Patents

Literature

162results about How to "Good microscopic appearance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-strength lithium disilicate glass ceramic and preparation method thereof

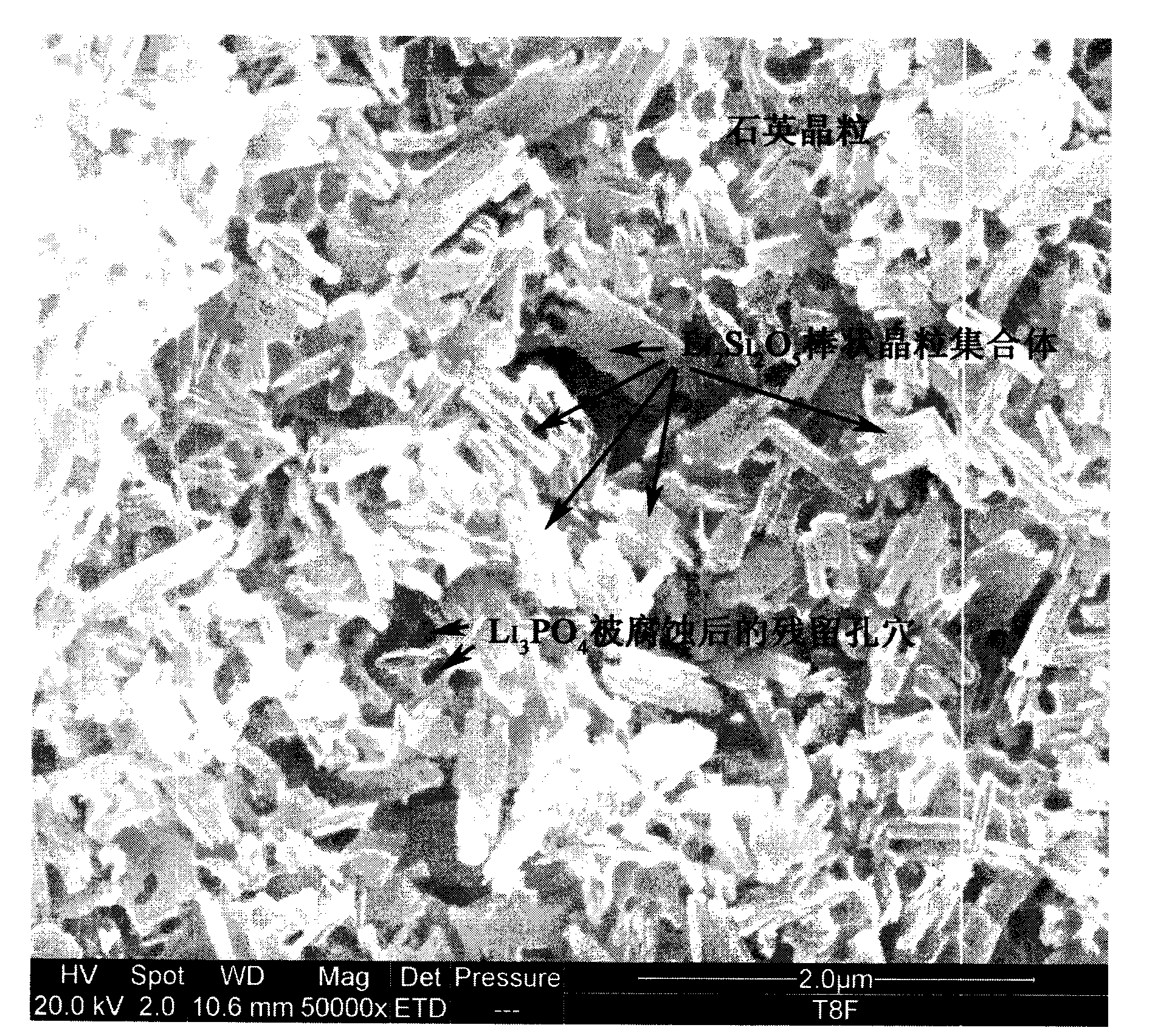

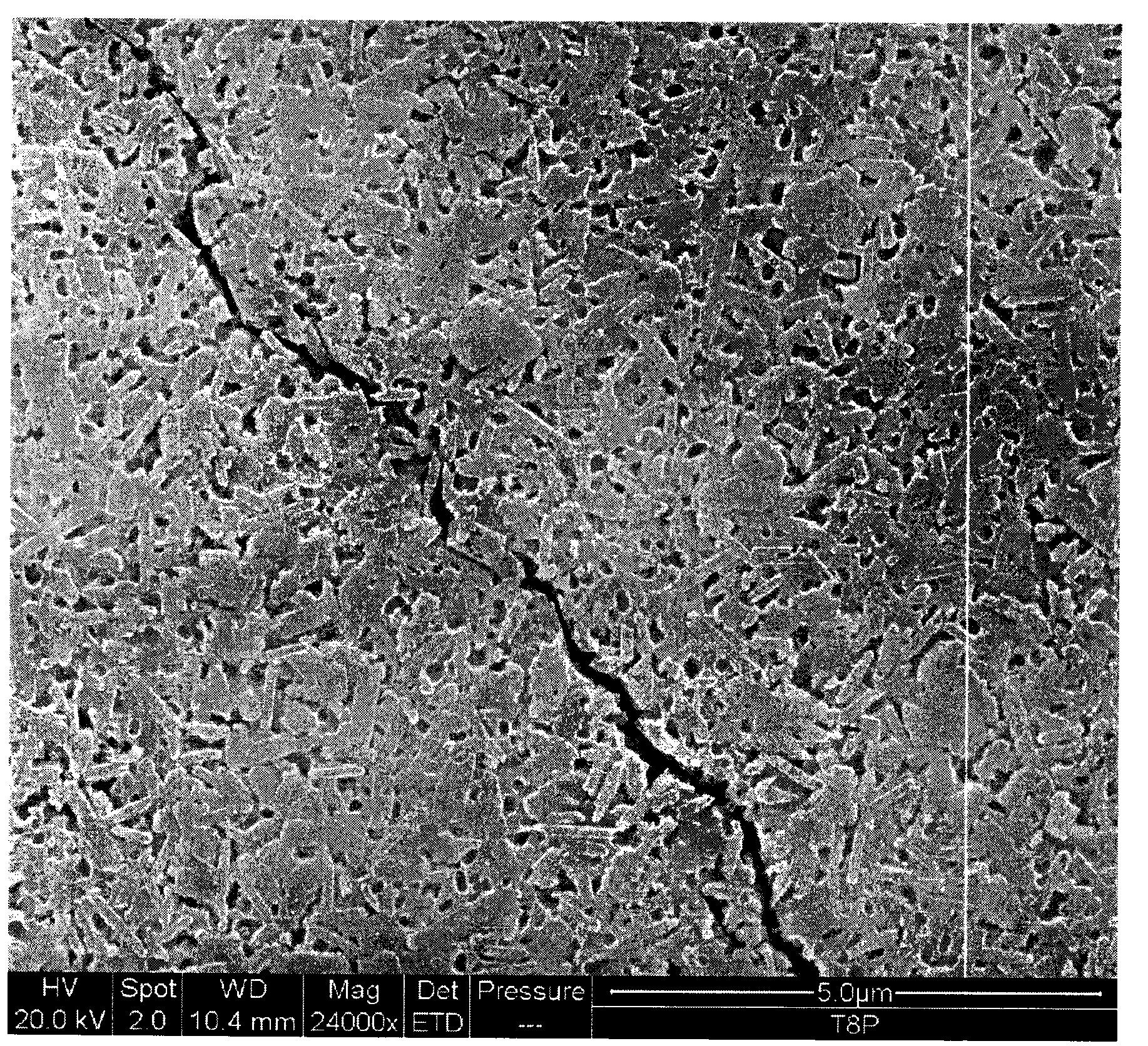

The invention discloses high-strength lithium disilicate glass ceramic and a preparation method thereof. The glass ceramic comprises the following chemical components in percentage by weight: 59-80% of SiO2, 10-18% of Li2O, 0.1-14% of MgO, 0-15% of Al2O3, 1-8% of P2O5, 0-5% of Na2O, 0-7% of CaO, 0-9% of K2O, 0.5-8% of stabilizer and 0-10% of colorant, wherein the stabilizer is selected from one or more of ZrO2, SrO, BaO and Y2O3, and the colorant is selected from one or more of Eu2O3, CeO<+>, Tb4O7, La2O3, Ta2O5, MnO2 and Fe2O3. The lithium disilicate glass ceramic is a material which contains a residual glass phase, a Li2Si2O5 principal crystalline phase and a small quantity of Li3PO1, quartz, cristobalite, zirconium oxide or magnesium-aluminum silicate phase and is prepared by controlling nucleation and crystallization processes after carrying out heat treatment on lithium disilicate matrix glass. The lithium disilicate glass ceramic is very high in bending strength and fracture toughness and favorable in translucence and chemical stability and can serve as a full-ceramic dental material applied to the field of dental restoration.

Owner:CHINA UNIV OF GEOSCIENCES (BEIJING)

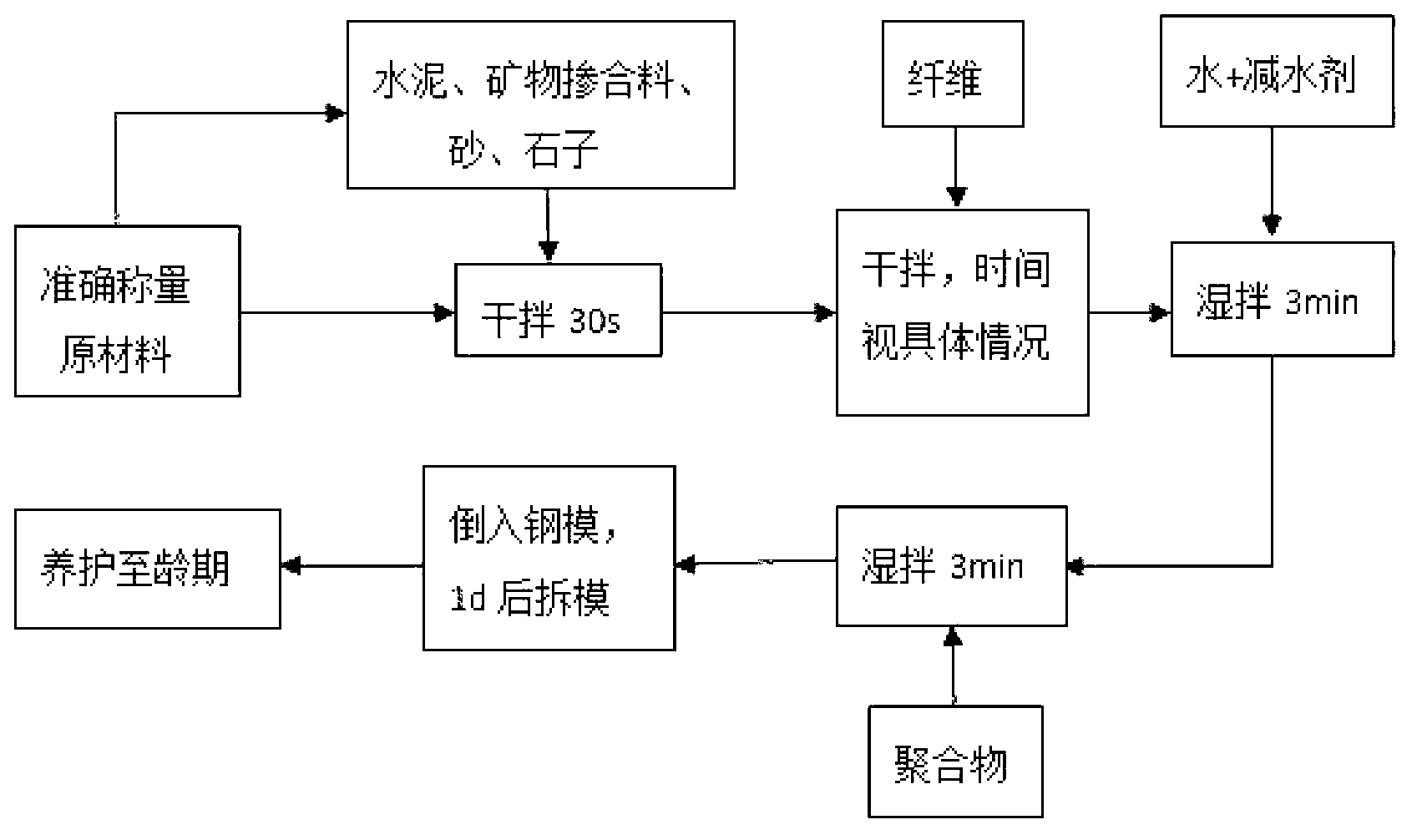

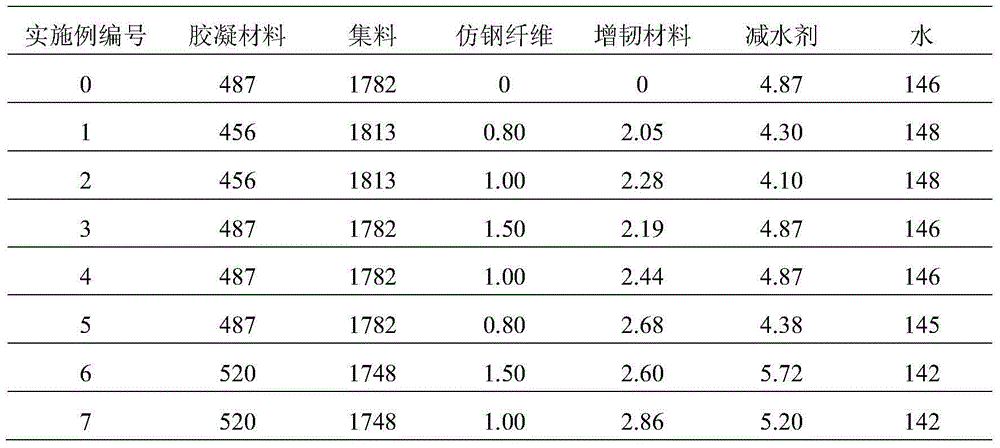

Fibre-polymer compound toughened concrete and preparation method for same

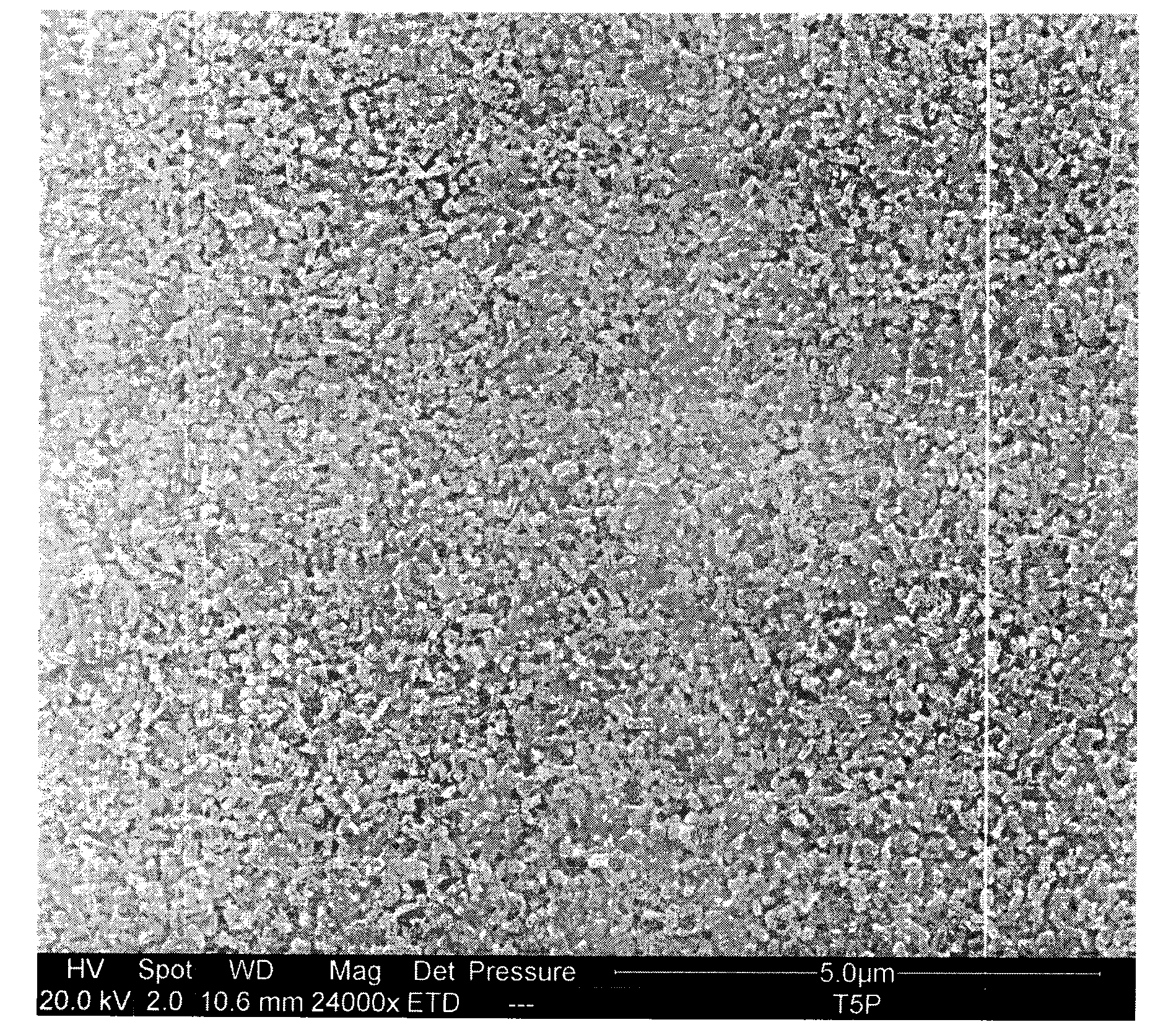

The invention discloses a fibre-polymer compound toughened concrete and a preparation method for the same. The basic raw materials of the concrete are coarse aggregate, fine aggregate, portland cement, fly ash and a polycarboxylic water reducer; moreover, fibres and a polymer are added, the fibres are any one of end-hook type steel fibres, superfine type steel fibres, modified polyester fibres, polyvinyl alcohol fibres, basalt fibres and cellulose fibres, and are doped in a ratio that the volume doped amount in per 1 m<3> concrete is 0.08%; and the polymer is any one of ethylene-vinyl acetate copolymer, ethyl acrylate, styrene-acrylate copolymer, vinyl acetate-acrylate copolymer and organosilicone acrylate, and the doped amount of each polymer is 10% based on the mass of the portland cement and the fly ash. The preparation method comprises the following steps of: pouring stone, sand, a gelling material, fibres, and water dissolved with a water reducer, and then stirring according to a blending mode of pouring dry materials at first and then pouring wet materials; and pouring the polymer, and stirring and forming.

