Patents

Literature

731 results about "Biomass c" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

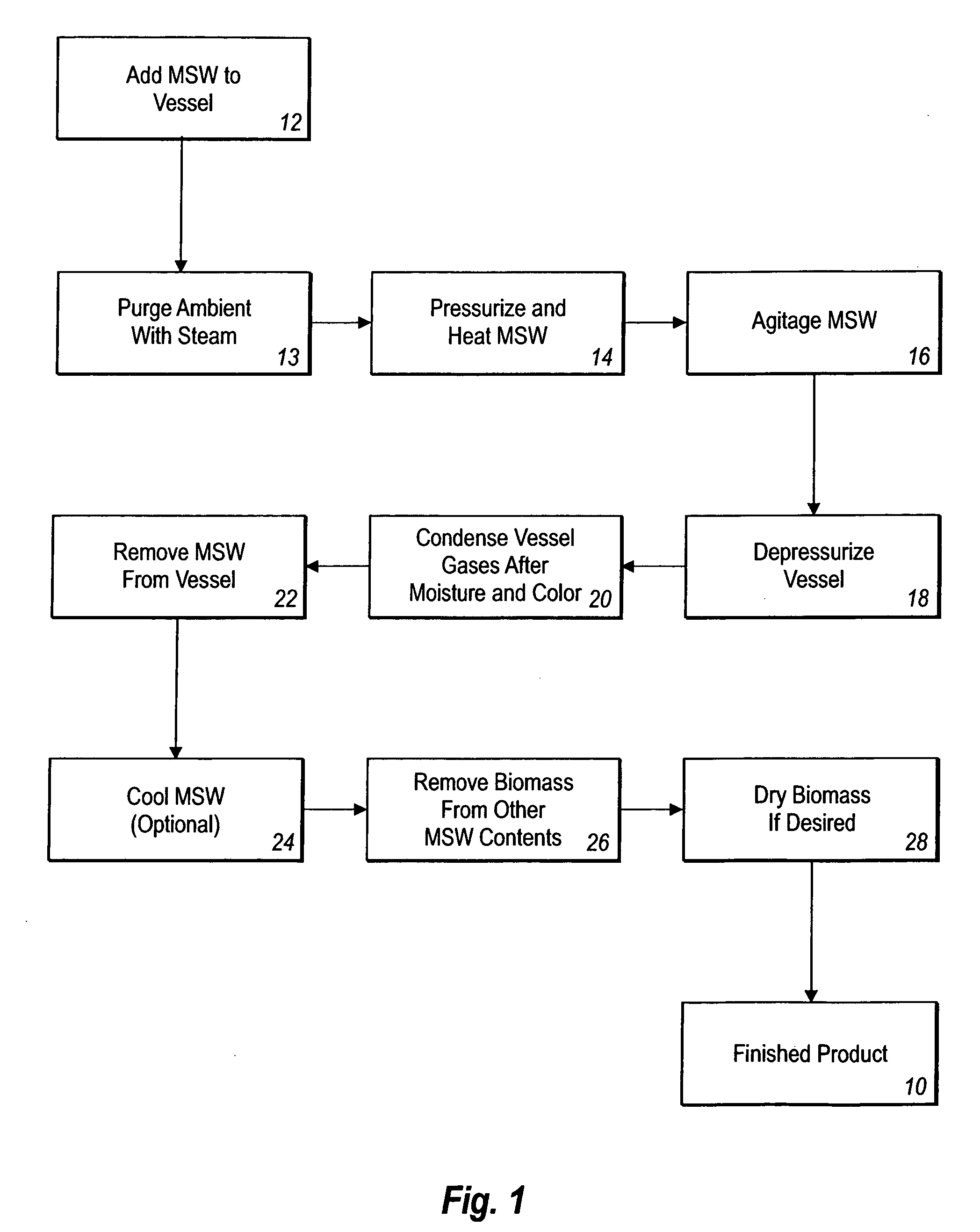

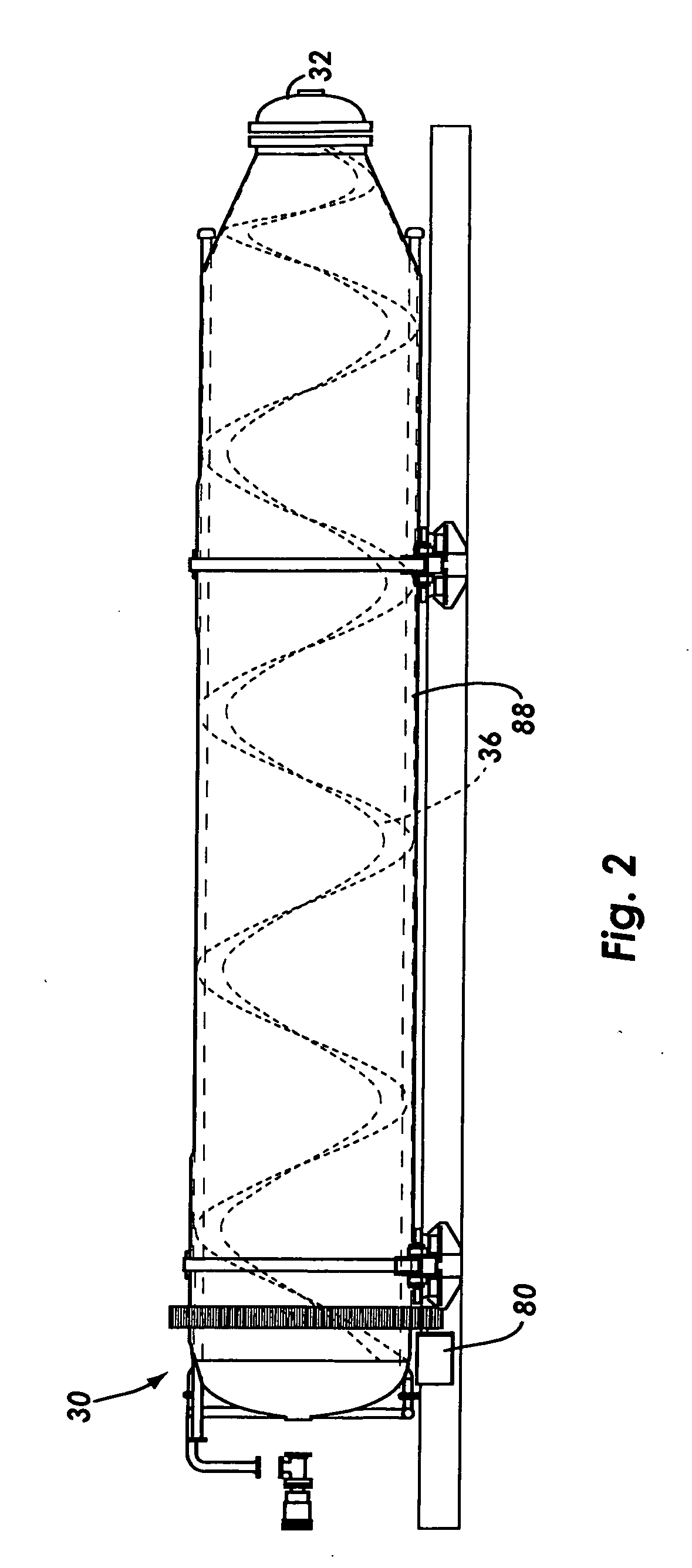

Biomass energy product and processing method

InactiveUS20060112616A1Increase concentrationCritical problemBiofuelsSolid fuelsEnergy productsProcess engineering

An energy product made from biomass, and a method of making an energy product from biomass. The energy product is made by processing biomass in a pressurizable reaction vessel with heat, pressure and agitation.

Owner:BIOMASS WORLDWIDE GROUP

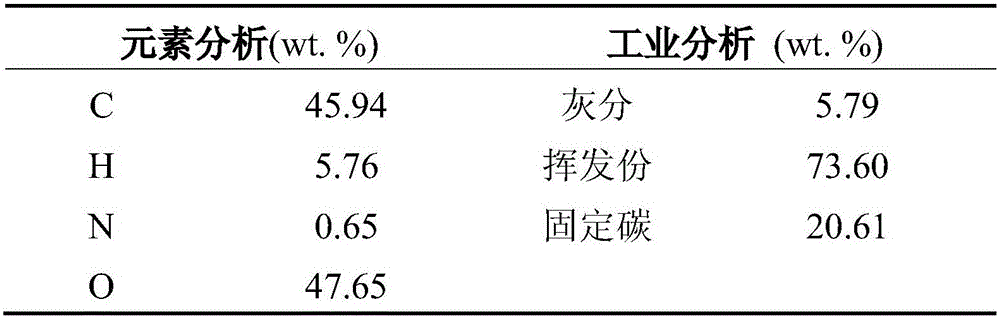

Method for preparing light phenol organic mixture through catalytic pyrolysis of biomass

ActiveCN102070408APromote dehydrationInhibition formationOrganic chemistryOrganic compound preparationPre treatmentPhosphate

The invention discloses a method for preparing a light phenol organic mixture through catalytic pyrolysis of biomass, and belongs to the field of utilization of biomass energy. The method comprises the following steps of: loading phosphate serving as a catalyst to a biomass raw material in an impregnation mode, performing pyrolytic reaction at the temperature of between 280 and 500 DEG C under the oxygen-free condition, and condensing pyrolysis gas to obtain a liquid product rich in the light phenol organic mixture. In the method, the phosphate serving as the catalyst is loaded to the biomassraw material in the impregnation mode, and the pretreated biomass raw material is pyrolyzed, so that the defects of low yield, low content, high separation and extraction cost and the like of phenol substances in biological oil obtained by the conventional biomass pyrolysis liquefying technology are overcome. The method is suitable for large-scale industrial production and has a good application prospect.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

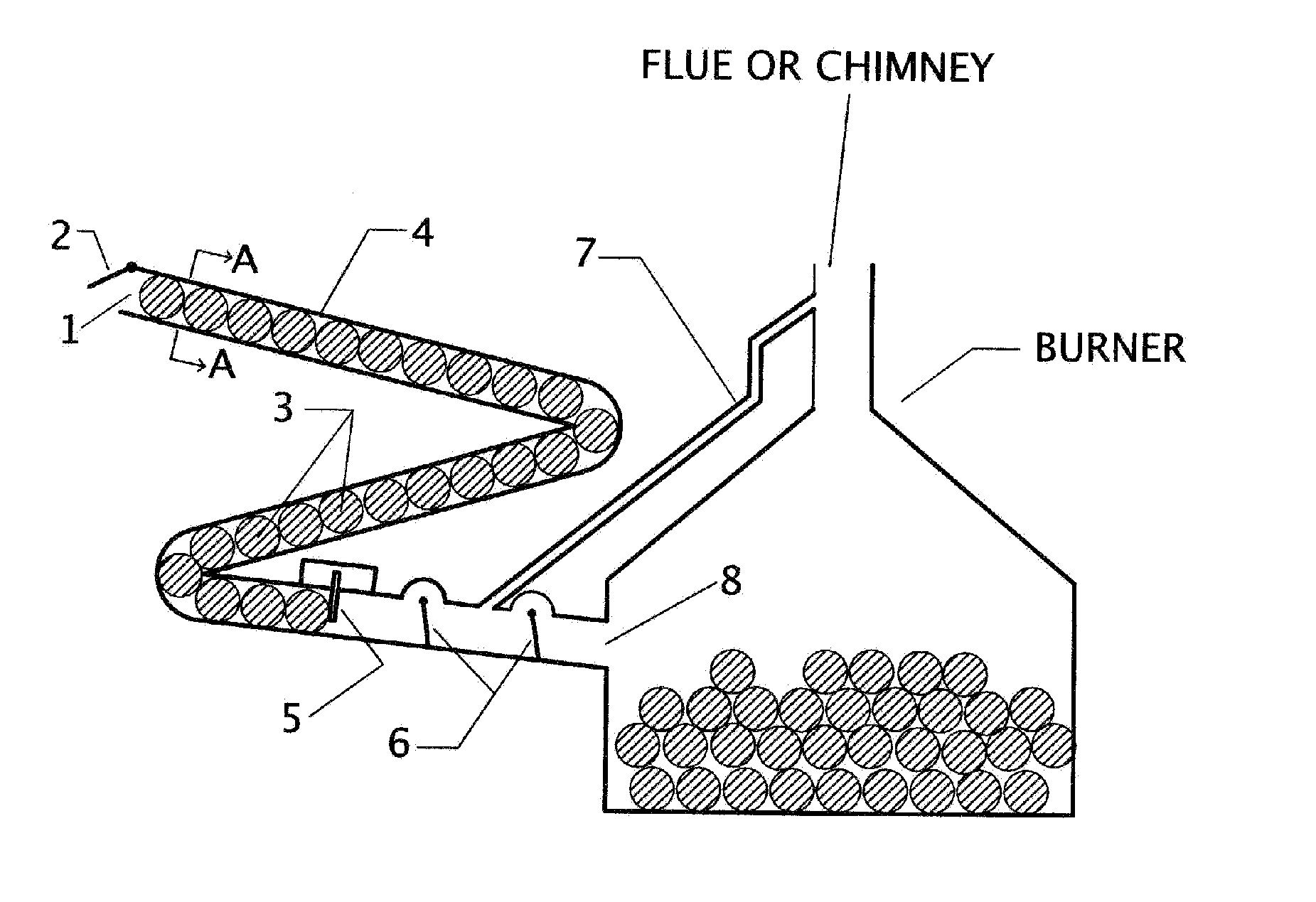

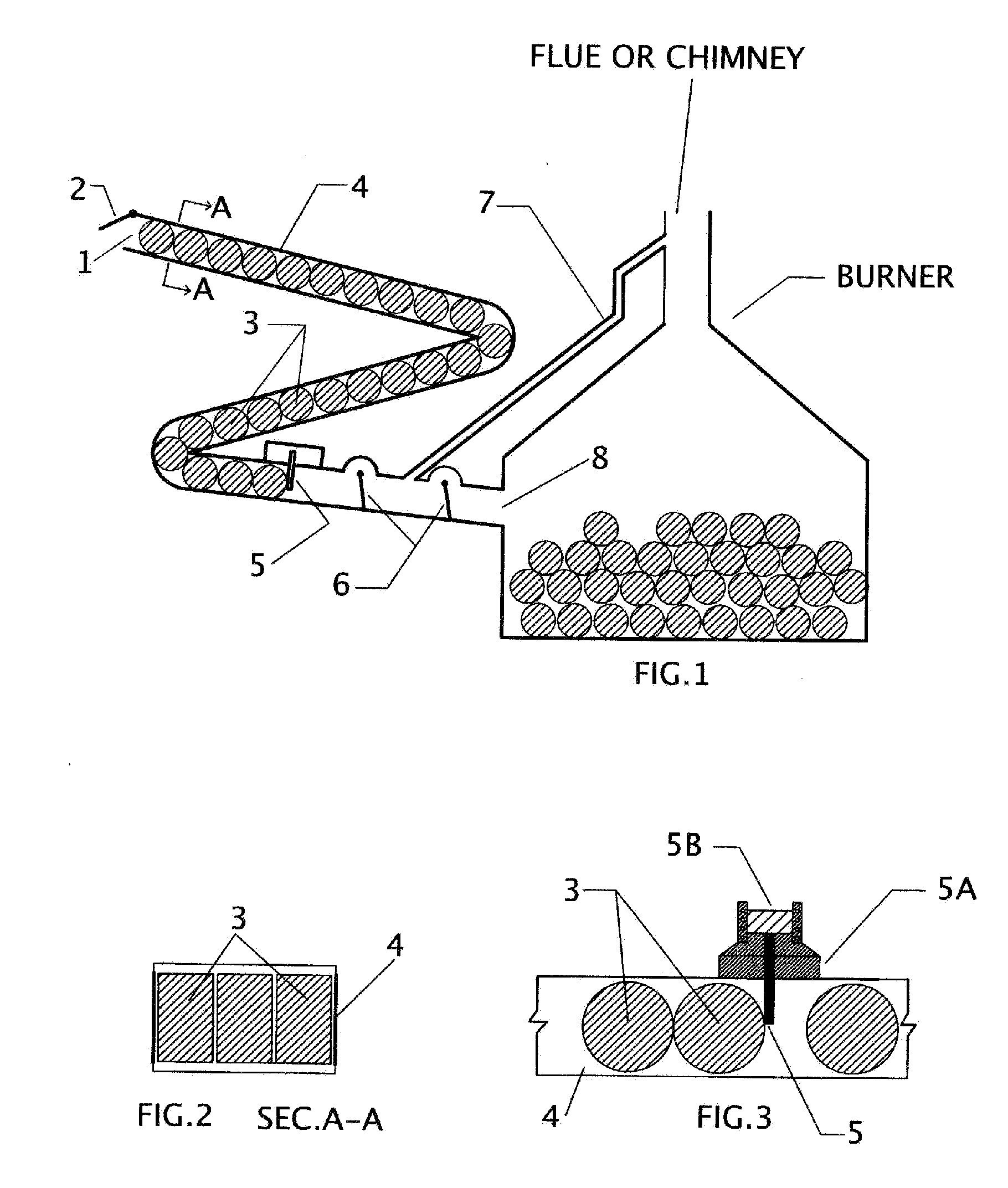

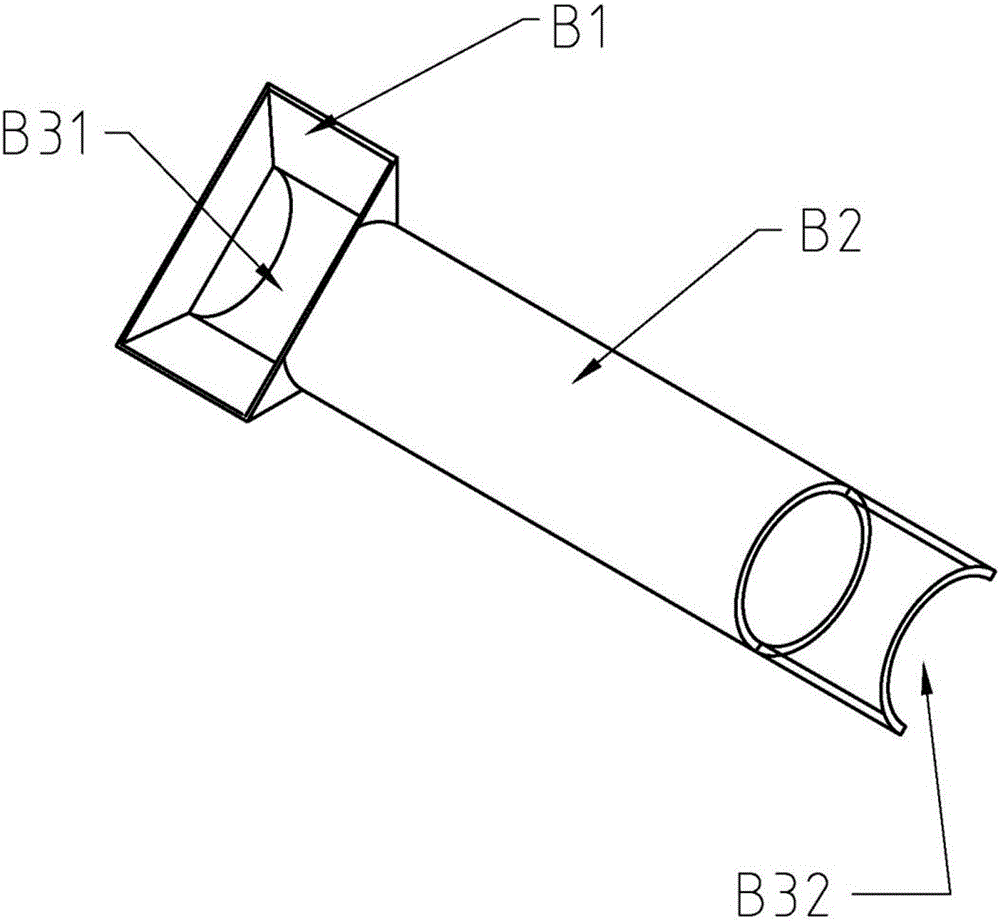

Method to feed biomass tablets and logs into burners

InactiveUS20060272557A1Simple, energy-efficientSolid fuel combustionLump/pulverulent fuel feeder/distributionElectricityCombustor

This invention pertains to a novel new method and device to feed or inject cylindrical fuel elements (logs and tablets), made of biomass and other carbonaceous materials, into burners (furnaces, boilers, stoves or fireplaces) for use as fuel in combustion. The same method and device can also be used in gasification and liquefaction plants to feed cylindrical fuel elements as the feedstock for the gasification or liquefaction reactors. The use of such a method and device to feed biomass and other carbonaceous materials into burners and gasification / liquefaction reactors enhances the use of biomass as a resource for heating, generating electricity, and converting to gaseous or liquid fuels. Increased use of biomass, which is a renewable energy source, reduces the consumption of fossil fuel, and hence reduces detrimental environmental impacts of using fossil fuel including air pollution and global warming.

