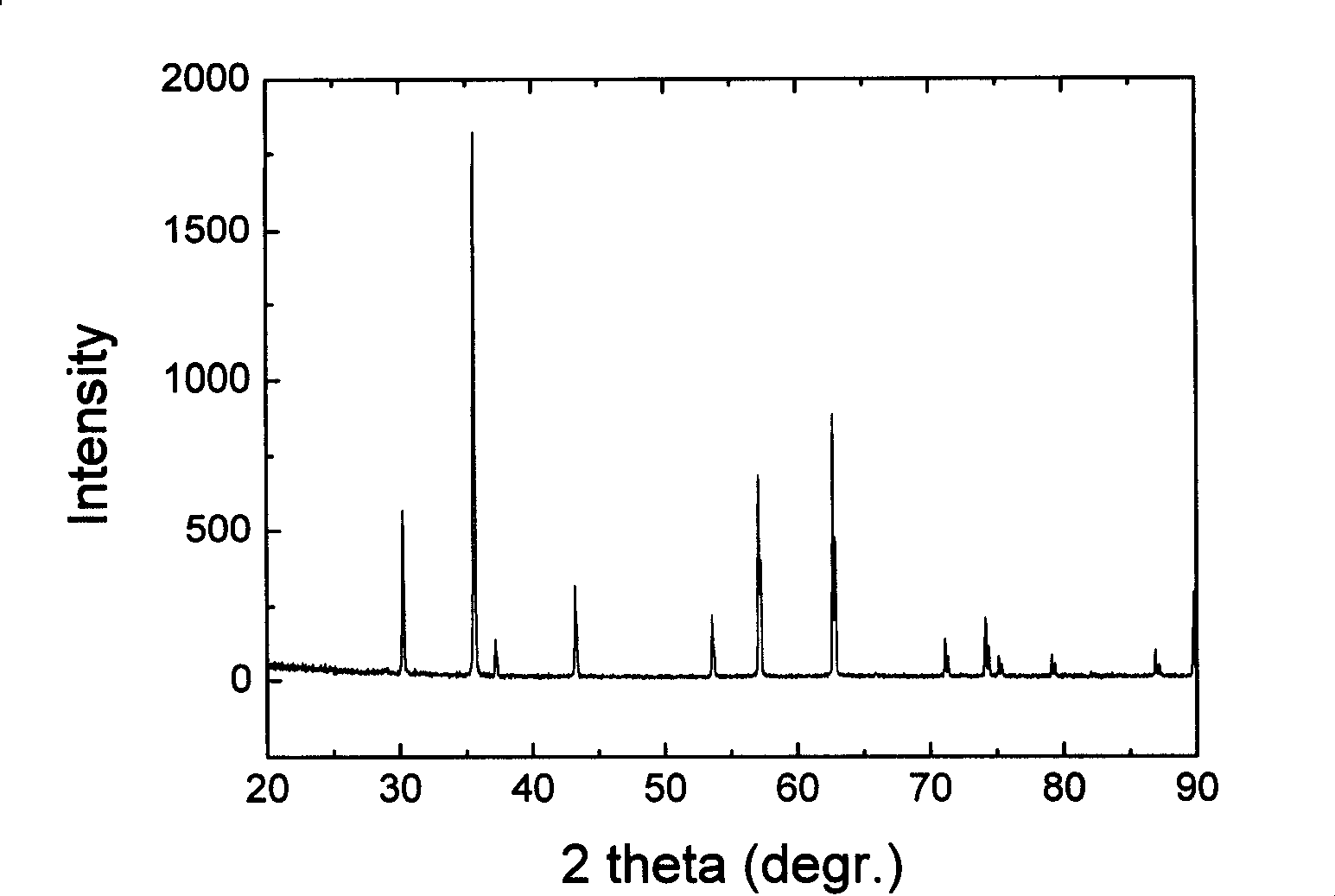

ZnTiNb2O8-series microwave dielectric ceramic material and preparing method thereof

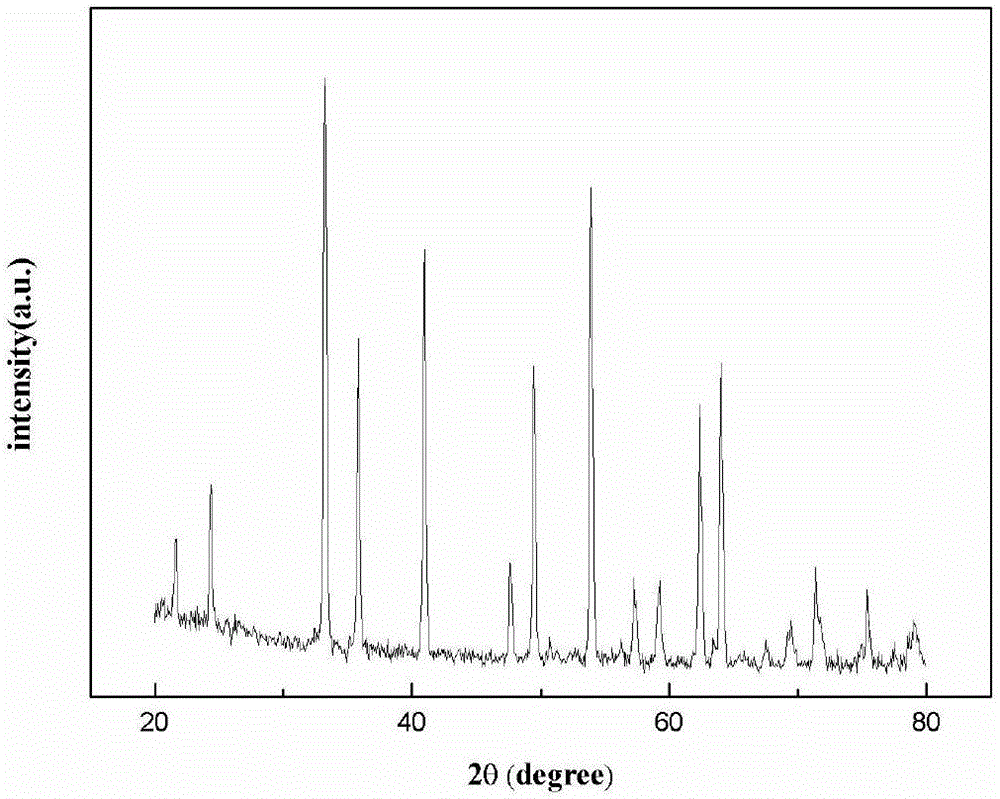

The invention belongs to the field of electronic ceramics and preparing methods thereof, and particularly relates to a ZnTiNb2O8-series microwave dielectric ceramic material and a preparing method thereof. According to the material, the dielectric constant is 30 to 46, the loss is smaller than or equal to 1.5*10<-4>, the frequency temperature coefficient tau<f> is larger than or equal to -10 ppm / DEG C and smaller than or equal to +10 ppm / DEG C, the major crystalline phase is ZnTiNb2O8, and the second phase is Zn0.17Nb0.33Ti0.5O2. The raw materials ZnO, TiO2, Nb2O5, Co2O3 and Ta2O5 are matched according to the general chemical formula (Zn1-xCox)0.5Ti0.5(Nb1-yTay)O4 (x is larger than or equal to 0 mol and smaller than or equal to 0.95 mol, and y ranges from 0.05 mol to 0.95 mol), the solid phase method is conducted, and the material is prepared. According to the material and the preparing method, Co ions and Ta ions are substituted for Zn ions and Nb ions respectively, a limited solid solution is formed, the portion beyond the solid solution forms the second phase with the positive temperature coefficient, the frequency temperature coefficient is adjusted to be nearly zero, the good microwave performance is kept, the preparing method is simple in technology, and industrial production is facilitated.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

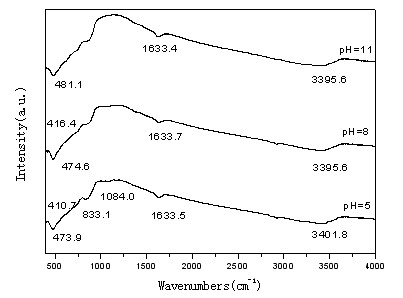

High-performance Pr series ZnO voltage sensitive ceramic material and preparation method thereof

The invention relates to a high-performance Pr series ZnO voltage sensitive ceramic material and a preparation method thereof, and belongs to the technical field of preparation and application of electronic ceramics. Nano composite ZnO ceramic powder is prepared by wrapping the surface of nano ZnO by a liquid phase deposition method, so that the doped components are mixed uniformly, the micro structure of a product is uniform, the performance of the Pr series ZnO voltage sensitive ceramic material is improved and the sintering temperature of the ceramic material is effectively reduced and the energy consumption is reduced. The Pr series ZnO voltage sensitive ceramic material with high electric potential gradient, a large nonlinear coefficient, and small leakage current is prepared by optimizing the reasonable ratio of all doped components and combining a liquid phase wrapping process, and meets the requirements of high-voltage and supervoltage high-quality arresters and other devices; and the variety of the doped elements for preparing the high-voltage ZnO voltage sensitive ceramic is few, the source of the doped elements is abundant, and the method is simple, so that production cost is lowered.

Owner:溧阳常大技术转移中心有限公司

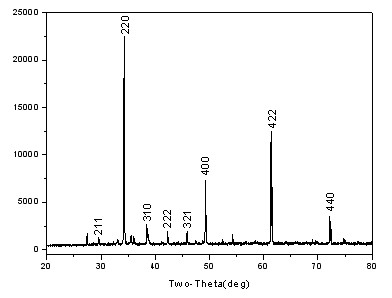

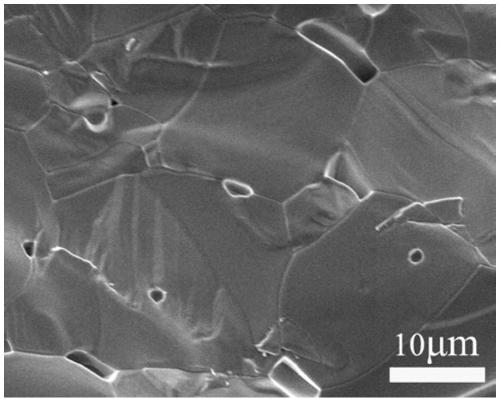

Novel method for preparing ferrite ceramic soft magnetic material

The invention relates to a preparation method of a ferrite ceramics soft magnetic material, which belongs to the technology field of electronic ceramics preparation and application. The ceramics is a pure phase spinelle phase ferrite. The material preparation method comprises the technology steps of dosing, high-energy ball milling, parching, mixing whole grain, sifting, forming, sintering, and the like. Compared to the traditional ferrite material preparation method, the method of the invention only needs once sintering, which is simply called one-step synthesis method; because the preparation technology is much easier, device and technology costs are reduced, and technology reliability and controllability are raised; high pure and high wear resistant zirconia grinding is adopted to precisely control doping element ratio; especial sintering fluxing agent is adopted, and sintering temperature is low. Because the material component can be precisely controlled, grain size can be evenly controlled, with little defect, the obtained ferrite material has exceptional magnetics performance, good high frequency characteristic and high quality factor, and can be widely used for preparing and producing high quality high frequency components. The invention also can be used for other types of electronic ceramics materials, and the like.

Owner:CHINA UNIV OF GEOSCIENCES (BEIJING) +2

High-temperature thermal shock resistant aluminum oxide ceramic burning loading plate and preparation process thereof

The invention provides a high-temperature thermal shock resistant aluminum oxide ceramic burning loading plate and a preparation process thereof. A corundum high-temperature thermal shock resistant burning loading plate with reasonable cost performance and good properties is prepared by improving raw materials and sintering processes. The obtained burning loading plate is non-deformable and good in thermal shock resistance when used at high temperature, and can be used as a burning loading plate applied to the field of electronic ceramics, high-temperature ceramics and the like under the condition of more than 1650 DEG C.

Owner:UNIV OF JINAN

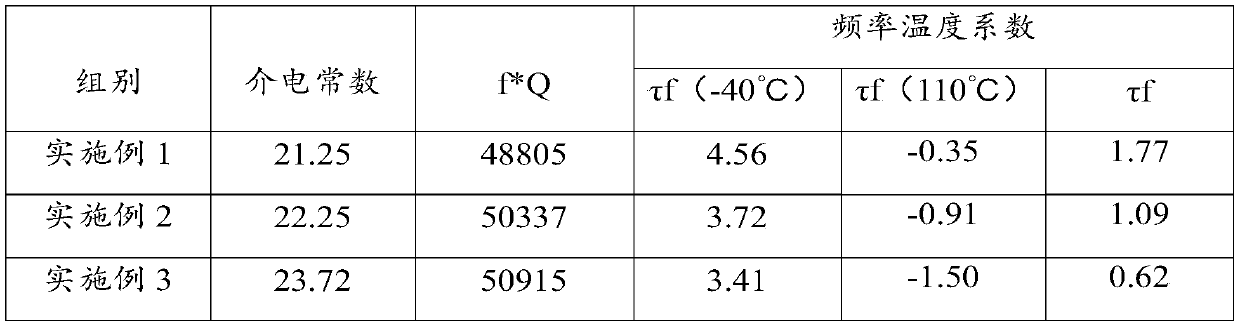

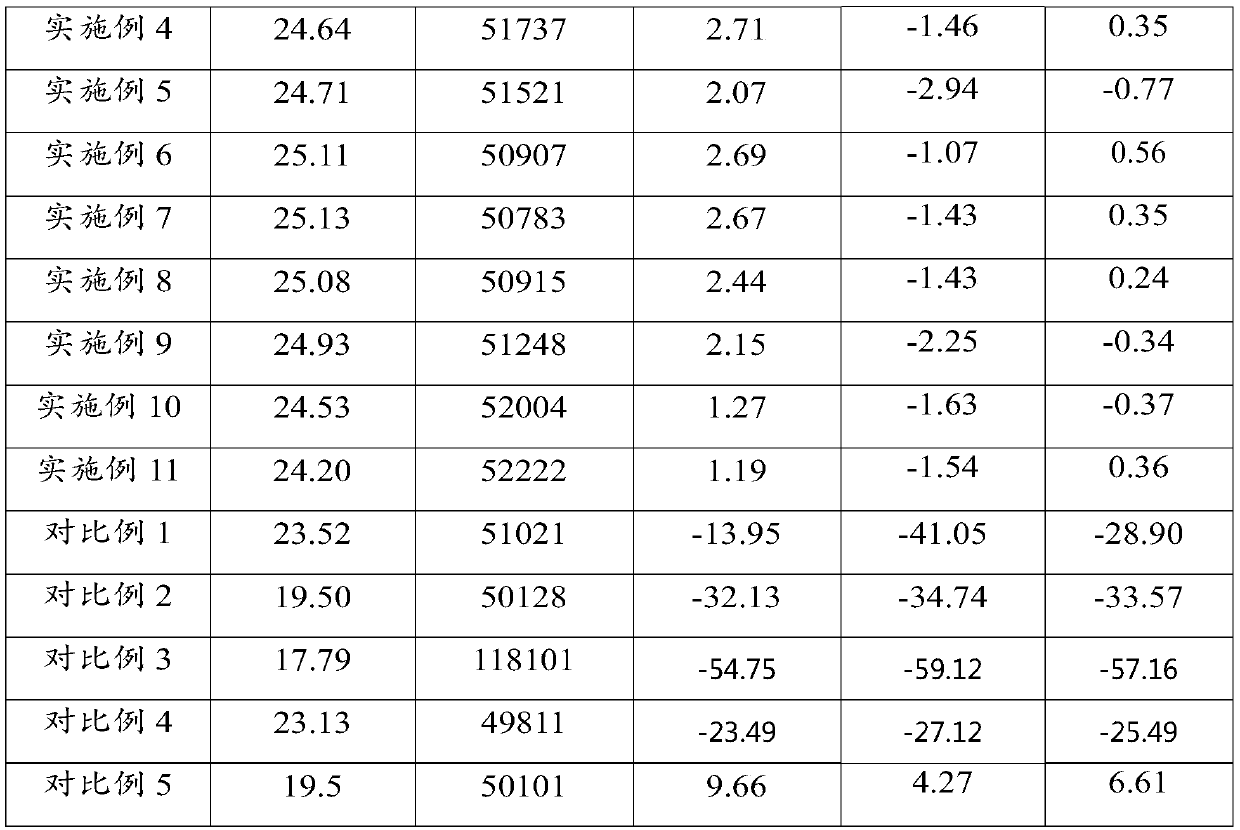

Microwave dielectric ceramic material, preparation method and application thereof, microwave dielectric ceramic body, preparation method and application of microwave dielectric ceramic body, and microwave device

