Patents

Literature

3367results about "Lump/pulverulent fuel feeder/distribution" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Reducing mercury emissions from the burning of coal

Processes and compositions are provided for decreasing emissions of mercury upon combustion of fuels such as coal. Various sorbent compositions are provided that contain components that reduce the level of mercury and / or sulfur emitted into the atmosphere upon burning of coal. In various embodiments, the sorbent compositions are added directly to the fuel before combustion; are added partially to the fuel before combustion and partially into the flue gas post combustion zone; or are added completely into the flue gas post combustion zone. In preferred embodiments, the sorbent compositions comprise a source of halogen and preferably a source of calcium. Among the halogens, iodine and bromine are preferred. In various embodiments, inorganic bromides make up a part of the sorbent compositions.

Owner:NOX II LTD

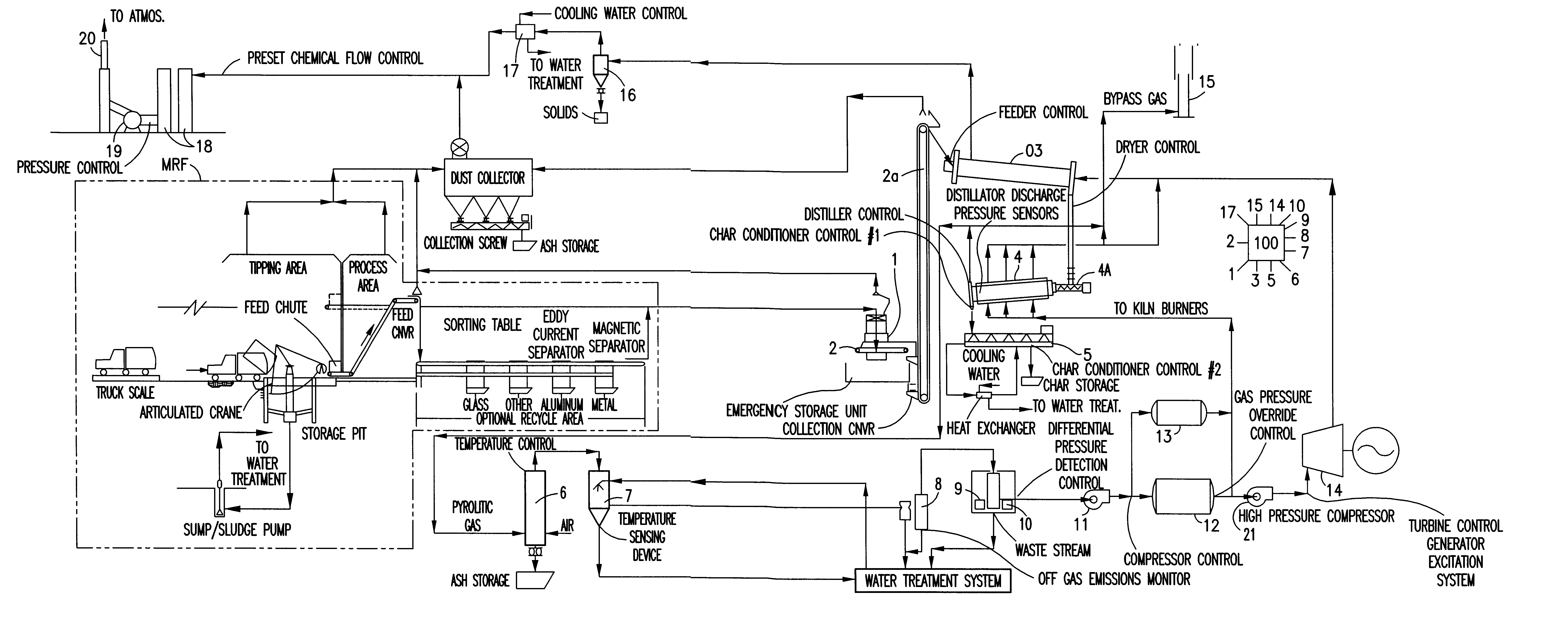

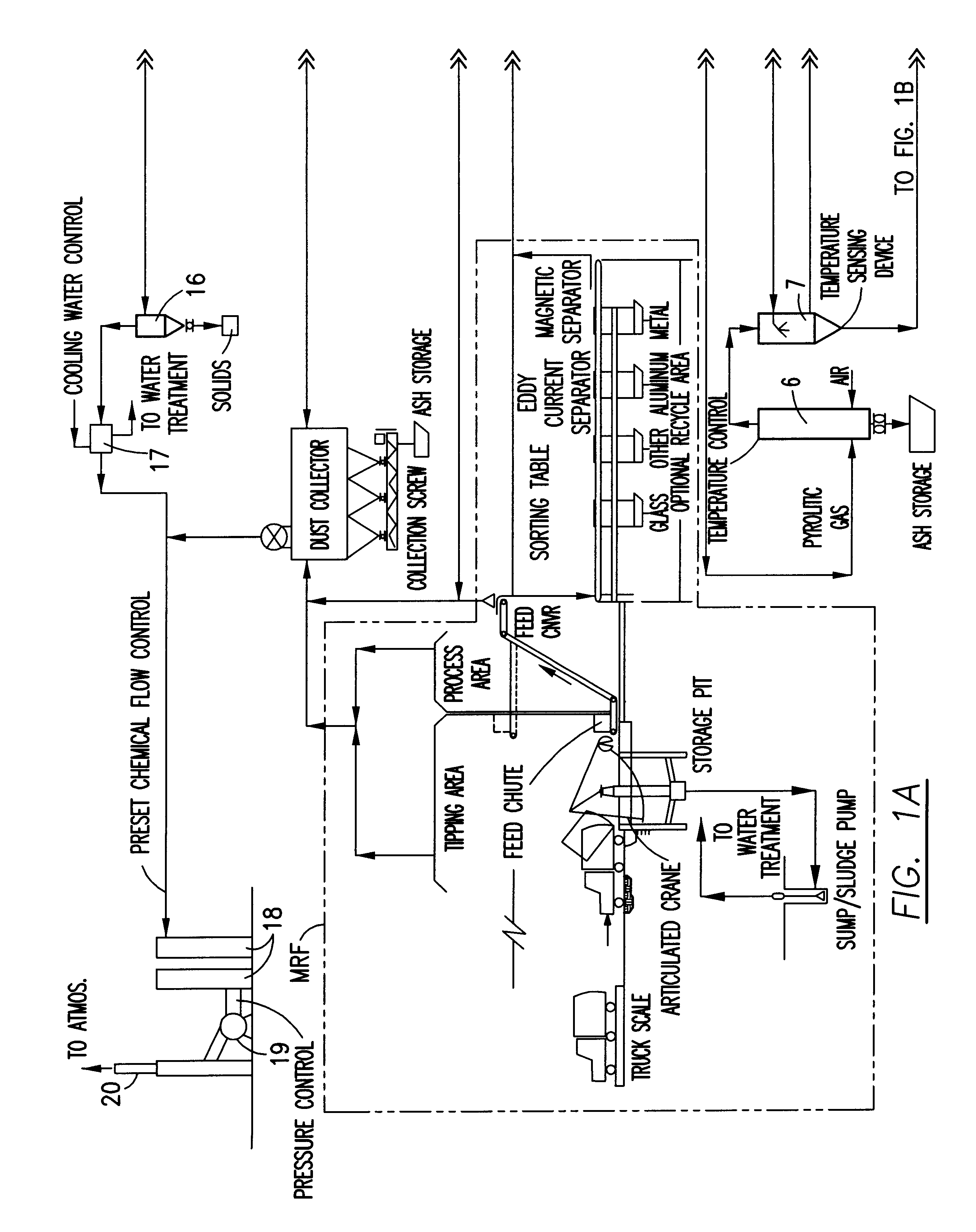

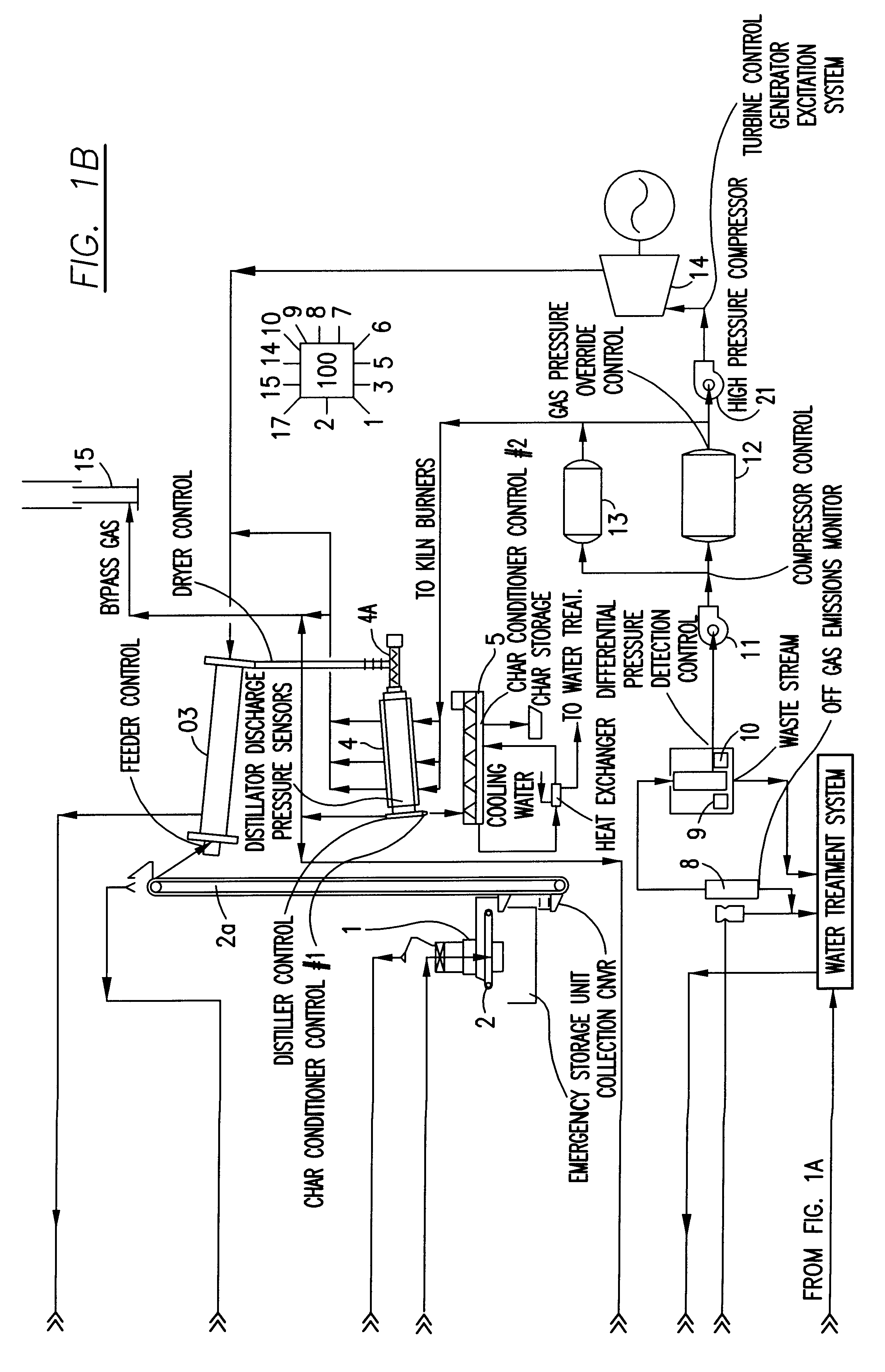

Integrated control and destructive distillation of carbonaceous waste

InactiveUS6182584B1High quantity and qualityEnhanced yield quantity and qualityHorizontal chamber coke ovensEmission preventionComputer control systemWaste stream

A system and process to provide integrated control for the pyrolytic composition of organic (biomass) waste products especially for municipal solid waste systems. The system includes integrated control that monitors biomass waste stream throughout the entire system and the products produced therefrom and includes presorting, controlling the amount of material processed in a continuous manner, shredding, removing moisture in a continuous process that is controlled and providing the waste stream to the distillation unit for pyrolytic action where it is converted into gaseous fuel and a char residue. The gaseous fuel is scrubbed clean and monitored and stored and reused to provide heat to the system. The entire system may be self-sustaining and continuous with very little or no human intervention. An integrated real time computer control system includes sensors and measuring devices with all the major components to ensure integrated efficiency.

