Patents

Literature

45results about How to "No bridging" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

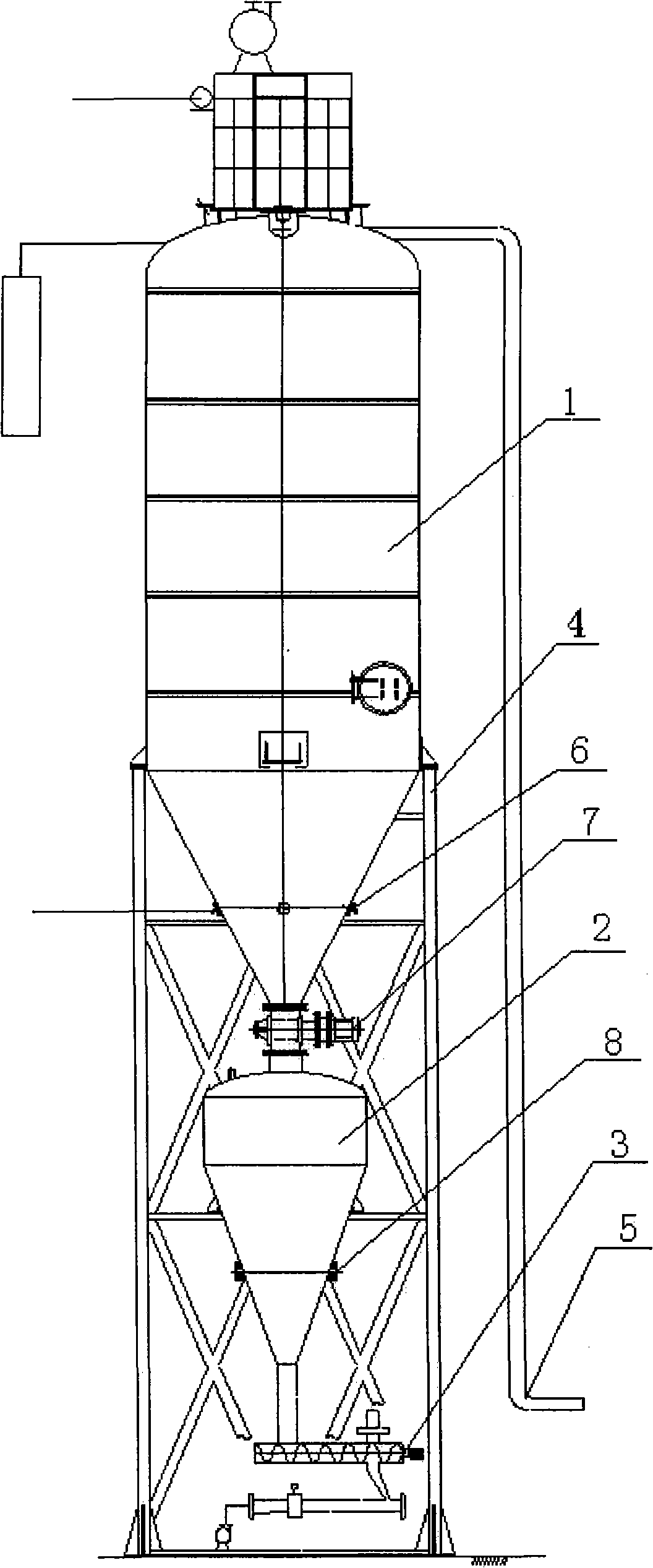

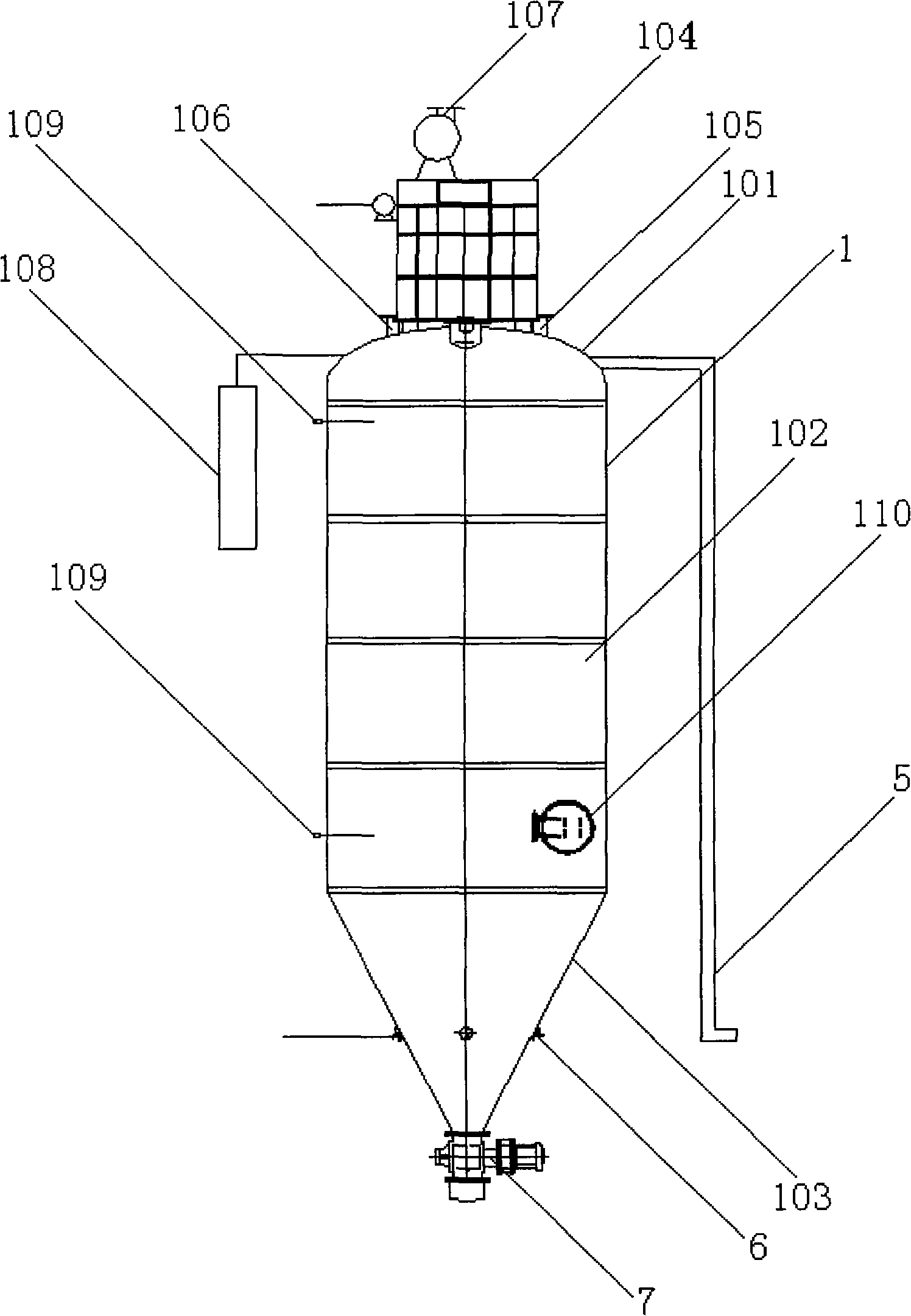

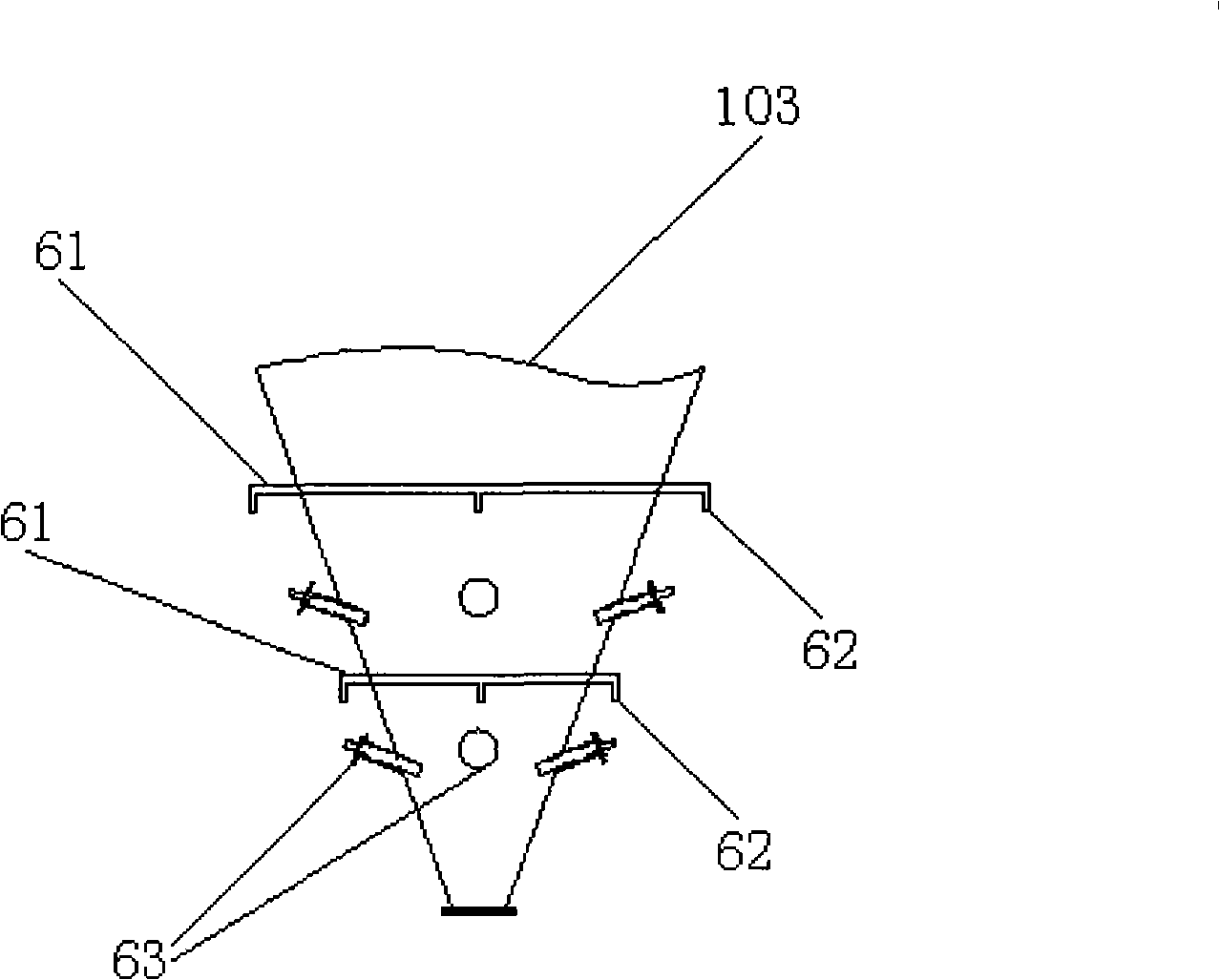

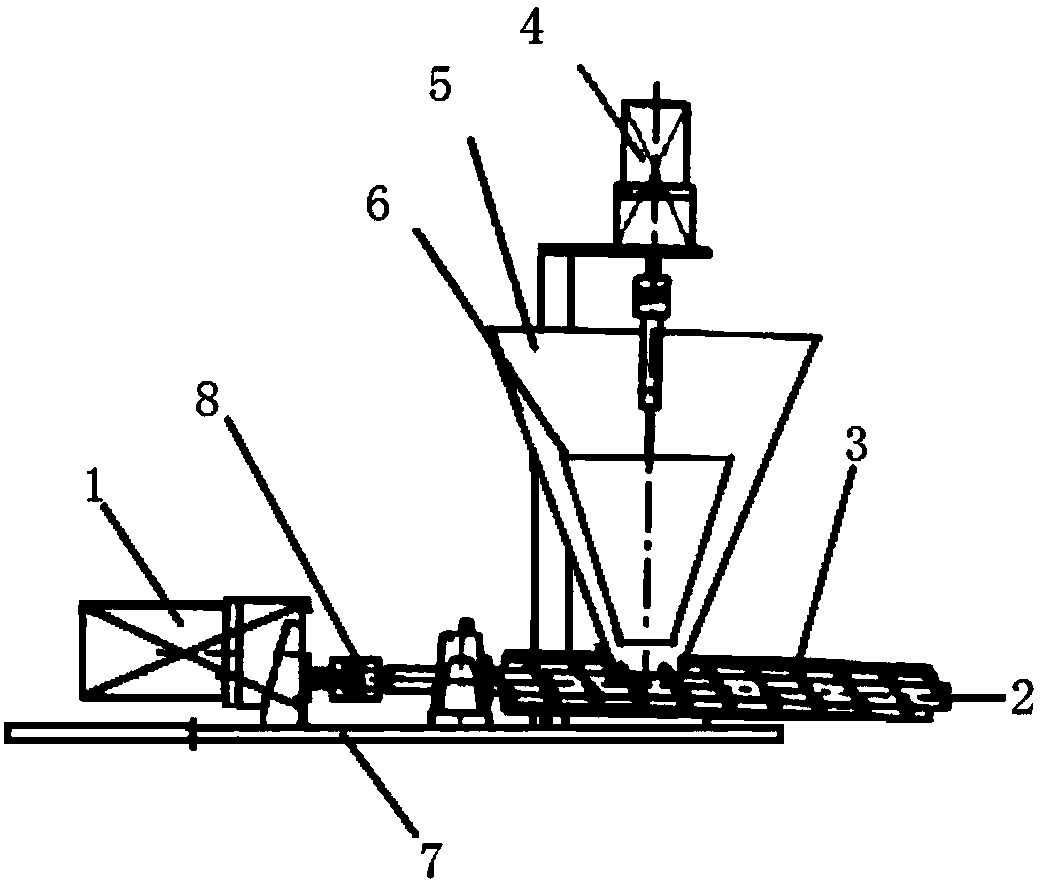

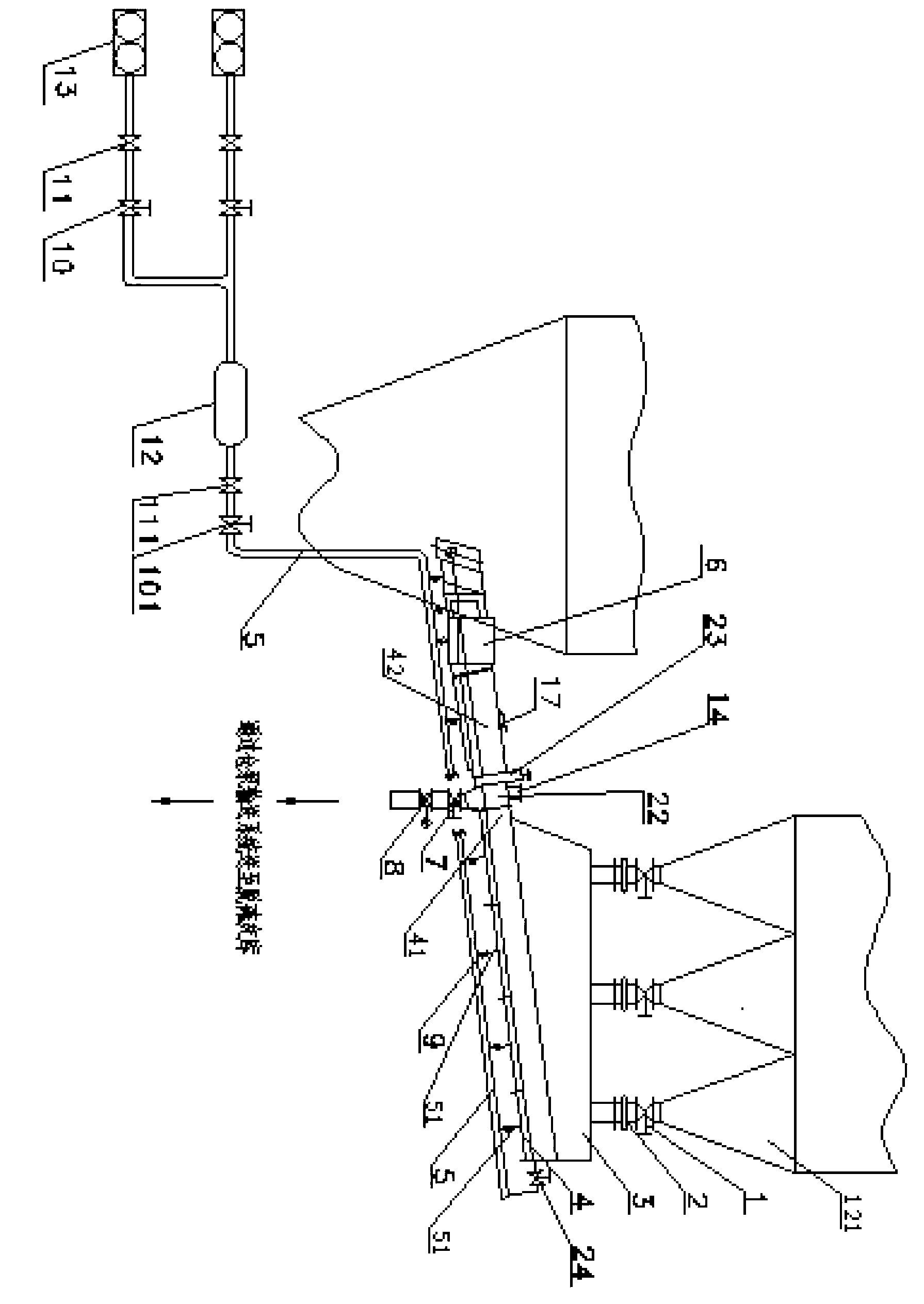

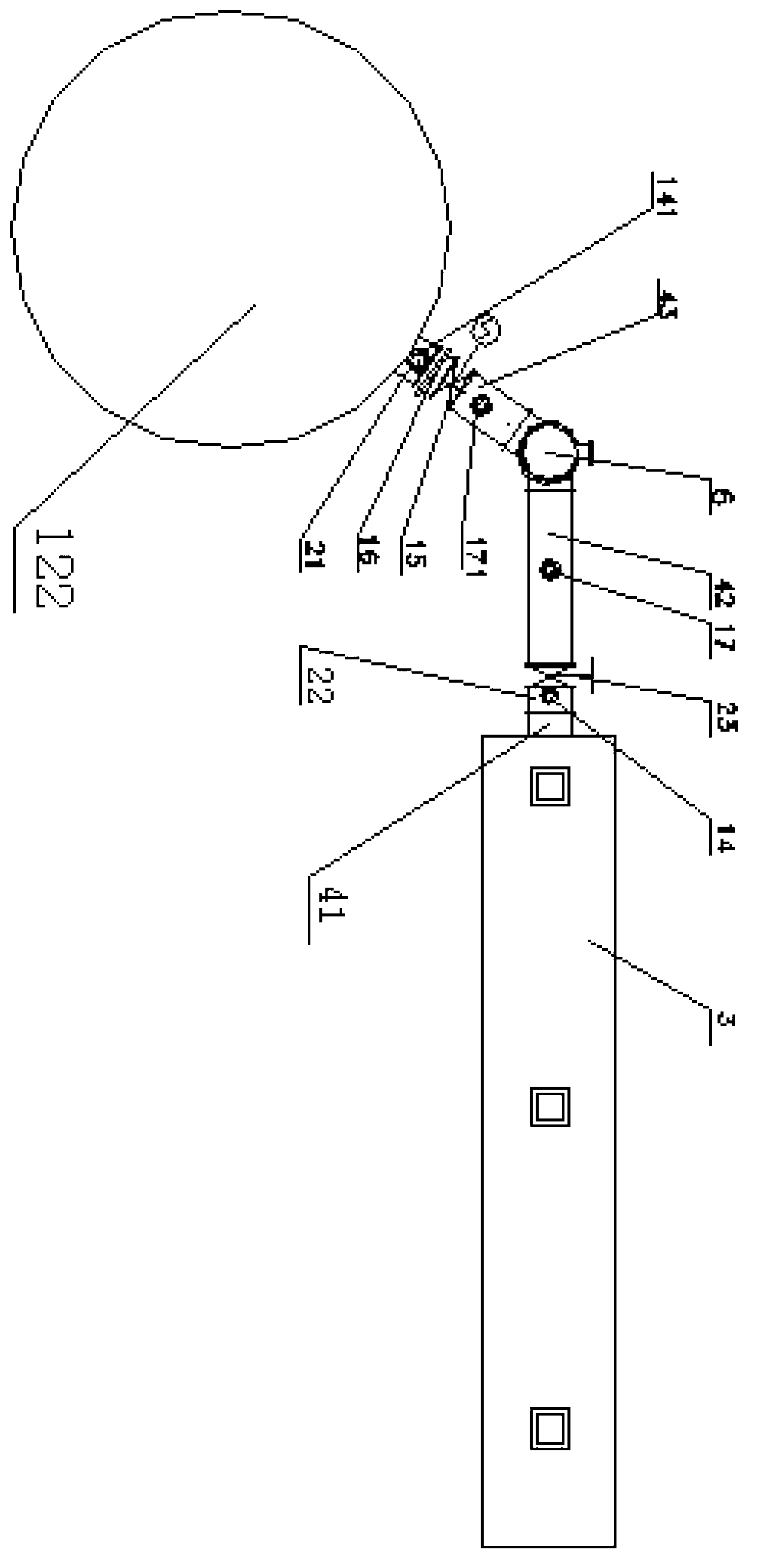

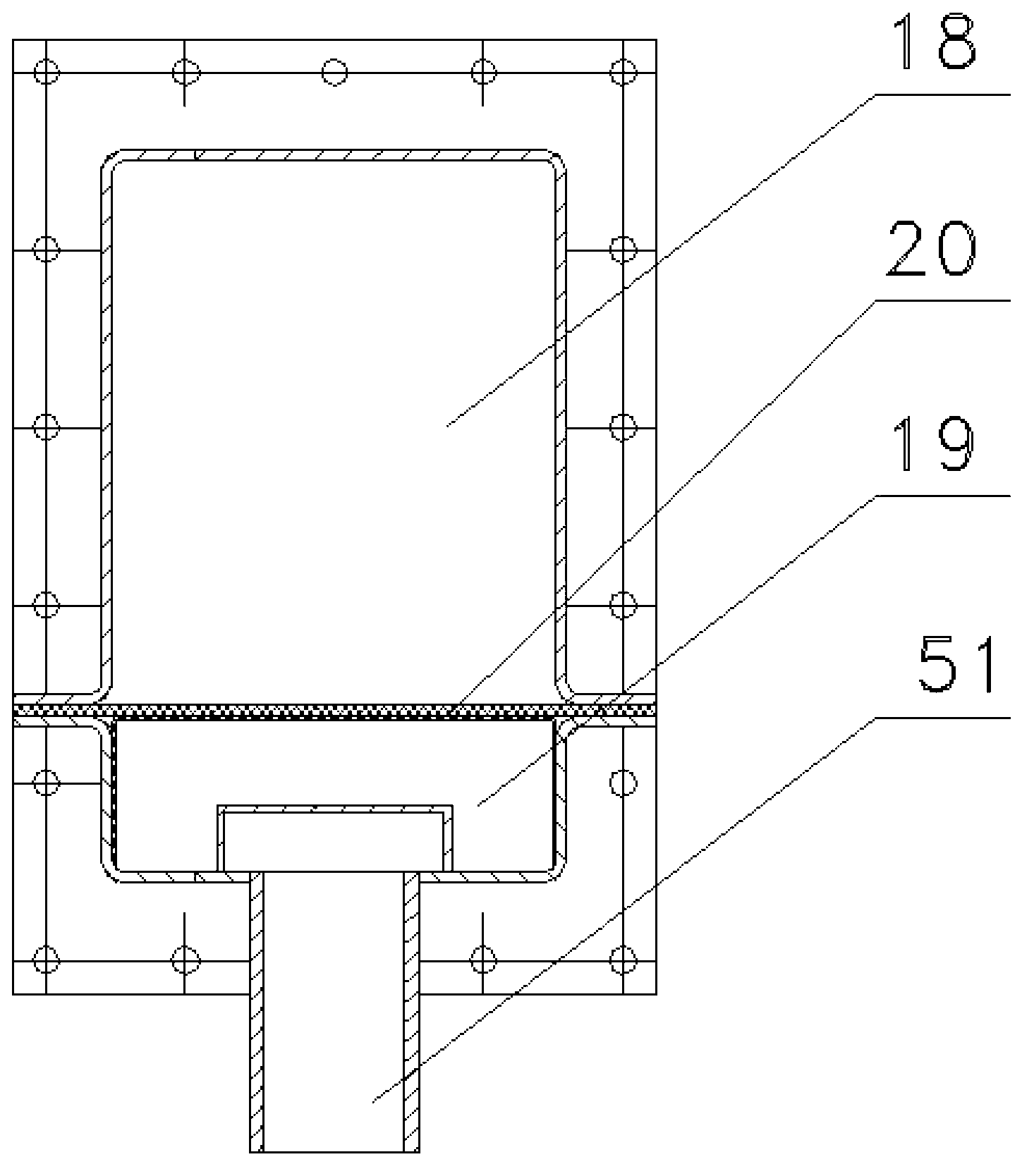

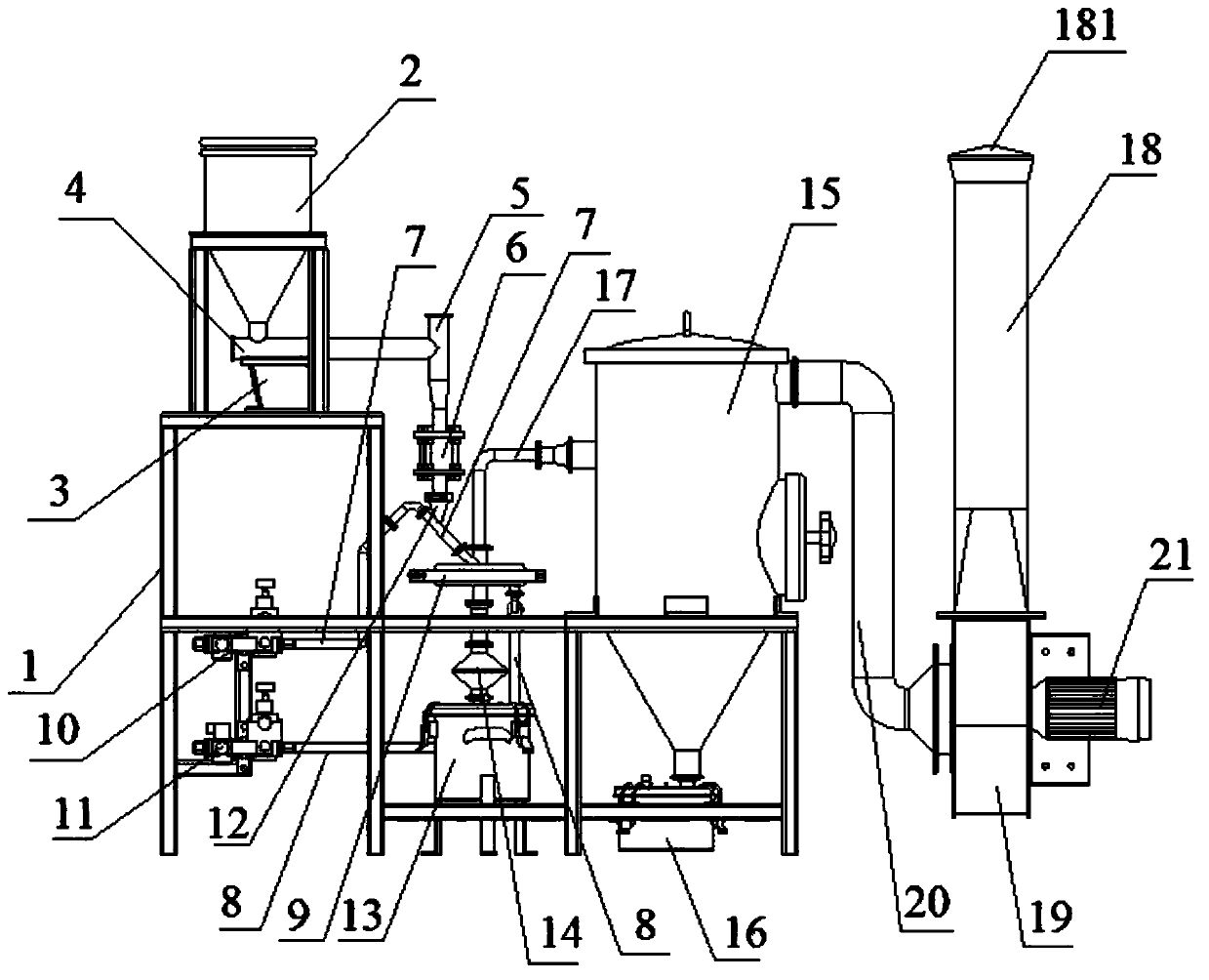

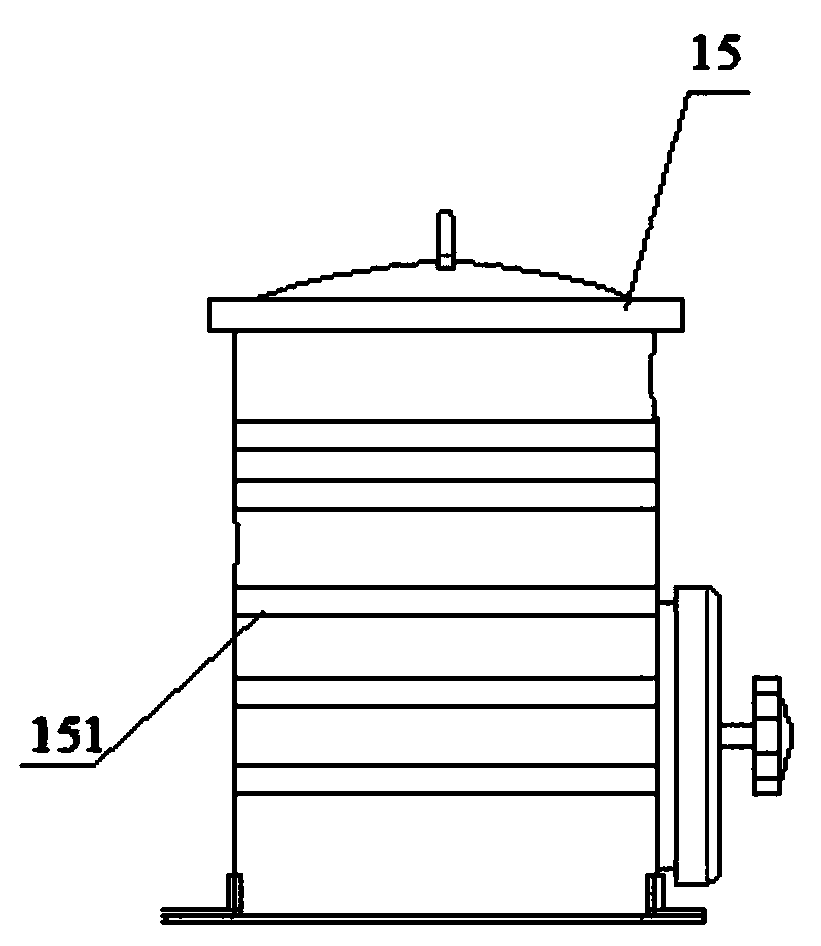

Combined coal powder storage and supply system

The invention relates to a combined coal powder storage and supply system which comprises a coal powder storage tank, a weighing coal powder supply silo, a pulse-free coal powder supply device and a support; the coal powder storage tank is vertically arranged at the top of the support, the weighing coal powder supply silo is vertically arranged on the support below the coal powder storage tank, the pulse-free coal powder supply device is arranged below a discharging opening of the weighing coal powder supply silo, and a flexible connector in the center at the top of a sealing head of the weighing coal powder supply silo is connected with a discharging opening of the coal powder storage tank through a rotary valve; and a fluidization component is arranged on the outer wall of a conical hopper of the coal powder storage tank, and a coal powder anti-arching stirring device is arranged on a hopper of the weighing coal powder supply silo. The invention has compact structure, reasonable layout, automatic feeding and stable supply and can solve the problems frequently existing in the ordinary coal storage silo and the supply silo of birdnesting, bridging, rat hole, channeling, wall build-up, breakage, self combustion, and the like; and the invention can be widely used in any situation where the small and medium-sized industrial coal powder boilers are required.