ActiveCN110668795AGood temperature characteristicsImprove temperature stabilityElectronic ceramicsCeramic materials

The invention relates to the field of electronic ceramics, and provides a microwave dielectric ceramic material, a preparation method and application thereof, a microwave dielectric ceramic body, a preparation method and application of the microwave dielectric ceramic body, and a microwave device. The microwave dielectric ceramic material is mainly prepared from ceramic main materials and optionaladditives, the ceramic main materials comprise the specific weight percentage of MgO, CaO, SiO2, Nd2O3, Sm2O3 and TiO2, the additives comprise the specific weight percentage of oxide of R, R comprises one or more of Nb, Zn, Zr, Mn, Y, Ni, Cu, Mo or Al, wherein the sum of the weight percentage of all the components is 100%. The dielectric constant of the microwave dielectric ceramic body is continuously adjustable within 15-30, f*Q at the temperature of 25 DEG C is greater than 45000, the good temperature characteristics are achieved, the frequency temperature coefficients at the temperaturesof minus 40 DEG C, 25 DEG C and 110 DEG C are each close to zero, and temperature stability is high.

Owner:SHANDONG SINOCERA FUNCTIONAL MATERIAL CO LTD

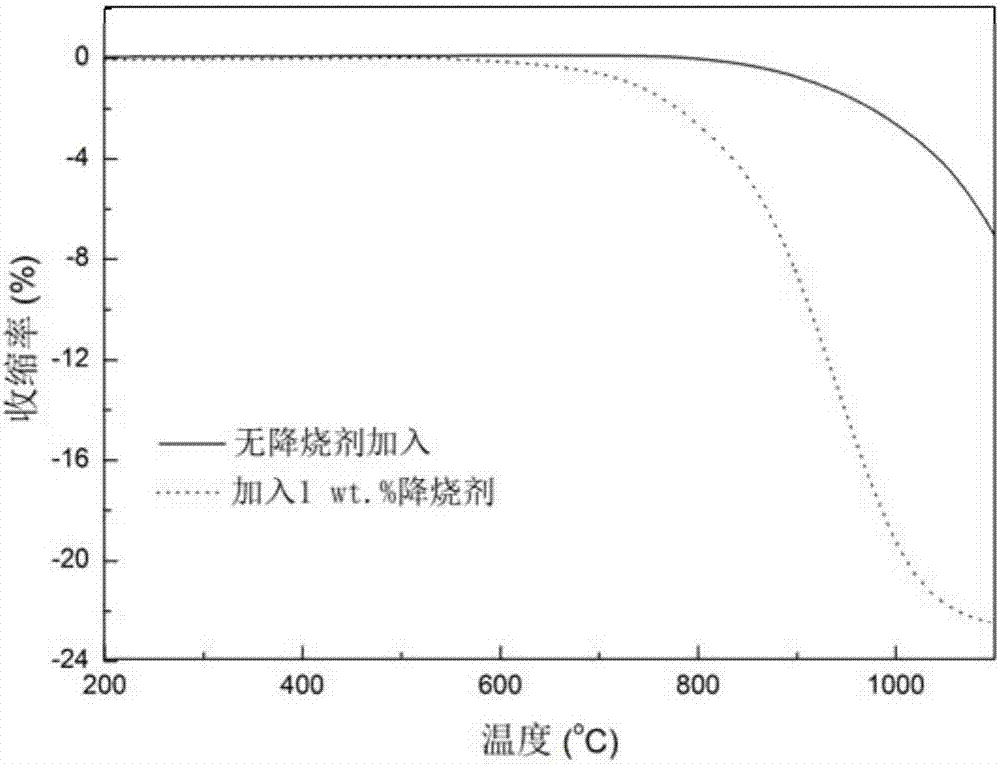

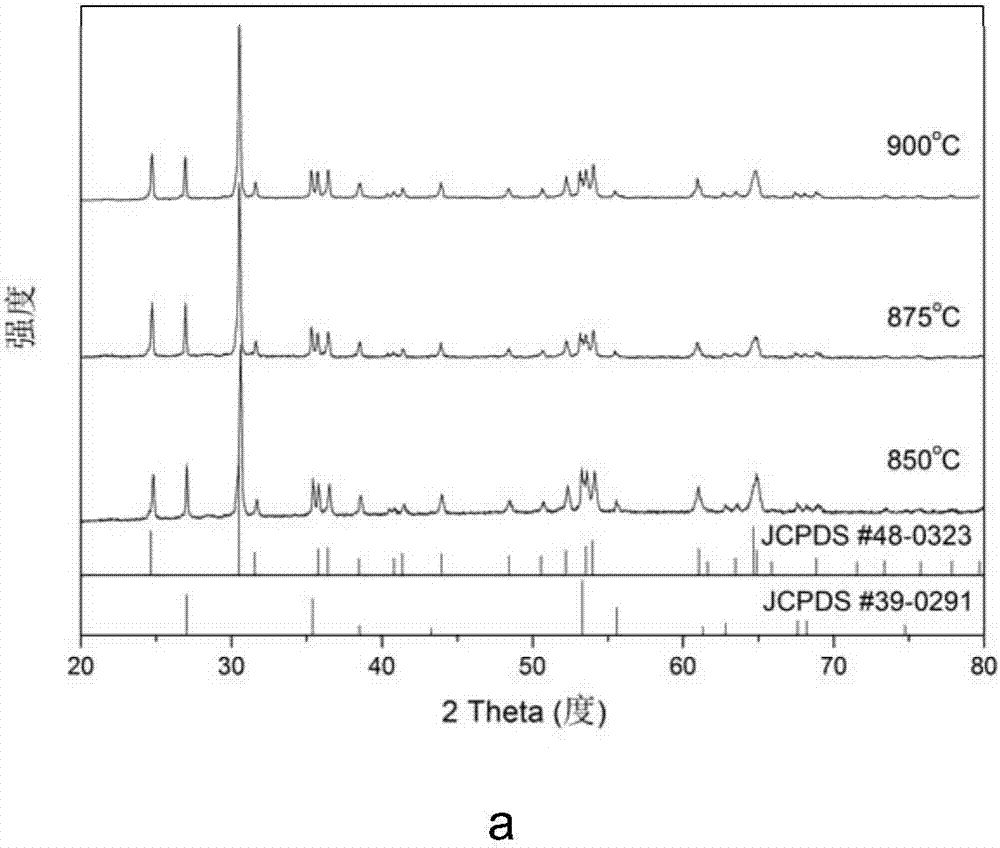

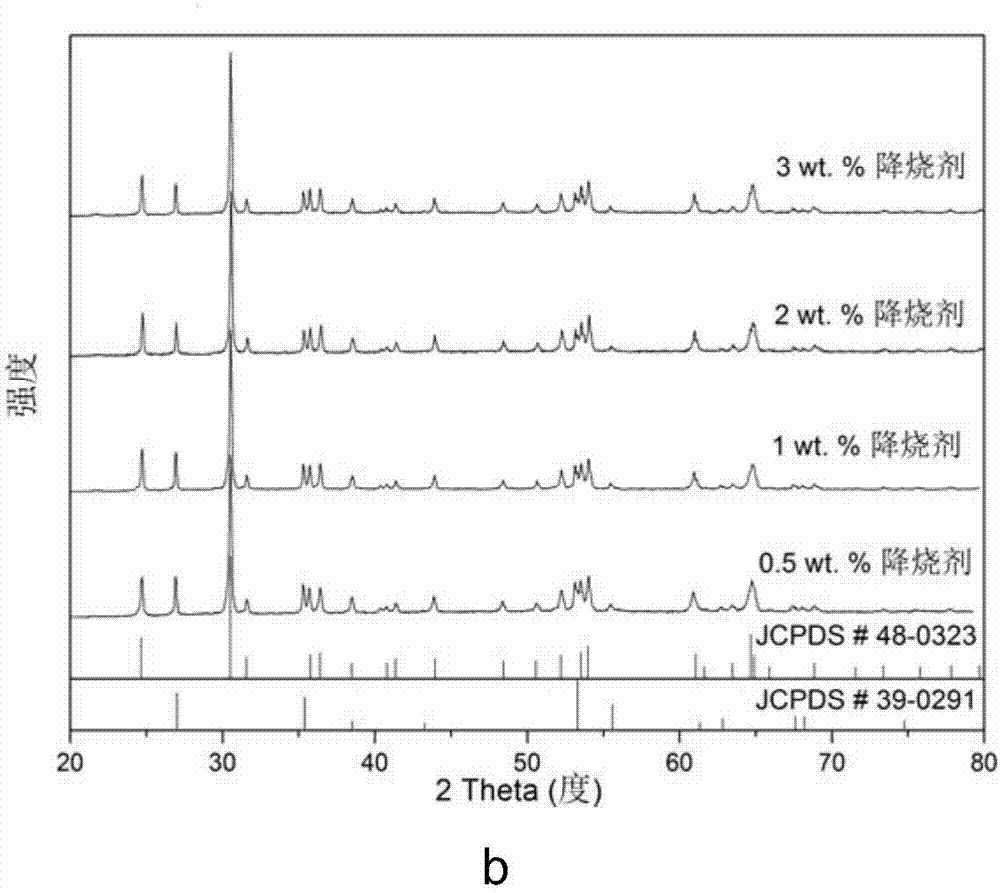

Low-temperature-sintered composite microwave dielectric ceramic material and preparation method thereof

The invention belongs to the fields of electronic ceramics and manufacturing thereof, and relates to a low-temperature-sintered composite microwave dielectric ceramic material and a preparation method thereof. The material provided by the invention is prepared from the following components in percentage by mass: 97 to 99.5 percent of (Zn1-xCox)0.5Ti0.5(Nb1-yTay)O4 base material and 0.5 to 3 percent of sintering reducer, wherein x is equal to 0.05 to 0.95; y is equal to 0.05 to 0.95; a primary crystalline phase is a ZnTiNb2O8 phase; a secondary crystalline phase is a Zn0.17Nb0.33Ti0.5O2 phase. According to the low-temperature-sintered composite microwave dielectric ceramic material, the ion doping of Co2O3 and Ta2O5 is carried out on the basis of Zn0.5Ti0.5NbO4; 0.5wt.% to 3wt.% of the sintering reducer is doped on a system subjected to the ion doping; the sintering densification is carried out at a sintering temperature lower than 900 DEG C; on the premise that the microwave dielectric performance is guaranteed to be excellent, a corrected [tau]f value of the system can be regulated; a dielectric constant is 20 to 34; the loss is not more than 10<-4>; a frequency temperature coefficient is stable that [tau]f is not less than -10ppm / DEG C, but is not more than +10ppm / DEG; a preparation process is simple; the industrialized production is easy.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Microwave dielectric ceramic material and preparation method thereof

ActiveCN111689771AImprove uniformityMeet Microwave Performance RequirementsSolid-phase synthesisElectronic ceramics