Owner:ENVIRONMENTAL SOLUTIONS & TECH

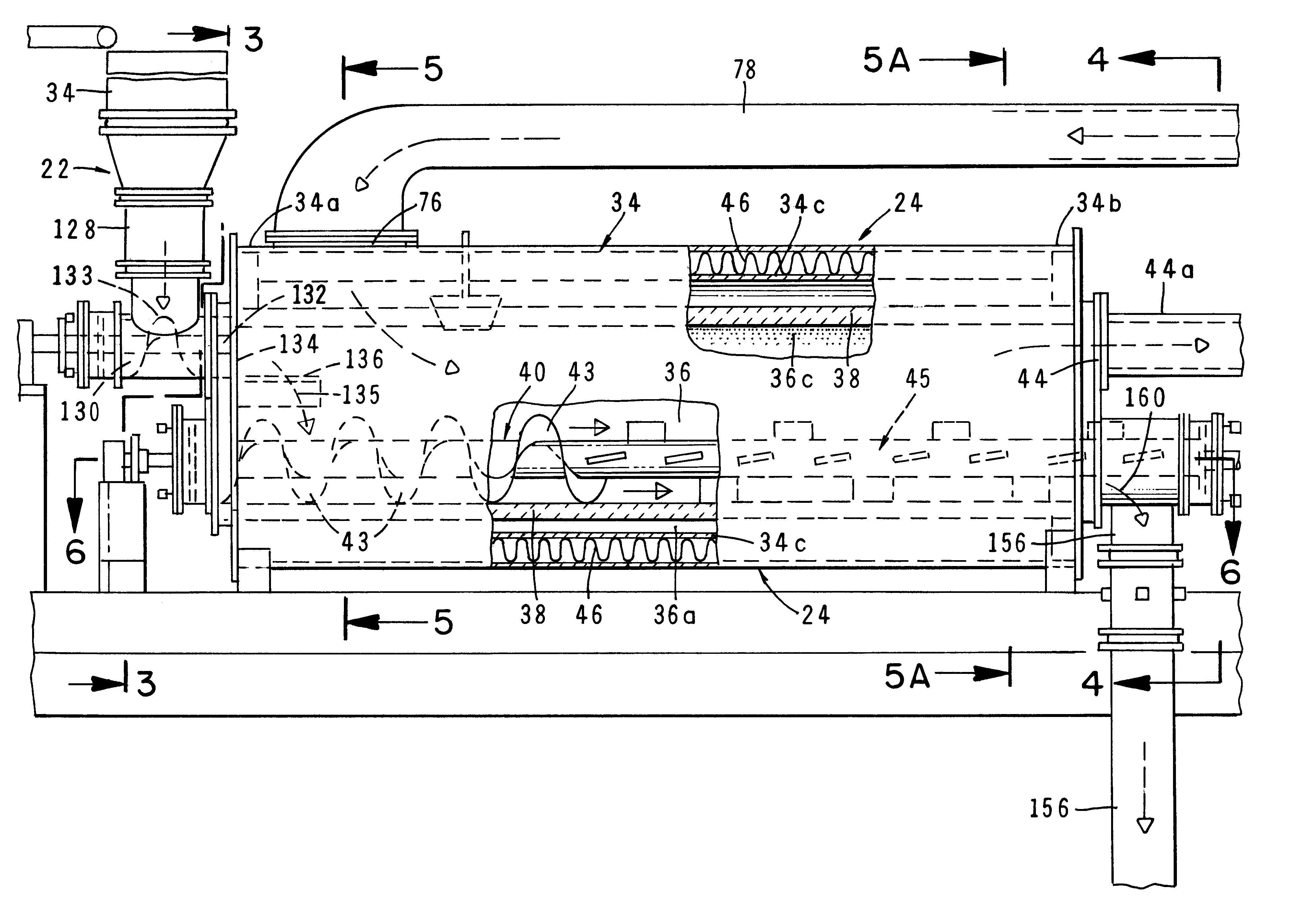

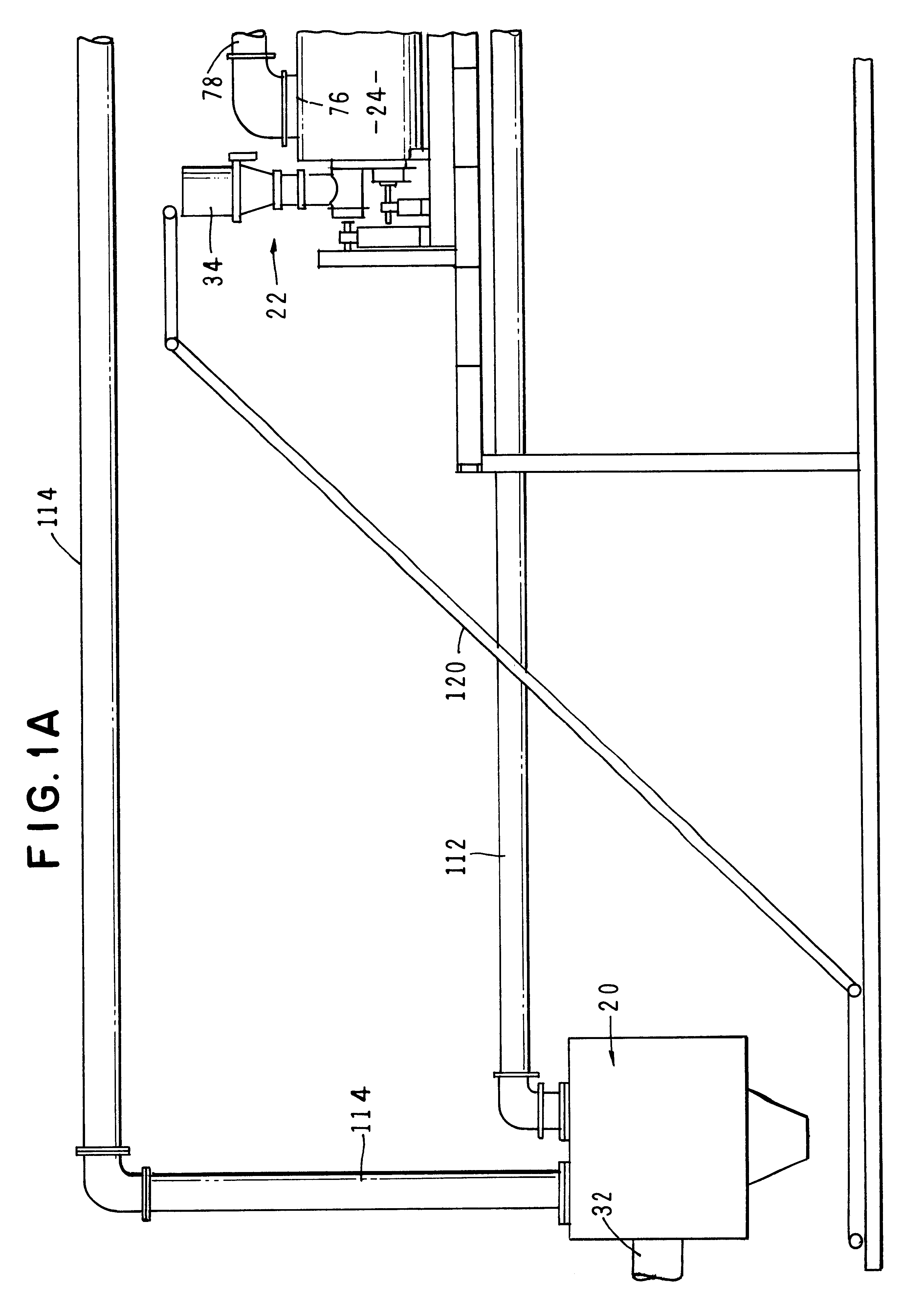

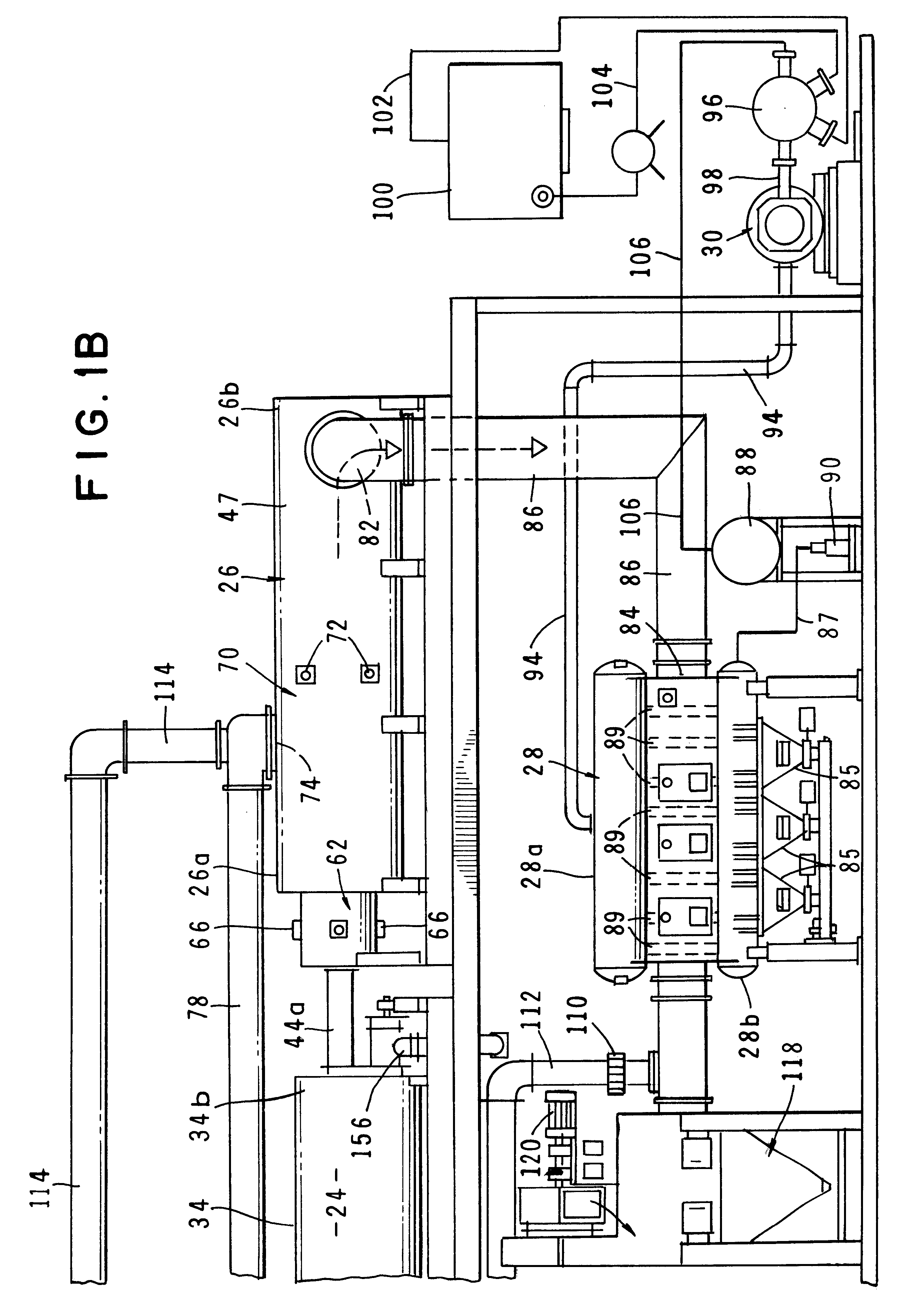

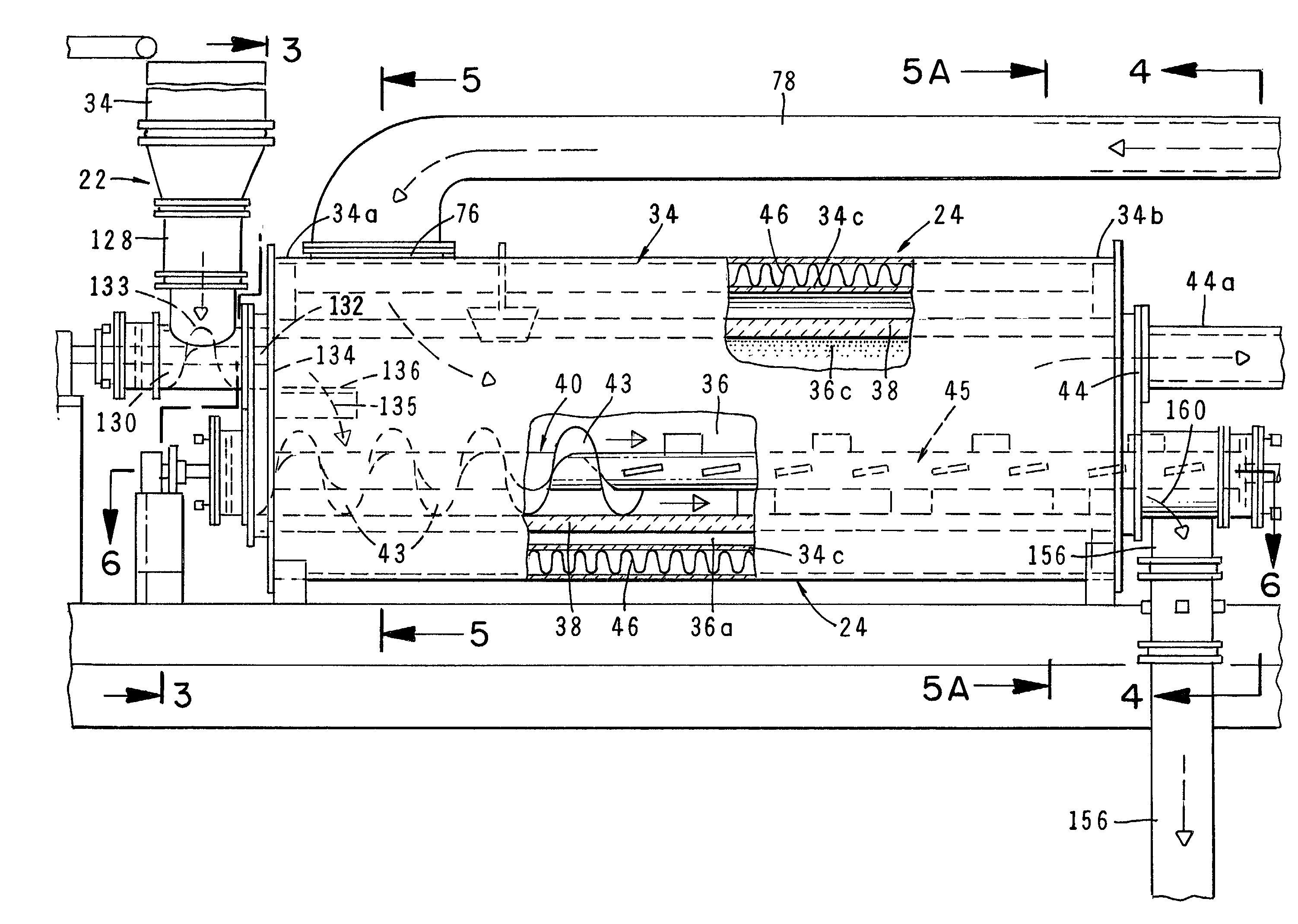

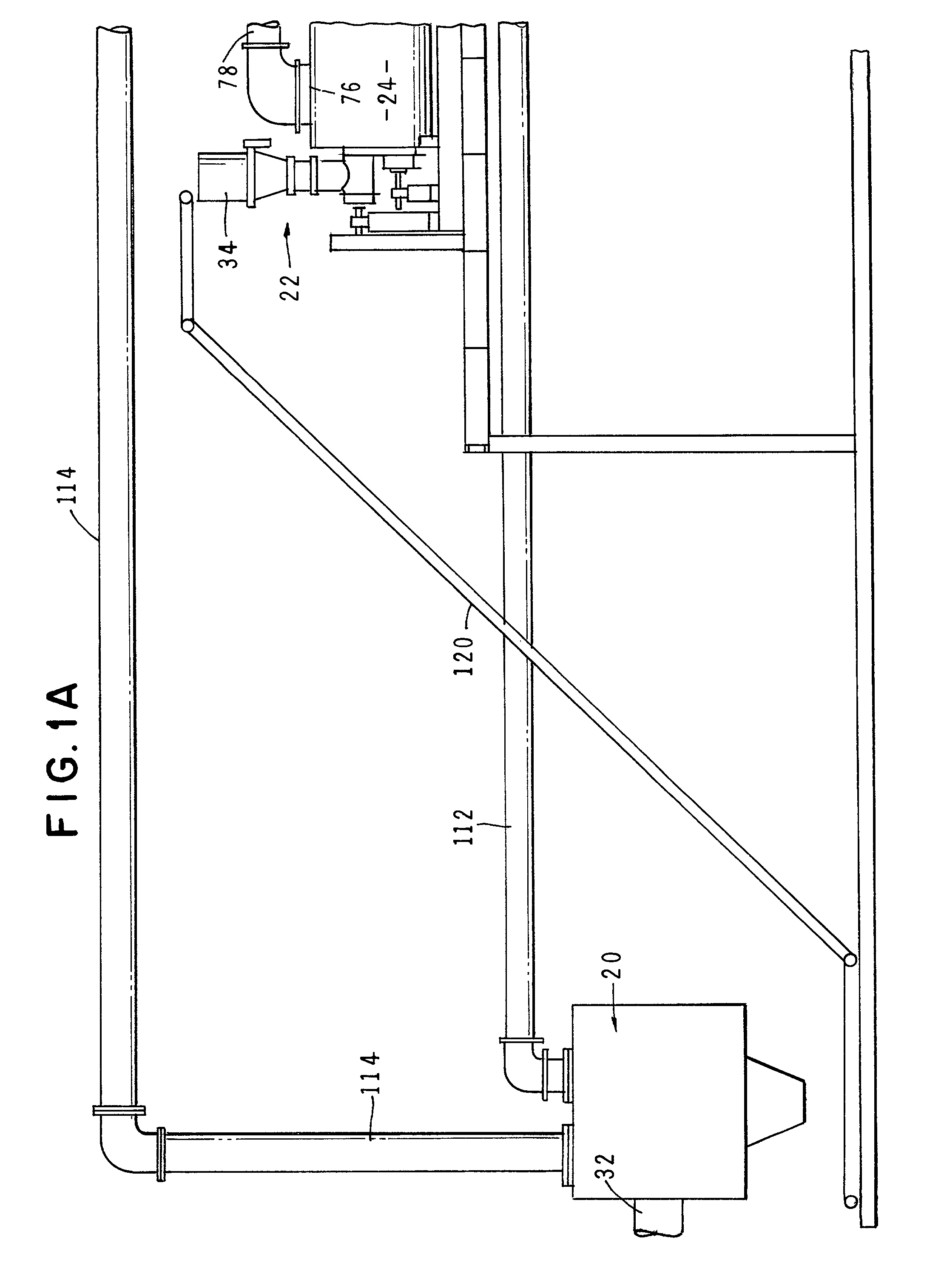

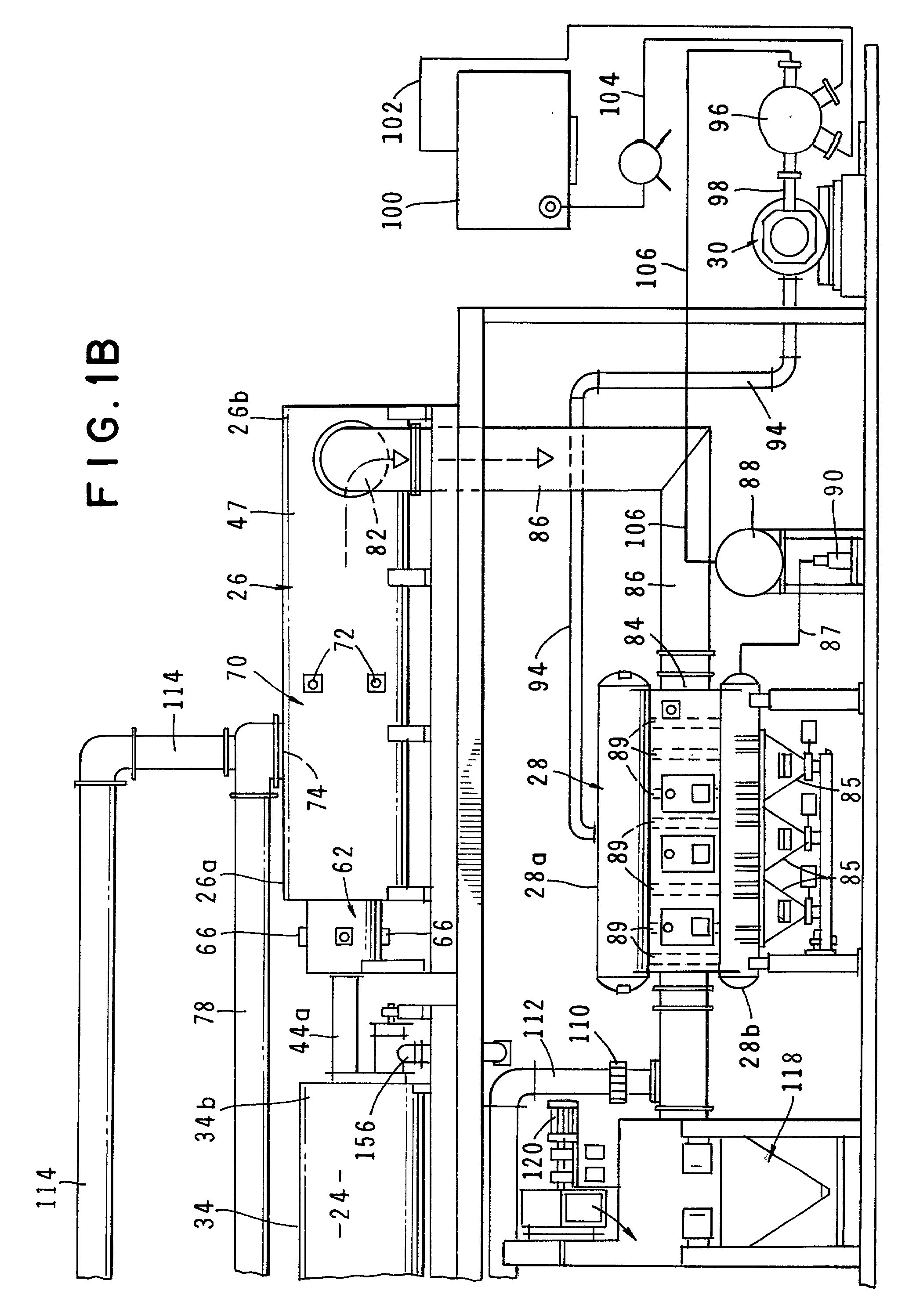

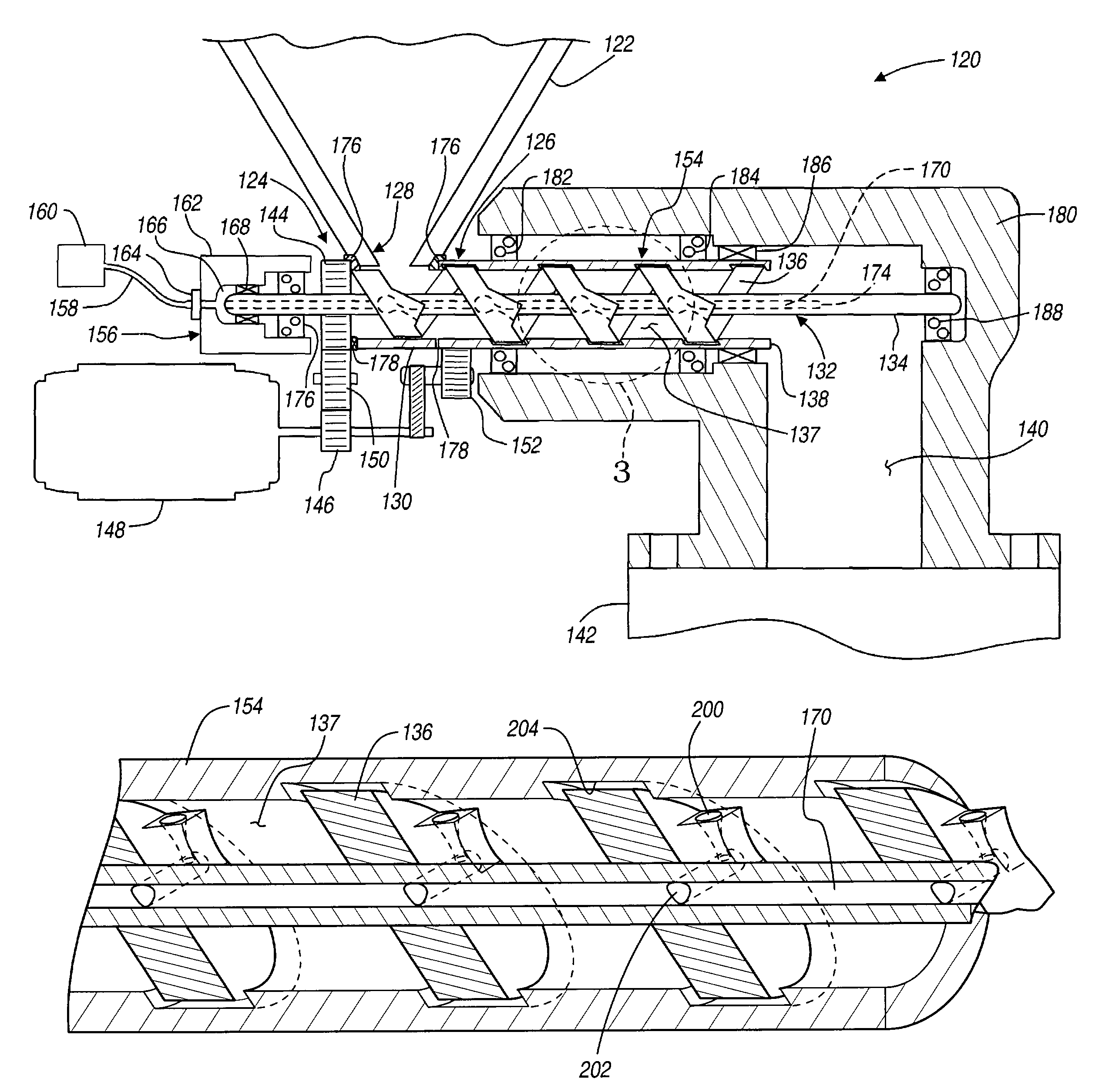

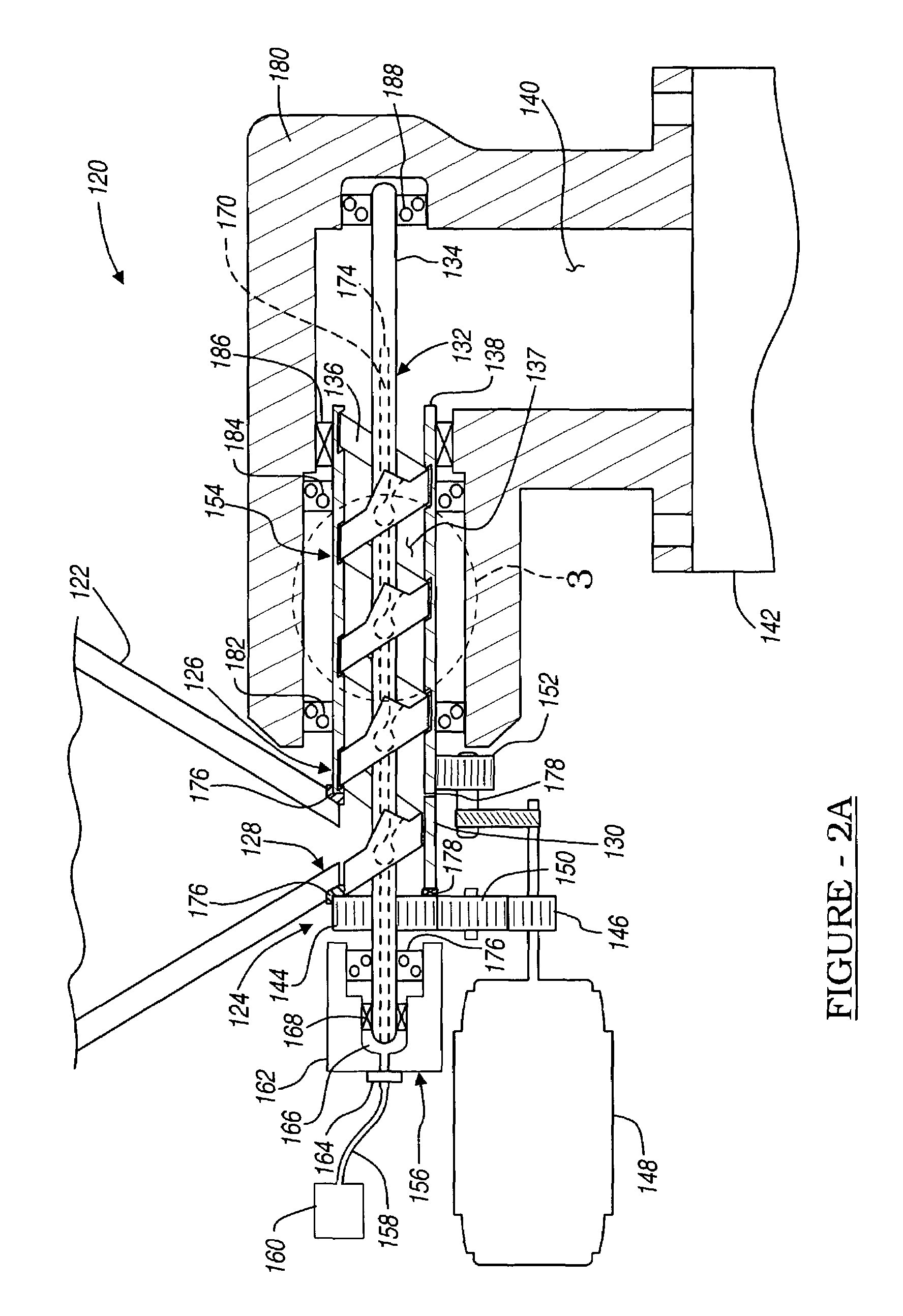

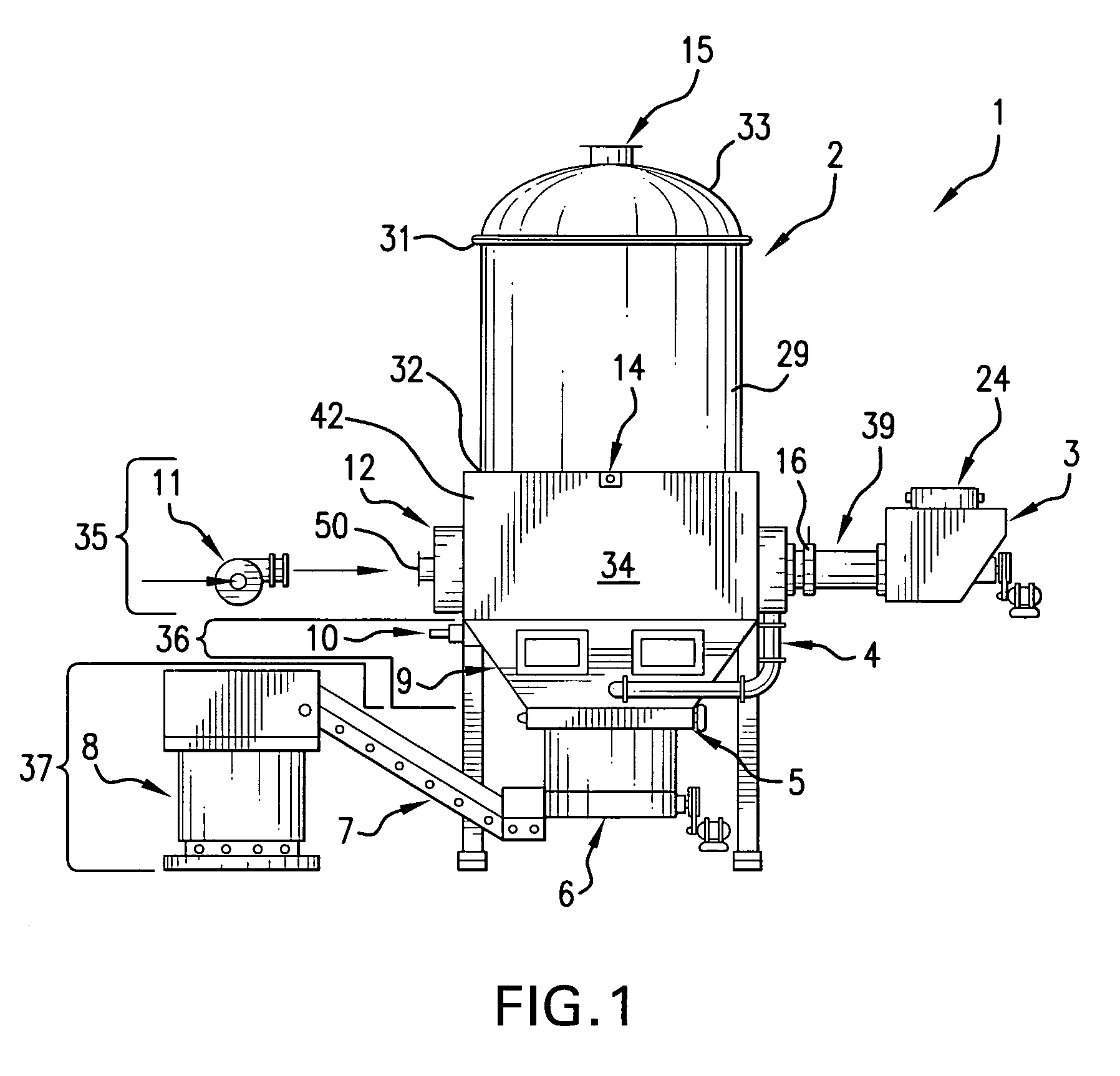

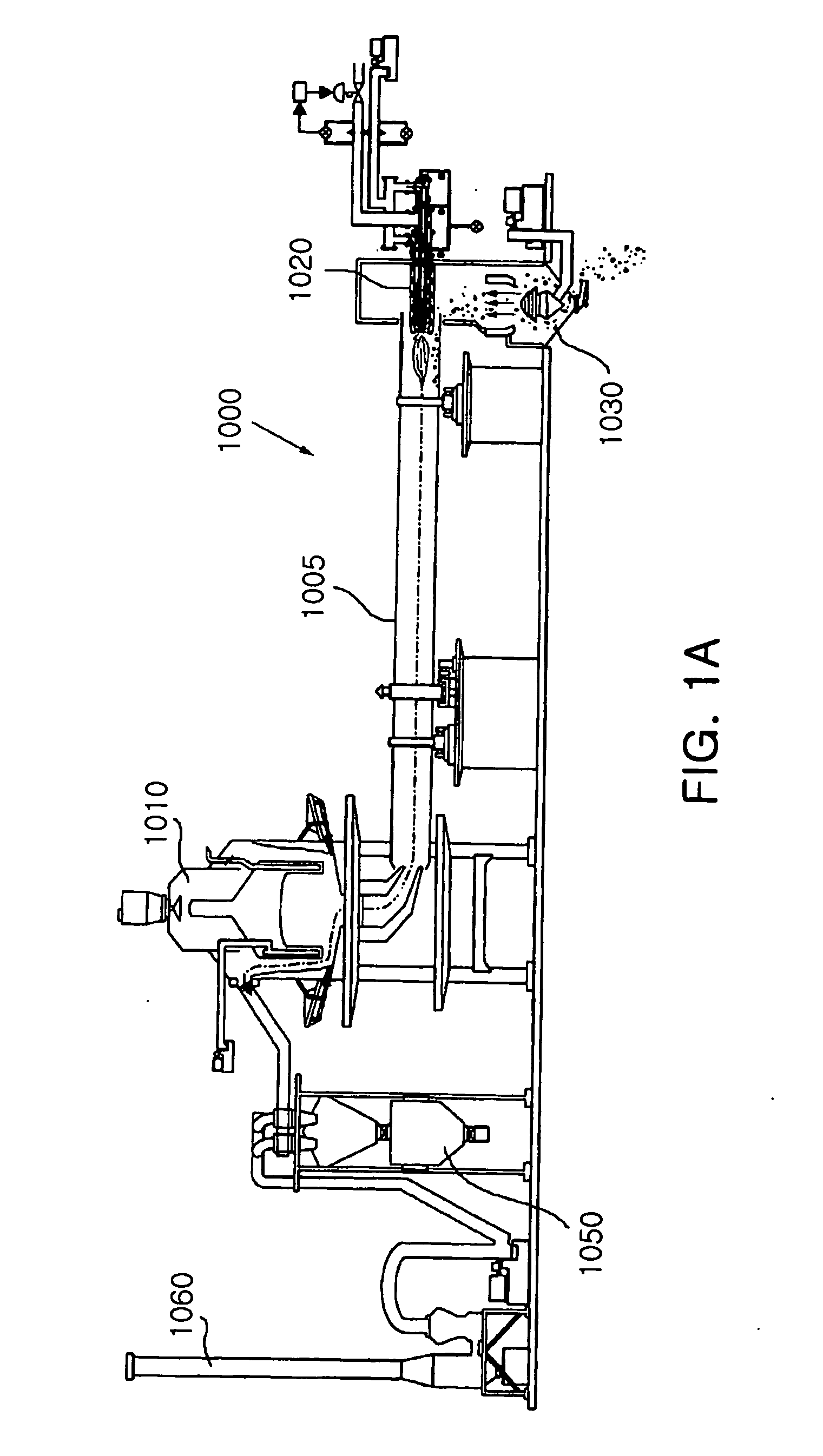

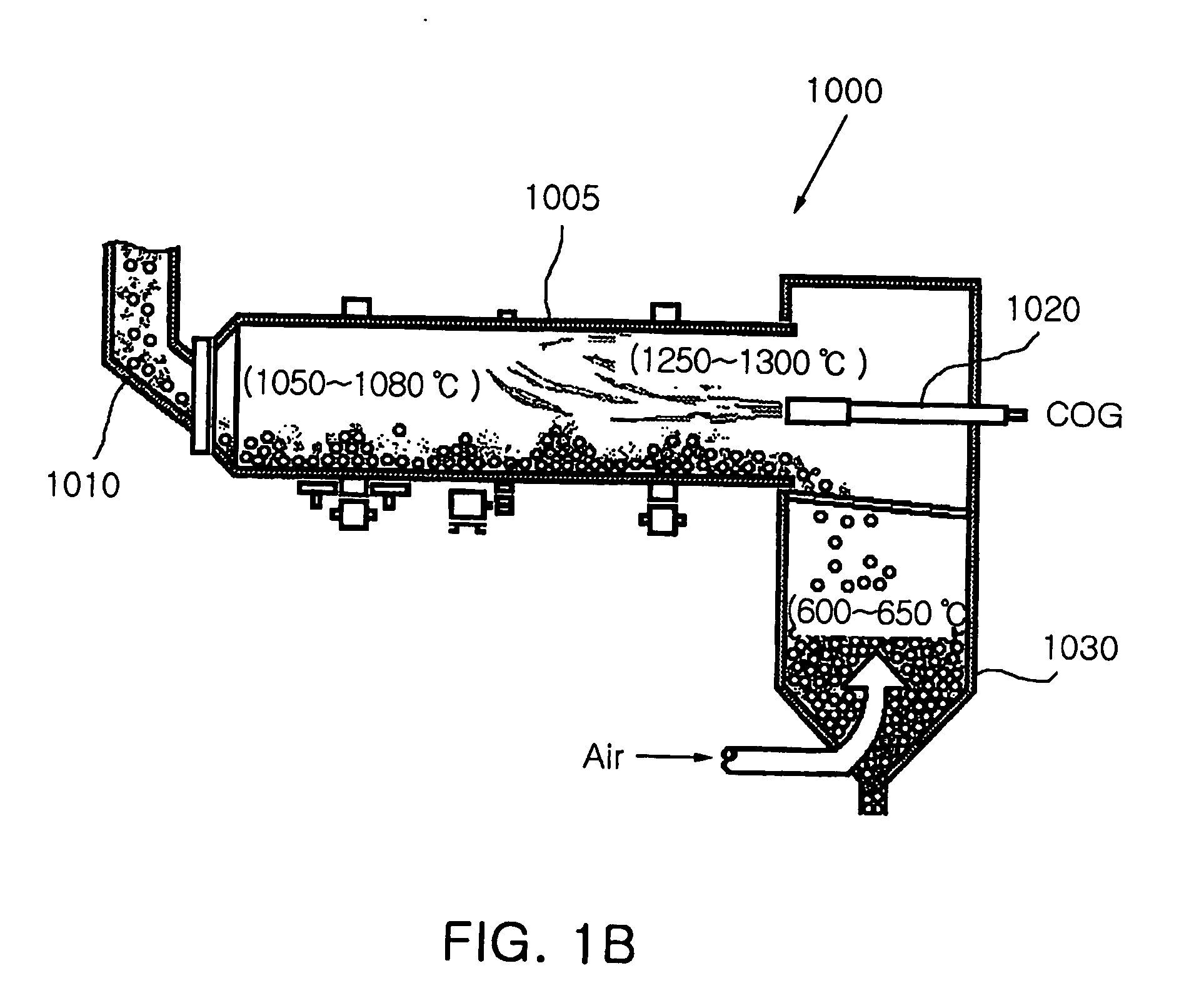

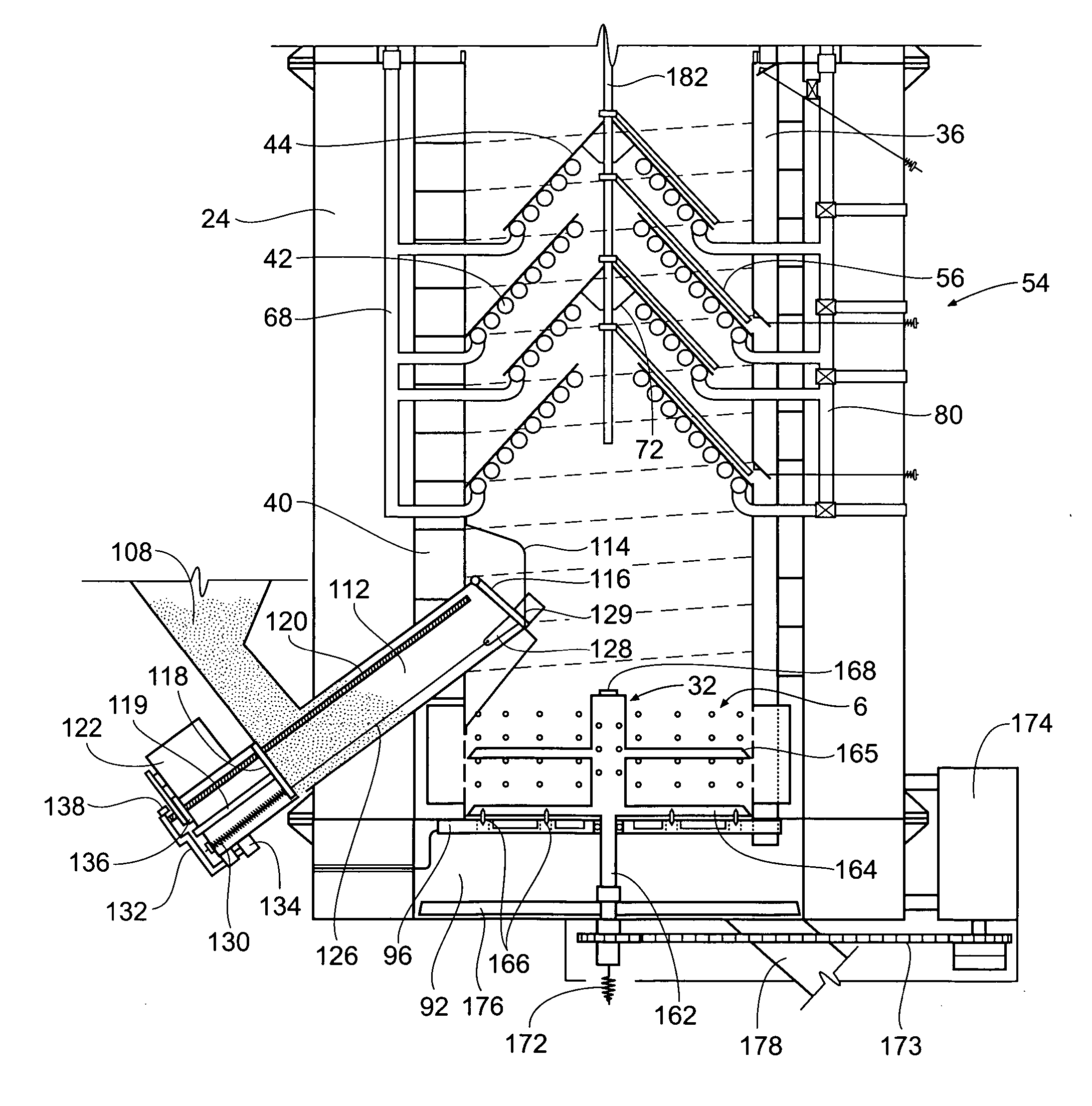

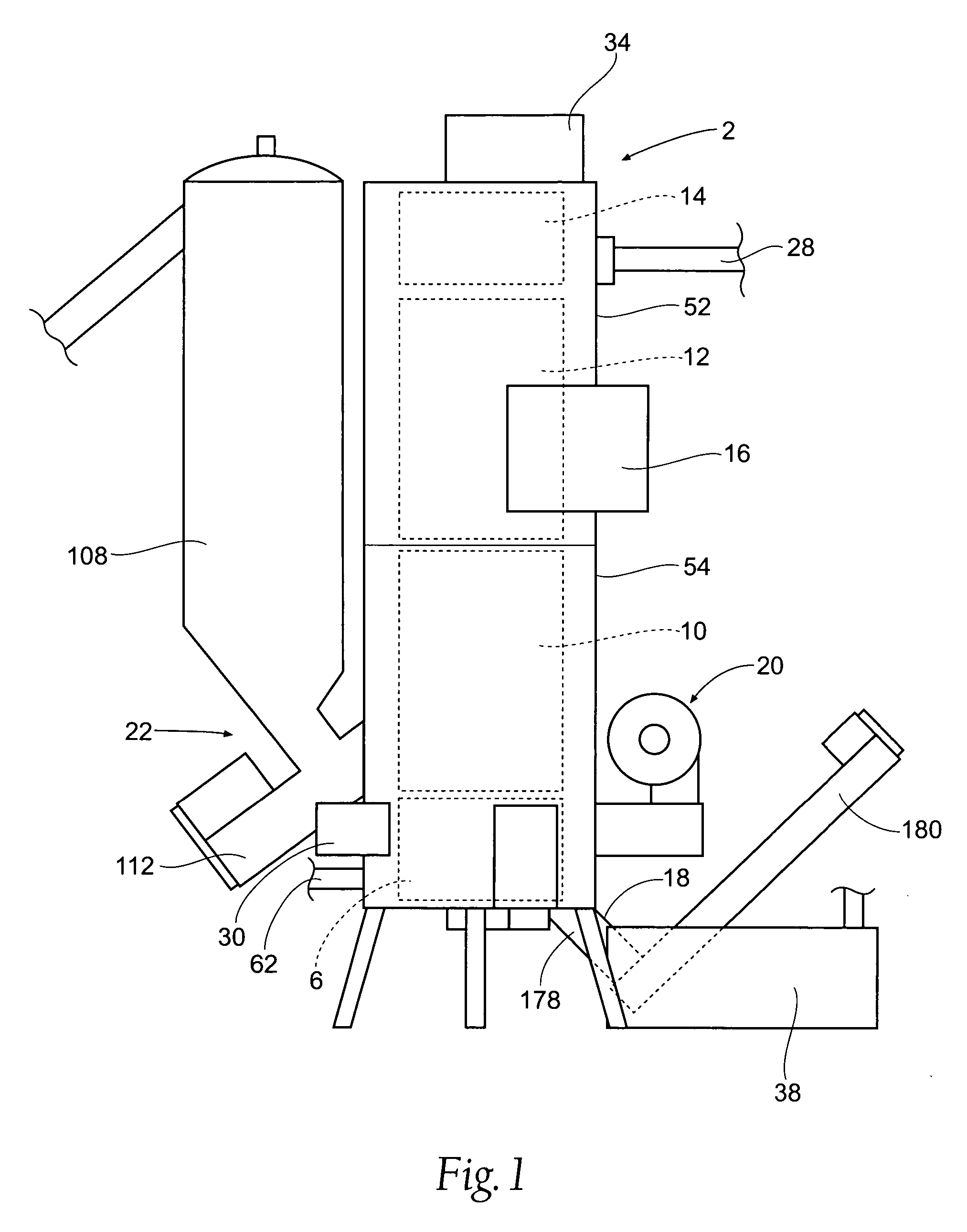

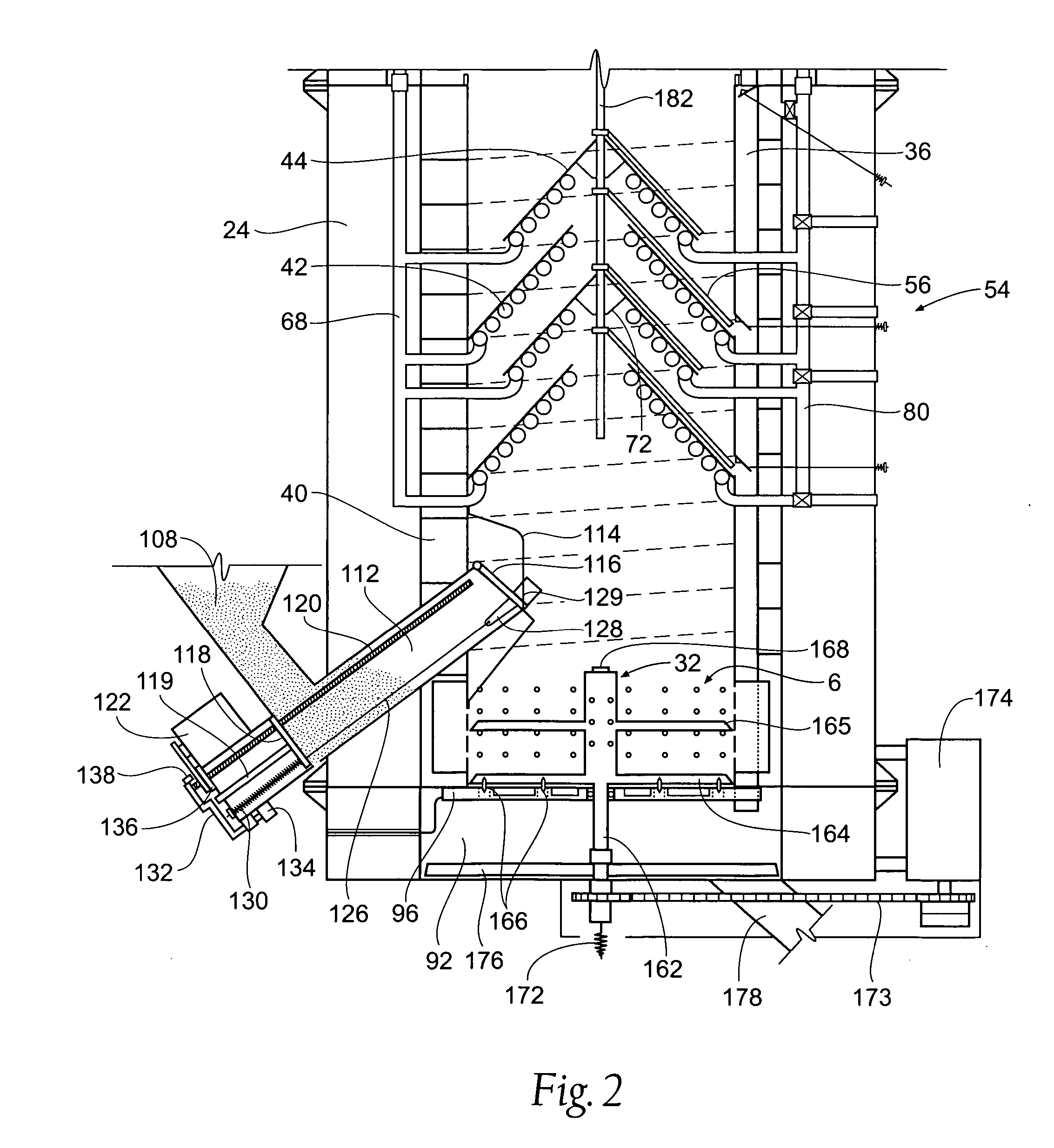

Method and apparatus for treatment of waste

InactiveUS6619214B2Efficient and reliable in operationEasy maintenanceSolid fuel combustionIncinerator apparatusEngineeringTransfer mechanism

An apparatus for treating waste material that comprises four major cooperating subsystems, namely a pyrolytic converter, a two-stage thermal oxidizer, a steam generator and a steam turbine driven by steam generated by the steam generator. In operation, the pyrolytic converter is uniquely heated without any flame impinging on the reactor component and the waste material to be pyrolyzed is transported through the reaction chamber of the pyrolytic converter by a pair of longitudinally extending, side-by-side material transfer mechanisms. Each of the transfer mechanisms includes a first screw conveyor section made up of a plurality of helical flights for conveying the heavier waste and a second paddle conveyor section interconnected with the first section for conveying the partially pyrolyzed waste, the second section comprising a plurality of paddle flights. Once operating, the apparatus is substantially self-sustaining and requires a minimum use of outside energy sources for pyrolyzing the waste materials.

Owner:APS IP HLDG

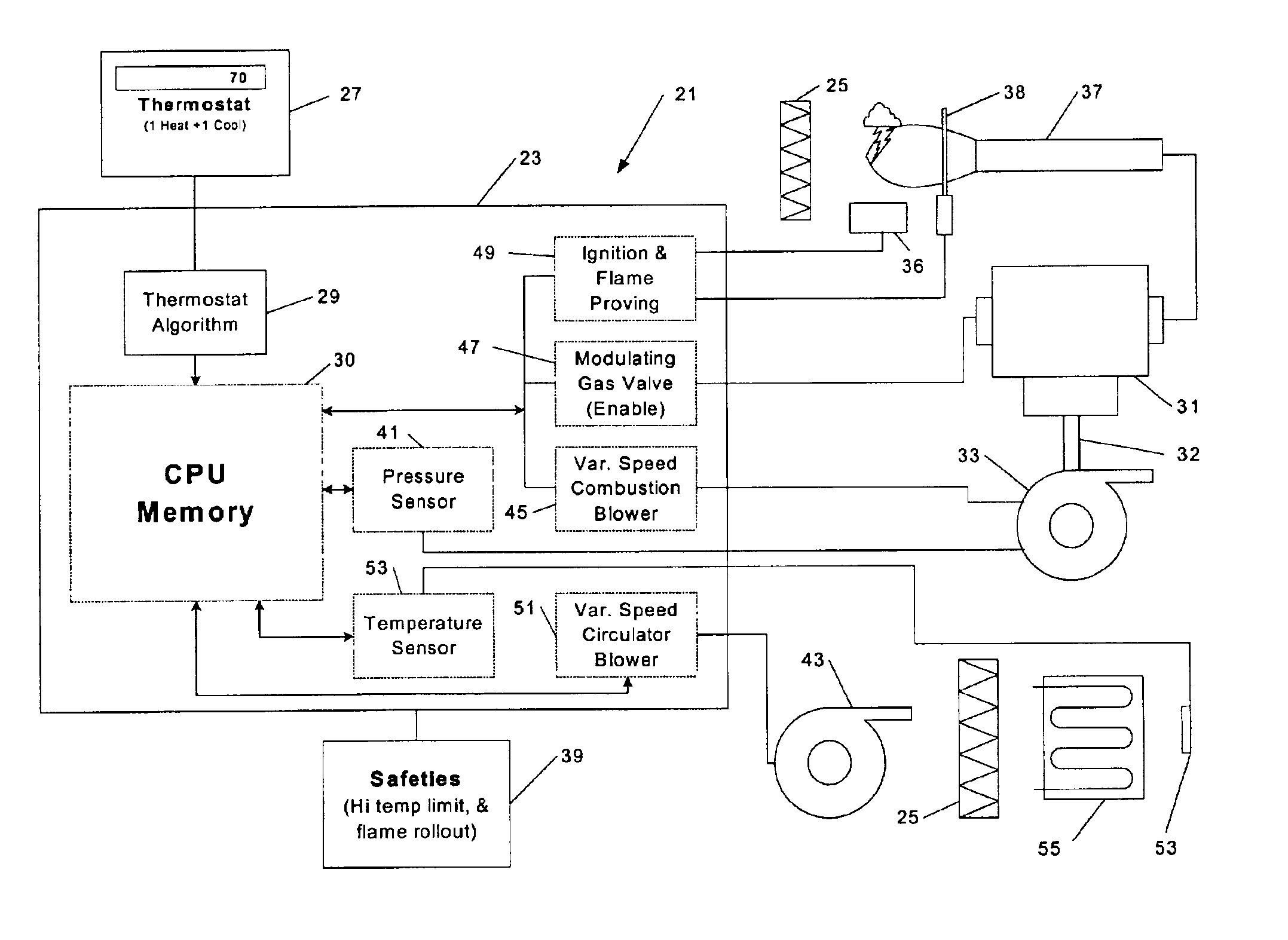

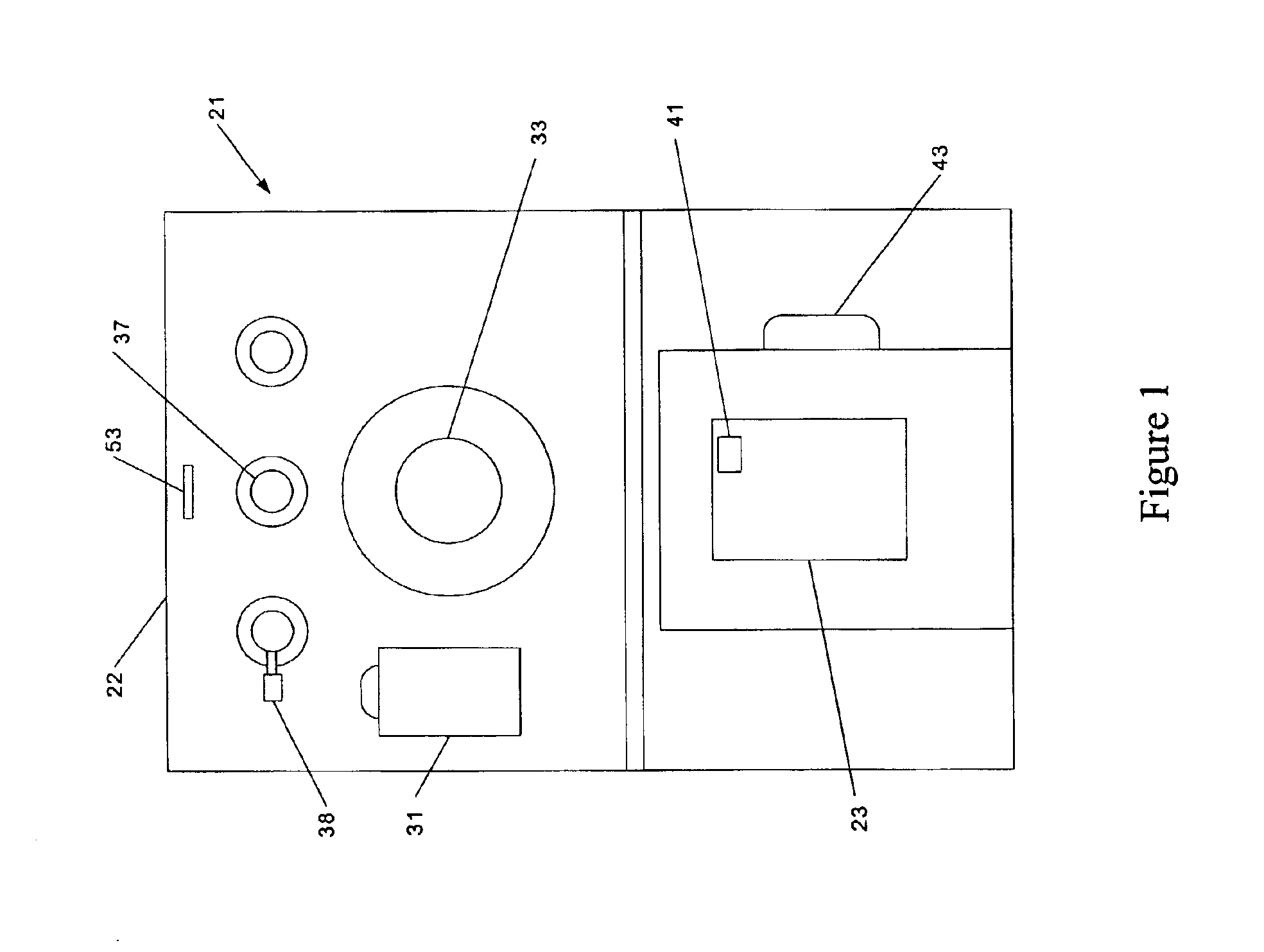

Variable output heating and cooling control

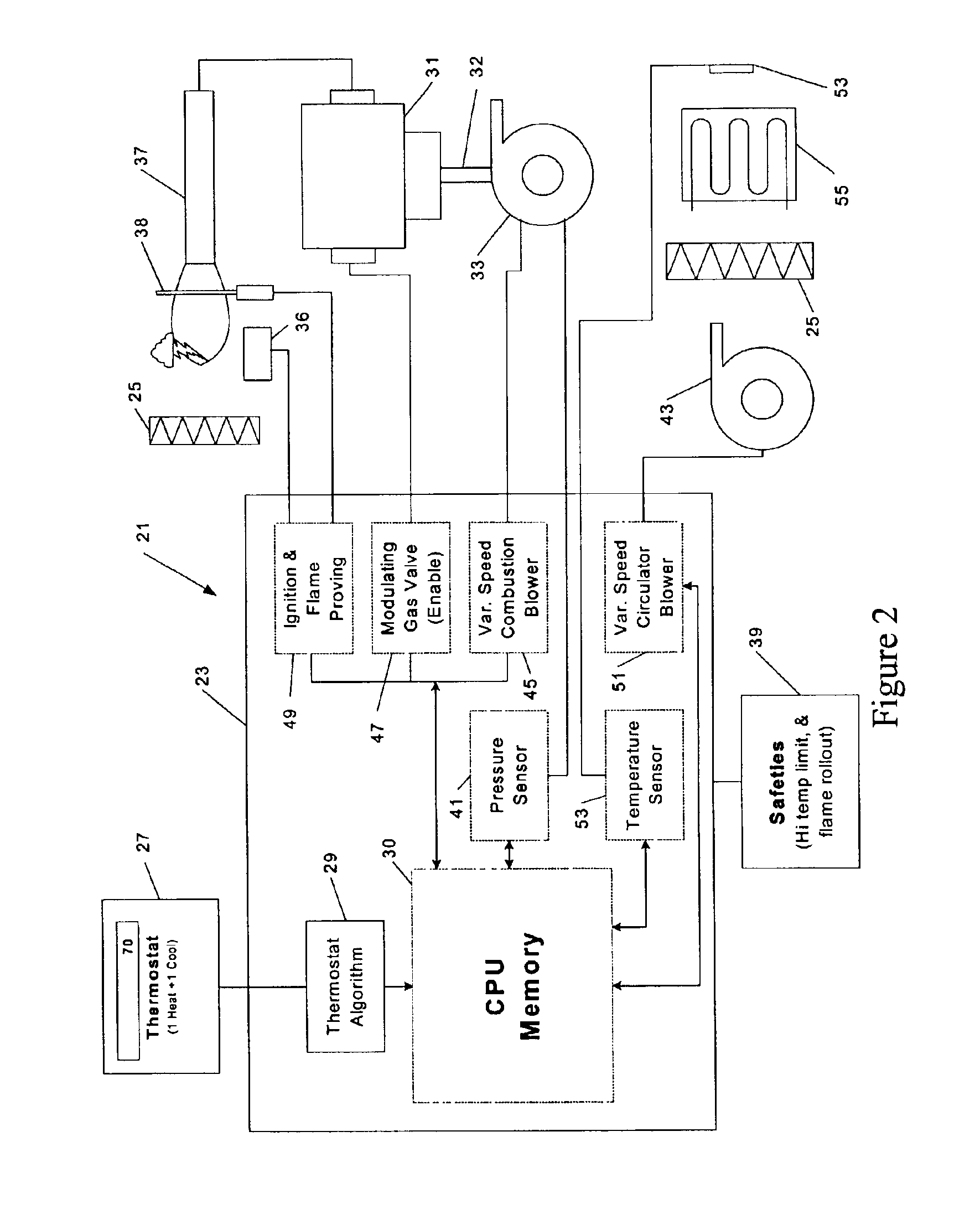

A heating or cooling system, such as an HVAC system, of variable output has a number of control elements and may include a variable speed compressor, a variable speed combustion (induced or forced draft) blower motor; a variable speed circulator blower motor; a variable output gas valve or gas / air premix unit; and a controller specifically developed for variable output applications. The system may utilize a pressure sensor to determine the actual flow of combustion airflow in response to actual space conditions, vary the speed of the inducer blower, and subsequently vary the gas valve output to supply the correct amount of gas to the burner system. A temperature sensor may be located in the discharge air stream of the conditioned air to provide an input signal for the circulator blower.