Owner:FREIGHT PIPELINE CO

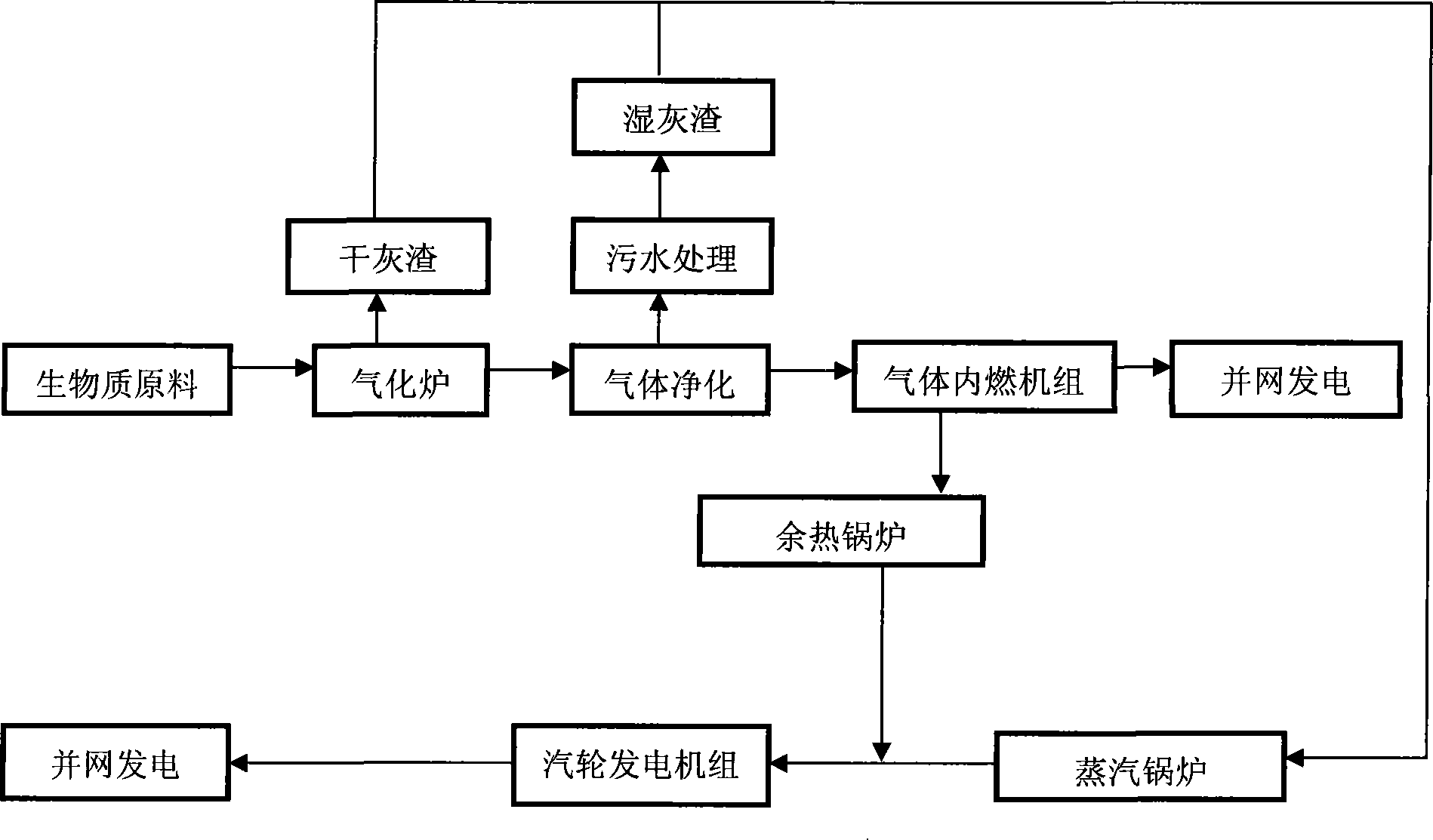

Biomass energy circulation electrification technique as well as generating system thereof

InactiveCN101251045ATake advantage ofImprove power generation efficiencyInternal combustion piston enginesFeed water supplyThermal energyInternal combustion engine

The invention provides a biomass energy IGCC technology which is characterized in that the technology comprises the following steps that: (1) the biomass raw material is gasified to be converted into the combustible gas which is dedusted and decoked as well as purified and is sent to a gas internal-combustion engine to generate electricity; (2) the biomass raw material or the clinker generated in the gasification and power generation process in the step 1 or the mixture of the two is sent to a steam boiler to be burnt in order to generate the superheated steam; the exhaust heat of the gas internal-combustion engine of the step 1 is inlet to an exhaust-heat boiler to generate the superheated steam; (3) the superheated steam generated by the steam boiler and the exhaust-heat boiler of the step 2 is sent to a turbonator set. The biomass energy IGCC technology takes full advantage of the heat energy and the product generated by each processing step in the biomass energy gasification and power generation process and generates electricity circularly, thereby greatly raising the power generation efficiency, taking full advantage of waste materials and lowering the running cost. The invention also discloses a power generation system for realizing the biomass energy IGCC technology.