Owner:XIAMEN SUNYEAR ELECTRONICS CO LTD

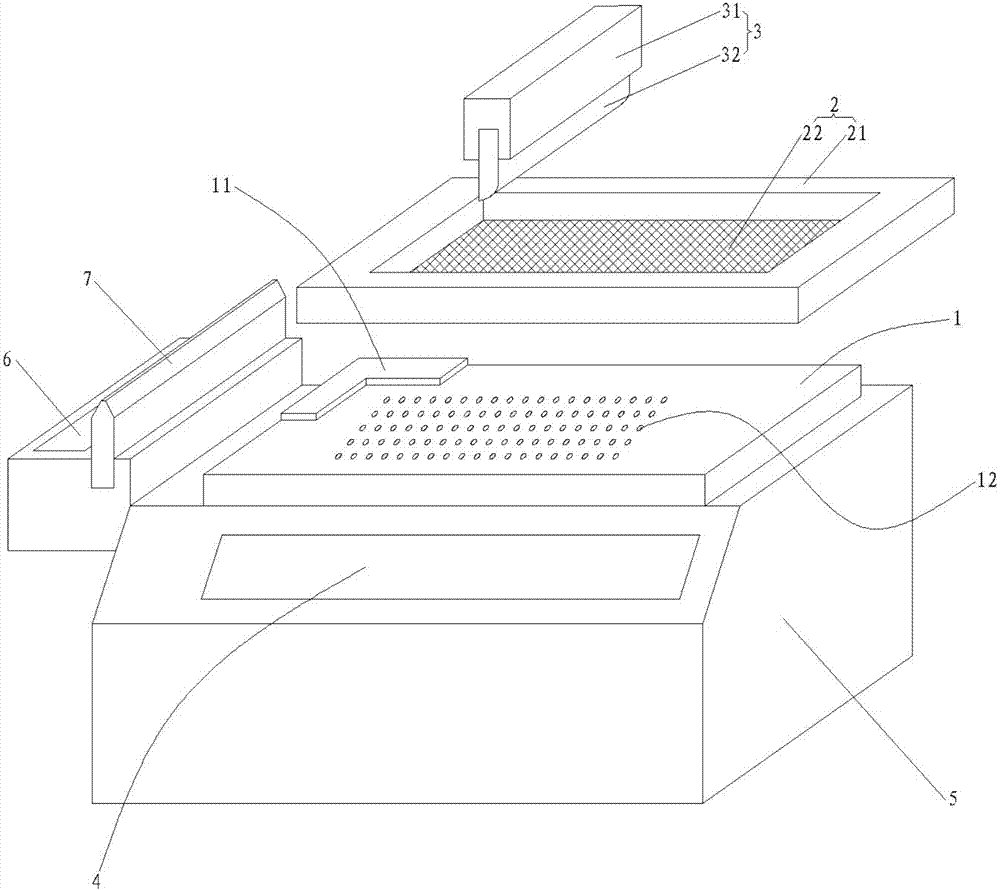

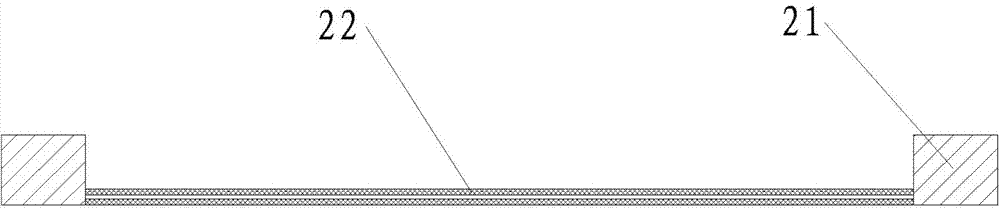

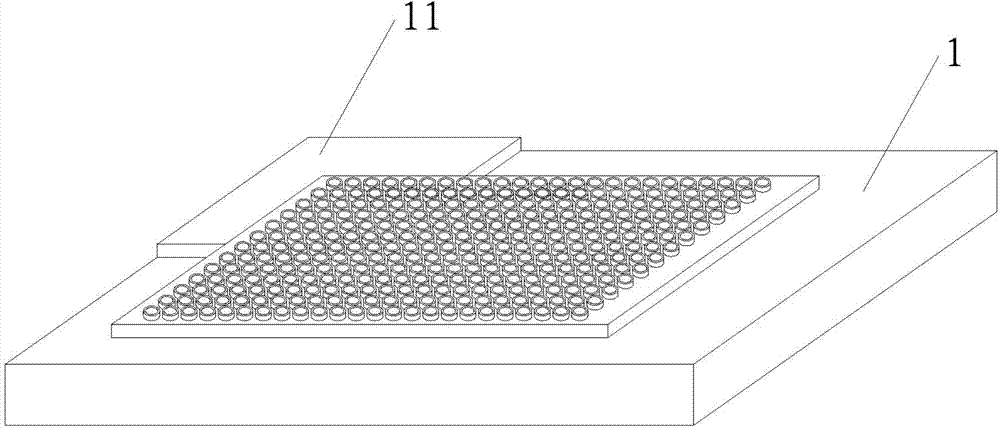

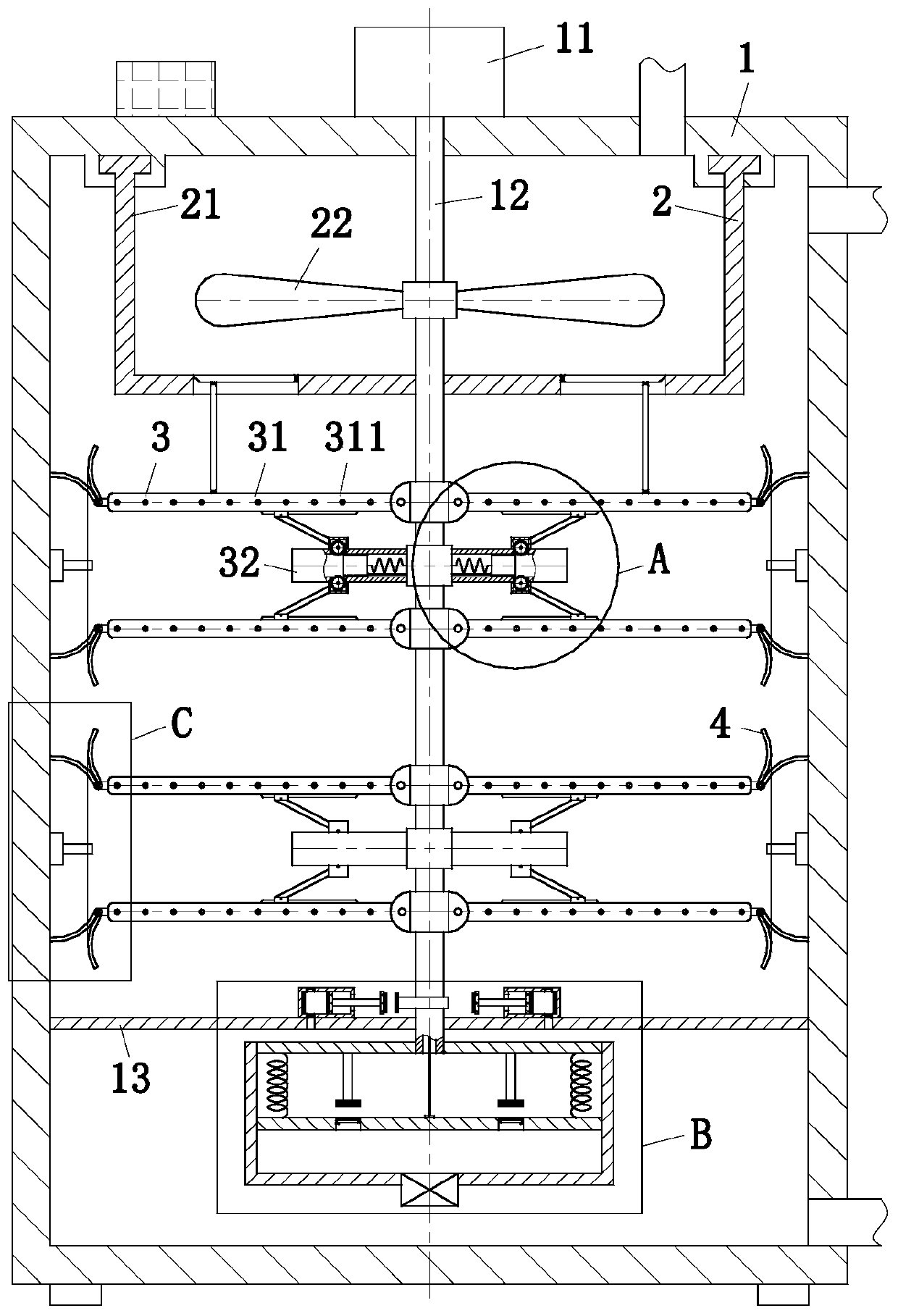

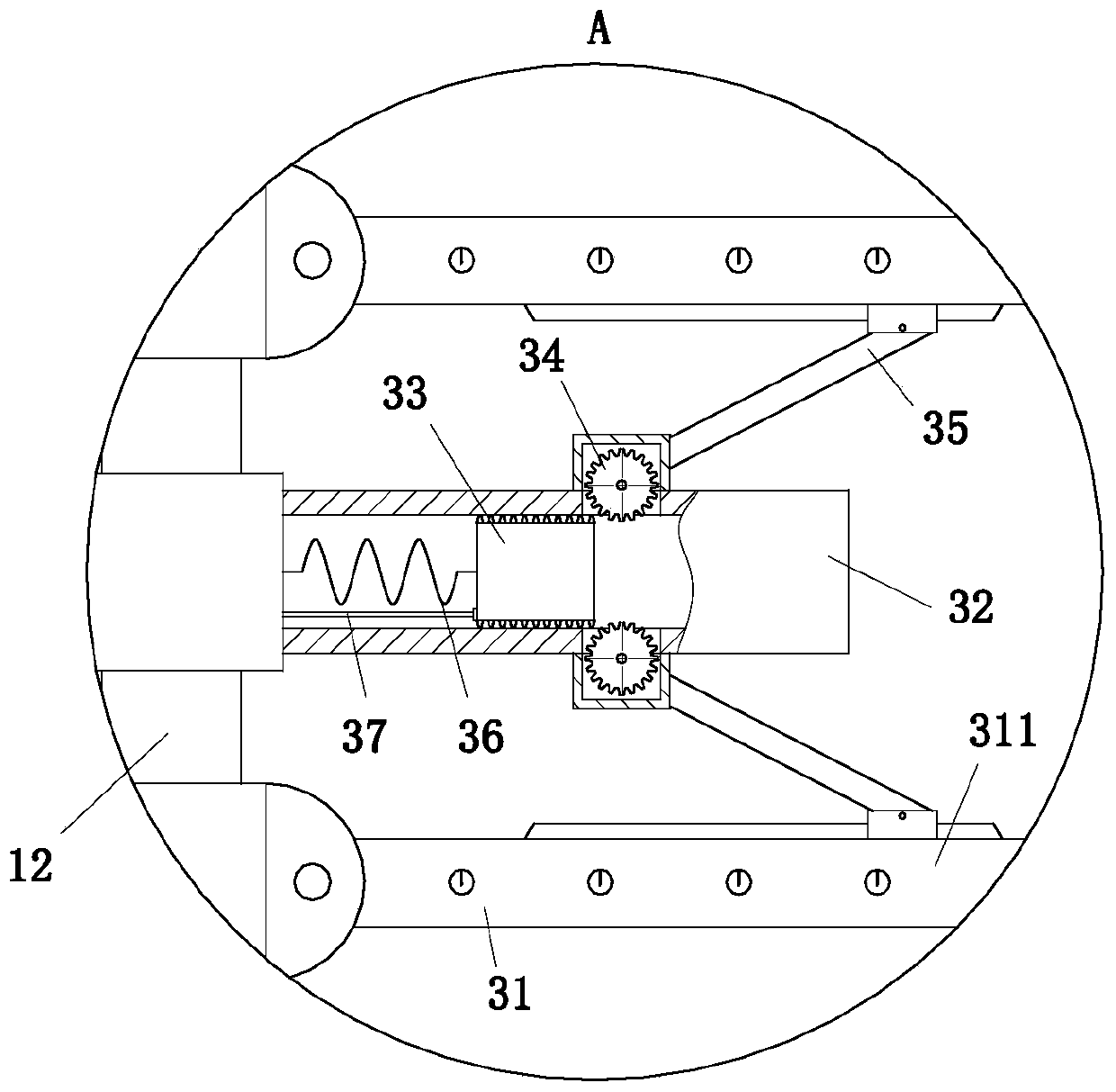

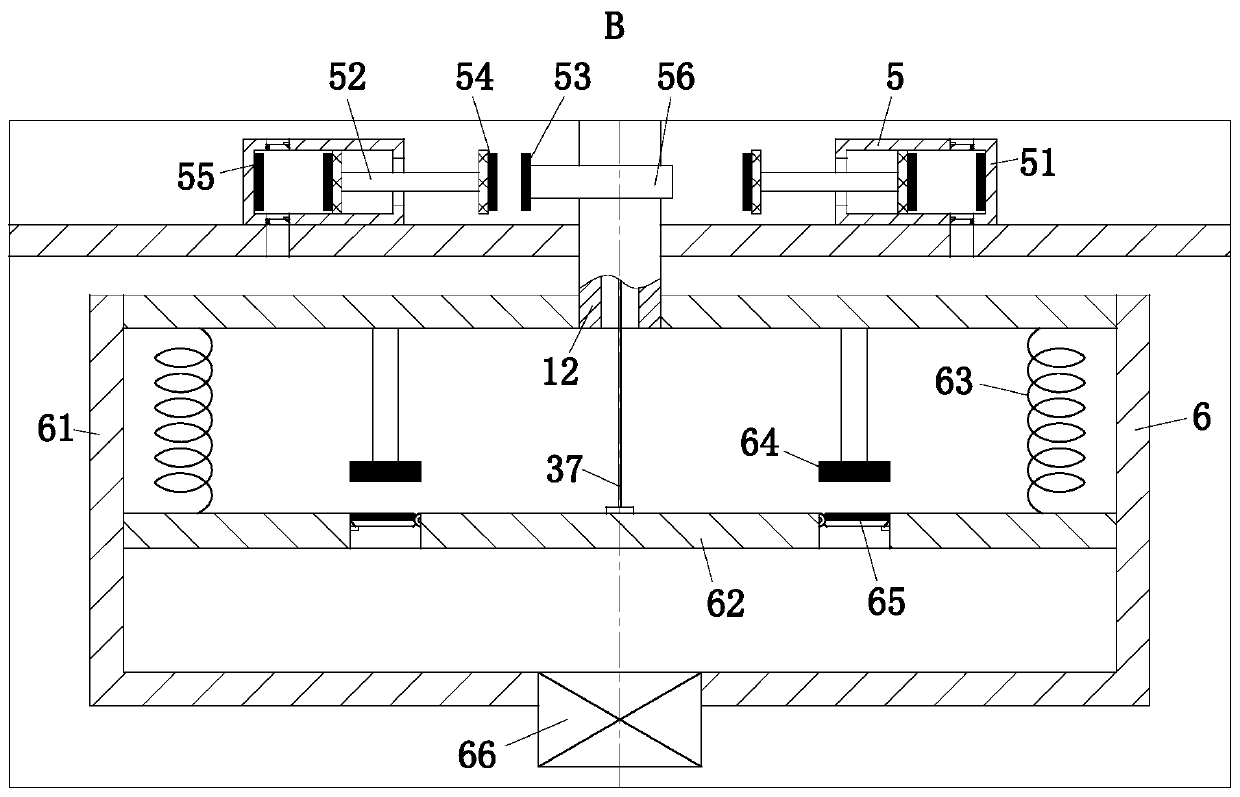

Precise automatic press for electronic ceramics

InactiveCN103481642AHigh precisionImprove uniformityScreen printersPrinting press partsEngineeringPrinting press

The invention discloses a precise automatic press for electronic ceramics. The precise automatic press comprises a printed electronic-ceramics supporting table face (1), a printing silk screen component (2), a sizing agent scraper component (3) and a control mechanism (4), wherein the printed electronic-ceramics supporting table face (1) and the control mechanism (4) are arranged on a press frame (5), the printing silk screen component (2) is arranged above the printed electronic-ceramics supporting table face (1), the sizing agent scraper component (3) is arranged above the printing silk screen component (2), and the control mechanism (4) controls the printing silk screen component (2) and the sizing agent scraper component (3) to move up and down along a lifting mechanism, and controls the printing silk screen component (2) and the sizing agent scraper component (3) to move left and right along a rail mechanism. The positions and operation of the printed electronic-ceramics supporting table face, the printing silk screen component and the sizing agent scraper component are all controlled through the control mechanism, precision is greatly improved, and printing uniformity and thickness consistency are greatly improved.

