Preparation method of potassium-sodium niobate-potassium-bismuth titanate nano ceramics

A technology of bismuth potassium titanate and sodium potassium niobate, which is applied in the field of functional ceramics, can solve the problem of excessive grain size of sodium potassium niobate-bismuth potassium titanate ceramics, achieve the purpose of inhibiting grain growth and improving microscopic morphology , Improve the effect of sintering power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

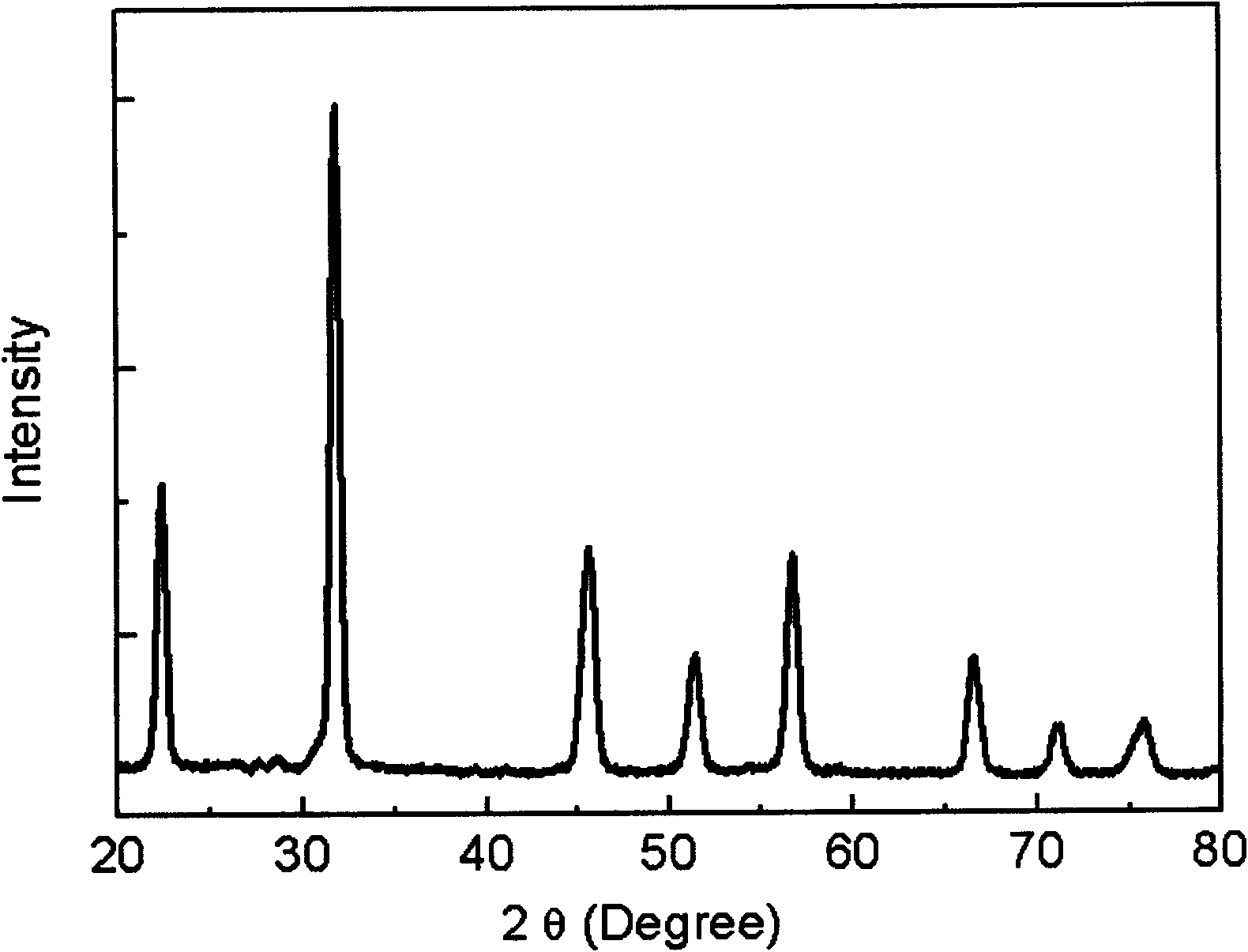

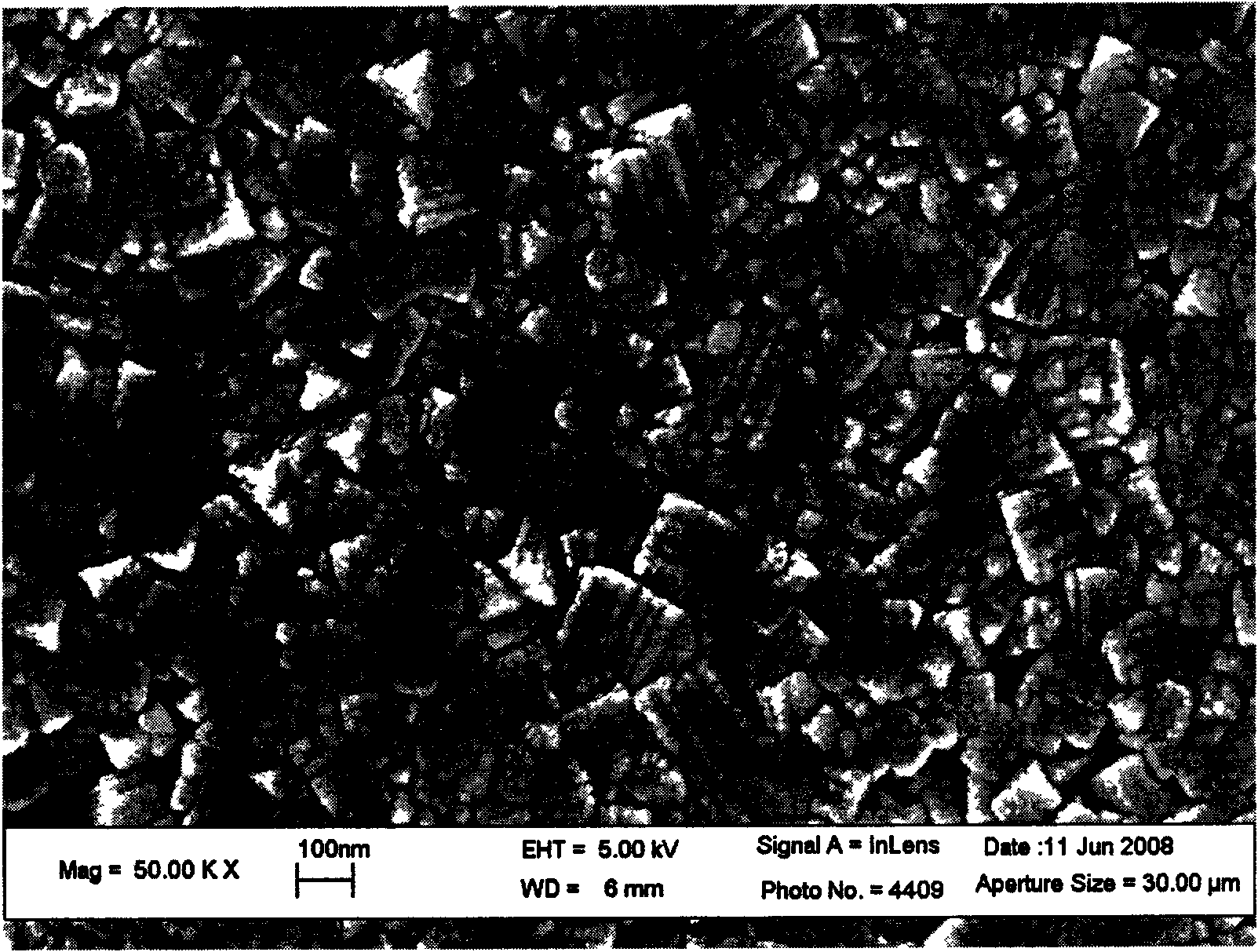

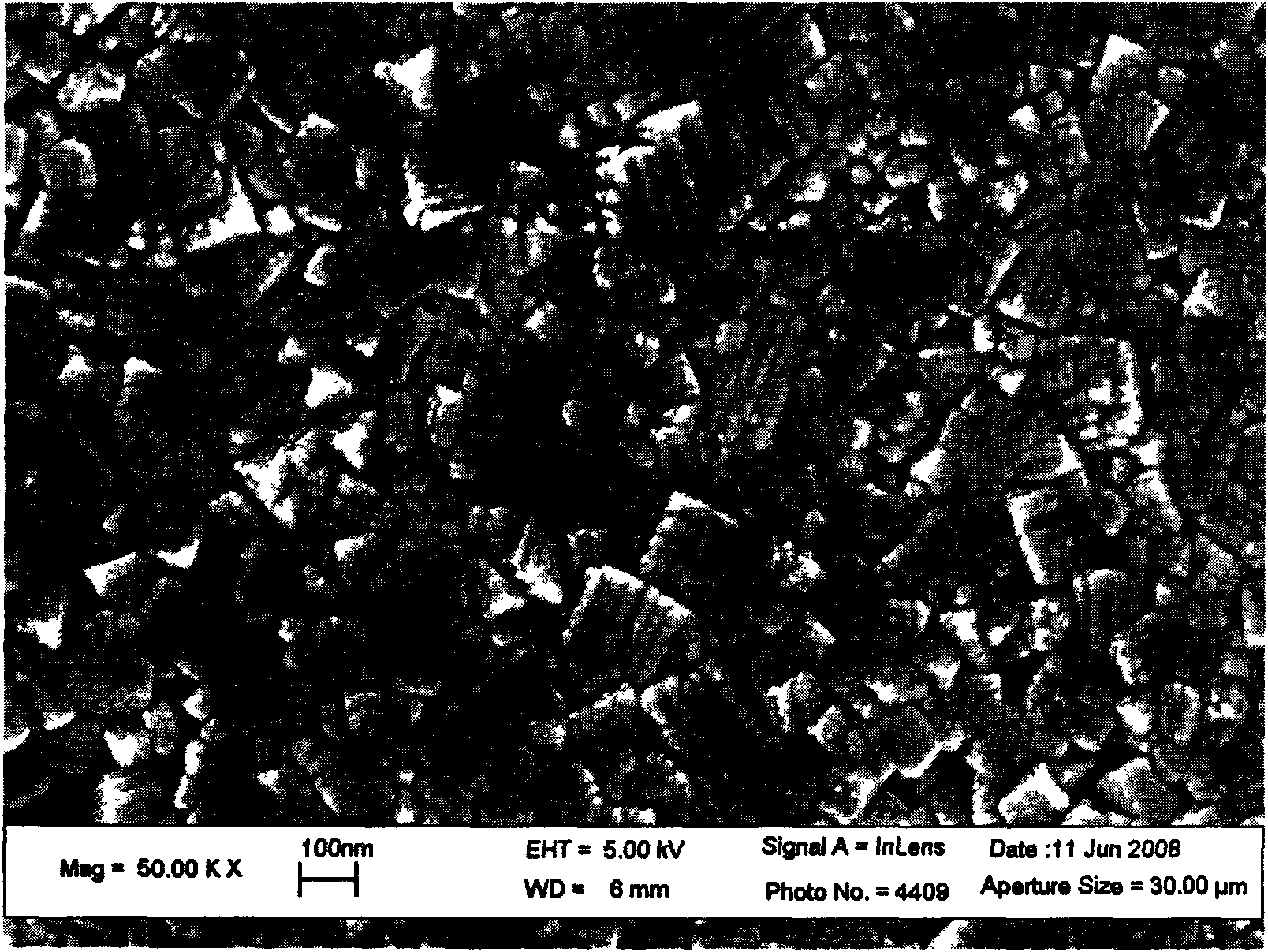

[0016] Using analytical grade niobium pentoxide, sodium carbonate, potassium carbonate, titanium dioxide, and bismuth trioxide powder as raw materials, after drying at 120°C for 24 hours, follow the chemical formula 0.85Na 0.5 K 0.5 NbO 3 -0.15Bi 0.5 K 0.5 TiO 3 Proportioning and weighing various raw material powders. The obtained powder is directly subjected to mechanical alloying ball milling without any special treatment. The quality of raw materials is 5% of the mass of the grinding ball; no ball milling medium is added, the milling time is 8 hours, and the rotation speed is 450 rpm; the powder