Owner:CHINA COAL RES INST CCRI ENERGY SAVING TECH CO LTD

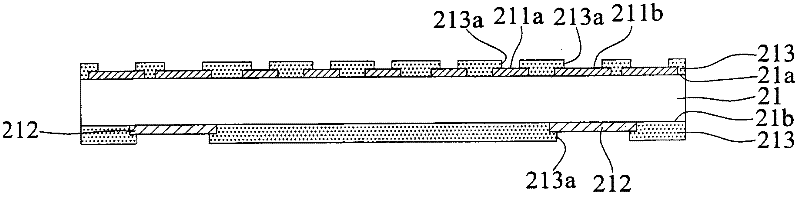

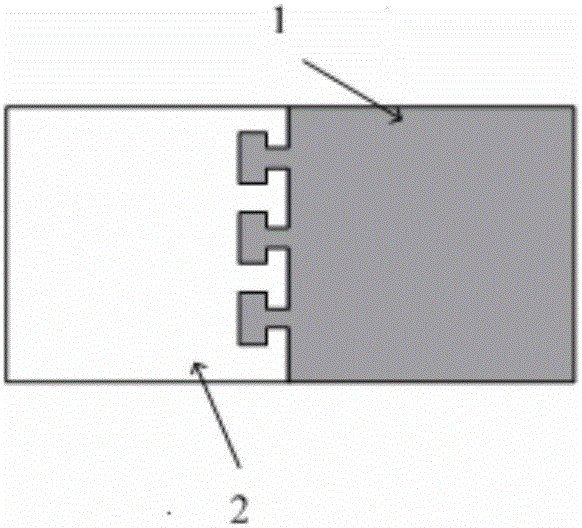

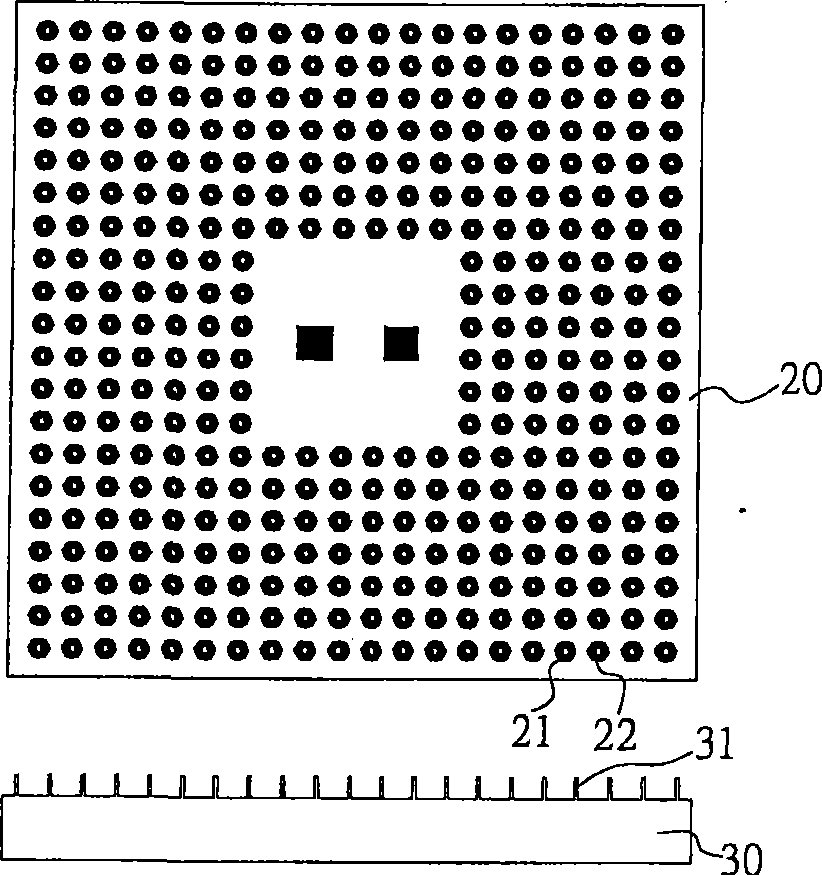

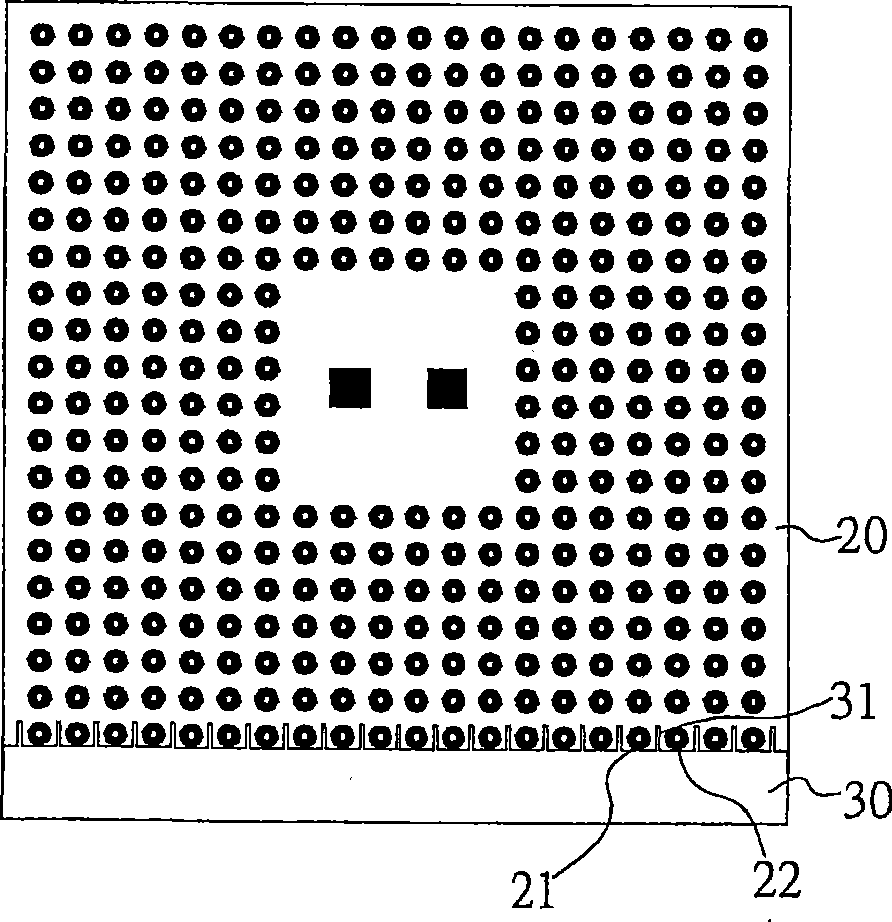

Packaging and stacking device and method for manufacturing same

InactiveCN102637678AWill not polluteEasy to stackSemiconductor/solid-state device detailsSolid-state devicesAdhesiveEngineering

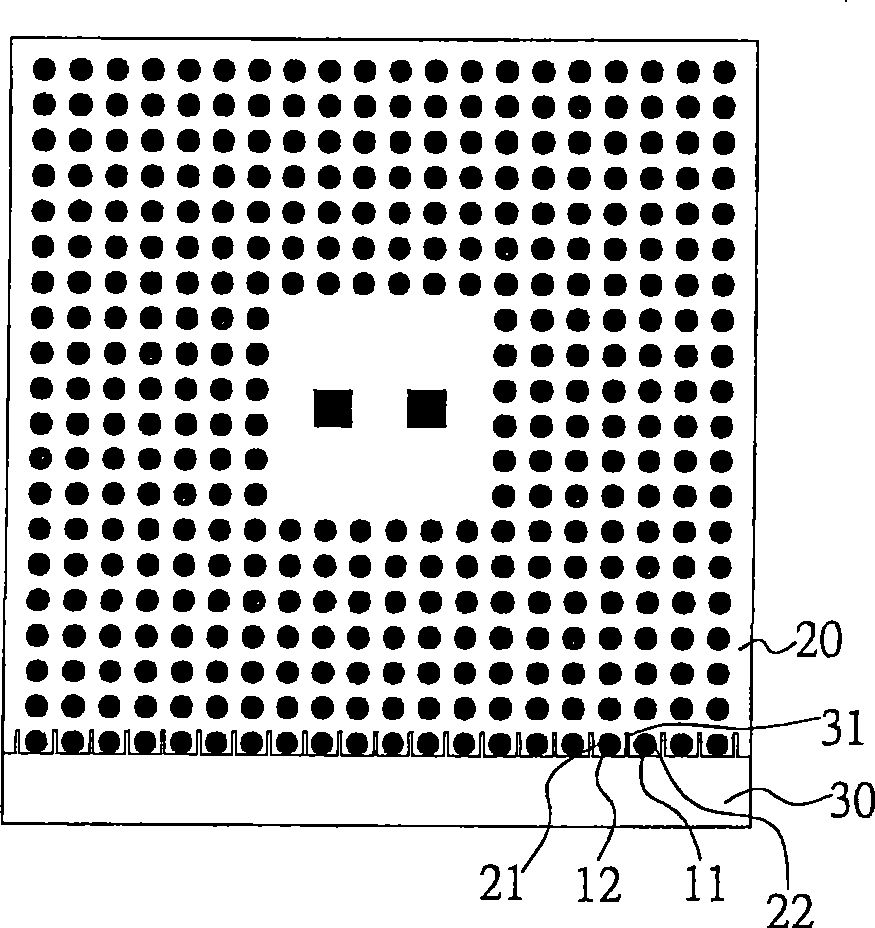

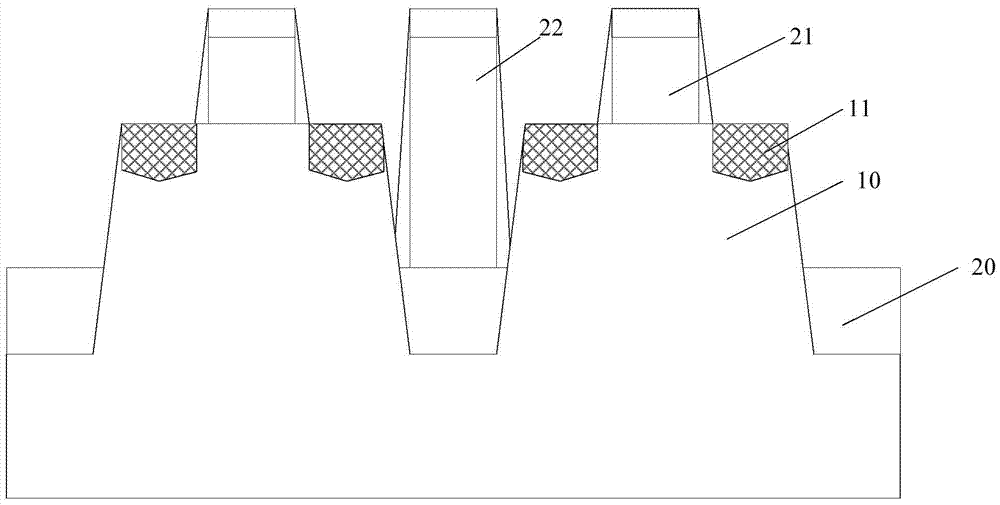

Disclosed are a packaging and stacking device and a method for manufacturing the same. The packaging and stacking device comprises a first packaging structure, a second packaging structure and packaging adhesive, a first metal column and a first electronic component are arranged on the surface of the first packaging structure, a second metal column and a second electronic component are disposed on the surface of the second packaging structure, the packaging adhesive is arranged between the first packaging structure and the second packaging structure and covers the first electronic component, the second packaging structure is stacked on the first packaging structure by means of connecting the second metal column with the first metal column, accordingly, the two packaging structures are not supported by the metal columns, a gap between the two packaging structures is filled by the packaging adhesive, and a substrate can be prevented from warping.