Owner:湖南省新化县鑫星电子陶瓷有限责任公司

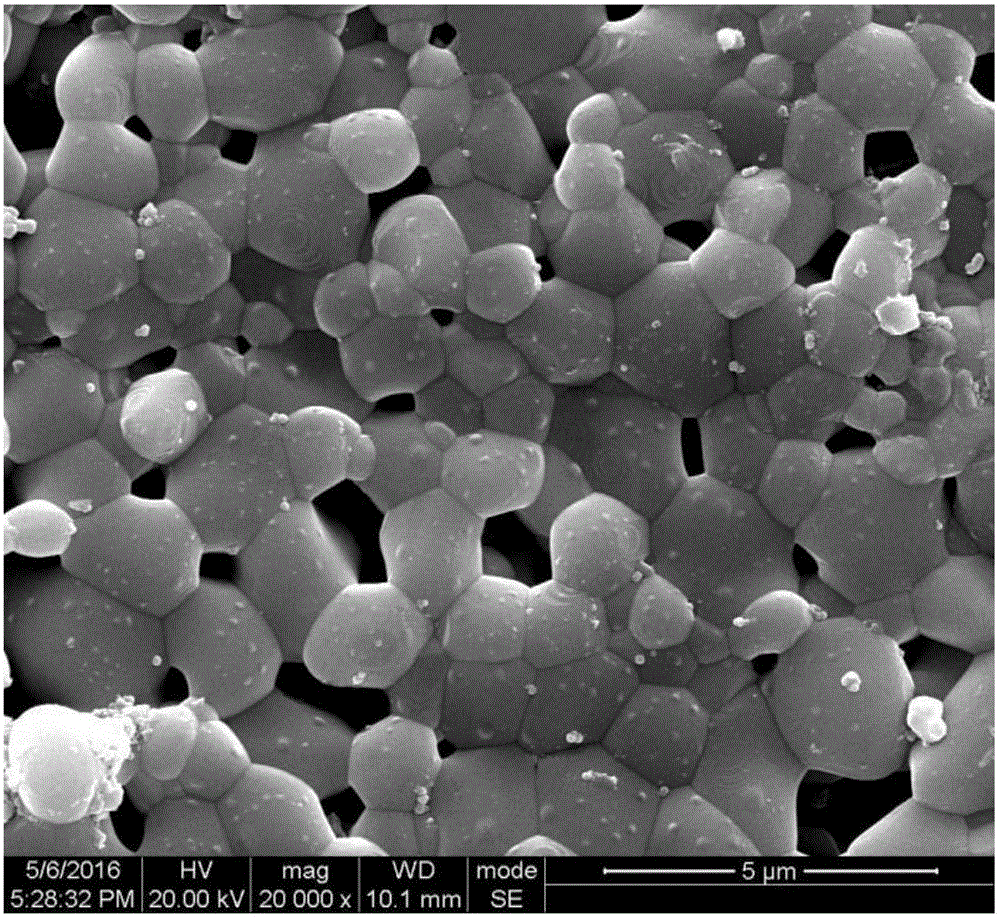

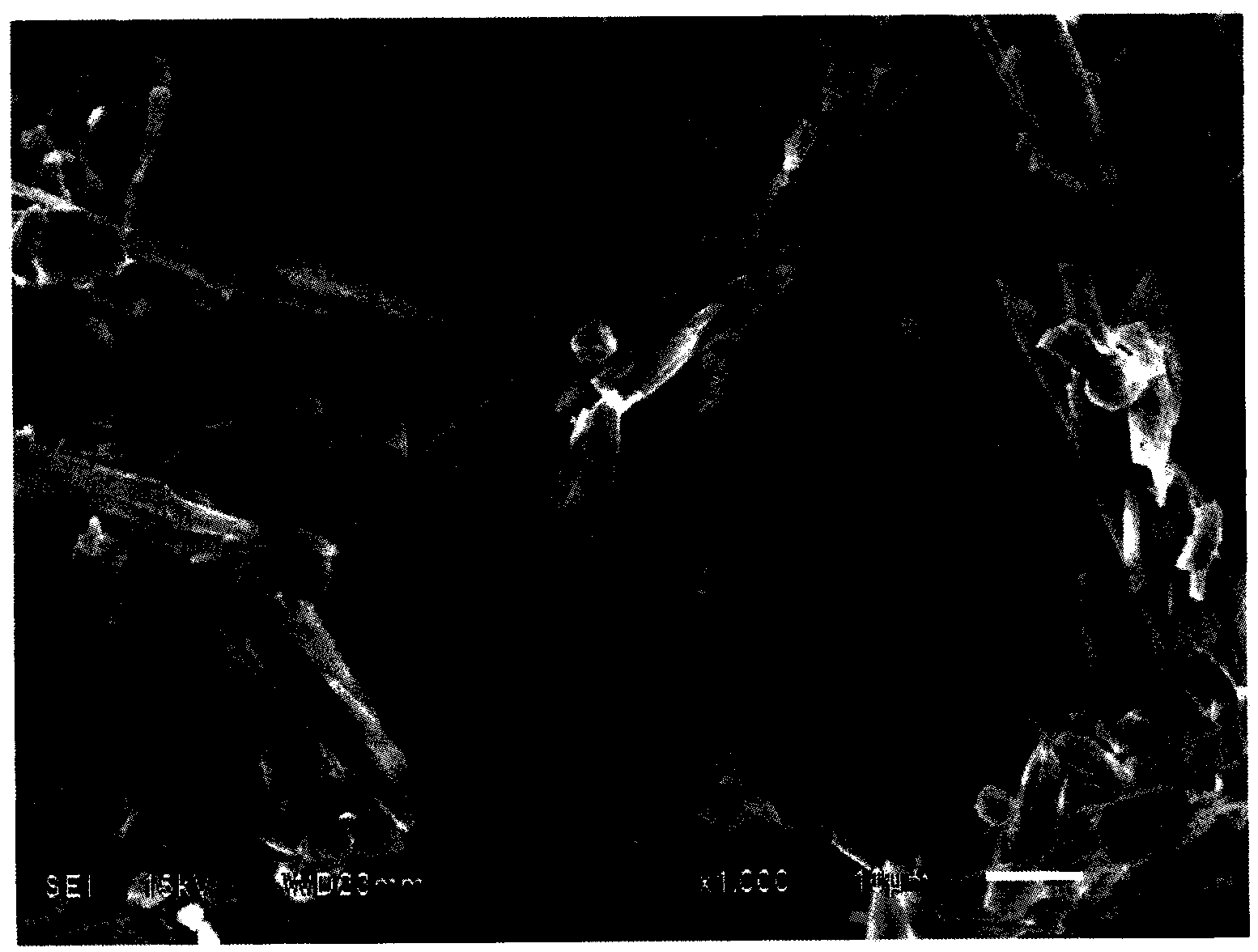

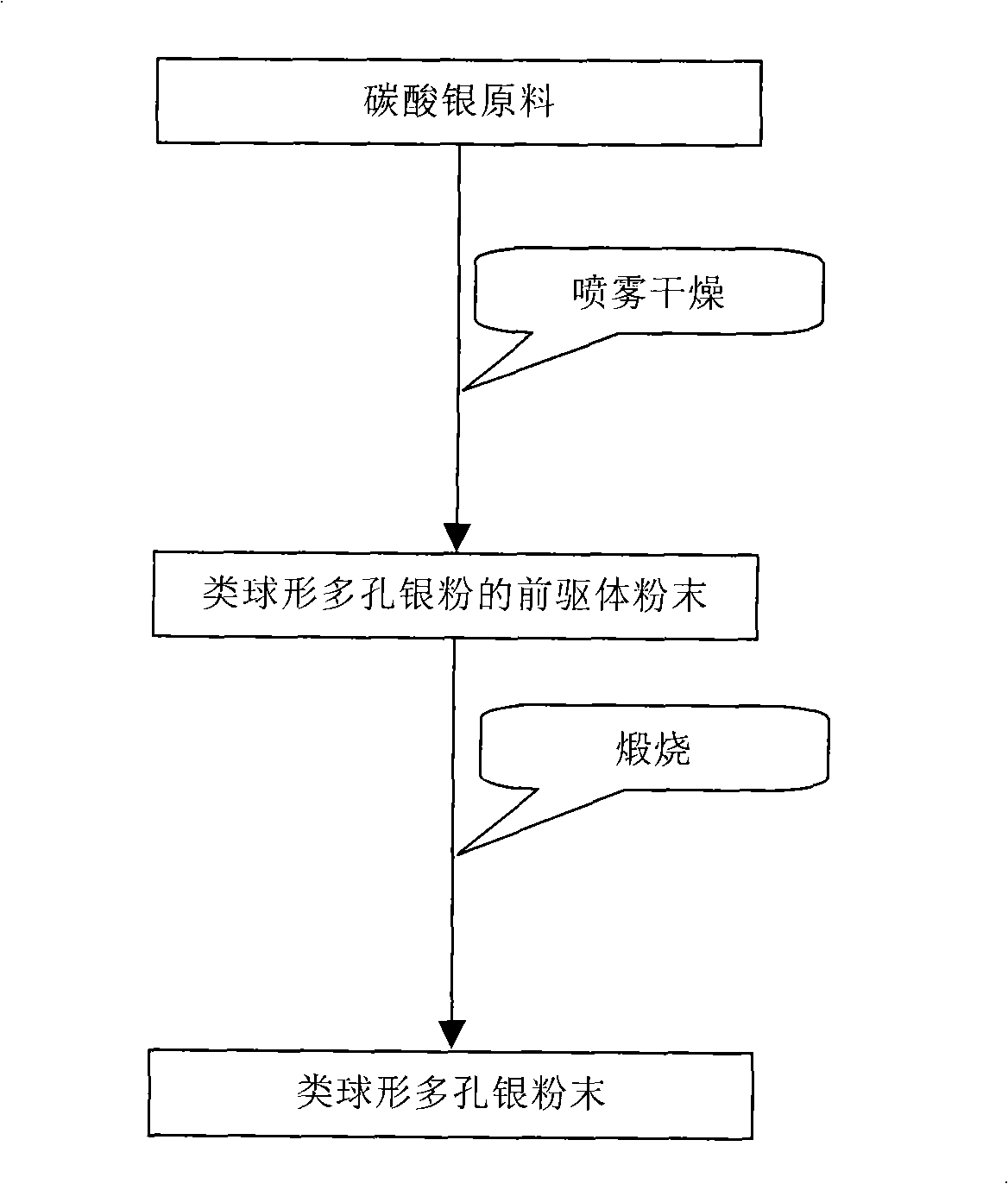

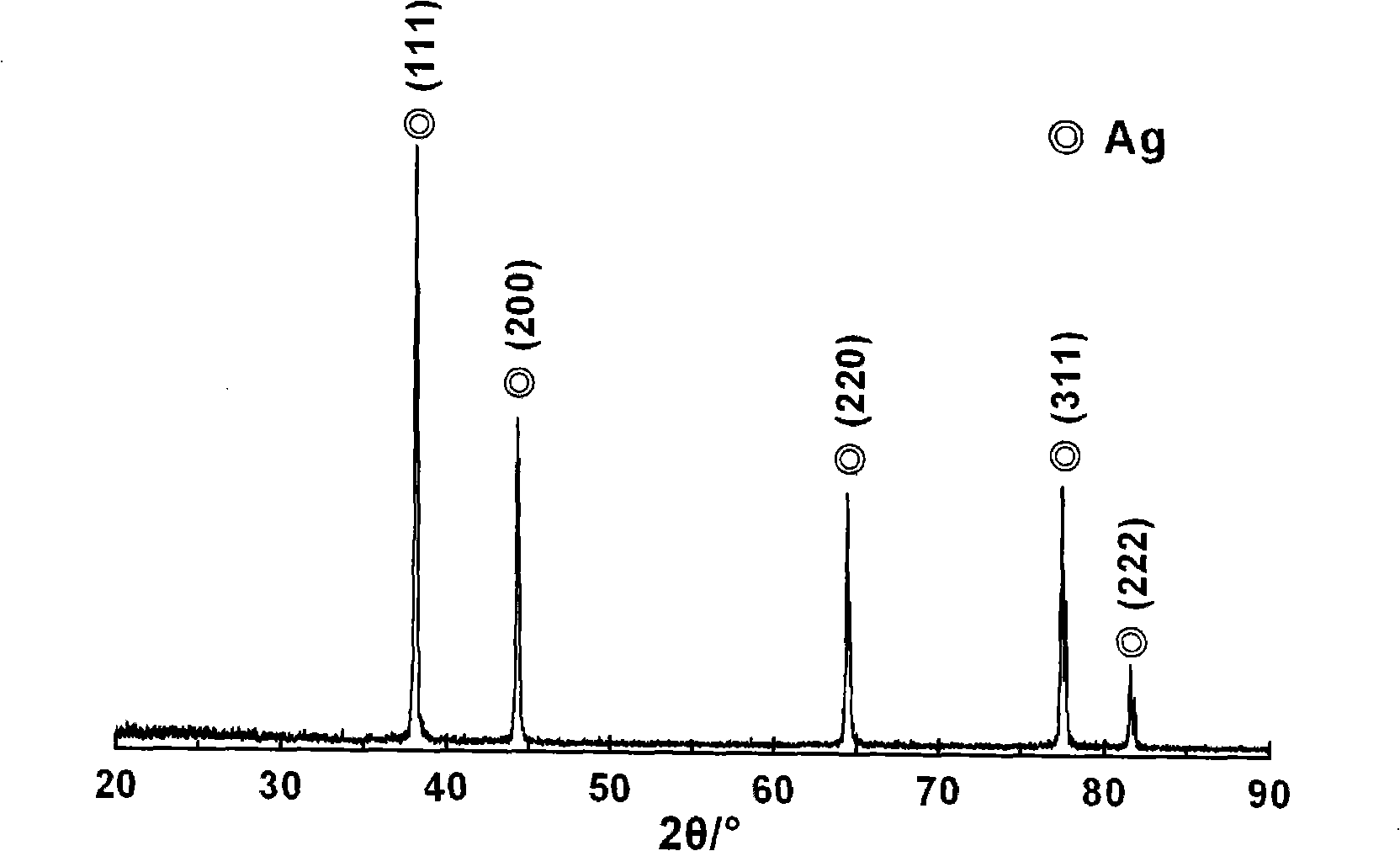

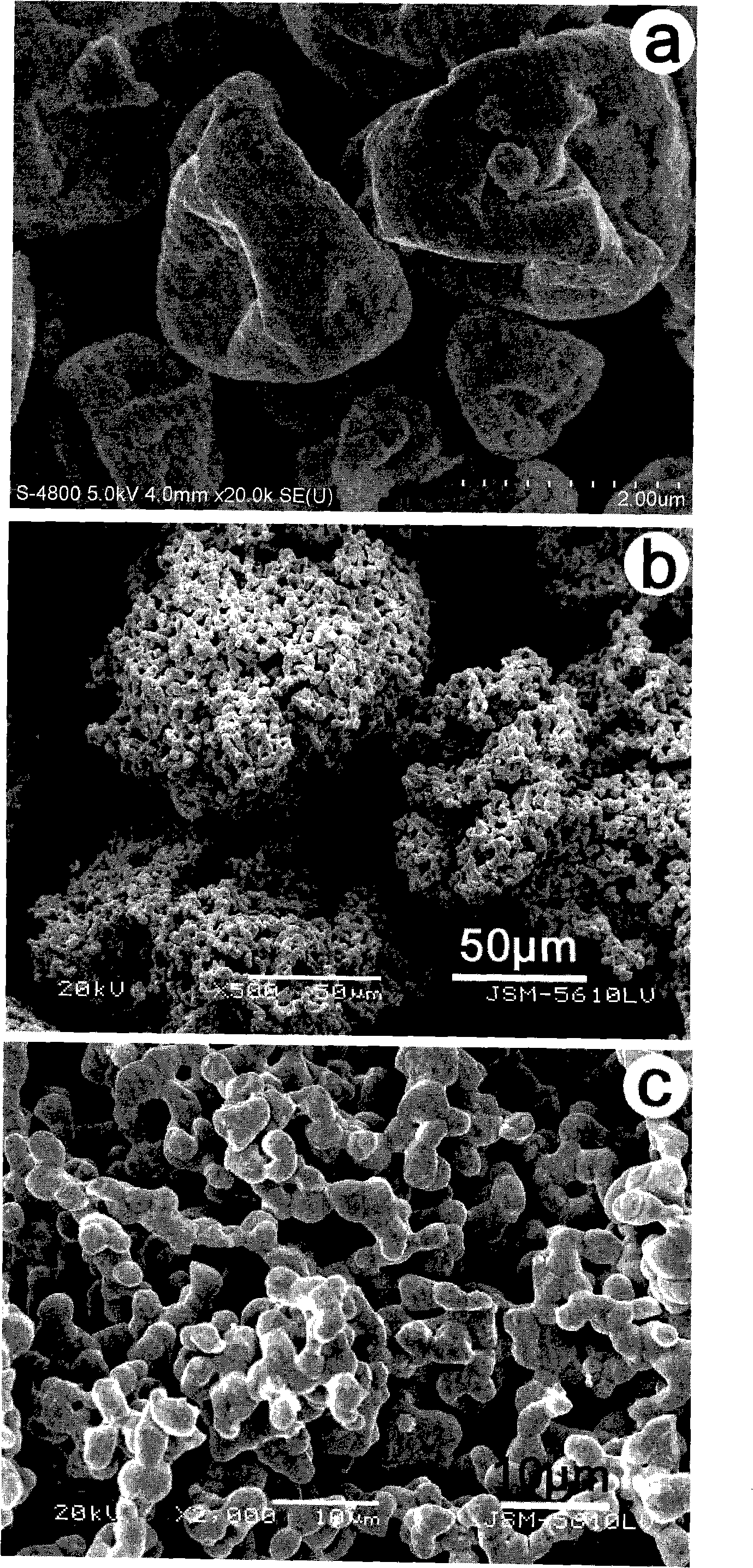

Industrialization preparation of sphere-like porous silver powder

The invention discloses a near-spherical porous silver powder industrialized preparation method, which comprises the following steps: (1) the material of silver carbonate is dissolved in the ammonia solution, mixed evenly and prepared into 5 to 25wt% silver ammonium solution, (2) the prepared silver ammonium solution is introduced into a spray drying device for spray drying, and the precursor powder of the near-spherical porous silver powder is acquired, and (3) the calcination of the precursor powder is conducted, and the near-spherical porous silver powder is acquired as the temperature is reduced to ambient temperature. The near-spherical porous silver powder industrialized preparation method has the advantages of simple process, easy control, low investment cost, thus being suitable for industrialized scale production and the preparation of catalyst material, electronic ceramics material, static-free material, low temperature superconducting material, electronic sizing agent, biosensor material, and inorganic antibacterial agent or deodorization and partial ultraviolet