Owner:HVAC MODULATION TECH

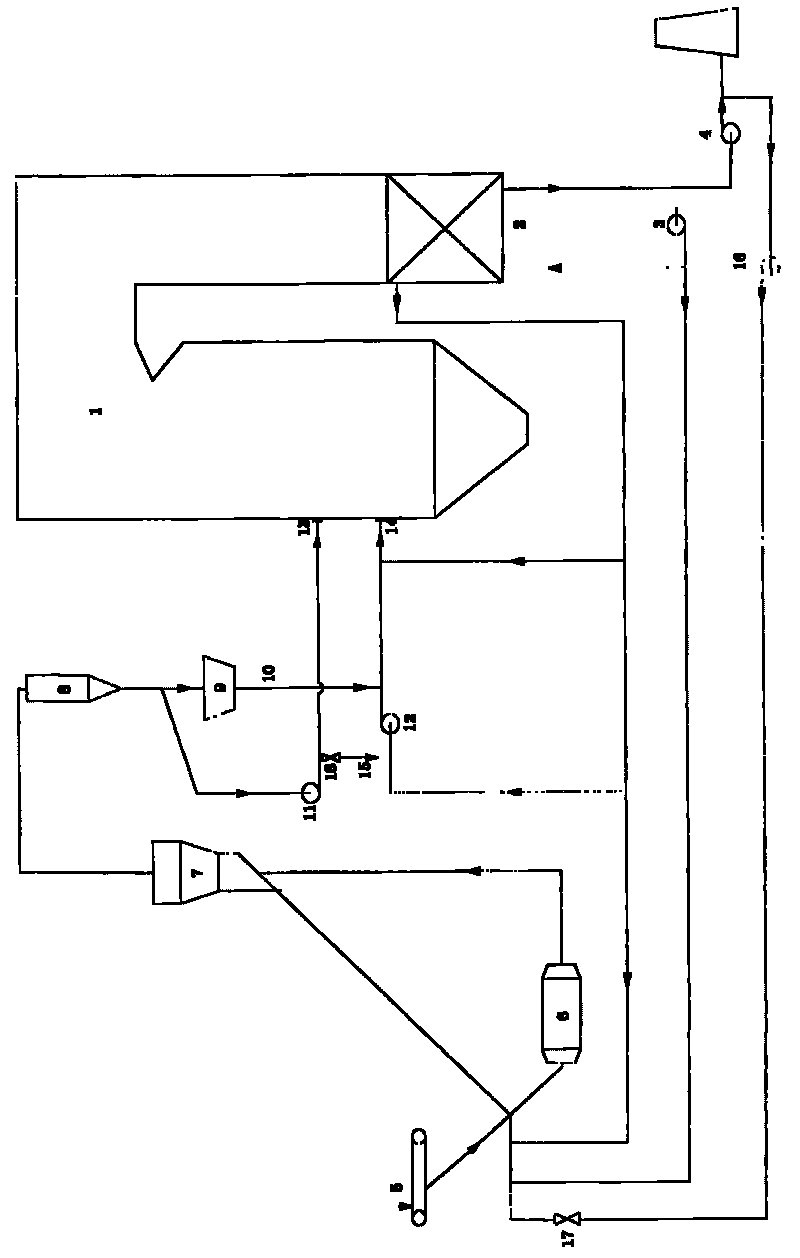

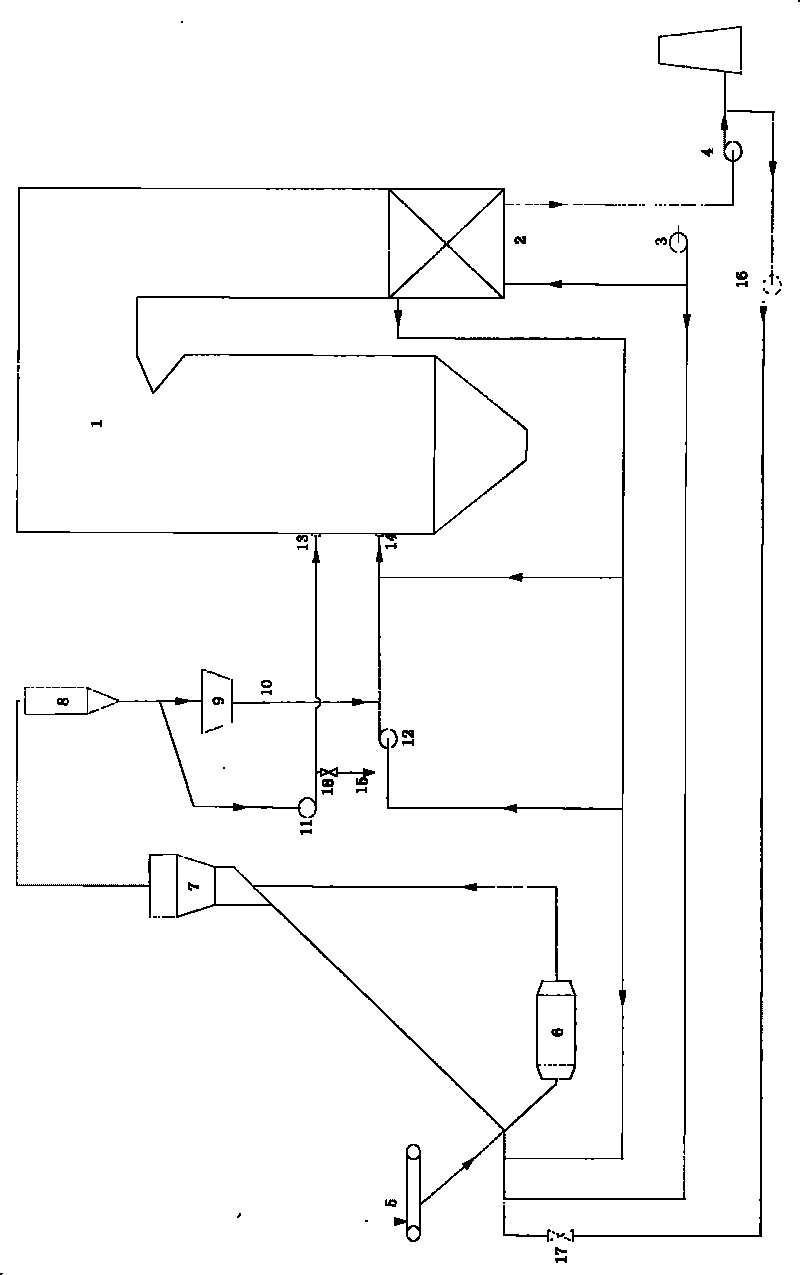

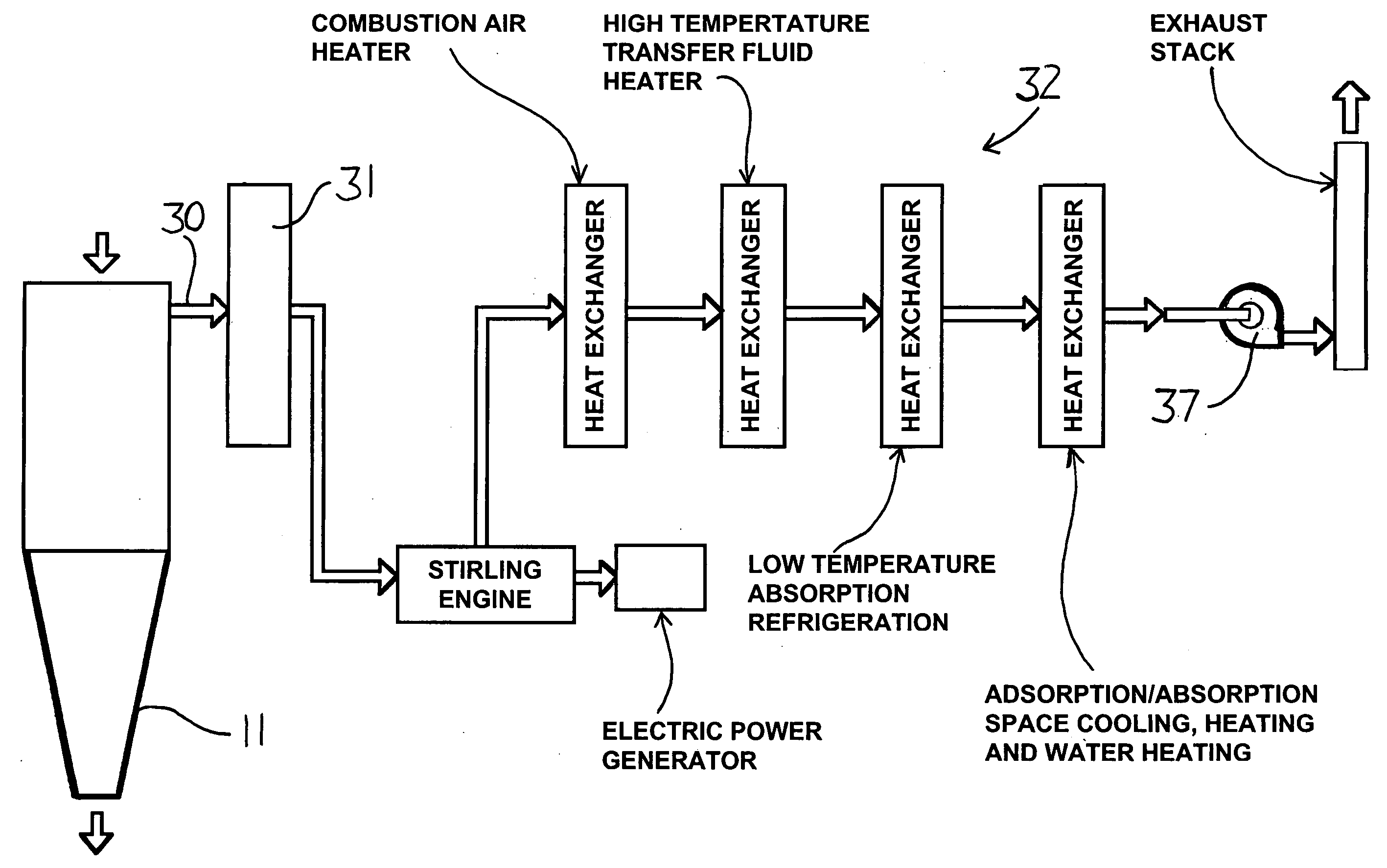

Pyrolyzing gasification system and method of use

InactiveUS20050109603A1High gasifier discharge temperatureEfficient processGasifier mechanical detailsBiofuelsHydrocotyle bowlesioidesExternal combustion engine

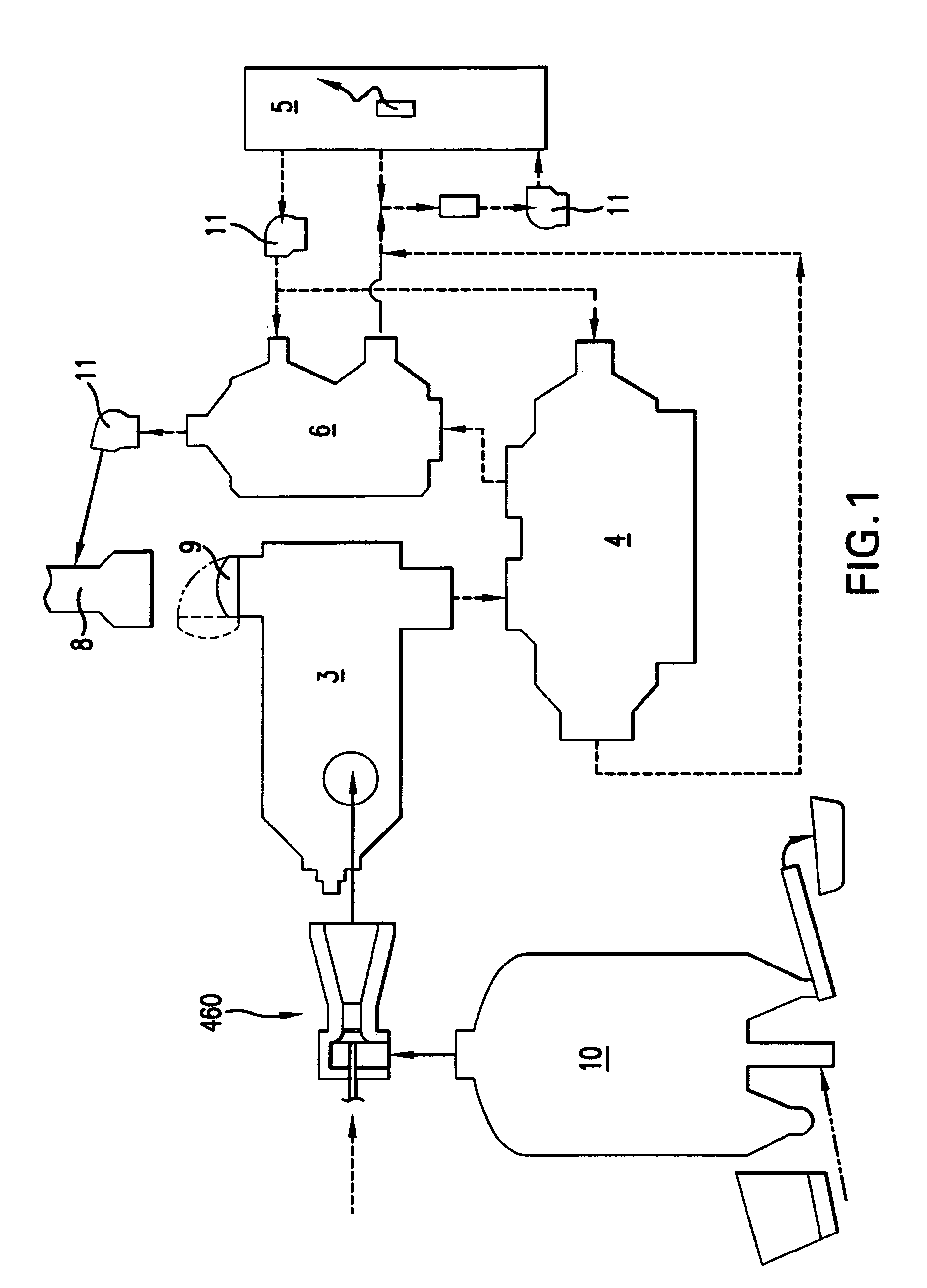

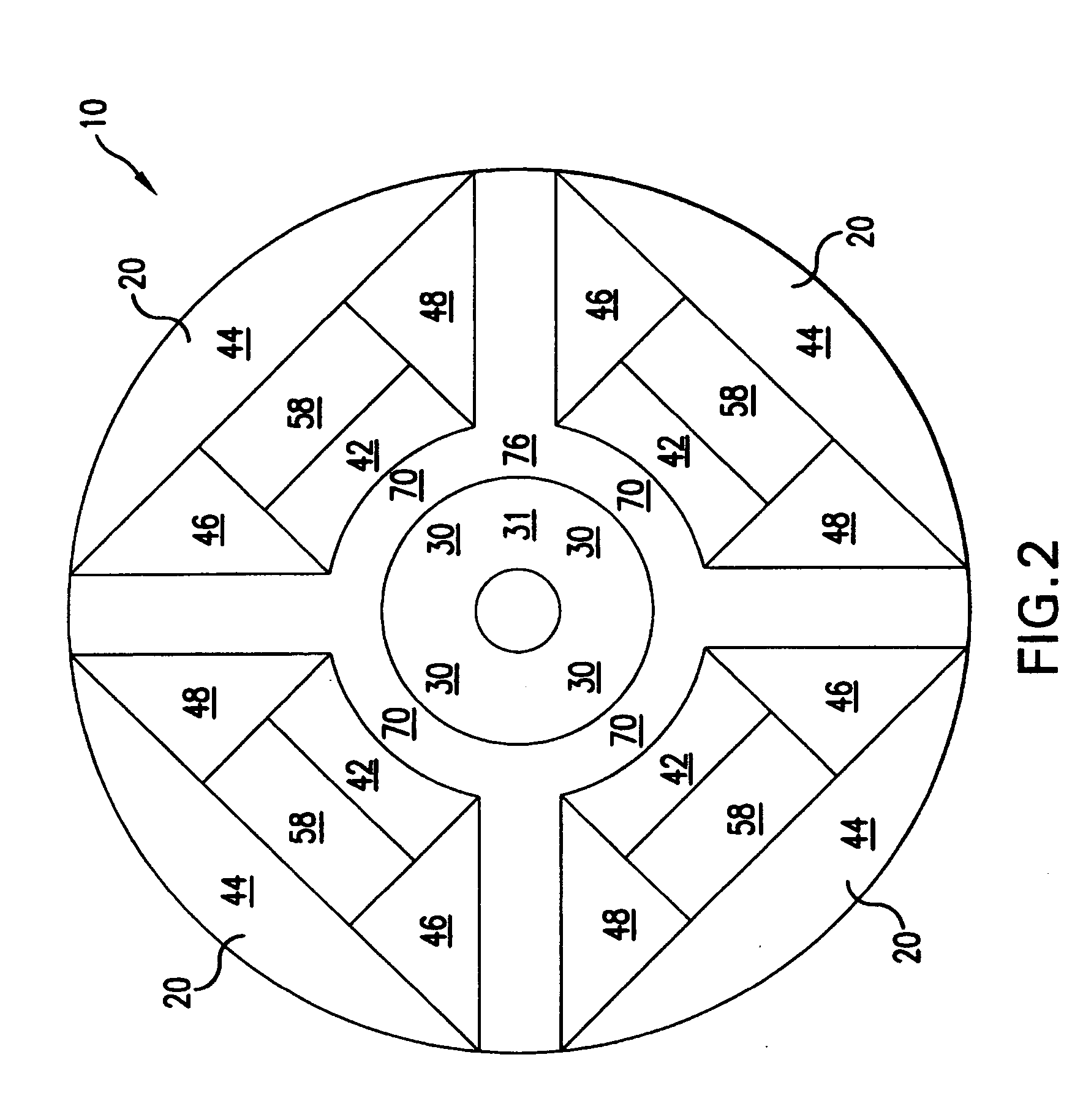

Pyrolyzing gasification system and method of use including primary combustion of non-uniform solid fuels such as biomass and solid wastes within a refractory lined gasifier, secondary combustion of primary combustion gas within a staged, cyclonic, refractory lined oxidizer, and heat energy recovery from the oxidized flue gas within an indirect air-to-air all-ceramic heat exchanger or external combustion engine. Primary combustion occurs at low substoichoimetric air percentages of 10-30 percent and at temperatures below 1000 degrees F. Secondary combustion is staged and controlled for low NOx formation and prevention of formation of CO, hydrocarbons, and VOCs. The gasifier includes a furnace bed segmented into individual cells, each cell is independently monitored using a ramp temperature probe, and provided with controlled air injection. Gasifier air injection includes tuyere arrays, lances, or both. The oxidizer includes three serially aligned stages separated by air injecting baffles, and ability to adjust the exit air temperature.

Owner:HEAT TRANSFER INT

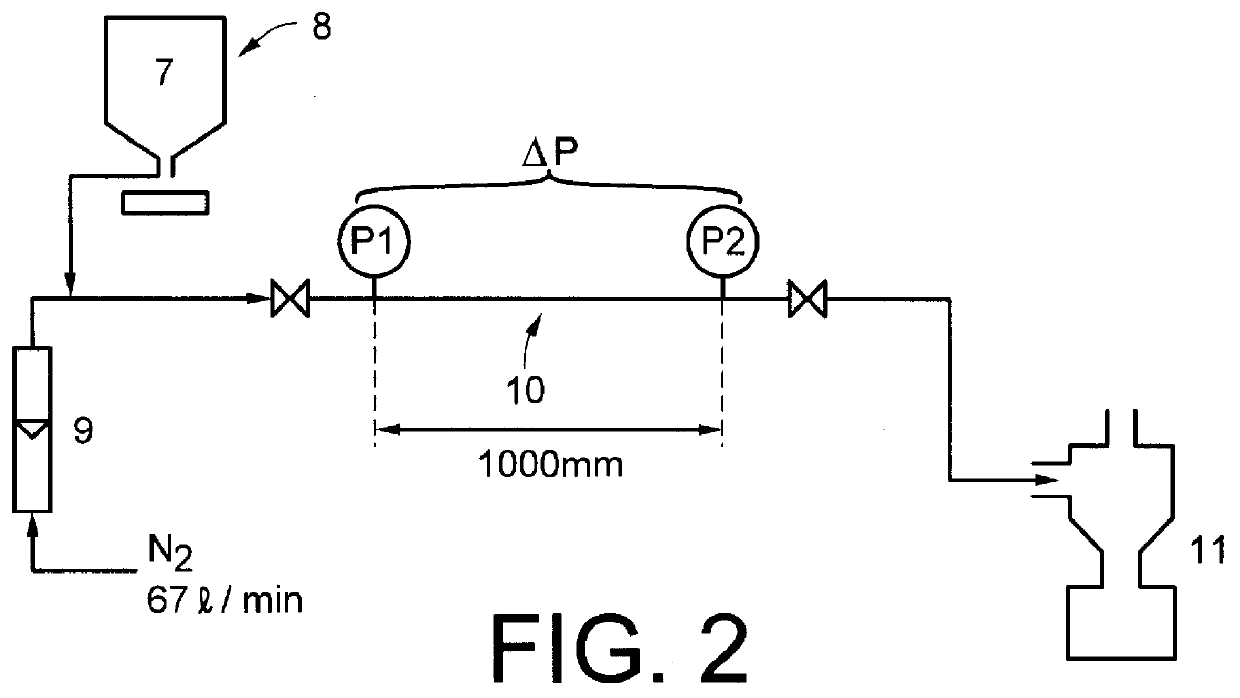

Pulverized coal carriability improver

InactiveUS6083289AGreat varietyImprove liquiditySolid fuel pretreatmentSolid fuelsInorganic saltsCombustion

PCT No. PCT / JP97 / 00668 Sec. 371 Date Sep. 25, 1998 Sec. 102(e) Date Sep. 25, 1998 PCT Filed Mar. 5, 1997 PCT Pub. No. WO97 / 36009 PCT Pub. Date Oct. 2, 1997The use of pulverized coal as the fuel to be injected into metallurgical or combustion furnace becomes possible enabled by improving the transportability thereof. Further, a pulverized coal is provided, which is inhibiting from bridging or channeling in a hopper, or piping choking. A water-soluble inorganic salt having a polar group is made to adhere to pulverized coal which is prepared from raw coal having an average HGI of 30 or above and which is in a dry state at the injection port of a metallurgical or combustion furnace, The inorganic salt is selected from among BaCl2, CaCl2, Ca(NO2)2, Ca(NO3)2, Ca(ClO)2, K2CO3, KCl, MgCl2, MgSO4, NH4BF4, NH4Cl, (NH4)2SO4, Na2CO3, NaCl, NaClO3, NaNO2, NaNO3, NaOH, Na2S2O3, Na2S2O5, HNO3, H2SO4, H2CO3, and HCl.

Owner:KAO CORP

Method and apparatus for treatment of waste

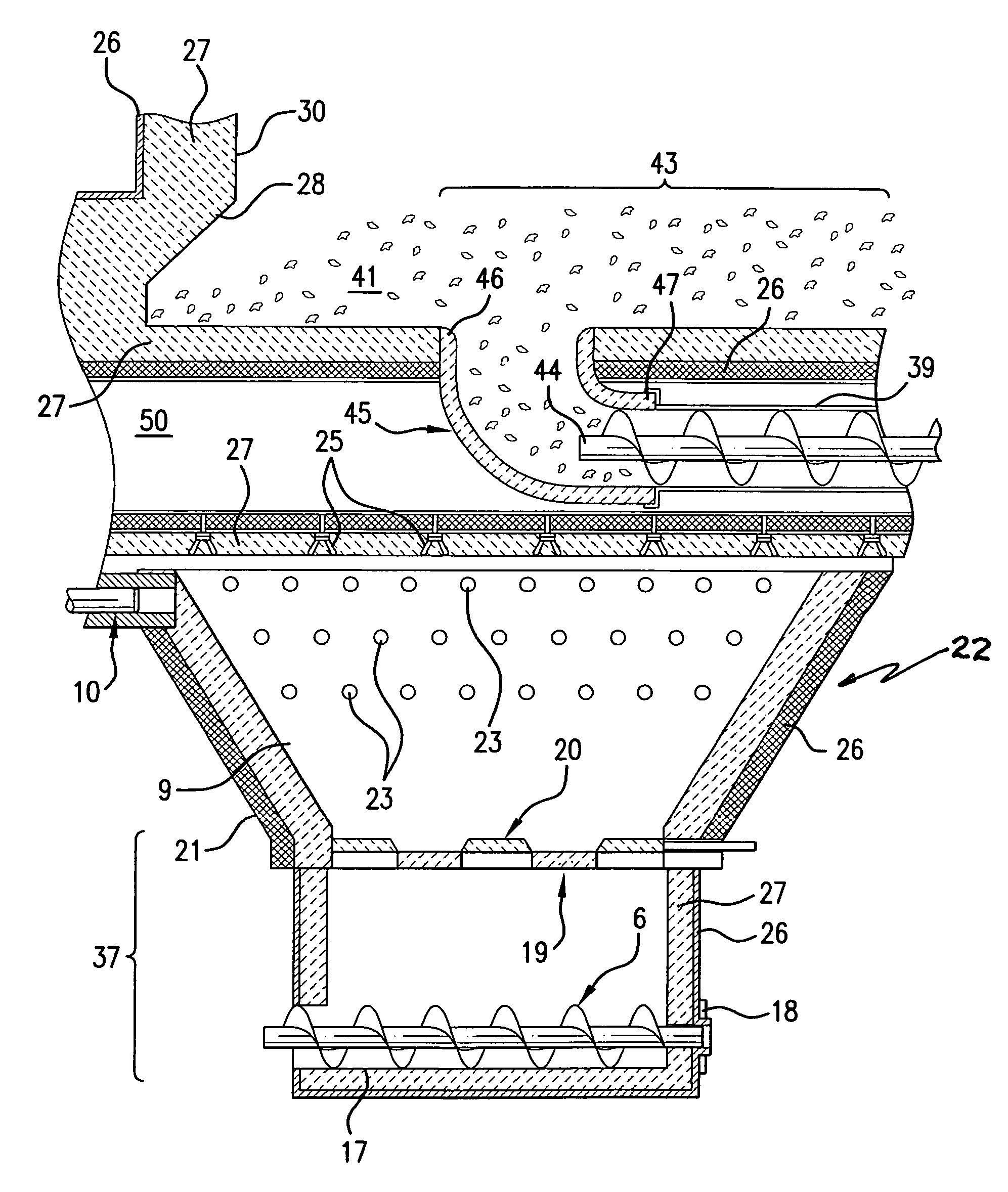

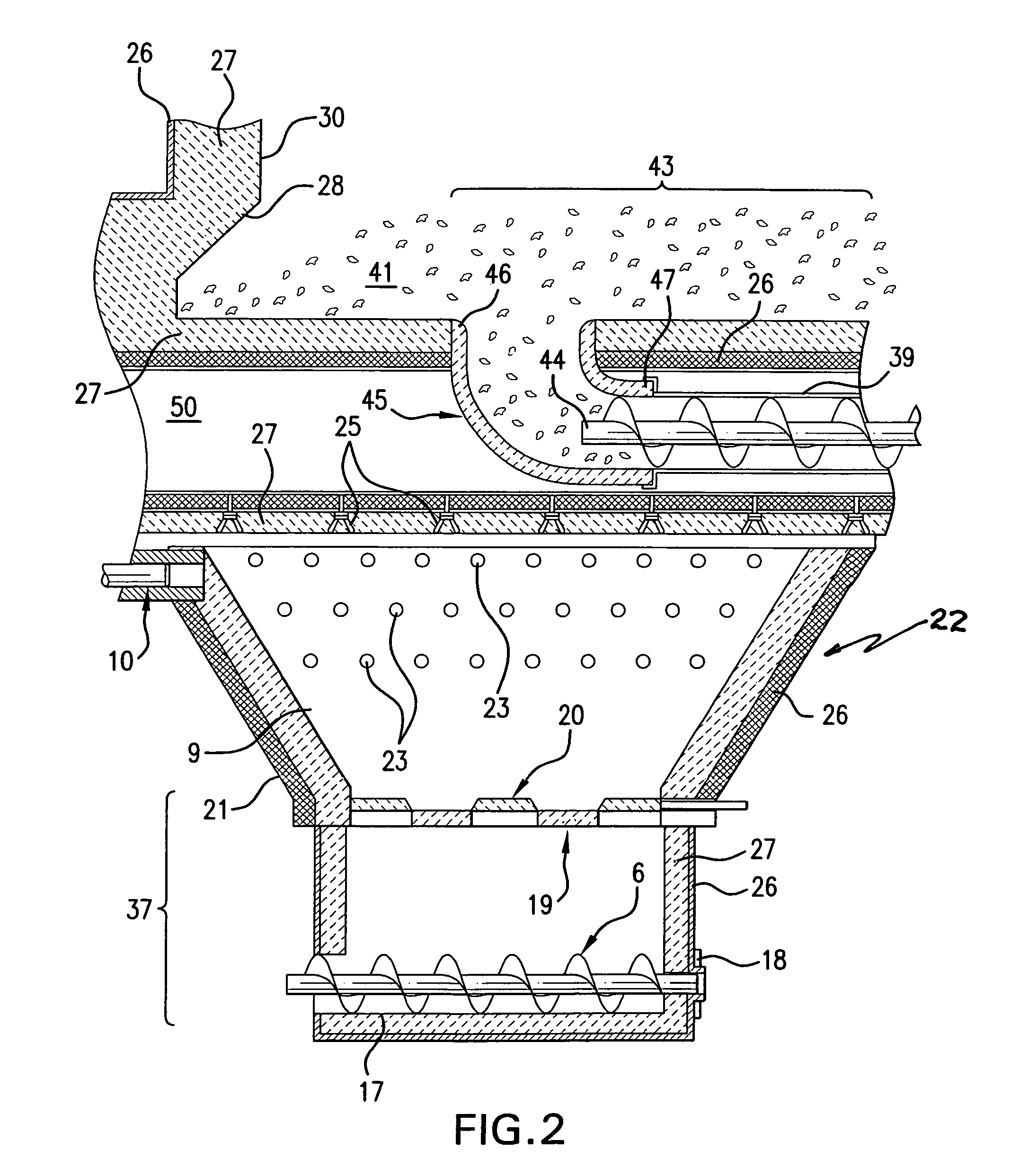

InactiveUS20020195031A1Efficient and reliable in operationEasy maintenanceSolid fuel combustionIncinerator apparatusEngineeringTransfer mechanism

An apparatus for treating waste material that comprises four major cooperating subsystems, namely a pyrolytic converter, a two-stage thermal oxidizer, a steam generator and a steam turbine driven by steam generated by the steam generator. In operation, the pyrolytic converter is uniquely heated without any flame impinging on the reactor component and the waste material to be pyrolyzed is transported through the reaction chamber of the pyrolytic converter by a pair of longitudinally extending, side-by-side material transfer mechanisms. Each of the transfer mechanisms includes a first screw conveyor section made up of a plurality of helical flights for conveying the heavier waste and a second paddle conveyor section interconnected with the first section for conveying the partially pyrolyzed waste, the second section comprising a plurality of paddle flights. Once operating, the apparatus is substantially self-sustaining and requires a minimum use of outside energy sources for pyrolyzing the waste materials.

Owner:APS IP HLDG

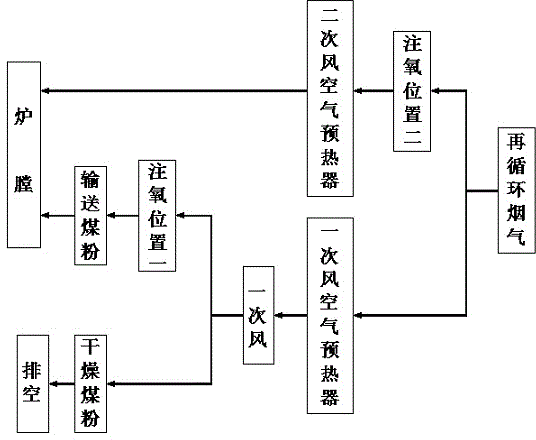

Low-temperature furnace smoke sucking exhaust gas and hot air drying composite powder feeding bituminous coal and meagre coal universal type powder preparing system

ActiveCN101761933ALow oxygenReduce the temperatureGrain treatmentsLump/pulverulent fuel feeder/distributionAir preheaterPowder mixture

The invention relates to a low-temperature furnace smoke sucking exhaust gas and hot air drying composite powder feeding bituminous coal and meagre coal universal type powder preparing system. A middle bin storage type steel ball coal mill hot air power feeding and meagre coal power preparation system is adopted as a prototype, and part of low-temperature furnace smoke is sucked from an outlet of a suction fan by a furnace smoke fan as an inert medium and part of drying mediums to be mixed with hot air taken from an outlet of an air preheater to enter a coal mill for drying and delivering coal powder; the oxygen content of the powder preparation system is reduced, and the explosion preventing requirement on grinding bituminous coal can be met. In addition, part of exhaust gas at an outlet of a power exhauster is led to an inlet of a heat primary fan by an exhaust gas transfer pipeline to be mixed with hot air to enter a primary bellows for delivering the coal powder; the temperature of a primary air and powder mixture and the oxygen concentration of the system are effectively reduced, and the combustion and explosion preventing requirement of bituminous coal delivery is met. Isolating doors are both installed on a furnace smoke system and an exhaust gas transfer system; by the switch control of the isolating doors, the switching of a typical hot air power feeding meagre coal system and a low-temperature furnace smoke exhaust gas and hot air drying composite powder feeding bituminous coal system is realized, and the invention is not only suitable for the meagre coal, but also suitable for the bituminous coal.