Owner:SOUTHEAST UNIV

Rare earth permanent magnetic material and method for preparing same

The invention provides a rare earth permanent magnetic material. The rare earth permanent magnetic material comprises a primary phase and a secondary phase, and the secondary phase is isolated from the primary phase or the secondary phase covers the periphery of the primary phase. The primary phase is composed of R1x1R2y1Fe(100-x1-y1-z1-w1)Coz1Bw1N1g1; R1 is selected from Pr or / and Nd, R2 is selected from at least one of Dy, Tb and Ho, 26wt%<=x1+y1<=36wt% and 0.01wt%<=y1<=10wt%; the secondary phase is composed of R3x2R4y2Fe(100-a-b-c-v-u)Coz2Bw2N2g2, R3 is selected from at least one of Pr, Nd, Dy and Tb, R4 is Ho, 35wt%<=x2+y2<=65wt% and 0.01wt%<=y2<=20wt%. The rare earth permanent magnetic material is prepared in a dual-alloy mode, is low in cost, strong in coercive force and high in magnetic induction, and a magnet of a smaller size can be used when the rare earth permanent magnetic material is applied to a motor,.

Owner:BYD CO LTD

Method of preparing yttrium aluminium garnet fluorescent powder

ActiveCN101012376ASolve pollutionGuaranteed uniformityLuminescent compositionsNitrateLiquid temperature

The invention discloses a making method of fluorescent powder of yttrium aluminium garnet, which comprises the following steps: allocating certain quantity of alumina powder, yttrium nitrate, cerous nitrate and gadolinium nitrate into sediment mother liquid; allocating sediment agent solution through at least one of NaOH, NH3.H2O or NH3HCO3; maintaining sediment mother liquid temperature between 10 and 70 deg.c; stirring evenly; adding sediment agent solution into sediment mother liquid; stopping adding sediment agent when pH value is 6.8-11; insulating and stirring; separating solid from liquid of sediment mother liquid; washing solid through clean water; drying; adding fluoride in the powder as reacting adjuvant; placing blended powder into high-temperature stove; heating protected by gas; cooling; obtaining sintered fluorescent powder bulk; grinding; sieving; obtaining the product.

Owner:JIANGSU BREE OPTRONICS CO LTD +1

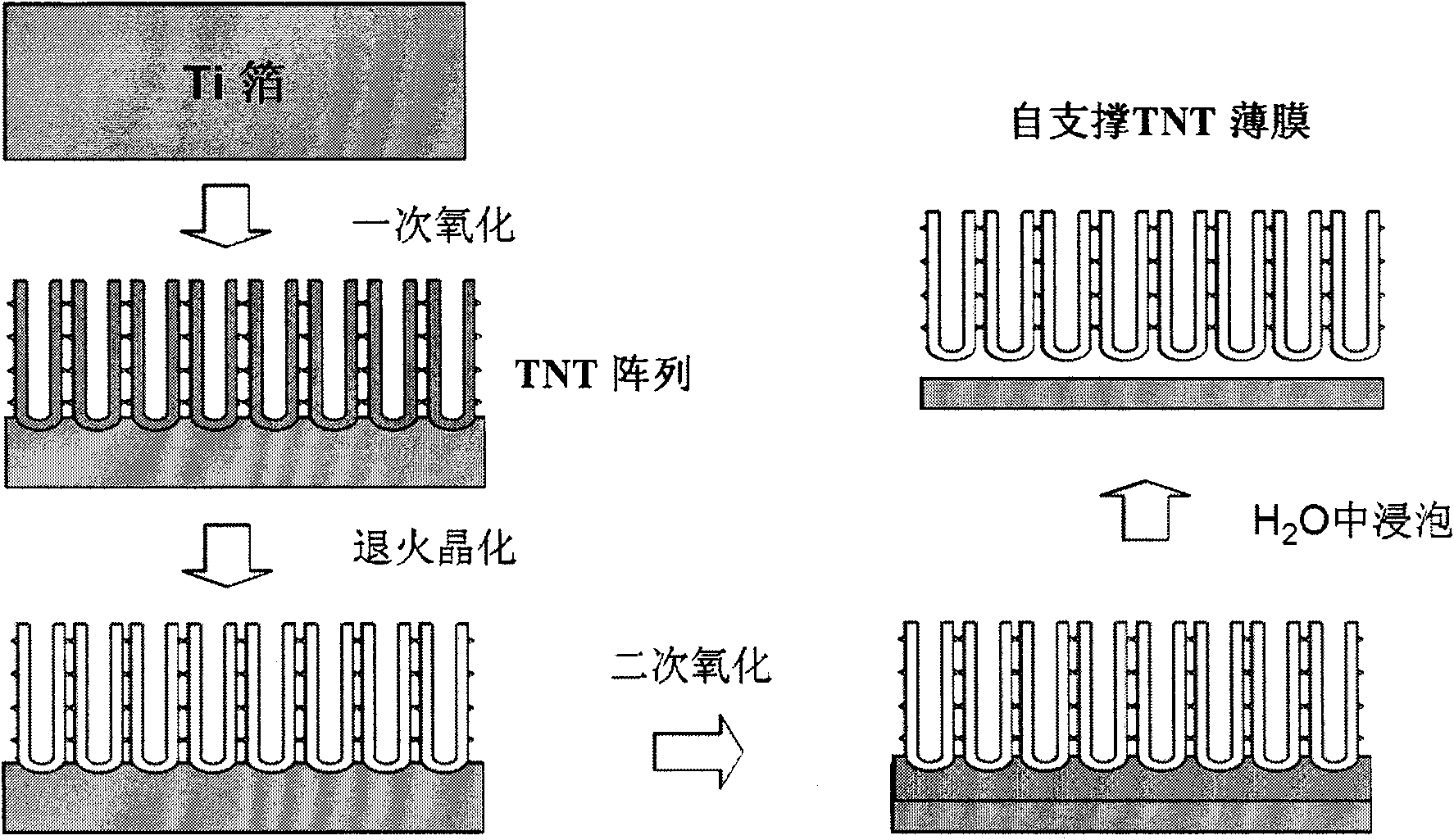

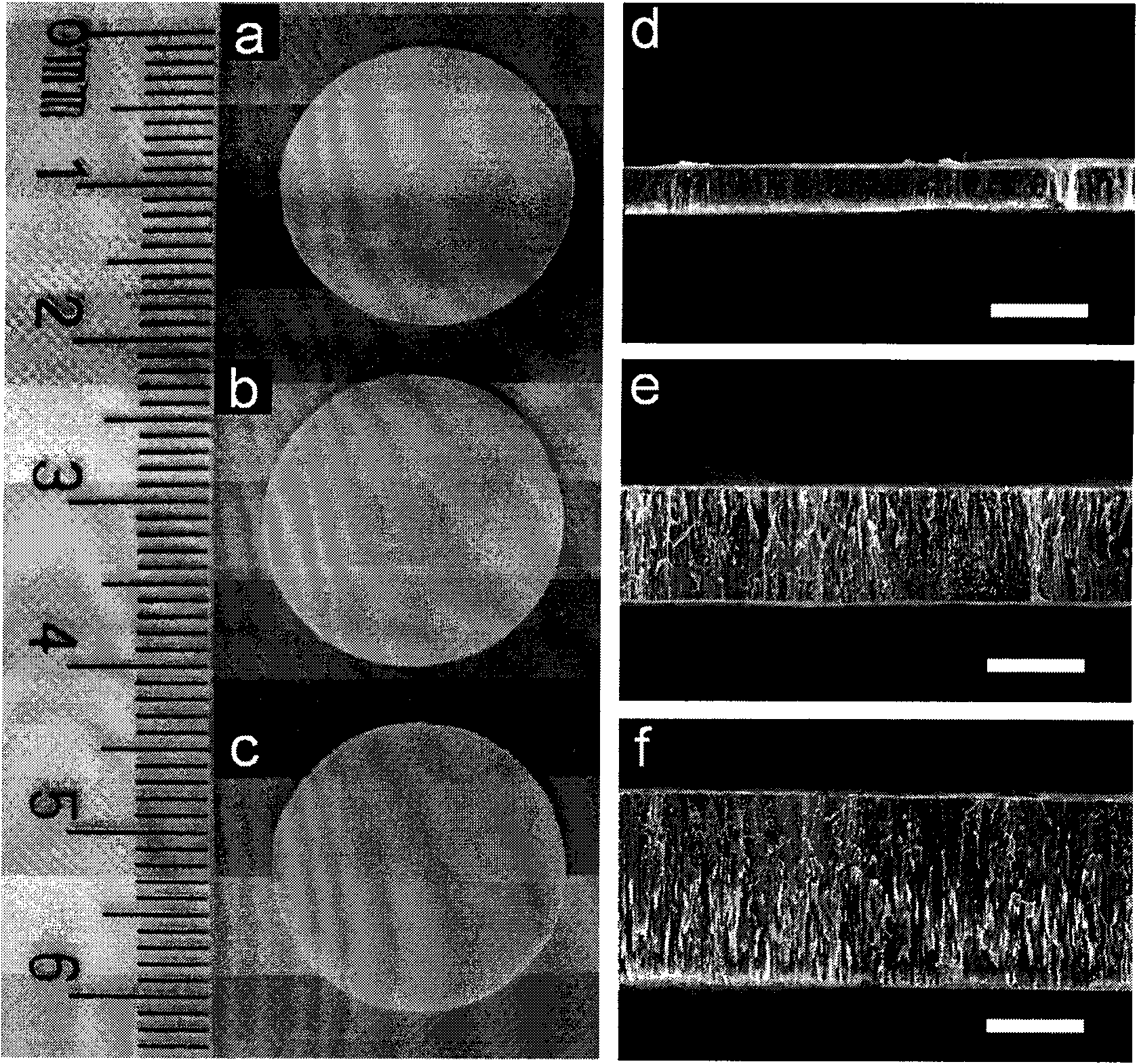

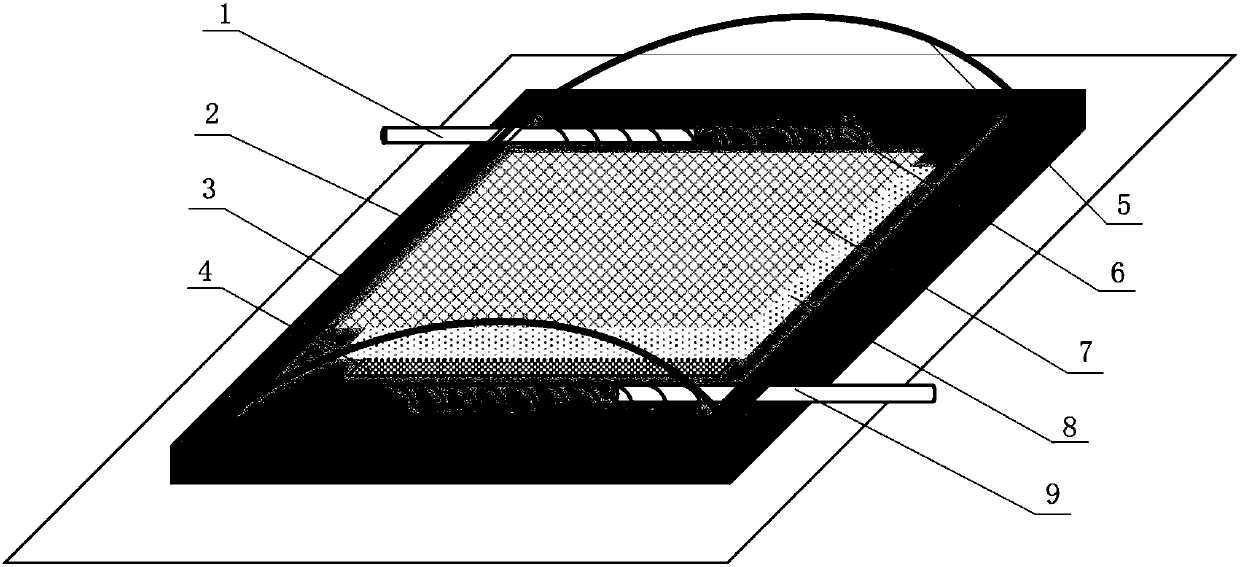

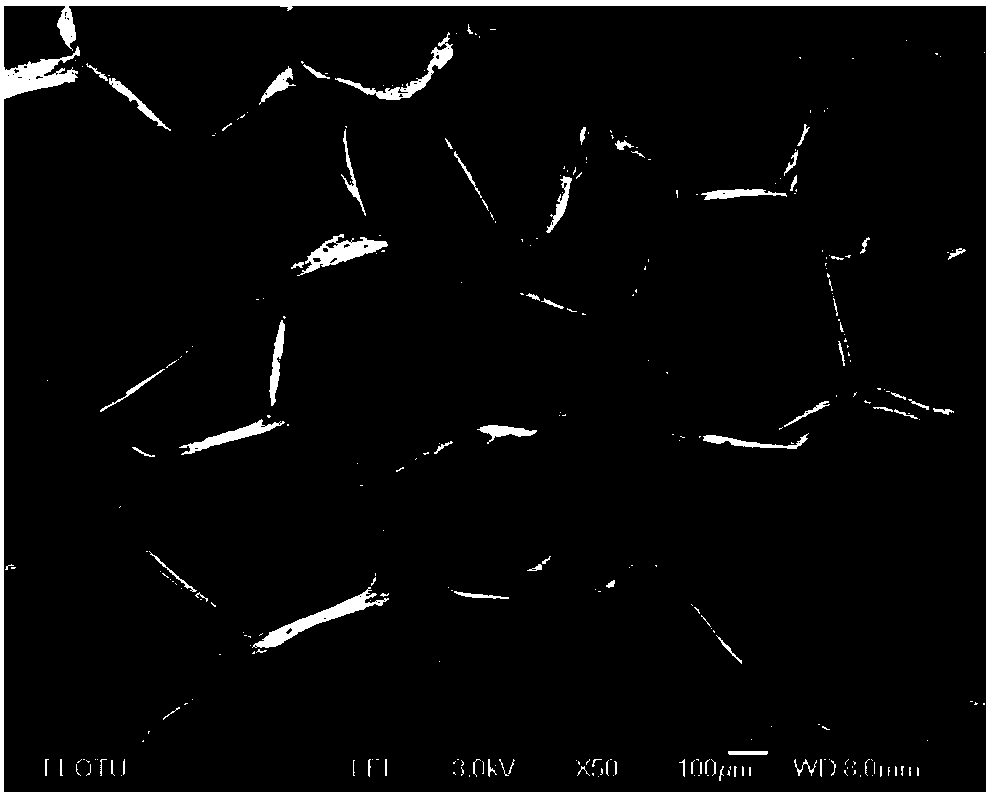

Self-standing TiO2 nanotube array membrane and preparation method thereof

InactiveCN101857966AHighly crystallineSimple structureLight-sensitive devicesSolid-state devicesTio2 nanotubeAnodic oxidation

The invention relates to a self-standing TiO2 nanotube array membrane and a preparation method thereof. The preparation method comprises: a), performing the primary anodic oxidation of a titanium foil, and forming a TiO2 nanotube array membrane on the titanium foil; b), annealing and crystallizing the titanium foil obtained by the processing of the step a); c) performing the secondary anodic oxidation of the processed titanium foil, and forming an amorphous oxide layer with a certain thickness between the titanium foil and the TiO2 nanotube array membrane; and d) stripping the TiO2 nanotube array membrane from the amorphous oxide layer. Meanwhile, the invention also provides a preparation method of the self-standing TiO2 nanotube array membrane and a dye-sensitized solar cell prepared by using the membrane. The self-standing TiO2 nanotube array membrane of the invention is flat in a large area and can be used for constructing an element such as the dye-sensitized solar cell based on the TiO2 nanotube array membrane conveniently.

Owner:PEKING UNIV

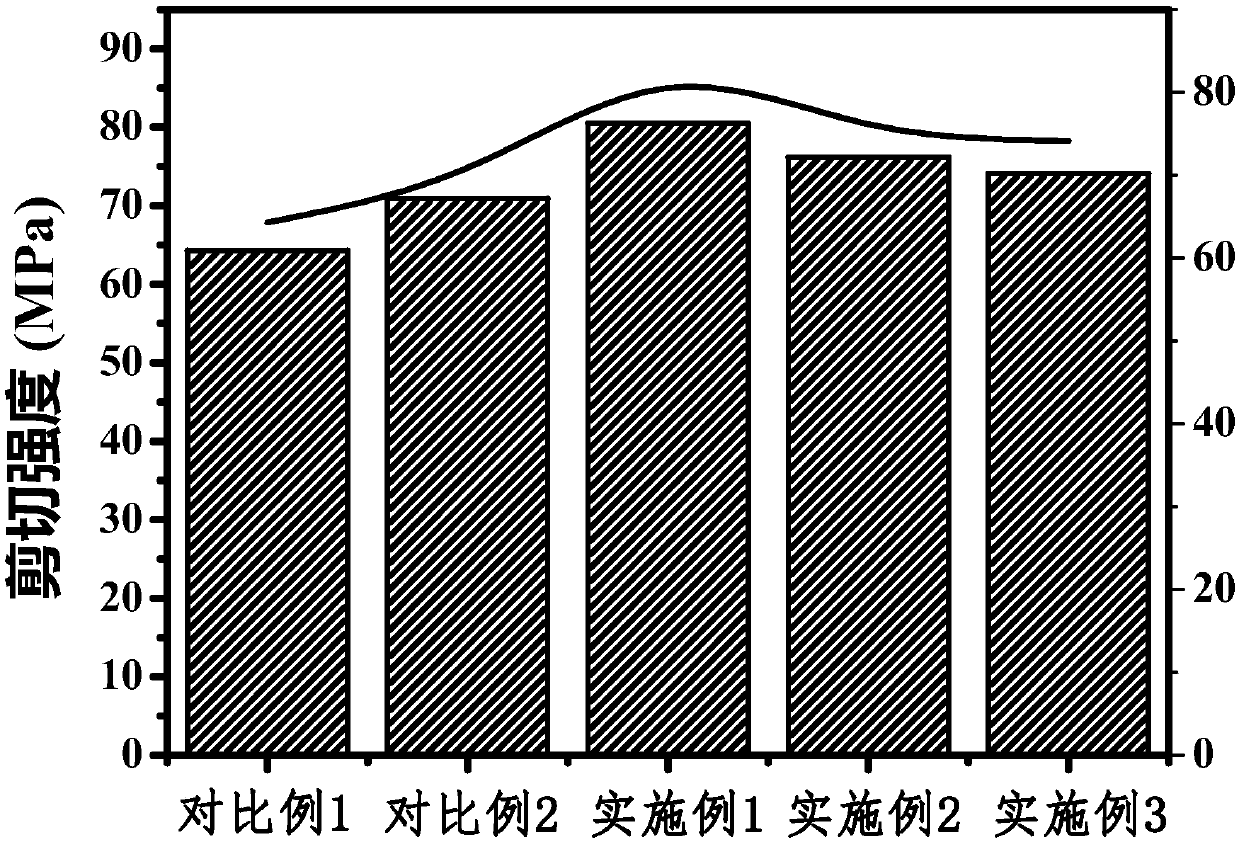

Preparation method of double sizing agent modified carbon fiber reinforced epoxy resin based composite

The invention relates to a preparation method of a double sizing agent modified carbon fiber reinforced epoxy resin based composite. According to the preparation method, through multi-layer modification of an OA-POSS mixed SiO2 sizing agent and a CNT sizing agent, introduction of complicated chemical bonds is avoided, grafting modification is performed on carbon fiber surfaces, and the modified carbon fiber reinforced epoxy resin based composite is obtained through curing at the normal temperature by use of a vacuum assisted forming process. The shearing performance of the composite is improved by 24%, the tensile property of the composite is improved by 29%, which are both higher than the mechanical properties in a thermosetting molding process.

