Method to feed biomass tablets and logs into burners

a biomass tablet and burner technology, applied in the direction of lump/pulverulent fuel feeder/distribution, combustion process, lighting and heating apparatus, etc., can solve the problems of inability to efficiently burn biomass in burners, boilers or furnaces, and bulky bulky biomass materials when first collected, etc., to achieve the effect of simple and energy-efficien

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

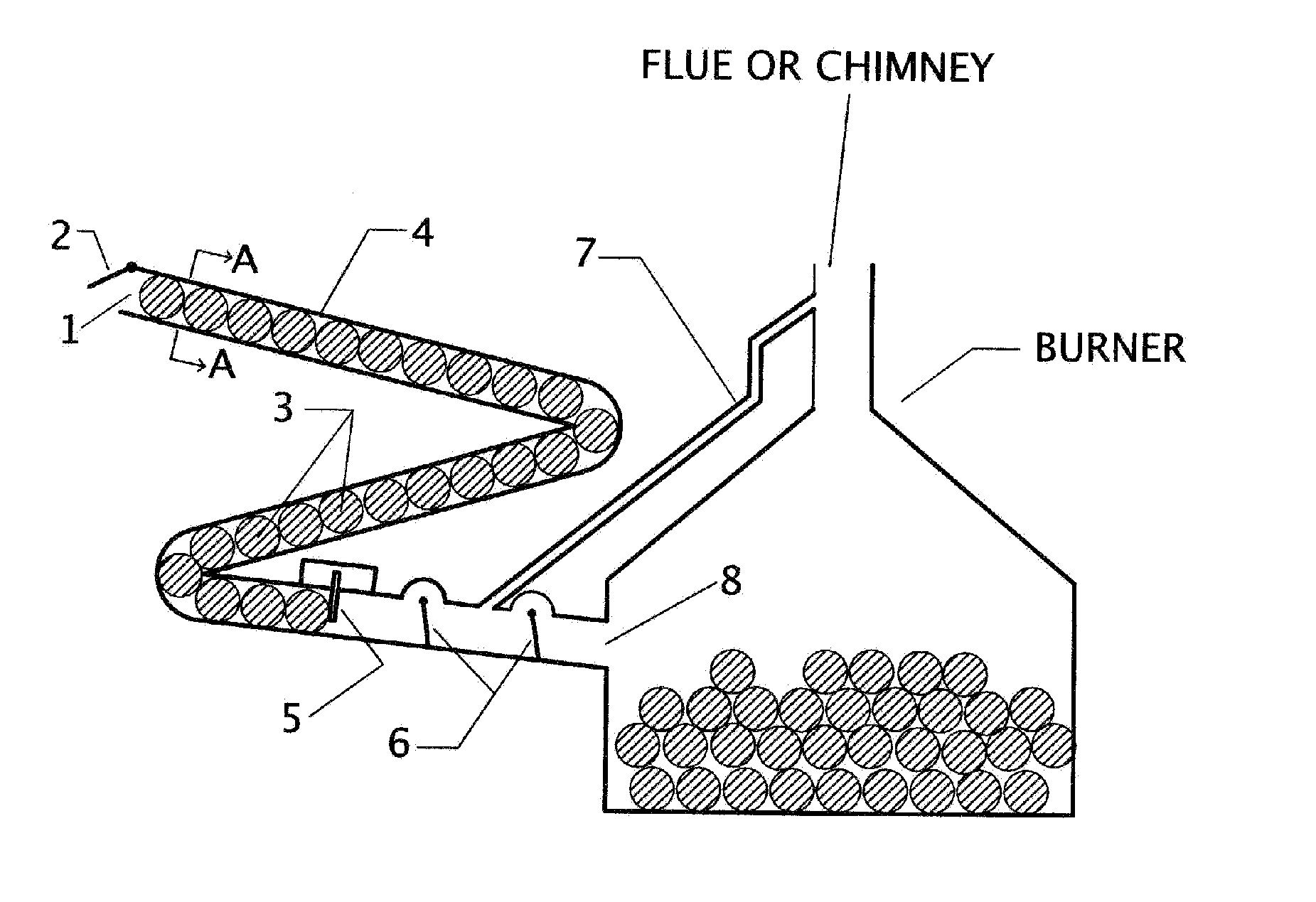

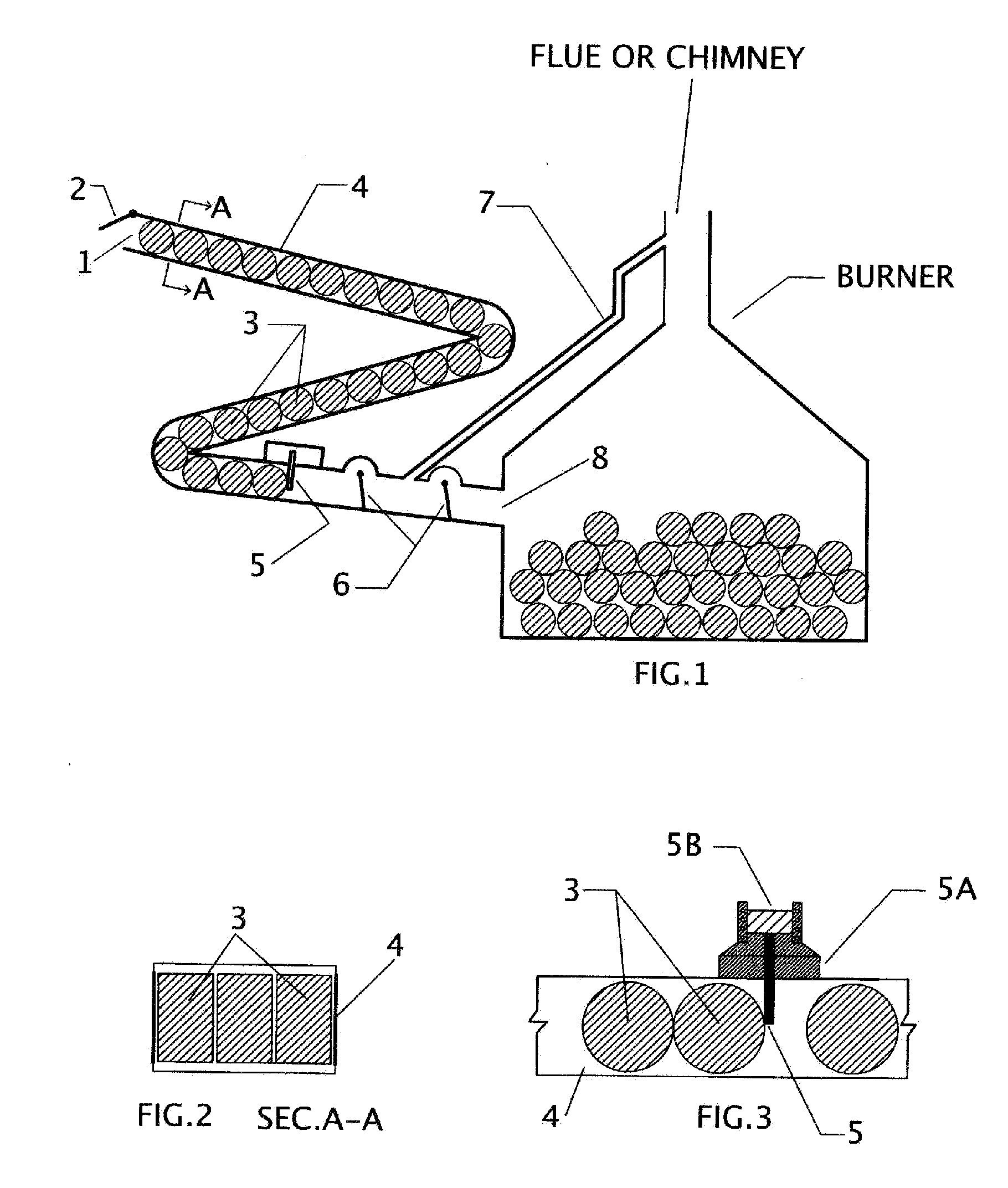

[0051] Invented here is a method and device to inject or feed cylindrical fuel elements (logs or tablets) that are made of biomass or other carbonaceous materials. The elements are fed into a burner, which may be a stove, boiler, furnace or fireplace, for combustion. The heat generated from such combustion can be utilized for producing hot water, heating buildings, producing steam, generating electricity, or other purposes.

[0052] The method takes advantage of the cylindrical shape and uniform dimensions of the fuel elements to be injected. It uses a specially designed injector or feeder to store and inject the fuel elements. Injection is done by the force of gravity and hence is simple, reliable and convenient. The principal part of the injector is a feed channel having a general downward slope towards the burner. Preliminary tests conducted by the inventors indicated that the minimum slope for causing biomass logs and tablets to roll on a metal plate or any other smooth and hard s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com