absorption functional materials; the prepared near-spherical porous silver powder has the advantages of a great amount of pore channels with dimension above micrometer connected with each other, high specific surface area and activity, high degree of crystallinity, and high yield.

Owner:WUHAN UNIV OF TECH

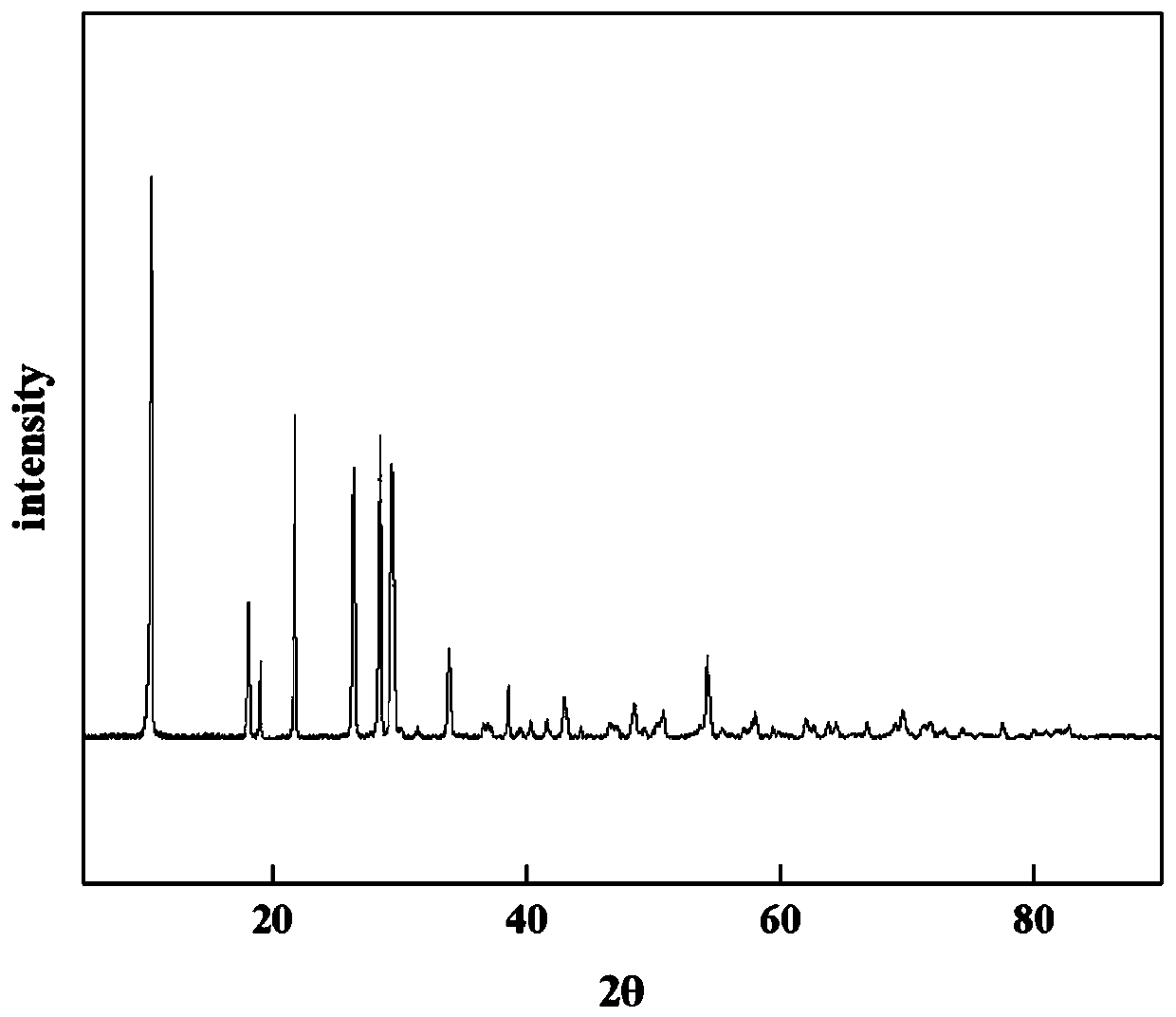

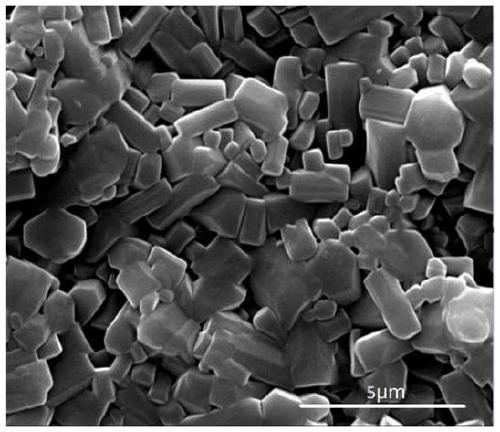

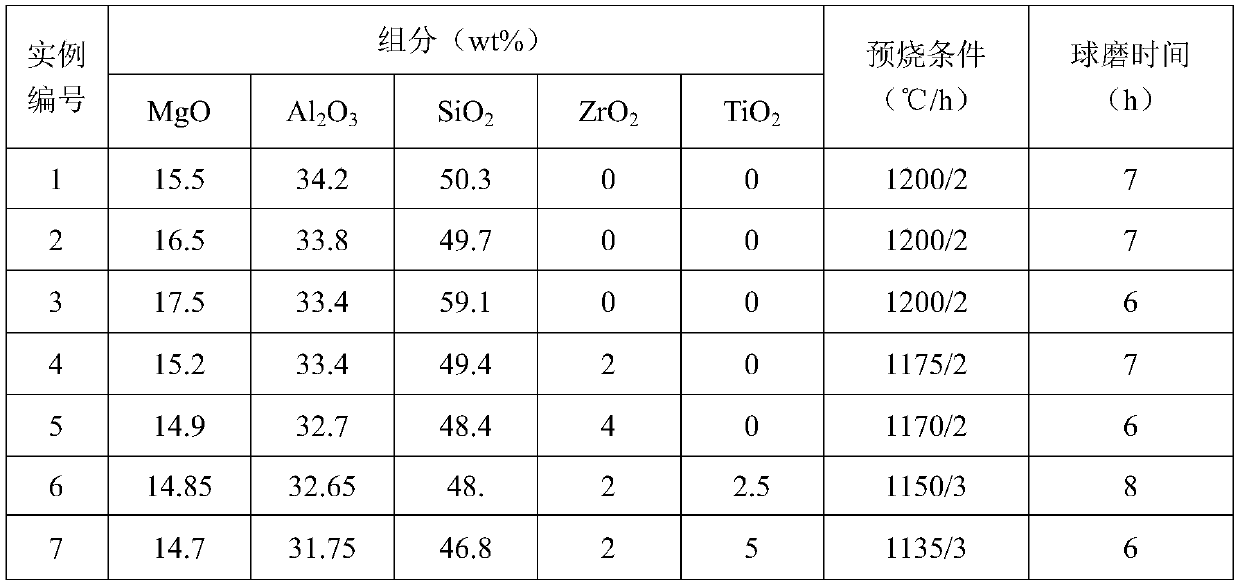

Cordierite microwave dielectric ceramic material and preparation method thereof

The invention discloses a cordierite microwave dielectric ceramic material and a preparation method thereof, and belongs to the technical field of electronic ceramic materials. The ceramic material comprises the components in percentage by mass: 13 to 18 wt% of MgO, 28 to 37 wt% of Al2O3, 45 to 55 wt% of SiO2, 0 to 10 wt% of TiO2 and 0 to 5 wt% of ZrO2. The method is simple in process and low in raw material cost; the obtained microwave dielectric ceramic material has excellent properties of low dielectric constant and high quality factor, the dielectric constant is 4-6, the quality factor Q*fvalue is 60000-90000 GHz, the loss is reduced, and the signal transmission speed is increased; and the frequency temperature coefficient is less than + / -15 ppm / DEG C, so that the temperature stability is improved.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