Owner:UNIMICRON TECH CORP

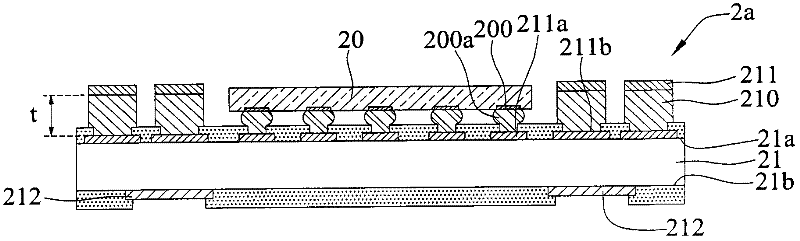

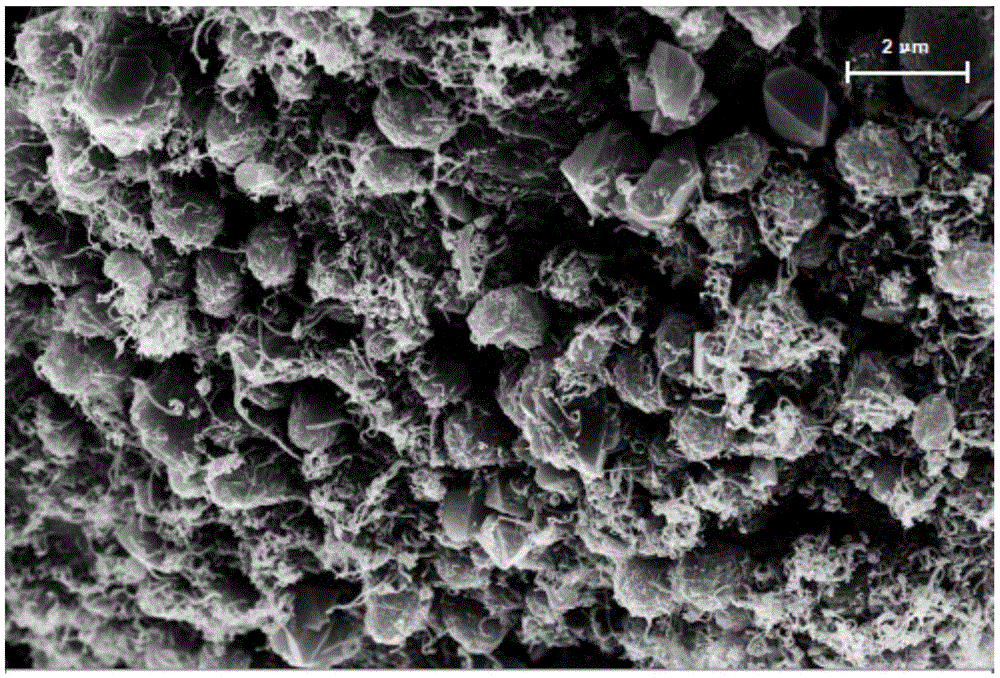

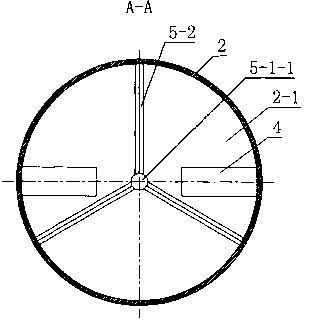

Preparation method for superparamagnetic nanoparticle photocatalyst with Fe3O4-PAMAM-TiO2 core-shell structure

InactiveCN104923309AReduce direct contactReduce in quantityOrganic-compounds/hydrides/coordination-complexes catalystsNanoparticlePolyamide

The invention relates to a method for preparing a superparamagnetic nanoparticle photocatalyst with a Fe3O4-PAMAM-TiO2 core-shell structure by using polyamide-amine (PAMAM) dendrimer as a template and an isolation layer in a low-temperature aqueous solution. The method is characterized by comprising the following steps: firstly, with the PAMAM dendrimer as the template, preparing a superparamagnetic Fe3O4-PAMAM nanoparticle colloidal solution by using a co-precipitation method; then adding the PAMAM dendrimer with different terminal groups and coating Fe3O4-PAMAM nanoparticles so as to form a dendrimer isolation layer; finally, dropwise adding a TiCl4 absolute ethanol solution, and carrying out normal pressure reaction and hydrothermal reaction so as to obtain the nanoparticles with the Fe3O4-PAMAM-TiO2 core-shell structure and a complete TiO2 shell layer; and carrying out washing and redispersion so as to obtain the nanoparticle photocatalyst with the Fe3O4-PAMAM-TiO2 core-shell structure.

Owner:SHANDONG UNIV OF TECH

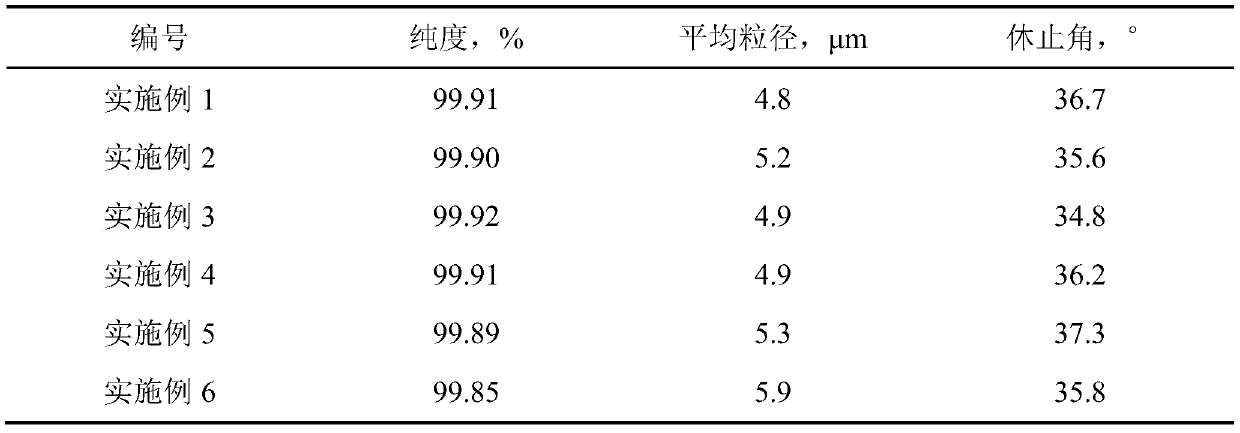

Sn0.3Ag0.7Cu lead-free solder paste and preparation method thereof

InactiveCN104785948AGood adhesionNon stickyWelding/cutting media/materialsSoldering mediaActive agentFilm-forming agent

The invention discloses Sn0.3Ag0.7Cu lead-free solder paste. The Sn0.3Ag0.7Cu lead-free solder paste particularly comprises, by mass, 9-11% of scaling powder and 89-91% of soldering tin powder. The scaling powder comprises, by mass, 20-25% of rosin, 15-20% of film-forming agent, 15-20% of active agent, 5-10% of thixotropic agent, 1-3% of acidity regulator and the balance solvent. The invention further discloses a preparation method of the Sn0.3Ag0.7Cu lead-free solder paste. The method comprises the steps that the solvent and the film-forming agent are stirred at 75 DEG C to be transparent, and the mixture is cooled to be at the temperature of 65 DEG C, added with the film-forming agent, cooled to be at the temperature of 55 DEG C and added with the active agent to be stirred to be transparent; the mixture is cooled to be at 55 DEG C and added with the thixotropic agent to be stirred to be transparent; the mixture is cooled to be at normal temperature and added with the acidity regulator to be stirred for 15 min, and then the mixture and solder powder are mixed and stirred to obtain the Sn0.3Ag0.7Cu lead-free solder paste. The solder paste is good in printing technology and welding performance, residues left after welding evenly cover the surface welding spots, and the effects of electrical insulation, welding spot protection and the like are achieved.

Owner:XIAN UNIV OF TECH

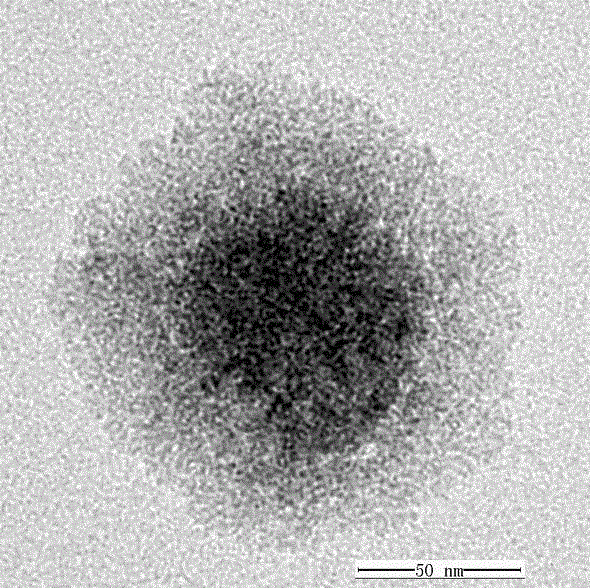

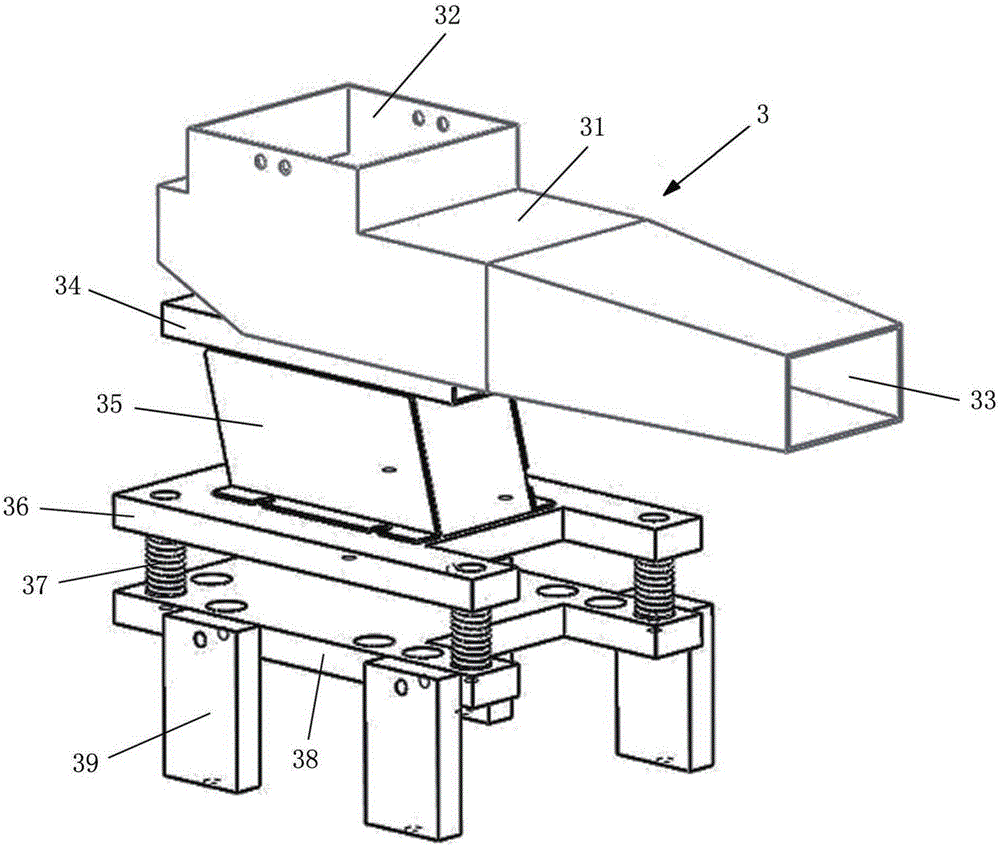

Automatic Chinese medicine acquisition device

PendingCN107436172ASimplify the drug dispensing processReduce labor inputWeighing apparatus with automatic feed/dischargeMedicinal herbsProcess engineering

The invention discloses an automatic Chinese medicine acquisition device. The automatic Chinese medicine acquisition device comprises a mounting support, a Chinese medicine storage case fixed on the support, a Chinese medicine outlet mechanism which is mounted on the support and is arranged below the Chinese medicine storage case to receive Chinese medicine falling from a Chinese medicine outlet, a Chinese medicine feeding mechanism which is mounted on the support, is used for receiving the Chinese medicine from the Chinese medicine outlet mechanism and outputting the received Chinese medicine and comprises a weighing unit used for weighing the received Chinese medicine, and a control system used for controlling Chinese medicine amount of the Chinese medicine outlet mechanism according to the weighing result of the weighing unit to acquire Chinese medicine at predetermined amount, wherein a bottom portion of the Chinese medicine storage case is provided with the Chinese medicine outlet. The automatic Chinese medicine acquisition device is advantaged in that automatic efficient Chinese medicine quantification is realized, processing efficiency of Chinese medicine prescriptions and Chinese medicine material acquisition precision are improved, and thereby artificial labor intensity is reduced.

Owner:杭州东程科技有限公司

Flexible die for molded composite material stringer and preparation method thereof

The invention belongs to the field of technical manufacturing, and particularly relates to a die for a molded composite material stringer, which can be used for guaranteeing that impressed pressure is effectively transferred in a curing process, effectively controlling the defects of layering and pores and meanwhile guaranteeing the dimensional accuracy of a work piece, and a preparation method thereof. The flexible die comprises at least one molding unit, wherein the section of the molding unit is in an L shape or a C shape; the molding unit which is in the L shape comprises at least one flexible module and two rigid modules; and the molding unit which is in the C shape comprises at least two flexible modules and three rigid modules. The die for the molded composite material stringer and the preparation method thereof have the beneficial effects that the defects of the layering and the pore can be effectively controlled; the location of the die is facilitated; the axis degree and the straightness degree of the stringer are guaranteed; the violent assembly of the die can be avoided; the labor intensity is decreased; the work efficiency is improved; a segmental structure is adopted; and the blocking partition of the flexible die is about to be more flexible.