Owner:HEBEI UNIV OF TECH

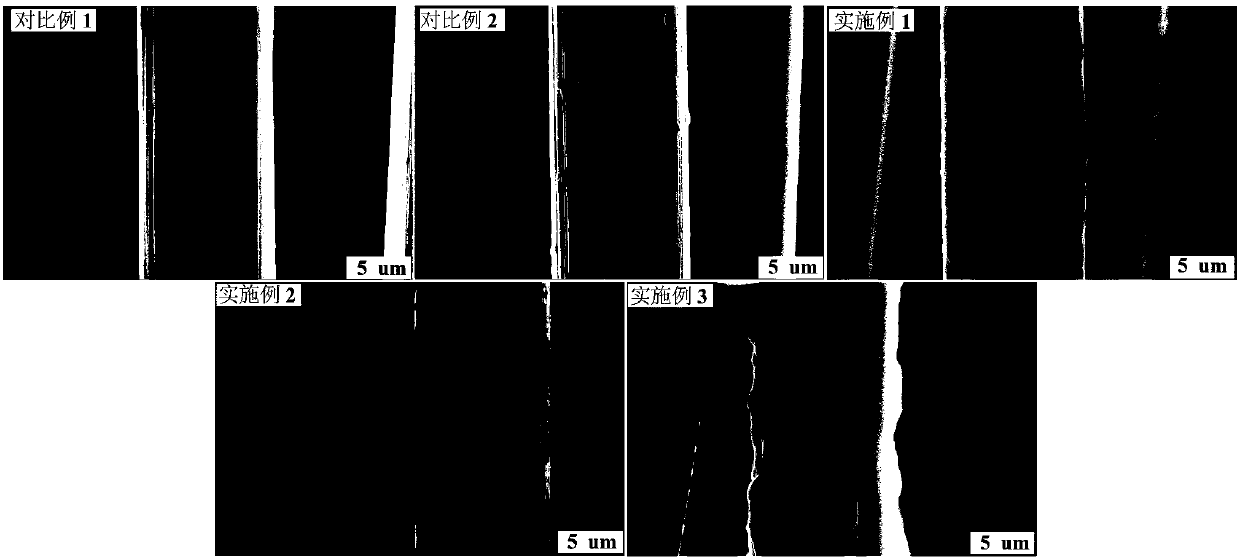

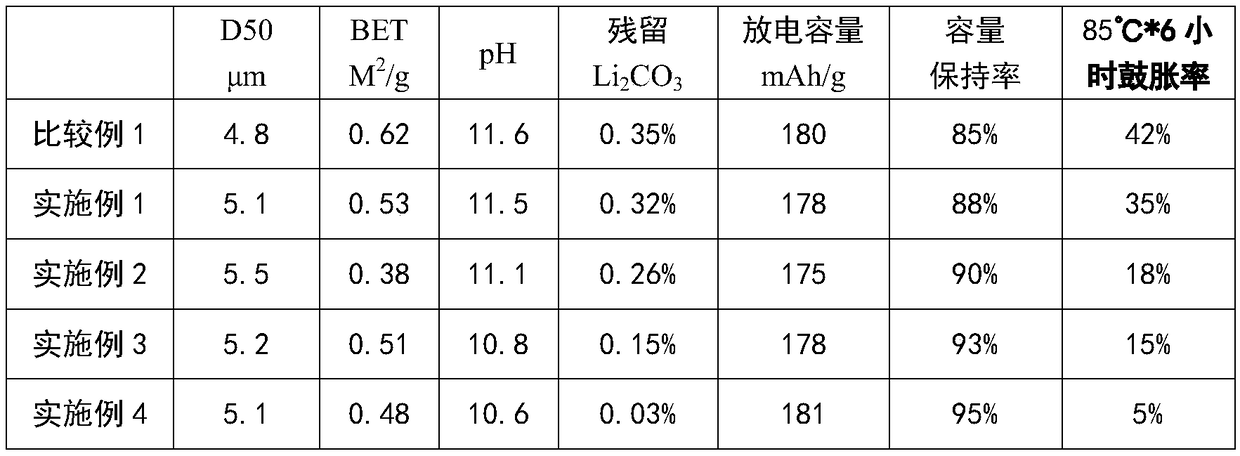

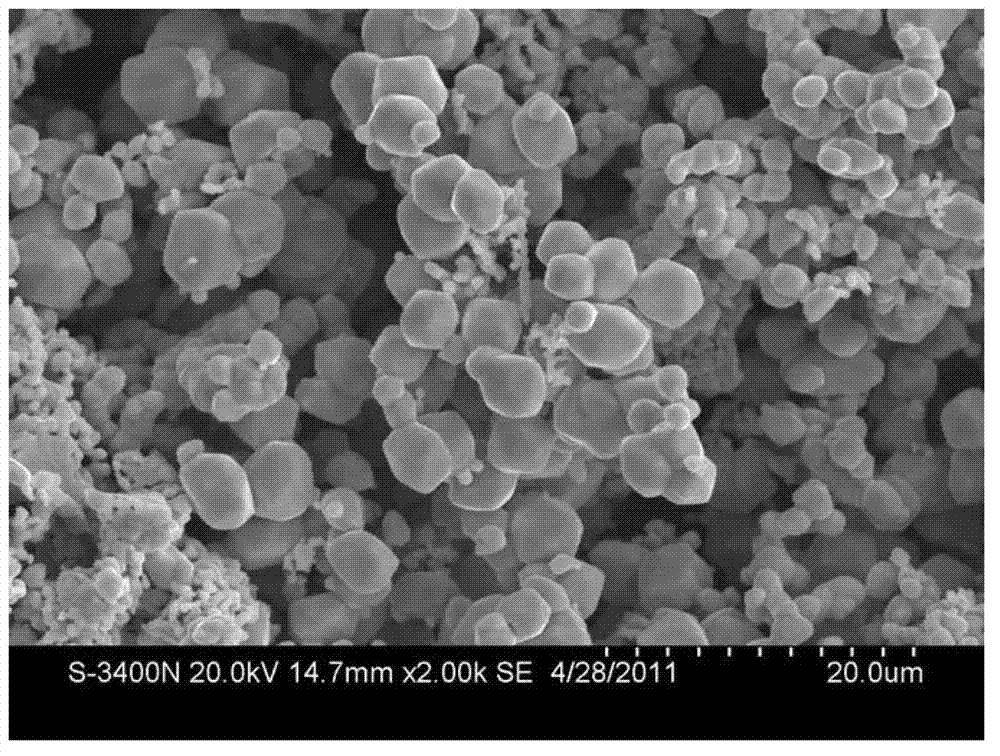

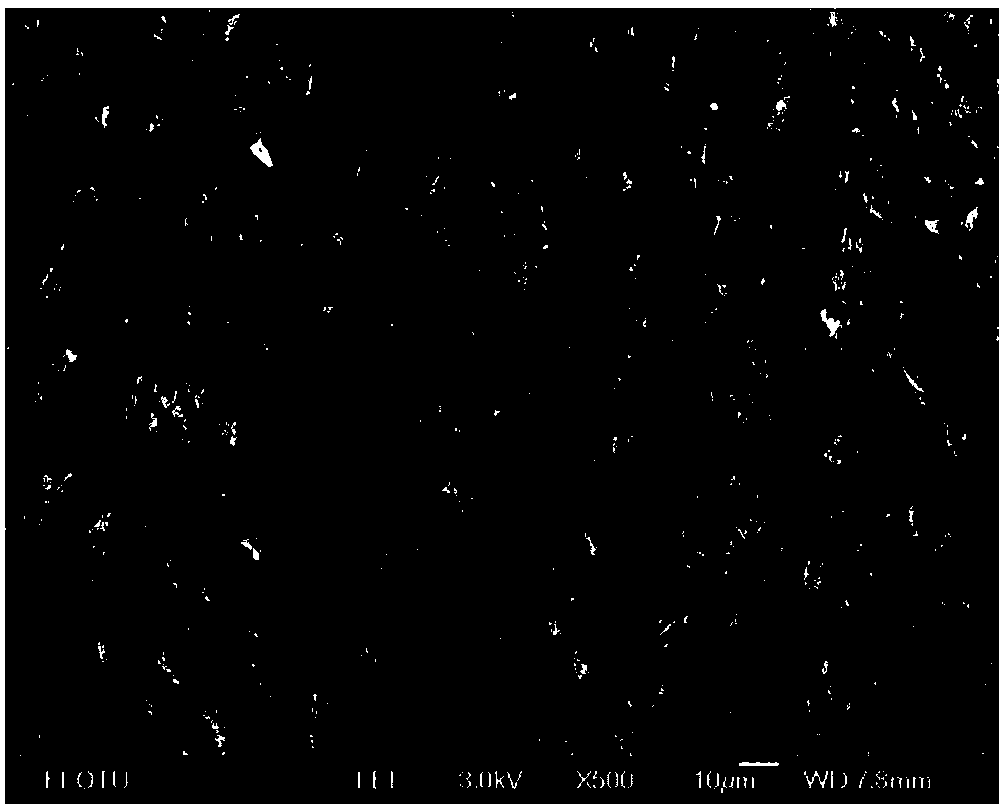

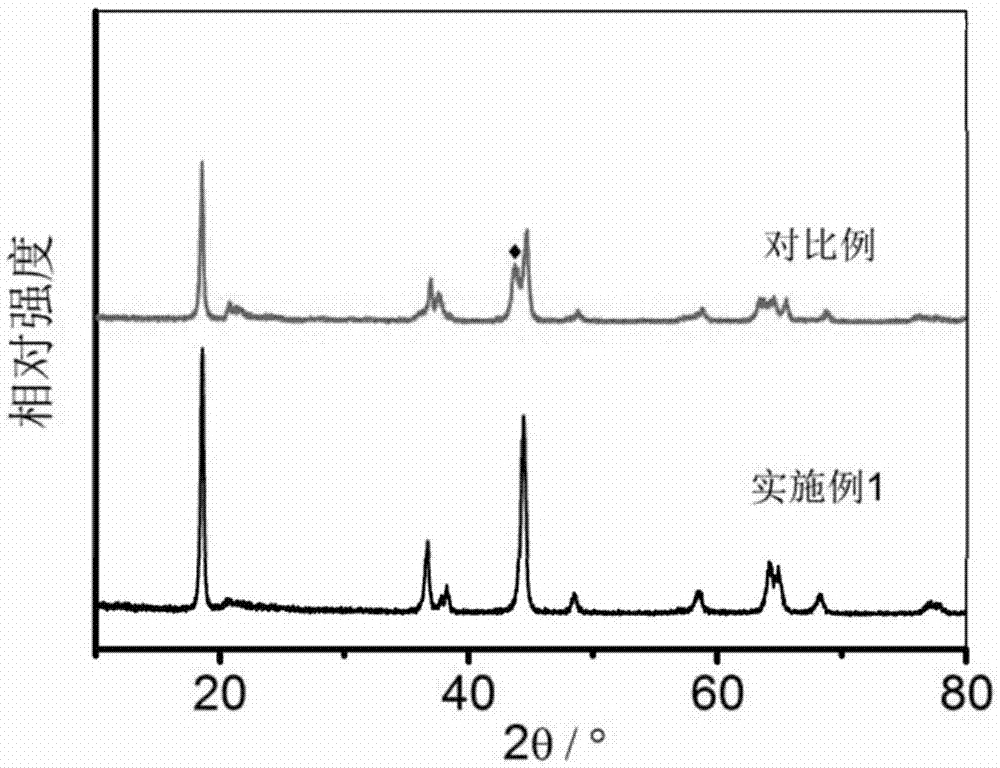

A high-voltage monocrystalline ternary material and a preparation method thereof

InactiveCN109065880AGood electrochemical propertiesGood microscopic appearanceCell electrodesChemistryElectrochemistry

The invention discloses a high-voltage single crystal ternary material and a preparation method thereof. The chemical formula of the high-voltage single crystal nickel-cobalt-manganese ternary material in the invention is LiNi0. 5Co0. 2Mn0. 3MxO2, wherein x=0. 01-0.1, coprecipitating Ni-Co-Mn hydroxide coprecipitate body is formed by coprecipitation method, and then proper amount of lithium carbonate or lithium hydroxide is added to form lithium carbonate or lithium hydroxide-Nickel cobalt manganese hydroxide co-sediment mixed paste, mixed with paste, evenly mixed, dried, ground, sieved with 160 mesh sieve, the obtained mixture is loaded into an alumina crucible, put into an oxidation furnace for burning, and the firing temperature is controlled at 900-1050 DEG C, heat preservation 10-15 hour, that sintered body is subject to crushing, airflow classification, surface coating treatment of the alumina sol and low-temperature atmosphere heat treatment to obtain a high-voltage monocrystalline nickel-cobalt-manganese ternary material powder. The invention has the characteristics of good electrochemical characteristics under the high-voltage condition, excellent micro-morphology, simplemanufacturing method and easy industrial production.

Owner:CAIHONG GRP ELECTRONICS CO LTD

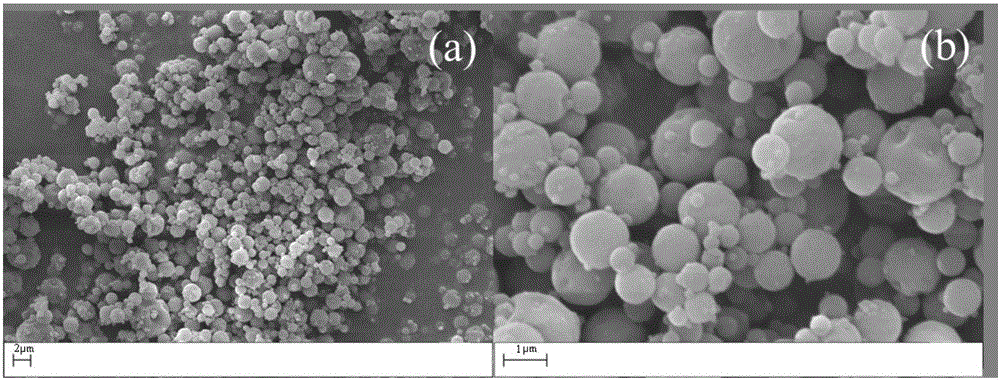

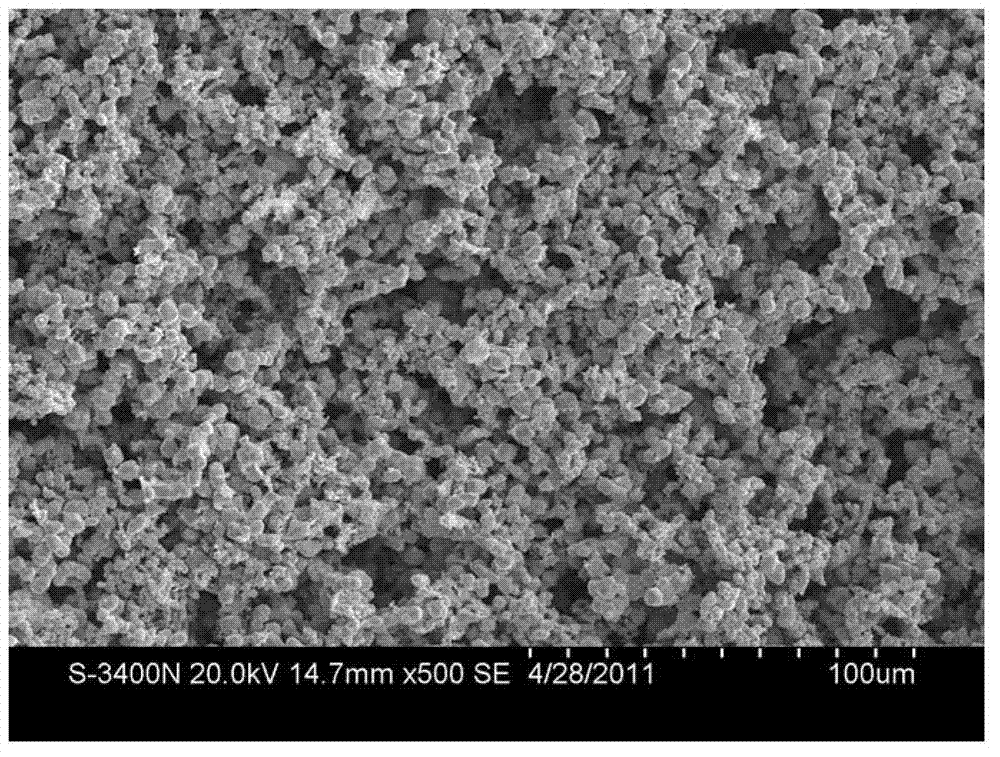

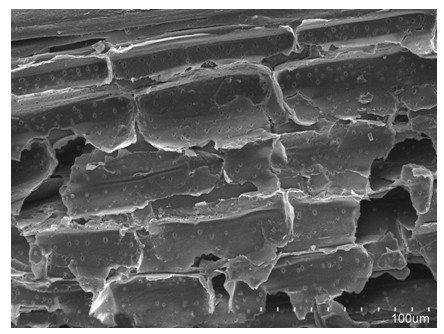

Alkali lignin carbon nanometer microsphere as well as preparation method and application thereof

InactiveCN105819426AGood microscopic appearanceGood dispersion performanceNanotechnologyDimethyl formamideNanometre

The invention belongs to the technical field of carbon nanometer materials, and discloses an alkali lignin carbon nanometer sphere, a preparation method and an application thereof. The preparation method is as follows: using N, N-dimethylformamide or glacial acetic acid as a solvent, configuring an alkali lignin electrostatic spray solution with a mass fraction of 20% to 50%, and then transferring it to an electrostatic spraying device , the alkali lignin nanospheres are obtained by electrostatic spraying, and then the alkali lignin nanospheres are pre-oxidized at a temperature of 250-280°C, and finally carbonized at a temperature of 400-900°C to obtain alkali lignin carbon nanospheres. The invention uses low-cost, renewable and degradable commercial alkali lignin as a carbon source, and has the advantages of energy saving and environmental protection. The obtained alkali lignin carbon nano-microspheres have good microscopic appearance and good dispersion performance, which improves the use performance of the lignin carbon material.