Owner:XIAN THERMAL POWER RES INST CO LTD

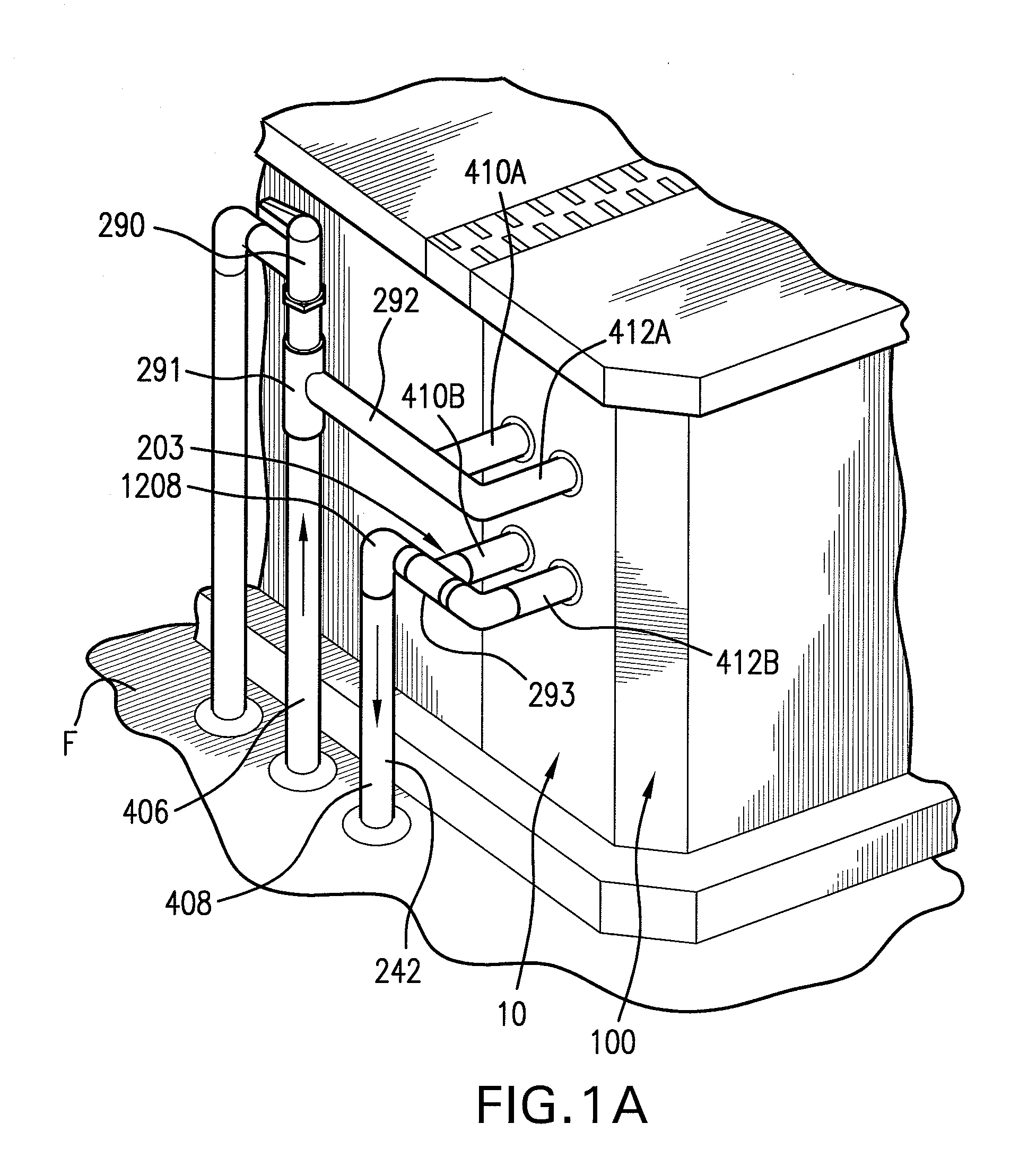

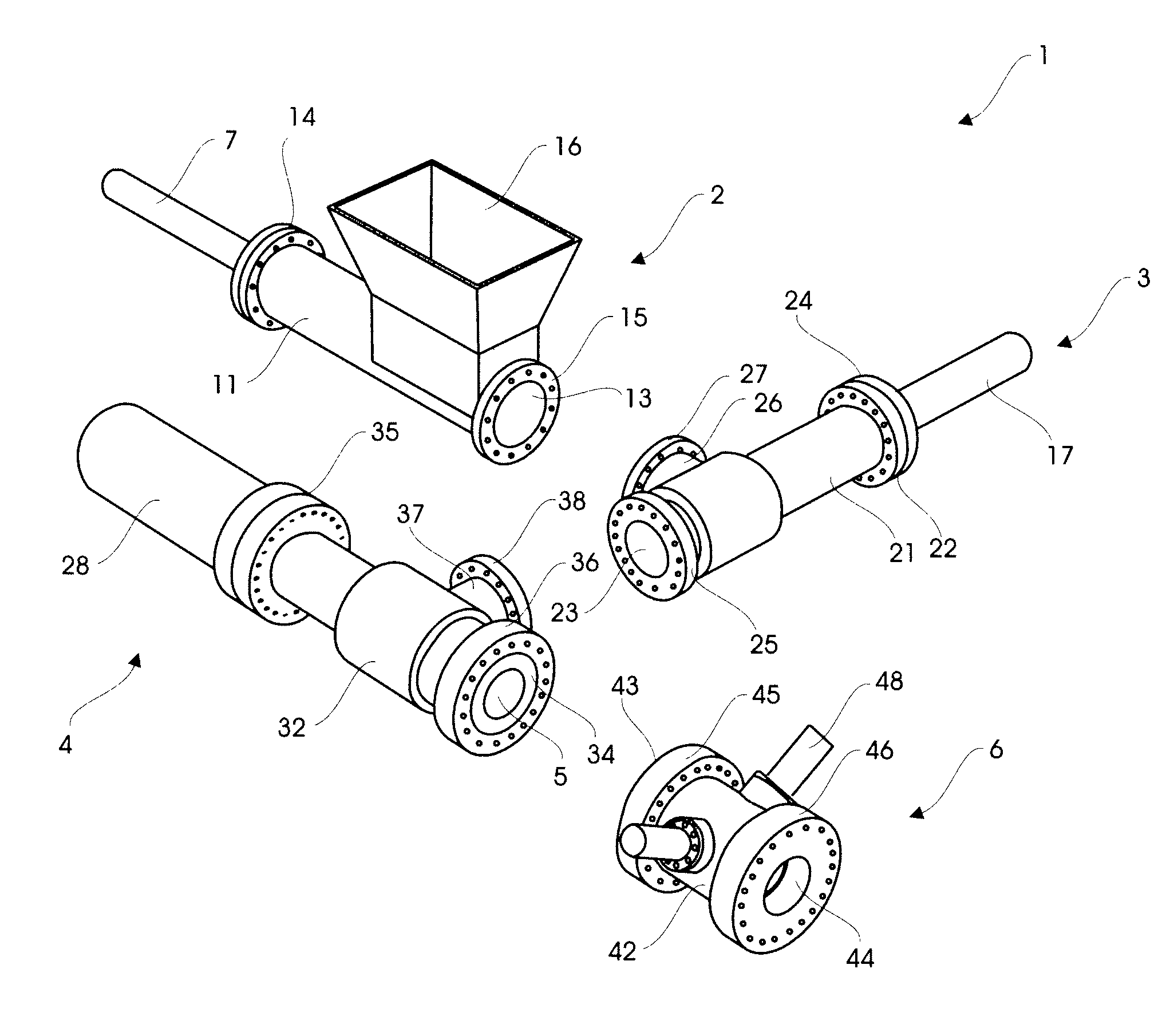

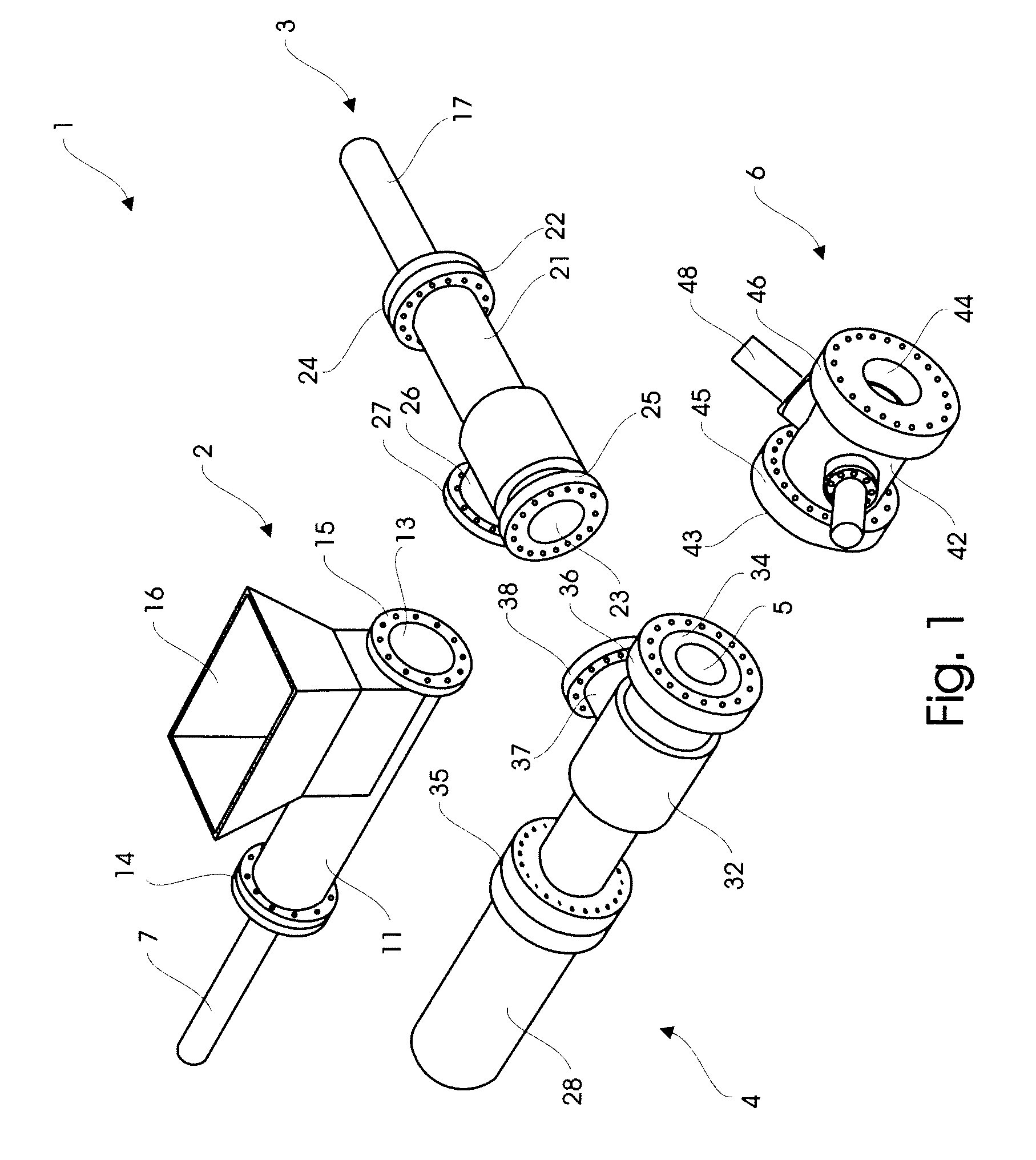

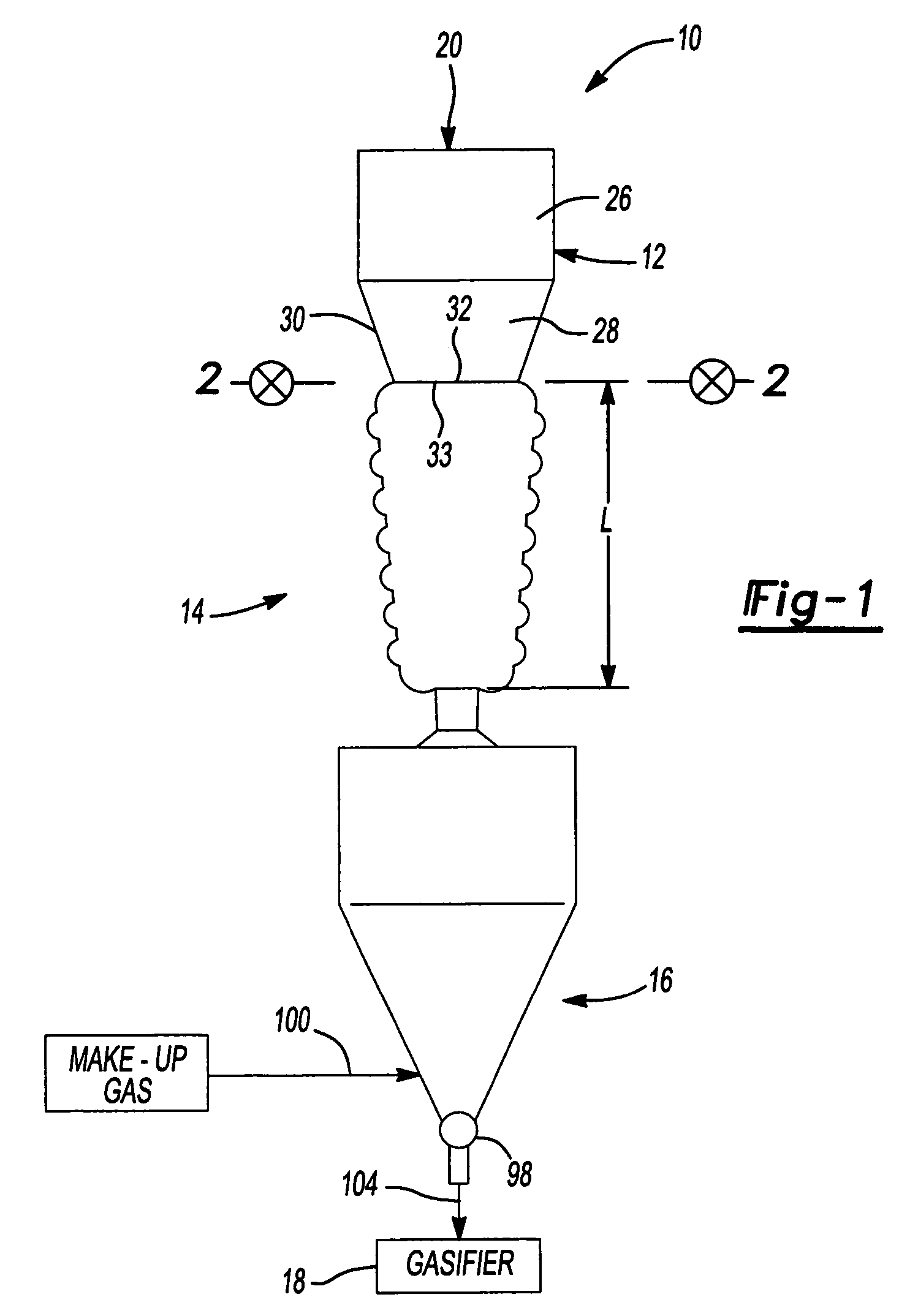

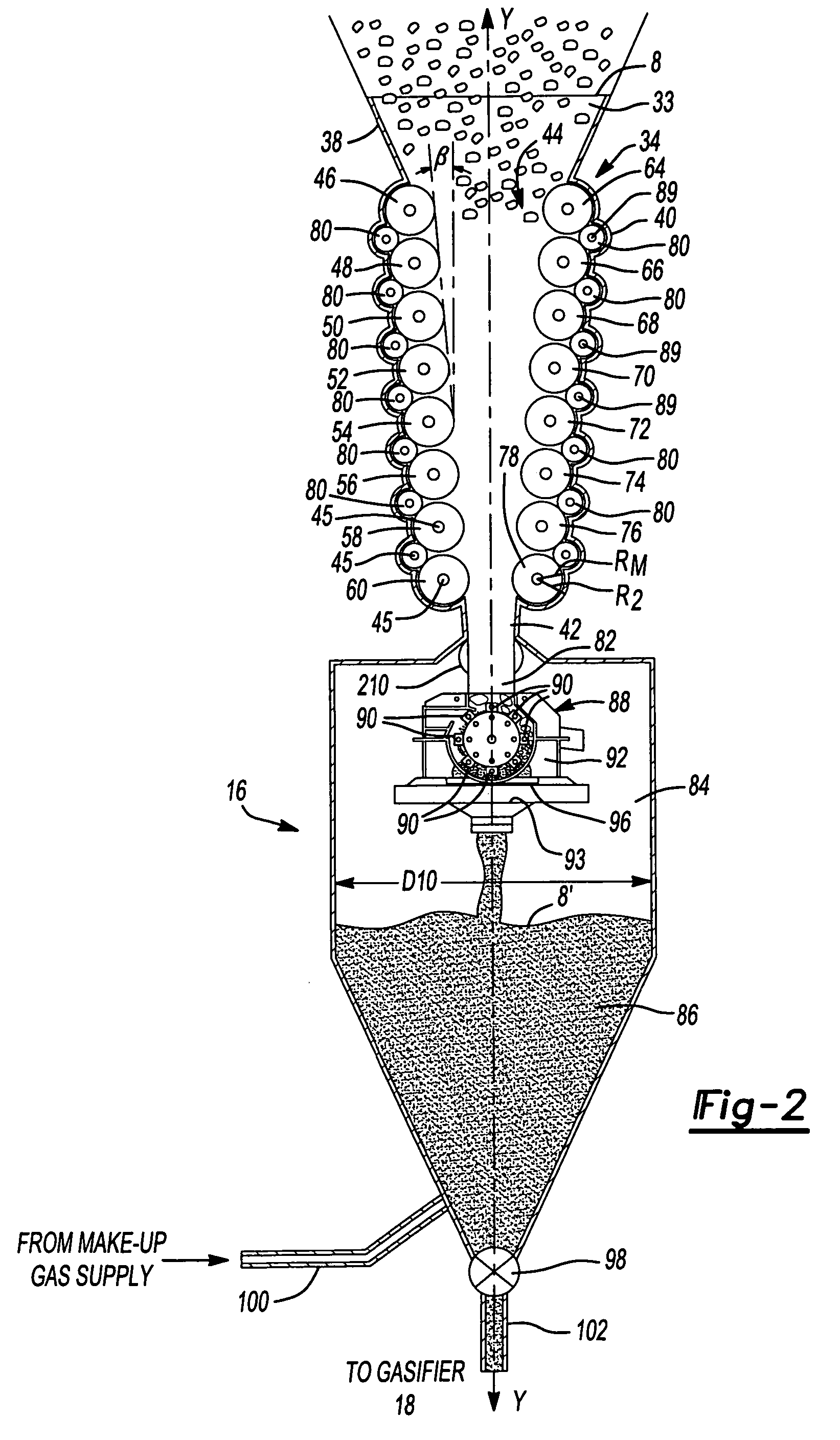

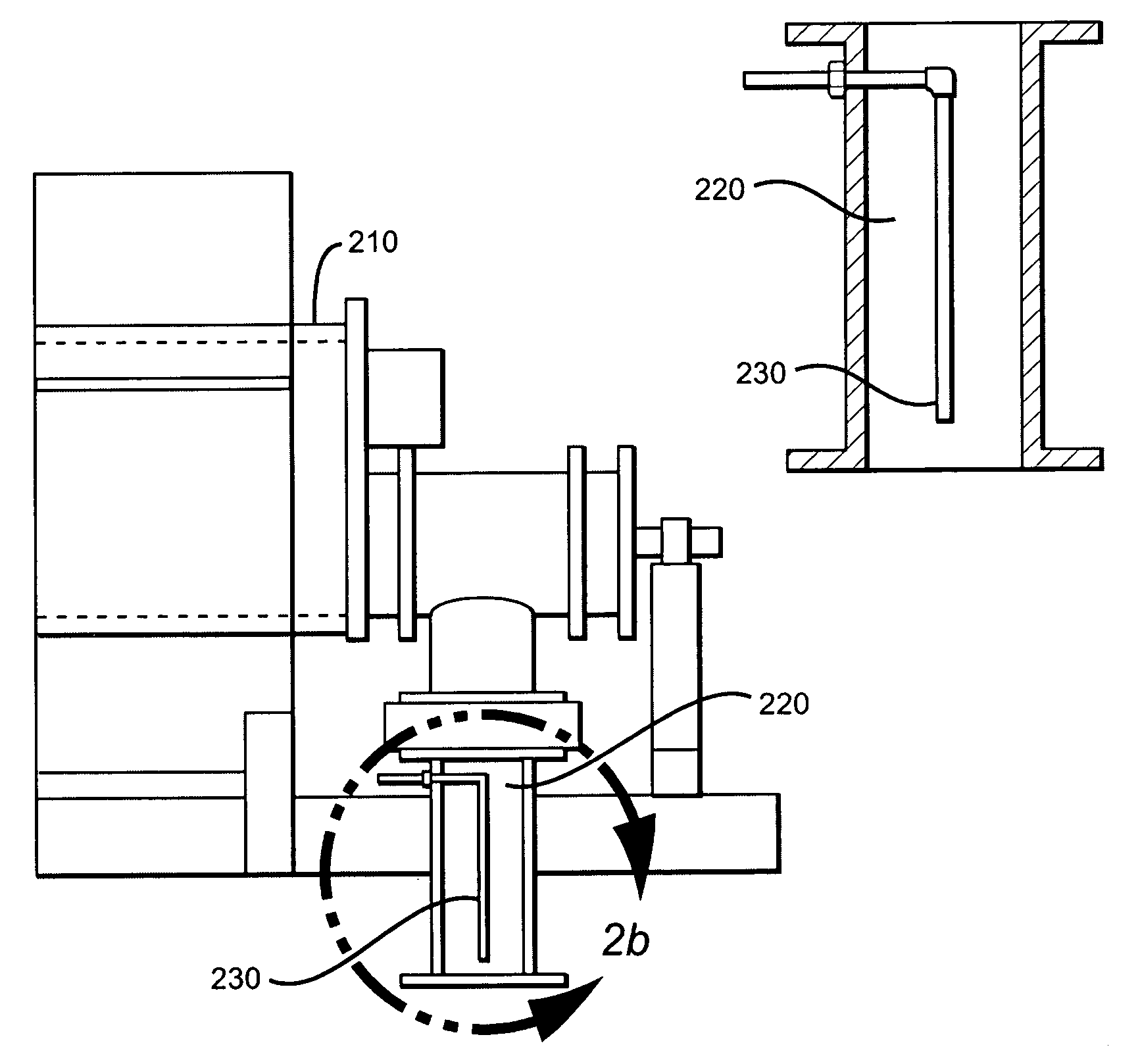

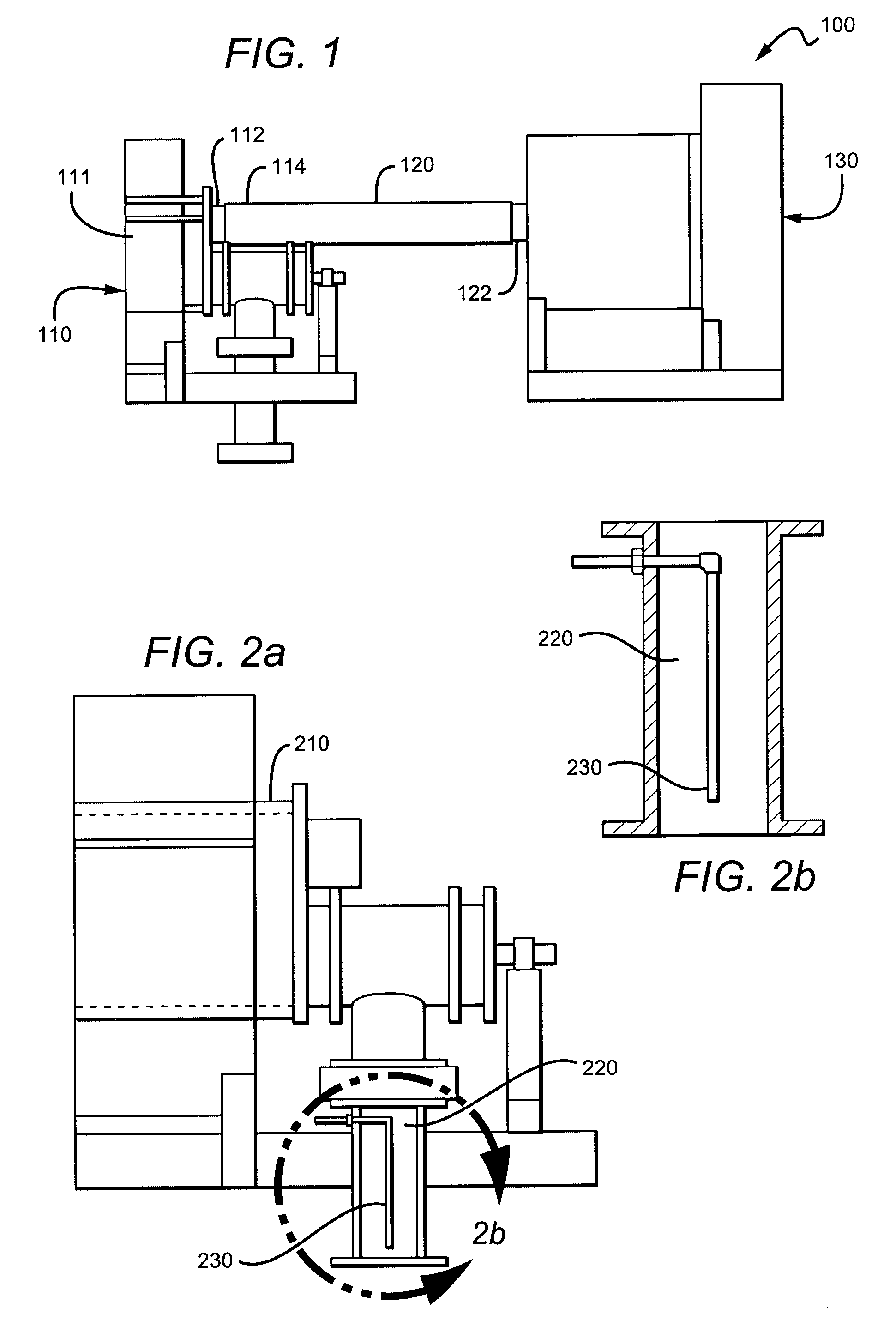

Method and apparatus for continuously feeding and pressurizing a solid material into a high pressure system

A system for substantially continuously providing a solid material, for example pulverized coal, to a pressurized container. The system provides the solid material to a first container of a first pressure elevated above an initial pressure of the solid material. Generally, a screw conveyor augmented with a jet port is used to move the material where the jet port provides a gas to provide a make-up volume of the solid material. The system also provides the material to a second high pressure container after the material has been formed into a slurry. Therefore, the solid material may be substantially continuously provided in a system to a high pressure container.

Owner:THE BOEING CO +1

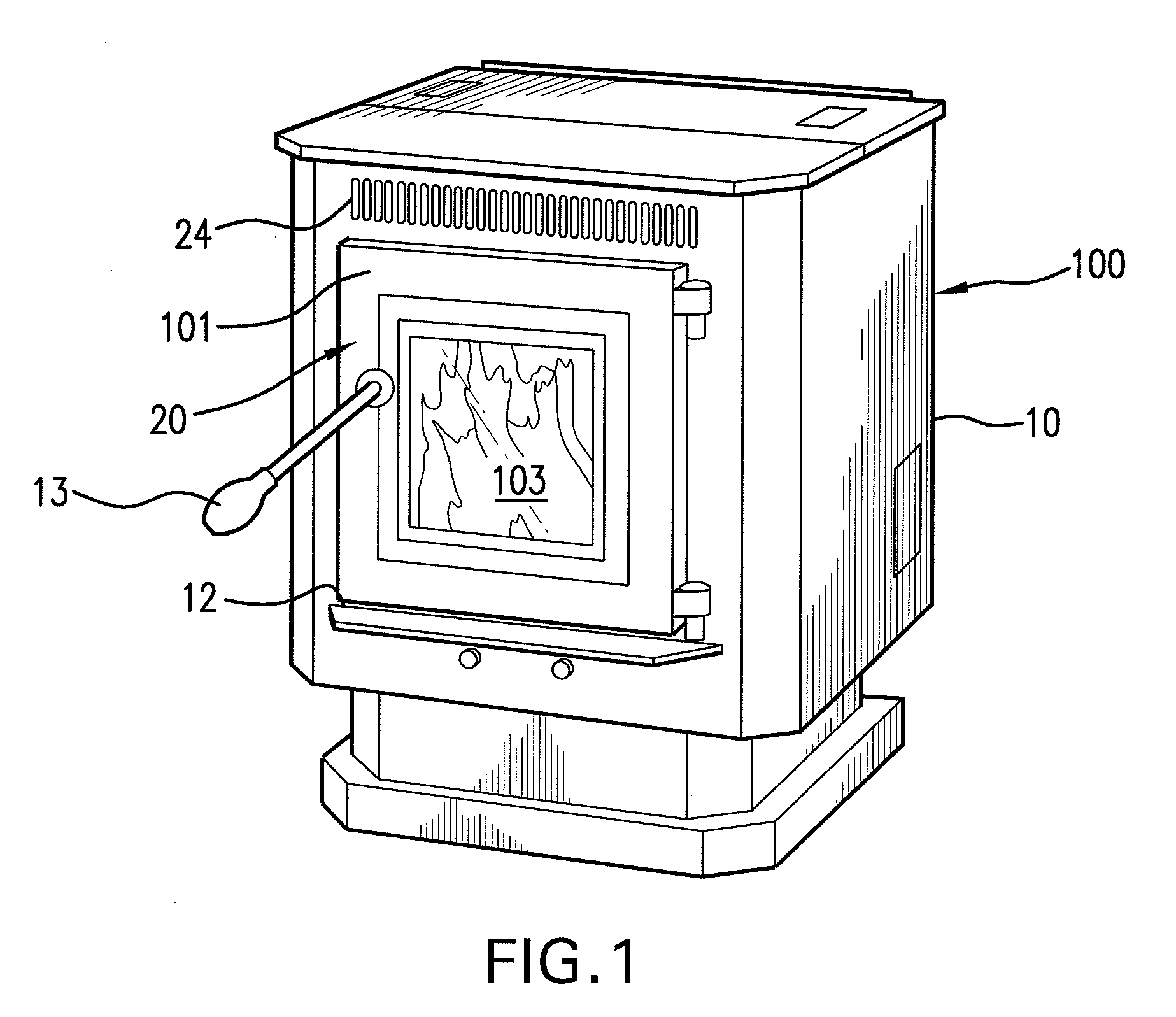

Fluid heating system

ActiveUS20100251973A1Facilitate control of fluid flowAvoid the needMechanical apparatusDomestic stoves or rangesEngineeringBiological activation

A fluid heat exchange system with a fluid flow circuit having a heat exchange fluid flow loop, a heat absorption component (as in a domestic hot water tank inclusive of small commercial use tanks as in tanks of 20 to 120 gallons), a heat exchanger and preferably also a pump. A controlled and automated fuel supply source based heater (as in a pellet stove) is in heat passage communication with the said heat exchanger. A control unit triggers activation of the pump upon fluid in the heat absorption component reaching or dropping below a preset temperature, and the fluid flow circuit is arranged such that, during times of non-activation of the pump, fluid is free to flow in a unidirectional flow within the fluid circuit based on thermodynamic temperature differentials alone. A retrofitting of a domestic hot water tank is also featured preferably making use of preexisting drain and safety vent porting for in-feed and out-feed porting in the exchange loop side. Also, the flow circuit preferably is free of check valves and steam accommodation equipment.