Owner:BEIJING AERONAUTIC SCI & TECH RES INST OF COMAC +1

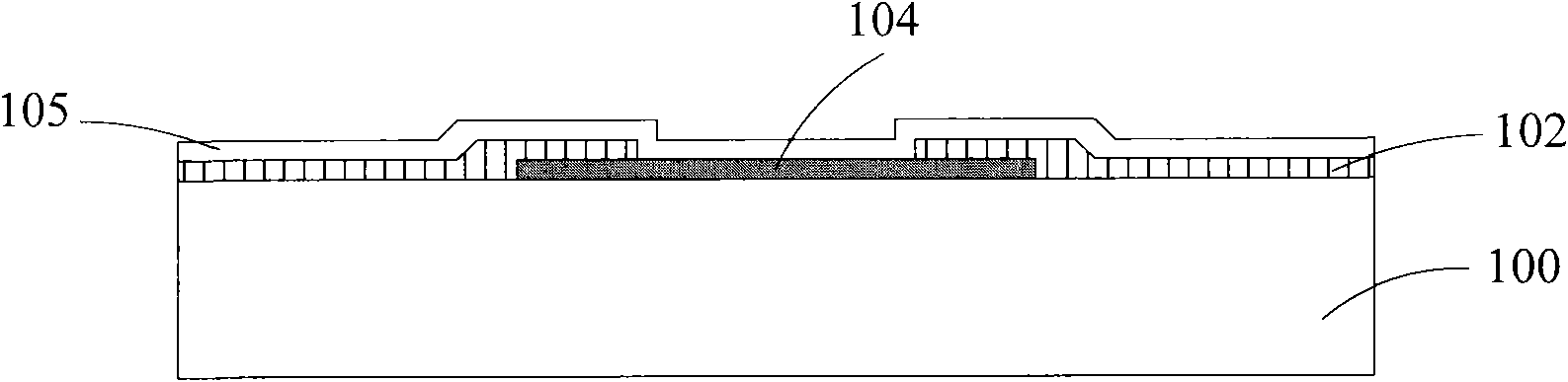

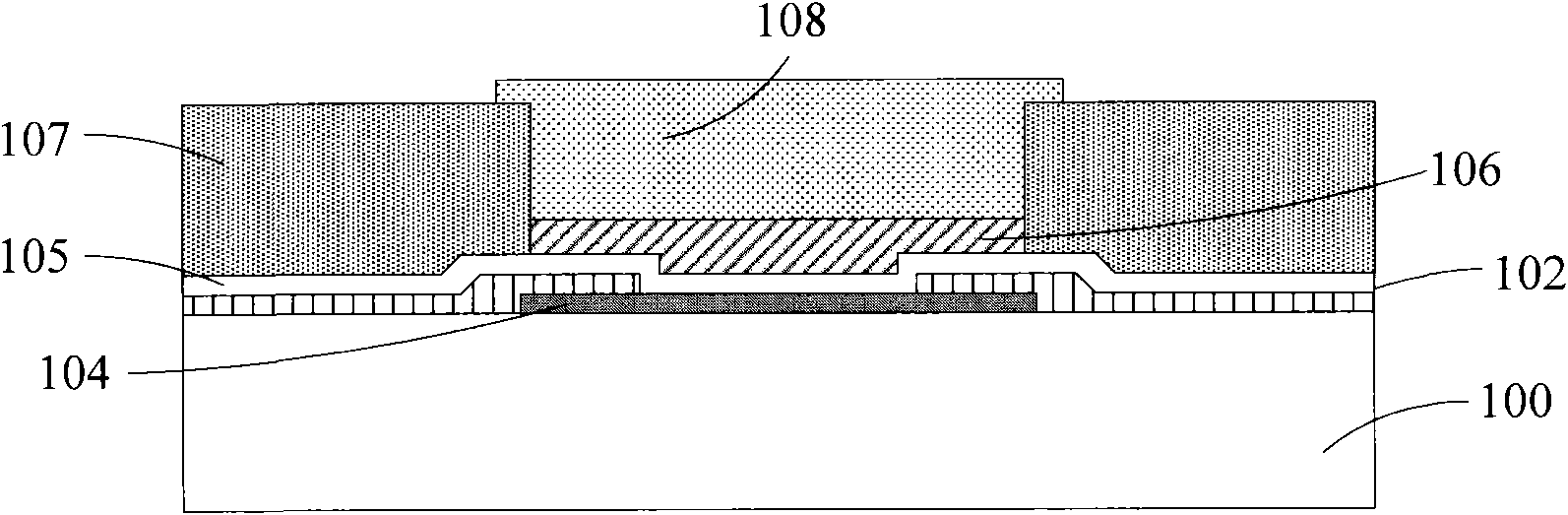

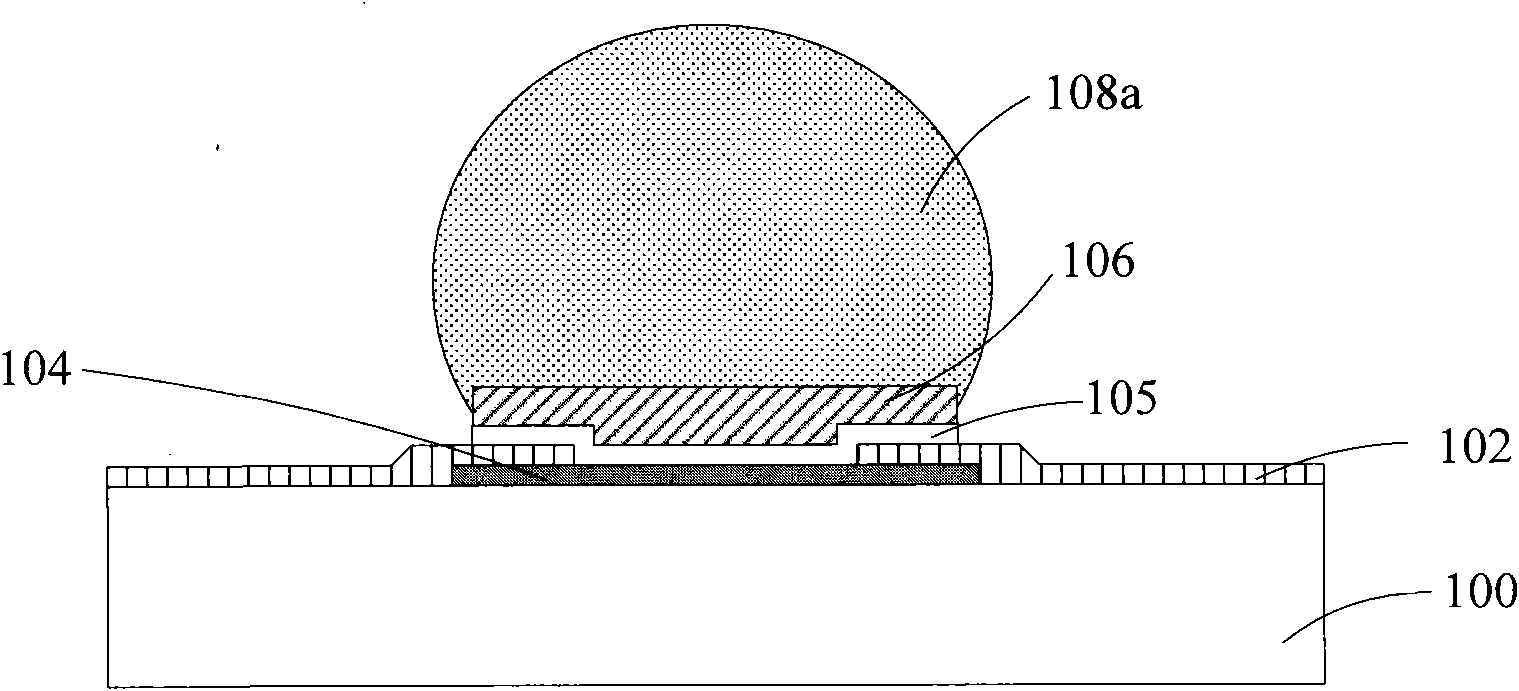

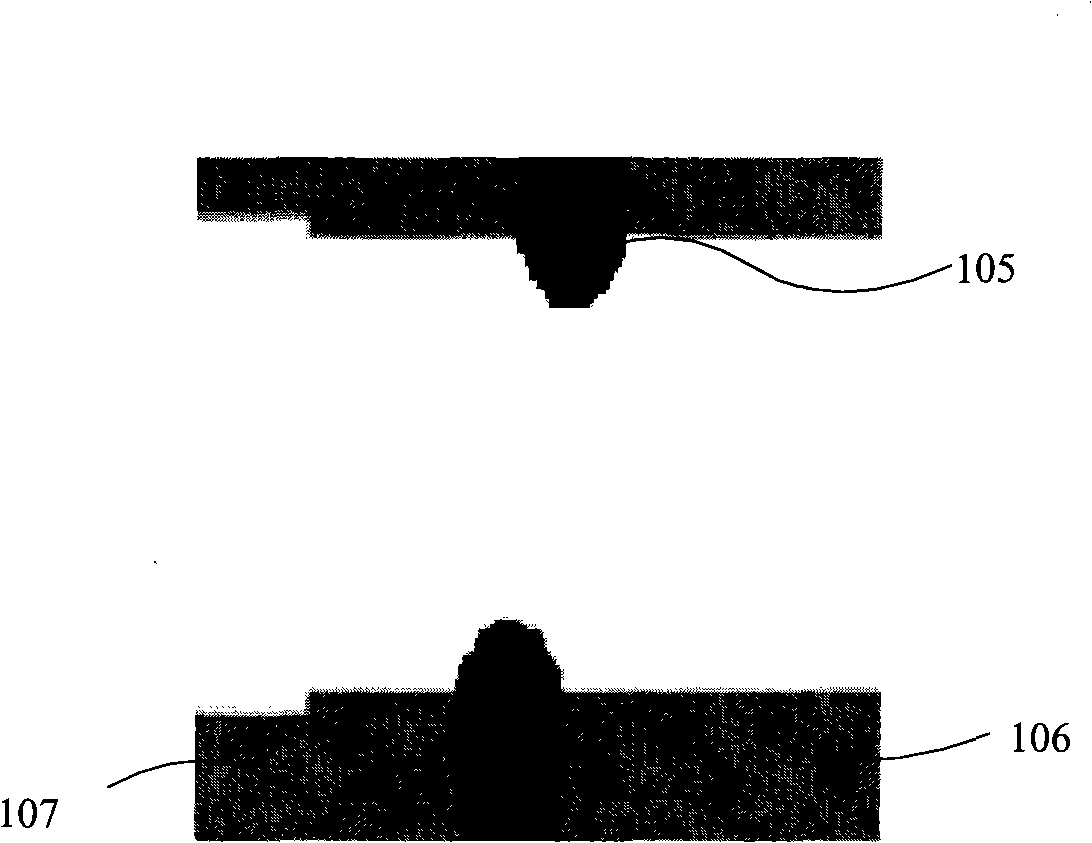

Method for fabricating bump

InactiveCN101740422ANo bridgingGuaranteed reliabilitySolid-state devicesSemiconductor/solid-state device manufacturingCopper metalCopper cylinder

The invention discloses a method for fabricating a bump. The method comprises the following steps of: providing a chip on which a solder layer is formed; placing the chip in a refluxing device, wherein the solder layer is positioned below the surface of the chip; and refluxing the solder layer to form the bump. The method for fabricating the bump ensures the reliability of a metal layer below the bump; the bump does not cause a bridging phenomenon so as to avoid a short circuit; and the electrical property of a copper metal layer is improved in the fabricating process of the bump of a copper cylinder.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

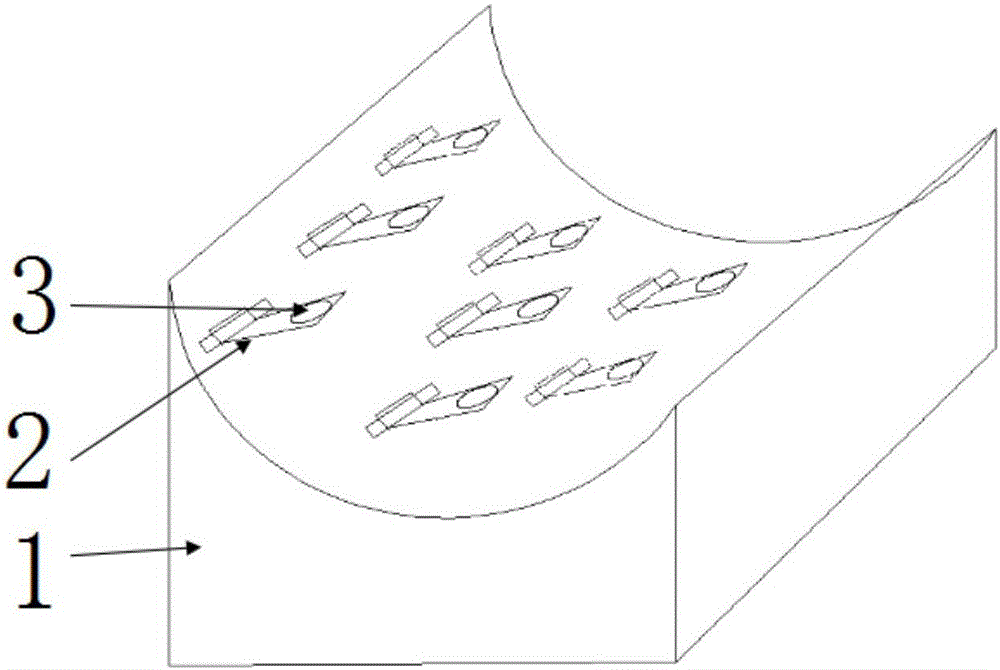

Metal frame reinforced ceramic composite material and preparation method and application thereof

ActiveCN109128005AControllable volumeControllable distributionFoundry mouldsFurnace typesTemperature controlCeramic composite

The invention belongs to the technical field of abrasion-resistant materials and discloses a metal frame reinforced ceramic composite material and a preparation method and application thereof. An outer shell of the metal frame reinforced ceramic composite material is a reinforced metal frame, and a reinforcement composite block is arranged in an inner cavity of the outer shell. The preparation method includes that raw materials are subjected to mixing, pressing and liquid-phase sintering to obtain the metal frame reinforced ceramic composite material for preparing high-abrasion-resistance composite lining plates or high-abrasion-resistance composite roller sleeves. The method is low in production cost, crack sources resulted from sudden heating and cooling of ceramic particles and metal frame leakage can be avoided through temperature-controlled sintering and cooling, and the ceramic particles are controllable in volume fraction and distribution state. After subsequent thermal treatment, the high-abrasion-resistance composite lining plates or high-abrasion-resistance composite roller sleeves prepared from the metal frame reinforced ceramic composite material are high in performance, great in interface bonding and free of macroscopic defects such as holes, segregation, cracks and the like.

Owner:一重集团(天津)新材料有限公司

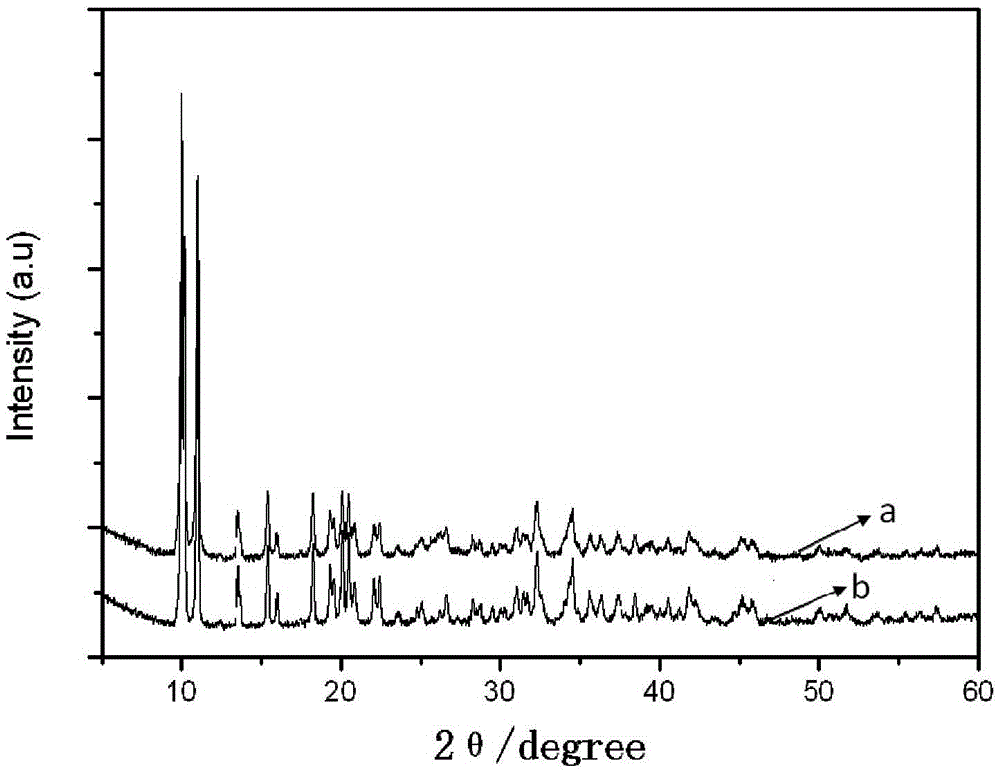

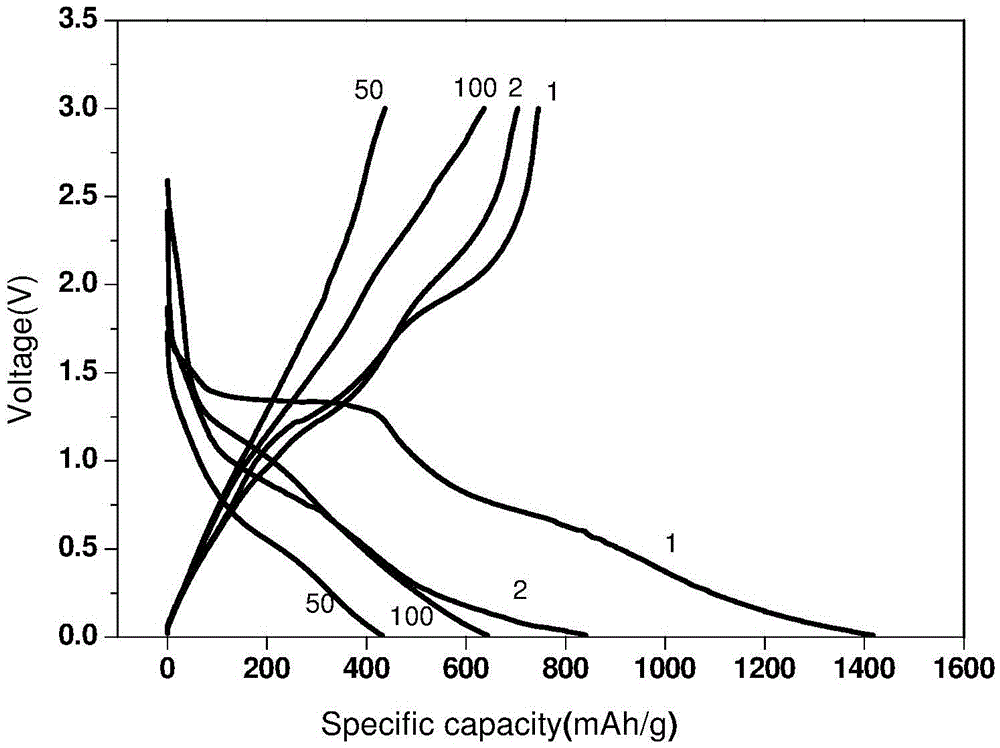

Metal formate/carbon nano tube lithium ion battery cathode material and preparing method thereof

InactiveCN105489894AGood electronic conductivityImprove conductivityCell electrodesSecondary cellsCarbon nanotubeFormic acid

The invention belongs to the technical field of lithium ion battery electrode materials, and discloses a metal formate / carbon nano tube lithium ion battery cathode material and a preparing method thereof. The lithium ion battery cathode material is prepared from metal nitrate, formic acid, N,N-dimethylformamide and acidized carbon nano tubes, wherein the metal nitrate includes nickel nitrate, cobalt nitrate, zinc nitrate and manganous nitrate, the molar ratio of the metal nitrate to formic acid is 1:5-1:8, and the mass of the acidized carbon nano tubes accounts for 10-40% that of the metal nitrate. The preparing method adopts a solvothermal method, conductivity of the obtained metal formate / carbon nano tube lithium ion battery cathode material is remarkably improved by means of effective cladding of the carbon nano tubes, the material has high specific capacity and circulation stability, respective advantages of the carbon nano tubes and a metal-organic framework material can be brought into play, and the material is an ideal lithium ion battery cathode material. The preparing method is simple in preparation technology and convenient and easy to operate.

Owner:CHANGAN UNIV

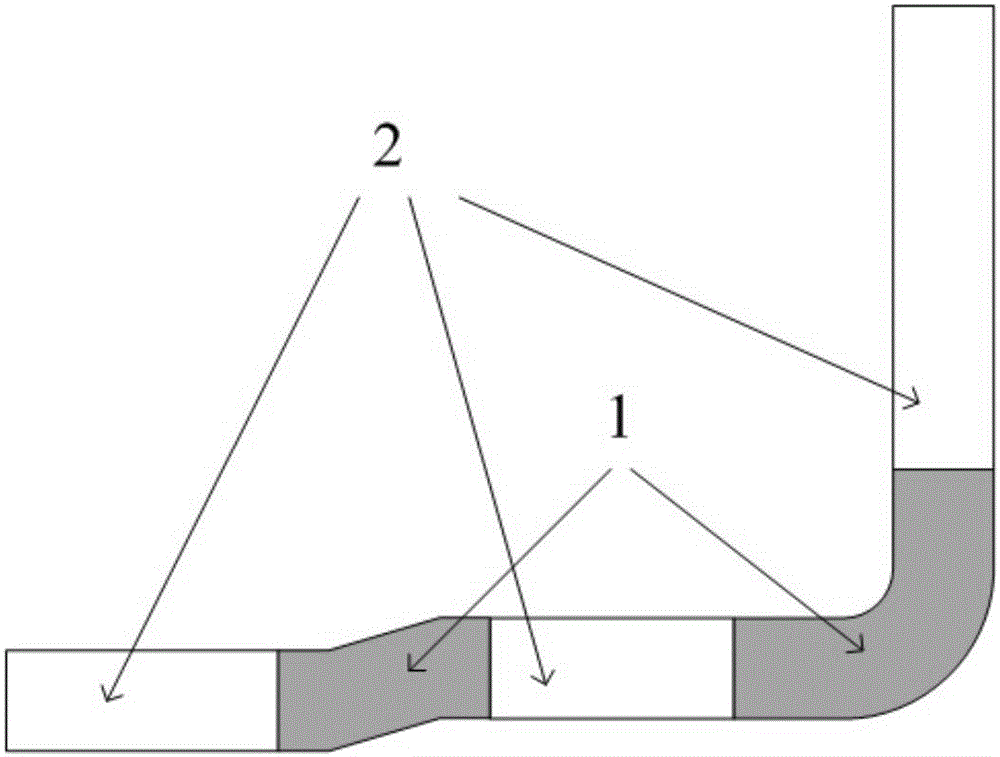

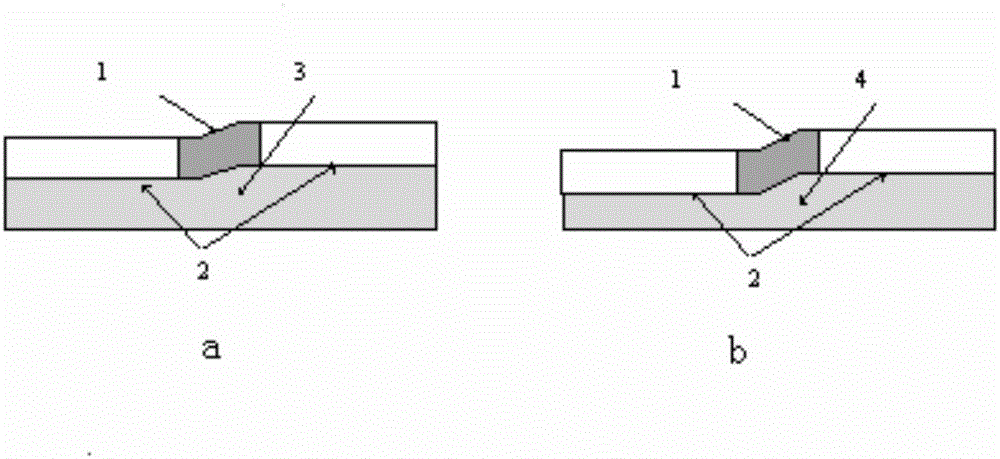

Method for avoiding solder bridge

ActiveCN101489359ANo bridgingImprove welding pass ratePrinted circuit assemblingPass rateEngineering

The present invention relates to a method for avoiding solder bridging. A plurality of insulation strips are respectively placed among a plurality of component holes of printed circuit board to be welded for insulating the adjacent component hole. Then welding is executed so that the component pins placed in the component hole are respectively combined fixedly with the printed circuit board through tin liquor, wherein the tin liquor is obstructed by the insulating strip. Thereby the improper solder bridging of two adjacent welding points on the component pins and component holes with small distance. Furthermore the welding pass rate can be increased and the maintenance cost of product in future is reduced.