Owner:SOUTH CHINA UNIV OF TECH

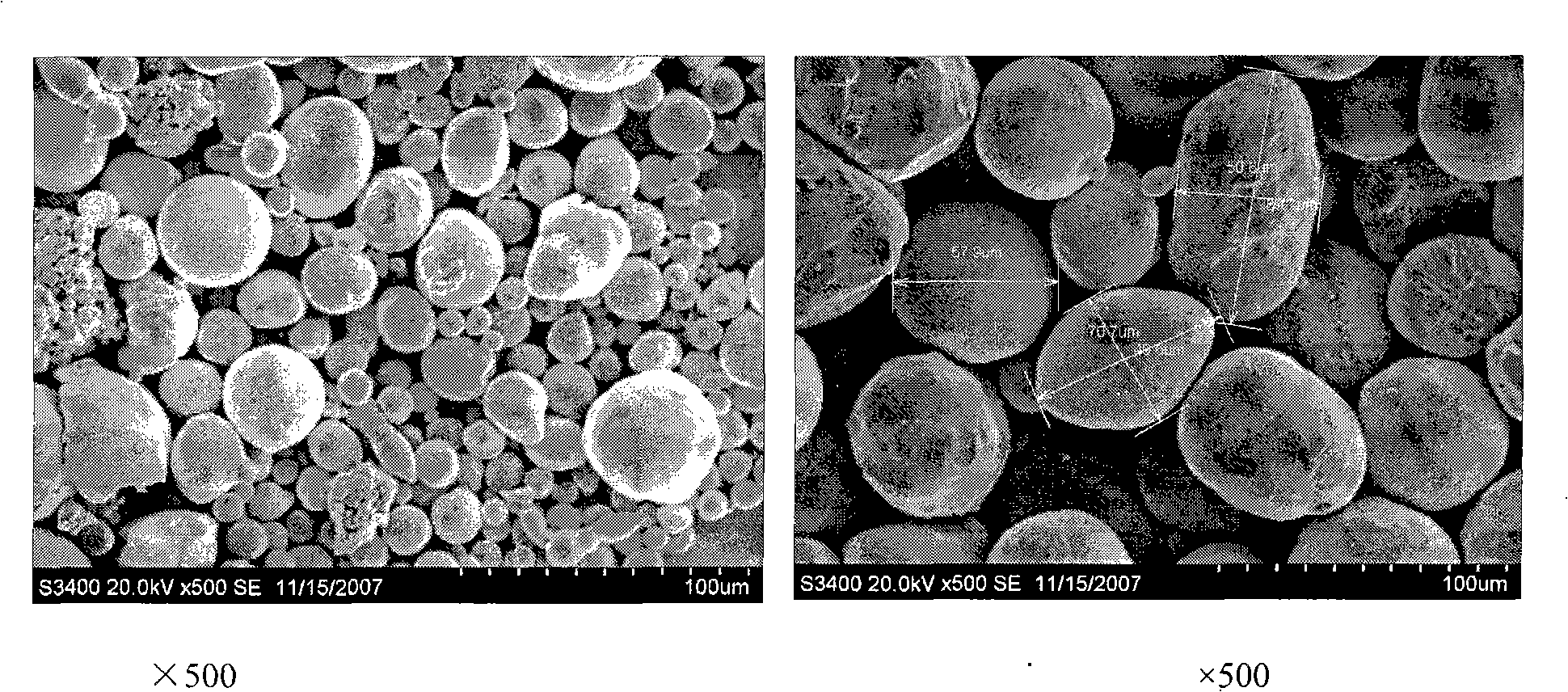

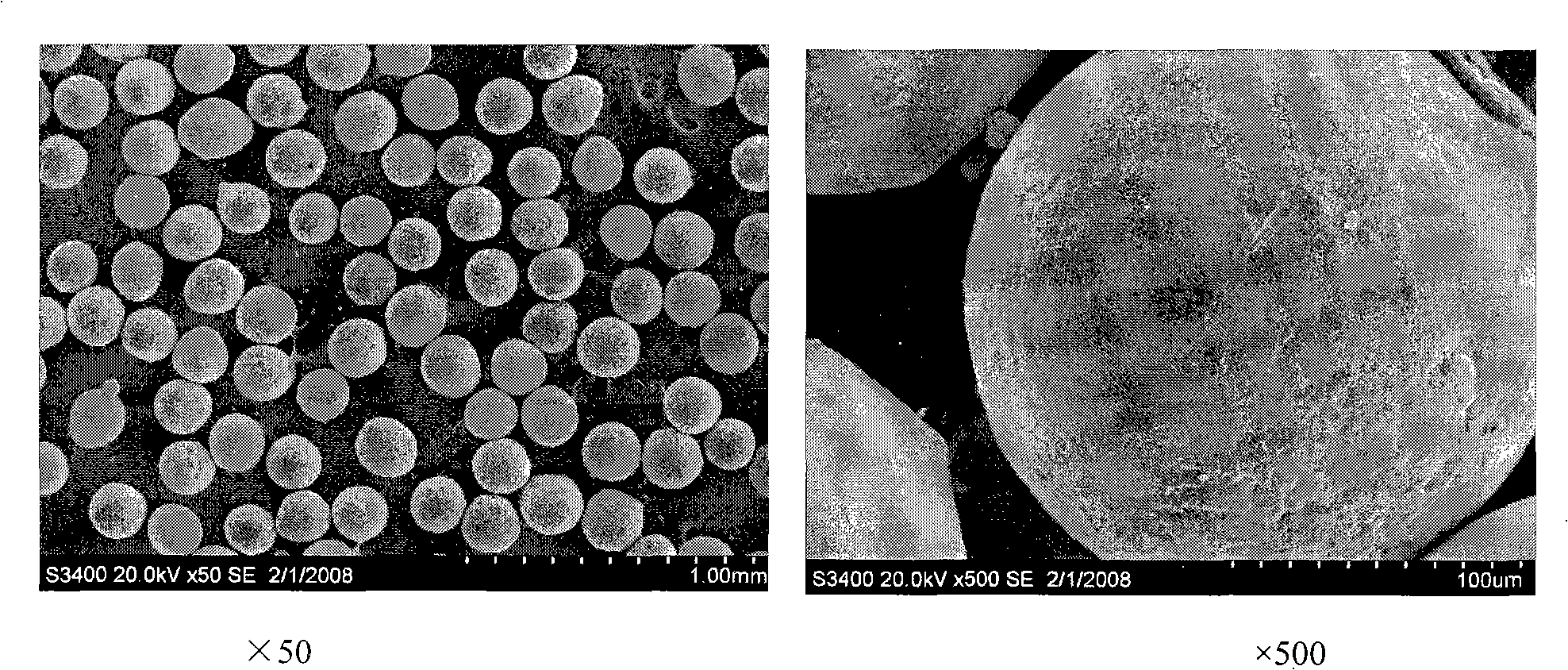

Method for preparing special type molybdenum powder

A method for preparing a special molybdenum powder relates to a method for preparing the molybdenum powder specially used for the industries of thermal spraying and machining as well as pressing fine apparatuses. The powder is characterized in that the preparing process includes the steps as follows: (1) sintering normal molybdenum powder for increasing the granularity; (2) grading the molybdenum powder, the granularity of which is increased; carrying out spheroidisation on the molybdenum powder with approximate granularity by a plasma device, then cooling and collecting the molybdenum powder; (3) reducing the molybdenum powder after being spheroidized, screening, grading and then obtaining the special molybdenum powder. The molybdenum powder prepared by the method of the invention has the advantages of good fluidity, simple technique, high finished product rate and relates to a technique for preparing the special molybdenum powder used in the fields of thermal spraying and pressing fine apparatuses.

Owner:JINDUICHENG MOLYBDENUM CO LTD

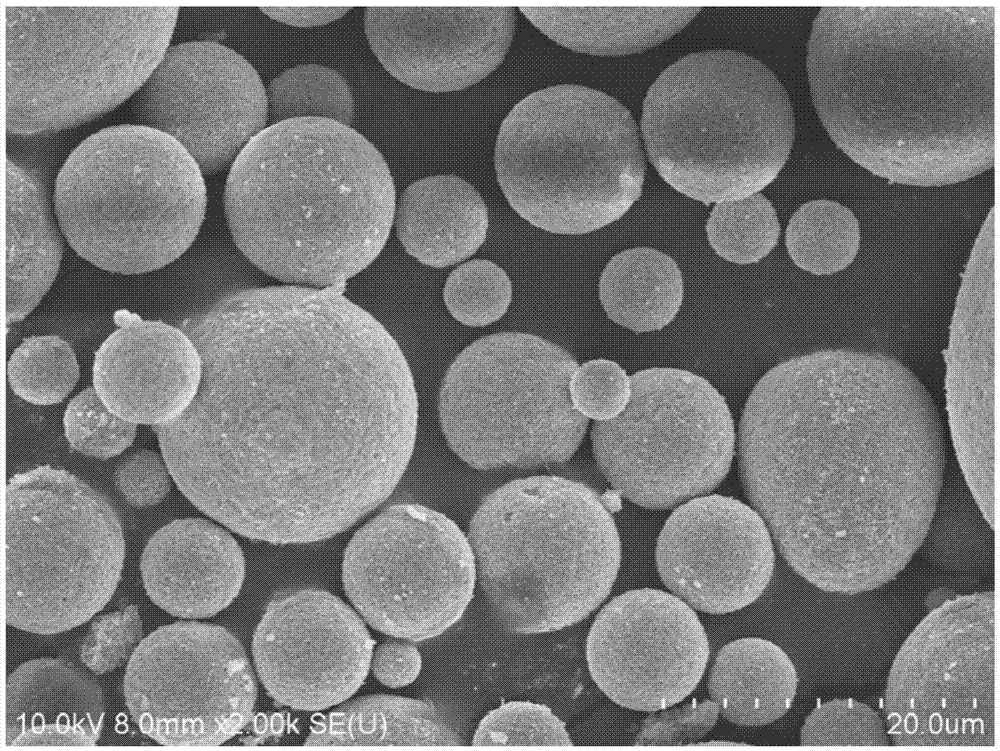

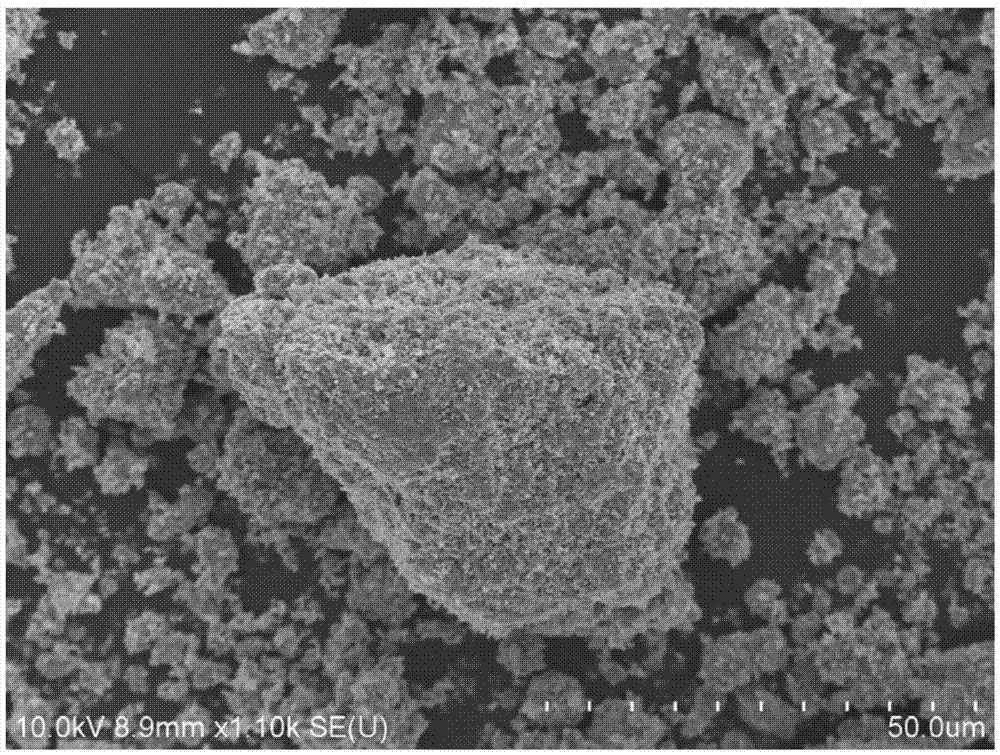

Method for preparing spherical molybdenum powder

The invention discloses a method for preparing spherical molybdenum powder. The method includes the following steps: pulverizing the molybdenum powder; preparing polyvinyl alcohol aqueous solution; adding the pulverized molybdenum powder into the polyvinyl alcohol aqueous solution, stirring the solution to be even and preparing the solution to be sizing agent; performing spray drying on the sizing agent to obtain granulation powder; and firstly performing ungrease treatment on the granulation powder, secondly performing heat treatment on the granulation powder, and eventually performing crushing and sieving to obtain the spherical molybdenum powder. The method for preparing the spherical molybdenum powder is simple in process, low in cost, high in finished product rate, and wide in application range. By adoption of the method, the microstructure of the molybdenum powder can be effectively improved, the properties including apparent density, mobility and the like of the powder can be improved, the apparent density of the prepared spherical molybdenum powder is 2.0-4.5g / cm<3>, the mobility is 15s / 50g-30s / 50g, the quality purity is larger than or equal to 99.95%, and the finished product rate is larger than or equal to 90%.

Owner:JINDUICHENG MOLYBDENUM CO LTD

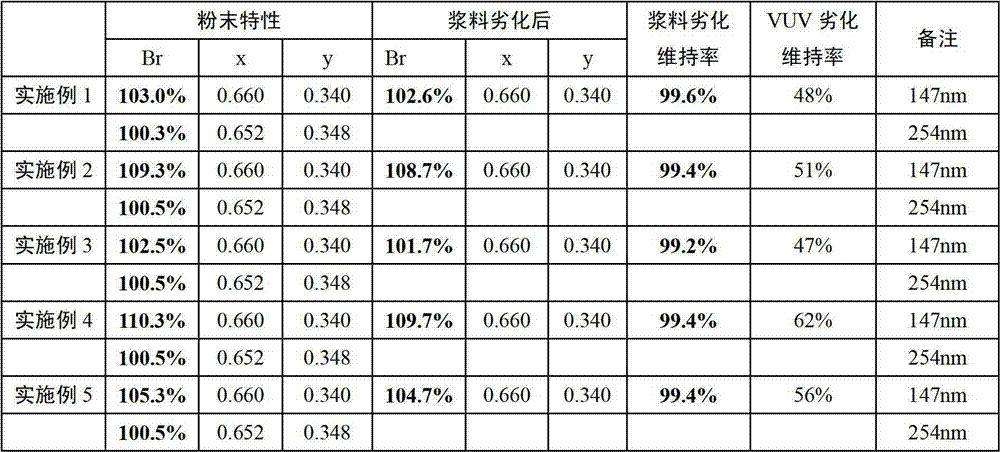

Preparation method for yttrium gadolinium europium oxide red fluorescent powder applicable to 3D PDP

InactiveCN102766457AReduce hydrolysisImprove surface integritySolid cathode detailsLuminescent compositionsRare earthYttrium

A preparation method for yttrium gadolinium europium oxide red fluorescent powder applicable to a 3D PDP (Plasma Display Panel) comprises the steps as follows: a rare earth oxalate coprecipitation body is prepared by adopting a coprecipitation method, rare earth metal oxide is balanced and dissolved in nitric acid or chlorhydric acid to form a rare earth metal salt solution; an oxalic acid solution or a carbonate solution is prepared and added into the rare earth metal salt solution to obtain rare earth metal oxalate or a carbonate precipitate; the carbonate precipitate is filtered and isolated, dried and burned to obtain a rare earth oxide coprecipitation body; the coprecipitation body is oxidized and burned to form a yttrium gadolinium europium oxide red fluorescent powder burned body; the rare earth oxide coprecipitation body is added with a cosolvent and is loaded in an aluminum oxide crucible and is burned under high temperature in an oxidizing furnace; after burned, the rare earth oxide coprecipitation body is shattered after burning to obtain a yttrium gadolinium europium finished product; and finally, the yttrium gadolinium europium oxide red fluorescent powder is obtained according to a downstream treatment process. The fluorescent powder prepared according to the method has the advantages of high lighting brightness, good color purity, complete crystal morphology, small powder center particle size, simple manufacturing method and low production cost, and is suitable for industrial production.

Owner:CAIHONG GRP ELECTRONICS CO LTD

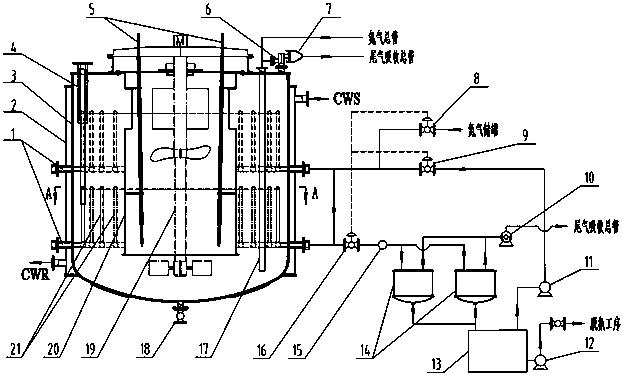

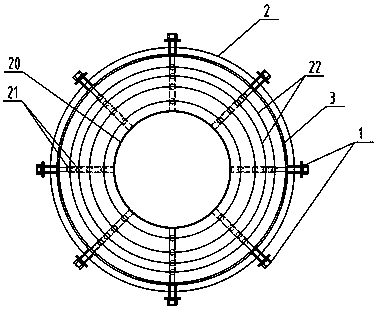

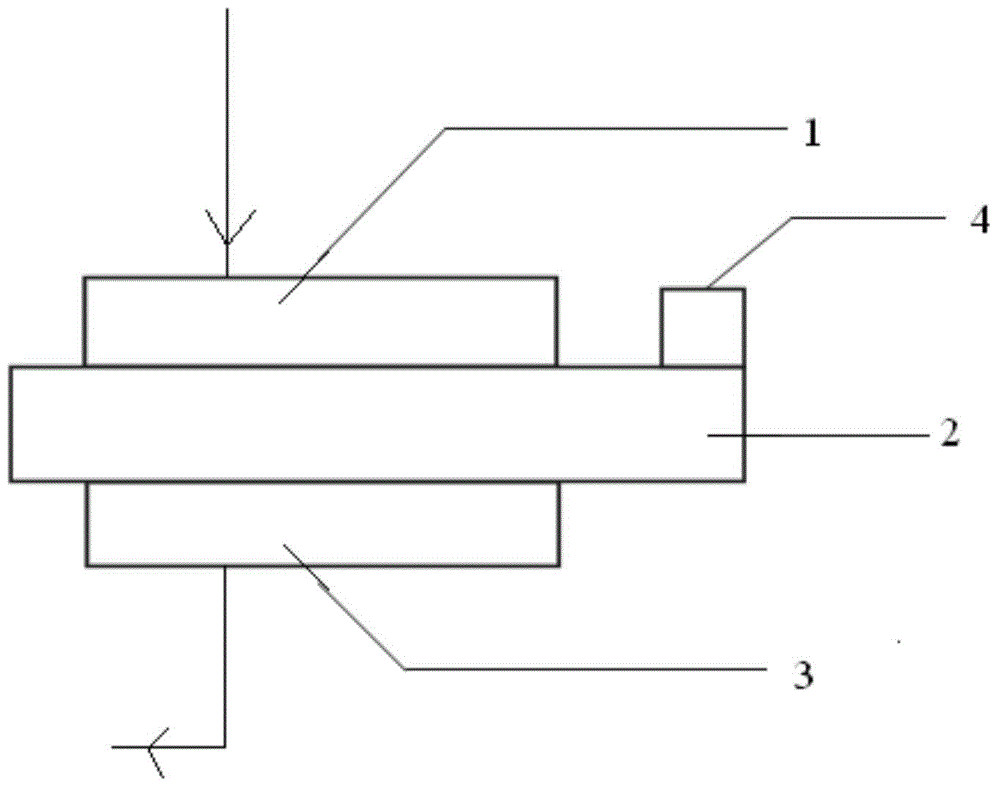

Method for material concentrating in ternary precursor synthesis reaction

ActiveCN110756140AReduce cloggingRelieve pressureChemical/physical/physico-chemical stationary reactorsInert gas productionCentrifugal pumpMother liquor

The invention relates to a method for material concentrating in a ternary precursor synthesis reaction. According to the method, a reaction vessel, a negative-pressure tank and a mother liquor tank are connected sequentially; a stirrer, a guide flow cylinder, a charging pipe, a nitrogen gas guide pipe, a liquid level meter, a clear-out pipe and a filter stick are arranged inside the reaction vessel; a vacuum pump is arranged at the top of the negative-pressure tank; and a centrifugal pump and a metering pump are arranged at the bottom of the mother liquor tank. According to the method, the problems of a ternary precursor synthesis reaction at present that concentrated particles are subjected to refluxing growth and the product is lost are solved. According to the method for material concentrating in the ternary precursor synthesis reaction, provided by the invention, reaction mother liquor can be directly drained outside the vessel, the problem of loss of the material particles is avoided, the particles are not required to be subjected to refluxing growth after concentration, and the problem that unaccepted products are produced due to secondary growth is avoided.