Owner:黄家笙 +1

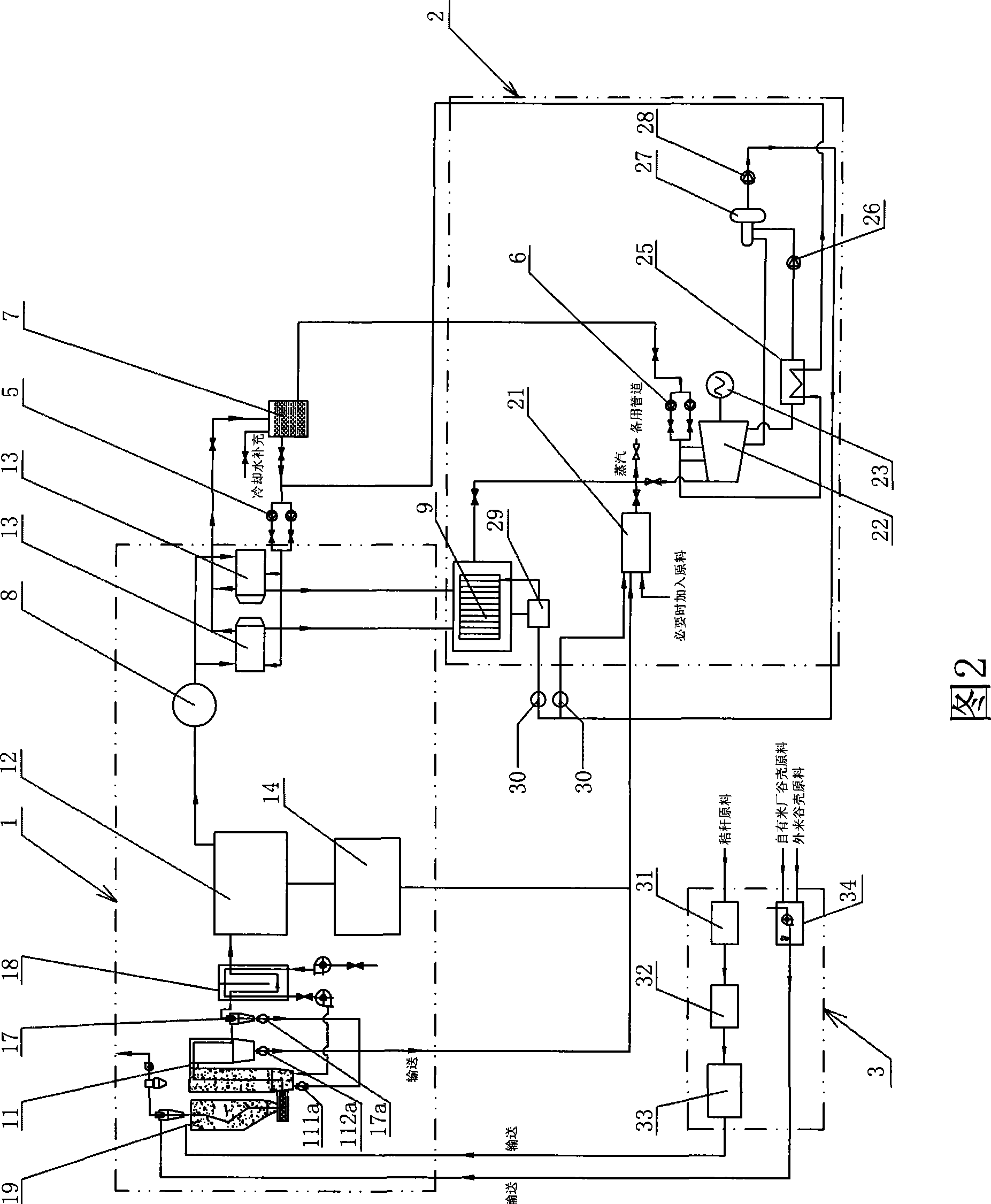

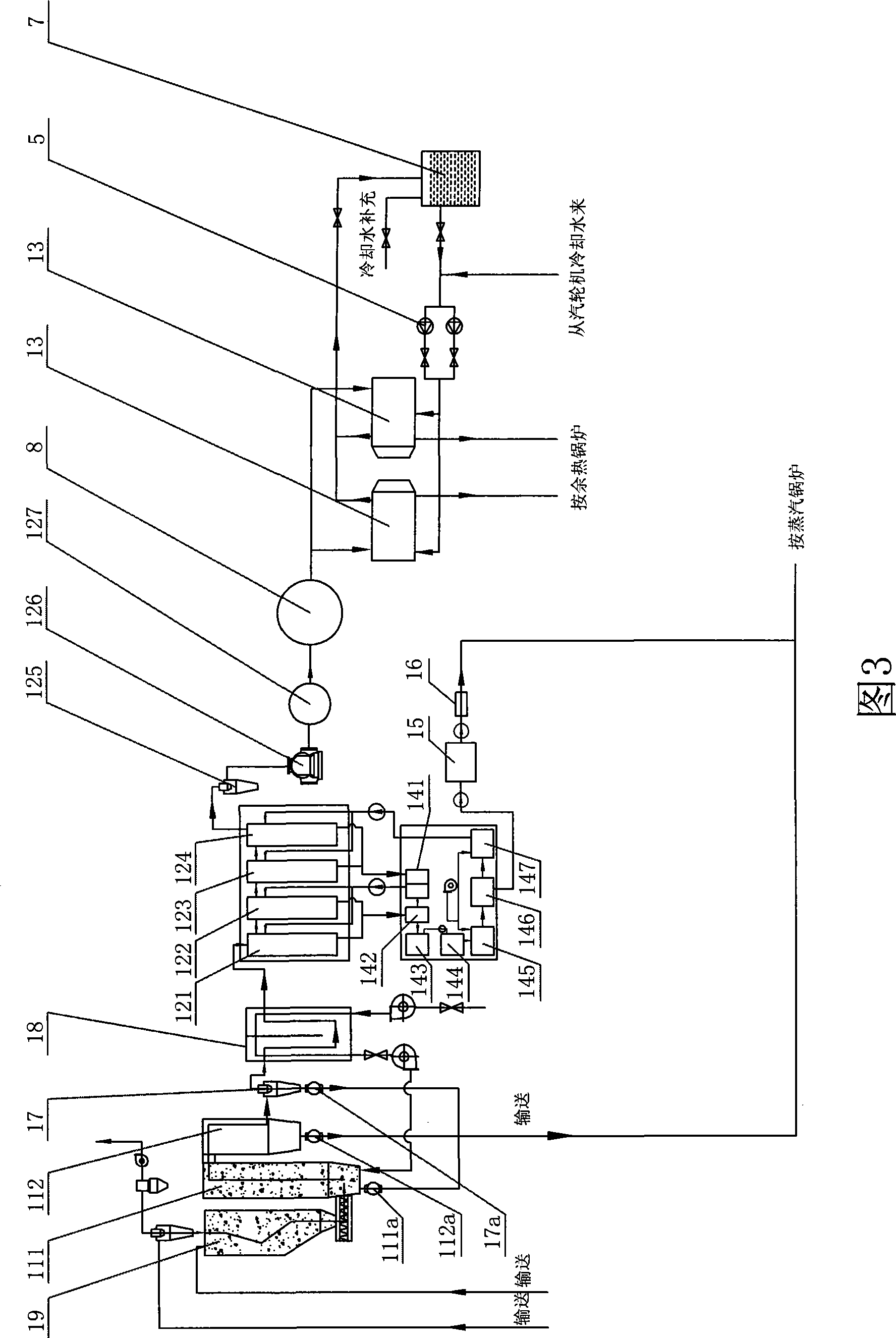

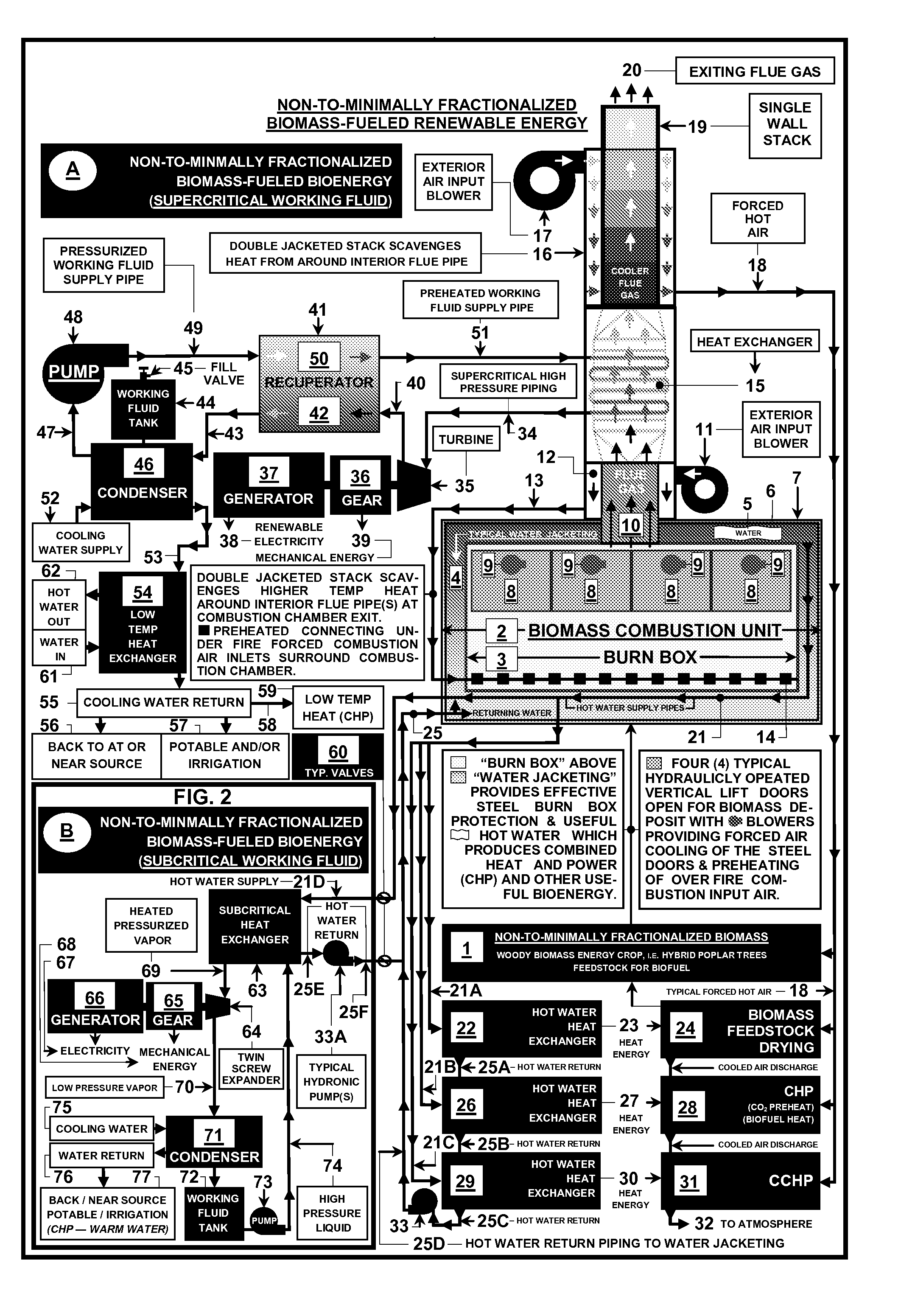

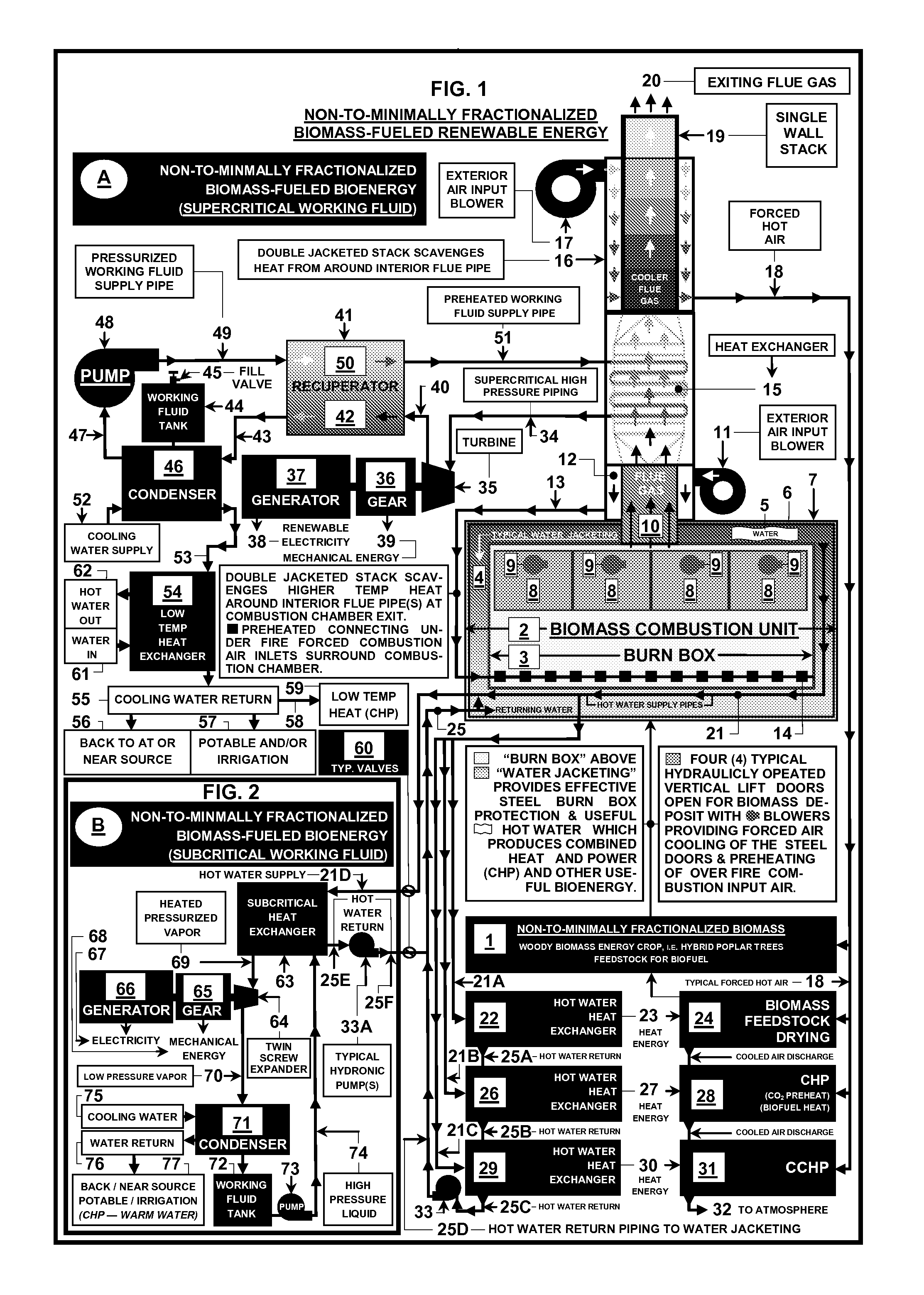

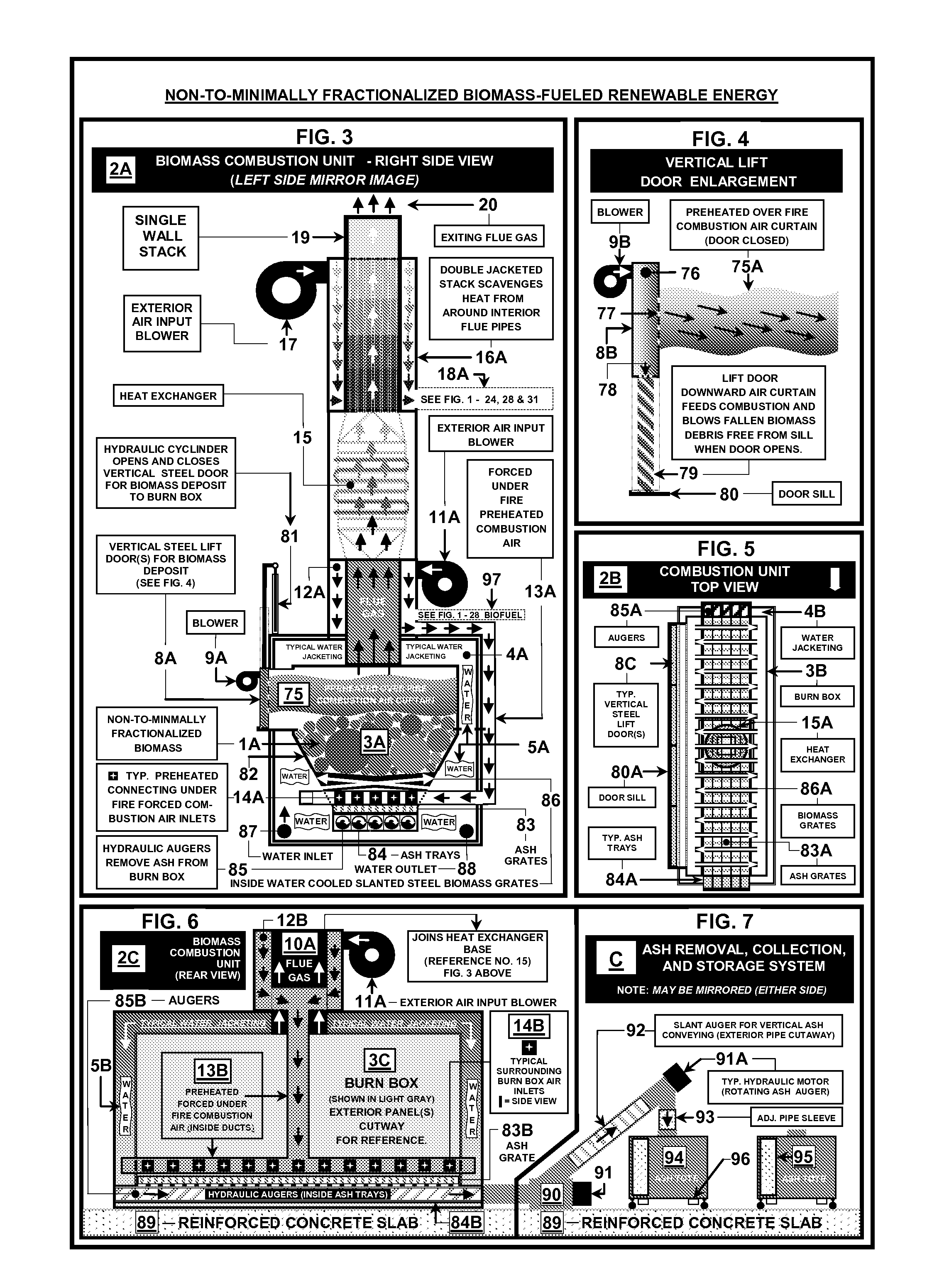

Non-to-minimally fractionalized biomass-fueled renewable energy

InactiveUS20130328322A1Simpler and more practical and economically viable conversionIncrease costSolid waste disposalBiofuelsForms of energyOrganic Rankine cycle

A novel Biomass Combustion Unit apparatus purposefully designed to be uniquely fueled with Non-To-Minimally Fractionalized Biomass for the intentional production of heat for conversion to a multiplicity of useful energy forms. More particularly, said apparatus provides useful heat for: (i) Power Generation, (ii) Heating Applications, (iii) Cogeneration or Combined Heat and Power (CHP), (iv) Trigeneration or Combined Cooling, Heat, and Power (CCHP), (v) Mechanical Energy and (vi) Facilitating the production of Biofuels. Additionally, methods and systems are presented wherein the abovementioned forms of energy deploy organic and inorganic working fluids, in both Subcritical and Supercritical Power Generation Cycles, via Organic Rankine Cycle and a modified Rankine Cycles, respectively. Further, Woody Biomass Energy Crops and Biofuel components are presented as well.

Owner:JULIAN MARVIN DUANE

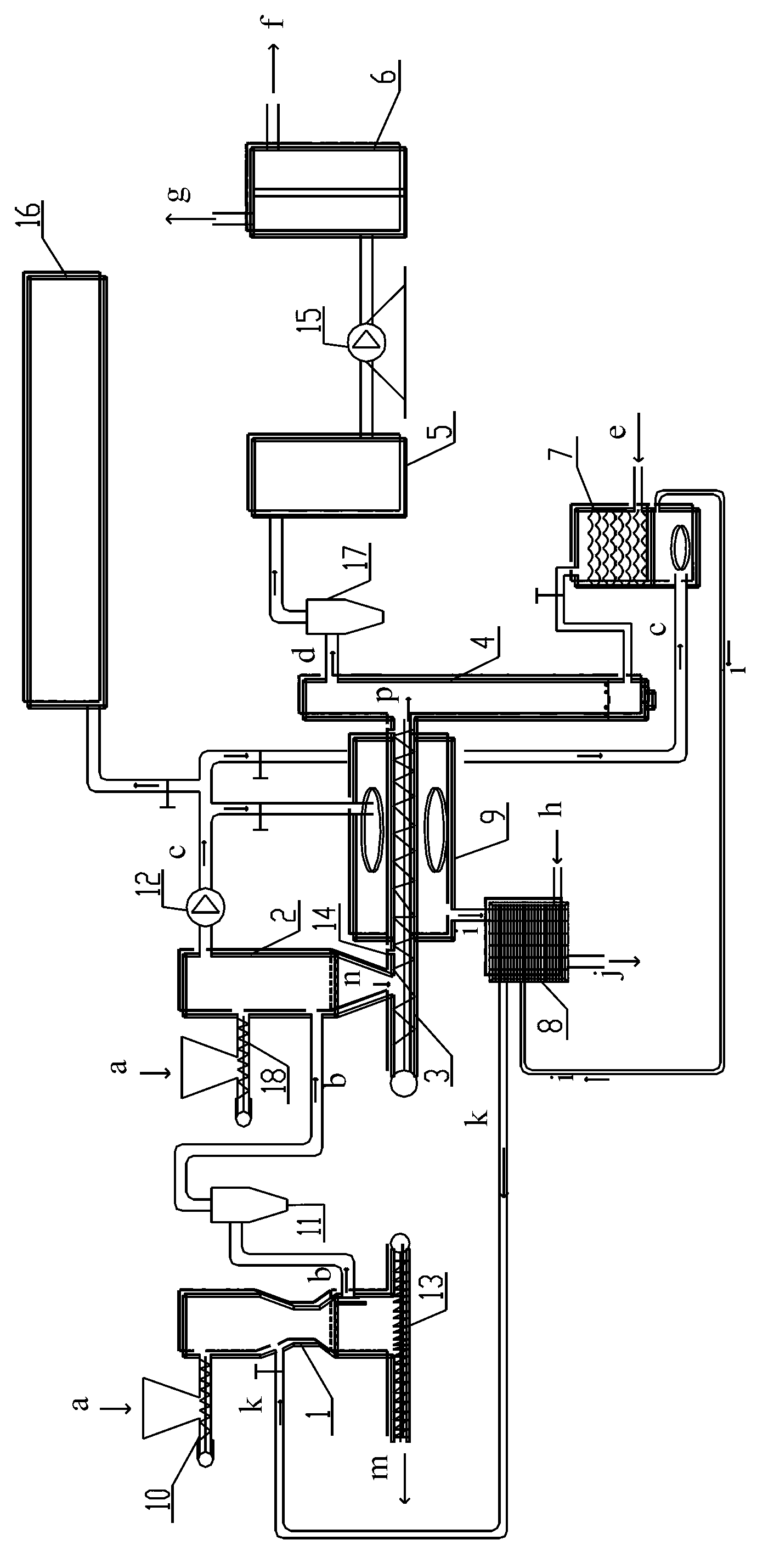

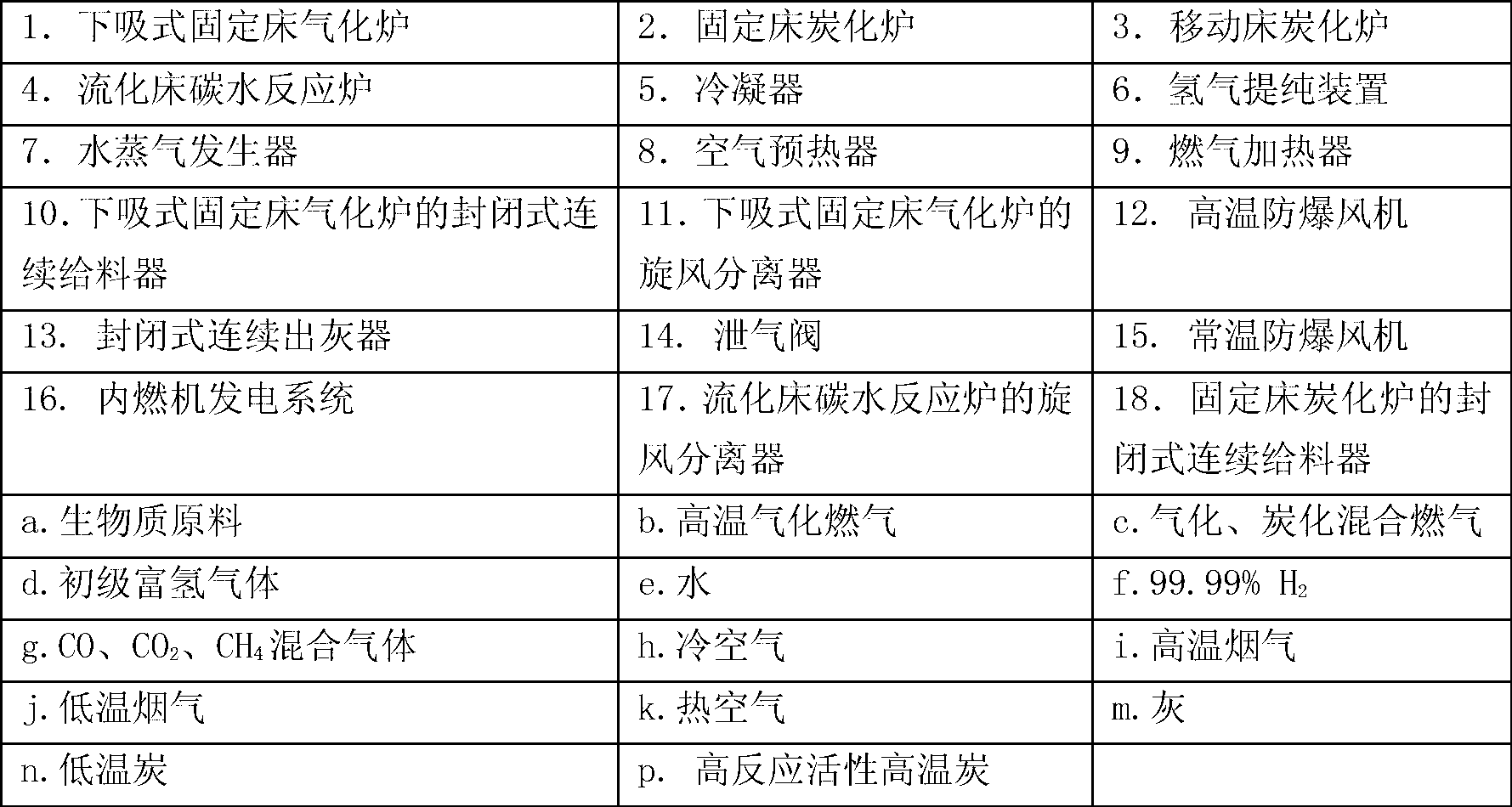

Method and device for preparing high-purity hydrogen from biomass

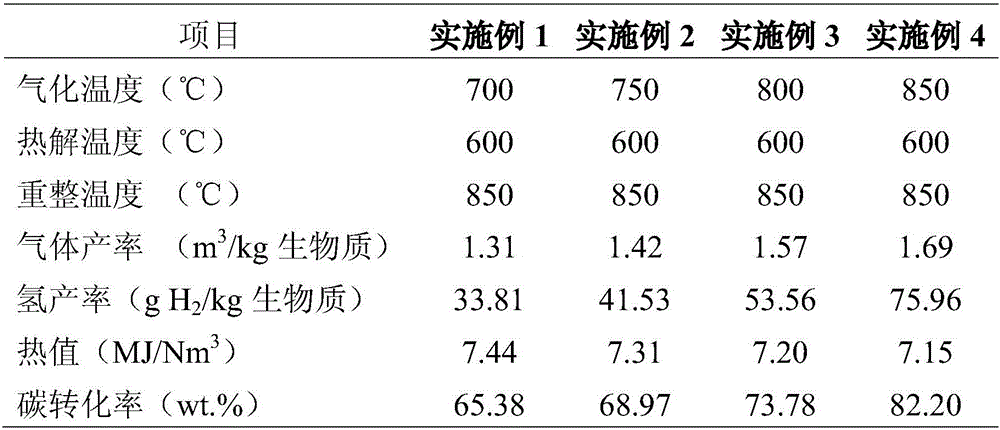

InactiveCN103011072ARapid responseHigh reactivityHydrogen separationDirect heating destructive distillationThermal energyCarbonization

The invention discloses a method and a device for preparing high-purity hydrogen from biomass. A thermal chemical hydrogen preparation process of biomass is divided into three steps, namely biomass gasification, step-by-step biomass carbonization and water-charcoal reaction. The combustible gas generated by biomass gasification provides heat energy required by the whole production line, and electricity is generated by gas to provide electric energy required by all power equipment, so that biomass is the only energy source of the whole process and ensures zero consumption of external power. The step-by-step biomass carbonization process overcomes the defects of low yield and low biomass charcoal reaction activity of the conventional carbonization process, and greatly improves the reaction activity of the biomass charcoal while ensuring a high yield of biomass charcoal by coupling a slow low-temperature carbonization reaction and a fast high-temperature carbonization reaction; therefore, the water-charcoal reaction is accelerated and the energy consumption in the water-charcoal reaction process is reduced. The content of hydrogen of the generated primary hydrogen-rich gas is over 85%, and can even be more than or equal to 99.99% after purification of a hydrogen purification device.

