Combined coal powder storage and supply system

A combined and pulverized coal technology, which is applied in the direction of block/powder supply/distribution, fuel supply, lighting and heating equipment, etc., can solve the problem of uneven combustion in the boiler furnace, long intervals of pulverized coal supply, and unfavorable pulverized coal blowing and other problems, to achieve real-time monitoring, ensure normal and stable operation, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

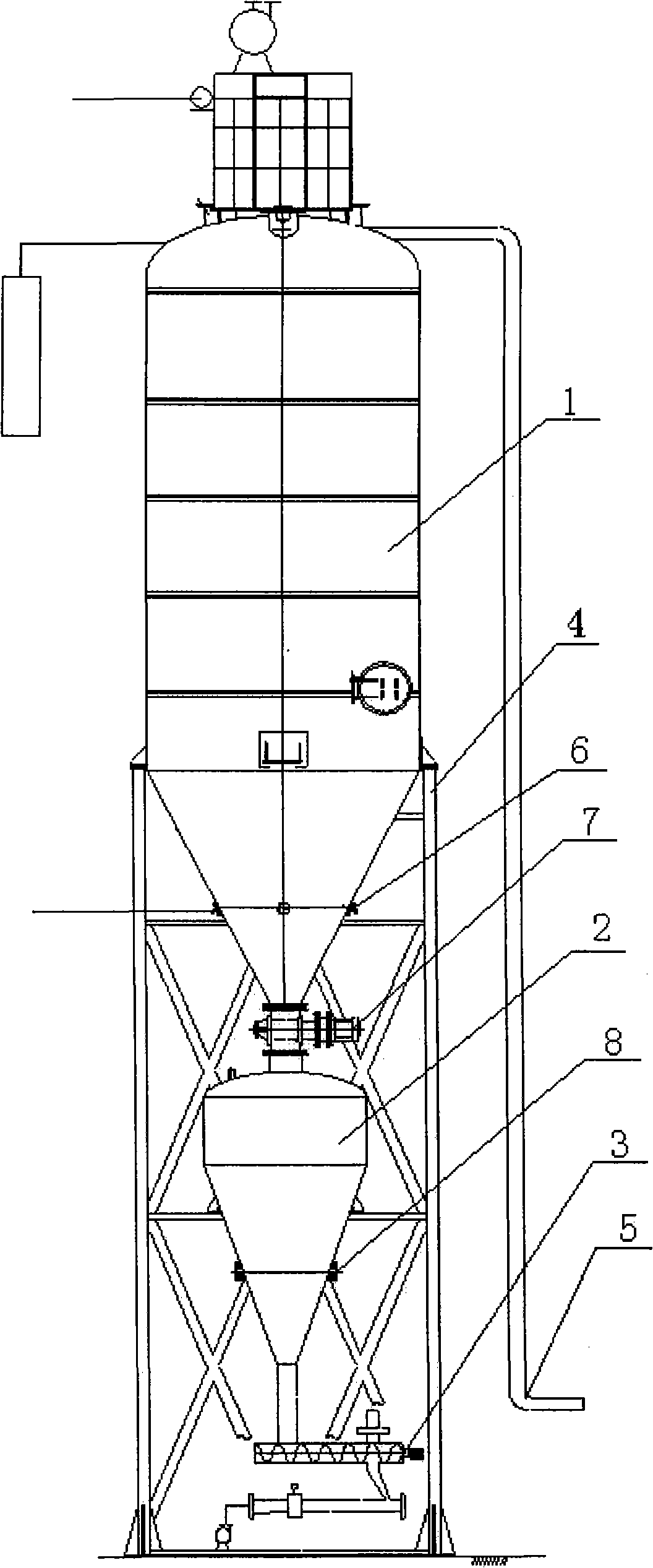

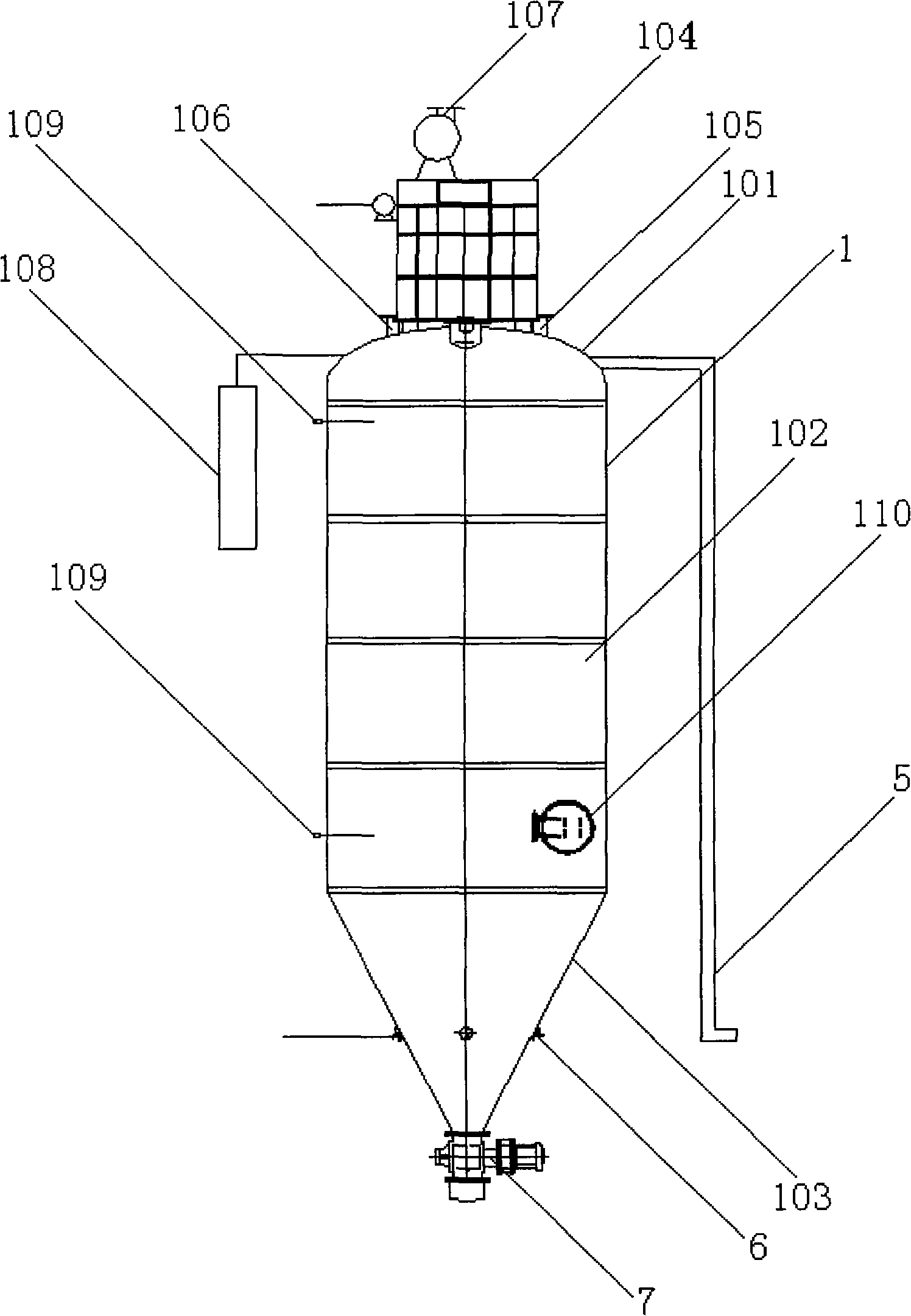

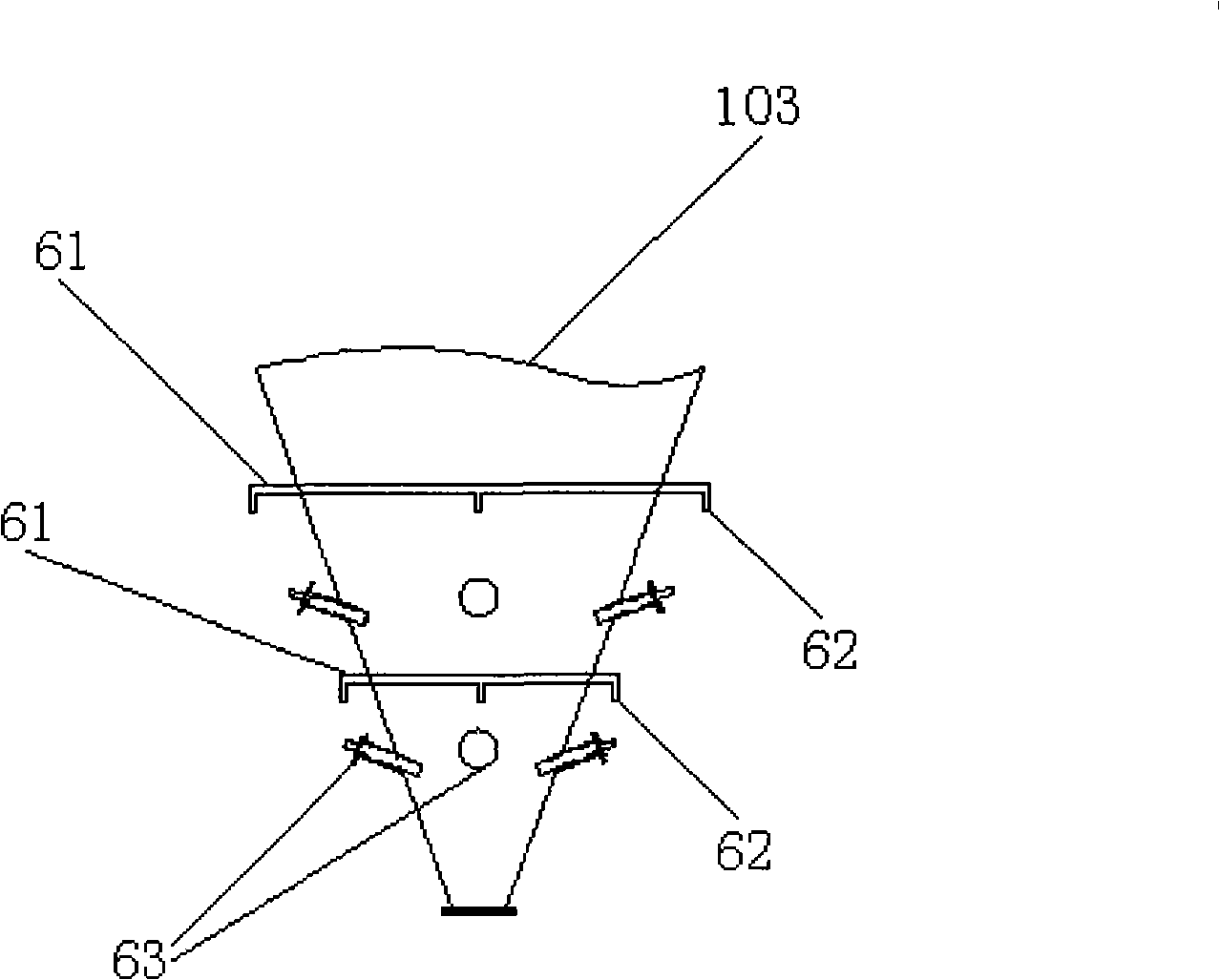

[0019] Such as figure 1 , figure 2 As shown, the present invention includes a pulverized coal storage tank 1, a pulverized coal feed bin 2 for weighing, a pulverized coal supply device 3 without pulse and a support 4. The pulverized coal storage tank 1 is vertically arranged on the top of the support 4, and it includes upper, middle and lower sections. The upper section is a dome-shaped head 101, which meets the standard of the head device for pressure vessels; the middle section is a cylindrical barrel 102 , is the main part of storing pulverized coal; the lower section is a conical hopper 103, which is convenient for pulverized coal to drop automatically. There is a feed port (not shown in the figure) on the sealing head 101, and the feed port is connected with a pulverized coal feed pipe 5. A bag filter 104 is arranged at the top center of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com