Owner:HUAYOU NEW ENERGY TECH (QUZHOU) CO LTD +1

Resin paint slag-containing PVC (Polyvinyl Chloride) foam composite material and preparation method thereof

The invention discloses a resin paint slag-containing PVC (Polyvinyl Chloride) foam composite material and a preparation method thereof, and belongs to the technical field of preparation of PVC foam composite materials and reutilization of resin paint slag. A hard cross-linked PVC foam composite material with the density of 40 to 200 kg / m<3>, the compressive strength of 0.5 to 5.0 MPa and the shearing strength of 0.4 to 3.5 MPa is prepared by mixing recycled resin paint slag serving as a modifying agent, PVC, isocyanate, epoxy resin, a foaming agent and inorganic filler by adopting a mould pressing and water boiling secondary foaming process; the hard cross-linked PVC foam composite material can serve as a core material of a composite material of a sandwich structure, and can be widely applied to the fields, such as buildings, recreational equipment and traffic transportation. According to the resin paint slag-containing PVC foam composite material and the preparation method thereof, the problems of secondary environment pollution caused by the resin paint slag and high treatment cost of a factory are effectively solved; compared with the conventional PVC foam material, the resin paint slag-containing PVC foam composite material has the advantages of low cost, high comprehensive performance and the like.

Owner:TSINGHUA UNIV

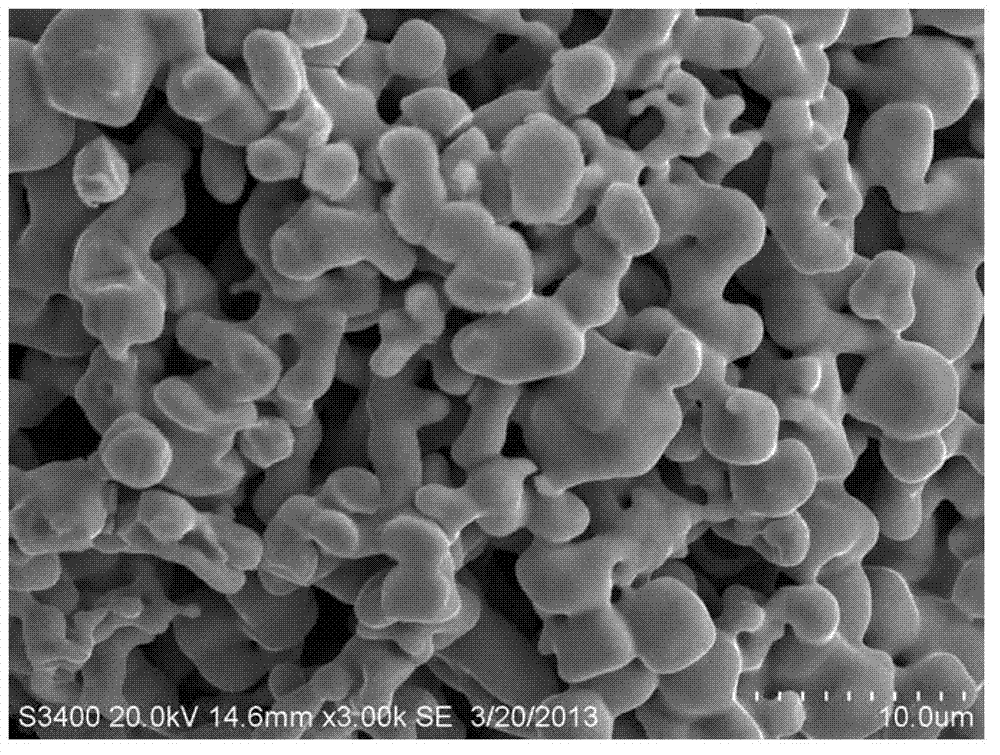

Lithium-rich manganese-based anode material, preparation method thereof and lithium ion battery containing anode material

ActiveCN106910887AThe problem of achieving compactionAchieve spherificationCell electrodesSecondary cellsManganeseLithium-ion battery

The invention discloses a lithium-rich manganese-based anode material, a preparation method thereof and a lithium ion battery containing the anode material. A chemical formula of the lithium-enrichment manganese-based anode material is Li1+xMnyMzAwOr, wherein the M is at least one of Ni, Co, Al, Mg, Ti, Fe, Cu, Cr, Mo, Zr, Ru and Sn; the A is at least one of S, P, B and F; the x is larger than 0 and smaller than or equal to 1, the y is larger than 0 and smaller than or equal to 1, the z is larger than or equal to 0 and smaller than 1, the w is larger than or equal to 0 and smaller than or equal to 0.2, and the r is larger than or equal to 1.8 and smaller than or equal to 3. The lithium-enrichment manganese-based anode material is prepared by methods of oxalate coprecipitation, spray drying and high-temperature roasting. The lithium-enrichment manganese-based anode material disclosed by the invention overcomes agglomeration of a material prepared through an oxalate coprecipitation method; a prepared material is controllable in particle size, meets requirements of engineering indexes and can achieve the purpose that transition metal ions are evenly mixed at an atom level; the particle size of the prepared lithium-enrichment manganese-based anode material is 3 to 25mu m, and the lithium-rich manganese-based anode material has good rate capability and circulation performance at the same time; furthermore, the lithium-enrichment manganese-based anode material has the advantages of simple preparation technology, low cost and wide application prospect.

Owner:CHINA AUTOMOTIVE BATTERY RES INST CO LTD +1

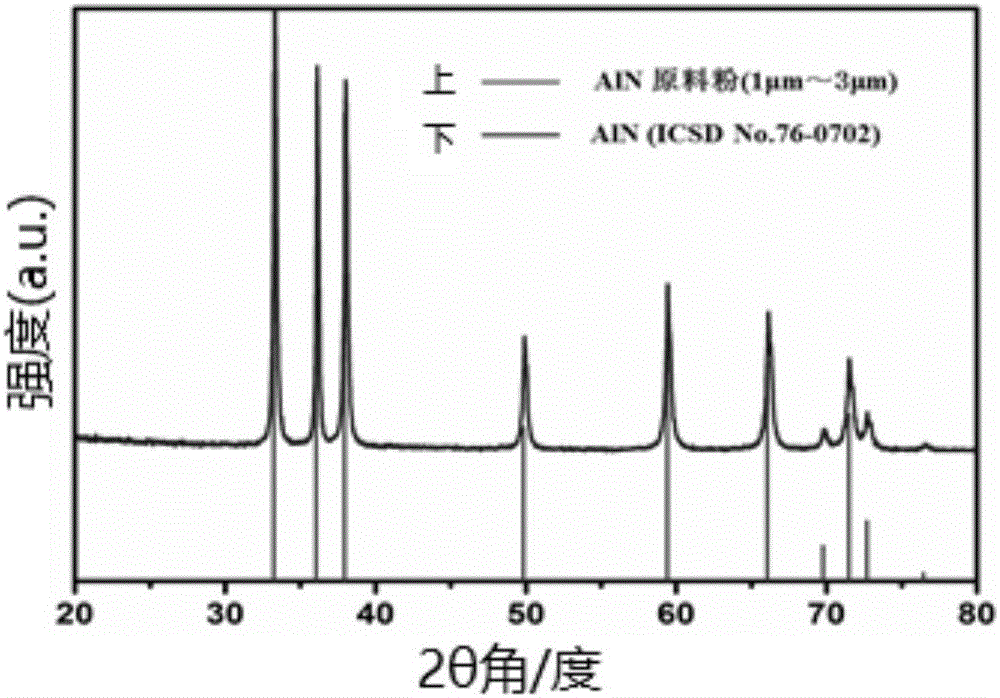

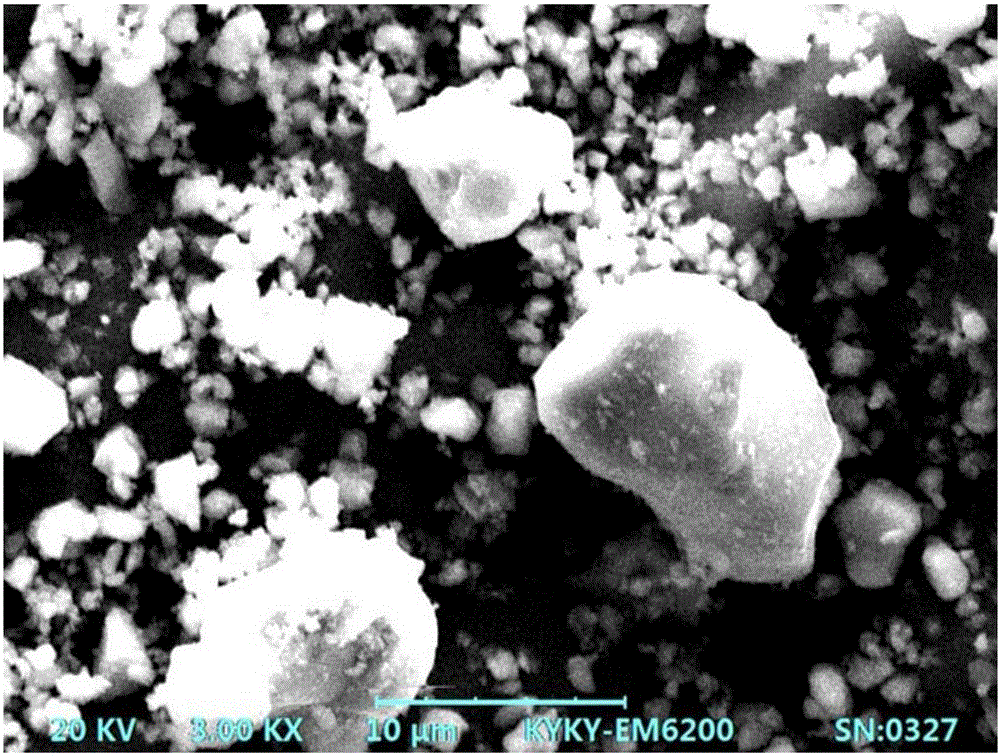

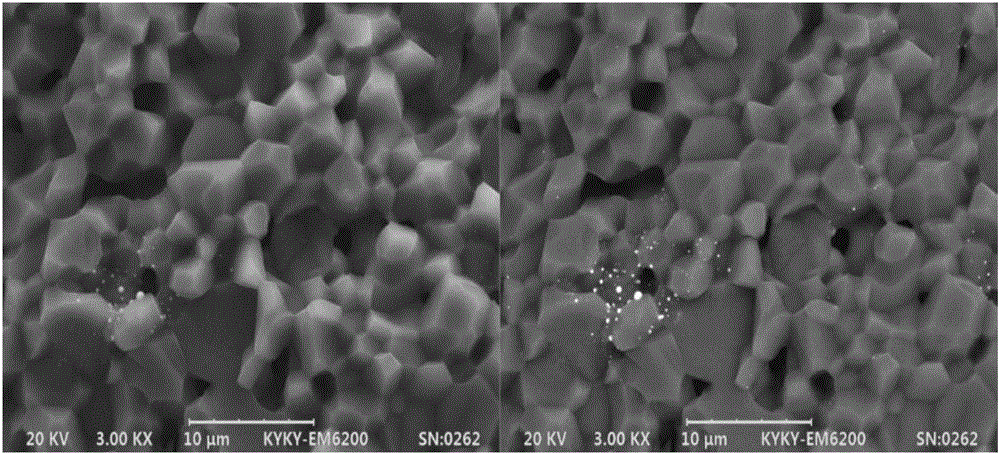

Method for preparing aluminum nitride electronic ceramic base plate by using tape casting method and solvent for tape casting method for preparing ceramic

ActiveCN107522495AImprove working conditionsSignificant environmental benefitsSlurryTriethylamine phosphate

The invention discloses a method for preparing an aluminum nitride electronic ceramic base plate by using a tape casting method. The method comprises the following steps: preparing tape casting slurry, and molding the tape casting slurry by using the tape casting method, thereby obtaining the aluminum nitride electronic ceramic base plate, wherein the tape casting slurry comprises a benzene-free mixed organic solvent, aluminum nitride ceramic powder and sintering aids; the benzene-free mixed organic solvent comprises three or more than three of absolute ethyl alcohol, isopropyl alcohol, n-butyl alcohol, triethyl phosphate and dibasic acid ester; and the solvent accounts for 28-40% of the mass of the aluminum nitride ceramic powder. The invention further provides a method for preparing high-solid content aluminum nitride tape casting by using an organic solvent which is non-toxic, relatively environmentally friendly and low in cost. The aluminum nitride electronic ceramic base plate which is high in density, uniform in microstructure and high in heat conductivity is prepared under a relatively low high temperature condition, and the tape casting production process is green and environmentally friendly and applicable to industrial popularization.

Owner:李军廷

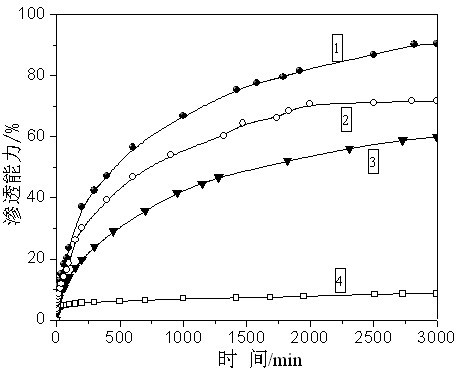

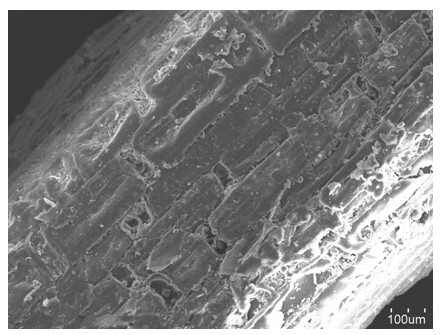

Pretreatment method for biomass fiber material

InactiveCN102321993AImprove permeabilityEfficient removalPaper material treatmentFiberPretreatment method

The present invention provides a pretreatment method for a biomass fiber material. The method comprises: mixing a surfactant, an cosurfactant and a oil phase, then stirring; adding a water phase material to the resulting mixture when no bubble is generated during stirring to obtain clear and transparent composite microemulsion; mixing a preprocessed biomass fiber material and the composite microemulsion according to a certain solid-to-liquid ratio, controlling a temperature to 30-120 DEG C and controlling pressure to 0.1-2.0 Mpa; carrying out washing through clear water after completing the reaction, wherein the resulting solid is the pretreated biomass fiber material. According to the present invention, the composite microemulsion is adopted for treating the biomass, such that the crystallization characteristic of the biomass fiber is changed, the specific surface area and the accessibility of the enzyme solution are increased, the pretreatment effect is improved; the used chemical drugs has characteristics of easy recovery and utilization and low environmental pollution; the reaction is performed at the low temperature under the low pressure so as to reduce the cost and the energy consumption of the pretreatment process.

Owner:SOUTH CHINA UNIV OF TECH

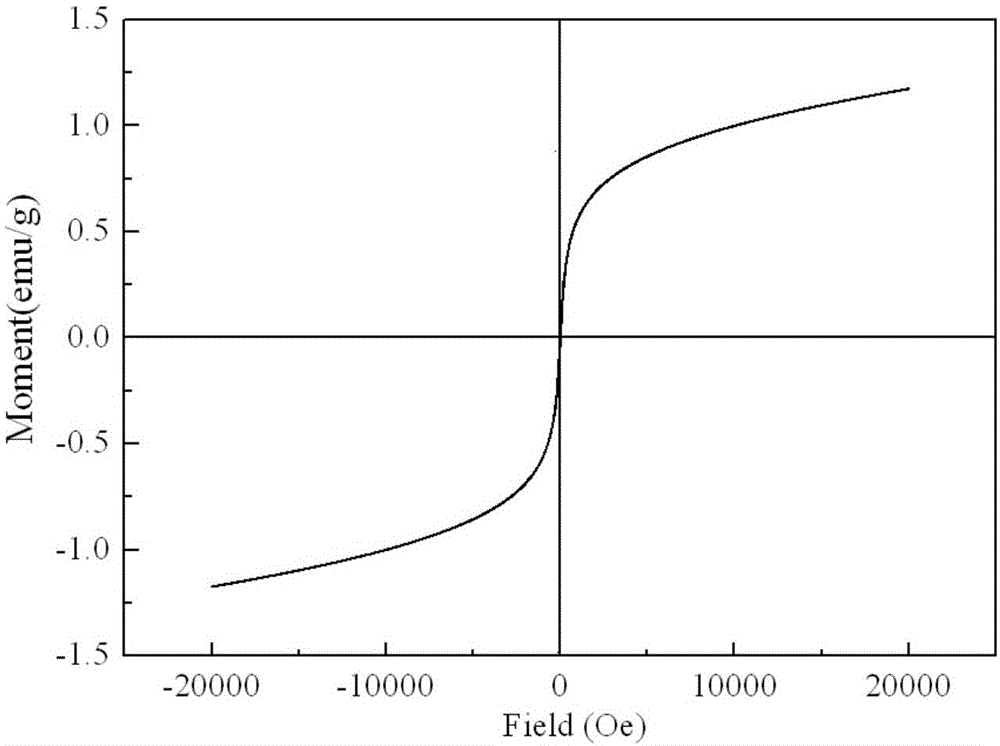

Magnetic carbon nano-microsphere taking lignin as carbon source and preparation method of magnetic carbon nano-microsphere

ActiveCN106219517ALow costRaw materials are easy to getInorganic material magnetismInductances/transformers/magnets manufactureN dimethylformamideNano composites

The invention belongs to the technical field of nanocomposites and discloses a magnetic carbon nano-microsphere taking lignin as a carbon source and a preparation method of the magnetic carbon nano-microsphere. The preparation method includes: dissolving the lignin and ferric acetylacetonate in N,N-dimethylformamide to obtain an electrostatic lignin spray solution containing the ferric acetylacetonate, and then obtaining the lignin nano-microsphere containinging the ferric acetylacetonate through electrostatic spraying; performing pre-oxidation on the obtained lignin nano-microsphere under the temperature ranging from 250DEG C to 280DEG C prior to carbonization treatment under the temperature of 400DEG C to 900DEG C to obtain the magnetic carbon nano-microsphere taking the lignin as the carbon source. The preparation method has the advantages that raw materials are easy to obtain, energy conservation and environment protection is achieved, the obtained product is good in microstructure and dispersing and magnetic performance, and good application prospect in fields of information, energy sources, detection, biology and the like is achieved.