Owner:TIANJIN UNIV

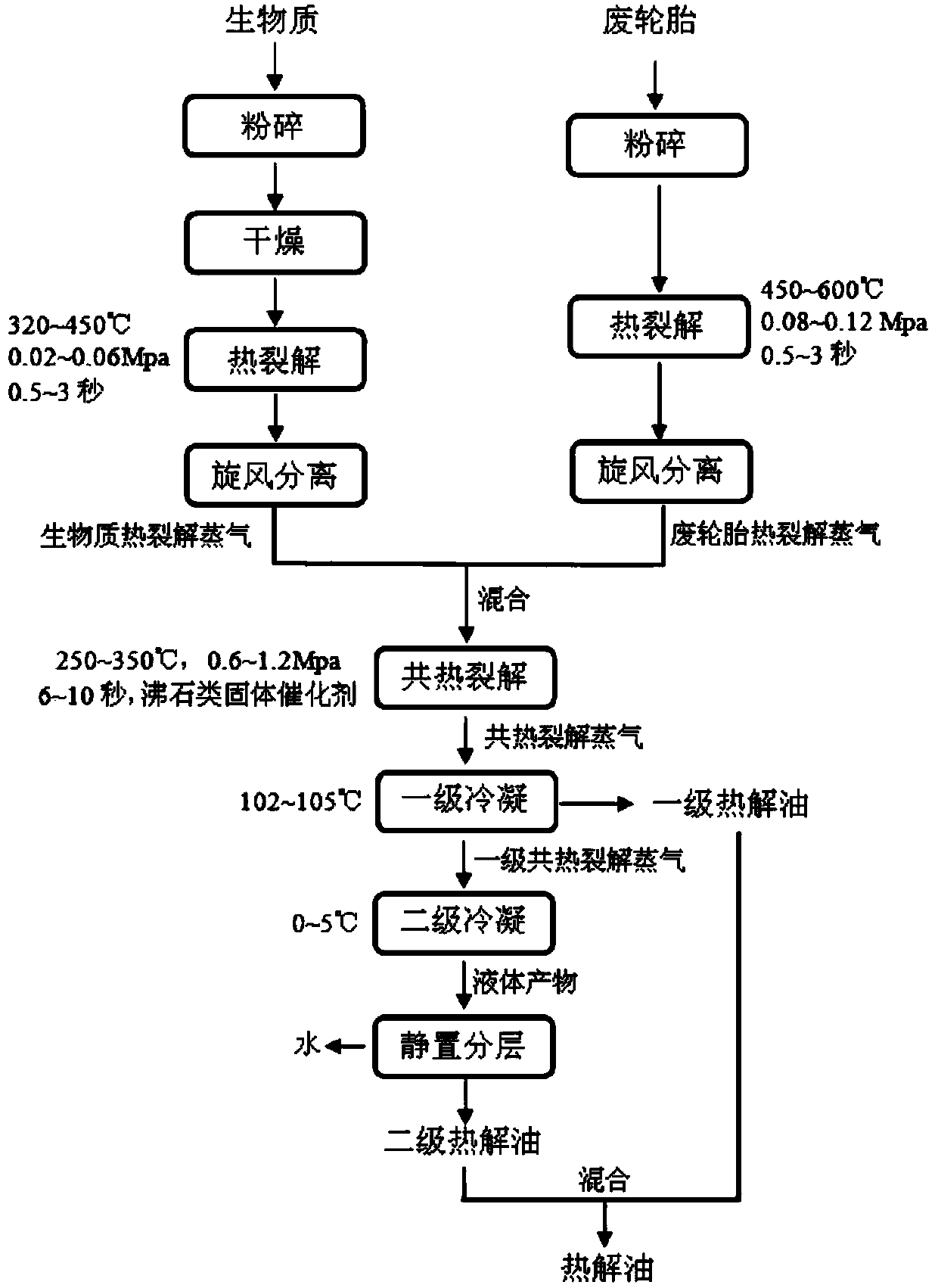

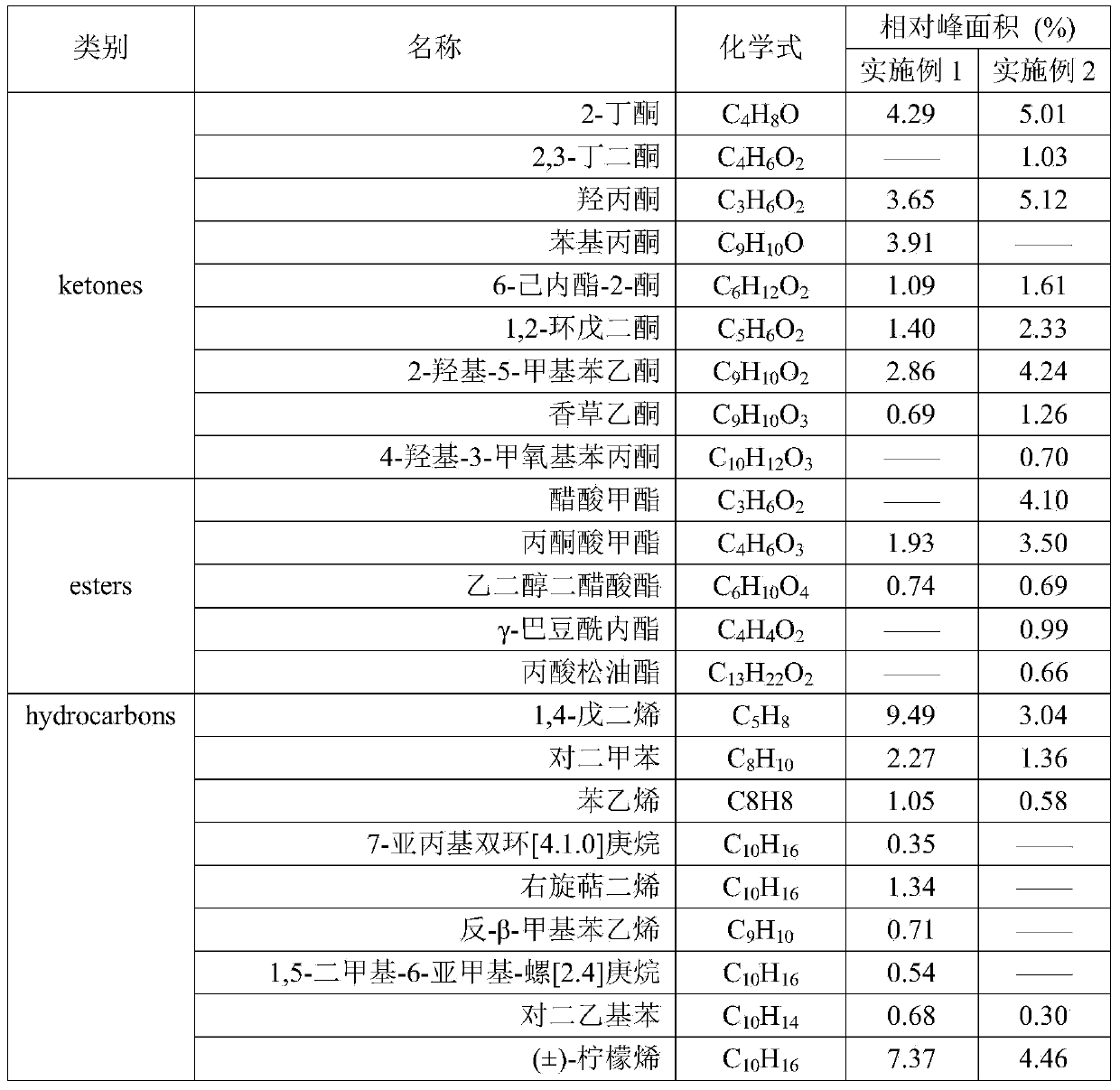

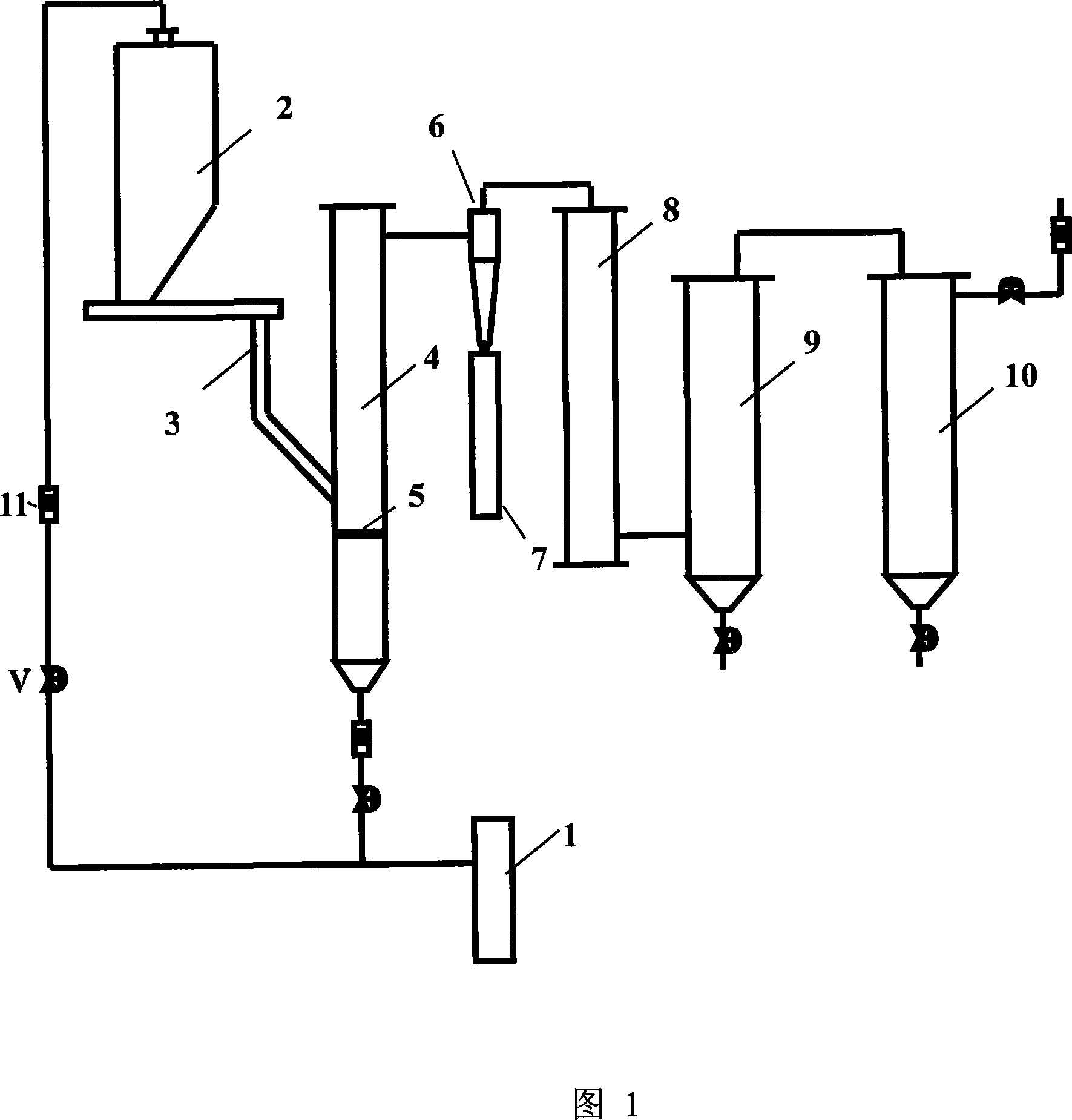

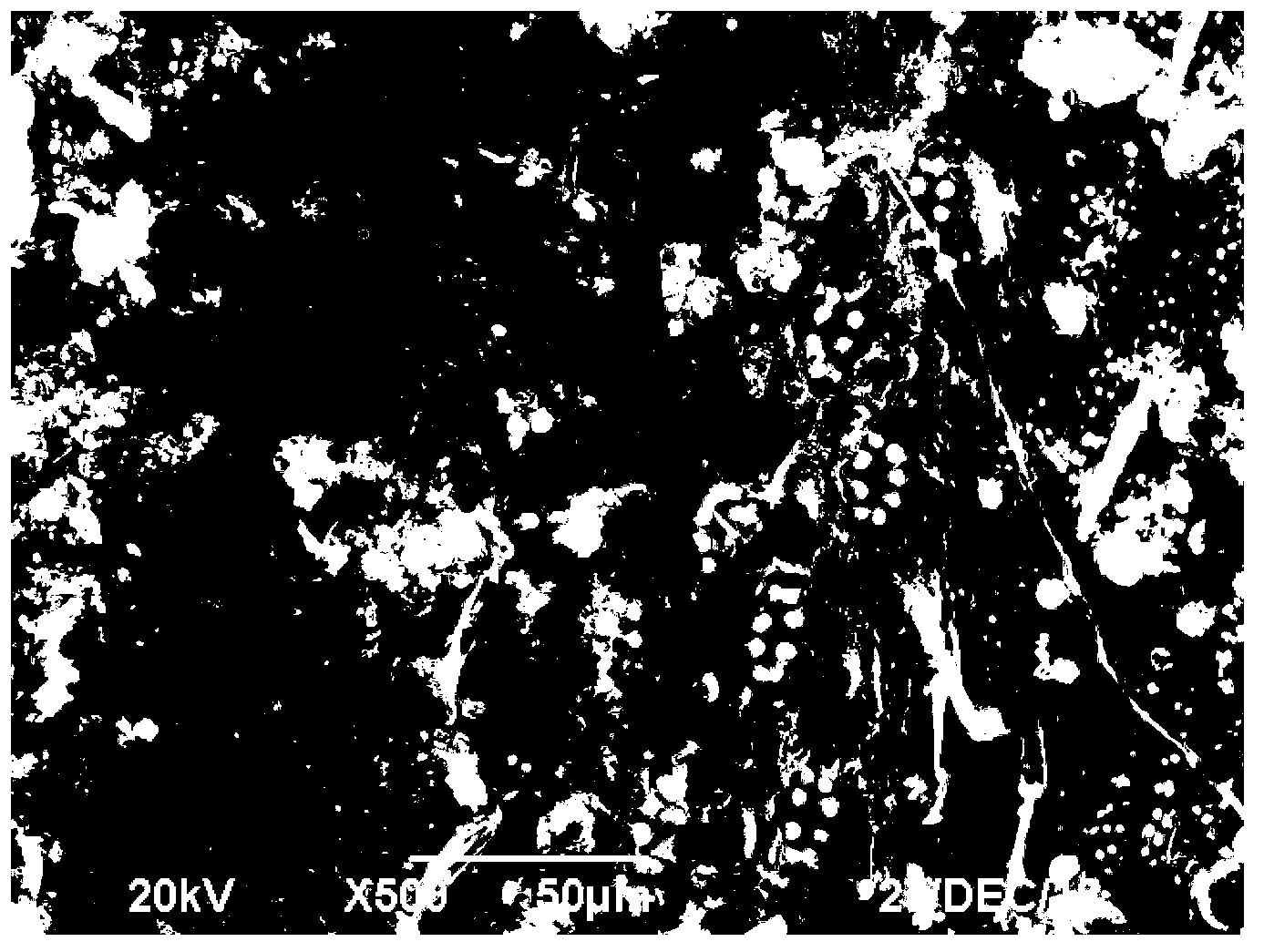

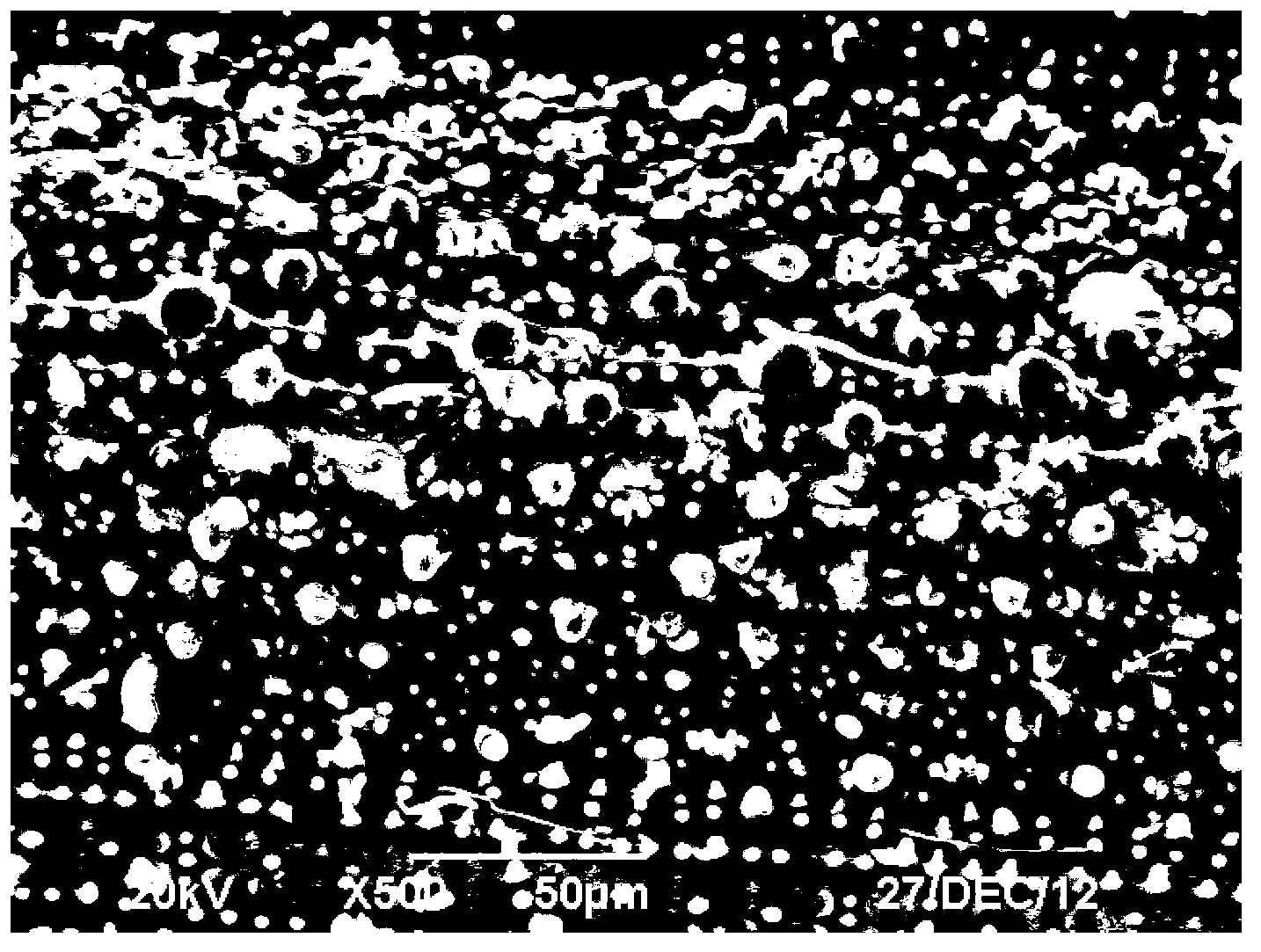

Method for preparing pyrolytic oil by co-heated pyrolysis and liquefaction of biomass and waste tire

InactiveCN103695021AImprove co-pyrolysis effectAchieve separationLiquid hydrocarbon mixture productionPtru catalystProcess engineering

The invention relates to a method for preparing pyrolytic oil by co-heated pyrolysis and liquefaction of biomass and waste tire, which belongs to the technical field of biomass energy. The method comprises the following steps: respectively crushing and drying the biomass raw material and the waste tire raw material, respectively pyrolyzing the two raw materials to obtain pyrolytic steam, mixing the two types of pyrolytic steam according to certain proportion, enabling the steam mixture to pass through zeolite type solid catalyst, performing co-heated pyrolysis reaction under the action of catalyst to generate co-heated pyrolytic steam, and performing first-level condensation and second-level condensation on the co-heated pyrolytic steam to obtain the pyrolytic oil. According to the method provided by the invention, mixing proportion of the two types of pyrolytic steam is controlled by controlling flow rate thereof, the problems of deficient co-heated pyrolysis and poor pyrolysis effect caused by difference of specific gravity and thermal weight loss region between the biomass and the waste tire are solved effectively, co-heated pyrolysis effect of the biomass and the waste tire is enhanced, and quality of the co-heated pyrolysis product, namely the pyrolytic oil, is improved.

Owner:BEIJING FORESTRY UNIVERSITY

Prepn and usage of plant repairing body for contaminated soil

InactiveCN1672822AIncrease resistanceImprove survival rateContaminated soil reclamationRevegetationEcological environment

The present invention belongs to the field of pollution treating technology in environment protecting technology. Turf as culturing medium for soil improvement, air, water maintaining agent, water soluble adhesive, rooting agent and long acting delayed releasing fertilizer are prepared into plant growth body in certain shape; and the plant seed or seedling for repairing polluted soil is first cultured in the plant growth body and then transplanted to the polluted soil. The said method can raise the survival capacity of plant in polluted soil, biomass and growth speed and improve the fertility of the repaired soil, and may be used in repairing soil polluted with heavy metal and organic matter, restoring the vegetation in waste mined place and repairing other destroyed ecological environment.

Owner:NORTHEAST NORMAL UNIVERSITY

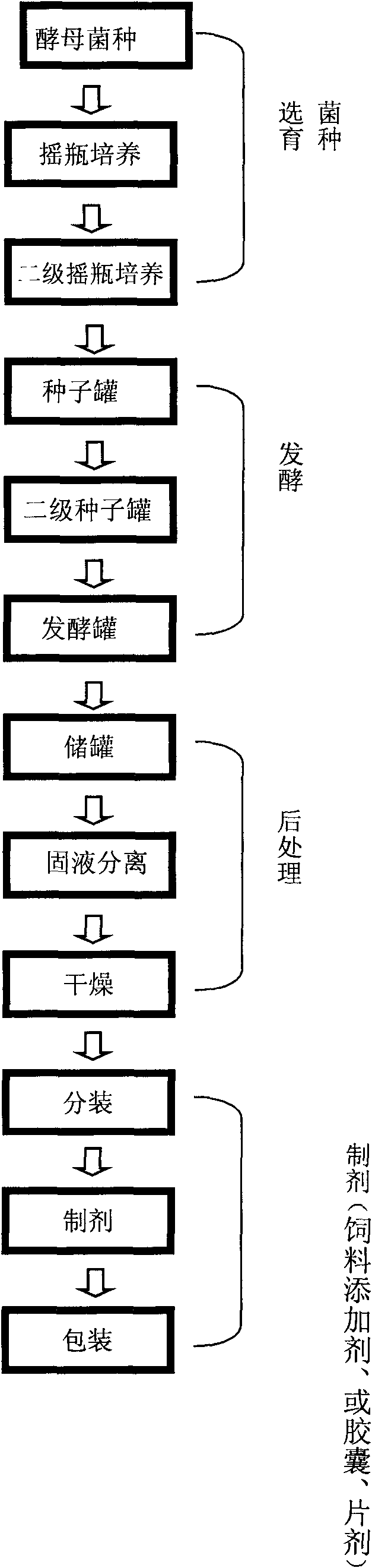

Compound microbial feed additive, preparation process and use thereof

The invention relates to a composite microbe forage additive and relative production, wherein said additive comprises Saccharomyces cerevisiae, Lactobacillus plantarum, and Lactobacillus casei subsp.casei, which are processed via slope cultivation, first-stage seeding, second-stage seeding, and mixture cultivation ferment, to optimize the ratio between composite bacterial. The effective viable bacterial number of said additive is more than 2*109cuf / mL. The inventive forage additive can improve the forge utilization and immunity ability, with reduced cost.

