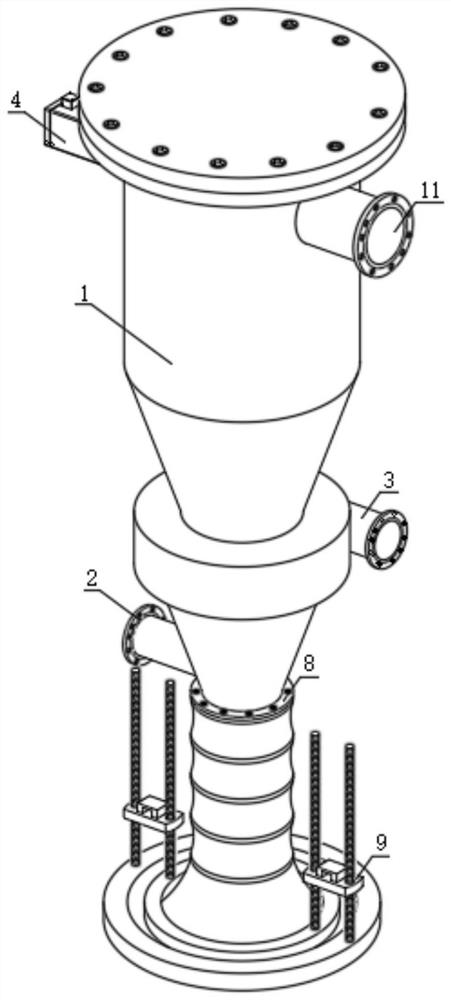

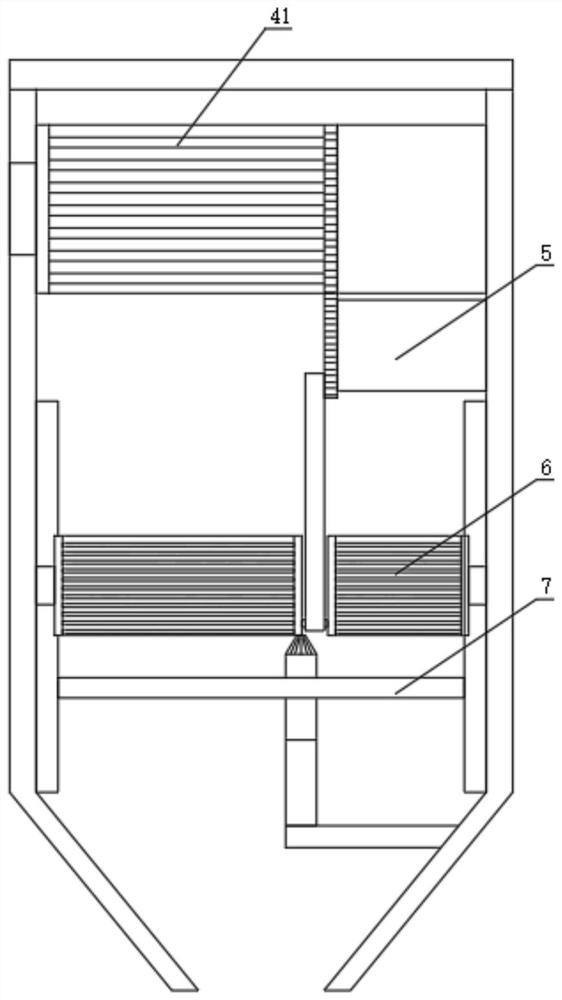

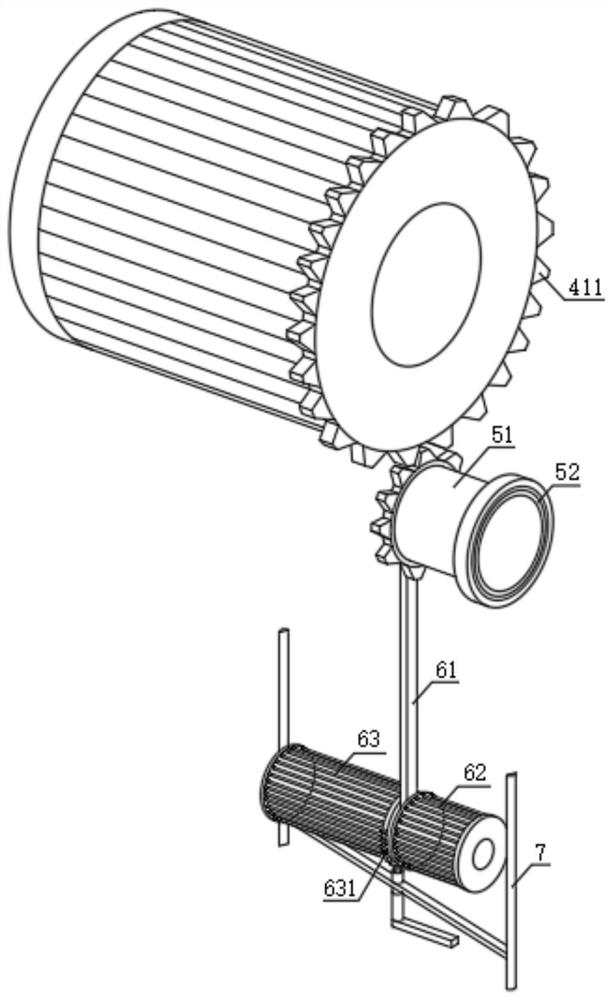

Airflow classification device for high-precision silicon carbide micro powder production and implementation method thereof

A silicon carbide micropowder and airflow classification technology, which is applied to the separation of solids from solids by airflow, chemical instruments and methods, solid separation, etc., can solve the problems of powder raising, air pollution, powder waste, etc. Secondary cleaning, uniform coarse and subdivided grading, and improved grading effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0056] Another technical solution proposed in the present invention: to provide an embodiment of a high-precision silicon carbide powder production airflow classification apparatus, comprising the following steps:

[0057] Step one: according to the diameter of the barrel where the silicon carbide powder is stored, the corresponding number of articulation balls 921 can be reasonably used, and connected by the card joint 9235 inserted into the groove, and then the first thread rod 941 thread is connected to the external adjustment assembly 93, the second thread rod 942 thread is connected to the internal adjustment assembly 92, and then by adjusting the adjustment support component 943 to the lowest end of the first thread rod 941 and the second thread rod 942, the entire dustproof mechanism 9 is set at the upper end of the barrel, and the opening of the barrel can be closed;

[0058] Step 2: The material enters from the raw material inlet 2, and the air supply port 3 is supplied w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com