Owner:DONGO KENNETH A +1

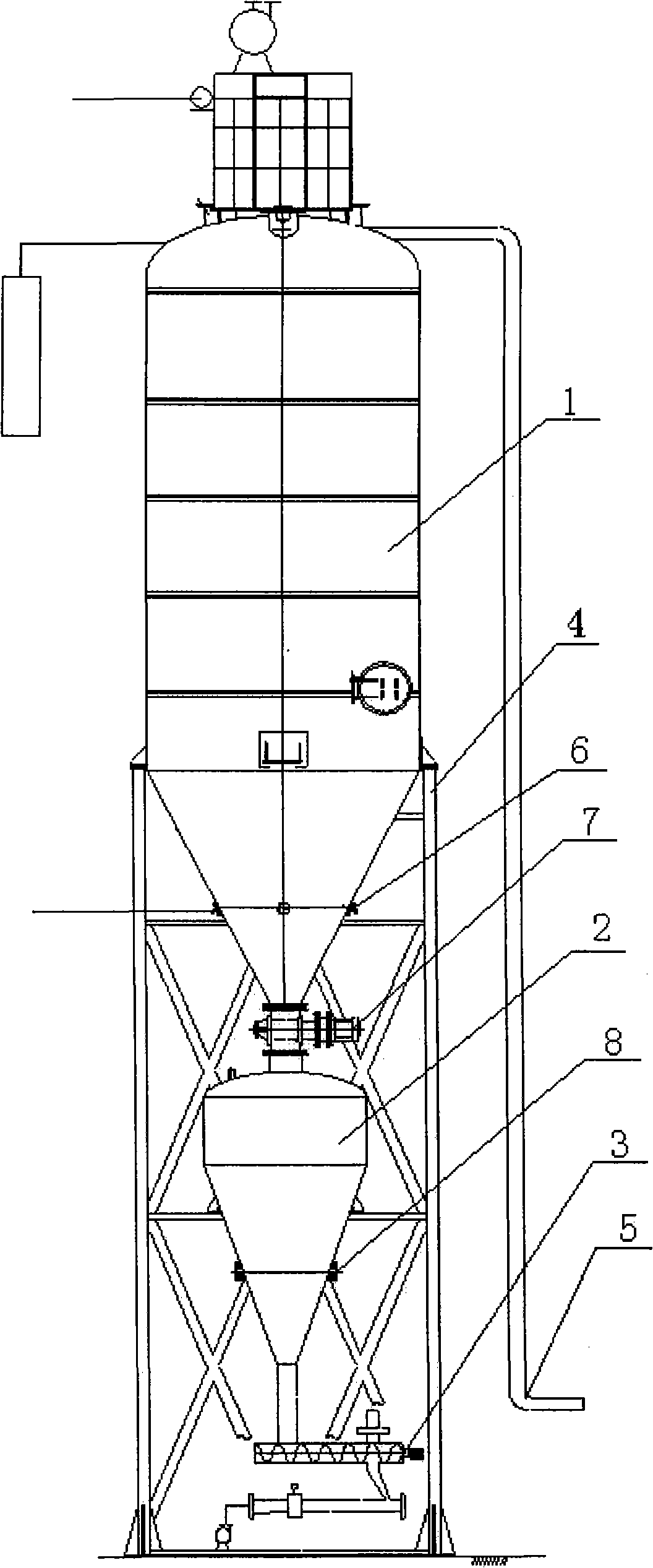

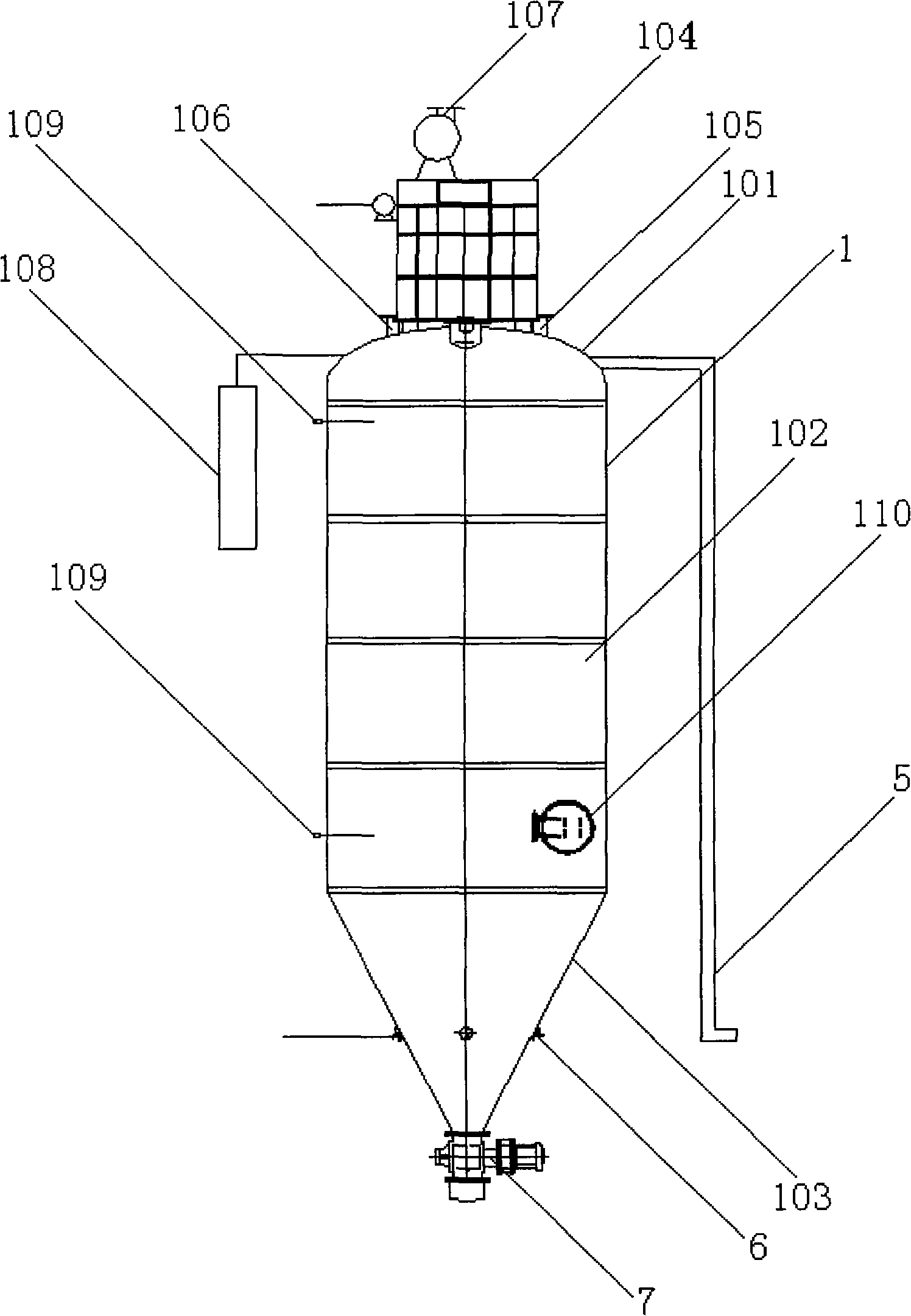

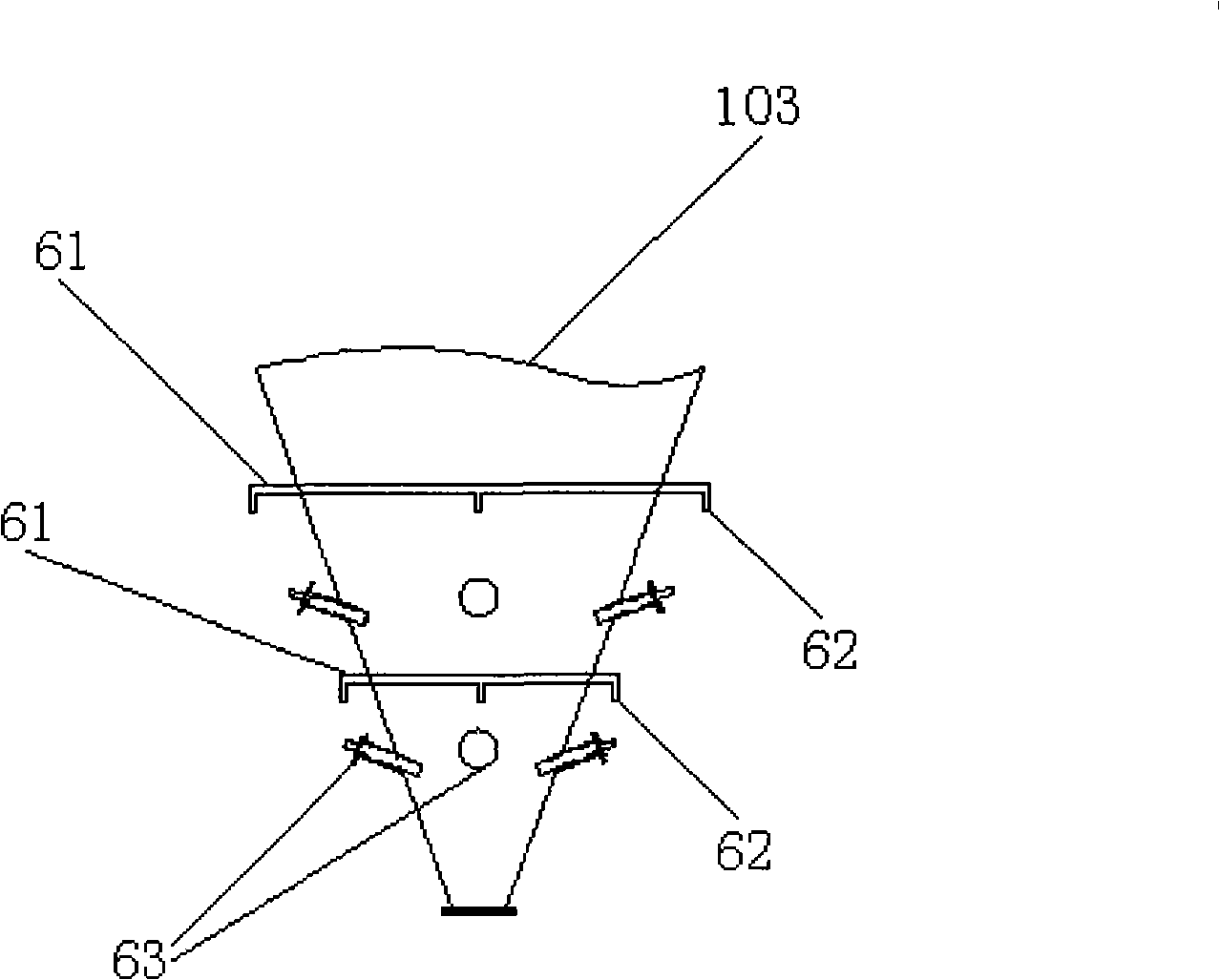

Combined coal powder storage and supply system

The invention relates to a combined coal powder storage and supply system which comprises a coal powder storage tank, a weighing coal powder supply silo, a pulse-free coal powder supply device and a support; the coal powder storage tank is vertically arranged at the top of the support, the weighing coal powder supply silo is vertically arranged on the support below the coal powder storage tank, the pulse-free coal powder supply device is arranged below a discharging opening of the weighing coal powder supply silo, and a flexible connector in the center at the top of a sealing head of the weighing coal powder supply silo is connected with a discharging opening of the coal powder storage tank through a rotary valve; and a fluidization component is arranged on the outer wall of a conical hopper of the coal powder storage tank, and a coal powder anti-arching stirring device is arranged on a hopper of the weighing coal powder supply silo. The invention has compact structure, reasonable layout, automatic feeding and stable supply and can solve the problems frequently existing in the ordinary coal storage silo and the supply silo of birdnesting, bridging, rat hole, channeling, wall build-up, breakage, self combustion, and the like; and the invention can be widely used in any situation where the small and medium-sized industrial coal powder boilers are required.

Owner:CHINA COAL RES INST CCRI ENERGY SAVING TECH CO LTD

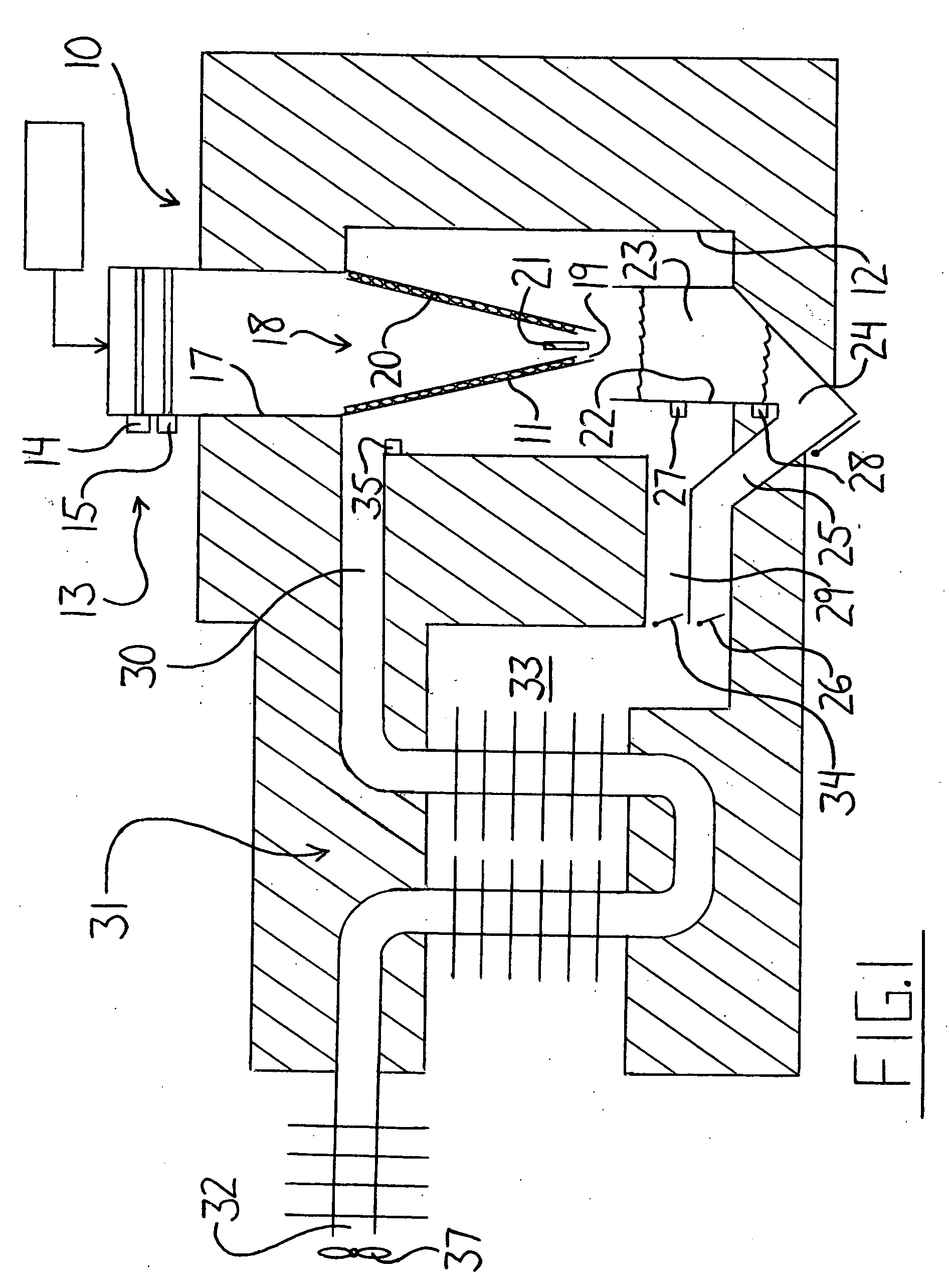

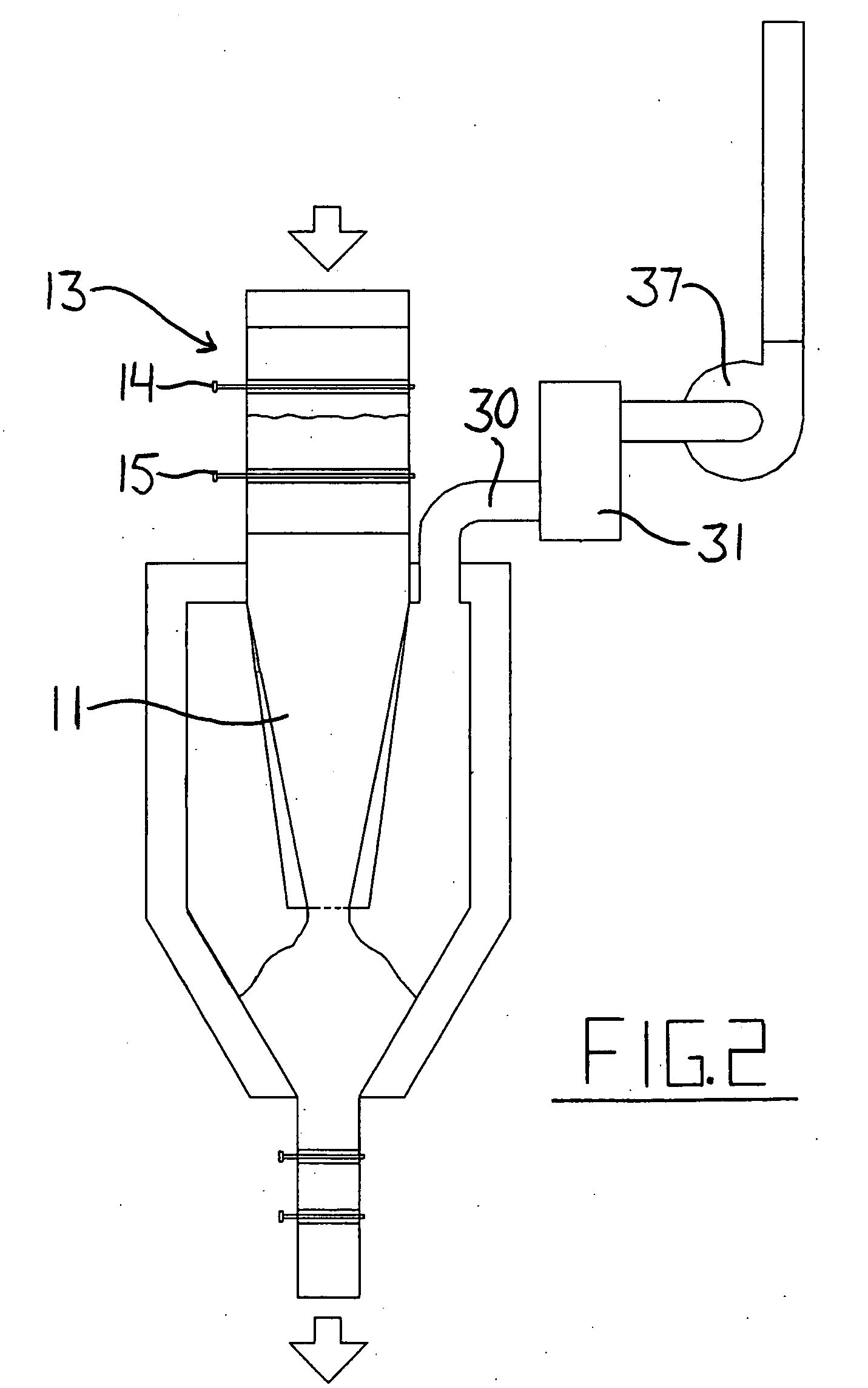

Gasifier and gasifier system for pyrolizing organic materials

InactiveUS7976593B2Lower buildCost of operationMuffle furnacesGasifier mechanical detailsMechanical engineeringEngineering

A gasifier and gasifier system based on the gasifier, which contains as a major component, a novel feed system for feeding organic materials into the burn pile of the gasifier. The gasifier feed system is a horizontal auger driven feed system that feeds directly through a ceramic elbow into the furnace without having to auger the feed through significant vertical elevations.

Owner:HEAT TRANSFER INT

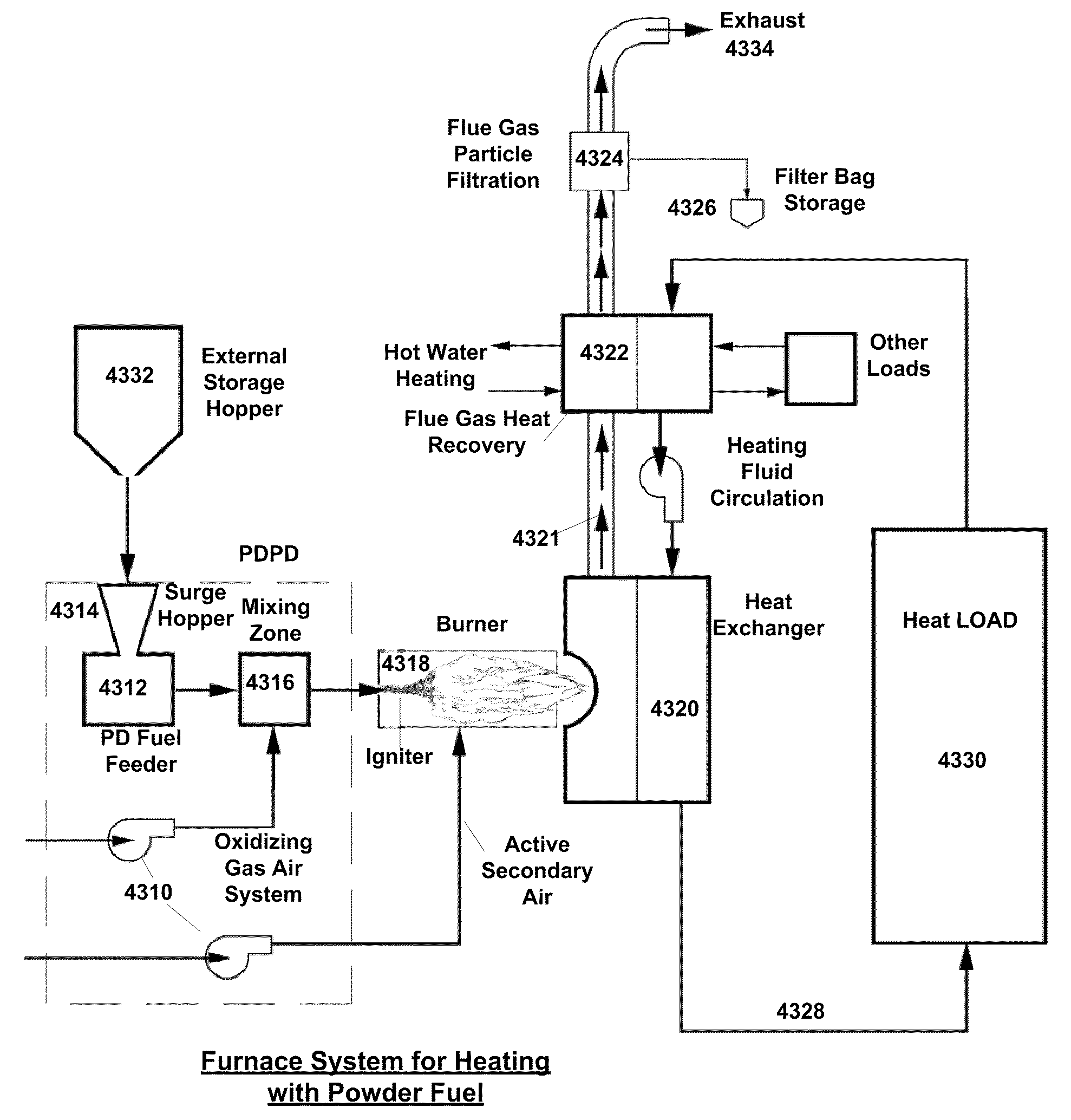

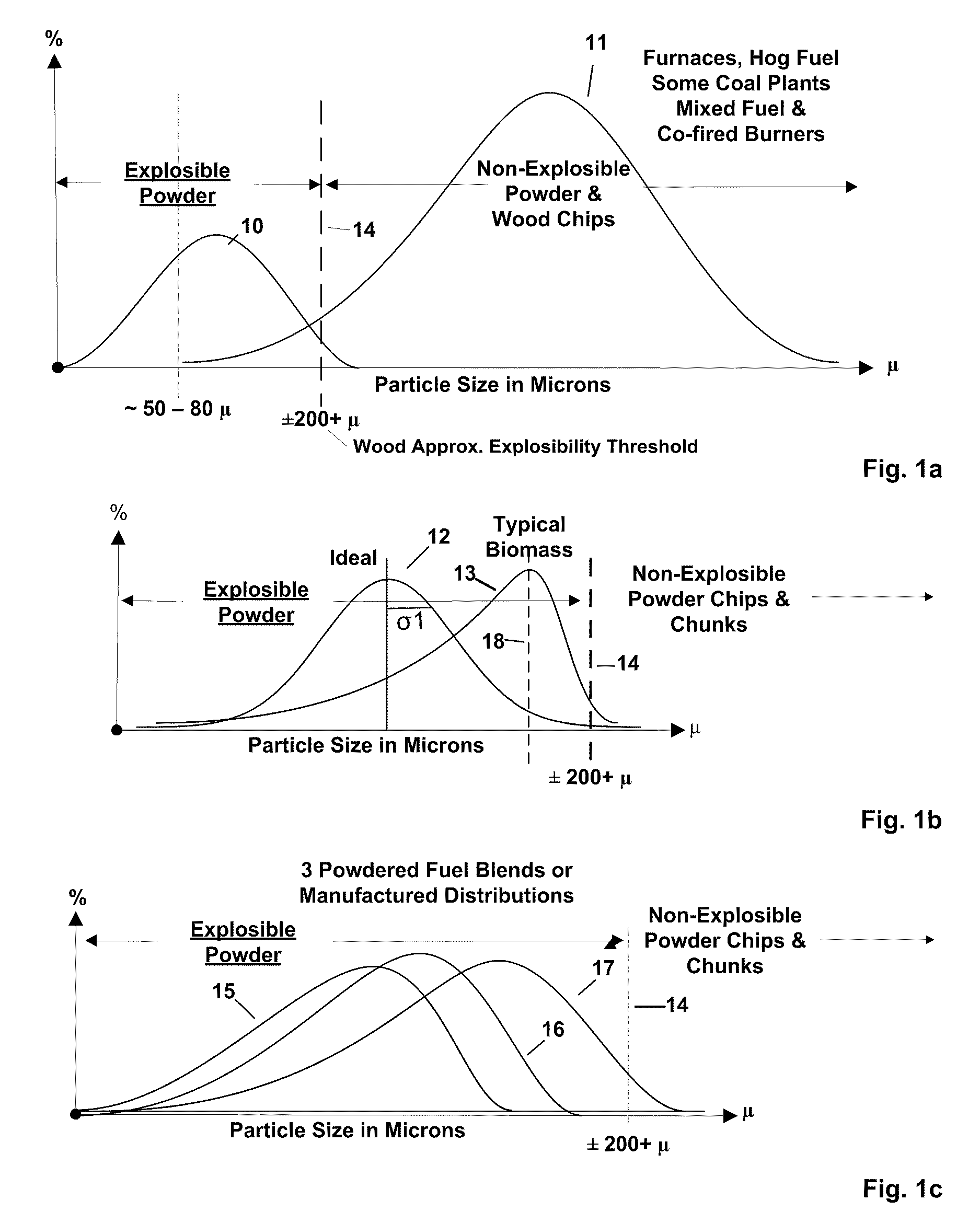

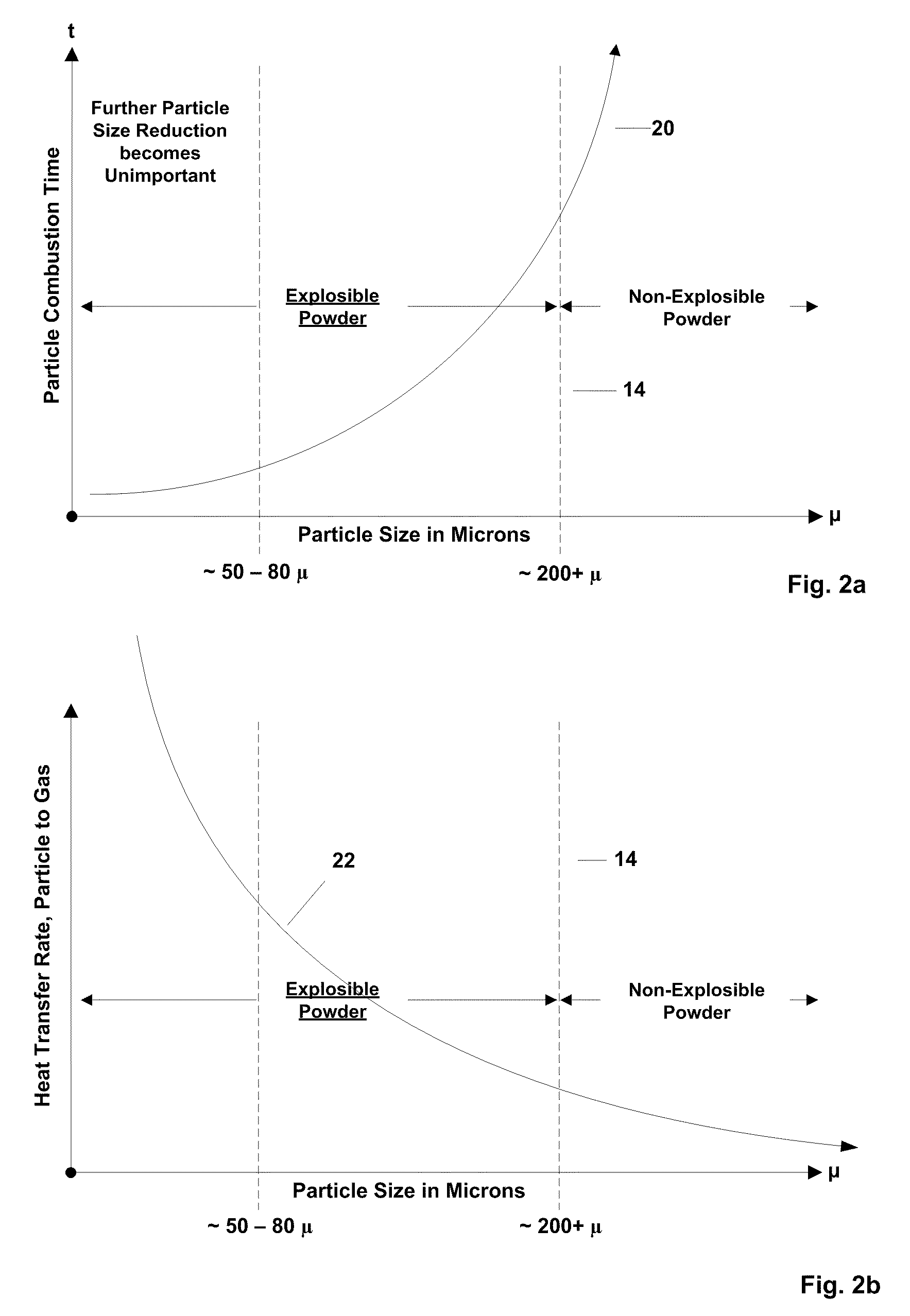

Powdered fuel conversion systems and methods

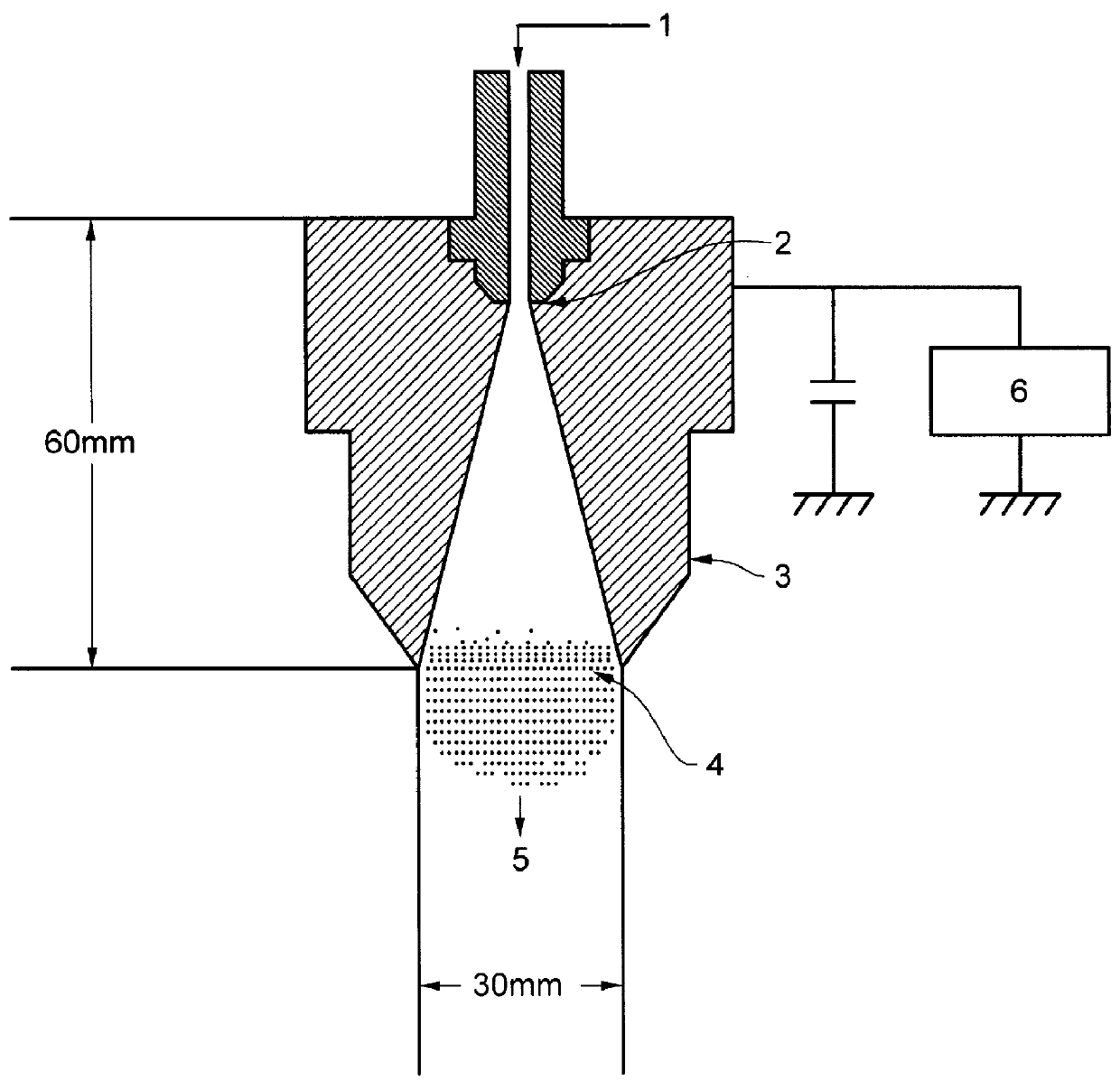

The burner preferably exclusively burns substantially explosible solid fuels and preferably has instant ON-OFF thermostat control, wastes no energy preheating the enclosure or external air supply, achieves stable combustion the moment the powder-air mix is ignited in our burner, is used in the upward vertical mode except for oil burner retrofits, burns a solid fuel in a single-phase regime as if it were a vaporized liquid or gas, is designed to complete combustion within the burner housing itself rather than in a large, high temperature furnace enclosure which it feeds, has an ultra-short residence time requirement, is a recycle consuming burner with self-contained management of initially unburned particles, is much smaller, simpler and lower cost, has a wider dynamic range / turndown ratio, is more efficient in combustion completeness and thermal efficiency, and operates with air-fuel mix approximately at the flame speed.

Owner:MCKNIGHT JAMES K +2

Method and burner apparatus for injecting a pulverized coal into rotary kilns, method and apparatus for producing cao using them

InactiveUS20060169181A1Reduce concentrationMinimize diameter variationPigmenting treatmentSolid fuel pretreatmentCombustorEngineering

The invention relates to a method and burner for injecting pulverized coal into a rotary kiln that uses pulverized coal as fuel in order to produce quick lime of excellent hydration level. The invention calcines lime stone charged into the rotary kiln, and uses pulverized coal as fuel of a heat source applied to the lime stone charged in the rotary kiln. The invention also provides a method and apparatus for producing quick lime by using the pulverized coal. The invention can use pulverized fossil fuel (hereinafter will be referred to as pulverized coal), which is created during coke manufacturing and cooling processes and collected by a dust collector, in order to produce quick lime of excellent hydration level while decreasing SOx (sulfide) and NOx (nitride) generation.

Owner:POHANG IRON & STEEL CO LTD

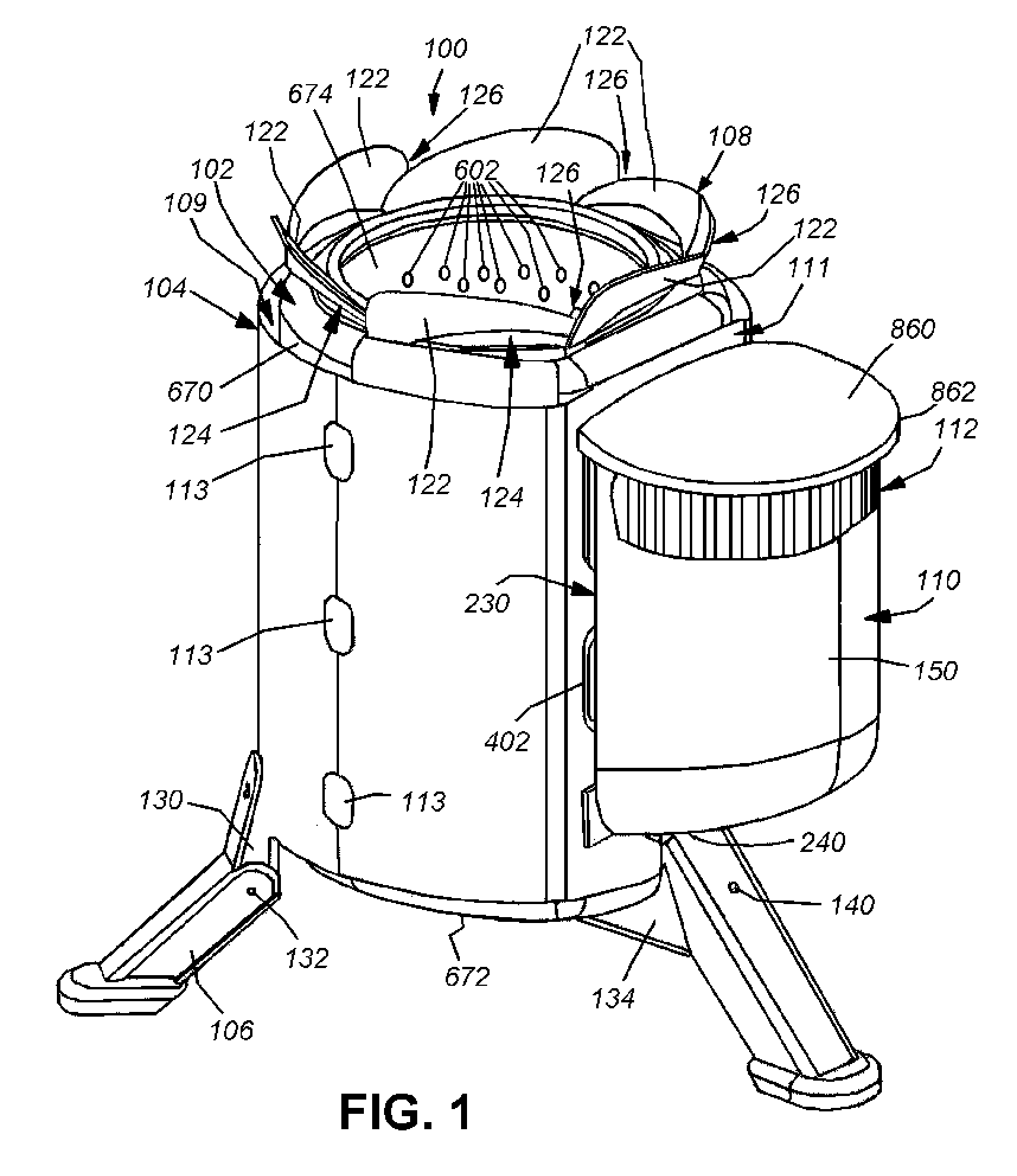

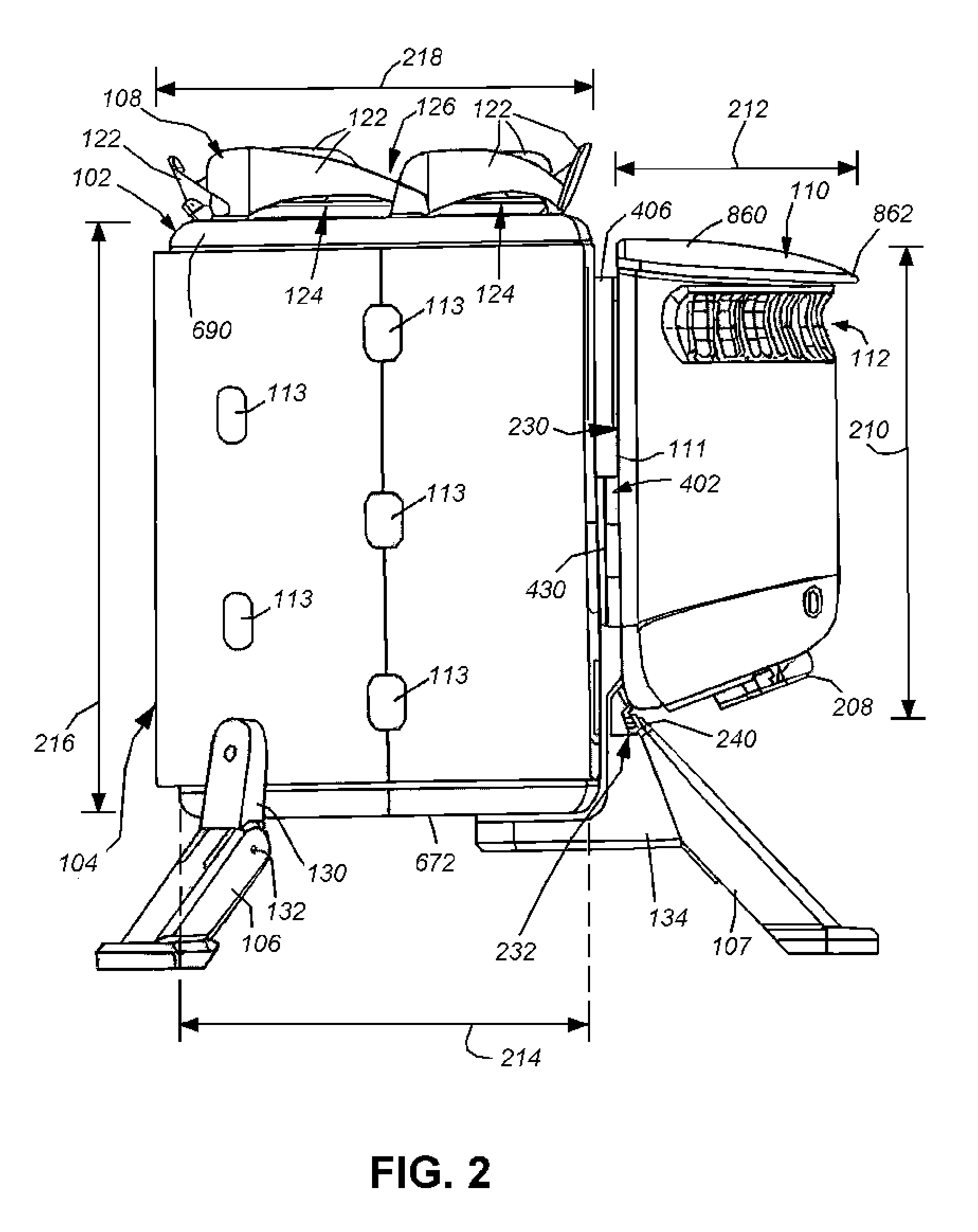

Portable combustion device utilizing thermoelectrical generation

ActiveUS20130112187A1Reduces kindling periodEfficient combustionTobacco treatmentThermoelectric device with peltier/seeback effectCelluloseCombustion chamber

This invention provides a portable combustion device that provides a cleaner combustion, reduces the kindling period, and provides a more efficient overall combustion through the use of a fan that directs a predetermined volume of airflow over the combustible fuel—typically wood or similar cellulose-based biological solids. The combustion device has a combustion chamber with a fuel source. A housing encloses the TEG on the side of the device that generates an electrical output based on a temperature differential between opposing TEG sides. A heat-conducting probe is mounted to the TEG and protrudes into the combustion chamber. The opposing TEG side contacts a heat sink that interacts with ambient air. A fan draws heated air away the heat sink, and forces the air onto the combusting fuel through a plurality of peripheral ports that connect with an air space located between inner and outer walls of the combustion chamber.