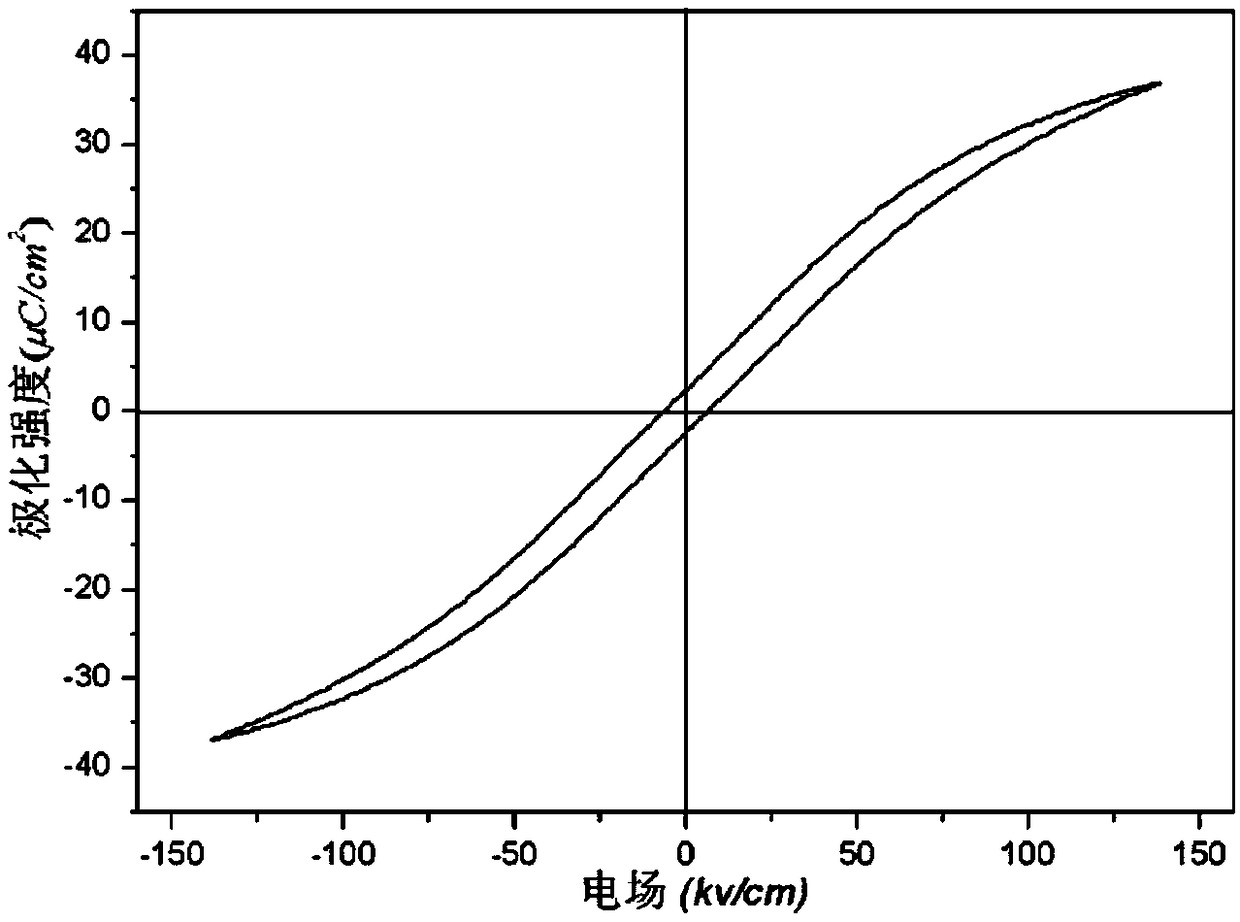

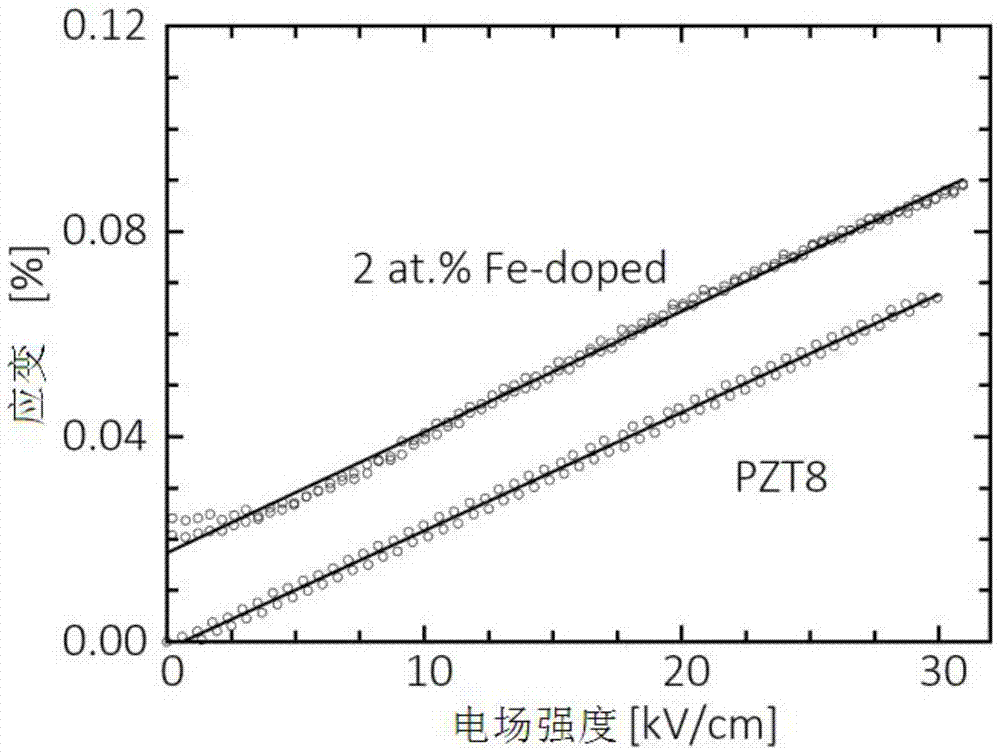

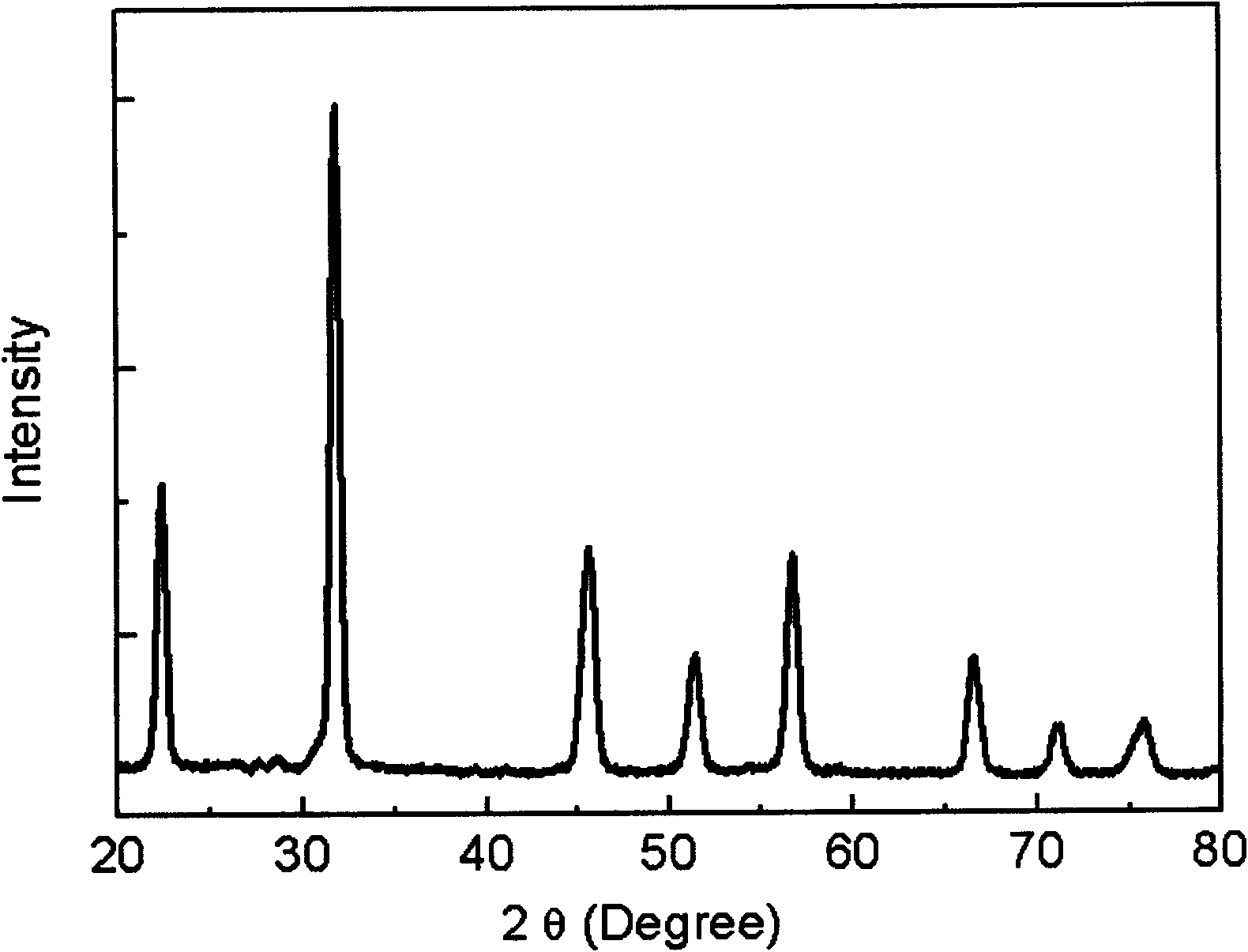

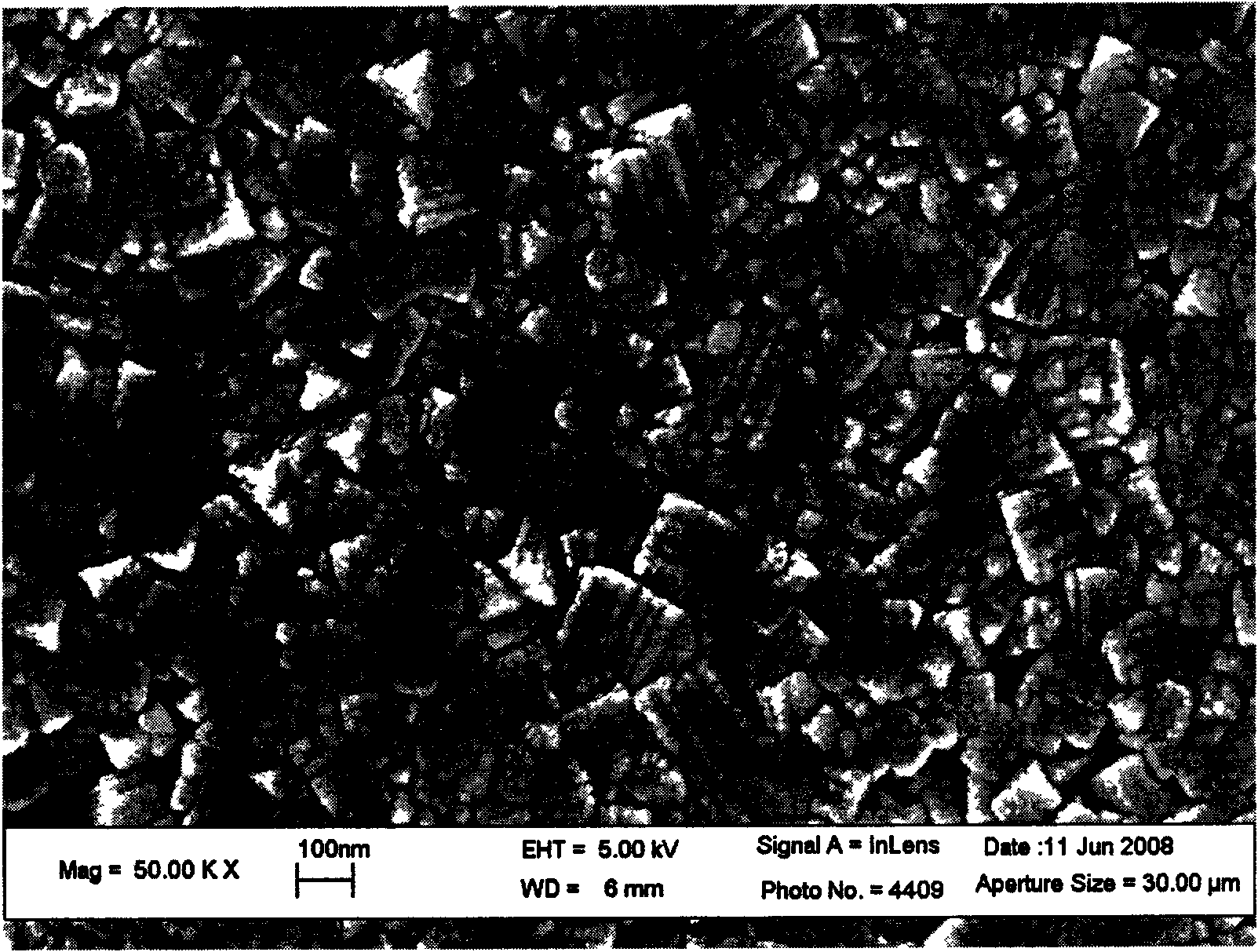

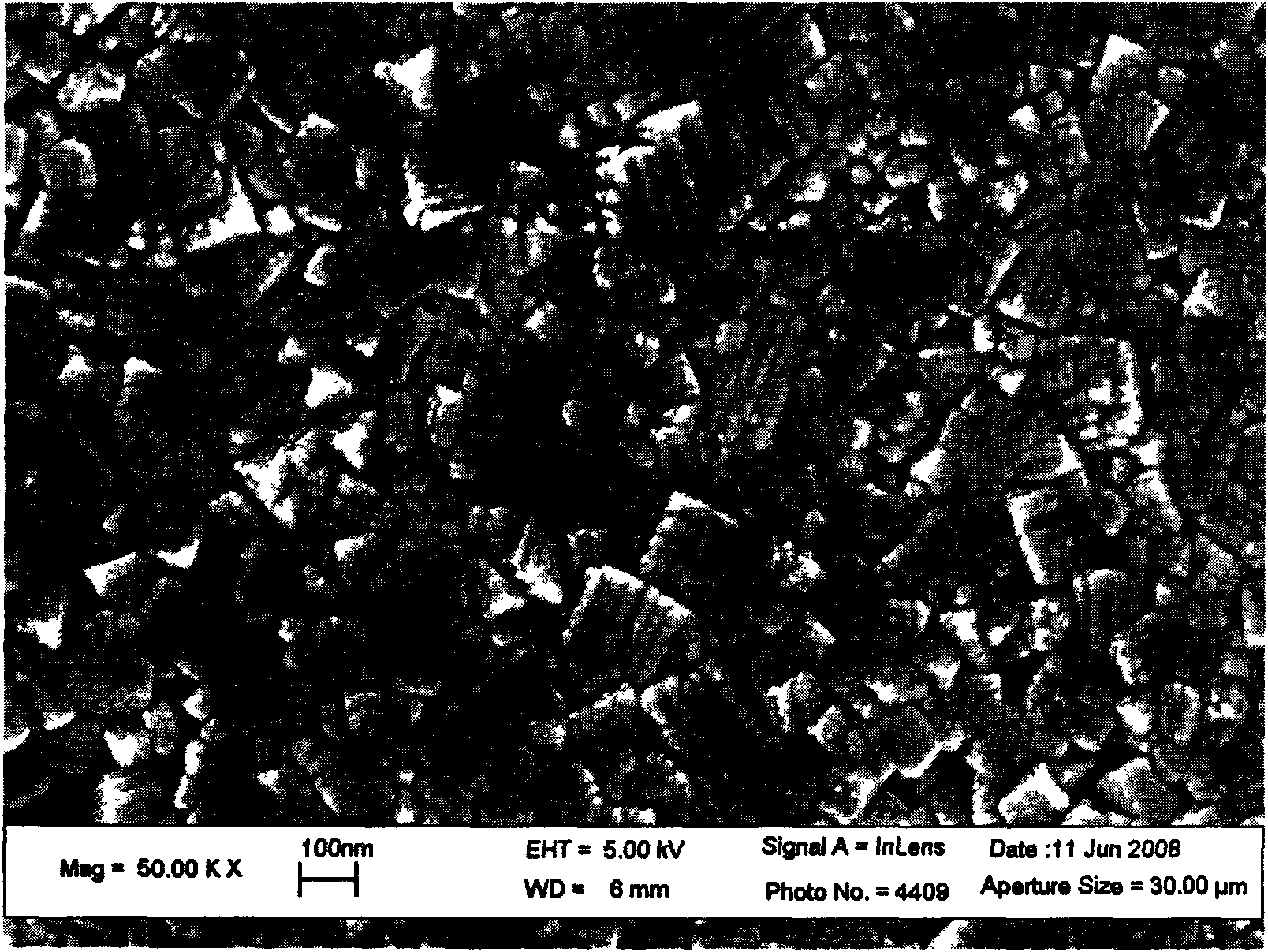

Linear electrostrictive-strain leadless piezoelectric ceramic material and preparation method thereof

InactiveCN104761259ASignificant relaxation featuresExcellent linear electrostrain response characteristicsCurie temperatureDopant

The invention discloses a linear electrostrictive-strain leadless piezoelectric ceramic material and a preparation method thereof and belongs to the technical field of electronic ceramic materials. The piezoelectric ceramic material is represented as the following component expression formula: Ba<0.85>Ca<0.15>(Zr<0.1>Ti<0.9>)<1-x>Fe<x>O<3>, wherein x=0.015-0.025. The piezoelectric ceramic material is prepared in a manner of solid-phase synthesis, wherein barium calcium zirconate titanate (BCZT) is obtained with barium titanate (BT) as a base body and zirconium and calcium as doping agents. On the basis of the BCZT, Fe2O3 is added to obtain the piezoelectric ceramic material of which the Curie temperature is about room temperature, has a significant relaxation characteristic and has an excellent linear electrostrictive-strain response characteristic. The preparation method is simple in raw mateiral components and technical processes, is easy to carry out, is good in repeatability and is high in rate of finished products.