Owner:MICRO-STAR INTERNATIONAL +1

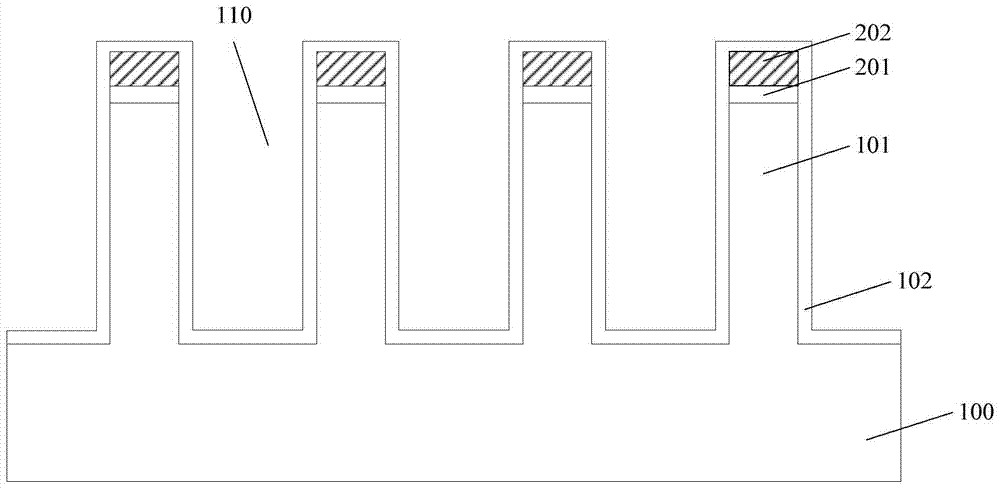

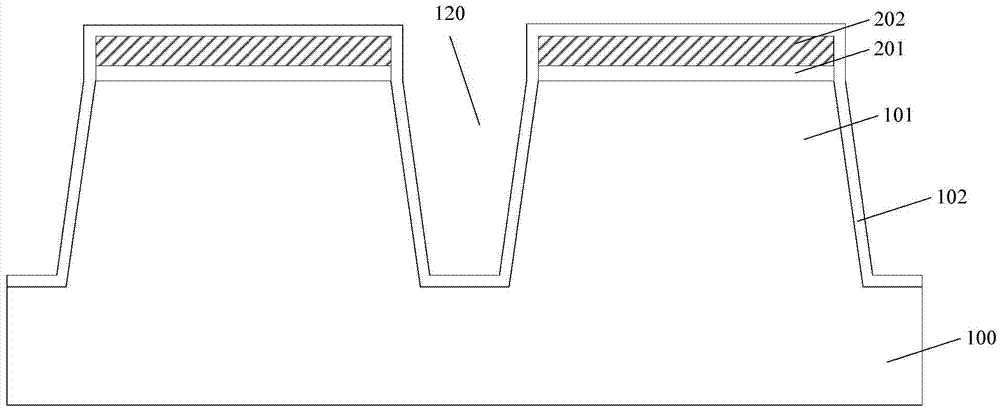

Formation method for semiconductor structure

ActiveCN106952818AIncreased stressImprove performanceSemiconductor/solid-state device manufacturingSemiconductor devicesEtching rateEngineering

Disclosed is a formation method for a semiconductor structure. The formation method comprises the steps of providing a semiconductor substrate; forming a plurality of fin parts, wherein a mask layer is arranged on the top arts of the fin parts, and first grooves and second grooves are formed between adjacent fin parts; forming an isolating layer in the first grooves and the second grooves; removing the mask layer to form a first dielectric layer and a second dielectric layer which cover the isolating layer and the fin parts; forming a patterned mask layer with openings on the surface of the second dielectric layer; performing ion implantation on the second dielectric layer along the openings; removing the patterned mask layer and performing annealing treatment to form a doping layer in the second dielectric layer, wherein the etching rate of the doping layer is less than that of the second dielectric layer; removing the second dielectric layer and a part of the doping layer of certain thickness; etching the first dielectric layer and remaining a part of the first dielectric layer of certain thickness; and etching the isolating layer to reduce the height, outside the second grooves, of the isolating layer. By virtue of the formation method, the non-etched isolating layer is formed, and a pseudo gate is formed on the surface of the non-etched isolating layer, so that performance of a to-be-formed transistor can be improved.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

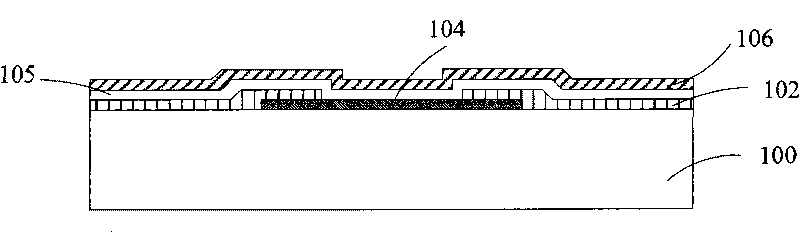

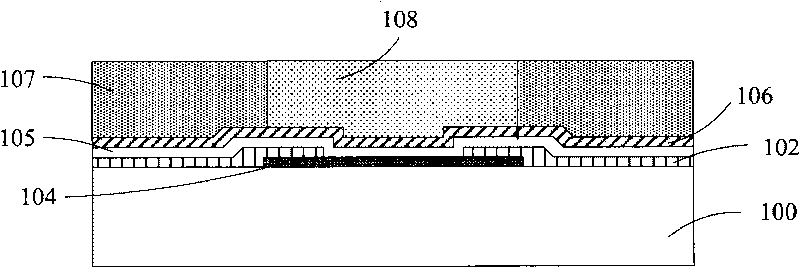

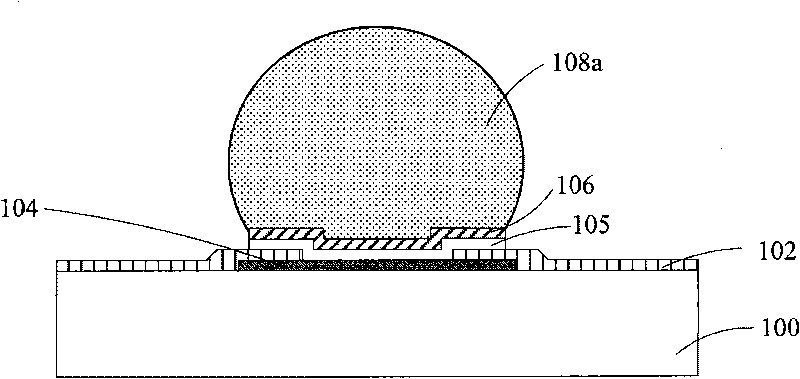

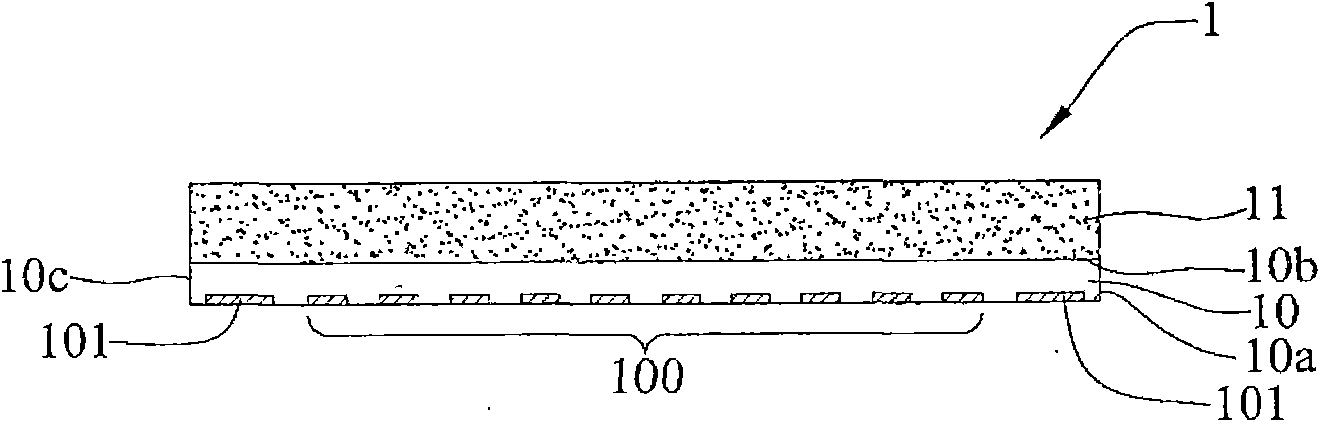

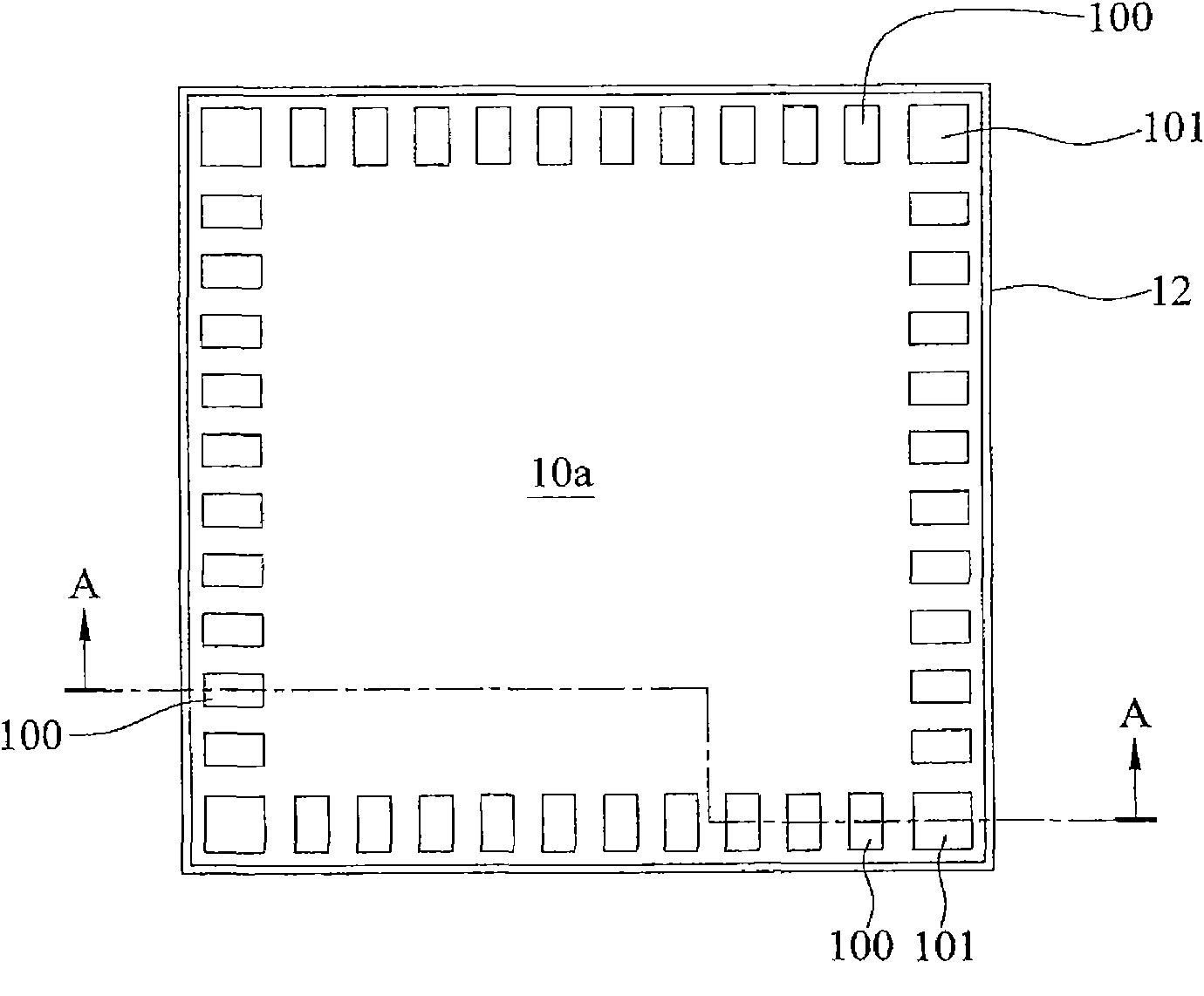

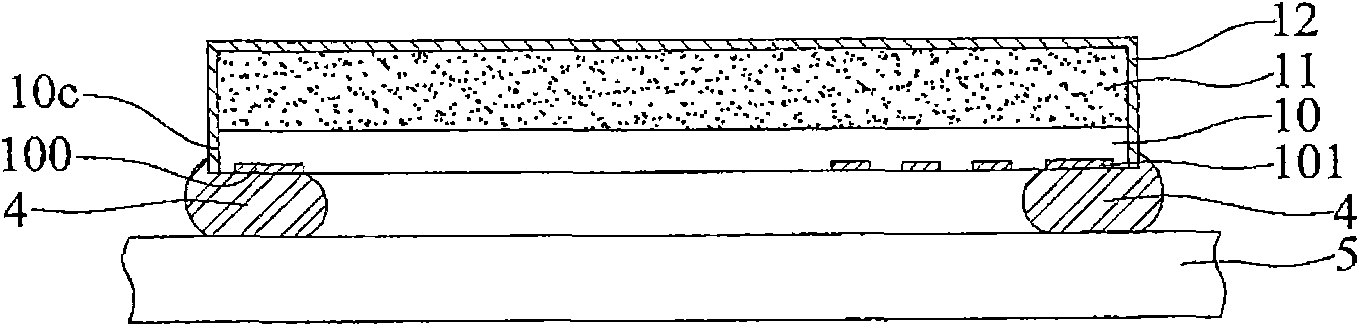

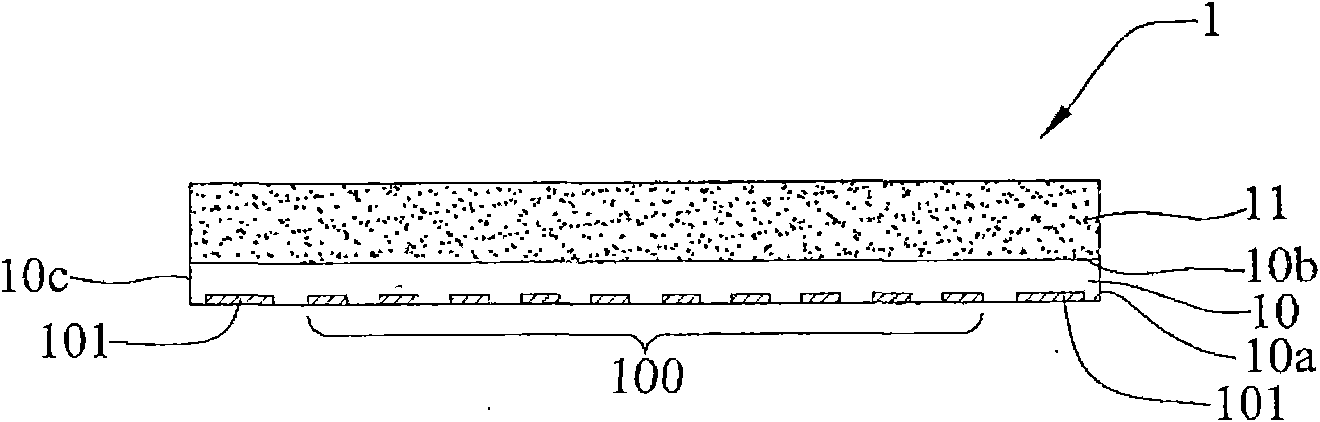

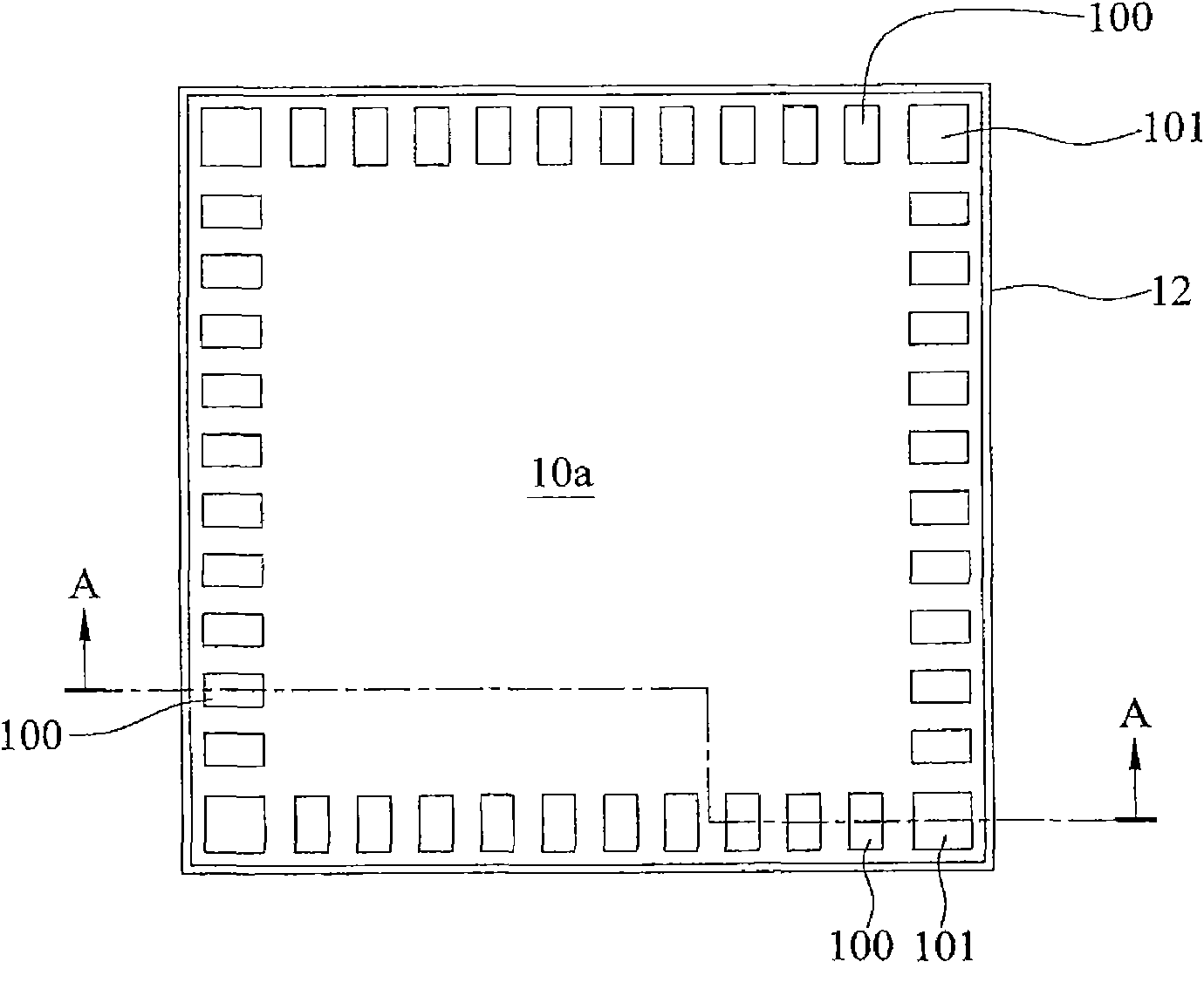

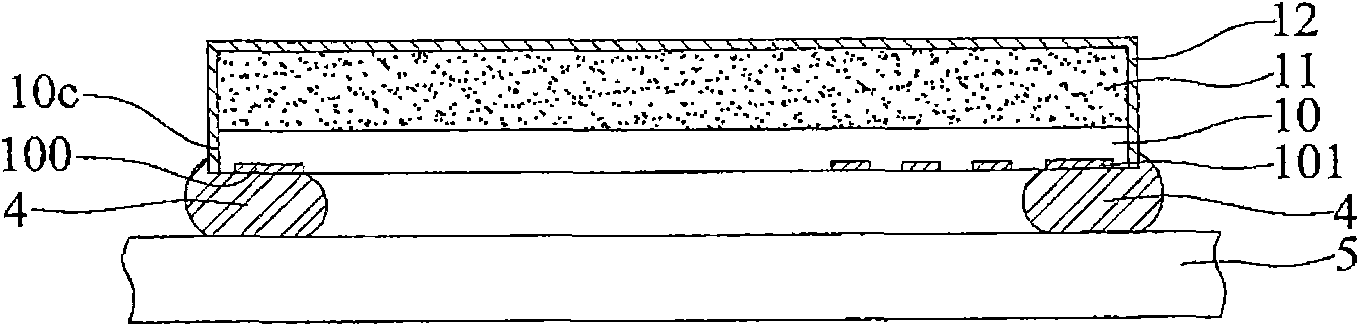

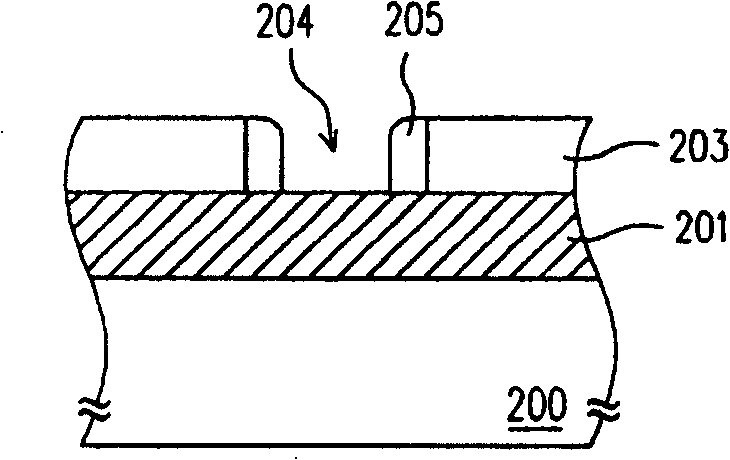

Semiconductor package and fabrication method thereof

ActiveCN102593104AAvoid short circuit conditionsNo bridgingFinal product manufactureSemiconductor/solid-state device detailsSemiconductor packageEngineering

A semiconductor package is provided, which includes a substrate unit having conductive pads and ESD protection pads formed on a bottom surface thereof; an encapsulant covering a top surface of the substrate unit; and a metal layer disposed on a top surface of the encapsulant and having connecting extensions formed on side surfaces of the substrate unit and the encapsulant for electrically connecting the ESD protection pads, wherein portions of the side surfaces of the substrate unit corresponding in position to the conductive pads are exposed from the metal layer so as to ensure that solder bumps subsequently formed to connect the conductive pads of the semiconductor package to a circuit board are not in contact with the metal layer, thereby effectively avoiding the risk of short circuits.