Owner:CHINA AGRI UNIV

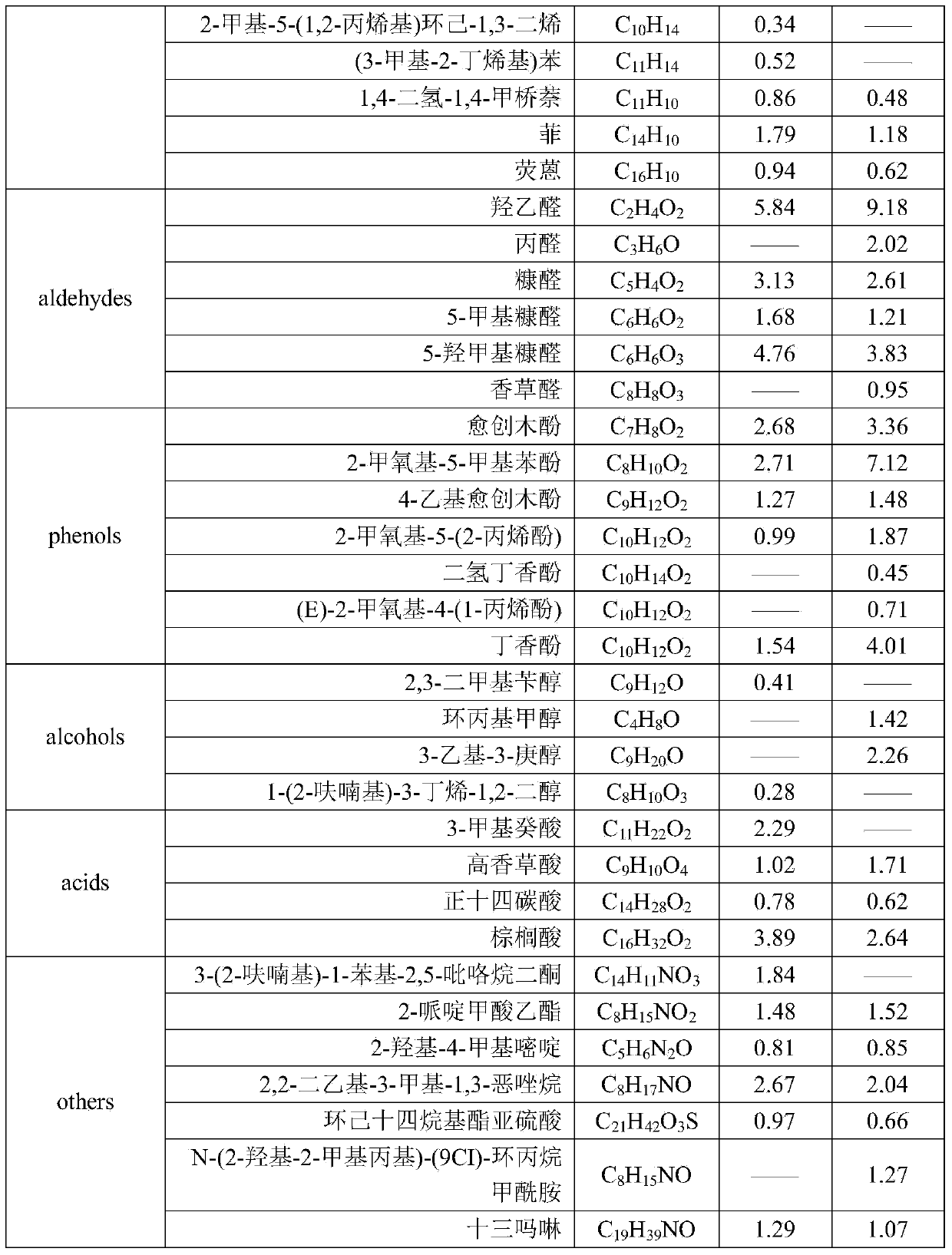

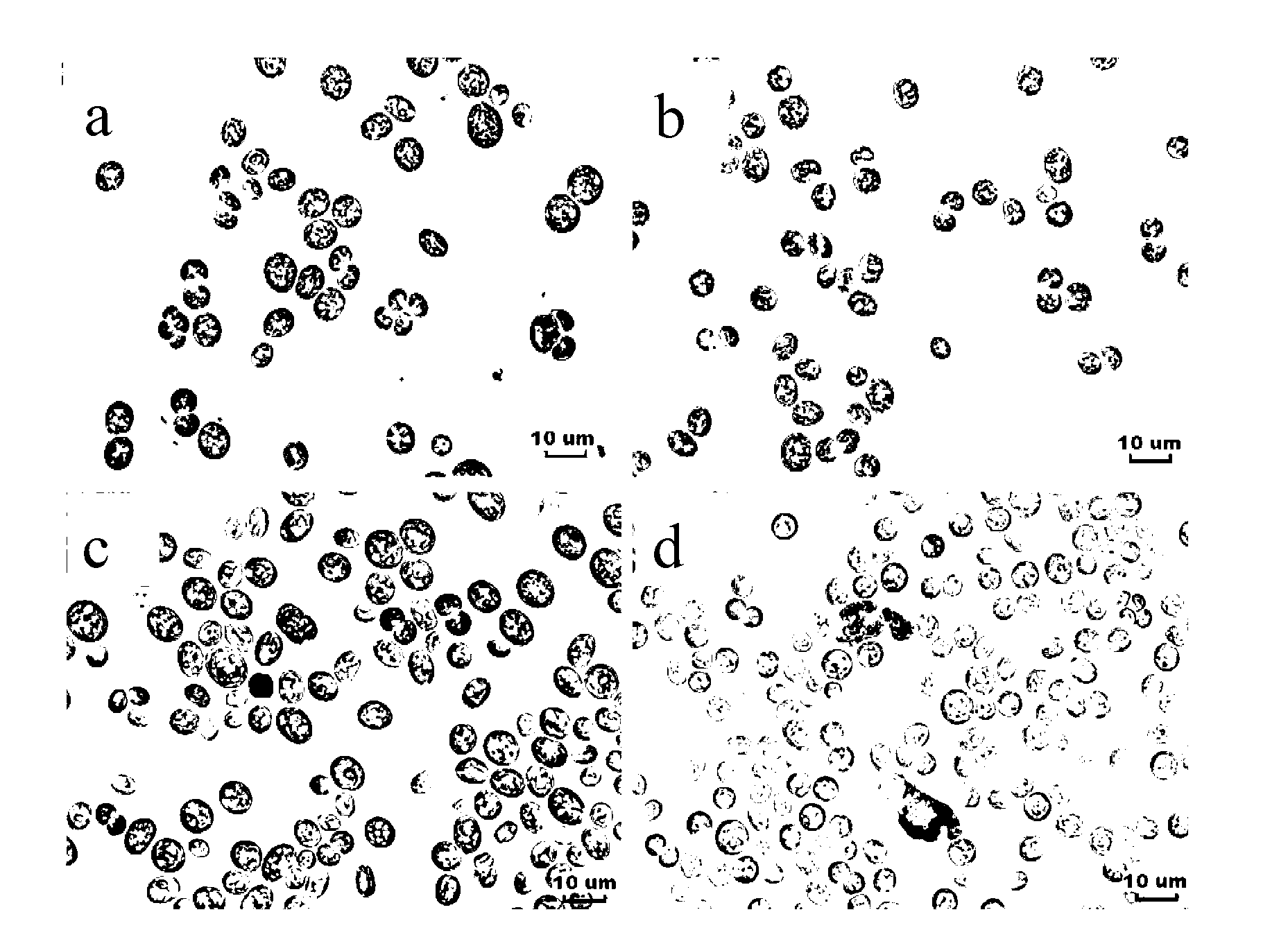

Method for separating microalgae through in-situ flocculation and application thereof

InactiveCN103266063AWide variety of sourcesEasy to operateUnicellular algaeMicroorganism based processesFlocculationBiology

The invention belongs to the field of biomass energy, and in particular relates to a method for separating microalgae through in-situ flocculation and application thereof. The method comprises the following steps of: adding acid liquor into a culture solution for culturing the microalgae, regulating the pH value to be acidic, flocculating and settling the microalgae, standing, demixing, and separating the supernate to obtain separated culture solution and microalgae. The separated microalgae culture solution is recycled for culturing the microalgae after alkali liquor neutralization and regulation. The method has the advantages of simplicity in operation, wide reagent source, low cost, high efficiency and low energy consumption, and the settling separation rate within 30 minutes reaches more than 90 percent.

Owner:JINAN UNIVERSITY

Granular fuel with crop straw and production thereof

InactiveCN1746274AWide range of materialsSimple processSolid fuelsWaste based fuelHigh densityEngineering

A crop straw particle fuel and its production are disclosed. The fuel is prepared by drying crop or plant waste under moisture content 16%, crushing them into powder with grain size under 8mm from side-rub multifunctional crusher, mixing one material or several materials with water, steam vaporizing, compression forming from special straw granulating flat die machine, cooling, and packing into particle fuel of which grain size is 6-9mm, length is 20-30mm and moisture content <=14wt%. Its advantages include low cost, high density, heat value and forming rate, simple process and no environmental pollution.

Owner:张建超

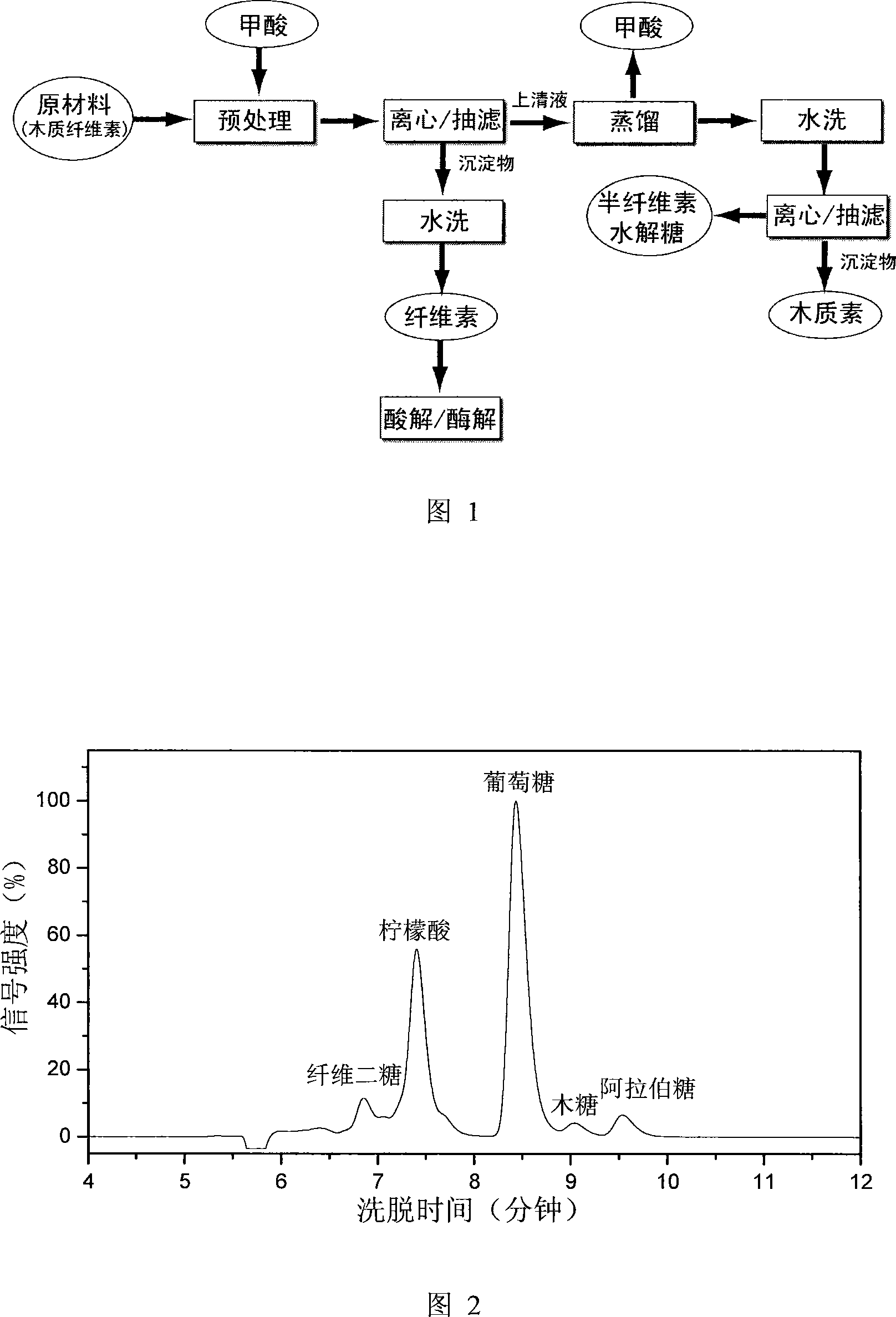

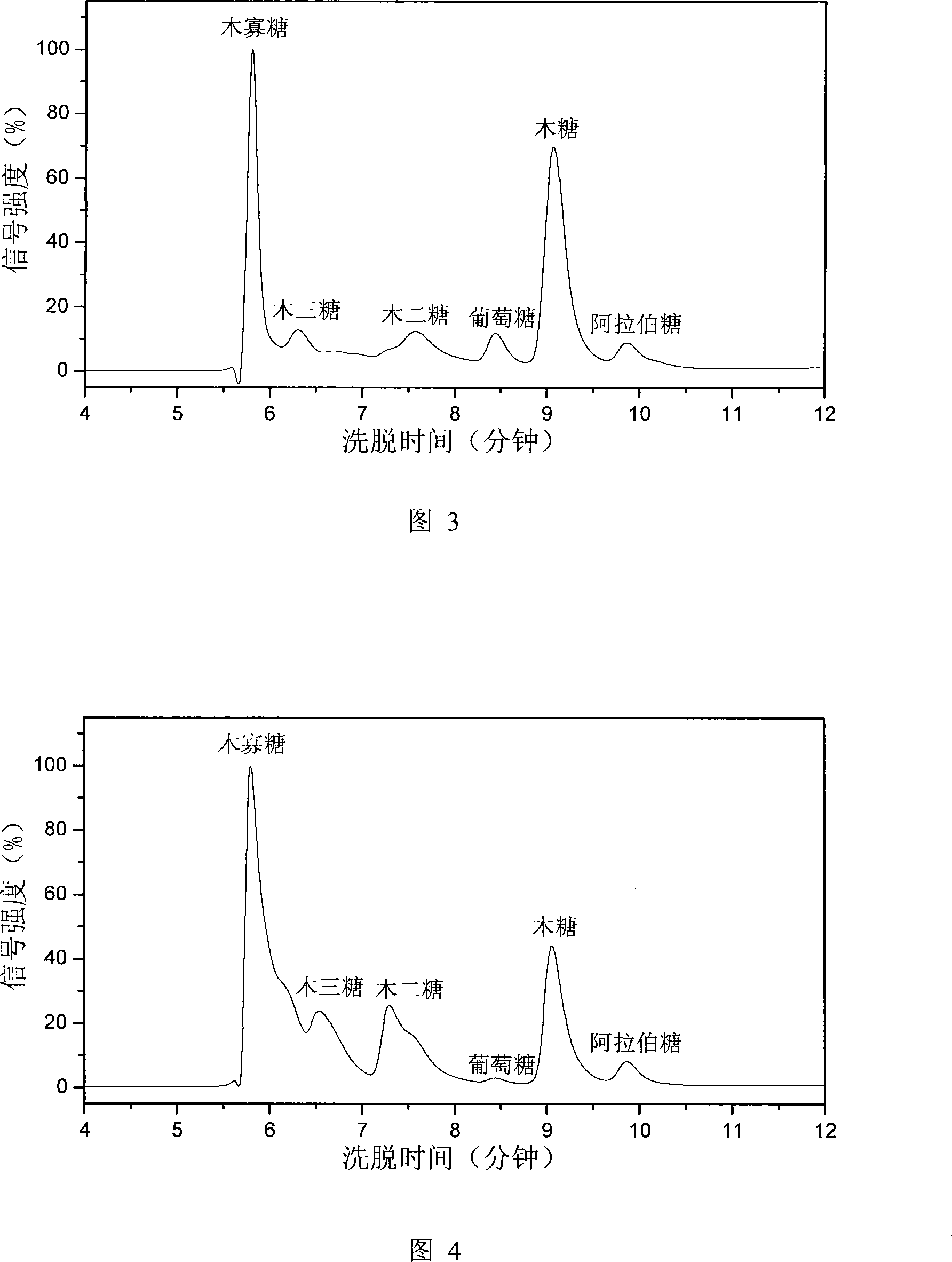

Method for separating lignocellulose-containing biomass with methanoic acid

InactiveCN101220566AEasy separation of componentsFast and easy method for component separationPaper material treatmentCellulaseSolvent

The invention relates to a method for using formic acid to separate biomass of lignocelluloses which includes the following steps: the formic acid solution with little hydrochloride is added into the agroforestrial waste, and reaction carries out for 1 to 10h at the temperature of 50 to 100 DEG C; the solid substances are separated and hydrolyzed after being water washed and dried in the buffer solution with the pH value of 4.8 by the cellulose enzyme under the temperature of 50 DEG C, the formic acid is recycled from the obtained liquid material, the lignose obtained by separating the lignose (formic acid lignose) solid-liquid, which is not dissolved in water can be used for the high-value transformation after being washed by water. The main components of the liquid material are reduced sugars obtained by hydrolyzing xylose, wood oligose and other hemicelluloses. The invention has the advantages of separating the lignocellulose into components, realizing the using of the whole biomasses, and finishing the green technique route of the solvent recovery.

Owner:TIANJIN UNIV

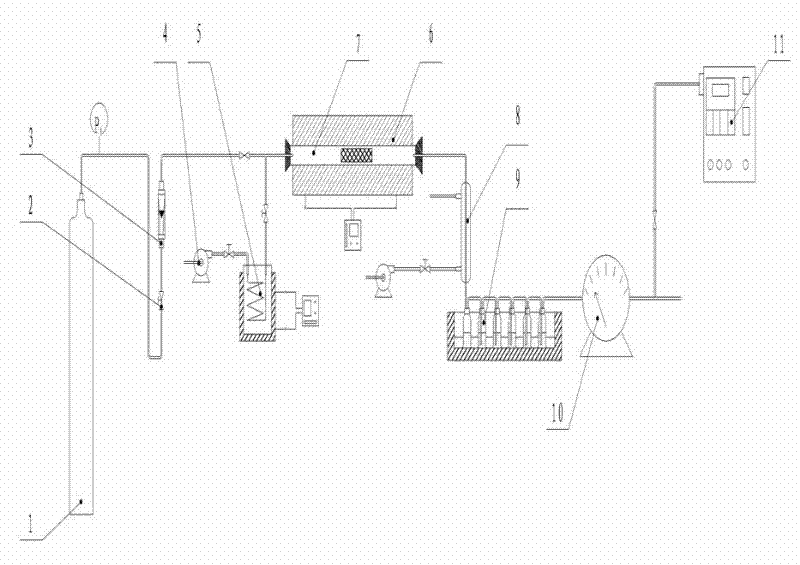

A method and device for producing hydrogen-rich gas by high-temperature steam gasification of biomass

InactiveCN102268295ASmall reaction spaceAvoid dilutionFixed-bed gasificationPtru catalystThermodynamics

The invention discloses a method and device for producing hydrogen-rich fuel gas by high-temperature steam gasification of biomass. It uses pure water vapor as the gasification medium under the condition of no catalyst, and superheats the water vapor to above 900°C. , using a constant flow pump and steam generator to control, adjust and meter the amount of water vapor added to the high-temperature gasification reactor, and carry out high-temperature steam gasification reaction in the fixed-bed gasification reactor at 900-1050 °C. Under appropriate process conditions such as reaction temperature, water vapor flow rate, raw material particle size, and reaction time, hydrogen-rich gas with high calorific value can be produced. The calorific value of the hydrogen-rich gas prepared by this method is 11-14MJ / Nm3, and the hydrogen content is above 45%-51%. It has the advantages of not using any catalyst; obtaining hydrogen-rich gas with high calorific value, improving energy utilization efficiency; converting low-quality biomass energy into high-quality hydrogen energy, etc.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY

Method for producing docosahexaenoic acid by using schizochytrium limacinum

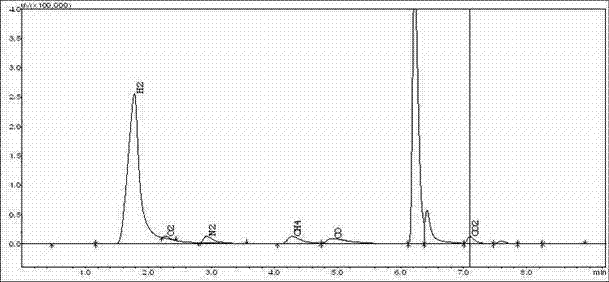

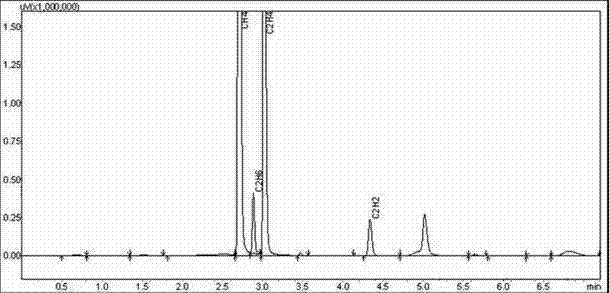

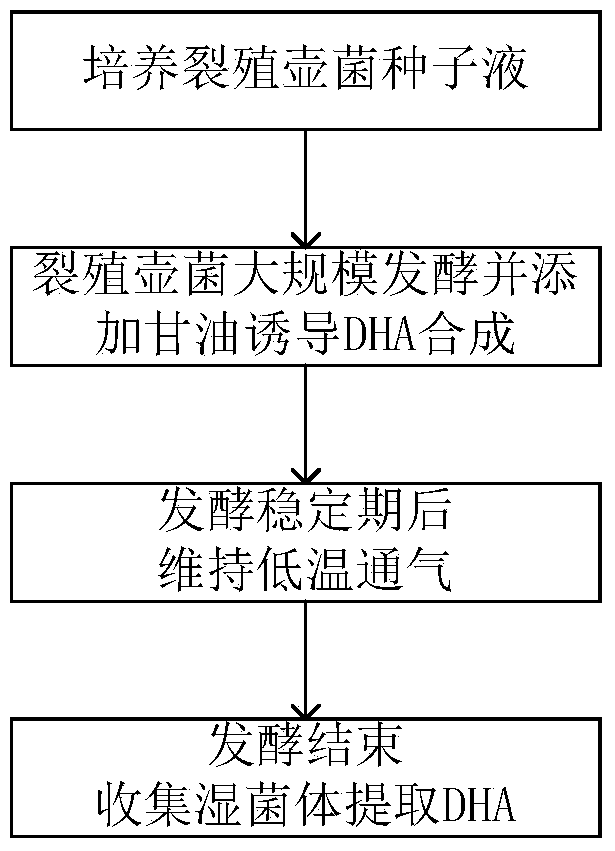

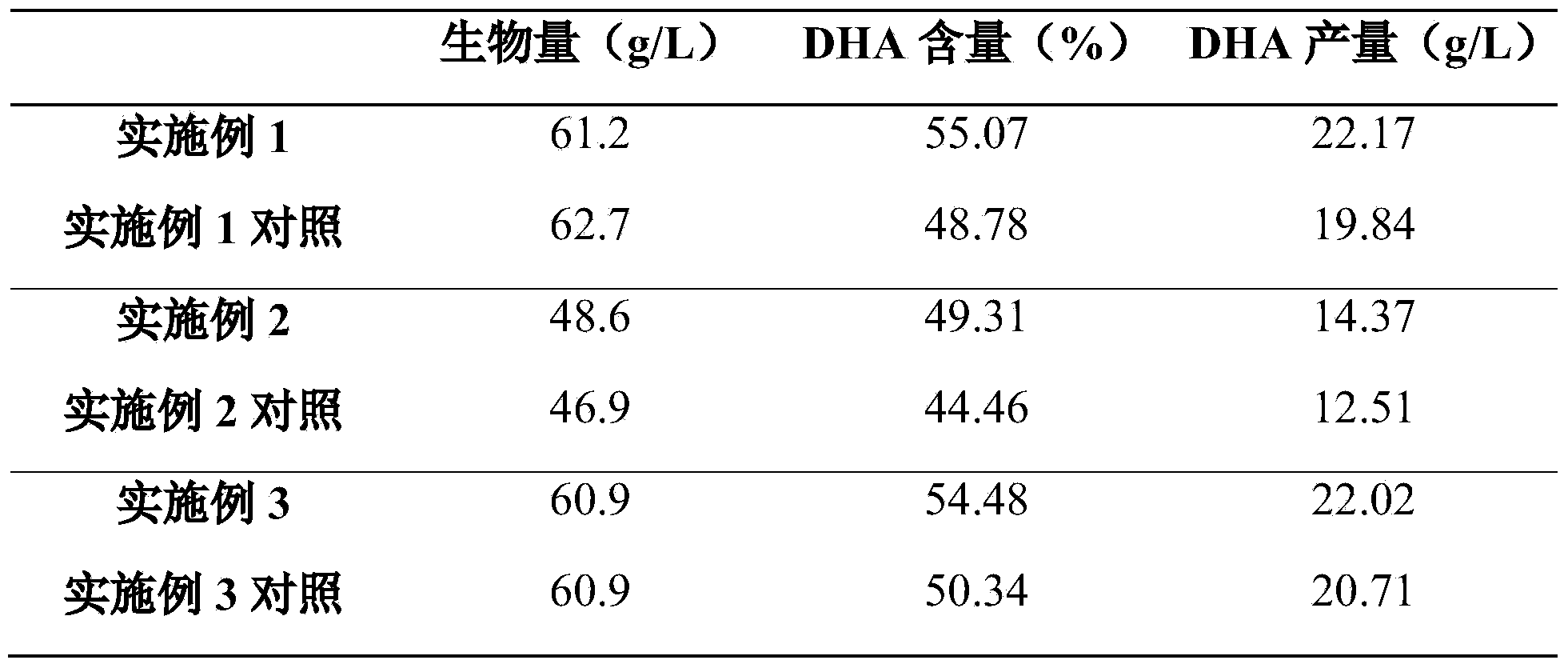

InactiveCN103882072AIncrease biomassIncrease productionMicroorganism based processesFermentationGlycerolNitrogen source

The invention discloses a method for producing a docosahexaenoic acid (DHA) by using schizochytrium limacinum. The method comprises the following steps of (1) activating and culturing schizochytrium limacinum into a schizochytrium limacinum seed solution; (2) introducing the schizochytrium limacinum seed solution into a fermentation tank for culturing under the culture condition of 25-28 DEG C, aerating and stirring at a constant rotation speed, meanwhile fluidly feeding materials including carbon sources, nitrogen sources and glycerin, and keeping the concentration of glycerin at 0-10.0 g / liter; (3) controlling the temperature of a fermentation stable period at 18-23 DEG C, aerating and stirring at a constant rotation speed; and (4) when the concentration of the carbon source in a fermentation liquor is less than 5.0 g / liter, completing fermentation and collecting wet cells to obtain docosahexaenoic acid-rich greases. After the method is applied to large-scale fermentation and production of docosahexaenoic acid, the biomass of schizochytrium limacinum and the DHA content can increase, the quality of a DHA grease product is greatly improved, the grease quality is further improved and the energy consumption and the production cost are reduced.

Owner:WUHAN HUASHITE IND BIOTECH DEV +2

Method for defining degradation degree of high-cold steppe

InactiveCN102138446AImprove scienceReasonableWeather influencing devicesHorticulture methodsContent distributionPlant community

The invention relates to a method for defining the degradation degree of a high-cold steppe. The method comprises the following steps of: (1) selecting a defining range; (2) determining various indexes of the degradation level of the high-cold steppe; (3) randomly selecting dozens of communities from the high-cold steppe and determining plant community dominant species in the high-cold steppe; (4) determining the coverage of graminaceous plants in each plant community dominant specie and initially classifying according to the indexes in the step (2); (5) determining the aboveground biomass relative scale of the plant community dominant species in each community and the aboveground biomass relative scale of edible grass and classifying once again according to the indexes in the step (2); (6) measuring the organic matter content distribution range of a surface soil sample of each community; and (7) comparing and verifying the organic matter content distribution range obtained in the step (6) with the organic matter content distribution range in the step (2) and finishing defining when the accuracy is over 90 percent. The method disclosed by the invention is simple, quick and accurate and ensures that the rehabilitation and protection of a degraded high-cold steppe are specific and scientific.

Owner:CHINA ACAD OF SCI NORTHWEST HIGHLAND BIOLOGY INST

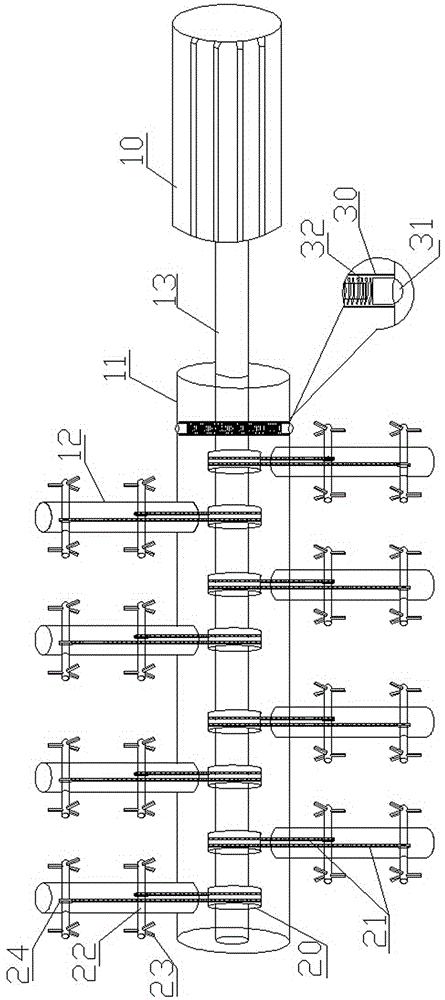

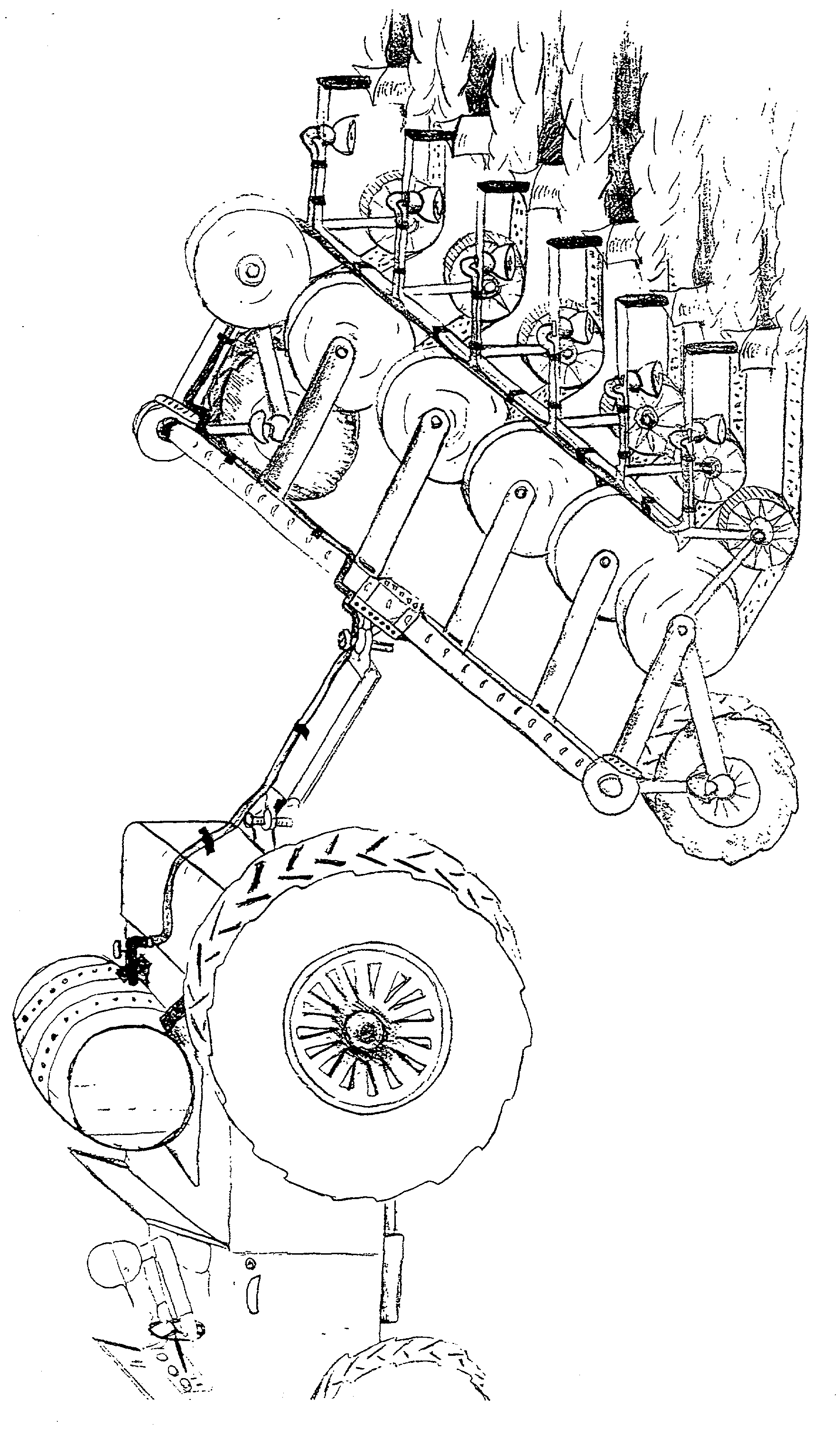

Material stirring device for biomass bin

InactiveCN104525015AImprove continuous feeding efficiencyMeet the needs of industrial applicationsTransportation and packagingRotary stirring mixersProcess engineeringIndustrial engineering

The invention belongs to the technical field of biomass energy processing and large-scale utilization, and particularly relates to a material stirring device for a biomass bin. The device comprises a transmission mechanism, a main stirring mechanism and an auxiliary stirring mechanism, wherein the main stirring mechanism comprises a cylinder, and a hollow stirring rod is arranged on the outer wall of the cylinder; the cylinder is connected with the transmission mechanism, and the auxiliary stirring mechanism comprises a rotating shaft which vertically penetrates through the hollow stirring rod; the two ends of the rotating shaft are provided with stirring blades, and the rotating shaft is connected with the transmission mechanism. The material stirring device provided by the invention has the advantages that the structure is simple and the design is skillful, a biomass material in the bin is reasonably stirred, and the defect that the stirring device is easily damaged due to too high density of the biomass material is overcome; through the automatic conversion and adjustment of the main stirring mechanism and the auxiliary stirring mechanism, the organic combination of overall stirring and local stirring is realized, the continuous discharging efficiency of the biomass material in the bin is improved, the requirement of industrial application of the biomass material is met, the processing efficiency of biomass is improved, the environmental pollution is reduced, and the large-scale utilization process of biomass energy is quickened.

Owner:ENERGY RES INST CO LTD HENAN ACADEMY OF SCI +1

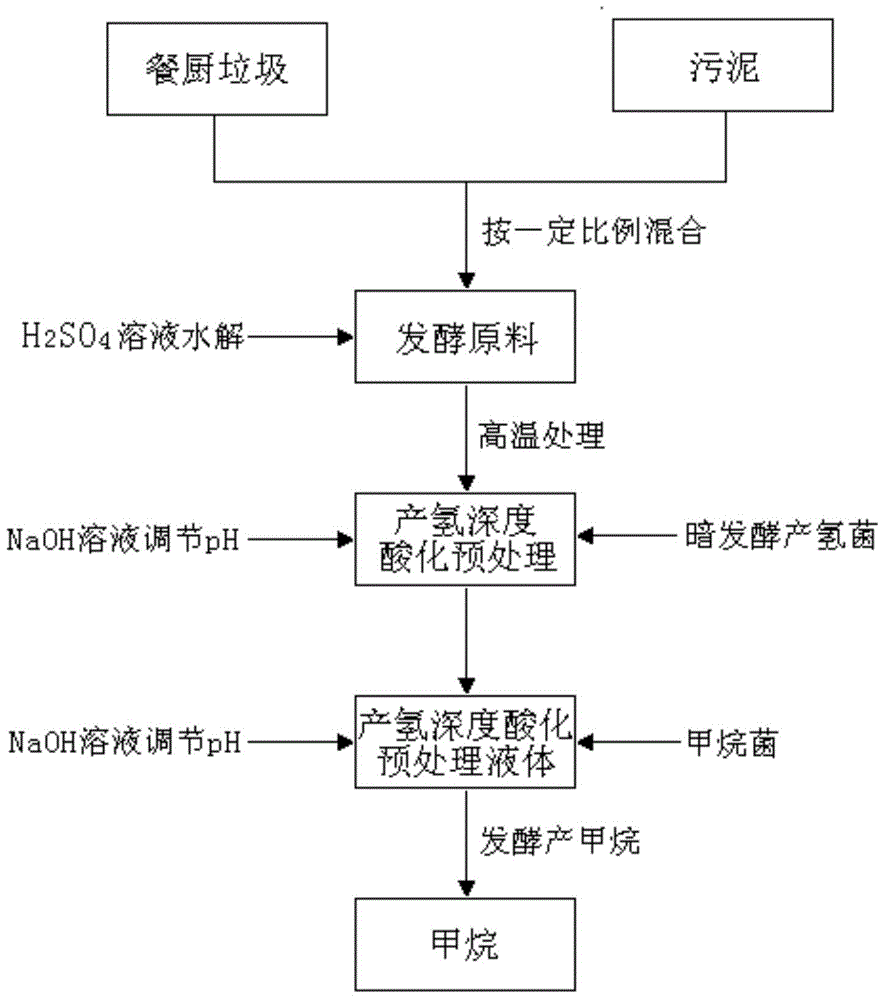

Kitchen waste and sludge hydrogen-producing acidification pretreatment method capable of increasing methane production rate

ActiveCN104561222AIncrease production rateIncrease throughputMicroorganism based processesWaste based fuelPretreatment methodSludge

The invention relates to the technology of biomass energy utilization, and aims to provide a kitchen waste and sludge hydrogen-producing acidification pretreatment method capable of increasing the methane production rate. The method comprises the following steps: mixing the kitchen waste and the sludge after crushing pretreatment, using the mixture and a sulfuric acid solution to prepare a mixed liquid, performing hydrolysis on the mixed liquid at 135 DEG C to obtain a starting crude; adding yeast powder into the starting crude, inoculating dark-fermentation hydrogenogens, feeding high-purity nitrogen to build an anaerobic fermentation environment, then performing dark-fermentation hydrogen-producing deep acidification pretreatment at the constant temperature of 37 DEG C, and obtaining a hydrogen-producing deep acidification pretreatment liquid; adding methanogens into the liquid, keeping the anaerobic environment at 37 DEG C, and performing methane fermentation and coproduction. According to the method disclosed by the invention, the hydrogen-producing deep acidification pretreatment is utilized to obviously increase the methane production rate; the rate peak time of the produced methane is reduced by about 50%; the waste treatment and degradation time of the fermentation tank with a unit volume is reduced by about 50%; the waste treatment capacity of the single equipment in unit time is improved by about one time.

Owner:ZHEJIANG UNIV

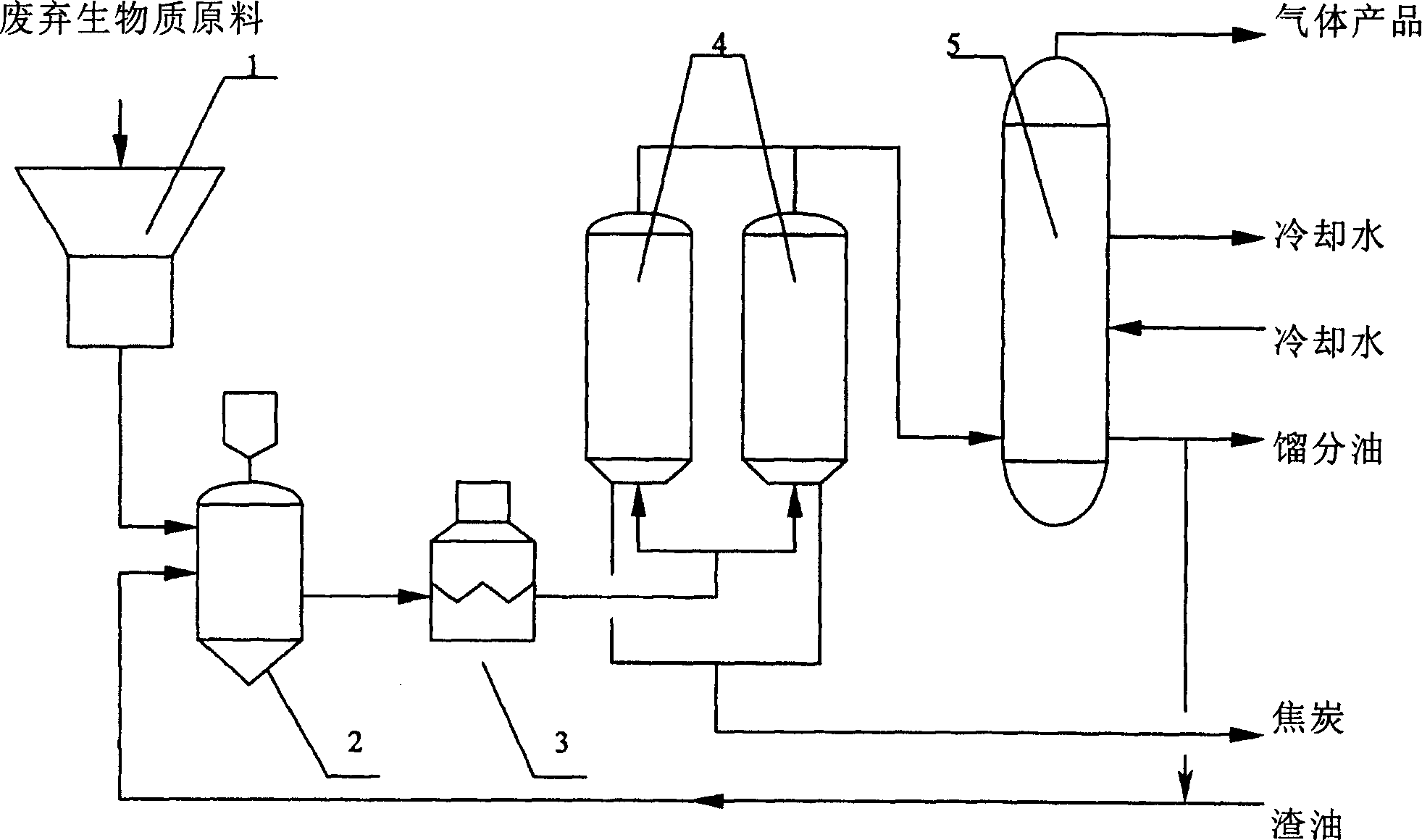

Delayed coking treatment method for waste biomass

InactiveCN1891789AAchieve reductionAchieving processing powerThermal non-catalytic crackingGranularityMass ratio

The invention offers delayed coking processing method used to process discarded biomass in large scale and effectively produce biomass energy sources. It belongs to discarded biomass processing field. And the method includes the follows steps: smashing the material to 0.1-2mm granularity; mixing it with oil with 0.05-15% mass ratio; heating to 190-300 centigrade degree; further heating to 420-510 centigrade degree; processing delayed coking; fractionating the oil gas product to gain fractionated product.