Owner:SOUTH CHINA UNIV OF TECH

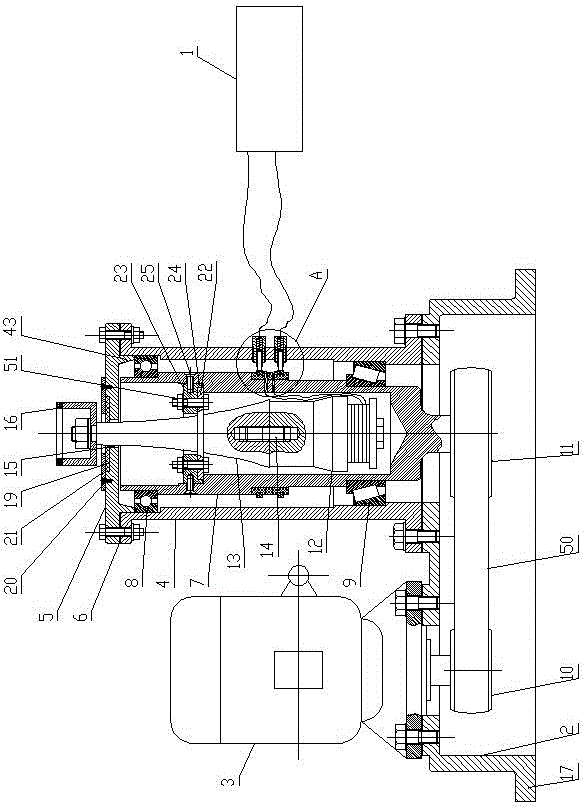

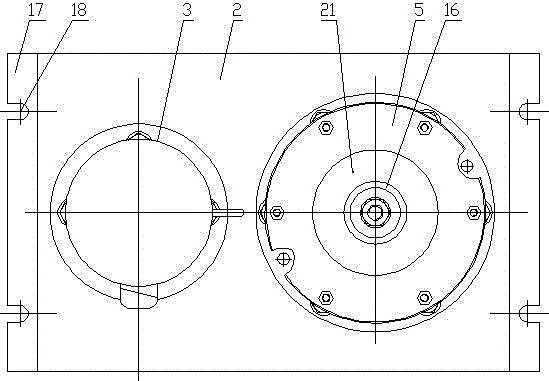

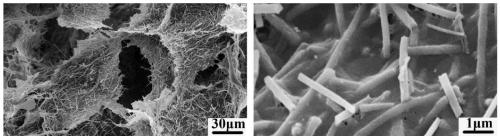

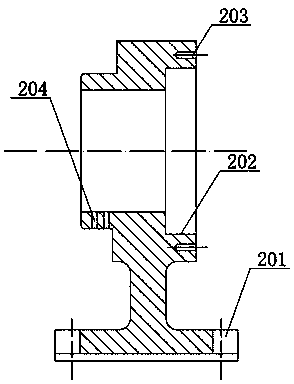

Ultrasonic vibration cup-shaped grinding wheel dresser for dressing super-hard abrasive grinding wheel

ActiveCN105643463ASimple structureReduce maintenance workAbrasive surface conditioning devicesUltrasonic generatorMicrostructure

The invention relates to an ultrasonic vibration cup-shaped grinding wheel dresser for dressing a super-hard abrasive grinding wheel. The grinding wheel dresser comprises an ultrasonic generator and a base, wherein a variable-frequency motor and a cylinder body are arranged on the base, the central line of the cylinder body is arranged in a vertical direction, and a cover plate is connected to the upper end of the cylinder body through a flange; a hollow shaft with an open upper-end and a plugged lower-end is coaxially arranged in the cylinder body, a bearing is arranged between the inner wall of the cylinder body and the outer wall of the hollow shaft, and the variable-frequency motor is in transmission connection with the lower end of the hollow shaft; an ultrasonic transducer and an amplitude-change pole are arranged in the hollow haft, the outside of the amplitude-change pole is fixedly arranged on the hollow shaft through a detachable connection structure, and the upper end of the amplitude-change pole is upward and penetrates the cover plate, and a top-opened cup-shaped grinding wheel is fixedly coaxially arranged at the upper end of the amplitude-change pole. The grinding wheel dresser provides ultrasonic vibration in the axial direction, therefore, the microstructure of the dressed grinding wheel can be well improved, dressing of abrasive particles is completed while shaping is completed, grinding heat and power consumption are beneficially reduced, blockage to the grinding wheel and dressing burns are avoided, and the service life of the external circular grinding wheel is prolonged.

Owner:KEYIZHAN INTELLIGENT EQUIP CO LTD +1

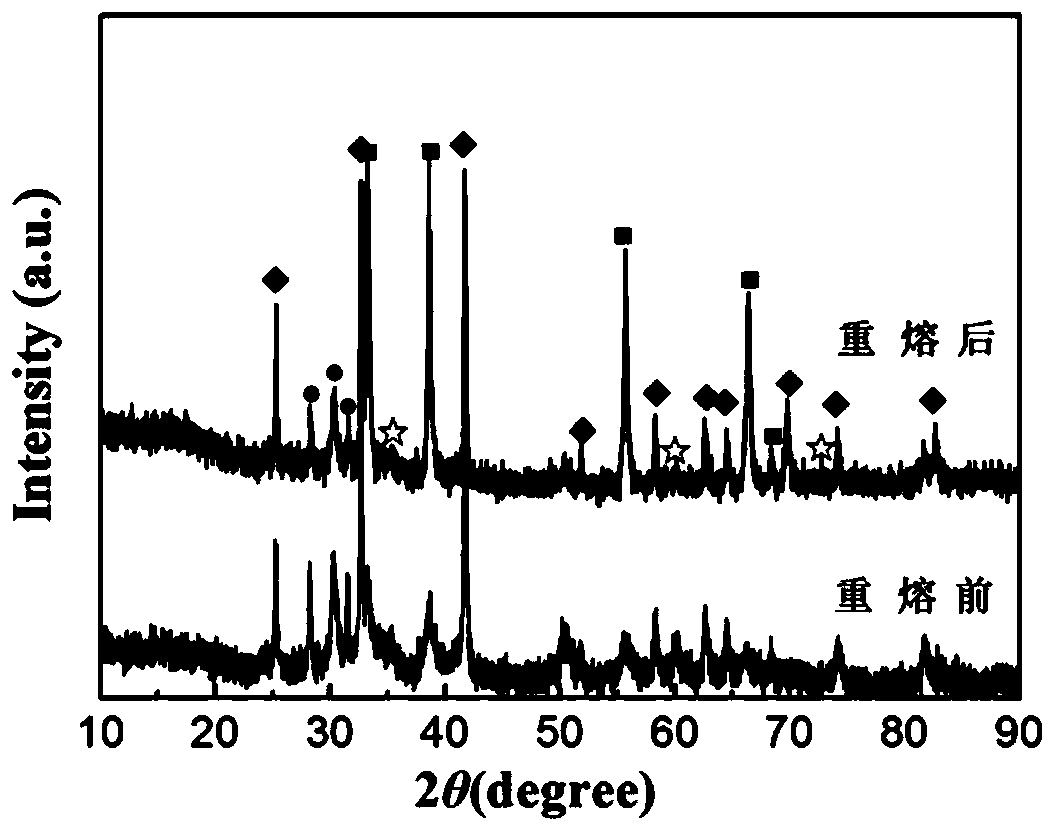

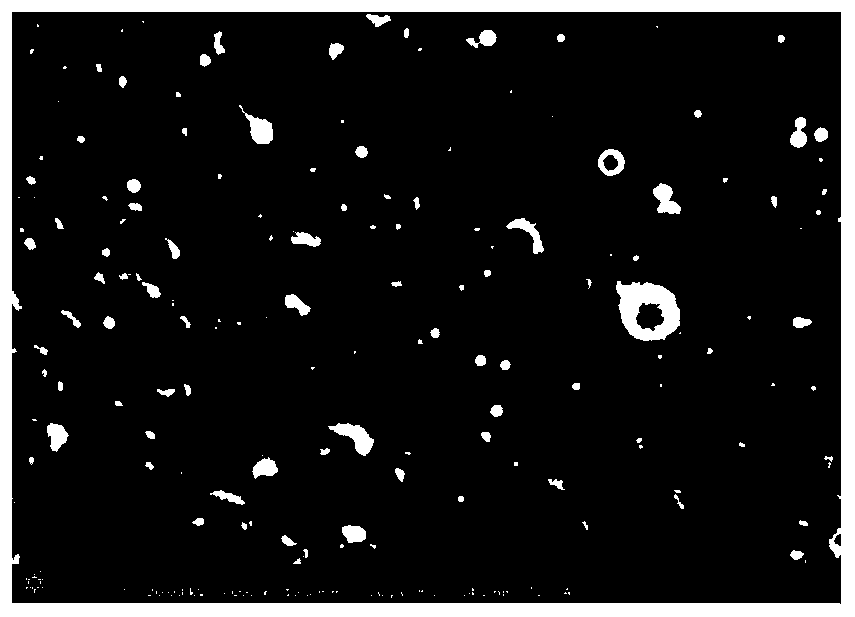

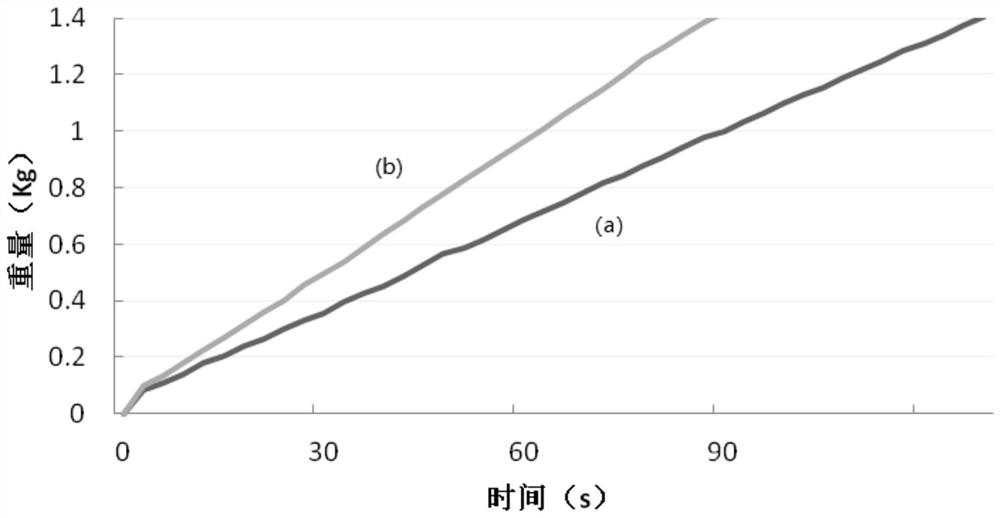

Preparation method of compact composite coating layer based on reactive plasma spraying and laser remelting

The invention discloses a preparation method of a compact composite coating layer based on reactive plasma spraying and laser remelting, relates to a surface treatment method, and in particular, relates to the preparation method of the compact composite coating layer based on reactive plasma spraying and laser remelting. The method aims to solve the problem of compactness of an in-situ endogenouscoating layer prepared by a reactive plasma spraying method in the prior art. The method comprises the steps: 1, mixing powder, deionized water, ammonium citrate and Arabic gum to obtain slurry, and carrying out spray granulation on the slurry to obtain mixed spray powder; 2, carrying out sand blasting treatment on the surface of a base body, cleaning and drying; 3, filling a plasma spray gun withthe mixed spraying powder, and spraying the mixed spraying powder on the base body obtained in the step 2 to obtain a coating layer; and 4, mounting a coating layer test piece on a workbench of a laser device, and carrying out laser remelting. According to the method, the microstructure of the coating layer can be improved, a uniform and compact laser remelting layer is formed, and the quality ofthe coating layer is effectively improved. The method is applied to the field of surface pretreatment.

Owner:HARBIN UNIV OF SCI & TECH

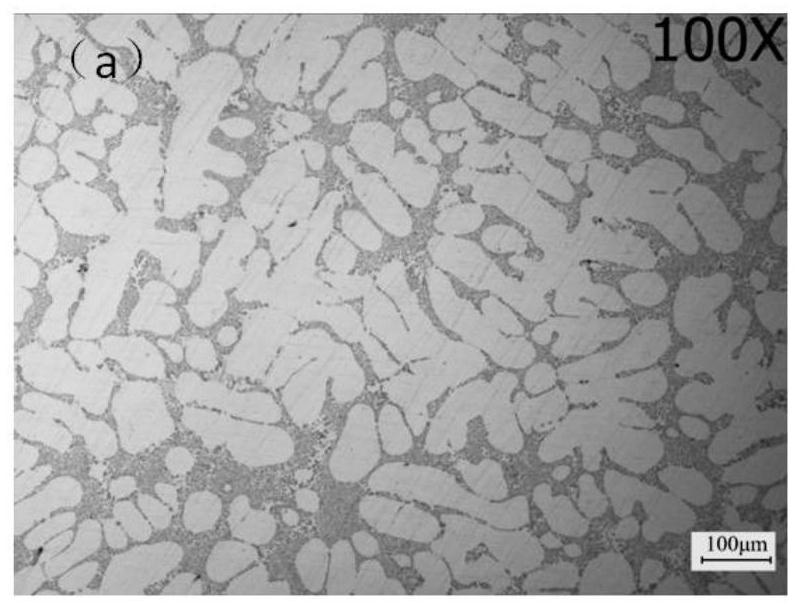

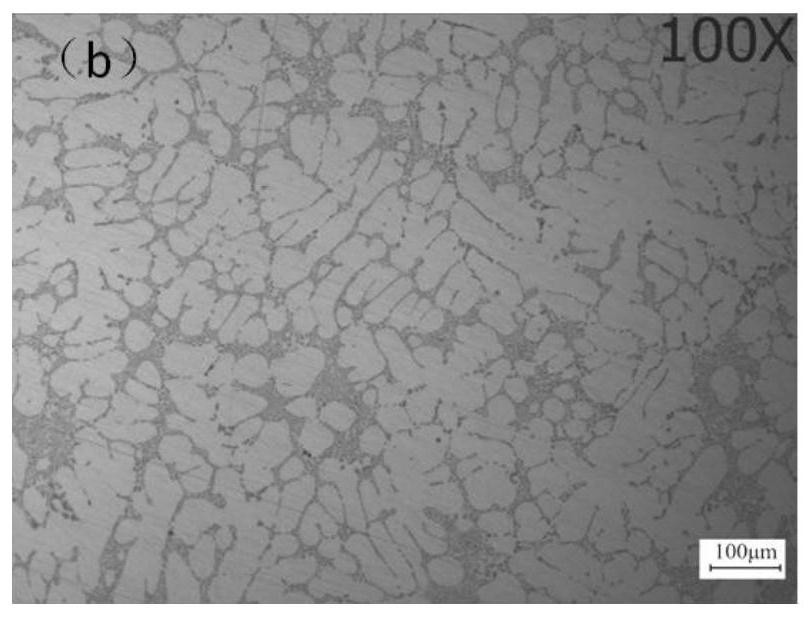

Rare-earth alloy and preparation method thereof

The invention provides a rare-earth alloy. Elements Mg and Si co-fine a strengthening phase Mg2Si in an ageing thermal treatment process, so that dislocation motion is effectively inhibited and the effect of strengthening a base body is achieved; Al-Ti-B and rare-earth elements are added to form a heterogeneous nucleation core with relatively low mismatching degree with an alpha-Al substrate lattice for performing grain reinforcement on the aluminum alloy, and impurities in the aluminum alloy are purified; elements Cr and Mn are added to inhibit growth advantages in single direction of a needle-like Fe phase, so that the needle-like Fe phase changed into a Chinese character shaped or granular Fe-containing phase; elements Sr and Ca are introduced to introduce eutectic silicon to form high-density twin crystal, so that optimization of the morphology of eutectic silicon is realized. Elements mutually act, so that a base phase alpha-Al, eutectic silicon and a Fe phase of the alloy have excellent microscopic morphology, and thus, the purposes of strengthening the alloy, refining the crystal grains and optimizing the structure morphology are achieved, and a rate of elongation of the alloy is remarkably increased.

Owner:BAODING CITY LIZHONG WHEEL MFG

Method for preparing anti-freezing abrasion-resistant baking-free brick by hematite tailing-slag-phosphate tailing sand

The invention discloses a method for preparing an anti-freezing abrasion-resistant baking-free brick by hematite tailings-slag-phosphate tailing sand. The method includes the steps: drying steel slagand slag in a baking oven, placing mixture into a ball grinder to grind the mixture into ultra-fine powder, placing steel slag powder, slag powder, limestone powder and phosphogypsum into a cement mortar stirrer to dryly stir mixture, adding water to wetly stir mixture, and adding phosphate tailing sand to stir mixture to prepare a slag-phosphate tailing sand mixed material; adding hematite tailings, aggregate and cementing materials into the cement mortar stirrer to dryly stir mixture, adding additives, water, pretreated glass fibers, modified steel fibers and the slag-phosphate tailing sandmixed material to wetly stir mixture, adding the stirred material into a stainless steel die, setting forming pressure on a microprocessor control electric-liquid pressure tester, performing pressingformation, setting steam-cure temperature and wet and heat curing, and naturally curing to prepare the baking-free brick. The baking-free brick has excellent permeability resistance, freezing resistance, abrasion resistance, softening resistance and alkali resistance.

Owner:枞阳县天筑新型建筑材料有限公司

Preparation method of double-layer oxide modified carbon fiber reinforced composite material

PendingCN110872428AImproved interfacial shear propertiesStratification reliefCarbon fiber reinforced compositeFiber-reinforced composite

The invention provides a preparation method of a double-layer oxide modified carbon fiber reinforced composite material, wherein the surface of carbon fiber filaments is coated with a SiO2-blended Al2O3 coating sizing agent, so that a layer of oxide thin film is formed on the surface; finally an epoxy resin substrate is introduced by means of a RTM process to infiltrate the epoxy resin onto the surface of the carbon fiber cloth, then the epoxy resin is solidified and shaped to manufacture the carbon fiber reinforced epoxy resin based composite material, of which shear performance is improved by 16% and anti-impact performance is improved by 27%.