Owner:SILICONWARE PRECISION IND CO LTD

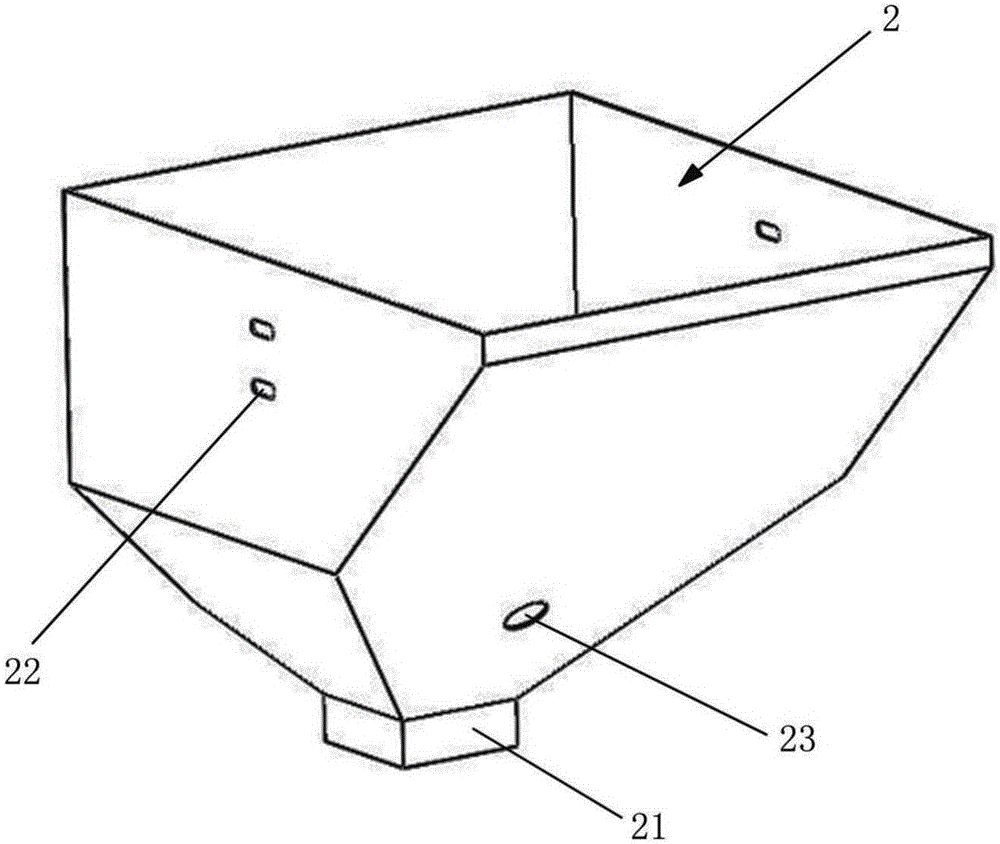

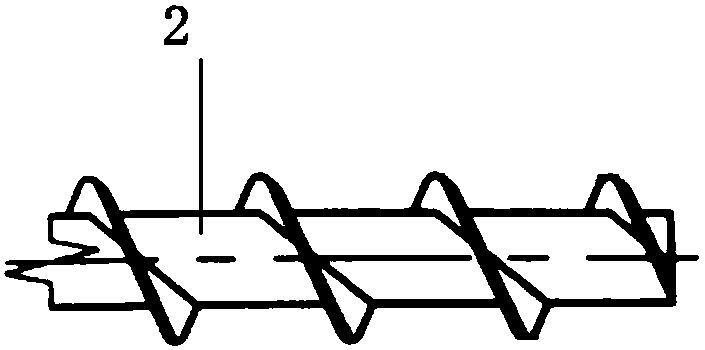

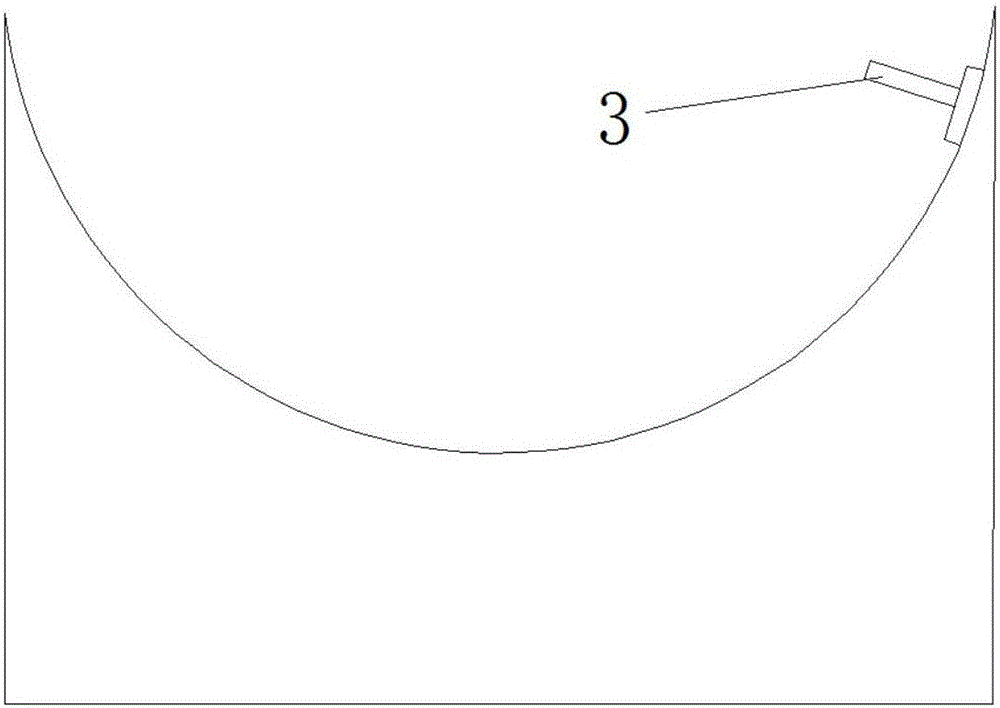

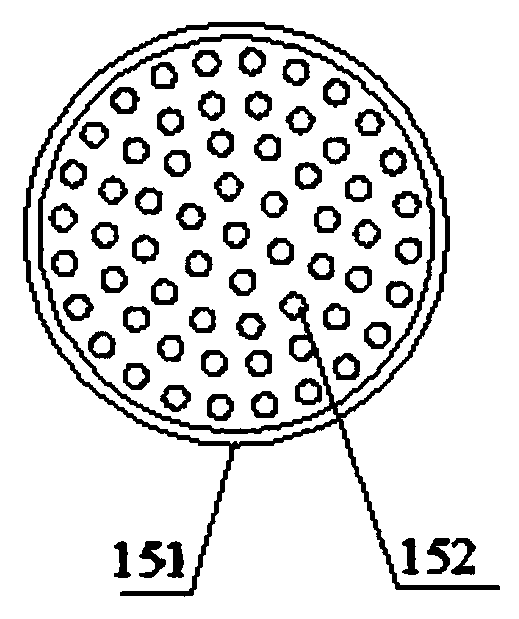

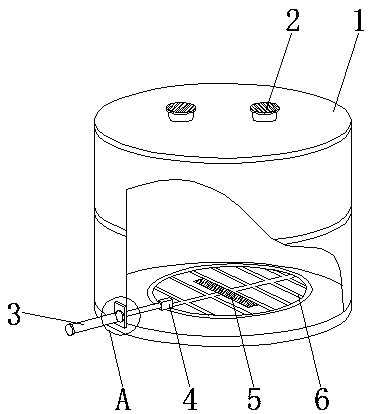

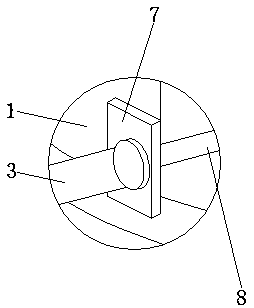

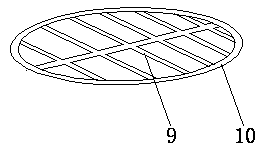

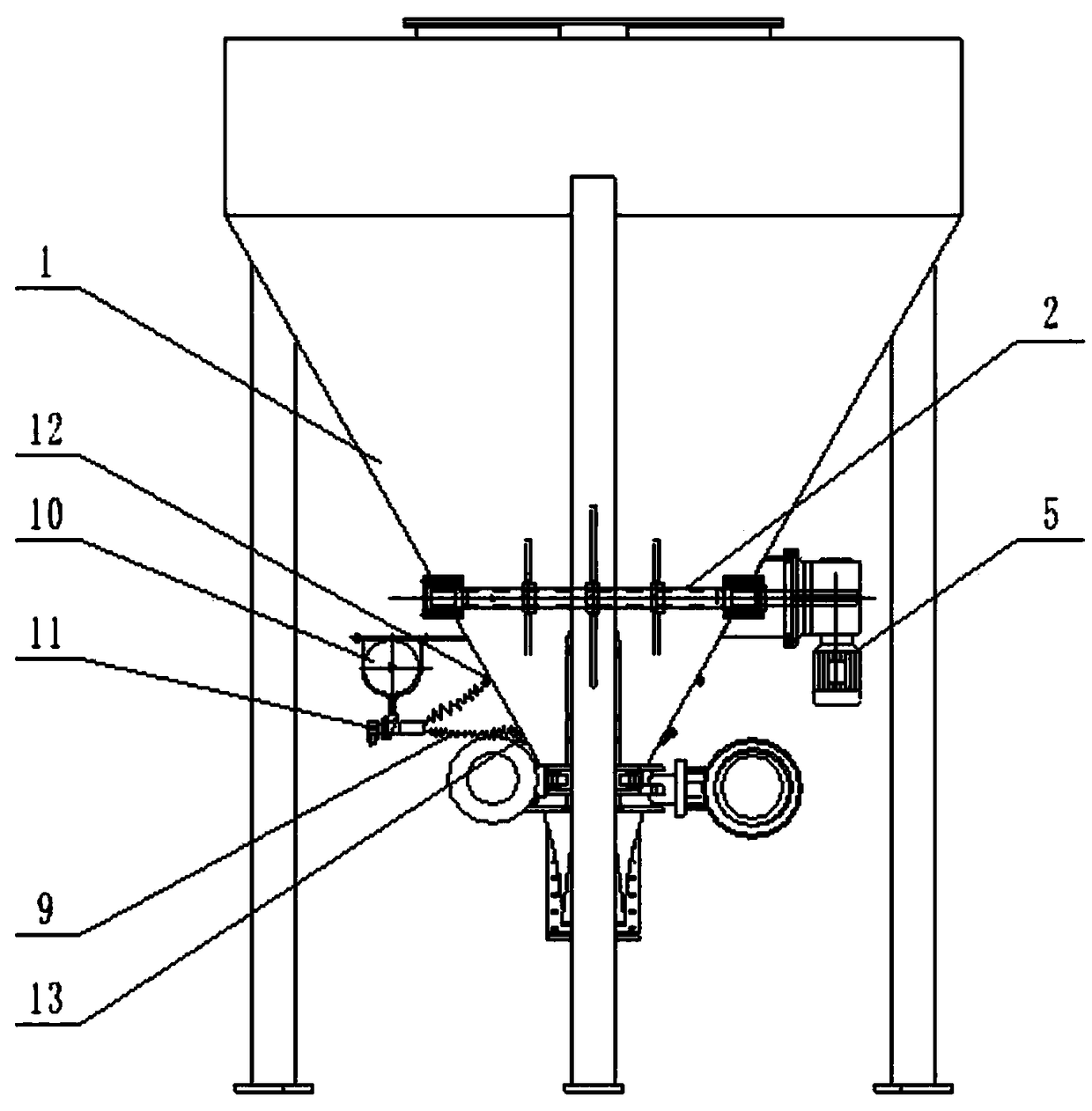

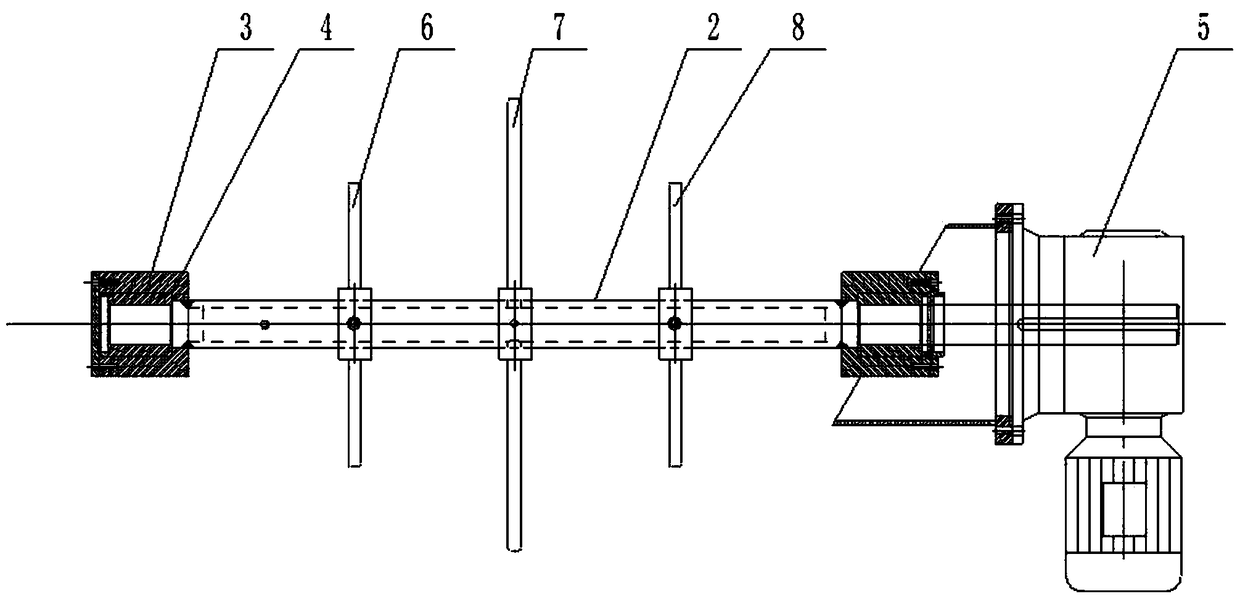

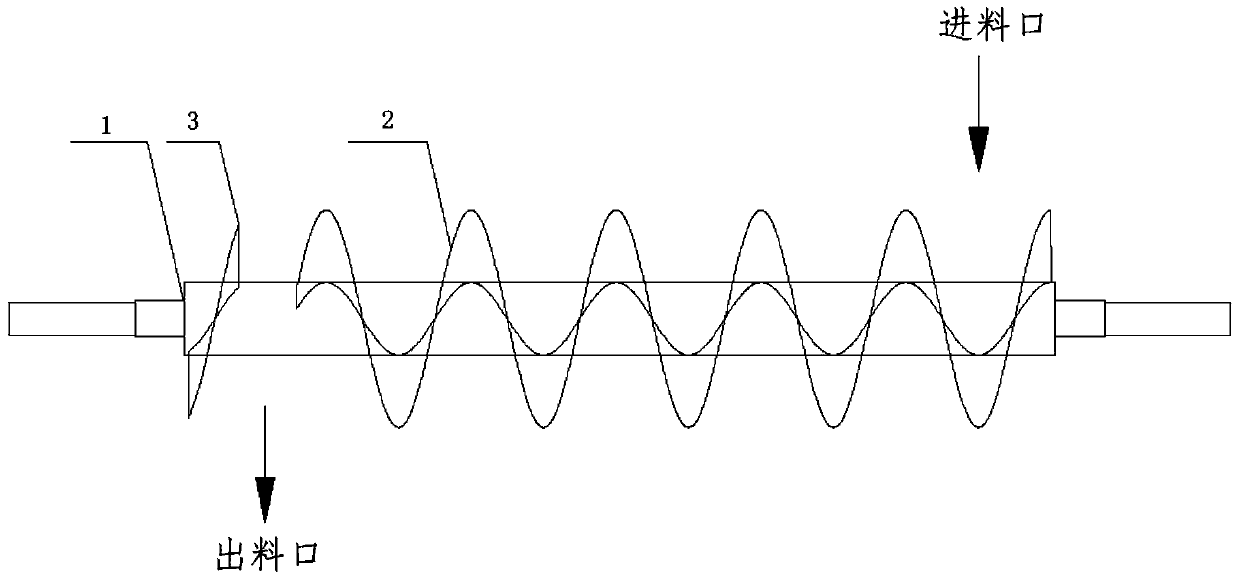

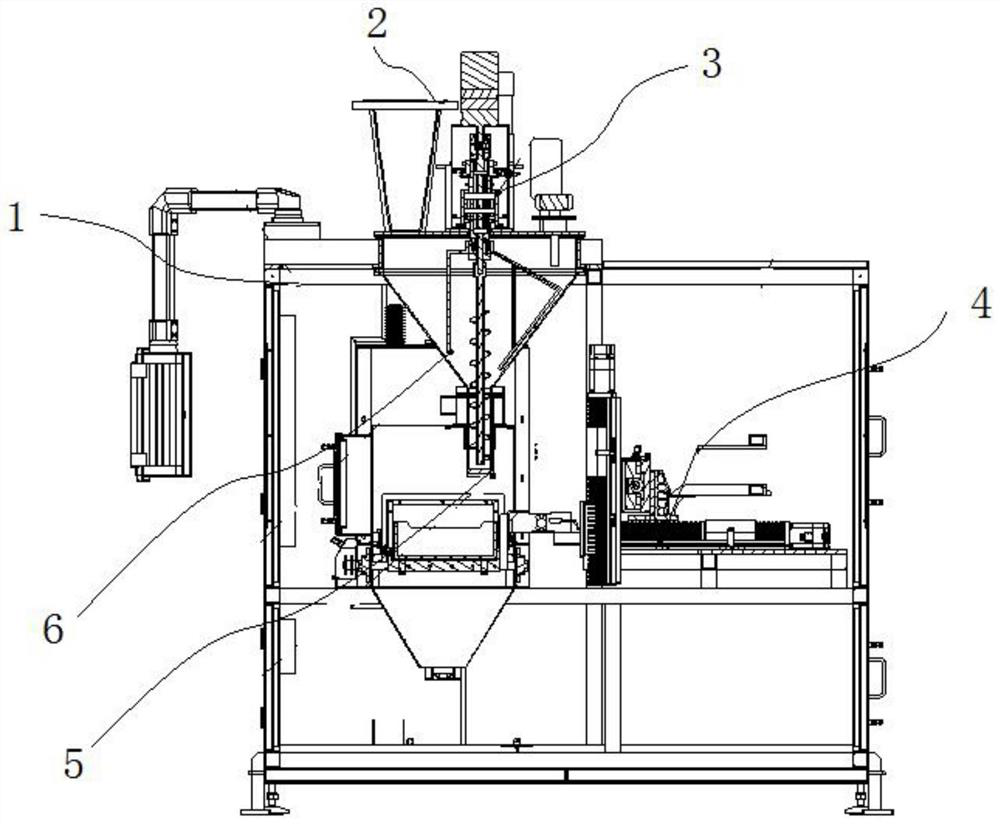

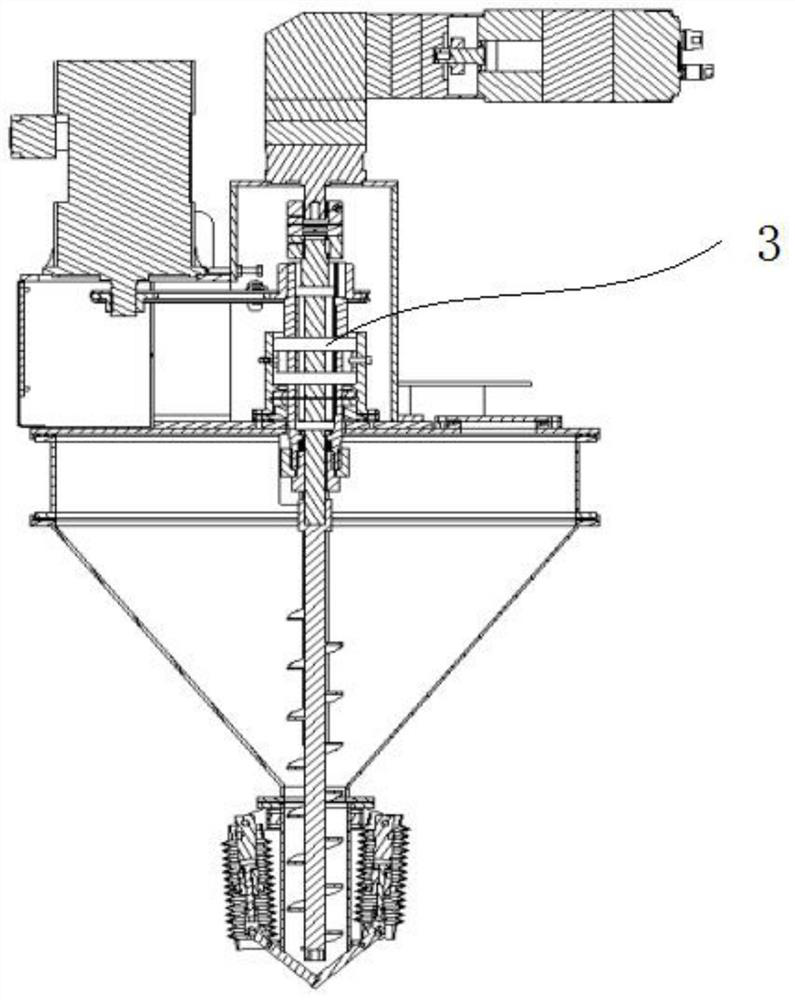

Powder feeding device

InactiveCN107618892AGuaranteed normal operationNo bridgingLarge containersLoading/unloadingCoalMaterials science

The invention belongs to the technical field of powder feeding. According to a powder feeding device, the technical problem that as for an existing powder feeding device, the coal powder bridging phenomenon is likely to occur, and thus feeding precision is low is solved. The powder feeding device comprises a feeding motor, a spiral shaft, a powder feeding pipe, a stirring motor, a hopper and a stirrer. The spiral shaft is arranged in the powder feeding pipe and connected with the output end of the powder feeding motor. An opening is formed in the upper portion of the powder feeding pipe. The lower end of the hopper is arranged over the opening. The stirrer is mounted in the hopper and connected with an output shaft of the stirring motor. The powder feeding device has the beneficial effectsthat the coal powder bridging phenomenon is avoided, normal operation can be achieved, and the powder feeding precision is high.

Owner:沈艳

Desulfurized ash delivery device

The invention provides a desulfurized ash delivery device which comprises a general ash hopper arranged below a secondary dust remover. The general ash hopper is provided with a plurality of ash hoppers. Each ash hopper is connected with the general ash hopper through a switch valve and a first extensible node. The general ash hopper is connected with an air supply pipe and is provided with a chute. The chute is connected with a first ash delivery channel. The first ash delivery channel is connected with a middle connecting pipe. The middle connecting pipe is connected with a shutoff valve. A first exhaust gas opening is formed in the upper portion of the middle connecting pipe. The middle connecting pipe is connected with a feeding machine. The shutoff valve is connected with a second ash delivery channel. The second ash delivery channel is connected with a third ash delivery channel through a diverting device. The other end of the third ash delivery channel is sequentially connected with a second extensible node and a connecting pipe. A second exhaust gas opening is formed in the upper portion of the connecting pipe. The desulfurized ash delivery device is capable of delivering desulfurized ash smoothly to a rection tower and preventing phenomena of building bridge, erecting bridge and jam from occurring in the process of the desulfurized ash delivery.

Owner:ZHENJIANG CITY POWER STATION AUXILIARY MACHINERY PLANT

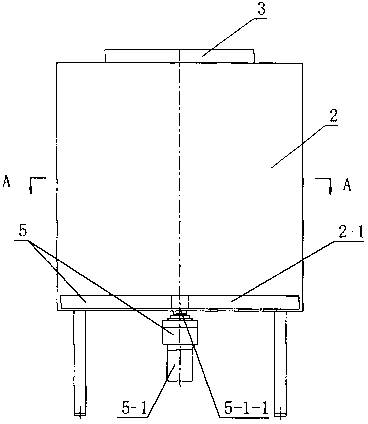

Bin

The invention relates to a storage device, in particular to a bin with a material sweeping device. The bin comprises a tubular bin body (2) arranged on a rack (1). A feed port (3) is reserved in the upper part of the bin body (2). A discharge port (4) is reserved in a bottom panel (2-1) of the bin body (2). The bin also comprises the material sweeping device (5). The material sweeping device (5) comprises a motor (5-1) and material sweeping blades (5-2). An output shaft (5-1-1) of the motor (5-1) is positioned at the central position of the bottom panel (2-1) of the bin body (5), and is connected with the material sweeping blades (5-2). The bin is provided with the material sweeping device, and has power, and the material sweeping blades are driven by the motor to rotate to push materials in the bin into the discharge port, so that blocking and bridging phenomena when the materials are discharged are avoided, and the materials can be discharged smoothly, uniformly and stably.

Owner:溧阳市华生机械制造有限公司

Preparation method for melamine cyanurate nanosheet microsphere and application thereof

The invention discloses a preparation method for a melamine cyanurate nanosheet microsphere and an application thereof. The preparation method comprises the following steps: performing a mixing reaction on a cyanuric acid, melamine, water and a dispersant in a double-planetary-type mixing machine and preparing melamine cyanurate, adding the dispersant in a reaction process, reducing interface freeenergy, and reducing a hydrogen bond binding force between nanosheets, thereby controlling agglomeration between the nanosheets, and forming 4-6 um of nanosheet microspheres. A product prepared by the preparation method has the advantages of good powder flowability, easy dispersion and high inflaming retarding efficiency, and is easy to feed and process in a PA66 application process. The nanosheet has a very large specific surface area, so the flame retarding effect of the melamine cyanurate is promoted to be developed, and flame retarding efficiency is improved.

Owner:JINAN TAIXING FINE CHEM

Vacuumizing method for composite-material forming process

The invention provides a vacuuming method used in composite material forming process. The invention uses the suspension method to place the vacuum nozzle, avoids the contact between the vacuum nozzle and the plate, raises the position of the vacuum nozzle, and avoids the problem that the air in the R corner area cannot be eliminated due to the thick honeycomb. Double layers of air felt are used under the vacuum nozzle, and two layers of breathable fibers are added between the air felts to form a good passage to completely remove the air and achieve a compaction effect of 80Kpa. Put an end to bridging, layering and other faults.

Owner:HARBIN

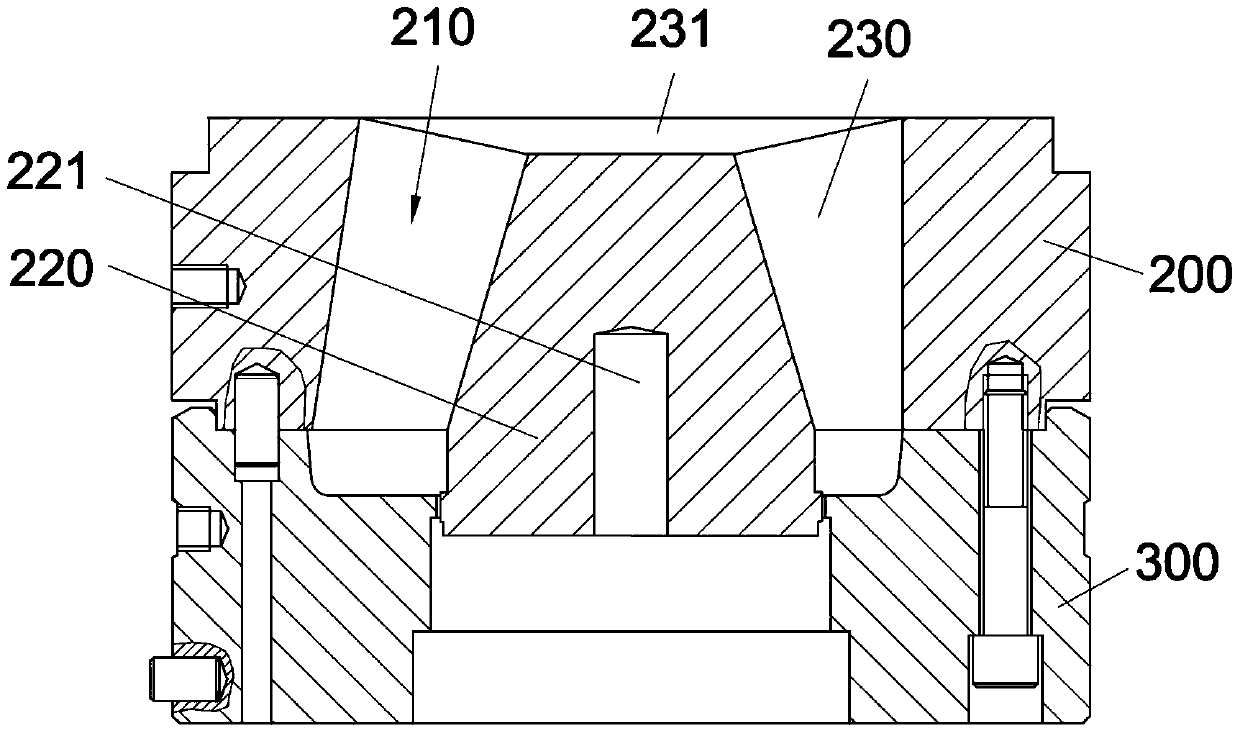