Owner:EAST CHINA UNIV OF SCI & TECH

Green geo-engineering system device for regulating global climate change

InactiveCN104472409AScale, size, area, depth and depth are easy to controlLow investment and construction costClimate change adaptationPisciculture and aquariaMarine ecosystemContinental shelf

The invention discloses a green geo-engineering system device for regulating global climate change. The device is engineering for artificially simulating a natural upwelling fishery and a continental shelf shallow sea ecosystem fishery; deep nutritive salt-rich seawater is induced to upwell to a marine euphotic layer by utilizing an artificial induction upwelling marine ranching device; nutritive salt is prevented from sinking by utilizing an artificial shallow sea ecosystem marine ranching device; coordination of photo-thermal water and fertilizer resources is realized; sunlight energy is absorbed and is converted into biomass energy; carbon dioxide is absorbed and is recovered into phytoplankton; the concentration of atmospheric carbon dioxide is regulated; the global climate change is regulated; the phytoplankton is converted into zooplankton and economic animals such as fish, shrimps, crabs, shellfish, sea cucumbers and squids through a food chain and a food web of a marine ecosystem; seafood, fish meat, fish meal and fish oil are produced by catching, the fish meat serves as food, the fish meal serves as a feed, the fish oil can be processed into the food and can also be processed into biodiesel serving as energy, and the sunlight energy and the carbon dioxide are finally converted into the food and the energy on the broad marine euphotic layer.

Owner:朱祖阳

Zinc-rich yeast with high biomass, breeding selection method and application thereof

The invention relates to a zinc-rich yeast with high biomass, a breeding selection method and application thereof. A zinc-rich yeast bacterial strain with high biomass is Sacharomyces cerevisiae) F-090428X. The bacterial strain is preserved in China General Microbiological Culture Collection Center (CGMCC for short) in July 2nd, 2009 with the preservation number of No.3156. The breeding selection method of the zinc-rich yeast with high biomass adopts microwave irradiation. The zinc-rich yeast with high biomass can be used for preparing high zincic human food or high zincic additives or high zincic medicaments, or can be used for preparing high zincic animal feed or high zincic feed addictive.

Owner:LANZHOU INST OF ANIMAL SCI & VETERINARY PHARMA OF CAAS

Species-specific biomass eclosor (EBES)

It is possible to obtain natural and highly functional vegetables for human nutrition if the conditions are present of having a substrate that will provide optimal conditions specific to each so as to achieve a maximum use of all biotic and abiotic elements for optimal germination and growth of vegetable organisms. This is maximized by producing a species-specific biomass eclosor, herein called EBES, which is the live or latently alive set of chemical, biochemical, biological and other specific related ingredients of the species that induce eclosion or germination in addition to providing nutritional-alimentary support specific to each plant throughout its entire productive cycle. This invention is applicable to optimize germination, growth and production of any type of cultivable vegetable and is also applicable to the human world.

Owner:INVERSIONES & ASESORIAS CARMIN

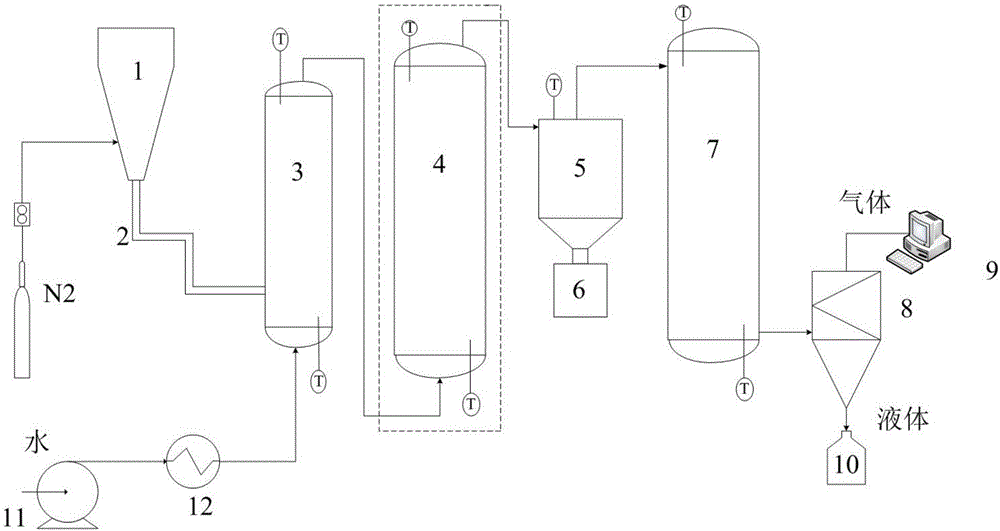

Method for preparing hydrogen-rich gas through gas-solid synchronous gasification of pyrolysis gas and biomass charcoal of biomass

ActiveCN105754662AIncrease profitImprove conversion rateCombustible gas catalytic treatmentGasification processes detailsComing outCatalytic reforming

The invention relates to the field of biomass energy, in particular to a method for preparing hydrogen-rich gas through gas-solid synchronous gasification of pyrolysis gas and biomass charcoal of biomass. The method comprises steps as follows: the pyrolysis gas and the biomass charcoal, which are produced through quick pyrolysis of the biomass, and steam enter an entrained-flow reactor for gas-solid synchronous gasification of the pyrolysis gas and the biomass charcoal; a product coming out of the entrained-flow reactor enters a fixed bed reactor for a catalytic reforming reaction for production of the hydrogen-rich gas after removal of solid particles. According to the method, the utilization rate of the biomass charcoal is high; the yield of the hydrogen-rich gas is high; compared with existing methods for producing hydrogen through gasification of the biomass, the energy consumption is low, and the problem of tar during gasification is solved; compared with existing methods for producing hydrogen through reformation of bio-oil, the energy consumption is low, and the charcoal conversion rate is high; the method is suitable for industrial production.

Owner:EAST CHINA UNIV OF SCI & TECH

Method For Increasing Yield of Biomass of and/or Components of Biomass From Marine Microorganisms

The present invention provides an optimized method of continuously culturing an auxotrophic marine microorganism in a fermentor under aerobic conditions at Y g / l of cell dry matter, CDM, wherein Y is in the range from 100-300 g / l, comprising culturing said auxotrophic marine microorganism in a culture medium comprising a carbon source, gradually added, in an amount of (Y×h) gram per litre of culture broth, wherein h is in the range from 1.1-3.0, and with a residence time of 20-100 h. The method maintains a high productivity of cellular lipids, especially polyenoic acids.

Owner:NOVOZYMES AS

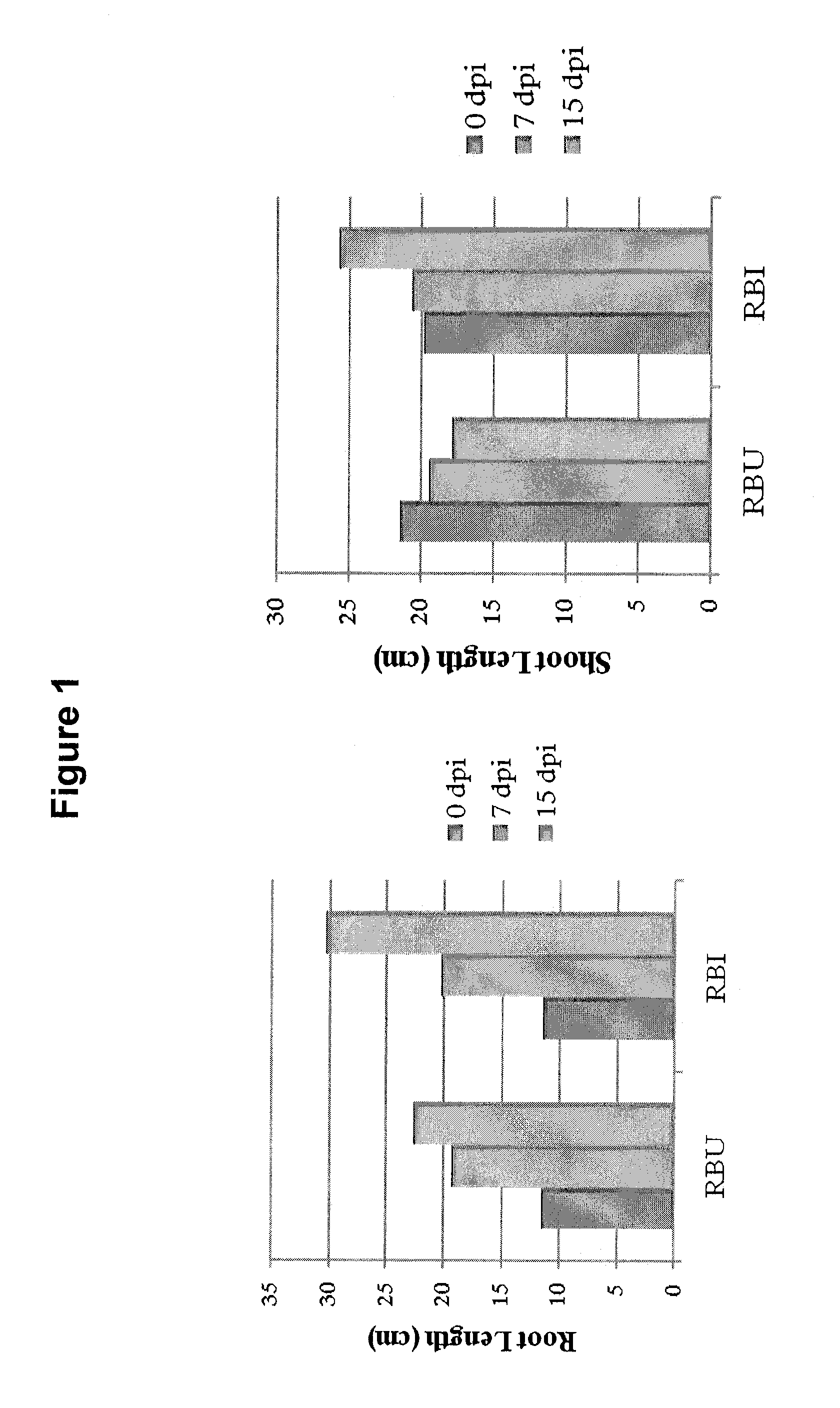

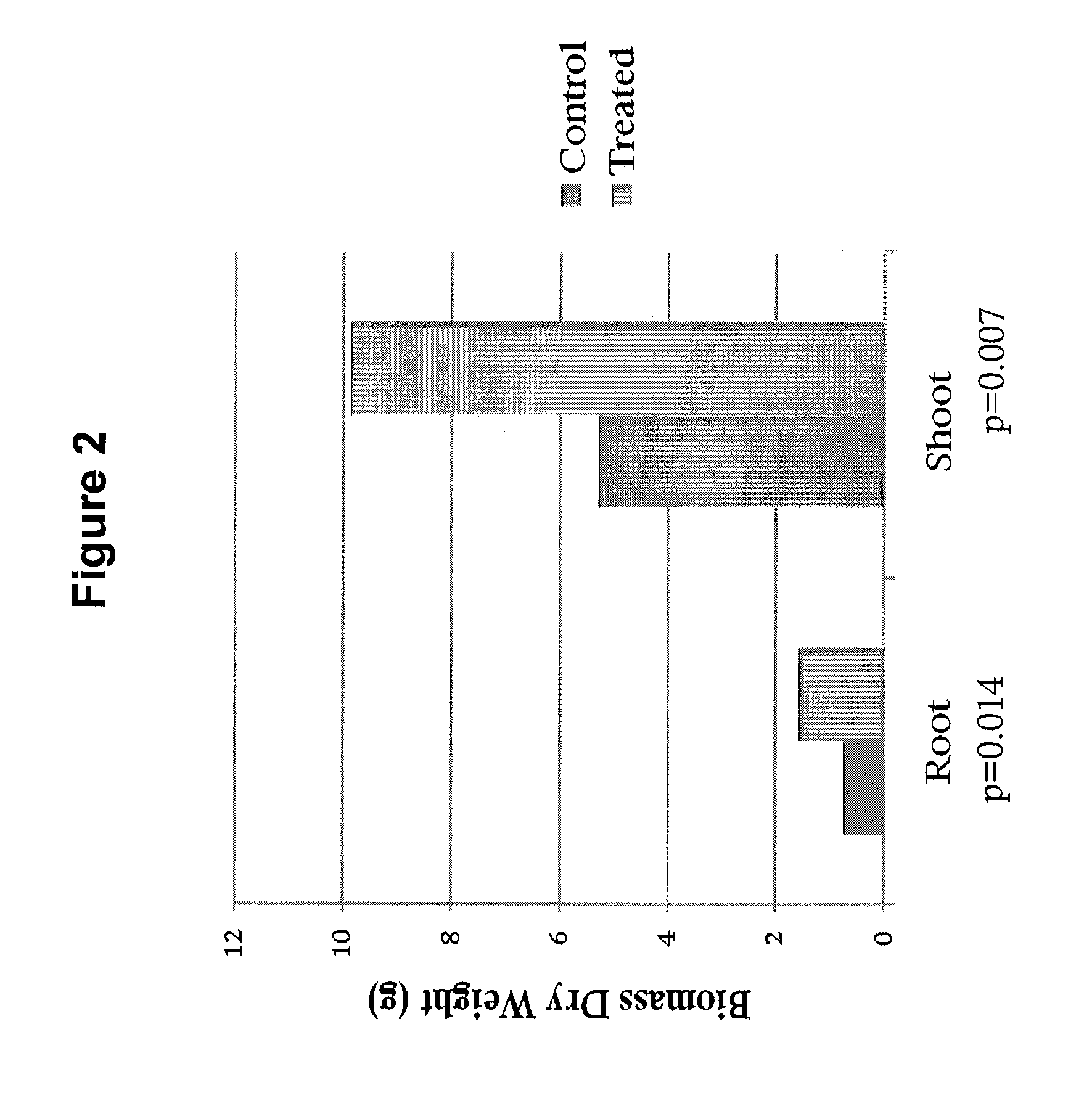

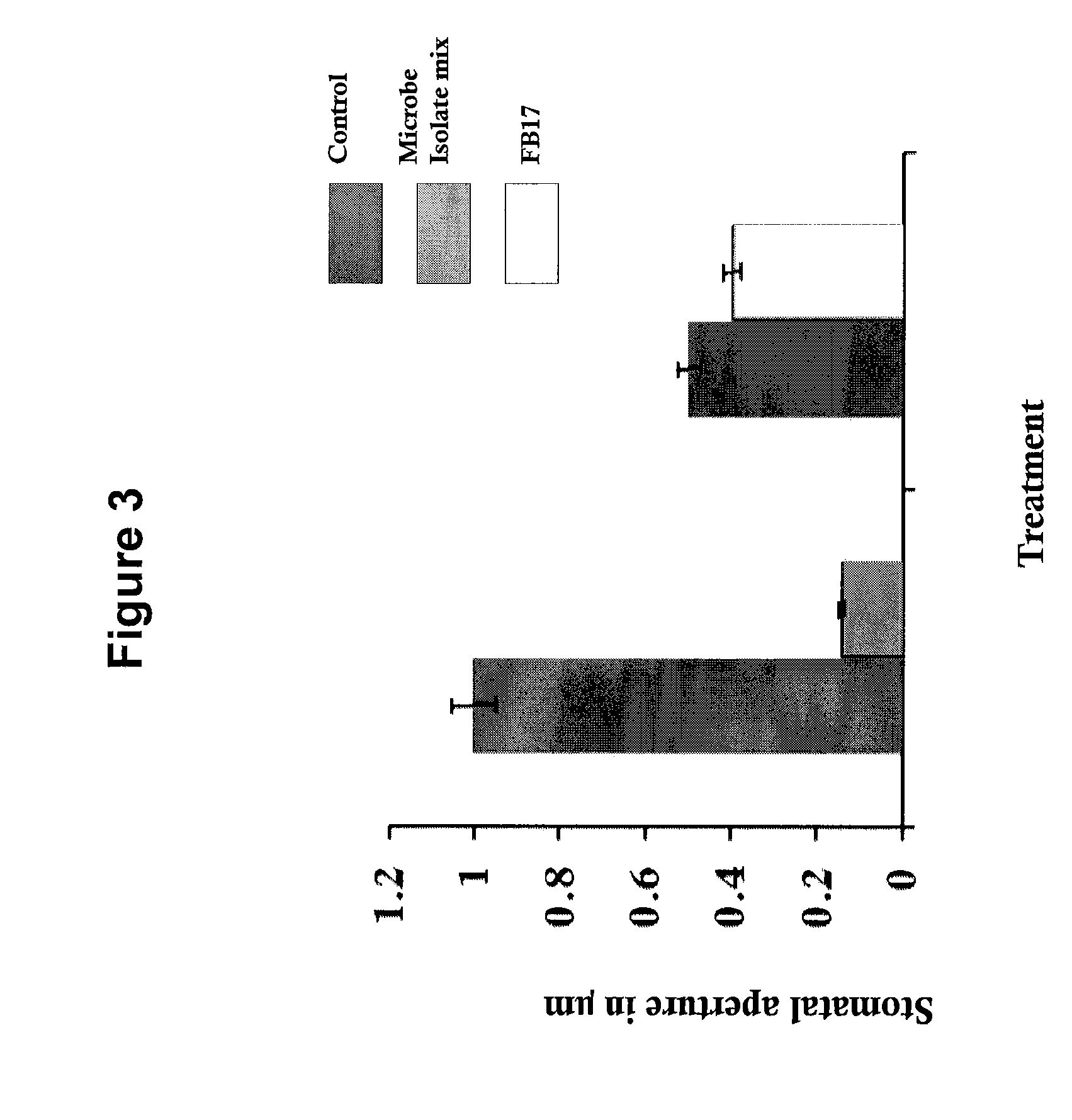

Compositions and methods for improving rice growth and restricting arsenic uptake

Methods according to the invention administering one or more rice rhizosphere isolates to a plant, particularly a rice plant, to the seed of the plant, or to soil surrounding the plant in an amount effective to inhibit infection by a plant pathogen, particularly rice blast, to increase the biomass of the plant, and / or to decrease arsenic uptake by the plant.

