Pretreatment method for biomass fiber material

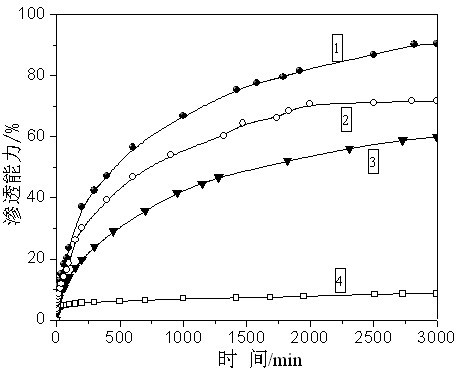

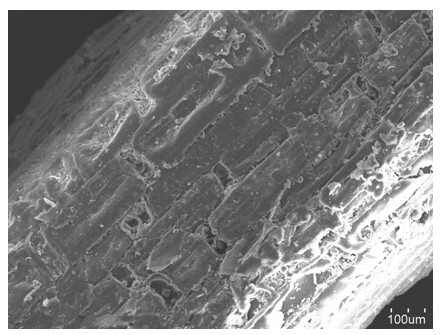

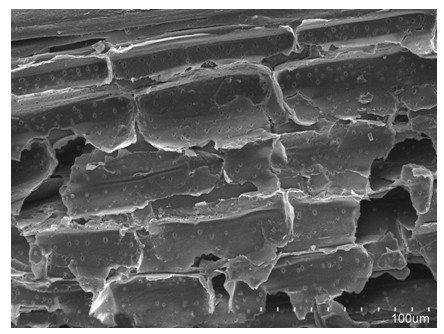

A biomass fiber and pretreatment technology, which is applied in fiber raw material processing, textile and papermaking, etc., can solve the problems of long cycle and poor practicability, and achieve the advantages of less environmental pollution, improved microscopic appearance, and improved pretreatment effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Preparation of Ammonia-1-Butyl-3-Methylimidazolium Chloride ([Bmin]Cl) Composite Microemulsion

[0031] Cyclohexane, cetyltrimethylammonium bromide (CTAB), n-butanol, ammonia water and [Bmin]Cl were used as the oil phase, surfactant, co-surfactant and hydrogen bond breaking of the microemulsion system, respectively. Agent and ionic liquid, wherein ammoniacal liquor, [Bmin]Cl and distilled water form aqueous phase substance, ammoniacal liquor: the mass ratio of [Bmim]Cl is 1:2, and the mass ratio of ammoniacal liquor and distilled water is 1:2, and CTAB, n-butyl After alcohol and cyclohexane are mixed, stir at 30°C at a speed of 150rpm. When there are no bubbles in the stirring process, add water phase substances to it, and continue stirring to obtain a clear and transparent ammonia water-[Bmin]Cl composite microemulsion. The prepared The mass ratio of each component of the composite microemulsion is CTAB: n-butanol: cyclohexane=2:1:2; wherein the water phase material ac...

Embodiment 2

[0037] Ammonia-1-ethyl-3-methylimidazolium chloride ([Emin]Cl) composite microemulsions were prepared by using n-octane, cetyltrimethylammonium bromide (CTAB), ethanol, ammonia and [ Emin]Cl) as the oil phase, surfactant, co-surfactant, hydrogen bond breaker and ionic liquid of the composite microemulsion system, wherein ammoniacal liquor, [Emin]Cl) and distilled water are mixed to form the water phase material, wherein ammoniacal liquor:[ The mass ratio of Emin]Cl) is 1:2, and the mass ratio of ammonia water:distilled water=1:2. After mixing CTAB, ethanol and n-octane, stir at 200rpm at 30°C. When there is no bubble in the stirring process Add water phase substance wherein again, continue to stir to obtain clear and transparent ammoniacal liquor-[Emin]Cl composite microemulsion, the mass ratio of each component of the composite microemulsion that makes is CTAB: ethanol: n-octane=2:1:2 , wherein the water phase material accounts for 70% of the total mass of the composite micro...

Embodiment 3

[0042] The urea-[Bmin]Cl composite microemulsion was prepared, and cyclohexane, cetyltrimethylammonium bromide (CTAB), n-butanol, urea and [Bmin]Cl were respectively used as the oil phase of the composite microemulsion system, Surfactant, co-surfactant, hydrogen bond breaker and ionic liquid, wherein urea, [Bmin]Cl and distilled water are mixed to form water phase substance, wherein the mass ratio of ammonia: [Bmin]Cl is 1:2, ammonia: The mass ratio of distilled water is 1:2. After mixing CTAB, n-butanol and cyclohexane, stir at 50°C at a speed of 300rpm. When there are no bubbles in the stirring process, add water phase substances to it, and continue stirring to obtain clarification. Transparent urea-[Bmin]Cl composite microemulsion, the mass ratio of each component of the composite microemulsion that makes is CTAB: n-butanol: hexanaphthene=2:1:2; 60% of the quality.

[0043] The air-dried straw is chopped by a cutting machine, and the straw with a length of 1 to 5 cm is tak...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com