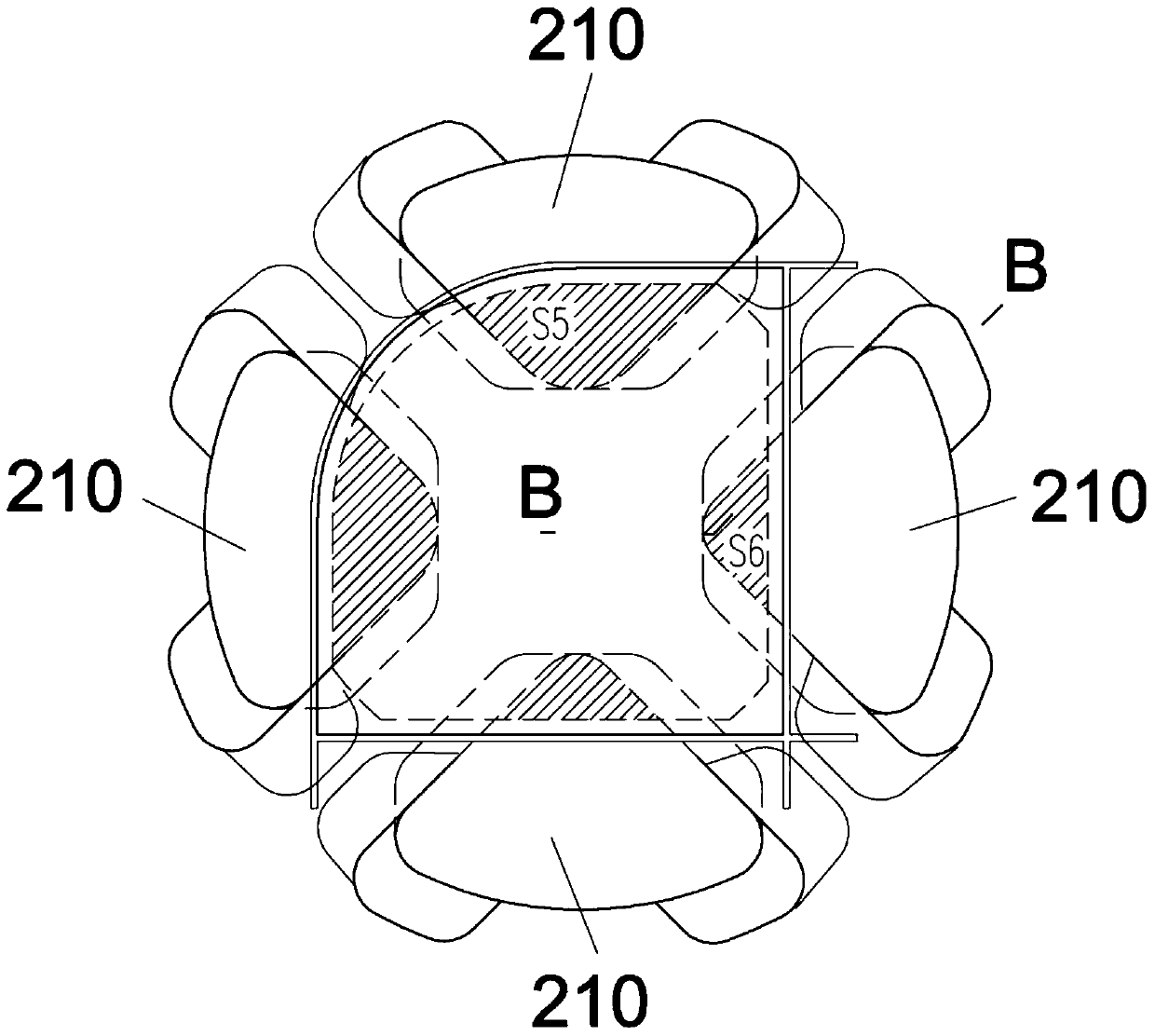

A corner aluminum profile extrusion die

ActiveCN105414232BUniform wall thicknessImprove structural strengthExtrusion diesUltimate tensile strengthAluminum extrusion

The invention discloses a cornered aluminum profile extruding die which comprises an upper die body and a lower die body. The upper die body comprises a die core. The lower die body comprises a welding chamber attached to the outer contour of a cornered aluminum profile. The upper die body and the lower die body are assembled together. A working zone used for forming the cornered aluminum profile is formed between the die core of the upper die body and the welding chamber of the lower die body. The portion, on the periphery of the die core, of the upper die body is provided with four dividing holes corresponding to the four edges of the cornered aluminum profile. A dividing bridge is arranged between every two adjacent dividing holes. The dividing holes are of a parallel inclined structure. The dividing holes are partially overlapped with the die core in the vertical direction. The overlapped area S5 of the dividing holes corresponding to the adjacent arc edge of the cornered aluminum profile and the die core is smaller than or equal to 1.5 times the overlapped area S6 of the dividing holes corresponding to the straight edges and the die core. According to the cornered aluminum profile extruding die, the die strength is greatly improved, die machining is simplified and facilitated, the production cost is greatly reduced, the phenomenon that bridge fracture occurs soon after the die is placed on a machine is avoided, the service life of the die is greatly prolonged.

Owner:GUANGZHOU VOCATIONAL COLLEGE OF SCI & TECH

Pesticide composition based on niclosamide ethanolamine salt and preparation method thereof

The invention discloses a pesticide composition based on niclosamide ethanolamine salt and a preparation method thereof, and relates to the technical field of molluscacidal preparations. The pesticidecomposition is prepared from niclosamide ethanolamine salt, a wetting agent, hyperbranched polyesteramide, a defoaming agent, an antifreeze agent and filler; a dry suspending agent type is obtained through the working procedures of premixing, airflow crushing, spray drying and granulation; on the basis of the prior art, the hyperbranched polyesteramide is used as a dispersant, and the dispersanthas a special branched molecular structure, more functional groups on the surface of a molecule can firmly wrap and adsorb the niclosamide ethanolamine salt, the bridging effect cannot occur, and thesolid content of a dry suspending agent system is effectively improved. The agricultural composition has good suspension rate and qualified high-low temperature stability, a suspending agent can be formed after the agricultural composition is mixed with water; the molluscicidal effect and the drug effect maintenance time of the composition are improved under the slow-release synergistic effect ofthe tea saponin after being sprayed and applied, and the agricultural composition is suitable for industrial application.

Owner:ANHUI TOPSUN PHARMA

Material flat-bottom bin arch-breaking collection device

InactiveCN109573359AIncrease unit volume ratioIncrease capacityLarge containersLow volumeEngineering

The invention discloses a material flat-bottom bin arch-breaking collection device. The material flat-bottom bin arch-breaking collection device comprises a bin body; feed inlets are formed in the topof the bin body, and the number of the feed inlets is two; a material collection outlet is formed in the center position of the lower end of the bin body; a reciprocating execution cylinder is installed at the bottom of the bin body; an output rod of the reciprocating execution cylinder extends into the bin body; a telescopic rod is fixed to a piston rod of the reciprocating execution cylinder; adrive block is welded to the other end of the telescopic rod; an unloading arch-breaking frame is laid at the lower end of the inner side of the bin body; the material collection outlet is designed in a rectangular shape; and a protective plate is fixed to the outer portion of the bin body. Through arrangement of the bin body, the reciprocating execution cylinder, the drive block, the material collection outlet, the unloading arch-breaking frame, the protective plate, the telescopic rod, a wedge-shaped support and a ring outer frame, the problems of low volume utilization rate, high buildingcost and poor running stability of a taper bin arch-breaking device are solved.

Owner:张家港市王牌机电设备有限公司

Automatic stirring and air blowing anti-bridging device

The invention relates to an automatic stirring and air blowing anti-bridging device. The device comprises a stirring device and an air blowing device, wherein the stirring device and the air blowing device are arranged at the lower part of a material bin, the stirring device comprises a stirring shaft arranged in the lower part of the material bin in a penetrating mode, the two ends of the stirring shaft are in sealing connection with the material bin, one end of the stirring shaft extends out of the material bin and is connected with a speed reducer, and paddles are arranged on the stirring shaft; and the air blowing device comprises an air pipe joint arranged at the lower part of the material bin, the air pipe joint communicates with the interior of the material bin, and the air pipe joint is connected with an air source through a pipeline. The stirring shaft and the paddles are arranged at the lower part of the material bin of the device, materials can be stirred, so that the materials cannot bond with one another, namely the materials are in a fluffy state; and the air blowing device is additionally arranged, so that the materials move under the action of airflow, the phenomenon of bridging is avoided, and the discharging is smooth.