Owner:XI AN JIAOTONG UNIV

Preparation method of potassium-sodium niobate-potassium-bismuth titanate nano ceramics

The invention discloses a preparation method of potassium-sodium niobate-potassium-bismuth titanate nano ceramics. The potassium-sodium niobate-potassium-bismuth titanate contains niobium pentaoxide, sodium carbonate, potassium carbonate, titanium dioxide and dibismuth trioxide with the stoichiometric ratio of (1-x)[(Na0.5K0.5)NbO3]-x[(Bi0.5K0.5)TiO3], wherein x is more than 0.1 but less than 0.9; the potassium-sodium niobate-potassium-bismuth titanate nano ceramics is prepared by the procedures of material blending, high-energy ball milling of the mixed material, pre-sintering, cold isostatic pressing formation, high-temperature sintering, grinding and polishing and sputtering of gold electrode. According to the invention, since the grain size of the ceramics is effectively varied owing to the different ingredient proportions adopted, a series of electronic ceramics from micron level to nanometer level is prepared and further, the electronic ceramics with different piezoelectricity and dielectricity is prepared. The preparation method adopting the method of high-energy ball milling and appropriate chemical proportions achieves great simplicity, proper cost and excellent suitability for batch production.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

Low-bubble electronic ceramic preparation system

ActiveCN109760199AReduce contentHigh strengthClay processing apparatusElectric machineryPulp and paper industry

The invention belongs to the technical field of electronic ceramic preparation, and particularly relates to a low-bubble electronic ceramic preparation system. The low-bubble electronic ceramic preparation system comprises a machine body, a motor, a stirring module, a bubble clearing module and a negative pressure module; the motor is installed at the center position of the top of the machine body, and a controller is installed at the position, located on one side of the motor, of the top of the machine body; a hollow rotating shaft is rotatably connected to a vertical center line position ofthe inner part of the machine body, and the motor is connected with the top end of the hollow rotating shaft in a transmission mode; the stirring module is installed at the top end of the inner part of the machine body; the bubble clearing module, a separating plate and the negative pressure module are sequentially arranged at the positions, located under the stirring module, in the machine body from top to bottom; a feeding module is arranged at the top of the separating plate; the stirring module comprises a mixing cabin and a stirring paddle; and the mixing cabin is rotatably connected to the bottom of a top plate of the machine body, and the bottom of the mixing cabin is fixedly connected with the outer pillar surface of the hollow rotating shaft. According to the low-bubble electronicceramic preparation system, thick liquid materials can be subjected to multi-stage debubble treatment, the content of the bubbles in the thick liquid materials is reduced effectively, and the improvement of the intensity of electronic ceramics is facilitated.

Owner:浙江新海动力设备股份有限公司

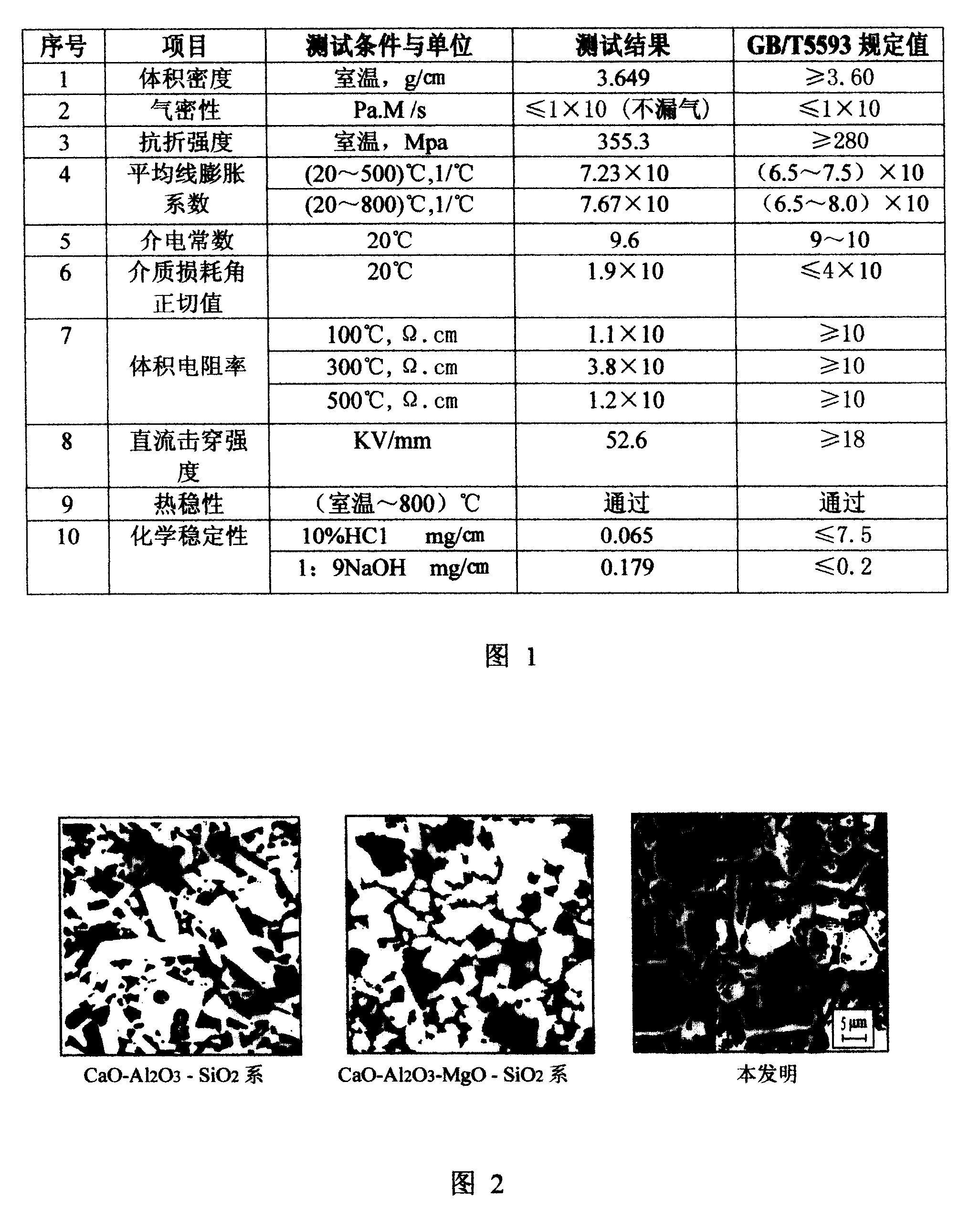

CaO-Al2O3-MgO-ZrO2-SiO2 series aluminum oxide electronic ceramics

InactiveCN101250057AEliminate yellow and gray spotsHigh tensile strengthFlexural strengthAir tightness

The invention discloses an aluminum oxide electronic ceramic of CaO-AI<2>O<3>-MgO-ZrO<2>-SiO<2> system, which is composed of 93-94 wt% of AI<2>O<3>, 3-4 wt% of SiO<2>, 0.2-0.6 wt% of ZrO<2>, 0.2-0.4 wt% of CaO, 0.8-1 wt% of MgO, 0.2-0.6 wt% of BaO and 0.01-0.05 wt% of Fe<2>O<3>, while the left is foreign material. The invention adds zirconium material into the prior ceramic materials to satisfy the glazing demand of user at expansion factor, grain phase and granularity and eliminate yellow brown spot at metallization sealing process, to improve the pass percentage of metal sealing quality of at least 96%, improve tensile strength and acid and alkali resistant degrees, and improve all quality indexes. The inventive product has better compressive performance, high air tightness, high flexural strength, high acid and alkali resistance, high direct current breakdown strength and non yellow brown spot, which is not easy to break.