after grinding Calcined at 850°C for 2 hours to fully react the raw material powders; figure 1 The XRD pattern of the powder is given, and the crystal grain size of the powder is 31 nanometers calculated by the Scherer formula. The calcined niobate material powder is granulated and placed in a metal mold with a diameter of 10 mm to be molded with a press at a pressure of 350 MPa, and ...

Embodiment 2

[0018] Using analytical grade niobium pentoxide, sodium carbonate, potassium carbonate, titanium dioxide, and bismuth trioxide powder as raw materials, after drying at 120°C for 24 hours, follow the chemical formula 0.80Na 0.5 K 0.5 NbO 3 -0.20Bi 0.5 K 0.5 TiO 3 Proportioning and weighing various raw material powders. The obtained powder is directly subjected to mechanical alloying ball milling without any special treatment. The quality of the raw material is 8% of the mass of the ball, without any ball milling medium, the ball milling time is 4 hours, and the rotation speed is 450 rpm; the powder after grinding Calcined at 950°C for 2 hours to fully react the raw material powders; pre-compress the calcined niobate material and put it into a vacuum bag, evacuate it, and put it into a hydraulic press at a pressure of 650 MPa and keep the pressure for 8 minutes; The green body was sintered at 1090°C for 4 hours to obtain a piezoelectric ceramic sample with a higher density. After...

Embodiment 3

[0020] Using analytically pure niobium pentoxide, sodium carbonate, potassium carbonate, titanium dioxide, and bismuth trioxide powder as raw materials, after drying at 120°C for 24 hours, follow the chemical formula 0.20Na 0.5 K 0.5 NbO 3 -0.80Bi 0.5 K 0.5 TiO 3 Proportioning and weighing various raw material powders. The obtained powder is directly subjected to mechanical alloying ball milling without any special treatment. The quality of the raw material is 15% of the mass of the milling ball. No ball milling medium is added. The milling time is 4 hours and the rotation speed is 400 rpm; the powder after grinding. Calcined at 650°C for 3 hours to fully react the raw material powder; put the calcined niobate material powder into a metal mold with a diameter of 10 mm and press it into a shape with a press at a pressure of 250 MPa. Then the green body was sintered at 1070°C for 2 hours to obtain a piezoelectric ceramic sample with a higher density. After sintering, the sample i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com