Owner:UNIVERSITY OF DELAWARE

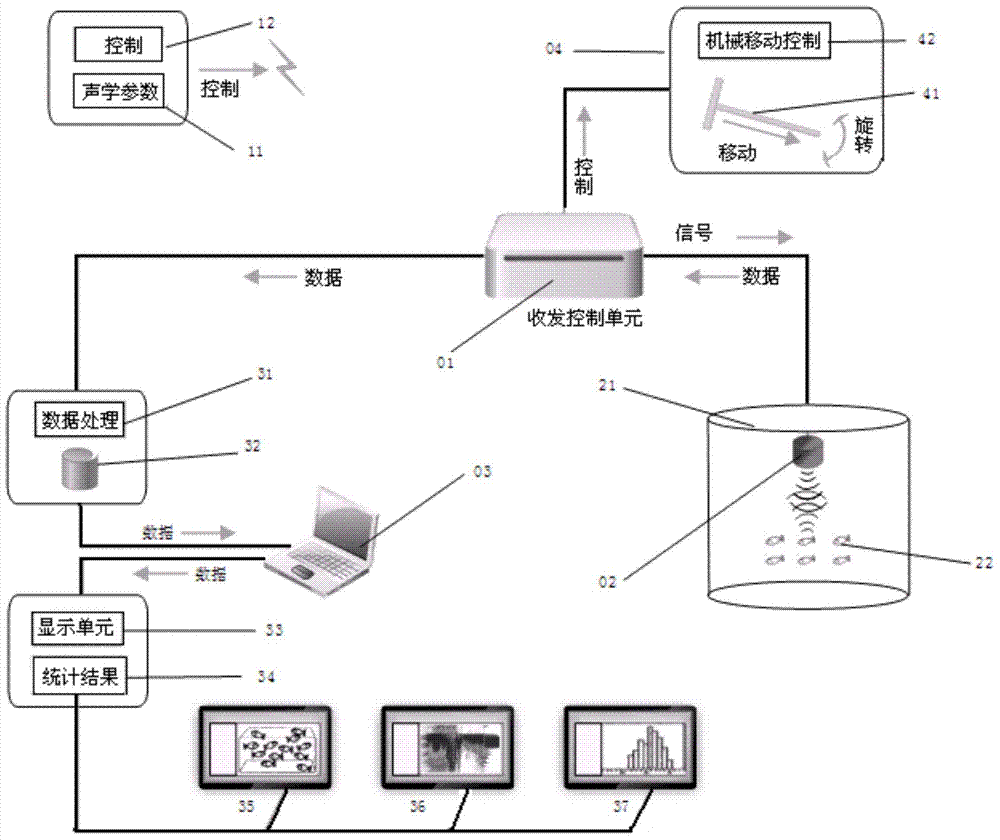

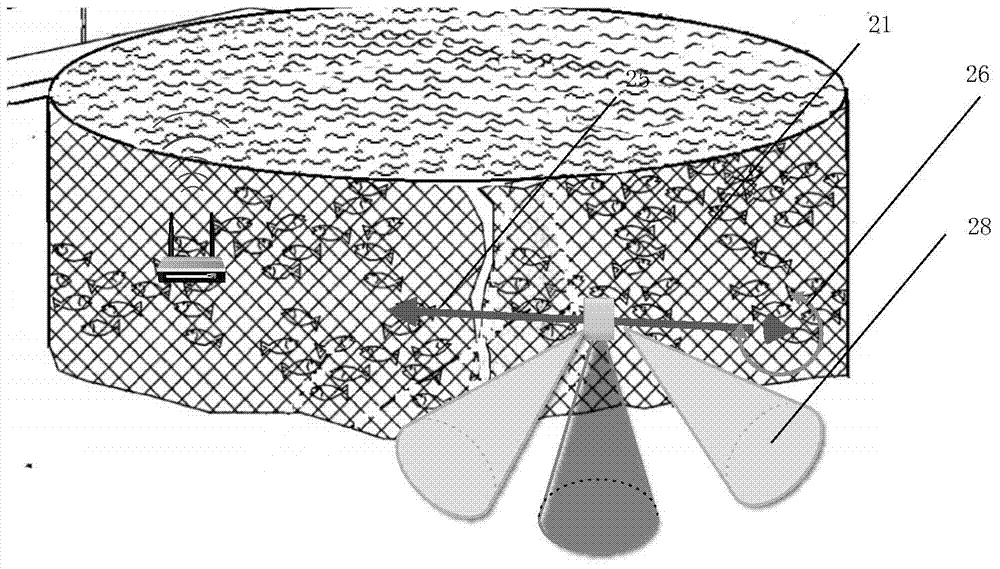

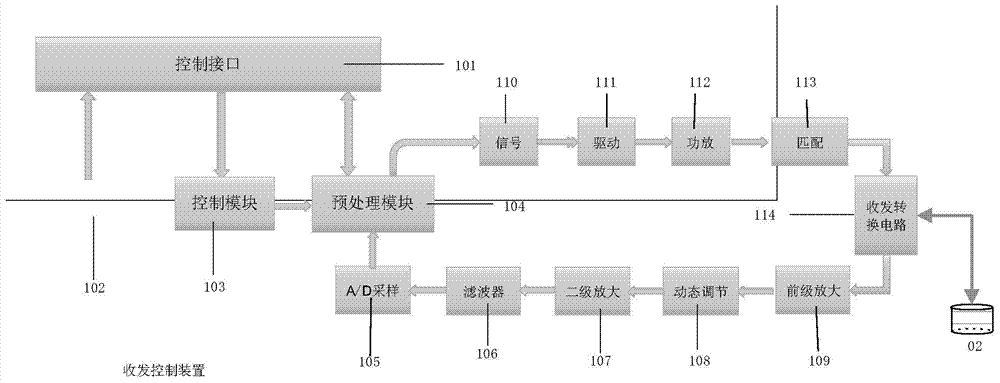

Cage culture biomass monitoring acoustic system and method

InactiveCN104285849AGuaranteed sizeGuaranteed accuracyClimate change adaptationUsing subsonic/sonic/ultrasonic vibration meansData processing systemTransceiver

The invention relates to a cage culture biomass monitoring acoustic system and method. According to the system and method, a free moving platform, an underwater sound transducer and a transceiver control device are installed in a net cage and are connected with a data processing system. Sound wave signals are transmitted to the net cage, sound scattering signals of fish in the net cage are received by the transceiver control device, sound scattering target strength of the fish is measured and processed by means of the data processing system, and the size, quality, density and total biomass of the fish in the net cage are detected by means of the system and method.

Owner:CHINA AGRI UNIV

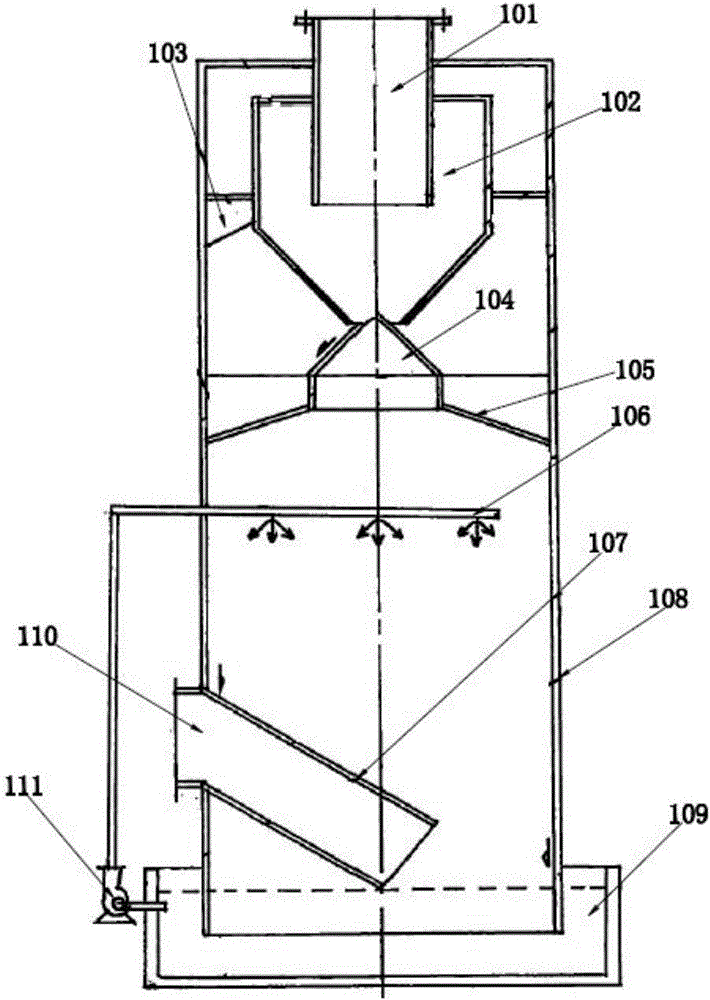

Method and device for on-line catalytic pyrolysis fine purification of biomass

The invention discloses a refining method and a device for online catalytic cracking of bio-oil. The technical proposal of the method is that: the biomass materials are fast paralyzed; catalytic cracking are directly performed to the acquired product in the form of gas, and then the bio-oil is acquired by condensation, wherein the product after the fast paralysis is catalyzed and paralyzed after solid particles are removed by gas-solid separation. Therefore, the fast cracking reactor and the catalytic cracking reactor in prior fast cracking units are connected into one body in present invention, and a gas-solid separation device is arranged in between. The invention has the advantages of reducing energy consumption and investment operating cost, and obviously displaying excellences of biomass energy.

Owner:EAST CHINA UNIV OF SCI & TECH

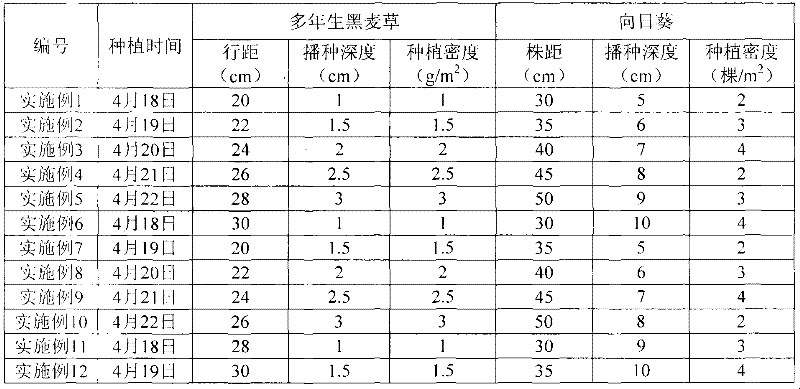

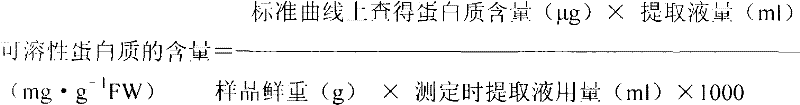

Method for substituting for flaveria bidentis by utilizing combination of sunflower and perennial ryegrass

InactiveCN101743837AReduce plant heightEasy to getWeed killersHorticultureFlaveria bidentisGenus Lolium

The invention provides a method for substituting for flaveria bidentis by utilizing combination of sunflower and perennial ryegrass; in the method, the combination of the sunflower and the perennial ryegrass is adopted to biologically substitute for the flaveria bidentis; the germination rate of the flaveria bidentis can be reduced by 51.52 percent, the plant height can be reduced by 77.71 percent, the branching quantity of the single plant is reduced by 98.23 percent averagely, the leaf quantity of the single plant is reduced by 97.57 percent averagely, the biomass liveweight of the single plant is reduced by 97.87percent averagely, and the average soluble protein content is reduced by 73.5 percent, and the method has remarkable control function to external invasion of the flaveria bidentis; the seeds of the perennial ryegrass and the sunflower are obtained easily, and the planting method is simple and is easy to operate; in addition, the perennial ryegrass is a good pasture, the sunflower is an important oil crop; by adopting method, while controlling the quantity of the flaveria bidentis, a certain of economic value can be realized.

Owner:INST OF ENVIRONMENT & SUSTAINABLE DEV IN AGRI CHINESE ACADEMY OF AGRI SCI

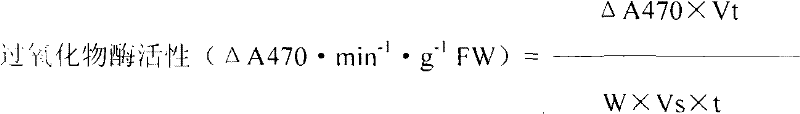

Sludge recycling utilization process and system

ActiveCN106007289AIncrease processing costReduce processing costsSludge treatmentMembrane filtersSludgeCarbonization

The invention discloses a sludge recycling utilization process and a system for realizing the process. The process comprises primary drying, secondary drying, carbonization, cooling and storage. According to the process, a biomass gasifier is utilized for heat supply, sludge treatment and biomass waste treatment are realized simultaneously, energy can be saved, environment can be protected, and according to the various discharge indexes, the dust emission concentration is less than 30 mg / m<3>, the SO2 discharge value is less than 20 mg / m<3>, the oxynitride discharge concentration is less than 250 mg / m<3>, and the Ringelmann black degree reaches level 1. According to the process and the system, biomass energy is taken as a main heat source for the system, and pyrolysis gas generated by a carbonizer in operation is taken as a supplementary heat source, so that heat is supplied to a primary dryer, a secondary dryer and the carbonizer; afterheat of tail gas of the carbonizer is recycled to the secondary dryer to be reused; tail gas of the primary dryer and the secondary dryer is subjected to dedusting through a cyclone dust collector and a water curtain spraying dust collector, and is subjected to desulfurization treatment to reach the standard to be discharged.

Owner:广西新嘉源环保科技有限公司

Method for processing lignocellulosic biomass at constant pressure with ammonia and diluted alkali combined

ActiveCN103255659AReduce pollutionReduce addRaw material pretreatmentProcess engineeringLignocellulosic biomass

The invention discloses a method for processing lignocellulosic biomass at the constant pressure with ammonia and diluted alkali combined and belongs to the field of biomass energy processing and application. The method comprises the following steps of the step 1, taking and cutting up dry lignocellulosic biomass, the step 2, preheating the lignocellulosic biomass to 40 DEG C to 60 DEG C, adding the certain amount of ammonia, adding moderate water vapor, insulating at the temperature of 40 DEG C to 60 DEG C for 1 to 4h in a sealed mode, or taking the lignocellulosic biomass and fumigating the lignocellulosic biomass by stronger ammonia water at the temperature of 40 DEG C to 60 DEG C for 1-4h, and the step 3, stirring the lignocellulosic biomass processed in the step 2 with diluted alkali solution at the temperature of 40 DEG C to 100 DEG C for 1-10h, filtering and washing the lignocellulosic biomass to be neutral to obtain lignocellulosic to be reserved. The lignosellulosic content of the lignocelulosic biomass processed by the method is smaller than or equal to 2%, and the glycation rate is not lower than 87%. Prepared glycation liquid has no restrain on following fermentation, can be used for fermenting and producing alcohol, lactic acid, feed protein and the like or be directly used for preparing feed sugar, and can be used as microcrystalline cellulose or raw materials of papermaking pulp.

Owner:安徽安生生物化工科技有限责任公司 +1

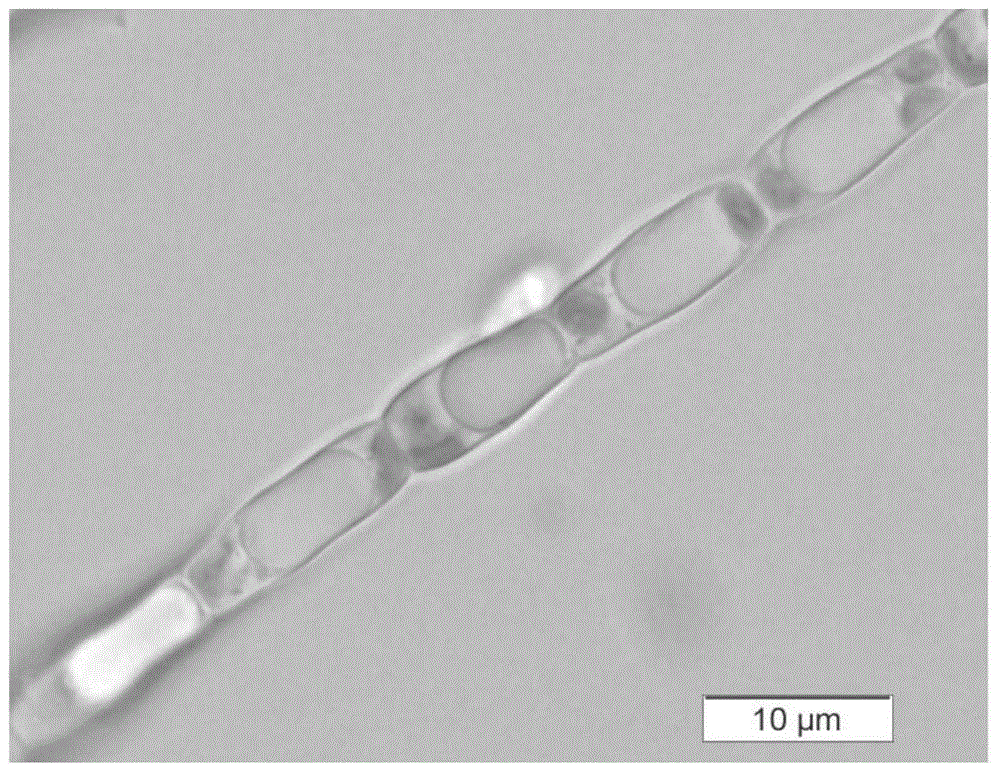

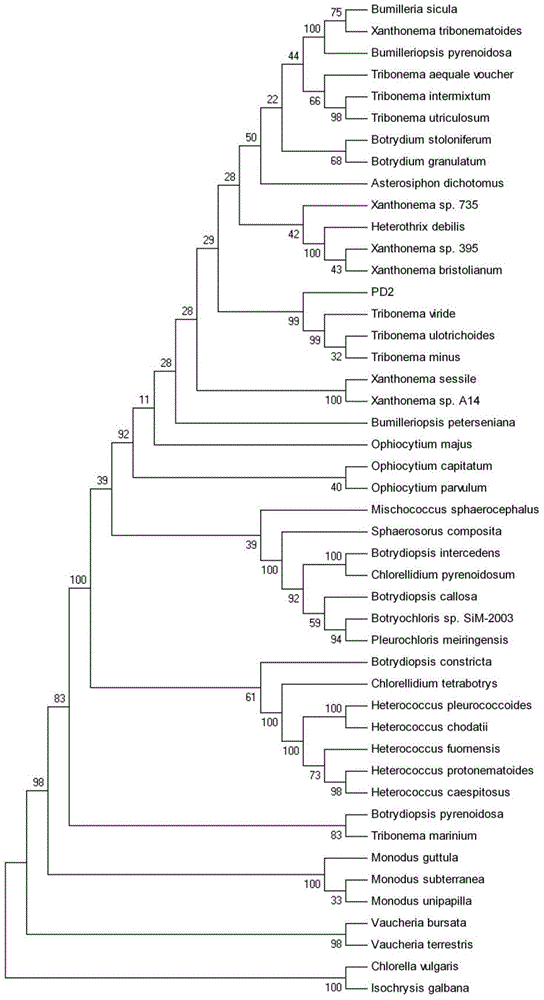

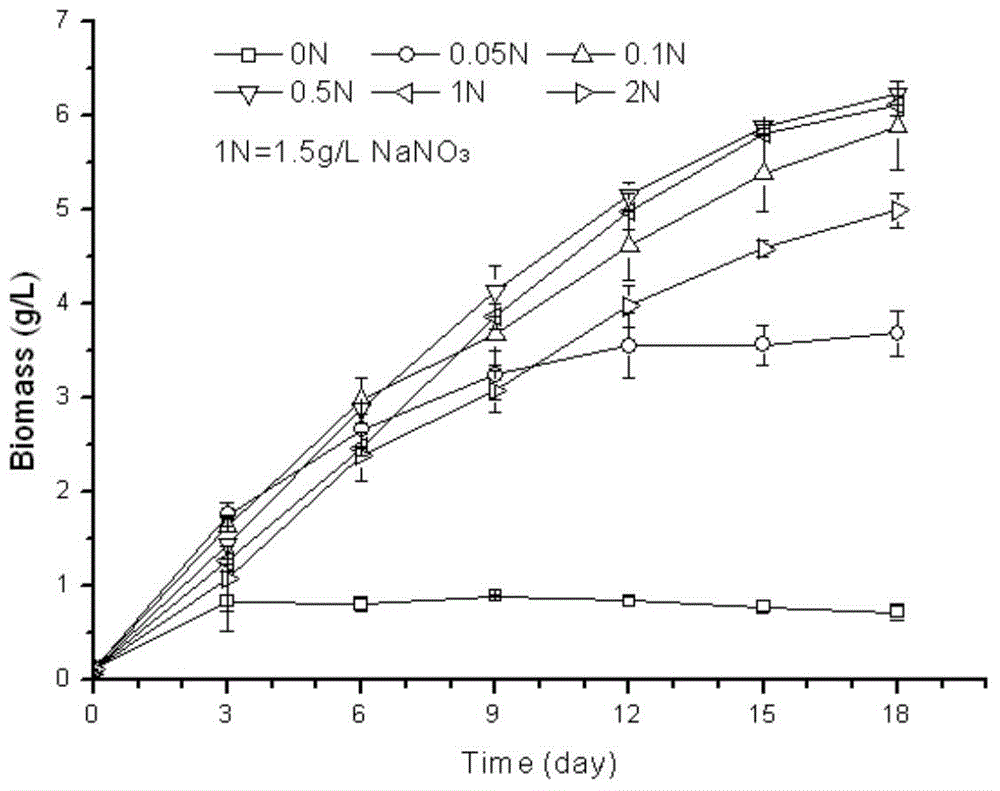

Novel-type tribonema and cultivation and application thereof

The invention discloses a Tribonema sp. PD2 strain with a preservation number of CGMCC No.10488, and application thereof in the production of biodiesel, palmitoleic acid, feed, food, skin care products, and therapeutic drugs for cardiovascular and cerebrovascular diseases, and in the carbon dioxide emission reduction, and waste gas treatment and / or wastewater treatment. The Tribonema sp. PD2 strain has the advantages of fast growth, high biomass and easiness in harvesting, and is suitable for industrial application. The oil content of the Tribonema sp. PD2 strain is as much as 60% or more of the dry biomass, wherein the content of C16-C18 is as much as 85% of the total fatty acids, the content of the palmitoleic acid (C16:1omega7) is no less than 45% of the total fatty acids, and the content of the total unsaturated fatty acids is as much as 65% of the total fatty acids. Therefore the Tribonema sp. PD2 strain is especially suitable for the production of biodiesel and the development of health care products and foods.

Owner:QINGDAO INST OF BIOENERGY & BIOPROCESS TECH CHINESE ACADEMY OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com