Owner:大埔县特陶科技有限公司

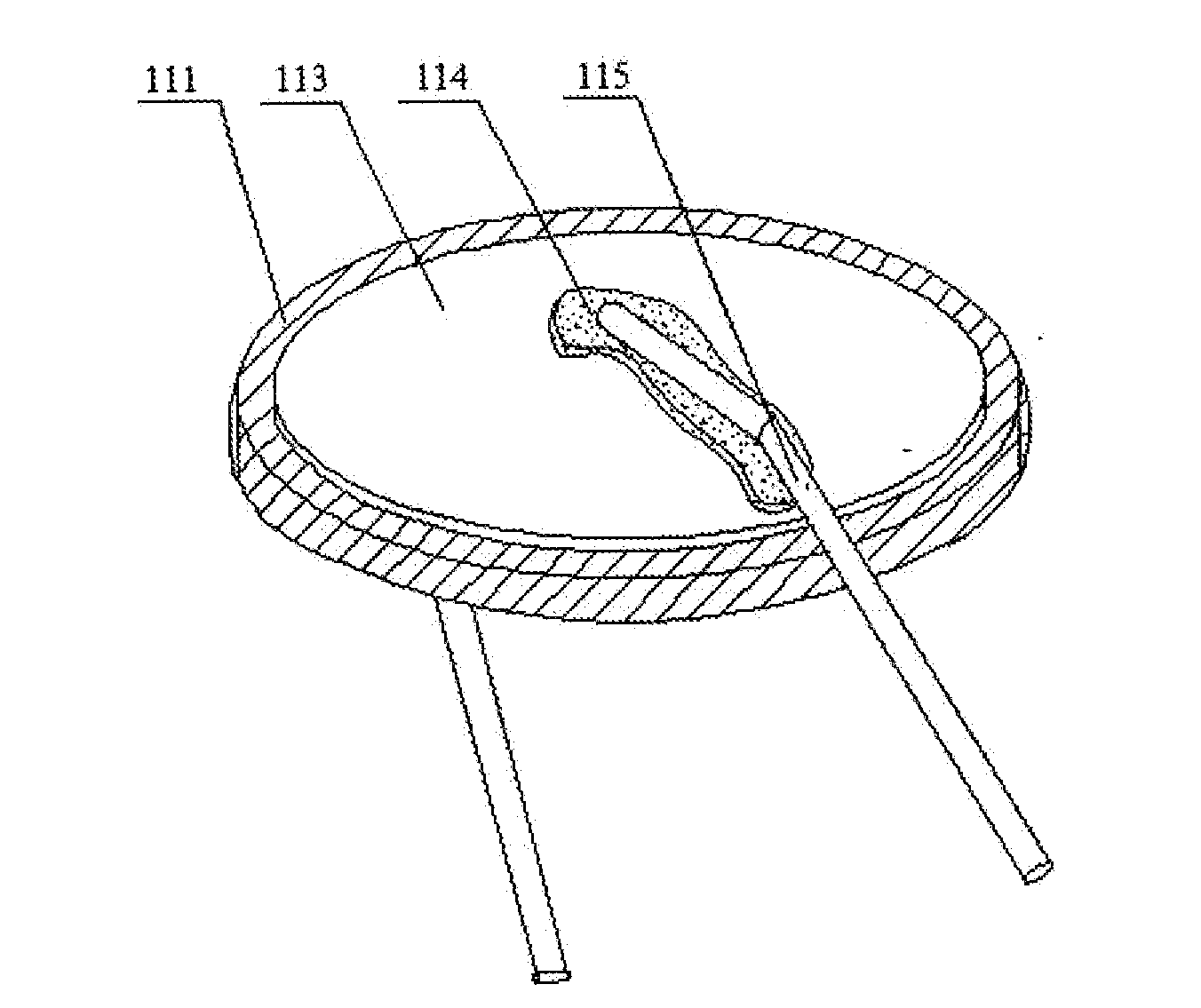

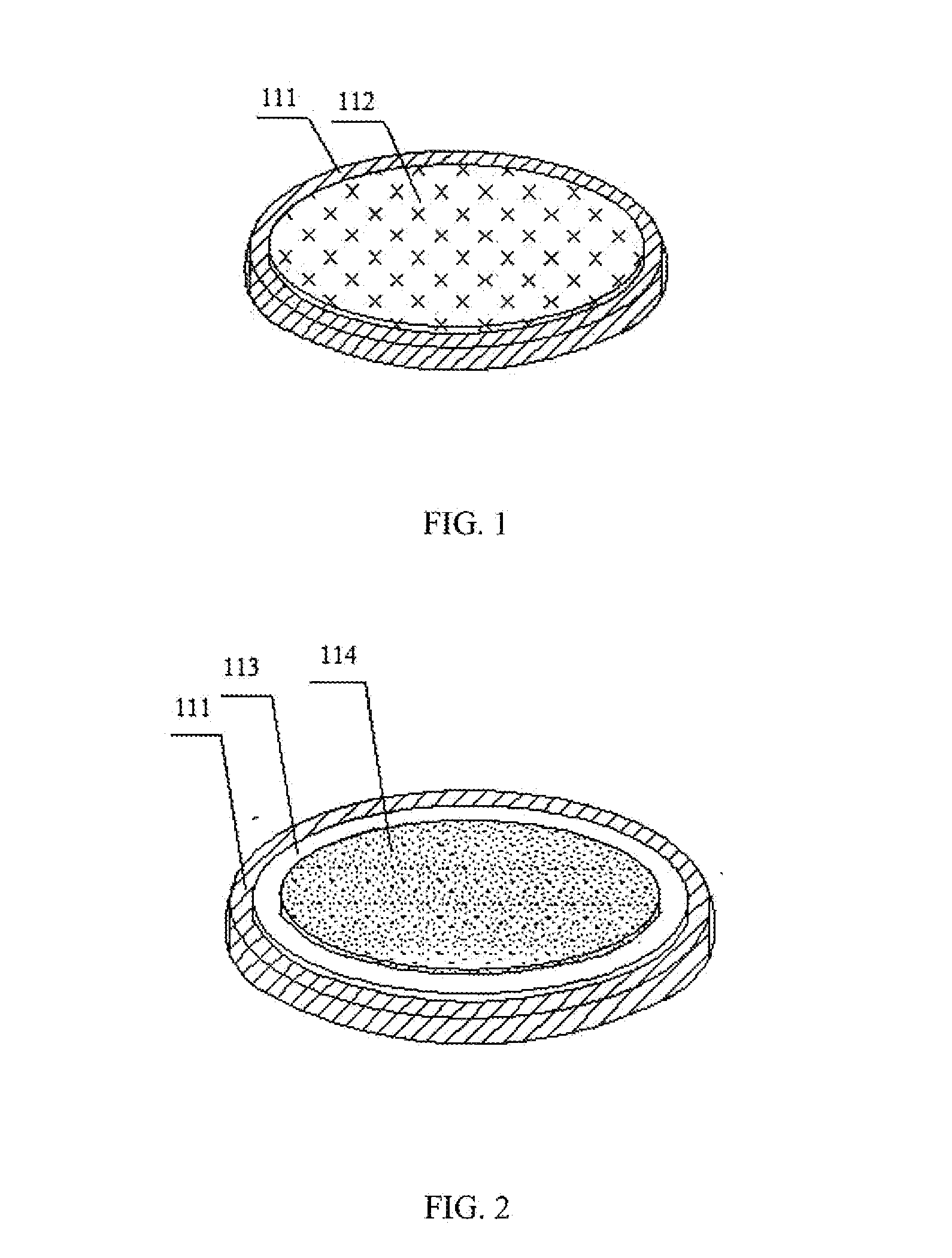

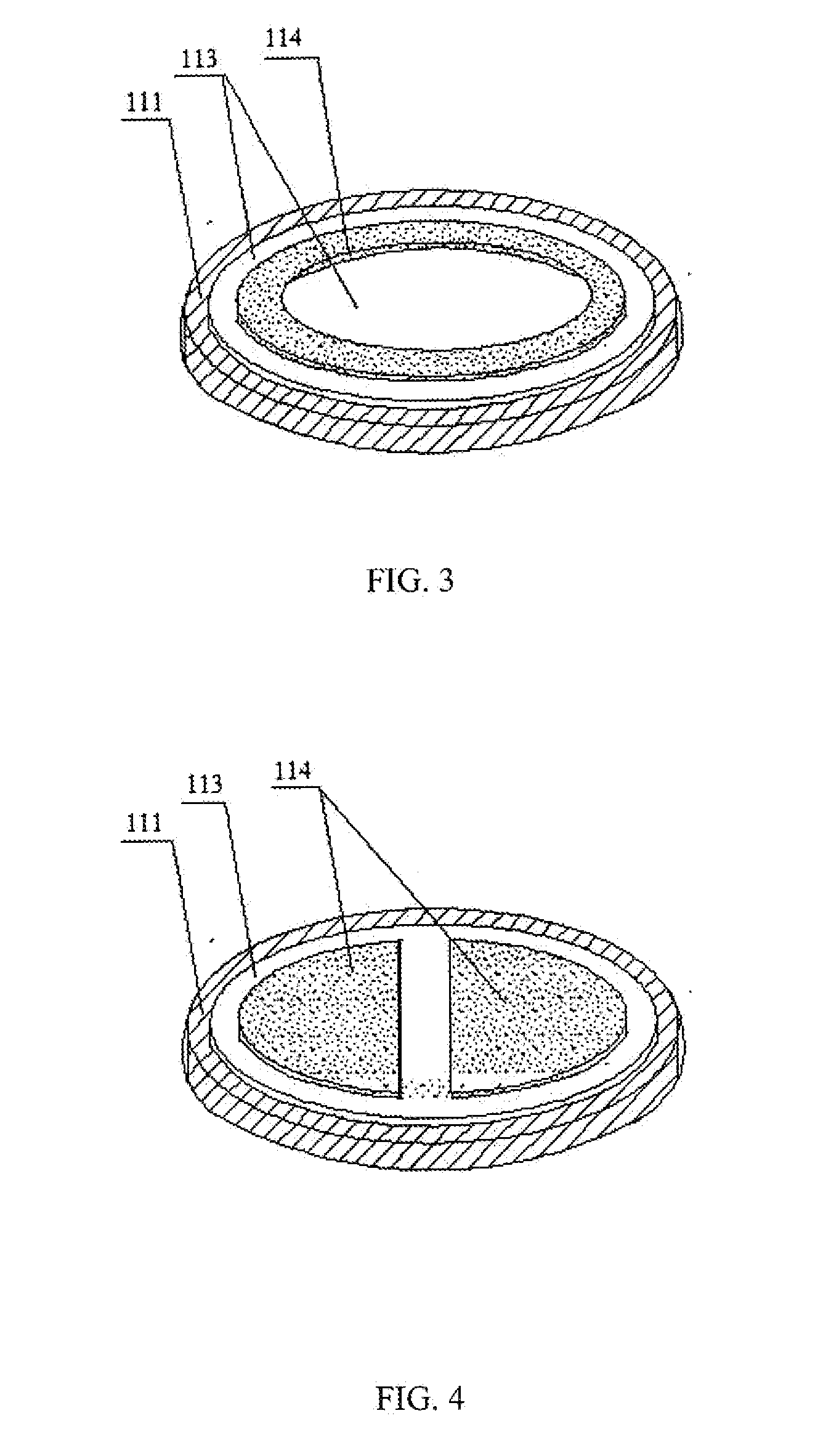

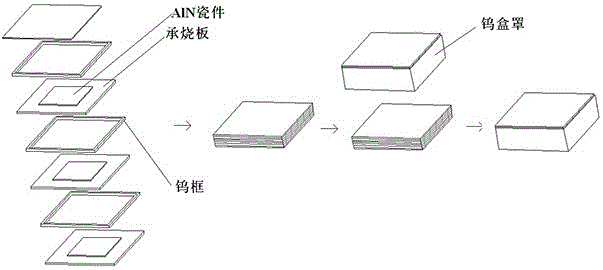

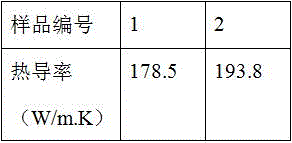

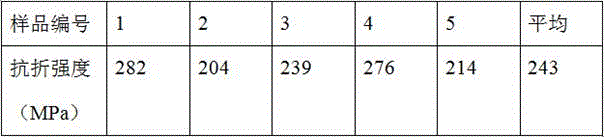

Sintering method of high-temperature co-firing aluminum nitride ceramics

InactiveCN106631036APrevent excessive volatilizationMeet the use requirementsSlurryUltimate tensile strength

The invention provides a sintering method of high-temperature co-firing aluminum nitride ceramics. The method comprises the following steps (1) manufacturing an aluminum nitride raw ceramic piece by using aluminum nitride raw ceramics and metal slurry according to a multilayer ceramic production process; (2) performing glue discharging on the aluminum nitride production ceramic piece in a glue discharging furnace; (3) putting the raw ceramic element subjected to glue discharging into a duplex sealing firing device; (4) putting the firing device containing the aluminum nitride production ceramic piece into a high-temperature atmosphere sintering furnace to be sintered. The method provided by the invention has the advantages that (1) the method can be used for preparing high-temperature co-firing aluminum nitride ceramics, and is applied to the fields of MCM (multi-chip module) base plates and encapsulation, base plates of high-power devices, cases, high-power LED (light-emitting diode) encapsulation cases and the like; (2) by using the method for sintering, the excessive volatilization of the second phase in the aluminum nitride ceramics can be avoided; the heat conductivity, the folding-resistant intensity and the metallization intensity of the obtained co-firing aluminum nitride ceramics can meet the use requirements of electronic ceramics.

Owner:NO 55 INST CHINA ELECTRONIC SCI & TECHNOLOGYGROUP CO LTD

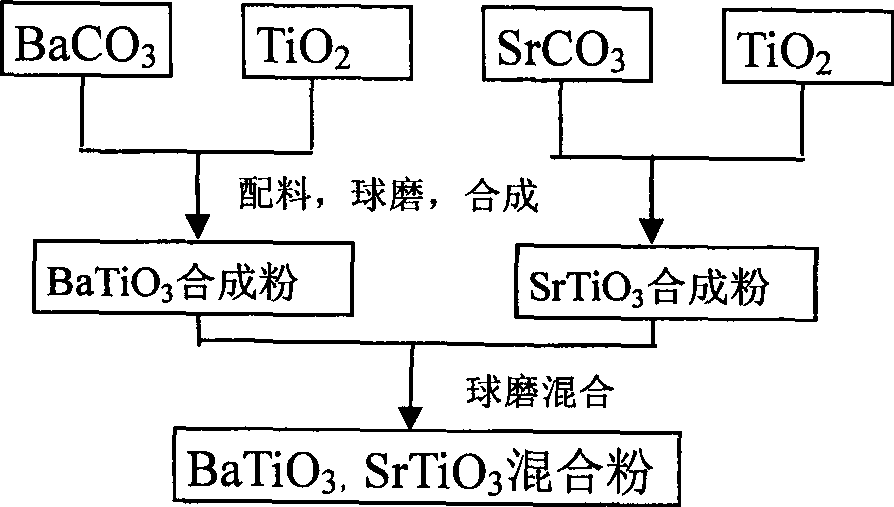

Method for preparing BaTiO3-SrTiO3 miscible ceramic powder

The invention relates to a method for preparing BaTiO3-SrTiO3 miscible ceramic powder, belonging to the technology filed of the preparation technology of the ceramic powder for special type ceramics. The invention essentially comprises the following steps: ultrasonic processing method and solid reaction process are respectively adopted to prepare sols and synthetical solid phase matrix powder materials; precursor sol solution which is prepared by the sol-gel method is used for packaging solid phase reaction matrix powder materials; ultrasonic treatment is used for realizing the complete and even mixing of the nanometer precursor sol solution and the solid phase reaction matrix powder materials; and heat treatment is used for realizing the package of the matrix powder materials by nanometer grains so as to obtain special electronic ceramics with good sintering capability. The ceramic components prepared by the miscible ceramic powder which is obtained by the method have predominant dielectric property.

Owner:SHANGHAI UNIV

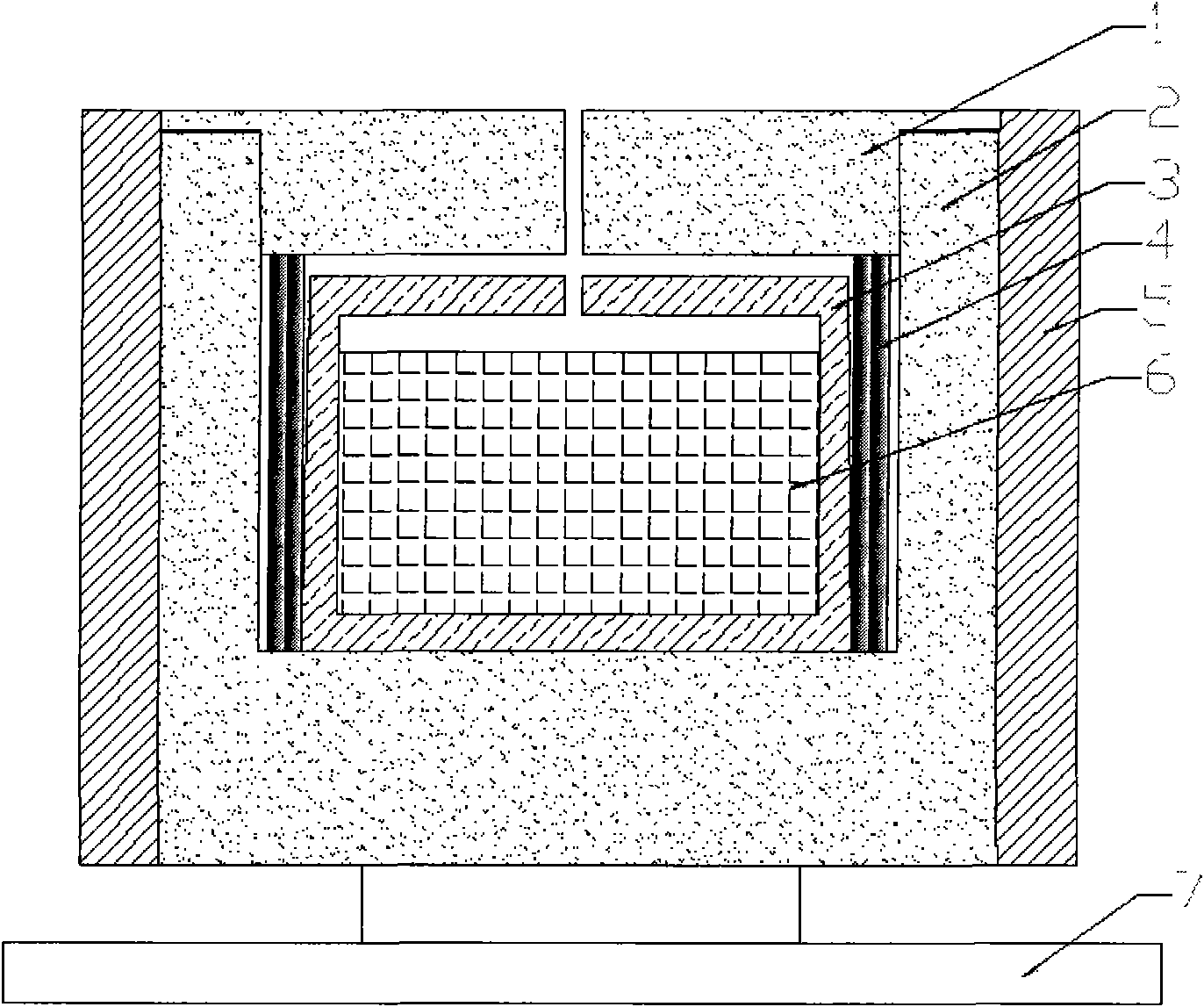

Microwave sintering method for PTC ceramics

InactiveCN101570440ALower sintering temperatureGood heating uniformityRevolutions per minuteElectric energy

The invention provides a microwave sintering method for PTC ceramics, and belongs to the technical field of electronic ceramic manufacturing process. In order to solve the problem that the PTC material has poor microwave absorbing property at a lower temperature, the method designs an assistant heating device, and the device can effectively improve the problem that the PTC green blank has low microwave absorbing efficiency at the temperature below 500 DEG C. In order to solve the problems that the PTC is heated unevenly and is easy to crack, the method designs an automatic rotating device with adjustable speed, and the rotating speed of the device is 5 to 30 revolutions per minute. The method provides a low-temperature insulation sintering process for the PTC: raising the temperature at the speed of 300 to 600 DEG C per hour from the room temperature to 500 DEG C, preserving the heat for 1 hour at 500 DEG C, then raising the temperature at the speed of 500 to 800 DEG C per hour, preserving the heat for 10 to 30 minutes with the high temperature of 1,200 to 1,250 DEG C, and then reducing the temperature to 1,100 DEG C at the speed of 500 to 600 DEG C per hour, and preserving the heat for 10 to 30 minutes at low temperature. The method also provides a process for previously removing glue in a common furnace and then carrying out microwave sintering. In order to avoid the problems that the temperature measurement for a thermoelectric couple is easily interfered under the microwave condition and has large error, the method adopts an infrared temperature gauge to measure the temperature. By using the method, the sintering time can be shortened, the sintering temperature can be reduced, and the electrical energy is greatly saved; and the performance of a product is superior to the performance of the product produced by the prior sintering method.

Owner:付明

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com