Owner:BIOLITE INC

Feeding apparatus for creation of one or more plugs of compressible material for feeding into a gasifier or reactor

ActiveUS7964004B2Large in humidityDensity variationPressurized chemical processConveyorsCompressible materialCombustion chamber

Owner:TK ENERGI +1

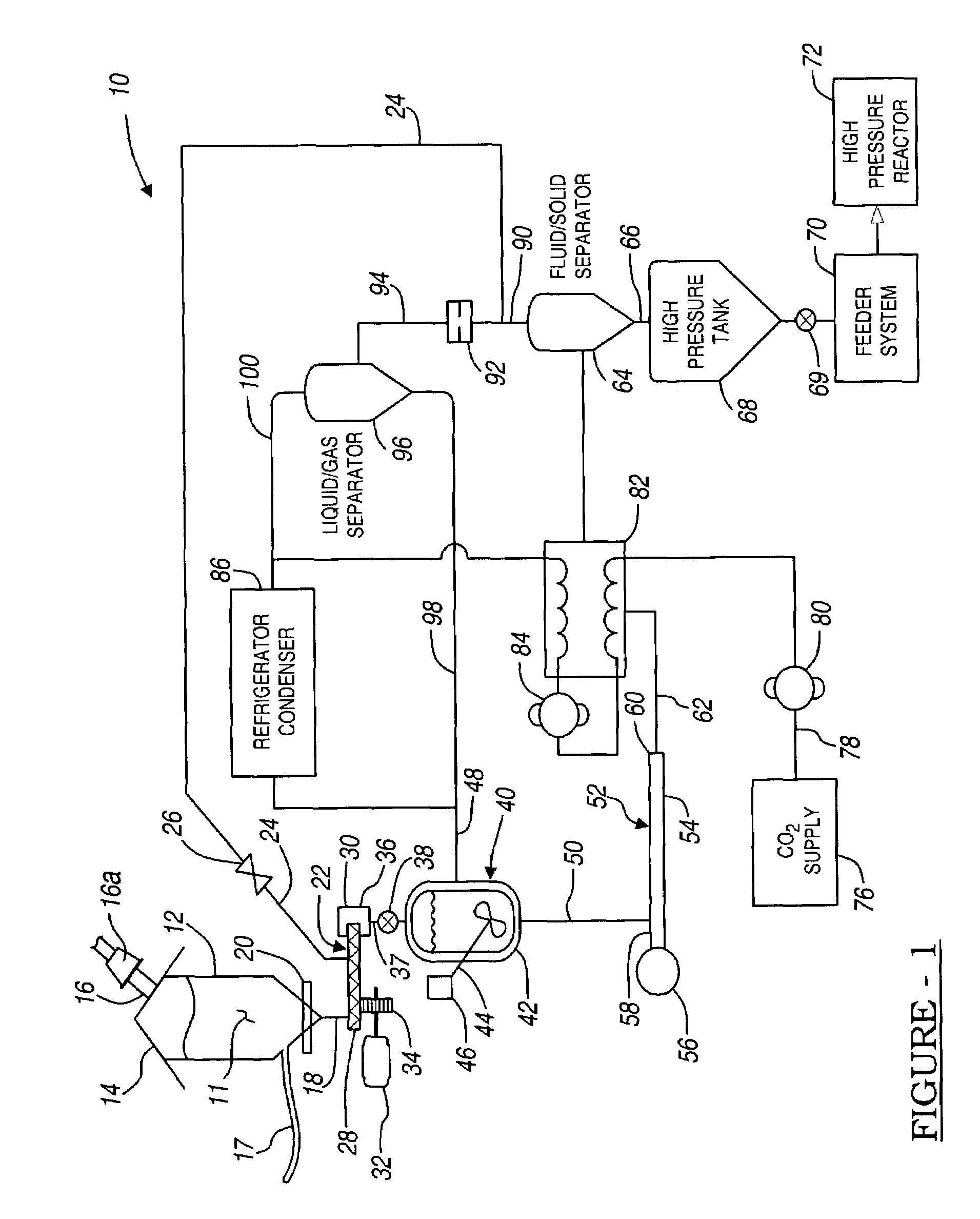

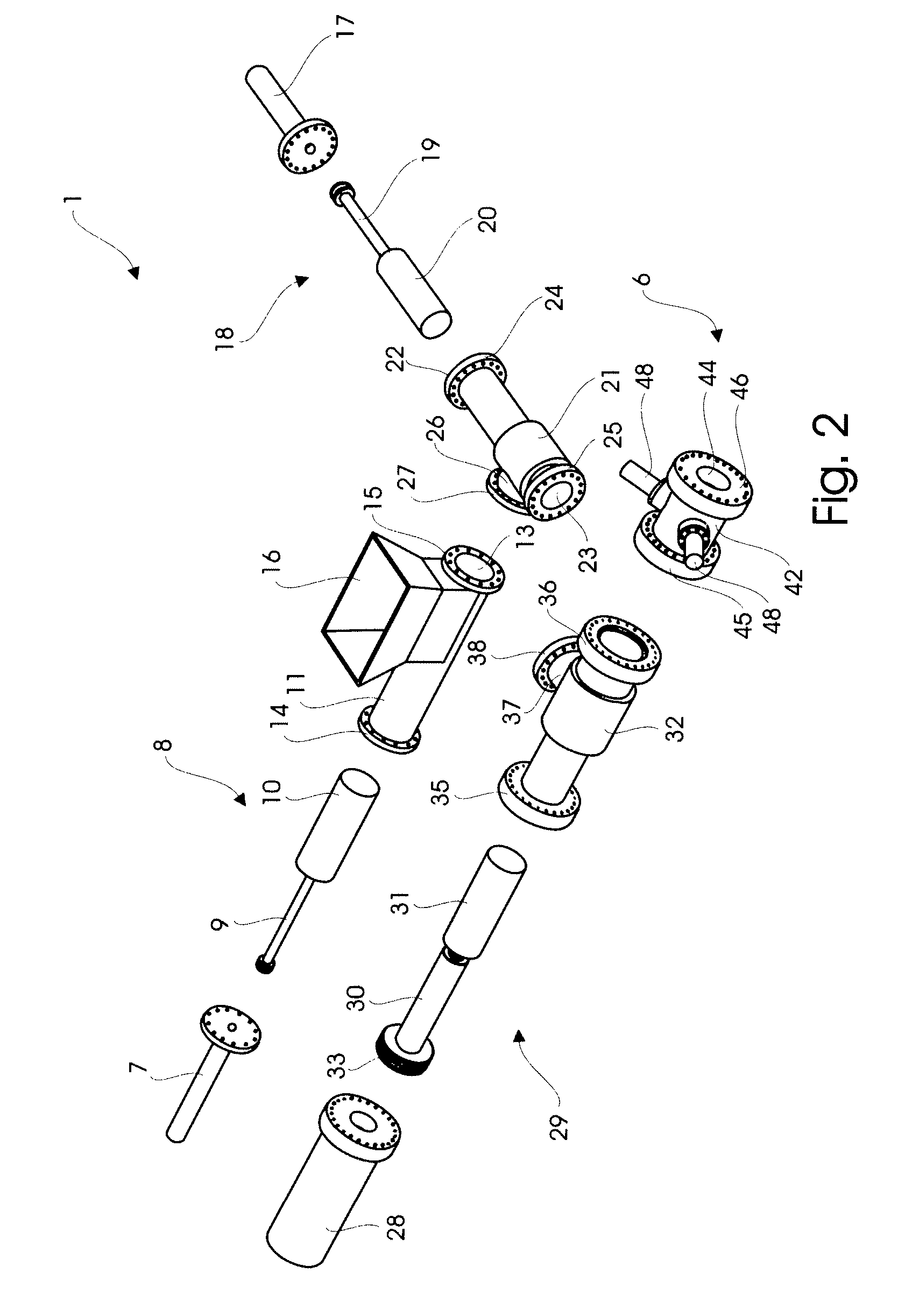

High pressure dry coal slurry extrusion pump

A system for providing highly pressurized raw fuel to a pressure reactor. The system includes an inlet for receiving the raw fuel and a roller system communicating with the inlet. The roller system includes a plurality of independent rollers arranged in two converging planes. The rollers of the roller system successively compress the raw fuel as the raw fuel passes through the roller system between the rollers, such that the fuel is highly pressurized when it reaches an output end of the roller system. An outlet is located adjacent the output end of the roller system to dispense the pressurized raw fuel to the pressure reactor.

Owner:THE BOEING CO +1

Outlets for a pyrolytic waste treatment system

The inventive subject matter is directed toward a pyrolytic waste treatment system comprising an outlet adapted to channel a composition out of a pyrolysis chamber. A mechanism is used for cleaning the outlet during operation of the pyrolytic system.

Owner:APS IP HLDG

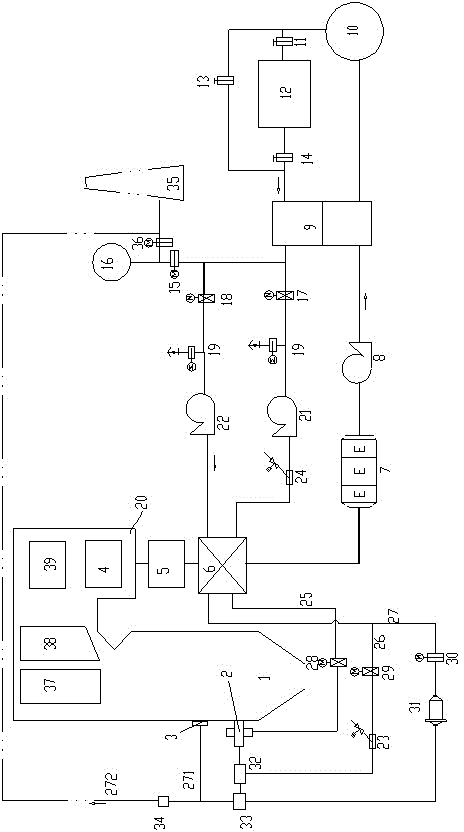

Oxygen-enriched combustion boiler system and operation method thereof

ActiveCN103953921ATaking into account uniformityTake security into considerationIndirect carbon-dioxide mitigationAir/fuel supply for combustionWater vaporEmission standard

The invention discloses an oxygen-enriched combustion boiler system and an operation method thereof. The oxygen-enriched combustion boiler system is capable of meeting the emission standard and retarding device corrosion. A denitration device is arranged between a tail part flue of the oxygen-enriched combustion boiler system and a preheater; a heat radiation smoke outlet of the preheater is connected with a heat radiation smoke inlet of a smoke heat exchanger through a dust remover; a heat radiation smoke outlet of the smoke heat exchanger is connected with a desulfurization device and a smoke cooler in sequence and is then returned to a heat absorption smoke inlet of the smoke heat exchanger; a part of the primary air of a combustor is fed into the combustor through a primary air oxygen injector after passing through the preheater and the rest part of the primary air of the combustor is used for pulverizing; the secondary air of the combustor enters the preheater through a secondary air oxygen injector and then is fed into the combustor. The operation method of the oxygen-enriched combustion boiler system emphatically controls the content of water vapor in recycling smoke and the circulation ratio of the recycling smoke and independently adjusts the oxygen injection ratios and amounts of the primary air and the secondary air. The oxygen-enriched combustion boiler system is environment-friendly and easy to implement, and has both oxygen injection safety and economy performances.

