Vacuumizing method for composite-material forming process

A composite material and molding process technology, applied in the field of composite material molding, can solve the problems of many R-angle areas, bridging of plates, inability to exhaust air, etc., to achieve good compaction effect, eliminate bridging, and eliminate surface depression failures Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The invention provides a vacuumizing method for a composite material forming process, comprising the following steps:

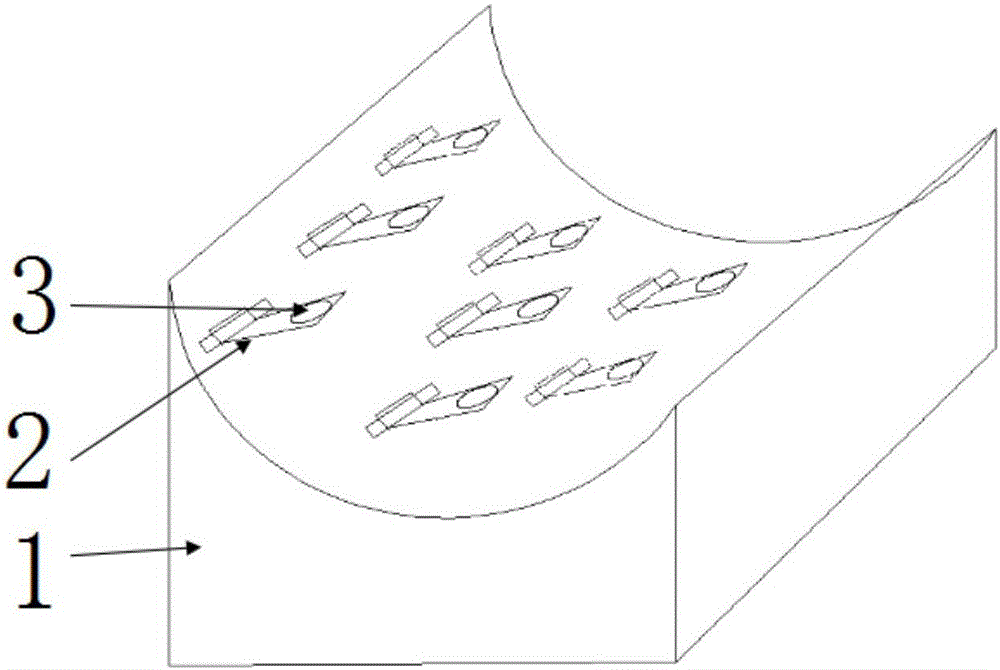

[0023] Step 1. Lay the composite material prepreg on the mold 1, and cover the prepreg with isolation film and air felt in sequence;

[0024] Step 2. Take another air felt and glass cloth, overlap the air felt and glass cloth into multi-layer strips, and ensure that the outermost two sides are air felt to form the air guide belt 2;

[0025] Step 3. Press and stick one end of the air guide belt to the air felt laid by the mold through adhesive tape;

[0026] Step 4, laying a vacuum bag on the air felt of the mould, and the air suction port 3 of the vacuum bag is arranged on the free end of the air guide belt;

[0027] Step 5. Vacuum through the exhaust port.

[0028] In particular, there are multiple air guide belts.

[0029] The length of the air guide belt is 30-50 centimeters.

[0030] The air felt of the air guide belt has 3 layers.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com