Owner:天津中科先进技术产业有限公司

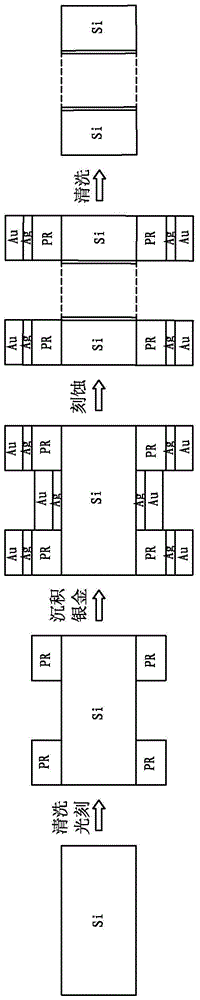

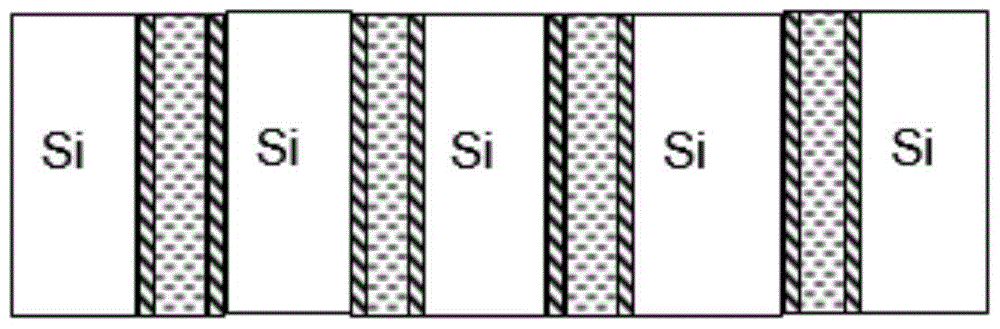

Method for etching micron silicon through hole

ActiveCN105668509AEtching speed is fastGood microscopic appearanceDecorative surface effectsChemical vapor deposition coatingPhotoresistMicrostructure

The invention discloses a method for etching a micron silicon through hole; the method comprises the following steps: (1) taking a silicon wafer, cleaning and drying by blowing; (2) coating photoresist at the two sides of the silicon wafer, carrying out photoetching after drying and developing; (3) depositing multiple layers of precious metal at the two sides of the photoetched silicon wafer; (4) placing the silicon wafer deposited with the precious metal into corrosion solution and reacting to form the through hole; and (5) cleaning and drying by blowing. According to the method disclosed by the invention, a double-side lithography is adopted and the etching process is also carried out at the two sides, so when the two sides are etched to together, the silicon through hole is formed; the etching speed is fast, no further treatment is needed after etching and the microstructure is good; and the micron silicon through hole can be produced in large scale.

Owner:领航医学科技(深圳)有限公司

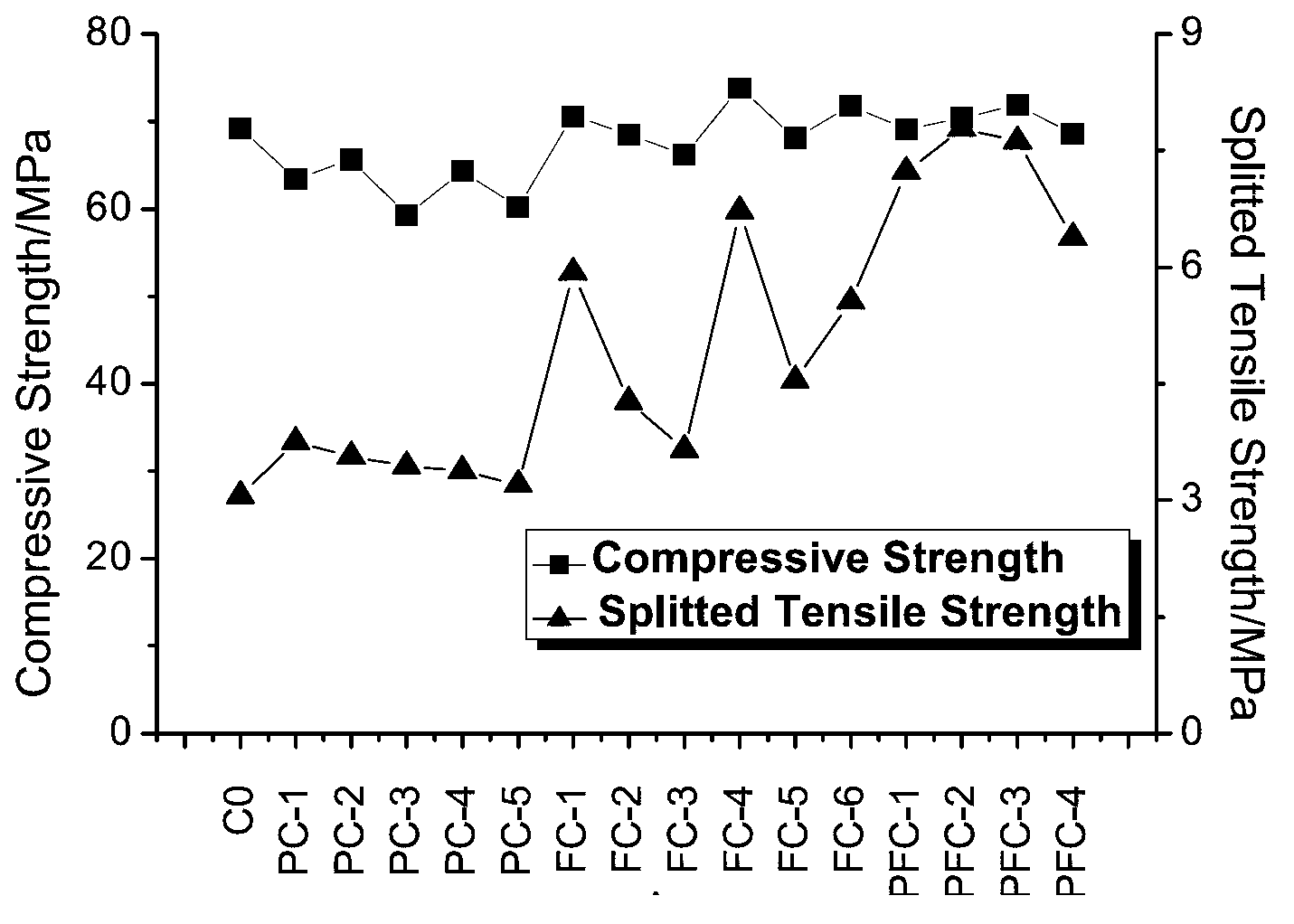

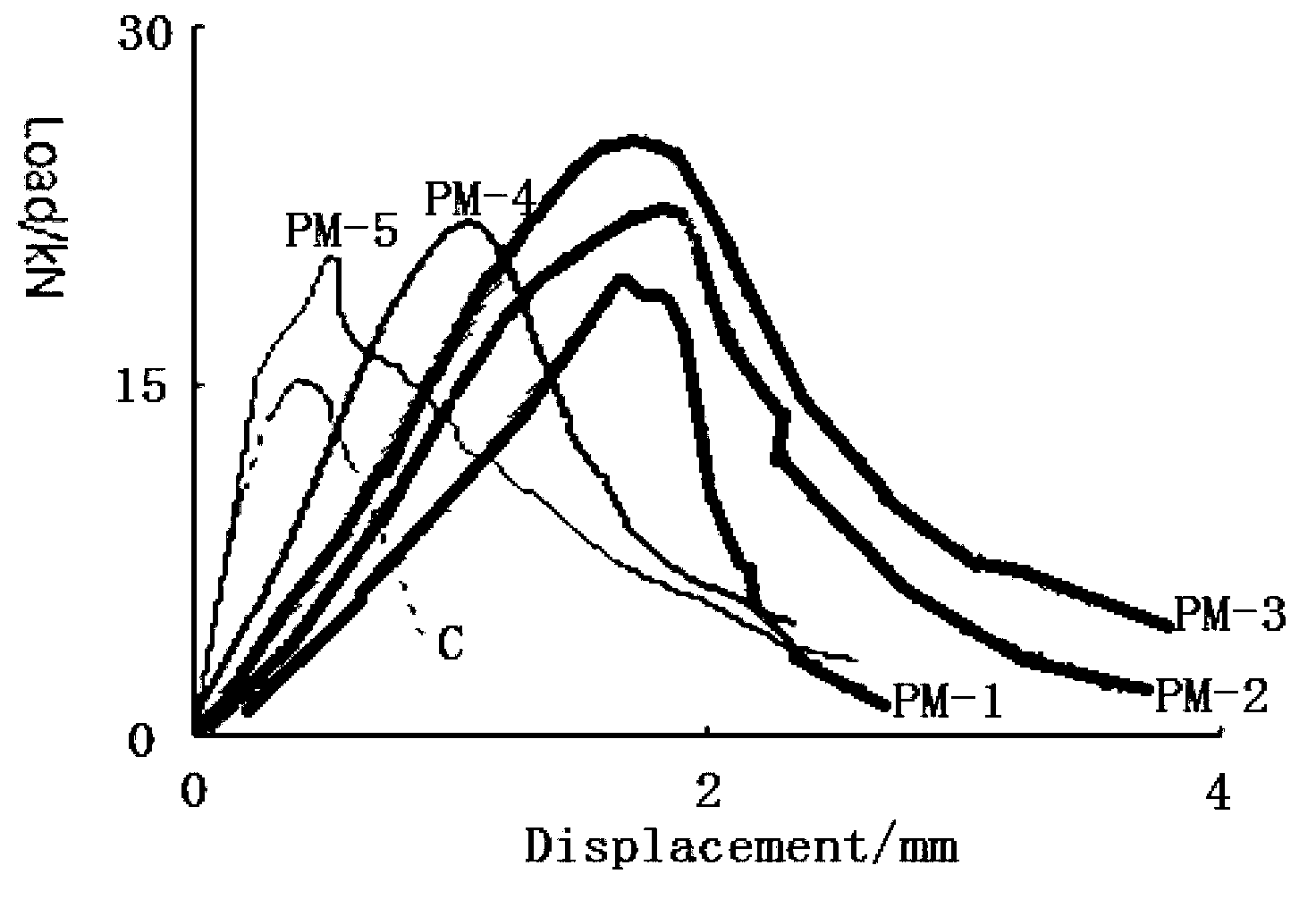

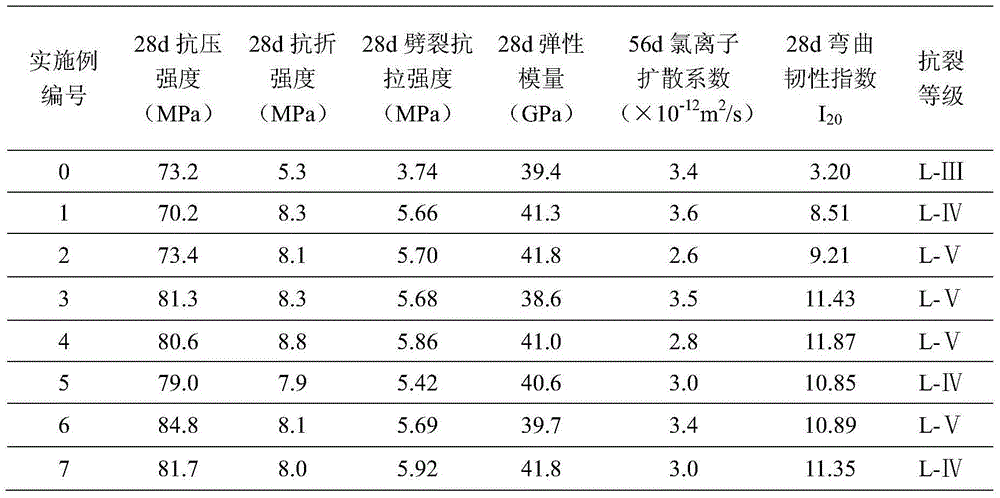

Long-service-life concrete for steel-concrete composite beam hogging moment area and preparation method long-service-life concrete

The invention discloses long-service-life concrete for a steel-concrete composite beam hogging moment area and a preparation method of the long-service-life concrete, and relates to the field of long-service-life concrete preparation. The long-service-life concrete comprises, in parts by mass, 456-520 parts of a cementing material, 1748-1813 parts of aggregates, 0.80-1.50 parts of imitation steel fibres, 2.05-2.86 parts of a toughening material, 4.10-5.72 parts of a water reducer and 142-148 parts of water; the 28-d compressive strength of the long-service-life concrete is not less than 69.0MPa, the 28-d breaking strength of the long-service-life concrete is not less than 7.0MPa, the 28-d splitting tensile strength of the long-service-life concrete is not less than 5.0MPa, the 28-d elasticity modulus of the long-service-life concrete is not less than 36.0GPa, the 56-d chloride ion diffusion coefficient of the long-service-life concrete is less than 4.0*10<-12>m<2> / s, the cracking resistance rank of the long-service-life concrete achieves L-IV rank, and the 28-d bend ductility index I20 of the long-service-life concrete is not less than 8. The flexural strength, bend ductility and crack resistance of the long-service-life concrete are high, the fragility of the concrete is changed, and the concrete is good in structure durability, long in service life, low in cost, and convenient to massively use.

Owner:CHINA RAILWAY MAJOR BRIDGE ENG GRP CO LTD

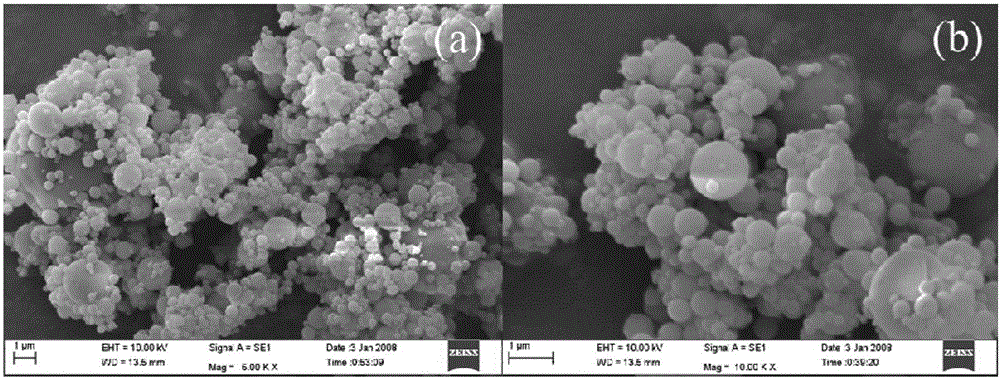

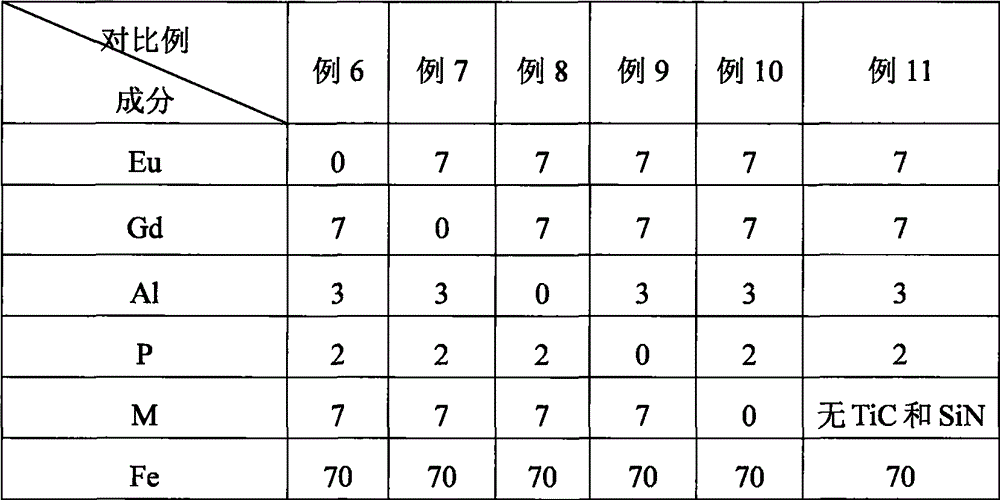

Composite permanent-magnetic material of motor and preparation method of composite permanent-magnetic material

ActiveCN106409458AImprove remanenceImprove coercive forceInorganic material magnetismMagnetic circuit characterised by magnetic materialsNanoparticleMagnetic energy

The invention provides a composite permanent-magnetic material of a motor and a preparation method of the composite permanent-magnetic material. The composite permanent-magnetic material of the motor is formed by a system of Eu, Gd, Fe, Al, P and M, wherein the M is formed by mixing nanoparticles of Fe2O3, Fe3O4, TiC and SiN; the mass ratio of Eu to Gd to Fe to Al to P to M in the system is (5-7) to (5-7) to (60-70) to (2-3) to (1-2) to (5-7); and the mass ratio of the Fe2O3 to the Fe3O4 to the TiC to the SiN in the M is 10 to 5 to 2 to 1. Therefore, the residual magnetism and the magnetic energy product are kept while the coercive force and the high-temperature stability of the permanent-magnetic material are improved, and the cost is effectively reduced.

Owner:慈溪市华夏电器实业有限公司

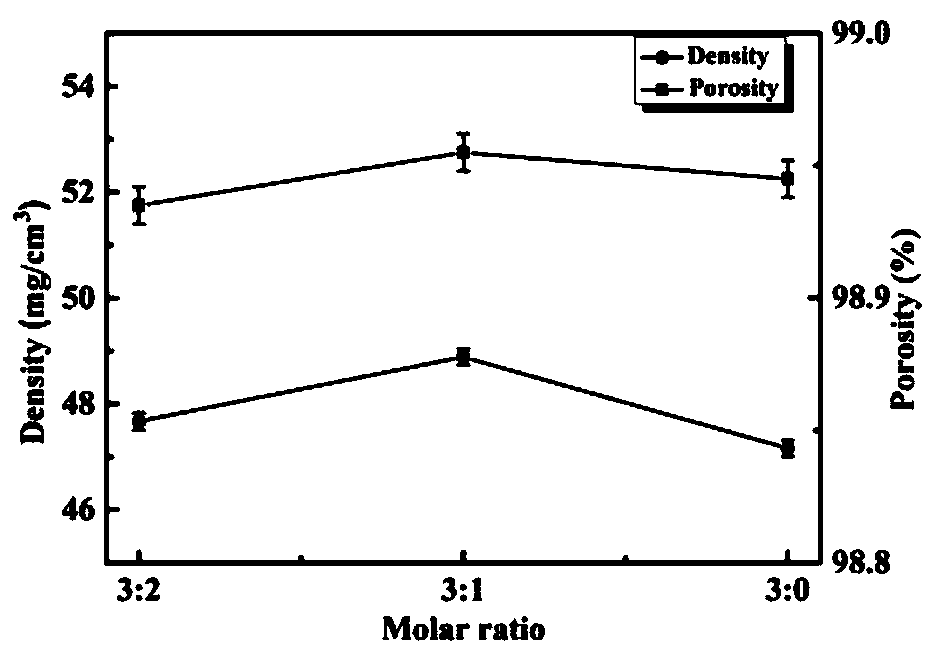

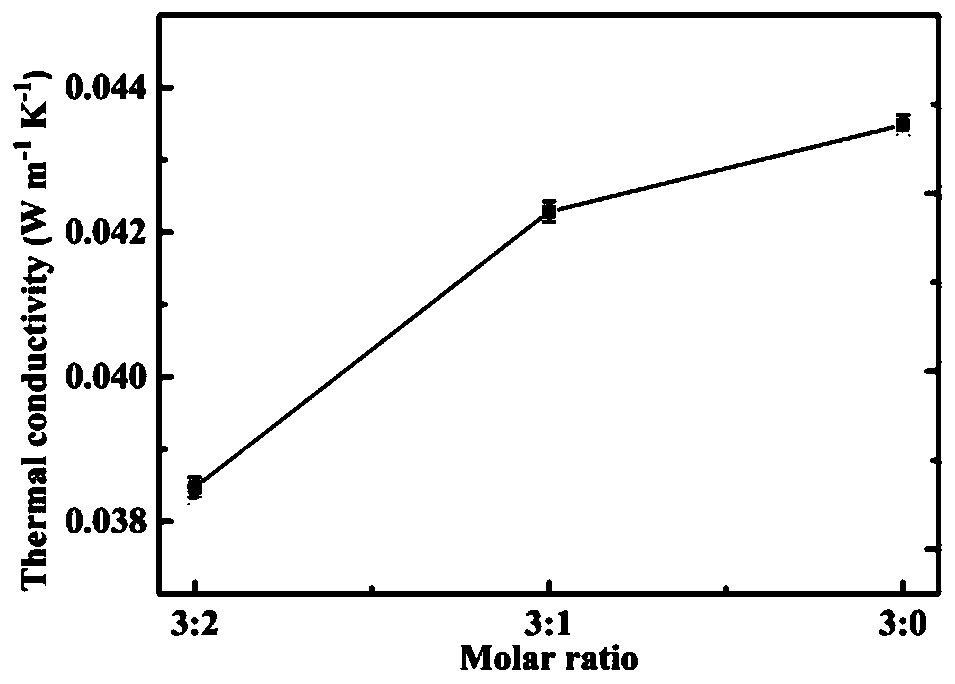

Preparation method of light heat-insulating mullite nanofiber aerogel

ActiveCN110078425AAvoid agglomeration wrappingImprove stabilityCeramicwareThermal conductivityNanofiber

The invention provides a preparation method of light heat-insulating mullite nanofiber aerogel with ultra-low solid content. The preparation method comprises the following steps: dispersing a nano mullite fiber membrane to obtain mullite single fibers; mixing silica sol and acrylamide system gel injection molding premix with the dispersed mullite single fibers to prepare gel; and freeze-drying thegel to obtain an aerogel blank, and finally calcining at high temperature to obtain the mullite nanofiber aerogel product. The product is light in weight, high in porosity and low in thermal conductivity, and the preparation method of the nanofiber aerogel which can be used at the temperature of 1300 DEG C is provided.