Owner:DONGFANG BOILER GROUP OF DONGFANG ELECTRIC CORP

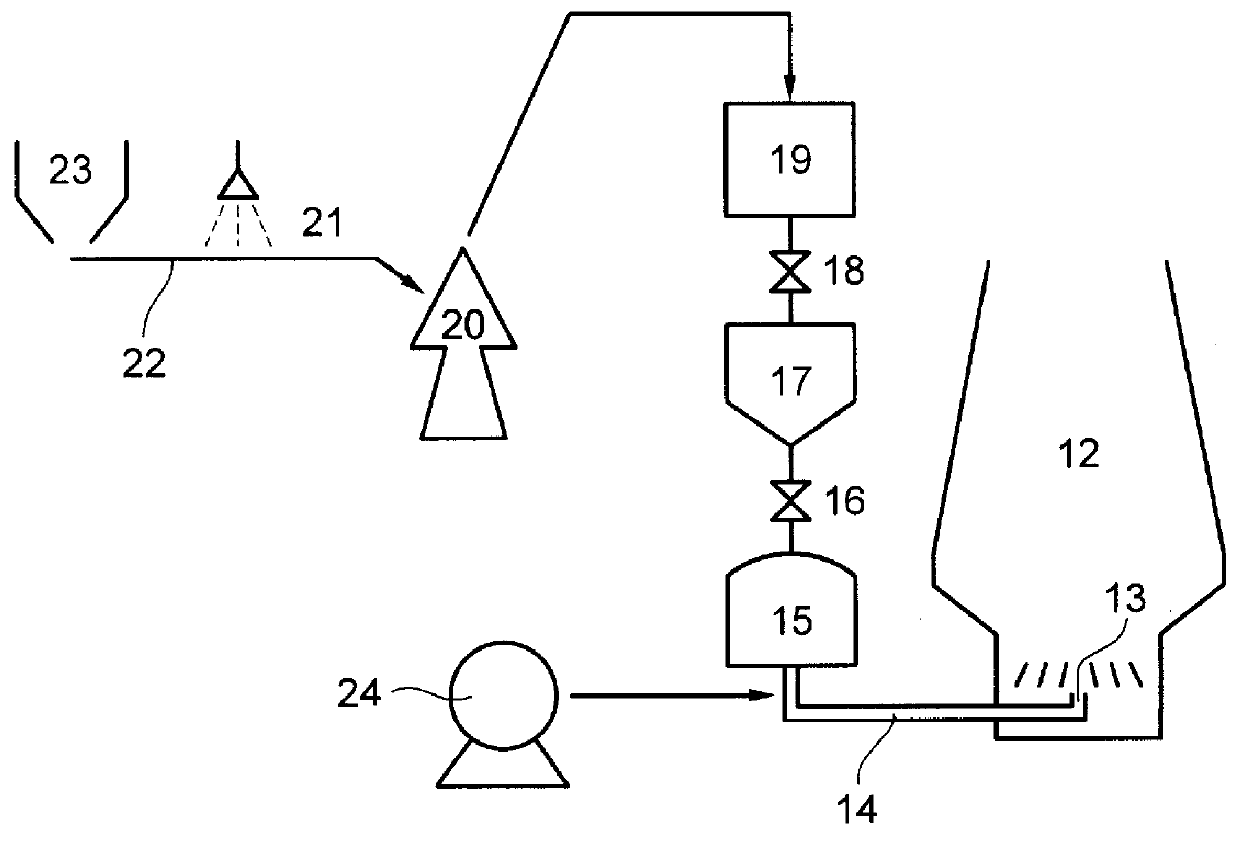

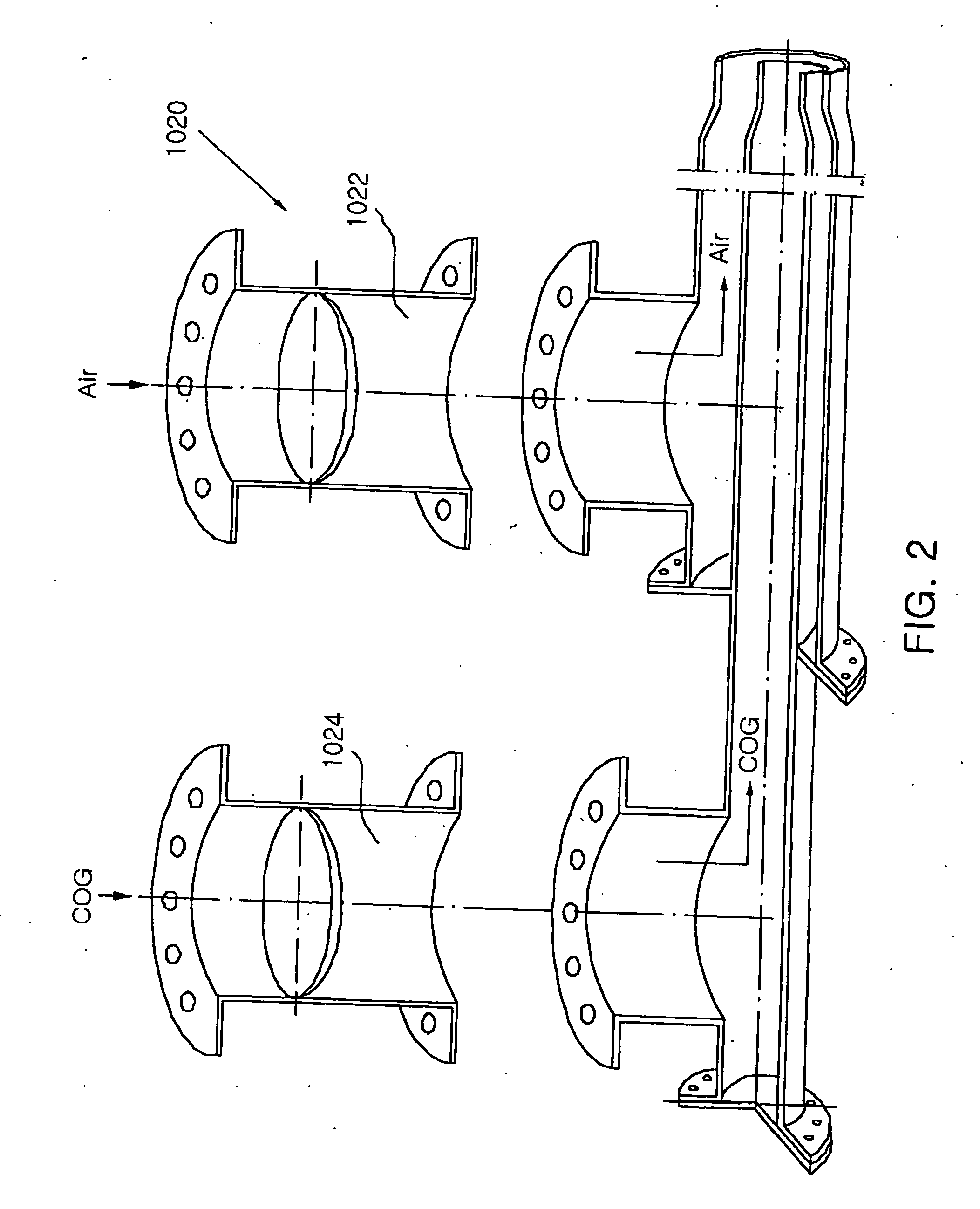

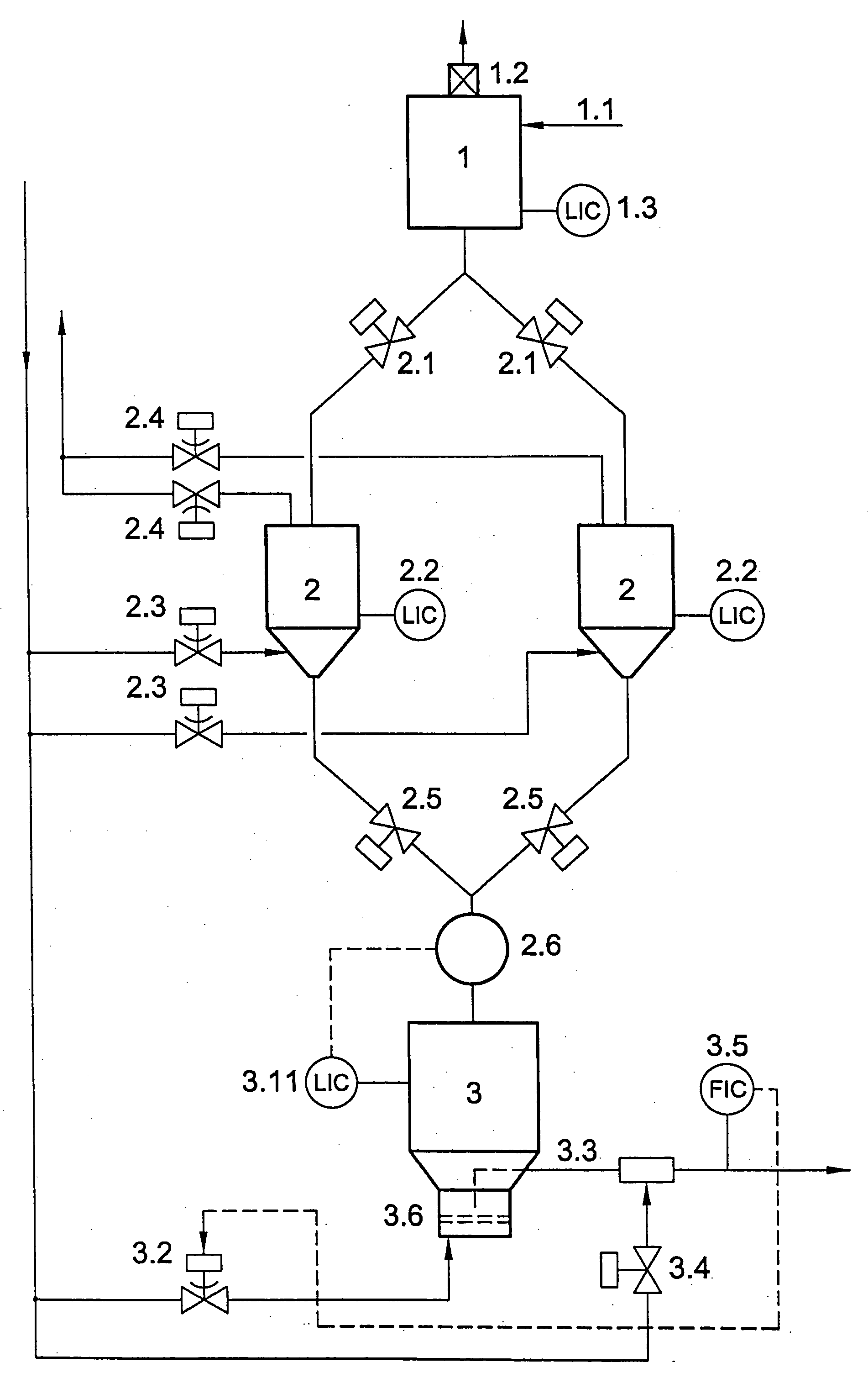

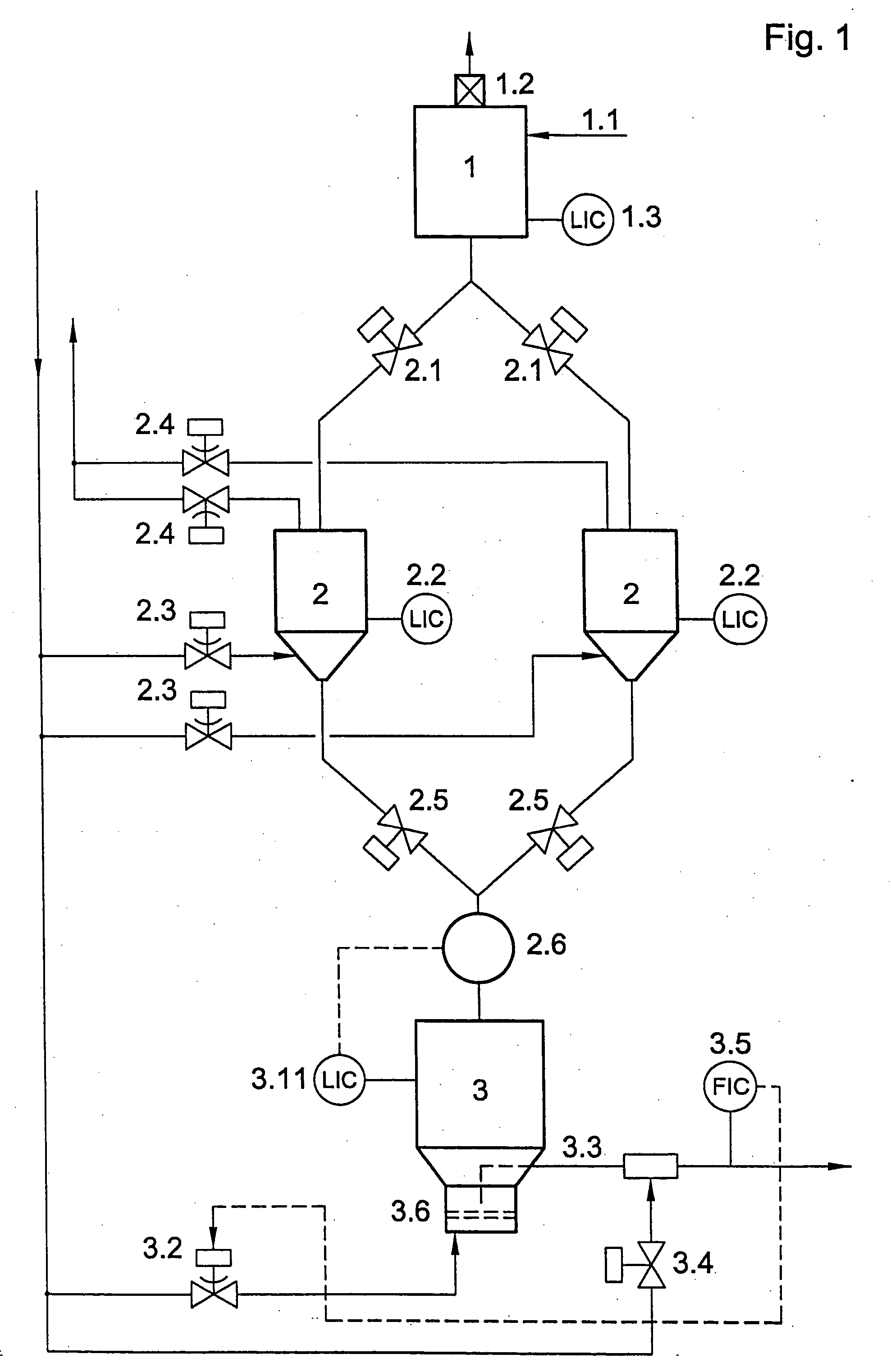

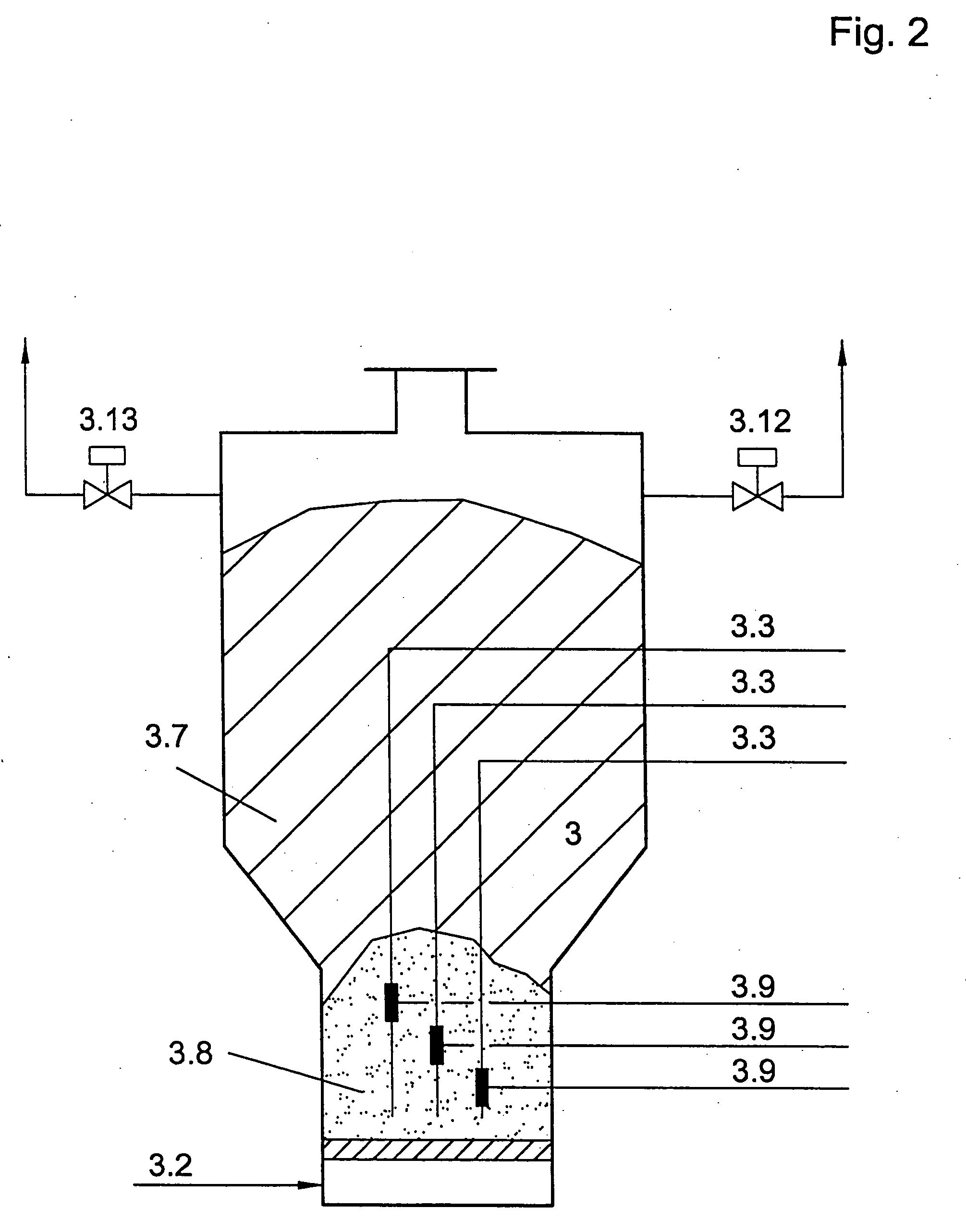

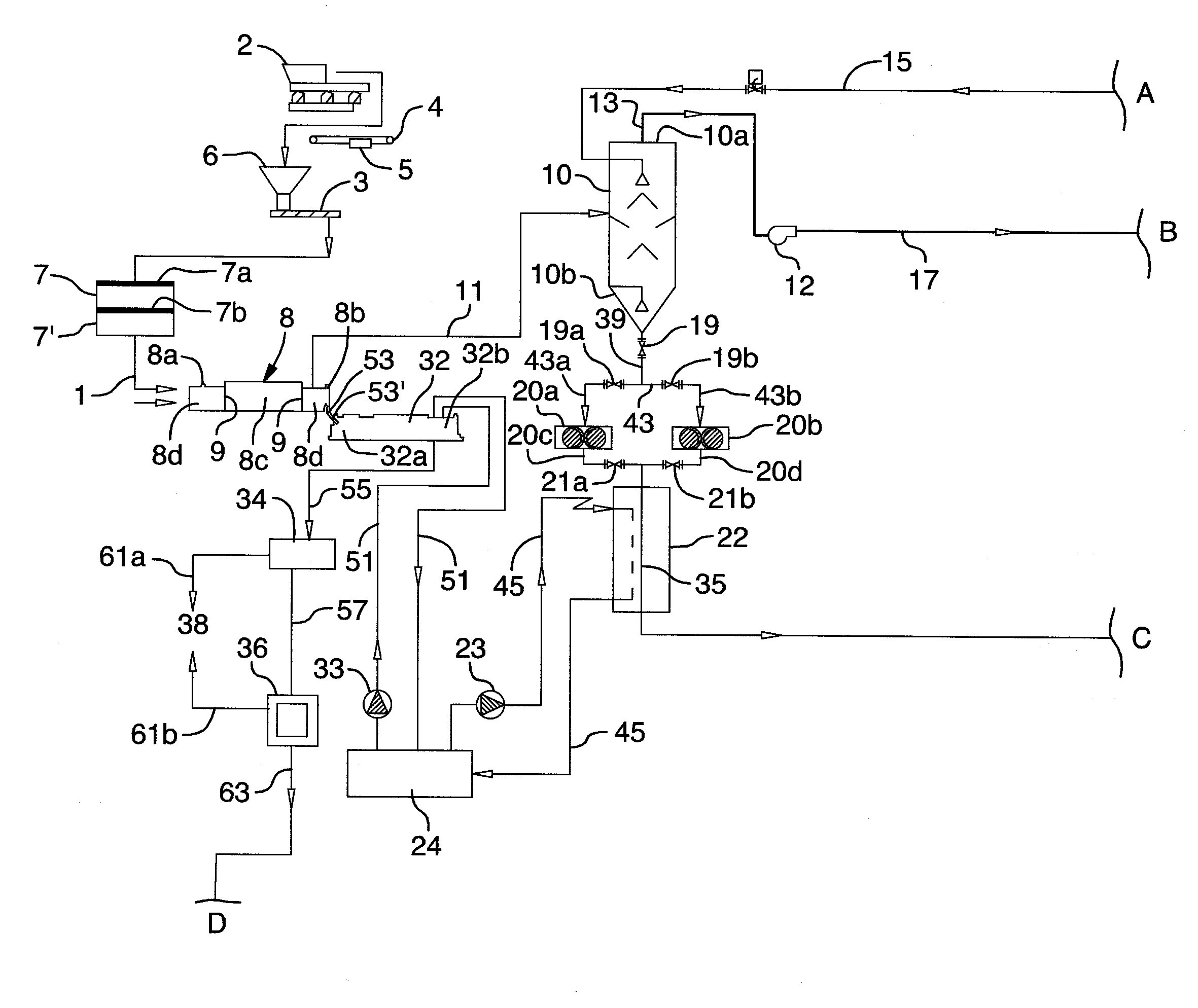

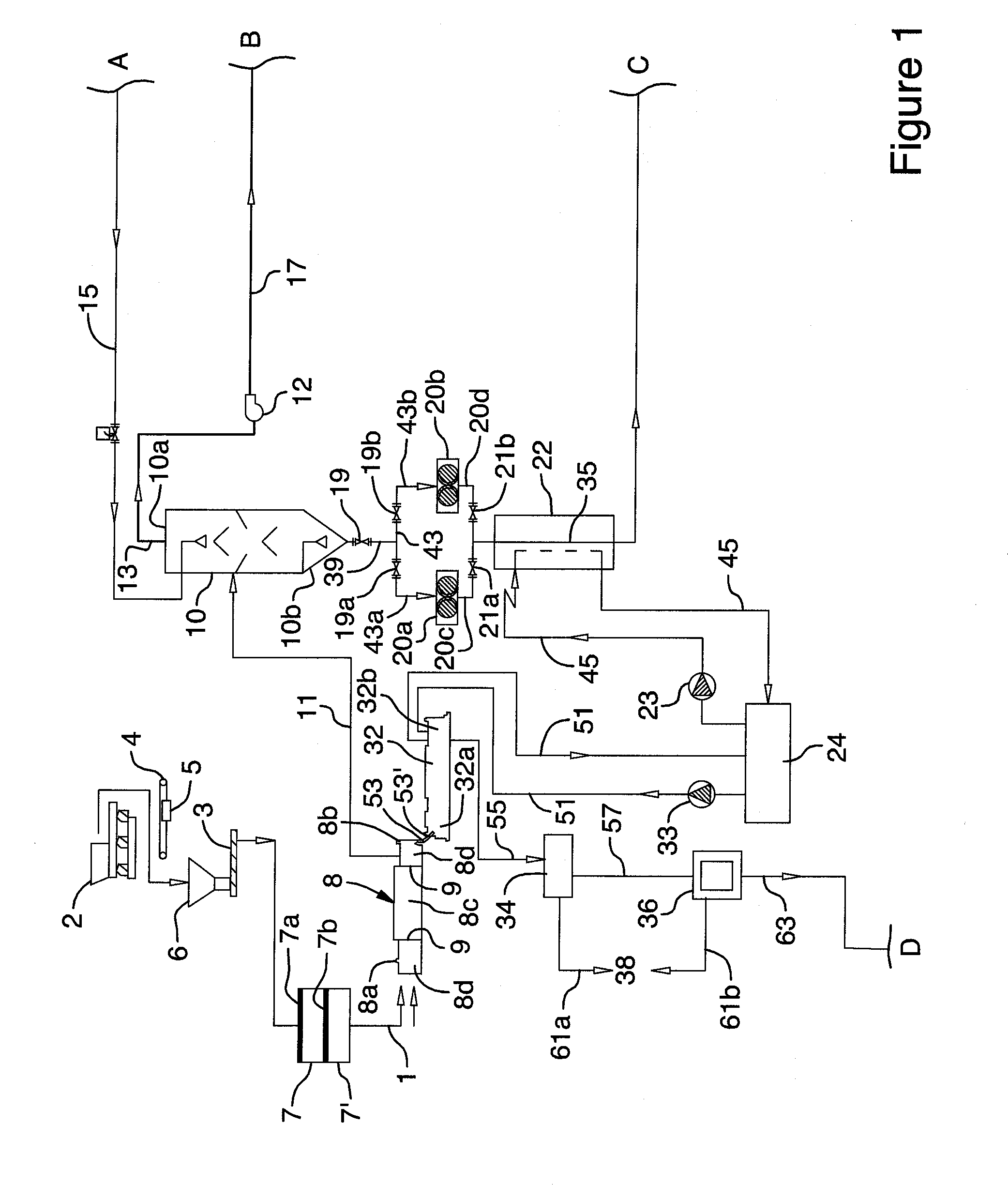

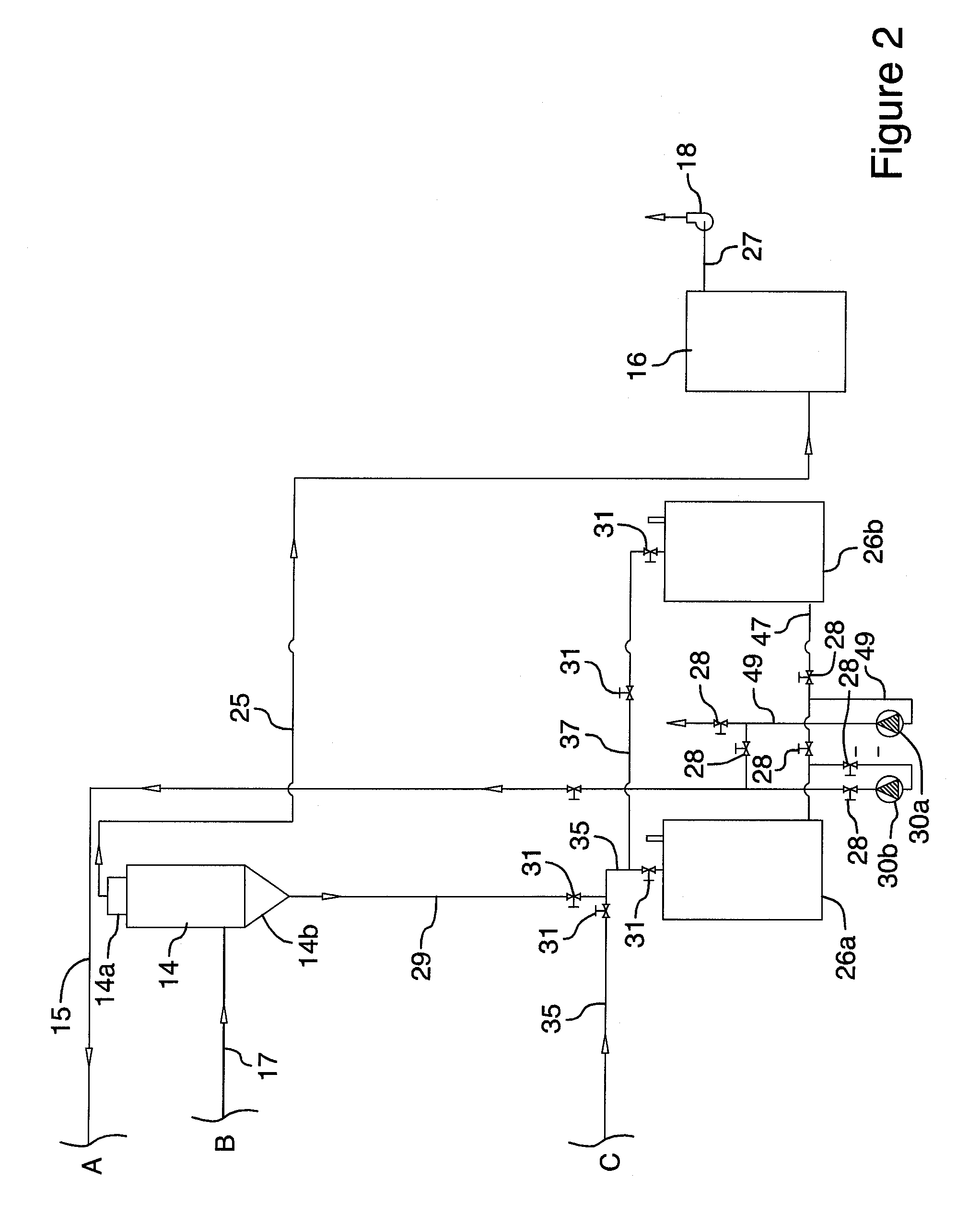

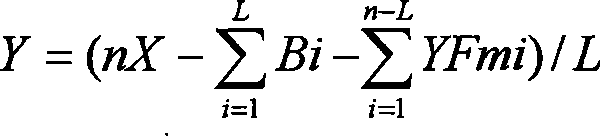

Method and device for the regulated feed of pulverized fuel to an entrained flow gasifier

ActiveUS20070074643A1Constant flowDouble gratePulverulent fuel combustion burnersCombustorFluidized bed

A method and device for metering and feeding pulverized fuels under pressure into gasification reactors, with the pulverized fuel being supplied alternately from an operational bunker through pressurized sluices to a metering tank, in the bottom of which a dense fluidized bed is formed by introducing fluidizing gas through a turbulence plate, with transport pipes immersed in the fluidized bed horizontally or vertically, by which the fluidized fuel is fed continuously through burners to a pressurized gasification reactor. By feeding in auxiliary gas in the immediate vicinity of the transport line inlet into the metering tank or the transport lines, the pressure differential between the metering tank and the gasification reactor is controlled and is utilized as a control parameter for pulverized fuel transport.

Owner:SIEMENS ENERGY GLOBAL GMBH & CO KG

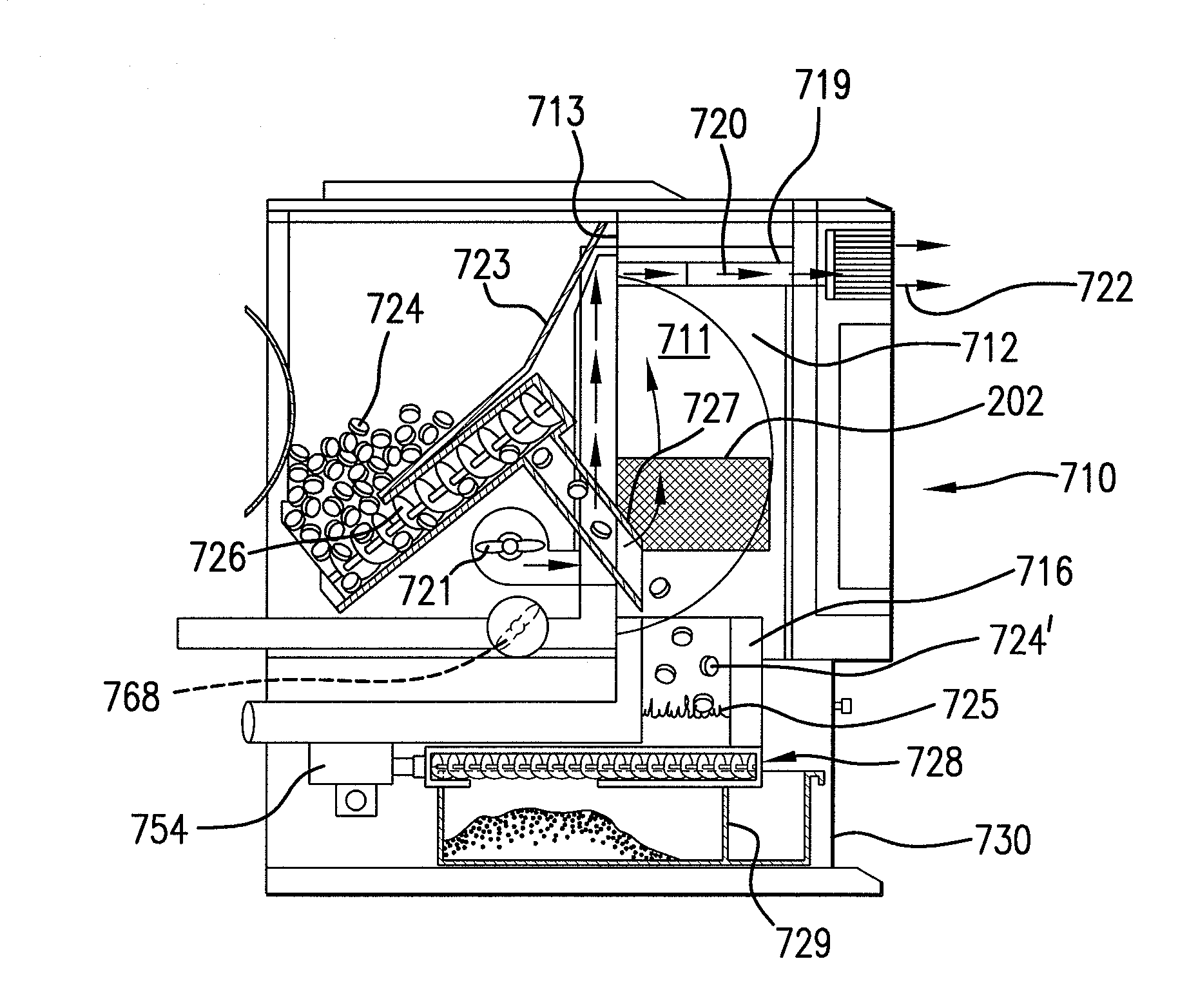

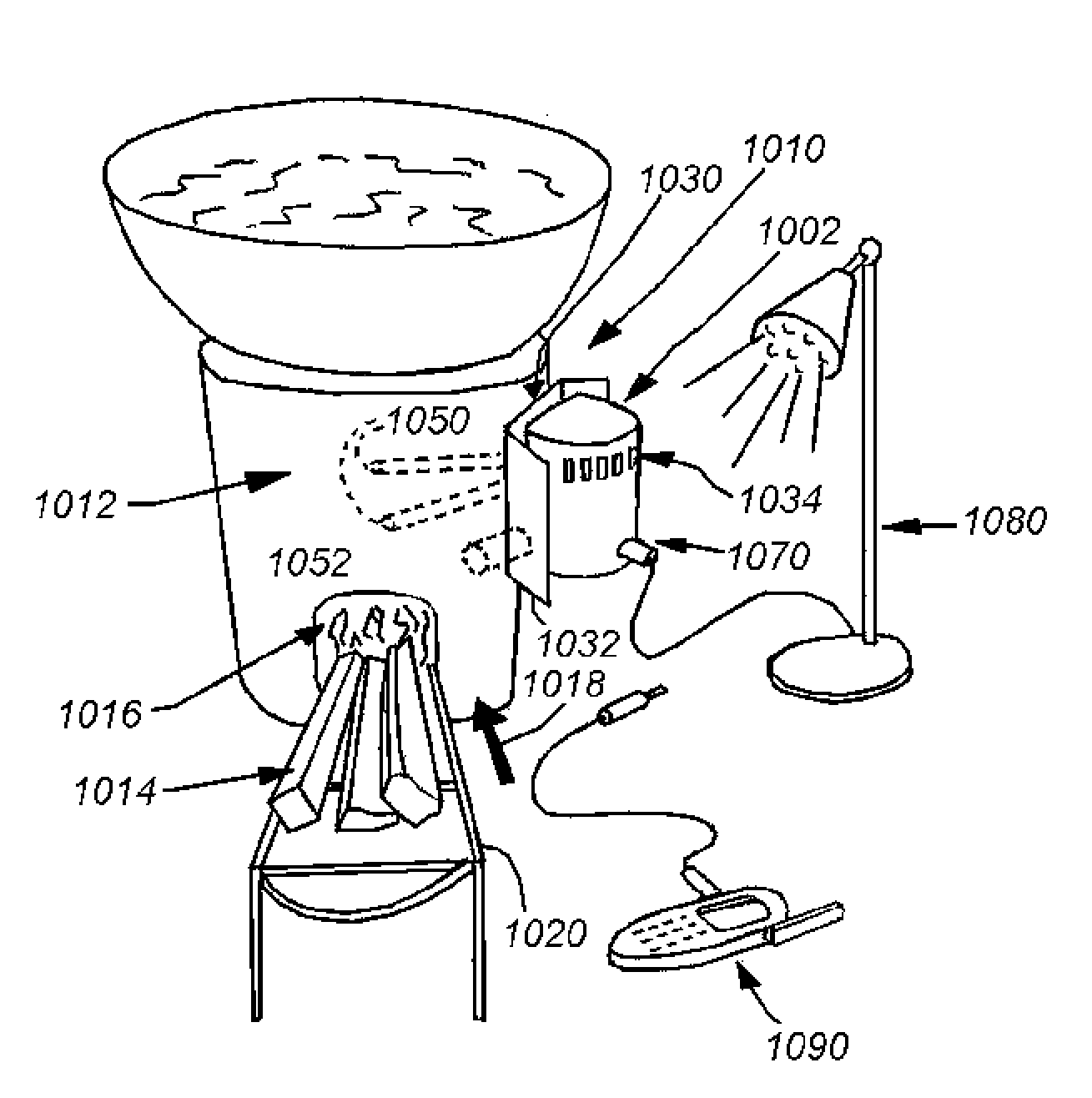

Granular biomass burning heating system

InactiveUS20070137538A1Improve unit efficiencyReduce lag timeAir supply regulationStirring devicesInformation controlProcess engineering

A granular biomass burning furnace for use with any appropriate granular biomass, such as grains, cherry pits, etc. The furnace includes a three stage heat exchanger, a fuel injector, a fuel stirrer, an ash ejector, a wash down system, a three stage air inducer, a fuel igniter, and supporting components. The unit includes a computer controller which controls all aspects of the operation of the unit based on information from sensors located throughout the unit. The unit includes a smart logic thermal controller to adjust the output heat of the unit via a variable speed air inducer. The three stage heat exchanger system includes a spiral water jacket surrounding the burn pot, a plurality of heat exchanger baffles in the unit, and a fine finned heat exchanger at the top of the unit. The air inducer provides air to the burn pot from three directions to promote complete combustion.

Owner:STERR KEVIN K

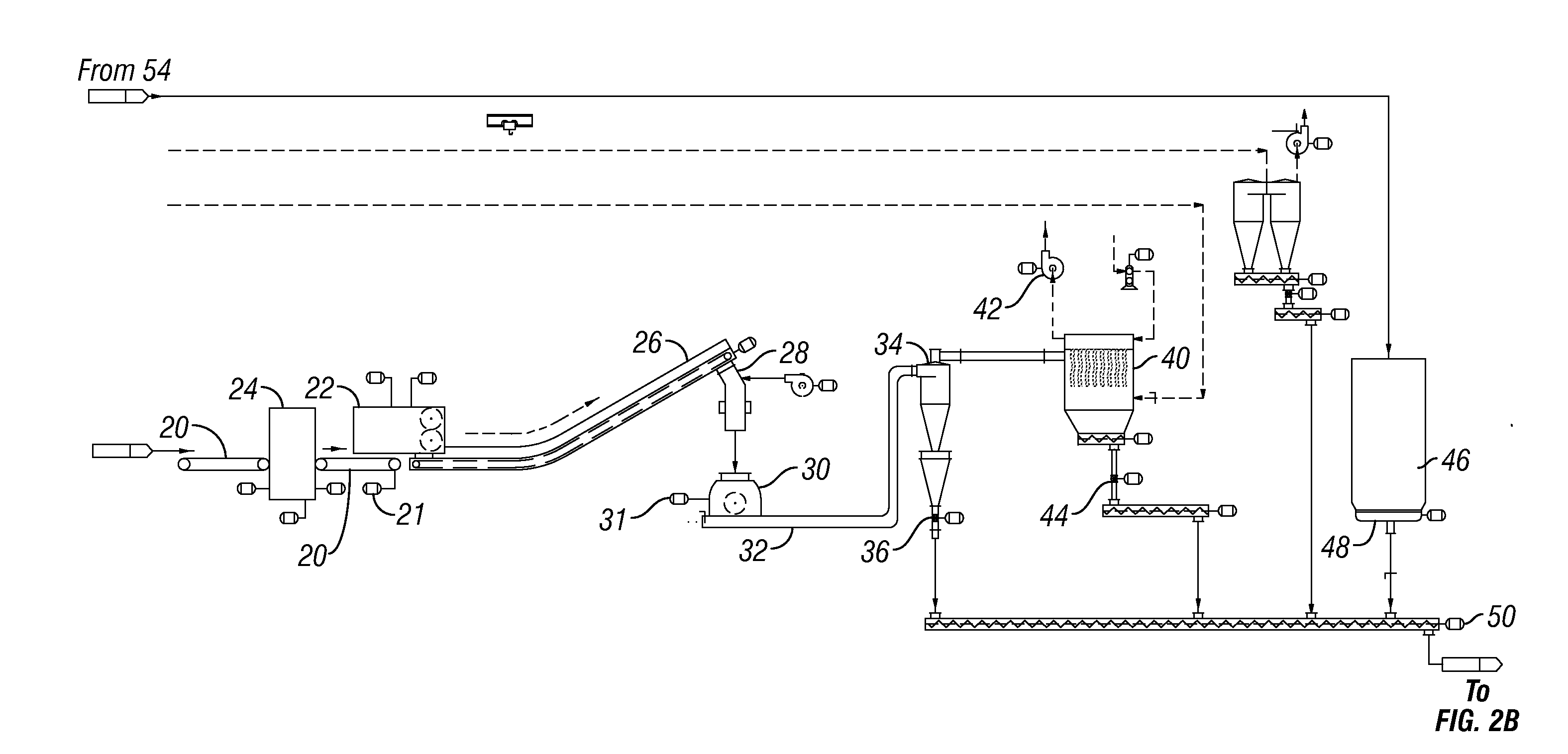

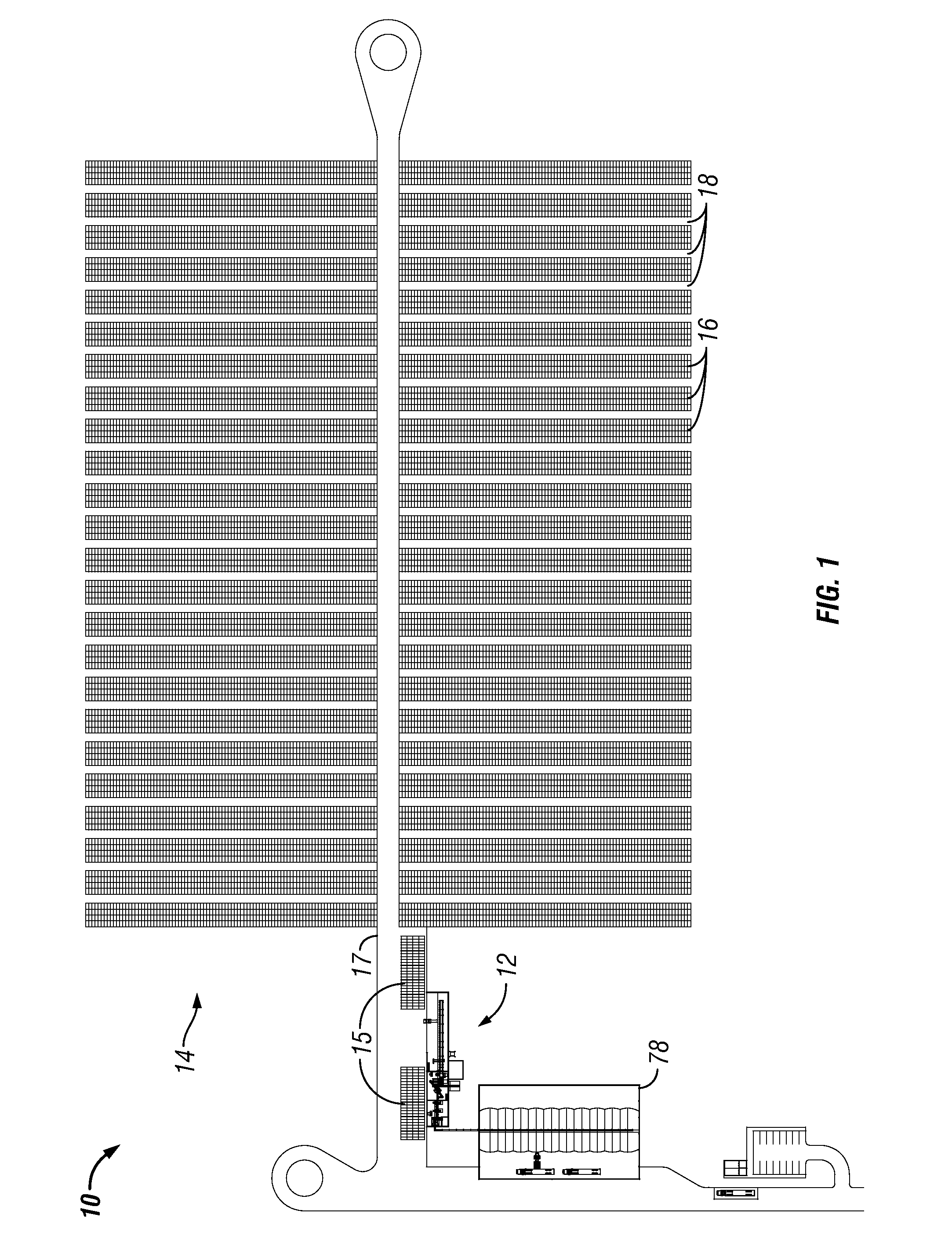

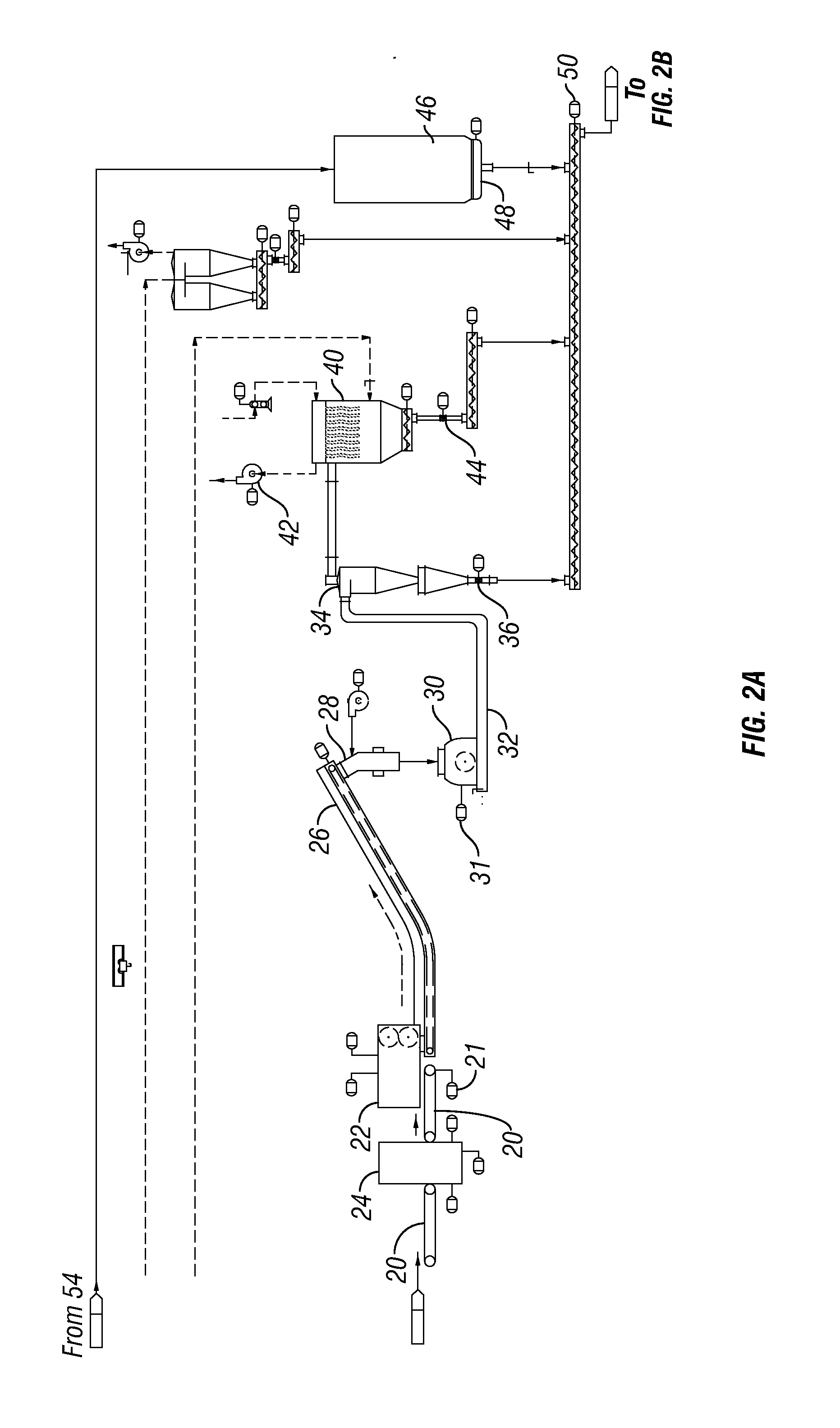

Biomass pelletizing process

ActiveUS20100281767A1Impact soil qualityImpact water useFuel feeding arrangementsSolid fuel pretreatmentAgricultural residueEngineering

A process is provided using non-food or limited-feed agricultural residue and energy crops for energy production, such as ethanol or electricity generation. The agricultural plant material is harvested and baled. The bales are transported to the processing site for storage or immediate processing. The bale strings are first removed, and then the broken bales are shredded. The shredded plant material is then ground to a small size. The ground material is then pelletized to produce densified pellets of the agricultural plant material. The pellets are cooled and then stored or transported to an end user.

Owner:PELLET TECH USA

Method of Reclaiming Carbonaceous Materials From Scrap Tires and Products Derived Therefrom

InactiveUS20100249353A1Constant production environmentQuality improvementGaseous chemical processesPressurized chemical processPyrolytic carbonMetal

The invention relates to recycled rubber produced by a process comprising the steps of: a) shredding cleaned rubber tires into shreds less than 2″ long; b) pyrolyzing the shreds in a reaction chamber of a thermal processor in a first anaerobic environment to produce a char; c) drawing off volatile organics from the reaction chamber; c) removing the char from the reaction chamber; d) cooling the char in a second anaerobic environment; e) removing metal and textile components from the char to obtain pyrolytic carbon black; f) milling and sizing the pyrolytic carbon black so obtained into particles of 325 mesh size or smaller; and, g) utilizing the pyrolytic carbon black from the previous step in a polymerization process that produces said recycled rubber. It also relates to the high quality pyrolytic carbon black recovered from this process.

Owner:BERDEKO TECH +1

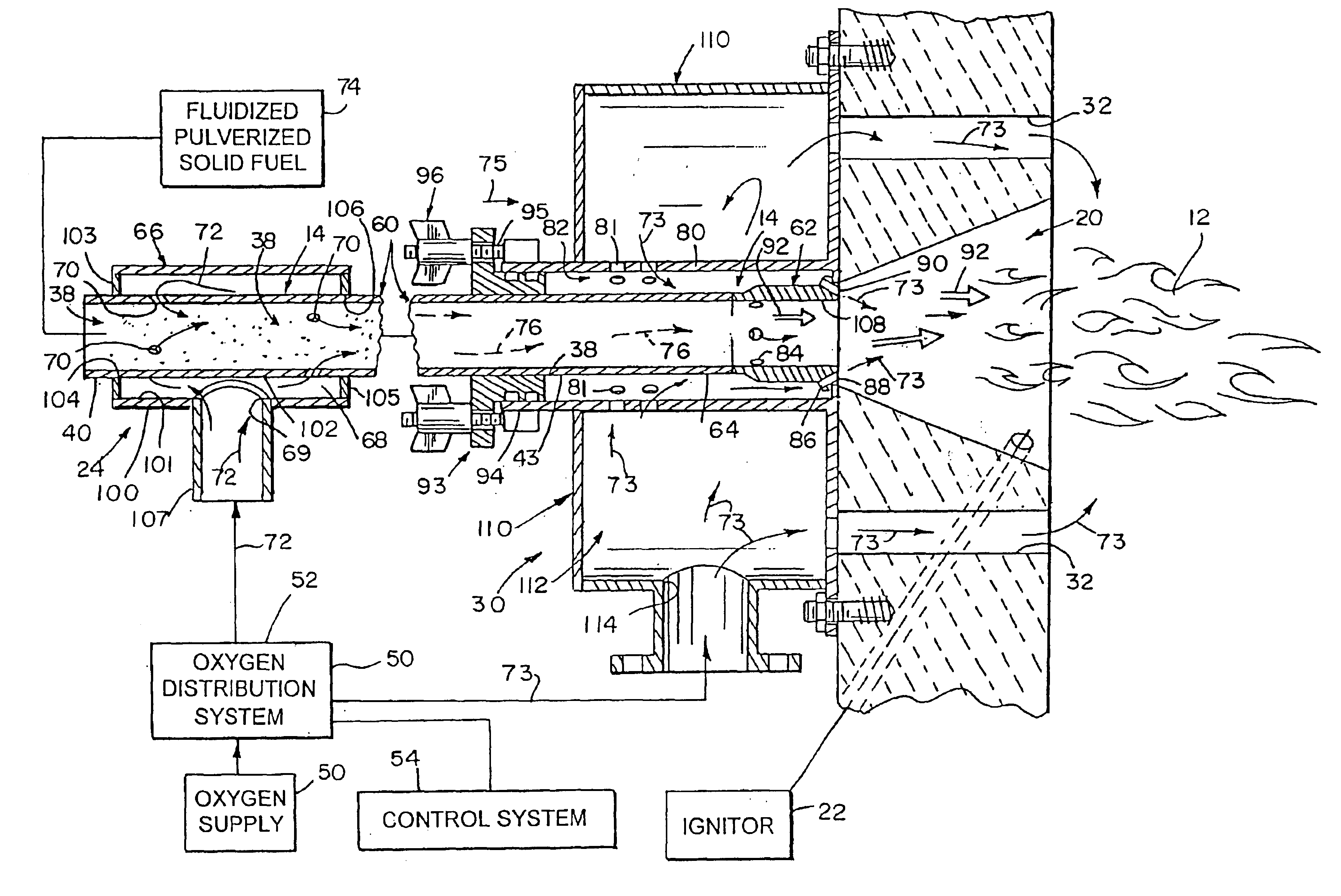

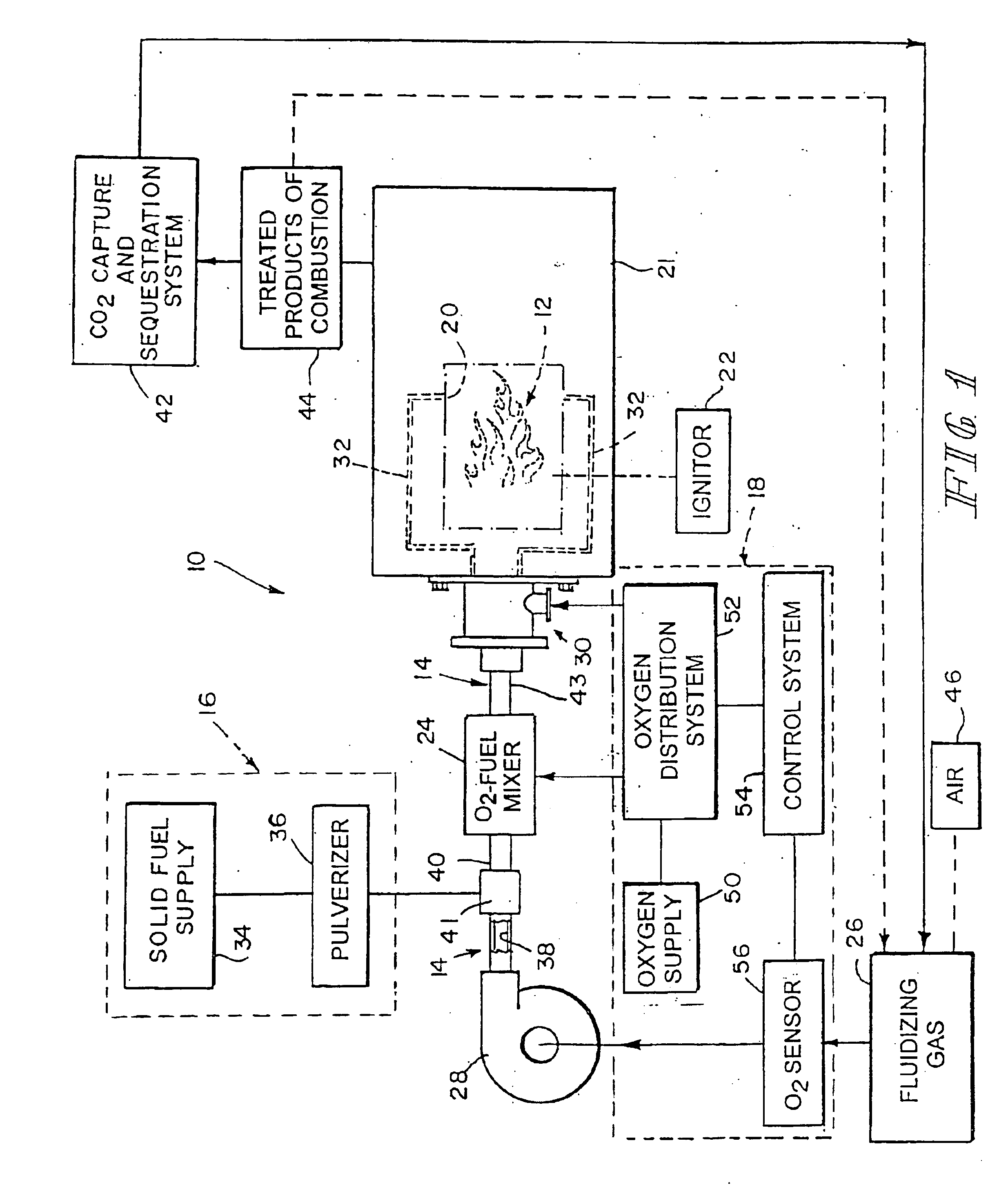

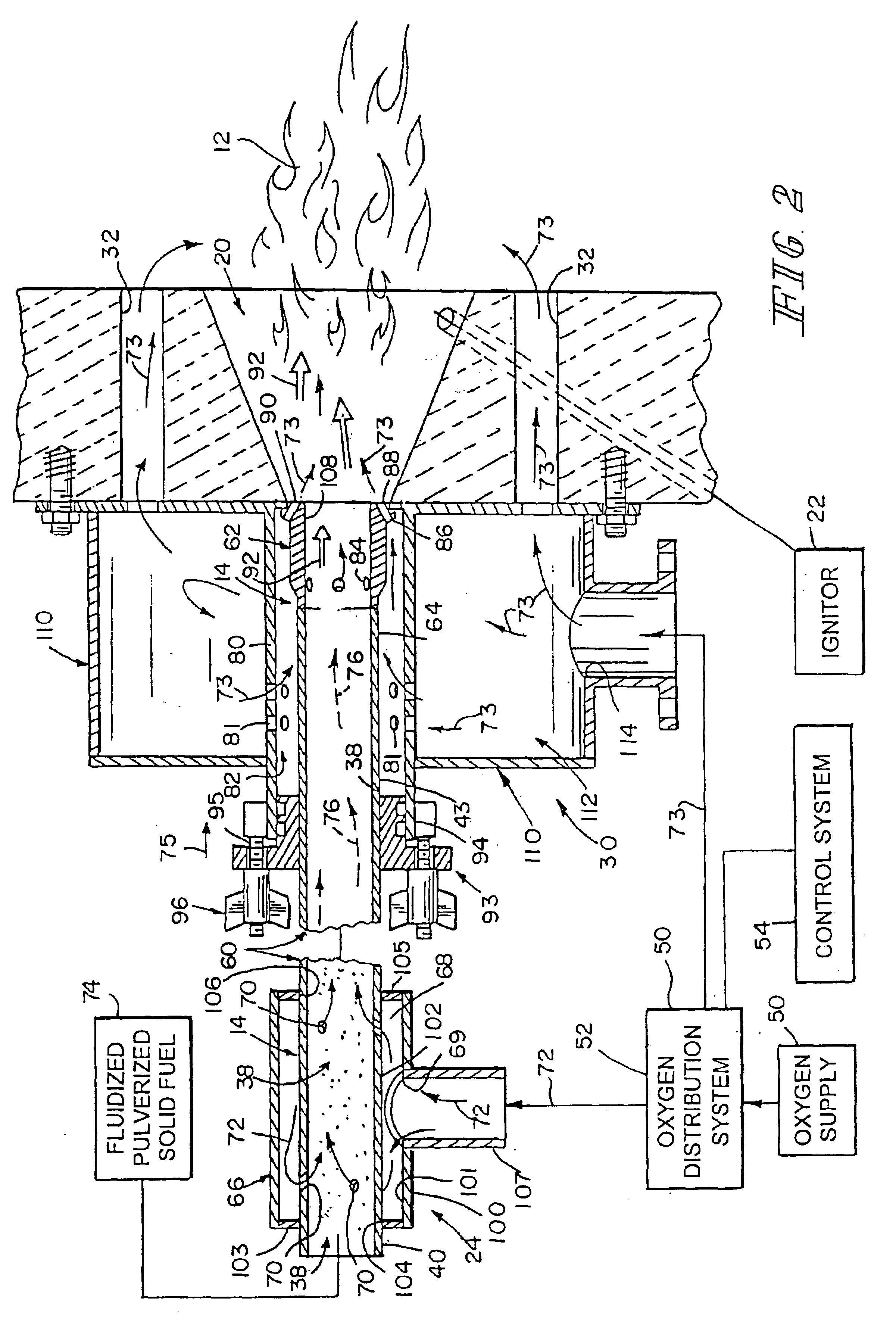

Burner with oxygen and fuel mixing apparatus

InactiveUS6843185B1Reduce nitrogen oxide emissionsCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelCombustion systemSolid fuel

An oxygen-fuel combustion system combines oxygen and fuel to produce a flame. The system distributes oxygen to a stream of fluidized, pulverized, solid fuel at various sites before and after ignition. The system is operable to vary the concentration of oxygen in an oxygen-fuel mixture extant at those sites.