Owner:张家港市繁昌机械有限公司

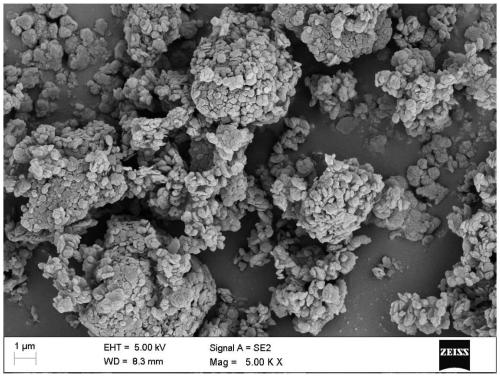

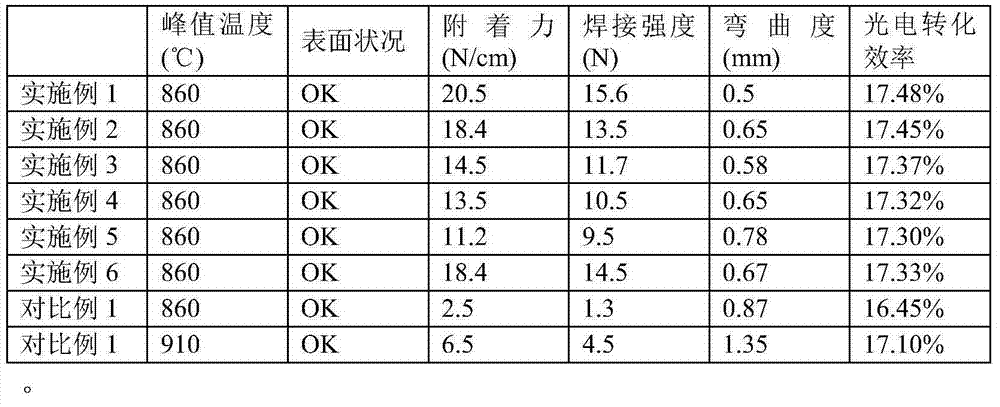

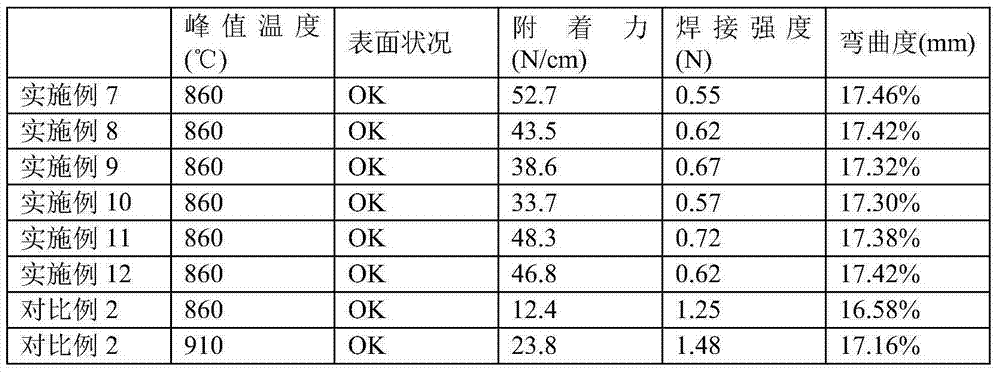

Conductive paste for solar cells and preparation method thereof

ActiveCN103295659BReduce bendingStrong adhesionNon-conductive material with dispersed conductive materialCable/conductor manufactureConductive pasteGranularity

The invention provides electrocondution slurry for a solar cell and a manufacturing method of the electrocondution slurry. The electrocondution slurry comprises electrocondution metal powder, inorganic glass powder and an organic carrier. D50 of the inorganic glass powder is 100-300nm, D10 of the inorganic glass powder is 10-70nm, and D90 of the inorganic glass powder is 400-700nm. The inorganic glass powder is manufactured through a sol-gel method, glass powder with a particle size smaller than 1 micron is obtained accidentally, the size distribution of the glass powder is even, and meanwhile doping is even. The manufactured electrocondution slurry is free of a cross phenomenon in the process that the solar cell is manufactured and sintered, the adhesive force of the electrocondution slurry and a silicon layer and the welding strength of the electrocondution slurry and a welding belt are greatly improved, and sintering temperature is low.

Owner:BYD CO LTD

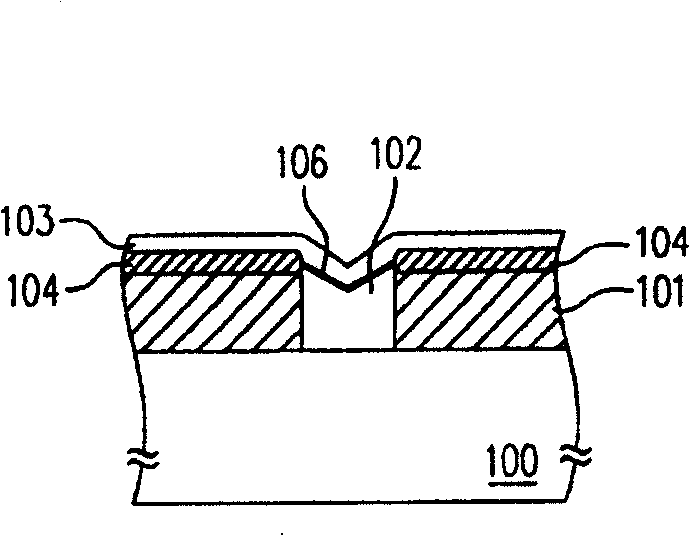

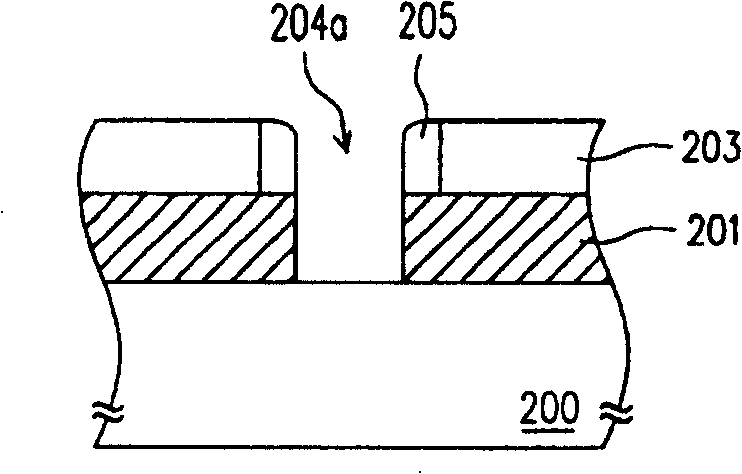

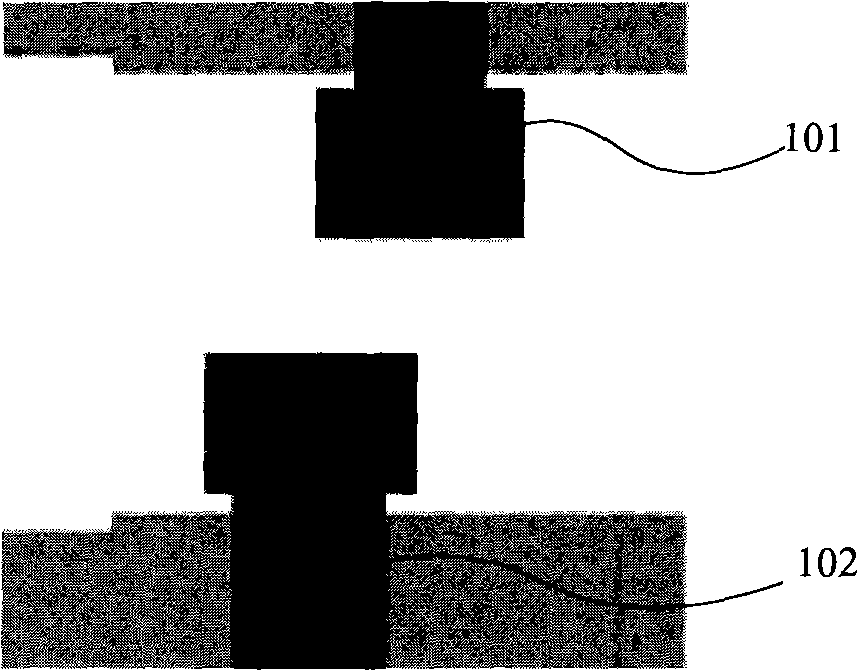

Salient point and forming method thereof

InactiveCN102044455ALimit scale outImprove electrical performanceSemiconductor/solid-state device detailsSolid-state devicesSemiconductorSeed crystal

The invention relates to a salient point and a forming method thereof, wherein the forming method of the salient point comprises the steps of: providing a semiconductor substrate, wherein a metal cushion layer and a passivation layer are formed on the semiconductor substrate, the metal cushion layer is embedded in the passivation layer and exposes through an opening on the passivation layer; forming metal shielding layers on the metal cushion layer in the opening of the passivation layer and the passivation layer; forming photoetching glue layers on the metal shielding layers, wherein an opening corresponding to the metal cushion layer is arranged on the photoetching glue layer; forming a seed crystal layer and a salient lower metal layer on the metal shielding layer in the opening of the photoetching glue layer; after removing the photoetching glue layer, etching to remove the metal shielding layer outside the metal cushion layer; forming side walls on two sides of the metal shielding layers, the seed crystal layer and the salient lower metal layer; placing the salient point on the salient point lower metal layer; and refluxing the salient point. The invention solves the problem of the bridging among the salient points and avoids the short circuit.

Owner:SEMICON MFG INT (SHANGHAI) CORP

Discharging structure of waste dryer

PendingCN110736337ASmooth dischargeSimple structureDrying solid materialsDrying machinesEnvironmental engineeringWaste material

The invention provides a discharging structure of a waste dryer. The discharging structure comprises a central shaft, a feeding spiral and a reverse spiral. The feeding spiral is welded to the front section of the central shaft to push waste to move. The reverse spiral is welded to the tail end of the central shaft. The reverse spiral and the feeding spiral are distributed on the two sides of a discharging opening. Under the squeezing effect of the reverse spiral and the feeding spiral, the waste can be smoothly discharged from the discharging opening, and the problem of bridging and blockingof the waste material discharging opening is solved.

Owner:深圳龙澄高科技环保股份有限公司

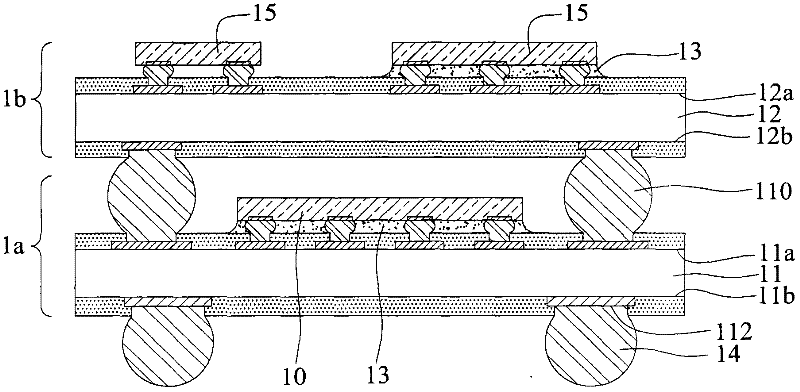

Semiconductor package and fabrication method thereof

ActiveCN102593104BAvoid short circuit conditionsNo bridgingFinal product manufactureSemiconductor/solid-state device detailsSemiconductor packageElectrostatic discharge

A semiconductor package is provided, which includes a substrate unit having conductive pads and ESD protection pads formed on a bottom surface thereof; an encapsulant covering a top surface of the substrate unit; and a metal layer disposed on a top surface of the encapsulant and having connecting extensions formed on side surfaces of the substrate unit and the encapsulant for electrically connecting the ESD protection pads, wherein portions of the side surfaces of the substrate unit corresponding in position to the conductive pads are exposed from the metal layer so as to ensure that solder bumps subsequently formed to connect the conductive pads of the semiconductor package to a circuit board are not in contact with the metal layer, thereby effectively avoiding the risk of short circuits.

Owner:SILICONWARE PRECISION IND CO LTD

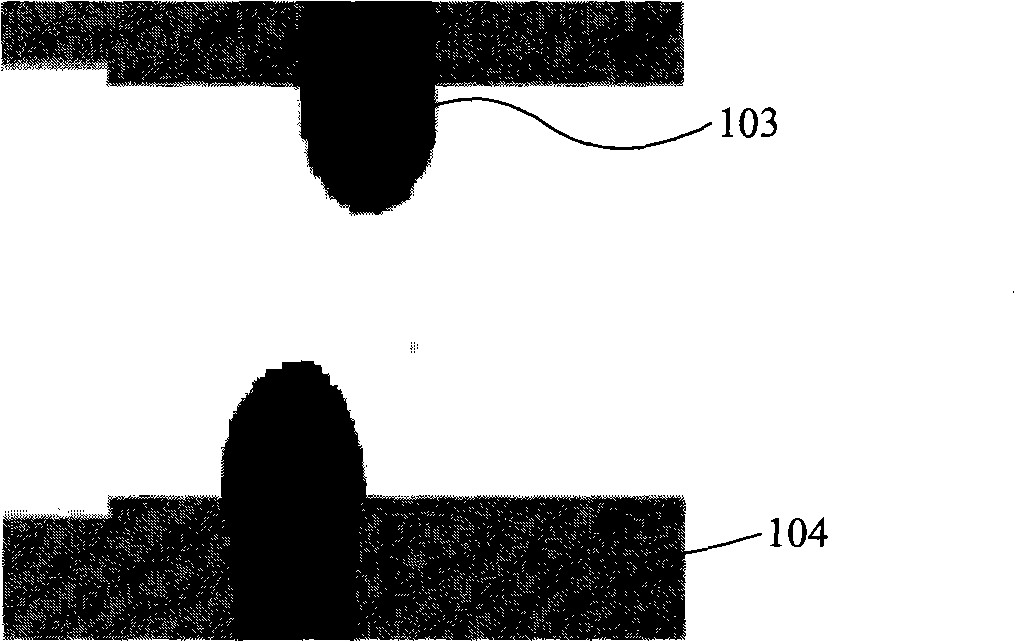

Production of conducting wire

ActiveCN100437938CNo bridgingAvoid short circuit problemsSemiconductor/solid-state device manufacturingMetal silicideOptoelectronics

The method comprises: providing a substrate on which a polycrystalline silicon layer has been already formed; forming a mask layer on the polycrystalline silicon layer; forming the spacer on the sidewall of the mask layer; using the mask layer having the spacer as the mask to remove a portion of polycrystalline silicon layer so as to expose the substrate; forming a insulating layer on the substrate filling out the opening, and the insulating layer and the mask layer has different etching selection; removing the mask layer to exposed the polycrystalline silicon layer; forming a metal silicides layer on the surface of the polycrystalline silicon layer.

Owner:NEXCHIP SEMICON CO LTD

Optical close distance correction method, optical mask manufacture method and graphical method

InactiveCN101311823ANo bridgingImprove performanceOriginals for photomechanical treatmentDistance correctionShortest distance

An optical short-distance correction method comprises the procedures as follows: a layout circuit pattern is provided and the layout circuit pattern is provided with at least two close terminals; and layout auxiliary patterns are arranged oppositely to the two terminals respectively. The invention also provides a method for manufacturing a light masking template and a patterned method. As a result, at least two circuit pattern terminals formed on a wafer are prevented from bridging connection in between.

Owner:SEMICON MFG INT (SHANGHAI) CORP

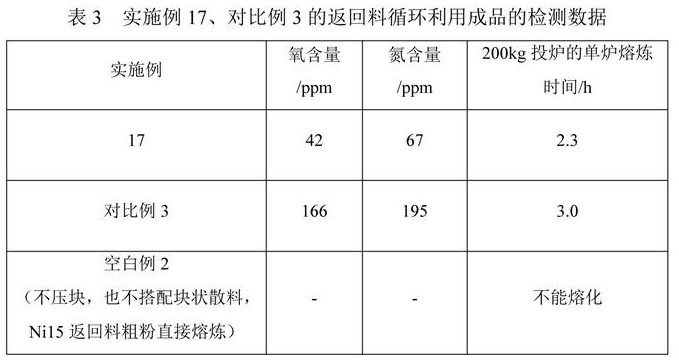

Recycling method of metal powder return scrap

ActiveCN114472885AAchieve recyclingImprove recycling ratesIncreasing energy efficiencyCompression moldingMolecular materials

The invention relates to a recycling method of metal powder return scraps, which comprises the following steps: placing the return scraps in a mixer for mixing, and uniformly mixing the return scraps into coarse powder; wrapping the coarse powder by adopting a volatile high polymer material sheath to form a powder sheath; the powder sheath is placed in a die cavity, a press machine with the pressure of 200 tons is adopted, compression molding is conducted on the powder sheath, the pressing rate is 2 times / min, and the return material is pressed into blocks; and the blocky return scrap is directly smelted to obtain a finished product, no master alloy or blocky bulk material needs to be added, and 98% or above of cyclic utilization is achieved. According to the recycling method for the return scrap, efficient recycling of the return scrap can be achieved, smelting can be directly conducted without matching of mother alloy or blocky bulk materials, and the ultrahigh recycling rate is achieved.

Owner:中航迈特增材科技(北京)有限公司

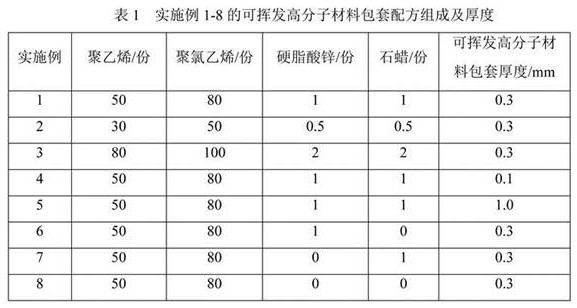

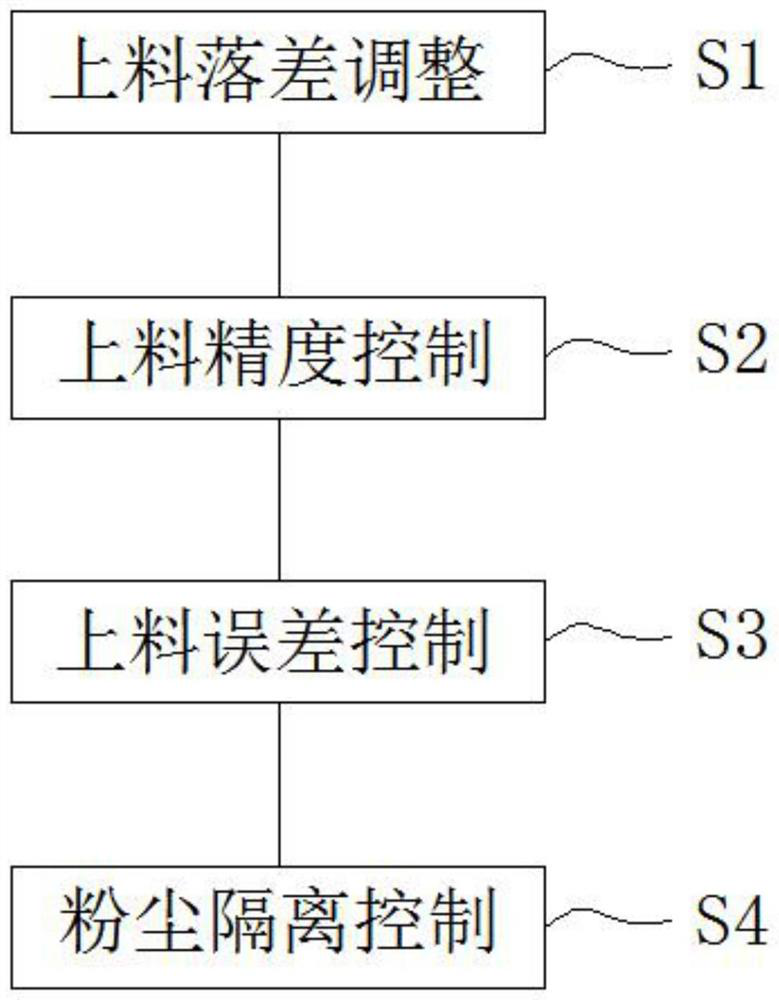

Vertical bowl loading method for production of lithium battery cathode material

InactiveCN112777011AGuaranteed liquidityGuaranteed uniformityLarge containersSolid materialThermodynamicsMechanical engineering

The invention provides a vertical bowl loading method for production of a lithium battery cathode material. The vertical bowl loading method comprises the following steps: S1, feeding fall adjustment: controlling a specific position of a carrier through a module system, and butting the carrier with a feeding port by controlling the carrier to move in three X-axis, Y-axis and Z-axis directions; and S2, feeding precision control: carrying out variable pitch design through carrying out matching on a feeding bin and a stirring system and through a screw in a screw feeding system. The vertical bowl loading method for production of the lithium battery cathode material, which is provided by the invention, is applicable to a vertical feeding process for the lithium battery cathode material, and is accurate to control dust raising and precision; the material compactness condition can be improved; the production capacity can be improved; moreover, in the feeding process, the situation that dust escapes all around is avoided; in addition, faults during operation are reduced; the vertical bowl loading method can be effectively compatible to multiple batches of materials; the bowl loading precision is improved; raised dust is reduced; the feeding efficiency is effectively improved; the sealing grade is greatly improved; dust is effectively isolated; and the like.

Owner:HENGLI ELETEK

Welding grease for electronic industry

ActiveCN1274460CImprove wettabilityGood storage stabilityWelding/cutting media/materialsSoldering mediaAlloyCarboxylic acid

Owner:深圳市唯特偶新材料股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com