Owner:TIANJIN UNIV

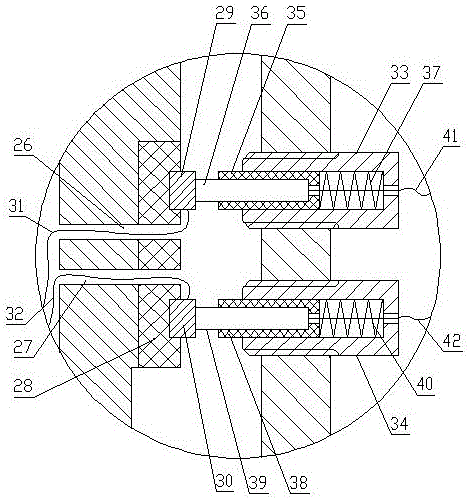

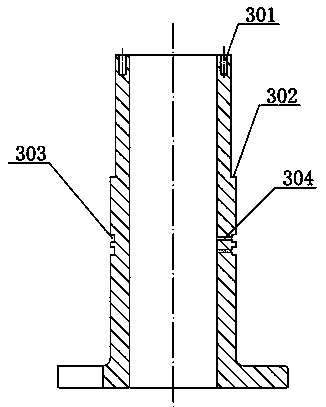

Ultrasonic grinding device for gear

PendingCN108746875AAchieve grindingImprove machining accuracyGear-cutting machinesGear teethEngineeringUltrasonic vibration

The invention discloses an ultrasonic grinding device for a gear. The ultrasonic grinding device comprises a rotary hollow shaft and a fixed base. The rotary hollow shaft is mounted in a penetrating hole in the fixed base in a sleeved mode, the rotary hollow shaft and the penetrating hole are rotationally connected, and one end of the rotary hollow shaft is fixedly connected with a connecting flange of an amplitude-change pole. A gear workpiece is fixed to the small end of the amplitude-change pole. The large end of the amplitude-change pole is located in the rotary hollow shaft and sequentially and fixedly connected with a vibration transmission pole, piezoelectric ceramic and an electrode slice. The piezoelectric ceramic and the electrode slice are connected with an ultrasonic generatorthrough an electric conduction mechanism. The other end of the rotary hollow shaft is connected with a rotary indexing device or a variable frequency motor. According to the ultrasonic grinding device, a gear ultrasonic vibration technology and a gear forming grinding technology are combined, ultrasonic grinding of the gear is achieved, the service life of a grinding wheel can be prolonged, the roughness of a tooth face is reduced, the machining precision of the gear is improved, the microscopic morphology of the tooth face is improved, and accordingly the anti-fatigue ability of the gear is improved.

Owner:HENAN POLYTECHNIC UNIV

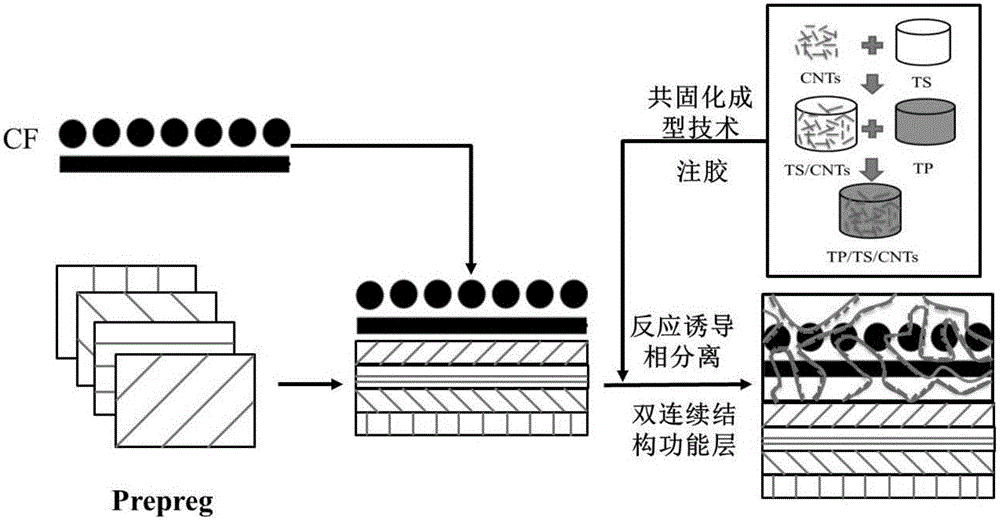

Composite material function modification method based on co-curing and reaction inductive phase separation

ActiveCN105086363ALower Conductive Percolation ThresholdReduce dosageSeparation technologyNanoparticle

The invention discloses a composite material function modification method based on co-curing and reaction inductive phase separation. Thermosetting resin serves as the carrier, thermoplastic resin serves as second-phase modified thermosetting resin, electric conduction and heat conduction nanoparticles serve as the function phase, a co-curing molding process is adopted, and based on the reaction inductive phase separation technology, a carbon fiber composite laminated plate which is provided with a surface function layer is prepared. Through the method, the low-cost and multi-functional carbon fiber composite laminated plate is obtained, and the design and preparation of a composite material by way of integration of structure and function are achieved.

Owner:SHANDONG UNIV

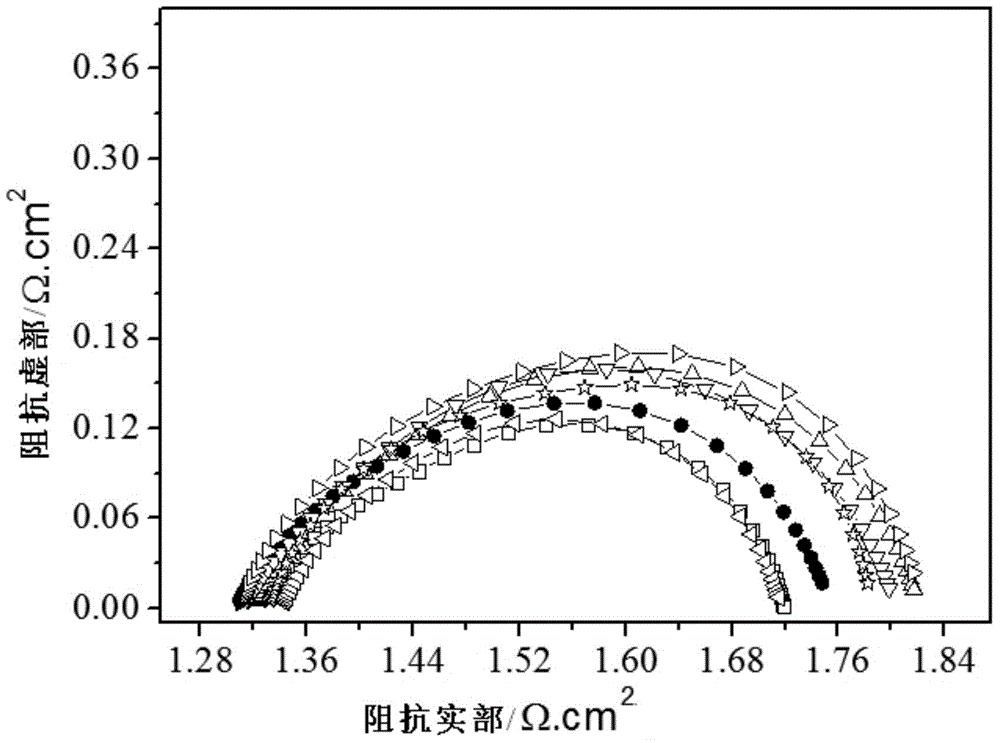

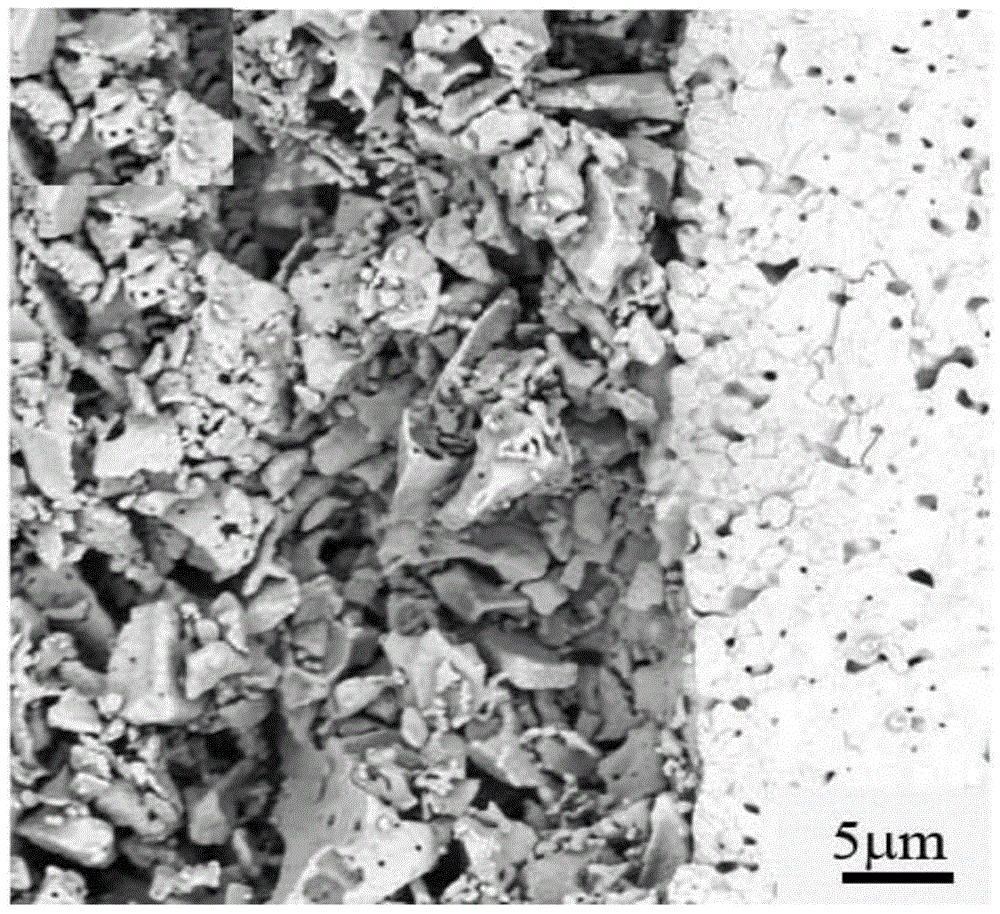

Method for regulating and controlling microstructure of oxide electrode in working period of fuel cell

InactiveCN104091960AIncrease surface areaGood microscopic appearanceCell electrodesFuel cell controlPorosityWork period

The invention provides a method for regulating and controlling the microstructure of an oxide electrode in the working period of a fuel cell, and relates to a method for regulating and controlling the microstructure of the oxide electrode. The method aims at solving the technical problems that material and manpower resources are greatly wasted and the preparation cost is increased due to the reduction of the effective reaction area and the internal porosity of the electrode as well as bad influence on the reaction process of the electrode caused by particle aggregation as the existing methods for regulating and controlling the microstructure of the oxide electrode are all implemented in the preparation process of the electrodes and each electrode needs to be sintered at high temperature. The method comprises the steps of firstly, connecting the fuel cell with an electrochemical workstation and heating, and secondly, performing anodic polarization treatment on the working electrode at high temperature, and cooling to room temperature. The method is mainly applied to control of the microstructure of the oxide electrode of the fuel cell.

Owner:HARBIN INST OF TECH

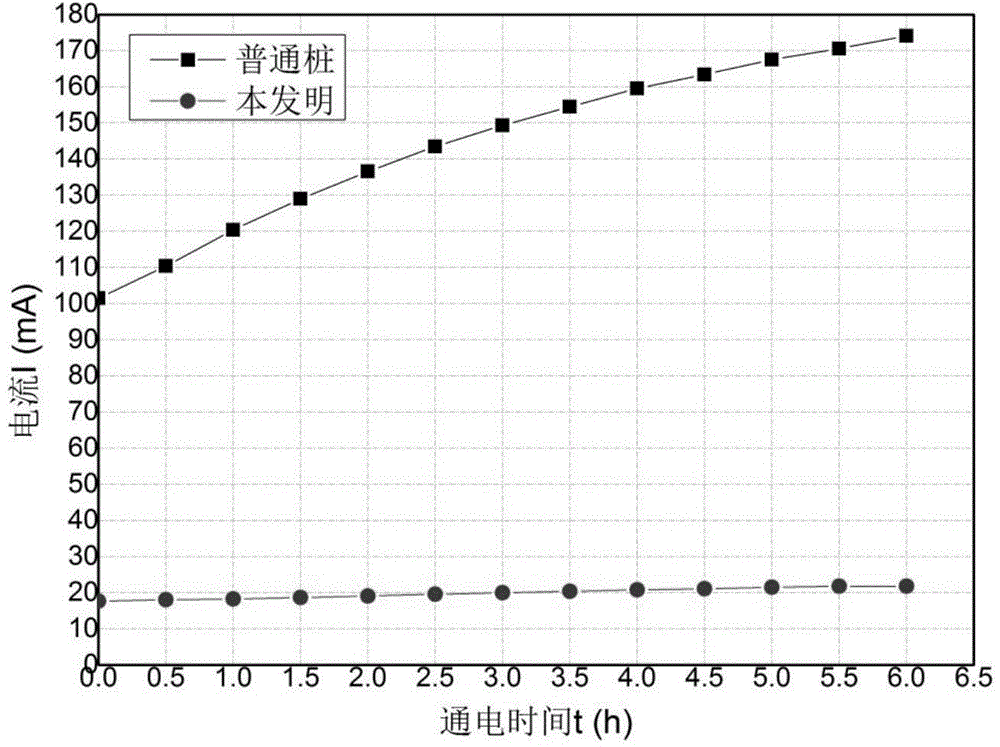

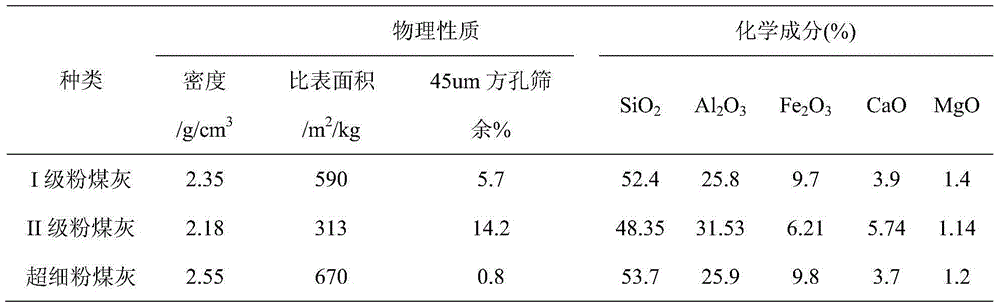

Autoclaved prestressed concrete tube pile applied to marine work environment and preparation method thereof

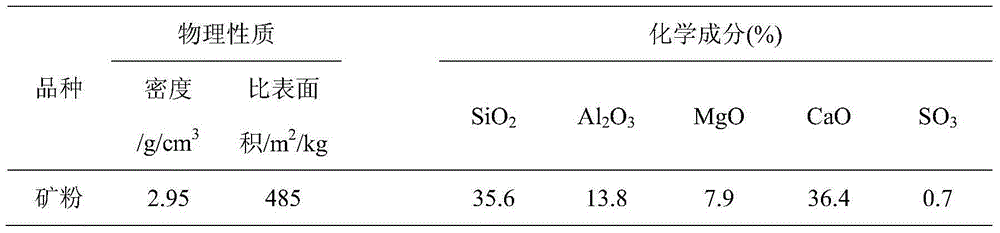

The invention discloses an autoclaved prestressed concrete tube pile applied to a marine work environment and a preparation method thereof. A coating layer is coated on the surface of a tube pile; a gel material consists of P.II52.5 silicate cement and a mineral admixture; the using amount of gel material is 450 to 550kg / m<3>; the using amount of mineral admixture is 30 to 50wt percent that of gel material; the admixture amount of I-level coal ash is 0 to 30wt percent that of gel material; the admixture amount of II-level coal ash is 0 to 25wt percent that of gel material; the admixture amount of ultra-fine coal ash is 0 to 20wt percent that of gel material; the admixture amount of S95-level mineral powder is 0 to 25wt percent that of gel material; the weight ratio of water and gel is 0.22 to 0.24; the water reducer is prepared by aliphatic series and polycarboxylic acid and the ratio is 1 to 2, the using amount of the water reducer is 2.1 to 2.3 wt percent of gel material; the coating layer consists of a primer, a middle paint and a finish paint; the thickness of the coating layer is 125 to 150 microns. The proportions of raw materials and parameters in a preparation process are optimized, and the specific coating layer is coated on the surface, so that the compressive strength and chlorine salt erosion resistance of the tube pile are greatly improved, the rusting risk of the tube pile is greatly reduced, and the service life of the tube pipe in the marine work environment can be greatly prolonged.

Owner:CHINA UNIV OF MINING & TECH +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com