Owner:MAXON

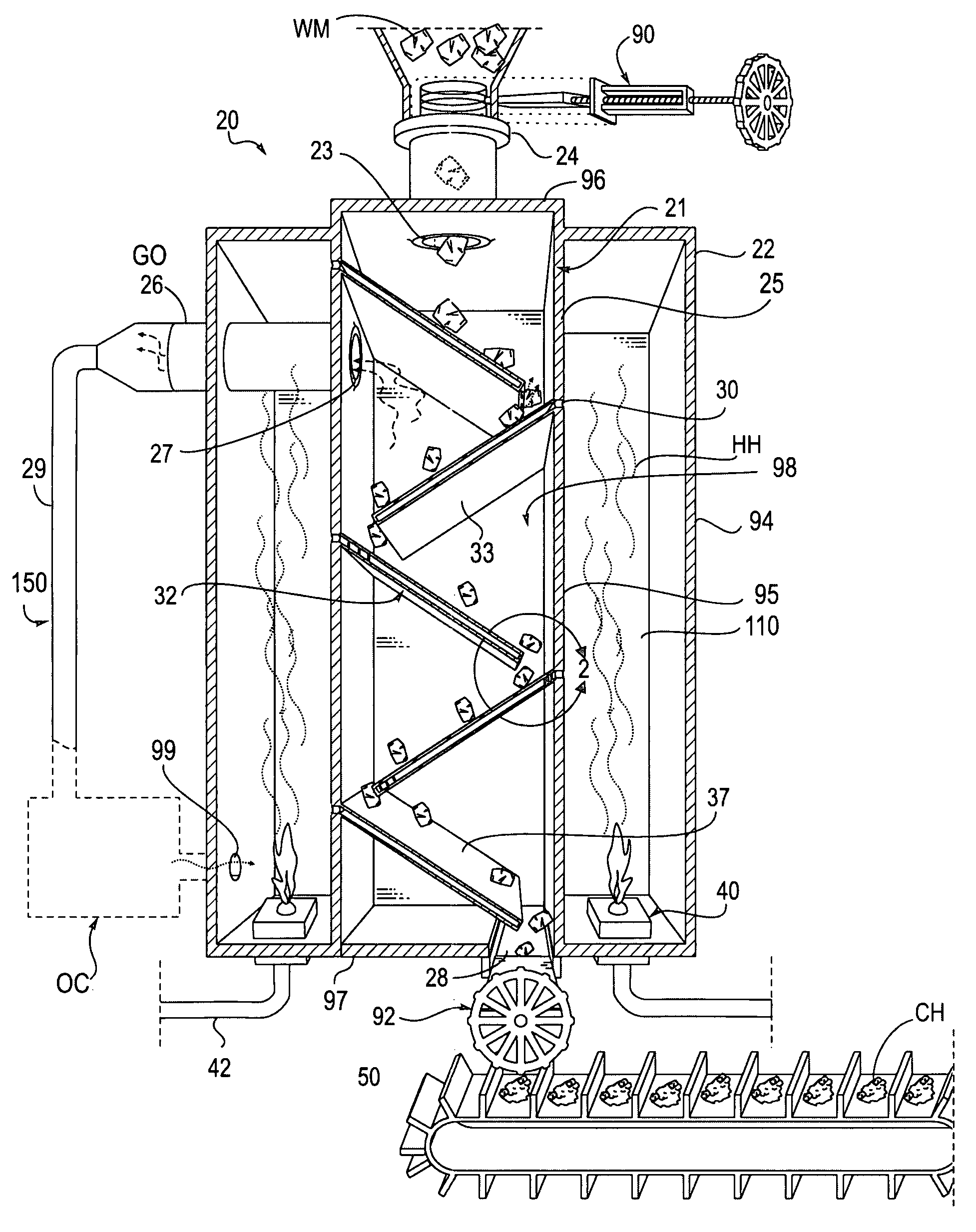

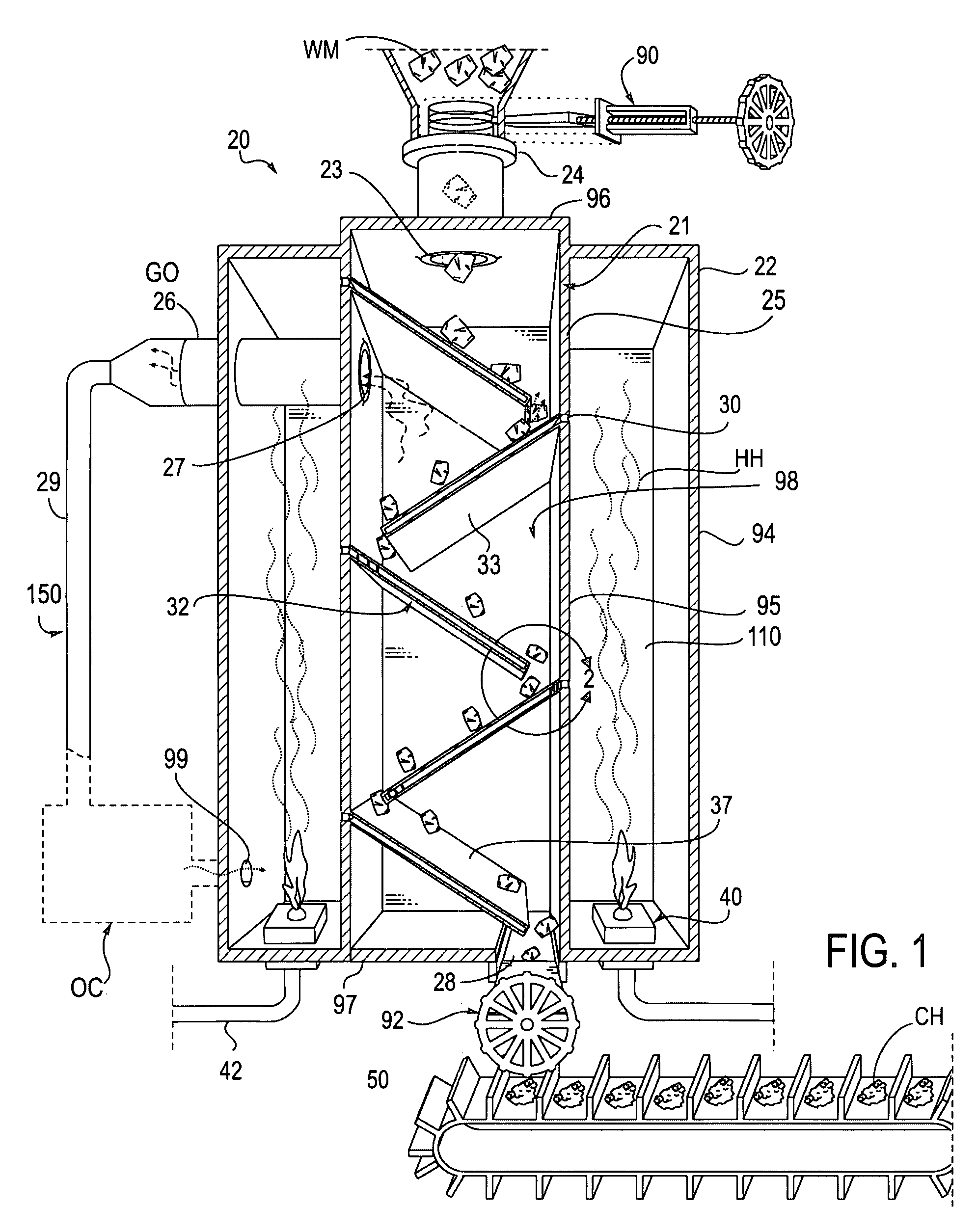

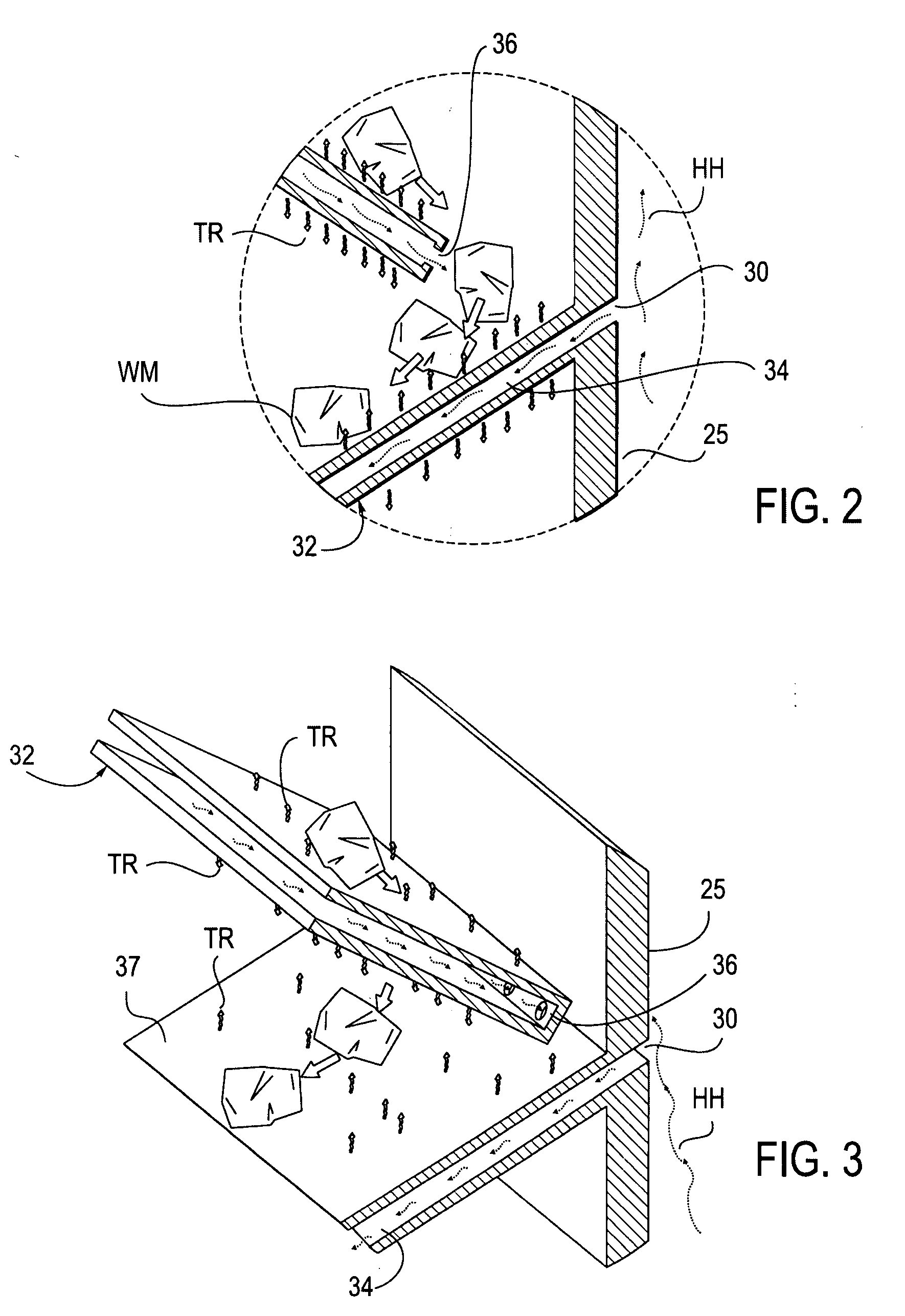

Freefall pyrolytic oven

A pyrolysis oven configured for vertical conveyance of material for incineration. The oven makes use of gravity and multiple plates to control the movement of material through the oven chamber. The plates and oven interior are heated in a low oxygen, pressurized environment to effect the decomposition of material as it freefalls down the chamber and makes contact with heated plates. The configuration and angle of declination of plates determines the freefall rate and retention time within the incinerating environment. The decomposition produces char and gas resultants, each of which are carried off through separate exits configured in the oven. The oven may be used as part of a waste management system in connection with a thermal oxidation chamber for the treatment of volatile organic compound gases that are a by-product of the pyrolytic process.

Owner:SIMEKEN

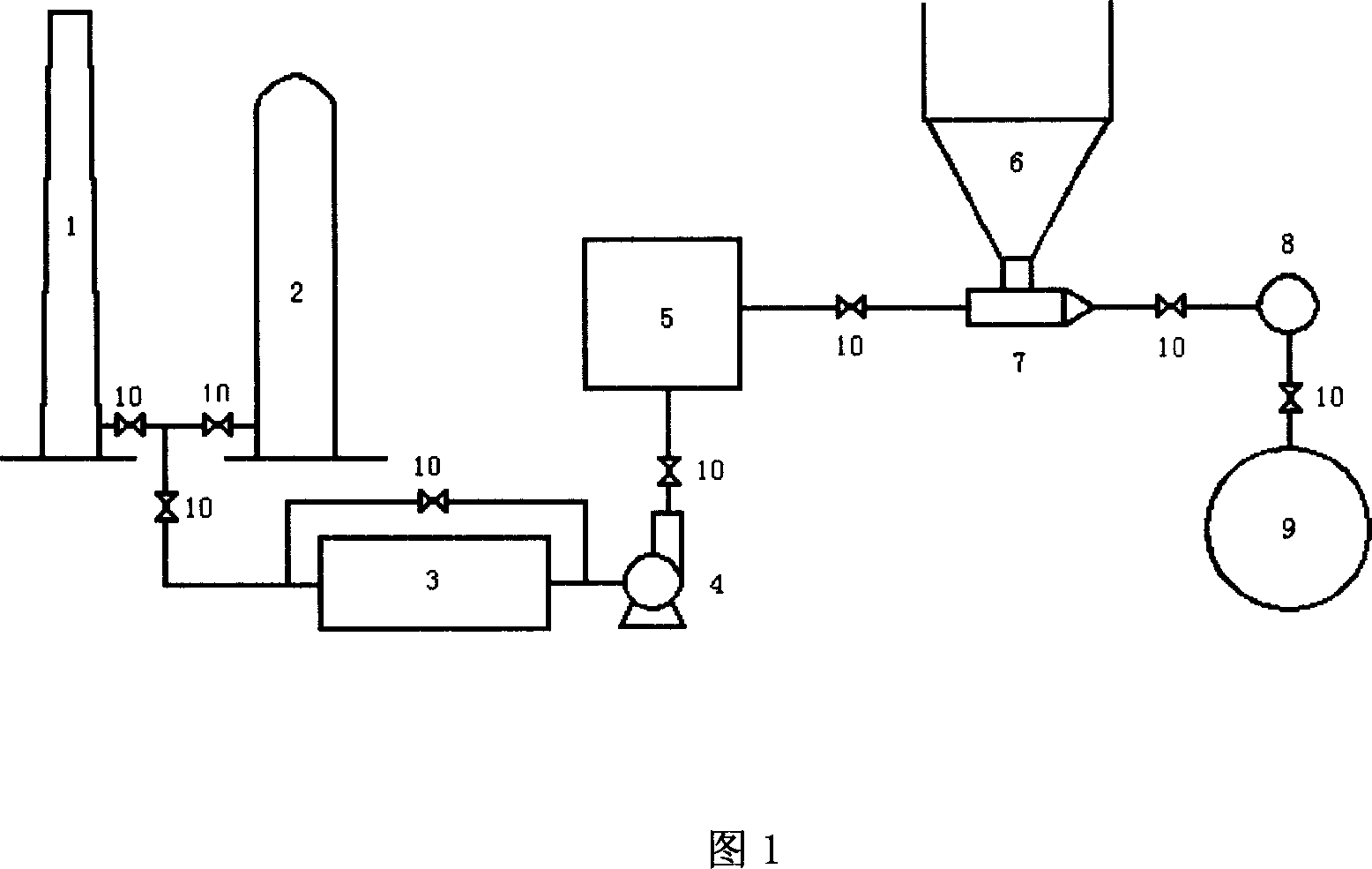

Blast-furnace coal powder injection method using waste gas of hot-blast stove flue as carrier

InactiveCN101000141AAvoid large emissionsReduce pollutionLump/pulverulent fuel feeder/distributionHot blastPrimary energy

The invention provides a blast furnace coal spraying method using flue gas of hot-air furnace, concretely using induced draft fan to draw the flue gas of hot-air furnace through special pipeline and control valve out of the flue, cooling by heat exchanger to enter air compressor, after compression, using coal feeder to blow the pulverized coal inputted by blowing tank to distributor, and thus spraying the pulverized coal into the blast furnace from each tuyere. And it implements waste gas utilization, saving primary energy sources; and helps indirect reduction reaction in furnace, so that secondary energy sources can be utilized; besides, largely avoids waste gas CO2 exhaust, reducing atmospheric pollution; can preheat pulverized coal, increasing combustion speed; and has the same system safety as N2 carrier, especially suitable for large scale blast furnace applications and having extremely remarkable energy saving and environmental protection effects.

Owner:ANGANG STEEL CO LTD

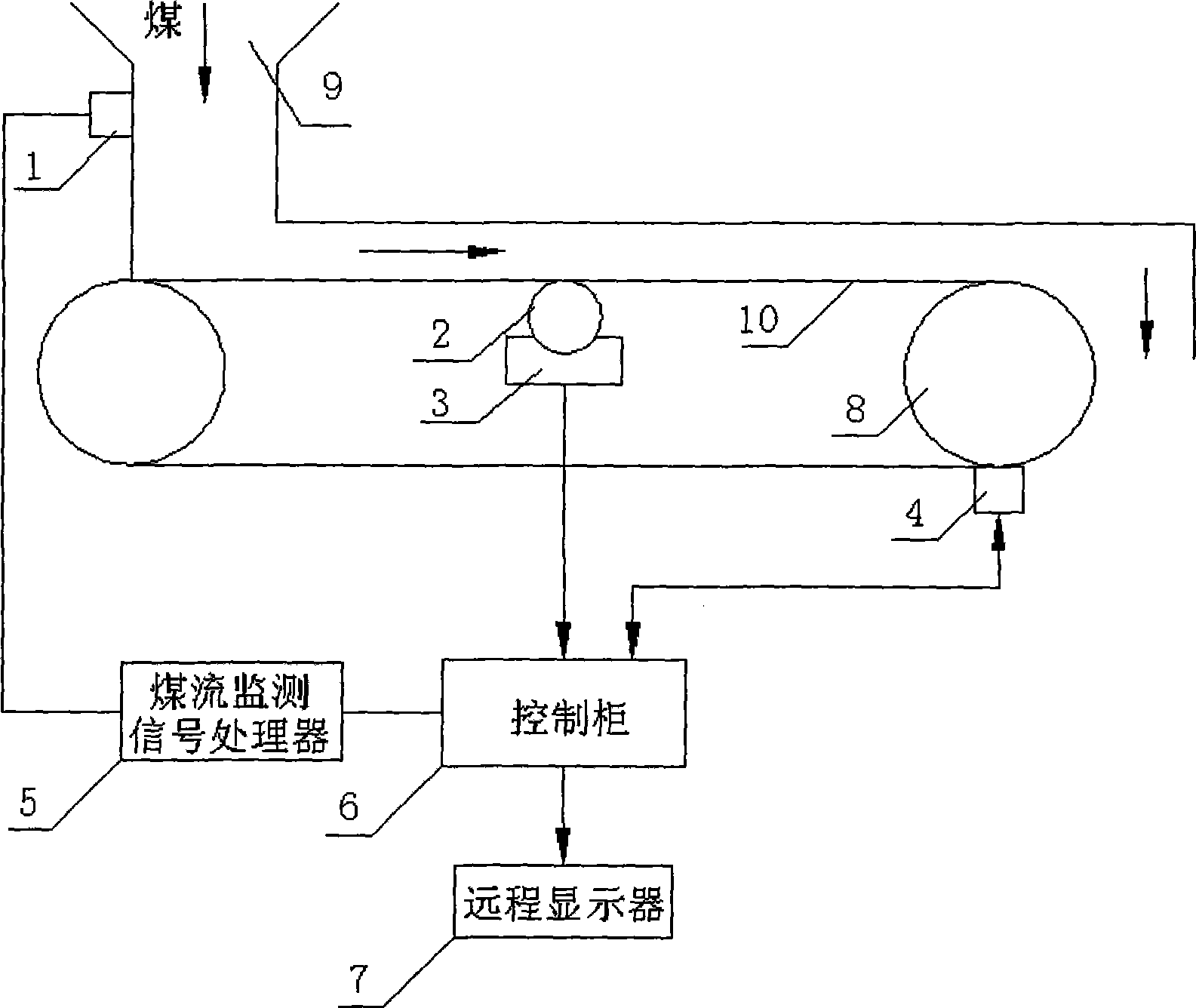

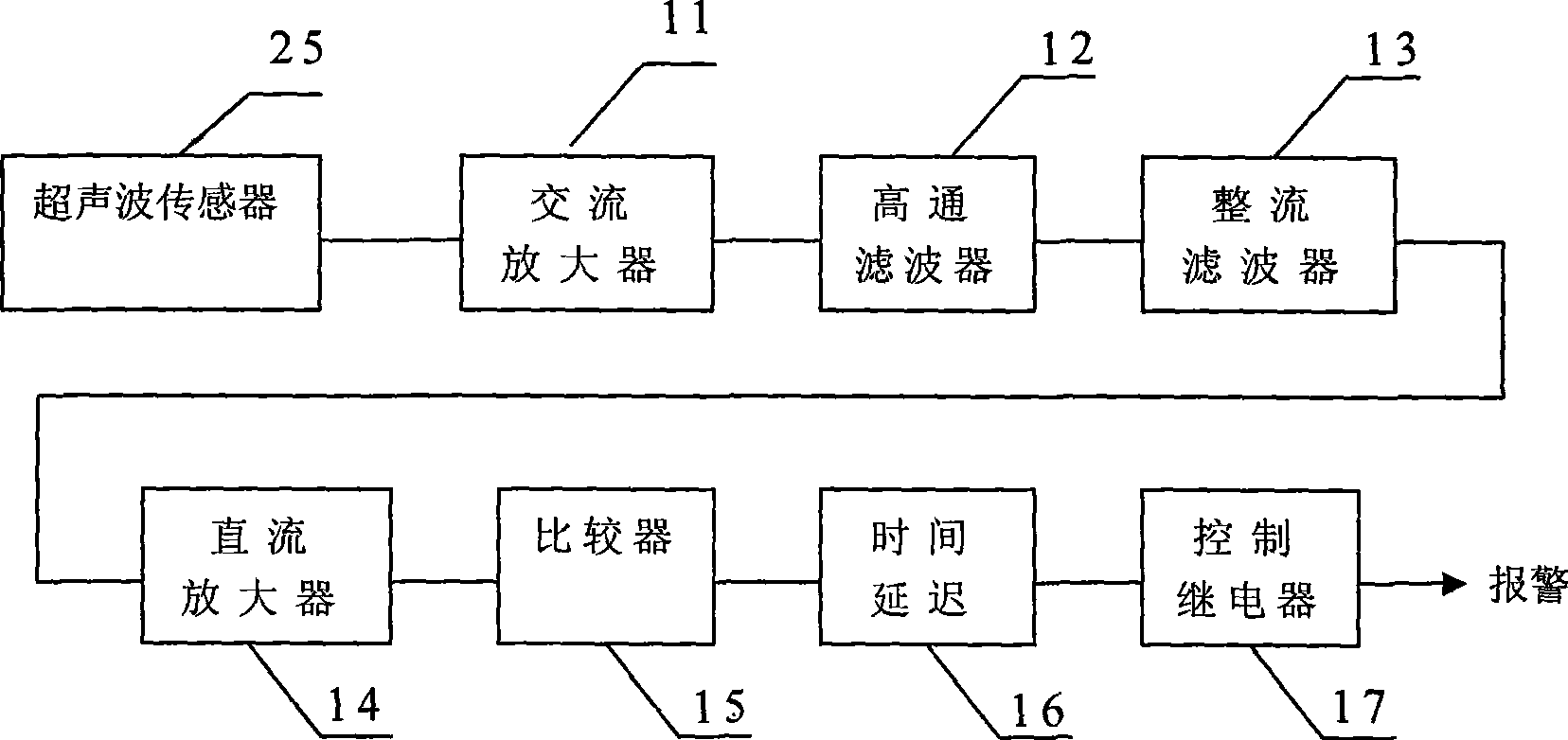

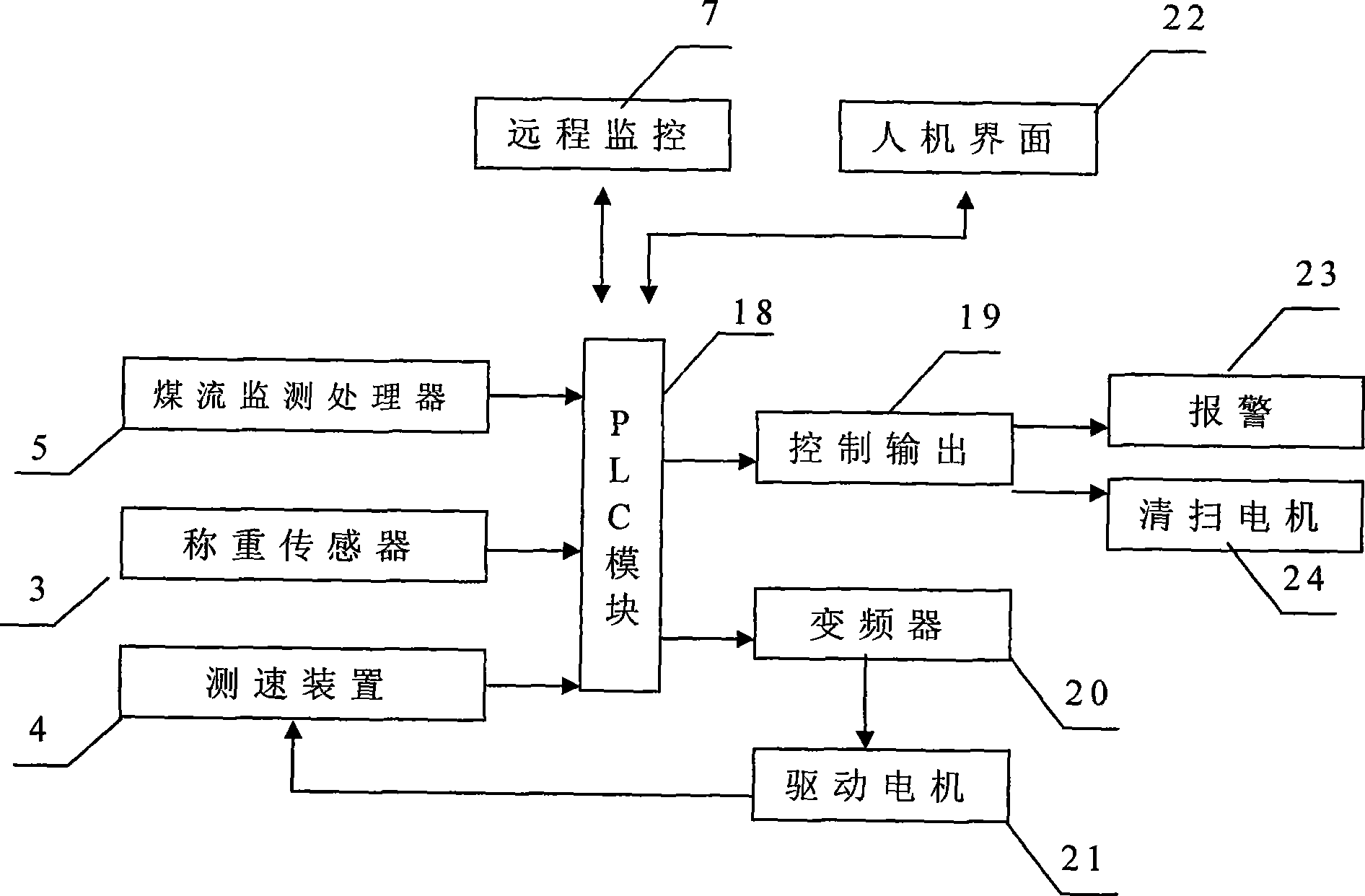

System and method for intelligently controlling electronic weighing type coal feeder

InactiveCN101544306AGuaranteed to burnAccurate adjustmentControl devices for conveyorsWeighing apparatus for continuous material flowProcess engineeringDrive motor

The invention provides a system for intelligently controlling an electronic weighing type coal feeder. The system comprises an ultrasonic wave coal stream monitoring sensor, a weighing carrier roller, a weighing sensor, a speed measuring device, a coal stream detecting signal processor, a control cabinet, a remote monitoring display and a drive motor. The working method comprises the following steps: 1) when the system detects no failure, an indicating lamp of 'normal operation' is lighted; 2) when the system has no failure and coal is on a belt, an indicating lamp of 'material to feed' is lighted in coal feeding; 3) under a condition that the sensor has an overlarge detection difference value or is damaged, when the system is converted into volume type operation, an indicating lamp of 'volume mode' is lighted; 4) the system controls the gross amount of accumulated fed coal of the coal feeder, and the gross amount of coal is sum of weight mode gross amount and volume mode gross weight; and 5) when the system detects the failure, an indicating lamp of 'failure warning' is lighted, and a 'failure search' key is pressed to enter a 'failure search' interface to check failure records.

Owner:SHANGHAI ORIENTAL MARITIME ENG TECH CO LTD

Combustion furnace with full-automatic feed and heath fuel feed device

InactiveCN102109181AMeet fire demandDomestic stoves or rangesSolid heating fuelCombustionProcess engineering

The invention belongs to the fuel supply of fuel equipment and in particular relates to a combustion furnace with full-automatic feed and a hearth fuel feed device, and a fuel can be combusted from top to bottom in the combustion furnace. The hearth fuel feed device provided by the invention comprises a rectilinear translation bedplate, a feed barrel, a translation device, a feed device and a control device, wherein the translation device comprises a translation motor, a translation variator, a translation position switch, a connecting device and a rectilinear and rotary translation device; the feed device comprises a fuel pallet hoisting mechanism, a feed motor, a feed variator, a feed position switch. a connecting device and a rectilinear and rotary translation feed device; and the control device comprises a translation position switch and a feed position switch control circuit. The combustion furnace provided by the invention comprises a burner part, a furnace body part and the hearth fuel feed device. According to the invention, a moving supply and propulsion feed mode is adopted and continuous and uninterrupted addition of the fuel is realized through circulated supply and continuous propulsion, thereby meeting continuous and long-time requirements for applying fire.

Owner:FUZHOU SUNSHI XIONGDI IND

Automatic control method of 300 MW grading circulating fluidized bed units

ActiveCN101225955AKeep the economy runningAvoid cokingFluidized bed combustionLiquid fuel feeder/distributionAir volumeAutomatic control

The invention relates to an automatic control method of 300MW grade circulating fluid bed unit, which sets the automatic control methods for the coordination of machine and furnace, the deviation of single bed pressure and double bed pressure, the water level of the deaerator and the condenser, the secondary air quantity / oxygen quantity and the secondary air pressure, the boiler bed temperature, the fuel flow and the limerock feeding during making the first 300 MW circulating fluid bed unit as the localization of manufactures, meanwhile, the 300 MW circulating fluid bed unit has the advantages of stable operation, safety, reliable and remarkable economic operation passing through the coordination and control for the system.

Owner:云南电力试验研究院(集团)有限公司

Biomass conversion by combustion

ActiveUS20060089516A1Eliminate requirementsHydrocarbon from carbon oxidesCell electrodesSupporting systemCombustion

Break down of waste materials such as animal parts is carried out by pyrolysis, gasification and combustion using a reactor vessel with a conical lower portion located within an exterior vessel. Feed material is deposited in continuous mode through an air lock at the top and falls by gravity alone into the lower cone portion. The cone geometry supports organic feedstocks, eliminating the requirement for grates or other combustion support systems. Organic material that may escape gasification and exit the bottom of the cone accumulates within the ash and carbon particle volume until burned. Carbon is sequestered from high energy feedstocks and is stored in a chamber below the gasification cone. This carbon supplements the energy output of lower energy feedstocks to maintain desired operating temperatures at all times.

Owner:DUNFORD HLDG INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com