Autoclaved prestressed concrete tube pile applied to marine work environment and preparation method thereof

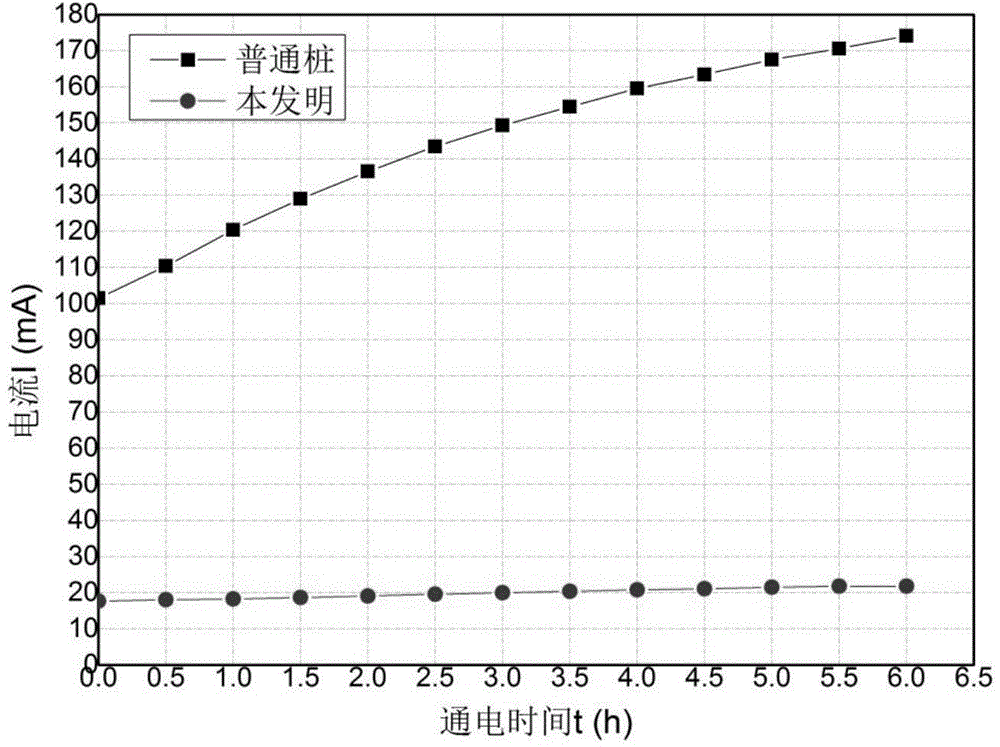

A concrete pipe pile and prestressing technology, applied in the field of building materials, can solve the problems of unfavorable industrialization and promotion of autoclave-free pipe piles, less research on autoclave-free pipe piles, unstable quality, etc. The effect of micro-morphology, reducing the risk of steel corrosion, and improving the corrosion resistance of chlorine salts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

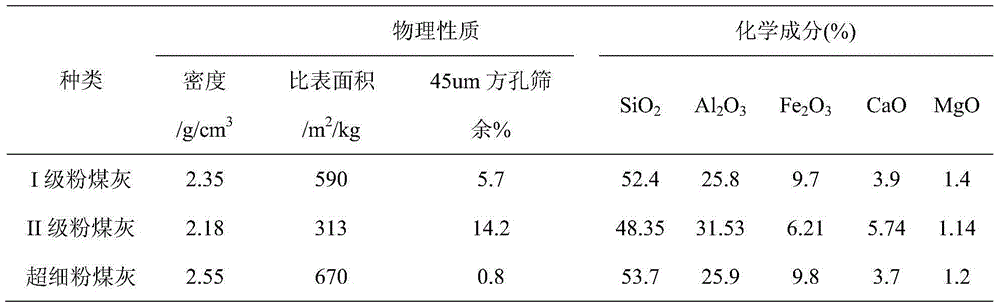

[0034] In this embodiment, the amount of each raw material of concrete is: the amount of sand and stone is 700kg / m 3 and 1280kg / m 3 ;The total amount of cementitious material is 513kg / m 3 , wherein the amount of mineral admixture is 40wt% of the amount of cementitious material. Mineral admixtures are Class I fly ash, Class II fly ash and ultra-fine fly ash, the amount of which accounts for 5wt%, 25wt%, and 10wt% of the cementitious material, and the water-binder ratio is 0.22; The composite water reducer prepared by aliphatic and polycarboxylic acid at a weight ratio of 1:2 has a solid content of 28wt%, and the amount of water reducer accounts for 2.23wt% of the gelled material.

[0035]Put the raw materials into a 60L forced automatic mixer and stir for 3 minutes according to the ratio of the above-mentioned pipe pile concrete raw materials to obtain the pipe pile concrete mixture, put it into a mold, and stop for 1.5 hours, then put the mold into the steam curing pool for ...

Embodiment 2

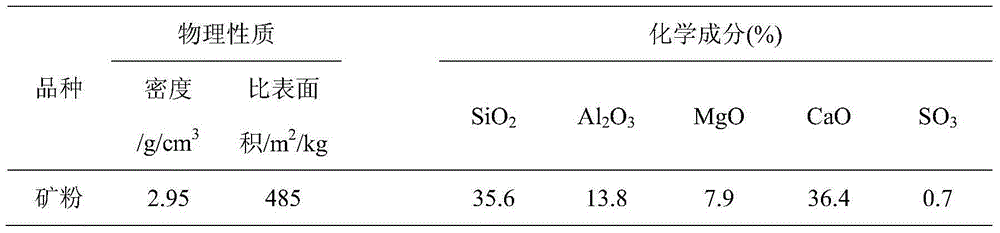

[0039] In this embodiment, the amount of each raw material of concrete is: the amount of sand and stone is 685kg / m 3 and 1275kg / m 3 ;The total amount of cementitious material is 450kg / m 3 , wherein the amount of mineral admixture is 30wt% of the amount of cementitious material. Mineral admixtures are superfine fly ash and S95 grade slag powder, the dosage accounts for 15wt% and 15wt% of the amount of cementitious material respectively, and the water-binder ratio is 0.22; the water reducing agent is aliphatic and polycarboxylic acid according to 1: 2 The composite water-reducer prepared in the weight ratio has a solid content of 28wt%, and the amount of the water-reducer accounts for 2.1wt% of the gelling material.

[0040] Put the raw materials into a 60L forced automatic mixer and stir for 2 minutes according to the ratio of the above-mentioned pipe pile concrete raw materials to obtain the pipe pile concrete mixture, put it into a mold, and stop for 1.5 hours, then put the...

Embodiment 3

[0043] In this embodiment, the amount of each raw material of concrete is: the amount of sand and stone is 710kg / m 3 and 1320kg / m 3 ;The total amount of cementitious material is 550kg / m 3 , wherein the amount of mineral admixture is 50wt% of the amount of cementitious material. Mineral admixtures are grade I fly ash, grade II fly ash, and S95 grade slag powder, the amount of which accounts for 30wt%, 10wt%, and 10wt% of the cementitious material, and the water-binder ratio is 0.24; the water reducer is The composite water reducer prepared by aliphatic and polycarboxylic acid at a weight ratio of 1:2 has a solid content of 28wt%, and the amount of the water reducer accounts for 2.3wt% of the amount of the gelling material.

[0044] Concrete agitation forming maintenance process is the same as embodiment 1, and after the maintenance is finished, spray paint treatment, and the consumption of each layer of paint is the same as embodiment 1, primer dry film thickness 30 μ m, inte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com